Page 1

TF 1500 BGA Rework Station

Operation and Maintenance Manual

Manual Number 5050-0525

Page 2

Table of Contents

Packing Contents, Standard Items......................................3

Specifications..........................................................................3

Parts Identification..................................................................4

Safety Information..................................................................5

Features...................................................................................5

Set-Up ......................................................................................7

Connect........................................................................7

Start up.........................................................................7

Inserting vacuum pick................................................7

Inserting nozzle...........................................................8

Set up screen features ..............................................9

Alignment screen features......................................11

Production screen features.....................................12

Profile development screen features.....................13

Inspection screen features......................................15

Calibration.................................................................16

Operation...............................................................................19

Production.................................................................19

Component removal.................................................22

Profile development .................................................23

Temperature Control ............................................................25

Available Nozzles/Accessories/Optional Items ...............25

Maintenance..........................................................................25

Regulation.............................................................................26

Service and Warranty..........................................................27

System Operations Manual

www.paceworldwide.com Page 2 of 38

Page 3

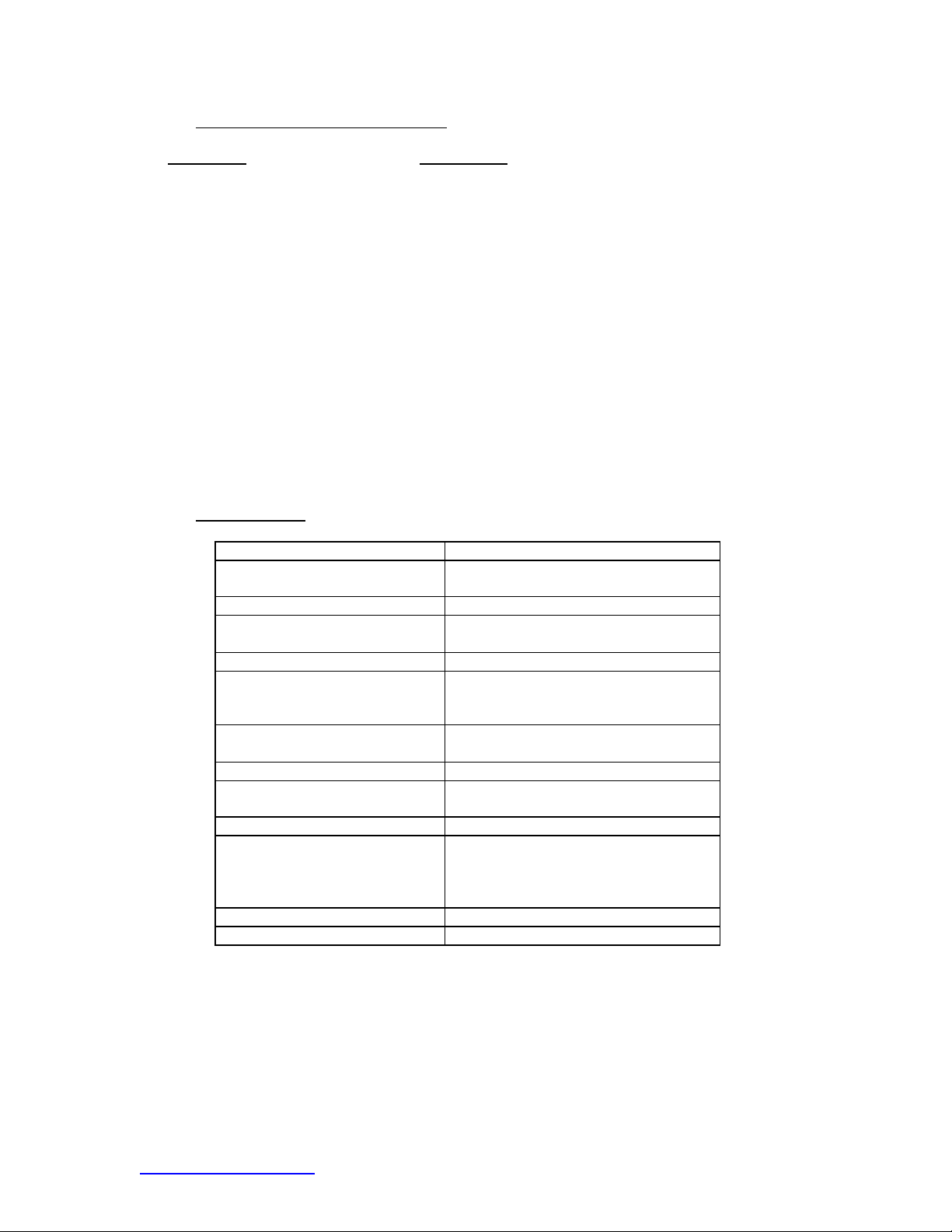

1. Packing Contents, Standard Items

Description Part Number

TF 1500 8007-0410 (120V)

8007-0411 (230V)

PC Monitor Keyboard Mouse Vacuum Pick 1272-0005-P1

Vacuum Pick Kit 6993-0060

Suction Cups 6993-0202-P1

Alignment Board 4018-0100-P1

Mounting Platform Stencil 1321-0725

Mounting Platform Flux Dip 1321-0735

Hot Grip Removal Pad 1100-0307

Thermocouples (4) 1340-0174-P1

Hex Wrench Kit 6016-0034

Power Cord 1332-0224

Video Cable 3008-0168

2. Specifications:

Part Number 8007-0410

Dimensions 737 mm H x 686 mm W x 737 mm D

(29” x 27” x 29”)

Weight (w/o computer) 45 kgs (100 lbs)

Power Requirements 115 VAC, 60 hz or 230 VAC, 50 Hz

2000 watts

PC Pentium 4, 256M Ram, Floppy, CD

Top Heater Adjustable convective air (air or N2),

Maximum 20 SLPM, 1600 watts

100 to 400 deg C, 212 to 750 deg F

Bottom Heater IR, 400 watts, 2 @ 200w each

100 to 221 deg C, 212 to 430 deg F

Vacuum 450 mm Hg

Optics High resolution, Dual Color Vision

Overlay System

Positioning Accuracy (Z travel) +/- 25 umeters (0.001”)

Video 2 Composite Video (external)

1 “S” Video (Internal)

15” Integrated color Flat Panel

Monitor

PC Board Size 305 x 305 mm, 12” x 12”

Component Size 35 mm x 35mm, 1.38” x 1.38” max.

