Page 1

TF 1000 BGA/CSP

Rework Station

Operation Manual

MANUAL NO. 5050-0501

REV. A

Page 2

Safety

The following are safety precautions that personnel must understand and

follow when using or servicing PACE products.

POTENTIAL SHOCK HAZARD -

1.

products should be performed by Qualified Service Personnel only.

Line voltage parts may be exposed when the equipment is

disassembled. Service personnel must avoid contact with these

parts when troubleshooting the product.

2. To prevent personnel injury, adhere to safety guidelines in

accordance with OSHA and all other applicable safety standards.

3. Always use PACE systems in a well ventilated area. A fume

extraction system, such as those available from PACE, is highly

recommended to help protect personnel from solder flux fumes.

4. Exercise proper precautions when using chemicals (e.g., solder

paste). Refer to the Material Safety Data Sheet (MSDS) supplied

with each chemical and adhere to all safety precautions

recommended by the manufacturer.

5. The following safety precautions cover use of PACE hot air

systems/hand pieces (e.g., ThermoFlo®, ThermoJet®).

a) Be careful when using in places w her e ther e ar e combusti ble

materials.

b) Do not use in the presence of an explosive atmosphere.

c) A fire may arise if a hot air hand piece is not used with care.

Do not leave the hand piece unattended when in use.

d) The heater assembly housing and any installed nozzle are

hot when the system is being cycled and for a period of time

thereafter. DO NOT touch the heater assembly housing,

nozzle or heated air stream. Severe burns may result.

Repair procedures on PACE

1

Page 3

Table of Contents

Heading

A. Introduction 3

B. Regulation 3

C. Features 4

D. Structure 5

E. TF 1000 Setup 6

F. Before Operation 7

Page #

G. Installing PCB 8

H. Preparation for Component Rework 9

I. Component Alignment 10

J. Component Placement 11

K. Component Reflow 12

L. Specifications 15

M. Accessories 16

N. Maintenance 19

2

Page 4

TF 1000 BGA/CSP Rework Station

A. Introduction

As electronic assemblies get smaller and lighter, PCB’s are steadily decreasing

in size, and semiconductor devices are slowly being replaced by smaller area

array packages such as BGA’s and CSP’s. The TF-1000 has been specifically

designed for the rework of these devices, with an emphasis on small boards and

components.

B. Regulation

The TF-1000 is in conformity with the European Machinery Directive 98/37/EC

and EMC Directive 89/336/EMC, modified 92/31/ECC, 93/68/EEC.

Caution!

During normal operation, the top heater, nozzle, bottom-side-heater(s) and

halogen lamps will get hot. Contacting them directly may result in serious

injury.

3

Page 5

C. Features

1. The TF 1000 System is lightweight and compact, with the placement

station and reflow station combined in one unit

2. Up to 40 reflow profiles can be stored by the TF 1000. Saved profiles

can be recalled at the touch of a button and are displayed on the LCD

display panel.

3. A colored LED indicates each phase of the reflow cycle so the status of

each operation can be easily seen and monitored.

4. Placement of small BGA/CSP is easily accomplished through the use

of microscope optics with image overlay.

5. A highly efficient, 700-watt topside heater used in conjunction with a

truly unique nozzle design insures the uniformity of the temperature

across the assembly.

6. The infrared bottom side heater with a wide heating area is

incorporated to prevent warping of the PCB, and to enhance the reflow

of BGA/CSP.

7. The blower and vacuum pumps are self-contained. No external air

supplies are required.

8. A cooling fan automatically activates at the end of the reflow cycle to

cool the component, PCB, and nozzle.

