Page 1

Operation and Maintenance Manual for

the TF 3000 BGA/CSP Rework System

MANUAL NO. 5050- 0482

REV B-PRM

www.paceworldwide.com Rev A-PRM Page 1 of 5151

Page 2

TABLE OF CONTENTS

Safety ....................................................................................................................................3

Introduction ............................................................................................................................4

Packing Contents ...................................................................................................................4

Parts Identification..................................................................................................................5

Set-Up...................................................................................................................................7

Operation ...............................................................................................................................7

Before Operating.............................................................................................................7

General Operating Procedure...........................................................................................8

Explanation of Each Operation .............................................................................................11

Placing PCB into Board Holder .......................................................................................11

Component Alignment and Placement ............................................................................11

Component Reflow ........................................................................................................12

Adjusting Airflow ............................................................................................................13

Component Removal .....................................................................................................13

Creating and Saving Profiles ................................................................................................. 14

TF3000 PC Software ............................................................................................................ 16

Setup Page...................................................................................................................17

Alignment Page .............................................................................................................19

Operation Page .............................................................................................................21

Profile Development Page..............................................................................................23

Profile Creation ........................................................................................................26

Inspection Page.............................................................................................................28

Print/Review Page.........................................................................................................32

Language Editor................................................................................................................... 33

Maintenance......................................................................................................................... 34

Cleaning the Blower Filter ..............................................................................................34

Replacing the Top Heater ...............................................................................................34

Alignment and Calibration ..................................................................................................... 37

PCB to Optics................................................................................................................37

Sliding Shaft Holder (Indexing) .......................................................................................38

Vacuum Nozzle Planarity ...............................................................................................38

Reflow Head Planarity....................................................................................................39

Reflow Head – “Y” Directional Adjustment .......................................................................39

Specifications ....................................................................................................................... 41

Accessory Items................................................................................................................... 42

Service & Warranty Information 49

www.paceworldwide.com Rev A-PRM Page 2 of 5151

Page 3

Safety

The following safety precautions must be understood and followed when using or servicing

PACE products.

1. POTENTIAL SHOCK HAZARD - Repair procedures on PACE products should

be performed by Qualified Service Personnel only. Line voltage parts may be

exposed when the equipment is disassembled. Service personnel must avoid

contact with these parts when troubleshooting the product.

2. To prevent personnel injury, adhere to safety guidelines in accordance with

OSHA and other applicable safety standards.

3. Always use PACE systems in a well ventilated area. A fume extraction system,

such as those available from PACE, is highly recommended to help protect

personnel from exposure to solder flux fumes.

4. Exercise proper precautions when using chemicals (e.g., solder paste or cleaning

solvents). Refer to the Material Safety Data Sheet (MSDS) supplied with each

chemical and adhere to all safety precautions recommended by the

manufacturer.

5. The following safety precautions cover use of PACE hot air systems/hand pieces

(e.g., ThermoFlo®, ThermoJet®).

a) Be careful when using in places where combustible materials are

present.

b) Do not use in the presence of an explosive atmosphere.

c) A fire may arise if a hot air hand piece is not used with care. Do not

leave the hand piece unattended when in use.

d) The heater assembly housing and any installed nozzle are hot when the

system is being cycled and for a period of time thereafter. DO NOT

touch the heater assembly housing, nozzle or heated air stream. Severe

burns may result!

Warning Symbols on Unit

HOT – DO NOT TOUCH

Warning, Use caution

www.paceworldwide.com Rev A-PRM Page 3 of 5151

Page 4

Introduction:

Thank you for purchasing the TF 3000 BGA/CSP Rework Station. As electronic devices

continue to get smaller, lighter and more compact, components and printed circuit boards are

also becoming smaller and the amount of available space on PCBs is continually decreasing.

In order to maximize board space, area array devices have become the popular choice. Area

array devices are BGAs, CSPs and “micro -BGAs”, LGAs, and Flip Chips. These devices

require an optical overlay vision system to ensure proper placement and high levels of

process control during installation to ensure successful installation. The TF 3000 has been

specifically designed to rework these types of components and can also install and remove a

variety of other SMT devices.

Agency Compliance

This device complies with part 15 of the FCC rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference and (2) This device must

accept any interference received, including interference that may cause undesired operation.

The TF 3000 also complies with 98/37/EC and 89/336/EEC.

Caution: During normal operation, the top heater, nozzle and bottom-side

heater(s) will get hot. Do not contact them directly as serious injury

may occur.

Environmental Requirements

Ambient Operating Temperature: 0 ºC to 50 ºC (32 ºF to 120 ºF)

Storage Temperature: -20 ºC to 75 ºC (-4 ºF to 170 ºF)

95% Humidity, non-condensing max.

Electrical Specification

15 Amp 115 VAC, 60 Hz Max OR 8 Amp, 230 VAC, 50 Hz Max

Fuse: .5 Amp, SloBlo 115 V System

.5 Amp TimeBlo, 230 V System

Packing Contents

TF 3000

1. TF 3000/E or TF 3000 L/E: 1 each

2. LCD VGA Display Monitor: 1 each

3. TF 3000 Software Package: Installed on PC

4. Hand Held Vacuum Pick for removal: 1 each

5. Rubber suction cups (spare for #4): 3 each

6. Vacuum nozzle for placement head: 1 each Large, Medium, Small and

extra-small sizes

7. Hex Wrench Set and Screwdriver: 1 each

8. TF 3000 Manual: 1 each on PC as pdf file

9. NET-OP manual - 1 each on PC as pdf file

10. K-Type Thermocouple: 4 each

11. LED Extension wire

12. USB Track Ball

13. PCB Supports: 1 each

14. Odd shaped PCB holders: 4 each

www.paceworldwide.com Rev A-PRM Page 4 of 5151

Page 5

15. Alignment board and component: 1 each

16. Wooden shipping crate.

The wooden shipping crate must be kept by the end user. If a TF 3000 has to be returned

to PACE for any reason, it MUST be returned in the original shipping crate. PACE is not

responsible for any unit not returned in its original crate. If a TF 3000 is returned for

service in a different container, the customer will be charge for a new crate for return

shipment.

www.paceworldwide.com Rev A-PRM Page 5 of 5151

Page 6

J I C

G K M

HF

P D B N E A L

O

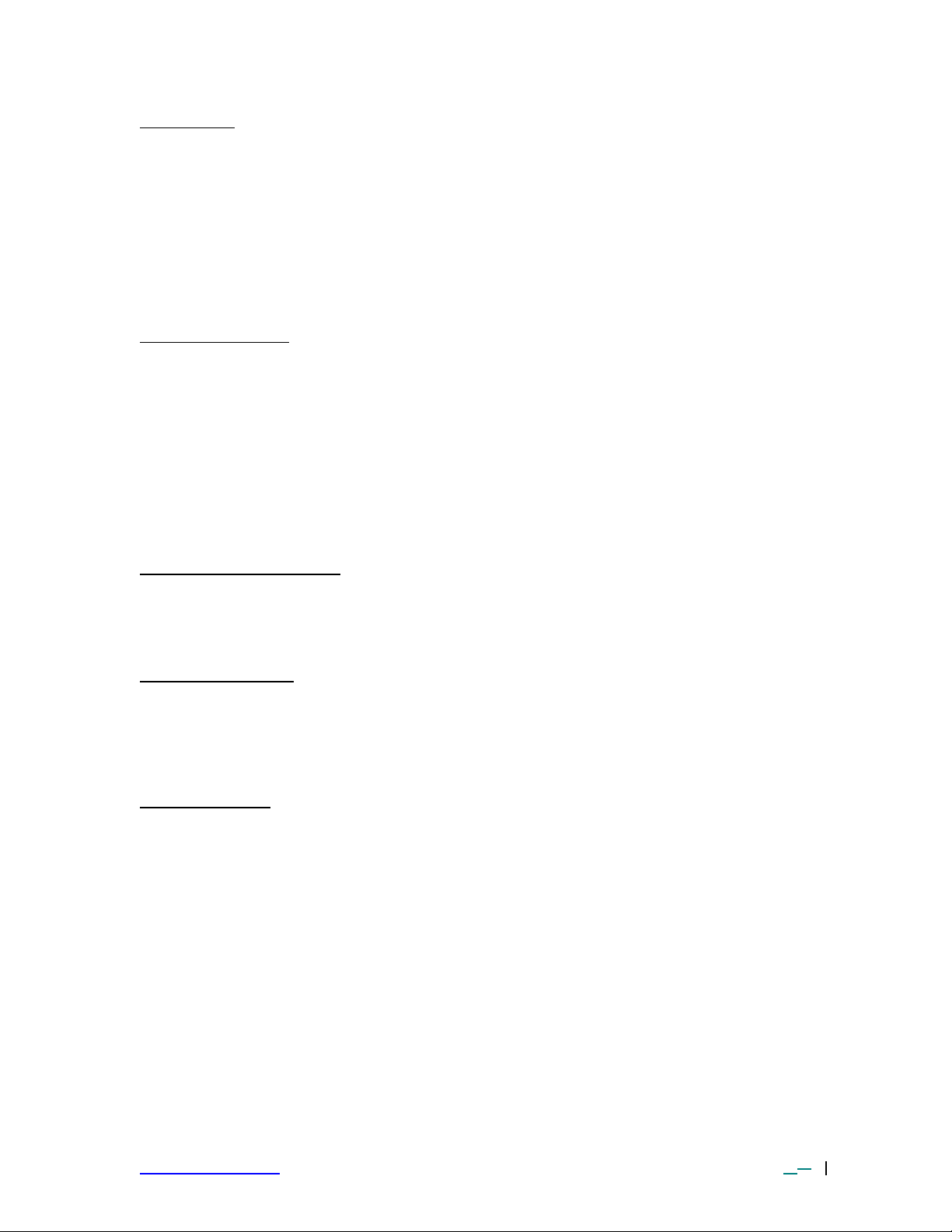

Parts Identification

Figure 1: TF 3000 BGA/CSP Rework Station

Features: Please refer to Figure 1.

A) Reflow Head Contains the top -side heater and moves up and down via an

electric motor that is controlled through the software. The

reflow head is clutched to prevent excessive downward force

from being applied.

B) Removal Nozzle Vacuum port to connect Nozzle Vacuum Hose for

Vacuum Port component removal

C) Air Flow Meter This device is used to control and monitor the airflow.

D) Sensor 1 thru 4 Inputs The sensor inputs are K-type thermo-couples. Measured

temperatures are displayed through the PC Software in real

time for use in making profile gr aphs.

E) Nozzle The nozzles for the TF 3000 are easily changed. Several

varieties are available. Use caution and proper hand

protection when changing nozzles, as they will be hot.

