Page 1

NB-Designer

OPERATION MANUAL

Cat. No. V106-E1-11

Programmable Terminals

NB3Q-TWB

NB5Q-TWB

NB7W-TWB

NB10W-TW01B

NB-series

Page 2

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written

permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of the information contained in this publication.

© OMRON, 2011

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan and other

countries for OMRON factory automation products.

• Windows, Windows 98, Windows XP, Windows Vista, Windows 7, Windows 8, and Excel are registered

trademarks of Microsoft Corporation in the USA and other countries.

• EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

• ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

• The SD and SDHC logos are trademarks of SD-3C, LLC.

Other company names and product names in this document are the trademarks or registered trademarks of their

respective companies.

Trademarks

Page 3

NB-series

NB3Q-TWB

NB5Q-TWB

NB7W-TWB

NB10W-TW01B

Programmable Terminals

NB-Designer Operation Manual

Revised July 2014

Page 4

Page 5

1

Introduction

NB-series Programmable Terminals NB-Designer Operation Manual(V106)

Introduction

Thank you for purchasing an NB-series Programmable Terminal.

NB-Series Programmable Terminals (PTs) are designed to handle information generated in FA production

sites. Be sure to understand the functions and performances etc thoroughly before using PT correctly.

This manual is intended for the following personnel, who must also have knowledge of electrical

systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems into production facilities.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and connecting FA facilities.

• Personnel in charge of managing FA systems and facilities

• The user must operate the product according to the perfo rmance specifications described in the

operation manuals.

• Do not use the PT touch switch input functions for applications where danger to human lif e or serious

property damage is possible, or for emergency switch applications.

• Before using the product under conditions which are not described in the manual or applying the

product to nuclear control systems, railroad systems, aviation systems, vehicles, combustion

systems, medical equipment, amusement machines, safety equipment, and other systems,

machines and equipment that may have a serious influence o n lives and pr operty if used impro perly,

consult your OMRON representative.

• Make sure that the ratings and performance characteristics of the product are sufficient for the

systems, machines, and equipment, and be sure to provide the systems, machines, and equipment

with double safety mechanisms.

• This manual provides information for connecting and setting up an NB-Series PT. Be sure to read

this manual before attempting to use the PT and k eep this manual clos e at ha nd for refer ence du ring

installation and operation.

Intended Audience

General Precautions

Page 6

NB-series Manuals

2

NB-series Programmable Terminals NB-Designer Operation Manual(V106)

NB-series Manuals

NB-series manuals are organized in the sections listed in the following tables. Refer to the appropriate

section in the manuals as required.

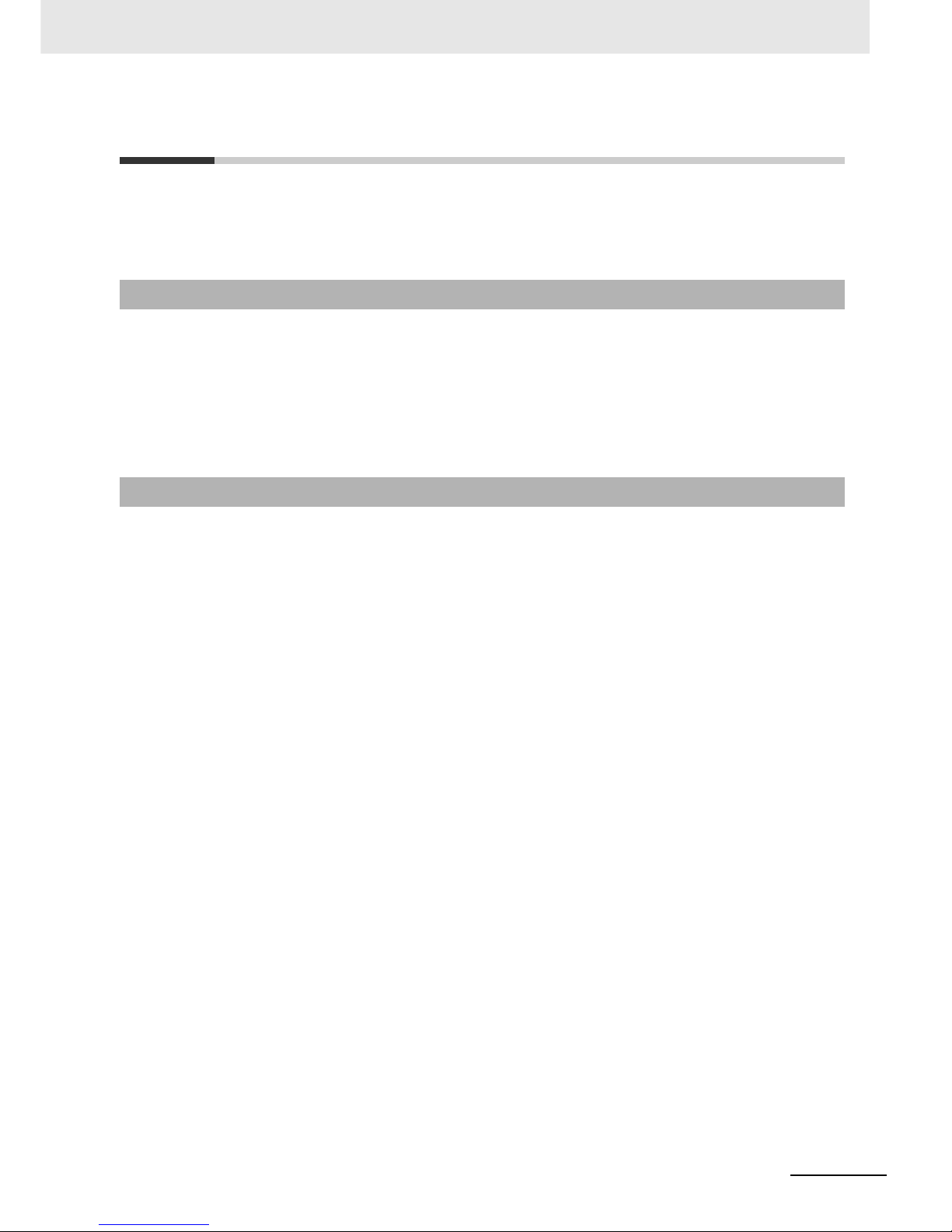

Programmable Terminals NB-Designer Operation Manual

(Cat. No. V106) (This manual)

Section Contents

Section 1 Introduction This section provides an outline of the NB-series PTs, including their

functions, features, connection types and communication methods.

Section 2 Installation and Startup of

NB-Designer

This section describes how to install and start the NB-Designer.

Section 3 Functions of NB-Designer This section describes the functions of NB-Designe r.

Section 4 Functions of NBManager This section describes the functions of NBManager.

Section 5 Maintenance and

Abnormality Handling

This section describes the maintenance and check to prevent the

abnormality occurrence and the handling of the abnormalities occurred

in NB Unit.

Section 6 Descriptions of New

Functions Added into NBTW01B

This section describes the new functions added into NB-TW01B,

the system Properties and the component Properties.

Section 7 PictBridge Function This section describes the PictBridge printing function.

Appendices The appendices provide lists of the NB Units, the Communication Units,

the applicable PLCs, the memories sapported by PLC, and the list of

NB-Designer functions.

Programmable Terminals Setup Manual (Cat. No. V107)

Section Contents

Section 1 Part Names and Functions This section describes the names and functions of the various parts of

an NB Unit.

Section 2 Installing the NB Unit and

Connecting Peripheral Devices

This section describes the methods used to install the NB Unit and

connect peripheral devices.

Section 3 System Setting Mode This section describes the System Setting Mode.

Section 4 Calibrate Mode This section describes the Calibrate Mode.

Appendices The appendices provide information on specifications, dimensions,

wirings, and lists of the NB Units, the applicable PLCs and options.

Page 7

3

NB-series Manuals

NB-series Programmable Terminals NB-Designer Operation Manual(V106)