9. The TF 1000 is versatile and ensures repeatable results

4

Page 6

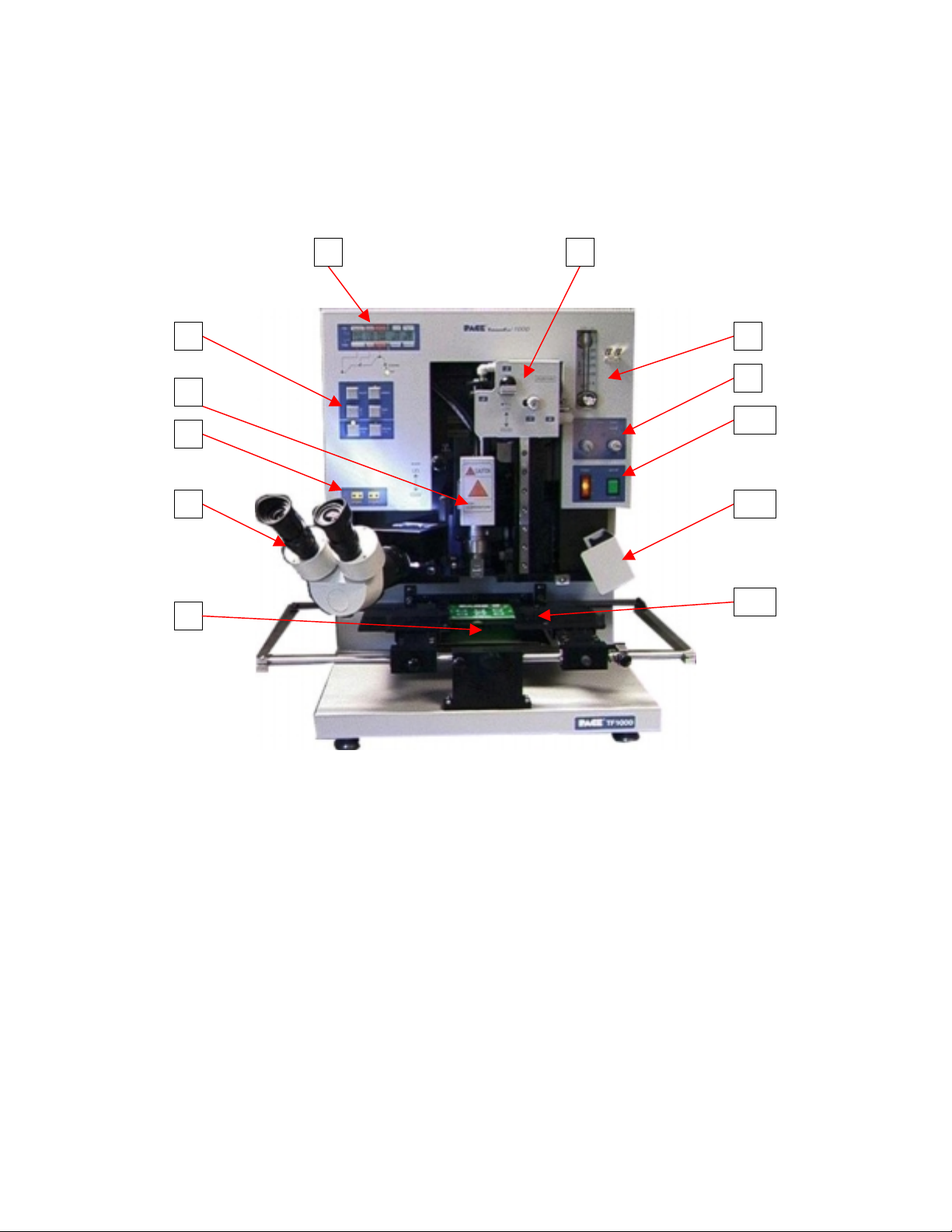

D. Structure

2345678

9

10

11

1

12

1. Infrared Bottom-Side heater

2. Microscope Optics

3. Thermocouple inputs 1 and 2

4. Top-Side Heater Assembly

5. Control Panel

6. LCD Display

7. Component Alignment/Placement apparatus

8. Airflow control/Indicator

9. PCB and Component light adjustment

10. Power and Vacuum On/Off switch

11. Cooling Fan

12. PCB Holder

5

Page 7

Operation Manual

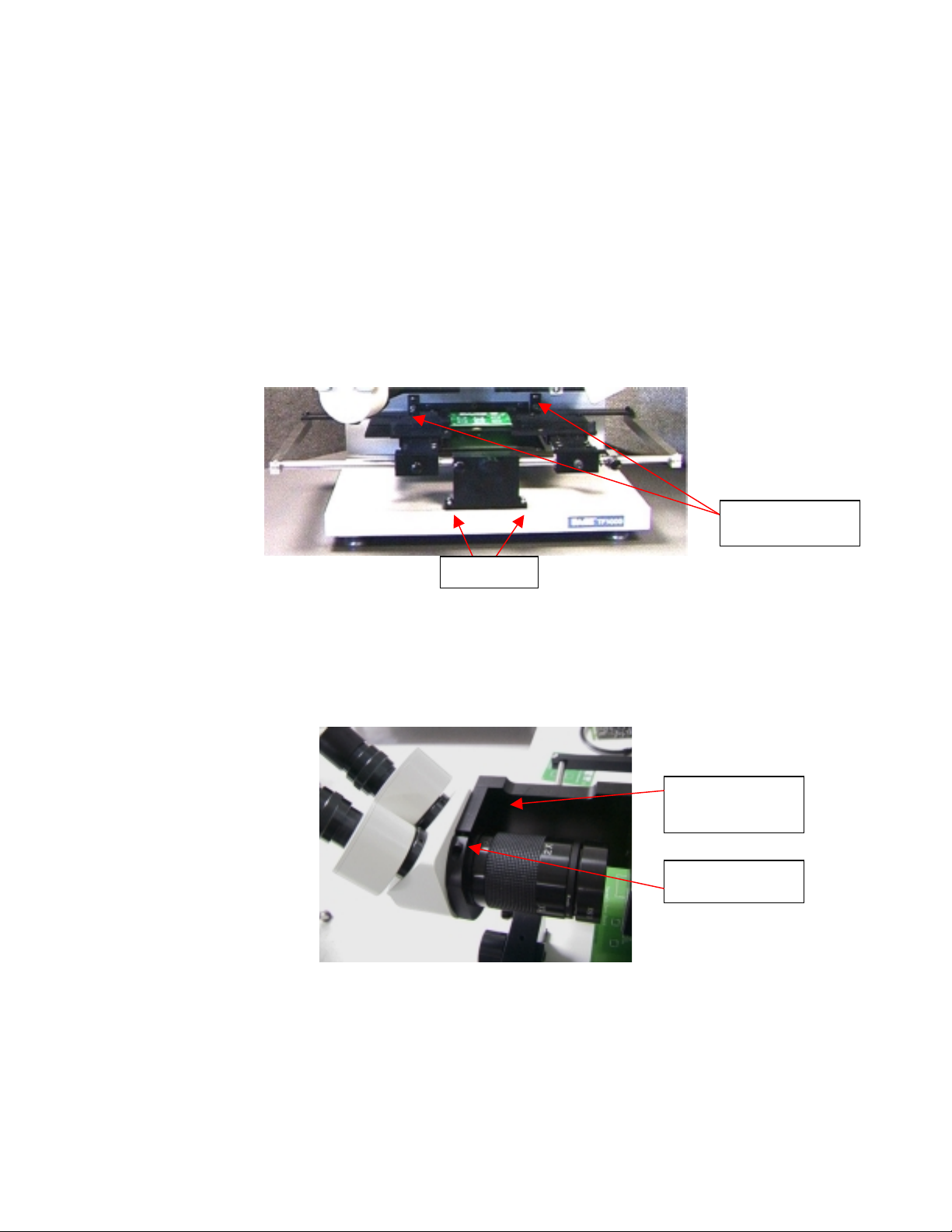

E. TF 1000 Setup

1. Place the T F 1000 on a flat and stable work surface.

2. Install the PCB Holder assembly by inserting the rear rail of the PCB

holder into the rolling guides on the TF 1000 housing and installing and

tightening the four screws shown in the figure below.

3. Insert the Microscope Optics into the Optics Holding Bracket and tighten

the Allen Screw after centering the Optics as shown below.

4 screws

Rolling Guides

Optics Holding

Bracket

Allen Screw

4. Connect the power cord to the AC power receptacle on the rear panel of

the TF 1000 and to the proper AC power source.

6

Page 8

F. Before Operation

1. Confirm the safety of the machine and the surrounding work area before

turning the power on.

