Page 1

Cat. No. V104-E1-04

NV Series

NV3W

NV4W

NV3Q

Programmable Terminals

PROGRAMMING MANUAL

Page 2

NV Series NV3W NV4W NV3Q

Programmable Terminals

Revised October 2011

Page 3

iv

Page 4

Notice

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller.

The abbreviation “host” means a controller, such as an IBM PC/AT or compatible computer, that controls a PT (Programmable Terminal).

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Precautions

for Safe Use

Precautions

for Correct Use

CS1G-CPU@@-V1 Boxes in model numbers indicate variable characters. For example, “CS1G-CPU@@-

OMRON, 2009

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or by any means,

mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving

to improve its high-quality products, the information contained in this manual is subject to change without notice. Every precaution has been

taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability

assumed for damages resulting from the use of the information contained in this publication.

Indicates precautions on handling the product to ensure that the product is used safely.

Indicates precautions to ensure that product functions and performances are realized, to

ensure that the reliability of the product is maintained, and to ensure that the product is

otherwise used correctly.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

Reference Indicates supplementary information on procedures, descriptions, and settings.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

EV1” indicates the following models: CS1G-CPU42-EV1, CS1G-CPU43-EV1, CS1GCPU44-EV1, and CS1G-CPU45-EV1.

v

Page 5

vi

Page 6

TABLE OF CONTENTS

SECTION 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 NV-Designer Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 System Versions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SECTION 2

PT Internal Data Structure and Display Methods . . . . . . . 7

2-1 Internal Data Types and Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-2 Displaying Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-3 Backlight Display Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

SECTION 3

NV-Designer Outline and Configuration . . . . . . . . . . . . . . . 15

3-1 System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3-2 NV-Designer Window Names and Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3-3 NV-Designer Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

SECTION 4

Overall Flow of NV-Designer Operation . . . . . . . . . . . . . . . 39

4-1 Overall Flow of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

4-2 Creating a Simple Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

SECTION 5

Creating and Saving Projects (Including Screen Data) . . . 53

5-1 Starting the NV-Designer and Creating New Projects. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5-2 Checking or Converting the Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5-3 Creating Base Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5-4 Positioning Character Strings, Graphics, and Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5-5 Copying and Moving Parts and Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5-6 Saving the Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5-7 Project and Execution Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

SECTION 6

NV Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6-1 NV Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6-2 Setting the NV Configuration from the NV-Designer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

vii

Page 7

TABLE OF CONTENTS

SECTION 7

Descriptions of Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

7-1 Character Strings and Graphics (Fixed Parts) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

7-2 Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

7-3 Specifying Addresses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

7-4 Bit Switches (“Switch”). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

7-5 Function Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

7-6 Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

7-7 Data Parts and Keyboard Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

7-8 Level Meters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

7-9 Clocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

7-10 Line Graphs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

7-11 Alarm Lists (NV4W/NV3Q) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

7-12 Custom Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

7-13 Multifunction Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

SECTION 8

Using PT Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

8-1 Switching Backlight Colors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .162

8-2 Repeated Copying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

8-3 Flow Display Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

8-4 Write Address Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

8-5 Recipes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

8-6 Security Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

8-7 Switching the Display Language. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

8-8 Displaying Resource Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

8-9 Base Screen Memory Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

SECTION 9

Transferring Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

9-1 Transferring Screens from the NV-Designer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

9-2 Transferring and Copying Data Using SD Memory Cards (NV4W/NV3Q). . . . . . . . . . . . . 198

Appendices

A NV Memory Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .203

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

viii

Page 8

About this Manual

This manual describes how to create screens for and maintain the NV-series PTs using the NVDesigner and includes the sections described below.

Please read this manual carefully and be sure you understand the information provided before

attempting to use the NV-Designer. Be sure to read the precautions provided in the following section.

Precautions

This section provides general precautions for using the NV-series PTs and related devices.

Section 1 Overview

This section introduces the features and functions of the NV-Designer.

Section 2 PT Internal Data Structure and Display Methods

This section describes the internal data structure of an NV-series PT, how to control the screens displayed on the PT, and how to control the backlight.

Section 3 NV-Designer Outline and Configuration

This section gives the system requirements for running the NV-Designer, describes the windows and

menus of the NV-Designer, and explains the parameters in the NV-Designer Configuration.

Section 4 Overall Flow of NV-Designer Operation

This section describes the overall procedure for using the NV-Designer to set up an NV-series PT for

operation.

Section 5 Creating and Saving Projects (Including Screen Data)

This section describes how to create, save, and manipulate projects for NV-series PTs, including

operations that can be performed between projects.

Section 6 NV Configuration

This section describes the parameters in the NV Configuration in detail.

Section 7 Descriptions of Parts

This section describes how to create screens using the various parts provided by the NV-Designer.

Section 8 Using PT Functions

This section describes special functions that can be used with NV-series PTs and the NV-Designer.

Section 9 Transferring Screens

This section describes how to transfer screens to and from an NV-series PT using both communications and SD memory cards.

Appendix

The appendix describes how to use the NV Memory Editor, which allow you to edit the internal memory of the PT from the NV-Designer.

ix

Page 9

x

Page 10

Related Manuals

The following manuals are used for NV-series PTs. (The boxes at the end of the catalog

numbers indicate the revision code.)

This

Manual

NV-series PT Programming Manual......................... V104-E1-@

This manual describes the software functionality of NV-series PTs, how to install the NVDesigner, and the features of the NV-Designer.

For more information on NV-Designer operating procedures, refer to the online help in the

NV-Designer.

NV-series PT Setup Manual ..................................... V103-E1-@

This manual describes how to connect an NV-series PT to an OMRON PLC, features and

specifications, methods to set up communications and operation, and procedures for

maintenance and troubleshooting.

Refer to the NV-series PT Programming Manual (V104-E1-@) for more information on PT

functions and specific operating procedures.

NV-series PT Host Connection Manual.................... V105-E1-@

This manual describes how to connect an NV-series PT to a PLC produced by a manufacturer other than OMRON, including PLC memory area designations, communications settings, and connection methods.

xi

Page 11

Terminology

The following terminology is used in this manual.

PT In this manual, indicates an NV-series Programmable Terminal.

NV Series Indicates products in the OMRON NV Series of Programmable Terminals.

PLC Indicates a Programmable Controller in the OMRON SYSMAC CS/CJ/CP,

C, or CVM1/CV Series of Programmable Controllers.

CPU Unit Indicates a CPU Unit in the OMRON SYSMAC CS/CJ/CP, C, or CVM1/CV

Series of Programmable Controllers.

NV-Designer Indicates the OMRON NV-Designer.

Host Indicates the PLC, IBM PC/AT or compatible computer, or personal com-

puter functioning as the control device and interfaced with the NV-series PT.

xii

Page 12

Introduction

● Intended Audience

This manual is intended for the following personnel, who must also have knowledge of

electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems into production facilities.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and connecting FA systems.

• Personnel in charge of managing FA systems and facilities.

● General Precautions

• The user must operate the product according to the performance specifications

described in the operation manuals.

• Do not use the PT touch switch input functions for applications where danger to

human life or serious property damage is possible, or for emergency switch applications.

• Before using the product under conditions which are not described in the manual or

applying the product to nuclear control systems, railroad systems, aviation systems,

vehicles, combustion systems, medical equipment, amusement machines, safety

equipment, and other systems, machines and equipment that may have a serious

influence on lives and property if used improperly, consult your OMRON representative.

• Make sure that the ratings and performance characteristics of the product are sufficient for the systems, machines, and equipment, and be sure to provide the systems,

machines, and equipment with double safety mechanisms.

• This manual provides information for connecting and setting up an NV-series PT. Be

sure to read this manual before attempting to use the PT and keep this manual close

at hand for reference during installation and operation.

xiii

Page 13

Safety Precautions

Notation Used for Safety Information

The following notation is used in this manual to provide precautions required to ensure

safe usage of the product.

The safety precautions that are provided are extremely important to safety.

Always read and heed the information provided in all safety precautions.

The following notation is used.

Definition of Precautionary Information

!WARNING

Symbols

Indicates a potentially hazardous situation which, if not avoided, will

result in minor or moderate injury, or may result in serious injury or

death. Additionally there may be significant property damage.

Prohibition

Indicates a general prohibition.

Caution

Indicates general cautionary, warning, or danger level information.

!WAR NING

Always ensure that the personnel in charge confirm that installation,

inspection, and maintenance were properly performed for the PT. “Personnel in charge” refers to individuals qualified and responsible for

ensuring safety during machine design, installation, operation, maintenance, and disposal.

Ensure that installation and post-installation checks are performed by

personnel in charge who possess a thorough understanding of the

machinery to be installed.

Do not use the input functions of the PT, such as the function switches

or switches on the touch panel, in applications that involve human life,

in applications that may result in serious injury, or for emergency stop

switches.

Do not attempt to disassemble, repair, or modify the PT. Doing so may

impair the safety functions.

Do not attempt to take the Unit apart and do not touch any internal

parts while the power is being supplied. Doing either of these may

result in electrical shock.

The PT uses an analog touch panel. Never press more than two points

on the panel at a time. Otherwise, it may activate a switch somewhere

between the two points.

xiv

Page 14

Precautions for Safe Use

1. When unpacking the Units, check carefully for any external scratches or other damage.

Also, shake the Units gently and check for any abnormal sound.

2. The PT must be installed in a control panel.

3. The mounting panel must be between 1.6 and 4.8 mm thick. Tighten the Mounting

Brackets evenly to a torque of between 0.1 and 0.25 N·m for the NV3W/NV3Q and between 0.2 and 0.3 N·m for the NV4W to maintain water and dust resistance. Make sure

the panel is not dirty or warped and that it is strong enough to hold the Units.

