Page 1

TF 2000

BGA/CSP Rework System

MANUAL NO. 5050-0482

REV. C

Page 1 of 67

Page 2

TABLE OF CONTENTS

Safety................................................................................................................... 4

Introduction .......................................................................................................... 5

Packing Contents................................................................................................. 5

Features............................................................................................................... 7

Set-Up................................................................................................................ 10

Operation ........................................................................................................... 13

Before Operating ..................................................................................... 13

General Operating Procedure ................................................................. 13

Explanation of Each Operation........................................................................... 17

Placing PCB into Board Holder ............................................................... 17

Component Alignment and Placement .................................................... 17

Component Reflow.................................................................................. 19

Adjusting Airflow...................................................................................... 20

Component Removal............................................................................... 20

Selecting a Profile .............................................................................................. 21

Creating and Saving Profiles.............................................................................. 21

PC Software....................................................................................................... 24

Setup Tab................................................................................................ 25

Optics Tab Alignment View ..................................................................... 27

Print/Review ........................................................................................... 29

Operation Tab ......................................................................................... 30

Process Control/Validation................................................................. 31

Profile Development Tab......................................................................... 33

General Information ........................................................................... 34

Profile Creation .................................................................................. 36

Maintenance....................................................................................................... 39

Cleaning the Blower Filter ....................................................................... 39

Replacing the Top Heater........................................................................ 39

Alignment and Calibration .................................................................................. 41

Page 2 of 67

Page 3

PCB to Optics.......................................................................................... 41

Sliding Shaft Holder (Indexing)................................................................ 42

Vacuum Nozzle Planarity ........................................................................ 33

Reflow Head Planarity............................................................................. 44

Reflow Head – “Y” Directional Adjustment .............................................. 46

General Troubleshooting.................................................................................... 47

Initial Operation Flow Chart..................................................................... 48

Nozzle Operation Flow Chart .................................................................. 49

Vacuum Pick Operation Flow Chart......................................................... 49

General Troubleshooting Table ............................................................... 51

TF 2000 L/LE Model Differences........................................................................ 52

Installing the Board Holder ...................................................................... 52

Bottom-Side Heaters ............................................................................... 53

Sliding Shaft Holder Indexing .................................................................. 54

Alignment and Calibration Differences .................................................... 55

Specifications..................................................................................................... 56

Instructions for using the Board Supports .......................................................... 58

Accessory Items................................................................................................. 59

Page 3 of 67

Page 4

Safety

The following are safety precautions that personnel must understand and

follow when using or servicing PACE products.

1. POTENTIAL SHOCK HAZARD - Repair procedures on PACE

products should be performed by Qualified Service Personnel only.

Line voltage parts may be exposed when the equipment is

disassembled. Service personnel must avoid contact with these

parts when troubleshooting the product.

2. To prevent personnel injury, adhere to safety guidelines in

accordance with OSHA and other applicable safety standards.

3. Always use PACE systems in a well ventilated area. A fume

extraction system, such as those available from PACE, is highly

recommended to help protect personnel from solder flux fumes.

4. Exercise proper precautions when using chemicals (e.g., solder

paste). Refer to the Material Safety Data Sheet (MSDS) supplied

with each chemical and adhere to all safety precautions

recommended by the manufacturer.

5. The following safety precautions cover use of PACE hot air

systems/hand pieces (e.g., ThermoFlo

®

, ThermoJet®).

a) Be careful when using in places where there are combustible

materials.

b) Do not use in the presence of an explosive atmosphere.

c) A fire may arise if a hot air hand piece is not used with care.

Do not leave the hand piece unattended when in use.

d) The heater assembly housing and any installed nozzle are

hot when the system is being cycled and for a period of time

thereafter. DO NOT touch either the heater assembly

housing, nozzle or direct heated air stream. Severe burns

may result!

Page 4 of 67

Page 5

Introduction:

Thank you for purchasing the TF 2000 BGA/CSP Rework Station. As

electronic devices continue to get smaller, lighter and more compact,

components and printed circuit boards are also becoming smaller and the

amount of available space on PCBs is continually decreasing. In order to

maximize board space, area array devices are growing in popularity. Area

array devices are BGAs, CSPs and “micro-BGAs”, and Flip Chips. These

devices require an optical overlay vision system to ensure proper placement

and high levels of process control during rework to ensure successful

installation. The TF 2000 has been specifically designed to rework these

types of components and can also install and remove a variety of other SMT

devices.

NOTE: This device complies with part 15 of the FCC rules. Operation

is subject to the following two conditions: (1) This device may

not cause harmful interference and (2) This device must accept

any interference received, including interference that may cause

undesired operation.

The TF 2000 also complies with 98/37/EC and 89/336/EEC.

Caution: During normal operation, the top heater, nozzle, bottom-

side-heater(s) and halogen lamps will get hot. Do not

contact them directly as serious injury could occur.

Packing Contents

TF 2000 with Video Monitor

1. TF 2000B, BE, BL, or BLE: 1 each

2. TF 2000R: 1 each

3. TF 2000P: 1 each

4. Video Monitor: 1 each

5. B/C Video Cable: 1 each

6. Hand Held Vacuum Pick for removal: 1 each

7. Suction rubber (spare for #9): 3 each

8. Vacuum nozzle for positioning: 1 each Large, Medium and

Small sizes

9. Hex Wrench Set and Screwdriver: 1 each

10. Top Heater Element (spare): 1 each

11. Halogen Lamp (spare): 2 each

12. TF 2000 Manual: 1 each

13. K-Type ThermoCouple: 2 each

Page 5 of 67

Page 6

TF 2000 with PC

1. TF 2000B, BE, BL, or BLE: 1 each

2. TF 2000R: 1 each

3. TF 2000P: 1 each

4. Computer: 1 each

5. Computer Monitor: 1 each

6. S-Video Cable: 1 each

7. TF 2000 Software Package: Installed on PC

8. Serial Cable: 2 each

9. Hand Held Vacuum Pick for removal: 1 each

10. Suction rubber (spare for #9): 3 each

11. Vacuum nozzle for positioning: 1 each Large, Medium and

Small sizes

12. Hex Wrench Set and Screwdriver: 1 each

13. Top Heater Element (spare): 1 each

14. Halogen Lamp (spare): 2 each

15. TF 2000 Manual: 1 each

16. K-Type ThermoCouple: 2 each

Page 6 of 67

Page 7

Features

1. The TF 2000 System is comprised of three self-contained stations:

The Reflow Station (Model TF 2000R)

The Placement Station (Model TF 2000P), and

The Base/Pre-Heater Station (Models TF 2000B, TF 2000BE, TF

2000BL, or TF 2000BLE)

Each individual station is lightweight and compact, allowing for easy

set-up and portability.

2. Up to 40 reflow profiles can be stored by the TF 2000. Saved profiles

can be recalled at the touch of a button and are displayed on the LCD

display panel.

3. A colored LED indicates each phase of the reflow cycle so the status of

each operation can be easily seen and monitored.

4. The Placement Station can easily handle components up to 70 mm

square. If needed, a split screen function is available through the

optional software package.

5. A highly efficient, 1000-watt topside heater used in conjunction with a

truly unique nozzle design insures the uniformity of the temperature

across the assembly.

6. The ceramic panel bottom side heater with a wide heating area is

incorporated to insure the co-planarity of the PCB, to prevent warping,

and to enhance the reflow of large BGAs.

7. The blower and vacuum pumps are self-contained. No external air

supplies are required.

8. A cooling fan automatically activates at the end of the reflow cycle to

cool the component, PCB, and nozzle.

9. The TF 2000 is versatile, adaptable and ensures repeatable results.

Page 7 of 67

Page 8

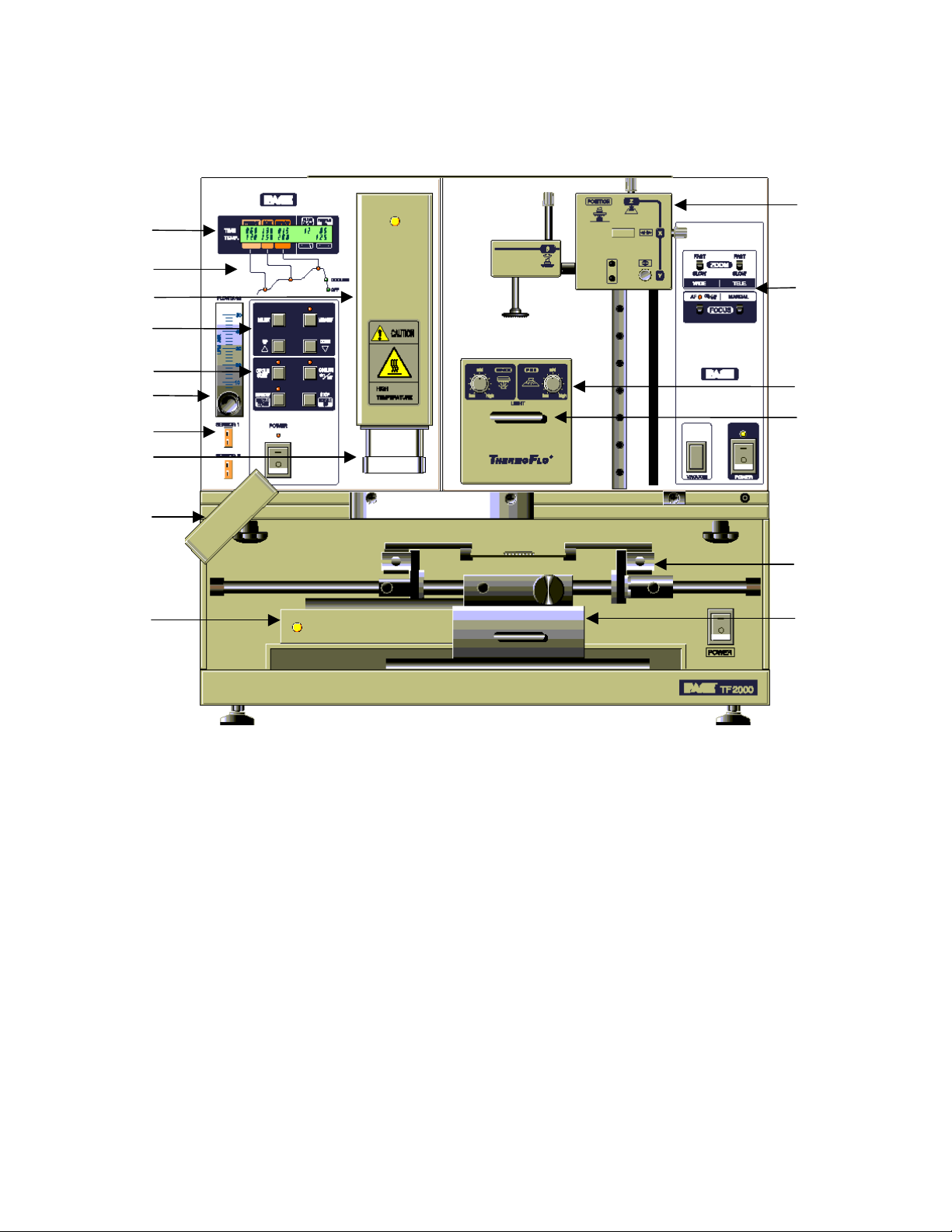

A

TF 2000R TF 2000P

G

B

O

C

D

E

N

P

F

H

I

J

L

K

TF 2000B or TF 2000BE

Figure 1: TF 2000 BGA/CSP Rework Station

Features:

Please refer to Figure 1.