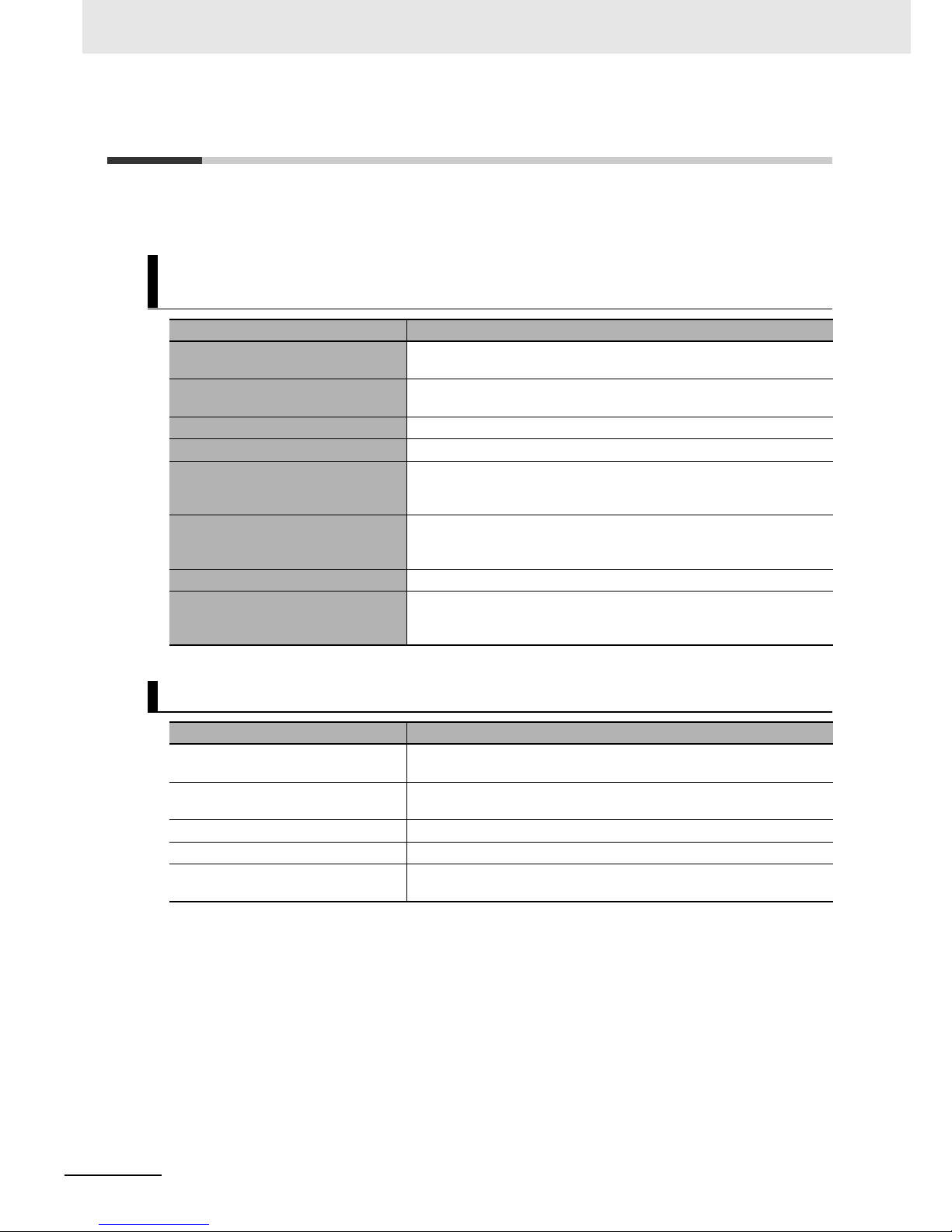

Programmable Terminals Host Connection Manual (Cat. No. V108)

Section Contents

Section 1 List for All PLCs

Supported by NB series

This section lists all PLCs supported by NB Units.

Section 2 Connecting to SIEMENS

PLCs

This section describes the connection to SIEMENS PLCs.

Section 3 Connecting to Mitsubishi

PLCs

This section describes the connection to Mitsubishi PLCs.

Section 4 Connecting to Schneider

PLCs

This section describes the connection to Schneider PLCs.

Section 5 Modbus Connection This section describes the connection on Modbus protocol.

Section 6 Connecting to Delta PLCs This section describes the connection to Delta PLCs.

Section 7 Connecting to LG PLCs This section describes the connection to LG PLCs.

Section 8 Connecting to Panasonic

PLCs

This section describes the connection to Panasonic PLCs.

Section 9 Connecting to AllenBradley (Rockwell) PLC

This section describes the connection to Allen-Bradley PLC.

Section 10 Connecting to PLC of GE

Fanuc Automation Inc.

This section describes the connection to PLC of GE Fanuc Automation

Inc.

Programmable Terminals Startup Guide Manual (Cat. No. V109)

Section Contents

Section 1 NB Overview This section provide specifications of the NB Unit, describes its names

and functions of the various parts.

Section 2 System Design This section describes the manual structure, takes NB7W as an

example to introduce the operation procedures of the NB system.

Section 3 Installation and Wiring This section describes how to install and wire the NB Unit.

Section 4 Screen Creation This section describes how to create a demonstration project through

NB-Designer.

Section 5 Run This section describes how to start running at the Host side and

prepare to send screen data to NB7W.

Section 6 Maintenance and

T roubleshooting

This section describes the maintenance and inspection methods for

preventing errors occurring, and troubleshooting measures when errors

occur.

WARNING

Failure to read and understand the information

provided in this manual may result in personal injury

or death, damage to the product, or product failure.

Please read each section in its entirety and be sure

you understand the information provided in the

section and related sections before attempting any

of the procedures or operations given.

Page 8

Manual Structure

4

NB-series Programmable Terminals NB-Designer Operation Manual(V106)

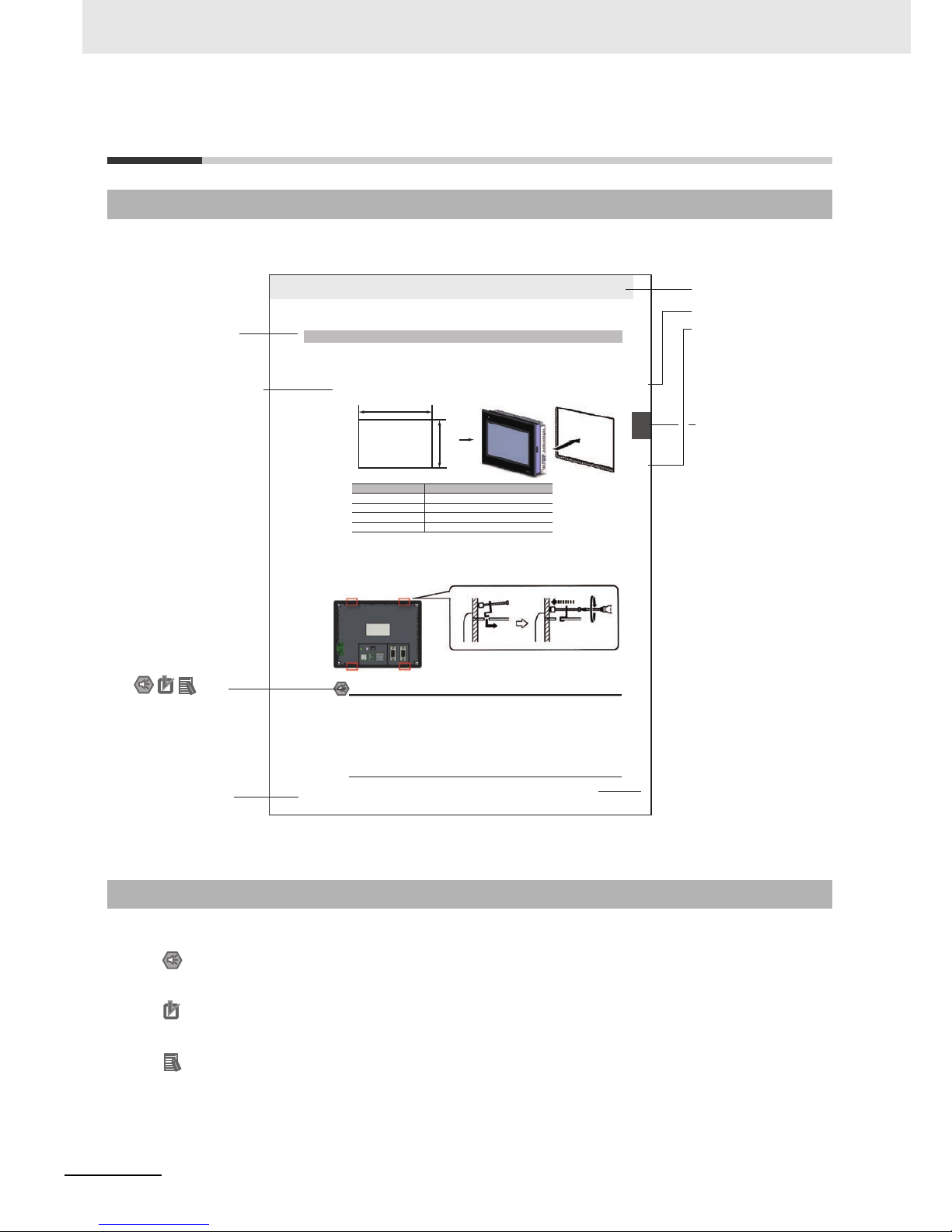

Manual Structure

The following page structure and icons are used in this manual.

