Page 1

Before attempting to connect, operate or adjust this product, please

read these instructions completely.

Indoor pan-tilt head

Model AW- P

F1101W

@

Printed in Japan

VQT9583

P

Page 2

2

indicates safety information.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE COVER (OR BACK).

NO USER SERVICEABLE PARTS INSIDE.

REFER TO SERVICING TO QUALIFIED SERVICE PERSONNEL.

The lightning flash with arrowhead symbol, within an equilateral triangle,

is intended to alert the user to the presence of uninsulated “dangerous

voltage” within the product’s enclosure that may be of sufficient

magnitude to constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle is intended to alert the

user to the presence of important operating and maintenance (service)

instructions in the literature accompanying the appliance.

WARNING:

TO REDUCE THE RISK OF FIRE OR SHOCK HAZARD, DO NOT

EXPOSE THIS EQUIPMENT TO RAIN OR MOISTURE.

CAUTION:

TO REDUCE THE RISK OF FIRE OR SHOCK HAZARD AND ANNOYING

INTERFERENCE, USE THE RECOMMENDED ACCESSORIES ONLY.

CAUTION:

TO REDUCE THE RISK OF FIRE OR SHOCK HAZARD, REFER

CHANGE OF SWITCH SETTING INSIDE THE UNIT TO QUALIFIED

SERVICE PERSONNEL.

Page 3

3

indicates safety information.

Replace battery with part No. CR2032 only.

Use of another battery may present a risk of fire or explosion.

Caution—Battery may explode if mistreated.

Do not recharge, disassemble or dispose of in fire.

FCC Note:

This device complies with Part 15 of the FCC Rules. To assure continued

compliance follow the attached installation instructions and do not make any

unauthorized modifications.

This equipment has been tested and found to comply with the limits for a class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his

own expense.

Page 4

4

OThis is a compact stand-alone type of

pan-tilt head which is capable of rotating

95 degrees upward and downward and

300 degrees on the horizontal.

OThis pan-tilt head can bear a total weight

of up to 8.8 lb (4 kg) for the camera and

lens combined.

OThe pan-tilt head can be controlled

directly using the Multi-Function

Controller (AW-RP605). Up to five pantilt heads can be connected to the MultiFunction Controller (AW-RP605).

OThe pan-tilt head can be controlled from

a PC, etc. by converting RS-232C to RS-

422.

OThe positions and settings for shooting

up to 50 points can be entered as data

into the preset memory.

Introduction

Tilting arm . . . . . . . . . . . . . . . . . . . . . .(a1)

Tilting arm fixing screws

M4a12 mm . . . . . . . . . . . . . . . . . . .(a4)

Safety chain . . . . . . . . . . . . . . . . . . . .(a1)

Chain attachment screws

(with flat and spring washers)

M4a8 mm . . . . . . . . . . . . . . . . . . . .(a1)

M4a6 mm . . . . . . . . . . . . . . . . . . . .(a1)

M2.6a6 mm . . . . . . . . . . . . . . . . . . .(a1)

Accessories

Please check the following accessories have been provided.

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . .4

Accessories . . . . . . . . . . . . . . . . . . . . . .4

Installation precautions . . . . . . . . . . . . .5

Precautions for use . . . . . . . . . . . . . . . .6

Parts and their functions . . . . . . . . . . . .7

Installation . . . . . . . . . . . . . . . . . . . . . . . .9

$ Assembling the pan-tilt head . . . . . . .9

$ Setting the installation direction

selector switch and landing

characteristics . . . . . . . . . . . . . . . . .10

$ Setting the cable compensation

circuit . . . . . . . . . . . . . . . . . . . . . . . .11

$ Moving the mounting position of the

base connector panel . . . . . . . . . . .12

$ Changing the mounting direction of the

base connector panel . . . . . . . . . . .12

$ Installing the pan-tilt head . . . . . . . .13

$ Mounting the camera . . . . . . . . . . . .14

Connections . . . . . . . . . . . . . . . . . . . . .18

$ Connecting the connector panel . . .18

$ Head connector panel . . . . . . . . . . .19

$ Connecting the base connector

panel . . . . . . . . . . . . . . . . . . . . . . . .20

$ Connecting the AC adapter for use

with the pan-tilt head . . . . . . . . . . . .21

$ Setting the printed circuit board

switches . . . . . . . . . . . . . . . . . . . . . .22

Examples of connections . . . . . . . . . .23

Limiters . . . . . . . . . . . . . . . . . . . . . . . . .29

$ Setting the limiters . . . . . . . . . . . . . .30

$ Releasing the limiters . . . . . . . . . . .31

$ Resetting the limiters . . . . . . . . . . . .31

Replacement of consumable parts . . .32

Specifications . . . . . . . . . . . . . . . . . . . .33

Page 5

5

Installation precautions

OAvoid using the pan-tilt head in kitchens or other places where there is excessive steam

and oil fumes.

OMake sure that the installation of the pan-tilt head has been completed before mounting

the camera onto it.

OThis pan-tilt head has a maximum load capacity of 8.8 lb (4 kg).

Do not use it for loads over 8.8 lb (4 kg).

ODo not use a lens that will cause the camera to be poorly balanced. Such a lens should

not be used even if the load capacity is under 8.8 lb (4 kg).

ODo not install the pan-tilt head outdoors or in any place where the temperature is over

113°F (45°C) or below 14°F (–10°C).

Further, it should be used where the ambient humidity is less than 90%.

OScrews for mounting the pan-tilt head are not provided with the stand and must therefore

be purchased separately.

They should be selected with due consideration given to the location where the pan-tilt

head is to be mounted and its load capacity.

OTo supply power to the pan-tilt head, use only the AC adapter (AW-PS300) designed for

use with this pan-tilt head.

OWhen handling the pan-tilt head, be sure to hold it by the base.

Do not lift the pan-tilt head by the head or tilting arm.

Doing so may cause the unit to malfunction.

ODo not turn the head or tilting arm by hand.

Doing so may cause the unit to malfunction.

ODropping the pan-tilt head or subjecting it to a strong shock may cause malfunctioning or

an accident.

OInstall the pan-tilt head so that a clearance of at least one meter is left around the

monitor.

OWhen mounting a camera onto the pan-tilt head, take due care to prevent the camera

from slipping out of position or dropping.

OInstall the pan-tilt head and set the limiters so as to ensure that none of the components

mounted on the pan-tilt head or cables will make contact with any other objects in the

vicinity when the pan-tilt head rotates.

Page 6

6

Precautions for use

This pan-tilt head uses a manganese dioxide-lithium battery (CR2032).

Be absolutely sure to remove this battery when disposing of the pan-tilt head or printed

circuit boards.

Be sure to dispose of any batteries removed according to the applicable regulations of the

country concerned.

Do not dispose of this type of battery as household garbage.

For details on how to remove the battery, refer to the section on replacing the battery in

“Replacement of consumable parts” (page 32).