A) LCD Display Panel Displays profile variables (time and temperature)

and allows the user to enter/modify profile

parameters.

B) Phase Display Panel Each phase of the reflow cycle is indicated by this

panel.

M

C) Data Entry Panel Used to enter/modify reflow profile parameters and

to save or recall profiles.

Page 8 of 67

Page 9

D) Operations Panel Allows the operator to start/stop a profile cycle,

turn on/off the cooling fan and raise/lower the

reflow head.

E) Air Flow Meter This device is used to control and monitor the

airflow.

F) Cooling Fan The component and the PCB are cooled down by

the cooling fan, which activates automatically,

after the reflow cycle is completed.

G) Alignment Apparatus X, Y, Z and Θ aspects of the component position

are adjusted in relation to the land pattern on the

PCB through this apparatus.

H) Camera Control The zoom and focus functions of the optical

overlay system are controlled at this location. The

Auto-focus feature may also be selected.

I) Light Control The upper (component side) and lower (PCB side)

lights within the optics housing can be adjusted for

intensity (overlay contrast) at this location.

J) Optics Housing Contains the camera and beam splitter. The

housing is retractable and should be kept in the

retracted position when not in use. The lights for

the optics will turn on/off automatically when the

housing is extended.

K) Bottom Side Heater Used to warm the PCB from the underside. It is

an IR type of heating source. The pre-heater

temperature is set in the “PRE-HEAT” display and

will remain on throughout the reflow cycle. When

the cycle enters the reflow phase, the bottom-side

heater temperature will increase by 30ºC to ensure

successful reflow. A power consumption indicator

light is mounted onto the pre-heater to indicate

when it is drawing power.

**NOTE: For TF 2000L/LE models, refer to

Section 10 for model differences.

L) Board Holder The board holder is fully adjustable in both the X

and Y directions. The right side of the holder is

spring loaded to hold the PCB securely. Fine

adjustment in the X direction is achieved by using

the adjustment knob on the Sliding Shaft Holder.

Page 9 of 67

Page 10

M) Sliding Shaft Holder Supports the rail system for the board holder. It is

also used to index the table from the Placement

Position to the Reflow Position using the handle

on the front.

N) Sensor 1 & 2 Inputs The sensor inputs have been designed to use K-

type thermo-couples. Measured temperatures are

displayed on the LCD display, real time, and can

be interfaced to a PC using the TF 2000 Software

(optional) through the serial port on the back of the

TF 2000R.

O) Reflow Head Contains the top-side heater and moves up and

down via an electric motor that is controlled

through the operations panel. A power

consumption indicator light is mounted onto the

front of the reflow head to indicate when it is

drawing power. The reflow head is clutched to

prevent excessive downward force from being

applied.

P) Nozzle The nozzles for the TF 2000 are easily changed.

Several varieties are available. Use caution and

proper hand protection when changing nozzles, as

they will be hot.

**NOTE: For TF2000 L/LE models, refer to Section 10 for a detailed

description of model differences.

Page 10 of 67

Page 11

1 SET-UP

TF 2000 Setup & Connection to Video Monitor

1-1 Place the TF 2000B, TF 2000BE, TF 2000BL, or TF 2000BLE on a

flat and stable bench. Refer to Section 10 for board holder

installation on L/LE models.

1-2 Place the TF 2000R and TF 2000P on the base as indicated in

Figure 1.

1-3 Secure the TF 2000R and TF 2000P by following the directions in

the box containing the base unit. Refer to Figure 1.

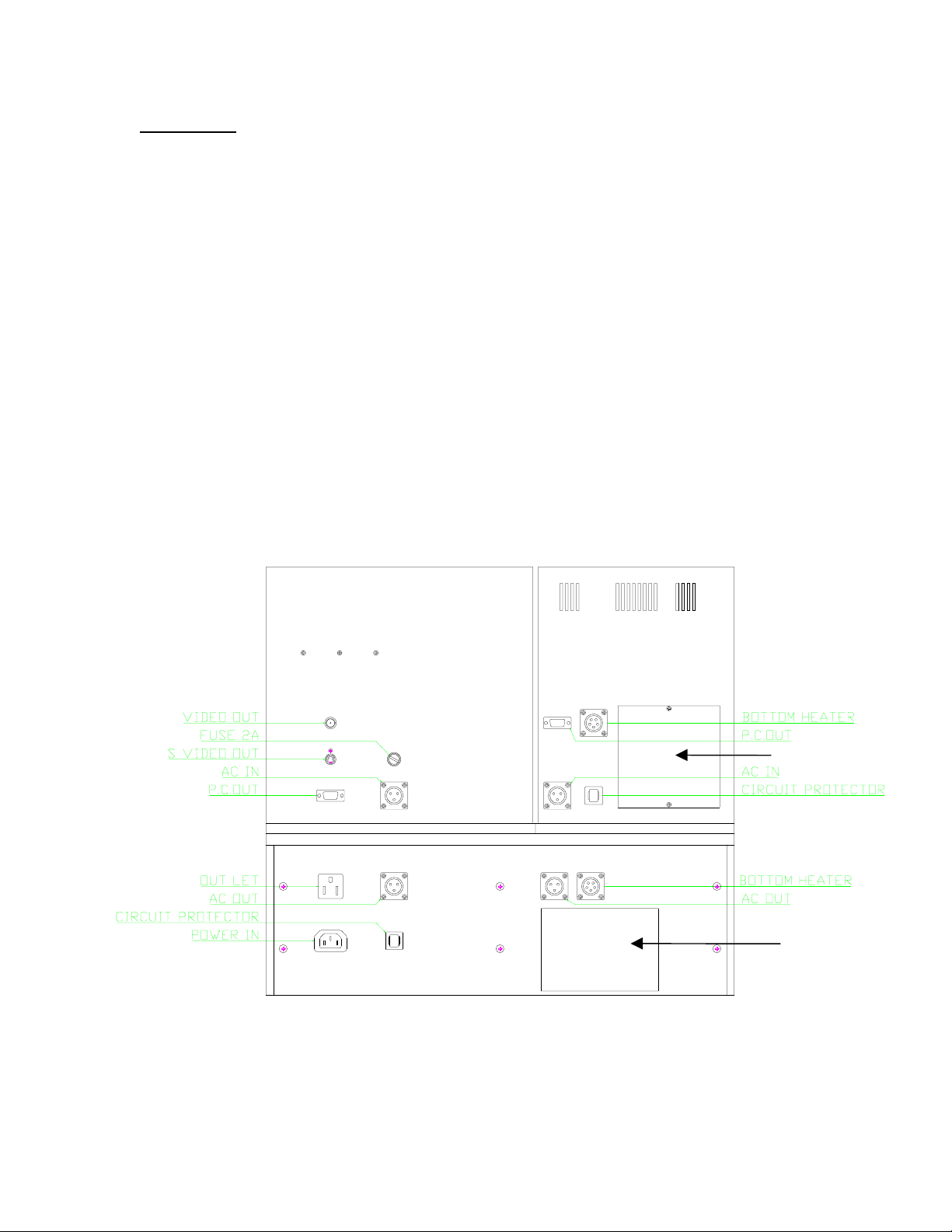

1-4 Connect the power cables as indicated in the wiring diagram label

on the back of the units. See Figure 2.

1-5 Connect the hand-held vacuum pick to the vacuum port on the front

of the TF 2000P and hang the vacuum pick on the side of the TF

2000P using the bracket provided.

1-6 Connect a B/C cable (included) and a power cable between the

video monitor and the TF 2000P

1-7 Connect the main power cable to an appropriate 115 VAC, 60 Hz or

230 VAC 50 Hz power supply.

Figure 2: Back of TF 2000

Page 11 of 67

Access Panel

Wiring Diagram

Page 12

TF 2000 Set up & Connecting to PC (Optional Package)

1-1 Place the TF 2000B, TF 2000BE, TF 2000BL, or TF 2000BLE

on a flat and stable bench.

1-2 Place the TF 2000R and TF 2000P on the base as indicated in

Figure 1.

1-3 Secure the TF 2000R and TF 2000P by following the directions

in the box containing the base unit. Refer to Figure 1.

1-4 Connect the power cables as indicated in the wiring diagram

label on the back of the units. See Figure 2.

1-5 Connect the hand-held vacuum pick to the vacuum port on the

front of the TF 2000P and hang the vacuum pick on the side of

the TF 2000P using the bracket provided.

