Page 1

PRC 2000 SYSTEMS

SERVICE MANUAL

Page 2

MANUAL NO. 5050-0344

REV. C

i

Page 3

PACE Incorporated retains the right to make changes to specifications contained herein at any time, without

notice.

Contact your local authorized PACE Distributor or PACE Incorporated to obtain the latest specifications.

The following are registered trademarks and/or servicemarks of PACE Incorporated, Laurel Maryland U.S.A. and

may only be used to identify genuine PACE products or services:

AdapTip, Arm-Evac, Cir-Kit, ComForm I, ConducTweez, CRAFT,

Dual Path, Flo-D-Sodr, FuseSet, HandiPik, HotSpot, LapFlo, MBT,

Micro Portable, MicroChine, MiniChine, Mini-Wave, PACE, Pacenter,

Ped-A-Vac, PETS, Pik-Vac, PRC, PRINT, Pro-Evac, Redi-Rak,

ResisTweez, SensaTemp, SMR, Snap-Vac, Sodr-Pen, Sodr-X-Tractor,

SR-3, SR-4, ST, StripTweez, SwaPlater, ThermoBand, Thermo-Drive,

ThermoJet, ThermoPart, ThermoPik, ThermoT weez, Tip-Evac, VisiFilter .

The following are trademarks and/or servicemarks of PACE Incorporated, Laurel Maryland U.S.A. and may only

be used to identify genuine PACE products or services:

Auto Off, Cubby-Vac, Datastore, Dust Evac, EKO, Lab Evac, MicroSpin,

PaceLink, PaceNet, Pik & Paste, Prep-Set, Pulse Plate, Spa-Kleen,

ThermoBond, TinSpin, TweezPik, Uni-Frame, V-A-N, Ventur-Evac.

Since 1958, PACE Incorporated has provided advanced technology training in all

aspects of hand soldering, rework and repair.

Additional copies of this manual or other PACE literature may be obtained from:

PACE Incorporated (301) 490 - 9860

Sales Administration (301) 498 - 3252 Fax

9893 Brewers Court

Laurel MD 20723-1990

©1995 PACE Incorporated, Laurel MD. All rights reserved. Printed in the U.S.A.

ii

Page 4

TABLE OF CONTENTS

TITLE PAGE

General Information ............................................................................................................................................... 1

Introduction ................................................................................................................................................. 1

Specifications............................................................................................................................................... 1

Parts Identification....................................................................................................................................... 4

Safety .................................................................................................................................................................... 16

Heading Guidelines ................................................................................................................................... 16

Precautions................................................................................................................................................. 17

Repair ................................................................................................................................................................... 19

Repair Procedure ....................................................................................................................................... 19

Service Hints.............................................................................................................................................. 20

Corrective Maintenance............................................................................................................................. 21

VisiFilter Element Replacement .......................................................................................................... 21

SensaTemp Handpieces........................................................................................................................ 22

MicroChine Handpiece ........................................................................................................................ 23

Power Source........................................................................................................................................ 25

Calibration ................................................................................................................................................. 30

Disassembly/Assembly.............................................................................................................................. 32

Disassembly ......................................................................................................................................... 32

Assembly.............................................................................................................................................. 37

Flow Charts................................................................................................................................................ 39

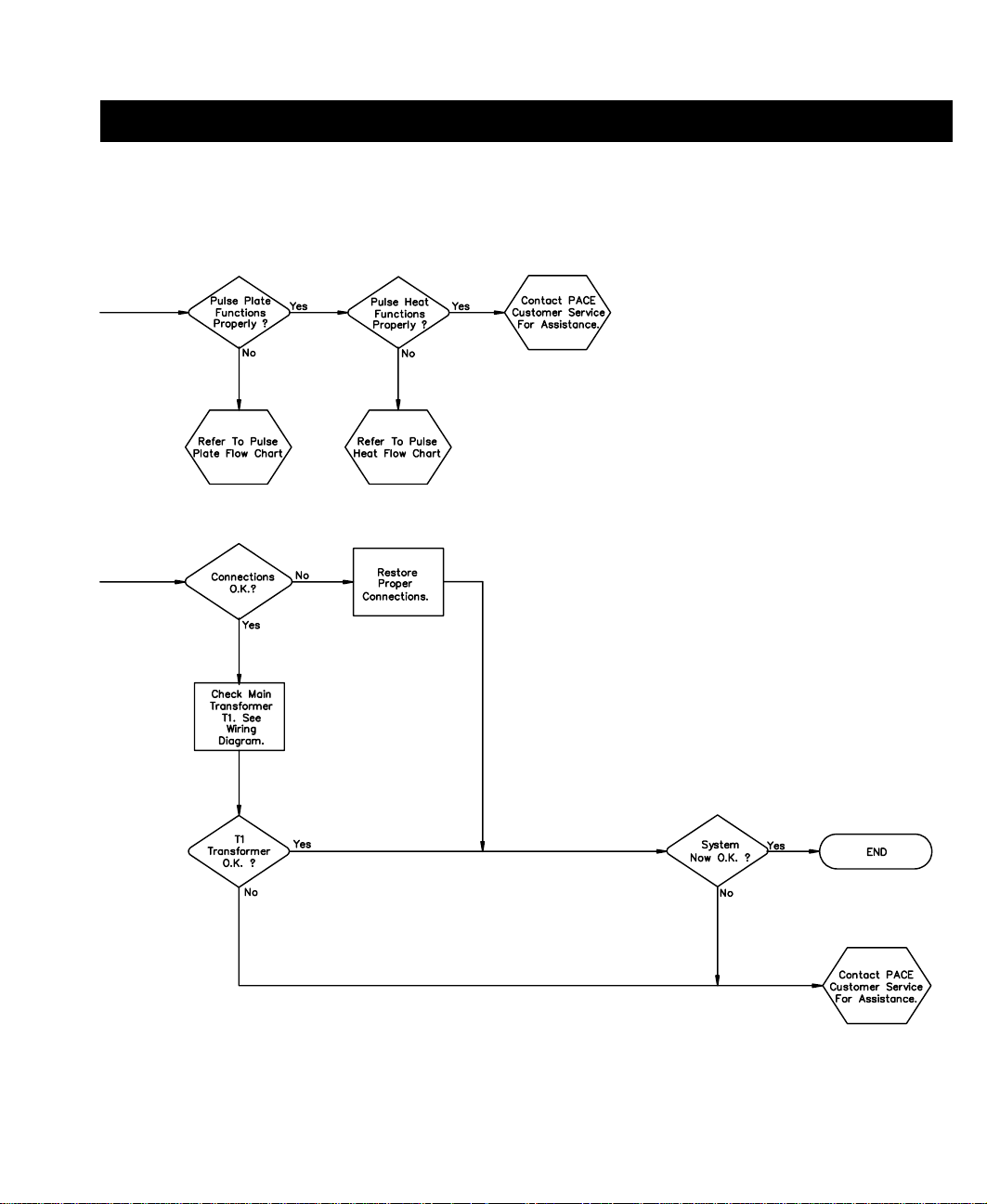

Power.................................................................................................................................................... 40

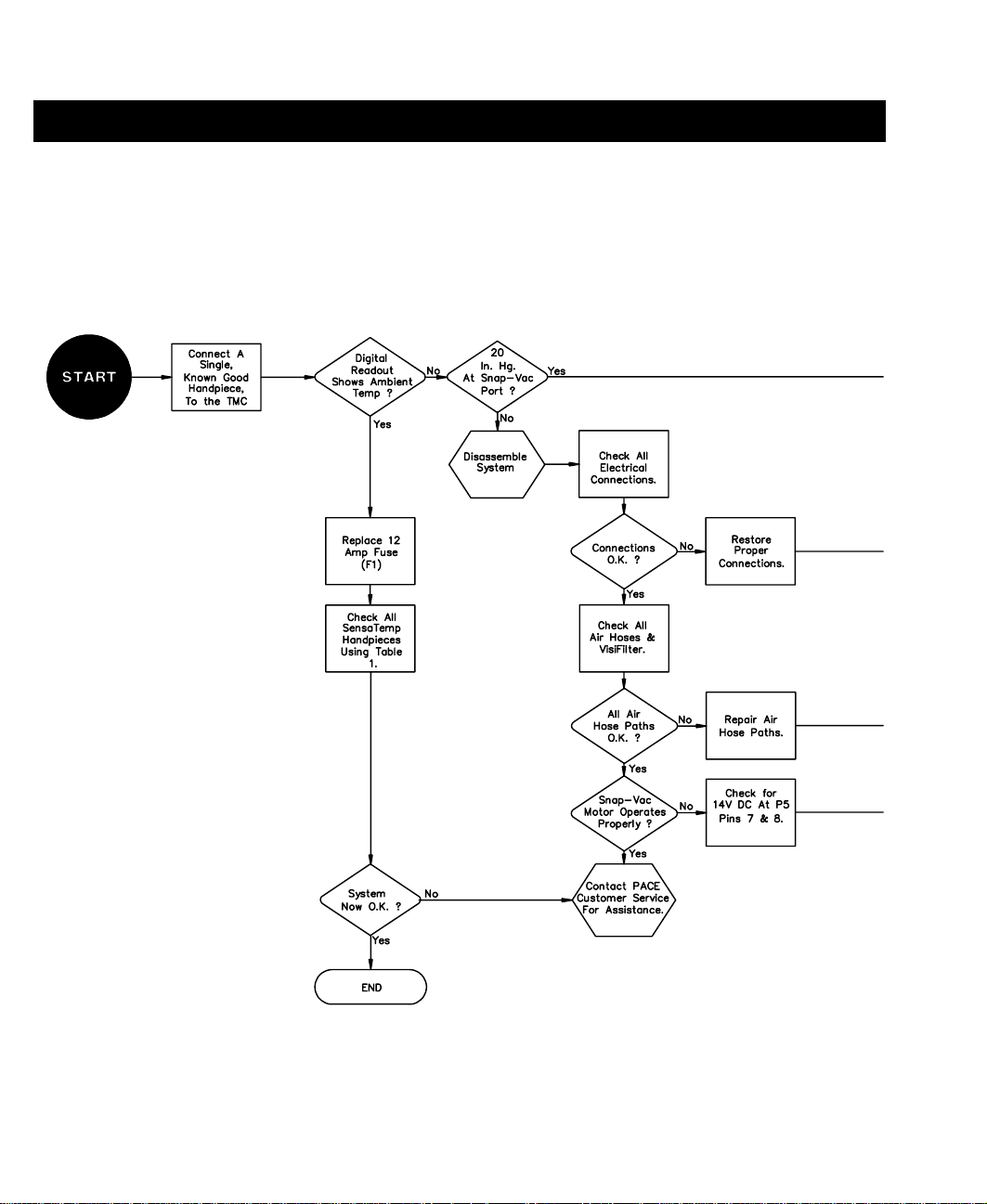

TMC ..................................................................................................................................................... 42

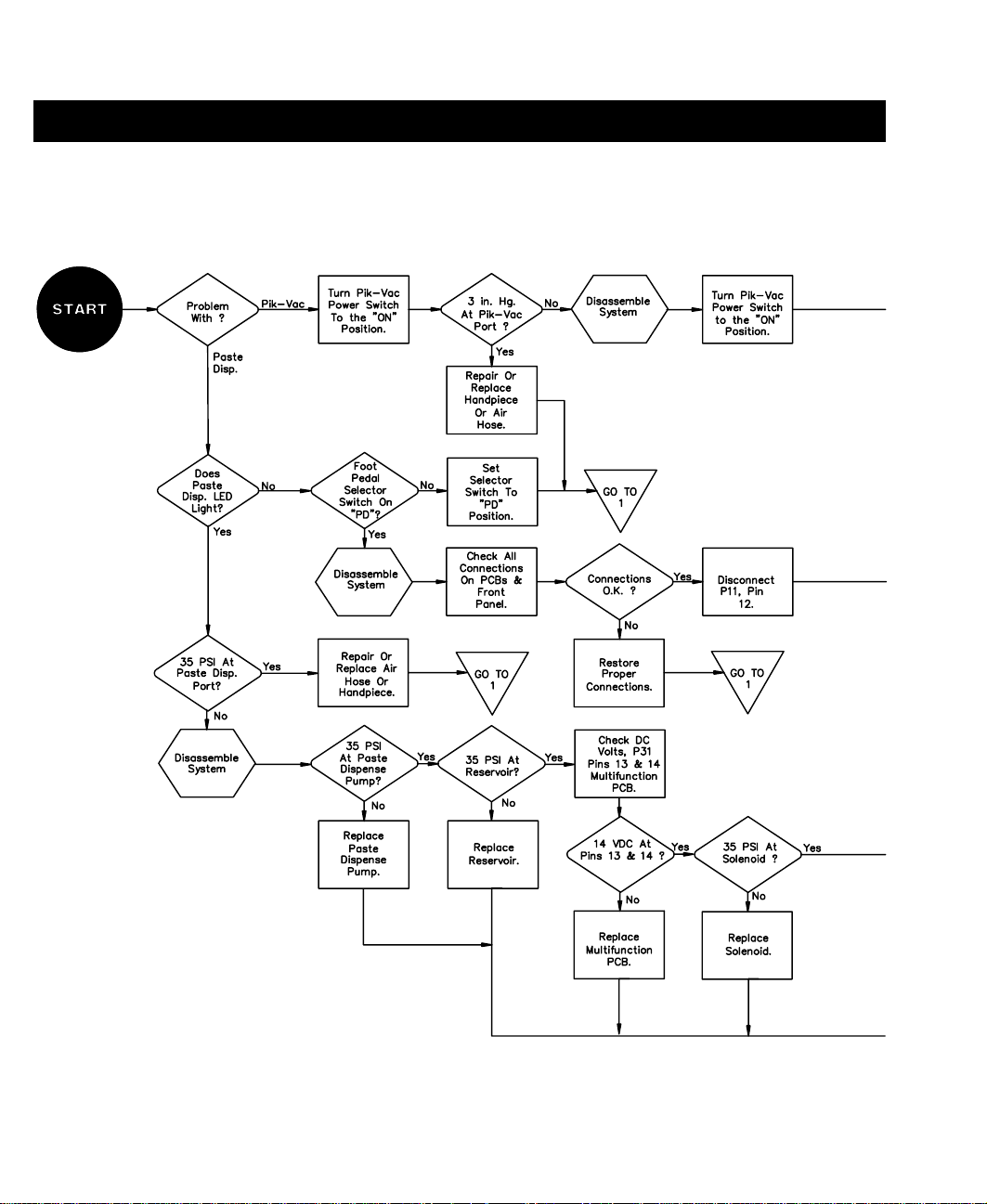

Pik & Paste ........................................................................................................................................... 44

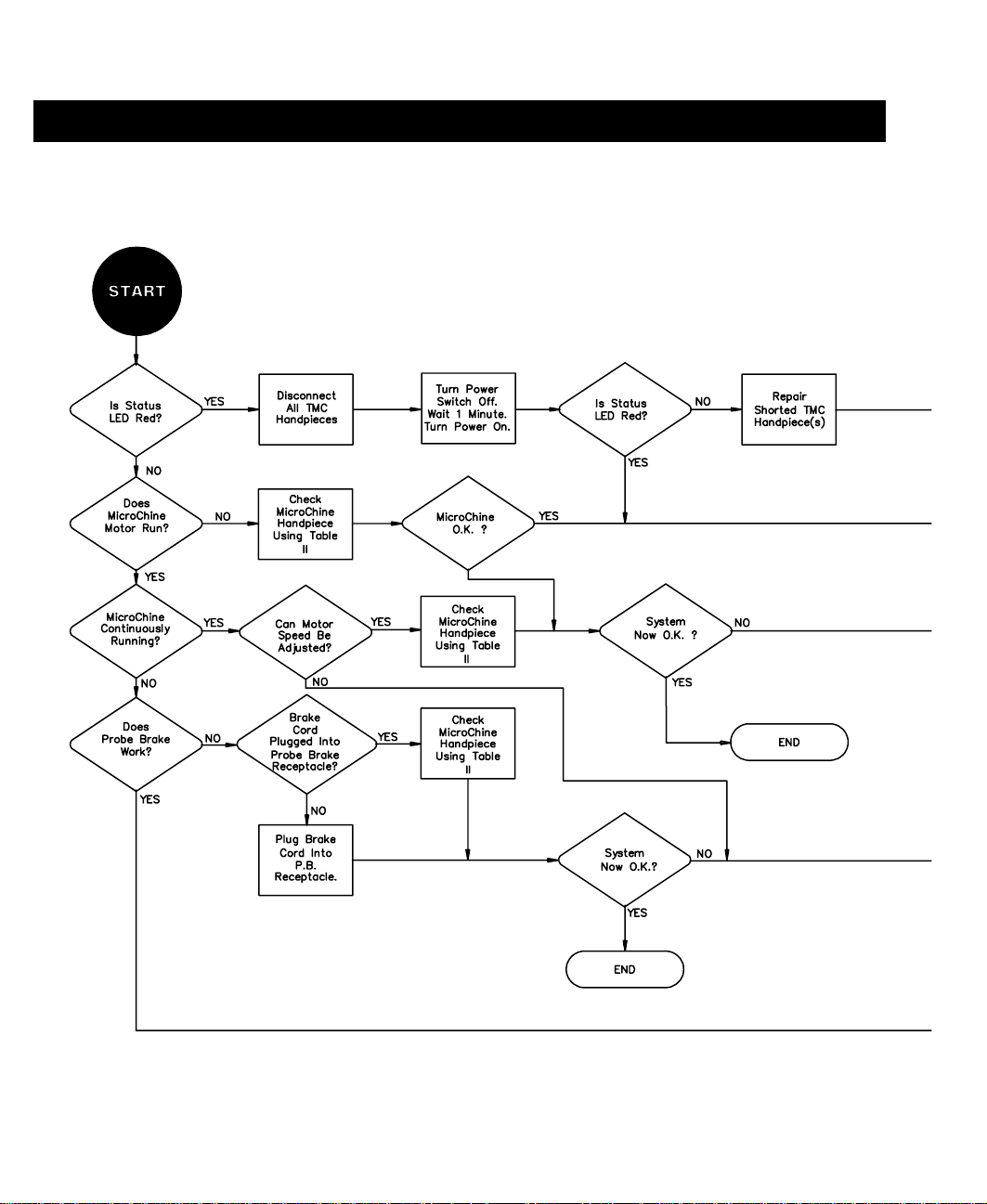

MicroChine .......................................................................................................................................... 46

Pulse Plate ............................................................................................................................................ 48

Pulse Heat............................................................................................................................................. 50

Wiring Diagram ......................................................................................................................................... 52

Multifunction PCB Assembly Schematic.................................................................................................. 54

Microprocessor PCB Assembly Schematic............................................................................................... 60

Display PCB Assembly Schematic............................................................................................................ 64

Assembly Drawing .................................................................................................................................... 66

Air Hose Routing....................................................................................................................................... 68

Replacement Parts ................................................................................................................................................ 69

Power Source ............................................................................................................................................. 69

Power Source Accessories......................................................................................................................... 73

Handpieces................................................................................................................................................. 74

Handpiece Accessories .............................................................................................................................. 76

Manual Improvement & Comment Form ............................................................................................................ 77

iii

Page 5

TABLES & FIGURES

TABLE PAGE

Table I Heater Assembly Checkout Procedures.......................................................................................... 22

