Page 1

NCP13992MM240WGEVB

Table 1. GENERAL PARAMETERS

Device

Applications

Input Voltage

Nominal Output

Output Power

V

Ripple

NCP1618

AOI,

90 – 265 Vac

12 Vdc / 20 A

240 W

<150 mV @ Full

Efficiency @

Standby Power

Operating

Cooling

Topology

Board size

Convection Open

L

F

All-in-One Power Supply

Evaluation Board User's

Manual

240 W Power Supply using NCP1618,

www.onsemi.com

NCP13992, NCP4306 and NCP431

Description

This evaluation board user’s manual provides basic information

about a high efficiency, low no−load power consumption reference

design that was tailored to power All−in−One PC or similar type of

equipment that accepts 12 V

implements PFC front stage to assure unity power factor and low

DC on the input. The power supply

THD, current mode LLC power stage to enhance transient response

and secondary side synchronous rectification to maximize efficiency.

This design note provides brief information about controllers’

implementation into design, their interconnections and cooperation.

Please use links in literature section to get detail technical information

about NCP1618, NCP13992, NCP4306 and NCP431.

The NCP1618 is an innovative multimode power factor controller.

The controller automatically change operation mode depending on

conditions so that the efficiency is optimized over the line and load

range. In very light−load conditions, the circuit enters a soft−skip

cycle mode. NCP1618 enters Continuous Conduction Mode (CCM)

under Heavy−Load Conditions, while Frequency−Clamped Critical

Conduction Mode (FCCrM) is used for Medium− and Light−Load

Conditions. PFC−OK Output serves as Brown−Out signal for LLC

controller as well as communication interface which sends NCP1618

into stand−by mode (using Soft−skip cycles).

The NCP13992 is a high performance current mode LLC controller

for half bridge resonant converters. This controller implements 600 V

gate drivers, simplifying layout and reducing external component

count. In applications where a PFC front stage is needed, the

NCP13992 features a dedicated output to drive the PFC controller.

This feature together with quiet skip mode technique further improves

light load efficiency of the whole application. Both controllers provide

a suite of protection features allowing safe power supply operation in

any application. Built−in high voltage input function ease

implementation of the controllers in all applications startup circuits.