1-6 Connect the S-video cable (included) to the S-video port on the

back of the TF 2000P. Then connect the other end of the cable

to the S-video port on the back of the video expansion card on

the PC. (See Figure 3)

1-7 Connect the serial port on the back of the TF 2000R to Serial

Port 1 (located next to the monitor port) on the computer using

one 9 pin serial cable (included). (See Figure 3)

1-8 Connect the serial port on the back of the TF 2000P to Serial

Port 2 on the computer using the other 9 pin serial cable

(included). (See Figure 3)

1-9 Connect the power cable to an appropriate 115 VAC, 60 Hz or

230 VAC 50 Hz power supply.

1-10 Do not plug the PC or PC monitor into 1 amp power receptacle

on the back of the TF 2000P.

SERIAL PORT 1 S-Video PORT SERIAL PORT 2

Figure 3: PC Back Panel

Page 12 of 67

Page 13

2 OPERATION

O

2-1 Before Operating

• Make sure the TF 2000 is on a stable platform

• It is recommended that the TF 2000 be turned on for at least 15

minutes before use to ensure the Bottom Side heater has reached

its set temperature and stabilized. Once the bottom-side heater is

at temperature it will deliver consistent heating, ensuring highly

repeatable heating from operation to operation.

• It is advisable to conduct a trial operation each day to ensure all

systems are operating properly. Also, it is important to verify the

airflow of the unit: Maximum airflow is 25 l/min and Minimum

airflow is 18 l/min.

• Verify that the devices/parts being soldered to the PCB do not

exceed the height limitations. Exceeding the limitations may

interfere with the operation of the machine.

1. The maximum height of any component or device on the top

of the PCB is limited to 30 mm (1.2”).

2. The maximum height of any component or device on the

bottom of the PCB is limited to 15 mm (0.6”).

PCB

BOARD

H

LDER

2-2 General Operating Procedure

1. Insert PCB into Board Holder. See Figure 4.

Figure 4: Board Holder and PCB

2. Apply flux or solder paste: One of the following methods is

applicable depending on the rework conditions, the specification of

Device/PCB, or operator preference.

A) Dispense flux on the land pattern using a brush or flux

pencil.

B) Apply solder paste to the land pattern using a conventional

stenciling technique

C) Apply paste or flux to the BGA, solder ball side, by means of

a flux application tool. See Reference Section.

Page 13 of 67

Page 14

D) Print paste on the BGA, solder ball side, by using a

component stenciling tool kit. See Reference Section.

Note: Method 2 must be completed prior to insertion of PCB into

board holder and methods 3 and 4 apply flux/paste to the

underside of the component, not the PCB. They should be

performed before placing component with vacuum pick on

TF 2000P.

3. Activate vacuum on TF 2000P and pick up component using

vacuum nozzle on placement station.

Figure 5: Component held by Vacuum Pick on TF 2000P

4. Pull the optics housing out from the front of the TF 2000P using the

handle. Be sure the Sliding Shaft Holder is in the placement

position.

5. Align component solder ball/lead pattern to the land pattern on the

PCB using the adjustment knobs on the alignment apparatus. See

Figure 6. The BGA ball side and the PCB pattern side are superimposed on the video or computer monitor, depending on chosen

configuration, by the optical system.

Page 14 of 67

10

Page 15

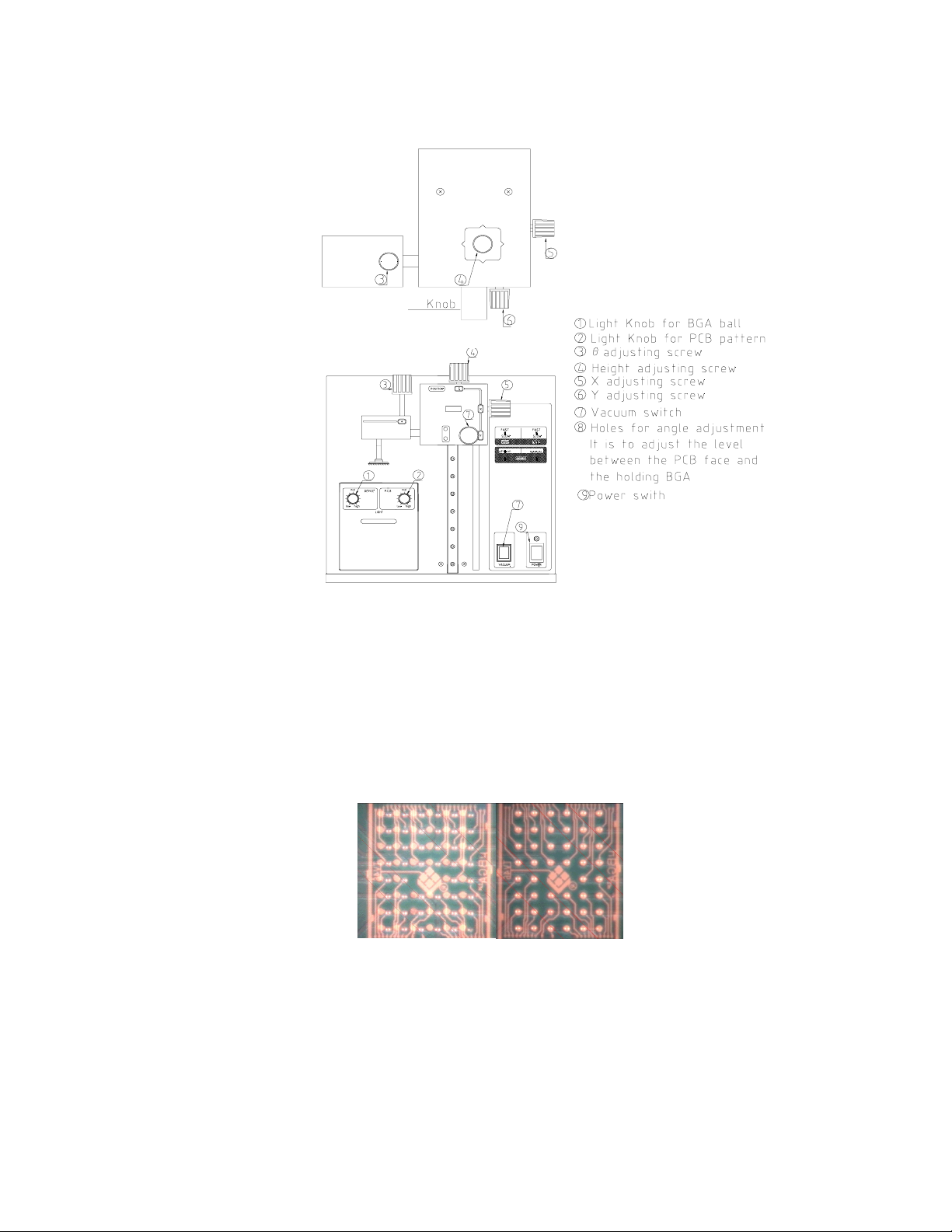

Figure 6: TF 2000P

A) Zoom in so the lands on the PCB fill the screen and center

the land pattern on the display.

B) Adjust the lighting so both images are clear.

C) Align the component to the land pattern using the X,Y and Θ.

See Figures 6 and 7.

(A) (B)

Figure 7 - Unaligned (A) and Aligned component (B) as they would appear.

6. Lower the Alignment Apparatus to PCB.

7. Release component by turning off the vacuum and return alignment

apparatus to the upper position. See Figure 6.

Page 15 of 67

Page 16

8. Using the handle on the Sliding Shaft Holder, index the table from

the Placement Position to the Reflow Position.

9. Select the desired profile or enter time and temperature parameters

for pre-heat, soak, and reflow phases. Those values will be shown

on the LCD display. See Figure 8. As each phase in the reflow

profile is entered, the LED indicator lights will show which phase

the process is in. See Figure 8.

Figure 8: Display and Data Entry Panel

10.Once the reflow profile has been completed, the reflow head will lift

up automatically and the cooling fan will turn on for 55 seconds.

Airflow from the cooling may be directed by loosening the locking

thumb screw on the fan and rotating it around its shaft.

