Page 1

CompoBus/S

Cat. No. W266-E1-09

C200HW-SRM21-V1

CS1W-SRM21

CJ1W-SRM21

CQM1-SRM21-V1

SRT1 Series

SRT2 Series

OPERATION MANUAL

Page 2

C200HW-SRM21-V1

CS1W-SRM21

CJ1W-SRM21

CQM1-SRM21-V1

SRT1 Series

SRT2 Series

CompoBus/S

Operation Manual

Revised August 2007

Page 3

Page 4

Notice:

r

f

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller and is not used as an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 1996

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 5

Page 6

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

SECTION 1

System Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 System Overview and Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 CompoBus/S System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-3 Compatible Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1-4 Startup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

SECTION 2

CompoBus/S System Specifications and Configuration 23

2-1 Communications Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2-3 Supplying Power to the Slaves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2-4 System Configuration Using Water-resistant Terminals . . . . . . . . . . . . . . . . . . . . . 41

2-5 I/O Response Time Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

SECTION 3

CompoBus/S System Wiring . . . . . . . . . . . . . . . . . . . . . . 53

3-1 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3-2 Connector Installation (Special Flat Cable Only). . . . . . . . . . . . . . . . . . . . . . . . . . 55

3-3 VCTF Cable Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

3-4 Master/Slave Connecting Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

3-5 Operations Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

SECTION 4

Master Unit Specifications and Operations . . . . . . . . . . 73

4-1 C200HW-SRM21-V1 Master Unit for CS-series,

C200HX/C200HG/C200HE-(Z)E, and C200HS PLCs . . . . . . . . . . . . . . . . . . . . . 74

4-2 CS1W-SRM21 Master Unit for CS-series PLCs . . . . . . . . . . . . . . . . . . . . . . . . . . 88

4-3 CJ1W-SRM21 Master Unit for CJ-series PLCs . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

4-4 CQM1-SRM21-V1 Master Unit for CQM1 PLCs . . . . . . . . . . . . . . . . . . . . . . . . . 126

4-5 SRM1-C0@-V2 Master Control Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

4-6 CPM2C-S Series CPM2C-S@@@C (-DRT). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

vii

Page 7

TABLE OF CONTENTS

SECTION 5

Slave Specifications and Operations . . . . . . . . . . . . . . . . 145

5-1 Remote Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

5-2 Connector Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

5-3 Remote I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

5-4 Water-resistant Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

5-5 Sensor Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

5-6 Fiber Amplifier Communications Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

5-7 Analog Input Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

5-8 Analog Output Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

5-9 I/O Link Units for CPM1A and CPM2A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

5-10 I/O Link Units for CPM2C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

5-11 Sensor Amplifier Terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

5-12 Application Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 350

SECTION 6

Starting Communications. . . . . . . . . . . . . . . . . . . . . . . . . 353

6-1 Turning the Power ON. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 354

6-2 Checking Operations for CS-series, C200HX/C200HG/C200HE-(Z)E,

and C200HS Master Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356

6-3 Checking Operations of CS-series and CJ-series Master Units. . . . . . . . . . . . . . . 365

6-4 Checking Operations of CQM1 Master Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . 377

6-5 Checking Slave Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 382

6-6 Cleaning and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 384

6-7 Precautions for Replacement of Units or Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . 385

Appendix

Standard Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 387

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 395

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 401

viii

Page 8

About this Manual:

This manual describes the installation and operation of the CompoBus/S system and includes the sections described below.

Please read this manual carefully and be sure you understand the information provided before

attempting to install and operate the CompoBus/S Master and Slave Units. Be sure to read the pre-

cautions provided in the following section.

Section 1 provides an overview of the CompoBus/S System and functions, and describes the various

Units that are used to configure a CompoBus/S System.

Section 2 provides details on the CompoBus/S System specifications and I/O response times, and

explains how to configure a CompoBus/S System.

Section 3 explains how to install Units in control panels, wire the signal and power lines, and make

other connections needed to assemble a CompoBus/S System. We recommend reading through the

information on wiring each Master and Slave that are provided in Section 4 and Section 5.

Section 4 explains the functions of each Master Unit, including information on specifications, switch

settings and allocation of Slave I/O.

Section 5 explains the functions of each Slave, including information on specifications, switch settings,

and I/O.

Section 6 provides information on error processing, periodic maintenance operations, and troubleshooting procedures needed to keep the CompoBus/S System operating properly. We recommend

reading through the error processing procedures before operation so that operating errors can be identified and corrected more quickly.

The Appendix provides tables of standard models including Masters, Slaves, and connecting devices.

In this manual, only the specifications of the CompoBus/S system and devices are described. For

details on Units, refer to their respective manuals. (Suffixes have been omitted from the catalog numbers.)

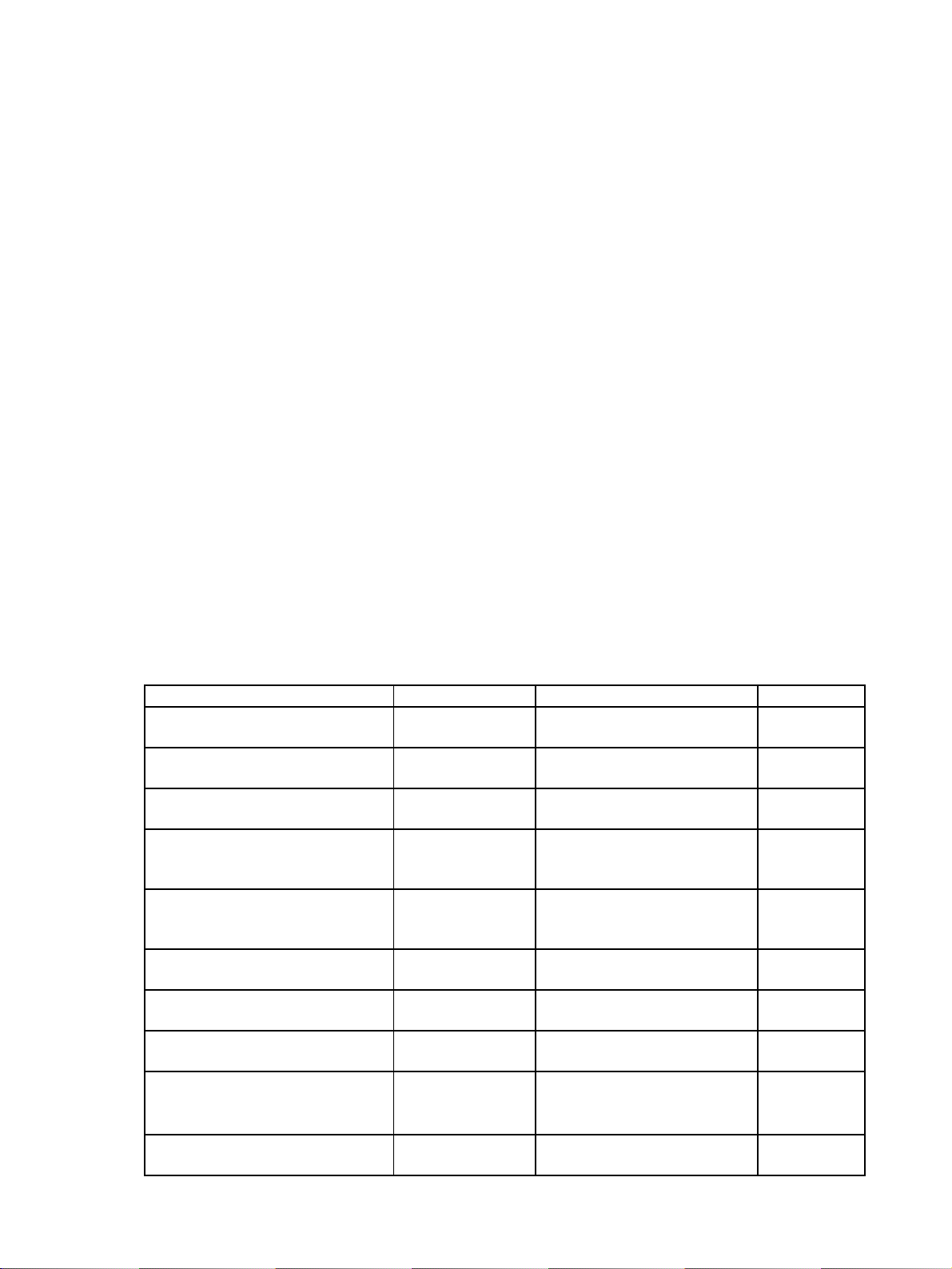

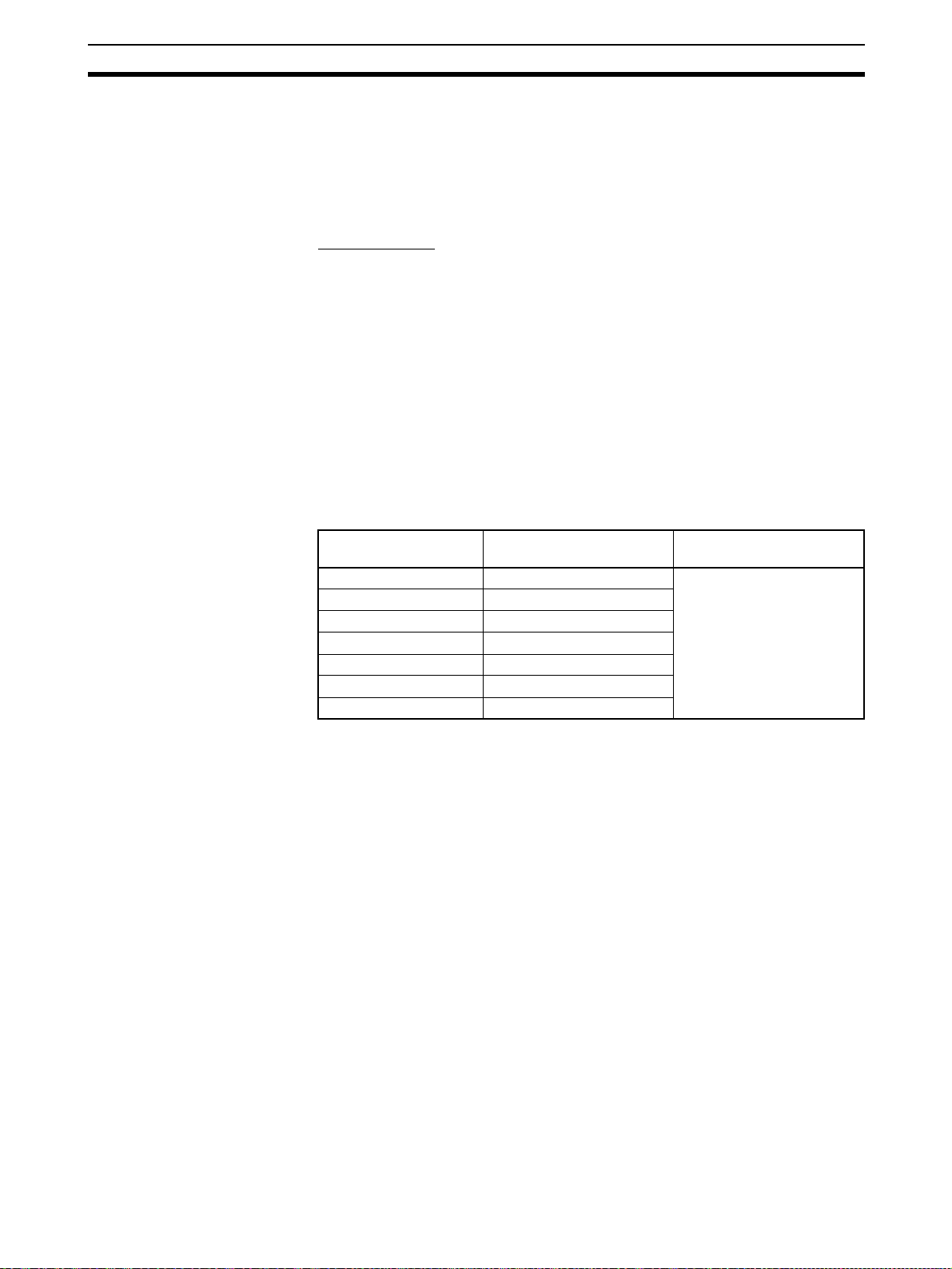

Product Name Series Manual Name Cat. No.

