Omron ZFV - V2.0, ZFV-SR10, ZFV-SR50, ZFV-A10, ZFV-A15 User Manual

...

USER’S MANUAL

Smart Sensors

ZFV Series (Ver 2.0)

Cat. No. Z207-E1-03

Introduction

INTRODUCTION

SECTION 1

SECTION 2

SECTION 3

SECTION 4

APPLICATION CONSIDERATIONS (Please read first)

Section 1 Section 2 Section 3 Section 4

FEATURES

INSTALLATION & CONNECTION

SETUP

APPENDIX

User’s Manual

Smart Sensors

with Ultra-high-Speed CCD Camera

ZFV Series

Introduction

Introduction

READ AND UNDERSTAND THIS DOCUMENT

Please read and understand this document before using the products. Please consult your OMRON

representative if you have any questions or comments.

WARRANTY

OMRON’s exclusive warranty is that the products are free from defects in materials and workmanship for

a period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL

DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR

STRICT LIABILITY.

In no event shall responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON’S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

SUITABILITY FOR USE

THE PRODUCTS CONTAINED IN THIS DOCUMENT ARE NOT SAFETY RATED. THEY ARE NOT

DESIGNED OR RATED FOR ENSURING SAFETY OF PERSONS, AND SHOULD NOT BE RELIED

UPON AS A SAFETY COMPONENT OR PROTECTIVE DEVICE FOR SUCH PURPOSES. Please refer

to separate catalogs for OMRON's safety rated products.

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to

the combination of products in the customer’s application or use of the product.

At the customer’s request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the

uses listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this document.

ZFV

2

User’s Manual

Introduction

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT IS PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PERFORMANCE DATA

Performance data given in this document is provided as a guide for the user in determining suitability and

does not constitute a warranty. It may represent the result of OMRON’s test conditions, and the users

must correlate it to actual application requirements. Actual performance is subject to the OMRON

Warranty and Limitations of Liability.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

Introduction

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the product may be

changed without any notice. When in doubt, special model numbers may be assigned to fix or establish

key specifications for your application on your request. Please consult with your OMRON representative

at any time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

ERRORS AND OMISSIONS

The information in this document has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user’s programming of a programmable product, or any

consequence thereof.

COPYRIGHT AND COPY PERMISSION

This document shall not be copied for sales or promotions without permission.

This document is protected by copyright and is intended solely for use in conjunction with the product.

Please notify us before copying or reproducing this document in any manner, for any other purpose. If

copying or transmitting this document to another, please copy or transmit it in its entirety.

ZFV

User’s Manual

3

Introduction

Introduction

Precautions for Safe Use

Precautions for Safe Use

Please observe the following precautions for safe use of the products.

(1) Installation Environment

• Do not use the product in environments where it can be exposed to inflammable/

explosive gas.

• Install the Amplifier Unit in such a way that the ventilation holes are not blocked.

• To secure the safety of operation and maintenance, do not install the product close to

high-voltage devices and power devices.

• During installation, make sure that screws are tightened firmly.

(2) Power Supply and Wiring

• The supply voltage must be within the rated range (DC24V±10%).

• Reverse connection of the power supply is not allowed.

• Open-collector outputs should not be short-circuited.

• Use the power supply within the rated load.

• High-voltage lines and power lines must be wired separately from this product. Wiring

them together or placing them in the same duct may cause induction, resulting in malfunction or damage.

(3) Others

• Do not attempt to dismantle, repair, or modify the product.

• Dispose of this product as industrial waste.

• Should you notice any abnormalities, immediately stop use, turn OFF the power supply, and contact your OMRON representative.

ZFV

4

User’s Manual

Introduction

Precautions for Correct Use

Precautions for Correct Use

Please observe the following precautions to prevent failure to operate, malfunctions, or

undesirable effects on product performance.

(1) Installation Location

Do not install the product in locations subjected to the following conditions:

• Ambient temperature outside the rating

• Rapid temperature fluctuations (causing condensation)

• Relative humidity outside the range of 35 to 85%

• Presence of corrosive or flammable gases

• Presence of dust, salt, or iron particles

• Direct vibration or shock

• Reflection of intense light (such as other laser beams or electric arc-welding

machines)

• Direct sunlight or near heaters

• Water, oil, or chemical fumes or spray

• Strong magnetic or electric field

Introduction

(2) Power Supply and Wiring

• When using a commercially available switching regulator, make sure that the FG terminal is grounded.

• If surge currents are present in the power lines, connect surge absorbers that suit the

operating environment.

• Before turning ON the power after the product is connected, make sure that the power

supply voltage is correct, there are no incorrect connections (e.g. load short-circuit)

and the load current is appropriate. Incorrect wiring may result in breakdown of the

product.

• Before connecting/disconnecting the Sensor Head, make sure that the Smart Sensor

is turned OFF. The Smart Sensor may break down if the Sensor Head is connected or

disconnected while the power is ON.

• Use extension cord ZFV-XC B(R)V2 sold separately for extending the cord between

the sensor head and amplifier unit. 2 ZFV-XC B(R)V2 cords can be coupled together

to extend the cord length. In addition, use a robot cable type extension cord (ZFVXC BRV2) at locations where the cord bends, to prevent damage to the cord.

• Use only combinations of Sensor Heads and Sensor Controllers specified in this manual.

• Do not turn the power OFF in the following instances

-Immediately after the MENU mode or ADJ mode is switched to the RUN mode

-While teaching with a parallel signal

-Wait for the ENABLE signal to turn ON before turning the power OFF as the bank

data may be initialized.

ZFV

User’s Manual

5

Introduction

Introduction

Precautions for Correct Use

(3) Orientation when Installing the Amplifier Unit

To improve heat radiation, install the Amplifier Unit only in the

orientation shown below.

Right

Do not install the Amplifier Unit in the following orientations.

Wrong Wrong

(4) Maintenance and Inspection

• Do not use thinner, benzene, acetone or kerosene to clean the Sensor Head and

Amplifier Unit.

• If large dust particles adhere to the front Panel of the Sensor Head, use a blower

brush (used to clean camera lenses) to blow them off. Do not blow the dust particles

with your mouth.

• To remove smaller dust particles, wipe gently with a soft cloth. Do not use excessive

force to wipe off dust particles. Scratches on the front Panel may cause errors.

(5) Optical Axis and Detection Range

The center of the guide light and detection range are for reference only.

The center of the optical axis sometimes differs according to each Sensor Head. During installation, be sure to check the center of the image and the detection range on the

LCD monitor of the Amplifier Unit.

(6) Ventilation Film

• Do not peel off or probe the ventilation film with a sharp-pointed object. If you so, the

specifications of the protective structure may no longer be satisfied.

• Do not block the ventilation film. Doing so might cause the front panel to be condensed.