Table II MicroChine Handpiece Checkout Procedures................................................................................ 24

Table III Corrective Maintenance, Power Source ......................................................................................... 25

Table IV Power Source Replacement Parts ................................................................................................... 69

Table V Power Source Accessories .............................................................................................................. 73

Table VI Replacement Handpieces................................................................................................................ 74

Table VII Replacement Handpiece Accessories ............................................................................................. 76

FIGURE PAGE

Figure 1. Power Switch/Foot Pedal Selector Switch ....................................................................................... 4

Figure 2. Pulse Heat Section ............................................................................................................................ 5

Figure 3. Pulse Plate Section............................................................................................................................ 6

Figure 4. MicroChine Section .......................................................................................................................... 7

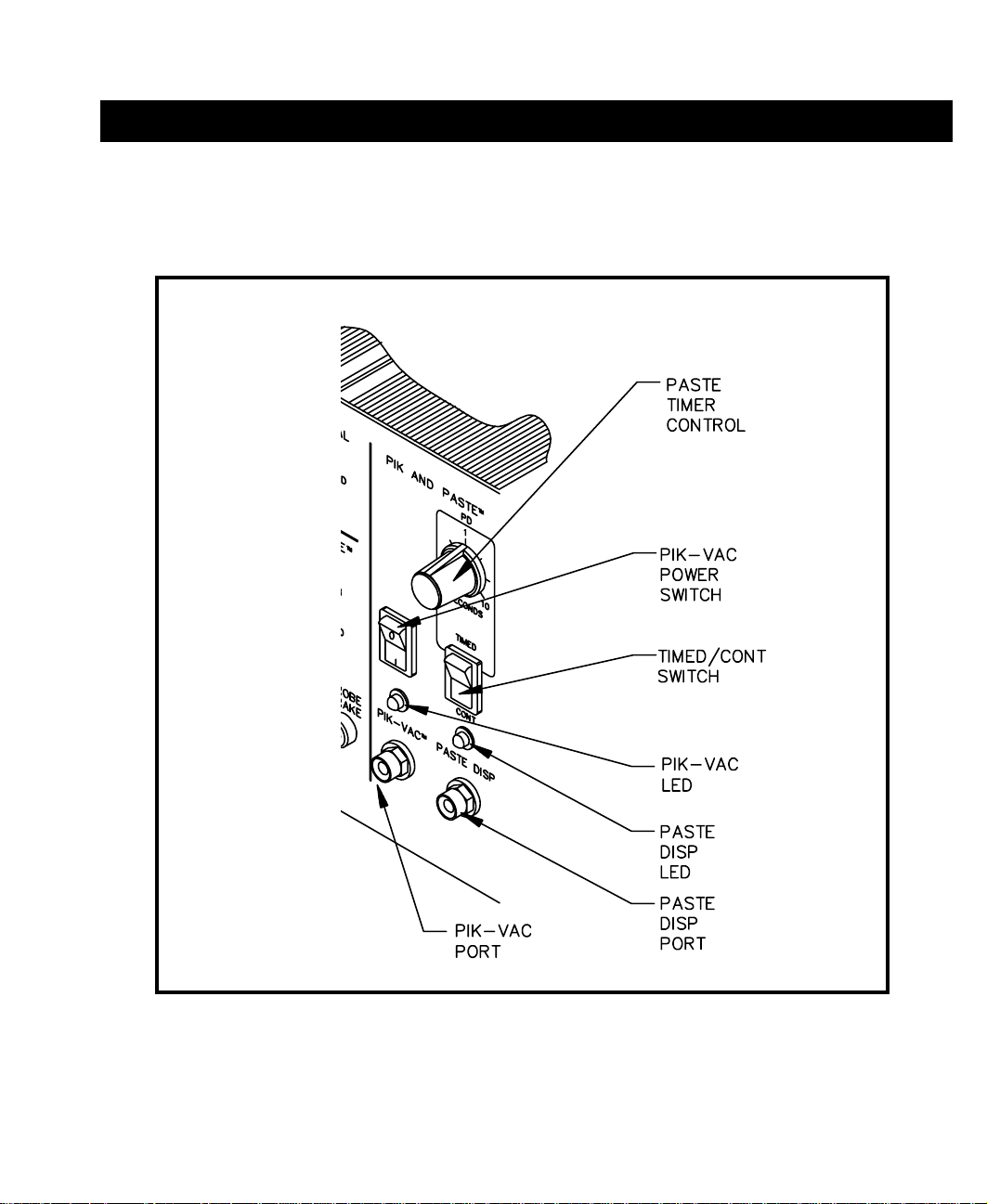

Figure 5. Pik And Paste Section....................................................................................................................... 9

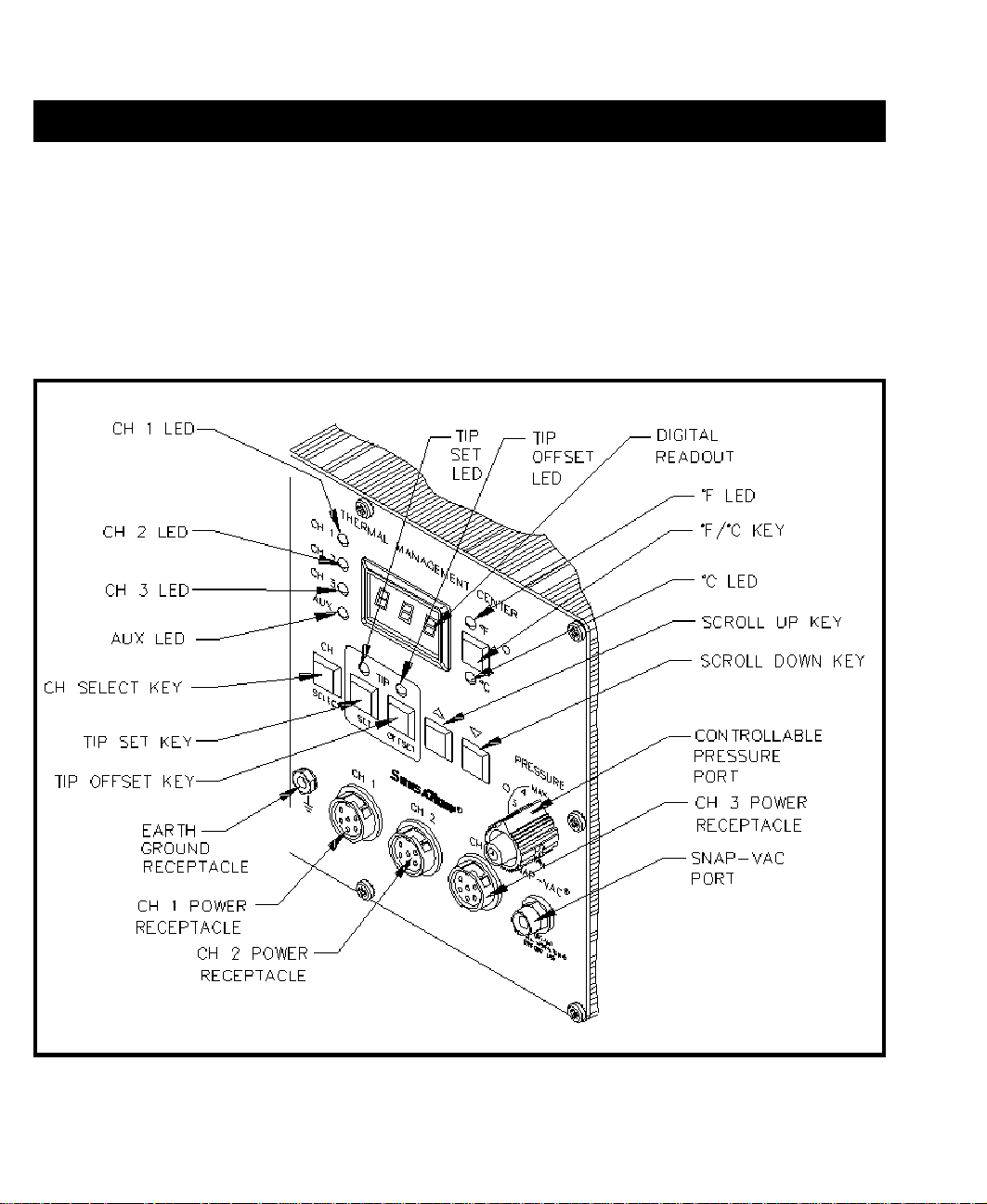

Figure 6. Thermal Management Center Parts I.D. ......................................................................................... 12

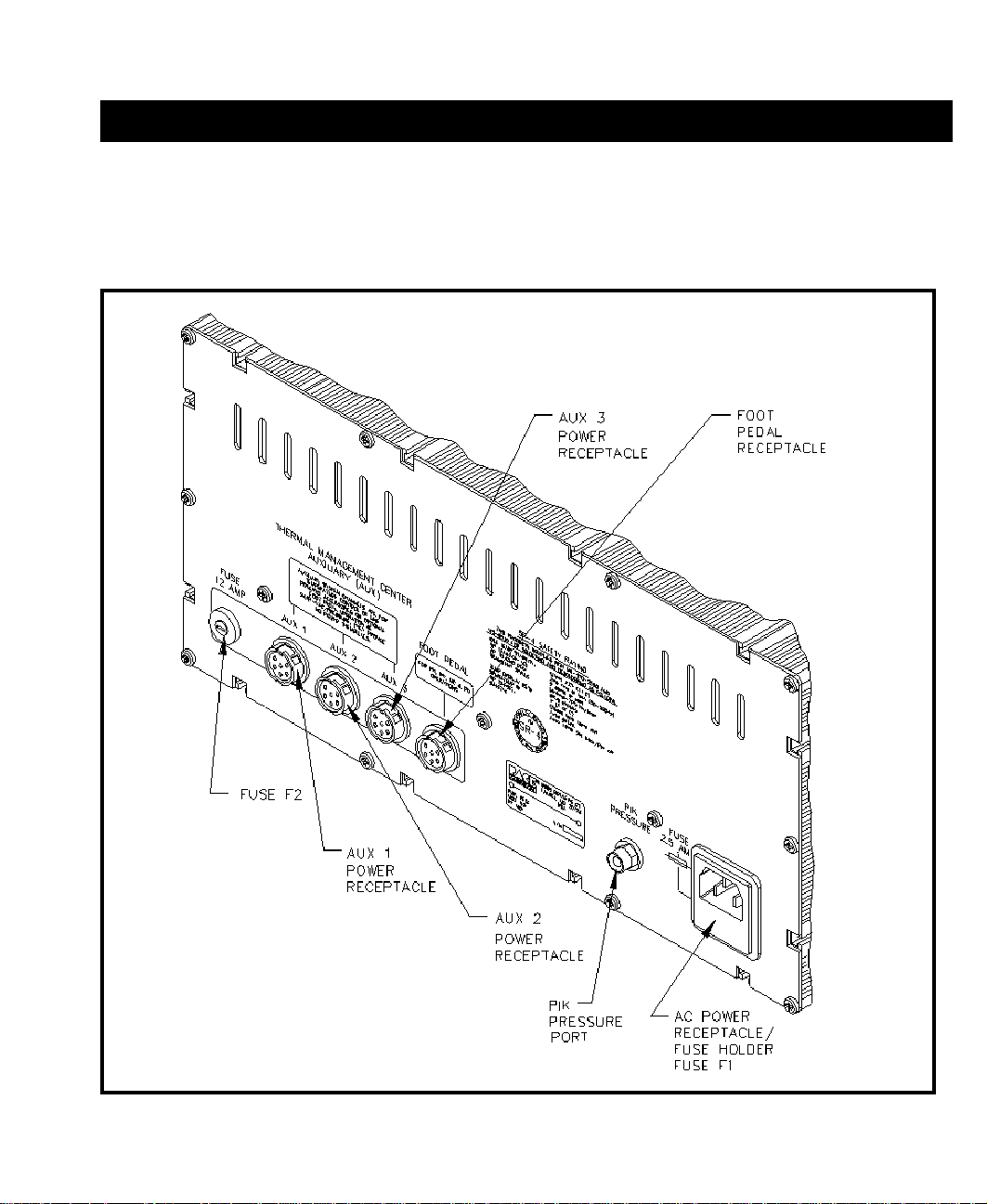

Figure 7. Rear Panel Parts I.D........................................................................................................................ 15

Figure 8. VisiFilter Element Replacement..................................................................................................... 21

Figure 9. Connector Plug Wiring ................................................................................................................... 23

Figure 10. MicroChine Wiring......................................................................................................................... 23

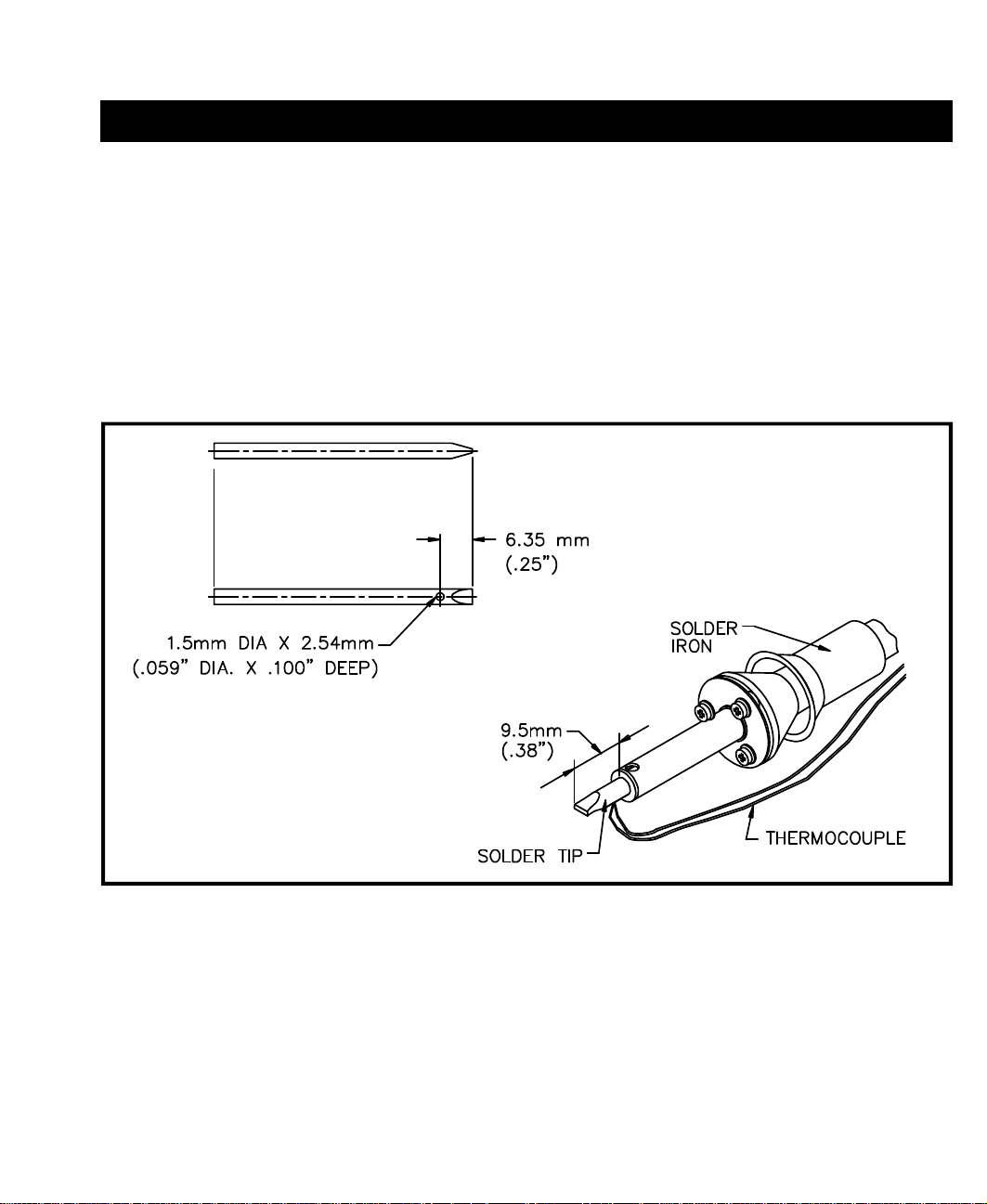

Figure 11. Thermocouple Attachment.............................................................................................................. 31

Figure 12. Removing Rear Panel Screws......................................................................................................... 33

Figure 13. Removing Front Panel .................................................................................................................... 34

Figure 14. Removing Bolt Assemblies............................................................................................................. 35

Figure 15. Removing Power Source From Case .............................................................................................. 36

Figure 16. Power Flow Chart ........................................................................................................................... 40

Figure 17. Thermal Management Center Malfunction Flow Chart ................................................................. 42

Figure 18. Pik & Paste Malfunction Flow Chart ............................................................................................. 44

Figure 19. MicroChine Malfunction Flow Chart ............................................................................................. 46

Figure 20. Pulse Plate Malfunction Flow Chart............................................................................................... 48

Figure 21. Pulse Heat Malfunction Flow Chart ............................................................................................... 50

Figure 22. PPS 400, PPS 400J, PPS 400E Wiring Diagram ............................................................................ 52

Figure 23. MultiFunction PCB Assembly Schematic ...................................................................................... 54

Figure 24. Microprocessor PCB Assembly Schematic .................................................................................... 60

Figure 25. Display PCB Assembly Schematic................................................................................................. 64

Figure 26. Assembly Drawing ......................................................................................................................... 66

Figure 27. Assembly Drawing Cont'd.............................................................................................................. 67

Figure 28. Air Hose Routing ............................................................................................................................ 68

Figure 29. Power Source Replacement Parts ................................................................................................... 70

Figure 30. Power Source Replacement Parts Cont'd........................................................................................ 71

Figure 31. Power Source Replacement Parts Cont'd........................................................................................ 72

iv

Page 6

GENERAL INFORMATION

INTRODUCTION

The information contained in this manual will assist the technician in performing preventive maintenance and

repair of the PACE PRC 2000 Systems. For details on operation of the system, refer to the System Operation &

Maintenance Manual (PACE part number 5050-0313). If you encounter any difficulty operating or repairing

your system, call PACE Customer Service directly at Tel. (301) 490-9860 or FAX (301) 604-9215.

The PRC 2000 is a Process Control System for Universal Assembly and Repair of Electronic Assemblies. The

system combines the latest technology available for all types of component installation/removal, circuit board

preparation and repair into one self-contained workstation.

The SR-4 “Safety Rating” designation on the back panel is your assurance that the PRC 2000 meets or exceeds

all applicable civilian and military standards (including *MIL-STD-2000A, and *WS-6536), EOS/ESD and

worldwide electrical codes. *NOTE - Systems equipped with a special current limiting option (1 meg ohm tip

to ground resistance) comply with EN 100015-1. PACE refers to these systems as "Soft Ground Systems".

The PRC 2000 system is available using power sources in either the 100 VAC version, the 115 VAC version or

the 230 VAC version. The 230 VAC version system (production as of Sept. 1995) bears the CE Conformity

Marking which assures the user that it conforms to all the requirements of council directive EMC 89/336/EEC.

SPECIFICATIONS

POWER REQUIREMENTS

PPS 400 (PRC 2000 system): 115 VAC System - Operates on 97-127 VAC, 60 Hz. 400 Watts.

