Cat.No.Z178-E1-01A Multi-Dimensional Sensor Setup Manual

OMRON Corporation

Industrial Automation Company

Application Sensors Division

Sensing Devices and Components Division H.Q.

Shiokoji Horikawa, Shimogyo-ku,

Kyoto, 600-8530 Japan

Tel: (81)75-344-7068/Fax: (81)75-344-7107

Regional Headquarters

OMRON EUROPE B.V.

Sensor Business Unit,

Carl-Benz-Str. 4, D-71154 Nufringen,

Germany

Tel: (49)7032-811-0/Fax: (49)7032-811-199

OMRON ELECTRONICS LLC

1 East Commerce Drive, Schaumburg, IL 60173

U.S.A.

Tel: (1)847-843-7900/Fax: (1)847-843-8568

OMRON ASIA PACIFIC PTE. LTD.

83 Clemenceau Avenue,

#11-01, UE Square,

239920 Singapore

Tel: (65)6835-3011/Fax: (65)6835-2711

Multi-Dimensional Sensor

Setup Manual

OMRON CHINA CO., LTD. BEIJING OFFICE

Room 1028, Office Building,

Beijing Capital Times Square,

No. 88 West Chang’an Road,

Beijing, 100031 China

Tel: (86)10-8391-3005/Fax: (86)10-8391-3688

Authorized Distributor:

Cat. No. Z178-E1-01A

©OMRON Corporation 2003 All Rights Reserved.

Note: Specifications subject to change without notice.

Printed in Japan.

0104-0.5C (0303) (M)

POWER

This manual provides information on

system hardware. Be sure to read this

manual first.

Cat.No. Z178-E1-01A

INTRODUCTION

Thank you for your purchase of Z5FP-MC10 (hereinafter referred to as the Controller). This manual explains

how to use the Controller. Please observe the following points when using the Controller.

•

Please read and understand this manual thoroughly before using the Controller so that it is not used incorrectly.

• Please keep this manual at hand so that you can refer to it at any time.

Operation Procedure and Reference Manual

The following shows main contents of operation steps and manuals. Select the manual suitable for your

purpose and read it before starting operation

Installation

Multi-Dimensional Sensor

Setup Manual

Wiring

POWER

This manual provides information on

system hardware. Be sure to read this

manual first.

Starting the Controller and Setting Workpieces in Place

Setup Manual

Contains information on safe use of the unit, series of procedures starting from

package content check, installation to cable connection, together with functions

and specifications of the unit and its peripheral devices.

Adjusting Images

Operation Manual

Setting Measurement Conditions and Starting Measurement

Outputting Data to External Device

Multi-Dimensional Sensor

Operation Manual

POWER

This manual explains menu operation method

and communication method with external

devices.

Explains menu operation method and communication method with external

devices.

INTRODUCTION

INTRODUCT

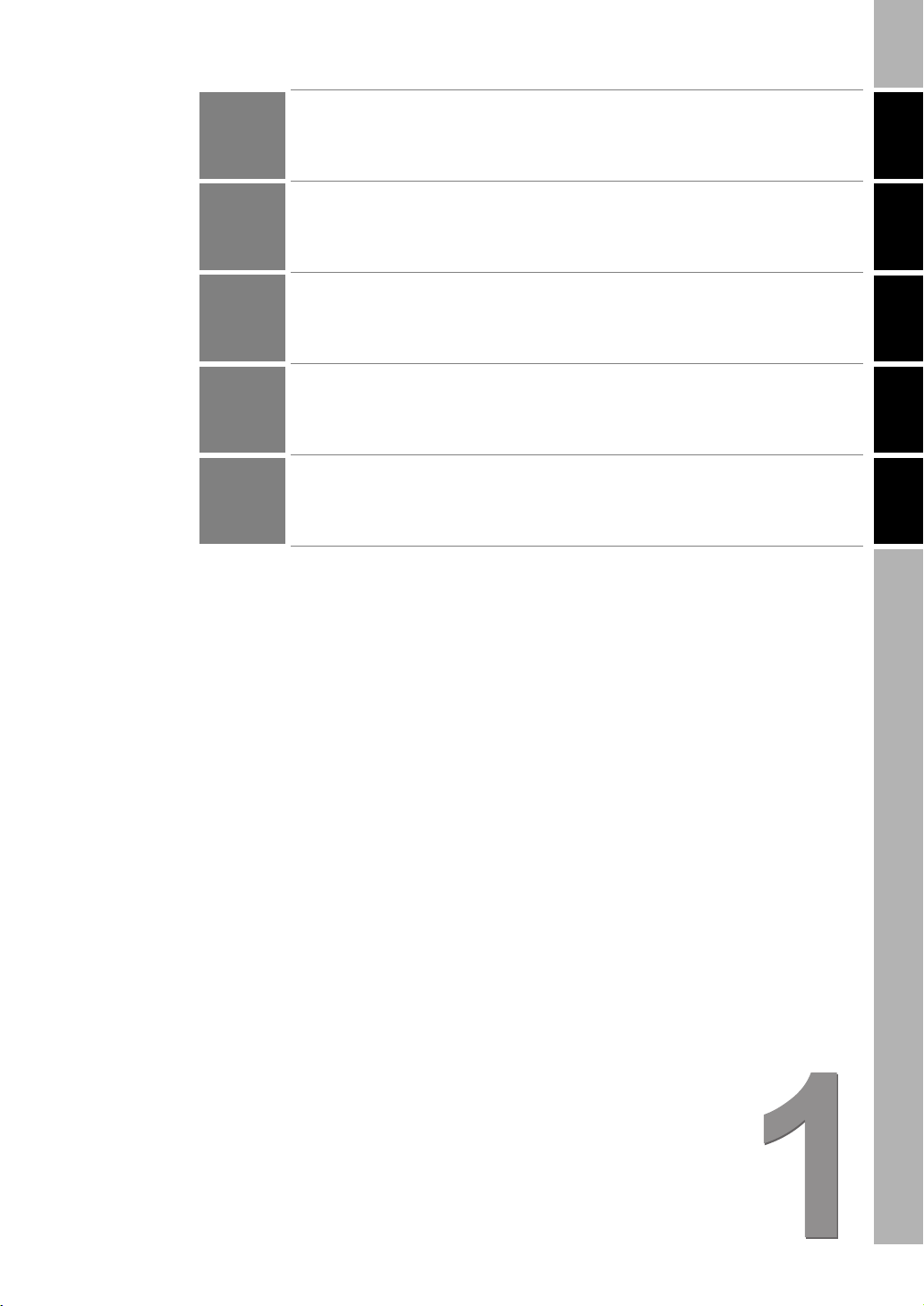

SECTION 1

SECTION 2

SECTION 3

SECTION 4

Precautions in using the Product(Be sure to read it.)

ION

Wiring and Connection

Installation

Connecting External Devices

Appendix

SECTION 1 SECTION 2 SECTION 3 SECTION 4

Setup Manual

Multi-Dimensional Sensor

INTRODUCTION

INTRODUCTION

Precautions in using the Product

Read and Understand this Manual

Precautions in using the Product

Please read and understand this manual before storing, installing, programming, operating, maintaining,

or disposing of the products. Please consult your OMRON representative if you have any questions or

comments.

