Panasonic AXD Specification Sheet

Connectors for industrial equipment

DIN CONNECTORS (AXD)

CONNECTORS FOR PC

BOARD TO PC BOARD

DIN CONNECTORS

(AXD)

UL

(for B and C type)

DIN Connector conforming to DIN/IEC standards

FEATURES

1. 2 pieces connectors conforming to

DIN 41612 and IEC 603-2.

2. Clip contact with reliable

construction on both sides for highly

reliable contact.

1) Withstands vibration and shock.

2) Long insertion/removal life and

insertion/removal force is stable.

3) Construction able to withstand

unreasonable twisting when inserting and

removing.

3. Supports time difference contact

function.

1) ICs are protected from damage at

connection even if the PC board is

inserted or removed without power

connected during maintenance or

inspection. This simplifies circuit design.

2) Time difference contacts can be

arranged as desired.

3) Possible for either header or socket.

4. Plenty of products with improved

functions

The following types are available in

addition to ones with the time difference

contact function.

-Flux-tight type that prevents flux from

creeping up from the connector bottom

and terminals.

-Self-clinching bracket, PC board top

mounting type.

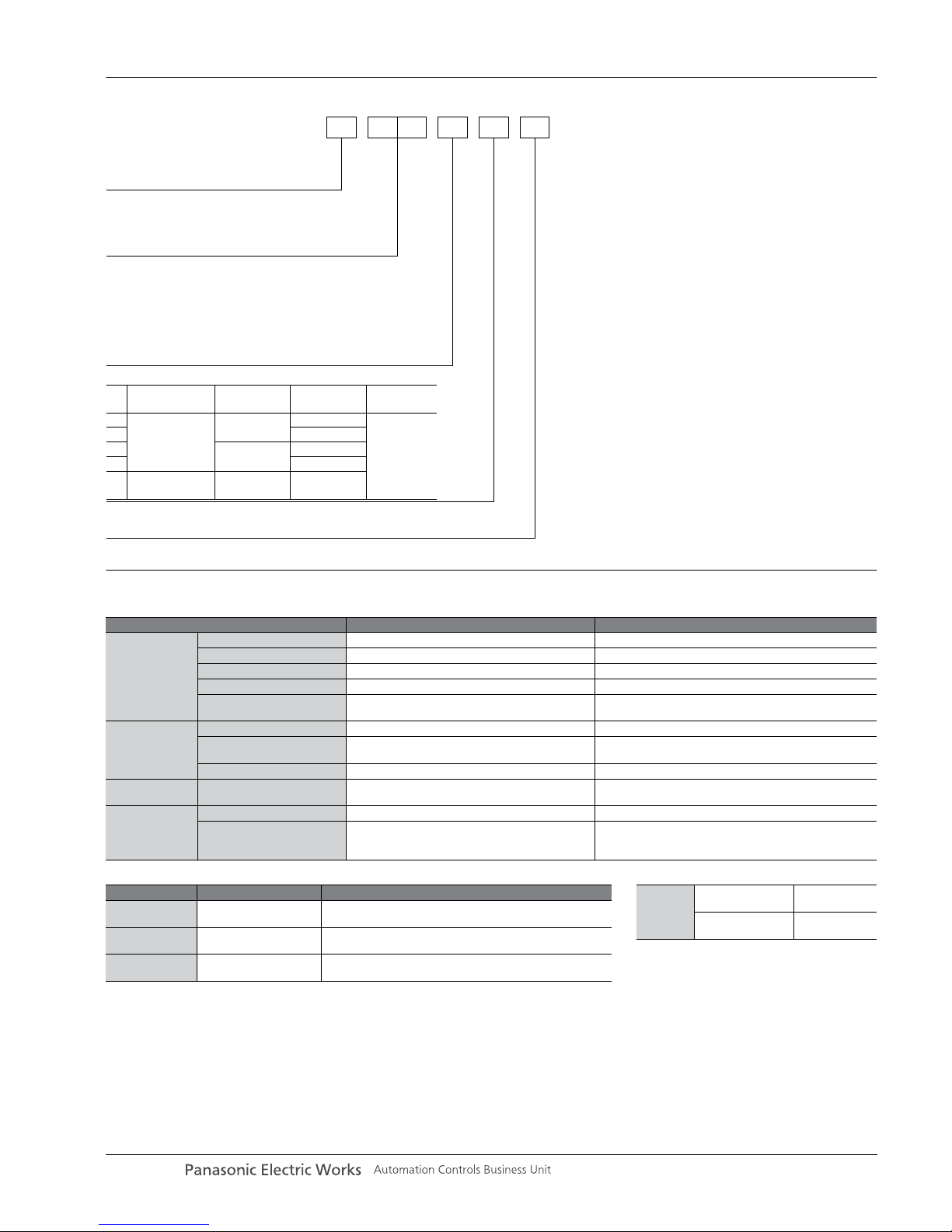

5. Constructed to prevent incorrect

insertion.

The construction is designed to prevent

reverse insertion of the connector

according to the DIN standard. We have

taken further measures with a dedicated

key that enables the easy prevention of

incorrect insertion of connectors with

identical poles.