Special information in this manual is classified as follows:

Page Structure and Icons

Special Information

2-3

2 Installing the NB Unit and Connecting Peripheral Devices

NB-series Programmable Terminals Setup Manual(V107)

2-1 Installing the NB Unit

2

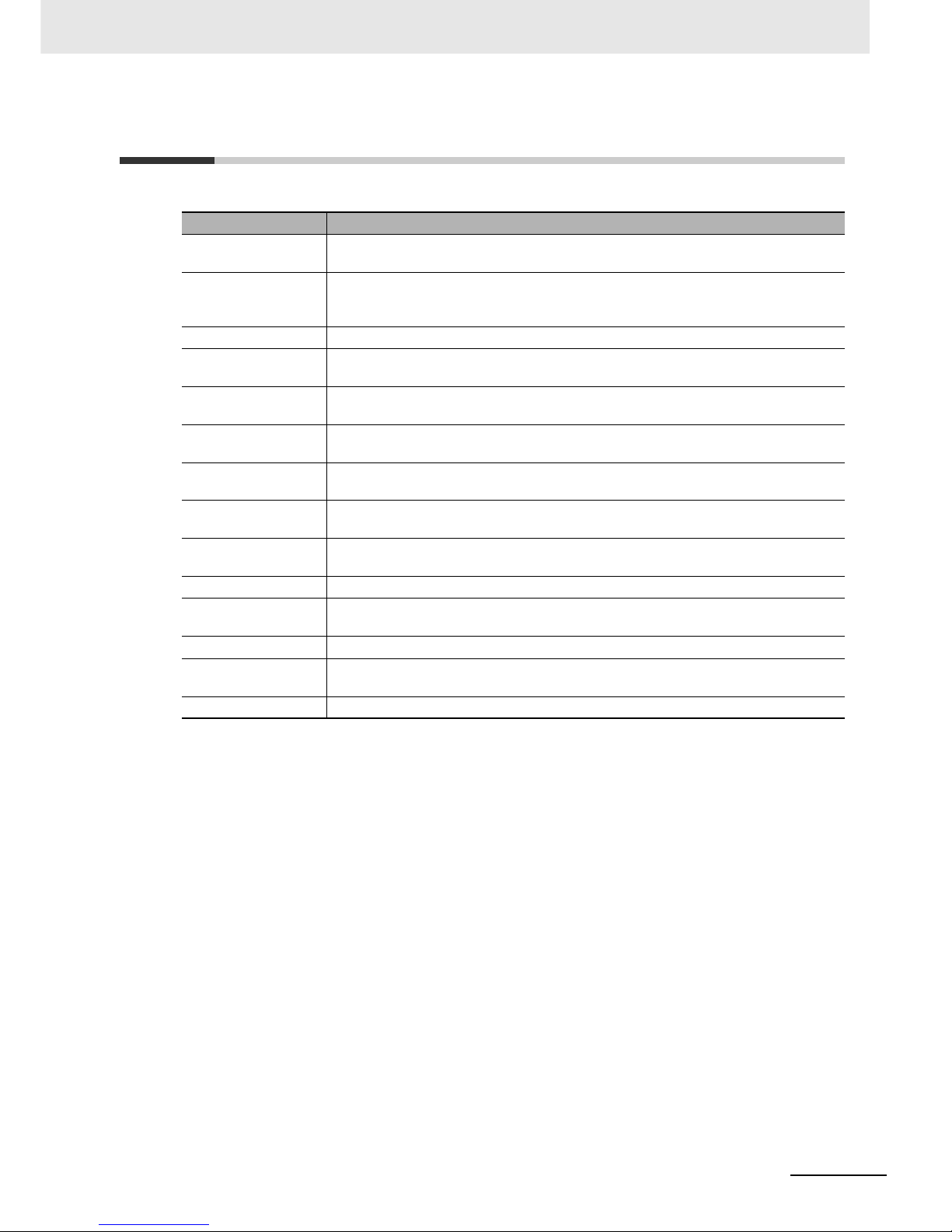

2-1-2 Installation onto the Operation Panel

Install the NB Unit by embedding it into the operation panel.

Use the metal kit and tool (a crosshead screwdriver) supplied with the Unit for installation.

Proceed the installation following the procedures below.

1

Panel cutout with dimensions is shown below. Fit the NB Unit into the panel from the front side.

2

As follows, insert panel fixators at the locations indicated by red box around the back of the NB Unit.

Insert the hooks of positioners into the square holes on the Unit to hold the fixators properly, and

tighten the screws firmly with the screwdriver.

NB5Q/NB7W-TWB

Precautions for Safe Use

• When operating on the operation panel, make sure to keep metal particles from entering the

Unit.

The mounting panel must be between 1.6 and 4.8 mm thick. The NB Unit must be installed

in a control panel.

For the sake of waterproof and dustproof, all the fixators must be evenly tightened to a

torque of 0.5~0.6 Nm. If the tightening torque exceeds the specified value, or the tightening

is not even, deformation of the front panel may occur.

Make sure that the operation panel is clean, unbent, and strong enough for the installation

process.

2-1-2 Installation onto the Operation Panel

Models Opening Dimension (W H mm)

NB3Q-TW00B/TW01B 119.0(+0.5/-0) 93.0(+0.5/-0)

NB5Q-TW00B/TW01B 172.4(+0.5/-0) 131.0(+0.5/-0)

NB7W-TW00B/TW01B 191.0(+0.5/-0) 137.0(+0.5/-0)

NB10W-TW01B 258.0(+0.5/-0) 200.0(+0.5/-0)

Opening dimensions

Width

Height

Level 1 heading

Level 2 heading

Level 3 heading

Step in a procedure

Manual name

Special Information

(See below.)

Level 3 heading

Page tab

Gives the current

headings.

Indicates a step in a

procedure.

Gives the number

of the section.

This illustration is provided only as a sample and may not literally appear in this manual.

Icons are used to indicate

precautions and

additional information.

Precautions for Safe Use

Precautions on what to do and what not to do to ensure using the product safely.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to increase understanding or make operation easier.

Page 9

5

Terminology

NB-series Programmable Terminals NB-Designer Operation Manual(V106)

Terminology

The following terminology is used in this manual.

Terms Descriptions

NB Unit Indicates the main Unit of the products in the OMRON NB Series of Programmable

Terminal.

NB Series Indicates products in the OMRON NB Series of Programmable Terminal.

In this manual, unless otherwise specified, NB Series is taken as the subject

concerned.

PLC Indicates a Programmable Controller.

CP Series Indicates the following products in the OMRON CP Series of Programmable Controllers:

CP1H, CP1L, CP1E

CS/CJ Series Indicates the following products in the OMRON CS/CJ Series of Programmable

Controllers: CS1G, CS1H, CS1G-H, CS1H-H, CJ1G, CJ1M, CJ2M, CJ2H

NJ Series Indicates the following OMRON SYSMAC NJ Series of Programmable Controllers:

NJ501, NJ301

C Series Indicates the following products in the OMRON C Series of Programmable Controllers:

C200HX(-Z), C200HG(-Z), C200HE(-Z), CQM1, CQM1H, CPM1A, CPM2A, CPM2C

Serial Communication

Unit

Indicates a Serial Communication Unit for an OMRON SYSMAC CS/CJ-Series PLC.

Serial Communication

Board

Indicates a Serial Communication Board for an OMRON SYSMAC CS/CJ-Series PLC.

Communication Board Indicates a Communication Board for an OMRON C200HX/HG/HE(-Z) PLC.

CPU Unit Indicates a CPU Unit in the OMRON CP, CS/CJ or SYSMAC C Series of Programmable

Controllers.

NB-Designer Indicates the OMRON NB-Designer.

Host Indicates the PLC and other units functioning as the control devices for NB-Series

Units.

PT Indicates an OMRON Programmable Terminal.

Page 10

Terminology

6

NB-series Programmable Terminals NB-Designer Operation Manual(V106)

Page 11

7

CONTENTS

NB-series Programmable Terminals NB-Designer Operation Manual(V106)

CONTENTS

Introduction............................................................................................................... 1

NB-series Manuals.................................................................................................... 2

Manual Structure ...................................................................................................... 4

Terminology .............................................................................................................. 5

Terms and Conditions Agreement........................................................................ 13

Safety Precautions ................................................................................................. 15

Precautions for Safe Use....................................................................................... 18

Precautions for Correct Use.................................................................................. 20

Conformance to EC Directives.............................................................................. 21

Related Manuals ..................................................................................................... 22

Sec. 1 Introduction............................................................................ 1-1

1-1 Functions and Structure of NB-Series PTs........................................................................... 1-2

1-1-1 How NB-Series PTs Work at FA Production Sites...................................................................... 1-2

1-1-2 Operations of NB-Series PTs.....................................................................................................1-2

1-2 Communicating with the Host................................................................................................ 1-4

1-2-1 What’s the Host Link?.................................................................................................................1-4

1-2-2 Connecting Methods...................................................................................................................1-5

1-2-3 Communicating with the PLC Manufactured by Other Companies.............................................1-6

1-3 System Configuration ............................................................................................................. 1-7

1-3-1 Connectable Peripheral Devices.................................................................................................1-7

1-4 Procedures for NB-Series PTs’ Operation ............................................................................ 1-8

Sec. 2 Installation and Startup of NB-Designer.............................. 2-1

2-1 Before Installation ................................................................................................................... 2-2

2-2 Installation/Uninstallation....................................................................................................... 2-3

2-2-1 Installation Procedure................................................................................................................. 2-3

2-2-2 Uninstallation Procedure............................................................................................................. 2-3

2-3 Startup & Quit .......................................................................................................................... 2-4

2-3-1 Starting Method..........................................................................................................................2-4

2-3-2 Quitting Method..........................................................................................................................2-4

2-4 Installation of USB Driver for NB ........ .... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... .. 2-5

Page 12

CONTENTS

8

NB-series Programmable Terminals NB-Designer Operation Manual(V106)

Sec. 3 Functions of NB-Designer.....................................................3-1

3-1 User Screen.............................................................................................................................. 3-4

3-2 Menus ....................................................................................................................................... 3-7

3-2-1 File Menu..................................... ... ....................................... ... ..................................................3-7

3-2-2 Edit Menu..................................................................................................................................3-10

3-2-3 View Menu................................................................................................................................3-15

3-2-4 Screen Menu...................................... ... .. ........................................ ..........................................3-26

3-2-5 Draw Menu................................................................................................................................3-29

3-2-6 Components Menu....................................................................................................................3-29

3-2-7 Tools Menu.............................................. ........................................ .. ........................................3-30

3-2-8 Option Menu...................... ... ....................................... ... ....................................... ....................3-30

3-2-9 Window Menu............................................... ... .........................................................................3-31