4. Do not let metal particles enter the Units when preparing the panel.

5. Do not connect an AC power supply to the DC power terminals.

6. Do not perform a dielectric voltage test.

7. Use a DC power supply that will provide a stable output even if the input is momentarily

interrupted for 10 ms, and which has reinforced or double insulation.

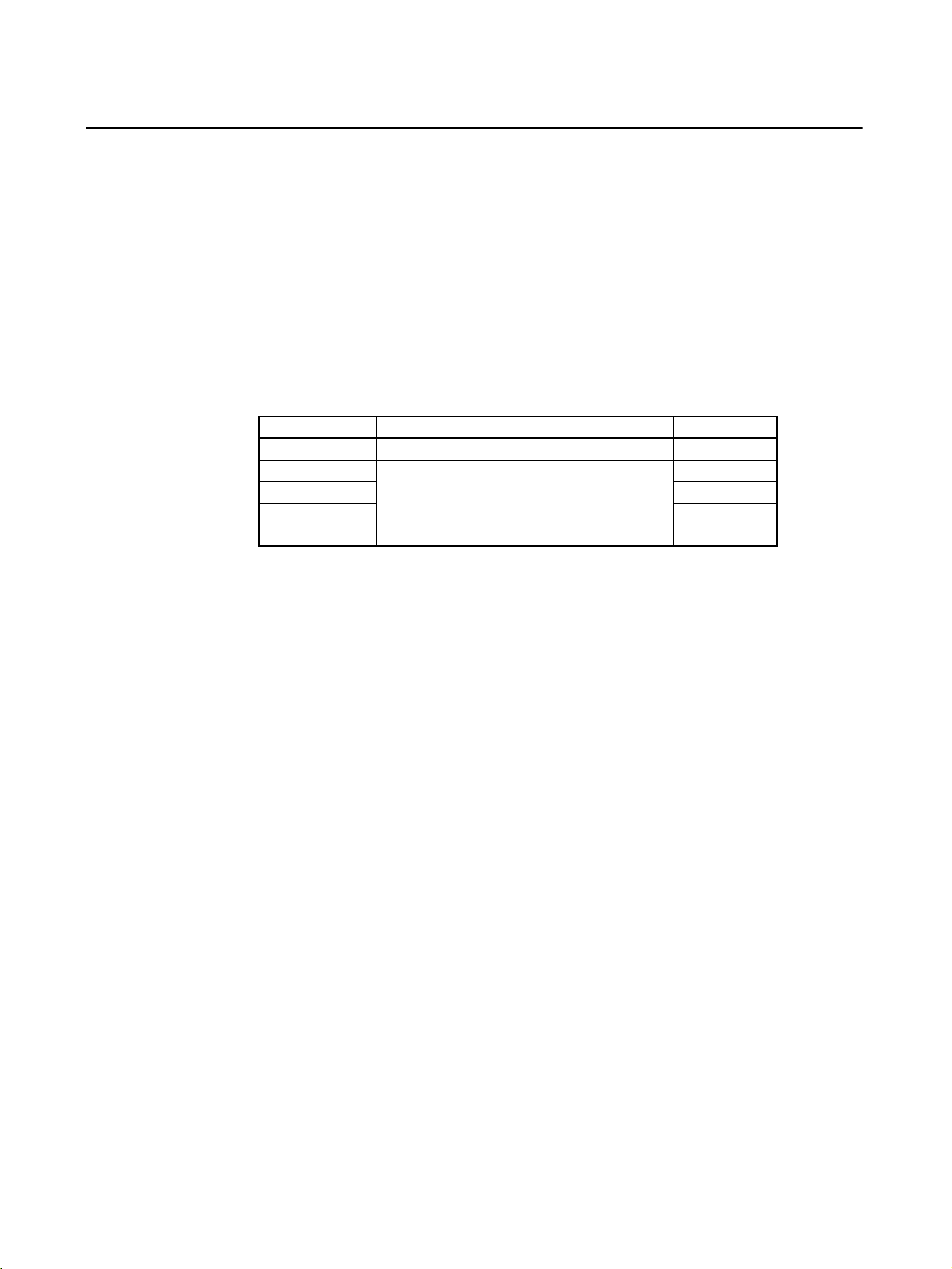

Model Rated power supply voltage Capacity

NV3W-M@20L 5 VDC (allowable range: 4.5 to 5.5 VDC) 1 W min.

NV4W-M@@@ 24 VDC (allowable range: 21.6 to 26.4 VDC) 1.7 W min.

NV3W-M@@@ 2 W min.

NV3Q-MR@@ 2.4 W min.

NV3Q-SW@@ 3.6 W min.

8. Use a twisted-pair cable to connect to the power terminals. Tighten the terminal screws

to a torque of between 0.22 and 0.30 N·m. Make sure the screws are properly tightened.

9. To prevent malfunctions caused by noise, ground the PT correctly.

10. Do not touch the surface of the circuit boards or the components mounted on them with

your bare hands. Discharge any static electricity from your body before handling the

boards.

11. Turn OFF the power supply before connecting or disconnecting cables.

12. The maximum tensile load for cables is 30 N. Do not apply loads greater than this.

13. Confirm the safety of the system before turning ON or OFF the power supply.

14. Cycle the power supply after changing the DIP switch settings.

15. Do not perform the following operations while the SD memory card is being accessed

(NV4W/NV3Q only):

• Turning OFF the power supply to the PT

• Removing the memory card

Always follow the specified procedure when removing the memory card.

16. Start actual system application only after sufficiently checking screen data and the operation of the program in the PLC (host).

17. Do not press the touch switch with a force greater than 30 N.

18. Do not use a screwdriver or any other tool to press a touch switch.

19. Confirm the safety of the system before pressing any touch switch.

20. Do not accidentally press touch switches when the backlight is not lit or when the display does not appear. Confirm the safety of the system before pressing touch switches.

21. Before initializing screen data, confirm that existing data is backed up at the NV-Designer.

22. When changing the password with the system menu, do not reset or turn OFF the power supply until writing is finished.

xv

Page 15

23. Before using the SPMA function to change memory values in the PLC or transfer ladder

programming, confirm that the PT is operating. The SPMA function cannot be used unless the PT is operating.

24. Dispose of any battery that has been dropped on the floor or otherwise subjected to

excessive shock.

25. Dispose of the Units and batteries according to local ordinances as they apply.

26. When mounting the Battery, be sure to use the correct Battery and mount it correctly.

27. Do not disassemble or short-circuit the battery.

28. Do not connect a USB connector to any device that is not applicable.

29. Before connecting a USB connector to a device, make sure that the device is free of

damage.

30. Do not turn OFF the power supply to the PT while downloading or uploading screen

data or the system program. Doing so may corrupt the screen data or system program.

31. Periodically inspect the installation condition of the PT if it is being used in an environment subject to contact with water.

32. The whole system may stop depending on how the power supply is turned ON or OFF.

Turn ON or OFF the power supply according to the specified procedure.

33. Signals from the touch switches may not be input if the switches are pressed consecutively at high speed. Confirm each input before proceeding to the next one.

34. To use numeric input functions safely, always make maximum and minimum limit settings.

35. Do not use benzene, paint thinner, or other volatile solvents, and do not use chemically

treated cloths.

36. The PT uses an analog touch panel. Deterioration over time can cause the touch points

to move. Calibrate the touch panel if the touch points move too much.

37. Water resistance will be lost if the front sheet is torn or is peeling off. Do not use the PT

if the front sheet is torn or is peeling off.

38. The Rubber Packing will deteriorate, shrink, or harden depending on the operating environment. Inspect and replace the Rubber Packing periodically (approximately once

per year).

39. To use the NV3W in an environment with strong noise, connect the following noise filter

to the power supply line: RSEL-2001W manufactured by TDK-Lambda Corp.

40. A Waterproof Packing cannot be reused. To ensure waterproof performance, replace

the Waterproof Packing with a new one each time you reinstall the PT.

41. Screen burn-in will occur if the same pattern is continuously displayed for a long period

of time (24 hours or longer, as a guideline). To prevent screen burn-in, use a screen

saver or switch displays periodically (NV3W only).

xvi

Page 16

Precautions for Correct Use

1. Do not install the PT in any of the following locations.

• Locations subject to rapid changes in temperature

• Locations subject to temperatures or humidity outside the range specified in the specifications

• Locations subject to condensation as the result of high humidity

• Locations subject to splashing chemicals or solvents

• Locations subject to oil splashes

• Locations subject to continuous water splashing

• Locations subject to corrosive or flammable gases

• Locations subject to strong shock or vibration

• Locations outdoors subject to direct wind and rain

• Locations subject to strong ultraviolet light

• Locations subject to dust

• Locations subject to direct sunlight

2. Take appropriate and sufficient countermeasures when installing systems in the following locations.

• Locations subject to static electricity or other forms of noise

• Locations subject to strong electromagnetic or magnetic fields

• Locations close to power supply lines

• Locations subject to possible exposure to radioactivity

xvii

Page 17

Conformance to EC Directives

This product is EMC compliant.

● Concepts

OMRON products are electronic devices that are incorporated in machines and manufacturing installations. OMRON PTs conform to the related EMC Directives (see note) so that

the devices and machines into which they are built can more easily conform to EMC directives. However, customers may use a wide variety of equipment and manufacturing installations. Therefore the customer must check whether the Directives are satisfied for the

actual system. EMC-related performance will vary depending on the configuration, wiring,

and other conditions of the equipment or control panel in which the PT is installed. The

customer must, therefore, perform final checks to confirm that the overall machine or

device conforms to EMC standards.