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for

a period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL

DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR

STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on

which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Setup Manual

2

INTRODUCTION

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to

the combination of the product in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the

uses listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

INTRODUCTION

Precautions in using the Product

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

Setup Manual

3

INTRODUCTION

Precautions in using the Product

INTRODUCTION

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be

changed without any notice. When in doubt, special model numbers may be assigned to fix or establish

key specifications for your application on your request. Please consult with your OMRON representative

at any time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

Meanings of Signal Words

The following signal words are used in this manual.

WARNING

Indicates a potentially hazardous situation which, if not avoided, will result in minor or

moderate injury, or may result in serious injury or death. Additionally there may be

significant property damage.

Meanings of Alert Symbols

The following alert symbols are used in this document.

4

Cautions to indicate potential laser beam hazard

Setup Manual

INTRODUCTION

Laser Safety

WARNING

Do not expose your eyes to the laser radiation either directly or indirectly (i.e., after

reflection from a mirror or shiny surface).

The laser radiation has a high power density and exposure may result in loss of sight.

Sensor Head is a Class 3B Laser Product according to EN60825-1 (IEC60825-1) and Class IIIB Laser

Product according to FDA (21 CFR1040.10) (see note). This product is meant to be built into final

system equipment. Pay special attention to the following precautions for the safe use of the product:

Note:Europe: Class 3B of EN60825-1: 1994 = IEC60825-1: 1993

U.S.A.: Class IIIB of FDA (21 CFR1040.10)

Z550-SW70

Wavelength 658 nm

Maximum pulse duration 17.5 ms

Cycle 0.5 to 25 ms

Peak power 15 mW max.

Classification 3B

INTRODUCTION

Precautions in using the Product

(1)Use this product as specified in this manual. Otherwise, you may be exposed to hazardous laser

radiation.

(2)This product radiates laser beams in the visible light range. Do not expose your eyes directly to the

laser radiation. Ensure that the laser beam path is terminated during use. If a mirror or shiny surface

is positioned in the laser beam path, ensure that the reflected beam path is also terminated. If the Unit

must be used without terminating the laser beam path, position the laser beam path so that it is not at

eye level.

(3)To avoid exposure to hazardous laser radiation, do not displace nor remove the protective housing

during operation, maintenance, and any other servicing.

(4)The user should return the product to OMRON for all repair and servicing.

(5)As for countries other than those of Europe and the U.S.A., observe the regulations and standards

specified by each country.

As for the Laser Product Classifications, refer to the Appendix.

p.55

Setup Manual

5

INTRODUCTION

DANGER

INTRODUCTION

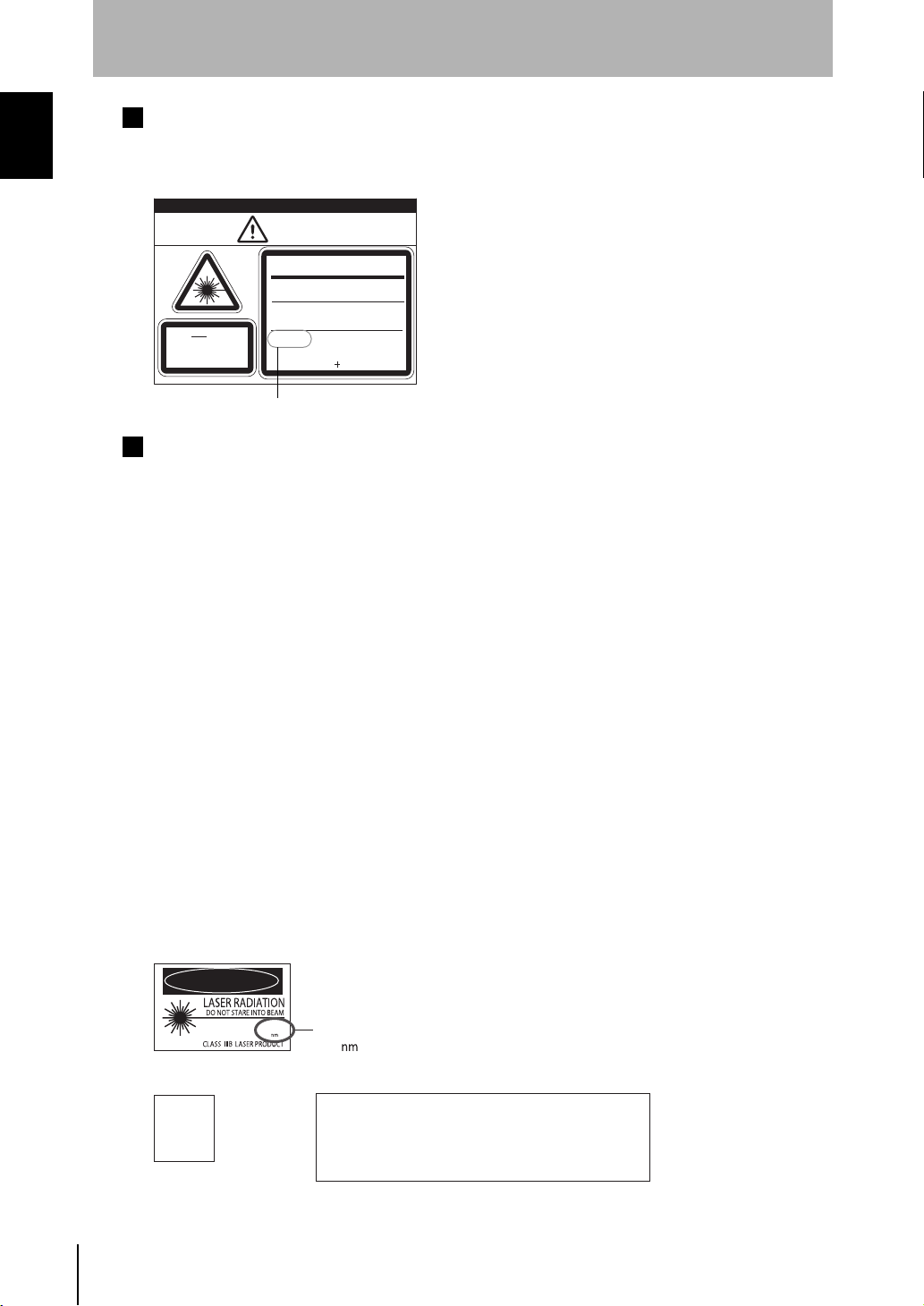

Labeling on Laser Use

The following warning label is attached to the side of the sensor.

Precautions in using the Product

Z550-SW70

⼊๔

䊧䊷䉱శ

䊎䊷䊛䉕⋥ធ䈢䉍

䇭䇭䇭䇭䇭䇭䇭䇭⸅䉏䈢䉍䈚䈭䈇䈖䈫

㪤㪸㫏㪅㩷㩷㪈㪌㫄㪮䇭㪉㪌㫄㫊㪼㪺

ᵈᗧ

㩷䈖䈖䉕㐿䈒䈫

䊧䊷䉱

శ䈏䈪䉁䈜

㩷

Re-labeling

The following labels are provided, to be used selectively according to countries.

for use in the U.S.: FDA label (Aperture label, Caution logo label, Certification and Identification

label)

for use in countries other than the U.S.: Warning label according to EN/IEC standards.