3-2-10 Help Menu.................................................................................................................................3-32

3-3 NB-Designer Software Window............................................................................................ 3-33

3-3-1 Project Library Window.............................................................................................................3-33

3-3-2 Project File Window..................................................................................................................3-37

3-3-3 Project Work Space..................................................................................................................3-37

3-3-4 Output Window..........................................................................................................................3-43

3-3-5 Component List Window.............................................................. .............................................3-44

3-4 Screen Concept ........................................................... ... ....................................... ... ... ... .......3-45

3-4-1 Screen Types .......................... .. ............................................. ... ... ... ..........................................3-45

3-4-2 Screen Property............................................................. ... .. ... ...................................................3-48

3-4-3 Screen Creation................................................................ .. ... ...................................................3-52

3-4-4 Screen Opening................................................................ .. ... ...................................................3-52

3-4-5 Screen Deletion.........................................................................................................................3-53

3-4-6 Components Related to Screen................................................................................................3-53

3-5 Basic Design Method ........................................................ .... ... ... ... ....................................... 3-54

3-5-1 Designing Components.............................................................................................................3-54

3-5-2 About ID No............................. .. ............................................. ... ... ... ..........................................3-55

3-5-3 Additional Comments (Descriptions).........................................................................................3-56

3-5-4 Read/Write Address for PLC............................................. ............................................. .. ... ......3-57

3-5-5 Vector Graphic ..........................................................................................................................3-58

3-5-6 Bitmap.......................................................................................................................................3-63

3-5-7 Creating Label...........................................................................................................................3-66

3-5-8 Task Bar and Operation Buttons...............................................................................................3-68

3-5-9 Fonts.........................................................................................................................................3-70

3-5-10 Basic Properties of Component ................................................................................................3-73

3-5-11 Control Setting of Component...................................................................................................3-74

3-5-12 Display Setting of Component...................................................................................................3-78

3-6 Parts........................................................................................................................................ 3-80

3-6-1 Bit Button...................................................................................................................................3-80

3-6-2 Bit Lamp....................................................................................................................................3-83

3-6-3 Bit Switch..................................................................................................................................3-86

3-6-4 Command Button......................................................................................................................3-87

3-6-5 Word Lamp.................. ........................................ .. ........................................ .. ..........................3-92

3-6-6 Word Switch...................................................................... .. ......................................................3-94

3-6-7 XY Graph..................................................................................................................................3-98

3-6-8 Moving Component....................................... ... ... ....................................................................3-107

3-6-9 Animation................................................................................................................................3-112

Page 13

9

CONTENTS

NB-series Programmable Terminals NB-Designer Operation Manual(V106)

3-6-10 Number Input................................................................... .......................................... ............. 3-114

3-6-11 Number Display.................................................... ... ............................................. ... ... ............ 3-120

3-6-12 Text Input................................................................................................................................ 3-123

3-6-13 Text Display............................................................................................................................. 3-127

3-6-14 Level Meter............................................................................ ................................................. 3-128

3-6-15 Analog Meter.......................................................................................................................... 3-139

3-6-16 Indirect Screen........................................................................................................................3-143

3-6-17 Direct Screen..........................................................................................................................3-146

3-6-18 Alarm...................................................................................................................................... 3-148

3-6-19 Data Log.................................................................................................................................3-150

3-6-20 Recipe.....................................................................................................................................3-160

3-6-21 Oscillograph............................................................................................................................3-160

3-6-22 Scroll Bar...................................................... ... .. .....................................................................3-164

3-6-23 Event....................................................................................................................................... 3-167

3-6-24 Note Book...............................................................................................................................3-174

3-6-25 Word Neon Lamp.................................................................................................................... 3-185

3-6-26 Bit Neon Lamp........................................................................................................................3-186

3-6-27 Touch Trigger..........................................................................................................................3-187

3-6-28 Table....................................................................................................................................... 3-189

3-6-29 Data History............................................................................................................................ 3-190

3-7 Function Parts ..................................................................................................................... 3-196

3-7-1 Scale....................................................................................................................................... 3-196

3-7-2 Function Key...........................................................................................................................3-197

3-7-3 Alarm Display.......................................................................................................................... 3-205

3-7-4 Timer.......................................................................................................................................3-209

3-7-5 Bitmap.....................................................................................................................................3-214

3-7-6 Vector Graphics......................................................................................................................3-215

3-7-7 Notepad..................................................................................................................................3-216

3-7-8 Data Transmission .................................................................................................................. 3-219

3-7-9 Freeplotting.............................................................................................................................3-222

3-7-10 Date/Time...............................................................................................................................3-223

3-7-11 Indirect Shape.........................................................................................................................3-225

3-7-12 User Information.....................................................................................................................3-229

3-7-13 Multifunction............................................................................................................................3-229

3-7-14 Event Display.......................................................................................................................... 3-232

3-8 Project Database ................................................................................................................. 3-234

3-8-1 Text Library .............................................................................................................................3-234

3-8-2 Variable Table ......................................................................................................................... 3-240

3-8-3 Alarm Setting..........................................................................................................................3-243

3-8-4 Event Setting ..........................................................................................................................3-248

3-8-5 PLC Control............................................................................................................................3-252

3-9 Macro Function.................................................................................................................... 3-260

3-9-1 Create a Simple Macro Program............................................................................................ 3-260

3-9-2 Macro and Specification of Operation with Read/Write Variables .......................................... 3-267

3-9-3 Macro Triggering..................................................................................................................... 3-268

3-9-4 Other Descriptions.................................................................... ... .. ... ...................................... 3-271

Page 14

CONTENTS

10

NB-series Programmable Terminals NB-Designer Operation Manual(V106)

3-10 System Parameters ........................................................ ... ....................................... ... ... .....3-285

3-10-1 PT............................................................................................................................................3-286

3-10-2 Task Bar..................................................................................................................................3-287

3-10-3 PT Extended Properties............................................................ ... .................................... .......3-289

3-10-4 System Information Setting............................................................. .. ... ... ................................3-298

3-10-5 Security Levels Setting............................................................................ ... .............................3-300

3-10-6 User Permission Setting..........................................................................................................3-302

3-10-7 Ev ent Hist ory Setting .......................................................... ... ... ... ...........................................3-316

3-10-8 COM1/COM2 Setting..............................................................................................................3-317

3-11 Address of System Memory ............................................................................................... 3-319

3-11-1 Local Bit (LB)...........................................................................................................................3-320

3-11-2 Local Word (LW).....................................................................................................................3-324

3-11-3 Nonvolatile Local Word (LW10000~10255).............................................................................3-327

3-11-4 System Information Table......................................... ... ............................................. ... ... .........3-329

3-12 Recipe Data.......................................................................................................................... 3-331

3-12-1 Process of Creating One Recipe Component.........................................................................3-331

3-12-2 Recipe Memory.......................................................................................................................3-333

3-12-3 Upload/Download of Recipe Data between PT and PLC........................................................3-337

3-13 Security Level ...................................................................................................................... 3-342

3-14 Test ....................................................................................................................................... 3-348

3-14-1 Offline test...............................................................................................................................3-348

3-14-2 Direct Online test..................................................................................................................... 3-349

3-14-3 Indirect Online test..................................................................................................................3-350

3-15 Download.............................................................................................................................. 3-351

3-15-1 Transmission Setting...............................................................................................................3-351

3-15-2 Download via USB Memory....................................................................................................3-353

3-15-3 Specification of Downloading Contents...................................................................................3-353

3-16 Other Functions...................................................................................................................3-357

3-17 RecipeEditor ........................................................................................................................ 3-399

Sec. 4 Functions of NBManager ...................................................... 4-1

4-1 Introduction of NBManager ....................................................................................................4-2

4-2 Download Operation.......................... ....................................... ... ... ... .... ... ............................... 4-3

4-2-1 Communication Setting...............................................................................................................4-3

4-2-2 Select Data................ .. ... ....................................... ........................................ .. ............................4-5

4-2-3 LOGO Setting..............................................................................................................................4-8

4-2-4 Clear Data...................................................................................................................................4-9

4-3 Upload Operation ........................... ... ... ... .... ...................................... .... ... ... ... .... ................... 4-11

4-4 System Operation. ... ... .... ... ... ....................................... ... ... .... ... ... ..........................................4-14

4-5 Get Version............................................................................................................................. 4-15

4-6 Decompile Operation ........................ ... ... ....................................... ... .... ... ... ... ....................... 4-16

4-7 Pass Through Communication............................................................................................. 4-17

4-8 Web Interface Operation ....................................................................................................... 4-19

Page 15

11

CONTENTS

NB-series Programmable Terminals NB-Designer Operation Manual(V106)

Sec. 5 Maintenance and Abnormality Handling ............................. 5-1

5-1 Maintenance............................................................................................................................. 5-2

5-2 Checking and Cleaning........................................................................................................... 5-4

5-3 Abnormality Handling ................................................................. ... .... ..................................... 5-6

5-4 Unit Replacement Precautions................................... ... ......................................................... 5-9

Sec. 6 Descriptions of New Functions Added into NB

-TW01B .....6-1

6-1 New Added Functions............................................................................................................. 6-2

6-1-1 Using Graphics From External Memory......................................................................................6-2

6-1-2 System Reserved memory......................................................................................................... 6-3

6-1-3 Recipe......................................................................................................................................... 6-3

6-1-4 Download through Ethernet........................................................................................................ 6-4

