Page 1

Cat. No. V063-E1-03

NT631 and NT631C

Programmable Terminals

Setup Manual

Page 2

NT631 and NT631C Programmable Terminals

Setup Manual

Revised September 2007

POWER

RUN

Page 3

iv

Page 4

Notice:

r

f

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 2000

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 5

vi

Page 6

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

1 Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

SECTION 1

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Role and Operation of the NT631/NT631C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Functions of the NT631/NT631C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-3 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1-4 Communications with the Host . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1-5 Communications Using Memory Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1-6 Before Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

SECTION 2

Preparing for Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2-1 Method for Connection to the Host . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

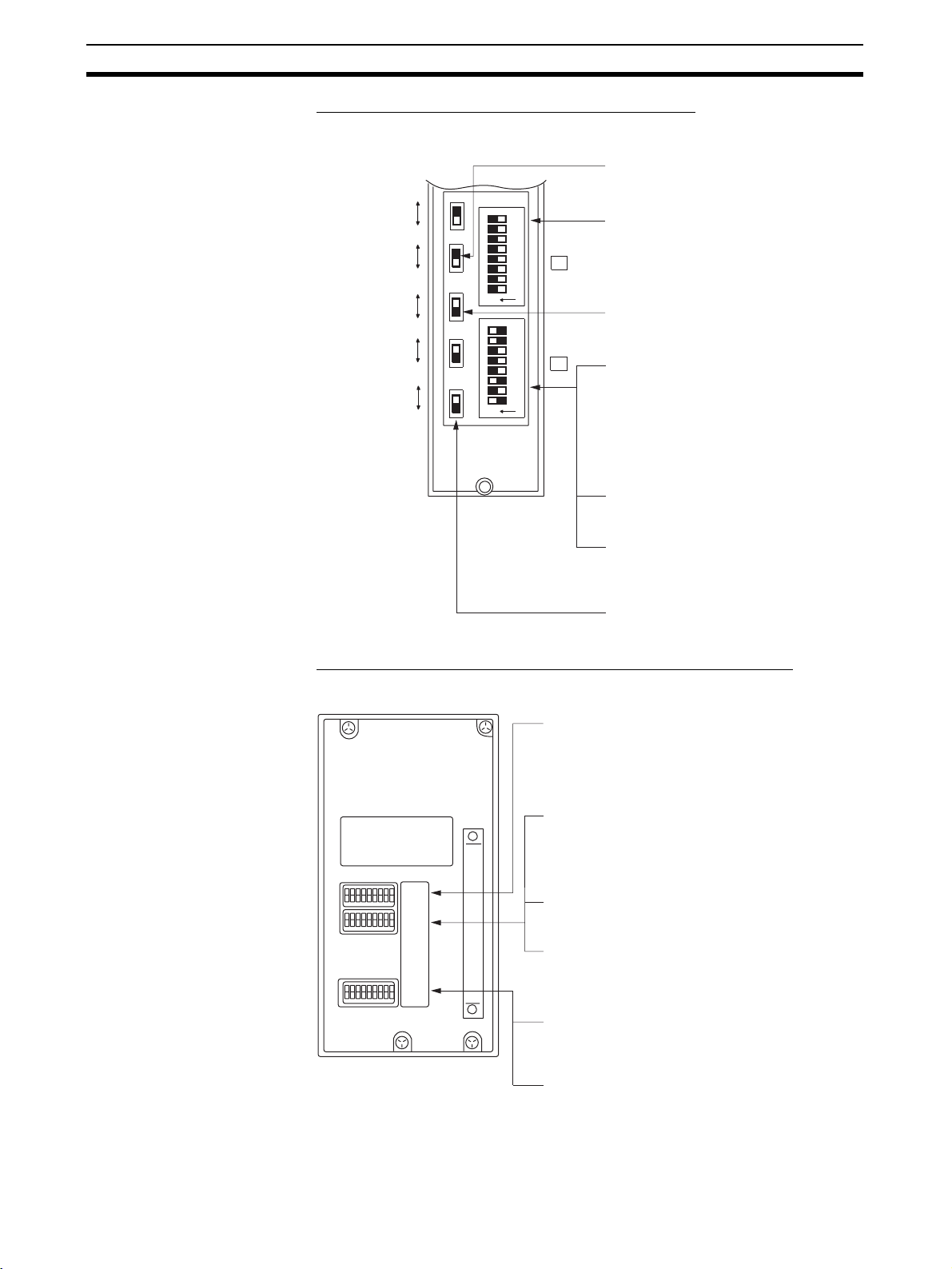

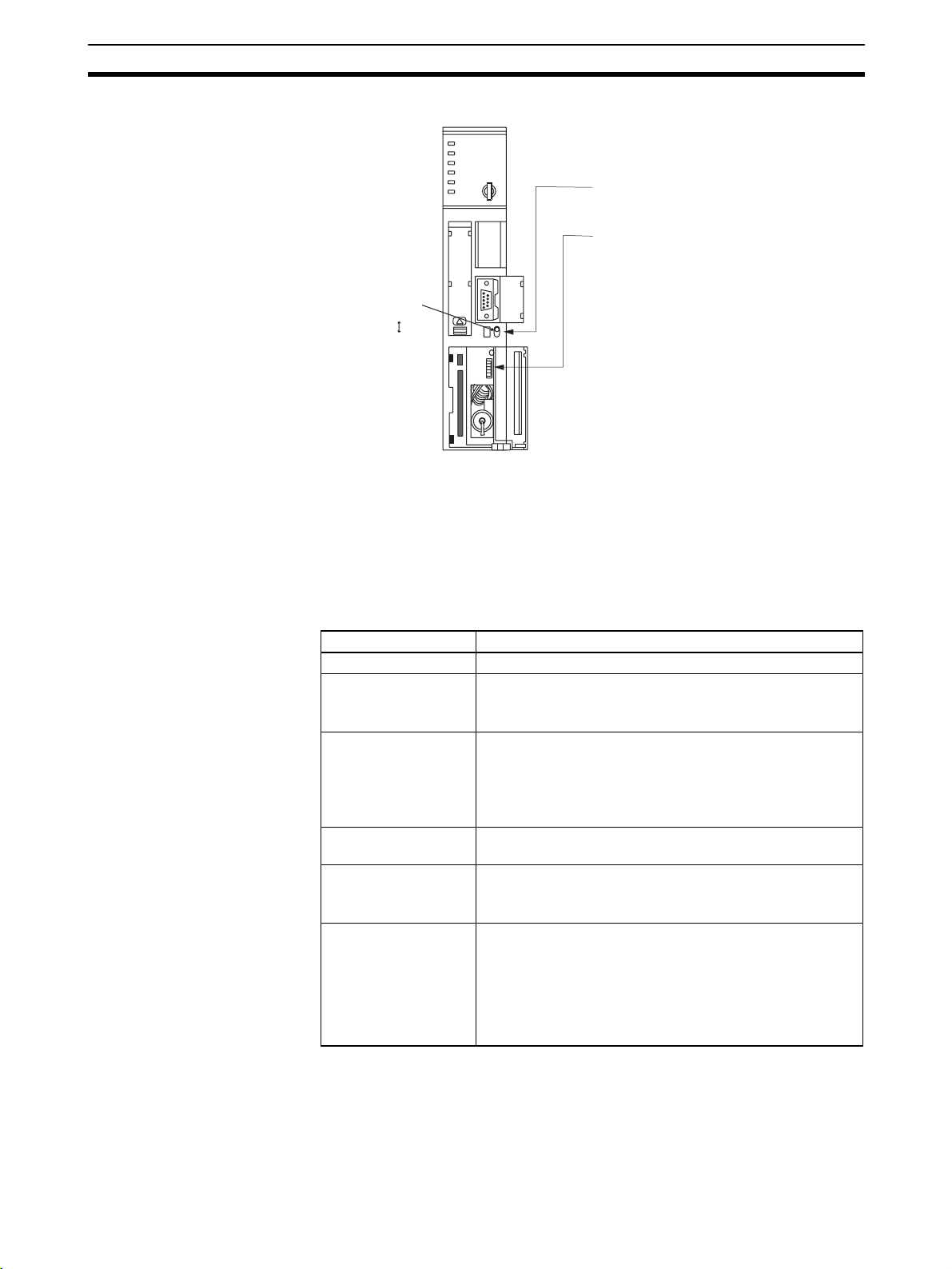

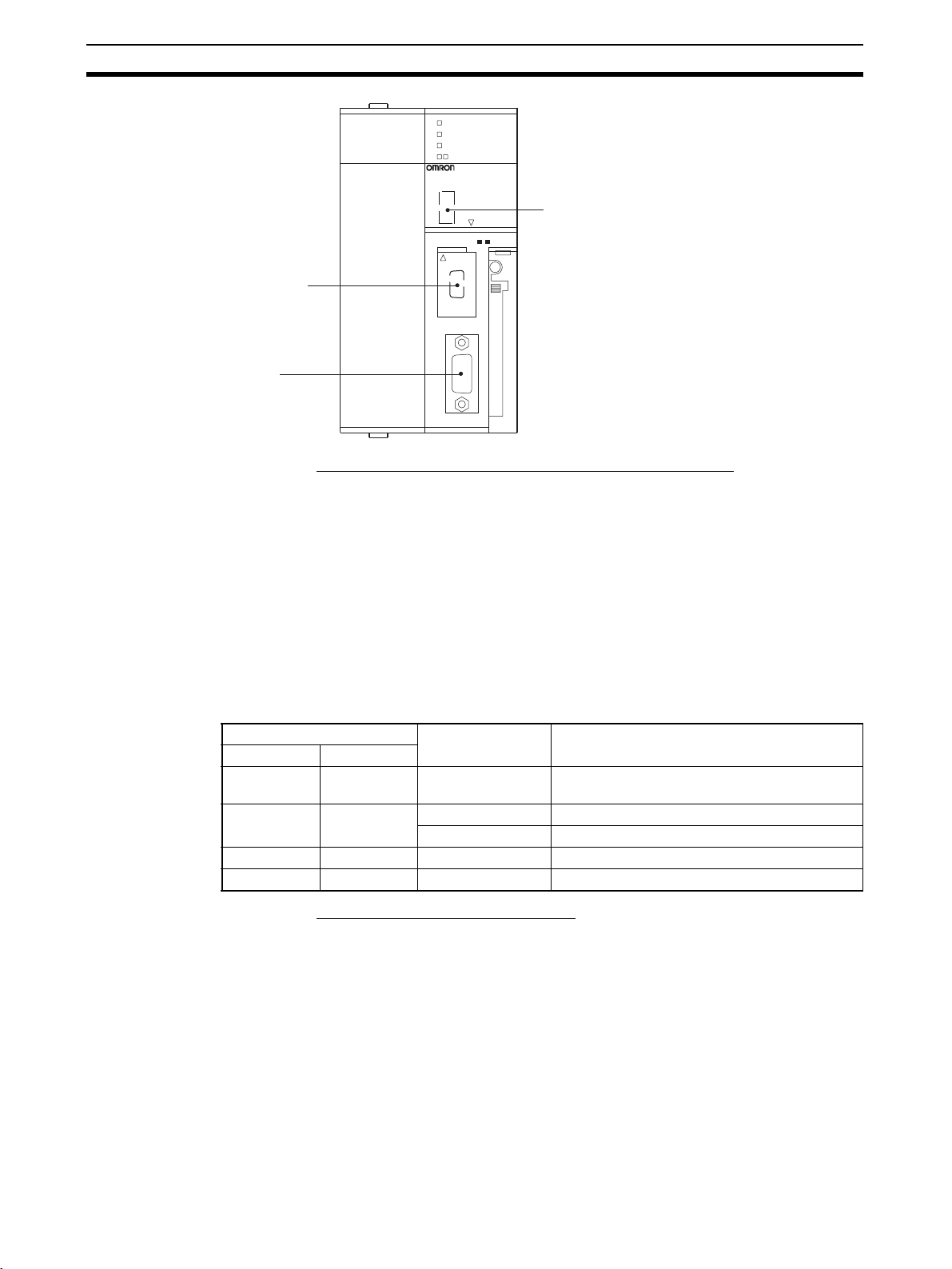

2-2 Names and Functions of Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

SECTION 3

Hardware Settings and Connections. . . . . . . . . . . . . . . . . . . 31

3-1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

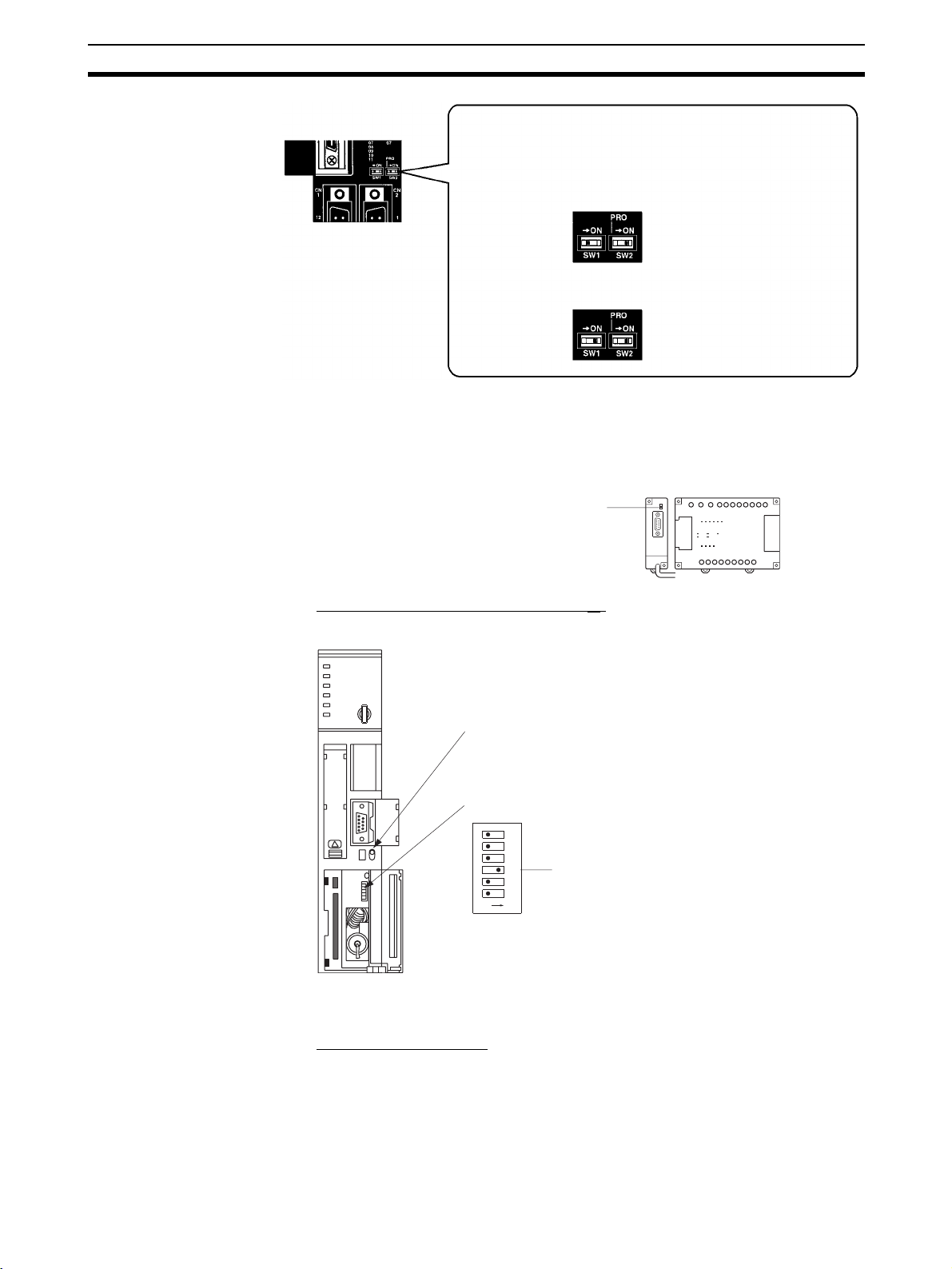

3-2 Connecting to the Support Tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3-3 Connecting a Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