2. The bottom heater will take approximately 5-6 minutes to warm up to the

desired temperature once power is applied. During this time the HEATER

START light will flicker on and off. Once the desired temperature is

reached the HEATER START light will remain lit, indicating the TF 1000 is

ready to use.

3. Confirm that components/devices mounted to the PCB do not exceed the

following height restrictions:

A. Top-side of PCB – 30 mm maximum height

B. Bottom-side of PCB – 15 mm maximum height

7

Page 9

G. Installing PCB

A

1. Loosen both (A) knobs to allow the PCB holders to glide freely in the X-

axis, and set the distance between them so that the spring loaded PCB

holder will hold the PCB firmly. T igh ten the (A) knob on the left first, and

then slide the spring-loaded PCB holder into position and tighten the (A)

knob on the right.

2. Pull back on the spring-loaded board holder and insert the PCB.

3. Once the PCB is in place, loosening knob (C) will allow the entire PCB to

glide freely in the X-axis using the fine adjustment job (D). The PCB will

also slide freely in the Y-axis. Tighten knob (C) to lock the PCB in place.

NOTE:

If profiling a PCB/Component and when using thermocouple(s), attach

the thermocouple(s) to the desired position on the PCB and plug them into the

Sensor 1 or 2 positions as shown below,

B B

C D

before

A (Spring Loaded)

inserting PCB into PCB holder.

Thermocouple Inputs

8

Page 10

H. Preparation for Component Rework

1. The reflow nozzle to PCB standoff height can be established prior to

component placement. Pull the Reflow Nozzle Control Handle out from the

housing and slide the Reflow Assembly down to the PCB as shown below.

Reflow

Nozzle

Control

Handle

2. Fine placement of the ref low nozzle down to the PCB can be achieved by

setting the Nozzle to PCB Offset Limiter and twisting the nozzle control

handle in either direction as shown below.

Start Finish

Nozzle to

PCB Offset

Limiter

3. The Reflow Nozzle can now be lowered gently to the PCB by twisting the

9

With the handle twisted so the

mechanics look like this…

Reflow Nozzle Control Handle back to the lowered position.

…the Reflow Nozzle will float

slightly off the PCB.

Page 11

I. Component Alignment

1. The TF 1000 has three positions for the alignment apparatus: Standby,

Alignment, and Placement. The positions are shown below.

2. The alignment apparatus is released by pulling the Z-Axis adjustment

Standby Alignment Placement

knob out as shown below.

Apparatus release

3. Bring the microscope into position by swinging the microscope into place.

Release the alignment apparatus from the standby position and slide it

down to the alignment position as shown above.

CAUTION:

Do not let the alignment apparatus drop freely to the position

below at any time. Damage to the TF 1000 or PCB may occur.

10

Page 12

4. Using the microscope, center the component pattern of the PCB in the

viewer as shown below. The crosshairs and focus are adjusted by turning

the eyepiece(s) on the microscope.

5. Center the vacuum pick so that it fills the viewer as shown below.

6. Press the “Vacuum On” button and attach the component to the vacuum

pick. Using the X, Y, and Theta adjustment knobs, align the component

over the PCB as shown below. Use the PCB/Device light adjustments to

increase or decrease the contrast as needed.

Misaligned Aligned

11

Page 13

J. Component Placement

1. Swing the Microscope out to the standby position. Release the alignment

apparatus and slide it down until the component gently touches the PCB

as shown below.

2. Press the “Vacuum Off” button to release the component onto the PCB.

3. Slide the alignment apparatus up to the standby position.

K. Component Reflow

1. Using the Reflow Nozzle Control Handle, pull the reflow assembly out from

the housing and slide it gently down to the PCB as shown below. Use the

Nozzle to PCB Offset Limiter if necessary.

Reflow

Nozzle

Control

Handle

Start Finish

12

Page 14

4. Select the desired profile using the LCD display. Push the Select button until

the flashing cursor is located under the “Profile No.” position and push the Up

and Down button until the desired profile number is displayed.

Cursor

LCD Display

5. Push the “Cycle Start” button to start the reflow process. If needed, lifting the

nozzle back up to the standby position will automatically stop the cycle at any

time.

6. The status indicator lo cated below the LCD display will track the reflow

process. Thermocouple readings are displayed at Sensor 1 and Sensor 2 as

shown below.

