Page 1

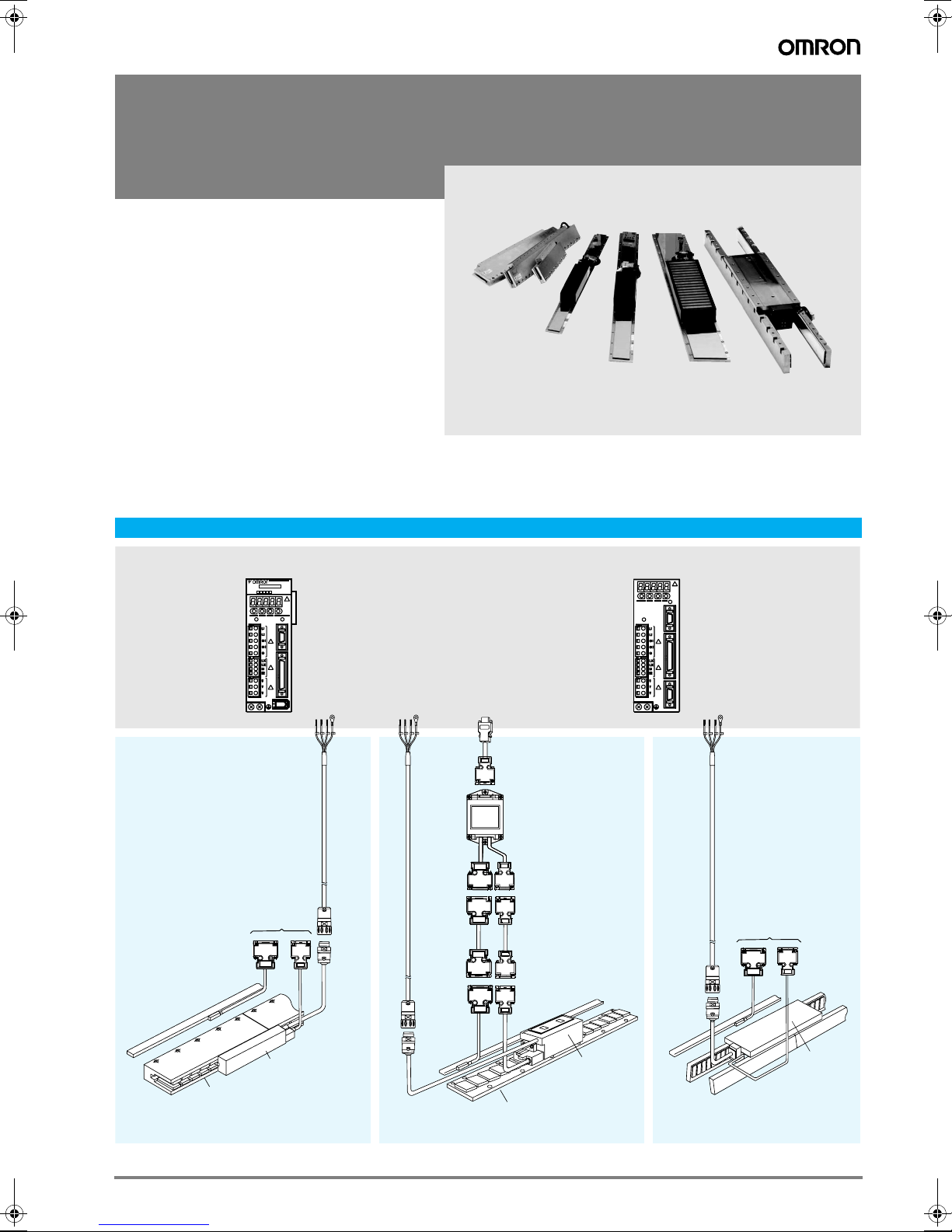

SGLG@, SGLF@, SGLT@

Sigma linear motors

Direct drive linear servo motors for faster

machine cycles

• Direct control of the motors using XtraDrive and

Sigma-II drives

• Improved machine performance

• Easy of operation & high reliability

• Designed for high force density in compact

packages

• Exhibit exceptional force linearity even at near peak

force regions

• Extremely energy efficient, due to its optimized

magnetic circuitry design and high-density windings

• Can reach speeds as high as 5 meters per second.

• Coreless and iron core types available

Ratings

• 230 VAC Single-phase 12.5 to 560 N (1200 N Peak)

• 400 VAC Three-phase 80 to 2250 N (7500 N Peak)

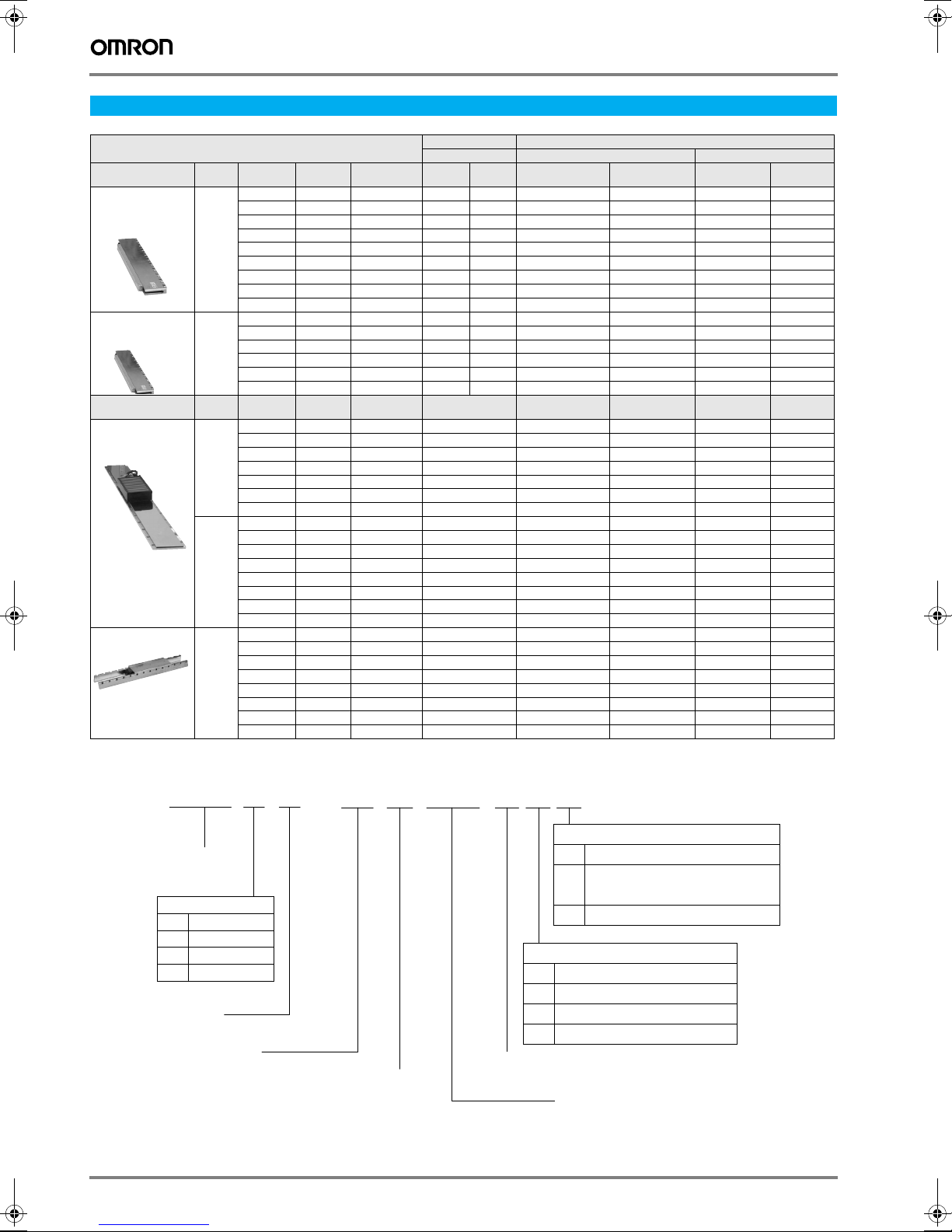

System configuration

(Refer to servo drive chapter)

SGDH-

Ver.

(To serial converter unit)

Linear

scale

Linear scale

CHARGE POWER

CN2

SERVOPACK

200V

Servo Drive with option

boards for

CN3

flexible system

configuration

CN1

Sigma-II

Servo Drive

Hall

sensor

Power

cable

Power

Power

cable

Linear scale

cable

(extension)

Linear

scale

Drive options

Serial

converter

cable

Serial converter

unit

Hall sensor

cable

(extension)

Power

cable

Hall

sensor

POWER

Intelligent

CN3

CHARGE

Servo Drive

CN1

XtraDrive

CN2

Power

cable

Power

(To serial converter unit)

Hall

Linear

scale

sensor

Linear coil

SGLGW

Magnetic way

SGLGM

SGLG_ Linear

Servo Motor

Power

SGLF_ Linear

Servo Motor

Magnetic way

SGLFM

Linear coil

SGLFW

Magnetic way

SGLTM

Linear coil

SGLTW

SGLT_ Linear

Servo Motor

195Sigma linear motors

Page 2

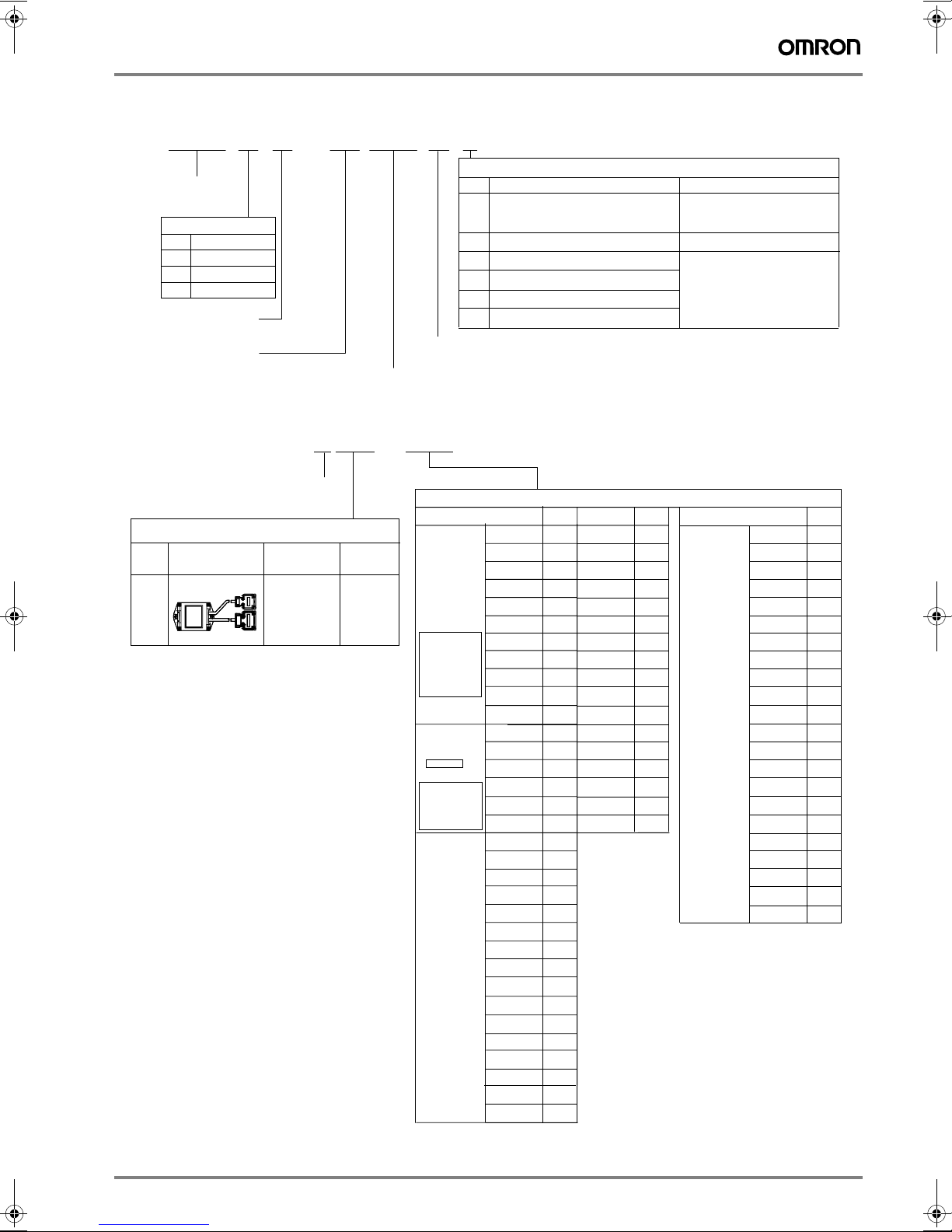

Servo Motor / Servo Drive Combination

Sigma series linear servo motor Serial converter Servo drive

Type Voltage Rated

SGLGW coreless

standard-force

magnetic ways

SGLGW coreless

high-force

magnetic ways

Type Voltage Rated

SGLFW

linear motors

SGLTW

linear motors

230 V 12.5 N 40 N 30A050 [B / C] 158 250 SGDH-A5AE-OY - XD-P5-MN01 -

230 V 57 N 230 N 40A140 [B / C] 059 255 SGDH-02AE-OY - XD-02-MN01 -

230 V 25 N 86 N 20A090A 017 SGDH-02AE-OY - XD-02-MN01

400 V 80 N 220 N 35D120A 211 - SGDH-05DE-OY - XD-05-TN

400 V 300 N 600 N 35D170H 193 - SGDH-10DE-OY - XD-10-TN

25 N 80 N 30A080 [B / C] 156 251 SGDH-01AE-OY - XD-01-MN01 47 N 140 N 40A140 [B / C] 001 252 SGDH-01AE-OY - XD-01-MN01 70 N 220 N 60A140 [B / C] 004 258 SGDH-02AE-OY - XD-02-MN01 93 N 280 N 40A253 [B / C] 002 253 SGDH-02AE-OY - XD-02-MN01 140 N 420 N 40A365 [B / C] 003 254 SGDH-04AE-OY - XD-04-MN01 140 N 440 N 60A253 [B / C] 005 259 SGDH-04AE-OY - XD-04-MN01 210 N 660 N 60A365 [B / C] 006 260 SGDH-08AE-S-OY - XD-08-MN 325 N 1300 N 90A200 [A / C] 101 264 SGDH-15AE-S-OY - XD-15-MN -