PPS 400J (PRC 2000J system): 230 VAC System - Operates on 90-115 VAC, 50/60 Hz. 400 Watts.

PPS 400E (PRC 2000E system): 100 VAC System - Operates on 195-264 VAC, 50/60 Hz. 400 Watts.

PHYSICAL PARAMETERS

Size: 35 cm W x 17.5 cm H x 23 cm D (13.75 in W x 6.9 in H x 9.25 in D)

Weight: 13.6 Kg (30 Lbs)

ENVIRONMENTAL REQUIREMENTS

Ambient Operating Temperature: 0°C to 50°C (32°F to 120°F).

Storage Temperature: -40°C to 100°C (-40°F to 212°F).

1

Page 7

GENERAL INFORMATION

THERMAL MANAGEMENT CENTER

VACUUM AND AIR

Measurements at Front Panel SNAP-VAC and PRESSURE Ports of power source.

Vacuum Rise Time : Evacuates 33 cc (2 cubic inch) volume

to 25 cm Hg. (10 in. Hg.) in 150 ms.

Vacuum: 51 cm Hg. (20 in. Hg.) (nominal)

Pressure: .48 Bar (7 P.S.I.) (nominal, "MAX" setting)

Air Flow: 13 SLPM (0.46 SCFM) maximum

HANDPIECES

Set T emperatur e Range

of SensaTemp Handpieces: 38°C to 482°C (100°F to 900°F) (see note).

Digital Readout Resolution: ± 1° (°C or °F)

Tip Temperature Stability: ± 1.1°C (± 2°F) at idle from Set Tip Temperature.

True minimum and maximum Operating Tip Temperatures may vary

depending on handpiece & tip selection.

EOS/ESD

Tip-To-Ground

Resistance: Less than 5 ohms.

AC Leakage : Less than 2 millivolts RMS from 50Hz to 500Hz.

PIK AND PASTE

Vacuum

(at PIK-VAC Port): 7.6 cm Hg. (3 in. HG.) min.

Pressure

(at PASTE DISP Port): 2.41 Bar (35 P.S.I.) min.

2

NOTE

Page 8

MICROCHINE

HANDPIECE

Nominal Output

Speed Range: 2,500 rpm, min. to 10,000 rpm, max.

Output T or que: 14 N•mm (2.0 inch-ounces), min.

Speed Regulation: +10/-15% over Line/Load range of 0 to 14 N•mm (0 to 2 inch-ounces)

Duty Cycle: Application Dependent. Continuous loading to maximum torque (Status

Shaft Run-Out at Collet: .13mm (0.005 inches) TIR (Total Indicator Reading) max.

EOS/ESD

Tip-To-Ground

Resistance: Less than 5 ohms.

GENERAL INFORMATION

from low line to high line voltage.

LED Amber in color) will cause the handpiece case to overheat.

Continuous heavy loading without a cooling period may cause damage

to the handpiece and/or the power source.

AC Leakage : Less than 2 millivolts RMS from 50Hz to 500Hz, min.

PULSE PLATE

Output Voltage Range: 0 - 10 volts unfiltered, full wave DC.

PULSE HEAT

Output Voltage Range: 0 - 2.3 VAC RMS

3

Page 9

GENERAL INFORMATION

PARTS IDENTIFICATION

SYSTEM

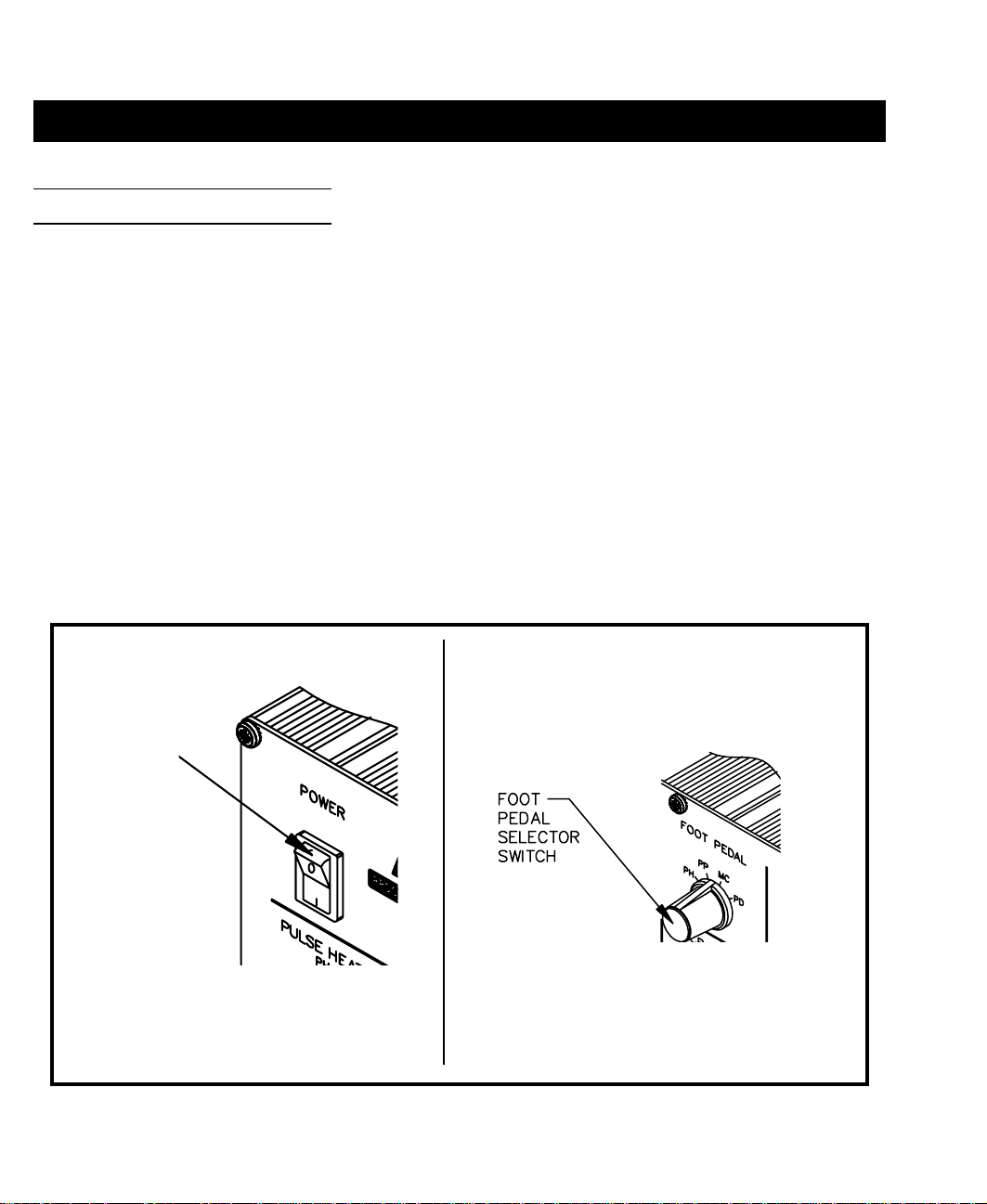

1. POWER SWITCH - Turns system ON (“1”) and OFF (“0”); controls input power to the system.

2. FOOT PEDAL SELECTOR SWITCH - Control knob provides foot pedal connection to Pik and

Paste (PD), MicroChine (MC), Pulse Plate (PP) or Pulse Heat (PH) features.

POWER

SWITCH

Figure 1. Power Switch/Foot Pedal Selector Switch

4

Page 10

GENERAL INFORMATION

FRONT PANEL FEATURES

PULSE HEAT

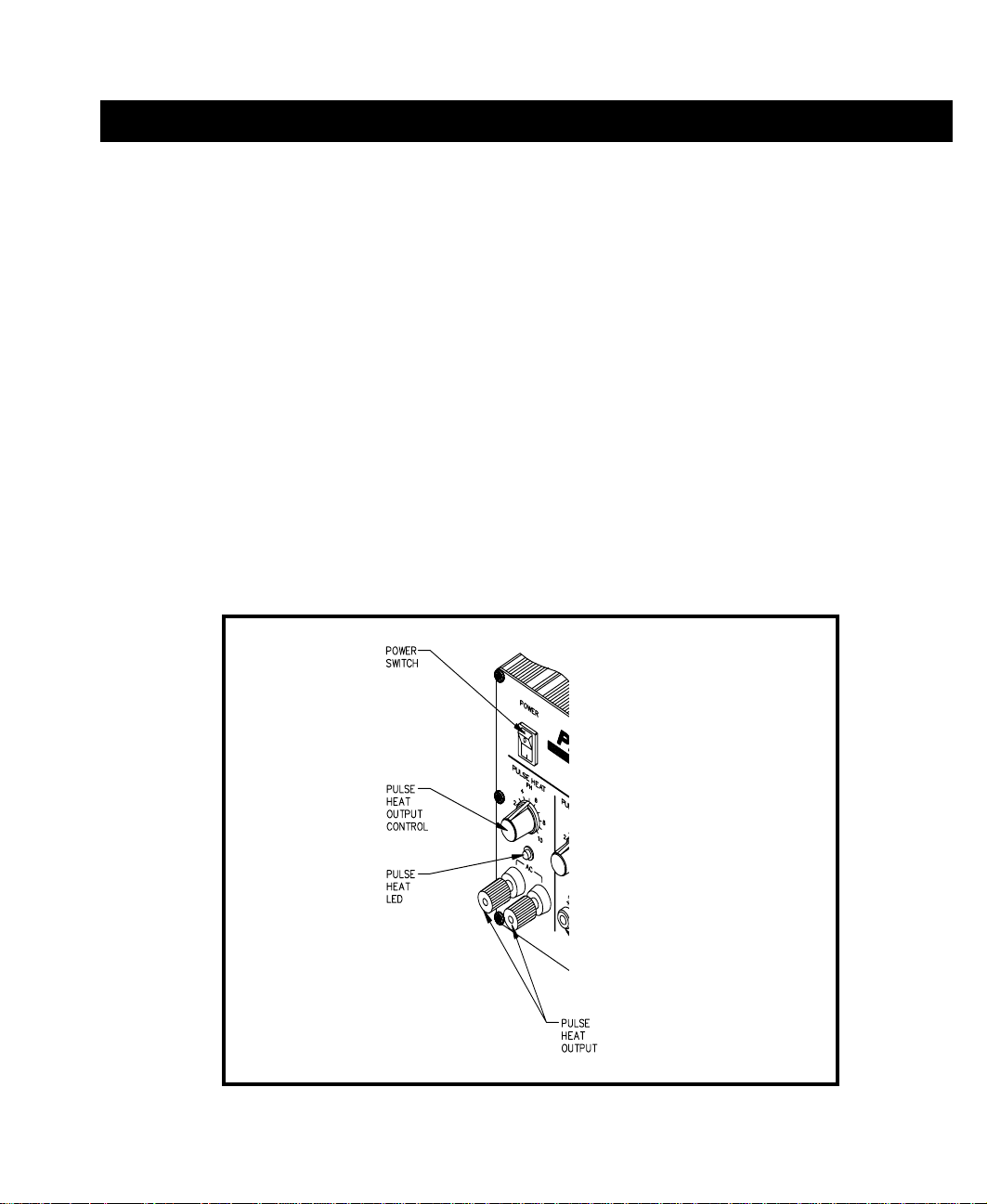

3. PULSE HEAT OUTPUTS - Low voltage AC power outputs for Low Voltage, Pulse Heat

handpieces.

4. PULSE HEAT OUTPUT CONTROL - Controls low voltage AC power at PULSE HEAT Outputs.

5. PULSE HEAT LED - Illuminates Green in color when power is applied (by foot pedal through

FOOT PEDAL Selector Switch) to the PULSE HEAT Outputs.

Figure 2. Pulse Heat Section

5

Page 11

GENERAL INFORMATION

PULSE PLATE

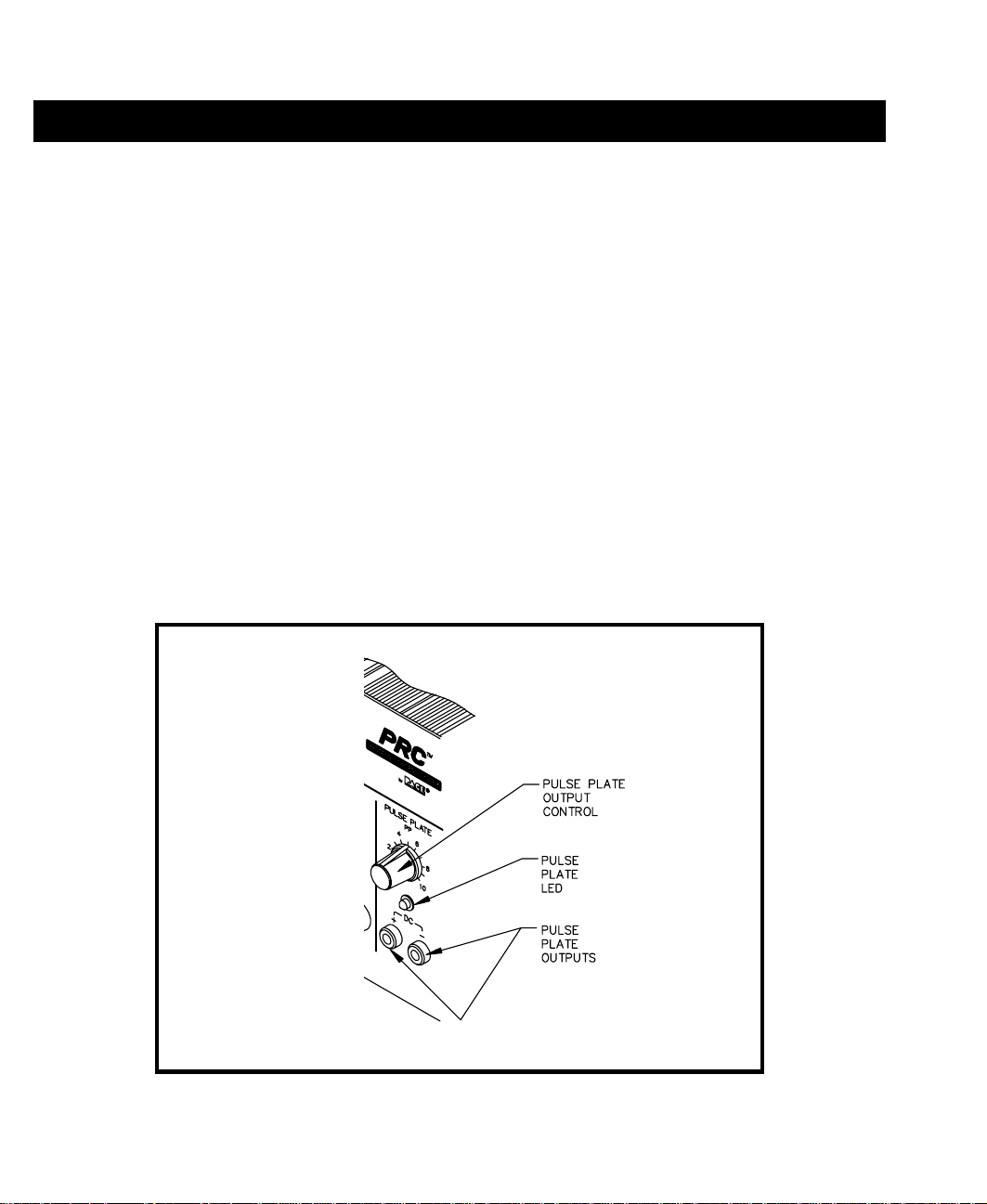

6. PULSE PLATE OUTPUTS - DC power connections for PACE SwaPlater plating system.

7. PULSE PLATE OUTPUT CONTROL - Controls DC power at PULSE PLATE Outputs.

8. PULSE PLATE LED - Illuminates Green to indicate when power is applied (upon foot pedal

actuation) at the PULSE PLATE Outputs. Illuminates Red if an overcurrent condition occurs during

plating.

Figure 3. Pulse Plate Section

6

Page 12

GENERAL INFORMATION

MICROCHINE

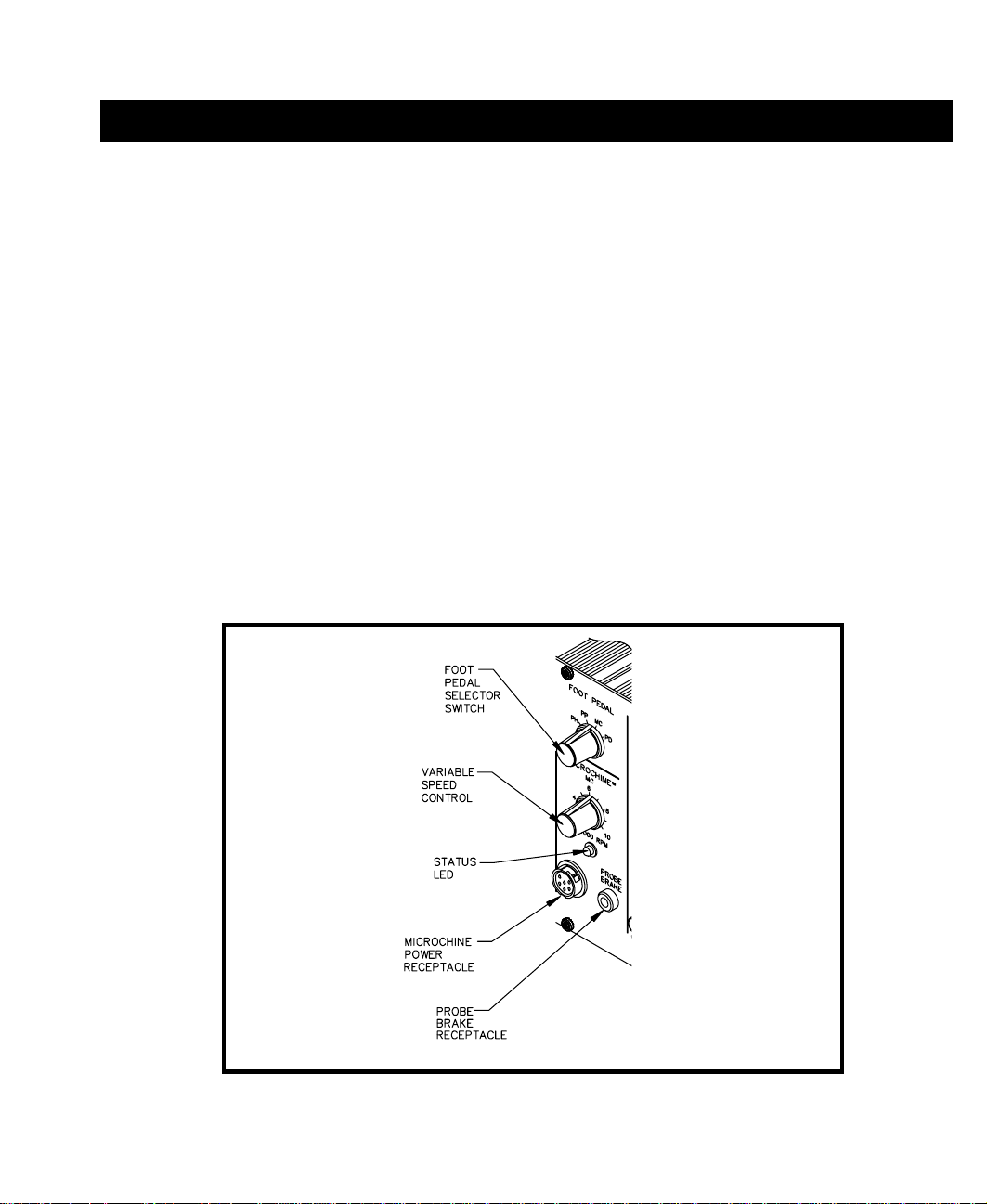

9. MICROCHINE POWER RECEPTACLE - Provides power, speed control, tip ground and finger

switch connection for the MicroChine handpiece.

