Page 1

4700 Series

Installation and Operating Manual

for MC4700, MCF4700, MCJ4700, MS4700 & MSF4700 Series

Original Instructions

. . . . .

O M RO N ScientificTechnologiesInc.

Manufacturing and Sales Office

6550 Dumbarton Circle

Fremont CA 94555 USA

1 / 888 / 510-4357

Tel: 510/608-3400

Fax: 510/744-1442

www.sti.com

© OSTI 1209 PN99584-0050 Rev.E

Page 2

NOTE:

This manual provides information for MC4700, MCF4700, MCJ4700, MS4700 and the

MSF4700 transmitters and receivers, for use with both the LCM metal enclosure as well as

the DIN box controller. Where information is common the term “4700 system” is used. Where

information is specific to a certain version the exact model number (example: safe mounting

distance calculation) is provided. The specifications and detailed information of the

MCF4700, MCJ4700, MS4700 and the MSF4700 information are located at the back of the

manual.

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

0

© OSTI 1209 PN99584-0050 Rev. E

Original Instructions

Page 3

4700 Series Safety Light Curtain

Table of Contents

Section 1 -- Important Safety Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

. . . . .

Section 2 -- Significant Features

2.1 Standard Features

2.2 Optional Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

Section 3 -- System Access, Components and Indicators

3.1 Access to Configuration Switches

3.1.1 LCM DIN Controller

3.1.2 LCM Metal Chassis Controller

3.2 Location of the components a

Section 4 -- System Operation

4.1 Operating States

4.1.1 Machine Run

4.1.2 Machine Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 16

4.1.3 Interlock

4.1.4 Alarm

4.2 Operating Modes

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 12

nd indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 16

4.2.1 Automatic Start

4.2.2 Start Interlock

4.2.3 Start/Restart Interlock

4.3 Operating Mode Selection

4.4 Start Switch Type Selection

Section 5 -- Detection Options

5.1 Exact Channel Select (ECS)

5.2 Multi Channel Select (MCS)

5.3 Floating Blanking

5.4 Using Exact Channel Select with Floating Blanking

5.4.1 The Effect of Exact Channel

Resolution

5.5 Activating and Programming Exact Channel Se

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 21

. . . . . . . . . . . . . . . . . . . . . . . . . . page 21

Select and Floating Blanking on Minimum Object

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 21

lect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 23

1

© OSTI 1209 PN99584-0050 Rev. E

Original Instructions

Page 4

5.6 MCS Programing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 23

5.7 Activating Floating Blanking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 24

5.8 Additional Guarding When Using Exact Cha

Section 6 -- Diagnostic and Test Features

6.1. Diagnostic Display

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 25

6.2 Individual Beam Indicators

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 25

6.3 Machine Primary Control Element (MPCE) Monitoring

6.3.1 Activating and Deactivating MPCE Monitoring

6.3.2 Activating and Deactivating MPCE Monitoring on the Metal Chassis Controller-

Relay Output Version

6.4. Status Indicator Lights

6.4.1 Safety Output status

6.4.2 Interlock Status

6.4.3 Alarm Status

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 26

6.4.4 Exact Channel Select and Floating Blanking Status . . . . . . . . . . . . . . . . . . . . page 26

Section 7 -- Outputs

7.1 Safety Outputs

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 27

nnel Select . . . . . . . . . . . . . . . . . . . . . . page 24

. . . . . . . . . . . . . . . . . . . . . . page 25

. . . . . . . . . . . . . . . . . . . . . . . page 26

7.1.1 Din Controller and Metal Chassis So

7.2.2 metal chassis Controller -

7.2. Auxiliary Outputs

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 27

7.2.1 DIN Controller and Metal Chassis Solid State Version . . . . . . . . . . . . . . . . . . page 27

7.2.2 metal chassis Controller -

7.2.3 Auxiliary Output Operating Modes

Section 8 -- Safe Mounting Distance

8.1 US Safe Distance Formulas

8.2 European Safety Distance Formulas

8.2.1 Safety Distance Formula for Systems with a Minimum Object Resolution of 40 mm or

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 29

Less

8.2.2 Safety Distance Formula for Systems with a Minimum Object Resolution Greater Than

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 30

40 mm

8.2.3 Factors Affecting The Safety Distance Formula

lid State Version. . . . . . . . . . . . . . . . . . . page 27

Relay Output Version . . . . . . . . . . . . . . . . . . . . . . . page 27

Relay Output Version . . . . . . . . . . . . . . . . . . . . . . . page 27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 29

. . . . . . . . . . . . . . . . . . . . . . . page 30

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

2

© OSTI 1209 PN99584-0050 Rev. E

Original Instructions

Page 5

Section 9 -- Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 31

. . . . .

9.1 Reflective Surface Interfer

ence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 31

9.2. Connecting Transmitter and Receiver to Controller

9.2.1 Cable Assemblies

9.2.2 Cable Connections

9.3 General Considerations

9.3.1 Additional Guarding

9.3.2 Installation of Multiple System

9.3.3 Detection Zone

9.3.4 Marking Minimum Object Re

9.3.5 Alignment

9.3.6 Input Power Requireme

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 34

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 34

s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 35

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 36

solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 36

nts/Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 36

9.3.7 Special Requirements for Perimeter Guarding

9.3.8 Presence Sensing Device Initiation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 36

Section 10 -- Connecting To The Machine Control Circuit

. . . . . . . . . . . . . . . . . . . . . . . . . page 32

. . . . . . . . . . . . . . . . . . . . . . . . page 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 37

10.1 Din Controller

10.1.1 Connecting to a S

10.1.2 Connecting Via an RM-1 Module

10.1.3 Connecting Via T

10.2 Metal Chassis Controllers

10.2.1 Connecting Via

10.2.2 Connecting Via

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 37

afety Monitoring Device . . . . . . . . . . . . . . . . . . . . . . . . . . page 38

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 39

wo Force-Guided Relays. . . . . . . . . . . . . . . . . . . . . . . . . . . page 40

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 41

Two Normally Open Relay Safety Outputs . . . . . . . . . . . . . . page 41

One Normally Open One Normally Closed Safety Relay Outputs . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.3 Connecting Solid State Safety Outputs

10.2.4 Connecting Vi

a a Safety Monitoring Device . . . . . . . . . . . . . . . . . . . . . . . . . page 44

Section 11 -- Checkout and Test Procedures

11.1 Checkout Procedur

11.2 Test Procedure

e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 45

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 45

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 45

to Two Force-Guided Relays . . . . . . page 43

11.3 Using the Test Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 45

page 42

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

3

© OSTI 1209 PN99584-0050 Rev. E

Original Instructions

Page 6

11.4 Test Considerations When Using Exact Channel Select or Floating Blanking. . . . . page 46

Section 12 -- Troubleshooting

Section 13 -- Cleaning

Section 14 -- Specifications and Additional Information

14.1 System Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 46

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 48

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 49

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 49

14.2 MicroSafe MC4700 Series Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 49

14.2.1 MC4700 Series Dimensio

14.2.2 MC4700 Spare Parts

14.3 MicroSafe Flexible MCF4700 Series

14.3.1 MCF4700 Series Dimensions

14.3.2 MCF4700 Spare Parts

ns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 55

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 56

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 55

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 55

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 60

14.4 MicroSafe Jointed MCJ4700 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 65

14.4.1 MCJ4700 Segment Dimensions

14.4.2 90° Jointed MicroSafe MCJ47

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 65

00 Dimensions . . . . . . . . . . . . . . . . . . . . . . page 56

14.4.3 Sensor Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 56

14.4.4 Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 56

14.4.5 Minimum Object Resolution

14.4.6 MCJ4700 Spare Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 56

14.5 MiniSafe MS4700 Series

14.5.1 MS4700 Dimensions

14.5.2 MS4700 Spare Parts

14.6 MiniSafe Flexible MsF4700 Series

14.6.1 MSF4700 Series Di

14.6.2 MSF4700 Spare

14.7 DIN and LCM NEMA Controllers

Section 15 -- Glossary

15.1 Glossary Definitions

Section 16 -- Others

16.1 Warranty

16.2 Patents

16.3 Trademarks

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 89

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 89

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 100

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 100

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 100

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 100

at Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 56

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 71

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 71

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 73

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 77

mensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 78

Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 79

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 84

16.4 Repairs

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 100

4

© OSTI 1209 PN99584-0050 Rev. E

Original Instructions

Page 7

16.5 Documentation Criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 100

. . . . .

Appendix A —Checkout Procedur

e. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 90

A.1 Checkout Procedure Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 90

Appendix B —Test Procedur

B.1 Test Procedure Log

Appendix C —DeviceNet Operating Instructions

e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 91

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 91

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 92

C.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 92

C.2 Features

C.2.1 System identification

C.2.2 System status

C.2.3 System Settings

C.2.4 Diagnostic Information

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 92

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 92

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 92

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 92

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 93

C.3 Basic DeviceNet Network Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 95

C.4 LCM-2XX series internal D-Net Wire Colors and Pin Outs

C.4.1 Screw Connectors for LCM-2XX series D-Net interface module

C.5 DeviceNet Configuration Switches

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 97

. . . . . . . . . . . . . . . . . . . . page 95

. . . . . . . . . . page 95

C.5.1 Switch Function Selecti

C.6 Quick Disconnect Option

on Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 98

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 99

Appendix D —Declaration of Comformity Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 101

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

5

© OSTI 1209 PN99584-0050 Rev. E

Original Instructions

Page 8

Table of Figures

Figure 3-1 Accessing the Configuration Switches

Figure 3-2 Accessing the Configuration Switches on

Figure 3-3 4700 Transm

Figure 3-4 DIN Contr

itter and Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 13

oller Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 14

on the LCM DIN Controller . . . . . . . . . . . . page 11

the LCM-Metal Chassis Controller . . . . page 12

Figure 3-5 Metal Chassis Controller Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 15

Figure 4-1 Functional Flow Diagram

Figure 5-1 Connection Re

commendations for LCM Metal Enclosure. . . . . . . . . . . . . . . . . . . . page 20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 17

Figure 5-2 Connection Recommendations for LCM DIN Box . . . . . . . . . . . . . . . . . . . . . . . . . . page 20

Figure 5-3 Adding Har

Figure 8-1 Safe Mounting Distance

d guarding to Light Curtain when Using Channel Select . . . . . . . . . . . page 23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 28

Figure 9-1 Correct Mounting Example with Proper Alignment. . . . . . . . . . . . . . . . . . . . . . . . . page 31

Figure 9-2 Unsafe Mounting Examp

Figure 9-3 Unsafe Mounting Examp

le . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 31

le . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 31

Figure 9-4 Worst Case Alignment Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 32

Figure 9-5 Minimum Distance from

Figure 9-6 Correct Light Curta

a Reflective Surface as a Function of Range . . . . . . . . . . page 32

in Installation Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 34

Figure 9-7 Multiple Light Curtain Installation Configurations. . . . . . . . . . . . . . . . . . . . . . . . . page 35

Figure 9-8 Mounting Orientation

Figure 10-1 Connecting to a Safe

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 35

ty Monitoring Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 38

Figure 10-2 Connecting via an RM-1 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 39

Figure 10-3 Connecting Vi

Figure 10-4 Connecting with Tw

Figure 10-5 Connecting with One

Figure 10-6 Connecting with Tw

Figure 10-7 Connecting with Safety

Figure 11-1 Test Object

Figure 14-1 MC4700 Series Dimensional D

Figure 14-2 MicroSafe Flex

Figure 14-3 MicroSafe Jointed MCJ4700

Figure 14-4 90° Jointed Micr

Figure 14-5 Assembly Instructions

Figure 14-6 MS4700 Mechanical Drawin

a Two Force-guided Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 40

o Normally Open Safety Outputs . . . . . . . . . . . . . . . . . . . . . . page 41

Normally Open One Normally Closed Safety Outputs . . . . page 42

o Force Guided Relay Outputs. . . . . . . . . . . . . . . . . . . . . . . . page 43

Monitoring Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 44

Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 45

rawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 55

ible MCF4700 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 58

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 65

oSafe MCJ4700 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 66

Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 67

g . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 71

Figure 14-7 MiniSafe Flexible MSF4700

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 77

6

© OSTI 1209 PN99584-0050 Rev. E

Original Instructions

Page 9

Figure 14-8 DIN Controller Dimension Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 84

. . . . .