F) Cooling Fan The component and the PCB are cooled by the cooling fan,

which can be set to activate automatically after the reflow

cycle is complete.

www.paceworldwide.com Rev A-PRM Page 6 of 5151

Page 7

G) Sliding Shaft Holder Supports the rail system for the board holder. It is also used

to index the table from the Placement Position to the Reflow

Position using the handle on the front.

H) On/Off Switch Used to turn the system on or off. When turning off the

system, always turn off the PC using the windows interface

first.

I) LCD Display Monitor Displays PC software. Shown with optional articulated arm.

J) Alignment Head X, Y, Z and T aspects of the component position are

adjusted in relation to the land pattern on the PCB through

this apparatus.

K) Optics Housing Contains the camera and beam splitter (prism). The housing

is retractable and should be kept in the retracted position

when not in use. The lights for the optics will turn on/off

automatically when the housing is extended.

L) Light Controls The upper (component side) and lower (PCB side) lights

within the optics housing can be adjusted for intensity

(overlay contrast) at this location.

M) Board Holder The board holder is fully adjustable in both the X and Y

directions. The right side of the holder is spring loaded to

hold the PCB securely. Fine adjustment in the “X” direction

is achieved by using the adjustment knob on the Sliding

Shaft Holder and adjustment in the “Y” direction is achieved

using the knob on the right rail.

N) Bottom Side Heater Used to warm the PCB from the underside. It is an IR type

of heating source.

O) Magnetic Lock Release Disengages magnetic lock to release platform when moving

from Reflow position to Placement position and vice-versa.

P) Keyboard Tray Door The keyboard is stored behind this door. To access the

keyboard, open the door and pull the tray out .

www.paceworldwide.com Rev A-PRM Page 7 of 5151

Page 8

1 SET-UP

2A

TF 3000 Set up

1-1 Place the TF 3000/E or TF 3000 L/E on a flat and stable bench that can

1-2 The TF 3000 weighs 77 kg (170 lbs). To lift it, grasp the underside of the

1-3 Connect the hand -held vacuum pick to the vacuum port on the side of the TF

1-4 Connect the LCD display monitor to

1-5 Connect the TF 3000 and LCD Display Monitor power cables to the power

2 OPERATION

2-1 Before Operating

• Make sure the TF 3000 is on a stable platform

• It is recommended that the TF 3000 be turned on for at least 15 minutes before

• It is advisable to conduct a trial operation each day to ensure all systems are

support at least 90 kgs (200 lbs).

frame. The unit should be moved by two people minimum. Each person

should be capable of lifting 45 Kgs (100 lbs).

3000 and hang the vacuum pick on the side of the TF 3000 using the bracket

provided (2A).

the VGA output on the side of the TF

3000. See Figure 2.

2 1

1. Hand Wand Vacuum Switch

2. 3.5” Floppy Drive

2A Hand Wand Bracket

3. VGA Output – to connect the

VGA monitor

4. Composite Video Inputs – to

connect alternative video inputs

5. 9 pin Serial I/O – to connect a 9

pin serial device

6. Modem I/O – to connect to a

phone line

7. Printer Port – to connect to a

printer

8. USB I/O – to connect to USB

compatable devices such as the

track ball provided.

5

7

8

8

9

4 3

6

9. Hand Wand Vacuum

Connection – to connect the

hand wand.

Figure 2: Image of Side Panel

inlet ports and then plug them into an appropriate 115 VAC, 60 Hz or 230

VAC 50 Hz power supply. The LCD Monitor can be plugged into the AC

outlet on the back of the TF 3000. Do not pl ug any equipment requiring more

than 1 amp into this outlet.

use to ensure the Bottom Side heater has reached its set temperature and

stabilized. Once the bottom -side heater is at temperature it will deliver consistent

heating, ensuring highly repeatable heating from operation to operation.

operating properly. Also, it is important to verify the airflow of the unit with each

profile to be run: The recommended maximum airflow is 22 l/min and the

recommended minimum airflow is 15 l/min.

www.paceworldwide.com Rev A-PRM Page 8 of 5151

Page 9

• Verify that the devices/parts being soldered to the PCB do not exceed the height

limitations. Exceeding the limitations may interfere with the operation of the

machine.

1. The maximum height of any component or device on the top of the PCB

is limited to 30 mm (1.2”).

2. The maximum height of any component or device on the bottom of the

PCB is limited to 15 mm (0.6”).

2-2 General Operating Procedure

1. Ensure sliding shaft holder is the placement position.

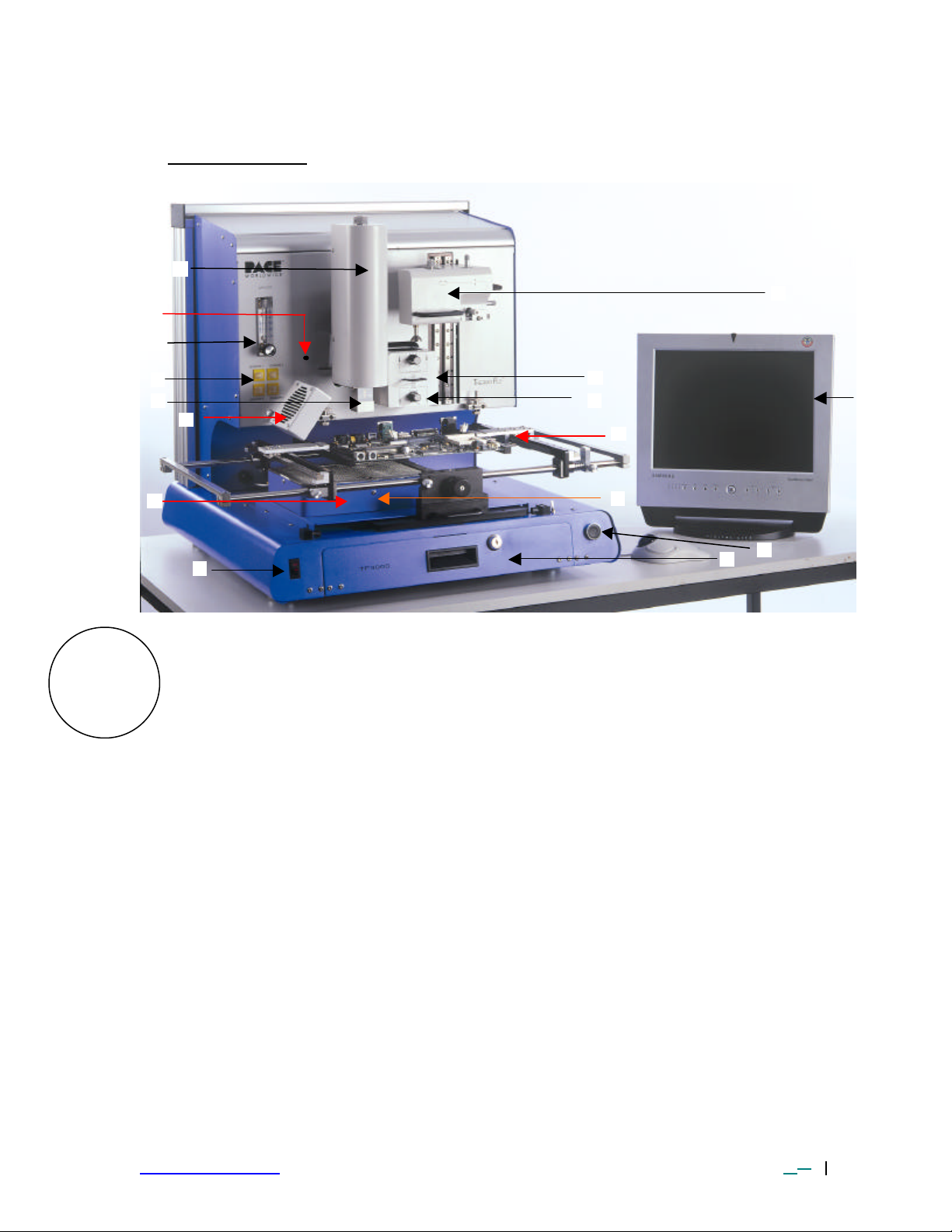

2. Insert PCB into Board Holder. See Figure 3.

Figure 3: Board Holder and PCB

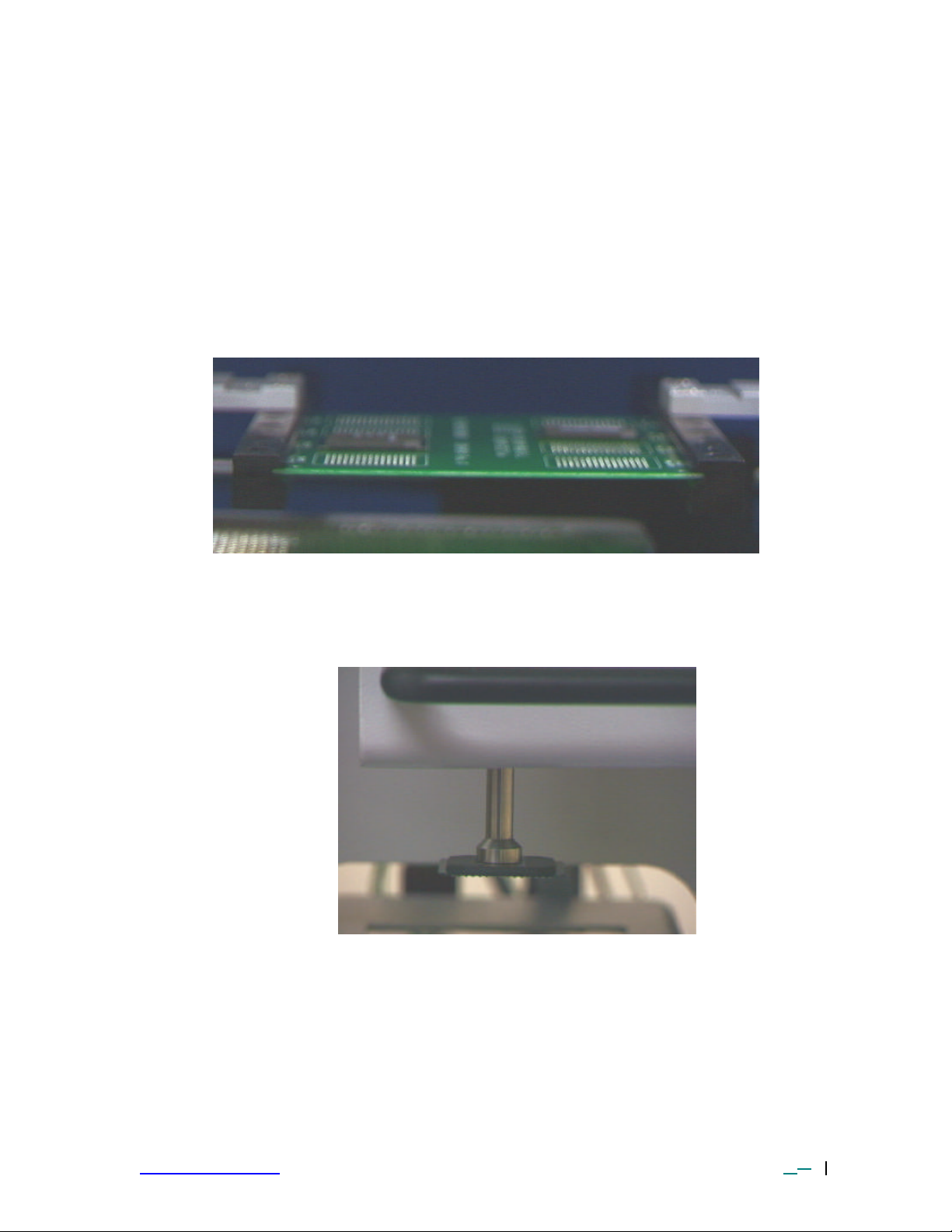

3. Activate vacuum on TF 3000 from the Alignment screen on the TF 3000

Software. Place component on vacuum nozzle on placement head. See Figure

4.

