Page 1

Page 2

ENGLISH VERSION

Safety precautions

DO NOT REMOVE PANEL COVERS BY

UNSCREWING.

To reduce the risk of electric shock, do not remove

the covers. No user serviceable parts inside.

Refer servicing to qualified service personnel.

WARNING:

• TO REDUCE THE RISK OF FIRE OR ELECTRIC

SHOCK, DO NOT EXPOSE THIS APPARATUS TO

RAIN OR MOISTURE.

• THE APPARATUS SHALL NOT BE EXPOSED

TO DRIPPING OR SPLASHING AND THAT NO

OBJECTS F I L L E D W I T H LI QU I DS, SU C H

AS VA S ES, SHALL BE PLACED ON T H E

APPARATUS.

WARNING:

TO PREVENT INJURY, THIS APPARATUS

MUST BE SECURELY ATTACHED TO THE

FLOOR/WALL IN ACCORDANCE WITH THE

INSTALLATION INSTRUCTIONS.

CAUTION:

TO REDUCE THE RISK OF FIRE OR SHOCK

HAZARD, REFER CHANGES OF SWITCH

SETTINGS INSIDE THE UNIT TO QUALIFIED

SERVICE PERSONNEL.

CAUTION:

TO REDUCE THE RISK OF FIRE OR SHOCK

HAZARD AND ANNOYING INTERFERENCE, USE

THE RECOMMENDED ACCESSORIES ONLY.

CAUTION:

In order to maintain adequate ventilation, do not

install or place this unit in a bookcase, built-in

cabinet or any other confined space. To prevent

risk of electric shock or fire hazard due to

overheating, ensure that curtains and any other

materials do not obstruct the ventilation.

The mains plug or an appliance coupler shall remain

readily operable.

A warning that an apparatus with CLASS I construction

shall be connected to a MAINS socket outlet with a

protective earthing connection.

indicates safety information.

1 (E)

Page 3

Information on Disposal for Users of Waste Electrical & Electronic Equipment (private households)

This symbol on the products and/or accompanying documents means that used electrical and electronic

products should not be mixed with general household waste.

For proper treatment, recovery and recycling, please take these products to designated collection points, where

they will be accepted on a free of charge basis. Alternatively, in some countries you may be able to return your

products to your local retailer upon the purchase of an equivalent new product.

Disposing of this product correctly will help to save valuable resources and prevent any potential negative

effects on human health and the environment which could otherwise arise from inappropriate waste handling.

Please contact your local authority for further details of your nearest designated collection point.

Penalties may be applicable for incorrect disposal of this waste, in accordance with national legislation.

For business users in the European Union

If you wish to discard electrical and electronic equipment, please contact your dealer or supplier for further information.

Information on Disposal in other Countries outside the European Union

This symbol is only valid in the European Union.

If you wish to discard this product, please contact your local authorities or dealer and ask for the correct method of disposal.

ENGLISH

2 (E)

Page 4

Contents

Safety precautions ................................................................................................................................................ 1

Operating precautions .......................................................................................................................................... 4

Introduction ........................................................................................................................................................... 4

Accessories ........................................................................................................................................................... 5

Installation precautions ........................................................................................................................................ 5

Parts and their function ........................................................................................................................................ 6

Installation ........................................................................................................................................................... 10

Assembling the pan-tilt head ........................................................................................................................ 10

Concerning the safety modes ....................................................................................................................... 12

Procedure for changing the settings of the CPU circuit board switches ....................................................... 13

Setting the CPU circuit board switches ......................................................................................................... 14

Pan-tilt head mounting conditions ................................................................................................................. 15

Installing the pan-tilt head ............................................................................................................................. 15

Mounting the camera (Convertible camera AW-E350/E650/E655/E750/E860) ............................................ 17

Attaching the wire (Convertible camera AW-E350/E650/E655/E750/E860) ................................................. 18

Mounting the camera (Mulit-purpose camera AK-HC1500G) ....................................................................... 19

Concerning the balance of the installed unit ................................................................................................. 20

Attaching the wire (Mulit-purpose camera AK-HC1500G) ............................................................................ 22

Connections ........................................................................................................................................................ 23

Cable specifications ........................................................................................................................................... 25

Replacing the consumable parts ....................................................................................................................... 26

Appearance .......................................................................................................................................................... 27

Specifications ...................................................................................................................................................... 28

3 (E)

Page 5

Operating precautions

Handle the unit carefully.

Dropping the unit or subjecting it to strong impact may

give rise to malfunctioning or accidents.

Turn off the power before connecting or

disconnecting the cables.

Be absolutely sure to turn off the power before connecting

or disconnecting the cables.

Install the unit near the main power outlet, and

position it in such a way that its power plug can

be plugged into and unplugged from the outlet

Do not use the unit outdoors.

Maintenance

Wipe the unit using a dry cloth. To remove stubborn dirt,

dip a cloth into a diluted solution of kitchen detergent,

wring it out well, and wipe the unit gently.

<Caution>

Avoid using benzine, paint thinners and other volatile

fluids.

If a chemical cleaning cloth is to be used, carefully read

through the precautions for its use.

easily.

Introduction

The stand-alone indoor pan-tilt head can be rotated through 300 degrees in the vertical direction and 300 degrees in the

horizontal direction.

Operations can be performed at high speeds of up to 45 degrees per second.

Equipment such as a camera and lens with a total weight of 15 kg can be mounted on the unit.

The shooting positions and settings for up to 50 positions can be registered as preset memory data.

When the AW-IF400 is used to connect the AW-RP400 to the unit

• The tracing memory function cannot be used.

• TILT RANGE cannot be set.

• MEMORY LENGTH cannot be set.

• DIAGONAL MOTION cannot be set to ON or OFF.

• Backlash cannot be compensated.

• When the ON/OFF setting of auto focus (AF) and extender (EXT) is switched from AW-RP400, use the OPTION SW

after allocating the “EXT” function to it.

ENGLISH

When using the IAS, WAS or VAS lens made by Canon or the RD lens made by Fujinon

• Communication with the pan-tilt head controller (such as the AW-RP655) commences as soon as the AW-PH405 is

started. Similarly, the startup process for the lens commences when the power of the camera is turned on. During the

startup process the zoom moves automatically, and none of the control operations can be performed from the pan-tilt

head controller (such as the AW-RP655).

• After completion of the startup process, refrain from adjusting the zoom speed control of the lens. To adjust this speed,

turn off the power of the AW-PH405 first, and then proceed with the adjustment.

• When the zoom offset automatic compensation selector switch of the lens is set to ON, the zoom position will be

automatically compensated. For this reason, the zoom seesaw switch of the lens cannot be used to control the zoom

in the desired manner.

• When the lens mounted on the camera has been changed, re-set the preset memory and tracing memory functions.

The zoom will not operate properly if the original settings for these functions are retained for use.

Notes

The AW-PH405 cannot be controlled from the AW-RP301, AW-RP305, AW-RP501, AW-RP505 controller.

The AW-RL400 roll unit cannot be used.

The current rating of the LENS I/F (2) connector is 500 mA (max).

The lens whose maximum current consumption exceeds 500 mA cannot be used. Concerning the maximum

current consumption of the lens, contact the lens manufacturer.

In order to protect the environment when the pan-tilt head is to be discarded at the end of its service life, ask

a specialized contractor to dispose of it properly.

With some lenses mounted on the camera, focusing and other operations may be performed in the opposite

direction.

To ensure that these operations are performed in the correct direction, change the DIRECTION setting of the

pan-tilt head controller (such as the AW-RP655).

If an auto-focusing lens is not going to be used, use the auto focus (AF)/extender (EXT) selector switch

(SW1: No.1) on the AW-PH405 at the OFF setting.

If this switch is set to ON and the EXT (AF) button on the pan-tilt head controller (such as the AW-RP655) is

also set to ON, it will not be possible to control the focusing.

4 (E)

Page 6

Accessories

Operating instructions ..................................................... 1

Rotary arm ......................................................................... 1

Camera mounting base .................................................... 1

Mounting screws for the rotary arm and camera

mounting base

(with flat washers, spring washers)

M5

Camera cable .................................................................... 1

Tally lamp .......................................................................... 1

Tally mounting screws (M36 mm) ................................ 2

22 mm ............................................................. 7

Installation precautions

Do not install the unit on any of its sides.

Avoid using the unit in the kitchen and other locations with

lots of steam and oily vapors.

Mount the camera on the pan-tilt head only when you

have finished installing it.

The maximum weight which can be borne by this unit is

15 kg.

Do not use a lens which will impair or upset the unit’s

balance.

Even if the weight by the unit is less than 15 kg, it cannot

be used if the unit will be set off-balance by the lens

mounted on it.

Do not install the unit outdoors or in places where the

temperature will be hotter than 45°C or colder than −5°C.

Use the unit in places where the humidity is below 90%.

Obtain separately the screws which will be used to install

the unit since they are not provided with the unit.

Do not hold or lift the unit by its rotating part. Doing so

may cause malfunctioning.

Do not connect a regular LAN line or telephone line to the

CONTROL IN RP connector or COM connector on the

unit. Doing so may cause malfunctioning.

When performing work high off the floor or ground, make

absolutely sure that the work is done by a qualified

contractor.

Blank panel for tally ......................................................... 1

Wire mounting screws

(with flat washers, spring washers)

M4

Inch screw ......................................................................... 1

Hexagon key wrench ........................................................ 1

AC cable ............................................................................ 2

Anti-camera-drop wire ..................................................... 1

Do not turn the unit’s rotating part by hand. Doing so may

cause malfunctioning.

Dropping the unit or subjecting it to strong impact may

give rise to malfunctioning.

Leave a clearance of at least 1 meter from around the

monitor when installing the unit.

When mounting the camera on the unit, take sufficient

steps to ensure that it will not become detached from the

unit or fall onto the floor.

A length of wire for preventing the camera from dropping

is provided. Read the operating instructions first, and

then be absolutely sure to attach the wire and take the

necessary measures to prevent the camera from falling.

Install the unit in such a way that the equipment mounted

on it and its cables will not come into contact with anything

when the pan-tilt head swivels, and set definite movement

limits.

( For details on the limiter settings, refer to the operating

When the unit is no longer going to be used, do not leave

it in place, and be absolutely sure to remove it.

8 mm ............................................................... 2

instructions of the controller.)