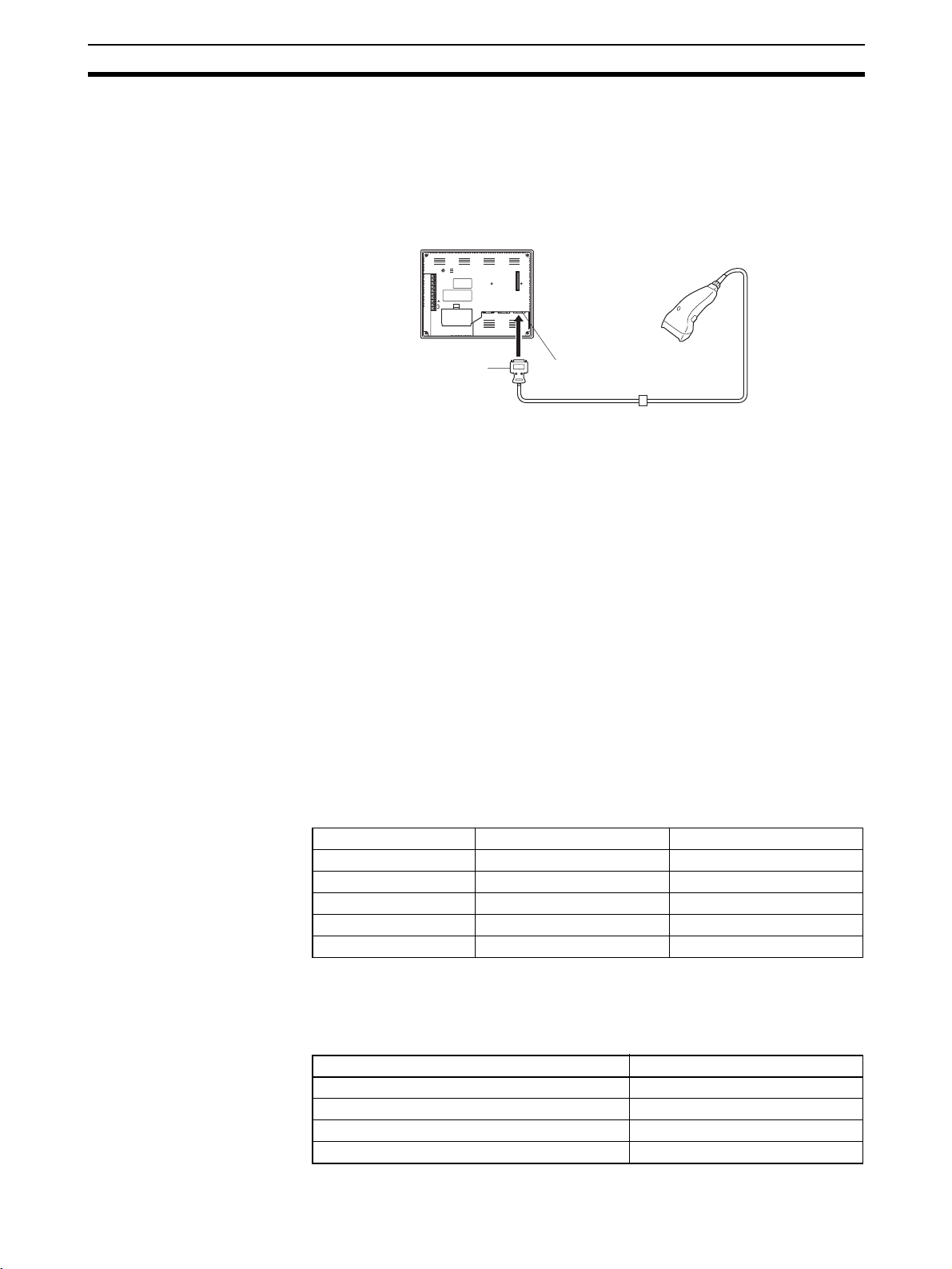

3-4 Connecting a Bar Code Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

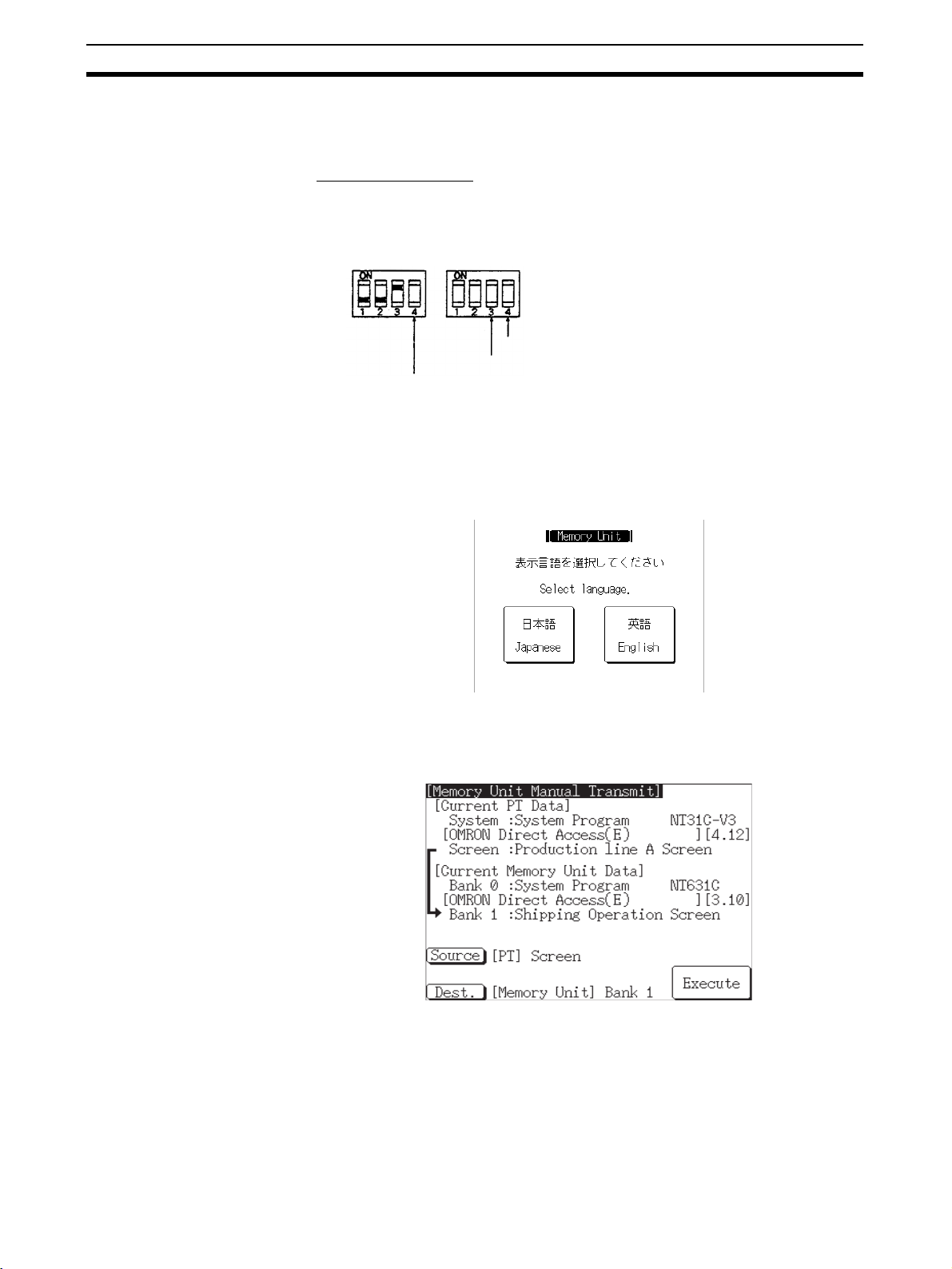

3-5 Using a Memory Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

SECTION 4

Connecting to the Host from the RS-232C Port. . . . . . . . . . 47

4-1 Connecting to the RS-232C Port at the Host . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

SECTION 5

Connecting to the Host from the RS-422A/485 Port . . . . . . 79

5-1 Connecting to the Host’s RS-232C Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5-2 Connecting to the Host’s RS-422A/485 Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

SECTION 6

System Menu Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

6-1 System Menu Operation Flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

6-2 Starting the NT631/NT631C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

6-3 Operation Modes and the System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

6-4 Memory Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

vii

Page 7

TABLE OF CONTENTS

6-5 Operations in the System Installer Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

6-6 Transmitting the Screen Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

6-7 Setting Conditions for Communications with Host by Using Memory Switches. . . . . . . . . 152

6-8 Starting Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

6-9 Various System Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

6-10 Setting the Bar Code Reader Input Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

6-11 System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

6-12 Programming Console Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

6-13 Device Monitor Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

6-14 Version Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

SECTION 7

Troubleshooting and Maintenance . . . . . . . . . . . . . . . . . . . . 225

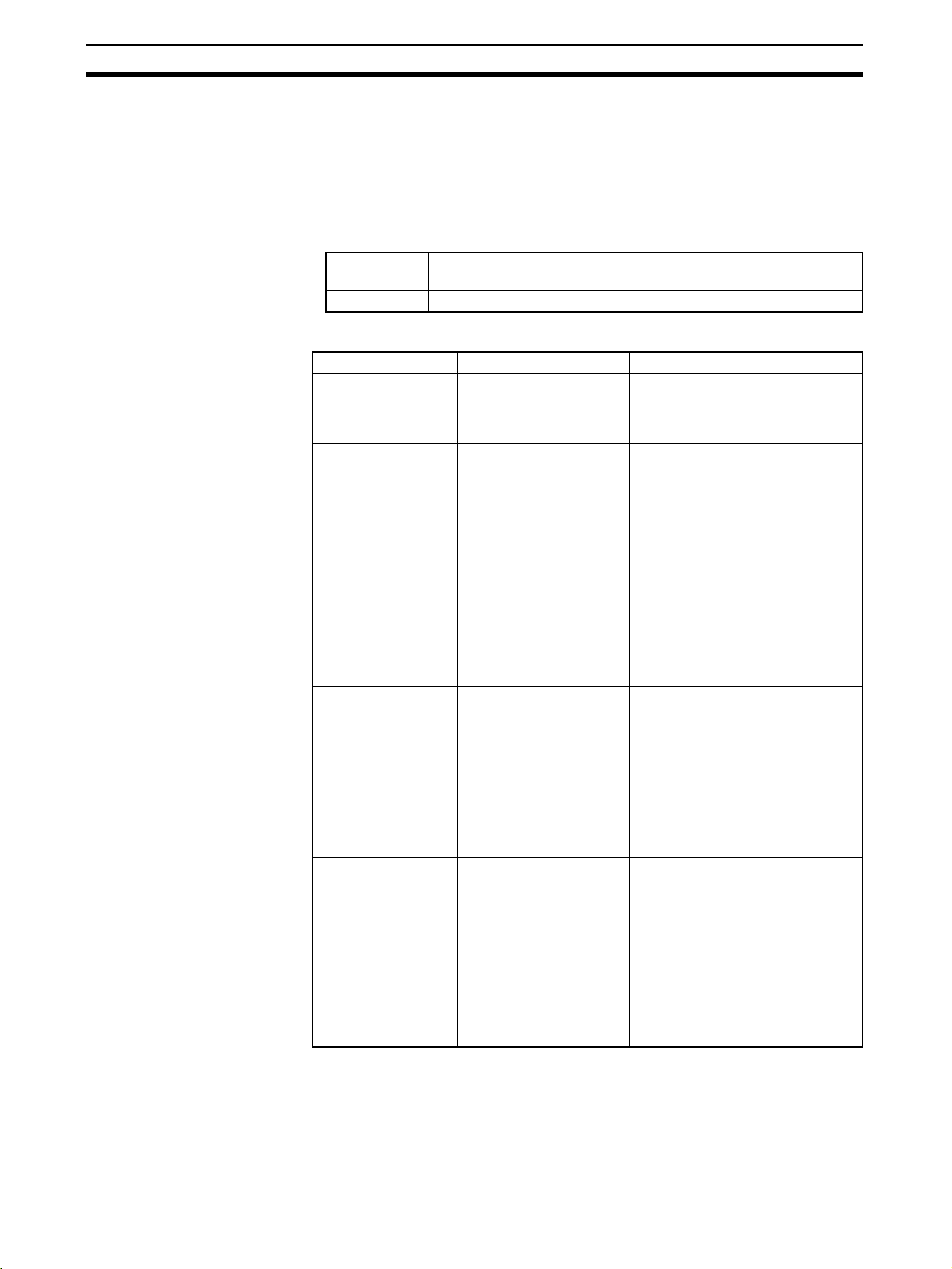

7-1 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

7-2 Responding to Displayed Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

7-3 Maintenance of the NT631/NT631C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

7-4 Inspection and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Appendices

A Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

B Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

C Using an RS-232C/RS-422A Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

D Transporting and Storing the NT631/NT631C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

E Making the Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

F Making the Cable for Connecting a PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

G Making the Cable for Connection to a Bar Code Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

H Making the Cable for Connection to a Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

I Relationship between system program and hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

J Model List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

K Option List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

viii

Page 8

About this Manual:

This manual describes connecting the NT-series NT631 and NT631C Programmable Terminals (PTs)

to a PLC (Programmable Controller) or other host and peripheral devices, and the settings required for

communications and applications. It includes the sections described below.

Please read this manual carefully and be sure you understand the information provided before

attempting to install and operate the Programmable Terminal.

Section 1 provides fundamental information about the functions and features of the PTs, types of connection, communications methods, etc. This information will enable you to understand the applications

of the PTs.

Section 2 describes the connection methods that are possible with the PTs, and the functions of the

parts of PTs, as the required knowledge before connecting to the host and to the peripheral devices.

Section 3 describes the settings of the PTs and methods for connection to peripheral devices.

Section 4 describes the method for connecting to the host using the RS-232C port of the PT.

Section 5 describes the method for connecting to the host using the RS-422A/485 port of the PT.

Section 6 describes the operation of the System Menu, focusing on the procedure to start the PT.

Functions that are convenient when using the PT and those that are useful for system maintenance

are also explained here.

Section 7 describes the action to take when errors occur in the PT, and how to carry out maintenance

and inspection to prevent the occurrence of errors.

The Appendices provide specifications, dimensions, procedures for using an RS-232C/RS-422A

Adapter, procedures for transporting and storing the PT, information on cable preparation, information

on the relationship between the system program and hardware, and product lists.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

ix

Page 9

Related Manuals:

Related manuals are listed below.

The @ symbol at the end of the catalog number is the revision number.

Connecting and Setting Up the Programmable Terminal

• NT631 and NT631C PT Setup Manual (V063-E1-@, this manual)

This manual describes connecting the Programmable Terminals to a host and peripheral devices and

settings required for communications and applications.

The functions and actual operating methods for the NT631 and NT631C PTs are provided in the Refer-

ence Manual (V064-E1-@).

Programmable Terminal Functions and Operation

• NT31/31C/631/631C PT Reference Manual (V064-E1-@)

This manual is used for any of the following PTs: NT31, NT31C, NT631, and NT631C. It describes

screen configurations, part functions, host control methods, and other application information.

PT connection and setup procedures are described in the NT631 and NT631C PT Setup Manual

(V063-E1-@).

Creating and Transferring Screen Data, and Installing the System Program

• NT-series Support Tool for Windows Ver. 4.@ Operation Manual (V061-E1-@)

The screens displayed on the NT631 and NT631C PTs are created with the Support Tool and transferred to the PT. This manual describes how to create and transfer screen data. It also describes how

to download a system program to a PT using the System Installer.

The NT-series Support Tool for Windows is normally referred to as merely the Support Tool.

Connecting to Controllers Not Made by OMRON

• PLC Connection Manual (V042-E1-@)

The NT631 and NT631C PTs can be connected to controllers in the following series: Mitsubishi A

Series and FX Series. This manual describes the connection and setup methods for these controllers.

The NT-series Support Tool for Windows Version 4.@ is required to connect the NT631 and NT631C

PTs to these controllers.

• NT31/NT631 Multi Vendor Connection Manual (V060-E1-@)

The NT631 and NT631C PTs can be connected to controllers in the following series: Allen-Bradley

SLC 500 Series, GE Fanuc 90-20 and 90-30 Series, and Siemens S7-300 and S7-400 Series. This

manual describes the connection and setup methods for these controllers.

x

Page 10

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xi

Page 11

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xii

Page 12

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xiii

Page 13

xiv

Page 14

PRECAUTIONS

This section provides general precautions for using the Programmable Terminal.

The information contained in this section is important for the safe and reliable application of the Programmable

Terminal. You must read this section and understand the information contained before attempting to set up or operate

a Programmable Terminal.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

xv

Page 15

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems into production facilities.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and connecting FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for using the Programmable Terminal. Be

sure to read this manual before attempting to use the software and keep this

manual close at hand for reference during operation.

!WARNING It is extremely important that Programmable Terminals and related devices be

used for the specified purpose and under the specified conditions, especially

in applications that can directly or indirectly affect human life. You must consult with your OMRON representative before applying Programmable Terminals to the above-mentioned applications.

!WARNING Do not use input functions such as PT touch switches for applications where

danger to human life or serious damage is possible, or for emergency switch

applications.

3 Safety Precautions

Read these safety precautions carefully and make sure you understand them

before using the Programmable Terminal so that you can use it safely and correctly.

Safety Conventions and their Meanings

This operation manual uses the following conventions and symbols to indicate

cautions, warnings, and dangers in order to ensure safe use of the NT631/

631C.

The cautions, warnings, and dangers shown here contain important information related to safety. This instructions in these cautions, warnings, and dangers must be observed.

The conventions used and their meanings are presented below.

xvi

Page 16

Safety Precautions 3

!WARNING Indicates information that, if not heeded, could possibly result in loss of life or

serious injury.

!Caution Indicates information that, if not heeded, could result in relatively serious or

minor injury, damage to the product, or faulty operation.

WARNING

Do not attempt to take the unit apart and do not touch any

internal parts while the power is being supplied. Doing either

of these may result in electrical shock.

WARNING

Switch OFF the NT631C power before replacing the

backlight. Otherwise you could sustain an electric shock.

xvii

Page 17

Safety Precautions 3

xviii

Page 18

SECTION 1

General

This section provides fundamental information about the functions and features of the NT631/NT631C, types of

connection, communications methods, etc. This information will enable you to understand the applications of the

NT631/NT631C.

1-1 Role and Operation of the NT631/NT631C. . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 Operation of an NT631/NT631C at an FA Production Site . . . . . . . 2

1-1-2 Operations of the NT631/NT631C . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-2 Functions of the NT631/NT631C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-2-1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-2-2 Comparison between NT631 and NT631C . . . . . . . . . . . . . . . . . . . 7

1-2-3 Comparison between NT620S/NT620C/NT625C and NT631/NT631C 8

1-2-4 Principal Functions of NT631/NT631C. . . . . . . . . . . . . . . . . . . . . . 10

1-2-5 Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1-3 System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1-3-1 Peripheral Devices That Can Be Connected . . . . . . . . . . . . . . . . . . 17

1-3-2 Connecting to the Host. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1-4 Communications with the Host . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1-4-1 Direct Connection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1-4-2 Host Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1-4-3 NT Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1-4-4 Connecting to Other Companies’ PLCs. . . . . . . . . . . . . . . . . . . . . . 21

1-5 Communications Using Memory Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1-5-1 Memory Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1-5-2 Comparison between Direct Connection and Memory Link . . . . . . 22

1-5-3 Memory Link Online Transfer Function . . . . . . . . . . . . . . . . . . . . . 22

1-6 Before Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1

Page 19

Role and Operation of the NT631/NT631C Section 1-1

1-1 Role and Operation of the NT631/NT631C

The NT631/NT631C is a sophisticated display unit (Programmable Terminal)

which automatically displays information and can also be used for operations

when necessary. The following gives a general description of the role and

operation of the NT631/NT631C for those using a programmable terminal

(PT) for the first time.

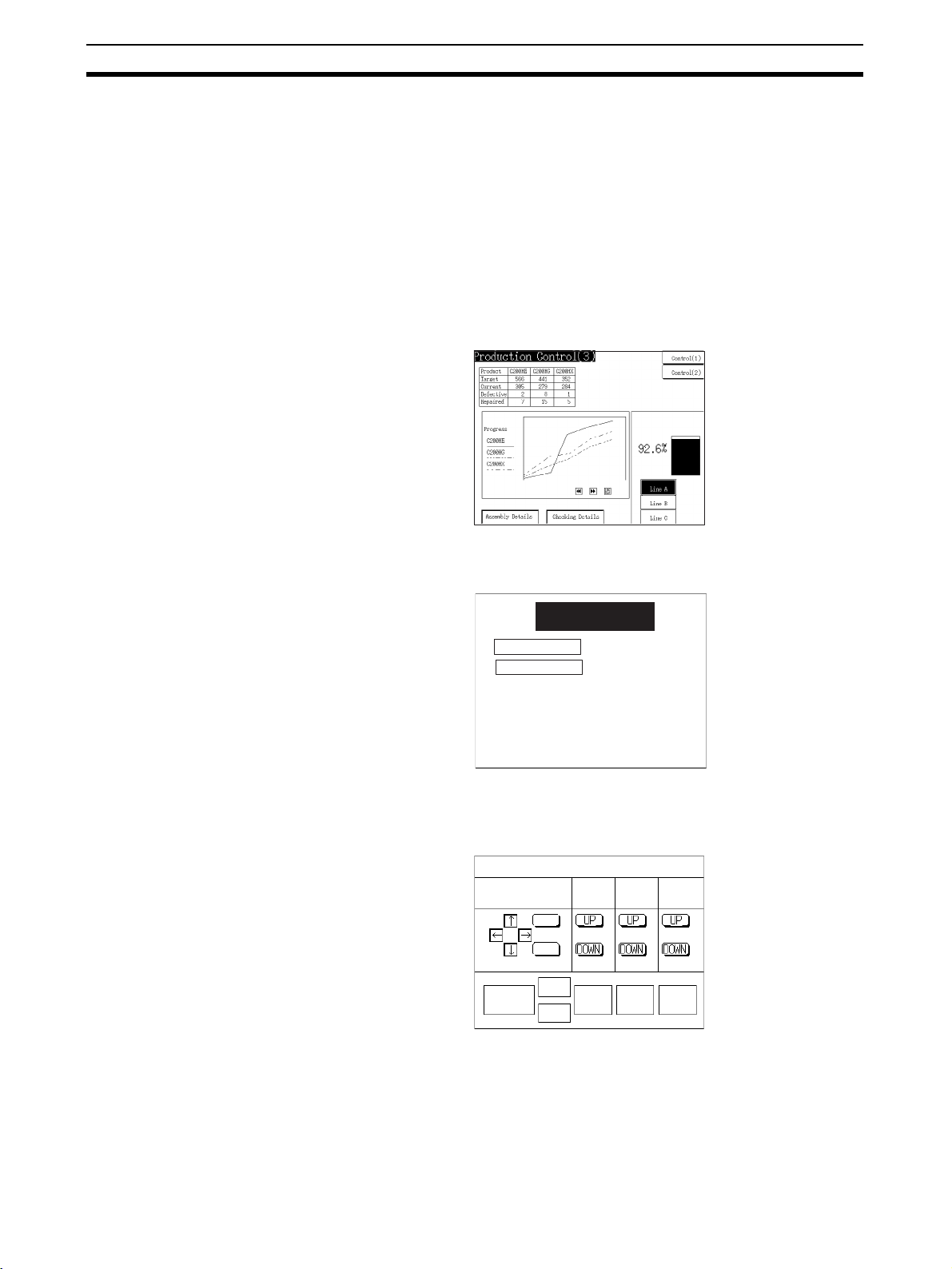

1-1-1 Operation of an NT631/NT631C at an FA Production Site

Production Line Status

Monitoring

Directions to Workers on

the Shop Floor

The NT631/NT631C displays real-time information about the system and

equipment operating status, etc. Its power of expression is enhanced by

graphs and other visuals, making the displays easy to understand.