Figure 4: Component held by Vacuum Pick

4. Pull the optics housing out from the front of the TF 3000 using the handle. Be

sure the Sliding Shaft Holder is in the Placement Position (Against the right

bumper).

5. Center the land pattern in the optics display.

6. Adjust the lighting so the lands and solder balls are clear.

www.paceworldwide.com Rev A-PRM Page 9 of 5151

Page 10

7. Align component solder ball/lead pattern to the land pattern on the PCB using the

adjustment knobs on the alignment apparatus. See Figure 5. The BGA (ball

side) and the PCB pattern side are super-imposed on the computer monitor, by

the optical system. See Figure 6.

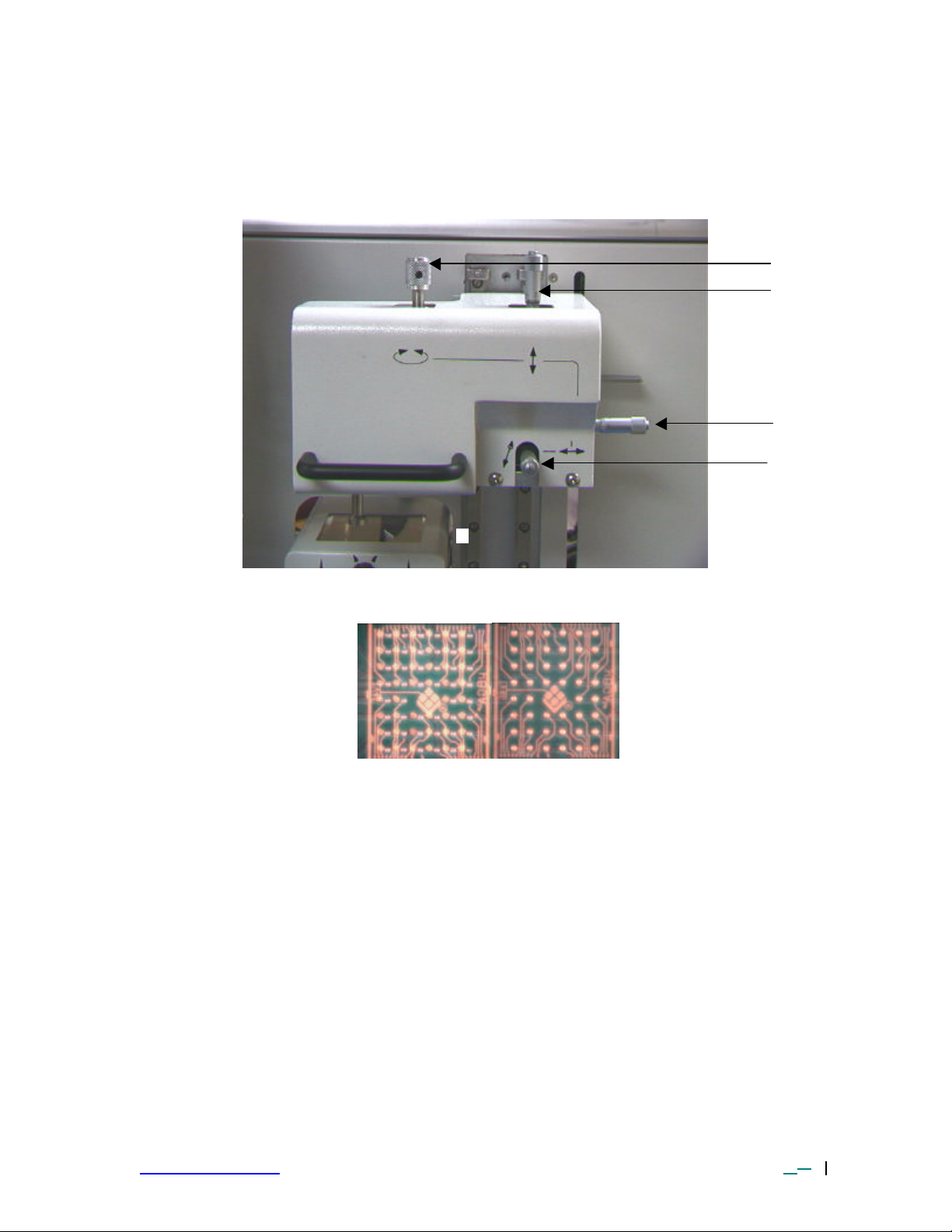

θ

Z

X

Y

10

Figure 5: Placement Head

(A) (B)

Figure 6 - Unaligned (A) and Aligned component (B) as they would appear.

8. Push optics housing back into unit.

9. Apply flux or solder paste: One of the following methods is applicable depending

on the rework conditions, the specification of Device/PCB, or operator

preference.

A) Dispense flux on the land pattern using a brush or flux pencil. (Most

common).

B) Apply solder paste to the land pattern using a conventional stenciling

technique.

C) Apply flux to the BGA, solder ball side, by means of a flux application

tool. See Reference Section.

D) Print paste on the BGA, solder ball side, by using one of PACE’s

component stenciling tool kits. See Reference Section.

Note: Method B must be completed prior to insertion of PCB into board

holder. Methods C and D apply flux/paste to the underside of the

component, not the PCB. They should be performed before placing

component with vacuum pick on TF 3000.

www.paceworldwide.com Rev A-PRM Page 10 of 5151

Page 11

10. Lower the Alignment Apparatus to PCB so the component is in contact with the

PCB.

11. Release component by turning off the vacuum and return alignment apparatus to

the upper position.

12. Index the sliding shaft holder from the Placement Position to the Reflow

Position.

13. Select the desired profile or enter time and temperature parameters for pre-heat,

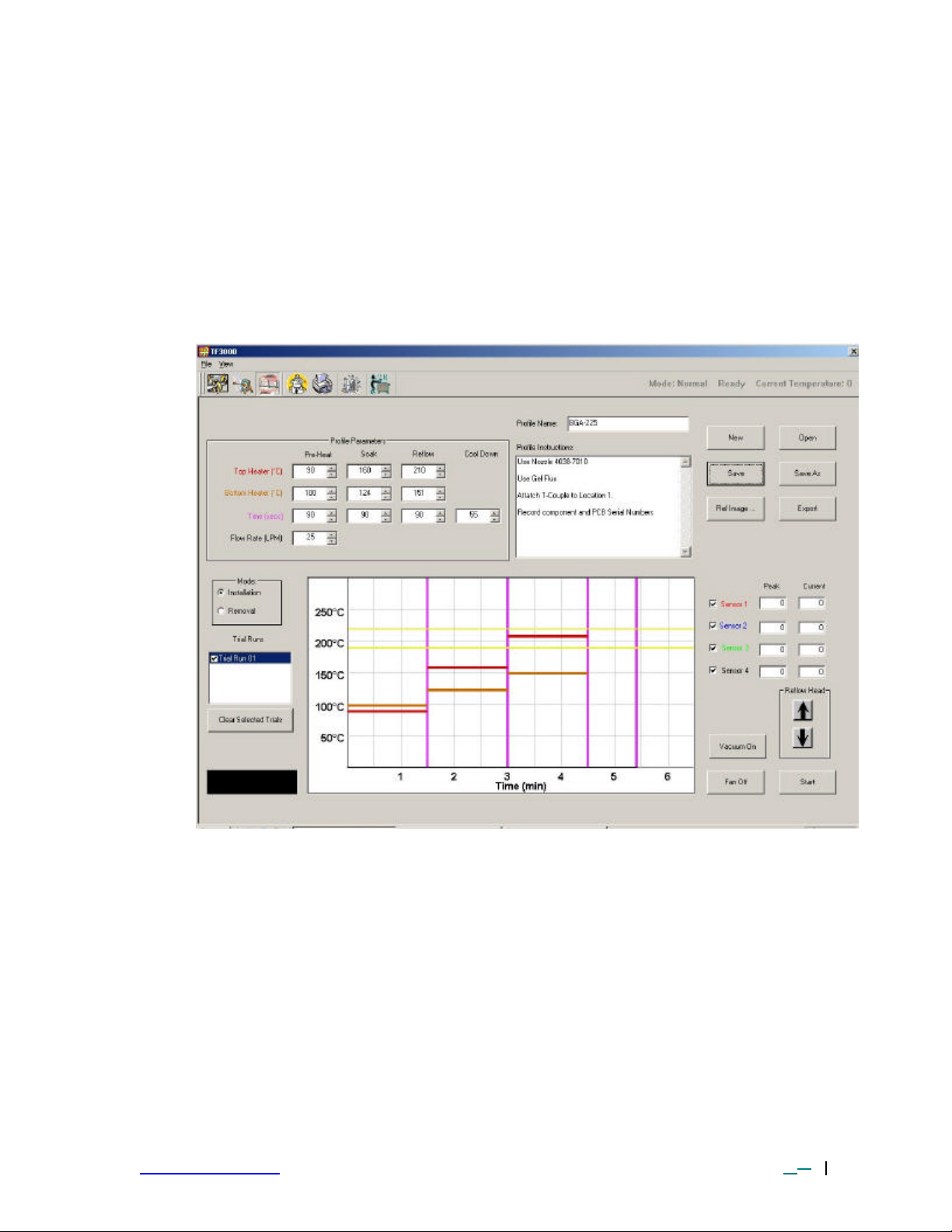

soak, and reflow phases. See Figure 7.

Figure 7: Profile Development Page

14. Lower the reflow head using the reflow head buttons (Fig 7) and start the cycle

by clicking on the “Start Button” on the profile development or Operations Page.