Page 16 of 67

Page 17

3 EXPLANATION OF EACH OPERATION

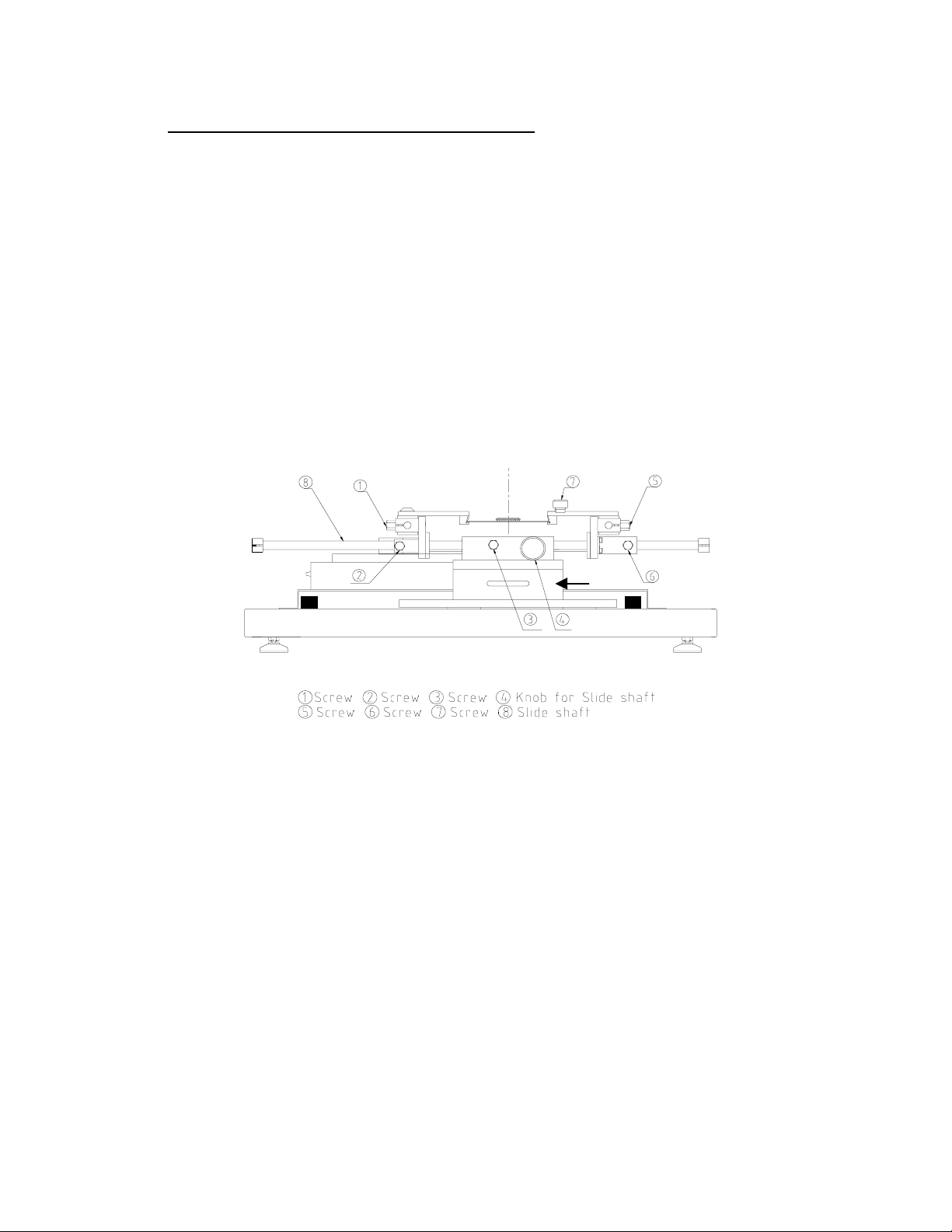

3-1 Placing BCB into Board Holder - Please see Figure 9.

1. Center the sliding shaft (8) in the holder (9).

2. Adjust the sides of the board holder so that the distance between

them is 3 mm smaller (half the width of the rail) than the width of

the PCB. Secure the sides by tightening the setscrews (6 & 2)

3. The right side of the board holder is spring loaded. Insert the PCB

into the support slots while holding the right side of the board holder

open. When the PCB is positioned, let the right side close.

9

Reflow Position Placement Position

9) Sliding Shaft Holder

Figure 9: Board Holder and Base

3-2 Component Alignment and Placement - Please refer to Figures 6

and 9.

1. Set the sliding shaft holder at the Placement Position at the far right

side of the base

2. Verify that the height (Z-axis) adjusting screw (#4, Fig. 6) is

positioned in the center of the square hole as shown in Figure 4.

This position is the reference point for all alignment procedures.

3. Extend the optical housing by pulling the handle towards you. The

lights will come on automatically.

4. Focus the array pattern on the PCB by focusing manually or by

using the AUTO FOCUS feature. When using the AUTO FOCUS

feature, switch the feature off after the array pattern has been

focused.

5. Center the PCB array pattern on the Display. Zooming in on the

array allows for easier centering.

Page 17 of 67

Page 18

6. Tighten the setscrews (#1 & 5, Fig. 9) to secure the “Y” position of

the PCB.

7. Tighten the setscrew (#3, Fig. 9) on the sliding shaft holder (#9, Fig.

9) to secure ”X” position of the PCB.

8. Switch on the vacuum switch (#7, Fig. 6).

9. Hold the component to be placed using the vacuum nozzle. See

Figure 7.

10. Adjust the lighting using the adjustment knobs (#1 & 2 Fig 5) so the

image of the PCB land pattern and the image of the solder balls on

the component can be seen clearly.

11. Adjust the height of the device with the height (Z-axis) adjusting

screw (#4 Fig 5) to bring solder balls/leads into focus. Failure to

focus the component may result in inaccurate alignment.

12. Turn the “AUTO-FOCUS” feature on after the PCB and component

are focused.

13. Adjust θ aspect of the component by turning the θ adjustment knob

(#3, Fig. 6).

14. Adjust the X and Y aspects of the component by adjusting the X

and Y adjustment knobs (#5 & 6, Fig. 6).

15. When the component is aligned (See Figure 7), return the optics

housing to its retracted position. The lights will turn off

automatically.

16. Using the handle, lift the alignment apparatus upwards by hand to

release, then lower the apparatus slowly. As the apparatus

reaches the PCB, the damper will engage to ensure the component

lands softly on the PCB.

NOTE: The alignment apparatus cannot be lowered while the

optics housing is extended.

DO NOT DROP THE ALIGNMENT APPARATUS FROM THE

UPPER POSITION.

NOTE: When repeating operations using the same PCB and

device, steps 4 and 11 may be eliminated. However,

when changing devices, it is important to include steps 4

and 11 in the initial setup procedure.

3) Confirm that the component has contacted the PCB. Turn off the

vacuum switch (#7, Fig 6).

When repeating operations using the same PCB and device, the

mechanical stop on the right side of the alignment apparatus may

be set to ensure repeatability.

4) Return the alignment apparatus to its original position.

Page 18 of 67

Page 19

19) Move the sliding shaft holder to the Reflow Position using the

handle.

NOTE: For TF 2000L/LE models, refer to the Sliding Shaft

Holder Indexing portion of Section 10 for a description of

model differences.

3-3 Component Reflow - Please refer to Figure 10

1) Make sure that an appropriately sized nozzle is fitted to the reflow

head.

2) Verify the sliding shaft holder is at the Reflow Position at the far left

side of the base

3) Select a profile or enter reflow parameters. Refer to section 4.

Figure 10: Operations Panel

4) Push the NOZZLE DOWN button. The nozzle will go down and

stop automatically 16 mm (will vary with PCB thickness) above the

PCB. See Figure 10.

5) Confirm that the component position is aligned with the nozzle.

Press and hold the NOZZLE DOWN button. The reflow head will

lower itself, slowly. Lower the reflow head until there is no gap

between the nozzle and the PCB. See Figure 11. If you need to

raise the reflow head up by a slight amount, press the NOZZLE UP

button briefly.

When repeating operations using the same PCB and device, the

mechanical stop on the left side of the reflow apparatus may be set

to ensure repeatability.

The reflow head has a clutch that will engage if the nozzle applies

pressure on the PCB or the mechanical stop. This ensures the

safety of the PCB and the motor that drives the reflow head.

NOTE: In some instances the space around a component will be

insufficient to bring the nozzle into contact with the PCB.

Should this occur, select a nozzle with dimensions that

Page 19 of 67

Page 20

are similar to the component body. For reflow, position

the nozzle 1 mm above the component. The time of the

reflow cycle may have to be adjusted to insure

satisfactory results. A thermo-couple should be used to

verify reflow conditions.

Figure 11: Properly Positioned Nozzle in Relation to PCB

6) When the nozzle is properly positioned, press the CYCLE START

button. The PREHEAT LED on the Phase Display Panel will light

and the reflow cycle will begin.

7) The Phase Display Panel (See Figure 8) will indicate the phase of

the reflow cycle (PREHEAT, SOAK, REFLOW and COOLDOWN)

and the time for each phase will be counted down on the LCD

Display. An audible alarm will sound seven (7) seconds before the

end of the reflow phase.

8) When the reflow cycle is complete, the nozzle will automatically

raise and the COOLING FAN will turn on, cooling the soldered

component, PCB and nozzle.

9) Do not remove the PCB from the board holder until the COOLING

LED has gone off and the OFF LED is lighted.

3-4 Adjusting Airflow

1) The knob on the air flow meter adjusts the air flow. Make sure to

match the air flow meter value with the value of FLOW on the

LCD Display. The actual air flow will not be changed by the flow

value of the display panel.

3-5 Component Removal

1) Component removal is accomplished in the same way as the

reflow.

2) When the audible alarm signals 7 seconds before the end of the

reflow phase, push the VACUUM button to turn on the vacuum

pump.

3) Once the reflow head raises up, remove the component by using

the hand held vacuum pick.

4) It is possible to shorten the profile for removals.

Page 20 of 67

Page 21

4 SELECTING A PROFILE

Please refer to Figure 8 for this section.

1. Using the SELECT button, move the cursor to the PROFILE NO.

position.

2. Select a profile by pressing the UP or DOWN buttons. The TF

2000 can store up to 40 profiles. Profile memory locations from 00

to 39 are available. The TF 2000 comes with three profiles loaded

(locations 00, 01, and 02). These should be used as baselines

when creating profiles. User profiles can be stored in locations 03

through 38. Location 39 is used as a working memory when

profiles are downloaded from a PC. See Software section. The

profile parameters in use are visible on the LCD display.

5 CREATING AND SAVING PROFILES

Please refer to Figure 8 for this section.

5-1 General Information

The TF 2000 comes with three profiles already installed that should be

used as baselines when developing profiles. The profile in memory

location 00 is recommended as a starting point for area arrays smaller

than 35 mm square. The profile in memory location 01 is

recommended for reflowing area arrays 35 mm square and larger.

Profile number 02 is essentially the same as profile number 01, but

adds a temperature spike (30 °C) from the Bottom Side heater during

the reflow phase.

5-2 How to install a profile:

1) Using the SELECT button, move the cursor to the item to be

changed.

2) Change the value by pressing the UP or DOWN button.

3) After all values have been set, press the MEMORY button once.

The LED above the MEMORY button will go on.

4) Press the SELECT button to move the cursor to PROFILE NO.

5) Using either the UP or DOWN button, choose a profile memory

location (03 through 38) to save the profile into.

6) When the memory location has been selected, press the MEMORY

button until the audible signal is heard indicating the profile has

been saved to the memory location selected.

7) Once the profile has been saved, the LED lamp will go out.

Page 21 of 67

Page 22

NOTE: The above procedure can be used to create and save new

profiles and to modify existing profiles. Saving a profile to

a memory location that is in use will overwrite the existing

profile.

5-3 Additional Information

1) Temperature settings are as follows:

• Preheat Temp is the temperature of the bottom side heater

• Soak Temp is the set temperature of the top heater during

soak, bottom heater remains at “pre-heat” temp.

• Reflow Temp is the temperature of the top heater during

reflow. The bottom-side heater can either remain at its set

temp or a “Spike” of 30 degrees C may be set. See

Software Section.

