Omron V1000 INVERTER DATASHEET

THE NEW V1000 INVERTER

1 0 x 1 0 0 = 1

D es i g n e d fo r:

»

1 0 ye ar s li fe t i m e

»

1 0 0 % e x p e c t a t i o n m a t c h

»

1 i n 10 ,00 0 fi e l d fa ilu re r ate

Quality has a new formula

The V1000 Inverter is the result of years

of experience as the European market leader and

represents a revolution in inverter design.

Compact and sensor-less, the V1000 has all of the

features and performance that you have grown

to expect from the world’s leading inverter/drive

manufacturer. But you have not met an inverter

quite like the V1000.

Its new features, not only enable it to outperform previous

inverters and make it even easier for users to install and

set up, it is also compacter by far. But the big difference

is that it takes quality and reliability to a new high level.

For no matter where you want it to operate, it will deliver

the same high performance for many years after you have

fitted it and forgotten about it.

Our obsession with quality

Our obsession with quality has resulted in the most

dependable products available in the industry today.

And we never stop working to improve quality even

further. This is fully reflected in our latest inverter, the

V1000, which incorporates decades of experience

in developing high quality industrial products.

10,00

8,00

6,00

4,00

2,00

Features of the V1000 Inverter

• Up to 15 kW

• World’s smallest compact inverter

• Built-in filter

• 10-years service life

• Control terminal board with memory (Patent pending)

• Faster CPU’s

• Current vector control

• Low-noise technology (Patent pending)

• IM & PM Motor control

• On-line tuning (Patent pending)

• Safety embedded

Temperature ºC

113.000

105.125

97.2500

89.3750

81.5000

73.6250

65.7500

57.8750

50.0000

New Heatsink temperature evaluation Conventional inverter vs V1000

OK

Failure rate for drives

Mechanical advances

The V1000 design has not only reduced

volume by up to 40% compared with

previous inverters, tests prove that

it has increased vibration resistance

from 20Hz to 50Hz (0.6G) and heat

dissipation has also been greatly

increased, thanks to a new, hybrid

Market standard

Omron-Yaskawa V1000

5%

3%

1%

1 5 10 15

years

Proven reliability

To improve quality even further,

a complete revision of production lines

has taken place and human error has

been reduced by installing the most

advanced robotic technology available.

The result is an expected failure rate

of less than 0.01%.

heat-sink system (patent pending).

