Page 1

INSTRUCTIONS FOR O.S. TYPE 3H AUTOMATIC CARBURETTOR

This new carburettor incorporates an automatic mixture control device which ensures that the engine receives a

correctly balanced mixture of fuel and air at all throttle settings. The device progressively reduces the effective size

of the fuel jet orifice as the throttle is closed, thereby preventing the engine from running too rich at low speeds. This

also means that an airbleed is no longer required and, with its elimination, maximum suction is maintained at the fuel

jet at all times. This is a most important factor where manoeuvres have to be executed at low engine speeds and

through wide variations of fuel level within the fuel tank.

Three adjustable controls are provided on this carburettor

• The Needle-Valve: For adjusting the mixture strength

when the throttle is fully open.

• The Mixture Control Screw: For manually adjusting the

automatic mixture control valve in order to obtain a

stable idle and a smooth transition through the medium

speed range.

• The Throttle Stop Screw: For setting the position where

the carburettor rotor is closed.

Note: The Mixture Control Screw has been factory set for

the approximate best result. However, different fuels

and/or climatic conditions may necessitate minor

compensatory adjustment. Therefore, first run the

engine as received and re-set the Mixture Control

Screw only if necessary.

PROVISIONAL SETTINGS

Before starting the engine, check that the controls are set as

follows:

1) In the case of a fixed-wing aircraft, use a muffler pressurized fuel feed, and open the Needle-Valve 1 1/2 to

2 turns from the fully closed position. For helicopter

use, open the Needle-Valve 2 1/2 turns (or 2 turns if a

muffler-pressurized fuel feed is used) from the fully

closed position.

2) Make sure that the Throttle Stop Screw is set, in conjunction with the throttle lever linkage, so that (a) the throttle

rotor is fully open when the transmitter throttle stick is

fully advanced and (b) that the throttle rotor is fully

closed when both the throttle'stick and throttle trim lever

are fully pulled back.