6-1-5 Download to USB1............................................ ... ... ... ............................................. ... .. ..............6-5

6-1-6 NBManager.................................................................................................................................6-6

6-1-7 Data Encryption.......................................................................................................................... 6-7

6-1-8 New Added Addresses f or System memories....................................................................... ... ..6-9

6-1-9 Change of System Language................................................................................................... 6-10

6-1-10 Usage of Forced Address Bit....................................................................................................6-10

6-2 System Parameters ............................................................................................................... 6-11

6-2-1 PT............................................................................................................................................. 6-11

6-2-2 PT Extended Properties ........................................................................................................... 6-12

6-2-3 Event History Setting................................................................................................................ 6-13

6-2-4 External Memory ...................................................................................................................... 6-14

6-2-5 Communication Setting............................................................................................................. 6-14

6-3 Component Improvement..................................................................................................... 6-15

6-3-1 Function Key.............................................................................................................................6-15

6-3-2 Event, Event History Display and Event Display....................................................................... 6-18

6-3-3 Data History, Data Log and XY Graph......................................................................................6-20

6-3-4 Operation Log ........................................................................................................................... 6-21

6-3-5 Recipe Data.............................................................................................................................. 6-24

6-3-6 PLC Control..............................................................................................................................6-25

6-3-7 File List..................................................................................................................................... 6-26

Sec. 7 PictBridge Printing ................................................................ 7-1

7-1 PictBridge Function ....................................... ... .... ...................................... .... ... ... ... ... ............ 7-2

7-2 Setting Method for Using Printing Function......................................................................... 7-4

7-3 Components Related to Printing and Setup Descriptions .................................................. 7-6

7-3-1 PLC Control................................................................................................................................7-6

7-4 List of System memories Related to Printing.................. ... ... ... ... .... ..................................... 7-8

7-5 List of Error Codes for Printing.............................................................................................. 7-9

7-6 Recommended Printer Models............................................................................................. 7-10

Page 16

CONTENTS

12

NB-series Programmable Terminals NB-Designer Operation Manual(V106)

Sec. 8 Web Interface..........................................................................8-1

8-1 Defining Web Interface............................................................................................................ 8-2

8-2 Setup Web Interface on a PC..................................................................................................8-3

8-3 Connection Method and Each Page Function ......................................................................8-4

8-4 URL List....................................................................................................................................8-9

Sec. A Appendices.............................................................................A-1

A-1 List of Models ..........................................................................................................................A-2

A-2 NB-Designer Function List .....................................................................................................A-6

A-3 List of memories supported by OMRON PLC.....................................................................A-11

Revision History........................................................................................................1

Page 17

13

Terms and Conditions Agreement

NB-series Programmable Terminals NB-Designer Operation Manual(V106)

Terms and Conditions Agreement

Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship for a period of tw elv e months from the date of sale b y Om ron (or such other p eriod e xp ressed in

writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be

responsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification . Return of

any Products by Buyer must be approved in writing by Omron before shipment. Omron Companies

shall not be liable for the suitability or unsuitability or the results from the use of Products in combination with any electrical or electronic components, circuits, system assemblies or any other materials or substances or environments. Any advice, recommendations or information given orally or in

writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS

IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN

CONTRACT, WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

Warranty, Limitations of Liability

Warranties

Limitation on Liability; Etc

Page 18

Terms and Conditions Agreement

14

NB-series Programmable Terminals NB-Designer Operation Manual(V106)

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer's application or use of the Product. At

Buyer's request, Omron will provide applicable third party certificat ion documents identifying ratings

and limitations of use which apply to the Product . This information by itself is not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine,

system, or other application or use. Buyer shall be solely responsible for determining appropriateness of the particular Product with respect to Buyer's application, product or system. Buyer shall

take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED

TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Omron Companies shall not be responsible for the user's programming of a programmable Product,

or any consequence thereof.

Data presented in Omron Company websites, catalogs and other materials is provided as a guide

for the user in determining suitability and does not constitute a warranty. It may represent the result

of Omron's test conditions, and the user must correlate it to actual application requirements. Actual

performance is subject to the Omron's Warranty and Limitations of Liability.

Product specifications and accessories may be changed at any time based on improvements and

other reasons. It is our practice to chang e part numbers when published ratings or features are

changed, or when significant construction changes are made. However, some specifications of the

Product may be changed without any notice. When in doubt, special part numbers may be assigned

to fix or establish key specifications for your application. Please consult with y our Omron' s represen tative at any time to confirm actual specifications of purchased Product.

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

Suitability of Use

Programmable Products

Disclaimers

Performance Data

Change in Specifications

Errors and Omissions

Page 19

15

Safety Precautions

NB-series Programmable Terminals NB-Designer Operation Manual(V106)

Safety Precautions

The following notation is used in this manual to provide precautions required to ensure safe usage of

the product. The safety precau tions that are provided are extremely important to safety. Always read

and heed the information provided in all safety precautions.

Notation Used for Safety Information

Symbols

The circle and slash symbol indicates operations that you must not do.

The specific operation is shown in the circle and explained in text.

This example indicates prohibiting disassembly.

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the triangle and explained in text.

This example indicates a general precaution.

WARNING

Indicates an imminently hazardous situation which,

if not avoided, will result in death or serious injury.

Additionally, there may be severe property damage.

Precautions for Safe Use

Indicates precautions on what to do and what not to do to ensure using the product safely.

Precautions for Correct Use

Indicates precautions on what to do and what not to do to ensure proper operation

and performance.

Note Indicates suggestive information and precautions on operation of the product.

Page 20

Safety Precautions

16

NB-series Programmable Terminals NB-Designer Operation Manual(V106)

Do not attempt to take the product ap art and do not touch the product inside while the

power is being supplied. Otherwise it may result in electric shock.

Always ensure that the personnel in charge confirm that installation, inspection, and

maintenance were properly performed for the NB Unit.

“Personnel in charge” refers to individuals qualified and responsible for ensuring

safety during machine design, installation, operation, maintenance, and disposal.

Ensure that installation and post-installation checks are performed by personnel in

charge who possess a thorough understanding of the machinery to be installed.

Do not use the input functions of the touch switch, etc. of the NB Unit, in applications

that involve huma n life, in applications that may result in serious injury, or for

emergency stop switches.

Do not attempt to disassemble, repa ir, or modify the NB Unit. Otherwise it ma y impair

the safety functions.

Never press more than two points on the touch panel of the NB Unit at a time.

Otherwise, it may activate a switch some wh ere between the two points.

WARNING

Page 21

17

Safety Precautions

NB-series Programmable Terminals NB-Designer Operation Manual(V106)

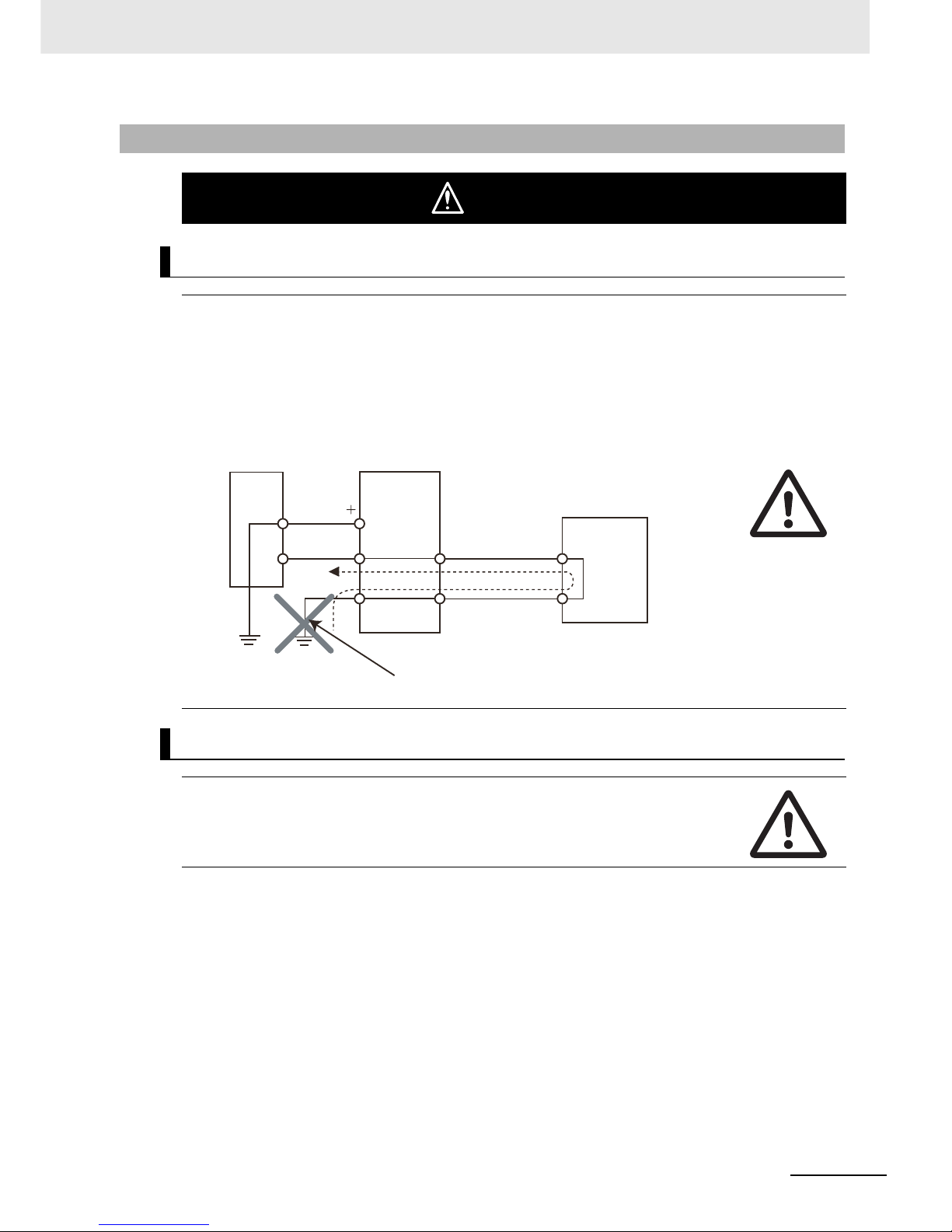

Precaution

Wiring

In the case of the NB Series, when grounding the positive terminal of power supply of 24 V to

the NB, do not ground functional grounding terminal at NB side. Some functions of a PC

connected to the NB may cause a short circuit and the NB Unit may cause damage.

