Page 1

●Thank you very much for

buying Panasonic Brushless

Motor.

●Read this instruction manual

carefully for proper use. In

particular, be sure to read

"Safety precautions"

before use for safety. Keep

this manual with care after

reading, and read as

necessary.

Be sure to give this manual to an end user.

■ CONTENTS

Safety Precautions · · · · · ··················

Introduction/Name of each part/

Cautions ·······························

Installation ·····························

Installation/System configuration

and wiring ·····························

Wiring/Test run ·························

Checking the load and use condition ·······

Maintenance and inspections/

Assembling of Gear Head ·················

Protective functions/How to clear trip ·······

Troubleshooting ·························

How to use Digital key pad ················

Operating Instruction ···················

Test run (Digital key pad) · · · · · · · · ········

Page

2

4

5

6

7

8

9

10

11

12

13

14

How to copy parameter ···················

Parameters (Default)·····················

LED display ····························

Detail of parameter ······················

Conformance to overseas standard··········

Specifications ····························

Options ··································

Warranty ·································

After-sale service (repair) ·············

Page

16

18

20

21

26

28

30

31

Back cover

Page 2

Safety precautions

See the following precautions in order to avoid damages on machinery and

injuries among the operators and other people during the operation.

■

The following symbols are used to indicate the level of danger possibly

occurred when you fail to observe the safety precautions.

Indicates a potentially hazardous situation,

!

△

DANGER

which if not avoided will result in death or

serious injury.

Important

!

△

CAUTION

Indicates a potentially hazardous situation,

which if not avoided, will result in minor

injury or physical damage.

■

The following symbols indicate what you must do.

(Shown below is an example of symbols.)

Indicates that the operation is prohibited to do

Indicates that the operation must be done.

!

Do not touch the rotating

part of the motor while

operating.

The failure could result in

injuries.

!

△

DANGER

Do not use in corrosive

atmosphere, flammable

gas atmosphere, or near

combustible substance.

Incompliance could result in

failure.

Do not expose the cables

to sharp objects,

excessive pressing or

pinching forces, and heavy

loads.

The failure could result in

electric shocks, damages,

or malfunction.

Install an external

emergency stop device to

shut down the main power

source in any emergency.

The failure could result in

electric shocks, injuries,

fire, damages or

!

malfunction.

2

Install the product

properly to avoid personal

accidents or fire in case of

an earthquake.

The failure could result in

electric shocks, injuries,

fire, damages or

!

malfunction.

An over-current protection,

earth leakage breaker,

over temperature protector

and emergency stop

device must be installed.

The failure could result in

electric shocks, injuries, or

!

fire.

Page 3

Make sure to secure the

safety after the earthquake.

Wiring must always be

performed properly and

reliably by a professional

electric worker.

Be sure to ground the

grounding wire of motor.

The failure could result in

electric shocks, injuries, or

!

fire.

△

Do not drive the motor

shaft from the outside.

The failure could result in

fire, electric shocks, or

damages.

Do not hold the cables or

motor shaft when

transporting the motor.

The failure could result in

injuries.

!

Never start and stop the

motor by magnet

contactor, etc. which is

provide on the main line.

The failure could result in

electric shock, injury, fire,

!

malfunction, and damage.

CAUTION

Do not block the

dissipation hole of

brushless inverter.

The failure could result in

fire, electric shocks, or

malfunction.

The failure could result in

damages.

The failure could result in

!

electric shock.

Do not modify, dismantle

or repair the product.

The failure could result in

electric shocks, injuries, or

fire.

Do not place any obstacle

that blocks ventilation

around the motor.

The failure could result

in burns or fire.

Do not touch the motor,

since they become hot.

The failure could result in

burns.

Attach to inflammable

matter such as metal.

The failure could result in

electric shocks, injuries, or

!

fire.

This product should be

treated as an industrial

waste when it is disposed.

Do not approach to the

equipment after recovery

from the instantaneous

stop because they may

restart suddenly.

The failure could result in

injuries.

If trip occurs, remove the

causes of the trip and

secure the safety before

restarting.

The failure could result

in injuries.

!

Maintenance and check

must be performed by an

expert.

The failure could result in

!

injuries and electric shock.

Install a safety device

against idling or locking of

gear head, and leakage of

grease.

The failure could result in

injuries, damages, and

!

contaminations.

Execute the trial-operations

with the motor fixed and a

load unconnected. Connect

a load to the motor after the

successful trial-operations.

The failure could result in

!

injuries.

Use the specified voltage

on the product.

The failure could result in

electric shocks, injuries, or

!

fire.

3

Page 4

Introduction/Name of each part/Cautions

After unpacking

● Make sure that the model is what you have ordered.

● Check whether the product has been damaged or not during transportation.

If any deficiency should be found, contact the dealer store where you bought this product.

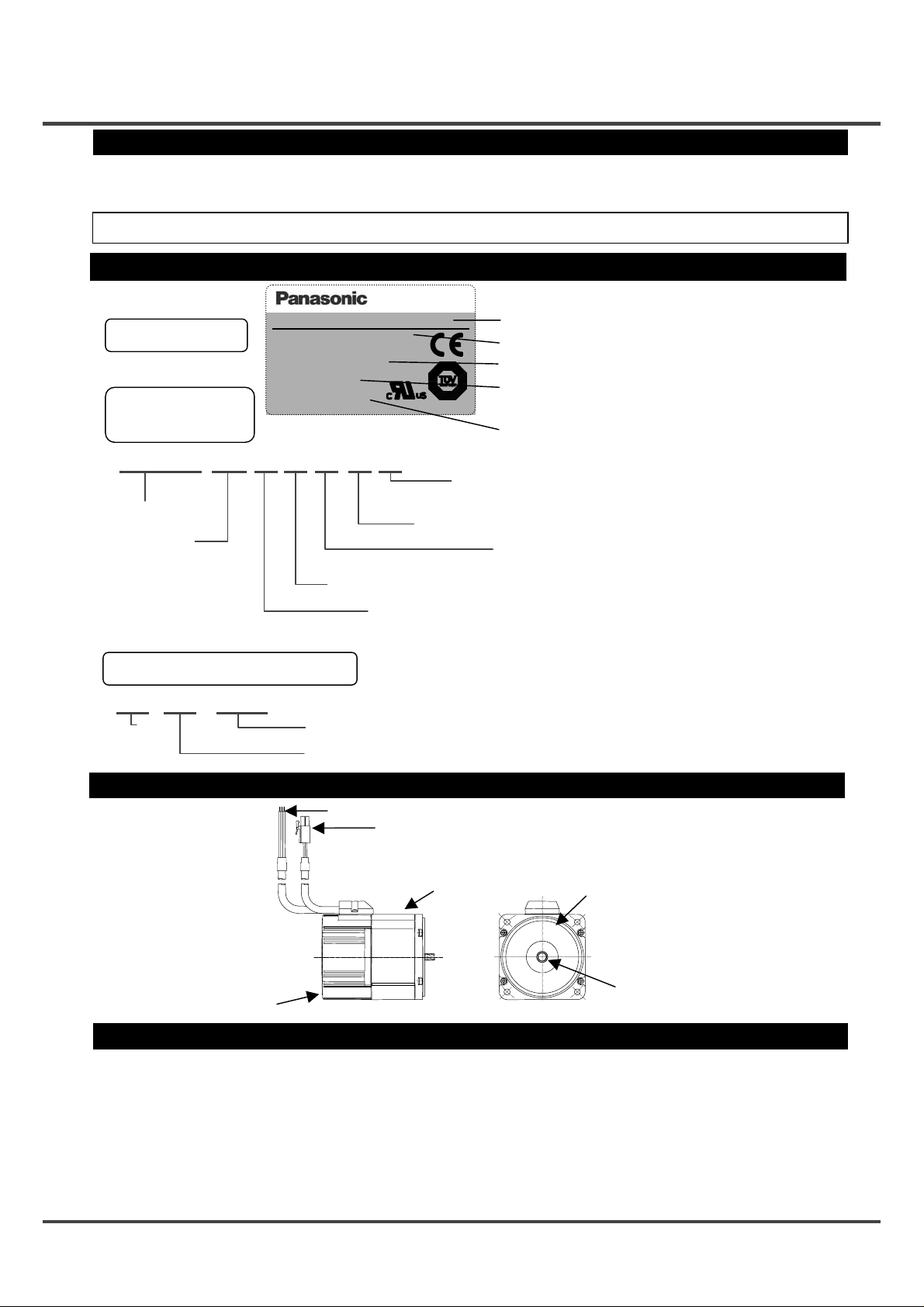

Checking the model of brushless motor

Brushless Motor

Nameplate

Check the

Model Name

MBMC 3A 1 A X A

Series name

Output

3A: 30 W

5A:50 W

9A:90 W

1E:130 W (Rating 30 min)

Check the Serial Number

*

03 11 0001*

Manufacturing

year

(Lower 2 digits of Christian Era)

Name of each part

Model No.

Input

Input Current

Ins. Class

Rated Output

Rated Speed

Rating

Ser. No. 03110001

Matsushita Electric Industrial Co.、Ltd.

MBMC3A1AXA

1Ph.100V-120V

1A

A(UL),E(TUV)

30W

3000r/min

S1

IP65

Made in Japan

C26701

Model name

Rated input voltage

Rated output

S1: Continuous rating,

S2: Short time rating

Set specification

Function A: Standard

Shaft specification

Structure A: Standard

Input power supply

1:

Single phase

Single phase

2:

Serial Number

Manufacturing month

Power input line

Connector for control signal

* Indicates production in November 2003, serial

Serial Number

(Blank): Console A attached

P: Console A attached

X: For gear head MX8G

Z: For gear head MZ9G

S: Round shaft

AC100 – 120 V

AC200 – 240 V

number 0001.

Control circuit unit

Motor unit

Label of safety precaution is affixed to the product.

O-ring (not attached in

specification of round

shaft)

Oil seal

Precaution for proper use

1. This motor incorporates control circuit. Control circuit is sensitive to temperature and impact, therefore read

this instruction manual carefully for proper installation.

2. This motor is controlled by switching the power element at a high speed.

Therefore, when the motor runs, leaking current may increase, which activates the leakage breaker.

In such a case, use a leakage breaker which is provided with measure against high frequency for inverter.

3. In starting and stopping the motor, use the operation instruction input "I1" or RUN/STOP switch of console A

and digital key pad. When the motor is turned on and off by turning on and off power supply, the life of inner

circuit may be shortened.