5 (E)

Page 7

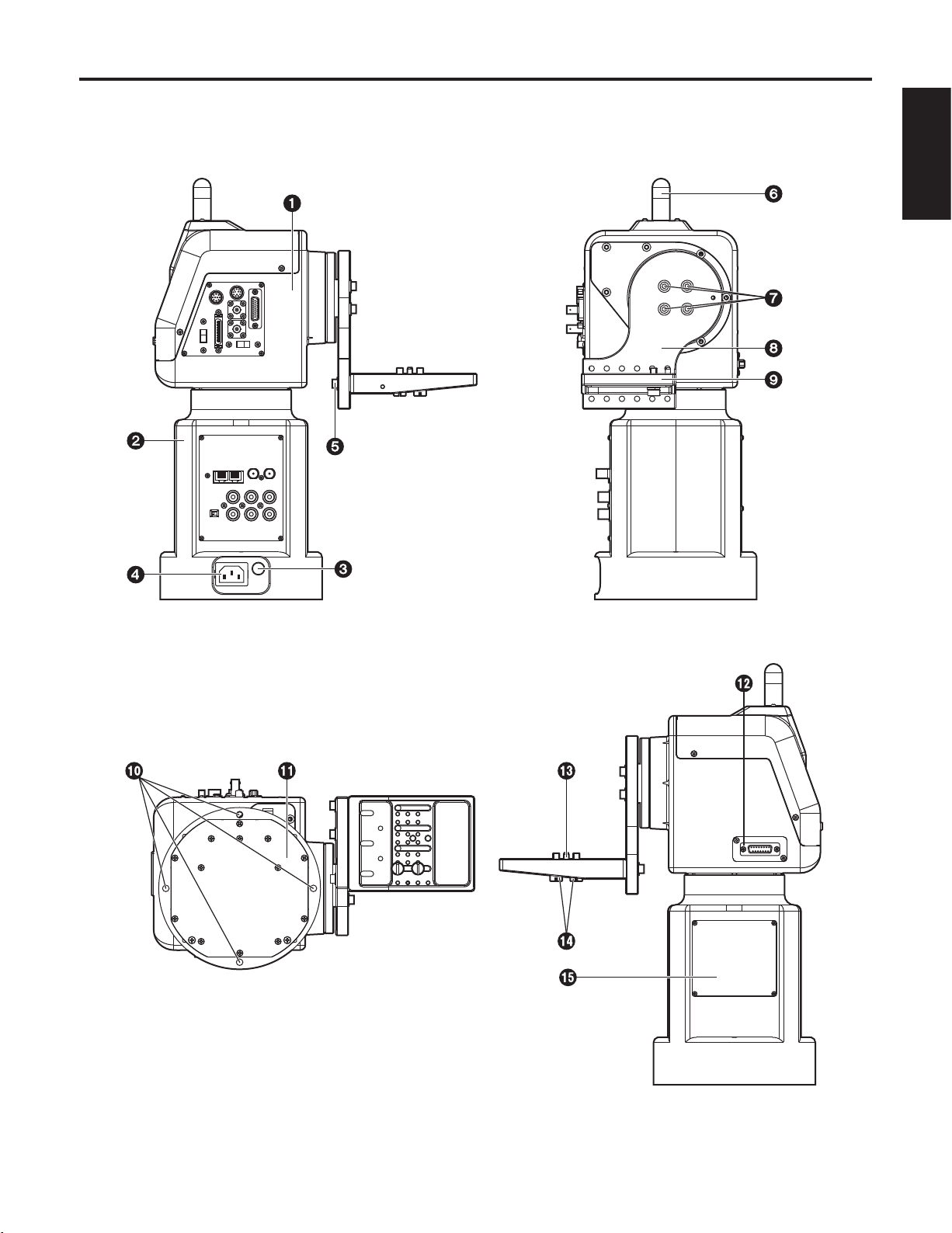

Parts and their function

ENGLISH

6 (E)

Page 8

Parts and their function

Rotary head

This rotates in the horizontal direction.

Pedestal

POWER ON/OFF switch

Where a switch is pushed in, the unit’s power is turned

on, and the unit’s power is turned off after the switch has

jumped out.

AC inlet [AC IN] (AC 3-point inlet)

Connect the accessory AC power cable to this inlet.

Camera mounting base mounting screws

M522 mm hexagon socket head screws (with flat

washers, spring washers) (3 of each provided as

accessories)

These parts are used to secure the camera mounting

base to the rotary arm.

Tally lamp (accessory)

This is lit up red by the selected signals.

Rotary arm mounting screws

M522 mm hexagon socket head screws (with flat

washers, spring washers) (4 of each provided as

accessories)

These parts are used to secure the rotary arm to the

rotary head.

Rotary arm

This rotates in the vertical direction.

Camera mounting base

Mount the convertible camera or multi-purpose camera

on this base.

Pan-tilt head mounting holes

These four holes are used when installing the pan-tilt

head.

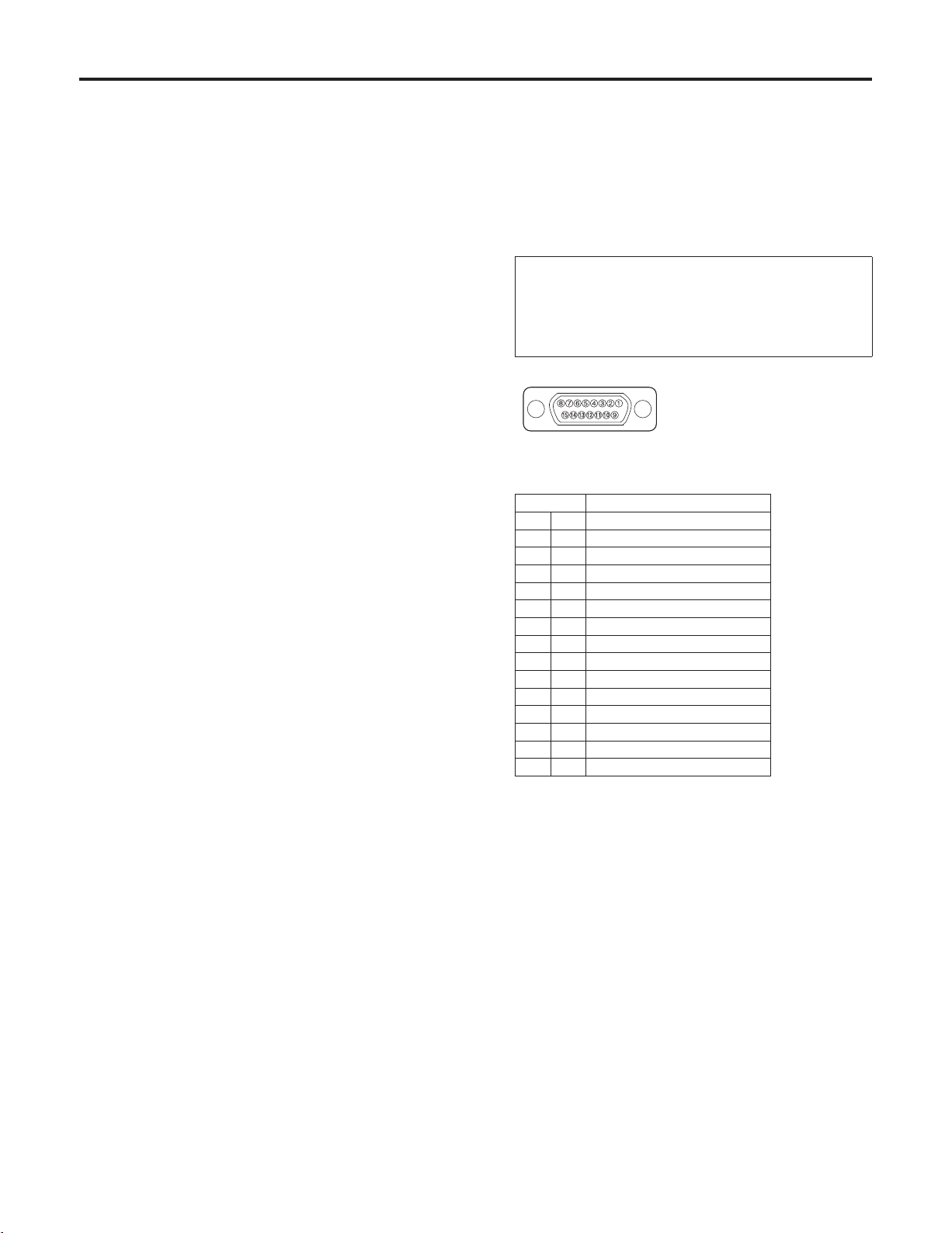

PROMPTER connector

The prompter is connected to this connector.

The maximum current which can be supplied from the DC

12 V OUT socket is 2.5 A.

When the prompter is connected, the pan-tilt head’s

speed is reduced to about one-third.

When connecting the prompter, be absolutely sure to

short-circuit the DETECT terminal (Pin No.14) and the

GND terminal (Pin No.15).

Note

Pin layout as seen facing

the prompter connector

Pin No. Signal Name

1 – – –

2 PROMPTER VIDEO

3 – – –

4 DC 12 V OUT

5 GND

6 – – –

7 – – –

8 – – –

Consult your dealer when a prompter is to

be installed since it will be necessary for

the balance between the mounting fixture

and overall weight and other aspects to be

checked.

9 – – –

10 PROMPTER VIDEO GND

11 – – –

12

13

14 DETECT

15 GND

– – –

– – –

Bottom panel

Use the unit with this panel in position.

Guide pin

Use this to determine the direction in which the camera is

to be mounted.

Camera mounting screws (U1/4” 20UNC)

These are used to secure the camera firmly after it has

been mounted.

Side blank panel

For normal operation, use the unit with this panel in

position.

7 (E)

Page 9

Parts and their function

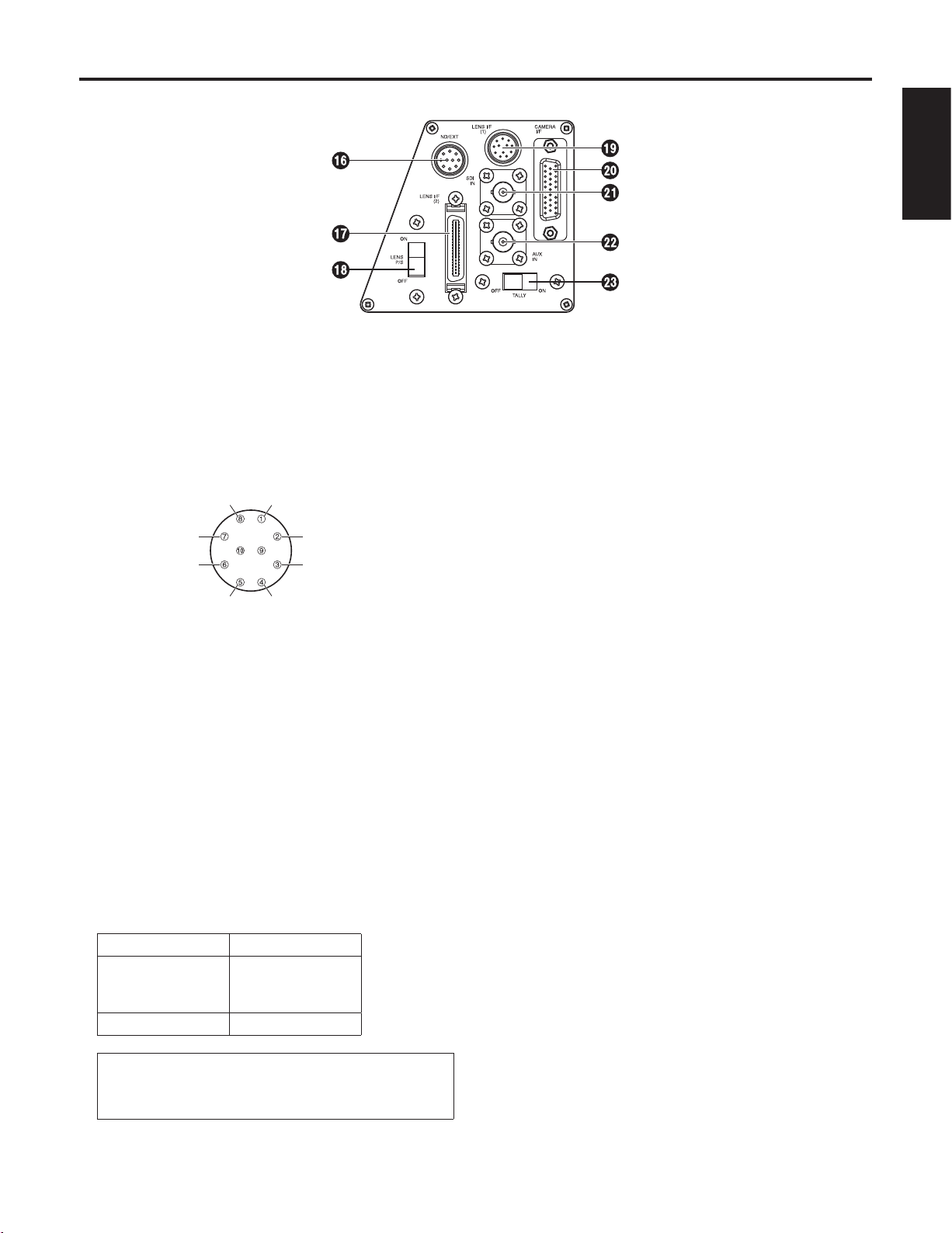

Rotary head connector panel

ENGLISH

ND/EXT connector [ND/EXT]

This is for the control of the ND filter and lens extender of

the motorized lens unit.

