Oregon Scientific JW3800, JW5200, JW5800, HY3800, JW4500 Assembly Manual

...

Original instructions

Petrol chainsaw

Guide for models - JW3800, JW4500, JW5200, JW5800

HY3800, HY4500, HY5200, HY5800

SLYD38, SL-YD45, SL-YD5200B, SL-YD58

Assembly / Operation Manual

©Trueshopping LTD Issue 01/MC

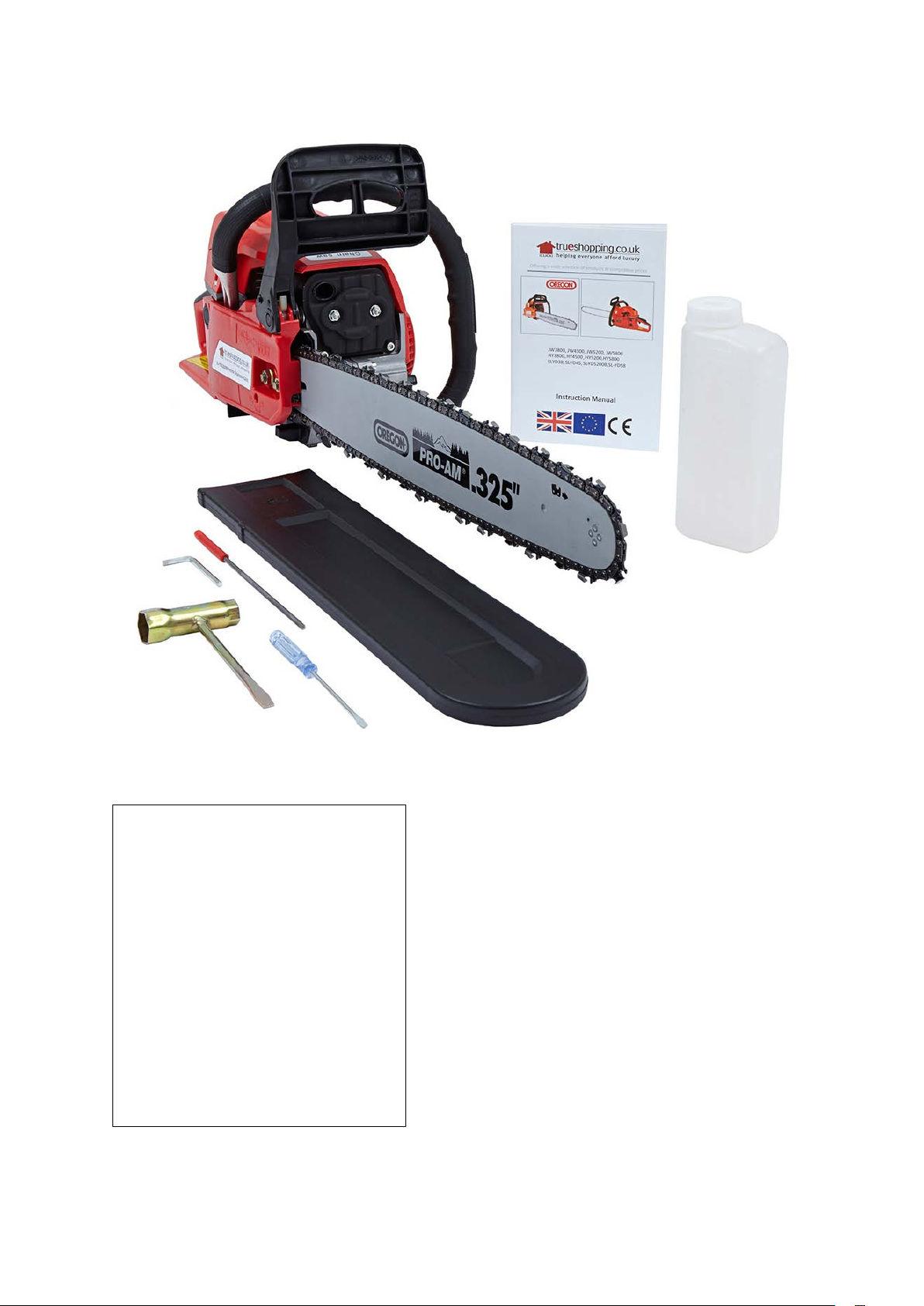

BOX CONTENTS –

MAIN ENGINE UNIT x1

2

GUIDE BAR x1 (Size/brand

may differ by model)

GUIDE BAR COVER x1

SAW CHAIN x1

TOOL KIT

FUEL BOTTLE

CONTENTS

l number information - Front Cover

Mode

Important safety information -

l mix and Fuelling 5

Fue

• Fuelling and first use preperation 5

• Idling speed adjustment 6

Assembling your chainsaw 6

• Attaching the chain spike 6

• Attaching the bar, chain and chain brake 7

St

arting your chainsaw 10

rating the chainsaw 11

Ope

• Chainsaw kickback 11

Fe

lling a tree 12

bing a tree 13

Lim

Buc

king a tree 13

Maintenance 13

a,b,4

hain oil 14

• C

• Changing oil supply 14

• Air filter 14

• Sprocket 14

• Saw chain 14

• Spark plug test / exchange 15

Fa

ult identification 18

l information 20

Mode

Ce

rtification Inside back cover

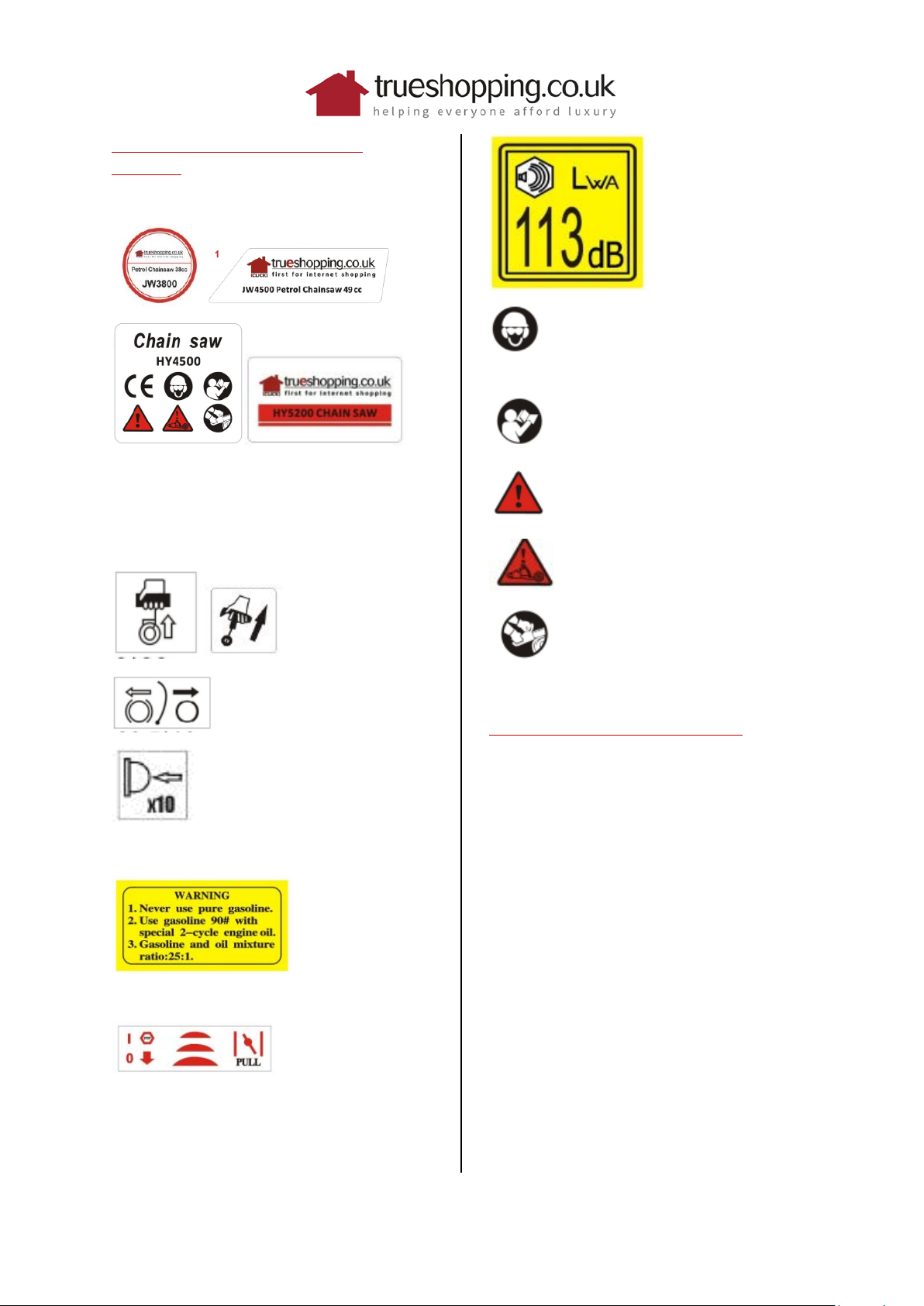

Warnings on the Machine and their

Model Information (location

and type differs by model)

Pull Direction

Fuel mix warning

information

Power/choke

Machine Noise level

Priming bulb information

Chain brake on/off

Meanings

information

Important

information

! Use

protection

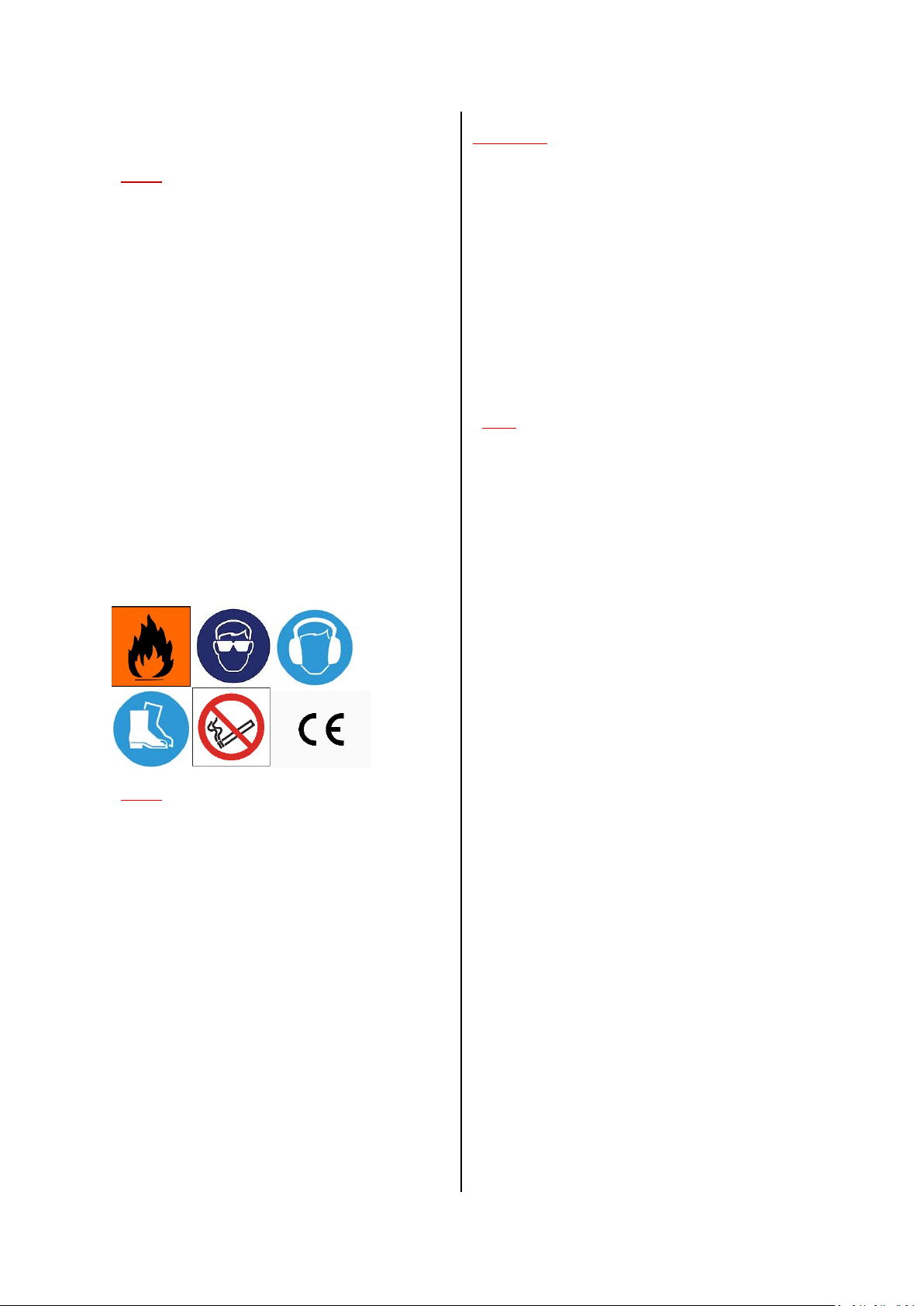

IMPORTANT SAFETY INFORMATION

• Please note that the cutting blade

• Do not lend or rent your power tool

• Persons with pacemakers only: The

• Do not use a pressure washer to clean

• Do not spray the machine with water.

