Page 1

Image Processing Device

10/2004

Advanced image processing

with color handling capability.

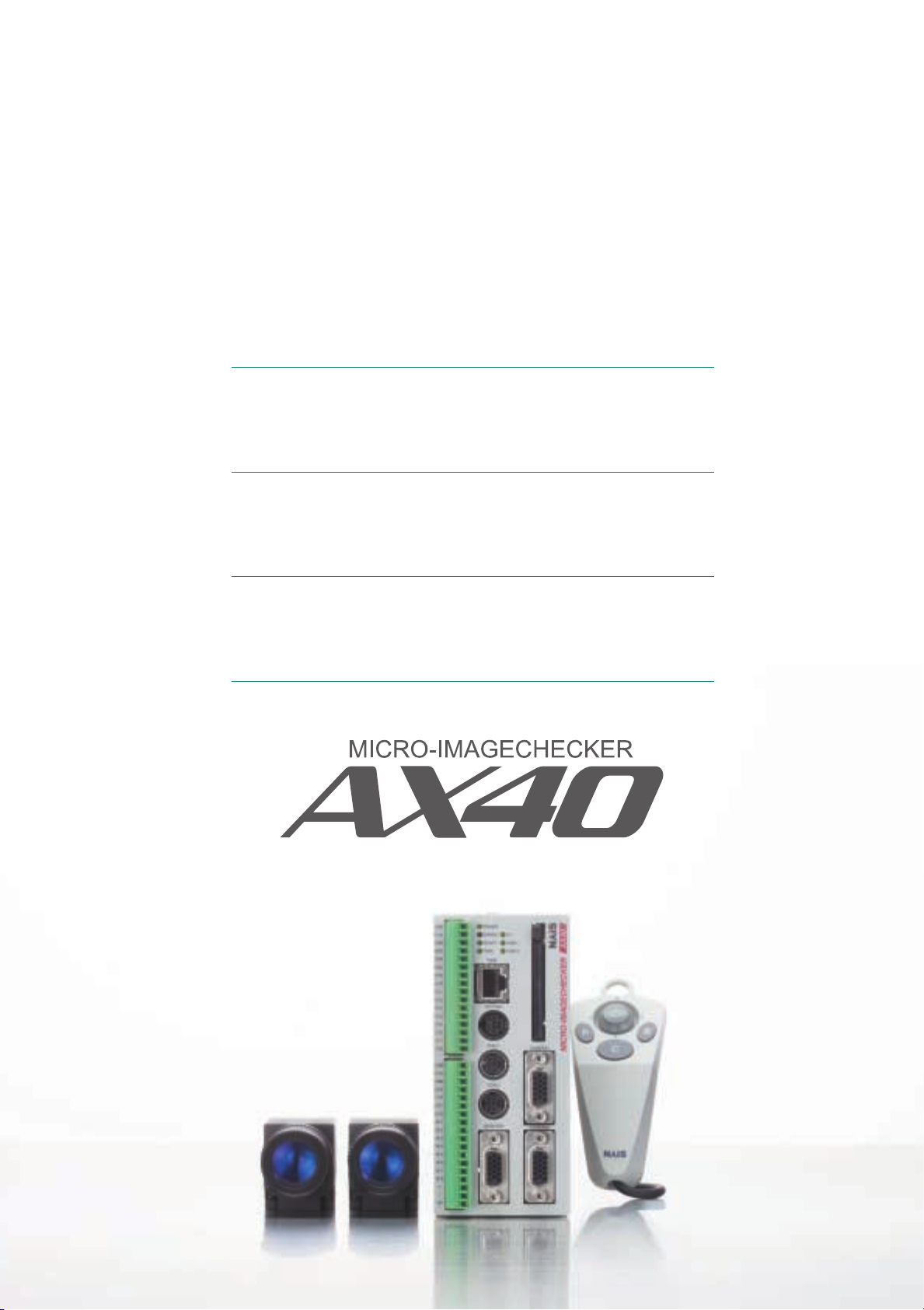

AX40 MICRO-IMAGECHECKER image processing device

ARCT1B229E ’04.1

New

Page 2

Image processing with advanced

10/2004

10/2004

functions that’s easy to use.

