Page 1

SERVICE INFORMATION

CONTENTS

1. Servicing Fixtures & Tools ..........................................................................................................INF-1

2. Alignment Tape ...........................................................................................................................INF-4

2-1. DVCPRO Alignment Tape.........................................................................................INF-4

3. List of Recommended Measuring and Instruments ....................................................................INF-5

4. Maintenance Schedule................................................................................................................INF-6

5. Layout of the Maintenance Parts & Sensors...............................................................................INF-7

6. Emergency Eject .........................................................................................................................INF-8

7. Cleaning Method.........................................................................................................................INF-9

7-1. Cylinder Head Cleaning Method: (Daily)...................................................................INF-9

7-2. Cylinder Lead Cleaning Method: (Weekly) ...............................................................INF-9

7-3. A/C Head Cleaning Method: (Week ly)......................................................................INF-9

7-4. Pinch Roller and Capstan Shaft Cleaning Method: (Weekly) ...................................INF-9

7-5. Post Cleaning Method: (Weekly)...............................................................................INF-9

8. Basic Setting Menu Operations....................................................................................................INF-10

8-1. Service Menu Operation ...........................................................................................INF-10

8-2. Design Menu Operation ............................................................................................INF-11

8-3. Displaying Sub-Menus and Setting Procedures .......................................................INF-12

8-4. Setting Menu Configurations.....................................................................................INF-14

9. Service Menu Item Contents.......................................................................................................INF-17

9-1. CAM SERVICE MENU..............................................................................................INF-17

9-2. CAM DESIGN MENU................................................................................................INF-18

9-3. VTR SERVICE 1/3 ....................................................................................................INF-20

9-4. VTR SERVICE 2/3 ....................................................................................................INF-21

9-5. VTR SERVICE 3/3 ....................................................................................................INF-21

9-6. VTR DESIGN MENU.................................................................................................INF-21

9-7. TEST MODE .............................................................................................................INF-22

9-8. ERROR LOG.............................................................................................................INF-22

10.Adjustment after Optical Unit Replacement................................................................................INF-23

10-1. Input the Adjustment Data.........................................................................................INF-23

10-2. Electrical Adjustment.................................................................................................INF-23

11. DIAG-MENU Display ................................................................................................................INF-24

12. Error Rate Display and Confirmation Method...........................................................................INF-26

12-1. Error Rate Display Method........................................................................................INF-26

13. Internal Switch Setting Method.................................................................................................INF-27

14. Circuit board layout...................................................................................................................INF-28

15. PLD Version Upgrade Method..................................................................................................INF-29

15-1. Preparation................................................................................................................INF-29

15-2. Connection................................................................................................................INF-29

15-3. Version-up Procedures .............................................................................................INF-30

16. Flash Memory Version Upgrade Method ...................................................................................INF-32

16-1. Preparation................................................................................................................INF-32

16-2. Version Upgrade for CAM_SYS P.C.Board..............................................................INF-33

16-3. Version Upgrade for VTR_SYS P.C.Board...............................................................INF-35

16-4. Version Upgrading for SERVO P.C.Board................................................................INF-37

Page 2

17. Blemish Compensation Method.................................................................................................INF-38

17-1. Preparation............................................................................................................... INF-38

17-2. Connection................................................................................................................ INF-38

17-3. Compensation flow................................................................................................... INF-39

17-4. Compensation Procedures.......................................................................................INF-40

17-5. Remarks ...................................................................................................................INF-44

17-6. Trouble Shooting ......................................................................................................INF-45

17-7. FAQ (Frequently Asked Question) ...........................................................................INF-45