Figure 14-9 LCM Nema Metal Chassis Contro

ller Dimension Drawing . . . . . . . . . . . . . . . . . page 85

Figure 15-1 DeviceNet Install Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 99

Figure 15-2 DevieNet Wi

Figure C-1 Basic Devi

Figure C-2 Pin Outs for

ring with Optional M12 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . page 99

ceNet configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 95

Internal Screw Connectors used internally in the LCM-2XX . . . . . . . page 96

Figure C-3 Pin Outs for Micro_Style Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 96

Figure C-4 Pin Outs for

Phoenix-style connectors used in the STI MC4700, LCM-2 interface

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 97

Figure C-5 LCM-2 Power/DeviceNet board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 97

Table of Tables

Table 3-1 System Component Identification for the 4700 Transmitter and Receiver

Table 3-2 System Component Identification for the LCM-1, LCM-2 and LCM-3 Controllers

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-1 Operating Mode Switch Settings

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 18

. . . . . . . . page 13

. . . . . . . . .

page 14

Table 5-1 System Response to Exact Channel Select

Table 5-3 System Response to Floating Blanking

Table 5-4 Icon Key for T

Table 5-5 Sample S and D

Table 5-6 Sample S and D

Table 5-7 Sample S and D

Table 5-8 Sample S and D

ables 5-1 and 5-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 21

Factors for 12 mm Resolution Systems. . . . . . . . . . . . . . . . . . . . . page 22

pf

Factors for 14 mm resolution Systems . . . . . . . . . . . . . . . . . . . . . page 22

pf

Factors for 20mm resolution Systems. . . . . . . . . . . . . . . . . . . . . . page 22

pf

Factors for 30 mm resolution Systems . . . . . . . . . . . . . . . . . . . . . page 23

pf

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 21

Table 5-9 Switch Settings, Exact Channel Select and Floating Blanking

Table 6-1 Operational Display Code Summary

Table 6-2 MPCE Switch Setting

s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 26

Table 7-1 Auxiliary Output Operating Mode S

Table 9-1 Color Code/Terminal Number Cr

Table 9-2 Color Code/Terminal Number Cr

Table 12-1 Operational Codes

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 46

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 25

witch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . page 28

oss Reference for DIN Controllers . . . . . . . . . . . . page 32

oss Reference Metal Chassis Controllers . . . . . . . page 32

. . . . . . . . . . . . . . . . . page 24

Table 12-2 DIP Switch Fault Codes

Table 12-3 Safety Output (OSSD) Faults

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 47

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 47

7

© OSTI 1209 PN99584-0050 Rev. E

Original Instructions

Page 10

Table 12-4 MPCE Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 47

Table 12-5 Controller

Table 14-1 Response T

Table 14-2 Response T

Table 14-3 Response

Table 14-4 12mm transm

Table 14-5 14mm,

Table 14-6 MC4700-12

Table 14-7 MC4700-14

Table 14-8 MC4700-20

Table 14-9 MC4700-30

Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 48

ime for 12 mm MC4700 and MS4700 . . . . . . . . . . . . . . . . . . . . . . . . . . page 52

ime for 14 mm and 20 mm MC4700 and MS4700 . . . . . . . . . . . . . . . . . page 52

Times for 30 mm MC4700 and MS4700 systems. . . . . . . . . . . . . . . . . . . page 53

itter and Receiver Lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 55

20 mm and 30 mmTransmitter and Receiver Lengths . . . . . . . . . . . . . . . . . page 55

Spare Transmitter and Receiver Model Number . . . . . . . . . . . . . . . . . page 56

Spare Transmitter and Receiver Model Number . . . . . . . . . . . . . . . . . page 56

Spare Transmitter and Receiver Model Number . . . . . . . . . . . . . . . . . page 57

Spare Transmitter and Receiver Model Number . . . . . . . . . . . . . . . . . page 57

Table 14-10 MCF4700-12 Dimensions First &

Table 14-11 MCF4700-12 Dimensions L

Table 14-12 MCF4700-14, MCF4700-20

Table 14-13 MCF4700-14, MCF4700-20

ast Segment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 59

and MCF4700-30 First and Middle Segment . . . . . page 59

and MCF4700-30 Last Segment . . . . . . . . . . . . . . . page 60

Middle Segment . . . . . . . . . . . . . . . . . . . . . . . page 59

Table 14-14 Transmitter

Table 14-15 MCJ470-12 Dimensions

and Receiver Segments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 60

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 68

Table 14-16 MCJ4700 Joint Resolution (Resolution at the

Table 14-17 Transmitter

Table 14-18 MS4700-12 Dimensions

Table 14-19 MS4700-14 & MS4700-20

Table 14-20 MS4700-30 Dimensions

Table 14-21 Transmitter

Table C-1 Specifications fo

Table C-2 4700 Status Information

Table C-3 I/O Data for Change of S

Table C-4 I/O Data

Table C-5 Configuration Switches for Dev

and Receiver Segments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 68

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 71

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 72

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 72

and Receiver Segments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 73

r 4700 System Controller with DeviceNet . . . . . . . . . . . . . . . . . . . page 93

Sent in Response to a poll command . . . . . . . . . . . . . . . . . page 94

tate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 94

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 94

ice-Net. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 98

Corner) . . . . . . . . . . . . . . . . . . . . . page 68

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

8

© OSTI 1209 PN99584-0050 Rev. E

Original Instructions

Page 11

. . . . .

▲

!

▲

!

1 I

MPORTANT

S

WARNING! Read and understand this section prior to installing a 4700 system.

A 4700 system is a general purpose presence sensing device designed to guard personnel working

around moving machinery.

Whether a specific machine application and light curtain installation complies with safety regulations

depends on

items are the responsibility of the purchaser, installer and employer.

The employer is responsible for the selection and tra

maintain the machine and its safeguarding systems. A 4700 system should only be installed, verified

and maintained by a

possession of a recognized degree or certificate of professional training, or who, by extensive

knowledge, training or experience, has successfully demonstrated the ability to solve problems relating

to the subject matter and work.” (ANSI B30.2-1983)

To use a 4700 series safety light curtain the following requirements must be met:

— The guarded machine

a press with a full-revolution clutch.

— The guarded machine must not present a hazard from flying parts.

AFETY

the proper application, installation, maintenance and operation of the light curtain. These

W

ARNINGS

ining of personnel to properly install, operate,

qualified person. A qualified person is defined as “a person or persons who, by

must be able to stop anywhere in its cycle. Do not use a safety light curtain on

1

and

— The guarded machine must have a consistent stopp

— Severe smoke, particulate matter and corrosives may degrade the ef

Do not use a 4700 system in this type of environment.

— All applicable governmental and local rules, codes, and regulations must be satisfied. This is the

e

mployer’s responsibility.

— All safety-related machine control elements must be designed so that a alarm in the control logic or

failure of the control circuit does not lead to

— Additional guarding may be required for access to dange

system.

— Perform the OMRON STI test procedure at installation and after

modification to the machine controls, tooling, dies or machine, or the 4700 series system.

— Perform only the test and repair procedures outlined in this manual.

— Follow all procedures in this manual for proper operation of the 4700 series system.

The enforcement of these requirements is beyond the control of OMRON STI. The employer has the

sole re

sponsibility to follow the preceding requirements

requirements specific to his machinery.

WARNING! Despite inherent safe design measures, safeguarding and complementary

protective measures adopted by the user, residual risk m

risks are strictly under the control of the end user and may include severe injury or death.

a failure to danger.

ing time and adequate control m

ficiency of a safety light curtain.

rous areas

and any other procedures, conditions and

ay remain in any installation. Potential

not covered by the 4700 series

maintenance, adjustment, repair or

echanisms.

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

9

© OSTI 1209 PN99584-0050 Rev. E

Original Instructions

Page 12

2

2 S

IGNIFICANT

F

EATURES

2.1 STANDARD FEATURES

Individual Beam Indicators

External Device Monitoring (MPCE Monitoring)

Automatic Start Mode

Start Interlock Mode

Start/Restart Interlock Mode

Adjustable Mounting Brackets

Floating Blanking

Exact Channel Select

Two Safety (PNP) Outputs

Auxiliary Output

Start Switch Input Selectable NO or NC

2.2 OPTIONAL FEATURES

Relay Safety Outputs (Metal Chassis Controllers only)

2

DeviceNet

Multi-Channel Select (Non-CE)

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

10

© OSTI 1209 PN99584-0050 Rev. E

Original Instructions

Page 13

. . . . .

3 S

I

NDICATORS

YSTEM

A

3.1 A CCESS TO CONFIGURATION SWITCHES

3.1.1 LCM DIN CONTROLLER

CCESS

, C

OMPONENTS

AND

3

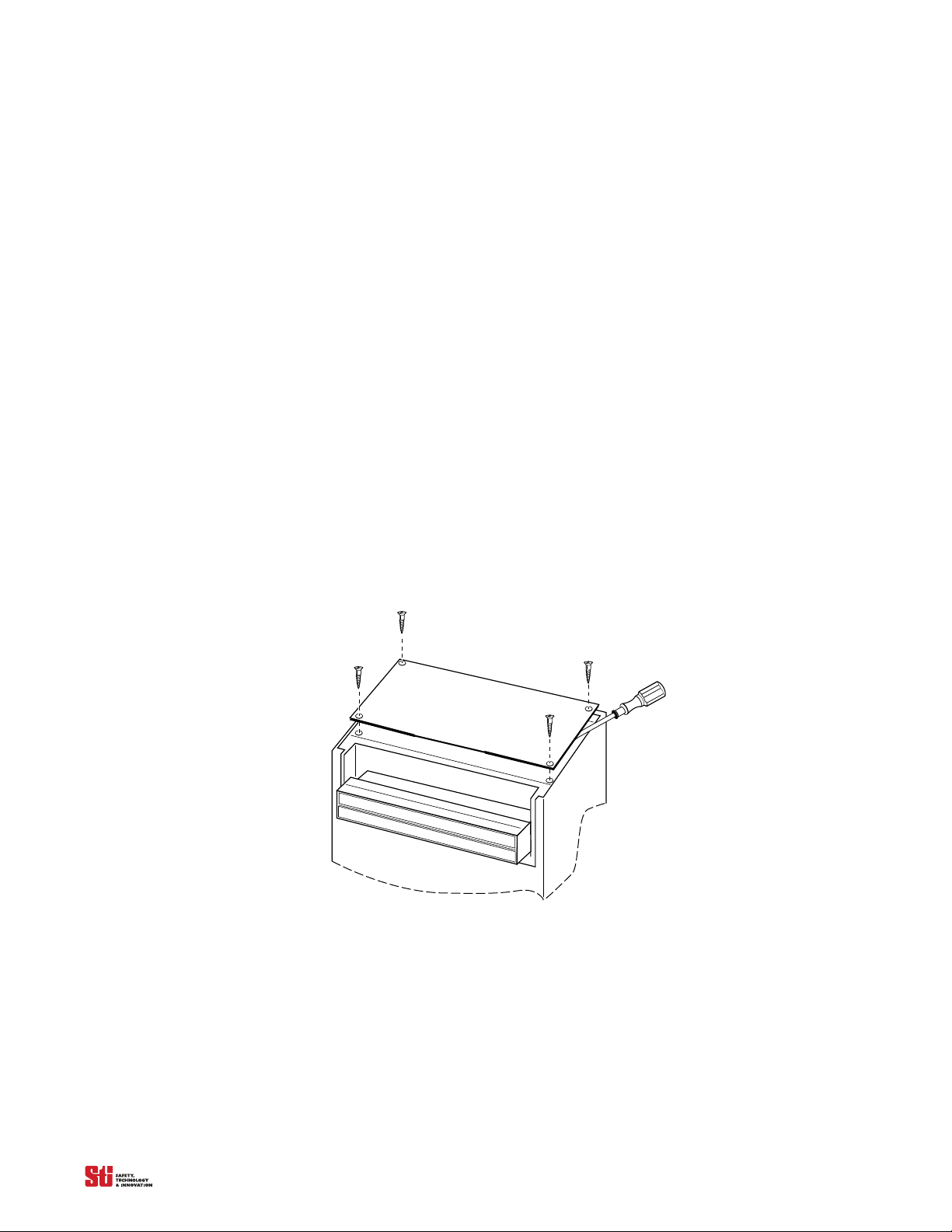

Switches for configuring system features are located under the front cover of the controller. Access to

these switches is gained by the following procedure:

1. Remove the four screws holding the cover in place (see Figure 3-1 for location).

2. Place the blade of a thin flat-blade screwdriver between the cover and the main controller housing

a

nd gently lift the c

removed.

To replace the cover:

1. Correctly position one end and push down on the opposite end to snap it in place.

2. Replace the four screws to properly retain the cover.

over off. See Figure 3-1 for detail. The cover is not hinged and will be completely

Figure 3-1 Accessing the Configuration Switches on the LCM DIN Controller

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

11

© OSTI 1209 PN99584-0050 Rev. E

Original Instructions

Page 14

3

STOP

RUN

RUN

START

INTERLOCK

FB/CS

W A R N I N G

Scientific Tec hnologies Inc, Fremont, CA 94555 U. S. A.

R

!

T

o test the light cur tain, use the appropr iate ST Isupplied test object, or proper ly siz ed opaque cyl indri cal

object.

If yo u are using the Channel Select or F loating

Blanki ng features and the object to be ignored does not

completely prevent acc ess to the haz ardous ar ea, ei ther

(1) use a mechanical guard or other means to block

access or (2) increase the minimum safe distance and

use a larger tes t object diameter as explained i n the

Installation and Operating Manual.

1. Di sable the ma chine. Pow er on the l ight cur tain.

2. Ins pect the machine to ensure entry to the

hazardous area is only through the light curtain sensing

field. I f not, additional guardi ng, incl uding mechanical

barriers may be required.

3. Veri fy that the mounting dis tance of the l ight

curtain i s equal to or gr eater than the mini mum safe

distance fr om the hazardous point. Ens ure the operator

is not able to stand undetec ted between the li ght curtai n

and the hazard.

4. Chec k f or exter nal dama ge to the li ght curtai n,

the machine, el ectri cal cabl es and w iri ng.

5. Inter rupt the sensing fi eld with the

test

object t

o check the eff ectiveness of the light c urtain.

Move the test obj ect ins ide the peri meter ( along the top,

Do Not Remove Or Cover This Label

http://www.sti.com1/888/510-4357

STI Label P/N 28621-0010 re

T

EST PROCEDURE

sides and bottom) of the sensing field and up and down

through the center of the sens ing fiel d. Veri fy that the

Red indi cat or i s ON and the G ree n indi cator is OF F w hil e

the test object is anywhere in the sensing field.

watch for any unprotected acces s to the point of ha zard.

6. Star t the machine. Interr upt the sensing f ield

with the test object. The machine shoul d stop

immediately. Never insert the test object into the

dangerous parts of the mac hine! Wi th the machine at

rest, inter rupt the sensi ng fi eld w ith the test obj ect.

that the machine wil l not s tart with the tes t object i n the

sensing field.

7. Ensure the braking and machine stop systems

are working properly in accordance with the machine

manufacturer Õs requirements. I f the machine does no t

stop fast enough, adjust the braking system or increase

the distance fr om the light c urtain to the poi nt hazard.

