Page 1

TJ-70

MINI THERMOJET HANDPIECE

PACE P/N 7023-0002

OPERATION & MAINTENANCE

INSTRUCTIONS

MANUAL NUMBER 5050-0349

REV . A

For any questions regarding the following instructions, contact your local authorized

P ACE dealer or contact P ACE directly at:

Telephone (301) 490-9860, Fax (301) 604-9215

PACE Incorporated

9893 Brewers Court

Laurel MD 20723-1990

1

Page 2

PACE Incorporated retains the right to make changes to specifications contained

herein at any time, without notice.

Contact your local authorized P ACE Distributor or PACE Incorporated to obtain the

latest specifications.

The following are registered trademarks and/or servicemarks of P ACE Incorporated,

Laurel Maryland U.S.A. and may only be used to identify genuine P ACE products or

services:

AdapTip, Arm-Evac, Cir-Kit, ComForm I, ConducTweez, CRAFT,

Dual Path, Flo-D-Sodr, FuseSet, HandiPik, HotSpot, LapFlo, MBT,

Micro Portable, MicroChine, MiniChine, Pacenter, PACE, Ped-A-Vac,

PETS, PIK-V AC, PRC, PRINT , Pro-Evac, ResisT weez, SensaT emp, SMR,

SNAP-VAC, Sodr-X-Tractor, SR-3, SR-4, ST, StripTweez, SwaPlater,

ThermoBand, ThermoJet, ThermoPart, ThermoPik, ThermoTweez, ThermoDrive, Tip-Evac, VisiFilter .

The following are trademarks and/or servicemarks of P ACE Incorporated, Laurel

Maryland U.S.A. and may only be used to identify genuine PACE products or

services:

EKO , Redi-Rak, Mini-Wave, Sodr-P en.

PACE Incorporated has provided training on all of its products since 1958

as well as advanced technology training in all aspects of hand soldering,

rework and repair.

Additional copies of this manual or other P ACE literature may be obtained from:

P ACE Incorporated (301) 490 - 9860

Sales Administration (301) 4983252 Fax

9893 Brewers Court

Laurel MD 20723-1990

©1993 PACE Incorporated, Laurel MD. All rights reserved. Printed in the U.S.A.

2

Page 3

3

This manual details the basic operational guidelines for using the TJ-70 Mini ThermoJet

handpiece. A detailed Operation & Maintenance Manual For Accessories (P/N 5050-

0350) is available from PACE.

CAPABILITIES

The TJ-70 Mini ThermoJet Handpiece provides safe, continuous flow of precision

focused hot air for component installation and SMT land preparation. It is primarily

an installation tool and can be used for hot air installation of most surface mount

components. Its slim-line, pencil grip design and finger actuated control switch

facilitates ease of use and manipulation in tight places. The TJ-70 is a member of the

PACE SensaTemp family of advanced handpieces.

CAUTION

Always return heated handpieces to the appropriate Hot Cubby when not

in actual use. Failure to do so may cause burns to the operator, equipment

or work surfaces, and may be a potential ignition source if combustible

materials are nearby. Always use this handpiece in a well ventilated area

to avoid inhalation of fumes created by solder flux gases.

HANDPIECE SETUP

Connect the handpiece power cable plug to one of the handpiece power receptacles

on your PACE power source. PACE recommends that air handpieces utilize the power

receptacles closest to the SNAP-VAC and Controllable PRESSURE Ports to minimize

cord tangles. Connect an Air Hose to the TJ-70 using the method listed below.

Determine the proper tip to install and install the tip in the method listed under “Tip

Installation”.

NOTE

If using your TJ-70 Mini ThermoJet Handpiece for the first time or if you have

just replaced the heater, we recommend that you follow the “TJ-70 Heater

Burn-in” procedure (Red tag on handpiece) to increase the life expectancy

of the heater and to minimize any smoke and fumes generated by the heater

on its initial power-up.