System Operations Manual

www.paceworldwide.com Page 3 of 38

Page 4

System Operations Manual

A B C

D

E F G H I

J

K L

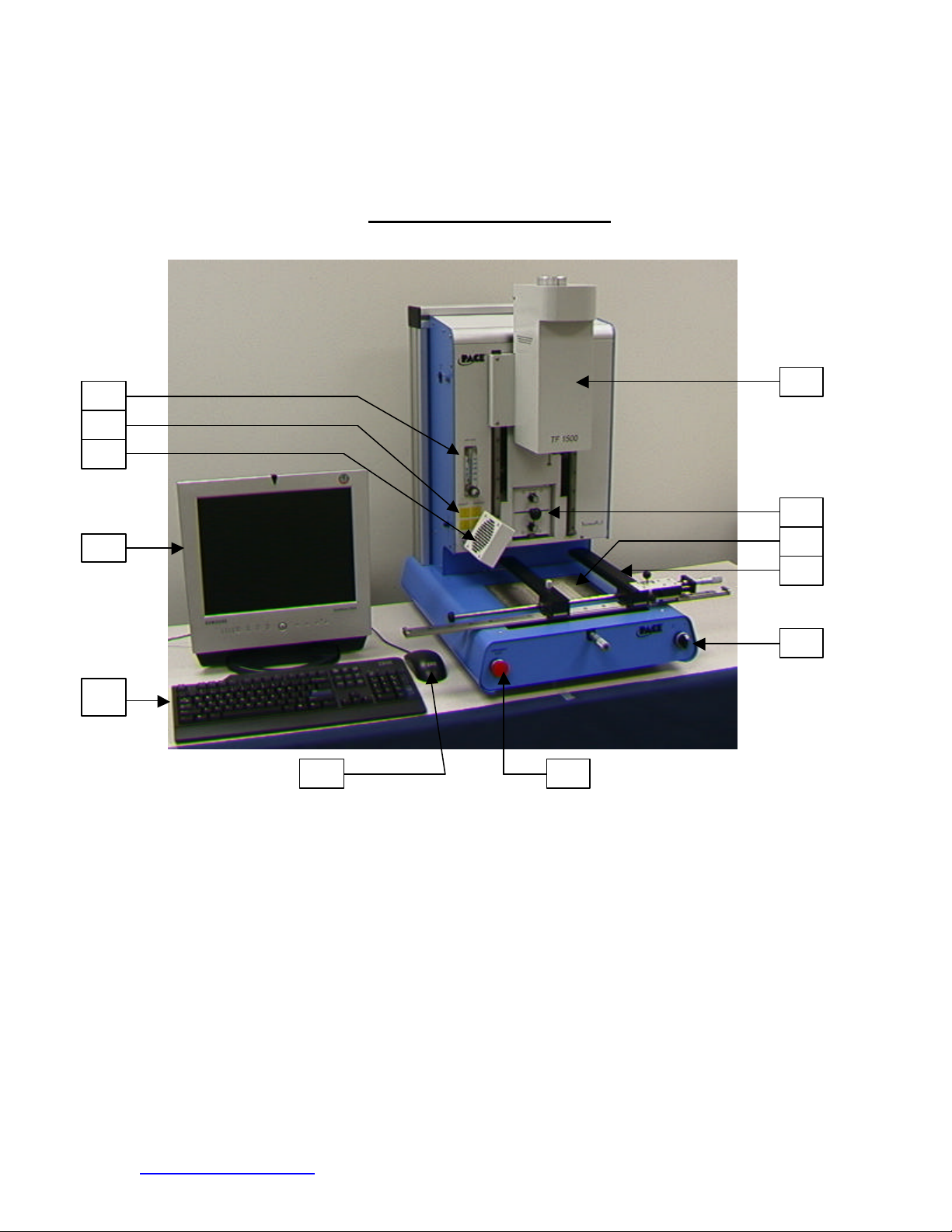

TF 1500 Parts Identification

Figure 1

A. Air Flow Meter This device is used to control and monitor the airflow

through the reflow head.

B. Sensor Input The sensor inputs are K-type thermo-couples.

Measured temperatures are displayed through the PC

software in real time for use in making profile graphs.

C. Cooling Fan The component and PCB are cooled by the cooling fan,

which can be set to activate automatically after the

reflow cycle is complete or operated manually.

D. LCD Display Monitor Displays PC software.

E. Keyboard Used to enter information into software.

F. Reflow Head Contains the top-side heater and moves up and down

via an electric motor that is controlled through the

software. The reflow head is clutched to prevent

excessive downward force from being applied.

www.paceworldwide.com Page 4 of 38

Page 5

System Operations Manual

G. Optics Housing Contains the camera and beam splitter (prism). The

housing is retractable and should be kept in the retracted

position when not in use. The lights for the optics will

turn on/off automatically when the housing is

extended/retracted.

H. Bottom Side Heater Used to warm the PCB from the underside. It is an IR

type heating source.

I. Board Holder The board holder is fully adjustable in the X direction

only. Fine adjustment of both the X and Y direction is

achieved by using the adjusting knobs on the end of the

holder for X and on the front of the machine for Y.

The right side of the holder is spring loaded to hold the

PCB securely.

J. On / Off Switch Used to turn the system on or off. When turning off the

system, always turn off the PC using the windows

interface first.

K. Mouse Used to enter information into software.

L. Emergency Off Switch In case an emergency shut down is necessary, press

this button.

3. Safety Information

a. Do not contact the Heater or its peripheral parts during operation.

b. Once turned off, let the unit cool completely before contacting.

c. When using fluxes, use fume extraction equipment or use in a well-ventilated

area to minimize operator exposure to fumes.

d. Do not use near combustible vapors.

e. Do not leave the equipment unat tended when in use.

f. Do not open rear panel without disconnecting power cable.

4. Features

a. The TF 1500 is ideal for post assembly rework, repair, and low volume/short run

production operations. The TF 1500 can remove and install PBGAs, CSPs, FCs,

LGAs, LCC’s and other SMDs.

b. Featuring unparalleled thermal performance, The TF 1500’s flexibility and state

of the art process software means no other system is easier to use. The TF 1500

is a PC driven, semi-automated system that requires a Pentium ® 4 PC featuring

Windows XP® Professional OS. The unique standard software package offers

much more than just an operator interface. TF 1500’s advanced vision and

placement system is highly accurate and can quickly magnify even the smallest

components for easy alignment. TF 1500 uses a combination of convective top

heating coupled with powerful IR bottom heating for an effective, repeatable

heating process.

c. Economical and easy to use, the TF1500 Rework System delivers high -end

BGA/CSP functionality, moving far beyond expe nsive, bulky rework machines by

offering unparalleled performance at an affordable price.

d. REFLOW FUNCTION

i. Unequalled programmability and process control ensures successful,

repeatable installation.

ii. The powerful and responsive 1600 Watt top heater, with closed loop

temperature control, coupled with proven TF 3000 nozzle design ensures

uniform temperature distribution when heating.

www.paceworldwide.com Page 5 of 38

Page 6

iii. High power bottom heaters allow for successful and repeatable reflow at

safe, low temperatures.

iv. Profiles are programmed through the PC software.

v. Creating the perfect profile is easy with real time adjustment of profile

parameters through the PC.

vi. Store and recall an infinite number of profiles.

vii. Two pre -defined profiles for use as baselines when developing custom

profiles are included.

viii. Self contained, no external air supply or vacuum connections required.

Can also be used with N2 from external source.

ix. Semi-automated, motorized reflow head.

x. Four thermo-couple sensor inputs ensure successful profile development

and monitoring.

xi. External fan to cool PCB and component to below solder melt

temperatures after reflow.

e. ALIGNMENT AND PLACEMENT FUNCTION

i. The component is held by a precision vacuum placement pick, which is

located within the heater assembly.

ii. High resolution Dual Color Vision Overl ay System (VOS) with color

camera and dichroic prism. VOS does not require routine calibration,

eliminating costly downtime and operator frustration.

iii. Color Camera with 72x zoom capability, featuring auto-focus zoom.

iv. Lighting system uses “Ultra Bright” Red and Blue LEDs for maximum

contrast of lands and solder balls on component.

v. Independent lighting controls for component and PCB to maximize

overlay contrast.

vi. Retractable optics housing protects VOS from dirt and contamination.

vii. Accurately places any array package up to 35mm (1.3") square and as

small as 1 mm (.04”) square.

viii. Precise micrometer adjustment for X, and Y axis with Theta adjustment

ensures placement accuracy.

ix. High-flow vacuum pick holds component securely.

x. Images are viewed through the PC in standa rd or full screen viewing

options.

f. PRE-HEAT FUNCTION AND BOARD HOLDER

i. Fully adjustable, precision, spring loaded board holder with top or bottom

PCB registration. Precise micrometer adjustment for X and Y adjustment

ensures placement accuracy for repeatability.

ii. Rugged, stable board platform to hold and support the PCB.

iii. Unique board holding fixtures that are able to hold very small and odd

shaped PCBs.

iv. Board supports are standard with the system.

v. Integrated, powerful, IR pre-heater with closed loop temperat ure control

ensures process integrity by delivering heat evenly, time after time.