Suitable face/hearing/head

! Read the Manual

! Warning

! Kickback warning

! Handle with care

continue to run for a short period

after you let go of the throttle trigger

–This is called the flywheel effect.

without the instruction manual. Be

sure that anyone using your power

tool understands the information

contained in this manual.

ignition system of your power tool

produces an electromagnetic field of a

very low intensity. This field may

interfere with some pacemakers.

Consult your doctor if you have

concerns.

your power tool. The solid jet of water

may damage parts of the power tool.

a.

• Work calmly and carefully – in

daylight conditions and only when

visibility is good. Stay alert so as not

to endanger others.

• Your power tool produces toxic

exhaust fumes as soon as the engine

is running. These fumes may be

colourless and odourless and contain

unburned hydrocarbons and benzoyl.

Never run the engine indoors or in

poorly ventilated locations.

• The dusts, vapour and smoke

produced during operation may be

dangerous to health. If the work area

is very dusty or smoky, wear

appropriate safety equipment.

• If your power tool is subjected to

unusually high loads for which it was

not designed (e.g. heavy impact or a

fall), always check that it is in good

condition before continuing work

• When working at heights:

– Always use a lift bucket

– Never work on a ladder or in a tree

– Never work on an insecure support

– Never operate your power tool with

one hand.

Be alert and cautious when wearing hearing

protection, your ability to hear warnings

(alarms, etc.) is restricted.

b.

IMPORTANT SAFETY INFORMATION

4

General

! This product must only be operated by competent

persons.

Maintenance

! Do not perform maintenance / repairs unless they are

outlined in this guide or you are given additional detailed

instructions from the manufacturer

! Do not perform repairs while the unit is still hot

! Do not smoke or use this product on or near sources of

combustion.

! Wear suitable safety equipment (Goggles, non-slip boots,

ear plugs and thick work gloves) at all times while

handling this product

! Do not operate while under the influence of alcohol or

any substance which may impair your physical function

and alertness

! If you sell or lend out this unit, please ensure that this

manual and all relevant documentation is sold along with

it

! This unit is not to be operated, loaned or sold to any

persons under the age of 18

! Empty all fuel from the unit before attempting

maintenance

! Unless otherwise required, ensure the chain bar cover is

in place when performing maintenance

! Place the unit on a flat solid surface when performing

maintenance or repair

Usage

! Before operation, always inspect the machine for

signs of damage and wear

! Before starting the engine, make sure that the saw

chain is not touching anything

! Ensure that people and animals are at a safe

distance of at least 10m

! Keep clear of the saw chain at all times as it will

start to rotate when the engine starts

! If felling a tree, take note of the diagram (fig1.)

opposite to give you the best understanding of your

situation

General

! This product must only be operated by competent

persons.

! Do not smoke or use this product on or near sources of

combustion.

! Wear suitable safety equipment (Goggles, non-slip boots,

ear plugs and thick work gloves) at all times while

handling this product

! Do not operate while under the influence of alcohol or

any substance which may impair your physical function

and alertness

! If you sell or lend out this unit, please ensure that this

manual and all relevant documentation is sold along with

it

! This unit is not to be operated, loaned or sold to any

persons under the age of 18

! For your own safety, limit the amount of time you

use the machine continuously to 10 min sessions

taking a break of 10- 20 minutes in between. Try to

keep the total amount of work in a single day to 2

hour sessions.

! This product will produce Carbon Monoxide when

in use, DO NOT use indoors

! Do not operate while tired as your attention will

be reduced, the user is liable for any injury caused

to others

! Do not leave this product unattended at any time

! Do not operate in adverse weather or any

other conditions that may make use of this

product unsafe

! Clearly mark out your working area with a

suitable barrier (Tape / Rope)

! Shut the unit down when not in use

FUEL MIX AND FUELLING

5

Mix a regular grade petrol (LEADED OR

UNLEADED, ALCOHOL FREE) and a good quality

motor oil designed for air cooled 2 cylinder

engines.

RECOMMENDED MIXING RATIO PETROL

25

:1 OIL

When us

ing for the first time, remember that

engine problems can be caused by using an

incorrect fuel mix or using the wrong type of

petrol / oil

Fuelling and first use preparation

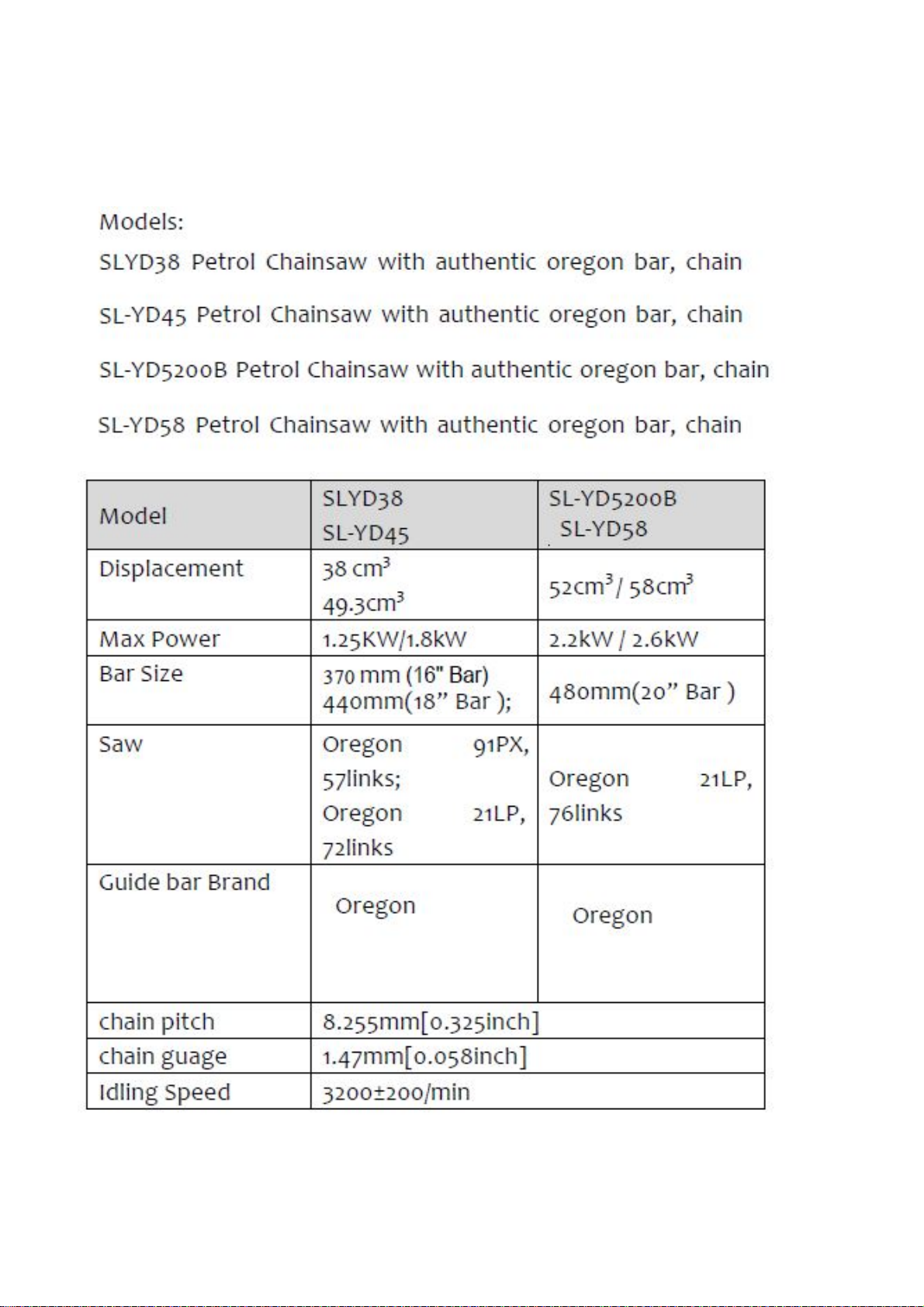

The petrol cap is clearly marked on the unit.

tate the cap Anti clockwise to release and add

Ro

your fuel mix to the engine. Then replace the

cap and rotate clockwise until secured tightly.

! When refuelling the tank ensure the engine is

off and check your surroundings for signs of

danger (open flames, sparks).

! Use a dry rag to mop up any spillages

! After refuelling carry the product away from

the refuelling location before use.

*Please note that the correct fuel mix ratio is

printed on the label located in the handle area

e chainsaw must be tipped on its side

Th

filling, not doing this will cause the fuel

overspill. To prevent spillage a small

when

tank to

funnel can

be used.

Ch

ain oil should be added to the unit before

use. It can be topped up as required.

Re

move the chain oil cap (shown below) by

turning the cap anti-clockwise.