2) Time and temperature parameters can be changed while a reflow

cycle is running. However, the PROFILE number itself can not be

changed.

3) To decide a temperature value, it is recommended to use a thermocouple to take temperature measurements. Profile creation is most

successful when thermo-couples are used. For assistance, contact

PACE.

4) To ensure a successful installation the following conditions should

be met in each profile.

During the PRE-HEAT phase, the PCB should experience a

temperature of between 95 and 105 ºC before entering into

SOAK

During the SOAK phase, the solder balls should experience a

temperature between 140 to 160 ºC for 45 to 60 seconds.

During the REFLOW phase, the solder balls should experience

a temperature of 205 to 220 ºC for 10 to 20 seconds.

5) The preset default profiles located in memory locations 00-02 are

as follows: (Time/Temperature)

Profile Preheat Soak Reflow

00 60/180 100/110 100/230

01 61/210 100/140 120/280

02 60/210 100/140 130/280

NOTE: Above values are expressed as seconds/°C.

Page 22 of 67

Page 23

6) During the Reflow phase, the Bottom Side heater provides a 30 °C

temperature spike to aid in the reflow process. This is an automatic

feature and can be disabled by entering “61” seconds in the

Preheat time field prior to the start of the reflow cycle. The “SPIKE”

allows for more even heating of PCB and Device as well as lower

“REFLOW” temperatures.

Page 23 of 67

Page 24

6 PC SOFTWARE

TF2000 application software comes pre-installed on the optional PC

configuration of the TF 2000 BGA/CSP Rework System. The software

provides numerous features not included with the standard monitor

configuration. These features include:

• Allows password to be entered to restrict creation and modification

of existing profiles.

• View images from the Vision Overlay System (VOS).

• The ability to save images electronically.

• Real time split screen function allows for quick alignment of large

components or components with numerous solder balls.

• Use up to 2 Thermo-Couple Sensor Inputs to monitor reflow profile.

• Time and Temperature parameters are displayed on screen.

• Incorporate work instructions for operators into profiles.

• Ensures process control by restricting operator access to profile

parameters.

• Allows for process validation using a thermo-couple.

• Document operations for quality assurance.

The TF 2000 application software consists of 5 operational screens

indicated by folder tabs across the top of the display. Click on the

associated folder tab to access the operational screen.

Page 24 of 67

Page 25

6-1 Setup Tab

The Setup screen allows for the configuration of the TF 2000 software.

Figure 12: Setup Tab

1) Setup Password Button – Restricts access so that profiles can not

be modified, deleted, or created by unauthorized users. Clicking

this button causes a pop up box to be displayed. (See Figure 13)

2) Select Language – Allows for selection from 6 different languages,

including English, German, French, Italian, Spanish and Swedish

from a drop down menu.

3) Video Image Flip – Provides a means to vertically or horizontally flip

the camera image (on the Optical Alignment screen) by digitally

manipulating the displayed image.

4) Video Image Rotation – Rotates the displayed image (on the

Optical Alignment screen) by the amount indicated for the selected

field.

NOTE: Selecting any of the Video Image Flip or Video Image

Rotation options may cause the displayed image to

Page 25 of 67

Page 26

appear “jerky” or “sluggish”, due to the calculation

time required to digitally flip or rotate an image.

5) Select Sensor trace to save with Profile – Allows one or both

thermocouple (sensor) inputs to be saved with any given profile.

6) Local PACE Representative Phone Number – Allows for entry of

PACE Local Representative or PACE customer service telephone

number for easy reference.

7) Set Upper and Lower Temperature Limits – Provides a reference

zone for reflow, typically set at 195 and 220°C. Horizontal green

lines on the graph represent upper and lower limits.

Figure 13: Password Setup Box

Page 26 of 67

Page 27

6-2 Optics Tab Alignment View

This screen is used for aligning the component solder balls to the PCB

land pattern using the vision overlay system (VOS). Camera Zoom

and Focus can be controlled from this screen as well as the Real Time

Split Screen feature.

Figure 14: Optics Tab Alignment View

Zone 1: The lower left-hand corner and the upper right-hand

corner up to the diagonal lines marked “1”.

Zone 2: The lower left-hand corner and the upper right-hand

corner up to the diagonal lines marked “2”.

**Refer to Figure 15 for an example of Real Time Split Screen

images.

Page 27 of 67

Page 28

(A) (B)

Figure 15: Results from the Real Time Split Screen Feature

Zone 1(A) and Zone 2(B)

• To access Zone 1, click anywhere in Zone 1.

• To access Zone 2, click in between the diagonal lines

marked “1” and “2”.

• Click anywhere on the Zone 1 or Zone 2 image to return

to the original image.

1) Image Area - Shows overlay image of device and PCB for quick

and easy alignment.

2) Real Time Split Screen feature – Provides 2 zones of split

magnification. (Refer to Figure 14) The diagonal lines on the

display indicate the zones.

3) AutoFocus/Manual Button – Allows the operator to toggle the

camera focus control between manual and auto focus.

4) Zoom Slide Bar – Controls the amount of zoom from Wide to

Telescopic viewing.

5) Focus Slide Bar – Allows focus to be adjusted

6) Review Button – Allows previously saved image to be recalled.

7) Capture Button – Saves current image to “Capture” folder or

location of choice.

8) Video Selection – Image from TF 2000 is displayed.

9) Inspection Selection – Image from Inspection Device is displayed.

Page 28 of 67

Page 29

6-2.1 Optics Tab Inspection View

This Screen is used in conjunction with the XR 2000 X-Ray Inspection

System. Real time X-Ray video can be viewed, stored and compared to a

reference library of common faults or desired results.

The Review and Capture Buttons operate the same as in Alignment View. The

Arrow Buttons scroll between images stored in the reference library.

To Add a Reference Image: Any Image captured as a .bmp file may be

converted to a .tif image using the “Imaging” program (located on the Windows

Accessories Menu) and added to the “XrayLib” folder under the TF 2000

Software directory.

Page 29 of 67

Page 30

6-2.2 Print/Review Tab

This Screen allows the operator to recall and view saved profiles and

operator records and output them to a specified printer.

1) Open Profile Button – Loads saved profile from disk and

displays it on screen.

2) Open Record Button – Loads saved operator record and

displays it in Record Comment.

3) Overlay Profile Button – Inserts a previously saved profile on

screen to compare the currently viewed profile to.

4) Overlay Record Button – Inserts previously saved record on

screen to compare currently viewed record to.

5) Close All Button – Clears all opened and overlaid Profiles and

Records.

6) Print Preview Button – Opens Print Preview Screen

7) Print Button – Brings up Print Screen to select printer to output

displayed record or profile.

Print Review Tab

Page 30 of 67

Page 31

6-3 Operation Tab

With the exception of the optical alignment, this screen allows the

operator to perform all essential operations including profile selection,

documenting operations for quality assurance, and process validation.

Page 31 of 67

Page 32

Page 32 of 67

Page 33

Figure 16: Operation Tab

1) Profile Name – Allows the operator to select the proper profile from

a dropdown menu. When a profile is selected, the profile

parameters are automatically downloaded to the TF 2000 working

memory, profile #39.

2) Profile Instructions – Displays instructions pertinent to the selected

profile.

3) Record Comment area – Provides a means for documenting

essential information.

4) Save Record Button – Stores profile name, date & time, operator

comments and graph information in “Records” folder.

5) Progress Indicator – Visual indication of the profile process.

NOTE: A record is defined as information associated with a

particular rework job. This information includes profile

parameters (via the graph), sensor input, and

operator recorded comments. A record can be saved

for each new component installation. When a record

is saved, the date, time and profile name are

automatically stored with that record.

6) Graph area – Graphically displays profile parameters (time and

temperature) and a sensor input. The box next to Sensor 1 in the

right hand margin must be checked to activate this function.

Page 33 of 67

Page 34

6-3.1 Process Control/Validation Feature

Figure 17: Process Validation

During the Profile Development phase, a temperature probe trace can

be saved with an associated profile. A reference point near the

component rework area (on an adjacent component lead for example)

must be used for temperature probe placement. Location can be

stored in “Profile Instructions”. Keep in mind that data must be

collected from the same Temp probe place at the selected location

when saving profile temperature and rate with the profile.

When an operator selects an appropriate profile, the temperature

probe trace will be displayed on the graph in blue. To validate the

rework process, the operator can place the temperature probe on the

designated reference point, check the box next to Sensor 1 in the right

hand margin and run the profile. As the profile progresses, the

temperature probe trace will be displayed in red. The two probe traces

can be compared to validate a particular rework process. (See Figure

17) Some variation may exist due to differences in Temp probes,

positioning, and operator error. The “shape” of the curves should be

similar.

Page 34 of 67

Page 35

6-4 Profile Development Tab

This screen is designed for the profile development engineers. Access

to this screen can be password protected. Profiles can be created,

modified, and/or deleted from this screen. Specific operator

instructions applicable to a particular profile can also be entered from

this screen.

Page 35 of 67

Page 36

Page 36 of 67

Page 37

Figure 18: Profile Development Tab

1) Profile Name and Parameters (upper left-hand corner) – Allows the

operator to select a stored profile and displays time and

temperature settings for each phase of the Reflow cycle.

2) Instruction Box – Provides a means to store and display operator

instructions applicable to the selected profile. Instructions may

pertain to

such items as nozzle type, type of solder paste or flux, reference

position of temperature probe for process validation, and any other

special needs.

3) “New” Button – Clears Profile Name field and resets all profile

parameter fields to 0. Allows the operator to enter the new time

and temperature values for each phase of the Reflow cycle.

4) “Save Profile” Button – Saves profile parameters for the selected

profile. Clicking this button will overwrite existing profile parameters

for named profiles. A pop-up box will appear for new unnamed

profiles.

5) “Transfer Profile” – Transfers the selected profile to the working

memory in the TF 2000. The working memory is profile number 39

on the TF 2000. Profile parameters transferred to the working

memory will automatically be displayed in the LCD window on the

TF 2000.

6) “Save As” Button – Used for renaming profiles and naming new

profiles. A pop-up box will appear when pressed.

7) “Reset” Button – Clears sensor input lines from the graph.