Note The applicable EMC (Electromagnetic Compatibility) standards for NV-series

PTs are as follows:

NV3W: EN 61000-6-2, EN 61000-6-4

NV4W/NV3Q: EN 61131-2

● Conformance to EC Directives

NV-series PTs conform to EC Directives. To ensure that the machine or device in which

the NV-series PT is used complies with EC Directives, the PT must be installed as follows:

• The NV-series PT must be installed in a control panel.

• You must use reinforced insulation or double insulation for the DC power supply and

the DC power supply must have minimal voltage fluctuations and provide a stable output even if the power supply input is interrupted for 10 ms.

• NV-series PTs complying with EC Directives also conform to the Common Emission

Standard (EN 61131-2 or EN 61000-6-4). Radiated emission characteristics (10-m

regulations) may vary depending on the configuration of the control panel used, other

devices connected to the control panel, wiring, and other conditions. You must therefore confirm that the overall machine or equipment complies with EC Directives.

• This is a class A product. It may cause radio interference in residential areas, in which

case the user may be required to take adequate measures to reduce interference.

xviii

Page 18

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xix

Page 19

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xx

Page 20

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xxi

Page 21

xxii

Page 22

This section introduces the features and functions of the NV-Designer.

1-1 NV-Designer Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 NV-Designer Features and Functions . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 System Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-2-1 NV-series PT Models and System Versions . . . . . . . . . . . . . . . . . . . 4

1-2-2 NV System Version Upgrade Procedure. . . . . . . . . . . . . . . . . . . . . . 4

SECTION 1

Overview

1

Page 23

NV-Designer Features Section 1-1

1-1 NV-Designer Features

The NV-series Programmable Terminals (PTs) are easy to operate and compact.

1-1-1 NV-Designer Features and Functions

The NV-Designer is a programming application used to create screens for NVseries PTs.

Design Screens Easily Like a Paint Application

The NV-Designer can be used to transfer screens to and data from an NVseries PT, to print data, and to perform other operations.

Drag and Drop Parts to the Screen

The libraries contain various “parts,” such as bit switches that allow you to turn

PLC I/O points ON and OFF by touching the bit switch, data parts for displaying PLC data, and keyboard parts that can rewrite PLC data.

Parts can be easily positioned by dragging and dropping them to the screen.

Easy to Register Original Parts

Custom parts created by the user can be dragged and dropped to a library to

be registered and used like normal parts.

Easy to Print Design Status and Settings

Screen previews can be printed together with the properties of the edited

base screen and edited part attributes.

2

Page 24

NV-Designer Features Section 1-1

Multi-language Support

With Windows XP, Windows Vista, or Windows 7 you can use of various languages, such as Japanese, English (Europe), Simplified Chinese, Traditional

Chinese, Korean, and Turkish.

Use True Type Fonts The NV-Designer features the True Type fonts commonly used for Windows

applications, MS Word, and Excel.

Characters can be displayed beautifully from small to large.

Exporting and Importing Character Strings Using the Display Language Switching

Function

Character strings changed by using the Display Language Switching that

appear on a base screen of the NV-Designer can be exported to a text file.

The text file can be opened and edited in Excel, then imported for use as the

character string displayed on the base screen.

Transferring Screens with an SD Memory Card (NV4W/NV3Q Only)

The screens can be transferred using an SD memory card even if the PT cannot be connected to the NV-Designer.

Project data can be transferred directly by using SD memory cards.

Multifunction Objects (NV4W/NV3Q Only)

Multifunction Objects are parts that enable performing multiple operations

with a single touch using a function switch or custom switch. The operations

that are set will be executed in sequence when the Multifunction Object is

touched. Up to 32 operations can be set. This enables using one touch to perform operations that were previously performed using combinations of multiple parts. (For the NV3Q, Multifunction Objects are supported for PT system

version 1.1 and higher.)

Automatic Firmware Update

The NV-series PT firmware can be updated to the most recent version when

screens are transferred from the NV-Designer.

3

Page 25

System Versions Section 1-2

-

)

1-2 System Versions

The system program version (abbreviated as "system version") in the NVseries PT determines the project system versions that can operate in the NVseries PT.

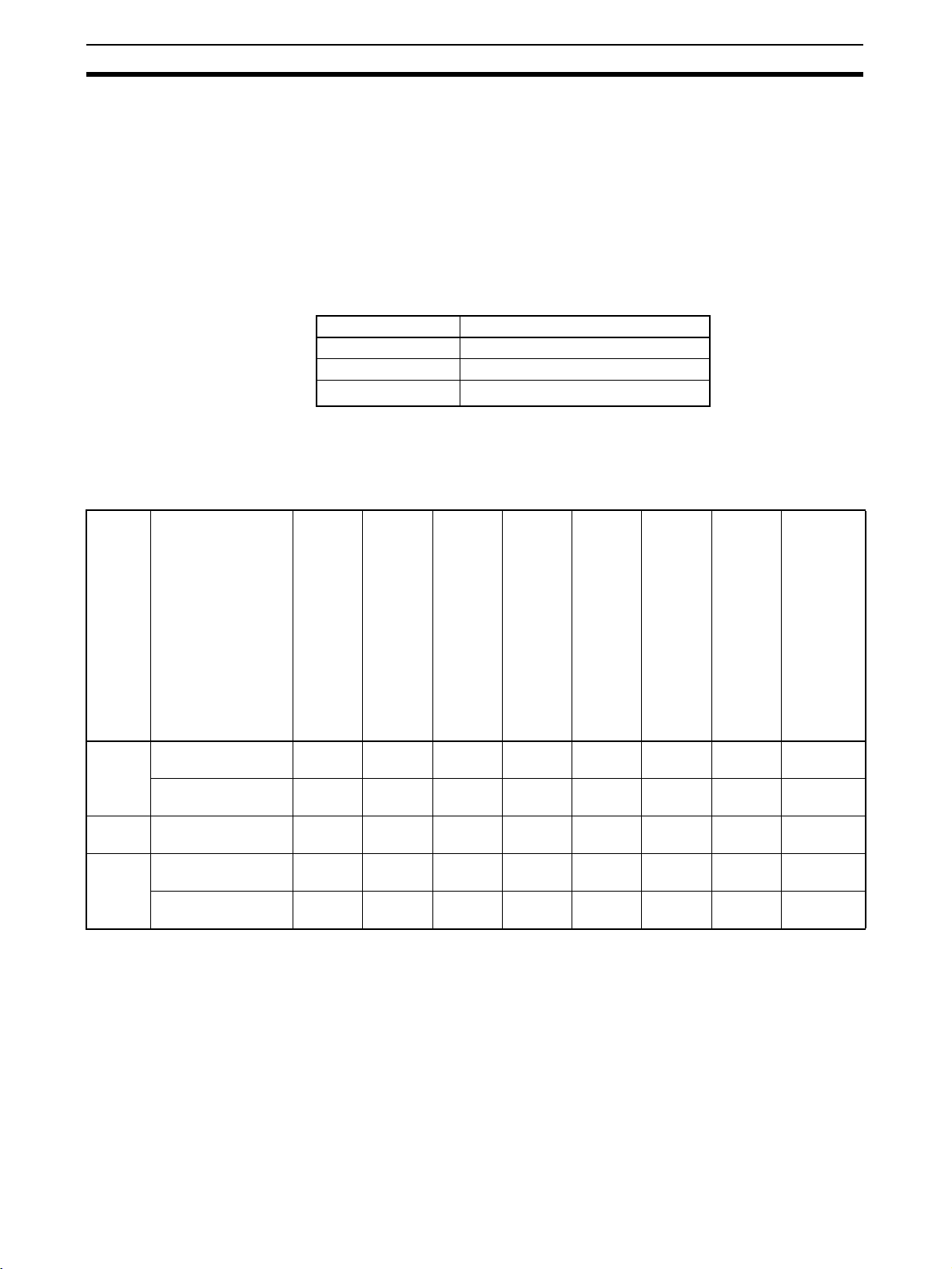

1-2-1 NV-series PT Models and System Versions

The system versions that can be installed depend on the model of the NVseries PT. The following table shows the possible combinations.

Applicable Versions for

the NV-series PTs

Functions and NV System

Versions

NV system version

NV Series NV-Designer System Version

NV3W Series Version 1.1 or higher

NV4W Series Version 1.1 or higher

NV3Q Series

Version 1.1 or higher

*1

*1 Version 1.2 or higher is required for an NV3Q-SW PT with lot number

111000 or later.

Larger SD memory cards (from

Not supported.

Not supported.

Supported.

Supported.

Not supported.

1 GB to 2 GB

NV-Designer version

Version 1.1

or higher

Version 1.0

or higher

Version 1.1

or higher

Version 1.1

or higher

Version 1.0

or higher

Vertical displays

NV3W Version 1.1 or higher Sup-

ported.

Version 1.0 or higher Sup-

ported.

NV4W Version 1.1 or higher Sup-

ported.

NV3Q Version 1.1 or higher Not sup-

ported.

Version 1.0 or higher Not sup-

ported.

Alarm lists and histories

Not supported.

Not supported.

Supported.

Supported.

Supported.

Operation security

Not supported.

Not supported.

Supported.

Supported.

Supported.

Multifunction objects

Not supported.

Not supported.

Supported.

Supported.

Not supported.

PLC multiple connections

Not supported.

Not supported.

Supported.

Supported.

Not supported.

fatal errors in OMRON PLCs

Continued PT operation for non

Supported.

Not supported.

Supported.

Supported.

Not supported.

The most recent NV system version can be installed using the Support Software.

1-2-2 NV System Version Upgrade Procedure

The NV system version must be upgraded to use new features. The most

recent firmware is included with the NV-Designer. Upgrade your NV-Designer

designer before you attempt to update the system version of your NV-series

PTs.