EVAL BOARD USER’S MANUA

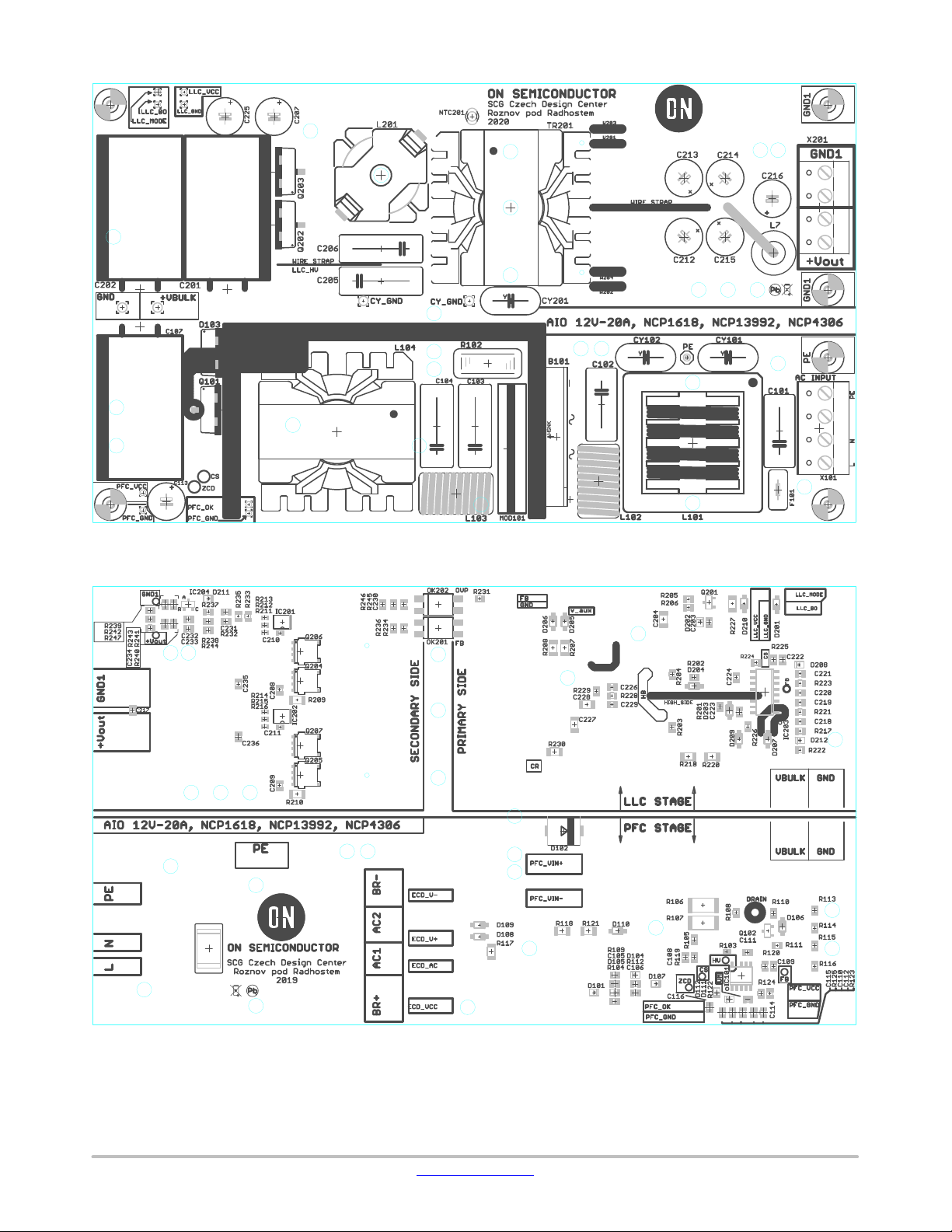

Figure 1. Evaluation Board Photo

eatures

• Wide Input Voltage Range

• PFC Controller with Multimode Operation

• High Efficiency/ Low No−load Power

Consumption

• No Auxiliary SMPS, Fast Startup

• Near Unity Power Factor

• Low Mains & Overload Protection

• Thermal Protection

• Regulated Output Under any Conditions

• Excellent Load & Line Transient Response

• All Magnetics Available as Standard Parts

• Small Form Factor

• Extremely Low No−load Consumption

NCP13992

NCP4306

230 V AC

4 point AVG

94.11%

© Semiconductor Components Industries, LLC, 2020

August, 2020 − Rev. 0

Server Power

Temperature

<130 mW 0 – 40 °C

Voltage / Current

Frame, Forced in

Frame

1 Publication Order Number:

PFC CrCM

LLC + SR

OUT

load

194 × 108 × 27 mm

7.11 W/inch

EVBUM2753/D

3

Page 2

NCP13992MM240WGEVB

E C D_AC

E C D_V C C

E C D_V−

E C D_V+

1 212

6

7

8

HV

10

G ND

DR V

V C C

ZC D

5

C S

4

V M

3

P F C _OK

2

F B

1

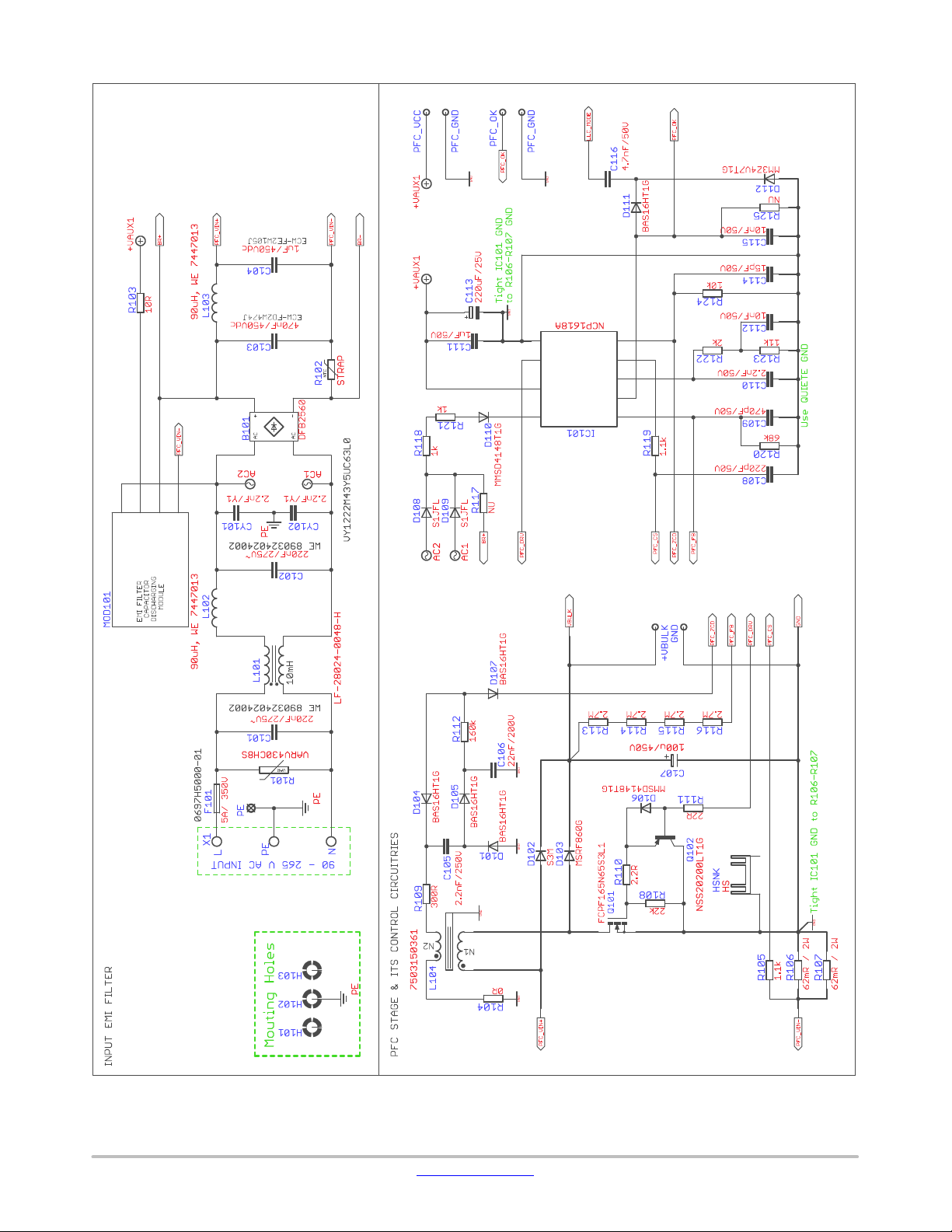

Figure 2. AOI Evaluation Board Schematic − PFC Front Stage

www.onsemi.com

2

Page 3

NCP13992MM240WGEVB

5

6

V C C

MIN_TOF F

DR V1G ND2C S

4

MIN_TON

3

11*2

5*2

1

4

5

6

V C C

MIN_TON

MIN_TOF F

DR V

G ND

C S

1

2

3

12

434

8*2

9*4

3

4

2

16

12

14

11

15

HB

MUP

G ND

MLOW

V B OOT

S K IP4V B /P F C -F B

HV_IN1LLC _C S

LLC _F B

3

6

5

9

10

V C C

MODE

F B _F R E E Z

OV P /OT P

7

8

R

AC

1

2

3

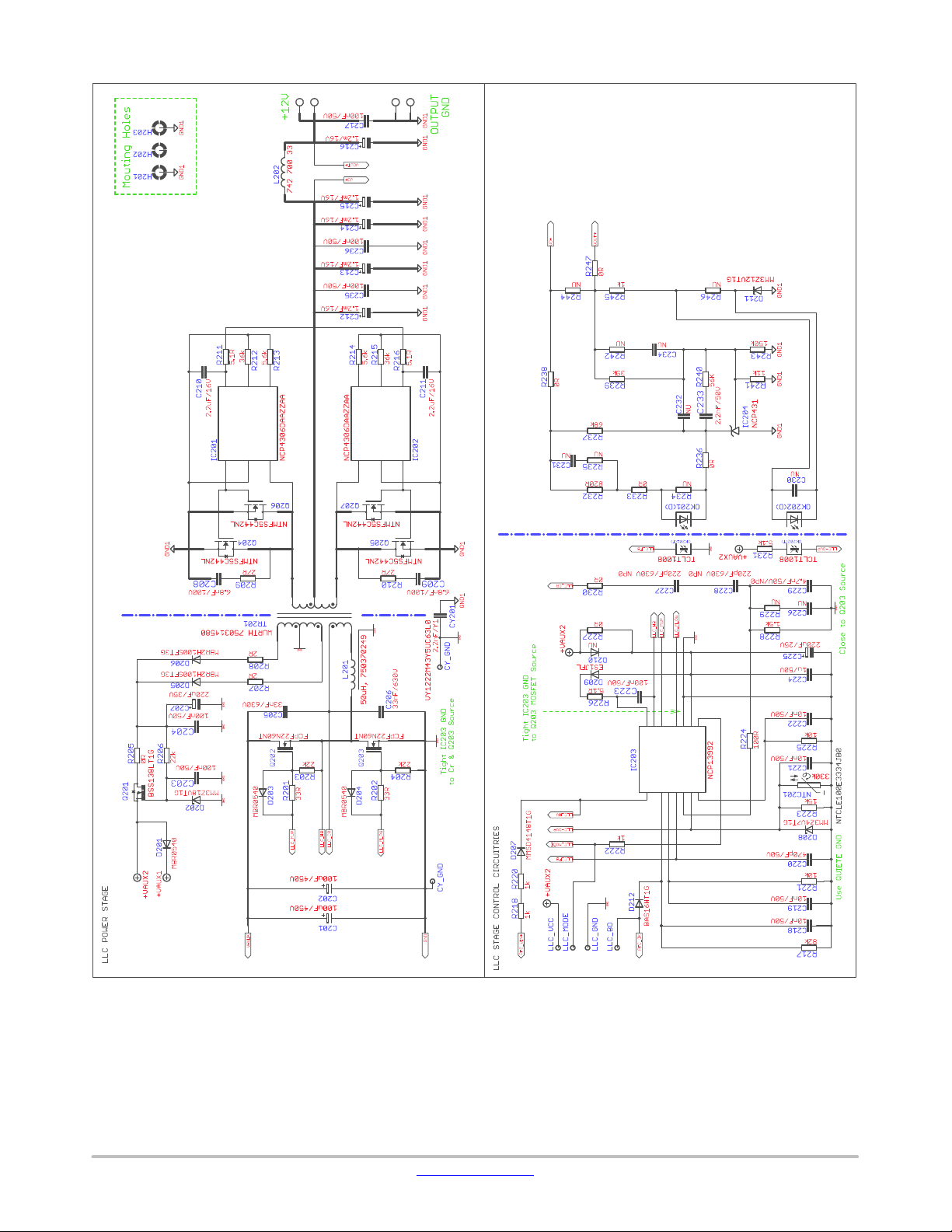

Figure 3. AOI Evaluation Board Schematic − LLC Stage

www.onsemi.com

3

Page 4

NCP13992MM240WGEVB

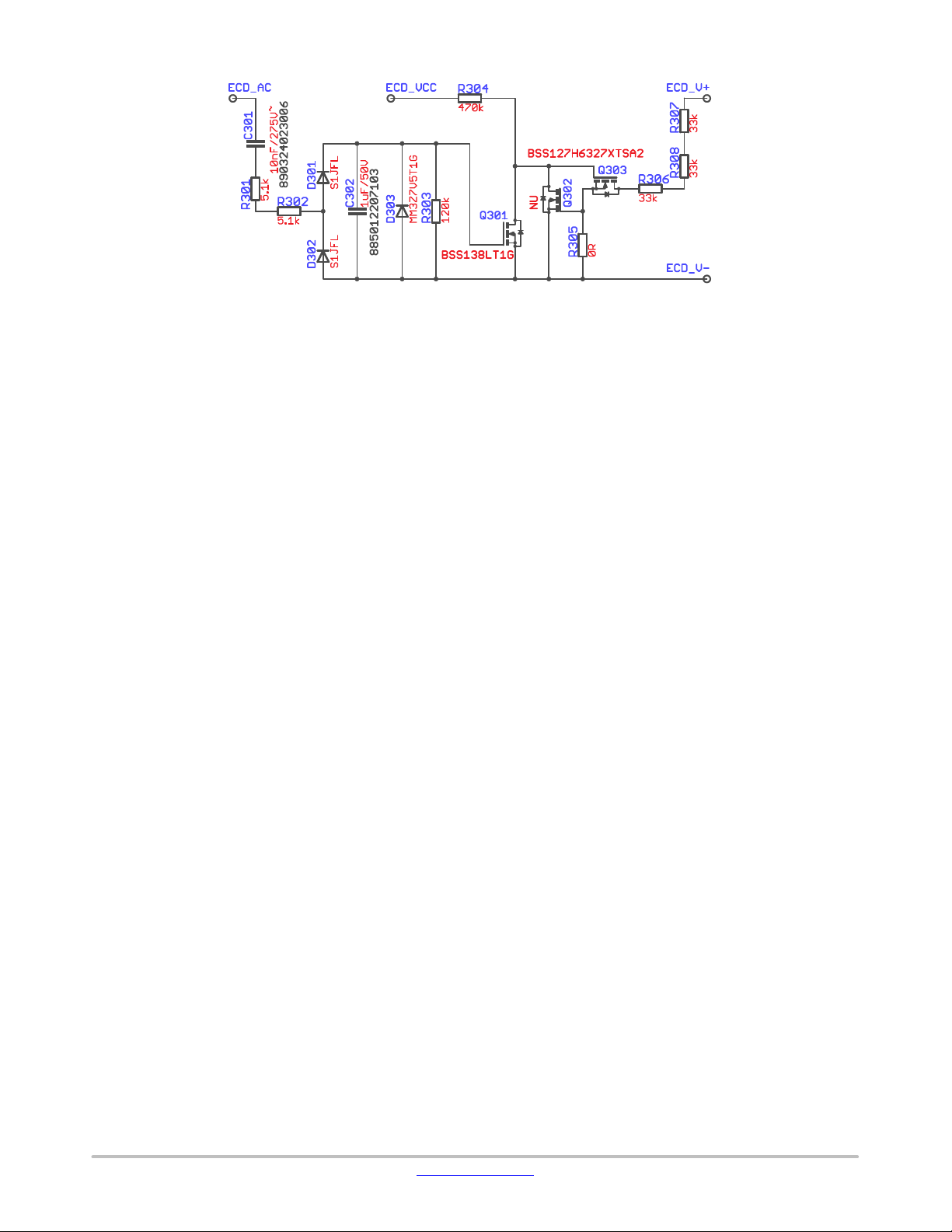

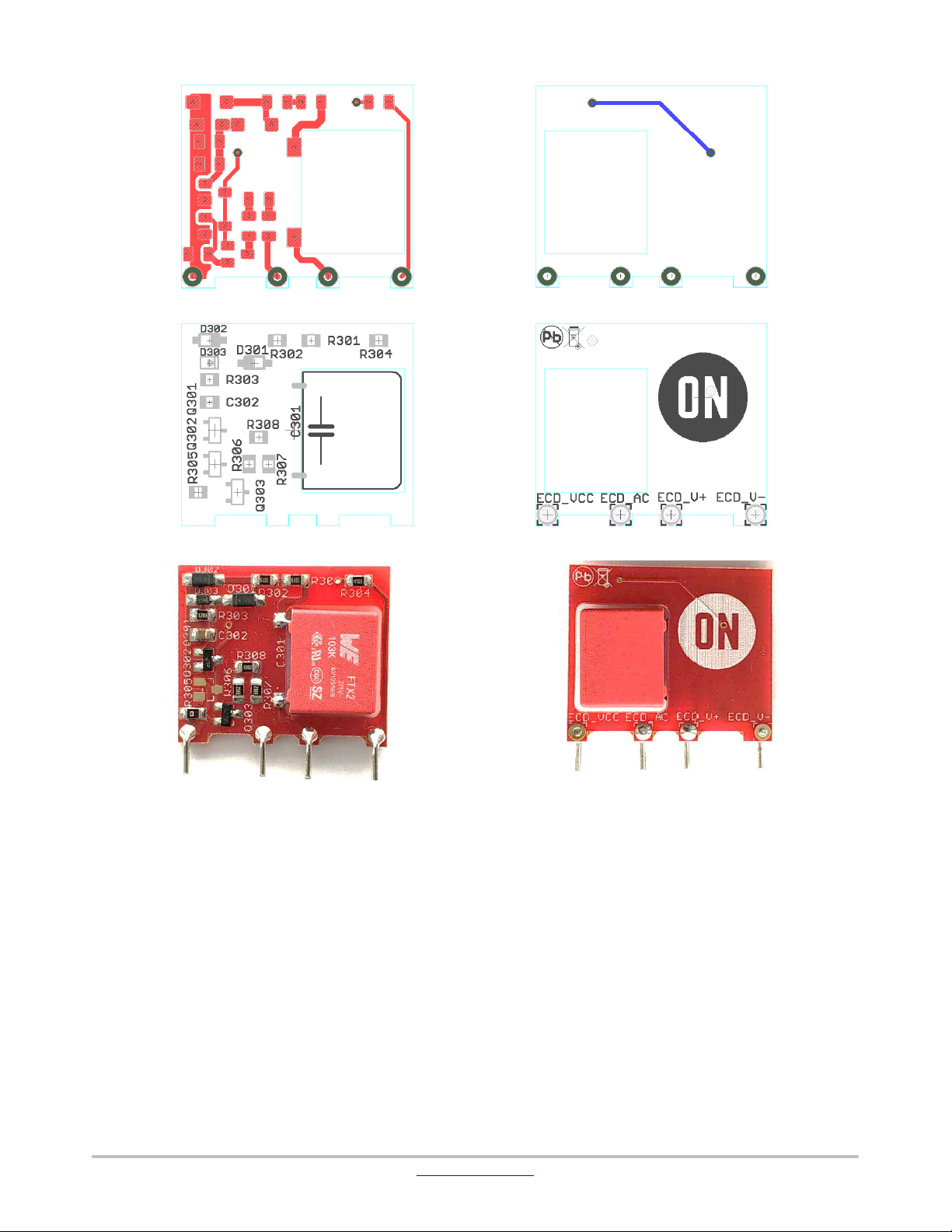

Figure 4. EMI Capacitor Discharging Module (MOD101)

Detailed Descriptions of the Evaluation Board

Input side of evaluation board is protected by a several

components. As first, it’s a 5 A slow reaction fuse F101,

which disconnects input in case wrong manipulation, line

overvoltage stress event and unexpected stresses or

conditions. Voltage dependent resistor R101 serves as input

overvoltage protection triggered at approximately 275 V

AC. Demo−board implements inrush−current limiting

device, R102 NTC thermistor which is not assembled to

allow clear efficiency measurement (Figure 2). It’s

recommended to assemble R102 in case of testing in hard

conditions (using power grid directly or AC power supply

without current limit). Use appropriate NTC inrush current

limiter in case of need.

EMI filter is formed by components L101, L102, L103,

C101, C102, C103, C104, CY101 and CY102 (Figure 2).

The IC101 − NCP1618 measures input line voltage via

diodes D108, D109, D1 10 and resistors R1 18, R121 to detect

present of Brown−out/ Brown−in and SAG conditions as

well as distinguishes input line level. This circuit also

provides PFC Vcc Start−up feature for building controller

Vcc supply. The Power Factor Corrector (PFC) power stage

implements standard boost PFC topology composed of

following power devices; bridge rectifier B101, power

(boost) inductor L104, power MOSFET switch Q101, boost

power diode D103, bypass diode D102, shunt resistors

R106−R107 and bulk capacitors C107, C201−C202. The

PFC controller IC101 (NCP1618) senses input voltage

directly via pin 10 (HV) through network of D108, D109,

D110 and resistors R118, R121. The PFC inductor current

is monitored on the shunt resistor R106−R107. The series

resistors R105−R1 19 set maximum current. Capacitor C108

that is connected between those resistors filters noise caused

by switching. Maximum current through resistors can be

calculated based on NC1618 datasheet. The PFC feedback

divider has high impedance (approximately 10.8 MW)

which ensures low consumption in no−load or light−load

mode conditions. PFC FB divider is created from upper

resistor R113−R116, lower resistor R120 and capacitor

C109. The PFC FB signal is filtered by capacitor C109 to

minimize noise caused by the parasitic capacitive coupling

between pin and other nodes that handle high dV/dt signals.

PFC FB divider sets nominal bulk voltage level which is

400 V approximately. NCP1618 features positive bulk

voltage hiccup, so that while LLC Stage runs under burst

mode, NCP13992 forces NCP1618 to enter skip mode

(stand−by mode), thus bulk−voltage is maintained between

+103% and 98 % of nominal bulk voltage i.e. between

~420 V and ~394 V on this design. NCP1618 can be sent

into soft−skip−mode (stand−by mode) by two ways. This

demo−board implements only one solution – via

pulling−down the PFC−OK pin. Refer to NCP1618

datasheet for more detailed description. Devices D111,

