Page 1

Flo Pump Assembly

(for PACE ThermoFlo power sources)

P/N 1336-0035-P1

Installation Instructions

Manual Number 5050-0433

Rev . A

For any questions regarding these instructions, contact the PACE Service

Department directly at:

Telephone (888) 535-PACE, Fax (301) 483-7030

P ACE Incorporated

9893 Brewers Court

Laurel MD 20723-1990

1

Page 2

To replace the Flo Pump Assembly, perform the following procedure step by step,

in sequence using the accompanying illustrations as a guide.

CAUTION

POTENTIAL SHOCK HAZARD - Disassembly of the ThermoFlo power

source exposes line voltage parts. Replacement of the Flo Pump Assembly

must be performed by qualified service personnel only . Service personnel

must insure that the AC power cord is disconnected prior to disassembly.

Contact the PACE Service Department for assistance at tel. 1-888-535PACE, FAX 1-301-483-7030.

1. Place the unit on a suitable work surface with the front of the power

source facing forward.

2. Disconnect the AC power cable from the unit (if present).

NOTE

Use all ESD control precautions when servicing the PACE ThermoFlo

system. The power source contains assemblies utilizing static sensitiv e

components.

3. Remove the 10 Front Panel mounting screws.

4. Pull the Front Panel forward.

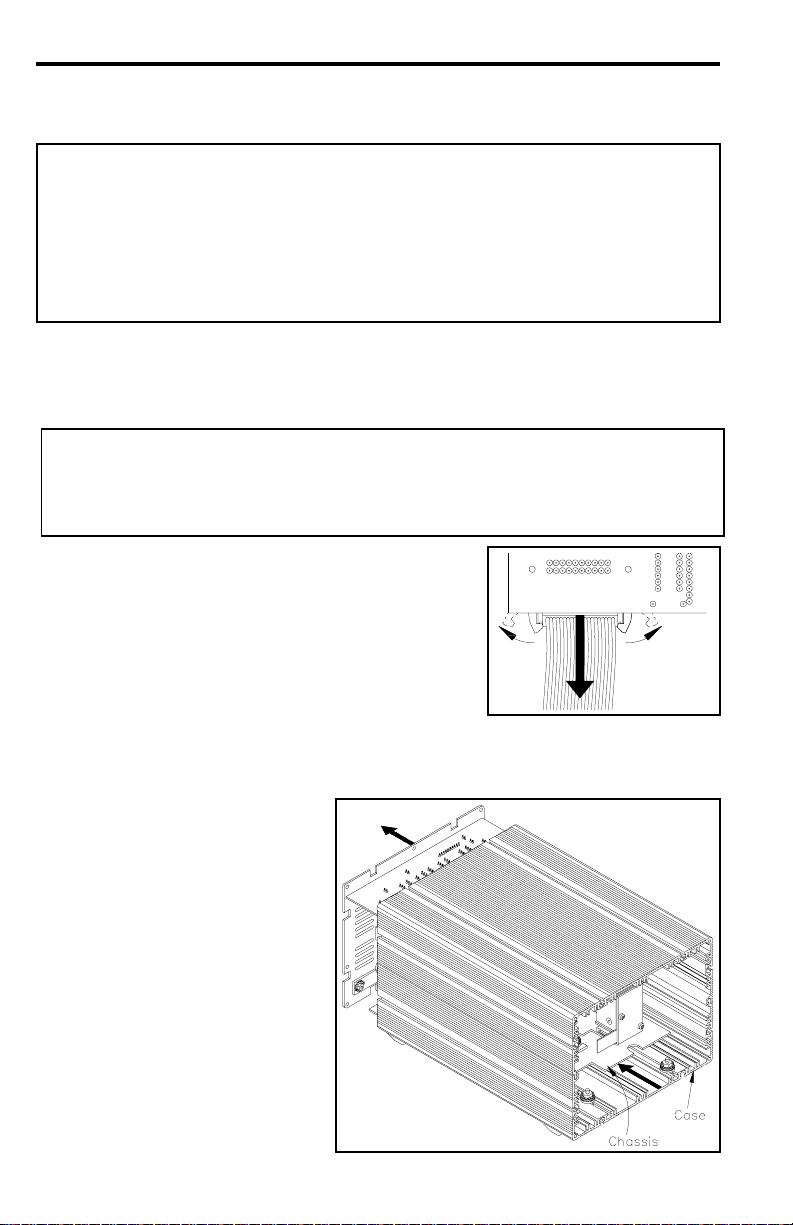

5. Disconnect the ribbon cable from the Front

Panel by pulling the 2 plastic locking tabs

away from the ribbon cable (see illustration)

then pulling the ribbon cable out of the Front

Panel connector. Set the Front Panel aside.

