Page 1

www.orioncontrols.com

®

PT-Link-LON

Technical Guide

VCM-X Controller Code: SS1026 & Y200920 Version 2.0 and up;

VCM-X Modular Controller Code: SS1030 & SS1034

VCM-X WSHP Controller Code: SS1032 & SS1033

SA Controller Code: Y200921

VCM Controller Code: SS1016, Y200409, Y200616, Y200822

Page 2

Table of Contents

General Information ......................................................................................................................................... 3

Data Sharing ................................................................................................................................................................................3

Hardware Specifi cations ..............................................................................................................................................................3

Connection and Wiring Information ................................................................................................................ 4

Confi guring the PT-Link Controller .................................................................................................................. 5

PT-Link Hardware Connection .....................................................................................................................................................5

Computer IP Address Set-up for Windows 98, NT, and XP ..........................................................................................................5

Connecting to The PT-Link ...........................................................................................................................................................7

Making Changes to the Confi guration File (confi g.csv) ................................................................................................................7

Upload Confi g.csv from the PT-Link .............................................................................................................................................7

Explicit and Implicit Addressing ....................................................................................................................................................8

Troubleshooting the PT-Link Controller .......................................................................................................... 9

Download Confi g.csv to the PT-Link ..........................................................................................................................................10

PT-Link Board LEDs ...................................................................................................................................................................11

ProtoCessor Module LEDs .........................................................................................................................................................12

Using RUINET ............................................................................................................................................................................13

Verifying Proper Communications ..............................................................................................................................................13

Verifying Proper Values ..............................................................................................................................................................13

Data Arrays .................................................................................................................................................... 14

Table 2: VCM-X Modular Data Array for Field Server................................................................................................................14

Table 3: VCM-X WSHP (Tulsa) Data Array for Field Server ......................................................................................................14

Table 4: VCM-X WSHP (Coil) Data Array for Field Server ........................................................................................................15

Table 5: VCM-X Data Array for Field Server..............................................................................................................................15

Table 6: SA Controller Data Array for Field Server ....................................................................................................................16

Table 7: VCM Data Array For Field Server ................................................................................................................................16

Appendix A ..................................................................................................................................................... 17

Figure 23: RJ-45 8P8C Cable for WattMaster Cross Over Networking - WattMaster Part #HZ000136 ....................................17

Appendix B ..................................................................................................................................................... 18

External Interface Files (XIF Files) .............................................................................................................................................18

Appendix C - VCM-X Modular and VCM-X WSHP LON Parameters ............................................................... 19

Appendix D - VCM-X LON Parameters ........................................................................................................... 21

Appendix E - SA Controller LON Parameters ................................................................................................ 27

Appendix F - VCM LON Parameters ............................................................................................................... 31

WattMaster Controls, Inc.

8500 NW River Park Drive · Parkville , MO 64152

Toll Free Phone: 866-918-1100

PH: (816) 505-1100 · FAX: (816) 505-1101 · E-mail: mail@wattmaster.com

Visit our web site at www.orioncontrols.com

Form: OR-PTLNKLON-TGD-01M Copyright 2010 WattMaster Controls, Inc.

®

LON

and LONWorks® are registered trademarks of Eschelon Corporation.

WattMaster Controls, Inc. assumes no responsibility for errors, or omissions.

This document is subject to change without notice.

Page 3

PT-Link-LON® Technical Guide

PC

ROTO ESSOR

General Information

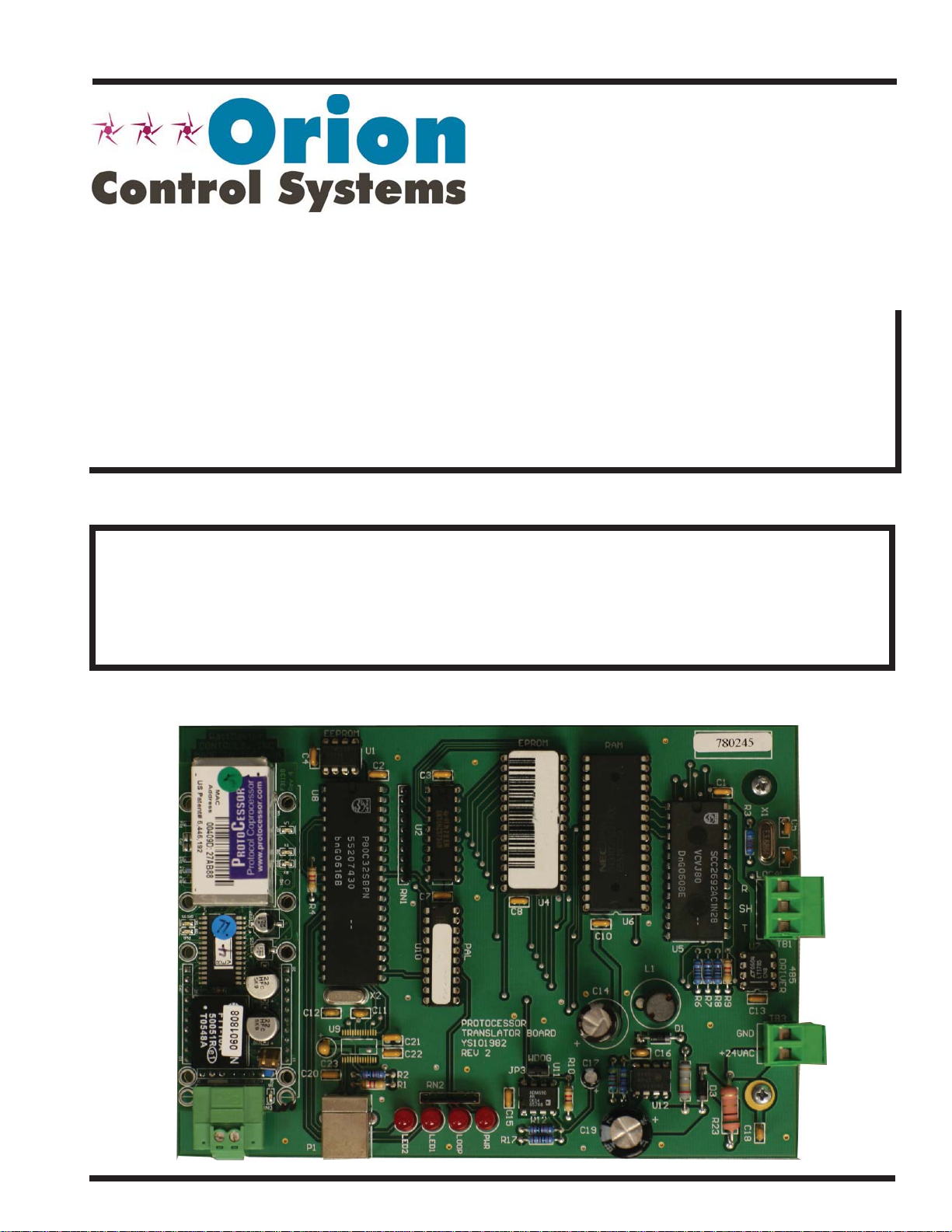

The OE368-23-LON, PT-Link-LON, provides bi-directional communication between ONE of the following types of Orion controllers—

VCM-X, SA, VCM, MUA II, or VAV/CAV:

VCM-X Controller (SS1026, SS1030, SS1032,

SS1033, SS1034, Y200920); SA Controller (Y200921)

VCM Controller (SS1016, Y200409, Y200616, Y200822)

*MUA II Controller (Y200405); VAV/CAV Controller (Y200301)

*NOTE: Documentation is available for MUA II/VAV/CAV on

our Orion Controls website: www.orioncontrols.com/

literature-new.html

NOTE: The PT-Link-LON device can be used to connect to only

one Orion controller. If more than one Orion controller is

present in a system, each one will require a PT -Link-LON

device for integration with a LON protocol network.

To determine what controller you have, you must look at the label located on the controller EPROM. If the controller label does not match

any of the SS or Y numbers listed above, your controller will not work

with the PT-Link-LON

®

.

Data Sharing

The PT-Link-LON interface provides the following data sharing capabilities:

• Provides values from points on the Orion side of the

gateway to LON® devices as if the values were

originating from LON® objects.

• Allows LON

®

devices to modify point values on the

Orion controller side of the PT-Link-LON® by using

standard LON® write services.

Hardware Specifi cations

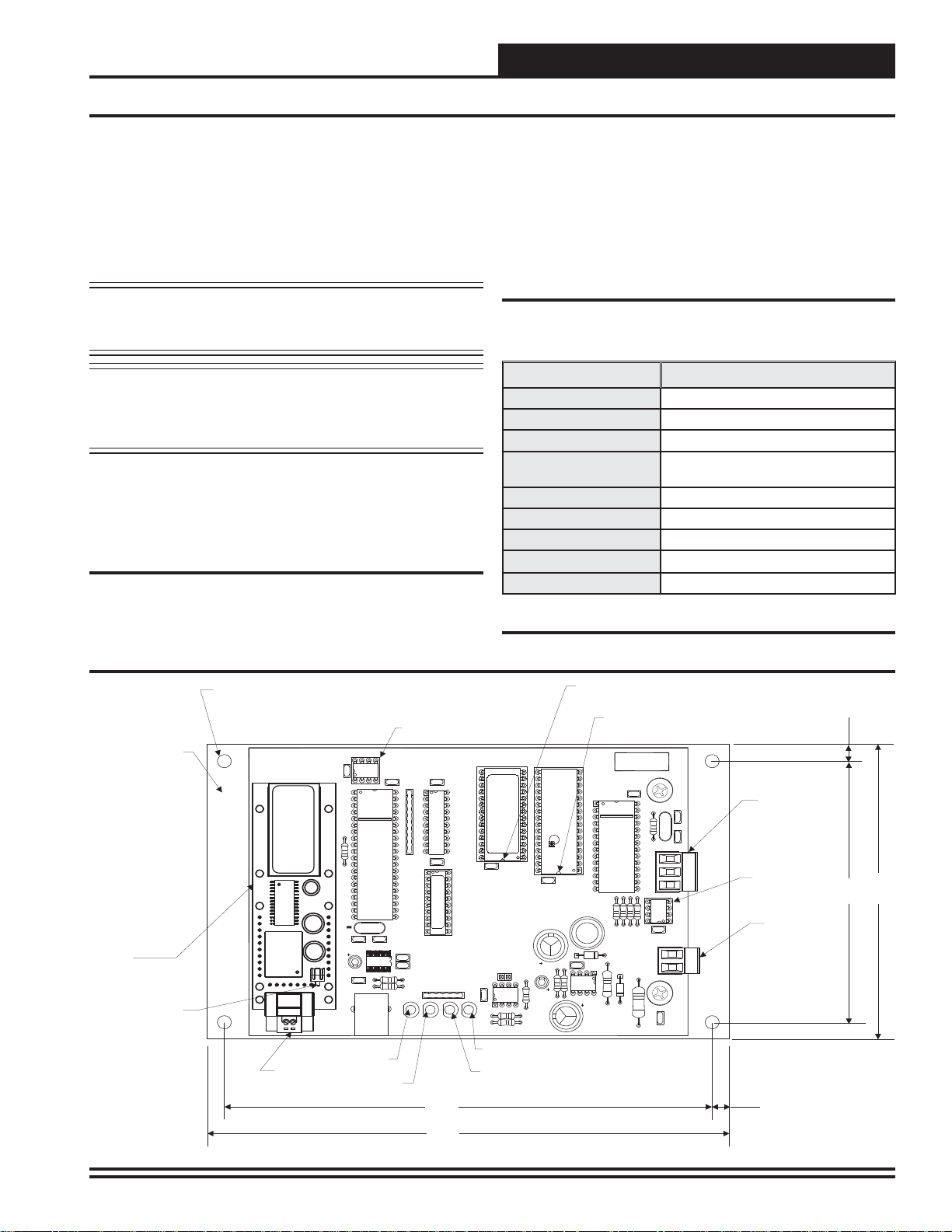

Table 1 contains the hardware specifi cations for the PT-Link-LON®

interface.

Technical Data

LON® Loop

Controller Loop

Network Protocol

Protocol

(WattMaster Loop)

Power Input Voltage

Power Consumption

Operating T emp

Operating Humidity

Weight

Table 1: PT-Link-LON® Interface Technical Data

TP/FT-10 (78 Kps)

RS-485, 9600 Baud Rate

LONWorks®

HSI Open Protocol Token Passing

24 VAC

10 VA Maximum

10°F to 149°F

90% RH Non-Condensing

8 oz.

0.20 Dia.

Mounting Hole

Typ. 4 PL.