10. VARIABLE SPEED CONTROL - Controls motor speed (2,500 - 10,000 RPMs) of MicroChine

handpiece.

11. PROBE BRAKE RECEPTACLE - Provides Probe Brake connection for the MicroChine Probe

Brake feature. See MicroChine portion of this manual for details.

12. STATUS LED - Illuminates Green to indicate MicroChine operation. Illuminates Amber if maximum

torque load is reached. Illuminates Red to indicate braking status when Probe Brake circuit is

activated.

Figure 4. MicroChine Section

7

Page 13

GENERAL INFORMATION

PIK AND PASTE

13. PIK-VAC POWER SWITCH - Turns power "ON" (1) or "OFF" (0). Controls power to the Pik-Vac

vacuum pump.

14. PIK-VAC LED - Illuminates Green to indicate Pik-Vac vacuum pump operation.

15. PIK-VAC PORT - Quick connect fitting which provides vacuum for Pik-Vac handpiece.

16. PIK AND PASTE TIMER CONTROL - Determines variable time controlled shot (0.1 - 10 seconds)

of Paste Dispense (PASTE DISP) air pressure upon foot pedal actuation (Foot Pedal Selector Switch

in PD position). Operates when TIMED/CONT Switch is in the TIMED position.

17. TIMED/CONT SWITCH - In CONT position, continuous air pressure is delivered from PASTE

DISP Port upon foot pedal actuation (Foot Pedal Selector Switch in PD position). In TIMED

position, measured interval of air pressure (0.1 - 10 seconds) is delivered from PASTE DISP Port

upon foot pedal actuation (Foot Pedal Selector Switch in PD position).

18. PASTE DISP LED - Illuminates Green when air pressure is delivered from the PASTE DISP Port.

Illuminates Yellow when the paste dispense pump reservoir is charging (no air pressure delivery from

P ASTE DISP Port).

19. PASTE DISP PORT - Quick connect fitting which provides air pressure (timed or continuous) to

dispensing barrel.

8

Page 14

GENERAL INFORMATION

Figure 5. Pik And Paste Section

9

Page 15

GENERAL INFORMATION

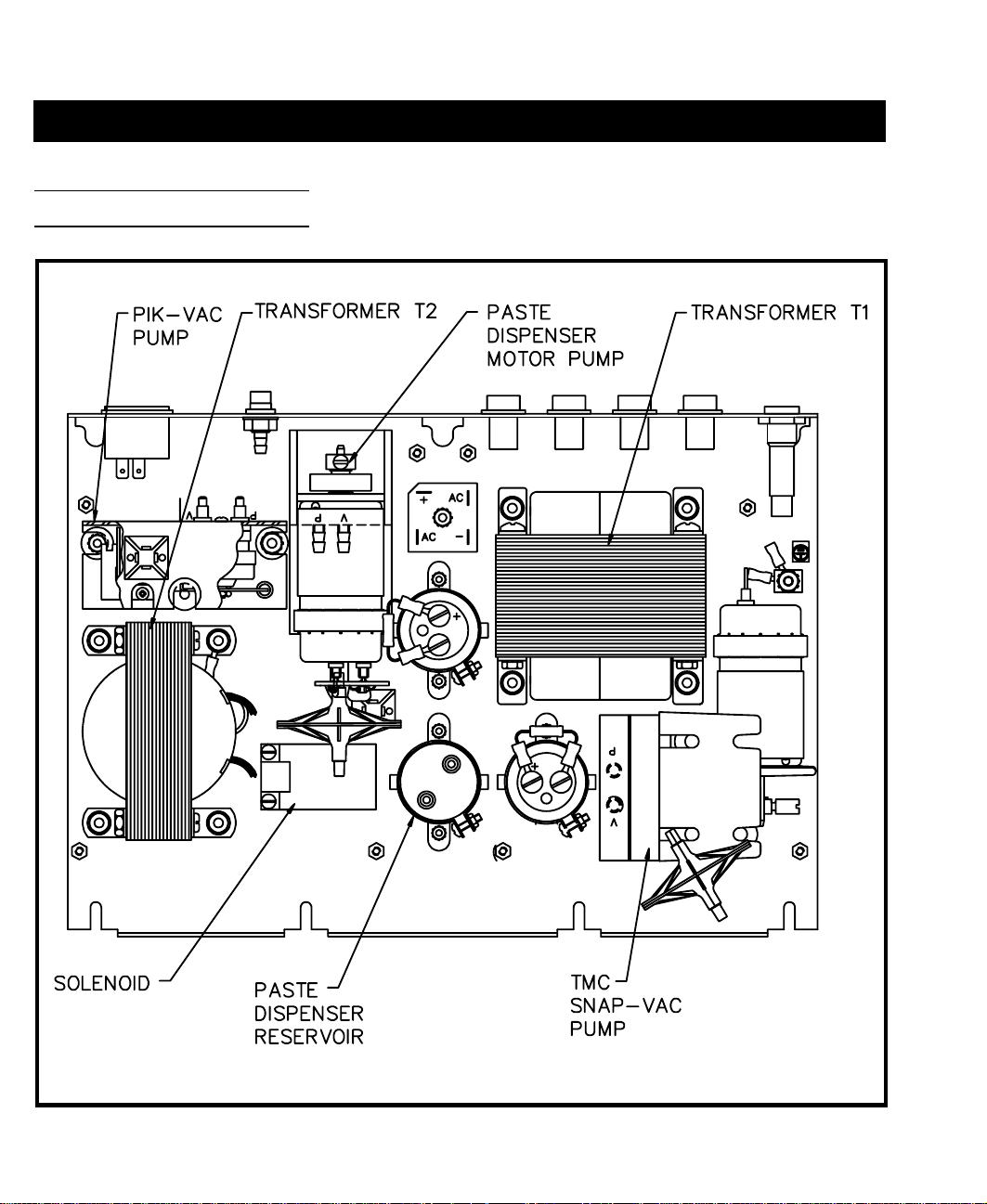

THERMAL MANAGEMENT CENTER

Refer to the illustration following for location of parts.

20. CH 1 POWER RECEPTACLE - Provides power, tip ground, sensing circuitry and finger switch

connection from PRC 2000 system to handpiece connected to Channel 1 (CH 1).

21. CH 2 POWER RECEPTACLE - Provides power, tip ground, sensing circuitry and finger switch

connection from PRC 2000 system to handpiece connected to Channel 2 (CH 2).

22. CH 3 POWER RECEPTACLE - Provides power, tip ground, sensing circuitry and finger switch

connection from PRC 2000 system to handpiece connected to Channel 3 (CH 3).

23. SNAP-VAC PORT - Quick connect fitting which provides quick-rise vacuum for Sodr-X-Tractor or

ThermoPik handpieces.

24. CONTROLLABLE PRESSURE PORT - Quick connect fitting with adjustable valve which

provides variable air flow for Mini ThermoJet handpiece and Sodr-X-Tractor handpiece (in Hot Jet

Mode).

25. DIGITAL READOUT - Provides a three digit display of the Current Channel (channel with

illuminated LED; CH 1, CH 2, CH 3 or AUX 1, AUX 2, AUX 3) temperature information. This

includes: Operating Tip Temperature in Temperature Display Mode (normal operation), Tip

Temperature Offset Constant in TIP OFFSET Mode, Set Tip Temperature in TIP SET Mode, and

other information in Calibration (CAL) Mode.

26. °F/°C KEY - Selects °F or °C display of Set and Operating Temperatures and Tip Temperature Offset

Constants.

27. °F LED - Illuminates when Set and Operating Tip Temperatures and Tip Temperature Offset Constants

are displayed in °F.

28. °C LED - Illuminates when Set and Operating Tip Temperatures and Tip Temperature Offset

Constants are displayed in °C.

29. CH 1 LED - Illuminates when Channel 1 (CH 1) or Auxiliary Channel (AUX 1) is the Current

Channel (i.e., the channel (with connected handpiece/tip or auxiliary accessory) whose temperature

information is displayed on the Digital Readout).

10

Page 16

GENERAL INFORMATION

30. CH 2 LED - Illuminates when Channel 2 (CH 2) or Auxiliary Channel (AUX 2) is the Current

Channel (i.e., the channel (with connected handpiece/tip or auxiliary accessory) whose temperature

information is displayed on the Digital Readout).

31. CH 3 LED - Illuminates when Channel 3 (CH 3) or Auxiliary Channel (AUX 3) is the Current

Channel (i.e., the channel (with connected handpiece/tip or auxiliary accessory) whose temperature

information is displayed on the Digital Readout).

32. AUX LED - Illuminates when an auxiliary channel (on system rear panel) is the Current Channel

(i.e., the channel (with connected handpiece/tip or auxiliary accessory) whose temperature information

is displayed on the Digital Readout). One of the CH 1, CH 2 or CH 3 LEDs will illuminate

simultaneously with the Auxiliary LED to indicate, respectively, which of the auxiliary channels is

active (AUX 1, AUX 2 or AUX 3).

33. CH SELECT KEY - Selects the Current Channel (among “Active Channels” i.e., those with a

connected handpiece or auxiliary accessory).

34. TIP SET KEY - Allows the operator to adjust the Set Tip Temperature for the handpiece/tip

combination or Set Temperature for the auxiliary accessory connected to the Current Channel. Places

the THERMAL MANAGEMENT CENTER in the TIP SET (Tip Temperature Set) Mode.

35. TIP SET LED - Flashes when TIP SET Key is pressed indicating that the THERMAL

MANAGEMENT CENTER is in TIP SET Mode.

36. TIP OFFSET KEY - Allows the operator to adjust the TIP OFFSET CONSTANT for the handpiece

or auxiliary accessory connected to the Current Channel. Places the THERMAL MANAGEMENT

CENTER in the TIP OFFSET (Tip Temperature Offset) Mode.

37. TIP OFFSET LED - Flashes when TIP OFFSET Key is pressed indicating that the THERMAL

MANAGEMENT CENTER is in the TIP OFFSET Mode. Remains illuminated (not flashing) in

Temperature Display Mode (normal operating mode) when a Tip Temperature Offset Constant of

greater than “3” for °C (“6” for °F) is entered.

38. SCROLL UP KEY - Increases the Set Tip Temperature (in TIP TEMPERATURE SET Mode) and Tip

Temperature Offset Constant (in TIP TEMPERATURE OFFSET Mode) in one, then ten degree

increments. Also used in “CAL” (Calibration) Mode.

11

Page 17

GENERAL INFORMATION

39. SCROLL DOWN KEY - Decreases the Set Tip Temperature (in TIP SET Mode) and Tip

Temperature Offset Constant (in TIP OFFSET Mode) in one, then ten degree increments. Also used

in “CAL” (Calibration) Mode.

40. EARTH GROUND RECEPTACLE - Provides positive earth ground to which a ground cable can be

connected from the workpiece or work surface as part of a static control program.

Figure 6. Thermal Management Center Parts I.D.

12

Page 18

GENERAL INFORMATION

13

Page 19

GENERAL INFORMATION

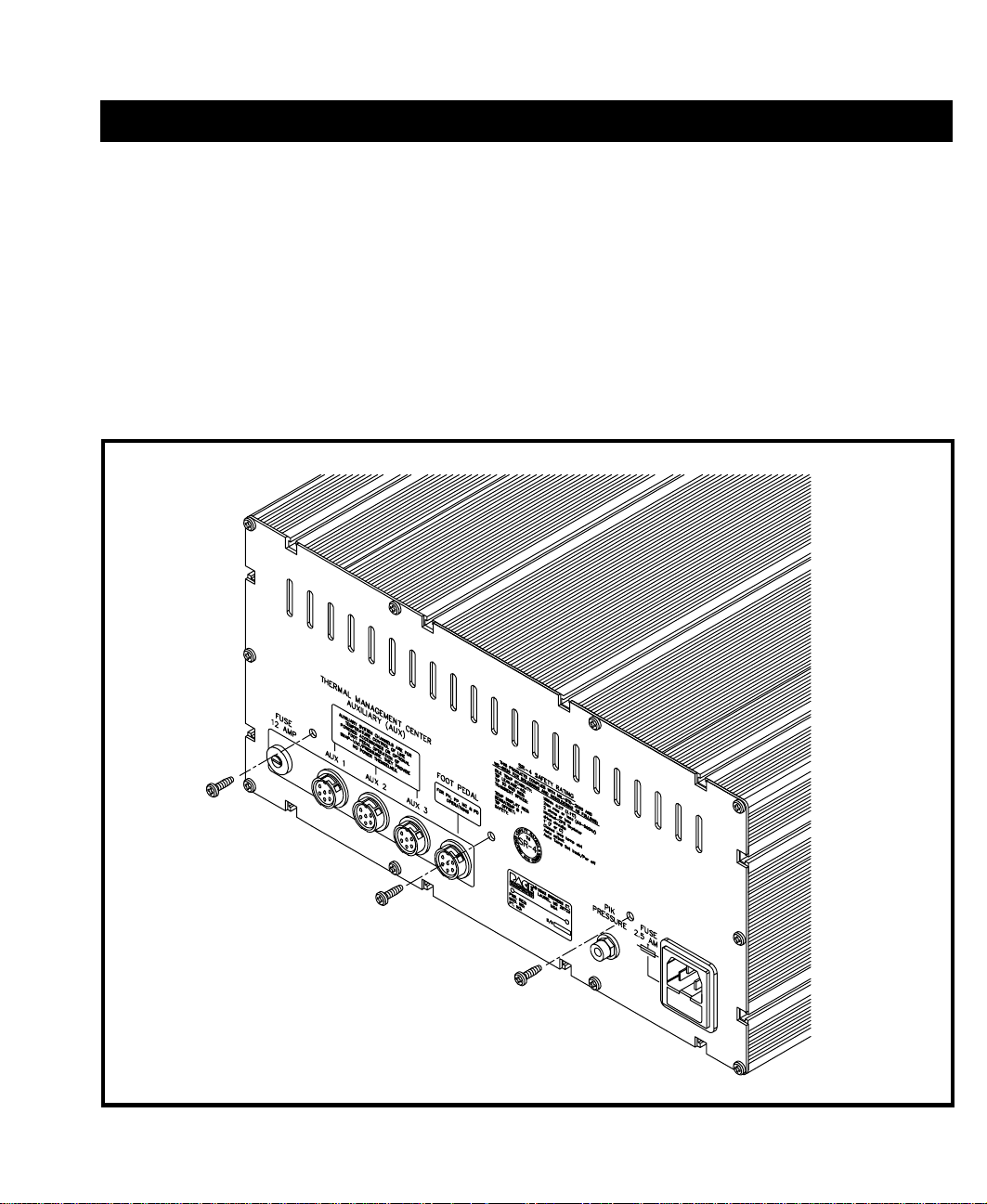

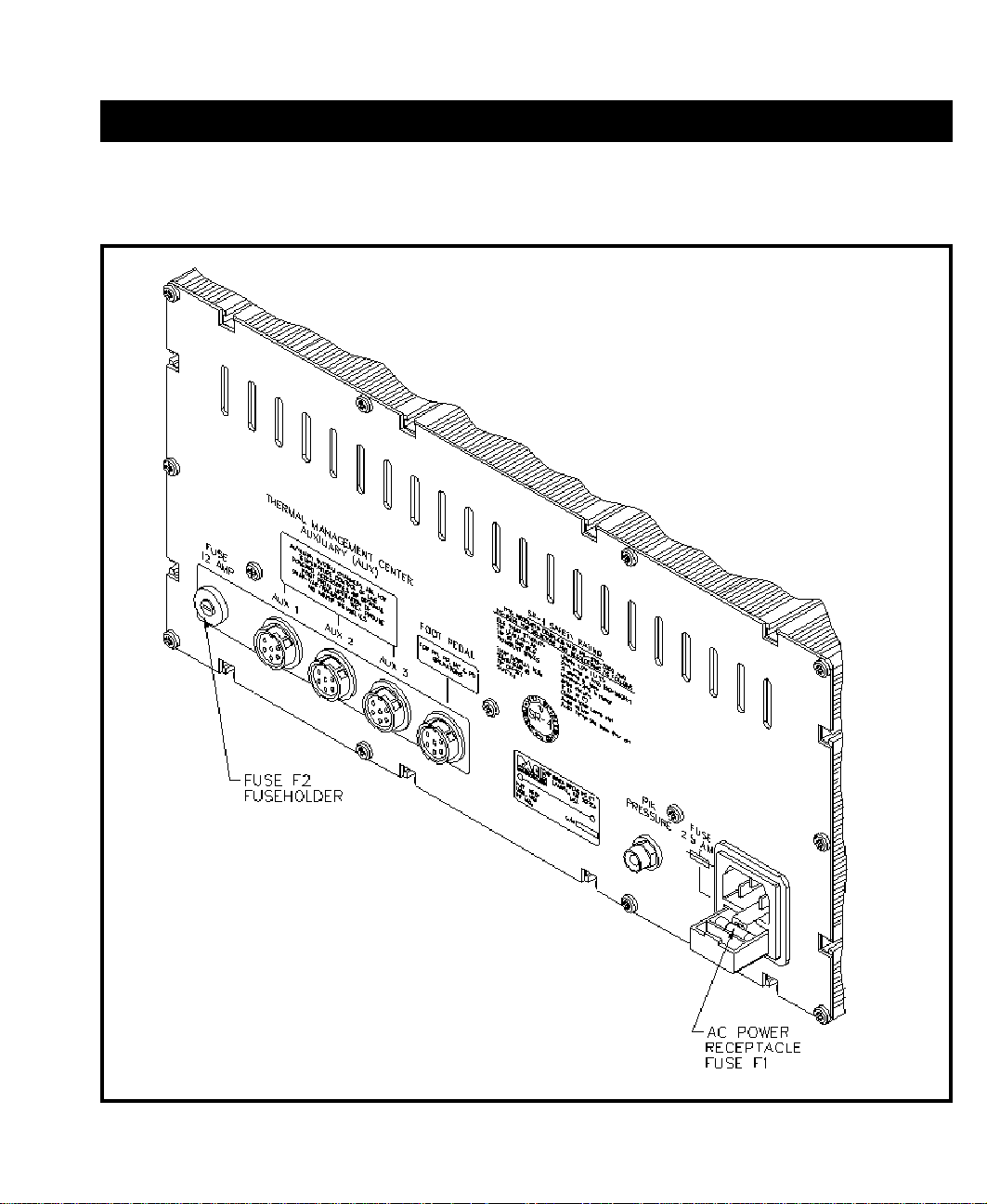

REAR PANEL

41. AC POWER RECEPTACLE/FUSE HOLDER - Receptacle for providing power to the PRC 2000

system from AC outlet through power cord. Also location of fuse (F1) which protects the system from

overcurrent conditions.