4

Page 26

System Versions Section 1-2

Upgrading the System

Program Version with an

SD Memory Card (NV4W/

NV3Q Only)

Version Upgrades when

Transferring Screens

Note (1) Updating the firmware in the NV-series PT and transferring the project are

With the NV4W or NV3Q, the version of the system program can be updated

using an SD memory card. When saving data to the SD memory card, save

the newest version of the system program on the same card. When the data is

read by the PT, the firmware and screen data for the newest version will automatically be transferred to the PT.

The firmware can be updated when transferring screens from the NVDesigner by selecting the automatic firmware update.

performed at the same time from the NV-Designer. It is not possible to update only the firmware. (The NV Ver_UP Tool is required.)

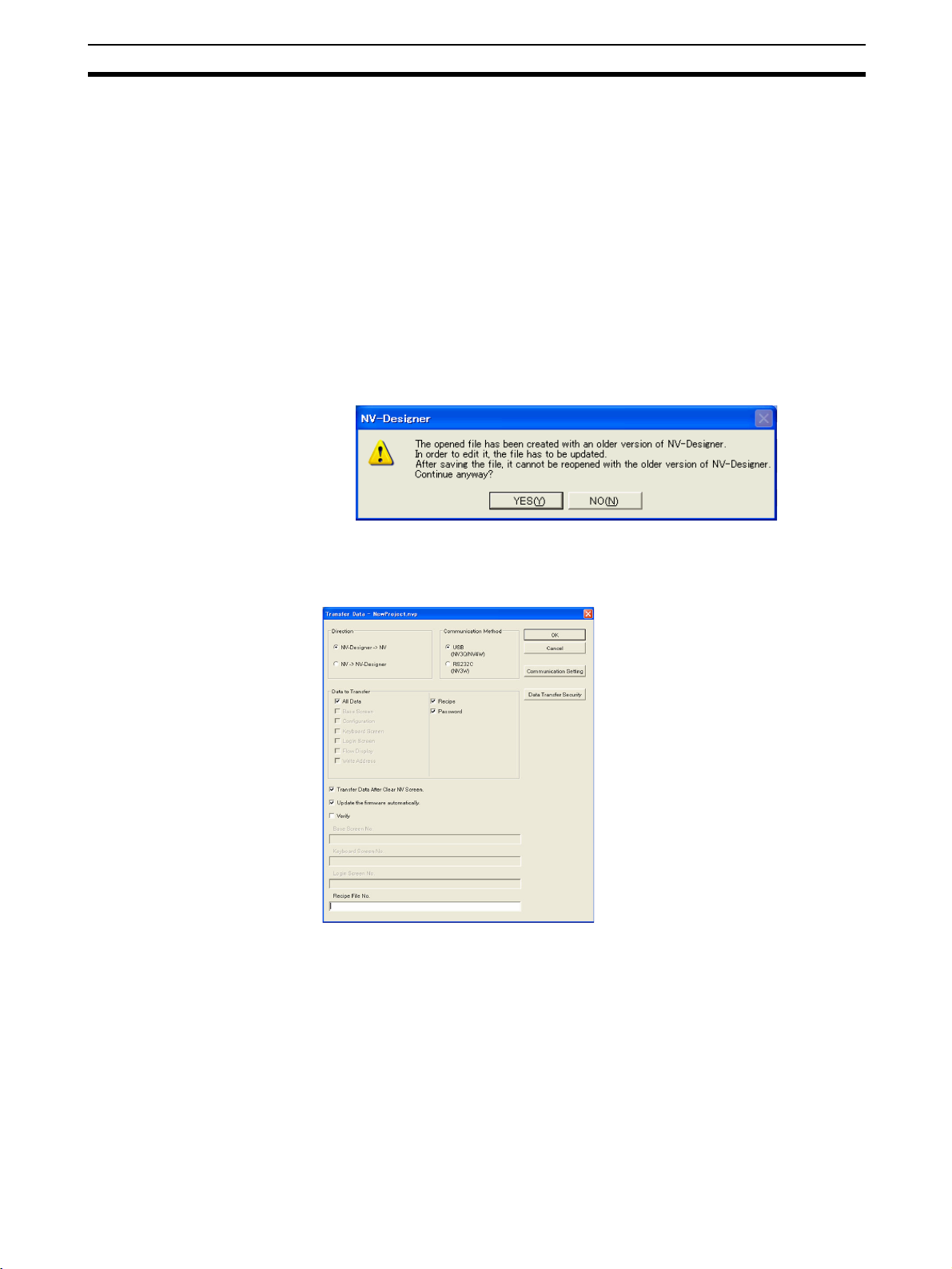

(2) When screen data that was created on an old version of the NV-Designer

is read with the new version of the NV-Designer, the screen data is automatically updated to the new version. (The following confirmation dialog

box will be displayed.)

The following dialog box will be displayed when Transfer is selected from the

PT Menu of the NV-Designer.

Data Transfer Dialog Box

Data to Transfer: All Data

Direction: NV-Designer → NV

Select the Update the firmware

automatically Check Box, and

then click the OK Button.

Updating the firmware and transferring the project will start at the

same time.

Note Automatically updating the

firmware is possible only

when all data is transferred.

Note (1) Never turn OFF the power supply to the PT while the version is being up-

graded. Also, do not unplug the cable between the computer and the NVseries PT. The PT may not restart if transferring the system fails.

(2) The SPMA function cannot be used while the version is being upgraded

or screens are being transferred.

5

Page 27

System Versions Section 1-2

Version Upgrade

Procedure Using NV

Ver_UP Tool

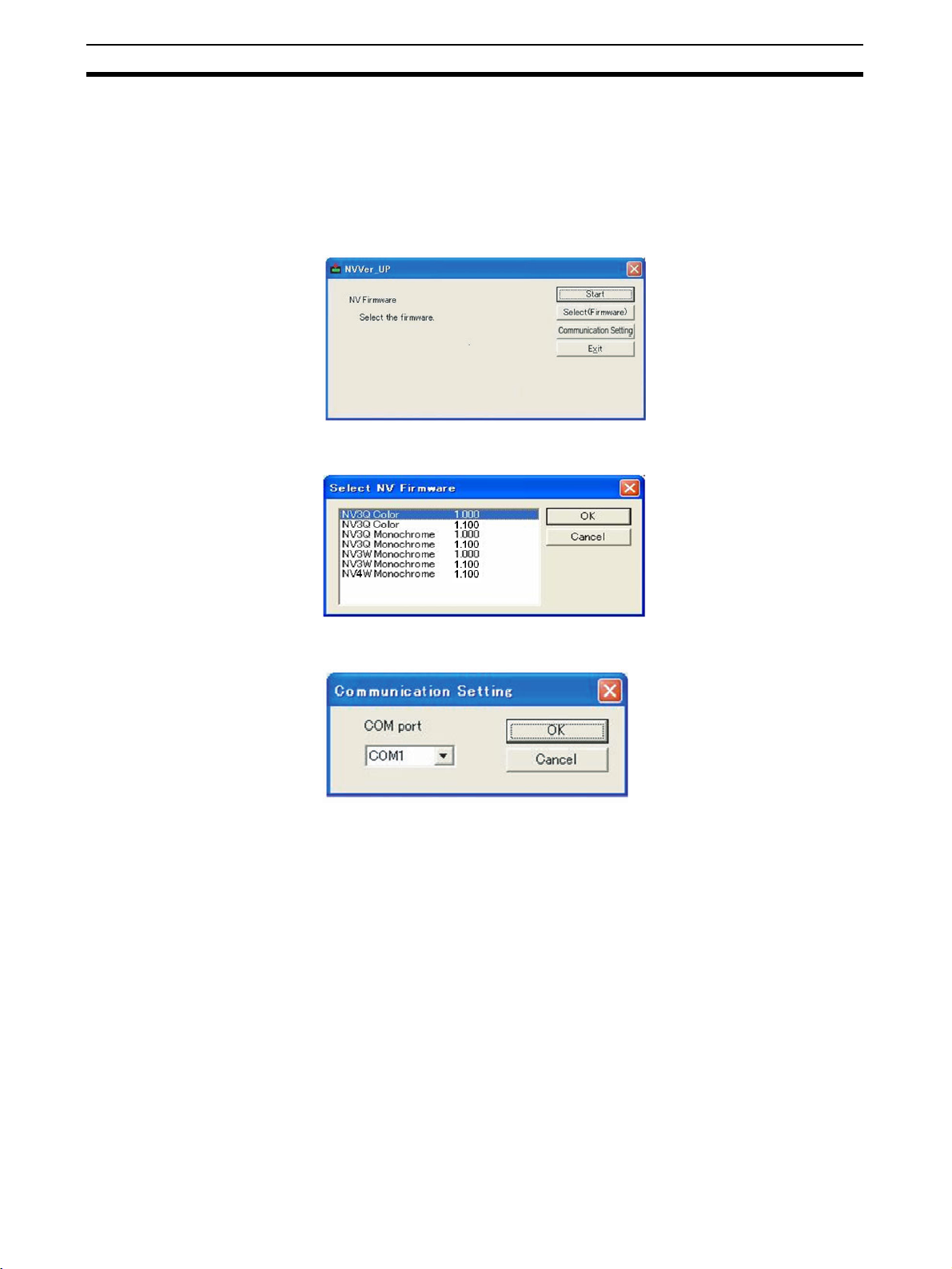

NV Ver_UP is a special tool to upgrade the firmware version of the PT.

The NV Ver_UP version upgrade tool is installed at the same time as the NVDesigner.

Click the Start Button at the bottom left of the window or select All Programs

from the menu displayed by pressing the Ctrl Key and the Esc Key, and then

select CX-One - NV-Designer - Tools - NV Ver_UP from the OMRON Menu.