Connect this connector when using a motorized lens

unit with ND filter and lens extender functions. The cable

described in “Cable specifications” on page 25 is required

in order to connect this connector.

CVCC (12 V)CanonEXT ()

CanonEXT ()

ND Signal

(Pin layout as seen from cable end)

The current rating of the CVCC and CGND pins is

500 mA (max). Any devices whose maximum current

consumption exceeds 500 mA cannot beused.

CGND

EXT Return

EXT SignalND Return

LENS I/F (2) connector [LENS I/F (2)]

This is used when an IAS, WAS or VAS lens made by

Canon or an RD lens made by Fujinon is to be used.

The optional connecting cable is required to connect the

lens with the connector.

The current rating of LENS I/F (2) connector is 500 mA

(max).

The lens whose maximum current consumption exceeds

500 mA cannot be used. Concerning the maximum

current consumption of the lens, contact the lens

manufacturer.

Lens Cable

Canon

Digital

Analogue

Fujinon AW-CA4FLZG

AW-CA4DLZG

AW-CA4ALZG

LENS P/S ON/OFF switch [LENS P/S]

When this is set to ON, power is supplied to the lens from

the LENS I/F (1) connector. When it is set to OFF, power

is no longer supplied to the lens from the LENS I/F (1)

connector.

Set this switch to OFF when power is to be supplied from

a source outside the unit without using the AW-PH405’s

dedicated camera cable.

LENS I/F (1) connector [LENS I/F (1)]

This is used to control the zooming and focusing of the

motorized lens unit.

Use the motorized lens unit’s remote (zoom/focus) control

cable to make the connection.

CAMERA I/F connector [CAMERA I/F]

This is used for the control of the convertible camera.

Use the camera cable supplied with the AW-PH405 to

connect the connector with the REMOTE connector on

the camera.

Depending on the functions of the optional card, a special

camera cable (sold separately) is required.

SDI IN connector [SDI IN]

Use a coaxial cable to connect this to the SDI OUT

connector on the AW-PB504 SDI card or other card

installed in the convertible camera.

AUX IN connector [AUX IN]

This connector is connected using a BNC coaxial cable

to the SDI OUT connector on the AW-PB504 SDI card

or other card installed in the convertible camera or to the

VBS connector on the AK-HDC1500G down converter

board or other board installed in the AK-HC1500G

multi-purpose camera.

TALLY OFF/ON switch [TALLY]

When this is set to ON, the tally lamp is lit by the selected

signals. When it is set to OFF, the () tally lamp will not

light even if the selected signals are supplied.

Note

Refer to the instructions for using the

connecting cable to ensure that it is

connected properly.

8 (E)

Page 10

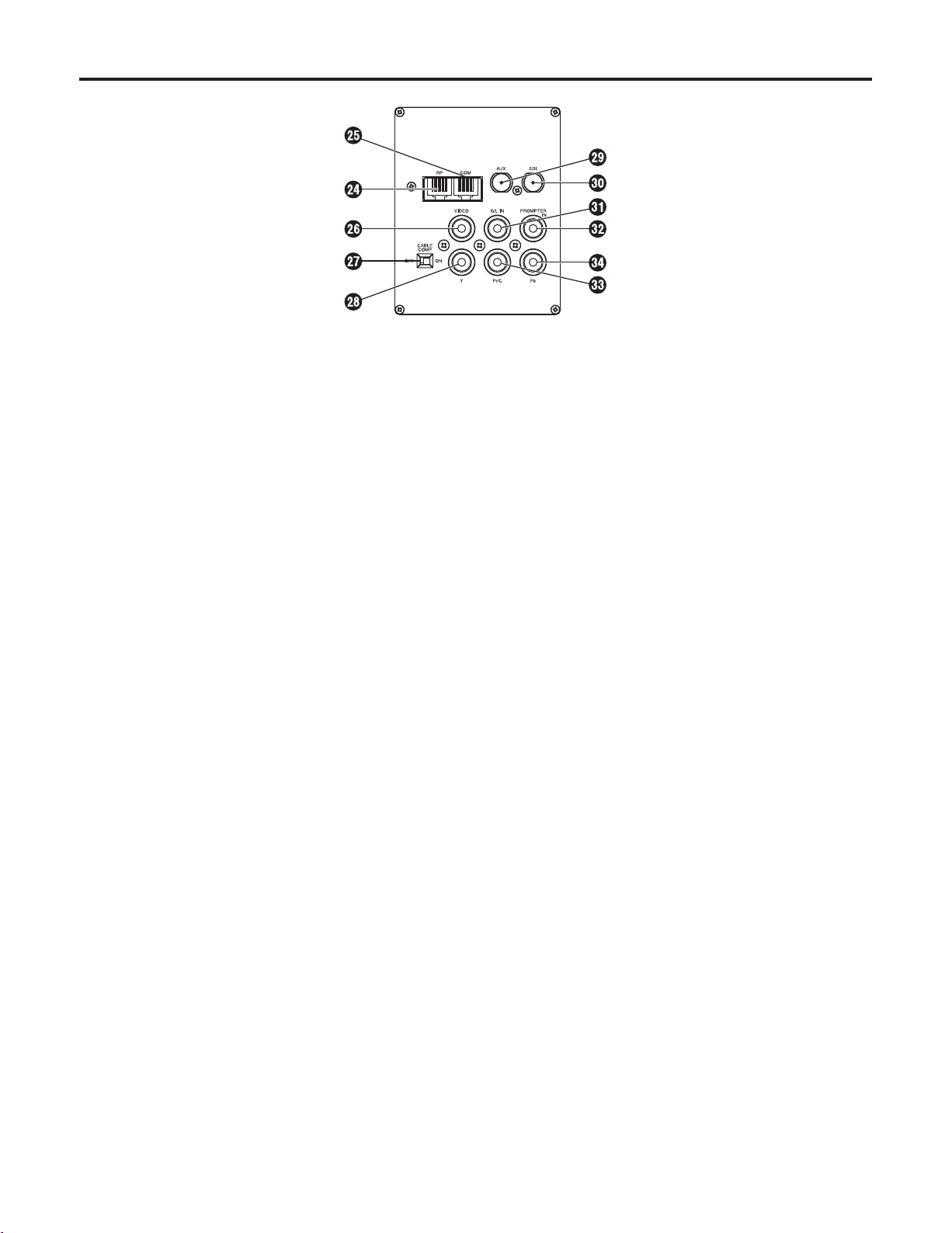

Parts and their function

Pedestal connector panel

CONTROL IN RP connector [RP]

This is the connector for the control of signals of the

camera and pan-tilt head.

It is connected to the TO PAN/TILT HEAD connector on

the AW-RP655 multi-function controller and AW-RP555

multi hybrid control panel.

Use a 10BASE-T (equivalent to UTP category 5) straight

cable for the connecting cable.

COM connector [COM]

This is the connector for the control signals used to

extend the camera’s functions.

VIDEO connector [VIDEO]

This the output connector for the convertible camera’s

video signals.

It is connected to the Y/VIDEO connector on the

AW-RC400 cable compensation unit or monitor, etc.

Use a BNC coaxial cable for the connecting cable.

CABLE COMP OFF/ON switch [CABLE COMP]

When this is set to ON, signals which have been cable

compensated for the equivalent of 500 meters are

output from the VIDEO connector and the Y, Pr and Pb

connectors.

When this switch is used in conjunction with the

AW-RC400 cable compensation unit, the video cable can

be extended up to a maximum of 1000 meters.

AUX connector [AUX]

This is the output connector for the camera’s video

signals.

It enables the SDI signals, VBS signals, etc. from the

BNC coaxial cable connected to AUX IN to be output.

Provide a BNC coaxial cable as the connecting cable.

No cable compensation is provided for the signals which

are output from this connector.

SDI connector [SDI]

This is the output connector for the camera’s video

signals.

It enables the SDI signals, VBS signals, etc. from the

BNC coaxial cable connected to SDI IN to be output.

Provide a BNC coaxial cable as the connecting cable.

No cable compensation is provided for the signals which

are output from this connector.

G/L IN connector [G/L IN]

This is the genlock signal input connector.

It is connected to the G/L OUT connector on the

AW-RC400 cable compensation unit or other unit.

Use a BNC coaxial cable for the connecting cable.

PROMPTER IN connector [PROMPTER IN]

The video signals for the prompter are input to this

connector.

Use a BNC coaxial cable for the connecting cable.

Y connector [Y]

This is the output connector for the camera’s video

signals.

It is connected to the Y/VIDEO connector on the

AW-RC400 cable compensation unit or monitor, etc.

Use a BNC coaxial cable for the connecting cable.

Pr/C connector [Pr/C]

This is the output connector for the camera’s video

signals.

It is connected to the Pr/C connector on the AW-RC400

cable compensation unit or monitor, etc.

Use a BNC coaxial cable for the connecting cable.

Pb connector [Pb]

This is the output connector for the camera’s video

signals.

It is connected to the Pb connector on the AW-RC400

cable compensation unit or monitor, etc.

Use a BNC coaxial cable for the connecting cable.

