Page 1

ThermoFlo Accessories

INSTALLATION &

Installation & Operation Instructions

Page 2

PACE Incorporated retains the right to make changes to specifications contained herein at any time, without

notice.

Contact your local authorized PACE Distributor or PACE Incorporated to obtain the latest specifications.

The following are registered trademarks and/or servicemarks of PACE Incorporated, Laurel Maryland U.S.A.

and may only be used to identify genuine PACE products or services:

AdapTip, Arm-Evac, Cir-Kit, ComForm I, ConducTweez, CRAFT,

Dual Path, Flo-D-Sodr, FuseSet, HandiPik, HotSpot, LapFlo, MBT,

Micro Portable, MicroChine, MiniChine, Mini-Wave, PACE, Pacenter,

Ped-A-Vac, PETS, Pik-Vac, PRC, Prep-Set, Pro-Evac, Redi-Rak,

ResisTweez, SensaTemp, Snap-Vac, Sodr-Pen, Sodr-X-Tractor, SR-3,

SR-4, ST , StripTweez, SwaPlater, ThermoBond, Thermo-Drive, ThermoJet,

ThermoPart, ThermoPik, ThermoTweez, Tip-Evac, V entur-Evac, VisiFilter.

The following are trademarks and/or servicemarks of PACE Incorporated, Laurel Maryland U.S.A. and may

only be used to identify genuine PACE products or services:

Heat Wave, Pik-Tip, SodrLink, Sodrtek, ThermoFlo, Toolnet,

Since 1958, PACE Incorporated has provided advanced technology training in all

aspects of hand soldering, rework and repair.

Additional copies of this manual or other PACE literature may be obtained from:

PACE Incorporated (301) 490 - 9860

Sales Administration (301) 498 - 3252 Fax

9893 Brewers Court

Laurel MD 20723-1990

©1998 PACE Incorporated, Laurel MD. All rights reserved. Printed in the U.S.A.

Page 3

MANUAL NO. 5050-0421

REV. B

i

Page 4

Table of contents

Title Page

Introduction ............................................................................................................................................................ 1

Work Platform ........................................................................................................................................................ 2

Installation ................................................................................................................................................... 2

Operation ..................................................................................................................................................... 2

Advanced Placement Platform .............................................................................................................................. 4

Installation ................................................................................................................................................... 4

Operation ..................................................................................................................................................... 4

Vertical Slide Assembly......................................................................................................................... 4

Ground Cable ......................................................................................................................................... 5

Fine Adjustment Table ........................................................................................................................... 6

ThermoFlo Handpiece ........................................................................................................................................... 8

Installation ................................................................................................................................................... 8

Operation ..................................................................................................................................................... 9

Standard Board Holder ........................................................................................................................................ 10

Installation ................................................................................................................................................. 10

Operation ................................................................................................................................................... 10

Heat Wave Interface ............................................................................................................................................. 12

Installation ................................................................................................................................................. 12

Operation ................................................................................................................................................... 12

Fiber Optic Lighting Attachment ........................................................................................................................ 13

Installation ................................................................................................................................................. 13

Operation ................................................................................................................................................... 13

Fume Extraction Ready Attachment.................................................................................................................... 14

Installation ................................................................................................................................................. 14

Operation ................................................................................................................................................... 15

Vision Systems ..................................................................................................................................................... 16

Introduction ............................................................................................................................................... 16

Precision Swivel ........................................................................................................................................ 16

Installation ........................................................................................................................................... 16

Operation.............................................................................................................................................. 17

Lens Vision Attachment ............................................................................................................................ 18

Installation ........................................................................................................................................... 18

Operation.............................................................................................................................................. 19

Camera Vision Attachment ....................................................................................................................... 20

Installation ........................................................................................................................................... 20

Operation.............................................................................................................................................. 21

Packing Lists ........................................................................................................................................................ 22

Systems ...................................................................................................................................................... 22

Optional Accessories ................................................................................................................................. 26

ii

Page 5

Introduction

This manual will provide you with the information necessary to properly install, operate and maintain all of the

available accessories (except Thermocouple Meter & Large Board Holder) for the PACE ThermoFlo systems.

Detailed installation instructions are provided for each available accessory. Currently available accessories are:

Work Platform Advanced Placement Platform

Heat Wave Preheating System Large Board Holder

Lens Vision Attachment Camera Vision Attachment

Fume Extraction "Ready" Attachment Thermocouple Meter (instructions supplied separately)

All ThermoFlo accessories are very easy to operate. Easy to understand guidelines are given for the operation of

each accessory (except Heat Wave & Large Board Holder). The Heat Wave and Large Board Holder are shipped

with separate manuals specific to that system/accessory only.

