Page 1

Fixed Frequency Current

f

Mode Controller for Flyback

Converters

NCP12400

The NCP12400 is a new fixed−frequency current−mode controller

featuring the Dynamic Self−Supply. This function greatly simplifies

the design of the auxiliary supply and the V

the internal startup current source to supply the controller during

start−up, transients, latch, stand−by etc. This device contains a special

HV detector which detects the application unplug from the ac input

line and triggers the X2 discharge current. This HV structure allows

the brown−out detection as well.

It features a timer−based fault detection that ensures the detection of

overload and an adjustable compensation to help keep the maximum

power independent of the input voltage.

Due to frequency foldback, the controller exhibits excellent

efficiency in light load condition while still achieving very low

standby power consumption. Internal frequency jittering, ramp

compensation, and a versatile latch input make this controller an

excellent candidate for the robust power supply designs.

A dedicated Off Mode allows to reach the extremely low no load

input power consumption via “sleeping” whole device and thus

minimize the power consumption of the control circuitry.

Features

• Fixed−Frequency Current−Mode Operation 65 kHz or 100 kHz

Frequency Options

• Frequency Foldback then Skip Mode for Maximized Performance

in Light Load and Standby Conditions

• Timer−Based Overload Protection with Latched (Option A) or

Autorecovery (Option B) Operation

• High−Voltage Current Source with Brown−Out Detection and

Dynamic Self−Supply, Simplifying the Design of the V

• Frequency Modulation for Softened EMI Signature

• Adjustable Overpower Protection Dependant on the Mains Voltage

• Fault Input for Overvoltage and Over Temperature Protection

• V

Operation up to 28 V, with Overvoltage Detection

CC

• 300/500 mA Source/Sink Drive Peak Current Capability

• 4/10 ms Soft−Start

• Internal Thermal Shutdown

• No−Load Standby Power < 30 mW

• X2 Capacitor in EMI Filter Discharging Feature

• These are Pb−Free Devices

Typical Applications

• Offline Adapters for Notebooks, LCD, and Printers

• Offline Battery Chargers

• Consumer Electronic Power Supplies

• Auxiliary/Housekeeping Power Supplies

• Offline Adapters for Notebooks

capacitor by activating

CC

Circuitry

CC

www.onsemi.com

SOIC−7

CASE 751U

MARKING DIAGRAM

8

XXXXX

ALYWG

G

1

400VWXYZf

(Note: Microdot may be in either location)

See detailed ordering and shipping information on page 44 o

this data sheet.

= Specific Device Code

(see page 2)

A = Assembly Location

L = Wafer Lot

Y = Year

W = Work Week

G = Pb−Free Package

PIN CONNECTIONS

1

FAULT

FB

CS

GND DRV

4

(Top View)

