Page 1

Factory Packaged Controls

LED BLINK C ODES

LED NAME

STATUS1

STATUS2

NORMAL OPERATION 0 1

OATFAIL 0 2

SATFAIL 1 2

SPC FAIL 3 2

MODULE ALARM 4 2

MECH COOL FAIL 1 3

MECH HEAT FAIL 2 3

FANPROOF FAIL 3 3

DIRTY FILTER 4 3

EMERGENCY SHUTDOWN 5 3

LOW SAT 1 4

HIGH SAT 2 4

CONT. TEMP COOL FAIL 3 4

CONT. TEMP HEAT FAIL 4 4

PUSH BUTTON OVR 1 5

ZONE OVR 2 5

OUTPUT FORCE ACTIVE 0 6

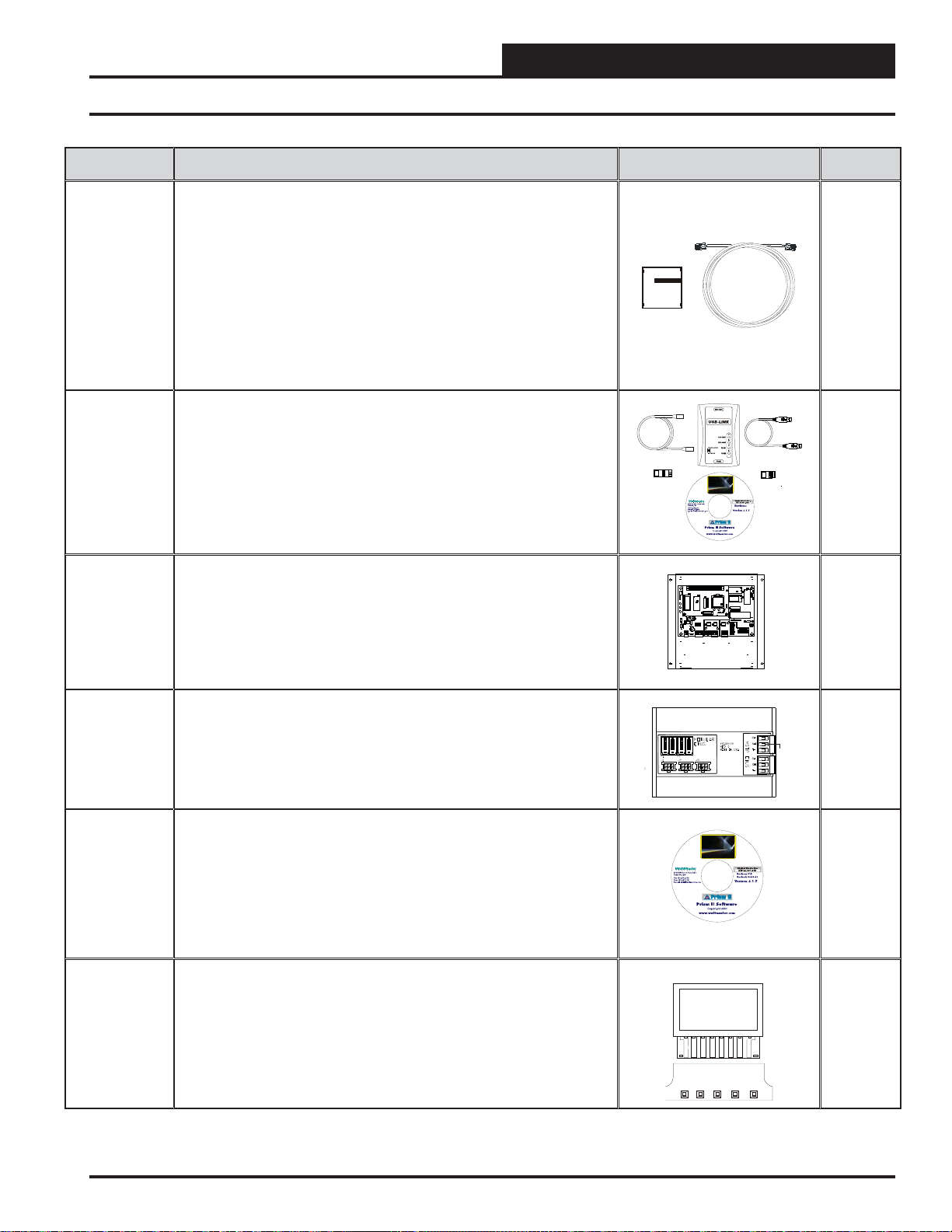

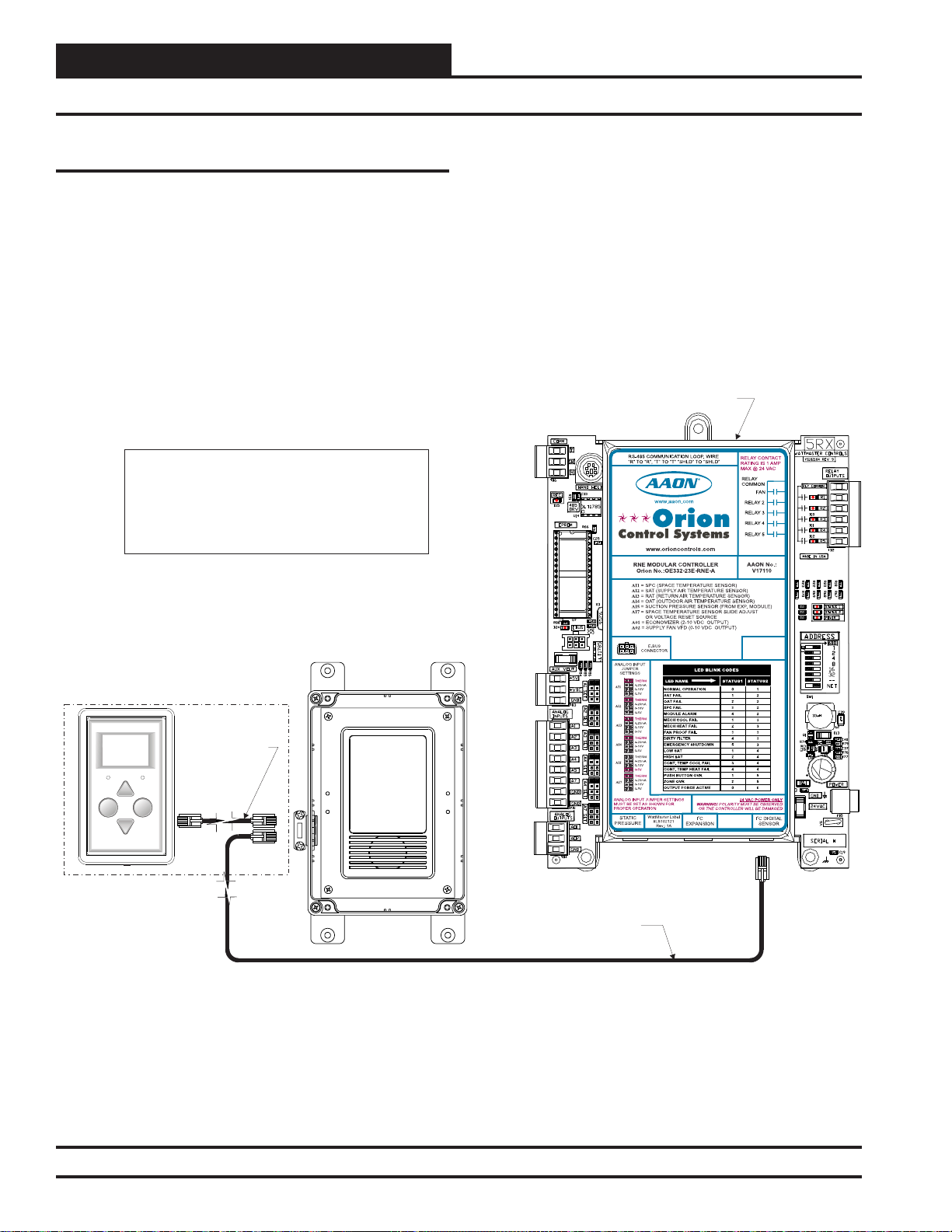

RNE Modular Controller

Technical Guide

RNE Modular Controller: Tulsa - SS1045

Requires Service Tool Code: SS1056 Version 1.0 and up

RS-485 COMMUNICATION LOOP. WIRE

“R” TO “R”, “T” TO “T” “SHLD”TO “SHLD”

www.aaon.com

www.orioncontrols.com

RNE MODULAR CONTROLLER

Orion No.:OE332-23E-RNE-A

AI1 = SPC (SPACE TEMPERATURE SENSOR)

AI2

= SAT(SUPPLY AIR TEMPERATURE SENSOR)

AI3

= RAT(RETURN AIR TEMPERATURE SENSOR)

AI4

= OAT(OUTDOOR AIR TEMPERATURE SENSOR)

AI5

= SUCTION PRESSURE SENSOR (FROM EXP. MODULE)

AI7

= SPACETEMPERATURE SENSOR SLIDE ADJUST

OR VOLTAGE RESETSOURCE

A01

= ECONOMIZER (2-10 VDC OUTPUT)

A02

= SUPPLYFAN VFD (0-10 VDC OUTPUT)

E-BUS

CONNECTOR

ANALOG INPUT

JUMPER

SETTINGS

THERM

4-20mA

AI1

0-10V

0-5V

THERM

4-20mA

AI2

0-10V

0-5V

THERM

4-20mA

AI3

0-10V

0-5V

THERM

4-20mA

AI4

0-10V

0-5V

THERM

4-20mA

AI5

0-10V

0-5V

THERM

4-20mA

AI7

0-10V

0-5V

ANALOG INPUT JUMPER SETTINGS

MUST BE SETAS SHOWN FOR

PROPER OPERATION

WattMaster Label

STATIC

#LB102121

PRESSURE

Rev.: 1A

EXPANSION

WARNING!POLARITY MUST BE OBSERVED

OR THE CONTROLLER WILL BE DAMAGED

2

IC

RELAYCONTACT

RATING IS 1AMP

MAX @ 24 VAC

RELAY

COMMON

FAN

RELAY2

RELAY3

RELAY4

RELAY5

AAON No.:

V17110

24 VAC POWER ONLY

2

I C DIGITAL

SENSOR

Page 2

TABLE OF CONTENTS

OVERVIEW ............................................................................................................................................................4

Features and Applications ..............................................................................................................................4

Part Number Cross Reference ........................................................................................................................6

Parts and Descriptions ....................................................................................................................................7

RNE Controller Dimensions .........................................................................................................................13

VCM-X Expansion Module for RNE Dimensions .........................................................................................14

12-Relay Expansion Module Dimensions ..................................................................................................15

4 Binary Input Expansion Module Dimensions .........................................................................................15

RNE Controller Component Locations ........................................................................................................16

INST ALLATION AND WIRING .............................................................................................................................17

Important Wiring Considerations .................................................................................................................17

RNE Controller Wiring ..................................................................................................................................18

Digital Room Sensor ...................................................................................................................................19

Wall Mounted Space CO

Duct Mounted CO2 Sensor ..........................................................................................................................20

Space Temperature Sensor ........................................................................................................................21

Remote SAT Reset Signal ..........................................................................................................................21

Supply Air & Return Air Temperature Sensor ..............................................................................................22

Outdoor Air Temperature Sensor ................................................................................................................23

Economizer Damper Actuator .....................................................................................................................24

Supply Fan VFD Signal or Zoning Bypass Damper Actuator Signal ...........................................................25

VCM-X Expansion Module Input Wiring for the RNE Controller ................................................................26

VCM-X Expansion Module Output Wiring for the RNE Controller .............................................................27

8 Binary Inputs ............................................................................................................................................28

4 Binary Inputs ............................................................................................................................................29

Outdoor Air Humidity Sensor ......................................................................................................................30

Indoor Wall-Mounted Humidity Sensor .......................................................................................................31

Return Air Mounted Humidity Sensor ..........................................................................................................32

Title 24 Economizer Actuator Feedback .....................................................................................................33

Building Pressure Sensor ...........................................................................................................................33

Building Pressure Control Output ...............................................................................................................34

Modulating Heating Device .........................................................................................................................35

Modulating Chilled Water Valve ..................................................................................................................36

Return Air Bypass .......................................................................................................................................37

12-Relay Expansion Module Wiring and Jumper Settings .........................................................................38

Airfl ow Monitoring Station Installation and Wiring ....................................................................................39

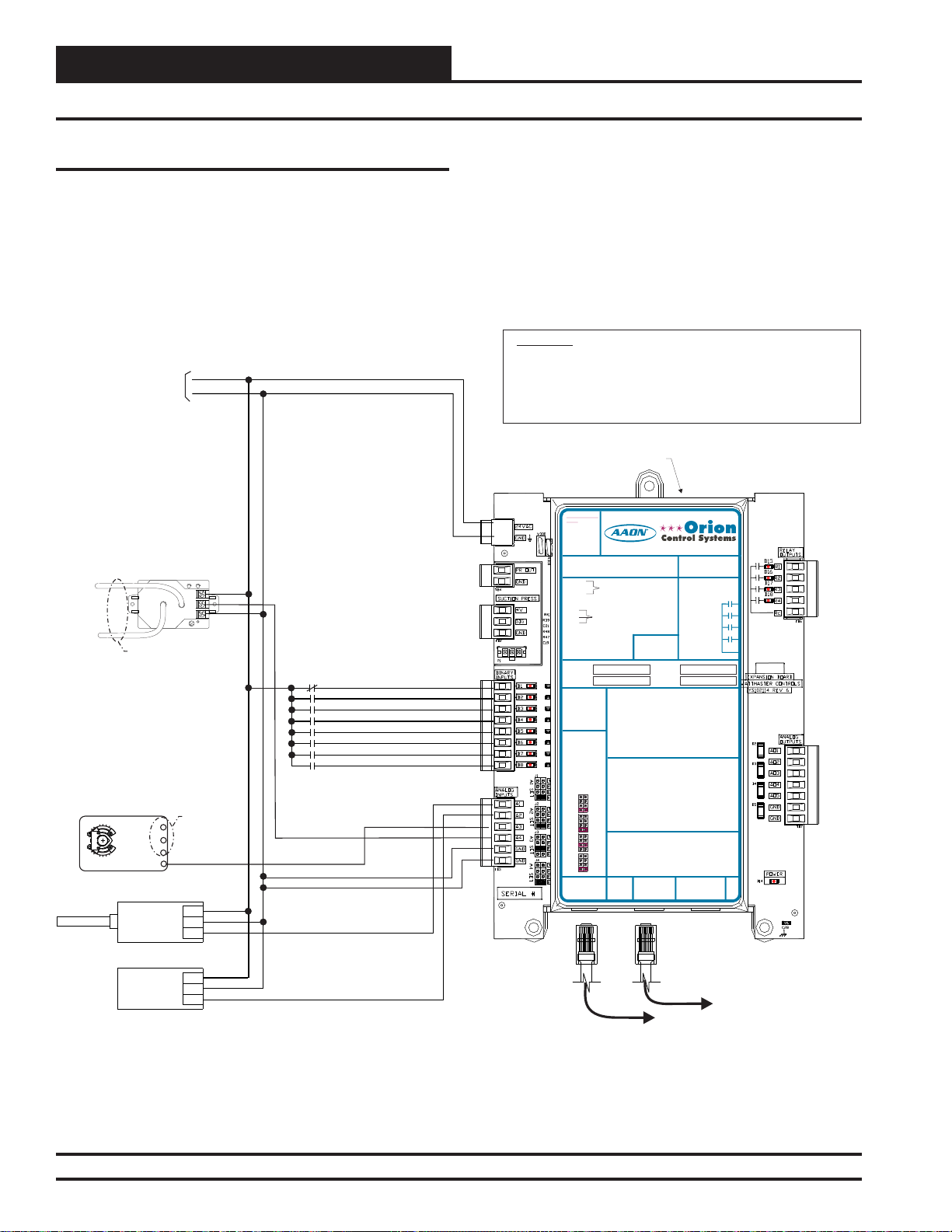

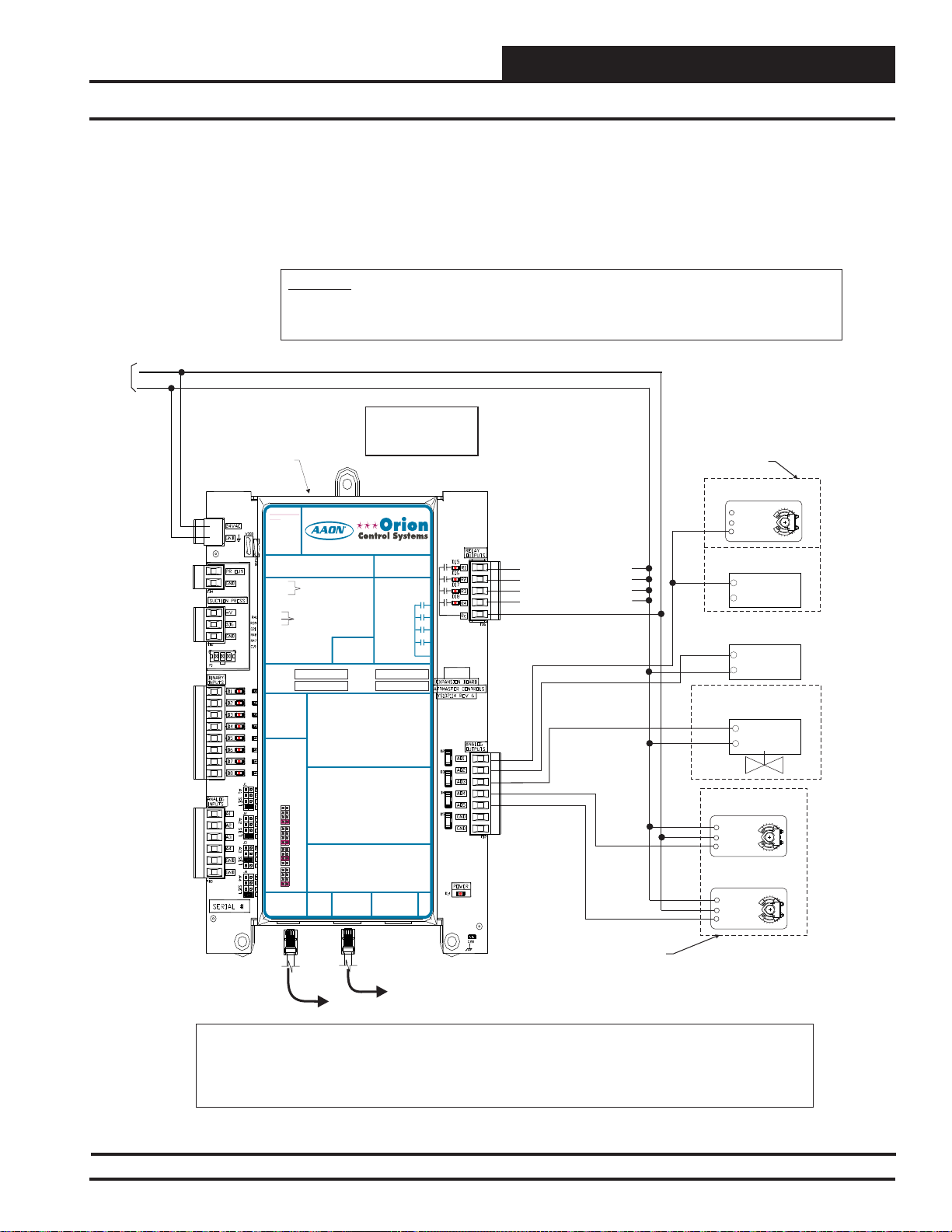

RNE 55 - 105 Ton Unit Two Compressors Wiring ........................................................................................40

Full Digital Module ......................................................................................................................................40

Water Source Heat Pump X-2 Module ........................................................................................................41

Two Condenser Head Pressure Module II ..................................................................................................42

Sensor ...............................................................................................................19

2

WattMaster Controls Inc.