CS-series Programmable Controllers CS Series SYSMAC CS Series Operation

CJ-series Programmable Controllers CJ Series SYSMAC CJ Series Operation

CS/CJ-series Programmable Controllers

C200HX/C200HG/C200HE-(Z)E Programmable Controllers

C200HX/C200HG/C200HE-(Z)E Programmable Controllers

C200HS Programmable Controllers C200HS SYSMAC C200HS Operation

C200HS Programmable Controllers C200HS SYSMAC C200HS Installation

CQM1H Programmable Controller CQM1H SYSMAC CQM1H Operation

CQM1H Programmable Controller CQM1H SYSMAC CQM1H Programming

Manual

Manual

CS/CJ Series SYSMAC CS/CJ Series Pro-

gramming Manual

C200HX/C200HG/

C200HE-(Z)E

C200HX/C200HG/

C200HE-(Z)E

SYSMAC C200HX/C200HG/

C200HE-(Z)E Programmable

Controllers Installation Guide

SYSMAC C200HX/C200HG/

C200HE-(Z)E Programmable

Controllers Operation Manual

Manual

Guide

Manual

Manual

W339

W393

W394

W302

W322

W235

W236

W363

W364

CQM1 Programmable Controller CQM1 SYSMAC CQM1 Operation Man-

ual

W226

ix

Page 9

Product Name Series Manual Name Cat. No.

CQM1/CPM1/CPM1A/SRM1 Programmable Controller

CompoBus/S SRM1 Master Control

Unit

CPM2C-S Programmable Controller CPM2C-S SYSMAC CPM2C-S Programma-

CPM1A/CPM2A I/O Link Unit CPM1A-SRT21 SYSMAC CPM2A I/O Link Units

CPM2C I/O Link Unit CPM2C-SRT21 SYSMAC CPM2C I/O Link Units

CQM1/CPM1/

CPM1A/SRM1

SRM1(-V2) SYSMAC CompoBus/S SRM1

SYSMAC CQM1/CPM1/CPM1A/

SRM1 Programming Manual

Master Control Units Operation

Manual

ble Controllers Operation Manual

Operation Manual

Operation Manual

W228

W318

W377

W352

W356

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

x

Page 10

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xi

Page 11

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xii

Page 12

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xiii

Page 13

Page 14

PRECAUTIONS

This section provides general precautions for using the CompoBus/S Units, Programmable Controllers, and related devices.

The information contained in this section is important for the safe and reliable application of the CompoBus/S and

PLC. You must read this section and understand the information contained before attempting to set up or operate

a CompoBus/S and PLC system.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

6-1 Applicable Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

6-2 Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

6-3 Conformance to EC Directives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

xv

Page 15

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for installing and operating OMRON CompoBus/S Units. Be sure to read this manual before operation and keep this

manual close at hand for reference during operation.

!WARNING It is extremely important that a PLC and all PLC Units be used for the speci-

fied purpose and under the specified conditions, especially in applications that

can directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PLC System to the above-mentioned applications.

3 Safety Precautions

!WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing

so may result in electric shock.

!WARNING Do not touch any of the terminals or terminal blocks while the power is being

supplied. Doing so may result in electric shock.

!WARNING Provide safety measures in external circuits, i.e., not in the Programmable

Controller (CPU Unit including associated Units; referred to as “PLC”), in

order to ensure safety in the system if an abnormality occurs due to malfunction of the PLC or another external factor affecting the PLC operation. Not

doing so may result in serious accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PLC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instruction is executed.

As a countermeasure for such errors, external safety measures must be

provided to ensure safety in the system.

xvi

Page 16

Operating Environment Precautions 4

• The PLC outputs may remain ON or OFF due to deposition or burning of

the output relays or destruction of the output transistors. As a countermeasure for such problems, external safety measures must be provided

to ensure safety in the system.

• When the 24-VDC output (service power supply to the PLC) is overloaded

or short-circuited, the voltage may drop and result in the outputs being

turned OFF. As a countermeasure for such problems, external safety

measures must be provided to ensure safety in the system.

!WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do

so may result in malfunction, fire, or electric shock.

!Caution Execute online edit only after confirming that no adverse effects will be

caused by extending the cycle time. Otherwise, the input signals may not be

readable.

!Caution Confirm safety at the destination node before transferring a program to

another node or editing the I/O area. Doing either of these without confirming

safety may result in injury.

!Caution Tighten the screws on the terminal block of the AC Power Supply Unit to the

torque specified in the operation manual. The loose screws may result in

burning or malfunction.

4 Operating Environment Precautions

!Caution Do not operate the control system in the following places:

• Locations subject to direct sunlight

• Locations subject to temperatures or humidity outside the range specified

in the specifications

• Locations subject to condensation as the result of severe changes in temperature

• Locations subject to corrosive or flammable gases

• Locations subject to dust (especially iron dust) or salts

• Locations subject to exposure to water, oil, or chemicals

• Locations subject to shock or vibration

!Caution Take appropriate and sufficient countermeasures when installing systems in

the following locations:

• Locations subject to static electricity or other forms of noise

• Locations subject to strong electromagnetic fields

• Locations subject to possible exposure to radioactivity

• Locations close to power supplies

xvii

Page 17

Application Precautions 5

!Caution The operating environment of the PLC System can have a large effect on the

longevity and reliability of the system. Improper operating environments can

lead to malfunction, failure, and other unforeseeable problems with the PLC

System. Be sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life

of the system.

5 Application Precautions

Observe the following precautions when using the CompoBus/S Units or the

PLC.

!WARNING Failure to abide by the following precautions could lead to serious or possibly

fatal injury. Always heed these precautions.

• Always connect to 100

to a ground of 100

• Always turn OFF the power supplies to the PLC, slaves, and communications before attempting any of the following. Not turning OFF the power

supplies may result in malfunction or electric shock.

• Mounting or dismounting Power Supply Units, I/O Units, CPU Units,

memory casettes, Master Units, or any other Units

• Mounting or dismounting circuits for Remote I/O Terminals with 3-tier

terminal blocks

• Assembling the Units or Racks

• Setting DIP switches or rotary switches

• Connecting or wiring the cables

• Connecting or disconnecting the connectors

!Caution Failure to abide by the following precautions could lead to faulty operation or

the PLC or the system or could damage the PLC or PLC Units. Always heed

these precautions.

• Failsafe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal

lines, momentary power interruptions, or other causes.

• Provide external interlock circuits, limit circuits, and other safety circuits in

addition to any provided within the PLC to ensure safety.

• Configure the control circuits to turn ON the power supply to I/O slaves

before turning ON the power supply to the PLC (Master Unit). If the I/O

slave power supply is turned ON after the PLC, correct operation may

temporarily not be possible.

• Do not attempt to disassemble, repair, or modify any Units. Any attempt to

do so may result in malfunction, fire, or electric shock.

• Do not drop the Unit or subject it to excessive vibration or shock.

• Be sure that all the Backplane mounting screws, slave mounting screws,

terminal screws, and cable connector screws are tightened to the torque

specified in the relevant manuals. Incorrect tightening torque may result in

malfunction.

• Wire correctly according to specified procedures.

Ω or less when installing the Units. Not connecting

Ω or less may result in electric shock.

xviii

Page 18

Application Precautions 5

• Pay careful attention to the polarity (+/−) when connecting the terminal

blocks or connectors. Wrong connections may cause malfunction of the

system.

• Wire all terminals, communications paths, power supplies lines, and I/O

lines with the specified polarity and voltages. Improper wiring may result

in faulty operation.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may result in burning.

• Do not mount the Unit near equipment that generates strong high-frequency noise.

• Leave the label attached to the Unit when wiring to prevent wire clippings

and other foreign matter from entering the Unit. Removing the label may

result in malfunction.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals. Connection of bare stranded wires may result in

burning.

• Wire correctly and double-check all the wiring or the setting switches

before turning ON the power supply. Incorrect wiring may result in burning.

• Be sure that the terminal blocks, connectors, expansion cables, and other

items with locking devices are properly locked into place. Improper locking

may result in malfunction.

• Disconnect the LG and GR terminals on the Power Supply Unit before

performing insulation resistance or dielectric strength tests.

• Always use the power supply voltage specified in the operation manual.

An incorrect voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied. Be particularly careful in places

where the power supply is unstable. An incorrect power supply may result

in malfunction.

• Do not apply voltages to the Input Units in excess of the rated input voltage. Excess voltages may result in burning.

• Do not apply voltages exceeding the maximum switching capacity to Output Units. The Output Units may be destroyed.

• Check the user program for proper execution before actually running it on

the Unit. Not checking the program may result in an unexpected operation.

• Always turn OFF the power supplies to the PLC, slaves, and communications before attempting any of the following. Not turning OFF the power

supply may result in malfunction or electric shock.

• Mounting or dismounting Power Supply Units, I/O Units, CPU Units,

memory casettes Master Unit, or any other Units

• Mounting or dismounting circuits for Remote I/O Terminals with 3-tier

terminal blocks.

• Assembling the Units

• Setting DIP switches or rotary switches

• Connecting or wiring the cables

xix

Page 19

Application Precautions 5

• Connecting or disconnecting the connectors

• Before touching the Unit, be sure to first touch a grounded metallic object

in order to discharge any static built-up. Not doing so may result in malfunction or damage.