9 (E)

Page 11

Installation

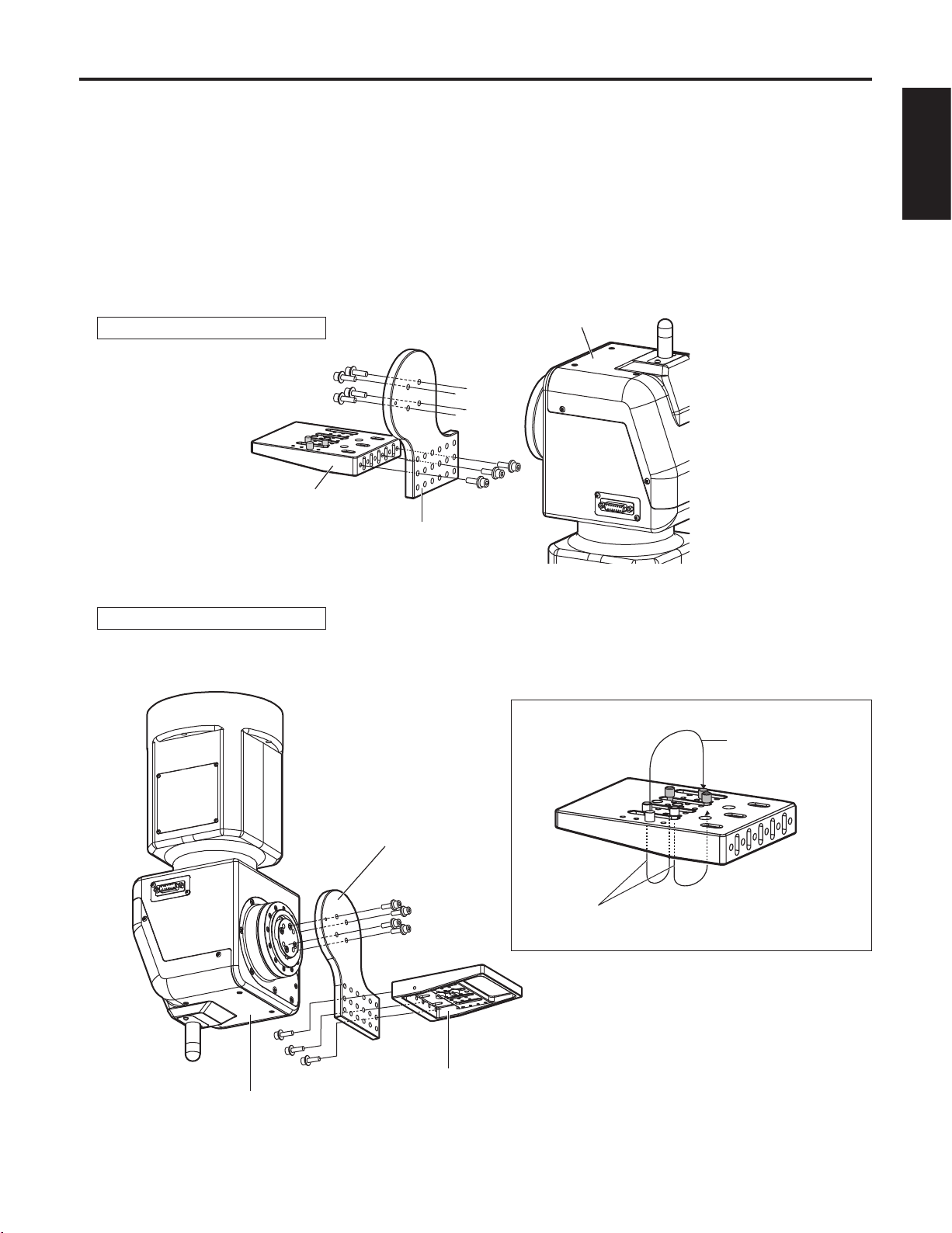

Assembling the pan-tilt head

When assembling the pan-tilt head, use the Allen key (provided) and screwdriver, and secure the head by tightening the screws

firmly. After mounting the pan-tilt head, check there is no play in its installation.

Attaching the camera mounting base

Attach the camera mounting base to the rotary arm using the three mounting screws (M522 mm, with flat washers, spring

washers) provided. The installation direction differs depending on how the base is installed.

Attaching the rotary arm

Attach the rotary arm to the rotary head using the four mounting screws (M522 mm, with flat washers, spring washers)

provided. The installation direction differs depending on how the arm is installed.

ENGLISH

For a stand-alone installation

Rotary head

Camera mounting base

Rotary arm

For installation on the ceiling

Change the guide pin and screw positions as shown in the figure below on the right, and then attach the camera mounting

base to the rotary arm.

Camera Mounting base

Change the positions

of the guide pins.

Rotary head

Rotary arm

Change the positions of the

camera mounting screws.

Camera mounting base

10 (E)

Page 12

Installation

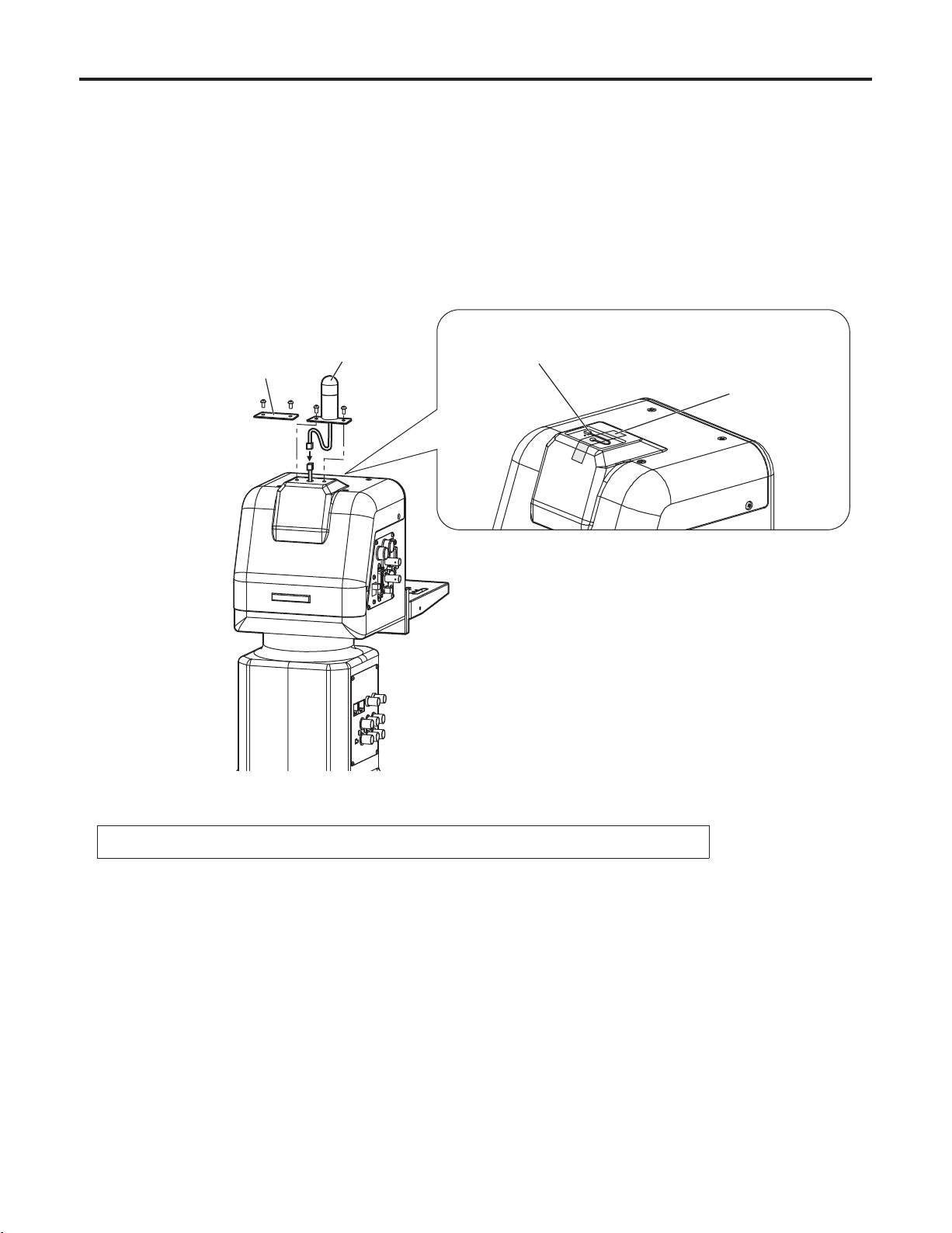

Mounting the tally lamp

Connect the cable connector which is taped to the top of the pan-tilt head to the tally cable connector.

Mount the tally lamp on the top of the pan-tilt head using the two screws provided.

Mount the lamp while paying attention to the wire.

The cable for the tally cable connector is about 50 mm long.

When connecting the cable to the connector, do not pull it out beyond this length.

If the tally lamp is not going to be used, insert the cable which is stuck to the top of the pan-tilt head inside the pan-tilt head,

and attach the blank panel for the tally lamp using the two screws provided.

Blank panel

Tally lamp

Tally cable connector

Taped

Note

Tighten up the screws securely to ensure that they will not come loose during use.

11 (E)

Page 13

Installation

Concerning the safety modes

This unit comes with two safety modes which are designed to safeguard the user and others from injury and to prevent damage

to the pan-tilt head.

1. Mode for ensuring safety in the case of collisions

When the rotary arm of the pan-tilt head or some other unit installed on the head keeps colliding with an obstruction or a

person (approx. 6 seconds when the head rotates at 45 degrees per second), the mode for ensuring safety in the case of

collisions is established.

In this mode, only the rotation of the head in the direction of the collision is stopped.

In the case of a low-speed collision, it will take longer for the safety mode to be established.

<Procedure for restoration from the safety mode>

The mode for ensuring safety in the case of collisions is released by bringing the joystick of the pan-tilt head controller

(such as the AW-RP655) back to its centre position.

A poor weight balance may cause the mode for ensuring safety in the case of collisions to be established.

Depending on the prevailing conditions, it may be necessary to adjust the balance, in which case consult your dealer.

2. Mode for ensuring safety in the case of trouble

When the pan-tilt head has detected trouble, the mode for ensuring safety in the case of trouble is established.

In this mode, the up/down and left/right rotation of the head is stopped.

<Procedure for restoration from the safety mode>

The mode for ensuring safety in the case of trouble is released by first pressing the POWER ON/OFF switch to turn off the

power and then by pressing the switch again to turn the power back on.

If the mode for ensuring safety in the case of trouble is established frequently, it may mean that the pan-tilt head is

malfunctioning. Consult your dealer.

ENGLISH

12 (E)

Page 14

Installation

Procedure for changing the settings of the CPU circuit board switches

Follow the steps below to change the settings of the CPU circuit board switches.

Remove the four screws, and gently remove the housing case.

Disconnect the tally cable connector.

Set the switches on the CPU circuit board.

After you have performed the settings, connect the tally cable connector, and then return the housing case to its original

position, and attach it using the screws. (Take care to ensure that the wiring is not pinched.)

Four screws

Note

Tally cable connector

Housing case

Magnification of the CPU circuit board

Be absolutely sure to turn off the power before changing the position of this switch.

