Panasonic AW-HE870N User Manual

AW-HE870

Operating Instructions

HD Convertible Camera

Model No. AW-HE870N

Installation instructions provided

HIGH

DEFINITION

HD Convertible Camera

Before operating this product, please read the instructions carefully and save this manual for future use.

F0109S1029

D

VQTB0350-1

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

REFER TO SERVICING TO QUALIFIED SERVICE PERSONNEL.

DO NOT REMOVE COVER (OR BACK).

NO USER SERVICEABLE PARTS INSIDE.

The lightning flash with arrowhead symbol,

within an equilateral triangle, is intended to

alert the user to the presence of uninsulated

“dangerous voltage” within the product’s

enclosure that may be of sufficient magnitude

to constitute a risk of electric shock to

persons.

The exclamation point within an equilateral

triangle is intended to alert the user to the

presence of important operating and

maintenance (service) instructions in the

literature accompanying the appliance.

For CANADA

This class A digital apparatus complies with

Canadian ICES-003.

Cet appareil numérique de la classe A est

conforme à la norme NMB-003 du Canada.

FCC Note:

This equipment has been tested and found to comply

with the limits for a class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful

interference when the equipment is operated in a

commercial environment. This equipment generates,

uses, and can radiate radio frequency energy, and if

not installed and used in accordance with the

instruction manual, may cause harmful interference

to radio communications. Operation of this equipment

in a residential area is likely to cause harmful

interference in which case the user will be required to

correct the interference at his own expense.

Warning:

To assure continued FCC emission limit compliance,

the user must use only shielded interface cables when

connecting to external units. Also, any unauthorized

changes or modifications to this equipment could void

the user’s authority to operate it.

- 2 -

indicates safety information.

WARNING:

• TO REDUCE THE RISK OF FIRE OR ELECTRIC

SHOCK, DO NOT EXPOSE THIS APPARATUS TO

RAIN OR MOISTURE.

• THE APPARATUS SHALL NOT BE EXPOSED TO

DRIPPING OR SPLASHING AND THAT NO

OBJECTS FILLED WITH LIQUIDS, SUCH AS

VASES, SHALL BE PLACED ON THE

APPARATUS.

indicates safety information.

CAUTION:

TO REDUCE THE RISK OF FIRE OR SHOCK

HAZARD AND ANNOYING INTERFERENCE, USE

THE RECOMMENDED ACCESSORIES ONLY.

Note:

The rating plate (serial number plate) is on the

bottom of the unit.

- 3 -

IMPORTANT SAFETY INSTRUCTIONS

Read these operating instructions carefully before using the unit. Follow the safety instructions on the unit and the

applicable safety instructions listed below. Keep these operating instructions handy for future reference.

1) Read these instructions.

2) Keep these instructions.

3) Heed all warnings.

4) Follow all instructions.

5) Do not use this apparatus near water.

6) Clean only with dry cloth.

7) Do not block any ventilation openings. Install in

accordance with the manufacturer’s instructions.

8) Do not install near any heat sources such

as radiators, heat registers, stoves, or other

apparatus (including amplifiers) that produce heat.

9) Do not defeat the safety purpose of the polarized

or grounding-type plug. A polarized plug has two

blades with one wider than the other. A groundingtype plug has two blades and a third grounding

prong. The wide blade or the third prong are

provided for your safety. If the provided plug does

not fit into your outlet, consult an electrician for

replacement of the obsolete outlet.

10) Protect the power cord form being walked on or

pinched particularly at plugs, convenience

receptacles, and the point where they exit from

the apparatus.

11) Only use attachments/accessories specified by

the manufacturer.

12) Use only with the cart, stand, tripod,

bracket, or table specified by the

manufacturer, or sold with the

apparatus. When a cart is used, use

caution when moving the

cart/apparatus combination to avoid

injury from tip-over.

13) Unplug this apparatus during lightning storms or

when unused for long periods of time.

14) Refer all servicing to qualified service personnel.

Servicing is required when the apparatus has

been damaged in any way, such as power-supply

cord or plug is damaged, liquid has been spilled or

objects have fallen into the apparatus, the

apparatus has been exposed to rain or moisture,

does not operate normally, or has been dropped.

- 4 -

indicates safety information.

Contents

Preface ............................................................................... 7

Standard accessories ...................................................... 7

Features ............................................................................. 8

Special notes on operation .............................................. 9

Precautions for use ........................................................ 10

Precautions for installation ........................................... 12

Major operating controls and their functions .............. 15

Front view / Top view / Rear view / Bottom view ........ 15

Mounting ......................................................................... 19

Lens mounting .......................................................... 19

Mounting the camera onto a pan-tilt head, tripod,

camera mounting bracket, or other part ................... 20

System configuration (Connections) ............................ 24

Connection of device with

a composite/component input connector ........ 24

Connection of a remote operation panel ................... 25

Connection with multiple cameras

(Supplying the external synchronizing signals) ........ 26

Connection of the Indoor Pan-tilt Head AW-PH360

...... 27

Connection of the Indoor Pan-tilt Head AW-PH400

Connection of the Indoor Pan-tilt Head AW-PH405

Connection of the Outdoor Pan-tilt Head AW-PH650

How to operate the system ............................................ 39

Control exercised from the

Remote Operation Panel AW-CB400 ................... 39

Control exercised from the

Multi-Function Controller AW-RP655 ................... 42

Control exercised from the

Multi Hybrid Control Panel AW-RP555 ................. 46

Use mode setting ............................................................ 49

Use Mode Setting ..................................................... 49

Selecting ................................................................... 50

Operating procedure ...................................................... 51

Adjustment ...................................................................... 52

Flange back adjustment ............................................ 52

Iris gain control in a lens ........................................... 52

White balance adjustment ......................................... 53

Black balance adjustment ......................................... 55

Total pedestal level adjustment ................................. 56

Genlock adjustment .................................................. 57

...... 30

...... 33

.... 36

- 5 -

Contents

Menu item setting/changing .......................................... 60

Menu item setting ...................................................... 60

Menu item setting/changing

(Halogen, Fluorescent, Outdoor Mode) ................... 62

Sub menu (Halogen, Fluorescent, Outdoor Mode) ... 62

Description of the setting screen ............................... 63

Menu item setting/changing (User Mode) .................... 70

Sub menu (User Mode) ............................................. 70

Description of the setting screen ............................... 73

Changing the settings .................................................... 86

Changing the format settings .................................... 86

Changing the component setting .............................. 87

Setting the EBU matrix .............................................. 88

Setting to initial set (Factory presets) .......................... 89

Setting to initial set .................................................... 89

Initial settings of the setting items

(Factory preset values) ................................... 90

Troubleshooting .............................................................. 93

Appearance ..................................................................... 98

Specifications ................................................................. 99

- 6 -

Preface

This is an HD/SD multi-format camera that adopts 14-bit analog to digital conversion and digital video signal processing, with

a compact and lightweight 2/3˝ 3CCD system offering high reliability and availability of multiple functions.

Setting and switching of the camera’s status and its various functions can be performed easily with the menu screen system.

The camera can be connected with peripheral devices, such as a remote control panel or a pan-tilt head, allowing for system

development according to the intended use.

The camera can be used for even more applications by inserting an option card.

Note

In order to protect the environment when the HD convertible camera is to be discarded at the

end of its service life, ask a specialized contractor to dispose of it properly.

Standard accessories

Operating Instructions .................... 1

DC cable (9.84 ft. [3 m]) .................... 1

Use this to supply the camera’s DC power.

(Refer to “ DC 12 V input connector” on page

18.)

Mounting spacer .............................. 1

Use this when mounting the drop-prevention

wire of the camera.

(Refer to “ Camera mounting screw holes” on

page 16.)

- 7 -

Features

The camera features high reliability through

adoption of 14-bit analog to digital conversion

and digital video signal processing.

Compatible with multiple formats

• The format can be switched between 1080i, 720p, and

480i. The transition from an SD format system to an

HD format system can be performed smoothly.

• “Squeeze” or “Sidecut” can be selected with the SD

format.

Down converter a standard feature

The SD (480i) composite signals can be output

continuously

simultaneously outputting HD (1080i, 720p) signals.

*1 from the VIDEO OUT terminal, while

Compact but multifunctional, making a diverse

range of video productions possible

• Features automatic functions such as ATW, ELC, and

AGC.

• Features Chroma Detail, Dark Detail, and digital Color

Matrix correction functions.

• Noise during imaging on computer screens is reduced

by the Synchro Scan function.

• An optimum condition can be selected to suit the

intended use from among four use modes (Halogen,

Fluorescent, Outdoor, and User).

• Supports the SDI card option

• Adopts operating procedures that are the same as

those of our convertible cameras*

•

Our pan-tilt heads*4 and control panels can be used*5.

*1: When using external synchronization, only the output

signal for the selected video output format (Format)

will be synchronized.

*2: Only the optional card (AW-HHD870) that supports

the AW-HE870 can be used. It is not possible to use

any other cards.

*3: Some operations may vary depending on function.

*4: Compatible models are AW-PH360, AW-PH400,

AW-PH405, and AW-PH650. Models AW-PH360 and

AW-PH400 are not able to output analog HD video

signals.

*5: Compatible models are AW-RP555, AW-RP655 and

AW-CB400/AW-RP400. The software version may

need to be upgraded. Please contact your dealer.

*2 (AW-HHD870).

3

.

- 8 -

Special notes on operation

Turn power off before connecting or disconnecting cables.

Connection or disconnection of any studio cable or other

cable to any unit of equipment must be performed while

power is off.

While the camera is in automatic mode;

Shooting of bright objects in ELC operation mode may

result in a smeared picture unique to the CCD.

The ATW function under fluorescent illumination can

adversely change the white balance.