ZFV

6

User’s Manual

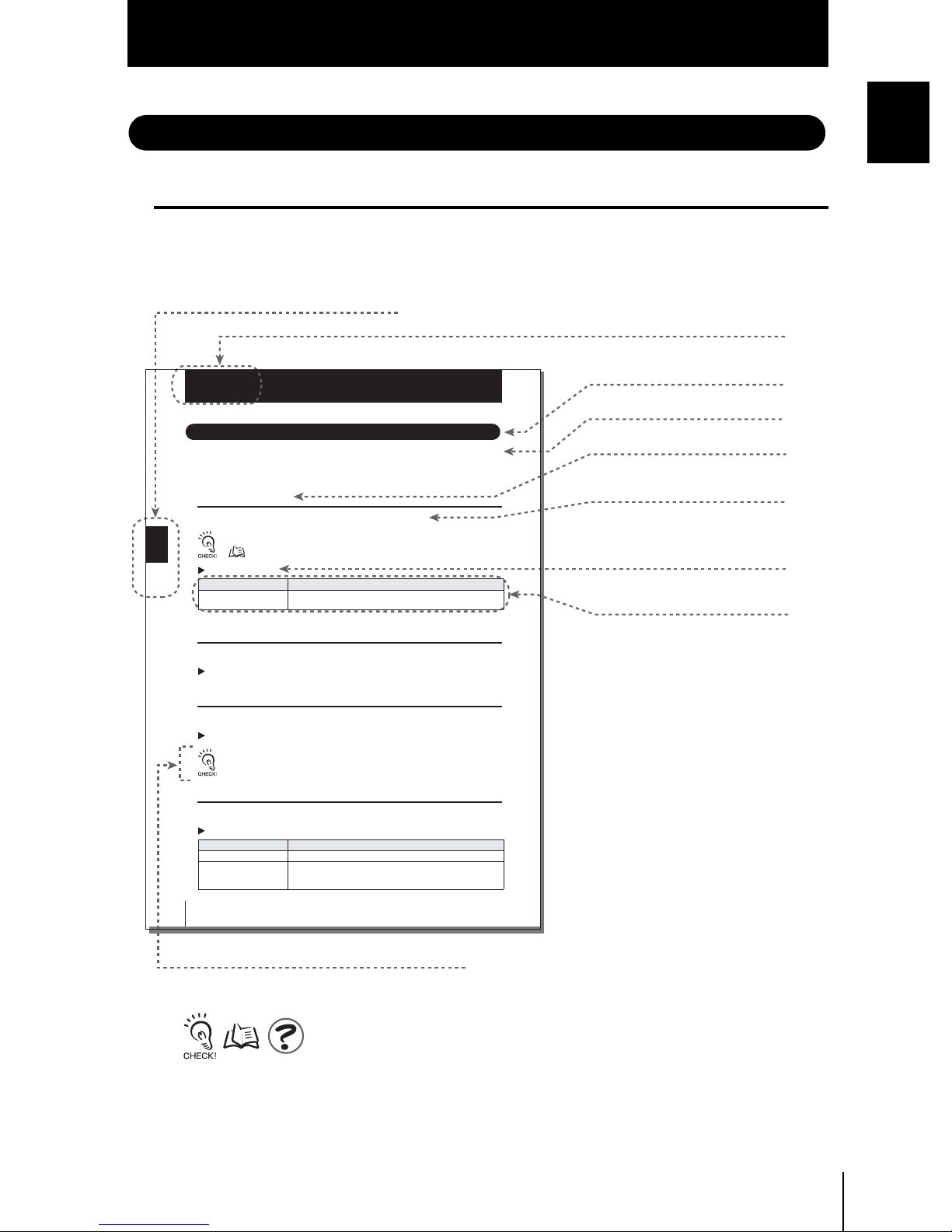

Editor's Note

Page Format

Index label

Indicates the section number and title.

Introduction

Precautions for Correct Use

Introduction

Title of each section

Section 3

Setting Banks

Setting Banks

The ZFV Series can hold up to eight sets of settings. These settings can be switched

externally when changing the device setup

A set of these settings is called a “bank.”

Switching banks

BANK 1 is selected as the default. BANK 2 and 8 are also available.

Section 3 SETUP

60

BANKs can also be switched from an external device.

Setting the bank switching method p.60

MENU mode-[BANK]

Setting Description

BANK 1~BANK 8

(default value: BANK 1)

Copying banks

Copy the settings of other bank numbers to an already selected bank number.

MENU Mode-[SYS1]-[BANKSET]-[COPY]

Clearing banks

“Clearing” deletes the settings of the currently selected bank number.

MENU Mode-[SYS1]-[BANKSET]-[CLEAR]

[SYS1], [SYS2] settings and RUN Mode display settings cannot be cleared.

Setting the bank switching method

Select how to switch banks.

MENU Mode-[SYS1]-[BANKSET]-[SWITCH]

Setting Description

KEY (default value) Banks are switched by the control keys on Amplifier Unit.

I/O Banks are switched by the control keys on Amplifier Unit and input lead sig-

ZFV

User’s Manual

Selects the target bank.

nals.

Switching by input lead signals is enabled only in the RUN mode.

Header

Overview

Cross-header

Overview of the

cross-header

Movement through

menus up to setting

items

Explanation of options

Supplementary Explanation

Helpful information regarding operation and reference

pages are introduced here using symbols.

ZFV

User’s Manual

7

Introduction

Introduction

Editor's Note

■ Meaning of Symbols

Menu items that are displayed on the Amplifier Unit’s LCD screen are indicated

enclosed by brackets [aa].

■ Visual Aids

Indicates points that are important to ensure full product performance, such as operational

precautions and application procedures.

Indicates pages where related information can be found.

Indicates information helpful in operation.

Indicates functions that can be set only when the setup menu has been switched

to EXP menu.

ZFV

8

User’s Manual

CONTENTS

Introduction

CONTENTS

Introduction

Precautions for Safe Use 4

Precautions for Correct Use 5

Editor's Note 7

Page Format 7

CONTENTS 9

SECTION 1 FEATURES 13

ZFV Smart sensor Features 14

Basic Configuration 16

Part Names and Functions 18

SECTION 2 INSTALLATION & CONNECTION 21

About Installation and Connection 22

Amplifier Unit 23

Attaching the ferrite core 23

Installing the Amplifier Unit 23

Section 1 Section 2 Section 3 Section 4

Gang mounting 27

About the I/O cable 31

Timing charts 34

Sensor Head 37

Attaching the ferrite core 37

Installing the mounting fixture 37

Installing the Sensor Head 38

Connecting the Sensor Head 40

ZFV

User’s Manual

9

Introduction

Introduction

CONTENTS

SECTION 3 SETUP 41

Setting Flow 42

About Setup 44

Basic Knowledge for Operation 44

List of Setting Items in MENU mode 46

Executing Teaching 48

Teaching Flow 48

Types of Teaching 51

Adjusting Threshold Values 55

Performing Measurement 59

Setting Banks 60

Switching banks 60

Copying banks 60

Clearing banks 60

Setting the bank switching method 60

Setting the System Environment 61

Adjusting the measurement speed 61

Selecting the measurement timing 61

Selecting the teaching mode from an external device 61

Setting/canceling the “Eco” mode 62

Initializing setup data 62

Initializing measurement data 62

Checking the version 63

Changing image capture timing on teaching screen 63

Setting communications environment 64

Changing the Input/output Conditions 65

Selecting the ON conditions 65

One-shot output 65

Setting the ON delay time 66

Setting the OFF delay time 67

I/O Monitor Function 68

Settings During Application Extended Connection 69

Specifying the Amplifier Unit to input the trigger 69

Setting the presence of Sensor Head 70

ZFV

10

User’s Manual

Introduction

CONTENTS

Setting output content 70

Customizing Measurement conditions 71

Introduction

Common items 71

PATTERN/SEARCH, MATCH 72

BRIGHT 73

AREA 74

WIDTH 75

POSITION 76

COUNT 77

CHARA/CHARA 1, CHARA 2 78

Saving the Set Measurement Conditions 82

SECTION 4 APPENDIX 83

Troubleshooting 84

Error Messages and Remedies 85

Q&A 86

Run Mode Display Item List 87

Section 1 Section 2 Section 3 Section 4

When Gang-mounting Amplifier Units 89

Gang-mounting example 89

Rules of gang-mounting 90

Data route 91

Teaching process when gang-mounting 92

Integrating judgment output 93

Restrictions when gang-mounting old and new amplifier units 94

Specifications and External Dimensions 95

Sensor Head 95

Amplifier Unit 97

Panel Mount Adapters 100

Control Link Unit 101

Extension Cord 102

Version Up Information 103

INDEX 105

Revision History 108

ZFV

User’s Manual

11

Introduction

Introduction

CONTENTS

MEMO

ZFV

12

User’s Manual

Section 1

FEATURES

ZFV Smart sensor Features 14

Basic Configuration 16

Part Names and Functions 18

Section 1 FEATURES

ZFV

User’s Manual

13

Section 1

ZFV Smart sensor Features

ZFV Smart sensor Features

Section 1 FEATURES

The ZFV sensor senses objects by its “surface.” How objects are being sensed can be

easily set while verifying on the LCD monitor.

The ZFV also incorporates a 250,000-pixel CCD equivalent to that of a Conventional

machine vision sensor. This allows presence detection and recognition of different objects,

which have up till now been performed visually, to be executed fast and accurately.

■ Recognition of top/rear side and orientation of electronic components

(1) Compact Sensor Head

The LED light emitting section and lens are built into the compact Sensor Head. The

Sensor Head takes up little installation space.

(2) Easy Installation and Adjustment

The range that can be sensed by Sensor Head can be confirmed by the guide light. So,

the Sensor Head can be installed by viewing the position of the guide light and its

focus.

ZFV

14

User’s Manual

Section 1

ZFV Smart sensor Features

(3) Business Card-size Amplifier Unit

• The Amplifier Unit is designed to be compact so that it can be installed at a wide

range of sites.

Specifications and External Dimensions p.95

• Outstanding operate ease has been achieved by a 1.8″color LCD motor, an industryfirst icon-based menu, and simple key layout.

Basic Knowledge for Operation p.44

• The ZFV incorporates an extensive range of measurement items which means that

numerous applications are supported.