4

Page 5

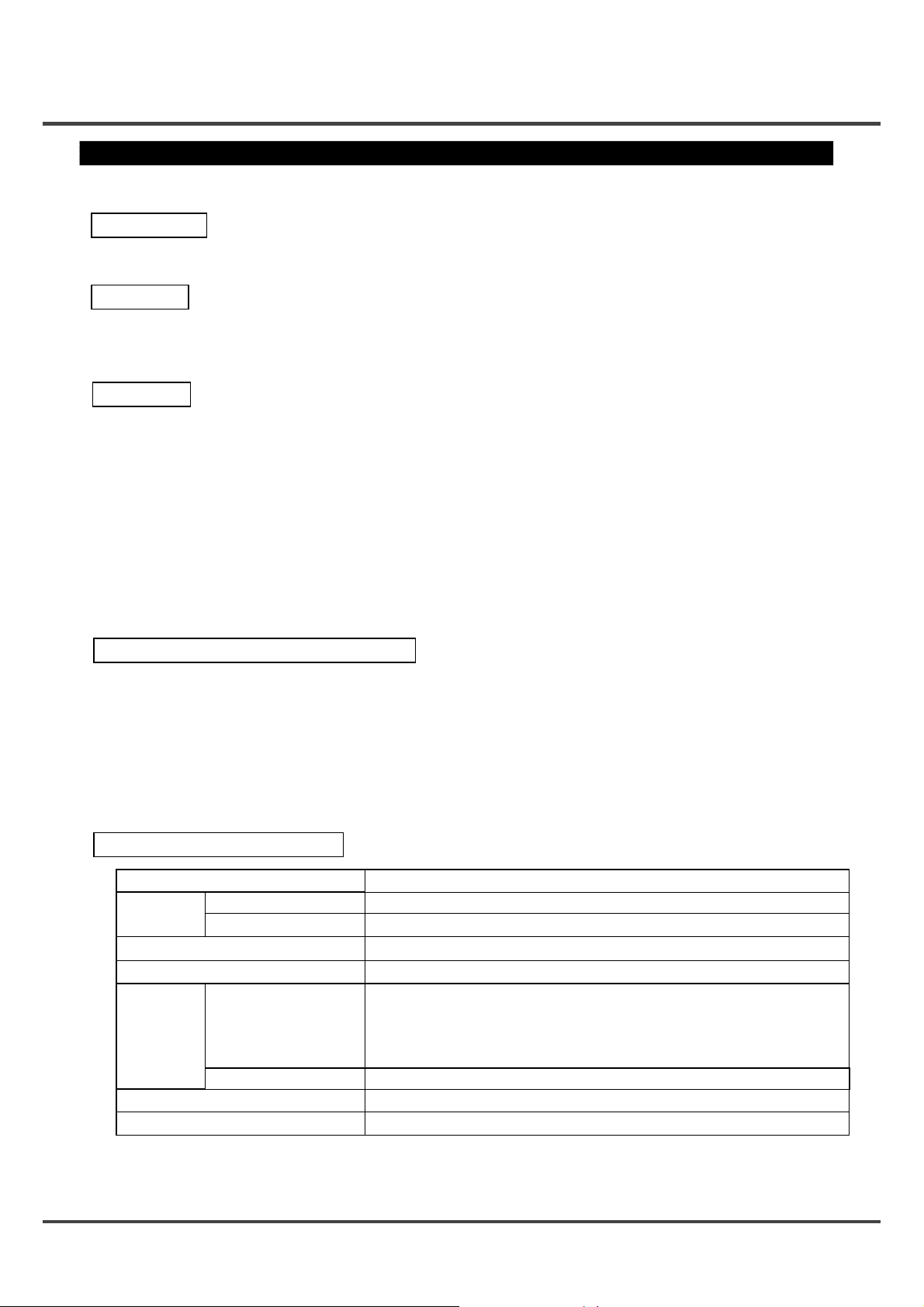

Installation

Installation

Install the brushless motor properly for preventing failure and accident.

Transport

● Use caution enough in transporting the unit to prevent injury by drop or fall, and avoid damage to

the equipment.

Storage

● Keep the unit indoors in a clean and dry place free from vibration with little change of tempe rature.

● In keeping a gear head alone, direct the output shaft down.

Location

● Location gives great influence upon the life of brushless motor, therefore choose a place in

conformance with the conditions below:

(1) Indoors where the motor is not subjected to rain water and direct sun beam.

(2) Do not use the motor in corrosive atmosphere such as hydrogen sulfide, sulfurous acid, chlorine, ammonia,

sulfur, gas chloride, gas sulfide, acid, alkali, and salt, in the atmosphere of combustible gas, or in the vicinity of

flammables.

(3) Place not exposed to grinding liquid, oil mist, iron powder, and cutting particle.

(4) Well-ventilated place with little moisture, oil, or inundation, and place far from heat source such as a furnace.

(5) Place easy to check and clean

(6) Place free from vibration

(7) Do not use the unit in an enclosed environment. Enclosing may raise the temperature of motor, and shorten

their life.

(Otherwise, grease leaking is possible.)

Caution in Installing Gear Head

● Idling by damaged tooth, locking by bite, grease leakage, and the like are possible on the life end of gear

head. Install a safety device in order to ensure safety even if such trouble should be found.

• Install a device for preventing drop by damaged teeth on a lifter or the like.

• As for application such as opening and closing of door, install a release device against locking by gear bit ing.

• As for food or textile equipment, install an oil pan for measure against grease leakage.

• Do not install an encoder, sensor, contact, etc in the proximity of gear head. If you should install such devices,

take measures against their grease leakage.

• Be sure to perform daily check in order to prevent unexpected accident.

Environmental condition

Item

Ambient

temperature

Brushless motor

Console A, Digital key pad (optional)

Ambient humidity

Storage temperature

Protection

structure

Brushless motor

Console A, Digital key pad (optional)

-10°C - 40°C (free from freezing)

-10°C - 50°C (free from freezing)

85% RH or below (free from condensation)

-20°C - 60°C (free from freezing)

IP65 (excluding output shaft rotating area, and tip of lead)

x This motor conforms to test condition specified in EN standard (EN60529 and

EN60034-5). This motor is not applicable to the use which requires long-term

waterproof performance, such as the case where the motor is always washed

with water.

Condition

Equivalent to IP20

※1

1

*

2

*

Vibration Not greater than 4.9 m/s2(10 – 60 Hz)

Altitude Not greater than 1000m

*1Ambient temperature is measured at a di st an ce of 5 cm from the motor.

2

Temperature which is acceptable for a short time, such as during transportation.

*

5

Page 6

Installation/System configuration and wiring

Others

● Oil and water protections

(1) Direct down the lead of cable as far as possible.

(2) Avoid use in such an environment where motor is always exposed to oil and water.

(3) Avoid use with cable immersed in oil and water.

● Cable: stress relieving

(1) Make sure that stress is not applied to the lead or connection of cable due to bending or dead weight.

(2) In installation where the motor moves, fix the cable of motor, incorporate the extension cable

connected beyond in the cable carrier to reduce stress by bending as small as possible.

(3) Allow the bending radius of cable as large as possible.

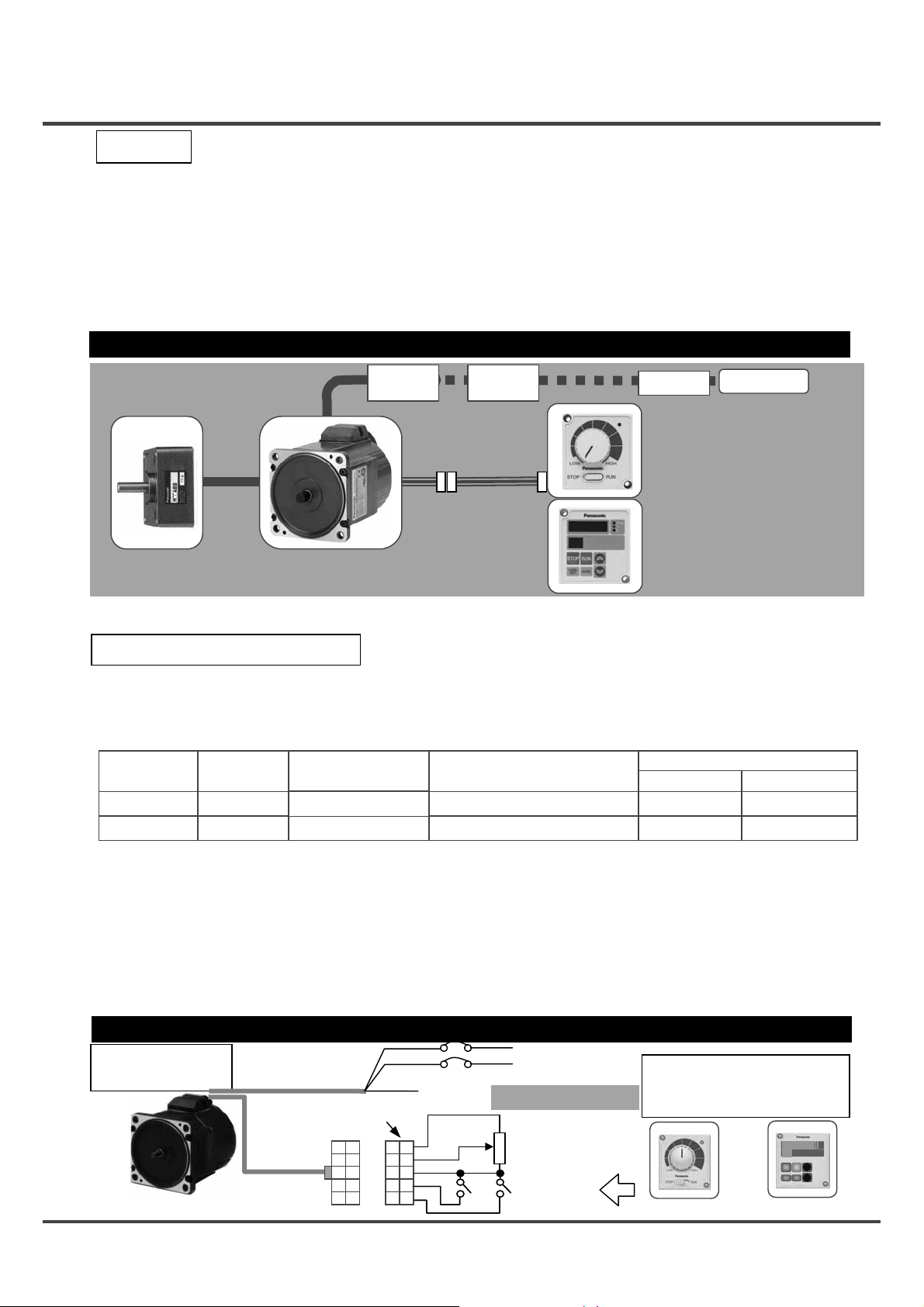

System configuration/general wiring diagram

The lead wire is 0.5m long.

Magnetic

contactor

Noise filter

NFB

AC power

supply

Console A

(attached, optional)

It allows switching

RUN/STOP and CCW/CW

and setting speed.

Digital key pad

(sold separately)

This is a digital display console.

It enables change of parameter.

(See the use of Digital key pad

on page 12 for detail.)

Gear head

(sold separately)

B1 Series

G Type

Extension cable

(sold separately)

Connector kit

(sold separately)

●Wiring work must always be performed by a professional electric worker.

●Do not turn on power before finishing wiring for avoiding electric shock.