first

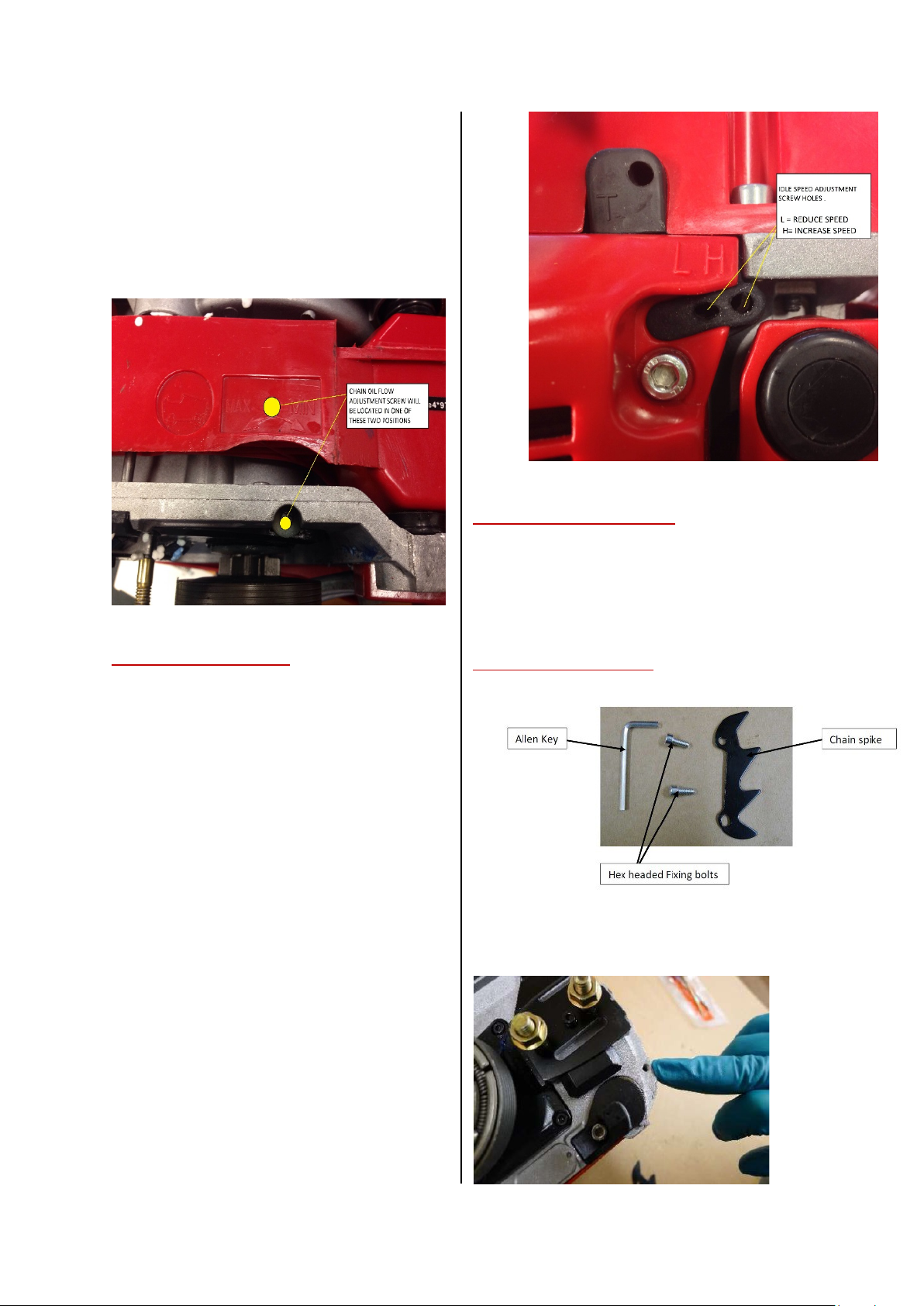

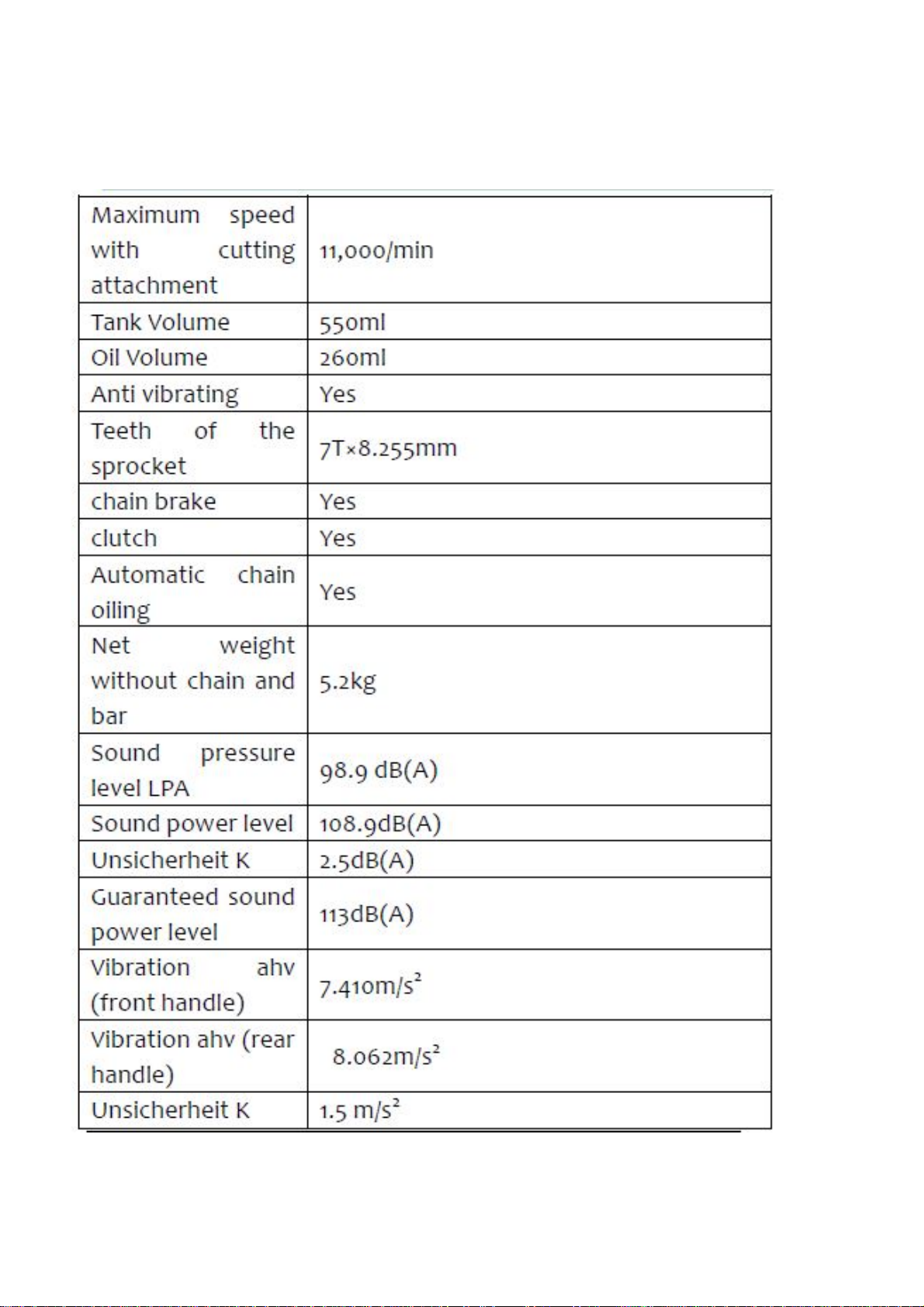

On the underside of the unit is the screw for

6

adjusting the flow of oil to the chain.

*The l

ocation of this screw may differ

dependent on model, the image below shows

the two possible locations.

justment can be made as shown on the

Ad

etching on the plastic.

Assembling your chainsaw

! Before you begin assembly, ensure that you

have accounted for all parts in the box, if

anything is missing, please contact the

manufacturer to advise.

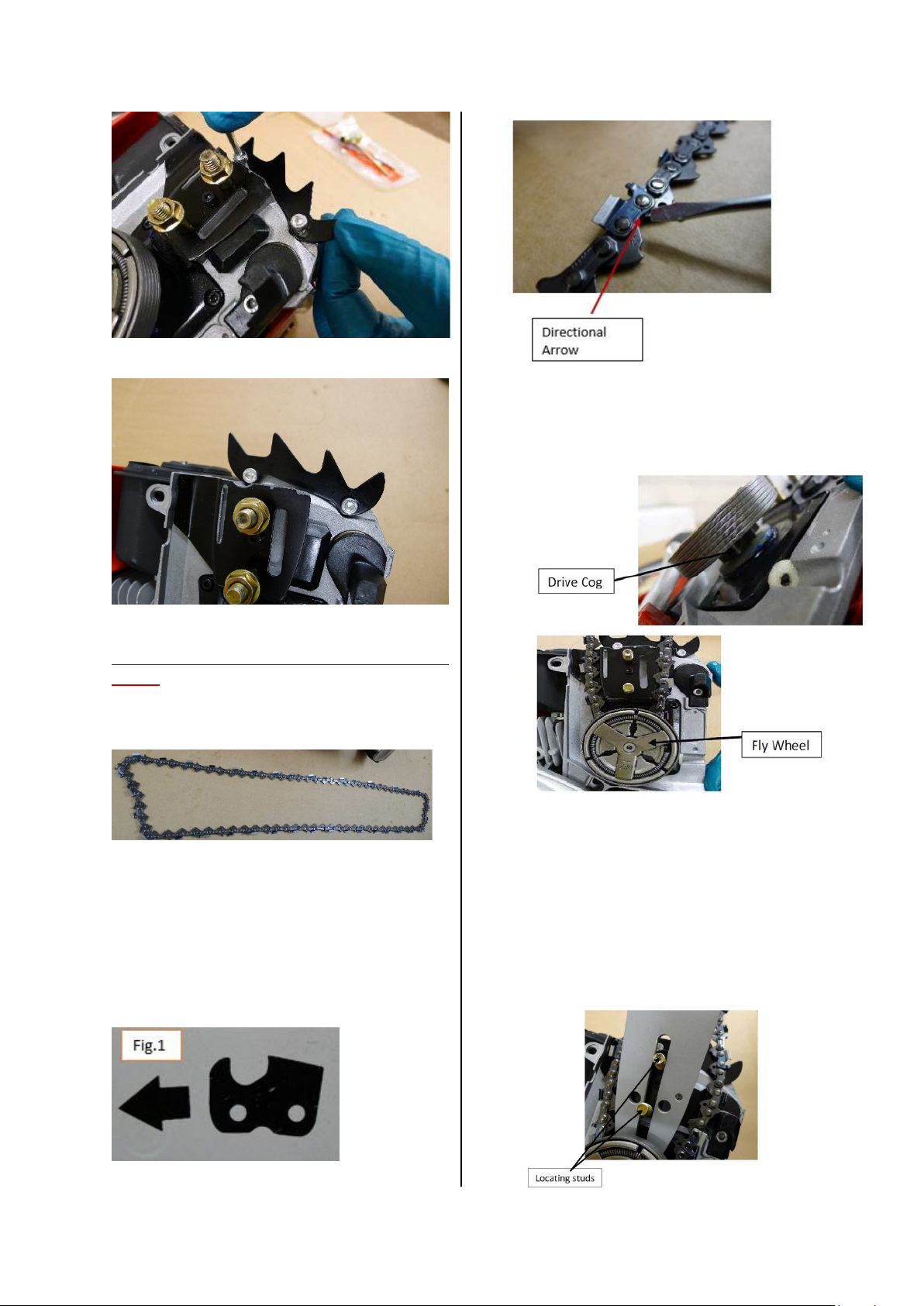

Idling speed adjustment

The following information shows how to adjust

the idling speed of the engine (the speed the

engine runs at when not cutting)

*Pl

ease note that a Carburetor adjusting tool is

required to perform this adjustment (not

provided)

As

a general guide colder working temperature

may require you to adjust for a higher idling

speed

just the idle speed Turn the low

To ad

screw (L) fully clockwise until it will no

longer move , then perform one full

turn anti - clockwise . Repeating this

with the high screw (H) will take the

carburettor back to factory settings.