Page 3

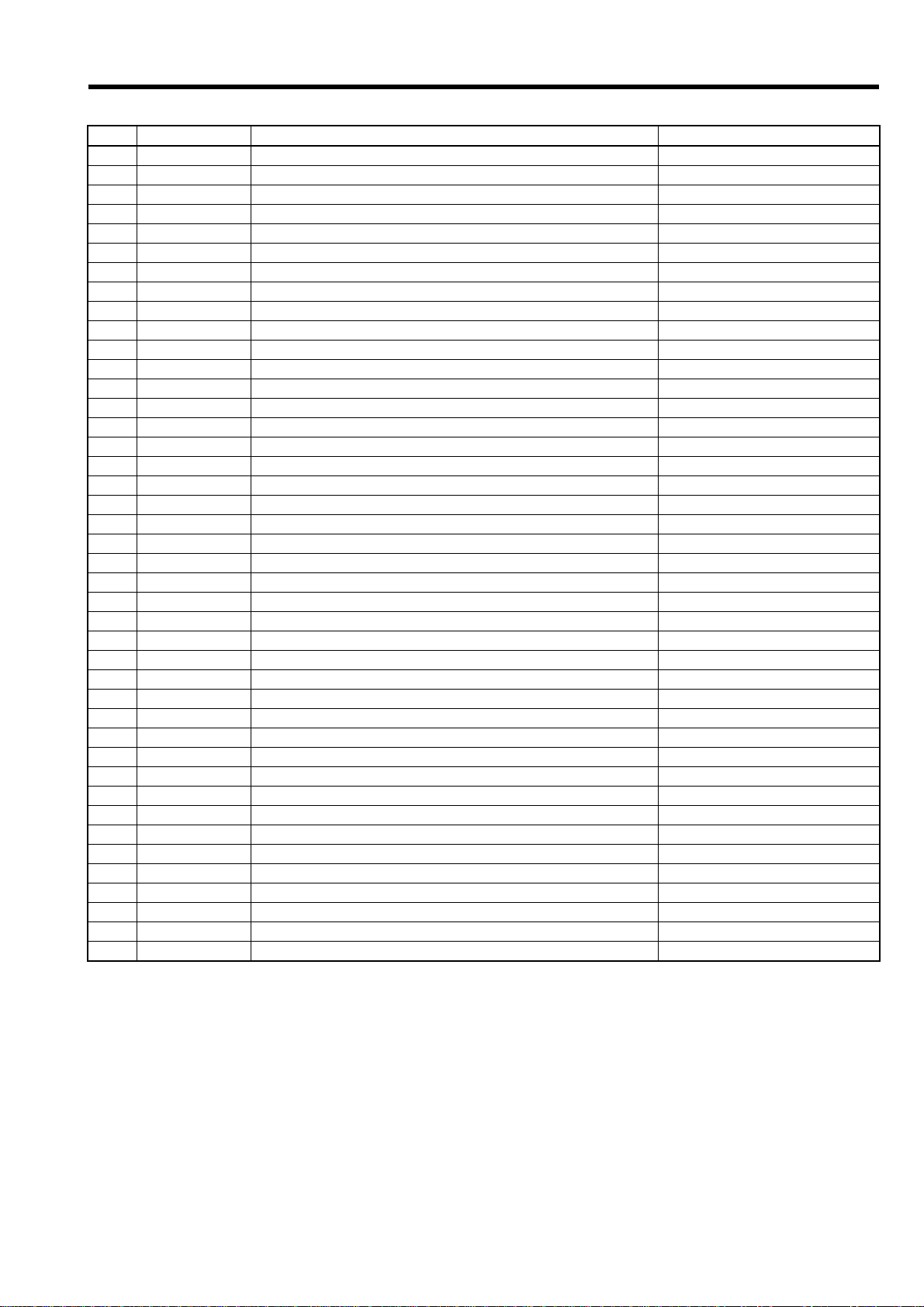

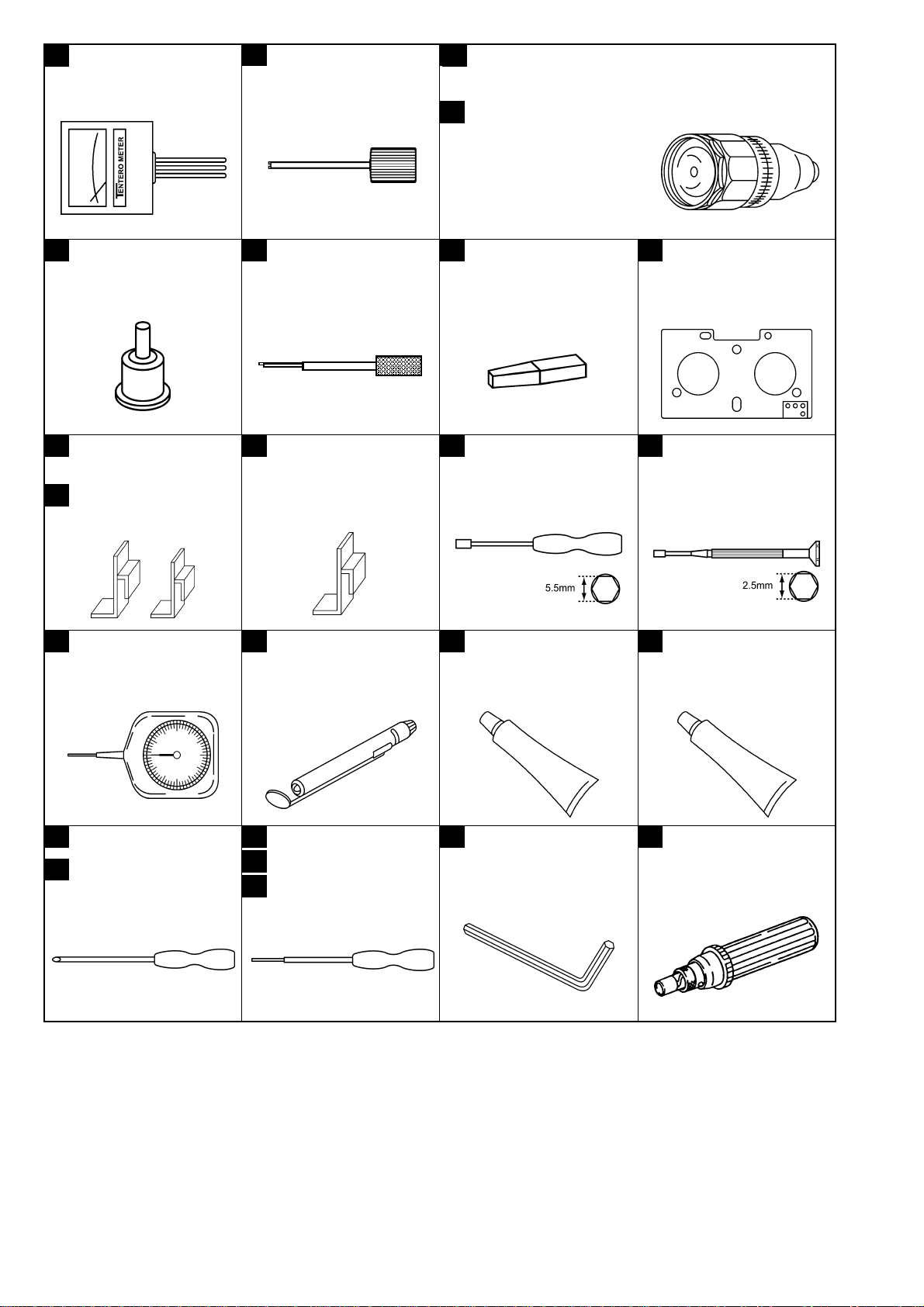

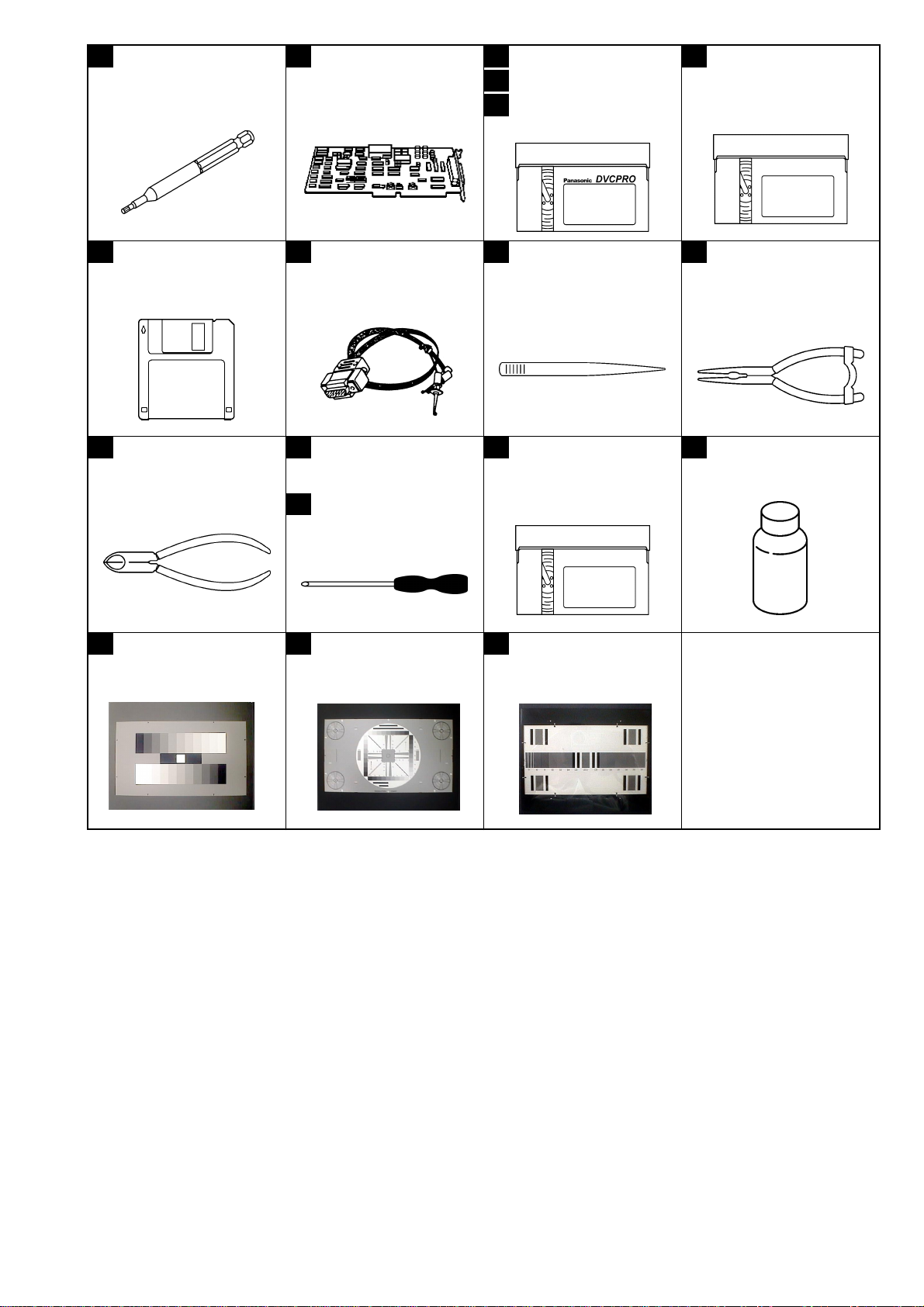

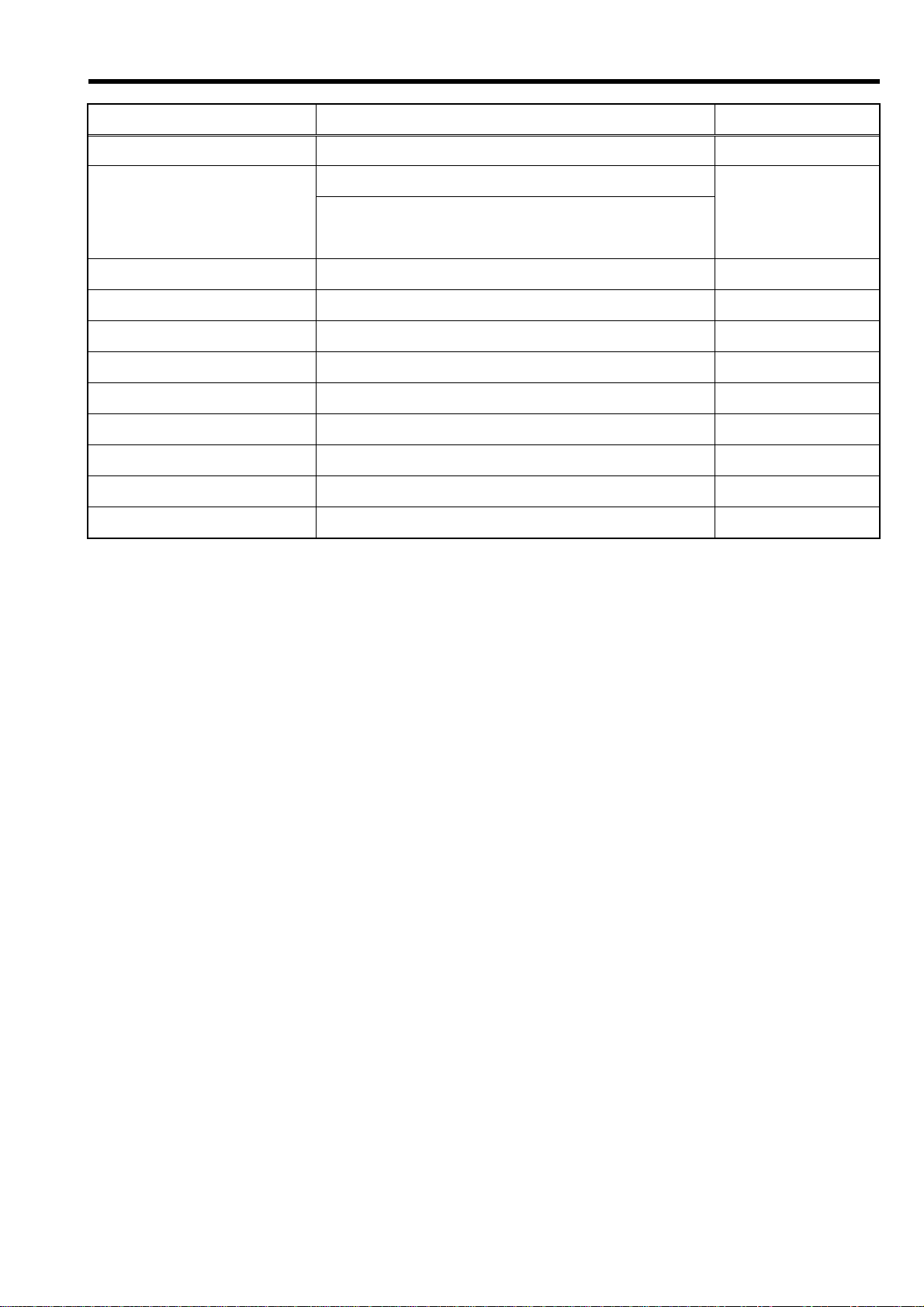

1. Servicing Fixtures & Tools

No. Part No. Fixture & Tool Name Remarks

1 VFK1145A Back Tension Meter (T2-M30-P)

2 VFK1149A Post Driver (2.5mm)

3 VFK71A Dial Torque Gauge (1.5cN-m) 150g

4 VFK1191A Dial Torque Gauge (0.45cN-m) 45g

5 VFK1152 Dial Torque Gauge Adapter

6 VFK0357 Eccentric Driver (1.5mm)

7 VFK1154 Post Height Fixture

8 VFK1586 Mech. Neutral Plate (L) For Post Height

9 VFK1155 REV Position Tool (Silver)

10 VFK1156 PLAY Position Tool (Black)

11 VFK1208 Neutral Position Tool (Black with Hole)

12 VFK1150 Nut Driver (5.5mm)

13 VFK1151 Nut Driver (2.5mm)

14 VFK1188A Dial Tension Gauge (30mN) 30g

15 VFK0948 Check Light

16 VFK0749 Froiral Grease For Plastic

17 MOR265 Morlytone Grease For Metallic

18 VFK1146 Phillips Driver (Fine) (00-75)

19 VFK1147 Phillips Driver (Fine) (0-100)

20 VFK1148 Hex. Driver (1.5mm)

21 VFK1178 Hex. Driver (0.89mm)

22 VFK1179 Hex. Driver (0.71mm)

23 VFK1190 Hex. Wrench

24 VFK1209A Torque Driver (4-30cN-m) 0.4-3kg

25 VFK1375 Hex. Bit (1.5mm)

26 VFK1300 AD Board (DAQ-12 Q uatec h)

27 VFM3580KL Alignment Tape (No.1) L-Cassette

28 VFM3581KL Alignment Tape (No.2) L-Cassette

29 VFM3582KL Alignment Tape (No.3) L-Cassette

30 AJ-CL12P Cleaning Tape SALES Route

31 VFK1481B LISTA Software

32 VFK1186 LISTA Cable

33 VFK0369 Tweezers

34 VFK0371 Radio Prier

35 VFK0372 Cutter Prier

36 VFK0337 Phillips Driver

37 VFK0338 Phillips Driver

38 VFK1369 Tape Sensor Adjustment Cassette

39 VFK0906 Lubrication Oil

40 VFK1642 Gray Scale Chart (Reflection type) 16:9

41 VFK1643 Resolution Chart (Reflection type) 16:9, For HD

42 VFK1644 Immega Cycle Chart (Transparency type) 16:9, For HD

INF-1

Page 4

1 VFK1145A (T2-M30-P)

Back Tension Meter

2 VFK1149A (2.5mm)

Post Driver

VFK71A (1.5cN-m)

3

3

(150g)

5 VFK1152

Dial Torque Gauge

Adapter

9 VFK1155

REV Position Tool (Silver)

10 VFK1156

PLAY Position Tool (Black)

6 VFK0357

Eccentric Driver

(1.5mm)

11 VFK1208

Neutral Position Tool

(Black with Hole)

VFK1191A (0.45cN-m)

4

(45g)

7 VFK1154

Post Height Fixture

12 VFK1150

Nut Driver (5.5mm)

Dial Torque Gauge

8 VFK1586

Mech. Neutral Plate (L)

13 VFK1151

Nut Driver (2.5mm)

VFK1188A 30mN14

Dial Tension Gauge

VFK1146

18

VFK1147

19

Phillips Driver (Fine)

VFK094815

Check Light

VFK1148 (1.5mm)20

VFK1178 (0.89mm)

21

22

VFK1179 (0.71mm)

Hex. Driver

VFK074916

Froiral Grease

(for Plastic)

VFK119023

Hex. Wrench

MOR26517

Morlytone Grease

(for Metallic)

VFK1209A 4-30cN-m

24

(0.4-3kg)

Torque Driver

INF-2

Page 5

VFK137525

Hex. Bit

VFK130026

AD Board

(DAQ-12 Quatech)

VFM3580KL27

VFM3581KL

28

VFM3582KL

29

Alignment Tape

AJ-CL12P

30

Cleaning Tape

VFK1481B31

LISTA Software

35 36

VFK0372

Cutter Prier

40 41 42

VFK1642

Gray Scale Chart

(16:9, Reflection Type)

VFK118632

LISTA Cable

VFK0337

Phillips Driver

37

VFK0338

Phillips Driver

VFK1643

Resolution Chart

(16:9,Reflection type)

33 34

38 39

VFK0369

Tweezers

VFK1369

Tape Sensor

Adjustment Cassette

VFK1644

Immega Chart (For HD,

Transpalency Type)

VFK0371

Radio Prier

VFK0906

Lubrication Oil

INF-3

Page 6

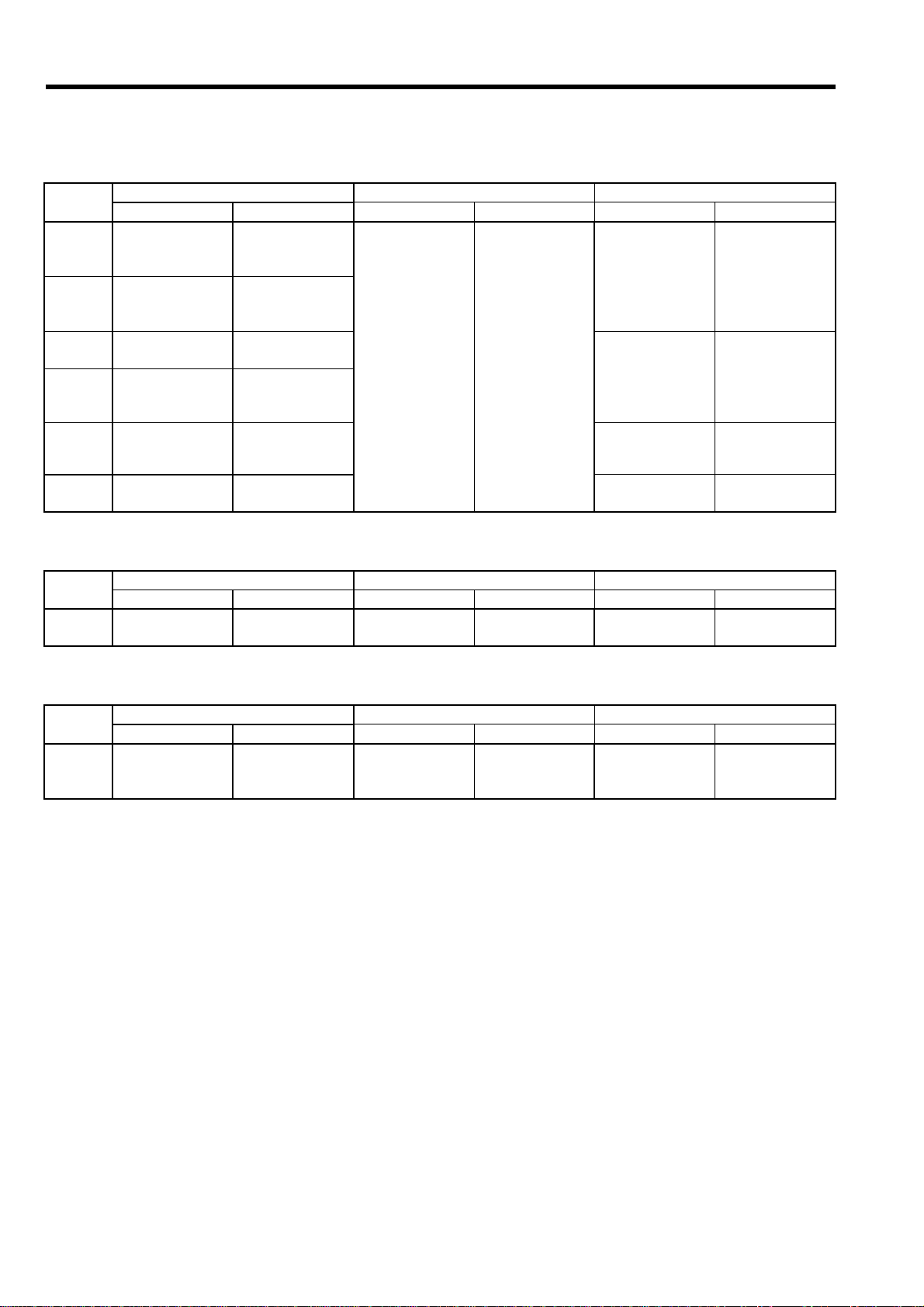

2. Alignment Tape

2-1. DVCPRO Alignment Tape

2-1-1. VFM3580KL

Time VIDEO PCM CUE

(min.) SIGN AL PORPOSE SIGNAL PORPOSE SIGNAL PO RPO SE

0:00

7:00

14:00

18:00

Color Bar

SMPTE (75%)

Color Bar

(100%)

H Sweep Frequency

Bowtie (500K) Y/C Timing

Confirmation of

the Composite

Video Level

Confirmation of

the Composite

Video Level

Characteristic

1KHz -20dB

1KHz 0VU Confirmation of

the CUE Level

Confirmation of

the Audio

Level

6KHz 0VU A/C Head

Azimuth

Adjustment

22:00

26:00

Pulse & Bar Y/C Timing 300, 500, 1K

2K, 4K, 6KHz

Area Marker Video Start

Timing

----- -----

Frequency

Characteristic

2-1-2. VFM3581KL

Time VIDEO PCM CUE

(min.) SIGNAL PORPO SE SIGNAL PORPOSE SIGNAL PO RPOSE

0:00

ITI Pattern Linearity

Adjustment --- --- --- ---

2-1-3. VFM3582KL

Time VIDEO PCM CUE

(min.) SIGNAL PORPOSE SIGNAL PORPOSE SIGNAL PORPOSE

0:00

Color Bar

(75%) (with

drop-out track)

X Value

Adjustment

--- ---

6KHz 10VU

X Value

Adjustment

INF-4

Page 7

3. List of Recommended Measuring and Instruments

MODEL No. (Example) NAME REMARKS

HD Monitor TV with SDI INPUT

Waveform Monitor · with SDI INPUT

LEADER LV5152DA Vector Scope · R,G,B/Y,Pb,Pr

Display Switching

Oscilloscope

Digital Volt Meter (D.V.M.)