The NT631/NT631C warns of system or equipment failures and prompts the

appropriate remedial action.

Alarm

Assembly line B

Positioning pin

is defective. Line stopped.

Check the following.

1. Defective pin L3

2. Position of dog M2

3. Mounting of photosensor P5

Panel Switch Functions Setting touch switches on the NT631/NT631C allows workers to use the

NT631/NT631C as an operating panel; the results of the operations are transmitted to the host.

Electroplating control

Wash .

Transpor t

Int. stop

Clamp

Unclamp

Adv.

Rev.

Electr.

head

Electrolyte

head

Wash

Corr. prv.

head

Corr.

prv.fluid

2

Page 20

Role and Operation of the NT631/NT631C Section 1-1

1-1-2 Operations of the NT631/NT631C

Displays Screens The information to be displayed (screen data) can be created on a computer

using the Support Tool and stored in the NT631/NT631C. The screen data

can be displayed on the NT631/NT631C in response to instructions from the

host or touch switch operation.

Host

The screen data designated by

instructions from the host or touch

switch operation is displayed.

Receives Data from a Host The NT631/NT631C can be connected to the host by a host link or NT link

and receive necessary data from the host.

Host Link, NT link

Host

Sends Data to a Host Data input using the touch panel (switch ON/OFF statuses, numeric values,

character strings) can be transmitted to the host.

Host

Touch panel

ON/OFF information, numeric

data, etc.

Screen Data The screen data to be displayed on the NT631/NT631C can be created on a

personal computer using the Support Tool. Connect the NT631/NT631C to

the personal computer with an RS-232C cable and transmit the screen data to

the NT631/NT631C.

Create screen data.

RS-232C

Screen data

Personal

computer

(Support Tool)

When the host is connected at serial port A,

the personal computer is only connected

when communicating screen data between

the NT631/NT631C and Support Tool.

3

Page 21

Functions of the NT631/NT631C Section 1-2

1-2 Functions of the NT631/NT631C

The NT631/NT631C has the following features.

1-2-1 Features

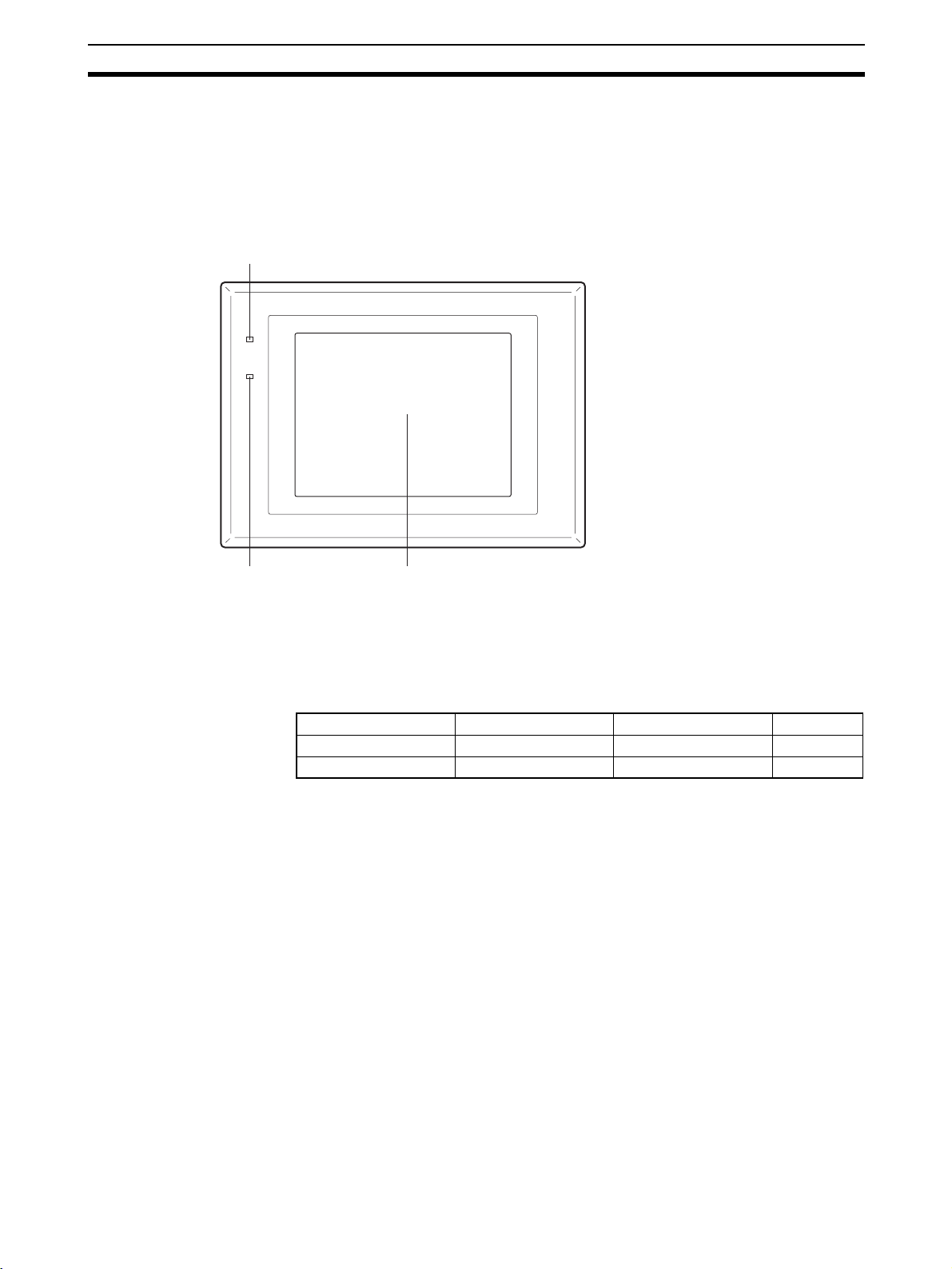

Slim Body • High-performance in a low-profile body (50 mm or less in the panel*).

• The communications cable connectors are housed in the PT so that they

do not protrude from the PT.

* When mounted in a panel of the recommended thickness (page 32).

Construction Best Suited

to the FA Environment

• The display panel is provided with a high-contrast monochrome EL display for the NT631-ST211@-EV2, an STN color LCD display with backlight for the NT631C-ST141@-EV2, and a TFT color LCD high-definition

display for NT631C-ST153@-EV3.

• The backlight unit and battery can be replaced at the operation site. (The

backlight for the NT631C-ST153@-EV3, however, cannot be replaced by

the user.)

• Protection equivalent to oil-proof IP65*, and waterproof structure equivalent to the NEMA4 standard*.

* The panel may not be usable in environments where it is exposed to oil

for long periods.

640 dots

POWER

RUN

480 dots

Wide angle of visibility

Touch Switch Operation Contrast and brightness are adjustable by touch switch operations (for

NT631C-ST141@-EV2 only).

Compatibility with Other

PTs

• There is upward compatibility between the NT631/NT631C and the following models for screen data and user programs: NT11S, NT20S, NT30,

NT30C, NT31, NT31 NT600S, NT610G, NT610C, NT620S, NT620C,

NT625C. (After being read to the Support Tool, screens must be modified

in accordance with the screen size. Depending on the function used, partial modification of programs may also be necessary. For details on the

compatibility of screen data, refer to the NT31/NT31C/NT631/NT631C

Programmable Terminal Reference Manual and the NT-series Support

Tool Operation Manual.

• The dimensions of the panel cut-out to accommodate the NT631/NT631C

are the same as for the NT625C.

4

Page 22

Functions of the NT631/NT631C Section 1-2

Two Ports Featured as

Standard:

Rapid System Program &

Screen Data Changes

Possible Using a Memory

Unit.

Screen Data Check

Function

Large Increase in

Maximum Number of

Registered Elements

Binary Data can be Read

to/Written from the Host

Character Display Using

High Definition Fonts

Port A for Common Use by Support Tool/Host and Port B for Exclusive

Use by the Host

• Communications with the host is possible via another port while connected to the Support Tool.

• Reading bar code data from a bar code reader is possible via another port

while communicating with the host.

• Installing a Memory Unit (type NT-MF261) on the rear of the NT631/

NT631C makes it easy to write screen data into the NT631/NT631C on

site. This enables a rapid response to setup changes.

• NT631/NT631C can store a system program into a Memory Unit. This

enables the system to handle more flexible setups.

Screen data can be checked simply by operations at the NT631/NT631C system menu, without connecting up to the Support Tool.

The number of elements that can be registered on one screen has been considerably increased, making it possible to create more expressive screens.

For details, refer to Display Restrictions in Appendix A Specifications of the

NT31/NT31C/NT631/NT631C Programmable Terminal Reference Manual.

It is now possible to write binary data stored in words at the host directly to the

NT631/NT631C. This makes data conversion by a program at the host unnecessary, reducing the load on the host.

Any quadrupled characters are displayed with a 32 dot high-definition font.

Simple Version Upgrades By using the system installer supplied with the Support Tool (Type NT-

ZJCAT1-EV4), the system program at the NT631/NT631C can be changed

easily from a personal computer.

Complies with

International Standards

Compatible with Other

Vendors’ Devices

Multiple Windows Up to 3 windows can be displayed simultaneously in the normal screen. A 9-

High-speed 1:N NT Link The V2 versions are compatible with the high-speed 1:N NT Link as well as

Additional Mathematical

Functions

The NT631/NT631C meets UL/CSA standards and EC directives.

Compatible with Sequencers in the following series: Mitsubishi A-series (Calculator Link) and FX-series (Programming Console), Allen-Bradley SLC 500

Series, GE Fanuc 90-20 and 90-30 Series, and Siemens S7-300 and S7-400

Series. Specialized system programs can be installed that allow the NT631/

NT631C to be controlled from other companies’ Sequencers.

word window control area has been allocated to the host; the contents of

these 9 words can be changed from the Host to open, close, and move windows.

the earlier standard 1:N NT Link.

Operands (values referenced by formula) can be registered to allow the PT to

perform calculations automatically and write the results of those calculations

to numeral memory tables or words in the host.

5

Page 23

Functions of the NT631/NT631C Section 1-2

Device Monitor Function The new device monitor function can be used to change the PLC’s operating

mode or display/change values in the PLC’s memory areas. The present values (PVs) of several words can be listed with the device monitor.

Interlock Function PT operations and inputs can be disabled from the PLC if interlock bits have

been allocated in the PLC for the corresponding PT touch switches, numeric

inputs, or string inputs.

Improved Lamp/Touch

Switch Labels

NT30/NT30C and NT620S/

NT620C/NT625C

Emulation

Additional CS/CJ-series

Data Areas Accessible

The following displays can be performed with lamp or touch switch labels:

• Display several lines of labels.

• Switch the display between different labels when OFF and ON.

• Display the numeral memory table contents as labels.

• Display the string memory table contents as labels.

The word configuration of the PT status control area and PT status notify area

can be set to emulate those of the NT30/NT30C or NT620S/NT620C/

NT625C; this mode is called NT30/620 compatible mode.

When the PT is operating in NT30/620 compatible mode, it will be equivalent

to an NT30/NT30C or NT620S/NT620C/NT625C in the functions listed below.

The PT retains full V2 functionality in all functions other than the ones listed

below. Refer to Appendix C in the NT31/NT31C/NT631/NT631C Programma-

ble Terminal Reference Manual for more details.

• Word configuration and functions of the PT status control area and PT

status notify area

• Image/library codes

• Insertion of image/library data into character strings

Data areas in CS/CJ-series PLCs that were previously inaccessible can be

accessed. The data areas listed below can be accessed (read/written).

All banks in the EM area, timer completion flags (TU), counter completion

flags (CU), Work areas (WR), Task flags (TK), and the HR area.

Recipe Function You can set the data (numeric values) for multiple words in record units using

the tabular elements on the PT screen, and write these settings in a single

operation to words on the host (i.e., PLC or PT memory) using a touch switch

operation on the PT Unit. Also, multiple words of numeric data can be read

from the host in one operation. In this way, groups of parameter settings can

be edited at the PT Unit, and written to or read from the host.

Adjusting Contrast and

Brightness During PT

Operation

You can display the brightness and contrast adjustment screen using either

the touch switch or commands from the host, even while the PT is in operation.

6

Page 24

Functions of the NT631/NT631C Section 1-2

1-2-2 Comparison between NT631 and NT631C

Two NT631 models — the NT631, which is capable of versatile graphic displays (EL display, yellow), and the NT631C, which is also capable of color display — are available. The differences between the NT631 and NT631C are

tabled below:

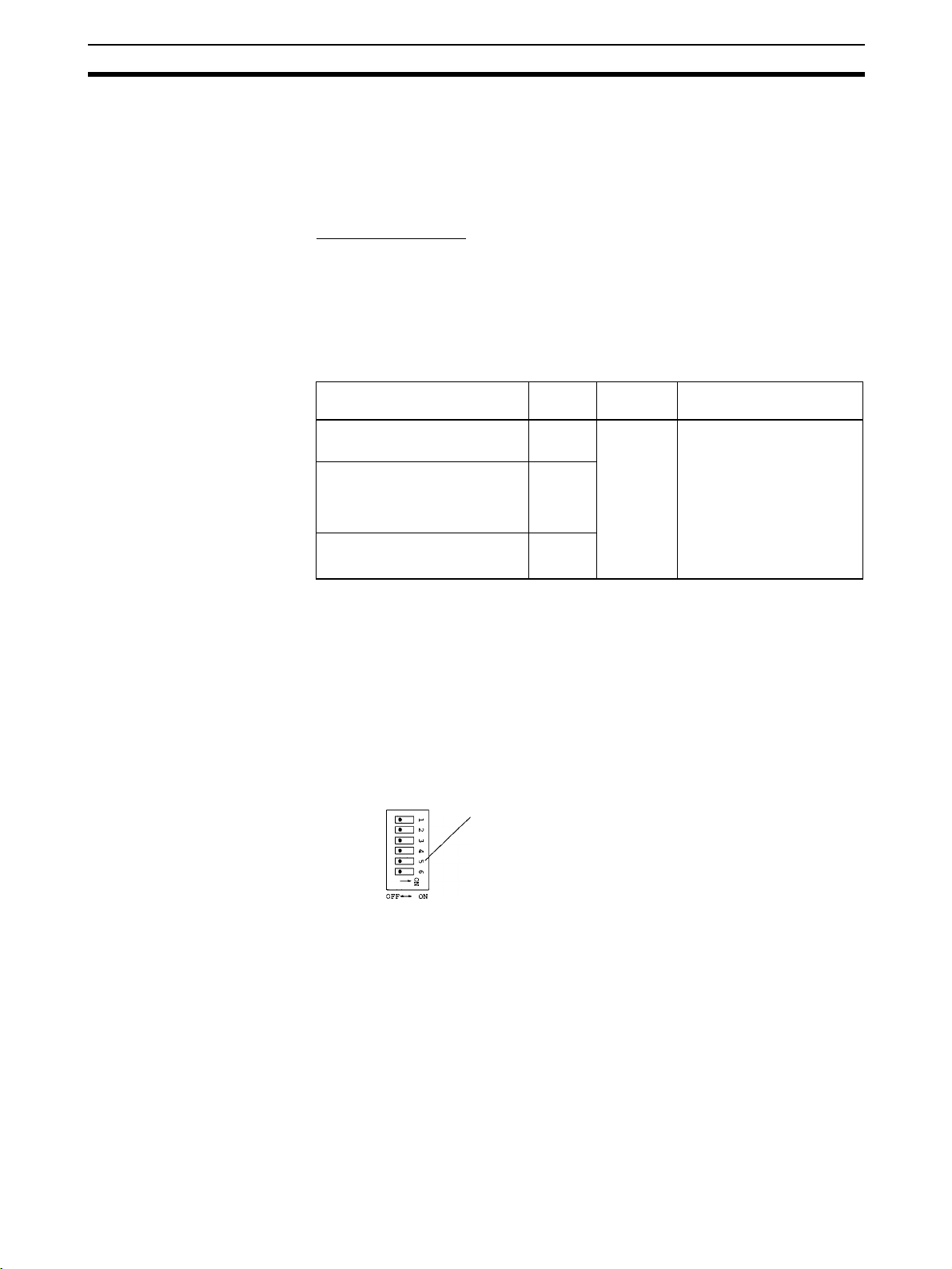

Function NT631-ST211@-EV2 NT631C-ST141@-EV2 NT631C-ST153@-EV3

Type NT631-ST211-EV2 (Beige)

Display

panel

NT631-ST211B-EV2 (Black)

Monochrome EL display STN color LCD display

Beige and black are the front panel colors of each NT631/NT631C types.

