Page 1

Cat. No. W334-E1-04

SYSMAC

C200HW-NC113/NC213/NC413

Position Control Units

Page 2

C200HW-NC113/NC213/NC413

Position Control Units

Operation Manual

Revised July 2003

Page 3

iv

Page 4

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

!

serious injury.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

!

serious injury.

Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

!

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 1997

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Note Indicates information of particular interest for efficient and convenient operation

of the product.

1, 2, 3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 5

vi

Page 6

TABLE OF CONTENTS

PRECAUTIONS xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Intended Audience xiv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xiv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xiv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1

Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 Features 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 System Configuration 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 Basic Operations 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 Control System Principles 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5 Exchanging Data 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-6 Before Operation 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

Specifications and Wiring 17. . . . . . . . . . . . . . . . . . . . . . . . .

2-1 Specifications 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Components 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 External I/O Circuitry 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 Connecting External I/O 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5 Connections in Each Operating Mode 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6 Connection of Unused Axes 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7 Servo Relay Unit 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3

Getting Started 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1 Basic Operations 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 System Configuration and Wiring 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Setting Data and Starting 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4

Data Areas 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1 Overall Structure 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Common Parameters 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Axis Parameters 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4 Operating Memory Area 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-5 Operating Data Area 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-6 Positioning Sequence Details 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-7 Setting Data With the SYSMAC-NCT Support Tool 93. . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-8 Setting Data for Unused Axes 93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5

Transferring and Saving Data 95. . . . . . . . . . . . . . . . . . . . .

5-1 Transferring and Saving Data 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Writing Data with the WRITE DATA Bit 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 Reading Data with the READ DATA Bit 103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-4 Writing Data with IOWR 107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5 Reading Data with IORD 110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-6 Creating and Transferring Data with the Support Tool 113. . . . . . . . . . . . . . . . . . . . . . . . . . .

5-7 Saving Data 114. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vii

Page 7

TABLE OF CONTENTS

SECTION 6

Defining the Origin 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1 Setting the Data for an Origin Search 118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2 Executing Origin Search 119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3 Origin Search Timing Charts 130. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4 Origin Return 134. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 7

Direct Operation 137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1 Outline 138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2 Setting Data for Use With Direct Operation 140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-3 Operations With Direct Operation 141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-4 Procedures for Setting Data for Direct Operation 143. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-5 Direct Operation Timing Charts 144. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-6 Sample Program 146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 8

Memory Operation 149. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-1 Outline 150. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-2 Setting Data for Use in Memory Operation 154. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-3 Operations With Memory Operation 155. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-4 Procedures for Setting Data for Memory Operation 162. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-5 Timing Chart for Memory Operation 162. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-6 Sample Program 165. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 9

Other Operations 169. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-1 Jogging 170. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-2 Teaching 171. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-3 Interrupt Feeding 173. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-4 Forced Interrupt 175. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-5 Deceleration Stop 177. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-6 Changing the Present Position 180. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-7 Override 181. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-8 Releasing Pulse Output Prohibition 182. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-9 Error Counter Reset Output and Origin Adjustment Command Output 184. . . . . . . . . . . . . .

9-10 Backlash Compensation 187. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 10

Program Examples 189. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-1 Operating Procedures for Program Examples 190. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-2 Memory Operation 192. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-3 Direct Operation 206. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-4 Linear Interpolation 211. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-5 Origin Search 216. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-6 Override 218. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-7 Transferring and Saving Data 221. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 11

Troubleshooting 227. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-1 Introduction 228. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-2 LED Error Indicators 230. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-3 Reading Error Codes 231. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-4 Error Code Lists 232. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-5 CPU Error Indicators 243. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

Page 8

TABLE OF CONTENTS

Appendices

A Data Calculation Standards 245. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Estimating Times and Pulses for Acceleration/Deceleration 251. . . . . . . . . . . . . . . . . . . . . . . . .

C Error Code List 253. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D Effect of Cable Length on Pulse Output 257. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E Parameter Coding Sheets 259. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F Using with CS1-series PCs 263. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 271. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History 277. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ix

Page 9

About this Manual:

This manual describes the operation of the C200HW-NC113/NC213/NC413 Position Control Units and

includes the sections described below.

Please read this manual carefully and be sure you understand the information provided before attempting

to install and operate the C200HW-NC113/NC213/NC413 Position Control Units.

Section 1 introduces the features of the Position Control Unit and explains the system configuration in

which it is used.

Section 2 provides the Position Control Unit’s specifications and explains the wiring.

Section 3 explains how to use the RELATIVE MOVEMENT command employing the direct operation

method, and provides examples of how to use a stepping motor.

Section 4 provides information on the data areas used by the Position Control Unit.

Section 5 explains how to transfer and save parameters and data.

Section 6 explains the origin search and origin return operations.

Section 7 provides an outline of direct operation, details about data areas and how to set data, and sam-

ple programs.

Section 8 provides an outline of memory operation, details about data areas and how to set data, and

sample programs.

Section 9 describes the following operations: jogging, teaching, interrupt feeding, forced interrupt, deceleration stop, changing the present position, override, releasing pulse output prohibition, deviation counter

reset output/origin-adjustment command output, and backlash compensation.

Section 10 provides examples of programs for using the Position Control Unit.

Section 11 describes how to diagnose and correct errors that can occur during operation.

The Appendices provide data calculation standards, information on estimating times and pulses for

acceleration/deceleration, error code list, information on the effect of cable length on pulse output, and

parameter coding sheets.

!

WARNING Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section in its entirety and be sure you understand the information provided in the section

and related sections before attempting any of the procedures or operations given.

xi

Page 10

PRECAUTIONS

This section provides general precautions for using the Programmable Controller (PC), Position Control Unit (PCU), and

related devices.

The information contained in this section is important for the safe and reliable application of the Programmable Controller and the Position Control Unit. You must read this section and understand the information contained before

attempting to set up or operate a PC system.

1 Intended Audience xiv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xiv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xiv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xiii

Page 11

1 Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications

described in the operation manuals.

Before using the product under conditions which are not described in the manual

or applying the product to nuclear control systems, railroad systems, aviation

systems, vehicles, combustion systems, medical equipment, amusement

machines, safety equipment, and other systems, machines, and equipment that

may have a serious influence on lives and property if used improperly, consult

your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide the

systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating Position Control Unit. Be sure to read this manual before attempting to use the PCU and keep

this manual close at hand for reference during operation.

3Safety Precautions

3 Safety Precautions

WARNING Never attempt to disassemble any Units while power is being supplied. Doing so

!

may result in serious electrical shock or electrocution.

WARNING Never touch any of the terminals while power is being supplied. Doing so may

!

result in serious electrical shock or electrocution.

WARNING Provide safety measures in external circuits (i.e., not in the Programmable

!

Controller), including the following items, to ensure safety in the system if an

abnormality occurs due to malfunction of the PC or another external factor

affecting the PC operation. Not doing so may result in serious accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PC will turn OFF all outputs when its self-diagnosis function detects any

error or when a severe failure alarm (FALS) instruction is executed. As a countermeasure for such errors, external safety measures must be provided to

ensure safety in the system.

• The PC outputs may remain ON or OFF due to deposits on or burning of the

output relays, or destruction of the output transistors. As a countermeasure for

such problems, external safety measures must be provided to ensure safety in

the system.

• When the 24-V DC output (service power supply to the PC) is overloaded or

short-circuited, the voltage may drop and result in the outputs being turned

OFF. As a countermeasure for such problems, external safety measures must

be provided to ensure safety in the system.

xiv

Caution Tighten the screws on the terminal block on the AC Power Supply Unit to the

!

torque specified in the C200H, C200HS, or C200HX/HG/HE-(Z)E installation

guide. Loose screws may result in short-circuits, malfunction, or burning.

Page 12

Caution Confirm safety at the destination node before transferring a program to another

!

node or editing the I/O area. Doing either of these without confirming safety may

result in injury.

4 Operating Environment Precautions

Do not operate the control system in the following places.

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified in

the specifications.

• Locations subject to condensation as the result of severe changes in tempera-

ture.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to shock or vibration.

• Locations subject to exposure to water, oil, or chemicals.

• Take appropriate and sufficient countermeasures when installing systems in

the following locations.

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electric fields or magnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

5Application Precautions

5 Application Precautions

Observe the following precautions when using the Position Control Unit (PCU)

and Programmable Controller (PC).

WARNING Failure to abide by the following precautions could lead to serious or possibly

!

fatal injury. Always heed these precautions.

• Always ground the system to 100 Ω or less when installing the system to pro-

tect against electrical shock.

• Always turn off the power supply to the PC before attempting any of the follow-

ing:

• Mounting or dismounting the Power Supply Unit, I/O Units, CPU Unit,

other Units, or Memory Casettes.

• Assembling the devices.

• Setting DIP switches or rotary switches.

• Wiring or connecting cables.

• Connecting or disconnecting the connectors.

Caution Failure to abide by the following precautions could lead to faulty operation of the

!

PC or the system or could damage the PC or PC Units. Always heed these precautions.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal lines,

momentary power interruptions, or other causes.

• Interlock circuits, limit circuits, and similar safety measures must be provided

by the customer as external circuits.

• Install external breakers and take other safety measures against short-circuit-

ing in external wiring.

xv

Page 13

• Tighten the PC mounting screws, terminal block screws, and cable screws to

the torque specified in this manuals.

• Always use the power supply voltage specified in this manual.

• Take appropriate measures to ensure that the specified power with the rated

voltage and frequency is supplied. Be particularly careful in places where the

power supply is unstable.

• Use crimp terminals for wiring. Do not connect bare stranded wires directly to

terminals.

• Leave the dustproof labels affixed to the top of the Unit when wiring. After wir-

ing, remove the labels for proper heat radiation.

• Do not apply voltages to the Input Units in excess of the rated input voltage.

• Do not apply voltages or connect loads to the Output Units in excess of the

maximum switching capacity.

• Check the user program for proper execution before actually running it in the

Unit.

• Be sure that the terminal blocks, memory units, extension cables, and other

items with locking devices are properly locked.

• Double-check all the wiring before turning on the power supply.

• Disconnect the functional ground terminal when performing withstand voltage

tests.

• Confirm that no adverse effect will occur in the system before performing the

following operations:

• Changing the operating mode of the PC.

• Force-setting/resetting the relay contacts.

• Changing the present values or set values.

• Changing positioning data or parameters.

• Resume operation only after transferring to the new CPU Unit the contents of

the DM and HR Areas required for operation.

• Do not attempt to disassemble, repair, or modify any Units.

• Do not pull on or bend the cables beyond their natural limit. Doing so may break

the cables.

• Do not place heavy objects on top of the cables. Doing so may break the

cables.

• Resume operation only after saving in the Position Control Unit the parameters

and position data required for resuming operation.

• Be sure that the set parameters and data operate properly.

• Be sure to check the pin numbers before wiring the connectors.

5Application Precautions

xvi

Page 14

SECTION 1

Introduction

This section introduces the features of the Position Control Unit and explains the system configuration in which it is used.

1-1 Features 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 System Configuration 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 Basic Operations 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3-1 Position Control 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3-2 Speed Control 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3-3 Other Operations 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 Control System Principles 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-1 Data Flow 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-2 Control System Principles 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-3 Basic Positioning System Design 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5 Exchanging Data 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5-1 Explanation 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-6 Before Operation 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

Page 15

1-1 Features

Position Control Unit

1-1SectionFeatures

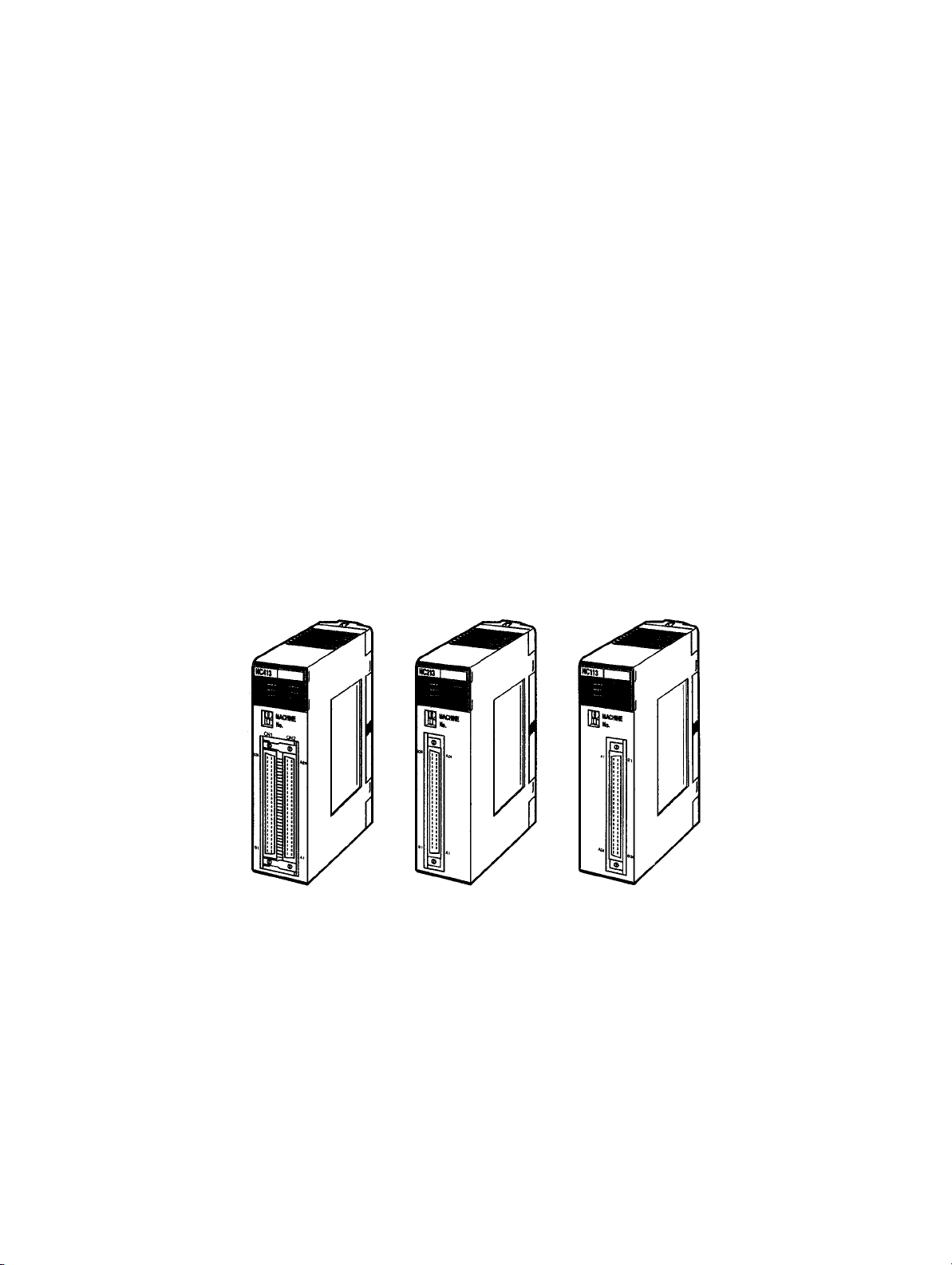

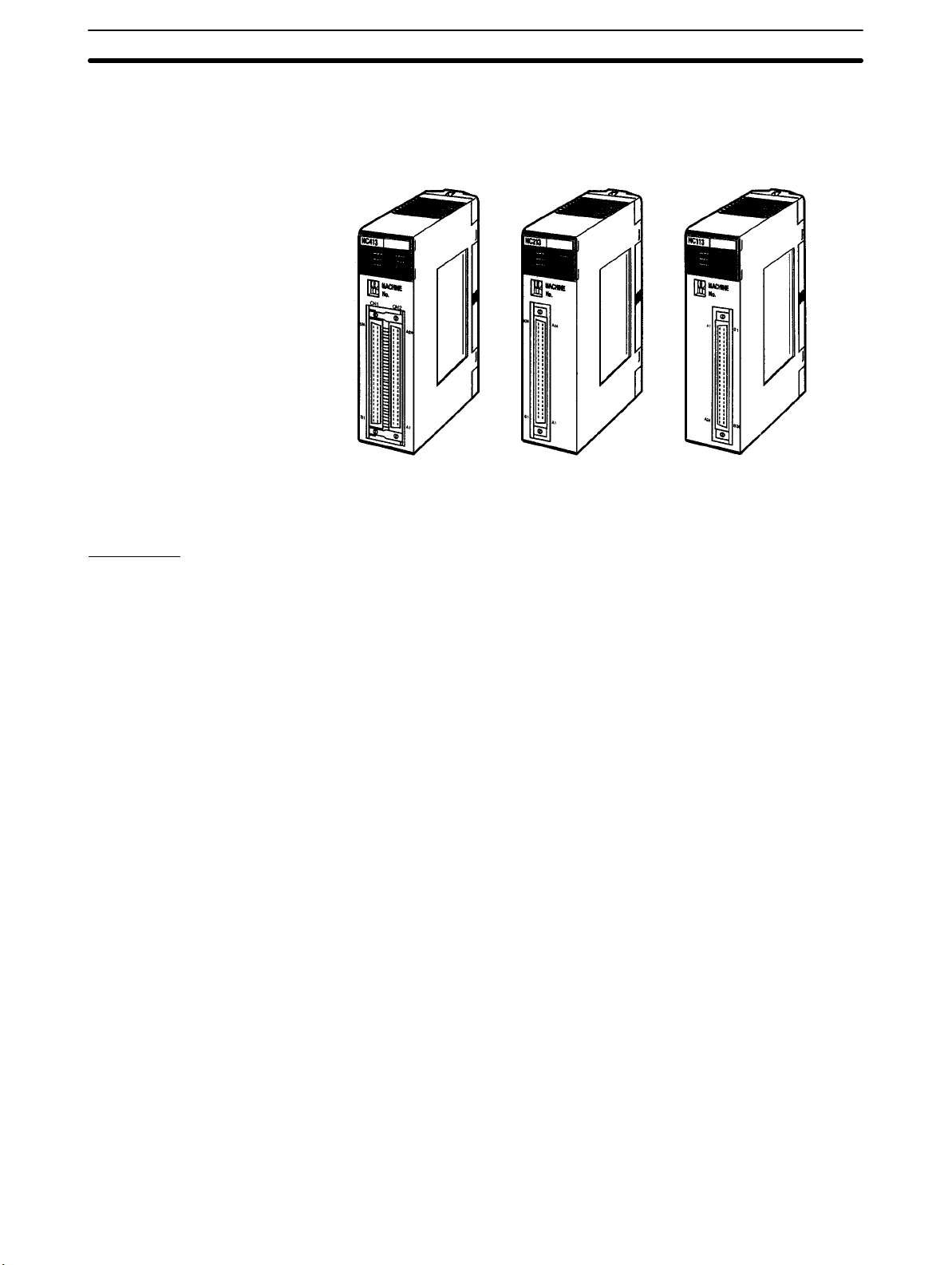

C200HW-NC413

(4-axis control)

These Position Control Units are C200HX/HG/HE-series and C200H/HS-series

Special I/O Units. The Units receive instructions from the Programmable Controller’s IR area and output pulse trains to various motor drivers for positioning.