• Caution:

Depending on the types of PC, SG terminals of RS-232C port or USB port and contour of connector can

be connected. As the contour of tool port of the NB and the functional grounding terminal are not insulated, they are connected. Therefore, connecting the PC allows GND terminal and functional grounding

terminal of the NB to be connected. If the power supply of 24V to the NB is grounded positively, grounding the functional grounding terminal allows a short circuit as shown in the diagram below and may result

in damage.

Test Function

The Test Function is performed on PC so that a problem may occur affected by the timing or

the differences with communication route. When the test function is performed, considering

possible unexpected circumstances on PC, confirm that any dangerous event will not occur

beforehand.

WARNING

NB

SG

SG

24V

0V

GND

Power

Supply

Grounding Grounding

Functional

Grounding

Cable

Contour Contour

PC

Do not ground the functional grounding.

Page 22

Precautions for Safe Use

18

NB-series Programmable Terminals NB-Designer Operation Manual(V106)

Precautions for Safe Use

• When unpacking the NB Units and the peripheral devices, check carefully for any external scratches

or other damages. Also, shake the Units gently and check for any abnormal sound.

• The NB Unit must be installed in a control panel.

•

The mounting panel must be between 1.6 and 4.8 mm thick. Tighten the Mounting Brackets evenly to a

torque of between 0.5 and 0.6 N

m to maintain water and dust resistance. If the tightening torque

exceeds the specified value, or the tightening is not even, deformation of the front panel may occur.

What is more, make sure the panel is not dirty or warped and that it is strong enough to hold the Units.

• Do not let metal particles enter the Units when preparing the panel.

• Do not connect an AC power supply to the DC power terminals.

• Use a DC power with a slight voltage fluctuation and reinforced or double insulation, and that will

provide a stable output even if the input is momentarily interrupted for 10 ms.

Rated Power Supply Voltage: DC 24 V (Allowable range DC 20.4 ~ 27.6 V)

• Do not perform a dielectric voltage test.

• Before connecting the power supply to the NB unit, mount the cable on the terminal block. Make the

connection by using terminal screws crimping on a twisted-pair cable with a crimping range of 12~26

AWG, and only 6.5 mm of insulation peel of the cable needs to be peeled off. Tighten the terminal

screws at a torque of between 0.3 and 0.5 N

m. Make sure the screws are properly tightened. Do not

use the terminal block of NB3Q-TW01B for other models. NB3Q-TW01B has different pin definitions

on the terminal block.

• To prevent malfunctions caused by noise, ground the Unit correctly.

• Do not touch the packaging part of the circuit board with your bare hands. Discharge any static

electricity from your body before handling the board.

• When using the No. 6 pin of the serial communication port COM1 connector for a voltage of DC+5V,

make sure the supply equipment’s current capacity is below 250mA before using it. The DC+5V

voltage output of the NB unit is +5V±5%, and the maximum current is 250mA. (The serial

communication port COM1 of NB3Q-TW00B and NB3Q-TW01B is unable to output the current.)

• Turn OFF the power supply before connecting or disconnecting cables.

• Always keep the connector screws firmly tightened after the communication cable is connected.

• The maximum tensile load for cables is 30 N. Do not apply loads greater than this.

•

Confirm the safety of the system before turning ON or OFF the power supply, or pressing the reset button.

• The whole system may stop depending on how th e power supply is turn ed ON or OFF. Turn ON/O FF

the power supply according to the specified proced ur e.

•

Reset by pressing the reset button, or restart the power supply, once the DIP switch settings are changed.

• To ensure the system’s safety, make sure to incorporate a program that can confirm the normal

functionality of the NB Unit before running the system.

• Start actual system application only after sufficiently checking screen data, macros and the operation

of the program at the host side.

• Do not press the touch panel with a force greater than 30 N.

• Do not use hard or pointed objects to operate or scrub the screen, otherwise the surface of the

screen may be damaged.

• Confirm the safety of the system before pressing the touch panel.

• Signals from the touch switches may not be input if the touch switches are pressed consecutively at

high speed. Confirm each input before proceeding to the next one.

• Do not accidentally press the touch panel when the backlight is not lit or when the display does not

appear. Make sure of the safety of the system before pressing the touch panel.

• To use numeric input functions safely, always make maximum and minimum limit settings.

• Before initializing screen data, confirm that existing data is backed up at the NB-Designer.

Page 23

19

Precautions for Safe Use

NB-series Programmable Terminals NB-Designer Operation Manual(V106)

• When changing the password with the screen, do not reset or turn OFF the power supply until writing

is finished. Failure to save the password may cause the screen to fail to function.

•

When using an equipment monitor, confirm the safety of the system before carrying out the following operations:

• Changing monitor data.

• Changing operation mode.

• Forced set/reset.

• Changing the current value or the set value.

• Do not connect a USB connector to any device that is not applicable.

• When connecting the equipment with the USB HOST connector , make sure the supply equipment’s

current capacity is below 150mA before using it. The DC+5V voltage output of the NB Unit is

+5V±5%, and the maximum current is 150mA.

• Before connecting a USB connector to a device, make sure that the device is free of damage.

• Commercially available and the recommended USB HUBs are different from the general

specifications of the NB Unit. The unit may not function well in an environment subject to noise, static

electricity. Therefore, when using a USB HUB, employ suff icient noise and st atic electricity insulat ion

measures, or install it at a site free of noise or static electricity.

• While uploading or downloading screen data or system programs, do not perform the following

operations that may corrupt the screen data or the system program:

• Turning OFF the power supply of the NB Unit.

• Pressing the PT’s reset switch.

• Dispose of the Units and batteries according to local ordinances as they apply.

•

Do not dispose the product into a fire. Doing so may cause the damage with the battery or electronic components.

• Do not apply an impact with the lithium cell, charge it, dispose it into a fire, or heat it. Doing either of

them may cause an ignition or a bursting.

• When exporting products with lithium primary batt er ies con taining pe rchlo rate at 6p pb or ab ove t o or

delivering them through California, USA, the following precautiona ry measures have to be publicized .

Perchlorate material - applicable through special processing. Refer to

http://www.dtsc.ca.gov/hazardouswaste/perchlorate.

NB-Series products contain lithium primary batter ies. When exporting produ cts containing this kind of

batteries to or delivering them through California, USA, label all the product packages as well as the

appropriate delivery packages.

•

Do not use benzene, paint thinner, or other volatile solvents, and do not use chemically treated cloths.

• Do not dispose the Units together with general was te at wast e yar ds . W he n dis po sin g th em , fo llow

the related local ordinances or rules.

• Cannot replace the backlight lamp inside the NB Unit.

• Deterioration over time can cause the touch points to move. Calibrate the touch panel periodically.

• Water and oil resistance will be lost if the front sheet is torn or is peeling off. Do not use the Unit, if the

front sheet is torn or is peeling off.

• The rubber packing will deteriorate, shrink, or harden depending on the operating environment.

Inspect the rubber packing periodically.

•

The communication cables of the COM1 and COM2 connectors are not interchangeable. Confirm the pins

of the ports before carrying out communications. (NB3Q-TW00B and NB3Q-TW01B only has COM1.)

•

Periodically check the installation conditions in applications where the PT is subject to contact with oil or water.

• Do not perform the following operations during the communication of the USB memory:

• Turning off the power supply of the NB Unit.

• Pressing the Reset button on the NB Unit.

• Removing the USB memory.

• Do not use the USB memory in the environment subject to strong vibration.

Page 24

Precautions for Correct Use

20

NB-series Programmable Terminals NB-Designer Operation Manual(V106)

Precautions for Correct Use

• Do not install the unit in any of the following locations:

Locations subject to severe changes in temperature

Locations subject to temperatures or humidity outside the range specified in the specifications

Locations subject to condensation as the result of high humidity

Locations subject to corrosive or flammable gases

Locations subject to strong shock or vibration

Locations outdoors subject to direct wind and rain

Locations subject to strong ultraviolet light

Locations subject to dust

Locations subject to direct sunlight

Locations subject to splashing oil or chemicals

• Take appropriate and sufficient countermeasures when installing systems in the following locations:

Locations subject to static electricity or other forms of noise

Locations subject to strong electric fiel d or magnetic field

Locations close to power supply lines

Locations subject to possible exposure to radioactivity

• Precautions for software:

The update, restoration, uninstall and reinsta llation of soft ware in running st atus is prohibited in order

to guarantee the correct use of the product.

