Page 1

. . . . .

Mat Controller

MC3 Series

Installation and Operating Manual

Original Instructions

OMRON Scientific Technologies Inc.

Manufacturing and Sales Office

6550 Dumbarton Circle

Fremont CA 94555-3605 USA

1 / 888 / 510-4357

Tel: 510/608-3400

Fax: 510/744-1442

www.sti.com

© OSTI 0411 PN99307-0010 Rev. D

Page 2

Page 3

. . . . .

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

3

©OSTI 0411 PN99307-0010 Rev. D

Original Instructions

MC-3 Mat Controller

Table of Contents

Section 1—Important safety message . . . . . . . . . . . . . . . . . . . . . .page 4

Section 2—Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 6

Section 3—Description of Controls . . . . . . . . . . . . . . . . . . . . . . . . page 6

Section 4—Operating Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 7

Section 5—Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

Section 6—Machine Control Connections . . . . . . . . . . . . . . . . . .page 11

Section 7—Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 15

Section 8—Trouble-shooting Faults . . . . . . . . . . . . . . . . . . . . . . .page 15

Section 9—Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 16

Section 10—Warranty and Additional Information . . . . . . . . . . .page 18

Section Appendix A —

Section Appendix B —Declaration of Conformity Information. ..page 21

Test Procedure . . . . . . . . . . . . . . . . . . . . . .page 20

Page 4

I M P O R T A N T S A F E T Y M E S S A G E

1

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

4

1 I

MPO RTA N T SAFE TY MES S AGE

A presence sensing mat and controller are general purpose presence sensing

devices designed to guard personnel working around moving machinery. The

use of this type of guarding system is regulated by government safety agencies.

Whether a specific machine application and presence sensing mat and

controller installation complies with government regulations depends upon

several items, including: the proper application, installation, maintenance and

operation of the presence sensing mat and controller. These items are the sole

responsibility of the purchaser, installer and employer.

The employer is also responsible for the selection and training of the personnel

necessary to properly install, operate and maintain the machine and its

safeguarding systems. For example, the presence sensing mat and controller

should be installed, checked out and maintained only by a qualified person,

defined as “a person who, by possession of a recognized degree in applicable

field or certificate of professional standing, or who by extensive knowledge,

training, and experience, has successfully demonstrated the ability to solve

problems relating to the subject matter and work.” (ASME B30.2-2001)

The machine operator must notify management if the machine, tooling or

safety devices are not operating properly. Never use the machine if it or the

safety equipment is not is proper working order.

The following additional requirements must be met before using a safety mat

and controller system:

• The machine on which the presence sensing mat and controller are installed

must be capable of stopping motion anywhere in its cycle or stroke. Never use a

presence sensing mat and controller on a power press with a full-revolution

clutch.

• Do not use a presence sensing mat and controller:

– on any device with inconsistent stopping time or inadequate control

devices or mechanisms.

– where the environment, such as corrosive chemicals, may degrade the

performance of the mat and/or controller.

– to initiate machine motion.

©OSTI 0411 PN99307-0010 Rev. D

Original Instructions

Page 5

. . . . .

I M P O R T A N T S A F E T Y M E S S A GE

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

5

• When a presence sensing mat and controller are used as a safety device, the

employer has the responsibility to ensure that all applicable federal, state, and

local requirements, rules, codes and regulations are satisfied.

• All safety related machine control circuit elements, including pneumatic,

electric or hydraulic controls, must be control reliable as defined by ANSI

B11.19-2003, 6.1 which states in part:

— prevent initiation of hazardous machine motion (or situation) until the

failure is corrected or until the control system is manually reset: or

— initiate an immediate stop command and prevent re-initiation of hazardous

machine motion (or situation) until the failure is corrected or until the

control system is manually reset; or

— prevent re-initiation of hazardous machine motion (or situation) at the next

normal stop command until the failure is corrected or until the control

system is manually reset.

• All other machinery or equipment must meet OSHA standard 1910.212 for

general machine guarding plus any other applicable regulations, codes and

standards.

• Additional guarding such as safety light curtains or mechanical guards may be

required if the presence sensing mat and controller do not protect all areas of

entry to the point of operation hazard.