114 N 460N 40A253 [B / C] 060 256 SGDH-04AE-OY - XD-04-MN01 171 N 690 N 40A365 [B / C] 061 257 SGDH-08AE-S-OY - XD-08-MN 85 N 360N 60A140 [B / C] 062 261 SGDH-02AE-OY - XD-02-MN01 170 N 720 N 60A253 [B / C] 063 262 SGDH-08AE-S-OY - XD-08-MN 255 N 1080 N 60A365 [B / C] 047 263 SGDH-15AE-S-OY - XD-15-MN -

40 N 125 N 20A120A 018 SGDH-02AE-OY - XD-02-MN01

80 N 220 N 35A120A 019 SGDH-02AE-OY - XD-02-MN01

160 N 440 N 35A230A 020 SGDH-08AE-S-OY - XD-08-MN01

280 N 600 N 50A200B 181 SGDH-08AE-S-OY - XD-08-MN

560 N 1200 N 50A380B 182 SGDH-15AE-S-OY - XD-15-MN

560 N 1200 N 1ZA200B 183 SGDH-15AE-S-OY XD-15-MN

160 N 440 N 35D230A 212 - SGDH-05DE-OY - XD-05-TN

280 N 600 N 50D200B 189 - SGDH-10DE-OY - XD-10-TN

560 N 1200 N 50D380B 190 - SGDH-15DE-OY - XD-15-TN

560 N 1200 N 1ZD200B 191 - SGDH-15DE-OY - XD-15-TN

1120 N 2400 N 1ZD380B 192 - SGDH-30DE-OY - XD-30-TN

1500 N 3600 N 1ED380B 333 - SGDH-20DE-OY - XD-20-TN

2250 N 5400 N 1ED560B 334 - SGDH-30DE-OY - XD-30-TN

600 N 1200 N 35D320H 194 - SGDH-20DE-OY - XD-20-TN

450 N 900 N 50D170H 195 - SGDH-10DE-OY - XD-10-TN

900 N 1800 N 50D320H 196 - SGDH-20DE-OY - XD-20-TN

670 N 2600 N 40D400B 197 - SGDH-30DE-OY - XD-30-TN

1000 N 4000 N 40D600B 198 - SGDH-50DE-OY - XD-50-TN

1300 N 5000 N 80D400B 199 - SGDH-50DE-OY - XD-50-TN

2000 N 7500 N 80D600B 200 - SGDH-75DE-OY - -

Peak force Model code for

force

Peak force Model code 230 V

force

JZDP-@008-[code] Sigma-II series XtraDrive

Rev A, B

code for

Rev C

230 V

(1-phase)

(1-phase)

400 V

(3-phase)

400 V

(3-phase)

230 V

(1-phase)

230 V

(1-phase)

400 V

(3-phase)

400 V

(3-phase)

Motor coil

㧙

WFSGL

Linear Σ series

Linear servo motor

Servo motor model

Code

Specifications

G

Coreless

F-type iron core

F

T-type iron core

T

W : Coil assembly

Magnet height

196 AC servo systems

35 D 120 A P

Code

P

C

H

Design revision order

Voltage

A㧦200 VAC

D㧦400 VAC

A,B,C

D

Cable connector for main circuit cable

Code

MS connector or connector made

−

by Tyco Electronics AMP K.K.

Connector made by Interconnectron

D

With hall sensor (standard)

With hall sensor and forced cooling

Length of coil assembly

Specifications

Options

Specifications

Forced cooling

Page 3

Magnetic way

SGL

FM

35 324 A C

Linear Σ series

Linear servo motor

Model

Code

Specifications

G

Coreless

F

F-type iron core

T

T-type iron core

M : Magnetic way

Magnet width

Length of magnetic way

Serial converter unit

D008JZDP – – 001

Design revision order

A,B,C

Serial converter unit model

Symbol

Note: * When using a linear scale made by Heidenhain an extension

cable is required

Appearance

A008

D008

Applicable

linear scale

Made by

Renishaw

or

(Heidenhain *)

Hall sensor

Yes

Code

C

With magnet cover

-Y

With base and magnet cover For SGLTM type

Mounting type 1

-M

Mounting type 1 & high thrust force

T-

Mounting type 2

T-M

Mounting type 2 & high thrust force

Design revision order

A,B,C

Servo motor model

30A050B

30A080B

40A140B

40A253B

SGLGW-

(coreless)

When a

standardforce

magnetic

way is used.

SGLGW +

SGLGM-

-M

(coreless)

When a

high-force

magnetic

way is used.

SGLFW-

(Iron core,

F-type)

40A365B

60A140B

60A253B

60A365B

90A200A

90A370A

90A535A

40A140B

40A253B

40A365B

60A140B

60A253B

60A365B

20A090A

20A120A

35A120A

35A230A

50A200B

50A380B

1ZA200B

1ZA380B

35D120A

35D230A

50D200B

50D380B

1ZD200B

1ZD380B

1ED380B

1ED560B

Options

Specifications Remarks

For iron-core types

- SGLFM

- SGLTM

For SGLGM type

Applicable linear servo motor

Symbol

158

156

001

002

003

004

005

006

101

102

103

059

060

061

062

063

047

017

018

019

020

181

182

183

184

211

212

189

190

191

192

333

334

Model

30A050C

30A080C

40A140C

40A253C

40A365C

60A140C

60A253C

60A365C

90A200C

90A370C

90A535C

40A140C

40A253C

40A365C

60A140C

60A253C

60A365C

Symbol

250

251

252

253

254

258

259

260

264

265

266

255

256

257

261

262

263

Servo motor model

SGLTW-

(Iron core,

T-type)

20A170A

20A320A

20A460A

35A170A

35A320A

35A460A

35A170H

35A320H

50A170H

50A320H

40A400B

40A600B

80A400B

80A600B

35D170H

35D320H

50D170H

50D320H

40D400B

40D600B

80D400B

80D600B

Symbol

011

012

013

014

015

016

105

106

108

109

185

186

187

188

193

194

195

196

197

198

199

200

Sigma linear motors 197

Page 4

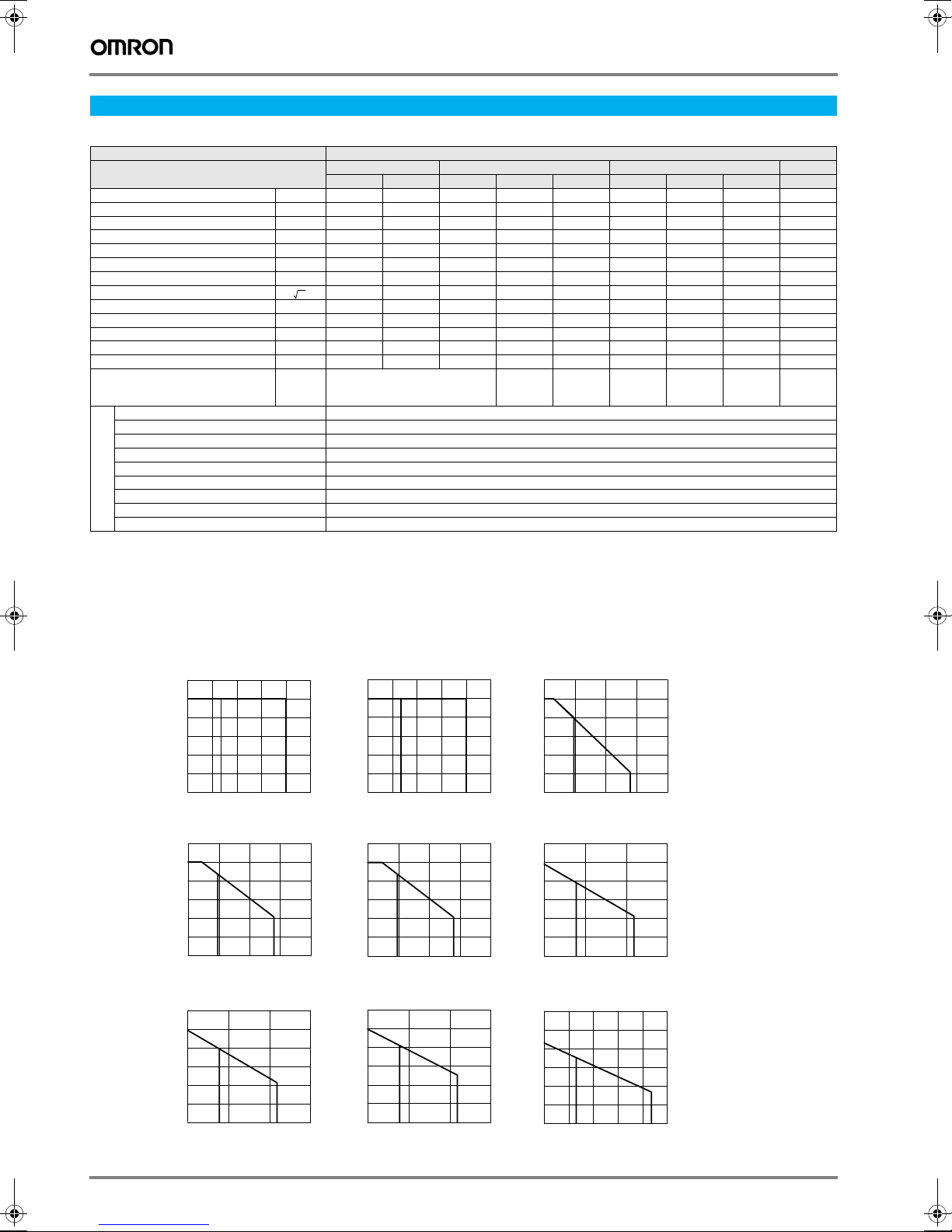

Servo motor specifications

Coreless SGLGW/SGLGM - (with standard-force magnetic ways)

Voltage 230 V

Linear servo motor

model SGLGW-

Rated force

Rated current

Instantaneous peak force

Instantaneous peak current

∗

∗

∗

∗

N 12.5 25 47 93 140 70 140 210 325

Arms 0,51 0,79 0.8 1.6 2.4 1,16 2,2 3,3 4.4

N 40 80 140 280 420 220 440 660 1300

Arms 1.62 2.53 2.4 4.9 7.3 3.5 7.0 10.5 17.6

Coil assembly weight kg 0.14 0.19 0.40 0.66 0.93 0.48 0.82 1.16 2.2

Force constant N / A

rms 26.4 33.9 61.5 61.5 61.5 66.6 66.6 66.6 78

BEMF constant V /(m / s) 8.8 11.3 20.5 20.5 20.5 22.2 22.2 22.2 26.0

Motor constant 3.7 5.6 7.8 11.0 13.5 11.1 15.7 19.2 26.0

Electrical time constant ms 0.2 0.4 0.4 0.4 0.4 0.5 0.5 0.5 1.4

N /

w

Mechanical time constant ms 7.30 4.78 5.59 4.96 4.77 3.41 3.08 2.98 3.18

Thermal resistance (with heat sink) K / W 5,19 3,11 1,67 0,87 0,58 1,56 0,77 0,51 0,39

Thermal resistance (without heat sink) K / W - - 3,02 1,80 1,23 2,59 1,48 1,15 1.09

Magnetic attraction N 000000000

Heat sink size mm 200 x

Time rating Continuous

Insulation class Class B

Ambient temperature 0 to +40 °C

Ambient humidity 20 to 80% (non-condensing)

Insulation resistance 500 VDC, 10 MΩ min.