Mounting

Backplate

WattMaster

CONTROLS, INC

MADE IN THE USA

MM1

EEPROM

C4

U8

EEPROM Chip

U1

C2

EPROM

TRANSLATOR

MODULE

X2

C11

Diagnostic

LED #1

RN1

R2

R1

C21

C22

LED2

C7

U10

RN2

LED1

SF000103

PAL

PROTOCESSOR

TRANSLATORBOARD

YS101982

REV 2

LOOP

C8

WDOG

JP3

PWR

R17

Power

LED

Communications

LED

U4

U11

R12

C19

LON®Protocessor

Module

Service Pin Button

ROTO ESSOR

PC

C20

C9

®

LONWorks

Communications

Wiring Terminal

R4

C12

P1

11.0592

U9

C23

Diagnostic

LED #2

7.00"

7.50"

Figure 1: PT-Link-LON® Board Components and Dimensions

EPROM Chip

Pin 1 Indicator

RAM Chip

Pin 1 Indicator

RAM

U6

C10

C14

C17

SERIAL #

C1

X1

C6C5

LOCAL

R

SH

T

TB1

D3

R23

R9R3R8R6R7

+24VAC

U7

DRIVER

485

C13

TB3

GND

C18

U5

L1

D1

C16

U12

Local Loop

Communications

Wiring Terminal

Local Loop

Communications

Driver Chip

24 VAC Power

Terminals

0.25”

4.00”

4.50"

0.25”

PT-Link Interface 3

Page 4

PT-Link-LON® Technical Guide

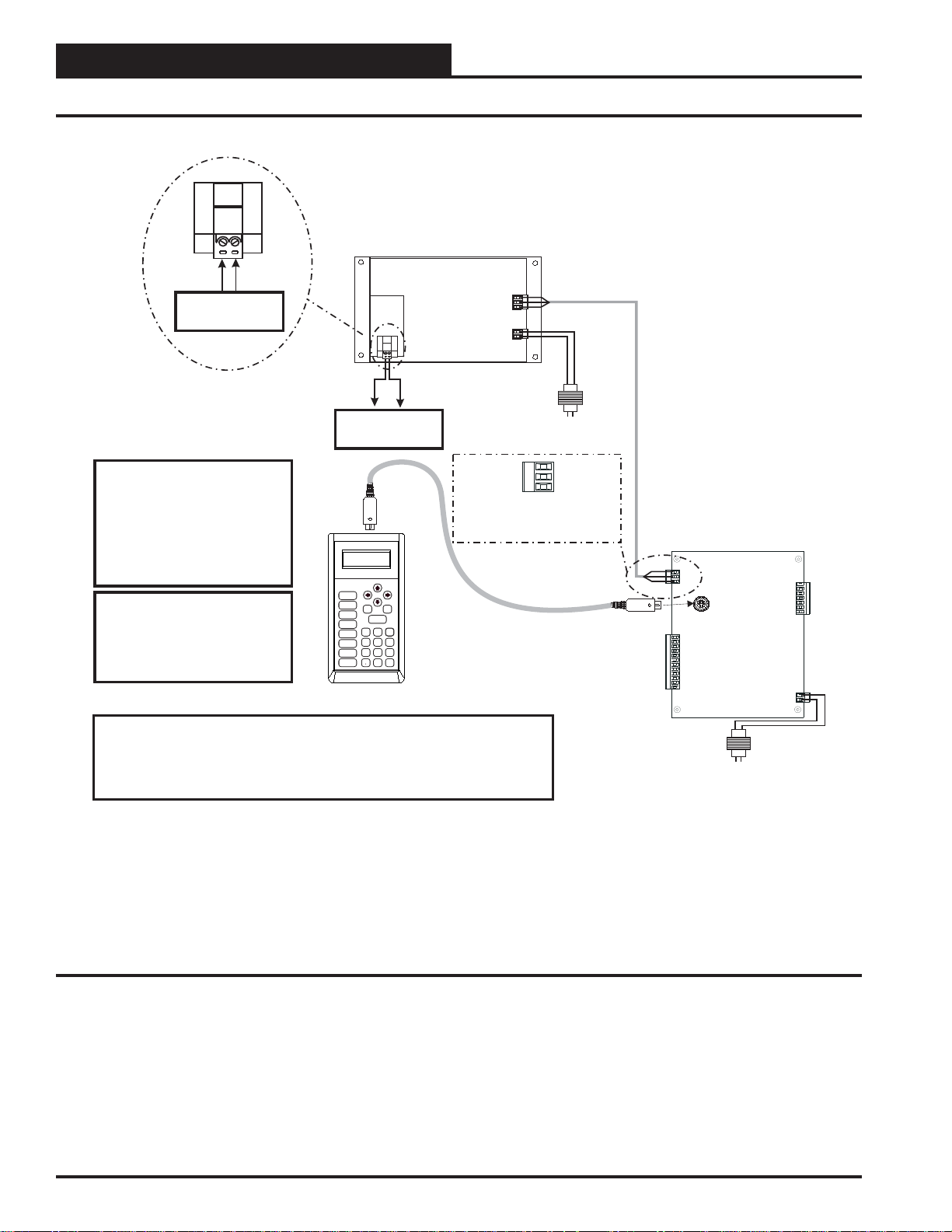

Connection and Wiring Information

®

LON Connection

®

To LON Network

Caution: The LON Network

®

Communication Terminal Block

Must Be Disconnected Before

Connecting The Modular Service

Tool. After Programming The

Controller, Disconnect

The Service Tool and Then

Reconnect The Communication

Terminal Block.

Note: All Programming Of

Controllers Must Be Done Using

The Modular Service Tool. The

Modular System Manager Should

Not Be Used On A System That

Has A PT-Link Installed.

PT- Link-LON Interface

®

LON Connection

®

To LON Network

UP

Mode

Selection

CONFIGURATION

BALANCE-TEST

STATUS

SETPOINTS

SCHEDULES

OVERRIDES

ALARMS

ON

PREV

DOWN

ESC

ENTER

13

2

708

DEC

NEXT

CLEAR

654

9

MINUS

-

Modular Service Tool

®

24 VAC

(10 VA)

Line Voltage

T

SHLD

R

Typical Terminal Blocks. All

Wiring To Be T To T, SHLD

(G) To SHLD (G)&RToR

Controller

Wiring Notes:

1.) All wiring to be in accordance with local and national electrical codes

and specifications.

2.) All communication wiring to be 18 gauge minimum, 2 conductor twisted pair with

shield. Use Belden #82760 or equivalent.

Figure 2: PT-Link-LON® Interface Wiring

24 VAC

(8 VA)

Line Voltage

4

PT-Link Interface

Page 5

PT-Link-LON® Technical Guide

Ethernet Cable

Ethernet Cable

Ethernet Hub

Connect Ethernet Cable

To Ethernet Hub Port

Connect Ethernet

Cables To Ethernet

Hub Ports

PT-Link Lon Board

Desktop Or Laptop PC

1

2

3

4

Connect Ethernet Cable To

PT-Link Ethernet Port

MADEINTHE USA

WattMaster

CONTROLS,INC

PROTOCESSOR

REV2

YS101982

PWR

LOOP

LED1

SERIAL#

TRANSLATORBOARD

DRIVER

EEPROM

PAL

RAM

EPROM

T

SH

R

LED2

+24VAC

GND

LOCAL

WDOG

TRANSLATOR

MODULE

485

U9

P1

R2

R1

C23

C22

C21

C20

C9

C18

U10

C12

C11

C2

C10

C4

C7

C8

C1

C13

C6C5

C17

C19

C16

C14

D3

D1

JP3

L1

R9R3R8R6R7

R12

R17

R23

RN1

RN2

TB3

U8

U1

U7

U11

U12

X2

X1

TB1

MM1

U6

U4

R4

U5

11.0592

SF000103

PC

ROTO ESSORPCROTO ESSOR

PC

ROTO ESSOR

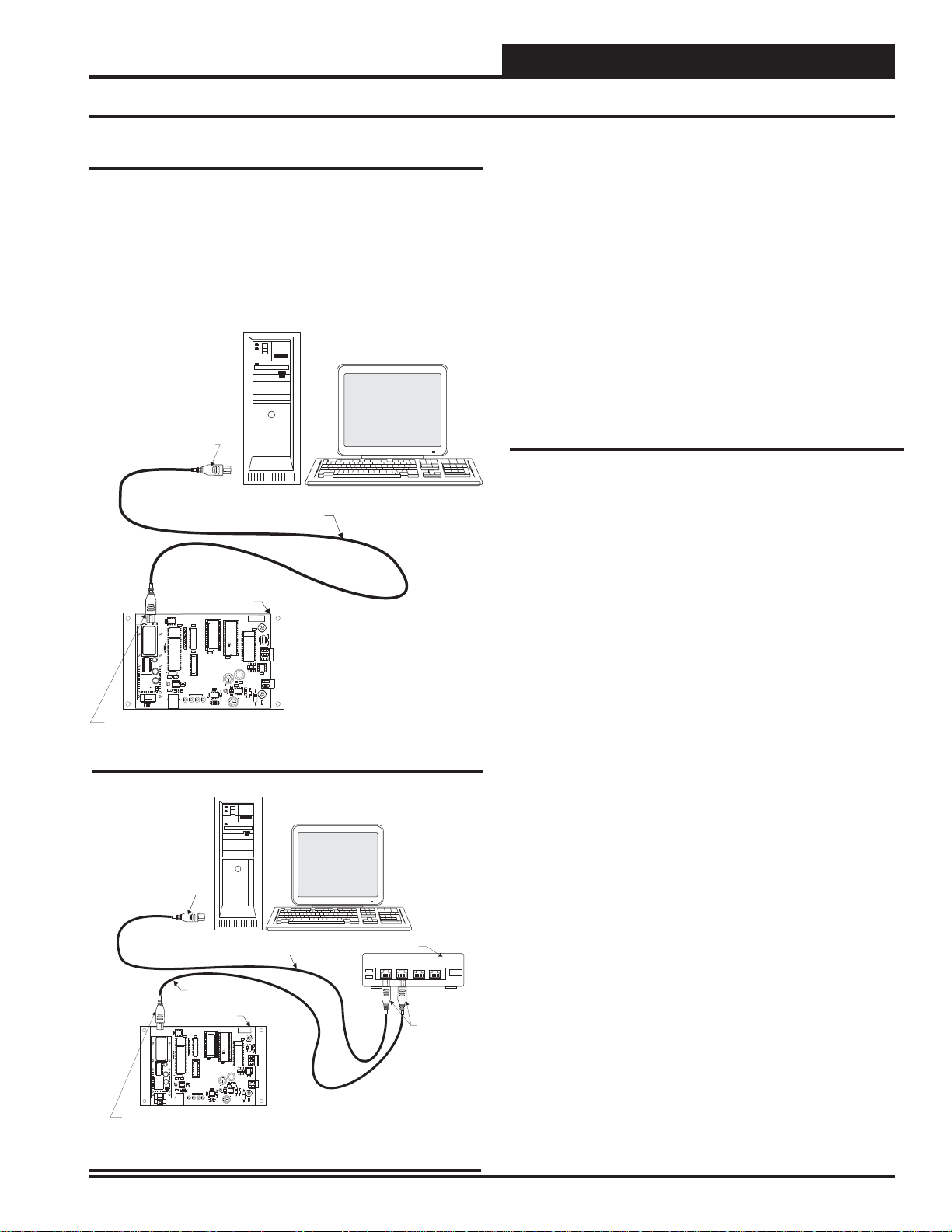

Confi guring the PT-Link Controller

PT-Link Hardware Connection

You have two options for connecting the PT-Link to your PC via Ethernet:

1.) You may connect the PT-Link directly to your PC by using

a crossover cable (by others) as shown. See Figure 3 for

details.

2.) You can also connect both your PC and the PT-Link to an

Ethernet Hub with standard CAT5 cables. See Figure 4

for details.

Connect Ethernet

Crossover Cable Directly

To PC Ethernet Card Port

PT-Link Lon Board

EEPROM

WattMaster

CONTROLS,INC

C4

U1

MADEINTHE USA

C2

MM1

U8

TRANSLATOR

MODULE

ROTO ESSOR

R4

PC

X2

11.0592

C11

C12

U9

C23

C20

C9

P1

Connect Ethernet Crossover

Cable To PT-Link Ethernet Port

Figure 3: Connecting With Crossover Cable

Desktop Or Laptop PC

Ethernet Crossover Cable

EPROM

RAM

RN1

C7

U4

C8

SF000103

U6

C10

PAL

U10

C21

C22

R2

R1

LED2

L1

C14

PROTOCESSOR

TRANSLATORBOARD

YS101982

REV2

C16

WDOG

U11

C17

JP3

RN2

LED1

U12

R12

C19

PWR

LOOP

R17

SERIAL#

C1

X1

C6C5

LOCAL

R

SH

T

TB1

U7

U5

DRIVER

485

R9R3R8R6R7

C13

TB3

D1

GND

+24VAC

D3

R23

C18

Locate a CA T5 cable and plug one end into your computer’s Ethernet

port (use a crossover cable if connecting directly to the PT-Link).

If connecting directly, plug the other end of the Cable into the Ethernet

port on the PT -Link. If connecting through an Ethernet Hub, plug the

other end of the PC cable into the hub, and use a second CAT5 cable

to connect the PT-Link to the hub as well.

Power up the PT-Link by plugging in the power cable. The PT-Link

may take up to three minutes to power up completely. Once the PTLink is powered up, you should notice that the green “GPI05” LED

light on the ProtoCessor Board remains on continuously. See Figur e

19 on page 12 for a diagram showing the location of the ProtoCessor

“GPI05” LED.

Computer IP Address Set-up for

Windows 98, NT, and XP

In order for the PT -Link to communicate properly, it is imperative to

set the IP address of both the PT-Link as well as the computer to be

within the same netmask. You need to change the IP address on your

computer. The following instructions will explain how to confi gure

the IP address for Microsoft

NT and XP computers.

Computer IP Address Set-up for

Windows 98

1.) From the Windows START button select Start->

Setting->Control panel.

2.) Double click on the Network icon.

3.) In the Confi guration window, select the TCP/IP entry.

4.) Select Properties and go to the IP Address tab.

®

Windows 98 and Microsoft® Windows

PT-Link Interface

Figure 4: Connecting With Ethernet Cable & Hub

5.) Select Specify an IP address and then enter the

following information:

a.) IP Address 192.168.1.5

b.) Netmask 255.255.255.0

6.) Select OK until the network confi guration program exits.

7.) You might have to reboot the computer before the IP

address is valid.