Page 4

4

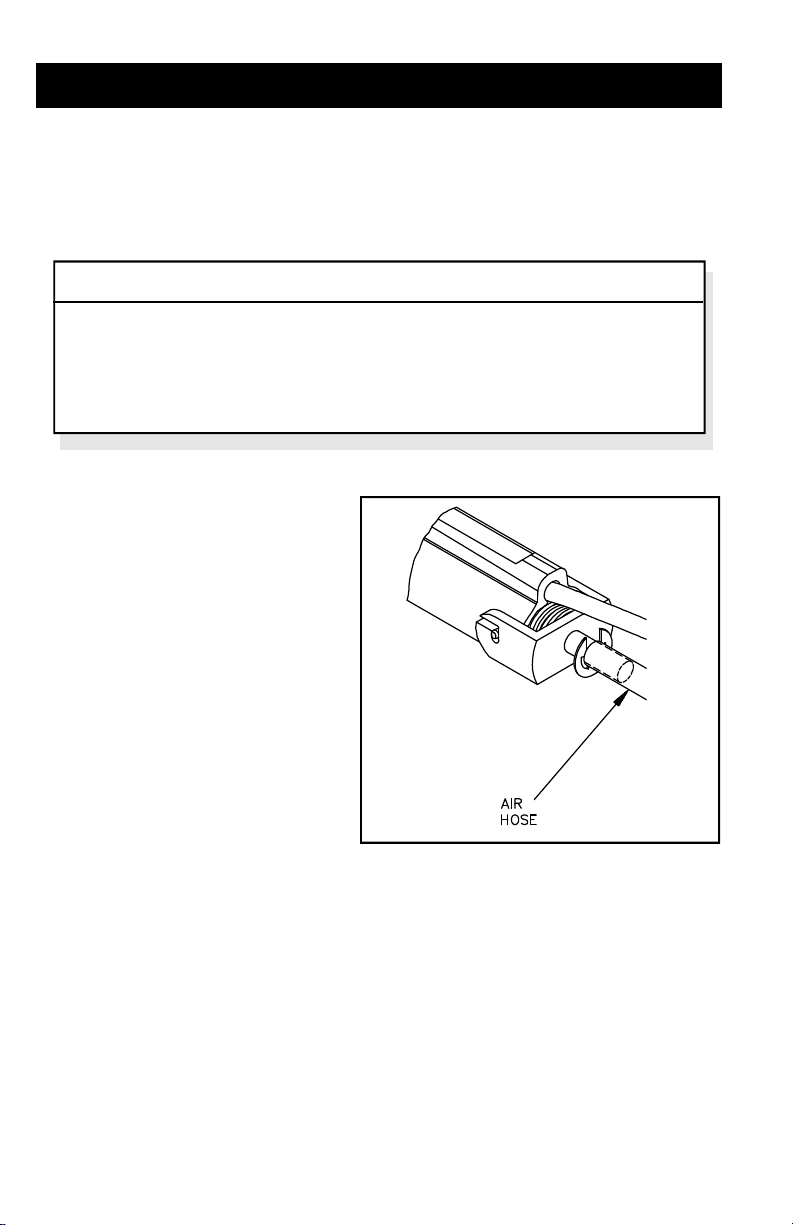

AIR HOSE CONNECTION

The Traditional Method of attaching the Air Hose from the power source is best

suited for use with the TJ-70.

NOTE

Ensure that no Air Hose is connected to the SNAP-VAC Port when using

the TJ-70 handpiece. The TJ-70 Air Hose must be connected to the

Controllable PRESSURE Port. Attachment to both ports simultaneously

will cause a deterioration of performance.

TRADITIONAL CONNECTION

1. Connect the 137cm (54 inch)

length of Air Hose to the metal

tube in the back of the

handpiece.

2. Insert the ridged end of a male

quick connect hose mount

fitting (P/N 1259-0087) into the

free end of the 137cm (54 inch)

length of Air Hose.

3. Secure the Air Hose to the

cable assembly with cable clips (P/N 1321-0085-01).

4. Attach the remaining end of the 137cm (54 inch) length of Air Hose (with

attached male fitting) to the power source Controllable PRESSURE Port.

5. To avoid confusion among handpieces, PACE recommends the use of

colored markers (P/N 6993-0136 Cable Marker Kit) to identify the Air Hose

connected to the handpiece. Attach any two like colored markers, one to

each end of the Mini ThermoJet Air Hose. Any Air Hose attached to

another handpiece should contain markers of another color.