8500 NW River Park Drive · Parkville , MO 64152

Toll Free Phone: 866-918-1100

PH: (816) 505-1100 · FAX: (816) 505-1101

E-mail: mail@wattmaster.com

Visit our web site at www.orioncontrols.com

WattMaster Form: AA-RNE-TGD-01H

Copyright March 2015 WattMaster Controls, Inc.

www.aaon.com

AAON Manual Part Number: V20490

AAON® is a registered trademark of AAON, Inc., Tulsa, OK.

EBTRON® is a registered trademark of Ebtron, Inc., Loris, SC.

Neither WattMaster Controls, Inc. nor AAON®

assumes any responsibility for errors or omissions in this document.

This document is subject to change without notice.

Page 3

TABLE OF CONTENTS

RNE 120 - 140 Ton Unit Four Compressors Wiring .....................................................................................43

Full Digital Module ......................................................................................................................................43

Water Source Heat Pump X-2 Module ........................................................................................................44

Two Condenser Head Pressure Module II ..................................................................................................46

START UP AND COMMISSIONING ....................................................................................................................48

Addressing & Powering Up ...........................................................................................................................48

Programming the Controller .........................................................................................................................49

INPUTS AND OUTPUTS .....................................................................................................................................50

RNE Controller Inputs ....................................................................................................................................50

RNE Controller Outputs .................................................................................................................................50

Expansion Module Inputs & Outputs ...........................................................................................................51

4 Binary Input Expansion Module ................................................................................................................52

12-Relay Expansion Module ..........................................................................................................................52

SEQUENCE OF OPERATION .............................................................................................................................53

Operation Modes ...........................................................................................................................................53

Occupied/Unoccupied Mode of Operation ..................................................................................................53

HVAC Modes of Operation ..........................................................................................................................53

Vent Mode and Cooling Mode .....................................................................................................................53

Economizer Operation ................................................................................................................................55

Supply Air Tempering .................................................................................................................................55

Dehumidifi cation Mode ...............................................................................................................................56

Heating Mode ..............................................................................................................................................58

Morning Warm Up .......................................................................................................................................60

Head Pressure Control ...............................................................................................................................61

Remote Control of HVAC Mode ..................................................................................................................61

Supply Air Temperature Setpoint Reset ......................................................................................................61

Air Flow Monitoring/Control .........................................................................................................................62

Supply Fan Control .....................................................................................................................................62

Duct Static Pressure Control .......................................................................................................................62

Duct Static Pressure Control for Filter Loading ...........................................................................................63

Building Pressure Control ...........................................................................................................................63

CAV/MUA Dual Mode (Hood On/Off Operation) .........................................................................................63

MUA Unoccupied Operation .......................................................................................................................63

IAQ (CO

Pre-Heater Operation ..................................................................................................................................64

Heat Wheel .................................................................................................................................................64

Single Zone VAV Mode ...............................................................................................................................64

Outdoor Air Lockouts ..................................................................................................................................65

Supply Air Cutoffs .......................................................................................................................................65

RNE Controller Alarms ................................................................................................................................66

VAV/Zone Controller Alarms ........................................................................................................................67

Scheduling ..................................................................................................................................................68

Internal Trend Logging ................................................................................................................................68

Force Modes or Overrides ..........................................................................................................................69

VAV Terminal Unit Controller Compatibility .................................................................................................69

VAV/Zone System .......................................................................................................................................69

) Operation ...................................................................................................................................64

2

TROUBLESHOOTING .........................................................................................................................................70

APPENDIX ...........................................................................................................................................................76

System Confi gurations ..................................................................................................................................77

INDEX...................................................................................................................................................................80

RNE Modular Controller Field Technical Guide

3

Page 4

OVERVIEW

Features and Applications

Features

The RNE Modular Controller (OE332-23E-RNE-A) is designed with 7

analog inputs, 2 analog outputs, and 5 relay outputs. Each RNE Controller’s input and output capabilities can be expanded with the VCM-X

Expansion Module (OE333-23-EM), the 12 Relay Expansion Module

(OE358-23-12R), and the 4 Binary Input Expansion Module (OE35601-BI) by means of a modular cable.

The RNE Controller also allows various E-BUS modules to connect

directly to it. These would include the Full Digital Module, the Two

Condenser Head Pressure Module, and the Water Source Heat Pump

Modules.

Each RNE Controller can be confi gured for control of VAV Units (with

or without VAV/Zone Controllers), Constant Volume Units, and MakeUp Air Units. Features include the following:

• Up to a Combined Total of 20 Stages of Heating & Cooling

• Modulating Cooling Outputs (VFD Compressor or Chilled

Water Valve Control)

• Modulating Heating Output ( Hot Water Valve,

Steam Valve, SCR Electric Heat Control)

• Full Integration with the AAON

Natural Gas Controller

• Full Integration with the AAON

Hot Gas Reheat Controller

®

MODGAS-X Modulating

®

MHGRV-X Modulating

• Confi gurable for Heat Pump Applications

• Advanced Dehumidifi cation Capabilities

• Air Flow Monitoring of Outdoor Air, Supply Air,

and Return Air Streams

• Air Flow Control of Outdoor Air Damper

• Single Zone VAV Control

• Primary/Secondary Heating Control

• Adaptive Supply Air Reset

• Selectable Control Sensor

• Fan Proving Interlock

• Dirty Filter Alarm

• Emergency Shutdown Input (Smoke Detector/Firestat or

other Shutdown Conditions)

• Drybulb/Wetbulb Control of Economizer Operation

• Building Pressure Control

• Remote Override Capabilities

• IAQ Economizer Reset

• Title 24 Economizer Certifi ed

• 7-Day, 2-Event-per-Day Scheduling

• 14 Holiday Event Scheduling

• Optimal Start Scheduling

• Trend Logging Capability

• Static Pressure Control for Filter Loading Applications

• Accepts Remote HVAC Mode Selection Via Contact

Closure On VCM-X Expansion Module

• Confi gurable for AAON

®

PAC and DPAC Applications

• Heat Wheel - On/Off Control

• Confi gurable for R22 and R410-A refrigerant

• Head Pressure Control

• Full Digital Control

• Water Source Heat Pump Monitoring

Most common HVAC unit control applications can be confi gured using

only the RNE Controller. If the application requires more inputs and/

or outputs, optional expansion modules are available to provide for additional analog, binary, or digital inputs and outputs as required.

The available expansion module confi gurations allow for 4 or 8 addition-

al binary inputs, 4 additional analog inputs, 5 additional analog outputs,

and up to 16 additional binary (relay) outputs. The various expansion

modules plug into the RNE Controller by means of a modular cable.

4

RNE Modular Controller Field Technical Guide

Page 5

OVERVIEW

Features and Applications

E-BUS Module Applications

The RNE Controller will interface with the Two Condenser Head

Pressure Module (OE370-23-HP2C2-A), the Full Digital Module

(OE370-23-FD-A), and the W ater Source Heat Pump Modules (OE33423-WPM-A, OE334-23-WPM-A20, OE334-23-WPM-A25, OE33423-WPM-A40, and OE334-23-WPM-22-A).

These E-BUS Modules allow independent control of multiple VFD

compressors, control of the condenser fan(s) or valve(s), and monitoring

functions for Water Source Heat Pump Units. See pages 40-47 of this

manual for detailed wiring and application details.

RNE Controller Applications

Variable Air Volume Unit

The RNE Controller can be confi gured to control a VFD Supply Fan

for Duct Static Pressure control. If the unit is not equipped with a VFD,

but Duct Static Pressure control is needed, a modulating Zoning Bypass

Damper can be controlled by the RNE Controller.

VAV units are typically designed for occupied Cooling with Morning

Warm-up Heating. This option is available with the RNE Controller.

The RNE Controller can also be used for a Zoning System that needs

Duct Static Pressure control and Occupied Cooling and Heating. The

RNE Controller also has the ability to be confi gured for Duct Static

Pressure Control by controlling the Supply Fan VFD for the purpose

of maintaining proper Duct Static Pressure in response to varying fi lter

loading conditions.

The RNE Controller allows Dehumidifi cation Priority on a VAV unit.

This could be useful on a building with a very low internal sensible

load, but which has a high internal and/or external latent load. During

VAV Dehumidifi cation, the RNE Controller activates Cooling based on

the Evaporator Coil Temperature and activates AAON® Modulating Hot

Gas Reheat to warm the Supply Air Temperature to the Active Supply

Air Temperature Setpoint.

Constant Air Volume Unit

The RNE Controller can be confi gured to activate a Constant Volume

Supply Fan. In most cases, this is a very basic unit with Space T emperature control. The RNE Controller can be used for kitchen, restaurant, or

lab environments that are 100% Outdoor Air part of the time and Return

Air part of the time. The Hood On input allows the RNE Controller to

know when to switch to 100% Outdoor Air control based on an exhaust

hood activating. The RNE Controller requires Outdoor and Indoor Air

Temperature Sensors to accomplish this application.

Make-Up Air Unit

The RNE Controller can be confi gured for 100% Outdoor Air control

for Make-Up Air. All HVAC Modes are determined from the Outdoor

Air Sensors. The Outdoor Air Volume must always be at least 50% or

higher to be confi gured for Outdoor Air control.

AAON® PAC (Precision Air Control)

This control scheme can only be used on Constant Volume HVAC units

that are equipped with a Return Air Bypass Damper and that use a Space

Temperature Sensor as the Controlling Sensor.

AAON® P AC Control provides improved moisture removal capabilities

while utilizing internal space loads for reheat by redirecting the Return

Air path from the upstream side of the DX Evaporator Coil to the downstream side of the coil.

For AAON® P AC confi gured units, the Return Air Bypass Damper is only

used during the Dehumidifi cation Mode. When the RNE Controller is in

Dehumidifi cation Mode, the Return Air Bypass Damper will modulate

open as the Space T emperature falls below the Cooling Setpoint. Modulation of the Return Air Bypass Damper is controlled using a proportional

range from 0% (when the Space Temperature is equal to the Cooling

Setpoint) up to 100% (when the Space T emperature falls to the halfway

point between the Cooling and Heating Setpoints). A separate Return Air

Damper Actuator will modulate the Return Air Damper slightly further

towards its closed position as the Return Air Bypass Damper opens. This

is to ensure that enough Return Air is bypassed around the Evaporator

Coil through the Return Air Bypass Damper to raise its temperature. The

rate which the Return Air Damper closes while the Return Air Bypass

Damper is open is user-adjustable.

AAON® DPAC (Digital Precision Air Control)

This control scheme can only be used on Constant Volume HVAC

units that are equipped with a Return Air Bypass Damper and VFD

Compressor(s). AAON® DPAC also uses a Space Temperature Sensor

as the Controlling Sensor.

The AAON® DP AC control scheme provides improved moisture removal

capabilities over the AAON® P AC control scheme and provides for tighter

temperature control by combining a VFD Compressor with the Return

Air Bypass Damper. See the Cooling Mode section starting on page 53

for detailed VFD Compressor operation. Refer to AAON® P AC Control

previously described for detailed Return Air Bypass Damper operation.

The VFD Compressor is used during both Cooling and Dehumidifi ca-

tion Modes. The Return Air Bypass Damper is used only during the

Dehumidifi cation Mode.