15. Once the reflow profile has been completed, the reflow head will lift up

automatically and the cooling fan will turn on for the user-selected amount of

time. Airflow from the cooling fan may be directed by loosening the locking

thumbscrew on the fan and rotating it around its shaft.

www.paceworldwide.com Rev A-PRM Page 11 of 5151

Page 12

Placement Position

3 EXPLANATION OF EACH OPERATION

r

3-1 Placing BCB into Board Holder - See Figure 8..

1. Center the sliding shaft (8) in the holder (9).

2. Adjust the sides of the board holder so that the distance

between them is 3 mm smaller (half the width of

the rail) than the width of the PCB. Secure the

sides by tightening the setscrews (6 & 2)

4. The right side of the

board holder is spring

loaded. Insert the PCB into

the support slots

while holding the

right side of the

board holder open.

When the PCB is

positioned, let the

right side close.

Figure 8: Board Holder and Base

3-2 Component Alignment and Placement - Refer to Figures 5 and 8.

1. Set the sliding shaft holder at the

Placement Position at the far right

side of the base

2. Extend the optical housing by pulling

the handle towards you. The LEDs

will turn on automatically.

3. Center the PCB array pattern on the

display. Zooming in on the array

allows for easier centering

4. Tighten the setscrews (#1 & 5, Fig.

8) to secure the “Y” position of the

PCB.

5. Tighten the setscrew (#3, Fig. 8) on the sliding shaft

holder (#9, Fig. 8) to secure ”X” position of the PCB.

6. Focus the array pattern on the PCB by focusing manually or by using the AUTO

FOCUS feature. Switch the feature off after the array pattern has been focused.

7. Switch on the vacuum on using the “Vacuum” button on the Alignment screen in

the software.

8. Place the component to be placed on the end of the vacuum nozzle. See Figure

4.

9. Adjust the lighting using the adjustment knobs (#L, Fig 1) so the image of the

PCB land pattern and the image of the solder balls on the component can be

seen clearly.

10. Adjust the height of the device with the height (Z-axis) adjusting screw (Fig 4) to

bring solder balls/lea ds into focus. Failure to focus the component may result in

inaccurate alignment.

11. Turn the “AUTO-FOCUS” feature on after the PCB and component are in focus.

12. Adjust ? aspect of the component by turning the ? adjustment knob (Fig. 5).

13. Adjust the X and Y aspects of the component by adjusting the X and Y

adjustment knobs (Fig. 5).

‰+n

Reflow Position

Figure 9

www.paceworldwide.com Rev A-PRM Page 12 of 5151

Page 13

14. When the component is aligned (See Figure 6), return the optics housing to its

retracted position. The lights will turn off automatically.

15. Using the handle, lift the alignment apparatus upward by hand to release, then

lower the apparatus slowly.

NOTE: The alignment apparatus can be lowered while the optics housing is

extended; DO NOT hit the glass with the component or vacuum

nozzle.

NOTE: When repeating operations using the same PCB and device, steps 4

and 11 may be eliminated. However, when changing devices, it is

important to include steps 4 and 11 in the initial setup procedure.

16. Confirm that the component is in contact with the PCB. Turn off the vacuum

switch using the “Vacuum” button on the Alignment screen in the software.

When repeating operations using the same PCB and device, the mechanical stop

on the right side of the alignment apparatus may be set to ensure repeatability.

17. Return the alignment apparatus to its original position.

18. Move the sliding shaft holder to the “Reflow Position” by disengaging the

magnetic lock and using the handle on the sliding shaft holder.

3-3 Component Reflow

1) Make sure that an appropriately sized nozzle is fitted to the reflow head.

2) Verify the sliding shaft holder is at the Reflow Position at the far left side of the

base

3) Select a profile or enter reflow parameters. Refer to section 4.

3) From either the “Operations” or “Profile Development” screens, click on the

NOZZLE DOWN button. (Figure 7) The nozzle will go down and stop

automatically 5 mm (will vary with PCB thickness) above the PCB.

5) Visually confirm that the component position is aligned with the nozzle. Press

and hold the NOZZLE DOWN button. The reflow head will lower itself, slowly.

Lower the reflow head until there is no gap between the nozzle and the PCB.

See Figure 10.

When repeating operations using the same PCB and device, the mechanical stop

on the left side of the reflow apparatus may be set to ensure repeatability. Once

set, simply lower the reflow head until the mechanical stop engages. The reflow

head is fitted with a clutch that will engage if the nozzle applies pressure on the

PCB or the mechanical stop. This ensures the safety of the PCB and protects

the motor that drives the reflow head.

NOTE: In some instances the available space around a component will be

insufficient to bring the nozzle into contact with the PCB. Should this

occur, select a nozzle with dimensions that are similar to the

component body. For reflow, position the nozzle 1 mm above the

component. The time of the reflow cycle may have to be adjusted to

insure satisfactory results. A thermo-couple should always be used

to verify reflow conditions.

www.paceworldwide.com Rev A-PRM Page 13 of 5151

Page 14

Figure 10: Properly Positioned Nozzle in Relation to PCB

6) When the nozzle is properly positioned, click the CYCLE START button. The

cycle will begin. An audible alarm will sound seven (7) seconds before the end of

the reflow phase.

7) When the reflow cycle is complete, the Reflow Head/nozzle will automatically

raise and the COOLING FAN will turn on (if activated), cooling the soldered

component, PCB and nozzle.

9) Do not remove the PCB from the board holder until the temperature of the

component and PCB has reached “below solder melt” temperatures.

3-4 Adjusting Airflow

1) The knob on the air flow meter adjusts the airflow. Make sure to match the air

flow meter value with the value of “Air Flow” field on the software. The actual

airflow will not be changed by the flow value displayed by the software.

However, this value affects the heating so it is important to make sure the

airflow regulator on the front panel of the machine matches in the airflow value

in the profile.

3-5 Component Removal

There are two methods for removing components from the PCB.

Method 1 - Use a removal nozzle fitted with a vacuum pick-up.

1) Fit a removal nozzle to the TF 3000

2) Connect the vac uum hose to the vacuum port on the front of the system.

3) Run the removal profile.

4) The component will be lifted off when the reflow head lifts up at the

completion of the cycle.

Method 2 – Using the hand wand.

1) Run the removal profile.

2) When the audible alarm signals 7 seconds before the end of the reflow

phase, turn on the vacuum pump using the switch on the right side of the TF

3000 and pick up the hand wand.

3) Once the reflow head raises up, remove the component by using the hand

held vacuum wand.

www.paceworldwide.com Rev A-PRM Page 14 of 5151

Page 15

4 CREATING AND SAVING PROFILES

Please refer to Figure 7 for this section.

4-1 General Information

The TF 3000 comes with two profiles already installed that should be used as

baselines when developing profiles. Profile Default 1 is recommended as a starting

point for area arrays larger than 21 mm square. The Default 2 profile is

recommended as a starting point for area arrays 21 mm square and smaller.

4-2 Additional Information

1) Temperature settings are as follows:

• Top Heater Pre -heat

• Bottom Heater Pre -heat

• Top Heater Soak

• Bottom Heater Soak

• Top Heater Reflow

• Bottom Heater Reflow

2) Time and temperature parameters can be changed while a reflow cycle is

running from the Profile Development Screen. However, the PROFILE itself

cannot be changed.

3) To determine a temperature, it is strongly recommended to use a thermo-couple

to take temperature measurements. Profile creation is most successful when

thermo-couples are used. For assistance, contact PACE or your local

representative.

4) To ensure a successful installation the following conditions should be met in each

profile.

During the PRE -HEAT phase, the PCB should experience a temperature of

between 95 and 105 ºC before entering into SOAK.

During the SOAK phase, the solder balls should experience a temperature

between 145 to 165 ºC for 30 to 60 seconds. Refer to your flux activation

temperature.

During the REFLOW phase, the solder balls should experience a

temperature of 190 to 220 ºC for 10 to 30 seconds. Always verify the

component’s maximum allowable temperature with its manufacturer.

www.paceworldwide.com Rev A-PRM Page 15 of 5151

Page 16

4) The preset default profiles are as follows: (Time (s)/Top Heater

Temperature/Bottom Heater Temperature)

Profile Preheat Soak Reflow AirFlow

Default 1 °F 60/212/320 80/275/350 70/410/375 22 lpm

Default 1 °C 60/100/160 80/135/175 70/210/190 22 lpm

Default 2 °F 60/212/300 70/375/330 60/375/355 15 lpm

Default 2 °C 60/100/150 70/135/165 60/190/180 15 lpm

Figure 11: Default Profile Table

www.paceworldwide.com Rev A-PRM Page 16 of 5151

Page 17

5 PC SOFTWARE

TF 3000 application software comes pre -installed on the PC of the TF 3000 BGA/CSP

Rework System. The software provides numerous features, which include:

• Allows password to be entered to protect existing profiles from unauthorized

modification.

• View images from the Vision Overlay System (VOS).

• The ability to save images electronically.

• Real time split screen function allows for quick alignment of large components or

components with numerous solder balls.

• Real time modification of profile parameters.

• Use up to 4 Thermo-Couple Sensor Inputs to monitor reflow profile.

• Time and Temperature parameters are displayed on screen.

• Incorporate work instructions for operators into profiles.

• Document operations for quality assurance.

• Integrate inspection devices.

The TF 3000 application software consists of 6 functional pages indicated by buttons

across the top of the display. Click on the associated button to access the appropriate

page.

www.paceworldwide.com Rev A-PRM Page 17 of 5151

Page 18

5-1 Setup Page

The Set -Up page is accessed by clicking on the second button from the right on the

toolbar within the TF 3000 application (See #1, Figure 12). The Setup page allows

the TF 3000 software to be configured.

1

2

3

4

11

6 5

7

8

9

12

10

Figure 12: Setup Page

2 Setup Password Button –

Restricts access so that

profiles cannot be modified,

deleted, or created by

unauthorized users. Clicking

this button causes a pop up

box to be displayed. (See

Figure 13)

3 Select °F or °C as a

temperature scale.

4 Select Language – Allows for

selection from 6 different

languages, including English,

German, French, Italian,

Figure 13

Spanish and Swedish from a drop down menu. Lan guages can be customized

and created using the language wizard. See Section 6.

5 Setback and Auto off. Enter a time for each to activate.

www.paceworldwide.com Rev A-PRM Page 18 of 5151

Page 19

5-1 Setback – When the system has been idle for the defined period of

time, the system will go into Setback, which will reduce the set

temperature of the bottom heater by 50%.

5-2 Auto Off – When the system has been in setback for the defined

period of time in the auto off field, the system will shut the bottom

heater off.

6 Set Upper and Lower Temperature Limits – Provides a reference zone for reflow,

typically set at 190 and 220°C. Horizontal yellow lines on the graph represents

upper and lower limits.

7 User defined labels for the Inspection page to label the composite video inputs.

For example, when using PACE’s XR 3000 either of the composite video inputs

could be labeled “XR 3000” or any name you wish to call it.