• Confirm that no adverse effect will occur in the system before attempting

any of the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PLC. (including the Startup Mode

setting)

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• When replacing parts, be sure to confirm that the rating of a new part is

correct. Not doing so may result in malfunction or burning.

• Resume operation only after transferring to the new CPU Unit and/or Special I/O Units the contents of the DM and HR Areas required for resuming

operation. Not doing so may result in an unexpected operation.

• When transporting the Units, use special packing boxes and protect them

from excessive vibration or shock during transportation.

• Connect all communications cables within the limits given in the specifications.

• Observe the following precautions when wiring communications cables.

• Separate the communications cables from power lines or high-tension

lines.

• Do not bend the communications cables.

• Do not pull on the communications cables with an excessive force.

• Do not place heavy objects on the communications cables.

• Be sure to put the communications cables inside conduits.

• Water-resistant Terminals used as Slaves are of IP67 construction. Do not

attempt to use the Watertight Terminals for applications where the Watertight Terminals are always underwater.

• Install the Unit properly as specified in the operation manual. Improper

installation of the Unit may result in malfunction.

xx

Page 20

Conformance to EC Directives 6

6 Conformance to EC Directives

6-1 Applicable Directives

•EMC Directives

6-2 Concepts

EMC Directives

OMRON devices that comply with EC Directives also conform to the related

EMC standards so that they can be more easily built into other devices or the

overall machine. The actual products have been checked for conformity to

EMC standards (see the following note). Whether the products conform to the

standards in the system used by the customer, however, must be checked by

the customer.

EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions of

the equipment or control panel on which the OMRON devices are installed.

The customer must, therefore, perform the final check to confirm that devices

and the overall machine conform to EMC standards.

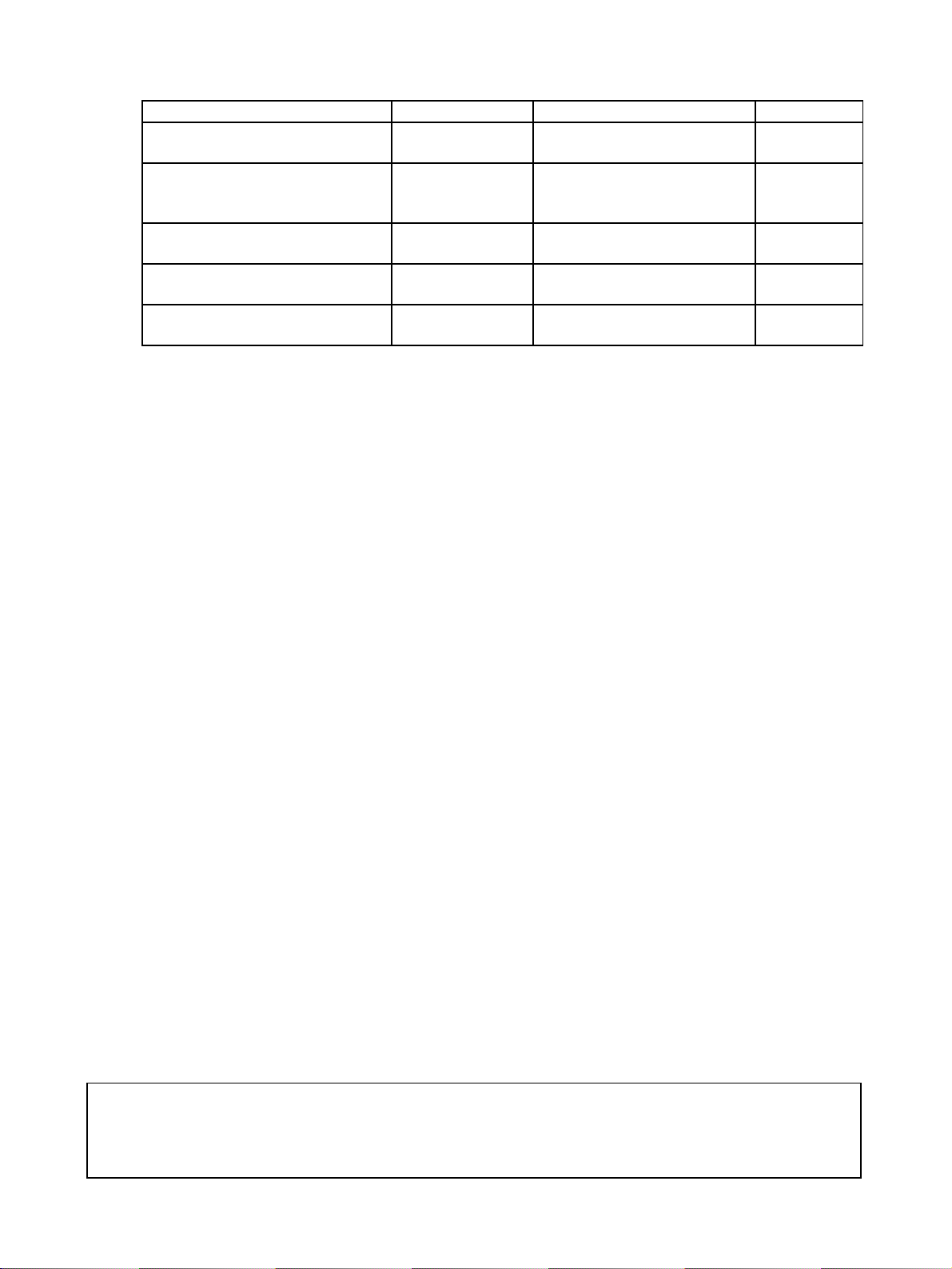

Note Applicable EMC (Electromagnetic Compatibility) standards are listed in the

following table.

Unit EMS (Electromagnetic

C200HW-SRM21-V1 EN61131-2 EN61000-6-4 (See note 2.)

CS1W-SRM21 EN61131-2

CJ1W-SRM21 EN61000-6-2 (See note 1.)

CQM1-SRM21-V1 EN61131-2

SRM1-C0@-V2 EN61000-6-2 (See note 1.)

CPM2C-S@@@C(-DRT) EN61131-2

SRT1 and SRT2 Series EN61000-6-2 (See note 1.)

Note 1. These products have configurations with less than 30 m of I/O wiring, and

less than 10 m of power supply wiring.

2. Radiated emission for EN61000-6-4: 10-m regulations

6-3 Conformance to EC Directives

Observe the follow precautions when installing the CompoBus/S Units that

conform to the EC Directives.

1,2,3... 1. Since the CompoBus/S Units are classified as built-in types, be sure to in-

stall the Units inside a control panel.

2. Provide reinforced insulation or double insulation for the DC Power Supplies that are used as power sources for the alarm output, communications

circuits, and I/O circuits.

Susceptibility)

EMI (Electromagnetic

Interference)

3. The CompoBus/S Units that conform to the EC Directives also conforms

to the Common Emission Standard (EN61000-6-4). When incorporated

into a device, however, the requirements may vary depending on the configuration of the control panel to be used, relationship with other devices to

be connected, wiring, etc. Users are therefore requested to confirm Unit

conformance to the EC Directives by themselves.

xxi

Page 21

Page 22

SECTION 1

System Design

This section provides an overview of the CompoBus/S System and functions, and describes the various Masters, Slaves,

and connection devices that are used to configure a CompoBus/S System.

1-1 System Overview and Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-2 Network Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-1-3 Communications Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-2 CompoBus/S System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-2-1 Basic System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-2-2 CompoBus/S System Components. . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-3 Compatible Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1-3-1 Compatible Masters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1-3-2 Slave Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1-3-3 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1-3-4 Connectors/Terminal Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1-4 Startup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1

Page 23

System Overview and Features Section 1-1

1-1 System Overview and Features

1-1-1 System Overview

The CompoBus/S System is a remote I/O communications system with

reduced wiring that retains the functionality and ease of use of the original

remote I/O system (wired type), while providing higher-speed, longer-distance, and highly reliable communications.

The CompoBus/S System allows connection of up to 32 I/O devices (Slaves)

to a Master Unit using only two signal wires, even on long production lines that

require multiple I/O control.

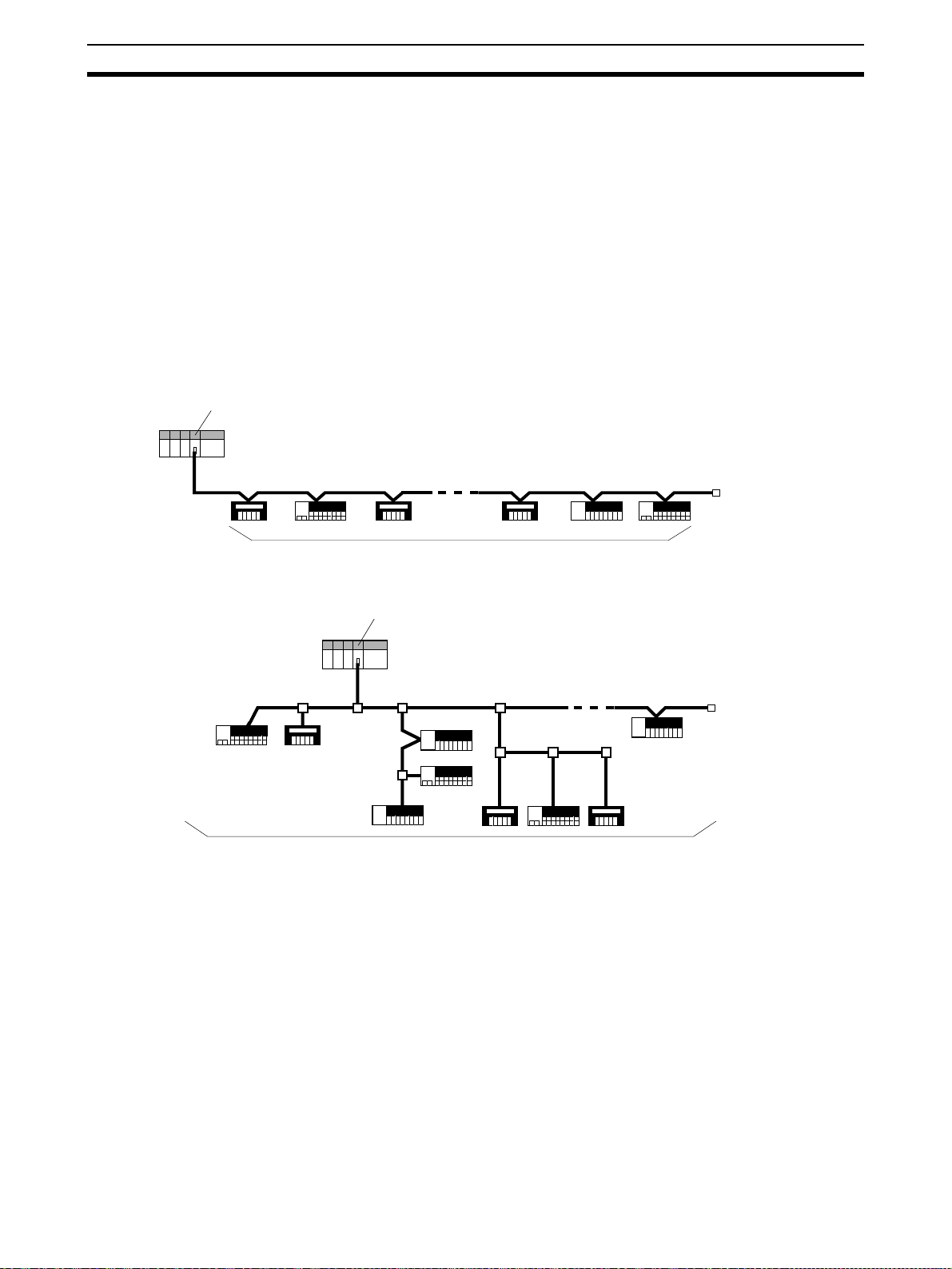

Connect up to 32 Slaves

(256 Points) for Each

Master Unit

CompoBus/S Master Unit

SYSMAC CS Series, C200HX/HG/HE-(Z)E,

C200HS, CJ Series, CQM1/CQM1H

(SRM1, CPM2C-S)