NT631C-ST141-EV2 (Beige)

NT631C-ST141B-EV2 (Black)

(with white backlight)

NT631C-ST153-EV3 (Beige)

NT631C-ST153B-EV3 (Black)

TFT color LCD display

(with white backlight)

7

Page 25

Functions of the NT631/NT631C Section 1-2

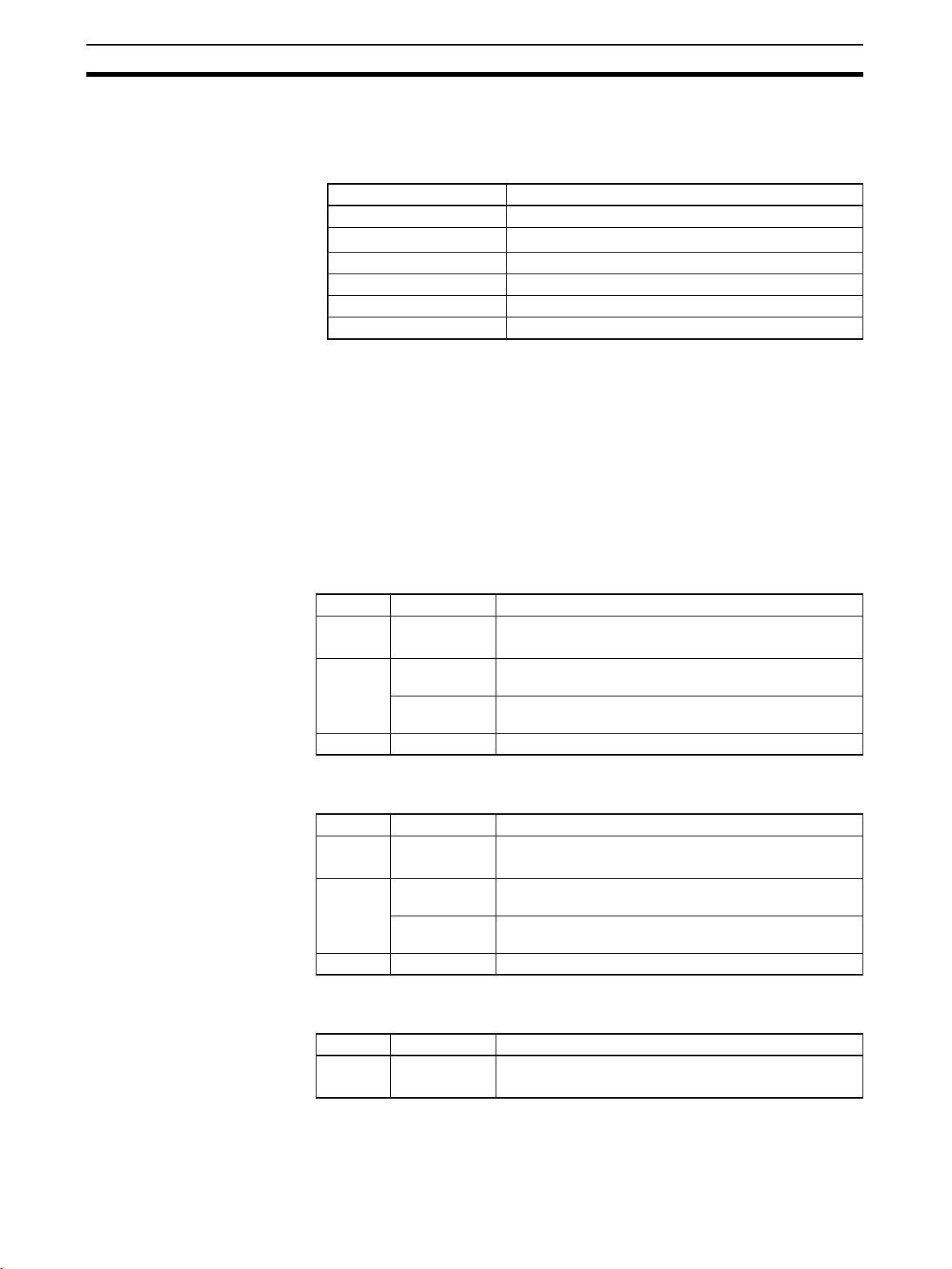

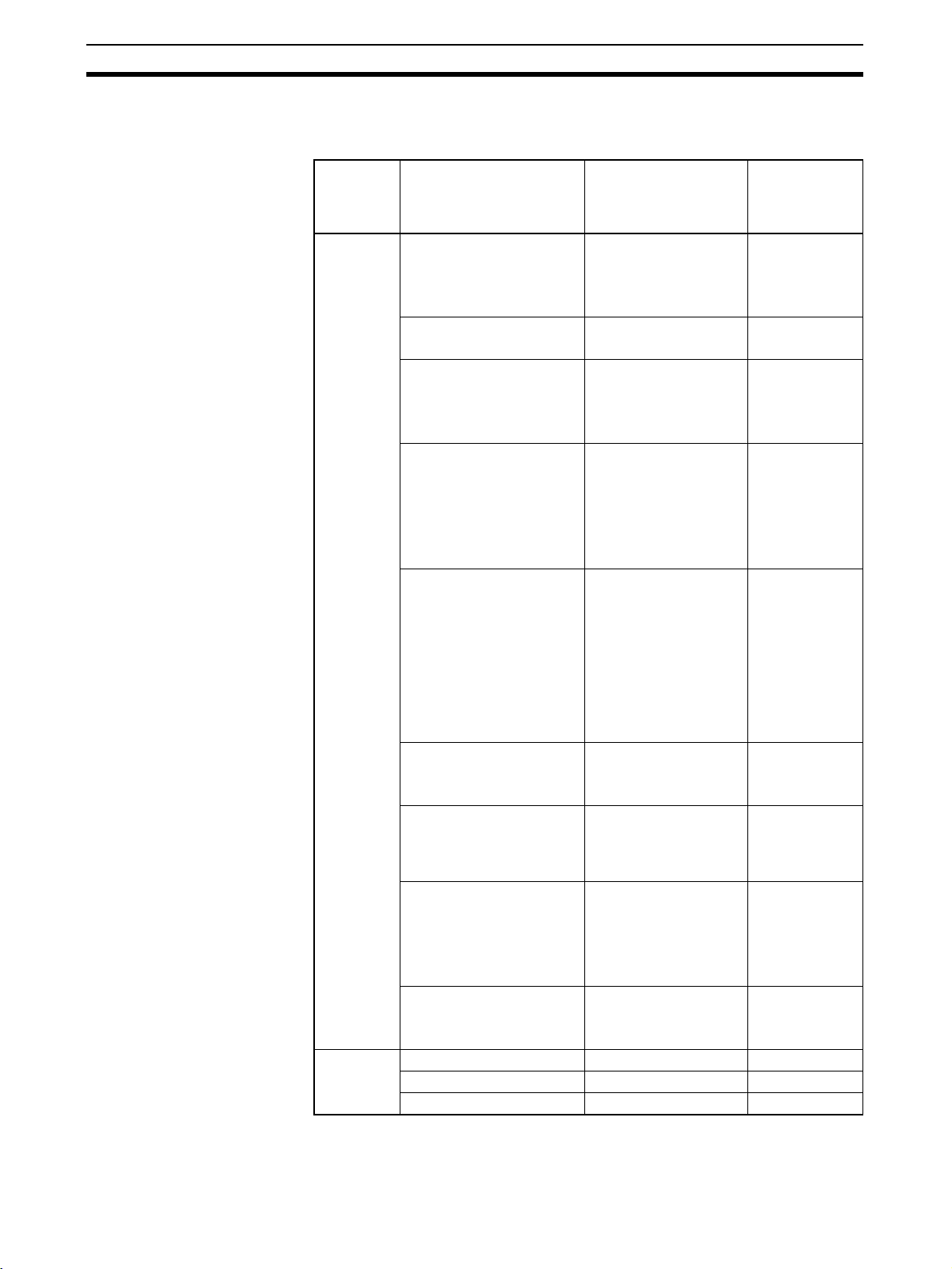

1-2-3 Comparison between NT620S/NT620C/NT625C and NT631/

NT631C

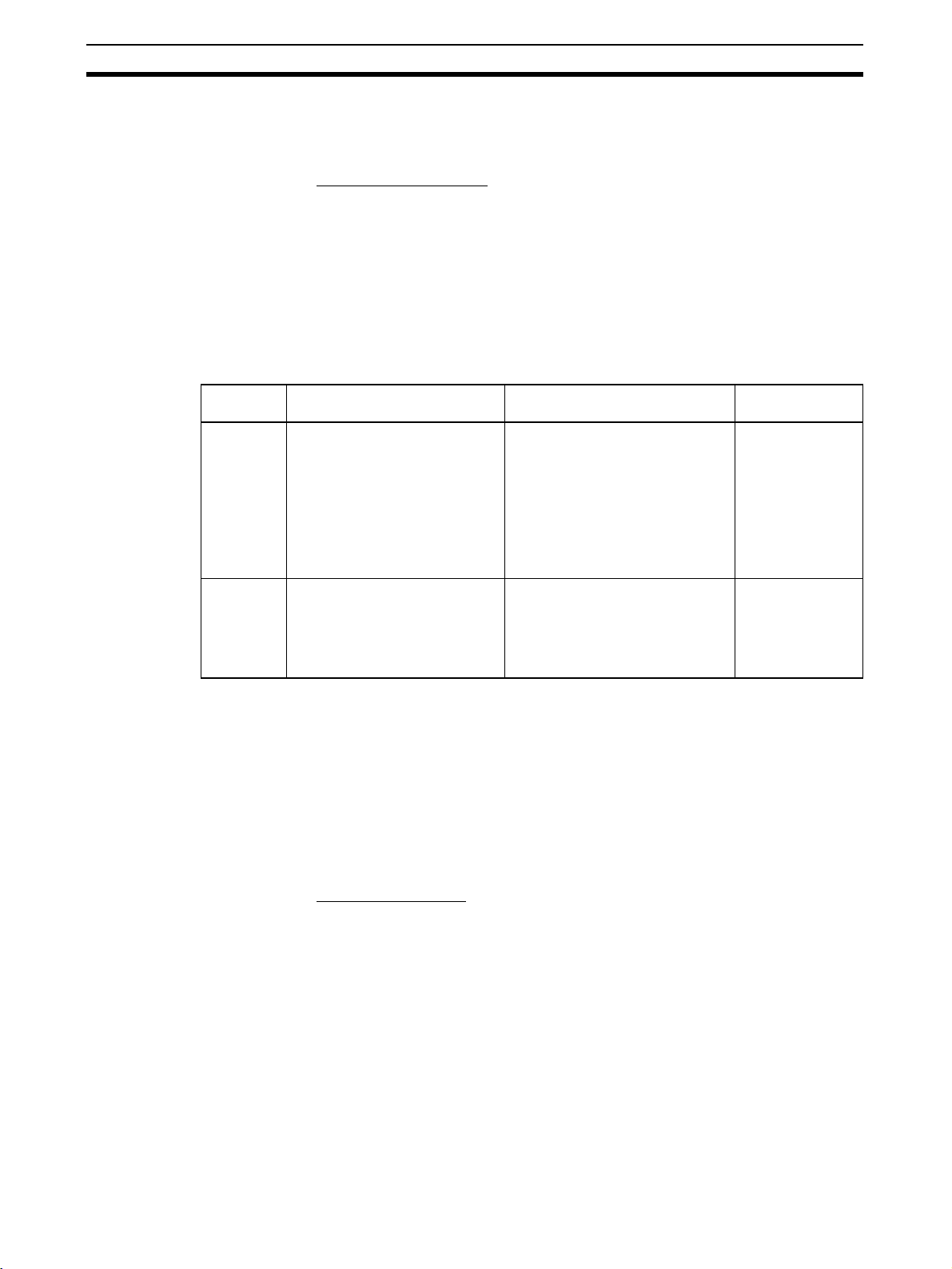

Item NT620S/NT620C/NT625C NT631/NT631C

Support Tool used NT-ZJCAT1-EV4 or NT-ZA3AT-EV2 NT-ZJCAT1-EV4

DIP switches On rear of PT None (software settings)

Use of Memory Unit Not possible Possible

RS-232C interface Connector (9-pin) also used as port for

screen data transfer.

RS-422A/485 interface NT620S/NT620C: None

NT625C: Terminal block (DIP-switch

selectable between RS232C and RS422A/485)

Replacement backlight NT620C-CFL01 (NT620C)

NT610C-CFL02 (NT625C)

NT631/NT631C system program data

High-speed 1:N NT Link Not possible Possible

Memory

Link

LCD contrast adjustment By a control on the rear of the PT By touch panel operation

Backlight brightness adjustment

Number of user-registered

screens

Screen data capacity

(User program memory)

Numeral string data Maximum of 1000 Maximum of 2000

Character string data Maximum of 1000 Maximum of 2000

Bit data 256 Maximum of 1000

Mathematical tables None 256 max.

Image data Maximum of 224

Library data Maximum of 896

Method for storing numeric

values

(numeral memory data and PT

status control area)

PT status control area size 4 words

PT status notify area size 3 words

Window control area size None 9 CH

Registering continuous screen Possible Not possible (Use a screen switchover as a sub-

Lamp/Touch switch labels Fixed display (1 line only) - Multiple lines can be displayed

System program Exclusive use by Memory Link Same as OMRON connection

Screen data Shared with OMRON connection Exclusive use by Memory Link

*1

NT620-ZS3AT-EV1/EMV1

(including system installer)

Not possible By touch panel operation

Maximum of 2000 Maximum of 3999

NT620S: 512 KB

NT620C/NT625C: 1 MB

Fixed as BCD (binary coded decimal) Selectable from BCD (binary coded decimal) or

- Serial port A connector (also used for screen

data transfer, 9-pin)

- Serial port B connector (for host communications only, 9-pin)

Terminal block (serial port B; memory-switch

selectable between RS232C and RS-422A/485)

NT631C-CFL01 (for ST151; the backlight for the

NT631C-ST152@-EV2, NT631C-ST153@-EV3,

however, cannot be replaced by the user)

NT631C-CFL02 (for ST141)

The system installer and system program data

are supplied with the Support Tool.

(Possible in the NT631-ST141@-V2 only.)

(Possible in the NT631-ST141@-V2 only.)

1 MB

Calculations can be executed automatically in

the PT.

Maximum of 4095

Maximum of 12288

binary

5 words (partial change of contents)

2 words (partial change of contents)

stitute.)

- ON/OFF switching is possible

- Numeral display is possible

- Character string display is possible

*2

*2

*2

*2

8

Page 26

Functions of the NT631/NT631C Section 1-2

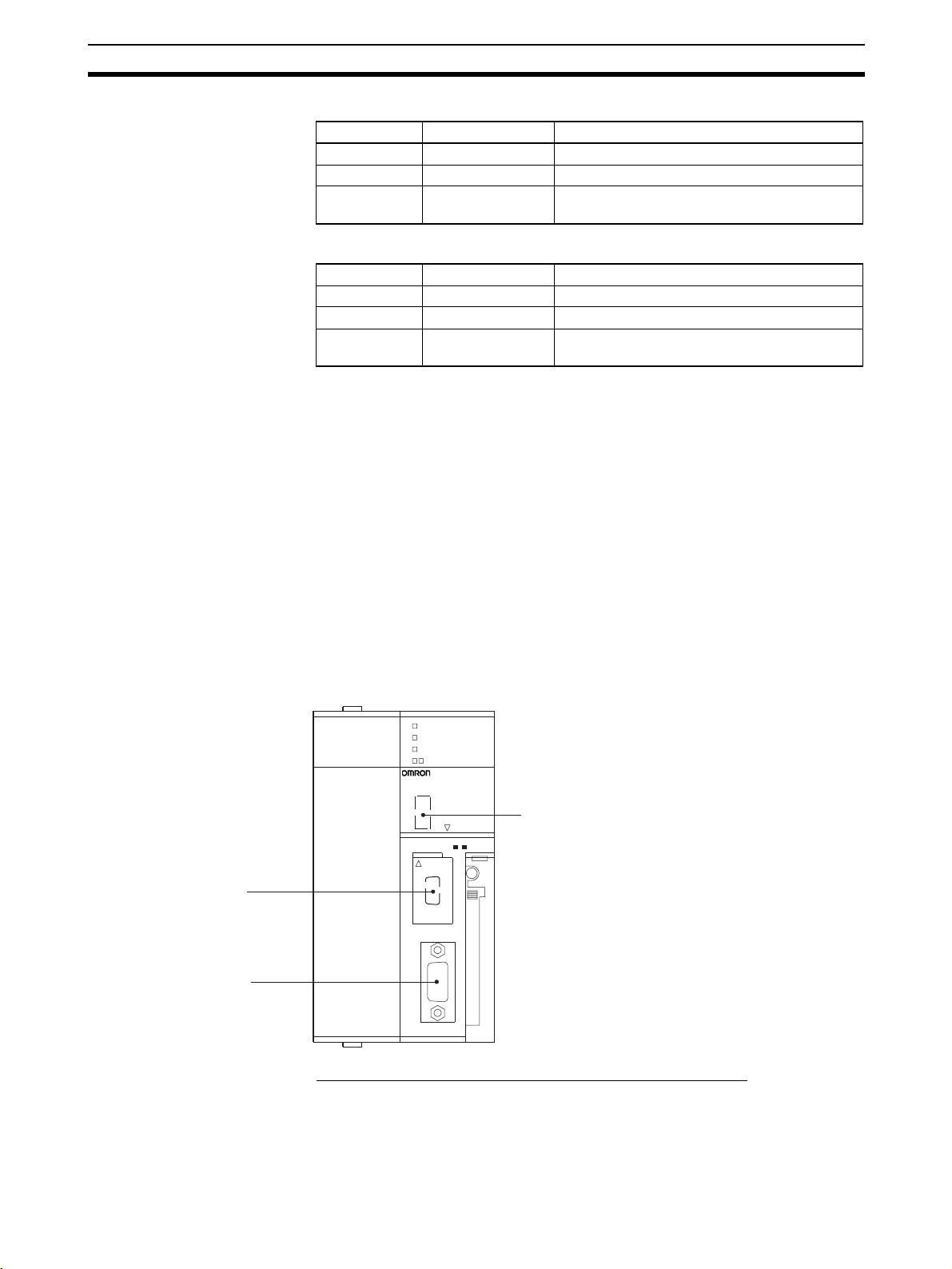

Item NT620S/NT620C/NT625C NT631/NT631C

Interlock function None Operations can be disabled from the PLC by

Device monitor function Not possible Possible

Recipe function None Possible

Accessible CS/CJ-series PLC

data areas

*1

This is the capacity of the flash memory that stores screen data.

*2

The values are the same as the NT30/NT30C when the PT is in NT30/620 compatible mode.

--- The data areas listed below can be accessed in

For differences in programming, refer to Appendix B in the NT31/NT31C/NT631/NT631C Programmable Termi-

nal Reference Manual.

allocating interlock bits to the corresponding

touch switch, numeral input, or character string

input.

addition to the data areas accessible with the

NT30/NT30C.

- EM banks (EM_0 to EM_C)

- Timer completion flags (TU)

- Counter completion flags (CU)

- Work areas (WR)

- Task flags (TK)

- HR area

9

Page 27

Functions of the NT631/NT631C Section 1-2

1-2-4 Principal Functions of NT631/NT631C

The following are the principal functions of the NT631/NT631C.

Functions relating to data display

Character display

Characters of various sizes can be displayed. Characters can be flashed and displayed in reverse

video. High grade fonts are available for the characters with their size enlarged.