System Operations Manual

www.paceworldwide.com Page 6 of 38

Page 7

System Operations Manual

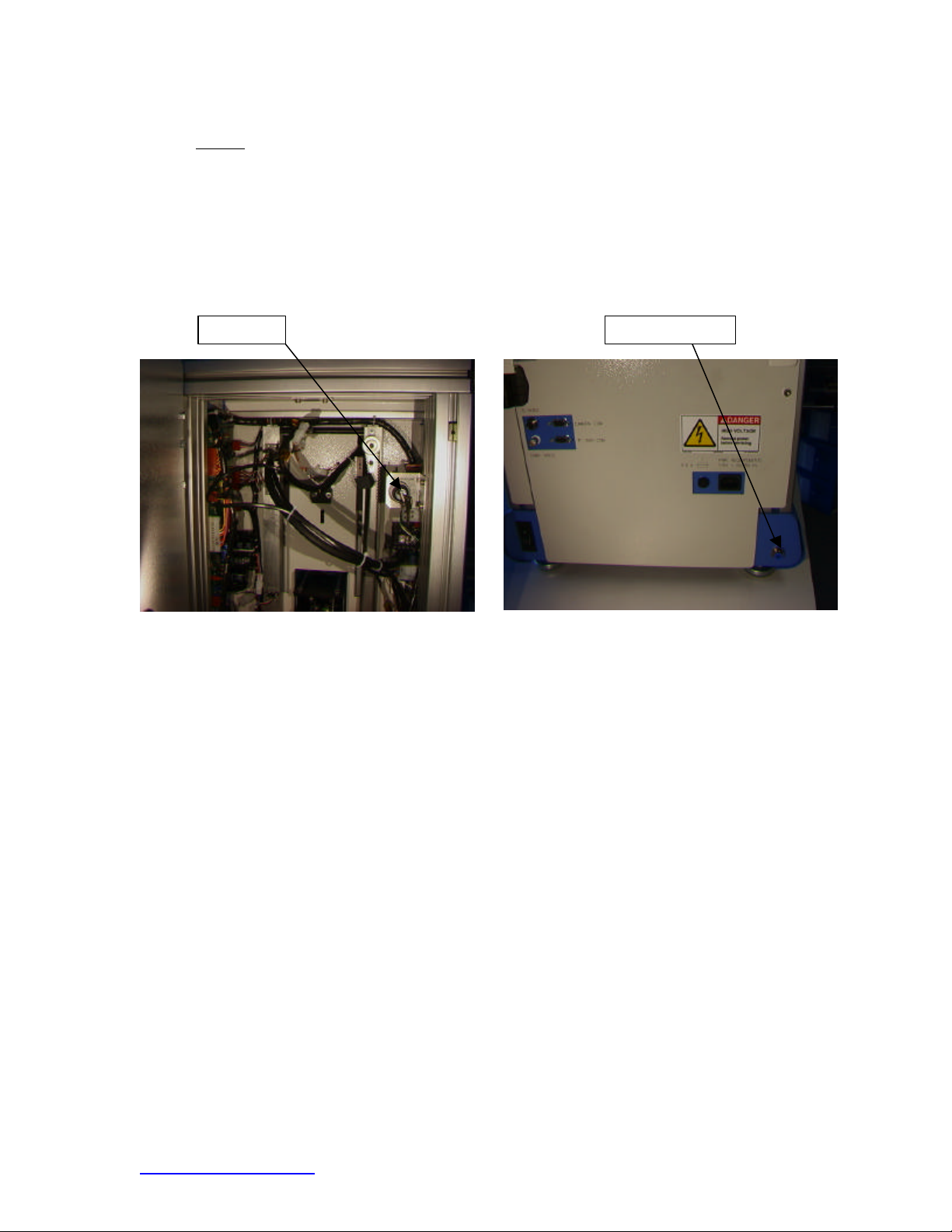

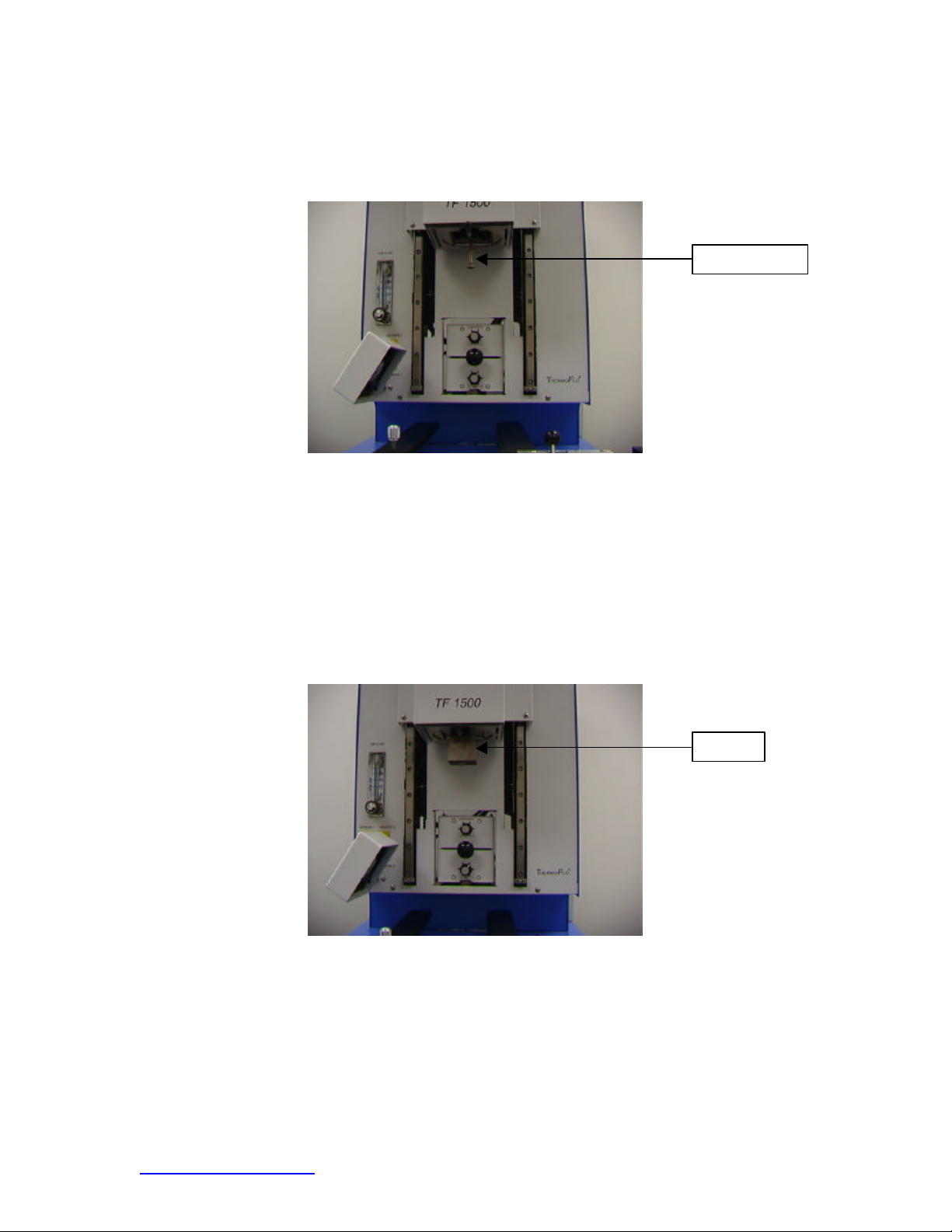

N2 Key N2 Connection

5. Set-Up

a. Connect

i. The TF 1500 comes configured for internal or external air. Select air

source; internal pump or external N2. (Figure 2a & 2b)

Warning: Do not run unit in N2 mode unless N2 supply is connected and

on.

1. Open rear panel.

2. Turn key to desired air supply.

3. Close rear panel.

Figure 2a Figure 2b

ii. Insert PC into brackets on back of PC.

iii. Monitor

4. Connect power cord.

5. Connect video cable to the 9-pin connector of the PC.

iv. Keyboard – connect cable to computer.

v. Mouse – connect cable to computer.

vi. Connect cables between PC and back of TF 1500 according to labels.

vii. Connect power cords to TF 1500 and PC.

b. Start up

i. Turn on circuit breaker on back of unit.

ii. Turn on power switch on front of unit.

iii. Turn on computer.

iv. Turn on monitor.

v. Mouse click on TF 1500 icon.

vi. Read and accept license.

www.paceworldwide.com Page 7 of 38

Page 8

System Operations Manual

Vacuum pick

Nozzle

c. Inserting/changing vacuum pick.

i. Insert proper size vacuum pick. The diameter needs to be smaller than

the top of the component. The pick screws into place. (Figure 3a)

Figure 3a

d. Inserting/changing nozzle. (Figure 3b)

i. Insert proper size nozzle. The nozzle should be 3 mm larger than the

outside of the component. If the proper nozzle size cannot fit onto the

PCB due to adjacent components being to close, use a smaller nozzle or

keep the nozzle approximately 1mm above the part. Align the nozzle

under the square hole in the reflow head. The nozzle snaps into place.

The nozzle can be positioned with the front surface parallel to the PCB or

at a diagonal by moving the lever by the nozzle housing.