Be sure to turn off the sensor before replacing the label, or your hand or other body parts may be

exposed to the hazardous laser beam radiating from the sensor.

§ Use in the U.S.

When a laser product mounted on a certain device is to be used in the U.S., it has to meet the

requirements set forth by the FDA (regulations for laser products set forth by the Food and Drug

Administration).

Applications have been approved by CDRH (Center for Devices and Radiological Health) for

Z550-SW70. Three different FDA labels are enclosed in the sensor package. Attach them to the

sensor body.

ඨዉ䊧䊷䉱䇭㪍㪌㪏㫅㫄

䉪䊤䉴㪊㪙䊧䊷䉱ຠ

䇭㩷㩷㪡㪠㪪䇭㪚䇭㩷㩷㩷㩷㩷㩷㪍㪏㪇㪉䇭㪈㪐㪐㪎

䇭䇭䇭䇭䇭䇭㩷㩷㩷㩷㩷㩷㩷㩷

ㅊ

CLASS 3B

㪈㩷㩷㪈㪐㪐㪏

Setup Manual

6

This product is designed to be built into the finished system unit. Refer to the following technical

standard for installation.

21CFR1040.10 and 1040.11

FDA Labels for Laser Products

Class III B DANGER logo type

DANGER

µw

15000

15000

25000

658

µw

µs

25000

658

µs

This laser product complies with

21 CFR 1040.10 and 1040.11.

OMRON Corporation

Shiokoji Horikawa, Shimogyo-ku,

Kyoto 600-8530 JAPAN

Place of manufacture:

AYABE Factory, OMRON Corp.

Manufactured in

PEAK POWER

PULSE DURATION

WAVE LENGTH

Aperture Label Certification and Identification Label

AVOID

EXPOSURE

Laser radiation

is emitted from

this aperture

Be sure to attach FDA labels; do not attach EN/IEC WARNING label by mistake.

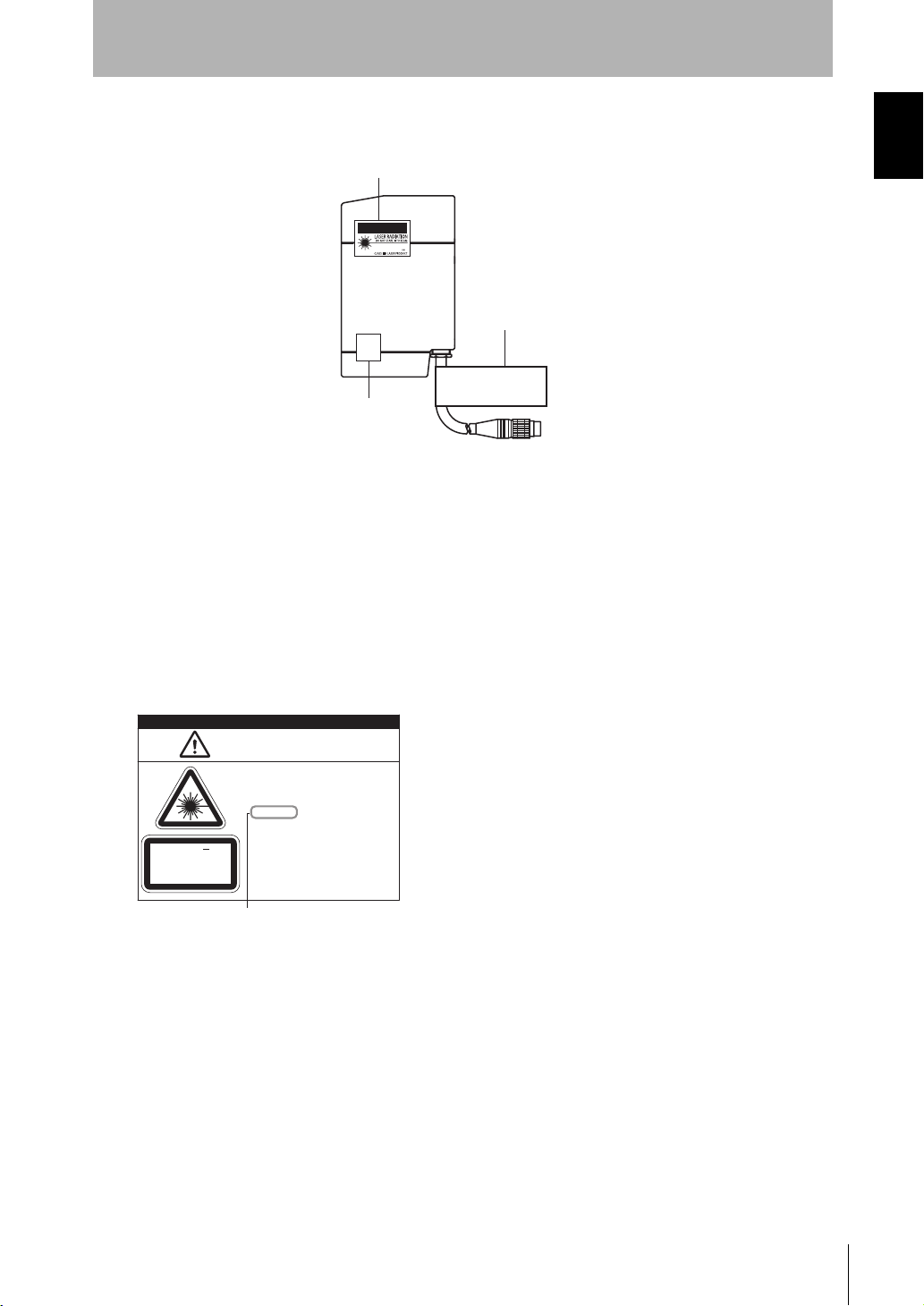

INTRODUCTION

DANGER

A

Areas to Attach Labels

Class III B

DANGER logo type

DANGER

µw

PEAK POWER

15000

µs

PULSE DURATION

25000

WAVE LENGTH

658

Certification and

AVOID

EXPOSURE

Laser radiation

is emitted from

this aperture

perture Label

Identification Label

This laser product complies with

21 CFR 1040.10 and 1040.11.

OMRON Corporation

Shiokoji Horikawa, Shimogyo-ku,

Kyoto 600-8530 JAPAN

AYABE Factory, OMRON Corp.

Manufactured in

§ Use in Countries Other than the U.S.

Replace the warning label in Japanese on the sensor main body with the attached EN/IEC

warning label upon use in countries other than the U.S. Attach the label in the area where the

original Japanese warning label was provided.

EN60825-1(IEC60825-1) standard is applied to products exported to European countries. This

product conforms to the standard.