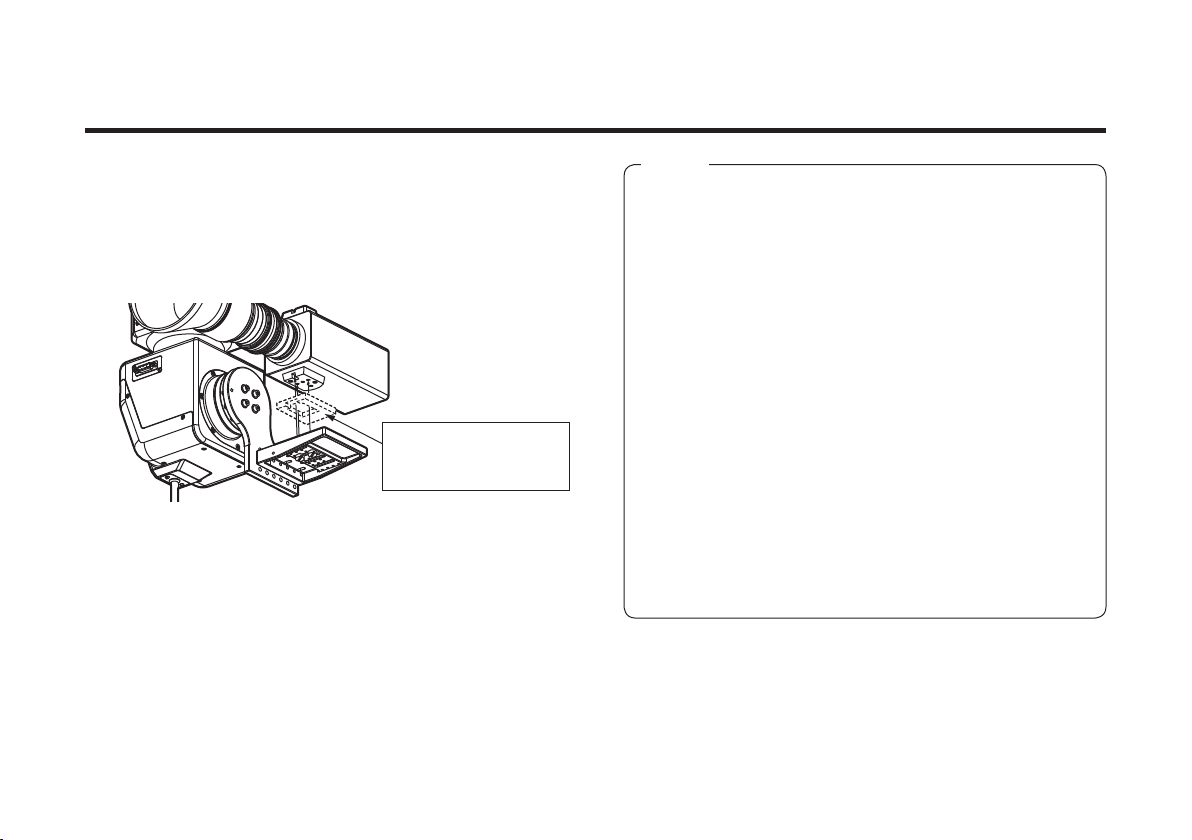

There is a cooling fan inside.

The cooling fan is a consumable part.

Replace it 3 to 5 years after installation as a general rule.

When the cooling fan malfunctions, the “Fan Error”

message is displayed when the power is turned ON.

When the “Fan Error” message is displayed, request

replacement of the cooling fan.

(Whenever fan replacement is necessary, be sure to ask

the store where you purchased the set.)

Fan Error

- 9 -

Precautions for use

DON’TS

Do not attempt to disassemble the camera or other units.

In order to prevent electric shock, do not remove screws

or covers. There are no user-serviceable parts inside.

Do not abuse the camera. Avoid striking, shaking, etc.

The camera contains sensitive components which could

be damaged by improper handling or storage.

Do not let the lens remain uncapped when the camera is

not in use. If the lens is not installed, do not leave the lens

mount hole uncovered.

Do not touch the surface of the lens or prism.

Do not use strong of abrasive detergents when cleaning

the camera body.

Do not aim the camera toward the sun, no matter whether

it is turned on or not.

Do not expose the camera or other units to rain or

moisture, and do not try to operate the equipment in wet

conditions. Do not operate the camera if it becomes wet.

Do not operate the camera or other units outdoors during

a lightning storm.

Do not use the camera in an extreme environment where

high temperatures or high humidity exist.

Do not leave the camera or other units turned on when

not in use.

Do not unnecessarily turn the camera power on and off

repeatedly.

- 10 -

Precautions for use

DOS

Refer any servicing to qualified service personnel.

Handle the camera with care.

Protect the precision made lens by placing the lens cap

over when the camera is not in use. If the lens is not

installed, protect the surface of the prism by placing the

body cap into the lens mount hole.

Use a mild blower or lens cleaning tissue designed for

coated lenses, to clean the surface of the lens or prism in

the event that it should become dirty.

Use a dry cloth to clean the camera if it is dirty. In case

the dirt is hard to remove, use mild detergent and wipe

gently.

Use caution when operating the camera in the vicinity

of spot lights or bright lights, as well as light reflecting

objects and surfaces.

Take immediate action if ever the camera should become

wet. Turn the power off and have the unit checked by an

authorized service facility.

Follow normal safety precautions to avoid personal injury.

Use the camera in an environment where the

temperature is within 14 °F to 113 °F (–10 °C to +45 °C),

and the relative humidity is within 20 % to 90 %.

Always turn the power off when the camera is not going

to be used. Operate the camera only when there is

adequate ventilation.

- 11 -

Precautions for installation

The connection and installation should be done by

qualified service personnel or system installers.

Refer any servicing to qualified service personnel.

Concerning the installation location of the camera

Ensure that the installation location is strong enough to bear

at least five times the total weight of the camera, lens, and

cables (approx. 55.1 lbs. [25 kg]).

When mounting to a pan-tilt head or to a mounting bracket

for installation, ensure that the location is strong enough to

accommodate its weight as well.

The camera cannot be installed or used in the following

locations.

Outdoor locations and locations where the camera may

be exposed to dripping, splashing or sprayed water

Locations such as swimming pools where chemicals are

used

Locations such as a kitchen where the high levels of

steam and oily vapors are present and locations with

flammable atmospheres or other unusual conditions

Locations where radioactive rays, X-rays or strong radio

waves or magnetic fields are generated

Locations where the temperature may be outside the

camera’s operating ambient temperature (14 °F to 113 °F

[–10 °C to 45 °C]) range

Locations near the air outlet of an air conditioner or near

a door where the camera will be exposed to incoming

outside air or other locations where the temperature is

subject to sudden change (since these locations may

cause the lens area to cloud over and/or condensation to

form)

Locations that are subject to significant vibration, such as

on top of a car

Locations with high levels of humidity or dust

When the camera is not going to be used, do not leave

it in place but be absolutely sure to remove it from its

mounting, and put it away.

Do not run the camera cable near the wiring of electric

lights.

This may result in noise interference.

Concerning electromagnetic interference

The camera’s images may become distorted or noise

interference may result if the camera is used near a

TV or radio transmission antenna or in strong electrical

or magnetic fields (such as one generated by motors,

transformers, etc.).

- 12 -

Precautions for installation

The connection and installation should be done by

qualified service personnel or system installers.

Refer any servicing to qualified service personnel.