13 (E)

Page 15

Installation

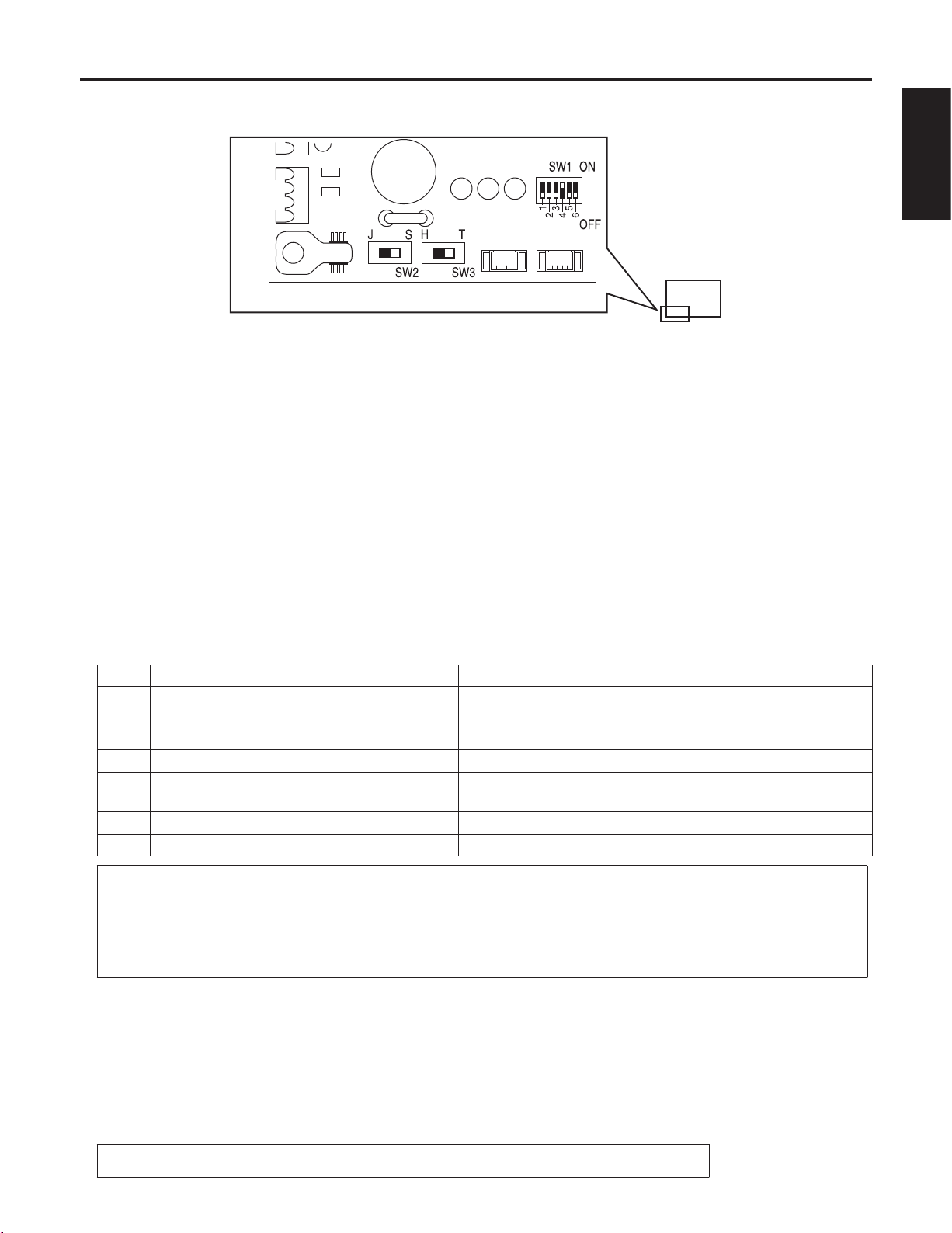

Setting the CPU circuit board switches

CPU circuit board

Magnification of the CPU circuit board

Setting SW1

These switches are used to set the operations of the AW-PH405. Before changing their settings, make sure that the power

has been turned off.

No.1: Auto focus (AF)/extender (EXT) selector switch.

Use this at the ON position when using an auto focus lens which is connected to the LENS I/F (1) connector; use it

at the OFF position when using a lens with a motorized extender connected to the ND/EXT connector.

No.2: Diagonal operation selector switch. Set this to ON to use the diagonal operation capability; set this to OFF to stop

using the diagonal operation capability.

The DIAGONAL MOTION menu setting can be changed from the AW-RP655 or other controller only when the

diagonal operation selector switch is at the ON position.

No.3: Tilt range selector switch. The tilt range is 300 degrees at ON and 190 degrees at OFF.

Settings can be changed from a personal computer or other external device only when the tilt range selector switch

is at the ON position.

No.4: Zoom offset automatic compensation switch of the lens which is connected to the LENS I/F (2) connector. This is

normally kept at the ON position for use.

Use this switch at the OFF position when zooming manually using the zoom seesaw switch of the lens.

When the zoom offset automatic compensation selector switch of the lens is set to ON, the zoom position will be

automatically compensated. For this reason, the zoom seesaw switch of the lens cannot be used to control the

zoom in the desired manner.

No.5, 6: These switches are not used. Do not change their factory settings.

ENGLISH

No. Functions ON OFF

No.1

Auto focus (AF)/extender (EXT) selector

No.2

Diagonal operation ON/OFF selector

No.3

Tilt range 300 degrees/190 degrees selector

Zoom offset automatic compensation ON/OFF

No.4

switching

No.5 Not used (used by the service technician) – (factory settings)

No.6 Not used (used by the service technician) – (factory settings)

The diagonal operation capability:

ON (factory settings)

300° (factory settings) 190°

Automatic compensation: ON

AF EXT (factory settings)

The diagonal operation capability:

(factory settings)

Automatic compensation: OFF

OFF

Concerning the zoom offset automatic compensation function

In the case of a lens which does not detect the control voltage used by the pan-tilt head to stop the zooming, a

difference in potential from the pan-tilt head side may arise, causing the zoom position to shift even when zoom control

is not exercised from the pan-tilt head controller (such as the AW-RP655). To prevent this phenomenon from occurring,

the zoom offset automatic compensation function works to automatically compensate the control voltage used by the

pan-tilt head to stop the zooming.

Setting the landing characteristics

When changing the landing characteristics, set the switch as follows:

Soft landing: Set SW2 to its right position (S). (factory settings)

Just landing: Set SW2 to its left position (J).

Setting the installation direction switch

For a ceiling installation, set the switch as follows:

Stand-alone installation: Set SW3 to its right position (T). (factory settings)

Installation on the ceiling: Set SW3 to its left position (H).

Note

Be absolutely sure to turn off the power before changing the position of this switch.

14 (E)

Page 16

Installation

Pan-tilt head mounting conditions

Pan-tilt

head weight

Approx. 10 kg

Mounting

specifications

Stand-alone

installation or

installation on

the celling

Compatible

cameras

Convertible

camera series

AW-E350

AW-E650

AW-E655

AW-E750

AW-E860

Multi-purpose

camera series

AK-HC1500G

Mounting the pan-tilt head

Recommended screws No. of screws

M6 screws (hexagonal nuts) 4 pcs

Notes

Refer to the above table for the total weight of the pan-tilt head with the camera, lens, cables and any

other accessories installed.

Install the equipment on an installation surface which is capable of ensuring a drop safety equivalent to

five times the figure for the total weight.

The maximum weight of the units which can be installed on the pan-tilt head is 15 kg or so (or

approximately 25 kg total for the weight of the pan-tilt head and weight of the units installed on the

head). When mounting the pan-tilt head on which units have been installed, be sure to mount it on an

installation surface which is itself capable of ensuring a satisfactory drop safety.

Camera

weight

Approx.

1.2 kg max.

Approx.

1.5 kg

Camera

anti-drop

measures

Wire provided

used for

mounting

Compatible

lenses

AW-LZ16MD55P

AW-LZ16MD73P

AW-LZ17MD9AG

HA21 series

HA22 series

HJ17e series

HJ21e series

Lens weight

Approx. 1.3 kg

Approx. 3.2 kg

max.

max.

Cable

weight

Approx. 0.3 kg

Total weight

Approx. 13 kg

Approx. 15 kg

Installing the pan-tilt head

Before installing the pan-tilt head, check that the above mounting conditions are satisfied, and observe the following precautions.

In order to prevent accidents resulting when the product becomes dislodged or falls down, be absolutely sure to proceed as

instructed. Do not install the pan-tilt head on its side since its prescribed operation and performance cannot be ensured.

After the pan-tilt head has been installed, mount the camera on it.

When installing the pan-tilt head, use the four mounting holes to secure the pan-tilt head firmly.

Ensure that the surface on which the pan-tilt head will be installed and the anchor bolts used are sufficiently strong.

Use the M6 hexagon head bolts (including one short bolt) for installation.

Use hexagon head bolts which are longer than the thickness (t) of the mounted member 25 mm.

As shown in the figure of next page, use flat washers, spring washers and hexagon nuts for the hexagon head bolts.

Use a wrench of the appropriate size to tighten up the hexagon head bolts.

Provide a wire which is strong enough to support the combined weight of the entire pan-tilt head system (which consists of the

pan-tilt head, camera, lens and cable).

Do not use a surface made of plaster board or wood as this kind of installation surface will not be strong enough. If mounting

on such a surface is unavoidable, take sufficient anti-drop measures.

Install the pan-tilt head in such a way that the equipment and cable attached to it will not make contact with any surrounding

objects when the head is swiveled.

When the unit is no longer going to be used, do not leave it in place, and be absolutely sure to remove it.

15 (E)

Page 17

Installation

For a stand-alone installation For installation on the ceiling

ENGLISH

Note

When installing the pan-tilt head, do not forcibly turn the rotary head or rotary arm

manually. Doing so may result in malfunctioning.

16 (E)

Page 18

Installation

Mounting the camera

[Convertible camera AW-E350/E650/E655/E750/E860]

When mounting the camera, take sufficient care to ensure that the camera will not come off or fall down.

Mount the lens onto the convertible camera.

(Before mounting a large lens, consult with your dealer.)

Mount the convertible camera after aligning it with the guide pins.

Use a tool to tighten up the mounting screws so that they are securely tightened.

For a stand-alone installation

Set the guide pin.

Mount the camera with the

mounting screws.

Mounting screws

For installation on the ceiling

<Recommended lenses>

Camera Lens

AW-E350

AW-E650

AW-E655

AW-E750

AW-E860

AW-LZ16MD55P

AW-LZ10MD6

AW-LZ16MD73P

AW-LZ16AF7G

AW-LZ17MD9AG

Set the guide pin.

Mount the camera with

the mounting screws.

Mounting screws

Be absolutely sure to use a screwdriver or other tool to tighten the two camera mounting screws

so that the camera is secured firmly.

After the camera has been mounted, check that there is no play in the way it was mounted.

17 (E)

Page 19

Installation

Attaching the wire

[Convertible camera AW-E350/E650/E655/E750/E860]

The camera comes with a wire for preventing the camera from dropping. Follow the instructions below to use it to couple the

camera to the pan-tilt head.

When mounting the cameras with fan (AW-E655, AW-E750, AW-E860)

Use the wire mounting screw (M48 mm with flat washer and spring washer) to attach one end of the wire to the pan-tilt

head’s arm.

Mount the mounting spacer on the top panel of the camera. (The mounting spacer is provided with the camera as an accessory.)

Use the wire mounting screw (M48 mm with flat washer and spring washer) to attach the other end of the wire to the screw

hole of the mounting spacer.

When mounting the cameras without fan (AW-E350, AW-E650)

Use the wire mounting screw (M48 mm with flat washer and spring washer) to attach one end of the wire to the pan-tilt

head’s arm.

Use the wire mounting screw (M48 mm with flat washer and spring washer) to attach the other end of the wire to the screw

hole of the top panel of the camera.

ENGLISH

For a stand-alone installation

Camera: AW-E750

M48 mm wire

mounting screw

with flat washer

and spring washer

Mounting spacer

( supplied with

AW-E750)

Wire

M48 mm wire

mounting screw

with flat washer

and spring washer

Arm

For installation on the ceiling

Camera: AW-E750

Camera: AW-E350, AW-E650 Camera: AW-E350, AW-E650

M48 mm wire

mounting screw

with flat washer and

spring washer

M48 mm

wire mounting

screw with flat

washer and

spring washer

Mounting spacer

( supplied with

AW-E750)

Be absolutely sure to tighten up the mounting spacer and screws securely using a tool such as a screwdriver.