8. If the saf ety dev ices or machi ne fai l any of these

tests, do not run the mac hine. I mmediately lockout the

machine to prevent i ts use and noti fy the su pervis or

9. If the Channel Select is reprogrammed or

disabled, you must repeat thes e test procedur es.

10. C lose and l ock the li ght curta in contr

enclosu re d oor, if appl i cabl e.

Diagnostic Codes:

00 Normal Operation

01 Normal Operation, waiting for Start signal

02 Normal Operation, Floating Blanking active

03 Normal Operation, Exact Channel Select active

04 Normal Operation, Exact Channel Select and

Floating Blanking active

20 G eneral DIP switch fault

21 Invalid switch setting

22 DIP switch settings changed during operation

23 Invalid Channel Select or MPCE switch settings

30 General Safety Output fault

40 G eneral MPCE fault

41 MPCE open before safety output (OSSD) activation

43 MPCE open when power is applied

50 Internal controller fault

51 Receiver fault

52 Transmitter fault

53 Transmitter and receiver length mismatch or transmitter

and receiver not connected

59 24 VDC power supply fault

Cla sp

PROGRAM

Opti ona l

Keyswitch

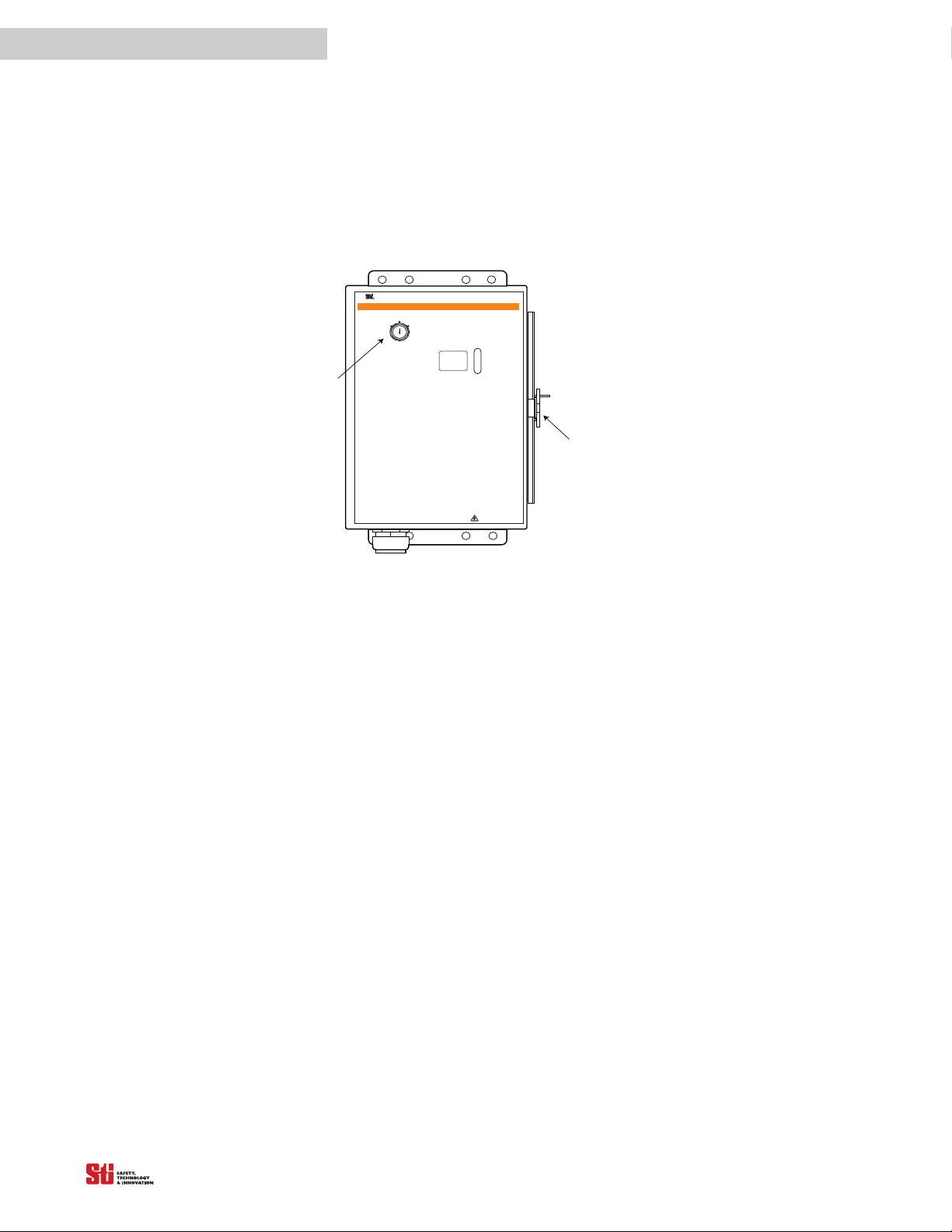

3.1.2 LCM METAL CHASSIS CONTROLLER

Switches for configuring system features are located inside the front cover of the controller. Access to

these switches is gained by the unlocking the clasp on the right-hand side of the controller box.

The Clasp has provisions to accept a user-provided padlock. On

ly a qualified p erson should have

possession of the key to the padlock, or to the optional Program/Start keyswitch.

Figure 3-2 Accessing the Configuration Switches on the LCM-Metal Chassis Controller

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

12

© OSTI 1209 PN99584-0050 Rev. E

Original Instructions

Page 15

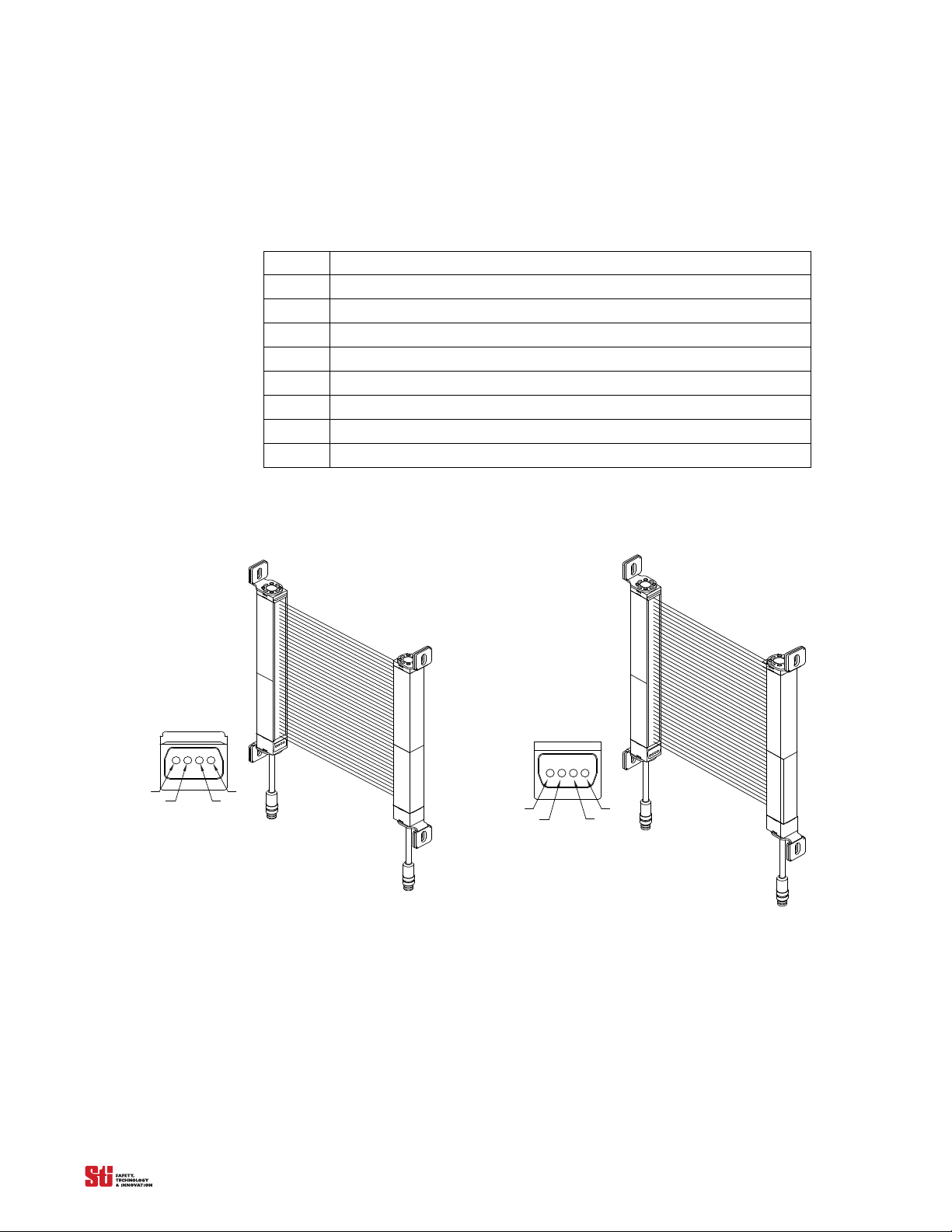

3.2 L OCATION OF THE COMPONENTS AND INDICATORS

2. YEL

4. RED - STOP/BLOCKED

3. GRN - RUN/CLEAR

2. YEL - INTERLOCK

OR CHANNEL SELECT

1. AMBER - FLOATING BLANKING

1. AMBER

4. RED

3. GRN

INDICATORS

LED

RECEIVER

DETECTION

ZONE

TRANSMITTER

MC4700

MC4700

2. YEL

4. RED - STOP/BLOCKED

3. GRN - RUN/CLEAR

2. YEL - INTERLOCK

OR CHANNEL SELECT

1. AMBER - FLOATING BLANKING

1. AMBER

4. RED

3. GRN

INDICATORS

LED

RECEIVER

DETECTION

ZONE

TRANSMITTER

MS4700

MS4700

Refer to Figure 3-3, Figure 3-4 and Figure 3-5 for the location of the components and indicators listed

below.

. . . . .

Table 3-1 System Component Identification

for the 4700 Transmitter and Receiver

Chart #

1 RECEIVER

2 Individual Beam Indicators (one for each beam) – Red

3 Channel Select or Floating Blanking Indicator – Amber

4 Interlock or Fault Indicator – Yellow

5 Machine Stop Indicator – Red

6 Machine Run Indicator – Green

7 TRANSMITTER

8 Detection Zone

Figure 3-3 4700 Transmitter and Receiver

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

13

© OSTI 1209 PN99584-0050 Rev. E

Original Instructions

Page 16

3

12

11

9

10

15

14

16

13

17

NOTE : F or DeviceNet Option,

LCM-2 Series,

Termina ls 13 to 17

are indica ted below.

131415

DeviceNet

CAN +

DATA H

1617

DATA L

CAN VÐ

13

LCM-1 Series

Fremont, CA, US A

Tel: 510/608-3400, Fax: 510/744-1442

www.sti. com

Scientific Technologies Inc.

OSSD 1

OSSD

RETURN

MPCE

0 VDC

MPCE

RETURN

BLUE

AUX1

OUT

ORANGE

OSSD 2

AUX2

OUT

BLACK

PINK

GRAY

VIOLET

TAN

YELLOW

RED

R

11

12

131415 123457

8

6910

Xmtr

24232221201918 34333231302827 292625

Rcvr

Do not defeat or bypass. Severe injury to

!

WARNING SAFETY DE VICE

personnel could result.

START

RETURN

START

+24 VDC

WHITE

BROWN

Xmtr/RcvrOutput

SHIELD

RS232 MPCE Remote

Power

Not Used

PROG RET

PROGRAM

Not Used

Not Used

FB/CS

Interlock

Stop

Run

Not Used

Not Used

DATA

1617

Not Used

Not Used

18

1

23

19

23

45

Cha nnel S elect

ECS 1

67

PROGRAM

ECS Return

ECS 2

NOTE : For Multi Channel S ele ct Option,

LCM-3 Series,

Terminals 4 to 7

are indica ted on below.