RNE Modular Controller Field Technical Guide

5

Page 6

OVERVIEW

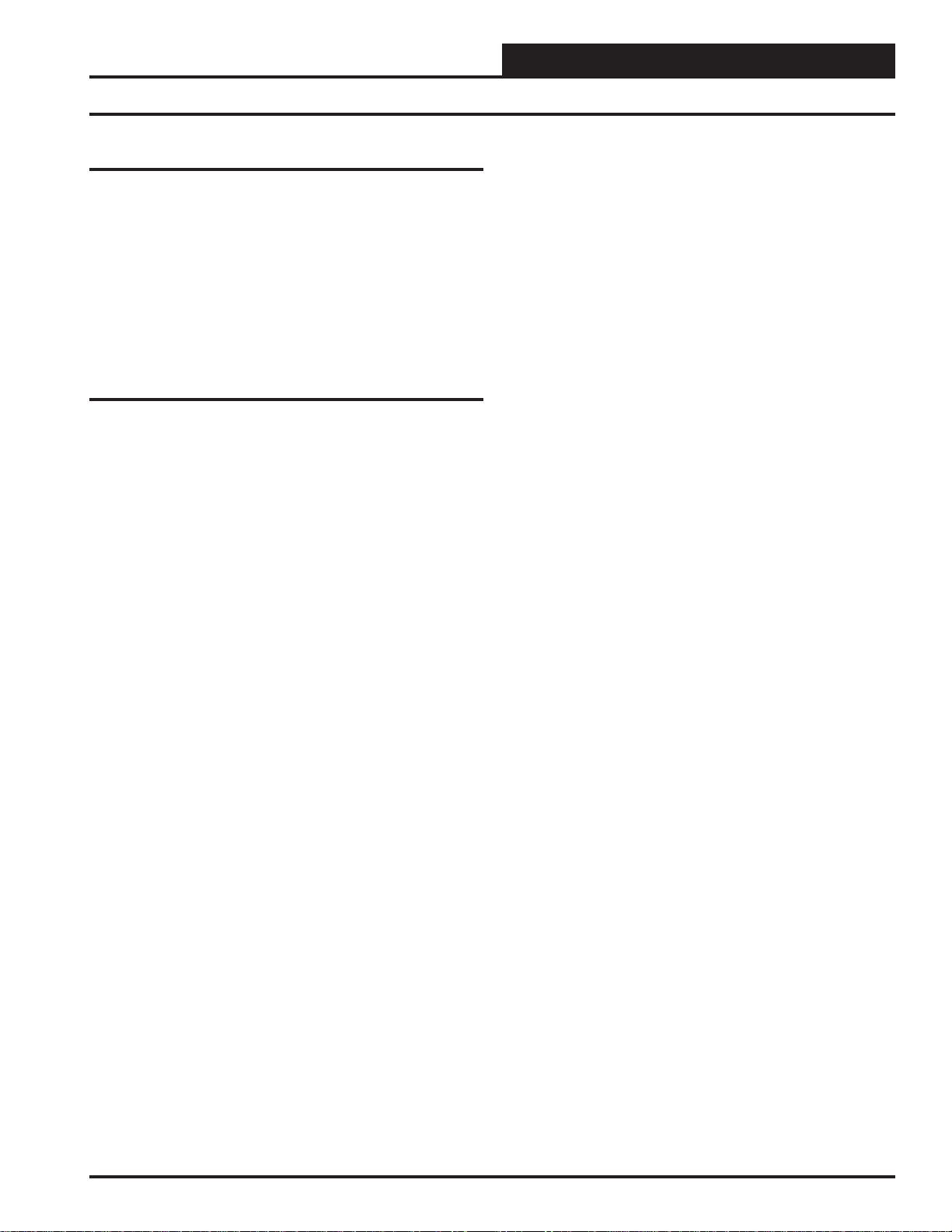

Part Number Cross Reference

PART DESCRIPTION

RNE Modular Controller OE332-23E-RNE-A V17110

VCM-X Expansion Module OE333-23-EM R69190

VCM-X 12-Relay Expansion Module OE358-23-12R R69180

VCM-X 4 Binary Input Expansion Module OE356-01-BI R82940

Full Digital Module OE370-23-FD-A R74870

Two Condenser Head Pressure Module II OE370-23-HP2C2 V20660

WSHP-X2 Module OE334-23-WSHP-X2 V48820

MHGRV-X Module OE377-00-00042 N/A

MODGAS-X Module OE377-00-00041 N/A

Building Static Pressure Sensor OE258-01 R37030

Bypass Damper Actuator OE281-04 N/A

Cable Coupler for TSDRSC Cables MS000029 N/A

CO

Sensor - Duct Mounted OE256-02 R82970

2

CO

Sensor - Space OE256-01 R82960

2

CommLink 5 Communications Interface OE361-13 V32950

Digital Room Sensor - Temp & Humidity OE217-01 R83870

Digital Room Sensor - Temp. Only OE217-00 R83860

Digital Sensor Cable Assembly TSDRSC-XX N/A

Duct Static Pressure Sensor OE271 P87100

Duct Temperature Sensor - 12" Probe OE231 R44940 / P87140

Duct Temperature Sensor - 6" Probe OE230 R36340

E-BUS Adapter Board OE365-15-EBA V15840

GPC-X Controller OE332-23-GPCX N/A

IP Module Kit OE415-02 R66770

MiniLink Polling Device OE364-22 N/A

Modular Service Tool SD - Operator Interface OE391-12 V28140

Modular System Manager SD - Operator Interface OE392-12 V36570

Outdoor Air RH Sensor - 3% - 0-5 VDC Output OE265-13 R34700

Outdoor Air Temperature Sensor OE250 P87150

Return Air RH Sensor - 3% - 0-5 VDC Output OE265-14 R34650

Room Mounted RH Sensor - 3% - 0-5 VDC Output OE265-11 R34690

Standard Room Sensor - Plain OE210 R31480

Standard Room Sensor - W/ Override OE211 P87040

Standard Room Sensor - W/ Override & Slide Adjust OE213 P94320

Standard Room Sensor - W/ Slide Adjust OE212 P94100

Static Pressure Pickup Tube OE290 S18780

Suction Pressure Transducer OE275-01 N/A

System Manager TS II - Operator Interface OE392-10 N/A

USB-Link 2 Kit OE366 R71870

ORION

PART NUMBER

AAON TULSA

PART NUMBER

6

RNE Modular Controller Field Technical Guide

Page 7

OVERVIEW

Parts and Descriptions

PART NO. PART DESCRIPTION ILLUSTRATION

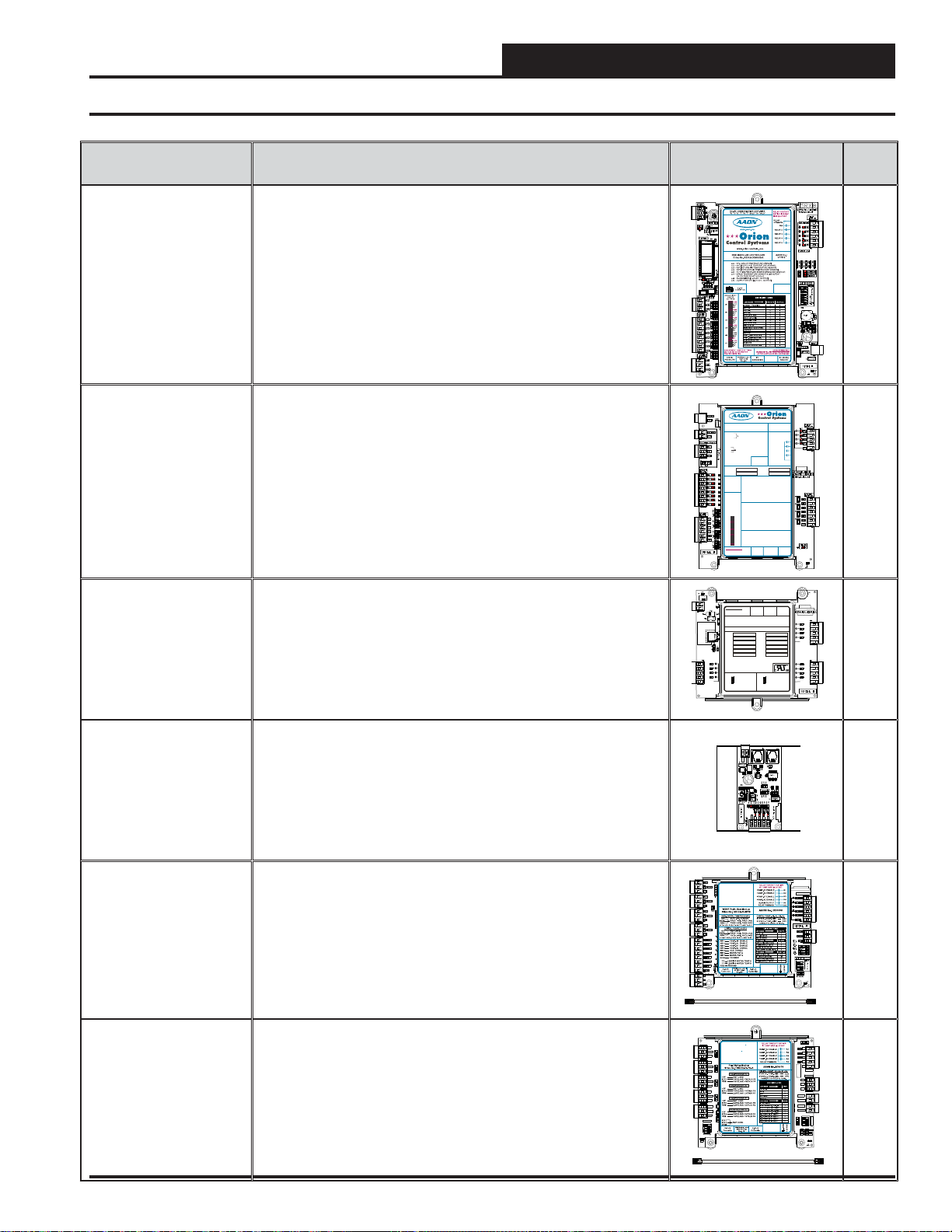

OE332-23E-RNE-A RNE Controller

The RNE Controller provides 7 analog inputs, 2 analog outputs, and 5

relays. It presently allows for the addition of the VCM-X Expansion Module, the 12 Relay Expansion Module, and hte 4 Binary Input Expansion

Module described below.

NOTE: Set-up, programming, and monitoring of the RNE Controller

requires one of the following communication interfaces—Prism 2 FrontEnd Software used with a personal computer, System Manager Touch

Screen II, or Modular Service Tool.

OE333-23-EM VCM-X Expansion Module

Includes: VCM-X Expansion Module mounted in plastic enclosure and

10 ft. I2C cable. The VCM-X Expansion Module adds VAV applications,

building pressure control, head pressure control, water source heat

pump monitoring, and other functions. It provides 4 additional analog

inputs, 2 binary inputs, 5 additional relays, and 3 analog outputs. It

connects with a modular cable to the RNE Controller.

OE358-23-12R VCM-X 12 Relay Expansion Module

Includes: 12 Relay Expansion Module mounted in plastic enclosure

and 10 ft. I2C cable. The VCM-X 12 Relay Expansion Module adds 12

confi gurable relays to the RNE Control System. It connects to the RNE

Controller using the included I2C cable.

POLARITY

WARNING

OBSERVE

POWER

24VAC

GND

EXP1

EXP2

RLY1

RLY2

RLY3

RLY4

RLYCOM

MADE IN USA

24 VAC POWER ONLY

WARNING!POLARITYMUST BE

OBSERVED OR THE BOARD

WILLBE DAMAGED

VCM-X Expansion Module

Orion No.:OE333-23-EM

PR OUT

GND

OE333-23-EM-AVCM-X EXPANSION MODULE

PR OUT

GND

+V

SIG

GND

+V

SIG

GND

RELAY1 = RELAY3 =

RELAY2 = RELAY4 =

RELAY1 = RELAY3 =

ITIS SUGGESTED

THATYOU WRITETHE

DESCRIPTION OF

RELAY2 = RELAY4 =

THE RELAYOUTPUTS

YOUARE USING IN

THE BOXES

ITIS SUGGESTED

PROVIDEDABOVE

THATYOU WRITETHE

WITHAPERMANENT

DESCRIPTION OF

MARKER (SHARPIE®)

THE RELAYOUTPUTS

YOUARE USING IN

THE BOXES

PROVIDEDABOVE

WITHAPERMANENT

ANALOG INPUT

MARKER (SHARPIE®)

JUMPER SETTINGS

MUSTBE SETAS

SHOWN FOR

PROPER

ANALOG INPUT

OPERATION

JUMPER SETTINGS

MUSTBE SETAS

SHOWN FOR

ANALOG INPUT

PROPER

JUMPER

OPERATION

SETTINGS

ANALOG INPUT

AI1

JUMPER

SETTINGS

AI1

AI2

AI2

AI3

AI3

AI4

AI4

24 VAC POWER ONLY

WARNING!POLARITYMUST BE

OBSERVED OR THE BOARD

WILLBE DAMAGED

24 VAC POWER ONLY

WARNING!POLARITYMUST BE

OBSERVED OR THE BOARD

WILLBE DAMAGED

OE358-23-12R 12 RELAYEXPANSION MODULE

RLY1 = RLY7 =

RLY2 = RLY8 =

RLY3 = RLY9 =

RLY4 = RLY10 =

RLY5 = RLY11 =

RLY6 = RLY12 =

NOTE:

ITIS RECOMMENDEDTHAT YOU WRITE THE

DESCRIPTION OFTHE RELAYOUTPUTS YOU

ARE CONNECTINGTOTHE RELAY EXPANSION

MODULE INTHE BOXES PROVIDEDABOVE

USINGAPERMANENT MARKER (SHARPIE)

FOR FUTURE REFERENCE.

J1

EXP1

EXP2

I2C

EXPANSION

www.aaon.com

TO VCM-X INPUT

TERMINALSAI5 & GND

TO VCM-X INPUT

TERMINALSAI5 & GND

SUCTION PRESSURE

TRANSDUCER CONNECTION

FOR HVAC UNITS WITHOUT

DIGITALCOMPRESSOR

SUCTION PRESSURE

TRANSDUCER CONNECTION

FOR HVAC UNITS WITHOUT

DIGITALCOMPRESSOR

BI1= EMERGENCYSHUTDOWN - N.C. INPUT

= DIRTYFILTER - N.O. INPUT

BI2

= PROOF OF FLOW - N.O. INPUT

BI3

= REMOTE FORCED OCCUPIED - N.O. INPUT

BI4

BI1= HOOD ON - N.O. INPUT

= REMOTE FORCED HEATING - N.O. INPUT

BI5

BI2

= DIRTYFILTER - N.O. INPUT

= REMOTE FORCED COOLING - N.O. INPUT

BI6

BI3

= PROOF OF FLOW - N.O. INPUT

= HOOD ON - N.O. INPUT

BI7

BI4

= REMOTE FORCED OCCUPIED - N.O. INPUT

= REMOTE DEHUMIDIFICATION - N.O. INPUT

BI8

= REMOTE FORCED HEATING - N.O. INPUT

BI5

= REMOTE FORCED COOLING - N.O. INPUT

BI6

NOTE:

= SMOKE DETECTOR - N.C. INPUT

BI7

ALLBINARYINPUTS MUST BE 24 VAC ONLY.

= REMOTE DEHUMIDIFICATION - N.O. INPUT

BI8

NOTE:

AO1=BUILDING PRESSURE CONTROL VFD OR

ALLBINARYINPUTS MUST BE 24 VAC ONLY.

DAMPERACTUATOR (0-10 OR 2-10 VDC)

AO2

= MODULATING HEATING SIGNAL

(0-10 VDC OR 2-10 VDC)

AO1=BUILDING PRESSURE CONTROL VFD OR

AO3

= MODULATING COOLING/DIGITALSCROLL

DAMPERACTUATOR (0-10 OR 2-10 VDC)

SIGNAL(0-10 VDC, 2-10 VDC OR 1.5-5 VDC)

= MODULATING HEATING SIGNAL

AO2

THERM

AO4

= RETURNAIR DAMPERACTUATOR

(0-10 VDC OR 2-10 VDC)

4-20mA

(0-10 VDC)

0-10V

= MODULATING COOLING/DIGITALSCROLL

AO3

AO5

= RETURNAIR BYPASS DAMPERACTUATOR

0-5V

SIGNAL(0-10 VDC, 2-10 VDC OR 1.5-5 VDC)

(0-10 VDC)

THERM

= RETURNAIR DAMPERACTUATOR

AO4

THERM

GND

= GROUND FORANALOG OUTPUTS

4-20mA

4-20mA

(0-10 VDC)

0-10V

GND

= GROUND FORANALOG OUTPUTS

0-10V

= RETURNAIR BYPASS DAMPERACTUATOR

AO5

0-5V

0-5V

(0-10 VDC)

THERM

THERM

= GROUND FORANALOG OUTPUTS

GND

AI1= OUTDOORAIR RH SENSOR (0-5 VDC)

4-20mA

4-20mA

= GROUND FORANALOG OUTPUTS

GND

0-10V

AI2

= INDOORAIR RH SENSOR (0-5 VDC)

0-10V

0-5V

0-5V

A3

= ECONOMIZER FEEDBACK

I

THERM

AI4

= BUILDING STATIC PRESSURE (0-5 VDC)

THERM

AI1= OUTDOORAIR RH SENSOR (0-5 VDC)

4-20mA

4-20mA

GND

= GROUND FORANALOG INPUTS

AI2

= INDOORAIR RH SENSOR (0-5 VDC)

0-10V

0-10V

GND

= GROUND FORANALOG INPUTS

0-5V

AI3

= CO2 (0-10 VDC)

0-5V

AI4

= BUILDING STATIC PRESSURE (0-5 VDC)

THERM

4-20mA

GND

= GROUND FORANALOG INPUTS

0-10V

= GROUND FORANALOG INPUTS

GND

I2C

0-5V

EXPANSION

I2C

EXPANSION

SETJUMPERAS

SHOWN WHEN

ONLY

THE 12 RELAY

EXPANSION MODULE

IS USED

EXP1

EXP2

WattMaster Label

#LB102034-01

www.orioncontrols.com

www.orioncontrols.com

WattMaster Label

#LB102034-01-A

Rev.: 1K

WattMaster Label

#LB102043

www.orioncontrols.com

®

J1

SETJUMPERAS

SHOWN WHEN BOTH

THE VCM EXPANSION

MODULEANDTHE

RELAYEXPANSION

MODULEARE USED

AAON No.:

R69190

RELAYCONTACT

RATING IS 1AMP

MAX @ 24 VAC

RELAYCONTACT

RATING IS 1AMP

MAX @ 24 VAC

RELAY1

RELAY2

RELAY

RELAY3

COMMON

RELAY4

RELAY

COMMON

PAGE

NO.

Page

18

OBSERVE

WARNING

POLARITY

I2C

EXPANSION

RELAY1

RELAY2

RELAY3

RELAY4

VCM

I2C

EXPANSION

RELAY

I2C

EXPANSION BOARD

EXPANSION

YS102228 REV 1

RLY5

RLY6

RLY7

RLY8

RLYCOM

RLY9

RLY10

RLY11

RLY12

RLYCOM

Pages

26-28

Page

38

OE356-01-BI VCM-X 4 Binary Input Expansion Module

Includes: 4 Binary Input Expansion Module mounted in Snap Track and

10 ft. I2C cable. Use the 4 Binary Input Expansion Module if your HVAC

unit only requires a Smoke Detector/Firestat, Dirty Filter, Proof of Flow,

or Remote Forced Occupied Inputs or all of these 4 inputs and you don’t

need any of the other inputs or outputs provided by the OE333-23-EM

VCM-X Expansion Module. The module connects to the RNE Controller

using the included I2C cable.

OE334-23-WSHP-X2 Water Source Heat Pump X2 Module

Includes: Water Source Heat Pump X2 Module in a plastic enclosure

with LCD display and E-BUS Modular cable. Provides monitoring and

compressor control for AAON Tulsa Water Source Heat Pump Units.

Used with the RNE Controller.

OE370-23-FD-A Full Digital Module

Includes: Full Digital Module in a plastic enclosure and E-BUS Modular

cable.Used with the RNE Controller. For AAON Tulsa units with multiple

Digital Scroll Compressors and that are not Water Source Heat Pump

Units.

RNE Modular Controller Field Technical Guide

GND

24VAC

Page

VCM BIN EXPBOARD

PWR

YS102364 REV1

COM

BI3

BI4

BI1

BI2

Y102374 REV 0S

WATTMASTER CONTROLS

MADE IN USA

29

Pages

41,44

R12

R53

R54

R11

4751

4751

4751

4751

TB3

+5V

1003

SIG 1

1002

10uF

GND

+5V

1003

www.orioncontrols.com

SIG 2

1002

10uF

GND

C2

+5V

1003

SIG 3

1002

10uF

GND

+5V

1003

SIG 4

1002

10uF

GND

4

R7

R9

300

BIN 1

4

R13

R14

BIN 2

300

1002

R23

COM

1002

R24

1002

R25

1002

R26

ADDRESS

1

OFF

2

4

8

SW1

PWR

D3

R1

D4

R2

D12

R3

D13

R4

Rc

RELAYS

SERIAL#

ANALOG

AO1

AO2

GND

PWM1-

PWM1+

R34 R50

PWM2-

PWM2+

SW2

1002

OFF

1002

1002

1002

R30

ALARM

R29

STAT

R28

COMM

C20

.01uF

Pages

40,43

OPTIONS

7

Page 8

OVERVIEW

Parts and Descriptions

PART NO. PART DESCRIPTION ILLUSTRATION

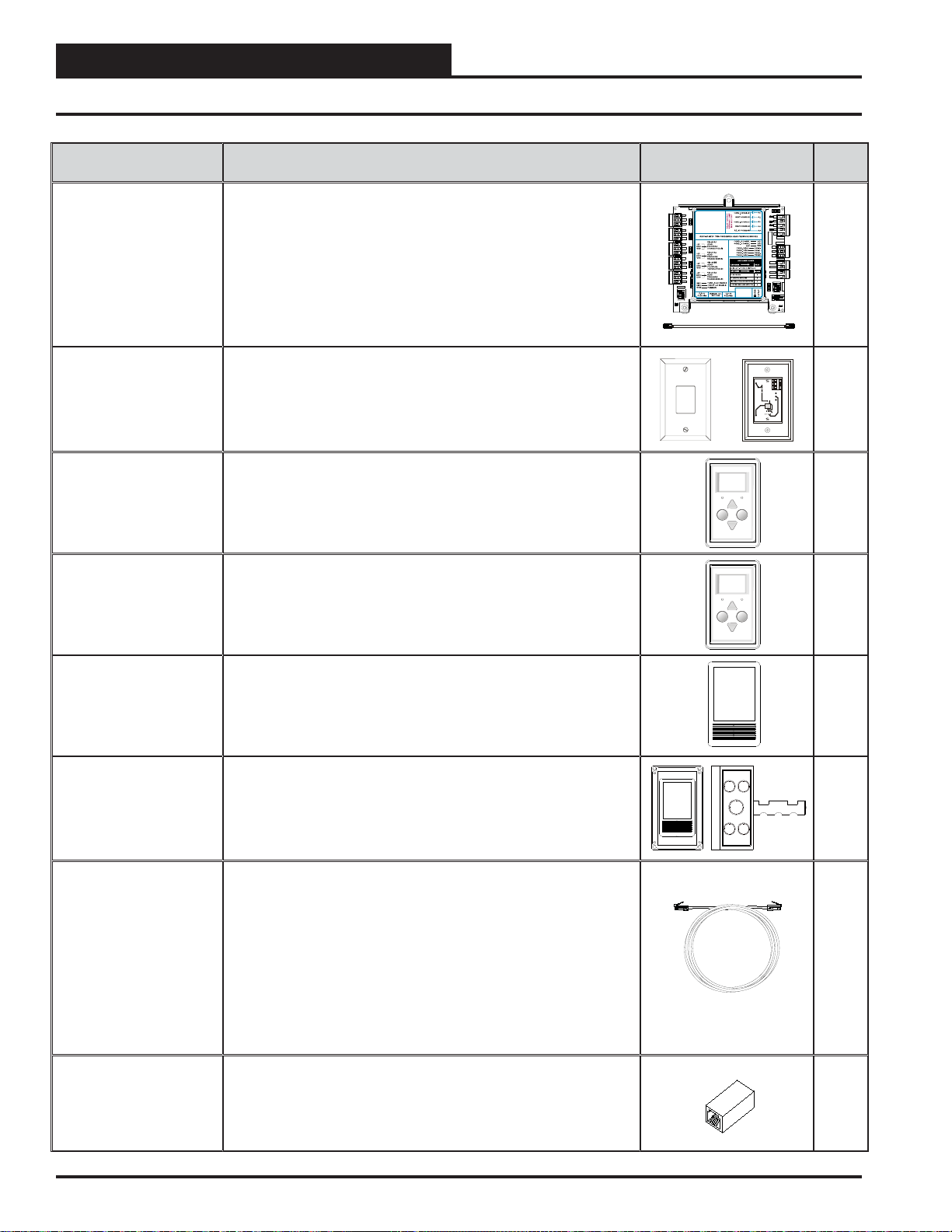

OE370-23-HP2C2-A Two Condenser Head Pressure Module

Includes: Two Condenser Head Pressure Module in a plastic enclosure

and E-BUS Modular Cable. This module is used on units with 2 physically separate condenser sections and is able to monitor up to 4 individual

head pressure transducers (2 per section) to control the Condenser

Fans or Water Valves based on the highest of the 2 readings for each

section. It is also capable of monitoring a Heating Enable control signal

(Heat Pump Mode) and forces the Condenser Signal to 100% while in

this mode. This module can be used as a communicating module with

the RNE Controller.