Excitation Permanent magnet

Dielectric strength 1500 VAC for 1 minute

Basic specifications

Protection methods Self-cooled, air-cooling

Allowable winding temperature 130 °C

30A 40A 60A 90A

050C 080C 140C 253C 365C 140C 253C 365C 200C

300 x

12

300 x

400 x

12

400 x

500 x

12

200 x

300 x

12

300 x

400 x

12

400 x

500 x

12

800 x

900 x

12

Note: 1. The items marked with an * and “force and speed characteristics” are the values at a motor winding temperature of 100 °C during oper-

ation in combination with a servo drive. The others are at 20 °C (68°F).

2. The above specifications show the values under the cooling condition when a heat sink (aluminium board) listed in the following table is

mounted on the coil assembly.

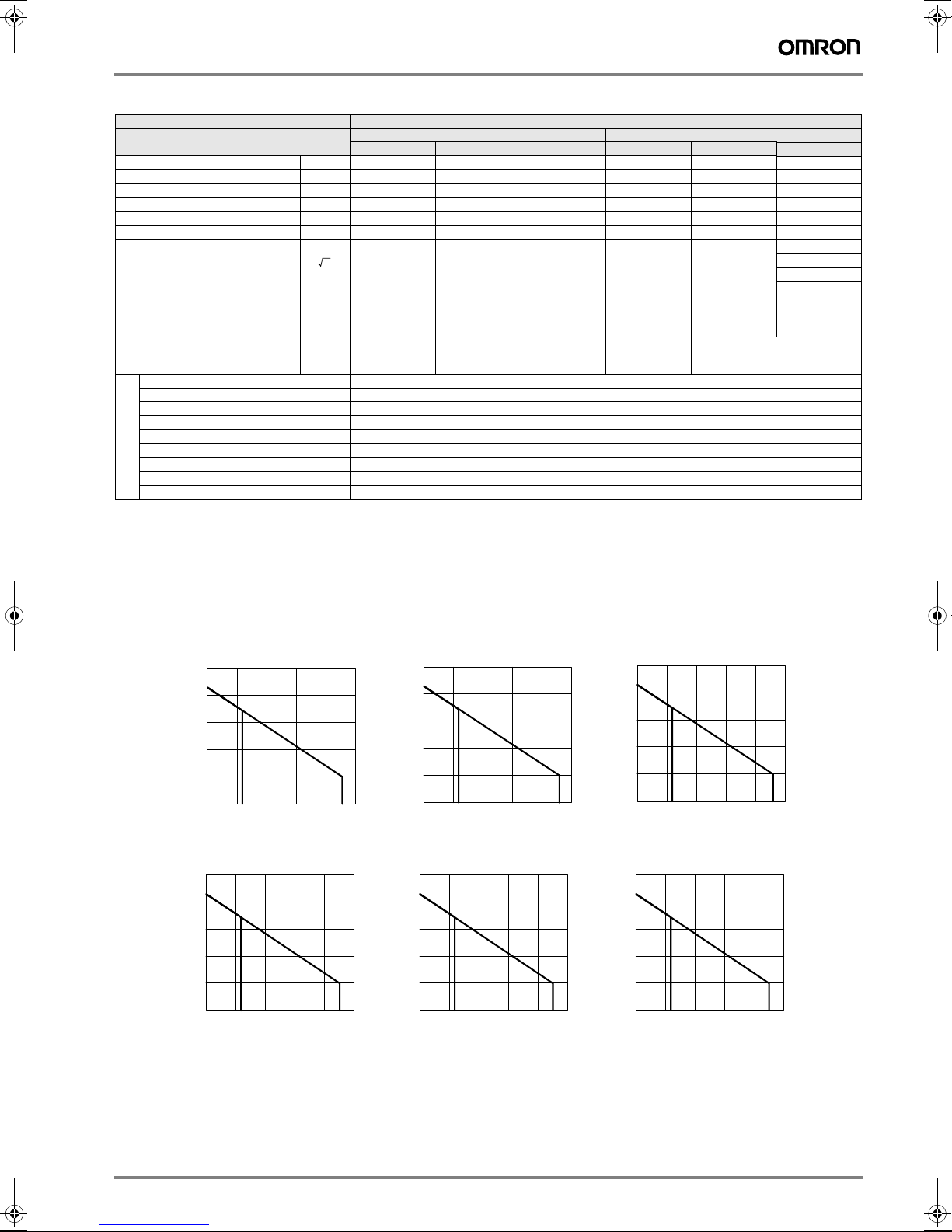

Force-speed characteristics - (with standard-force magnetic ways)

A: Continuous duty zone

B: Intermittent duty zone

SGLGW-30A050C

6.0

5.0

Motor

4.0

speed

3.0

(m/s)

A

2.0

1.0

0

0 10203040

SGLGW-40A253C

6.0

5.0

Motor

4.0

speed

(m/s)

Motor

speed

(m/s)

A

3.0

2.0

1.0

0

0 100 200 300 400

SGLGW-60A253C

6.0

5.0

4.0

A

3.0

2.0

1.0

0

0 200 400 600

Force (N)

Force (N)

Force (N)

SGLGW-30A080C

6.0

5.0

Motor

4.0

speed

3.0

(m/s)

B

50

A

2.0

1.0

0

0 20406080

Force (N)

Motor

speed

(m/s)

B

100

SGLGW-40A365C

6.0

5.0

Motor

4.0

speed

(m/s)

B

Motor

speed

(m/s)

B

A

3.0

2.0

1.0

0

0 150 300 450 600

SGLGW-60A365C

6.0

5.0

4.0

A

3.0

2.0

1.0

0

0 300 600 900

B

Force (N)

B

Force (N)

Motor

speed

(m/s)

Motor

speed

(m/s)

SGLGW-40A140C

6.0

5.0

4.0

A

3.0

2.0

1.0

0

0 50 100 150 200

SGLGW-60A140C

6.0

5.0

4.0

A

3.0

2.0

1.0

0

0 100 200 300

SGLGW-90A200C

6.0

5.0

4.0

A

3.0

2.0

1.0

0

0 300 600 900 1200 1500

B

Force (N)

B

Force (N)

Force (N)

B

198 AC servo systems

Page 5

Coreless SGLGW/SGLGM - (with high-force magnetic ways)

Voltage 230 V

Linear servo motor

model SGLGW-

Rated force

Rated current

Instantaneous peak force

Instantaneous peak current

Coil assembly weight kg 0.40 0.66 0.93 0.48 0.82 1.16

Force constant N / A

BEMF constant V /(m / s) 25.3 25.3 25.3 25.8 25.8 25.8

Motor constant 9.6 13.6 16.7 12.9 18.2 22.3

Electrical time constant ms 0.4 0.4 0.4 0.5 0.5 0.5

Mechanical time constant ms 3.69 3.24 3.12 2.52 2.29 2.21

Thermal resistance (with heat sink) K / W 1.67 0.87 0.58 1.56 0.77 0.51

Thermal resistance (without heat sink) K / W 3.02 1.80 1.23 2.59 1.48 1.15

Magnetic attraction N 0 0 0 0 0 0

Heat sink size mm 200 x

∗

∗

∗

∗

N 57 114 171 85 170 255

Arms 0.81.62.41.22.23.3

N 230 460 690 360 720 1080

Arms 3.2 6.5 9.7 5.0 10.0 14.9

rms 76.0 76.0 76.0 77.4 77.4 77.4

N /

w

Time rating Continuous

Insulation class Class B

Ambient temperature 0 to +40 °C

Ambient humidity 20 to 80% (non-condensing)

Insulation resistance 500 VDC, 10 MΩ min.

Excitation Permanent magnet

Dielectric strength 1500 VAC for 1 minute

Basic specifications

Protection methods Self-cooled, air-cooling

Allowable winding temperature 130 °C

140C 253C 365C 140C 253C 365C

300 x

12

40A 60A

300 x

400 x

12

400 x

500 x

12

200 x

300 x

12

300 x

400 x

400 x

12

500 x

12

Note: 1. The items marked with an * and “force and speed characteristics” are the values at a motor winding temperature of 100 °C during oper-

ation in combination with a servo drive. The others are at 20 °C (68°F).

2. The above specifications show the values under the cooling condition when a heat sink (aluminium board) listed in the following table is

mounted on the coil assembly.

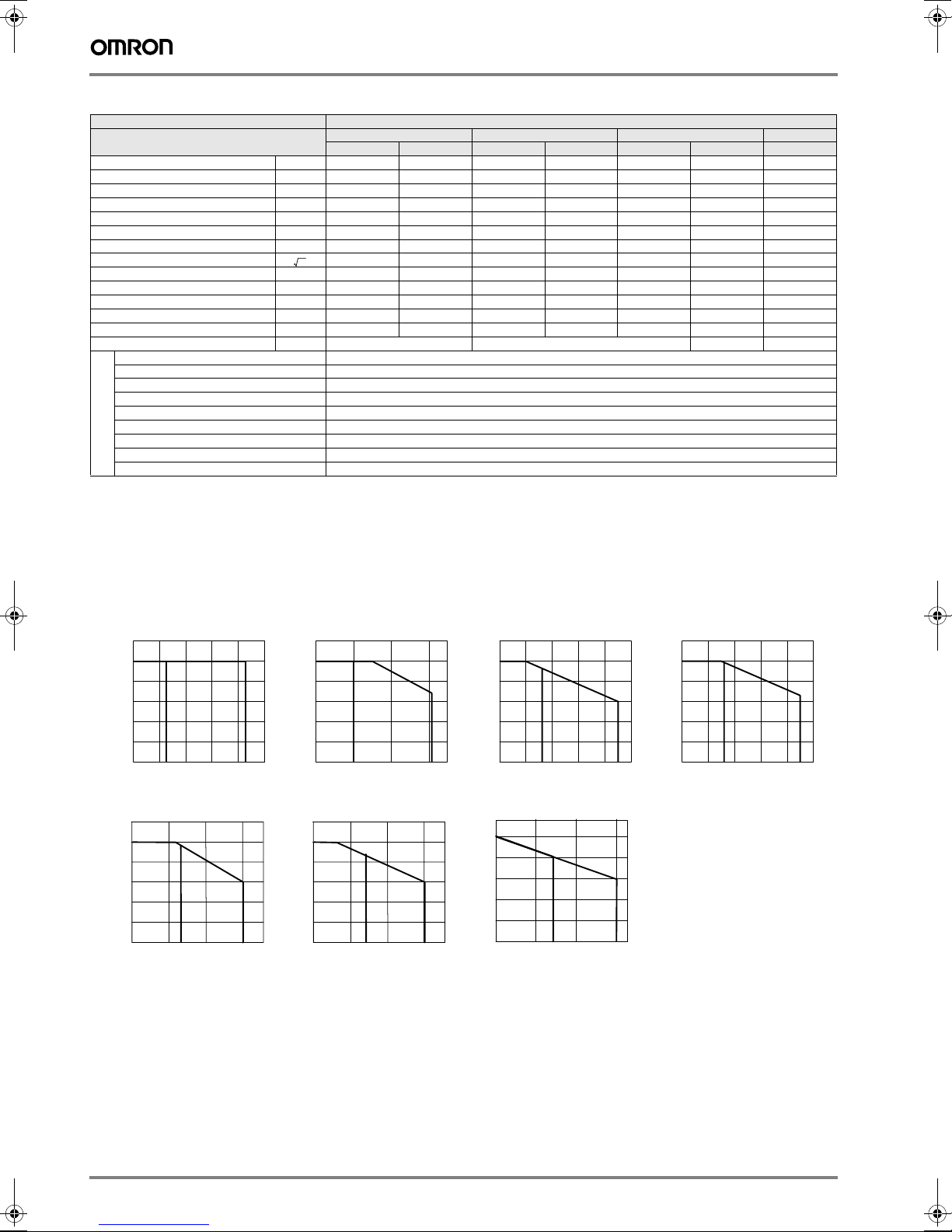

Force-speed characteristics - (with high-force magnetic ways)

A: Continuous duty zone

B: Intermittent duty zone

SGLGW-40A365C

5

4

3

2

A

1

0

0 150 450300 600 750

B

Force (N)

SGLGW-60A365C

5

4

3

2

A

1

0

0 240 720480 960 1200

B

Force (N)

Motor

speed

(m/s)

Motor

speed

(m/s)

SGLGW-40A140C

5

4

3

2

A

1

0

0 50 150100 200 250

B

Force (N)

SGLGW-60A140C

5

4

3

2

A

1

0

0 80 240160 320 400

B

Force (N)

Motor

speed

(m/s)

Motor

speed

(m/s)

SGLGW-40A253C

5

4

3

2

A

1

0

0 100 300200 400 500

B

Force (N)

SGLGW-60A253C

5

4

3

2

A

1

0

0 160 480320 640 800

B

Force (N)

Motor

speed

(m/s)

Motor

speed

(m/s)

Sigma linear motors 199

Page 6

Iron-core SGLFW/SGLFM (200 V)

Voltage 230 V

Linear servo motor

model SGLFW-

Rated force

Rated current

Instantaneous peak force

Instantaneous peak current

∗

∗

∗

∗

N 25 40 80 160 280 560 560

Arms 0.7 0.8 1.4 2.8 5.0 10.0 8.7

N 86 125 220 440 600 1200 1200

Arms 3.0 2.9 4.4 8.8 12.4 25.0 21.6

Coil assembly weight kg 0.7 0.9 1.3 2.3 3.5 6.9 6.4

Force constant N / A

rms 36.0 54.0 62.4 62.4 60.2 60.2 69.0

BEMF constant V /(m / s) 12.0 18.0 20.8 20.8 20.1 20.1 23.0

Motor constant 7.9 9.8 14.4 20.4 34.3 48.5 52.4

Electrical time constant ms 3.2 3.3 3.6 3.6 15.9 15.8 18.3

N /

w

Mechanical time constant ms 11.0 9.3 6.2 5.5 3.0 2.9 2.3

Thermal resistance (with heat sink) K / W 4.35 3.19 1.57 0.96 0.82 0.32 0.6

Thermal resistance (without heat sink) K / W 7.69 5.02 4.10 1.94 1.48 0.74 0.92

Magnetic attraction N 314 462 809 1586 1650 3260 3300

Heat sink size mm 125 x 125 x 13 254 x 254 x 25 400 x 500 x 40 254 x 254 x 25

Time rating Continuous

Insulation class Class B

Ambient temperature 0 to +40 °C

Ambient humidity 20 to 80% (non-condensing)

Insulation resistance 500 VDC, 10 MΩ min.