Frequency Counter

Audio Analyzer

Spectrum Analyzer

Halogen Lump (X2) 500W 3200K

Lux Meter

Color Pyrometer

Special Light Box Spherical Type

INF-5

Page 8

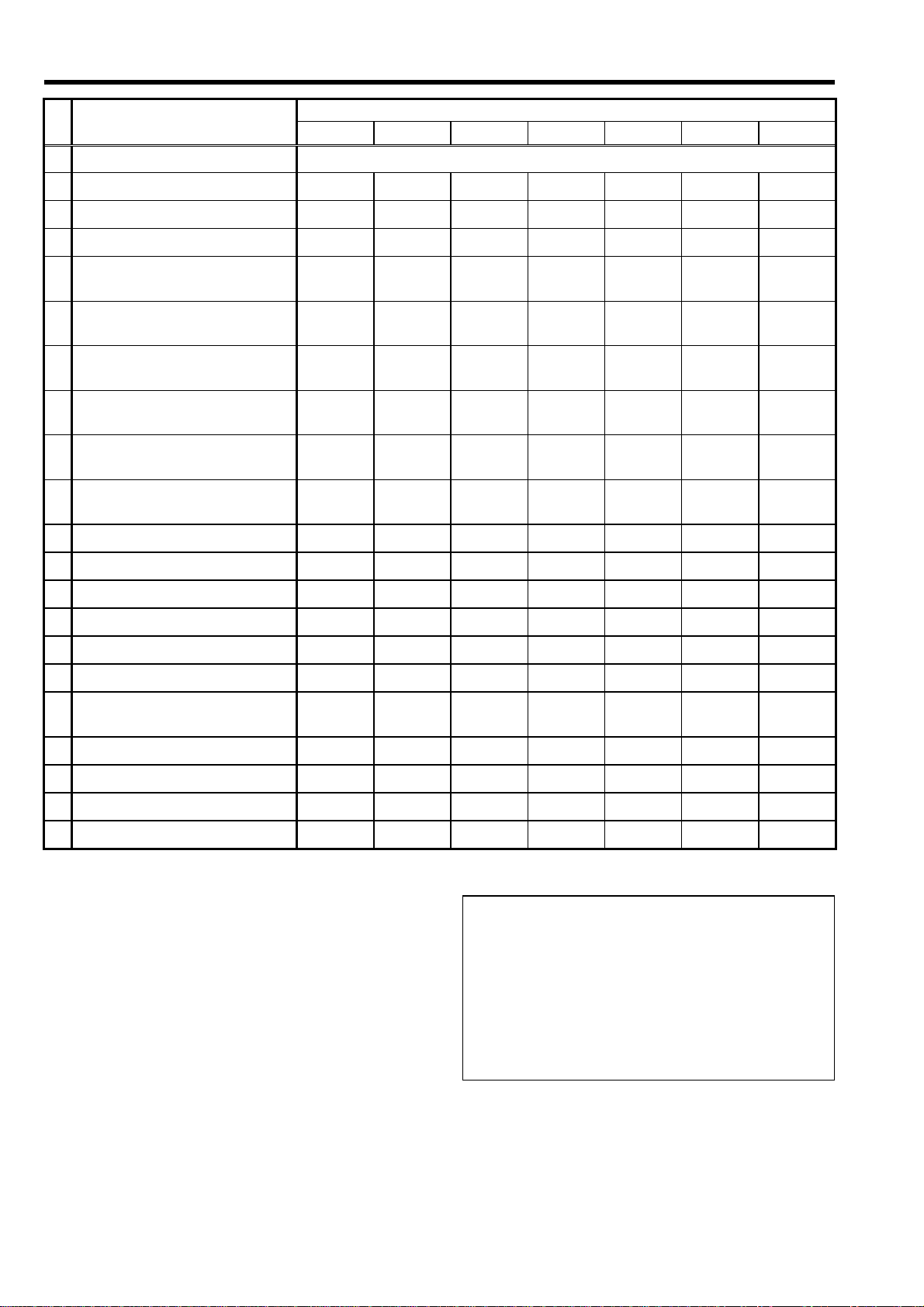

4. Maintenance Schedule

Part Name

- Cleaning of the tape transport

1 Cylinder Ass’y

2 Pinch Arm Unit

3 Cleaning Arm Unit

4 S,T Reel Motor Unit

5 Thrust Screw Unit

6 S1 Loading Arm Unit

7 T1 Boat Unit

8 S5 Post Base Unit

9 Tension Arm Unit

10 S,T Cass. Brake Arm U.

Hours of Use (unit hours)

1,000H 2,000H 4,000H 6,000H 8,000H 10,000H 12,000H

"C": every 500 hours

RRRRRIM

R, Y, G R, Y, G R, Y, G R, Y, G R, Y, G R, Y, G IM

R, Y R, Y R, Y R, Y R, Y R, Y IM

RRIM

R R,L IM

RIM

RIM

RIM

RIM

RIM

11 Mode Switch Unit

12 A/C Head

13 Loading Motor (1) Arm Unit.

14 Pinch Solenoid

15 S,T Brake Solenoid

16 L Switch Base Unit

17 Cleaner Solenoid

18 Main Cam Gear

19 Mechanism Unit

20 Cassette Compartment Unit

RIM

Replacement of the mechanism chassis unit is recommended for the 12,000 h maintenance.

“C” : Perform cleaning.

“R” : Assembly subject to exchange.

“Y” : The timing of replacement with Cleaning Arm Unit,

either 1000 hours or 1 year as timing come earlier.

“G” : At the time of replacement, wipe off the old grease

and apply new grease. (Molytone Grease)

“L” : Lubrication is necessary.

“IM” : Included in the mechanical chassis unit

when the mechanical chassis unit is not replaced,

replacement as a single part is required.

<Note:>

The Hours of use indicates the cylinder rotation time

(DRUM RUN).

The maintenance execu tio n tim e shown in the ch art

is recommendation for standard maintenance

execution.

This is not the life of the various parts.

The life is influenced by temperature, humidity, dust,

etc.

IM

IM

IM

IM

IM

IM

IM

IM

IM

INF-6

Page 9

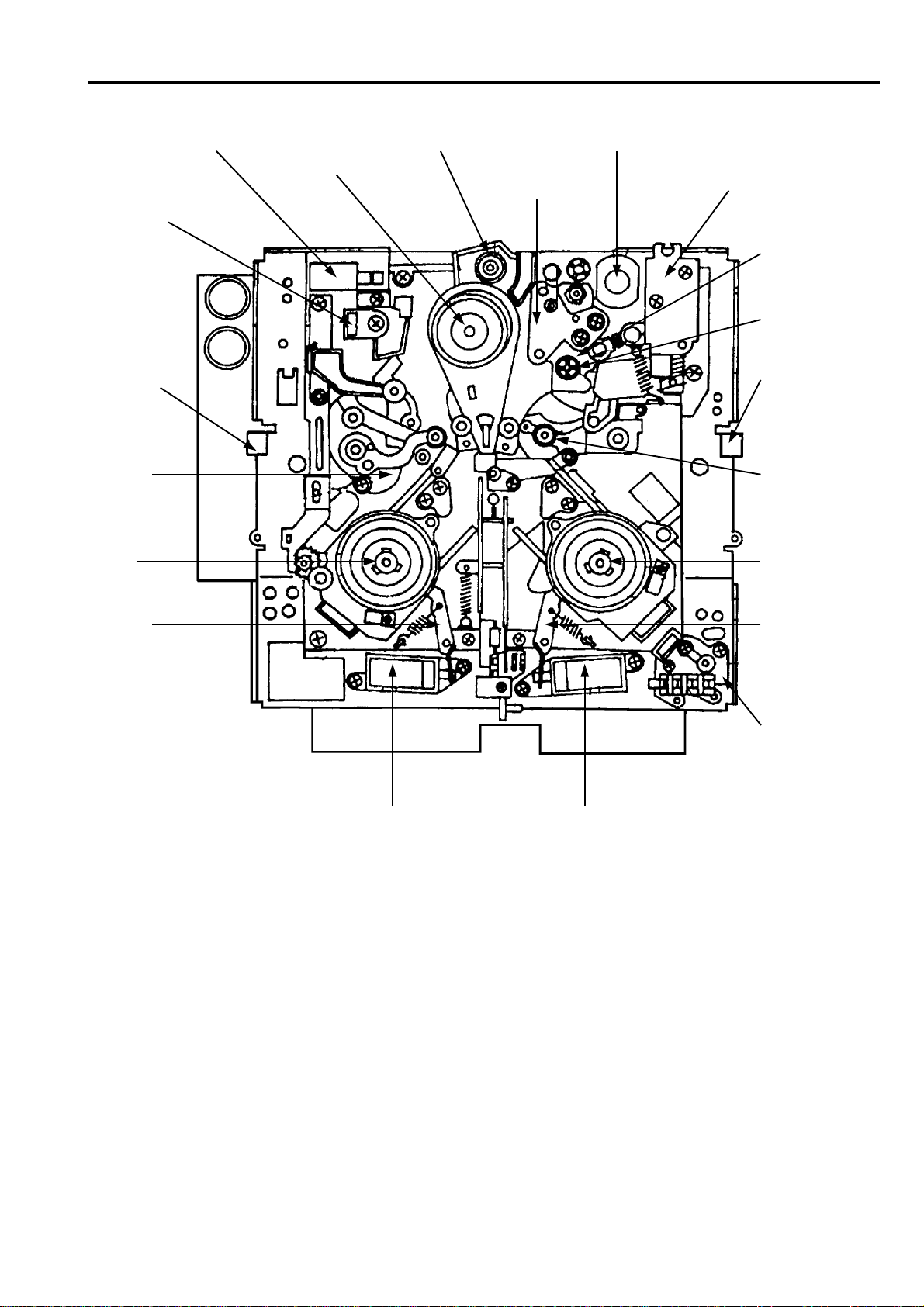

5. Layout of the Maintenance Parts & Sensors

Cleaning Solenoid

DEW Sensor

Tape End

Detect Sensor

Tension

Sensor

T Reel

Motor Unit

Cleaning Arm Unit

Cylinder Unit

Loading Motor

A/C Head

Pinch Solenoid

Capstan

Motor

Thrust Screw

Unit

Tape BEG/END

Detect Sensor

Pinch Arm

Unit

T Reel Motor

Unit

T Brake

Arm Unit

T Brake Arm

Unit

L Switch Base

Unit

T Brake SolenoidS Brake Solenoid

INF-7

Page 10

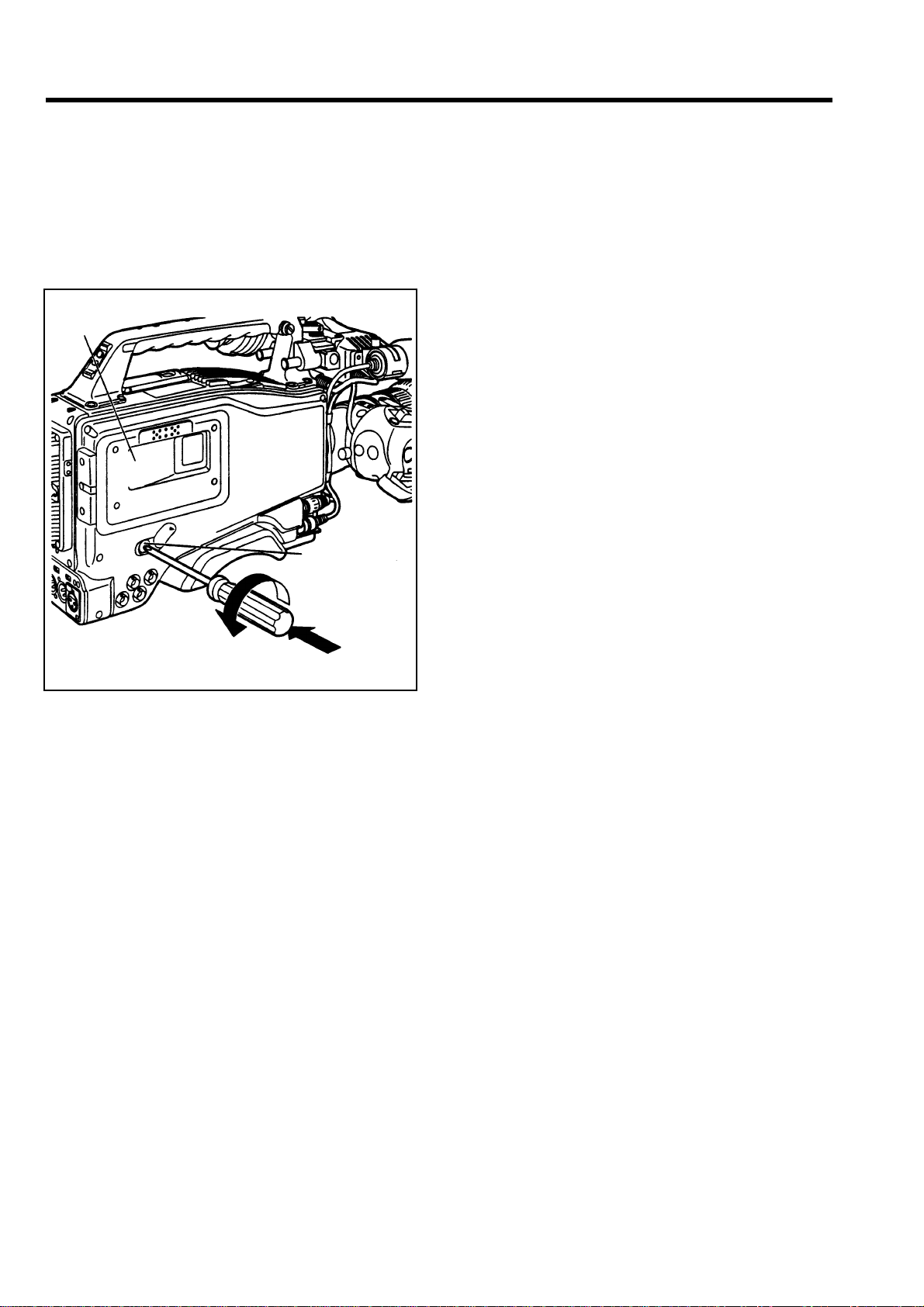

6. Emergency Eject

If the cassette cannot be ejected by pressing the

EJECT button, use a screwdriver or similar tool to

press and turn the EME RGENCY s crew. This enables

the cassette to be removed.

1. Turn the power OFF.

2. Remove the rubber cap where shown in the figure.

Insert a Phillips head screwdriver into the crossshaped part of the EMERGENCY screw (red).