• All brakes and stopping mechanisms must be inspected regularly to ensure

proper working order. If the stopping mechanisms are not working properly, the

machine may not stop safely even though the presence sensing mat and

controller are functioning properly.

• The Omron STI Test Procedure must be performed at installation and after any

maintenance, modification or adjustment is performed on the machine controls

or on the presence sensing mat and controller. The Test Procedure is presented

in this manual.

• Do not perform any test or repairs other than those outlined in this manual. All

electrical wiring must be installed in accordance with local electrical codes and

regulations.

• The user must follow all procedures in this manual for proper operation of the

MC3 controller.

The enforcement of these requirements is beyond Omron STI’s control. The

employer has the sole responsibility to follow the preceding requirements and

any procedures, conditions and requirements specific to your machinery.

©OSTI 0411 PN99307-0010 Rev. D

Original Instructions

Page 6

I N T R O D U C T I O N

Output Relays

2

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

6

2 I

NTRODUCTION

2

Presence sensing mats and the MC3 controller are used where perimeter access

guarding is required, such as around robots, manufacturing work cells, food

processing equipment and automated assembly equipment.

The MC3 controller is designed to meet the applicable sections of ANSI B11.192003, OSHA 1910.212, EN1760-1:1997 and ISO13856-1:2001. CE standards are met

only when used in conjunction with OMRON STI UM and UMQ series presence

The MC3 controller is designed to work in conjunction with a four-wire,

normally open safety mat (such as the Omron STI UM and UMQ series safety mats).