5

Page 6

PT-Link-LON® Technical Guide

Confi guring the PT-Link Controller

Computer IP Address Set-up for Windows

NT or XP

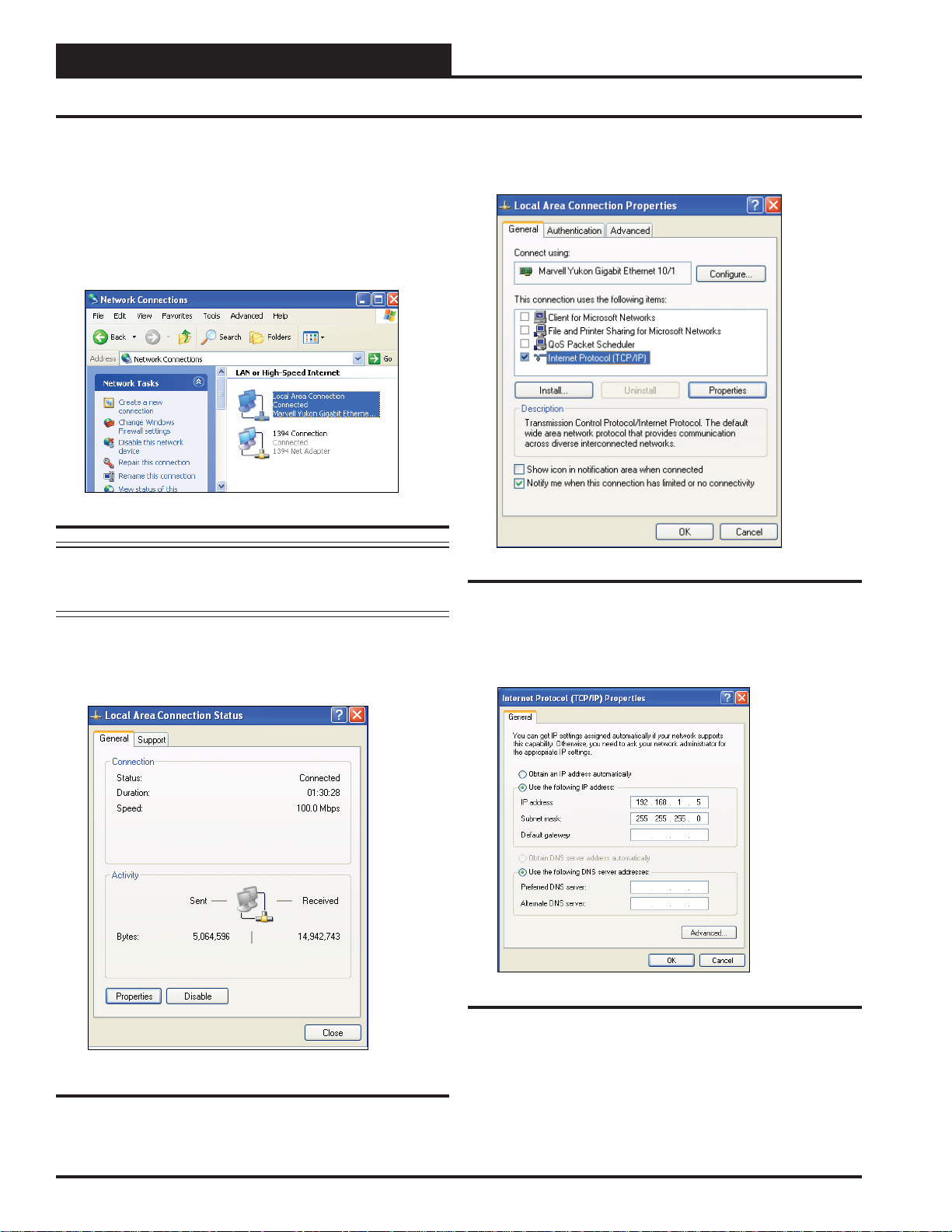

1.) Click <start>; then click <Control Panel>.

2.)

Double-click on the Network Connections icon.

The Network Connections Window will appear.

Figure 5: Network Connections Window

NOTE: If any wireless connections are listed, disable them

by

right-clicking the connection and selecting

<Disable>.

3.) In the Network Connections window, select the Local

Area Connections entry. The Local Area Connection Status

Window will appear.

4.) Click <Properties> in the lower left of the window.

The Local Area Connection Properties window will appear.

Figure 7: Local Area Connection Properties Window

5). In the Connection Items list box, be sure the Internet

Protocol (TCP/IP) is checked. Select the Internet Protocol

(TCP/IP) item to highlight it and then

The Internet Protocol Properties window will appear.

click <Properties>.

Figure 6: Local Area Connection Status Window

6

Figure 8: Internet Protocol Properties Window

6).

Type in the following information:

a.) IP address 192.168.1.5

b.) Subnet mask 255.255.255.0

c.) Default Gateway is blank

7.)

Select <OK> until all of the above network confi guration

windows are closed. You may have to

before the new values are valid.

PT-Link Interface

reboot the computer

Page 7

PT-Link-LON® Technical Guide

Confi guring the PT-Link Controller

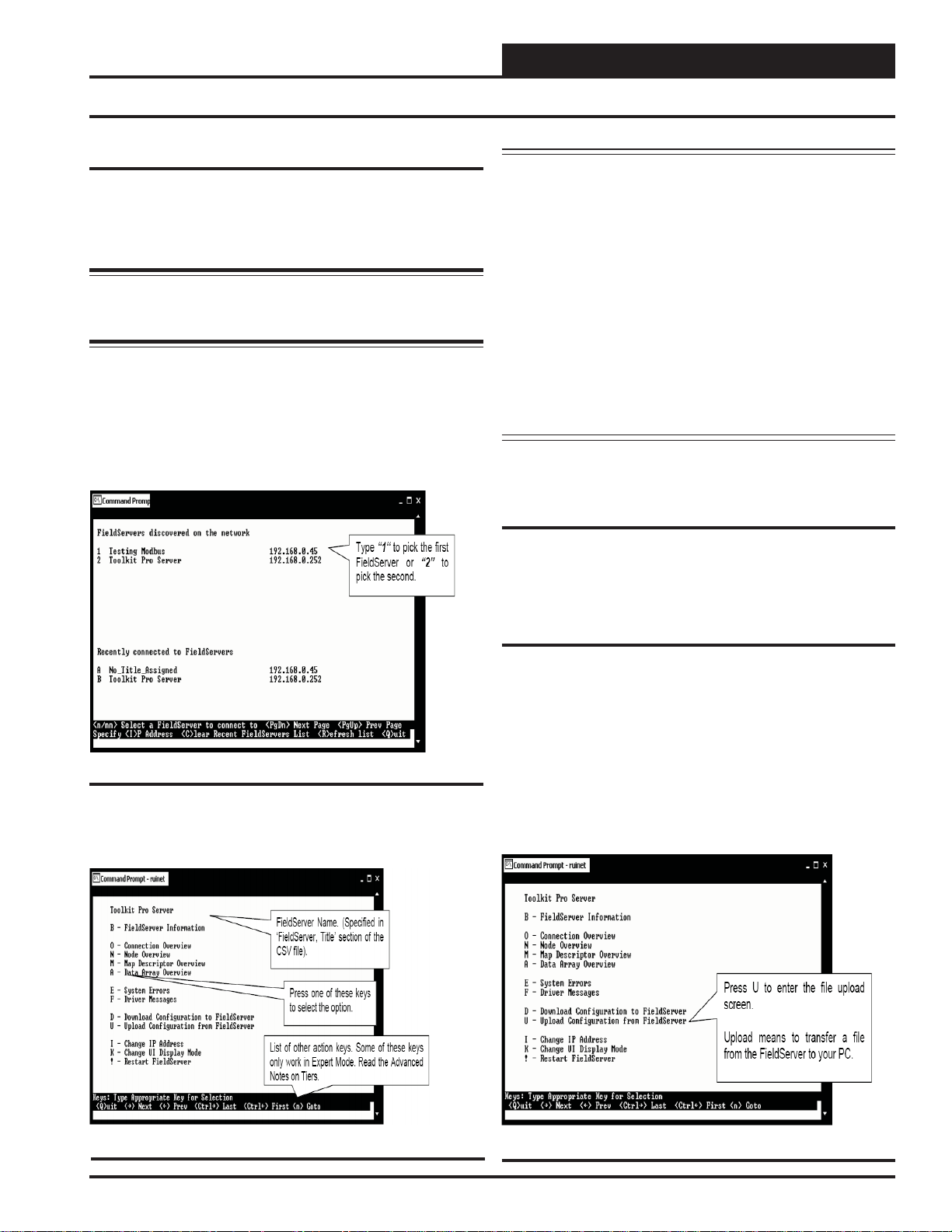

Connecting To The PT-Link

In order to communicate and program the PT-Link you will need to

install RUINET software on your computer. If you do not have the

software, it is available for downloading at www.orioncontrols.com in

the software area of the web site. After installing the software, proceed

with the following instructions.

WARNING: Make sure to load RUINET onto your hard drive

and run the program from your hard drive. DO NOT under any

circumstances run RUINET from your cd drive.

If RUINET is in the desktop directory (if it isn’t, locate its directory),

double-click on RUINET , and the RUINET program should run. If you

have only one PT-Link connected to the network, then RUINET will

automatically connect to that particular PT -Link; otherwise, a menu will

appear to allow the selection of the desired PT-Link.

This menu will look similar to the one shown in Figure 9.

Note: If RUINET is unable to establish a connection, there

are a few simple procedures you can perform to try to

determine the problem. To verify your network cables,

observe the “Yellow” LED displayed below “Ethernet

Connection” on the PT-Link’s ProtoCessor Module.

This LED should be on if the 10 BaseT cable is good.

Secondly, observe the “Green” LED below “Ethernet

Connection”. This LED should be solid while RUINET

is running. If the LEDs are lit as expected, and RUINET

still does not receive replies, then the netmask is probably incorrect. If this does not help, then your Ethernet

setup on your PC is possibly not compatible. Ensure that

you have an Ethernet adapter installed in your software

confi guration and that it is confi gured to run the TCP/IP

protocol. If you are still unable to connect, please contact

WattMaster Controls, Inc.

Making Changes to the Confi guration

File (confi g.csv)

To make changes to the confi guration fi le on the PT-Link, use the pro-

cedures outlined that follow — Upload, Address, Poll, and Download

the Confi guration File.

Figure 9: RUINET PT-Link Selection Menu

Select the required PT-Link by typing the Number or Letter in the left

hand column. You should now have a menu that looks like Figure 10.

You are now ready to send and receive fi les to and from the PT-Link.

Upload Confi g.csv from the PT-Link

The PT-Link contains a confi guration fi le (confi g.csv) that includes

information such as addressing. This fi le can be uploaded from the

PT-Link for modifi cation if needed. The PT-Link also contains an

external interface fi le otherwise called an XIF fi le (fserver.xif). The

XIF fi le includes information such as SNVT names and LON network

information. This fi le can be uploaded for use with LON programming

software. When uploaded, these fi les can be located in the same directory

that the RUINET executable fi le is stored and run from. Be sure when

uploading that the correct fi le is specifi ed in the upload window. Refer

to Figures 11 & 12 for screen details. Refer to Appendix B for details

on uploading XIF fi les.

Figure 10: RUINET PT-Link Main Menu

PT-Link Interface

Figure 11: RUINET PT-Link Main Menu - Upload

7

Page 8

PT-Link-LON® Technical Guide

Confi guring the PT-Link Controller

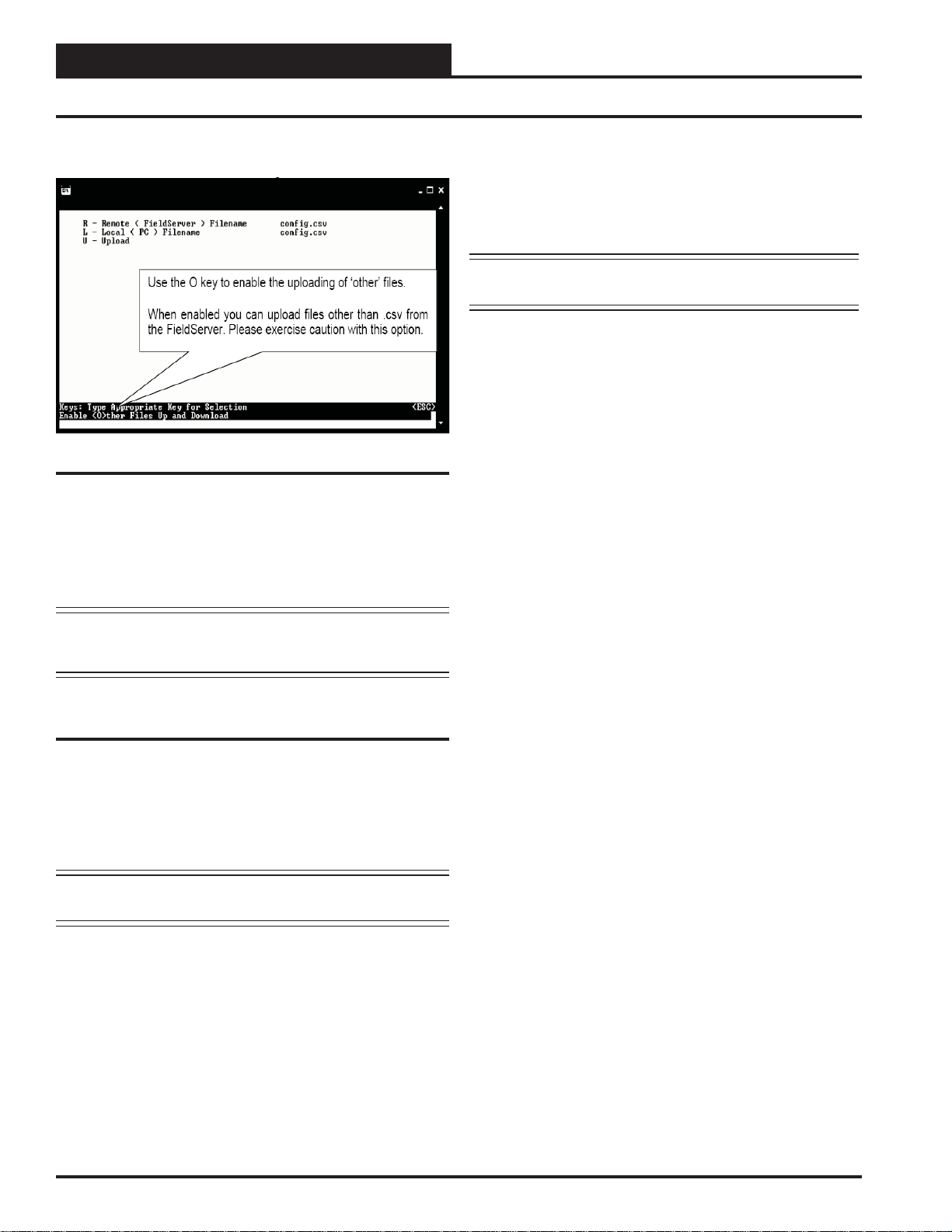

From the Main Menu, type “U”. The menu shown in Figure 12 will appear .