8) “Save Excel” Button – Saves profile in .csv format that can be

opened in MS Excel.

9) “Delete Profile” Button – Deletes the selected profile from the PC.

Deleted profiles cannot be retrieved.

10) Graph Area – Graphically displays profile parameters (time and

temperature) and sensor inputs. Right Clicking the mouse on any

area of this graph will display the temperature at the point selected.

Left clicking the mouse on any two points will give the temperature

slope rate between the two points.

6-4.1 General Information concerning the Profile Development

Screen

1) The Reflow Graph area displays a representation of the Reflow

cycle profile. Time in minutes is graphed along the X-axis and

temperature in degrees Celsius is plotted along the Y-axis. The

time and temperature axes incorporate a dynamic scaling feature to

optimize the display for extremely short or long profiles. Profile

graphs can be saved with profiles to be used for process validation

by operators while using the Operation screen. Profile graphs can

Page 37 of 67

Page 38

also be stored as individual records for each rework job for quality

control purposes. Solid and dotted lines are used to indicate profile

parameters.

a) Horizontal Green Lines – Indicates upper and lower temperature

limits as set on the Setup Tab.

b) Horizontal Dotted Line – Indicates the Bottom Heater set

temperature. The dotted line becomes solid as the reflow cycle

progresses.

c) 3-Tiered Dotted Line – Indicates Top Heater activity for each

phase of the reflow cycle. The dotted line becomes solid as the

reflow cycle progresses.

d) Red Line – Sensor 1 temperature over the period of the reflow

cycle. Sensor 1 Box must be checked to allow for display of the

sensor input.

e) Blue Line – Sensor 2 temperature over the period of the reflow

cycle. Sensor 2 Box must be checked to allow for display of the

sensor input.

Each Sensor input has a Temp and Peak field (right hand margin)

associated with it. The Temp reading displays the current temperature

reading and changes as the reflow cycle progresses. The Peak

reading displays the highest temperature measured during the reflow

cycle.

Page 38 of 67

Page 39

Figure 19: Sample Profile Development Screen

2) Profile parameters can be changed while the profile is running.

Perform the following procedure to modify profile parameters while

the profile is running:

a) On the TF 2000, press the “Select” button until the cursor is at

the parameter field to be changed.

b) Press the “UP” or “DOWN” buttons to change the selected field.

Numeric values change by increments of 2 for each press of the

“UP” or “DOWN” button. See Figure 20.

Page 39 of 67

Page 40

Figure 20: LCD Display and UP and DOWN Buttons

As the profile parameters are changed on the TF 2000, the profile

parameter fields on the Profile Development screen will change to

reflect the increase or decrease in time. The dotted lines on the graph

will also change to reflect the new parameters. The Time fields on the

software reflect “total” time after modification.

6-4.2 Profile Creation

There are 2 recommended methods for developing a profile. The first,

involves an actual component installation, while the second uses a

previously installed package. Either method can be used to develop a

reliable profile. However, there are some issues and considerations to

be aware of with each.

When developing profiles through actual component installation, it is

critical to make sure the thermocouples remain in contact with the

solder balls throughout the entire process. Unreliable data will be

collected should a thermocouple lose contact with the solder balls. If

Page 40 of 67

Page 41

measuring the temperature on the top of the package it is best to use a

preinstalled component.

When using a previously installed package, the placement of the

thermocouples is important. They must be in contact with the existing

solder joints. This task is best accomplished by drilling through the

bottom of the PCB into a solder joint and attaching the thermocouple or

by sliding the thermocouple under the package. When sliding a

thermo couple under a component, it is critical that the thermo couple

be in contact with a solder ball.

Information from the thermocouples will assist in determining the

proper time and temperature parameters. In general, the following

guidelines should be adhered to when developing profiles.

Ramp and Maximum Temperatures

Acceptable ramp rates and maximum temperatures should be obtained

from the package manufacturer. It is recommended to select a

maximum temperature below the manufacturer’s specification to

provide for a margin of safety. Typically, 20 °C below maximum is

selected.

Pre-Heat Phase

1. In a “step profile”, the top of the PCB and package should reach a

stable temperature of 95-105 °C. If plotting the temperature curve,

the trace should level off within this temperature range.

2. If a “linear slope” is desired, pre-heat and soak phases are

combined. Both the package and the PCB are warmed at a

constant ramp rate (usually 1-3 °C/second) until the desired soak

temperature is reached.

Soak Phase

The soak phase is a crucial part of the reflow process. During this

period, the flux activates and drives off volatiles and excess flux. A

stable temperature of 145-170 °C (determined by the activation

temperature of the flux used) should be maintained for approximately

40-60 seconds. This allows for uniform ramping across the entire

package and PCB during reflow.

Reflow Phase

Page 41 of 67

Page 42

During this phase, the solder balls reach solder melt and form a joint

between the package and the pads. It is critical for all areas of the

array to reach solder melt together and all solder balls remain in a

liquid state for at least 15-20 seconds.

Generally, the device should not be exposed to temperatures higher

than 220 ºC. Always consult the device specifications for maximum

temperature recommendations. As a rule of thumb, a safe “maximum

temperature” is the maximum temp specified by the manufacturer

minus 20ºC. Lower temperatures and shorter times are common in

CSPs and FCs. The lowest temperatures possible should always

be used to ensure safety of the device and PCB.

Cool Down Phase

The cool down phase is necessary to bring the temperature of the

package, solder joints and PCB under the package below solder melt

temperatures. Cooling should be controlled. A good reference is to

use the same cool down rate as for ramp up. The cooling fan on the

TF 2000R will remain on for 55 seconds from the start of the cool down

cycle. Some types of components (like CBGAs) should be allowed to

cool without external assistance from the cooling fan.

General

Using the baseline defaults in memory locations 00, 01 and 02 will provide

a good starting point for profile development. The reflow graph provides

an excellent tool for monitoring profile parameters and fine tuning or

perfecting the profile development process.

When adjusting profile parameters “on-the-fly”, all changes are reflected

immediately on the profile development screen and graph.

Page 42 of 67

Page 43

7 MAINTENANCE

The TF 2000 is designed to operate with a minimum level of maintenance.

However, replacement of some parts will be required from time to time.

Please follow the maintenance instructions below when replacing parts. If

there are any questions, contact PACE.

CAUTION: Disconnect the main power supply and computer

7-1 Cleaning the Blower Filter

Clean the filter every three (3) months.

1) Take off the cover on the back of the TF 2000R. Please see

Figure 2.

2) Loosen the butterfly screw fitted inside.

3) Remove the filter from the housing.

4) Clean the inside filter using warm water.

5) Make sure the filter is dry before re-assembly.

cables, if applicable, BEFORE opening the TF 2000B,

TF 2000BE, TF 2000BL, TF 2000BLE, TF 2000R, TF

2000P, BEFORE replacing any component of the TF

2000, and BEFORE performing ANY routine

maintenance.

7-2 Replacing the Top Heater

Please refer to Figure 21 for heater replacement.

1) Disconnect the TF 2000 from ALL power supplies.

2) Remove the protective cover from the reflow head by removing

the four screws on the left side.

3) Loosen the two screws in the terminal block that affix the wires

from the top fan.

4) Set the fan aside.

5) Loosen the two bolts on the top of the assembly.

6) Lift off the connectors that secure the wires from the power

indicator lamp on the front of the protective cover.

7) Set the cover aside.

8) Lift off the heater wires from the mounting posts.

9) Remove the terminal block taking out the two screws that

secure it to the assembly.

10) Pull off the rubber hose from the connection on the top of the

assembly.

11) Loosen the three Philips head screws from the sides of the

housing and the hex bolt in the back that secure the top cover

of the assembly

Page 43 of 67

Page 44

12) Lift off the cover and pull out the heater.

13) Replace heater and reassemble assembly.

Figure 21: Heater Assembly

Page 44 of 67

Page 45

8 ALIGNMENT & CALIBRATION

All PACE TF 2000 BGA/CSP Rework Systems are factory aligned and

calibrated prior to shipment. Due to adverse shipping and handling

conditions, it may be necessary to perform one or more of the following

alignment and calibration procedures prior to use. Proper alignment and

calibration of system components should also be performed on a semiannual basis to ensure peak performance.

8-1 Board to Optics Aalignment

This alignment should be performed when the land pattern on the PCB

appears skewed on the video display.

NOTE: For TF 2000L/LE models, refer to the Alignment and

Calibration Differences in Section 10.

1) Position testing PCB in Board Holder.

2) Pull the optics housing out from the front of the TF 2000P using the

handle.

3) Zoom in so the lands on the PCB fill the screen.

4) Observe land pattern. If land pattern is skewed, proceed to step 5.

See figure 22. If land pattern appears aligned, omit steps 5-7.

5) Loosen 8 setscrews found on both sides of the board holder.

6) Shift the board holder by hand until the image is no longer skewed.

7) Retighten setscrews, alternating from one side of the board holder

to the other, until all 8 setscrews are tight.

Figure 22: Skewed Land pattern

Page 45 of 67

Page 46

8-2 Sliding Shaft Holder Alignment (Indexing)

This alignment will correct X aspect errors when indexing the sliding

shaft holder from the placement position to the reflow position and vice

versa.

NOTE: For TF 2000L/LE models, refer to section 10 for the

Sliding Shaft Holder Alignment.

NOTE: A reference point must be established for this

procedure. The reflow position will serve as a

reference point for this alignment calibration.

1) Position testing PCB in the board holder.

2) Set the sliding shaft holder at the reflow position flush against

the left indexing tab.

3) Lower reflow heater nozzle to approximately 1/8” above a PCB

component.

4) Visually center component in the “X” direction under nozzle

using the adjustment knob on the sliding shaft holder.

5) Using the handle on the sliding shaft holder, index the table

from the reflow position to the placement position.

6) Pull the optics housing out from the front of the TF 2000P using

the handle.

7) Zoom in so the lands on the PCB fill the screen.

8) The land pattern should be centered on the display horizontally

(X direction). If centered, omit steps 9-16. Otherwise, proceed

to step 9.