Slaves

Each CompoBus/S Master Unit can be connected to up to 32 Slaves of various types, including I/O Terminals and Sensor Terminals, and allows I/O communications for up to 256 points (128 inputs, 128 outputs).

Main line length: 500 m max.

Terminator

Up to 32 Slaves of various types

Flexible Wiring Configuration

CompoBus/S Master Unit

SYSMAC CS Series, C200HX/HG/

HE-(Z)E, C200HS, CJ Series, CQM1/

CQM1H (SRM1, CPM2C-S)

Total length: 200 m max.

Terminator

I/O Data Exchange without

Special Programming

2

Up to 32 Slaves of various types

I/O data can be exchanged between the Master and Slaves without requiring

any special ladder programming for communications. I/O information for each

Slave is exchanged between Slaves and the corresponding I/O Area in the

Master by simply setting the node number of each Slave.

Page 24

System Overview and Features Section 1-1

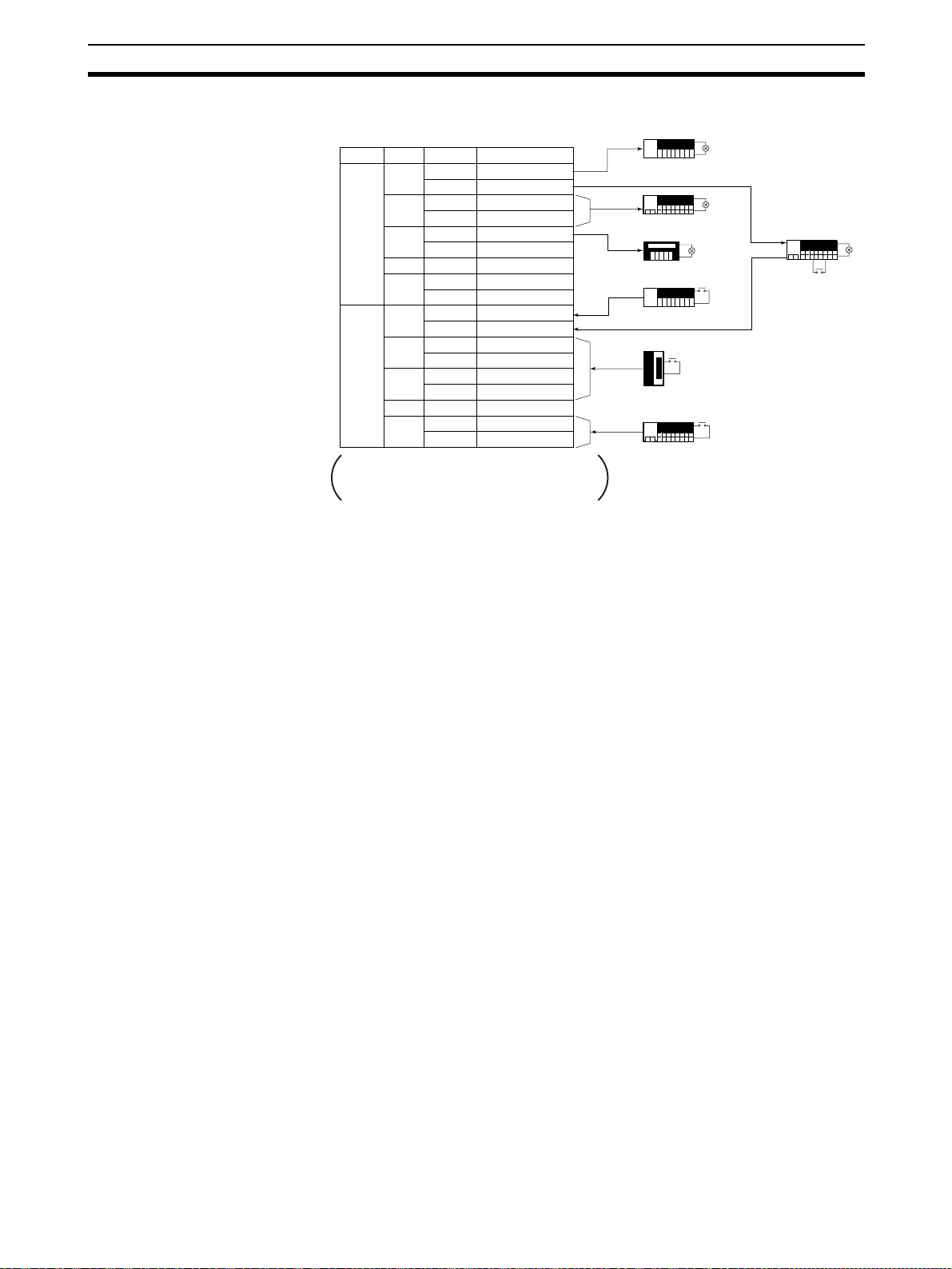

Input Slave

CPU Unit's I/O Area

to

to

Node number

00

01

02

03

04

05

to

14

15

00

01

02

03

04

05

to

14

15

Word Bit

00 to 07

CIO

2000

08 to 15

00 to 07

CIO

2001

CIO

2002

to

CIO

2007

CIO

2008

CIO

2009

CIO

2010

to

CIO

2015

08 to 15

00 to 07

08 to 15

00 to 07

08 to 15

00 to 07

08 to 15

00 to 07

08 to 15

00 to 07

08 to 15

00 to 07

08 to 15

OUT

data

IN

data

Example settings using CJ1W-SRM21 Master

Unit with unit #00, connected to 32 Slaves.

Output

OUT node 0

8-point Output Slave

OUT node 2

16-point Output Slave

OUT node 4

8-point Output Slave

Input

IN node 0

8-point Input Slave

IN node 2

32-point Input Slave

IN node 14

16-point Input Slave

IN/OUT node1

8-point Input/

8-point Output

Slave

1-1-2 Network Features

The CompoBus/S has the following features.

Communications Modes Select either a High-speed Communications Mode or Long-distance Commu-

nications Mode for the CompoBus/S according to the system configuration.

The differences between the High-speed Communications Mode and the

Long-distance Communications Mode are described in 1-1-3 Communica-

tions Modes.

Flexible Wiring Up to

200 m

Long-distance

Communications Up to

500 m

High-speed

Communications

Water-resistance Slaves Water-resistant Terminals (IP67) can be used as Slaves to exchange I/O in

In Long-distance Communications Mode, flexible wiring is possible up to a

total cable length of 200 m with no restrictions on branching or node connections, provided that 4-conductor VCTF cable or Special Flat Cable is used.

In Long-distance Communications Mode, communications over the main line

of up to 500 m are possible to control I/O devices in a wide area, provided that

2-conductor VCTF cable is used. In this case, however, each branch line can

be connected to a single Slave only, because the branch line cannot be further branched. Furthermore, the Master must be connected to either end of

the main line.

In High-speed Communications Mode, up to 16 Slaves with 128 I/O points

can be connected with a high-speed communications cycle time of only

0.5 ms. This cycle is fast enough for time-critical factory automation applications.

places exposed to water. Water-resistant Terminals are, however, available

only when the communications cable is 4-conductor VCTF cable.

Reduced Wiring A Slave can be connected to a Master or another Slave with just one connect-

ing cable. If the 4-wire Special Flat Cable or 4-conductor VCTF cable is used,

the Slave’s communication power supply is also supplied through the cable,

so floor wiring can be reduced dramatically. Also, special connectors simplify

branching from a main cable.

3

Page 25

System Overview and Features Section 1-1

Connecting to 4conductor VCTF Cable

Use Both T-branch and

Multidrop Methods

Wide Variety of Masters Master Units are available as Special I/O Units for the CS-series,

Wide Variety of Slaves Units in a wide range are available as I/O Slaves for a variety of applications.

Easy Startup The CompoBus/S System can be started just by wiring the cables and making

Easy-to-obtain 4-conductor VCTF cable can be used instead of the Special

Flat Cable. Furthermore improvement in the environmental resistance of the

system is possible by using shielded connectors.

Both the T-branch and multidrop methods can be combined flexibly when wiring. In combination with the floor cables, this wiring feature allows a very flexible system configuration. There are three types of cables (2-conductor VCTF

cable, 4-conductor VCTF cable, and Special Flat Cable), and when the Special Flat Cable is used, T-branch Connectors can be installed by simply snapping the connector on.

C200HX/C200HG/C200HE-(Z)E, C200HS, CS-series, CJ-series, and CQM1

PLCs and also available integrated with a CPU for the SRM1 and CPM2C-S.

The variety of Masters provides flexibility in configuring a system to match

your application needs.

Such Units include Remote Terminals and Sensor Terminals, which vary with

the number of I/O points or I/O type, Connector Terminals, which allow easy

wiring, and Water-resistant Terminals, which have a better protective construction. There are many Slaves available with advanced functions, including

Analog I/O Terminals for analog-to-digital or digital-to-analog conversion, and

CPM1A/CPM2A/CPM2C I/O Link Units for sharing data with the host PLC.

some simple settings. Replacement of earlier Remote I/O Systems is also

easy.

Slave Node Number

Provided on Indicators

and in PLC Memory

Slave Monitoring for

Improved Reliability

Troubleshooting is easy because the Slave’s node number is shown on the

Master’s indicators if an error occurs with a Slave. When a CS-series,

C200HX/HG/HE-(Z)E, or C200HS Master Unit is used, error information is

also stored in PLC memory.