Figure 12: RUINET PT-Link Uploading Files

1.) Begin the upload by pressing “U.”

2.) When the upload is completed, open the uploaded fi le with

Microsoft® Notepad. This program is supplied with

Microsoft® Windows. Type “N” to open using Notepad.

Implicit Addressing Commissioning Using

LonMaker

1.) Ensure that the correct fi rmware and latest confi guration is

loaded on the PT-Link-LON.

NOTE: Each change in the PT-Link-LON requires re-commis-

sioning of the PT-Link-LON in LonMaker.

2.) Ensure that the PT-Link-LON and the LonMaker machine

are on the same network.

3.) Open the existing Network in LonMaker or create a new

Network.

4.) Click on “Create New Network” and follow the network

wizard, making the following selections:

Network Interface: Choose Network Attached

Management Mode: Choose Onnet unless you are

working offl ine

Registered Plug-ins required: None

5.) Once Visio is open with the Network showing, drag a new

device onto the drawing from the toolbox.

WARNING: Only edit the confi g.sys fi le using Notepad. Do

not use Excel. Using Excel to edit the confi g.sys fi le will corrupt

its contents!

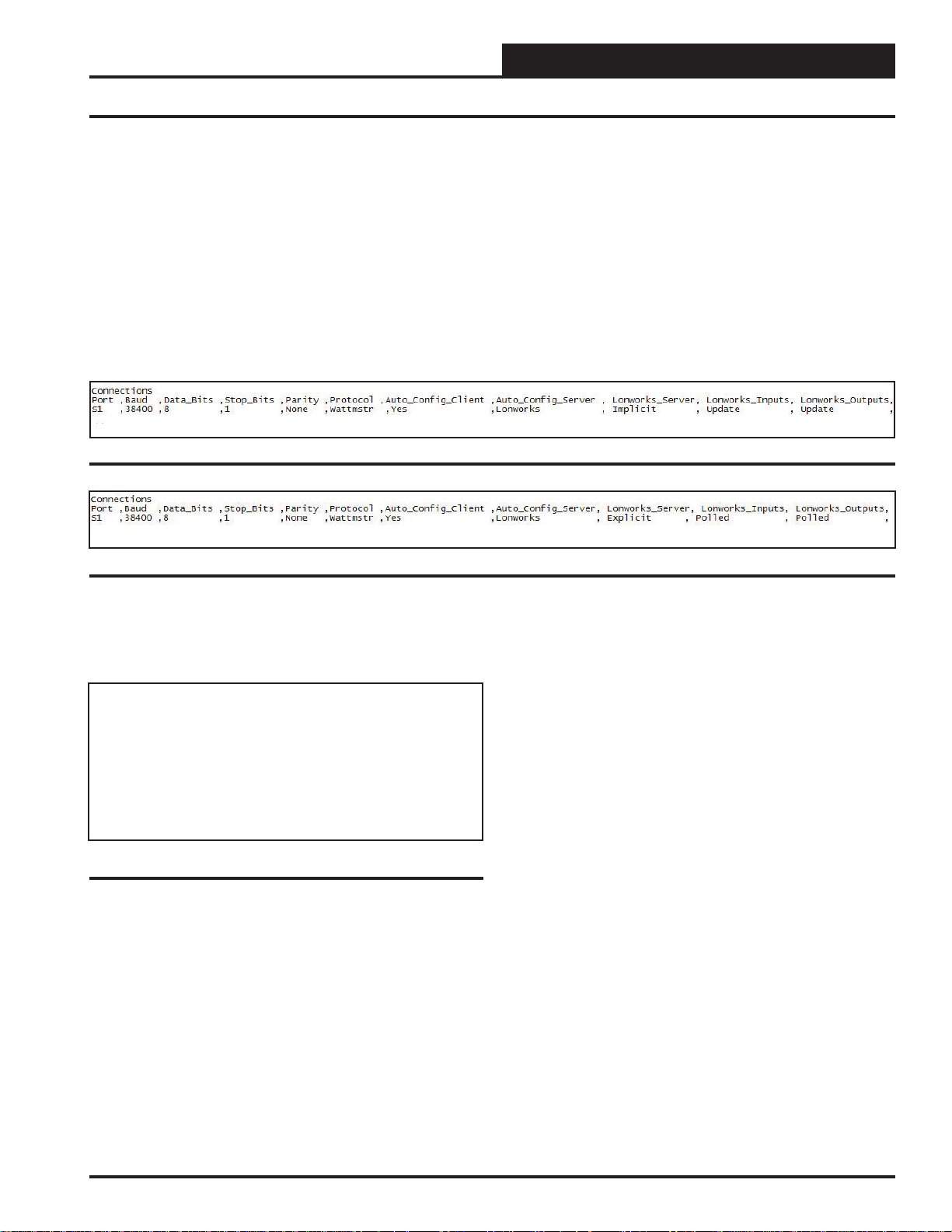

Explicit and Implicit Addressing

Clients can address the PT-Link using explicit or implicit addressing.

Clients using explicit addressing obtain their data transfer parameters

directly from the PT -Link-LON confi guration fi le (confi g.csv). Implicit

addressing is used when a Network Management T ool such as LonMaker®

is used to connect a PT-Link-LON to other LonWorks nodes—the

PT-Link-LON is assigned its data transfer (binding) parameters by the

Network Management Tool.

NOTE: The PT-Link-LON is confi gured from the factory to use

implicit addressing.

Implicit Addressing — Network Manager assigns addresses for

communication and ensures (via address tables in the devices) that

communication connections are known.

Explicit Addressing — Device knows the address of the point in

the remote device and communicates directly without the assistance of

the Network Manager.

6.) Follow the Device Network, making the following

selections:

Enter Device Name: Choose commission device

Specify Device Template: Choose upload from device

Specify Device Channel: Choose Auto Detect

Specify Device Properties: Leave as is (Ping is optional)

Identify Device: Choose service pin

Device Application Image: Leave unchecked

Initial State: Leave as is

7.) Press the service pin on the PT-Link-LON when asked to

do so, and the PT-Link-LON will be commissioned.

8.) Drag a new function block onto the drawing from the

toolbox. Give the function block a name and ensure that it

is allocated to the PT-Link-LON device.

9.) Once the function block is on the drawing, you can drag

input and output variables onto the function block. When

you do this, LonMaker will show you the variables

avail able for binding. Click on the variables you require

(or use the select “all” option), and they will be

commissioned onto the function block.

10.) You are now ready to connect these variables to other

devices by dragging connections from the toolbox and

connecting the variables.

8

PT-Link Interface

Page 9

Troubleshooting the PT-Link Controller

Explicit Addressing & Domain Table Setup

To use explicit addressing, the client needs to change the factory settings

contained in the PT-Link-LON’s confi guration fi le (confi g.csv). The

following are the steps to change the confi guration fi le from implicit to

explicit addressing:

1.) Upload and open the confi g.csv fi le.

2.) Locate the “Connections” section.

3.) Locate the “Lonworks_Server” column and change the

value from “Implicit” shown in Figure 13 to “Explicit”

shown in Figure 14. You should also change the “Lon

works _Input” and “Lonworks_Outputs” from Update to

Polled.

Figure 13: PT-Link-LON Implicit Confi guration

PT-Link-LON® Technical Guide

Figure 14: PT-Link-LON Explicit Confi guration

In addition, the PT-Link-LON must have its domain, subnet, and node

IDs set. This feature is enabled in the confi guration fi le by fi lling out

the Title and System_Address fi elds of the PT-Link-LON parameters

as follows:

//==================================================

//

// Common Information

//

Bridge

System_Address ,Title

23 ,”:D48:S01:Wattmaster Explicit Lon v1.00d”

Figure 15: PT-Link-LON Domain and Subnet Setting

The Title fi eld must start with “:D”, followed by the domain_id in

hexadecimal notation, followed by “:S”, followed by the subnet_id in

hexadecimal notation, and enclosed by “:”. The domain length is automatically determined by the number of digits in the [domain_id] fi eld.

With 2 hexadecimal digits constituting 1 byte, “:D123456:”, for example,

would have a length of 3.

Once the domain table has been set, the “:Dxx:Sxx:” part of the Title

fi eld will be removed.

Now the Title fi eld will be left with [Title continued…] which may be

the Node self documentation string or any title.

After the changes are done, do not forget to save the fi le, download

the new confi guration fi le, and restart the PT-Link-LON. Refer to the

Download Section that follows.

PT-Link Interface

9

Page 10

PT-Link-LON® Technical Guide

Troubleshooting the PT-Link Controller

Download Confi g.csv to the PT-Link

NOTE: Before attempting to send fi les to the PT -Link, make sure

that these fi les are in the same directory as the RUINET

utility being used for sending.

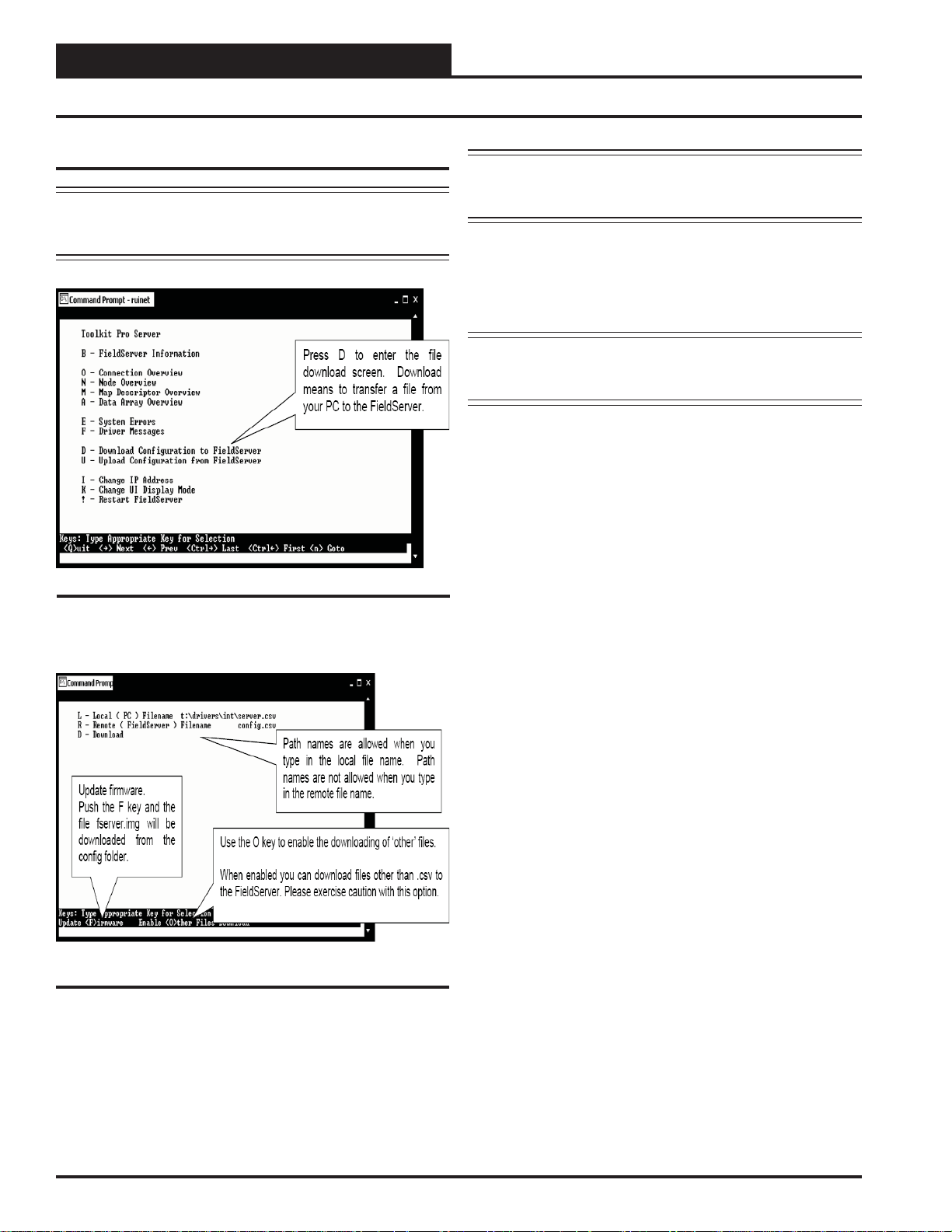

Figure 16: RUINET PT-Link Main Menu - Download

NOTE: The utility will indicate when downloading is complete.

DO NOT reset the PT-Link until this message is displayed, as this will corrupt the PT-Link.

2.) Once the download is complete, push <Esc> to get back to

the main menu and use the “!” option (or simply cycle

power to the PT-Link) to put the new fi le into operation.

It is possible to do multiple downloads to the PT-Link

before resetting it.