C200HW-NC213

(2-axis control)

C200HW-NC113

(1-axis control)

Functions

Motor Driver Selectable

by Axis Unit

Number of Control Axes

and Control Capacity

Memory Operation and

Direct Operation

Interrupt Feeding

High-speed Response

Compact Size

The operating mode can be set by axis unit, so it is possible to select the motor

driver by axis unit. The Position Control Unit outputs pulse trains, so it can easily

be connected to the following motor drivers.

• Stepping motor driver

• Servomotor drivers with pulse input.

The Position Control Unit is available with one, two, or four control axes. With the

two-axis model, the two axes can either be used together for linear interpolation

or they can be operated independently. With the four-axis model, up to four axes

can be used together for linear interpolation or the axes can all be operated independently.

There are two different control methods. The first is memory operation, in which

the data required for positioning is transferred to the Position Control Unit and

then specified for position control, and the second is direct operation, in which

the target position and target speed are set each time from the Programmable

Controller.

When an interrupt is input during pulse output, positioning is continued for only

the specified number of pulses and then stopped.

The Position Control Unit responds to instructions from the Programmable Controller within 10 ms. (This applies to the C200HW-NC113.)

The single-axis, two-axis, and four-axis models are all one size, so space efficiency can be maximized by using multi-axis control with the two-axis and fouraxis models.

Special Support Tool

(SYSMAC-NCT)

2

A special support tool, SYSMAC-NCT, that runs on Windows 95 can be used

with C200HX/HG/HE-series Programmable Controllers. The SYSMAC-NCT

Support Tool can be used for writing data created or edited at a personal computer to the PCU, for reading data from the PCU, and for saving or printing out

data. It also enables the monitoring of status such as I/O and positioning

sequence numbers during execution. For details on operating this Support Tool,

refer to the SYSMAC-NCT Support Tool Operation Manual.

Page 16

1-1SectionFeatures

The SYSMAC-NCT Support Tool can only be used to access PCUs mounted on

a CPU Rack or an Expansion I/O Rack. It cannot access PCUs mounted on

Slave Racks. The SYSMAC-NCT Support Tool cannot be used with

C200H/C200HS CPU Units.

Data Capacity and

Backup

High-speed Data Transfer

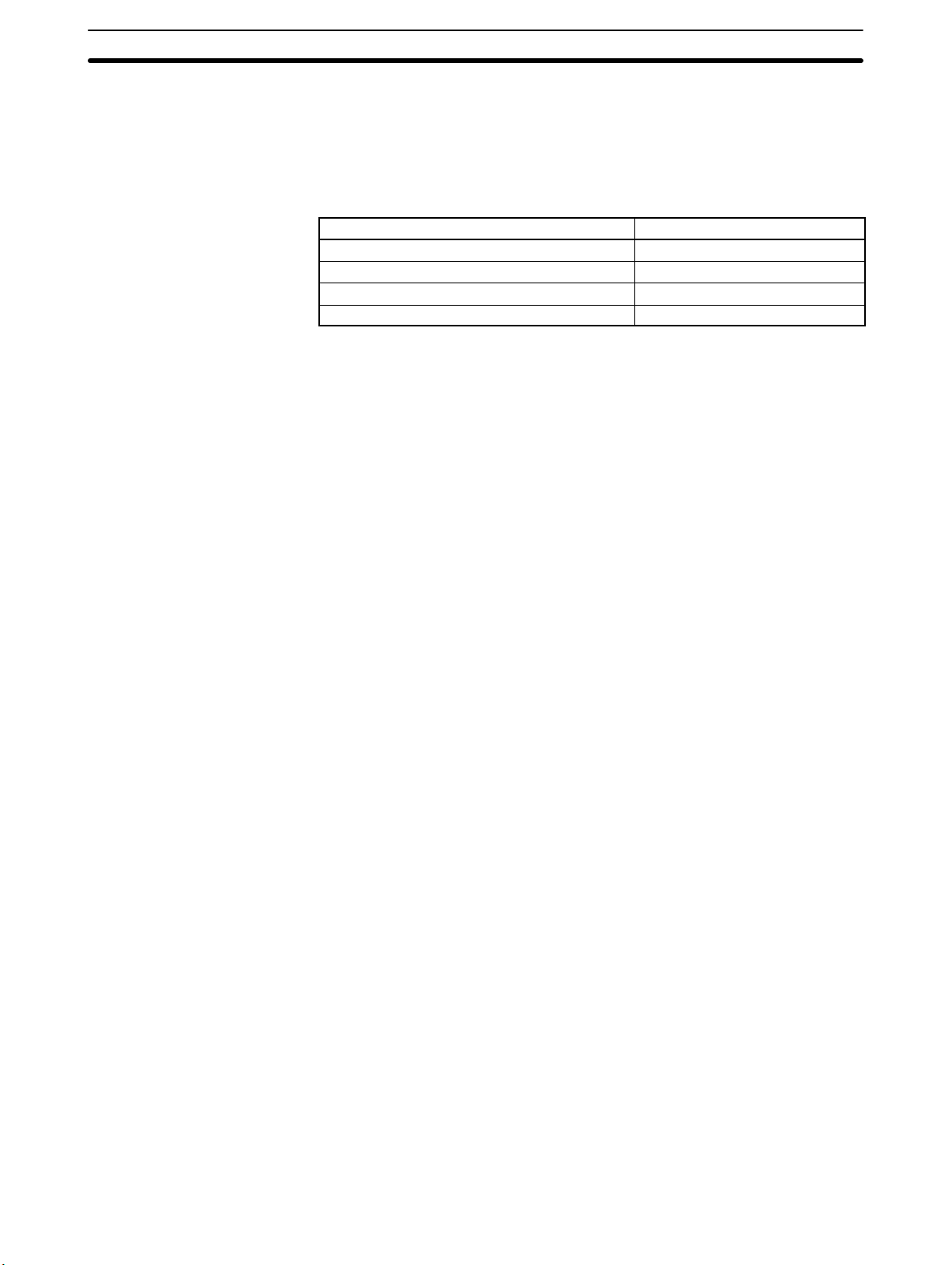

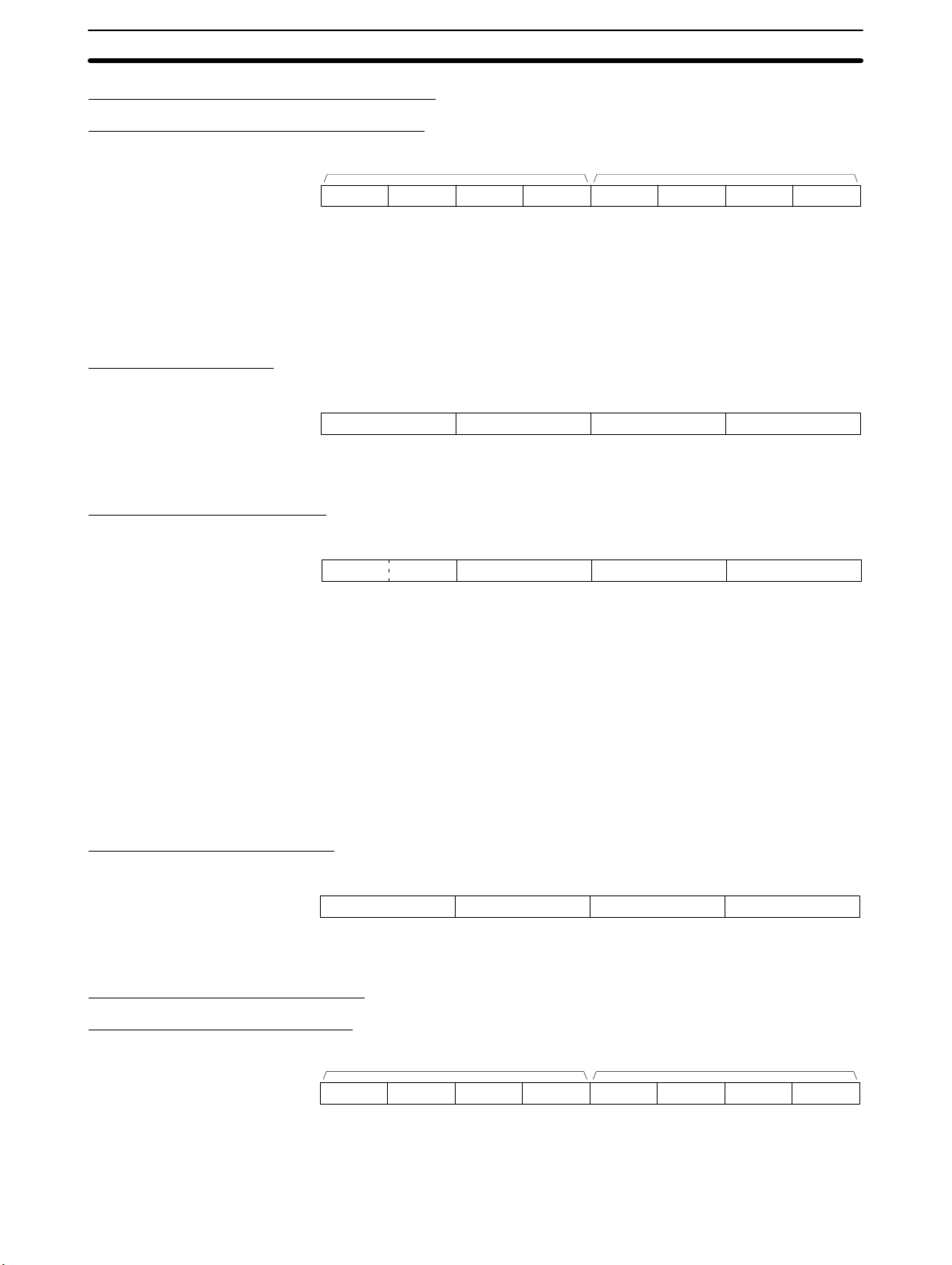

The amounts of data that can be set for memory operation are shown in the following table:

Type of data Number of data items per axis

Positioning sequences, speeds, positions 100

Acceleration times, deceleration times 9

Dwell times 19

Zones 3

These data items are transferred to the PCU for use. Once they have been transferred to the PCU they can be saved to the PCU’s flash memory, so there is no

need for battery maintenance.

Note There is a limit to the service life of the flash memory. A total of up to 100,000 data

saving operations can be performed.

With C200HX/HG/HE-series Programmable Controllers, not only can data be

transferred by means of data transfer bits and SYSMAC-NCT Support Tool, but

high-speed data transfers can also be performed by means of the Intelligent I/O

Write (IOWR) and Intelligent I/O Read (IORD) instructions.

3

Page 17

1-2 System Configuration

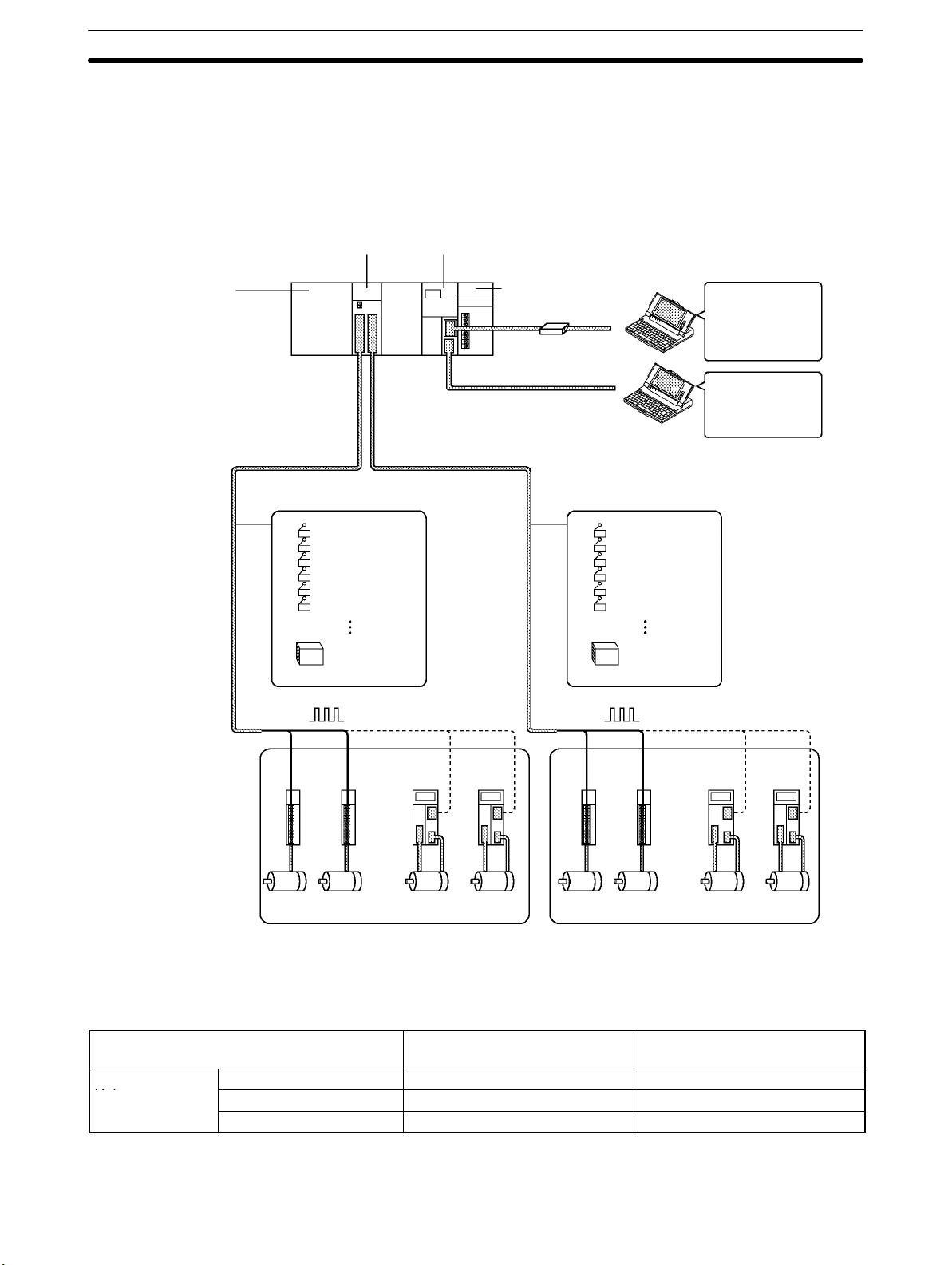

The Position Control Unit receives control signals (CW limit, CCW limit, origin,

origin proximity, emergency stop, and external interrupt input signals) from

devices and a control panel, and outputs pulse trains to stepping motor drivers

and servomotor drivers.