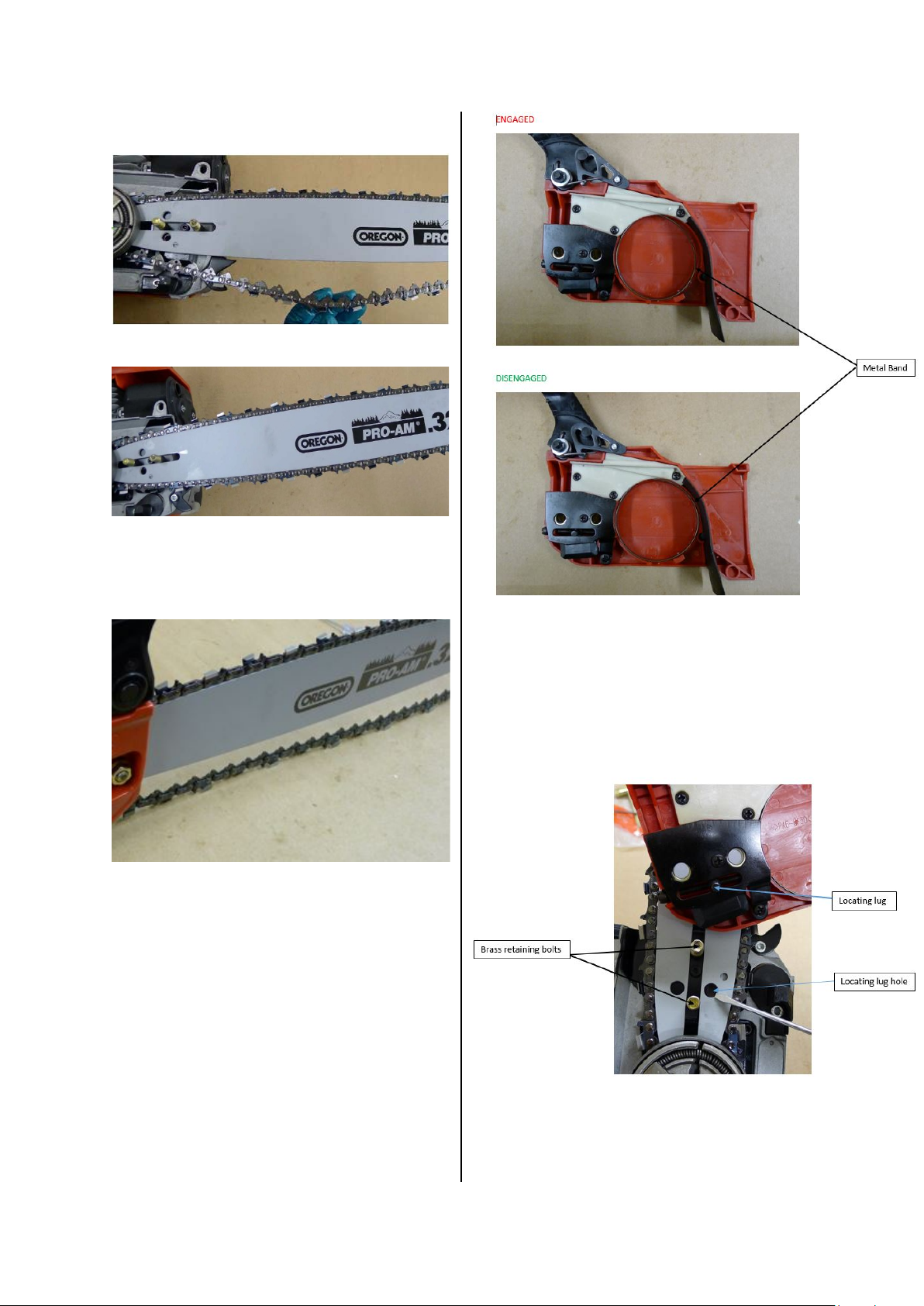

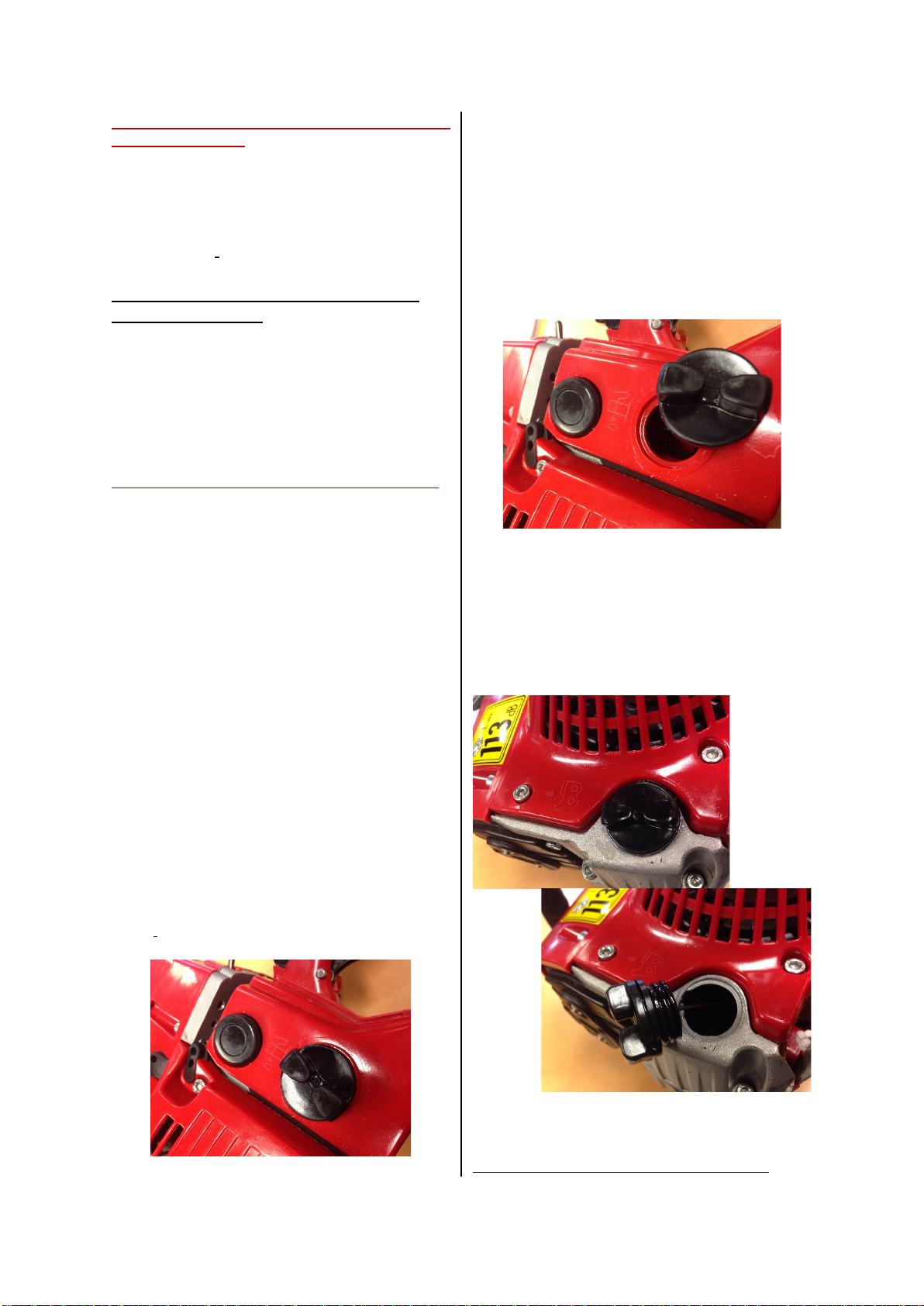

Attaching the chain spike

e the chain spike onto the engine body and

Plac

fasten in place as shown –

Attaching the Bar , chain and chain brake to the

7

engine

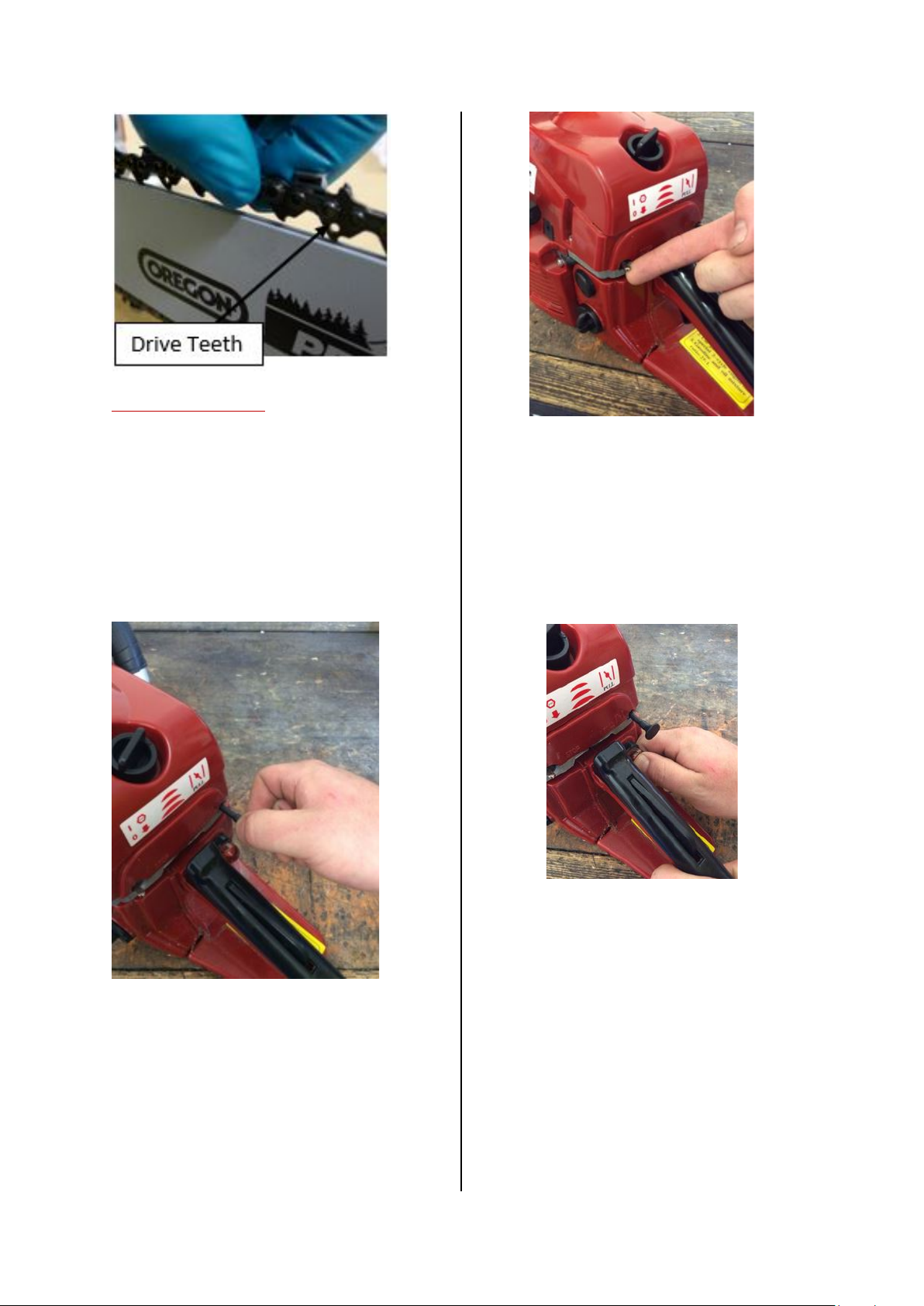

Carefully remove the chain from the bag and

spread it out on a flat surface.

fore continuing note the directional arrow on

Be

the chain link, once attached to the chain bar

this arrow should be pointing away from the

main unit along the top of the bar, and towards

the unit along the bottom of the chain bar. The

chain bar also shows the direction of travel for

the chain (see fig 1.)

The chain should now be attached to the

drive cog that is located beneath the

flywheel.

Plac

e the Chain Bar onto the main unit at an

angle over the two locating studs and carefully

push the Chain into the groove around the

edge of the bar, once the chain is in place along

the top of the Chain, gently pull the chain bar

away from the main unit, this will relieve some

of the slack on the chain allowing you to push it

in place along the bottom of the bar.

*The c

8

hain may hang loose from the underside

of the bar when the unit is Horizontal (see

image below), this will be rectified later.