Figure 3b

www.paceworldwide.com Page 8 of 38

Page 9

System Operations Manual

i ii iii iv v vi

vii

viii ix x xi

xii xiii

xiv xv xvi xvii xviii

xix

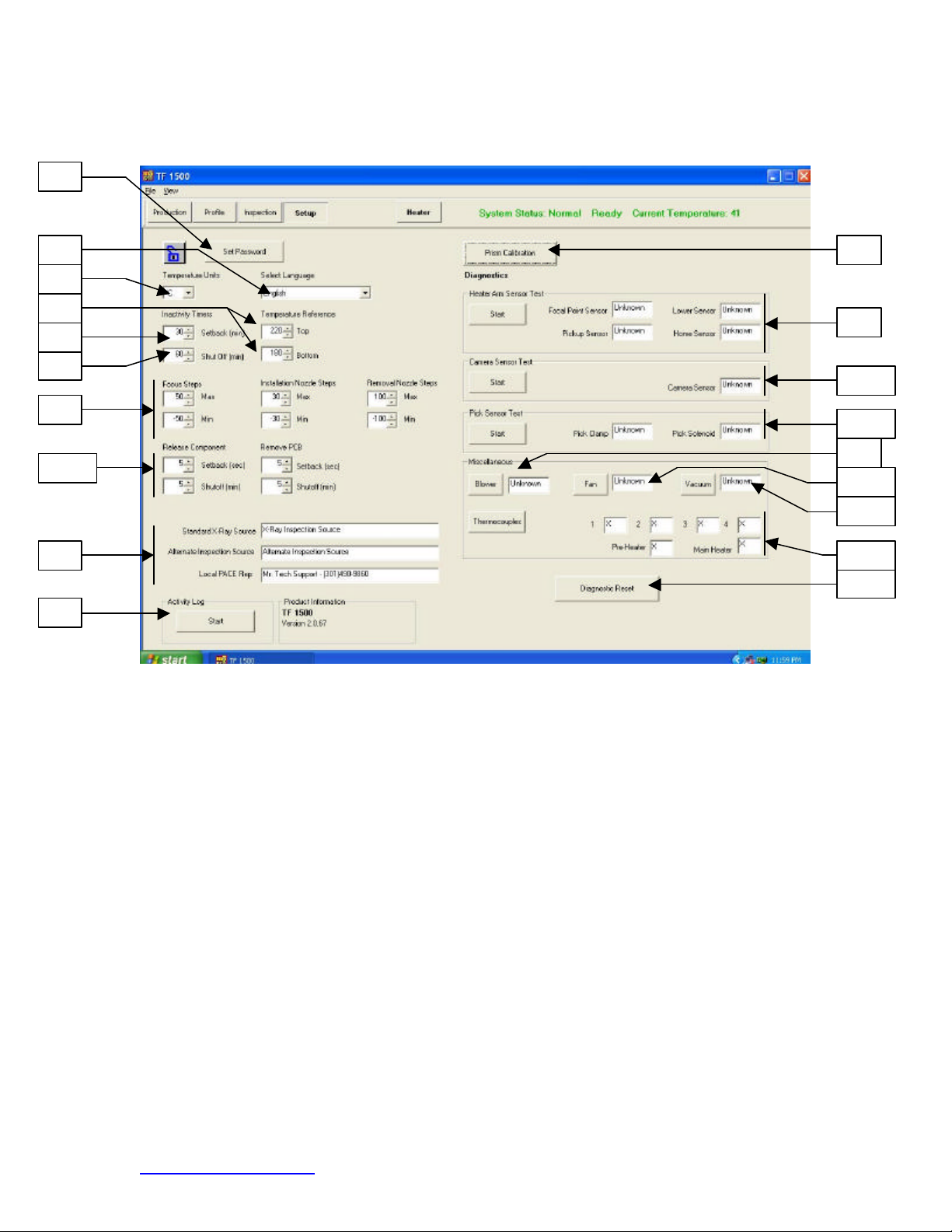

e. Set up screen features. (Figure 4)

Figure 4

i. Set Password. Setup and profile settings can be password protected.

ii. Set Language. Software text language can be changed.

iii. Set temperature for Celsius or Fahrenheit.

iv. Set yellow temperature reference lines on the profile graph.

v. Set setback time. Machine will go into setback after selected idle time.

Setback reduces heater temperatures during extended idle times to

extend heater life.

vi. Set auto shutoff time. Machine will completely shut down after selected

idle time.

vii. Set the limit on the focus range and nozzle movement.

viii. Set setback and auto shutoff times for component release and PCB

removal.

ix. Type the text for these three displays.

x. Run the activity log.

xi. Initiate prism calibration sequence. Further explanation is in par. 5e.

xii. Initiate heater arm sensor test. Checks proper orientation and operation

of heat er arm position sensors.

xiii. Initiate camera sensor test. Checks proper orientation and operation of

camera position sensor.

xiv. Initiate pick sensor test. Checks proper orientation and operation of pick

position sensor.

xv. Blower test. Checks operation of heater blower.

xvi. Cooling fan test. Checks operation of cooling fan.

www.paceworldwide.com Page 9 of 38

Page 10

System Operations Manual

xvii. Vacuum pump test. Tests operation of vacuum pump.

xviii. Thermocouple test. Tests active thermocouple circuitry.

xix. Reset diagnostics. Must be clicked after any diagnostic test is performed

to reset the tests to default settings.

www.paceworldwide.com Page 10 of 38

Page 11

System Operations Manual

i

ii iii iv

v

vii vi

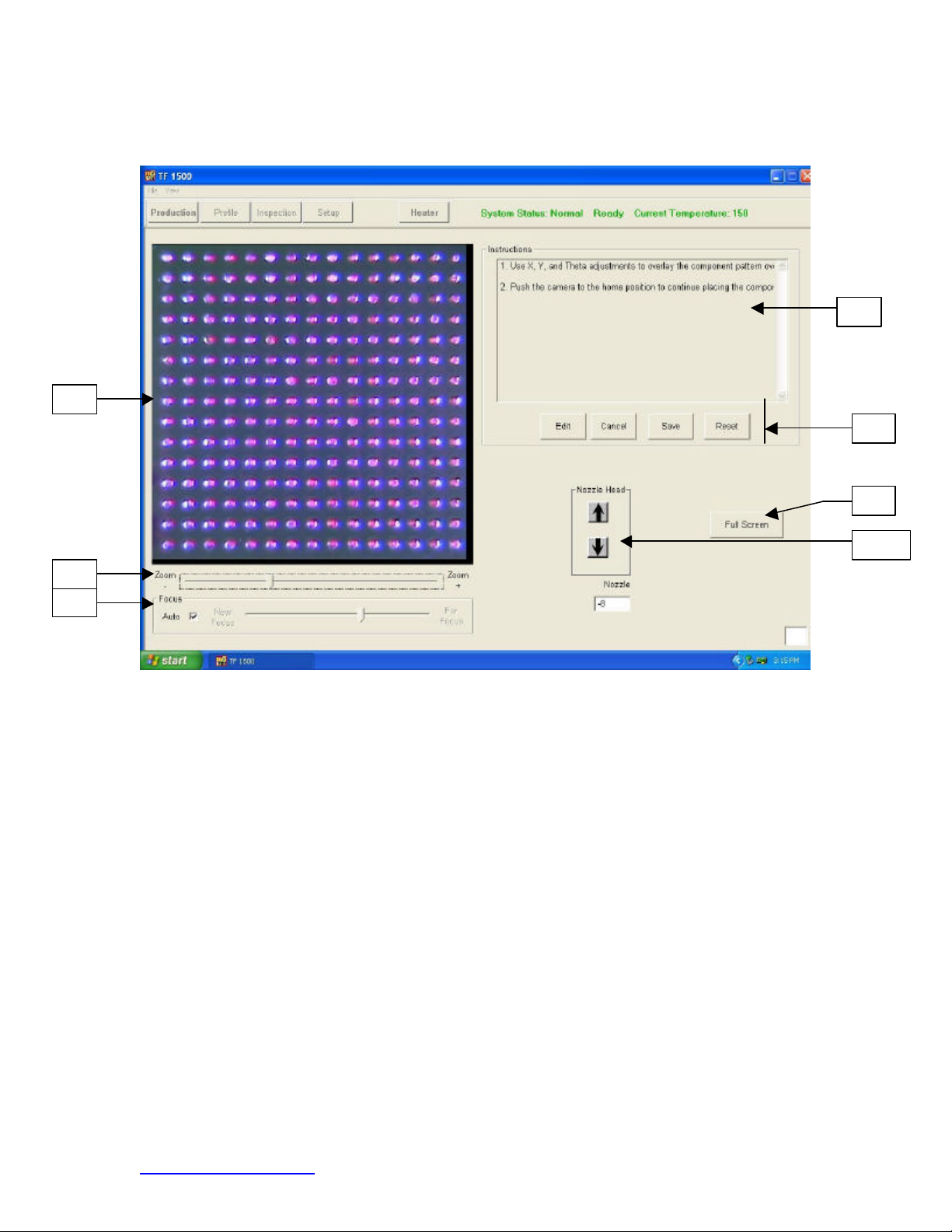

f. Alignment Screen Features (Figure 5)