42. FUSE F1 - Provides overload protection for PRC 2000 system.

43. FOOT PEDAL RECEPTACLE - Input for foot pedal which operates the Pik and Paste, MicroChine,

Pulse Plate or Pulse Heat features of the system as determined by the FOOT PEDAL Selector Switch.

This receptacle is not connected to the Thermal Management Center controls.

NOTE

The Auxiliary Power Receptacles listed below (items 44-46) will provide

temperature control for line operated auxiliary accessories or foot pedal

operation only. SensaTemp handpieces will not function properly if

connected to these outputs.

44. AUX 1 POWER RECEPTACLE - Provides temperature control, tip ground sensing circuitry and

finger switch connection from THERMAL MANAGEMENT CENTER to the auxiliary accessory

connected to Auxiliary Channel 1. Foot pedal attachment to this receptacle will allow vacuum/

pressure pump operation through foot pedal actuation.

45. AUX 2 POWER RECEPTACLE - Provides temperature control, tip ground sensing circuitry and

finger switch connection from THERMAL MANAGEMENT CENTER to the auxiliary accessory

connected to Auxiliary Channel 2. Foot pedal attachment to this receptacle will allow vacuum/

pressure pump operation through foot pedal actuation.

46. AUX 3 POWER RECEPTACLE - Provides temperature control, tip ground sensing circuitry and

finger switch connection from THERMAL MANAGEMENT CENTER to the auxiliary accessory

connected to Auxiliary Channel 3. Foot pedal attachment to this receptacle will allow vacuum/

pressure pump operation through foot pedal actuation.

47. FUSE F2 - Provides overload protection for CH 1, CH 2 and CH 3 power receptacles.

48. PIK PRESSURE PORT - Low pressure output with quick connect fitting. Controlled by PIK-VAC

Power Switch (front panel).

14

Page 20

GENERAL INFORMATION

Figure 7. Rear Panel Parts I.D.

15

Page 21

SAFETY

The purpose of this "SAFETY" section is to inform users of the heading guidelines used in this manual to indicate

special Notes, Cautions, Warnings or Dangers. Also included are recommended precautions which must be

observed when operating or servicing this product.

HEADING GUIDELINES

PACE adheres to the following Heading Guidelines (based on OSHA guidelines) when listing special information

or precautions to be taken. Especially important are all procedures and practices which, if not strictly observed,

could result in injury or loss of life.

These "NOTES", "CAUTIONS","WARNINGS" and "DANGERS" are inserted in this manual whenever deemed

necessary. They appear in a blocked off form with double outline and a shaded background to highlight the

information as shown below.

NOTE

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

NOTE

Used to indicate a statement of company recommendation or policy. The message may relate directly or

indirectly to the safety of personnel or protection of property. NOTE is not associated directly with a hazard or

hazardous situation and is not used in place of "CAUTION", "WARNING" or "DANGER".

CAUTION

Used to indicate a hazardous situation which may result in minor or moderate injury. May also be used to alert

personnel to conditions, procedures and practices which, if not observed, could result in damage to or destruction

of the product or other equipment.

WARNING

Used to define additional information that if not closely followed might result in serious damage to equipment

and represent a potential for serious personnel injury.

DANGER

Defines additional information that if not closely followed might result in severe personnel injury or death.

Danger is not used for property damage unless personnel injury risk is present.

16

Page 22

SAFETY

PRECAUTIONS

The following are general safety precautions which personnel must understand and follow when using or

servicing this product. These precautions may or may not be included elsewhere in this manual.

USEAGE PRECAUTIONS

CAUTIONS

1. SensaTemp handpiece heaters and installed tips are hot when handpiece is powered on. DO NOT

touch either the heater or tip. Severe burns may result! Always store handpiece in the appropriate

cubby when not in use.

2. Always use this system in a well ventilated area. A fume extraction system such as those available

from PACE are highly recommended to protect personnel from solder flux fumes.

3. Exercise proper precautions when using materials (e.g., fluxes & solder paste). Refer to the Material

Safety Data Sheet (MSDS) supplied with each chemical and adhere to all safety precautions

recommended by the manufacturer.

4. The use of Safety Glasses is recommended when plating or machining.

NOTES

1. The solder collection chamber in the PACE Sodr-X-Tractor is made of glass. Never remove this

chamber using pliers. Breakage of the chamber may result. Always remove using the procedures

recommended by PACE in the associated handpiece manual.

2. The glass solder collection chamber in the PACE Sodr-X-Tractor is hot when the handpiece is in use.

When removing the chamber for cleaning, never touch the glass with bare hands. Allow the chamber

to cool before cleaning.

3. Disconnect the MicroChine handpiece from the power source or turn the power switch off before

installing or changing tools.

17

Page 23

SAFETY

SERVICING PRECAUTIONS

DANGERS

POTENTIAL SHOCK HAZARD - Repair procedures performed on this product should be

performed by qualified service personnel only. Line voltage parts will be exposed when equipment is

disassembled. Service personnel must avoid contact with these parts when troubleshooting the power

source.

NOTES

To insure continued peak performance, use genuine PACE replacement parts.

18

Page 24

REPAIR

REPAIR PROCEDURE

The "REPAIR" section of this manual provides the technician with the information necessary to determine the

source of a malfunction and take the necessary steps to correct it. In order to perform the most expedient

repair, the technician must follow the process listed below step by step, in order. Failure to do so will make

the diagnosis and repair much more difficult.

1. PERIODIC MAINTENANCE - No periodic or special maintenance is required on this system.

2. SERVICE HINTS - Read these helpful hints which give information on operation and

troubleshooting.

3. CORRECTIVE MAINTENANCE - A guide for resolving malfunctions caused by improper

maintenance or handpiece failure. Locate the "Symptom" in the "Corrective Maintenance" section

which best describes the malfunction of the failed unit. Check each point described under "Solution"

in order of listing.

4. CALIBRATION - Lists procedures for performing tip temperature tests to check handpieces.

Perform these procedures periodically or if operating tip temperatures appear to be incorrect.

5. DISASSEMBLY/ASSEMBLY - Contains Disassembly/Assembly instructions which enables the

technician to disassemble and assemble the unit properly.

6. FLOW CHARTS, SCHEMATICS - Easy to follow Flow Charts, Assembly Drawings, Schematics and

Wiring Diagrams which enable the technician to determine the source of a malfunction down to an

assembly (e.g., Main PCB Assembly) level. Locate the Flow Chart which best describes the

malfunction of the failed unit. Follow the instructions on the Flow Chart and perform the checks

indicated to determine the source of the malfunction. The schematics shown are for systems

produced at the time of publication of this manual. If any variances in components or wiring are

detected on your system contact PACE Customer Service for assistance (see step #7 below).

7. PACE CUSTOMER SERVICE - If the cause for the malfunction has not been determined at this

point, call PACE Customer Service at TEL:(301) 490-9860, FAX (301) 604-9215.

WARNING

POTENTIAL SHOCK HAZARD Repair Procedures are to be per-

formed by qualified service personnel only. Removal of the power

source panels exposes line voltage parts. Service personnel must

insure that the AC Power Cord is disconnected prior to disassembly.

19

Page 25

REPAIR

SERVICE HINTS

1. OPERATIONAL PROBLEMS: Refer to the PACE Operation & Maintenance Manual (P/N 5050-

0313) for complete operational instructions on use of this product. If a Password has been installed by

the system user, remove the Password before proceeding with the repair. The user can reinstall the

Password after the system is repaired.

2. VACUUM FAILURES: Failures of this nature can be caused by either the unit or the SensaTemp

handpiece. Remove the Air Hose (and attached VisiFilter) from the SNAP-VAC Port and check for

vacuum at the port. If sufficient vacuum is present, the malfunction exists in the handpiece. Further,

if vacuum is sufficient at the port, check the vacuum level at the end of the glass solder collection

chamber (Sodr-X-Tractor handpieces only, chamber must be checked cold). Take the applicable steps

shown following.

a) Handpiece Failures: Replace VisiFilter if necessary; clean heater bore and replace tip, check air

hose for holes and ensure that glass solder collection chamber (Sodr-X-Tractor handpieces only) is

properly seated against heater seal.

b) Unit Failures: Remove the unit front panel (see "Disassembly/Assembly"). Check internal hosing

for kinks and replace internal VisiFilter (attached to pressure port on motor pump assembly).

3. HEATING CONTROL CIRCUITS: Must be checked under load (with handpiece/s plugged in). The

output(s) are obtained by switching triacs on and off. The voltage level to the handpiece(s) does not

change when adjusting the Set Tip Temperature. The control circuit of the unit varies the duty cycle of

voltage application as required to achieve and maintain the set temperature of the handpiece.

4. HEATING FAILURES: Usually caused by defective SensaTemp handpiece heaters. Refer to the

"Heater Assembly Checkout Procedures", Table I. When checking the system power source, use a

known good handpiece.

20

Page 26

REPAIR

CORRECTIVE MAINTENANCE

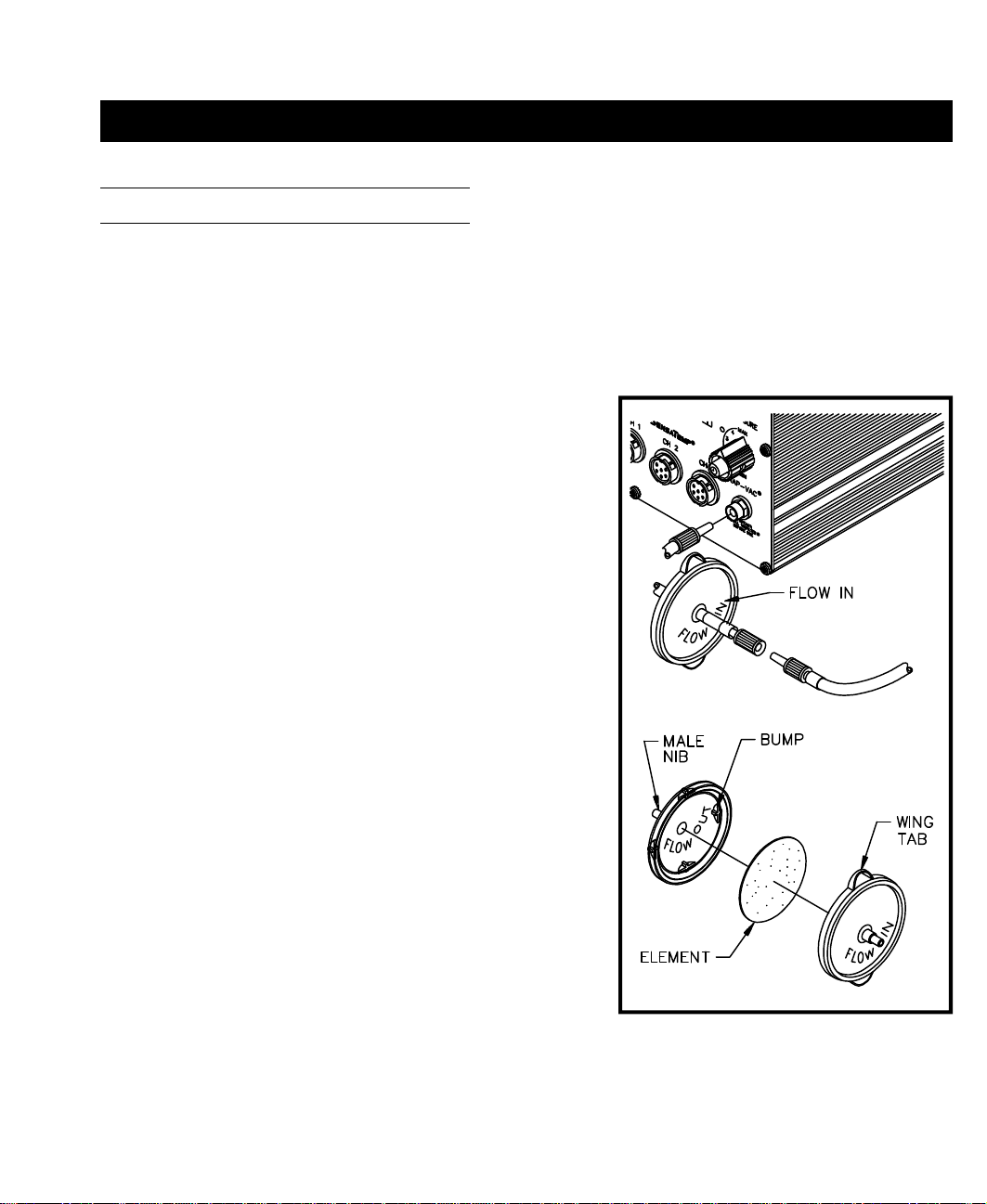

VISIFILTER ELEMENT REPLACEMENT

Follow the procedure listed below to replace the VisiFilter element when it becomes clogged or discolored.

1. Disconnect the handpiece air hose by gently turning and

pulling the coupled Fittings.

2. Disconnect the Visifilter and hose assembly from the

Power Source by gently turning and pulling the male

Fitting inserted into the SNAP-VAC Port.

3. Disconnect VisiFilter from both attached 1 inch air hoses

by gently turning and pulling the VisiFilter while holding

each of the hoses.

4. Separate the 2 plastic housing halves of the VisiFilter in the

following manner.

a) Grasp the VisiFilter in the palm of the hand with the

Male Nib (air hose connection) marked "FLOW IN"

facing you.

b) Pull against one of the Wing Tabs while pulling on the

Male Nib with the free hand to open the

interconnection of the plastic housings at that Wing

Tab.

c) Pull against the second Wing Tab while pulling on the

Male Nib to open the remaining interconnection and

separate the plastic housings.

5. Remove the old or discolored Element and discard.

6. Insert the replacement VisiFilter Element into the housing

marked "FLOW IN". Center the Element in the housing

well.

7. Squeeze the 2 plastic housing halves together using 4 plastic

Bumps on the housing marked "FLOW OUT" as pressure

points. The 2 plastic housings will snap together and lock the

VisiFilter Element in position.

8. Reconnect the 1 inch air hoses (removed in step 3) to the

VisiFilter.

9. Attach VisiFilter and hose assembly to Power Source by

inserting male Fitting into the SNAP-VAC Port.

Figure 8. VisiFilter Element Replacement

21

Page 27

REPAIR

SENSATEMP HANDPIECES

The following "Heater Assembly Checkout Procedures" are applicable to all PACE SensaTemp handpieces

except for the TT-65 ThermoTweez handpiece. Refer to either of the TT-65 manuals (P/N 5050-0300 or

5050-0336) for troubleshooting procedures pertinent to that handpiece.

Perform the "Heater Assembly Checkout Procedures" shown below with the handpiece (and heater) at room

temperature. If the handpiece is warm, resistance readings will be different from those shown.

SYMPTOM CHECKOUT PROCEDURE CAUSE SOLUTION

No heat Check resistance - Pin 2 to Pin 5.

Refer to handpiece manual for

resistance tolerances.

Handpiece

overheating

Fuse blows

when unit is

turned on.

No Ground

on Tip.

If resistance is high - Open Heater

Check resistance - Pin 3 to Pin 6.

If circuit reads open -

Check resistance - Pin 3 to Pin 6.

Resistance should be 110 ohms.

If circuit reads less than 105 ohms

Check resistance - Pin 2 to Pin 5.

Refer to handpiece manual for

resistance tolerances.

If resistance is low -

Check resistance - Pin 4 to a

NEW Tip. Resistance should be

less than 2 ohms.

If not -

Open Sensor

Shorted Sensor

Solder short in

Handpiece.

Shorted Heater Replace Heater

Oxidation buildup

in Heater Bore.

Defective Heater Replace Heater

Replace Heater

Assembly.

Replace Heater

Assembly.

Replace Heater

Assembly.

Remove Short.

Replace Heater

Assembly & Fuse F1.

Assembly & Fuse F1.

Clean Heater Bore

using appropriate

wire brush.