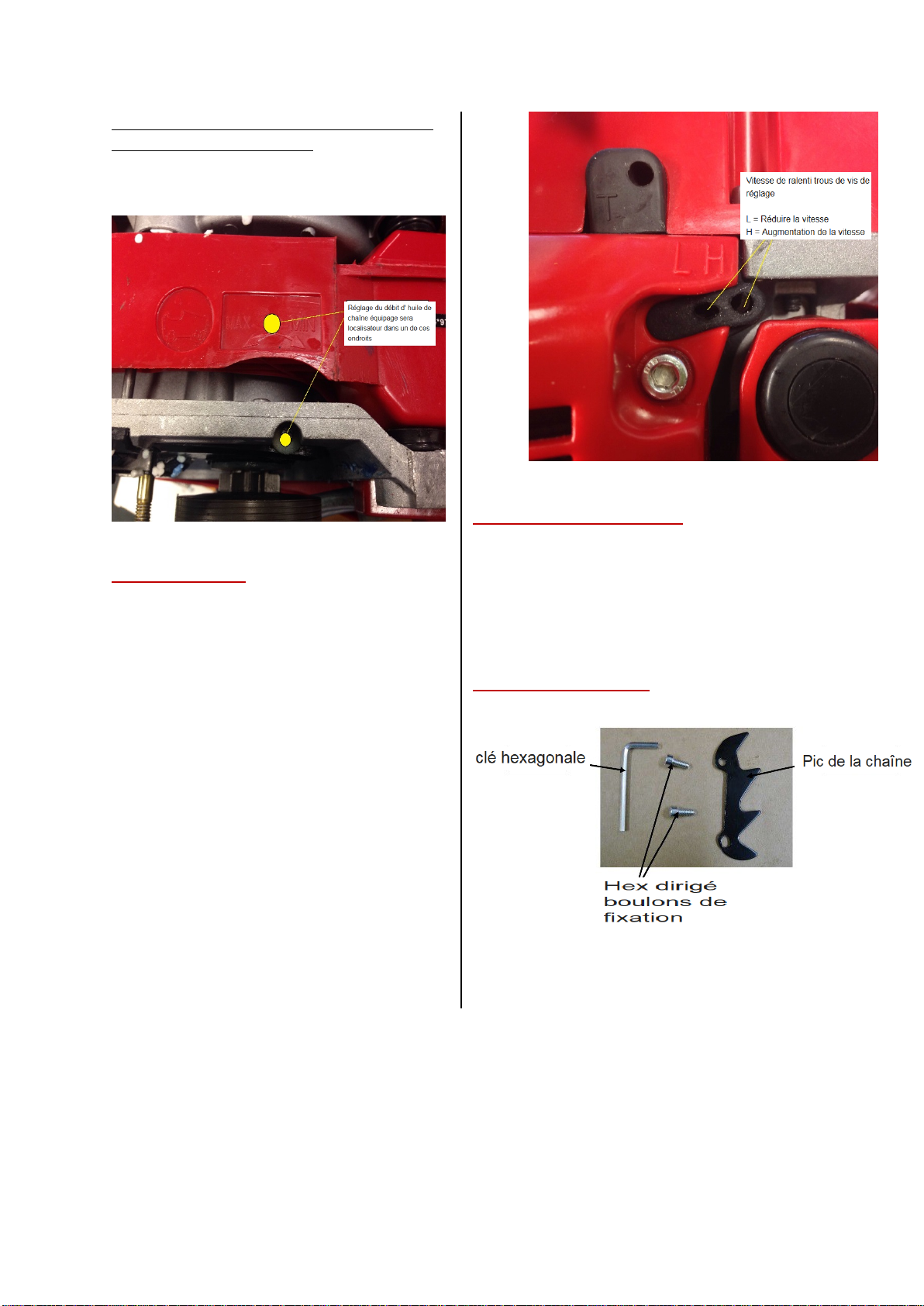

t, we will attach the chain brake.

Nex

Be

fore doing this we need to ensure that the

Chain Brake is disengaged, note the location

of the metal band in the images overleaf for

the correct position. If engaged pull back on

the Guard/Lever to Disengage an audible click

will be heard when done correctly .

The next step is to line the two holes on the chain

brake with the two brass retaining bolts on the

main unit. Once done, push the chain break in

place. You will notice that it does fully locate onto

the unit, as the locating lug on the chain brake

needs to be adjusted to fit into the corresponding

hole on the chain bar.

(Please see the section at the end of the

guide Re: Chain brake removal)

e Locating lug can be moved by turning the

Th

adjustment screw on the chain brake, either

clockwise to move the locating lug, toward the

back of the chainsaw or anti-clockwise to move

9

the locating lug to the front of the chainsaw, to

line up the locating lug with the locating lug hole

in the chain bar, using the flat blade screw

driver, or the box spanner/screw driver,

whichever is the easiest, until the locating lug

falls into the locating lug hole. *Adjustment

screw is on the side of chain brake on 58cc

Model

No

w we will tighten up the chain and chain bar

–

e the chainsaw upright onto a solid flat

Plac

surface and use the provided small flatheaded

screwdriver to turn the adjustment screw in a

clockwise direction , this will begin to tighten

the chain . The aim is to tighten to a point so

that when you pull on the chain , you can only

see 4-5 of the drive teeth . when you are close

to this point use the larger flat head screwdriver

on the provided multi tool to make the final

adjustment as this gives added torque (See

overleaf)

On

ce the chain break is fully in position , hand

tighten the retaining nuts onto the retaining

bolts protruding through the chain brake .

Starting the chainsaw

10

! Ensure that you are using the correct fuel mix

see Fuel mix and fuelling.

! Ensure that the chain brake is fully pushed

forward into the locked position, this will

prevent the chain from spinning freely when

starting and ignoring this may cause serious

injury.

Pu

ll the choke lever out fully

No

w we need to prime the engine to ensure the

chainsaw will start .To prime, push the priming

bulb in and out several times*.

*Please note, you cannot over prime the unit,

however under priming may prevent the

chainsaw from operating correctly.

xt, push the engine switch upwards into the

Ne

start position

The uni

! N

t is now ready to be started.

EVER START YOU CHAINSAW USING THE

DROP METHOD (dropping the saw with one

hand while pulling the cord with the other)

THIS IS DANGEROUS AND CAN LEAD TO SEVERE

INJURY!

Lay the unit onto the ground and position

yourself with one foot placed in the Throttle

handle area, firmly keeping the unit still.

At the same time firmly hold the main handle,

using your other hand pull the cord firmly until

the engine starts.

! E

11

nsure that you do not let go of the cord

while starting, this will cause the cord to

quickly retract and may damage the pull cord

unit.

Once you have heard a single cough or splutter

from the machine, slowly return the

handle/cord to its original position and push the

choke lever back in towards the machine.

No

w pull the starter cord until the unit starts,

this may require excessive force which is

normal.

The unit is now ready for use.

Operating the Chainsaw

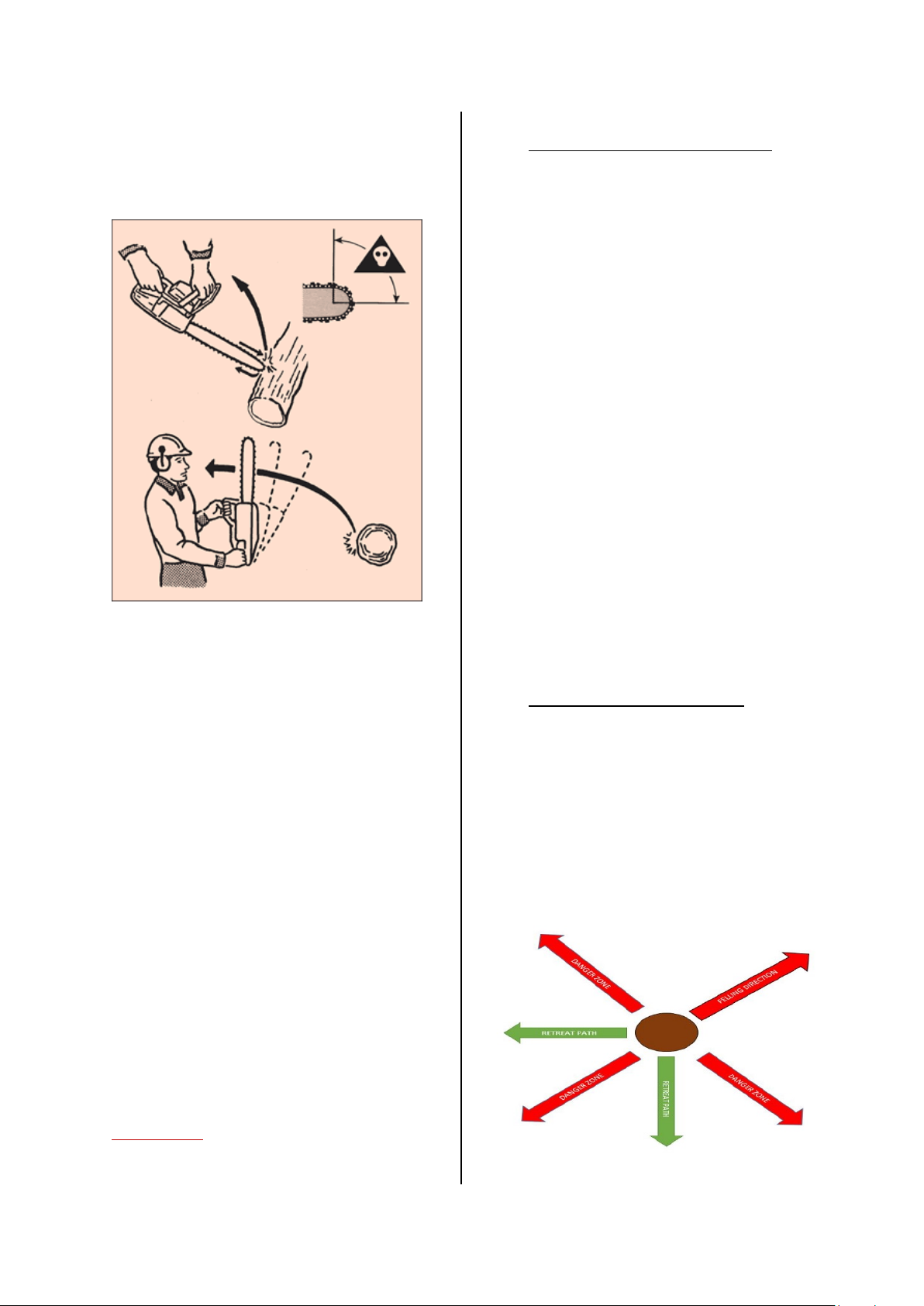

**CHAINSAW KICKBACK**

LEASE READ THE FOLLOWING INFORMATION

! P

CAREFULLY!

Chainsaw kickback can occur when the tip of the

bar comes into contact with a relatively massive

or immovable object with the chain under

power. The area of the bar tip most likely to be

involved is known as the "kickback quarter".

looking from the side of the bar, the kickback

quarter is the 90° section of bar found between

a line going along the centreline of the bar, and

another line at 90° to the first, rising upwards

from the centre of the nose sprocket. If this area

of chain comes into contact with - for instance a log, the chain will initially cut the wood, but

will also produce a reaction force which pushes

the bar upwards. As the bar rises, the chain is

forced harder into contact with the wood and

climbs upwards even harder. In a fraction of a

second the chain may jam hard into the wood

and hurl the bar upwards towards the operator,

often causing very severe injury or death. The

violence of a full kickback event is such that no

evasive action is possible, and if the operator's

head, neck or shoulders are in line with the

plane of the bar, he will certainly be struck by it.

At this point, he must rely on the chain brake

and protective clothing to save him from injury

or worse.

ce the engine has started and you are ready

On

to cut, disengage the chain brake.

Another form of kickback may occur where the

top of the bar is used for cutting and becomes

suddenly pinched by the wood moving. In this

case the saw may be forced backwards towards

the operator, or forced into a position where the

tip is pinched and the saw transitions into a

classic tip-driven kickback. Kickback may also

occur as a result of a failed or improperly

executed boring cut. Bore cutting is a

specialised technique requiring proper training,

12

and should not be attempted without such

training.

*******

*****************************

When using a chainsaw to cut firewood, trim

trees or harvest large timber you need to

perform 3 basic operations – Felling, limbing

and bucking

FELLING – Involves cutting a standing tree and

opping it in the correct manner

dr

LIMBING – The removal of branches from either

standing or downed trees

BUCKING – The process of cutting a downed

tree into the appropriate lengths

1.

Examine the tree and surroundings

spect the tree and check for any signs of

In

Rot.

! Unless you are a qualified tree surgeon,

do not touch a rotting tree. It may fall in a

haphazard manor

Make a note of the branches are laid out

and note the height of the tree.

Check your surroundings to ensure the tree

is

not going to fall on power lines / property,

and ensure that the area is clear of

pedestrian traffic.

*As

an example if the tree is 3M high,

ensure

that you have a clear circle of 4M around

the tree

! Ensure that no branches are liable to fall

on you, branches can become dislodged

during felling

! Take note of any other trees which are in

the vicinity and make sure the felled tree

will not fall into them, as this can cause the

tree to bounce and cause serious injury

2.

Plan at least two escape routes

e first should be opposite the planned

Th

direction of the tree and the other at 45 degrees

of the first (See diagram below)

Ensure that both routes are clear of people and

obstacles and do not put your tools in these

areas.

! Should you have to quickly vacate the area in

an emergency, drop the chainsaw .NEVER RUN

WHEN HOLDING A CHAINSAW.

To

correctly cut, you need to place the running

saw blade down onto the wood and rock the

blade upwards before levering it downwards

again. The saw spike will grip into the wood and

give you good leverage. This represents a more

efficient means than just pushing downwards.