Excitation Permanent magnet

Dielectric strength 1500 VAC for 1 minute

Basic specifications

Protection methods Self-cooled

Allowable winding temperature 130 °C

20A 35A 50A 1ZA

090A 120A 120A 230A 200B 380B 200B

Note: 1. The items marked with an * and “force and speed characteristics” are the values at a motor winding temperature of 100 °C during oper-

ation in combination with a servo drive. The others are at 20 °C (68°F).

2. The above specifications show the values under the cooling condition when a heat sink (aluminium board) listed in the following table is

mounted on the coil assembly.

Force-speed characteristics (200 V)

A: Continuous duty zone

B: Intermittent duty zone

SGLFW-20A090A

6

5

Motor

4

speed

3

(m/s)

A B

2

1

0

0 20 40 60 80 100

Force (N)

SGLFW-50A200B

6

5

Motor

4

speed

3

(m/s)

2

1

0

0 400200 600

Force (N)

Motor

speed

(m/s)

Motor

speed

BA

(m/s)

SGLFW-20A120A SGLFW-35A120A SGLFW-35A230A

6

5

4

3

A

2

1

0

0 40 80 120 140

Force (N)

SGLFW-50A380B

6

5

4

3

2

1

0

0 800400 1200

Force (N)

BA

6

5

Motor

4

speed

(m/s)

B

3

A

2

1

0

0 50 100 150 200 250

6

5

4

Motor

speed

3

(m/s)

2

1

0

0 800400 1200

Force (N)

SGLFW-1ZA200B

B

BA

Force (N)

6

5

Motor

4

speed

3

(m/s)

A

2

1

0

0 100 200 300 400 500

B

Force (N)

200 AC servo systems

Page 7

Iron-core SGLFW/SGLFM (400 V)

Voltage 400 V

Linear servo motor

model SGLFW-

Rated force

Rated current

Instantaneous peak force

Instantaneous peak current

∗

∗

∗

∗

N 80 160 280 560 560 1120 1500 2250

Arms 0.7 1.4 2.3 4.5 4.9 9.8 6.4 9.6

N 220 440 600 1200 1200 2400 3600 5400

Arms 2.3 4.6 5.6 11.0 12.3 24.6 18.1 27.2

Coil assembly weight kg 1.3 2.3 3.5 6.9 6.4 11.5 22 33

Force constant N / A

rms 120.2 120.2 134.7 134.7 122.6 122.6 250 250

BEMF constant V /(m / s) 40.1 40.1 44.9 44.9 40.9 40.9 83.2 83.2

Motor constant 13.8 19.5 33.4 47.2 51.0 72.1 95.4 117

Electrical time constant ms 3.5 3.5 15.0 15.0 17.4 17.2 19.7 19.6

N /

w

Mechanical time constant ms 5.5 5.5 3.2 3.2 2.5 2.2 1.8 1.8

Thermal resistance (with heat sink) K / W 1.57 0.96 0.82 0.32 0.6 0.28 0.21 0.13

Thermal resistance (without heat sink) K / W 4.1 1.94 1.48 0.74 0.92 0.55 0.50 0.35

Magnetic attraction N 810 1590 1650 3260 3300 6520 9780 14600

Heat sink size mm 254 x 254 x 25 400 x 500

Time rating Continuous

Insulation class Class B

Ambient temperature 0 to +40 °C

Ambient humidity 20 to 80% (non-condensing)

Insulation resistance 500 VDC, 10 MΩ min.

Excitation Permanent magnet

Dielectric strength 1500 VAC for 1 minute

Basic specifications

Protection methods Self-cooled

Allowable winding temperature 130 °C

35D 50D 1ZD 1ED

120A 230A 200B 380B 200B 380B 380B 560B

x 40

254 x 254

x 25

400 x 500

x 40

609 x 762

x 50

762 x 1270

x 64

Note: 1. The items marked with an * and “force and speed characteristics” are the values at a motor winding temperature of 100 °C during oper-

ation in combination with a servo drive. The others are at 20 °C (68°F).

2. The above specifications show the values under the cooling condition when a heat sink (aluminium board) listed in the following table is

mounted on the coil assembly.

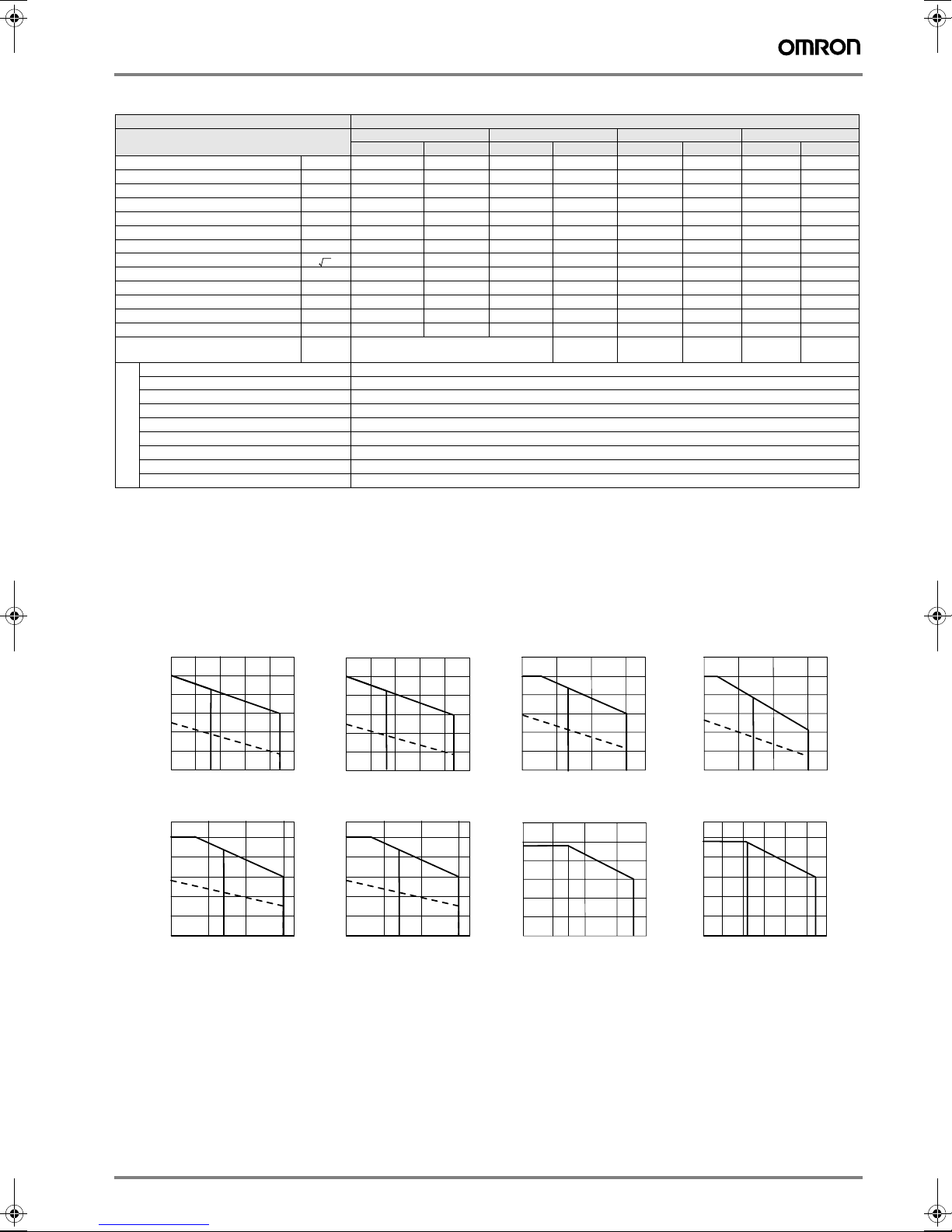

Force-speed characteristics (400 V)

A: Continuous duty zone

B: Intermittent duty zone

SGLFW-35D120A

6

5

Motor

4

speed

3

(m/s)

2

1

0

0 15050 100 200

SGLFW-1ZD200B

6

5

4

Motor

speed

3

(m/s)

2

1

0

0 800400 1200

Force (N)

A

Force (N)

SGLFW-35D230A

6

5

Motor

4

speed

(m/s)

BA

250

B

3

2

1

0

0 100 200 300 400 500

6

5

4

Motor

speed

3

(m/s)

2

1

0

0

Force (N)

SGLFW-1ZD380B

A

Force (N)

BA

B

1600800 2400

Motor

speed

(m/s)

Motor

speed

(m/s)

SGLFW-50D200B

6

5

4

3

A

2

1

0

0 400200 600

3.0

2.5

2.0

1.5

1.0

0.5

0

0

Force (N)

SGLFW-1ED380B

A

1000

2000

Force (N)

Motor

speed

4000

(m/s)

Motor

speed

(m/s)

B

B

3000

SGLFW-50D380B

6

5

4

3

A

2

1

0

0 800400 1200

Force (N)

SGLFW-1ED560B

3.0

2.5

2.0

A

1.5

1.0

0.5

0

0

30002000 5000

Force (N)

B

B

600040001000

Note: The dotted line indicates characteristics when the linear servo motor for 400 VAC is used with an input power supply for 200 VAC. In this

case, the serial converter should be changed. Contact your OMRON Yaskawa representatives.

Sigma linear motors 201

Page 8

Iron-core SGLTW/SGLTM (400 V)

Voltage 400 V

Linear servo motor

model SGLTW-

Rated force

Rated current

Instantaneous peak force

Instantaneous peak current

∗

∗

∗

∗

N 300 600 450 900 670 1000 1300 2000

Arms 3.2 6.5 3.2 6.3 3.7 5.5 7.2 11.1

N 600 1200 900 1800 2600 4000 5000 7500

Arms 7.5 15.1 7.3 14.6 20.7 30.6 37.6 56.4

Coil assembly weight kg 4.7 8.8 6 11 15 23 25 36

Force constant N / A

rms 99.6 99.6 153.3 153.3 196.1 196.1 194.4 194.4

BEMF constant V /(m / s) 33.2 33.2 51.1 51.1 65.4 65.4 64.8 64.8

Motor constant 36.3 51.4 48.9 69.1 59.6 73 85.9 105.2

Electrical time constant ms 14.3 14.3 15.6 15.6 14.4 14.4 15.4 15.4

N /

w

Mechanical time constant ms 3.5 3.5 2.5 2.5 4.2 4.2 3.2 3.2

Thermal resistance (with heat sink) K / W 0.76 0.4 0.61 0.3 0.24 0.2 0.22 0.18

Thermal resistance (without heat sink) K / W 1.26 0.83 0.97 0.8 0.57 0.4 0.47 0.33

Magnetic attraction

Magnetic attraction

∗1

∗2

N 00000000

N 1400 2780 2000 3980 3950 5890 7650 11400

Heat sink size mm 400 x 500 x 40 609 x 762 x 50

Time rating Continuous

Insulation class Class B

Ambient temperature 0 to +40 °C

Ambient humidity 20 to 80% (non-condensing)

Insulation resistance 500 VDC, 10 MW min.