Page 25

21

Conformance to EC Directives

NB-series Programmable Terminals NB-Designer Operation Manual(V106)

Conformance to EC Directives

NB-Series Programmable Terminals are EMC compliant.

OMRON products are electronic devices that are incorporated in machines and manufacturing

installations. OMRON PTs conform to the related EMC Directives (see note) so that the devices and

machines into which they are built can more easily conform to EMC Directives. The actual products

have been throug h inspections and are completely in accordance with EMC directives. However, when

they are built into customers’ systems, whether the systems also comply with these Directives is up to

the customers for further inspection.

EMC-related performance of OMRON PTs will vary depending on the configuration, wiring, and other

conditions of the OMRON equipment or control panel. The customer must, therefore, perform final

checks to confirm that the overall machine or device conforms to EMC standards.

Note The applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic sensitivity): EN61131-2: 2007

EMI (Electromagnetic Interference): EN61131-2: 2007

NB-Series Programmable Terminals are EC compliant. Heed the following precautions in order to

ensure that the customer’s overall machine and device conform to EC Directives.

1

The PT must be installed in a control panel.

2

You must use reinforced insulation or double insulation for the DC power supply and the DC

power supply must have minimal voltage fluctuations and provide a stable output even if the

power supply input is interrupted for 10 ms.

3

The PTs conform to the standard EN 61131-2, but radiated emission characteristics (10m

regulations) may vary depending on the configuration of the control panel used, other devices

connected to the control panel, wiring, and other conditions. You must theref ore con firm that the

overall machine or equipment complies with EC Directives.

4

This is a Class A product (Product for industry purpose). It may cause r adio interference in

residential areas, in which case the user may be required to take adequate measure s to re duce

interference.

Observe the following precaution if you use NB-series Programmable Terminals in Korea.

Class A Device (Broadcasting Communications Device for Office Use)

This device obtained EMC registration for office use (Class A), and it is intended to be used in

places other than homes.

Sellers and/or users need to take note of this.

Concepts

Conformance to EC Directives

Conformance to KC Standards

Page 26

Related Manuals

22

NB-series Programmable Terminals NB-Designer Operation Manual(V106)

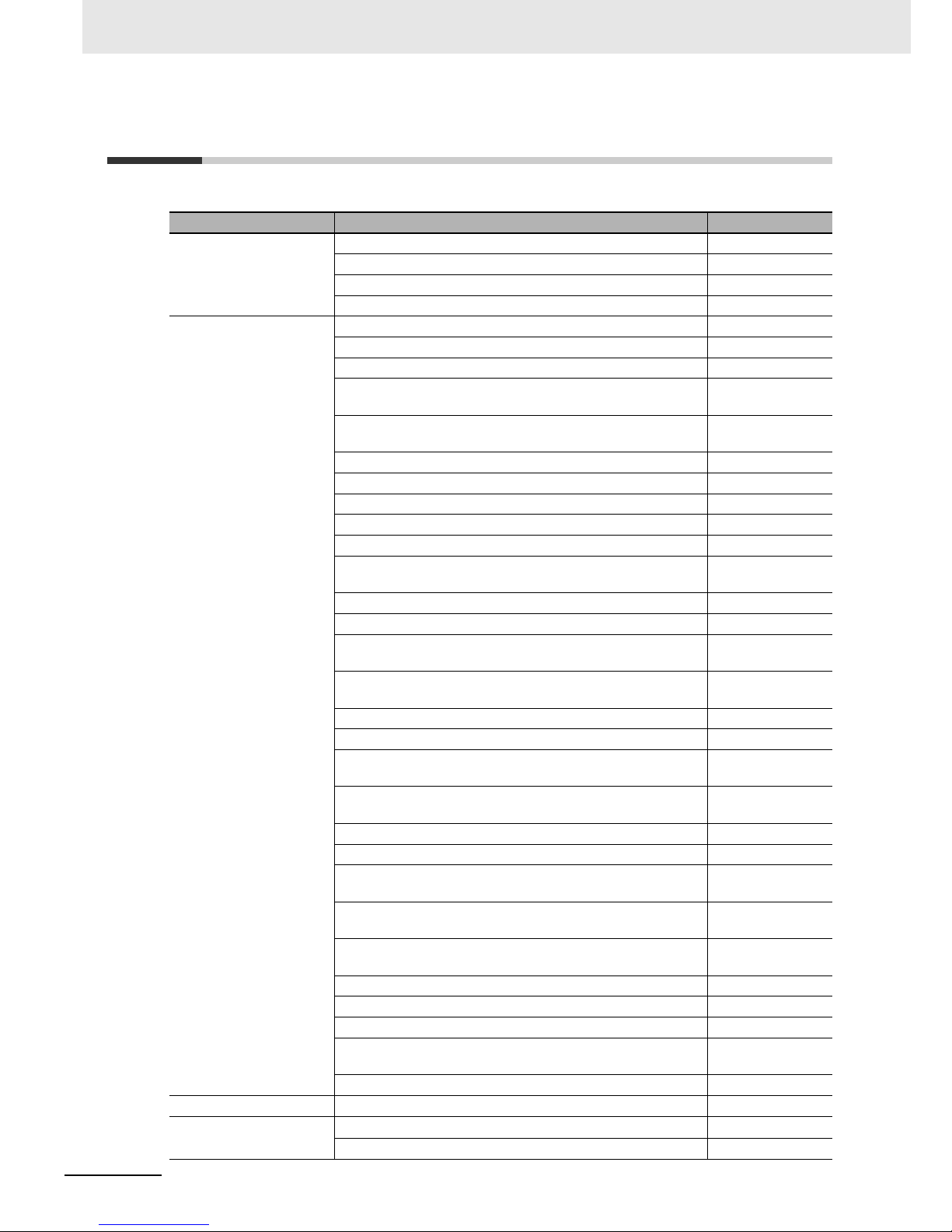

Related Manuals

The related manuals are as follows:

Devices and Software Manual Name Manual No.

NB series NB Series NB-Designer Operation Manual (This manual) V106

NB Series Setup Manual V107

NB Series Host Connection Manual V108

NB Series Startup Guide V109

PLC SYSMAC CP Series CP1L CPU Unit Operation Manual W462

SYSMAC CP Series CP1H/L CPU Unit Programming Manual W451

SYSMAC CP Series CP1H CPU Unit Operation Manual W450

SYSMAC CP Series CP1E CPU Unit Hardware USER’S

Manual

W479

SYSMAC CP Series CP1E CPU Unit Software USER’S

Manual

W480

SYSMAC C200HX/HG/HE(-E/-ZE) Installation Guide W302

SYSMAC C200HX/HG/HE Operation Manual W303

SYSMAC C200HX/HG/HE(-ZE) Operation Manual W322

SYSMAC CPM1A Operation Manual W317

SYSMAC CPM2A Operation Manual W352

SYSMAC CPM1/CPM1A/CPM2A/CPM2C/SRM1(-V2)

Programming Manual

W353

SYSMAC CPM2C Operation Manual W356

SYSMAC CS1 Series CS1G/H Operation Manual W339

SYSMAC CS/CJ Series Serial Communications Boards and

Serial Communications Units Operation Manual

W336

SYSMAC CJ Series CJ1G/H(-H) CJ1M CJ1G Operation

Manual

W393

SYSMAC CS/CJ Series Programming Manual W394

SYSMAC CS/CJ Series INSTRUCTIONS Reference Manual W340

SYSMAC CS/CJ Series Programming Consoles Operation

Manual

W341

SYSMAC CS/CJ Series Communications Commands

Reference Manual

W342

SYSMAC CJ Series CJ2 CPU Unit Hardware USER’S Manual W472

SYSMAC CJ Series CJ2 CPU Unit Software USER’S Manual W473

SYSMAC CS/CJ Series CS1W/CJ1W-ETN21 (100Base-TX)

Ethernet Units Operation Manual Construction of Networks

W420

SYSMAC CS/CJ Series CS1W/CJ1W-ETN21 (100Base-TX)

Ethernet Units Operation Manual Construction of Applications

W421

SYSMAC CS/CJ Series CS1W/CJ1W-EIP21 (100Base-TX)

EtherNet/IP

TM

Units Operation Manual

W465

SYSMAC CP Series CP1L-EL/EM CPU Unit Operation Manual

W516

NJ Series CPU Unit Hardware USER’S Manual

W500

NJ Series CPU Unit Software USER’S Manual

W501

NJ Series CPU Unit Built-in EtherNet/IPTM Port USER’S

Manual

W506

NJ Series Troubleshooting Manual W503

Safety Controller G9SP Series Safety Controller OPERATION MANUAL Z922

External Tool

CX-Programmer Ver.9.

Operation Manual

W446

Sysmac Studio Version 1 Operation Manual W504

Page 27

1-1

NB-series Programmable Terminals NB-Designer Operation Manual(V106)

1

\

This section provides an outline of the NB-Series PTs, including their functions,

features, connection types and communication methods.

