Page 1

Operation and Maintenance Manual for the

SODRTEK

ST 125 Soldering System

P/N 5050-0534

®

Page 2

TITLE PAGE

General Information .......................................................................................................3

Introduction...........................................................................................................3

Specifications .......................................................................................................3

Parts Identification................................................................................................4

Safety Guidelines...........................................................................................................5

System Set-Up...............................................................................................................6

Tip & Tool Stand......................................................................................................6

Handpiece Connection............................................................................................6

TEKLINK..................................................................................................................6

System Power Up ..........................................................................................................7

Burn In Procedure..........................................................................................................7

Operation........................................................................................................................7

Tip Offset.................................................................................................................7

Variable Temperature Control.................................................................................8

Temperature/Dial Lock ...........................................................................................8

LED Operation.........................................................................................................8

Temperature Dial Adjustment ........................................................................................8

Vacuum Pump Operation........................................................................................9

Handpiece Vacuum Pressure..................................................................................9

Corrective Maintenance................................................................................................10

Power Source......................................................................................................10

Handpieces..........................................................................................................10

Packing List...................................................................................................................11

Spare Parts...................................................................................................................11

Service ..........................................................................................................................11

“SODRTEK by PACE” LIMITED WARRANTY STATEMENT.......................................12

Contact Information.......................................................................................................13

©2004 PACE Inc., Annapolis Junction, Maryland Page 2 of 13

All Rights Reserved

Page 3

General Information

Introduction

Thank you for purchasing the PACE SODRTEK

®

model ST 125 Analog Desoldering System. This

manual will provide you with the information necessary to properly set up, operate and maintain the

ST 125.

The ST 125 system is available in either 115 VAC or 230 VAC versions, which incorporates a highly

responsive SensaTemp (closed loop) control system providing up to 80 Watts of total power to a

single output channel. The 230 VAC version system bears the CE Conformity Marking, which

assures the user that it conforms to EMC 89/336/EEC.

The 115 VAC version systems conform to FCC Emission Control Standard, Title 47, Subpart B, Class

A. This standard is designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment.

Specifications

System Power Source Power Requirements

ST 125 Operates on 97-127 VAC, 50/60Hz, 90 Watts maximum at 115 VAC,

60Hz

ST 125E Operates on 197-253 VAC 50/60Hz, 80 Watts maximum at 230 VAC,

50Hz

Temperature Specifications

Handpieces Tip Temperature Range: 204 to 455°C (400 to 850°F) nominal.

Temperature Stability: ±1.1°C (±2°F) at idle from set tip temp.

NOTE: Actual minimum and maximum Operating Tip Temperatures may vary depending on

Handpiece, Tip Selection and application.

Vacuum And Air

Measurements at front panel Vacuum and Controllable Pressure Ports.

Vacuum Rise Time: ------- 150 ms average.

Vacuum: ............................ 51 cm Hg. (20 in. Hg.) (nominal)

Pressure: .......................... 1.44 Bar (21 P.S.I.) (nominal at MAX setting)

Air Flow: ........................... 6 SLPM (0.22 SCFM) maximum

EOS/ESD Specifications

The specifications shown below apply except on "Soft Ground Systems" which have a 1meg ohm

current limiting resistance and a label placed on the power source f ront panel referring to EN

100015-1.

Tip-To-Ground Resistance: Less than 2 ohms.

AC Leakage: Less than 2 Millivolts RMS from 50Hz to 10MHz.

Transient Level: Less than 500mV peak, out to 100MHz.