HEATER

SPECIFICATIONS

SX-70 = 8 - 10

ohms

SP-2A = 8 - 10

ohms

SP-1A = 10 - 12

ohms

TP-65 = 9 - 11

ohms

TJ-70 = 6 - 8 ohms

Table I. Heater Assembly Checkout Procedures

22

Page 28

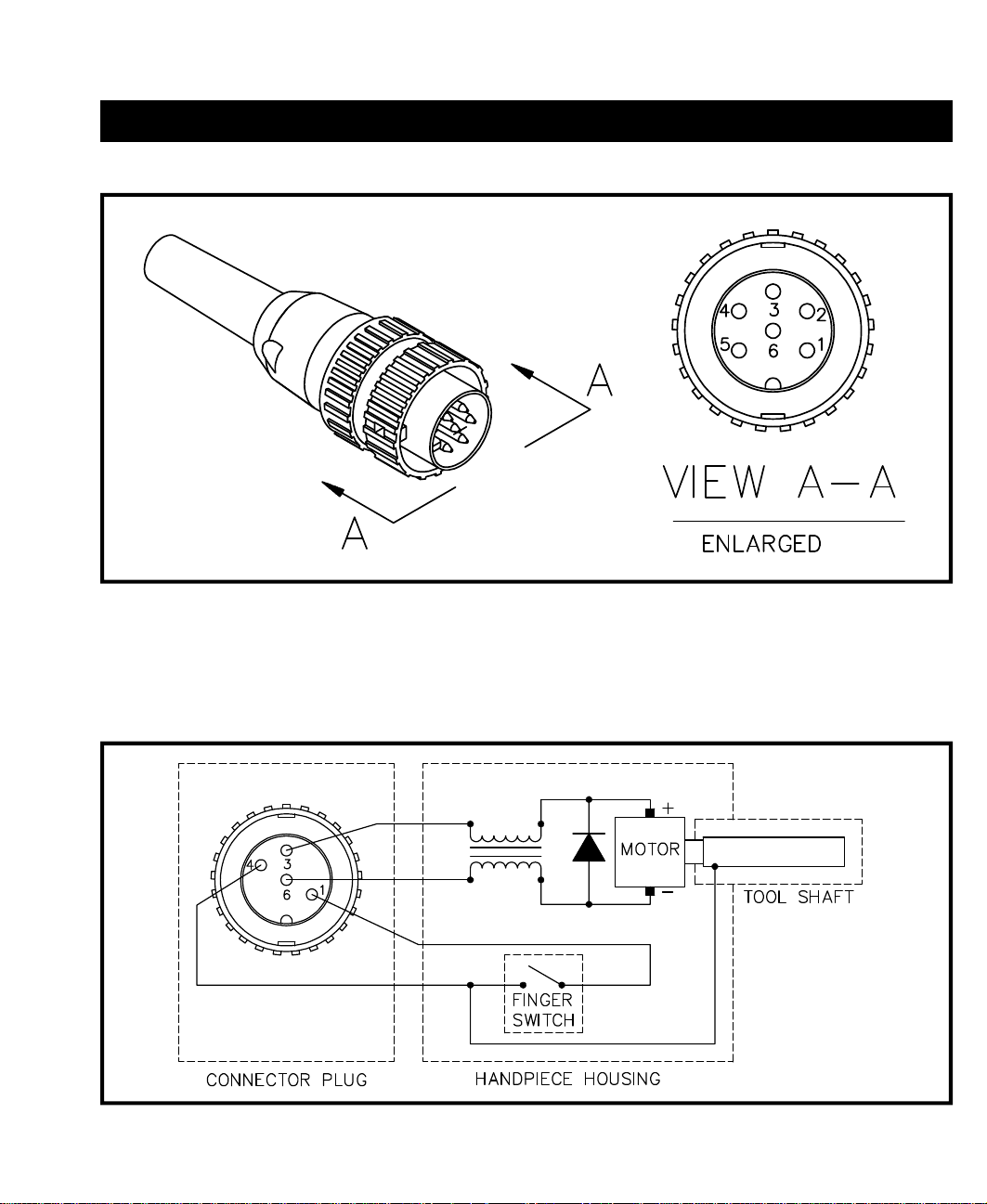

Figure 9. Connector Plug Wiring

REPAIR

MICROCHINE HANDPIECE

Figure 10. MicroChine Wiring

23

Page 29

REPAIR

MICROCHINE HANDPIECE CONT'D

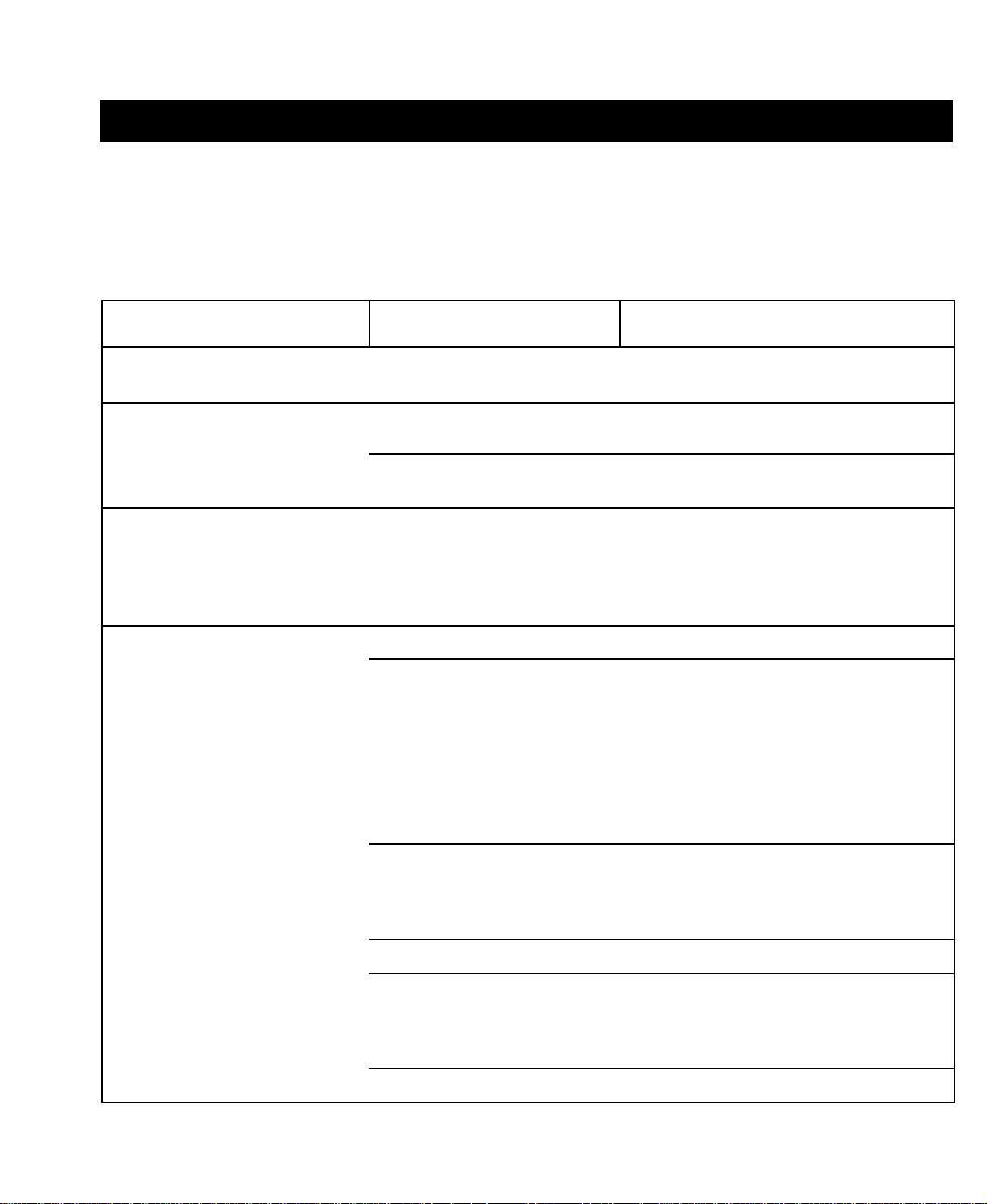

SYMPTOM CHECKOUT PROCEDURE CAUSE SOLUTIO

Motor will not run.

Status LED

illuminated Red

in color.

Motor will not run.

Status LED not

illuminated Red

in color.

Motor runs

continuously.

No Ground

on tip of installed

Tool.

Unplug all SensaTemp

handpieces. If motor now runs

and Status LED turns off -

Check resistance - Pin 1 to Pin 4

with Finger Switch depressed.

If resistance is greater than 1

ohm -

Check resistance - Pin 3 to Pin

6. Resistance should be 3 to 40

ohms. If not -

Check resistance - Pin 1 to Pin

4. Resistance should read

open circuit. If not -

Check resistance - Pin 4 to a

NEW Tip. Resistance should

be less than 2 ohms.

If not -

Shorted

SensaTemp

handpiece.

Open Switch

circuit.

Defective

Motor circuit.

Shorted Finger

Switch.

Oxidation in

drill collet.

Open ground

circuit.

Repair

shorted

SensaTem

handpiece.

Replace

MicroChine

Handpiece.

Replace

MicroChine

Handpiece.

Replace

MicroChine

Handpiece.

Clean

MicroChine

Collet.

Replace

MicroChine

Handpiece.

Table II. MicroChine Handpiece Checkout Procedures

24

Page 30

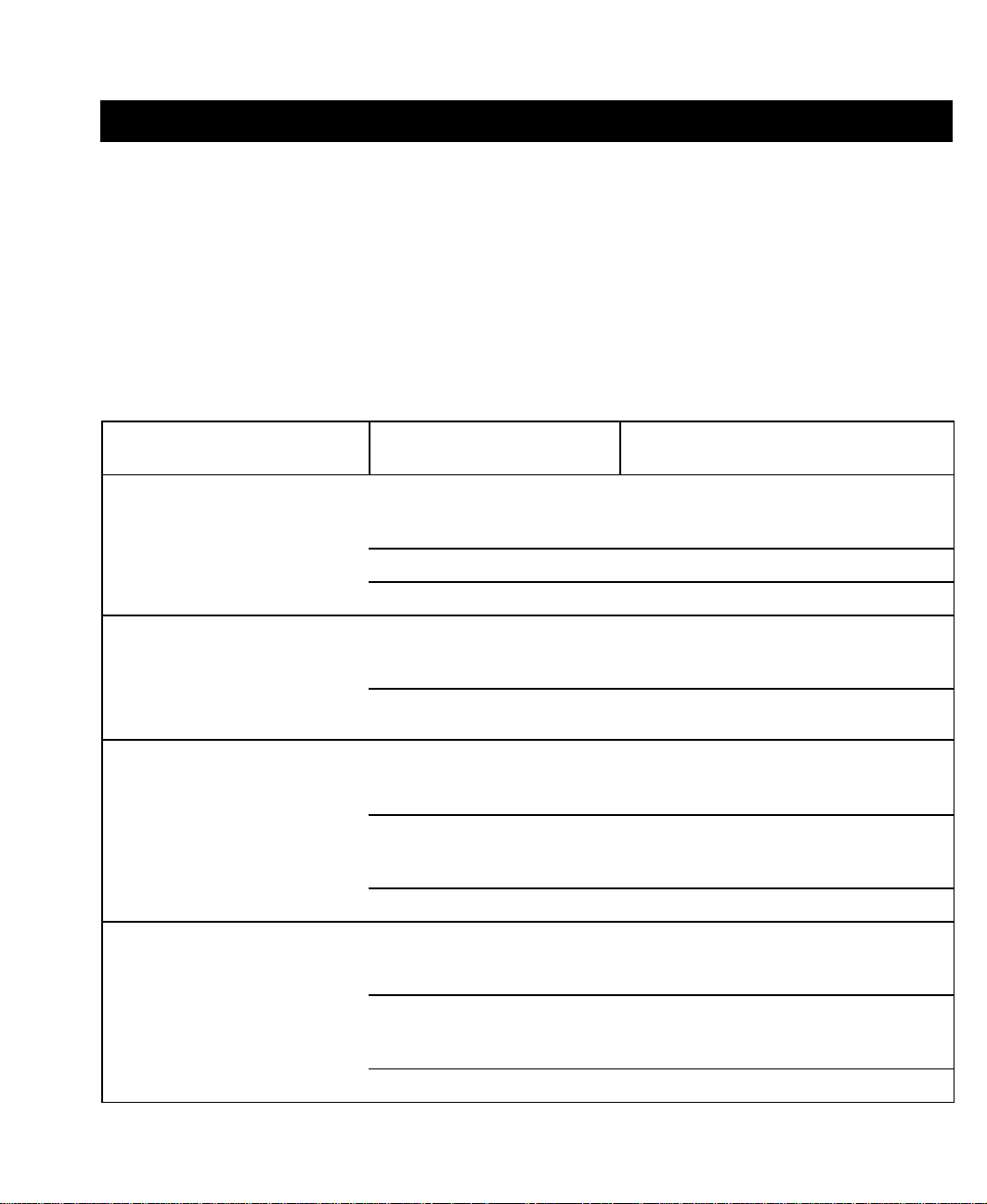

REPAIR

POWER SOURCE

Contact PACE Customer Service at Tel. (301) 490-9860, FAX (301) 604-9215 to obtain any replacement parts.

Refer to the "Replacement Parts" section of this manual for part numbers.

SYMPTOM PROBABLE CAUSE SOLUTION

Digital Readout is blank.

No functions on system.

E-1 displayed on Digital

Readout.

E-2, E-3 or E-4 displayed

on Digital Readout.

No heat on SensaTemp

handpiece(s) at Thermal

Management Center.

Digital Readout displays

very low temperature.

Blown Fuse (F1) Replace Fuse F1 located on rear of

Power Source in the AC Receptacle.

All Channels are unplugged

on Thermal Mgmt. Center.

Open sensor in SensaTemp

handpiece.

Defective heater assembly in

SensaTemp handpiece.

Open heater. Refer to handpiece Operation Manual.

Blown 12 Amp Fuse. Replace 12 amp Fuse located on rear of

Handpieces connected to

AUX receptacles.

SensaTemp handpieces are

not AUX compatible.

Damaged Power Receptacle. Replace Power Receptacle.

Plug SensaTemp handpiece into CH 1,

CH 2 OR CH 3.

Refer to handpiece Operation Manual for

Corrective Maintenance procedures.

Unplug all SensaTemp handpieces.

Plug handpieces back in one at a time.

When defective handpiece is

connected, "E" code will be displayed.

Refer to handpiece Operation Manual.

Power Source.Disconnect all

SensaTemp handpieces before

powering system up. Plug SensaTemp

handpieces back in one at a time. If the

fuse blows when a handpiece is plugged

in, the handpiece is shorted. Repair the

handpiece.

Disconnect incompatible handpieces

from AUX Receptacles. Connect to

Power Receptacles on front panel.

System overload. Check for

defective SensaTemp

handpiece.

Microprocessor pcb defect. Replace Microprocessor pcb.

Table III. Corrective Maintenance, Power Source

Disconnect defective handpiece.

220 Volt version only: Overtemp cutout

in transformer may open. Allow

transformer to cool.

25

Page 31

REPAIR

POWER SOURCE CONT'D

Contact PACE Customer Service at Tel. (301) 490-9860, FAX (301) 604-9215 to obtain any replacement parts.

Refer to the "Replacement Parts" section of this manual for part numbers.

SYMPTOM PROBABLE CAUSE SOLUTION

Foot Pedal does not activate

vacuum or air pressure for

Thermal Management Center.

Keys on Thermal Management

Center don't function properly.

Cannot adjust Offset or Set Tip

Temperature on Thermal

Management Center. Digital

Readout displays "P--".

Digital Readout on Thermal

Management Center is

inaccurate when using a

known good handpiece.

Foot Pedal connected to

incorrect receptacle for

Thermal Mgt. Center motor

pump activation.

Defective Foot Pedal. Check switch closure at Foot Pedal

Defective Motor Pump. Replace Motor Pump.

Microprocessor pcb defect. Replace Microprocessor pcb.

Key caps binding. Clean and/or adjust Key caps.

Display pcb misaligned or

defective.

Microprocessor pcb defect. Replace Microprocessor pcb.

System is requesting

Password entry.

Operator forgot Password. Clear Password. See "Clearing a

System out of calibration. Wait 4 minutes for system to perform

Microprocessor pcb defect. Replace Microprocessor pcb.

Connect Foot Pedal to any spare AUX

Power Receptacle on Thermal

Management Center.

connector plug. Repair Foot Pedal if

defective.

Replace Display pcb.

Enter Password.

Password" instructions.

automatic internal recalibration.

Table III. Corrective Maintenance, Power Source Cont'd

26

Page 32

REPAIR

Contact PACE Customer Service at Tel. (301) 490-9860, FAX (301) 604-9215 to obtain any replacement parts.

Refer to the "Replacement Parts" section of this manual for part numbers.

SYMPTOM PROBABLE CAUSE SOLUTION

Insufficient SNAP-VAC

(vacuum) or air pressure.

Excessive motor pump noise.

Digital Readout display is erratic. Shorted handpiece or

Paste dispenser pressure is

insufficient or nonexistent.

Excessive noise during paste

dispense operation.

Table III. Corrective Maintenance, Power Source Cont'd

Air hose(s) and/or filter(s)

clogged.

Defective motor pump. Replace motor pump.

Microprocessor pcb defect. Replace Microprocessor pcb.

accessory.

Low AC line voltage. Check line voltage.

Display pcb defect. Replace Display pcb.

Microprocessor pcb defect. Replace Microprocessor pcb.

Poor air hose connections. Check air hose connections outside and

Clogged air filter. Replace filter.

Defective pump, valve or

reservoir.

Defective dispense pump. Replace dispense pump.

Multifunction pcb defect. Replace Multifunction pcb.

Replace any clogged filters and clear all

air hoses.

Disconnect handpieces and accessories

one at a time until Digital Readout

display is normal.

inside of system power source.

Replace defective part.

27

Page 33

REPAIR

POWER SOURCE CONT'D

Contact PACE Customer Service at Tel. (301) 490-9860, FAX (301) 604-9215 to obtain any replacement parts.

Refer to the "Replacement Parts" section of this manual for part numbers.

SYMPTOM PROBABLE CAUSE SOLUTION

MicroChine Status LED

continuously illuminated

Red in color.

MicroChine Probe Brake

activates prematurely.

MicroChine continues to run

after release of finger switch or

foot pedal.

MicroChine Probe Brake

reacts sluggishly or is

inoperable.

Shorted SensaTemp

handpiece or accessory on

Thermal Management Center.

Multifunction pcb defect. Replace Multifunction pcb.

Probe Brake test lead is

connected to or exciting a

circuit having less than 500

ohms resistance to ground.

Defective MicroChine

handpiece.

Probe Brake test lead is

connected to inappropriate

conductor on workpiece.

Bit in MicroChine is not

conductive (non metallic).

Defective MicroChine

handpiece.

Multifunction pcb defective. Replace Multifunction pcb.

Turn system power OFF for 1 minu te.

Disconnect handpieces and

accessories. Turn system power ON

and run MicroChine. LED will turn off if

the problem is caused by a handpiece or

accessory. Repair handpiece or

accessory.

Remove ground lead from pcb.

Refer to Table II to check MicroChine

handpiece. Replace MicroChine

handpiece if defective.

Connect Probe Brake test lead to proper

conductor.

Install conductive bit.

Replace handpiece.

MicroChine will not operate.

Probe Brake LED is illuminated

Green in color.

Damaged Power Receptacle. Replace Power Receptacle.

Defective MicroChine

handpiece.

Multifunction pcb defective. Replace Multifunction pcb.

Table III. Corrective Maintenance, Power Source Cont'd

28

Replace handpiece.

Page 34

REPAIR

Contact PACE Customer Service at Tel. (301) 490-9860, FAX (301) 604-9215 to obtain any replacement parts.

Refer to the "Replacement Parts" section of this manual for part numbers.

SYMPTOM PROBABLE CAUSE SOLUTION

MicroChine speed is grossly

inaccurate.

Pik-Vac has insufficient

vacuum.

Pulse Heat handpieces do not

heat. Pulse Heat LED is

illuminated Green in color.

Foot Pedal does not operate

in PH, PP, MP or

PD position.

MicroChine is overloaded.

Status LED is illuminated

Yellow in color.

Defective handpiece. Replace handpiece.

Multifunction pcb defect. Replace Multifunction pcb.

"Low Pressure" output on

power source rear panel is

obstructed.

Defective Pik-Vac pump

assembly.

Loose connection at Pulse

Heat Outputs or handpiece

connector.

Defective Universal Power

Cord.

Multifunction pcb defect. Replace Multifunction pcb.

Foot pedal connected to

incorrect receptacle.

Defective foot pedal switch. Check for switch closure at foot pedal

Multifunction pcb defect. Replace Multifunction pcb.

Disengage MicroChine from workpiece.

Resume operation exerting less pressure

on handpiece.

Remove obstruction.

Replace Pik-Vac pump.

Tighten connections.

Check voltage at Pulse Heat Outputs.

Replace Universal Power Cord if

defective.

Connect foot pedal to receptacle on rear

panel of power source marked "FOOT

PEDAL".

connector plug pins. Repair foot pedal if

defective.

Table III. Corrective Maintenance, Power Source Cont'd

29

Page 35

REPAIR

CALIBRATION

All PACE SensaTemp controllers can be checked for calibration without the need to adjust any internal controls.

If there is a requirement to check the actual tip temperature of a SensaTemp handpiece, perform the following

procedure for attaching a thermocouple wire to the handpiece tip. A Process Monitor is available from PACE

which will provide a temperature readout and can perform a variety of additional tests such as Tip to Ground

resistance and vacuum checks.

A thermocouple may be attached to a tip by spot welding a thermocouple wire onto the end of the tip or by

embedding the wire into a drilled hole at the tip end. Either method will produce accurate results. Tips (for

PACE equipment) with embedded K type thermocouples are available from PACE.

Pulse Heat handpieces are not closed loop temperature controlled and require no calibration.

MATERIALS REQUIRED

1. PACE Process Monitor or Temperature Meter.

2. Soldering Iron Tip. Listed below are the available tips PACE uses (with and without embedded

thermocouples).

a) Use PACE part number 7021-0004-P1 tip with embedded thermocouple or tip only part

number 1121-0337 on handpieces with 4.76 mm (3/16 inch) heater bore.

b) Use PACE part number 7021-0003-P1 tip with embedded thermocouple or tip only part

number 1121-0130 on handpieces with 3.18 mm (1/8 inch) heater bore.