Status

Indicators

Thermocouple

Sensor Display

13

Page 15

7. Changes can be made during the reflow process by pressing the “Select”

button to move the cursor to the desired setting to be changed and then

pressing the Up/Down buttons until the desired setting is achieved.

Move

Cursor

Cycle

Start

Change

Setting

8. At the end of the reflow process, an audible tone will be heard and the

Reflow display will count down to 0. The cooling fan will activate

automatically and can be turned off by pressing the “Cooling Off” button.

Additionally, the angle of the fan can be adjusted so that the fan does not

blow towards the PCB/Component at all. This may be required for CBGA to

ensure the cooling process does not occur too rapidly.

9. The Reflow Nozzle assembly may now be returned to the standby position by

lifting the Reflow Nozzle Control Handle up and in. If performing component

removal, remove the component using the provided vacuum pick wand.

10. Pressing the “Memory” button twice will now save changes made to the

profile during the reflow process. To save the changed profile as a new

profile, press the “Memory” button once, select the profile number to save as,

then press the “Memory” button again. An audible tone verifies the profile

has been saved.

14

Page 16

L. Specifications

1. Heater (top-side)

2. Pre-heater (bottom-side) IR Heater, 450W (TF1000E 400W)

3. Heating Control K type thermocouple with closed loop control

4. Applicable Devices BGA/CSP/SMT 42mm x 42mm (1.65” x 1.65”) Max

5. Applicable PCB 280 mm x 450 mm (11” x 17.5”) Max

6. Hot Air Flow 16 LPM Max

7. Adjusting Range of X, Y, Z ± 10 mm (.4”)

8. Adjusting volume of X, Y, Z 0.5 mm (.02”) per revolution

9. Positioning Accuracy ± 25 µm (0.001”)

10. Maximum Vacuum 450 mm Hg

11. Power Source 100-120 VAC, 220-230 VAC (Export)

Convective style, 700 W

12. Power Consumption 1.1 KW

400 mm W x 400 mm L x 520mm H

13. Dimensions

14. Weight 25 Kg (55 lbs.)

15.74” W x 15.74” L x 20.47” H

15

Page 17

M. Accessories

Note:

for 1.5 mm clearance between the edge of the component and the nozzle wall.

Example: The 30mm x 30mm nozzle will fit a 27mm x 27mm component.

Note:

for CBGA. Other components are specified as listed.

Example: 27mm – 2 will fit a 27m m x 27mm PBGA

27mm – 4 will fit a 27mm x 27mm CBGA

Description Dimensions Part Number

Nozzle

Nozzle

Nozzle

Nozzle

Nozzle

Nozzle

Nozzle

Nozzle

Nozzle

Nozzle

Nozzle 30mm x 30 mm (1.18” x 1.18”) 4028-5027

Nozzle 27mm x 27mm (1.1” x 1.1”) 4028-5001

Nozzle 26.4mm x 26.4mm (1.04” x 1.04”) 4028-5026

Nozzle 25mm x 32.3mm (.98” x 1.27”) 4028-5028

Nozzle 25mm x 25mm (.99” x .99”) 4028-5011

Nozzle 23mm x 23mm (.91” x .91”) 4028-5002

Nozzle 22mm x 14mm (.87” x .55”) 4028-5023

Nozzle 21mm x 21mm (.83” x .83”) 4028-5016

Nozzle 19.25mm x 19.25mm (.76” x .76”) 4028-5024

Nozzle 19mm x 19mm (.75” x .75”) 4028-5019

Nozzle 18.5mm x 18.5mm (.73” x .73”) 4028-5025

Nozzle 17mm x 17mm (.67” x .67”) 4028-5015

Nozzle 16.25mm x 17.75mm (.64” x .70”) 4028-5006

Nozzle 16mm x 16mm (.63” x .63”) 4028-5022

Nozzle 15mm x 15mm (.59” x .59”) 4028-5005

Nozzle 13.45mm x 14.97mm (.53” x .59”) 4028-5007

Nozzle 13mm x 13mm (.51” x .51”) 4028-5004

Nozzle 11.97mm x 13.21mm (.47” x .52”) 4028-5009

Nozzle 10.42mm x 10.42mm (.41” x .41”) 4028-5008

Nozzle 8.64mm x 8.90mm (.34” x .35”) 4028-5010

Nozzle dimensions are the outside diameter of the nozzle. Please allow

Component Stenciling Tool Kits dimensions: - 2 are for PBGA and - 4 are

47.5mm x 47.5mm (1.87” x 1.87”)