Page 7

7

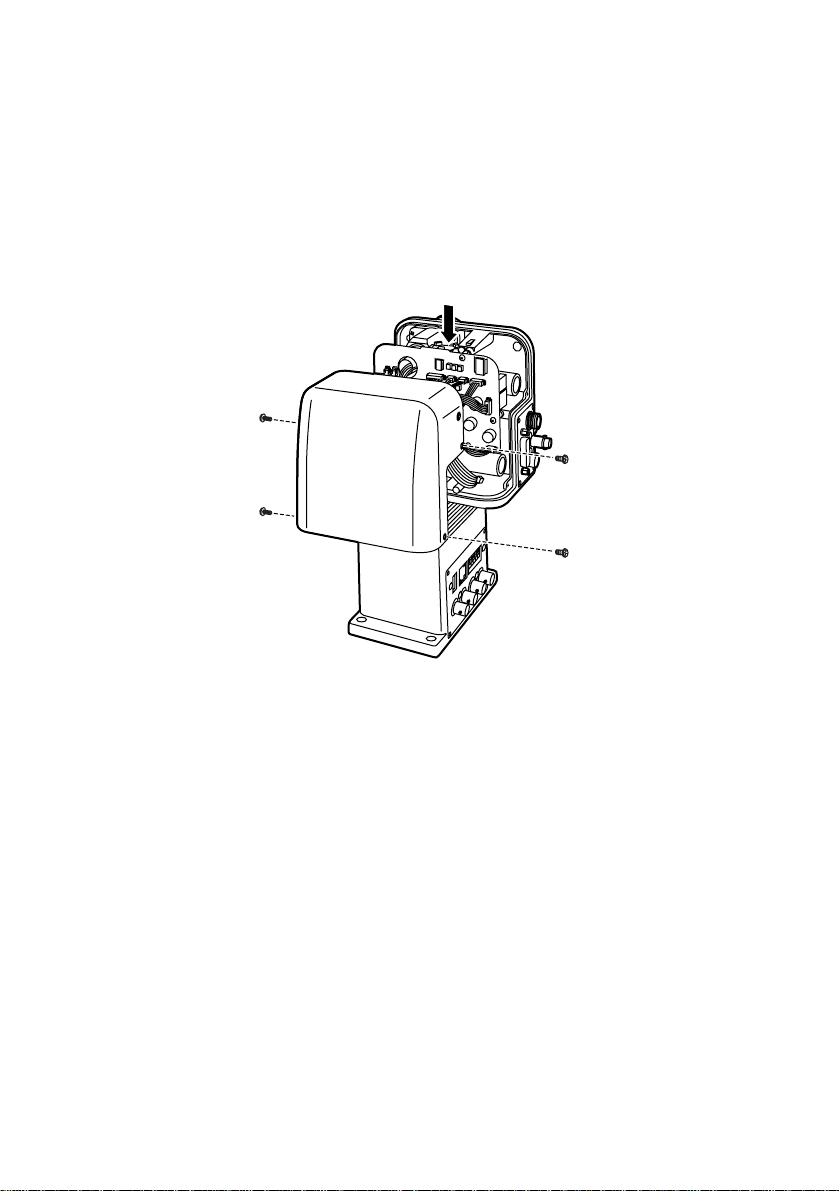

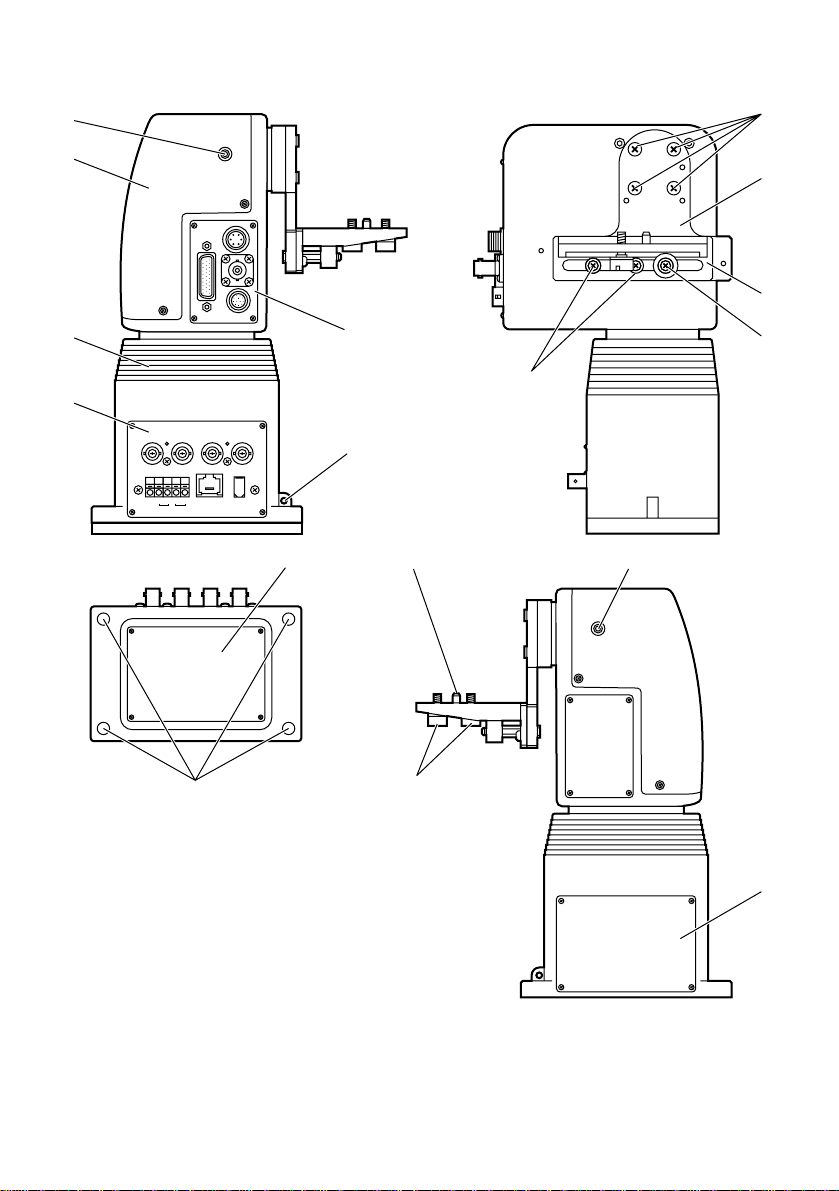

Parts and their functions

G/L I N Pb OUT Pr / SDI

OUT

Y/VIDEO

OUT

1394

CONTROL IN

IP/RP

DC12V

IN

CAMERA I/F

LENSE I/F

ND/EXT

SDI

IN

CSOP

+-

LAMP

CONTROL

2

1

6

4

3

?

8

9

;

@

<

:

=

95

7

>

Page 8

8

Parts and their functions

=Safety wire mounting hole

This is used when attaching a wire to

prevent the pan-tilt head from dropping.

>Base connector panel

This is used for connection with a

controller, multi-port hub or AC adapter

for the pan-tilt head.

?Blank side panel

This is used when changing the

mounting position of the base connector

panel.

@Blank bottom panel

This is used when changing the

mounting position of the base connector

panel.

1Tilting arm

This tilts in the vertical direction.

2Tilting arm fixing screws

M4a12 mm (4 screws supplied)

3Camera mounting plate

This is used to mount the convertible

camera.

4Guide screws

These are used to maintain the camera’s

balance and anchor the camera

mounting plate.

5Guide pin

This determines the mounting direction

of the camera.

6Guide roller

This serves as the fulcrum for

maintaining the camera’s balance.

7Camera mounting screws (U1/4˝-20

UNC)

These are used to mount the camera

and anchor it securely.

8Head

This rotates in the horizontal direction.

9Tally lamps (a2)

These light (red) in response to the

selection signals.

:Head connector panel

This is used for connection with the

camera and lens.

;Base

<Pan-tilt head mounting holes

These four holes are used for mounting

the pan-tilt head.

Page 9

9

Installation

(The installation work must be performed by your dealer without fail.)