ORDERING INFORMATION

8

HV

V

CC

5

© Semiconductor Components Industries, LLC, 2017

February, 2021 − Rev. 6

1 Publication Order Number:

NCP12400/D

Page 2

NCP12400

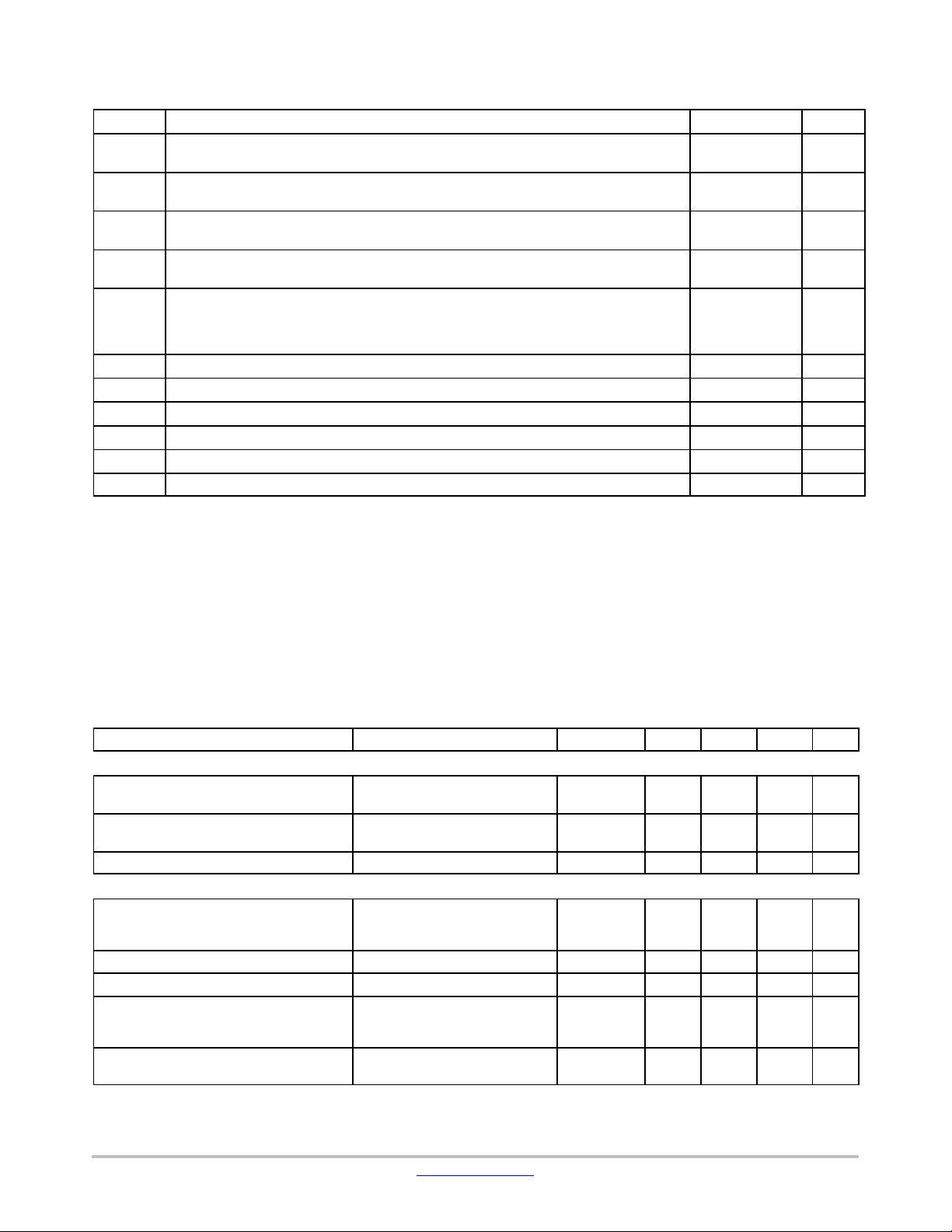

Table 1. OPTIONS

Part

OPN

Brown Out

OCP Fault

Frozen

Quiet skip

Soft

Frequency

OTP/OVP

NCP12400BAHAB0DR2G

103 − 100 V

Latched

300 mV

No, min. 3 pulses

4 ms

65 kHz

Latched

NCP12400BAHBB0DR2G

111 − 103 V

Latched

300 mV

Yes, min. 3 pulses,

4 ms

65 kHz

Latched

NCP12400BBBBB2DR2G

111 − 103 V

Autorecovery

150 mV

Yes, min. 3 pulses,

4 ms

65 → 100

Latched

NCP12400BBHAA1DR2G

111 − 103 V

Autorecovery

300 mV

No, min. 3 pulses

10 ms

100 kHz

Autorecovery

NCP12400CAHAB0DR2G

95 − 93 V

Latched

300 mV

No, min. 3 pulses

4 ms

65 kHz

Latched

NCP12400CBAAB0DR2G

95 − 93 V

Autorecovery

No

No, min. 3 pulses

4 ms

65 kHz

Latched

NCP12400CBBAB0DR2G

95 − 93 V

Autorecovery

150 mV

No, min. 3 pulses

4 ms

65 kHz

Latched

NCP12400CBHAA0DR2G

95 − 93 V

Autorecovery

300 mV

No, min. 3 pulses

10 ms

65 kHz

Autorecovery

NCP12400EAHBB0DR2G

Brown In, No

Latched

300 mV

Yes, min. 3 pulses,

4 ms

65 kHz

Latched

NCP12400BBBBA0DR2G

111 − 103 V

Autorecovery

150 mV

Yes, min. 3 pulses,

10 ms

65 kHz

Latched

NCP12400BBHAB0DR2

111 − 103 V

Autorecovery

300 mV

No, min. 3 pulses

4 ms

65 kHz

Latched

NCP12400BBEBA0DR2G

111 − 103 V

Autorecovery

210 mV

Yes, min. 3 pulses,

10 ms

65 kHz

Latched

NCP12400BBAAA0DR2G

111 − 103 V

AutorecoveryNoNo

10 ms

65 kHz

Latched

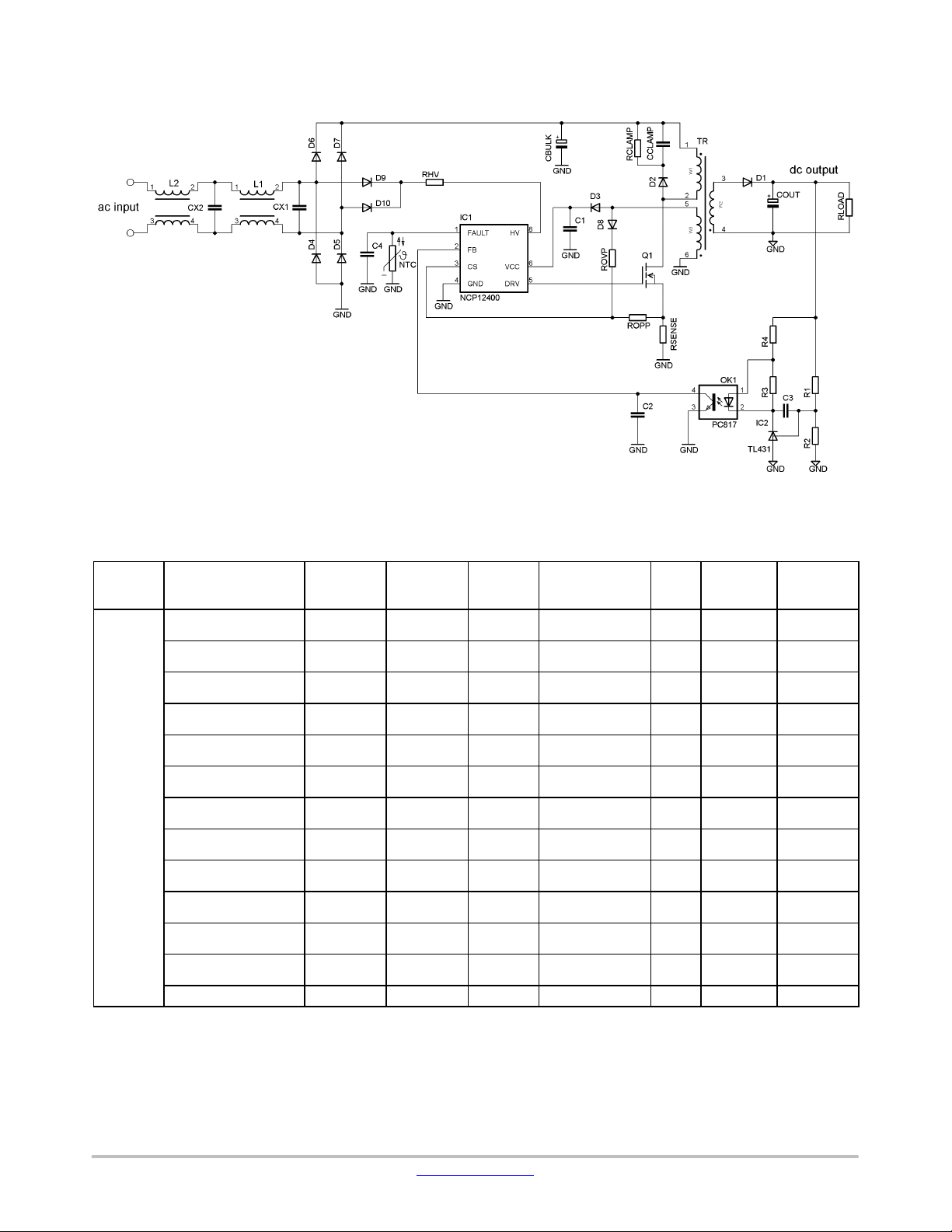

TYPICAL APPLICATION SCHEMATIC

Figure 1. Flyback Converter Application using the NCP12400

NCP12400

Start − Stop

BO

Current

Setpoint

only

800 Hz burst

800 Hz burst

only

only

only

only

only

800 Hz burst

800 Hz burst

only

800 Hz burst

Start

kHz

www.onsemi.com

2

Page 3

NCP12400

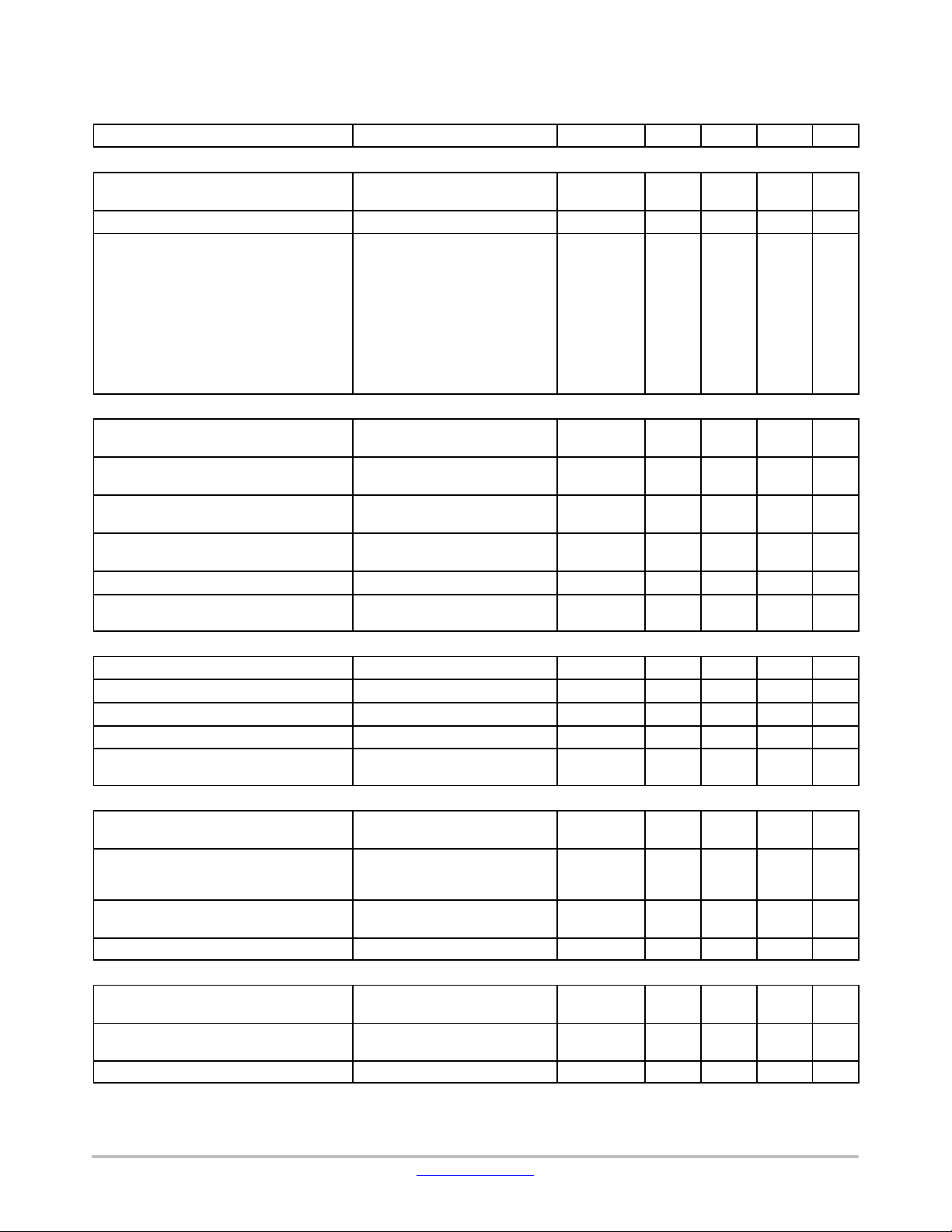

Table 2. SPECIFIC DEVICE CODE KEY

400VWXYZf

BO

OCP Fault

Frozen Current

Quiet Skip

Soft Start

Frequency

A − 229−211 V

A − Latched

A −No

A − No, min. 3

A − 10 ms

0 − 65 kHz

Table 3. PIN FUNCTION DESCRIPTION

Pin #

Pin Name

Function

Pin Description

1

FAULT

FAULT Input

Pull the pin up or down to stop the controller. An internal current source allows the

2FBFeedback + Shutdown

An optocoupler connected to ground controls the output regulation. The part goes to

3CSCurrent Sense

This input senses the primary current for current−mode operation, and offers an

4

GND

The controller ground.

5

DRV

Drive Output

Drives external MOSFET.

6

VCCVCC Input

This supply pin accepts up to 28 Vdc, with overvoltage detection. The pin is

8HVHigh−Voltage Pin

Connects to the rectified ac line to perform the functions of start−up current source,

Part

B − 111−103 V

C − 95−93 V

D − No BO

E − Brown In, no BO

Pin

B − Autorecovery

direct connection of an NTC for over temperature detection. Device can restart in

autorecovery mode or can be latched depending on the option.

the low consumption Off mode if the FB input pin is pulled to GND.

overpower compensation adjustment. This pin implements over voltage protection

as well.

connected to an external auxiliary voltage.

Setpoint

B − 150 mV

C − 170 mV

D − 190 mV

E − 210 mV

F − 230 mV

G − 250 mV

H − 300 mV

pulses

B − Yes, min. 3

pulses,

800 Hz burst

B − 4 ms

1 − 100 kHz

2 − 65 → 100 kHz

Self−Supply, brown−out detection and X2 capacitor discharge function and the HV

sensing for the overpower protection purposes.

It is not allowed to connect this pin to a dc voltage.

www.onsemi.com

3

Page 4

FAULT

FB

CS

GND

Vdd

Intc

Intc

1k

Rcla m p

1. 2 V

Vclamp

SS_end

Brown_Out

RESET

VCC

5u A

Von

Vfb(reg)

Voff

Rfb1

Internalresitance40k

Vhv DC sample

V to I

Iopc = 0 .5u*(Vhv −125)

Vdd

1uA

Vfb < 1.64 V fix current setpoint 210mV

OVP_CMP

Vov p

2. 5V

OTP_CMP

Votp

0. 4 V

Off_mode_CMP1

2.2V

Off_mode_CMP2

0. 6V

NCP12400

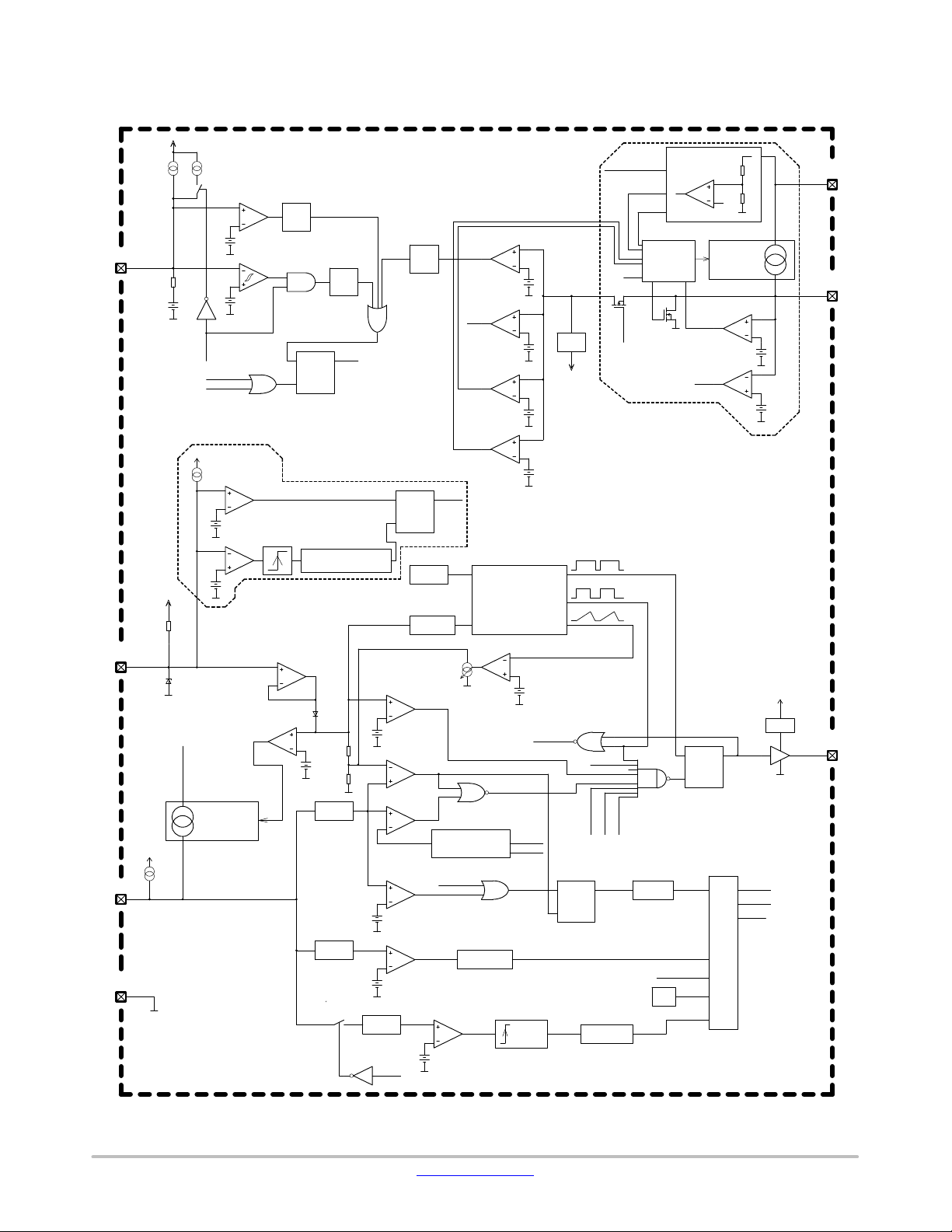

SIMPLIFIED INTERNAL BLOCK SCHEMATIC

300 us

Filter

Vfb(o pc)

Div i sion ratio 4

LEB 250 ns

LEB 120 ns

Latch

Rfb2Rf b3

OVP

OTP

Vskip

Vilim

VCSs to p

LEB 1 us

VccOVP

Set Q

Reset Qb

Skip_CMP

PWM_CMP

SoftStart_CMP

Ilimit_CMP

0.7V

CSstop_CMP

1.05V

10us

Filter

ICstart

jittering

freq folback

CSref

SkipB

Soft Start timer

VccMIN

PWM

MAX_ton

Ilimit

OVP_CMP

VccOVP_CMP

UVLO_CMP

UVLO

ON_CMP

VccON

STOP_CMP

FM input

OSC 65kHz

PFM input

Ramp_OTA

4uMho

4 events timer

26V

9.5V

12V10.5 V

Square output

ton_ max output

Saw output

1.4V

Vramp_offset

MAX_ton

Enable

SS_end

VccOVP

Vcc_Int

Vdd reg

VccOFF

Vdd

VccONVccMI N

Reset

55us

Filter

Set Q

Reset Qb

GoToOffMode timer 500ms

FBbuffer

2. 6V

Bro wn_Ou tB

QSet

Qb

4 events timer600ns timer

IC stopB

FaultB

Vhv DC sample

Brown_In

AC_Off

OM & X2 & Vcc

TSD

X2 discharge

ICstar tB

11V regulator

3. 0V

LatchB

Fault timer

control

PowerOnReset_CMP

Fault

Brown_Out

TSD

Reset

TSD

Dual HV

start−up

current source

Vcc regulator

RESET

QSet

Qb

HV

8mA

VCC

10.8V7V

Vcc( reg )VccRESET

VCC

Clamp

DRV

RESET

IC stop

Latch

Latch management

Vovp

DRV

1.05V

Figure 2. Simplified Internal Block Schematic

www.onsemi.com

4

Page 5

NCP12400

Table 4. MAXIMUM RATINGS

Rating

Symbol

Value

Unit

DRV

Maximum voltage on DRV pin

–0.3 to 20

V

V

VCCPower Supply voltage, VCC pin, continuous voltage

–0.3 to 36

VmAHV

Maximum voltage on HV pin

–0.3 to 500

V

V

Maximum voltage on low power pins (except pin 5, pin 6 and pin 8)

–0.3 to 5.5

V

R

Thermal Resistance SOIC−7

C/W

R

Thermal Resistance Junction−to−Case

73

C/W

T

Operating Junction Temperature

−40 to +150

C

T

Storage Temperature Range

−60 to +150

C

ESD Capability, HBM model (All pins except HV) (Note 1)

> 4000

V

ESD Capability, HBM model (pin 8, HV)

> 2000

V

ESD Capability, Charge Discharge Model (Note 1)

> 500

V

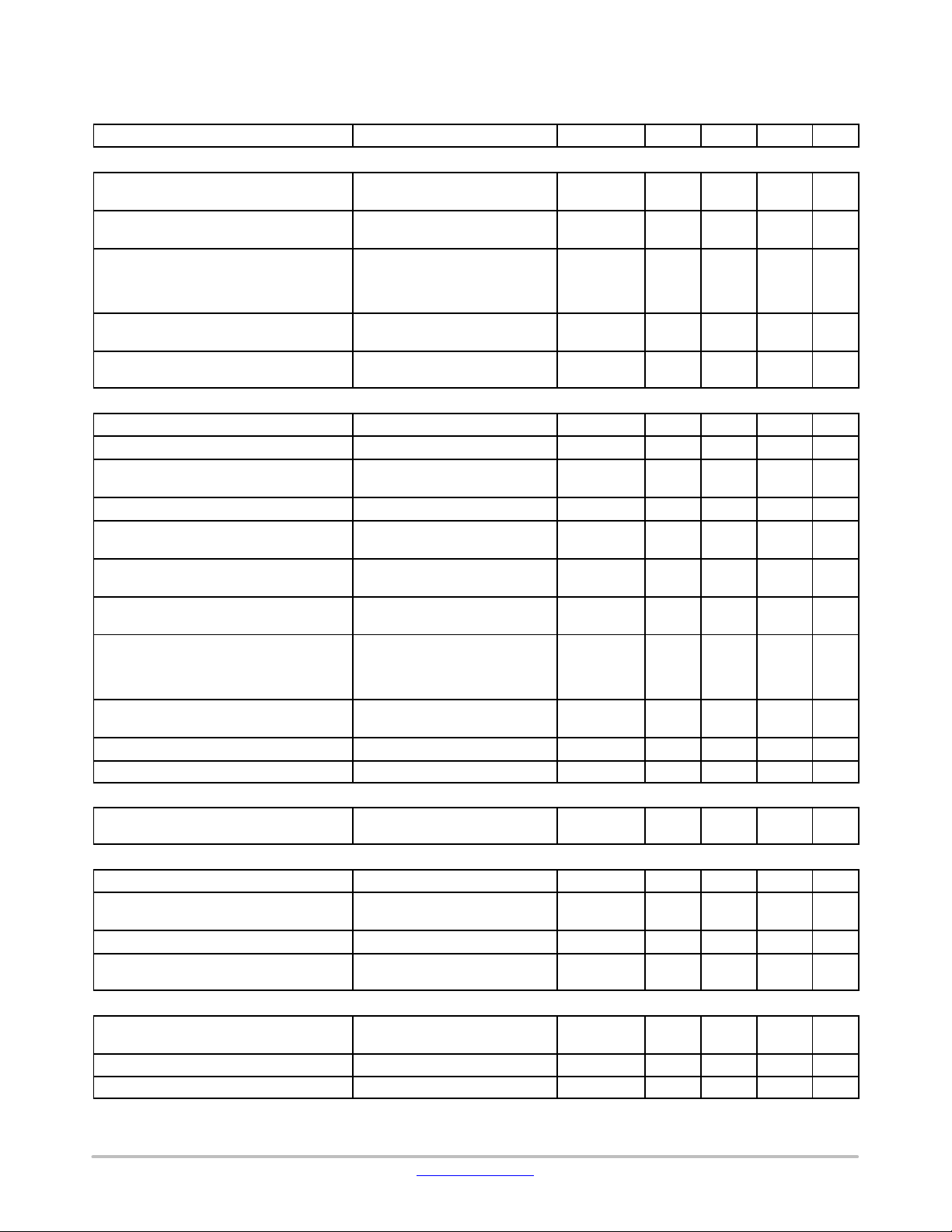

Table 5. ELECTRICAL CHARACTERISTICS

Characteristics

Test Condition

Symbol

Min

Typ

Max

Unit

HIGH VOLTAGE CURRENT SOURCE

Minimum voltage for current source

V

−3040

V

Current flowing out of VCC pin

VCC = 0 V

I

0.250.580.811mA

Off−state leakage current

VHV = 500 V, VCC = 15 V

I

−26

A

SUPPLY

Turn−on threshold level, VCC going up

V

11.0

12.0

13.0

V

HV current source restart threshold

V

9.5

10.5

11.5

V

Turn−off threshold

V

8.4

8.9

9.3

V

Overvoltage threshold

V

253026.5322834V

Blanking duration on V

and V

t

−10−

s

(pin 5)