NOTE: The Remote Filename option must always be named

“confi g.csv” for confi gurations; otherwise, they will be

ignored by the PT-Link.

From the Main Menu, type “D”. The menu shown in Figure 17 will appear .

Figure 17: RUINET PT-Link Downloading Files

1.) Begin the download by selecting “D.”

10

PT-Link Interface

Page 11

PT-Link-LON® Technical Guide

Troubleshooting the PT-Link Controller

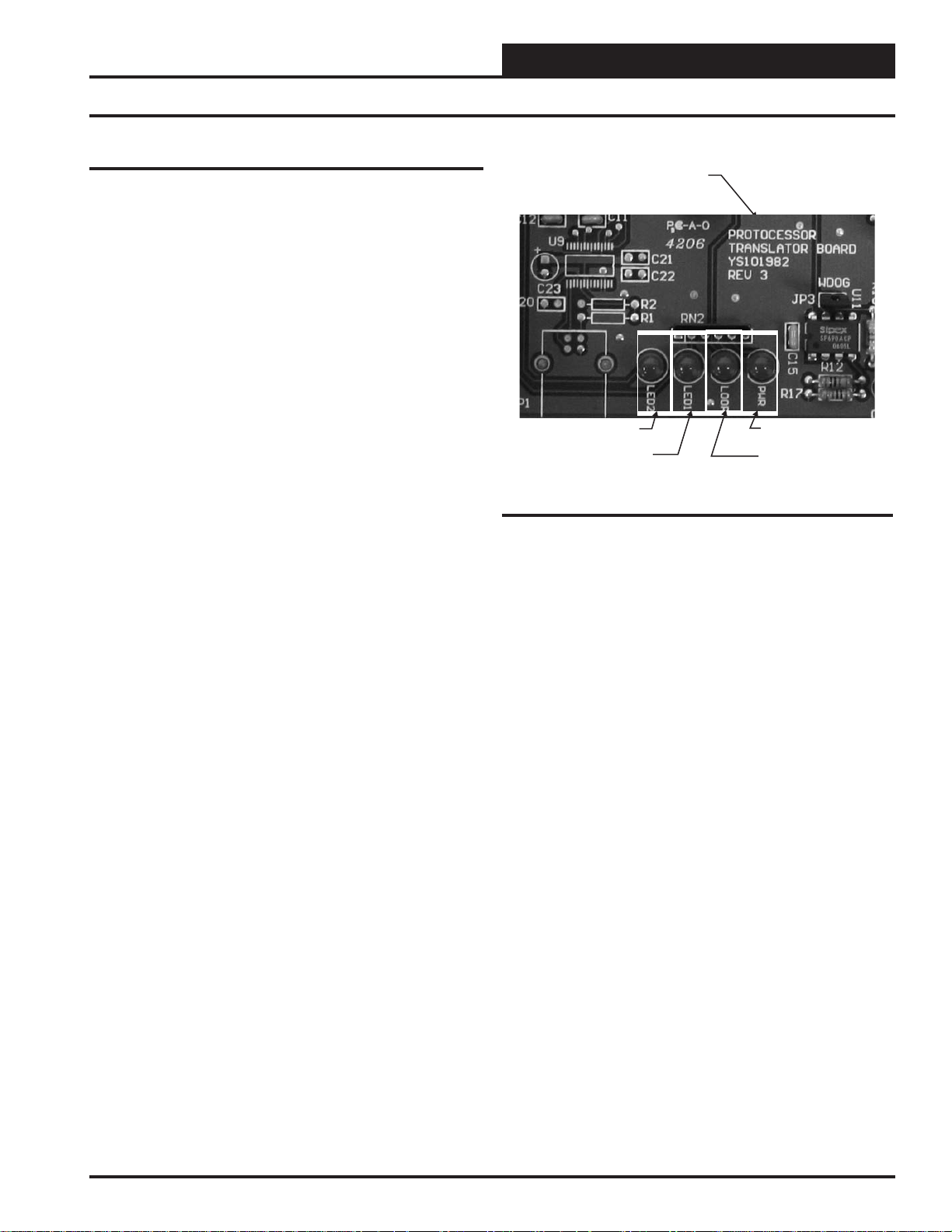

PT-Link Board LEDs

The PT -Link-LON® is equipped with LEDs that can be used for troubleshooting. There are four LEDs on the PT -Link board. See Figur e 18 for

the locations of the LEDs on the PT-Link board. The LED descriptions

and functions are listed in the following paragraphs.

PWR LED

When the PT -Link-LON® is powered up, the “PWR” LED should light

up and stay on continuously. If it does not light up, check to be sure

that you have 24 VAC connected to the board, that the wiring connections are tight, and that they are wired for correct polarity. The 24 VAC

power must be connected so that all ground wires remain common. If

after making all these checks the “PWR” LED still does not light up,

please contact WattMaster Controls Technical Support at our Toll Free

number—866-918-1100—for assistance.

LOOP LED

When power is applied to the PT-Link-LON

also light up. The LED should fl icker rapidly, indicating that the PT -Link

is trying to communicate with the controllers on the loop. A “fl icker”

is defi ned as a brief moment when the LED turns off and back on. If the

“LOOP” LED does not operate as indicated above, fi rst power down

the unit and then reapply power. If this does not work, please contact

W attMaster Controls Technical Support at our Toll Free number—866918-1100—for assistance.

®,

the “LOOP” LED will

PT-Link Base

Board

LED2

LED1

Figure 18: PT-Link-LON® LED Locations

PWR

LOOP

LED 1

When power is fi rst applied, “LED 1” will be off temporarily and then

will blink once if it is communicating with the controller. If the LED

is not blinking, there is a communication problem between the HVAC

controller and the PT-Link board. The “COMM” LED on the HVAC

controller also should be solid and will fl icker occasionally indicating

communication with the PT-Link-LON

not fl icker, then there is no communication between the PT Link and

the controller.

®

. If the “COMM” LED does

LED 2

When power is fi rst applied, “LED 2” will be off temporarily and then

will blink slowly indicating that the PT -Link baseboard is communicating

with the Protocessor Module. If “LED 2” does not blink, check that the

Protocessor Module is installed correctly in the PT-Link baseboard.

PT-Link Interface

11

Page 12

PT-Link-LON® Technical Guide

Troubleshooting the PT-Link Controller

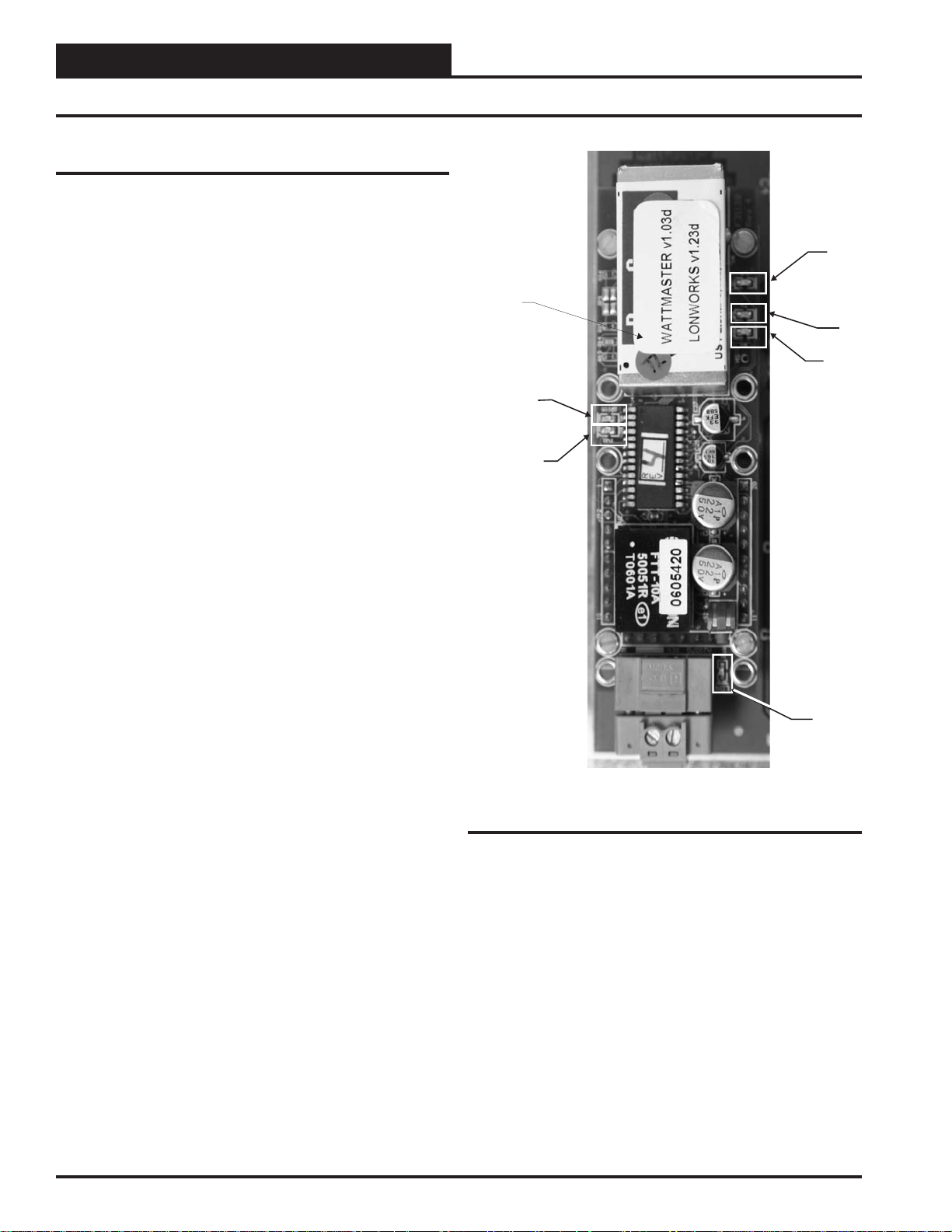

ProtoCessor Module LEDs

PWR LED

When the PT -Link is fi rst powered up, the “PWR” LED should light up

and stay on continuously. See Figure 19. If the LED doesn’t light up,

check that the ProtoCessor is installed correctly and fi rmly connected

to the Base Board.

Protocessor

GPI05 LED

The “GPI05” LED will light up when the Base Board and the ProtoCessor Module have established communications. This can take up to 3

minutes depending on the number of units connected to the PT -Link. If

it fails to light up after 3 minutes, check that the ProtoCessor is installed

correctly and fi rmly to the Base Board.

LON LED

When the unit is fi rst powered up, before commissioning has occurred,

this LED will be blinking to indicate the unit has not been commissioned yet. Once the unit is commissioned, the LED will stay off during

normal operations.

LON

GPI05

LA

TX

RX

PWR

LA LED

When the unit is fi rst powered up, this LED should be blinking constantly .

If this LED is constantly on or constantly off, the Module is not working

properly and needs to be replaced.

TX & RX LEDs

These LEDs work together to indicate that communication is being

established with the desired protocol network. If both LEDs are blinking, then communication is working properly. If both are not blinking,

check the protocol network wiring.

If all of these tests are made and the controller still doesn’t operate,

please contact WattMaster Controls Technical Support at our Toll Free

number—866-918-1100—for assistance.

LON

Figure 19: PT-Link-LON® LED Locations

12

PT-Link Interface

Page 13

Troubleshooting the PT-Link Controller

Using RUINET

Before continuing with the troubleshooting, make sure the PT-Link is

connected correctly and the RUINET software is installed, running, and

functioning correctly.

Verifying Proper Communications

From the Main Screen, press “O” to go the Connection Overview

Screen. This screen supplies information on communication between the

PT-Link and remote devices. A number of aspect screens are available,

and some of the aspect screens have more than one page. Use the space

bar to toggle between aspects and use the <PgUp> and <PgDn> keys

to toggle between pages of the same aspect. The Connection Overview

and Settings Aspect Screen is shown in Figure 20.

The main purpose in this screen is to verify that messages and characters

are being transmitted and received. In addition, it shows the number of

communication errors. If the PT-Link connection “03” is the protocol

connection, verify that is communicating appropriately. If it is not, check

that the PT -Link LEDs are working properly , the unit is wired correctly ,

and the PT-Link is confi gured correctly (Baud Rate, Unit Address &

MAC Address). If the number of errors is constantly increasing, move

to the Error Screen by pressing the <Space Bar> 3 times to fi nd out

the cause of the errors. Use the <PgUp> and <PgDn> keys to toggle

between pages of the Error Screen.

PT-Link-LON® Technical Guide

Figure 20: Connection Overview Screen

Verifying Proper Values

To verify that the correct values for each unit are being communicated

to the PT-Link, move to the Data Array Overview Screen. To get to

the screen, press “A” from the Main Menu. See Figure 21 for screen

details.

In the Data Array Overview Screen (Figure 21) you will be able to

see the data arrays of all the units connected to the PT -Link denoted by

an array name “DA_XXX_IY”—Y being the address of the unit minus

one. The Address of the unit is determined by a set of dip switches.

To view the values being communicated from a specifi c unit, move to

the Data Array Detail Screen (Figure 22) of the unit by entering the

number under which it is listed. For example, for the unit listed in the

third position, enter “03”.

To understand what each value means, look at the Data Array T ables for

the desired unit type, VA V/CAV, MUA II, or VCM. You can change the

writable values from this screen by using the modify command. T o use

the modify command press “M” from the Data Array Detail Screen

and then enter the Offset you want to change followed by a space and

the new value. Example: To change the Cooling Supply Setpoint to 60

in the VAV/CAV, press “M”, enter “58 60”, and then press <Enter>.

This could be useful to prove that the unit can take and keep the setpoints properly.