3 D

ESC RIPT ION OF

C

ONT ROLS

3

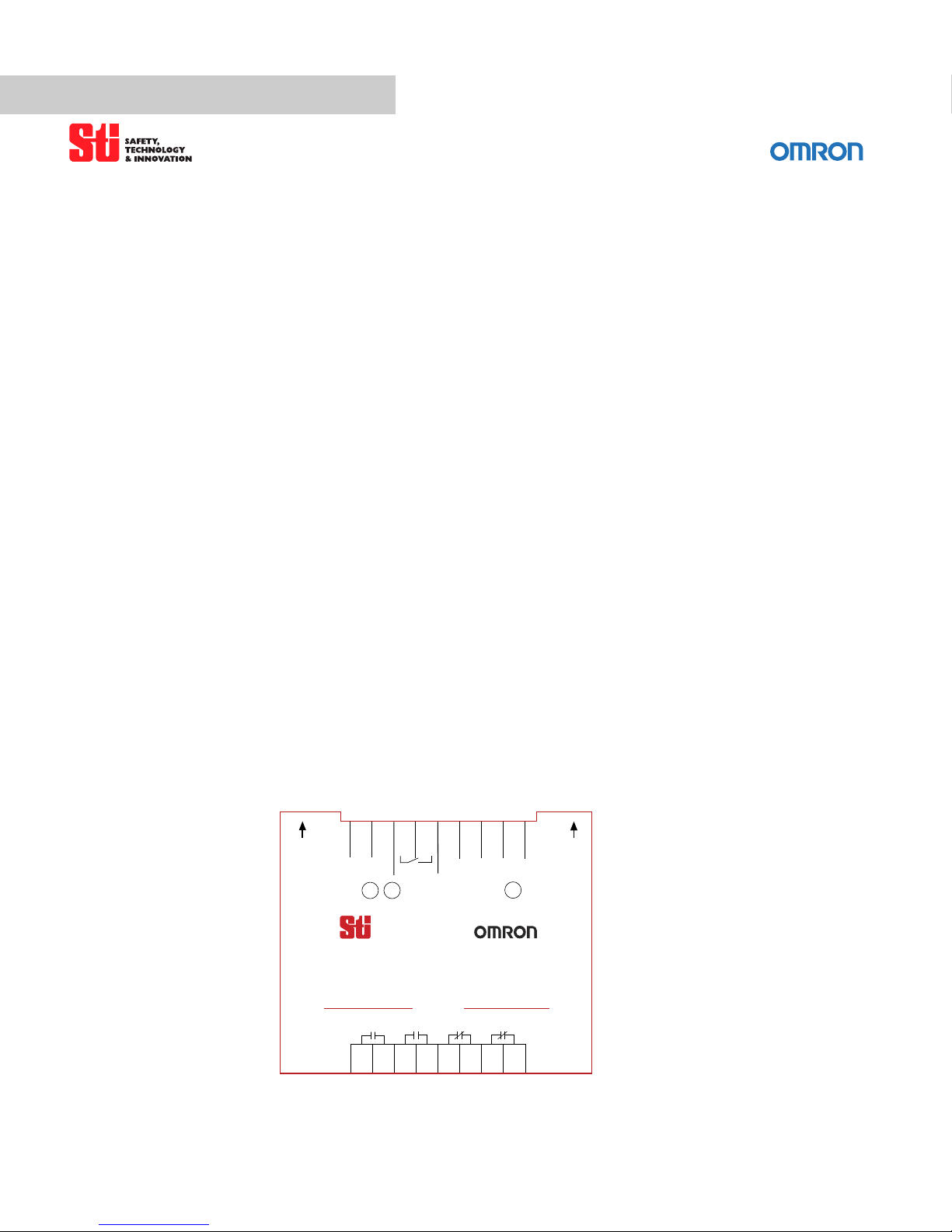

3 . 1 . O U T P U T R E L A Y S

The safety-rated outputs of the MC3 controller are referred to as Output Signal

Switching Devices. (OSSD). When the mat surface is activated by suf cient

weight, the OSSD will respond by going to an OFF state. Two-normally open

OSSD are provided across terminal 13/14 and 23/24. Two normally closed

OSSD are provided across terminals 31/32 and 41/42.

Figure 3-1 MC3 Mat Controller

©OSTI 0411 PN99307-0010 Rev. D

Original Instructions

No User Serviceable Parts Inside

24 VDC

2.2 VA

13 14 23 24 31 32

Outputs

250 VAC 6 A 1500 VA Max

41 42

MC3 Mat Controller

M11

Blk

M12

Brn

M21

Blu

M22

Wht

X2X1

Y1Y2

+

–

Mat Clear

Stop

Run

Start

Mat

Start/Restart Interlock – Remove 3 Jumpers

Mode Select Jumpers Located under Terminal Block

Automatic Start – Install 3 Jumpers

sensing safety mats.

Page 7

. . . . .

OP ERA TI N G MO DE

Indicators

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

7

3.2 . I ND I CA T O RS

RUN: Will be lit when the OSSD relays are in the MACHINE RUN state.

STOP: Will be lit when the OSSD relays are in the MACHINE STOP state.

MAT CLEAR: A diagnostic indicator. Shows that the mat is properly wired, that

it is clear, and that it is possible to energize the relays.

3.3 . M AT IN P UT S

Four terminal positions (M11-Blk, M12-Brn, M21-Blu, M22-Wh) are provided

for input of a four-wire safety mat or a series of four-wire safety mats. See

details in Section 5.2.—Input Wiring.

4 O

PERATING

M

ODE

4

4.1 . A UT O MA T I C R ES T AR T

The MC3 controller will energize relays whenever the mat is clear, and deenergize whenever it has been stepped upon. During both power up and normal

operation, an ON-delay of approximately 1/10 to 2/10 second is normal. The

RUN indicator will follow the MAT CLEAR light.

4.2 . S TA R T/R ES T A RT IN T ER L OC K

The MC3 controller will interlock in de-energized state both upon application

of power and also whenever the mat is stepped upon. Requires a manual reset

operation to cause the system to energize relays. The MAT CLEAR light will

indicate that it is possible to activate the start switch and enter into the

MACHINE RUN state. The controller attempts to enter the RUN STATE upon

the release of the start switch. Press and hold the start switch for more than

0.15 seconds. The safety mat area must be clear at the time the start switch is

pressed and released.

©OSTI 0411 PN99307-0010 Rev. D

Original Instructions

Page 8

I NSTALLATION

Mounting

5

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

8

5 I

NSTALLATION

5

WARNING! Read this manual completely before installing the MC3

controller. The MC3 controller should only be installed, checked out, tested

and maintained by a qualified person (as described in the Important Safety

Message at the beginning of this manual). It is important that the user be

familiar with the installation requirements, safe mounting distance, controls

and features of the MC3 controller before using the guarding system

.