Types of Teaching p.51

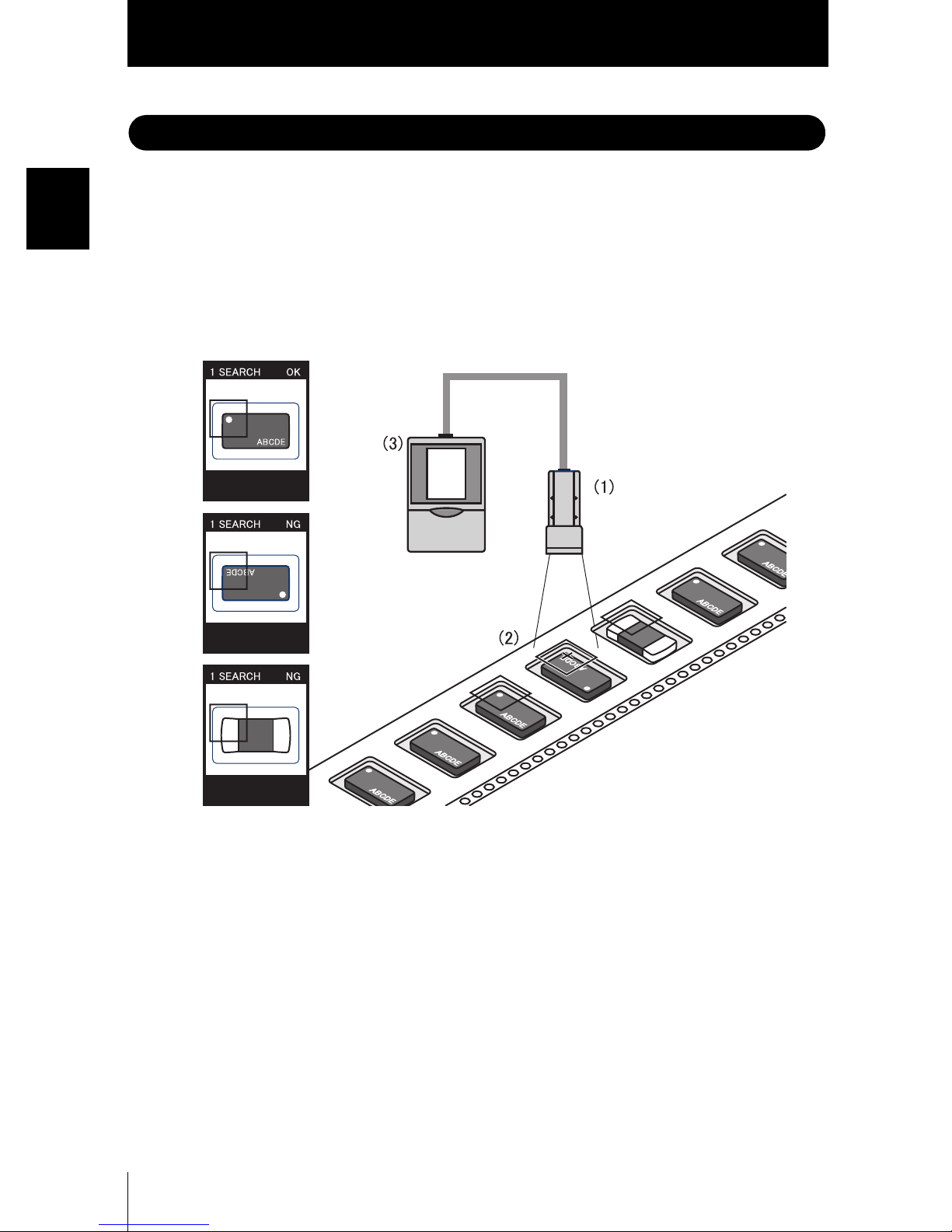

(4) Logging measured images (Ver. 2.0 and later)

Measurement images can be logged by connecting to data storage unit ZS-DSU. Set

NG occurrence as a trigger to log before/after images and measurement values. This is

useful for investigating the cause of defectives. Logged data is saved to the memory

card inserted into the data storage unit, and can be easily be loaded to a personal computer.

Section 1 FEATURES

Data Storage

Unit

OUTPUT

RUN

Personal Computer

Data storage unit ZS-DSU User's Manual

ZFV

(5) Enables bank extension (Ver. 2.0 and later)

A maximum 128 bank data items can be saved to the memory card mounted to the

data storage unit if connected to data storage unit ZS-DSU. Bank data can be transferred from the data storage unit to the ZFV as needed for the device setup.

Data storage unit ZS-DSU User's Manual

ZFV

User’s Manual

15

Section 1

Basic Configuration

Basic Configuration

Section 1 FEATURES

The figure below shows the Basic Configuration of the ZFV Series.

Sensor Head

Detects workpieces as images.

• Narrow view type ZFV-SR10

• Wide view type ZFV-SR50

Extension Cord

ZFV-XC3BV2(3m)/XC8BV2(8m)/XC3BRV2(3m)

Used between a Sensor Head and Amplifier Unit.

Two ZFV-XC B(R)V2 cords can be coupled together to

extend the cord length.

OUTPUT

RUN

Amplifier Unit

Used for confirming images and menus, performing measurement

processing, and outputting the result of processing.

• Single-function type ZFV-A10/-A15

• Standard type ZFV-A20/-A25

Power supply

DC24V (+10%, -15%)

Recommended OMRON power supply

(1) When 1 Amplifier Unit is connected

S82K-01524 (DC24V, 0.6A)

(2) When 2 or 3 Amplifier Units are connected

S82K-05024 (DC24V, 2.1A)

(3) When 4 or 5 Amplifier Units are connected

Prepare the required number of (1) and (2)

power supplies above.

■ Application Expanded Configuration

Up to five Amplifier Units can be gang-mounted.

When the Amplifier Unit is gang-mounted, a wider range of applications can be supported as simultaneous processing of multiple areas and measurement items can be

combined.

The image captured by the Sensor Head is transferred to the leftmost Amplifier Unit, so

connect to the rightmost Amplifier Unit.

Right

Wrong

• The maximum number of Amplifier Units that can be connected is five regardless of the number

of connected Sensor Heads.Six or more Amplifier Units cannot be connected.

• Provide power to all gang-mounted Amplifier Units.

Right

Wrong

ZFV

16

User’s Manual

Section 1

Basic Configuration

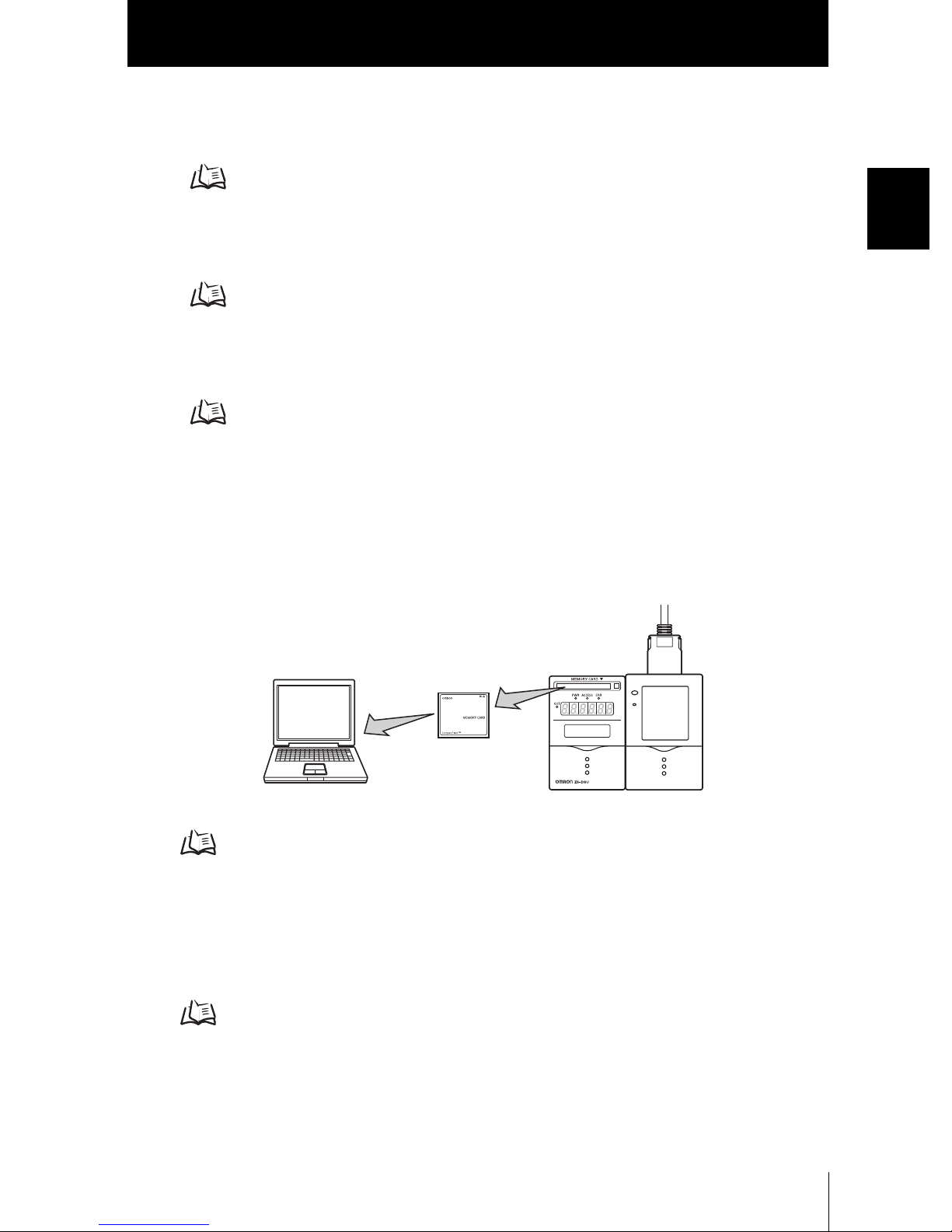

● Example 1

In this configuration, multiple parts of an image from a single Sensor Head are measured and multiple inspection item are performed.