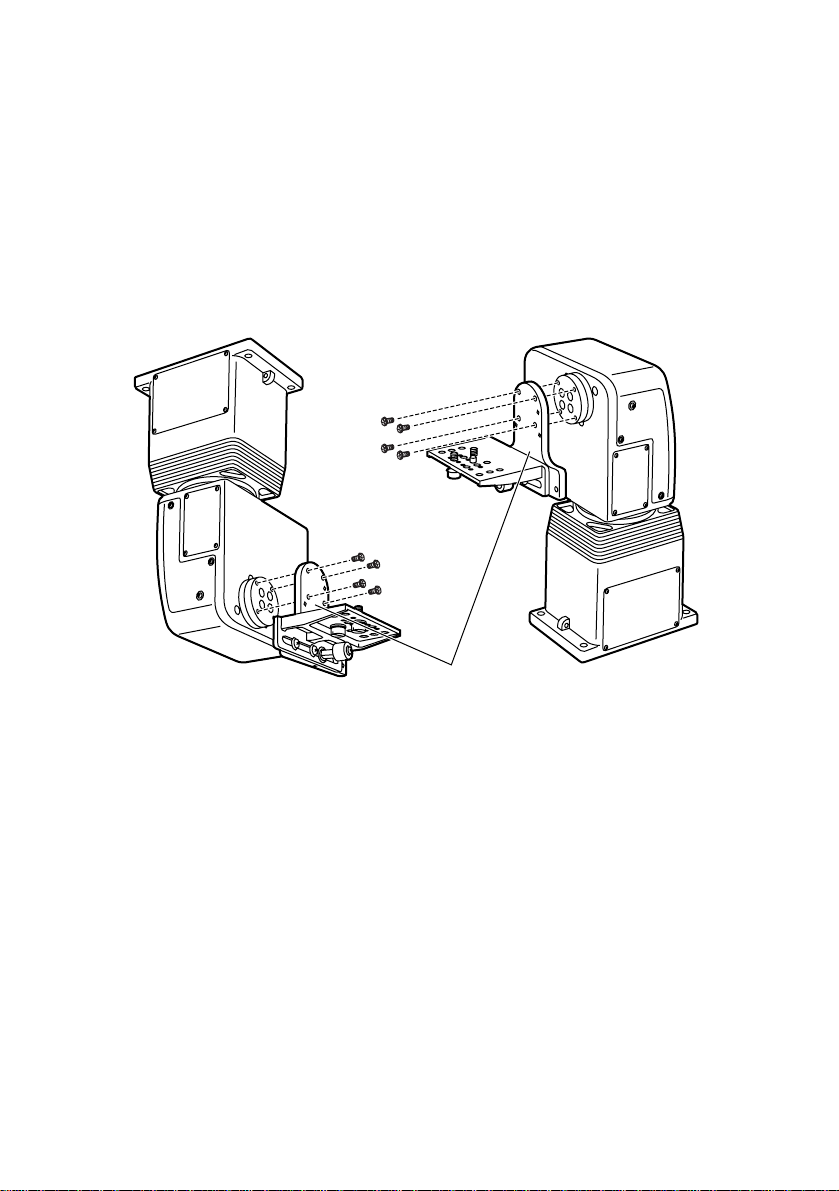

$Assembling the pan-tilt head

Be absolutely sure to hold the pan-tilt head by the base when handling it.

OAttaching the tilting arm

Use the tilting arm fixing screws to attach the tilting arm. The way in which the arm is

mounted differs depending on the direction in which it is installed. (See the figure

below.)

Stand-alone installationSuspended installation

Tilting Arm

<Note>

Do not use other than the supplied tilting arm fixing screws to fasten the tilting arm.

Page 10

10

SW3

SW4

OFF

ONSW2

1 23 4

Installation

(The installation work must be performed by your dealer without fail.)

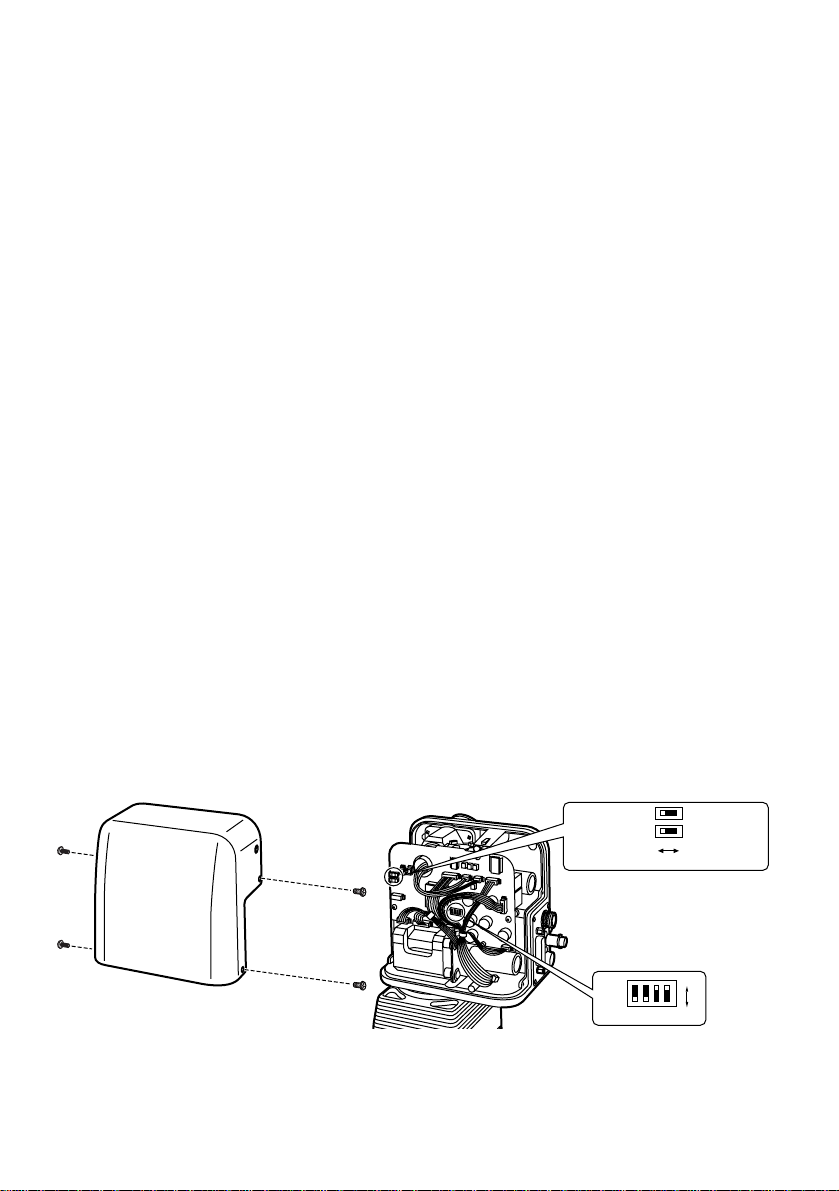

$Setting the installation direction selector switch and landing

characteristics

Set the switches as follows to perform a stand-alone installation and/or to select the

landing characteristics. (Suspended installation and soft landing are the factory

settings.)

1. Remove the four head cover screws, and remove the cover slowly. (Take care not to

disturb the tally LED lamp wiring connections when removing the cover.)