Excitation Permanent magnet

Dielectric strength 1500 VAC for 1 minute

Basic specifications

Protection methods Self-cooled

Allowable winding temperature 130 °C

*1. The unbalanced magnetic gap resulting from the coil assembly installation condition causes a magnetic attraction on the coil assembly.

*2. The value indicates the magnetic attraction generated on one side of the magnetic way.

Note: 1. The items marked with an * and “force and speed characteristics” are the values at a motor winding temperature of 100 °C during oper-

ation in combination with a servo drive. The others are at 20 °C (68 °F).

2. The above specifications show the values under the cooling condition when a heat sink (aluminium board) listed in the following table is

mounted on the coil assembly.

35D 50D 40D 80D

170H 320H 170H 320H 400B 600B 400B 600B

Force-speed characteristics (400 V)

A: Continuous duty zone

B: Intermittent duty zone

SGLTW-35D170H SGLTW-35D320H

5

4

Motor

3

speed

(m/s)

2

1

0

0 400200 600

BA

Force (N)

6

5

Motor

4

speed

(m/s)

3

2

1

0

0 800400 1200

Force (N)

Motor

speed

BA

(m/s)

SGLTW-40D400B SGLTW-40D600B

Motor

speed

(m/s)

4

3

A

2

1

0

0 40002000

Motor

speed

(m/s)

B

4

3

Motor

speed

(m/s)

A

2

1

0

0 20001000 3000

Force (N) Force (N)

B

Note: The dotted line indicates characteristics when the linear servo motor for 400 VAC is used with an input power supply for 200 VAC. In this

case, the serial converter should be changed. Contact your OMRON Yaskawa representatives.

SGLTW-50D170H SGLTW-50D320H

5

4

3

2

1

0

0 600300 900

Force (N) Force (N)

BA

5

4

Motor

3

speed

(m/s)

2

1

0

0 1200600 1800

SGLTW-80D400B SGLTW-80D600B

4

3

A

2

1

0

0 4000 60002000

B

Force (N) Force (N)

Motor

speed

(m/s)

4

3

2

1

0

0 4000 6000 80002000

A

BA

B

202 AC servo systems

Page 9

Dimensions

Coreless SGLG@-30

Coil assembly: SGLGW-30A@@@@@D

Coil assembly model

SGLGW-

30A050D 50 48 30 20 20 0.85 0.14 *The value indicates the weight of coil assembly with a

30A080D 80725030250.95 0.19

Magnetic way: SGLGM-30@@@A

Magnetic way model

SGLGM-

30108A 108 54 2 0.6

30216A 216 162 4 1.1

30432A 432 378 8 2.3

L1 L2 L3 L4 L5 G(Gap) Approx.

2×screw

#4-40 UNC

Cable

UL20276,AWG26

22

12

44

(57)

(1)

G (Gap)

24

Hall sensor

connector specifications

9

5

Pin connector type:

17JE-23090-02 (D8C)

made by DDK Ltd.

The mating connector

Socket connector type:

17JE-13090-02 (D8C)

Stud type:17L-002C or

17L-002C1

L1

mm

G (Gap)

6

1

L2

mm

Name

plate

±50

(φ5.3)

500

(φ5)

AW

ޓغޓغ

N

Ins.

YASKAWA ELECTRIC CORPORATION JAPAN

Pin No.

Name

+5V (Power supply)

1

Phase U

2

Phase V

3

Phase W

4

0V (Power supply)

5

Not used

6

Not used

7

Not used

8

Not used

9

N Approx. weight

ߌ߇ߩᕟࠇࠅ

⏛ᕈࠍㄭߠߌࠆߥ㧍

May cause injury.

ෂ㒾

Keep magnetic materials

away.

9#40+0)

±50

500

Linear servo motor

Connector specifications

1

6

7

5

The coil assembly moves in the direction indicated by the arrow

when current flows in the order of phase U, V, and W.

Cable

UL2517,AWG25

L1

15

L3

L2

2

Extension: SROC06JMSCN169

3

Pin type: 021.423.1020

made by Interconnectron

4

The mating connector

Plug type: SPOC06KFSDN169

Name

Pin No.

Phase U

1

Phase V

2

Phase W

3

Not used

4

5

Not used

FG

6

Not used

7

kg

∗

weight

kg

17

L5

2×2-M4

Mounting screw depth: 5 mm on both sides

3

48.5

Units: mm

Hall sensor output signals

When the coil assembly moves in the

direction indicated by the arrow in the

figure, the relationship between the hall

sensor output signals Su, Sv, Sw and

the inverse power of each motor phase

Vu, Vv, Vw becomes as shown in the

following figure.

Lead color

Red

White

Blue

Green/yellow

Inverse

power

(V)

hall sensor unit.

4×M4 mounting screw,

depth 5

L4

Vu

Su

Vv

Sv

Vw

0 180 360 540

Electrical angle (° )

Sw

Name plate

CORELESS LINEAR SERVO MOTOR

غغغغغ㧙غغغغغغغغ

ޓغޓغ

W

ޓغޓغ

N

㧻㧛㧺غغغغغغ㧙غ

㧿㧛㧺غغغغغغغغغغغغغغغ

YASKAWA ELECTRIC CORPORATION JAPAN

A

غޓغ

Ins.

غ

Warning label

ෂ㒾

WARNING

4.5

36

Sigma linear motors 203

ߌ߇ߩᕟࠇࠅ

⏛ᕈࠍㄭߠߌࠆߥ㧍

May cause injury.

Keep magnetic materials

away.

Pitch 54

N×4.5 holes

8×counter boring 5L

L2

-0.1

L1 (1 unit)

-0.3

(18)

7.6

44

24

Units: mm

Page 10

Coreless SGLG@-40

Coil assembly: SGLGW-40A@@@@@D

Coil assembly model

SGLGW-

40A140D 140 125 90 30 52.5 45 3 4 0.40 *The value indicates the weight

40A253D 252.5 237.5 180 37.5 60 135 5 8 0.66

40A365D 365 350 315 30 52.5 270 8 14 0.93

L1 L2 L3 L4 L5 L6 N1 N2 Approx.

weight

kg

∗

of coil assembly with a hall sensor unit.

2×screw

#4-40 UNC

±50

25.4

6.5

4.8

±50

500

(φ5.3)

7.2

500

(φ

7)

0.5

14

15

1

30

L5

45

17

The coil assembly moves in the direction indicated by the arrow in the order of phase U, V, and W.

16

L4

45

4

78

L6

Mounting holes

N2×M4 tapped, depth 6 mm

L1

L3

Mounting holes on both sides

N1×M4 tapped, depth 6mm

Name plate

W

N

Ins.

㧻㧛㧺غغغغغغ㧙غ

㧿㧛㧺غغغغغغغغغغغغغغغ

YASKAWA ELECTRIC CORPORATION JAPAN

(7.5)

15

63

7

Gap 0.8

Gap 0.8

Hall sensor

connector specifications

9

5

Pin connector type:

17JE-23090-02 (D8C)

made by DDK Ltd.

The mating connector

Socket connector type:

17JE-13090-02 (D8C)

Stud type: 17L-002C or

ޓޓޓޓޓ17L-002C1

Linear servo motor

Pin No.

6

1

+5V (Power supply)

1

2

3

4

0V (Power supply)

5

6

7

8

9

Name

Phase U

Phase V

Phase W

Not used

Not used

Not used

Not used

connector specifications

2

1

Extension: SROC06JMSCN169

3

6

Pin type: 021.423.1020

made by Interconnectron

7

4

The mating connector

5

Plug type: SPOC06KFSDN169

Pin No.

Phase U

1

2

Phase W

3

Not used

4

5

Not used

6

Not used

7

Name

Phase V

FG

Lead color

Red

White

Blue

Green/yellow

Hall sensor output signals

When the coil assembly moves in the direction indicated by the arrow in the figure, the relationship between the hall sensor output signals Su, Sv, Sw and the inverse power of

each motor phase Vu, Vv, Vw becomes as

shown in the figure below.

Vu

Su

Inverse

Vv

power

(V)

Sv

Vw

0 180 360 540

Electrical angle (° )

Units: mm

Sw

Standard-force magnetic way: SGLGM-40@@@C@ High-force magnetic way: SGLGM-40@@@C@-M

Standard-force magnetic way

model SGLGM-

Mounting

type 1

Mounting

type 2

40090C 40090CT 90 45 2 0.8

40225C 40225CT 225 180 5 2.0

40360C 40360CT 360 315 8 3.1

40405C 40405CT 405 360 9 3.5

40450C 40450CT 450 405 10 3.9

L1mmL2 mmN Approx. weight

kg

High-force magnetic way model

Mounting

type 1

SGLGM-

Mounting

type 2

L1

L2 mmN Approx. weight

mm

40090C-M 40090CT-M 90 45 2 1.0

40225C-M 40225CT-M 225 180 5 2.6

40360C-M 40360CT-M 360 315 8 4.1

40405C-M 40405CT-M 405 360 9 4.6

40450C-M 40450CT-M 450 405 10 5.1

kg

-0.1

(1 unit)

L1

-0.3

%14'.'55.+0'#45'481/1614

ߌ߇ߩᕟࠇࠅ

غغغغغ㧙غغغغغغغغ

⏛ᕈࠍㄭߠߌࠆߥ㧍

#

ޓغޓغ غޓغ

9

/C[ECWUGKPLWT[

+PU

ޓغޓغ غ

0

ෂ㒾

-GGROCIPGVKEOCVGTKCNU

㧻㧛㧺غغغغغغ㧙غ

㧿㧛㧺غغغغغغغغغغغغغغغ

CYC[

9#40+0)

;#5-#9#'.'%64+%%14214#6+10,#2#0

Nameplate

Warning label

X

Pitch 45 (1.77)

X

7 (0.28)

22.5

(0.89)

N×φ5.5 (φ0.22) mounting hole (per unit)

22.5

(0.89)

Pitch 45 (1.77)

X

N×M5 mounting screws, depth 13 (0.51) (per unit)

X

Only for SGLGM- ޓCT.)

(

L2

L2

22.5

(0.89)*

22.5

(0.89)*

Note: Mounting dimensions of magnets revision B are equivalent to magnets revision C mounting type 2

204 AC servo systems

7.4

(0.29

12.2

(0.48

62 (2.44)

φ5.5 (φ0.22)

±0.2

φ10 (φ0.39)

±0.01

7.4

±0.2

(0.29

±0.01

)

4-C1

SGLGM40CT-M

31.8

)

(1.25)

0.01)

12.2

(0.48

15.9

(0.63)

5.4

(0.21)

13 (0.51)*

X-X

* Reference length

Units: mm (in)

±0.2

±0.01

62 (2.44)

φ10 (φ0.39)

φ5.5 (φ0.22)

)

SGLGM-

7.4

(0.29

40C-M

31.8

±0.2

±0.01

)

(1.25)

0.01)

4-C1

5.4

(0.21)

X-X

9

±0.2

(0.35

62 (2.44)

φ5.5 (φ0.22)

±0.01

)

7.4

±0.2

(0.29

±0.01

4-C1

φ10 (φ0.39)

* Reference length

Units: mm (in)

SGLGM40CT

25.4

(1.0)

)

13 (0.51)*

5.4

(0.21)

X-X

9

(0.35

(0.50)

±0.2

12.7

±0.01

62 (2.44)

φ10 (φ0.39)

φ5.5 (φ0.22)

-0.1

L1 (1 unit)

ෂ㒾

WARNING

Warning label

ߌ߇ߩᕟࠇࠅ

⏛ᕈࠍㄭߠߌࠆߥ㧍

May cause injury.

Keep magnetic materials

away.

-0.3

L2

L2

22.5

(0.89)*

22.5

(0.89)*

)

Nameplate

CORELESS LINEAR SERVO MOTOR

-

A

W

Ins.

N

O/N -

S/N

YASKAWA ELECTRIC CORPORATION JAPAN

X

Pitch 45

X

7 (0.28)

(1.77)

22.5

(0.89)

N×φ5.5 (φ0.22) mounting holes (per unit)

22.5 (0.89)

Pitch 45 (1.77)

X

N-M5 screws, depth 13 (0.51) (per unit)

X

(Only for SGLGM- ޓCT-M.)

SGLGM-

40C

25.4

±0.2

(1.0)

±0.01

)

4-C1

5.4

(0.21)

X-X

Page 11

Coreless SGLG@-60

㧿㧛㧺غغغغغغغغغغغغغغغ

㧻㧛㧺غغغغغغ㧙غ

N

Ins.

A

W

Coil assembly: SGLGW-60A@@@@@D

2×screw

#4-40 UNC

L5

45

L6

Mounting holes

N2×M4 tapped, depth 6 mm

Name plate

17

25.4

6.5

7.2

4.8

0.5

14

15

1

±50

500

(φ5.3)

(φ7)

98

±50

500

The coil assembly moves in the direction indicated by the arrow in the order of phase U, V, and W.