8 Folder management: Assigns access to a defined folder for:

8-1 Profiles

8-2 Records

8-3 Captured Images

8-4 Inspection Images

8-5 Language Libraries

When a password is entered, this feature locks the operator into using the

defined folders. For example, if you are working on a job that requires three

profiles, you can create a directory that only contains the three profiles. This

way, the choices an operator has to make when selecting a profile are restricted,

reducing the likelihood of selecting an incorrect profile.

If records of each profile run are to be created and maintained for documentation

purposes, the operator can be limited to saving them to a specific directory to

keep them all together under a folder associated with a specific board run, job

number, or customer name.

9 User defined Local PACE Representative Phone Number – Allows for entry of

PACE Local Representative or PACE customer service telephone number for

easy reference.

10 Enable/Disable activity log. When activated, this button logs all communication

activity between the PC and the microprocessor in the TF 3000. This is useful

when trouble shooting the unit.

11 Camera controls. The camera settings can be changed and changes are

immediately reflected in the video display window, lower right hand corner. (#12)

12 Display of video from TF 3000 alignment camera so you can see the effect of the

changes made to the camera settings.

www.paceworldwide.com Rev A-PRM Page 19 of 5151

Page 20

5-2 Alignment Page

3

2

15

13

9

8 7

10 12 14

5

11 16

The Alignment page is accessed by clicking on the second button from the left on the

toolbar within the TF 3000 application (See #16, Figure 14). This screen is used for:

1

4

6

Figure 14: Alignment Page

1. Name of profile selected from Operation Page displayed here.

2. Allows for user to set Horizontal or Vertical Flip of image

3. Allows for user to set Image rotation

NOTE: Selecting any of the Video Image Flip or Video Image Rotation

options may cause the displayed image to appear “jerky” or “sluggish”,

due to the calculation time required to digitally flip or rotate an image.

4. Displays name of the reference image file.

5. Display pane for live video from TF 3000 alignment camera.

6. Display pane for reference image or image review

7. Zoom adjust slide bar

www.paceworldwide.com Rev A-PRM Page 20 of 5151

Page 21

8. Manual focus adjust slide bar. (Auto-Focus must be disabled before slide bar can be

Figure 15: Full Screen Mod

e not aligned

used)

9. Auto Focus enable/disable

10. Full screen button –

when activated displays

video feed full screen.

See Figure 15.

11. Image capture button.

Captures image

displayed in #5 and

saves electronically.

12. Review Button – allows

for review of images

captured with #11.

Images will be displayed

in #6. When image is

displayed, button will

change to “Normal”

which will return the

user to reference

alignment image or

clear pane is no image

is available.

13. Alignment instructions –

See Reference alignment

(Component =Red, PCB=Blue)

Image in Section 5-4.

14. Turn vacuum on/off to vacuum nozzle on alignment head.

15. Split screen line. Refer to Figure 16 for an example of Real Time Split Screen images.

Clicking on the image between the corner and blue line will display the image in split

screen mode. This means that the lower left -hand corner and the upper right-hand

corner up to the diagonal lines marked “15” on Figure 14 are magnified and placed

together in the display, See Figure 16. Click the split image display (Figure 16)

anywhere to return to normal display mode.

www.paceworldwide.com Rev A-PRM Page 21 of 5151

Figure 16: Results from the Real Time Split Screen Feature

Page 22

5-3 Operations Page

14 13 12

The Operations page is accessed by clicking on the first button from the left on the

toolbar within the TF 3000 application (See #1, Figure 17). With the exception of the

optical alignment, this screen allows the operator to perform all essential operations

including profile selection, documenting operations for quality assurance, and process

validation.

1

2

3

5

6

4

8 7

9

11

10

Figure 17: Operation Page

2. System Status Bar – Displays system status:

Normal

Ready

Not Ready

Setback

Auto Off

and current temperature of bottom heater. This bar is to ensure the bottom heaters

are at the specified temperature and will not allow a cycle to start until the bottom

heaters are within the defined tolerance. If the system has entered “Setback” or

“AutoOff” modes, click the right most button on the tool bar to reset the bottom

heater temperature.

3. Drop down box containing the profiles available to be selected. Click on the arrow

and select the desired profile and it will be loaded.

5. Profile Instructions – Specific operator instructions for the chosen profile are

displayed here. These are created during profile development and are saved with

the profile.

www.paceworldwide.com Rev A-PRM Page 22 of 5151

15

Page 23

6. Profile Parameters – Display of time and temperature parameters for the chosen

profile. Values are displayed but CANNOT be changed.

7. Operator Comments - Provides a means for documenting essential information. A

record is defined as information associated with a particular rework job. This

information includes profile parameters, sensor input (via the graph), and operator

recorded comments. A record can be saved for each new component installation.

When a record is saved, the date, time and profile name are automatically stored

with that record.

8. Save Record Button – Stores profile name, date & time, operator comments and

graph information in “Records” folder.

9. Print Record Button – Prints the current record.

10. Sensor inputs #3 and #4. Check box to display thermocouple data. “Peak” field

displays highest temperature reached during profile. “Current” field displays the

current temperature measured by the thermocouple.

11. Progress Indicator – Visual indication of the profile process. Color coordinated with

the phases as indicated in #5.

12. Graphing Area – Graphically displays profile parameters (time and temperature)

and thermocouple data from Sensors #3 and #4.

13. Reflow head Up/Down buttons. Clicking the down arrow once brings the reflow

head down to 5 mm above the PCB. Click and hold the down button for fine

control. Clicking the up arrow returns the reflow head to its up position.

14. Turns the vacuum pump for the nozzle on or off.

15. Turns the cooling fan on or off.

16. Start/Stop Cycle button.

5-3.1 Process Control/Validation Feature

During the Profile Development phase, a temperature probe trace can be saved from

Sensor #1 and #2 with a profile. To validate profile and system performance from the

operation screen, a reference point near the component rework area (on an adjacent

component lead for example) must be used for temperature probe placement. The

location of sensor area can be stored in “Profile Instructions”. Keep in mind that data

must be collected from the same Tem p probe location used when developing the

profile.

When an operator selects an appropriate profile, the temperature probe trace(s) will

be displayed on the graph as gray lines. To validate the rework process, the operator

can place one or two temperature probes or thermocouples on the designated

reference point and run the profile. The check boxes next to Sensor #3 and #4 on

the operations screen must be checked to display data. As the profile progresses,

the temperature probe trace(s) will be display ed in green or black. The probe traces

can be compared to validate a particular rework process. (See Figure 17) Some

variation may exist due to differences in Temp probes, positioning, and operator

error. The “shape” of the curves should be similar.

www.paceworldwide.com Rev A-PRM Page 23 of 5151

Page 24

5-4 Profile Development Page

2 9 11 7 5 10 8 3 6 4 18 19 17 20 16 21 15 22 14 13 12 23 24

The Profile Development page is accessed by clicking on the third button from the left

on the toolbar within the TF 3000 application (See #1, Figure 18). With the exception

of the optical alignment, this screen allows an Engin eer or supervisor to perform all

essential functions to develop and verify a profile.

1

Figure 18: Profile Development Page

1) Profile Development Page Button. Clicking this button changes the software to

the Profile Development Page if a Password is not entered into the system. If

a password has been entered, you will be prompted to enter it before the page

is displayed.

2) System Status Bar – Displays system status:

Normal

Ready

Not Ready

Setback

Auto Off

and current temperature of bottom heater. This bar is to ensure the bottom

heaters are at the specified temperature and will not allow a cycle to start until

the bottom heaters are with in the defined tolerance. The bottom heater

tolerance can be adjusted (more or less stringent) by changing the value of the

bottom heater tolerance file in the TF 3000 folder using the “RegEdit” software

application found in the windows directory.

www.paceworldwide.com Rev A-PRM Page 24 of 5151

Page 25

To change the value, start the RegEdit software.

a. On the left hand side, double click on “Local Machine”

b. Double click on Software

c. Double click on PACE

d. Double click on TF 3000

e. In the right hand side, double click on Btm_Htr_Tol

f. The value should always be set in “Decimal” and in F degrees.

g. Save changes and restart the TF 3000 software.

3) Name of current profile.

4) Profile Parameters – Display of time and temperature parameters for the

chosen profile. Values can be changes using the up and down arrows or

simply click in each box, delete the text, and type a new number. The variable

in the Flow Rate box does not control the airflow. The operator must verify the

flow rate is set properly on the regulator on the front of the machine. This

variable does affect the heat transfer of the top heater and it is important that

the proper airflow be entered into this field. Generally a flow rate of 22 lpm is

used for most applications. When reworking small components, a flow rate of

15 lpm is recommended.

5) Instruction Box – Provides a means to store and display operator instructions

applicable to the selected profile. Instructions may pertain to such items as

nozzle type, type of solder paste or flux, reference position of temperature

probe for process validation, and any other special needs.

6) “New” Button – Clears Profile Name field and resets all profile parameter fields

to the defaults. Top Heater 100 °C (212 °F): Bottom Heater 150 ºC (300ºC):

Time 90 seconds.

7) “Open” Button – Opens a profile.

8) “Save Profile” Button – Saves profile parameters for the selected profile.

Clicking this button will overw rite existing profile parameters for named profiles.

A pop-up box will appear for new unnamed profiles.

9) “Save As” Button – Saves a profile under a different name.

10) “Ref Image” Button – Associates a reference image with a profile. The

Alignment page should first be accessed to capture the image to be associated

with the profile.

For example,

capture an

image of the

component to

be reworked

while it is on the

PCB to clearly

identify to the

operator the

location and

orientation of

the component.

To associate the

reference image

Figure 19: Reference Image Window

with the profile,

click on the “Ref image button and window will open. See Figure 19. Click on

the box with the three dots on it and select the image to be associated with the

profile. You can also enter alignment instructions that will also appear on the

alignment page to remind the operator of any tasks he must complete before

placing the component.

www.paceworldwide.com Rev A-PRM Page 25 of 5151

Page 26

11) “Export” Button – Saves profile and thermocouple data in .csv format that can

be opened in MS Excel.

12) Mode – Select Installation or Removal mode. Selecting Removal mode will

turn on the vacuum pump 5 seconds before the reflow phase ends to lift the

component off of the PCB.

13) “Trial Runs” Window – Allows for the management of trial run profiles while

creating a profile. Up to three profiles can be simultaneously displayed on the

graphing area at one time. This is useful for comparing runs and to view the

effects in changes to the profile parameters. To display a trial run, the check

box to the left of the name must be checked. If three trial runs are present and

a cycle is started an error message will appear and you must delete at least

one of the trials.

14) Reference lines – The yellow lines are for reference on the graph. Their value

is set from the “Set -Up Page”.