When an error occurs with a Slave using a CS-series or CJ-series Master

Unit, the Slave's node number is stored in the DM Area using the Slave registration function.

Reliability of the CS-series and CJ-series Master Units has been further

improved by the addition of the following functions.

Slave Registration Function

Registering Slaves in the Master allows the user to check whether connected

Slaves are joined to the network, and to detect whether Slaves are illegally

joined due to incorrect connection, or missing from the network due to a delay

in startup or malfunction of registered Slaves.

Communications Stop Mode

System malfunctions can be avoided by setting remote I/O communications to

stop when a communications error occurs.

4

Page 26

System Overview and Features Section 1-1

1-1-3 Communications Modes

Both High-speed Communications Mode and the Long-distance Communications Mode are supported by the CompoBus/S.

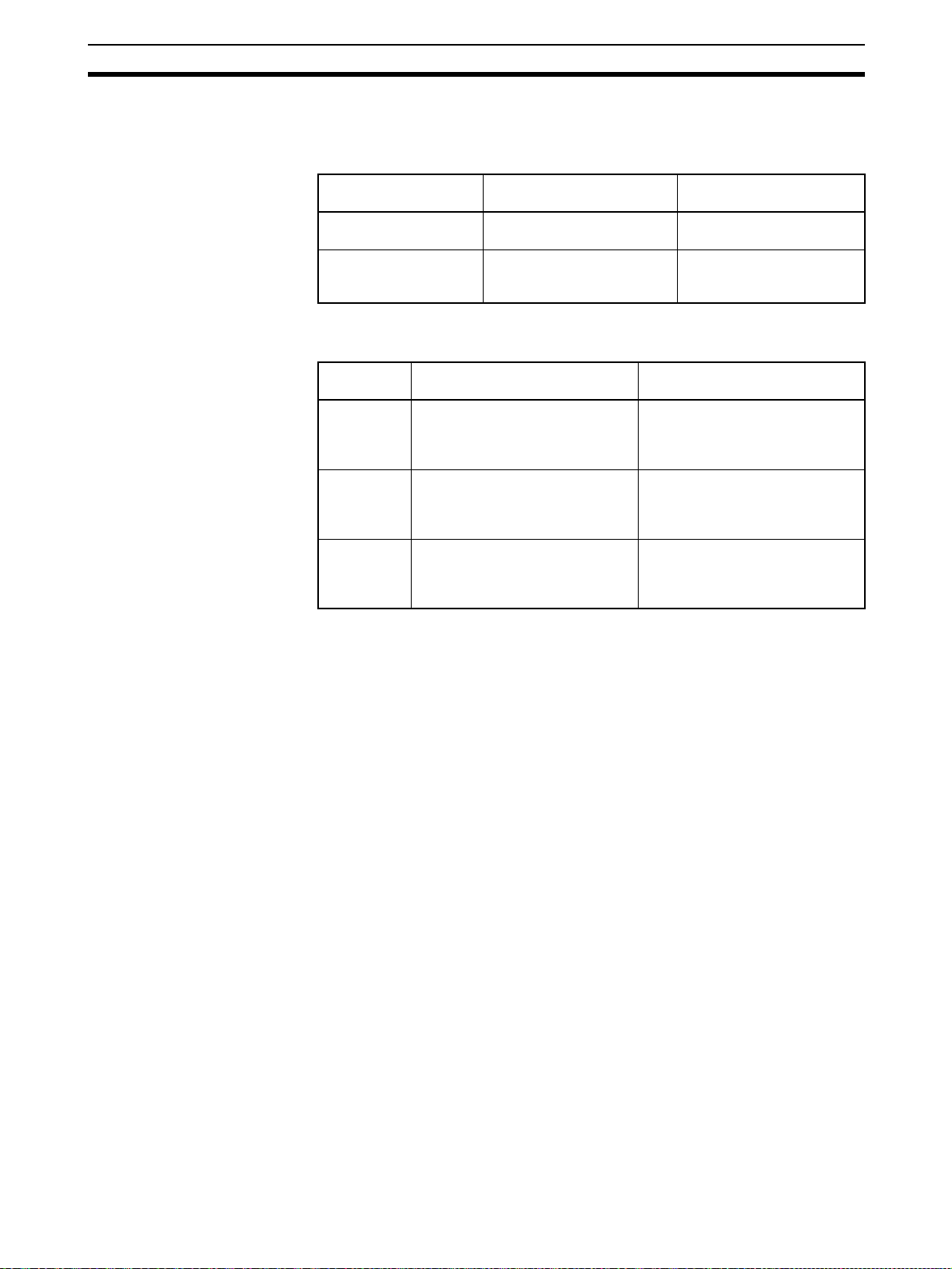

Item High-speed Communica-

Communications baud

rate

Communications cycle

time

750 kbps 93.75 kbps

0.5 ms or 0.8 ms (depending

on maximum number of I/O

points)

tions Mode

The communications distance and the connection configuration vary with the

communications mode and communications cable.

Cable High-speed Communications

2-conductor

VCTF cable

4-conductor

VCTF cable

Special Flat

Cable

Length of main line: 100 m max.

Length of branch line: 3 m max.

Total length of branch lines:

50 m max.

Length of main line: 30 m max.

Length of branch line: 3 m max.

Total length of branch lines: 30 m

max.

Length of main line: 30 m max.

Length of branch line: 3 m max.

Total length of branch lines:

30 m max.

Mode

Long-distance Communi-

cations Mode

4.0 ms or 6.0 ms (depending on maximum number of

I/O points)

Long-distance Communica-

tions Mode

Length of main line: 500 m max.

Length of branch line: 6 m max.

Total length of branch lines:

120 m max.

Flexible branching, provided that

the total length of cable is a maximum of 200 m.

Flexible branching, provided that

the total length of cable is a maximum of 200 m.

Note The I/O response time may be slower when using Long-distance Communica-

tions Mode compared with High-speed Communications Mode. Refer to

O Response Time Characteristics

.

2-5 I/

5

Page 27

CompoBus/S System Configuration Section 1-2

1-2 CompoBus/S System Configuration

1-2-1 Basic System Configuration

Remote Input

Terminals

Photoelectric Sensors,

Proximity Sensors, or

Limit Switches

Fiber Amplifier

Communications

Units

Master Unit

Photoelectric Sensors, Proximity Sensors, Limit Switches

Fiber

Amplifier

Units

C200HW-SRM21-V1 for CS1,

C200HX/C200HG/C200HE (-ZE), and C200HS

CS1W-SRM21 for CS Series, CJ1W-SRM21 for CJ Series,

CQM1-SRM21-V1 for all CQM1 PLCs

SRM1 Master Control Unit

CPM2C-S Series

Remote Input

Terminals

(3-tier terminal

block)

Remote Output Terminals

Solenoids or

valves

Remote I/O

Module

Remote Output Terminals

(3-tier terminal block)

Solenoids or

valves

Analog Input

Terminal

Remote I/O

Terminals

(3-tier terminal block)

Connector I/O

Terminals

Analog Output

Terminal

CPM2A or

CPM1A

Photoelectric Sensors or

Proximity Sensors with connectors

Sensor Terminals

Terminal-block Terminator

I/O Link Unit for

CPM1A/CPM2A

PCB

Optical Fiber Sensors

1 to 5 V,

4 to 20 mA

Master Characteristics

CS-series, C200HX/HG/HE-(Z)E, C200HS Master Units

• Multiple Masters (up to 16) can be connected to a single PLC.

• Up to 128 or 256 I/O points (DIP switch used to switch setting).

• Communications status stored in CPU Unit's I/O Area.

CS-series Master Units

• Multiple Masters (up to 96) can be connected to a single PLC.

• Up to 128 or 256 I/O points (DIP switch used to switch setting).

• Communications status stored in CPU Unit's I/O Area.

• Uses the Slave registration function to monitor which Slaves are joined to

the network.

• Communications can be stopped when a communications error occurs.

CJ-series Master Units

• Multiple Masters (up to 40) can be connected to a single PLC.

• Up to 128 or 256 I/O points (DIP switch used to switch setting).

• Communications status stored in CPU Unit's I/O Area.

Inverters or valves

6

Page 28

CompoBus/S System Configuration Section 1-2

• Uses the Slave registration function to monitor which Slaves are joined to

the network.

• Communications can be stopped when a communications error occurs.

CQM1 Master Units

• Only one Master can be connected to a single PLC.

• Up to 32, 64, or 128 I/O points (DIP switch used to switch setting).

• Alarm output terminal provided to detect errors.

SRM1 and CPM2C-S Master Units with Built-in CPU Units

• Compact CPU Unit with built-in CompoBus/S communications functions.

• Up to 256 I/O points for CompoBus/S functions.

• Communications status stored in CPU Unit's AR Area.

Slave Characteristics

Remote Terminals

• Input or Output Terminals for general-purpose use.

• 4-point, 8-point, and 16-point Transistor Remote Terminals.

• Remote Terminals with no-contact transistor I/O, connector transistor outputs, or relay contact outputs.

Remote Terminals (3-tier Terminal Blocks)

• Input or Output Terminals for general-purpose use.

• 16 points: 8 inputs and 8 outputs mixed.

• Wiring is simple because common terminals for I/O wiring are located at

each point on the 3-tier terminal block.

Connector Terminals

• All I/O wiring can be done using connectors, reducing the amount of labor

for wiring.

• Mounting brackets allow the direction of mounting to be changed.

Water-resistant Terminals

• Input or output terminals of IP67 construction.

• 4 or 8 inputs or outputs.

• Connecting to communications cable, I/O power supply, and I/O through

shielded connectors.

Remote I/O Modules

• Modular type that allows PCB mounting.

• 16-input model and 16-output model.

• User’s devices can be customized as CompoBus/S Slaves.

Sensor Terminals

• Easily connects to Photoelectric Sensor or Proximity Sensor with XS8

Connectors.

• 8-input/8-output model and 4-input/4-output model.

• Remote teaching and external diagnosis are possible by using output signals of the Sensor Terminal.

Fiber Amplifier Communications Units

• Reduced wiring with ON/OFF output and power supply wiring not

required.

• Connecting a Fiber Amplifier Unit allows connection of up to 14 Optical

Fiber Sensors.

7

Page 29

CompoBus/S System Configuration Section 1-2

• Mobile Console can be connected without the Head (Photoelectric Sensor setting, teaching, and adjustment can be executed on site.)

Analog Input Terminals

• Convert analog inputs to binary data.

• The number of analog input points can be switched between 4 points, 3

points, 2 points, and 1 point using a DIP switch.

• The following input ranges are supported:

0 to 5 V, 1 to 5 V, 0 to 10 V, –10 to 10 V, 0 to 20 mA, 4 to 20 mA

Analog Output Terminals

• Convert binary data to analog outputs.