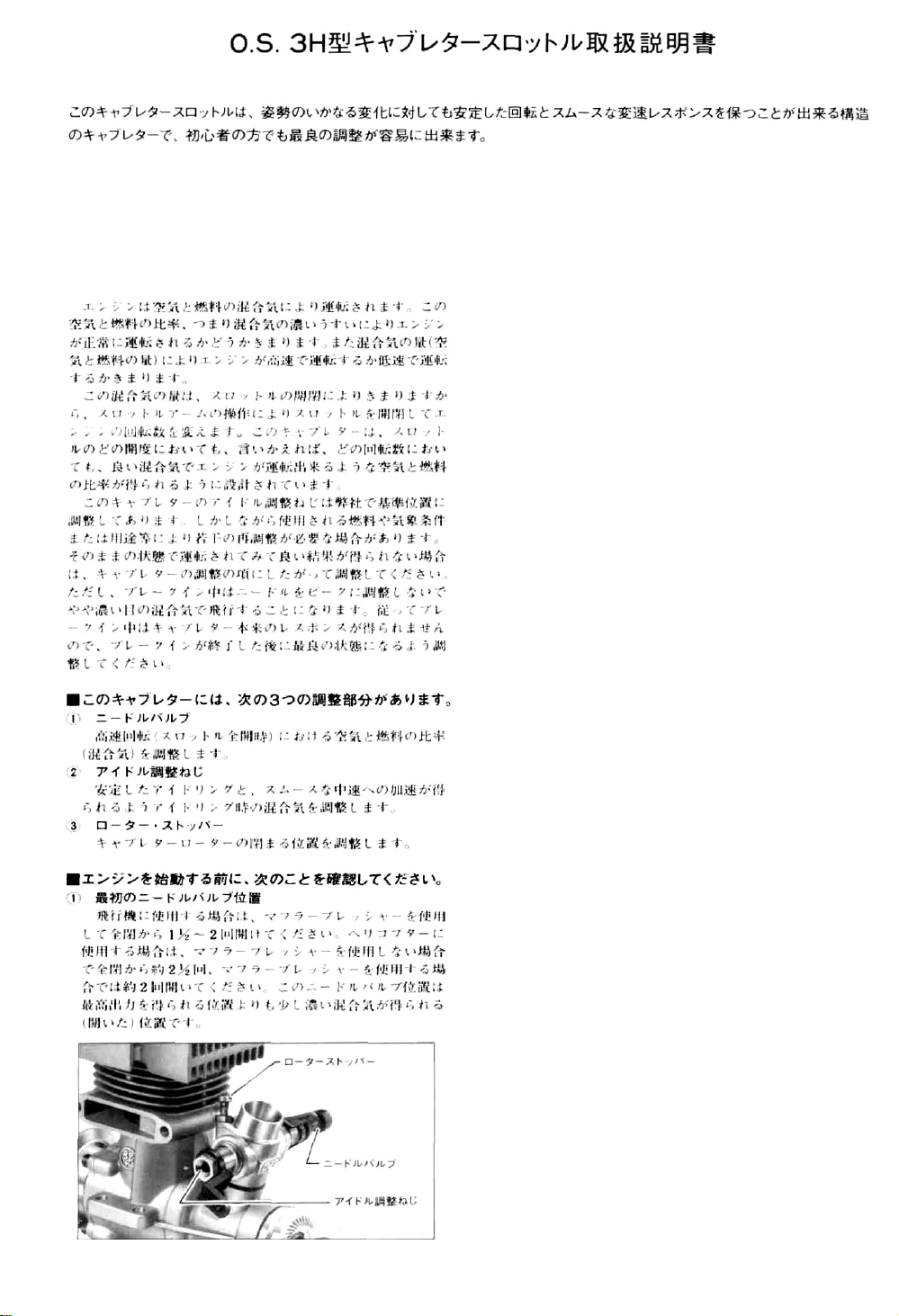

Throttle Rotor Set-Screw

Needle Valve

Mixture Control

Screw

ADJUSTMENT (HELICOPTERS)

In helicopter flight, throttle response at medium revolutions

(i.e. hovering speeds) is most important, since this is a speed

range widely used in helicopter flight. The optimum mixture

at mid range will be obtained with a balanced adjustment of

both the Needle-Valve and the Mixture Control Screw.

A — Low Speed Performance — Mixture Control Screw

1) Start the engine with the transmitter throttle stick in the

closed position and the throttle trim lever set at the mid

position.

2) Adjust the throttle trim so that the highest possible idling

r.p.m. are obtained without actually engaging the clutch.

3) Now increase engine r.p.m. by means of the throttle stick

until the helicopter just 'floats' above the ground, allow

the engine to warm up for about 10 seconds, then gradually reduce r.p.m. and allow the engine to idle for about 5

seconds.

4) Repeat, several times, this procedure of increasing r.p.m.

so that the model 'floats' after idling for 5 seconds on the

ground. While doing this, carefully observe the exhaust

smoke and the behaviour of the engine. If, as the throttle

is opened, the engine tends to hesitate and to run with a

low-pitched exhaust note and an excess of exhaust smoke,

the mixture is too rich.

Page 2

If, on the other hand, when the throttle is opened, there

is a marked lack of exhaust smoke and the engine quickly

speeds up but runs 'hard', with a higher pitched exhaust

note and a tendency to overheat, the mixture is too lean.

5) If the mixture is too rich. turn the Mixture Control

Screw clockwise 45 degrees. If, on the other hand, the

mixture is too lean, turn the Mixture Control Screw

counter-clockwise about 90 degrees, then turn it clock-

wise 45 degrees.

Turn the Mixture Control Screw 30 to 45 degrees at a time in

the early stages. When the response improves, turn the Mixture Control Screw 10 to 15 degrees at a time. Carry out

adjustments progressively and patiently, remembering the

symptoms of rich and lean running, quoted above, until the

engine responds quickly and positively to the throttle.