CASSETTE

HOLDER

EMERGENCY

SCREW

4. Remove the cassette.

5. Return the rubber cap to its original position.

< Notes >

· Do not turn the EMERGENCY screw except in an

emergency.

· Do not turn the screw clockwise. Stop turning the

screw as soon as the tape is ejected. Otherwise, the

mechanism may be damaged.

· Af ter the tape is ejec ted, the cassette holder wil l not

be locked even when it is closed. Be sure to turn the

power off and turn it back on to reset the

mechanism’s operation, and then close the cassette

holder.

· A clicking sound will be heard while the

EMERGENCY screw is been turning: this sound is

made by the reel drive operation. Therefore it isn't

indication of a malfunction.

Turn the emergency screw by pushing it

3. While pushing in with the screwdriver, turn the

EMERGENCY screw counterclockwise until the

tape is ejected.

· This screw needs to be rotated through about 20

turns after the firs t turn until the unloading can

be started.

· This screw needs to be rotated through about 90

turns after the first turn until the tape is ejected.

INF-8

Page 11

7. Cleaning Method

Note:

Turn the power OFF during cleaning.

Make sure the power is OFF before cleaning.

Use ethanol (more than 9 9% purit y) as c leaning

liquid.

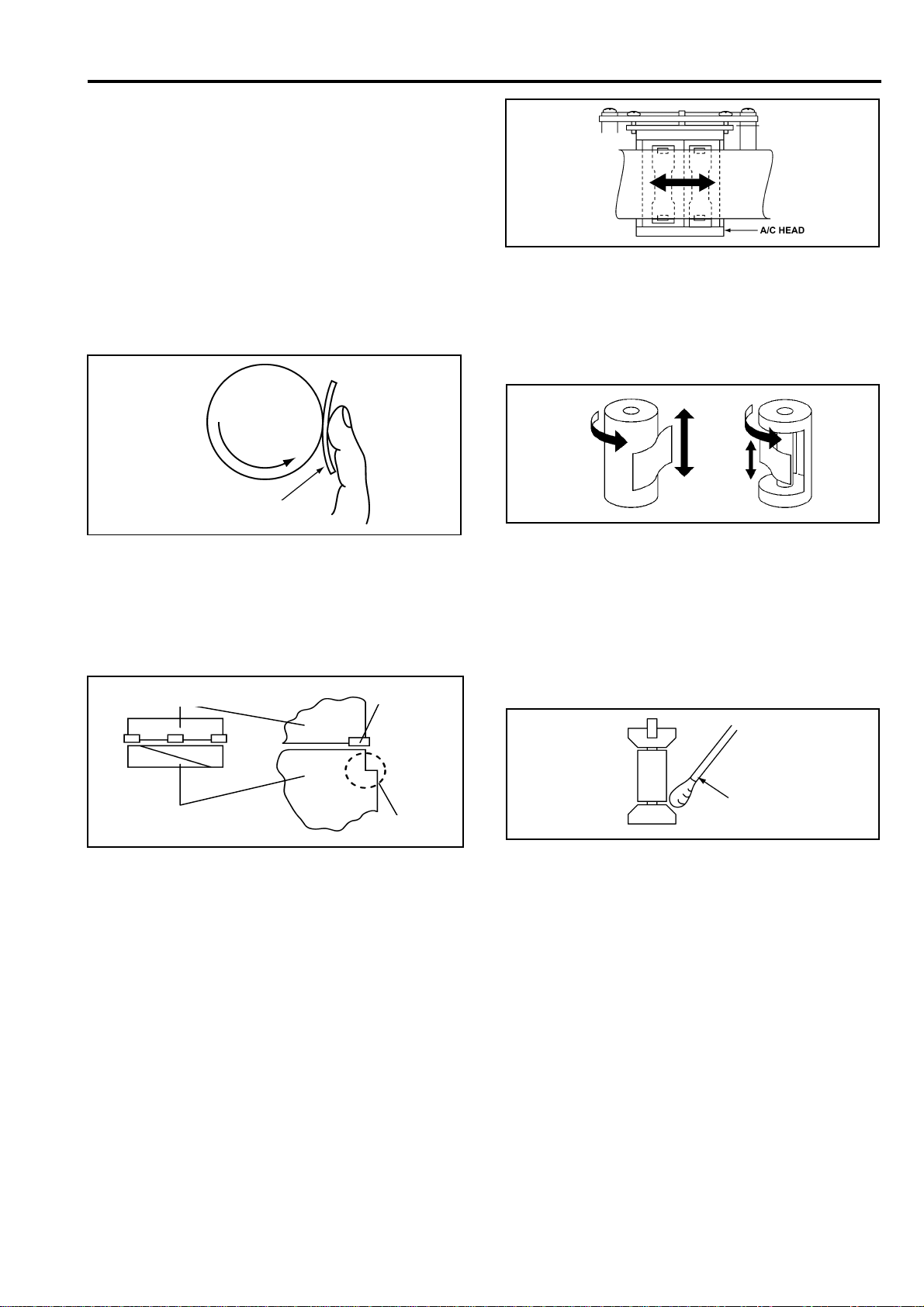

7-1. Cylinder Head Cleaning

Method: (Daily)

Clean heads by applying even pressure and rotating

cylinder a few times. Never wipe in up and down

motion. Never touch a c ylinder by bare hand. At firs t

wipe with a cloth dippe d in cleaning liqu id. Then wipe

with dry cloth.

CYLINDER

Cleaning Cloth

7-2. Cylinder Lead Cleaning

Method: (Weekly)

Don’t touch a head chip. Clea n the drum lead with a

pick.

Upper Cylinder

Head

7-4. Pinch Roller and Capstan Shaft

Cleaning Method: (Weekly)

Wipe the Pinch Roller and Capstan with a cloth dipped

in cleaning liquid.

7-5. Post Cleaning Method: (Weekly)

Wind a cloth on a pick. Wipe each posts with that pick.

Wipe again with a dry cloth. For metal posts wipe with

a cloth dipped in cleaning liquid. Then wipe it again

with dry cloth.

Lower Cylinder

Lead

7-3. A/C Head Cleaning Method:

(Weekly)

Wipe the A/C head with a cloth dipped in cleaning

liquid. Wipe again with a dry cloth.

Cotton

Swab

Notes :

Use the clean cloth f or cleaning purpose. Do not use

any dirty cloth.

The cleaning cloth can be ordered as spare parts.

The part number is indicated as below.

CLEANING CLOTH : VZZ0095

INF-9

Page 12

8. Basic Setting Menu Operations

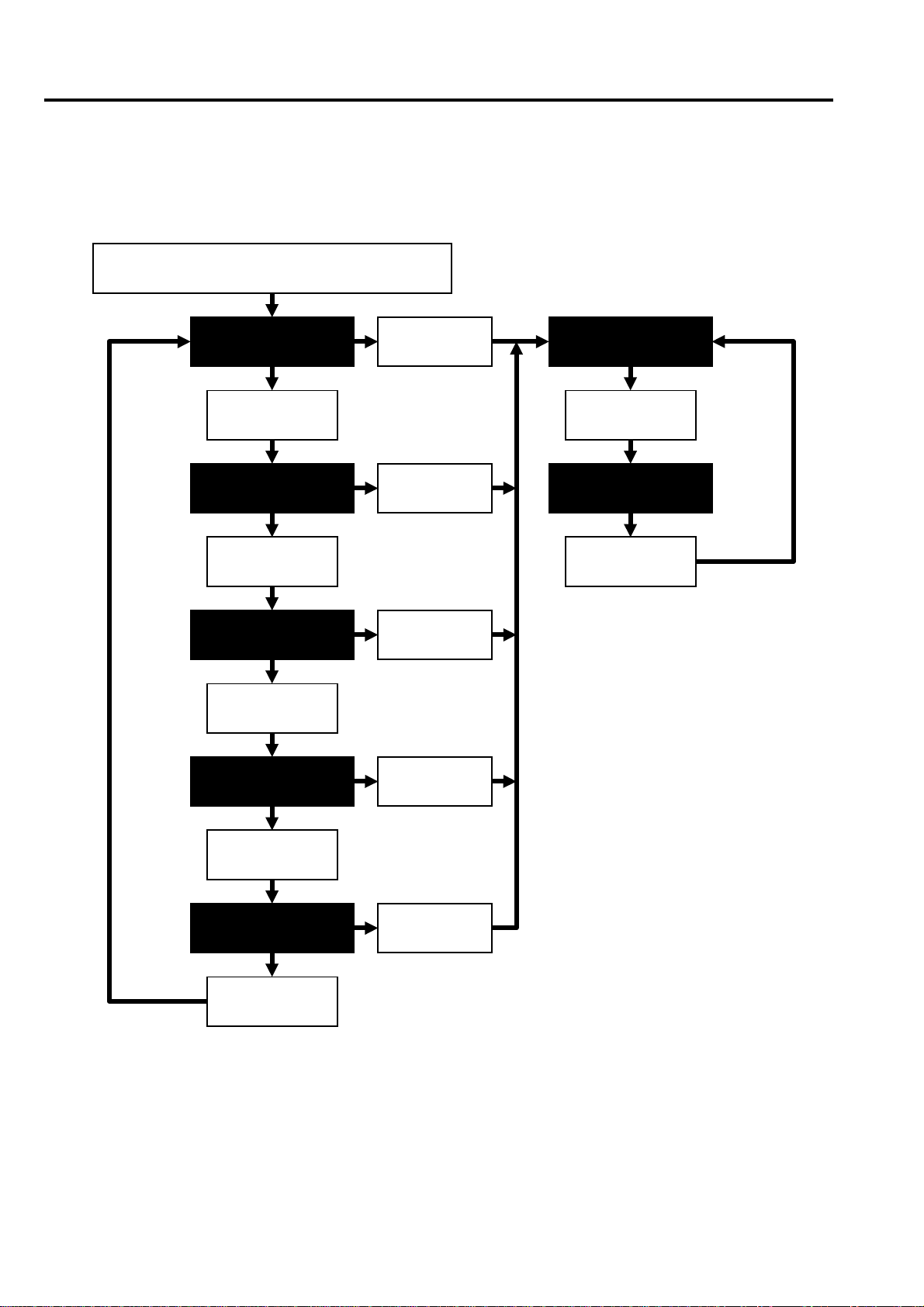

8-1. Service Menu Operation

1. Press the “SHIFT” and “+” buttons of the Tim e Code Operation Button simultaneously and press the MENU

button, and CAMERA unit’s SERVICE MENU screen is displayed.

2. When the MENU button is pressed again, the VTR unit’s SERVICE MENU screen is displayed.

Press the “SHIFT” & “+” buttons

simultaneously, and press the MENU button.

CAM MAIN MENU1

Press the JOG

dial button.

CAM MAIN MENU2

Press the JOG

dial button.

CAM MAIN MENU3

Press the JOG

dial button.

CAM MAIN MENU4

Press the

MENU button.

Press the

MENU button.

Press the

MENU button.

Press the

MENU button.

VTR MAIN MENU

Press the JOG

dial button.

VTR SERVICE MENU

Press the JOG

dial button.

Press the JOG

dial button.

CAM SERVICE MENU

Press the JOG

dial button.

Press the

MENU button.

INF-10

Page 13

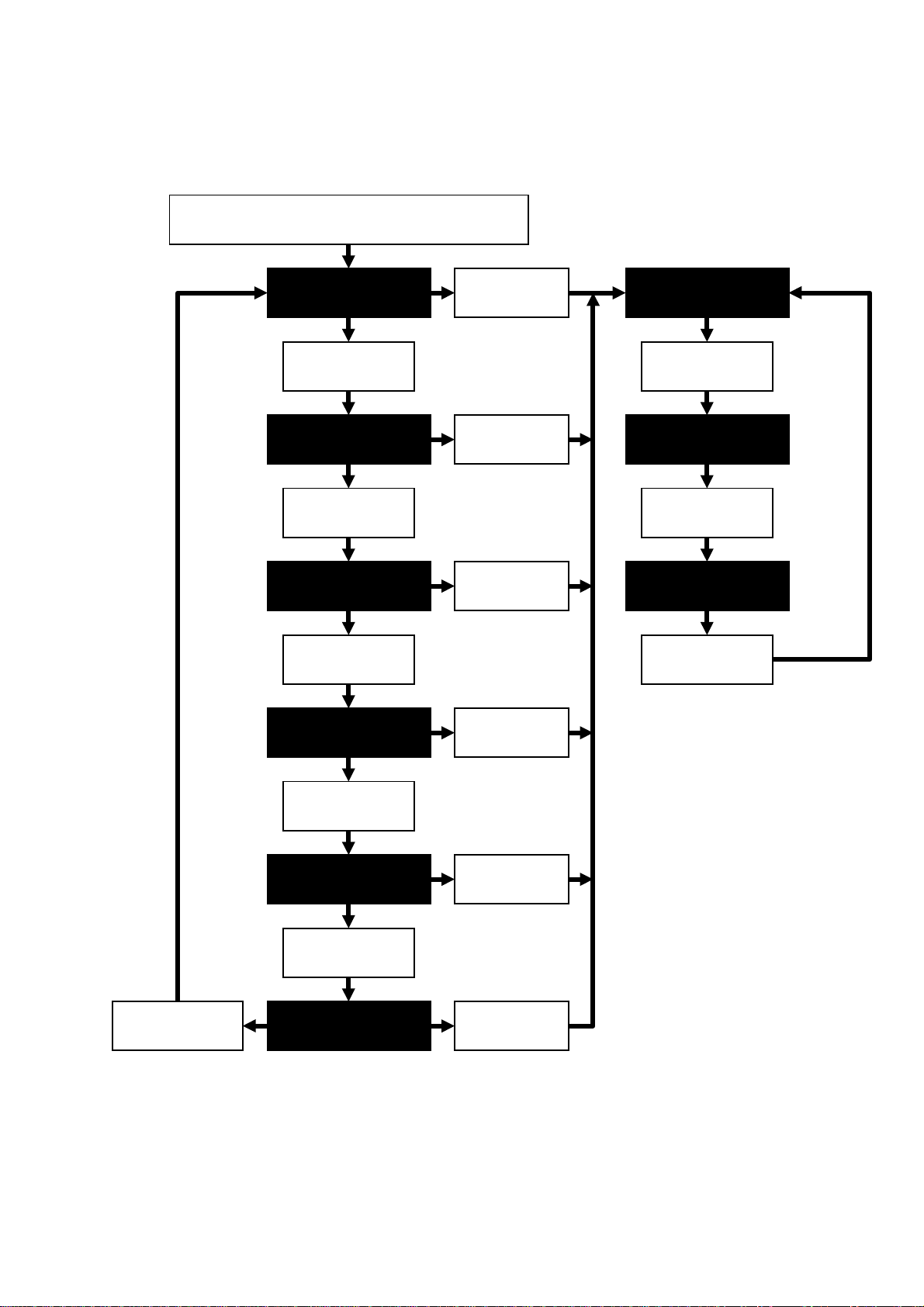

8-2. Design Menu Operation

1. Press the “SHIFT ” and “RESET” buttons of the Time Code Operation Button simultaneo usly and press the

MENU button, and s witch to the CAMERA unit’s SERVICE MENU screen d isplay mode. At f irst “CAM MAIN

MENU1” screen is displa yed as shown below, but by pressing the JOG Dial button follo wing screen through

the “CAM DESIGN MENU” is displayed .