1

Page 6

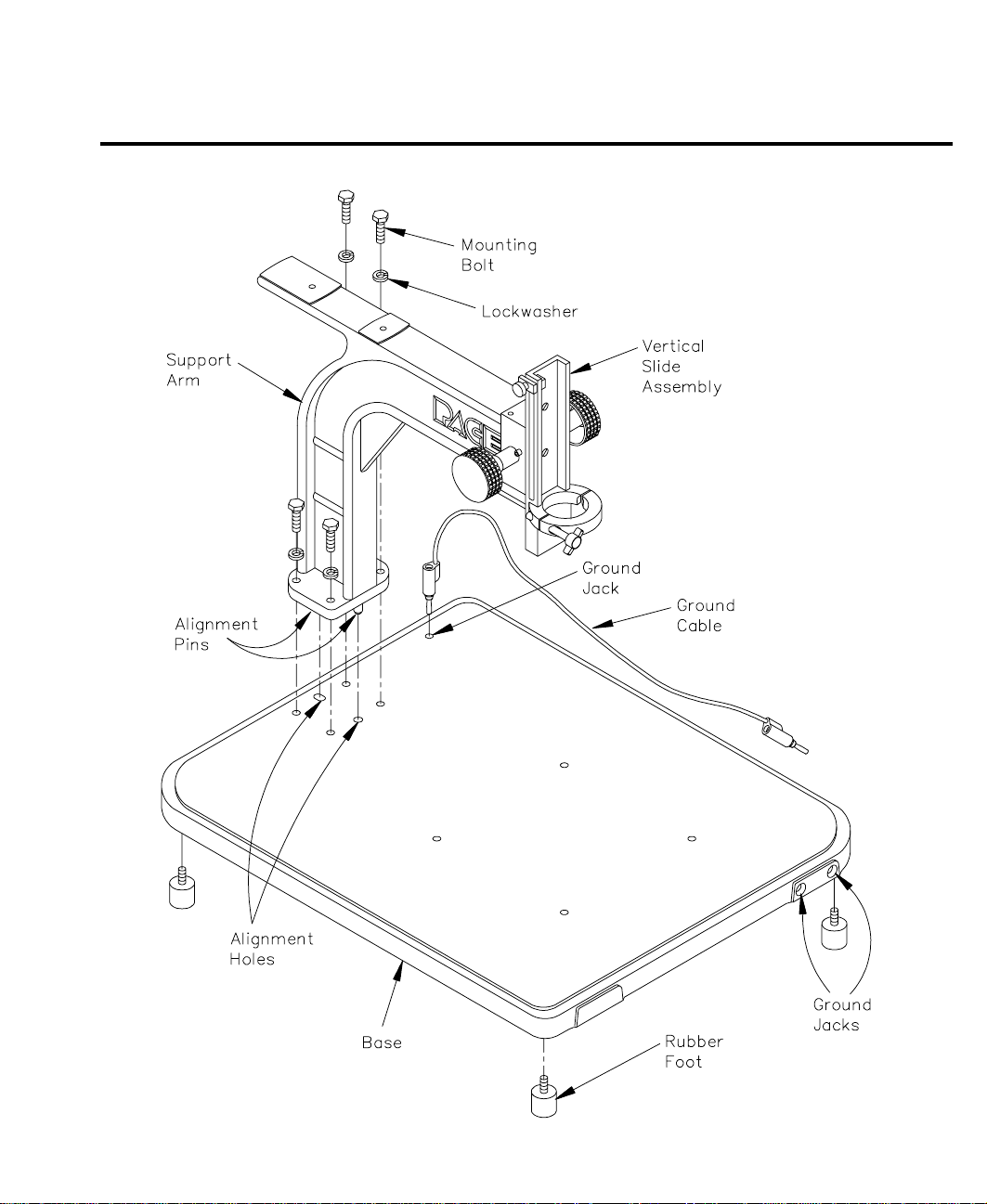

Work Platform

Installation

The Work Platform is provided with each TF 500 ThermoFlo System.

Use the following instructions and accompanying illustrations as a guide to assemble the Work Platform.

1. Place the Base upside down on a work surface and install the 4 Rubber Feet (with built-in screws) at

the corners of the Base.

2. Turn the Base over and position as shown.

3. There are 2 Alignment Pins located on the bottom of the Support Arm. Insert the 2 Alignment Pins

fully into the 2 Alignment Holes in the Base.

4. Install the 4 Mounting Bolts and Lock Washers. Tighten each bolt to secure the Support Arm to the

Base.

5. Insert one end of the supplied Ground Cable into the Base as shown or into either of the 2 Groun Jacks

at the front, right side of the Base.

Operation

Ground Cable

The Ground Cable is supplied to provide a connection to the Work Platform as a part of your static control

program.

Slide Assembly

The Vertical Slide Assembly holds the ThermoFlo handpiece in a vertical position for precise component

removal and installation operations. The handpiece is installed vertical to the work platform base; the bottom

edge of any installed nozzle (except Curved, Single Jet) is horizontal to any PCB (installed on a board holder)

on the Work Platform. Refer to the Handpiece Installation procedure to properly install the handpiece.

Simply rotate either of the Vertical Control Knobs to raise or lower an installed ThermoFlo handpiece (with

attached nozzle). Refer to "ThermoFlo Handpiece" "Operation" for additional information

2

Page 7

Work Platform

3

Page 8

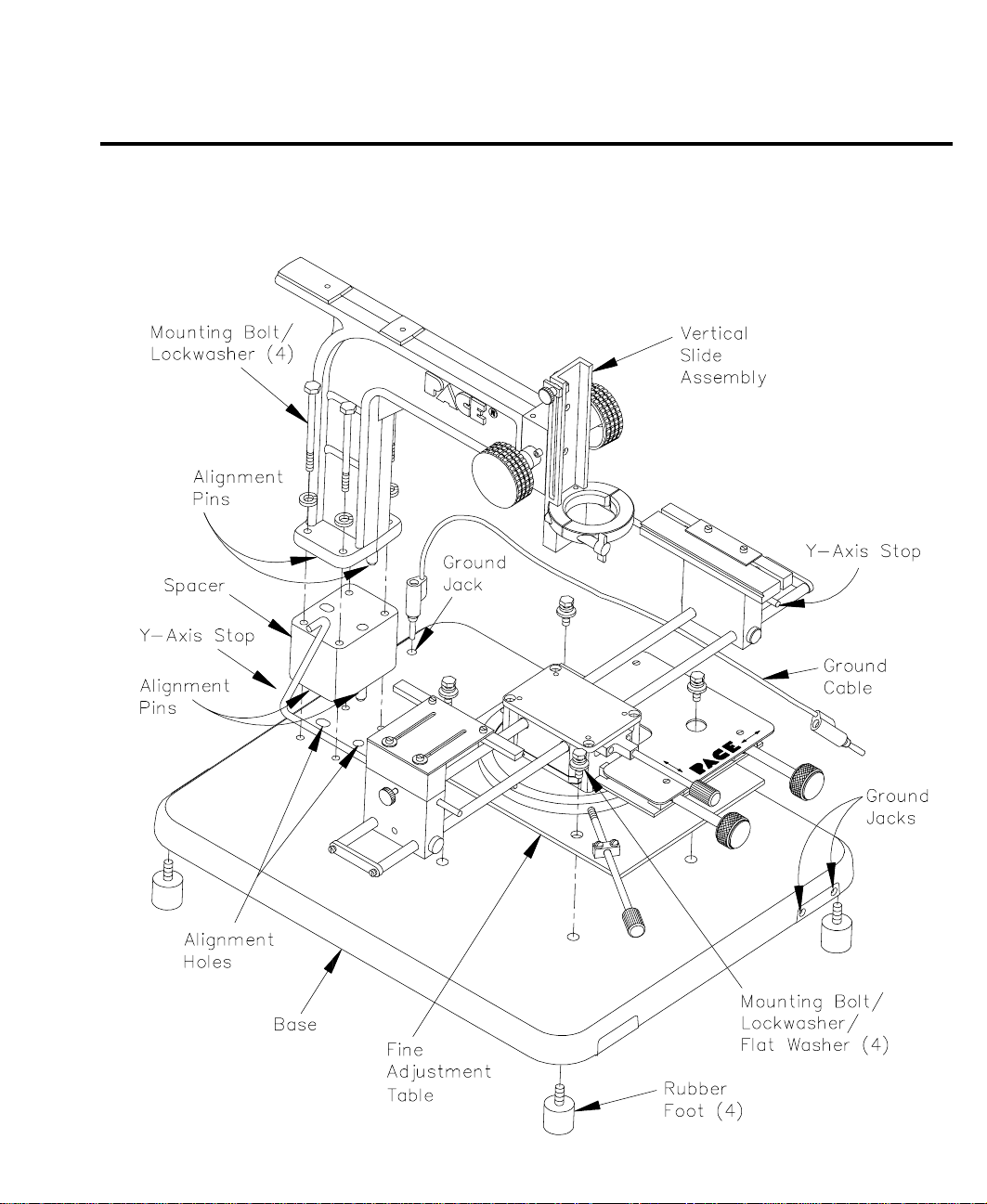

Advanced Placement Platform

Installation

The Advanced Placement Platform (including Fine Adjustment Table) is provided with each TF 700 ThermoFlo

System. Use the following instructions and accompanying illustrations as a guide to assemble the Advanced

Placement Platform.