Figure 5

i. Component/PCB alignment image. Proper alignment is viewed here

showing the PCB pads (blue) directly under the component pads (red).

ii. Zoom bar. The image can be zoomed in or out using this bar or the up

and down arrows on the keyboard.

iii. Focus bar. The image can be manually focused using the slider on this

bar or it can be automatically focused by checking the box by ‘auto’.

iv. Instructions. Follow these instructions to proceed through the alignment

sequence.

v. Screen options.

1. Edit – Change Instructions.

2. Cancel – Cancel changes made to instructions.

3. Save – Save changes made to instructions.

4. Reset – Returns to factory set instructions.

vi. Full Screen. Click on here to view image full screen.

vii. Nozzle step adjustment. If component (red) cannot be aligned to PCB

(blue) or you cannot focus, adjust nozzle height up or down with this

option until better alignment or focus is achieved.

www.paceworldwide.com Page 11 of 38

Page 12

System Operations Manual

ii iii iv

v

vi ix x xi xii

xiii xiv

xv xvi i vii viii

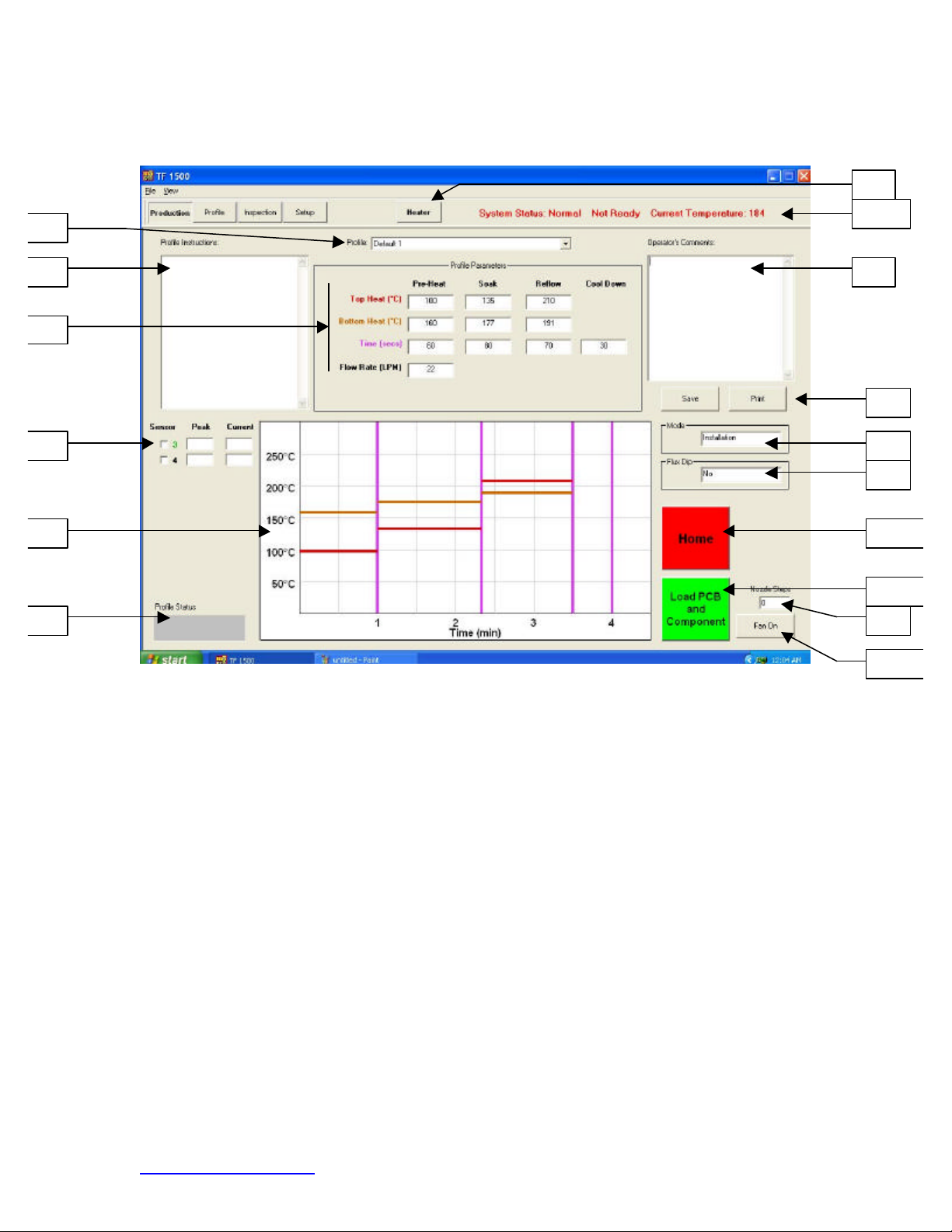

g. Production Screen Features (Figure 6)

Figure 6

i. Profile Indicator. Indicates currently selected profile. A new profile can

be selected from a list of saved profiles by clicking on the arrow.

ii. Profile Instructions. Instructions entered by the developer can be viewed

here.

iii. Temperature and time settings. Settings for the profile are indicated

here.

iv. Sensor indicators. Real-time sensor readings can be viewed here if

thermocouples are used.

v. Graph. A saved graph and, if thermocouples are used, an active trace

graph are viewed here.

vi. Profile Status Bar. Indicates the current status of a running profile.

vii. Heater Button. Used to turn the heater back on after the machine has

been in setback. Blinks red if in setback and must be selected to

continue sequence.

viii. Status Bar.

1. System status – shows if system is ‘normal’, in ‘setback’ or

‘shutdown’.

2. Heater status – Shows ‘ready’ if bottom heater is in range.

Shows ‘not ready’ if bottom heater is not in range. The software

will not continue until it is in ‘ready’ status.

3. Bottom heater temperature – Shows real time bottom heater

temperature.

www.paceworldwide.com Page 12 of 38

Page 13

System Operations Manual

i

ii iii

iv

v vi viii ix x xi xii xiii xiv

xv xvi xvii

xviii

vii

ix. Operator’s Comments. Provides a space for the operator to write

comments.

x. Options. Save to save operator’s comments and reset to clear screen.

xi. Mode. Indicates whether this is an installation or removal profile.

xii. Flux Dip Option. Indicates if the Flux Dip option is selected.

xiii. Abort Button. Click at any time to abort the process and return to the

beginning.

xiv. Sequencing Button. Click here to proceed to next step in the operation.

xv. Nozzle Step Indicator. Indicates how many steps the nozzle will lower to

properly position itself for operation.

xvi. Fan On/Off Selector. Manual on/off switch for the cooling fan.

h. Profile Development Screen Features (Figure 7)

Figure 7

i. Temperature and Time Settings. Used to indicate and set the

temperatures and times for the profile.

ii. Graph. Draws a trace graph of temperatures measured by

thermocouples. Colored bars indicate the times and temperatures

selected in the settings. Times and temperatures can be changed before

and during a profile by dragging these lines to a different setting.

1. red – top heater

2. brown – bottom heater

3. purple – time dividing lines between zones

4. yellow – reference lines set in the setup screen

www.paceworldwide.com Page 13 of 38

Page 14

System Operations Manual

iii. Sensor Indicators. Indicates real -time temperature of thermocouples in

use.

iv. Trial Run Window. Indicates which trial runs are showing on the graph.