CS Prog

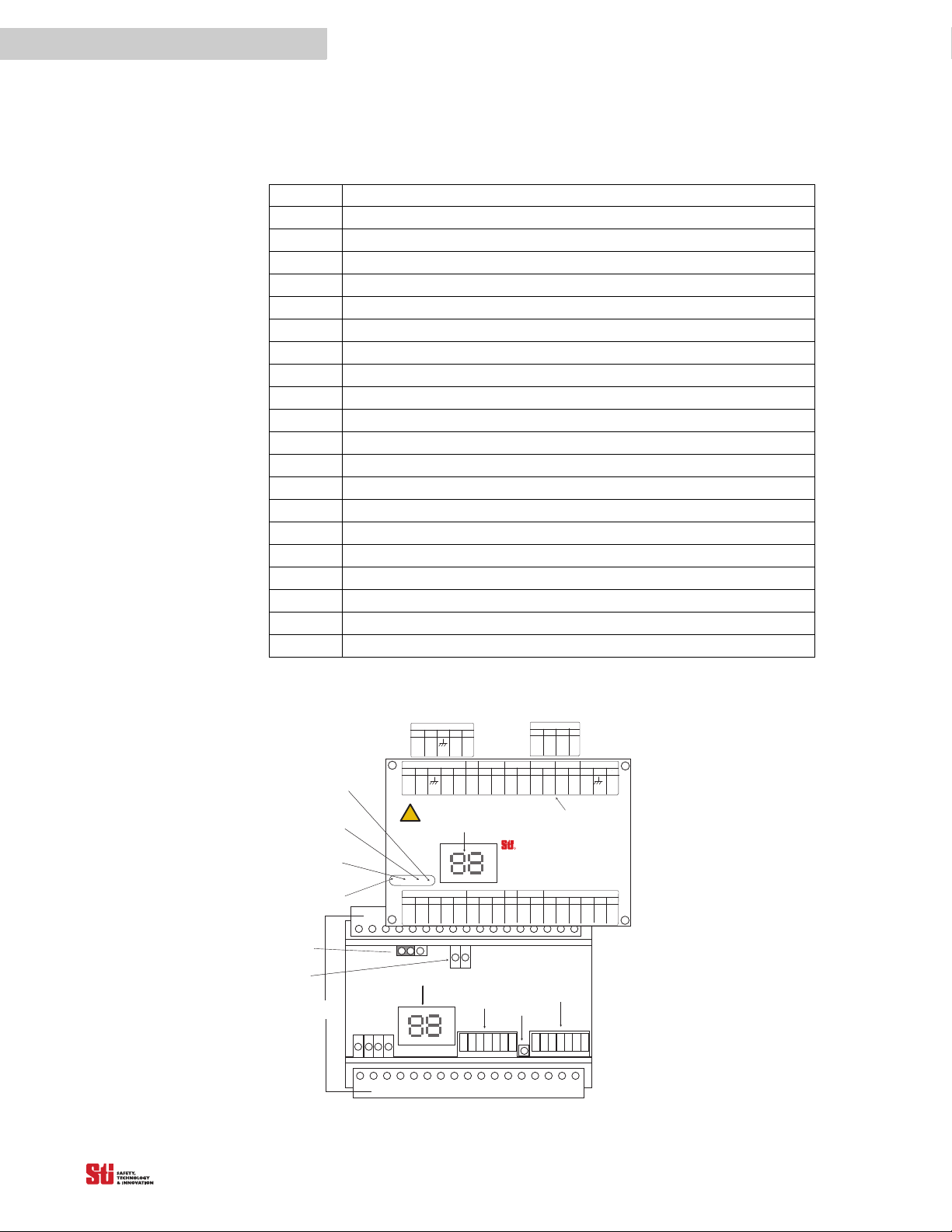

Table 3-2

System Component Identification for the LCM-1, LCM-2 and LCM-3 Controllers

Chart #

4 EXact Channel Select 1 beam

5 EXact Channel Select 2 beams

6 EXact Channel Select 3 beams

7 EXact Channel Select Return

9 Channel Selector Floating Blanking Indicator - Amber

10 Interlock or Alarm Indicator - Yellow

11 Machine Stop Indicator - Red

12 Machine Run Indicator - Green

13 Diagnostic Code Display

14 Switch A

15 Program Button

16 Switch B

17 Removable Terminal Blocks for input and output connections

18 DeviceNet status indicators (optional)

19 Start Switch Type Jumper

20 Relay Board (metal chassis only)

21 Power In (metal chassis only)

22 MPCE Monitoring (metal chassis only)

23 Multi-channel Select terminals

24 Optional Keyswitch

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Figure 3-4 DIN Controller Components

14

© OSTI 1209 PN99584-0050 Rev. E

Original Instructions

Tel: 1/888/510-4357 in USA and Canada

Page 17

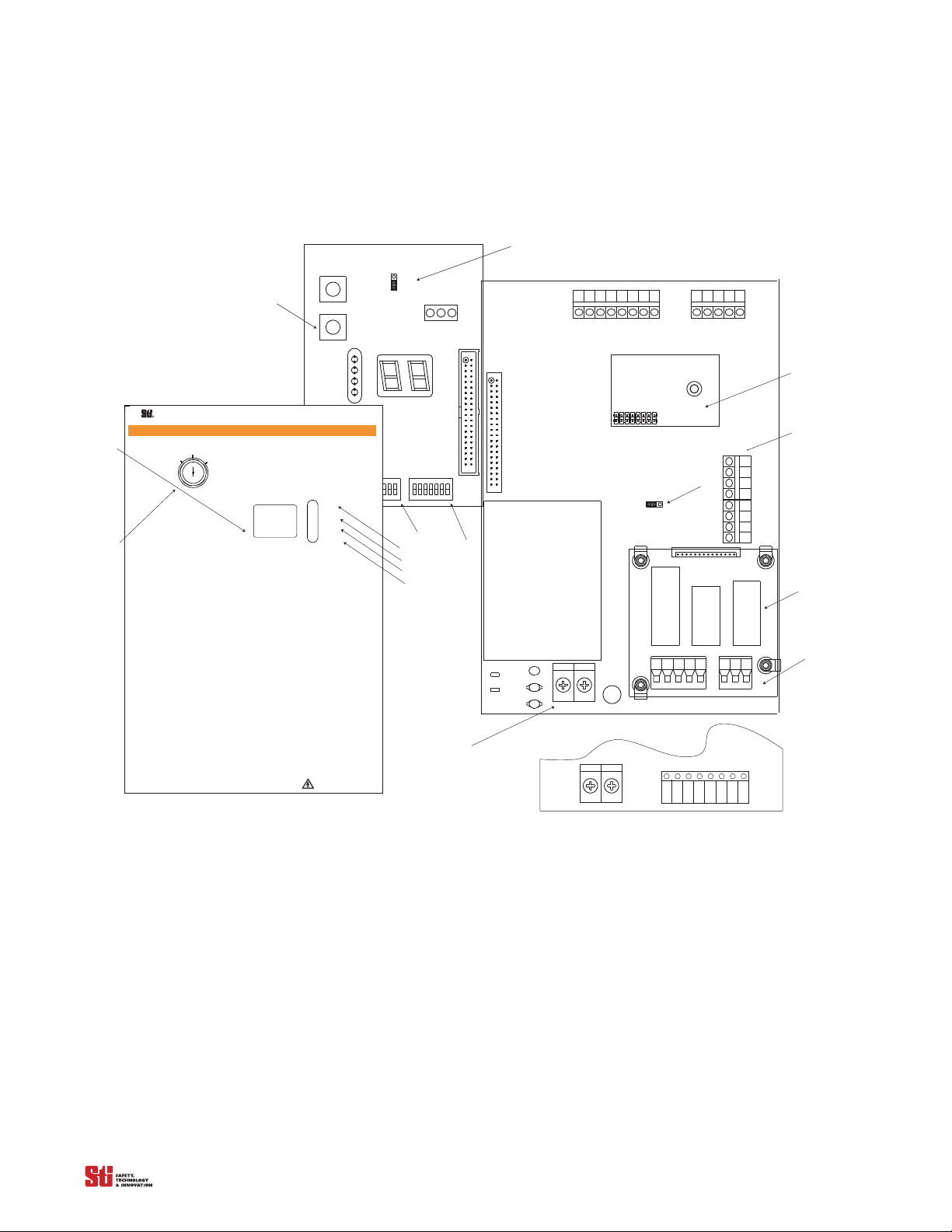

1 2 3451 2 3 456 7 8

2

1

2

1

MPCE MON

ON

OFF

JMP2

BOARD

DEVICENET

OPTIONAL

-Note: Shown with optional Relay Board.

P2

R44

R45

C8

C9

RV1

MCS

TB5

TX

TB6

RX

J1

J3

TB7

AUX

K2

K1

0SSD2 AUX

TB3

TB1

TB2

PS1

0SSD1

F1

N

L

KEYSWI TCH

J2

N.O.

N.C.

PROGRAM

START

J1

SWA

SWB

STOP

RU N

RUN

STA R T

INTERLOC K

FB/C S

W A R N I N G

Scientific Technologies I nc, Fremont, CA 94555 U. S. A.

R

!

T

o test the light curtain, use the appropriate S TI supplied test object, or properly sized opaque cylindrical

object.

If y ou are using the C hannel Select or Floating

Blanki ng features and the object to be ignored does not

completely prevent access to the hazardous area, either

(1) use a mechanical guard or other means to block

access or (2) increase the minimum safe distance and

use a larger test object diameter as explained in the

In

stallation and Operating Manual.

1. Disable the machine. Power on the light curtain.

2. Inspect the machine to ensure entry to the

hazardous area is only through the light curtain sensing

field. If not, additional guarding, including mechanical

barriers may be required.

3. Verify that the mounting distance of the light

curtain is equal to or greater than the mini mum safe

distance from the hazardous point. E nsure the operator

is not able to stand un

detected between the light curtain

and the hazard.

4. Check for external damage to the light curtain,

the machine, electrical cables and wiri ng.

5. Interrupt the sensing f ield wi th the

test

object t

o check the eff ectiveness of the light curtain.

Move the test object inside the perimeter (along the top,

Do Not Remove Or Cover This Label

http://www.sti.com1/ 888/ 510-4357

ST I L abel P /N 28621- 0010 re

T

EST

P

RO C EDU RE

sides and bottom) of the sensing field and up and down

through the center of the sensing fi eld. V erify that the

Red indicator is ON and the Green indicator is OFF while

the test object i s anywhere in the sensing field.

watch for any unprotected access to the point of hazard.

6. Start the machine. Interrupt the sensing field

with the test o bject. T he machi ne s hould stop

immediatel y. N ever ins ert the tes

t object into the

dangerous parts of the machine! With the machine at

rest, interrupt the sensing field with the test object.

that the machine will not start with the test object in the

sensing field.

7. E nsure the braking and machine stop systems

are working properly in accordance with the machine

manufacturerÕs r equirements. I f the machine does not

stop fast enough, adjust the braking system or i ncrease

the distance from the light curtain to the

point hazard.

8. If the safety devices or machine fail any of these

tests, do not run the machine. I mmediately lockout the

machine to prevent its use and notif y the supervisor

9. If the C hannel S elect is reprogrammed or

disabled, you must repeat these test procedures.

10. Close and lock the light curta in contr

enclosure door, if applicable.

Dia g no sti c C od es :

00 Normal O pera tion

01 Normal O pera tion, waiting for S tart signal

02 Normal Opera

tion, Floating Blanking a ctive

03 Normal O pera tion, Exact C hannel Select active

04 Normal O pera tion, Exact C hannel Select and

Floating Blanking active

20 General DIP switch fault

21 Invalid switch setting

22 DIP switch settings changed during operation

23 Invalid Channel Select or MPC E switch settings

30 General Safety O utput fa ult

40 General MPCE fault

41 MPCE open before safety output (OSSD) activation

43 MPCE open when power is applied

5

0 Internal controller fault

51 Receiver fault

52 Transmitter fault

53 Transmitter and receiver length mismatch or transmitter

and receiver not connected

59 24 VDC power supply fa ult

Inside Front Lid of the metal chassis controller

19

15

16

14

18

17

20

21

13

9

10

11

12

23

TB4

TB1

Shown with DC Solid State Configuration

Note: For Solid State Configuration, JMP2 and

PS1 are not available.

+

_

22

PR O G RA M

24

2

1

2

1

PROG

START

MPCE

. . . . .

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

Figure 3-5 Metal Chassis Controller Components

15

© OSTI 1209 PN99584-0050 Rev. E

Original Instructions

Page 18

4

☛☛

4 S

YSTEM

O

PERATION

The 4700 system is a microprocessor-controlled, infrared transmitted-beam safety light curtain. The

system consists of a receiver assembly and a transmitter assembly. Quick disconnect cables link the

controller to the transmitter and receiver.

The safety light curtain is often used where personnel protection is

include mechanical power presses, robotic work cells, filter presses, injection molders, food

processing equipment and automated assembly equipment.

required. Typical applic

4.1 OPERATING STATES

The operating condition of a 4700 system is described in terms of states. The following operating

states exist for the 4700 system.

4.1.1 MACHINE RUN

The two system safety outputs are in the ON state, the green machine run indicator is lit, and the

auxiliary output is in a state consistent with its configuration. See

machine is allowed to operate. Pressing and releasing the start button

4.1.2 MACHINE STOP

The two system safety outputs are in the OFF state, the red machine stop indicator is lit, and the

auxiliary output is in a state consistent with its configuration. See section

protected machine is not allowed to operate. Press and releasing the start switch has no effect.

Section 7 on page 27. The protected

has no effect.

Section 7 on page 27. The

4

ations

4.1.3 INTERLOCK

The two system safety outputs are in the OFF state, the red machine stop indicator and yellow

interlock indicator are lit. The auxiliary output is in a state consistent with its configuration. See

Section 7 on page 27. The interlock state does not allow the protected machine to operate until the

detection zone is clear of obstructions and the start button is pressed and released.

4.1.4 ALARM

The two system safety outputs are in the OFF state, the red machine stop indicator is lit, the yellow

interlock indicator is flashing, and the auxiliary output is in the OFF state. The alarm state does not

allow the protected machine to operate. The primary difference between alarm and interlock is that the

4700 system will remain in the alarm state until power is recycled or the start switch is pressed and

released and the system has run a self-test.

4.2 OPERATING MODES

System operating modes determine the start-up and operating behavior of the 4700 system. Operating

mode definitions rely on the operating states presented above. Operating mode selection is performed

via configuration switches under the front cover of the controller.

NOTE! If internal faults are detected by the 4700 system during power-up or operation, it will enter

the alarm state with its safety outputs in the OFF state.