©2004 PACE Inc., Annapolis Junction, Maryland Page 3 of 13

All Rights Reserved

Page 4

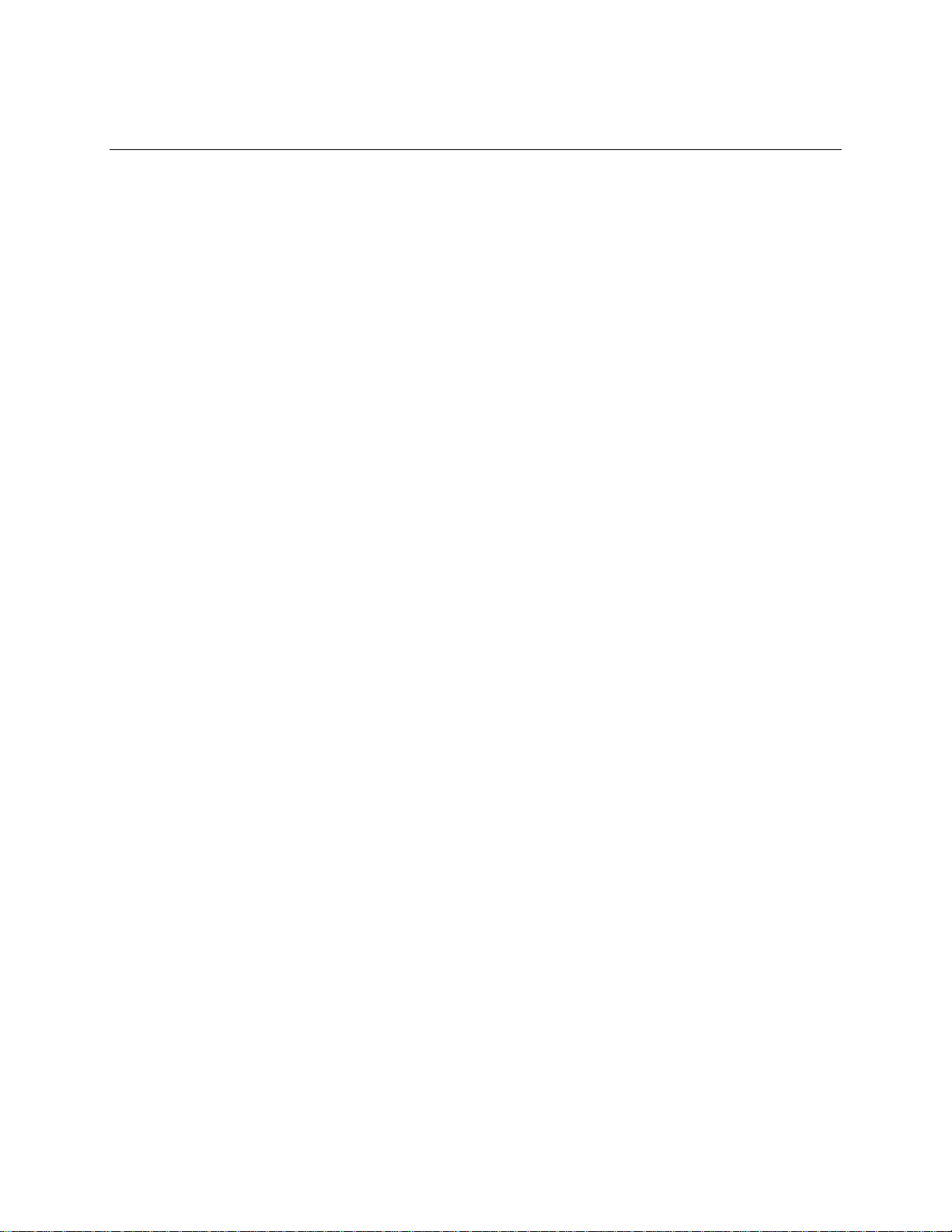

Parts Identification

Switc

p

p

Temperature Selection Dial

Power Switch

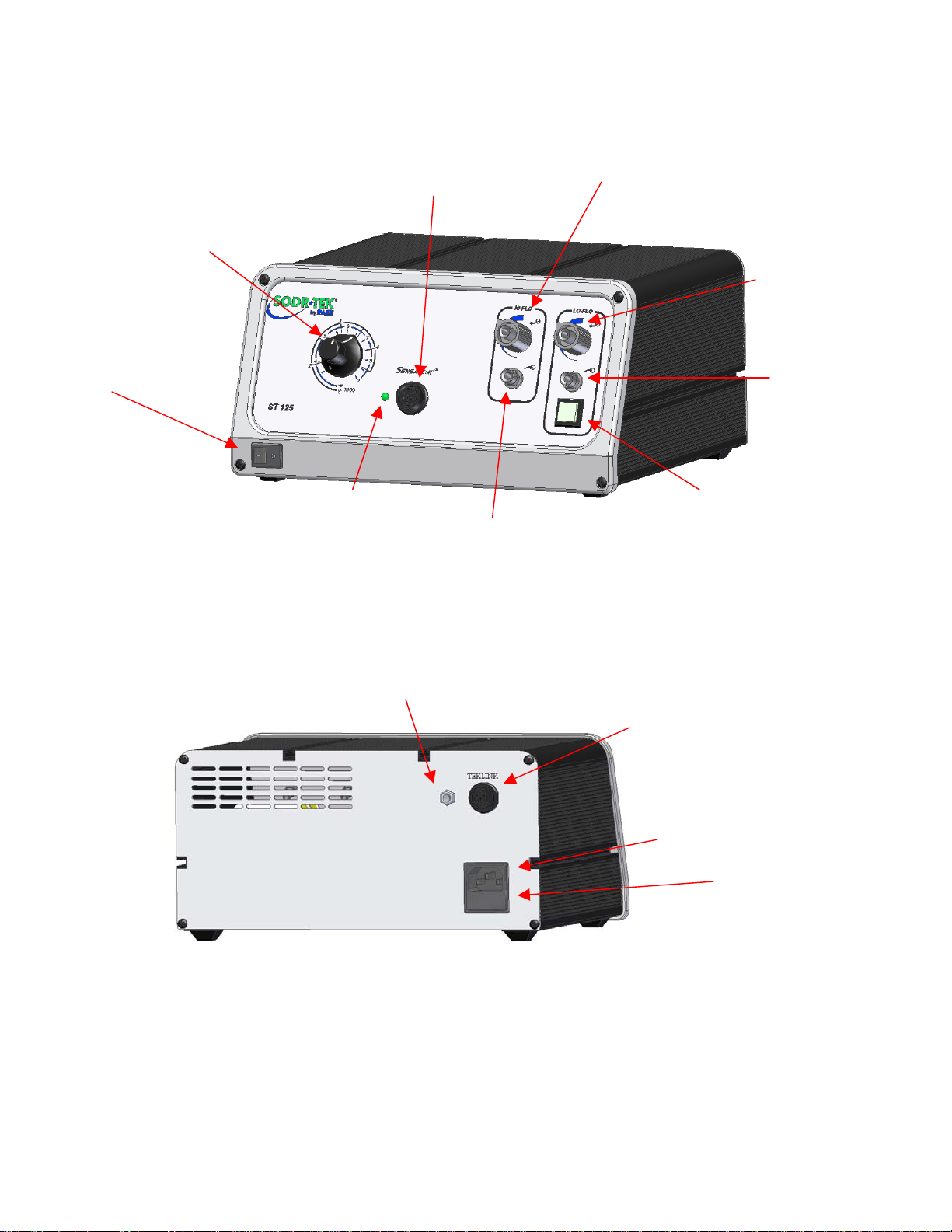

Power Receptacle HiFlo Pressure Port

Front Panel LED

Earth Ground Rece

HiFlo Vacuum Port

tacle

TEKLINK Rece

LoFlo Pressure Port

LoFlo Vacuum Port

Illuminated LoFlo Pump

h

tacle

AC Power Receptacle/Fuse Holder

Fuse

©2004 PACE Inc., Annapolis Junction, Maryland Page 4 of 13

All Rights Reserved

Page 5

Safety Guidelines

The following are safety precautions that personnel must understand and follow when using or servicing

this product.

1. POTENTIAL SHOCK HAZARD - Repair procedures on PACE products should be performed

by Qualified Service Personnel only. Line voltage parts may be exposed when the

equipment is disassembled. Service personnel must avoid contact with these parts when

troubleshooting the product.

2. To prevent personnel injury, adhere to safety guidelines in accordance with OSHA and other

applicable safety standards.

3. SensaTemp handpiece heaters and installed tips are hot when the handpiece is powered on

and for a period of time after power off. DO NOT touch either the heater or the tip. Severe

burns may result.

4. PACE Tip & Tool Stands and handpiece cubbies are designed specifically for use with the

associated handpiece and houses it in a manner that protects the user from accidental burns.

Always store the handpiece in its holder. Be sure to place the handpiece in its holder after

use and allow for cooling before storing.

5. Always use PACE systems in a well ventilated area. A fume extraction system such as those

available from PACE are highly recommended to help protect personnel from solder flux

fumes.

6. Exercise proper precautions when using chemicals (e.g., solder paste). Refer to the Material

Safety Data Sheet (MSDS) supplied with each chemical and adhere to all safety precautions

recommended by the manufacturer.