Example) Inspection of the number of leads

Section 1 FEATURES

● Example 2

In this configuration, multiple Sensor heads are used to simultaneously inspect multiple

locations on a workpiece.

When the TRIG signal is input from a single specified Amplifier Unit, the connected

Amplifier Unit starts sensing immediately. The result of sensing is integrated on the

Amplifier Unit to which the TRIG signal was input, and is output as a total judgment

result.

Example) Alignment of products

AMP 1 AMP 2

NG1.SEARCH

NG1.SEARCH

OK1.SEARCH

AMP 3

NG1.SEARCH

OK1.SEARCH

OK1.SEARCH

NG1.SEARCH

AMP 1 AMP 2 AMP 3

NG1.SEARCH

OK1.SEARCH

Vitamin C

min C

ita

V

itamin C

V

ZFV

User’s Manual

17

Section 1

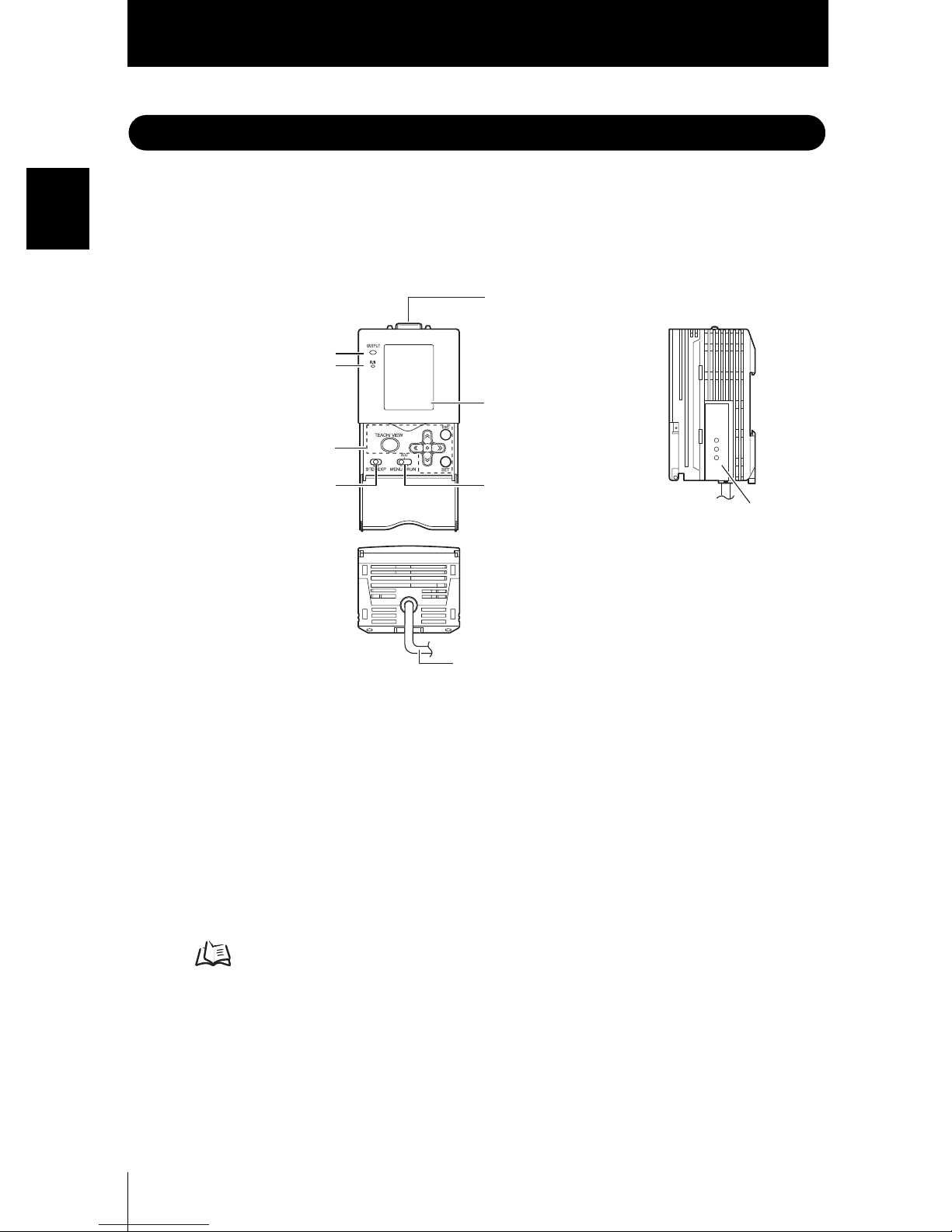

Part Names and Functions

Part Names and Functions

Section 1 FEATURES

The following describes the names and functions of parts on the Amplifier Unit and Sensor

Head.

■ Amplifier Unit

(7) Sensor Head connector

(1) OUTPUT indicator

(2) RUN indicator

(6) LCD monitor

(3) Control keys

(4) Menu selector switch

(5) Mode selector switch

(8) Coupler

(9) I/O cable

(1) OUTPUT indicator

The Output indicator lits when the OUTPUT signal turns ON.

(2) RUN indicator

The RUN indicator turns ON in the RUN mode.

(3) Control keys

The Control Keys are for setting measurement conditions and other information.

Displays and Key Operations p.45

(4) Menu selector switch

This switch selects the setup menu.

STD...Standard menu. Select this when setting the minimum required items for

measurement.

EXP...Expert menu. Select this item when making a more detailed setup.

ZFV

18

User’s Manual

Section 1

Part Names and Functions

(5) Mode selector switch

This switch selects the operating mode.

MENU...Select this mode when setting measurement conditions.

ADJ...Select this mode when adjusting the judgment threshold value.

RUN...Select this mode when performing measurement.

Output is performed only when the RUN mode is currently selected.

(6) LCD monitor

The LCD monitor displays setup menus and images captured from the Sensor Head.

(7) Sensor Head connector

This connector connects the Sensor Head.

(8) Coupler

This connector is used to connect two or more Amplifier Units. It is located on both

sides of the Amplifier Unit.

Section 1 FEATURES

(9) I/O Cable

The I/O cable connects the Amplifier Unit to the power supply and external devices,

such as timing sensors or programmable controllers.

ZFV

User’s Manual

19

Section 1 FEATURES

Section 1

Part Names and Functions

■ Sensor Head

(1) Lighting part

(2) Receiver part

(3) Connector

(5) Focus adjustment

control

(6) Ventilation film

(4) Sensor Head mounting fixture

(1) Lighting part

This section emits light.

(2) Receiver part

This section captures the image.

(3) Connector

This connector is connected to the Amplifier Unit.

(4) Sensor Head mounting fixture

This fixture is for mounting the Sensor Head.

This fixture can be mounted on all of the four mounting surfaces.

(5) Focus adjustment control

This control is used for adjusting the focus of the image.

(6) Ventilation film

This film prevents the front panel from condensation.

ZFV

20

User’s Manual

Section 2

INSTALLATION & CONNECTION

About Installation and Connection 22

Amplifier Unit 23

Attaching the ferrite core 23

Installing the Amplifier Unit 23

Gang mounting 27

About the I/O cable 31

Timing charts 34

Sensor Head 37

Attaching the ferrite core 37

Installing the mounting fixture 37

Installing the Sensor Head 38

Connecting the Sensor Head 40

Section 2 INSTALLATION & CONNECTION

ZFV

User’s Manual

21

Section 2

About Installation and Connection

About Installation and Connection

■ Checking the installation environment

Read “Precautions for Safe Use” at the beginning of this manual, and check the installation environment.

Section 2 INSTALLATION & CONNECTION

■ Checking the installation site

Read “Precautions for Correct Use” at the beginning of this manual, and check the

installation site.