APPLICATIONS

PBX, Factory Automation Equipment

Compliance with RoHS Directive

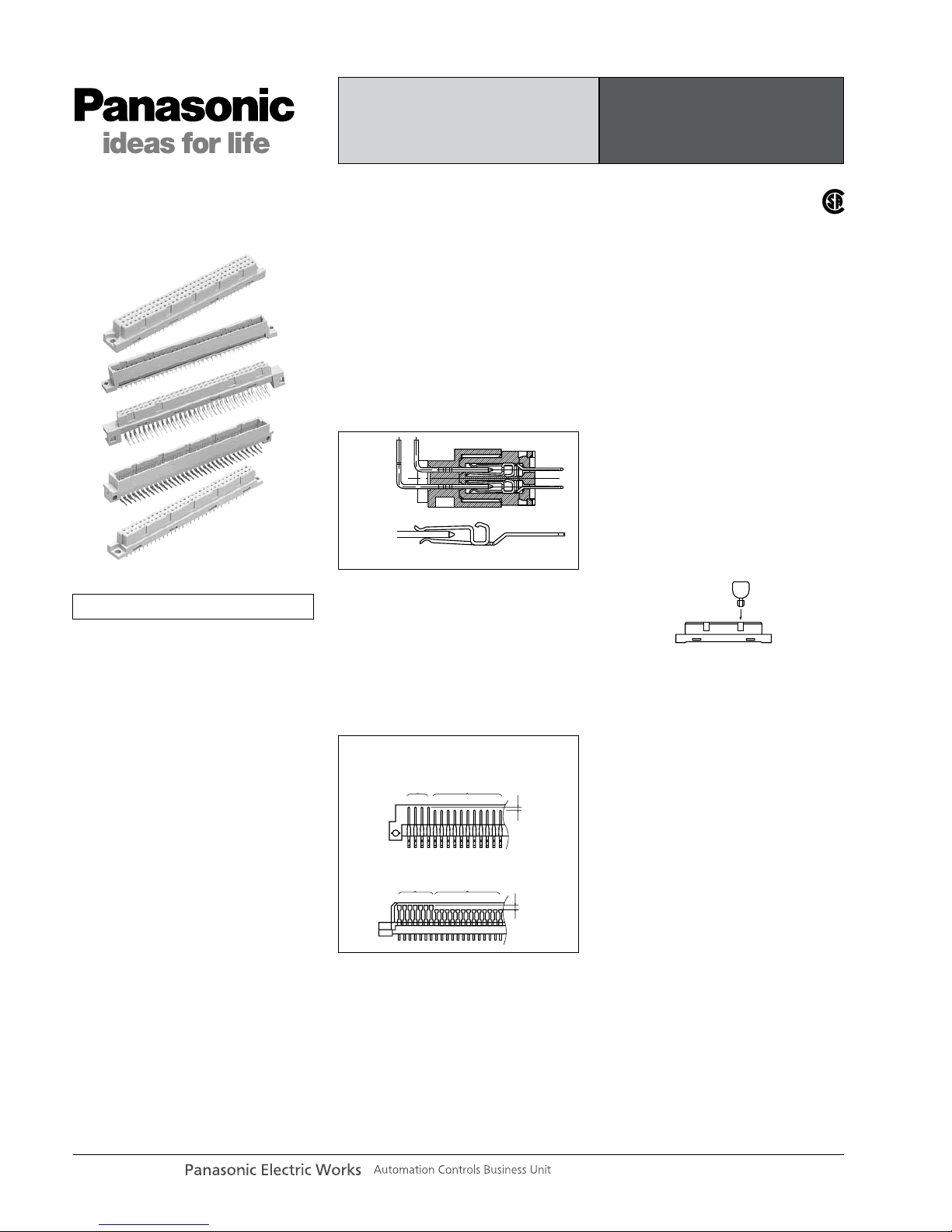

• Time difference contact function

Header

Socket

Dual surface contacting construction

Mating

diagram

Standard

contacts

Time difference

contacts

1mm

1.2mm

Standard

contacts

Time difference

contacts

Incorrect insertion prevention key

panasonic-electric-works.net/ac

Connectors for industrial equipment

DIN CONNECTORS (AXD)

ORDERING INFORMATION

SPECIFICATIONS

1. Characteristics

Item Specifications Conditions

Electrical

characteristics

Rated current 2A

Rated voltage 300V AC

Breakdown voltage 1,000 V AC for 1 min. Detection current: 1mA

Insulation resistance Min. 1,000MΩ at 500V DC megger

Contact resistance Max. 20mΩ

Measured based on the HP4338B measurement method of

JIS C 5402.

Mechanical

characteristics

Composite insetion force Max. 0.843N {86gf} × no. of contact

Unit removal force Min. 0.15N {15.3gf}

Measured by steel gauge with 0.56(t)×0.8(W)mm and

smoothness 0.1s.

Post holding force Min. 19.6N {2kgf} (header side)

Lifetime

characteristics

Insertion and removal life 1,000 times

Environmental

characteristics

Ambient temperature –55°C to +125°C At less than 85% R.H. (No freezing at low temperature)

Soldering temperature

resistance

260°C: within 10 sec.

300°C: within 5 sec.

350°C: within 3 sec.

<Surface treatment (Contact portion/Terminal portion>

1: Au plating/Sn plating

DIN connectors

1: Socket

2: Header