B — High Speed Performance — Needle-Valve

The optimum Needle-Valve setting is usually 1/2 turn (or 1/4

turn if a muffler pressurized fuel feed is used) closed from

the starting position [i.e. 2 1/2 turns open (or 2 turns open if

a muffler-pressurized fuel feed is used) from the fully closed

position]. The precise setting depends on (a) the individual

characteristics of the helicopter and its engine/muffler installation, (b) the fuel used and (c) atmospheric conditions.

The Needle-Valve should be gradually closed until the highest

performance is obtained in flight at full power.

However, take care not to close the needle-valve to too lean a

setting and risk overheating the engine, in the pursuit of

maximum performance.

C — Mid-Range Performance — Throttle Response

As previously stated, in helicopter flight, throttle response at

medium (hovering) speeds — i.e. engine speeds widely used in

helicopter flight — is most important. If the Mixture Control

Screw (low speed) and Needle-Valve (high speed) are proper-

ly balanced, the mixture will be correct, also, through the

medium speed range. If, however, minor readjustments prove

to be necessary for the best possible throttle response, proceed

as indicated by the following symptoms and required corrective action:

1) If the mixture at mid-range is lean, gradually increased

engine speed is accompanied by diminished exhaust

smoke and a high-pitched exhaust note if hovering is

prolonged. In extreme cases, the engine will overheat

and lose speed, so that hovering cannot be maintained.

In this event, open the Needle-Valve 15 to 30 degrees and

turn the Mixture Control Screw 30 to 45 degrees counter-

clockwise.

2) If the mixture at mid-range is too rich, positive and quick

throttle response will not be obtained, the exhaust smoke

will be dense and the exhaust note will be lower, probably

accompanied by fuselage vibration.

In this event, close the Needle-Valve 30 to 60 degrees and

turn the Mixture Control Screw 45 to 90 degrees clock-

wise.

Note: It is most important to make the Needle-Valve adjust-

ment in small increments of not more than 15—30

degrees and the Mixture Control Screw adjustment not

more than 30 — 45 degrees as advised, when seeking

optimum

adjustment will upset either (A) Low-Speed Performance or (B) High-Speed Performance. Carry out readjustments patiently until the best balance of idling,

hovering and high-speed performance is achieved and

the engine responds quickly and positively to the

throttle control.

Throttle response at hovering speeds is also affected

by the relationship of the main rotor pitch angle to

throttle opening. If the optimum mid-range throttle

response cannot be obtained by the carburettor adjustments described above, try adjusting the helicopter's

pitch control characteristics.

mid-range

throttle

response.

Excessive

re-

Page 3

ADJUSTMENT (FIXED-WING AIRCRAFT)

1. Start the engine and, with the throttle fully open, gradually close the Needle-Valve until it is running at its maximum speed.

Caution: Do not close the Needle-Valve to too "lean" a

2. Having set the Needle-Valve as detailed above, close the

Note 1 If the engine stops when the transmitter throttle

Note 2 As previously stated, the Mixture Control Screw is

setting as this will cause the engine to overheat

and slow up. Set the Needle-Valve very slightly

to

the

"rich"

Make sure that the engine is fully "broken-in"

side of the

(about 1 hour of total running time in short runs)

before operating it continuously at full throttle.

throttle. The engine should idle continuously and steadily

without further adjustment.

(a) If, however, the engine begins to idle unevenly, open

the throttle. If the engine then hesitates before picking up to full speed, it is probable that the idling

mixture is too rich. Check this by closing the throttle

again and letting the engine idle for a little longer

before again opening up. If the engine now puffs out

a good deal of smoke and hesitates or even stops, it

will be necessary to close the Mixture Control Screw.

Do this by turning it clockwise: about 10~20 degrees

should be sufficient.