■ About the power supply

Before installing and connecting the Smart Sensor, be sure to turn it OFF.

Also read “Precautions for Safe Use” and “Precautions for Correct Use” at the beginning of this manual, and check the power supply and wiring.

ZFV

22

User’s Manual

Section 2

Amplifier Unit

Amplifier Unit

This section describes installation of the Amplifier Unit, and connection of the I/O cable.

Before connecting/disconnecting peripheral devices, make sure that the Smart Sensor is turned OFF.

The Smart Sensor may break down if the Smart Sensor is connected or disconnected while the power

is ON.

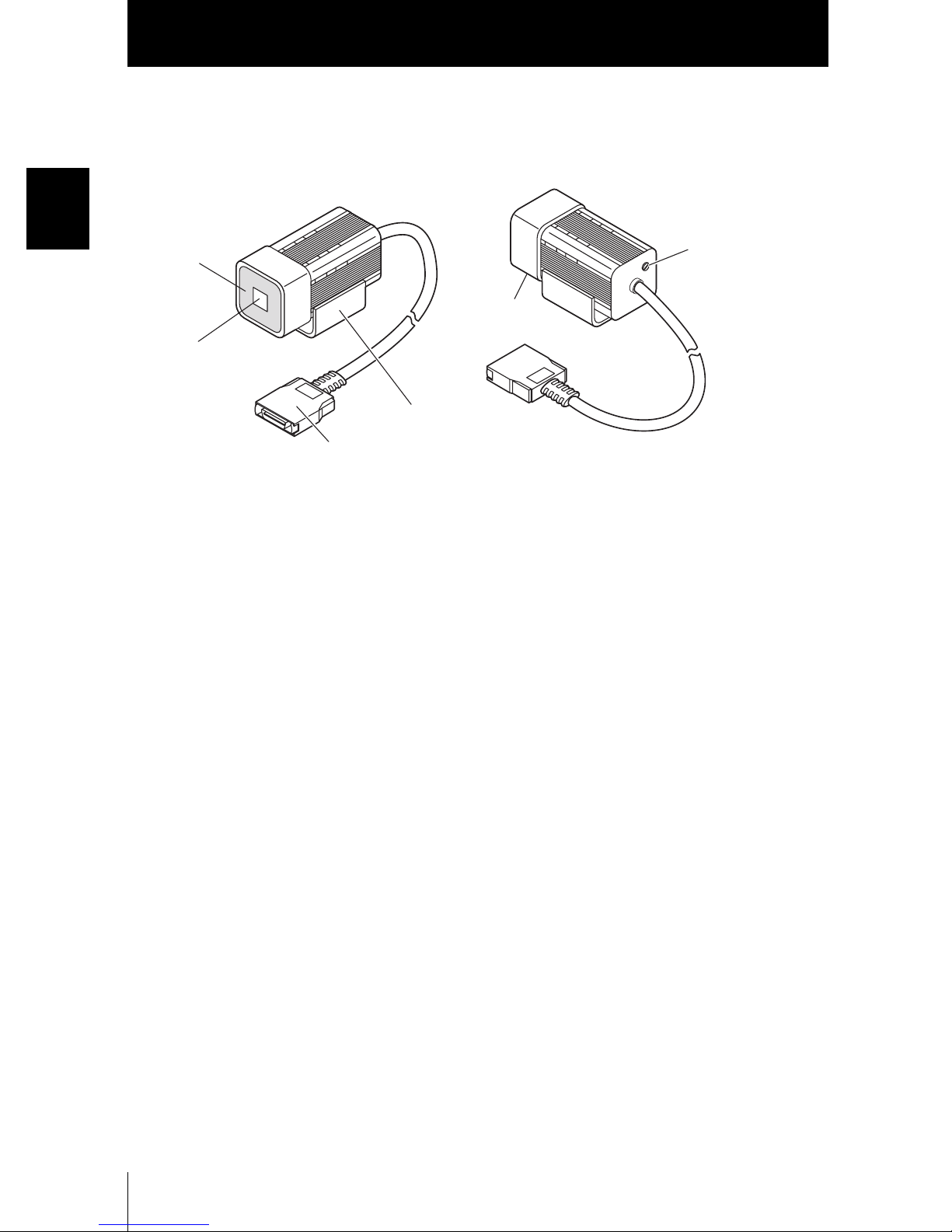

Attaching the ferrite core

Attach the ferrite core (provided with the Smart Sensor) to the I/O cable of the Amplifier

Unit.

Section 2 INSTALLATION & CONNECTION

Ferrite core

Installing the Amplifier Unit

■ Installing on the DIN track

Amplifier Units can be easily mounted on the 35-mm DIN track.

DIN track (sold separately)

PFP-100N (1 m)

PFP-50N (0.5 m)

PFP-100N2 (1 m)

ZFV

User’s Manual

End plate (sold separately)

PFP-M

23

Section 2

Amplifier Unit

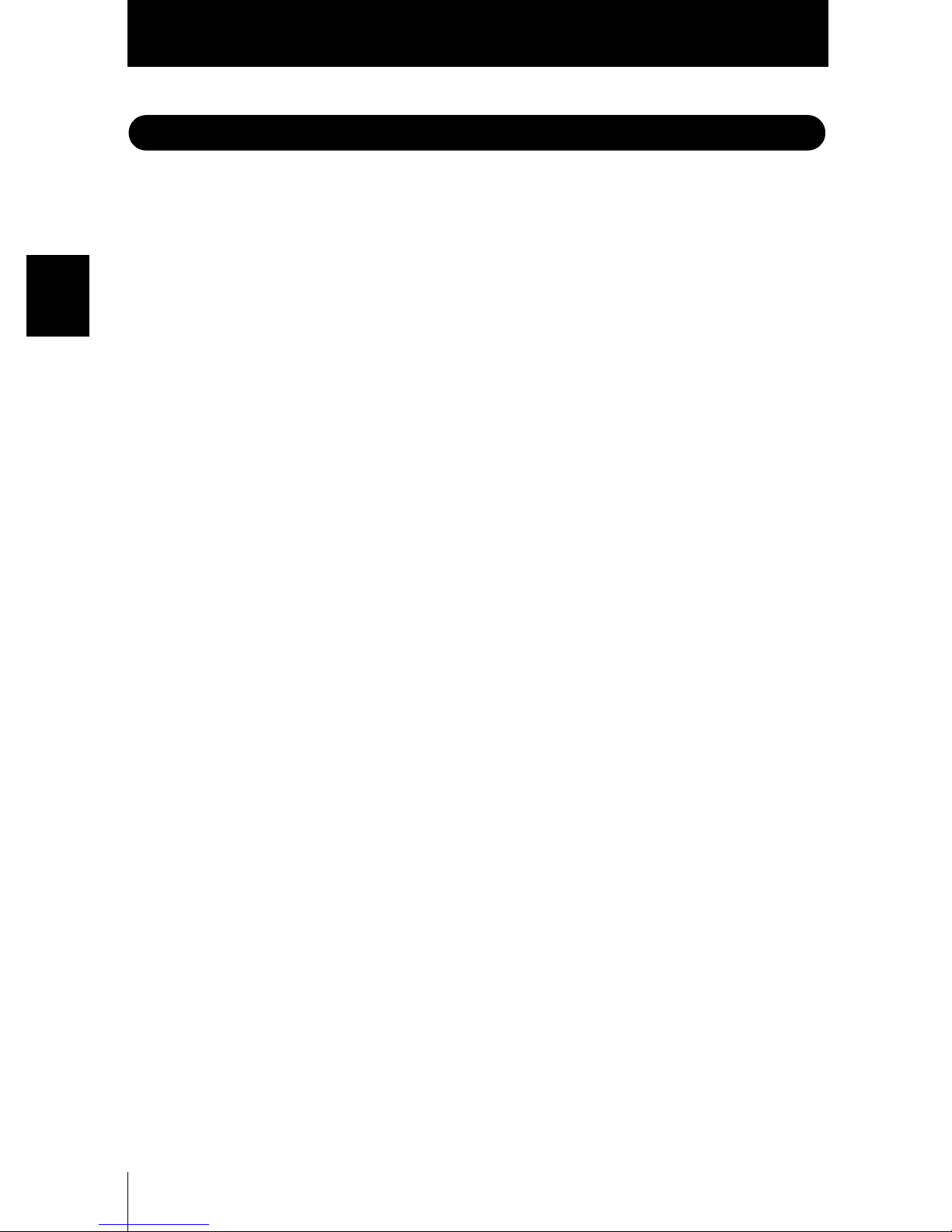

● Installation procedure

1. Hook the connector end of the Amplifier Unit

onto the DIN track.

Hook on connector

end

Section 2 INSTALLATION & CONNECTION

2. Push the Amplifier Unit down onto the DIN

track until the hook on the I/O cable side is

locked.