The AX40 inherits image processing technology built up over many years and

know-how derived from hands-on experience in the field. Even more important,

it is designed for the kind of performance requirements demanded by

our customers. Combining ease of use with sophisticated

functions, we have created an image processing device

that reaches a new level of perfection.

2 3

Page 3

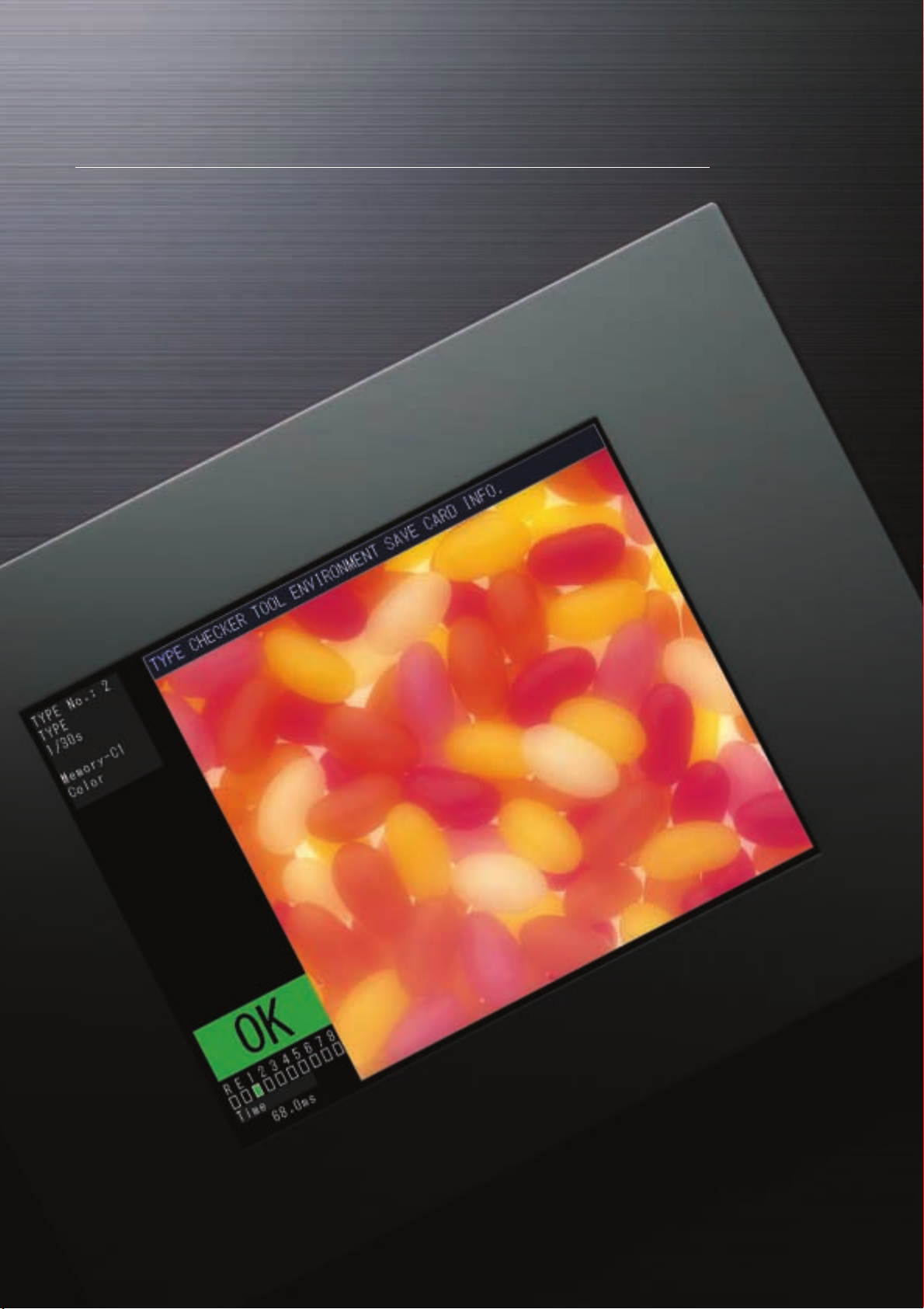

Color images are displayed at high accuracy during inspection

10/2004

and both color and gradation are processed.

The AX40 offers easy-to-grasp visual comprehension.

[Functions]

Fully featured with basic functions such as 360° contour matching,

smart matching, and versatile rotation and positional adjustment.