C200HW-NC413 System Configuration Example

C200HW-NC413

Position Control Unit

C200HX/HG/HE

CPU Unit

1-2SectionSystem Configuration

C200HW-BCjj

Backplane

External input signals

CCW limit

CW limit

Origin

Origin Proximity

Emergency stop

External interrupt

Pulse

output

24-VDC power

supply for I/F

Power Supply Unit

Tool Bus

Host Link

External input signals

Pulse

output

CCW limit

CW limit

Origin

Origin Proximity

Emergency stop

External interrupt

24-VDC power

supply for I/F

SYSMAC Support

Software:

Ladder program

creation and transfer,

monitoring, file

management, etc.

SYSMAC-NCT:

Data creation and

monitoring, PCU

monitoring, file

management, etc.

Number of Usable Units

Item C200H, C200HS, C200HE,

Number of usable

Units

C200HW-NC113 10 max. 16 max.

C200HW-NC213 10 max. 16 max.

C200HW-NC413 5 max. 8 max.

Stepping

Motor

Drivers

Servomotor

Drivers

Or

ServomotorsStepping Motors

Stepping

Motor

Drivers

Or

Stepping Motors

Servomotor

Drivers

Servomotors

The Position Control Unit belongs to the SYSMAC C200H, C200HS, and

C200HX/HG/HE Special I/O Unit group. The numbers of Special I/O Units

(including PC Link Units) that can be mounted to a single CPU Unit are shown in

the following table.

C200HX/HG-CPU5j/6j-(Z)E

C200HX/HG-CPU3j/4j-(Z)E

• For details on the particular Units that belong to each of the Special I/O Unit

groups, refer to the appropriate Programmable Controller operation manual.

4

Page 18

1-2SectionSystem Configuration

• There are restrictions on the maximum current provided to each Rack and the

the current consumption for each Unit. For details, refer to the appropriate Programmable Controller operation manual.

• There are restrictions on the use of Remote I/O Slave Racks. These restric-

tions are explained in Restrictions on Using Remote I/O Slave Racks below.

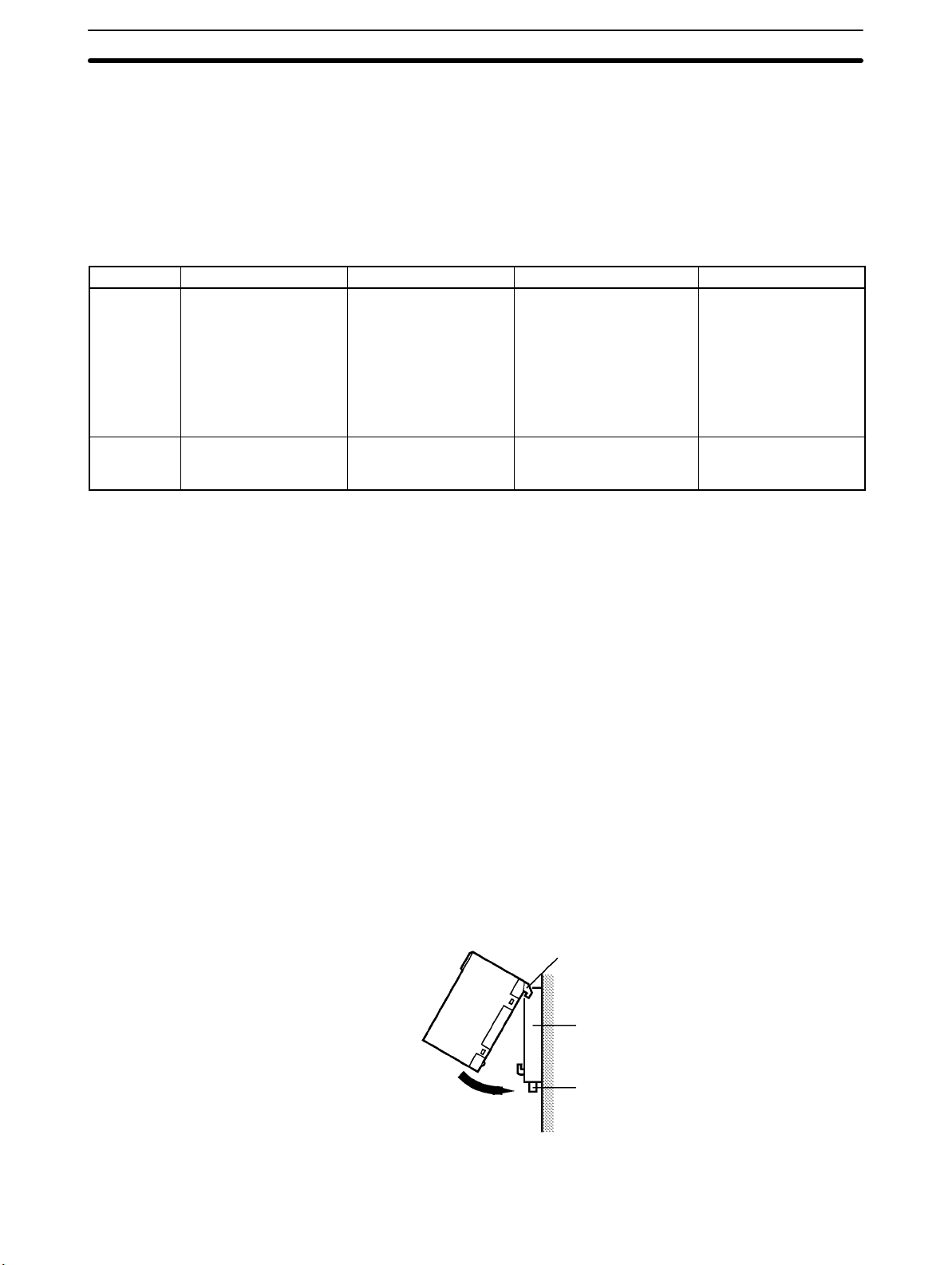

Restrictions on Using

Remote I/O Slave Racks

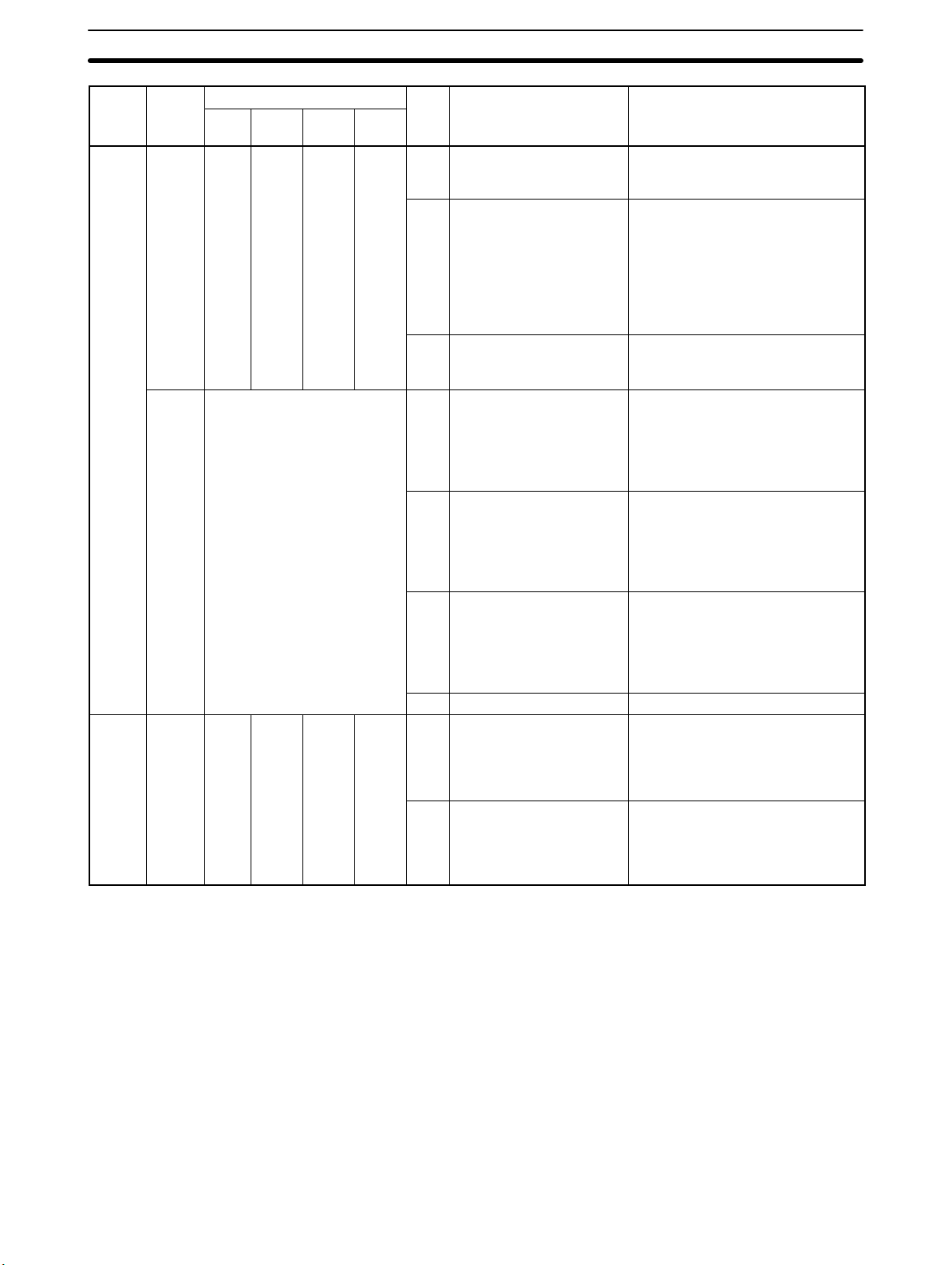

As shown in the following table, the number of Special I/O Units that can be used

on a single Remote I/O Slave Rack is determined by the the particular Special

I/O Unit group (A, B, C, or D).

Group A Group B Group C Group D

Units in

group

Number of

Units that

can be used

High-speed Counter

Units

Position Control Unit

(NC111/112)

(NC113/213)

ASCII Units

Analog I/O Units

ID Sensor Units

Fuzzy Logic Units

4 Units 8 Units 6 Units 2 Units

High-density I/O Units

Temperature Control

Heat/Cool Temperature

PID Control Units

Cam Positioner Unit

• If Special I/O Units from different groups are to be mixed, then use a combina-

tion that satisfies the following two formulas:

3A + B + 2C + 6D x 12

A + B + C + D x 8

• There are restrictions on the number of Units that can be used with particular

CPU Units. For details, refer to Number of Usable Units described previously.

System Configuration Considerations

• The I/O bits allocated to a particular Special I/O Unit are determined by the unit

number that is set by the switch on the front panel of the Unit, and not by the slot

in which the Unit is mounted.

• With the C200H, do not mount a Position Control Unit in the two slots adjacent

to the CPU Unit. If it is mounted in those slots, it will not be possible to mount

tools such as the Programming Console.

• Special I/O Units cannot be used with C200H Remote I/O Slave Racks that are

connected to Remote I/O Master Racks for other SYSMAC Programmable

Controller models (such as C120, C500, C1000H, and C2000H).

Units

Control Units

Temperature Sensor Units

Voice Unit

Position Control Units

(NC211)

(NC413)

Mounting the Unit

Follow the procedure outlined below to mount the Position Control Unit to the

Backplane.

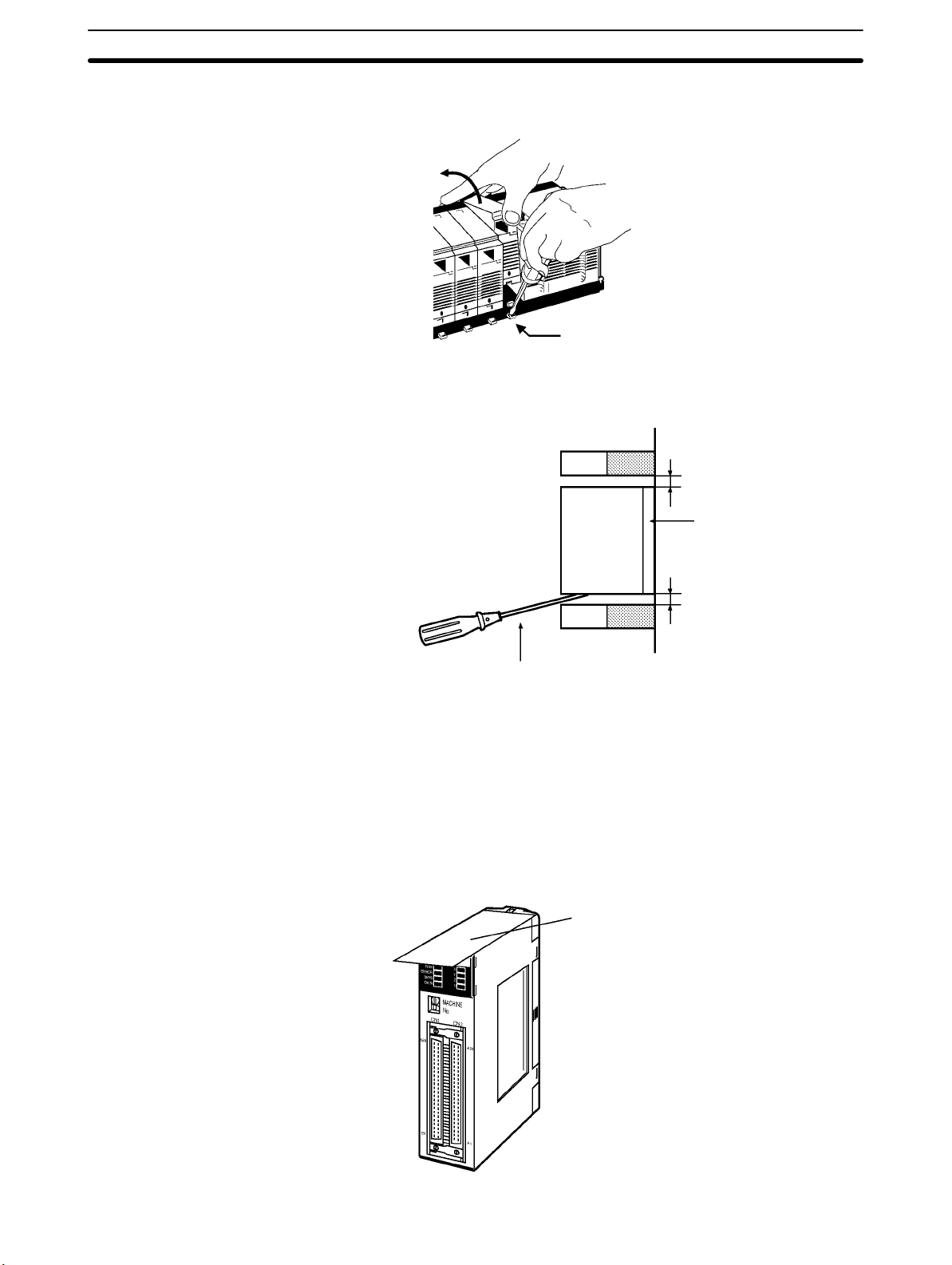

1, 2, 3... 1. Insert the hook on the upper rear of the Unit into the slot in the Backplane.

Hook

Backplane

Lock lever

2. Carefully insert the Unit into the connector on the Backplane.

5

Page 19

1-2SectionSystem Configuration

3. To remove the Unit. use an implement such as a screwdriver to press down

on the lock lever and then carefully lift the Unit out.

Lock lever

Note When installing Units on a Rack, leave adequate space for mounting and remov-

ing the Units as shown in the following diagram.

20 mm min.

Precautions When Handling the Unit

• Before installing or disconnecting the Unit or connecting cable, be sure to first

turn off both the Programmable Controller and the power supply.

• To minimize any influence from noise, place I/O wiring, high-voltage lines, and

power lines in separate ducts.

• Wire clippings tend to get scattered around during wiring, so leave the label in

place on top of the Unit to prevent any clippings from getting inside the Unit.

Once the wiring has been completed, be sure to remove the label to provide

ventilation.

Backplane

20 mm min.

Flathead screwdriver

Remove the label after

completing the wiring.

6

Page 20

1-3 Basic Operations

The C200HW-NC113 (one axis), C200HW-NC213 (two axes), and C200HWNC413 (four axes) Position Control Units are designed for use with C200HX/

HG/HE-series and C200H/C200HS-series systems.

1-3-1 Position Control

Positioning can be executed with either an absolute value (i.e., to an absolute

position from the origin) or with an incremental value (i.e., to a relative position

from the present position).

There are two methods for positioning: memory operation and direct operation.

Interrupt feeding, in which operation proceeds for the specified amount after an

interrupt input, is also possible.