18 (E)

Page 20

Installation

Mounting the camera

[Multi-purpose camera AK-HC1500G]

When mounting the camera, take sufficient care to ensure that the camera will not come off or fall down.

Mount the lens onto the multi-purpose camera.

(1) Lenses that can be used

• Use any of the portable lenses which are listed below.

Fujinon HA18, HA21, HA22 series

Canon HJ17e, HJ21e series

(2) Lenses that cannot be used

• Do not use the large-sized lenses (with a weight of 5 kg or more

and a length of 400 mm or more) with the model numbers which

are listed below since when they are mounted on the camera,

the camera’s overall balance will be upset.

Fujinon HA42 series

Canon HJ40 series, J35 series

Align the multi-purpose camera with the guide pins and mount it.

Change the positions of the guide pins and screws of the camera mounting base as shown in the figure below, and then

attach the camera mounting base to the rotary arm.

Do not use the rubber piece.

Note

The current rating of LENS

I/F (2) connector is 500 mA

(max).

Even with the lenses in a

series which can be used,

any lens whose maximum

current consumption

exceeds 500 mA cannot be

used.

Concerning the maximum

current consumption of

the lens, contact the lens

manufacturer.

For a stand-alone installation

Camera Mounting base

Change the positions

of the guide pins.

Change the positions of the camera mounting

screws. (Change them over to the second row.)

Tighten up the two mounting screws securely using the tool.

For installation on the ceiling

Camera Mounting base

Change the positions

of the guide pins.

Set the guide pin.

Mount the camera

with the mounting

screws.

Mounting screws

Set the guide pin.

Mount the camera with

the mounting screws.

Change the positions of the camera mounting

screws. (Change them over to the third row.)

Just as for a convertible camera, change the positions of the guide pins and screws of the camera mounting base as shown

in the figure above, and then attach the camera mounting base to the rotary arm.

Mounting screws

19 (E)

Page 21

Installation

Concerning the balance of the installed unit

The weight balance may be impaired when the pan-tilt head is used in combination with a camera and long lens.

Follow steps to below to check the balance, and then mount the camera. If, after this, the balance is still impaired and

operations cannot be performed smoothly, it means that the balance must be adjusted. Consult your dealer.

How to obtain the balance

Check the centre of gravity position with the camera and lens set up on the pan-tilt head.

Position where the balance between left and

right is attained (centre of gravity)

The less the deviation between the centre of gravity position and the head’s centre of rotation, the more the balance is

attained. Check these positions when mounting the pan-tilt head.

ENGLISH

Head’s centre of rotation

Deviation between centre of gravity position

and the head’s centre of rotation

If the proper balance cannot be attained in steps and , re-attach the camera mounting base and rotary arm to shift the

position of the entire camera so that the centre of gravity position is brought closer to the head’s centre of rotation.

When doing this, bear in mind the following points.

(1) Depending on the specifications of the lens and its installation direction, the protruding parts of the lens or grip area may

come into contact with the rotary arm or other parts, in which case do not re-attach the camera mounting base and rotary

arm.

(2) If the protrusion of the connectors from the camera makes contact with the mounting surface of the pan-tilt head, insert a

spacer as described on the next page between the pan-tilt head and mounting surface or set the limiters.

(3) Be absolutely sure to secure the camera mounting base and rotary arm firmly using the three screws.

Centre of gravity position with camera and

lens set up

Head’s centre of rotation

Camera mounting base

Re-attach the camera

mounting base to a

position further back.

Rotary arm

Minimize the deviation between

the centre of gravity position

and the head’s centre of

rotation here.

20 (E)

Centre of gravity position

with camera and lens set up

Page 22

Installation

Precautions for mounting the camera

Bearing in mind the length of the lens, set the movement range of the pan-tilt head using the limiters in such a way that the

hood at the edge of the lens will not come into contact with the surface on which the pan-tilt head is installed when the pan-tilt

head is tilted.

Note

To point the lens any further straight down in a

stand-alone installation, insert a spacer between

the pan-tilt head and mounting surface to raise the

pan-tilt head position.

Make sure that the spacer has a strong enough

construction. Also ensure that the mounting bolts

used are long enough.

Spacer

Lens must not come into contact with

mounting surface.

When the pan-tilt head is installed on the ceiling, contact with the pan-tilt head body may be made by the protrusion of the

drive unit when tilting operations are performed. For this reason, set the limiters before proceeding with the installation work.

Protrusion of drive unit

must not come into contact

with pan-tilt head body.

Do not tie the connected lens cable and camera cable together as a bundle. During operation, excessive strain may be placed

on cables which have been bundled together. Instead, be absolutely sure to tie them separately.

Be absolutely sure to use a screwdriver or other tool to tighten the two camera mounting screws

so that the camera is secured firmly.

After the camera has been mounted, check that there is no play in the way it was mounted.

21 (E)

Page 23

Installation

Attaching the wire

[Multi-purpose camera AK-HC1500G]

The camera comes with a wire for preventing the camera from dropping. Follow the instructions below to use it to couple the

camera to the pan-tilt head.

Use the wire mounting screw (M48 mm with flat washer and spring washer) to attach one end of the wire to the pan-tilt

head’s arm.

Use the wire mounting screw (Inch screw with flat washer and spring washer) to attach the other end of the wire on the top

panel of the camera.

ENGLISH

For a stand-alone installation

Camera: AK-HC1500G

Wire mounting

screw (Inch

screw with flat

washer and

spring washer)

M48 mm wire

mounting screw with

flat washer and spring

washer

Wire

Arm

For installation on the ceiling

Camera: AK-HC1500G

M48 mm wire mounting

screw with flat washer and

spring washer

Wire mounting

screw (Inch screw

with flat washer and

spring washer)

Be absolutely sure to tighten up the screws securely using a tool such as a screwdriver.

22 (E)

Page 24

Connections

Turn off the power of all the equipment before proceeding with the connections.

Connect the AC power cable supplied with the AW-PH405 for the AW-PH405 indoor pan-tilt head.

Use 10BASE-T straight cables to connect the RP connectors on the pan-tilt heads with the CONTROL OUT TO PAN/TILT

HEAD (1 to 5) connectors on the AW-RP655 multi-function controller and AW-RP555 multi hybrid control panel. The maximum

extension distance is 1000 meters when using UTP category 5 cables or their equivalent.

Use the camera cables supplied with the pan-tilt head to connect the AW-PH405 to the convertible camera.

Connect the iris control cable of the motorized zoom lens to the IRIS connector on the camera, and connect the zoom/focus

cable to the LENS I/F (1) connector on the pan-tilt head.

For a convertible camera

Motorized zoom lens Iris control cable

To the

10BASE-T

straight cable

LENS I/F (1)

connector

AW-PH405

Indoor Pan-tilt Head

Pan-tilt head/camera control signals

Zoom/focus

control cable

Camera cable

supplied with

AW-PH405

AW-RP655

Multi-function controller

AW-CB400

Remote operation

panel

AW-RP555

Multi Hybrid Control Panel

AW-RP400

Pan-tilt control panel

AW-PS505A

AC adapter

AW-PS505A

AC adapter

Convertible camera

BNC cable video signal

AC power cable

supplied with

AW-PH405

Monitor

• AW-IF400

Switch settings

SW1 SW2

ON ON OFF OFF OFF OFF

AW-IF400

Protocol converter

SET UP

1 2 3 4

23 (E)

AW-PS505A

AC adapter

AW-PS505A

AC adapter

Page 25

Connections

For the AK-HC1500G

Note

10BASE-T

straight cable

Set the menu items to protocol 4.

Pan-tilt head/camera control signals

AW-RP555

Multi Hybrid Control Panel

Motorized zoom lens Iris control cable

To the

LENS I/F (1)

connector

AW-PH405

Indoor Pan-tilt Head

AW-PS505A

AC adapter

Zoom/focus

control cable

HD SDI video signal

ENGLISH

Camera cable

AW-CA15H29G

AC power cable

supplied with

AW-PH405

• AW-IF400

AW-RP655

Multi-function controller

AW-RP400

Pan-tilt control panel

AW-CB400

Remote operation

panel

AW-PS505A

AC adapter

AW-PS505A

AC adapter

Use the connecting cables below to connect the pan-tilt head and camera.

AW-CA15H29G

Refer to the operating instructions for using the connecting cable to ensure that it is connected properly.

Switch settings

SW1 SW2

ON ON OFF OFF OFF OFF

AW-IF400

Protocol converter

Monitor

SET UP

1 2 3 4

AW-PS505A

AC adapter

24 (E)

Page 26

Cable specifications

When connecting a Canon lens with motorized extender unit

Connector: HR10A-10P-10P (73)

made by Hirose Electric

CVCC (12 V)

CGND

EXT Return

EXT Signal

ND Return

ND Signal

CanonEXT ()

CanonEXT ()

GND

GND

SHELL

Connect this connector to the ND/EXT

connector on the pan-tilt head

When connecting a Fujinon extender change unit

Connector: HR10A-7P-6S (73)

made by Hirose Electric

SHELL

Connect this connector

to the EXT connector on

the lens

Connector: HR10A-10P-10P (73)

Connector: HR10A-7P-5P (73)

made by Hirose Electric

CVCC (12 V)

CGND

EXT Return

EXT Signal

ND Return

ND Signal

CanonEXT ()

CanonEXT ()

GND

GND

SHELL

Connect this connector to the ND/EXT

connector on the pan-tilt head

SHELL

Connect this connector

to the 5-pin connector on

the extender change unit

For details on how to connect the extender change unit to the lens, consult the information

provided by the manufacturer of the lens.

made by Hirose Electric

25 (E)

Page 27

Replacing the consumable parts

Replacing the motor

Replace the motor when it ceases to operate properly.

For details on the motor replacement, consult your dealer.

Replacing the belt

Replace the belt when the preset stop accuracy has deteriorated.

For details on the belt replacement, consult your dealer.

Replacing the gear

Replace the gear when the preset stop accuracy has deteriorated.

For details on the gear replacement, consult your dealer.

ENGLISH

The motor, gear and belt are consumables.

They need to be replaced at periodic intervals.

As a general guideline, replace them when the cumulative

total time for all the rotation operations reaches 3,000 hours.

26 (E)

Page 28

Appearance

Unit: mm

319

137 182

ø146

71

97

ø160

168

42

165209

416

47

ø160

ø146

ø160

<Mounting hole specifications>

27 (E)

4-M6 screws

Page 29

Specifications

Supply voltage: AC 220 to 240 V, 50 Hz

Power consumption: 120 W

indicates safety information.

Genlock input: BNC

Black burst or composite video signal, Tri Sync

Prompter input

(PROMPTER IN): BNC

Prompter output

(PROMPTER OUT): D-SUB 15-pin

Camera video output

VIDEO: BNC, 75-ohm output

Y: BNC, 75-ohm output

Pr/C: BNC, 75-ohm output

Pb: BNC, 75-ohm output

SDI: BNC

AUX: BNC

Camera, pan-tilt head control: RJ45, RS-422, pan-tilt head control signal output

RP Connecting cable: 10BASE-T straight cable (equivalent to UTP category 5),

Functions/performance: Maximum weight capacity: 15 kg

Pan range: 300 degrees (approx. ±150 degrees)

(Maximum operating speed with prompter mounted: 15 degrees/sec.)

Stop accuracy: ±3´

Through output to PROMPTER connector

max. 1000 meters

Tilt range: 300 degrees (approx. ±150 degrees)

The tilt range is subject to restrictions depending on the cable and lens of camera to be

mounted on pan-tilt head.