Page 5

5

TIP INSTALLATION

Tip selection is very important. Referring to the list of Available Tips (Table III),

select the appropriate tip for your application.

The following instructions are for tip installation only. If a tip is currently installed in

the handpiece, follow the “Tip Removal” procedure prior to the installation of a new

tip.

1. Select the proper tip for your

application. Refer to Table III.

2. Holding the handpiece in a

horizontal position, the selected

tip should be fully inserted until

the tip seats itself against the

heating element.

NOTE

Holding the handpiece tip down may cause the tip to fall out before the set

screw has been tightened.

3. Orient the tip with the finger switch on the handpiece as desired for

optimum use.

4. Using the tip tool or small screwdriver, tighten heater set screw to secure.

Do not over tighten.

5. Apply power to the handpiece and set the operating temperature to 482°C

(900°F). After a short period (1-2 minutes) recheck the tip set screw to

ensure that it remains snug. On very light boards, you may need to lower

the temperature to protect the board from damage.

Page 6

6

TIP PREPARATION

TJ-70 tips are not tinnable and require little maintenance. Keep tips clean and free of

any foreign particles. Insure that all tip air jets are kept clean to prevent air flow

obstruction.

TIP REMOVAL

NOTE

To avoid tip damage, the Mini ThermoJet handpiece heater must be at a

temperature of at least 177°C (350°F) before attempting to remove an

installed tip. After removal, always place the hot tip in a tip holder or on a

metal surface to prevent burns or scorches. Hold the handpiece with the

heater body pointing up to prevent injury to personnel when cleaning a hot

handpiece. Dispose of any loose debris properly. The debris is hot.

1. Loosen the heater assembly set screw.

2. Remove the tip using a tip tool or needle nose pliers.

3. Clean the heater bore to remove any foreign particles (i.e., flux) using the

3/16 inch diameter wire brush. Do not push the brush more than 0.64cm

(1/4 inch) into the heater bore to avoid damage to the metal cylinder

installed at the rear of the heater bore.

4. Replace the TJ-70 handpiece in the Hot Cubby.

Page 7

7

TEMPERATURE SETTING

Set the operating tip temperature of the channel powering the TJ-70 handpiece to

482°C (900°F). On very light boards, you may need to lower the temperature to

protect the board from damage.

On MBT 250 and PRC 2000 systems, set the tip temperature offset to 3°C (6°F)

(default setting).

CONTROLLABLE PRESSURE PORT ADJUSTMENT

Air flow is actuated by depressing the finger switch on the handpiece or the optional

foot pedal switch. The rate of air flow can be controlled by the Controllable

PRESSURE Port on the front panel of the power source. Select and install a tip (see

Tip Installation). Experiment using the procedure following to determine an

appropriate level of air flow for your application.

1. Place a tissue paper (or like material) on the surface of your work bench.

NOTE

Insure that no flammable materials are positioned beneath the tissue. A

Controllable PRESSURE Port setting of MIN to 3 is the best for general use.

A setting of MIN to 1 are recommended when installing very small

components such as chip capacitors.

2. With the Controllable PRESSURE Port set at minimum (MIN), press the

finger switch on the handpiece and direct the hot air at the tissue from a

distance of about 0.64cm (1/4 inch).

3. While continuing to depress the finger switch, slowly draw a series of

burn lines on the tissue paper while increasing the Controllable

PRESSURE Port setting slowly with the free hand.

4. Continue to experiment drawing the burn lines. Vary the the speed of

handpiece movement, distance of the tip from the tissue and the

Controllable PRESSURE Port setting until you become comfortable with

handpiece use.

Page 8

8

COMPONENT INSTALLATION

Perform the following procedure to install the component.

NOTE

To prevent damage to the component during placement, PACE recommends

handling the component with a vacuum pick device such as the PACE PikVac or HandiPik. Always place the hot tip in a tip holder or on a metal

surface to prevent burns or scorches.

1. Carefully clean the replacement component leads (or terminations) and

substrate land pattern area using an approved solvent. Insure that no

leads or terminations become deformed during the process.

2. Apply solder paste to the lands.

3. Properly orient the replacement component with respect to the land

pattern; centering the component leads (or terminations) with their

corresponding lands.