INTRODUCTION

Precautions in using the Product

EN/IEC Warning Labels

Z550-SW70

㪮㪘㪩㪥㪠㪥㪞

㪣㪘㪪㪜㪩㩷㪩㪘㪛㪠㪘㪫㪠㪦㪥

㪘㪭㪦㪠㪛㩷㪜㪯㪧㪦㪪㪬㪩㪜㩷㪫㪦㩷㪙㪜㪘㪤

㩷㪚㪣㪘㪪㪪㩷㪊㪙㩷㪣㪘㪪㪜㪩㩷㪧㪩㪦㪛㪬㪚㪫

㪤㪘㪯㪠㪤㪬㪤㩷㪦㪬㪫㪧㪬㪫䋺㪈㪌㫄㪮

㪧㪬㪣㪪㪜㩷㪛㪬㪩㪘㪫㪠㪦㪥䇭䋺㪉㪌㫄㫊㪼㪺

㪚㪘㪬㪫㪠㪦㪥

㪣㪘㪪㪜㪩

㪩㪘㪛㪠㪘㪫㪠㪦㪥

㪮㪟㪜㪥㩷㩷㪦㪧㪜㪥

㪮㪘㪭㪜㩷㪣㪜㪥㪞㪫㪟䇭䇭 䋺㪍㪌㪏㫅㫄

㪤㪜㪛㪠㪬㪤䋺㪪㪜㪤㪠㪚㪦㪥㪛㪬㪚㪫㪦㪩㩷㪣㪘㪪㪜㪩

㪠㪜㪚㩷㪍㪇㪏㪉㪌㪄㪈䋺㪈㪐㪐㪊

㪂㪘㪈䋺㪈㪐㪐㪎

CLASS 3B

Setup Manual

7

INTRODUCTION

INTRODUCTION

Precautions for Safe Use

Precautions in using the Product

Please observe the following precautions for safe use of the products.

Installation Environment

• Do not use the product in environments where it can be exposed to inflammable/explosive gas.

• Do not install the product close to high-voltage devices and power devices in order to secure

the safety of operation and maintenance.

Power Supply and Wiring

• Make sure to use the product with the power supply voltage specified by this manual.

• Make sure to use crimp terminals when performing the wiring of the product. Do not simply

connect the twisted ends of the wires directly to the terminal block.

• Use a power supply cable and crimp terminals of the specified size.

• Check carefully that the wiring is correct before turning the power supply on.

• Make sure to install the terminal block protection cover after wiring.

• Use a DC power supply with safety measures against high-voltage spikes (safety extra low-

voltage circuits on the secondary side) for the power supply to the terminal blocks of the

Controller.

p.20

• Make sure to tighten all installation screws securely.

Other

• Do not disassemble, repair, or modify the product.

• Dispose of this product as industrial waste.

8

Setup Manual

Precautions for Correct Use

INTRODUCTION

INTRODUCTION

Please observe the following precautions to prevent failure to operate, malfunctions, or undesirable

effects on product performance.

Installation of the Controller

Installation Site

Do not install the Controller in locations subjected to the following conditions:

• Ambient temperature outside the range of 0 to +50°C

• Condensation due to rapid temperature fluctuations

• Relative humidities outside the range of 35 to 85%

• Corrosive or flammable gases

• Dust, salt, or iron particles

• Direct vibration or shock

• Reflection of intense light (such as other laser beams or electric arc-welding machines)

• Strong magnetic fields

• Direct sunlight

• Contact with water, oil, and chemical agents

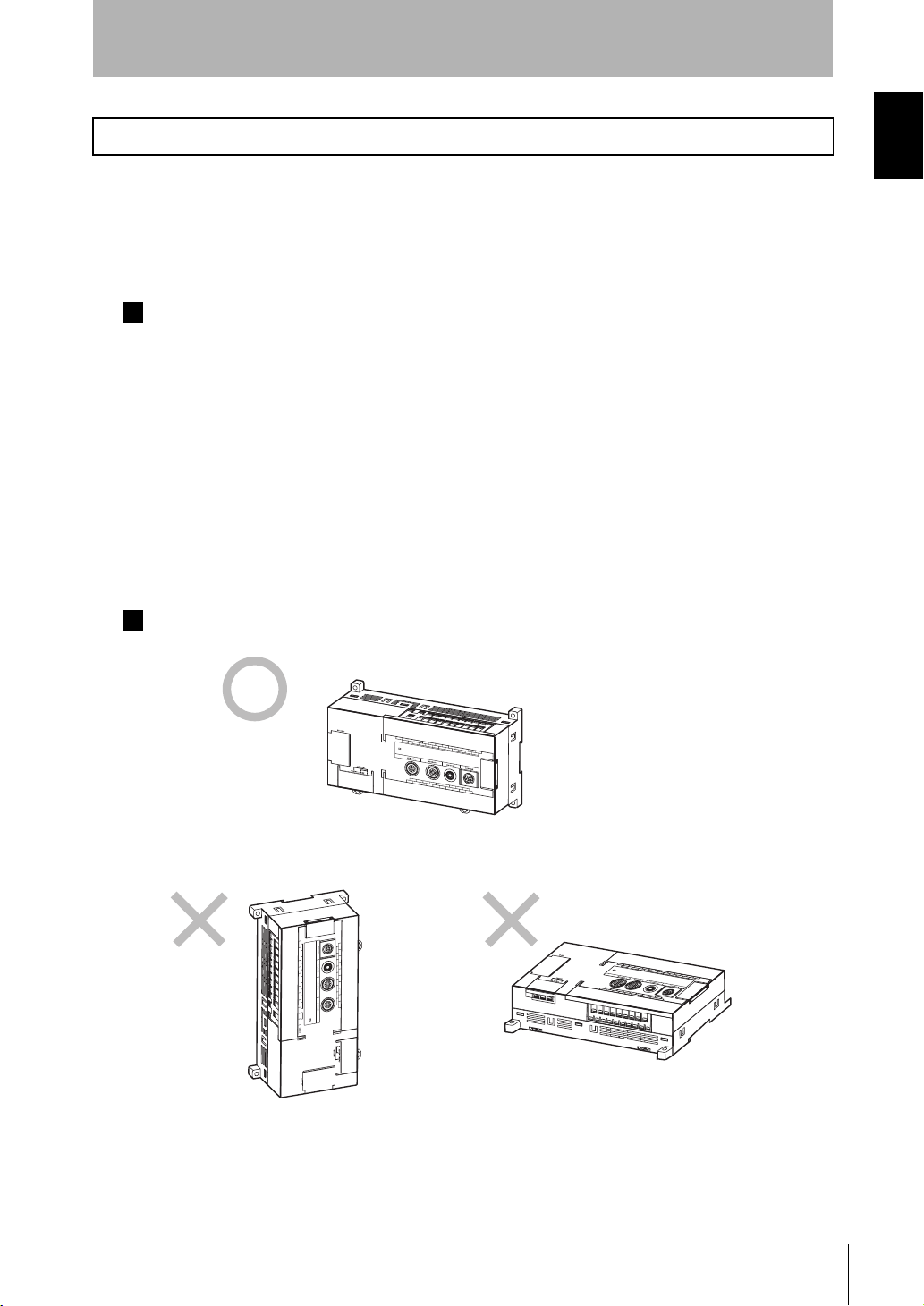

Mounting of the Controller

To improve heat dissipation, install the controller in the following direction only:

Precautions in using the Product

Do not install the controller in the orientations shown in the following diagram.