(pin 6)

(pin 8)

max

q

q

JMAX

STRGMAX

(Dc−Current self−limited if operated within the allowed range) (Note 2)

CC

Power Supply voltage, VCC pin, continuous voltage (Note 2)

(Dc−Current self−limited if operated within the allowed range)

(Dc−Current self−limited if operated within the allowed range) (Note 2)

J−A

Junction-to-Air, low conductivity PCB (Note 3)

Junction-to-Air, medium conductivity PCB (Note 4)

Junction-to-Air, high conductivity PCB (Note 5)

J−C

±1000 (peak)

±30 (peak)

±20

±10 (peak)

162

147

115

mA

mA

mA

°

°

°

°

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

1. This device series contains ESD protection and exceeds the following tests:

Human Body Model 4000 V per JEDEC standard JESD22, Method A114E

Charge Discharge Model Method 500 V per JEDEC standard JESD22, Method C101E

2. This device contains latch-up protection and exceeds 100 mA per JEDEC Standard JESD78.

3. As mounted on a 80 x 100 x 1.5 mm FR4 substrate with a single layer of 50 mm

for a JEDEC 51-1 conductivity test PCB. Test conditions were under natural convection or zero air flow.

4. As mounted on a 80 x 100 x 1.5 mm FR4 substrate with a single layer of 100 mm

for a JEDEC 51-2 conductivity test PCB. Test conditions were under natural convection or zero air flow.

5. As mounted on a 80 x 100 x 1.5 mm FR4 substrate with a single layer of 650 mm

2

of 2 oz copper traces and heat spreading area. As specified

2

of 2 oz copper traces and heat spreading area. As specified

2

of 2 oz copper traces and heat spreading area. As specified

for a JEDEC 51-3 conductivity test PCB. Test conditions were under natural convection or zero air flow.

(For typical values TJ = 25°C, for min/max values TJ = −40°C to +125°C, VHV = 125 V, VCC = 11 V unless otherwise noted)

operation

HV current source stop threshold

VCC = V

CC(on)

− 0.5 V

HV(min)

start1

I

start2

start(off)

CC(on)

15.0

16.2

(depending on the version)

CC(min)

CC(off)

Overvoltage threshold (option EAHBB,

CC(ovp)

BBBBB)

detection

CC(off)

CC(ovp)

VCC(blank)

6. Guaranteed by design.

7. CS pin source current is a sum of I

bias

and I

, thus at VHV = 125 V is observed the I

OPC

only, because I

bias

is switched off.

OPC

m

17.5

m

www.onsemi.com

5

Page 6

NCP12400

VCC decreasing level at which the internal

V

4.8

7.0

7.7

V

VCC level for I

to I

transition

V

1.0

2.1

3.0

V

Internal current consumption

DRV open, VFB = 3 V, 65 kHz

I

1.0

1.3

2.0

mA

BROWN−OUT

Brown−out thresholds (option A)

VHV going up

V

210

229

248

V

Brown−out thresholds (option B)

VHV going up

V

10294111

120

V

Brown−out thresholds (option BAHAB)

VHV going up

V

9390103

113

V

Brown−out thresholds (option C)

VHV going up

V

87859593103

V

Brown−out thresholds (option E)

VHV going up

V

90

100

110

V

Timer duration for line cycle drop−out

tHV424864738698ms

X2 DISCHARGE

Comparator hysteresis observed at HV pin

V

2.0

3.0

4.0

V

HV signal sampling period

t

−

1.0−ms

Timer duration for no line detection

t

213243

ms

Discharge timer duration

t

213243

ms

Shunt regulator voltage at VCC pin during X2

V

10.0

11.0

12.0

V

OSCILLATOR

Oscillator frequency 65 kHz version

f

619465

69

kHz

Maximum duty−ratio (corresponding to

D

758085

%

Frequency jittering amplitude, in percentage

A

3.0±4.0±5.0

kHz

Frequency jittering modulation frequency

F

85

125

165

Hz

FREQUENCY FOLDBACK

Feedback voltage threshold below which

TJ = 25°C

V

2.4

2.5

2.6

V

Feedback voltage threshold below which

TJ = 25°C

V

2.05

2.15

2.25

V

Minimum switching frequency

VFB = V

+ 0.1

f

252831

kHz

Table 5. ELECTRICAL CHARACTERISTICS

(For typical values T

SUPPLY

logic resets

= 25°C, for min/max values TJ = −40°C to +125°C, VHV = 125 V, VCC = 11 V unless otherwise noted)

J

Characteristics UnitMaxTypMinSymbolTest Condition

START1

START2

Cdrv = 1 nF, V

DRV open, VFB = 3 V, 100 kHz

Cdrv = 1 nF, VFB = 3 V, 65 kHz

= 3 V, 100 kHz

FB

Skip or before start−up

Fault mode (fault or latch)

Off−mode

VHV going down

VHV going down

VHV going down

VHV going down

CC(reset)

CC(inhibit)

CC1

I

CC2

I

CC3

I

CC4

I

CC5

HV(start)

V

HV(stop)

HV(start)

V

HV(stop)

HV(start)

V

HV(stop)

HV(start)

V

HV(stop)

HV(start)

1.1

1.5

2.0

400

300

−

194

1.4

2.1

2.6

500

430

25

211

103

100

2.1

2.9

3.4

650

550

−

228

116

110

101

mA

mA

mA

mA

mA

mA

(depending on the version)

discharge event

Oscillator frequency 100 kHz version

maximum on time at maximum switching

frequency)

of F

OSC

frequency foldback starts

frequency foldback is complete

HV(hyst)

sample

DET

DIS

CC(dis)

OSC

MAX

jitter

jitter

FB(foldS)

FB(foldE)

100

110

±

6. Guaranteed by design.

7. CS pin source current is a sum of I

bias

and I

skip(in)

, thus at VHV = 125 V is observed the I

OPC

www.onsemi.com

6

OSC(min)

only, because I

bias

is switched off.

OPC

Page 7

NCP12400

OUTPUT DRIVER

Rise time, 10 to 90% of V

VCC = V

+ 0.2 V,

t

−4070

ns

Fall time, 90 to 10% of V

VCC = V

+ 0.2 V,

t

−3060

ns

Current capability

VCC = V

+ 0.2 V,

mA

Clamping voltage (maximum gate voltage)

VCC = V

– 0.2 V, DRV high,

V

101214

V

High−state voltage drop

VCC = V

+ 0.2 V,

V

−−1

V

CURRENT SENSE

Input Pull−up Current

VCS = 0.7 V

I

−1−

A

Maximum internal current setpoint

VFB > 3.5 V

V

0.66

0.70

0.74

V

Propagation delay from V

detection to

VCS = V

t

−5070

ns

Leading Edge Blanking Duration for V

t

180

250

320

ns

Threshold for immediate fault protection

V

0.95

1.05

1.15

V

Leading Edge Blanking Duration for V

)

t

75

120

150

ns

Soft−start duration (option A)

From 1st pulse to VCS = V

t

−

10

13

ms

Frozen current setpoint (option B)

V

100

150

200

mV

Over voltage protection threshold when DRV

VCS going up

V

1.00

1.05

1.10

V

Blanking duration on OVP detection

t

0.7

1.0

1.3

s

Delay time constant before OTP confirmation

t

−

600−ns

INTERNAL SLOPE COMPENSATION

Slope of the compensation ramp

S

−−−32.5

−−mV /

FEEDBACK

Internal pull−up resistor

TJ = 25°C

R

304050

k

VFB to internal current setpoint division ratio

KFB−4−

−

Internal pull−up voltage on the FB pin

V

4.555.5

V

Offset between FB pin and internal FB

TJ = 25°C

V

−

0.8−V

SKIP CYCLE MODE

Feedback voltage thresholds for skip mode

VFB going down, TJ = 25°C

V

0.9

1.0

1.1

V

Minimum number of pulses in burst

n

3−−

Skip out delay

t

−−38

s

Table 5. ELECTRICAL CHARACTERISTICS

(For typical values T

DRV off

activation

= 25°C, for min/max values TJ = −40°C to +125°C, VHV = 125 V, VCC = 11 V unless otherwise noted)

J

Characteristics UnitMaxTypMinSymbolTest Condition

CC

CC

Ilimit

ILIM

C

C

C

DRV high, V

DRV low, V

CC(ovp)

R

= 33 kW, C

DRV

R

= 33 kW, DRV high

DRV

CC(off)

DRV

CC(off)

DRV

CC(off)

DRV

CC(min)

= 1 nF

= 1 nF

= 1 nF

DRV

DRV

load

ILIM

= 0 V

= V

CC

= 220 pF

rise

fall

I

DRV(source)

I

DRV(sink)

DRV(clamp)

DRV(drop)

bias

ILIM

delay

LEB

CS(stop)

−

−

300

500

−

−

m

(Note 6)

Soft−start duration (option B)

Frozen current setpoint (option D)

Frozen current setpoint (option E)

Frozen current setpoint (option H)

is low

(Note 6)

divider

CS(stop

ILIM

BCS

SSTART

I(freeze)

OVP(CS)

OVP,CS

OVP,del

comp(65kHz)

S

comp(100kHz)

FB(up)

FB(ref)

FB(off)

3.2

140

145

250

4.0

190

210

300

−50

4.8

240

270

350

m

ms

W

6. Guaranteed by design.

7. CS pin source current is a sum of I

skip(in)

V

skip(out)

P,skip

skip

only, because I

bias

1.05

1.15

is switched off.

OPC

1.25

m

bias

and I

VFB going up, TJ = 25°C

, thus at VHV = 125 V is observed the I

OPC

www.onsemi.com

7

Page 8

NCP12400

REMOTE CONTROL ON FB PIN

The voltage above which the part enters the

VCC > V

, VHV = 60 V

VON−

2.2−V

The voltage below which the part enters the

VCC > V

V

0.5

0.6

0.7

V

Minimum hysteresis between the VON and

VCC > V

, VHV = 60 V

V

500−−

mV

Pull−up current in off mode

VCC > V

I

−5−

A

Go To Off mode timer

VCC > V

t

400

500

600

ms

OVERLOAD PROTECTION

Fault timer duration

t

108

128

178

ms

Fault timer reset time

VCS < 0.7 V, D < 90% D

t

150

200

250

s

Autorecovery mode latch−off time duration

t

0.85

1.00

1.35

s

OVERPOWER PROTECTION

VHV to I

conversion ratio

K

−

0.54

−

A / V

Current flowing out of CS pin (Note 7)

VHV = 125 V

I

−

0

−

A

FB voltage above which I

is applied

VHV = 365 V

V

−

2.6−V

FB voltage below which is no I

applied

VHV = 365 V

V

−

1.6−V

FAULT INPUT

High threshold

V

going up

V

2.43

2.50

2.57

V

Low threshold

V

going down, TJ = 25°C

V

0.380

0.400

0.420

V

OTP resistance threshold (TJ = 25°C)

External NTC resistance is going

R

7.6

8.0

8.5

k

OTP resistance threshold (TJ = 80°C)

External NTC resistance is going

R

−

8.5

−

k

OTP resistance threshold (TJ = 110°C)

External NTC resistance is going

R

−

9.5

−

k

Current source for direct NTC connection

V

= 0.2 V

A

Current source for direct NTC connection

V

= 0.2 V, TJ = 25°C

I

475053

A

Blanking duration on high latch detection

t

355070

s

Blanking duration on low latch detection

t

−

350

−

s

Clamping voltage

I

= 0 mA

V

1.0

1.2

1.4

V

TEMPERATURE SHUTDOWN

Temperature shutdown

TJ going up

T

−

150

−°C

Temperature shutdown hysteresis

TJ going down

T

−30−°C

6. Guaranteed by design.

Table 5. ELECTRICAL CHARACTERISTICS

(For typical values T

on mode

off mode

V

OFF

OPC

= 25°C, for min/max values TJ = −40°C to +125°C, VHV = 125 V, VCC = 11 V unless otherwise noted)

J

Characteristics UnitMaxTypMinSymbolTest Condition

OPC

OPC

CC(off)

CC(off)

CC(off)

CC(off)

CC(off)

VHV = 162 V

= 325 V

V

HV

V

= 365 V

HV

MAX

OFF

HYST

OFF

GTOM

fault

fault,res

autorec

OPC

OPC(125)

I

OPC(162)

I

OPC(325)

I

OPC(365)

FB(OPCF)

FB(OPCE)

−

−

105

20

110

130

m

m

m

m

−

−

150

During normal operation

During soft−start

During normal operation

7. CS pin source current is a sum of I

bias

and I

Latch

Latch

down

down

down

Latch

Latch

Latch

I

= 1 mA

Latch

, thus at VHV = 125 V is observed the I

OPC

OVP

OTP

OTP

OTP

OTP

I

NTC

I

NTC(SSTART)

NTC

Latch(OVP)

Latch(OTP)

clamp0(Latch)

V

clamp1(Latch)

TSD

TSD(HYS)

only, because I

bias

30

60

1.8

50

100

2.4

is switched off.