• The number of analog output points can be switched between 2 points

and 1 point using a DIP switch.

• Supports the following output ranges:

1 to 5 V, 0 to 10 V, –10 to 10 V, 0 to 20 mA, 4 to 20 mA

I/O Link Terminals for CPM1A/CPM2A

• Create I/O Links (8 inputs, 8 outputs) with CPM1A and CPM2A PLCs.

CPM2C I/O Link Unit

• Creating I/O Links (8 inputs, 8 outputs) with CPM2C-series PLCs.

1-2-2 CompoBus/S System Components

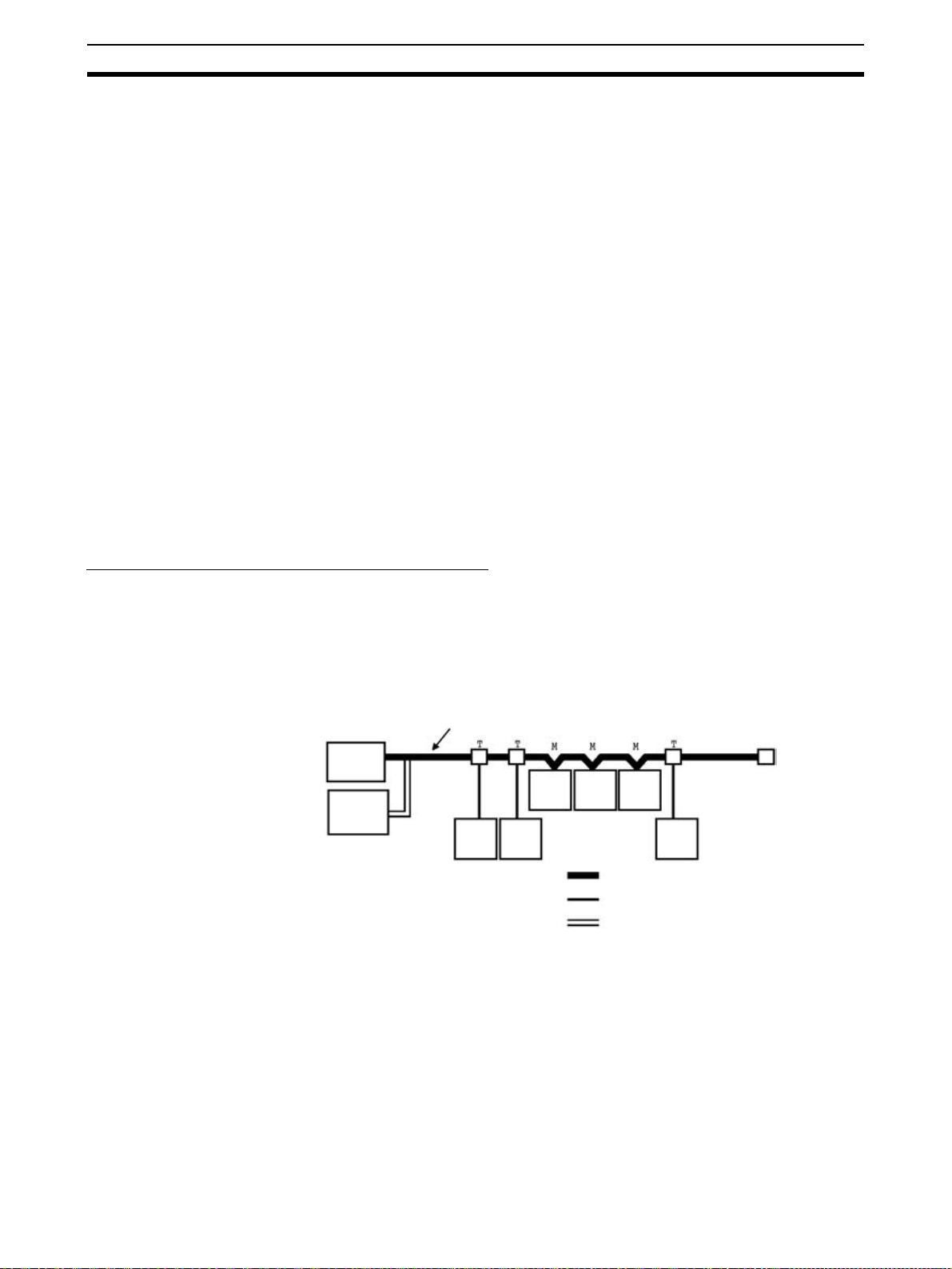

System with Distinct Main and Branch Lines

The diagram below shows a CompoBus/S System in which the main line must

be distinguished from the branch lines under either of the following conditions.

• The system operates in High-speed Communications Mode.

• The system operates in Long-distance Communications Mode with 2-conductor VCTF cable. (The maximum length of the main line varies with the

type of communications cable.)

Communications Cable

Te r mi n a to r

Master

Communications Power

Supply

Slave Slave

Master The Master administers the CompoBus/S System and manages the external

I/O of the Slaves. There is only 1 Master in a CompoBus/S System and the

Master must be connected at the end of the main line, as shown in the preceding diagram.

Slave Slave Slave

Main line

Branch line

Power supply cable

Slave

T: T-branch connection

M: Multidrop connection

Slaves The external I/O connected to the Slaves is processed by communicating with

the Master through the CompoBus/S System.

Main/Branch Lines The main line is the main cable that connects the two most distant points of

the system. Cables branching from the main line are known as branch lines.

Cables CompoBus/S communications are transmitted through 2-conductor VCTF, 4-

conductor VCTF, or Special Flat Cable. When 4-conductor VCTF or Special

8

Page 30

CompoBus/S System Configuration Section 1-2

Flat Cable is used, the communications power supply can be supplied through

the cable. The system shown in the preceding diagram uses 4-conductor

VCTF or Special Flat Cable. When 2-conductor VCTF cable is used, power

must be supplied to the Slaves through a separate cable.

Connection Methods Two methods can be used to connect CompoBus/S Slaves: the T-branch

method and the multidrop method. With the T-branch method, the Slave is

connected to a branch line which branches off from the main line. With the

multidrop method, the Slave is connected directly to the main line.

These two connection methods can both be used in the same system,

although it is not possible to make a secondary branch from a branch line.

Use OMRON’s Branch Connector, a T-joint for a shielded connector, or a commercially available terminal block to create a branch from the main line.

Termina tor A terminator must be connected to the end of the main line opposite the Mas-

ter in order to stabilize communications. There are three kinds of terminating

resistors available, a connector for use with Special Flat Cable, a terminal

block, and a shielded connector.

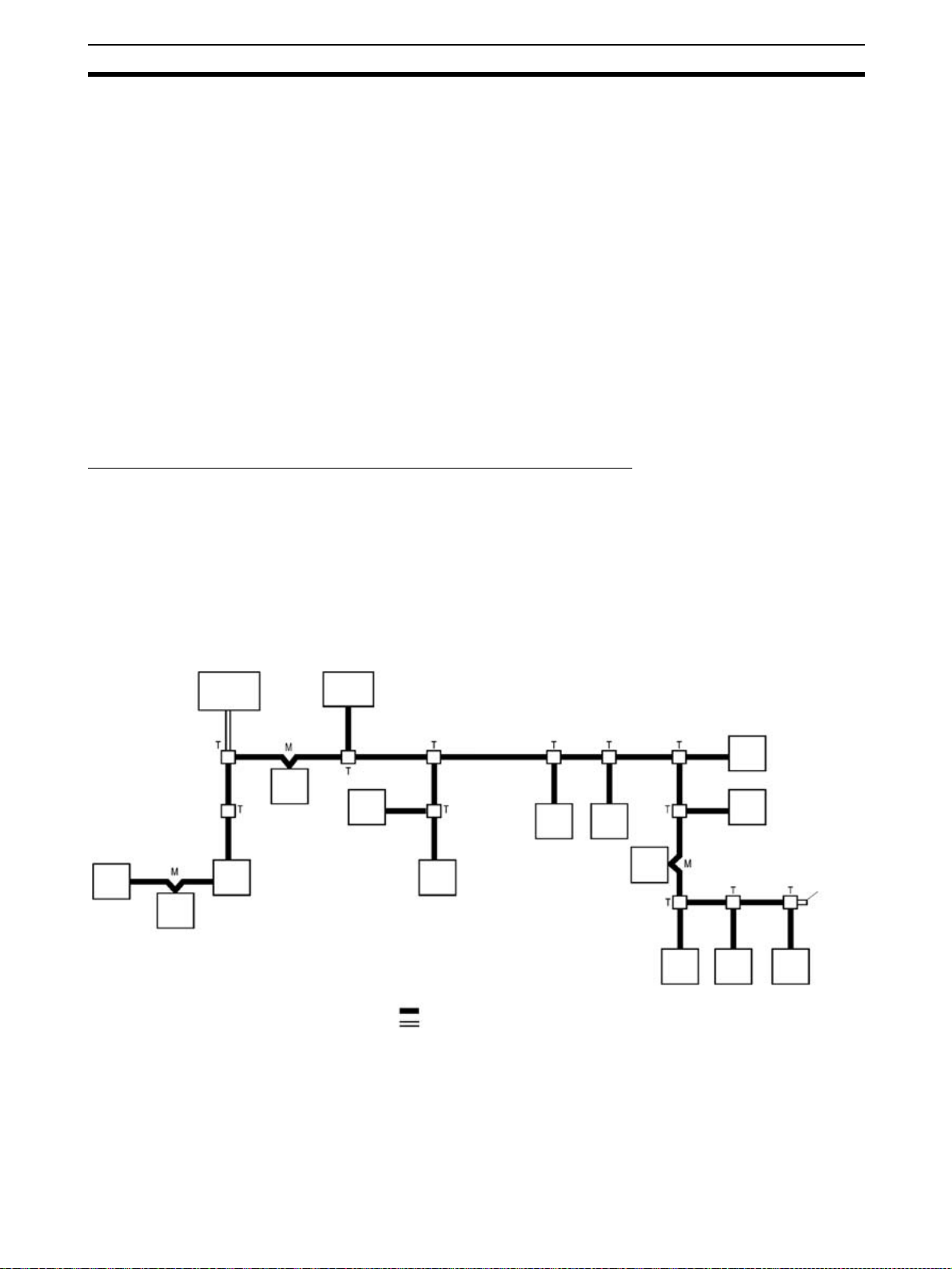

System with No Distinction between Main and Branch Lines

The diagram below shows a CompoBus/S System in which it is not necessary

to distinguish between the main line and branch lines. This applies to the following conditions.

• The system operates in Long-distance Communications Mode with 4-conductor VCTF cable.

• The system operates in Long-distance Communications Mode with Special Flat Cable.