1. Place the Base upside down on a work surface and install the 4 Rubber Feet (with built-in screws) at

the corners of the Base.

2. Turn the Base over and position as shown.

3. There are 2 Alignment Pins located on the bottom of the Spacer. Insert the 2 Alignment Pins fully into

the 2 Alignment Holes in the Base.

4. There are 2 Alignment Pins located on the bottom of the Support Arm. Insert the 2 Alignment Pins

fully into the 2 Alignment Holes in the Spacer.

5. Install the 4 long Mounting Bolts and Lock Washers. Tighten each bolt to secure the Support Arm and

Spacer to the Base.

6. Place the Fine Adjustment Table in position on the Base. Align the 4 threaded Mounting Holes in the

center of the Base with the 4 Mounting Holes of the Fine Adjustment Table.

7. Secure Fine Adjustment Table to the Base using the 4 short Mounting Bolts, Lockwashers & Flat Washers.

8. The 4 mounting screws that secure the ends of the 2 metal slide rods in position together may loosen

during shipment. Loosen all 4 mounting screws and perform the following procedure.

a) Move the Clamp Assemblies to the ends of the metal slide rods.

b) Move the metal slide rods to their Right side limit and tighten the 2 mounting screws on the Left

side ends of the metal slide rods. NOTE: You may need to loosen the X-Axis Lock.

c) Move the metal slide rods to their Left side limit and tighten the 2 mounting screws on the Right

side ends of the metal slide rods.

9. Insert one end of the supplied Ground Cable into the Base as shown or into either of the 2 Ground

Jacks at the front, right side of the Base.

10. Install the Y-Axis Stops into the Clamp Assemblies as shown. One of the Y-Axis Stops has a longer

curved "L" section than the other. This larger stop should be installed onto the left side of the Fine

Adjustment Table (facing as shown in illustration).

Operation

Vertical Slide Assembly

The Vertical Slide Assembly holds the ThermoFlo handpiece in a vertical position for precise component removal and

installation operations. Refer to the Handpiece Installation procedure to properly install the handpiece.

Simply rotate either of the Vertical Control Knobs to raise or lower an installed ThermoFlo handpiece (with

attached nozzle). Refer to "ThermoFlo Handpiece" "Operation" for additional information.

4

Page 9

Advanced Placement Platform

Ground Cable

The Ground Cable is supplied to provide a connection to the Work Platform as a part of your static control program.

5

Page 10

Fine Adjustment Work Platform

Fine Adjustment Table

The Fine Adjustment Table facilitates the installation of fine pitch SMT components. The table can hold your PCB

(up to 45.7cm X 45.7cm (18" X 18")) assemblies in position for rework. Fine adjustment x & y axis controls allow

easy component to land pattern alignment. Following is a description of the features. Refer to the illustration.

Parts Identification

À

PCB Clamp Assembly (2) - Holds PCB assembly on Fine Adjustment Table.

Á

Clamp Assembly Locks (2 on each Clamp Asembly) - Locks PCB in place preventing X-axis (side to

side) movement along the 2 metal slide rods. Two locks on each PCB Clamp Assembly must be fully

depressed to allow clamp movement along the slide rods.

Â

Y-Axis Fine Adjust Control - Allows fine adjustment of Y-Axis (front to back) table position.

Ã

X-Axis Fine Adjust Control - Allows fine adjustment of X-Axis (side to side) table position.

Ä

Y-Axis Stop (2) - Memory retention feature allows Y (front to back) directional stop reference for

repeatable PCB positioning.

Å

Y-Axis Locks - Locks Y-Axis Stops in place.

Æ

X-Axis Lock - Locks the metal slide rods in position to prevent X-Axis (side to side) movement.

Ç

Theta Lock - Locks table in position to prevent Theta Rotation.

Operation

1. Install the PCB to be repaired/reworked in the following manner.

a) Press the 2 Clamp Assembly locks on each PCB Clamp Assembly. Adjust the spacing of the 2

PCB Clamp Assemblies to the size of the PCB.

b) Orient the PCB as desired and insert side edges into the "V" grooved slot at the top of each PCB

Clamp Assembly. Slide PCB into clamp assemblies.

c) Adjust the PCB Clamp Assembly on the Right side of the table toward the PCB to apply a slight

spring pressure. Depress item Á Clamp Assembly Lock to release Clamp Assembly

2. Adjust the coarse center position of the PCB rework area relative to the ThermoFlo handpiece and

Nozzle in the following manner:

a) Lower the Nozzle to a position just above the PCB.

b) Position PCB in PCB Clamp Assemblies (item À) with rework area centered (front to back).

c) Turn the X-Axis Lock knob (item ±) counterclockwise to free side to side movement of the metal

slide rods (and PCB). Move metal slide rods to position component rework area beneath

ThermoFlo handpiece and Nozzle. Turn the X-Axis Lock knob clockwise to lock in position.

d) Repeat 2a and 2b as necessary to center component rework area under Nozzle.

6

Page 11

Fine Adjustment Work Platform

e) Turn the Theta Lock knob (item Ç) counterclockwise to loosen. Grasp the ends of the metal slide

rods; push one end while pulling the other to rotate table. Rotate table until component/land

pattern is square to nozzle. Turn Theta Lock knob clockwise to lock table in position.

d) Adjust the Y-Axis Stops if desired. Loosen (turn knobs counterclockwise) the 2 Y-Axis Locks

(item Å) and position the raised portion of the stops to contact the back edge of the PCB. Lock in

position with the Y-Axis Locks.

3. Fine adjust the position of the component to be removed to the nozzle or the component being placed

to the PCB land pattern in the following manner.

a) Turn the X-Axis Lock knob (item ±) fully clockwise to lock metal slide rods in position.

b) Adjust table side to side position using the X-Axis Fine Adjust Control (item Ã).

c) Adjust table front to back position using the Y-Axis Fine Adjust Control (item Â).

d) Adjust Theta Rotation as necessary (see step 2e).

7

Page 12

ThermoFlo Handpiece

Installation

If the Fiber Optic Lighting Attachment or any of the Vision Attachments

(Lens or Camera) have been purchased, they should be installed bef ore

performing the following procedure.

1. Unscrew the Plastic Heat Shield (marked "HOT")

from the ThermoFlo handpiece and set aside.

2. Install the metal Swivel Ring (part number 1321-

0320) onto the ThermoFlo handpiece.

3. Turn the Locking Knob counterclockwise several

turns to release the Clamping Socket.

NOTE

4. Pull the Locking Knob forward. The Clamping

Socket will swing open at the knob.

5. Place the ThermoFlo handpiece, positioned at an

angle with the heater down, through the center of

the Clamping Socket.

6. The Clamping Socket and the Swivel Ring (on

handpiece) form a ball and socket attachment

mechanism. Slide the Swivel Ring into the

Clamping Socket.