©2004 PACE Inc., Annapolis Junction, Maryland Page 5 of 13

All Rights Reserved

Page 6

System Set-Up

Set up the ST 125 system using the following steps and associated drawings.

1. Store the shipping container in a convenient location. Reuse of these

containers will prevent damage if you store or ship your system.

2. Place the Power Switch in the “OFF” or “0” position.

Tip & Tool Stand

The Tip & Tool Stand can be mounted to the power source. If the system will be placed on the

workbench, this is recommended. If the ST 125 is to be mounted under the workbench or shelf, the

Tip & Tool Stand should not be mounted to the power source.

1. To attach the stand to the power source:

a) Insert the 2 Mounting Screws (head first) into the

power source mounting slots (plastic case shown).

Slide the screws toward rear of the power source.

b) Place the Tip & Tool Stand beside the power source.

Insert ends of the 2 Mounting Screws into the 2 Tip &

Tool Stand mounting holes as shown.

c) Install a Thumb Nut onto the end of each Mounting

Screw and tighten Thumb Nuts.

2. Place the handpiece into its Tip & Tool Stand.

Handpiece Connection

Connect the handpiece connector plug into the Power Receptacle in

the following manner.

1. Align guide on connector with slot on power receptacle.

2. Insert connector into power receptacle.

3. Turn the connector housing clockwise to lock in place.

TEKLINK

The TEKLINK receptacle located on the back panel of the power supply allows

you to interface the VACUUM and PRESSURE features of your ST 125/145

with the SodrTek ST 25/45 system. This feature gives you the freedom to

operate air-controlled handpieces (SX-70/80, TP-65, or TJ-70/80) from an ST

25/45 system through the VACUUM and PRESSURE ports of your ST

125/145. To link your ST 125 system to the ST 25/45 system, perform the

following procedure.

1. Place the ST 25/45 system adjacent to (side by side) or stacked on top

of your ST 125/145 system.

TEKLINK Receptacle

2. Use the TEKLINK cable (sold separately) to connect the systems together. The TEKLINK

Receptacle is located on the back panel of each power supply.

©2004 PACE Inc., Annapolis Junction, Maryland Page 6 of 13

All Rights Reserved

Page 7

3. Ensure the VisiFilter assembly is connected to either the ST 125/145 VACUUM Port.

4. Connect the air hose of the handpiece being used, to either the VisiFilter assembly or the

controllable PRESSURE port.

The TEKLINK Remote Box (sold separately) allows the connection of up to three ST 25/45 systems in

any combination.

NOTE: Systems connected together through the TEKLINK system must be used and controlled

by a single operator. Any attempt to operate by more than one individual can create a

hazardous condition and will cause deterioration in performance.

System Power Up

1. Insert the female end of the power cord into the AC Power Receptacle on the rear panel of

the power source.

2. Plug the prong end (male end) of the power cord into an appropriate 3 wire grounded AC

supply receptacle.

CAUTION: To insure operator and ESD/EOS safety, the AC power supply receptacle must be

checked for proper grounding before initial operation.

Heater Burn In Procedure

Use the following instructions to perform the Heater Burn In procedure.

1. Place the Power Switch in the “OFF” (0) position.

2. Ensure that the handpiece is connected to the power source. If a plastic cap is present on

the heater assembly, remove it and discard. The cap is used for shipping purposes only.

Place the handpiece in the Tip & Tool Stand.

3. Turn on the power source.

4. Turn the Temperature dial to 315°C (600 °F) for 10 minutes.

5. Next, increase the temperature to 427°C (800°F) for 15 minutes.

6. Turn off the power source.

CAUTION: The heater will be hot at the conclusion of the Burn In procedure.

NOTE: This procedure should be performed whenever a ne w handpiece or new heater is

connected to the system. Ensure that the system is placed in a well-ventilated area.

Smoke will be generated during the burn in cycle and while soldering. Fume extraction

equipment is recommended.

Operation

Tip Offset

Differences between the temperature settings and true tip temperatures are negligible when using

Thru-Hole, single point soldering tips. With any heating system however, True Tip Temperatures can

differ greatly from temperature settings when using larger SMT soldering tips. This difference is

called Tip Temperature Offset. PACE recommends the use of the Tip & Temperature Selection

©2004 PACE Inc., Annapolis Junction, Maryland Page 7 of 13

All Rights Reserved

Page 8

System booklet (PACE P/N 5050-0251) as a guide to accurately set and maintain a true tip

temperature for any size and type of SMT tip.