D112, C116 and R222 are used for PFC−OK pulling−down

purpose. Once, IC203 NCP13992 enters to skip, MODE pin

(9) goes low level and pulls down PFC−OK for interval

longer than 29 ms, which results in establishing PFC

stand−by soft skip mode. NCP1618 PFC−OK pin generates

signal which is green−light for down−stream LLC converter .

If no fault occurs and bulk voltage level is in regulation

range, PFC−OK pin sources current which is translated into

drop at R217 and this voltage enables NCP13992 operation.

NCP1618 has integrated driver but the external PNP

transistor Q102 was implemented. The Q102 is connected

directly to source of Q101 in order to minimize discharge

loop and thus allow faster PFC switch turn−off and also

minimizing EMI caused by the driver loop. Q101 Gate

turn−on path is secured by R110, R111 and D106, on the

contrary turn−off path is realized mainly via R1 10 and Q102.

This solution enables to define required switching speeds for

both processes independently. The PFC choke auxiliary

winding voltage is processed by circuit R109, R112, R124,

C105, C106, C114, D10, D104, D105 and D107. Processed

signal is fed into ZCD pin, which detects valleys

zero−current and OVP2 events. This pin provides a voltage

VM for duty cycle modulation when the circuit operates in

continuous conduction mode. The NCP1618 external

network connected to the VM pin adjusts the maximum

power which can be delivered by the PFC stage. R122−R123

set maximum power in CCM mode, C110−C112 filter noise

coupled to this pin.

Schematics diagram in Figure 2 contains module with

designator MOD101. Internal schematic diagram of this

module is displayed in Figure 4. MOD101 was designed as

a part of PFC stage and it’s a discrete solution for discharging

EMI filter differential capacitors. This element was named

as “EMI Capacitor Discharging Module”. Module works in

very simple way based on charge pump principle made of

www.onsemi.com

4

Page 5

NCP13992MM240WGEVB

C301, R301, R302, D301 and D302. When AC voltage is

presented at pin ECD_AC, charge pump creates voltage (at

C302/R303) which is clamped by Zener−diode D303. This

voltage turn−on MOSFET Q301, which pull−down Gate

voltage of Q303. While AC line is presented charge pump

continues to operate and generates voltage/current which

disables Q303. Once, AC line turns out, charge pump stops

and Q303 is turned on and discharges differential capacitors

in EMI filter (through bridge rectifier B101).

Entire LLC power stage is displayed in Figure 3. Power

stage at primary side of LLC converter is composed of these

devices: MOSFETs Q202, Q203, external resonant inductor

L201, transformer TR201 and resonant capacitors C205 and

C206. The IC203 NCP13992, LLC controller senses

primary current indirectly, via resonant capacitor voltage,

which is divided down by a capacitive divider, using

capacitors C227−C228 and C229. The capacitive divider

has to be optimally loaded and in the same time assure fast

signal stabilization after application startup. This is

achieved by resistor R228. Scaled signal from CS divider

passes through resistor R224 which limits maximum current

that can flow into the LLC_CS pin. The FB optocoupler

OK201 is connected to the LLC_FB pin and defines

converter output voltage by pulling down this pin when

lower output power is needed. Capacitor C220 forms high

frequency pole in FB loop characteristics and helps to

eliminate eventual noise that could be coupled to the FB pin

by parasitic coupling paths. The VB/PFC−FB pin allows

LLC converter operation once input level is approximately

above 1.1 V. VB/PFC−FB signal is provided by PFC

controller NCP1618, which sources current from PFC−OK

pin as aforementioned. VB/PFC−FB pin voltage is filtered

by C218. The Skip/REM pin of the NCP13992 is sued for

skip threshold adjustment. Resistor R221 is used for this

purpose together with noise filtering capacitor C219. The

over−voltage and over−temperature protections are

implemented via OVP/OTP pin by using resistor R223,

temperature dependent resistor NTC201, Zener−diode

D208, filtering capacitor C221 and optocoupler OK202.

Simple OVP detector is located on the secondary side and it’s

made of resistor R245, Zener−diode D211 OK202

optocoupler diode. The FB_FREEZE pin (8) defines

minimum internal feedback voltage (lower saturation level),

which influences maximum switching frequency. Resistor

R225 sets FB freeze level and C222 decouples noise. The

PFC stand−by mode (or PFC soft−skip) is activated by

MODE pin ( 9 ) , w hich goes high during LLC stage switching

and stays low during idle mode– as described in PFC section.