7. Straighten the ThermoFlo handpiece up into a

vertical position. Ensure that the Swivel Ring

remains inside the Clamping Socket.

8. Push the Locking Knob and turn clockwise to

secure the ThermoFlo handpiece in position.

8

Page 13

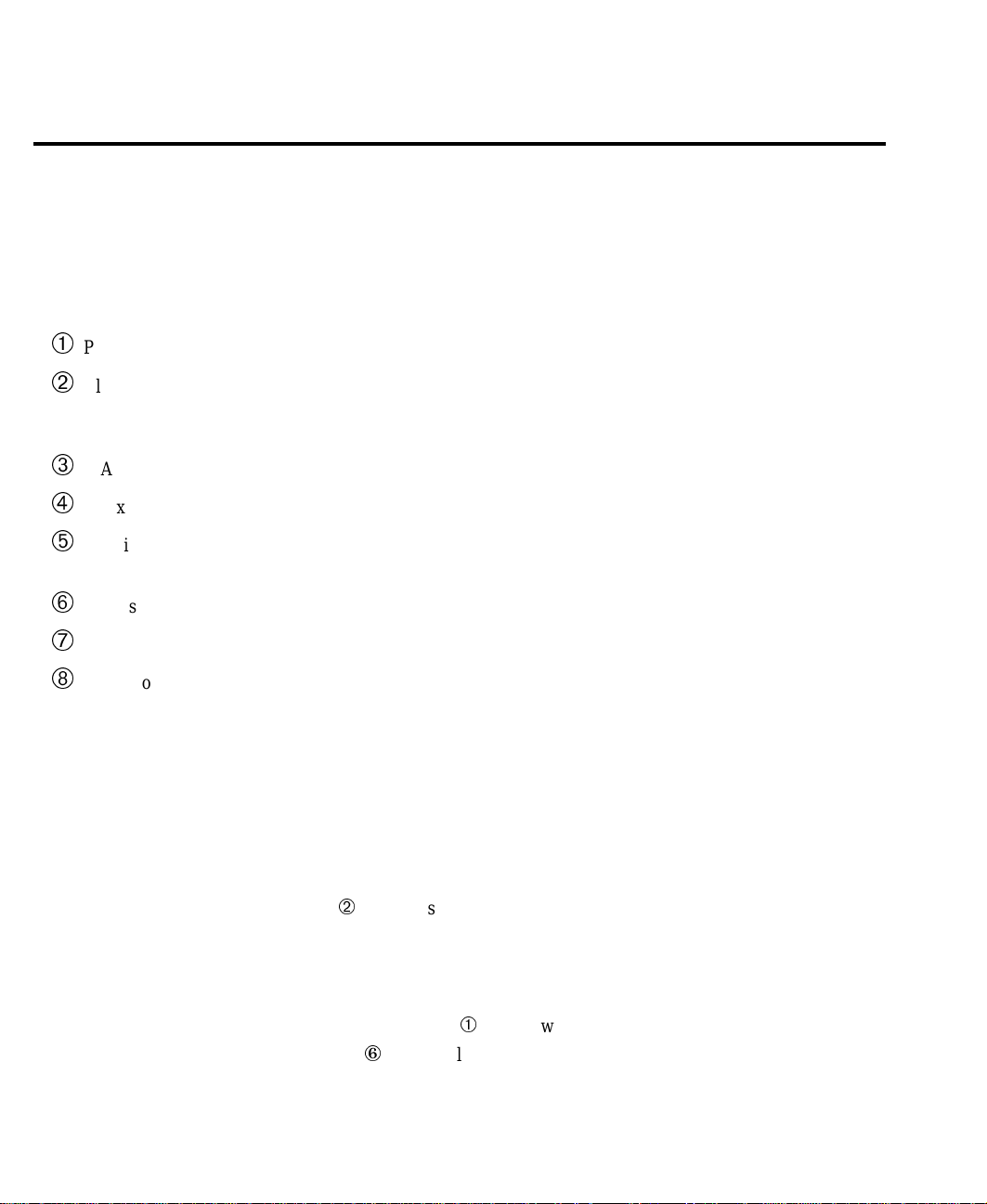

Operation

The ThermoFlo handpiece can be easily raised or lowered

using either of the Height Adjustment Knobs.

To provide repeatable clearance of an attached nozzle

assembly relative the the surface of PCB assembly (Nozzleto-PCB clearance), do the following:

1. Loosen the Locking Knob. The Clearance

Limiter Assembly will now fall down against the

Stop.

2. Lower the handpiece to the desired distance of

Nozzle-to-PCB clearance using the Height

Adjustment Knobs.

3. Ensure contact between the Clearance Limiter

Assembly and the Stop. Tighten the Clearance

Limiter Locking Knob to secure the Clearance

Limiter Assembly in position on the Vertical

Slide.