Figure 21: Data Array Overview Screen

PT-Link Interface

Figure 22: Data Array Detail Screen

13

Page 14

PT-Link-LON® Technical Guide

Data Arrays

VCM-X Modular Data Array For Field Server

Offset 01234567

0

8

16

24

32

40

48

56

64

72

80

88

96

104

AppVer ClSt HtSt OaWtbl TpDmnd SpcTp SaTp RaTp

OaTp DuctPr OaRh UnitMode CtrlSts ClEnbl HtEnbl EcoEnbl

FanDly PofCfg CO2Cfg MdHt2Ins Rt2Ins OnRlys ExRlys12 ExRlys34

EcoPos VfdBwPos VfdExPos AlrmSts AlrmGrp1 AlrmGrp2 AlrmGrp3 SaTpAlm

OaTpAlm SpcTpAlm MchClAlm MchHtAlm PofAlm DrtFAlm SmokeAlm LoSaAlm

HiSaAlm CtrlTpCF CtrlTpHF CtrlTp InRh InRhStM DptStM MdClPos

MdHtPos MdHt2Pos Rt2Pos OcpClSt OcpHtSt UnClOst UnHtOst WtblSt

SaClSt SaHtSt WmupSt SpcTpOst SaTpOst RaTpOst OaTpOst CoilTpSt

DptSt InRhSt DuctPrSt RfPrSt SchdFrc OnRly1 OnRly2 OnRly3

OnRly4 OnRly5 ExRly1 ExRly2 ExRly3 ExRly4 ExRly5 ExRly6

ExRly7 ExRly8 ExRly9 ExRly10 ExRly11 ExRly12 ExRly13 ExRly14

ExRly15 ExRly16 CO2St MinEcoSt CO2Level ByPasDmp RaDmp RfPr

OaDwpt CoilTp SaTpStM PreHtSp OaCFM EtCFM SaCFM OACfmSt

OACfmRs OACfmStM MdCmp2 HdPr1 HdPr2 CdFan1 CdFan2 –

Table 2: VCM-X Modular Data Array For Field Server

VCM-X WSHP (Tulsa) Data Array For Field Server

Offset 01234567

0

8

16

24

32

40

48

56

64

72

80

88

96

104

112

120

AppVer ClSt HtSt OaWtbl TpDmnd SpcTp SaTp RaTp

OaTp DuctPr OaRh UnitMode CtrlSts ClEnbl HtEnbl EcoEnbl

FanDly PofCfg CO2Cfg MdHt2Ins Rt2Ins OnRlys ExRlys12 ExRlys34

EcoPos VfdBwPos VfdExPos AlrmSts AlrmGrp1 AlrmGrp2 AlrmGrp3 SaTpAlm

OaTpAlm SpcTpAlm MchClAlm MchHtAlm PofAlm DrtFAlm SmokeAlm LoSaAlm

HiSaAlm CtrlTpCF CtrlTpHF CtrlTp InRh InRhStM DptStM MdClPos

MdHtPos MdHt2Pos Rt2Pos OcpClSt OcpHtSt UnClOst UnHtOst WtblSt

SaClSt SaHtSt WmupSt SpcTpOst SaTpOst RaTpOst OaTpOst CoilTpSt

DptSt InRhSt DuctPrSt RfPrSt SchdFrc OnRly1 OnRly2 OnRly3

OnRly4 OnRly5 ExRly1 ExRly2 ExRly3 ExRly4 ExRly5 ExRly6

ExRly7 ExRly8 ExRly9 ExRly10 ExRly11 ExRly12 ExRly13 ExRly14

ExRly15 ExRly16 CO2St MinEcoSt CO2Level ByPasDmp RaDmp RfPr

OaDwpt CoilTp SaTpStM PreHtSp OaCFM EtCFM SaCFM OACfmSt

OACfmRs OACfmStM MdCmp2 HdPr1 HdPr2 CdFan1 CdFan2 WaterTpA

WaterTpB A1LSPAlm A1LktAlm A2LSPAlm A2LktAlm B1LSPAlm B1LktAlm B2LSPAlm

B2LktAlm LWT1Alm LWT2Alm POWF1Alm POWF2Alm ComMAlm – –

Table 3: VCM-X WSHP (Tulsa) Data Array For Field Server

14

PT-Link Interface

Page 15

PT-Link-LON® Technical Guide

Data Arrays

VCM-X WSHP (Coil) Data Array For Field Server

Offset 01234567

0

8

16

24

32

40

48

56

64

72

80

88

96

104

112

AppVer ClSt HtSt OaWtbl TpDmnd SpcTp SaTp RaTp

OaTp DuctPr OaRh UnitMode CtrlSts ClEnbl HtEnbl EcoEnbl

FanDly PofCfg CO2Cfg MdHt2Ins Rt2Ins OnRlys ExRlys12 ExRlys34

EcoPos VfdBwPos VfdExPos AlrmSts AlrmGrp1 AlrmGrp2 AlrmGrp3 SaTpAlm

OaTpAlm SpcTpAlm MchClAlm MchHtAlm PofAlm DrtFAlm SmokeAlm LoSaAlm

HiSaAlm CtrlTpCF CtrlTpHF CtrlTp InRh InRhStM DptStM MdClPos

MdHtPos MdHt2Pos Rt2Pos OcpClSt OcpHtSt UnClOst UnHtOst WtblSt

SaClSt SaHtSt WmupSt SpcTpOst SaTpOst RaTpOst OaTpOst CoilTpSt

DptSt InRhSt DuctPrSt RfPrSt SchdFrc OnRly1 OnRly2 OnRly3

OnRly4 OnRly5 ExRly1 ExRly2 ExRly3 ExRly4 ExRly5 ExRly6

ExRly7 ExRly8 ExRly9 ExRly10 ExRly11 ExRly12 ExRly13 ExRly14

ExRly15 ExRly16 CO2St MinEcoSt CO2Level ByPasDmp RaDmp RfPr

OaDwpt CoilTp SaTpStM PreHtSp OaCFM EtCFM SaCFM OACfmSt

OACfmRs OACfmStM MdCmp2 HdPr1 HdPr2 CdFan1 CdFan2 WaterTpA

A1LSPAlm A1LktAlm B1LSPAlm B1LktAlm LWT1Alm POWF1Alm ComMAlm –

Table 4: VCM-X WSHP (Coil) Data Array For Field Server

VCM-X Data Array For Field Server

Offset 01234567

0

8

16

24

32

40

48

56

64

72

80

88

96

104

AppVer ClSt HtSt OaWtbl TpDmnd SpcTp SaTp RaTp

OaTp DuctPr OaRh UnitMode CtrlSts ClEnbl HtEnbl EcoEnbl

FanDly PofCfg CO2Cfg MdHt2Ins Rt2Ins OnRlys ExRlys12 ExRlys34

EcoPos VfdBwPos VfdExPos AlrmSts AlrmGrp1 AlrmGrp2 AlrmGrp3 SaTpAlm

OaTpAlm SpcTpAlm MchClAlm MchHtAlm PofAlm DrtFAlm SmokeAlm LoSaAlm

HiSaAlm CtrlTpCF CtrlTpHF CtrlTp InRh InRhStM DptStM MdClPos

MdHtPos MdHt2Pos Rt2Pos OcpClSt OcpHtSt UnClOst UnHtOst WtblSt

SaClSt SaHtSt WmupSt SpcTpOst SaTpOst RaTpOst OaTpOst CoilTpSt

DptSt InRhSt DuctPrSt RfPrSt SchdFrc OnRly1 OnRly2 OnRly3

OnRly4 OnRly5 ExRly1 ExRly2 ExRly3 ExRly4 ExRly5 ExRly6

ExRly7 ExRly8 ExRly9 ExRly10 ExRly11 ExRly12 ExRly13 ExRly14

ExRly15 ExRly16 CO2St MinEcoSt CO2Level ByPasDmp RaDmp RfPr

OaDwpt CoilTp SaTpStM PreHtSp OaCFM EtCFM SaCFM OACfmSt

OACfmRs OACfmStM ––––––

Table 5: VCM-X Data Array For Field Server

PT-Link Interface

15

Page 16

PT-Link-LON® Technical Guide

Data Arrays

SA Controller Data Array For Field Server

Offset 01234567

0

8

16

24

32

40

48

56

64

72

80

88

AppVer ClSt HtSt TpDmnd SpcTp SaTp DuctPr UnitMode

CtrlSts ClEnbl HtEnbl EcoEnbl FanDly MdHt2Ins Rt2Ins EcoPos

VfdBwPos SaTpAlm SpcTpAlm MchClAlm MchHtAlm PofAlm DrtFAlm LoSaAlm

HiSaAlm CtrlTpCF CtrlTpHF CtrlTp InRh InRhStM DptStM MdClPos

MdHtPos MdHt2Pos Rt2Pos OcpClSt OcpHtSt UnClOst UnHtOst SaClSt

SaHtSt WmupSt SpcTpOst SaTpOst CoilTpSt DptSt InRhSt DuctPrSt

SchdFrc OnRly1 OnRly2 OnRly3 OnRly4 OnRly5 ExRly1 ExRly2

ExRly3 ExRly4 ExRly5 ExRly6 ExRly7 ExRly8 ExRly9 ExRly10

ExRly11 ExRly12 ExRly13 ExRly14 ExRly15 ExRly16 CoilTp SaTpStM

PreHtSp EaTp EwTp EaRH HdPr1 HdPr2 CoilTp2 EaDpt

WSEByp WSEByp2 MdCmp2 CoilTpSt CdPos1 CdPos2 EaTpAlm EmerAlm

PoWFAlm DrnAlm EaTpOst EwTpOst ––––

Table 6: SA Controller Data Array For Field Server

VCM Data Array For Field Server

Offset 01234567

0

8

16

24

32

40

48

56

64

72

80

88

96

AppVer ClSt HtSt OaWtbl TpDmnd SpcTp SaTp RaTp

OaTp DuctPr OaRh UnitMode CtrlSts ClDmnd HtDmnd DehmDmnd

ClEnbl HtEnbl EcoEnbl FanDly WmupDmnd PofCfg CO2Cfg MdHt2Ins

Rt2Ins OnRlys ExRlys12 ExRlys34 EcoPos VfdBwPos VfdExPos AlrmSts

AlrmGrp1 AlrmGrp2 AlrmGrp3 SaTpAlm OaTpAlm SpcTpAlm MchClAlm MchHtAlm

PofAlm DrtFlAlm SmokeAlm LoSaAlm HiSaAlm CtrlTpCF CtrlTpHF CtrlTp

InRh InRhStM DptStM MdClPos MdHtPos MdHt2Pos Rt2Pos OcpClSt

OcpHtSt UnClOst UnHtOst WtblSt SaClSt SaHtSt WmupSt SpcTpOst

SaTpOst RaTpOst OaTpOst CoilTpSt DptSt InRhSt DuctPrSt RfPrSt

SchdFrc OnRly1 OnRly2 OnRly3 OnRly4 OnRly5 ExRly1 ExRly2

ExRly3 ExRly4 ExRly5 ExRly6 ExRly7 ExRly8 ExRly9 ExRly10

ExRly11 ExRly12 ExRly13 ExRly14 ExRly15 ExRly16 CO2St MinEcoSt

CO2Level ByPasDmp RaDmp RfPr OaDwpt CoilTp SaTpStM PreHtSp

Table 7: VCM Data Array For Field Server

16

PT-Link Interface

Page 17

PT-Link-LON® Technical Guide

Appendix A

Brown/White

White/Brown

Orange/White

White/Blue

Blue/White

White/Orange

RJ-45 Connector as viewed

from the bottom side

8

7

6

5

4

3

Use the standard EIA/TIA color code for "CROSS OVER CABLE" as shown.

It is the same as a standard Cat 5 patch cabling. The outer cable jacket should

not

Be "Orange" in color. This is a straight thru pin 1 to pin 1 cable.

not

RJ-45 Connector as viewed

from the bottom side

White/Orange

1

Orange/White

2

White/Green

3

Blue/White

4

White/Blue

5

Green/White

6

Figure 23: RJ-45 8P8C Cable for WattMaster Cross Over Networking - WattMaster Part #HZ000136

PT-Link Interface

17

Page 18

PT-Link-LON® Technical Guide

Appendix B

External Interface Files (XIF Files)

At start-up the PT-Link-LON creates an external interface fi le (XIF)

called fServer.xif based on the information contained in the PT-LinkLON’s confi guration fi le (confi g.csv). The PT-Link-LON’ s confi guration

can be changed by uploading and editing the confi g.csv fi le; therefore,

the XIF fi le must be obtained by uploading it from the PT-Link-LON.

The recommended procedure for obtaining the XIF fi le for the PT -Link-

LON is to upload it. Remember that this XIF fi le will change whenever

the confi guration fi le has been changed and downloaded and the PT-

Link-LON restarted. The following are the steps to extract the external

interface fi le (XIF) from the PT-Link-LON:

1.) Start RUINET application.

2.) Select Fieldserver option “1” (this step may be skipped

when application auto detects PT Link).

3.) In the Main Menu select “A” – Data Array Overview.

4.) You should see 2 array items that are labeled wattmstr dump and wattmstr-stats. Ignore these.

5.) You should see 2 additional arrays for the controller

connected.

Example: DA_C162_I0 and DA_C162_I0b.

6.) After connection has been verifi ed, you can

now exit to the Main Menu using the escape key.

7.) Type “U” – Upload Confi guration.

8.) Type “O” to select other fi les.

9.) If prompted, press any key to continue.

10.) Type “R” – Remote Filename.

11.) Type “fserver.xif”

12. You should now see the name fserver.xif in the column to

the right.

13. Type “U” to upload the XIF fi le.

14. Once fi nished you will have an .xif fi le available in the

same directory as the RUINET executable fi le you were

running from.

WARNING: For easier confi guration, set the unit address to 1.

5.1.) The “b” at the end of the Data Array Name indicates

that it is a mirror array. You can ignore these.