OPC

W

W

W

m

70

140

m

m

m

3.0

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

www.onsemi.com

8

Page 9

NCP12400

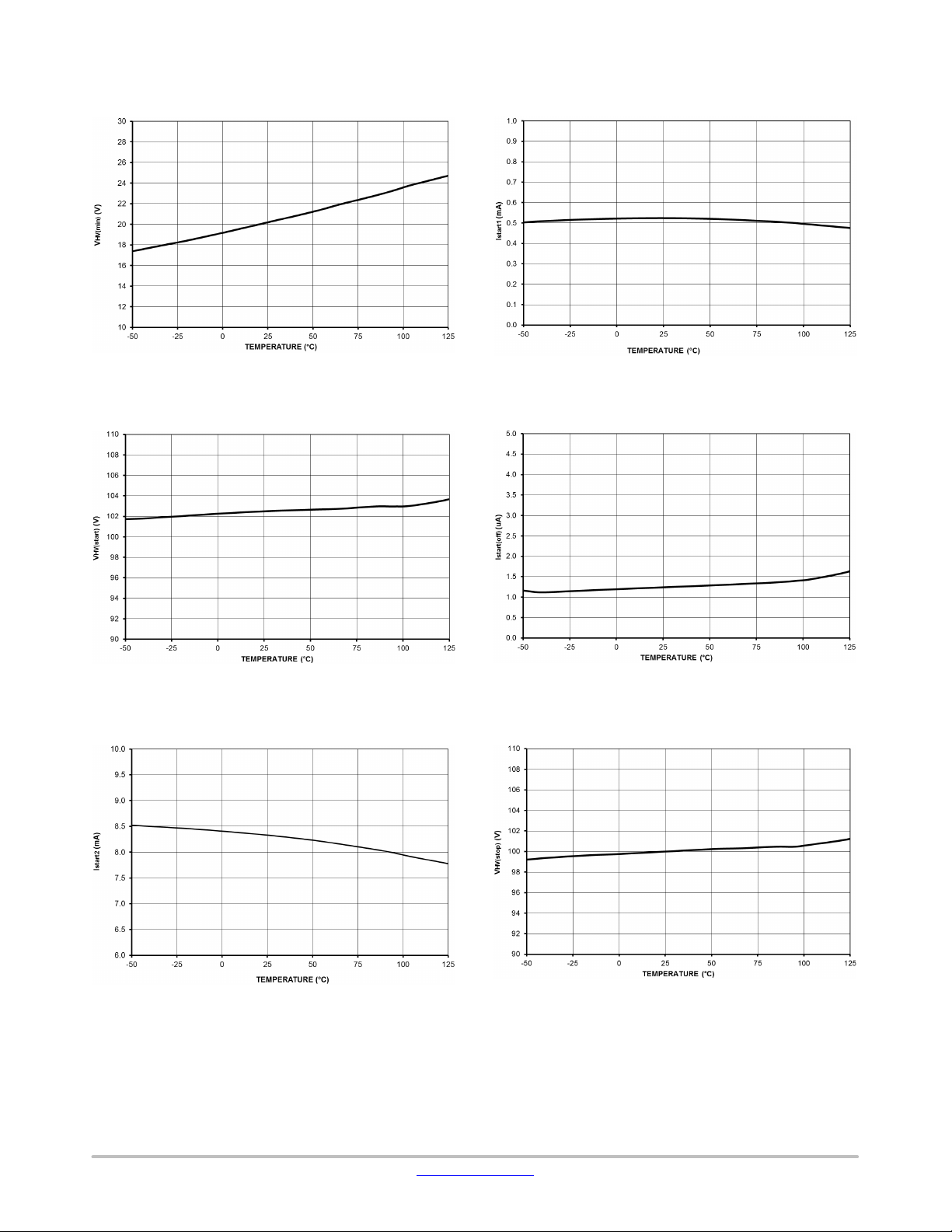

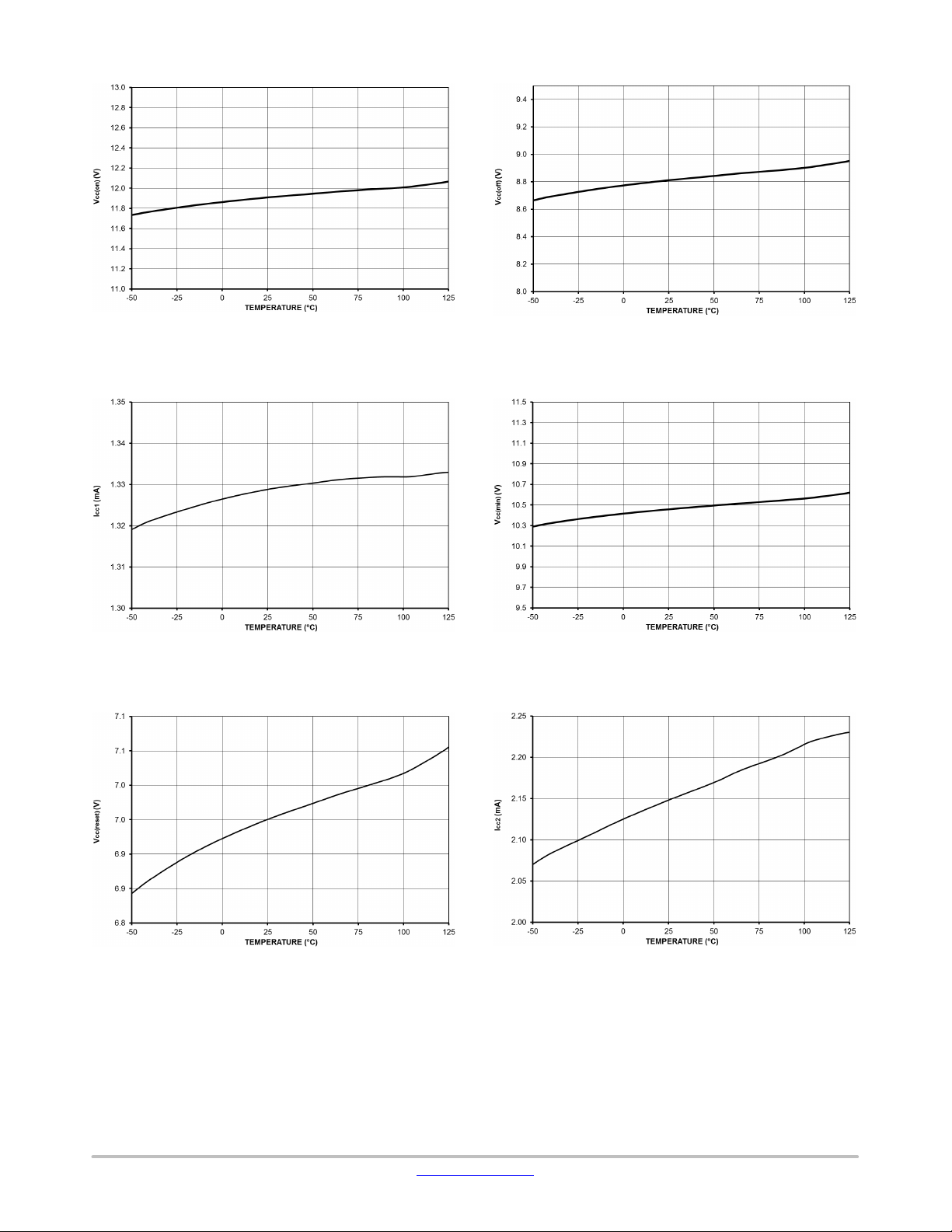

TYPICAL CHARACTERISTIC

Figure 3. Minimum Voltage for HV Current Source

Operation V

HV(min)

Figure 5. HV Pin Device Startup Threshold

V

HV(start)

Figure 4. High Voltage Startup Current Flowing

Out of V

CC

Pin I

of VCC Pin Fault/Short

start1

Figure 6. Off−state Leakage Current from HV Pin

I

start(off)

Figure 7. High Voltage Startup Current Flowing

Out of V

CC

Pin I

start2

www.onsemi.com

Figure 8. HV Pin Device Stop Threshold V

9

HV(stop)

Page 10

NCP12400

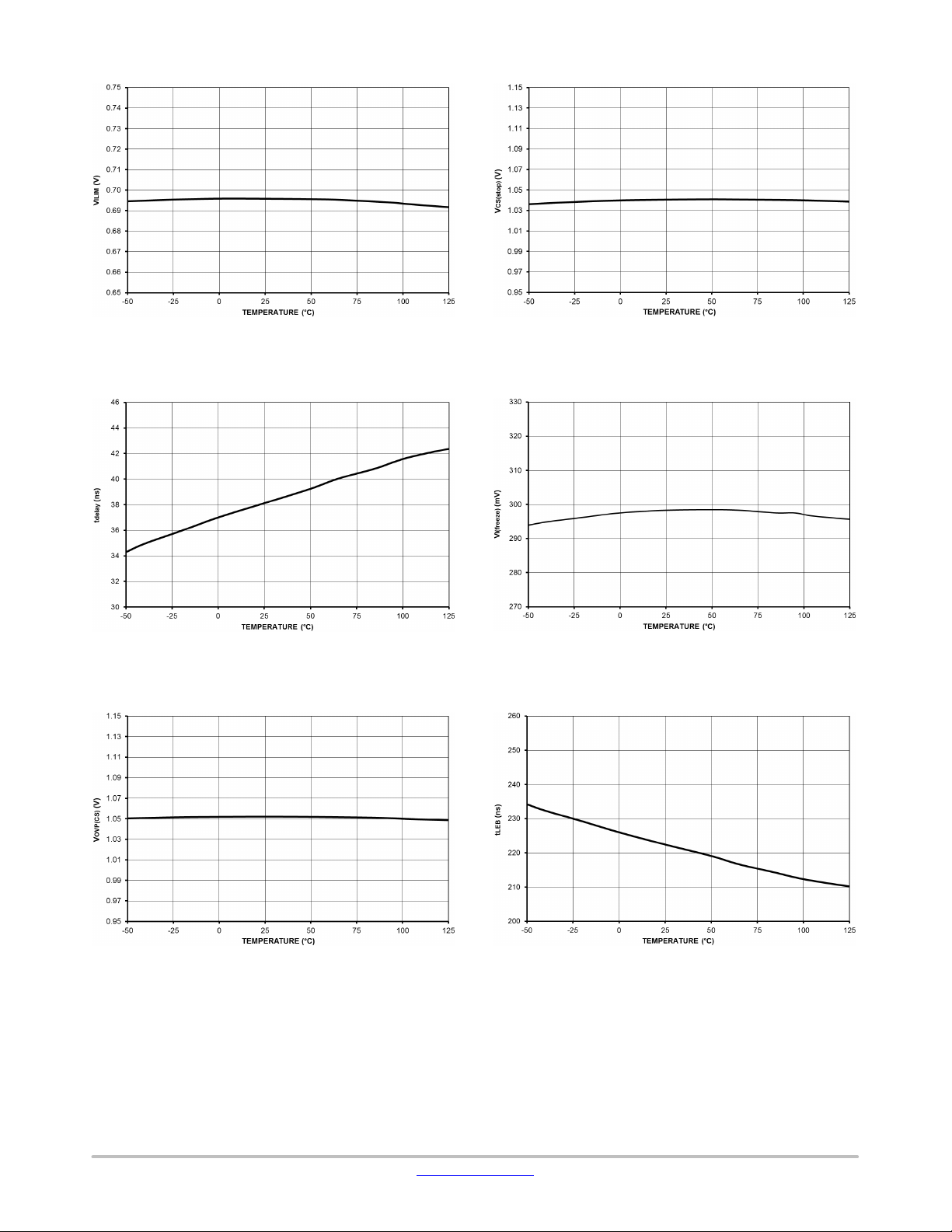

Figure 9. Maximum Internal Current Setpoint

V

ILIM

Figure 11. Propagation Delay t

delay

Figure 10. Threshold for the Very Fast Fault

Protection Activation V

Figure 12. Frozen Current Setpoint V

CS(stop)

I(freeze)