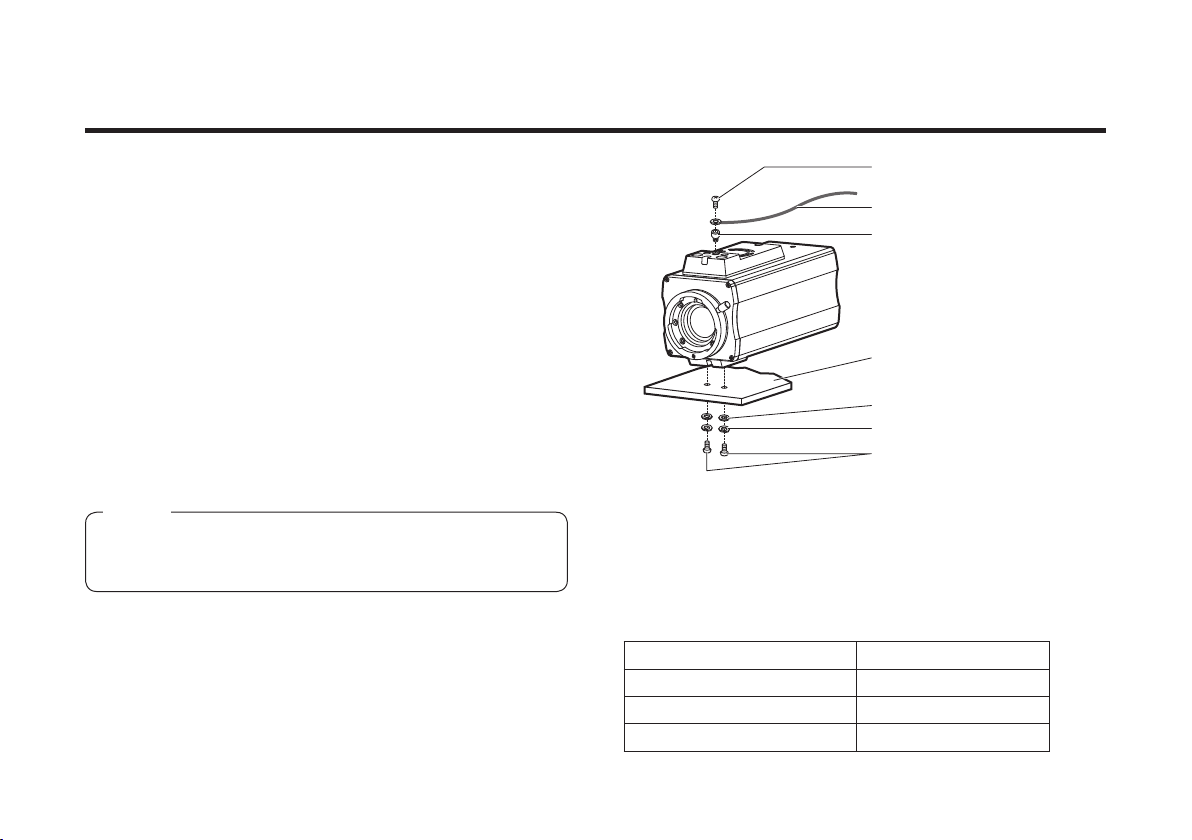

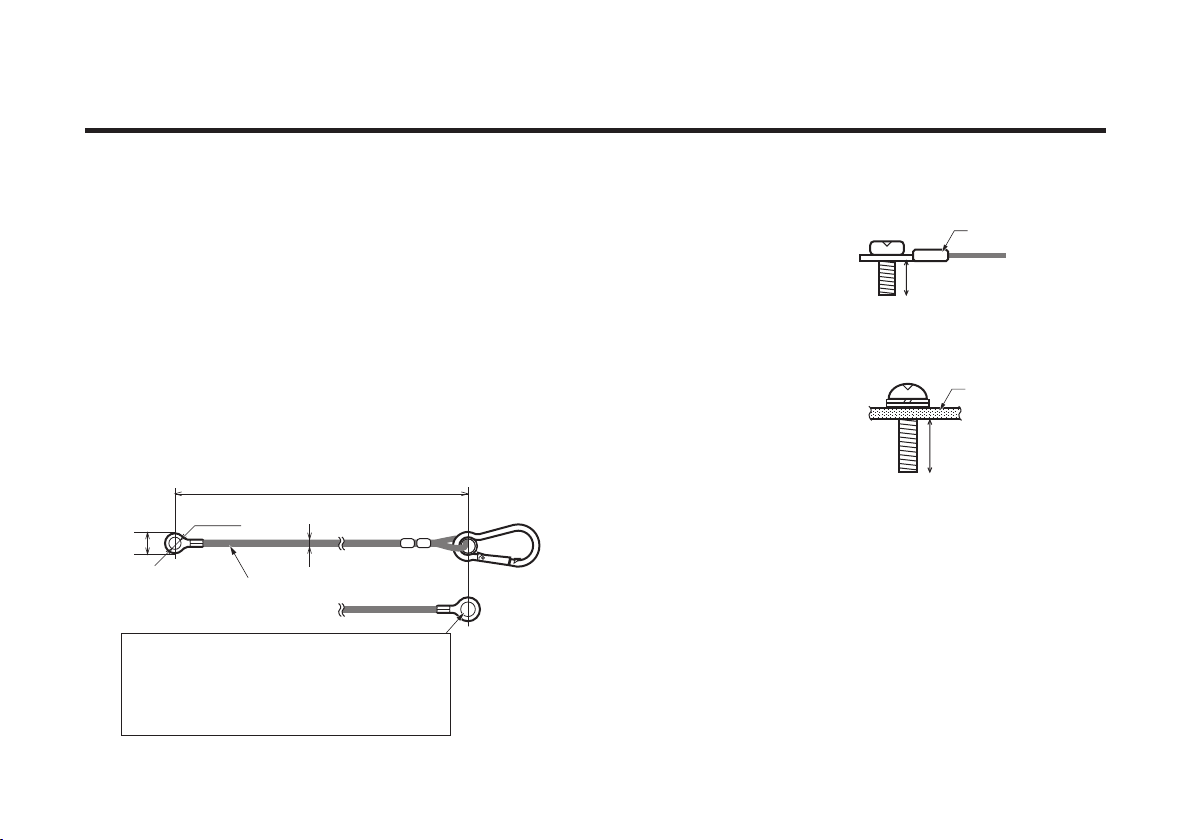

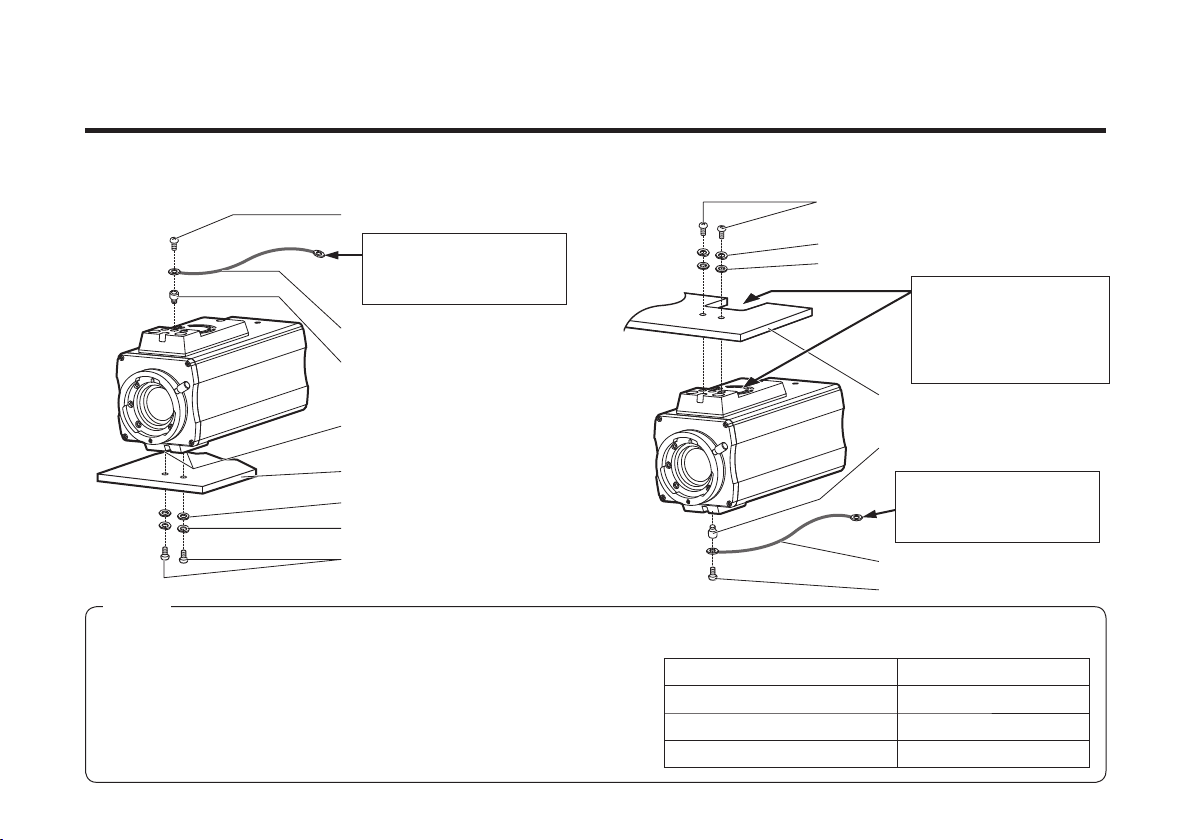

Concerning the mounting screws and drop-prevention

wire

Attach the drop-prevention wire as a way to prevent the

camera from dropping.

When the unit is to be mounted onto a Panasonic pan-tilt

head, use the mounting screws and drop-prevention wire

that are supplied with the pan-tilt head.

When the unit is to be mounted onto a surface other

than a pan-tilt head, provide your own drop-prevention

wire, mounting screws, washers, and camera mounting

bracket.

For details of the parts to be provided, refer to the next

page.

Before attaching the drop-prevention wire, fit the supplied

mounting spacer in the camera mounting screw hole.

Note

The mounting spacer must be fitted securely using a

flathead screwdriver.

Mounting screw (M4)

Drop-prevention wire

Mounting spacer (supplied)

Pan-tilt head or

camera mounting bracket

Flat washers

Spring washers

Mounting screws

(Inch screws: 1/4-20UNC)