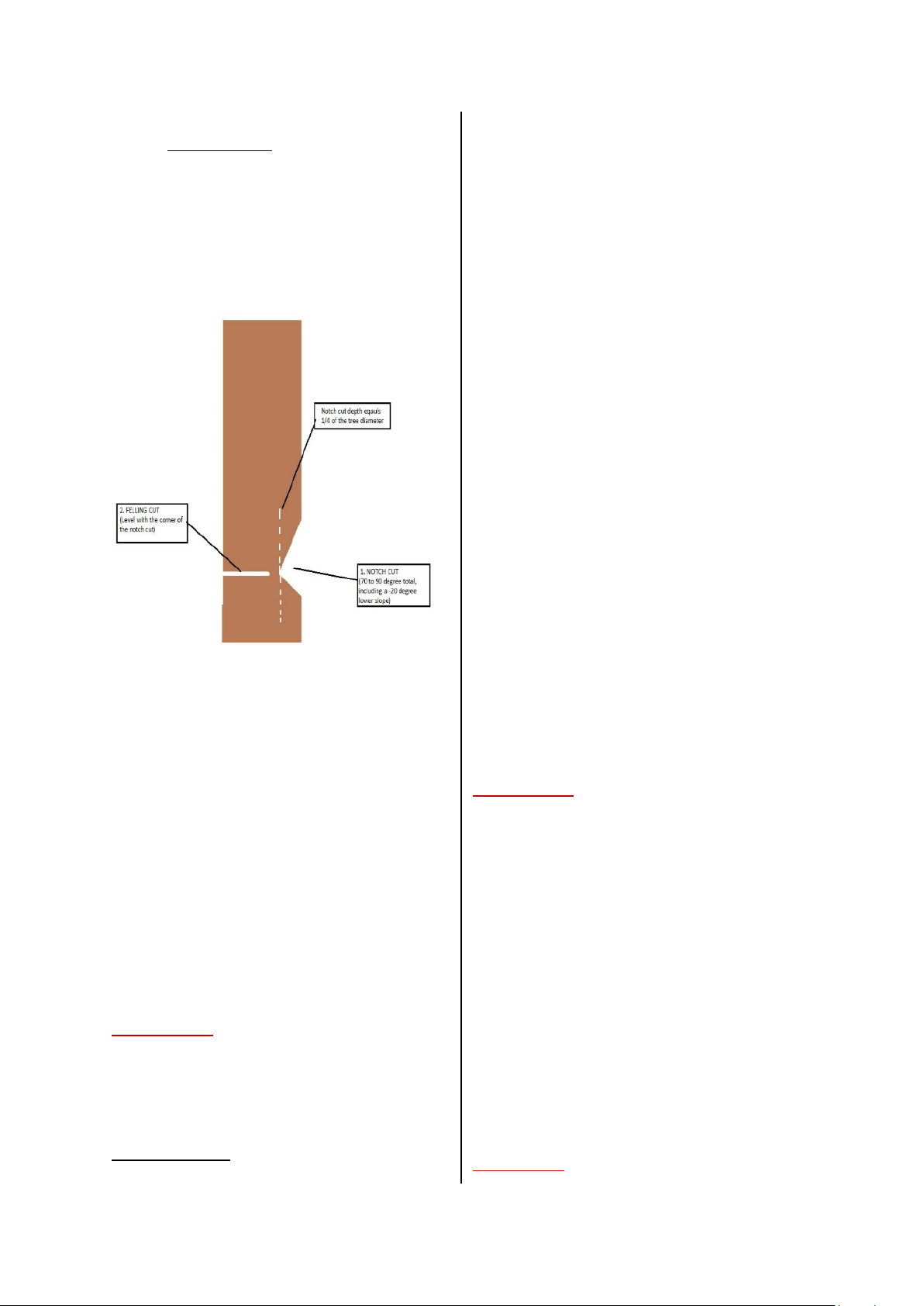

Felling a tree

Felling a tree can be summarised into three

steps

3.

13

Making the cut

ar the area surrounding the base of the tree

Cle

from all brush, tree limbs and other obstruction.

If the tree is less than 250mm then make the cut

through the trunk. If the tree is larger. Two cuts

are required, the undercut (notch cut) and the

back cut (the felling cut). See diagram below

lodged onto another tree and potentially not

fully fallen to the ground. This is a potentially

dangerous situation and is best left to a

professional.

Check and ensure the following are clear –

! Are smaller trees trapped by the tree to be

limbed?

! Is the tree to be limbed totally and safely

laying on the floor?

! Is the tree to be limbed on level ground?

! Is there debris on the tree that could fall onto

you during limbing?

Once you have removed all potential obstacles

and sources of danger, stand uphill of the tree

to be limbed.

! If you stand downhill and free a limb, the tree

could potentially roll down onto you.

and firmly on the ground in a balanced

St

position that allows for full freedom of

movement. Ensure that you will not slip.

e angled cut (notch cut) is made first as

Th

shown above followed by the back cut (felling

cut).

e tree will start to fall onto the narrow section

Th

of the notch while the wood at the thicker

section remains intact therefore the tree is

pulled forward. Making these cuts is a bit of

and requires some practice.

an art

Once the tree starts to fall, turn off the saw and

take your chosen escape path so that you are

clear of the falling tree.

! Falling trees can sometimes bounce

backwards over the stump and injure an

unwary person. EXERCISE CAUTION.

Limbing a tree

ever limb a tree when the branch is above

! N

shoulder height as this can cause you to lose

control of the chainsaw.

Start at the bottom of the tree and work your

way to the top removing limbs and debris on

both sides as you go. ALWAYS cut away from

yourself and beware of kickback.

Place cut limbs in a safe location away from your

limbing location.

Cutting the limbs off close to the trunk makes

the tree easier to roll once finished. Beware of

the trunk moving as you remove heavier limbs.

Bucking a tree

This is the process of cutting the felled tree into

useable lengths and can be done as you are

limbing the tree.

! I

f the tree is laying on the ground ensure

t you do not get the saw blade caught in the

tha

earth or other debris.

and uphill of the tree and make sure you have

St

a strong, firm stance on the ground, be ready to

move quickly if the log rolls.

**A SAWBUCK OR SAWHORSE MAKES CUTTING

EASIER AND SAFER **

Examine the tree

Evaluate a fallen tree to ensure that it is not

Maintenance

! Always be sure to turn the engine off before

14

performing any maintenance checks /

procedures

! Any maintenance NOT outlined in this guide

should be left to the manufacture / supplier

! Only use replacement bars and chains

specified by the manufacturer or equivalent

! Follow the manufactures instructions

! Always carry the unit with the engine

switched off, the guide bar covered with the

protector to your rear and exhaust away from

your body

Chain oil

e following oils can be used –

Th

ALL YEAR ROUND - 10W30

Or

SUMMER – 10W30 / 10W40

WINTER – 10W20

Do not use wasted or regenerated oil as this can

cause damage to the oil pump.

Changing oil supply

sure to refill the oil tank every time you

Be

refuel the unit.

vice versa.

Saw chain

ear gloves while checking the following

! W

It is very important for smooth and safe

operation that the cutting teeth remain sharp.

Your chain will need to be replaced when –

awdust becomes powder like

! S

! You need to apply excessive force to cut

! The cut is not straight

! Vibration increases

! Fuel consumption increases

NTACT THE MANUFACTURER REGARDING

CO

ANY ADDITIONAL ADVICE WITH REGARDS TO

MAINTAINENCE / REPAIR

Spark plug Test /exchange procedure

rts required –

Pa

1x Replacement sparkplug

1x Multi tool with socket attachment (provided

with chainsaw)

The following will explain how to check for a

spark and if required how to exchange a spent

spark plug.

Th

e chain oil flow can be adjusted as outlined on

page 5

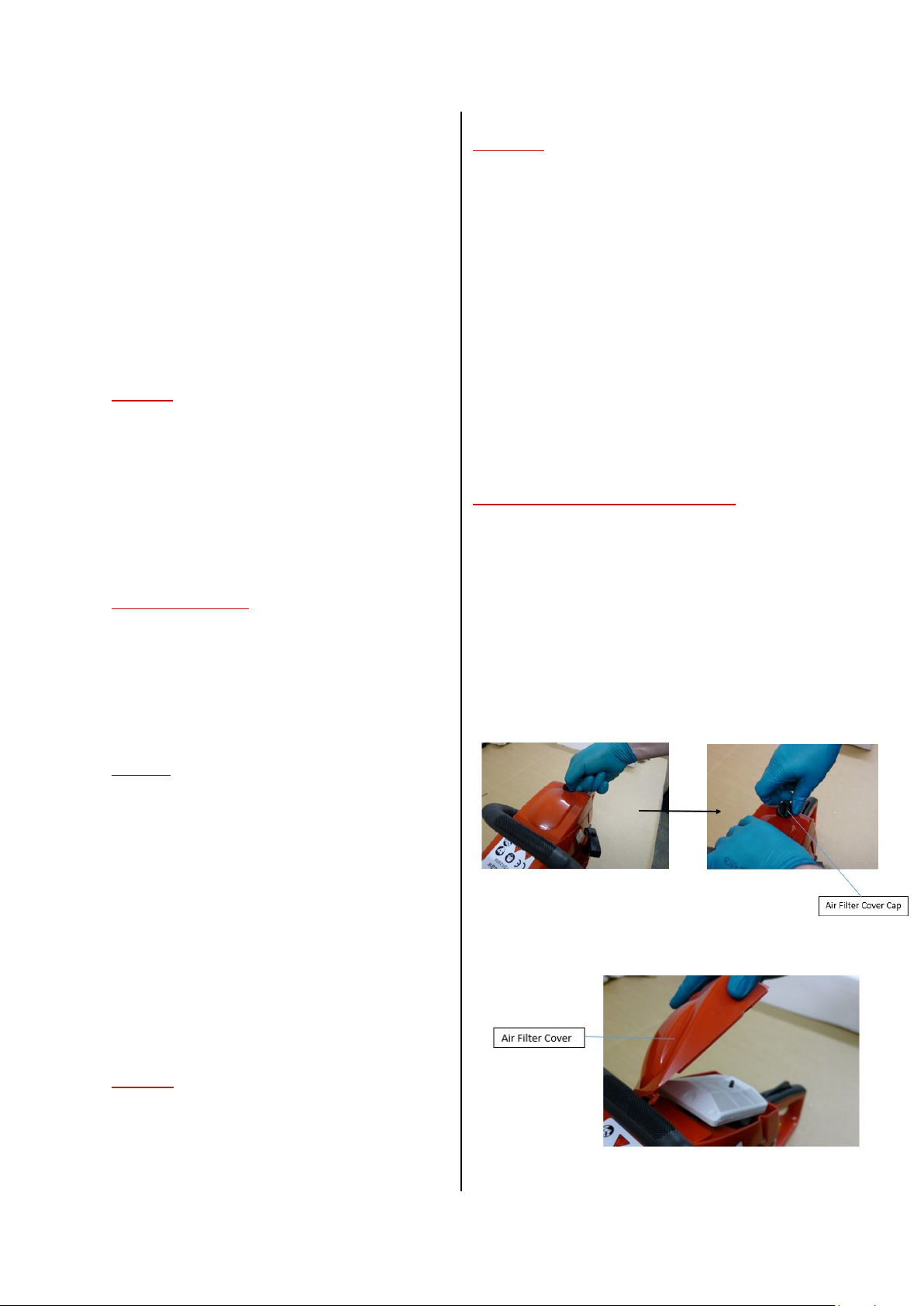

Air filter

Clean the air filter on a regular basis and change

as required.

To

access the air filter, turn the air filter cover

cap in an anti-clockwise direction to loosen and

then lift the air filter cover.

Firmly grip both sides of the air filter and pull to

remove it from the engine body.

Remove any debris and wash under a cold tap if

required.

! Ensure the filter is completely dry before

replacing in the machine.

Sprocket

Check the sprocket for cracks and signs of wear

that may be interfering with the chain drive. If

any wear is found then replace it with a new

one. Never fit a new chain onto a sprocket or

Re

move the spark plug cover cap by rotating it

anti clockwise.

Re

move the air filter cover by lifting it upwards.

Re

15

move the air filter by holding the sides and

pulling firmly upwards.