(b) If instead of being set too rich, the Mixture Control

Screw is set too lean, the engine will stop when the

throttle is closed, or will lose speed while idling and

then cut-out abruptly (without smoking) when the

throttle is opened again. In this case, turn the Mixture

Control Screw counter-clockwise about 90 degrees,

then turn it clockwise slowly to find the best setting.

Mixture Control Screw adjustment is not critical and

by remembering the symptoms of rich and lean run-

ning quoted above, it is a very simple matter to

establish the best setting.

stick is fully pulled back, advance the throttle trim

lever so that the idling speed is slightly raised. Do

not change the Needle-Valve setting.

pre-set before the engine leaves the factory. If the

original setting is lost, it may be reestablished as

follows: 1. Close the throttle completely. 2. Screw

in the Mixture Control Screw carefully until it

stops. 3. Unscrew the Mixture Control Screw

exactly 2 1/2 turns.

peak

r.p.m. setting.

CARBURETTOR CLEANLINESS

The correct functioning of the carburettor depends on its

small fuel orifices remaining clear. The minute particles of

foreign matter that are present in any fuel, can easily partially obstruct these orifices and upset mixture strength so that

engine performance becomes erratic and unreliable.

O.S. 'Super-Filters'

extras, to deal with this problem. One of these filters, fitted

to the outlet tube inside your refueling container, will prevent the entry of foreign material into the fuel tank. It is also

recommended that a good in-line filter be installed between

the tank and carburettor.

Do

not

forget

lint that accumulate on the filter screens. Also, clean the

carburettor itself occasionally.

If, despite the use of filters, foreign matter should reach the

carburettor, causing it to malfunction, it should be carefully

dismantled and cleaned as follows:

1. Remove complete carburettor from engine. Clean off any

external dirt.

2. Remove throttle stop screw.

3. Withdraw rotor from carburettor body, taking care not to

lose the rotor spring placed behind rotor.

to

(large

clean

and

small)

the

filters regularly

are

available,

to

as

remove

optional

dirt

and

Page 4

4. Remove needle from needle-valve assembly, followed by

hexagonal retaining nut and ratchet spring. Now push

nozzle unit through body from outside.

5. Remove fuel inlet nipple.

6. Immerse parts in solvent (e.g. gasoline, alcohol or carbontetrachloride) and clean thoroughly.

7. Re-assemble in reverse order. Note that periphery of

nozzle flange is specially shaped to key into carburettor

body.

Note:

This carburettor

is

fitted

with a short

tubular

seal

(2.5

mm

bore, 5.0 mm outer dia., 7 mm length) between the needle

and body to prevent air leakage into, or fuel leakage from,

the needle-valve. When the seal becomes worn or damaged

after a long period of use, replace with the spare seal provided, or cut a short piece of silicone fuel tubing as a replacement.

PARTS LIST

Description

Throttle lever assembly

Throttle lever assembly

Throttle lever fixing screw

Throttle lever

Throttle lever

Mixture control screw

"0" ring

Throttle rotor

Rotor spring

Carburettor body

Throttle stop screw (w/nut)

Nipple (w/washer)

Carburettor rubber gasket

Carburettor fixing screws

Needle valve assembly

Needle

Set-screw

Nozzle assembly

Ratchet spring

"0" ring

The specifications are subject to alteration for improvement without notice

c°,8=]-h

Code No.

22981400

22781401

22781420

22981410

22781411

22981600

22781800

22981200

22481506

22981100

22681306

22681953

22615000

23081706

22981900

45181973

26381501

22981960

22611302

24881824

6-15 3-chome Imagawa Higashisumiyoshi-ku

Osaka 546, Japan TEL (06) 702-0225

© Copyright 1992 by O.S. Engines Mfg. Co., Ltd. All rights reserved. Printed in Japan.

FAX (06)704-2722

109301

Loading...

Loading...