Tightening the mounting screws and mounting

spacer

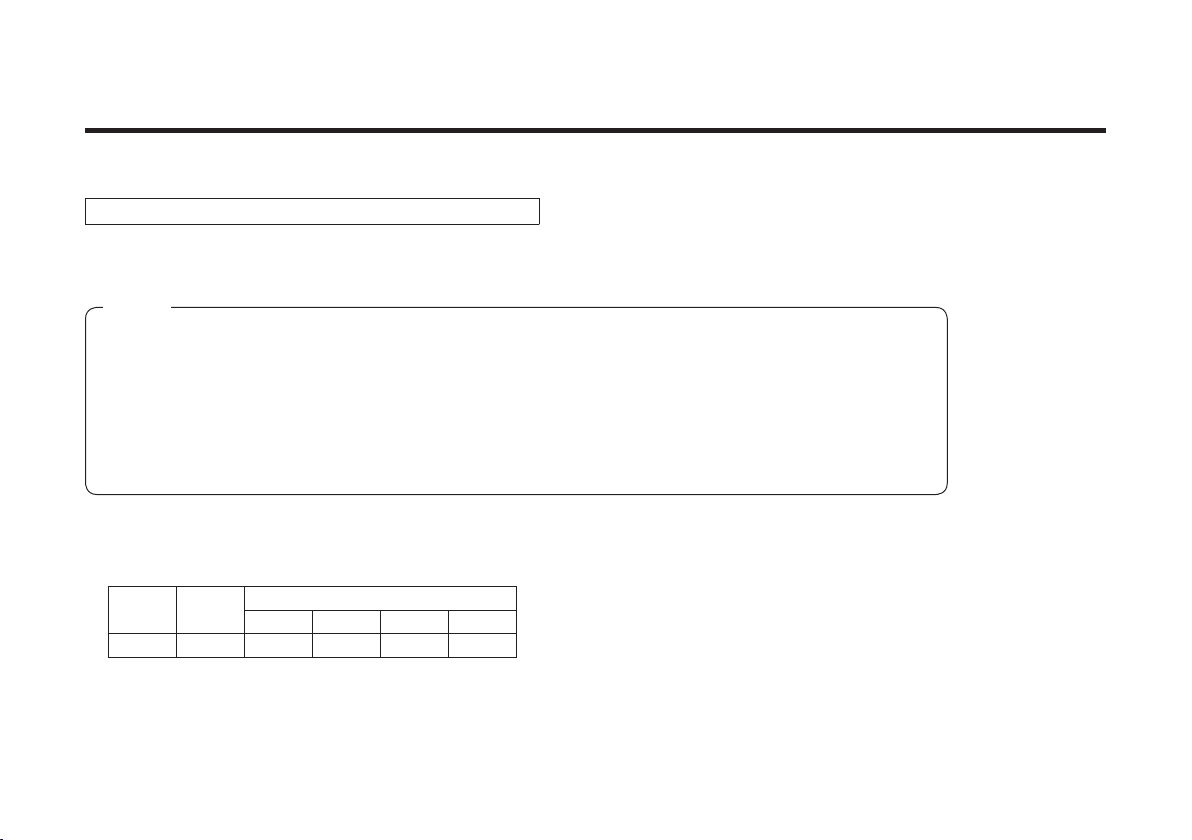

Tighten using the torque levels shown in the table below.

After tightening, check for play and unsteadiness.

Screws/Spacer Clamping torque

Mounting screws (M4) 1.5N • m (15 kgf • cm)

Mounting screws (Inch screws) 2.0N • m (20 kgf • cm)

Mounting spacer 2.0N • m (20 kgf • cm)

- 13 -

Precautions for installation

Parts to be provided by the customer for installation

Provide the following parts when the unit is to be mounted

onto a surface other than a pan-tilt head.

When the unit is to be mounted onto a Panasonic pan-tilt

head, use the mounting screws and drop-prevention wire

that are supplied with the pan-tilt head.

Drop-prevention wire: 1

Either crimp the two ends of the wire using stainless steel

terminals or attach metal hooks to the two ends of the

wire. Use a wire that is sufficiently strong.

Consider the installation location and mounting method

to be used, and cut the wire to a length that will have no

slack when attached.

( Camera

side)

8.5 mm

Shape the end of the wire so that it can be

attached using an M6 or M8 bolt and nut.

Provide the bolt and nut or anchor bolt

ø4.2

Stainless steel wire

that is best suited for the installation

location and mounting method used.

Wire length

ø1.2 or more

(Hook type)

(Crimping type)

The connection and installation should be done by

qualified service personnel or system installers.

Refer any servicing to qualified service personnel.

Mounting screws (M4): 1

(For attaching the drop-prevention wire)

Determine the length of

Drop-prevention wire

this screw by factoring

in the thickness of the

drop-prevention wire’s

5 mm

terminal.

Mounting screws (Inch screws: 1/4-20UNC): 2

(For mounting the camera)

Determine the length of

these screws by factoring

Camera mounting

bracket

in the thickness of the

camera mounting bracket.

8 mm

Flat washers: 2 (For mounting the camera)

Spring washers: 2 (For mounting the camera)

Camera mounting bracket: 1

Provide a bracket of a material and shape sufficiently

capable of withstanding the total weight to be borne.

To determine the position of the holes used for mounting

the camera, refer to <Bottom view> on page 15, and

make holes with a diameter of 7 mm (to support 1/420UNC mounting screws).

- 14 -

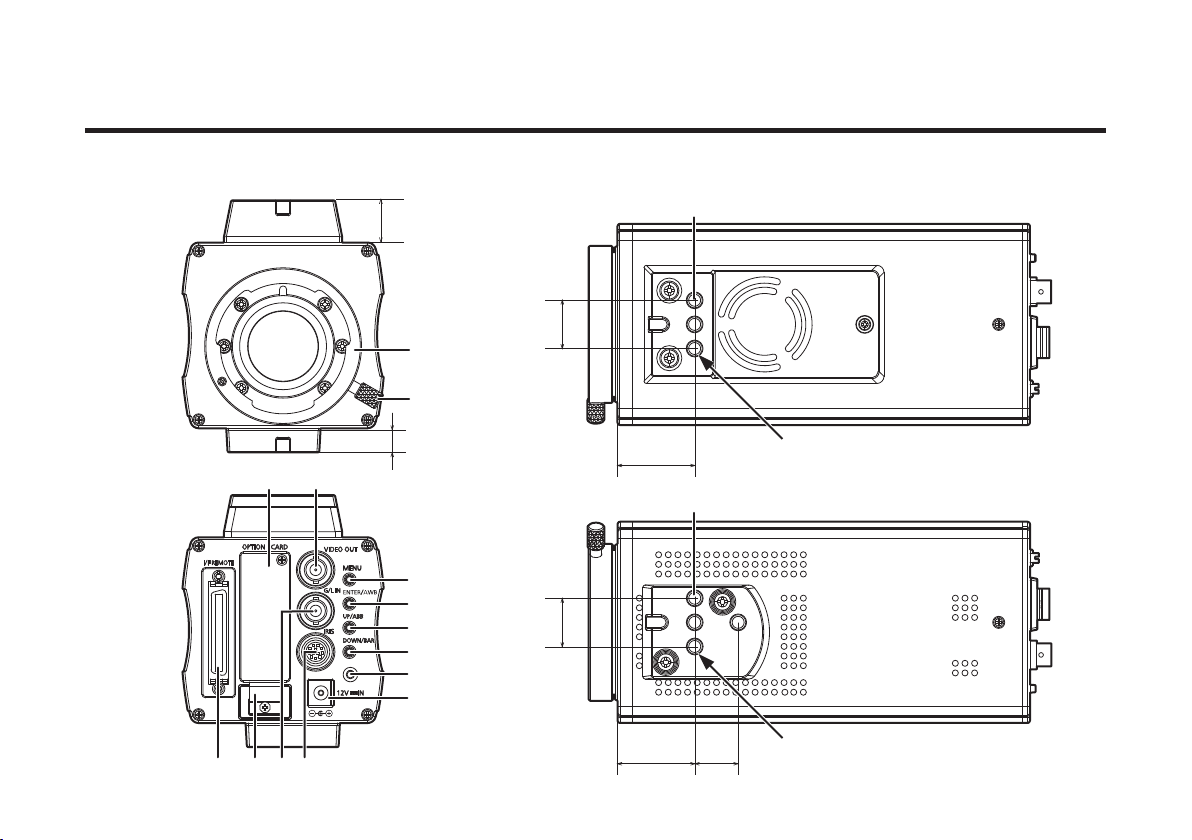

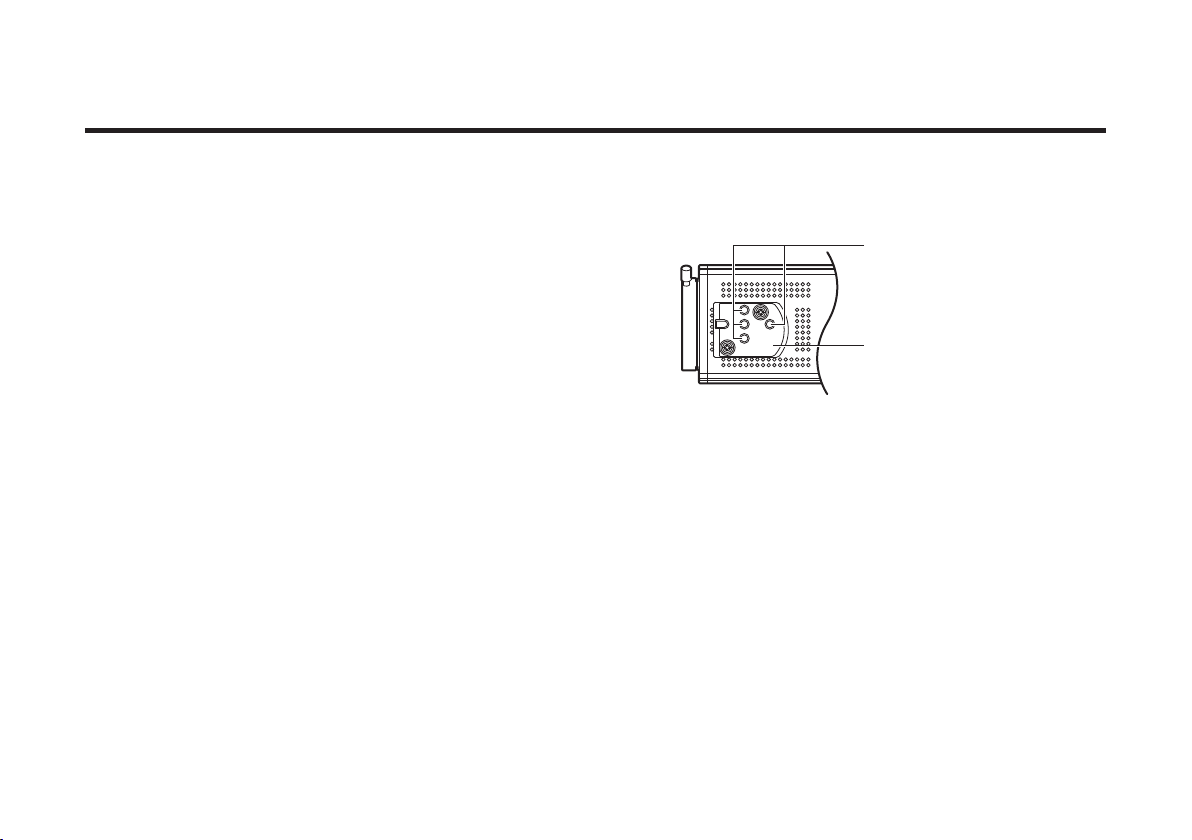

Major operating controls and their functions

Front view / Top view / Rear view / Bottom view

<Front view> <Top view>

11/16˝ (17.5 mm)

13/16˝

(20 mm)

<Rear view>

3/8˝ (10 mm)

<Bottom view>

13/16˝

(20 mm)

1-1/4˝

(32 mm)

1-1/4˝

(32 mm)

11/16˝

(18 mm)

Mounting screws (Inch screws)

1/4-20UNC, Depth: 3/8˝ (10 mm)

Mounting screws (Inch screws)

1/4-20UNC, Depth: 3/8˝ (10 mm)

- 15 -

Major operating controls and their functions

Lens mount

2/3˝ bayonet type lens or a microscope adapter can be

mounted.