Setup Manual

9

INTRODUCTION

Precautions in using the Product

INTRODUCTION

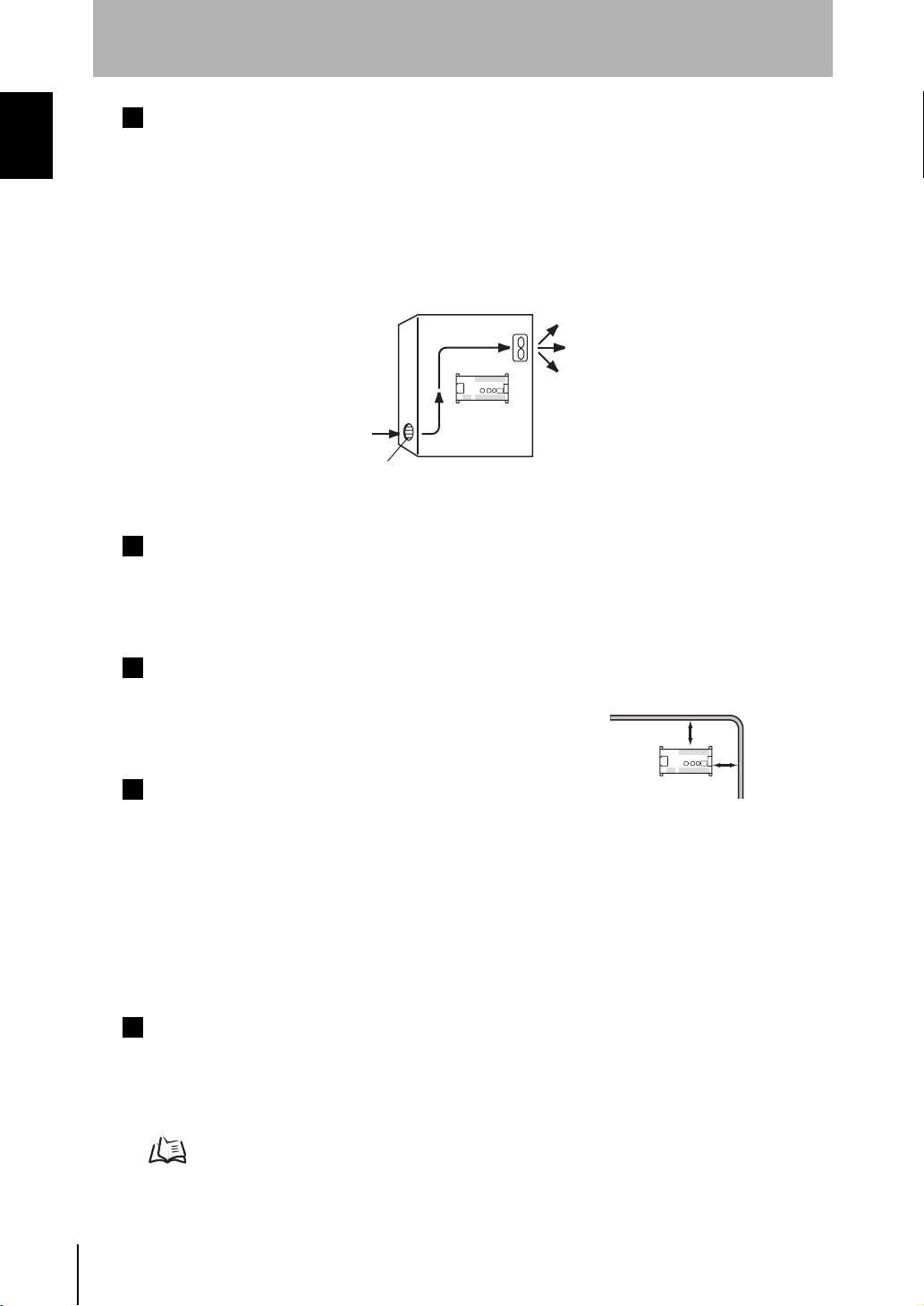

Ambient temperature

• Maintain a minimum clearance of 50 mm above and below the Controller to improve air

circulation.

• Do not install the Controller immediately above significant heat sources, such as heaters,

transformers, or large-capacity resistors.

• Do not let the ambient temperature exceed 50°C.

• Provide a forced-air fan cooling or air conditioning if the ambient temperature is near 50°C so

that the ambient temperature never exceeds 50°C.

Control panel

Louver

Ambient Illumination

• Do not let the ambient illumination exceed 3000 lx.

• When using the Controller near lighting equipment that turns on and off continuously, reduce

the influence of the light by, for example, using a light baffle.

Noise Resistance

• Do not install the Controller in a cabinet containing highvoltage equipment.

• Do not install the Controller within 200 mm of power cables.

Power cable

200 mm min.

200 mm min.

Sensor

Install the sensor in a clean environment and keep the optical

filter on the front panel of the sensor free from oil and dust. If affected by oil or dust, clean the

filter as follows:

• Use a blower brush (normally used to clean camera lenses) to blow large dust particles away

from the surface. Do not blow the dust away with your mouth.

• Use a soft cloth (for lenses) with a small amount of alcohol to remove the remaining dust.

Never use strong force when wiping the sensor. The filter may become scratched, which can

cause errors.

When replacing the sensor connected to the Controller:

Turn off the download function when replacing the sensor.

If the sensor is replaced while the download function is on, measurements cannot be taken

correctly with the new sensor because the old sensor information (such as the measurement

range) is still stored.

Operation Manual p.179

10

Setup Manual

Environment

The sensor cannot detect the following types of objects accurately: Materials with extremely

small reflectances, objects with small curvatures, or objects tilted to a large degree

Component Installation and Handling

Dedicated Components

Make sure to use the dedicated components for the sensor and console connected to this

controller.

• Sensor: Z550-SW70

• Console: Z300-KP

Connecting/Disconnecting Cables

Always turn the power supply off before connecting or disconnecting any cables.

INTRODUCTION

INTRODUCTION

Precautions in using the Product

Touching Signal Lines in Connectors or Terminals

To prevent damage from static electricity, use a wrist strap or another device for preventing

electrostatic discharges when touching terminals or signal lines in connectors.