4. Gently place the component

onto the land pattern taking

care to maintain proper lead to

land alignment.

5. Apply a very small downward

pressure to the component

body; forcing the leads (or

terminations) gently into the

solder paste.

Page 9

9

6. Bring the tip of the handpiece to a distance of 2.5cm (1 inch) from the

component leads (or terminations). Press the finger switch to begin air

flow. Direct the air flow to one side of the component and begin to heat

the leads and lands in a side to side sweeping motion across the lead (or

termination) or along the length of one row of leads. After evaporation of

solder paste flux is observed, move the tip closer to the component with a

continuous air flow until complete solder reflow occurs.

7. Continue to heat the lead/land contact area(s) until formation of shiny

solder fillets is observed. Fillets on chip components and SOICs will be

slightly concave on each lead; fillets on extended lead devices should

cover the sides, toe and heel of each lead.

8. Release the finger switch to stop air flow.

9. Repeat the above procedure for leads on all sides of the component.

10. Clean and inspect per your company specifications.

NOTE

If this process has not been successful, preheating of the PC Assembly

and/or adjustment of the Controllable PRESSURE Port may be required.

SPECIAL APPLICATIONS

If you require assistance in the use of this handpiece or require assistance with a

special application, contact PACE Applications Engineering at:

Tel: (301) 490 - 9860

Fax: (301) 604 - 9215

Page 10

10

CORRECTIVE MAINTENANCE

Your TJ-70 requires no special maintenance other than being kept clean. The

heater bore and the heater assembly set screw which secures the tip must be

kept free of oxidation and debris in order to maintain the proper tip to ground

resistance. Periodically inspect the cable, connector and handpiece itself for

evidence of physical damage. Do not use a handpiece with a damaged cable.

Refer to Table I (TJ-70 Heater Assembly Checkout Procedures) and the

Connector Plug illustration below for information on troubleshooting most

handpiece problems. Table II lists the common handpiece parts.

SYMPTOM CHECKOUT PROCEDURE CAUSE SOLUTION

No heat Check resistance - Pin 2 to Pin 5.

If the resistance is greater than

Handpiece

overheating

No Ground

on Tip

7 ohms -

Check resistance - Pin 3 to Pin 6.

If circuit reads open -

Check resistance - Pin 3 to Pin 6.

Resistance should be 110 ohms. If

circuit reads less than 105 ohms -

Check resistance - Pin 4 to a NEW

Tip. Resistance should be less than

2 ohms. If not -

Open Heater

Open Sensor

Shorted

Sensor

Oxidation

buildup in

Heater Bore

Defective

Heater

TABLE I. TJ-70 HEATER ASSEMBLY CHECKOUT PROCEDURES

Replace

Heater

Assembly

Replace

Heater

Assembly

Replace

Heater

Assembly

Clean Heater

Bore using

appropriate

wire brush

Replace

Heater

Assembly

Page 11

11

CONNECTOR PLUG WIRING

PART

DESCRIPTION

NUMBER

HEATER ASSEMBLY 6010-0084-P1

CORD/SWITCH ASSEMBLY 6993-0134

HEATER SET SCREW 1348-0547

WIRE BRUSH, 3/16" DIAMETER 1127-0014

Handpiece tips listed following page - - - - - - - -

TABLE II. TJ-70 REPLACEMENT PARTS

Page 12

12

TIP DESCRIPTION TIP SIZE

PART

NUMBER

Small, Straight, Single

Jet Tip

Small, Curved Single

Jet Tip

SOT/Chip Component

Tip (dual-jet)

SOIC Tip (dual-jet) A = 0.17" (4.32mm) 1121-0330

A

SOICL Tip (dual-jet) A = 0.37" (9.40mm) 1121-0331

Flat End Tip

A

B

TABLE III. TJ-70 AVAILABLE TIPS

--------- 1121-0366

--------- 1121-0338

A = 0.14" (3.56mm) 1121-0329

A = 0.28" (7.11mm)

B = 0.074" (1.88mm)

A = 0.24" (6.10mm)

B = 0.074" (1.88mm)

1121-0365

1121-0371

Loading...

Loading...