Lens fixing ring knob

Mount the lens on the camera and rotate the lens fixing

ring knob clockwise in order to fix the lens securely.

Camera mounting screw holes

(Inch screws: 1/4-20UNC)

When installing the camera, use these screw holes to

secure the camera.

Furthermore, fit the supplied mounting spacer into these

screw holes, and use the mounting screws (M4) to attach

the drop-prevention wire.

For more details, refer to page 21.

MENU switch [MENU]

A menu will appear on the monitor screen when MENU

switch is pressed for at least 3 seconds.

The menu screen is cleared when the switch is pressed

for at least 3 seconds while the menu is displayed.

When this switch is pressed while an item is being

changed on a sub menu screen, the set values will revert

back to those prior to making changes.

ENTER/AWB switch [ENTER/AWB]

If this switch is pressed on the main menu screen, a

sub menu screen with selection items appears, and

if it is pressed on the sub menu screen, the selection

items start flashing to indicate that their settings can be

changed.

Pressing this switch while the camera is in a status where

settings can be changed finalizes changes.

This switch finalizes the “O.K.” or “CANCEL” selection

when pressed in individual confirmation screens (see

pages 86 to 89 for details).

When the menu is not displayed or the camera is in

shooting mode, the automatic white balance control

(AWB) can be set with this switch.

- 16 -

Major operating controls and their functions

UP/ABB switch [UP/ABB]

The item just above can be selected by pressing this

switch while the menu is displayed.

When this switch is pressed while an item is able to be

changed on a sub menu screen, the value is adjusted

higher.

When the menu is not displayed or the camera is in

shooting mode, the automatic black balance control

(ABB) can be set with this switch.

DOWN/BAR switch [DOWN/BAR]

The item just below can be selected by pressing this

switch while the menu is on the screen.

When this switch is pressed while an item is able to be

changed on a sub menu screen, the value is adjusted

lower.

When the menu is not displayed, the color bar and the

shooting conditions are indicated by pressing the switch

for about 2 seconds.

Video output connector [VIDEO OUT]

A composite video signal is provided at this connector.

(1 V [p-p], 75 BNC connector)

Iris connector [IRIS]

Connect the IRIS cable of the motor drive lens (such

as the AW-LZ17MD9AG and AK-LZ20M85G) to this

connector.

I/F Remote connector [I/F REMOTE]

This connector is used to connect the remote operation

panel (AW-CB400) or pan-tilt head (such as the

AW-PH400).

If the AW-CB400 is to be connected to this connector, a

camera control cable (AW-CA50T8) is required.

Power indicator

Green LED lamp lights to indicate that the specified DC

power is supplied to the DC 12 V input connector .

- 17 -

Major operating controls and their functions

DC 12 V input connector [12 V IN]

The model AW-PS510A AC adapter (optional accessory)

is connected here.

For the connection, use a DC cable with ø5.5 plug which

is supplied with AW-HE870.

Cautions

1. Connect this to a DC 12 V class 2 power supply only.

2. To prevent fire or shock, the UL listed wire VW-1,

style 1007 should be used as for the cable for DC

12 V input connector.

Note

The polarities of the DC 12 V input connector are

reversed on the unit from the polarities on existing

convertible cameras.

Be absolutely sure to use the DC cable provided

with the main unit.

Cable clamp

Clamp the DC cable with ø5.5 plug connected to the DC

12 V input connector to prevent it from slipping out.

Be absolutely sure to secure the DC cable using the

cable clamp.

G/L input connector [G/L IN]

External synchronizing signals (BB) are to be supplied

to this connector when the camera is to be synchronized

with the external synchronizing signals.

Three-value synchronizing signals of the HD format are

not supported.

Optional card slot [OPTION CARD]

Slot for inserting an optional card. For details, refer to the

manual for optional cards.

Note

Only the optional card (AW-HHD870) that supports

the unit can be used. It is not possible to use any

other cards.

- 18 -

Mounting

The connection and installation should be done by qualified service personnel

or system installers. Refer any servicing to qualified service personnel.

Lens mounting

Use the 2/3˝ bayonet type lens (such as the

AW-LZ17MD9AG and AK-LZ20M85G), available as an

optional accessory.

Note

Use the AW-LZ17MD9AG lens when using the

camera mounted on the pan-tilt head AW-PH360.

Lenses other than the AW-LZ17MD9AG cannot be

used.

Do not mount the camera on the AW-PH360 when

the AK-LZ20M85G is installed.

Weight balance cannot be secured.

Use the lens extension cable AW-CA12T12A if your IRIS

cable is too short.

1. Rotate the lens fixing ring knob counterclockwise and

remove the lens mount cap.

2. Mount the lens on the camera and rotate the lens

fixing ring knob clockwise in order to fix the lens

securely.

3. Connect the IRIS cable to the IRIS connector on the

back panel of the camera.

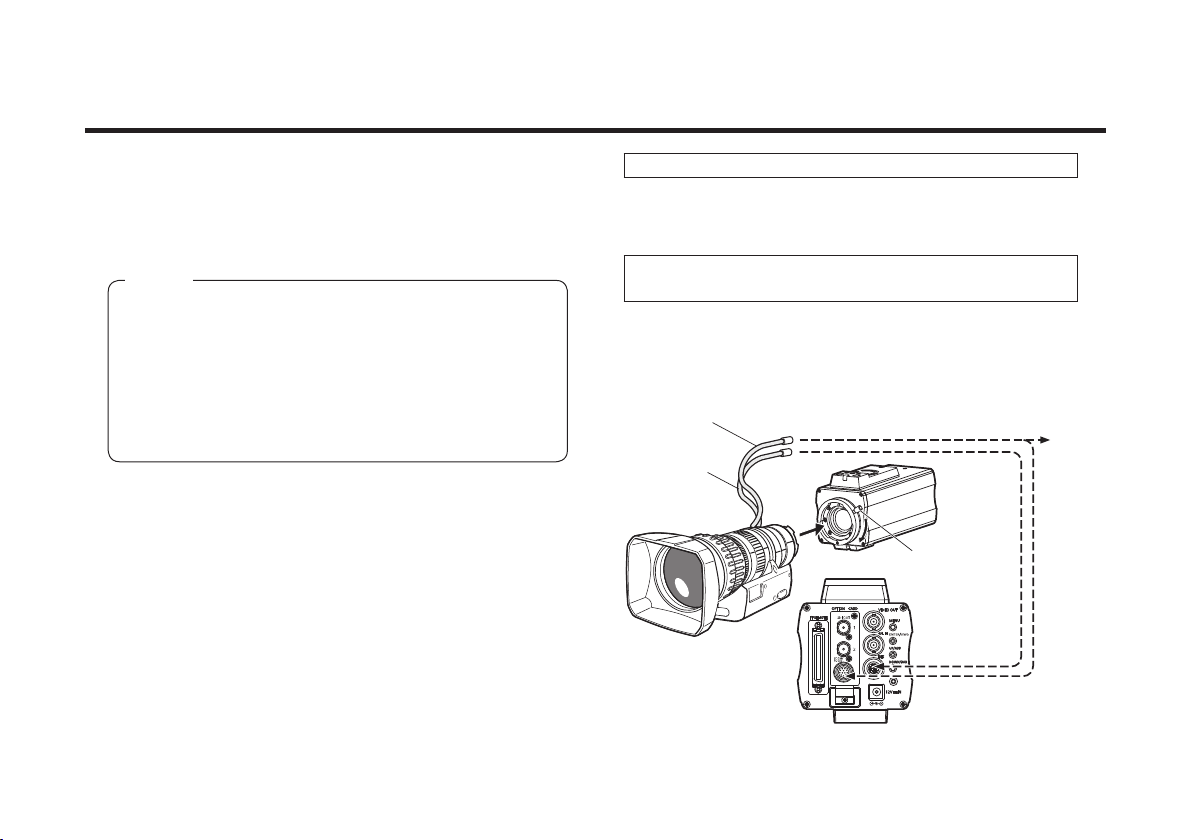

When the pan-tilt head has been used

Connect the remote cable of the lens to the LENS IF (1)

terminal on the pan-tilt head.

When the SDI card (AW-HHD870) is installed

without using the pan-tilt head

Connect the remote cable of the lens to the

ZOOM/FOCUS terminal of the SDI card.

Remote (for zoom/focus control) cable

(When the pan-tilt head is used, connect this

cable to the pan-tilt head)

To lens I/F connector of pan-tilt head

IRIS cable

Lens fixing

ring knob

To iris

connector

To the ZOOM/FOCUS

terminal when the SDI

card is installed without

using the pan-tilt head

- 19 -

Mounting

The connection and installation should be done by qualified service personnel

or system installers. Refer any servicing to qualified service personnel.

Mounting the camera onto a pan-tilt head, tripod, camera mounting

bracket, or other part

1. Use the camera mounting screw holes to mount onto a

pan-tilt head, tripod, camera mounting bracket, or other

part.