15) Red Lines – Thes e lines correspond to the top heat parameters in the Profile

Parameters section (#4). These lines can be clicked on and dragged up or

down to increase or decrease the amount of top heat being applied. These

can be used to modify profile parameters instead of using the text boxes in #4

above, or to modify the profile while one is running. All changes are reflected

immediately in the profile parameters area (#4) and on the graph.

16) Orange Lines – These lines correspond to the bottom heat parameters in the

Profile Parameters section (#4). These lines can be clicked on and dragged up

or down to increase or decrease the amount of bottom heat being applied.

These can be used to modify profile parameters instead of using the text boxes

in #4 above, or to modify the profile while one is running. All changes are

reflected immediately in the profile parameters area (#4) and on the graph.

17) Purple Lines – These lines correspond to the time parameters in the Profile

Parameters section (#4). These lines can be clicked on and dragged left or

right to increase or decrease the amount of time within each phase. These can

be used to modify profile parameters instead of using the text boxes in #4

above, or to modify the profile while one is running. All changes are refl ected

immediately in the profile parameters area (#4) and on the graph.

18) Sensor inputs 1, 2, 3 and 4. Check box to display thermocouple data. The

“Peak” field displays highest temperature reached during profile. The “Current”

field displays the current temperature measured by the thermocouple. The

thermocouple traces are colored to match the text labels for Sensor 1, Sensor

2, etc.

19) Reflow head Up/Down buttons. Clicking the down arrow once brings the reflow

head down to 5 mm above the PCB. Click and hold the down button for fine

control. Clicking the up arrow returns the reflow head to its up position.

20) “Vacuum” Button - Turns the vacuum pomp for the nozzle on or off.

21) “Fan” Button - Turns the cooling fan on or off.

22) Start/Stop Cycle button – Starts or Stops the cycle.

23) Progress Indicator – Visual indication of the profile process.

Yellow = Preheat

Orange = Soak

Red = Reflow

Blue = Cool down

24) Graph Area – Graphically displays profile parameters (time and temperature)

and sensor inputs. Right Clicking the mouse and holding the button down on

any sensor trace will display the temperature at the point selected. Right

clicking the mouse on any two points will give the temperature ramp rate

between the two points.

www.paceworldwide.com Rev A-PRM Page 26 of 5151

Page 27

5-4.1 General Information concerning the Profile Development Screen

1) The Reflow Graph area displays a representation of the Reflow cycle profile.

Time in minutes is graphed along the X-axis and temperature in degrees Celsius

or Fahrenheit is plotted along the Y-axis. The time and temperature axes

incorporate a dynamic scaling feature to optimize the display for extremely short

or long profiles. Profile graphs can be saved with profiles to be used for process

validation by operators while using the Operation screen. Profile graphs can also

be stored as individual records for each rework job for quality control purposes.

Solid and dotted lines are used to indicate profile parameters.

5-4.2 Profile Creation

There are 2 recommended methods for developing a profile. The first, involves an

actual component installation, while the second uses a previously installed package.

Either method can be used to develop a reliable profile. However, there are some

issues and considerations to be aware of with each.

When developing profiles through actual component installation, it is critical to make

sure the thermocouples remain in contact with the solder balls throughout the entire

process. Unreliable data will be collected should a thermocouple lose contact with

the solder balls. If measuring the temperature on the top of the package it is best to

use a preinstalled component, as the thermocouple wire will typically cause the

component to not lay flat on the PCB.

When using a previously installed package, the placement of the thermocouples is

important. They must be in contact with the existing solder joints. This task can be

accomplished by either (1) drilling through the bottom of the PCB into a solder joint

and attaching the thermocouple or by (2) sliding the thermocouple under the

package. When sliding a thermo couple under a component, it is critical that the

thermo couple be in contact with a solder ball. Method 2 is the most commonly used.

Information from the thermocouples will assist in determining the proper time and

temperature param eters. In general, the following guidelines should be adhered to

when developing profiles.

Ramp and Maximum Temperatures

Acceptable ramp rates and maximum temperatures should be obtained from the

component manufacturer. Typical ramp rates are 2-5 ºC/s (4 -9 ºF/s) for plastic parts

and 1 ºC/s (2 ºF/s) for ceramic parts. It is recommended to select a maximum

temperature below the manufacturer’s specification to provide for a margin of safety.

Typically, 20 °C below maximum specified temperature is selected.

Pre-Heat Phase

1. In a “step profile”, the top of the PCB and package should reach a stable

temperature of 95 -105 °C. If plotting the temperature curve, the trace will usually

level off within this temperature range.

2. If a “linear slope” is desired, pre-heat and soak phases are combined. Both the

package and the PCB are warmed at a constant ramp rate (usually 2-4

°C/second) until the desired soak temperature is reached.

www.paceworldwide.com Rev A-PRM Page 27 of 5151

Page 28

Soak Phase

The soak phase is a crucial part of the reflow process. During this period, the flux

activates and drives off volatiles and excess flux. A temperature of 145 -165 °C

(determined by the activation temperature of the flux used) should be maintained for

approximately 20-40 seconds. This allows for uniform ramping across the entire

package and PCB during reflow.

Reflow Phase

During this phase, the solder balls reach solder melt and form a joint between the

package and the lands. It is critical for all areas of the array to reach solder melt

together and all solder balls remain in a liquid state for at least 10-20 seconds.

Generally, plastic packages should not be exposed to temperatures higher than 220

ºC. Always consult the device specifications for maximum temperature

recommendations. As a rule of thumb, a safe “maximum temperature” is the

maximum temp specified by the manufacturer minus 20ºC. Lower temperatures and

shorter times are common in CSPs and FCs. The lowest temperatures possible

should always be used to ensure safety of the device and PCB.

Cool Down Phase

The cool down phase is necessary to bring the temperature of the package, solder

joints and PCB under the package below solder melt temperatures. Cooling should

be controlled. A good reference is to use the same cool down rate as for ramp up.

The cooling fan on the TF 3000 will remain on for a minimum of 30 seconds from the

start of the cool down cycle. Some types of components (like CBGAs) should be

allowed to cool without external assistance from the cooling fan. When installing

these packages, turn the fan away from the PCB so the air doesn’t blow on it.

General

Using one of the two baseline profiles will provide a good starting point for profile

development. The reflow graph provides an excellent tool for monitoring profile

parameters and fine tuning or perfecting the profile development process.

When adjusting profile parameters “on -the-fly”, all changes are reflected immediately on

the profile development screen and graph.

www.paceworldwide.com Rev A-PRM Page 28 of 5151

Page 29

5-5 Inspection Page

2

The Inspection page is accessed by clicking on the fourth button from the left on the

toolbar within the TF 3000 application (#1, Figure 20). This page allows for the

integration of the inspection function within the TF 3000 software. Up to two pieces of

inspection equipment that have a composite video output can be connected to the TF

3000. Examples of inspection equipment are X-Ray inspection equipment and

microscope inspection devices. These are connected through the panel on the right side

of the TF 3000.

1

4

3

6

Figure 20: Inspection Page

2. Flip Field – Flips the image displayed in pane 4 horizontally or vertically.

3. Rotate Field – Rotates the image displayed

in pane 4 in 90 degree increments.

4. Display pane for image from either

composite video input.

5. Reference image library display pane.

6. Video in put Display selection. These radio

buttons allow the video/image from either

composite video input to be displayed.

They can be named by the specific source

of the image in the “Set -Up” Page.

7. Full Screen Button – Changes display mode

from Figure 20 to full screen. See Figure

21. To return to normal display mode, click

the “Normal Mode” Button.

7

8 10

9

Figure 21: Full Screen Di splay Mode

5

www.paceworldwide.com Rev A-PRM Page 29 of 5151

Page 30

8. Capture/Review Button - The Review and Capture Buttons operate the same as in

Alignment View.

9. The Arrow Buttons scroll between images stored in the reference library. To Add a

Reference Image: Any captured image may be added to the Reference Image

Folder under the TF 3000 Software directory.

10. Radio Buttons allow the user to change from Reference Defect Image mode to

Thumbnail mode. See Section 6-5.1.

www.paceworldwide.com Rev A-PRM Page 30 of 5151

Page 31

6-5.1 Inspection Thumbnail Mode

To enter Thumbnail mode, click on the radio button labeled “Thumbnails” (#10 Figure 20). The

display will change to resemble Figure 22.

1

2

3

4

5

Figure 22: Inspection Thumbnail Mode.

The Thumbnail mode allows

for images that are too large

to appear in the viewing pane

(#1) to be viewed in parts.

See Figure 23. This creates a

composite image where the

entire component or desired

viewing area may be

reviewed. Additionally, the

thumbnail panes may be

loaded with images identifying

defects, potential problem

Actual Viewable Area –

Entire Component

cannot be displayed in

Pane

areas, or areas that may

indicate further evaluation is

required. To load images into

the thumbnail frames, simply

display the desired image on

the display pane (#1, Figure

22), then click the Capture

Button. The images will be

transferred to the Thumbnail

Figure 23: Thumbnails

Pane (#2, Figure 22) in sequential order, i.e. Thumbnail 1, Thumbnail 2, Thumbnail 3, and

www.paceworldwide.com Rev A-PRM Page 31 of 5151

Page 32

Thumbnail 4. The thumbnail panes can also be selected individually if a different fill order is

desired by right clicking on the thumbnail pane to be filled first and selecting “Capture” from the

pop-up menu. Thumbnails can be copied over by recapturing an image or by right clicking on a

thumbnail pane and selecting an option from the pop-up menu. The choices on the pop-up

menu are: Capture, Delete thumbnail, and Delete all thumbnails.

This screen can also be used to create reports such as defect or failure analysis reports. To add

comments associated with each thumbnail, double click on the thumbnail and a text box will

appear where text can be entered. When finished with adding comments, click on the “SAVE”

Button (#4, Figure 22) and the report and images will be saved as an Adobe Acrobat file that can

be emailed, printed, stored, or saved to disk for future reference.

The Review button (#5, Figure 22) is used to review the PDF files that are saved from this mode.

www.paceworldwide.com Rev A-PRM Page 32 of 5151

Page 33

1

9 8 7 6 5

4

3 2

5-6 Print/Review Page

The Inspection page is accessed by clicking on the third button from the right on the toolbar

within the TF 3000 application (#1, Figure 24). This Screen allows the operator to recall and

view saved profiles and operator records and output them to a specified printer.

Figure 24: Print/Review Page

1) Open Profile Button – Loads saved profile from disk and displays it on screen.

2) Open Record Button – Loads saved operator record and displays it in Record

Comment.

3) Overlay Profile Button – Inserts a previously saved profile on screen to compare the

currently viewed profile to.

4) Overlay Record Button – Inserts previously saved record on screen to compare

currently viewed record to.

5) Close All Button – Clears all opened and overlaid Profiles and Records.

6) Remove Overlay Button – Removed the overlay from the graph area.

7) Print Button – Brings up Print Screen to select printer to output displayed record or

profile.