Push down until you hear it snap into place.

Always hook the connector end of the Amplifier Unit on the DIN track first. Hooking the I/O cable

end on the DIN track first may impair the mounting strength of the DIN track attachment.

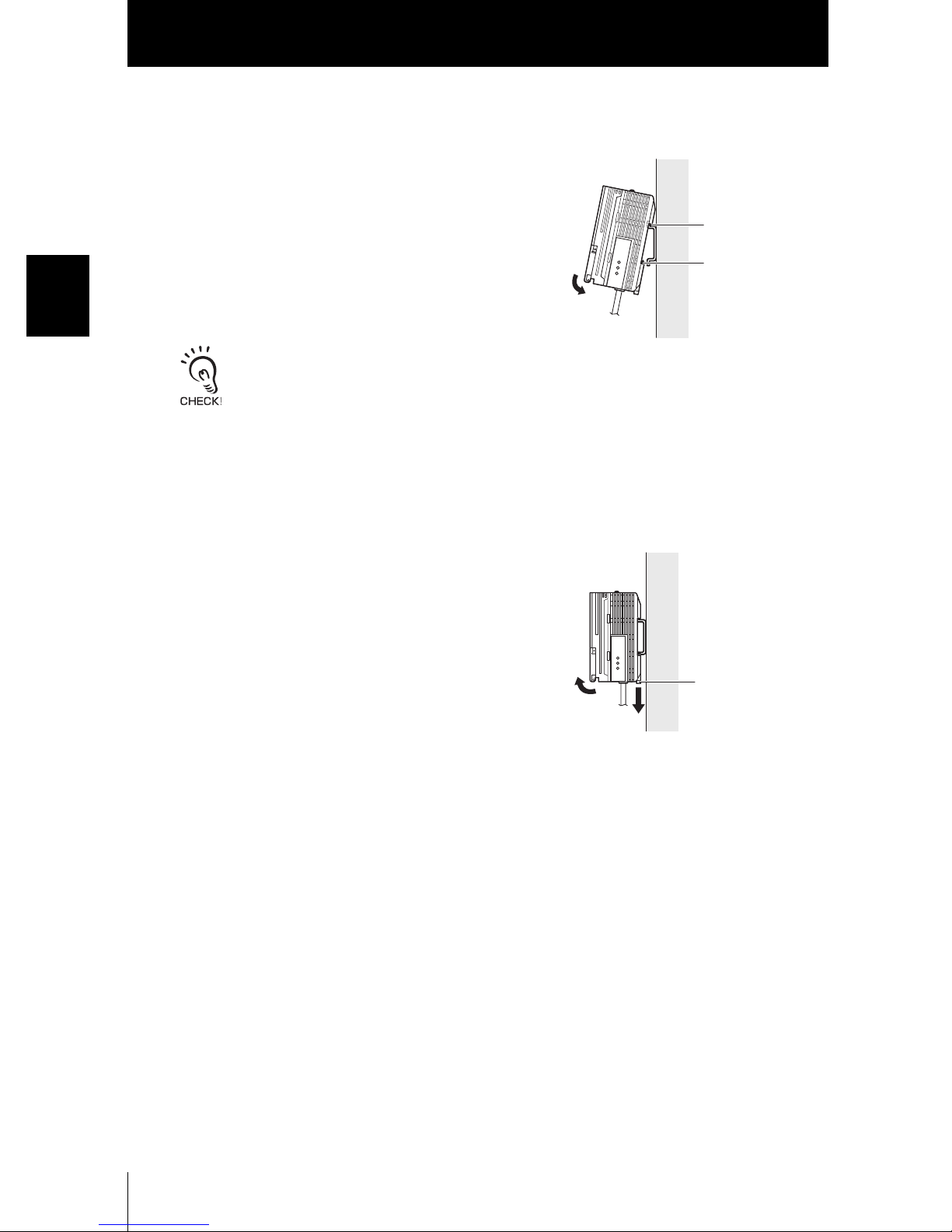

● Removal procedure

The following describes how to remove the Amplifier Unit from the DIN track.

Hook on I/O cable

1. Pull the hook on the I/O cable end of the

Amplifier Unit downwards.

2. Lift up the Amplifier Unit from the I/O cable

end, and remove it from the DIN track.

Hook on I/O cable

ZFV

24

User’s Manual

Section 2

Amplifier Unit

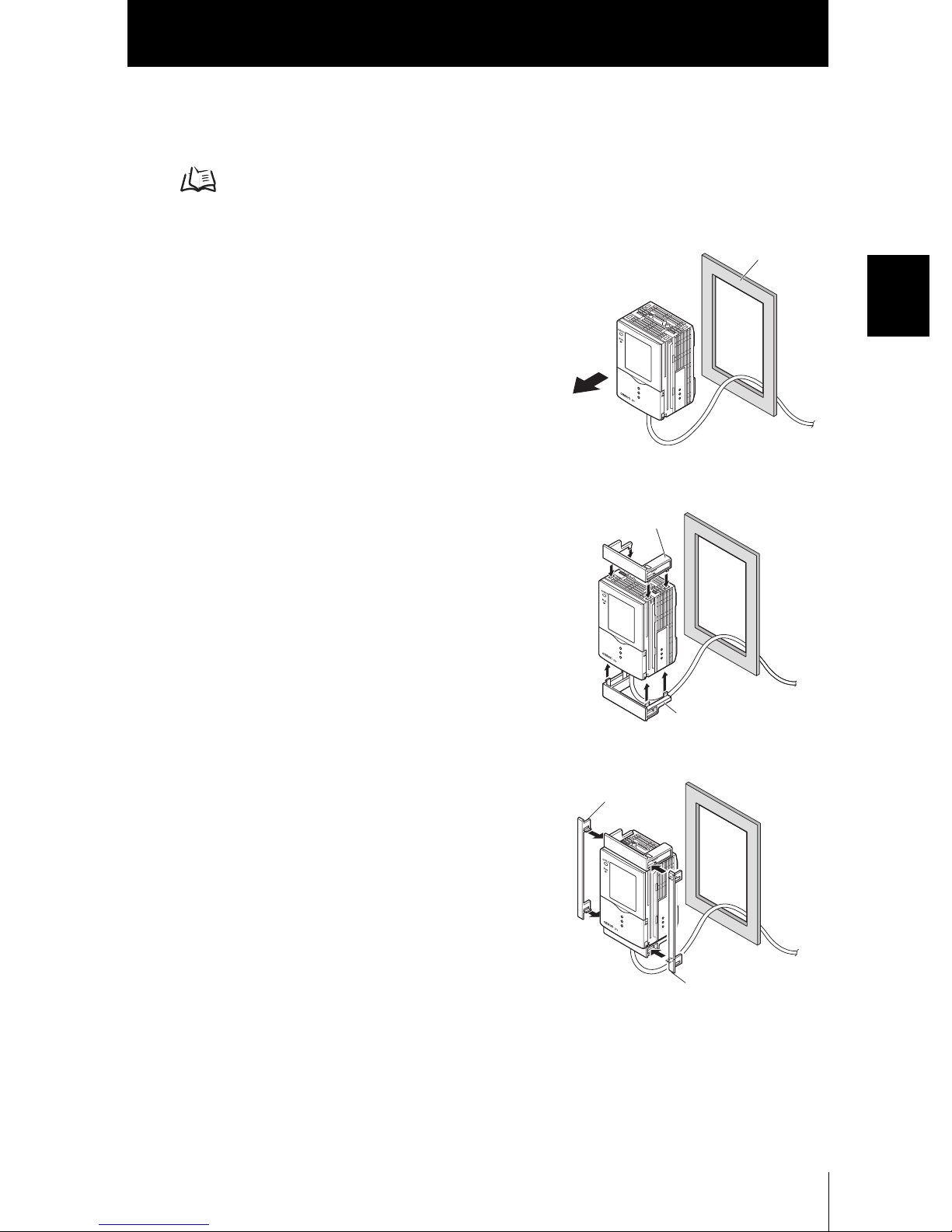

■ Mounting on a panel

The Panel Mount Adapters (sold separately ZS-XPM1) can be used to mount the

Amplifier Unit on a panel.

Panel Mount Adapters p.100

1. Push out the Amplifier Unit from the rear of

the panel towards the front.

2. Install the small Mount Adapters on the four

holes on the Amplifier Unit.

Panel Mount

Adapter

Panel

Section 2 INSTALLATION & CONNECTION

3. Install the long Mount Adapters on the two

holes on the small Mount Adapter.