The VCC decoupling capacitor C224 and also bootstraps

capacitor C223 for high side driver powering are located as

close to the LLC controller package as possible to minimize

parasitic inductive coupling to other IC adjust components

due to high driver current peaks that are present in the circuit

during drivers rising and falling edge transitions. The

bootstrap capacitor is charged via HV bootstrap diode D209

and series resistor R226 which limits charging current and

VBOOT to HB power supply slope during initial C223

charging process. The gate driver currents are reduced by

added series resistors R201, R202 to optimize EMI signature

of the application. Schottky diodes D203 and D204 are used

to speed−up the MOSFETs turn−off process. The primary

controllers are biased by voltage limiter circuitry, which is

used in order to not exceed VCC pin maximum ratings. The

upper value of the primary VCC voltage is clamped to

approximately 15 V. The VCC clamp is composed of these

components: R205, R206, Q201, D202 and C203. The VCC

clamp is fed from auxiliary windings via rectifier

D205−D206 and current limiting resistor R207−R208. The

secondary side synchronous rectification uses IC201 and

IC202 NCP4306 SR controllers. Two MOSFTEs are

connected in parallel for each SR channel to achieve low

total voltage drop − Q204, Q206 and Q205, Q207. RC

snubber circuits C208−R209 and C209−R210 are used to

damp down the parasitic ringing and thus limit the

maximum peak voltage on the SR MOSFETs. The SR

controllers are supplied from converter output via resistors

R211 and R216. These resistors with decoupling capacitors

C210 and C211 form RC filter. The minimum on−time –

R213, R214 and minimum off−time – R212, R215 resistors

define needed blanking periods that help to overcome SR

controllers false triggering to ringing in the SR power stage.

Each SR controller implements clever light load detection

feature LLD. After first incoming pulse from skip burst, the

LLD feature wakes−up the controller from low power mode

(50 mA). SR controller enters to stand−by mode after defined

period of time (68 ms) once the last pulse from the skip burst

ends. Internal setup cares about LLD feature timing thus

eliminates need for complicated external light−load guard

circuitry. The NCP4306 LLD feature offers great benefits

compare to the traditional solutions, in which SR operation

and no−load consumption is much less efficient. The output

filtering capacitor bank composes from low ESR

electrolytic capacitors C212 to C215 and ceramic capacitors

C217, C235 and C236. Output filter L202, C216 is used to

smooth output voltage from switching glitches. The output

voltage of the converter is regulated by standard shunt

regulator NCP431− IC204. The regulation optocoupler

OK201 is driven via resistor R232 which defines loop gain.

The NCP431 is biased via resistor R237 in case there is no

current flowing via regulation optocoupler –which can

happen before the nominal V

level is reached or during

OUT

transients from no−load to full−load conditions. The output

voltage is adjusted by divider R239, R241, and R243. The

feedback loop compensation network is formed partially by

resistor R240 and capacitor C233.

PCB layout is prepared with options so user can modify

demo−board accordingly if needed – please refer to

schematics. The PCB consists of a 2 layer FR4 board with

70 mm copper thickness to minimize resistance in secondary

side where high currents are conducted. Leaded components

are assembled form the top side of the board and all SMT

components are place from the bottom only. The board was

designed to work as open frame with natural air flow

cooling. Forced air flow cooling management should be

considered in case the board is packed into some box or

target application.