NOTE

When using tips with embedded K type thermocouples supplied by PACE

with a K type Temperature Meter, a PACE part number 1332-0164-P1

RCA to Omega-style, K-type, thermocouple adapter must be used.

The following items are needed if you are NOT using the PACE part number 7021-0003-P1 or 7021-0004-P1

embedded tips.

3. Thermocouple, 30 AWG ("K" type when using Process Monitor or type compatible with Temperature

Meter).

4. Copper Wedge (used when embedding thermocouple) or 16 AWG Bare Copper Wire (1.22 mm

(.048 inch) O.D.).

5. Drill Bit (used when embedding thermocouple), 1.5 mm (.059 inch) diameter.

SPOTWELDING PROCEDURE

1. Place the thermocouple end onto the tip just past the tinned end (approximately 6.35 mm (.25 inch)).

2. Spotweld the thermocouple to the tip. Check to insure that the thermocouple is properly attached to

the tip.

30

Page 36

REPAIR

EMBEDDING PROCEDURE

1. Drill a 1.5 mm (.059 inch) hole just past the tinned end of the soldering tip (approximately 6.35 mm

(.25 inch) when using one of the recommended PACE tips). Drill to a depth of 2.54 mm (.100 inch).

2. Place the end of the thermocouple wire into the hole. Ensure that the end of the wire bottoms out in

the hole.

3. Wedge the thermocouple into place using the copper wedge or bare copper wire. The thermocouple

should be wedged as air tight as possible.

Figure 11. Thermocouple Attachment

TIP TEMPERATURE TEST

1. Install the tip into the handpiece to be tested with the end of the tip properly seated. The

recommended PACE tips are shown extending out of the heater 9.5mm (3/8 inch).

2. Connect the free end of the thermocouple wire to the PACE Process Monitor (or temperature meter).

3. Apply power to the handpiece and allow temperature to stabilize.

31

Page 37

REPAIR

DISASSEMBLY/ASSEMBLY

DISASSEMBLY

To disassemble the unit for servicing, perform the following procedure step by step, in sequence using the

illustrations as a guide. The procedure directs the technician to remove the power source from the chassis.

WARNING

POTENTIAL SHOCK HAZARD The following procedures are to be

performed by qualified service personnel only. Removal of the Power

Source panels exposes line voltage parts. Service personnel must insure

that the AC Power Cord is disconnected prior to disassembly.

1. Place the unit on a suitable work surface. Insure that the Power Cord has been disconnected from the

back of the power source.

32

Page 38

REPAIR

2. Position the PRC 2000 power source with the rear panel facing forward.

3. Remove the 3 rear panel mounting screws indicated on the rear panel. DO NOT remove any other

rear panel mounting screws.

Figure 12. Removing Rear Panel Screws

33

Page 39

REPAIR

DISASSEMBLY CONT'D

4. Reposition the unit with the Front Panel of the Power Source facing forward.

5. Remove the 10 Front Panel Mounting Screws.

6. Pull the Front Panel forward 2 inches to expose the interior of the Power Source. DO NOT disconnect

any electrical or air hose connections.

Figure 13. Removing Front Panel

34

Page 40

REPAIR

7. Locate the 4 Bolt Assemblies across the front, inside, bottom edge of the Power Source case.

8. Loosen each of the Hex Nuts on the 4 Bolt Assemblies.

9. Slide each of the Bolt Assemblies forward and remove the assemblies from the Power Source.

Figure 14. Removing Bolt Assemblies

35

Page 41

REPAIR

DISASSEMBLY CONT'D

10. Remove the power source from the case by grasping 2 of the metal posts which connect the pc boards

to the power source chassis. Pull the power source forward and out of the case.

11. Set the case aside.

12. The unit can now be connected to the house AC supply to troubleshoot the system.

Figure 15. Removing Power Source From Case

36

Page 42

ASSEMBLY

1. Disconnect the AC power cord.

WARNING

POTENTIAL SHOCK HAZARD Insure that the AC power is

disconnected before proceeding to step 2.

2. Place the case directly behind the power source. Insure that the power source is facing forward.

3. Slide the power source back into the case.

REPAIR

4. Reposition the power source with the rear panel facing forward. Reinstall the 3 rear panel mounting

screws.

5. Reposition the power source with the front panel facing forward. Reinstall the 4 bolt assemblies.

Tighten the hex nuts on each bolt assembly to secure the power source in position.

6. Insure that all air hoses are properly connected to the front panel. Refer to the "Air Hose Routing"

illustration.

7. Install the 10 front panel mounting screws to secure the panel to the case.

8. Check the power source for proper operation.

37

Page 43

REPAIR

38

Page 44

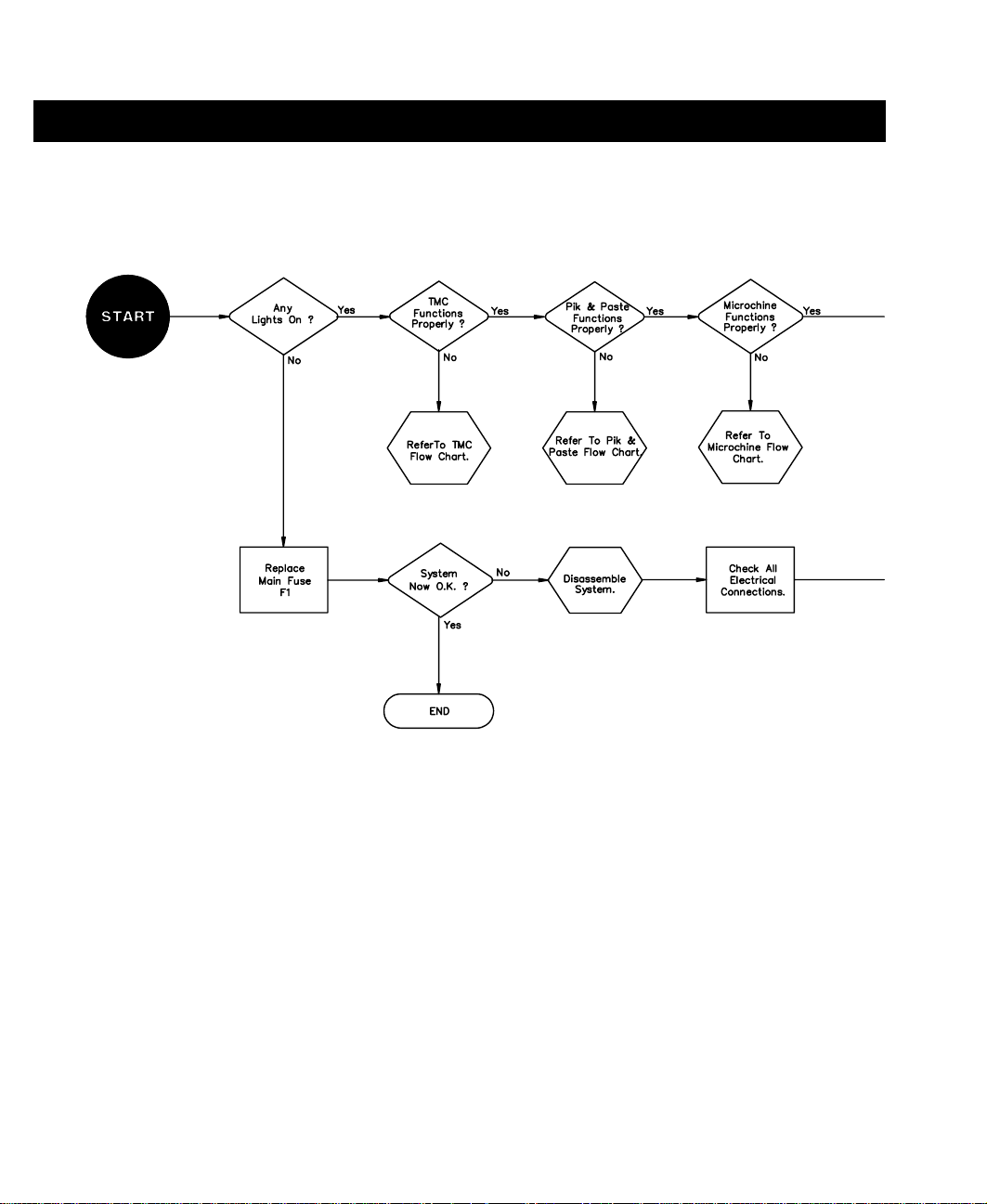

REPAIR

FLOW CHARTS

The following flow charts should be used to determine the source of a malfunction down to an assembly level.

Locate the flow chart which best describes the malfunction. If you are unsure about which flow chart to use,

begin with the "Power" flow chart which will direct you to the area of concern.

Insure that the power source has been removed from its case before performing the applicable procedure.

WARNING

POTENTIAL SHOCK HAZARD The follo wing Flow Chart procedures

are to be performed by qualified service personnel only. Line voltage

parts are exposed. Service personnel must avoid contact with these

parts when troubleshooting the power source.

39

Page 45

REPAIR

POWER

Figure 16. Power Flow Chart

40

Page 46

REPAIR

41

Page 47

REPAIR

TMC

I.