2. Set the SW2, SW3 and SW4 switches on the front printed circuit board as follows.

For suspended installation:

Set SW3 and SW4 to their left-side positions (HANGING). (Factory setting)

For stand-alone installation:

Set SW3 and SW4 to their right-side positions (TOP).

For a soft landing:

Set SW2 switch No.4 to its top (ON) position. (Factory setting)

For a precise landing:

Set SW2 switch No.4 to its bottom (OFF) position.

3. Upon completion of the settings, return the rotary head cover to its original position,

and secure it with the screws (while taking care not to pinch the wires).

<Notes>

OBefore setting the switches, make absolutely sure that the power of the AC adapter

which is to be connected to the pan-tilt head is set to OFF.

OThe landing characteristics are not changed simply by selecting the switch positions.

They are changed only after the power is turned off and back on again after the switches

have been set.

Suspension Stand-alone

Page 11

11

OFFON

Installation

(The installation work must be performed by your dealer without fail.)

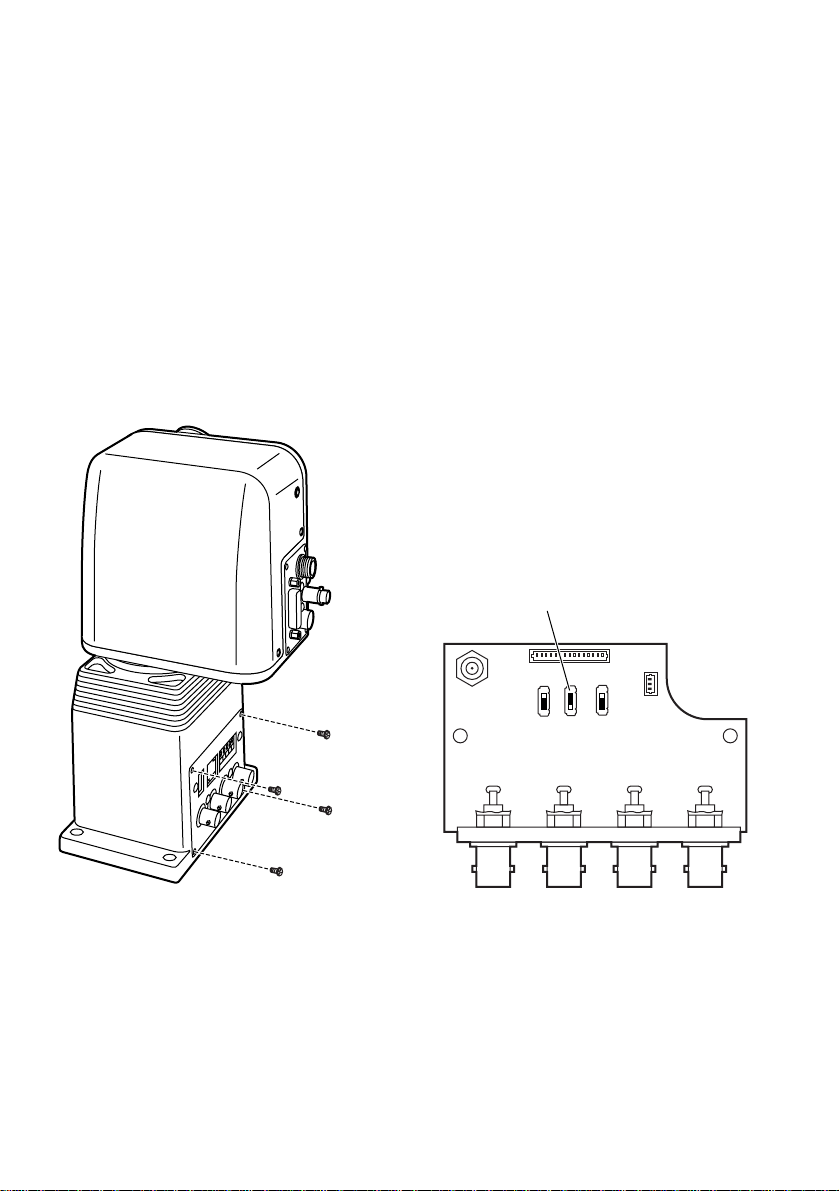

$Setting the cable compensation circuit

A maximum length of up to 3,280 feet (1,000 meters) is allowed for the cable between

each pan-tilt head and the multi-function controller (AW-RP605) (when BELDEN 8281

coaxial cables are used). However, if the cable length is to exceed 1,640 feet (500

meters), set the cable compensation circuit to ON by following the steps below.

(Factory setting: OFF)

1. Remove the four screws of the base connector panel, and pull the panel out toward

you.

2. Set the COMP switch on the COMP printed circuit board on the back side of the panel

to ON.

3. Return the panel to its original position, and secure it using the screws.

COMP printed circuit board

COMP switch

Page 12

12

Installation

(The installation work must be performed by your dealer without fail.)

$Moving the mounting position of the base connector panel

If necessary, the mounting position of the base connector panel can be moved. (When

the pan-tilt head is shipped, it is positioned for suspended installation.)

1. Remove the blank panel at the position where the base connector panel is to be

mounted.

2. Remove the screws of the base connector panel, and pull out the panel toward you.

3. Disconnect all the connectors (a6) of the printed circuit board on the back of the

panel.

4. Move the base connector panel to the new position, and connect the connectors of

the printed circuit board as before.

5. Secure the base connector panel and blank panel using their respective screws.

$Changing the mounting direction of the base connector panel

If necessary, the mounting direction of the base connector panel can be rotated by 180

degrees.

1. Remove the screws of the base connector panel, and pull the panel out toward you.

2. Turn the panel by 180 degrees, and place it back in position.

3. Secure the panel with the screws.

Base connector panel

Blank panel

<Note>

The mounting position and direction of the head connector panel cannot be changed.

Page 13

13

t

t

Installation

(The installation work must be performed by your dealer without fail.)

$Installing the pan-tilt head

Be absolutely sure to follow the instructions below when installing the pan-tilt head.

Failure to do so may cause the pan-tilt head to slip out of position or fall.

OMake sure that the installation of the pan-tilt head has been completed before

mounting the camera onto it.

OTo mount the pan-tilt head, use the four mounting holes and secure it firmly in place.

OHave M6 hexagonal bolts ready as these must be used for mounting the pan-tilt head.

OThe hexagonal bolts must be long enough to meet the requirement of “mounting

material thickness (t) plus 25 mm or longer.”

OUse flat washers, spring washers and hexagonal nuts with the hexagonal bolts, as

shown in the figure.

OUse a wrench that fits the size of hexagonal bolt heads to tighten the hexagonal bolts.

OFor suspended installation, pass a wire through the safety wire mounting hole, and

fasten it securely to the ceiling or other structurally sound object.

OHave a wire ready which is strong enough to bear the weight of the entire pan-tilt head

system (pan-tilt head, camera, lens and cable).

OInstall the pan-tilt head so as to ensure that none of the components mounted on the

pan-tilt head or cables will come into contact with any objects in the vicinity when the

pan-tilt head rotates.

<Note>

When installing the pan-tilt head, refrain from forcibly turning the head or tilting arm by

hand.

Doing so may cause the unit to malfunction.

Safety wire

Page 14

14

Installation

(The installation work must be performed by your dealer without fail.)

$Mounting the camera

The pan-tilt head’s camera mounting section has a mechanism for maintaining the

camera’s balance that moves the camera mounting plate using a guide roller as a

fulcrum.

1. Change the position of guide pin A and/or the camera mounting screws to suit the

camera and lens to be used before mounting the camera.