Panel Mount

Adapter

Panel Mount

Adapter

Panel Mount

Adapter

ZFV

User’s Manual

25

Section 2

Amplifier Unit

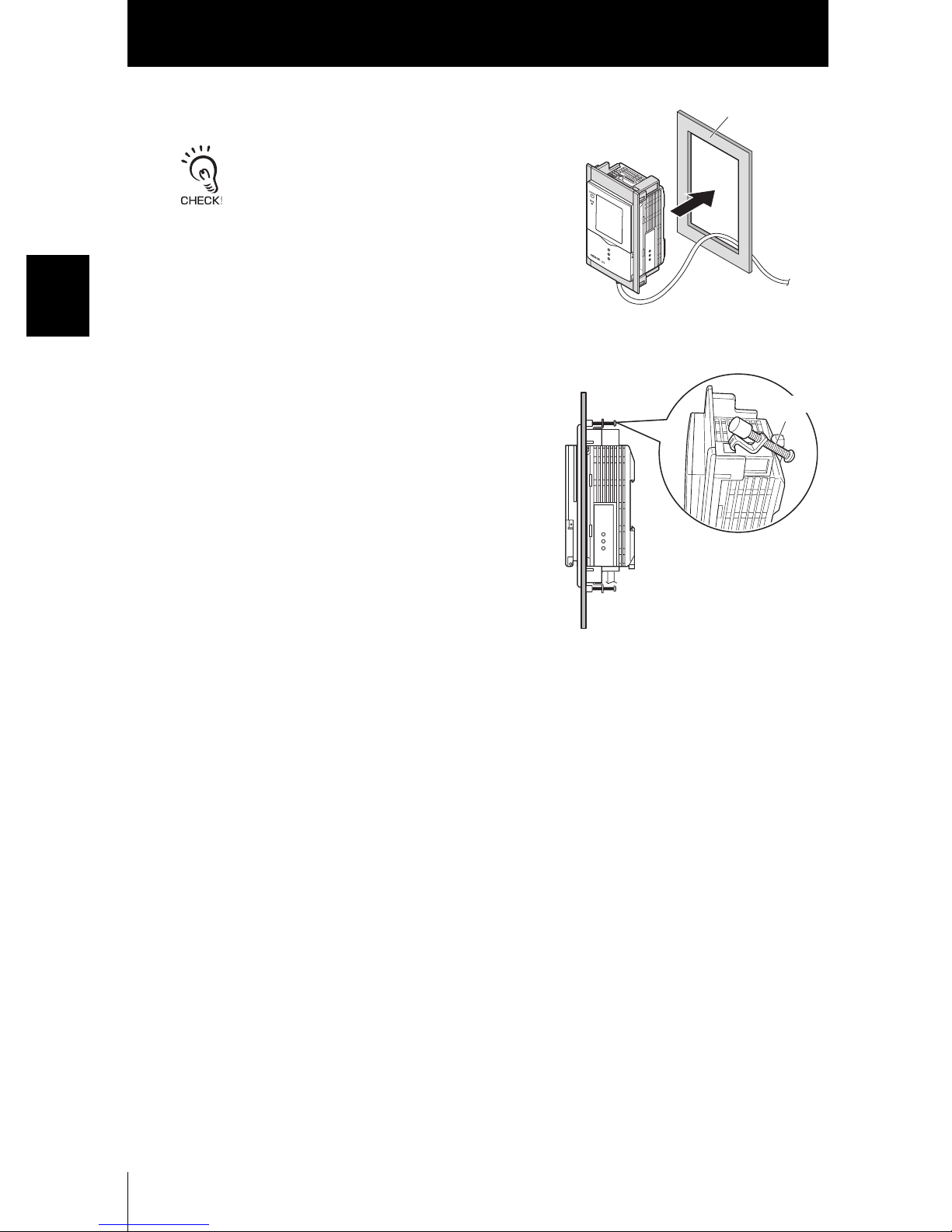

4. Install the Amplifier Unit with Mount Adapters

attached onto the panel from the front.

Take care not to pinch the I/O cable.

Section 2 INSTALLATION & CONNECTION

Panel

5. Hook the hooks of the mounting fixture onto

the two holes of the smaller Mount Adapters

and tighten the screws.

Mounting

fixture

6. Make sure that the Amplifier Unit is firmly

fixed on the panel.

ZFV

26

User’s Manual

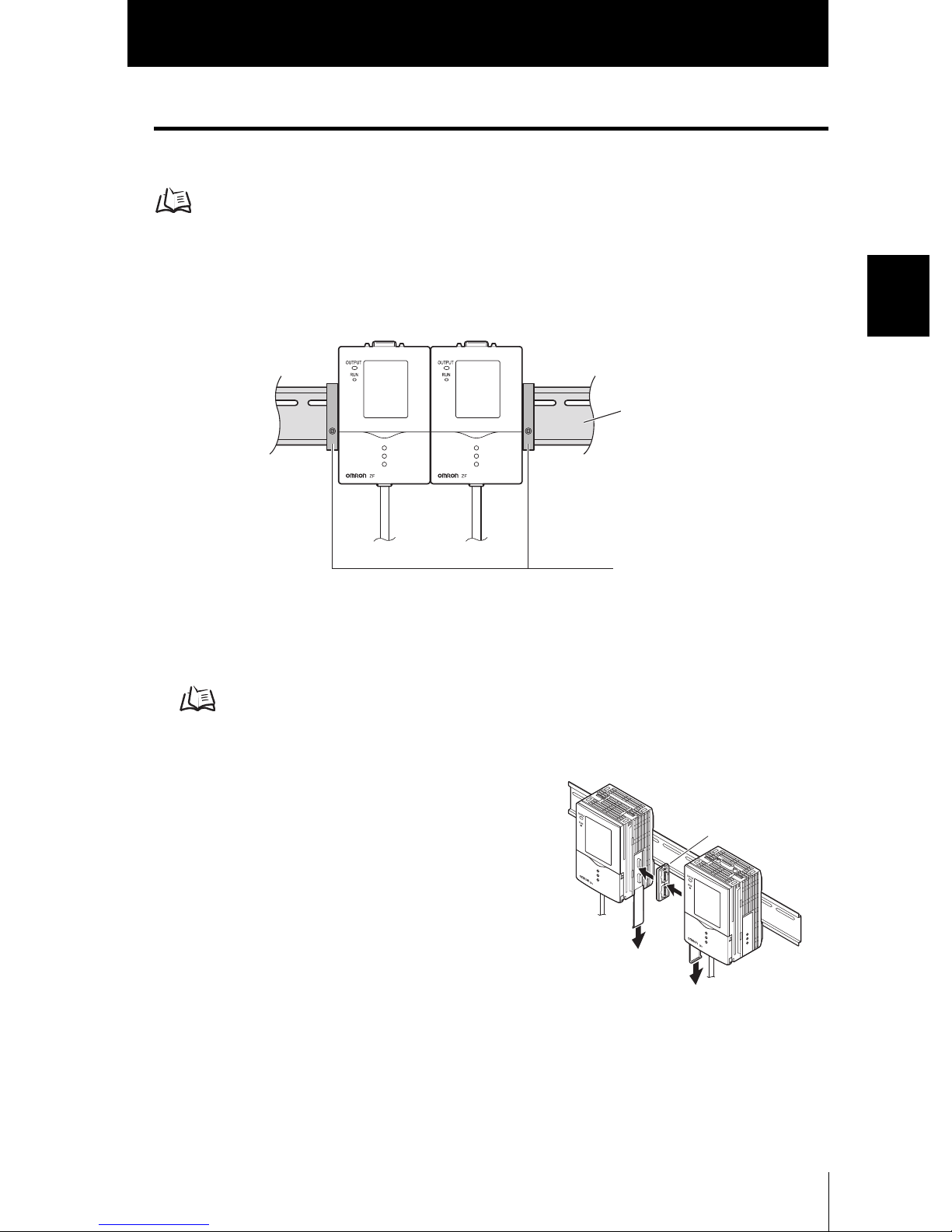

Gang mounting

Up to five Amplifier Units can be gang-mounted.

Application Expanded Configuration p.16

Section 2

Amplifier Unit

■ Installing on the DIN track

Amplifier Units can be easily mounted on the 35-mm DIN track.

● Installation procedure

1. Install Amplifier Unit on the DIN track.

p.24

Section 2 INSTALLATION & CONNECTION

DIN track (sold separately)

PFP-100N (1 m)

PFP-50N (0.5 m)

PFP-100N2 (1 m)

End plate (sold separately)

PFP-M

2. Open the connector cover on the Amplifier

Unit.

Slide the cover to remove.

3. Insert the Controller Link Unit into the

connector on the Amplifier Unit.