Figure 17. Thermal Management Center Malfunction Flow Chart

42

Page 48

REPAIR

43

Page 49

REPAIR

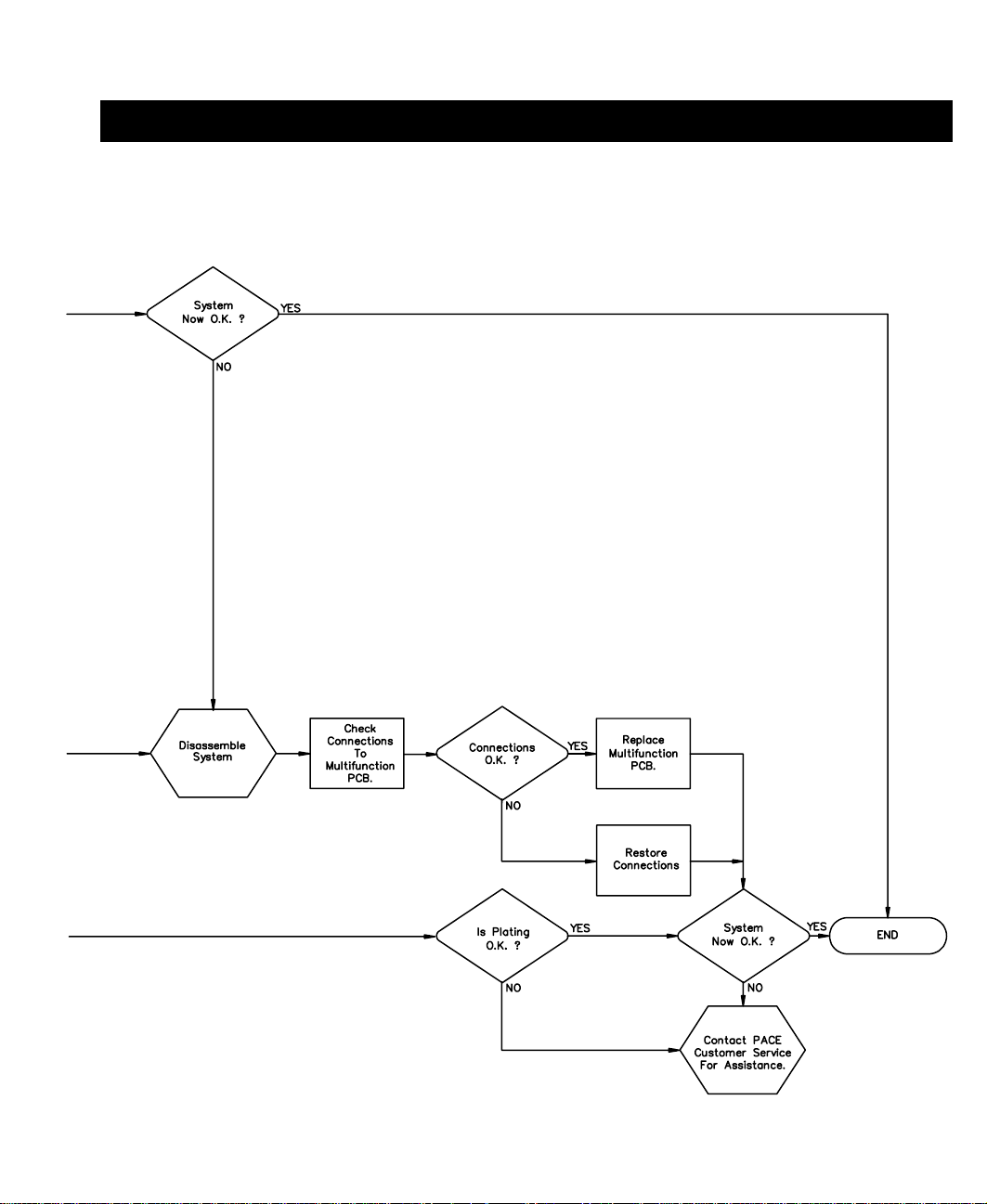

PIK & PASTE

Figure 18. Pik & Paste Malfunction Flow Chart

44

Page 50

REPAIR

45

Page 51

REPAIR

MICROCHINE

Figure 19. MicroChine Malfunction Flow Chart

46

Page 52

REPAIR

47

Page 53

REPAIR

PULSE PLATE

Figure 20. Pulse Plate Malfunction Flow Chart

48

Page 54

REPAIR

49

Page 55

REPAIR

PULSE HEAT

Figure 21. Pulse Heat Malfunction Flow Chart

50

Page 56

REPAIR

51

Page 57

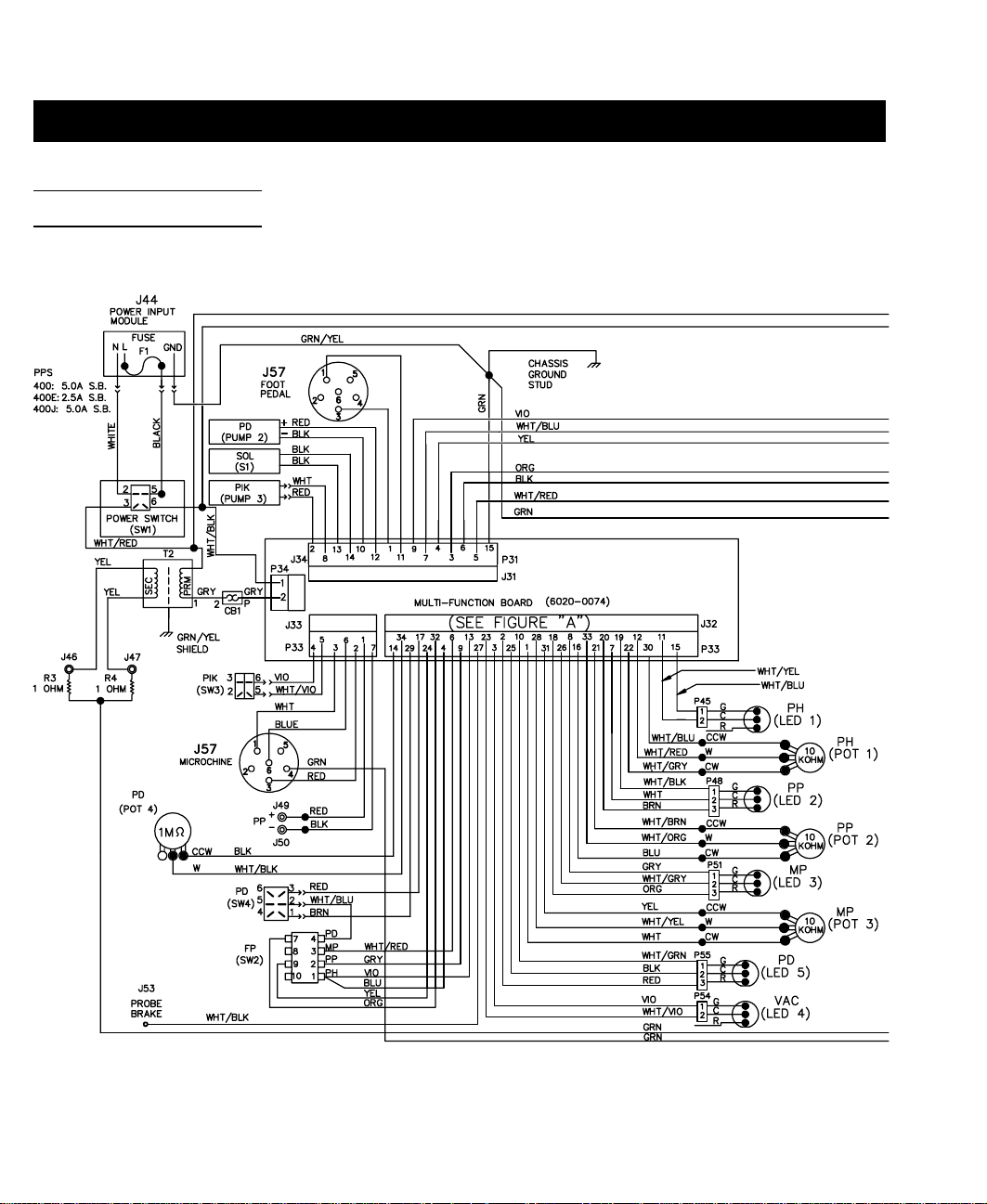

REPAIR

WIRING DIAGRAM

Figure 22. PPS 400, PPS 400J, PPS 400E Wiring Diagram

52

Page 58

REPAIR

53

Page 59

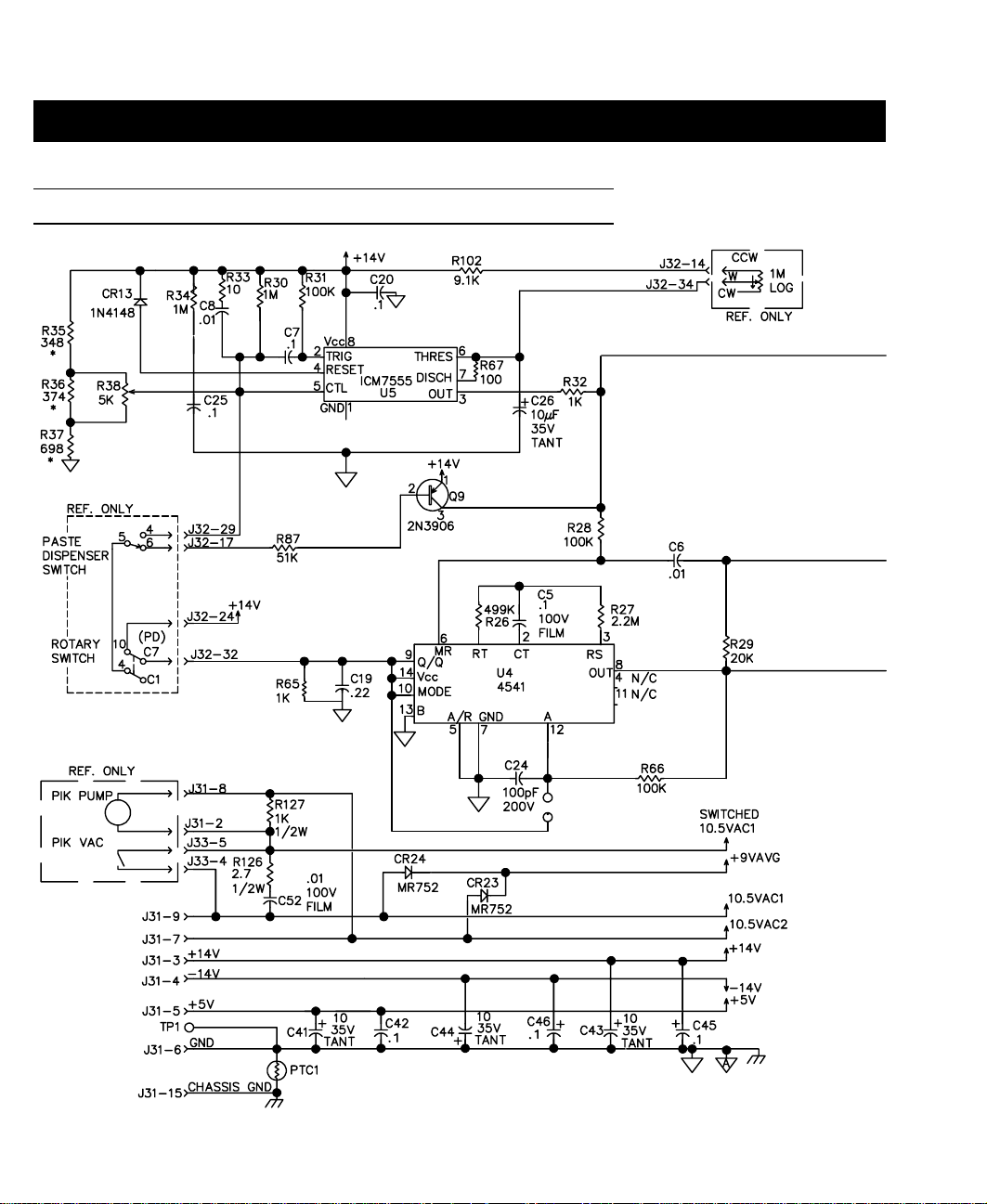

REPAIR

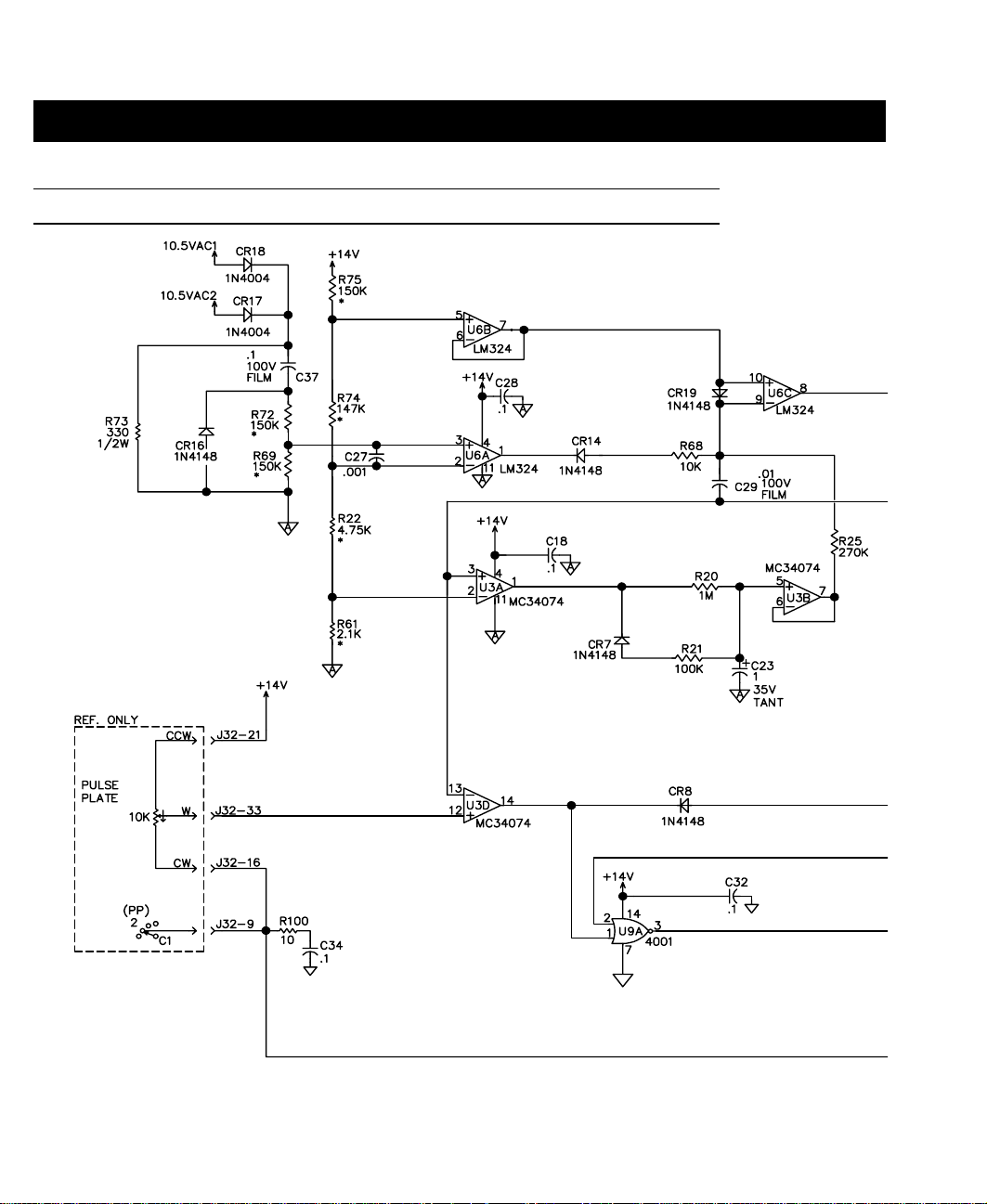

MULTIFUNCTION PCB ASSEMBLY SCHEMATIC

Figure 23. Multifunction PCB Assembly Schematic

54

Sheet 1 of 3

Page 60

REPAIR

55

Page 61

REPAIR

MULTIFUNCTION PCB ASSEMBLY SCHEMATIC CONT'D

Figure 23. Multifunction PCB Assembly Schematic Cont'd

56

Sheet 2 of 3

Page 62

REPAIR

57

Page 63

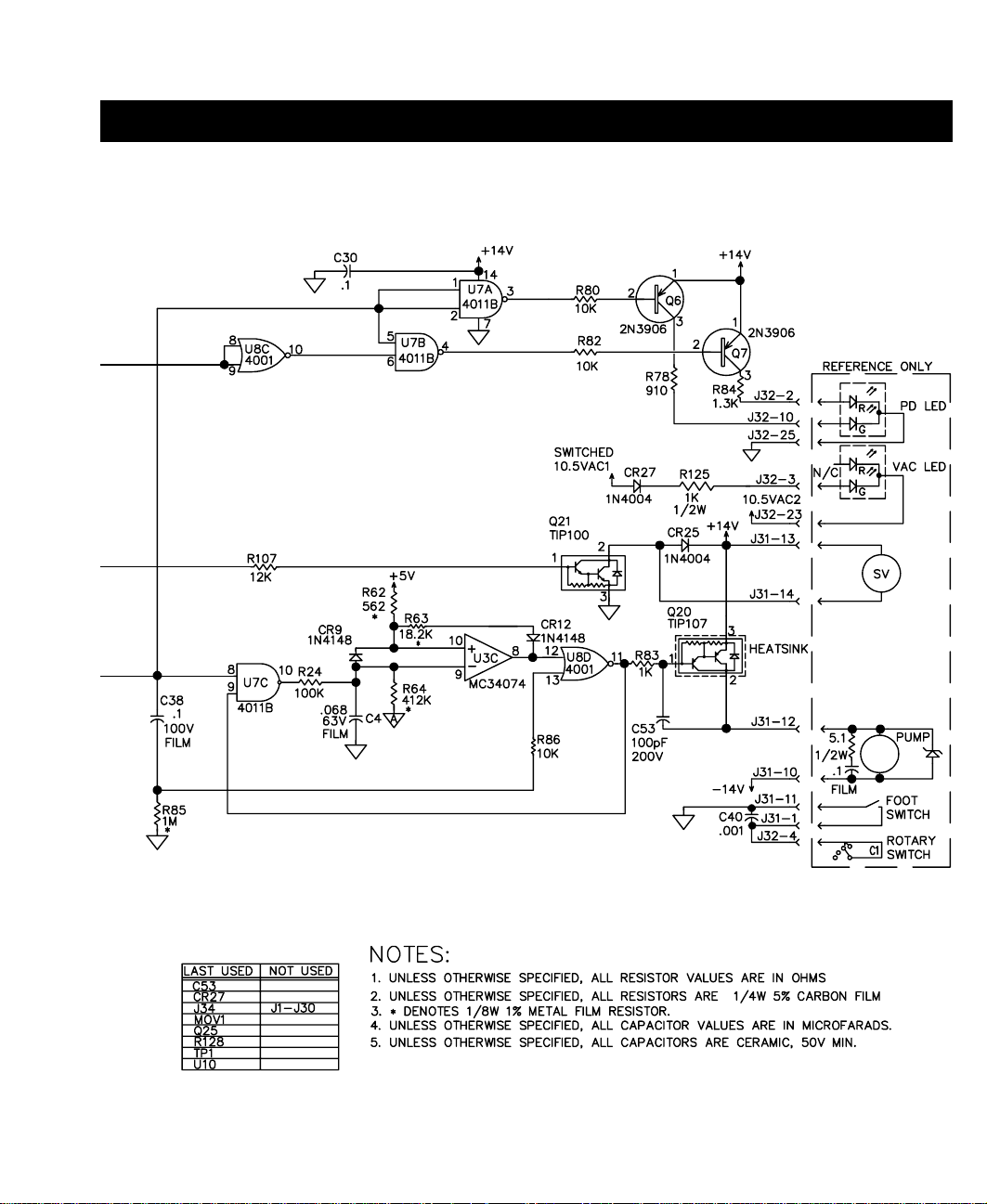

REPAIR

MULTIFUNCTION PCB ASSEMBLY SCHEMATIC CONT'D

Figure 23. Multifunction PCB Assembly Schematic Cont'd

58

Sheet 3 of 3

Page 64

REPAIR

59

Page 65

REPAIR

MICROPROCESSOR PCB ASSEMBLY SCHEMATIC

Figure 24. Microprocessor PCB Assembly Schematic

60

Sheet 1 of 2

Page 66

REPAIR

61

Page 67

REPAIR

MICROPROCESSOR PCB ASSEMBLY SCHEMATIC CONT'D

Figure 24. Microprocessor PCB Assembly Schematic Cont'd

62

Sheet 2 of 2

Page 68

REPAIR

63

Page 69

REPAIR

DISPLAY PCB ASSEMBLY SCHEMATIC

Figure 25. Display PCB Assembly Schematic

64

Page 70

REPAIR

65

Page 71

REPAIR

ASSEMBLY DRAWING

Figure 26. Assembly Drawing

66

Page 72

REPAIR

Figure 27. Assembly Drawing Cont'd

67

Page 73

REPAIR

AIR HOSE ROUTING

Figure 28. Air Hose Routing

68

Page 74

REPLACEMENT PARTS

POWER SOURCE

Listed below are the power source parts which may be ordered directly from PACE sales or your local

authorized PACE distributor. Refer to Table IV plus Figures 29-31. For handpiece and accessory replacement

parts, refer to Tables V, VI and VII or the associated Operation and Maintenance Manual. To obtain parts other

than those shown, contact PACE Customer Service directly at Telephone (301) 490-9860, Fax (301) 604-9215.

PART NUMBER

ITE

NO. DESCRIPTION

PPS 400

PPS 400J

PPS 400E

1 Main Power Switch 1157-0052 1157-0052

2 Fuse (F1), 5.0 Amp, Time Lag 1159-0253

2.5 Amp, Time Lag 1159-0220

3 Fuse (F2), 12.0 Amp, Fast Acting 1159-0257 1159-0257

4 AC Power Receptacle, Fused 1207-0151 1207-0274

5 Fuseholder 1161-0012 1161-0012

6 Motor Pump Assembly, SNAP-VAC 1336-0028 1336-0028

7 Motor Pump Assembly, Paste Disp. 1336-0027 1336-0027

8 Pump Assembly, Pik-Vac 1334-0021 1334-0021

9 Microprocessor PCB Assembly 6020-0072 6020-0072

10 Multifunction PCB Assembly 6020-0074 6020-0074

11 Display PCB Assembly 6020-0073 6020-0073

12 Pressure Reservoir 1140-0034 1140-0034

13 Solenoid, 12 Volt 1194-0016 1194-0016

VisiFilter, External (installed between Snap-Vac

14

Port & handpiece air hose)

1309-0028 1309-0028

15 VisiFilter Replacement Elements 1309-0027-P50 1309-0027-P50

16 VisiFilter, Internal (located inside power source) 1309-0020 1309-0020

Table IV. Power Source Replacement Parts

69

Page 75

REPLACEMENT PARTS

POWER SOURCE CONT'D

Figure 29. Power Source Replacement Parts

70

Page 76

REPLACEMENT PARTS

Figure 30. Power Source Replacement Parts Cont'd

71

Page 77

REPLACEMENT PARTS

Figure 31. Power Source Replacement Parts Cont'd

72

Page 78

POWER SOURCE ACCESSORIES

REPLACEMENT PARTS

ITEM

NO. DESCRIPTION

Power Cord

1

PRC 2000/J (100 VAC & 115 VAC Systems) 1332-0094

PRC 2000E (230 VAC Export Systems) 1332-0093

Foot Pedal 6008-0115

2

Paste Dispenser Kit 6993-0152

3

Tip Redi-Rak 6021-0007

4

Handpiece Redi-Rak 6019-0023

5

Tip & Temperature Chart Holder Assembly 1257-0186-P1

6

Cleaning Station (Complete) 6021-0006

7

8

9

10

Fiber Cleaning Tool 1100-0232

Fiber Filler, Replacement 1127-0013

Sponge Cleaning Tool 1100-0233

PART

NUMBER

11

12

13

14

15

16

Table V. Power Source Accessories

SX Tip & Tool Stand (for air handpieces) 6019-0044

SP Tip & Tool Stand (for SP handpieces) 6019-0043

ThermoTweez Tip & Tool Stand 6019-0046

Paste Dispenser Cubby 6019-0038

SMR Cubby 6019-0022

Sponge Filler, Replacement 4021-0006

73

Page 79

REPLACEMENT PARTS

HANDPIECES

ITEM

NO. DESCRIPTION

1 SX-70 Sodr-X-Tractor Handpiece 6010-0077-P1

2 Heater & Seal Assembly 6010-0080-P1

3 Glass Chamber 1265-0009-P1

4 Filter 1309-0018

5 Heater Set Screw 1348-0547

6 AdapTip 1360-0083-P1

7 SX-65A Sodr-X-Tractor Handpiece 6010-0073-P1

8 Heater & Seal Assembly 6010-0074-P1

9 Glass Chamber 1265-0009-P1

10 Filter 1309-0018

11 Heater Set Screw 1348-0547

12 SP-2A Sodr-Pen Soldering Iron Handpiece (54 Watts) 6025-0014-P1

13 Heater Assembly 6010-0086-P1

14 Heater Set Screw 1348-0547

15 SP-1A Sodr-Pen Soldering Iron Handpiece (37 Watts) 6025-0013-P1

PART

NUMBER

16 Heater Assembly 6010-0085-P1

17 Heater Set Screw 1348-0547

18 TJ-70 Mini ThermoJet Handpiece 7023-0002-P1

19 Heater Assembly 6010-0084-P1

20 Heater Set Screw 1348-0547

Table VI. Replacement Handpieces

74

Page 80

REPLACEMENT PARTS

ITEM

NO. DESCRIPTION

21 TP-65 ThermoPik Handpiece 7024-0001-P1

22 Heater Assembly 6010-0081-P1

23 Heater Set Screw 1348-0547

24 Vacuum Cups - - - - - - 25 4.4mm (0.175") O.D. 1121-0382-P5

26 7.6mm (0.300") O.D. 1121-0383-P5

27 12.7mm (0.500") O.D. 1121-0384-P5

28 TT-65 ThermoTweez Handpiece 7025-0001-P1

29 Heater Assembly With Sensor 6010-0082-P1

30 Heater Assembly Without Sensor 6010-0083-P1

31 Heater Set Screw 1348-0547

32 Cushion Grip Kit 6993-0155

33 Replacement Pads For Cushion Grips 1317-0029-P2

34 Tip Alignment Tool 1100-0234

35 PV-65 Pik-Vac Handpiece 7027-0001-P1

36 Metal Tip, 45° Angle 1121-0413-P5

PART

NUMBER

37 Vacuum Cups & Tips; See TP-65 Handpiece - - - - - - - - - 38 MC-65 MicroChine Handpiece 7026-0001-P1

39 Probe Brake Patch Cord 1332-0159

40 Deluxe Tool Kit 6005-0013

PULSE HEAT HANDPIECES

41 CT-15 ConducTweez Handpiece 7020-0001-P1

42 TW-15 ResisTweez Handpiece 7009-0005-P1

43 TS-15 StripTweez Handpiece 7012-0002-P1

44 LF-15 LapFlo Handpiece 7013-0004-02-P1

45 Universal Power Cord 7000-0023

46 Tip Screw, 2-56 x 5/32" Lg. (used on items 41 & 42) 1405-0182

Table VI. Replacement Handpieces Cont'd

75

Page 81

REPLACEMENT PARTS

HANDPIECE ACCESSORIES

ITEM

NO. DESCRIPTION

1 VisiFilter (replaceable element) 1309-0028

2 VisiFilter Replacement Elements 1309-0027-P50

3 Tubing, Clear PVC, 66" Lg. 1342-0001-14

4 Tubing, Clear PVC, 1 inch long 1325-0003-07

5 Tubing, Silicone, Translucent, 54" Lg. 1342-0001-13

6 Hose Clamps 1321-0085-01-P6

7 Cable Marker Kit 6993-0136

8 Quick Change Hose Mount, Female 1259-0086

9 Quick Change Hose Mount, Male 1259-0087

10 Bristle Brush 1127-0002

11 Wire Brush, 3/16" Diameter 1127-0014

12 Wire Brush, 1/8" Diameter 1127-0006

13 Tip Cleaner Kit 6993-0151

14 Tip Tool 1100-0206

15 PACE Screwdriver 1100-0230

PART

NUMBER

Table VII. Replacement Handpiece Accessories

76

Page 82

MANUAL IMPROVEMENT & COMMENT FORM

REPLACEMENT PARTS

Instructions

1.

Duplicate this form and submit comments on the copy. Keep the original to make future

comments.

2.

Complete all requested information.

3.

Submit completed form to: PACE Incorporated

Applications Engineering Fax: (301) 604 - 8782

9893 Brewers Court

Laurel MD 20723-1990 U.S.A.

Document Nbr:

Nature of Change (Identify page and paragraph and include proposed rewrite, if possible.)

5050-0344

Revision Level:

C

Date of Submission:

Reason for Recommendation

Submitter:

Name: Company or Organization:

Mailing Address: Telephone (Include Area Code)

Voice:

Fax:

77

Loading...

Loading...