<Type and contacts layout>

2: B type (2 rows terminal pitch: 2.54 mm)

3: C type (The middle row is removed terminal pitch: 5.08 mm)

4: C type (3 rows terminal pitch: 2.54 mm)

6: R type (The middle row is removed terminal pitch: 5.08 mm)

7: R type (3 rows terminal pitch: 2.54 mm)

8: Q type (2 rows terminal pitch: 2.54 mm)

AXD 1

<No. of contacts (2 digits)>

20: 20 contacts 32: 32 contacts 44: 44 contacts

50: 50 contacts 64: 64 contacts 90: 90 contacts

96: 96 contacts 00: 100 contacts

<Terminal shape and product types>

No.

PC board

mountig form

0

1

PC board top

mounting type

PC board edge

mounting type

Self-clinching

bracket

Not available

Not available

Flux

resistant

Not available

Not available

Terminal

shape

DIP terminal

2 Available

5

Available

Not available

7 Available

2. Material and surface treatment

Note) Please consult us for different plating requirements.

Part name Material Surface

Molded portion

Glass reinforced PBT

(UL94V-0)

—

Socket contact Copper alloy

Contact portion: Ni plating on base, Au plating on surface

Te r minal portion: Ni plating on base, Sn plating on surface

Header post Brass

Contact portion: Ni plating on base, Au plating on surface

Te r minal portion: Ni plating on base, Sn plating on surface

3. Applicable PC board

PC board

thickness

B, C type socket

Q, R type header

1.6 to 2.4mm

B, C type header

Q, R type socket

1.6mm

panasonic-electric-works.net/ac

Connectors for industrial equipment

DIN CONNECTORS (AXD)