ThermoFlo Handpiece

9

Page 14

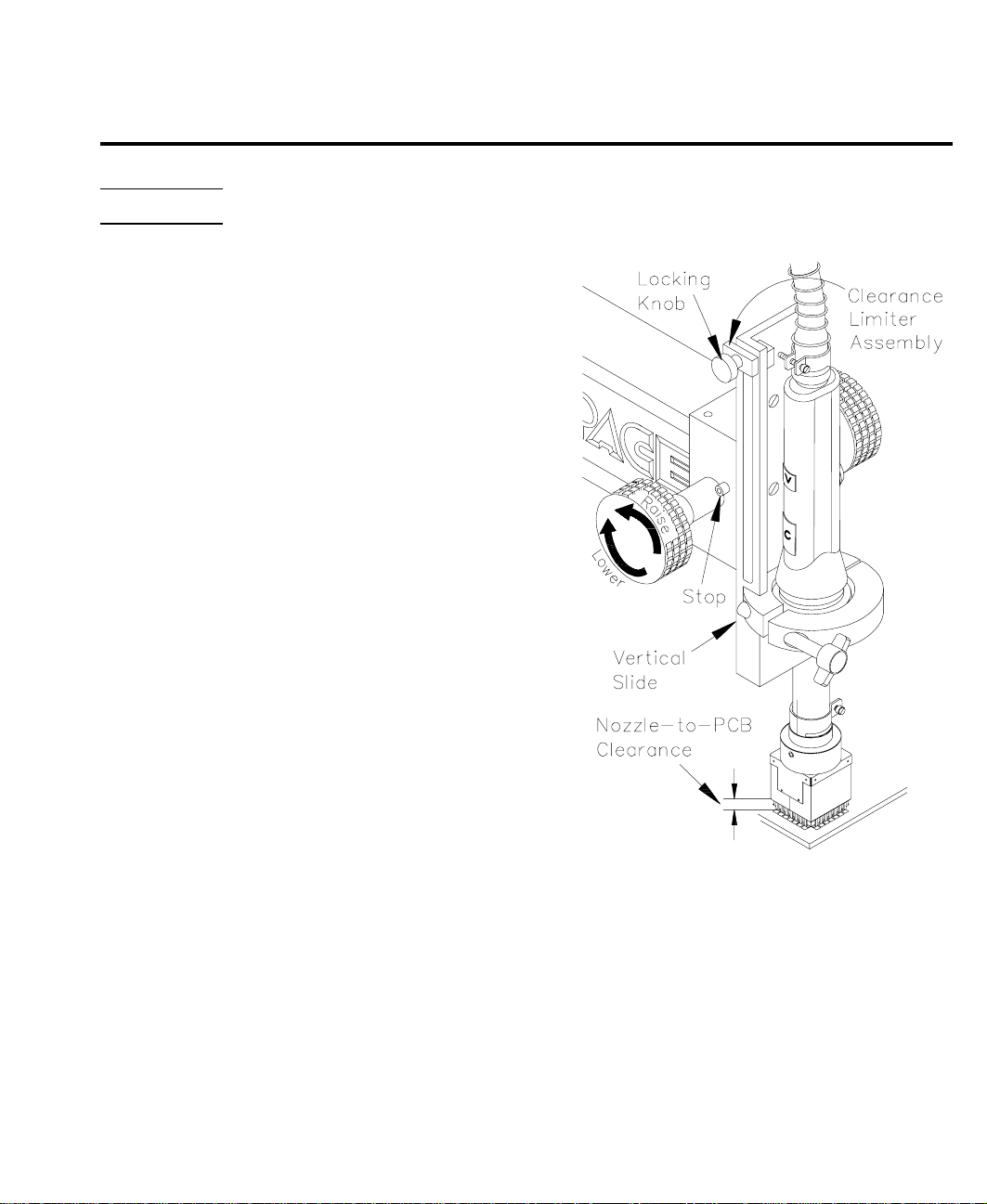

Standard Board Holder

Installation

This accessory (part number 6018-0098) is provided with each TF 500 ThermoFlo System. You can use this

accessory to hold your PCB (up to 20.3 cm X 20.3 cm (8" X 8") size) assemblies in position for rework. If you are

using a Heat Wave Preheating System, it is not necessary to assemble this accessory; use the board holder on the Heat

Wave.

Use the following instructions and accompanying illustrations as a guide to assemble the standard Board Holder.

1. Place the Base (item ´) upside down on a work surface and install the 4 Rubber Feet (item É) using

the 4 Mounting Screws (item

2. Turn the Base over and position as shown.

3. Mount the Large Bracket (item ¬) to the left side of the Base (item °) using 2 Mounting Screws (item ).

There are mounting holes at 2 different heights on each of the supplied

brackets. Use the holes which provide the correct height f or use with your

PCB assemblies.

11 ).

NOTE

4. Place the Long Holding Clamp (item ¯) in position on the Large Bracket (item ¬). Secure clamp in

position using a Locking Screw (item ®) and Flat Washer (item ³).

5. Install the Leveling Screw (item ²) Adjust Leveling Screw until its end just touches the bottom of the

Long Holding Clamp (item ¯).

6. Mount the Small Bracket (item °) to the right side of the Base (item ´) using 2 Mounting Screws

(item ).

7. Place the Short Holding Clamp (item ±) in position on the Small Bracket (item °). Secure the clamp

in position using the Locking Screw (item ®) with Flat Washer (item ³).

Operation

To install a PCB assembly, simply adjust the holding clamps as necessary, place the PCB in the “V” grooves on

the clamps and tighten the Locking Screws to secure in position.

Position the Board Holder with the component rework area directly beneath the ThermoFlo handpiece.

Move the PCB or Board Holder as necessary for proper component-to-nozzle alignment.

10

Page 15

Standard Board Holder

11

Page 16

Heat Wave Interface

Installation

An interface cable must be installed when using the HS 200 Heat Wave system with the ThermoFlo. If an

Advanced Placement Platform has been purchased, an adapter plate must be installed on the bottom of the Heat

Wave heater unit to allow mounting onto the Fine Adjustment Table.

1. The Heat Wave Interface Cable (part number

1332-0187) connects the ThermoFlo Unit to the

Heat Wave power source to provide on/off

control of the pump assembly in the Heat Wave.

Connect the cable between the Heat Wave

connector on the rear panel of the ThermoFlo

Unit and the like connector on the rear panel of

the Heat Wave power source.

2. If you have purchased a Fine Adjustment Work Platform, install the enclosed Adapter Plate onto the

bottom of the Heat Wave Heater Unit using the 4 mounting screws supplied with the plate. Place the

Heat Wave Heater Unit on Fine Ajustment Table, inserting the 4 pins on the Adapter Plate into the 4

pin holes on the table. Refer to illustrations.

Operation

The Heat Wave Preheating System can be used at any time in conjunction with the ThermoFlo but the Heat Wave

motor pump is controlled by the ThermoFlo unit in the Program Mode only. The stored parameters of the Profile

in use will control activation of the motor pump. The temperature of the Heat Wave is not set or controlled by the

ThermoFlo. The temperature must always be set on the Heat Wave power source.

12

Page 17

Fiber Optic Lighting Attachment

Installation

Use the following instructions and accompanying illustrations as

a guide to assemble the Fiber Optic Lighting Attachment.

1. Orient the Light Bracket as shown on the Support

Arm.

2. Install the 2 enclosed Mounting Screws to secure

the Light Bracket in position on the Support Arm.

3. Place the Light Power Supply in position on the

Light Bracket. The 4 rubber feet on the bottom of

the power supply fit in the punched holes at the

corners of the bracket.

4. Install the Goose Neck Assembly onto the Light

Power Supply as shown. Secure in position with

the Locking Screw .

5. Plug the female end of the enclosed power cord

into the power receptacle on the rear panel of the

Light Power Source.

6. Plug the male end of the power cord into the house

AC supply .

Operation

1. Turn the power switch(on Light Power Supply

front panel) to the On position.

2. Position both necks of the Goose Neck Assembly

for best application of light to the workpiece.

3. Adjust the light intensity control knob (on Light

Power Supply front panel) for best light

brightness.

Replacement Lamp (Light Power Supply) - PACE Part

Number 1165-0027

For complete information on operation, servicing and

replacement parts of the VL405 Light Power Supply,

refer to the enclosed Operation Manual.