There can only be three trial runs saved in this window.

v. Clear Trial Run Selector. Clears the checked trial runs when clicked.

vi. Profile Status Bar. Indicates the current status of a running profile.

vii. Status Bar. Same as production screen.

viii. Profile Name. Indicates current selected profile.

ix. Options.

1. New – clears all settings

2. Open – opens a profile saved on the computer

3. Save – saves profile to file name showing in the profile name

window

4. Save as – saves profile to new file name

5. Print – prints current settings

6. Export – saves profile as a spreadsheet file

x. Profile Instructions. Insert instructions for the operator.

xi. Cycle Start Button. Start the selected profile.

xii. Mode. Select whether this is to be an installation or removal profile.

xiii. Flux Dip Option Selector. Select whether this option will be used.

xiv. Home Button. Aborts the profile when clicked and returns to the

beginning screen.

xv. Nozzle Head Position Selector. When the reflow head lowers

automatically, it stops above the PCB. Use this to lower the PCB flush to

the PCB. The number of steps it is lowered is indicated in the window

below the buttons. This nu mber is saved for operation.

xvi. Sequencing Button. Click here to proceed to next step in the operation.

xvii. Nozzle Steps Indicator. Indicates the number of steps the head is

lowered by the nozzle head buttons.

xviii. Fan On/Off Button. Manual on/off switch for the cooling fan.

www.paceworldwide.com Page 14 of 38

Page 15

System Operations Manual

i ii iii

iv

v vi

i. Inspection Screen Features

i. Inspection Image. The inspection image selected is viewed here.

ii. Select Inspection Source. Select whether the image is from an x-ray or

alternate source.

iii. Select Full Screen Image.

iv. Library Image. The computer has a stored library of x-ray images with

explanations of the viewed defects.

v. Select Library Image. Use these arrows to select a different library

image.

vi. Capture or Print Inspection Image. Click on capture to freeze the current

image in the window. Click print to send the image to a printer.

www.paceworldwide.com Page 15 of 38

Page 16

System Operations Manual

Prism Calibration

j. Prism Calibration – This step is required to ensure the prism is properly aligned

so when the software shows the PCB and component visually aligned, they are

actually physically aligned.

i. Select set up screen. (Figure 8)

Figure 8

ii. Select prism calibration.

iii. Monitor now shows calibration screen. (Figure 9)

Figure 9

iv. Place alignment board with BGA in place in mounting brackets.

www.paceworldwide.com Page 16 of 38

Page 17

System Operations Manual

Camera Housing

v. Align PCB so red laser sighting light is roughly centered on BGA.

(Figure 10)

Figure 10

vi. Mouse click on green button, “Pickup.”

vii. Pull camera out. Make sure it is all the way out into the detent.

(Figure 11)

Figure 11

viii. Mouse click on green button, “Focus.”

ix. Adjust focus with up and down arrows on keyboard or by moving slide on

screen. Refer to para. 5g.

www.paceworldwide.com Page 17 of 38

Page 18

System Operations Manual

x. Image in the window should be aligned like figure 12.

Figure 12

xi. If it is not, adjust prism until it is.

1. Loosen the setscrews from the light adjustment knobs (Figure

13)

2. Remove the knobs

3. Remove the four screws (2 on each side) from the cameras’

sheet metal cover (Figure 13)

4. Remove the cover

5. Loosening the top screws (A) and tightening the bottom screws

(B) adjusts the prism down.

6. Loosening the bottom screws (B) and tightening the top screws

(A) adjusts the prism up.

7. Loosening the right center screw © allows you to rotate the prism

around the y-axis.

8. Replace the cover

9. Replace the four screws

10. Replace the knobs

11. Adjust the light adjustment knobs and tighten the setscrews

xii. Return to setup screen. Mouse click on button, “Return to Setup.”

www.paceworldwide.com Page 18 of 38

Page 19

Cover

A B

C

Light

Adjustment

Knobs

System Operations Manual

Figure 13 Figure 14

6. Operation

Note: It is recommended that the TF 1500 be turned on for at least 15 minutes before

use to ensure the bottom side heater has reached its set temperature and stabilized.

Once the bottom side heater is at operating temperature it will deliver consistent heating,

ensuring highly repeatable heating from operation to operation.

It is advisable to conduct a trial operation each day to ensure all systems are

operating properly. Also, it is important to verify the airflow of the unit with each profile to

be run.

Verify that the devices/parts being soldered to the PCB do not exceed the height

limitations. Exceeding the limitations may interfere with the operation of the machine.

The maximum height of any component or device on the top of the PCB is limited

to 30mm (1.2”).

The maximum height of any component or device on the bottom of the PCB is

limited to 15 mm (0.6”).

a. Production. Component alignment and install ation – Note: If at any time you

need to abort the process mouse click on the Red “Home” button.

i. Mouse click on Production to switch to the production screen. (Figure

6)

ii. Select a profile.

iii. Insert the proper vacuum pick. (Para. 5d)

iv. Insert the proper nozzle. (Para. 5e)

v. Place the PCB between the arms on the TF 1500 and tighten the

retention screw. (Figure 15)

www.paceworldwide.com Page 19 of 38

Page 20

System Operations Manual

Retention Screw

Release Handle

Figure 15

vi. Position the board so the red laser sighting light is roughly in the center

of the placement site. To move the board forward and bac k simply

move the PCB in the arms. To move the assembly left and right push

the release handle away from you and move the assembly. Pull the

release handle towards you to secure the assembly.

vii. Pull the camera out. (Figure 16)

Figure 16

viii. Mouse click on the green button.

ix. Place the component in the mounting plate on top of the camera

housing. (Figure 17a )

www.paceworldwide.com Page 20 of 38

Page 21

System Operations Manual

Component

Figure 17a

x. Mouse click on the green button. TF 1500 will pick up component.

xi. Remove component mount from the top of the camera housing.

xii. If Flux Dip option was selected, place the flux dip assembly on top of

the camera housing. (Figure 17b) Mouse click to dip, then remove flux

dip assembly.

xiii. Mouse click on the green button again to switch to the alignment

screen and lower component to focus point. (Figure 5)

Flux

Dip

Tray

Figure 17b

www.paceworldwide.com Page 21 of 38

Page 22

System Operations Manual

Nozzle on board

Rotate

Forward and Back

xiv. Zoom in and align using the 3 axis adjustments until the component

fills the screen and is aligned. (Figures 5 & 18)

Left and Right

Figure 18

xv. Push camera in until the screen changes.

xvi. Mouse click on the green button, “Place” to low er the component.

(Figure 19)

Figure 19

xvii. Mouse click on the green button again, “Start.”

xviii. Allow the PCB to cool and remove.

b. Component removal – Note: If at any time you need to abort the process mouse

click on the Red Home button.

i. Conduct steps i – v in paragraph 6a.

ii. Position the board so the red laser sighting light is roughly in the center

of the component. To move the board forward and back simply move

the PCB in the arms. To move the assembly left and right push the

release handle away from you and move the assembly. Pull the release

handle towards you to secure the assembly. (Figure 20)

ready to start

heating

www.paceworldwide.com Page 22 of 38

Page 23

System Operations Manual

Figure 20

iii. Mouse click on Start button.

iv. Allow PCB and component to cool before removing.

c. Profile development

Note: General Information concerning the Profile Development Screen

The Reflow Graph area displays a representation of the Reflow cycle profile.

Time in minutes is graphed along the X-axis and temperature in degrees Celsius

or Fahrenheit is plotted along the Y-axis. The time and temperature axes incorporate

a dynamic scaling feature to optimize the display for extremely short or long profiles.

Profile graphs can be saved with profiles to be used for process validation by

operators while using the Operation screen. Profile graphs can also be stored as

individual records for each rework job for quality control purposes. Solid and dotted

lines are used to indicate profile parameters.

Profile Creation

There are 2 recommended methods for developing a profile. The first, involves an

actual component installation, while the second uses a previously installed package.

Either method can be used to develop a reliable profile. However, there are some

issues and considerations to be aware of with each.

When developing profiles through actual component installation, it is critical to make

sure the thermocouples remain in contact with the solder throughout the entire

process. Unreliable data will be collected should a thermocouple lose contact with

the solder. If measuring the temperature on the top of the pac kage, it is best to use

a preinstalled component, as the thermocouple wire will typically cause the

component to not lay flat on the PCB.