[Setting and Operation]

Maintenance and initial setup support functions included

and an easy-to-use operation menu.

Interface

Operator stress is reduced thanks to a high-speed memory slot,

high-speed Ethernet (100BASE-TX), and software tools.

Page 4

Features

10/2004

10/2004

Versatile image processing that enables gray scale and color processing.

Differentiation processing is possible in addition to color and gray scale processing and binarization. High precision image processing

means you can use it in a wide range of applications.

Full color

Gray scale Gray scale differentiation

A world first!

∗

Color extraction Binary Binary differentiation

Verify images on a beautiful color monitor. View two images simultaneously.

The AX40 uses a dedicated LCD VGA color

monitor. Visual clarity is in a league apart

from conventional NTSC monitors.

Judgment results are displayed large and in

color, which makes them easier to see. A

font consisting of 18-dot characters is used,

so even Japanese kana and kanji

characters can be displayed.

Simultaneous image display from two cameras

(This shows an image processed with gray scale and binary differentiation.)

A world first!

∗

4 5

Page 5

360° contour matching Smart matching

10/2004

A world first!

∗

A world first!

Numerical calculation/

∗

judgment output

Top class

By calculating contour lines and judging,

stable positional detection is possible even

for hidden, overlapped objects that have

been difficult to detect up to now. Thanks to

this, better yields are achieved.

AX40Previous

Gray scale matching makes sub-pixel

positional detection possible. Furthermore,

shape inspection, such as for the detection

of chipped objects, can be carried out

simultaneously with the gray scale

difference processing function.

Template

Detected

image

Difference result

Versatile rotational and positional adjustment

Top class

The computation function, which has been

troublesome up to now, now supports

Japanese, so settings can be easily made,

even by beginners to image processing.

Also, operation has become even easier

thanks to the ability to set both numerical

calculation and judgment output on the

same screen.

Mask

Highly accurate and reliable inspection is

realized by automatically adjusting object

orientation and stop position deviation.

Since adjustment is done using gray scale

data, the AX40 shows its strength when it

comes to changes in brightness.

Complicated adjustments are possible

because of the priority adjustment function.

■ Multiple adjustment

● Positional adjustment

● Rotational adjustment

● Multiple adjustment

● Priority adjustment

Reliable positional adjustment

by filter processing

In order to boost rotational position

accuracy, filter processing is used to

realize stable image processing even for

images containing much noise.

Noise

Without filter

processing

Noise removed

With filter

processing

The shape of the

inspection area can

be set to match

particular targets.

Also, mask area

settings can also be

combined so that

efficient inspection

can be carried out

just for a required

part.

Inspection area

Mask

Color tone diagram

Fine adjustment for

color inspection is

possible. Even

when colors

resemble each

other, the target

color alone can be

extracted to enable

highly accurate

inspection.

*As of October 2003 (MEW data)

Page 6

Settings, operation, and applications

10/2004

10/2004

Easy operation

Setting is easy using the operation menus

which are designed to be easy to

understand. Basic keypad operation, too,

only requires you to align the cursor with

the menu and press the Enter key.

Large capacity memory

Internal memory capacity has been

increased. Convenient for multi-product

production, the number of templates that

can be stored in the unit is three times

more than previous.* Templates can, of

course, be saved to CompactFlash cards.

*Compared to A210

Previous

(approx.

2 templates)

Approx.

3 times more

AX40

(approx. 6 templates)

Image storage

With the calendar function, the date of

defect and the number of inspections can

be added to saved color images. This is

useful for post verification (checking a

defective product against a saved image)

and for analyzing defect tendencies.

NEWNEW Original function Original function

Global support

(English/Japanese switchable and CE compliant)

Taking into consideration that equipment

might be shipped overseas, the display can

be switched between Japanese and

English. The controller and dedicated color

cameras are standardized items, which are

CE compliant.

Setting help

This function sets the focus and adjusts the

aperture, tasks that used to rely on human

judgment, to values that are ideal for image

inspection. This reduces setting variation

when setting up multiple devices.

Movement all at once

Checkers that have been set can be moved

all at once. This is useful for fine adjustment

when setting cameras up again. It is also

convenient when deploying product type

data that have been set on another device.

Security

The AX40 has a security function, which

requires password verification to safeguard

setting data.