6. Reposition the unit with the rear of the power source facing forward.

7. Remove the 8 Rear Panel

mounting screws.

8. Gently pull the Rear Panel

away from the power

source. Attached to the

Rear Panel are the main

PCB and the Inner Chassis.

Pull these parts completely

out of the power source

case. Set the power source

Case aside.

2

Page 3

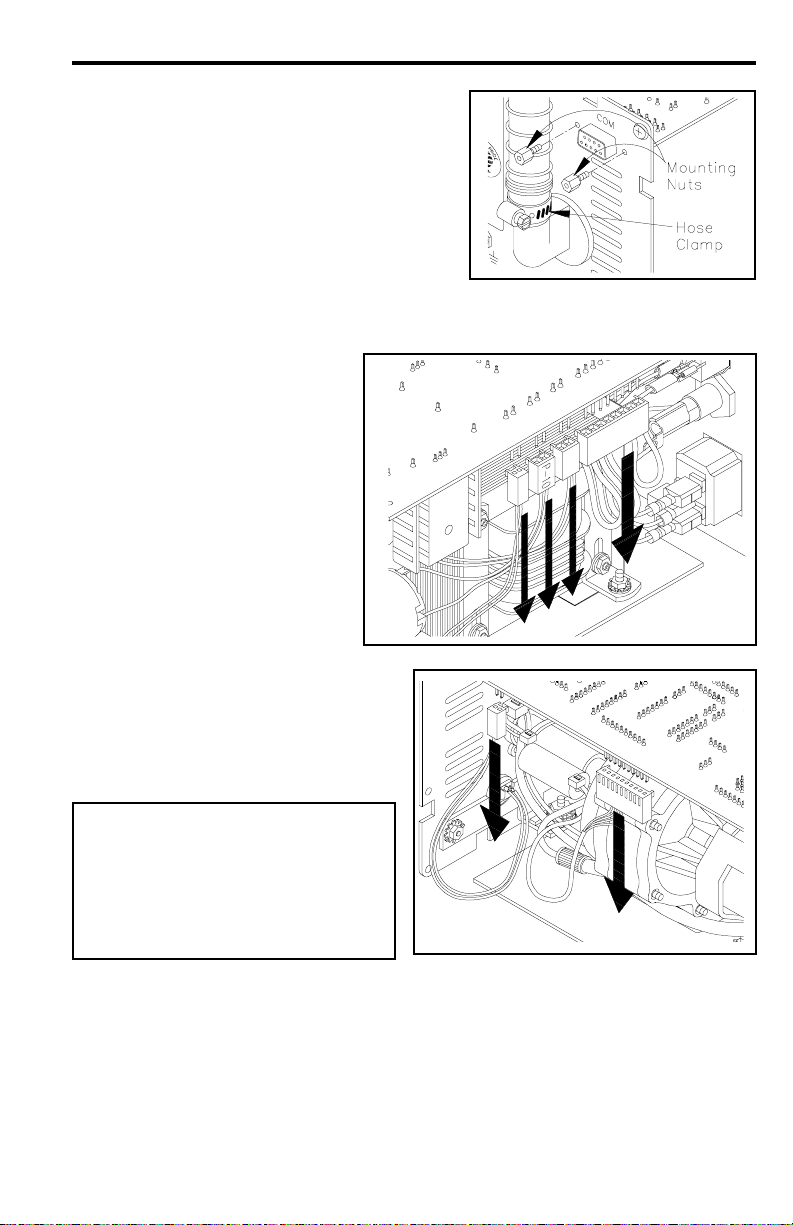

9. The COM Port is located on the upper

right portion of the Rear Panel.

Remove the two (2) Mounting Nuts

located on either side of the COM Port.

10. Position the Chassis as shown with the Flo Pump Assembly facing

forward.

11. Disconnect the four (4)

connectors shown from the

Main PCB. Make note of

the location of each

connector (the Flo Pump

harness plug should be

marked "P10").

12. Disconnect two (2)

connectors shown from the

Main PCB.

CAUTION

The larger of these two

connectors has very fine wires

attached. Handle this connector

with care to prevent any

damage to these wires.

13. Pull the Main PCB forward to release pins on PCB plug from the

connector on the HV Board. Set Main PCB aside.

3

Page 4

14. Remove the three (3) Hex Nuts and Washers from the Flo Pump

Assembly.

15. Make a note of the location of the Vacuum Hose attached to the Flo

Pump Assembly. Remove the Vacuum Hose by gently pulling and

twisting the hose.