Graphic display

Polylines, rectangles, polygons, circles, circular arcs, and sector shapes can be displayed.

They can also be tiled with various patterns, flashed, or displayed in reverse video.

Memory data display

The contents of character string memory tables and numeral memory tables can be displayed.

The contents of memory tables can be changed from the host.

Graph display

Not only bar graphs but also broken line graphs, trend graphs, and analogue meter graphs can

be displayed using numeral memory tables

Lamp display

Lamps can be turned on and flashed under the control of the host. It is also possible to display

different graphics in the ON and OFF states.

Alarm list/history display

Warning messages are automatically displayed in a list in response to the state of a host bit. The

time and the number of times of the messages appeared can also be displayed.

Functions relating to data output

Buzzer

A built-in buzzer can be sounded.

Screen printing

A hard copy of the currently displayed screen can be printed at the

printer connected to the NT631/NT631C.

10

Page 28

Functions of the NT631/NT631C Section 1-2

Functions relating to data input

Input by touch switches

Data can be input by simply touching touch switches displayed on the screen.

The possible functions of touch switches include sending data to the host and changing the screen display.

Inputs can be enabled and disabled from the host when interlock bits have been allocated.

Pop-up window function

A window overlaying the currently displayed screen can be alternately opened and closed by pressing a touch

switch.In addition to fixed character and graphic displays, control keys and character keys created as touch

switches can also be set inside the window.

A maximum of three windows can be displayed simultaneously.

Since the window need only be opened when input is required, the screen can be used efficiently.

Numeral/character string setting function

Numeric keys and character keys can be assigned to touch switches so that numeric values and character strings

can be input at the operation site.

The input data is written to numeral/character string memory tables and also sent to the host. It is also possible to

disable input by control from the host.

Recipe function

Several words of numeric data can be edited at the PT Unit, and written to or read from the host in one operation.

Input from a bar code reader

Data read with a bar code reader can be input to a character string input field.

Functions relating to communications

Communications with the host

The NT631/NT631C can communicate with the host by four methods: host link, 1:1 NT link, 1:N NT link (standard

or high-speed), and Memory link. Data can be read from the host, and data input by means of touch switches and

numeral/character string settings can be sent to the host. It is also possible to connect with other model PCs.

Functions relating to the system

System menu

System settings and maintenance can be performed by selecting from system menus displayed on the screen.

Creation of screen data

Screen data created using the Support Tool at a personal computer can be transferred and stored in the built-in screen

data memory.

Resume function

The status and memory table contents of the NT631/NT631C immediately before its operation is stopped can be stored

while operation is stopped, or while the power is off, and then displayed on the screen again when operation is restarted.

Screen saver function

This function serves to extend the service life of the backlight and EL and prevent the formation of an afterimage on the screen.

Clock function

The time can be displayed in accordance with the internal clock data.

Programming Console function

When the NT631/NT631C is connected to a C-series CPM1, CPM2A, CPM2C, CQM1, CQM1H, or C200HX/HG/

HE(-Z)E Programmable Controller in an NT link (1:1) connection, or is connected to CS/CJ-series in an NT link (1:N)

connection, operations equivalent to those of a Programming Console (C200H-PR027-E) are possible.

Device Monitor function

When the PT is connected to a PLC in a 1:1 NT Link or 1:N NT Link, the PT can be used for operations such as

changing the PLC's operating mode, displaying or changing the PVs of words, or reading the error log.

System program install function

The system program of the NT631/NT631C can be changed by using the system installer supplied with the Support Tool

(NT-ZJ3AT1/ZJCAT-EV2). It can also be installed by using a memory unit (NT-MF261).

Screen display history function/alarm history function

The screen display history function records the time at which specific screens are displayed and the number of times

they are displayed. The alarm history function records the time at which specific bits at the host are turned ON and the

number of times they are turned ON.

Trend graph logging function and background function

Changes in the contents of numeral memory tables displayed in trend graphs can be recorded (logging function). Also, the

record can be maintained even when the trend graph is not displayed (background function).

Mathematical function

This function allows calculations to be executed continuously during PT operation when mathematical table have been set

in screen data. Arithmetic operations, bit operations, logic operations, and comparison operations can be performed.

Operations with up to 5 terms are possible.

11

Page 29

Functions of the NT631/NT631C Section 1-2

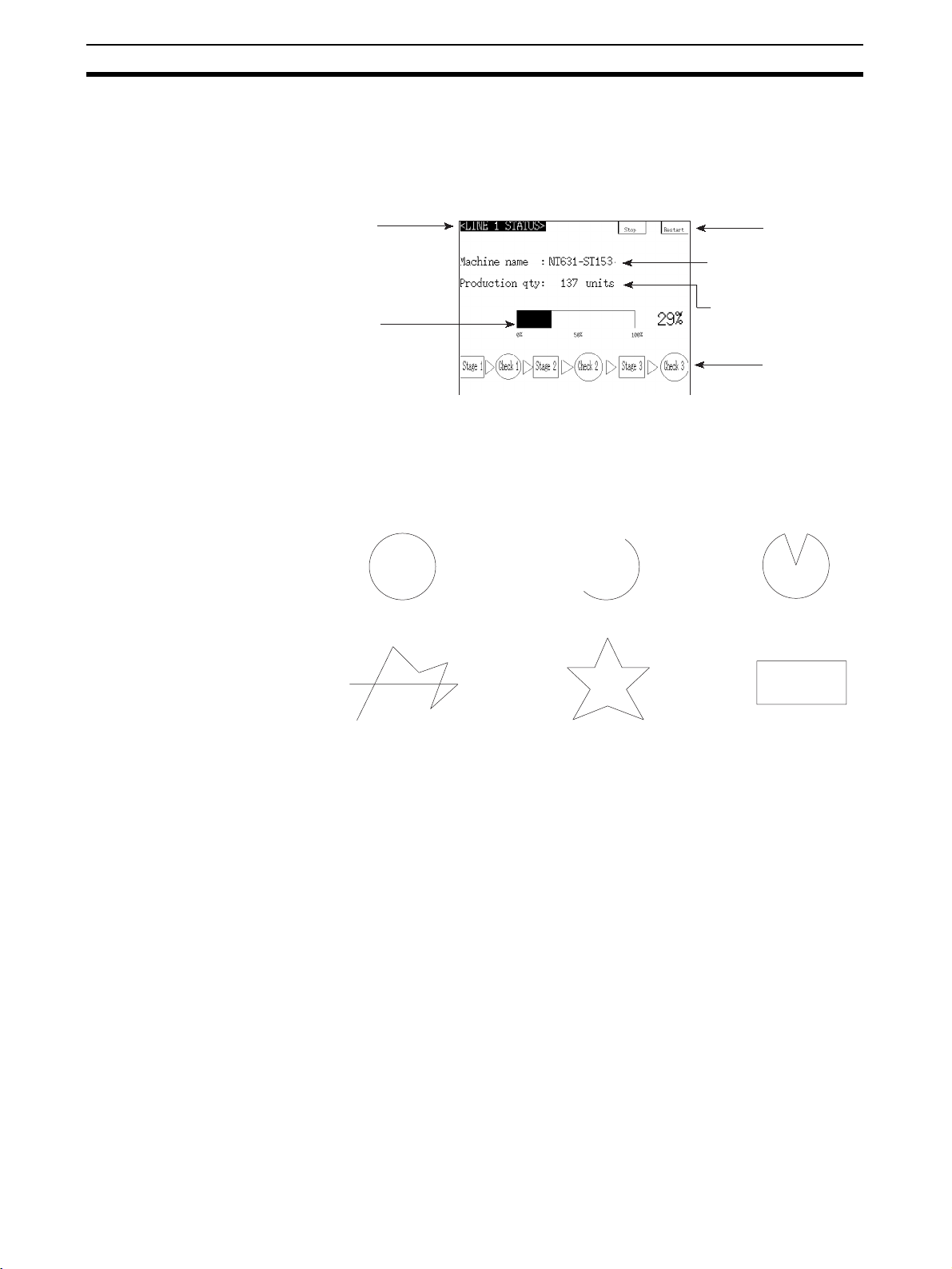

1-2-5 Displays

The NT631/NT631C can display various kinds of elements such as characters, numeric values, graphs, lamps, and touch switches, on a screen. The

screen data displayed by the NT631/NT631C are created by using the Support Tool at a personal computer.

Characters

(fixed display)

Bar graph

Characters

(character string display)

Numeric values

(numeral display)

Touch switches

Lamps

Fixed Displays Characters and various graphics (circles, circular arcs, sectors, polylines,

polygons and rectangles) whose display does not have to be changed, and

mark data, image data, and library data that has already been registered, can

be written directly onto the screen.

Circle SectorArc

Polyline Polygon Rectangle

* A continuous straight line

with up to 256 points can

be drawn.

* A polygon with up to

255 vertices can be

drawn.

Marks are graphics comprising 16 by 16 dots that can be used as characters.

They can be used as custom characters within character strings.

Image data are graphics comprising any required area of dots. They are registered in advance and as many as required can be displayed at any position on

the screen.

Windows bit map (BMP) data can be used for images.

There is a two-color mode, in which the display color and background color of

the image are specified when it is registered in a screen, and an eight-color

mode in which colors are assigned to the image in advance.

Since image data is composed of dots, it requires a large data size but offers

great powers of expression.

Library data are combinations of fixed display graphics registered as a single

graphic. They are registered in advance and as many as required can be displayed at any position on the screen.

Since it is generated by combining graphics, library data has a small data

size.

12

Page 30

Functions of the NT631/NT631C Section 1-2

Mark Image data Library data

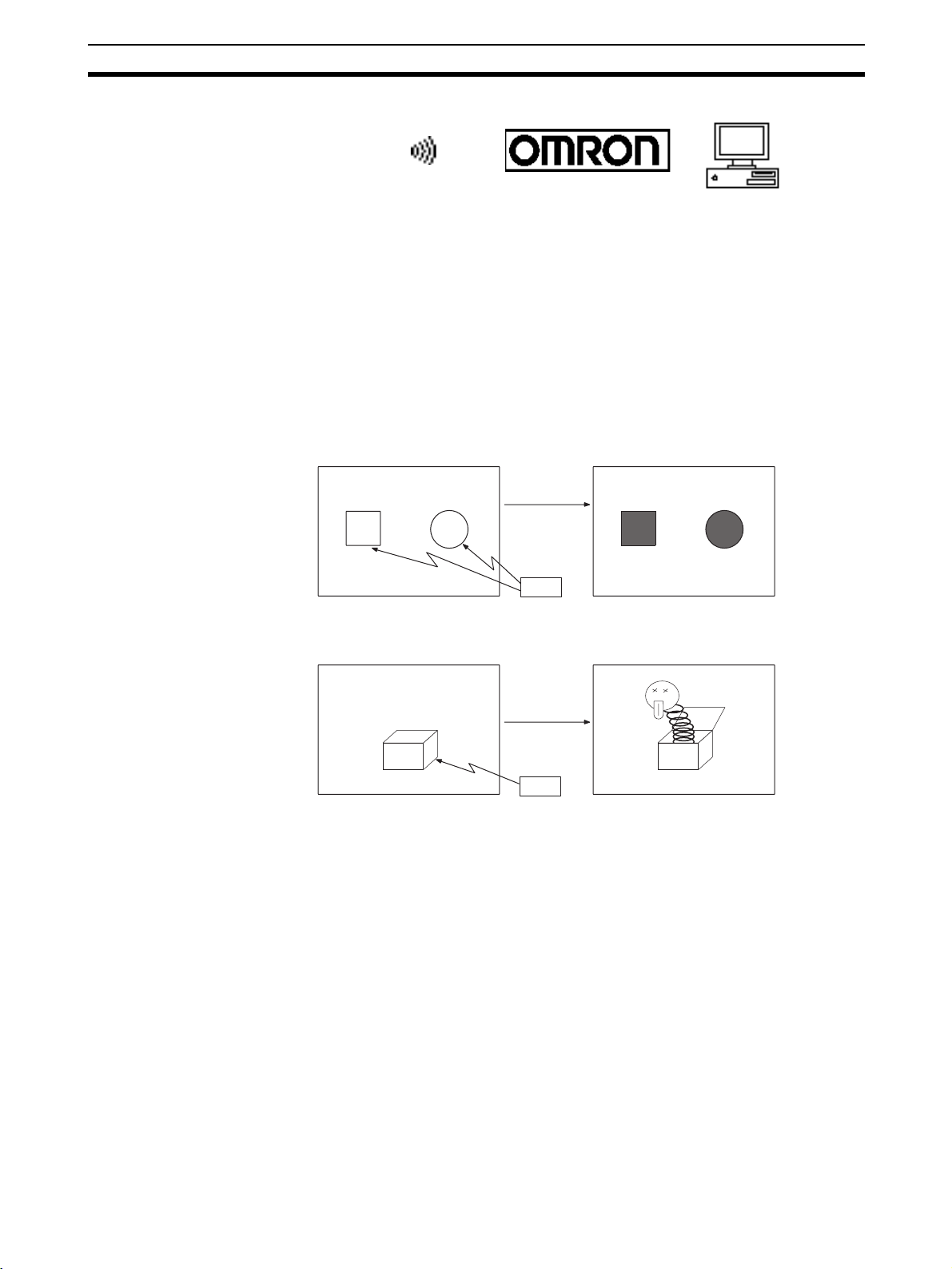

Lamps These are graphics whose display status changes in accordance with the

states of bits at the host. Squares, circles, sectors and polygons can be used

for lamps (normal (standard) lamps). In accordance with the status of the host

bit, they can be lit (displayed in reverse video) or flashed (repeated alternation

between normal and reverse video display states).

Lamps can also display different image/library data for the ON and OFF states

of the host bit (such lamps are called image/library lamps).

There are four standard lamp labels: fixed display character strings, ON/OFF

switching character strings, numeral displays, and character string displays.

When fixed display character strings or ON/OFF switching character strings

are used, several lines of labels can be displayed.

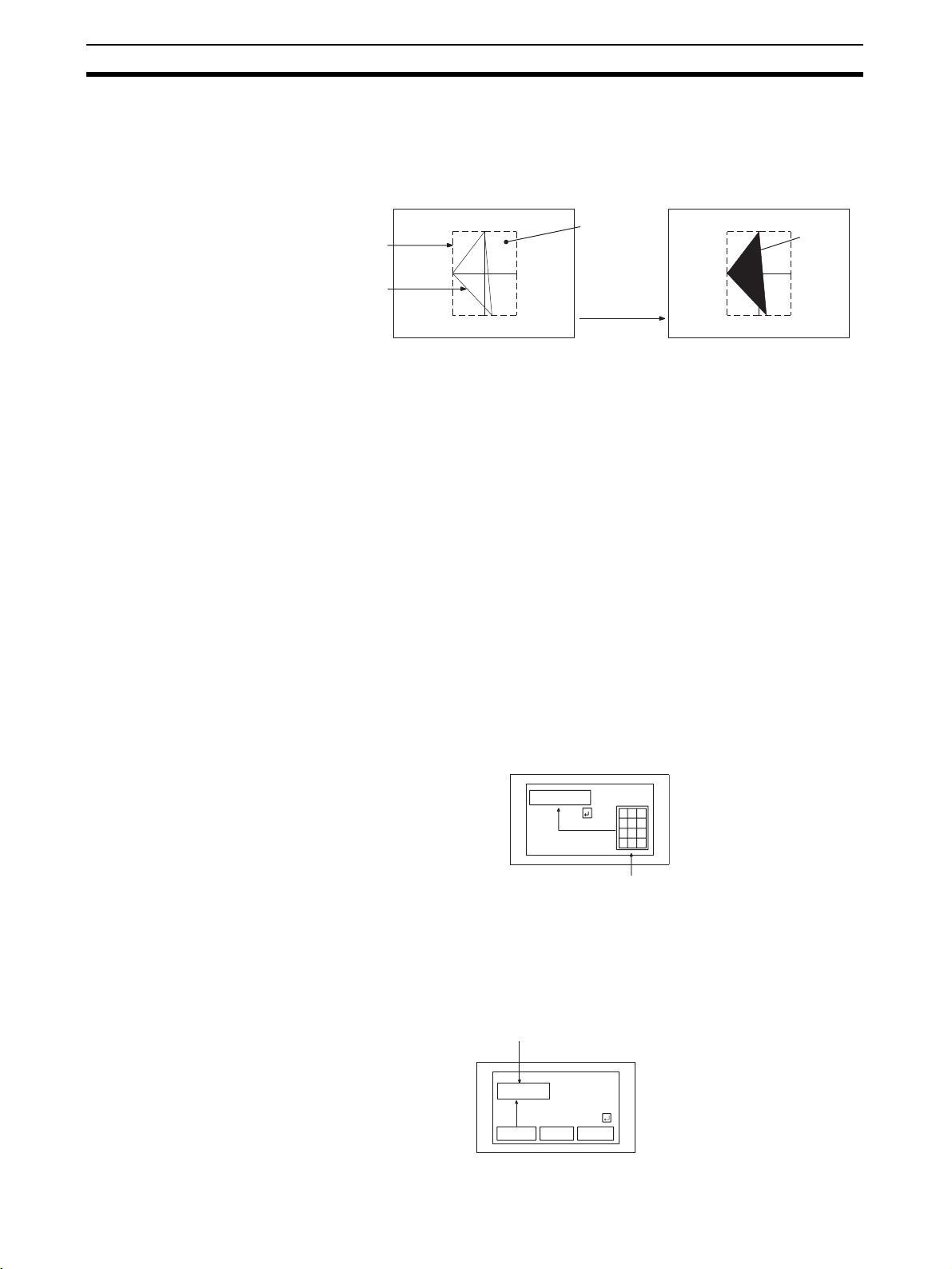

Normal (Standard) Lamps

ON

ON

Unlit state Lit state

Host

Image/Library Lamps

ON

Unlit state Lit state

Host

Touch Switches These switches can be set at any location on the screen. Pressing a touch

switch on the screen where a touch switch has been set can have the following effects:

Notification to a host bit (input notification function)

Changing the displayed screen (screen switching function)

Input of a numeric value or character string (input key function)

Copying of a numeric value or character string (copy key function)

Shifting to another numeric value or character string input field (cursor

moving key function)

Obtaining a hard copy of the screen (screen print function)

Opening / Closing a window

Moving a window

Touch switches can be made to light or flash in accordance with the status of

a host bit in the same way as lamps.

The following 8 types of display graphic can be used for touch switches:

13

Page 31

Functions of the NT631/NT631C Section 1-2

Standard, shadow, 3-dimension, no display frame, rectangle, circle, polygon, sector

When rectangle, circle, polygon, or sector is selected as the shape, the area

within which pressing of the touch switch is sensed (the touch switch area)

can be set independently of the position where the display graphic is set.

Touch

switch area

Display

frame

When this

position is

pressed...

Function executed

Shown

in

reverse

video

There are four touch-switch labels: fixed display character strings, ON/OFF

switching character strings, numeral displays, and character string displays.

When fixed display character strings or ON/OFF switching character strings

are used, several lines of labels can be displayed.