www.onsemi.com

5

Page 6

NCP13992MM240WGEVB

0

0

R

R

0

R

Figure 5. Evaluation Board − Top Side Components

−4+4

4321 4321

Figure 6. Evaluation Board − Bottom Side Components

www.onsemi.com

6

Page 7

NCP13992MM240WGEVB

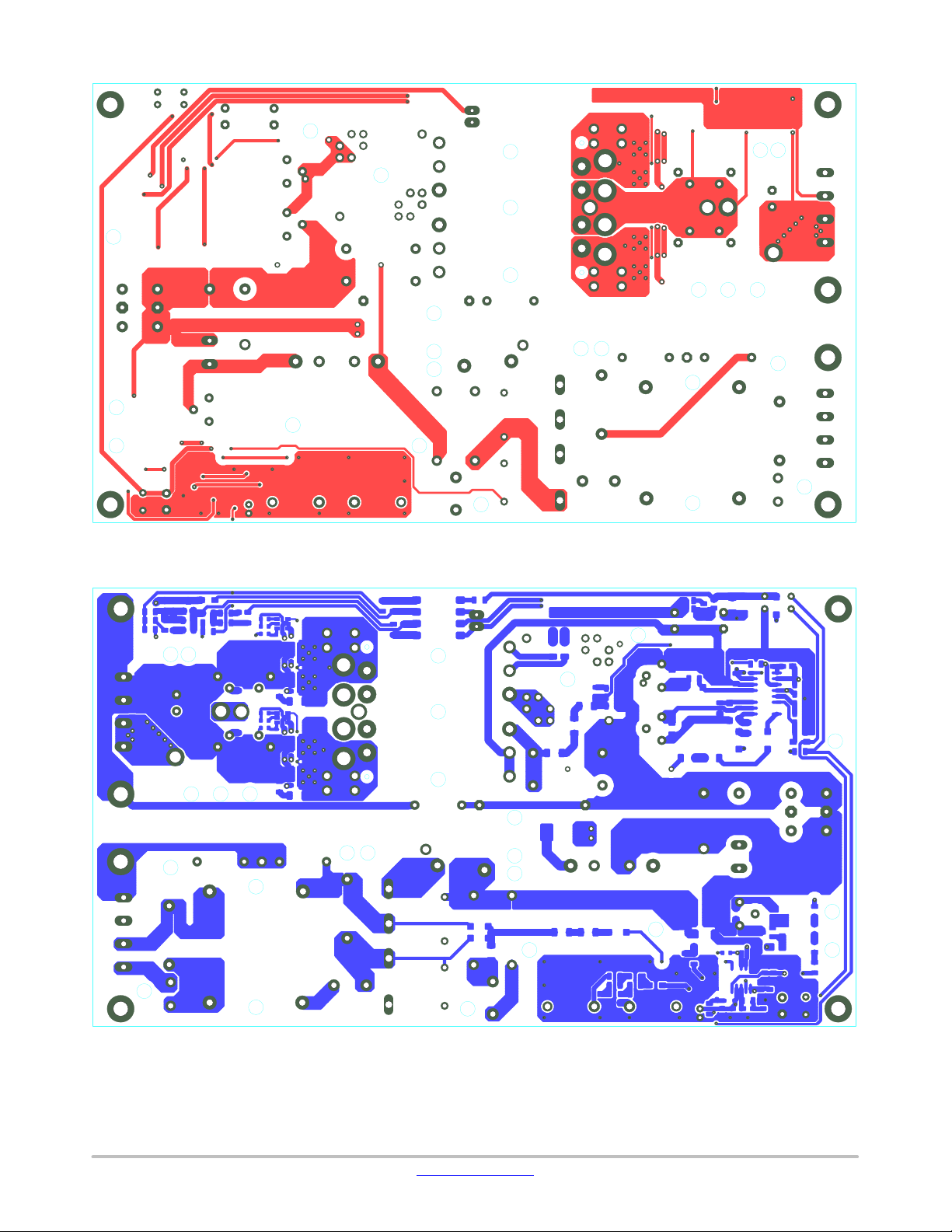

Figure 7. Evaluation Board − PCB Design of Top Layer

Figure 8. Evaluation Board − PCB Design of Bottom Layer

www.onsemi.com

7

Page 8

NCP13992MM240WGEVB

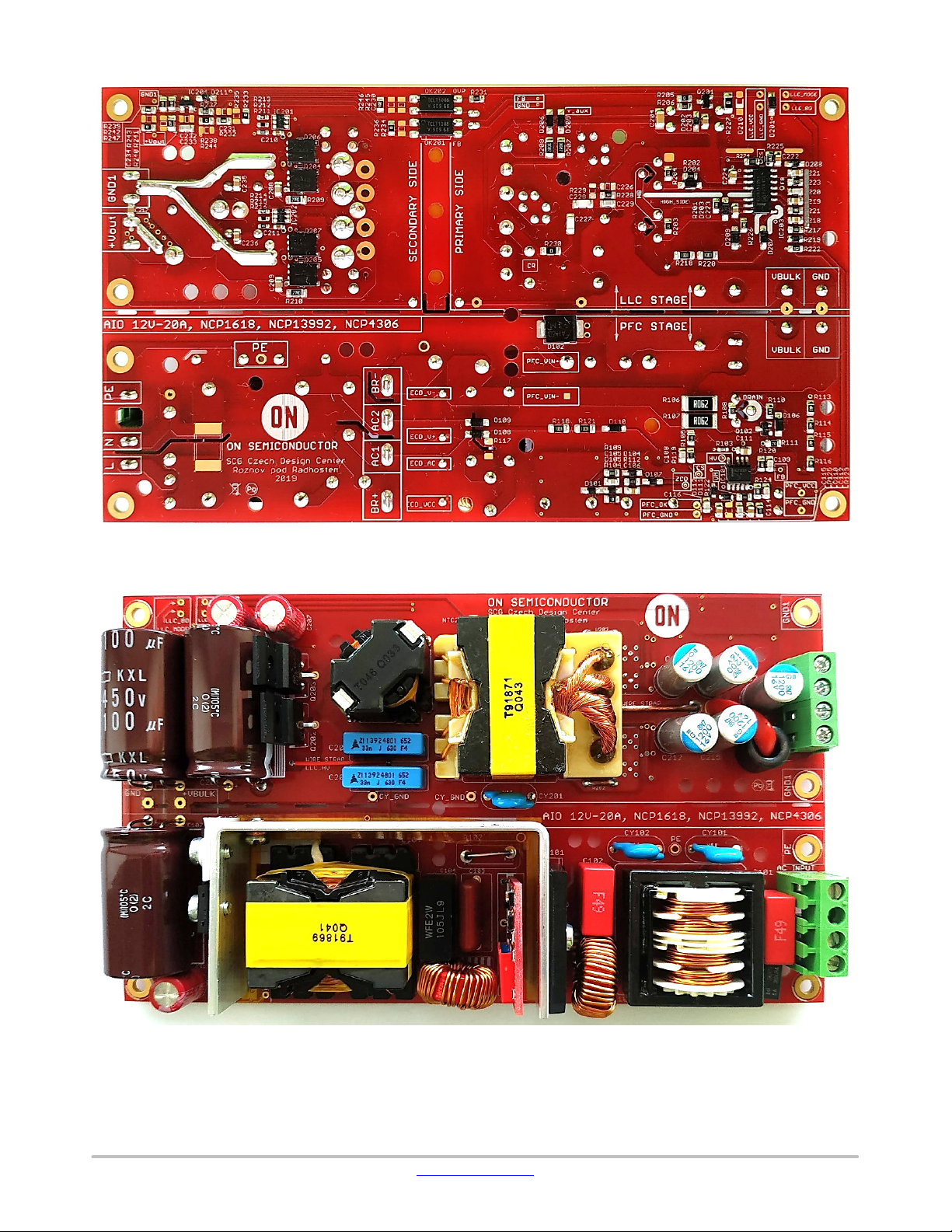

Figure 9. Evaluation Board Photograph − Bottom Side

Figure 10. Evaluation Board Photograph − Top Side

www.onsemi.com

8

Page 9

NCP13992MM240WGEVB

Figure 11. EMI Capacitor Discharging Module (MOD101) − PCB Layout Design, Assembling, Photographs

www.onsemi.com

9

Page 10

NCP13992MM240WGEVB

96

95

94

93

92

91

90

89

Efficiency [%]

88

87

86

85

84

20 40 60 80 100 120 140 160 180 200 220 240

Output Power [W]

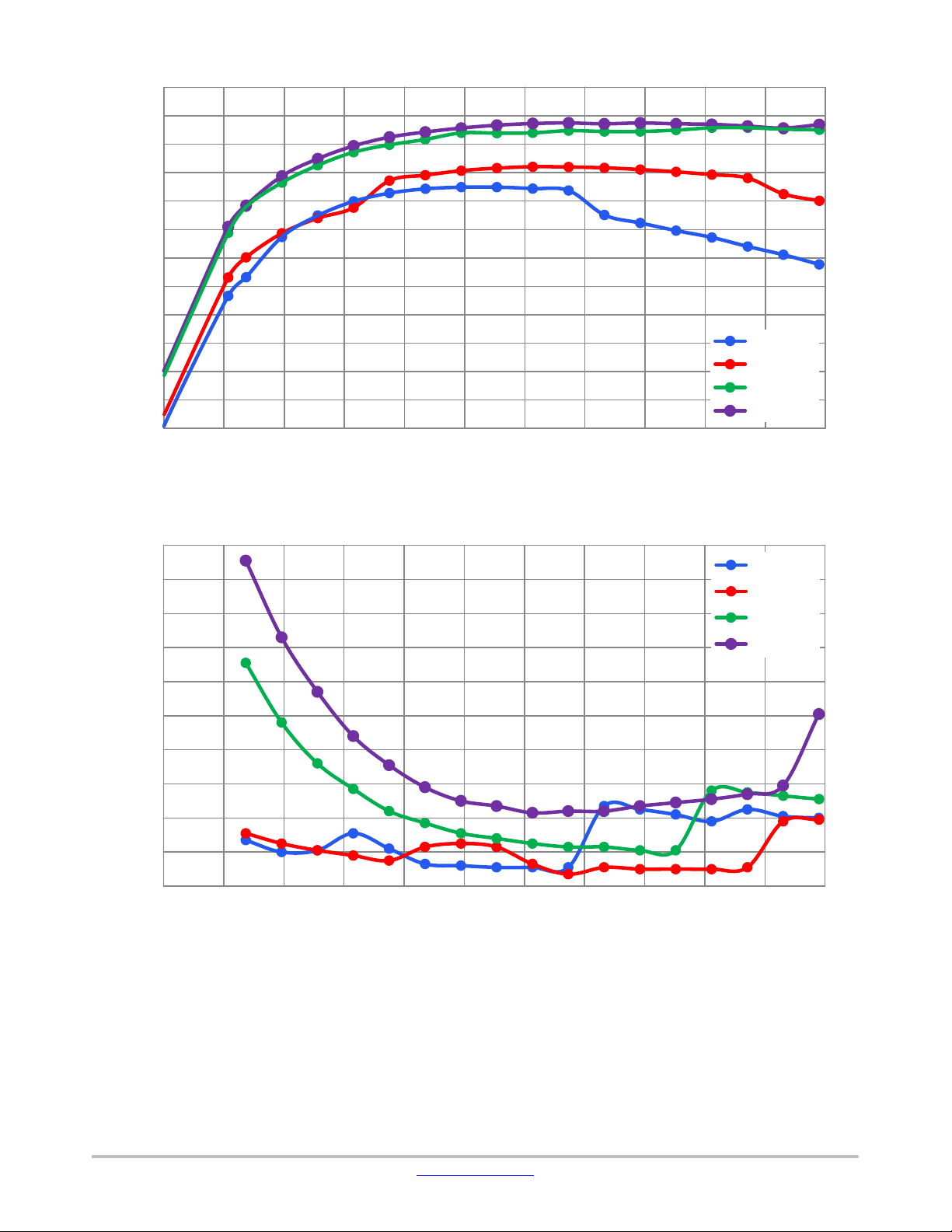

Figure 12. EFFICIENCY vs. Output Power

90 V AC

110 V AC

230 V AC

265 V AC

20

90 V AC

18

16

14

12

10

THD [%]

8

6

4

2

0

20 40 60 80 100 120 140 160 180 200 220 240

Output power [W]

110 V AC

230 V AC

265 V AC

Figure 13. Input Current vs. Output Power

www.onsemi.com

10

Page 11

1.00

0.95

0.90

THD [%]

NCP13992MM240WGEVB

0.85

0.80

20 40 60 80 100 120 140 160 180 200 220 240

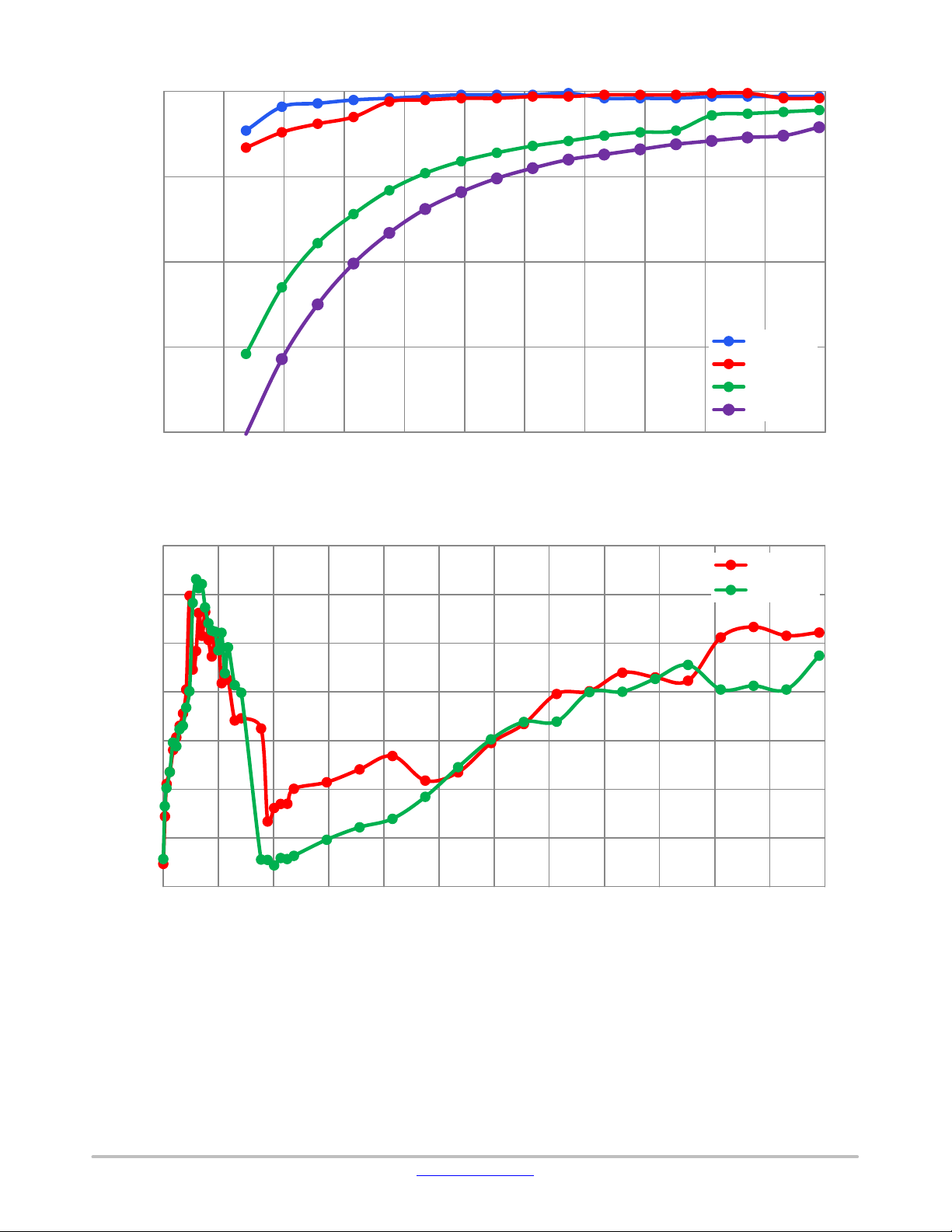

Output Power [W]

90 V AC

110 V AC

230 V AC

265 V AC

Figure 14. POWER FACTOR vs. Output Power

160

140

120

100

80

110 V AC

230 V AC

60

Vout pk−pk Ripple [mV]

40

20

0 20 40 60 80 100 120 140 160 180 200 220 240

Output Power [W]

Figure 15. Output Voltage Ripple (pk−pk) vs. Output Power

www.onsemi.com

11

Page 12

NCP13992MM240WGEVB

Table 2. EFFICIENCY DATA MEASURED AND AVERAGED FROM 10 BUILT EVALUATION BOARDS

Consumption [mW] or Efficiency [%]

@ 110 V AC

@ 230 V AC

@ 265 V AC

NO−LOAD

< 110

< 120

< 130

Load 120 mW

< 250

< 250

< 260

Load 500 mW

< 660

< 670

< 680

Load 20% − 4 A

90.02

91.80

91.85

Load 25% − 5 A

91.40

92.65

92.88

Load 50% − 10 A

93.07

94.40

94.57

Load 75% − 15 A

93.11

94.45

94.75

Load 100% − 20 A

92.01

94.51

94.69

4 point AVG

92.40

94.00

94.22

LOAD

The following figures illustrate conduced EMI signatures

under full loading for different input line voltage levels.