2. Adjust the balance by loosening the guide screws and moving the camera mounting

plate.

3. Upon confirming the position where the balance is maintained, firmly tighten the guide

screws. If the balance cannot be maintained, change the position of guide pin B or

the positions of the guide screws, and adjust the balance again.

<Note>

The guide roller is fixed in place. Do not remove the guide roller screw.

Camera mounting plate

Camera mounting screws

Guide screw

Guide roller

Guide screw

Guide pin B

Guide pin A

<Mounting example 1>

Adjust the balance by

moving the camera

mounting plate.

Page 15

15

Adjust the balance by

moving the camera

mounting plate.

<Mounting example 2>

Installation

(The installation work must be performed by your dealer without fail.)

<Recommended lenses>

Camera Lens

AW-E300 AW-LZ14MD55

AW-E600

AW-S14aBMD

AW-E800A AW-LZ17MD9

Page 16

16

Installation

(The installation work must be performed by your dealer without fail.)

OAttaching the chain

1. Attach one end of the chain to the

pan-tilt head using a chain attachment

screw (M4a8 mm: with flat

washer/spring washer).

2. Position the other end of the chain

over the screw hole on the top of the

camera and attach it using a chain

attachment screw (M4a6 mm: with

flat washer/spring washer).

<Notes>

OBe sure to tighten all screws firmly

with a screwdriver or similar tool.

OWhen the hole on the camera is M2.6,

attach the chain with the M2.6a6 mm

(with flat washer/spring washer) chain

attachment screw.

OWhen using the AW-E800A camera,

the mounting spacer must be attached

to the top panel of the camera before

attaching the chain. Position the end

of the chain over the hole on the

mounting spacer and attach it using a

chain attachment screw (M4a6 mm:

with flat washer/spring washer).

Be sure to tighten the mounting

spacer and all screws firmly with a

screwdriver or similar tool.

Chain

Chain

Chain attachment screw

M4a8 mm:

with flat washer/spring

washer

Chain attachment screw

M4a8 mm:

with flat washer/spring

washer

Chain attachment screw

M4a6 mm or M2.6a6 mm:

with flat washer/spring

washer

Chain

With the AW-E800A

Chain attachment screw

M4a8 mm:

with flat washer/spring

washer

Chain attachment screw

M4a6 mm:

with flat washer/spring

washer

Mounting spacer

(included with the

AW-E800A)

This chain is for use with the AW-E300,

AW-E600 and AW-E800A convertible

cameras. It cannot be used with any

other camera.

When attaching any other camera to the

pan-tilt head, carefully check the pan-tilt

head operation and that appropriate

measures have been taken to ensure the

camera does not fall.

Page 17

17

Installation

(The installation work must be performed by your dealer without fail.)

OMounting a camera

When mounting a camera to the pan-tilt

head, take appropriate measures to

prevent the camera from falling or being

stolen.

1. Place the camera on the camera

mounting base and insert the guide

pin into the guide hole on the camera.

2. Tighten the 2 camera mounting

screws to fix the camera firmly in

place.

3. After mounting the camera, check that

it is firmly attached and that there is

no play.

<Notes>

OBe sure to tighten all screws firmly

with a screwdriver or similar tool.

OWhen there is only 1 hole on the

camera, remove the 2 camera

mounting screws from the camera

mounting base, then insert 1 camera

mounting screw into the center hole

on the camera mounting plate and

tighten it to fix the camera in place.

O

Adjusting slack in the chain

The chain length allows for some

degree of slack.

Remove any slack after attaching the

camera to the pan-tilt head by twisting

the chain around as shown in the figure

at right, then firmly tighten the screw to

fix it in place.

Camera mounting

Screw

Camera guide pin

Camera mounting Screw

With the AW-E800A

Page 18

18

G/L I N Pb OUT Pr /SDI

OUT

Y/VIDEO

OUT

1394

CONTROL IN

IP/RP

DC12V

IN

CAMERA I/F

LENSE I/F

ND/EXT

SDI

IN

CSOP

O I

CAMERA I/F

LENSE I/F

ND/EXT

SDI

IN

1

3

G/L I N Pb OUT Pr /SDI

OUT

Y/VIDEO

OUT

1394

CONTROL IN

IP/RP

DC12V

IN

CSOP

+-

LAMP

CONTROL

: 9 8 7

65 ; <

=

2

4

2

+

4

;

-

6

:

9

8

7

Zoom lens

Head connector panel

Base connector panel

Convertible camera

AC adapter:

AW-PS300

Multi-Function Controller:

AW-RP605

Connections

$Connecting the connector panel

When component signals are to be used as the video

signals, the AW-PB302 RGB card (optional accessory)

must be installed in the convertible camera.

Page 19

19

Connections

$Head connector panel

The camera and lens control cables are connected to this panel.

1ND/EXT connector

This is for controlling the ND filter and

lens extender of the power lens unit.

Connect it when using a power lens unit

equipped with an ND filter and lens

extender function.

4CAMERA I/F connector

This is for convertible camera control.

Connect this to the REMOTE connector

on the camera.

Use a pan-tilt head cable (optional

accessory) suitable for the application

for the connecting cable.

(See pages 23 to 28.)

2LENS I/F connector

This is for controlling the zoom/focus

functions of the power lens unit.

Connect the remote (zoom/focus) control

cable of the power lens unit here.

3SDI IN connector

This is for SDI signal input.

Using a coaxial cable (BELDEN 8281),

connect this with the SDI OUT connector

of an SDI card (AW-PB304), etc.

installed in the convertible camera.

(As viewed from cable end)

ND signal

ND return

CVCC (+15V)

CGND

EXT return

EXT signal

BE

AF

CD

Page 20

20

Connections

$Connecting the base connector panel

51394 connector

This is for controlling the convertible

camera, in which an IEEE 1394 card

(AW-PB310), etc. has been installed,

and the pan-tilt head.

As the connecting cable, use an IEEE

1394 cable.

6CONTROL IN IP/RP connector

This is for camera/pan-tilt head control

signals.

Connect this to the CONTROL OUT TO

PAN/TILT HEAD connector on the multifunction controller (AW-RP605) or to a

PC, etc. Use a 10BaseT straight cable

(UTP category 5) for the connecting

cable.

<Note>

To control the camera and pan-tilt head

directly from a PC, etc., first convert from

RS-232C to RS-422.

7Y/VIDEO OUT connector

This is for camera video signal output.

Connect this to the VIDEO/Y IN

connector on the multi-function controller

(AW-RP605) or to a monitor, etc.

Video signals will be output from this

connector when a convertible camera is

used as a standard accessory.

Y signals can be output when an RGB

card (AW-PB302) is installed in the

convertible camera for use.

Use a coaxial cable (BELDEN 8281) for

the connecting cable.

8Pr/SDI OUT connector

This is for camera video signal output.

Connect this to the Pr IN connector on

the multi-function controller (AWRP605), etc. or to a monitor, etc.

Pr signals can be output when an RGB

card (AW-PB302), etc. is installed in the

convertible camera for use.

Alternatively, SDI signals can be output

when an SDI card (AW-PB304), etc. is

installed in the convertible camera for

use.

Use a coaxial cable (BELDEN 8281) for

the connecting cable.

9Pb OUT connector

This is for camera video signal output.

Connect this to the Pb IN connector on

the multi-function controller (AW-RP605,

etc.) or to a monitor, etc.

Install an RGB card (AW-PB302), etc. in

the convertible camera for use.

Use a coaxial cable (BELDEN 8281) for

the connecting cable.