5.1. M O UNTING

5.1.1

MODE SELECT

The installer must select whether the MC3 controller will operate in

AUTOMATIC START or START/RESTART INTERLOCK mode. To make the

selection, remove the terminal block on the input side of the controller box.

Behind this terminal block are three yellow jumpers.

With all three jumpers installed, the controller is configured for AUTOMATIC

START operation. This is the factory setting.

To configure for START/RESTART INTERLOCK operation, all three jumpers

must be removed.

WARNING!

Perimeter Guarding Special Requirements: Perimeter guarding

refers to installations where the presence sensing mats are positioned

around the outside perimeter of the machine, robot or area to be guarded.

This could leave sufficient space for an operator to stand between the mats

and the machine.

For perimeter guarding installations, the guarded machine or robot must be

wired such that any interruption of the sensing area will cause an immediate

stop of the hazardous motion. The machine or robot must only be restarted

by actuation of a start switch. This start switch must be located outside the

area of hazardous motion and positioned such that the hazardous area may

be observed by the start switch operator.

Unexpected or automatic restart of the machine or robot may cause severe

injury or death to the operator or other personnel.

Always contact the machine manufacturer for advice and assistance on the

proper connection of any safety device.

!

!

©OSTI 0411 PN99307-0010 Rev. D

Original Instructions

Page 9

. . . . .

I NSTALLATION

Input Wiring

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

9

5.1.2 ENCLOSURE

The MC3 controller is designed to be installed inside a machine control cabinet

which has an environmental rating of at least IP54.

5.2. INPUT WI RI N G

5.2.1 POWER

A 24VDC power source is required. Connect PLUS to terminal block Y1 position

and MINUS (0, Return) to terminal block Y2 position. (Note: see separate

discussion of “earth”)

5.2.2 START

Used only in START/RESTART INTERLOCK mode. If AUTOMATIC START mode

is used, no connection is required. If required, customer-supplied remote start

switch with a single set of normally open contacts is used.

Two optional wiring configurations are acceptable:

— Connect the remote start switch between terminals X1 and X2.

— Connect one terminal of the remote start switch to +24VDC (must share a

common return with MC3 power supply), and the second terminal to X2.

5.2.3 SAFETY M AT

An Omron STI 4-wire mat is expected. For an Omron STI Universal safety mat

the blue and black conductors are connected to the bottom electrode plate. The

brown and white conductors are connected to the top electrode plate. For a

single mat installation, black is connected to M11 and blue to M21. The brown

conductor is connected to M12 and white conductor is connected to M22.

Multiple mats must be connected to the controller in series. To wire an STI UM

series multiple mat system in series, follow the wiring as shown in the drawing

below:

Figure 5-1 Hookup Drawing

M12

M11

M21

M22

2 TAM1 TAM

MAT 3

BROWNWHITE

BLACKBLUE

BROWN

BLACK

WHITE

BLUE

BROWN

BLACK

WHITE

BLUE

WHITE

BLUE

©OSTI 0411 PN99307-0010 Rev. D

Original Instructions

Page 10

I NSTALLATION

Output Wiring

5

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

10

WARNING! Connecting mats in parallel will appear to work, but it is an

UNSAFE installation. In this configuration, it is possible for one or more

mats to be disconnected or have an open wire and the controller will not

detect that these mats are non-functioning.

5.2.4 EARTH CONSIDERATIONS

Normally, earthing of the house system is not a consideration. Presence

sensing mats are sealed - any wiring to them should not be in contact with

earth. Likewise, the mat controller operates between +24VDC and it’s return, so

the selection of an earth scheme is not significant.

However, there are abnormal conditions that could cause current flow due to

house earth. This is related to the fact that mats lie on the floor, and are

typically in close proximity to true “earth”. Under certain conditions (e.g.

wetting of the mat cable connectors), it is possible that one of the plates of the

mat might become referenced to earth.

Note: If the entire connector becomes immersed, this is the equivalent of the

mat being shorted, and the system will simply indicate so, i.e. the mat clear

indicator will not be able to light.

One of the mat plates is electrically connected through the mat controller to

the 24VDC return. (minus, Y2). If the plus side of the 24VDC power supply is

earthed, and the minus side of the mat is also earthed, ground current will

attempt to flow through the mat controller. This will cause the primary power

fuse to blow. However, the fuse is a self-mending type, and will continue to remake and blow again.