When using a previously installed package, the placement of the thermocouples is

important. They must be in contact with the existing solder joints. This task can be

accomplished by either (1) drilling through the bottom of the PCB into a solder joint

and attaching the thermocouple or by (2) sliding the thermocouple under the

package in the case of a BGA or along side in the case of other SMD’s. When sliding

a thermo couple under a component, it is critical that the thermocouple be in contact

with the solder. Method 2 is the most commonly used. Information from the

thermocouples will assist in determining the proper time and temperature

parameters. In general, the following guidelines should be adhered to when

developing profiles.

Ramp and Maximum Temperatures

Acceptable ramp rates and maximum temperatures should be obtained from the

component manufacturer. Typical ramp rates are 2-5 ºC/s (4-9 ºF/s) for plastic parts

and 1 ºC/s (2 ºF/s) for ceramic parts. It is recommended to select a maximum

www.paceworldwide.com Page 23 of 38

Page 24

System Operations Manual

temperature below the manufacturer’s specification to provide for a margin of safety.

Typically, 20 ºC below maximum specified temp erature is selected.

Pre-Heat Phase

1. In a “step profile”, the top of the PCB and package should reach a stable

temperature of 95 -105 ºC. If plotting the temperature curve, the trace will usually

level off within this temperature range.

2. If a “linear slope” is desired, pre-heat and soak phases are combined. Both the

package and the PCB are warmed at a constant ramp rate (usually 2-4 ºC/second)

until the desired soak temperature is reached.

Soak Phase

The soak phase is a crucial part of the reflow process. During this period, the flux

activates and drives off volatiles and excess flux. A temperature of 145-165 ºC

(determined by the activation temperature of the flux used) should be maintained for

approximately 20-40 seconds. This allows for uniform ramping across the entire

package and PCB during reflow.

Reflow Phase

During this phase, the solder reaches solder melt and forms joints between the

package and the lands. It is critical for all areas of the component to reach solder

melt together and all solder joints remain in a liquid state for at least 10-20 seconds.

Generally, plastic packages should not be exposed to temperatures higher than

220 ºC. Always consult the device specifications for maximum temperature

recommendations. As a rule of thumb, a safe “maximum temperature” is the

maximum temp specified by the manufacturer minus 20ºC. Lower temperatures and

shorter times are common in CSPs and FCs. The lowest temperatures possible

should always be used to ensure safety of the device and PCB.

Cool Dow n Phase

The cool down phase is necessary to bring the temperature of the package, solder

joints and PCB under the package below solder melt temperatures. Cooling should

be controlled. A good reference is to use the same cool down rate as for ramp up.

The cooling fan on the TF 1500 will remain on for a minimum of 30 seconds from the

start of the cool down cycle. Some types of components (like CBGAs) should be

allowed to cool without external assistance from the cooling fan. When installing

these packages, turn the fan away from the PCB so the air doesn’t blow on it.

General

Using one of the two baseline (default) profiles will provide a good starting point for

profile development. The reflow graph provides an excellent tool for monitoring

profile parameters and fine tuning or perfecting the profile development process.

When adjusting profile parameters “on -the-fly”, all changes are reflected immediately

on the profile development screen and graph.

Procedure

i. If the component needs to be placed first, conduct steps in paragraph 6a

to step xv then do sections ii, vii thru x below.

ii. Mouse click on Profile for the Profile Development Screen. (Figure 7)

iii. Conduct steps ii thru v in paragraph 6a.

iv. Position the board so the red laser sighting light is roughly in the center

of the component. To move the board forward and back simply move

the PCB in the arms. To move the assembly left and right push the

release handle away from you and move the assembly. Pull the release

handle towards you to secure the assembly.

v. Mouse click the cycle start button. Make adjustments in accordance with

paragraph 5i.

vi. To return to the beginning of the development stage mouse click on the

cycle start button.

vii. If you’re finished, allow the PCB to cool and remove.

www.paceworldwide.com Page 24 of 38

Page 25

7. Temperature Control

a. Heater temperatures are adjusted by changing the numbers on the profile screen

by clicking on the arrows, moving the temperature bars or using the up and down

arrows on the keyboard. (See paragraph 6.c.ii.)

8. Available Nozzles/Accessories/Optional Items

a. A complete list of nozzles and accessories is on our web site,

paceworldwide.com

9. Maintenance

Caution: Disconnect the main power supply and computer cables before

opening the TF 1500 door, replacing any component or before performing any

routine maintenance.

a. Cleaning the Blower Filter. Clean the filter every three months.

i. Open the cover on the back of the TF 1500. (Figure 21)

ii. Identify the blower pump, mounted on the base of the machine.

iii. Loosen the screw fitted to the end of the filter housing.

iv. Remove the housing, then the filter.

v. Clean the filter using warm water.

vi. Make sure the filter is dry before reassembly.

System Operations Manual

pump filter housing

screw

Figure 21

b. Periodically inspect the power cords and other cables for signs of wear or

damage. If wear or damage is found, replace the cord or cable immediately.

c. The work surface and housing should be cleaned periodically with a soft damp

cloth.

d. The camera glass window should be cleaned periodically with glass cleaner and

a soft cloth.

e. Maintenance beyond this should only be completed by a qualified PACE service

technician.

www.paceworldwide.com Page 25 of 38

Page 26

System Operations Manual

10. Regulation

a. This product is CE approved.

b. PACE products meet or exceed all applicable military and civilian EOS/ESD,

temperature stability and other specifications, including ANSI-J-STD -001, IPC7711, IPC-7721 and IPC-A-610.

12. Service and Warranty

Please contact PACE or your local distributor for service and repair.

LIMITED WARRANTY

Seller warrants to the first user that products manufactured by it and supplied hereunder are free

of defects in materials and workmanship for a period of three (3) years from the date of receipt by

such user. Blowers and motor pumps (which wear out during normal use) are warranted for a

period of one (1) year.

This warranty does not cover wear and tear under normal use, repair or replacement required as

a result of misuse, improper application, mishandling or improper storage. Consumable items

such as tips, heaters, filters, etc. which wear out under normal use are excluded. Failure to

perform recommended routine maintenance, alterations or repairs made other than in accordance

with Seller’s directions, or removal or alteration of identification plates in any way will void this

warranty. This warranty is available only to the first user, but the exclusions and limitations herein

apply to all persons and entities.

SELLER MAKES NO OTHER WARRANTY, EXPRESS OR IMPLIED, AND MAKES NO

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Seller will, at its option, repair or replace any defective products at its facility or other location

approved by it at no charge to user, or provide parts without charge for installation by the user in

the field at user’s expense and risk. User will be responsible for all costs of shipping equipment to

Seller or other location for warranty service.

EXCEPT FOR THE REMEDY ABOVE DESCRIBED, UNLESS OTHERWISE REQUIRED BY

APPLICABLE LAW, SELLER WILL HAVE NO OTHER OBLIGATION WITH REGARD TO ANY

BREACH OF WARRANTY OR OTHER CLAIM WITH RESPECT TO THE PRODUCTS, OR

LIABILITY FOR ANY DIRECT, INDIRECT, CONSEQUENTIAL, OR INCIDENTAL LOSS OR

DAMAGE CAUSED BY OR OCCURRING IN CONNECTION WITH ANY OF THE PRODUCTS.

Warranty service may be obtained by contacting the appropriate PACE Company or local

Authorized PACE distributor as set forth below to determine if return any item is required or, if

repairs can be made, by the user in the field.

Defective products may not be returned to PACE without a Service Authorization (“SA”) Number.

Any warranty or other claim with respect to the products must be made in writing delivered to

PACE (or local Authorized PACE distributor for Buyers outside the USA and the United Kingdom)

within a reasonable time of the expiration date of this warranty with sufficient evidence of

purchase and date of receipt, otherwise user’s rights under this wa rranty shall be deemed

waived.

www.paceworldwide.com Page 26 of 38

Page 27

System Operations Manual

www.paceworldwide.com

PACE USA PACE Europe

9030 Junction Drive Sherbourne House

Annapolis Junction, MD 20701 Sherbourne Drive

USA Tilbrook, Milton Keynes

MK7 8HX

United Kingdom

Tel: (301) 490-9860 (44) 1908 -277666

(888) -535-PACE

Fax: (301) 498 -3252 (44) 1908 -277777

PACE Incorporated retains the right to make changes to specifications contained herein at any

time, without notice. Contact your local authorized PACE Distributor or PACE Incorporated to

obtain the latest specifications.