INTRODUCTION OF OTHER TYPES

2. FEATURES AND CONSTRUCTION OF DIN CONNECTOR WITH HIGHER FUNCTION

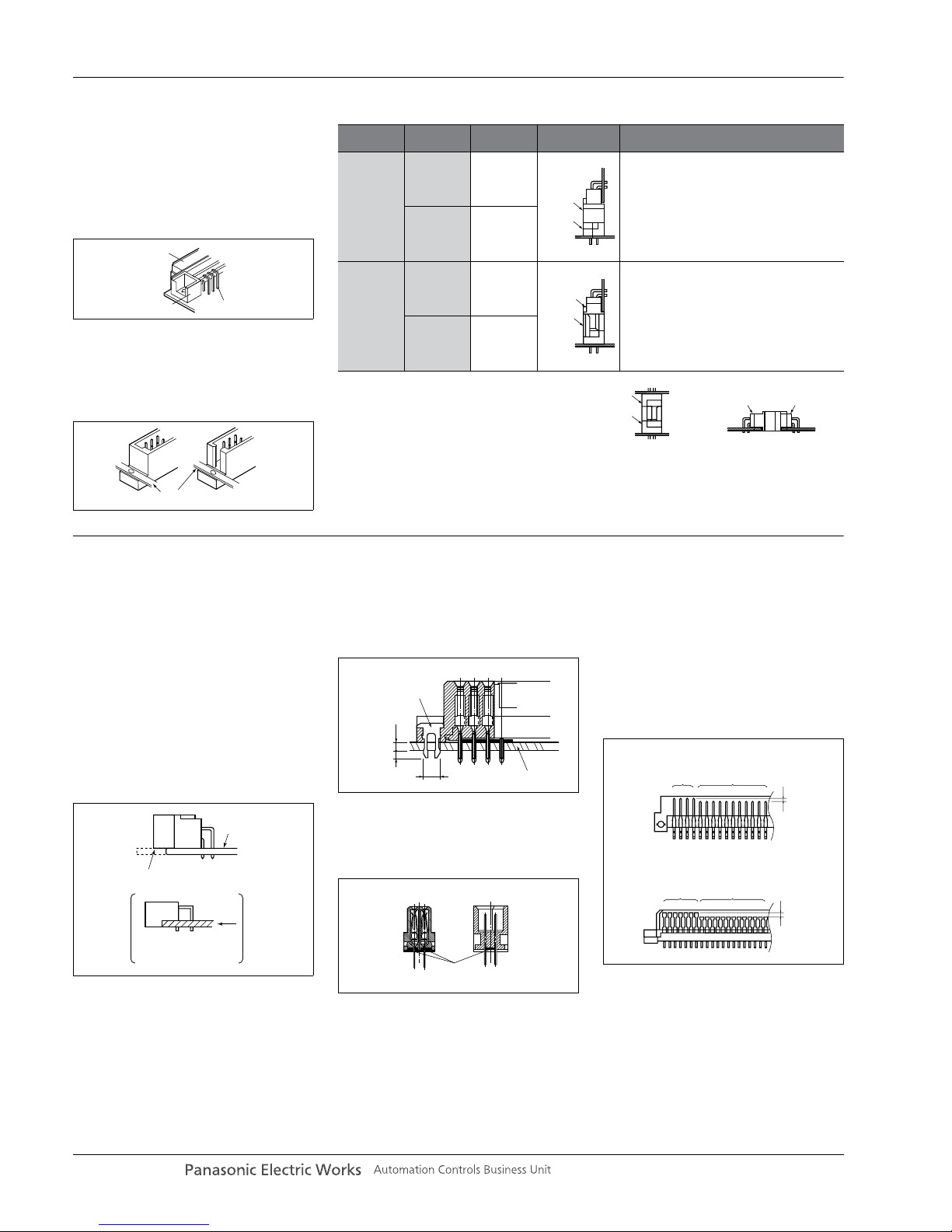

1. FEATURES OF REVERSE TYPE DIN

CONNECTOR

New series of reverse types popular in

the U.S.A.

1) Shock resistant socket construction

Integrated construction of the flange and

housing prevent damage to the terminals

from shock.

2) Box-shaped header provides excellent

electrical performance

Box-shaped headers feature long

insulation distance between the

connector and mounting panel and low

capacitance.

Body

Contact

Flange

OPEN type

Former product

BOX type

Mounting panel

Standard type and reverse type

Types

Header/

socket

Te r minal

shape

Form

Standard

type

Header Angle

The contacts of the socket mounted on the

mother board (power supply side) are covered

to prevent electrical shock and entry of foreign

matter.

Socket Straight

Reverse

type

Header Straight

1. Reduction of total cost

Since the cost of the header is low, it is more

economical to use the header for mother

boards which require multiple pins for

expansion.