NV Ver_UP Dialog Box

Select the firmware (Select

(Firmware) Button) and set

the communications conditions (Communication Setting

Button). The applicable settings dialog box will be displayed when either of the

buttons is clicked.

Select NV Firmware Dialog Box

Select the most recent firmware version (i.e., highest version number) for the model

that you are using. Click the

OK Button to return to the NV

Ver_UP Dialog Box.

Communication Setting Dialog Box

Make the communications

setting, and then click the OK

Button to return to the NV

Ver_UP Dialog Box. These

selections cannot be made for

the NV4W and NV3Q.

For the NV3W, select the

COM port that you are actually using.

Upgrading the version will start when the Start Button is clicked.

The NV Ver_UP version upgrade tool will end when the Exit Button is clicked.

Note (1) Never turn OFF the power supply to the PT while the version is being up-

graded.

(2) Do not unplug the cable between the computer and the NV-series PT.

Otherwise, the PT may not restart.

6

Page 28

SECTION 2

PT Internal Data Structure and Display Methods

This section describes the internal data structure of an NV-series PT, how to control the screens displayed on the PT, and

how to control the backlight.

2-1 Internal Data Types and Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-1-1 Overview of Internal Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-1-2 Details of Internal Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2-2 Displaying Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-2-1 Startup Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-2-2 Switching Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-3 Backlight Display Methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-3-1 Specifying Backlight Colors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-3-2 Automatic Backlight OFF Function . . . . . . . . . . . . . . . . . . . . . . . . . 14

7

Page 29

Internal Data Types and Structure Section 2-1

2-1 Internal Data Types and Structure

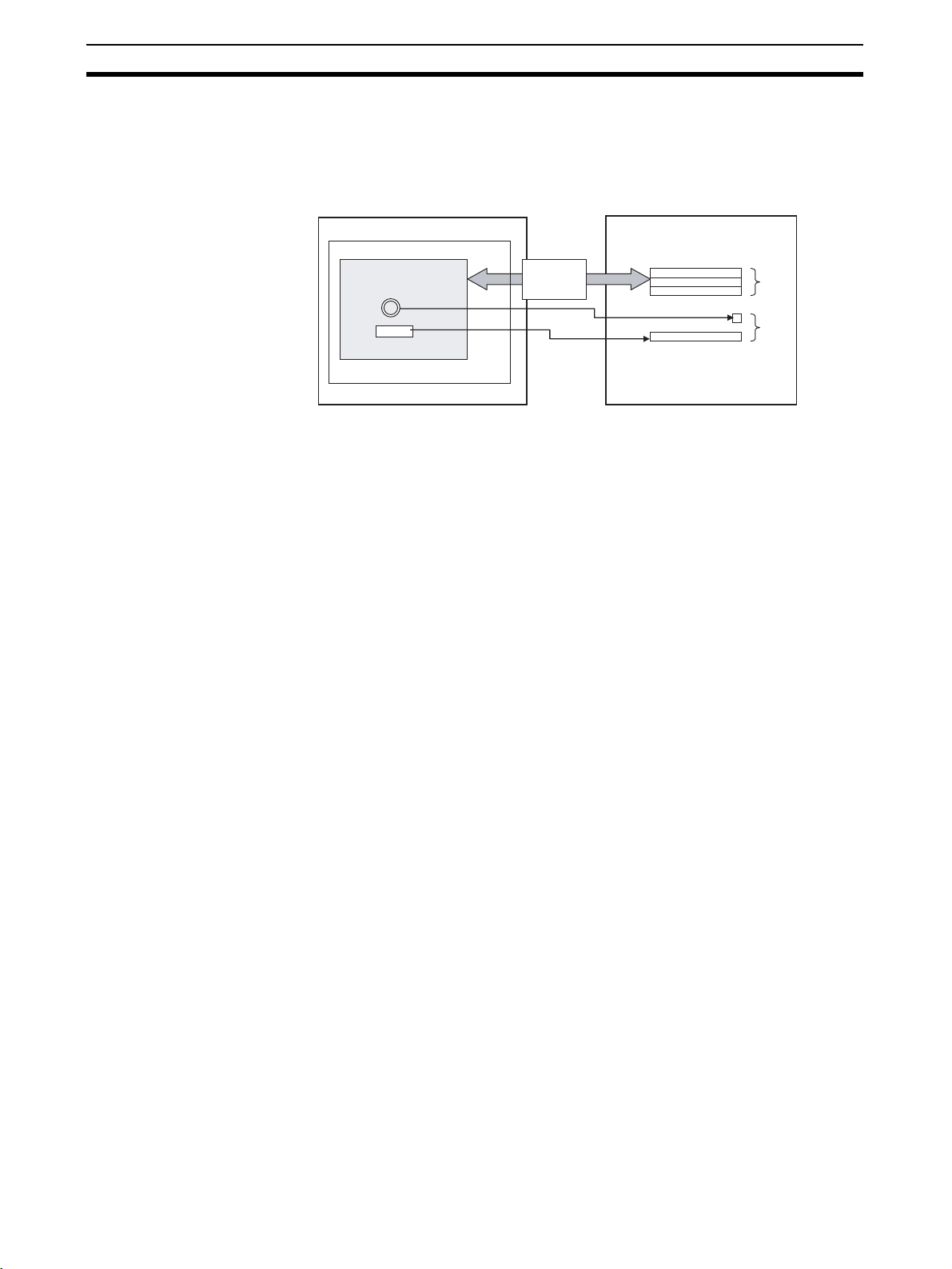

2-1-1 Overview of Internal Operation

This section describes the structure of internal data of an NV-series PT.

NV-series PT

FROM (built-in Flash Memory)

2. Screen is displayed.

Part s

1. System

information is

exchanged.

Screen number,

backlight color,

etc.

The internal data can be largely divided into two parts.

1. System information is exchanged.

System information is constantly exchanged between the PT and PLC, including the screen number and backlight color from the PLC, or to notify

the PLC of PT status.

The system information area is stored in an area called the system memory. System memory must be initialized using the NV-Designer before use.

PLC

System memory

Fixed

area

2. Screen is displayed.

The NV-series PT has multiple screens that contain functional parts selected from the parts libraries. One of the screens can be displayed.

The functional parts specify the desired PLC address and they read/write

data.

8

Page 30

Internal Data Types and Structure Section 2-1

a

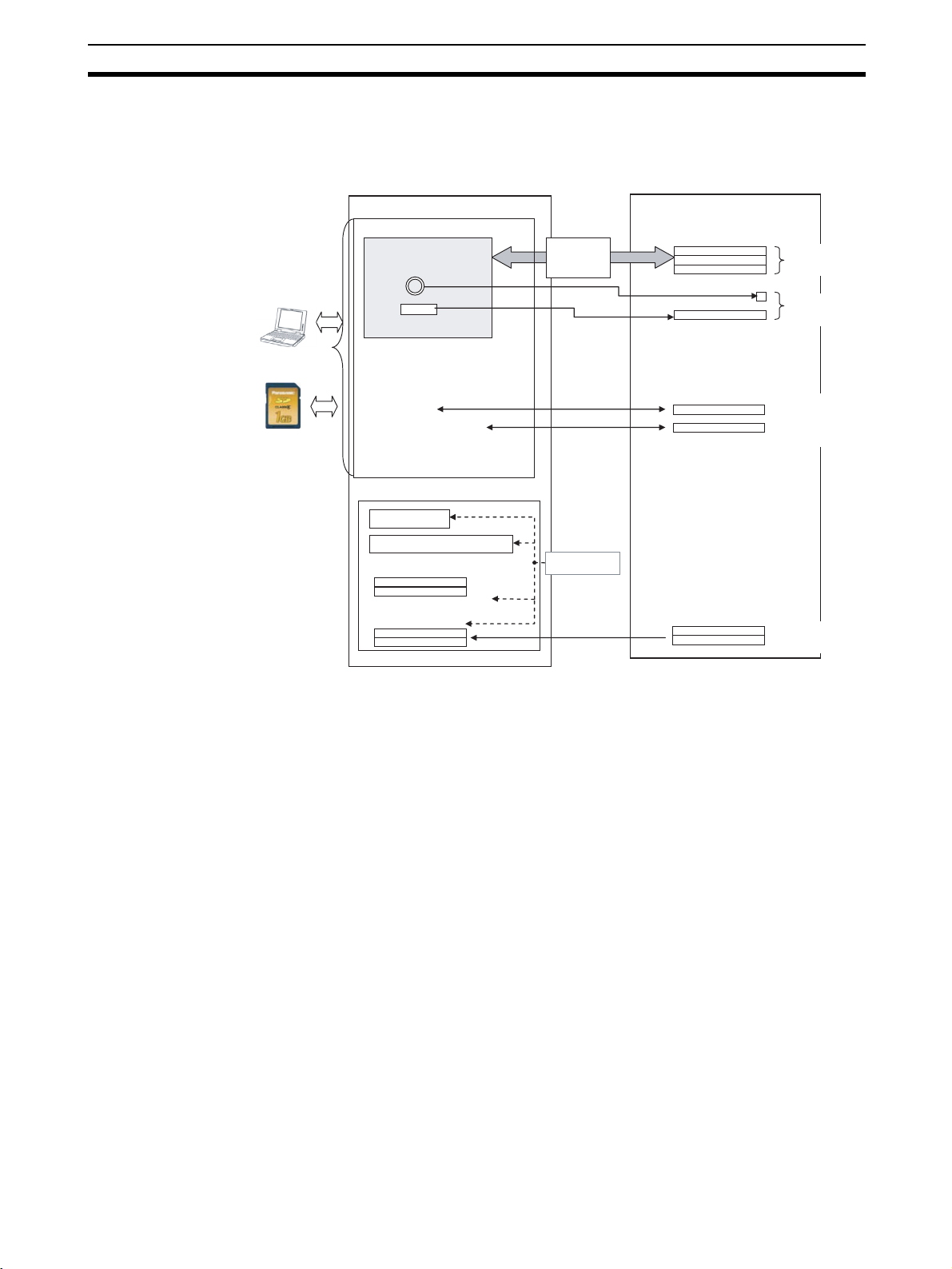

2-1-2 Details of Internal Operation

The NV-series PT has FROM (internal Flash Memory) and SRAM (built-in

RAM). Data is exchanged with the PLC as shown in the following diagram.