1-3SectionBasic Operations

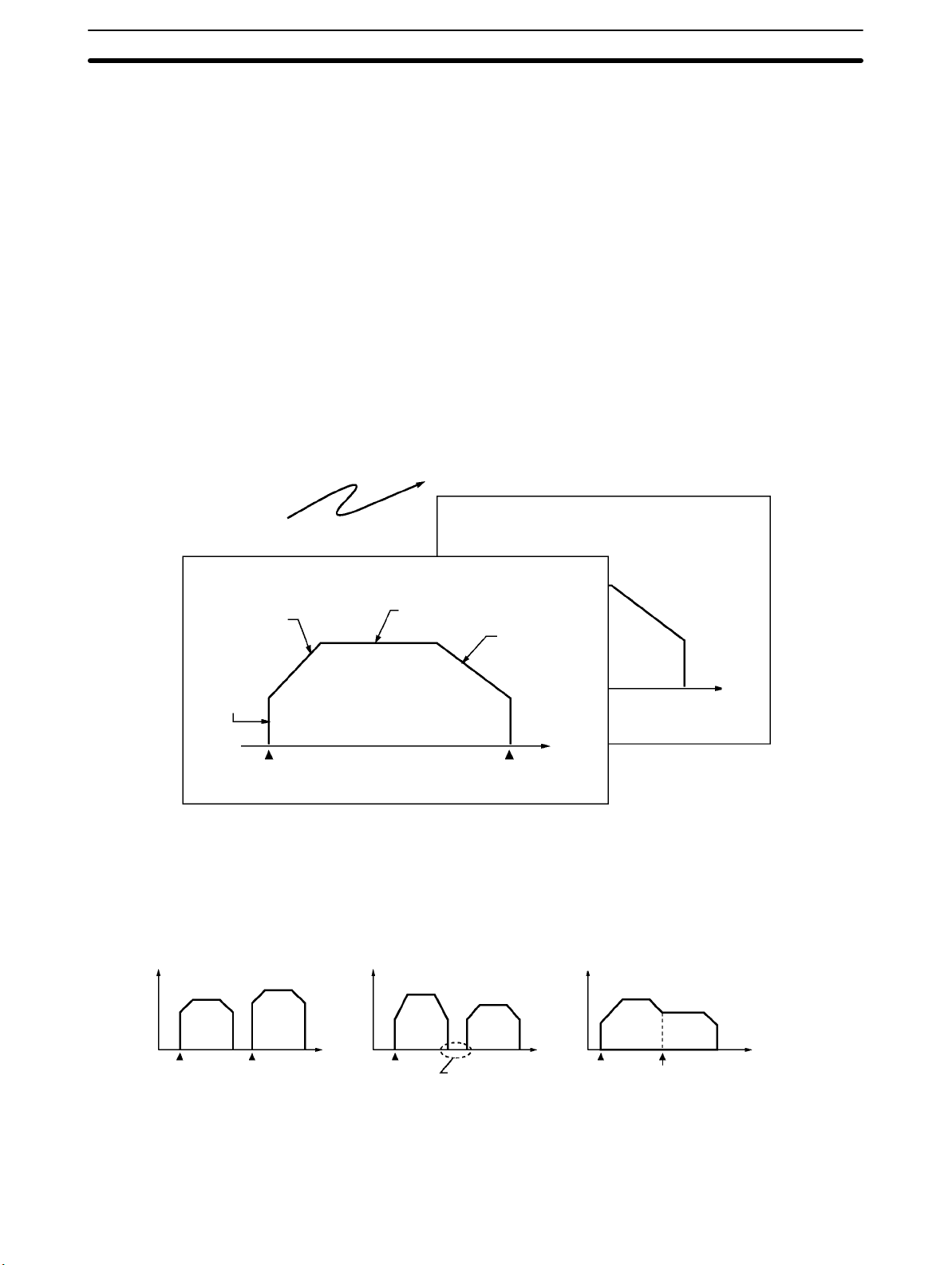

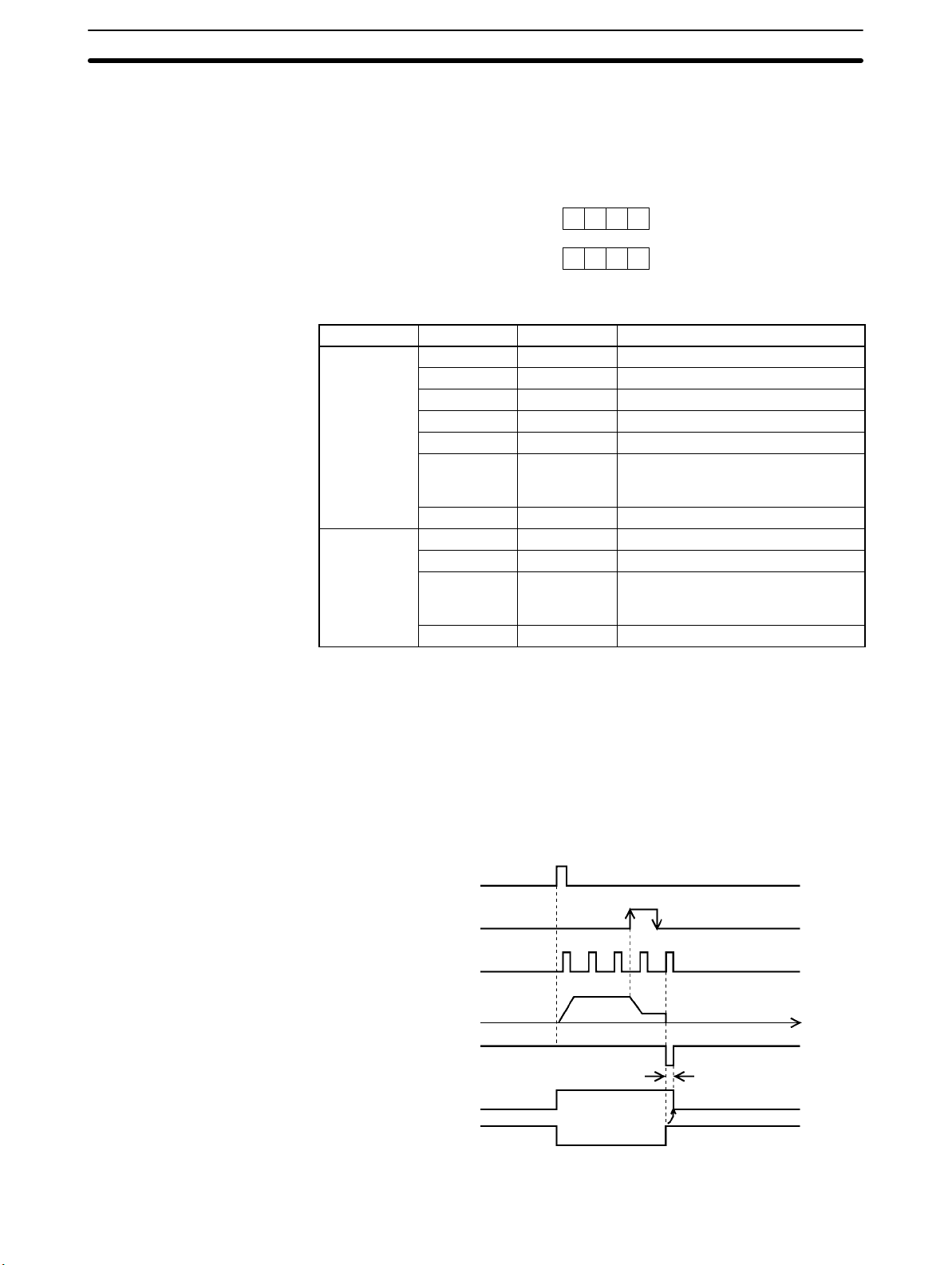

Memory Operation

Positioning sequence #0

Acceleration time number

Initial speed

number

With memory operation, positioning sequences (i.e., individual positioning

operations, which include data such as positions and speeds) are transferred to

the Position Control Unit in advance, and then positioning is executed from the

Programmable Controller by specifying those positioning sequences by number.

Executed in order

Start Target position

Positioning sequence #99

Target speed number

Deceleration time

number

Position

Position

Terminating Positioning Automatic Positioning Continuous Positioning

Pulse output Pulse output Pulse output

#0 #1

Start Start

Direct Operation

Depending on the completion code that is set, positioning sequences can be

executed using terminating positioning, automatic positioning, or continuous

positioning. In the following illustrations, “#0” and “#1” indicate positioning

sequence numbers.

#0

Time

Start

#1

Time

Pauses for length of

dwell time that is set.

#0

Start Does not stop.

#1

Time

With direct operation, positions and speeds are set in allocated areas in the Programmable Controller’s DM and EM areas, and positioning is executed using

that data.

7

Page 21

1-3SectionBasic Operations

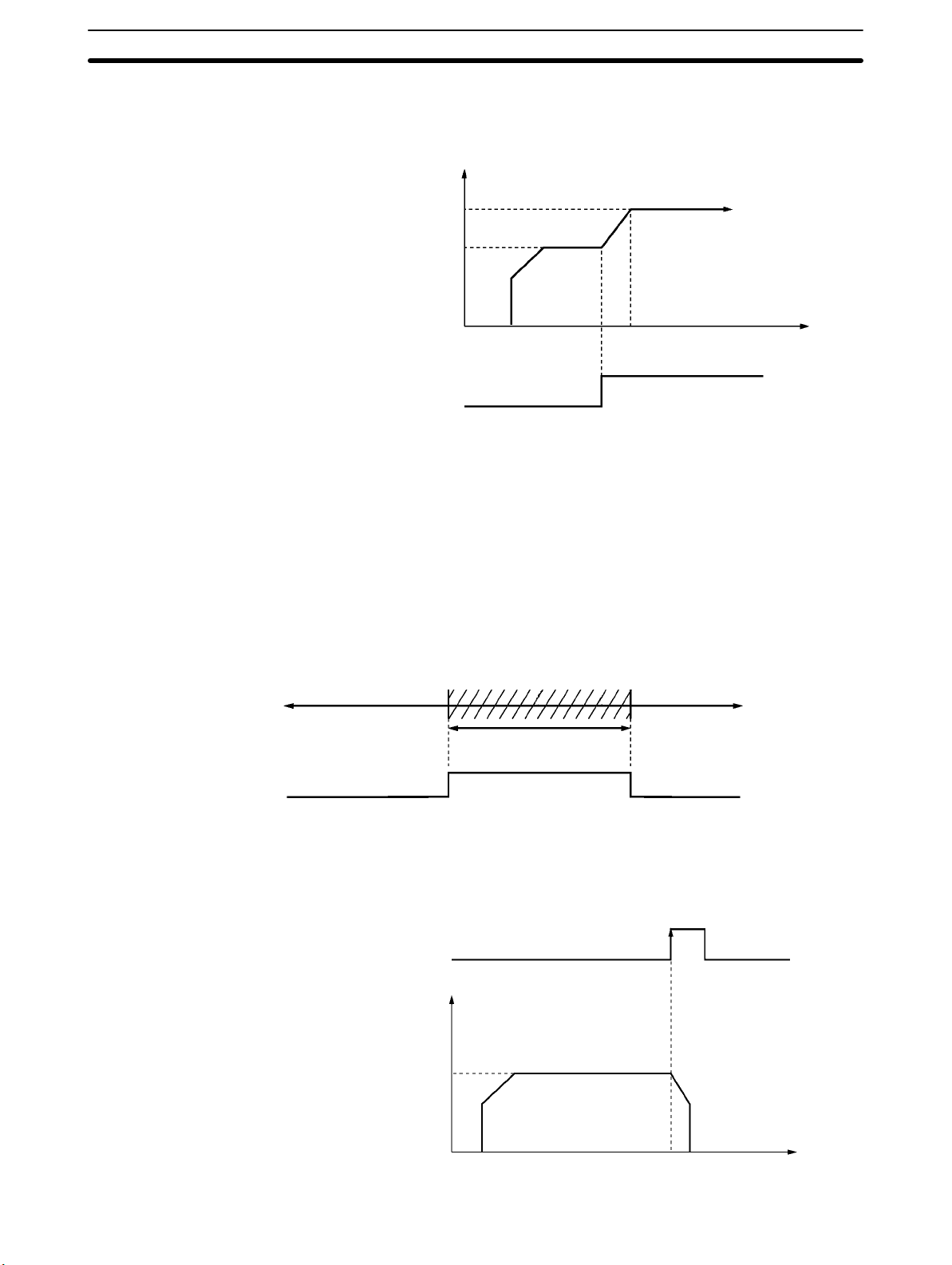

Interrupt Feeding

1-3-2 Speed Control

When an interrupt input signal is received, positioning is continued for the specified amount of pulses and then stopped.

Interrupt input signal

Speed

Specified amount

of pulses

Time

When a start is executed once, pulses are continuously output at a constant rate.

The pattern depends on the completion code that is set for “memory operation”

positioning sequences. To stop the sequence, use the STOP command.

Speed

STOP

1-3-3 Other Operations

Origin Search

Jogging

Teaching

The origin search operation finds the origin for the designated axis.

The jogging operation moves a specified axis at a designated speed and then

stops it.

The teaching operation takes the present position for the specified positioning

sequence.

Time

Start

Present position

Origin

Specified positioning sequence number

8

Page 22

1-3SectionBasic Operations

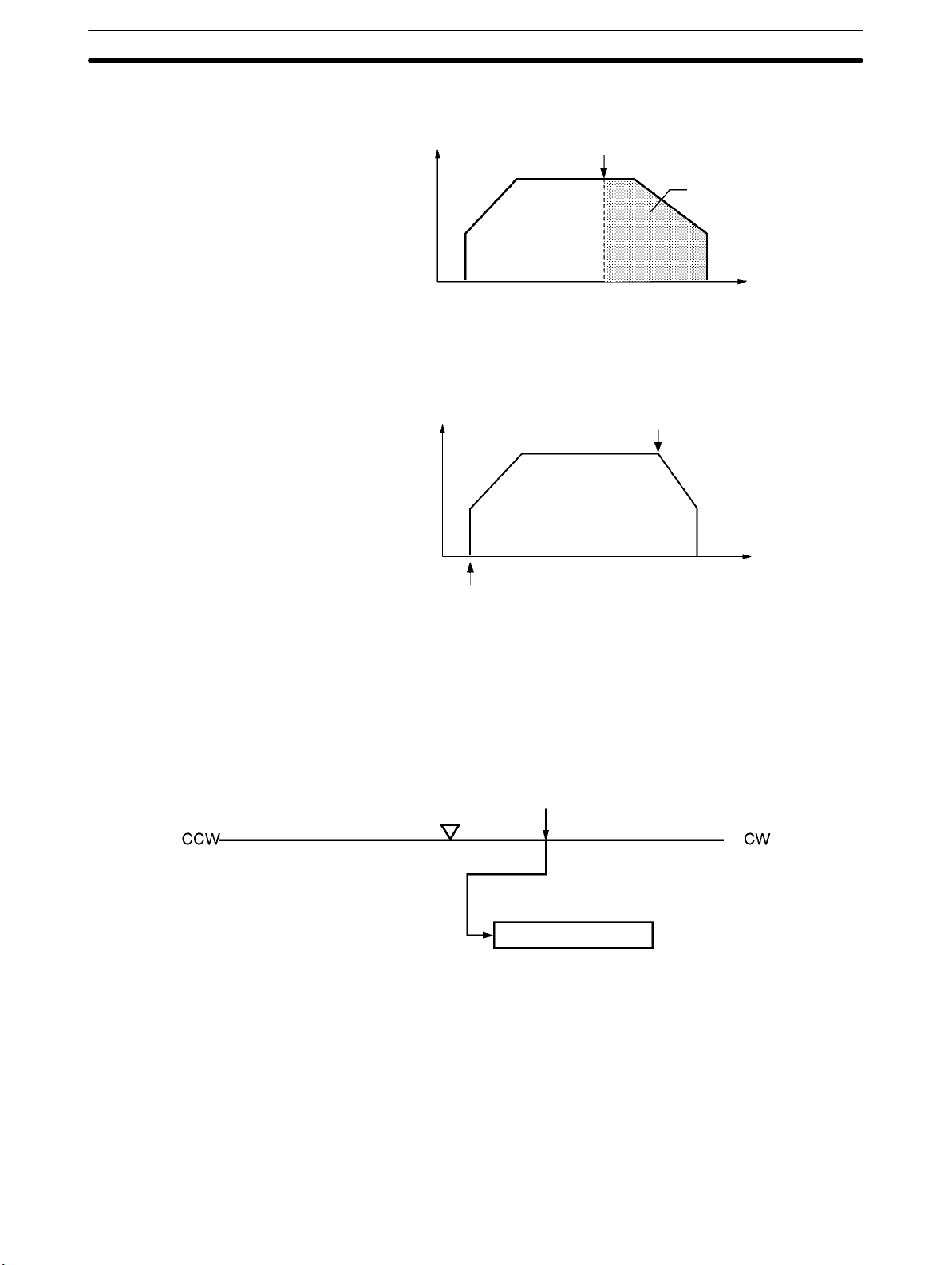

Override

Changing the Present

Position

Backlash Compensation

When the override is enabled during positioning, the target speed is changed to

the override speed.

Speed

A x 1.5

Override enable

A

1

0

Override setting: 150%

Time

The PRESENT POSITION CHANGE command changes the present position to

a specified position.