9) Set the sliding shaft holder in between the reflow and

placement position.

10) Remove rubber stopper from right indexing tab on the base

assembly.

11) Loosen center set screw on top of right indexing tab. See

Figure 23.

12) Depending on the direction and amount of offset in the X plane,

tighten or loosen the large setscrew on the side of right

indexing tab.

Note: Tightening the large setscrew will shift the displayed

image to the right. Loosening the same setscrew

will shift the image to the left.

13) Reinstall rubber bumper on large setscrew.

14) Return sliding shaft holder to the placement position.

Page 46 of 67

Page 47

15) Observe proper centering of land pattern on video display. If

centered, proceed to step 16. Otherwise, repeat steps 9-14

until proper centering is achieved.

16) Tighten center set screw on top of right indexing tab.

Figure 23: Top and Side View of Indexing Tab

8-3 Vacuum Nozzle Planarity

The Vacuum Pick nozzle must land flush on the PCB component in

order to achieve parallelism and adequate suction. Performing the

following procedure can rectify problems in vacuum nozzle planarity.

1) Remove the cover on the Alignment Apparatus by removing the

three bolts on the top of the cover and the “Y” adjustment knob.

The “Y” adjustment may have to be brought forward to allow the

cover to clear the shaft.

2) Place a PCB on the board holder and install the large nozzle.

3) Lower the alignment apparatus to the PCB.

NOTE: To achieve parallelism in the “X” direction, perform

steps 4-7. In order to achieve parallelism in the “Y”

direction, perform steps 8-11.

Page 47 of 67

Page 48

Figure 24: Three vertical setscrews on the alignment apparatus

8-3.1 X Correction Refer to Figure 24

1) Loosen the top 2 setscrews facing the front of the alignment

apparatus.

2) Lightly press right over the vacuum pick to suck the PCB.

3) Turn the “Z” knob right or left to meet the parallel face of the

vacuum pick nozzle and the PCB. When parallel, the vacuum

noise will be low.

4) Retighten the 2 setscrews while maintaining light pressure over the

vacuum pick assembly.

8-3.2 Y Correction Refer to Figure 24

1) Loosen the bottom setscrew facing the front of the alignment

apparatus.

2) Lightly press right over the vacuum pick to suck the PCB.

3) Turn the “Z” knob right of left to meet the parallel face of the

vacuum pick nozzle and the PCB. When parallel, the vacuum

noise will be low.

4) Retighten the bottom setscrew while maintaining light pressure over

the vacuum pick assembly.

8-4 Reflow Head Planarity Alignment

When lowered and properly aligned, the nozzle on the reflow head

should land flush with the PCB. Errors in reflow head planarity (both X

and Y aspects) can be corrected by performing the following

alignment.

8-4.1 X Correction

Page 48 of 67

Page 49

1) Position the test PCB in the board holder and index the sliding

shaft holder to the reflow position.

2) Lower reflow head and nozzle to just above the PCB.

3) Turn off the power to the Reflow unit.

4) Loosen 2 setscrews located on the backside of the reflow head,

on both sides of the arm that extends out to the reflow head.

NOTE: Allow ample time for cooling before handling the reflow

head.

5) Adjust position of the reflow head by hand until parallelism is

achieved in the “X” direction.

6) Retighten 2 setscrews on the back of the reflow head while

holding reflow head in correct position.

8-4.2 Y Correction Refer to Figure 25.

1) Remove the screws on the front and back of the base assembly,

which are used to secure the Reflow unit to the base unit.

2) Remove the reflow assembly from the base and place on a

stable platform.

3) Remove 8 philips head screws securing the housing for the

Reflow unit and slide the housing assembly off.

4) Loosen 4 setscrews on the reflow head arm, located directly

behind the front panel.

5) Manually adjust the reflow head until parallelism is achieved in

the “Y” direction.

6) Retighten 4 large setscrews maintaining position of reflow head.

Adjustment

Setscrews

Adjustment

Setscrews

Figure 25: Y Correction setscrews for Reflow Head Planarity Alignment

8-5 Reflow Head – “Y” Directional Adjustment

Page 49 of 67

Page 50

This adjustment should be performed when the Reflow Head is either

too far forward or too far back (“Y” aspect) when lowered down onto

the PCB. If the nozzle does not land flush (planar) on the PCB,

perform the Reflow Head Planarity alignment before this adjustment.

NOTE: Ensure the nozzle assembly is properly seated in the

Reflow head. If the nozzle if improperly seated, the nozzle

and Reflow head may appear to be too far forward when

lowered down onto the PCB.

1) Remove the screws on the front and back of the base assembly,

which are used to secure the Reflow unit to the base unit.

2) Remove the reflow assembly from the base and place on a

stable platform.

3) Remove 8 philips head screws securing the housing for the

Reflow unit and slide the housing assembly off.

4) Place the reflow assembly (uncovered) back on the base and

secure with the screws on the front and back.

The Reflow Head is attached to a vertical structure (block) that

is secured to the bottom of the reflow unit by 2 allen head

screws.

5) Locate the slot for the allen head screws on the underside of the

base assembly directly under the reflow head.

6) Loosen the two allen head screws.

7) Slide the vertical structure either forward or back to compensate

for the “Y” directional aspect error of the Reflow Head.

8) When the “Y” aspect error is corrected, retighten the 2 allen

heads.

9) Re-install the cover on the reflow unit.

Page 50 of 67

Page 51

9 GENERAL TROUBLESHOOTING

The following procedures are designed to allow the operator to perform

basic visual inspections of system components. (ie. loose connections,

equipment misalignment, etc.) If you ever have any questions, contact

PACE.

Page 51 of 67

Page 52

Initial Operation

g

The Reflow unit will conduct an initialization sequence each time the

power is turned on. The following flow diagram can be used to isolate

failures during this initialization sequence.

POWER ON

Power and Off

LEDs are lit,

LCD is on, and

Cycle Start LED

is flickerin

AIRFLOW

ON

18-25 l/min

TOP

HEATER

ON,

SENSOR

TEMP

< 250°C

TOP

HEATER

OFF IN 30

SEC., AND

FLOW IS

OFF IN 20

SEC.

.

1. Check AC power input

2. Are circuit breakers tripped?

3. Check electrical connection on

PCB RD200c

1. Is knob open at Flow meter?

2. Check CR1 of PCB RD200Po

1. Check connections of CN3 and

CN9of PCB RD200Po

2. Check BCR1 of PCB RD200Po

(Warning Buzzer is buzzing)

1. Check for breakage of Sensor

Connection, CN10 of PCB RD200c.

2. Check for breakage of Heater

Connection, CN9 of PCB RD200c.

BOTTOM

HEATER

LAMP IS ON

AND

FLICKERS

AFTER 3 MIN.,

BOTTOM

HEATER

TEMP IS UP

INITIAL

OPERATION

OVER

Page 52 of 67

Check BCR2 of PCB RD200Po

Page 53

Nozzle Up/Down Operation

N

N

PRESS THE “STAND BY”

BUTTON

OZZLE

COMES

DOWN,

STAND BY

LAMP ON

PUSH THE “STOP”

BUTTON

OZZLE

COMES UP,

STAND BY

LAMP IS

OFF

1. Check connection CN2

of PCB RD200c.

2. Possible faulty

components: IC9 or R107

of PCB RD200c.

END

Page 53 of 67

Page 54

Vacuum Nozzle Operation

N

PRESS VACUUM BUTTON

TO TURN VACUUM ON

USING YOUR

FINGER,

CHECK FOR

SUCTION AT

THE END OF

THE VACUUM

PICK NOZZLE

Remove housing cover of the

Positioning unit. Check Pump

and Leak valves, M1 and S1, and

associated hoses.

WHEN

LOWERED,

VACUUM PICK

OZZLE

SHOULD LAND

FLUSH ON THE

COMPONENT

(PARALLEL)

END

Perform Vacuum Nozzle

Planarity calibration (See page

39)

Page 54 of 67

Page 55

General Troubleshooting

SYMPTOM CORRECTIVE ACTION

Profile memory not storing profiles. Check battery back up connection to

CN5 of PCB RD200c.

Land pattern on PCB appears

skewed or crooked on video display.

Reflow head is not parallel with PCB Perform Reflow Head Planarity

Lamps in the optical housing

assembly are not operational.

The camera does not operate. Check the wiring and connection of

Perform Board to Optics Alignment.

(See page 37)

Alignment. (See page 41)

1. Replace failed lamp or lamps.

2. Check transistors T1 (PCB side)

and T2 (BGA side), or Microswitch S1 located on the chassis.

the camera. If nothing is found

abnormal, replace the camera.

Page 55 of 67

Page 56

10 TF 2000 L/LE MODEL DIFFERENCES

Figure 26: TF 2000L/LE Model

The TF 2000L/LE models are designed for rework and repair of larger PCBs.

With the exception of the Bottom Side Heater, the Reflow and Placement

stations are identical to the standard model. There are actually 2 Bottom Side

heaters to provide bottom-side heating. The rails for the board supports are

significantly longer than the standard model as well. These differences will be

discussed in greater detail in the following paragraphs.

10-1 Installing the PCB Holder

1. Place the “Rail” between the two rows of bearings on the base of

the TF 2000 L/LE.

2. Place sliding shaft holder onto slide with the knob facing out.

3. Install two screws on each side of the sliding shaft holder to secure

board holder.

4. Install board supports by laying them across the front and back rails

as indicated in Figure 27.

Page 56 of 67

Page 57

10-2 Bottom Side Heaters

The larger version of the TF 2000 houses 2 bottom-side heaters. The

large bottom heater is movable in both the X and Y direction and is

designed to heat the overall PCB. (See Figure 27) The TEMP knob

on the bottom heater Switch Panel (See Figure 28) controls the

temperature variation for the movable Bottom Side heater.

Figure 27: Both Bottom-Side Heaters

Figure 28: Switch Panel for the Movable Bottom Heater

Page 57 of 67

Page 58

TEMP knob settings:

TEMP knob set to 10 = 130 °C on the PCB

TEMP knob set to 8 = 80 °C on the PCB

**TEMP knob should be set at 8 or above during normal use

The small bottom-side pre-heater (located directly below the Reflow head)

is non-movable and designed to provide intense heat directly under the

BGA placement area. The temperature is controlled via the temperature

profile.