5.3. O U TPUT WI R IN G

Two safety outputs must be connected to, and operate, the two MPCE of the

guarded machine. One to each. The product offers two normally closed and two

normally open FSD (final switching device) outputs for this purpose. Customer

shall wire by normal methods. External over-current protection must be

provided by the user.

The remaining two connections may be used for indicator/communications

purposes as desired.

!

©OSTI 0411 PN99307-0010 Rev. D

Original Instructions

Page 11

. . . . .

M ACHINE C ONTROL C ONNECTIONS

Two Normally Open Preferred Connection Method

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

11

6 M

ACHINE

C

ONTROL

C

ONNECTIONS

6

6.1. T W O N OR M ALL Y O PEN P REF ERRED CO NNECTION

M

ETHOD

The following connection scheme uses both of the normally open output relay

contacts to control the machine. This is the Omron STI recommended wiring

method.

In the machine control circuit, locate the two machine primary control

elements (MPCE1 & MPCE2). These are defined as “The electrically powered

element that directly controls the normal operation of a machine in such a

way that it is the last element (in time) to function when machine operation is

to be initiated or arrested.” IEC 61496-1

The method to arrest hazardous machine motion will vary depending on the

type of machine. Control methods include hydraulic, pneumatic, clutch and

mechanical braking systems. For example, an MPCE may consist of relays,

contactors, solenoids or electromechanical valves. If relays, the MPCE must use

force-guided contact type relays.

©OSTI 0411 PN99307-0010 Rev. D

Original Instructions

Page 12

M ACHINE C ONTROL C ONNECTIONS

Two Normally Open Preferred Connection Method

6

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

12

Figure 6-1 Two Normaly Open Preffered Connection

TWO NORMALLY OPEN

PREFERRED CONNECTION DIAGRAM

Power

L

End user

supplied push

button or key

switch

Neutral

N

13

14

23

24

41

42

31

32

Safety Input #1

Safety Input #2

Y1

Y2

M11

M12

M22

M21

X1

X2

Reset

Output #1

N.O.

Arc suppressor

MPCE 1

Output #2

N.O.

Output #4

N.C.

Output #3

N.C.

Customer-supplied

over current protection

Neutral

N

Arc suppressor

MPCE 2

+

–

Black

Blue

Brown

White

Mat Sample

1

1

1

24 VDC

Blu

Black

Brn

Wht

©OSTI 0411 PN99307-0010 Rev. D

Original Instructions

Page 13

. . . . .

M ACHINE C ONTROL C ONNECTIONS

Suggested PLC Connection

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

13

6.2. S U GGEST E D P LC C O NNECTION

The wiring from the MC3 controller to the machine control must be control

reliable as explained in ANSI B11.19-2003 section 6.1 or OSHA

1910.217(b)(13). Normally, PLCs are not designed to be control reliable and

thus safety devices, such as safety mat systems, must not depend on a PLC to

stop a guarded machine.

Figure 6-2 shows a connection diagram which provides for an extra set of

contacts on each MPCE to be used as a signal input to a PLC. Note that in this

diagram, the PLC is not wired directly to the MC3 controller and thus removes

the PLC from the safety mat controller stop signal circuit.

Always contact the manufacturers of the PLC and the guarded machine before

using a PLC in conjunction with an operator safety control.

The PLC control system design, wiring, installation and programming are the

sole responsibility of the employer.

©OSTI 0411 PN99307-0010 Rev. D

Original Instructions

Page 14

M ACHINE C ONTROL C ONNECTIONS

Suggested PLC Connection

6

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

14

Figure 6-2 Suggested PLC Connection

WARNING! To prevent severe injury to the operator or other personnel, DO

NOT operate this presence sensing safety device (mat and controller

system) unless it is properly installed, tested and inspected in accordance

with all OSHA, ANSI, government, industry and company safety regulations.

The guarded machine must be capable of stopping motion anywhere in it

stroke or cycle. Do not use this safety device on a full revolution clutch

machine.

SUGGESTED PLC

CONNECTION DIAGRAM

Power

L

End user

supplied push

button or key

switch

Neutral

N

13

14

23

24

41

42

31

32

Safety Input #1

Safety Input #2

Y1

Y2

M11

M12

M22

M21

X1

X2

Reset

Output #1

N.O.