OE210

OE211

OE212

OE213

Standard Room Sensor–Plain, w/Override,

w/Override & Slide Adjust & w/Slide Adjust Only

Includes: Standard Room Sensor - Plain, with Override, with Override

and Slide Adjust & with Slide Adjust only. For wall mounting. Use with

RNE Controller only. Connects to controller via fi eld fabricated wiring.

+5V

1003

SIG 1

1002

10uF

GND

+5V

1003

SIG 2

1002

10uF

GND

C2

+5V

1003

SIG 3

1002

10uF

GND

+5V

1003

SIG 4

1002

10uF

GND

R7

R9

BIN 1

R13

R14

BIN 2

R23

COM

R24

R25

R26

ADDRESS

1

OFF

2

4

8

SW1

PWR

OE217-00 Digital Room Sensor - Temp. Only

LCD Display and keypad allow for setpoint adjustment, override, and

display of certain status and setpoints. The OE217-00 is used with the

RNE Controller for room air temperature sensing applications. Uses I2C

cable.

OE217-01 Digital Room Sensor - Temp and Humidity

LCD Display and keypad allow for setpoint adjustment, override, and

display of certain status and setpoints. The OE217-01 is used with the

RNE Controller for room air temperature and humidity sensing applications. Uses Uses I2C cable.

PAGE

NO.

R53

R12

R11

R54

4751

4751

4751

4751

TB3

D3

R1

D4

R2

D12

R3

D13

R4

Rc

RELAYS

SERIAL#

ANALOG

AO1

AO2

GND

PWM1-

4

300

4

300

1002

1002

1002

1002

OVERRIDE ALARM

Display

OVERRIDE ALARM

Display

PWM1+

R34R50

PWM2-

PWM2+

SW2

1002

OFF

1002

1002

1002

R30

ALARM

R29

STAT

R28

COMM

C20

.01uF

TMP

GND

AUX

OUT

Override

Override

Pages

42,46

OPTIONS

Page

21

Page

19

Page

19

OE256-01 CO2 Wall-Mounted Sensor

Used with the RNE for CO2 sensing applications where wall mounting in

the space is desired. Connects to the RNE Controller with an I2C cable

of required length. Cable sold separately.

OE256-02 CO2 Duct Sensor with Pickup Tube

Used with the RNE Controller for duct mounted CO2 sensing applications. Connects to the RNE Controller with an I

TSDRSC-05

TSDRSC-10

TSDRSC-25

TSDRSC-40

TSDRSC-80

TSDRSC-120

TSDRSC-160

length. Includes: Duct Mounted CO

Airfl ow Pickup Tube and 10 ft. I2C Cable.

Digital Sensor Cable Assembly

Includes: Digital Sensor Cable Assembly. Cable assembly has male

RJ-45 modular connectors on both ends. For use with the Digital Room

Temperature Sensor, Digital Room & Temperature Sensor, Wall Mounted

CO2 Sensor & Duct Mounted CO2 Sensor. These cables are used

with the OE332-23E-RNE – RNE Controller and the OE742-31-VAVZ,

OE742-32-VAVZ, OE744-31-VAVZ, and OE744-32-VAVZ – VAV/Zone

Controller Actuator Packages. The TSDRSC Cables are available in 5,

Sensor, Integral Aspiration Box,

2

10, 25, 40, 80, 120 & 160 feet lengths. The maximum length of cable

allowed is 160 feet for a CO2 Sensor and 160 Feet for a Digital Room

Sensor. The total combined length of cable allowed when both a CO2

Sensor and Digital Room Sensor is used is 160 feet.

MS000029 Cable Coupler for TSDRSC Cables

Includes: Sensor Cable Coupler. Used to connect TSDRSC cables

together when lengths inbetween available cable sizes are required.

Female RJ-45 to Female RJ-45. Maximum 1 Cable Coupler per cable

run.

2

C cable of required

Page

19

Page

20

Page

19

Page

19

8

RNE Modular Controller Field Technical Guide

Page 9

OVERVIEW

Parts and Descriptions

PART NO. PART DESCRIPTION ILLUSTRATION PAGE NO.

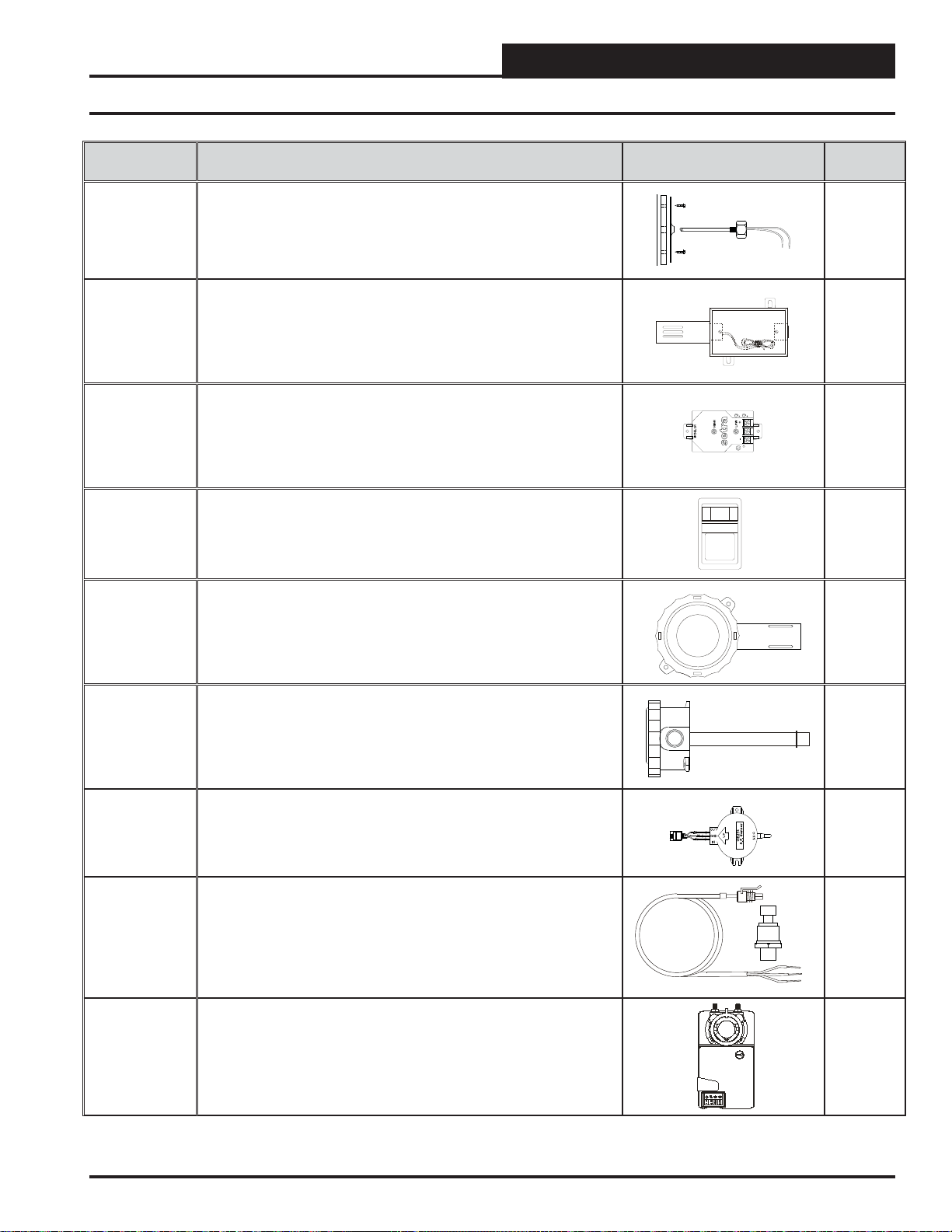

OE230

OE231

Duct Temperature Sensor - 6” Probe

Duct Temperature Sensor - 12" Probe

OE230 = 6″ probe length. OE231 = 12″ probe length. Used for return or

supply air temperature sensing applications. Includes: 10k Ohm Duct

Temperature Sensor, 2 wire only.

OE250 Outdoor Air Temperature Sensor

Used for temperature sensing applications. Includes: 10k Ohm Outside

Air Temperature Sensor, 2 wire, mounted in a weatherproof handy box

only.

OE258-01 Building Static Pressure Sensor

Used for Building Pressure Sensing. Includes: -0.25 to +0.25″ W.C., 0-5

VDC, 24 VAC/VDC supply power Building Pressure Sensor only.

OE265-11 Room Mounted RH Sensor - 3% - 0-5 VDC Output

Includes: 0-5 VDC, Room Mounted Relative Humidity Transmitter only.

Used for room air humidity sensing applications.

OE265-13 Outdoor Air Temperature & Humidity Sensor

Includes: 0-5 VDC, Outside Air Relative Humidity Transmitter mounted

in a weatherproof, round handy box only. Used for outside air humidity

sensing applications.

Page 22

Page 23

Page 33

Page 31

Page 30

OE265-14 Return Air RH Sensor - 3% - 0-5 VDC Output

Includes: 0-5 VDC, Return Air Relative Humidity Transmitter mounted in a

weatherproof, round handy box only. Used for return air humidity sensing

applications.

OE271 Duct Static Pressure Sensor

Used for duct static pressure sensing applications. Includes: 0-5″ W.C.,

0-5 VDC, Static Pressure Sensor only.

OE275-01 Suction Pressure Transducer

Includes: Suction Line Pressure Transducer with modular cable. The cable

is supplied with a modular connector on one end and bare stripped wires

on the other end. The OE275-01 Suction Pressure Transducer is used to

monitor refrigerant suction line pressure of a DX cooling coil when a digital

compressor is used. The Suction Pressure Transducer is provided with a

¼″ SAE Flare connection for connection to the refrigerant suction line.

OE281-04 Bypass Damper Actuator

Includes: OE281-04 Modulating Damper Actuator. Used when a terminal

unit is to be used as a bypass damper for fi eld or factory controls mounted

by others. Accepts a 0-10 VDC signal.

Page 32

Page 18

Pages

40,41

43,44

Page 37

RNE Modular Controller Field Technical Guide

9

Page 10

OVERVIEW

STATUS

Parts and Descriptions

PART NO: PART DESCRIPTION ILLUSTRATION PAGE NO.

OE290 Static Pressure Pick-up Tube

Used with OE271 Static Pressure Sensor for static pressure sensing applications. Includes: Static Pressure Pick-up Tube with 1 ft. length of FRP tubing,

gasketed mounting bracket, and screws.

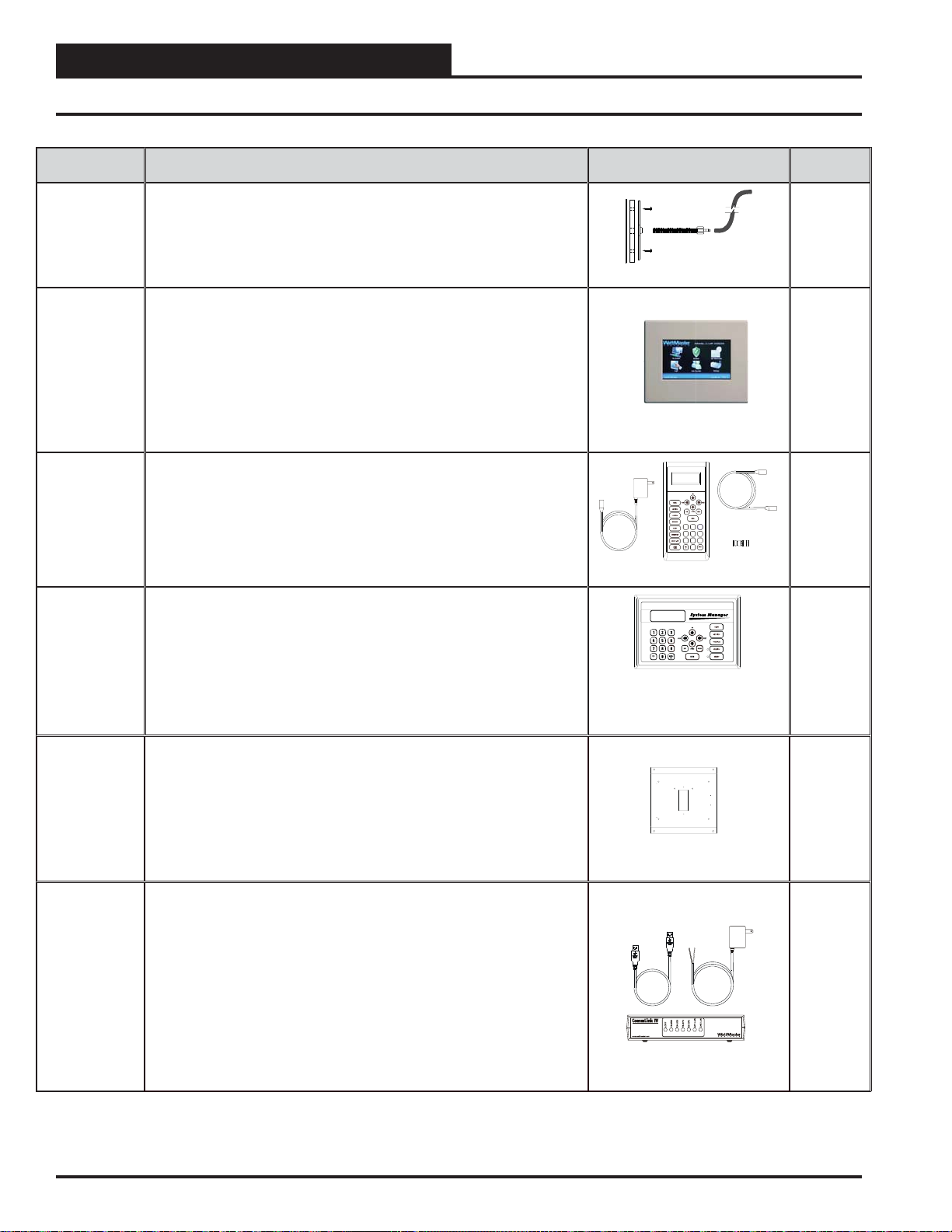

OE392-10 System Manager TS II Operator Interface

The System Manager TS II provides a direct, graphic-enhanced, menu-driven

link to enable the system operator to view the status and adjust the setpoints

of any controller on the RNE control system. The System Manager TS II is

equipped with a 4.3” 480 x 272 WQVGA RGB TFT LCD Touch Screen

Display. The System Manager TS is furnished with hardware for fl ush

mounting into hollow drywall or surface mounting on concrete brick or

plaster surfaces. Includes: System Manager TS with 12 ft. long pigtail cable

assembly.

OE391-12 Modular Service Tool SD

Includes: Modular Service Tool SD, power supply, communication cables,

adapter plug, and (4) AA batteries. Used to program and monitor all Orion

controllers.

OE392-12 Modular System Manager SD

Includes: Modular System Manager SD with 4 Gigabyte SD card and 12 ft.

long pigtail cable assembly. Used to program and monitor all Orion

controllers. Designed for hollow core wall mounting. When System Manager

is to be mounted on a solid wall (concrete), you will also need to order the

solid wall mounting bracket below. Modular System Manager and

communication cables.

Mode

Selecti on

13

2

654

9

708

-

Page 18

See the

System

Manager

Touch

Screen II

Technical

Guide

See the RNE

Controller

Operator

Interfaces

SD

Technical

Guide

See the RNE

Controller

Operator

Interfaces

SD

Technical

Guide

EB101505 Solid Wall Mounting Bracket for Modular System

Manager SD

Includes: 22 gauge galvanized sheet metal mounting bracket with mounting

holes and wire routing opening. Dimensions are 9.25″W x 8.00″H x 0.50″DP.

The Wall Mounting Bracket provides wiring clearance between the System

Manager and the wall mounting surface when the System Manager is to be

mounted on a concrete or other solid wall surface. Not for use with System

Manager TS.