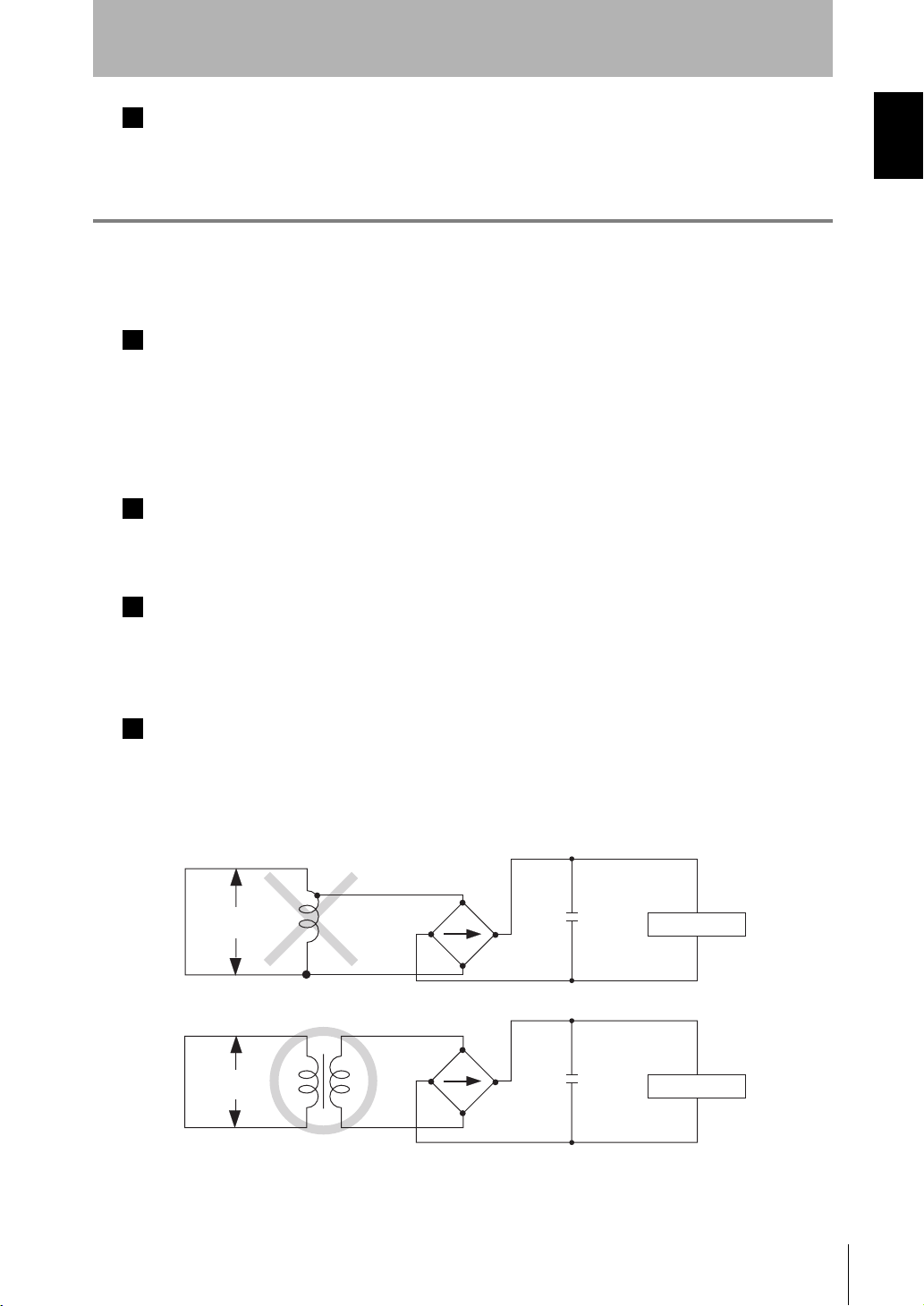

Wiring

When using a transformer for the Controller's driving power supply, use an isolation transformer

in the way shown below.

Do not use an auto-transformer. Doing so may result in equipment failure.

Auto-transformer

Commercial

power supply

Isolation transformer

Commercial

power supply

䋫

䋭

䋫

䋭

Z5FP-MC10

Z5FP-MC10

Setup Manual

11

INTRODUCTION

Precautions in using the Product

INTRODUCTION

Turning off the Power

Do not turn the power supply off while the message indicating that processing is being performed

is being displayed. Data in the memory will be destroyed, and the Controller may not operate

correctly the next time it is started.

Example: Saving

Scn 0䂯

Saving

Save䂯

Using the RESET Signal

Do not input the RESET signal immediately after power supply is turned on. When using the

RESET input to synchronize startup timing, wait at least 1 second after the Controller's power

supply is turned on before turning on the RESET terminal.

Securing the Video Monitor (When Using the Recommended F150-M09)

If the video monitor case is metallic, observe the following precautions to prevent noise

interference, because the video monitor case is connected to the 0V line in the internal circuits.

• Do not ground the video monitor.

• Do not ground the metallic part of the connector.

• Secure the video monitor with plastic screws if it is being mounted to a metallic surface.

12

Warming Up

After turning on the power supply, allow the Controller to stand for at least 30 minutes before

use. The circuits are unstable immediately after the power supply is turned on and attempting

measurement may result in inconsistent measurement values.

Setup Manual

Editor's Note

INTRODUCTION

INTRODUCTION

Visual Aids

Indicates information required to take full advantage of the functions and performance of the product.

Incorrect application methods may result in data corruption or damage to the product. Read and follow all

precautionary information.

Indicates points that are important to achieve the full product performance, such as operational precautions

and application procedures.

Indicates where to find related information.

Indicates information helpful in operation.