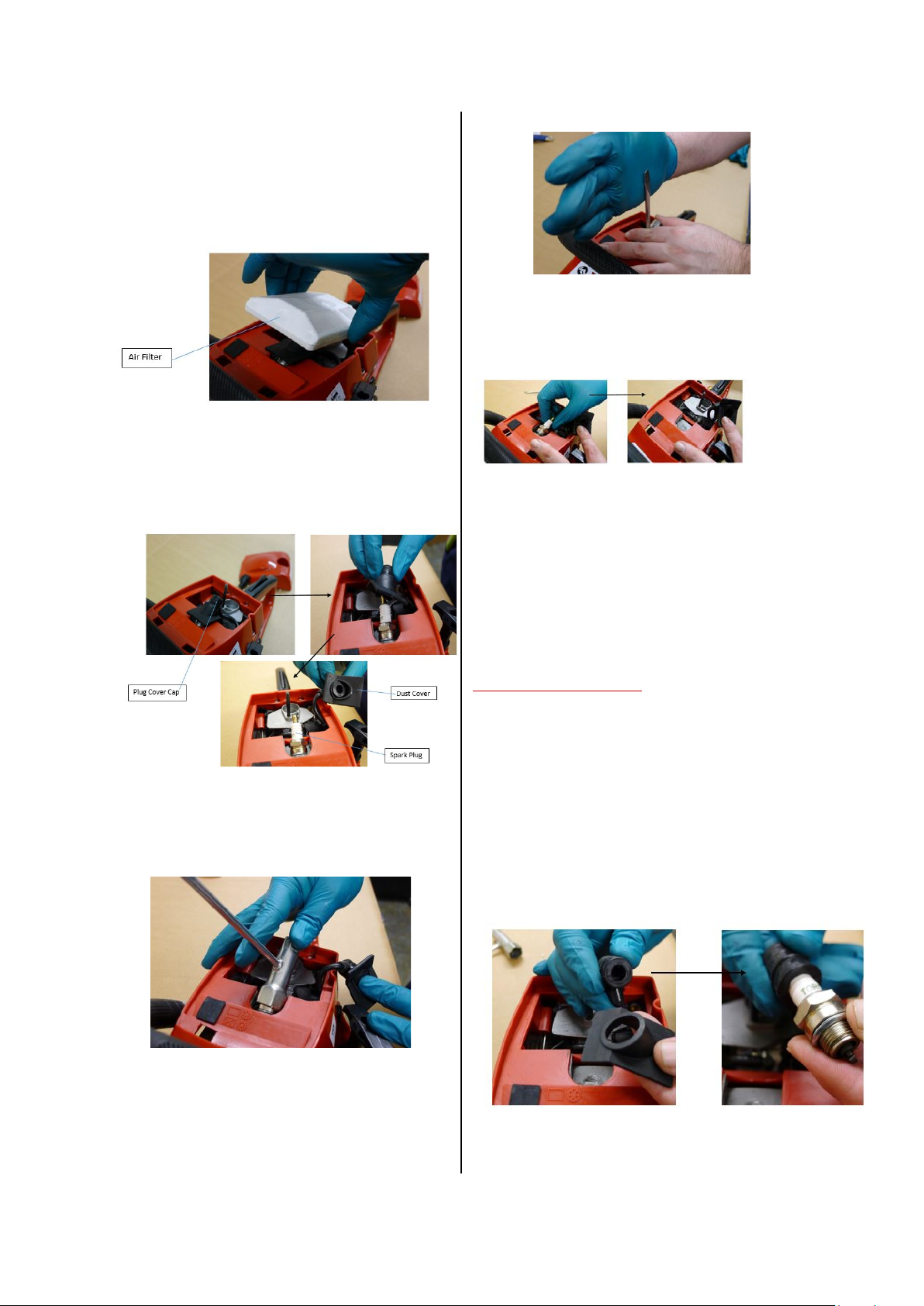

Next,

we need to remove the spark plug cover

cap and dust shield. This is attached snugly so a

firm pull may be required.

Unscrew and remove the spark plug by hand

Screw the replacement plug into the Chainsaw

body and push the Plug cap/ dust cover, then

tightening firmly into position* . Then simply

follow the instruction in reverse to re-assemble

the unit .

f the plug cap is not firmly pushed into

*I

position , the unit will not work

Using the provided multi/socket tool, place the

socket over the spark plug so that it fits as

shown.

Firmly but carefully strike the arm of the multi

tool with the palm of your hand, this should

loosen the spark plug.

Checking the Spark plug

The following can be performed after you have

removed the plug in the preceding instruction

and be

fore fitting a new plug.

This is a simple method for diagnosing if a

problem exists with the spark plug.

Re

move the dust cover and push the spark plug

firmly into the cover cap.

lding the cover cap / plug in your hand,

Ho

position the plug so that the tip makes contact

with the metal plate surrounding the area of the

16

body from which the plug was removed .

!! DO

NOT TOUCH THE METAL PART OF THE

PLUG OR ANY METAL PARTS ON THE SAW

FROM THIS POINT ESPECIALLY IF YOU SUFFER

FROM A MEDICAL CONDITION THAT COULD BE

AGGREVATED BY CONTACT WITH AN

ELECTRICAL CURRENT !!

Pu

sh the Stop / Start switch upwards into the

start position, and ensuring the plug is making

contact with the metal plate quickly pull the

recoil starter handle, if the plug is working you

should at this point see a Spark at the base of

the plug.

Online Guides

15

17

Further advice for operation and basic

maintenance of your chainsaw can be found

by following the links below or by scanning

the relevant QR code . This information can

also be accessed by visiting

www.trueshopping.co.uk

and inputting the

product code

STARTING YOUR CHAINSAW

http://www.youtube.com/watch?v=XoPn

STTkGf8

FUEL MIX SETTING

http://www.youtube.com/watch?v=pVxSqaYS

pLQ

REPLACING THE FUEL FILTER

http://www.youtube.com/watch?v=DreW99

d9gaQ

SETTING CHAIN RETENTION

http://www.youtube.com/watch?v=pOP1Ltnf

t0A

REPLACING RECOIL

http://www.youtube.com/watch?v=xUnKT76

qoiI

CHANGING THE SPARK PLUG

http://www.youtube.com/watch?v=7h3cOLbS

bCs

Troubleshooting

16

18

If the problem you are having is not covered below, or is not solved by following the advice outlined,

please call our technical helpline or visit the website for further guidance.

The Engine will not start.

• Have you added fuel to the engine?

• Check that the engine is not flooded by closing the throttle and trying to start the unit,

also remove the spark plug and dry.

• Is the spark plug dirty , remove the plug and check for carbon residue

Engine stalling

• Adjust the idle speed (page 5)

• Check fuel for water contamination and replace

• Clean the air filter

• Check oil quality and replace if required

The saw is not cutting properly

• Check chain tension

• Sharpen chain with a chain file

• Replace chain

I have a faulty part

• Go to www.trueshopping.co.uk to order the required spare.

ease note that while every attempt has been made to keep this guide up to date, changes can

Pl

occur due to design / manufacturing changes, if you have a question regarding a feature that your

product has or is missing, please visit www.trueshopping.co.uk

to download the most up to date

version of this manual.

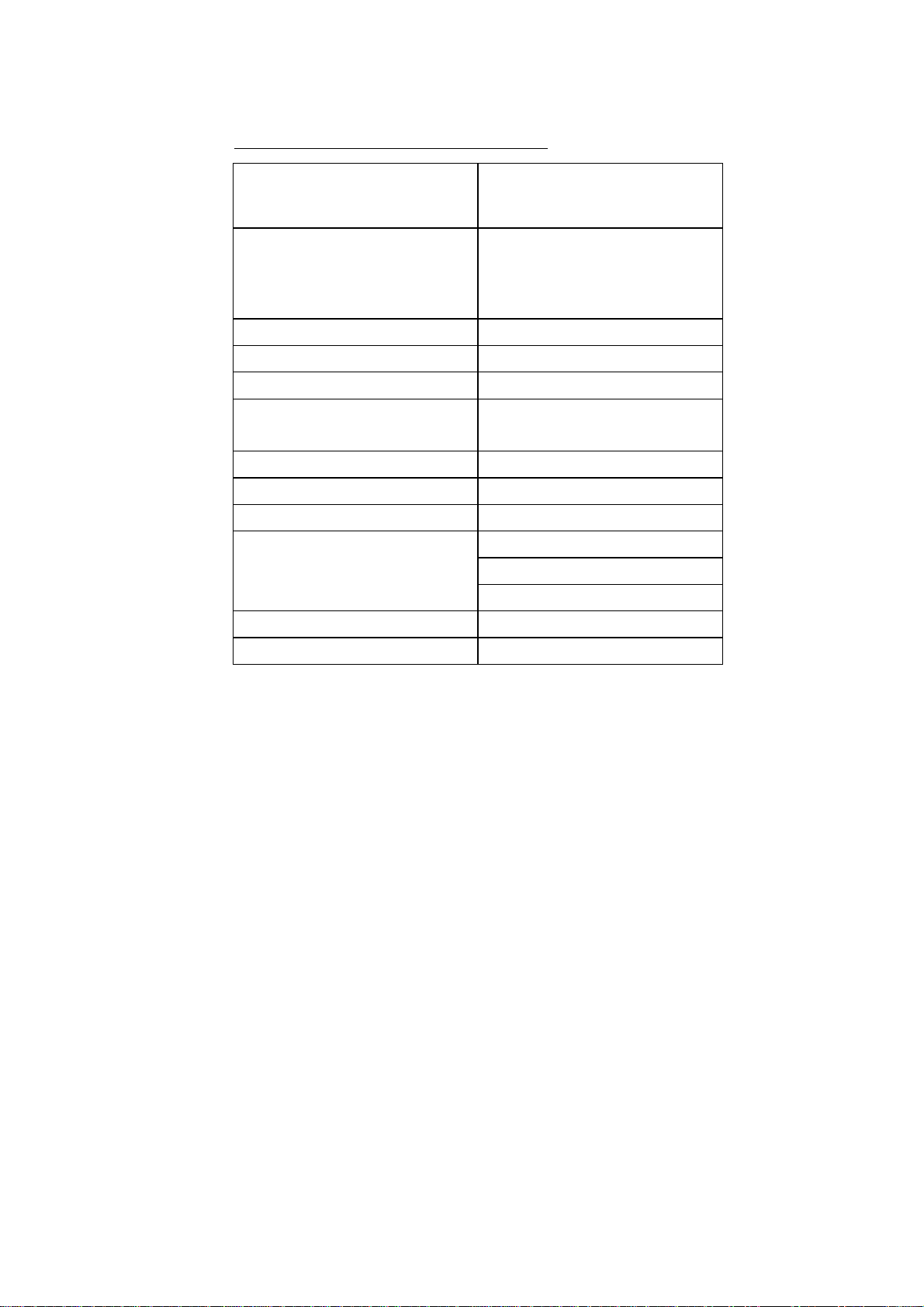

Chainsaw Technical Specifications -

17

19

Engine type

52 cc/58cc

Air-cooled, Two-stroke, petrol

engine

Dry weight (without guide

bar, chain and with empty

4.90KGS

tank)

Volume of Fuel Tank 550ml

Volume of Oil Tank 260ml

Cutting length(mm) 480mm

Max. engine speed

9000

(min-1)