4.2.1 AUTOMATIC START

The 4700 system will power-up with its safety outputs OFF, and perform system initialization and self

tests. The 4700 system will enter the machine run state if no obstructions are present in the detection

zone. In this state, when an object is sensed entering the detection zone, the 4700 system will change

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

16

© OSTI 1209 PN99584-0050 Rev. E

Original Instructions

Page 19

from machine run to machine stop and remain in this state until the obstruction is removed. Once the

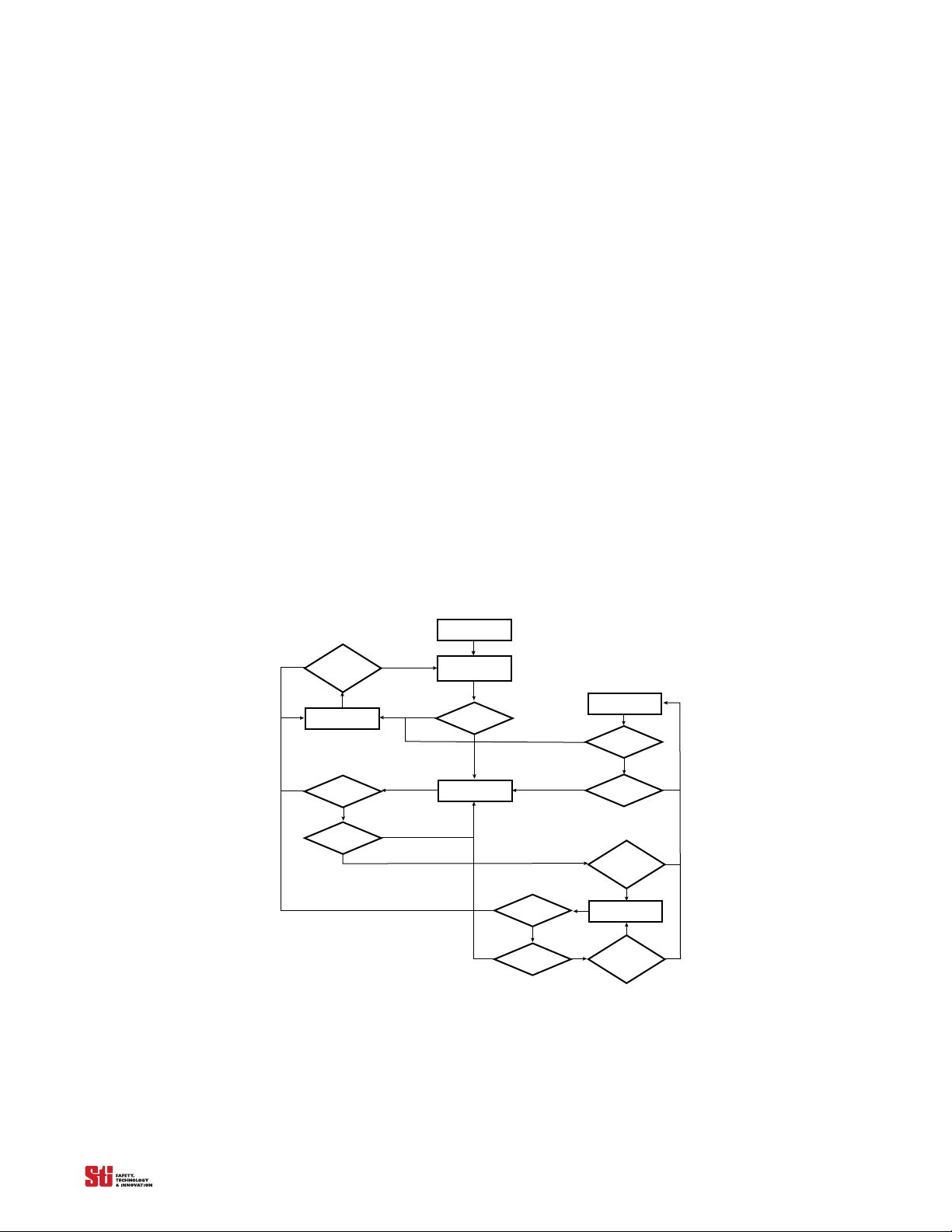

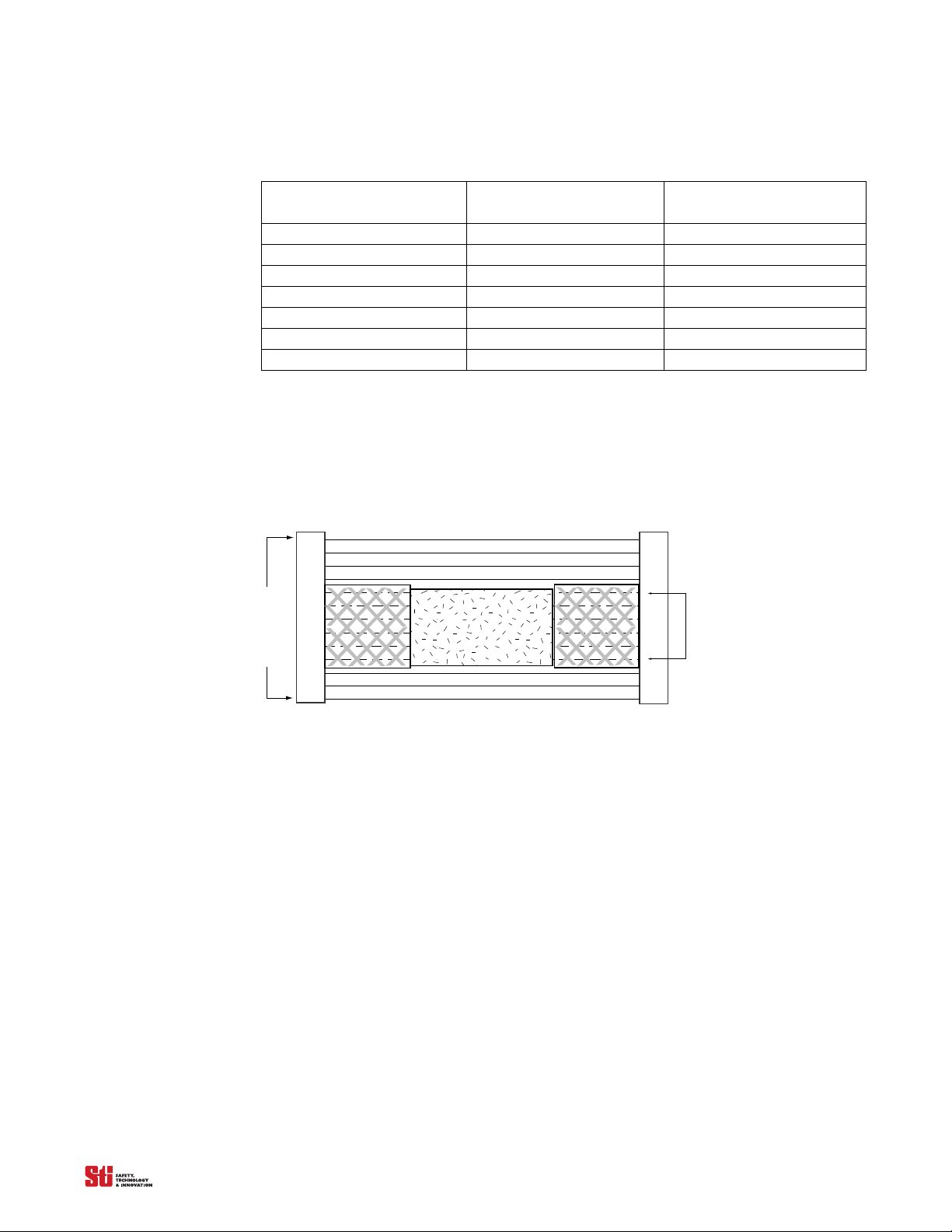

Power-Up

Power-On

Self-Test

Failure

Mach ine S top

Start

Pressed &

Released

Fault

Failure

Beam

Cleared

Mach ine ru n

Failure

Beam

blocked

Start/

Restart

Interlock

Interlock

Failure

Beam

Blocked

Start

Pressed &

Released

No

Yes

No

No

No

No

No

No

YesYes

YesYes

Yes

Yes

Yes

Yes

Yes

Yes

detection zone is clear, the 4700 system will automatically change from machine stop to machine run.

4.2.2 START INTERLOCK

The 4700 system will power-up with its safety outputs OFF and perform system initialization and selftests. If no obstructions are detected in the protected zone, (or an exact channel select pattern satisfied),

the 4700 system enters the interlock state. To enter the machine run state, the detection zone must be

clear (or an exact channel select pattern satisfied), and then the operator must press and release the start

switch. In the machine run state, when an object is sensed entering the detection zone the 4700 system

will change from machine run to machine stop. Once the detection zone is clear, the 4700 system will

automatically change from machine stop to machine run.

4.2.3 START/RESTART INTERLOCK

The 4700 system will power-up with its safety outputs OFF, and, if no faults are detected, enter the

interlock state. To enter the machine run state, the detection zone must be clear (or an exact channel

select pattern satisfied), and then the operator must press and release the start switch. In the machine

run state, when an object is sensed entering the detection zone the 4700 will change from machine run

to interlock. The 4700 system will remain in the interlock state even after the obstruction is removed

from the detection zone. To enter the machine run state, the operator must press and release the start

switch. If any obstruction is present in the detection zone when the start switch is pressed and released,

the 4700 will remain in the interlock state.

. . . . .

NOTE! The definitions above mention a start switch. See Section 10–“Connecting to the Machine

Control Circuit” for wiring of the start switch.

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

Figure 4-1 Functional Flow Diagram

17

© OSTI 1209 PN99584-0050 Rev. E

Original Instructions

Page 20

5

▲

!

▲

!

▲

!

4.3 OPERATING MODE SELECTION

Operating mode is selected by setting positions 1 and 2 of Switches A and B, located under the

controller cover. Refer to Table 4-1. Any mismatch between the settings of Switch A and B will result

in an alarm condition. In addition, if the configuration switch settings change

will enter the alarm state with the safety outputs off.

Warning! Disconnect power before accessing the controller assembly.