8) Print Preview Button – Opens Print Preview Screen.

www.paceworldwide.com Rev A-PRM Page 33 of 5151

Page 34

6 Language File Creation and Modification

The TF 3000 comes standard with the software in 6 languages: English, German, Spanish,

Italian, Swedish and French. To change languages please refer to the set -up page section in

Chapter 6. The TF 3000 also comes with a piece of software that allows for the modification of

existing language files or for the creation of new language files. To modify the language files,

open the “Language File Editor” located on the desktop, under the TF 3000 icon.

As the default language, English will always be displayed in the first column.

If you wish to modify an existing language file, follow the procedure below:

1. Under the “FILE” menu, “LOAD” the lang uage you wish to modify. The file will be

loaded into the second column of the language editor. This is the language file

that will be used as a reference file and cannot be modified.

2. Next, under the “FILE” menu, “OPEN” the language file. The file will be opened

in the third column of the language editor. This is the column you will actually

modify. It is normal to “open” a language file, then “load” the same one. This is

done so there is an uncorrupted set of data to use as a reference.

3. Next, place the cursor into the cell you wish to modify and make your changes.

4. The modified file must then be saved in the language folder. The standard

language files cannot be overwritten, so any modified file must be saved under

another name. For example, if the “English” file has been modified, the new file

would have to be named something other than “English”. This is to maintain the

original set of language files incase they are needed for reference purpose.

5. Saved files will appear in the language selection menu on the set -up page of the

TF 3000 software.

To create a “New” language follow the procedure below:

1. Under the “FILE” menu, “LOAD” the language you wish to modify. The file will be

loaded into the second column of the language editor. This is the language file

that will be used as a reference file and cannot be modified.

2. Next, under the “FILE” menu, select “New” and the new language file will be

opened in the third column of the language editor. This is the column you will

actually create.

3. Next, place the cursor into the first cell in the new column. Type the reference

text in whatever language you are creating and go on to the next cell.

4. The new file must then be saved in the language folder. The standard language

files cannot be overwritten, so any new file must be saved under another name.

This is to maintain the original set of language files incase they are needed for

reference purpose.

5. Saved files will appear in the language selection menu on the set -up page of the

TF 3000 softwar e.

www.paceworldwide.com Rev A-PRM Page 34 of 5151

Page 35

7 Maintenance

The TF 3000 is designed to operate with a minimum level of maintenance. However,

replacement of some parts will be required from time to time. Please follow the

maintenance instructions below when replacing parts. If there are any questions, contact

PACE.

CAUTION: Disconnect the main power supply and computer cables, if

8-1 Cleaning the Blower Filter (See Figure 25)

Clean the filter every three (3) months.

Figure 25: Blower Filter Access

8-2 Replacing the Top Heater

Please refer to Figure 26 and Figure 27 for heater replacement.

1) Disconnect the TF 3000 from ALL power supplies.

2) Remove the protective cover from the reflow head by removing two screws

from each side of the cover.

3) Open the back panel and disconnect electrical connections AS and HS.

4) Feed the wires through the front panel. (you will have to remove several

wire ties.)

5) Remove the white cap on the heater assembly

6) Remove the electrical connections under the cap.

7) Remove the wire ties holding the air hose onto the connection on the back

of the reflow head assembly and remove the hose.

8) Remove all four screws shown in Figure 27 and the heater assembly can be

removed.

9) Be careful not to lose the steel ball bearing positioned behind the reflow

head.

10) Fix the replacement reflow head assembly to the support arm using the 4

screws removed in #8 above. Make sure the steel ball bearing has been

replaced as well.

11) Reconnect the Air hose and thermocouples.

12) Reconnect the electrical connections

13) Reinstall the white cap.

applicable, BEFORE opening the TF 3000/E or TF 3000 L/E,

BEFORE replacing any component and BEFORE performing

ANY routine maintenance.

1) Open the cover on the back of the TF

3000.

2) Identify the Blower pump, mounted on the

base of the machine.

3) Loosen the screw fitted to the end of the

filter housing.

4) Remove the housing, then the filter.

5) Clean the filter using warm water.

6) Make sure the filter is dry before re assembly.

www.paceworldwide.com Rev A-PRM Page 35 of 5151

Page 36

14) Install the replacement wire ties that came with the heater assembly in the

same locations as the removed ones.

15) Realign the reflow head. See section 9-4.

16) Replace protective cover.

Figure 26: Replacement Heater Assembly

3

4

Figure 27: Heater Assembly Attachment Screw locations

8-3 Identification of Electrical Connections.

1

2

Label Description

HVJ5 High Voltage Board J5 - Blower

BLOW Blower connector

COM1 Computer COM port 1

J3 Main PCB J3 - RS232 control

PH Pre-Heater AC power connection

HVJ4 High Voltage Board J4 - PH

MH Main Heater AC power connection

HVJ3 High Voltage Board J3 - MH

J5 Main PCB J5 - LED control

J2 Main PCB J2 - HV control

HVJ1 High Voltage J1 - Input control

J10 Main PCB J10 - Camera Interface

CIJ2 Camera Interface Board J2 connector

FG Frame Grabber Card

www.paceworldwide.com Rev A-PRM Page 36 of 5151

Page 37

J11 Main PCB J11 - Frame Grabber

CIJ1 Camera Interface Board J1 connector

V1 Video 1

V2 Video 2

AS Air Stream Temperature Sensor

HS Heater Core Temperature Sensor

PH Pre-Heater Sensor

E1 External TC1

E2 External TC2

E3 External TC3

E4 External TC4

J1 Main PCB J1 connector - TC Input

J4 Main PCB J4 connector - Sensor Input

J8 Main PCB J8 connector - LED control

J7 Main PCB J7 connector - DC control

MP Magnet Power

VS Vacuum Solenoid Power

HM Heater Head Motor

FAN Fan Power

V+, V- Vacuum Power

PV Pick Vacuum

PVSW Pick Vacuum Switch

XFMR Transformer Secondary Power Output

J2 Main PCB J2 connector – AC input

NS Nitrogen Solenoid

CIJ3 Camera Interface Board J3 connector

www.paceworldwide.com Rev A-PRM Page 37 of 5151

Page 38

9 Alignment & Calibration

All PACE TF 3000 BGA/CSP Rework Systems are factory aligned and calibrated prior to

shipment. Due to adverse shipping and handling conditions, it may be necessary to

perform one or more of the following alignment and calibration procedures prior to use.

Proper alignment and calibration of system components should also be performed on a

semi-annual basis to ensure peak performance.

9-1 Board to Optics Alignment

This alignment should be performed when the land pattern on the PCB appears

skewed on the video display.

1) Position testing PCB in Board Holder.

2) Pull the optics housing out from the front of the TF 3000 using the handle.

3) Zoom in so the lands on the PCB fill the screen.

4) Observe land pattern. If land pattern is skewed, proceed to step 5. See figure

22. If land pattern appears aligned, omit steps 5-7.

5) Loosen 8 setscrews found on both sides of the board holder.

6) Shift the board holder by hand until the image is no longer skewed.

7) Retighten setscrews, alternating from one side of the board holder to the other,

until all 8 setscrews are tight.

Figure 28: Skewed Land pattern

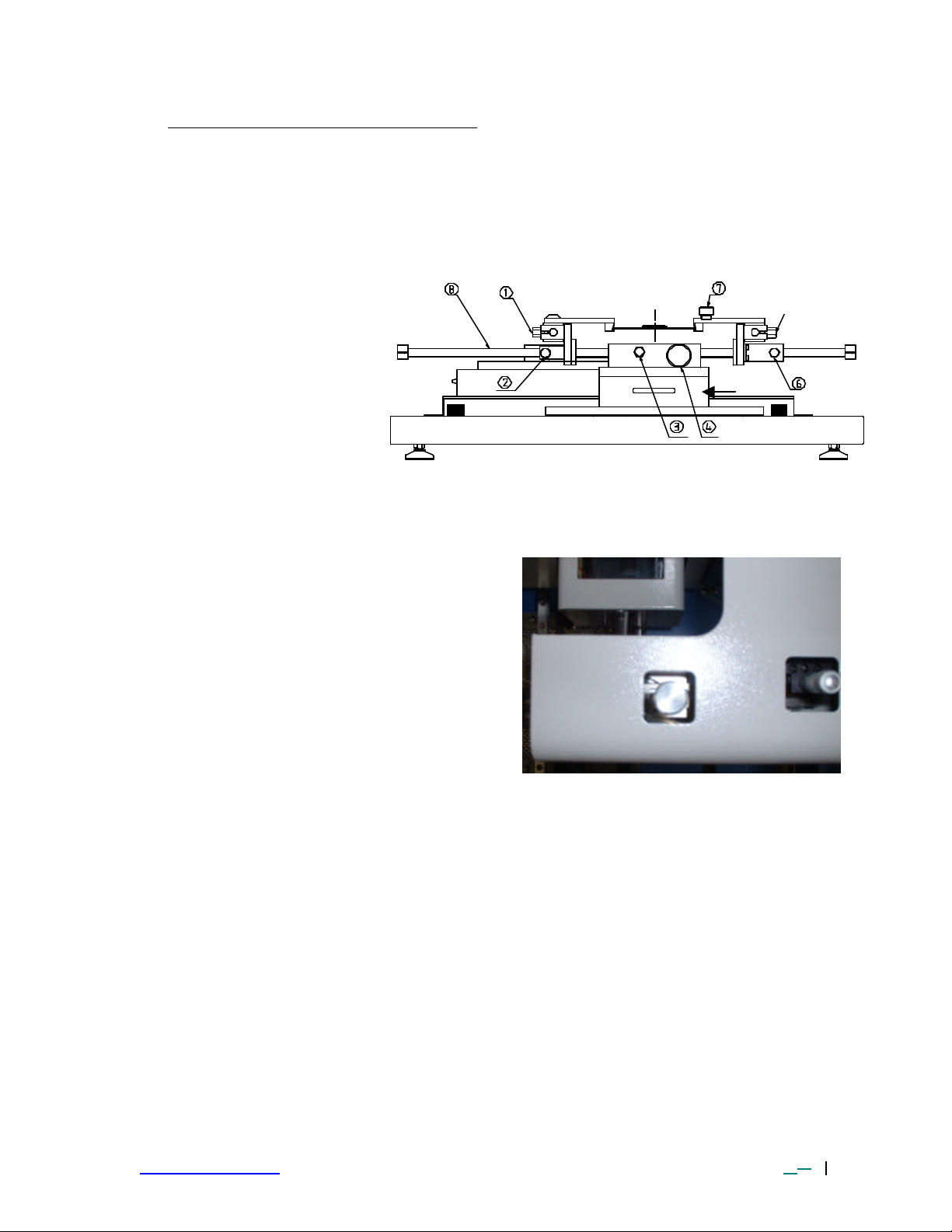

9-2 Sliding Shaft Holder Alignment (Indexing)

This alignment will correct X aspect errors when indexing the sliding shaft holder from

the placement position to the reflow position and vice versa.