This operation compensates for the amount of mechanical play, or “looseness,”

present in gears.

Zones

Zone Flag

Deceleration Stop

A zone is a range of positions which can be defined so that flags are turned ON

whenever the present position is within the range.

CCW CW

Zone setting

ON

OFF

The STOP command decelerates positioning to a stop.

STOP

Speed

1

0

Time

9

Page 23

1-3SectionBasic Operations

The C200HW-NC113/NC213/NC413 Position Control Unit’s operations are as

follows:

PCU operations Position control Memory

operation

Direct operation

Interrupt feeding

Speed control

Other operations Origin search

Independent

Automatic

Continuous

Jogging

Teaching

Override

Present position

change

Backlash

compensation

Zone setting

Deceleration stop

10

Page 24

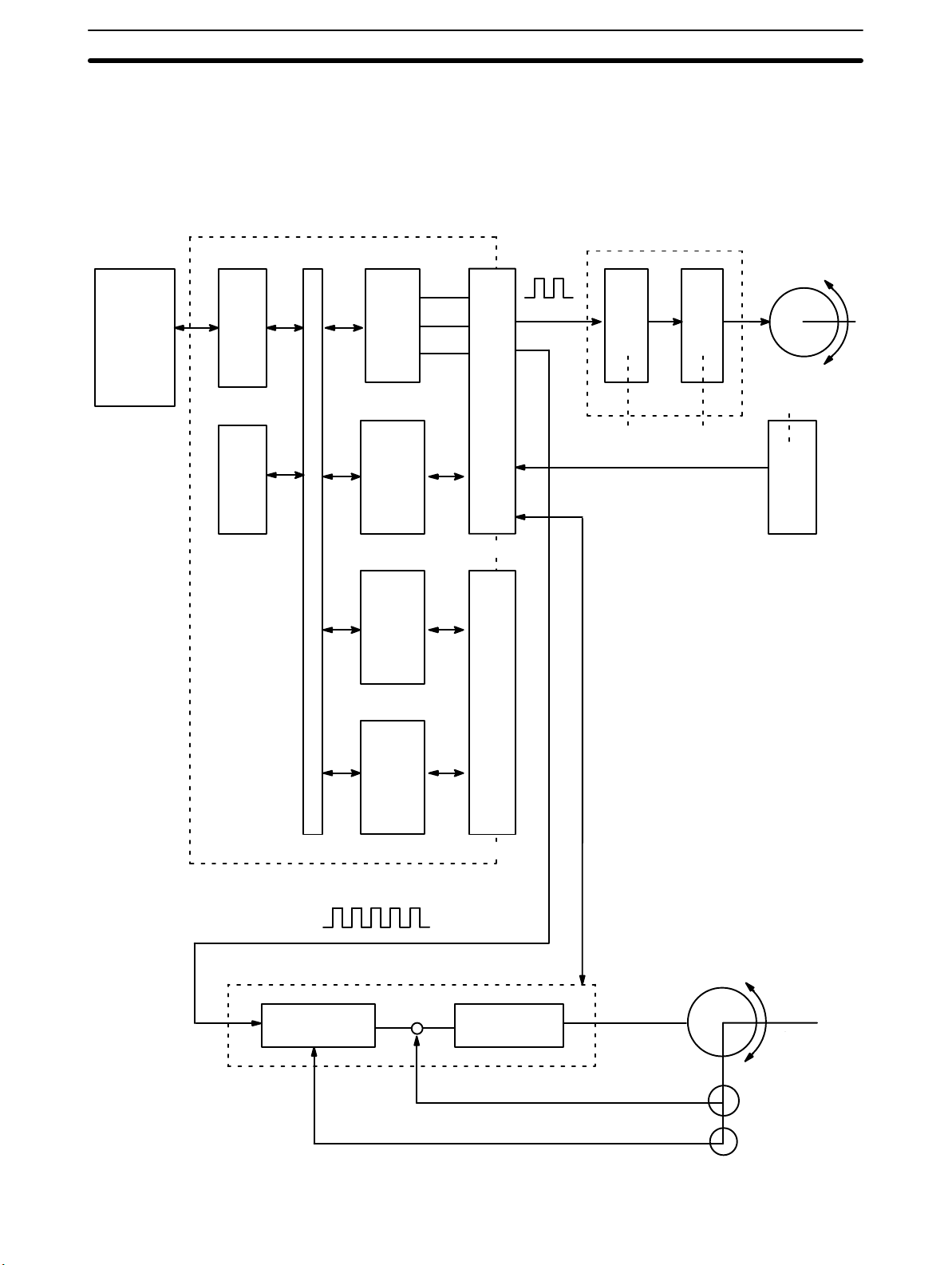

1-4 Control System Principles

1-4-1 Data Flow

C200HW-NC113/NC213/NC413 Position Control Unit

Pulse train

1-4SectionControl System Principles

Stepping motor driver

Stepping motor

SYSMAC

C200HX/HG

/HE

C200HS/Hseries PC

PC

BUS

MPU

I/F

Memory

Pulse

generator

I/O

interface

Pulse

generator

I/O connector

Magnetizing distribution circuit

External

input

Power

amplifier

I/O

interface

I/O connector

Note For the NC113, the circuitry is for just one axis.

Pulse train

Servomotor driver

Error counter Power amplifier

Servomotor

(Positioning output)

Tachogenerator

Rotary encoder

11

Page 25

1-4-2 Control System Principles

1-4SectionControl System Principles

Open-Loop System

In an open-loop system, positioning is controlled according to the number of

input pulses that the motor receives, and no position feedback is provided. The

C200HW-NC113/NC213/NC413 PCUs all employ pulse-output-type open-loop

systems, and the most commonly used motor for this type of control system is a

stepping motor. The angle of rotation of a stepping motor can be controlled

through the number of pulse signals supplied to the motor driver. The number of

rotations of the stepping motor is proportional to the number of pulses supplied

by the PCU, and the rotational speed of the stepping motor is proportional to the

frequency of the pulse train.

Angle of

rotation

1 2 n

Positioning pulses

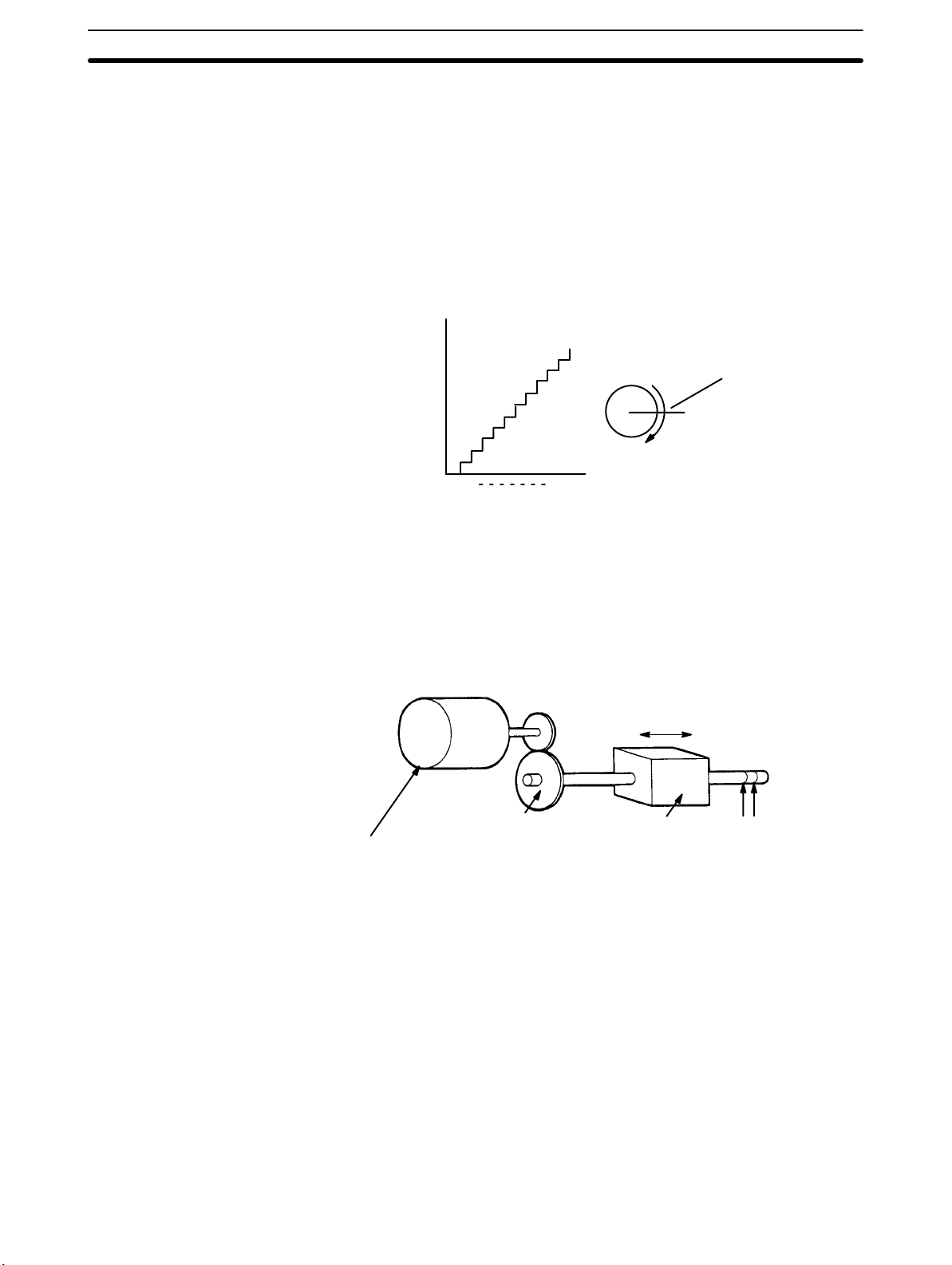

1-4-3 Basic Positioning System Design

The following diagram and parameters illustrate a simplified positioning system.

M : Reduction ratio

P : Feed screw pitch (mm/revolution)

V : Feed velocity of object being positioned (mm/s)

: Stepping angle per pulse (degree/pulse)

θ

s

Angle of rotation

Positioning output

N

Stepping motor

Reduction gear

M

Object being

positioned

V

Feed screw pitch

P

The positioning accuracy in mm/pulse is computed as follows:

Positioning accuracy = P/(pulses per revolution x M)

= P/((360/ θ

= (P x θ

) x M))

s

)/(360 x M)

s

The required pulse frequency from the PCU (pulses/second) is computed as follows:

Pulse frequency = V/Positioning accuracy

= (360 x M x V)/(P x θ

)

s

And the required number of pulses to feed an object by a distance L in mm is

computed as follows:

Number of pulses = L/Positioning accuracy

= (360 x M x L)/(P x θ

)

s

12

Page 26

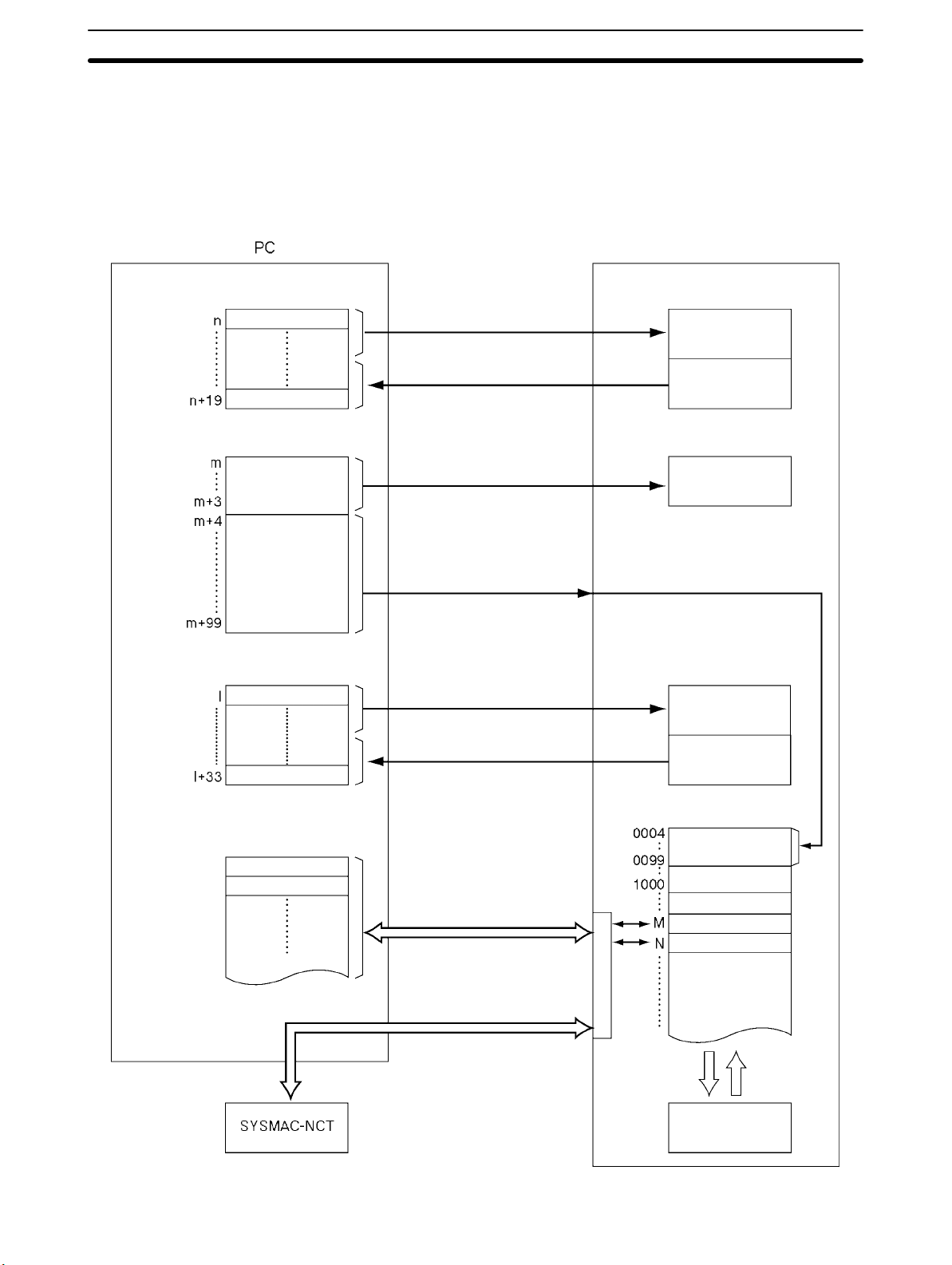

1-5 Exchanging Data

The Position Control Unit exchanges data with the Programmable Controller as

shown in the following diagram. This explanation is provided using the

C200HW-NC413 as an example. The size of the allocated areas differs with the

NC113 and NC213. For details regarding the data areas for the various PCUs,

refer to Section 4 Data Areas.

Operating Memory Area

IR area

Parameter area

I/O refresh

(Operation commands, data

transfer commands, etc.)

I/O refresh (PCU status)

1-5SectionExchanging Data

PCU

Command

interpretation

Status

DM area

DM or EM area

DM or EM area

Common

parameters

Axis parameters

Operating Data Area

Data transfer area

Address M data

Address N data

At power-up or restart

(Common parameters)

At power-up or restart

(Axis parameters)

I/O refresh

(Data transfer and operation

command information)

I/O refresh (PCU status)

When data transfer

commands are executed.

When IOWR or IORD is

executed.

Address

Common

parameters

Data transfer and

operation command

information

Status

Internal memory

Axis parameters

(Data for positioning)

When data is transferred

Saving

data

Power-up

or restart

Flash memory

13

Page 27

1-5-1 Explanation

1-5SectionExchanging Data

Note The axis parameter data stored in addresses 0004 to 0099 can be transferred

from words (m+4) through (m+99) of the DM area, and data can also be transferred for the data transfer area at the Programmable Controller. Moreover, data

can be saved to the flash memory.

The explanations provided here use the C200HW-NC413 PCU as an example.

With the NC213 and NC113, the sizes of the various areas differ depending on

the number of axes. For details, refer to Section 4 Data Areas.