Numeral Display Numeric values stored in the numeral memory tables are displayed. The dis-

played numerals can be changed by changing the data stored in the numeral

memory tables.

Hexadecimal values can also be displayed.

When decimal values are displayed, the number of digits for the integral part

and fractional part of displayed values can be specified in advance.

String Display Character strings stored in the character string memory tables are displayed.

The displayed character strings can be changed by changing the data stored

in the character string memory tables.

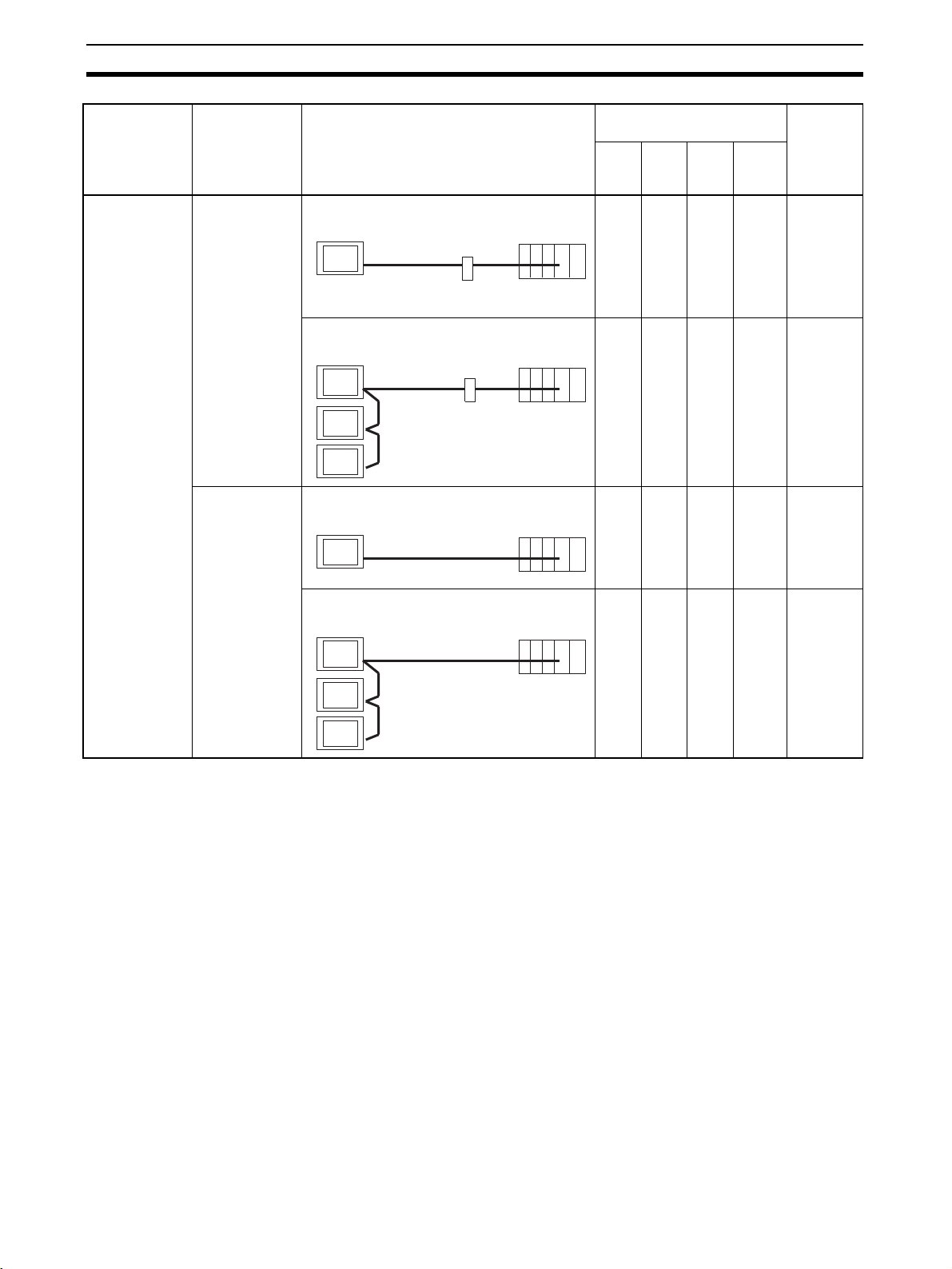

Numeral Input Numeric values can be input at the PT by using touch switches. The input

numeric values can also be stored in a numeral memory table and notification

sent to the host.

Numeral inputs can be enabled and disabled from the host when an interlock

bit has been allocated.

12345678

Input

7 8 9

4 5 6

1 2 3

"

0 .

Window

String Input Character strings can be input at the PT by using touch switches, bar code

readers, etc. The input character strings can also be stored in a character

string memory table and notification sent to the host.

String inputs can be enabled and disabled from the host when an interlock bit

has been allocated.

Character string setting input field

Display

NT631C

Input

NT631C NT631

NT31C

14

Page 32

Functions of the NT631/NT631C Section 1-2

Thumbwheel Switches Numeric values can be input by incrementing or decrementing each digit with

the corresponding touch switch (+, –). The input numeric values can also be

stored in a numeral memory table and notification sent to the host.

Thumbwheel switch inputs can be enabled and disabled from the host when

an interlock bit has been allocated.

Graphs These are graphics whose display changes in accordance with the numeric

values stored in numeral memory tables. There are the following four types.

Bar graphs:

Bar graphs display the present value in a numeral memory table converted to

a percentage within the range –100% to +100% of a preset value.

60%

Analogue meter:

Analogue meters display, using a quarter, half, or full circle shape, the present

value in a numeral memory table converted to a percentage within the range –

100% to +100% of the preset value. Users can choose from moving pointer

type and filling area type displays. Users can also add graduation to the

graph.

60%

Broken line graphs:

Broken line graphs display, in an easy-to-read form, a sequence of numeral

memory table values converted to a percentage within the range –100% to

+100% of a preset value.

100%

0%

Example showing a series of

11 numeral memory table

values (with a check mark

set for the display sign)

−100%

Trend graphs:

Trend graphs display chronological changes in the value in a numeral memory

table, converting the value to a percentage within the range –100% to +100%

of a preset value. The trend graph shifts position with the passage of time.

Past data can also be recorded, and the numeral memory table can be read

(sampled) even while the trend graph is not being displayed.

The user can choose to stop sampling, restart sampling, or display past data,

by pressing touch switches.

15

Page 33

System Configuration Section 1-3

Alarm List/History The alarm list/history function displays messages in list form, or graphics

(image/library data), in accordance with changes in bit memory table statuses.

For the alarm list, a series of bit memory tables are monitored, and messages

(contents of character string memory tables) set for bit memory tables that

come ON are displayed.

For the alarm history, bit memory tables for which the history property is set

are continually monitored, and the time when they come ON and number of

times they come ON are recorded and displayed together with the message

(character string) set for the bit memory table.

The NT631/NT631C allows selection of the display order as the newest

record first or the oldest record first by memory switch setting.

The alarm list function is used to determine which bits are ON at the present

time. The alarm history function is used to determine the times at which

alarms occurred in the past and how many times alarms have occurred

Alarm List

Message (character string table No. 32)

set for bit memory table No. 14

Character string table No. 32

Image/library

data 113C

Character string table No. 50

Image/library data 1002

Character string table No. 32

Image/library data 113C

Character string table No. 54

Image/library data 1125

No.13

No.14

No.15

Bit

0

1

0

A000000

L001003

D010015

HOST

1(ON)

When the message displayed is pressed, the image/library

data (113C) set for bit memory table No. 14 is displayed.

Alarm History

Message (character string table No. 13)

set for bit memory table No. 24

Recorded data

Character string table No. 13

Character string table No. 12

Image/library

data 102B

Character string table No. 11

Image/library data 005F

Character string table No. 12

Image/library data 102A

Character string table No. 13

Image/library data 102B

No. 22

No. 23

No. 24

Bit memory table No. 24

97/12/04 11:19:20

Bit memory table No. 23

97/12/04 11:25:12

When the upper message displayed is pressed, the image/library

data (102B) set for bit memory table No. 13 is displayed.

Recipe You can set several words of numeric data at the PT in tabular format, and

write it to the host. You can also read several words of numeric data from the

host and display it on the PT screen.

1-3 System Configuration

This section shows the configuration of a system that uses an NT631/

NT631C. For details on product models, refer to Appendix J Model List

(page 281).

16

Page 34

System Configuration Section 1-3

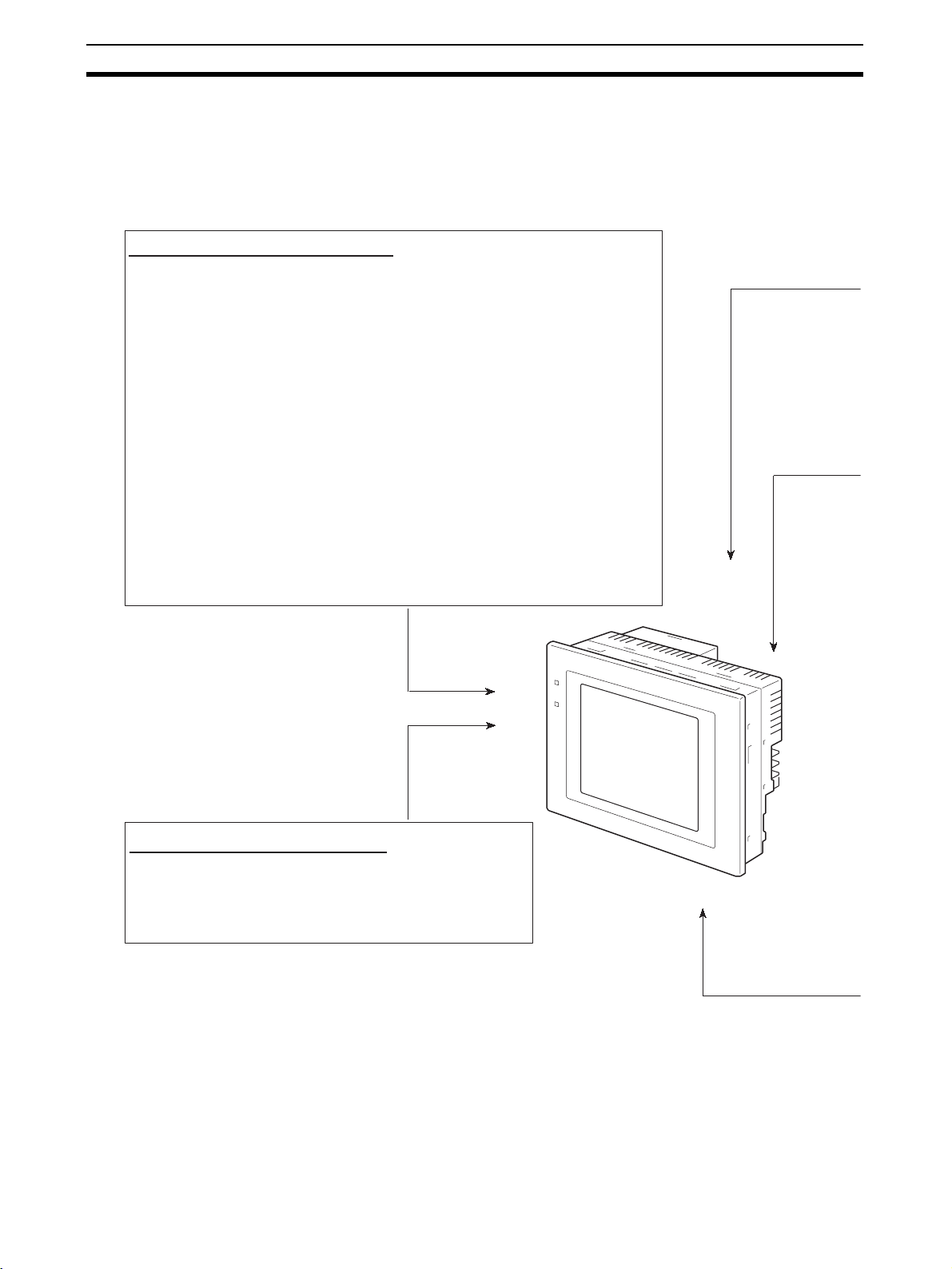

1-3-1 Peripheral Devices That Can Be Connected

The following peripheral devices can be connected to an NT631/NT631C.

Host

Controls the NT631/NT631C as required while controlling machines and

monitoring the production line.

Host Link: CS/CJ-series, C-series, and CVM1/CV-series PLC, and SRM1

Bar code reader

Bar codes can be read

as character strings.

Printer

For printing out the

currently displayed

NT631/NT631C screen.

RS-232C cable

(max. 15 m) or

RS-422A/485 cable

(max. 500 m)

Can be connected to CPU Units, Host Link Units, and SRM1.

NT link: CS/CJ-series, C-series, and CVM1/CV-series PLC, and SRM1

Can be connected to CPU Units and SRM1. However,

Memory link: Can be connected to a personal computer, FA computer, etc.

Other companies' PLCs can also be connected.

However, connection is not possible to some models of CPU

Unit and SRM1.

connection is not possible to some models.

Personal computer

Running Windows 95/98/NT

Support Tool

Used to create screens for the

NT631/NT631C at the personal

computer and transmit them to

the NT631/NT631C, and to

make NT631/NT631C settings.

System installer

Used to change the system

program of the NT631/NT631C.

Memory unit NT631/NT631C

Can store screen data

and system program to

be read out

automatically at

startup.

Displays production line monitoring and

instructions to the operation site, and

notifies the host of the switch ON/OFF

status and numeric value inputs.

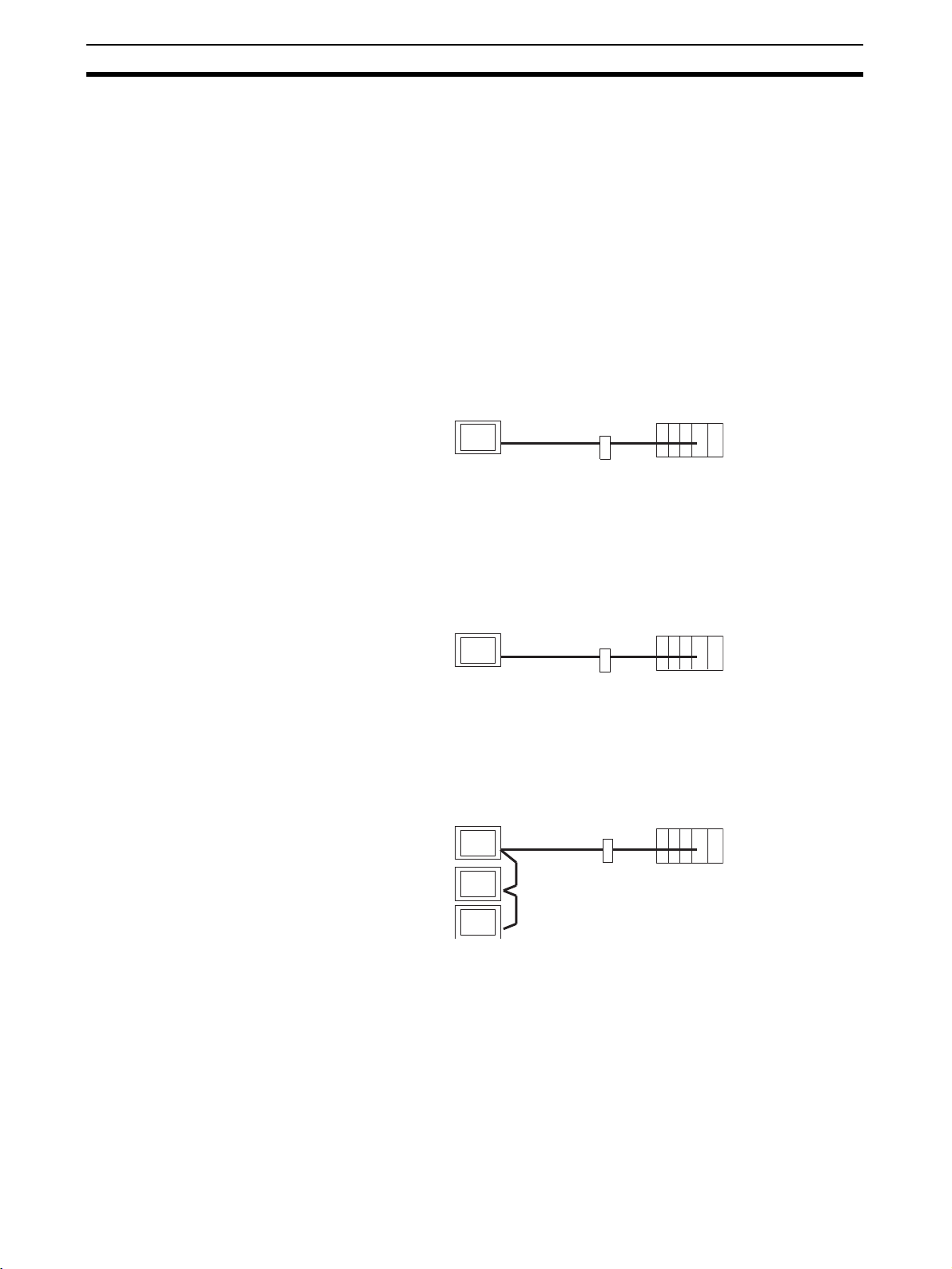

When a 1:N NT Link is being used, up

to 8 PTs can be connected to a single

PLC.

• Bar code reader (page 36)

• Recommended printers (page 36)

It is also possible to use printers that can emulate an NEC PC-PR201H

(using the NEC PC-PR201PL control protocol), and printers that comply

with one of the following EPSON control standards: ESC/P 24-J83C (color), or ESC/P 24-J82 (monochrome).

• Memory Unit (page 39)

• NT-MF261 (made by OMRON)

• Support Tool (page 35)

NT-series Support Tool Version 4.@ for Windows (Made by OMRON)

• NT-ZJCAT1-EV4 (CD-ROM version)

• System installer (page 35)

• System installer (made by OMRON)

The system installer is supplied as a standard accessory with the Support

Tool (NT-ZJCAT1-EV4).

Reference: The following optional devices are available. All of them can be used either

with NT631 or NT631C.