2. Fit the supplied mounting spacer into the camera

mounting screw holes on the camera’s top surface when

mounting the camera with its bottom surface, or on the

camera’s bottom surface when mounting the camera

with its top surface, and attach the drop-prevention wire

using the mounting screw (M4).

When the unit is to be mounted onto a Panasonic pan-tilt

head, use the mounting screws and drop-prevention wire

that are supplied with the pan-tilt head.

When the unit is to be mounted onto a tripod, camera

mounting bracket, or other part, refer to page 14, and

provide your own drop-prevention wire, mounting screws,

and washers.

Camera mounting screw holes

(Inch screws: 1/4-20UNC),

Depth: 3/8˝ (10 mm)

Camera mounting adapter

- 20 -

Mounting

The connection and installation should be done by qualified service personnel

or system installers. Refer any servicing to qualified service personnel.

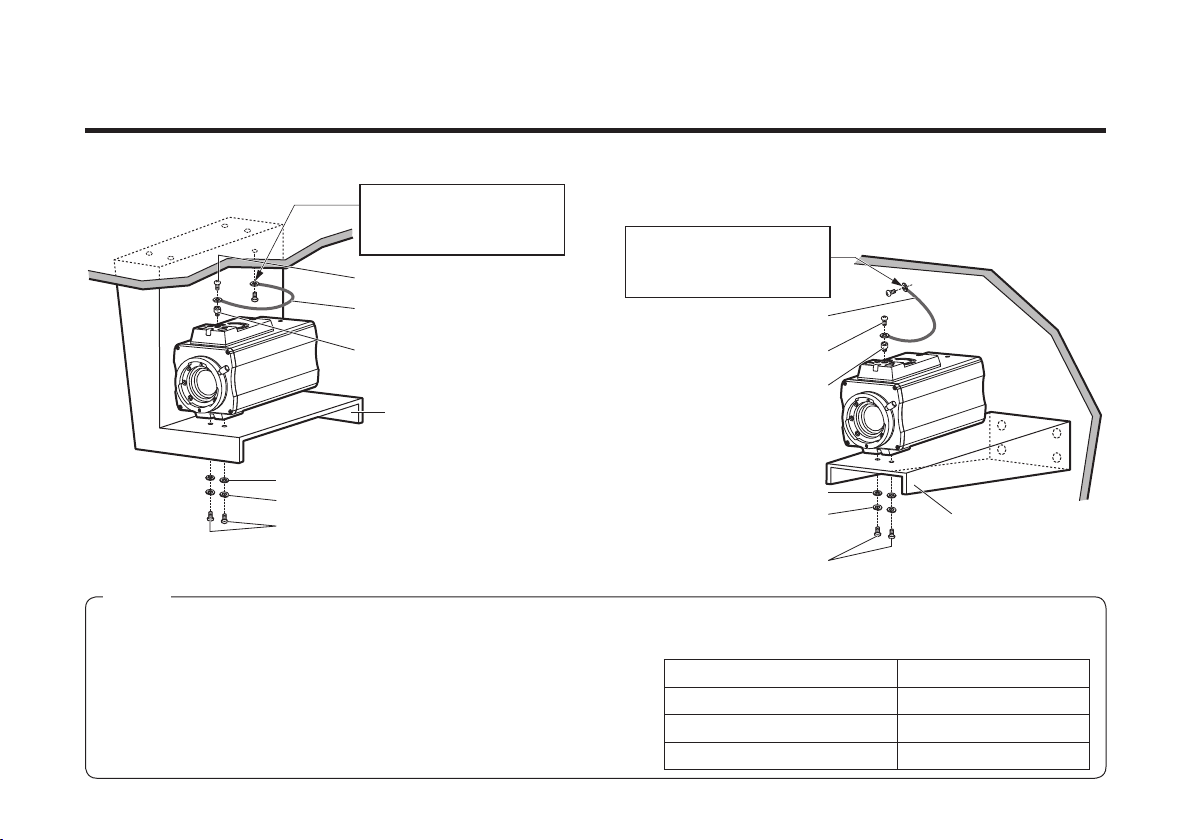

Example where the camera is mounted on a ceiling or wall

(Ceiling)

Hitch the end of the wire

onto the anchor bolt by

tightening the nut or

screw or by using a hook.

Mounting screw (M4)

Drop-prevention wire

(Wall)

Hitch the end of the wire

onto the anchor bolt by

tightening the nut or

screw or by using a hook.

Drop-prevention wire

Mounting spacer

(supplied)

Camera mounting

bracket

Flat washers

Spring washers

Mounting screws

(Inch screws: 1/4-20UNC)

Notes

When attaching one end of the drop-prevention wire to the

surface of a ceiling or wall, ensure that it is strong enough to bear

at least five times the total weight including the mounting bracket

or other part.

Tighten the mounting screws and mounting spacers using the

torque levels shown in the table to the right, and then check for

play and unsteadiness.

- 21 -

Mounting screw (M4)

Mounting spacer

(supplied)

Flat washers

Spring washers

Mounting screws

(Inch screws: 1/4-20UNC)

Screws/Spacer Clamping torque

Mounting screws (M4) 1.5N • m (15 kgf • cm)

Mounting screws (Inch screws) 2.0N • m (20 kgf • cm)

Mounting spacer 2.0N • m (20 kgf • cm)

Camera mounting

bracket

Mounting

The connection and installation should be done by qualified service personnel

or system installers. Refer any servicing to qualified service personnel.

Example of mounting the camera onto a bracket

or tripod made by another manufacturer

Mounting screw (M4)

Hitch the end of the wire

onto the anchor bolt by

tightening the nut or screw

or by using a hook.

Drop-prevention wire

Mounting spacer (supplied)

Camera mounting screw holes

Bracket or tripod made by

another manufacturer

Flat washers

Spring washers

Mounting screws

(Inch screws: 1/4-20UNC)

Notes

Ensure that the installation location is strong enough to bear at

least five times the total weight.

Even when the camera has been mounted on a tripod, be

absolutely sure to take steps to prevent the camera from falling.

Tighten the mounting screws and mounting spacers using the

torque levels shown in the table to the right, and then check for

play and unsteadiness.

Example of mounting on a surface above the

camera

Screws/Spacer Clamping torque

Mounting screws (M4) 1.5N • m (15 kgf • cm)

Mounting screws (Inch screws) 2.0N • m (20 kgf • cm)

Mounting spacer 2.0N • m (20 kgf • cm)

Mounting screws

(Inch screws: 1/4-20UNC)

Spring washers

Flat washers

Adjust the camera

mounting bracket on the

surface above the camera

so that the ventilation

holes of the cooling fan

will not be blocked.

Camera mounting bracket

Mounting spacer (supplied)

Hitch the end of the wire

onto the anchor bolt by

tightening the nut or screw

or by using a hook.

Drop-prevention wire

Mounting screw (M4)

- 22 -

Mounting

The connection and installation should be done by qualified service personnel

or system installers. Refer any servicing to qualified service personnel.

3. When mounting the camera onto a pan-tilt head

(AW-PH400), do not use the anchoring rubber piece

supplied with the pan-tilt head.

If this rubber piece is used, the camera’s ventilation

holes will be blocked, causing the temperature inside the

camera to rise and possibly resulting in a malfunction.

Do not use the anchoring

rubber piece when

mounting the AW-HE870

camera.

Indoor Pan/tilt Head AW-PH400

Notes

For the specifications of the camera mounting screw

holes, refer to “Major operating controls and their

functions” on page 15.

When using the camera mounting screw holes on the

camera’s top surface (when mounting the camera by

suspending it), take care not to block the ventilation

holes of the cooling fan.

When using the camera mounting screw holes on the

camera’s top surface (when mounting the camera by

suspending it), attach the drop-prevention wire to the

camera mounting screw holes on the camera’s bottom

surface.

Do not mount the camera upside down because this

will cause the temperature inside the camera to rise,

possibly resulting in a malfunction.

When mounting the camera onto a pan-tilt head,

mount it securely after obtaining a full understanding

of the mounting procedure in the operating

instructions of the pan-tilt head.