2. The SERVICE MENU and DESIGN MENU Can be displayed by pressing the JOG Dial button.

Press the “SHIFT” & “RESET” buttons

simultaneously, and press the MENU button.

CAM MAIN MENU1

Press the JOG

dial button.

CAM MAIN MENU2

Press the JOG

dial button.

CAM MAIN MENU3

Press the JOG

dial button.

CAM MAIN MENU4

Press the

MENU button.

Press the

MENU button.

Press the

MENU button.

Press the

MENU button.

VTR MAIN MENU

Press the JOG

dial button.

VTR SERVICE MENU

Press the JOG

dial button.

VTR DESIGN MENU

Press the JOG

dial button.

Press the JOG

dial button.

Press the JOG

dial button.

CAM SERVICE MENU

Press the JOG

dial button.

CAM DESIGN ME NU

Press the

MENU button.

Press the

MENU button.

INF-11

Page 14

8-3. Displaying Sub-Menus and

Setting Procedures

Setting procedures are same for both the USER

MENU and ENGINEER MENU.

2. Move the cursor to the desired SUB MENU item ,

and press the JOG Dial button.

The SUB MENU is now displayed.

(The cursor appears besidce the title part of the

SUB MENU.)

1. Turn the JOG Dial button while the USER MENU

screen or MAIN MENU screen is displayed.

The cursor moves to the SUB MENU item.

Example :

Turn the JOG

Dial button.

**** CAM MAIN MENU1 ****

ROP

MATRIX

COLOR CORRECTION1

COLOR CORRECTION2

LOW SETTING

MID SETTING

HIGH SETTING

ADITIONAL DTL1

ADITIONAL DTL2

SKIN TONE DTL

KNEE / LEVEL

GAMMA

CAMERASETTING

Example :

Press the JOG

Dial button.

**** CAM MAIN MENU1 ****

ROP

MATRIX

COLOR CORRECTION1

COLOR CORRECTION2

LOW SETTING

MID SETTING

HIGH SETTING

ADITIONAL DTL1

ADITIONAL DTL2

SKIN TONE DTL

KNEE / LEVEL

GAMMA

CAMERASETTING

< ROP >

MASTER PED : +008

MASTER DTL : +00

MASTER GAMMA : 0.45

R GAIN : +000

G GAIN : +000

B GAIN : +000

R PEDESTAL : +000

G PEDESTAL : +000

B PEDESTAL : +000

INF-12

Page 15

3. Turn the JOG Dial button to m ove the c ursor to the

desired item to be set, and press the JOG Dial

button.

The digit which value is to be set now flashes.

Example :

7. To move to the an other SUB MENU, turn the JO G

Dial button to move the cursor to the title part of the

SUB MENU, and press the JOG Dial button.

The USER MENU screen or MAIN MENU screen is

now displayed, so proceed with operation by

following the same steps.

Press the JOG

Dial button.

< ROP >

MASTER PED : +008

MASTER DTL : +00

MASTER GAMMA : 0.45

R GAIN : +000

G GAIN : +000

B GAIN : +000

R PEDESTAL : +000

G PEDESTAL : +000

B PEDESTAL : +000

4. Turn the JOG Dial button to change the setting.

5. When the desired settin g is shown, press the J OG

Dial button.

The setting is now entered.

6. When other items are to be set, turn the J OG Dial

button to move the cursor, and charge and enter

the settings by repeating steps 3 through 5.

Example :

Press the JOG

Dial button.

< ROP >

MASTER PED : +008

MASTER DTL : +00

MASTER GAMMA : 0.45

R GAIN : +000

G GAIN : +000

B GAIN : +000

R PEDESTAL : +000

G PEDESTAL : +000

B PEDESTAL : +000

8. Upon completion of the settings , press the MENU

button. Then the settings are now saved, exit the

settings menu mode, and return-to the normal

operation mode.

NOTE :

To exit the camera unit’s menu, press the MENU

button twice. W hen the M ENU butt on is pres s ed o nc e,

operation is transferred to the VTR unit’s menu.

INF-13

Page 16

8-4.Setting Menu Configurations

)

)

(

)

(

)

)

)

CAM SERVICE MENU

SERVICE ADJ R GAMMA

G GAMMA (SERV

B GAMMA (SERV

DEFECT COMPENSATION COMPENSATION

COMP ON GAIN

INTERLACE MODE

R CH

G CH

B CH

TRIPLE OFFSET

CURSOR BOX

READ DATA

WRITE DATA

ENTRY (AUTO

ENTRY (MANUAL

PICKUP LEVEL R

PICKUP LEVEL G

PICKUP LEVEL B

START

NG LIST NO

SELECT

ENTRY

CURSOR DISP

H CURSOR COARSE

H CURSOR FINE

V CURSOR COARSE

V CURSOR FINE

DEFECT SIZE

DEFECT COLOR

GAIN

OFFSET LEVEL A

OFFSET LEVEL B

ENTRY

CANCEL

SERV

EDIT / DELETE

WHITE SHADING

CAM SERVICE CARD R/W

INF-14

DEFECT NO.

DEFECT SIZE

DEFECT COLOR

GAIN

OFFSET LEVEL A

OFFSET LEVEL B

CHANGE

DELETE

ALL DATA CLEAR

DETECTION

R/W SEL

READ

WRITE

DIGITAL

Page 17

CAM DESIGN ME NU

)

)

(+)

)

)

)

VDRIVE 1

VDRIVE 2

PREPRO 1 G_WS_OFFSET

PREPRO 2

LSI REG SET 1

LSI REG SET 2

SHAD DA SET

KNEE APA SET

LSI C REG SET

AD READ TEST

DSP D/A SET

NO COMPENSATION

DESIGN MENU ALL INIT

VAH

VA13M

VA24M

VAL

VBL

LG

HPP

0D

P16V

R_PADC

G_PADC

B_PADC

DA RESET

R_GAIN

G_GAIN

B_GAIN

R_PED

G_PED

B_PED

M_PED

R_KNPT

G_KNPT

B_KNPT

A (0) or B (1

MEMORY SEL

ADR-H

ADR-L

DATA-H

DATA-L

THRESH LEVEL

SLOPE

FREQ.

GAIN

CORING LVL

DTL COMP

DTL COMP(–

DTL CLIP (+

DTL CLIP (–

KNEE SET

IRIS POS

ZOOM POS

FOCUS POS

LENS EXT

CC FILT

ND FILT

PEAKING

FRAME

ZEBRA

MARK SW

POSITION 1 R

B

POSITION 2 R

B

POSITION 3 R

B

POSITION 4 R

B

FACTORY MENU

R_0G

R_SUB

R_RESET DC

G_0G

G_SUB

G_RESET DC

B_0G

B_SUB

B_RESET DC

H1DC

H2DC

VSHIN

B_WS_OFFSET

R_WS_OFFSET

G_PRE_CLIP

B_PRE_CLIP

R_PRE_CLIP

G_PULCAN

B_PULCAN

R_PULCAN

A (0) or B (1

MEMORY SEL

ADR-H

ADR-L

DATA-H

DATA-L

WRITE

READ

BSHD_R

BSHD_G

BSHD_B

WSHD_G_SUB

WSHD_B

WSHD_G

WSHD_R

IRIS_C

ADR

DATA

WRITE

GAIN G

GAIN B

GAIN R

CPL G

CPL B

CPL R

INF-15

Page 18

VTR SERVICE MENU

VTR SERVICE 1/3

VTR SERVICE 2/3

CONCEAL

INNER ECC

OUTER ECC

VITERBI

ADJUST ADDRESS

ADJUST DATA

BER ADJ

BER SPEED

CW REC

AUTO EQ

RDS. REC ADJ

RDS TYPE

SERVO MODE

T TORQUE

S TORQUE

PG SHIFT 100

HSW_A_RIZE

HSW_A_FALL

HSW_C_RIZE

HSW_C_FALL

RPL GAIN 100

RPL LIN 100

CTL ADJ

X VALUE SET

X VALUE 100

TRK VAL 100

SERVO MODE

VTR SERVICE 3/3

VTR D/A DATA

VTR DESIGN MENU

VTR DESIGN MENU

TEST MODE

ERROR LOG

AUDIO PB SEL

AUDIO SAVE

AUDIO CH7/8

ADJUST ADDRESS

ADJUST DATA

MENU ALL INIT

DRUM RUNNING RESET

THREADING RESET

AGING MODE

FILE No.

LOG ALL CLEAR

ERROR CODE

SEQUENCE No.

DATE

TIME

OPERATION TIME

TAPE TOTAL

TAPE REMAIN

BATTERY ME TE R

OBJ/MODE

INF-16

Page 19

9. Service Menu Item Contents

< CAMERA Section >

9-1. CAM SERVICE MENU

ITEM

SERVICE ADJ R GAMMA (SERV) -30-+30 00 Adjustment for R GAMMA.

G GAMMA (SERV) -30-+30 00 Adjustment for G GAMMA.

B GAMMA (SERV) -30-+30 00 Adjustment for B GAMMA.

DEFECT COMPENSATION ON/OFF ON ON/OFF switching of blemish compensation.

COMPENSA- COMP ON GAIN -3dB-+30dB 12dB Specified gain of blemish compensation.

TION INTERLACE MODE PDMIX/FRAME PDMIX Select a way of correct operation.

R CH AVE/OFSET AVE Adjacent Picture Element Compensation/

G CH AVE/OFSET AVE Level Decrease

B CH AVE/OFSET AVE

TRIPLE OFFSET BAB/BBA BAB 3 adjacent picture elements decrease.

CURSOR BOX ON/OFF ON Indicate the box on the cursor.

READ DATA ON/OFF OFF Read the defect data.

WRITE DATA ON/OFF OFF Write the defect data.

ENTRY (AUTO) PICKUP LEVEL R 1-40 15 Detection Level of blemish.

PICKUP LEVEL G 1-40 10 Detection Level of blemish.

PICKUP LEVEL B 1-40 25 Detection Level of blemish.

START ON/OFF OFF ON/OFF Switching of Auto detection.

NG LIST NO 0-63 000 Display the NG List No.

SELECT OFF/A/B OFF Factory Use

ENTRY ON/OFF OFF Factory Use

CURSOR DISP ON/OFF ON Factory Use

ENTRY

(MANUAL)

EDIT/DELETE DEFECT NO. 0-255 0 Indicate the blemish data of specified number.

WHITE

SHADING

CAM SERVICE

CARD R/W

H CURSOR

COARSE

H CURSOR FINE 00-FF 80 Fine Adjustment for Horizontal Cursor Position

V CURSOR

COARSE

V CURSOR FINE 00-FF 80 Fine Adjustment for Vertical Cursor Position

DEFECT SIZE 1-3 1 Sequential Number of blemish.

DEFECT COLOR Y/R/G/B Y The color which has blemish.

GAIN ON/OFF ON ON/OFF switching of compensation followed gain.

OFFSET LEVEL A 0-255 100 Set the decrease value.

OFFSET LEVEL B 0-255 100 Set the decrease value.

ENTRY ON/OFF OFF ON/OFF switching of blem ish entry of above data.

CANCEL ON/OFF OFF Cancel for just before entry.

DEFECT SIZE 1-3 1 Sequential Number of blemish.

DEFECT COLOR Y/R/G/B Y The color which has blemish.

GAIN ON/OFF ON ON/OFF switching of compensation followed gain.

OFFSET LEVEL A 0-255 100 Set the decrease value.

OFFSET LEVEL B 0-255 100 Set the decrease value.

CHANGE ON/OFF OFF Entry the above data.

DELETE ON/OFF OFF Delete above entry data.

ALL DATA CLEAR ON/OFF OFF Delete all of entry data.

DETECTION

(DIGITAL)

R/W SEL DESIGN/SHADI

READ --- --- Read the DATA from the card.

WRITE --- --- Write the DATA to the ca rd.

SETTING

RANGE

00-08 03 Coarse Adjustment for Horizontal Cursor Position

00-04 02 Coarse Adjustment for Vertical Cursor Position

--- --- Execute the Digital white shading.

NG/DEFECT

INIT.

VALUE

--- Select the R/W DATA

MEANING of SETTING &

OUTLINE of FUNCTION

INF-17

Page 20

9-2. CAM DESIGN MENU

ITEM

VDRIVE 1 R_OG 00-FF FF OG voltage setting of R CCD.

R_SUB 00-FF 7E Sub voltage setting of R CCD.

R_RESET DC 00-FF 26 Reset DC voltage setting of R CCD.

G_OG 00-FF FF OG voltage setting of G CCD.

G_SUB 00-FF 7E Sub voltage setting of G CCD.

G_RESET DC 00-FF 26 Reset DC voltage setting of G CCD.

B_OG 00-FF FF OG voltage setting of B CCD.

B_SUB 00-FF 7E Sub voltage setting of B CCD.

B_RESET DC 00-FF 26 Reset DC voltage setting of B CCD.

H1DC 00-FF 80 H1 DC setting value of CCD.

H2DC 00-FF 80 H2 DC setting value of CCD.

VSHIN 00-FF FF Read voltage of CCD.

VDRIVE 2 VAH 00-FF 2E Read Out Pulse voltage of CCD (VH)

VA13M 00-FF 00 Transfer Pulse voltage of CCD (VM13)

VA24M 00-FF FF Transfer Pulse voltage of CCD (VM24)

VAL 00-FF 40 Transfer Pulse voltage of CCD (VAL)

VBL 00-FF 40 Transfer Pulse voltage of CCD (VBL)

LG 00-FF 6A Output Amp Voltage of CCD (LG)

HPP 00-FF FF H Transfer Pulse voltage of CCD (H)

0D 00-FF FF Output Amp Voltage of CCD (OG)

P16V 00-FF FF CCD Drive voltage (16V)

R_PADC 00-FF A8 Offset Adjustment for Rch Pre Amp

G_PADC 00-FF 98 Offset Adjustment for Gh Pre Amp

B_PADC 00-FF C7 Offset Adjustment for Bch Pre Amp

DA RESET OFF/ON OFF Initialize the all DA data.