Anti-reflective Protective NT610C-KBA04

Sheet (5 pcs/set)

Chemical-resistant Cover NT625-KBA01

Replacement Battery 3G2A9-BAT08

17

Page 35

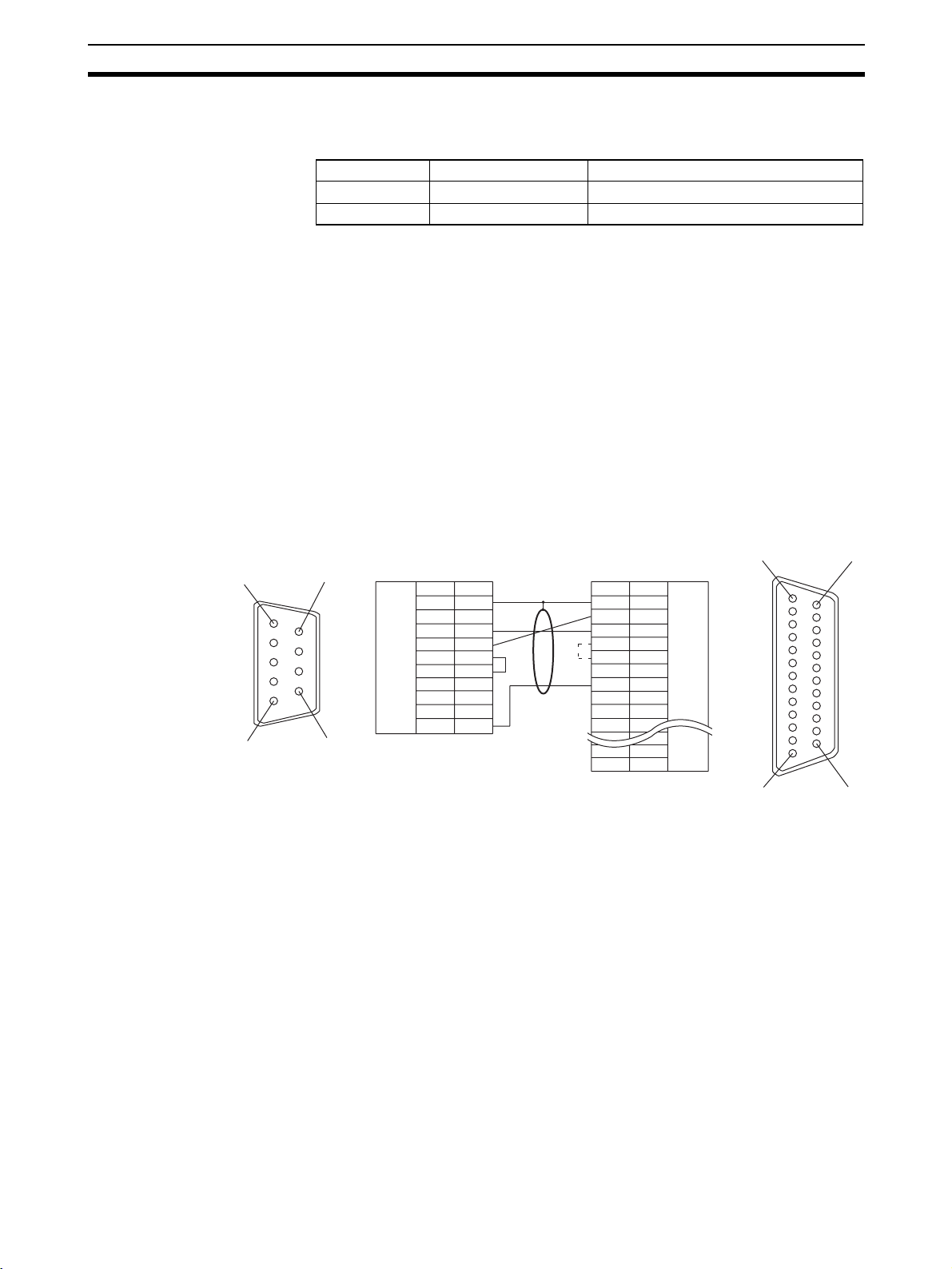

Communications with the Host Section 1-4

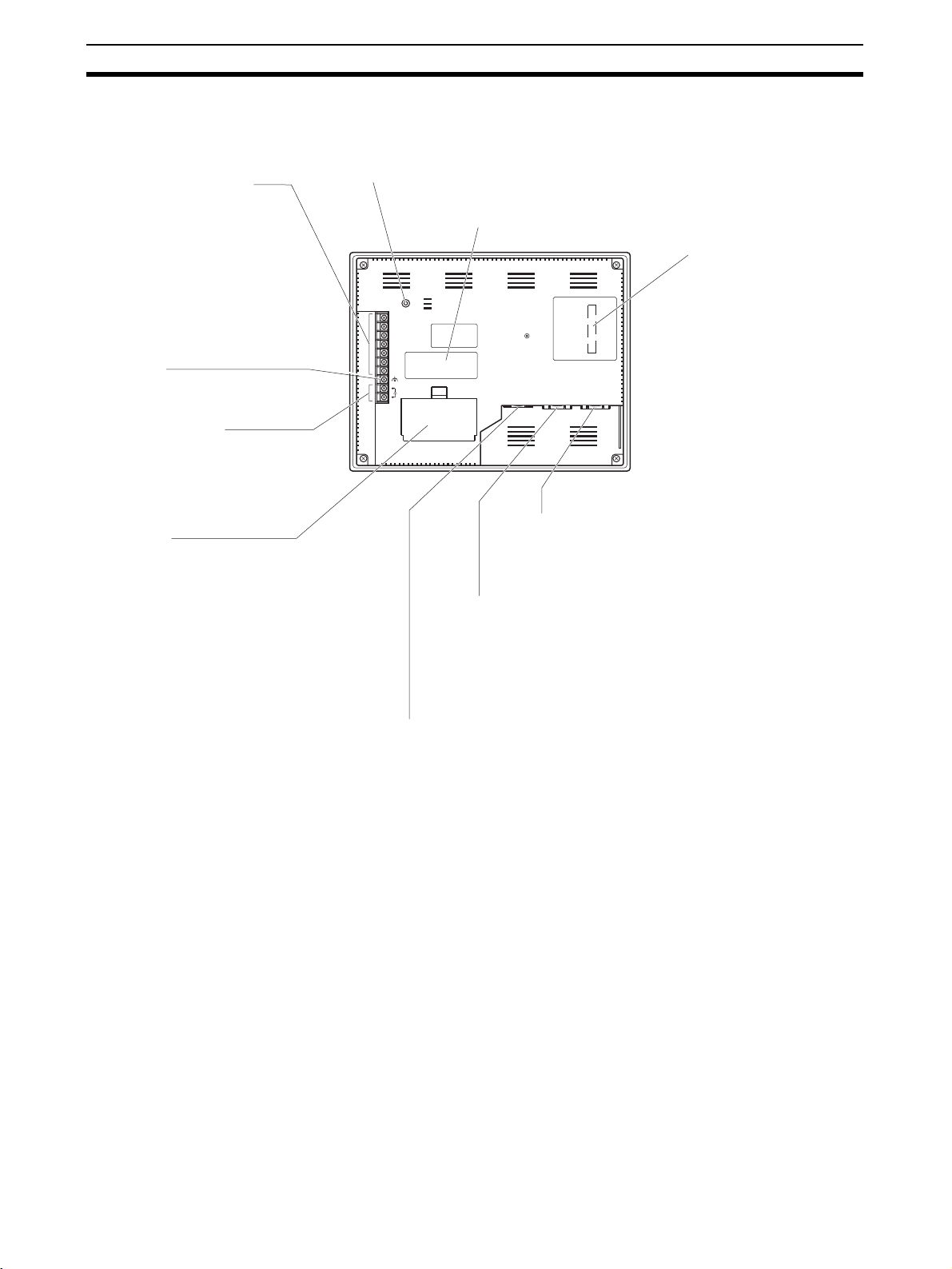

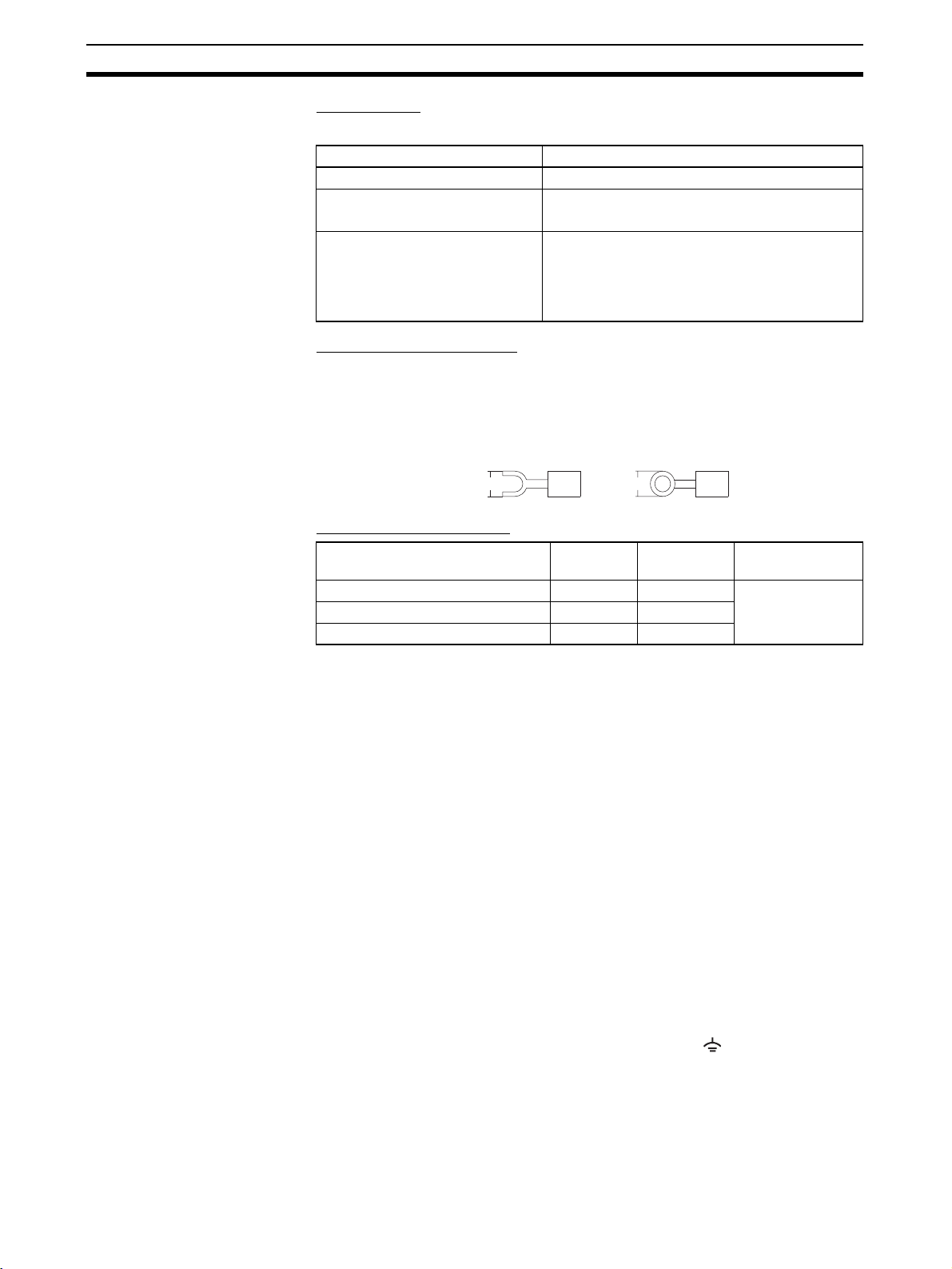

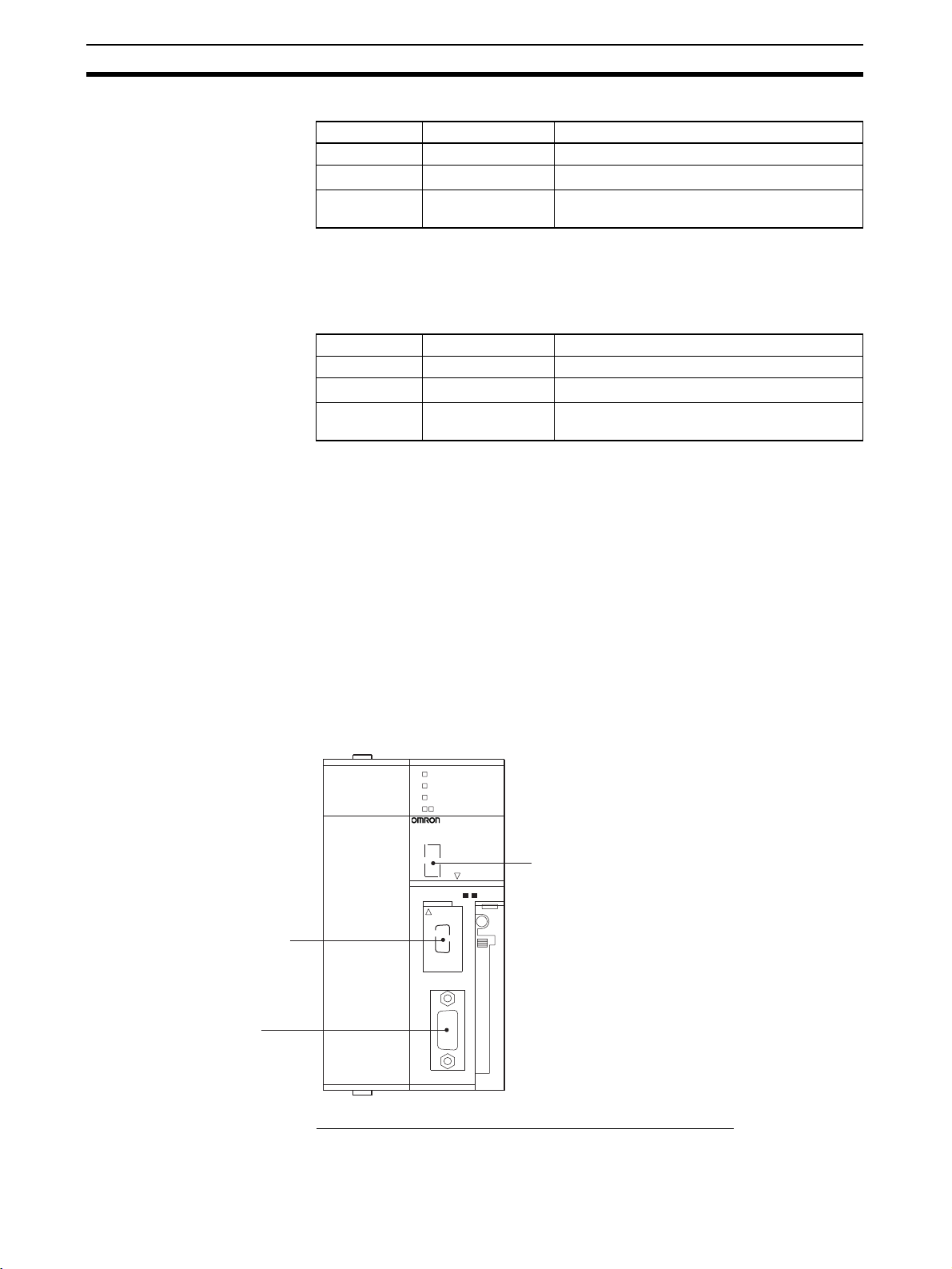

1-3-2 Connecting to the Host

The NT631/NT631C has the following two communications ports.

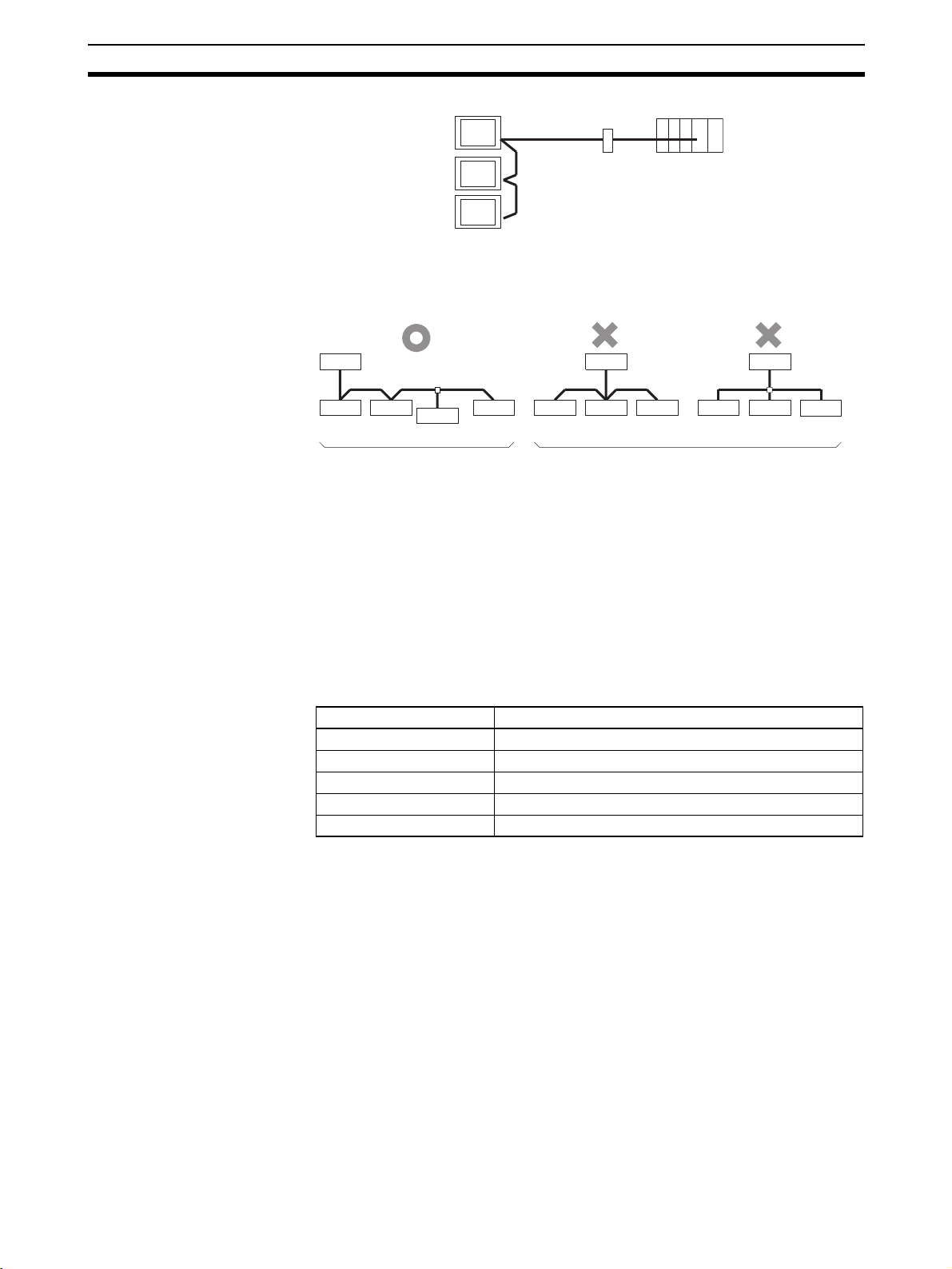

The serial port B is equipped with an RS-232C connector and an RS-422A/

485 terminal block (selectable by memory switch).

Serial Port A:

D-SUB 9-pin connector

For RS-232C use only (The Support Tool and bar code readers can be connected here.)

Serial Port B:

D-SUB 9-pin connector for RS-232C use only (The Support Tool and bar code

readers can be connected here) or Terminal block for RS-422A/485 use only.

The host can be connected at either of these two ports.

The connection methods for each communications method at the PT and host

sides are indicated below. Make the settings in accordance with the communications method that can be used with the PLC to be connected and the conditions at the operation site.