Arc suppressor

MPCE 1

Output #2

N.O.

Output #4

N.C.

Output #3

N.C.

Customer-supplied

over current protection

Neutral

N

Arc suppressor

MPCE 2

+

–

Black

Blue

Brown

White

Mat Sample

1

1

1

24 VDC

MPCE1

MPCE2

MPCE1 MPCE2

Contacts to Control

Hazardous Machine

Motion

Input to PLC

L1

Blu

Black

Brn

Wht

!

©OSTI 0411 PN99307-0010 Rev. D

Original Instructions

Page 15

. . . . .

T EST P ROCEDURE

Performing Test Procedure

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

15

7 T

EST

P

ROCEDURE

7

7.1. P ERF ORMING TEST PR O CEDURE

The test procedure given in Appendix A must be performed by a qualified

person at installation and after any maintenance, adjustment, or modification

to the presence sensing mats, the MC3 controller or the machine and machine

control circuitry. Testing ensures that the mats, MC3 controller, machine and

machine control circuitry work properly to stop the machine. Failure to test

properly could result in serious injury to personnel.

8 T

ROUBLE-SHOOTING

F

AULTS

8

Symptom

No indicators lit.

Possible Solutions

No power to the controller. Check 24VDC power supply and its connections to

Y1/Y2. Also see earth discussion in Section 5.2.4 “Earth Considerations”.

Symptom

MAT CLEAR indicator cannot be made to light.

Possible Solutions

1. Mat wired improperly. Check connections.

2. Mat wire broken. Replace mat.

3. Mat is shorted. Is there something on the sensing area? Is the surface

deformed?

Symptom

Cannot start in START/RESTART INTERLOCK mode.

©OSTI 0411 PN99307-0010 Rev. D

Original Instructions

Page 16

S PECIFICATIONS

Mat Controller—MC3

9

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

16

Possible Solutions

1. Check wiring and operation of START switch. Is 24VDC being delivered

when START is depressed and not delivered when it is released?

2. This line is internally fused with a self-mending fuse. Does it blow and reset

repeatedly? If so, see earth discussion Section 5.2.4 “Earth Considerations”.

Symptom

All other conditions

Possible Solutions

Controller is defective. Replace. Call Omron STI for details.

9 S

PECIFICATIONS

9

9.1. M A T C ON T R OLLER —MC 3

9.1.1 GENERAL SPECIFICATIONS

Category: Category 3 safety device

Operating Modes: Automatic Start or Start/Restart Interlock

9.1.2 ELECTRICAL

Power Input: 24 VDC (±15%, < 3W.)

Safety Input: Connections for a four-wire mat system

Indicators: Green=Mat Clear; Green=Run; Red=Stop

Reset Function: User-supplied pushbutton or key switch

Safety Outputs: 2 NO and 2 NC outputs. 230VAC, 6A, 1500VA Maximum (non-

fused)

Response time: < 0.030 seconds (STI UM series safety mat and controller

combined)

9.1.3 CONSTRUCTION

Case Material: Polycarbonate

IP Rating: IP20

©OSTI 0411 PN99307-0010 Rev. D

Original Instructions

Page 17

. . . . .

SP ECI FI C AT I ON S

System Drawings

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

17

Mounting Type: 35mm DIN rail or screw mount to panel

Shipping Weight: 0.8 pounds (0.32 kg)

9.1.4 ENVIRONMENTAL

Temperature: 0° to +55°C (32° to 131°F)

Shock & Vibration: Per IEC 68-2-6, 0.15mm displacement, 10 to 55 Hz

Relative Humidity: 95%

9.1.5 STANDARDS CONFORMITY

9.2 . S YS T EM D R A W IN G S

Figure 9-1 Mat Controller MC3 Dimensional Drawing

75 mm

110 mm

35.5 mm

Side View

61.2 mm

38 mm

1.5 mm

Bottom View

55 mm

98 mm

15.25 mm

Designed in Accordance with: EN1760-1:1997 + A1:2009, EN 62061:2005,

EN ISO 13849-1:2008, IEC 61508, parts 1-7:1998-2000, EN 50178:1997, EN

60204-1:2006, Machinery Directive 2006/42/EC, ANSI/RIA 15.06-1999, ANSI

B11.19-2003, OSHA 1910.212 & 1910.217(b)

©OSTI 0411 PN99307-0010 Rev. D

Original Instructions

9.1.6

Approvals

CE, TUV, CSA

9.1.7

Conformities

PSPD Type 3 (EN 1760-1:2997 + A1:2009),

Category 3 / PL d (EN ISO 13849-1),

SIL 2 / SIL2 CL2 (IEC 61508 / EN 62061).