16

L4

45

4

L1

L3

Mounting holes on both sides

N1×M4 tapped, depth 6mm

15

30

L2

(7.5)

83

7

Gap 0.8

Gap 0.8

Hall sensor

Connector Specifications

9

5

Pin connector type:

17JE-23090-02 (D8C)

made by DDK Ltd.

The mating connector

Socket connector type:

17JE-13090-02 (D8C)

Stud type: 17L-002C or

ޓޓޓޓޓ17L-002C1

Coil assembly model

SGLGW-

6

Pin No.

+5V (Power supply)

1

Phase U

1

2

3

4

5

6

7

8

9

Phase V

Phase W

0V (Power supply)

Not used

Not used

Not used

Not used

L1 L2 L3 L4 L5 L6 N1 N2 Approx.

Name

Linear servo motor

Connector specifications

2

1

Extension: SROC06JMSCN169

3

6

Pin type: 021.423.1020

made by Interconnectron

7

4

5

The mating connector

Plug type: SPOC06KFSDN169

Name

Pin No.

Phase U

1

Phase V

2

Phase W

3

Not used

4

5

Not used

FG

6

Not used

7

Lead Color

Red

White

Blue

Green/yellow

Hall sensor output signals

When the coil assembly moves in the direction indicated by the arrow in the figure, the relationship between the hall sensor output signals Su, Sv, Sw and the inverse power of

each motor phase Vu, Vv, Vw becomes as

shown in the figure below.

Vu

Su

Inverse

Vv

power

(V)

Sv

Vw

0 180 360 540

Electrical angle (° )

weight

60A140D 140 125 90 30 52.5 45 3 4 0.48 *The value indicates the weight of

60A253D 252.5 237.5 180 37.5 60 135 5 8 0.82

60A365D 365 350 315 30 52.5 270 8 14 1.16

Units: mm

Sw

∗

kg

coil assembly with a hall sensor

unit.

Standard-force magnetic way: SGLGM-60@@@C@ High-force magnetic way: SGLGM-60@@@C@-M

Standard-force magnetic way

model SGLGM-

Mounting

type 1

Mounting

type 2

60090C 60090CT 90 45 2 1.1

60225C 60225CT 225 180 5 2.6

60360C 60360CT 360 315 8 4.1

60405C 60405CT 405 360 9 4.6

60450C 60450CT 450 405 10 5.1

-0.1

(1 unit)

L1

-0.3

%14'.'55.+0'#45'481/1614

ߌ߇ߩᕟࠇࠅ

غغغغغ㧙غغغغغغغغ

⏛ᕈࠍㄭߠߌࠆߥ㧍

غޓغ

#

9

ޓغޓغ

May cause injury.

+PU

غ

0

ޓغޓغ

ෂ㒾

Keep magnetic materials

㧻㧛㧺غغغغغغ㧙غ

㧿㧛㧺غغغغغغغغغغغغغغغ

away.

WARNING

;#5-#9#'.'%64+%%14214#6+10,#2#0

Nameplate

Warning label

X

Pitch 45

X

7 (0.28)

(1.77)

22.5

(0.89)

N×φ5.5 (φ0.22) mounting holes (per unit)

22.5 (0.89)

Pitch 45 (1.77)

X

N×M5 mounting screws, depth 13 (0.51) (per unit)

X

(

Only for SGLGM- ޓCT.)

L2

L2

Note: Mounting dimensions of magnets revision B are equivalent to magnets revision C mounting type 2.

22.5

(0.89)*

22.5

(0.89)*

L1

mm

L2 mmN Approx. weight

SGLGM-

60C

7.4

±0.2

25.4

9

±0.2

(1.0)

(0.29

±0.01

)

(0.35

5.4

(0.21)

±0.01

82 (3.23)

φ10 (φ0.39)

φ5.5 (φ0.22)

X-X

4-C1

7.4

±0.2

(0.29

)

kg

SGLGM60CT

25.4

±0.01

)

(1.0)

4-C1

13 (0.51)*

5.4

(0.21)

X-X

* Reference length

Units: mm (in)

9

±0.2

(0.35

±0.01

82 (3.23)

12.7

(0.50)

φ10 (φ0.39)

φ5.5 (φ0.22)

High-force magnetic way model

Mounting

type 1

SGLGM-

60090C-M 60090CT-M 90 45 2 1.3

60225C-M 60225CT-M 225 180 5 3.3

60360C-M 60360CT-M 360 315 8 5.2

60405C-M 60405CT-M 405 360 9 5.9

60450C-M 60450CT-M 450 405 10 6.6

)

Nameplate

Warning label

CORELESS LINEAR SERVO MOTOR

ߌ߇ߩᕟࠇࠅ

-

⏛ᕈࠍㄭߠߌࠆߥ㧍

A

W

May cause injury.

Ins.

N

ෂ㒾

Keep magnetic materials

O/N -

S/N

away.

WARNING

YASKAWA ELECTRIC CORPORATION JAPAN

X

Pitch 45

X

7 (0.28)

(1.77)

22.5

(0.89)

N×φ5.5 (φ0.22) mounting holes (per unit)

22.5 (0.89)

Pitch 45 (1.77)

X

N×M5 mounting screws, depth 13 (0.51) (per unit)

X

(Only for SGLGM- ޓCT-M.)

Mounting

-0.1

L1 (1 unit)

-0.3

L2

L2

type 2

mm

22.5

(0.89)*

22.5

(0.89)*

L1

L2 mmN Approx.

SGLGM-

60C-M

7.4±0.2

31.8

(0.29±0.01)

(1.25)

4-C1

5.4

(0.21)

X-X

12.2±0.2

(0.48±0.01)

82 (3.23)

φ10 (φ0.39)

φ5.5 (φ0.22)

7.4

(0.29±0.01)

weight

SGLGM60CT-M

±0.2

4-C1

13 (0.51)*

* Reference length

Units: mm (in)

31.8

(1.25)

5.4

(0.21)

kg

12.2

±0.2

(0.48±0.01)

82 (3.23)

15.9

(0.63)

φ10 (φ0.39)

φ5.5 (φ0.22)

X-X

Sigma linear motors 205

Page 12

Coreless SGLG@-90

Coil assembly: SGLGW-90A200@@D

Coil assembly model

SGLGW-

90A200D 199 189 130 40 60 95 3 4 2.2 *The value indicates the weight of

L1 L2 L3 L4 L5 L6 N1 N2 Approx.

weight

∗

L6L5

95

N2×M6 mounting screws, depth 9 mm

kg

coil assembly with a hall sensor

unit.

49

Gap1

Gap1

11.8

50.8

Hall sensor

connector specifications

6

9

5

Pin connector type:

17JE-23090-02㧔D8C㧕

made by DDK Ltd.

The mating connector

Socket connector type:

17JE-13090-02㧔D8C㧕

Stud type: 17L-002C or

ޓޓޓޓޓ17L-002C1

2×screws

#4-40 UNC

Cableޓޓޓޓޓޓޓ

UL20276,AWG26

2

26

138

110

1

φ5.3

Pin No.

1

2

3

4

5

6

7

8

9

±50

500

Cable

UL2517,AWG15

Name

㧗5V (Power supply)

Phase U

Phase V

Phase W

0V (Power supply)

Not used

Not used

Not used

Not used

Name plate

±50

500

65

φ10.5

Note: The coil assembly moves in the direction

indicated by the arrow when current

flows in the order of phase U, V, and W.

Linear servo motor

Connector specifications

2

1

Extension: SROC06JMSCN169

3

6

Pin type: 021.423.1020

made by Interconnectron

7

4

5

The mating connector

Plug type: SPOC06KFSDN169

Name

Pin No.

Phase U

1

Phase V

2

Phase W

3

Not used

4

5

Not used

FG

6

Not used

7

Lead color

Red

White

Blue

Green/yellow

L3L4

(See note.)

2×N1-M6 Mounting screws, depth 9 mm

(on both sides)

L1

L2

Hall sensor output signals

When the coil assembly moves in the direction indicated by the arrow in the figure, the relationship between the hall sensor output signals Su, Sv, Sw and the

inverse power of each motor phase Vu,

Vv, Vw becomes as shown in the figure

below.

Vu

Su

Inverse

Vv

power

(V)

Vw

0 180 360 540

Electrical angle㧔° 㧕

32

8

121

Units: mm

Sv

Sw

Magnetic way: SGLGM-90@@@A

Magnetic way model

SGLGM-

90252A 252 189 4 7.3

90504A 504 441 8 14.7

8.5

L1

mm

Name plate

CORELESS LINEAR SERVO MOTOR

ߌ߇ߩᕟࠇࠅ

غغغغغ㧙غغغغغغغغ

⏛ᕈࠍㄭߠߌࠆߥ㧍

A

ޓغޓغ

غޓغ

W

Ins.

May cause injury.

ޓغޓغ

غ

N

ෂ㒾

㧻㧛㧺غغغغغغ㧙غ

Keep magnetic materials

㧿㧛㧺غغغغغغغغغغغغغغغ

away.

WARNING

YASKAWA ELECTRIC CORPORATION JAPAN

X

X

Pitch 63

31.5

N-mounting holes (per unit)

L2

mm

Warning label

L1

N Approx.

weight kg

-0.1

(1 unit)

-0.3

L2

㧔31.5㧕

18.5

110

13.8

95.5

50.8

φ12

φ6.6

6.5

X-X

Units: mm

206 AC servo systems

Page 13

Iron-core SGLF@-20

Coil assembly: SGLFW-20A@@@A@D

Coil assembly model

SGLFW-

20A090A 91 36 72 2 0.7

20A120A 127 72 108 3 0.9

L1 L2 L3 N Approx.

weight kg

㧔44㧕

㧔22㧕㧔22㧕

㧔10.2㧦With magnet cover)

㧔10㧦 Without magnet cover)

Hall sensor

Connector specifications

9

5

Pin connector type:

17JE-23090-02㧔D8C㧕

made by DDK Ltd.

The mating connector

Socket connectoro type:

17JE-13090-02㧔D8C㧕

Stud type: 17L-002C or

ޓޓޓޓޓ17L-002C1

㧔32㧕

2

㧔6㧕

0.5

㧔4.2: With magnet cover)

34

㧔4: Without magnet cover)

㧔Gap 0.8: With magnet cover)

㧔Gap 1: Without magnet cover)

45±

0.1

SGLFW-20A090AD

20

30 36

12.5

Pin No.

6

1

5.5

17.5

22

40

㧔20㧕

12.5

22.5

2×M4 tapped holes, depth 5.5

22.5

Name

+5V (Power supply)

1

Phase U

2

Phase V

3

Phase W

4

0V (Power supply)

5

Not used

6

Not used

7

Not used

8

Not used

9

Magnetic way

2×screws

#4-40 UNC

500

㧔φ4.2㧕

Linear servo motor

Connector specifications

2

1

3

6

7

4

5

Pin No.

1

2

3

4

5

6

7

50 min.

Hall sensor

50

±

50

30 min.

±

㧔φ6.1㧕

500

Nameplate

Note: The coil assembly moves in the direction indicated by the arrow,

when current flows in the order of phase U, V, and W.

SGLFW-20A120AD

20

30

12.5

Extension: SROC06JMSCN169

Pin type: 021.423.1020

made by Interconnectron

The mating connector

Plug type: SPOC06KFSDN169

Name

Lead color

Phase U

Red

Phase V

White

Phase W

Blue

Not used

Not used

Green/yellow

FG

Not used

L1

㧔25㧕

L23030

36

㧔12㧕

㧔7.5㧕

20

AA

㧔10㧕

㧔12.5㧕

See the figures

and

12

36

below.

L3

3×M4 tapped holes, depth 5.5

72

Hall sensor output signals

When the coil assembly moves in the di-

rection indicated by the arrow in the figure, the relationship between the hall sensor output signals Su, Sv, Sw and the

inverse power of each motor phase Vu,

Vv, Vw becomes as shown in the figure

below.

Inverse

power

(V)

7

2.55.5

A㧙A

22.5

Vu

Vv

Vw

0 180 360 540

(See note.)

8

Units: mm

Su

Sv

Sw

Electrical angle㧔° 㧕

Magnetic way: SGLFM-20@@@A@

Magnetic way model

SGLFM-

20324A 324 270 (54 × 5) (331.6) 6 0.9

20540A 540 486 (54 × 9) (547.6) 10 1.4

20756A 756 702 (54 × 13) (763.6) 14 2

10

Note: 1. Multiple SGLFM-20A magnetic ways can be connected. Connect magnetic ways so that the reference marks match one on the

other in the same direction as shown in the figure.

2. The magnetic way may affect pacemakers. Keep a minimum distance of 200 mm from the magnetic way

-0.1

L1

-0.3

Coil assembly

㧔17.5㧕

㧔40㧕

4

6

45±0.1

(22.5)

(34)

㧔Gap1㧕

(Two φ4 marks are engraved.)

Mounting screw

Sigma linear motors 207

L2 (L3) N Approx.