PRE PROCESS1 G_WS_OFFSET ----- ----- G WHITE SHADING OFFSET Adjustment

B_WS_OFFSET ----- ----- B WHITE SHADING OFFSET Adjustment

R_WS_OFFSET ----- ----- R WHITE SHADING OFFSET Adjustment

G_PRE_CLIP ----- ----- Factory Use (Fixed at Factory)

B_PRE_CLIP ----- ----- Factory Use (Fixed at Factory)

R_PRE_CLIP ----- ----- Factory Use (Fixed at Factory)

G_PULCAN ----- ----- G PULSE CANCEL Adjustment

B_PULCAN ----- ----- B PULSE CANCEL Adjustment

R_PULCAN ----- ----- R PULSE CANCEL Adjustment

PRE PROCESS2 R_GAIN ----- -----

G_GAIN ----- ----B_GAIN ----- ----R_PED ----- ----G_PED ----- ----B_PED ----- ----M_PED ----- ----- Master Pedestal Value (For 0IRE Adjustment)

G_KNPT ----- ----- G Knee point value

B_KNPT ----- ----- B Knee point value

R_KNPT ----- ----- R Knee point value

SETTING

RANGE

INIT.

VALUE

AWB Adjustment Value

ABB Adjustment Value

MEANING of SETTING &

OUTLINE of FUNCTION

INF-18

Page 21

(CAM DESIGN MENU)

ITEM

LSI REG SET1 A (0) or B (1) ----- ----- Not used

MEMORY SEL ----- ----- Not used

ADR_H ----- ----ADR_L ----- ----DATA_H ----- ----DATA_L ----- ----WRITE ----- ----- STORE command of Adjustment data

READ ----- ----- READ command of Adjustment data

LSI REG SET2 A (0) or B (1) ----- ----- Not Used

MEMORY SEL ----- ----- Not Used

ADR_H ----- ----- Not Used

ADR_L ----- ----- Not Used

DATA_H ----- ----- Not Used

DATA_L ----- ----- Not Used

SHAD DA SET BSHD_R ----- -----

BSHD_G ----- ----BSHD_B ----- ----WSHD_G_SUB ----- ----WSHD_B ----- ----WSHD_G ----- ----WSHD_R ----- ----IRIS_C ----- -----

KNEE APA SET TRESH LEVEL ----- -----

SLOPE ----- ----FREQ ----- ----GAIN ----- ----CORING LVL ----- ----DTL-COMP (+) ----- ----DTL-COMP (–) ----- ----DTL-CLIP (+) ----- ----DTL-CLIP (–) ----- ----KNEE SET ----- -----

LSIC REGSET ADR ----- ----- Not Used

DATA ----- ----- Not Used

WRITE ----- ----- Not Used

AD READ TEST IRIS POS ----- ----- Lens iris position info rmation

ZOOM POS ----- ----- Lens zoom position information

FOCUS POS ----- ----- Lens focus position information

LENS EXT ----- ----- Lens extender position information

CC FILT ----- ----- CC Filter position information

ND FILT ----- ----- ND Filter position information

PEAKING ----- ----- Not Used

FRAME ----- ----- Not Used

ZEBRA ----- ----- Information of Zebra pattern on Viewfinder

MARK SW ----- ----- Not Used

SETTING

RANGE

INIT.

VALUE

MEANING of SETTING &

OUTLINE of FUNCTION

Data address of Flash memory (at CAM_SYS)

Data value of Flash memory (at CAM_SYS)

(To Flash memory)

(From Flash memory)

Factory Use only (Fixed at Factory)

Not Used

(ON or OFF Information)

INF-19

Page 22

(CAM DESIGN MENU)

ITEM

DSP D/A SET GAIN G ----- ----- G A/D converter input gain adjustment

GAIN B ----- ----- B A/D converter input gain adjustment

GAIN R ----- ----- R A/D converter input gain adjustment

CPL G ----- ----- G A/D converter input clamp level adjustment

CPL B ----- ----- B A/D converter input clamp level adjustment

CPL R ----- ----- R A/D converter input clamp level adjustment

ND POSITION1 R -127-+128 0 R GAIN Adjustment at ND FILTER POSITION 1.

COMPENSATION POSITION1 B -127-+128 0 B GAIN Adjustment at ND FILTER POSITION 1.

POSITION2 R -127-+128 0 R GAIN Adjustment at ND FILTER POSITION 2.

POSITION1 B -127-+128 0 B GAIN Adjustment at ND FILTER POSITION 2.

POSITION3 R -127-+128 0 R GAIN Adjustment at ND FILTER POSITION 3.

POSITION1 B -127-+128 0 B GAIN Adjustment at ND FILTER POSITION 3.

POSITION4 R -127-+128 0 R GAIN Adjustment at ND FILTER POSITION 4.

POSITION1 B -127-+128 0 B GAIN Adjustment at ND FILTER POSITION 4.

SETTING

RANGE

INIT.

VALUE

MEANING of SETTING &

OUTLINE of FUNCTION

< VTR Section >

9-3. VTR SERVICE 1/3

ITEM

CONCEAL ON/OFF ON NG NG CONCEAL setting

INNER ECC ON/OFF ON NG NG INNER ECC setting

OUTER ECC ON/OFF ON NG NG OUTER ECC setting

VITERBI ON/OFF ON NG NG VITERBI setting

ADJUST ADDRESS 01-24h 01 NG NG

ADJUST DATA 00-FFh ----- OK NG

BER ADJ OFF/

BER SPEED SLOW/FAST SLOW NG NG Speed setting of Error rate display

CW REC OFF/

AUTO EQ ON/OFF ON NG NG AUTO RF,EQ setting

RDS. REC ADJ OFF/

RDS. TYPE OFF/BOTH/

SERVO MODE ATF/CTL ATF NG NG Servo mode setting

SETTING

RANGE

L1L3/R1R3/

L2L4/R2R4

20M/5M

L1/L3/

R1/R3/

L2/L4/

R2/R4

REC/SPLAY

INIT.

VALUE

OFF NG NG

OFF NG NG

OFF NG NG

BOTH OK NG

Backup

Backup

(INH.)

MEANING of SETTING &

OUTLINE of FUNCTION

EVR adjustment for VTR part

Error rate display mode setting

Frequency setting for RF,EQ adjustment

Head select for RDS (REC SIGNAL DETECTIO N

SYSTEM) adjustment

RDS setting

INF-20

Page 23

9-4. VTR SERVICE 2/3

ITEM

T TORQUE -128-+127 0 OK NG Take-up reel torque adjustment

S TORQUE -128-+127 0 OK NG Supply reel torque adjustment

PG SHIFT 100 ----- ----- PG shifter adjustment

HSW_A_RIZE 0-4095 0x500 OK NG Rising edge

HSW_A_FALL 0-4095 0x500 OK NG Falling edge

HSW_C_RIZE 0-4095 0x500 OK NG Rising edge

HSW_C_FALL 0-4095 0x500 OK NG Falling edge

RPL GAIN 100 -128-+127 64 OK NG RPL head ATF pre-filter gain adjustment

RPL LIN 100 OFF/ON OFF NG NG RPL head LISTA linearity adjustment

CTL ADJ OFF/ON OFF NG NG CTL Adjust mode setting

X VALUE SET OFF/ON OFF NG NG X value adjustment

X VALUE 100 -128-+127 0 OK NG Fine adjustment for X value

TRK VAL 100 -128-+127 0 NG NG CTL tracking offset setting

SERVO MODE ATF/CTL ATF NG NG Servo mode setting

SETTING

RANGE

INIT.

VALUE

Backup

Backup

(INH.)

MEANING of SETTING &

OUTLINE of FUNCTION

9-5. VTR SERVICE 3/3

ITEM

AUDIO PB SEL CH1,2/

AUDIO SAVE ACTIVE/OFF

AUDIO CH7/8 EE FORCH/

SETTING

RANGE

CH3,4/

CH5,6/

CH7,8

EE,PB

INIT.

VALUE

CH1,2 NG NG

ACTIV

E

EE,PB OK OK

Backup

NG NG

Backup

(INH.)

MEANING of SETTING &

OUTLINE of FUNCTION

9-6. VTR DESIGN MENU

ITEM SETTING RANGE INIT. VALUE

MENU ALL INIT ----- ----DRUM RUNNING

RESET

THREADING

RESET

----- -----

----- -----

INF-21

MEANING of SETTING &

OUTLINE of FUNCTION

Page 24

9-7. TEST MODE

ITEM SETTING RANGE INIT. VALUE

AGING MODE OFF/ON OFF

ON : TEST MODE (VTR RUNNING TEST)

(Repeat 5 minutes REC and 1 minute STAND-BY)

MEANING of SETTING &

OUTLINE of FUNCTION

9-8. ERROR LOG

ITEM SETTING RANGE INIT. VALUE

FILE No. 1-5 1 Be able to select 1 through 5.

1 : Old Error Data ® 4 : Recent Error Data

5 : First Error

(Cannot delete until execute LOG ALL CLEAR)

LOG ALL CLEAR OFF/ON OFF ON : All Clear

Finally, turn OFF or POWER OFF.

ERROR CODE E-00

SEQUENCE NO 00

DATE 00/01/01

TIME 12 : 34 : 56

OPERATION

TIME

TAPE TOTAL 120min

TAPE REMAIN 90min

BAT T E RY METER 1-F Example : “a-F”

OBJ/MODE 00 00 00 : 00 : 00 00 00 12 : 34 : 56 Indicate the time when OBJ/MODE occurred.

00 00 00 : 00 : 00 00 00 12 : 34 : 56 Upper - occurred lately

00 00 00 : 00 : 00 00 00 12 : 34 : 56 ¯

00 00 00 : 00 : 00 00 00 12 : 34 : 56 Lower - occurred formerly

00 00 00 : 00 : 00 00 00 12 : 34 : 56

000000Hr

“a” indicates the meter number.

”-F” indicates the blink (flash).

MEANING of SETTING &

OUTLINE of FUNCTION

¯

INF-22

Page 25

10. Adjustment after Optical Unit Replacement

When replace the Optical Unit (PRE AMP, CCD

PULSE, DRIVE Board included), execute the

adjustment as following procedures.

In this case, do not ne ed to execute the Optical Unit

Adjustment on the “Section 5 : Electrical Adjustment”.

10-1. Input the Adjustment Data

1. Set the Shading Correction to “OFF” as follows.

*** CAM MAIN MENU 4 ***

< BLACK SHADING >

® CORRECT (DIG) : “ON“ ® “OFF”

< WHITE SHADING >

® CORRECT : “ON“ ® “OFF”

2. Input the adjustm ent data following th e Adjustm ent

Data Sheet which is included with optical unit.

< Items mentioned on the Adjustment Data Sheet >

(8 items)

*** CAM DE SIGN MENU ***

< VDRIVE 1 >

® R-SUB ® R-RESET DC

® G-SUB ® G-RESET DC

® B-SUB ® B-RESET DC

10-2. Electrical Adjustment

Execute the Confir m ation and Adjus tm ent as f ollowing

items. (Refer to “Section 5 : Electrical Adjustment”)

1. 0IRE PED Adjustment

2. R,G,B PRE AMP DC Confirmation

3. R,G,B PULCAN Adjustment

4. R,G,B PREPRO Level Confirmation

5. R,G,B PED TRACK Adjustment

6. Modulation Confirmation

7. R,G,B W/S (WHITE SHADING) OFFSET Adj.

8. Digital W/S (WHITE SHADING) Adjustment

9. Digital D/S (DARK SHADING) Adjustment

10. FLARE Adjustment

11. R,B GAMMA Adjustment

*** CAM DE SIGN MENU ***

< VDRIVE 2 >

® H1-DC

® VSHIN

3. Input or execute the following setting by menu.

(Memory of Setting Value)

*** CAM DE SIGN MENU ***

< LSI REG SET 1 >

® ADR_H : “FF” (input)

® ADR_L : “01” (input)

® WRITE : “OFF” ® “ON” (execute)

INF-23

Page 26

11.DIAG-MENU Display

11-1-1. Version Display Operation Procedure (CAMERA Part)

1. Open the “ENG menu” (Press “MENU Button” more than 3 second.)

2. Open “

3. Select “DIAGNOSTIC” page (Turn and Press JOG Dial), then the Software version for each item can be

comfirmed.

11-1-2. How to read the Version Display

CAM MAIN MENU 4

< DIAGNOSTIC >

®

CAMSOFT (IN) Ver T1.00-01-1.00

CAMSOFT (OUT) Ver T1.00-01-1.00

GAMMA GAIN Ver T1.00-01-1.00

GAMMA RAM Ver T1.00-01-1.00

KNEE Ver T1.00-01-1.00

ALC Ver T1.00-01-1.00

PLD Ver T1.00-01-1.00

” page (Press JOG Dial)

Flash memory (Included IC1) Software Version

Flash Memory (IC2) Software Versi on

GAMMA Table Software Version

Black GAMMA Table Software Version

KNEE Table software Version

ALC Software Version

PLD Software Version

Ver T1.00-01-1.00

T

: 59.94Hz

E

: 59.94Hz/50Hz

P

: 50Hz

Software Version

11-2-1. Version Display Operation and Hour Meter Display (VTR Part)

1. Open the “ENG menu” (Press “MENU Button” more than 3 second.)

2. Press “MENU Button” again to open the “VTR MAIN MENU”.

3. Sel ect “DIAGNOSTICS” page (Turn and Pres s JOG Dial), then the Software version for each item can be

comfirmed.

< DIAGNOSTIC >

®

OPERATION 99999X10h

DRUM RUNNING 99999X10h

THREADING 99999

VTR SYSCON n1.00-01-1.00

SERVO n1.00

MECHACON n1.00

FRONT n1.00-01-1.00

Operation Hour (: 10HOUR x)

Cylinder Moter running Hour (: 10HOUR x)

Loading, Unloading Times

VTR SYSCON FLASH memory Software Version

SERVO ROM

MECHANISM CONTROL ROM

AUDIO LCD ROM

11-2-2. How to read the Version Display

n1.00-01-1.00

n

p

Brank : NTSC/PAL

:NTSC

:PAL

Software Version

INF-24

Page 27

11-2-3. How to Reset Hour Meter

1. Open the “Design Menu” and then press “MENU Button”.

2. Open “

3. Select “VTR DESIGN MENU” item. (Turn & press JOG Dial)

4. After the following figure is displayed, move “®” to the item to reset.

VTR DESIGN MENU

**** VTR DESIGN MENU ****

VTR DESIGN MENU

®

TEST MDOE

ERROR LOG

VM PLD V0.00

VTR SYSCON V18388a

<VTR DESIGN MENU>

MENU ALL INIT

®DRUM RUNNING RESET

THREADING RESET

” page. (Press JOG Dial)

00.06.13

INF-25

Page 28

12. Error Rate Display and Confirmation Method

12-1. Error Rate Display Method

1. Open the “VTR SERVICE MENU”.

2. Select “

3. Confirm “

4. Select "

BER ADJ item :

5. The Error rate will be displayed in the Audio meter on the Audio LCD panel.

VTR SERVICE 1/3

BER SPEED

BER ADJ

” setting is “

" by rotating JOG Dial and Select R/P head to be confirmed.