NV-series PT PLC

Project Data

FROM (built-in Flash Memory)

• Base screen data

Par ts

888

System

Information

Screen number, backlight

color, etc.

System memory

Fixed area

Allocatable are

NV-Designer

SD memory card

• Keyboard screen data

• Login screen data

• NV configuration data

• Recipe data

*1

• Write Address data

• Flow display data

• Passwords

SRAM (internal RAM)

*1

Clock data

Alarm history data

PT internal memory

Internal memory can be held.

PLC memory hold area

*1: Not supported by the NV3W.

*1

Allocatable area

*1

*1

*1

Battery

Held when power

*1

*1

supply is OFF

Allocatable area

Allocatable area

9

Page 31

Internal Data Types and Structure Section 2-1

■ FROM (built-in Flash Memory)

Stores project data created with the NV-Designer (function data, such as base

screens and NV Configuration).

Project data can be backed up or restored using SD memory cards.

Data Description

Screen

data

Base screen

data

Keyboard screen

data

Login screen

data

NV configuration data

Recipe data Settings to read/write multiple values at one time from or

Write Address

data

Flow display

data

Passwords Settings to restrict displays and operations depending on

Screen data containing parts that have been selected

from the parts libraries.

Screen data containing keyboard parts that open when

the corresponding data parts are pressed.

The Screen data is used to enter passwords according to

the password levels specified for operation security. (Not

supported by the NV3W)

Configuration data related to the NV-series PT that

includes the setting information for functions, such as the

system memory, startup screen number, language

switching, and other functions.

to PLC memory.

Condition and operation settings for writing data to the

PLC according to the status of a memory location in the

PLC while the specified screen is displayed.

Settings for character flows displayed on the bottom of

the screen and the display conditions.

the part and user.

(Not supported by the NV3W)

■ SRAM (Internal RAM)

Stores alarm history data collected by the PT, internal memory values, and

clock data.

Data saved in the built-in RAM will be deleted 1 minute after power supply is

turned OFF, but it can be backed up with an optional Battery. (These functions

are not supported by the NV3W.)

Data Description

Clock data Clock data in PT.

Alarm history data PLC data defined as alarms is constantly monitored and the

PT internal memory NV-series PT internal memory.

PLC memory hold

area

time when the alarm occurred and was removed is recorded

as history data.

The specified area can be held while the power supply is OFF.

PLC data that is constantly read from the specified memory

locations and can be held even when the power supply is

turned OFF.

10

Page 32

Displaying Screens Section 2-2

2-2 Displaying Screens

2-2-1 Startup Screen

Screen 0 is displayed as default when the PT is started.

This screen can be changed in NV Configuration from the NV-Designer.

2-2-2 Switching Screens

One of the following three methods can be used to change the displayed

screen registered in the NV-series PT.

• Switching screens using function switches (functional parts) on PT

screens

• Switching screens using the ladder program

• Switching screens after a specified time (automatic paging)

Switching Screens Using

Function Switches

(Functional Parts) on PT

Screens

The PT screen can be switched using a function switch from a parts library.

The operation depends on the operating mode set for the function switch.

■ Operating Mode: Change Screen

When the function switch is touched, the screen will change to the preset

screen number.

However, the information in the PLC internal system memory (first word in the

Word Area (screen number specified by PLC)) will not be updated.

You can also return to the previous screen by using a function switch with the

operating mode set to.

Example:

NV

Changes to

screen 2.

Switch turned ON.

Operating mode = Change screen

Screen 2

Screen 2

Return to

previous screen

Screen 2

Switch turned ON.

Operating mode = Return to previous screen

11

Page 33

Displaying Screens Section 2-2

■ Operating Mode: Set Value

When the switch is touched, the PT writes the screen number to switch to in

the PLC internal system memory (first word in the Word Area (screen number

specified by PLC)) and the screen is switched.

Example: Data format: 1 word

Output word: D100 (first word in the Word Area of System Memory)

Value: 2 (desired screen number in hexadecimal)

NV

Switch turned ON.

A value is set.

Set D100 to 2. (D100 is the first word in

the Word Area of the Basic

Communications Area.)

PLC

Basic Communications Area

Word Area

D100

2 hex

Screen Number

from PLC

Refer to 7-5 Function Switches for details on Switch Functions.

NV

Screen 2

Changes to screen 2.

PLC

Basic Communications Area

Word Area

D100

2 hex

Screen Number

from PLC

12

Page 34

Displaying Screens Section 2-2

Switching Screens Using

the Ladder Program

Create a ladder program that writes the screen number to the first word of the

PLC system memory to switch the screen.

Communications between the PT and the PLC

PLC

Ladder program

MOV

NV

Continuous communications

Basic Communications Area: Word Addresses

First word

2nd word

3rd word

PLC internal memory

Screen number specified from PLC.

Do not use.

Current Screen Number

Read

Write

Example: Changing from Screen 1 to Screen 2

Screen 1

Screen 2

Specification to

change to screen 2.

Changed to

screen 2.

Example: D100

Example: D100

Basic Communications Area: Word Addresses

2

D101

D102

Basic Communications Area: Word Addresses

D101

D102

Do not use.

1

PLC internal memory

2

Do not use.

2

PLC internal memory

Write

The number of the screen to

display (2) is stored in D102.

Ladder program

MOV

&2

D100

Switching Screens after a

Specified Time (AutoPaging)

Precaution for Correct Operation

Screen numbers are displayed in decimal on the NV-Designer but they must be

in hexadecimal when writing the screen number to the PLC internal system

memory.

The automatic paging function can be used to automatically switch to a specified screen after a specified period of time has passed. Settings are made in

the NV Configuration of the PT.

Application Example:

1. Screen 1 is displayed for 10 seconds and then screen 2 is displayed.

2. Screen 2 is displayed for 5 seconds and then screen 3 is displayed.

NV

Screen 1

Screen 2

After 10 s

Refer to 6-2-6 Auto-Paging Tab Page for details.

After 5 s

Screen 3

13

Page 35

Backlight Display Methods Section 2-3

2-3 Backlight Display Methods

2-3-1 Specifying Backlight Colors

The backlight color of a monochrome NV3W, NV4W or NV3Q can be specified.

It can be specified using one of the following two methods.

1. Initial Settings Backlight colors and operation are set in the base screen properties from the

NV-Designer.

Model Backlight color Operation

NV3W, NV4W White (green), pink (orange), or red Lit or flashing

NV3Q monochrome White, pink, or red Lit or flashing

NV3Q color Not supported. Not supported.

The specified backlight color will be displayed in a rectangle on the left edge

of the title bar.

Indicates that the base screen is white or green.

The backlight colors depend on the model of the PT.

2. Changing the Backlight during Operation

The backlight color can be changed by using specifications from the PLC.

Application Example That Switches the Backlight Color

Color That Indicates an Alarm

Color That Indicates

Normal Operation

"Green"

Color That Indicates an Alarm

Specify the color and either lit or flashing in the Bit Area in system memory.

Refer to 8-1 Switching Backlight Colors for details.

2-3-2 Automatic Backlight OFF Function

The PT can be set so that the backlight automatically turns OFF if the touch

screen not touched for a specified period of time. This can be done on the

Setup 1 Tab Page of the NV Configuration. The time can be set between 1

and 30 minutes.

"Orange"

"Red"

14

Page 36

SECTION 3

NV-Designer Outline and Configuration

This section gives the system requirements for running the NV-Designer, describes the windows and menus of the NVDesigner, and explains the parameters in the NV-Designer Configuration.

3-1 System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3-1-1 System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3-1-2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3-1-3 Re-installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3-1-4 Precautions for Windows Vista and Windows 7. . . . . . . . . . . . . . . . 16

3-2 NV-Designer Window Names and Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3-2-1 Names of Window Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3-2-2 Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3-2-3 Toolbar Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3-2-4 Graphic Bar Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3-2-5 Screen Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3-2-6 Base Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3-2-7 Parts Libraries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3-3 NV-Designer Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3-3-1 Customizing the Screen Creation Display . . . . . . . . . . . . . . . . . . . . 29

3-3-2 NV-Designer Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3-3-3 Drive Tab Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3-3-4 File Tab Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3-3-5 Grid Tab Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3-3-6 Screen Tab Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3-3-7 Graphic Tab Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3-3-8 Language Tab Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

15

Page 37

System Requirements Section 3-1

3-1 System Requirements

3-1-1 System Requirements

Refer to the CX-One Version 4.@ Setup Manual (Cat. No. W463) for the system requirements to operate the NV-Designer.

3-1-2 Installation

Install the NV-Designer using the CX-One or CX-One Lite Installer.

For details, refer to the CX-One Version 4.

provided with the CX-One.

3-1-3 Re-installation

Uninstall the NV-Designer and then re-install it.

For details on how to uninstall the NV-Designer, refer to the CX-One Version

@

Setup Manual (Cat. No. W463) provided with the CX-One.

4.

3-1-4 Precautions for Windows Vista and Windows 7

Because of the operating specifications of Windows Vista and Windows 7, the

file may be saved in a different location to that of a previous version of Windows. Be careful of the following points if you are using Windows Vista and

Windows 7.