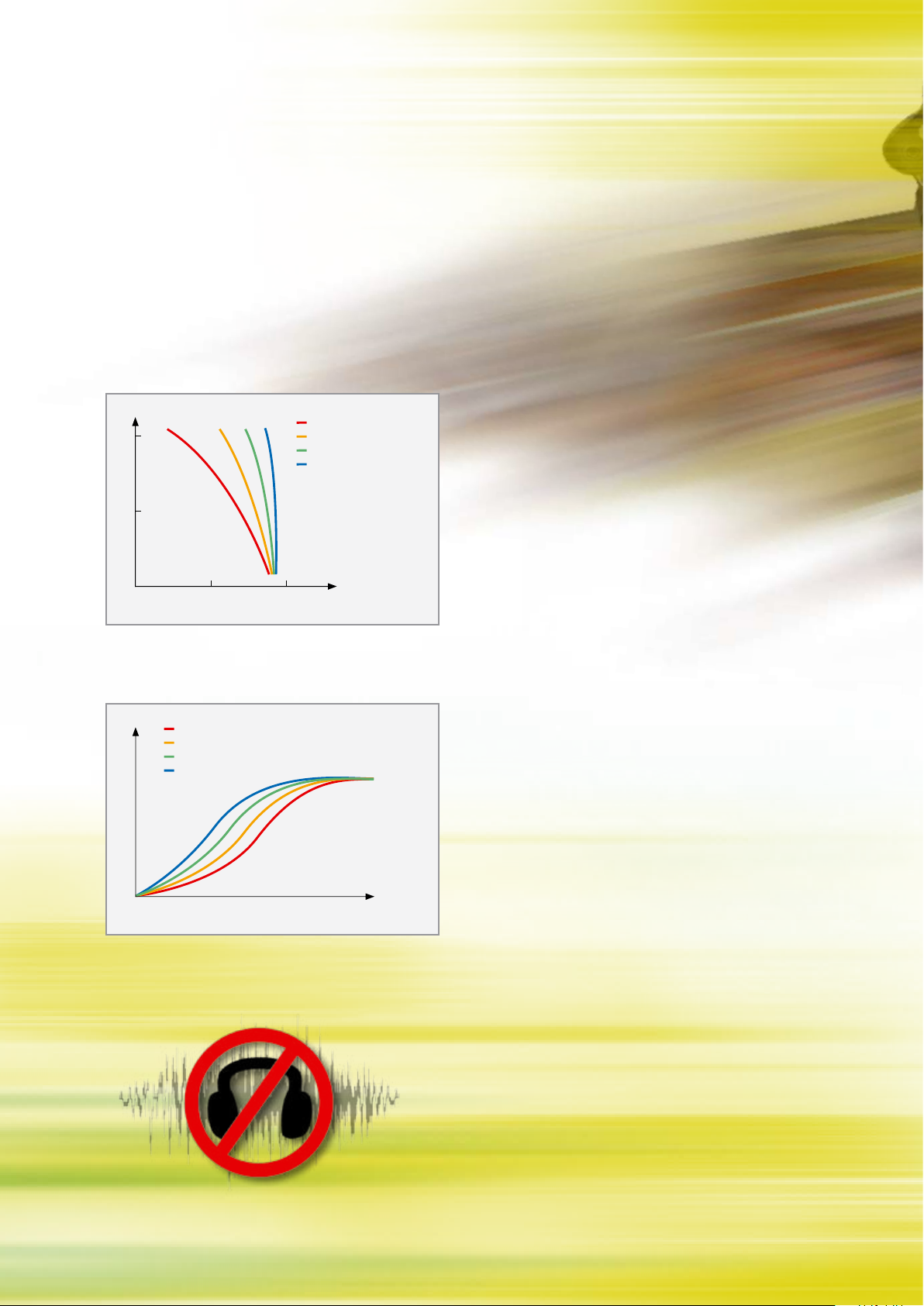

V1000 double rating

Market standard

Omron-Yaskawa V1000

12

11,1

20%

10

8

6

Amps

4

2

Noisy operation Silent operation

0

2,5 3 5 6 7,5 10 12 14

C.Frq. (KHz)

Performance guaranteed

V1000 is able to increase the output

current by around 20% when moving

down in frequency carrier thanks to its

double rating. The standard setting

is heavy duty (HD: 150% rated current/

1min) and increasing output current

when in the normal duty mode

(ND: 120% rated current/1 Min).

Advanced Industrial Automation

Time and space saving 100% guaranteed

Easy Shielding

Space-saving side-by-side mounting

Remember when side-by-side

mounting meant having to leave

spaces for ventilation? Well, not with

the V1000. A special alloy, hybrid

cooling fin (patent pending) allows you

to mount multiple units close together

without overheating problems and

saving vast amounts of panel space.

Time-saving screw-less terminals

Have you ever stopped to think how

much time it takes to wire hundreds

of terminals with twelve screws per

inverter? With the V1000, you can

reduce installation time (and therefore

costs) considerably thanks to the use

of screw-less terminals.

Cost-saving EMC filter

A built-in EMC filter will save you the

task of having to take special

precautions for EMC shielding during

installation. The optional, factory-

installed filter will not only save on

installation costs, it also reduces the

bill of materials for external parts and

simplifies logistics.

Work-saving set-up

Setting up Omron inverter and servo drives is now easier than

ever, following the release of a new version of the company’s

versatile CX-Drive drive configuration software package.

New features, all of which save time, include automatic recognition

of drive series and type, an oscilloscope function, and facilities

for connecting a single PC running Configurator to multiple drives.

During parameter selection, all parameters are fully described,

and many, including those associated with PID loops and jump

frequency operation, are set with the aid of graphical control

diagrams. Extensive help screens and tool tips are also provided.