Light Load Operation

for the

Figure 13. Over Voltage Protection Threshold at

CS Pin V

OVP(CS)

www.onsemi.com

10

Figure 14. Leading Edge Blanking Duration t

LEB

Page 11

NCP12400

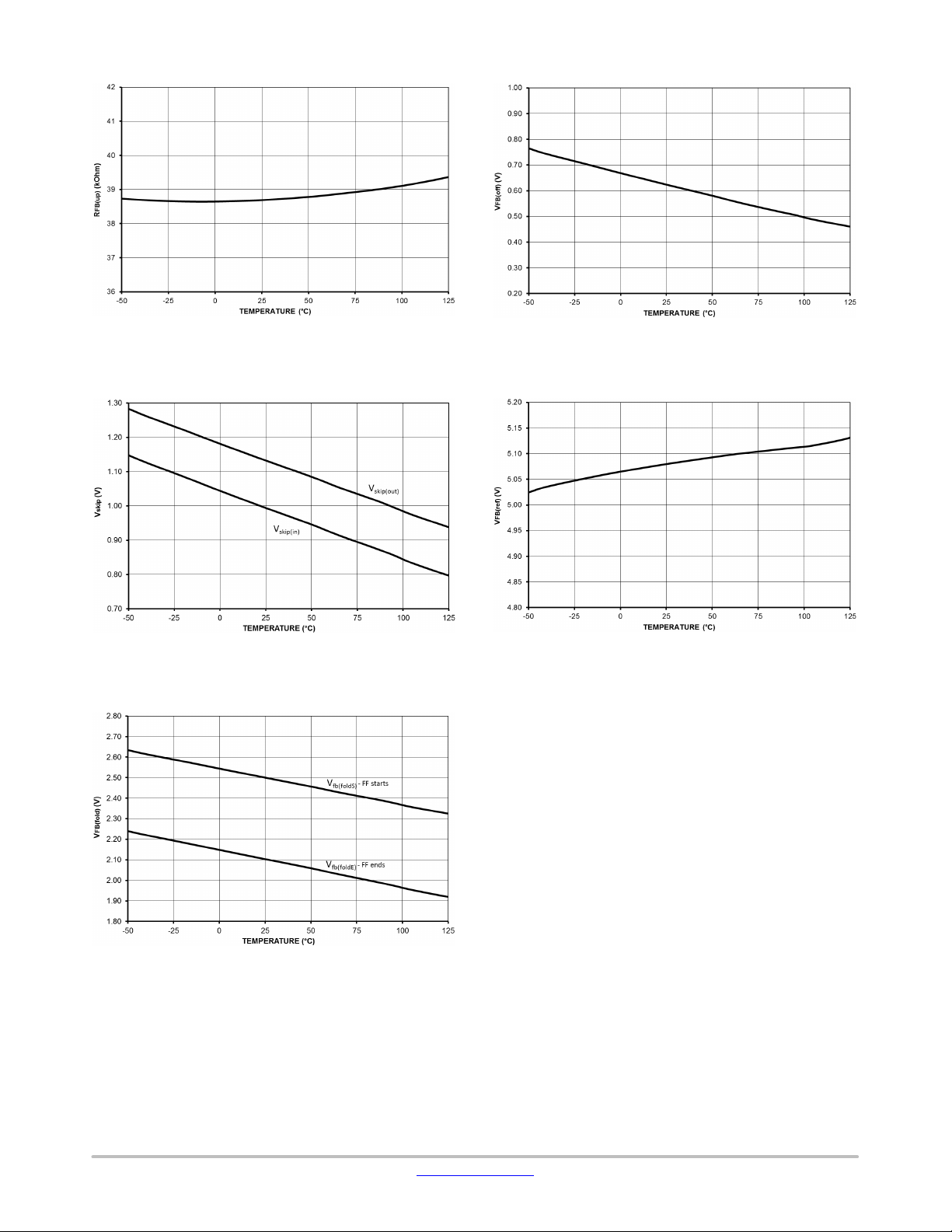

Figure 15. FB Pin Internal Pull−up Resistor

R

FB(up)

Figure 17. FB Pin Skip−In and Skip−Out Levels

V

skip(in)

and V

skip(out)

Figure 16. Built in Offset between FB Pin and

Internal Divider V

Figure 18. FB Pin Open Voltage V

FB(off)

FB(ref)

Figure 19. FB Pin Frequency Foldback Thresholds

V

FB(foldS)

and V

FB(foldE)

www.onsemi.com

11

Page 12

NCP12400

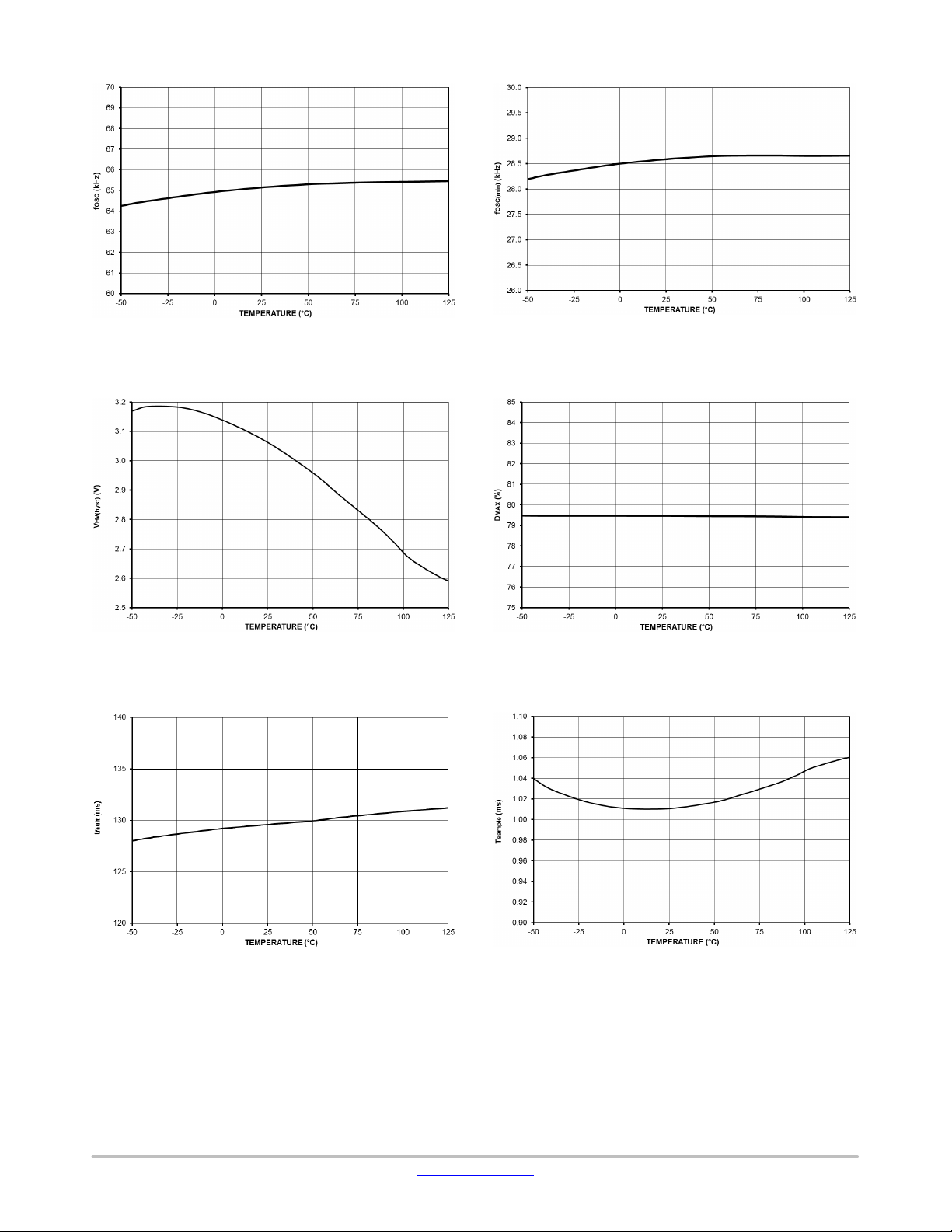

Figure 20. Oscillator Switching Frequency f

OSC

Figure 22. X2 Discharge Comparator Hysteresis

Observed at HV Pin V

HV(hyst)

Figure 21. Minimum Switching Frequency

f

OSC(min)

Figure 23. Maximum Duty Cycle D

MAX

Figure 24. The Fault Timer Duration t

fault

www.onsemi.com

12

Figure 25. HV Signal Sampling Period T

sample

Page 13

NCP12400

Figure 26. VCC T urn−on Threshold Level, VCC Going

Up HV Current Source Stop Threshold V

CC(on)

Figure 28. Internal Current Consumption when

DRV Pin is Unloaded I

CC1

Figure 27. VCC Turn−off Threshold (UVLO) V

CC(off)

Figure 29. HV Current Source Restart Threshold

V

CC(min)

Figure 30. VCC Decreasing Level at which the

Internal Logic Resets V

CC(reset)

Figure 31. Internal Current Consumption when

www.onsemi.com

13

DRV Pin is Loaded by 1 nF Capacitance I

CC2

Page 14

NCP12400

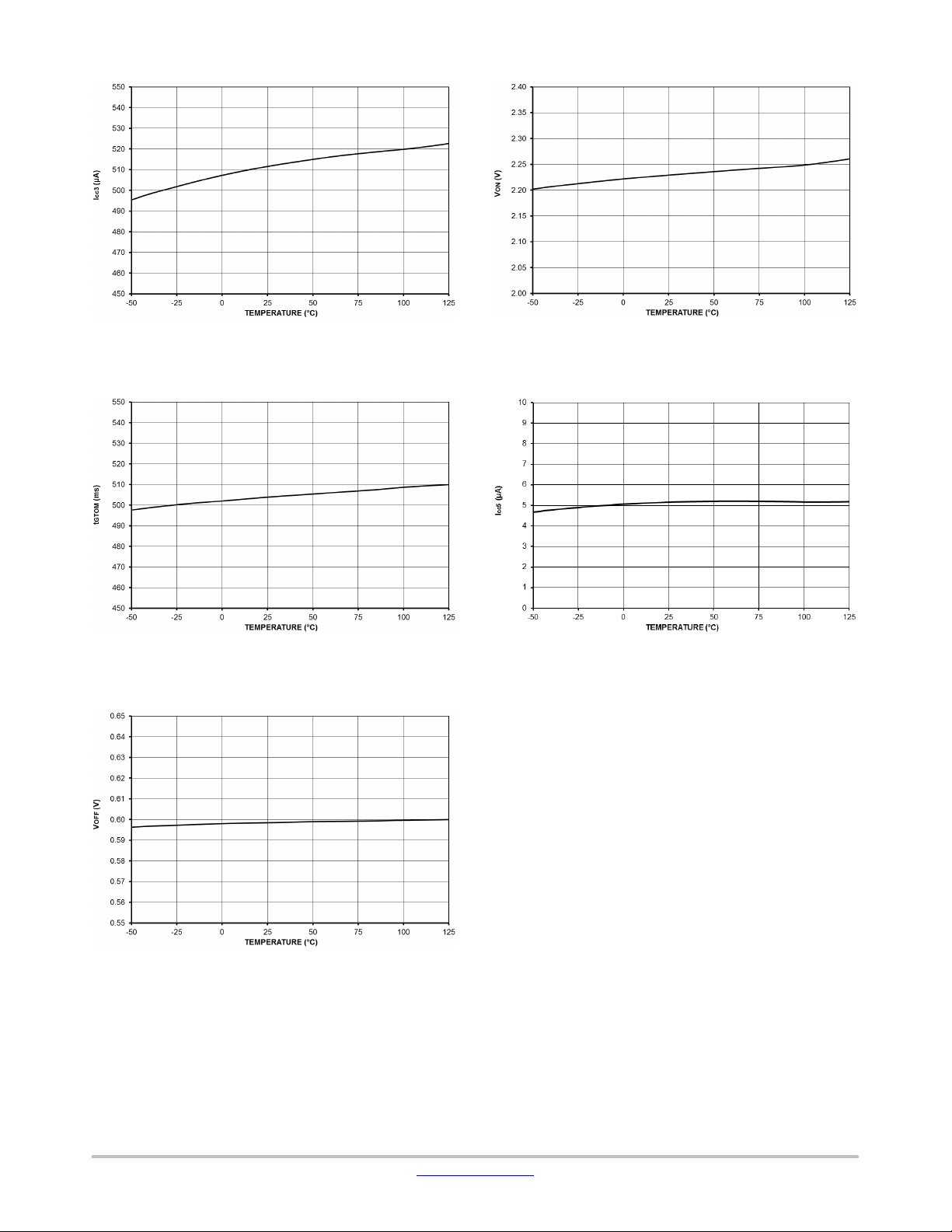

Figure 32. Internal Current Consumption in Skip

Mode I

CC3

Figure 34. Go To Off Mode Timer Duration t

GTOM

Figure 33. FB Pin Voltage Level Above which is

Entered Normal Operating Mode V

ON

Figure 35. Internal Current Consumption in Off

Mode I

CC5

Figure 36. FB Pin Voltage Level Below which is

Entered Off Mode V

OFF

www.onsemi.com

14

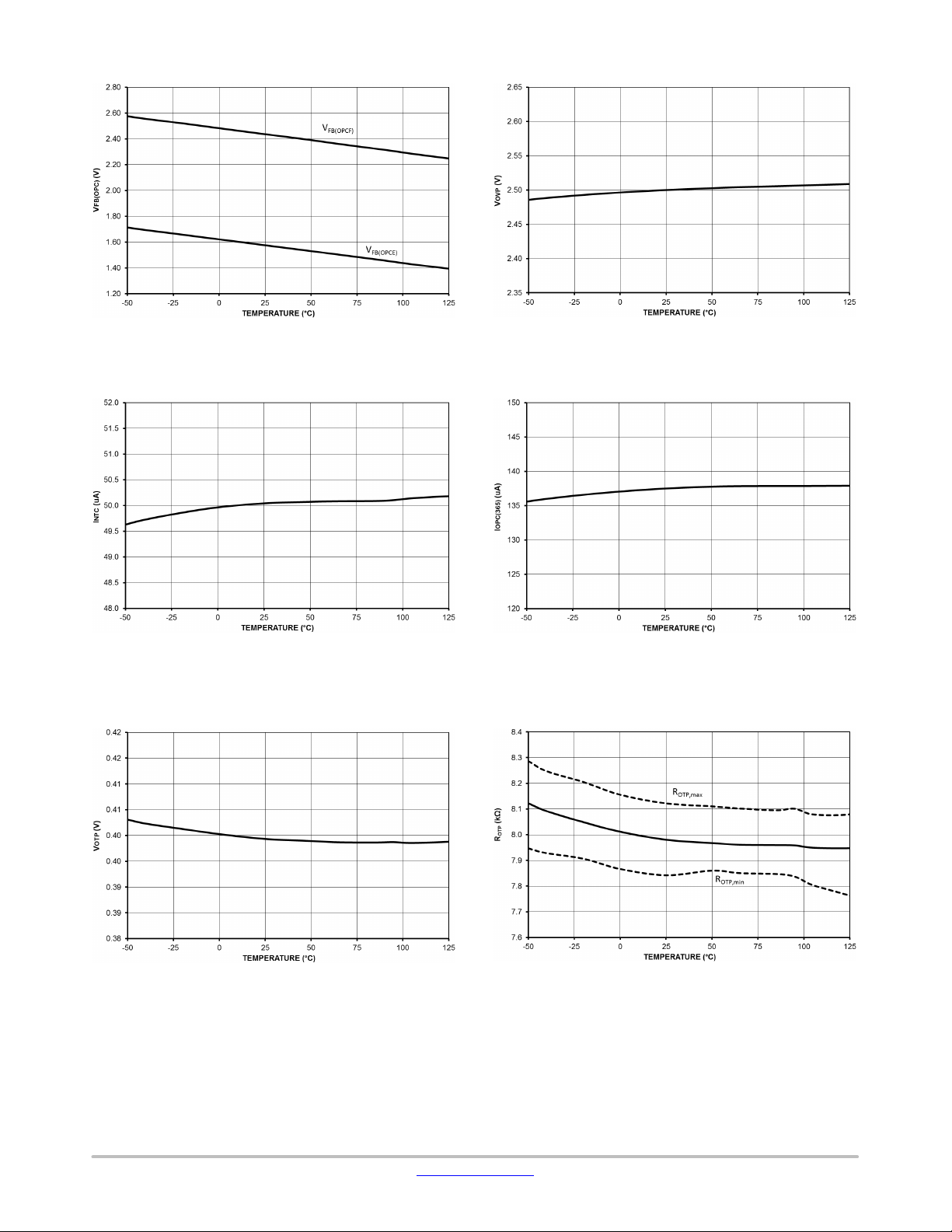

Page 15

NCP12400

Figure 37. FB Pin Voltage Thresholds for

Overpower Compensation

Figure 39. Current I

Sourced Out from the

NTC

Fault Pin, allowing Direct NTC Connection

Figure 38. Fault Pin High Threshold for OVP V

Figure 40. Current Flowing Out from CS Pin for

Over Power Compensation @ 365 V at HV Pin

I

OPC(365)