9.1.8

Safety Related Parameters

PFH = 3.97 E-08 1/h

Proof Test Interval = 20 years

MTTFd = 94 years

Page 18

W ARRANTY AND A DDITIONAL I NFORMATION

Omron STI Warranty

1 0

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

18

10 W

ARRANTY AND

A

DDITIONAL

I

NFORMATION

10

10.1. O MRON S TI W ARRANT Y

Omron STI warrants its products to be free from defects of material and

workmanship and will, without charge, replace or repair any equipment found

defective upon inspection at its factory, provided the equipment has been

returned, transportation prepaid, within one year from the date of installation

and not to exceed 18 months from date of factory shipment.

The foregoing warranty is in lieu of and excludes all other warranties not

expressly set forth herein, whether expressed or implied by operation of law or

otherwise including but not limited to any implied warranties of

merchantability or fitness for a particular purpose. No representation or

warranty, express or implied, made by any sales representative, distributor, or

other agent or representative of Omron STI which is not specifically set forth

herein shall be binding upon Omron STI. Omron STI shall not be liable for any

incidental or consequential damages, losses or expenses directly or indirectly

arising from the sale, handling, improper application or use of the goods or

from any other cause relating thereto and Omron STI’s liability hereunder, in

any case, is expressly limited to repair or replacement (at Omron STI’s option)

of goods.

Warranty is specifically at the factory or an Omron STI authorized service

location. Any on site service will be provided at the sole expense of the

Purchaser at standard field service rates.

All associated equipment must be protected by properly rated

electronic/electrical protection devices. Omron STI shall not be liable for any

damage due to improper engineering or installation by the purchaser or third

parties. Proper installation, operation and maintenance of the product becomes

the responsibility of the user upon receipt of the product.

10.1.1 PATENTS

Elements of the electronics and optics essential to meet the specifications and

performance standards of Omron STI controls are covered by one or more of the

©OSTI 0411 PN99307-0010 Rev. D

Original Instructions

Page 19

. . . . .

W ARRANTY AND A DDITIONAL I NFORMATION

Omron STI Warranty

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

19

following U.S. Patent Numbers: 3,774,039; 3,867,628; 3,967,111; 3,996,476;

4,007,387; 4,101,784; 5,015,840; Design 255,031, and other patents pending.

10.1.2 R EPAIRS

Omron STI offers product repair service at our factory. If you need repairs made to

any Omron STI product contact our Customer Service Department.

10.1.3 R ETURNS

Whenever you return a product to Omron STI (even if the product is in warranty)

please contact our Customer Service Department and request a Returned Goods

Authorization number (RGA).

10.1.4 D OCUMENTATION CRITERIA

This publication has been carefully checked for accuracy and is believed to be

fully consistent with the products it describes. However, Omron STI does not

assume liability for the contents of this publication; the examples used within

or the use of any product described herein. Omron STI reserves the right to

make changes to products and/or documentation without further notification.

©OSTI 0411 PN99307-0010 Rev. D

Original Instructions

Page 20

T EST P ROCEDURE

Test Procedure Log

A ppe ndix A —

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

20

A

PPENDIX

A — T

EST

P

ROCEDURE

A.1. T EST P R O CEDURE LO G

The following test procedure must be performed by qualified personnel at

installation and after any maintenance, adjustment or modification to the

presence sensing mats, the MC3 controller or the machine and machine control

circuitry. Testing ensures that the presense sensing mats, MC3 controller,

machine and machine controll circuitry work properly to stop the machine.

Failure to test properly could result in serious injury to personnel. Familiarity

with this installation and operating manual is required before procedding.

WARNING!