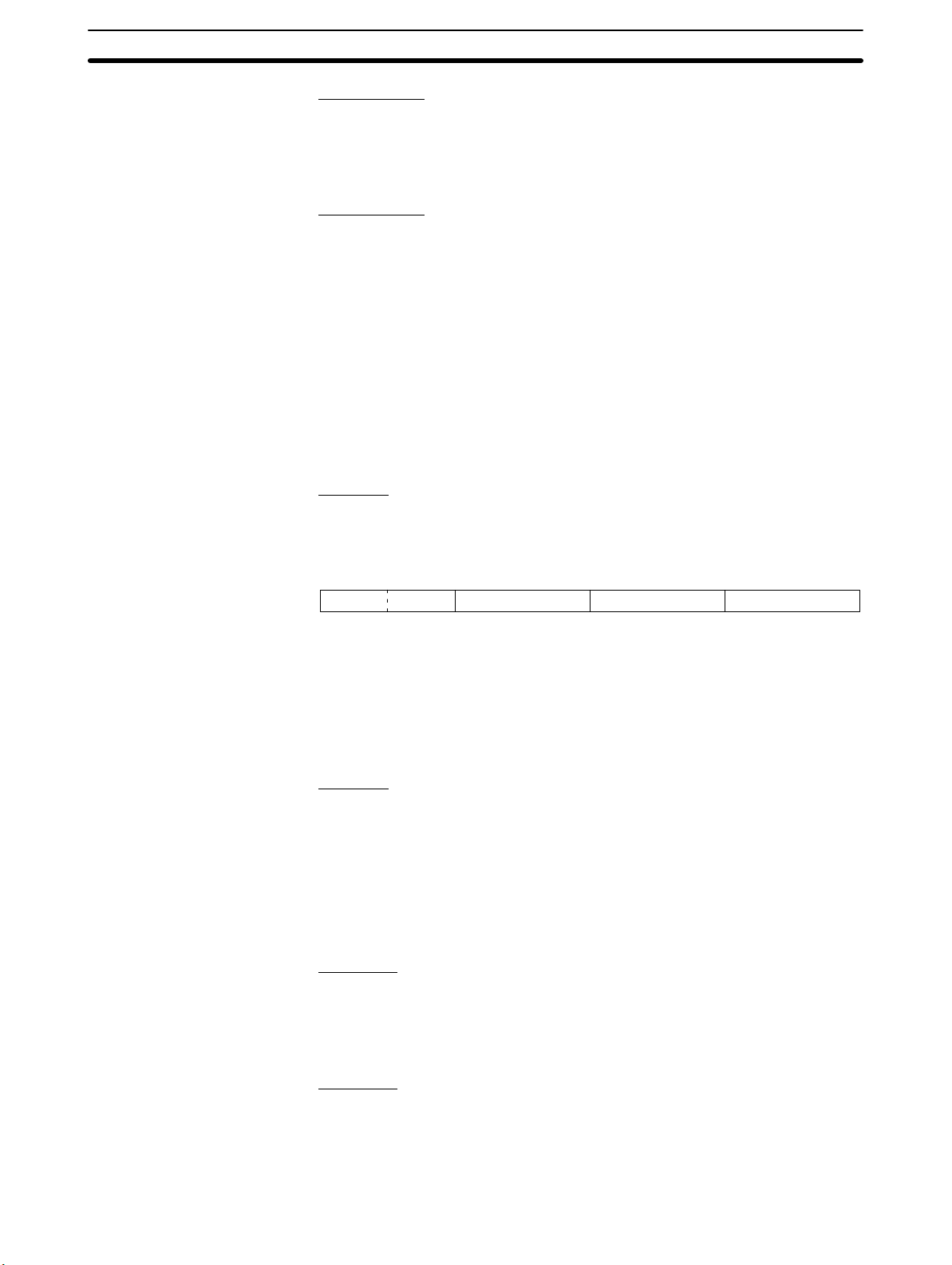

Operating Memory Area

(IR Area)

Parameter Area

(DM Area)

Operating Data Area

The PCU occupies 20 words of the Special I/O area within the Programmable

Controller’s IR area. Of these, eight words are used during I/O refreshing for outputting information related to instructions for operations such as transferring

data from the Programmable Controller to the PCU. The remaining 12 words are

used for inputting the PCU’s status during I/O refreshing.

The PCU occupies 100 words of the Special I/O Unit data area within the Programmable Controller’s DM area. When the PCU is powered up or restarted,

common parameters and axis parameters related to control are transferred to

the PCU. The axis parameters are stored in the PCU’s internal RAM by address.

It is also possible, when the PCU is powered up or restarted, to use axis parameters previously stored in the PCU’s internal flash memory, without having them

transferred from the Programmable Controller. The selection as to which of

these two methods to use is made by a common parameter setting. For details,

refer to 4-2 Common Parameter Area.

Note The common parameter area settings are required when the PCU is used. If

these settings are not made, a common parameter error (error codes 0010 to

0013) will be generated.

Depending on a common parameters setting, 34 words are reserved in the Programmable Controller’s data areas. Of these, 26 words are used during I/O

refreshing for outputting information related to data transfers from the Programmable Controller to the PCU, and information used for operations. The remaining eight words are used for inputting the PCU’s status during I/O refreshing.

Data Transfer Area

Internal Memory and

Flash Memory

14

When data is transferred according to the data transfer information set in the

operating data area, only the portion of data transferred is used. When the data

transfer instructions, Intelligent I/O Write (IOWR) and Intelligent I/O Read

(IORD), are executed, the positioning data is transferred to the PCU.

Data in internal memory can be saved to flash memory by executing a data save

instruction from the Programmable Controller. The saved data is automatically

written to the internal memory when the PCU is powered up or restarted. However, whether axis parameters are read from the parameter area (DM) or from

flash memory is determined by a common parameters setting.

Page 28

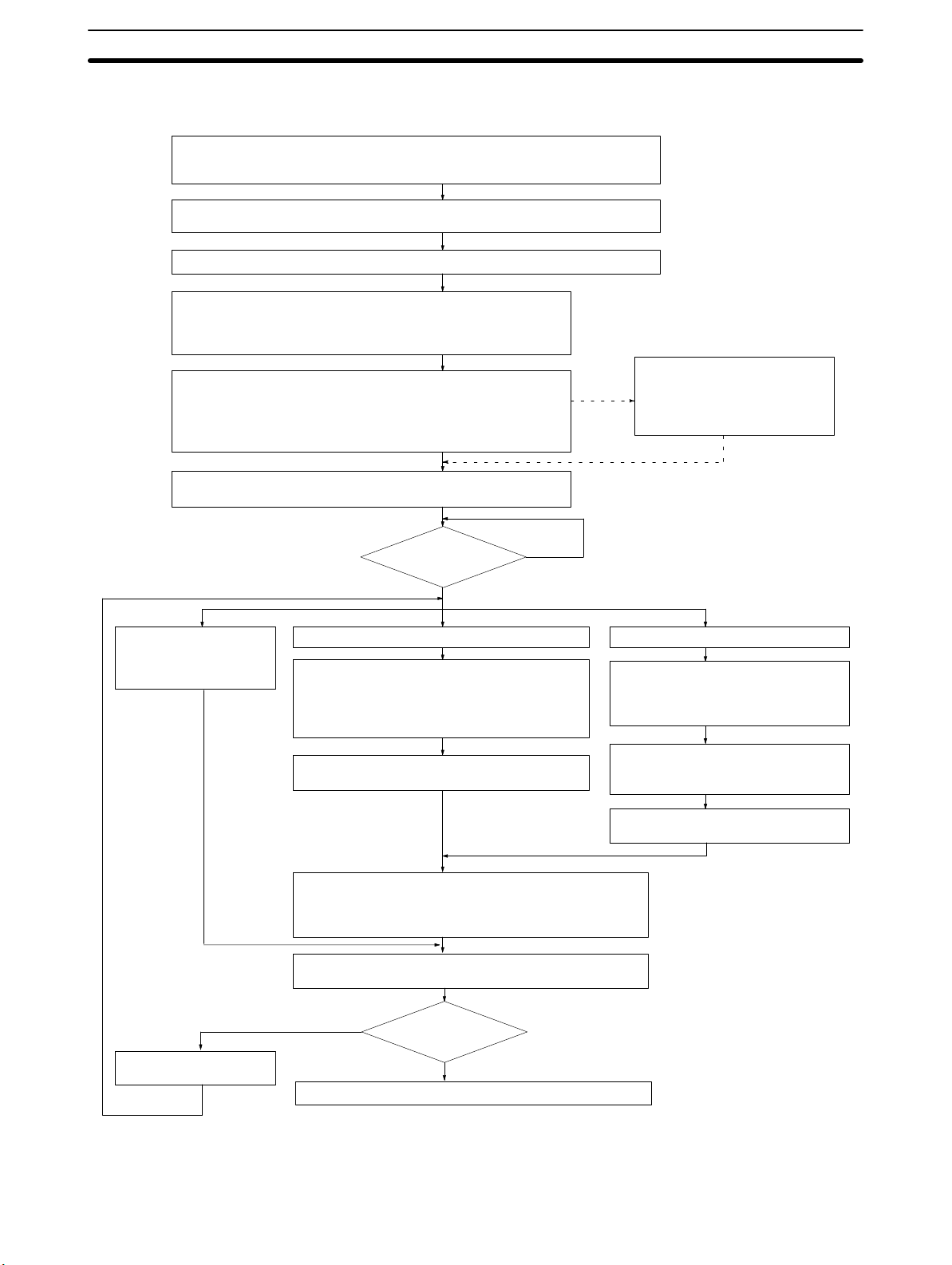

1-6 Before Operation

Wiring external inputs. (Refer to Section 2 Specifications and Wiring.)

Wire the origin input signal, origin proximity input signal, CW and CCW limit input

signals, emergency stop input signal, and interrupt input signal.

Wiring the motor and motor driver.

Wire the motor and motor driver as described in the installation manual.

Wiring the motor driver and PCU. (Refer to Section 2 Specifications and Wiring.)

Setting common parameters. (Refer to 4-2 Common Parameter

Area.) (See note 1.)

Set the operating data area, the mounting position, and the

parameters.

Setting axis parameters. (Refer to 4-3 Axis Parameter Area.) (See

note 2.)

Set the data required for PCU control, the I/O settings, the operation mode, the origin search method, the origin search speed, the

acceleration/deceleration curve, the CW and CCW limit signals, etc.

Re-powering or restarting the PCU. (See note 5.)

The common and axis parameter settings will go into effect.

1-6SectionBefore Operation

Saving axis parameters.

(Refer to 5-7 Saving Data.)

If setting axis parameters by

means of a data transfer, save

the settings to flash memory.

Interrupt feeding and

other operations.

(Refer to Section 9

Other Operations.)

Busy Flag

(See note 6.)

OFF

(When using direct operation.)

Setting the operating data area.

(Refer to 4-1 Overall Structure, 4-5 Operating

Data Area)

Set the positions, speeds, and acceleration/deceleration times

Creating the ladder program.

(Refer to Section 7 Direct Operation.)

Origin search. (Refer to Section 6 Defining the Origin.)

(See note 4.)

Executing direct operation, memory operation (Refer to

Section 7 Direct Operation, Section 8 Memory Operation.)

Trial operation, debugging. (Refer to Section 11 Trouble-

shooting.) (See note 5.)

ON

(When using memory operation.)

Transferring data. (Refer to Section 5

Transferring and Saving Data.)

Transfer to the PCU the data to be

used for memory operation.

Saving the data (Refer to 5-1 Transfer-

ring and Saving Data, 5-7 Saving

Data.) (See note 3.)

Creating the ladder program.

(Refer to Section 8 Memory Operation.)

Correcting the data and

the ladder program.

NG

Operation. (Refer to Section 11 Troubleshooting.)

Trial operation

(See note 5.)

OK

Note 1. These settings are required when first using the PCU, or when changing the

operating data area, the mounting position, or the parameter settings.

15

Page 29

1-6SectionBefore Operation

2. The user can select whether to use the axis parameters set in Data Memory

or the axis parameters saved at the PCU.

3. All saved data is automatically read to the PCU’s internal memory when the

PCU is powered up. If the common parameters are set so that data saved at

the PCU is used, then the axis parameters will be automatically read at power-up.

4. For operations that cannot be performed when the origin is not established,

it will be necessary to first execute an origin search or a present position

change to establish the origin.

5. For the operational flow when an error or alarm is generated, refer to Section

11 Troubleshooting.

6. When powering up or restarting the PCU, wait for the X-axis Busy Flag to

turn OFF before executing any commands.

16

Page 30

Specifications and Wiring

This section provides the Position Control Unit’s specifications and explains the wiring.

2-1 Specifications 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-1 General Specifications 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-2 Operations and Performance Specifications 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-3 I/O Electrical Specifications 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-4 Dimensions (Unit: mm) 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Components 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 External I/O Circuitry 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-1 Connector Pin Arrangement 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-2 External I/O Connector Arrangement 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-3 I/O Circuitry 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 Connecting External I/O 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4-1 Output Connection Examples 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4-2 Input Connection Examples 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4-3 Connecting Origin and Positioning Completed Input Signals 35. . . . . . . . . . . . . . . .

2-4-4 Wiring Precautions 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5 Connections in Each Operating Mode 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6 Connection of Unused Axes 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6-1 C200HW-NC213 – X Axis Only 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7 Servo Relay Unit 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

17

Page 31

2-1 Specifications

q

p

2-1-1 General Specifications

The general specifications conform to the specifications for the SYSMAC

C200H, C200HS, and C200HX/HG/HE.

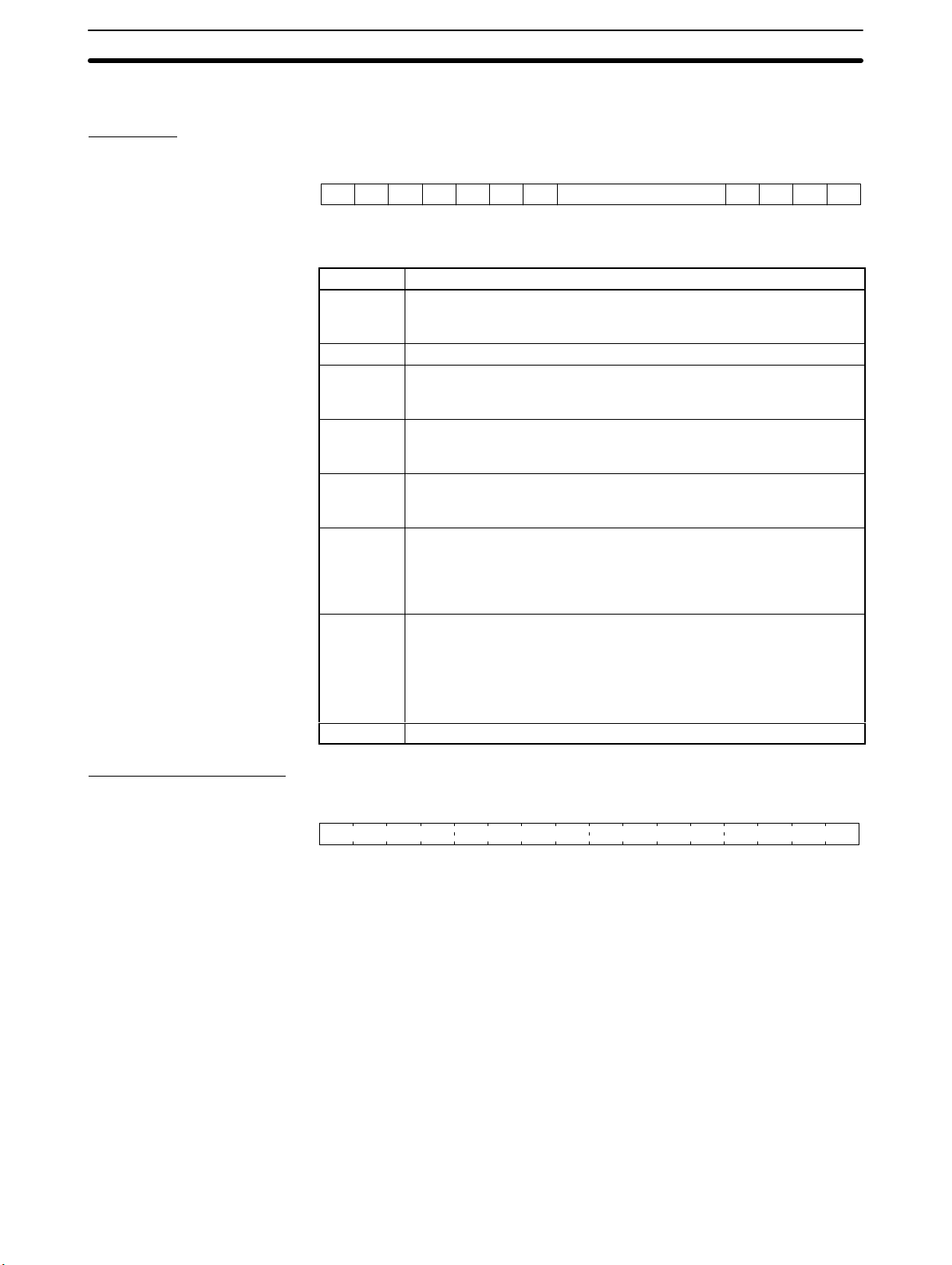

2-1-2 Operations and Performance Specifications

2-1SectionSpecifications

Item

C200HW-NC113 C200HW-NC213 C200HW-NC413

Applicable PC models C200HX/HG/HE-series and C200HS/H-series

I/O requirements

Controlled driver Pulse-train input-type servomotor driver or stepping motor driver

Control

Control unit Pulse

Positioning operations Two types: memory operation and direct operation

Positions

Speeds

Acceleration and

deceleration times

Functions and

settings

Words 5 words 10 words 20 words

Slots 1 slot

Control system Open-loop control by pulse train output

Number of control

axes

Independent 1 axis 2 independent axes 4 independent axes

Linear interpolation None 2 axes max. 4 axes max.