2. Matches the designer's requirements for

maximum simplicity in the mother board design.

Socket Angle

The header and socket for the standard

type and reverse type fit each other,

this permits the connections shown in

the figure on the right.

Stacking connection Horizontal connection

Srandard

header

Standard

socket

Reverse

header

Reverse

socket

Standard

socket

Reverse

header

Reverse

socket

Srandard

header

DIN connector enhancement products

which support user circuit designs and

solve problems that occur during

connector mounting.

• PC board top mounting type

• Self-clinching bracket (with temporary

fastening function)

• Flux resistant construction

• Time difference contacts

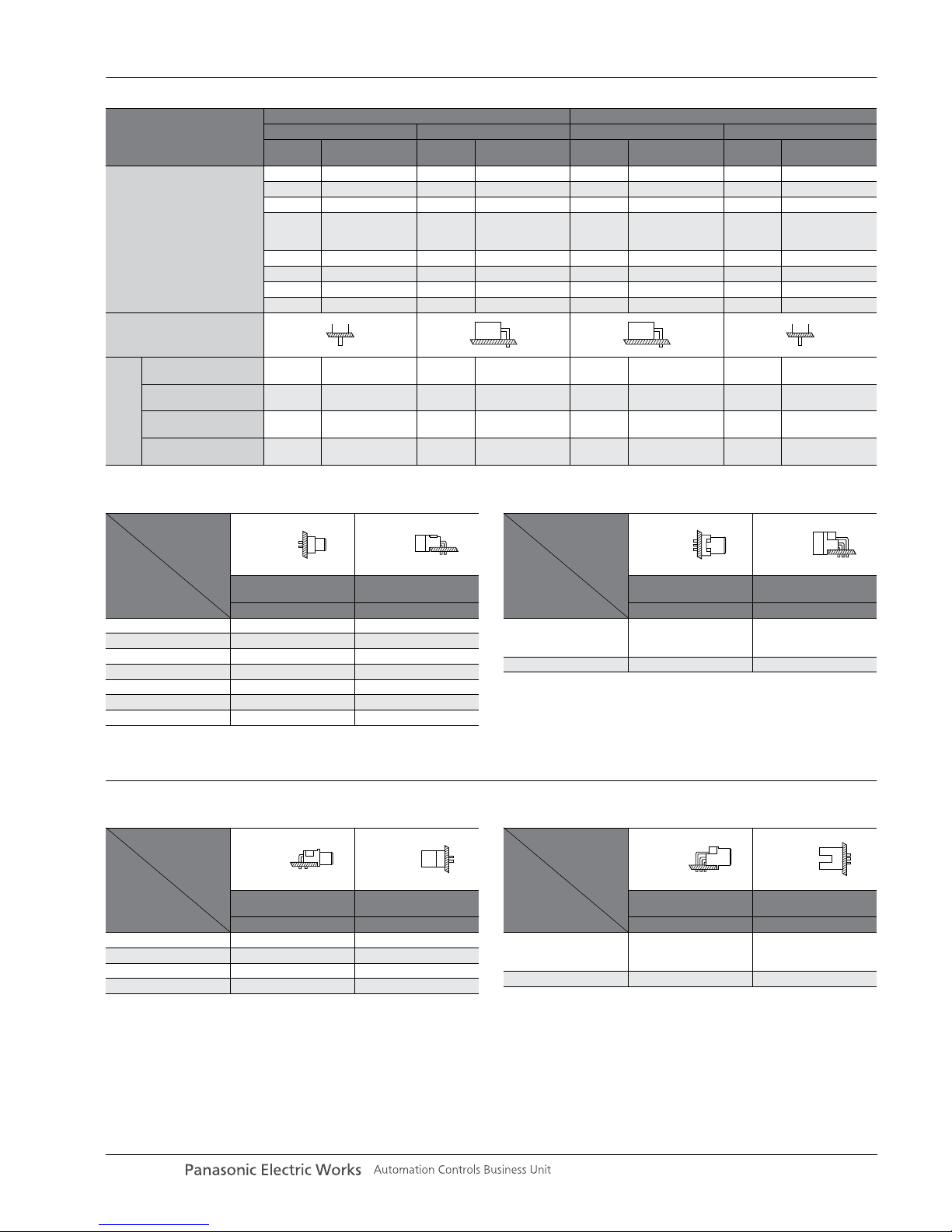

1) PC board top mounting type

• Prevents the entry of flux during

automatic soldering.