44mm x 44mm (1.73” x 1.73”)

43mm x 43mm (1.69” x 1.69”)

42.5mm x 42.5mm (1.67” x 1.67”)

40mm x 40mm (1.57” x 1.57”)

37.5mm x 37.5mm (1.48” x 1.48”)

35mm x 35mm (1.38” x 1.38”)

33mm x 33mm (1.29” x 1.29”)

32mm x 32mm (1.26” x 1.26”)

31mm x 31mm (1.22” x 1.22”)

4028-5034

4028-5030

4028-5029

4028-5013

4028-5012

4028-5018

4028-5003

4028-5033

4028-5020

4028-5014

16

Page 18

Nozzle 7.75mm x 5.6mm (.31” x .22”) 4028-5501

Nozzle 4.1mm (0.16”) Jet Spacing x 6.1mm (0.24”) Jet Length 4028-4001

Nozzle 4.1mm (0.16”) Jet Spacing x 10.9mm (0.43”) Jet Length 4028-4002

Nozzle 7.9mm (0.31”) Jet Spacing x 10.9mm (0.43”) Jet Length 4028-4003

Nozzle 7.9mm (0.31”) Jet Spacing x 13.5mm (0.53”) Jet Length 4028-4004

Nozzle 7.9mm (0.31”) Jet Spacing x 16mm (0.63”) Jet Length 4028-4005

Nozzle 7.9mm (0.31”) Jet Spacing x 18.5mm (0.73”) Jet Length 4028-4006

Nozzle 11.68mm (0.46”) Jet Spacing x 20.83mm (0.82”) Jet Length 4028-4007

Nozzle 11.42mm (0.45”) Jet Spacing x 27.17mm (1.07”) Jet Length 4028-4008

Nozzle 18.6mm (0.73”) Jet Spacing x 12.8mm (0.50”) Jet Length 4028-4505

Nozzle 10.4mm (0.41”) Jet Spacing x 21.35mm (.84”) Jet Length 4028-4506

Component Stenciling Tool Kit, 40mm - 2 7016-0016

Component Stenciling Tool Kit, 35mm - 4 7016-0006

Component Stenciling Tool Kit, 35mm - 2 7016-0030

Component Stenciling Tool Kit, 33mm - 4

Component Stenciling Tool Kit, 31mm - 2

Component Stenciling Tool Kit, 31mm - 4

Component Stenciling Tool Kit, 27mm - 4 7016-0007

Component Stenciling Tool Kit, 27mm - 2 7016-0029

Component Stenciling Tool Kit, 25mm - 2 7016-0017

Component Stenciling Tool Kit, 25mm - 4 7016-0020

Component Stenciling Tool Kit, 23mm - 2 7016-0008

Component Stenciling Tool Kit, 23mm - 4 7016-0013

Component Stenciling Tool Kit, 17mm - 2 7016-0009

Component Stenciling Tool Kit, 17mm - 4 7016-0012

Component Stenciling Tool Kit, 15mm - 2 7016-0010

Component Stenciling Tool Kit, 15mm - 1 7016-0023

Component Stenciling Tool Kit, 13mm - 2 7016-0011

Component Stenciling Tool Kit, 13mm x 10mm 7016-0027

Component Stenciling Tool Kit, 12mm CSP 7016-0014

Component Stenciling Tool Kit, 11mm x 8mm CSP 7016-0015

Component Stenciling Tool Kit, 19mm 7016-0018

Component Stenciling Tool Kit, 19mm Socket 7016-0026

Component Stenciling Tool Kit, 16.5 x 8mm, CSP 7016-0019

Component Stenciling Tool Kit, 22mm x 14mm 7016-0022

Component Stenciling Tool Kit, 4mm LCC 7016-0024

Component Stenciling Tool Kit, 8mm x 10mm 7016-0031

Component Stenciling Tool Kit, PLCC 28 7016-0033

Component Stenciling Tool Kit, 9mm 7016-0034

Component Stenciling Tool Kit, 24mm - 4 7016-0035

Component Stenciling Tool Kit, 6mm 7016-0036

Stencil, 40mm x 503 1040-0503-P1

Stencil, 40mm x 432 1040-0432-P1