1-1 Functions and Structure of NB-Series PTs . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-1-1 How NB-Series PTs Work at FA Production Sites . . . . . . . . . . . . . . . . . . . . . . 1-2

1-1-2 Operations of NB-Series PTs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 Communicating with the Host . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-2-1 What’s the Host Link? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-2-2 Connecting Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-2-3 Communicating with the PLC Manufactured by Other Companies . . . . . . . . . 1-6

1-3 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-3-1 Connectable Peripheral Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-4 Procedures for NB-Series PTs’ Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Introduction

Page 28

1 Introduction

1-2

NB-series Programmable Terminals NB-Designer Operation Manual(V106)

1-1 Functions and Structure of NB-Series

PTs

The NB-Series Programmable Terminals (PTs) are sophisticated operator interfaces that can indicate

information and perform operations as required at FA production sites. This section provides a brief of

the roles and performances of the NB Series PTs for beginning users.

• Monitoring Line Operating Status

The device and operation status of the system can be displayed in real t ime . Using g raphic cha rts or

other allows display data in easy-to-understand format.

• Instructing FA Staff

PTs can be used to notify system operators if there is a system or devic e erro r an d to indicate

countermeasures and necessary information.

• Controlling Panel Switches

NB-Series PTs allow the users to create various kinds of switches on the displayed screen. The

values allocated to the switches can be sent to the host by clicking the switches.

Transferring Screen Data

The screen data displayed on NB-Series PTs is created by using NB-Designer in the PC. The

screen data is transferred to the NB units through the USB, Ethernet, and the RS-232C or using

USB memory.

Displaying Screens

The data to be displayed on the screens is created by using NB-Designer in PC and the data is

transferred to the PT. The required screen can be displayed by a command from the host or by

operating the touch switches.

1-1-1 How NB-Series PTs Work at FA Production Sites

1-1-2 Operations of NB-Series PTs

USB, Ethernet, RS-232C

or USB memory

Screen data

Create screen data.

Only when transferring screen data or using the

NB-Designer, the computer can connect with PT.

Computer

(NB-Designer)

Host

The required screens can be displayed by

using commands from the host or touch

switch operations.

Page 29

1-3

1 Introduction

NB-series Programmable Terminals NB-Designer Operation Manual(V106)

1-1 Functions and Structure of

NB-Series PTs

1

1-1-2 Operations of NB-Series PTs

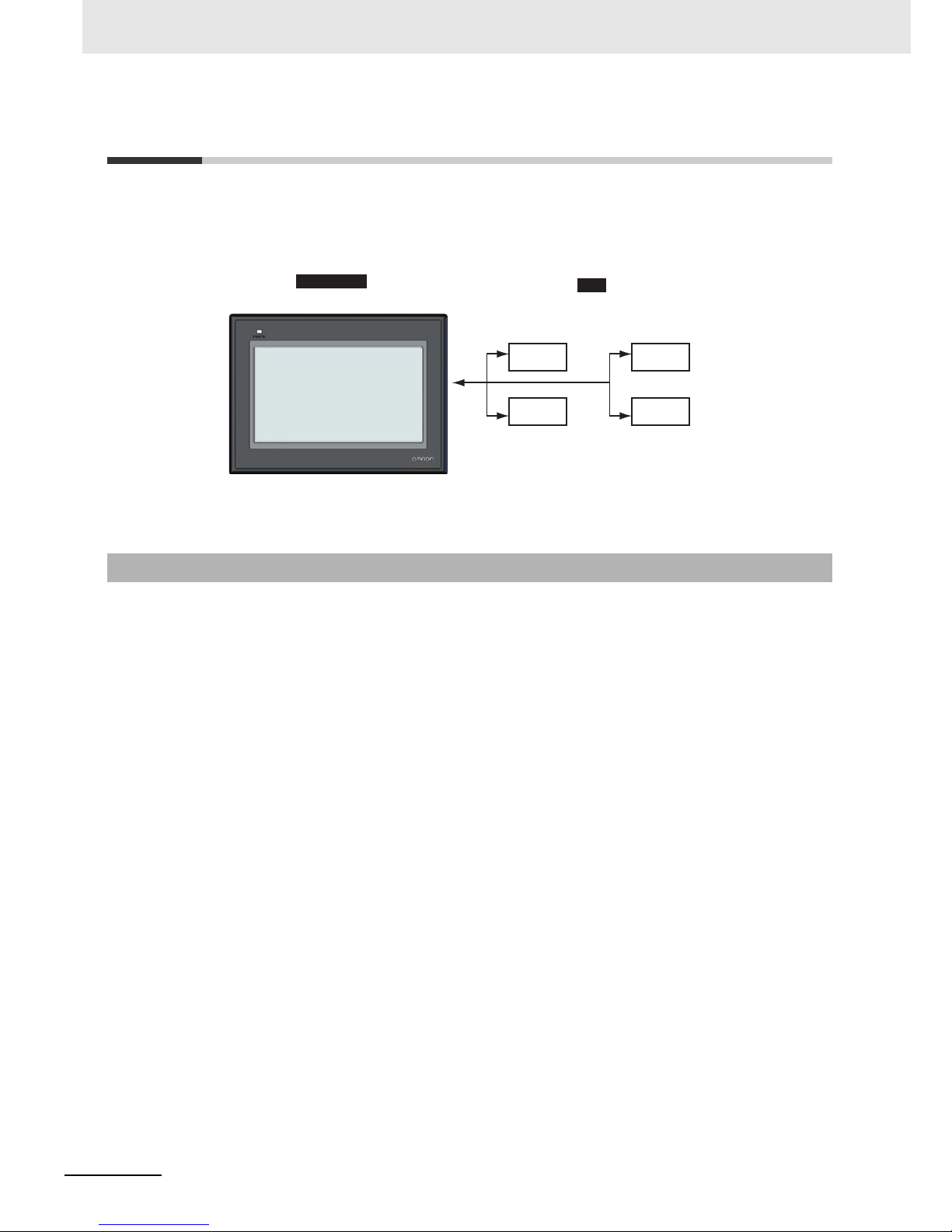

Reading Data from the Host

NB-Series PTs can be connected to the host by using communication methods such as RS-232C,

RS-485, RS-422A, or Ethernet to automatically re ad the required data from the host.

Sending Data to the Host

The data entered from the touch panel (ON/OFF button status, numeric data and character strings)

can be sent to the host.

RS232, RS485, RS422,

or Ethernet

Host

Host

ON/OFF status,

numeric data, etc.

Touch panel

Page 30

1 Introduction

1-4

NB-series Programmable Terminals NB-Designer Operation Manual(V106)

1-2 Communicating with the Host

With NB-series PTs, data required for display can be accessed and the words and bits where the

entered data will be stored can be allocated to any area in the PLC. The operations include the direct

reading and writing of the allocated words and bits, the modification of the display status for the

functional objects on the PT screen, and the control and report of the PT status.

NB-Series PTs can be connected to the PLC manufactured by OMRON using the Host Link method.

The Host Link is a kind of optimized and economical communication method for FA system, which is

applicable to link one PT with one PLC or more. The PC can be used to transfer programs to the PLC,

monitor the data area of PLC and control the operation of PLC.

In the system using Host Link system, one PT sends Host Link commands to the PLC and the

commands' processing is completed followed by returning the results of th e processing by the PLC (the

host).

System Features:

Connection method: RS-232C or RS-422A

Transmission rate (baud rate): 4800, 9600, 14400, 19200, 38400, 56000, 57600, 115200 and 187500

bps.

The transmission rates of 14400, 56000 and 187500 bps are not supported by the PLC manufactured

by OMRON.

Host monitoring: The PC can be used to transfer or read the PLC programs, and perform reading and

writing of the data area of PLC.

Error check system: Both parity and frame check are performed to estimat e the erro rs occurring dur ing

all the communications.

1-2-1 What’s the Host Link?

I/O area

DM area

Auxiliary area

timers/counters

NB-Series PT

PLC

Page 31

1-5

1 Introduction

NB-series Programmable Terminals NB-Designer Operation Manual(V106)

1-2 Communicating with the

Host

1

1-2-2 Connecting Methods

RS-232C is a kind of serial physical interface standard formulated by Electric Industry Association

(EIA).

RS-232C method is based on 1:1 communication, which is applied to the point-to-point communication

within 15-meter distance due to the existence of common-ground noise and the unavoidable commonmode interference etc.

RS-485 uses the differential signal negative logic and the common 2-wire method, and the connectabl e

node on the same bus is up to 32. The master-slave communication method, i.e. one master

communicating with multiple slaves, is generally used in the RS-485 communication network.

RS-485 and RS-422A methods can realize 1:N communication, i.e. one host communicating with

multiple PLCs or PTs. The maximum number of PLCs or PTs that can be connected to the host is up to

32, and the maximum transmission distance is 500 meters.

RS-485 is half-duplex communication method that cannot allow the transmission and receiving to be

performed simultaneously.

It is unnecessary to control the data direction due to 4-wire RS-422A interface using separate

transmission and receiving channels. Any necessary signal exchange among t he equipments can be

performed by using software method (XON/XOFF Handshaking) or hardware method (control wires).

RS-422A standard with its full name “Electrical Characteristics of Balanced Voltage Digital Interface

Circuits” specifies the characteristics of the interface circuit. Actually, there is also a signal ground, total

5 wires. Because the receiver uses high input impedance and the driving performance of the

transmission driver is more powerful than that of RS-232C, therefore the same transmission wire can

be connected with multiple receiving nodes, and the number of the connectab le node is up to 10. That’s

to say, one is the master and the others are the slaves. Due to the RS-422A which is impossible to

communicate between the slaves, therefore the RS-422A supports one-point-to-multiple full-duplex

communications.

Ethernet is a kind of baseband LAN specification, established by Xerox company and jointly develope d