Selection of wiring equipment

● Recommended noise filter Option part number: DVOP3611-5

Manufacturer's part number: SUP-EQ5-ER-6

● Selection of non-fuse breaker (NFB), magnetic contactor (made by Matsushita Electric Works, Ltd),

and electric wire (wiring within equipment)

(See "Adaptation to overseas standard" for compatibility with overseas standard.)

Voltage

Single phase 100V

Single phase 200V

Capacity

(w)

30 - 90

30 - 130

NFB (rated current)

BBC25N(5A)

BBC25N(5A)

Magnetic contactor

(contact structure)

BMFT61041N(3P+1a)

BMFT61042N(3P+1a)

Main circuit/

Grounding wire

0.5(AWG20) 0.13(AWG26)

0.5(AWG20) 0.13(AWG26)

■ Be sure to ground the grounding terminal.

In wiring to power supply (outside of equipment) from NFB, use an electric wire of 1.6 mm

diameter (2.0 mm

2

) or more both for main circuit and grounding. Apply grounding class D (100

ohms or below) for grounding.

(Okaya Electric

Industries Co., Ltd)

Electric wire (mm2)

Control circuit

●Selection of relay

As for use for control circuit such as control input terminal, use a relay for small signal (minimum guarantee

current 1 mA or less) for preventing poor contact. <Reference example> Matsushita Electric Works, Ltd: DS

type, NK type, HC type, OMRON: G2A type

● Control Circuit Switch

When using a switch instead of relay, use one for minute current in order to prevent poor contact.

<Example> Nihon Kaiheiki: M-2012J-G

Wiring

Standard

wiring diagram

Nihon Molex

( )

39-01-2105(5557-10R-210)

<Power input line>

(Connector kit A)

<Control

signal connector>

(Motor side)

10

Black

White

Green/

Yellow

5

6

1

NFB (No-fuse breaker)

Grounding

Rotation

speed

5

4

Control gland

3

2

1

Rotation

direction

Power input

Be sure to ground the

grounding terminal.

External speed setting

Variable resistor 5 kΩ

B characteristics 1/4 W or

above

Operation

stop

Do not tighten the ground

wires together, but

connect them individually.

(Console A) (Digital key pad)

6

Page 7

Wiring/Test run

Function of terminal

<Power input line>

Wire color

White/Black (L1, L2)

Green/Yellow (E)

<Control signal connector>

Terminal

10

Terminal

number

1

2

symbol

I1

I2

5

3 GND

4 FIN

6

1

Terminal name Description of function

*1

Operation instruction input

Rotation speed changeover

*1

input

Control ground

Analog speed

command input

Name Description of function

Power input line

Grounding wire

Nihon Molex 39-01-2105(5557-10R-210)

Connect the terminal to commercial power supply conforming to voltage

specification.

Wire for grounding the motor

Motor runs when "I1" and "GND" are shorted, and stops when they are opened.

CW operation when "I2" and "GND" are shorted, and CCW operation

when they are opened.

Common ground terminal for control signal.

Speed can be set by applying voltage DC0 – 5V.

Input impedance 100 kΩ.

*3

*2

Wire

color

Brown

Red

Orange

Yellow

(Motor side)

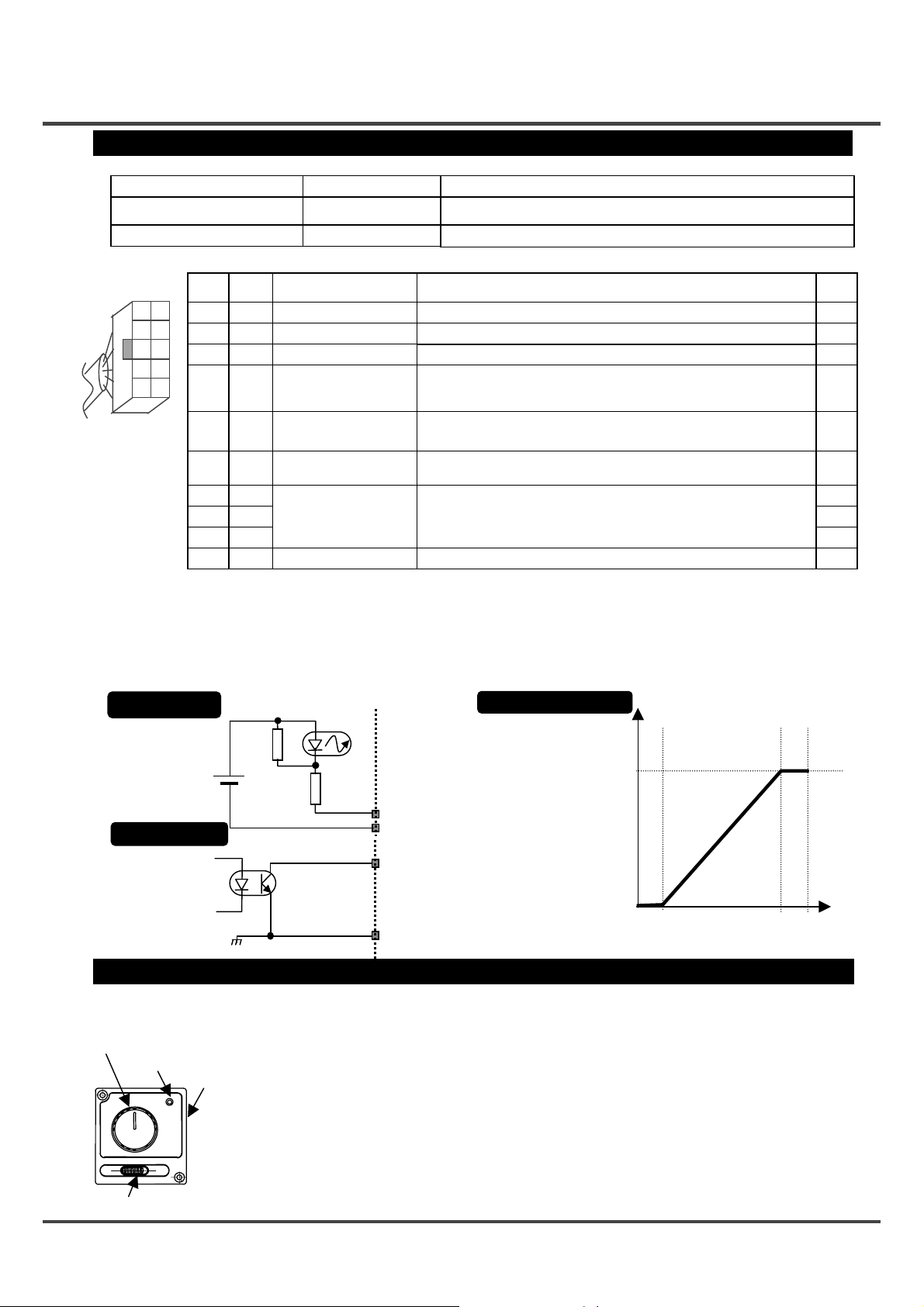

Input circuit

Internal

power supply

(+5V)

Output circuit

5 +5V

6 O1

External speed setting

power supply

*1

Trip output

Power output dedicated when connecting an external variable resistor

(5 kΩ, B characteristics) to FIN input (Cannot be used for any other purpose.)

Trip signal output. *1"L" in trip (Contact ON)

Open collector Vce max: DC30V, Ic max: 50mA

7 SCK

8 SIN

Digital key pad I/F

Interface for digital key pad

9 SOT

10 (N/A) −

*1Function of input/output can be changed by the Digital key pad. Default is shown.

2

Rotation direction is that on motor shaft. When gear head is incorporated, the rotation direction of motor and that of gear output shaft

*

are reversed for some gear reduction ratio. See the allowable shaft torque table on page 8.

(CW: Rotation clockwise when seen from the motor shaft, CCW: Rotation counterclockwise when see from the motor shaft)

3

When resistor and control GND are disconnected in use of external variable resistor, 5V is input to FIN irrespective of setting of

*

variable resistor, and upper speed limit is directed; therefore use caution enough for connecting GND.

■ See the optional connector kit A (DVOP3600) for compatible connector.

In extending the control signal wire, keep it below 5m long, and use wire rod above AWG26 (0.12mm

Photo-coupler

(Do not connect anything.)

FIN characteristics

Preset speed

2

).

(Typical value)

(r/min)

1.5kΩ

I1, I2

(Upper speed limit)

3000

GND

01

Green

Blue

Purple

(Pink)

Gray

White

Black

V

ce max

cmax

I

GND

Inspection prior to test run (Console A)

・ Connect the

Console A

Speed

potentiometer

Power

lamp

RUN/STOP switch

Rotation

direction

selecting

switch

(Check before operation)

(1) Any mistake found in wiring? (2) Input power supply conforms to rating?

(Test run)

When RUN/STOP switch is changed to RUN, the motor rotates, and when the switch is returned to

STOP, the motor stops.

Rotation direction can be changed by rotation direction selecting switch on the side of console.

When the rotation direction is changed in RUN, the motor is inverted suddenly, and the motor may

trip due to some inertia of load.

Rotation speed can be adjusted by the speed potentiometer.

Turn off power when the motor is to be stopped for a long time.

■ When power is turned off with RUN/STOP switch on RUN side, and power is turned on again,

the motor may start again, which is dangerous. In turning on power, always make sure that

the switch is on STOP side.

■

When a gear head is incorporated, rotation direction of gear head output shaft may be inverted

for some gear reduction ratio. See the table of allowable shaft torque on page 8.

DC30V

50mA

0

(Lower speed limit)

0V 0.5V 4.5V 5V

FIN input voltage

7

Page 8

Checking the load and use condition

Check use condition for eternal use of this product. Some use conditions may possibly lead to heating or

damage to the shaft. Fully check use conditions, and use the motor in a permissible range.

Standard life

Standard life is 5,000 hours for the motor equipped with gear head (MB8G and MB9G). Standard life is the same

10,000 hours for motor alone (round shaft). (Standard life of sealing performance of oil seal is 5,000 hours.)

Standard life refers to design life for operation 8 hours per day (service factor: Sf = 1.0) at a normal temperature and

humidity, under uniform load (permissible shaft torque of gear head and rated torque of motor).

Service factor (Sf)

Service factor (Sf) depends on the magnitude of shock of load or operating time. Service factor is shown below

for different load conditions:

Expected of life =

Example of load Type of load

Uniform load

Light shock

Middle shock

Heavy shock

Permissible shaft torque

Required shaft torque TA of gear head can be obtained from service factor and actual load torque T1.

One direction continuous operation

Start, stop, or cam shock

Instantaneous rotation/reverse rotation and instantaneous stop

Middle shock at a high frequency

TA=T1×Sf

Select a gear head and motor to ensure that required torque (continuous) is within permissible shaft torque in

the table below. Here, the torque T1 must not exceed permissible shaft torque TA irrespective of Sf.

Reduction

Model

name

MBMC3A□AXA

MBMC5A□AXA

MBMC9A□AZA

MBMC1E□AZA

ratio

MX8G□B

MX8G□B

MZ9G□B

MZ9G□B

5

0.38

0.64

1.12

1.69

* Rotation direction is the same as that of motor in shaded portion, and reverse for others.