13

Page 18

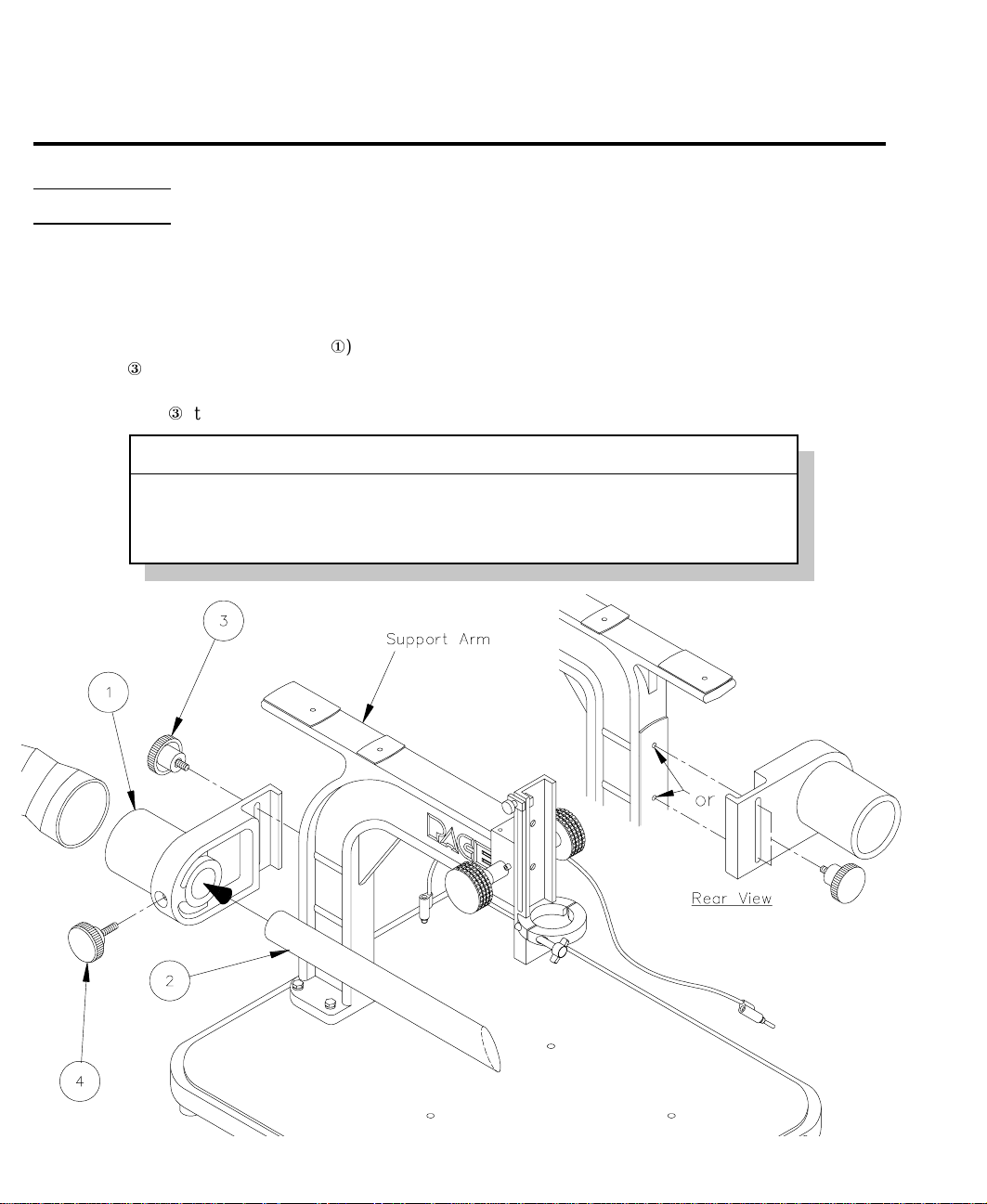

Fume Extraction Ready Attachment

Installation

This Kit (part number 6018-0105) allows the user to easily connect a 7.6mm (3 inch) fume extraction hose to the

Work Platform. Use the following instructions and accompanying illustrations as a guide to assemble the Fume

Extraction Ready Attachment.

1. Install the Hose Connector (item ¬) onto the Support Arm as shown. Install the Height Locking Knob

(item ®, the shortest of the 2 knobs supplied) through the slot in the Hose Connector and into either of

the 2 mounting holes in the Support Arm (see Rear View on illustration). Tighten the Height Locking

Knob(item ®) to secure the Hose Connector in position.

NOTE

The 2 mounting holes offer the user a wide range of height adjustment. For

lower height adjustments, use the low er mounting hole; f or greater height

requirements, use the upper mounting hole.

14

Page 19

Fume Extraction Ready Attachment

2. Install the Tube Locking Knob (item ¯) loosely into its mounting hole.

3. Slide the straight end of the Tube (item ) into its mounting hole on the Hose Connector.

4. Adjust the Tube (item ) in position where the straight end is flush with the rear of the Hose

Connector (item ¬) and the angled end is vertical to the Work Platform.

5. Tighten the Tube Locking Knob (item ¯) to secure the Tube (item ) in position.

6. Connect a 7.6mm (3 inch) diameter, flexible air hose (not supplied) between the Hose Connector (item

¬

) and your fume extraction system.

Operation

1. Place a PCB assembly

(mounted on board holder,

fine adjustment table or

Heat Wave) in position on

the work platform.

2. Adjust the position of the

Tube with its angled end

aligned next to and facing

the PCB.

3. Position the height of the

Tube slightly above the

PCB by adjusting the height

of the Hose Connector.

4. Reposition the Tube as

necessary during rework

operations to provide

optimal fume extraction.

15

Page 20

Vision Systems

Introduction

The following procedures detail the steps required to install and operate any of the ThermoFlo vision accessories.

The Precision Swivel is supplied with each vision system purchased. Install the Precision Swivel and then install

your Lens Vision or Camera Vision Attachment using the applicable procedure.

Precision Swivel

Installation

Installation of this accessory is required before installing a Lens Vision or Camera Vision Attachment. . Use the

following instructions and accompanying illustrations as a guide to install the Precision Swivel.

1. The Precision Swivel is supplied with its 2 Mounting Screws secured with 2 hex nuts to hold the

Spacer in place during shipment. Remove the 2 hex nuts and hold the Spacer, Precision Swivel and

Mounting Screws together.

2. Ensure that the Support Bracket is positioned as shown, opposite (180° from) the Mounting Screws. If

not, turn the Precision Swivel to place the Support Bracket in the proper position.

3. Place the Precision Swivel (with Spacer) in position on the Vertical Slide as shown with the 2

Mounting Screws aligned with the 2 mounting holes on the Vertical Slide.

4. Insert the 2 Mounting Screws into the 2 mounting holes on the Vertical Slide. Tighten the screws to

secure the Precision Swivel on the Vertical Slide.

5. Move the Vertical Slide up and down through its full range of travel to ensurefree movement. If the

Clearance Limiter Assembly Locking Knob hits the Precision Swivel, loosen the 2 Mounting Screws

and align the Precision Swivel to clear the Locking Knob. Tighten Mounting Screws to secure in

position.

16

Page 21

Vision Systems

Operation

The Precision Swivel allows the Support Bracket (with attached Vision accessory) to be rotated 180° around the

work. Spring detents at 0°, 90° and 180° provide quick reference stops.

To position the attached Vision accessory, simply grasp the Support Bracket or accessory and move left or right

(in an arc) as desired.

17

Page 22

Vision Systems

Lens Vision Attachment

Installation

Use the following instructions and accompanying illustrations as a guide to install the Lens Vision Attachment,

part number 6018-0104.

1. Remove the Clamp Screw from the end of the Support Shaft Assembly.

2. Hold the Support Shaft Assembly as shown with the flat portion of the rod on the right side. Insert the

rod end of the Support Shaft Assembly up through the hole in the Pivot.