Inspection mode

The AX40 is equipped with a variety of

inspection modes such as positional

adjustment, rotational adjustment, gray

scale and binarization, to support a wide

variety of inspection needs.

• Positional

adjustment

• Rotational

adjustment

• Binary

window

• Gray scale

window

• Binary edge

• Gray scale edge

• Feature extraction

• Smart matching

• Contour matching

Binary edge

Gray scale edge

Feature extraction

Matching

Binary horizontal edge

Binary vertical edge

Gray scale horizontal edge

Gray scale vertical edge

Feature extraction

Matching

Contour watching

Applications

The AX40 can be used for a wide range of

applications, such as presence, color

extraction, area, and dimensional

inspection.

●Part dimension inspection

●Part direction inspection

●Printed date inspection

●Serial number inspection

●Product nameplate label inspection

●Remote controller switch printing inspection

●Logo letter printing inspection

●Cap tightness inspection

●Flat cable width inspection

●Label position inspection

●Cap color inspection

●Debris/dirt on parts inspection

●7-segment illumination inspection

●Cupped food content inspection

●Substrate positioning inspection

●Metal parts picking inspection

●Other applications

6 7

Page 7

Supports

10/2004

Data monitor

Up to 50 inspection results are displayed on

the monitor in chart form for operator

verification. Also, threshold adjustment

(upper and lower limit values) can be

changed on the data monitor without

entering them in the setting menu.

Statistical support

Data can be tracked such as maximum

value, minimum value, average value, and

number of NG (no-go) results. Verification is

possible of maximum, minimum, average

and other OK judgment values, which is

useful as a guide for making upper and

lower limit settings.

Print screen

In-operation displays or displays when

making settings can be saved as bitmaps

into a memory card. This is convenient for

creating documents or for verifying

previously shot images.

AXTOOL Vision Support Tool fills out peripheral lineup!

The new AXTOOL Vision Support Tool is packed with handier functions than ever.

A high-speed interface (100Base-Tx) provides the functions suited to your application.

PC

<AXTOOL Operation Screen>

Navigator

Saved image

display

Set data display

screen

Ethernet

100BASE-TX

AX40

1. Backup/restore image and set data

2. Copy/move/delete image and set data

3. Check saved images on a PC

4. Save set data as CSV document:

Can be edited in Excel

Original function

(Optional products)

Message area Communication screen

Page 8

System configuration

10/2004

10/2004

CompactFlash and Ethernet

Ethernet

AX40s can be connected to a LAN using highspeed Ethernet (100BASE-TX) to meet various

application requirements. Measurement data

during operation can be transmitted at high speed

to a PC. Also, the inspection status of multiple

AX40s can be monitored from a single PC. Image

backups are also easy thanks to this high-speed

interface.

PC

Keypad operation

The amazingly easy-to-operate

keypad, which resembles the feel

of a game and which was popular

in the A series, has been inherited

by the AX40.

CompactFlash storage

Backup and restoration of setting data and saved

images are possible. Also, up to 512 MB of

measurement data can be directly written to a

CompactFlash card, even during operation.

Add power by using spreadsheet software such

as Excel to interpret data and analyze trends.

* Backed up image data can be used as regular bitmap files

on a PC.

DIN rail installation

At the rear, one touch is all

that's required for DIN rail

installation.

PLC link function

Using the RS232C port,

communicate easily with external

devices such as PLCs! Without

programming, connect using our

own PLC protocol or connect to

the PLCs of other makers.

Two-camera connection

Up to two dedicated

color cameras can be

connected.

Color monitor

Supports a dedicated

6.5 inch LCD VGA

color monitor.

8 9

Page 9

Dimensions (Unit: mm inch)

10/2004

Dimensions

● Main unit (Controller)

ANMX400

COM

FLA

COM

RDY

ERR

REN

STR

OVF

D1

D2

D3

D4

D5

D6

D7

D8

COM

STA

COM

FCT1

FCT2

ACK

TYP

IN1

IN2

IN3

IN4

IN5

IN6

IN7

IN8

+

-

5

.197

ø4.6

ø.181

● Dedicated color camera: C mount

ANMX8310

1.142

2-M3 .118

(Depth: 4 mm .157 inch)