Variable Temperature Control

Adjust the Variable Temperature Control Knob to the desired temperature

setting. Notice that the control panel has an outer graphic scale denoting

temperature in °C (Celsius) and an inner graphic scale denoting temperature in

°F (Fahrenheit). These numerical scales denote the set tip temperature times

100 (e.g., “3” on the outer scale is 3 x 100 or 300°C).

Temperature/Dial Lock

The Variable Temperature Control Knob can be locked in position to avoid

accidental or unauthorized changes of the temperature setting.

1. Adjust the Temp. Control Knob to the desired temperature setting.

2. Using the Temp. Locking Key (hex key supplied with system), tighten the

set screw on the Temp. Locking Ring closest to the front panel.

LED Operation

The Green colored LED on the power source front panel indicates System Status and Power

Receptacle output status (LED OFF, ON or Flashing).

LED Full On - Continuous power is being delivered to the handpiece.

This condition is evident when the system is first powered up (handpiece

heater cold) or the Variable Temperature Control setting is increased.

LED Flashing - Indicates that the set tip temperature (as set on the

Variable Temperature Control) has been reached. Power to the

handpiece is cycling Off and On to maintain set temperature.

LED Off - No power is being delivered to the handpiece heater. This condition is evident for a

short period of time when set temperature is reached and stabilizing or if the Variable

Temperature Control setting is decreased. If the LED never

illuminates, check for a faulty

handpiece (see Corrective Maintenance section). Also, if no handpiece is connected to the

power source, the LED will not illuminate.

Temperature Dial Adjustment

The ST 125 system is tested for temperature accuracy at the factory and can be checked for

calibration according to PACE requirements. Also, a temperature setting normally used by the

operator can be adjusted to the precise temperature indicated on the Dial/Display. No internal

adjustments can be made to the power supply. To verify calibration of the Temperature selection

dial, perform the following procedure.

1. Install a tip with an embedded thermocouple into the handpiece connected to

the system. Tips with K type thermocouples are available from PACE.

2. Connect the thermocouple assembly to an appropriate temperature meter.

3. When set fully counterclockwise, the pointer of the Variable Temperature

Control knob will align to the Calibration Mark as shown. With the system turned on,

adjust the Variable Temperature Control to obtain a stable tip temperature of 300°C (for

©2004 PACE Inc., Annapolis Junction, Maryland Page 8 of 13

All Rights Reserved

Page 9

PACE factory specifications) or the temperature setting normally used by the operator. If

the temperature displayed on temperature meter is within ±15°C (27°F), perform steps 4

thru 6 to obtain a precise reading. If the temperature is off by more than ±15°C, the

handpiece may require maintenance. Recheck the temperature using a

second handpiece.

4. Carefully lock the Variable Temperature Control in position by tightening the

inner set screw (closest to front panel).

5. Loosen the outer set screw on the Variable Temperature Control knob (furthest

from front panel) using the Temp. Locking Key (hex key) supplied with the

system. Position the knob with the pointer aligned to match the temperature

indicated on the temperature meter. Secure the knob in position by tightening

the outer set screw. Loosen the inner set screw to unlock the Variable

Temperature control if adjustment of operating tip temperature is desired.

Vacuum Pump Operation

The PACE ST 125 contains two different vacuum pumps.

1. HiFlo Pump

a) To activate, depress the handpiece activation button.

b) Optional Foot Pedal can be used to actuate the HiFlo pump via the rear TEKLINK

socket.

2. LoFlo Pump

a) This pump is activated by the front Illuminated LoFlo Pump Switch.

b) Used for the TJ-70/80 and PV-65 Pik Vac Wand.

CAUTION: Ensure that only one air hose is connected to the VACUUM or controllable PRESSURE

port at one time. Attachment to both ports simultaneously will cause deterioration in

performance.

Handpiece Vacuum/Pressure

To set up your Sodr-X-Tractor air hose connection, perform the following steps:

1. Air Hose To Handpiece Connection:

a) Attach one end of a 137cm (54 inch) length of air hose to the metal

tube in the back of the handpiece.