:G/L IN connector

This is for genlock signal input.

Connect this to the G/L OUT connector

on the multi-function controller (AWRP605), etc.

Use a coaxial cable (BELDEN 8281) for

the connecting cable.

Pin No. Signal

1 DC 12V

2 GND

3

TPB 2

4 TPB

5

TPA 2

6 TPA

12

34

56

Page 21

21

G/L I N Pb OUT Pr /SDI

OUT

Y/VIDEO

OUT

1394

CONTROL IN

IP/RP

DC12V

IN

CAMERA I/F

LENSE I/F

ND/EXT

SDI

IN

CSOP

+-

LAMP

CONTROL

<

;

=

Connections

$Connecting the AC adapter for use with the pan-tilt head

Connect the pan-tilt head with the AW-PS300 AC adapter designed for use with the pantilt head.

Approx. 1 cm

It is recommended that the tip be soldered.

AC adapter for use with the

pan-tilt head:

AW-PS300

;DC 12V IN terminal board

Connect this to the DC 15V OUT

connector on the AC adapter (AWPS300). (The voltage output from the

AC adapter is set to 15V: this takes into

consideration the voltage drops due to

the possible extension of the DC cable

between the pan-tilt head and AC

adapter.)

Make sure that the positive + and

negative - ends of the wires are

connected to the same signs on the

connector.

Use a cable with a nominal cross section

of 1.25 mm

2

or more which complies

with the Electrical Appliance and

Material Control Law for the connection.

<LAMP CONTROL terminal board

Connect this only when the power of a

halogen lamp is to be supplied from the

LAMP AC OUT connector on the AC

adapter (AW-PS300).

This connector is connected to LAMP

CONTROL on the AC adapter for the

pan-tilt head.

The symbols C and S on the wires must

match the same symbols on the

connector.

Use a cable with a nominal cross section

of 0.3 mm

2

or more that complies with

the Electrical Appliance and Material

Control Law for the connection.

=OP terminal board

Connect this only when the OP SW

CONTROL OUT connector on the AC

adapter (AW-PS300) is to be used.

Connect it to the OPTION SW

CONTROL IN connector on the AC

adapter (AW-PS300).

Use a cable with a nominal cross section

of 0.3 mm

2

or more that complies with

the Electrical Appliance and Material

Control Law for the connection.

Page 22

22

ON OFF

RET PB

SDI PR

WEB 1394

WEB RP422

Connections

$Setting the printed circuit board switches

OAnalog settings

SDI/PR switch : Pr

WEB/1394 switch : 1394

WEB/RP422 switch : RP422

OSDI settings

SDI/PR switch : SDI

WEB/1394 switch : 1394

WEB/RP422 switch : RP422

OWEB settings

SDI/PR switch : Pr

WEB/1394 switch : WEB

WEB/RP422 switch : WEB

COMP printed circuit board

The switches on the COMP and

CONNECTOR printed circuit boards must

be set to correspond to the signals to be

transmitted and components to be

connected to the pan-tilt head.

(When shipped, the analog settings are

supported.)

RET/PB switch

Do not change the setting of this switch – use it at

the PB position.

COMP switch

Use this at the ON position if the length of the

cable exceeds 1,640 feet (500 meters).

SDI/PR switch

CONNECTOR printed circuit board

WEB/1394 switch

WEB/RP422 switch

Page 23

O I

CONTROL OUT TO

PAN/TILT HEAD

VIDEO/Y IN

G/L OUT

VIDEO IN

VIDEO/Y OUT

Y/VIDEO OUT

G/L IN

CONTRTOL IN IP/RP

REMOTE

Examples of connections

1. When controlling the camera and pan-tilt head using the AW-RP605 multi-function

controller and transmitting composite signals

Color monitor

Pan-tilt head cable:

AW-CA50T29

Printed circuit board

switches:

Analog settings

Multi-Function Controller:

AW-RP605

Genlock signals must be supplied when

more than one camera and pan-tilt head

are to be used.

AC adapter:

AW-PS300

Coaxial cables:

BELDEN 8281, max. 3,280 feet

(1,000 meters)

Cable with a nominal cross

section of 1.25 mm

2

or more

max. 98.4 feet (30 meters)

Coaxial cable:

BELDEN 8281

10BASET straight cable:

UTP category 5,

max. 3,280 feet (1,000 meters)

OUse the camera/pan-tilt head connecting cable (AW-CA50T29) to connect the pan-tilt

head with the convertible camera.

OSet the printed circuit board switches to the analog settings.

OUse a coaxial cable (BELDEN 8281) to connect the Y/VIDEO OUT connector on the

pan-tilt head with the VIDEO/Y IN connector on the controller.

OUse a 10BaseT straight cable (UTP category 5) to connect the CONTROL IN IP/RP

connector on the pan-tilt head with the CONTROL OUT TO PAN/TILT HEAD

connector on the controller.

OUse a coaxial cable (BELDEN 8281) to connect the VIDEO/Y OUT connector on the

controller with the VIDEO input connector on the color monitor.

OCheck that the pan-tilt head and camera can be controlled using the controller.

Personal computer

(Windows)

23

Page 24

24

O I

REMOTE

VIDEO/Y IN

Pr IN

Pb IN

G/L OUT

Y IN

Pr IN

Pb IN

VIDEO/Y OUT

Pr OUT

Pb OUT

CONTROL IN IP/RP

Y/VIDEO OUT

Pr/SDI OUT

Pb OUT

G/L IN

CONTROL OUT TO

PAN/TILT HEAD

Examples of connections

2. When controlling the camera and pan-tilt head using the AW-RP605 multi-function

controller and transmitting component signals

Color monitor

Pan-tilt head cable:

AW-CA50C29

Printed circuit board

switches:

Analog settings

Multi-Function Controller:

AW-RP605

AC adapter:

AW-PS300

Coaxial cables:

BELDEN 8281

Coaxial cables:

BELDEN 8281, max. 3,280 feet

(1,000 meters)

10BaseT straight cable:

UTP category 5, max. 3,280 feet

(1,000 meters)

OUse the camera/pan-tilt head connecting cable (AW-CA50C29) to connect the pan-tilt

head with the convertible camera in which an RGB card (AW-PB302), etc. has been

installed.

OSet the printed circuit board switches to the analog settings.

OUse coaxial cables (BELDEN 8281) to connect the Y/VIDEO OUT, Pr/SDI OUT and

Pb OUT connectors on the pan-tilt head with the VIDEO/Y IN, Pr IN and Pb IN

connectors on the controller, respectively.

OUse a 10BaseT straight cable (UTP category 5) to connect the CONTROL IN IP/RP

connector on the pan-tilt head with the CONTROL OUT TO PAN/TILT HEAD

connector on the controller.

OUse coaxial cables (BELDEN 8281) to connect the VIDEO/Y OUT, Pr OUT and Pb

OUT connectors on the controller with the respective component input connectors on

the color monitor.

OCheck that the pan-tilt head and camera can be controlled using the controller.

Cable with a nominal cross

section of 1.25 mm

2

or more

max. 98.4 feet (30 meters)

Personal computer

(Windows)

Genlock signals must be supplied when

more than one camera and pan-tilt head

are to be used.