The following are trademarks and/or service marks of PACE, Incorporated, MD, USA.

INSTACAL®, FUMEFLO®, HEATWISE®, PACEWORLDWIDE®, PERMAGROUND®,

POWERMODULE®, and TEMPWISE®

The following are registered trademarks and/or service marks of PACE Incorporated, Laurel

Maryland U.S.A.

ARM-EVAC®, FLO -D-SODR®, MINIWAVE®, PACE®, SENSATEMP®, SNAPVAC®,

SODRTEK®, SODR-X-TRACTOR®, THERMOFLO®, THERMOJET®, THERMOTWEEZ®, and

VISIFILTER®

PACE products meet or exceed all applicable military and civilian EOS/ESD, temperature stability

and other specifications including MIL STD 2000, ANSI/JSTD 001, IPC7711, and IPC A-610.

www.paceworldwide.com Page 27 of 38

Page 28

System Operations Manual

FIRST ADDENDUM – TOP HEATER REPLACEMENT

It is recommended you return the machine to PACE, Inc. or call a PACE representative to replace

the heater element.

CAUTION: REMOVE POWER CORD FROM MACHINE.

1. Remove the nozzle and vacuum pick.

2. Remove the 4 screws on each rail cover on the left and right sides

of the heater.

This shows the right rail cover removed.

3. Remove the heater cover screws, 2 on each side.

www.paceworldwide.com Page 28 of 38

Page 29

System Operations Manual

4. In order to remove the heater cover the

wire will need to be disconnected. First

cut the ties as shown here. There is one

on each side.

5. Now you can disconnect the heater

cables, one on each side. Once these two

cables have been disconnected you can

remove the cover.

6. Remove the 4 screws attaching the

heater base assembly to its mounting, 2

on each side. Be sure to hold the

assembly or it will fall.

www.paceworldwide.com Page 29 of 38

Page 30

System Operations Manual

This shows the heater base loose and

being lowered off the heater.

7. Disconnect the blower motor wiring on

the side of the heater assembly.

8. Disconnect the hose on the right side

of the heater assembly.

www.paceworldwide.com Page 30 of 38

Page 31

System Operations Manual

9. Inside the back of the TF 1500, locate

the 2 sensor wires, cut the ties and

disconnect them. DO NOT CUT THE

WIRES. Pull these 2 wires thru to the

front. Identify and mark the wires so they

are not reversed.

10. Remove the 4 screws holding the

heater to its mount, one on each corner.

11. Carefully lower heater off the vacuum

shaft. Make sure as it is lowered that it is

free of hoses and wires.

www.paceworldwide.com Page 31 of 38

Page 32

System Operations Manual

12. Install new heater. The two hoses

must run under the bracket.

13. Install 4 heater screws. Make sure

these hoses are not pinched.

14. Run sensor wires thru front panel

the way they came out, reconnect and

tie. Make sure they are connected to

the right one.

www.paceworldwide.com Page 32 of 38

Page 33

System Operations Manual

15. Reconnect hose.

16. Reconnect motor wiring. It does

not matter which one is attached to

which.

17. Replace base assembly.

www.paceworldwide.com Page 33 of 38

Page 34

System Operations Manual

18. Reinstall the 4 base assembly

screws.

19. Reconnect the wires on each side

and tie them back to their mounts. Be

sure to pull the wires up taught so they

do not contact the heater.

20. Put the heater cover back on

making sure not to pinch hoses or wires.

Reinstall the 4 screws.

21. Replace the 2 rail covers.

22. Test the heater.

www.paceworldwide.com Page 34 of 38

Page 35

System Operations Manual

SECOND ADDENDUM – ALIGNMENTS AND ADJUSTMENTS

1. Platform planarity. This procedure is only necessary if the vacuum pick does not pick up the

component.

a. Insert the large vacuum pick.

b. Insert a PCB into holder.

c. Advance the production process to the 'place' step. Do not pick up a component.

d. Lower the heater head to the PCB by clicking the green button during the place step.

When the vacuum pick contacts the PCB click the heater stop button.

e. Loosen the four large screws on the front of the platform.

f. Adjust the smaller four screws to bring the platform and PCB level with the vacuum pick.

Loosening a screw will raise that portion of the platform. Tightening a screw will lower

that portion of the platform. To keep the screws tight for every bit you loosen a screw,

tighten the opposite screw equally as much.

g. Once the platform is level, tighten the four large screws.

h. Raise the heater by clicking the red button.

2. Camera alignment. The camera must be aligned to the nozzle on the heater head.

a. Insert a nozzle in the heater head.

b. On the Profile screen, adjust all the heaters to minimum temperatures then advance to

the focus step and click on the green focus button.

c. Loosen the nozzle retention screw and rotate the nozzle so its 4 sides are aligned with

the edges of the viewing window.

d. Zoom in on the image so it fills the viewing area.

e. If the nozzle edges are too far back:

i. Open the back of the TF 1500. WARNING: DO NOT TOUCH LIVE CIRCUITS!

www.paceworldwide.com Page 35 of 38

Page 36

System Operations Manual

ii. With the camera pulled out, loosen the two screws on the top right of the

camera.

iii. Reposition the camera until the front and back edges are centered in the viewing

window and tighten the screws.

f. If the nozzle edges are off right to left:

i. Open the back of the TF 1500. WARNING: DO NOT TOUCH LIVE CIRCUITS!

ii. In front, loosen the screw protruding under the camera housing.

www.paceworldwide.com Page 36 of 38

Page 37

System Operations Manual

iii. In the back, loosen the screw in the center on the back of the camera housing.

iv. Rotate the camera until the left and right sides of the nozzle are centered

between the sides of the viewing area.

v. Tighten the screws.

3. Laser alignment. This adjustment is necessary if, after spotting the PCB with the laser, the

PCB is grossly out of alignment with the nozzle and camera viewing area.

a. Pull out the camera housing.

b. Orient a component on the PCB so it is centered in the viewing area. (Figure ) Make

sure the camera is aligned with the nozzle first. (Step 2)

c. Open the back of the TF 1500. WARNING: DO NOT TOUCH LIVE CIRCUITS!

d. Loosen the two screws holding the laser mount. (Figure)

e. Adjust the laser to a spot roughly in the center of the component and tighten screws.

4. Component Nest Platform alignment. This adjustment is necessary if the component is not

aligned with the nozzle and vacuum pick.

a. Place the component nest platform on the camera housing with the component.

b. Advance the Production procedure to the 'pickup' step and click on the green button.

c. Click on the stop button when the vacuum pick contacts the component.

d. Loosen the screw on the mechanical stop on the right of the platform and the two screws

on the left of the platform and move it until the component is aligned with the nozzle.

e. Adjust the mechanical stop and tighten all three screws.

www.paceworldwide.com Page 37 of 38

Page 38

System Operations Manual

THIRD ADDENDUM - CORRECTIONS

Section 5d

Step i. To rotate the nozzle, first loosen the retention screw in front of the housing.

Section 5e

Step xi. Initiate prism calibration sequence. Further explanation is in par. 5j.

Section 6a Production Procedure.

Step ix. The component needs to be oriented the same as the nozzle. To rotate the

platform, loosen the retention set screw, turn to align the component with the nozzle, then tighten

the set screw.

Section 6c, Profile Development Install Procedure.

Step i. Mouse click on Profile for the Profile Development Screen. (Figure 7)

Step ii. If the component needs to be placed first, conduct steps ii to xv in paragraph 6a, then

do sections iv thru x below.

After Section 6c. vii.

Section 6d. Profile Development Removal Procedure

Step i. Load PCB and align component with red laser light roughly in the center of the

component.

Step ii. Click on Load PCB button.

Step iii. Click on Lower Heater Arm button.

Step iv. Align component so nozzle will fit down over without contacting the component.

Click on Align component button.

Step v. Adjust nozzle flush with the PCB using the up and down arrows. Click on Lower

Nozzle button.

Step vi. Click Start button to begin profile.

www.paceworldwide.com Page 38 of 38

Loading...

Loading...