5.2) Verify that your controller is visible or the XIF will not

be generated.

18

PT-Link Interface

Page 19

PT-Link-LON® Technical Guide

Appendix C - VCM-X Modular and WSHP LON Parameters

NOTE: The following points for the VCM-X Modular and VCM-

X WSHP Controllers are additional points. All points and

property identifi ers in the VCM-X Controller table (pages

21-26) also apply to the VCM-X Modular and VCM-X

WSHP Controllers.

SNVT s f or the VCM-X Modular

Binary Output SNVTs are SNVT_lev_disc

all other SNVTs are SNVT_count_inc_f

Parameter Name Object Description Limits

Modulating

Compressor 2

Head

Pressure 1

Head

Pressure 2

Condenser

Fan 1

Condenser

Fan 2

MdCmp2 Analog

Output

HdPr1 Analog

Output

HdPr2 Analog

Output

CdFan1 Analog

Output

CdFan2 Analog

Output

Current position

of the 2nd Stage

of Compressor

Modulation.

Head Pressure for

1st Compressor

Head Pressure for

2nd Compressor

Condenser Fan 1

Signal Status

Condenser Fan 2

Signal Status

SNVT s f or the VCM-X WSHP (Tulsa)

Binary Output SNVTs are SNVT_lev_disc

all other SNVTs are SNVT_count_inc_f

Parameter Name Object Description

Modulating

Compressor 2

Head Pressure 1 HdPr1 Analog

Head Pressure 2 HdPr2 Analog

Condenser Fan 1 CdFan1 Analog

Condenser Fan 2 CdFan2 Analog

Water Temp. A WaterTpA Analog

Water Temp. B WaterTpB Analog

MdCmp2 Analog

Output

Output

Output

Output

Output

Output

Output

Current position of the

2nd Stage of Compressor

Modulation.

Head Pressure for

1st Compressor

Head Pressure for

2nd Compressor

Condenser Fan 1

Signal Status

Condenser Fan 2

Signal Status

Current water

temperature of refrigerant for

System A.

Current water

temperature of refrigerant for

System B.

SNVT s f or the VCM-X WSHP (Tulsa)

Binary Output SNVTs are SNVT_lev_disc

all other SNVTs are SNVT_count_inc_f

Parameter Name Object Description

Compressor A1

Low Suction

Pressure Alarm

Compressor A1

Lockout Alarm

Compressor A2

Low Suction

Pressure Alarm

Compressor A2

Lockout Alarm

Compressor B1

Low Suction

Pressure Alarm

Compressor B1

Lockout Alarm

Compressor B2

Low Suction

Pressure Alarm

Compressor 4

Lockout Alarm

Low Water

Temperature 1

Alarm

Low Water

Temperature 2

Alarm

Proof of Water 1

Flow Alarm

Proof of Water 2

Flow Alarm

Module

Communications

Alarm

A1LSPAlm Binary

Output

A1LktAlm Binary

Output

A2LSPAlm Binary

Output

A2LktAlm Binary

Output

B1LSPAlm Binary

Output

B1LktAlm Binary

Output

B2LSPAlm Binary

Output

B2LktAlm Binary

Output

LWT1Alm Binary

Output

LWT2Alm Binary

Output

POWF1Alm Binary

Output

POWF2Alm Binary

Output

ComMAlm Binary

Output

Alarm that indicates

Suction Pressure for

Compressor A1 is below the

Low Suction Pressure Cooling

(Heating) Setpoint.

Alarm that indicates

Compressor A1 is locked out.

Alarm that indicates

Suction Pressure for

Compressor A2 is below the

Low Suction Pressure Cooling

(Heating) Setpoint.

Alarm that indicates

Compressor A2 is locked out.

Alarm that indicates

Suction Pressure for

Compressor B1 is below the

Low Suction Pressure Cooling

(Heating) Setpoint.

Alarm that indicates

Compressor B1 is locked out.

Alarm that indicates

Suction Pressure for

Compressor B2 is below the

Low Suction Pressure Cooling

(Heating) Setpoint.

Alarm that indicates

Compressor B2 is locked out.

Alarm that indicates water

temperature is below the

Leaving Water Safety Setpoint

(Heating only) for System A.

Alarm that indicates water

temperature is below the

Leaving Water Safety Setpoint

(Heating only) for System B

Alarm that indicates no Proof

of Water Flow for System A

(A1/A2)

Alarm that indicates no Proof

of Water Flow for System B

(B1/B2)

Alarm that indicates that one

or more Modules are not

communicating with the

VCM-X WSHP Controller.

PT-Link Interface

19

Page 20

PT-Link-LON® Technical Guide

Appendix C - VCM-X Modular and WSHP LON Parameters

SNVT s f or the VCM-X WSHP (Coil)

Binary Output SNVTs are SNVT_lev_disc

all other SNVTs are SNVT_count_inc_f

Parameter Name Object Description

Modulating

Compressor 2

Head Pressure 1 HdPr1 Analog

Head Pressure 2 HdPr2 Analog

Condenser

Fan 1

Condenser

Fan 2

Water Temp. A WaterTpA Analog

Compressor A

Low Suction

Pressure Alarm

Compressor A

Lockout Alarm

Compressor B

Low Suction

Pressure Alarm

Compressor B

Lockout Alarm

Low Water

Temperature

Alarm

Proof of Water

Flow Alarm

Module

Communica-

tions

Alarm

MdCmp2 Analog

Output

Output

Output

CdFan1 Analog

Output

CdFan2 Analog

Output

Output

A1LSPAlm Binary

Output

A1LktAlm Binary

Output

B1LSPAlm Binary

Output

B1LktAlm Binary

Output

LWT1Alm Binary

Output

POWF1Alm Binary

Output

ComMAlm Binary

Output

Current position of the

2nd Stage of Compressor

Modulation.

Head Pressure for

1st Compressor

Head Pressure for

2nd Compressor

Condenser Fan 1

Signal Status

Condenser Fan 2

Signal Status

Current water

temperature.

Alarm that indicates

Suction Pressure for Circuit A

is below the Low

Suction Pressure Cooling

(Heating) Setpoint.

Alarm that indicates Circuit A

Compressors are locked out.

Alarm that indicates

Suction Pressure for Circuit B

is below the Low

Suction Pressure Cooling

(Heating) Setpoint.

Alarm that indicates Circuit B

Compressors are locked out.

Alarm that indicates water tem-

perature is below the Leaving

Water Safety

Setpoint (Heating only).

Alarm that indicates no

Proof of Water Flow.

Alarm that indicates that one

or more Modules are not com-

municating with the VCM-X

WSHP Controller.

20

PT-Link Interface

Page 21

PT-Link-LON® Technical Guide

Appendix D - VCM-X LON Parameters

SNVT s f or the VCM-X Controller

Binary Output SNVTs are SNVT_lev_disc utput

all other SNVTs are SNVT_count_inc_f

Parameter Name Object Description

Alarm

Status

Control

Status

Occupied/

Mode

Enable

Cooling

Setpoint

Mirror

Control

Temperature

Duct Static

Pressure

Economizer

Position

Occupied/

Mode

Enable

Heating

Setpoint

Mirror

Modulating

Gas Valve

Position

On Board

Relays

Outdoor Air

Dewpoint

Outdoor Air

Humidity

Outdoor Air

Temperature

Outdoor Air

Wetbulb

Reheat

Value

Position

Relief

Pressure

Return Air

Temperature

AlrmSts Analog

CtrlSts Analog

ClSt Analog

CtrlTp Analog

DuctPr Analog

EcoPos Analog

HtSt Analog

MdHt-

2Pos

OnRlys Analog

OaDwpt Analog

OaRh Analog

OaTp Analog

OaWtbl Analog

Rt2Pos Analog

RfPr Analog

RaTp Analog

Output

Output

Output

Output

Output

Output

Output

Analog

Output

Output

Output

Output

Output

Output

Output

Output

Output

Needed only in

legacy application.

Current operational

status.

Occupied/ Mode

Enable Cooling

Setpoint Mirror.

Current value of the

control temperature

sensor.

Current value of the

duct static pressure

sensor.

Current position

of the economizer

damper.

Occupied/ Mode

Enable Heating

Setpoint

Mirror.

Current position

of MODGAS II

modulating gas

valve control.

Needed only in

legacy application.

Current calculated

outdoor air

dewpoint added on

version 1.09.

Current value of the

outdoor humidity

sensor.

Current value of the

outdoor tempera-

ture sensor.

Current calculated

value of the out-

door wetbulb

temperature.

Current position of

MHGRV modulat-

ing hot gas reheat

valve control.

Current value of the

building pressure

sensor.

Current value of the

return temperature

sensor.

Limits

SNVT s f or the VCM-X Controller

Binary Output SNVTs are SNVT_lev_disc utput

all other SNVTs are SNVT_count_inc_f

Parameter Name Object Description

Indoor

Humidity

Space

Temperature

Current

Supply Air

Setpoint

Supply Air

Temperature

Temperature

Demand

VFD

Blower Fan

VFD

Relief Fan

Application

Software

Version

Alarm

Group 1

Alarm

Group 2

Alarm

Group 3

Dewpoint

Setpoint

Mirror

External

Relays 1-2

External

Relays 3-4

Indoor Rh

Setpoint

Mirror

Modulating

Cool

Position

InRh Analog

SpcTp Analog

SaTpStM Analog

SaTp Analog

TpDmnd Analog

VfdBw-

Pos

VfdExPos Analog

AppVer Analog

AlrmGrp1 Analog

AlrmGrp2 Analog

AlrmGrp3 Analog

DptStM Analog

ExRlys12 Analog

ExRlys34 Analog

InRhStM Analog

MdClPos Analog

Output

Output

Output

Output

Output

Analog

Output

Output

Output

Output

Output

Output

Output

Output

Output

Output

Output

Current value of

the indoor humidity

sensor.

Current value of the

space temperature

sensor.

Current SAT

Cooling or Heating

setpoint if there

is no reset source;

Current calculated

SAT setpoint with

Reset Source.

Current value of the

supply air

temperature sensor.

Based on the

comparison

between the

current Control

Temperature and

the Heating or

Cooling Setpoint

Temperatures. Does

not work for supply

air control

Current position of

the VFD blower fan

signal.

Current position of

the VFD relief

fan signal.

Current version of

the software in the

unit.

Needed only in

legacy application.

Needed only in

legacy application.

Needed only in

legacy application.

Mirror of the DPtSt

“read only.”

Needed only in

legacy application.

Needed only in

legacy application.

Mirror of the

InRhSt “read only.”

Current position of

the modulating

cooling signal

(Chilled water or

digital compressor).

Limits

PT-Link Interface

21

Page 22

PT-Link-LON® Technical Guide

Appendix D - VCM-X LON Parameters

SNVT s f or the VCM-X Controller

Binary Output SNVTs are SNVT_lev_disc

all other SNVTs are SNVT_count_inc_f

Parameter Name Object Description

Modulating

Heat

Position

Unit Mode UnitMode Analog

Return Air

Level

CO

2

Bypass

Damper

Position

Return

Damper

Position

Coil

Temperature

Outdoor Air

CFM

Exhaust

CFM

Supply Air

CFM

Current

Calculated

OA CFM

setpoint

Dewpoint

Setpoint

Occupied/

Mode

Enable

Cooling

Setpoint

MdHtPos Analog

CO2Level Analog

ByPas-

Dmp

RaDmp Analog

CoilTp Analog

OaCFM Analog

EtCFM Analog

SaCFM Analog

OACfm-

StM

DptSt Analog

OcpClSt Analog

Output

Output

Output

Analog

Output

Output

Output

Output

Output4

Output

Analog

Output

Input

Input

Current position of

the modulating

heating signal (hot

water or SCR heat).

Needed only in

legacy application.

Current value of the

CO2 sensor.

Current position of

the bypass damper

signal.

Current position of

the return damper

signal.

Current coil

temperature reading

added on version

1.09.

Current Outdoor

Airfl ow

Measurement

Current Exhaust

Airfl ow

Measurement

Current Supply

Airfl ow

Measurement

Current calculated

Outdoor Air CFM

based on CO

If the outdoor

dewpoint rises

above this setpoint,

the unit will

Dehumidifi cation

If the control tem-

perature rises one

degree above this

setpoint, the control

will activate the

cooling demand.

If the control

temperature is the

Supply Air Sensor,

then the cooling

demand is always

level.

2

activate the

Demand.

active.

Limits

35 80

099

SNVT s f or the VCM-X Controller

Binary Output SNVTs are SNVT_lev_disc

all other SNVTs are SNVT_count_inc_f

Parameter Name Object Description

Occupied/

Mode

Enable

Heating

Setpoint

Outdoor

Air Sensor

Offset

Return

Air Sensor

Offset

Schedule

Force

Space

Sensor

Offset

SAT/Reset

Source

Cooling

Setpoint

SAT/Reset

Source

Heating

Setpoint

Supply

Air Sensor

Offset

OcpHtSt Analog

Input

OaTpOst Analog

Input

RaTpOst Analog

Input

SchdFrc Analog

Input

SpcTpOst Analog

Input

SaClSt Analog

Input

SaHtSt Analog

Input

SaTpOst Analog

Input

If the control

temperature drops

one degree below

this setpoint,

the control will

activate the heating

demand. If the

control

temperature

is the Supply

Air Sensor, then

there is no heating

demand.

If the Outdoor

Temperature Sensor

is reading

incorrectly, you can

use this option to

enter an offset

temperature to

adjust the Sensor’s

Temperature.

If the Return Tem-

perature Sensor is

reading incorrectly,

you can use this

option to enter an

offset temperature

to adjust the Sen-

sor’s T emperature.

0 = Auto/

Unoccupied Mode

1 = Forced On

2 = Forced Off

If the Space

Temperature

Sensor is reading

incorrectly, you can

use this option to

enter an offset

temperature to

adjust the Sensor’s

Temperature.