16. Pull the Flo Pump Assembly up and off of its three (3) mounting studs.

17. There are three (3) Blue grommets (with metal sleeves) on the Flo Pump

Assembly mounting bracket. Remove each of the grommets and install

in position on the replacement Flo Pump Assembly. Set the old Flo

Pump Assembly aside.

18. Push the Flo Pump Assembly down, sliding the three (3) Blue grommets

(with metal sleeves) over the three (3) mounting studs on the Chassis

plate.

NOTE

Insure that wires are not trapped under the Flo Pump Assembly mounting

bracket.

4

Page 5

19. Install the Vacuum Hose removed in step 15 onto the Flo Pump

Assembly mounting bracket.

NOTE

Insure that the small Vacuum Air Hose is installed in the proper location

(at port marked with arrow pointed in) on the Flo Pump.

20. The Vacuum Air Hose is routed between the Flo Pump Assembly and the

Rear Panel. Check to insure that there are no kinks in this length of

hose or in the smaller air hose it connects to near the Rear Panel..

21. Secure the Flo Pump Assembly in position by installing the three (3)

Hex Nuts and Washers removed in step 14.

22. Position the Main PCB as shown over

the Chassis and with the ribbon cable

facing forward.

23. Align the COM Port receptacle at the

rear of the Main PCB with its rear panel

cutout

24. There is a ten (10) pin plug mounted at

the rear of the Main PCB. Carefully

insert these pins into the matching 10

pin connector on the HV Board.

NOTE

Insure that the plug pins are lined up correctly with the connector

receptacle. The system will not operate if this connection is incorrect.

25. Install the two (2) Mounting Nuts

removed in step 9 on either side of

the COM Port.

5

Page 6

26. Install the 6 connectors

removed in steps 11 &

12. Insure that each

connector is pushed

fully onto its PCB

connection. Insure that

the connector marked

"P10" is plugged into

the proper location.

Refer to illustration

27. Slide the Chassis into the rear of the Case with the Main PCB entering

the Case as shown in the illustration below. Located at the front, inside

of the Case are two (2) mounting studs with Blue grommets. The two

(2) slots at the front of the chassis plate must slide into the slots in the

two (2) Blue grommets.

NOTE

Wire harnesses are located along the edges of the Chassis. Insure that

these wires do not get caught or pinched against the edges of the Case

or the rear panel as the Chassis slides in.

VIEWED FROM REAR

28. Install the 8 Rear Panel mounting screws removed in step 7.

29. Position the power source facing forward.

30. Connect the ribbon cable (removed in step 5) to the Front Panel

Connector; the two (2) plastic locking tabs will automatically lock the

cable in position when it is fully seated in the connector.

31. Install the 10 Front Panel mounting screws removed in step 3.

6

VIEWED FROM FRONT

Page 7

PACE Incorporated retains the right to make changes to specifications contained

herein at any time, without notice.

Contact your local authorized PACE Distributor or PACE Incorporated to obtain the

latest specifications.

The following are registered trademarks and/or servicemarks of PACE

Incorporated, Laurel Maryland U.S.A. and may only be used to identify genuine

PACE products or services:

AdapTip, Arm-Evac, Cir-Kit, ComForm I, ConducTweez, CRAFT,

Dual Path, Flo-D-Sodr, FuseSet, HandiPik, HotSpot, LapFlo, MBT,

Micro Portable, MicroChine, MiniChine, Mini-Wave, PACE, Pacenter,

Ped-A-Vac, PETS, Pik-Vac, PRC, Prep-Set, Pro-Evac, Redi-Rak,

ResisTweez, SensaTemp, Snap-Vac, Sodr-Pen, Sodr-X-Tractor, SR-3,

SR-4, ST, StripTweez, SwaPlater, ThermoBond, Thermo-Drive, ThermoJet,

ThermoPart, ThermoPik, ThermoT weez, Tip-Evac,Ventur-Evac VisiFilter.

The following are trademarks and/or servicemarks of PACE Incorporated, Laurel

Maryland U.S.A. and may only be used to identify genuine PACE products or

services:

Heat Wave, Pik-Tip, Pulse Plate, Sodrtek, ThermoFlo, Toolnet.

Since 1958, PACE Incorporated has provided

advanced technology training in all aspects of hand

soldering, rework and repair.

Additional copies of this manual or other PACE literature may be obtained from:

PACE Incorporated (301) 490 - 9860

Sales Administration (301) 498 - 3252 Fax

9893 Brewers Court

Laurel MD 20723-1990

© 1998 PACE Incorporated, Laurel MD. All rights reserved. Printed in the U.S.A.

7

Loading...

Loading...