Editor's Note

Setup Manual

13

INTRODUCTION

INTRODUCTION

Table of Contents

Table of Contents

INTRODUCTION 1

Precautions in using the Product 2

Wiring and Connection 15

Editor's Note 13

Table of Contents 14

SECTION 1

SECTION 2

Wiring and Connection 15

Basic System Configuration 16

Component Names and Functions 17

Wiring Power Supply and Ground 19

Installation 21

Mounting the Controller 22

Mounting the Sensor 24

14

SECTION 3

SECTION 4

Setup Manual

Connecting External Devices 29

Terminal Block Connections 30

RS-232C Connections 34

Linear Sensor Controller Connections 36

Appendix 41

Troubleshooting 42

Inspection 44

Specifications and Dimensions 45

Laser Product Classifications 55

SECTION 1 Wiring and Connection

Basic System Configuration 16

Component Names and Functions 17

Wiring Power Supply and Ground 19

SECTION 1

Wiring and Connection

Setup Manual

15

SECTION 1

Wiring and Connection

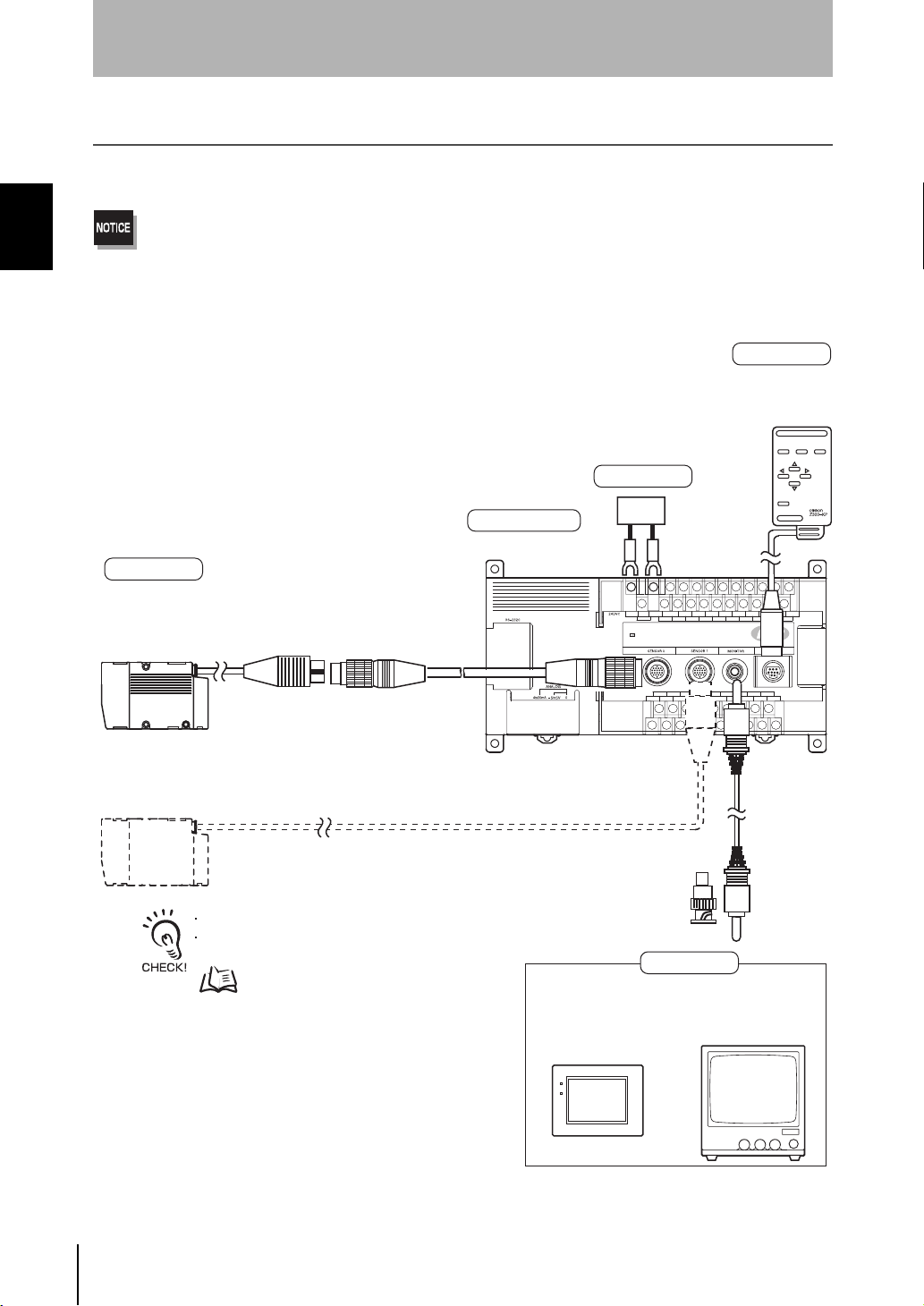

Basic System Configuration

SECTION 1

Basic System Configuration

The following diagram shows the basic Controller system configuration.

•

Dedicated products must be used for some of the components. Some of the devices may be damaged if

products other than the specified dedicated products are used. These items are indicated with asterisks.

• Always turn the power supply off before connecting or disconnecting cables. The peripheral devices may

be damaged if connected or disconnected while the power supply is turned on.

Controller

*

Sensor

Z550-SW70 (0.5m cable

)

*

Sensor Extension Cable

Z519-SC1R (1.5m,3m, 6m, 8m or 13m)

Z5FP-MC10

Power Supply

Recommended model:

OMRON S82K-05024

㬍㬍 㬍 㬍 㬍 㬍 㬍 㬍 㬍 㬍 㬍 㬍

㬍㬍 㬍 㬍 㬍 㬍 㬍㬍

POWER

* Console

Z300-KP

(2m cable)

ESC TRIG

SHIFT

CONSOLE

㬍 㬍 㬍

ENT

Specify the required cable

length when ordering.

Up to 2 sensors can be connected.

To replace the sensor being connected to the

controller, turn off the download function.

Operation Manual

p.179

㬍 㬍 㬍 㬍 㬍 㬍 㬍

㬍 㬍 㬍 㬍 㬍 㬍 㬍 㬍 㬍 㬍

㬍 㬍

F150-VM

Monitor

Cable (2m)

BNC Jack

(included with

the F150-VM)

Monitors

F150-M05L

Color Liquid

Crystal Monitor

(pin input)

SYNC

POWER

F150-M09

Monochrome

CRT Video Monitor

(BNC input)

The Monitor is used to check the image

and display menu where making settings.