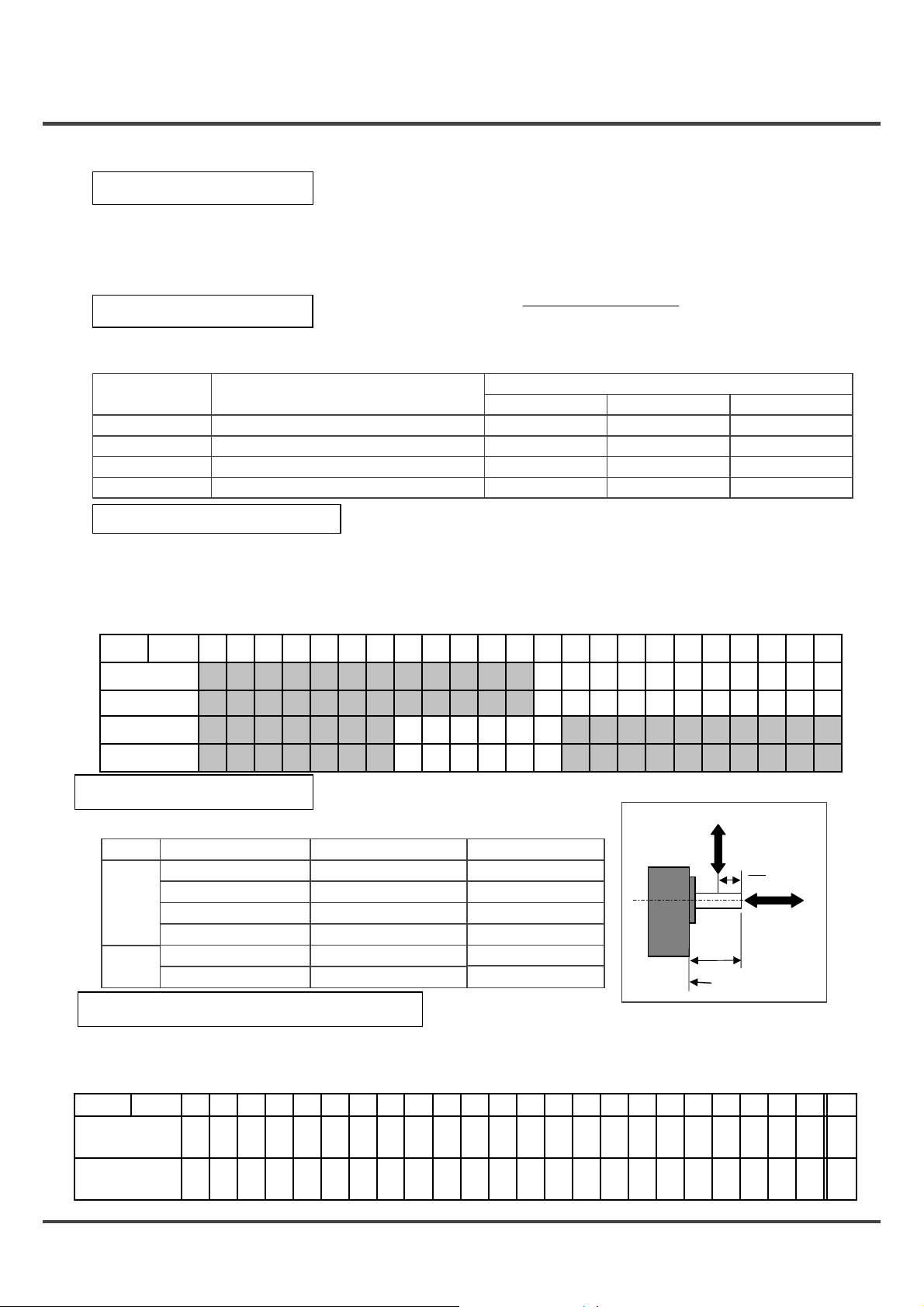

Permissible shaft load

Use the permissible shaft load within the load shown below:

Permissibleoverhang (w) Permissible thrust (F)

Motor

alone

Gear

head

Model name

MBMC3A□ASA 100N 10N

MBMC5A□ASA 100N 10N

MBMC9A□ASA 150N 20N

MBMC1E2ASA 150N 20N

MX8G type 294N 49N

MZ9G type 588N

Standard life

Service factor (Sf)

Service factor

5 hours/day 8 hours/day 24 hours/day

0.8

1.2

1.5

2.5

1.931.551.391.150.960.770.690.580.460.280.23

2.16

3.61

3.232.592.331.921.611.291.160.960.770.460.39

6.22

9.34

147N

30

1.0

1.5

2.0

3.0

Motor and

gear head

Overhang load

(W)

L

Mounting surface

1.5

2.0

2.5

3.5

Unit: N m

7.847.847.846.996.455.434.363.552.60

7.847.847.847.847.847.847.295.934.33

L

2

Thrust load

(F)

スラスト荷重

20018015012010090756050362520181512.51097.563.63

−

−

19.619.619.619.619.017.314.711.79.816.965.274.113.723.062.542.282.021.691.340.810.67

19.619.619.619.619.619.619.617.514.710.57.916.175.584.593.823.423.042.542.021.211.01

Permissible load inertia moment

Apply permissible load inertia moment within the value shown below:

(Acceptable value on round shaft applies when stopping operation in free-run stop. In speed reduction stop, the value is 1/4 of

indication below only on round shaft due to regeneration. Set a longer speed reduction time if the inertia is not to be lessened. )

name

MX8G□B

MZ9G□B

Reduction

ratio

5

3.42

16.4

Model

MBMC3A□AXA

MBMC5A□AXA

MBMC9A□AZA

MBMC1E□AZA

Set the acceleration/deceleration time 0.3 seconds or longer.

Unit: ×10 kg-4・m

30

127

589

18015012010090756050362520181512.51097.563.63

34234234234234234234234218386.955.845.230.621.613.811.27.724.901.791.25

1684168416841684168416841684168484742325721114298.367.653.437.323.68.475.93

8

200

−

1684

2

Round

shaft

2.5

5.6

Page 9

Maintenance and inspections/Assembling of Gear Head

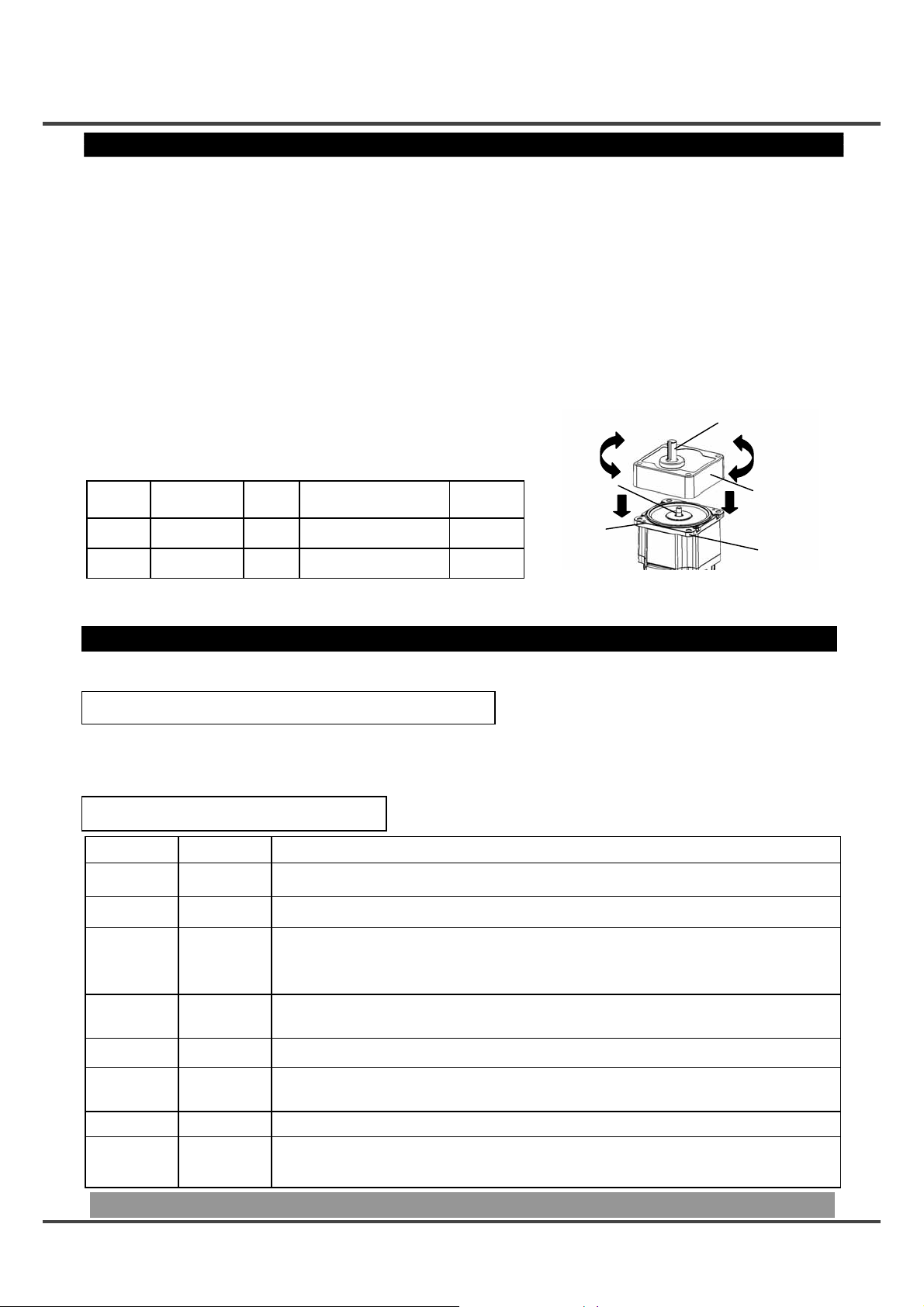

Assembling of Gear Head

● Preparation before assembling

(1) Compatible gear head described on this instruction manual is MX8G□B (for 30, 50W) and MZ9G□B

(for 90, 130W). Never combine anything other than compatible gear head in use. Failure to observe this

direction may result in malfunction. (□ represents speed reduction ratio.)

(2) Make sure that the O-ring is attached to the bottom of motor flange.

If the gear head is assembled with O-ring floating, it may result in grease leakage.

(3) When grease adheres to the end surface of gear head, wipe off sufficiently.

If the gear head is assembled with grease adhered, it may cause grease to exude.

● Assembling

(1) Direct the motor pinion upward, and make sure that the relation between direction of motor lead wire

and output shaft matches with the equipment.

(2) Turn the motor pinion finely clockwise and counterclockwise for assembling, ensuring that the tip of

motor pinion does not hit the tooth of gear head.

(3) In installing the motor and gear head to the mating equipment, use "mounting screws" attached to the

gear head, tighten them sufficiently to eliminate clearance

between the motor flange surface and gear head end

surface while paying attention to bite of O-ring.