To prevent severe injury to the operator or other personnel, DO

NOT operate this presence sensing safety device unless it is properly installed,

tested and inspected in accordance with all applicable ANSI, OSHA,

government, industry and company safety regulations. The guarded machine

must be capable of stopping motion anywhere in its cycle or stroke. Do not use

this safety device on a full revolution clutch machine.

stnemmoCnoitidnoCmetI

1. With the machine power off, the MC3 controller power on and no

pressure on the mat sensing area, verify that either a) a green RUN

indicator is on, if set for AUTOMATIC START mode, or b) the red

STOP indicator is on if set for START/RESTART INTERLOCK

mode. In both cases the green MAT CLEAR indicator should be on.

Pass

Fail

2. If installed, press the START button to restart the controller from

an interlocked state. The green RUN indicator should now be on

and the output relays should be engergized. The mat clear indicator

should be on.

Pass

Fail

3. Step on the mat sensing area to activate the MC3 controller. The

green RUN indicator should go off and, in all operating modes, the

red STOP indicator should go on and the green MAT CLEAR

indicator should go off. Repeat steps 2 and 3 for each mat in the

sensing area.

Pass

Fail

4. With the MC3 controller in the RUN condition, start the machine

to be guarded. Step on each mat in the sensing area and verify that

the machine stops immediately and that the red STOP indicator

illuminates.

Pass

Fail

5. If the presence sensing mats, MC3 controller or the machine fail

any of these tests, DO NOT run the machine. Immediately tag or

lockout the machine to prevent its use and notify the supervisor.

Pass

Fail

©OSTI 0411 PN99307-0010 Rev. D

Original Instructions

Page 21

D

ECLARATION OF COMFORMITY INFORMATION

A p p e n d i x B —

OMRON SCIENTIFIC TECHNOLOGIES INC.

Fremont CA USA

Tel: 1/888/510-4357 in USA and Canada

21

A

PPENDIX

B — D

ECLARATION OF

C

OMFORMITY

I

NFORMATION

©OSTI 0411 PN99307-0010 Rev. D

Original Instructions

OMRON SCIENTIFIC TECHNOLOGIES INCORPORATED

EC Declaration of Conformity

OMRON Scientific Technologies Incorporated (at 6550 Dumbarton Circle, Fremont, CA 94555-3605, U.S.A.), hereby declares that the

following series manufactured products listed below conform with the relevant Essential Health and Safety Requirements (EHSRs) of the

European Machinery Directive (2006/42/EC), the relevant requirements of the Low Voltage Directive

(2006/95/EC),

with the essential protection requirements of the Electromagnetic Compatibility (EMC) Directive (2004/108/EC), and with the RoHS

Directive (2002/95/EC) - the restriction of the use of certain hazardous substances in electrical and electronic equipment.

Universal Safety Mat Systems UM, UMM, UMQ & UMMQ Series with Safety Mat Controller MC3,

(Pressure-sensitive protective device – consisting of pressure-sensitive mats and controllers. Not suitable for

the detection of children)

The Universal Safety Mat UM Series with MC Series Safety Mat Controllers products have been type-examined per

EC Type Examination Certificate,

Registration No: 01/205/0676/09

issued by notified body TUV Rheinland Industie Service GmbH, Certification Body for Machinery (NB No. 0035).

The following transposed harmonized European and IEC Standards were used to form the basis for the requirements and tests:

EN 1760-1:1997: + A1:2009 - Safety of Machinery – Pressure-sensitive protective devices

Part 1: General principles for the design and testing of pressure-sensitive mats and pressure-sensitive floors.

EN 62061:2005 – Safety of machinery. Functional safety of safety-related electrical, electronic and programmable electronic control systems.

EN ISO 13849-1:2008 – Safety of machinery. Safety-related parts of control systems. General principles for design

IEC 61508, parts 1 – 7:1998 – 2000 - Functional Safety Of Electrical/Electronic/Programmable electronic Safety-Related Systems.

IEC 50178:1997 - Electronic equipment for use in power installations

EN 60204-1:2006: Safety of machinery – Electrical equipment of machines, Part 1: General requirements.

OMRON Europe B.V.

Wegalaam 67 - 69

2132 JD Hoofddorp

Netherlands

Tel: +31 (0)23 568 13 00

Tel: +31 (0)23 568 13 88

Loading...

Loading...