- 23 -

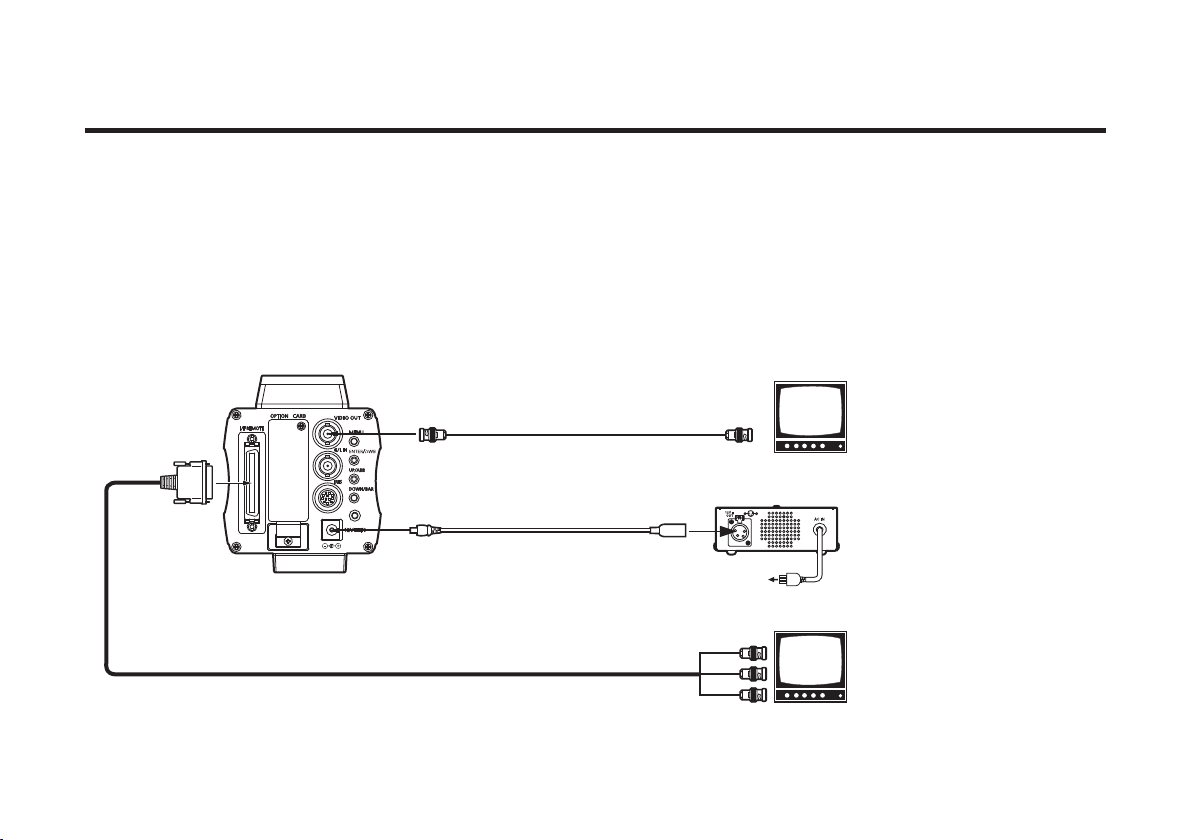

System configuration (Connections)

Connection of device with a composite/component input connector

Connection to any device which has a composite signal input connector, such as a monitor or a VTR, must be made through

the VIDEO OUT connector.

Use the AW-CA50T8 camera control cable, which is available as an optional accessory, to connect the I/F REMOTE

connector on the unit with the device equipped with HD/SD component signal input connectors.

Composite signals (from the VIDEO OUT connector) and component signals (from the I/F REMOTE connector) can be output

at the same time.

Use the DC cable with ø5.5 plug, supplied with the AW-HE870, for connection to the 12 V input connector.

VIDEO OUT

connector

DC cable with ø5.5 plug

(supplied with AW-HE870)

75 coaxial cable

Composite video input

connector (VIDEO IN)

Monitor

(Composite signal input)

AC Adapter

AW-PS510A

Camera control cable AW-CA50T8 (32.8 ft. [10 m])

- 24 -

Y

Pb

Pr

Monitor

(Component signal input)

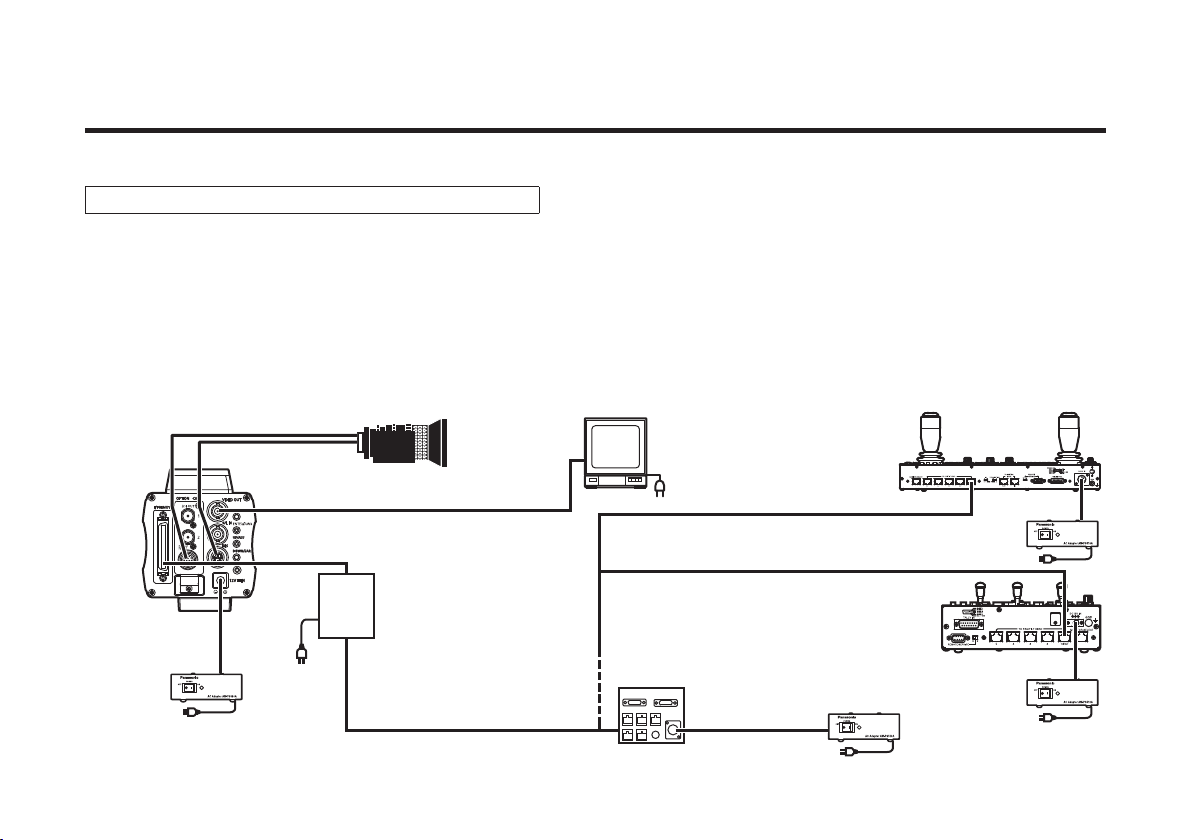

System configuration (Connections)

Connection of a remote operation panel

When an SDI card (AW-HHD870) has been installed

First, turn off the power of all the equipment before proceeding with the connections.

Use the AW-PS510A for the AC adapter of the unit.

Connect the DC 12 V OUT socket on the AW-PS510A to the DC 12 V IN socket on the unit using the DC cable provided with

the AW-HE870.

Connect the CONTROL OUT TO CAMERA connectors [1] to [5] on the ROP with the I/F REMOTE connectors on the unit

through the connecting cables (optional accessory) AW-CA50T8 (or AW-CA50T9 + RS-422/RS-232C converter).

The distance between the ROP and the AW-CA50T8 (or AW-CA50T9 + RS-422/RS-232C converter) can be extended up to a

maximum of about 3280 ft. (1000 m) using a 10BASE-T (equivalent to UTP category 5) straight cable.

Zoom/Focus control

DC cable

provided with

AW-HE870

AC Adapter

AW-PS510A

Iris control

Zoom lens

Video signal

AW-CA50T8

or AW-CA50T9 +

RS-422/RS-232C

()

converter

Control signal

10BASE-T straight cable

Monitor

Remote

Operation

Panel

AW-CB400

Cable

provided with

AC adapter

- 25 -

Multi-Function

Controller

AW-RP655

AC Adapter

AW-PS510A

Multi Hybrid

Control Panel

AW-RP555

AC Adapter

AW-PS510A

AC Adapter

AW-PS510A

System configuration (Connections)

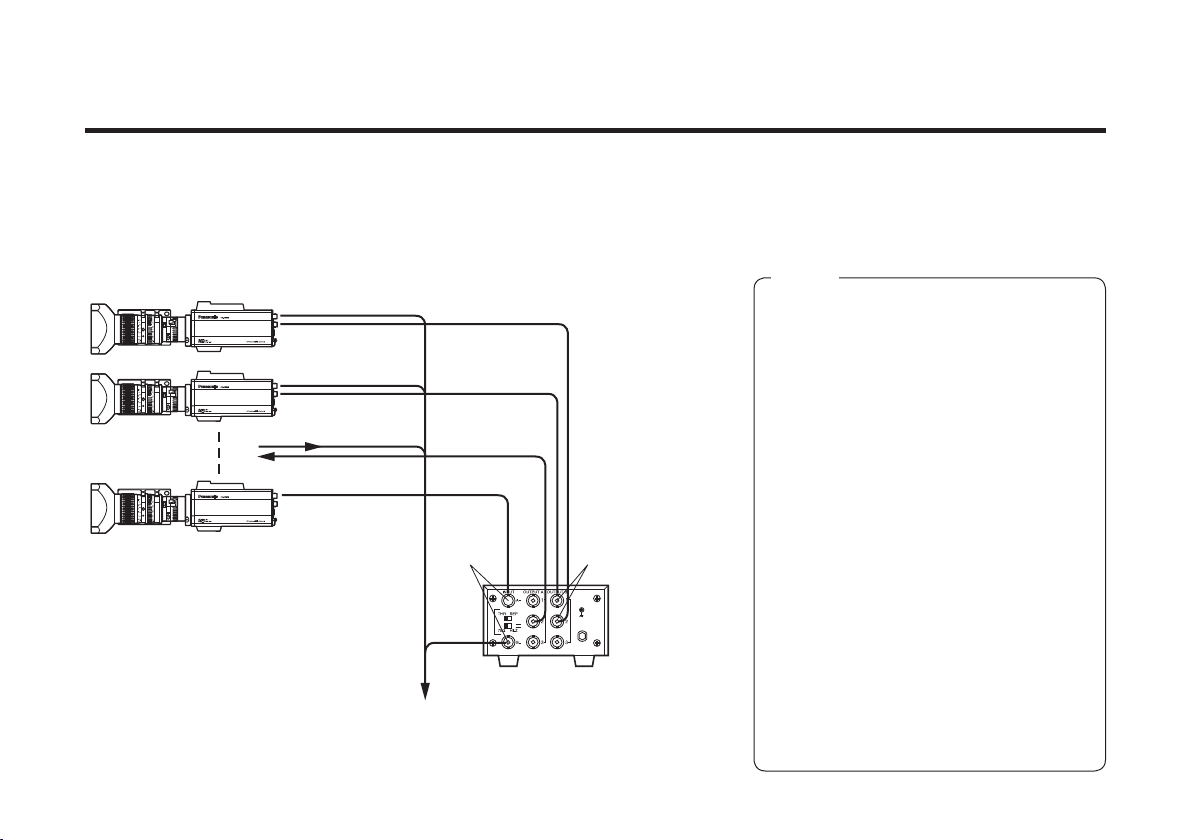

Connection with multiple cameras (Supplying the external synchronizing signals)

Supply a synchronizing signal (BB) to the G/L input connectors of each camera.