Recommended tightening torque is shown below:

Mounting

Angle

dimension

Type of

gear head

Screw

size

Tightening torque

Mounting

pitch

diameter

□80 MX8G M5 2.45N・m 94mm

□90 MZ9G M6 2.94N・m 104mm

Motor

pinion

O-ring

Output shaft

Gear head

Flange

Note) Excessive force to assemble the motor and gear, or damage to the tip of

motor pinion or tooth of gear head may generate abnormal noise or reduce the life.

Maintenance and inspection

Routine maintenance and inspection are essential for proper and satisfactory operation of

the motor.

Notes to Maintenance/Inspection Personnel

● Power-on/off operations should be done by the operators themselves for ensuring safety in checking.

● Do not touch the motor while power on.

● In performing the measuring insulation resistance, remove all connections. Measuring insulation

resistance with connection can cause motor failure.

Maintenance/ Inspection item

Maintenance/

Check item

Input voltage Voltmeter Must be within ±10% of rating.

Input current Ammeter Must be within rated input current described on nameplate.

Insulation

resistance

Noise

Inspection

procedure

Insulation

resistance

tester

Hearing

Condition

Measure the insulation resistance of motor with 500V Megger. It must be above 1Mohm.

Measuring position: Between power input line (L1, L2) and grounding wire

Noise level must not be different from the usual level. In addition, abnormal noise

such as rumbling noise must not be heard.

Vibration By hand Free from abnormal vibration.

Grease

leakage

Installation

bolt

Use

environment

By sight

Torque wrench

By sight

Check that periphery of motor or gear head is not wet by grease or oil. Protect them with

a cover etc. in application which is deteriorated by grease leakage.

Check for loosening of bolt, and tighten additionally as necessary.

Check the ambient temperature and humidity, and make sure that dirt, dust, or foreign

substance is not found.

Make sure that the opening of brushless inverter is free from lint.

Be sure to contact our service division or sales agent for disassembling and repairing of the motor.

9

Page 10

Protective functions/How to clear trip

Protective functions

■ When the protection fu nction is activated, motor stops and trip signal output turns on.

Description of trip can be displayed only when the Digital key pad (option) is connected.

Protection function works even when the Digital key pad is not connected, but it is not displayed.

Protective item Description

When the internal DC voltage is below specified value,

operation is stopped; when voltage is recovered, operation

Undervoltage warning

(default)

Undervoltage error

Overload warning

(Electronic thermal)

Overload error

(Electronic thermal

relay)

Overcurrent error

Overvoltage error

User

parameter error

System

parameter error

System error

Sensor error

Overspeed error

Overheat error

Setting change

warning

is started again. (This is not trip, and no trip output is

made.)

■Trip can be set by parameter 50.

100V product: Approx DC100V,

200V product: Approx DC200V

The motor trips when internal DC voltage is below

specified value only if trip is set by parameter 50.

100V product: Approx DC100V,

200V product: Approx DC200V

When load factor exceeds specified value, the electronic

thermal relay operates and monitor display flashes.

It is a warning for electronic thermal trip.

30-90W: 100%

130W : 80%

The motor trips when motor torque is output continuously

above specified value.

30-90W: 115%

130W : 105%

The motor trips when the motor current exceeds specified

current.

The motor trips when internal DC voltage (voltage of

smoothing function of power supply) rises and exceeds

specified value.

Product of 100V: Approx DC200V,

Product of 200V: Approx DC400V

Parameter data saved in EEPROM is abnormal.

Internal parameter data saved in EEPROM is abnorma l. Failure is possible.

The motor trips when trouble of control microcomputer is

detected.

The motor trips when trouble of CS sensor signal is

detected.

The motor trips when rotation speed (actual speed)

exceeds specified value.

Approx 4500r /min

The motor trips when the temperature in control section

rises above specified value.

Approx 105℃

The motor trips when any important parameter such as

" 30 Run command selection" is changed

Investigate the condition of wiring and circumstances of

power supply.

Reduce the load.

Check the load factor in monitor mode.

Investigate the cause of overload, and reduce the load,

change the operating pattern by making acceleration

and deceleration time longer, or apply design to increase

the capacity of motor.

Excessive acceleration/deceleration setting or gain

setting is possible. Set the longer

acceleration/deceleration time and the smaller gain.

If this trip should occur as soon as the unit is started,

failure is possible.

If the motor should trip in running, too short deceleration

time is one of the causes. Adjust deceleration time. No

measure can be taken in continuous regenerative

operation such as lowering.

Check all parameters again and set them again. If this

protection works frequently, failure is possible

①Malfunction due to external noise is possible.

Investigate for noise source in the vicinity and

eliminate such source.

②Internal circuit may be in failure.

Ensure that the actual speed does not exceed rated

rotation speed, such as overshooting by unmatching

between load and gain.

Check the ambient temperature and cooling condition of motor.

Check the load factor.

If the ambient temperature is low enough, and the protection

occurs soon after power-on, failure is possible.

This is not abnormal. Trip reset in order to make change

effective.

Measure

Display on

Digital key pad

L

E-LV

5-digit LED

flashes.

THr

E-OC

E-OV

E-UPr

E-SPr

Err

E-CS

E-OS

E-OH

CAU

How to clear trip

If the motor should trip, eliminate the cause and use any of the procedures [1] – [3] below for clear.

[1] Turn off power, and when power LED has gone out, turn on po wer again.

[2] Press the switch and of the Digital key pad simultaneously for one second or more with present trip

>>

>>

state displayed.

[3] Input the trip reset signal.

(When F-r or r-F is chosen in " 33 I1/I2 function selection", enter "I1" and "I2" at the same time; when F-rST or

r-rST is chosen, enter "I2" for trip reset.

Trip reset signal, when continued to be input, is designed to become ineffective in order to prevent inadvertent

restarting. Enter trip reset signal only when necessary.)

Note: As for overcurrent error E-OC , sensor error E-CS , System error Err , and user parameter error E-Upr , reset

them by turning off power as shown in [1] above. No other procedure is effective.

(Caution) In clear trip, be sure to find and remove the trip factor before clear.

10

Page 11

Troubleshooting

If any trouble should be found, follow the steps below for check and countermeasure.

● If the cause cannot be found, it is recommended to use the Digital key pad and check

the detail of trip. If failure is likely, or when any part is damaged, or when you are in any

other trouble, contact the sales agent of purchase or our company.

Phenomenon Detail of checking Measure, etc

Check for abnormality of wiring. Apply proper wiring.

Motor does not

rotate.

Motor does not

rotate or stops

during operation.

Motor stops during

deceleration.

Motor does not

stop quickly when

stop command is

input.

Check whether protective function is

activated.

(Only when the motor is connected to the

key pad )

Check whether 7-segment LED of on the

key pad is lighted up.

Check whether voltage on input power is

normal.

Check whether operation start signal is

input.

Check whether Analogue speed

instruction is set at 0V.

Check whether protective function is

activated.

Check whether the inertia of load is too

large.

The motor with large inertia does not stop

quickly because default stop mode is

Free-run stop.

Check the detail of trip by the Digital key pad.

Turn off power once, and turn on again.

If the LED is off when power is input to the motor,

failure is possible.

Contact us for repair.

Check the supply voltage.

Check the condition of operation instruction.

Raise the analogue speed instruction little by little.

Overload is possible. Reduce the load or increase

the output capacity.

Regenerative voltage protection may have

worked. Decrease the inertia. Turn off power

once, and turn on again, and reset the trip state.

Make deceleration time longer by the Digital key

pad. Alternatively, apply free-run stop.

Stop motor by 0V analogue speed command.

Change stop mode to deceleration stop by Digital

key pad .

Large vibration or

noise.

Motor rotates

reversely.

Rotation speed is unstable

during operation

(actual speed).

Parameter dose

not change.

Output shaft of motor (gear head) and shaft

of load are not aligned.

Motor and gear head are not assembled

correctly.

Damage to gear head or bearing. Contact us for repair.

Check whether Setting of rotation

direction changeover input is wrong.

Rotation direction of the motor and gear

output shaft may be reversed for some

gear reduction ratio of gear head.

Check whether the load fluctuates greatly.

Check whether operation start signal is

input.

Check the joint between the output shaft and load

shaft of the motor (gear head).

Check the assembling condition between motor

and gear head, and their combination, and

assemble them properly.

Check the position of rotation direction choosing

switch for the console A. As for others, check the

status of "I2".

Check the gear ratio and rotation direction. See

the list of permissible shaft torque on page 8.

Reduce the fluctuation of load. Increase the

output capacity.

Some parameters cannot be changed when

operation instruction is on. (See the check

column of parameter list on page 18.)

Turn off operation instruction before changing.

11

Page 12

How to use Digital key pad

Name of each part and Installation

●What can be done by Digital key pad

x Monitoring of rotation speed (actual speed) and load factor, etc

(Rotation speed can be displayed being multiplied by the factor set by parameter 47 and 48 .)

x Display detail of trip, and trip history. Trip reset by pressing and .

x Parameter setting, initialization, and copying function at the same time.

x Start and stop of motor by RUN / STOP switch

required.)

■ When using the digital key pad and control signal input at the same time, buy an optional control signal branch

cable (DVOP37505).

(Setting of parameter " 30 Run command selection" is

●Name of each part

>>

>>

5-digit LED

2-digit LED

MODE switch

DATA

switch

SET

>>

>>

switch

RUN switch

STOP switch

2-digit LED

STOP switch

DATA

SET

RUN

switch

switch

5-digit

>>

switch

>>

switch

MODE

LED

switch

Displays rotation speed (actual speed), commanded speed, trip history, setting of parameter,

and the like.

Displays the number of parameter (in editing parameter).

Displays the rotation direction in operation. Displays 00 when the motor is stopped.

(CCW as viewed from the output shaft of motor … F and CW … r )

Rotation direction of gear head output shaft may be reversed for some gear reduction

ratio when gear head is incorporated. See the table of acceptable shaft torqu e o n

page 8.

Switch for changing monitor mode. Whenever this switch is pressed, the mode changes in

this sequence: Rotation speed (actual speed) Æ Internal DC voltage (voltage of smoothing

capacitor of power supply) Æ Load factor Æ Torque Æ Comm anded speed Æ Rotation

speed (actual speed) Æ …. *

* When you press this switch in the parameter setting mode, setting is stored.

This is a switch for changing between parameter number mode and parameter setting mode,

and for storing parameter setting.

This switch enables selection of parameter, and setting and changing of contents.

When the motor is tripped, pressing and at the same time enables clear of trip.

>>

>>

This switch is for instruction of operation. (Only when " 30 Operation instruction selection" is

PnL )

■See " 33 Choosing I1/I2 function" (2) on page 23 for rotation direction.

This switch is for instruction of stopping. (Only when " 30 Choosing operation instruction" is

PnL )

●Description

Displays rotation speed (actual speed), command speed, internal DC voltage, load factor,

and torque on 5-digit LED. When power is turned on, this mode is set.

Monitor mode

This mode is set when power is turned on.

Control changes to this mode when MODE switch is pressed in parameter number mode,

parameter setting mode.

Parameter

number mode

Parameter setting

mode

Displays a parameter number (00 – F0) in flashing.

Control changes to this mode when switch is pressed in parameter number mode.