80

EMI signature, V

70

60

50

Amplitude [dBmV]

40

30

20

0.1 1.0 10.0

= 110 Vac, P

IN

Frequency [MHz]

OUT

= 240 W

Quasi−peak Limit

110 V (L−N) MAX PEAK

Figure 16. EMI Signature Comparison @ 110 VAC & Full−load (measured MAX Peak)

www.onsemi.com

12

Page 13

NCP13992MM240WGEVB

EMI signature, V

80

70

60

50

40

Amplitude [dBmV]

30

20

0.1 1.0 10.0

= 230 Vac, P

IN

Frequency [MHz]

OUT

= 240 W

Quasi−peak Limit

230 V (L−N) MAX PEAK

Figure 17. EMI Signature Comparison @ 230 VAC & Full−load (measured MAX Peak)

Evaluation Demo−board Connections and Power−up

and

Test Procedure

IMPORTANT NOTES:

• Do not apply extreme voltage to the input terminals!

• Be careful, high DC voltage is presented!

• Do not apply DC voltage to the input terminals!

• The demo is not optimized for surge, lightning, etc.

• This reference board requires thermal management

especially at very low line voltage. Use fan for

excessive heat spreading.

• Follow up power−up and power−down sequences.

Power−up sequence:

1. Connect AC Supply to the demoboard AC input.

2. Connect Electronic Load at the output terminals

with proper polarity

3. Set AC Supply voltage in range 85 to 265V AC.

4. Turn AC Supply on.

5. Check output terminals voltage, approximately

12 V.

6. Modify electronic load current to desired level

while output voltage is monitored.

Power−down sequence:

1. Turn AC Supply off.

2. Discharge bulk capacitor for manipulating further

www.onsemi.com

13

Page 14

NCP13992MM240WGEVB

CH1

CH2

CH3

CH4

Figure 18. 110 V AC/ STEP LOAD 0 – 20 A

CH1

CH2

CH3

CH4

Figure 19. 110 V AC/ STEP LOAD 20 – 0 A

OPERATING WAVEFORM

V

MLOWER

V

Out_AC

VHB (t)

I

out

(t)

(t)

(t)

V

MLOWER

V

Out_AC

VHB (t)

I

out

(t)

(t)

(t)

www.onsemi.com

14

Page 15

NCP13992MM240WGEVB

CH1

CH2

CH3

CH4

Figure 20. 110 V AC/ STEP LOAD 2 A – 20 A

CH1

CH2

CH3

CH4

Figure 21. 110 V AC/ STEP LOAD 20 A – 2 A

V

MLOWER

V

Out_AC

VHB (t)

I

out

(t)

(t)

(t)

V

MLOWER

V

Out_AC

VHB (t)

I

out

(t)

(t)

(t)

www.onsemi.com

15

Page 16

NCP13992MM240WGEVB

CH1

CH2

CH3

CH4

Figure 22. 110 V AC/ LLC SKIP MODE, No−load

CH1

CH2

CH3

CH4

Figure 23. 110 V AC/ LLC SKIP MODE, No−load − detailed view

V

MLOWER

V

LLC_FB

VHB (t)

I

prim

(t)

(t)

(t)

V

MLOWER

V

LLC_FB

VHB (t)

I

prim

(t)

(t)

(t)

www.onsemi.com

16

Page 17

NCP13992MM240WGEVB

CH1

CH2

CH3

CH4

Figure 24. 110 V AC/ LLC NORMAL MODE, LOAD 3.15 A

CH1

CH2

CH3

CH4

Figure 25. 110 V AC/ LLC NORMAL MODE, LOAD 5 A

V

MLOWER

V

LLC_FB

VHB (t)

I

prim

(t)

(t)

(t)

V

MLOWER

V

LLC_FB

VHB (t)

I

prim

(t)

(t)

(t)

www.onsemi.com

17

Page 18

NCP13992MM240WGEVB

CH1

CH2

CH3

CH4

Figure 26. 110 V AC/ LLC NORMAL MODE 10 A

CH1

CH2

CH3

CH4

Figure 27. 110 V AC/ LLC NORMAL MODE, LOAD 20 A

V

MLOWER

V

LLC_FB

VHB (t)

I

prim

(t)

(t)

(t)

V

MLOWER

V

LLC_FB

VHB (t)

I

prim

(t)

(t)

(t)

www.onsemi.com

18

Page 19

NCP13992MM240WGEVB

CH1

CH2

CH3

CH4

Figure 28. 110 V AC/ LLC START−UP into 0 A

CH1

CH2

CH3

CH4

Figure 29. 110 V AC/ LLC START−UP into 2 A

V

MLOWER

V

Out

VHB (t)

I

prim

(t)

(t)

(t)

V

MLOWER

V

Out

VHB (t)

I

prim

(t)

(t)

(t)

www.onsemi.com

19

Page 20

NCP13992MM240WGEVB

CH1

CH2

CH3

CH4

Figure 30. 110 V AC/ LLC START−UP into 5 A

CH1

CH2

CH3

CH4

Figure 31. 110 V AC/ LLC START−UP into 10 A

V

MLOWER

V

Out

VHB (t)

I

prim

(t)

(t)

(t)

V

MLOWER

V

Out

VHB (t)

I

prim

(t)

(t)

(t)

www.onsemi.com

20

Page 21

NCP13992MM240WGEVB

CH1

CH2

CH3

CH4

Figure 32. 110 V AC/ LLC START−UP into 20 A

CH1

CH2

CH3

CH4

Figure 33. 90 V AC/ Load 20 A, PFC START−UP (No inrush limiter)

V

MLOWER

V

Out

VHB (t)

I

prim

(t)

(t)

(t)

V

Line

V

PFC_Vcc

V

Bulk

I

line

(t)

(t)

(t)

(t)

www.onsemi.com

21

Page 22

CH1

V

CH2

CH3

CH4

Figure 34. 110 V AC/ Load 20 A, PFC START−UP (No inrush limiter)

CH1

CH2

CH3

CH4

Figure 35. 230 V AC/ Load 20 A, PFC START−UP (No inrush limiter)

Line

NCP13992MM240WGEVB

(t)

V

PFC_Vcc

V

Bulk

I

line

V

Line

(t)

(t)

(t)

(t)

V

PFC_Vcc

V

(t)

(t)

Bulk

I

(t)

line

www.onsemi.com

22

Page 23

CH1

Q101 VGS (t)

CH2

CH3

CH4

Figure 36. 90 V AC/ Load 20 A, PFC/ LLC START−UP (No inrush limiter)

CH1

CH2

CH3

CH4

Figure 37. 110 V AC/ Load 20 A, PFC/ LLC START−UP (No inrush limiter)

V

(t)

out

V

(t)

Bulk

I

(t)

line

NCP13992MM240WGEVB

Q101 VGS (t)

V

(t)

out

V

(t)

Bulk

I

(t)

line

www.onsemi.com

23

Page 24

CH1

Q101 VGS (t)

CH2

CH3

CH4

Figure 38. 230 V AC/ Load 20 A, PFC/ LLC START−UP (No inrush limiter)

CH1

CH2

CH3

CH4

Figure 39. 90 V AC/ Load 13 A, PFC CrM MODE – before entering CCM

V

(t)

out

V

(t)

Bulk

NCP13992MM240WGEVB

I

(t)

line

Q101 VGS (t)

IC101 V

(t)

M

Q101 VDS (t)

I

(t)

L103

www.onsemi.com

24

Page 25

CH1

Q101 VGS (t)

CH2

CH3

CH4

Figure 40. 90 V AC/ Load 14 A, PFC CCM MODE

CH1

CH2

CH3

CH4

Figure 41. 90 V AC/ Load 20 A, PFC CCM MODE

NCP13992MM240WGEVB

IC101 V

(t)

M

Q101 VDS (t)

I

(t)

L103

Q101 VGS (t)

IC101 V

(t)

M

Q101 VDS (t)

I

(t)

L103

www.onsemi.com

25

Page 26

CH1

Q101 VGS (t)

CH2

CH3

CH4

Figure 42. 110 V AC/ Load 18 A, PFC CrM MODE – before entering CCM

CH1

CH2

CH3

CH4

Figure 43. 110 V AC/ Load 20 A, PFC CCM MODE

NCP13992MM240WGEVB

IC101 V

(t)

M

Q101 VDS (t)

I

(t)

L103

Q101 VGS (t)

IC101 V

(t)

M

Q101 VDS (t)

I

(t)

L103

www.onsemi.com

26

Page 27

CH1

Q101 VGS (t)

CH2

CH3

CH4

Figure 44. 230 V AC/ Load 20 A, PFC CrM MODE

CH1

CH2

CH3

CH4

Figure 45. 265 V AC/ Load 18 A, PFC CrM MODE

NCP13992MM240WGEVB

IC101 V

(t)

M

Q101 VDS (t)

I

(t)

L103

Q101 VGS (t)

IC101 V

(t)

M

Q101 VDS (t)

I

(t)