Do not switch off the camera used for supplying the external synchronizing signals.

Genlock adjustment is needed when supplying the external synchronizing signals. (page 57)

Camera

Camera for external sync

(or special effect generator)

VIDEO OUT

G/L IN

External sync

signal (BB)

VIDEO OUT

INPUT OUTPUT

Video distributor

Video output

To special effect generator or monitoring system

Notes

Three-value synchronizing signals of

the HD format are not supported.

When using external synchronization,

only the output signal for the selected

video output format (Format) will be

synchronized (1080i, 720p, or 480i).

When selecting an HD format

(1080i or 720p), neither the VIDEO

OUT signal (composite signal)

nor the Y/C signal output from the

AW-CA50T8 S-Video terminal will

be synchronized with the external

synchronizing signal.

To synchronize the VIDEO OUT

signal (composite signal) or

the Y/C signal output from the

AW-CA50T8 S-Video terminal with

the external synchronizing signal,

use “480i” as the video output

format (selected from the camera

menu).

- 26 -

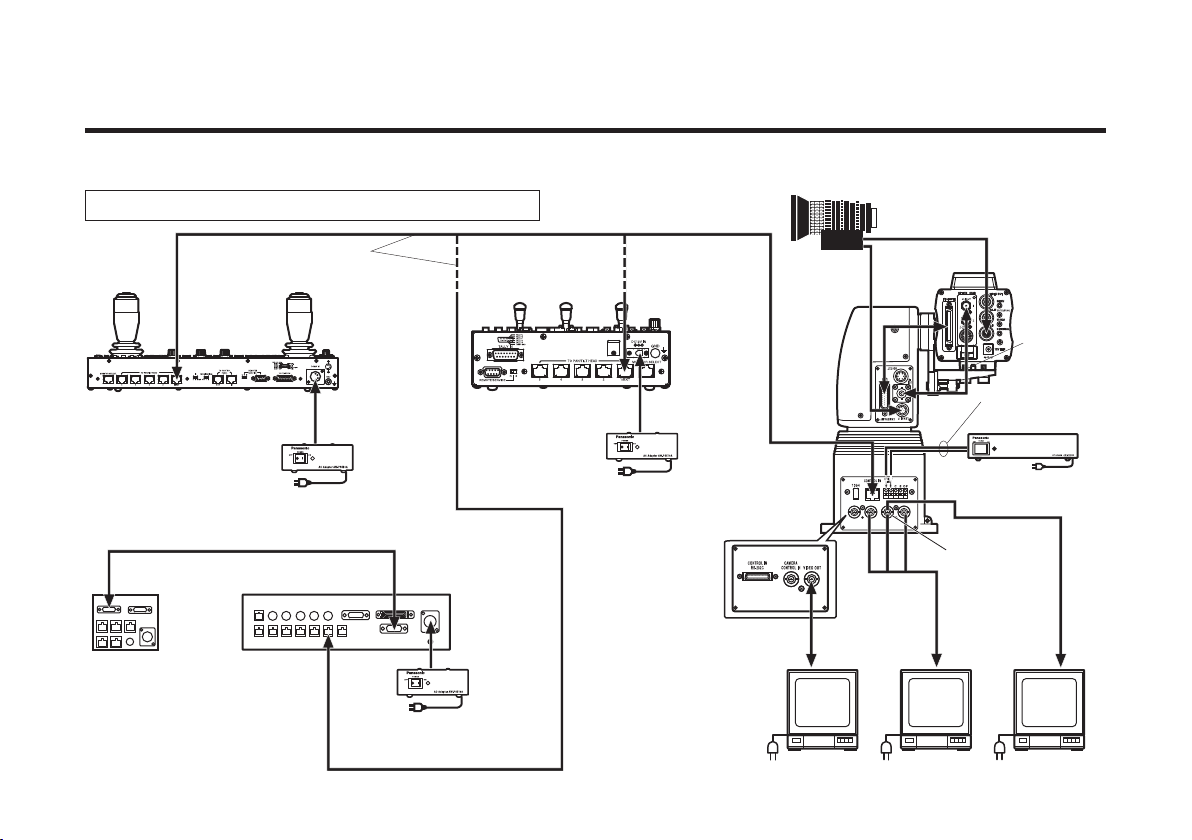

System configuration (Connections)

Connection of the Indoor Pan-tilt Head AW-PH360

Turn off the power of all the equipment before proceeding with the connections.

Connect the AC adapter (AW-PS300A) to the AW-PH360 indoor pan-tilt head.

Use 10BASE-T straight cables to connect the RP connectors on the pan-tilt heads with the CONTROL OUT TO PAN/TILT

HEAD (1 to 5) connectors on the AW-RP655 multi-function controller and AW-RP555 multi hybrid control panel.

The maximum extension distance is 3281 ft. (1000 m) when using UTP category 5 cables or their equivalent.

Connect the CONTROL OUT TO PAN/TILT HEAD terminals (P1 to P5) of the AW-RP400 and the RP terminal of the

AW-PH360 with a 10BASE-T straight cable when using the AW-RP400 pan/tilt control panel.

The maximum extension distance is 1640 ft. (500 m) when using UTP category 5 cables or their equivalent.

Use the camera cable provided with the pan-tilt head to connect the AW-PH360 to the unit.

Connect the iris control cable of the motorized zoom lens to the IRIS connector on the camera, and connect the zoom/focus

cable to the LENS I/F (1) connector on the pan-tilt head.

Set the Controller Selection switch SW1 located inside the AW-PH360 to the “Left Side (RP605)”.

Select “SDI supported” as the transmission signal selection setting.

- 27 -

System configuration (Connections)

Connection of the Indoor Pan-tilt Head AW-PH360 (continued)

When an SDI card (AW-HHD870) has been installed

Use a coaxial cable to connect the SDI OUT connector on the SDI card and the SDI IN connector on the AW-PH360.

Use a coaxial cable to connect the Pr/SDI OUT connector on the AW-PH360 to the SDI input connector on the color monitor.

Notes

HD (1080i or 720p) analog component signals cannot be output from the AW-PH360.

Refer to the operating instructions of the AW-PH360 for details relating to internal switch settings, etc.

of the pan-tilt head.

Use the AW-LZ17MD9AG lens when using the camera mounted on the pan-tilt head AW-PH360.

Lenses other than the AW-LZ17MD9AG cannot be used.

Do not mount the camera on the AW-PH360 when the AK-LZ20M85G is installed.

Weight balance cannot be secured.

AW-IF400 Switch settings (when the AW-RP400 is used)

SW1 SW2

OFF ON OFF ON OFF OFF

1234

SET UP

- 28 -

System configuration (Connections)

Connection of the Indoor Pan-tilt Head AW-PH360 (continued)

When an SDI card (AW-HHD870) has been installed

10BASE-T straight

cable

Multi-Function Controller

AW-RP655

Remote

Operation

Panel

AW-CB400

Pan/Tilt

Control

Panel

AW-RP400

AC Adapter

AW-PS510A

AC Adapter

AW-PS510A

Multi Hybrid

Control Panel

AW-RP555

Pan-tilt head/camera

control signals

AC Adapter

AW-PS510A

- 29 -

Indoor

Pan-tilt

Head

AW-PH360

signal

Motorized zoom lens

Camera

cable

(supplied)

Coaxial

cable

(to SDI

connector)

DC cable (UL Type SPT-2

216 AWG or UL Type

NISPT-2 216 AWG, to be

locally purchased)

AC Adapter

AW-PS300A

• The SDI

YPrPb

SD

component

signal*

Monitor

*: The HD component signal cannot be output.

Monitor

connector

is the same

position as Pr.

HD/SD-SDIComposite

Monitor

System configuration (Connections)

Connection of the Indoor Pan-tilt Head AW-PH400

Turn off the power of all the equipment before proceeding with the connections.

Connect the AC power cable provided with the AW-PH400 to the AW-PH400 indoor pan-tilt head.

Use 10BASE-T straight cables to connect the CONTROLLER connectors on the protocol converter AW-IF400 with the

CONTROL OUT TO PAN/TILT HEAD (1 to 5) connectors on the AW-RP655 multi-function controller and AW-RP555 multi

hybrid control panel.

The maximum extension distance is 3281 ft. (1000 m) when using UTP category 5 cables or their equivalent.

Connect the PAN/TILT HEAD terminal of the protocol converter AW-IF400 and the RP terminal of the AW-PH400 with a

10BASE-T straight cable.

The maximum extension distance is 1640 ft. (500 m) when using UTP category 5 cables or their equivalent.

Connect the CONTROL OUT TO PAN/TILT HEAD terminals (P1 to P5) of the AW-RP400 and the RP terminal of the pan-tilt

head using a 10BASE-T straight cable when using the AW-RP400 pan/tilt control panel.

The maximum extension distance is 1640 ft. (500 m) when using UTP category 5 cables or their equivalent.

Use the camera cable provided with the pan-tilt head to connect the AW-PH400 to the unit.

Connect the iris control cable of the motorized zoom lens to the IRIS connector on the camera, and connect the zoom/focus

cable to the LENS I/F (1) connector on the pan-tilt head.

- 30 -

Loading...

Loading...