31

1.220

8

.315

29

19

.748

13

.512

No mounting

● Color camera cable

32

1.260

44

1.732

59

2.323

POWER

CF

ERROR

COM.1

READY

COM.2

TOOL

KEYPAD

COM.1

COM.2

MONITOR

54.5

2.146

(46.5)

(1.831)

24.5±0.6

.965±.024

bracket

CAMERA1

CAMERA2

L

(10)

(.394)

10

.394

4-M3 .118

(Depth 2.5 mm

.098 inch)

26±0.6

1.024±.024

100

3.937

(19)

(.748)

(31.3)

(1.232)

24.5±0.6

.965±.024

50

1.969

1.220

(3.25)

(.128)

130

5.118

(5.5)

(.217)

31

1/4-20UNC

(Depth 9 mm

.354 inch)

2.5

.098

With mounting

bracket

ø15

ø.591

(9.5) (.374) (Pullout dimensions)

31

1.220

54.4

● Operation keypad

2.142

ANM85202

ENTER

B

A

124.6

C

4.906

L

ø11.5

● Keypad cable

(VGA monitor with keypad connector

and Controller connection)

ø12

ø.472

40

1.575

ø.453

L

● Lens

Mounting screw (lenses with lock only)

A

B

C mount lens A B

ANB842

ANB843

ANB845N(L)

ANB846N(L)

ANB847(L)

ANM88161

ANM88251

ANM8850

ANM88501

f=6.5 .256

f=8.5 .335

f=16 .630

f=25 .984

f=50 1.969

f=16 .630

f=25 .984

f=50 1.969

f=50 1.969

46

1.811

40

1.575

ø48 ø1.890

ø42 ø1.654

ø30 ø1.181

ø30 ø1.181

ø48 ø1.890

ø30.5 ø1.201

ø30.5 ø1.201

ø27.5 ø1.083

ø30.5 ø1.201

18

.709

ø12

ø.472

42 1.654

40 1.575

33 1.299

37.3 1.469

48 1.890

25 .984

25.5 1.004

38.5 1.516

38.5 1.516

● Color LCD VGA monitor

ANMX8300

55

2.165

55

2.165

258

10.157

255

10.039

VGA monitor cable

2

.079

35

1.378

10

160

.394

6.299

40

1.575

Keypad connector

With keypad connector

41

1.614

20

30

.787

1.181

45

1.772

43

1.693

ANMX8301

L

55

2.165

55

2.165

41

1.614

20

.787

30

1.181

223

8.780

220

8.661

45

1.772

43

2

1.693

.079

90

160

3.543

6.299

With keypad connector

Page 10

Product Numbers and Specifications

10/2004

10/2004

Table of Product Numbers

Product name Specification Part No.

AX40 Series Controller

Color camera

Color camera cable

VGA monitor

Product set for

installation on

main unit

Mounting brackets for installation

of VGA monitor on controller

VGA monitor cable

Keypad cable (VGA monitor

with keypad connector and

Controller connection)

C mount lens

Adapter ring

Operation keypad

COM port connecting cable

Vision Support Tool

AXTOOL

NPN output; English/Japanese switchover (No manual)

NPN output; English/Japanese switchover (English manual)

PhotoMOS output; English/Japanese switchover (No manual)

PhotoMOS output; English/Japanese switchover (English manual)

Random color camera

Camera cable: 3 m

Camera cable: 5 m

Camera cable: 10 m

Camera cable: 15 m

Camera cable: 20 m

With keypad connector

No keypad connector

With keypad connector

Mounting brackets (ANMX835)/

Monitor cable: 0.5 m/Keypad cable: 0.5 m

Without keypad connector

Mounting brackets (ANMX835)/Monitor cable: 0.5 m

Brackets for mounting VGA monitor on the

controller

Monitor cable length: 0.5 m

(dedicated for all-in-one mounting)