If you have a PACE system incorporating only one handpiece, attach

b)

the air hose to the power cable using the supplied Hose Clamps.

Space them evenly along the length of the power cable starting at a

point 6 inches from the ends of the handpiece.

c) If you have a PACE system incorporating 2 or more air handpieces,

you may wish to leave the air hose assembly unattached to allow a quick change to any

air handpiece being used.

2. Prepare a VisiFilter in the following manner:

©2004 PACE Inc., Annapolis Junction, Maryland Page 9 of 13

All Rights Reserved

Page 10

a) Connect a 1 inch (2.5cm) length of clear pvc air hose to the FLOW OUT side of the

VisiFilter; push and turn the hose onto the VisiFilter nipple to seat.

b) Insert the ribbed end of a male quick connect hose mount fitting (P/N 1259-0087) into the

free end of the 1 inch (2.5cm) length of air hose connected to the FLOW OUT side of the

VisiFilter.

c) Connect the free end of the 137cm (54 inch) length of air hose to the FLOW IN side of

the VisiFilter.

d) Insert the end of the quick connect hose mount fitting (on VisiFilter FLOW OUT side) into

the power source Vacuum Port.

3. When using air pressure, and/or utilizing multiple air handpieces, PACE recommends the use

of the following set up procedure which utilizes additional quick connect hose mount fittings.

An assortment of quick connect air fittings are supplied with each additional air handpiece.

a) Disconnect the 137cm (54 inch) length of air hose from the FLOW IN side of the VisiFilter

assembly. Insert the ribbed end of a male quick connect hose mount fitting (P/N 1259-

0087) into the free end of this air hose.

b) Connect the free end of a 1 inch (2.5cm) length of air hose with an installed female quick

connect hose mount fitting (P/N 1259-0086) to the FLOW IN side of the VisiFilter

Assembly.

c) The 137cm (54 inch) length of air hose can now be easily moved between the VisiFilter

Assembly and the Controllable Pressure Port. The VisiFilter assembly remains

connected to the Vacuum Port.

4. Additional fittings may also be added to the hose connection at the rear of each air handpiece

to ease changing of handpieces.

NOTE: When removing any air hose, turn and pull. Do not attempt to pull hose directly off.

Damage to or breakage of fitting or VisiFilter may occur. Use your Sodr-X-Tractor with

a clean VisiFilter element. Otherwise a deterioration in performance or damage to the

unit may occur.

Corrective Maintenance

Power Source

Refer to the table below. Most malfunctions are simple and easy to correct.

Symptom Probable Cause Solution

No power to

system

Blown Fuse Check handpiece using the appropriate handpiece

manual. Replace the fuse (located in the AC

Receptacle Fuse Holder) with one of the same

rated value.

Defective Heater Refer to the appropriate handpiece manual Handpiece will

not heat

Power Source

Contact PACE

Malfunction

©2004 PACE Inc., Annapolis Junction, Maryland Page 10 of 13

All Rights Reserved

Page 11

Handpieces

Please refer to the specific handpiece manual for the “Heater Assembly Checkout Procedures.”

Packing List

Item # Description Part Number ST 125

1 System Power Supply 1 0

2 System Power Supply (Export) 0 1

3 Power Cord, 115V 1332-0094 1 0

4 Power Cord, 230V 1332-0093 0 1

5 Hex Key, .050 1100-0237 1 1

6 Operations Manual CD CD5050-0459 1 1

Only

Spare Parts

Item # Description PACE Part Number

Fuse, 1.25 Amp, 250 V, Time Lag (ST 125) 1159-0251-P5 1

Fuse, 0.63 Amp, 250 V, Time Lag (ST 125E) 1159-0252-P5

2 Tip & Temperature Selection Chart 5050-0251

3 TEKLINK Cable 1332-0252-P1

4 TEKLINK Remote Box 3008-0218-P1

Service

Please contact PACE or your local distributor for service and repair.

ST 125 E

Only

©2004 PACE Inc., Annapolis Junction, Maryland Page 11 of 13

All Rights Reserved

Page 12

“SODRTEK by PACE” LIMITED WARRANTY STATEMENT

Limited Warranty

Seller warrants to the first user that products manufactured by it and supplied hereunder are free of

defects in materials and workmanship for a period of one (1) year from the date of receipt by such user.