Page 25

25

SDI IN

Pr/SDI OUT

O I

REMOTE

CONTROL OUT TO

PAN/TILT HEAD

G/L IN

G/L OUT

CONTROL IN IP/RP

Examples of connections

3. When controlling the camera and pan-tilt head using the AW-RP605 multi-function

controller and transmitting SDI signals

Color monitor

Pan-tilt head cable:

AW-CA50T29

Printed circuit board

switches:

SDI settings

Multi-Function Controller:

AW-RP605

AC adapter:

AW-PS300

OUse the camera/pan-tilt head connecting cable (AW-CA50T29) to connect the pan-tilt

head with the convertible camera in which an SDI card (AW-PB304), etc. has been

installed.

OSet the printed circuit board switches to the SDI settings.

OUse a coaxial cable (BELDEN 8281) to connect the SDI OUT connector on the

convertible camera with the SDI IN connector on the pan-tilt head. Select the coaxial

cable of a length at which the pan-tilt head will operate smoothly.

OUse a coaxial cable (BELDEN 8281) to connect the Pr/SDI OUT connector on the

pan-tilt head with the SDI IN connector on the color monitor.

OUse a 10BaseT straight cable (UTP category 5) to connect the CONTROL IN IP/RP

connector on the pan-tilt head with the CONTROL OUT TO PAN/TILT HEAD

connector on the controller.

OCheck that the pan-tilt head and camera can be controlled using the controller.

Coaxial cable:

BELDEN 8281, max. 3,280 feet

(1,000 meters)

Coaxial cable:

BELDEN 8281, max. 656 feet

(200 meters)

Coaxial cable:

BELDEN 8281

10BaseT straight cable:

UTP category 5, max. 3,280 feet

(1,000 meters)

Cable with a nominal cross

section of 1.25 mm

2

or more

max. 98.4 feet (30 meters)

Personal computer

(Windows)

Genlock signals must be supplied when

more than one camera and pan-tilt head

are to be used.

Page 26

26

O I

CONTROL IN IP/RP

Examples of connections

4. When connecting a pan-tilt head through a network and controlling the camera

and pan-tilt head using a personal computer

Personal computer

(Windows)

Pan-tilt head cable:

AW-CA50F29

Printed circuit board

switches:

WEB settings

AC adapter:

AW-PS300

HUB

OUse the camera/pan-tilt head connecting cable (AW-CA50F29) to connect the pan-tilt

head with the convertible camera in which a WEB card (AW-PB309), etc. has been

installed.

OSet the printed circuit board switches to the WEB settings.

OUse a 10BaseT straight cable (UTP category 5) to connect the personal computer

(Windows) and convertible camera via a hub.

OInstall browser software (Netscape or Internet Explorer) in the personal computer

(Windows).

OUse the browser software to input the IP address which was set on the WEB card,

and check that the pan-tilt head and camera can be controlled using the personal

computer.

10BaseT straight cable:

UTP category 5, max. 328 feet (100 meters)

10BaseT straight cable:

UTP category 5, max. 328 feet (100 meters)

Cable with a nominal cross

section of 1.25 mm

2

or more

max. 98.4 feet (30 meters)

Page 27

27

O I

CONTROL IN IP/RP RS-422 RS-232C

Y/VIDEO OUT

VIDEO IN

Examples of connections

5. When controlling the camera and pan-tilt head using a personal computer, etc.

and transmitting composite signals

Personal computer

(Windows)

Pan-tilt head cable:

AW-CA50T29

Printed circuit board

switches:

Analog settings

AC adapter:

AW-PS300

Coaxial cable:

BELDEN 8281

(Cable compensation is

necessary if this cable it going

to be run over a long distance.)

Color monitor

RS-232C crossover cable

max. 49.2 feet (15 meters)

RS-232C/RS-422 converter:

Consult your dealer.

OUse the camera/pan-tilt head connecting cable (AW-CA50T29) to connect the pan-tilt

head with the convertible camera.

OSet the printed circuit board switches to the analog settings.

OUse a coaxial cable (BELDEN 8281) to connect the Y/VIDEO OUT connector on the

pan-tilt head with the VIDEO input connector on the color monitor.

OConnect the CONTROL IN IP/RP connector on the pan-tilt head to the RS-232C

connector on the personal computer (Windows) via an RS-232C/RS-422 converter.

(Consult your dealer)

OCheck that the pan-tilt head and camera can be controlled using the personal

computer.

10BaseT straight cable:

UTP category 5, max. 3,280 feet

(1,000 meters)

2 RXD

3 TXD

4 DTR

5 GND

6 DSR

7 RTS

8 CTS

1 TXD+

RS-422 RS-232C

2 TXD–

3 RXD+

1 kΩ

390 Ω

1 kΩ

VCC

AD7306JR

4 RXD–

5 GND

RS-232C/RS-422 converter

Cable with a nominal cross

section of 1.25 mm

2

or more

max. 98.4 feet (30 meters)

Page 28

28

Examples of connections

6. When controlling the camera and pan-tilt head using a personal computer, etc.

and transmitting component signals

O I

CONTROL IN IP/RP RS-422 RS-232C

Y/VIDEO OUT

Pr/SDI OUT

Pb OUT

Y IN

Pr IN

Pb IN

Personal computer

(Windows)

Pan-tilt head cable:

AW-CA50C29

Printed circuit board

switches:

Analog settings

AC adapter:

AW-PS300

Color monitor

RS-232C crossover cable

max. 49.2 feet (15 meters)

RS-232C/RS-422 converter:

Consult your dealer.

Coaxial cables:

BELDEN 8281

(Cable compensation is

necessary if this cable it going

to be run over a long distance.)

OUse the camera/pan-tilt head connecting cable (AW-CA50C29) to connect the pan-tilt

head with the convertible camera.

OSet the printed circuit board switches to the analog settings.

OUse coaxial cables (BELDEN 8281) to connect the Y/VIDEO OUT, Pr/SDI OUT and

Pb OUT connectors on the pan-tilt head with the Y IN, Pr IN and Pb IN connectors on

the color monitor, respectively.

OConnect the CONTROL IN IP/RP connector on the pan-tilt head to the RS-232C

connector on the personal computer (Windows) via an RS-232C/RS-422 converter.

(Consult your dealer)

OCheck that the pan-tilt head and camera can be controlled using the personal

computer.

10BaseT straight cable:

UTP category 5, max. 3,280 feet

(1,000 meters)

Cable with a nominal cross

section of 1.25 mm

2

or more

max. 98.4 feet (30 meters)

Page 29

29

Limiters

Be absolutely sure to set the limiters (travel range) of the pan/tilt head before use.

Depending on where the pan/tilt head system has been installed, obstacles may be

present within the travel range with which the camera may come into contact. Contact with

any such obstacle by the camera may cause malfunctioning or accidents.

In this case, contact can be prevented by setting the limiters directly before any such

obstacle.

The multi-function controller (AW-RP605) is used to set the limiters.

The positions of four limiters—namely, the upper, lower, left-most and right-most limits of

the travel range—can be set.

Once they have been set, the positions will not be lost even after the power has been

turned off.

Page 30

30

Limiters

OSetting the left-most limit position of

the travel range

1. Using the controller, rotate the camera

to the position which is to serve as the

left-most limit.

2. While holding down the OK button on

the controller, press

TRACING/PRESET

MEMORY

button 44 .

3. The setting is completed as soon as

the lamp of the TRACING/PRESET

MEMORY button 41 [LIMIT ON]

comes on.

4. Using the controller once again, check

whether the left-most limit position has

been set correctly.

OSetting the right-most limit position of

the travel range

1. Using the controller, rotate the camera

to the position which is to serve as the

right-most limit.

2. While holding down the OK button on

the controller, press

TRACING/PRESET

MEMORY

button 45 .