Speed control 1 axis 2 independent axes 4 independent axes

Interrupt feeding 1 axis 2 independent axes 4 independent axes

Range –9,999,999 to 9,999,999 pulses

Data items 100/axis

Range 1 pps to 500 Kpps

Data items 100/axis

Range 0 to 250 s, until maximum speed is reached.

Data items 9/axis for acceleration and deceleration each

Origin search Origin proximity input signal: selectable (absent, N.O. or N.C. contact).

Jogging Jogging can be executed at a specified speed.

Dwell times 19/axis can be set from 0 to 9.99 s (unit: 0.01 s).

Acceleration/

deceleration curves

Zones Zone Flag turns ON when present position is within a specified zone.

Software limit Can be set within a range of –9,999,999 to 9,999,999 pulses.

Backlash

compensation

Teaching With a command from the PC, the present position can be taken as the

Deceleration stop The STOP command causes positioning to decelerate to a stop

Emergency stop Pulse outputs are stopped by an external emergency stop command.

1 axis 2 axes 4 axes

Origin input signal: selectable (N.O. or N.C. contact)

Origin compensation: –9,999,999 to 9,999,999 pulses

Origin search speed: High-speed or proximity-speed can be set.

Origin search method: May be set to stop upon origin input signal after

proximity input signal has turned ON, to stop upon origin input signal

after proximity input signal has turned OFF, to stop upon origin input

signal without using proximity input signal, or to stop upon origin input

signal after limit input signal has turned OFF.

N.O. = Normally open

N.C. = Normally closed

Trapezoidal or S-curve (Can be set separately for each axis.)

Three zones can be set for each axis.

0 to 9,999 pulses. Compensation speed can also be set.

position data.

according to the specified deceleration time.

Model

18

Page 32

Item ModelItem

se gs

s ope co ec o

spec ca o s

0sa

sede

s g a co espo d g o

0sa

C200HW-NC413C200HW-NC213C200HW-NC113

Functions and

settings

External I/O

Pulse output distribution period 4 ms

Response time Refer to Appendix A Data Calculation Standards.

Self-diagnostic function Flash memory check, memory loss check, I/O bus check

Error detection function Overtravel, CPU error, software limit over, emergency stop

Internal current consumption (provided from

Backplane)

Dimensions (one size) 130 (H) x 34.5 (W) x 100.5 (D)

Weight (excluding connectors) 250 g max. 300 g max. 350 g max.

Present position

change

Override When the override enabling command is executed during positioning,

Data saving 1) Saving to flash memory. (Can be written 100,000 times.)

Inputs Prepare the following inputs for each axis:

Outputs Prepare the following outputs for each axis:

The PRESENT POSITION CHANGE command can be used to change

the present position to a specified value.

the target speed is changed by applying the override coefficient.

Possible to set to a value from 1 to 999% (by an increment of 1%)

2) Reading to PC area by data reading instruction.

3) Reading by SYSMAC-NCT Support Tool and saving to personal

computer hard disk or floppy disk.

CW and CCW limit input signals, origin proximity input signal, origin

input signal, emergency stop input signal, positioning completed signal,

interrupt input signal

Pulse outputs (open collector outputs)

CW/CCW pulses, pulse outputs and direction outputs can be switched.

Either error counter reset or origin-adjustment command outputs can

be selected depending on the mode.

5 VDC at 300 mA

max.

5 VDC at 300 mA

max.

5 VDC at 500 mA

max.

2-1SectionSpecifications

2-1-3 I/O Electrical Specifications

Input Specifications

Voltage 24 VDC ±10%

Current 4.3 mA (at 24 V) typ.

ON voltage 17.4 VDC min.

OFF voltage 5.0 VDC max.

ON response time 1 ms max. (0.1 ms max.: Interrupt input)

OFF response time 1 ms max.

Origin-signal Input

Specifications

Item Connection

External signal

is open-collector

signal

External signal

is line-driver

signal

Item Specification

Specification Response

Terminal

X/Z Axis A15

A14

Y/U Axis B15

B14

X/Z Axis A16

A14

Y/U Axis B16

B14

Conform to above input

specifications

Signal is a line-driver output

signal corresponding to

Am26LS31

Time

N.O. contact:

0.1 ms max.

N.C. contact:

1 ms max.

N.O. contact:

0.1 ms max.

N.C. contact:

1 ms max.

19

Page 33

2-1SectionSpecifications

Output Specifications

CW/CCW Pulse Output

Specifications

Maximum switching

capacity

Minimum switching

capacity

Leakage current 0.1 mA max.

Residual voltage 0.6 V max.

External power supply 24 VDC ±10% NC413: 90 mA max.

The minimum CW/CCW pulse widths are shown below.

The OFF and ON refer to the output transistor.

Item Specification

30 mA at 4.75 to 26.4 VDC (NPN open collector)

(16 mA: Terminals with 1.6-kΩ limit resistance)

7 mA at 4.75 to 26.4 VDC (NPN open collector)

NC213: 50 mA max.

NC113: 30 mA max.

The output transistor is ON at level “L.”

B

OFF

90%

10%

ON

A

Pulse

frequency

50 Kpps 9.7 µs min. 9.7 µs min. 9.8 µs min. 9.8 µs min. 9.7 µs min. 9.7 µs min. 9.7 µs min. 9.7 µs min.

100 Kpps 4.7 µs min. 4.7 µs min. 4.8 µs min. 4.8 µs min. 4.7 µs min. 4.7 µs min. 4.8 µs min. 4.8 µs min.

200 Kpps 2.3 µs min. 2.3 µs min. 2.3 µs min. 2.3 µs min. 2.2 µs min. 2.2 µs min. 2.3 µs min. 2.3 µs min.

500 Kpps 0.76 µs

7 mA/5 VDC±5% 30 mA/5 VDC±5% 7 mA/24 VDC±10%

A B A B A B A B

0.82 µs

min.

min.

Open or close current / Loaded power-source voltage

(1.6-kΩ resistance)

0.77 µs

min.

0.88 µs

min.

0.74 µs

min.

0.72 µs

min.

16 mA/24 VDC±10%

(1.6-kΩ resistance)

0.76 µs

min.

0.85 µs

min.

Note 1. The load in the above table is the net resistance load, and the connecting

cable impedance with the load is not considered.

2. Due to distortions in pulse waveforms as a result of connecting cable impedance, pulse widths during actual usage may be smaller than those shown in

the above table.

2-1-4 Dimensions (Unit: mm)

Mounted Dimensions

Backplane

Cable

Approx. 230

20

Page 34

2-2 Components

Nomenclature

C200HW-NC413 C200HW-NC213 C200HW-NC113

2-2SectionComponents

LED indicators

Show the PCU’s

operating status.

X/Y axis connector

Connects stepping

motor driver or

servomotor driver.

(2-axis control)

Unit number setting switch

Sets the unit number for the

PCU.

Z/U axis connector

Connects stepping motor

driver or servomotor

driver. (2-axis control)

X, Y axis

connector

X axis

connector

21

Page 35

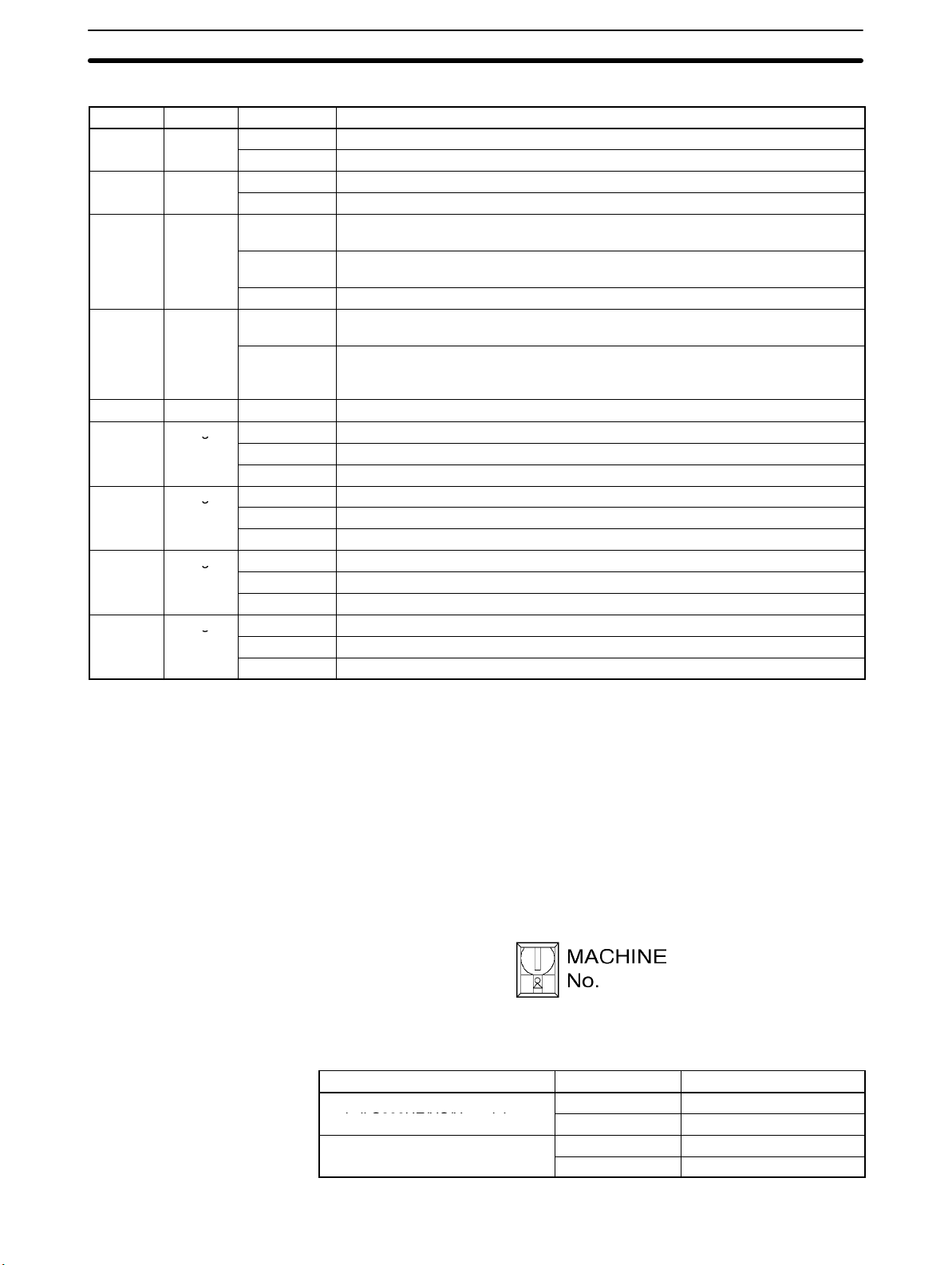

LED Indicators

g

g

g

g

j j

j j

Name Color Status Explanation

RUN Green

ERR Red

SENS Red

DATA Red

DATA Red Not lit None of the above has occurred.

X Orange

Y Orange

Z Orange

U Orange

Lit Lit during normal operation.

Not lit Hardware error, or PC notified of PCU error.

Lit / flashing An error has occurred.

Not lit No error has occurred.

Lit Either a CW/CCW limit signal or an emergency stop input signal is being input. At

this time the LED indicator for the relevant axis (X to U) will flash.

Flashing Either a parameter loss, a data loss, or an operating data area designation error

has occurred.

Not lit None of the above has occurred.

Flashing The check of all data (parameters, positions, etc.) following power up shows that

data is lost or corrupted.

Lit Data is incorrect (e.g., the parameters or positions transferred are out of the

permissible range). At this time the LED indicator for the relevant axis (X to U)

will flash.

Lit Pulses are being output to the X axis (either forward or reverse).

Flashing An error has occurred, such as incorrect cable type for the X axis or faulty data.

Not lit None of the above has occurred.

Lit Pulses are being output to the Y axis (either forward or reverse).

Flashing An error has occurred, such as incorrect cable type for the Y axis or faulty data.

Not lit None of the above has occurred.

Lit Pulses are being output to the Z axis (either forward or reverse).

Flashing An error has occurred, such as incorrect cable type for the Z axis or faulty data.

Not lit None of the above has occurred.

Lit Pulses are being output to the U axis (either forward or reverse).

Flashing An error has occurred, such as incorrect cable type for the U axis or faulty data.

Not lit None of the above has occurred.

2-2SectionComponents

Unit Number Setting

Switch

Note For details regarding errors, refer to Section 11 Troubleshooting.

• For the C200HW-NC213, this applies only to the X axis; for the C200HW-

NC213, it applies only to the X and Y axes.

• When not all of the axes are used for the C200HW-NC213 or C200HW-

NC413, either connect the CW/CCW limit inputs for the unused axes to the

input power supply and turn them ON or set the contact logic to N.O. Connect

the emergency stop to the input common and turn it ON. If it is not connected,

the ERR indicator will light. Operation will be normal, however, for all axes that

are used.

This switch sets the unit number (i.e., the machine number) for the PCU.

The permissible range of unit number settings depends on the type of Programmable Controller and the PCU model, as shown in the following table.

PC type PCU model Setting range

C200HX/HG-CPU3j/4j

and all C200HE/HS/H models

C200HX/HG-CPU5j/6j

NC113/NC213 0 to 9

NC413 0 to 8

NC113/NC213 0 to 9, A to F

NC413 0 to 8, A to E

22

Page 36

Any unit number within the permissible range can be set, as long as it does not

overlap with the unit numbers that are set for any other Special I/O Units

mounted to the same Programmable Controller.

Caution Be sure to turn off the power supply before making the settings.

!

The IR and DM areas are allocated according to the unit numbers that are set.

For details regarding allocated word addresses, refer to the memory area

allocation tables in Section 4 Data Areas.

2-2SectionComponents

23

Page 37

2-3 External I/O Circuitry

2-3-1 Connector Pin Arrangement

X/Y axis X/Y axis X axisZ/U axis

C20HW-NC413 C20HW-NC213 C20HW-NC113

2-3SectionExternal I/O Circuitry

Connector pin arrangement for X and Z axes Connector pin arrangement for Y and U axes

Pin

No.

A1 IN Output power supply, 24 VDC B1 IN Output power supply, 24 VDC

A2 IN Output GND, 24 VDC B2 IN Output GND, 24 VDC

A3 --- Not used B3 --- Not used.

A4 --- Not used B4 --- Not used.

A5 OUT CW pulse output B5 OUT CW pulse output

A6 OUT CW pulse/pulse output with 1.6 kΩ

A7 OUT CCW pulse/direction output B7 OUT CCW pulse/direction output

A8 OUT CCW pulse/direction output with 1.6 kΩ

A9 --- Not used B9 --- Not used.

A10 OUT Error counter reset output Origin-adjustment

A11 OUT Error counter reset output with 1.6 kΩ

A12 IN Positioning completed input signal B12 IN Positioning completed input signal

A13 --- Not used B13 --- Not used.

A14 IN Origin common B14 IN Origin common

A15 IN Origin input signal (24 V) B15 IN Origin input signal (24 V)

A16 IN Origin input signal (5 V) B16 IN Origin input signal (5 V)

A17 --- Not used B17 --- Not used.

A18 --- Not used B18 --- Not used.

A19 IN Interrupt input signal B19 IN Interrupt input signal

A20 IN Emergency stop input signal B20 IN Emergency stop input signal

A21 IN Origin proximity input signal B21 IN Origin proximity input signal

A22 IN CW limit input signal B22 IN CW limit input signal

A23 IN CCW limit input signal B23 IN CCW limit input signal

A24 IN Input common B24 IN Input common

I/O Designation Pin

No.

B6 OUT CW pulse/pulse output with 1.6 kΩ

resistance

B8 OUT CCW pulse/direction output with 1.6 kΩ

resistance

B10 OUT Error counter reset output Origin-adjustment

command output

B11 OUT Error counter reset output with 1.6 kΩ

resistance

Origin-adjustment command output with

1.6KΩ resistance

I/O Designation

resistance

resistance

command output

resistance

Origin-adjustment command output with

1.6KΩ resistance

24

Page 38

Note 1. Use either the 24-V origin input signal or the 5-V origin input signal, but not

both.

2. Use 24 ±10% VDC as the pulse output power supply.

3. The leakage current must be less than 1.0 mA when two-wire-type sensors

are used.

4. Be sure to connect a load to the output terminals. If the load is short-circuited, it will damage the PCU’s internal components.

5. The 24-V output power supply (A1/B1) for all axes and the 24-V output

ground (A2, B2) are connected in the PCU, and are shared by all axes.

6. When installing connectors to the PCU, tighten the connector screws to a

torque of 0.34 N S m.

• The commons for all outputs are connected to the 24-V output ground.

• The commons for all inputs except for the 24-V and 5-V origin input signals and

positioning completed input signals are connected to the input common.