Engine Displacement 52 cc/58cc

Max. Power 2.2KW

Max Idle Speed(min-1) 3400

JW52 00/JW5800

Model

HW5200/HY5800

SL-YD5200B /SL-YD58

Petrol-oil-mixture 25:1

Sound Power Level 113db

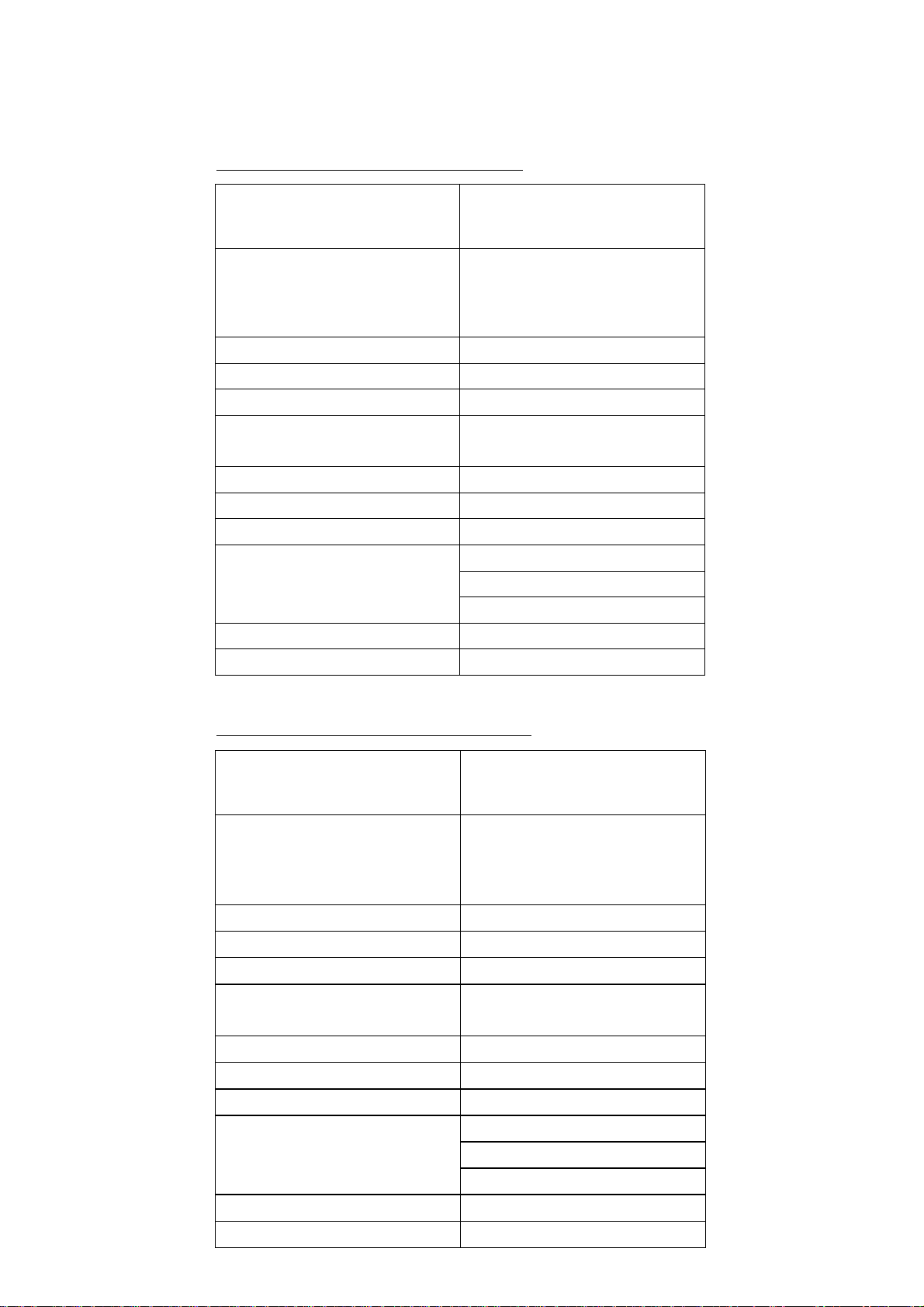

Chainsaw Technical Specifications -38c

Engine type

Air-cooled, Two-stroke, petrol

engine

Dry weight (without guide

bar, chain and with empty

tank)

4.50KGS

Volume of Fuel Tank 310ml

Volume of Oil Tank 210ml

Cutting length(mm) 370mm

Max. engine speed

(min-1)

9000

Engine Displacement 37.2cc

Max. Power 1.25KW

Max Idle Speed(min-1) 3400

Model

JW3800

HY3800

SLYD38

Petrol-oil-mixture 25:1

Sound Power Level 113db

Chainsaw Technical Specifications -49cc

Engine type

Air-cooled, Two-stroke, petrol

engine

Dry weight (without guide

bar, chain and with empty

tank)

4.90KGS

Volume of Fuel Tank 550ml

Volume of Oil Tank 260ml

Cutting length(mm) 440mm

Max. engine speed

(min-1)

9000

Engine Displacement 49.3cc

Max. Power 1.8KW

Max Idle Speed(min-1) 3400

Model

JW4500

HY4500

SL-YD45

Petrol-oil-mixture 25:1

Sound Power Level 113db

1820192120

22

Tronçonneuse à essence

23

Guide des modèles - JW3800, JW4500, JW5200, JW5800

HY3800, HY4500, HY5200, HY5800

SLYD38, SL-YD45, SL-YD5200B, SL-YD58

©Trueshopping LTD Issue 1 m.c

CONTENUS

Informations sur le numéro du modèle 23

Consignes de sécurité importantes 25

Mélange de carburant et ravitaillement 26

• Ravitaillement et préparation pour une première utilisation 26

•

Réglage du ralenti 27

Monter la scie 27

• Montage de entraîneurs 27

Montage du guide-chaîne, de la chaîne et du frein de la chaîne 28

Démarrer la scie 31

Utilisation de la scie 33

•

*

Abattage d’un arbre 33

Ebranchage d’un arbre 34

Tronçonnage d’un arbre 34

Maintenance 35

Eviter le recul de la scie 33

• Huile de chaîne 36

• Changer l’huile 36

• Filtre à air 36

• Pignon 36

• Chaîne 36

• Test de bougie d’allumage / échange 36

Recherche de pannes 38

Consignes de sécurité importantes

25

! Avant de mettre l’outil en marche, assurez-vous

que la chaîne ne touche rien

Générale

! Ce produit ne doit être utilisé que par des personnes

compétentes.

! Interdit de fumer ou d’utiliser ce produit sur/ou près

des sources de combustion.

! Porter des équipements de sécurité adéquate (Lunettes,

bottes glissantes, protège-oreilles et des gants de travail

épais*) à chaque fois que vous utilisez ce produit.

! Ne pas utiliser la tronçonneuse lorsqu’on est sous

l’influence d’alcool ou toute autre substance qui

pourrait altérer votre jugement, vos capacités

physiques et votre état d’esprit.

! Si vous vendez ou prêtez cet ensemble, veuillez-vous

assurer que ce manuel et toute la documentation

afférente soit vendue avec l’ensemble

! Cet appareil ne doit pas être utilisé, loué ou vendu aux

personnes de moins de 18 ans

! Assurez-vous que les personnes et les animaux

soient à une distance de sécurité de 10m au moins

! Toujours garder ses distance par rapport à la scie

car elle commencera à tourner au démarrage du

moteur

! Si vous abattez un arbre, voir la note du

diagramme (fig1) à côté pour avoir une meilleure

compréhension de la situation

! Pour votre propre sécurité, réduisez le temps que

vous utilisez la machine de façon continue à des

sessions de 10 min, en prenant des pauses de 10-20

minutes d’intervalles. Eviter de dépasser un total de

2 heures de travail par jour.

! Cet appareil produit du monoxyde de carbone

lorsqu’il est en fonctionnement, NE PAS utiliser cet

appareil dans un espace fermé

! Ne pas utiliser cet appareil lorsque vous êtes

fatigué car votre concentration sera réduite,

l’utilisateur est responsable de toute blessure

causée à autrui

Maintenance

! Ne pas faire de maintenance / réparation à moins qu’elles aient

été décrite dans ce guide ou que vous ayez reçu des instructions

additionnelles détaillées du fabricant

! Ne pas faire de réparation tant que l’appareil est chaud

! Vider toute l’essence de l’appareil avant de faire toute

maintenance

! Sauf spécification contraire, assurez-vous que la protection de la

chaîne soit en place lorsque vous faites la maintenance

! Placer l’appareil sur une surface solide plate lorsque vous

faites la maintenance ou la réparation

! Ne pas laisser ce produit sans surveillance

! N’utilisez pas l’appareil dans des conditions

météorologiques difficiles qui pourraient

rendre ce produit dangereux

! Marquer clairement votre zone de travail avec

une barrière adéquate (bande / Corde)

! Éteignez l’appareil lorsque vous ne l’utilisez pas

Utilisation

! Avant tout utilisation, toujours vérifier si machine n’est

pas endommagée ou usée

MELANGE DE CARBURANT ET

26

RAVITAILLEMENT

Mélanger l’essence (avec plomb ou sans plomb,

sans alcool) et une huile à moteur de bonne

qualité conçu pour les moteurs à 2 cylindres

refroidis à l’air.

Le b

sur l’outil.

To

l’aiguille d’une montre pour l’ouvrir et ajouter

votre mélange de carburant au moteur. Ensuite

replacez le bouchon et tournez-le dans le sens

de l’aiguille d’une montre jusqu’à ce ça soit bien

TAUX D’ESSENCE MELANGE RECOMMANDE

: HUILE

rs de la première utilisation, rappelez-vous

Lo

serré.

que les problèmes de moteur peuvent être

causés par un mauvais mélange de carburant

ou l’utilisation du mauvais type d’essence /

d’huile

Remplissage du carburant et première utilisation

! Lors du remplissage du réservoir assurezvous que le moteur est éteint et vérifiez

autour de vous s’il y a des signes de danger

(feu, étincelles).

Aj

utilisation. Cela peut être remplit tel que requis.

ouchon du réservoir est clairement marqué

urnez le bouchon dans le sens contraire à

outer de l’huile à chaîne avant la première

! Utiliser un tissu sec pour nettoyer toute

éclaboussure

! Après remplissage, déplacer le produit loin du

site de remplissage avant utilisation

*Veuillez noter que le bon taux de mélange

d’essence est imprimé sur l’étiquette placé sur

la zone de la poignée

tronçonneuse doit être penchée sur le côté

La

lors du remplissage, sinon cela causera un

débordement du réservoir. Pour éviter pour

toute éclaboussure, un petit entonnoir peut être

utilisé

.

Re

tirer le bouchon de l’huile à chaîne (décrit cidessous) en tournant le bouchon dans le sens

inverse à l’aiguille d’une montre.

dessous de l’outil, vous trouverez se trouve la

En

vis de réglage du débit d’huile de la chaine.

*L’emplacement de cette vis peut varier en

fonction du modèle, l’image ci-dessous montre

27

deux emplacements possible.

justements peuvent être faits tel que

Des a

décrit sur la gravure sur le plastique.

Réglage du ralenti

L’information suivante montre comment régler

le ralenti du moteur (la vitesse à laquelle le

moteur tourne lorsqu’il n’est pas en train de

couper)

*Veuillez noter qu’un outil de réglage du

carburateur est nécessaire pour faire ce réglage

(non fourni)

Montage de la tronçonneuse

! Avant de commencer l’assemblage,

assurez-vous que vous avez toutes les

pièces dans la boite, s’il manque une

pièce, veuillez contactez xxxxx l’ assistance

pour information

Montage des entraîneurs

A titr

e de guide générale, le travail dans une

température plus froide peut nécessiter le

réglage à une vitesse de ralenti plus élevée

Pou

r régler la vitesse du ralenti Tourner la petite

vis (L) complétement dans le sens de l’aiguille

d’une montre jusqu’elle ne bouge plus, ensuite

faites un tour complet dans le sens contraire à

l’aiguille d’une montre. Répétez ceci avec la

grande vis (H) va réinitialiser le carburateur au

paramètres d’usine.

r l’entraineur dans le moteur et serrez tel

Place

que décrit –

Ce guide-chaîne montre également le sens de

28

déplacement de la chaîne (voir fig 1.)

Fixation de la barre, la chaîne et le frein de

chaîne pour le moteur

ver la chaîne du sac et

Enle

étaler sur une surface plane

Avan

t de continuer, notez la flèche directionnelle

.

sur le lien de la chaîne, après avoir monté le

guide-chaîne cette flèche doit pointer en

direction opposée à l’unité centrale en haut de la

barre, et vers l’unité en bas du guide-chaîne.

Cet

te chaîne doit être vissée au pignon

d’entrainement sous le volant

le guide-chaîne dans l’unité principale

Placer

dans un angle sur les deux goujons de

positionnement et poussez délicatement la

chaîne dans la rainure du guide-chaîne, une fois

la chaîne en place le long de la partie supérieure

de la chaîne, retirez délicatement le guide-chaîne

de l’unité principal, ceci va donner un peu de lest

Loading...

Loading...