Parameter number can be changed and selected by and switch.

Displays the detail of parameter (setting) in flashing.

Control changes to this mode when switch is pressed in monitor mode.

Change setting by and switch.

DATA

When switch is pressed after change of setting, it is saved in EEPROM.

SET

>>

>>

DATA

SET

DATA

SET

>>

>>

* Displays rotation speed r/min in norma l monitor mode. Displays torque a nd load factor assuming the

rated motor torque at 100%.

* Display is just a guide. Do not use the Digital key pad for a measuring instrument.

12

Page 13

Operating Instruction

Turn on

power.

Only

" 00 "

>

>

Storage

>

>

Press

MODE

Monitor mode

Press

MODE

Parameter

number

mode

Press

DATA

SET

Storage

Press

DATA

SET

Press

DATA

SET

●Press

MODE

Rotation

speed

MODE

Internal DC

voltage

MODE

Load factor

switch for changing display.

●

r/min

○

○

Internal speed (0-th speed)

○

○

●

V

Flashing

○

●

%

○

MODE

can be directly set by and

in monitor mode.

0

>

>

Flashing

00

MODE

○

Torque

MODE

Speed

setting

●

%

○

Flashing

●

r/min

○

○

●2-digit LED blinks and allows selection of parameter number.

0.30

10

Flashing

00

0

Flashing

>

>

>

>

Change (select) a parameter number

by or .

>

>

>

>

>

>

>

>

>

>

>

>

>

>

●5-digit LED blinks and allows change of parameter value.

Parameter

setting mode

0.30

10

>

When switch or MODE switch is

DATA

SET

pressed in parameter setting mode, data is

stored.

>

>

>

● When or is pressed in monitor mode, detail of " 00 Internal speed (0-th speed)" is

>

displayed in blinking, and speed setting can be changed by and . When 31 Speed

command selection is PnL , the motor speed also changes following the speed setting if the

motor is running.

Data is stored only when switch is pressed. Note that data returns to settings when power is

DATA

SET

turned off.

>

Change (select) a parameter value by

>

>

>

>

Flashing

>

>

or .

0.31

10

>

>

>

>

>

>

>

>

Flashing

13

Page 14

Test run (Digital key pad)

Inspection prior to test run

(Inspection prior to test run)

(1) Make sure that all wiring is correct. (2) Make sure that input power supply conforms to rating.

(Test run)

Test run procedure by the Digital key pad is as follows:

An example is introduced here where the motor runs CW at 1800r/min with the Digital key pad.

(1)Be sure to first perform the work below for safety.

Separate the motor from machine or equipment, and make sure that the motor alone can be

operated.

(2)Then turn on power and follow the step below for test run.

Description of

operation

[1] Turn on

power

[2] Change of

initial setting

(Change the choice

of operation

instruction from I1/I2

TEr to the Digital

key pad PnL)

[3] Trip reset

Switch LED display

Press

Press several

DATA

SET

>

>

times to choose

parameter number 30 .

Press

Press to change

DATA

SET

>

>

parameter value.

Store by .

Setting change warning is

issued because setting of

operation instruction has

been changed.

Press and at

DATA

>

>

SET

>

>

the same time.

Digital key pad

●

0

○

○

00

○

0

00

TEr

○

○

Flashing

○

○

○

30

CAU

○

CAU

○

○

Flashing

30

PnL

30

0

00

TEr

●

○

○

○

○

○

Flashing

○

○

○

Flashing

[4] Change of

(Change the choice

of speed instruction

from analogue

speed instruction

input to " 00 Speed

setting (the 0-th

speed)" to enable

use of Digital key

pad.)

[5] Trip reset

14

initial setting 2

DATA

Press

Press several

SET

>

>

times to choose

parameter number 31 .

Press

Press to change

DATA

SET

>

>

parameter value.

>

>

DATA

SET

>

>

Store by .

Setting change warning is

issued because setting of

operation instruction has

been changed.

Press and at

the same time.

0

00

Flashing

VoL−A

31

30

CAU

CAU.

CAU

○

○

○

VoL−A

31

○

○

○

Flashing Flashing

PnL

○

○

○

Flashing

○

○

○

31

30

○

○

○

0

●

○

○

00

Page 15

Description of

operation

[6] Choosing

rotation

direction*

(This operation is

not required for

rotation forward

[CCW].)

[7] Trip reset

Switch LED display

DATA

Press

Press several

SET

>

>

times to choose

parameter number 33 .

Press

Press to change

DATA

SET

>

>

parameter value.

>

>

DATA

SET

>

>

Store by .

Setting change warning is

issued because setting of

operation instruction has

been changed.

Press and at

the same time.

Digital key pad

0

00

Flashing Flashing

rS.Fr

33

30

CAU

CAU.

CAU

○

○

○

○

○

○

○

○

○

Flashing

rS.Fr

33

r−F

33

30

0

00

○

○

○

○

○

○

●

○

○

Flashing

[8] Speed setting

Press

>

>

○

○

0

○

Flashing

x Internal speed (0-th speed) is

displayed (setting at 0r/min).

00

○

>

Press to set a speed.

>

1800

○

○

Flashing

x Set the Internal speed (0-th sp eed)

at 1800 r/min.

00

●

○

r

0

0

○

x Data is still stored if power is cut off

here.

●

○

○

x Displa y of rotation spe ed changes

little by little toward 1800 r/min

x Displa y of rotation direction *

(r indicates that the motor is rotating

CW.)

●

○

○

x Displa y of rotation spe ed changes

little by little toward 0 r/min.

[9] Reset to

monitor mode.

Press MODE

00

[10] Operation

instruction

[11] Stop

instruction

Press RUN

Press STOP

1800

00

[12] Power OFF

<Checkpoint in Test run>

(1) Check whether the motor rotates smoothly. Check for abnormal noise and vibration.

(2) Check whether the motor is accelerated and decelerated smoothly.

(3) Rotation direction and rotation speed of the motor are matched?

* Rotation direction of gear head output shaft may sometimes be reversed due to reduction gear ratio when

gear head is installed.

(See the list of permissible shaft torque on the page 8)

* Rotation direction can also be changed by use of "I2". See " 33 I1/I2 function selection " (2) on page 23.

■ Setting is still stored when power is turned off. When operating the motor with Digital key pad only in trial

run, either reset the setting or initialize parameters after completion of trial run. (Parameter 54)

Here, note that all parameters return to default when parameters are initialized.

15

Page 16

How to copy parameter

1. Reading a parameter value from motor to the Digital key pad

■Once parameters are read into the console, their details are stored in the Digital key pad.

Description of

operation

[1] Turn on

power.

[2] Call 57

Parameter

Copy.

[3] P.LOAd

Choose reading

a parameter into

the Digital key

pad.

[4] Read a

parameter

into the

Digital key

pad.

[5] Wait about 30

seconds.

[6]

Reading of

parameter into

the Digital key

pad completed

Switch LED display

DATA

Press

Hold down to

SET

>

>

choose parameter

number 57 .

DATA

Press

Press twice to

SET

>

>

choose P.LOAd .

DATA

Press for 1 second

SET

while holding down

STOP .

Press STOP

Digital key pad

0

00

Parameter

value

00

Flashing

n0

Flashing

57

P.LOAd

57

P.End

0

00

●

○

○

●

○

○

○

○

○

○

○

Flashing Æ Slow flashing

○

(once per second)

○

○

○

●

○

○

n0

57

P. LOAd

57

○

○

○

Flashing

○

○

○

Flashing

16

2.

Copy a parameter value saved in the Digital key pad onto th e m ot o r.

Description of

operation

Switch LED display

Digital key pad

Turn on power. Call out 57 Parameter. (Same operation as 1. [1] and [2])

[1] P.PrOG

Choose writing

a parameter to

the motor.

[2] Write a

parameter to

the motor.

[3] Wait about 10

Press twice.

Press three times to

choose P.PrOG .

Press for 1

second while holding

down STOP .

DATA

SET

>

>

DATA

SET

n0

57

P.PrOG

57

P.End

○

○

○

Flashing

○

○

Flashing Æ Slow flashing

○

(once per second)

○

○

○

seconds.

P.PrOG

Flashing

57

○

○

○

Page 17

Description of

operation

[4]

Completion of

writing a

parameter from

the Digital key

pad to the motor

Digital key pad

Switch LED display

○

CAU

○

○

[5] Reset to

monitor mode.

>

Press and at

>

>

>

the same time for

clear trip.

0

00

●

○

○

Error while copying a parameter

P.Err1 : Data is abnormal while copying.

ÆPress STOP switch for clearing, and then copy data again. If data is still abnormal, initialize

the Digital key pad and retry.

P.Err2: Copy error

Æ This error occurs in an attempt to copy data between products of different function. Press

STOP switch for clear.

Parameters can be copied between the same models (B1-G Series standard unit), but

parameters should be copied between the same output in principle because gain setting is

different.

3. Initializing of data of Digital key pad

■ When any trouble occurs during copying, it can be often solved by initializing the Digital key pad.

(Stored data is cleared by initializing.)

Description of

operation

Switch LED display

Digital key pad

Turn on power and call 57 Parameter. (Same operation as 1. [1] and [2])

[1] P.InIT

Press

Choose

initialization of

data of Digital

key pad.

[2] Initialization

of Digital key

pad

Press once and

choose P.InIT .

Press for 1

second while holding

down STOP.

[3] Wait about 30

seconds.

[4]

Initializing of

data of Digital

key pad

completed

■ Do not turn off power or disconnect the cable of Digital key pad during operation such as "Reading a

parameter from the motor to the Digital key pad", "Copying a parameter value stored in the Digital key pad

to the motor", and "Initializing the data of Digital key pad".

Press STOP

DATA

SET

DATA

SET

○

>

>

n0

57

P.InIT

57

P.End

0

○

○

Flashing

○

Flashing Æ Continuous lighting

○

○

LED display changes from flashing to continuous

lighting during initializing operation.