OVP

Figure 41. Fault Pin Low Threshold for OTP V

OTP

NOTE: The OTP resistance maximum and minimum courses

are not the guaranteed limits, but the maximum and minimum

measured data values from the device characterization.

www.onsemi.com

15

Figure 42. The OTP Resistance Threshold R

OTP

Page 16

NCP12400

APPLICATION INFORMATION

Functional Description

The NCP12400 includes all necessary features to build a

safe and efficient power supply based on a fixed−frequency

flyback converter. The NCP12400 is a multimode controller

as illustrated in Figure 43. The mode of operation depends

upon line and load condition. Under all modes of operation,

the NCP12400 terminates the DRV signal based on the

switch current. Thus, the NCP12400 always operates in

current mode control so that the power MOSFET current is

always limited.

Under normal operating conditions, the FB pin commands

the operating mode of the NCP12400 at the voltage

thresholds shown in Figure 43. At normal rated operating

loads (from 100% to approximately 33% full rated power)

the NCP12400 controls the converter in a fixed−frequency

PWM mode. It can operate in the continuous conduction

mode (CCM) or discontinuous conduction mode (DCM)

depending upon the input voltage and loading conditions. If

the controller is used in CCM with a wide input voltage

range, the duty−ratio may increase up to 50%. The build−in

slope compensation prevents the appearance of

sub−harmonic oscillations in this operating area.

Low consumption off mode

For loads that are between approximately 32% and 10%

of full rated power, the converter operates in frequency

foldback mode (FFM). If the feedback pin voltage is lower

than 1.4 V the peak switch current is kept constant and the

output voltage is regulated by modulating the switching

frequency for a given and fixed input voltage V

HV

.

Effectively, operation in FFM results in the application of

constant volt−seconds to the flyback transformer each

switching cycle. Voltage regulation in FFM is achieved by

varying the switching frequency in the range from 65 kHz

to 28 kHz. For extremely light loads (below approximately

6% full rated power), the converter is controlled using bursts

of 28 kHz pulses. This mode is known as skip mode. The

FFM, keeping constant peak current and skip mode allows

design of the power supplies with increased efficiency under

the light loading conditions. Keep in mind that the

aforementioned boundaries of steady−state operation are

approximate because they are subject to converter design

parameters.

OFF

Skip mode

0 V

V

OFF

V

skip(in)

V

skip(out)

V

FB(foldE)

Figure 43. Mode Control with FB Pin Voltage

There was implemented the low consumption off mode

allowing to reach extremely low no load input power. This

mode is controlled by the FB pin and allows the remote

control (or secondary side control) of the power supply

shut−down. Most of the device internal circuitry is unbiased

in the low consumption off mode. Only the FB pin control

circuitry and X2 cap discharging circuitry is operating in the

low consumption off mode. If the voltage at feedback pin

ON

FFM

ON

V

FB(foldS)

PWM at f

OSC

FBilimV

decreases below the 0.6 V the controller will enter the low

consumption of f mode. The controller can start if the FB pin

voltage increases above the 2.2 V level.

See the detailed status diagrams for the both versions fully

latched A and the autorecovery B on the following figures.

The basic status of the device after wake–up by the V

the off mode and mode is used for the overheating protection

mode if the thermal shutdown protection is activated.

V FBV

is

CC

www.onsemi.com

16

Page 17

NCP12400

LatchCondition =

Conditions for Latched version (A)

OVP + OTP + V

Dynamic Self−Supply

CCovp

*t

VCC(blank)

+ (V

CSstop

*4clk ) + ( V

ILIM

+MaxDC )*t

fault

AutoRec

LatchCondition

AutorecoveryCondition = (V

LatchCondition = OVP + OTP + V

Conditions for Autorecovery version (B)

V

CC

<V

CCreset

AutoRec =0

Power On

Latch = 0

Reset

V

CC

<V

CCreset

(V

FB

<V

OFF

AutoRec =X

Off Mode

Latch =X

V

FB

>V

ON

AutoRec = X

Latch =X

Check

)*GTOMtimer *(V

CC

>V

CCoff

)

Latch *AutoRec

BO

AutoRec =0

Latch =1

Latch

BO

AutoRec =0

Latch =0

Reset

BO+TSD

Extra Low Consumption

V

HV

>V

HV(min)

Discharge

Latch = 0

X2 cap

No AC

CSstop

*4clk ) + ( V

ILIM

+MaxDC )*t

fault

+ (V

CC

<V

CCoff

)*t

VCC(blank )

CCovp

*t

VCC (blank )

V

CSstop

V

CC

<V

CCoff

Dynamic Self−Supply

(if not enoughgh auxiliary voltage is

AutoRec =1

fault

mode

present)

Autorecovery

Latch

V

CC

>V

CCoff

V

CC

Skip

Skip out

delay

BO

Skip in

Stop

(V

CC

>V

CCon

)*BO

Start

Soft

SSend

Running

BO+TSD

Efficient operating mode

Skip in

Figure 44. Operating Status Diagram of the Device

www.onsemi.com

17

Page 18

NCP12400

Before start

Normal mode

Overload

V

CC(inhibit)

source= I

HV current

start1

source=I

HV current

start2

V

CC(min)

CC(dis)

V

V

CC(on)

V

CC(off)

VCC

is trigged before OCP timer elapsed

t

Fault mode

Low consumption off mode

discharge

X2

autorec

time

Figure 45. VCC Management Timing Diagram

UVLO level V

CC(off)

The information about the fault (permanent Latch or

Autorecovery) is kept during the low consumption off mode

due the safety reason. The reason is not to allow unlatch the

device by the remote control being in off mode.

www.onsemi.com

Start−up of the Controller

At start−up, the current source turns on when the voltage

on the HV pin is higher than V

V

18

reaches V

CC

, then turns on again when VCC reaches

CC(on)

, and turns off when

HV(min)

Page 19

NCP12400

V

proper start−up, i.e. when V

controller actually starts the next time V

, until the input voltage is high enough to ensure a

CC(min)

reaches V

HV

reaches V

CC

HV(start)

. The

CC(on)

The controller then delivers pulses, starting with a soft−start

period t

during which the peak current linearly

SSTART

increases before the current−mode control takes over.

Even though the Dynamic Self−Supply is able to maintain

the V

voltage between V

CC

CC(on)

and V

CC(min)

by turning

the HV start−up current source on and off, it can only be used

in light load condition, otherwise the power dissipation on

VHV

V

HV(start)

the die would be too much. As a result, an auxiliary voltage

source is needed to supply V

.

The Dynamic Self−Supply is useful to keep the controller

during normal operation.

CC

alive when no switching pulses are delivered, e.g. in

brown−out condition, or to prevent the controller from

stopping during load transients when the V

The NCP12400 accepts a supply voltage as high as 28 V,

with an overvoltage threshold V

that latches the

CC(ovp)

controller off.

might drop.

CC

V

HV(min)

V

CC(on)

V

CC(min)

V

CC(inhibit)

DRV

VCC

HV current

source = I

start1

Figure 46. VCC Start−up Timing Diagram

HV current

source = I

start2

Waits next

before starting

V

CC(on)

time

time

time

For safety reasons, the start−up current is lowered when

V

is below V

CC

case the V

CC(inhibit)

pin is shorted to GND (in case of VCC capacitor

CC

failure, or external pull−down on V

, to reduce the power dissipation in

to disable the

CC

www.onsemi.com

controller). There is only one condition for which the current

source doesn’t turn on when V

voltage on HV pin is too low (below V

19

reaches V

CC

HV(min)

CC(inhibit)

).

: the

Page 20

V

HV(start)

V

V

V

HV(min)

VCC

CC(on)

CC(min)

VHV

NCP12400

Device starts at

V

event

CC(on)

time

V

CC(off)

HV current

source = I

V

CC(inhibit)

HV current

source = I

start1

DRV

Figure 47. Latch After the Preshort

HV Sensing of Rectified AC Voltage

The NCP12400 features on its HV pin a true ac line

monitoring circuitry. It includes a minimum start−up

threshold and an autorecovery brown−out protection; both

of them independent of the ripple on the input voltage. It is

allowed only to work with an unfiltered, rectified ac input to

ensure the X2 capacitor discharge function as well, which is

described in following. The brown−out protection

start2

UVLO level V

is trigged before OCP timer elapsed

Device stops thanks

to pre−short protection

CC(off )

time

time

thresholds are fixed, but they are designed to fit most of the

standard ac−dc conversion applications.

When the input voltage goes below V

HV(stop)

brown−out condition is detected, and the controller stops.

The HV current source maintains V

V

V

levels until the input voltage is back above

CC(min)

HV(start)

.

between V

CC

CC(on)

, a

and

www.onsemi.com

20

Page 21

NCP12400

V

HV(start )

V

HV(stop)

HV stop

V

CC(on)

V

CC(min)

VHV

VCC

HV timer elapsed

time

Brown−out

t

HV

detected

Waits next

VccON before

starting

time

DRV

Figure 48. Ac Line Drop−out Timing Diagram

When VHV crosses the V

HV(start)

can start immediately. When it crosses V

a timer of duration t

, this ensures that the controller

HV

threshold, the controller

HV(stop)

, it triggers

doesn’t stop in case of line cycle drop−out.

When V

starts when the V

it crosses V

crosses the V

HV

CC

HV(stop)

HV(start)

crosses the next V

threshold, the controller

event. When

CC(on)

, it triggers a timer of duration tHV, this

ensures that the controller doesn’t stop in case of line cycle

Brown−out

condition

resets the

Internal Latch

time

time

drop−out. The device restart after the ac line voltage

drop−out is protected to the parasitic restart initiated e.g. the

spikes induced at HV pin immediately after the device is

stopped by the residual energy in the EMI filter. The device

restart is allowed only after the 1

st

watch dog signal event.

The basic principle is shown at Figure 49 and detail of the

device restart is shown at Figure 50.

www.onsemi.com

21

Page 22

NCP12400

V

HV(start)

V

HV(stop)

HV stop

V

CC(on)

VHV

V

CC

HV timer elapsed

Spike induced by

residual energy in

EMI filter

Brown−out

t

HV

detected

Waits next

VccON before

starting

time

time

V

CC(min)

DRV

Brown−out

condition

resets the

Internal Latch

Figure 49. Ac Line Drop−out Timing Diagram with the Parasitic Spike

time

time

www.onsemi.com

22

Page 23

NCP12400

VHV

SAMPLE

V

HV( start )

V

HV( stop )

V

HV (hyst )

Comparator

Output

Sample clock

T

SAMPLE

1stHV edge

resets the watch

dog and starts

the peak

detection of HV

pin signal

time

time

Watch dog

signal

HV stop

VCC

V

CC(on )

V

CC(mini)

DRV

2ndsample clock

pulse after last

HV edge initiates

the watch dog

signal

t

HV

Brown−out

detected

Device is stopped

Device restarts

2ndsample clock

pulse after last

HV edge initiates

the watch dog

signal

Device can restart after

st

1

Watch dog signal

when HV signal

crosses V

HV(start )

level

time

time

time

time

Figure 50. Detailed Timing Diagram of the Device Restart after the Short ac Line Drop−out

www.onsemi.com

23

time

Page 24

NCP12400

X2 Cap Discharge Feature

The X2 capacitor discharging feature is offered by usage

of the NCP12400. This feature save approx. 16 mW –

25 mW input power depending on the EMI filter X2

capacitors volume and it saves the external components

count as well. The discharge feature is ensured via the

start−up current source with a dedicated control circuitry for

this function. The X2 capacitors are being discharged by

current defined as I

when this need is detected.

start2

There is used a dedicated structure called ac line unplug

detector inside the X2 capacitor discharge control circuitry.

See the Figure 51 for the block diagram for this structure and

Figures 52, 53, 54 and 55 for the timing diagrams. The basic

idea of ac line unplug detector lies in comparison of the

direct sample of the high voltage obtained via the high

voltage sensing structure with the delayed sample of the high

voltage. The delayed signal is created by the sample & hold

structure.

The comparator used for the comparison of these signals

is without hysteresis inside. The resolution between the

slopes of the ac signal and dc signal is defined by the

sampling time T

SAMPLE

and additional internal offset NOS.

These parameters ensure the noise immunity as well. The

additional offset is added to the picture of the sampled HV

signal and its analog sum is stored in the C

storage

1

capacitor. If the voltage level of the HV sensing structure

output crosses this level the comparator CMP output signal

resets the detection timer and no dc signal is detected. The

additional offset N

can be measured as the V

OS

HV(hyst)

on

the HV pin. If the comparator output produces pulses it

means that the slope of input signal is higher than set

resolution level and the slope is positive. If the comparator

output produces the low level it means that the slope of input

signal is lower than set resolution level or the slope is

negative. There is used the detection timer which is reset by

any edge of the comparator output. It means if no edge

comes before the timer elapses there is present only dc signal

or signal with the small ac ripple at the HV pin. This type of

the ac detector detects only the positive slope, which fulfils

the requirements for the ac line presence detection.