Maximum operating speed: 45 degrees/sec.

( when the centre of gravity of the units installed on the pan-tilt head has been aligned with

the head’s centre of rotation)

Noise level: Less than NC35 (at less than 30 degrees/sec.)

ENGLISH

Ambient operating temperature: –5°C to +45°C

Storage temperature: –20°C to +65°C

Ambient operating humidity: 30% to 90% (no condensation)

Dimensions (WHD): 319416168 mm

Weight: Approx. 10 kg

Finish: AV ivory paint (colour resembling Munsell 7.9Y6.8/0.8)

Weight and Dimensions indicated above are approximate.

Specifications are subject to change without notice.

28 (E)

Page 30

РУССКАЯ ВЕРСИЯ

(RUSSIAN VERSION)

Меры предосторожности

НЕ ОТВИНЧИВАЙТЕ КРЫШКИ ПАНЕЛЕЙ.

Для снижения риска удара электрическим током не снимайте

панели. Внутри устройства нет деталей, подлежащих

обслуживанию пользователем.

Обратитесь за сервисным обслуживанием к

квалифицированному персоналу.

ОСТОРОЖНО:

ДЛЯ СНИЖЕНИЯ РИСКА ВОЗНИКНОВЕНИЯ ПОЖАРА ИЛИ

УДАРА ЭЛЕКТРИЧЕСКИМ ТОКОМ И ВОЗНИКНОВЕНИЯ

ПОМЕХ ИСПОЛЬЗУЙТЕ ТОЛЬКО РЕКОМЕНДУЕМЫЕ

ДОПОЛНИТЕЛЬНЫЕ ПРИНАДЛЕЖНОСТИ.

ВНИМАНИЕ:

•

ДЛЯ СНИЖ ЕНИЯ РИС КА ВОЗН ИКНОВ ЕНИЯ ПОЖАРА

ИЛИ УДАРА ЭЛЕКТРИЧЕСКИМ ТОКОМ НЕ ПОДВЕРГАЙТЕ

ДАННОЕ ОБОРУДОВАНИЕ ВОЗДЕЙСТВИЮ ДОЖДЯ ИЛИ

ВЛАГИ.

•

НЕ ПОДВЕРГАЙТЕ АППАРАТ ВОЗДЕЙСТВИЮ КАПЕЛЬ ИЛИ

БРЫЗГ ЖИДКОСТЕЙ; ТАКЖЕ НЕ СТАВЬТЕ НА АППАРАТ

КАКИЕ-ЛИБО ЕМКОСТИ, НАПОЛНЕННЫЕ ЖИДКОСТЬЮ,

ТАКИЕ КАК ВАЗЫ.

ВНИМАНИЕ:

ВО ИЗБЕЖАНИЕ ПОВРЕЖДЕНИЯ ДАННЫЙ ПРИБОР

ДОЛЖЕН БЫТЬ НАДЕЖНО ЗАКРЕПЛЕН НА ПОЛУ/

СТЕНЕ В СООТВЕТСТВИИ С ИНСТРУКЦИЕЙ ПО

УСТАНОВКЕ.

ОСТОРОЖНО:

ДЛЯ СНИЖЕНИЯ РИСКА ПОЖАРА ИЛИ ПОРАЖЕНИЯ ТОКОМ

ИЗМЕНЕНИЯ РЕГУЛИРОВКИ ВЫКЛЮЧАТЕЛЯ ВНУТРИ

ДОЛЖНЫ ПРОИЗВОДИТЬСЯ КВАЛИФИЦИРОВАННЫМ

СЕРВИСНЫМ ПЕРСОНАЛОМ.

ОСТОРОЖНО:

Для обеспечения надлежащей вентиляции не

устанавливайте и не размещайте данное устройство на

книжном стеллаже, во встроенном шкафу или в другом

закрытом пространстве. Для предотвращения риска

поражения электрическим током или опасности возгорания

вследствие перегрева убедитесь, что занавески или другие

материалы не препятствуют вентиляции.

Сетевaя штепcельнaя вилкa или пpибopный coединитель

дoлжны ocтaвaтьcя гoтoвыми к paбoте.

Имейте в виду, что аппарат, относящийся по конструкции к

КЛАССУ 1, следует подключать к СЕТЕВОЙ розетке с защитным

заземлением.

Данный знак обозначает информацию,

относящуюся к технике безопасности.

1 (R)

Page 31

Информация для пользователей по утилизации электрического и электронного оборудования

(бытового использования)

Данный символ на изделиях и/или сопутствующих документах означает, что применяемые электрические и

электронные изделия не следует выбрасывать вместе с остальными бытовыми отходами.

Для проведения надлежащего ухода, восстановления и утилизации, пожалуйста, доставьте данные устройства

в обозначенные пункты приема, где они будут приняты бесплатно. Кроме того, в некоторых странах у Вас может

быть возможность вернуть Ваши изделия местному распространителю в счет приобретения эквивалентного нового

изделия.

Правильная утилизация данного изделия поможет в сохранении ценных ресурсов и предотвратит любое возможное

отрицательное влияние на здоровья человека и состояние окружающей среды, которое могло бы возникнуть при неправильном

обращении с отходами.

Для получения подробной информации о ближайшей к вам точке сбора утиля, пожалуйста, свяжитесь с местными властями.

В соответствии с национальным законодательством за неправильную утилизацию данного изделия может быть назначен штраф.

Для бизнес-пользователей Европейского союза

Если Вы хотите утилизировать электрическое и электронное оборудование, для получения дополнительной информации,

пожалуйста, свяжитесь с Вашим дилером или поставщиком.

Информация по утилизации в других странах за пределами Европейского союза

Данный символ имеет силу только в Европейском союзе.

Если Вы хотите утилизировать данное изделие, пожалуйста, свяжитесь с Вашими местными властями или дилером и узнайте

корректный способ утилизации.

2 (R)

РУССКИЙ

Page 32

Содержание

Меры предосторожности ................................................................................................................................... 1

Меры предосторожности во время использования ..................................................................................... 4

Введение ............................................................................................................................................................... 4

Принадлежности .................................................................................................................................................. 5

Предосторожности по установке ..................................................................................................................... 5

Компоненты и их функции ................................................................................................................................ 6

Установка ............................................................................................................................................................ 10

Сборка наклонно-поворотной головки ...................................................................................................... 10

Режимы безопасности устройства ............................................................................................................. 12

Процедура изменения установки переключателей платы ЦПУ .............................................................. 13

Установка переключателей на плате ЦПУ ................................................................................................ 14

Условия крепления наклонно-поворотной головки .................................................................................. 15

Монтаж наклонно-поворотной головки ...................................................................................................... 15

Установка камеры (Съемная камера AW-E350/E650/E655/E750/E860) .................................................. 17

Присоединение троса (Съемная камера AW-E350/E650/E655/E750/E860) ........................................... 18

Установка камеры (Многоцелевая камера серии AK-HC1500G) ............................................................. 19

Сведения о балансировке установленного оборудования ...................................................................... 20

Присоединение троса (Многоцелевая камера серии AK-HC1500G) ....................................................... 22

Соединения ........................................................................................................................................................ 23

Технические характеристики кабеля ............................................................................................................. 25

Замена изнашиваемых деталей ..................................................................................................................... 26

Внешний вид ...................................................................................................................................................... 27

Технические характеристики ........................................................................................................................... 28

3 (R)

Page 33

Меры предосторожности во время использования

Соблюдайте меры безопасности при

транспортировке устройств.

При падении или при сильном ударе устройств может

произойти нарушение их работоспособности или

возникновение аварийных ситуаций.

Выключайте питание перед соединением или

отсоединением кабелей.

Перед соединением или отсоединением кабелей

обязательно убедитесь в том, что питание выключено.

Установите устройство возле сетевой розетки

питания и расположите его таким образом,

чтобы вилка питания легко вставлялась в

Не используйте устройства вне помещения.

Техобслуживание

Протирайте устройство сухой тряпкой. Для удаления

несмываемой грязи смочите тряпку в разбавленном

растворе кухонного чистящего средства, тщательно

отожмите ее и аккуратно протрите устройство.

<Осторожно>

Не используйте бензин, растворители красок и

другие легкоиспаряющиеся жидкости.

При необходимости использования материалов

химической очистки внимательно ознакомьтесь с

инструкцией по их применению.

розетку и вынималась из нее.

Введение

Автономная внутренняя наклонно-поворотная головка может поворачиваться на 300 градусов в вертикальном

направлении и на 300 градусов в горизонтальном направлении.

Повороты могут выполняться с максимальной скоростью до 45 градусов в секунду.

На наклонно-поворотной головке могут крепиться такие устройства, как камера с объективом, суммарным весом до 15 кг.

В предварительной памяти данных можно записать до 50 позиций положения камеры.

При использовании AW-IF400 для подключения AW-RP400 к устройству

• Невозможно использовать функцию трассировки памяти.

• Нельзя задать диапазон углов наклона TILT RANGE.

• Невозможно установить значение параметра MEMORY LENGTH.

• Нельзя задать значения ON или OFF для параметра DIAGONAL MOTION.

• Невозможна компенсация люфта.

• При переключении значения ON/OFF автофокуса (AF) и экстендера (EXT) через AW-RP400, используйте

OPTION SW после присвоения ему функции “EXT”.

При использовании объективов IAS, WAS или VAS производства Canon, объектива RD производства Fujinon

• Связь с контроллером наклонно-поворотной головки (например, AW-RP655) начинается сразу после

включения AW-PH405. Аналогично, процесс инициализации объектива начинается при включении питания

камеры. В процессе инициализации увеличение устанавливается автоматически и невозможно выполнение

функций управления контроллером наклонно-поворотной головки (например, AW-RP655).

• По завершении процесса инициализации не следует производить настройку регулятора скорости увеличения

объектива. Для регулировки этой скорости, сначала отключите питание AW-PH405, а затем продолжайте

процесс настройки.

• При положении ON переключателя автоматической компенсации изменения увеличения производится

автоматическая компенсация параметра увеличения. Поэтому невозможно правильное использование

самовозвратного регулятора увеличения объектива.

• После смены объектива камеры следует повторно выполнить функции настройки и трассировки памяти. Если

сохранить исходные настройки этих функций, увеличение объектива будет работать неправильно.

Примечания

Устройство AW-PH405 не может управляться от контроллеров AW-RP301, AW-RP305, AW-RP501, AW-RP505.

Не допускается применение устройства поворота камеры AW-RL400.

Нагрузка по току разъема LENS I/F (2) составляет 500 мА (макс.).

Не допускается использовать объективы, максимальная нагрузка по току которых превышает 500 мА.

Информацию о максимальном потреблении тока можно получить у производителя объектива.

В целях защиты окружающей среды при отбраковке

наклонно-поворотного устройства по завершении срока его службы обратитесь в

специализированную организацию в целях правильной утилизации.

Для некоторых объективов, установленных на камере, фокусировки и другие операции могут

выполняться в противоположном направлении.

Для обеспечения правильного направления выполнения этих операций следует правильно установить

значение параметра DIRECTION контроллера наклонно-поворотной головки (например, AW-RP655).

Если не предполагается использовать объектив с автофокусировкой, следует установить

переключатель выбора автофокуса (AF)/экстендера (EXT) (SW1: №.1) на AW-PH405 в положение OFF.