• Large position tolerance when mounting

the connector to the PC board permits

the use of automatic mounting.

2) Self-clinching brackets

(with temporary function)

• Prevents the connector from shifting

due to vibration and shock.

• Uses the same mounting hole as the

mounting screw.

3) Flux resistant construction

The terminals are sealed with resin to

prevent seepage of flux through the

terminals or entry of flux from the bottom

of the connector.

4) Time difference contacts

• ICs are protected from damage at

connection even if the PC board is

inserted or removed without power

connected during maintenance or

inspection. This simplifies circuit design.

•A contact time difference of 1mm for

headers and 1.2mm for sockets is

obrained.

• Time difference contacts can be

arranged as desired.

PC board

Snap off at the notches

after soldering

PC board edge

mounting type

(DIN connector)

mm

Self-clinching bracket

PC board

PC board

mounting hole

2.8±0.05 dia.

1.6

1.4

Sealed

with

resin

Cross section

HeaderSocket

Header

Socket

Standard

contacts

Time difference

contacts

1mm

1.2mm

Standard

contacts

Time difference

contacts

panasonic-electric-works.net/ac

Connectors for industrial equipment

DIN CONNECTORS (AXD)

PRODUCT TABLE

PRODUCT TYPES (STANDARD)

PRODUCT TYPES (REVERSE)

Type

Socket Header

Standard types Reverse types Standard types Reverse types

B type

2 rows

C type

3 rows

Q type

2 rows

R type

3 rows

B type

2 rows

C type

3 rows

Q type

2 rows

R type

3 rows

No. of contacts

100 100 100 100

96 96 96 96

90 90

64

64

(The middle row

is removed)

64

64

(The middle row

is removed)

64

64

(The middle row

is removed)

64

64

(The middle row

is removed)

50 50 50 50

44 44

32 32 32 32

20 20

Te r minal shape

Higher functional

products availability

PC board top mounting

type

——Available Available Available Available — —

Self-clinching bracket

(temporary fastening)

Available Available Available Available Available Available Available Available

Flux-resistant

construction

Available Available ————Available Available

Time difference

contacts

Available Available — — Available Available Available Available

1) B type (standard 2 rows)

Notes: 1. All are tray packaged. Packing quantity for outer carton is 200 pcs.

2. For the available foreign standard products, refer to “STANDARDS

CHART” on the end of the catalog.

2) C type (standard 3 rows)

Notes: 1. All are tray packaged. Packing quantity for outer carton is 200 pcs.

2. For the available foreign standard products, refer to “STANDARDS

CHART” on the end of the catalog.

Shape

No. of contacts

Socket Header

Solder-dip

straight terminals

Solder-dip

angle terminals

Par t No. Part No.

20 AXD120201 AXD220211

32 AXD132201 AXD232211

44 AXD144201 AXD244211

50 AXD150201 AXD250211

64 AXD164201 AXD264211

90 AXD190201 AXD290211

100 AXD100201 AXD200211

Shape

No. of contacts

Socket Header

Solder-dip

straight terminals

Solder-dip

angle terminals

Par t No. Part No.

64

(The middle row is

removed)

AXD164301 AXD264311

96 AXD196401 AXD296411

1) Q type (reverse 2 rows)

Notes: 1. All are tray packaged. Packing quantity for outer carton is 200 pcs.

2. Adopting box shape, Q types differ from DIN international standards

(open shape) on the mounting spacing.

2) R type (reverse 3 rows)

Note: All are tray packaged. Packing quantity for outer carton is 200 pcs.

Shape

No. of contacts

Socket Header

Solder-dip

angle terminals

Solder-dip

straight terminals

Par t No. Part No.

32 AXD132811 AXD232801

50 AXD150811 AXD250801

64 AXD164811 AXD264801

100 AXD100811 AXD200801

Shape

No. of contacts

Socket Header

Solder-dip

angle terminals

Solder-dip

straight terminals

Par t No. Part No.

64

(The middle row is

removed)

AXD164611 AXD264601

96 AXD196711 AXD296701

panasonic-electric-works.net/ac

Loading...

Loading...