3. The setting is completed as soon as

the lamp of the TRACING/PRESET

MEMORY button 41 [LIMIT ON]

comes on.

4. Using the controller once again, check

whether the right-most limit position

has been set correctly.

$Setting the limiters

OSetting the upper limit position of the

travel range

1. Using the controller, tilt the camera to

the position which is to serve as the

upper limit.

2. While holding down the OK button on

the controller, press

TRACING/PRESET

MEMORY

button 47 .

3. The setting is completed as soon as

the lamp of the TRACING/PRESET

MEMORY button 41 [LIMIT ON]

comes on.

4. Using the controller once again, check

whether the upper limit position has

been set correctly.

OSetting the lower limit position of the

travel range

1. Using the controller, rotate the camera

to the position which is to serve as the

lower limit.

2. While holding down the OK button on

the controller, press

TRACING/PRESET

MEMORY

button 46 .

3. The setting is completed as soon as

the lamp of the TRACING/PRESET

MEMORY button 41 [LIMIT ON]

comes on.

4. Using the controller once again, check

whether the lower limit position has

been set correctly.

Page 31

31

Limiters

$Releasing the limiters

A limiter position which has been set can

be released by following the steps

below.

OReleasing the upper limit position

setting of the travel range

1. While holding down the OK button on

the controller, press

TRACING/PRESET

MEMORY

button 47 .

2. The setting is released when the lamp

of the TRACING/PRESET MEMORY

button 50 [LIMIT OFF] comes on.

OCanceling the lower limit position

setting of the travel range

1. While holding down the OK button on

the controller, press

TRACING/PRESET

MEMORY

button 46 .

2. The setting is released when the lamp

of the TRACING/PRESET MEMORY

button 50 [LIMIT OFF] comes on.

OCanceling the left-most limit position

setting of the travel range

1. While holding down the OK button on

the controller, press

TRACING/PRESET

MEMORY

button 44 .

2. The setting is released when the lamp

of the TRACING/PRESET MEMORY

button 50 [LIMIT OFF] comes on.

OCanceling the right-most limit

position setting of the travel range

1. While holding down the OK button on

the controller, press

TRACING/PRESET

MEMORY

button 45 .

2. The setting is released when the lamp

of the TRACING/PRESET MEMORY

button 50 [LIMIT OFF] comes on.

$Resetting the limiters

The same series of operations are

performed either for setting the limiters

or for releasing them: these steps serve

to set the limiters once they have been

released or release the limiters once

they have been set.

To reset the limiters, release the

currently established settings, and set

the limiters again.

The limiter positions which have been

set can be set at different positions by

following the steps below.

1. Follow the steps in “Releasing the

limiters” to release the settings of the

limiter positions which are to be set

again.

2. Follow the steps in “Setting the

limiters” to set the limiter positions.

Page 32

32

Replacement of consumable parts

OReplacing the battery

The battery lasts for about 5 years.

The pan-tilt head stores the present

positions, limiter positions and other data

in its memory. Although this data is

retained even after the power has been

turned off, it will be lost when the power

is turned off once the battery has

reached the end of its service life.

Replace the battery once it has lost its

effectiveness. (The pan-tilt head uses a

CR2032 manganese dioxide-lithium

battery.)

Removing the battery

1. Remove the four cover screws, and

remove the head cover.

2. Press the battery in the direction

shown by the arrow in the figure, and

slide it.

3. From this position, lift the battery from

the bottom of its arrow area.

4. Once the arrow part of the battery has

been removed from the battery holder,

pull the battery forward and out to

remove it completely.

Installing the new battery

1. With the “+” pole of the new battery

turned toward you, insert the end into

the battery holder from the direction of

the arrow.

2. While pushing the battery in the

direction of the arrow, push it right into

the holder.

Replacing the motor

Replace the motor if it is not working

properly.

OConsult your dealer on how to replace

the motor.

Replacing the gear

Replace the gear when its preset stop

accuracy has deteriorated.

OConsult your dealer on how to replace

the gear.

The motor and gear are consumable

parts.

They must be replaced at regular

intervals.

Page 33

33

Specifications

Power supply:

DC +12 V (connector)

Power consumption:

DC +12 V 2.5 A

(camera power included),

DC +12 V 0.7 A

(pan-tilt head only)

Genlock input

Black burst or composite video,

1 V [p-p]/75 Ω (BNC connector)

Camera video output

Composite video:

1 V [p-p]/75 Ω

Component video:

Y = 1 V [p-p]/75 Ω

Pr = 0.7 V [p-p]/75 Ω

Pb = 0.7 V [p-p]/75 Ω

SDI

Camera/pan-tilt head control

RS-422 (8-pin modular jack)

Lamp control

Control signals (connector)

Option control

Control signals (connector)

Maximum cable length

3,280 feet (1,000 meters)

(when BELDEN 8281 coaxial cable and

10BaseT straight cable equivalent to

UTP category 5 are used)

Maximum load capacity

8.8 lb (4 kg)

Allowable operating temperature

14°F to 113°F (–10°C to +45°C)

Allowable operating humidity

Max. 90%

Dimensions (WaHaD)

5

1

/8˝a9 5/8˝a7 9/16˝

(130a244a192 mm)

Weight

Approx. 7.7 lb (3.5 kg)

Finish

AV ivory paint (color approximating

Munsell 7.9Y 6.8/0.8)

$Functions/performance

Tilt range

190 degrees (approx. ±95 degrees)

Tilt range may be subject to restrictions

depending on the mounted camera

cable, lens, etc.

Panning range

300 degrees (approx. ±150 degrees)

Maximum operating speed

25 degrees/sec. for panning,

20 degrees/sec. for tilting

Repeatability

Less than ±3´

Noise level

Less than NC30

indicates safety information.

Page 34

PANASONIC BROADCAST & TELEVISION SYSTEMS COMPANY

DIVISION OF MATSUSHITA ELECTRIC CORPORATION OF AMERICA

Executive Office:

3330 Cahuenga Blvd W., Los Angeles, CA 90068 (323) 436-3500

EASTERN ZONE:

One Panasonic Way 4E-7, Secaucus, NJ 07094 (201) 348-7621

Southeast Region:

1225 Northbrook Parkway, Ste 1-160, Suwanee, GA 30024 (770) 338-6835

Central Region:

1707 N Randall Road E1-C-1, Elgin, IL 60123 (847) 468-5200

WESTERN ZONE:

3330 Cahuenga Blvd W., Los Angeles, CA 90068 (323) 436-3500

Government Marketing Department:

52 West Gude Drive, Rockville, MD 20850 (301) 738-3840

Broadcast PARTS INFORMATION & ORDERING:

9:00 a.m. – 5:00 p.m. (EST) (800) 334-4881/24 Hr. Fax (800) 334-4880

Emergency after hour parts orders (800) 334-4881

TECHNICAL SUPPORT:

Emergency 24 Hour Service (800) 222-0741

Panasonic Canada Inc.

5770 Ambler Drive, Mississauga, Ontario L4W 2T3 (905) 624-5010

Panasonic de Mexico S.A. de C.V.

Av angel Urraza Num. 1209 Col. de Valle 03100 Mexico, D.F. (52) 1 951 2127

Panasonic Sales Company

Division of Matsushita Electric of Puerto Rico Inc.

San Gabriel Industrial Park, 65th Infantry Ave., Km. 9.5, Carolina, Puerto Rico 00630 (787) 750-4300

Loading...

Loading...