In case of the dc signal presence on the high voltage input,

the direct sample of the high voltage obtained via the high

voltage sensing structure and the delayed sample of the high

voltage are equivalent and the comparator produces the low

level signal during the presence of this signal. No edges are

present at the output of the comparator, that’s why the

detection timer is not reset and dc detect signal appears.

The minimum detectable slope by this ac detector is given

by the ration between the maximum hysteresis observed at

HV pin V

HV(hyst),max

and the sampling time:

V

+

HV(hyst),max

T

sample

S

min

(eq. 1)

Than it can be derived the relationship between the

minimum detectable slope and the amplitude and frequency

of the sinusoidal input voltage:

V

V

max

HV(hyst),max

+

2 @ p @ f@ T

+ 22.7 V

sample

+

2 @ p @ 35@ 1@ 10

5

−3

+

(eq. 2)

The minimum detectable AC RMS voltage is 16 V at

frequency 35 Hz, if the maximum hysteresis is 5 V and

sampling time is 1 ms.

The X2 capacitor discharge feature is available in any

controller operation mode to ensure this safety feature. The

detection timer is reused for the time limiting of the

discharge phase, to protect the device against overheating.

The discharging process is cyclic and continues until the ac

line is detected again or the voltage across the X2 capacitor

is lower than V

. This feature ensures to discharge

HV(min)

quite big X2 capacitors used in the input line filter to the safe

level. It is important to note that it is not allowed to

connect HV pin to any dc voltage due this feature. e.g.

directly to bulk capacitor.

During the HV sensing or X2 cap discharging the V

is kept above the V

voltage by the Self−Supply in any

CC(off)

CC

net

mode of device operation to supply the control circuitry.

During the discharge sequence is not allowed to start−up the

device.

www.onsemi.com

24

Page 25

NCP12400

Figure 51. The ac Line Unplug Detector Structure Used for X2 Capacitor Discharge System

Figure 52. The ac Line Unplug Detector Timing Diagram

www.onsemi.com

25

Page 26

NCP12400

Figure 53. The ac Line Unplug Detector Timing Diagram Detail with Noise Effects

www.onsemi.com

26

Page 27

VHV

NCP12400

V

HV(start)

V

HV(stop)

Starts

only at

V

CC(on)

One Shot

DRV

X2 discharge

current

HV

timer

starts

HV

timer

restarts

AC line unplug

X2 capacitor

discharge

time

AC line Unplug

detector starts

No AC detection

t

HV

t

DET

time

Brown−out

X2 discharge

time

t

DIS

V

CC

V

CC(on)

V

CC(dis)

V

CC(min)

Figure 54. HV Pin ac Input Timing Diagram with X2 Capacitor Discharge Sequence when the Application is

Unplugged Under Extremely Low Line Condition

time

time

www.onsemi.com

27

Page 28

NCP12400

VHV

V

HV(start)

V

HV(stop)

Starts

only at

V

CC(on)

One Shot

DRV

X2 discharge

current

HV

timer

starts

HV

timer

restarts

AC line unplug

AC line Unplug

detector starts

t

DET

X2 capacitor

discharge

No AC detection

X2 discharge

t

DIS

X2 capacitor

discharge

t

HV

time

t

DET

time

Device is stopped

X2 discharge

t

DIS

time

V

CC

V

CC(dis)

Device shunts the

X2 discharge

current internally

Figure 55. HV Pin ac Input Timing Diagram with X2 Capacitor Discharge Sequence When the Application is

Unplugged Under High Line Condition

The Low Consumption Off Mode

There was implemented the low consumption off mode

allowing to reach extremely low no load input power as

described in previous chapters. If the voltage at feedback pin

decreases below the 0.6 V the controller enters the off mode.

The internal V

low V

CC

is turned−off, the IC consumes extremely

CC

current and only the voltage at external V

CC

capacitor is maintained by the Dynamic Self−Supply circuit.

The Dynamic Self−Supply circuit keeps the V

between the V

CC(on)

and V

levels. The supply for the

CC(off)

voltage

CC

FB pin watch dog circuitry and FB pin bias is provided via

the low consumption current sources from the external V

CC

capacitor. The controller can only start, if the FB pin voltage

increases above the 2.2 V level. See Figure 56 for timing

Only the X2 cap discharge and Self−Supply features is

enabled in the low consumption off mode. The X2 cap

discharging feature is enable due the safety reasons and the

Self−Supply is enabled to keep the V

very low V

consumption appears in this mode. Any other

CC

supply, but only

CC

features are disabled in this mode.

The information about the latch status of the device is kept

in the low consumption off mode and this mode is used for

the TSD protection as well. The protection timer

GoToOffMode t

is used to protect the application

GTOM

against the false activation of the low consumption off mode

by the fast drop outs of the FB pin voltage below the 0.4 V

level. E.g. in case when is present high FB pin voltage ripple

during the skip mode.

diagrams.

time

time

www.onsemi.com

28

Page 29

NCP12400

e

f

f

f

VHV

V

HV(start)

VFB

V

ON

V

OFF

VCC

V

CC(on)

V

CC(dis)

V

CC(off)

V

CC(inhibit)

One Shot

DRV start

condition

Low consumption mode

DSS start to

charge the Vcc

cap

HV

timer

starts

Ready to RUN

Starts

only at

V

CC(on)

RUN

HV

timer

restarts

Low consumption off mode

t

GTSG

Self−Supply

in off mode

AC line unplug

Dynamic

AC line Unplug

detector starts

X2 capacitor

discharge

No AC detection

X2 capacitor

discharge

time

No AC detection

time

DRV

current

X2 discharge

Figure 56. Start−up, Shut−down and AC Line Unplug Time Diagram

Oscillator with Frequency Jittering

The NCP12400 includes an oscillator that sets the

switching frequency 65 kHz or 100 kHz depending on the

version. The maximum duty−ratio of the DRV pin is 80%.

In order to improve the EMI signature, the switching

frequency jitters ±4 kHz around its nominal value, with a

triangle−wave shape and at a frequency of 125 Hz. This

frequency jittering is active even when the frequency is

decreased to improve the efficiency in light load condition.

Skip mode

+ 4 kHz

OSC

Nominal f

− 4 kHz

OSC

OSC

OSC

t

DET

t

DET

time

X2 cyclic discharge

process starts

time

t

DIS

t

DIS

time

8 ms

Tim

(125 Hz)

Figure 57. Frequency Modulation of the Maximum

Switching Frequency

www.onsemi.com

29

Page 30

NCP12400

Low Load Operation Modes: Frequency Foldback

Mode (FFM) and Skip Mode

In order to improve the efficiency in light load conditions,

the frequency of the internal oscillator is linearly reduced

from its nominal value down to f

OSC(min)

. This frequency

foldback starts when the voltage on FB pin goes below

Vfb(foldS), and is complete when Vfb reaches Vfb(foldE).

The maximum on−time duration control is kept during the

f

OSC

f

OSC(min)

Fsw

Skip

V

skip(in) V

V

skip(out)

Figure 58. Frequency Foldback Mode Characteristic

V

FB(foldE)

Fixed I

peak

V

FB(freeze)

frequency foldback mode to provide the natural transformer

core anti−saturation protection. The frequency jittering is

still active while the oscillator frequency decreases as well.

The current setpoint is fixed to 300 mV in the frequency

foldback mode if the feedback voltage decreases below the

Vfb(freeze) level. This feature increases efficiency under

the light loads conditions as well.

FB

FB(foldS)

V

offset+KFB

V

X

ILIM

Internal current setpoint

V

V

I(freeze)

ILIM

V

skip(in) V

V

skip(out)

Fixed I

V

FB(foldE)

peak

V

Figure 59. Current Setpoint Dependency on the Feedback Pin Voltage

When the FB voltage reaches V

while decreasing,

skip(in)

skip mode is activated: the driver stops, and the internal

consumption of the controller is decreased. While V

below V

soon as V

, the controller remains in this state; but as

skip(out)

crosses the skip out threshold, the DRV pin

FB

FB

is

starts to pulse again.

FB(freeze)

V

FB

K

V

X

FB

FB(foldS)

ILIM

The NCP12400 device includes logic which allows going

into skip mode after the DRV cycle is finished by reaching

of the peak current value. This technique eliminates the last

short pulses in skip mode, which increases the system

efficiency at light loads and makes easier the application of

active secondary rectification circuitry.

www.onsemi.com

30

Page 31

FB

NCP12400

Figure 60. Skip Mode Timing Diagram

V

skip(out)

V

skip(in)

OSC

(internal signal)

CS

V

I(freeze)

Skip signal does

not immediately

stop the pulse

Enters

skip

Figure 61. Technique Preventing Short Pulses in Skip Mode

time

time

time

www.onsemi.com

31

Page 32

NCP12400

Quiet−Skip

To further avoid acoustic noise, the circuit prevents the

burst frequency during skip mode from entering the audible

range by limiting it to a maximum of 800 Hz. This is

achieved via a timer t

that is activated during

quiet

Quiet−Skip. The start of the next burst cycle is prevented

until this timer has expired. As the output power decreases,

the switching frequency decreases. Once it hits minimum

switching frequency f

OSC(min)

, the skip−in threshold is

reached and burst mode is entered − switching stops as soon

as the current drive pulses ends – it does not stop

immediately.

Once switching stops, FB will rise. As soon as FB crosses

the skip−exit threshold, drive pulses will resume, but the

controller remains in burst mode. At this point, a 1250 ms

(typ) timer t

pulses counter. This n

is started together with a count to n

quiet

pulses counter ensures the

P,sk ip

P,sk ip

minimum number of DRV signal pulses in burst. The next

time the FB voltage drops below the skip−in threshold, DRV

pulses stop at the end of the current pulse as long as n

P,sk ip

drive pulses have been counted (if not, they do not stop until

the end of the n

−th pulse). They are not allowed to start

P,sk ip

again until the timer expires, even if the skip−exit threshold

is reached first. It is important to note that the timer will not

force the next cycle to begin – i.e. if the natural skip

frequency is such that skip−exit is reached after the timer

expires, the drive pulses will wait for the skip−exit

threshold.

This means that during no−load, there will be a minimum

of n

drive pulses, and the burst−cycle period will likely

P,sk ip

be much longer than 1250 ms. This operation helps to

improve efficiency at no−load conditions.

In order to exit burst mode, the FB voltage must rise higher

than V

skip(tran)

level. If this occurs before t

expires, the

quiet

drive pulses will resume immediately – i.e. the controller

won’t wait for the timer to expire. Figure 63 provides an

example of how Quiet−Skip works, while Figure 62 shows

the immediate leaving the quiet skip mode by crossing the

transient enhancement level V

skip(tran)

.

www.onsemi.com

32

Page 33

V

skip(tran)

V

skip(out)

V

skip(in)

NCP12400

V

FB

Crossing the transient

enhancement level

stops the quiet skip

immediately

Exits skip

after quiet

timer

expires

Time

V

V

V

DRV

V

skip(out)

skip(in)

DRV

V

skip(out)

V

skip(in)

quiet

t

t

quiet

Enters

skip

Enters

skip

Time

Figure 62. Leaving the Quiet−Skip Mode during Load Transient

FB

Running just above skip

mode with f

Sequence of events

1; 2; 3 starts the quiet

FB

2

1

3

skip mode

sw=fosc(min)

The DRV pulses does not

start even when V

in the quiet skip mode

FB>Vskip(out)

time

time

V

skip(tran)

V

skip(out)

V

DRV

V

FB

skip(in)

DRV

n

P,skip

n

P,skip

forces at least n

pulses in skip mode

t

quiet

n

P,skip

t

quiet

DRV pulses does

not start because

V

FB<Vskip(in)

Quiet skip mode

burst

p,skip

n

P,skip

Figure 63. Quiet−Skip Timing Diagram − option

When VFB>V

skip (tran )

mode immediately finishes

t

quiet

the quiet skip

t

quiet

n

P,skip

time

time

time

time

www.onsemi.com

33

Page 34

NCP12400

Clamped Driver

The supply voltage for the NCP12400 can be as high as

36 V , but most of the MOSFET s that will be connected to the

DRV pin cannot accept more than 20 V on their gate. The

driver pin is therefore safely clamped below 16 V. This

driver has a typical capability of 500 mA for source current

and 800 mA for sink current.

Current−Mode Control With Slope Compensation and

Soft−Start

NCP12400 is a current−mode controller, which means

that the FB voltage sets the peak current flowing in the

transformer primary inductance and the MOSFET. This is

done through a PWM comparator: the current is sensed

across a res i s t o r and the resulting voltage is applied to the CS

pin. It is applied to one input of the PWM comparator

through a 250 ns LEB block. On the other input the FB

VFB

KFBx V

ILIM

voltage subducted by offset typically 0.8 V and divided by

4 sets the threshold: when the voltage ramp reaches this

threshold, the output driver is turned off. The maximum

value for the current sense is 0.7 V, and it is set by a dedicated

comparator.

Each time the controller is starting, i.e. the controller was

off and starts – or restarts – when V

reaches V

CC

CC(on)

, a

soft−start is applied: the current sense set−point is increased

by 32 discrete steps from 0 (the minimum level can be higher

than 0 because of the LEB and propagation delay) until it

reaches V

(after a duration of t

ILIM

), or until the FB

SSTART

loop imposes a setpoint lower than the one imposed by the

soft−start (the 2 comparators outputs are OR’ed).

During the soft−start the oscillator frequency increase

from the minimum switching frequency to the maximum

switching frequency following the ramp applied to current

sense set−point.