Monitor cable length: 1 m

Monitor cable length: 2m

Monitor cable length: 3m

Cable length: 0.5 m

Cable length: 1 m

Cable length: 2 m

Cable length: 3 m

f6.5 C mount lens

f8.5 C mount lens

f8.5 C mount lens with lock

f16 C mount compact lens

f16 C mount compact lens with lock

f16 C mount super-compact lens with lock

f25 C mount compact lens

f25 C mount compact lens with lock

f25 C mount super-compact lens with lock

f50 C mount lens

f50 C mount lens with lock

f50 C mount compact lens

f50 C mount compact lens with lock

5 mm adapter ring

(0.5/1/5/10/20/40 mm) adapter ring

With 2 m cable

With 3 m cable

With 2 m cable: CE

With 3 m cable: CE

COM port and PC (D-SUB: 9pins)

connection; 3m

COM port and PLC (discrete-wire cable)

connection; 3m

English version

ANMX401

ANMX402

ANMX403

ANMX408

ANMX8310

ANMX833003

ANMX833005

ANMX833010

ANMX833015

ANMX833020

ANMX8300

ANMX8301

ANMX8302

ANMX8303

ANMX835

ANMX83310

ANMX83311

ANMX83312

ANMX83313

ANMX83330

ANMX83331

ANMX83332

ANMX83333

ANB842

ANB843

ANB843L

ANB845N

ANB845NL

ANM88161

ANB846N

ANB846NL

ANM88251

ANB847

ANB847L

ANM8850

ANM88501

ANB84805

ANB848

ANM85202

ANM85203

ANM85202CE

ANM85203CE

ANM81103

ANM81303

ANMX8321V2

Functional specification

Product name Specification

CPU

Settings data storage

capacity

Frame memory

Operation environment

Monitor display

Connected camera

Number of

connected cameras

Gray scale processing

Differentiation processing

Process

Color extraction processing

Number of product types

Inspection functions

Position adjustment

function

Rotation adjustment

function

Binary window

Binary edge

Feature extraction

32-bit RISC CPU

Approx. 4 MB

512 x 480 (pixels)

Menu selection using dedicated keypad (Japanese/English switchable)

Menu selection using key emulation serial commands

Full color VGA/gray scale image/binary image/extraction color +

brightness image through

Memory + data display area

Two-screen compressed display

Random color camera (progressive)

2

When 1 camera is connected 2 processes can be selected among

gray scale, differentiation and color extraction processing.

When 2 cameras are connected, gray scale, differentiation or color

extraction can be selected for each camera.

8 bit 256 gradations (binarization processing possible, 8 groups/product type)

8 bit 256 gradations (binarization processing possible, 8 groups/product type)

Max. 8 color simultaneous extraction/camera

16

Max 99/product type

99/product type positional adjustment function (multiple adjustment possible)

Binary edge (with priority designation)

Gray scale edge (with priority designation)

*Only when gray scale and differentiation processing are selected.

Feature extraction (mask setting possible)

Matching (template mask setting possible)

*Only when gray scale and differentiation processing is selected.

Max. 99/product type (multiple adjustment possible)

Horizontal binary ede

Vertical binary edge

Horizontal gray scale edge

*Only when gray scale and differentiation processing are selected.

Vertical gray scale edge

*Only when gray scale and differentiation processing are selected.

Feature extraction (mask setting possible)

Matching (template mask setting possible)

*Only when gradation and differentiation processing are selected.

Contour matching (±180 degrees)

Max. 99/product type

Shape: rectangle/polygon (3 to 16 points)/ellipse; 16

mask shape: rectangle/polygon/ellipse; 16

white (extraction)/black (no extraction) selectable

Expansion and contraction filter

Judgement = surface value

Output = surface value

Max. 99/product type

Shape = line/plane

Selection possible among white (extraction) → black (no extraction)

and white (extraction) → black (no extraction)

Depth/width designation function

Judgement = detection/no detection

Output = edge detection coordinate

Max. 99/product type

Shape: rectangle/polygon (3 to 16 points)/ellipse;

mask shape: rectangle/polygon/ellipse; 16

white (extraction)/black (no extraction) selectable

Expansion and contraction filter

Judgment: number of detections

Output: number of detections/barycentric coordinate/area value/

projection width/main axis angle/circumference

10

Page 11

Product name Specification Product name Specification

10/2004

Gray scale

Inspection

window

function

Gray scale

edge

Smart

matching

Contour

matching

Numerical computation

Judgment output

Data monitor

Statistics

Operation data

Marker

Max. 99/product type

*Only when gray scale and differential processing are selected.

Shape: rectangle/polygon (3 to 16 points)/ellipse;

mask shape: rectangle/polygon/ellipse; 16

Upper and lower brightness levels can be set.

Judgment: average gray scale value

Output: average gray scale value

Max 99/product type

*Only when gray scale and differentiation processing are selected.