3. Tighten the Shaft Locking Knob to secure the Support Shaft Assembly in position.

4. Install the Clamp Screw (removed in step 3) onto the end of the Shaft Support Assembly.

5. Position the Lens Bracket on the Support Shaft Assembly as shown with the holes in the bracket

aligned with the mounting holes in the Support Shaft Assembly.

6. Secure the Lens Bracket to the Support Shaft Assembly as shown using the 2 Mounting Screws.

7. Place the Lens in position on the Lens Bracket in the following manner.

a) Position the Lens as shown with the Lens directly beneath the Lens Bracket.

NOTE

T o ease installation of the Lens, you ma y wish to loosen the Shaft Locking

Knob, raise the Support Shaft Assembly (with attached Lens Brack et) and

secure in position by tightening the Shaft Locking Knob.

b) Place one of the rotation knobs (on ends of the Lens) into one of the Rotation Cylinders on the

Lens Bracket.

c) Gently pull the second Rotation Cylinder out slightly and place the second Lens rotation knob in

the free cylinder.

d) Release the Lens Bracket. The bracket will now spring back together to hold the Lens in position.

18

Page 23

Vision Systems

Operation

Adjust the Lens to the best height , distance and angle for best viewing using the following guidelines.

Height - To adjust height, loosen the Shaft Locking Knob. Raise or lower Lens and lock in position

by tightening the Shaft Locking Knob.

Distance - To adjust distance, loosen the Pivot Locking Knob. Move the Lens in or out and lock in

position by tightening the Pivot Locking Knob.

Angle - To adjust angle, simply move the angle of the Lens in the Lens Bracket for best viewing.

19

Page 24

Vision Systems

Camera Vision Attachment

Installation

Use the following instructions and accompanying illustrations as a guide to install the Camera Vision Attachment,

part number 6018-0102 (NTSC) or 6018-0103 (PAL).

1. Position the Camera Mounting Bracket on the Camera as shown. Secure in position using the 2 hex

head Mounting Bolts and Lockwashers.

2. Screw the Camera Lens onto the Camera.

3. Remove the Clamp Screw from the end of the Support Shaft Assembly.

4. Hold the Support Shaft Assembly with the flat portion of the rod on the right side. Insert the rod end

of the Support Shaft Assembly up through the hole in the Pivot.

5. Tighten the Shaft Locking Knob to secure the Support Shaft Assembly in position.

6. Position the Camera (with Camera Mounting Bracket) on the Support Shaft Assembly as shown with the

holes in the Camera Mounting Bracket aligned with the mounting holes in the Support Shaft Assembly.

7. Insert the 2 enclosed Mounting Screws through the Camera Mounting Bracket and into the mounting

holes on the Support Shaft Assembly. Tighten the screws to secure the Camera in position.

8. Plug one end of your Video Cable (RG59/U type - not supplied by PACE) into the video connector at

the rear of the Camera.

9. Plug the free end of the Video Cable into your video monitor (75 ohm input). PACE does not provide

a monitor.

NOTE

A Camera Po wer Supply is provided with the NTSC system (part number

6018-0102); a supply is not provided with the PAL version (par t number

6018-0103). When purchasing a Camera Power Supply f or a P AL version,

it must comply with the following requirements:

12 V DC Output, 500ma. Current Rating

Cable terminates with Mini-Plug, 5.5mm O.D., 2.1mm I.D., Center Positive

10. Plug the Camera Power Supply cable mini-plug into the power connector at the rear of the Camera.

11. Wrap the supplied length of plastic Spiral Wrap around both the Video and Camera Power Supply

Cables. Begin at a point approximately 10.2cm (4 inches) from the Camera connections.

12. Place the Clamp over the cables & Spiral Wrap as shown.

13. Install the Clamp Screw (removed in step 3) through the Clamp and into the end of the Shaft Support

Assembly. Do not tighten the screw.

14. Adjust the cables and Spiral Wrap for best use. Rotate the Camera around the Precision Swivel to

ensure that dress of cables allows free movement. Tighten Clamp Screw to secure cables in position.

20

Page 25

Vision Systems

Operation

Adjust the Camera for your application using the following guidelines.

Height - To adjust height, loosen the Shaft Locking Knob. Raise or lower Camera and lock in

position by tightening the Shaft Locking Knob.

Distance - To adjust distance, loosen the Pivot Locking Knob. Move the Camera in or out and lock in

position by tightening the Pivot Locking Knob.

Angle - To adjust angle, simply move the Camera in an arc around the Precision Swivel.

Focus - The Camera has a built-in automatic focus control.

Lens - A Zoom control is located at the end of the Lens and an Aperture control is located closest

to the Camera body. Adjust these controls as necessary for best viewing.

21

Page 26

Packing Lists

The following tables list the items shipped with each ThermoFlo system and optional accessory. The

Thermocouple Meter and Large Board Holder are shipped with separate instructions and are not listed in

the tables. All items listed with a part number are items which can be ordered through your local,

authorized PACE distributor.

Systems

TF 200 PACKING LIST

Item

No.

Description Part Number

1 ThermoFlo Unit (115 VAC) - - - - - 1 - - - - 2 ThermoFlo Unit (230 VAC) - - - - - - - - - - 1

3 ThermoFlo Cubby Kit - - - - - 1 1

4 Hose Retention Kit - - - - - 1 1

5 Angle Bracket Kit 6018-0097-P1 1 1

6 Nozzle Removal Rubber Pad 1100-0303 1 1

Detachable Power Cord, 115 VAC

7

Systems

Detachable Power Cord, 230 VAC

8

Systems

9 Vacuum Cup Kit 6993-0196-P1 1 1

1332-0094 1 - - - - -

1332-0093 - - - - - 1

-

Quantity Supplied

115 VAC

Systems

Table 1. TF 200 Packing List

230 VAC

Systems

22

Page 27

Packing Lists

TF 500 PACKING LIST

Item

Description Part Number

No.

1 ThermoFlo Unit (115 VAC) - - - - - 1 - - - - 2 ThermoFlo Unit (230 VAC) - - - - - - - - - - 1

3 ThermoFlo System Work Platform 6018-0099 1 1

4

5

6

7

8

9

10

11

12

13

14

15 ThermoFlo Cubby Kit - - - - - 1 1

16 Hose Retention Kit - - - - - 1 1

17 Angle Bracket Kit 6018-0097-P1 1 1

18 Nozzle Removal Rubber Pad 1100-0303 1 1

19 Detachable Power Cord, 115 VAC Systems 1332-0094 1 - - - - 20 Detachable Power Cord, 230 VAC Systems 1332-0093 - - - - - 1

21 Vacuum Cup Kit 6993-0196-P1 1 1

22 Nozzle Adapter Assembly 4028-0001 1 1

Vertical Slide Assembly (w/Support

Arm)

Board Holder Assembly

Platform Accessory Kit

Base Plate

Swivel Ring

Patch Cord (ground cable)

Interface Cable Assembly

Nozzle/Chip Tool Assembly

Mounting Hardware

Rubber Feet

ThermoFlo Accessories Manual

- - - - - 1 1

- - - - - 1 1

- - - - - 1 1

- - - - - 1 1

1321-0320 1 1

- - - - - 1 1

- - - - - 1 1

1100-0231 1 1

- - - - - - - - - - - - - - -

- - - - - 4 4

5050-0421 1 1

Quantity Supplied

115 VAC

Systems

230 VAC

Systems

Table 2. TF 500 Packing List

23

Page 28

Packing Lists

TF 700 PACKING LIST

Item

No.