@

Setup Manual (Cat. No. W463)

Having Multiple Users of

NV-Designer

File Save Location If you try to save a file in the Program File Folder or other system folders, it will

Files Saved in the

Program File Folder or

Other System Folders

Files saved in the Program Files Folder or other system folders cannot be

shared. To share the Parts Libraries, use a file that can be shared, or copy the

file to each user.

be saved in another location. We recommend that you save files in another

folder, such as the My Documents Folder.

Note The screen data cannot be saved in the Program File Folder or oth-

er system folders.

The file will not be displayed in Explorer even if you open the folder where it is

saved.

Open the folder where the file is saved and click the Compatible Files Button

displayed at the top of the screen to display the file screen.

Additional Information

Additional Information Operating Specifications of Windows Vista and Windows

7

When using Windows Vista or Window 7, files cannot be saved in the Program File Folder or other system folders even if it is specified as the save location in application software, such as NV-Designer. They will be saved it in a

virtual folder (VirtualStore). VirtualStore is a unique folder for each user. It

cannot be shared with other users.

16

Page 38

NV-Designer Window Names and Menus Section 3-2

3-2 NV-Designer Window Names and Menus

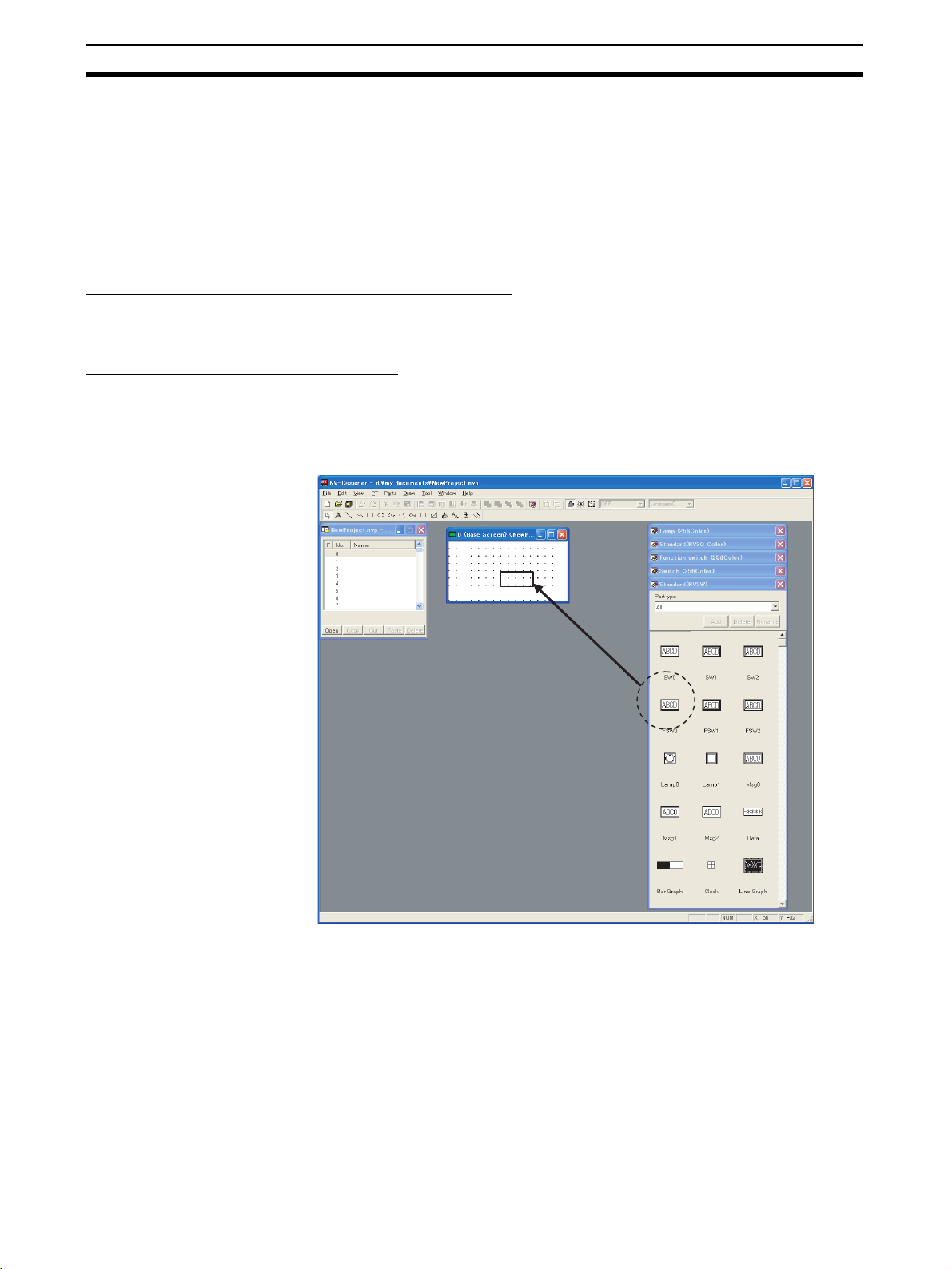

3-2-1 Names of Window Components

Graphic bar

Toolbar

Menu bar

Screen Manager

Base Screen

Parts Library

Menu Bar All NV-Designer functions are displayed in the menus.

Toolbar Frequently used commands are displayed as icons on the menu bar.

Graphic Bar Frequently used drawing commands are displayed as icons on the menu bar.

Screen Manager The screens are managed by base screen numbers.

Base Screen Creates a screen. The screen is displayed at the PT’s screen size. The size

cannot be changed, but the display can be zoomed in or out.

Parts Library Parts used for creating screens are displayed in parts libraries.

Additional Information

When the NV-Designer is started, the Standard Parts Libraries for all parts for

the model that is set will be displayed in front.

17

Page 39

NV-Designer Window Names and Menus Section 3-2

3-2-2 Menus

The NV-Designer’s operations and functions are displayed on menus according to their application.

Menu Submenu/Command Description

File New Displays the Model Selection Dialog Box.

Open Opens the specified NV-Designer project file (*.nvp).

Close Closes an open NV-Designer project file (*.nvp).

Save Saves the specified NV-Designer project file (*.nvp).

Save As Saves the specified NV-Designer project file (*.nvp) with a

Delete Deletes the specified NV-Designer project file (*.nvp).

Print Displays the Print Dialog Box. Specifies the data to be

Print Style Setup Prints the selected items.

Printer Setup Sets up the printer before printing.

Keyboard Screen Displays the Edit Keyboard Screen Dialog Box. Used to

Login Screen Displays the Edit Login Screen Dialog Box. The Login

Export Text The character strings for switching the display language can

Import Text Imports text from a text file. The imported text can be

Exit Exits the NV-Designer.

different name.

printed.

name or delete keyboard screens.

Screens are used to enter passwords according to the password levels specified for the operation security function.

be exported to a text file. The text data can also be edited

and imported.

checked by selecting PT - Multi Language Exchange String

List.

18

Page 40

NV-Designer Window Names and Menus Section 3-2

Menu Submenu/Command Description

Edit Undo Undoes the previous operation.

Redo Redoes the previous operation.

Cut Cuts the selected parts.

Copy Copies the selected parts.

Repeat Creates a base part which is copied to enable the creation of

Paste Pastes the parts that were last cut or copied.

Copy Bitmap of Base

Screen

Align Left Aligns the left sides of the selected graphics.

Right Aligns the right sides of the selected graphics.

Top Aligns the top edges of the selected graphics.

Bottom Aligns the bottom edges of the selected graphics.

Horizontal Center Aligns the horizontal centers of the selected graphics.

Vertical Center Aligns the vertical centers of the selected graphics.

Centering Centers multiple graphics figures.

Rotate Rotates the selected graphics.

Flip Right/Left Flips the selected graphics left to right.

Top/Bottom Flips the selected graphics top to bottom.

Delete Deletes the selected items.

Erase Screen Deletes the base screen

Bring Previous Moves the selected graphic up one layer.

Bring Next Moves the selected graphic back one layer.

Bring Forefront Places the selected graphics on the top.

Bring Behind All Places the selected graphics on the back.

Group Creates a group of character strings, graphics, or parts.

Ungroup Ungroups a group of parts.

Select Selects character strings, graphics, and parts.

Select All Selects all character strings, graphics, and parts on the base

multiple parts with different functions.

Copies the base screen contents as bitmap data.

screen.

19

Page 41

NV-Designer Window Names and Menus Section 3-2

Menu Submenu/Command Description

View Redraw Redraws the contents of the screen that is being edited.

Grid Sets the grid on base screens edited with the NV-Designer.

Toolbar Displays and hides the toolbar.

Status bar Displays or hides the status bar.

Graphic bar Displays and hides the graphic bar.

Zoom 400% Changes the magnification of the base screen that is being

200%

100%

75%

50%

Zoom Box Displays a Zoom Box so that detailed sections can be drawn

Parts No. Displays the parts numbers of all parts on the base screen

Parts Attribute Displays the attributes of all parts on the base screen that is

Status OFF Places a bit switch, function switch, or lamp on the screen in

ON Places a bit switch, function switch, or lamp on the screen in

Language No. Changes the language number when switching the display

Address Cross Reference

edited.

and fine adjustments can be made to positions when creating a base screen.

that is being edited.

being edited.

OFF status.

ON status.

language is being used.

The system memory used for communications with the PLC

and the communications addresses used by parts on the

screen are displayed in a list.

20

Page 42

NV-Designer Window Names and Menus Section 3-2

Menu Submenu/Command Description

PT Transfer Transfer Transfers the base screen data, NV Configuration data, and

Verify Compares the file that is open on the NV-Designer and the

Create SD Memory

Card File

Read from SD Memory Card File

NV Configuration Displays the NV Configuration Dialog Box.