○

○

○

●

○

○

P.InIT

57

○

○

○

Flashing

00

17

Page 18

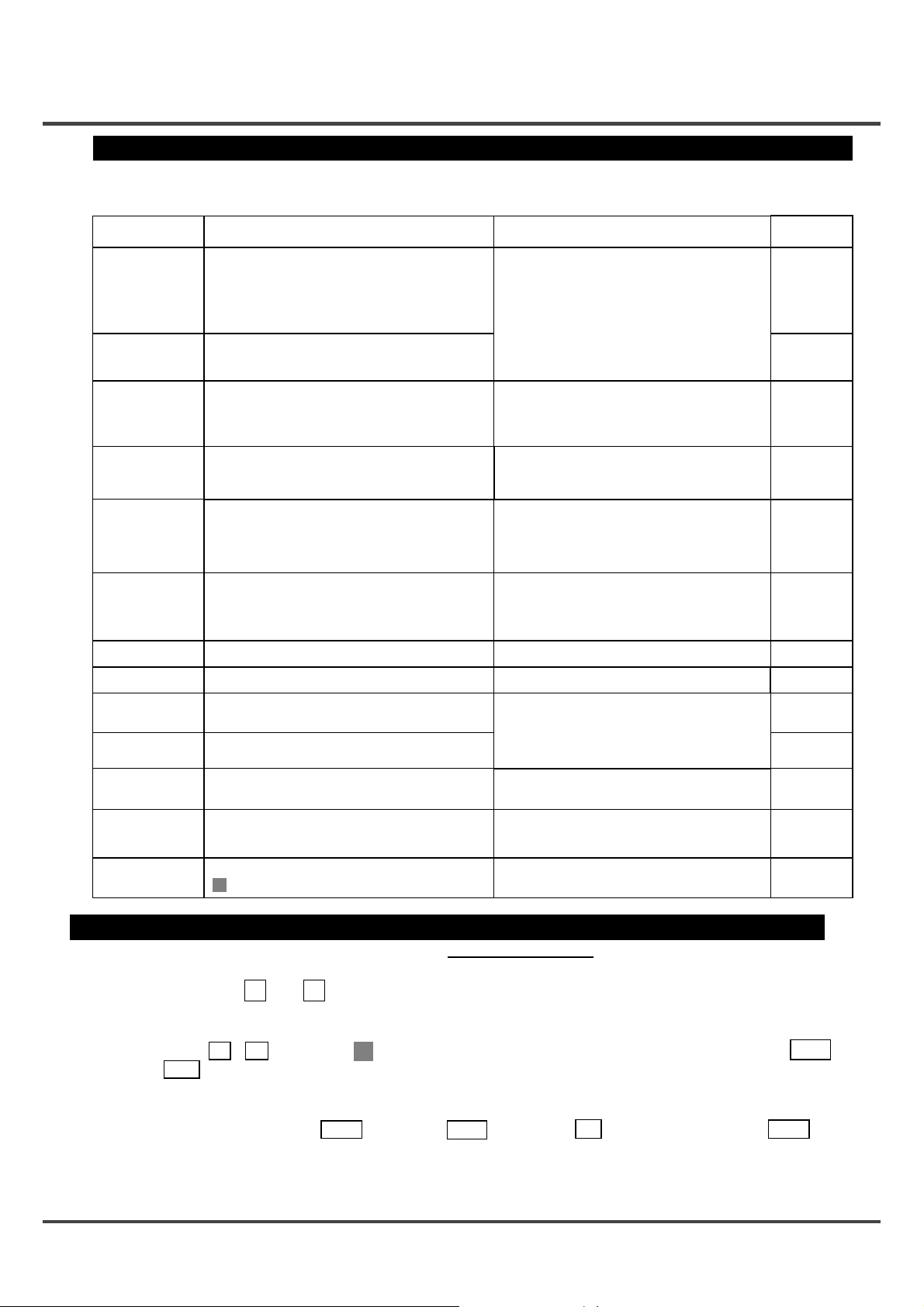

Parameters

Overview of parameter

Motor of this series is provided with various parameters for adjusting and controlling its characteristics and

function. Purpose and function of respective parameter are described. Understand them well enough and adjust

the unit at your optimum operation condition.

List of parameter composition and setting

Parameter

No.

00

10

12

14

15

16

17

1A

1b

30

31

Name of parameter

Internal speed (0-th speed)

1st

acceleration time

1st

deceleration time

Acceleration mode

selection

Deceleration mode

selection

Stop mode

selection

Free-run waiting time

Velocity loop

proportional gain

Velocity loop

integration gain

Run command

selection

Speed command

selection

Parameter setting

Setting range Minimum unit Default

0 – " 3b Upper speed limit"

- 3 sec : Incremented by 0.01 sec.

0.01 3 - 30 sec : Incremented by 0.1 sec.

- 3600 sec. 30 - 3600 sec : Incremented by 1 sec.

- 3 sec : Incremented by 0.01 sec.

0.01 3 - 30 sec : Incremented by 0.1 sec.

- 3600 sec. 30 - 3600 sec : Incremented by 1 sec.

LIn

S−1

S−2

FrEE

dEC

PnL

TEr

PnL

VoL−A

Linear

S shape-1

S shape-2

Free-run stop

Speed reduction stop

0.0 - 10.0 sec

0 - 10000

0 - 10000

RUN STOP

I1/I2

" 00 Internal speed (0-th speed)"

FIN

and of Digital key pad

*3

*4

1 r/min

0.1 sec

1

1

0

0.30

0.30

LIn

LIn

FrEE

1.0

400(800)

500(1000)

TEr

VoL−A

*2

*2

Check *

C

C

1

F−r

r−F

33

3A

3b

3C

*1When parameter marked with C in the check column is changed and stored, the unit is tripped for safety. It

2

*

3

*

4

*

I1/I2 function

selection

Lower speed limit

Upper speed limit

Torque limit

is not allowed to change them while the motor is running.

Parameter in ( ) is the default of 90W and 130W.

Corresponds to RUN/STOP switch of the console A or signal input.

Corresponds to the speed potentiometer or analogue speed instruction of the console A.

rS.Fr

F−rST

r−rST

0 – " 3b Upper speed limit "

I1: CCW run/stop

I2: CW run/stop

I1: CW run/stop

I2: CCW run/stop

I1: run/stop

I2: CW /CCW direction

I1: CCW run/stop

I2:Trip reset

I1: CW run/stop

I2:Trip reset

0 - 3000 r/min

50 - 150

1 r/min

1 r/min

1%

rS.Fr

0

3000

150

18

C

C

C

Page 19

Parameter

Name of parameter

No.

40

42

44

45

46

47

48

4A

4b

4C

4d

4E

4F

50

51

52

54

O1 function

O1 output polarity

Speed matching range

Output pulse count

Monitor mode

Numerator of display

magnification factor

Denominator of disp la y

magnification factor

Trip history clear

Trip history 1

Trip history 2

Trip history 3

Trip history 4

Trip history 5

Undervoltage

trip selection

Retrial selection , 1 - 4

Retrial start time

Parameter

initializing

selection

selection

selection

selection

Setting range Minimum unit Default

TrIP

STbL

rUn

FrEE

Ck−L

POUT

nOr

rEV

20 – " 3b Upper speed limit"

O.−r

O.−L

AV.−L

S.−r

dC−V

1 ‒ " 48 Denominator of display

nO

YES

nO

YES

nO

nO

YES

Trip

Arriving

Running

Free-run

CCW run

F

CW run

r

Overload detection

Speed pulse signal

Normal polarity

Reverse polarity

1, 2, 3, 4, 6, 8, 12, 24

Rotation speed (Actual speed)

Torque

Load factor

Command speed

Internal DC voltage

magnification factor" x 10

1 - 1000

No operation

Clear trip history

No trip

Trip

1 - 120 sec

No operation

Initialize to default

Parameter setting

TrIP

nOr

1 r/min

1 time

1 time

-

1 sec

50

24

O.−r

1

1

nO

-

-

-

-

nO

nO

5

nO

Check *

C

C

1

57

F0

Parameter copy

For manufacturer use

function

nO

P.InIT

P.LOAd

P.PrOG

No copying of parameter

Initializing the data of Digital key pad

Reading a parameter to the Digital key pad

Writing a parameter to the motor

-

nO

-

19

Page 20

LED display

LED display

Figures displayed on the 7 segment display of the Digital key pad are shown below:

Alphanumeric

LED display LED display

*

Alphanumeric

20

Example of LED display

Example)

Description in the text

Display on Digital key pad

* LED display of "0" is available in two types.

Example)

Description in the text

Display on Digital key pad

Page 21

Detail of parameter

時間

Parameter

Name of parameter Description

No.

Internal speed

00

10

acceleration time

12

deceleration time

Acceleration mode

14

Deceleration mode

15

16

(0-th speed)

1st

1st

selection

selection

Stop mode

selection

Desired running speed can be set. T his is effective when " 31 Speed instruction selection" is

PnL

(PANEL).

Upper limit is limited by " 3b Upper speed limit".

The change factor of output speed in acceleration can be determined.

x Set by time for changi ng 1000r/min.

When it is 0.3 sec (default), time taken for accelerating from 0 to 3000 r/min is 0.9 sec.

x T ime can be incremented by 0.01 sec for below 3 sec, by 0.1 sec from 3 sec up to 30 sec

exclusive, and by 1 sec from 30 sec upward.

The change factor of output speed in deceleration can be determined.

x Set by time for changi ng 1000r/min.

When it is 0.3 sec (default), time taken for decelerating from 0 to 3000 r/min is 0.9 sec.

x T ime can be incremented by 0.01 sec for below 3 sec, by 0.1 sec from 3 sec up to 30 sec

exclusive, and by 1 sec from 30 sec upward.

Straight line acceleration/deceleration and curve (S-shape) acceleration and decel eration can be

chosen individually for acceleration and deceleration.

LIn

LINEAR “S”SHAPE-1 “S”SHAPE-2

回転速度

Rotation speed

0

Straight line up to speed setting.

Standard mode for accelerating and

decelerating.

Time

時間

S−1

回転速度

Rotation speed

0

Relaxes the speed change in

start and end of acceleration and

deceleration.

Time

時間

S−2

回転速度

Rotation speed

0

Curve is emphasized more than

S shape-1.

Time

You can select how to stop the motor.

FrEE

(FREE)

Power supply to the motor is cut off and the motor is stopped naturally when stop command is

input (free-run stop). It takes longer for the motor to completely stop when load inertia is big.

dEC

(DECEL)

When stop command is input, the motor reduces its speed according to preset deceleration time,

Electric-brake is performed by Zero-speed control, and then power is cut off to the motor after

elapse of time set by " 17 Free-run waiting time", and the motor is set in free-run state.

<Example or running pattern in deceleration stop>

■ The motor is servo-locked in

Zero-speed control.

(Electrically controlled so that

motor speed is Zero)

Run command

Speed setting

Motor speed

off

Deceleration by preset

change factor of deceleration

time

Time set by " 17 Free-run waiting time"

17

1A

1b

30

waiting time

Velocity loop

proportional gain

Velocity loop

integration gain

Run command

selection

Free-run

Free-run

Deceleration running

When " 16 Stop mode selection" is set to (DECEL) deceleration stop, servo lock

dEC

Zero-speed control

time(Zero-speed control)after deceleration can be adjusted.

(Free-run state is set after that.)

Enables setting of proportional gain of velocity amplifier. It need not be changed normally.

When this value is made greater, gain is increased, which improves responsiveness of the motor.

When this value is made too large, operation is vibratory.

Setting range: 0 – 10000, Setting resolution: 1

Enables setting of integration gain of velocity amplifier. It need not be changed normally.

When this value is made greater, gain is increased, which improves rigidity of the motor (strength

of servo lock). When this value is made too large, overshooting becomes greater, and the motor

is vibratory.

Setting range: 0 – 10000, Setting resolution: 1

Run Command can be chosen from the following:

PnL

(PANEL) : command the motor to stop with switch of Digital key

pad. The motor cannot be operated by signal input "I1" and "I2".

RUN STOP

Signal input is effective only in setting rotation direction, etc.

TEr

(TERMINAL) : Only the input terminal "I1" and "I2" are effective.