9.9q

㧔4.5㧕

㧔22㧕

44

22

4.5 35

Reference marks

The height of screw head: 4.2 mm max.

30.8

0

-0.2

SNSN

YASKAWA

TYPE:

54

O/N

S/N

MADE IN JAPAN

Name plate

weight kg

㧔L3㧕

L2

L1

-0.1

-0.3

2×N×φ4.8

mounting holes

Reference mark

SNSN

(54)

(30.8)

Units: mm

YASKAWA

YASKAWA

TYPE:

Reference mark

O/N

S/N

MADE

Page 14

Iron-core SGLF@-35

Coil assembly: SGLFW-35@@@@A@D

Coil assembly model

SGLFW-

35120AD 127 72 108 6 1.3

35230AD 235 180 216 12 2.3

L1 L2 L3 N Approx.

weight kg

(10.2: With magnet cover)

(10: Without magnet cover)

Hall sensor

Connector specifications

Pin connector type:

7JE-23090-02 (D8C)

made by DDK Ltd.

The mating connector

Socket connector type:

17JE-13090-02 (D8C)

Stud type: 17L-002C or

ޓޓޓޓޓ17L-002C1

6

9

5

1

(32)

(30)

(60)

(30)

(6)

34

45±

SGLFW-35120AD

18

35

30 36

8.5

12.5

Pin No.

1

2

3

4

5

6

7

8

9

2

5.5

37

(35)

0.5

12.5

(4.2: With magnet cover)

(4: Without magnet cover)

(Gap 0.8: With magnet cover)

(Gap1: Without magnet cover))

0.1

6×M4 tapped holes, depth 5.5

72

Name

+5V (Power supply)

Phase U

Phase V

Phase W

0V (Power supply)

Not used

Not used

Not used

Not used

Magnetic way

25

55

30

2×screws

#4-40 UNC

30

SGLFW-35AAD

Linear servo motor 200 V

Connector specifications

1

2

6

3

7

4

5

Pin No.

1

2

3

4

5

6

7

Hall sensor

50

500±

50

(φ4.2)

500±

(φ6.1)

Name plate

ޓ SGLFW-35230AD

35

12.5

Extension: SROC06JMSCN169

Pin type: 021.423.1020

made by Interconnectron

The mating connector

Plug type: SPOC06KFSDN169

Name

Phase U

Phase V

Phase W

Not used

Not used

FG

Not used

50 min.

30

30

30 min.

12

A㧙A

188.5

30 36

SGLFW-35DAD

Linear servo motor 400 V

Connector specifications

5

4

L1

L2

36

(10.5)

18

(8.5)

See the figures

and below.

L3

8

2.5

The coil assembly moves in the

direction indicated by the arrow

when current flows in the order

of phase U, V, and W.

5.5

12×M4 tapped holes, depth 5.5

180 (36 × 5)

Extension: LRRA06AMRPN182

6

1

Pin type: 021.279.1020

made by Interconnectron

2

The mating connector

Plug type: LPRA06BFRBN170

Name

Pin No.

Phase U

1

Phase V

2

Phase W

4

Not used

5

Not used

6

Ground

AA

25

(7.5)

35

(12.5)

7

30

Units: mm

Hall sensor output signals

When the coil assembly moves in the di-

rection indicated by the arrow in the figure, the relationship between the hall sensor output signals Su, Sv, Sw and the

inverse power of each motor phase Vu,

Vv, Vw becomes as shown in the figure

below.

Vu

Inverse

power

Vv

(V)

Vw

Su

Sv

Sw

0 180 360 540

Electrical angle (° )

Magnetic way: SGLFM-35@@@A@

Coil assembly

㧔34㧕

45±

0.1

-0.1

L1

-0.3

㧔25㧕

60

㧔55㧕

㧔30㧕

㧔Two f4 marks are engraved.)

㧔Gap1㧕

The height of screw head must be 4.2 mm max.

Assembly dimensions

L2 (L3) N Approx.

㧔4.5㧕

51

30 㧔30㧕

4.5

Reference marks

32.2

Magnetic way model

SGLFM-

35324A 324 270 (54 × 5) (334.4) 6 1.2

35540A 540 486 (54 × 9) (550.4) 10 2

35756A 756 702 (54 × 13) (766.4) 14 2.9

6104

Note: 1. Multiple SGLFM-35A magnetic ways can be connected. Connect magnetic ways so that the reference marks match one on the

other in the same direction as shown in the figure.

2. The magnetic way may affect pacemakers. Keep a minimum distance of 200 mm from the magnetic way.

208 AC servo systems

weight kg

9.9˚

㧔L3㧕

2´N-f4.8 mounting holes

SSNSSNNN

O/N

YASKAWA

S/N

TYPE:

0

-0.2

DATE

MADE IN JAPAN

Name plate

54

L2

-0.1

L1

-0.3

Reference mark

㧔54㧕

㧔32.2㧕

Units: mm

YASKAWA

TYPE:

Reference mark

O/N

S/N

MADE

Page 15

Iron-core SGLF@-50

k

Coil assembly: SGLFW-50@@@@B@D

Coil assembly model

SGLFW-

50200BD 215 120 180 6 3.5

50380BD 395 300 360 12 6.9

L1 L2 L3 N Approx.

weight kg

(40)

(37.5)

(75)

(37.5)

(9)

58±

(14.2: With magnet cover)

(14: Without magnet cover)

Hall sensor

Connector specifications

Pin connector type:

7JE-23090-02 (D8C)

made by DDK Ltd.

The mating connector

6

9

5

1

Socket connector type:

17JE-13090-02 (D8C)

Stud type: 17L-002C or

ޓޓޓޓޓ17L-002C1

50 min.

30

3

7

33.7537.75

50.5

(47.5)

14

0.5

(5.2: With magnet cover)

43

(5: Without magnet cover)

0.1

(Gap 0.8: With magnet cover)

(Gap1: Without magnet cover))

SGLFW-50200BD ޓ SGLFW-50380BD

23.5

47.5

12

14

30 60

Pin No.

1

2

3

4

5

6

7

8

9

71.5

2×screws

#4-40 UNC

120

Name

+5V (Power supply)

Phase U

Phase V

Phase W

0V (Power supply)

Not used

Not used

Not used

Not used

Magnetic way

6×M4 tapped holes, depth 7

Hall sensor

50

500±

(φ4.2)

50

500±

(φ7.4)

Name plate

SGLFW-50AAD

Linear servo motor 200 V

Connector Specifications

1

6

7

5

Pin No.

1

2

3

4

5

6

7

2

3

4

Phase W

Not used

Not used

Not used

55

See the figures

25

and below.

23.5

47.5

12

14

50 min.

Extension: SROC06JMSCN169

Pin type: 021.423.1020

made by Interconnectron

The mating connector

Plug type: SPOC06KFSDN169

Name

Phase U

Phase V

FG

30 60

L1

60

L3

SGLFW-50DAD

Linear servo motor 400 V

Connector Specifications

4

L2

(15)

23.5

The coil assembly moves in the

(12)

direction indicated by the arrow

when current flows in the order of phase U, V, and W.

12×M4 tapped holes, depth 7

300 (60 × 5)

Extension: LRRA06AMRPN182

6

5

1

Pin type: 021.279.1020

made by Interconnectron

2

The mating connector

Plug type: LPRA06BFRBN170

Name

Pin No.

Phase U

1

Phase V

2

Phase W

4

Not used

5

Not used

6

Ground

40

(10)

47.5

(14)

10

Units: mm

Hall sensor output signals

When the coil assembly moves in the direction indicated by the arrow in the figure, the relationship between the hall sensor output signals Su, Sv, Sw and the

inverse power of each motor phase Vu,

Vv, Vw becomes as shown in the figure

below.

Vu

Inverse

power

Vv

(V)

Vw

Su

Sv

Sw

0 180 360 540

Electrical angle (° )

Magnetic way: SGLFM-50@@@A@

9

14

L1

㧔Gap1㧕

58±

-0.1

-0.3

Coil assembly

5

㧔43㧕

0.1

㧔33.75㧕

㧔71.5㧕

㧔37.75㧕

㧔Two φ4 marks are engraved.)

The height of screw head must be 5.2 mm max.

Assembly dimensions

Magnetic way model

SGLFM-

50135A 135 67.5 (67.5 × 1) (146.3) 2 1.0

50405A 405 337.5 (67.5 × 5) (416.3) 6 2.8

50675A 675 607.5 (67.5 × 9) (686.3) 10 4.6

50945A 945 877.5 (67.5 × 13) (956.3) 14 6.5

Note: 1. Multiple SGLFM-50A magnetic ways can be connected. Connect magnetic ways so that the reference marks match one on the

other in the same direction as shown in the figure.

2. The magnetic way may affect pacemakers. Keep a minimum distance of 200 mm from the magnetic way

Sigma linear motors 209

L2 (L3) N Approx.

8.6°

㧔5㧕5

㧔37.5㧕

75

65

37.5

Reference marks

39.4

0

-0.2

SSSNSNNN

O/N

YASKAWA

S/N

TYPE:

MADE IN JAPAN

DATE

Name plate

67.5

L2

L1

㧔L3㧕

-0.1

-0.3

weight kg

2×N-φ5.8 mounting holed

Reference mark

㧔67.5㧕

39.4㧕

Units: mm

YASKAWA

TYPE:

Reference mar

Page 16

Iron-core SGLF@-1Z

k

Coil assembly: SGLFW-1Z@@@@B@D

Coil assembly model

SGLFW-

1Z200BD 215 120 180 8 6.4

1ZD380BD 395 300 360 18 11.5

L1 L2 L3 N Approx.

(40)

3

7

Magnetic way

Hall sensor

50 min.

weight kg

5530

L1

60

L2

(15)

40

(10)

57.561.5

98

(95)

(125)

(62.5) (62.5)

(9)

43

r0.1

58

(14.2: With magnet cover)

(14: Without magnet cover)

119

2×screws

#4-40 UNC

14

0.5

(5.2: With magnet cover)

(5: Without magnet cover)

(Gap 0.8: With magnet cover)

(Gap1: Without magnet cover))

(φ4.2)

500

r50

500r50

(φ8.4)

50 min.

25

Name plate

Hall sensor

Connector specifications

6

9

5

1

Pin connector type:

17JE-23090-02 (D8C)

made by DDK Ltd.

The mating connector

Socket connector type:

17JE-13090-02 (D8C)

Stud type: 17L-002C or

ޓޓޓޓޓ17L-002C1

SGLFW-1Zغ200BغD

35.535.5

95

12

14

55

Pin No.

Name

+5V (Power supply)

1

2

Phase U

3

Phase V

4

Phase W

5

0V (Power supply)

6

Not used

7

Not used

8

Not used

9

Not used

9×M5 tapped holes, depth 7

60

120

SGLFW-1ZA200AD

Linear servo motor 200 V

Connector Specifications

1

6

7

5

Pin No.

95

14

2

Extension: SROC06JMSCN169

3

Pin type: 021.423.1020

made by Interconnectron

4

The mating connector

Plug type: SPOC06KFSDN169

Name

Phase U

1

Phase V

2

Phase W

3

Not used

4

5

Not used

FG

6

Not used

7

SGLFW-1ZD380BغD

35.535.5

12

55

Magnetic way: SGLFM-1Z@@@A@

Magnetic way model

SGLFM-

1Z135A 135 67.5 (67.5 × 1) (153.9) 2 1.7

1Z405A 405 337.5 (67.5 × 5) (423.9) 6 5

1Z675A 675 607.5 (67.5 × 9) (693.9) 10 8.3

1Z945A 945 877.5 (67.5 × 13) (963.9) 14 12

L1

-0.3

-0.1

L2 (L3) N Approx.

35.535.5

See the figures

and below.

The coil assembly moves in the

(12)

direction indicated by the arrow

when current flows in the order of phase U, V, and W.

18×M5 tapped holes, depth 7

60

300 (605)

SGLFW-1ZDAD

Linear servo motor 400 V

Connector specifications

Extension: LRRA06AMRPN182

6

5

1

Pin type: 021.279.1020

made by Interconnectron

2

4

The mating connector

Plug type: LPRA06BFRBN170

Name

Pin No.

Phase U

1

Phase V

2

Phase W

4

Not used

5

Not used

6

Ground

weight kg

95

(14)

10L3

Units: mm

Hall sensor output signals

When the coil assembly moves in the di-

rection indicated by the arrow in the figure, the relationship between the hall sensor output signals Su, Sv, Sw and the

inverse power of each motor phase Vu,

Vv, Vw becomes as shown in the figure

below.

Vu

Su

Inverse

power

Vv

(V)

Sv

Vw

Sw

0 180 360 540

Electrical angle (° )

Coil assembly

㧔119㧕

㧔61.5㧕㧔57.5㧕

5

9

14

㧔43㧕

㧔Gap1㧕

±

0.1

58

㧔Tow φ4 marks are engraved.)