OFF / L1L3 / R1R3 / L2L4 / R2R4 (exept OFF)

” page.(Turn & press JOG Dial)

SLOW

”.

AUDIO LCD METER

- 0 -

- 10 -

- 20 -

- 30 -

- 40 -

-

-

¥¥¥¥

CH1 CH2

L1

R1

L2

R2

dB

L3

R4

L3

R4

Error rate Spec. ”A”

INF-26

Page 29

13. Internal Switch Setting Method

The switche settings on each circuit board are shown below.

“Factory use only” switches must be set to the “Factory setting”.

BOARD Ref. No. SW

AUDIO LCD 1-7 ON (FIXED) Factory use only

SW40001

SW40002

1-5 OFF(FIXED) Factory use only

SW47001

SW41001 - -60 REAR CH1 MIC input level setting (-60dBu / -40dBu)

SW42001 - -60 REAR CH2 MIC input level setting (-60dBu / -40dBu)

SW41002 - -40 FRONT CH1 MIC input level setting (-50dBu / -40dBu)

SW42002 - -40 FRONT CH2 MIC input level setting (-50dBu / -40dBu)

VTR SYSCON 1 OFF (FIXED) Not used

SW500

3-4 OFF (FIXED) Factory use only

SW501

FACTORY

SETTING

8 ON Not used

6 OFF ON : ENG SEQURITY ON

1 ON Factory use only

2 OFF Factory use only

3 ON Factory use only

4 OFF Factory use only

2 OFF EE-ROM write protect (allow is ON side)

1 OFF (FIXED) Not used

EE-PROM initia li ze

<ROM initialization procedur e >

1. Turn Off the unit

2OFF

2. Switch SW201-2 and SW 500-2 to ON ® Turn On the

unit.

3. After 5 second, initialization is completed ® Turn Off the

unit.

3 OFF (FIXED) Factory use only

4 OFF (FIXED) Factory use only

FEATURE

AUDIO LCD board

SW40001

SW40002

SW7001

SW2001

SW1001

SW2002 SW1002

VTR SYSCON board

SW501

SW500

INF-27

Page 30

14. Circuit board layout

E5. CAMERA MOTHER P.C.BOARD

E7-2. MEMORY P.C.BOARD

E7-1. DSP MAIN P.C.BOARD

E2. TG P.C.BOAR D

E1. PRE AMP P.C.BOARD

E25. CCD SENSOR P.C.BOARD

E3. DRIVE P.C.BOARD

E34. SD CARD P.C.BOARD

E28. FRONT TOGGLE P.C.BOARD

E12. SERVO P.C.BOARD

E9. VTR MOTHER P.C.BOARD

E11. SERVO FLEX P.C.BOARD

E13. HEAD BUFF P.C.BOARD

E32. OPERAT E P.C.BOARD

E38. BACK TALLY P.C.BOARD

E39. SIDE BNC P.C.BOARD

E30. REAR SW P.C.BOARD

E31. CUE P.C.BOARD

E18. REAR JACK P.C.BOARD

E40. SDI BNC P.C.BOARD

E26. HEAD PHONE P.C.BOARD

E27. EXT DC P.C.BOARD

E15. POWER MAIN P.C.BOARD

E16. POWER SUB P.C.BOARD

E17. AUDIO LCD P.C.BOARD

E22. SYNCHRO SW P.C.BOARD

E29. JOG MENU P.C.BOARD

E33. FRONT MIC P.C.BOARD

E4. PRE PROCESS P.C.BOARD

E6. CAMERA SYSCON P.C.BOARD

E8. VIDEO OUT P.C.BOARD

E21. MONITOR SW P.C.BOARD

E23. USER SW P.C.BOARD

E20. TOGGLE SW P.C.BOARD

E24. MENU SW P.C.BOARD

E19. POWER SW P.C.BOARD

E14. RF EQ P.C.BOARD

E36. VIDEO MAIN P.C.BOARD

E10. VTR SYSCON P.C.BOARD

E37. HD SDI TX P.C.BOARD

INF-28

Page 31

15. PLD Version Upgrade Method

The AJ-HDC27A has two Programmable Logic Devices (PLD) b y ALTERA Cor poration on CAM_S YS P.C. Board

(IC100) and VM (Video Main) P.C.Board (IC321). See following procedures for details.

15-1. Preparation

Equipment Remarks

CPLD WRITER

D-sub 25pin-25pin Cable Straight type (male - female), Length must be within 1meter

Upgrade tool software

Version Upgrade data

Personal Computer With WINDOWS 95Ò or 98Ò

15-2. Connection

IC100 (CAM_SYS P.C.Board)

1. Connect D-sub cable between connector CN201 on VFK1590 and PC.

2. Connect CPLD Writer cable between connector P201 on VFK1590 and connector P100 on CAM_SYS

P.C.Board. (Refer to Figure 15-1)

3. Turn on the power of camcorder and then boot-up PC.

VFK1590 (Interface board)

VFK1590P2 (Connection cab le: Su pp lie d with VFK 1590)

MAX+plus II Software : www.altera.com/pub/software/asap2.exe

Download from above URL and then install to any directory of PC.

IC100 : TDF format file (Include it in “vsi xxxx”)

IC321 : POF format file (Include it in “vsi xxxx”)

Notice: Flash memory software versions on each P.C.Board sometimes need to be

upgraded together with PLD version up. Before PLD version up, confirm the

instruction of each vsi file.

IC321 (VM P.C.Board)

1. Connect D-sub cable between connector CN201 on VFK1590 and PC.

2. Connect CPLD Writer c able (VFK1590P 2) betwee n connector P20 1 on VFK15 90 and co nnector P3 20 on VM

P.C.Board. (Refer to Figure 15-1)

3. Turn on the power of camcorder and then boot-up PC.

D-SUB 25 pins

Cable

PC

Connector P201

VFK1590P2

Connector

VFK1590

CN201

P100

P320

Figure 15-1 Connection

INF-29

Page 32

15-3. Version-up Procedures

1. Boot up MAX+plus II 9.6 programmer only.

2. On main window, select tab “MAX-plus II” and then ”Programmer”.

3. On main window (Programmer window is displayed), select tab “Option” and then “Hardware setup”.

4. On Hardware Setup dialog, set Hardware Type to “ByteBlaster (MV)”.

5. On main window, select tab “File”, “Project” and then “Name”.

6. On Dialog of Project Name, select the “TDF file (IC100)” or “POF file (IC321)” and then Click “OK button”.

INF-30

Page 33

7. Click “Program button” on Programmer dialog.

8. When Progress bar r eaches at point of “100”, the mes sage “Programm ing completed” appears, th en PLD

version upgrade is completed.

9. Click “OK Button” on “Programming complete” message dialog.

Progress bar

10. Turn the power of camcorder OFF and ON.

11. Confirm the current version of PLD on DIAGNOSTIC page (IC100: CA M SYS Board) and VTR DESIGN

page (IC321: VM Board). (See page of INF-10 through 16 in this service manual for how to open each menu

screen.)

<DIAGNOSTIC>

®

CAMSOFT (IN)

CAMSOFT (OUT)

GAMMA GAIN

GAMMA RAM

KNEE

PLD

Ver T1.xx-01-1.xx

Ver T1.xx-01-1.xx

Ver T1.xx-01-1.xx

Ver T1.xx-01-1.xx

Ver T1.xx-01-1.xx

Ver T1.xx-01-1.xx

**** VTR DESIGN MENU****

®

DESIGN MENU

TEST MODE

ERROR LOG

VM PLD

VTR SYSCON

V x.xx

V1.8126a

00.00.00

DIAGNOSTIC page VTR DESIGN page

* MAX+PLUS is registered trademark of Altera Corporation in the Unit ed Stat es and/or other countries.

* Windows95 and Windows98 are either registered trademarks of Microsoft corporation in the United States and/or other countries.

INF-31

Page 34

16. Flash Memory Version Upgrade Method

The AJ-HDC27A has Flash memories IC202 on CAM_SYS P.C.Board, IP100 on VTR_SYS P.C.Board and IC100

on ERVO P.C.Board. Version upgrade procedures for each Memory is shown below.

IC 202

SW1

(Component side) (Solder side)

CAM_SYS P.C.B

IC 100

SERVO P.C.B (Component side)

P2 Connector

IP 100

P6100

Connector

VTR_SYS P.C.B (Component side)

16-1. Preparation

16-1-1. Equipment

Name Remarks

Flash memory versionup tool

RS-232C Cable 9pins – 9pins, Cross type, D-SUB

Version upgrade Software

Version-up Data

Personal Computer With MS-DOS, Windows95 or Windows 98

* MS-DOS, Windows95 and Windows98 are either registered trademarks of Micros oft corporation in the United States and/or other countri es.

VFK1304 (Connection Board and Flat cable)

CAM_SYS P.C.B

VTR_SYS P.C.B

SERVO P.C.B

VVVSI File

: XXXXX.BAT (come with each Version-up data)

: VFK1248E (For WINDOWS 95Ò or 98Ò type)

: VFK1503

INF-32

Page 35

16-1-2. Setting of VFK1304A

Before executing version upgrade, Set “Cable type setting” and ”W riting function setting” on VFK1304A as

shown below. If any settings are wrong, it can not communicate to PC.

Writing function setting (SW1)

SW1 SW2 SW3 SW4

ON ON OFF OFF

ON ON OFF OFF

ON OFF OFF OFF

(R1, R2, R3, R4)

ON

1

2

3

4

ON

1

2

3

4

1

2

3

4

R1 = OPEN

R2 = OPEN

R3 = SHORT

R4 = SHORT

ON

SW1

VFK1304A

Figure 16-1

R3

R1

R4

Board

CAM_SYS

VTR_SYS

R2

SERVO

16-2. Version Upgr ade for CAM_SYS P.C.Board

16-2-1. Getting the user data

1. Get the User data with Multimedia Card (See Op erating Instructions pa ge numbers 59 – 63 for Details of

Getting the User data.)

Cable type

setting

16-2-2. Connection

1. Connect RS-232C Cable between connector P2 on VFK1304A and COM 1 port on PC. (Refer to Figure.

16-2)

2. Connect Flat cable bet ween connec tor P1 on VFK130 4A and conn ector P2 on CAM_ SYS P.C.Boar d, and

then set SW1 on VFK1304A according to Figure. 16-1.

3. Set “SW201” on CAM_SYS P.C.Board to “ON” (Up-side at condition of slot into the unit)

4. Turn on the power of the unit and then boot-up PC (MS-DOS mode).

D-SUB 9pins

PC

cable

VFK1304A

Camcorder

SW201

CAM_SYS P.C.B

Figure 16-2

ON

INF-33

Page 36

16-2-3. Software Version Upgrading

1. Copy all files in “Version up data (vvvsi file)” to arbitrary directory. (Please make a directory)

2. Type “xxxxx.bat” and then hit RETURN key.

3. Data transfer will be started from PC to camcorder. Data transferring scheme is shown below.

Scheme of Flash memory writing

ERASE : Data all clear on Flash memory

WIRTE : Data writing to Flash memory

VERIFY : Verifying data between wrote data

and original data

4. When progress bars reaches at 100% position, data

transfer is completed.

5. Set “SW201” to OFF side.

6. Turn OFF®ON the power of camcorder and then

confirm software’s version.

NOTE:

Each software version is indicated on <DIAGNOSTIC> menu screen (CAM MAIN MENU4 page).

16-2-4. Restoring User Data

1. Restore the User data with Multimedia card. (See Operating Instructions page numbers 59 – 63 for Details

of restoring the User data.)

16-2-5. Trouble Shooting

Symptoms

Cause

Check point

Error message “ERROR: RS232C: Line Open Error” is ap peared and then

data transferring is interrupte d.

Could not communicate between PC and camcorder.

* Did you use RS-232C cable as designated? (9pins-9pins, Cross)

* Did you set SW201 on CAM_SYS P.C.B to “ON” side?

* Did you turn on the power of camcorder?

INF-34

Page 37

16-3. Version Upgrade for VTR_SYS P.C.Board

16-3-1. Connection

1. Connect RS-232C Cable between connector P2 on VFK1304A and COM1 port on PC. (Refer to Figure. 16-

2.)

2. Connect Flat cable between connector P1 on VFK1304A and conn ector P6100 on VTR_SYS P.C.Board,

and then set SW1 on VFK1304A according to Figure. 16-1.

3. Turn on the power of the unit and then boot-up PC (WINDOWS mode).

16-3-2. Software Version Upgrading

1. Copy all files of VFK1248E to arbitrary directory.

2. Double-click the program file icon

3. When this Software is started, a dialog will be opened as shown below.

“VSI2312E.EXE”

.

4. Set parameters on

Microcomputer select............................. M32160F4UFP

Writing data ............................................ File data

Enter new version-up data name (XXXX.mot) with full path. You can also use “Browse…” button on

the “Setup panel” to select the file name and location of the new version-up data.

Target machine ID check ....................... Off

Port......................................................... Set the port which RS-232C Cable is connected to PC.

Baud Rate .............................................. 115200

Stop Bits................................................. 1Bit

Byte Size ................................................ 8Bits

Parity ...................................................... None

“Setup Panel”

window.

INF-35

Page 38

5. When settings on the “Setup panel” is completed, click “OK(O)” button. “VSI212E Main panel” will be

opened as shown below.

6. Click “Start (S)” button on the “Mai n pa ne l” windo w, (C lic k “Exit” button to quit, C lic k “Setup (Z) to RET URN

to Setup panel”)

7. After erasing data of the Flash memory, New version-up data will be written to the Flash memory. While

processing, progress status can be confirmed by means of “Process” indicator. If the Indicator doesn’t

advance for some reason, click “Emergency stop (C)” button and then confirm settings.