OE361-13 CommLink 5 Communications Interface

The CommLink 5 connects to your control system using a USB computer

connection to provide direct on-site communications with the control system

from a computer with the Prism 2 software installed. For remote communications, see OE415-02 IP Module Kit.

Includes: CommLink 5, 6 ft. long USB cable, and 120/24 VAC power supply.

Required on all networked systems or if direct computer or remote computer

connection is required. Connects to your computer’s USB 1.1 or 2.1 port.

Prism 2 computer front-end software must be installed on the direct connected or remote connected computer in order to communicate with your system.

10

RNE Modular Controller Field Technical Guide

N/A

See the

CommLink

5 Technical

Guide

Page 11

OVERVIEW

Parts and Descriptions

PART NO. PART DESCRIPTION ILLUSTRATION PAGE NO.

OE415-02 IP Module Kit - Internet/LAN Connection

Used for Internet or Local Area Network communications with the control

system. Field installs by plugging into the CommLink IV circuit board and

provides an addressable Ethernet connection to the controls system from

any computer connected to your building’s LAN. It can also be confi gured to

allow access to the control system from the Internet through your LAN if your

Ethernet fi rewall is confi gured for this option.

Includes: IP Link module, 10 ft. long Ethernet cable, and installation instructions. Prism 2 computer front-end software must be installed on the remote

computer in order to dial-up and communicate with the controls system.

OE366 USB-Link 2 Kit

The USB-Link 2 is a pocket-sized communications interface used to connect

a laptop computer to your controls system for programming and monitoring

purposes, utilizing a modular cable to allow connection to the service port

connector on the controllers and a USB cable to connect to a laptop computer.

Includes: USB-Link 2 for multiple or single loop systems, USB cable, modular

connection cable, two mini-DIN to terminal adapters, and Prism 2 software.

OE364-22 MiniLink Polling Device

Control enclosure is for indoor use only. Used with all Orion controllers to

provide network communications, zone voting, alarming, and tenant logging

capabilities. A MiniLink Polling Device is required on each loop of a Networked system. Includes: MiniLink Polling Device mounted in the EE00007501 control enclosure. Control Enclosure cover is shown removed in picture.

See the IP

Module

Technical

Guide

See the

USB-Link 2

Technical

Guide

U1

CX7

RV1

CX3

VREF

U3

U4

CX2

R4

LED 1

LED 2

EPROM

POWER

C8

C7

R25

R26

V1

1

AIN

R27

THERM

4-20mA

U12

0-10V

R31

OFF=0-5V

D4

+5V

GND

24VAC

C11

D5

TB2

TB1

U7

P1

CX1

C4

C1

R3

YS101818P552

X1

CX4

PROCESSORPBOARD

C1

C2

CX5

U5

RAM

CX2

AIN2

THERM

4-20mA

0-10V

GND

AIN 2

AIN 1

X1

CX6

C3

U6

PHILIPS

U10

YS101900PMINILINK

D1

POLLING

U1

DEVICE

1

REV. 1

R1

U6

CX1

C3

U2

CX6

RN2

U11

R2

WDOG

R24

C10

C9

RN3

LD4

PROC.

LOOP

NETWORK

DRIVER

DRIVER

DRIVER

X2

CX15

CX14

CX13

P3

R28

U14

U15

U13

R29

R30

LD6

LD5

NETWORK

LOCAL LOOP

LOOP

2

4

8

1

32

16

P5

P4

SHLD

T

R

SHLD

T

R

ADD

OFF

TB3

TB4

SW1

See the

CommLink

IV Technical

Guide

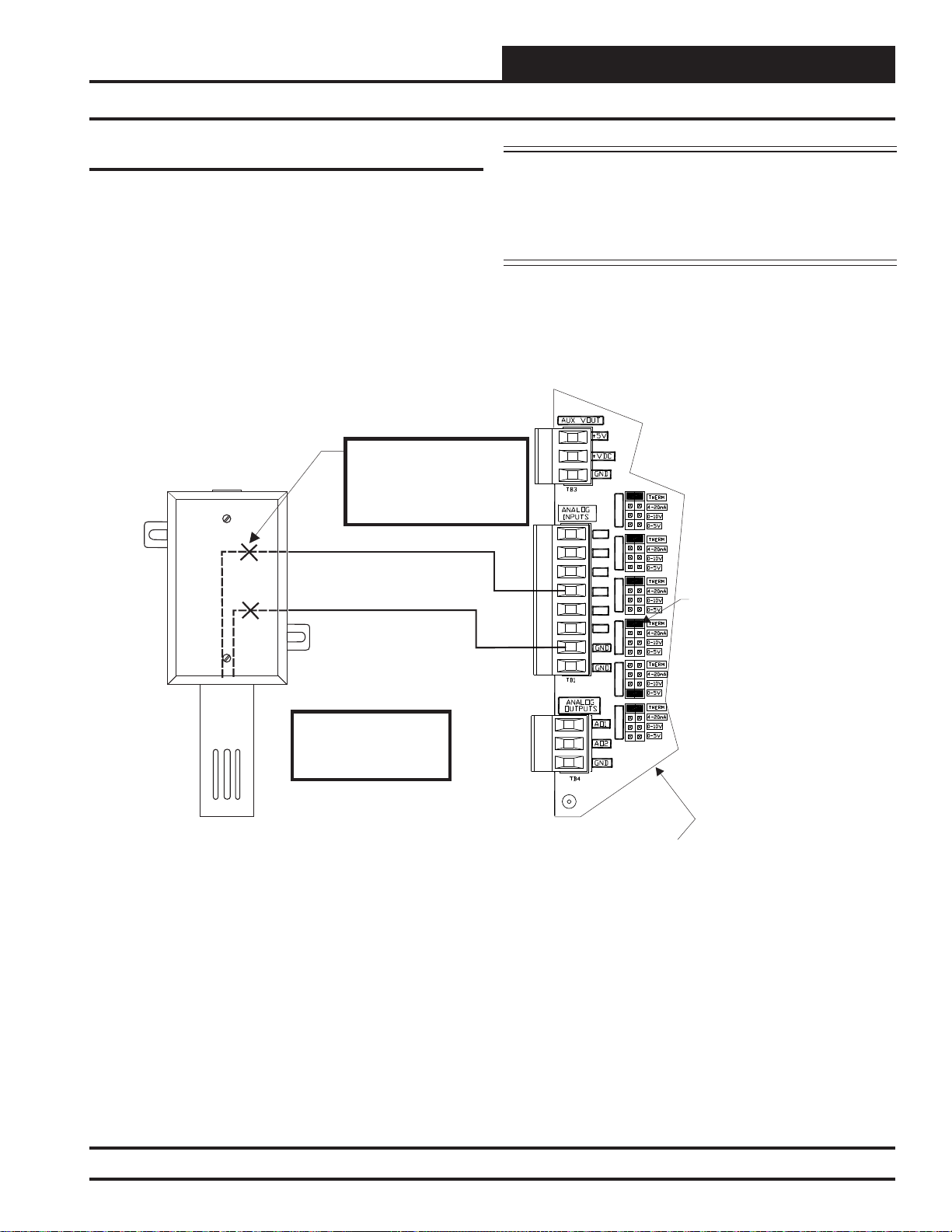

OE365-15EBA

E-BUS Adapter Board

The E-BUS Adapter Board is used for connecting the EBTRON®, GreenTrolTM

or Paragon Airfl ow Measurement Digital Transmitter to the VCB-X Control

System. The E-BUS Adapter Board connects to the VCB-X Controller with an

EBC E-BUS cable. Cable supplied separately.

OE508 Prism 2 Front-End Computer Software

Prism 2 provides standard, easy to understand status screens for each

type of RNE equipment installed. Prism software has provisions for custom

screens which allow fl oor plans, equipment photos, or user-defi ned summary

screens to be implemented to meet their own individual needs. All controlling

setpoints, trend logs, and alarm conditions are accessed in the Prism environment. Prism can be confi gured for direct on-site installation, remote modem

connection, or TCP/IP Internet connection to several installations.

OE437-03 Communication Surge Protector Kit

Used to isolate power surges to the communications wiring caused by

lightning strikes for communications wiring loops that are routed outdoors or

between buildings. One kit is required at each point where the communications wiring leaves or enters a building.

Includes: Communication Bus Surge Protector, Base Module, and Mounting/

Wiring Instructions.

See

Page 39.

See the

Prism 2

Technical

Guide

N/A

RNE Modular Controller Field Technical Guide

11

Page 12

OVERVIEW

Parts and Descriptions

PART NO. PART DESCRIPTION ILLUSTRATION PAGE NO.

OE377-0000042

OE377-0000041

OE332-23GPCX

MHGRV-X Controller

The MHGRV-X Controller controls a Modulating Hot Gas Reheat Valve to

maintain a desired Supply Air Temperature and Dehumidifi cation setpoint.

The MHGRV-X Controller connects to the RNE Controller via an I2C

cable. Available only from AAON®.

MODGAS-X Controller

The MODGAS-X Controller modulates up to (2) gas valves to maintain

a desired Discharge Air Temperature. It also controls the speed of the

induced draft fan to maintain proper combustion in the heat exchanger.

The MODGAS-X Controller connects to the RNE Controller via an I2C

cable. Available only from AAON®.

GPC-X Controller

The GPC-X Controller provides the fl exibility to control, schedule, and/or

monitor equipment such as unit heaters, exhaust fans, motorized louvers,

etc. The GPC-X has (6) confi gurable inputs which will accept signals from

thermistor temperature sensors, 4-20mA or 0-5 VDC transmitters, or dry

contact closures. An additional modular input is provided for connection

of an OE271 Static Pressure Sensor. The GPC-X has (5) relay outputs for

on/off control and (2) analog outputs. The GPC-X also has (5) separate

2-events-per-day schedules, each with its own optimal start functions built

in. In addition, the GPC-X provides Lead/Lag start capabilities. Use the

GPC-X to provide additional schedules for your controllers.

TB3

CLG OVR

GND

HTG OVR

RHTIN

SHLD

R

SAT

T

PJ1

R12

PU

D2

PJ1

2

I C IN

D1

R19

+24VAC

YS101826PREV 1

MODULATING

GAS BOARD

R

SHLD

T

D8

V4

24VAC

GND

R4

2

I C OUT

COMM

VR1

RV1

C3

D6

R11R1D5R3R3

R20

WDOG

U2

C12

CX6

U6

U1

D1

D1

C13

C2

GND

C4

P1

TB4

P1

RV1

SAT

+VDC

C1

VR1

R7

D1

P

R15

WDOG

POWER

CX6

U6

U1

C7

U5

C2

C4

P1

R13R5R6D4D3

R2

U2

R1

C3

CX1

1

PHILIPS

U5

CX5

C1

X1

YS101818P552

PROCESSORPBOARD

STATUS

RESET

LIMIT

O

F

F

1

RSTIN

AUX IN

GND

HEATEN

2

4

J01

8

16

C2

32

64

128

ADD

R8

D2

R9

R1R3R1

P

R2

U2

C3

CX1

R1

1

PHILIPS

PHILIPS

U5

CX5

C1

YS101818

552 PROCESSOR

BOARD

C1

R18

L1

C8

L2

V5

R31

D11

R38

I2C IN

TB2

R26

R26

C6

R25

POWER

TB3

FAN

V1

CW/HW

CB/HB

CG/HR

CR/HG

+VDC

GND

GND

AUX IN

RSTIN

CX2

DISCHARGE

SETPOINT

R4

K1

YS101894 REV 1

HOTGAS REHEAT

V2

COMP

R2

U1

AUX IN

SETUP

THERM

STEP

4-20MA

0-10V

C4

C2

R9R8R7

RAM

EPROM

U4

CX4

U3

CX3

TB1

O

F

F

1

AUX

COM

LO SPD

FAN

2

4

8

16

32

64

LO SPD

FAN

AUX

128

ADD

CX2

EPROM

RAM

SERIAL#

K2

V3

VALVE

R17

K3

AUX

V4

TB5

FAN

R23

K4

COMP

U5

VALVE

AUX

CX5

COM

RESETLIMIT

SW1

ADD

128

SETPOINT

STATUS

R39

1286416

POWER

R40

V1 V3K3V2

K2

K1

FT

N/A

16

421

8

64

32

SW2

ADD

1

2

32

4

8

C15

N/A

SER. #:

U4

CX4

U3

GAS

CX3

VALVE

D9

VOUT

GND

C13

V5

TB4

See GPC-X

Technical

Guide

OE310-21-LP Lighting Controller

Adds lighting control capability to the RNE Control System. Lighting Controller provides up to (7) independent time schedules. Provisions for photocell or light sensor light level control are also provided. Lighting Controller

only provides Pilot Duty Relay Outputs. An external Lighting Contactor

must be provided by others. If a Light Sensor OE259 is to be used with

the Lighting Controller, it must also be ordered from WattMaster. Includes:

Lighting Controller with Backplate.

OE259 Light Sensor

Ambient Light Sensor

(Use with Lighting Controller for light sensing.)

24VDC power, 1m Ohm to 1.5k Ohm output signal. Supplied with weatherproof handy box for outdoor or indoor mounting. Light Sensor threads into

conduit fi tting. Includes: Light Sensor and weatherproof handy box.

N/A

N/A

12

RNE Modular Controller Field Technical Guide

Page 13

OVERVIEW

RNE Modular Controller Dimensions

5.985.98

8.388.38

0.290.29

7.837.83

2.752.75

1.49

4.104.10

0.700.70

Figure 1: OE332-23E-RNE – RNE Modular Controller Dimensions

OBSERVE

WARNING

POLARITY

0.980.98

RNE Modular Controller Field Technical Guide

13

Page 14

OVERVIEW

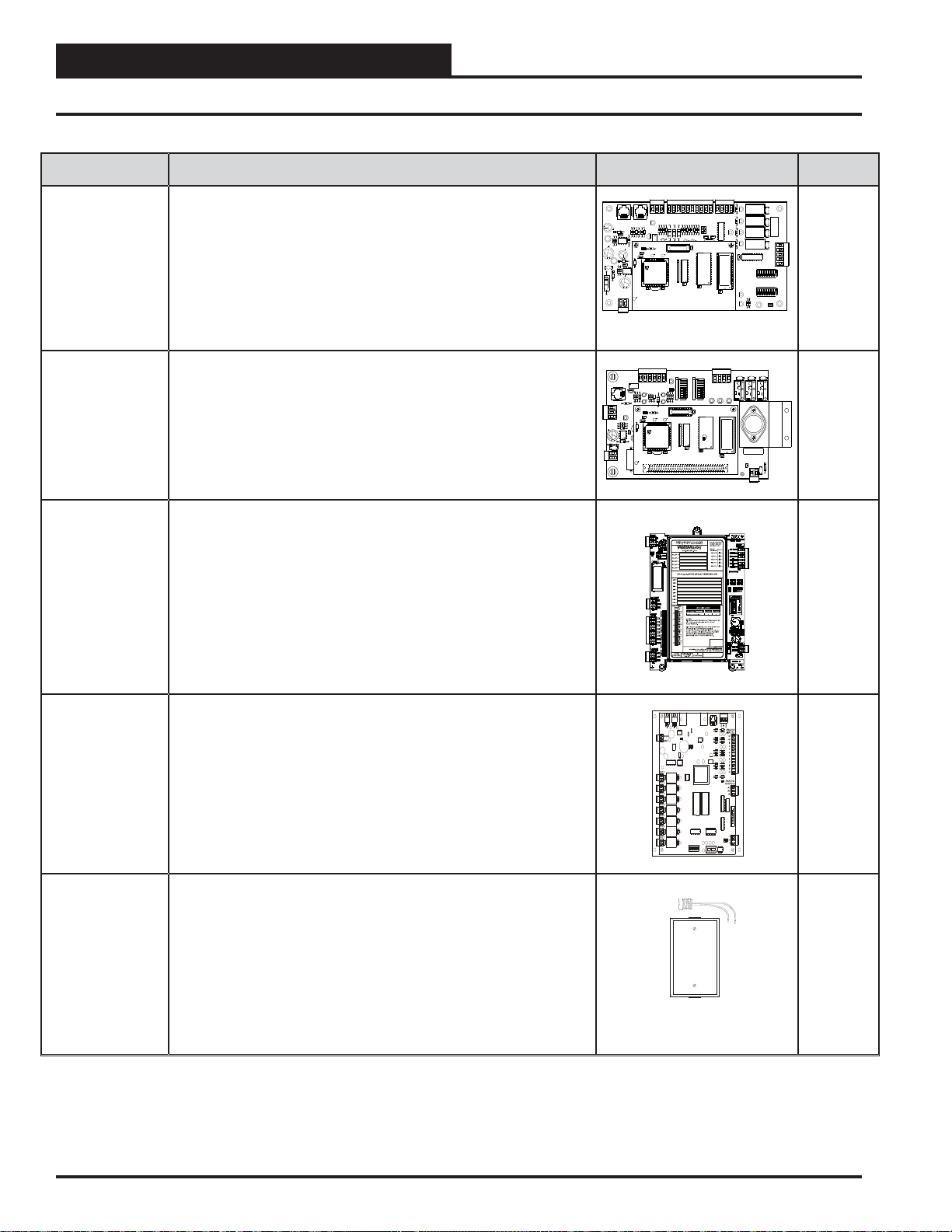

VCM-X Expansion Module for RNE Dimensions

5.98

2.75

24 VAC POWER

24 VAC POWER ONLY

ONLY

WARNING! POLARITYMUST BE

WARNING!