• The positioning completed input signal common is connected to the 24-V out-

put power supply through a diode.

• The origin common is used with either the 24-V or the 5-V origin input signal.

2-3-2 External I/O Connector Arrangement

2-3SectionExternal I/O Circuitry

Wiring Power Lines

Connector Pin Numbers

• The connectors that are included with this Unit are solder-type connectors.

• Use wires with cross-sectional areas of 0.2 mm

2

or less.

• Be careful not to short-circuit neighboring terminals when soldering.

• Cover the soldered part of the wire with insulation tubing.

Insulator

Lead

Connector

Outline of connector

(rear panel)

Pin number marks

(View from soldered side)

25

Page 39

Assembling Connectors Supplied with the Unit

)

M2x8 pan-head screws (two)

Connector

The following connectors (Fujitsu 360 Jack) can be used:

1, 2, 3... 1. FCN-361J048-AU (solder-type)

FCN-360C048-D (connector cover)

2. FCN-363J048 (crimp-type housing)

FCN-363J-AU/S (contact)

FCN-360C048-D (connector cover)

3. FCN-367J048-AU (crimp-type)

2-3SectionExternal I/O Circuitry

M2 nut (four)

M2x6 pan-head screws (two

Cable holder (two)

Case

Screw (two)

Cover Dimensions

Cable holder

26

Page 40

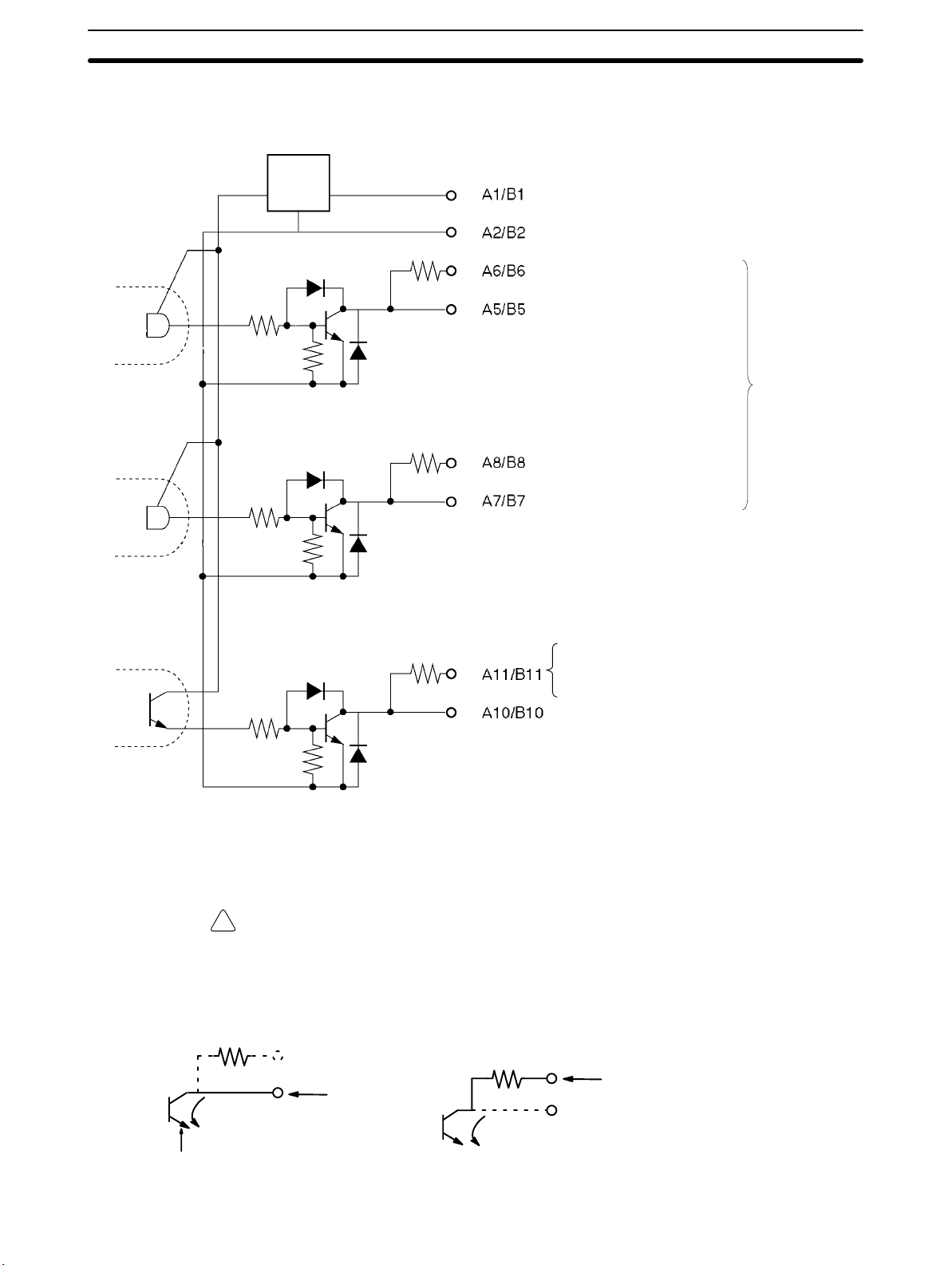

2-3-3 I/O Circuitry

Outputs

Constant

voltage

circuit

2-3SectionExternal I/O Circuitry

Output power supply, 24 VDC

1.6 kΩ (1/2W)

1.6 kΩ (1/2W)

1.6 kΩ (1/2W)

Output GND, 24 VDC

CW pulse/pulse output

(with 1.6 kΩ resistance)

CW pulse output

See

note.

CCW pulse/direction output

(with 1.6 kΩ resistance)

CCW pulse/direction output

Note Output switching depends on the

axis parameter settings. (Refer to

4-3 Axis Parameters Area.)

Error counter reset output (with 1.6 kΩ

resistance)

Origin-adjustment command output (with

1.6 kΩ resistance)

Error counter reset output

Origin-adjustment command output

Output Circuitry

Open collector output

Output transistor

The pulse output and error counter reset circuitry of the Position Control Unit are

provided with two types of terminals: terminals with 1.6 kΩ (1/2 W) limit resistance and terminals with no resistance. Select the terminals in accordance with

the power requirements and the specifications of the motor driver to be used.

Caution Connect a load of 7 to 30 mA (or 7 to 16 mA for terminals with 1.6 kΩ limit resis-

!

tance) to the output section. If a current greater than this is used, it will cause

damage to the PCU’s internal components. Also, be sure to use the CW/CCW

output method when using pulse output terminals with limit resistance.

Open collector output with 1.6 k

Output

7 to 30 mA

7 to 13 mA

Ω series resistance

Output

27

Page 41

(Circuit example)

PCU

2-3SectionExternal I/O Circuitry

Add bypass resistance for loads less than 7 mA.

24 VDC

power

supply

Driver

7 mA

1 mA

Bypass resistance

6 mA

28

Page 42

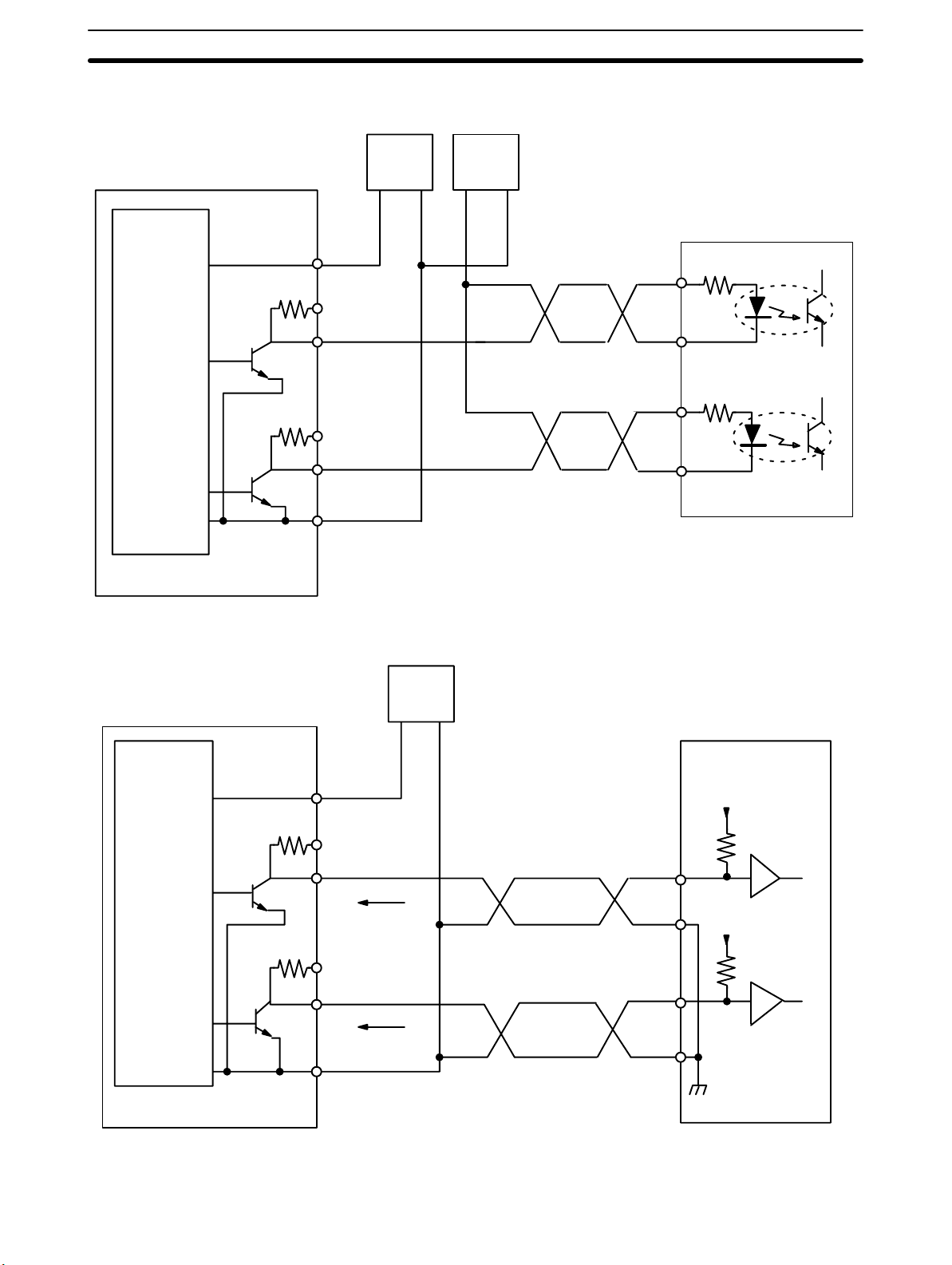

Inputs

680 Ω

680 Ω 4.7 kΩ (1/2W)

680 Ω 4.7 kΩ (1/2W)

680 Ω 4.7 kΩ (1/2W)

4.7 kΩ (1/2W)

2-3SectionExternal I/O Circuitry

Output power supply, 24 VDC

Positioning completed input signal

Input common

External interrupt input (N.O. contact)

Emergency stop (N.C. contact)

(see note)

Origin proximity input

(N.O./N.C. contact) (see

note)

680 Ω 4.7 kΩ (1/2W)

CW limit input (N.O./N.C.

contact) (see note)

680 Ω

680 Ω

4.7 kΩ (1/2W)

4.7 kΩ (1/2W)

150 Ω

CCW limit input (N.O./N.C.

contact) (see note)

Origin input signal (24 V)

(N.O./N.C. contact) (see note)

Origin input signal

(N.O./N.C. contact) (see

note)

Origin common

Line driver output

Note Either N.C. or N.O. can be set by the axis parameters. (Refer to 4-3 Axis Param-

eters Area.)

Connect a switch with a switching capacity of at least 5 mA to the 24-V origin

input signal terminal.

The origin input signal’s operating modes are used as follows:

Mode 0: Response time: 0.1 ms (N.O. contact setting)

Use a sensor such as a photoelectric switch with no chattering.

Modes 1/2: Response time: 0.1 ms (N.O. contact setting)

Use when connecting the encoder’s Z-phase output (line driver

output).

Caution Use either the 24-VDC origin input signal or the 5-VDC origin input signal, but not

!

both. If both are connected it will damage the internal circuitry.

Do not connect the 5-VDC origin input signal input to any output circuit except

the line driver.

29

Page 43

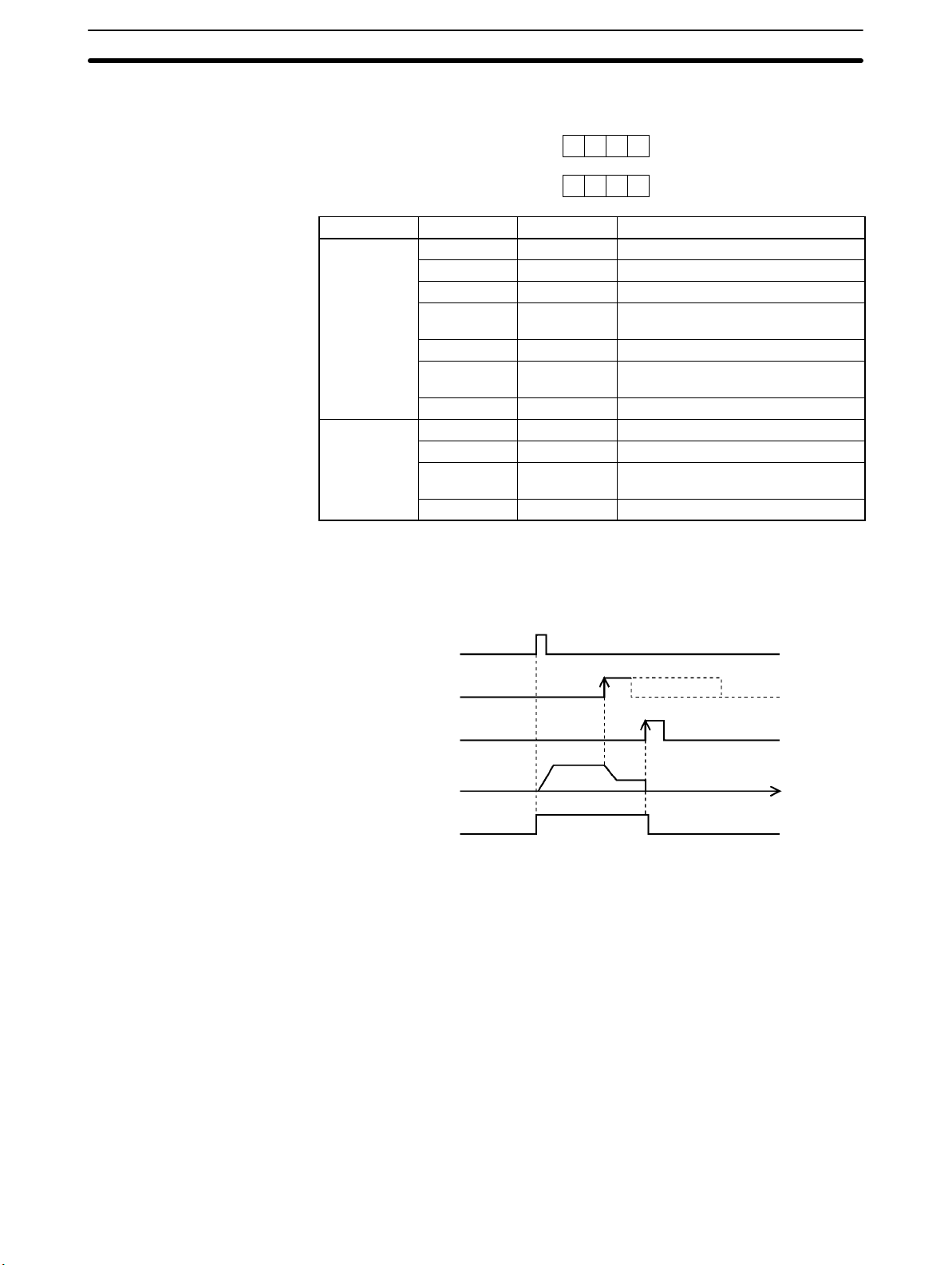

2-4 Connecting External I/O

This section provides motor driver connection examples. When actually connecting a motor driver, be sure to first check the specifications of the motor driver

to be used.

2-4-1 Output Connection Examples

Pulses are not output when the output transistor in the pulse output section is

OFF. (For direction output, OFF indicates CCW.)

Do not use a 24-VDC power supply for pulse output in common with the power

supply for other I/O.

Output transistor

CW/CCW Pulse Outputs

CW

2-4SectionConnecting External I/O

ON

OFF

During pulse output

CW CCW

CCW

Pulse and Direction Outputs

Pulses

Direction

CW CCW

Output transistor ON

Output transistor OFF

30

Page 44

2-4SectionConnecting External I/O

Outputting CW and CCW

Pulses

Position Control Unit

24-VDC

input

CW pulse

output

CCW pulse

output

1.6 kΩ

1.6 kΩ