Recipes Specifies the first control address and creates the settings

Flow displays Text messages can be displayed like an electric scoreboard

Writing memory

(Write Address)

Password Displays the Edit Operation Security Password Dialog Box

Multi Language

Exchange String List

Screen Properties Used to set the properties of a base screen (i.e., the name,

Parts Open Parts Library Opens the Parts Library Selection Dialog Box. Select the

Edit Attributes Edits the selected parts.

Draw Used to edit screens of custom switch parts.

Parts List Displays the parts attributes used by a base screen in a list.

other data created on the NV-Designer to the PT.

file transferred to an NV-series PT. If the contents differ, the

differences will be displayed. Compares files read to the NVDesigner.

Names a file in the SD memory card and saves the base

screen data in it.

Reads base screen data from a file on the SD memory card.

Sets basic items, such as the PT’s system memory, parameters for communications with PLCs and computers (NVDesigner), PLC multiple connection, auto-paging, startup

screen settings, Setup 1 settings (clock, backlight, key press

sound, battery error display, file compression, system menu

language, switching display language, backlight brightness,

contrast adjustment), Setup 2 settings (SD memory card

menu), memory hold, recipes, alarm history, line graphs, and

operation security.

for each model for the function that reads and writes the settings for a model from and to the specified PLC address as

commanded by the PLC.

moving across the Flow Display Dialog Box from right to left.

Used to set operations to set or reset bits, set values, perform calculations, etc. in PLC memory when conditions in

the PLC are met while the specified screen is displayed.

so that you can set the passwords when the operation security password function is being used.

If the Switch Display Language Option is selected in the NVDesigner Configuration, the language number and language

type can be selected. The character string for each language number can also be edited in the list.

background, and backlight operation).

parts library to use and click the Open Button.

21

Page 43

NV-Designer Window Names and Menus Section 3-2

Menu Submenu/Command Description

Draw Select Used to select a character string, graphic, functional part,

Text Creates a character string.

Line Creates a straight line.

Continuous line Creates continuous lines.

Rectangle Creates a rectangle.

Pie/Oval Creates a circle or oval.

Arc Creates a circular or oval arc.

Spline Creates a curved line.

Sector Creates a circular or oval sector.

Rounded Rectangle Creates a square with rounded corners.

Polygon Creates a polygon.

Fill In Fills areas enclosed by lines and graphics with a color.

Character Type Sets the language, font, character size, attributes (e.g.,

Color Setup Sets the colors and patterns for graphics.

Line Type Sets the line thickness and type.

Toolbar Resource Report Displays the resource report (amount of free memory and

Base Screen Memory

Usage

NV-Designer Configuration

Convert PLC Model Convert Changes the model of the selected PLC in the file that is

NV Model Convert Changes the model of PT in the file that is being edited.

Close All Closes all open base screens.

Window Cascade Overlaps more than one base screen and displays them.

Arrange Displays more than one base screen side-by-side.

Arrange Icons Returns the toolbar icons to the defaults.

Help Contents Displays the contents of NV-Designer help.

Keyword Displays the window for keyword-based searches of NV-

About NV-Designer Displays the version of the NV-Designer.

etc.

bold), and colors (character and background colors).

memory used by NV configuration, base screens, and keyboard screens).

Displays the amount of memory used by the base screens.

Displays the amount of memory and the communications

addresses used by the parts.

Displays the NV-Designer Configuration Dialog Box.

Sets the configuration of the NV-Designer screen display,

the folder where the parts libraries used by the NV-Designer

are stored, the current folder, whether to enable automatic

backup, the backup time interval, items for creating graphics,

menu and dialog languages, and whether to enable switching the display language.

being edited.

Designer help.

Pop-up Menus on Base Screens

Pop-up Menus Description

Paste Pastes the parts.

Screen Attribute Sets the background colors and patterns.

22

Page 44

NV-Designer Window Names and Menus Section 3-2

guag

Pop-up Menus When a Functional Part or Character String Is Selected

Pop-up Menus Description

Cut Cuts the selected parts.

Copy Copies the selected parts.

Paste Pastes the parts that were last cut or copied.

Functional Parts: Attribute Sets the attributes of a part.

Character String: Character Type Sets the language, font, character size, attributes (e.g., bold), and colors (character

Status ON Places a bit switch, function switch, or lamp on the screen in OFF status.

OFF Places a bit switch, function switch, or lamp on the screen in ON status.

Align Left Aligns the left sides of the selected graphics.

Right Aligns the right sides of the selected graphics.

Top Aligns the top edges of the selected graphics.

Bottom Aligns the bottom edges of the selected graphics.

Horizontal Center Aligns the horizontal centers of the selected graphics.

Vertical Center Aligns the vertical centers of the selected graphics.

Delete Deletes the selected items.

Order Bring Forefront Places the selected graphics on the top.

Bring Behind All Places the selected graphics on the bottom.

Bring Previous Moves the selected graphic up one layer.

Bring Next Moves the selected graphic back one layer.

Group Creates a group of character strings, graphics, or parts.

Ungroup Ungroups a group of parts.

and background colors).

3-2-3 Toolbar Functions

Part Names and

Functions

The names of icons and other items on the toolbar are given below.

Undo Button

Redo Button

Undo Button

Undoes the previous operation.

Redo Button

Redoes the operation that was undone using the Undo Button.

Align Button

Aligns character strings, graphics, and parts.

Enable/Disable Snap Button

Redraw Button

Display/Hide the Graphic Bar Button

Ungroup Button

Group Button

Open a Parts Library Button

Align Button

Lan

Order Button

Parts State Button

e Number Button

Order Button

Changes the order of character strings, graphics, and parts if they are overlapped.

23

Page 45

NV-Designer Window Names and Menus Section 3-2

Parts are set at the foreground as a default.

Open a Parts Library Button

Opens a parts library.

Group Button

Creates a group of character strings, graphics, or parts.

Ungroup Button

Ungroups a group of parts.

Display/Hide the Graphic Bar Button

Displays and hides the graphic bar.

Redraw Button

Redraws the contents of the screen that is being edited.

Enable/Disable Snap Button

Enables/disables the snap function when positioning character strings, graphics, or parts.

Parts State Button

Turns ON/OFF the selected switches and lamps or changes the message part

number.

Language Number Button

Changes the language number of the selected base screen.

Precaution for Correct Operation

The Undo Button is effective only for operations such as drawing and editing

character strings, graphics, and parts, and some operations in editors activated

from the menu bar.

The Undo Button cannot be used for other operations.

3-2-4 Graphic Bar Functions

Part Names and

Functions

Arc/Elliptical Arc Button

Circle/Oval Button

Rectangle Button

Continuous Line Button

Continuous Line Button

Character String Button

Select Button

The names of icons and other items on the graphic bar are given below.

Select Button

Used to select a character string, graphic, functional part, etc.

Curve Button

Segment/Oval Segment Button

Rounded Rectangle Button

Polygon Button

Fill Button

Character Type Button

Color Button

Line Type Button

24

Character String Button

Creates a character string.

Continuous Line Button

Creates a straight line.

Page 46

NV-Designer Window Names and Menus Section 3-2

Continuous Line Button

Creates continuous lines.

Rectangle Button

Creates a rectangle.

Circle/Oval Button

Creates a circle or oval.

Arc/Elliptical Arc Button

Creates a circular or oval arc.

Curve Button

Creates a curved line.

Segment/Oval Segment Button

Creates a circular or oval sector.

Rounded Rectangle Button

Creates a square with rounded corners. The radius of the rounded corners

can be changed in the line settings.

Polygon Button

Creates a polygon.

Fill Button

Fills areas enclosed by lines and graphics with a color.

Character Type Button

Sets the size and style (bold, outline, underline) of characters.

Color Button

Changes the color of character strings and graphics.

Line Type Button

Sets the line thickness and type.

25

Page 47

NV-Designer Window Names and Menus Section 3-2

3-2-5 Screen Manager

The Screen Manager is a dialog box for managing the base screens in a

project.

It can be used as a list for opening screens.

Screens can be copied, pasted, cut, and deleted using the Screen Manager.

Multiple projects can be started simultaneously and editing can be performed

between the Screen Managers.

Project Name and Base

Screen List

The project name is displayed at the upper left of the window.

Serial numbers starting from 0 will be assigned to projects that have not yet

been saved.

This is how projects can be distinguished if multiple projects are created.

Project name

List of screens

0 to 1,023

Command Buttons

A base screen is displayed by its number and name.

Note The number of screens that can be registered depends on the con-

tents of the screens.

Creating Screens Double-click the number of the base screen that you want to create, or select

the number and click the Open Button.

Editing the Screen Copy: Select the screen to copy, click the Copy Button, input a different

screen number, and click the Paste Button.

Move: Select the screen to move, click the Cut Button, input a different

screen number, and click the Paste Button.

Delete: Select the screen to delete and then click the Delete Button.

Additional Information

• The copy, paste, cut, and delete functions can also be accessed by right-clicking on the desired screen.

• The “+” sign will be displayed in the F column if a screen is copied and pasted.

• Multiple Screen Managers can be displayed simultaneously and screens can

be copied or moved between files. However, if the models of NV-series PT are

different and the screen cannot be pasted, a message saying so will be displayed.

26

Page 48

NV-Designer Window Names and Menus Section 3-2

3-2-6 Base Screens

Base screens are essentially the same size as the screens displayed on the

PT.

(You can zoom the screen display in and out.)

Character strings and parts are positioned on the screen to create a base

screen.

Opening a Base Screen

Double-click a number in the number column in the Screen Manager (or

select the number and click the Open Button) to open a base screen.

Double-click a number,

or select the number and

click the Open Button.

Parts of Base Screens

The screen number will be displayed on the top left of the base screen, and