OBSERVED OR THE BOARD

POLARITY

WILL BE DAMAGED

MUST BE

OBSERVED OR

THE BOARD

WILL BE

DAMAGED

VCM-X Expansion Module

Orion No.:OE333-23-EM

OE333-23-EM-A VCM-X EXPANSION MODULE

PR OUT

TO VCM-X INPUT

GND

TERMINALS AI5 & GND

PR OUT

TO VCM-X INPUT

GND

TERMINALS AI5 & GND

SUCTION PRESSURE

+V

TRANSDUCER CONNECTION

SIG

FOR HVAC UNITS WITHOUT

GND

DIGITALCOMPRESSOR

SUCTION PRESSURE

+V

TRANSDUCER CONNECTION

SIG

FOR HVAC UNITS WITHOUT

GND

DIGITALCOMPRESSOR

RELAY 1 = RELAY 3 =

RELAY 2 = RELAY 4 =

RELAY 1 = RELAY 3 =

IT IS SUGGESTED

THATYOU WRITE THE

DESCRIPTION OF

RELAY 2 = RELAY 4 =

THE RELAYOUTPUTS

YOUARE USING IN

THE BOXES

IT IS SUGGESTED

PROVIDEDABOVE

THATYOU WRITE THE

WITHA PERMANENT

DESCRIPTION OF

MARKER (SHARPIE®)

THE RELAYOUTPUTS

YOUARE USING IN

THE BOXES

PROVIDEDABOVE

ANALOG INPUT

WITHA PERMANENT

MARKER (SHARPIE®)

JUMPER SETTINGS

MUST BE SETAS

SHOWN FOR

PROPER

ANALOG INPUT

OPERATION

JUMPER SETTINGS

MUST BE SETAS

SHOWN FOR

ANALOG INPUT

PROPER

JUMPER

OPERATION

SETTINGS

THERM

ANALOG INPUT

4-20mA

AI1

0-10V

JUMPER

0-5V

SETTINGS

THERM

THERM

4-20mA

4-20mA

AI2

AI1

0-10V

0-10V

0-5V

0-5V

THERM

THERM

4-20mA

4-20mA

AI3

AI2

0-10V

0-10V

0-5V

0-5V

THERM

THERM

4-20mA

4-20mA

AI4

AI3

0-10V

0-10V

0-5V

0-5V

THERM

4-20mA

AI4

0-10V

I2C

0-5V

EXPANSION

I2C

WattMaster Label

EXPANSION

#LB102034-01

www.aaon.com

BI1 = EMERGENCY SHUTDOWN - N.C. INPUT

= DIRTY FILTER - N.O. INPUT

BI2

= PROOF OF FLOW - N.O. INPUT

BI3

= REMOTE FORCED OCCUPIED - N.O. INPUT

BI4

= REMOTE FORCED HEATING - N.O. INPUT

BI5

BI1 = HOOD ON - N.O. INPUT

= DIRTY FILTER - N.O. INPUT

BI2

= REMOTE FORCED COOLING - N.O. INPUT

BI6

= PROOF OF FLOW - N.O. INPUT

BI3

= HOOD ON - N.O. INPUT

BI7

= REMOTE FORCED OCCUPIED - N.O. INPUT

BI4

= REMOTE DEHUMIDIFICATION - N.O. INPUT

BI8

= REMOTE FORCED HEATING - N.O. INPUT

BI5

= REMOTE FORCED COOLING - N.O. INPUT

BI6

NOTE:

= SMOKE DETECTOR - N.C. INPUT

BI7

ALL BINARY INPUTS MUST BE 24 VAC ONLY.

= REMOTE DEHUMIDIFICATION - N.O. INPUT

BI8

AO1 = BUILDING PRESSURE CONTROL VFD OR

NOTE:

DAMPER ACTUATOR (0-10 OR 2-10 VDC)

ALL BINARY INPUTS MUST BE 24 VAC ONLY.

AO2

= MODULATING HEATING SIGNAL

(0-10 VDC OR 2-10 VDC)

AO1 = BUILDING PRESSURE CONTROL VFD OR

AO3

= MODULATING COOLING/DIGITALSCROLL

DAMPER ACTUATOR (0-10 OR 2-10 VDC)

SIGNAL (0-10 VDC, 2-10 VDC OR 1.5-5 VDC)

AO2

= MODULATING HEATING SIGNAL

AO4

= RETURN AIR DAMPERACTUATOR

(0-10 VDC OR 2-10 VDC)

(0-10 VDC)

AO3

= MODULATING COOLING/DIGITALSCROLL

AO5

= RETURN AIR BYPASS DAMPERACTUATOR

SIGNAL (0-10 VDC, 2-10 VDC OR 1.5-5 VDC)

(0-10 VDC)

AO4

= RETURN AIR DAMPERACTUATOR

GND

= GROUND FOR ANALOG OUTPUTS

(0-10 VDC)

GND

= GROUND FOR ANALOG OUTPUTS

AO5

= RETURN AIR BYPASS DAMPERACTUATOR

(0-10 VDC)

AI1 = OUTDOOR AIR RH SENSOR (0-5 VDC)

GND

= GROUND FOR ANALOG OUTPUTS

= INDOOR AIR RH SENSOR (0-5 VDC)

AI2

GND

= GROUND FOR ANALOG OUTPUTS

= ECONOMIZER FEEDBACK

I

A3

= BUILDING STATIC PRESSURE (0-5 VDC)

AI4

AI1 = OUTDOOR AIR RH SENSOR (0-5 VDC)

= GROUND FOR ANALOG INPUTS

GND

= INDOOR AIR RH SENSOR (0-5 VDC)

AI2

= GROUND FOR ANALOG INPUTS

GND

= CO2 (0-10 VDC)

AI3

= BUILDING STATIC PRESSURE (0-5 VDC)

AI4

= GROUND FOR ANALOG INPUTS

GND

= GROUND FOR ANALOG INPUTS

GND

EXPANSION

www.orioncontrols.com

I2C

www.orioncontrols.com

AAON No.:

RELAY CONTACT

RATING IS 1AMP

MAX @ 24 VAC

RELAY CONTACT

RATING IS 1AMP

MAX @ 24 VAC

WattMaster Label

#LB102034-01-A

EXPANSION

R69190

RELAY 1

RELAY 2

RELAY 1

RELAY 3

RELAY 2

RELAY 4

RELAY 3

RELAY

RELAY 4

COMMON

RELAY

COMMON

Rev.: 1L

I2C

8.38

7.83

0.29

POLARITY

WARNING

OBSERVE

0.98

VCM

0.70

4.10

Figure 2: OE333-23-EM – VCM-X Expansion Module for RNE Dimensions

14

RNE Modular Controller Field Technical Guide

1.49

Page 15

OVERVIEW

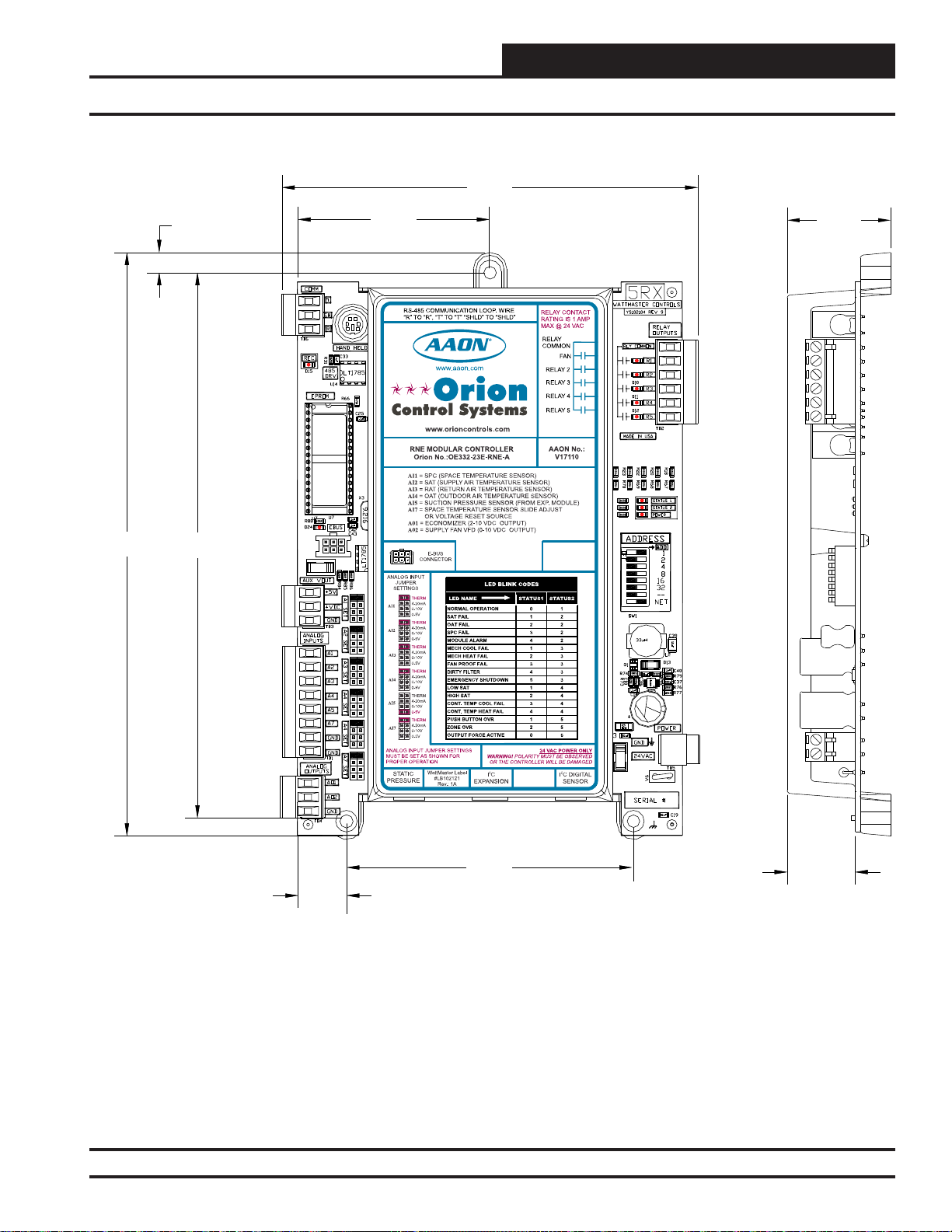

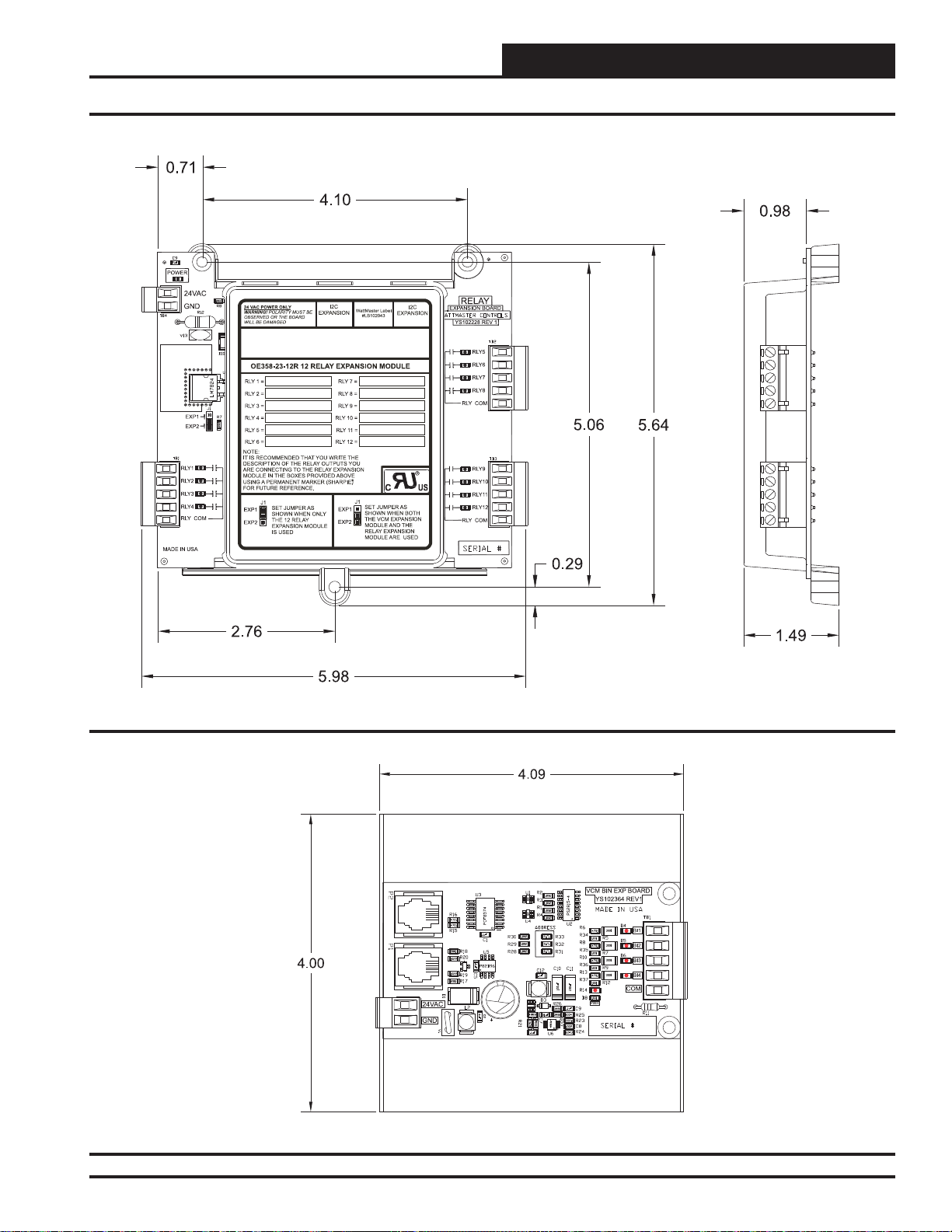

12-Relay & 4 Binary Input Expansion Module Dimensions

Figure 3: OE358-23-12R – 12-Relay Expansion Module Dimensions

Figure 4: OE356-01-BI – 4 Binary Input Expansion Module Dimensions

RNE Modular Controller Field Technical Guide

15

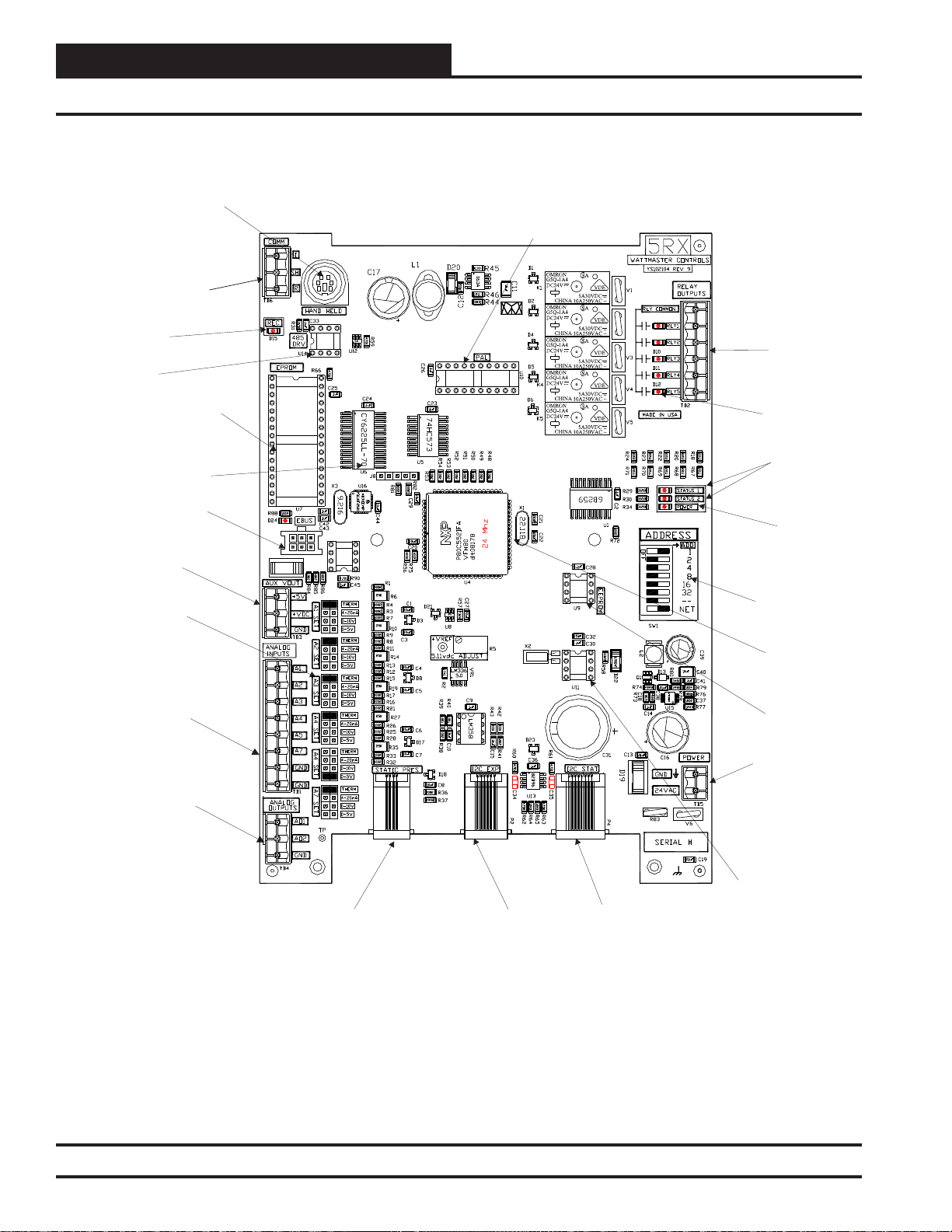

Page 16

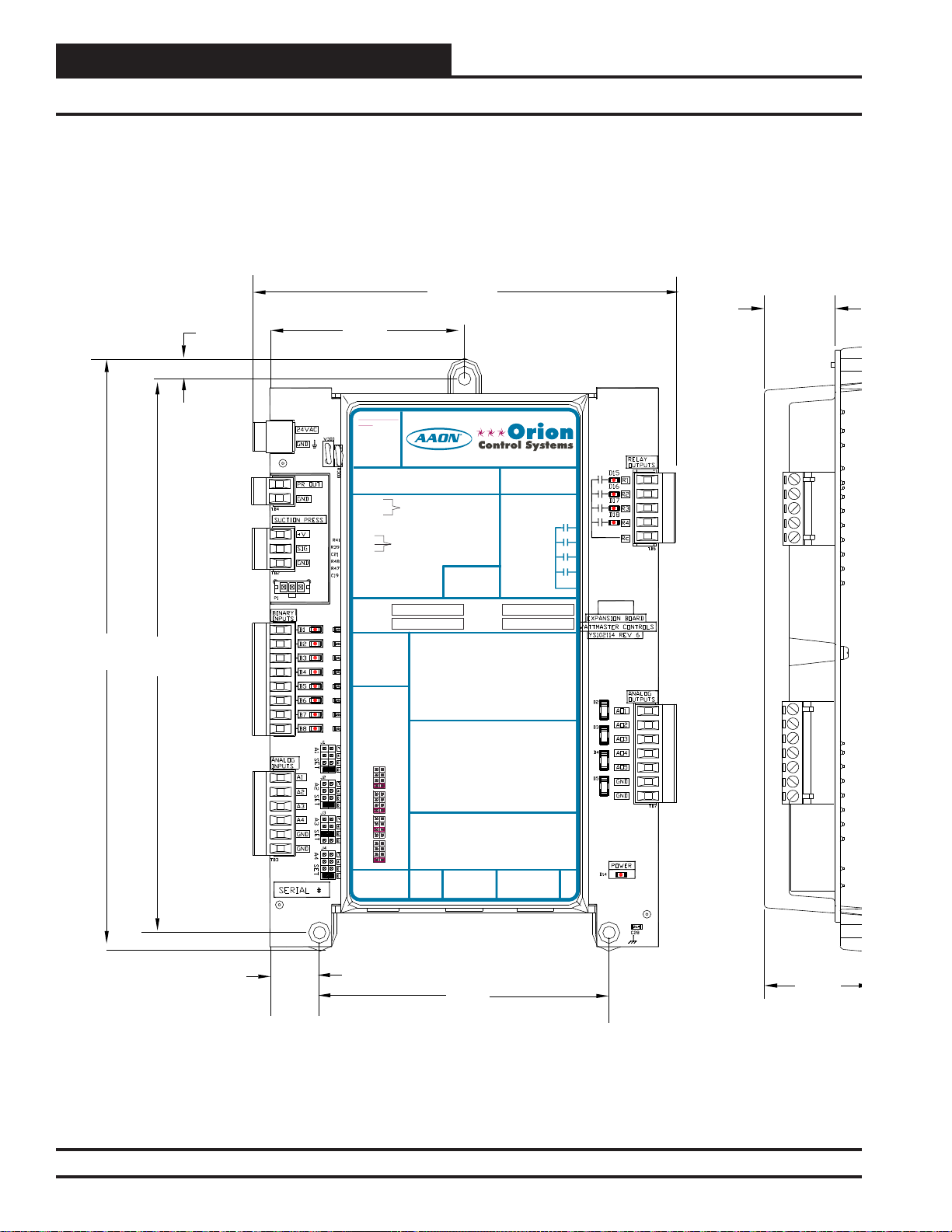

OVERVIEW

RNE Controller Component Locations

Modular Service

Tool - Mini Din

Connector

RS-485

Communications

Loop Connection

Comm

RS-485

Communications

Driver Chip

LED

Zone

Zone

PAL

Chip

Relay Output

Terminal Block

RAM Chip

E-BUS Connection

.

Auxiliary Voltage

Out Terminal Block

.

Signal Input Jumpers

For Analog Inputs-Typ.

Analog Input

Terminal Block

Analog Output

Terminal Block

EPROM

Chip

Relay Output

LED - Typ. of 5

Diagnostic

Blink Code

LEDs

Power LED

Address Switch

CPU

EEPROM

24 VAC

Power Input

Static Pressure

(Modular Connector)

Expansion Module

(Modular Connector)

(Modular Connector)

Figure 5: OE332-23E-RNE – RNE Modular Controller Component Locations

16

RNE Modular Controller Field Technical Guide

Real Time

Clock Chip

Sensor

Page 17

INSTALLATION AND WIRING

Important Wiring Considerations

General

Correct wiring of the RNE Modular Controller is the most important

factor in the overall success of the controller installation process. In

general, most RNE Controllers are factory installed and wired at the

AAON®factory . It is also possible to purchase these controllers through

your local AAON®/Orion representative for installation in the fi eld.

Some of the following information pertains to fi eld wiring and may not

apply to your installation since it was pre-wired at the factory. However ,

in the unlikely event that troubleshooting of the controller is required,

it is a good idea to be familiar with the system wiring, no matter if it

was factory or fi eld wired.

Controller Mounting

The RNE Controller is housed in a plastic enclosure. It is designed to be

mounted by using the 3 mounting holes in the enclosure base. The RNE

Controller needs to be installed in an environment which can maintain

a temperature range between -30°F and 150°F not to exceed 90% RH

levels (non-condensing). It is important to mount the controller in a

location that is free from extreme high or low temperatures, moisture,

dust, and dirt. Be careful not to damage the electronic components when

mounting the controller. See Table 1 for a list of the required operating

conditions for the RNE Controller and associated expansion modules.

Considerations

The RNE Controller and expansion modules must be connected to a

24 VAC power source of the proper size for the calculated VA load

requirements. All transformer sizing should be based on the VA rating

listed in Table 1.

Device

Control

OE332-23E-RNE

RNE Modular Controller

Voltage

24VAC 8

VA Load

Temperature

-30°F to

150°F

(Non-

Humidity

Condensing)

90% RH

WARNING: When using a single transformer to power more

than one controller or expansion module, the correct polarity must

always be maintained between the boards. Failure to observe

correct polarity will result in damage to the RNE Controller and

expansion modules.

Please carefully read and apply the following information when wiring

the RNE Controller or the Expansion Modules. See Figure 6 on page

18 for the RNE Controller wiring diagram. See Figures 17 and 18 on

pages 26 and 27 for Expansion Module Wiring.

1. All wiring is to be in accordance with local and national

electrical codes and specifi cations.

2. Minimum wire size for 24 VAC wiring should be 18-gauge.

3. Minimum wire size for all sensors should be 24-gauge.

Some sensors require 2-conductor wire and some require

3-or 4-conductor wire.

4. Be sure that all wiring connections are properly inserted

and tightened into the terminal blocks. Do not allow wire

strands to stick out and touch adjoining terminals which

could potentially cause a short circuit.

5. When communication wiring is to be used to interconnect

RNE Controllers together or to connect to other

communication devices, all wiring must be plenum-rated,

minimum 18-gauge, 2-conductor, twisted pair with shield.

WattMaster can supply communication wire that meets this

specifi cation and is color coded for the network or local

loop. Please consult your WattMaster distributor for

information. If desired, Belden #82760 or equivalent wire

may also be used.

6. Before applying power to the RNE Controller, be sure to

recheck all wiring connections and terminations

thoroughly.

OE333-23-EM

VCM-X Expansion Module

OE358-23-12R

12 Relay Expansion

Module

OE356-01-BI

4 Binary Expansion

Module

24VAC 10

24VAC 15

24VAC 5

-30°F to

150°F

-30°F to

150°F

-30°F to

150°F

90% RH

90% RH

90% RH

Table 1: Voltage and Environment Requirements

RNE Modular Controller Field Technical Guide

17

Page 18

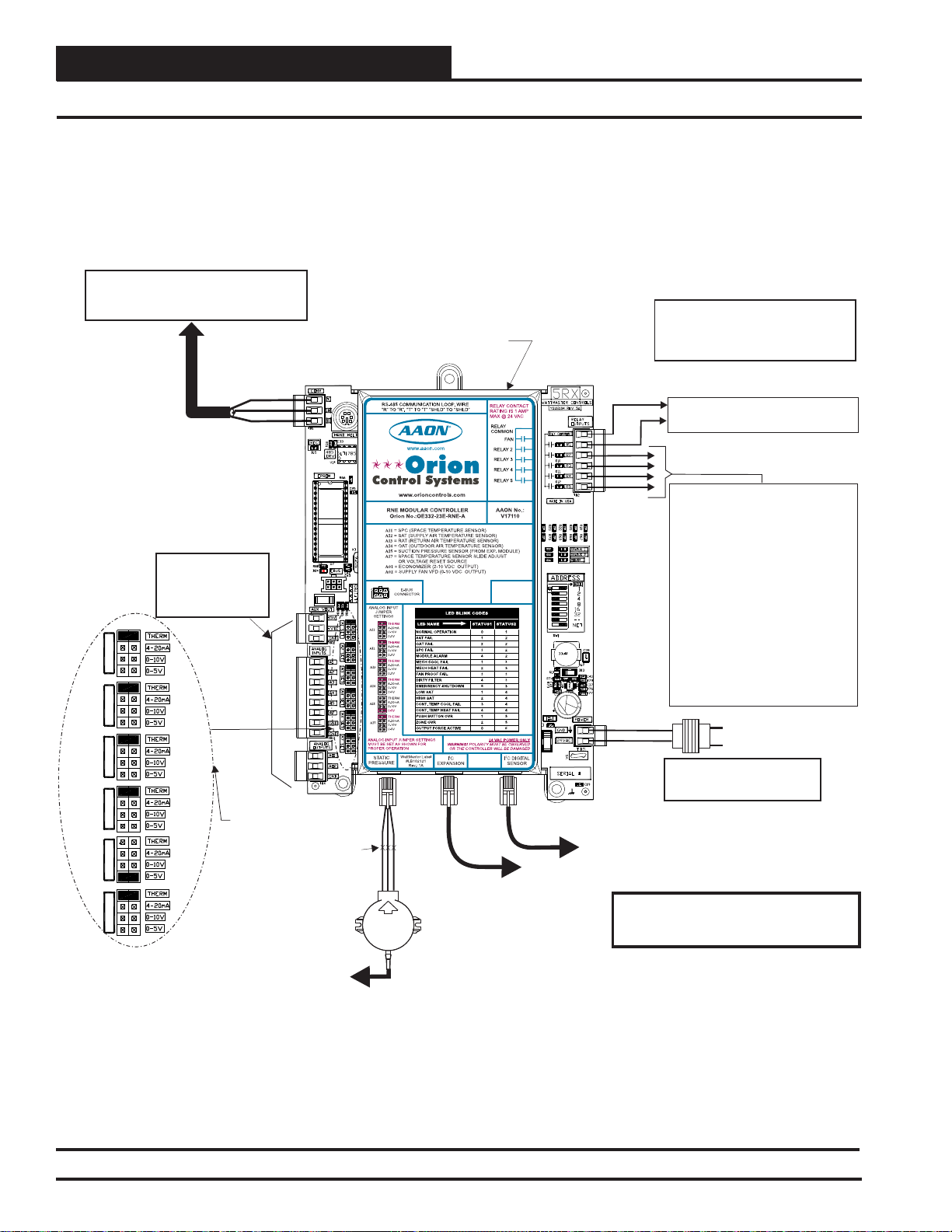

INSTALLATION AND WIRING

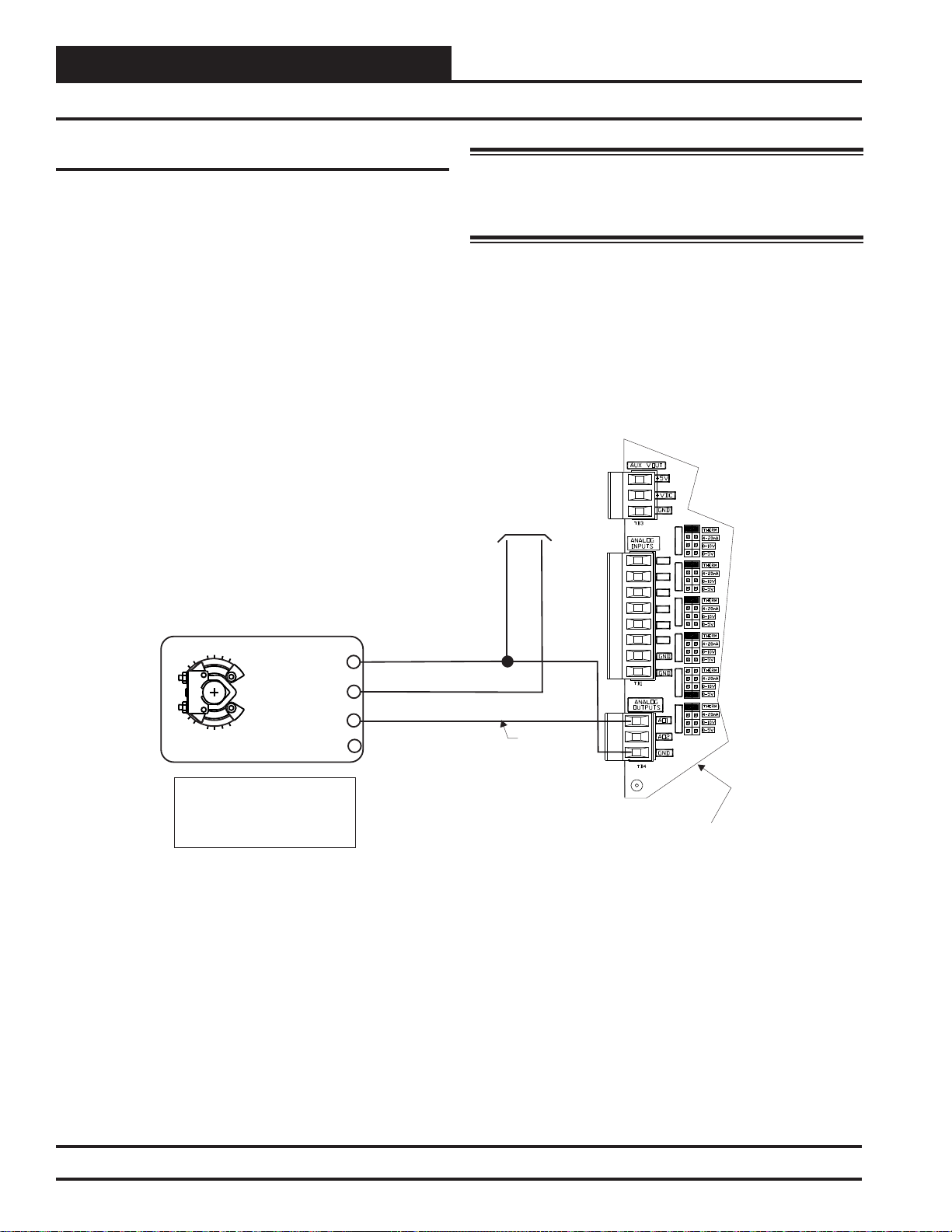

RNE Controller Wiring

For Stand Alone Applications,

Connect To System Manager. For Network

Applications Connect To Next Controller And/Or

MiniLink PD On Local Loop.

Local Loop

RS-485

9600 Baud

All Comm Loop Wiring Is

T to T, R to R & SHLD to SHLD

Straight Thru

RNE Controller

Zone

Zone

Note:

All Relay Outputs Are Normally Open

And Rated For 24 VAC Power Only.

1 Amp Maximum Load.

R - 24VAC

G - Fan ON/OFF Only

AI1 SET AI2 SET AI3 SET

AI4 SET AI5 SET AI7 SET

See Individual

Component Wiring

Diagrams For Detailed

Wiring Of Analog Inputs

And Outputs

Jumpers

Splice If Required

OE271

Static Pressure

Transducer

Connect To Digital Room Sensor And/Or

Connect To

Expansion Module(s)

(When Used)

Digital CO Sensor

Relay Output Contacts

R2 Through R5 May Be UserConfigured For The Following:

1 - Heating Stages

2 - Cooling Stages

3 - Warm-up Mode Command (VAV Boxes)

4 - Reversing Valve (Air To Air Heat Pumps)

5 - Reheat Control (Dehumidification)

6 - Exhaust Fan Interlock

7 - Preheater For Low Ambient Protection

8 - Alarm

9 - Override

10 - Occupied

11 - OA Damper

12 - Heat Wheel

13 - Emergency Heat

Note: A Total Of 20 Relays Are Available By

Adding Relay Expansion Modules. All

Expansion Module Relay Outputs Are User

Configurable As Listed Above.

GND

24VAC

Size Transformer For Correct

Total Load.

RNE Controller = 8 VA

2

Warning:

24 VAC Must Be Connected So That All Ground

Wires Remain Common. Failure To Do So Will

Result In Damage To The Controllers.