Reference: When using an RS-232C/422A adapter (NT-AL001) with the host link or NT

link (1:1) communications method, RS-485 cannot be used. The connection

must be made with RS-232C or RS-422A.

1-4 Communications with the Host

The NT631/NT631C is connected to the host by one of the following communications methods.

The following communications can be used to connect an OMRON PLC:

• Host Link

• 1:1 NT Link

• 1:N NT Link (standard or high-speed)

The following communications can be used to connect another companies’

PLC or FA computer:

• Communications protocol supported by the other company’s PLC

• Memory link

In all of these communications methods that can be used with NT631/

NT631C, data communications with host are by direct connection (Memory

link is, however, a quasi-direct connection).

In the following, the host link and NT link that carry out the direct connection

will be discussed. Memory link will be explained in 1-5 Communications Using

Memory Links.

1-4-1 Direct Connection Function

With the NT631/NT631C, the bits and words referring to data required for display, and those for storing input data, can be allocated to any part of the PLC

memory area.

The NT631/NT631C can directly write to and read from such allocated bits

and words to change the display status of the elements on the PT screen,

control the PT operating status, and notify the host of the status.

This function, which directly reads and writes the statuses of words and bits

without using a PLC program is called the direct connection function.

18

Page 36

Communications with the Host Section 1-4

The words and bits allocated for direct connection are called the allocated

words and allocated bits.

The direct connection function allows the data to be displayed at the NT631/

NT631C to be read from the memory area in the PLC and written to memory

tables in the NT631/NT631C. Also, the data input at the NT631/NT631C can

be written to the memory area in the PLC. The NT631/NT631C screen can be

changed in accordance with statuses in the PLC memory area, and the

NT631/NT631C’s status data can be written to the PLC’s memory area.

Features of the Direct

Connection Function

NT631/NT631C

Auxiliary relay area Timers/counters

The direct connection function has the following features.

• The bits and words referring to operating status and work instruction information and those for storing input data can be freely allocated to almost

any area of the PLC memory.

• Since the NT631/NT631C can directly refer to PLC bit and word data without using the program at the PLC, it can be connected to the PLC without

changing the PLC program which controls the currently running production line.

• The area to control and provide notification of the NT631/NT631C status,

including display screens, display/no display status, and buzzer output,

can be freely allocated to any part of the PLC data area. This means that

the PLC status can be read and controlled just by reading this area at the

PLC side, without preparing a special communications program.

The direct connection function allows the NT631/NT631C to directly read and

write almost all bits and words in the PLC and to automatically change the

NT631/NT631C screen display. This function can reduce the load on the PLC

so that its program development efficiency is improved.

PLC

DM area I/O relay area

1-4-2 Host Link

1-4-3 NT Link

The host is connected to a PT in a 1:1 connection, and the words and bits of

the host are read and displayed by host link communications. This method

can be used for connection to the majority of PLC types.

NT link is a method for high-speed communications with a PLC using the

direct connection function. The PLCs that can be connected with the NT link

are as follows.

CPM1, CPM2A, CPM2C, CQM1, CQM1H, C200HS, C200HX/HG/

HE(-Z)E, CS1G/CS1H-E(V1), CS1D, CJ1G/CJ1H/CJ1M, CVM1/CV-series

PLC (-EV1 or later version), SRM1

Besides the 1:1 NT link method, in which one PLC is connected to one PT, the

NT631/NT631C can also use the 1:N connection NT link method, which

allows a maximum of eight PTs to be connected to one PLC port.

PLCs that can be connected with the 1:N connection NT Link method are as

follows: CQM1H, C200HX/HG/HE(-Z)E, CS1G/CS1H-E(V1), CS1D, CJ1G/

CJ1H/CJ1M.

19

Page 37

Communications with the Host Section 1-4

The NT631/NT631C also supports OMRON’s high-speed 1:N NT Link that

provides faster 1:N communications. The only PLCs that support the highspeed 1:N NT Link are CS1G/CS1H PLCs of version -EV1 and higher, CS1D

PLCs, and CJ1G/CJ1H/CJ1M PLCs.

In the following sections, the term NT Link is used to refer to the NT Link communications method in general, the term 1:1 NT Link is used to refer specifically to NT Links with a 1:1 connection, and the term 1:N NT Link is used to

refer to both standard and high speed NT Links with 1:N connections. When

necessary, the standard 1:N NT Link is distinguished from the high-speed 1:N

NT Link.

Features of the NT Link The NT link has the following features.

• High-speed communications with specific types of PLCs can be executed.

The NT631/NT631C also supports OMRON’s high-speed 1:N NT Link.

• Writing in units of bits to the PLC memory area is possible.

This enables the other bits of words to which a touch switch has been allocated to be allocated for other purposes (e.g. a lamp).

However, since data is written to the DM area in word units, the other bits

of words allocated to touch switches in this area cannot be used for other

purposes.

• The NT link can be used even when the PLC is in the RUN mode. (When

the host link method is used, the NT631/NT631C switches to the monitor

mode when the PLC is in the RUN mode.)

• In the case of PTs that support the standard 1:N NT Link (NT20S, NT31,

NT31C, NT600S, NT620S, NT620C, NT625C, NT631, NT631C) up to 8

PTs can be connected to one port of the PLC and used at the same time.

Up to 8 PTs (NT31, NT31C, NT631, and NT631C) can also be connected

simultaneously when the high-speed 1:N NT Link is being used.

All of the PTs connected to a PLC port must use either the standard or

high-speed 1:N NT Link; the two communications systems cannot share a

single port.

• When using a C200HX/HG/HE(-Z)E PLC and standard 1:N NT Links, up

to three 1:N NT Link systems (i.e., 24 PTs) can be connected by installing

a Communications Board in the option slot of the CPU Unit. (Only the

standard 1:N NT Link can be used.) For details on the Communications

Board, refer to the SYSMAC Communications Board Operation Manual

(W304-E1-@).

• When using a CQM1H PLC and standard 1:N NT Links, multiple 1:N NT

Link systems can be connected by installing Serial Communications

Boards in the Inner Board slots. For details on the Serial Communications

Board, refer to the CQM1H Serial Communications Board Operation Man-

ual (W365-E1-@).

• Multiple 1:N NT Link systems (standard or high-speed) can be connected

by installing a Communications Board in the Inner Board slot of the CPU

Unit for a CS1G/H/D PLC or installing a Serial Communications Unit on

the Backplane for a CS1G/H/D or a CJ1G/M/H PLC. For details on the

Communications Board/Communications Unit, refer to the CS/CJ-series

Serial Communications Board/Unit Operation Manual (W336-E1-@).

• If the PLC supports the Programming Console function, the NT631/

NT631C can be used as a Programming Console.

• If the PLC supports the Device Monitor function, the NT631/NT631C can

be used to change the PLC’s operating mode and read/change data in the

PLC’s memory areas.

20

Page 38

Communications Using Memory Links Section 1-5

The NT link is compatible with the host link. The NT631/NT631C screen data

and PLC programs used with the host link direct connection method can be

used with the NT link method as they are.

1-4-4 Connecting to Other Companies’ PLCs

Installing a system program for multi-venders by using a specific system

installer enables the NT631/NT631C to be connected to the PLCs of other

models in direct connection. This system installer is supplied with the Support

Tool (NT-ZJCAT1-EV4).

Compatible PLC The NT631/NT631C can be connected to the following model PLCs.

• Mitsubishi A-series programmable controller (computer link module)

• Mitsubishi FX-series programmable controller

• SLC 500 Series by Allen-Bradley

• 90-20 and 90-30 Series by GE Fanuc

• S7-300 and S7-400 Series by Siemens

For details on the procedure for connecting to other model PLCs, refer to the

PLC Connection Manual or NT31/631 Multi Vendor Connection Manual.

1-5 Communications Using Memory Links

1-5-1 Memory Link

In this section, a communications method other than the direct connection,

called the memory link, is discussed.

Memory link is a method to send and receive data between a personal computer or a FA computer and the NT631/NT631C by using RS-232C/422A

communications.

In memory link, there is an area called PT Memory, as shown below, inside

the NT631/NT631C, and this area is treated as a virtual area on the PLC. This

allows PT memory and the display elements of the NT631/NT631C to make a

quasi-direct connection. By sending a command for the memory link, the host

can make the NT631/NT631C execute processes through PT memory. Frequently used commands are kept handy for read and write tasks of the

numeral memory table, character-string memory table, and bit memory table.

PT

Numeral

memory

table

Lamp

Direct connection

PT memory

RS-232C/422A

communications

In the memory link method, the only difference is that the NT631/NT631C

finds its communications target inside instead of outside. In the memory link

method, therefore, change of the target is all that is needed to be capable of

using the exact screen data that is acquired by the direct connection. (With

the NT631/NT631C, the Support Tool must be used to convert the data to

screen data for the memory link.)

When compared to the direct connection of the host link or NT link methods,

the memory link method has some restrictions regarding the use of some

functions, as described below.

21

Page 39

Communications Using Memory Links Section 1-5

• The Programming Console and Device Monitor functions cannot be used.

• The following strobes of PT status notify bits do not turn ON (pages 7 to

27).

• Screen switching strobe

• Numerals input strobe

• Character-string input strobe

• The usable area for allocation is the PT memory only.

1-5-2 Comparison between Direct Connection and Memory Link

The major differences between the direct connection and the memory link are

as follows:

1,2,3... 1. In the memory link method, the communications with the host should be

carried out by using commands. Compared to the ordinal direct connection, which can be used requiring almost no programs, the memory link

method requires a program that is necessary for interchange of commands.

This, however, gives advantages to the memory link method by using a

large variety of functions available in the direct connections from major

models such as a personal computer and a FA computer equipped with

RS-232C/RS-422A communications means, allowing the PT to be suited

for larger usage.

2. Actual PLCs have many kinds of areas, where as PT memory is a single

area with only one kind. When creating screen data by using the memory

link methods, it is always necessary to allocate display parts in the PT

memory.

For communications between the host and the PT by the memory link method

and for handling screen display elements, refer to the NT31/NT31C/NT631/

NT631C Programmable Terminal Reference Manual.

1-5-3 Memory Link Online Transfer Function

When memory link communications are being used, the NT631/NT631C can

be switched to Transmit mode from the host even if the NT631/NT631C is

operating and screen data can be written. (The NT631/NT631C can be

returned to RUN mode after the screen data is written.)

The memory link online transfer function can be used to replace screen data

at a fixed time each day or replace screen data with maintenance screen data

for maintenance.

For more details on the memory link online transfer function, refer to informa-

tion on the memory link online transfer function in the NT31/NT31C/NT631/

NT631C Programmable Terminal Reference Manual.

22

Page 40

Before Operating Section 1-6

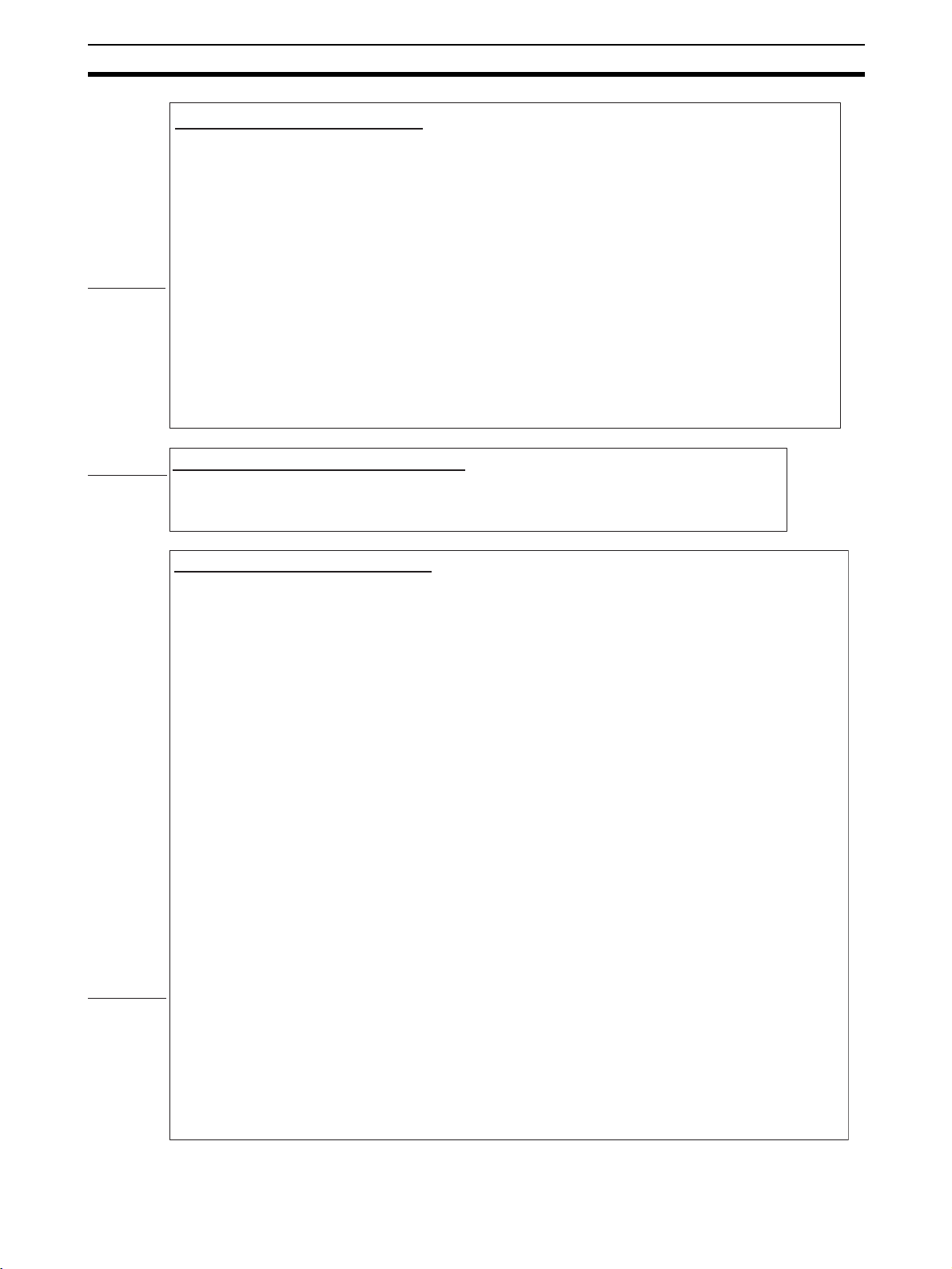

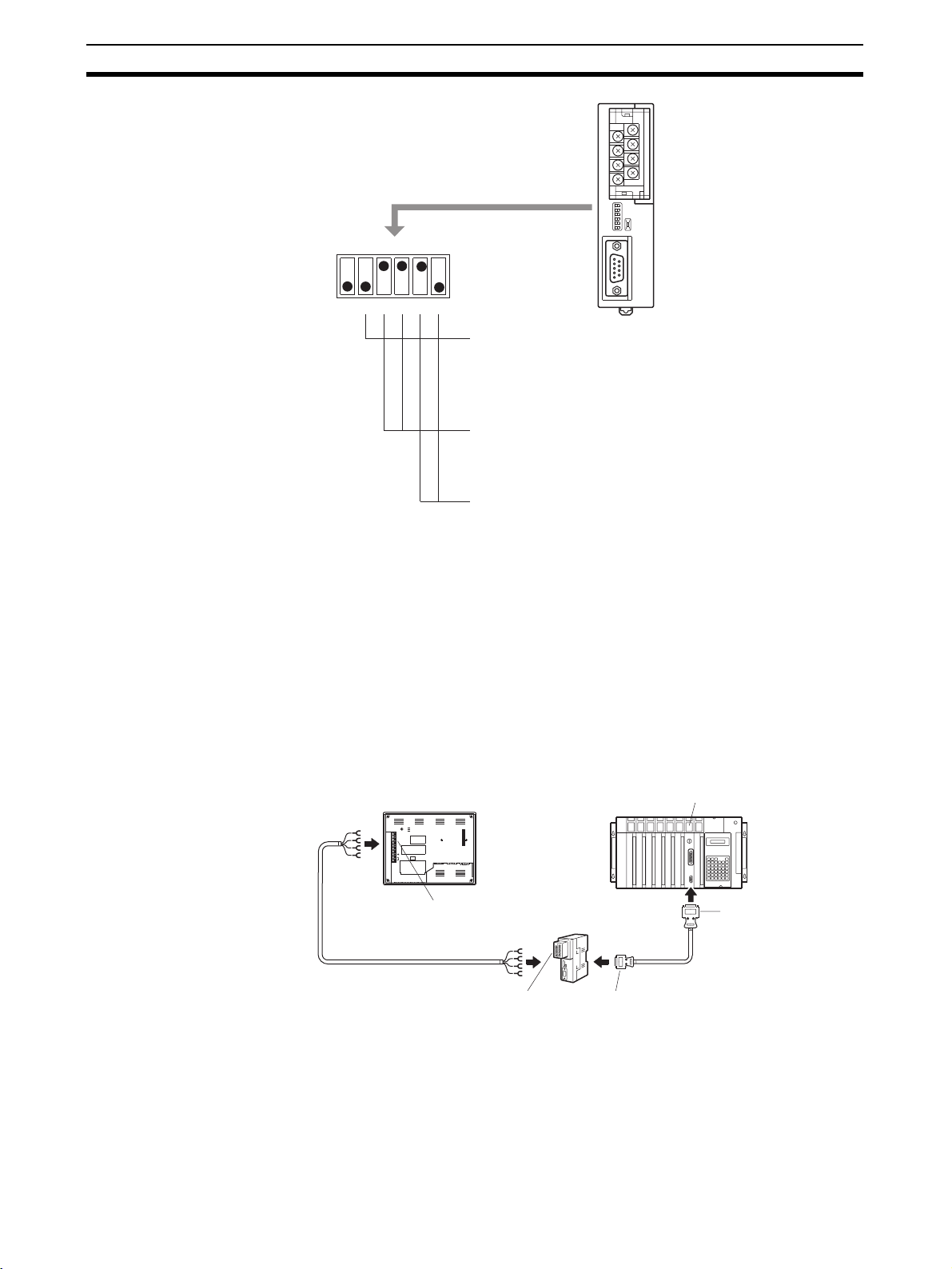

1-6 Before Operating

Follow the procedure given below to start the system of the NT631/NT631C.

Host

Set the host settings.

• For the host link, refer to

pages 48 and 94, and the

manuals for the Host Link

Unit and Programming

Devices.

• For the NT link (1:1), refer

to pages 61 and 106.

• For the NT link (1:N), refer

to pages 65 and 108.

• For the high-speed NT

link (1:N), refer to pages

70 and 112.

• For the Memory link, refer

to pages 73 and 114.

Connect to the

NT631/NT631C.

Create the host program.

NT631/NT631C

Install the PT in the

operation panel.

(page 32)

Connect the power supply.

(page 33)

Install the system program.

(Refer to page 145 and the

Support Tool manual)

Make the settings in the

system installer mode.

(page 144)

Transmit the screen data.

Set the memory switches.

(page 152)

Connect to the host.