L103

www.onsemi.com

27

Page 28

CH1

Q101 VGS (t)

CH2

CH3

CH4

Figure 46. 90 V AC/ Load slowly rising through margin (13 / 14 A), PFC Transition from CrM to CCM

CH1

CH2

CH3

CH4

Figure 47. 90 V AC/ Load slowly decreasing through margin (14/ 13 A), PFC Transition from CCM to CrM

NCP13992MM240WGEVB

IC101 V

(t)

M

Q101 VDS (t)

I

(t)

L103

Q101 VGS (t)

IC101 V

(t)

M

Q101 VDS (t)

I

(t)

L103

www.onsemi.com

28

Page 29

NCP13992MM240WGEVB

CH1

CH2

CH3

CH4

Figure 48. 110 V AC/ No−load, PFC Soft−skip mode − V

Hiccups

CH1

CH2

CH3

CH4

Figure 49. 110 V AC/ No−load, PFC Soft−skip mode − V

Hiccups/ PFC Burst detail

IC101 V

IC203 V

V

Bulk

I

line

PFC_OK

(t)

MODE

(t)

(t)

(t)

Bulk

V

V

Line

Out

N/A

I

line

(t)

(t)

(t)

Bulk

www.onsemi.com

29

Page 30

CH1

V

CH2

CH3

CH4

Figure 50. 90 V AC/ Load 20 A, Hold−up time for 5% regulation – 20 ms

CH1

CH2

CH3

CH4

Figure 51. 110 V AC/ Load 20 A, Hold−up time for 5% regulation – 20 ms

V

Line

Out

N/A

I

Out

NCP13992MM240WGEVB

(t)

(t)

(t)

V

V

Line

Out

N/A

I

Out

(t)

(t)

(t)

www.onsemi.com

30

Page 31

CH1

V

CH2

CH3

CH4

Figure 52. 230 V AC/ Load 20 A, Hold−up time for 5% regulation – 20 ms

CH1

CH2

CH3

CH4

Figure 53. 265 V AC/ Load 20 A, Hold−up time for 5% regulation – 20 ms

V

Line

Out

N/A

I

Out

NCP13992MM240WGEVB

(t)

(t)

(t)

V

V

Line

Out

N/A

I

Out

(t)

(t)

(t)

www.onsemi.com

31

Page 32

NCP13992MM240WGEVB

Literature

High−Voltage, Multimode Power Factor Controller

NCP1618: https://www.onsemi.com/pub/Collateral/NCP1618−D.PDF

High Performance Current Mode Resonant Controller with Integrated High Voltage Drivers:

NCP13992: https://www.onsemi.com/pub/Collateral/NCP13992−D.PDF

Secondary Side Synchronous Rectifier Controllers:

NCP4306: https://www.onsemi.com/pub/Collateral/NCP4306−D.PDF

Voltage Reference, Programmable Shunt Regulator

NCP431: https://www.onsemi.com/pub/Collateral/NCP431−D.PDF

N−Channel SupreMOS® MOSFET 600 V, 22 A, 165 mW

FCPF22N60NT: https://www.onsemi.com/pub/Collateral/FCPF22N60NT−D.pdf

Power Rectifier, Soft Recovery, Switch−mode, 8 A, 600 V

MSRF860G: https://www.onsemi.com/pub/Collateral/MSR860−D.PDF

N−Channel SupreMOS® MOSFET 600 V, 13 A, 258 mW

FCPF165N65S3L1: https://www.onsemi.com/pub/Collateral/FCPF165N65S3L1−D.PDF

Single N−Channel Power MOSFET 40 V, 130 A, 2.5 mW

NVMFS5C442NL: https://www.onsemi.com/pub/Collateral/NVMFS5C442NL−D.PDF

SUPREMOS is a registered trademark of Semiconductor Components Industries, LLC (SCILLC) or its subsidiaries in the United States and/or other countries.

www.onsemi.com

32

Page 33

Table 3. BILL OF MATERIALS

Parts

Qty

Value

Package

Description

Manufacturer

Part Number

Substitution

MAIN BOARD

C101,

C102

2

220nF/275V~

C102−064X133

CAPACITOR

Wurth

890324024002

Not allowed

C1031470nF/450Vdc

C150−072X183

CAPACITOR

Panasonic

ECW−FD2W474J

Not allowed

C10411uF/450Vdc

C150−072X183

MPP CAPACITOR

Panasonic

ECW−FE2W105J

Not allowed

C10512.2nF/250V

C0805

CAPACITOR

Wurth

885342007005

Not allowed

C106122nF/200V

C0805

CAPACITOR

Wurth

885342207006

Not allowed

C107,

3

100u/450V

EC_18X30_7.5

CAPACITOR

United Chemi−Con

EKXL451ELL101MM30S

Allowed

C1081220pF/50V

C0805

CAPACITOR

Wurth

885012007059

Allowed

C109,

2

470pF/50V

C0805

CAPACITOR

Wurth

885012007061

Allowed

C110,

2

2.2nF/50V

C0805

CAPACITOR

Wurth

885012007065

Allowed

C111,

2

1uF/50V

C0805

CAPACITOR

Wurth

885012207103

Allowed

C112,

6

10nF/50V

C0805

CAPACITOR

Wurth

885012207092

Allowed

C113,

2

220uF/25V

E3.5−8

CAPACITOR

Wurth

860040474004

Allowed

C114115pF/50V

C0805

CAPACITOR

Wurth

885012007052

Allowed

C11614.7nF/50V

C0805

CAPACITOR

Wurth

885012007067

Allowed

C203,

3

100nF/50V

C0805

CAPACITOR

Wurth

885012207098

Allowed

C2041100nF/50V

C1206

CAPACITOR

Wurth

885012208087

Allowed

C205,

2

33nF/630V

C150−064X183

CAPACITOR

Epcos

B32652A6333J

Allowed

C2071220uF/35V

E3,5−8

CAPACITOR

Wurth

860010574011

Allowed

C208,

2

6.8nF/100V

C0805

CAPACITOR

Wurth

885012207121

Allowed

C210,

2

2.2uF/16V

C0603

CAPACITOR

Wurth

885012106018

Allowed

C212,

5

1.2mF/16V

E3.5−8

CAPACITOR

United Chemi−Con

APSG160ELL122MH20S

Not allowed

C227,

2

220pF/630V NP0

C1206

CAPACITOR

KEMET

C1206C221JBGACAUTO

Not allowed

C22914.7nF/50V/NP0

C0805

CAPACITOR

Wurth

885012007067

Not allowed

CY101,

3

2.2nF/Y1

YC10B5

Y CAPACITOR

Murata

DE1E3KX222MN4AP01F

Not allowed

F10115A/ 350V SLOW

0697H

FUSE

Bel Fuse

0697H5000−01

Allowed

L101110mH

LF−280XX

COMMON MODE

ICE

LF−28024−0048−H

Not allowed

L102,

2

90uH

TO18

DIF. MODE

Wurth

7447013

Not allowed

L1041260uH

PQ32/20−4

PFC INDUCTOR

Sumida

T91869

7503150361

L201150uH

RM8

Resonant inductor

Sumida

T91870

750370249

L20211 turn

FERRITE BEAD

POWER FERRITE

Wurth

74270033

Not allowed

NTC2011330k, 5%

THT

NTC

Vishay

NTCLE100E3334JB0

Allowed

R1011275 VAC

LITTELFUSE

VARISTOR

Littelfuse

V430CH8S

Not allowed

R1021STRAP

N/A

NTC THERMISTOR

N/A

N/A

N/A

R103110R

R0603

RESISTOR

VARIOUS

VARIOUS

Allowed

NCP13992MM240WGEVB

C201,

C202

C220

C233

C224

C115,

C218,

C219,

C221,

C222

C225

C217,

C223,

C235,

C236

C206

C209

C211

Electrolytic

Electrolytic

Electrolytic

C213,

C214,

C215,

C216

C228

CY102,

CY201

L103

09X05

POLYMER

INDUCTOR

INDUCTOR

BEAD

www.onsemi.com

33

COMPONENTS

Page 34

Table 3. BILL OF MATERIALS (continued)