(The maximum length of cable is 200 m regardless of the type of communications cable.)

Slave

Slave

Communications Power

Supply

Slave

Slave

Master

Slave

Slave

Communications cable

Power supply cable

Slave

Slave

Slave

Slave

Slave

Terminator

Slave Slave Slave

T: T-branch connection

M: Multidrop connection

Master The Master administers the CompoBus/S System and manages the external

I/O of the Slaves. There is only one Master in a CompoBus/S System and the

Master can be connected anywhere.

Slaves The external I/O connected to the Slaves is processed by communicating with

the Master through the CompoBus/S System.

9

Page 31

Compatible Devices Section 1-3

Cables CompoBus/S communications are transmitted through Special Flat Cable or

4-conductor VCTF cable. The communications power supply can be supplied

through either of the cables.

Connection Methods Two methods can be used to connect the CompoBus/S Master and Slaves:

the T-branch method and the multidrop method. With the T-branch method,

the Slave is connected to a line that branches off from the communications

cable wherever desired. With the multidrop method, the Master or Slave is

connected directly to the communications cable. These two connection methods can both be used in the same system and it is possible to make a secondary branch from a branch line. Use OMRON’s Branch Connector for Special

Flat Cable, a T-joint for a shielded connector, or a commercially available terminal block to create a branch from the communications cable.

Termina tor A terminator must be connected to the end of the communications cable far-

thest from the Master in order to stabilize communications. There are three

kinds of terminating resistors available, a connector for use with Special Flat

Cable, a terminal block, and a shielded connector. In a system in which distinguishing between the main and branch lines is not necessary, only a single

terminator farthest from the Master is required regardless of the position the

Master is connected to the communications cable.

1-3 Compatible Devices

1-3-1 Compatible Masters

Masters with

Communications

Functions

PLC C200HX-CPU3@-

Master

Unit

Communications

mode

Analog I/O

Te r mi n al

connection

Max. number of Masters

Master

Unit

mounting

location

(Z)E/ CPU4@-(Z)E,

C200HG-CPU3@-

(Z)E/CPU4@-(Z)E,

C200HE, C200HS

C200HW-SRM21-V1 CS1W-SRM21 CJ1W-SRM21 CQM1-SRM21-V1

High-speed Communications Mode or Long-distance Communications Mode (switched using the DIP switch

on front panel)

Possible

10 Units (when

using a single Special I/O Unit node

number (i.e., 10

words))

5 Units (when using

two Special I/O Unit

node number (i.e.,

20 words))

Can be mounted on the CPU Backplane or Expansion I/O Backplane. Can’t be mounted on a SYSMAC BUS Slave (RT) Rack.

There are three types of Master Units which can be used in CompoBus/S

Systems. The model of the Master Unit which must be used depends on the

PLC being used.

C200HX-CPU5@-

(Z)E/ CPU6@-(Z)E/

CPU8@-(Z)E,

C200HG-CPU5@-

(Z)E/ CPU6@-(Z)E,

CS Series

16 Units (when

using a single Special I/O Unit node

number (i.e., 10

words))

8 Units (when using

two Special I/O Unit

node number (i.e.,

20 words))

CS Series CJ Series CQM1, CQM1H

96 Units (when

using a single Special I/O Unit node

number (i.e., 10

words))

95 Units (when

using two Special

I/O Unit node number (i.e., 20 words))

40 Units CQM1: 1 Unit

CQM1H: Up to the

number corresponding to the maximum

I/O points for the

CPU Unit.

Can be connected

in the CPU Rack or

Expansion Rack.

No restrictions.

10

Page 32

Compatible Devices Section 1-3

PLC C200HX-CPU3@-

Max. number of I/O

points per

Master

Number of

points per

node number

Number of

usable

node numbers per

Master

Master

Unit power

supply

(Z)E/ CPU4@-(Z)E,

C200HG-CPU3@-

(Z)E/CPU4@-(Z)E,

C200HE, C200HS

256 points (128 inputs/128 outputs) or 128 points (64 inputs/64 outputs)

The max. number of I/O points depends on the DIP switch settings.

The area allocated to Special I/O Units is used for I/O.

8-point mode 8-point mode 8-point mode or 4-

IN0 to IN7 and OUT0 to OUT7 or IN0 to

IN15 and OUT0 to OUT15

Not required. (Power is supplied from the

PLC.)

C200HX-CPU5@-

(Z)E/ CPU6@-(Z)E/

CPU8@-(Z)E,

C200HG-CPU5@-

(Z)E/ CPU6@-(Z)E,

CS Series

CS Series CJ Series CQM1, CQM1H

CQM1-CPU11-E/

21-E:

32 points (16 inputs/

16 outputs) or

64 points (32 inputs/

32 outputs)

CQM1-CPU41-EV1/

42-EV1/

43-EV1/44-EV1:

32 points (16

inputs/16 outputs)

or

64 points (32

inputs/32 outputs)

or

128 points

(64 inputs/

64 outputs)

The max. number of

I/O points depends

on the DIP switch

settings.

The IR area is used

for I/O.

point mode

IN0 to IN7 and OUT0 to OUT7 or IN0 to

IN15 and OUT0 to OUT15

Not required. (Power is supplied from the

PLC.)

When 8 points are

used per node:

IN0 to IN1/OUT0

to OUT1 or

IN0 to IN3/OUT0

to OUT3 or

IN0 to IN7/OUT0

to OUT7

When 4 points are

used per node:

IN0 to IN3/OUT0

to OUT3 or

IN0 to IN7/OUT0

to OUT7 or

IN0 to IN15/OUT0

to OUT15

Not required.

(Power is supplied

from the PLC.)

11

Page 33

Compatible Devices Section 1-3

PLC C200HX-CPU3@-

Te r mi n al

for connecting

communications

power supply for

Slaves

Status indicators

(Z)E/ CPU4@-(Z)E,

C200HG-CPU3@-

(Z)E/CPU4@-(Z)E,

C200HE, C200HS

Not provided Provided Not provided

The PLC’s AR Area contains the active

node flags and communications error flags

for each Slave.

C200HX-CPU5@-

(Z)E/ CPU6@-(Z)E/

CPU8@-(Z)E,

C200HG-CPU5@-

(Z)E/ CPU6@-(Z)E,

CS Series

CS Series CJ Series CQM1, CQM1H

The PLC’s Auxiliary Area contains the

active node flags and communications

error flags for each Slave. The DM Area

contains an area for Slave registration and

setting communications stop mode.

There is an alarm

output terminal in

the terminal block.

Note 1. Previous Master Unit models (without -V1), which do not support the Long-

distance Communications Mode, cannot be used when an Analog I/O Terminal is connected as a Slave. If used, incorrect data may be transmitted.

2. Refer to

SECTION 4 Master Unit Specifications and Operations for more

details on the Master Units.

Master with Built-in CPU The following Master Control Unit models, which have a built-in CPU Unit, are

used for distributed I/O control in CompoBus/S Systems. Refer to the SRM1

Master Control Unit Operation Manual (W318-E1-@) and the CPM2C-S PLC

Operation Manual (W377-E1-@) for details.

SRM1 Master Control Unit

Item Master Control Unit

SRM1-CPU01-V2 SRM1-CPU02-V2

Peripheral port Yes Yes

RS-232C port --- Yes

Program capacity 4K words

Max. number of I/O points 256 (128 inputs/128 outputs)

Communications mode High-speed Communications Mode or Long-distance

Number of points per node

number

Number of usable node

numbers per Master

Status indicators The PLC’s AR Area contains the active node flags and

Communications Mode (switched using PLC Setup)

8-point mode

IN0 to IN7 and OUT0 to OUT7 or IN0 to IN15 and

OUT0 to OUT15

communications error flags for each Slave.

CPM2C-S PLC

The CPM2C-S PLC has built-in CompoBus/S Master and DeviceNet Slave

functions. Models that support I/O links with host PLCs are available as well.

Item Master Control Unit

CPM2C-S@@@CCPM2C-S@@@C-DRT

Peripheral port The same connector is used.

RS-232C port

Program capacity 4K words

Max. number of I/O points 256 (128 inputs/128 outputs)

Communications mode High-speed Communications Mode or Long-distance

Communications Mode (switched using PLC Setup)

12

Page 34

Compatible Devices Section 1-3

Item Master Control Unit

CPM2C-S@@@CCPM2C-S@@@C-DRT

Number of points per node

number

Number of usable node

numbers per Master

Status indicators The PLC’s AR Area contains the active node flags and

DeviceNet Slave function Not provided Provided

8-point mode

IN0 to IN7 and OUT0 to OUT7 or IN0 to IN15 and OUT0

to OUT15

communications error flags for each Slave.

Master Units and

Corresponding

Communications Modes

Master Units support only High-speed Communications Mode or both Highspeed Communications Mode and Long-distance Communications Mode.

Slave Analog Terminals can be connected to the Units that support both Highspeed and Long-distance Communications Modes. These Units are an

upgraded version and, by switching the communications mode, can be used

instead of the Units that support only the High-speed Communications Mode.

Item Unit supporting

Communications modes

Analog I/O Terminal connections No Yes

High-speed Communications Mode

Long-distance Communications Mode

High-speed Communications only

Ye s Y e s

No Yes

Unit supporting

High-speed and

Long-distance

Communications

The following models are available.

PLC Units supporting

CS-series, C200HX/C200HG/

C200HE-(Z)E, and C200HS

Master Units

CS-series Master Units --- CS1W-SRM21

CJ-series Master Units --- CJ1W-SRM21

CQM1 Master Units CQM1-SRM21 CQM1-SRM21-V1

SRM1 SRM1-C0@

CPM2C-S --- CPM2C-S@@@ (-DRT)

High-speed Com-

munications

C200HW-SRM21 C200HW-SRM21-V1

SRM1-C0@-V1

Units supporting High-

speed and Long-distance

Communications

SRM1-C0@-V2

Note Master Units that do not support Long-distance Communications Mode can-

1-3-2 Slave Units

not be used when connecting an Analog Terminal as a Slave. If used, incorrect data may be transmitted.

The SRT1/SRT2 Series provides Slaves that support only High-speed Communications Mode or both High-speed Communications Mode and Long-distance Communications Mode. The SRT2-series Slaves that support Highspeed and Long-distance Communications Modes are an upgraded version

13

Page 35

Compatible Devices Section 1-3

and, by switching the communications mode, can be used instead of the

Slaves that support only the High-speed Communications Mode.

Item Slaves supporting

Slave Series SRT1 Series SRT2 Series

Communica-

tions modes

High-speed Communications Mode

Long-distance Communications Mode

High-speed Com-

munications

Ye s Y e s

No Yes

Available models are shown in the following table.