Soft−start ramp

V

ILIM

CS Setpoint

V

ILIM

VFB takes

over soft −start

Time

Soft−start ramp

V

ILIM

t

SSTART

Time

OSC frequency

f

SW

f

SW,min

Figure 64. Soft−Start Feature

t

SSTART

t

SSTART

TimeTime

Time

www.onsemi.com

34

Page 35

NCP12400

Under some conditions, like a winding short−circuit for

instance, not all the energy stored during the on−time is

transferred to the output during the off−time, even if the

on−time duration is at its minimum (imposed by the

propagation delay of the detector added to the LEB

duration). As a result, the current sense voltage keeps on

increasing above V

, because the controller is blind

ILIM

during the LEB blanking time. Dangerously high current

can grow in the system if nothing is done to stop the

controller. That’s what the additional comparator, that

senses when the current sense voltage on CS pin reaches

V

CS(stop)

( = 1.5 x V

), does: as soon as this comparator

ILIM

toggles, the controller immediately enters the protection

mode.

In order to allow the NCP12400 to operate in CCM with

a duty−ratio above 50%, the fixed slope compensation is

internally applied to the current−mode control. The slope

appearing on the internal voltage setpoint for the PWM

comparator is −32.5 mV/ms typical. The slope compensation

can be observable as a value of the peak current at CS pin.

The internal slope compensation circuitry uses a saw−tooth

signal synchronized with the internal oscillator is subtracted

from the FB voltage divided by K

FB

.

Internal PWM setpoint

/ K

V

FB

V

/ KFB − 0.2 V

FB

Figure 65. Slope Compensation Block Diagram

FB

40% 100%80%0%

Figure 66. Slope Compensation Timing Diagram

www.onsemi.com

35

Duty Cycle

Page 36

NCP12400

Internal Overpower Protection

The power delivered by a flyback power supply is

proportional to the square of the peak current in

discontinuous conduction mode:

P

OUT

1

+

@ h @ LP@ FSW@ I

2

I

peak

I

LIMIT

Figure 67. Needs for Line Compensation For True Overpower Protection

P

High

Line

2

t

delay

(eq. 3)

To compensate this and have an accurate overpower

protection, an offset proportional to the input voltage is

added on the CS signal by turning on an internal current

source: by adding an external resistor in series between the

sense resistor and the CS pin, a voltage offset is created

across it by the current. The compensation can be adjusted

by changing the value of the resistor.

I

OPC

Unfortunately, due to the inherent propagation delay of

the logic, the actual peak current is higher at high input

voltage than at low input voltage, leading to a significant

difference in the maximum output power delivered by the

power supply.

DI

to be

peak

compensated

Low

Line

time

t

delay

But this offset is unwanted to appear when the current

sense signal is small, i.e. in light load conditions, where it

would be in the same order of magnitude. Therefore the

compensation current is only added when the FB voltage is

higher than V

FB(OPCE)

. However, because the HV pin is

being connected to ac voltage, there is needed an additional

circuitry to read or at least closely estimate the actual voltage

on the bulk capacitor.

V

HV

V

V

FB(OPCE) V

FB(OPCF)

FB

Figure 68. Overpower Protection Current Relation to Feedback Voltage

I

OPC

I

OPC(365)

I

OPC(125)

125 V

365 V

V

HV

Figure 69. Overpower Protection Current Relation to Peak of Rectified Input Line AC voltage

www.onsemi.com

36

Page 37

NCP12400

Figure 70. Block Schematic of Overpower Protection Circuit

A 5−bit A/D converter with the peak detector senses the

ac input, and its output is periodically sampled and reset, in

order to follow closely the input voltage variations. The

sample and reset events are given by the output from the ac

line unplug detector. The sensed HV pin voltage peak value

is validated when no HV edges from comparator are present

after last falling edge during 2 sample clocks. See Figure 71

for details.

Overcurrent Protection with Fault Timer

The overload protection depends only on the current

sensing signal, making it able to work with any transformer,

even with very poor coupling or high leakage inductance.

When an overcurrent occurs on the output of the power

supply, the FB loop asks for more power than the controller

www.onsemi.com

can deliver, and the CS set−point reaches V

event occurs, an internal t

timer is started: once the timer

fault

. When this

ILIM

times out , D RV pulses are stopped and the controller is either

latched of f . This latch is released in autorecovery mode. The

controller tries to restart after t

. The other possibilities

autorec

of the latch release are the brown−out condition or the VCC

power on reset. The timer is reset when the CS set−point

goes back below VILIM before the timer elapses. The fault

timer is also started if the driver signal is reset by the

maximum on time. The controller also enters the same

protection mode if the voltage on the CS pin reaches 1.5

times the maximum internal set−point V

CS(stop)

(allows to

detect winding short−circuits) or there appears low V

supply. See Figure 71 for the timing diagram.

37

CC

Page 38

NCP12400

Figure 71. Overpower Compensation Timing Diagram

www.onsemi.com

38

Page 39

NCP12400

Table 6. PROTECTION MODES AND THE LATCH MODE RELEASES

Event

Timer Protection

Next Device Status

Release to Normal Operation Mode

Overcurrent

Fault timer

Latch

Autorecovery

Maximum on time

Fault timer

Latch

Brown−out

Maximum duty cycle

Fault timer

Latch

Brown−out

Winding short

4 consecutive pulses

Latch

Autorecovery

Low supply

10 ms timer

Latch

Autorecovery

External OTP, OVP

55 ms

Latch

Brown−out

High supply

10 ms timer

Latch

Brown−out

Brown−out

HV timer

Device stops

(VHV > V

) & (VCC > V

)

Internal TSD

10 ms timer

Device stops, HV start−up

(VHV > V

) & (VCC > V

) & TSDb

Off mode

500 ms timer

Device stops and internal

(VHV > V

) & (VCC > V

) &

VCS > V

VCS > V

VCC < V

VCC > V

VHV < V

VFB < V

ILIM

CS(stop)

CC(off)

CC(ovp)

HV(stop)

OFF

current source stops

VCC is turned off

V

VCC < V

VCC < V

VCC < V

VCC < V

VCC < V

VCC < V

HV(start)

HV(start)

HV(start)

Brown−out

< V

CC

CC(reset)

CC(reset)

CC(reset)

Brown−out

CC(reset)

Brown−out

CC(reset)

CC(reset)

CC(reset)

(VFB > VON)

CC(on)

CC(on)

CC(on)

www.onsemi.com

39

Page 40

V

CC(on)

V

CC(min)

NCP12400

Figure 72. Latched Timer−Based Overcurrent Protection

www.onsemi.com

40

Page 41

NCP12400

Output Load

Max Load

Fault Flag

VCC

V

CC(on )

V

CC(min)

DRV

Overcurrent

applied

Fault

timer

starts

Restart

At V

CC

ON

(new burst

cycle if Fault

still present)

Fault

disappears

time

time

time

Fault timer

t

fault

Controller

stops

t

fault

t

autorec

Figure 73. Timer−based Protection Mode with Autorecovery Release from Latch−off

time

time

www.onsemi.com

41

Page 42

FAULT Input

NCP12400

Figure 74. OVP/OTP Detection Schematic

The FAULT input pin is dedicated to the latch−off

function: it includes 2 levels of detection that define a

working window, between a high latch and a low latch:

within these 2 thresholds, the controller is allowed to run, but

as soon as either the low or the high threshold is crossed, the

controller is latched off. The controller can be released from

the latch mode by the autorecovery, but it depends on the

version of the product. The lower threshold is intended to be

used with an NTC thermistor, thanks to an internal current

source I

NTC

.

An active clamp prevents the voltage from reaching the

high threshold if it is only pulled up by the I

current. T o

NTC

reach the high threshold, the pull−up current has to be higher

than the pull−down capability of the clamp (typically

1.5 mA at V

OVP

).

To avoid any false triggering, spikes shorter than 50 ms

(for the high latch and 65 kHz version) or 350 ms (for the low

latch) are blanked and only longer signals can actually latch

the controller.

@ I

NTC(SSTART) min

V

OTP max

C

FAULT max

t

SSTART min

+

Reset occurs when a brown−out condition is detected or

the V

is cycled down to a reset voltage, which in a real

CC

application can only happen if the power supply is

unplugged from the ac line.

Upon startup, the internal references take some time

before being at their nominal values; so one of the

comparators could toggle even if it should not. Therefore the

internal logic does not take the latch signal into account

before the controller is ready to start: once V

V

, the latch pin High latch state is taken into account

CC(on)

reaches

CC

and the DRV switching starts only if it is allowed; whereas

the Low latch (typically sensing an over temperature) is

taken into account only after the soft−start is finished. In

addition, the NTC current is doubled to I

NTC(SSTART)

during

the soft−start period, to speed up the charging of the FAULT

pin capacitor The maximum value of FAULT pin capacitor

is given by the following formula (The standard start−up

condition is considered and the NTC current is neglected):

3.2@ 10

+

−3

@ 60 @ 10

0.420

−6

F + 457 nF

(eq. 4)

www.onsemi.com

42

Page 43

V

CC(on)

V

CC(min)

NCP12400

Figure 75. Latch Timing Diagram

Temperature Shutdown

The NCP12400 includes a temperature shutdown

protection with a trip point typically at 150°C and the typical

hysteresis of 30°C. When the temperature rises above the

high threshold, the controller stops switching

instantaneously, and goes to the off mode with extremely

low power consumption. There is kept the V

supply to

CC

keep the TSD information. When the temperature falls

below the l o w t h r e shold, the start−up of the device is enabled

again, and a regular start−up sequence takes place. See the

status diagrams at the Figure 44.

www.onsemi.com

43

Page 44

NCP12400

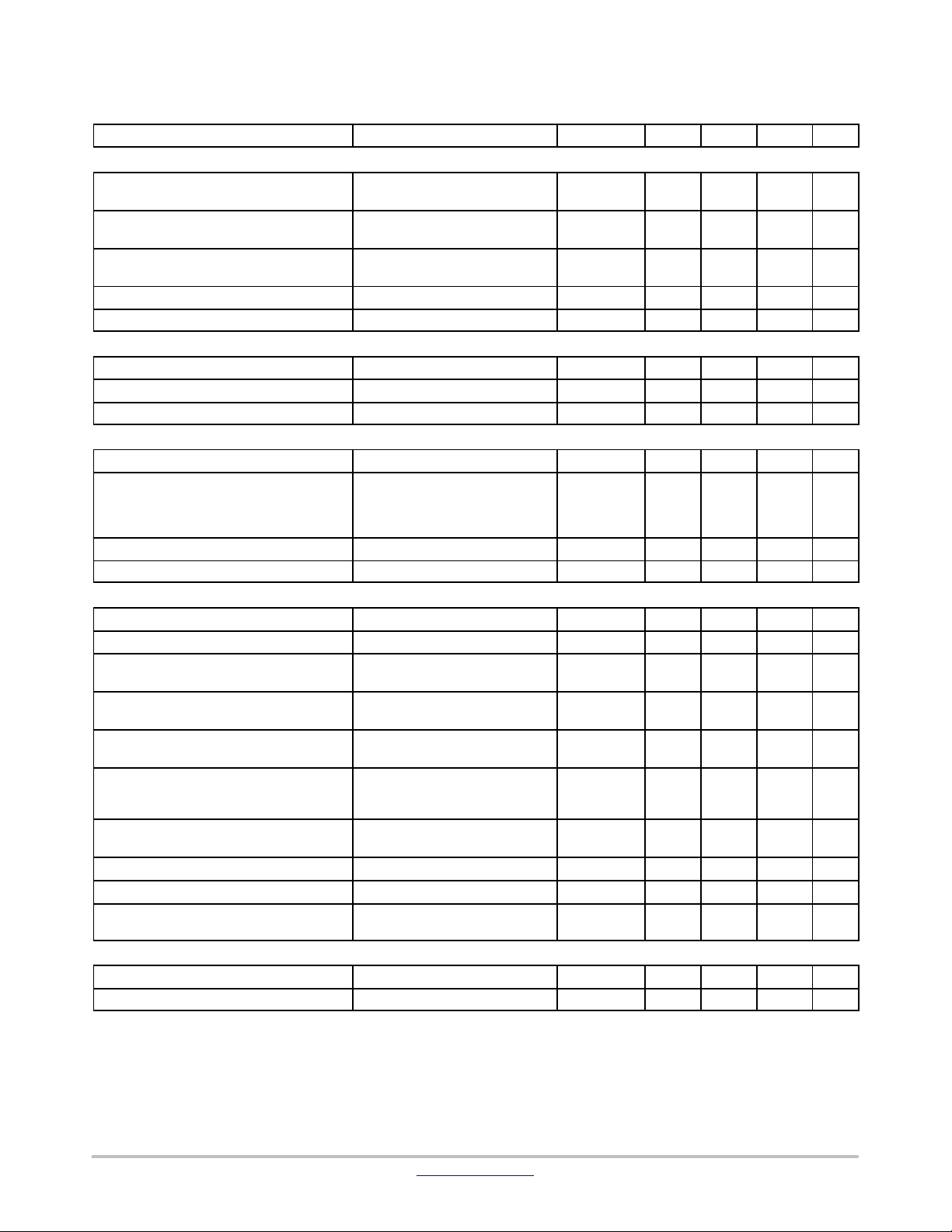

ORDERING INFORMATION

Ordering Part No.

Overload Protection

Switching Frequency

Package

Shipping

†

NCP12400BAHAB0DR2G

Latched

65 kHz

NCP12400BAHBB0DR2G

Latched

65 kHz

NCP12400BBBBB2DR2G

Autorecovery

65 → 100 kHz

NCP12400BBHAA1DR2G

Autorecovery

100 kHz

NCP12400CAHAB0DR2G

Latched

65 kHz

NCP12400CBAAB0DR2G

Autorecovery

65 kHz

NCP12400CBBAB0DR2G

Autorecovery

65 kHz

NCP12400CBHAA0DR2G

Autorecovery

65 kHz

NCP12400EAHBB0DR2G

Latched

65 kHz

NCP12400BBBBA0DR2G

Autorecovery

65 kHz

NCP12400BBHAB0DR2

Autorecovery

65 kHz

NCP12400BBEBA0DR2G

Autorecovery

65 kHz

NCP12400BBAAA0DR2G

Autorecovery

65 kHz

SOIC−7

(Pb−Free)

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

2500 / Tape & Reel

www.onsemi.com

44

Page 45

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

SCALE 1:1

SOIC−7

CASE 751U−01

ISSUE E

DATE 20 OCT 2009

−A−

58

S