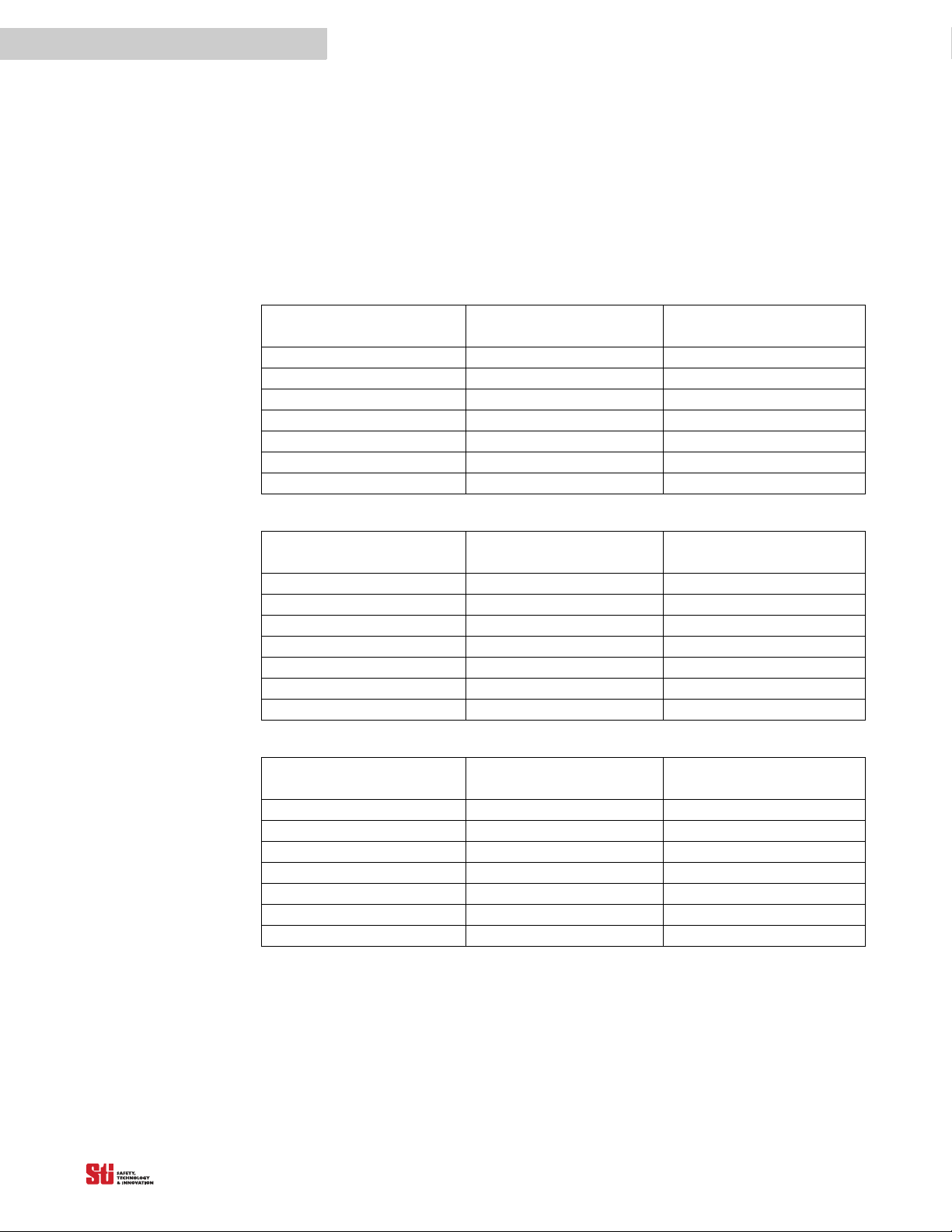

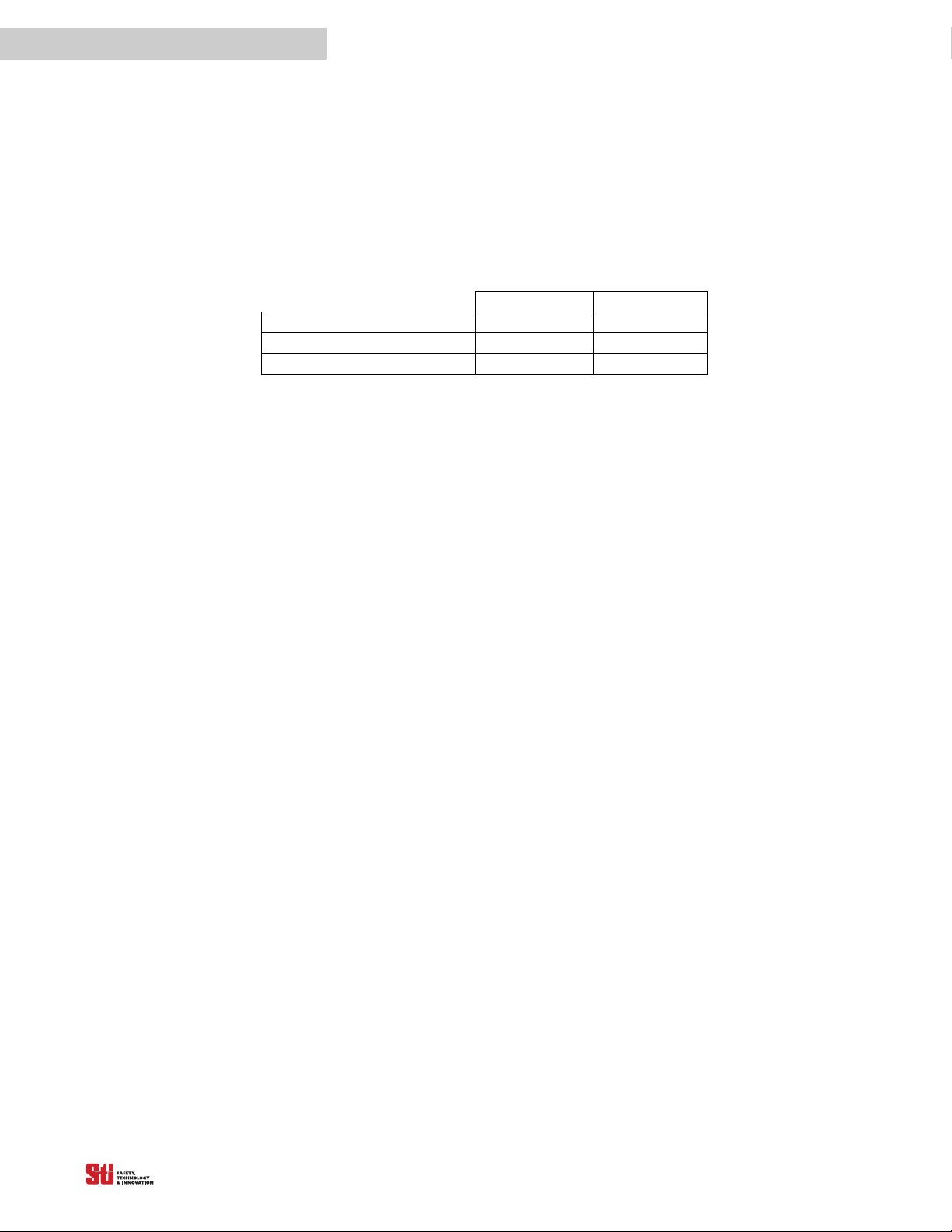

Table 4-1 Operating Mode Switch Settings

SWITCH A SWITCH B

OPERATING MODE 1 2 1 2

Automatic Start (default setting) CLOSED/ON CLOSED/ON CLOSED/ON CLOSED/ON

Start interlock OPEN/OFF CLOSED/ON OPEN/OFF CLOSED/ON

Start/Restart interlock OPEN/OFF OPEN/OFF OPEN/OFF OPEN/OFF

Not Allowed CLOSED/ON OPEN/OFF CLOSED/ON OPEN/OFF

while the system is on, it

4.4 START SWITCH TYPE SELECTION

The type of Start switch (Normally Open or Normally Closed) used by the 4700 system is selectable

by a jumper located under the controller cover. Refer to Figure 3-4 DIN Controller

Figure 3-5 Metal Chassis Controller Components. Placin

selects a Normally Closed Start Switch. Placing the jumper between 2 and 3 selects a Normally Open

Start switch.

g the jumper between Pins 1 and 2 of JMP 1

Components and

18

type of Start

or Floating Blanking, to avoid unexpected areas where the

selected and used, (i.e. jump

to personnel. Exact Channel

Additional Guarding When Using Exact Channel

m controller should be inst

prevent access to the hazardous

gramming may be inadvertently

er between Pins 1

alled in an

increase.

© OSTI 1209 PN99584-0050 Rev. E

Original Instructions

5

Note: If there is a mismatch between the

and 2 and Normally Open Start Switch used) the switch must be pressed and released twice before

the system will enter a Run state.

5 D

ETECTION

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

O

PTIONS

Warning! Use of Exact Channel Select and/or Floating Blanking will make the 4700 system less sensitive to

objects in the detection zone. Improper use of either can result in severe injury

Select may require a hard barrier guard (see Section 5.8

Select

), Exact Channel Select or Floating Blanking requires an increase in the safety distance. Read the

following section carefully.

- To prevent unauthorized modification of the detection zone. The syste

enclosure with supervisor-controlled access.

- If the object to be ignored by the Channel Selected beams does not completely

area, then either use a hard guard or other means to block access or increase the minimum safe distance as

required by the proper formula.

- Any beams which are not in alignment at the time of Channel Select pro

deselected. Use the OMRON STI Test Procedure to verify the correct configuration.

- Floating Blanking increases the minimum safety distance therefore test object size will

- After programming or activating Channel Select

system may not sense an intrusion into the detection zone, use a proper size test object to perform the OMRON

STI Test Procedure.

Page 21

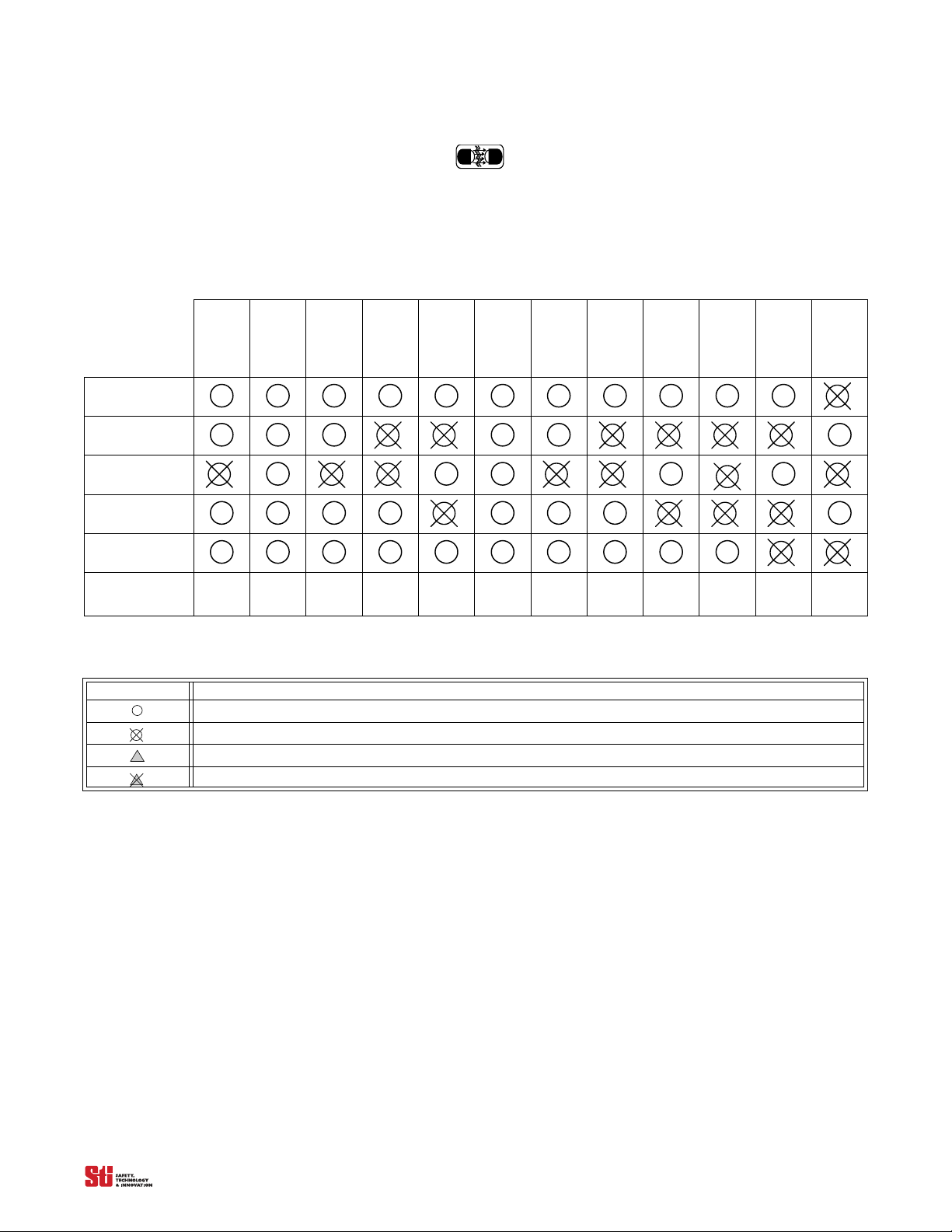

5.1 E XACT CHANNEL SELECT (ECS)

ECS disables selected, fixed areas of the detection zone by masking off specific, fixed beam locations.

ECS is helpful when stationary objects such as tooling and fixtures permanently obstruct a portion of

the detection zone.

. . . . .

Channel Select

s

Statu

Channel 1

Channel 2

Channel 3

Channel 4

Channel 5...

System Response

ECS requires that any portion of the detection zone which is block

ed remain blocked

. If the obstruction

is removed the 4700 system will enter a machine stop state. When selecting channels to be masked, one

channel must remain unblocked. A channel is defined as one transmitter/receiver pair or “beam”.

See Table 5-1, System Response to Exact Channel Select for a diagram of 4700 system response during

operation with ECS active.

Table 5-1

Exact Channel Select

Inactive

machine run machine stop machine run machine stop machine stop

System Response to Exact Channel Select

Exact Channel Select

Inactive

Exact Channel Select

Active

Exact Channel Select

Active

Exact Channel Select

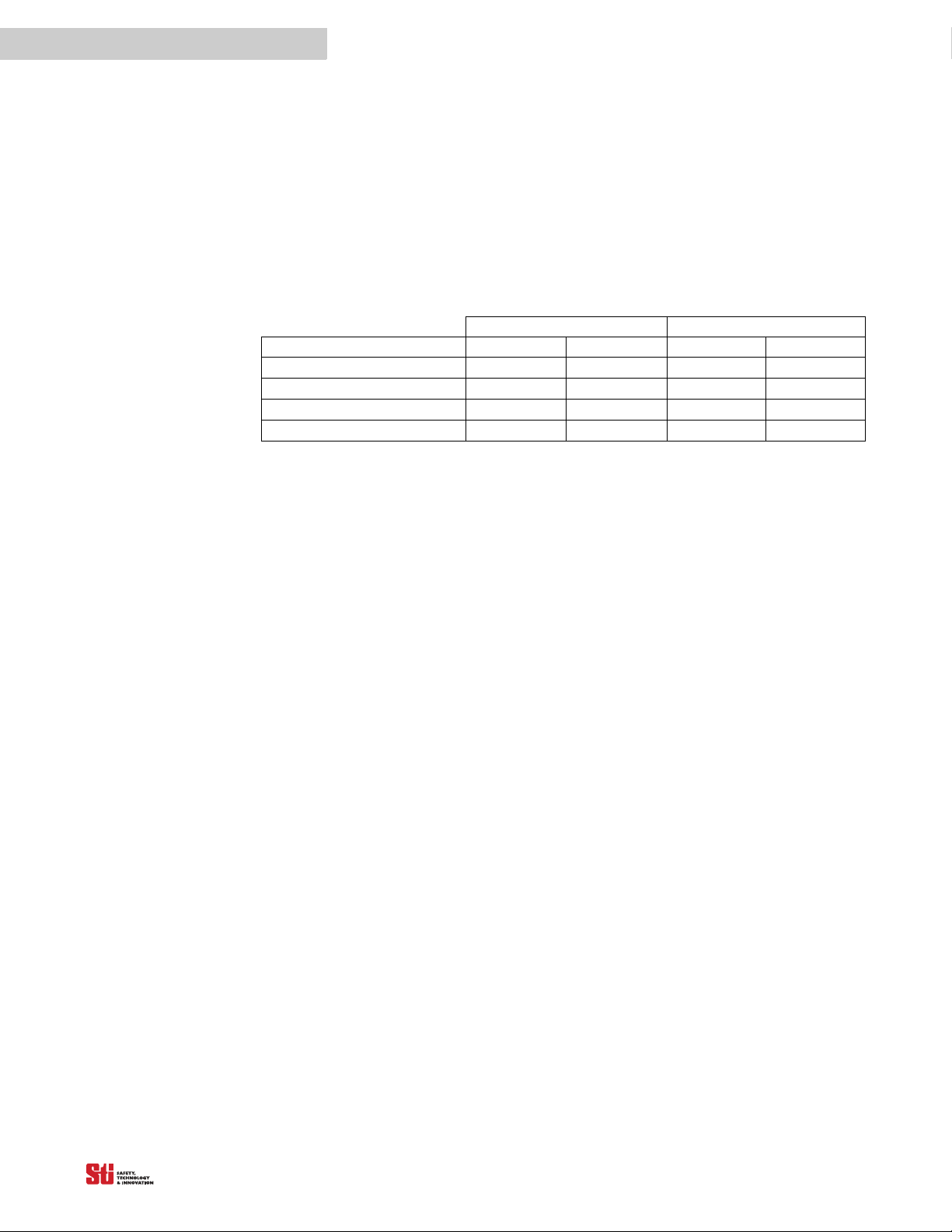

5.2 M ULTI CHANNEL SELECT (MCS)

MCS stores up to four patterns of selected beams. Just as the ECS disables selected, fixed areas of the

detection zone by masking off specific, fixed beam locations, the MCS can be programmed to store

four different patterns. MCS is helpful when a machine requires multiple setups where stationary

objects such as tooling, fixtures, or material frequently obstruct a portion of the detection zone. Access

and programming is performed using a PLC or switch inputs. The suggested logic patterns for

identification of the stored program are in Table 5-2 on page 20. Refer to drawings Figure 5-1 and

Figure 5-2 for connection recommendations.