1.5

φ11.5

The height of screw head must be 6.7 mm max.

Assembly dimensions

Note: 1. Multiple SGLFM-1ZA magnetic ways can be connected. Connect magnetic ways so that the reference marks match one on the

other in the same direction as shown in the figure.

2. The magnetic way may affect pacemakers. Keep a minimum distance of 200 mm from the magnetic way

210 AC servo systems

㧔62.5㧕62.5

125

1126.5 㧔6.5㧕

Reference marks

O/N

S/N

MADE IN JAPAN

Name plate

㧔L3㧕

2×N-φ7 mounting holes

φ11.5 counter boring, depth 1.5

YASKAWA

㧔67.5㧕

㧔43.2㧕

TYPE:

Reference mar

DATE

L2

-0.1

L1

-0.3

Reference mark

8.6°

S

SSSNNNN

YASKAWA

TYPE:

67.5

0

43.2

-0.2

Units: mm

Page 17

Iron-core SGLF@-1E

YASKAWA

DATE

MADE IN JAPAN

TYPE:

O/N

S/N

MADE IN JAPAN

TYPE:

O/N

S/N

YASK

TYP

E

O/N

S/N

Linear S

ERVO M

OTOR

A

W

V

ins.

m/s

N

YASK

AWA

ELE

CTRI

C

MAD

E IN

JAPA

N

DATE

YASKAWA

DATE

MADE IN JAPAN

TYPE:

O/N

S/N

YASKAWA

DATE

MADE IN JAPAN

TYPE:

O/N

S/N

Coil assembly: SGLFW-1ED@@@B@

Coil assembly model

SGLFW-

1ED380B 395 120 - 12 0.3 22

1ED560B 605 135 135 18 0.5 33

(200)

Nameplate

(14.2)

(100) (100)

*

76±0.1

O/N

S/N

YASKAWA ELECTRIC

MADE IN JAPAN

DATE

L1 L2 L3 N P Approx.

Magnetic way

Cable

UL20276,AWG28

(Ø4.2)

YASKAWA

TYPE:

O/N

S/N

MADE IN JAPAN

DATE

Linear SERVO MOTOR

TYPE

W

A

V

N

ins.

m/s

28

61

Motor terminal

(83)

92

P

(Gap0.8)

Hall sensor terminal

175

2-Screws

#4-40 UNC

weight kg

70

(23)

60 60

YASK

TYPE:

32

O/N

S/N

MADE IN JAPAN

84.2

60 60 60

"N"-M8 tapped holes,depth 16

Tightening torque:3000 N.cm

L1

L2 L3

1ED560 type only

The coil assembly moves in the

direction indicated by the arrow

when current flows in the order of phase U, V, and W.

500±50

Min.80

Hall sensor

Units: mm

Hall sensor

Connector specifications

9

5

Pin connector type:

17JE-23090-02 (D8C)

made by DDK Ltd.

The mating connector

Socket connector type:

17JE-13090-02 (D8C)

Stud type: 17L-002C or

ޓޓޓޓޓ17L-002C1

6

1

Pin No.

1

2

3

4

5

6

7

8

9

Name

+5V (Power supply)

Phase U

Phase V

Phase W

0V (Power supply)

Not used

Not used

Not used

Not used

Linear servo motor

Connector Specifications

Receptacle type: MS3102A-22-22P

made by DDK Ltd.

The mating connector

L-shaped plug type: MS3108E22-22S

Pin No.

A

B

C

D

Name

Phase U

Phase V

Phase W

Ground

Hall sensor output signals

When the coil assembly moves in the direction indicated by the arrow in the figure, the relationship between the hall sensor output signals Su, Sv, Sw and the

inverse power of each motor phase Vu,

Vv, Vw becomes as shown in the figure

below.

Vu

Su

Inverse

power

Vv

(V)

Sv

Vw

0 180 360 540

Sw

Electrical angle (˚ )

Magnetic way: SGLFM-1E135A@

(145.5)

3˚

Coil assembly

(83)(92)

(175)

9

5.2

(61)14.2

(Gap0.8)

76±0.1

Includes magnet cover,

0.2 thick

Mounting holes Ø10

Ø15 Spot facing 3.5 depth

Qty. " 2 x 2 "

3.5

Ø10

Ø15

Max.8.7

Height of screw head

is less than 8.7mm.

Detail drawing of mounting

Note: 1. Multiple SGLFM-1EA magnetic ways can be connected. Connect magnetic ways so that the reference marks match one on the

other in the same direction as shown in the figure.

2. The magnetic way may affect pacemakers. Keep a minimum distance of 200 mm from the magnetic way

200

(10)

(100)

180

100

10

Reference mark

NS NS*N

150

0

43.2

-0.2

135

67.5

-0.1

-0.3

Units: mm

Approx. weight: 2.5 kg

SNSNS

Name plate for magnet track

(67.5)

Serial number label

Sigma linear motors 211

Page 18

Iron-core SGLT@-35

Coil assembly: SGLTW-35D@@@H@D

Coil assembly model

SGLTW-

35D320HD 315 288 (48 × 6) (17) 14 8.8

L1 L2 (L3) N Approx.

weight kg

0.15

±0.1

20

±0.05

901515

80

70

X

66

X

62.5

12

1

Linear SERVO MOTOR

TYPE

O/N

S/N

YASKAWA ELECTRIC MADE IN JAPAN

W

AV

28

DATE

ins.

m/sN

30

30

Name plate

2×screws

#4×40 UNC

㧔19.2: With magnet cover)

㧔19: Without magnet cover)

㧔Gap 0.8: With magnet cover)

㧔Gap 1: Without magnet cover)

Cable

UL20276AWG28

Wiring specification

of hall sensor cable

96

5

Pin connector type:

17JE-23090-02㧔D8C㧕

made by DDK Ltd.

The mating connector

Socket connector type:

17JE-13090-02㧔D8C㧕

Stud type: 17L-002C or

ޓޓޓޓޓ17L-002C1

Pin No.

1

+5VDC

2

1

Phase U

3

Phase V

4

Phase W

5

6

Not used

7

Not used

8

Not used

9

Not used

Magnetic way: SGLTM-35@@@H

Magnetic way model

SGLTM-

35324H 324 270 (54 × 5) 6 4.8

35540H 540 486 (54 × 9) 10 8

35756H 756 702 (54 × 13) 14 11

-0.1

L1

-0.3

±0.1

15

±0.3

90

(preshipment)

∗

91.5±1

∗

123 max. (preshipment)

∗

±0.1

15

R0.5 max.

Mount the magnetic way

so that its corner surfaces

are flush with the inner

step.

L2 N Approx.

P

Y

(0.8)

0.2 Y

0.2 X

C1

C1

±0.3

±0.1

P

X

0.8

4.2

Gap

Includes a 0.2 mm-thick magnet cover.

R1 max.

+0.6

82

0

∗

±0.3

90

Assembly dimensions

60

Name

P

±0.1

120

0V

(70)

55

47

Magnetic way

Hall sensor

500

±50

φ4.2

500

±50

Linear servo motor

Connector specifications

6

5

4

Extension: LRRA06AMRPN182

Pin type:

021.279.1020

made by Interconnectron

The mating connector

Plug type:

LPRA06BFRBN170

weight kg

Coil assembly

(120)

(8)

2×N-M6 tapped holes, depth 8

3

Mount the magnetic way

so that its corner surfaces

are flush with the inner

step.

30 L1

10

48

±0.15

20

±0.15

100

Protective tube

35

43

63 min.

1

2

Note: 1. Two magnetic ways for both ends of coil assembly make one set.

0

-0.2

54

9.9°

34.5

0

33

-0.2

54

∗

107

±0.3

34.5

2.4

∗

2.4

(12)

R6

(30.6)

×

2

9.9°

±0.3

0

-0.2

N×M6 tapped holes, depth 12

L2

The coil assembly moves in the direction

indicated by the arrow when current flows

in the order of phase U, V, and W.

L3

Units: mm

Hall sensor output signals

When the coil assembly moves in the di-

Name

Pin No.

Phase U

1

Phase V

2

Phase W

4

Not used

5

Not used

6

Ground

2. The magnetic way may affect pacemakers. Keep a minimum distance

3. Two magnetic ways in a set can be connected to each other.

4. The dimensions marked with an * are the dimensions between the

5. Use socket headed screws of strength class 10.9 minimum for mag-

Name plate

YASKAWA

TYPE:

N-φ7 mounting holes (See the sectional view for the depth.)

54

rection indicated by the arrow in the figure, the relationship between the hall sensor output signals Su, Sv, Sw and the

inverse power of each motor phase Vu,

Vv, Vw becomes as shown in the figure

below

Vu

Su

Inverse

Vv

power

(V)

Spacers are mounted on magnetic ways for safety during transportation. Do not remove the spacers until the coil assembly is mounted on

a machine.

Sv

Vw

Sw

0 180 360 540

Electrical angle㧔° 㧕

of 200 mm from the magnetic way.

magnetic ways. Be sure to follow exactly the dimensions specified in

the figure above. Mount magnetic ways as shown in Assembly Dimensions. The values with an * are the dimensions at preshipment.

netic way mounting screws. Do not use stainless steel screws.

-0.1

L1

O/N

S/N

MADE IN JAPA N DATE

-0.3

L215

L2

MADE IN JAPAN DATE

S/N

O/N

L239

-0.1

L1

-0.3

(54)

(30.6)

(54)

TYPE:

YASKAWA

Spacer: Do not remove them until the coil

assembly is mounted on the machine.

(4)

(54)

212 AC servo systems

Page 19

Iron-core SGLT@-50

Coil assembly: SGLTW-50D@@@H@D

Coil assembly model

SGLTW-

50D170HD 170 144 (48 × 3) (16) 8 6

50D320HD 315 288 (48 × 6) (17) 14 11

L1 L2 (L3) N Approx.

weight kg

(85)

X

81

62.5

12

Linear SERVO MOTOR

TYPE

1

O/N

S/N

YASKAWA ELECTRIC

W

AV

2830

N

MADE IN JAPAN

DATE

ins.

m/s

(19.1)

(90)

0.2

±0.1

20

±0.05

80

Name plate

(19.1)

2×screws

#4×40 UNC

㧔23.3: With magnet cover)

㧔23.1: Without magnet cover)

㧔Gap 0.8: With magnet cover)

㧔Gap 1: Without magnet cover)

Cable

UL20276,AWG28

Wiring specification

of hall sensor cable

96

5

Pin connector type:

17JE-23090-02㧔D8C㧕

made by DDK Ltd.

The mating connector

Socket connector type:

17JE-13090-02㧔D8C㧕

Stud type: 17L-002C or

ޓޓޓޓޓ17L-002C1

Pin No.

1

1

2

3

4

5

6

7

8

9

Magnetic way: SGLTM-50@@@H

Magnetic way model

SGLTM-

50324H 324 270 (54 × 5) 6 8

50540H 540 486 (54 × 9) 10 13

50756H 756 702 (54 × 13) 14 18

L1

-0.3

-0.1

L2 N Approx.

X

60

+5VDC

Phase U

Phase V

Phase W

Not used

Not used

Not used

Not used

P

Name

0V

Magnetic way

(4.1)

±0.1

120

500

500

30 L1

10

Hall sensor

±50

(φ4.2)

±50

35

43

63 min.

Linear servo motor

Connector specifications

6

5

1

2

4

Extension: LRRA06AMRPN182

Pin type: 021.279.1020

made by Interconnectron

The mating connector

Plug type: LPRA06BFRBN170

weight kg

0

-0.2

42

±0.15

48

20

±0.15

100

Protective tube

54

N×M6 tapped holes, depth 12

L2

The coil assembly moves in the direction

indicated by the arrow when current flows

in the order of phase U, V, and W.

(L3)

Units: mm

Hall sensor output signals

When the coil assembly moves in the direction indicated by the arrow in the figu-

Name

Pin No.

Phase U

1

Phase V

2

Phase W

4

Not used

5

Not used

6

Ground

Note: 1. Two magnetic ways for both ends of coil assembly make one set.

2. The magnetic way may affect pacemakers. Keep a minimum distance

3. Two magnetic ways in a set can be connected to each other.

4. The dimensions marked with an * are the dimensions between the

5. Use socket headed screws of strength class 10.9 minimum for mag-

-0.1

L1

-0.3

L29

re, the relationship between the hall sensor output signals Su, Sv, Sw and the

inverse power of each motor phase Vu,

Vv, Vw becomes as shown in the figure

below

Vu

Su

Inverse

Vv

power

(V)

Spacers are mounted on magnetic ways for safety during transportation. Do not remove the spacers until the coil assembly is mounted on

a machine.

Sv

Vw

Sw

0 180 360 540

Electrical angle㧔° 㧕

of 200 mm from the magnetic way.

magnetic ways. Be sure to follow exactly the dimensions specified in

the figure above. Mount magnetic ways as shown in Assembly Dimensions. The values with an * are the dimensions at preshipment.