NOTE: A reference point must be established for this procedure. The

reflow position will serve as a reference point for this alignment

calibration.

1) Position testing PCB in the board holder.

2) Set the sliding shaft holder at the reflow position flush against the left

indexing tab.

3) Lower reflow heater nozzle to approximately 1/16” above a PCB

component.

4) Visually center component in the “X” direction under nozzle using the

adjustment knob on the sliding shaft holder.

www.paceworldwide.com Rev A-PRM Page 38 of 5151

Page 39

5) Using the handle on the sliding shaft holder, index the table from the reflow

Figure 30: Four vacuum nozzle

position to the placement position.

6) Pull the optics housing out from the front of the TF 3000P using the handle.

7) Zoom in so the lands on the PCB fill the screen.

8) The land pattern should be centered on the display horizontally (X

direction). If centered, omit steps 9-16. Otherwise, proceed to step 9.

9) Loosen center set screw on top of right indexing tab. See Figure 29.

10) Depending on the direction and amount of offset in the X plane, tighten or

loosen the large rubber stopper on the side of right indexing tab.

Note: Tightening the rubber stopper will shift the displayed image to

the right. Loosening the same rubber stopper will shift the

image to the left.

11) Return sliding shaft holder to the placement position.

12) Observe proper centering of land pattern on video display. If centered,

proceed to step 16. Otherwise, repeat steps 9-14 until proper centering is

achieved.

13) Tighten center set screw on top of right indexing tab.

Figure 29: Top and Side View of Indexing Tab

9-3 Vacuum Nozzle Planarity

The Vacuum Pick nozzle must land flush on the PCB component in order to achieve

planarity and adequate suction. Performing the following procedure can rectify

problems in vacuum nozzle planarity.

1) Remove the cover on the Alignment Apparatus by removing the 4 bolts on

the cover.

2) Place a PCB on the board holder

and install the large vacuum

nozzle.

3) Lower the alignment apparatus

to the PCB.

1

2

4) Observe the relationship of the

vacuum nozzle to the PCB. If

the noz zle is not planar to the

3

4

PCB adjustment must be made.

To adjust the planarity of the

vacuum nozzle, use the four

adjustment screws shown in

figure 30.

planarity adjustment screws (Looking

down on assembly)

www.paceworldwide.com Rev A-PRM Page 39 of 5151

Page 40

9-3.1 X Correction Refer to Figure 30

1) If adjustment is required in the “X” direction, follow the procedure below.

2) If the right side of the vacuum nozzle is higher than the left side, loosen

screws 1 and 3 and tighten screws 2 and 4.

3) If the left side of the vacuum nozzle is higher than the back side, loosen

screws 2 and 4 and tighten screws 1 and 3.

4) Replace the cover.

9-3.2 Y Correction Refer to Figure 30

1) If adjustment is required in the “Y” direction, follow the procedure below.

2) If the front side of the vacuum nozzle is higher than the back side, loosen

screws 1 and 2 and tighten screws 3 and 4.

3) If the back side of the vacuum nozzle is higher than the front side, loosen

screws 3 and 4 and tighten screws 1 and 2.

4) Replace the cover.

9-4 Reflow Head Planarity Alignment

When lowered and properly aligned, the nozzle on the reflow head should land flush

with the PCB. Errors in reflow head planarity (both Y and skew aspects) can be

corrected by performing the following alignment. Before proceeding with any

adjustments, DISCONNECT THE ELECTRICAL POWER AND MAKE SURE THE

REFLOW HEAD IS COOL AS ELECTRROCUTION OR BURN INJURY MAY

OCCUR. Place a test PCB into the board holder and lower the reflow head to the

PCB. Observe the relationship between the nozzle and the test PCB.

3

1

4

2

Figure 31: Four Reflow Head Assembly adjustment/replacement screws

NOTE: Allow ample time for cooling before handling the reflow head.

9-4.1 Y Correction Refer to Figure 31

1) If adjustment is required in the “Y” direction (back to front), follow the

procedure below.

2) Remove the 2 screws on the right and 2 screws on the left side of the reflow

head that secure the cover on the reflow head.

3) If the front side of the Reflow head is higher than the back side, loosen

screws 1 and 2 and tighten screws 3 and 4.

4) If the back side of the vacuum nozzle is higher than the front side, loosen

screws 3 and 4 and tighten screws 1 and 2.

5) Replace the cover.

www.paceworldwide.com Rev A-PRM Page 40 of 5151

Page 41

9-4.2 Skew Correction Refer to Figure 31.

1) If the reflow head is skewed (twisted in relation to the PCB), follow the

procedure below.

2) Remove the 2 screws on the right and 2 screws on the left side of the reflow

head that secure the cover on the reflow head.

3) If the reflow head is skewed to the right, loosen screws 1 and 3 and tighten

screws 2 and 4.

4) If the reflow head is skewed to the left, loosen screws 2 and 4 and tighten

screws 1 and 3.

5) Replace the cover.

www.paceworldwide.com Rev A-PRM Page 41 of 5151

Page 42

10 Specifications

PC Pentium III, 850 MHz minimum

256 MB Ram

10 GB Hard Drive

8 MB Video Ram

High Resolution Video Capture Card

89mm (3.5”) Floppy Disk Drive

2 USB Ports

1 Serial Port

1 Parallell Port

Keyboard

Mouse

Operating System Windows XP Professional

Video Display 380mm (15”) LCD Display

Heaters

Top Heater: Convective (air or N2), 1600 Watts

TF 3000 Pre-Heater: IR, 400 Watts (200 Watts x 2),

220mm x 155mm (8.6" x 6.1")

TF 3000L Pre-Heater:

Large Area Heater 900 Watts, 305mm x 610 mm (12” x 24”)

Component Size: 65mm x 65mm (2.6" x 2.6") maximum

PCB Size:

Air Flow: Self-contained, manual adjust, 22 SLPM maximum

N2 Option Standard

Resolution on Optics Adjustment: 25 µmeters (0.001")

Positioning Accuracy (Z travel): ±25 µmeters (0.001")

Vacuum: -800 mbar

Power Requirements: 115 VAC, 60 Hz or 230 VAC, 50 Hz

2.3 kW maximum (3 kW for L version)

Optics: High resolution, Vision Overlay System

126 X Magnification

Video inputs: 2 Composite Video (external)

1 “S” Video (Internal for alignment optics)

Temperature Setting Range:

Top Heater: 50° to 500°C (106° to 932°F)

Pre-Heater: 50° to 220°C (106° to 430°F)

Dimensions: 635m H x 641mm W x 660mm D

(25” H x 25.5” W x 26” D )

Weight: TF 3000, 115 VAC: 78 kg (170 pounds)

TF 3000E, 230 VAC 85 kg (185 pounds)

TF 3000L, 115 VAC 88 kg (195 pounds)

TF 3000LE, 230 VAC 95 kg (210 pounds)

Board Supports Included

Optical Alignment Kit Included

Localized Heater IR, 120 Watts, 65mm x 100mm (2.5” x 4”)

TF 3000 460mm x 500mm (18" x 20")

TF 3000L 500mm x 500mm (20” x 24”)

www.paceworldwide.com Rev A-PRM Page 42 of 5151

Page 43

11. Accessory Items

11-1. Instructions for using the Board Supports

When performing rework on larger PCBs, the use of board supports may be required

to keep the PCB level at all times. The PCB Supports can be left in place for all

operations. To adjust them, simply loosen or tighten the screws to raise or lower the

support pins so they make contact with the underside of the PCB or components on

the bottom of the PCB. (See Figure 35)

Figure 32: PCB Supports

11-2. Instructions for using the Nitrogen/Compressed Air Bi -pass

The TF 3000 is completely self-contained. However, it

can also be used with compressed air or compressed

Nitrogen. To use the system with Compressed gas,

you must provide a clean, dry gas supply to the press

fit bulkhead fitting on the left side of the unit (#1,

Figure 33). Then turn the key on the locking switch

button (#2, Figure 33) to activate. The system will

utilize the compresses gas supply instead of the

internal blower pump.

DO NOT ENGAGE THE N2 SWITCH UNLESS A

COMPRESSED GAS SUPPLY IS CONNECTED AND

TURNED ON. ENGAGING THE SWITCH WITHOUT

THE PROPER GAS SUPPLY MAY CAUSE THE TOP

HEATER AND CONTROL SENSOR TO OVERHEAT

AND EVENTUALLY FAIL, REQUIRING

REPLACEMENT.

Figure 33: Compressed Gas Panel

2

1

www.paceworldwide.com Rev A-PRM Page 43 of 5151

Page 44

11-3 Spares and Accessory Items

1121-0841-P1 Micro Vacuum Nozzle

1159-0271-P5 FUSE

1159-0272-P5 FUSE

1199-0006-P1 TF3000 Software

1199-0007-P1 NET OPS Software

1272-0005-P1 Hand Held Vacuum Pick, TF3000

1321-0694-P1 Board Support

1321-0695-P1 Odd Shaped PCB Holder (ea)

1321-0696-P1 LED Monitor Articulated Arm

1334-0021-P1 Hand Wand Vacuum Pump

1334-0031-P1 Gear Motor

1340-0174-P4 Set of 4 K-Type Thermo -couples

1348-0614-P1 Main Vacuum Pump

1360-0320-p1 Blower Pump 230 VAC

1360-0368-p1 Blower Pump 120 VAC

3008-0142-P1 PC Cables Set

4018-0100-P1 Alignment PCB

6000-0223-P1 Reflow head Assembly, 120 VAC

6000-0224-P1 Reflow head Assembly, 230 VAC

6016-0033 HEX KEY SET

6020-0154-P1 Main PCB

6020-0155-P1 High Voltage PCB

6993-0202-P1 Suction Cup, 5 each

6993-0203-P1 Vacuum Nozzle Kit (4 nozzles)

6993-0218 Flux Applicator Tool

7015-0010-P1 LCD Monitor

11-4 TF 3000 Nozzles

Standard Optional

MAXIMUM COMPONENT SIZE NOZZLE DIMENSIONS NOZZLE P/N NOZZLE P/N

5mm x 5mm (0.19" x 0.19") 8mm x 8mm (0.31" x 0.31") 4038-7001

6mm x 6mm (0.24" x 0.24") 9mm x 9mm (0.35" x 0.35") 4038-7042

6mm x 8mm (0.24" x 0.31") 9mm x 11mm (0.35" x 0.43") 4038-7002

7.3mm x 7mm (0.29" x 0.28") 10.3mm x 10mm (0.40" x 0.40") 4038-7040

8mm x 8mm (0.31" x 0.31") 11mm x 11mm (0.43" x 0.43") 4038-7041