See " 33 I1/I2 function selection".

(Corresponds to RUN/STOP, rotation direction selection switch of Console-A.)

21

Page 22

Detail of parameter

Parameter

No.

31

Name of parameter Description

You can choose whether to use " 00 Internal speed (0-th speed)" or analog input terminal

Speed command

selection

"FIN" for speed command.

PnL

VoL−A

(1) For setting "I1" or "I2" function

State of I1 and I2

I1

OFF

ON

OFF

r−F

State of I1 and I2

(PANEL) " 00 Internal speed (0-th speed)"

(VOL-A) Analog input terminal "FIN" (voltage instruction DC 0-5V)

(Corresponds to speed potentiometer of Console-A.)

F−r

(FORWARD-REVERSE)

I2

OFF

OFF

ON

ONON

(REVERSE - FORWARD)

Deceleration stop when " 16 Stop mode selection" is

Trip reset (which must be retained 0.2 sec or longer) *

I1 I2

Action

Stop

dEC

CCW run

CW run

Free-run stop

Action

33

I1/I2 function

selection

OFF

ON

OFF

rS.Fr

State of I1 and I2

I1 I2

OFF

ON

OFF

F−rST

State of I1 and I2

I1 I2

OFF

OFF

ON

ONON

(RUNSTOP. FORWARD-REVERSE)

OFF

OFF

ON

ONON

(FORWARD-TRIP RESET)

Deceleration stop when " 16 Stop mode selection" is

Free-run stop

Trip reset (which must be retained 0.2 sec or longer) *

Deceleration stop when " 16 Stop mode selection" is

Deceleration stop when " 16 Stop mode selection" is

Stop

dEC

CW run

CCW run

Action

Stop

dEC

CCW run

Stop

dEC

CW run

Action

* Effective only when trip occurs

22

OFF

ON

−

−

−

ON

Stop

Deceleration stop when " 16 Stop mode selection" is

CCW run

Trip reset (which must be retained 0.2 sec or longer) *

dEC

Page 23

Parameter

No.

Name of parameter Description

r−rST

State of I1 and I2

(REVERSE-TRIP RESET)

I1 I2

Action

33

I1/I2 function

Selection

(continued)

OFF

ON

−

(2) When " 30 Run command selection" is (PANEL), the motor can be

commanded with switch of Digital key pad.

Rotation direction in this case can be set by parameter and "I1""I2" state.

When only the digital key pad is connected, "I1" and "I2" are set to OFF .

F−r

State of I1 and I2

−

−

ON

(FORWARD-REVERSE)

Deceleration stop when " 16 Stop mode selection" is

Trip reset (which must be retained 0.2 sec or longer) *

RUN STOP

I1 I2

−

OFF

r−F

State of I1 and I2

OFF

ON

ONON

(REVERSE-FORWARD)

Free-run stop irrespective of switch

Trip reset (which must be retained 0.2 sec or longer)*

CCW rotation selection

CW rotation selection

I1 I2

−

OFF

OFF

ON

ONON

Free-run stop irrespective of switch

Trip reset (which must be retained 0.2 sec or longer)*

CW rotation selection

CCW rotation selection

Stop

dEC

CW run

PnL

Action

RUN

Action

RUN

* Effective only when trip occurs

rS.Fr

State of I1 and I2

(RUNSTOP. FORWARD-REVERSE)

I1 I2

−

−

F−rST

CCW run with switch

State of I1 and I2

OFF

ON

(FORWARD-TRIP RESET)

RUN

I1 I2

−

r−rST

CW run with switch

State of I1 and I2

ON

(REVERSE-TRIP RESET)

RUN

I1 I2

−

ON

Action

CCW rotation selection

CW rotation selection

Action

Trip reset(which must be retained 0.2 sec or longer) *

Action

Trip reset(which must be retained 0.2 sec or longer) *

23

Page 24

Detail of parameter

Parameter

No.

3A

3b

3C

40

Name of parameter Description

When " 31 Speed command selection" is

Lower speed limit

analogue speed instruction

(VOL-A), motor setting speed at 0V input is

VoL−A

set.

Upper limit of motor command speed.

Upper speed limit

When " 31 Speed command selection" is analogue speed command

(VOL-A), motor setting speed at 5V input is set. Further, upper limit of " 00 Internal speed

(0-th speed)" is limited by this parameter.

Upper limit of motor output torque is set.

Torque limit

(No precision is provided because torque is not controlled. Use as a guide.)

100% indicates the rated torque.

Output terminal " 01 " can also be selected as follows.

Polarity of " 40 O1 function selection " can be inverted by " 42 O1 output polarity selection".

TrIP

STbL

(TRIP) : Trip signal (Trip: ON)

(STABLE) : Arriving signal (When reached to a command value ON)

Æ See " 44 Speed matching range".

O1 function

selection

rUn

FrEE

Ck−L

(RUN) : Run/Stop signal (When running: ON)

(FREE) : F ree-run signal (During free run: ON)

(FORWARD) : CCW run signal (During CCW run: ON)

F

(REVERSE) : CW run signal (During CW run: ON)

r

(CHECK−L) : Overload detection

Output when load exceeds 100%

(Load exceeds 100%:ON)

POUT

(PULSE-OUT): Speed pulse signal

Æ See " 45 Output pulse count selection".

Speed instruction value

Upper speed

limit

Lower speed

limit

0.5 4.5

0

Input voltage

5V

VoL−A

O1 output polarity

42

Speed matching

44

45

46

Output pulse

count selection

Monitor mode

selection

range

selection

This is a function for inverting the polarity of signal output between output terminal "O1"

and "GND".

nOr

nOr

rEV

rEV

When " 40 O1 function selection " is set to (STABLE) Arriving signal,

(NORMAL) : Transistor "ON" when activated

(REVERSE) : Transistor "OFF" when activated

STbL

" Speed matching range " for output arrivi ng signal can be adjusted.

x When difference between actual rotation speed and speed setting is smaller than

"Speed matching range", arriving signal is output.

x Even if the speed is reached, when speed matching range is set too small, arriving

signal may turn on and off due to speed fluctuation.

x Arriving signa l is not output when CCW/CW changes.

When " 40 O1 function selection " is set to (PULSE-OUT), pulse count is

POUT

set to be output to " O1" while the motor makes one turn.

(To be selected from 1, 2, 3, 4, 6, 8, 12, and 24)

T

500±100μs

(Ex) When rotation number is 3000 r/min, in the

case where

"

45 Output pulse selection" is 24,

T = =0.83ms

Frequency f = 1/T = 1.2kHz

60

3000×24

You can choose description to be displayed on 5-digit LED when turning on power.

O.−r

O.−L

AV.−L

S.−r

dC−V

(OUTPUT-REVOLUTION) : Rotation speed

(OUTPUT-LOAD) : Torque

(AVERAGE-LOAD) : Load factor (average torque)

(SETTING-REVOLUTION) : Speed command

(DC-VOLTAGE) : Internal DC voltage

(Voltage of smoothing capacitor of power

supply)

In speed display mode, the value multiplied by " 47 Numerator of display multiplying

factor" / " 48 Denominator of display multiplying factor" is displayed.

24

Page 25

Parameter

No.

47

48

4A

4b

4C

4d

4E

50

51

52

54

57

F0

Name of parameter Description

Numerator of

display

magnification

factor

Denominator of

display

magnification

factor

Trip history clear

Trip history 1

Trip history 2

Trip history 3

Trip history 4

Trip history 5

Undervoltage

trip selection

Retrial selection

Retrial start time

Parameter

initializing

Parameter copy

For manufacturer

use

You can set the multiplying factor of a value displayed on 5-digit LED.

Value of 47 ÷ 48 is a display multiplying factor. Set a value in the range where

calculated display magnifying factor is 10 – 1/1000.

Rotation number of gear output shaft and the speed of line can be displayed.

When the display magnifying factor is changed, the parameter relating to speed (below)

is displayed by a value multiplied by display multiplying factor.

" 00 Internal speed (0-th speed)" " 3A Lower speed limit" " 3b Upper speed limit "

" 44 Speed matching range"

Trip history 1 – 5 can be cleared.

<Clearing procedure>

Cut off power with (YES) selection, and turn on power again after display

has disappeared, then is displayed, and trip history is cleared.

When power is turned on again, normal operation is started.

Trip history for 5 times in the past is stored. Trip history 1 is the latest history.

See "Protective function" for displayed description.

When no history is available, is displayed.

When (NO) is selection, the motor is not tripped at insufficient voltage. If

voltage should fall and undervoltage status is found while the motor is running, the motor

stops after running free, while if operation instruction is input after recovery of po wer, the

motor is restarted automatically. (

When (YES) is selection, the motor is tripped at undervoltage, and trip

signal is output. When normal power is off, trip is not stored in trip history. Trip is stored

only when power has stopped instantaneously. (Trip is stored in trip history only when

undervoltage once becomes short and then i s recovered normal)

Automatic reset in trip (trip retrial) can be set here. Trip can be is automatically reset to

allow operation to continue.

Use this function only on such equipment that has no problem of safety even if the motor

is automatically restarted.

■ Retrial is impossible if trip is by Overcurrent error , Sensor error

When (NO) is selection, retrial is not effective.

When –

When 2 hours has elapsed with no trip, the number of retrying times is initialized to 0.

Set the interval between retrials by 52 Retrial start time.

When trip occurs in excess of preset number of trials, the motor outputs trip signal and

stops.

■ During retrial trip signal is not output (It is stored in trip history.)

You can set waiting time until retrial operation is performed after trip is found.

You can set 1 to 120 seconds.

Parameters can be initialized to the factory default.

<Initializing procedure>

Cut off power with (YES) selected, and turn on power again after display

has disappeared, then is displayed , and parameters are initialized to the

factory default.

Parameters can be copied.

See " How to copy parameter " on page 16 for details.

It cannot be changed.

nO

YES

E−CS

E−UPr

nO

nO

P.InIT

P.LOAd

P.PrOG

,System error , User parameter error

, or System parameter error .

1

(NO) Parameters are not copied

(PARAMETER-INITIALIZE) : Initialization of Digital ke y pad data

(PARAMETER-LOAD) :

(PARAMETER-PROGRAM): Writing parameters to the brushless inverter

YES

−−−−−

−−−−−

YES

−−−−−

■

Be cautious.)

Err

is selection, retrial is made for the set number of times.

4

Reading parameters into Digital key pad data

E−OC

E−SPr

25

Page 26

Conformance to EC directive and UL standard

EC Directives

The EC directives apply to all such electronic products as those having specific functions and directly sold to

general consumers in EU countries. These products are required to meet the EU unified standards and to be

furnished with CE marking.

Our brushless motor meet the EC Directives for Low Voltage Equipment so that the machine or equipment

comprising our AC servo can meet relevant EC Directives.

EMC Directives

Our brushless motor can meet EMC Directives and related standards. However, to meet these requirements,

the systems must be limited with respect to configuration and other aspects, e.g. the installation and some

special wiring conditions must be met. This means that in some cases machines and equipment comprising

our servo systems may not satisfy the requirements for wiring and grounding conditions specified by the