In addition to aiding drive setup, Omron’s CX-Drive also provides

comprehensive facilities, status indications and alarms to assist

with commissioning and fault-finding. Drive inputs and outputs

can be monitored in real time, while the oscilloscope function

allows detailed analysis of drive operation, without the need for

additional test equipment CX-Drive enhances connectivity through

Omron’s PLC and motion controllers by supporting DeviceNet,

SCU, Mechatrolink and Profibus connectivity.

Convenient on-line tuning

Unlike previous inverters, the V1000

has a smart ‘on-line tuning’ feature

that takes ‘auto-tuning’ a stage further.

This continuous method of tuning

ensures that any temperature

deviation large enough to affect

electrical parameters governing the

motor speed will be adjusted before

any speed variance can occur.

Time-saving safety feature

Safety is embedded in the V1000 from the inside out, making it easy for you to integrate

the inverter into your machine system and avoid difficult connections to safety controllers.

Dual safety inputs (acc. To EN954-1 Safety Category 3) will disconnect the motor faster

at the first sign of trouble, while reducing external wiring and contactors.

Advanced performance…

Accurate speed control

100

torque (%)

50

Speed Fluctuation Rates

V/F: 5%

Voltage Vector Control: 1%

Open Loop Current Vector Control: 0,2%

V/F + PG: 0,03%

speed (r/min)

Unlike previous inverters, the V1000 delivers optimum speed

control and high starting torque thanks to the current vector

control. As opposed to other techniques, such as voltage vector

control, current vector control uses the flux current, which is

an actual measurement rather than an estimated value.

V/F: 5%

Voltage Vector Control: 1%

Open Loop Current Vector Control: 0,2%

V/F + PG: 0,03%

speed

Speed Response Accuracy

Fast scan cycle

The V1000 employs a dual CPU concept with a CPU device that

is four times faster than those on board previous inverters.

This means a faster-than-ever scan cycle that boosts motor

control performance, especially in current vector control

applications where speed is of the essence.

time

Silent operation

A feature of the V1000 that will delight your customers is the

noise-suppression function that decreases motor noise at low

carrier frequencies. This puts machine operators at less risk

to safety hazards and has a positive effect on the general

working ambience.

…Easy maintenance

Save repetition

Control parameters need only be set once with the V1000.

They are automatically saved to a control terminal board

memory that allows you to replace an inverter and simply

forget it. The new inverter will be immediately updated with

the current settings.

Minimize downtime

The V1000 has an ingenious pre-maintenance function that will

calculate the condition of electronic components and advise

about their replacement based not only on the number of hours

they have been in service, but also on factors such as stress

due to load, temperature, the number of times they have been

powered up, output frequency and carrier frequency, etc.

Keeps running

Assuring that new data and communications keep flowing

in the event of a power failure is critical in many applications.

Naturally, the V1000 is available with a 24Vdc power supply

that will keep the CPU working in any power-down situation.

Main Power Supply

24 Vdc

1V1000

VZ

V1000

More performance & Quality in less space

• Current vector control

• High starting torque (200% / 0.5 Hz)

• 1:100 speed control range

• Double rating ND 120%/1min and HD 150%/1 min

• IM&PM motor control

• Online Tuning

• Low-noise Low carrier technology

• 10 years lifetime design

• Built-in filter

• Screw-less terminals

• Control Terminals with memory backup

• 24 VDC control board power supply option

• Fieldbus communications: Modbus, Profibus, CanOpen,

DeviceNet, Lonworks, CompoNet, Ethernet

• Safety embedded (EN954-1 safety cat. 3)