Line Voltage

Connect FRP Tubing To High Pressure

Port (Bottom Tube) and Route To Static

Pressure Pickup Probe Located In Unit

Discharge. Leave Port Marked “Lo” Open

To Atmosphere

Figure 6: OE332-23E-RNE – RNE Controller Wiring

18

RNE Modular Controller Field Technical Guide

Page 19

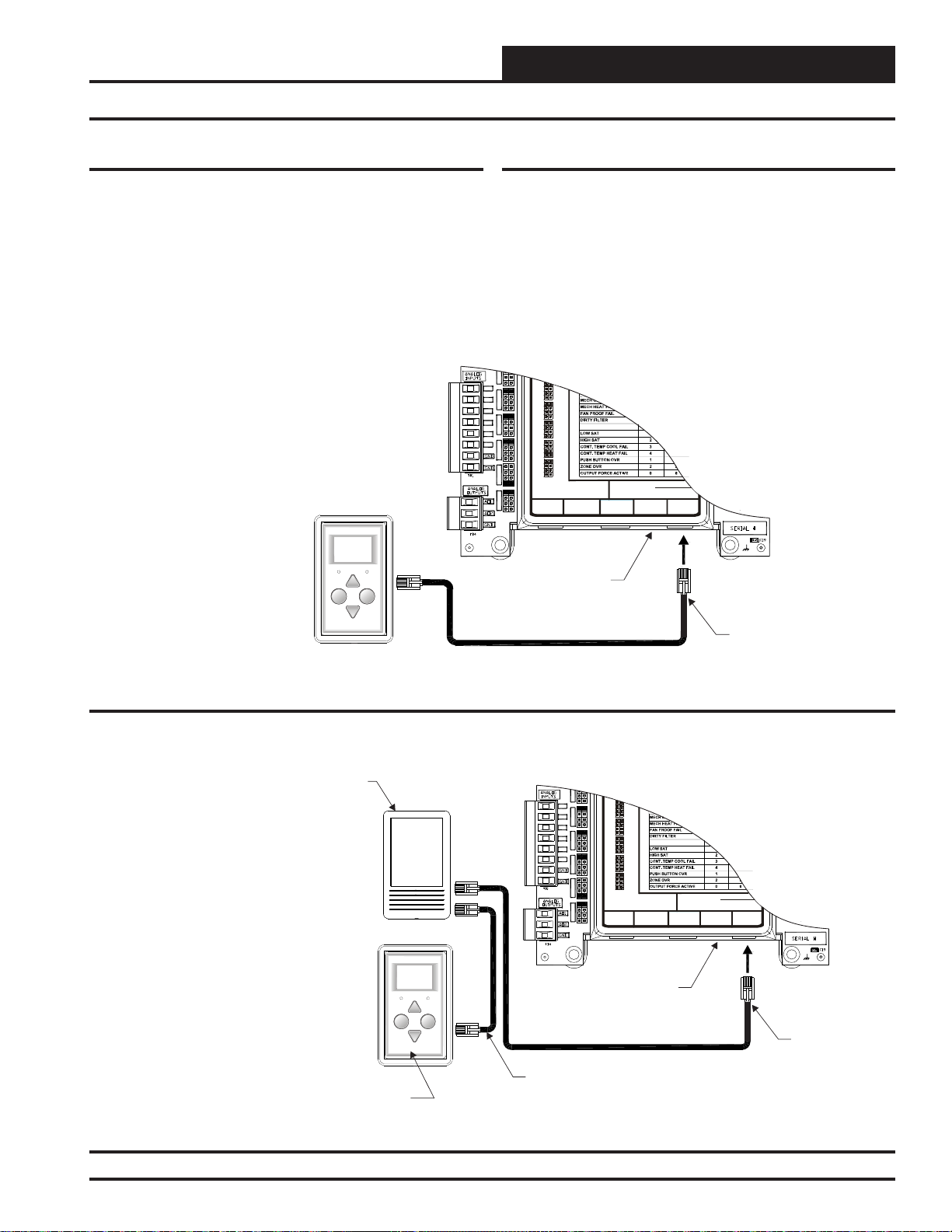

INSTALLATION AND WIRING

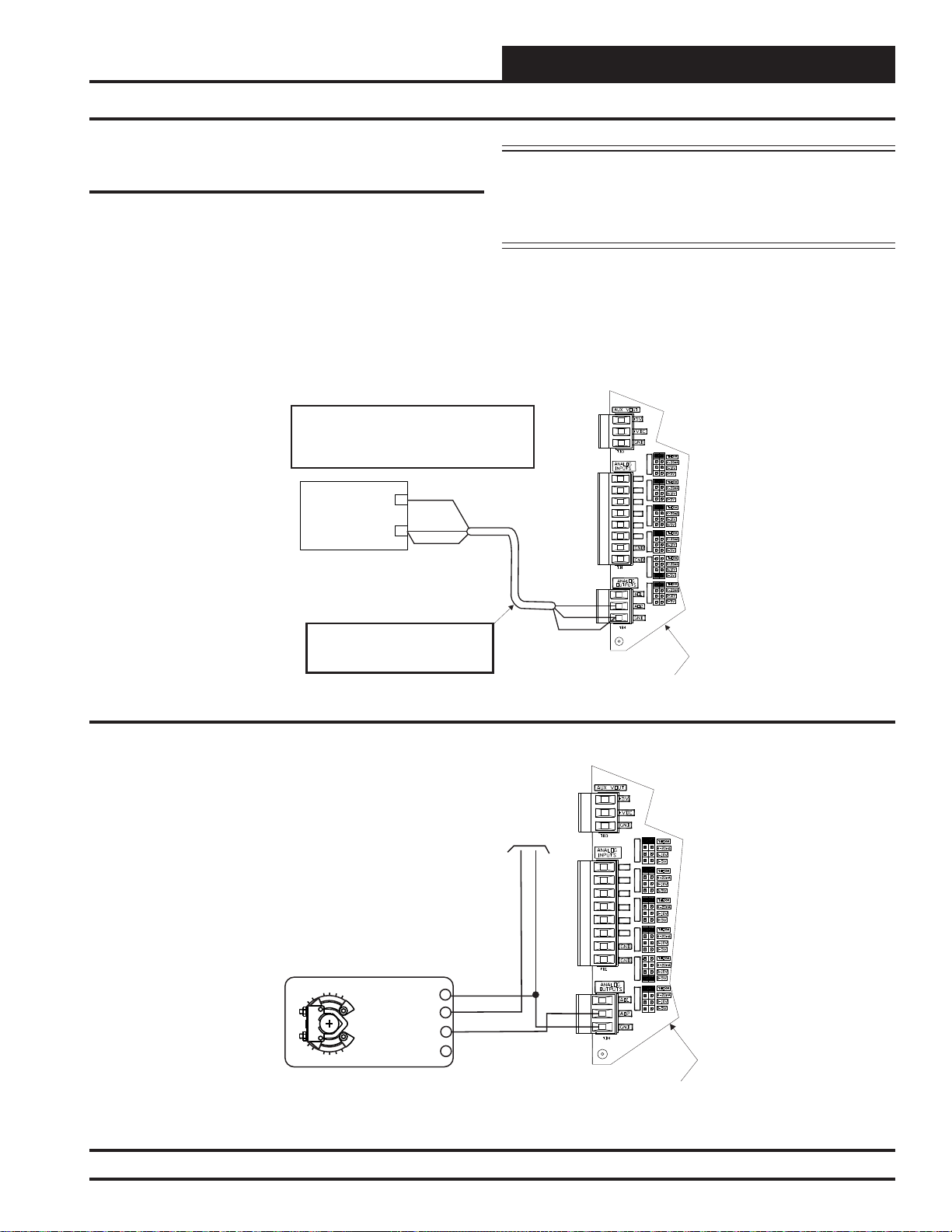

Digital Room Sensor & Wall Mounted Space CO2 Sensor

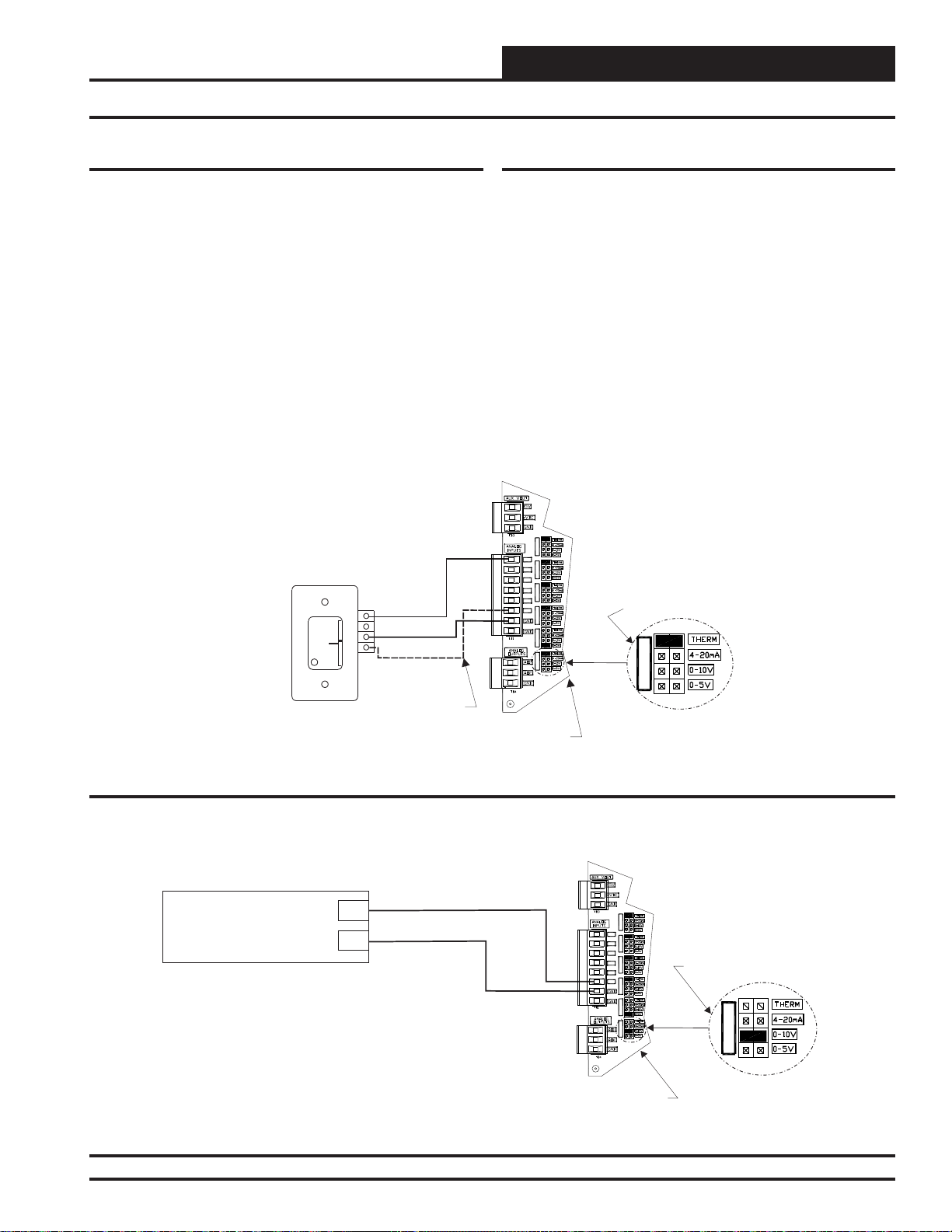

Digital Room Sensor

The OE217-00 Digital Room Sensor is used to sense Space Temperature and the OE217-01 Digital Room Sensor is used to sense Space

Temperature and Space Humidity. The Sensor connects to the RNE

Controller with the TSDRSC modular cable. It can be daisy-chained

with the OE256-01 CO2 Sensor for applications requiring both a room

CO2 sensor and room temperature sensor. It should be mounted at approximately 5 Ft. above the fl oor on the wall in an area that does not have

drafts or is exposed to direct sunlight. See Figure 7 for wiring details.

Note: When Only The

Is Used, It

Connects Directly To The RNE

Controller Using A Of The

Appropriate Length.

Allowed Is 160 Feet. See For

Connection When The Space CO Sensor Is

Also Used.

Digital Room Sensor

TSDRSC Cable

The Maximum Length

Figure 8

2

OVERRIDE ALARM

Display

Override

Wall Mounted Space CO2 Sensor

The OE256-01 Wall Mounted Space CO2 Sensor is used to monitor

CO2 levels in the space served by the HVAC unit. The CO2 Sensor connects to the RNE Controller with the TSDRSC modular cable. It can be

daisy-chained with the Digital Room Sensor (OE217) for applications

requiring both a room CO2 sensor and room temperature sensor. It should

be mounted at approximately 5 Ft. above the fl oor on the wall in an area

that does not have drafts or is exposed to direct sunlight. See Figure 8

for wiring details and installation notes. A Duct Mounted

can be used if desired instead of the Wall Mounted Space CO2 Sensor.

See Figure 9 on page 20 for Duct Mounted CO2 Sensor wiring details.

I1 SET

AI1

AI2 SET AI3 SET

AI2

AI3

AI4

AI5

AI4 SET AI5 SET AI7 SET

AI7

4-20mA

AI2

0-10V

0-5V

THERM

4-20mA

AI3

0-10V

0-5V

THERM

EMERGENCY SHUTDOWN

4-20mA

AI4

0-10V

0-5V

THERM

4-20mA

AI5

0-10V

0-5V

THERM

4-20mA

AI7

0-10V

0-5V

ANALOG INPUT JUMPER SETTINGS

MUST BE SETAS SHOWN FOR

PROPER OPERATION

STATIC

WattMaster Label

#LB102033-01

PRESSURE

RNE Controller

24 VAC POWER ONLY

WARNING!POLARITY MUST BE OBSERVED

OR THE CONTROLLER WILL BE DAMAGED

I2C

EXPANSION

I2C DIGITAL

SENSOR

CO

2

Sensor

Digital Room Sensor

Figure 7: OE217-00/01 – Digital Room Sensor Wiring

CO Sensor

2

Note: When a Digital Room Sensor Is

Used In Combination With The

The r Always

Sensor, CO Senso

Connects To The RNE Controller First

2

Using a TSDRSC Cable Of The

Length. The Digital Room Sensor Then

Connects To The CO Sensor With

Another Cable.

TSDRSC

2

At Least 5 Feet Above Floor. See The

C Sensor Technical GuideO

2

Wiring Details.

CO

2

Required

Mount Sensor(s)

For Further

Digital Room Sensor

OVERRIDE ALARM

Display

Override

I1 SET

AI1

AI2 SET AI3 SET

AI2

AI3

AI4

AI5

AI4 SET AI5 SET AI7 SET

AI7

RNE Controller

TSDRSC Cable

4-20mA

AI2

0-10V

0-5V

THERM

4-20mA

AI3

0-10V

0-5V

THERM

EMERGENCY SHUTDOWN

4-20mA

AI4

0-10V

0-5V

THERM

4-20mA

AI5

0-10V

0-5V

THERM

4-20mA

AI7

0-10V

0-5V

ANALOG INPUTJUMPER SETTINGS

MUSTBE SET AS SHOWN FOR

PROPER OPERATION

STATIC

WattMaster Label

#LB102033-01

PRESSURE

24 VAC POWER ONLY

WARNING!POLARITY MUST BE OBSERVED

OR THE CONTROLLER WILLBE DAMAGED

I2C

EXPANSION

TSDRSC Cable

I2C DIGITAL

SENSOR

TSDRSC Cable

Figure 8: OE256-01 – Wall Mounted Space CO2 Sensor Wiring

RNE Modular Controller Field Technical Guide

19

Page 20

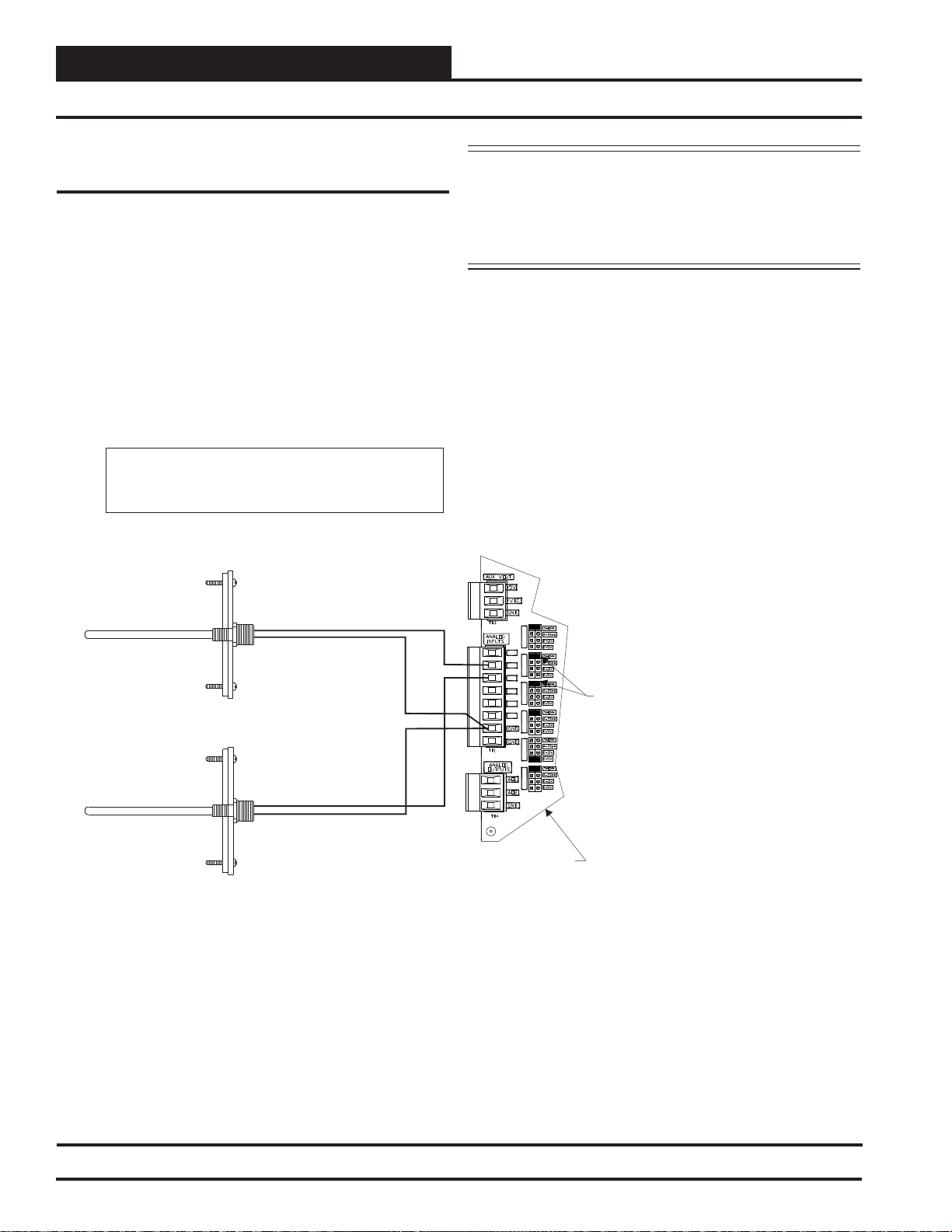

OVERVIEW

Ducted Mounted CO2 Sensor

Zone

Zone

Duct Mounted CO2 Sensor

The OE256-02 CO2 Sensor is used for sensing the current CO2 level

in the HVAC unit’s return air stream. This is useful when you want an

average CO2 reading in the area served by the HVAC unit or when you

don’t want a wall mounted CO2 sensor due to sensor tampering concerns

in the space.

Note:

1.) The CO Sensor Always Connects To The RNE Controller

Using A TSDRSC Cable Of The Required Length. If Also

Using A Digital Room Sensor, Connect The Digital Room

Sensor To The C Sensor Using Another TSDRSC Cable

Of The Required Length. The Total Length Of Cable For All

Sensor Cables Combined Cannot Exceed 160 Feet.

Wall Mounted

Digital Room Sensor

OVERRIDE ALARM

Display

Override

2

O

2

TSDRSC Cable

Duct Mounted CO Sensor

2

The OE256-02 Duct Mounted Return Air CO

the OE256-01 CO2 Sensor and the WattMaster Aspiration Box Assembly .

The Duct Mounted Return Air CO

the return air duct of the HVAC unit and uses its integral aspiration box

to sample the CO

tion information in Figure 9 below for wiring and installation details.

level in the duct. See the dimensional and installa-

2