Active

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

19

© OSTI 1209 PN99584-0050 Rev. E

Original Instructions

Page 22

LCM-3XX

SW2

SW1

0vdc

LCM-3XX

Out 1

Out 2

PLC

TB7

Switch Selection Connection

PLC Selection Connection

1

2

MPCE

Start

Prog

MCS

1

2

1

2

1

2

TB7

1

2

MPCE

Start

Prog

MCS

1

2

1

2

1

2

5

RET

ECS 2

ECS 1

LCM-3

SW2

SW1

LCM-3

Out 1

Out 0

0vdc ref.

PLC

Switch Selection Connection PLC Selection Connection

+24 VDC

Earth

0 vdc

7

6

5

4

3

2

1

RET

ECS 2

ECS 1

+24 VDC

Earth

0 vdc

7

6

5

4

3

2

1

Figure 5-1 Connection Recommendations for LCM Metal Enclosure

Figure 5-2 Connection Recommendations for LCM DIN Box

Switch Switch 2 Switch 1

Pattern1 0 0

Pattern 2 0 1

Pattern 3 1 0

Pattern 4 1 1

Note: 0 = Open, 1 = Closed.

Table 5-2 Switches for Multi Channel Select

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

20

© OSTI 1209 PN99584-0050 Rev. E

Original Instructions

Page 23

5.3 F LOATING BLANKING

▲

!

Up to two channels can be disabled at any location in the detection zone without the 4700 system going

to the machine stop state. The disabled channels are not fixed at a single location but “float” through

the detection zone.

See Table 5-3 for a diagram of 4700 system response during operation with Floating Blanking active.

. . . . .

Blanking

Channel 1

Channel 2

Channel 3

Channel 4

Channel 5...

System Response

Symbol Description

Floating

Inactive

1

Exception

machine

stop

Table 5-3

Chann

loati

F

Blanking

Active

Exceptions

machine

run

Table 5-4

System Response to Floating Blanking

1

0

el

Channel

ng

F

Blanking

Exception

1

loating

Active

1

machine

run

1

Channel

loating

F

Blanking

Active

2

Exceptions

machine

stop

1

Channel

loating

F

Blanking

Active

2

Exceptions

machine

stop

Icon Key for Tables 5-1 and 5-2

2

Channel

ting

Floa

Blanking

Active

0

Exceptions

machine

run

2

Channel

oating

Fl

Blanking

Active

1

Exception

machine

run

Optical channel is not blocked.

Optical channel is blocked.

Optical channel is selected by Exact Channel Select.

Optical channel is selected by Exact Channel Select and is blocked.

2

Channel

loating

F

Blanking

Active

2

Exceptions

machine

run

2

Channel

loating

F

Blanking

Active

2

Exceptions

machine

run

2

Channel

loating

F

Blanking

Active

3

Exceptions

machine

stop

2

Channel

loating

F

Blanking

Active

3

Exceptions

machine

stop

2

Channel

loating

F

Blanking

Active

3

Exceptions

machine

stop

5.4 U SING EXACT CHANNEL SELECT WITH FLOATING BLANKING

Warning! Using Exact Channel Select with Floating Blanking is an advanced feature. All situations which

may occur to the 4700 system detection zone must be carefully considered.

objects in the detection zone. The safety distance must be increased. Failure to do so may cause serious injury.

When both Exact Channel Select and Floating Blanking are selected, the floating channels are allowed

to occur anywhere within the detection zone, even within the area selected by Exact Channel Select. In

these areas, a channel that should normally be blocked is allowed to be clear.

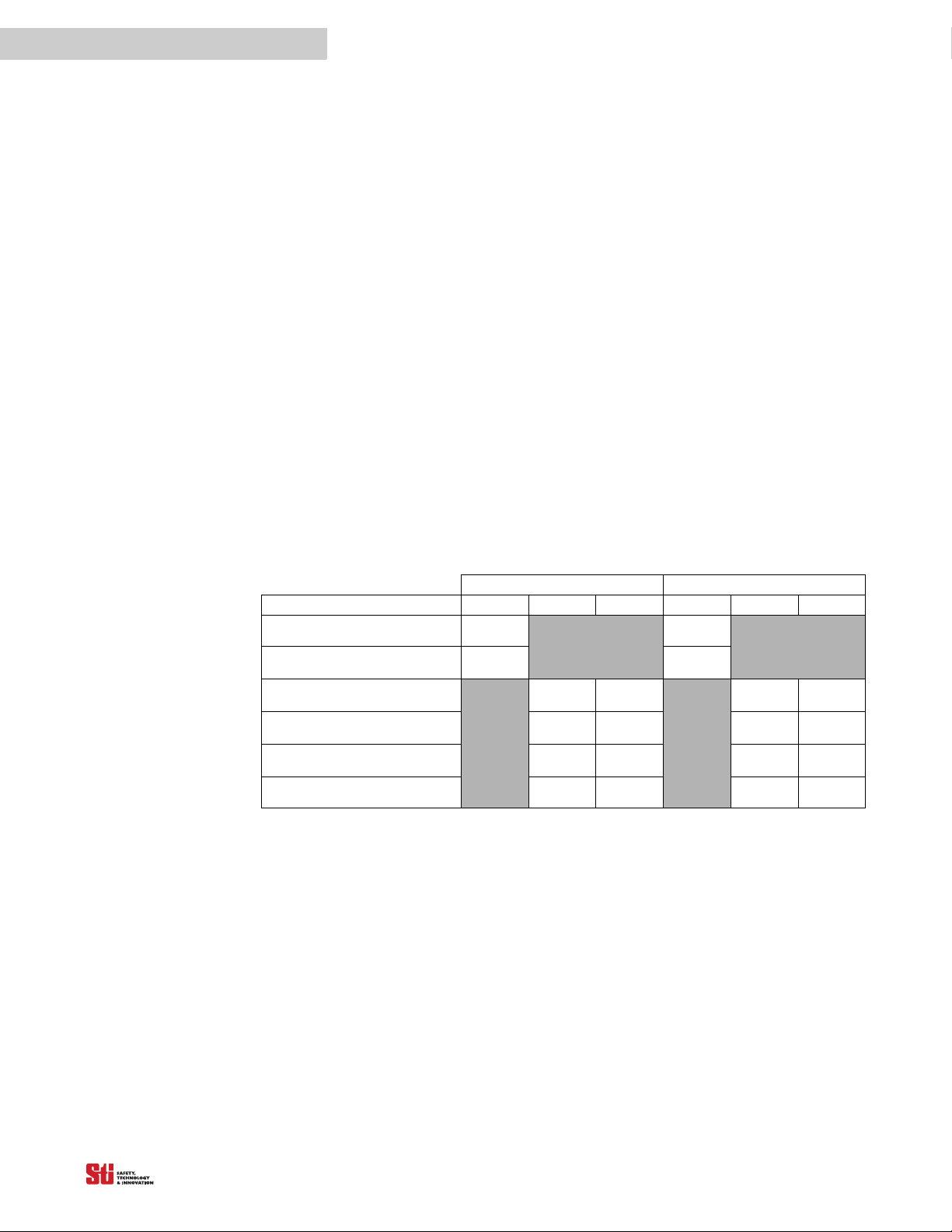

5.4.1 THE EFFECT OF EXACT CHANNEL SELECT AND FLOATING BLANKING ON MINIMUM OBJECT RESOLUTION

When Exact Channel Select and/or Floating Blanking is active, the safety distance is affected. Exact

Channel Select and Floating Blanking desensitize the light curtain and increase the size of the

minimum object detected. The increase is equal to the channel spacing distance for each channel that is

disabled.

• A 4700 system with 12 mm minimum object resolution and one channel disabled has a minimum object

sensitivity of:

12 mm + 6.25 mm = 18.25 mm (0.72 inches).

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

21

The 4700 system is less sensitive to

© OSTI 1209 PN99584-0050 Rev. E

Original Instructions

Page 24

5

• A 4700 system with 12 mm minimum object resolution and two channels disabled has a minimum object

sensitivity of:

12 mm + 6.25 mm + 6.25 mm = 24.5 mm (0.96 inches).

If the size of the object detected by the 4700 system increases, the minimum safe distance must

increase. Use the minimum object sensitivity given in T

determine the new figure to use when computing the safety distance.

able 5-5, Table 5-6, Table 5-7 & Table 5-8 to

Table 5-5

Select and/or Floating Blanking

Sample S and Dpf Factors for 12 mm Resolution Systems

Total Number of Beams

Disabled by Exact Channel

None 12 mm (0.47 inches) 0.67 inches (16.96 mm)

1 Beam 19 mm (0.75 inches) 1.61 inches (40.93 mm)

2 Beams 26 mm (1.02 inches) 2.53 inches (64.25 mm)

3 Beams 33 mm (1.30 inches) 3.48 inches (88.43 mm)

4 Beams 40 mm (1.57 inches) 4.40 inches (111.75 mm)

5 Beams 47 mm (1.85 inches) 5.35 inches (135.93 mm)

etc...

Table 5-6

Select and/or Floating Blanking

Sample S and Dpf Factors for 14 mm resolution Systems

Total Number of Beams

Disabled by Exact Channel

None 14 mm (0.55 inches) 0.9 inches (24 mm)

1 Beam 25 mm (0.98 inches) 2.4 inches (61 mm)

2 Beams 36 mm (1.42 inches) 3.9 inches (99 mm)

3 Beams 47 mm (1.85 inches) 5.4 inches (136 mm)

4 Beams 58 mm (2.28 inches) 6.8 inches (173 mm)

5 Beams 69 mm (2.72 inches) 8.3 inches (211 mm)

etc...

Minimum

Object Resolution S

Minimum

Object Resolution S

Depth Penetration Factor, Dpf

for use with

Depth Penetration Factor, Dpf

for use with

ANSI Formula (Dpf

= 3.4 (S-.276) inches)

ANSI Formula (Dpf

= 3.4 (S-.276) inches)

Table 5-7

Select and/or Floating Blanking

Sample S and Dpf Factors for 20mm resolution Systems

Total Number of Beams

Disabled by Exact Channel

None 20 mm (0.79 inches) 1.75 inches (44.45 mm)

1 Beam 31 mm (1.22 inches) 3.21 inches (81.53 mm)

2 Beams 42 mm (1.65 inches) 4.60 inches (118.96 mm)

3 Beams 53 mm (2.09 inches) 6.16 inches (156.86 mm)

4 Beams 64 mm (2.52 inches) 7.63 inches (193.76 mm)

5 Beams 75 mm (2.95 inches) 9.1 inches (231.16 mm)

etc...

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

Object Resolution S

22

Minimum

Depth Penetration Factor, Dpf

r use with

fo

ANSI Formula (Dpf

= 3.4 (S-.276) inches)

© OSTI 1209 PN99584-0050 Rev. E

Original Instructions

Page 25

. . . . .

Light

Detection Zone

Light

Channel S elec t Area

Obstruction

▲

!

Table 5-8

Select and/or Floating Blanking

Sample S and Dpf Factors for 30 mm resolution Systems

Total Number of Beams

Disabled by Exact Channel

None 30 mm (1.18 inches) 3.07 inches (78.0 mm)

1 Beam 52 mm (2.05 inches) 6.03 inches (153.2 mm)

2 Beams 74 mm (2.01 inches) 8.96 inches (227.6 mm)

3 Beams 96 mm (3.78 inches) 11.91 inches (302.5 mm)

4 Beams 118 mm (4.65 inches) 14.87 inches (377.7 mm)

5 Beams 140 mm (5.51 inches)‘ 17.80 inches (452.0 mm)

etc...