4. Slide the Amplifier Unit, and insert into the connector on the Controller Link Unit.

ZFV

User’s Manual

Controller

Link Unit

27

Section 2

Amplifier Unit

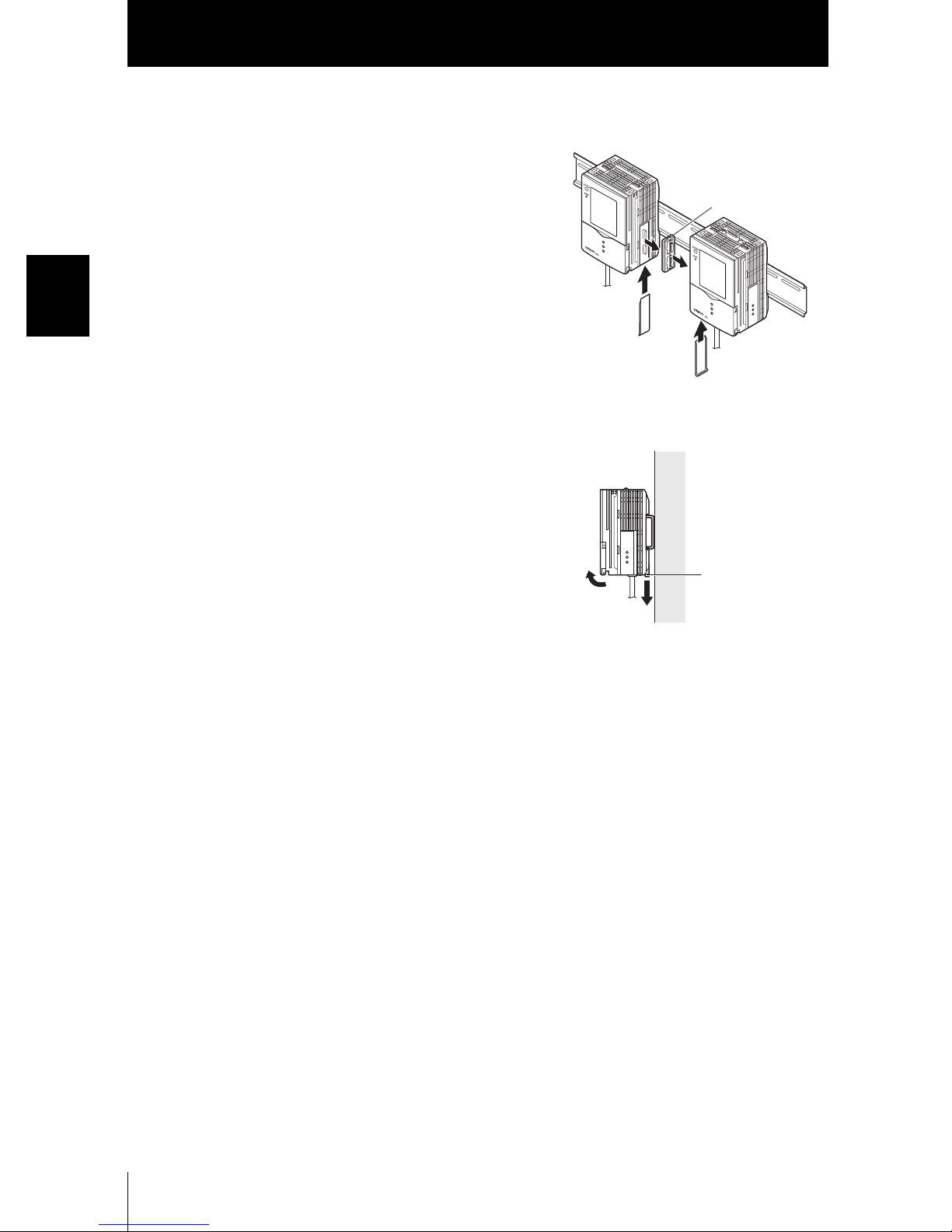

● Removal procedure

1. Slide the Amplifier Unit, and remove from the

connector on the Controller Link Unit.

Controller

Link Unit

Section 2 INSTALLATION & CONNECTION

2. Slide the Controller Link Unit and remove from

the connector on the Amplifier Unit.

3. Install the cover on the coupler of the Amplifier

Unit.

4. Pull the hook on the I/O cable end downwards.

5. Lift up the Amplifier Unit from the I/O cable

end, and remove it from the DIN track.

Hook on I/O cable

end

ZFV

28

User’s Manual

Section 2

Amplifier Unit

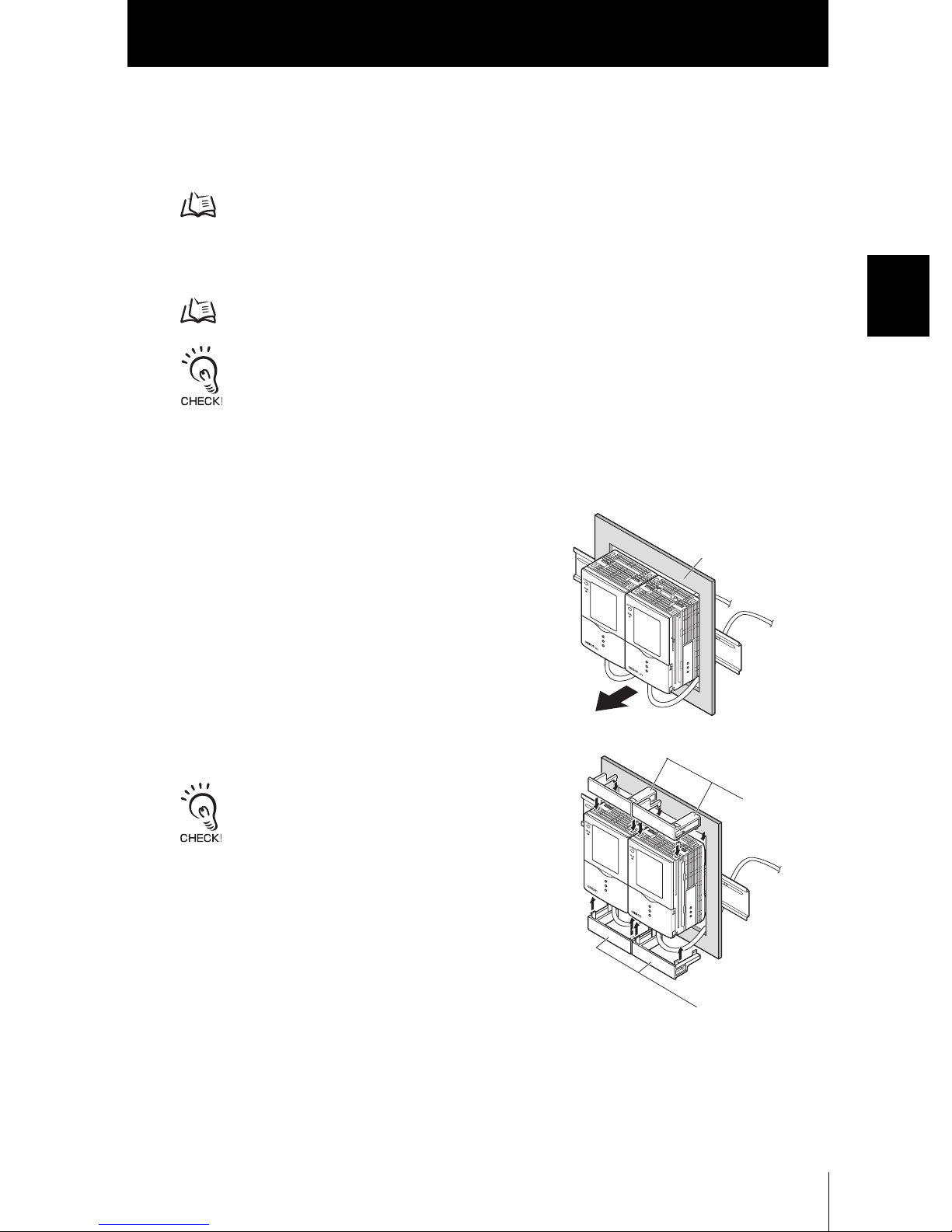

■ Mounting on a panel

The Panel Mount Adapters (sold separately ZS-XPM1/XPM2) can be used to mount

the Amplifier Unit on a panel.

Panel Mount Adapters p.100

1. Install the Amplifier Unit on the DIN track.

p.27

When mounting on a panel, be sure to install the DIN track on the rear side of the Amplifier Unit for

support.

2. Push out the Amplifier Unit from the rear of

the panel towards the front.

Section 2 INSTALLATION & CONNECTION

Panel

3. Install the small Mount Adapters on the four

holes on the Amplifier Unit.

Install the small Mount Adapters on all gang-mounted

Amplifier Units.

ZFV

User’s Manual

Panel

Mount

Adapter

Panel Mount Adapter

29

Loading...

Loading...