10-3 Sliding Shaft Holder Indexing

In the standard model, the Sliding Shaft Holder slides freely from the

placement position to the reflow position. For the TF 2000L/LE

models, a locking mechanism must be released to index the Sliding

Shaft Holder from one position to the other. A ball joint located on

either side of the Sliding Shaft Holder seats into the locking

mechanism. See Figure 29. To release the lock in the placement

position, push the handle on the Sliding Shaft Holder to the right. The

lock will release and spring tension inside the locking mechanism will

push the Sliding Shaft Holder towards the Reflow position. When

locked in the Reflow position, push the handle on the Sliding Shaft

Holder to the left to release the lock.

Figure 29: Ball Joint and Locking Mechanism

Page 58 of 67

Page 59

10-4 Alignment and Calibration Differences

With the exception of the Board to Optics and Sliding Shaft Holder

(Indexing) alignments, all alignments and calibrations are performed as

previously described in Section 7.

The Board to Optics alignment is performed in essentially the same

manner as the standard version. The only difference is on Step 5.

Phillips head screws need to be loosened instead of Allen head

setscrews.

The Sliding Shaft Holder Alignment (Indexing) for the TF 2000L/LE

model is slightly different due to the locking mechanisms at the Reflow

and Placement positions. Use the following procedure to perform this

alignment.

NOTE: A reference point must be established for this

procedure. The reflow position will serve as a

reference point for this alignment calibration.

1) Position the test PCB in the board holder.

2) Set the sliding shaft holder at the reflow position flush against

the left indexing tab.

3) Lower reflow heater nozzle to approximately 1/8” above a PCB

component.

4) Visually center component in the “X” direction under nozzle

using the adjustment knob on the sliding shaft holder.

5) Using the handle on the sliding shaft holder, release the locking

mechanism and index the table from the reflow position to the

placement position. Be sure the lock latches.

6) Pull the optics housing out from the front of the TF 2000P using

the handle.

7) Zoom in so the lands on the PCB fill the screen.

8) The land pattern should be centered on the display horizontally

(X direction). If centered, omit steps 9-11. Otherwise, proceed

to step 9.

9) Loosen the 4 Phillips head screws on the mounting bracket for

the placement position locking mechanism. (See Figure 30)

10) Shift the mounting bracket to the right or the left until the image

appears centered on the display.

11) Re-tighten Phillips head screws.

Page 59 of 67

Page 60

Figure 30: Locking Mechanism Mounting Bracket (Top View)

Page 60 of 67

Page 61

11 SPECIFICATIONS

1. Heater (top-side): Convective style, 1200 W heater

Operating Temperature Range: 100ºC – 500ºC

2. Pre-heater (bottom-side): Light IR 400 Watt (200 W x 2)

Operating Temperature Range: 100ºC – 260ºC

Standard Pre-heater Size: 220mm x 155mm (8.6” x 6.1”)

Large version Pre-heater Size: 340mm x 470mm (13.3” x

18.5”)

3. Heating control: K type thermo-couple with closed-loop control

4. Applicable Devices: BGA, CSP, LGA, BCC and etc. Max. 50 mm x

50 mm

5. Maximum PCB Size: Standard 360 mm (14”) x 430 mm (17”)

With Optional Long Rails or L version: 500 mm (19.5) x 430 mm

(17”)

6. Airflow MAX: 25 l/min.

7. Component Adjustment Range of X,Y & Z: ±10 mm (±.4”)

8. Adjusting volume of X, Y & Z: 0.5 mm (0.02”) per revolution.

9. Positioning accuracy: 25 µm (0.001”)

10. Maximum Vacuum: 450 mm Hg

11. Video Output: NTSC/BNC to Video Monitor, NTSC/S-Video for PC.

12. Power Source: 100V-120 VAC, 60 Hz, 230 VAC, 50 Hz

13. Power consumption (MAX):

θ: Infinite

Rotation

TF 2000 & TF 2000E: 1.6 KW

TF 2000L & TF 2000LE: 2.1 KW

14. Dimensions:

TF 2000 and TF 2000E

516 mm (20.3”) W x 491 mm (19.4”) H x 517 mm (20.3”) L

TF 2000L and TF 2000LE

710 mm (28”) W x 491 mm (19.4”) H x 680 mm (26.8”) L

15. Weight: TF 2000, 115 VAC: 57 kg (125.5 pounds)

TF 2000E, 230 VAC 66 kg (145 pounds)

TF 2000L, 115 VAC 75 kg (165 pounds)

TF 2000LE, 230 VAC 84 kg (185 pounds)

Page 61 of 67

Page 62

Page 62 of 67

Page 63

Instructions for using the Board Supports

When performing rework on larger PCBs, the use of board supports

may be required to keep the PCB level at all times. PACE supplies a

set of board supports as optional equipment with the TF 2000. The set

consists of 6 cast iron support bars. The two longest bars are

positioned across the slide shafts on either side of the sliding shaft

holder. The remaining four attach quickly to both sides of the board

holder and rest on the bars positioned across the slide shafts providing

a level surface for PCB placement. The following procedure details the

proper usage for the board supports. (See Figure 26)

1) Install retaining screws at both ends of the bars to be positioned

across the slide shafts. (2 longest bars)

2) Place supports across the slide shafts, one on each side of the

sliding shaft holder.

3) Install an appropriate board support screw on the end of one of

the remaining board supports.

4) Place a thumbscrew in one of the four holes on one side of the

board holder.

5) Place a slide clip on the bottom of the board support and

position under the board holder, directly beneath the

thumbscrew.

6) Tighten thumbscrew just enough to hold the board support in

place.

7) Position the board support in the desired location and tighten

the thumbscrew for the associated board support. Repeat steps

3-7 for the remaining board supports.

Page 63 of 67

Page 64

12 ACCESSORY ITEMS

Custom Nozzles can be ordered by contacting PACE.

Extended Rail for PCB 4018-0098-P1

Board Supports 4018-0099-P1

Optical Alignment Kit 4018-0100-P1

Nozzle, 5mm SQ 4038-7001

Nozzle, 6mm x 8mm 4038-7002

Nozzle, 8.2MM x 12.7mm 4038-7003

Nozzle, 9mm SQ 4038-7004

Nozzle, 10mm SQ 4038-7005

Nozzle, 13mm SQ 4038-7006

Nozzle, 15mm SQ 4038-7007

Nozzle, 17mm SQ 4038-7008

Nozzle, 23mm SQ 4038-7009

Nozzle, 27mm SQ 4038-7010

Nozzle, 35mm SQ 4038-7011

Nozzle, 44.5mm SQ 4038-7012

Nozzle, LQFP, 22mm SQ 4038-7013

Nozzle, LQFP, 16mm SQ 4038-7014

Nozzle, LQFP, 30mm SQ 4038-7015

Nozzle, LQFP, 9mm SQ 4038-7016

Nozzle, LQFP, 12mm SQ 4038-7017

Nozzle, LQFP, 26mm SQ 4038-7018

Nozzle, LQFP, 16mm x 22mm 4038-7019

Nozzle, LQFP, 14mm SQ 4038-7020

Nozzle, 14mm x 22mm 4038-7021

Nozzle, 50mm SQ 4038-7022

Nozzle, 60mm sq. 4038-7023

Nozzle, 40mm sq. 4038-7024

Nozzle, 25mm sq. 4038-7025

Nozzle 19mm sq. 4038-7026

Nozzle, 16.5mm x 8mm 4038-7027

Nozzle, 33mm sq. 4038-7028

Nozzle, 21mm x 25mm 4038-7029

Nozzle, 29mm sq. 4038-7030

Nozzle, 31mm sq. 4038-7031

Nozzle, 42mm sq. 4038-7032

Nozzle, Conn, 16mm x 13mm 4038-7033

Nozzle, Conn, 27mm x 13mm 4038-7034

Nozzle, Conn, 30mm x 12mm 4038-7035

Page 64 of 67

Page 65

Nozzle, Conn, 19mm x 8mm 4038-7036

Nozzle, 56mm x 17mm 4038-7037

Nozzle, w/ Baffle 28mm x 16 4038-7038

Nozzle, 13mm x 10mm 4038-7039

Nozzle, 7.3mm x 7mm 4038-7040

Nozzle, 8mm SQ 4038-7041

Nozzle, 6mm SQ 4038-7042

Nozzle, 44mm SQ 4038-7043

Nozzle, 30mm SQ 4038-7044

Nozzle, 43mm SQ 4038-7045

Nozzle, 46mm SQ 4038-7046

Nozzle, 41mm SQ 4038-7047

Nozzle, 28mm SQ 4038-7048

Nozzle, 48mm SQ 4038-7049

Nozzle, 11.42mm X 5.08mm 4038-7050

Nozzle, 23mm X 32.5mm 4038-7051

Nozzle, 11mm X 17mm 4038-7052

Nozzle, 17mm X 32mm 4038-7053

Component Stenciling Tool Kit, 35mm-4 layer substrate 7016-0006

Component Stenciling Tool Kit, 27mm-4 layer substrate 7016-0007

Component Stenciling Tool Kit, 23mm 2 layer substrate 7016-0008

Component Stenciling Tool Kit, 23mm 4 layer substrate 7016-0013

Component Stenciling Tool Kit, 17mm 2 layer substrate 7016-0009

Component Stenciling Tool Kit, 17mm 4 layer substrate 7016-0012

Component Stenciling Tool Kit, 15mm-2 layer substrate 7016-0010

Component Stenciling Tool Kit, 15mm x 1 layer substrate 7016-0023

Component Stenciling Tool Kit, 13mm-2 layer substrate 7016-0011

Component Stenciling Tool Kit, 12mm CSP 7016-0014

Component Stenciling Tool Kit, 11x8 CSP 7016-0015

Component Stenciling Tool Kit, 40mm sq. 7016-0016

Component Stenciling Tool Kit, 25mm x 2 layer substrate 7016-0017