Shape: line/plane

Projection/individual scan

Light to dark; dark to light; designation of both possible

Edge; leading edge and trailing edge; maximum derivative; multiple

Depth/width designation function

Judgment: number of detections

Output: number of detections/edge detection coordinate

Max. 99/product type

*Only when gray scale and differentiation processing is selected.

Shape: rectangle template; mask shape: rectangle/polygon/ellipse; 16

Difference setting possible

Judgment: number of detections and number of differences

Output: number of detections/detected coordinates/detected angle/

correlation value/difference area value/number of differences

Max. 2/product type

Shape: rectangle

±180 degree detection possible

Judgment: correlation

Output: detected coordinate/detected angle/correlation

Max. 99/product type

4-operation computation/√/arc tangent/distance between 2 points/

case arc/Sin/Cos/absolute value of difference

Possible to quote output of each inspection function.

Reference previous data.

Max. 99/product type

NOT/AND/OR/XOR/case arc

Image storage condition setting/general judgment condition setting/

output setting

Max. 50/product type

Data can be displayed in chart format when running.

Title input or numerical calculation results, judgment output

results, statistical results and product numbers can be quoted.

External output settings of quoted items

Upper and lower limit values of numerical computations can be

changed from the chart while running.

Max. 16 per product type

Numerical calculation and judgment output results can be quoted.

The following can be calculated: number of scans, number of OK

results, number NG (no-go) results, OK average, OK dispersion,

max. value, min. value, and range.

Quoting is possible to the data monitor.

Max. 4/environment

Quoting to numerical computation is possible.

Comment input is possible

Max. 8/product type

Graphic display on screen while running (rectangle/circle and

ellipse/straight lines)

External Serial

I/O

Parallel

Ethernet

CompactFlash

Other Display

function

Movement

at once

Screen storage

Setting help

Calendar

Password

RS232C: 2 channels (max. speed 115,200 bps)

Input: start/product type switching/camera display switching/

template re-registration/CompactFlash restore/reference of

numerical computation upper and lower limits and changes/data

storage/statistical initialization/reference and change of binarization

level/reference and change of gray scale edge threshold value

Output: judgment output and quoted data from data monitor

Computer link support: Matsushita Electric Works' FP series and

Mitsubishi's A, Q and FX series/Omron's C, CV and CS1 series/

Allen-Bradley's SLC500 series

Input: 13 points; output: 14 points; removable screw-down terminal block

Input: start, product type switching, camera display switching,

template re-registration

Output: ready/error/flash/judgment output data

Ethernet: 1 channel

Output: judgment output, data quoted from data monitor (TCP/IP)

Setting data and image backup, restore, documentation of setting

data (AXTOOL)

Compact flash: 1 slot

Output: judgment output and data quoted from data monitor (text file)

Setting data, image backup/restore, screen hard copy

Transparent menu

Output status monitor

Reference coordinate display (quoting to numerical computation possible)

Numerical setting of set color and center color display

Checkers with NG (no-go) results displayed with different color

Checker movement all at once is possible for each position and

rotation adjustment group.

Max. 16 images/camera

Each time/storage possible by judgment result

Test execution possible with saved images.

Display of date saved.

Function to keep last image to be saved displayed.

White balance setting

Focusing/aperture adjustment (only when gray scale processing is selected)

Parallel monitor

Calendar data added to saved images

Password function for moving between setting modes

11

Page 12

Internet Homepage

10/2004

10/2004

North America

Europe

: http://www.aromat.com/

: http://www.mew-europe.com/

Asia & others

• (Japanese)

• (Chinese)

These materials are printed on ECF pulp.

These materials are printed with earth-friendly vegetable-based (soybean oil) ink.

Please contact ..........

Matsushita Electric Works, Ltd.

Automation Controls Company

Head Office: 1048, Kadoma, Kadoma-shi, Osaka 571-8686, Japan

Telephone: +81-6-6908-1050

Facsimile: +81-6-6908-5781

http://www.nais-e.com/

ARCT1B229E 200311-3YT

Specifications are subject to change without notice. Printed in Japan.

: http://www.nais-e.com/

: http://www.mac-j.co.jp/

: http://www.cmew.com.cn/

COPYRIGHT © 2004 All Rights Reserved

Loading...

Loading...