Minimum

Object Resolution S

Depth Penetration Factor, Dpf

for use with ANSI Formula

= 3.4 (S-.276) inches)

(Dpf

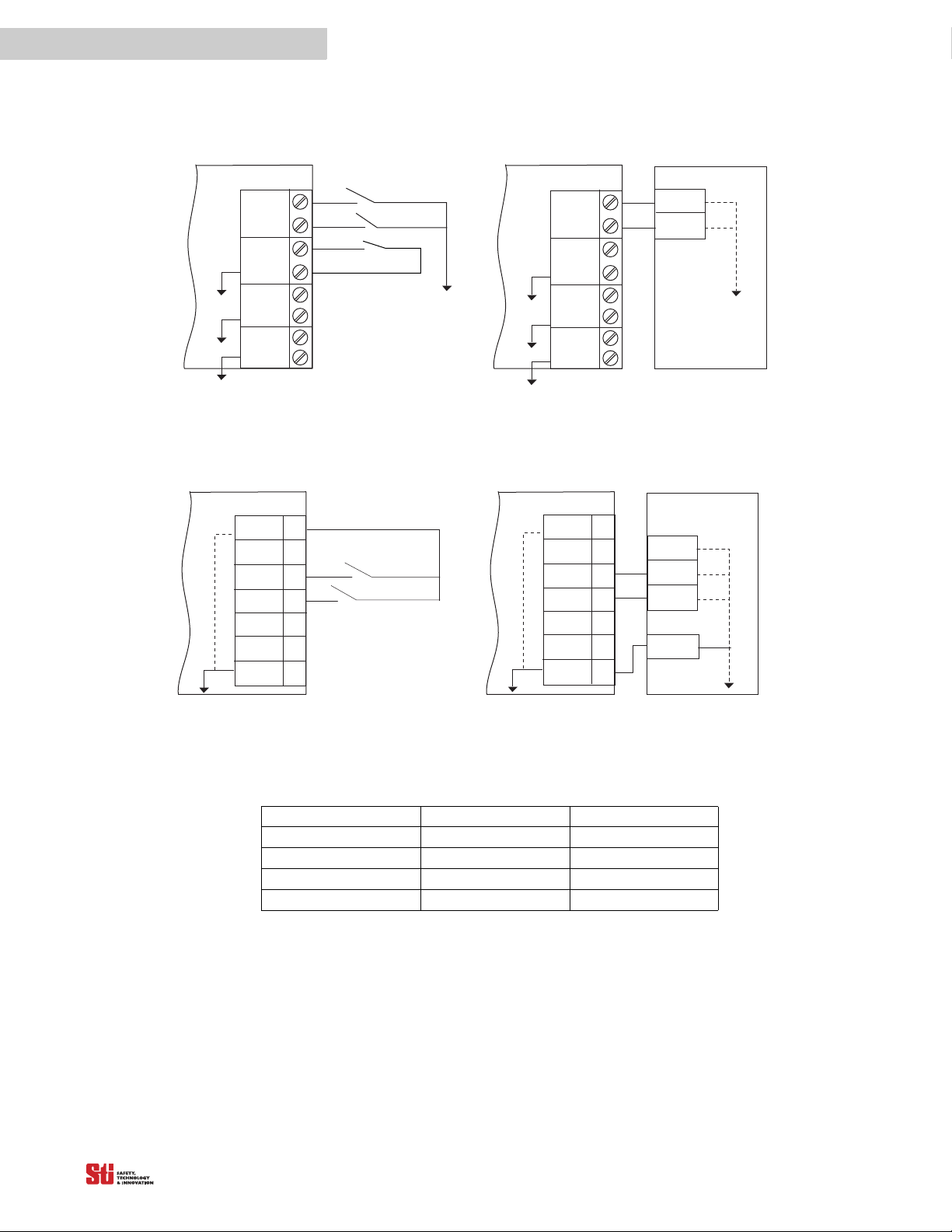

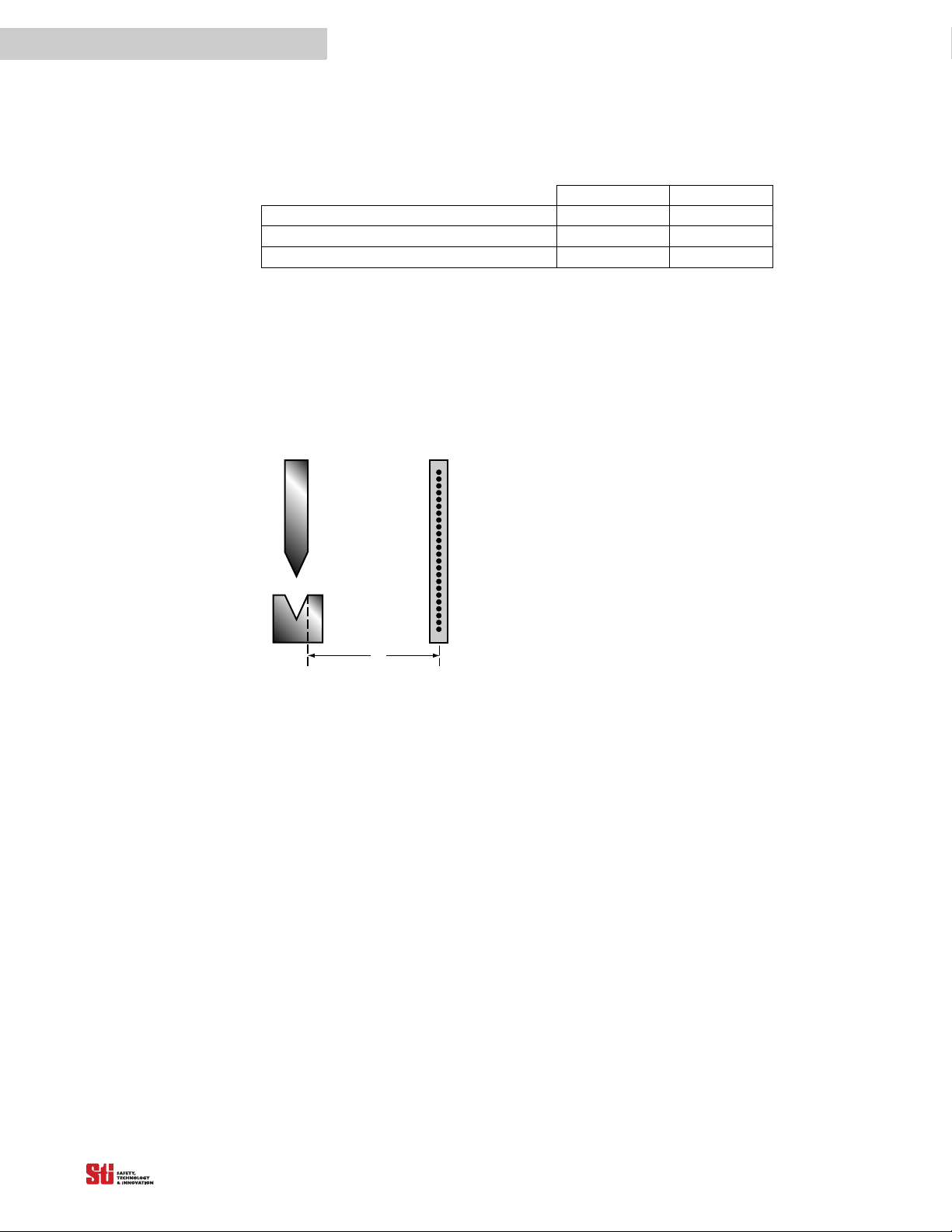

Hard guarding refers to mechanical barriers such as sheet or expanded metal, etc. See Figure 5-3

Adding Hard guarding to Light Curtain when Using Channel Select for an example.

Floating Blanking changes the resolution (object size) of the 4700 system and will require different

mounting distance

.

Figure 5-3 Adding Hard guarding to Light Curtain when Using Channel Select

5.5 A CTIVATING AND PROGRAMMING EXACT CHANNEL SELECT

Warning! To prevent unauthorized modification of the sense field, the system controller should be installed in

an enclosure with supervisor-controlled access.

Exact Channel Select is activated by setting position 4 of Switches A and B, located under the

controller cover. Refer to Figure 3-1. Any mismatch between the settings of the switches will result in

a alarm condition.

To program an ECS pattern, the 4700 system must be in the machine stop state. An ECS pattern is

stored

by blocking th

e appropriate area of the detection zone and pressing, then releasing the program

button (See Figure 3-4 and Figure 3-5 for locations). The MCS works the same as the ECS except in

addition to blocking the appropriate area of the detection

zone, an four position binary

switch or PLC

or two SPST switches are needed to differentiate the four possible pattern.

5.6 MCS PROGRAMING

1. Ensure that power is supplied to the controller, and that the light curtain is green and showing all

beams are clear. The display should read “00”.

2. Set position 4 of switches A and B to the closed position a

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

“03”.

23

nd press “Start”,

the display should red

© OSTI 1209 PN99584-0050 Rev. E

Original Instructions

Page 26

5

3. Set the Pattern select inputs, see Table 5-2 Switches for Multi Channel Select.

4. Place the desired object in field (block beams) and press the “program” button, the display should

read “01”.

5. Push the “start” button, and the display should read “03”. The light curtain will enter the Machine

Run

state.

add more patterns (a total of eight possible) Set the Pattern select inputs to another program the

6. To

display will read

7. To change from one pattern to another, change the ECS inputs to the desired program and push the

sta

rt button.

“27”, press the start button and continue to step 4. Repeat steps 4 and 5.

The 4700 syste

mode. The Start button m

m will then enter the interlock or machine stop condition, regardless of the operating

ay be pressed-and-released or power may be cycled to enter the machine run

state. Subsequent power cycles will result in operation in accordance with the configured operating

mode.

A new ECS pattern is recorded when the system is

in the machine stop

state with no alarms, the

configuration switches are correctly set, and the Program button is pressed and released. If the

configuration switches are subsequently set to disable ECS, the stored ECS pattern is cleared.

NOTE! Replace controller cover after changing system configuration. See

Section 3.1.2 on page 12 for details.

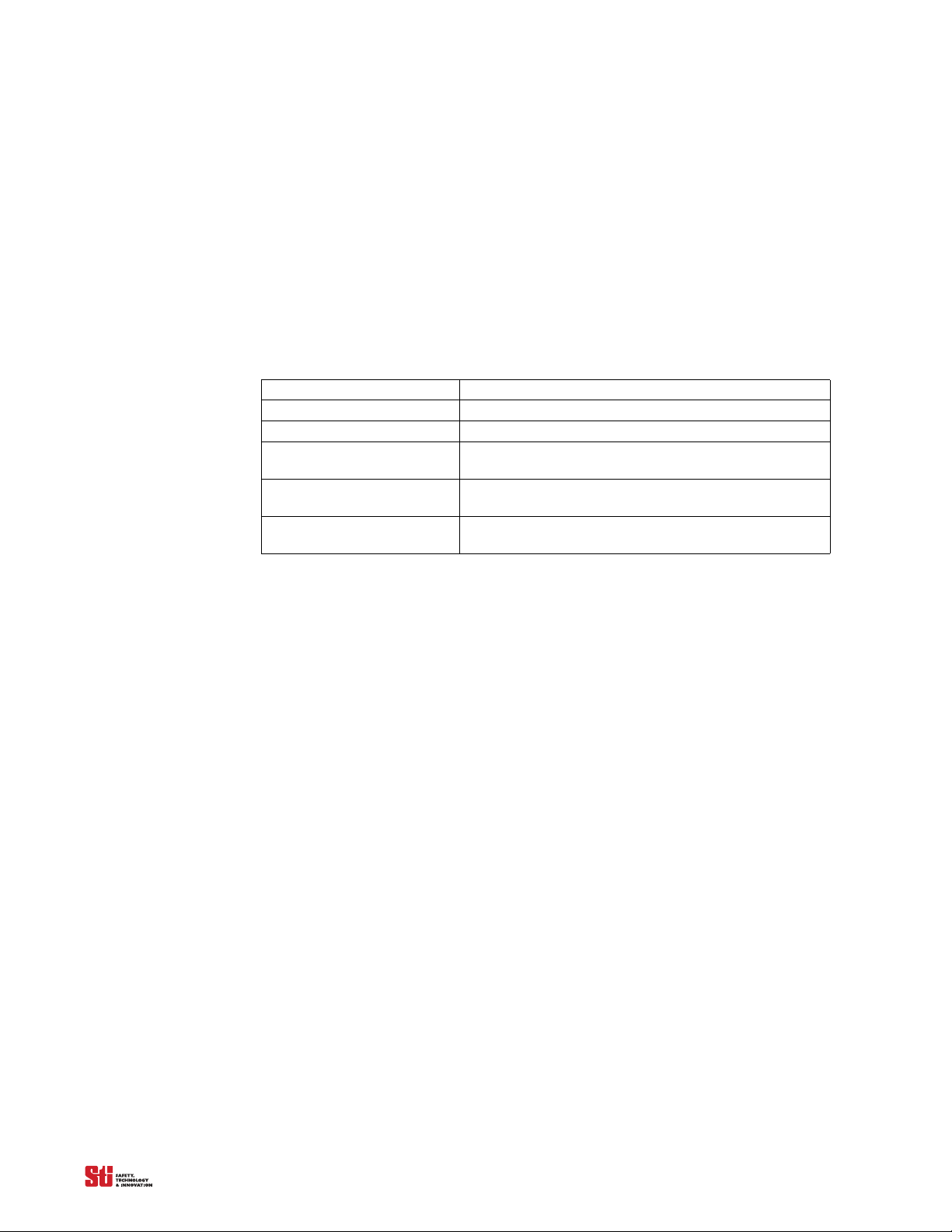

and

SWITCH A SWITCH B

OPERATING MODE 4 5 6 4 5 6

Exact Channel Select Active CLOSED

Exact Channel Select Inactive

(default setting)

One-channel Floating Blanking

Two-channel Floating Blanking

Floating Blanking Inactive (default

Not Allowed – alarm Condition CLOSED

Table 5-9 Switch Settings, Exact Channel Select and Floating Blanking

Active

Active

setting)

/ON

OPEN

/OFF

CLOSED

/ON

OPEN

/OFF

OPEN

/OFF

/ON

OPEN

/OFF

CLOSED

/ON

OPEN

/OFF

CLOSED

/ON

Section 3.1.1 on page 11

CLOSED

/ON

OPEN

/OFF

CLOSED

/ON

OPEN

/OFF

OPEN

/OFF

CLOSED

/ON

OPEN

/OFF

CLOSED

/ON

OPEN

/OFF

CLOSED

/ON

5.7 ACTIVATING FLOATING BLANKING

Floating Blanking (either one- or two- beam) is activated by setting positions 5 and 6 of Switches A

and B located under the controller cover. Refer to . Any mismatch between the settings of Switches

will result in an alarm condition. Use of the program button is not required.

5.8 ADDITIONAL GUARDING WHEN USING EXACT CHANNEL SELECT

Exact Channel Select creates “holes” in the detection zone. These “holes” are required for certain

applications. If an obstruction does not completely fill these “holes” one of two actions will need to

happen: (Refer to Figure 5-3 Adding Hard guarding

1. The safe mounting distance will need to be increased to account for the larger opening in the curtain.

2. The area not filled by an obstruction must be guarded, typically by some method of hard guarding.

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

24

to Light Curtain when Using Channel Select).

© OSTI 1209 PN99584-0050 Rev. E

Original Instructions

Page 27

. . . . .

6 D

IAGNOSTIC AND

T

EST

F

EATURES

6.1. DIAGNOSTIC DISPLAY