Supply Air setpoint

or Reset Source

target temperature

in Cooling Mode.

Supply Air setpoint

or Reset Source

target temperature

in Heating Mode.

If the Supply Air

Temperature Sensor

is reading incor-

rectly, you can use

this option to enter

an offset

temperature to

adjust the Sensor’s

Temperature.

Limits

99

-100 100

-100 100

02

-100 100

40 80

40 200

-100 100

22

PT-Link Interface

Page 23

PT-Link-LON® Technical Guide

Appendix D - VCM-X LON Parameters

SNVT s f or the VCM-X Controller

Binary Output SNVTs are SNVT_lev_disc

all other SNVTs are SNVT_count_inc_f

Parameter Name Object Description

Warm Up

Setpoint

Wet Bulb

Setpoint

Coil

Temperature

Setpoint

Relief

Pressure

Setpoint

Indoor

Humidity

Setpoint

Unoccupied

Cooling

Offset

WmupSt Analog

Input

WtblSt Analog

Input

CoilTpSt Analog

Input

RfPrSt Analog

Input

InRhSt Analog

Input

UnClOst Analog

Input

In a VAV

application, upon

entering the

occupied mode,

the Warm-up

Demand will be

activated if the

return air tem-

perature falls one

degree below this

setpoint.

The economizer is

enabled if the

outdoor tempera-

ture or wetbulb

falls below this

setpoint.

This is the coil

suction temperature target during

dehumidifi cation

mode. Produces

dewpoint in the

supply air

approximately

10°F above this

setpoint.

This is the target

building pressure

to be maintained

by the VFD Relief

signal.

If the indoor

humidity rises

above this set-

point, the unit will

activate the

Dehumidifi cation

Demand.

During the

Unoccupied Mode

of Operation, this

Setpoint spreads

the Occupied

Cooling Setpoint

out by a user

adjustable amount.

If you do not want

Cooling to operate

during the

Unoccupied

Mode, use the

default setting

of 30°F for these

setpoints.

Limits

080

35 70

-0.2 0.2

0 100

030

SNVT s f or the VCM-X Controller

Binary Output SNVTs are SNVT_lev_disc

all other SNVTs are SNVT_count_inc_f

Parameter Name Object Description

Unoccupied

Heating

Offset

CO

Setpoint

Minimum

Outside Air

Setpoint

Static

Pressure

Setpoint

Preheater

Setpoint

Outdoor

Air CFM

Setpoint

Outdoor Air

CFM Reset

Limit

UnHtOst Analog

CO2St Analog

2

MinEcoSt Analog

DuctPrSt Analog

PreHtSp Analog

OACfmSt Analog

OACfmRs Analog

Input

Input

Input

Input

Input

Input

Input

During the

Unoccupied Mode

of Operation, this

Setpoint spreads

the Occupied

Heating Setpoint

out by a user

adjustable amount.

If you do not want

Heating to operate

during the Unoccupied Mode, use

the default setting

of 30°F for these

setpoints.

When the CO2

level rises above

the CO2 Protection

Limit Max Level,

the Economizer’s

Minimum Position

will begin to reset

open proportion-

ally between the

CO

Protection

2

Limit Max Level

Setpoint and the

Reset Range

Setpoint.

This is the

minimum position

of the economizer

in the occupied

modes.

This is the target

duct pressure to

be maintained by

the VFD blower

signal.

Low Outside Air

Ambient

Protection Set-

point

Minimum desired

Outdoor Air CFM.

Maximum desired

Outdoor Air CFM

when CO

reaches

2

its reset limit.

Limits

030

0 3000

1 100

0.01 3

0 100

0.10 K 200 K

0.10 K 200 K

PT-Link Interface

23

Page 24

PT-Link-LON® Technical Guide

Appendix D - VCM-X LON Parameters

SNVT s f or the VCM-X Controller

Binary Output SNVTs are SNVT_lev_disc

all other SNVTs are SNVT_count_inc_f

Parameter Name Object Description Limits

Bad Supply

Air Sensor

CO

Sensor

2

Installed

Cooling

Enabled

Economizer

Enabled

Fan Start Up

Delay

Fan

Proving

Alarm

Heating

Enabled

High

Supply Air

Temperature

Alarm

Low Supply

Air

Temperature

Alarm

MODGAS

II

Connected

Proof of

Flow

Confi gured

REHEAT II

Connected

SaTpAlm Binary

Output

CO2Cfg Binary

Output

ClEnbl Binary

Output

EcoEnbl Binary

Output

FanDly Binary

Output

PofAlm Binary

Output

HtEnbl Binary

Output

HiSaAlm Binary

Output

LoSaAlm Binary

Output

MdHt2Ins Binary

Output

PofCfg Binary

Output

Rt2Ins Binary

Output

Alarm that

indicates a failure

in the

supply air sensor.

Status that

indicates the CO2

function has been

confi gured.

Status that indicates

mechanical cooling

is enabled.

Status that indicates

the economizer is

enabled.

Status that indicates

the fan is

commanded to run,

but it is in the start

up delay mode.

Alarm that

indicates a failure

in the fl ow of the

VFD blower.

Status that

indicates that

mechanical heating

is enabled.

The Supply Air

has risen above

the Hi SAT Cutoff

Setpoint. Heating

stages begin to deac-

tivate and the fan

continues to run.

The Supply Air has

fallen below the Hi

SAT Cutoff Setpoint

and cooling stages

will begin to deactivate. If the unit is in

Economizer, Vent,

or Heating Mode

the Supply Fan will

shut off.

Status that indicates

the MODGAS II

controller is

connected.

Status that indicates

the proof of fl ow

function has been

confi gured.

Status that indicates

the MHGRV

controllers is

connected to the

system.

SNVT s f or the VCM-X Controller

Binary Output SNVTs are SNVT_lev_disc

all other SNVTs are SNVT_count_inc_f

Parameter Name Object Description Limits

Mechanical

Cooling

Alarm

Mechanical

Heating

Alarm

Dirty Filter

Detected

Control

Temperature

Cool Failure

Control

Temperature

Heat Failure

Outdoor Air

Temperature

Lost

Smoke

Detected

Alarm

Space

Temperature

Sensor Lost

MchClAlm Binary

Output

MchHtAlm Binary

Output

DrtFlAlm Binary

Output

CtrlTpCF Binary

Output

CtrlTpHF Binary

Output

OaTpAlm Binary

Output

SmokeAlm Binary

Output

SpcTpAlm Binary

Output

Compressor Relays

are enabled but

the Supply Air

Temperature has

not fallen 5°F w/in

a user-adjustable

time period. This

does not indicate

compressors are

active and will not

shut the unit down.

Heating Mode has

been initiated but

the Supply Air

Temperature has

not risen 5°F w/in

a user-adjustable

time period. This

does not indicate

heat stages are

active and will not

shut the unit down.

Alarm that indicates

the fi lters are dirty.

This alarm is

activated if the

control temperature

does not get within

5°F to the occupied

cooling setpoint

in an hour in the

cooling mode. This

alarm is not used

in 100% outside air

units or supply air

control.

This alarm is

activated if the

control temperature

does not get within

5°F to the occupied

heating setpoint

in an hour in the

heating mode. This

alarm is not used

in 100% outside air

units or supply air

control.

Alarm that

indicates a failure

in the outdoor air

temperature.

Alarm that indicates

the Smoke sensor

has been activated.

Alarm that indicates

a failure in the

space temperature

sensor.

24

PT-Link Interface

Page 25

PT-Link-LON® Technical Guide

Appendix D - VCM-X LON Parameters

SNVT s f or the VCM-X Controller

Binary Output SNVTs are SNVT_lev_disc

all other SNVTs are SNVT_count_inc_f

Parameter Name Object Description Limits

On Board

Relay 1

On Board

Relay 2

On Board

Relay 3

On Board

Relay 4

On Board

Relay 5

Expansion

Relay 1

Expansion

Relay 2

Expansion

Relay 3

Expansion

Relay 4

Expansion

Relay 5

Expansion

Relay 6

Expansion

Relay 7

Expansion

Relay 8

Expansion

Relay 9

Expansion

Relay 10

Expansion

Relay 11

Expansion

Relay 12

Expansion

Relay 13

Expansion

Relay 14

Expansion

Relay 15

Expansion

Relay 16

OnRly1 Binary

Output

OnRly2 Binary

Output

OnRly3 Binary

Output

OnRly4 Binary

Output

OnRly5 Binary

Output

ExRly1 Binary

Output

ExRly2 Binary

Output

ExRly3 Binary

Output

ExRly4 Binary

Output

ExRly5 Binary

Output

ExRly6 Binary

Output

ExRly7 Binary

Output

ExRly8 Binary

Output

ExRly9 Binary

Output

ExRly10 Binary

Output

ExRly11 Binary

Output

ExRly12 Binary

Output

ExRly13 Binary

Output

ExRly14 Binary

Output

ExRly15 Binary

Output

ExRly16 Binary

Output

Current status of

relay 1.

Current status of

relay 2.

Current status of

relay 3.

Current status of

relay 4.

Current status of

relay 5.

Current status of

relay 6.

Current status of

relay 7.

Current status of

relay 8.

Current status of

relay 9.

Current status of

relay 10.

Current status of

relay 11.

Current status of

relay 12.

Current status of

relay 13.

Current status of

relay 14.

Current status of

relay 15.

Current status of

relay 16.

Current status of

relay 17.

Current status of

relay 18.

Current status of

relay 19.

Current status of

relay 20.

Current status of

relay 21.

VCM-X PT-Link-LON®

Property Identifi er:

The PT -Link-LON® Link amends the following property identity to the

LON® property identifi er.

LONPropertyIdentifi er :

WattLONScheduleForce ::= ENUMERATED {

NormalOperation (0),

ForceOccupied (1),

ForceUnoccupied (2)

}

VcmxUnitMode ::= ENUMERATED {

Unoccupied (0),

RemoteContactOccupied (1),

NormalScheduleOccupied (2),

PushButtonOrZoneOverride (3),

HolidayModeActive (4),

UnoccupiedZoneDemand (5),

RemoteScheduleOverride (6),

CurrentOutputForceMode (7),

SATHighOrLowCutOff (8),

CO2OverrideInProgress (9),

PurgeModeActive (10)

}

VcmxControlStatusBits ::= ENUMERATED {

Off (0),

Vent (1),

Cool (2),

Heat (3),

Dehum (4),

Dehum Cool (5),

Dehum Heat (6),

Warm Up Mode (7)

}

VcmxOnBoardRelaysBits ::= BIT STRING {

OnBoardRelay1 (0),

OnBoardRelay2 (1),

OnBoardRelay3 (2),

OnBoardRelay4 (3),

OnBoardRelay5 (4)

}

PT-Link Interface

25

Page 26

PT-Link-LON® Technical Guide

Appendix D - VCM-X LON Parameters

VcmxExternal Relays1-2Bits::= BIT STRING {

ExpansionBoard1Relay1 (0),

ExpansionBoard1Relay2 (1),

ExpansionBoard1Relay3 (2),

ExpansionBoard1Relay4 (3),

ExpansionBoard2Relay1 (4),

ExpansionBoard2Relay2 (5),

ExpansionBoard2Relay3 (6),

ExpansionBoard2Relay4 (7)

}

VcmxExternal Relays2-4Bits::= BIT STRING {

ExpansionBoard3Relay1 (0),

ExpansionBoard3Relay2 (1),

ExpansionBoard3Relay3 (2),

ExpansionBoard3Relay4 (3),

ExpansionBoard4Relay1 (4),

ExpansionBoard4Relay2 (5),

ExpansionBoard4Relay3 (6),

ExpansionBoard4Relay4 (7)

}

VcmxAlarmStatusBits ::= BIT STRING {

Alarm Group1 (0),

Alarm Group2 (1),

Alarm Group3 (2)

}

VcmxAlarmGroup1Bits ::= BIT STRING {

SupplyTempSensorFailure (0),

LostOutdoorTempSensorSignal (1),

LostSpaceTempSensorSignal (2)

}

VcmxAlarmGroup2Bits ::= BIT STRING {

MechanicalCoolingAlarm (0),

MechanicalHeatingAlarm (1),

FanProvingAlarm (2),

DirtyFilterDetected (3),

SmokeDetected (4)

}

VcmxAlarmGroup3Bits ::= BIT STRING {

LowSupplyAirTempAlarm (0),

HighSupplyAirTempAlarm (1),

LowControlTempAlarm (2),

HighControlTempAlarm (3)

}

26

PT-Link Interface

Page 27

PT-Link-LON® Technical Guide

Appendix E - SA Controller LON Parameters

SNVT s f or the SA Controller

Binary Output SNVTs are SNVT_lev_disc

all other SNVTs are SNVT_count_inc_f

Parameter Name Object Description

Control Status CtrlSts Analog

Occupied/

Mode

Enable

Cooling

Setpoint

Mirror

Control

Temperature

Duct Static

Pressure

Economizer

Position

Occupied/

Mode

Enable

Heating

Setpoint

Mirror

Modulating

Gas Valve

Position

Reheat Value

Position

Indoor

Humidity

Space

Temperature

Current

Supply Air

Setpoint

Supply Air

Temperature

Temperature

Demand

VFD Blower

Fan

Application

Software

Version

Coil

Temperature

Setpoint

Dewpoint

Setpoint

Mirror

ClSt Analog

CtrlTp Analog

DuctPr Analog

EcoPos Analog

HtSt Analog

MdHt-

2Pos

Rt2Pos Analog

InRh Analog

SpcTp Analog

SaTpStM Analog

SaTp Analog

TpDmnd Analog

VfdBw-

Pos

AppVer Analog

CoilTpSt Analog

DptStM Analog

Output

Output

Output

Output

Output

Output