Если этот переключатель находится в положении ON и кнопка EXT (AF) контроллера наклонно-поворотной

головки (например, AW-RP655) также включена, управление фокусировкой невозможно.

РУССКИЙ

4 (R)

Page 34

Принадлежности

Инструкция по эксплуатации ........................................ 1

Поворотное плечо .......................................................... 1

Подставка для крепления камеры .............................. 1

Крепежные винты поворотного плеча и подставки

для крепления камеры

(с плоскими шайбами, пружинными шайбами)

M5

Кабель камеры ................................................................ 1

Индикаторная лампа ...................................................... 1

Винты крепления ярлыка (M36 мм) .......................... 2

22 мм .............................................................. 7

Глухая панель для ярлыка ........................................... 1

Винты крепления троса

(с плоскими шайбами, пружинными шайбами)

M4

Винт с дюймовой резьбой ............................................ 1

Торцевой шестигранный ключ ..................................... 1

Кабель сети питания переменного тока ..................... 2

Трос защиты камеры от падения ................................. 1

8 мм ................................................................ 2

Предосторожности по установке

Не ставьте устройство на боковые стороны.

Не устанавливайте устройство на кухне и в других

помещениях со значительными водными и масляными

испарениями.

Крепить камеру на наклонно-поворотной головке

можно только после полной ее установки.

Максимальный вес, допустимый для данного

устройства составляет 15 кг.

Не применяйте объективы, которые могут ослабить

или нарушить балансировку устройства.

Даже если весовая нагрузка на устройство не

превышает 15 кг, нельзя использовать камеру с

объективом, нарушающим балансировку.

Не устанавливайте устройство вне помещения, или в

местах, где температура поднимается выше 45°C, или

опускается ниже –5°C.

Применение устройства допускается только в тех

местах, где влажность не превышает 90%.

Винты, необходимые для монтажа устройства, следует

приобрести отдельно, поскольку они не входят в

комплект поставки.

Не держите и не поднимайте устройство

за поворотные части. В противном случае

работоспособность устройства может нарушиться.

Не подключайте обычную сетевую линию LAN или

телефонную линию к разъему CONTROL IN RP или

к разъему COM устройства. В противном случае

работоспособность устройства может нарушиться.

Монтаж устройства высоко над уровнем пола

или земли должен выполняться исключительно

квалифицированным персоналом сервисных фирм.

Не трогайте вращающиеся части устройства руками.

В противном случае работоспособность устройства

может нарушиться.

Падение устройства, или сильные удары по нему

могут существенно ухудшить работоспособность.

При установке устройства оставляйте свободный

промежуток вокруг монитора не менее 1 метра.

При креплении камеры на устройстве, принимайте

меры для того, чтобы камера не отсоединилась от

него и не упала на пол.

Длина троса крепления предотвращает падение

камеры. Внимательно ознакомьтесь с инструкцией

по эксплуатации и обязательно убедитесь в том,

что трос прикреплен и примите необходимые меры,

предотвращающие возможность падения камеры.

Монтируйте устройство таким образом, чтобы

установленное на нем оборудование и кабеля не

соприкасались с другими предметами при вращении

наклонно-поворотной головки, и задайте нужные

пределы перемещения.

(

Подробная информация об установке ограничителей

приведена в инструкции по эксплуатации контроллера.

Если дальнейшая эксплуатация устройства не

предполагается, не оставляйте его на месте, а

обязательно демонтируйте устройство.

)

5 (R)

Page 35

Компоненты и их функции

6 (R)

РУССКИЙ

Page 36

Компоненты и их функции

Поворотная головка

Предназначена для вращения камеры в

горизонтальном направлении.

Подставка

Выключатель питания POWER ON/OFF

Когда эта кнопка нажата, питание устройства

включено, а когда она отжата, питание выключено.

Входной разъем переменного напряжения

[AC IN]

(3-контактное гнездо переменного напряжения)

Подключите к этому гнезду кабель переменного

напряжения питания, который входит в комплект

принадлежностей.

Винты крепления камеры к подставке

Винты с шестигранной головкой под торцевой ключ

M522 мм (с плоскими шайбами, пружинными

шайбами) (в комплект принадлежностей входит по

3 шт.)

Эти детали нужны для крепления подставки камеры к

поворотному плечу.

Индикаторная лампа (принадлежности)

Эта лампа светится красным светом при поступлении

выбранных сигналов.

Винты крепления поворотного плеча

Винты с шестигранной головкой под торцевой ключ

M522 мм (с плоскими шайбами, пружинными

шайбами) (в комплект принадлежностей входит по

4 шт.)

Эти детали нужны для крепления подставки камеры к

поворотному плечу.

Поворотное плечо

Предназначено для вращения в вертикальном

направлении.

Подставка для крепления камеры

Эта подставка служит для установки съемной или

многоцелевой камеры.

Разъем PROMPTER

К этому разъему подключается телесуфлер.

Максимальный ток, потребляемый от гнезда

постоянного напряжения 12 V OUT составляет 2,5 А.

При подключенном телесуфлере, скорость

перемещения наклонно-поворотной головки

уменьшается приблизительно на треть.

При подключении телесуфлера обязательно

убедитесь в том, что закорочены выводы DETECT

(Контакт №14) и вывод GND (Контакт №15).

Примечание

Расположение контактов со

стороны разъема телесуфлера

Контакт №

1 – – –

9 – – –

2 PROMPTER VIDEO

10 PROMPTER VIDEO GND

3 – – –

11 – – –

4 DC 12 V OUT

12 – – –

5 GND

13 – – –

6 – – –

14 DETECT

7 – – –

15 GND

8 – – –

Проконсультируйтесь со своим

поставщиком при установке

телесуфлера, поскольку

необходимо соблюдать баланс

между крепежными деталями и

общим весом устройства, а также

выяснить другие вопросы.

Наименование сигнала

Отверстия крепления наклонно/поворотного

устройства

Эти четыре отверстия служат для монтажа наклонно/

поворотного устройства.

Нижняя панель

Устанавливайте эту панель при использовании

устройства.

Направляющий штырь

Задает направление крепления камеры.

Винты крепления камеры (U1/4” 20UNC)

Служат для надежной фиксации камеры после ее

установки.

Боковая глухая панель

Устанавливайте эту панель для нормальной работы

устройства.

7 (R)

Page 37

Компоненты и их функции

Панель подключения поворотной головки

Разъем ND/EXT [ND/EXT]

TСлужит для управления ND фильтром и

экстендером объектива с электромеханическим

приводом.

Нужно подключить этот разъем при использовании

объектива с электромеханическим приводом

с функциями ND фильтра и экстендера. Для

подключения этого разъема необходим кабель,

указанный в разделе “Спецификации кабеля” на

странице 25.

CVCC (12 V)CanonEXT ()

CanonEXT ()

ND Signal

( Расположение контактов со стороны

оконечного разъема кабеля)

Hагрузка по току на контактах CVCC и CGND

составляет 500 мА (макс.). Недопустимо использовать

любые устройства, максимальное потребление тока

которыми превышает 500 мА.

CGND

EXT Return

EXT SignalND Return

LENS I/F (2) разъем [LENS I/F (2)]

Используется в случае применения объективов IAS,

WAS или VAS производства Canon, или объектива RD

производства Fujinon.

Для подключения объектива к разъему необходим

дополнительный соединительный кабель.

Hагрузка по току разъема LENS I/F (2) составляет

500 мA (макс.).

Недопустимо использовать объективы, максимальное

потребление тока которыми превышает 500 мА.

Информацию о максимальном потреблении тока

можно получить у производителя объектива.

Объектив Кабель

Canon

Цифровой

Аналоговый

Fujinon AW-CA4FLZG

Примечание

AW-CA4DLZG

AW-CA4ALZG

Для правильного подключения

соединительного кабеля

обратитесь к соответствующим

инструкциям.

Переключатель LENS P/S ON/OFF [LENS P/S]

При положении ON этого переключателя, питание

на объектив подается с разъема LENS I/F (1). При

положении OFF питание на объектив с разъема LENS

I/F (1) не подается.

Установите этот переключатель в положение OFF

при подаче питания от внешнего источника без

использования специального кабеля из комплекта

камеры AW-PH405.

LENS I/F (1) разъем [LENS I/F (1)]

Служит для управления увеличением и фокусировкой

объектива с электромеханическим приводом.

Для подключения используйте специальный кабель

дистанционного управления (увеличение/фокус)

объектива.

Разъем CAMERA I/F [CAMERA I/F]

Служит для управления съемной камерой.

Используйте специальный кабель из комплекта

поставки AW-PH405 для соединения этого разъема с

разъемом REMOTE на камере.

В зависимости от функций дополнительной платы

может потребоваться специальный кабель камеры

(продается отдельно).

Разъем SDI IN [SDI IN]

С помощью коаксиального кабеля подключите этот

разъем к разъему SDI OUT платы AW-PB504 SDI, или

другой платы, установленной в съемной камере.

Разъем AUX IN [AUX IN]

Этот разъем с помощью BNC коаксиального кабеля

подключается к разъему SDI OUT платы AW-PB504

SDI, или другой платы, установленной в съемной

камере, или к VBS разъему AK-HDC1500G или другой

панели преобразователя с понижением частоты,

установленной в многоцелевой камере AK-HC1500G.

Переключатель TALLY OFF/ON [TALLY]

Когда этот переключатель находится в положении

ON, индикаторная лампа светится при поступлении

выбранных сигналов. Если этот переключатель

находится в положении OFF, () индикаторная

лампа не светится даже при поступлении выбранных

сигналов.

РУССКИЙ

8 (R)

Page 38

Компоненты и их функции

Панель подключения подставки

Разъем CONTROL IN RP [RP]

Через этот разъем передаются управляющие сигналы

камеры и наклонно-поворотной головки.

Он подключается к разъему TO PAN/TILT HEAD

многофункционального контроллера AW-RP655 и к

гибридной управляющей панели AW-RP555.

Для подключения используйте линейный кабель

10BASE-T (адекватный категории UTP 5).

Разъем COM [COM]

Этот разъем предназначен для вывода управляющих

сигналов, которые служат для расширения

функциональных возможностей камеры.

Разъем VIDEO [VIDEO]

Это выходной разъем видеосигналов сменная

камера.

Он подключается к разъему Y/VIDEO блок

компенсации кабеля, или монитора, и т.д.

Для этого подключения следует использовать BNC

коаксиальный кабель.

Переключатель CABLE COMP OFF/ON

[CABLE COMP]

Когда этот переключатель находится в положении

ON, сигналы, скомпенсированные на длину кабеля,

эквивалентную длине 500 метров выводятся на

разъем VIDEO и на разъемы Y, Pr и Pb.

Если этот переключатель включен в сочетании

с блоком компенсации кабеля AW-RC400, длину

видеокабеля можно увеличить максимум до

1000 метров.

Разъем Y [Y]

Это выходной разъем видеосигналов камеры.

Он подключается к разъему Y/VIDEO блока

компенсации кабеля AW-RC400, монитора, и т.д.

Для этого подключения следует использовать BNC

коаксиальный кабель.

Разъем AUX [AUX]

Это выходной разъем видеосигналов камеры.

Он обеспечивает вывод сигналов SDI, сигналов VBS,

и т.д., подаваемых через BNC коаксиальный кабель

на разъем AUX IN.

Для подключения используйте BNC коаксиальный

кабель.

Для сигналов, которые выводятся с этого разъема, не