Monitors, computers and other brand equipment supplied but not manufactured by PACE are covered

under their respective manufacturer’s warranty in lieu of this Warranty.

This warranty does not cover wear and tear under normal use, repair or replacement required as a result

of misuse, improper application, mishandling or improper storage. Consumable items such as tips,

heaters, filters, etc. which wear out under normal use are excluded. Failure to perform recommended

routine maintenance, alterations or repairs made other than in accordance with Seller’s directions, or

removal or alteration of identification markings in any way will void this warranty. This warranty is

available only to the first user, but the exclusions and limitations herein apply to all persons and entities.

SELLER MAKES NO OTHER WARRANTY, EXPRESS OR IMPLIED, AND MAKES NO WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Seller will, at its option, repair or replace any defective products at its facility or other location approved by

it at no charge to user, or provide parts without charge for installation by the user in the field at user’s

expense and risk. User will be responsible for all costs of shipping equipment to Seller or other location

for warranty service.

EXCEPT FOR THE REMEDY ABOVE DESCRIBED, UNLESS OTHERWISE REQUIRED BY

APPLICABLE LAW, SELLER WILL HAVE NO OTHER OBLIGATION WITH REGARD TO ANY BREACH

OF WARRANTY OR OTHER CLAIM WITH RESPECT TO THE PRODUCTS, OR LIABILITY FOR ANY

DIRECT, INDIRECT, CONSEQUENTIAL, OR INCIDENTAL LOSS OR DAMAGE CAUSED BY OR

OCCURRING IN CONNECTION WITH ANY OF THE PRODUCTS.

Warranty service may be obtained by contacting the appropriate PACE Company or local Authorized

PACE distributor as set forth below to determine if return of any item is required, or if repairs can be made

by the user in the field. Any warranty or other claim with respect to the products must be made with

sufficient evidence of purchase and date of receipt, otherwise user’s rights under this warranty shall be

deemed waived.

For PACE USA Customers:

PACE, INCORPORATED

9030 Junction Drive

Annapolis Junction, Maryland 20701

Tel. 301-317-3588

FAX. 301-498-3252

For PACE EUROPE Customers:

PACE EUROPE LIMITED

Sherbourne House, Sherbourne Drive,

Tilbrook, Milton Keynes

MK7 8HX

United Kingdom

Tel. (44) 1908 277666

WARRANTY SERVICE FAX: (44) 1908 277 777

All other Customers:

Local Authorized PACE Distributor

©2004 PACE Inc., Annapolis Junction, Maryland Page 12 of 13

All Rights Reserved

Page 13

PACE Incorporated retains the right to make changes to specifications contained herein at any time,

without notice. Contact your local authorized PACE Distributor or PACE Incorporated to obtain the latest

specifications.

The following are trademarks and/or service marks of PACE, Incorporated, MD, USA:

INSTACAL

POWERPORT

™

, FUMEFLO™, HEATWISE™, PACEWORLDWIDE™, PERMAGROUND™,

™

, POWERMODULE™, TEMPWISE™, TIP-BRITE™, AUTO-OFF™, and

TEKLINK™.

The following are registered trademarks and/or service marks of PACE Incorporated, Annapolis Junction

Maryland U.S.A.

ARM-EVAC

SODRTEK

VISIFILTER

®

, FLO-D-SODR®, MINIWAVE®, PACE®, SENSATEMP®, SNAP-VAC®,

®

, SODR-X-TRACTOR®, THERMOFLO®, THERMOJET®, THERMOTWEEZ®,

®

, THERMO-DRIVE®, and TOOLNET®.

PACE products meet or exceed all applicable military and civilian EOS/ESD, temperature stability and

other specifications including MIL STD 2000, ANSI/JSTD 001, IPC7711, and IPC A-610.

www.paceworldwide.com

PACE USA PACE Europe

9030 Junction Drive Sherbourne House

Annapolis Junction, MD 20701 Sherbourne Drive

USA Tilbrook, Milton Keynes

MK7 8HX

United Kingdom

Tel: (301) 490-9860 (44) 01908-277666

Fax: (301) 498-3252 (44) 01908-277777

©2004 PACE Inc., Annapolis Junction, Maryland Page 13 of 13

All Rights Reserved

Loading...

Loading...