Type Previous models New models I/O points Power supply

Slave SRT1 Series SRT2 Series

Remote Terminals

with Transistors

SRT1-ID04 SRT2-ID04 4 inputs (NPN) Multiple supSRT1-ID04-1 SRT2-ID04-1 4 inputs (PNP)

SRT1-ID08 SRT2-ID08 8 inputs (NPN)

SRT1-ID08-1 SRT2-ID08-1 8 inputs (PNP)

SRT1-ID16 SRT2-ID16 16 inputs (NPN)

SRT1-ID16-1 SRT2-ID16-1 16 inputs (PNP)

SRT1-ID16T SRT2-ID16T 16 inputs

(NPN, 3-tier terminal block)

SRT1-ID16T-1 SRT2-ID16T-1 16 inputs

(PNP, 3-tier terminal block)

SRT1-OD04 SRT2-OD04 4 outputs (NPN)

SRT1-OD04-1 SRT2-OD04-1 4 outputs (PNP)

SRT1-OD08 SRT2-OD08 8 outputs (NPN)

SRT1-OD08-1 SRT2-OD08-1 8 outputs (PNP)

SRT1-OD16 SRT2-OD16 16 outputs (NPN)

SRT1-OD16-1 SRT2-OD16-1 16 outputs (PNP)

SRT1-OD16T SRT2-OD16T 16 outputs

(NPN, 3-tier terminal block)

SRT1-OD16T-1 SRT2-OD16T-1 16 outputs

(PNP, 3-tier terminal block)

SRT1-MD16T SRT2-MD16T 8 inputs, 8 outputs

(NPN, 3-tier terminal block)

SRT1-MD16T-1 SRT2-MD16T-1 8 inputs, 8 outputs

(PNP, 3-tier terminal block)

Slaves supporting

High-speed and

Long-distance

Communications

plies

14

Page 36

Compatible Devices Section 1-3

Type Previous models New models I/O points Power supply

Slave SRT1 Series SRT2 Series

Connector Terminals (8-point/16point Transistors)

Connector Terminals (32-point Transistors)

Remote Terminals

with Relays

Remote Terminals

with Power MOS

FETs

Water-resistant Terminals (Transistors)

Sensor Terminals SRT1-ID08S SRT2-ID08S 8 inputs Network

Remote I/O Modules

None SRT2-VID08S 8 inputs

(NPN, sensor connectors)

SRT2-VID08S-1 8 inputs

(PNP, sensor connectors)

SRT2-VID16ML 16 inputs

(NPN, MIL connectors)

SRT2-VID16ML-1 16 inputs

(PNP, MIL connectors)

SRT2-VOD08S 8 outputs

(NPN, sensor connectors)

SRT2-VOD08S-1 8 outputs

(PNP, sensor connectors)

SRT2-VOD16ML 16 outputs

(NPN, MIL connectors)

SRT2-VOD16ML-1 16 outputs

(PNP, MIL connectors)

None SRT2-ID32ML 32 inputs

(NPN, MIL connectors)

SRT2-ID32ML-1 32 inputs

(PNP, MIL connectors)

SRT2-OD32ML 32 outputs

(NPN, MIL connectors)

SRT2-OD32ML-1 32 outputs

(PNP, MIL connectors)

SRT2-MD32ML 16 inputs, 16 outputs

(NPN, MIL connectors)

SRT2-MD32ML-1 16 inputs, 16 outputs

(PNP, MIL connectors)

SRT1-ROC08 SRT2-ROC08 8 outputs Local

SRT1-ROC16 SRT2-ROC16 16 outputs

SRT1-ROF08 SRT2-ROF08 8 outputs

SRT1-ROF16 SRT2-ROF16 16 outputs

None SRT2-ID04CL 4 inputs (NPN) Multiple sup-

SRT2-ID04CL-1 4 inputs (PNP)

SRT2-ID08CL 8 inputs (NPN)

SRT2-ID08CL-1 8 inputs (PNP)

SRT2-OD04CL 4 outputs (NPN)

SRT2-OD04CL-1 4 outputs (PNP)

SRT2-OD08CL 8 outputs (NPN)

SRT2-OD08CL-1 8 outputs (PNP)

SRT1-ND08S SRT2-ND08S 4 inputs, 4 outputs

SRT1-OD08S SRT2-OD08S 8 outputs

(NPN, connector outputs)

SRT1-ID16P SRT2-ID16P 16 inputs (NPN, PCB attachment) --SRT1-OD16P SRT2-OD16P 16 outputs (NPN, PCB attach-

ment)

Multiple supplies

plies

Local

15

Page 37

Compatible Devices Section 1-3

Type Previous models New models I/O points Power supply

Slave SRT1 Series SRT2 Series

Fiber Amplifier

Communications

Unit

Analog Input Terminals

Analog Output Terminals

I/O Link Units None CPM1A-SRT21 8 inputs, 8 outputs

CPM2C I/O Link

Units

Network Power Supply These Slaves use a single power supply and can be supplied with power from

None E3X-SRT21 8-point input or 16 point input (with

Fiber Amplifier Unit connected)

None SRT2-AD04 Switchable between 4-point, 3-

point, 2-point, and 1-point analog

input

None SRT2-DA02 Switchable between 2-point and 1-

point analog output

(For CPM1A/CPM2A)

None CPM2C-SRT21 8 inputs, 8 outputs (For CPM2C) ---

Network

---

Note 1. The power supply requirements are described below. Refer to 2-3 Supply-

ing Power to the Slaves

for details on these power supplies.

2. Refer to SECTION 5 Slave Specifications and Operations for details on

Slaves.

the Special Flat Cable for CompoBus/S.

Multiple Power Supplies These Slaves require two separate power supplies for communications and I/

O.

The communications power can be supplied from the Special Flat Cable for

CompoBus/S.

Local Power Supply These Slaves require a single external power supply. The power cannot be

supplied from the Special Flat Cable for CompoBus/S.

1-3-3 Cables

Cables The following table lists the cables that can be used in a CompoBus/S Sys-

tem.

Cable Specifications

2-conductor VCTF cable

(sold commercially)

4-conductor VCTF cable

(sold commercially)

Special Flat Cable

(OMRON SCA1-4F10,

100 m)

Vinyl-clad VCTF JIS C 3306

Two 0.75 mm

Resistance: 25.1 Ω/km at 20°C

Use only 2-conductor VCTF cable.

Vinyl-clad VCTF JIS C 3306

Four 0.75 mm

supply wires)

Resistance: 25.1 Ω/km at 20°C.

Four 0.75 mm

(2 signal wires and 2 power supply wires)

Maximum ambient temperature: 60°C

2

conductors (2 signal wires)

2

conductors (2 signal wires and 2 power

2

conductors

16

Note 1. Do not use cables other than those specified above.

2. For information on communications cables specified by overseas manufacturers, refer to

Appendix Standard Models.

Page 38

Compatible Devices Section 1-3

The communications distance depends on the cable used, as follows:

Cable Mode Main line

2-conductor VCTF

cable

4-conductor VCTF

cable

Special Flat Cable High-speed Commu-

High-speed Communications Mode

Long-distance Communications Mode

High-speed Communications Mode

Long-distance Communications Mode

nications Mode

Long-distance Com-

munications Mode

length

100 m max. 3 m max. 50 m max.

500 m max. 6 m max. 120 m max.

30 m max.

(See note.)

Flexibly branched, provided that the

total length of cable is a maximum of

200 m.

30 m max.

(See note.)

Flexibly branched, provided that the

total length of cable is a maximum of

200 m.

Note When 4-conductor VCTF cable or Special Flat Cable is used to connect fewer

than 16 Slaves, the main line can be up to 100 m long and the total branch

line length can be up to 50 m in High-speed Communications Mode. (These

are the same conditions as when 2-conductor VCTF cable is used.)

Branch

line length

3 m max.

(See note.)

3 m max.

(See note.)

Tot al

branch

line length

30 m max.

(See note.)

30 m max.

(See note.)

1-3-4 Connectors/Terminal Blocks

The following table lists the connectors that can be used in a CompoBus/S

System.

Connector Model Comments

Branch Connector SCN1-TH4 Use this connector to create a branch line

Extension Connector SCN1-TH4E Use this connector to extend the Special Flat

Connector Terminator SCN1-TH4T This connector has a built-in terminator.

Connectors with Cable with a

socket and plug

Connector with Cable with a

female socket

Connector with Cable with a

male plug

XS2W-D42@-@81-@ Connectors with cable used to connect the

XS2F-D42@-@80-@ A connector with cable used to connect the

XS2H-D421-@80-A A connector with a cable used to connect the

from the main line.

(Used with Special Flat Cable only.)

Cable.

(Used with Special Flat Cable only.)

Water-resistant Terminal to a T-joint.

Can be used as a power supply cable (with

the female socket connected to the Waterresistant Terminal).

Can be used as an I/O cable for sensors that

have connectors (with the male plug connected to the Water-resistant Terminal, if the

product has a model number suffix “A”).

Water-resistant Terminal to a T-branch connector.

Can be used as a power supply cable (with

the female socket connected to the Waterresistant Terminal) and the other end wired to

a commercially available terminal block.

Water-resistant Terminal to an I/O device.

Can be used as an I/O cable (with the male

plug connected to the Water-resistant Terminal) and the other end wired to the I/O device.

17

Page 39

Compatible Devices Section 1-3

Connector Model Comments

Connector Socket Assembly

(female for screw, crimp, solder terminals)

Connector Plug Assembly

(male for screw, crimp, solder

terminals)

T-joint XS2R-D427-5 A joint used to T-branch a VCTF cable (e.g., a

Communications Connector

(6 pins)

Shielded Terminator Plug

(Male)

Terminal-block Terminator SRS1-T This terminal block has a built-in terminator.

XS2C-D4S7 A connector used to connect to the communi-

XS2C-D4@@ A connector used to connect to the external

XS2G-D4S7 A connector used to connect to the T-joint

XS2G-D4@@ A connector used to connect to the I/O con-

FK-MCP1.5/6-STF-

3.81

MC1.5/6-STF-3.81 A communications connector for connecting

SRS2-1 A shielded connector terminator model con-

cations connector or external power supply

connector of the Water-resistant Terminal or a

T- j oi n t p l ug .

Applicable cable dia.: 6 to 8 mm

Applicable conductor size: 0.18 to 0.75 mm

power supply connector of the Water-resistant

Terminal or a T-joint plug.

Applicable cable dia.: 3 to 6 mm

Applicable conductor size: 0.18 to 0.3 or 0.5

to 0.75 mm

socket.

Applicable cable dia.: 6 to 8 mm

Applicable conductor size: 0.18 to 0.75 mm

nector of the Water-resistant Terminal or a Tjoint socket.

Applicable cable dia.: 3 to 6 mm

Applicable conductor size: 0.18 to 0.3 or 0.5

to 0.75 mm

communications cable or power supply