16

Setup Manual

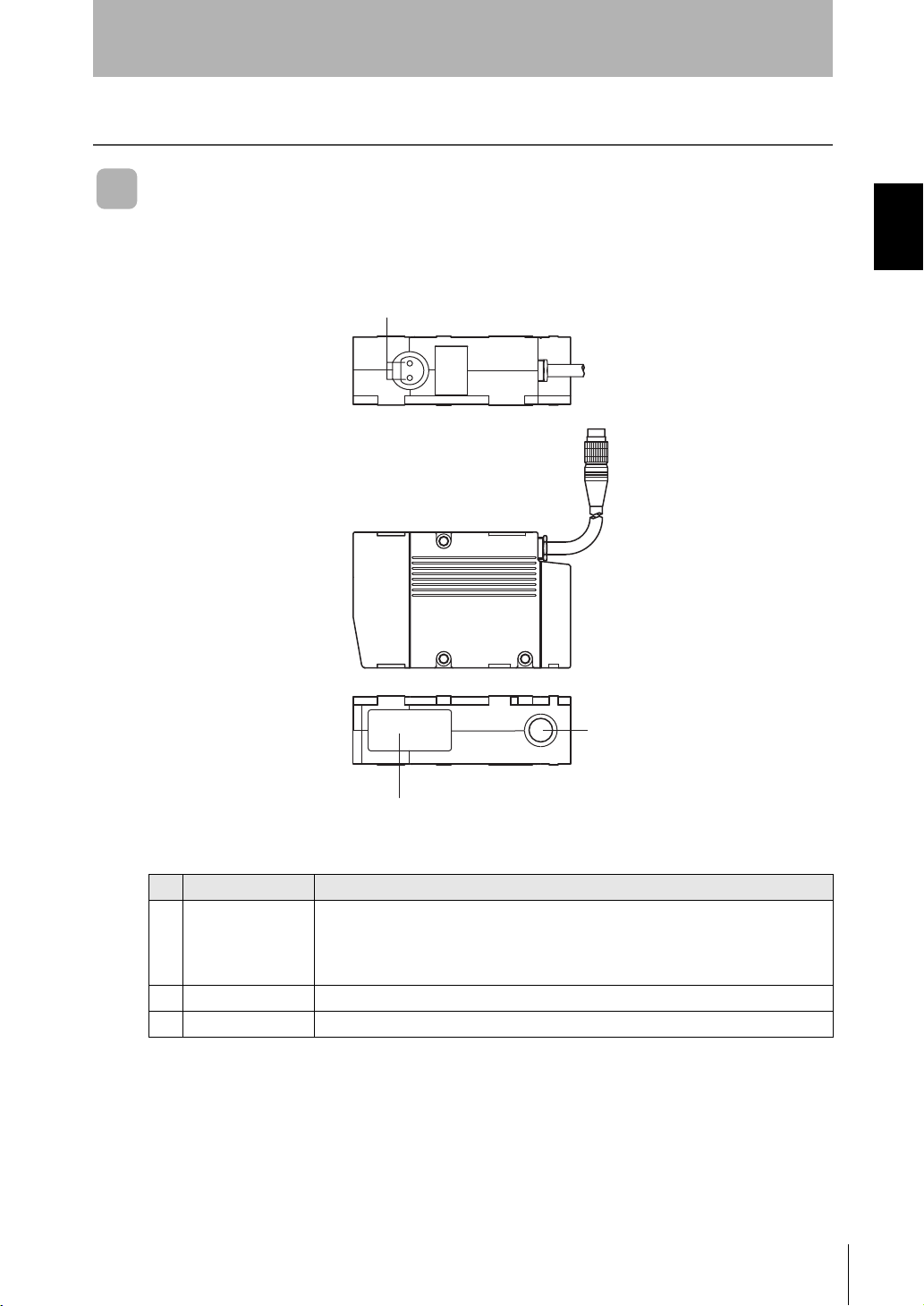

Component Names and Functions

SECTION 1

Wiring and Connection

Sensor

㪈

SECTION 1

Component Names and Functions

Z550-SW70

㪊

No. Name Function

1 Laser beam

warning indicators

2 Laser emitter Emits the laser beam.

3 Laser receiver Receives the laser beam.

When the laser beam is turned on, both indicators will turn on.

When the laser beam is turned off, both indicators will turn off.

For 15 to 25 seconds after the power supply is turned on, both indicators will be

off indicating that the laser beam is off.

㪉

Setup Manual

17

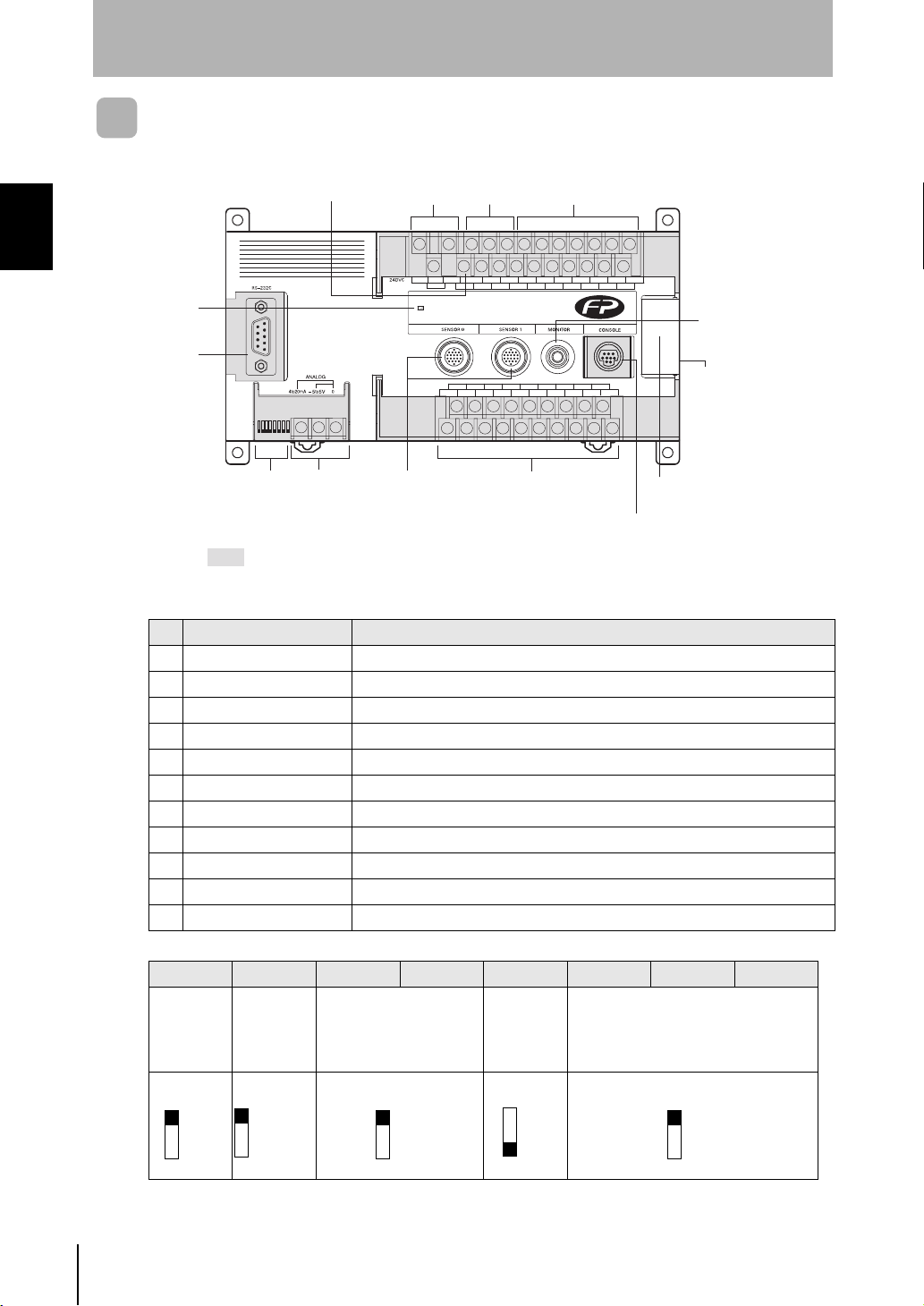

SECTION 1

Wiring and Connection

Controller

SECTION 1

Component Names and Functions

Z5FP-MC10

11

1

2

POWER

3

㬍㬍㬍 㬍 㬍 㬍 㬍 㬍 㬍 㬍 㬍 㬍

㬍㬍 㬍 㬍 㬍 㬍 㬍 㬍

4

㬍 㬍 㬍

5

10

Do not remove the

㬍 㬍 㬍 㬍 㬍 㬍 㬍

㬍 㬍 㬍

8

9

㬍 㬍 㬍 㬍 㬍 㬍 㬍 㬍 㬍 㬍

7

㬍 㬍

3

sticker on the side.

Do not open.

6

Shading indicates parts that are lifted to see the terminals underneath.

No. Name Function

1 Ground wire terminal Connected to the ground wire.

2 Power supply terminal Connected to the power supply.

3 Output terminals Connected to external devices such as a PLC.

4 Input terminals Connected to external devices such as a PLC.

5 Monitor connector Connected to the monitor.

6 Console connector Connected to a console.

7 Sensor connector Connected to the sensor.

8 Analog output terminals Connected when using analog output.

9 Dip switch Used to select the language of the messages displayed on the screen.

10 RS-232C connector Connected to external devices such as a personal computer or PLC.

11 POWER indicator lamp Lit while the power is on.

*

18

* Dip switch settings

Always off Off:

Setup Manual

Switch 1 Switch 2 Switch 3 Switch 4 Switch 5 Switch 6 Switch 7 Switch 8

Always off Always on Always off

Japanese

On:

English

OFF

Japanese

English

OFF

OFF

ON

Loading...

Loading...