R104,

60RR0805

RESISTOR

VARIOUS

VARIOUS

Allowed

R105,

2

1.1k

R0805

RESISTOR

VARIOUS

VARIOUS

Allowed

R106,

2

62m / 2W

R6332W

RESISTOR

TE Connectivity /

RLP73N3AR062JTE

Similar type

R108,

4

22k

R0805

RESISTOR

VARIOUS

VARIOUS

Allowed

R1091300R

R0805

RESISTOR

VARIOUS

VARIOUS

Allowed

R11012.2R

R0805

RESISTOR

VARIOUS

VARIOUS

Allowed

R111122R

R0805

RESISTOR

VARIOUS

VARIOUS

Allowed

R1121160k

R0805

RESISTOR

VARIOUS

VARIOUS

Allowed

R113,

4

2.7M 1%

R0805

RESISTOR

ROHM

KTR18EZPF2704

Similar type

R118,

41kR1206

RESISTOR

VARIOUS

VARIOUS

Allowed

R120,

2

68k

R0805

RESISTOR

TE Connectivity /

CRGCQ0805F68K

Similar type

R12212k

R0805

RESISTOR

VARIOUS

VARIOUS

Allowed

R123,

2

11k

R0805

RESISTOR

VARIOUS

VARIOUS

Allowed

R124,

3

10k

R0805

RESISTOR

VARIOUS

VARIOUS

Allowed

R201,

2

33R

R0805

RESISTOR

VARIOUS

VARIOUS

Allowed

R207,

22RR1206

RESISTOR

VARIOUS

VARIOUS

Allowed

R209,

2

27R

R1206

RESISTOR

VARIOUS

VARIOUS

Allowed

R211,

2

5.1R

R0603

RESISTOR

VARIOUS

VARIOUS

Allowed

R212,

2

36k

R0603

RESISTOR

VARIOUS

VARIOUS

Allowed

R213,

2

5.6k

R0603

RESISTOR

VARIOUS

VARIOUS

Allowed

R217182k

R0805

RESISTOR

VARIOUS

VARIOUS

Allowed

R222,

21kR0805

RESISTOR

VARIOUS

VARIOUS

Allowed

R223115k

R0805

RESISTOR

VARIOUS

VARIOUS

Allowed

R2241100R

R0805

RESISTOR

VARIOUS

VARIOUS

Allowed

R22615.1R

R0805

RESISTOR

VARIOUS

VARIOUS

Allowed

R227,

20RR1206

RESISTOR

VARIOUS

VARIOUS

Allowed

R22811.5k

R0805

RESISTOR

VARIOUS

VARIOUS

Allowed

R23115.1k

R0805

RESISTOR

VARIOUS

VARIOUS

Allowed

R2321820R

R0805

RESISTOR

VARIOUS

VARIOUS

Allowed

R239139k

R0805

RESISTOR

VARIOUS

VARIOUS

Allowed

R240156k

R0805

RESISTOR

VARIOUS

VARIOUS

Allowed

R2431150k

R0805

RESISTOR

VARIOUS

VARIOUS

Allowed

TR2011600uH/ n = 16

PQ3220

LLC TRANSFORMER

Sumida

T91871

Not allowed

X101,

4

Pitch 5.08 mm

WR−TBL Series 2365

SCREW TERMINAL

Wurth

691236510002

Allowed

C226,

5

NOT USED

C0805

CAPACITOR

N/A

N/A

N/A

R1171NOT USED

R1206

RESISTOR

N/A

N/A

N/A

Parts SubstitutionPart NumberManufacturerDescriptionPackageValueQty

R205,

R233,

R236,

R238,

R247

R119

NCP13992MM240WGEVB

R107

R203,

R204,

R206

R114,

R115,

R116

R121,

R218,

R220

R237

R241

R221,

R225

R202

R208

R210

Holsworthy

Smiconductor

Holsworthy

R216

R215

R214

R245

R230

X201

C230,

C231,

C232,

C234

www.onsemi.com

34

Page 35

Table 3. BILL OF MATERIALS (continued)

R125,

7

NOT USED

R0805

RESISTOR

N/A

N/A

N/A

B1011DFB2560

SIP−4

Bridge Rectifier

ON Semiconductor

DFB2560

Not allowed

D201,

3

MBR0540

SOD123

DIODE

ON Semiconductor

MBR0540

Similar type

D101,

6

BAS16HT1G

SOD323

DIODE

ON Semiconductor

BAS16HT1G

Similar type

D1021S3M

SMC

DIODE

ON Semiconductor

S3M

Similar type

D1031MSRF860G

TO−220−2 FullPak

POWER DIODE

ON Semiconductor

MSRF860G

Similar type

D106,

3

MMSD4148T1G

SOD123

DIODE

ON Semiconductor

MMSD4148T1G

Similar type

D108,

2

S1JFL

SOD123

DIODE

ON Semiconductor

S1JFL

Allowed

D112,

2

MM3Z4V7T1G

SOD323

ZENER DIODE

ON Semiconductor

MM3Z4V7T1G

Not allowed

D2021MM3Z18VT1G

SOD323

ZENER DIODE

ON Semiconductor

MM3Z18VT1G

Not allowed

D205,

2

MBR2H100SFT3G

SOD123

DIODE

ON Semiconductor

MBR2H100SFT3G

Not allowed

D2091ES1JFL

SOD123

DIODE

ON Semiconductor

ES1JFL

Not allowed

D2111MM3Z12VT1G

SOD323

ZENER DIODE

ON Semiconductor

MM3Z12VT1G

Not allowed

IC1011NCP1618A

SO10

PFC CONTROLLER

ON Semiconductor

NCP1618A

Not allowed

IC201,

2

NCP4306

TSOP6

SR DRIVER

ON Semiconductor

NCP4306DAAZZAA

Not allowed

IC2031NCP13992

SO16

LLC CONTROLLER

ON Semiconductor

NCP13992

Not allowed

IC2041NCP431

SOT23

SHUNT REGULATOR

ON Semiconductor

NCP431BISNT1G

Not allowed

OK201,

2

TCLT1008

SOP−4

OPTOCOUPLER

VISHAY

TCLT1008

Not allowed

Q1011FCPF165N65S3L1

TO−220−2 FullPak

POWER MOSFET

ON Semiconductor

FCPF165N65S3L1

FCPF22N60N

Q1021NSS20200LT1G

SOT23

NPN Transistor

ON Semiconductor

NSS20200LT1G

Similar type

Q2011BSS138LT1G

SOT23

MOSFET

ON Semiconductor

BSS138LT1G

Similar type

Q202,

2

FCPF22N60NT

TO−220−2 FullPak

POWER MOSFET

ON Semiconductor

FCPF22N60NT

Similar type

Q204,

4

NTMFS5C442NL

SO8FL

POWER MOSFET

ON Semiconductor

NTMFS5C442NLT1G

Similar type

D2101NOT USED

SOD123

DIODE

N/A

N/A

N/A

MOD101 − EMI FIL TER CAPACITOR DISCHARGING MODULE

Parts

Qty

Value

Package

Description

MANUFACTURER

PART NUMBER

Substitution

C301110nF/275V~

C102−043X133

MPP CAPACITOR

Wurth

890324023006

Allowed

C30211uF/50V

C0805

CAPACITOR

Wurth

885012207103

Similar type

D301,

2

S1JFL

SOD123

DIODE

ON Semiconductor

S1JFL

Not allowed

D3031MM3Z7V5T1G

SOD323

ZENER DIODE

ON Semiconductor

MM3Z7V5T1G

Not allowed

Q3011BSS138LT1G

SOT23

MOSFET

ON Semiconductor

BSS138LT1G

Similar type

Q3031BSS127

SOT23

MOSFET

Infineon

BSS127H6327XTSA2

Not allowed

R301,

2

5.1k

R0805

RESISTOR

VARIOUS

VARIOUS

Allowed

R3031120k

R0805

RESISTOR

VARIOUS

VARIOUS

Allowed

R3041470k

R0805

RESISTOR

VARIOUS

VARIOUS

Allowed

R30510R

R0805

RESISTOR

VARIOUS

VARIOUS

Allowed

R306,

3

33k

R0805

RESISTOR

VARIOUS

VARIOUS

Allowed

Q3021NOT USED

SOT23

MOSFET

N/A

N/A

N/A

Parts SubstitutionPart NumberManufacturerDescriptionPackageValueQty

R229,

R234,

R235,

R242,

R244,

R246

D203,

D204

D104,

D105,

D107,

D111,

D212

D110,

D207

D109

D208

NCP13992MM240WGEVB

D206

IC202

OK202

Q203

Q205,

Q206,

Q207

D302

T

R302

R307,

R308

www.onsemi.com

35

Page 36

ON Semiconductor and the ON Semiconductor logo are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or

other countries. ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s

product/patent coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

subject to all applicable copyright laws and is not for resale in any manner.

The evaluation board/kit (research and development board/kit) (hereinafter the “board”) is not a finished product and is as such not available for sale to consumers. The board is only intended

for research, development, demonstration and evaluation purposes and should as such only be used in laboratory/development areas by persons with an engineering/technical training

and familiar with the risks associated with handling electrical/mechanical components, systems and subsystems. This person assumes full responsibility/liability for proper and safe handling.

Any other use, resale or redistribution for any other purpose is strictly prohibited.

The board is delivered “AS IS” and without warranty of any kind including, but not limited to, that the board is production−worthy, that the functions contained in the board will meet your

requirements, or that the operation of the board will be uninterrupted or error free. ON Semiconductor expressly disclaims all warranties, express, implied or otherwise, including without

limitation, warranties of fitness for a particular purpose and non−infringement of intellectual property rights.

ON Semiconductor reserves the right to make changes without further notice to any board.

You are responsible for determining whether the board will be suitable for your intended use or application or will achieve your intended results. Prior to using or distributing any systems

that have been evaluated, designed or tested using the board, you agree to test and validate your design to confirm the functionality for your application. Any technical, applications or design

information or advice, quality characterization, reliability data or other services provided by ON Semiconductor shall not constitute any representation or warranty by ON Semiconductor,

and no additional obligations or liabilities shall arise from ON Semiconductor having provided such information or services.

The boards are not designed, intended, or authorized for use in life support systems, or any FDA Class 3 medical devices or medical devices with a similar or equivalent classification in

a foreign jurisdiction, or any devices intended for implantation in the human body. Should you purchase or use the board for any such unintended or unauthorized application, you shall

indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that ON Semiconductor

was negligent regarding the design or manufacture of the board.

This evaluation board/kit does not fall within the scope of the European Union directives regarding electromagnetic compatibility, restricted substances (RoHS), recycling (WEEE), FCC,

CE or UL, and may not meet the technical requirements of these or other related directives.

FCC WARNING – This evaluation board/kit is intended for use for engineering development, demonstration, or evaluation purposes only and is not considered by ON Semiconductor to

be a finished end product fit for general consumer use. It may generate, use, or radiate radio frequency energy and has not been tested for compliance with the limits of computing devices

pursuant to part 15 of FCC rules, which are designed to provide reasonable protection against radio frequency interference. Operation of this equipment may cause interference with radio

communications, in which case the user shall be responsible, at its expense, to take whatever measures may be required to correct this interference.

ON Semiconductor does not convey any license under its patent rights nor the rights of others.

LIMITATIONS OF LIABILITY: ON Semiconductor shall not be liable for any special, consequential, incidental, indirect or punitive damages, including, but not limited to the costs of

requalification, delay, loss of profits or goodwill, arising out of or in connection with the board, even if ON Semiconductor is advised of the possibility of such damages. In no event shall

ON Semiconductor’s aggregate liability from any obligation arising out of or in connection with the board, under any theory of liability, exceed the purchase price paid for the board, if any.

For more information and documentation, please visit www.onsemi.com

.

. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This literature is

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

◊

www.onsemi.com

1

Loading...

Loading...