8. When Process bar reaches at 100% position and “Waiting to start or Completed” indicator is marked,

Version-up is completed, then click “Exit (X)” button.

9. Turn off the power of DC po wer supply and th en set the power SW of camcorder to off. ( In this situation,

Power SW should not work.)

10. Disconnect VFK1304A and then turn on the power of camcorder.

INF-36

Page 39

16-4. Ver sion Upgr ading for SERVO P.C.Board

16-4-1. Connection

1. Connect RS-232C Cable between connector P2 on VFK1304A and COM1 port on PC. (Refer to Figure. 16-

2.)

2. Connect Flat cable between connector P1 on VFK1304A and connector P9811 on VTR MOTHER

P.C.Board, and then set SW1 on VFK1304A according to Figure. 16-1.

P9811

Figure 16-3 Operation side of the Unit

3. Turn on the power of camcorder and then boot up PC (MS-DOS mode).

4. Copy all files of version-up data and SERVO Version upgrade software (VFK1503) to the same directory.

SERVO Version upgrade software (VFK1503) “fw103u.exe”

SERVO Version upgrade data “vsiXXXX.obf”

“vsiXXXX.bat”

“vsiXXXX.ex”

5. Type “vsixxxx.bat” and then hit RETURN key.

6. Type “Y” and then hit RETURN key after display message “DO YOU CONTINUE? Y / N>”.

7. Data transfer will be started.

8. After data transfer is finished, turn off the power of the Unit.

9. Disconnect VFK1304A.

10. Turn on the power of camcorder and then confirm software version.

* Windows95, Windows98 and MS-DOS are either registered trademarks of Microsoft corporation in the United States and/or other countries.

INF-37

Page 40

17. Blemish Compensation Method

Features

a ) Possible to compensate each color signal individually (R, G and B). (Total amount : 256 points)

b ) It is possible to compensate blemish without extra equipment (PC, Service fixtures etc.).

Automatic blemish compensation function

c )

17-1. Preparation

1. Need about 2-hours aging before start an adjustment.

2. Set WHITE BAL SW, CC and ND filter wheels as shown below.

WHITE BAL SW : PRST

CC FILTER : Position “B”

ND FILTER : Position No. “1”

3. Close LENS Iris and then execute “A BB” b y the front switc h.

17-2. Connection

T o facilitat e b lemish compensation’s work, connect the cam c order and the HD T V- monitor through HD SDI output.

(With 75-ohm termination.)

. Also it is (possible to manual compensate too.)

HD-SDI

Panasonic

HD TV-monitor

INF-38

Page 41

17-3. Compensation flow

)

The AJ-HDC27AP has Automatic blemish compensation function. Execution procedure of Automatic compensation

is shown below.

<DEFECT COMPENSATION>menu setting

Execute automatic com pensation

“<ENTRY (AUTO)> menu”

Automatic Blemish detection through compensation in whole

screen.

Result confirmation (at TV monitor)

Fine adjustment by cursor manually.

(Only when it cannot compensate completely by automatic

compensation

Store result of compensation (To built-in Memory)

(Only when executed manual adjustment)

INF-39

Page 42

17-4. Compensation Procedures

4-1. Initial setting (Menu setting of DEFECT COMPENSATON page)

Before start an adjustm ent, Set items (CAM SERVICE le vel) following portion. ( port ion , Sometimes it

isn’t possible to compensate blemish (es) in case of wrong setting.)

<DEFECT COMPENSATION>

COMPENSATION

®®®®

COMP ON GAIN

INTERACE MODE

R CH

G CH

B CH

TRIPLE OFFSET

CURSOR BOX

READ DATA

WRITE DATA

Figure Ble-1 Defect Compensation page

4-2. Execution of Automatic compensation (ENTRY (AUTO) page)

1. Open the “<DEFECT COMPENSATION> page” in CAM SERVICE level.

2. Set “COMP ON GAIN” item to des ired gain va lue. (Com pensation work s in the gain beyond the va lue set

up in this item.)

3. Open the “<ENTRY (AUTO) page>” in CAM SERVICE level.

4. Set the automatic c ompensation signal le vel (contrast ra tio *

AJ-HDC27AP detects blemish which bevel is more than the specified level by this set up.

: ON

: 12dB

: PDMIX

: AVE

: AVE

: AVE

: BAB

: ON

: OFF

: OFF

1

) with “PICKUP LEVEL R/ G or B” it em s. T he

<ENTRY (AUTO)>

PICKUP LEVEL R

®®®®

PICKUP LEVEL G

PICKUP LEVEL B

START

: 000

: 000

: 000

: OFF

NG LIST NO.

SELECT

ENTRY

CURSOR DISP

: 000

: OFF

: OFF

Figure Ble-2 ENTRY (AUTO) page

*1 contrast ratio: blemish signal level patio at the Built-in color

bars signal is 100%.

5. Set “START” item to ON by JOG DIAL in the unit. By this operation, The unit will execute blemish detection

for compensation in whole screen, automatically. And while executing automatic compensation, blink

“PICKUP” character on the lower right of the screen. (It takes about 30 seconds)

6. When “OK” character appears in the place of “PICKUP”, automatic compensation is completed.

7. Close menu screen and then turn off the power of the Unit. (Compensation result will be stored in the builtin memory of the Unit automatically.)

INF-40

Page 43

4-3. Result conf irmation

After execution of automatic compens ation the num ber of detection result and the number of blemish which

wasn’t compensated will be displayed in lower part of “ENTRY (AUTO)” page as the result status table. (Refer

to Figure Ble-3) P lease conf irm whether al l blem ishes were c ompens ated with th is status displa y by vie wing

the TV-monitor. As the standard of a confirmation, Blemish compensation specification is shown below.

LVL CNT

R

G

B

Y

015 003

010 006

025 004

001

NG 001

Figure Ble-3 Result status table

Observation enviro nment

Measurement part HD SDI OUT connector

Circumstance temperature

GAIN setting +18dB

AWB SW setting PRST (PRESET)

SETUP level 0%

Specification

LVL

CNT

NG

:

Display PICKUP LEVEL menu item’s value

:

The number of the points which were detected and

compensated as blemish(es). (Display the each color, “Y”

shows two or more blemishes were detected at the same

position)

:

The number of the position because that was which

wasn’t compensated in "compensation inhibition

position (refer to 5-4.)".

77°F (25°C)

Zone 2

Zone 1

H

4/5H

Contrast ratio*

1

Zone 1 Zone 2

0% - 8% No count No count

8% - 13% less than 2 less than 2

13% - 15% 0 less than 2

15% or more 0 0

*1 Contrast ratio: blemish signal level patio at the Built-in col or bars signal is 100%.

3/5V

V

INF-41

Page 44

4-4. Manual compensation procedure

In case it couldn’t com pensate all blemis h in automatic com pensation, it is also possible to perf orm blemis h

compensation manual ly b y using curs or. Follo win g shows c oncr ete m anual compensation procedur es by the

case required.

I ) Manual compensation for position which was not detected automatically

1. Close LENS iris and then execute “ABB” by front switch.

2. Open the “<DEFECT COMPENSATION> page” in CAM SERVICE level.

3. Set “COMP ON GAIN” item to desired gain value. (Compensation work s in the gain beyond the value se t

up in this item.)

4. Open the “<ENTRY (MANUAL) page>” in CAM SERVICE level.

5. Set menu items are shown below.

DEFECT SIZE : 3

GAIN : OFF

6. Set “DEFECT COLOR” item to R / G / B or Y, according to co lor of blemish. (If two or more color of

blemish appear in the same position, select “Y”.)

<ENTRY (MANUAL)>

H CURSOR COARSE

®®®®

H CURSOR FINE

V CURSOR COARSE

V CURSOR FINE

DEFECT SIZE

DEFECT COLOR

GAIN

OFFSET LEVEL A

OFFSET LEVEL B

ENTRY

CANCEL

Figure Ble-4 ENTRY (MANUAL) page

: 03

: 80

: 02

: 80

: 3

: Y

: OFF

: 100 (*2)

: 100 (*2)

: OFF

: OFF

7. Observe TV-monitor and then adjust “H CURSOR COARSE a nd FINE” item so that the H cursor position

comes to target blemish.

8. Observe TV-m onitor and then a dj ust “ V CUR SO R CO ARSE and FINE” it em so that the V cursor pos ition

comes to reduce the blemish.

9. Set “ENTRY” item to ON.

10. When “ENTRY” character appears on the lower right of the screen, data store will be completed.

11. Close menu screen and then turn off the power of the Unit.

NOTE:

*2 ”OFFSET A, B” menu ite ms don’t work in current camera system con t rol software Version T1.01-00-0.01, a s o f March/ ’01.

(A future schedule is undecided.)

INF-42

Page 45

II ) When compensation is fully impossible

In this case, there are two solutions by manual compensation.

a ) Re-setup of PICKUP LEVEL

1. Open “<ENTRY (AUTO)>” page in CAM SERVICE level.

2. Re-Setup “PICKUP LEVEL R/ G or B” items to level down (down detection level).

3. Execute automatic compensation again. (Set “START” item in “<ENTRY (AUTO)>” page to ON.)

b ) Fine adjustment of cursor position

1. Open “<EDIT / DELETE>” page in CAM SERVICE level.

2. Select Defect number desired position of fine cursor adjustment by “DEFECT NO.” item.

3. Set “DELETE” item to ON (turn JOG DIAL) and then press JOG DIAL.

4. Open “<ENTRY (MANUAL)>” page in CAM SERVICE level.

5. Set menu items are shown below.

DEFECT SIZE : 3

GAIN : OFF

6. Set “DEFECT COLOR” item to R / G / B or Y, acc ording to co lor of blem ish. (W hen two or m ore color of

blemish appear in the same position, select “Y”.)

<ENTRY (MANUAL)>

H CURSOR COARSE

®®®®

H CURSOR FINE

V CURSOR COARSE

V CURSOR FINE

DEFECT SIZE

DEFECT COLOR

GAIN

OFFSET LEVEL A

OFFSET LEVEL B

ENTRY

CANCEL

Figure Ble-5 ENTRY (MANUAL) page

: 03

: 80

: 02

: 80

: 3

: Y

: OFF

: 100

: 100

: OFF

: OFF

7. Observe TV-monitor and then adjust “H CURSOR COARSE a nd FINE” item so that the H cursor position

comes to target blemish.

8. Observe TV-m onitor and then a dj ust “ V CUR SO R CO ARSE and FINE” it em so that the V cursor pos ition

comes to reduce the blemish.

9. Set “ENTRY” item to ON (turn JOG DIAL) and then press JOG DIAL.

10. When “ENTRY” character appears on the lower right of the screen, data store will be completed.

11. Close menu screen and then turn off the power of the Unit.

INF-43

Page 46

17-5. Remarks

5-1. Delete all cursor position data in the built-in memory

1. Open “<EDIT / DELETE>” page in CAM SERVICE level.

2. Set “ALL DATA CLEAR?” item to ON by JOG DIAL operation.

3. Set “REALY ALL CLEAR?” item to ON by JOG DIAL operation.

4. When “ALL CLR” character appears on the lower right of the screen, data deletion will be completed.

5. Close menu screen and then turn off the power of the Unit.

5-2. Delete registered data one by one

1. Open “<EDIT / DELETE>” page in CAM SERVICE level.

2. Select “DEFECT NO.” to desired position of cursor.

3. Set “DELETE” item to ON by JOG DIAL operation.

4. When “DELETE” character appears on the lower right of the screen, data deletion will be completed.

5. Close menu screen and then turn off the power of the Unit.

5-3. Change Parameter about blemish compensation

1. Open “<EDIT / DELETE>” page in CAM SERVICE level.

2. Select “DEFECT NO.” to desired position of cursor.

3. Change some parameters in “<EDIT / DELETE>” page (DEFECT COLOR, DEFECT SIZE etc.).

4. Set “CHANGE” item to ON by JOG DIAL operation.

5. When “CHANGE” character appears on the lower right of the screen, data change will be completed.

6. Close menu screen and then turn off the power of the Unit.

5-4. About the position inhibited to register the compensation data

Depending on the posit ion for the blem ish compensation, blem ish compensation doesn’t work properly. In that

case, it display “NG” on the lower right position on the screen and inhibit registration of the blemish compensation

position. The condition “a)” is shown below.

a) : position of V CURSOR is the same line of the blemish compensated position and H cursor is +/- 2.

a)

Figure Ble-6 The position inhibited to register the compensation data

: Registered blemish compensation position

: Registration inhibited position

INF-44

Page 47

17-6. Trouble Shooting

Symptom Cause Check point

Blemish can’t be compensat ed

even COMPENSATION item

on menu is set to “ON”.

Blemish compensation posi tion

number (DEFECT No.) is

different from before.

“NG" display appeared on the

lower right of the screen when

trying to register a blemish

compensation position.

Wrong setting of fixed set ting

item.

DEFECT N o. is changed. DEFECT No. is automatically set fr om top left of monit or by the

Tried to execute registration

for the registrati on prohibited

position.

17-7. FAQ (Frequently Asked Question)

Question Answer

When execute blemish

compensation, Which

should I set to position

of GAIN SW on the

unit?

Can I store the blemish

compensation data as

backup to some place?

In the AJ-HDC27AP, GAIN setting while the blemish compensation used by only MENU setup.

·

Therefore you don’t have to set GAIN SW to some position.

By setting value of “COMP ON GAIN” item in the <DEFECT COMPENSATION> page, it is

·

possible to enable compensation in case of level more than the setting value on “COMP ON

GAIN” item.

When you want to enable the blemish compensation in all GAIN SW positions, Set “GAIN” item

·

in the ENTRY (MANUAL) menu page to OFF.

Yes

·

Normally , bl emish compe nsation dat a is s tored in IC201 (NV RAM ) on the CAM _SYS P.C.Board.

·

The AJ-HDC27AP is possible to store and read all blemish compensation data in IC202 (Flash

·

memory) on the CAM_ SYS P.C.Board as the BACKUP. by following operation in the DEFECT

COMPENSATION menu page.

<DEFECT COMPENSATION> page has items which must have

fixed setting.

Confirm if those items are fixed as factory default. (See "4-1.

Initial Setting” for details.)

direction of scanning. Therefore when new compensation

position is regis tered, another DEFECT No. may be c hanged.

Refer to the “5-4. About the position inhibited to register the

compensation data” page.

DATA WRITE: Set ”READ DATA” item to ON.

DATA READ: Set “WRITE DATA” item to ON.

Blemish compensation data is not stored to any extra media (SD CARD etc.)

·

INF-45

Loading...

Loading...