• CE, UL, cUL and TUV

Ratings

• 200 V Class single-phase 0.1 to 4 kW

• 200 V Class three-phase 0.1 to 15 kW

• 400 V Class three-phase 0.2 to 15 kW

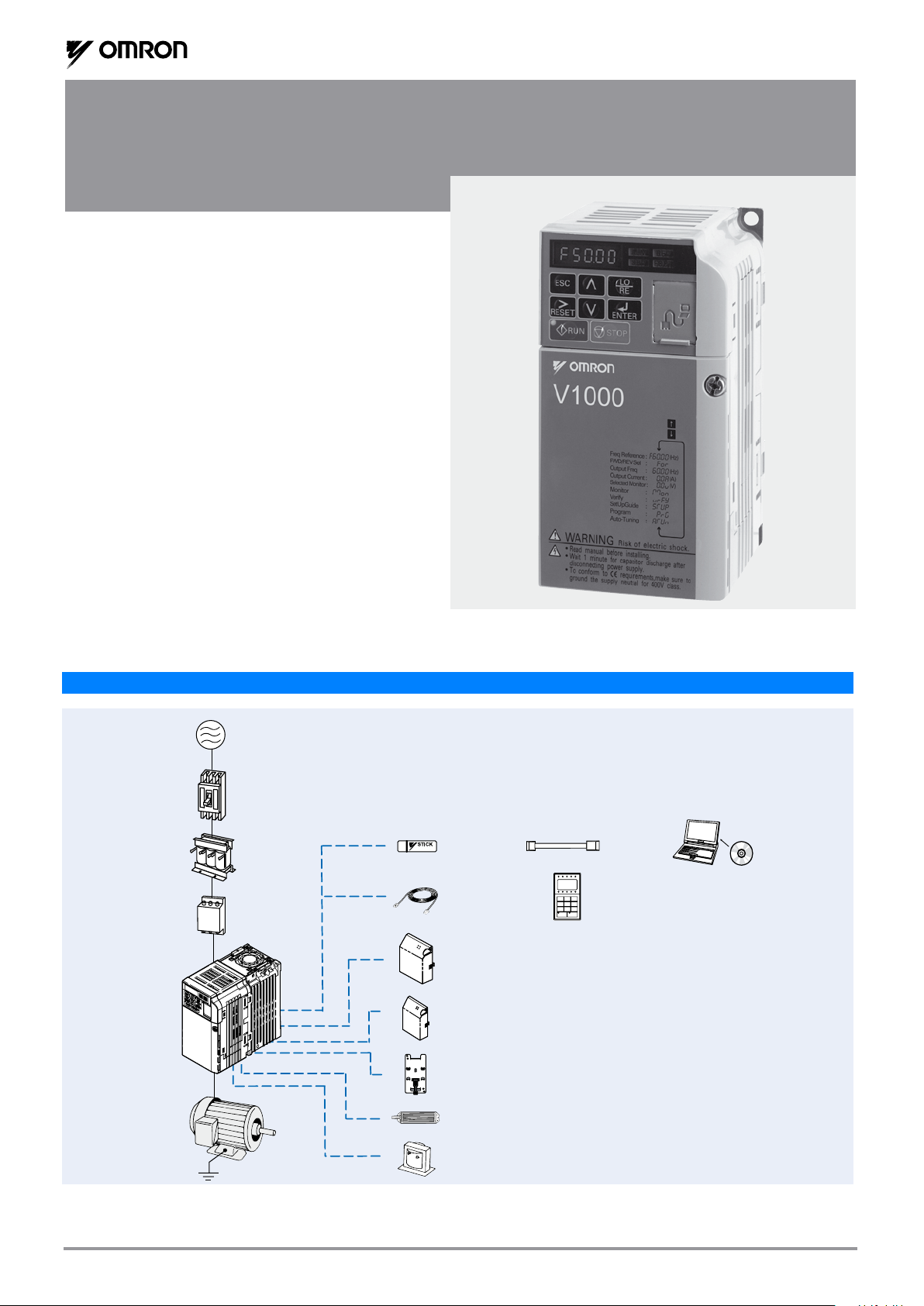

System configuration

RJ-45 / USB

Adapter

Remote Operator

Extansion Cable

USB Cable

24Vdc Control Board Power Supply

Communication Option Board

Braking Resistor

DC Reactor

Mounting Accesories

LCD Remote

Operator

MCCB

V1000

Filter

AC Reactor

Motor

Ground

Power

Supply

CX-Drive

CX-One

V10008

Loading...

Loading...