Description Part Number

1 ThermoFlo Unit (115VAC) - - - - - 1 - - - - 2 ThermoFlo Unit (230VAC) - - - - - - - - - - 1

3 ThermoFlo Advanced Placement Platform - - - - - 1 1

4

5

6

7

8

9

10

11

12

13

14

15

16

17 ThermoFlo Cubby Kit - - - - - 1 1

18 Hose Retention Kit - - - - - 1 1

19 Angle Bracket Kit 6018-0097-P1 1 1

20 Nozzle Removal Rubber Pad 1100-0203 1 1

21 Detachable Power Cord, 115 VAC Systems 1332-0094 1 - - 22 Detachable Power Cord, 230 VAC Systems 1332-0093 - - - 1

23 Vacuum Cup Kit 6993-0196-P1 1 1

24 Nozzle Adapter Assembly 4028-0001 1 1

Vertical Slide Assembly (w/Support

Arm)

Fine Adjustment Table

Platform Accessory Kit

Base Plate

Spacer

Swivel Ring

Patch Cord (ground cable)

Mounting Plate, Heater Unit

Interface Cable Assembly

Nozzle/Chip Tool Assembly

Mounting Hardware

Rubber Feet

ThermoFlo Accessories Manual

- - - - - 1 1

- - - - - 1 1

- - - - - 1 1

- - - - - 1 1

- - - - - 1 1

1321-0320 1 1

- - - - - 1 1

- - - - - 1 1

- - - - - 1 1

1100-0231 1 1

- - - - - - - - - - - - - - -

- - - - - 4 4

5050-0421 1 1

Quantity Supplied

115 VAC

Systems

230 VAC

Systems

24

Table 3. TF 700 Packing List

Page 29

Packing Lists

PRC 1500 PACKING LIST

Item

No.

Description Part Number

1 ThermoFlo Unit (115 VAC) - - - - - 1 - - - - 2 ThermoFlo Unit (230 VAC) - - - - - - - - - - 1

3 MBT 250A System, Complete (115 VAC) 8007-0206 1 - - - - 4 MBT 250AE System, Complete (230 VAC) 8007-0207 - - - - - 1

5 ThermoFlo Cubby Kit - - - - - 1 1

6 Hose Retention Kit - - - - - 1 1

7 Angle Bracket Kit 6018-0097-P1 2 2

8 Power Source Interlock Kit 6993-0141-P1 1 1

9 Nozzle Removal Rubber Pad 1100-0303 1 1

10 Detachable Power Cord, 115 VAC Systems 1332-0094 1 - - - - 11 Detachable Power Cord, 230 VAC Systems 1332-0093 - - - - - 1

12 Vacuum Cup Kit 6993-0196-P1 1 1

13 Nozzle Adapter Assembly 4028-0001 1 1

14 Operation & Maintenance Manual 5050-0420 1 1

Quantity Supplied

115 VAC

Systems

230 VAC

Systems

Table 4. PRC 1500 Packing List

25

Page 30

Packing Lists

Optional Accessories

FUME EXTRACTION "READY" ATTACHMENT

Item

Description Part Number

No.

1 Fume Extraction "Ready" Attachment 6018-0105 1

2

3

4

5

6

Table 5. Fume Extraction "Ready" Attachment Packing List

Item

No.

1 Lens Vision Attachment 6018-0104 1

2

3

4

5

6

7

8

9

10

11

Hose Connector

Knob, 5/16-18 x .50" Lg.

Knob, 5/16-18 x 1.0" Lg.

Tube

ThermoFlo Accessories Manual

Description Part Number

Lens Bracket Assembly

Precision Swivel Attachment

Support Shaft Assembly

Magnifying Lens

Screw, 6-32 x .25" Lg.

ThermoFlo Accessories Manual

PACKING LIST

- - - - - 1

- - - - - 1

- - - - - 1

- - - - - 1

5050-0421 1

LENS VISION ATTACHMENT

PACKING LIST

Precision Swivel

Spacer

Mounting Screw, 6-32 x 1.75" Lg.

Hex Nuts, 10/32

Quantity

Supplied

Quantity

Supplied

- - - - - 1

- - - - - 1

- - - - - 1

- - - - - 1

- - - - - 2

- - - - - 2

- - - - - 1

- - - - - 1

- - - - - 2

5050-0421 1

26

Table 6. Lens Vision Attachment Packing List

Page 31

Packing Lists

CAMERA VISION ATTACHMENT

PACKING LIST

Item

No.

Description Part Number

1 Camera Vision Attachment (115 VAC) 6018-0102 1 - - - - 2 Camera Attachment (230 VAC) 6018-0103 - - - - - 1

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Precision Swivel Attachment

Precision Swivel

Spacer

Mounting Screw, 6-32 x 1.75"

Lg.

Hex Nut, 6-32

Support Shaft Assembly

Camera Vision Kit

Camera, NTSC

Camera, PAL

Zoom Lens

Camera Power Supply (115

VAC)

Camera Mounting Bracket

Screw, M6 x 6mm Lg.

Screw, 6-32 x .25" Lg.

Spiral Wrap, 6 ft. Lg.

- - - - - 1 1

- - - - - 1 1

- - - - - 1 1

- - - - - 2 2

- - - - - 2 2

- - - - - 1 1

- - - - - 1 1

- - - - - 1 - - - - -

- - - - - - - - - - 1

- - - - - 2 2

- - - - - 1 1

- - - - - 2 2

- - - - - 2 2

- - - - - 1 1

-----

Table 7. Camera Vision Attachment Packing List

Quantity Supplied

115 VAC

Systems

1 - - - - -

230 VAC

Systems

FIBER OPTIC LIGHTING ATTACHMENT

PACKING LIST

Item

No.

Description Part Number

Fiber Optic Lighting Attachment (115

1

VAC)

Fiber Optic Lighting Attachment (230

2

VAC)

3

4

5

6

Light Power Supply (115 VAC)

Light Power Supply (230 VAC)

Goose Neck Assembly

Light Bracket

-

"

6018-0100 1 - - - - -

6018-0101 - - - - - 1

- - - - - 1 - - - - -

- - - - - - - - - - 1

- - - - - 1 1

- - - - - 1 1

-----

Table 8. Fiber Optic Lighting Attachment Packing List

Quantity Supplied

115 VAC

Systems

230 VAC

Systems

27

Loading...

Loading...