7016-0021

7016-0028

7016-0032

17

Page 19

Stencil, 35mm x 388 1035-0388-P1

Stencil, 35mm x 456 1035-0456-P1

Stencil, 35mm x 313 1035-0313-P1

Stencil, 35mm x 352 1035-0352-P1

Stencil, 35mm x 480 1035-0480-P1

Stencil, 33mm x 503 1033-0503-P1

Stencil, 31mm x 304 1031-0304-P1

Stencil, 31mm x 329 1031-0329-P1

Stencil, 27mm x 352 1027-0352-P1

Stencil, 27mm x 316 1027-0316-P1

Stencil, 27mm x 225 1027-0225-P1

Stencil, 27mm x 256 1027-0256-P1

Stencil, 27mm x 272 1027-0272-P1

Stencil, 27mm x 292 1027-0292-P1

Stencil, 27mm x 324 1027-0324-P1

Stencil, 27mm x 328 1027-0328-P1

Stencil, 27mm x 336 1027-0336-P1

Stencil, 23mm x 169 1023-0169-P1

Stencil, 23mm x 288 1023-0288-P1

Stencil, 23mm x 324 1023-0324-P1

Stencil, 23mm x 208 1023-0208-P1

Stencil, 23mm x 256 1023-0256-P1

Stencil, 23mm x 484 1023-0484-P1

Stencil, 17mm x 208 1017-0208-P1

Stencil, 17mm x 256 1017-0256-P1

Stencil, 15mm x 156 1015-0156-P1

Stencil, 15mm x 160 1015-0160-P1

Stencil, 15mm x 196 1015-0196-P1

Stencil, 15mm x 196 1015-0196-P1

Stencil, 13mm x 144 1013-0144-P1

Stencil, 13mm x 64 1013-0064-P1

Stencil, 12mm x 144 1012-0144-P1

Stencil, 12mm x 160 1012-0160-P1

Stencil, 11mmx 8 x 72 1011-0072-P1

Stencil, 25m x 357 1025-0357-P1

Stencil, 25mm x 360 1025-0360-P1

Stencil, 19m x 225 1023-0256-P1

Stencil, 19m x 52 1023-0052-P1

Stencil, 16.5 x 8 x 52 1016-0052-P1

Stencil, 14 x 22 x 119 1014-0119-P1

Stencil, 4mm x 24 1004-0024-P1

Stencil, 4mm x 28 1004-0028-P1

Stencil, 4mm x 24 1004-2024-P1

18

Page 20

Stencil, 8mm x 48 1008-0048-P1

Stencil, PLCC 28 1012-0028-P1

Stencil, 9mm x 56 1009-0056-P1

Stencil, 24mm x 241 1024-0241-P1

Stencil, 6mm x 40 1006-0040-P1

Hand Held Vacuum Pick, TF1000 1272-0005-P1

Flux Applicator Tool Kit 6993-0218

K-Type Thermo Couple (2) 1340-0174-P5

19

Page 21

N. Maintenance

The TF 1000 is designed to be basically maintenance free. However, the Top

Heater and consumable parts may need to be changed from time to time.

1. The Vacuum filter should be cleaned every three months. Remove the

cover on the side of the TF 1000 as shown below. Remove the filter from

the filter assembly and clean with mild soap and water. Let the filter dry

completely before reassembling.

2. The Top Heater is easily replaced. Unplug the TF 1000 from the power

source. Ensure the heater is cool. Remove the heater protection cover

and remove the four screws that retain the heater assembly. Pull the

heater assembly downwards to remove it from the socket and install the

new heater. Install the four retaining screws and the protection cover.

Filter Assembly Location Remove and clean filter

Remove 4

Screws

Remove 4

Screws

Heater Protection Cover Heater Assembly

20

Loading...

Loading...