Page 1

NEW Product

For the most recent information on models that have been certified for

safety standards, refer to your OMRON website.

Single-phase Voltage Relay

K8AK-VS

Ideal for Voltage Monitoring for

Industrial Facilities and Equipment.

• Monitor for overvoltages or undervoltages.

• Manual resetting and automatically resetting supported by one

Relay.

• One SPDT output relay, 5 A at 250 VAC (resistive load).

• Output relay can be switched between normally open and

normally closed.

• Process control signal (0 to 10 V) and current splitter input

supported.

• Output status can be monitored using LED indicator.

• Input frequency of 40 to 500 Hz supported.

• Inputs are isolated from the power supply.

Refer to Safety Precautions on page 9.

Refer to page 8 for commonly asked questions.

Ordering Information

List of Models

Setting range Power supply voltage Model

1 to 10 V AC/DC

3 to 30 V AC/DC

15 to 150 V AC/DC

20 to 200 V AC/DC

30 to 300 V AC/DC

60 to 600 V AC/DC

24 VAC/DC K8AK-VS2 24 VAC/DC

100 to 240 VAC K8AK-VS2 100-240 VAC

24 VAC/DC K8AK-VS3 24 VAC/DC

100 to 240 VAC K8AK-VS3 100-240 VAC

Ratings and Specifications

Input Range

Model Range* Connection terminal Setting range Input impedance Overload capacity

0 to 10 V AC/DC V1-COM

K8AK-VS2

K8AK-VS3

* The range is selected using connected terminals.

0 to 30 V AC/DC V2-COM Approx. 320 kΩ

0 to 150 V AC/DC V3-COM Approx. 1.6 MΩ

0 to 200 V AC/DC V1-COM

0 to 300 V AC/DC V2-COM Approx. 1.7 MΩ

0 to 600 V AC/DC V3-COM Approx. 3.1 MΩ

1 to 10 V AC/DC,

3 to 30 V AC/DC,

15 to 150 V AC/DC

20 to 200 V AC/DC,

30 to 300 V AC/DC,

60 to 600 V AC/DC

Approx. 120 kΩ

Approx. 1.2 MΩ

Continuous input at

115% of maximum input

10 s at 125%

(up to 600 VAC)

1

Page 2

K8AK-VS

Ratings

Power supply

voltage

Power consumption

Operating value setting range (SV)

Operating value 100% operation at set value

Reset value setting range (HYS.) 5% to 50% of operating value

Reset method

Operating time setting range (T) 0.1 to 30 s

Power ON lock time (LOCK) 1 s or 5 s (Switched using DIP switch.)

Indicators Power (PWR): Green, Relay output (RY): Yellow, Alarm outputs (ALM): Red

Input impedance Refer to Input Range on previous page.

Output relays One SPDT relay (NO/NC switched using DIP switch.)

Output relay ratings

Ambient operating temperature −20 to 60°C (with no condensation or icing)

Storage temperature −25 to 65°C (with no condensation or icing)

Ambient operating humidity 25% to 85% (with no condensation)

Storage humidity 25% to 85% (with no condensation)

Altitude 2,000 m max.

Terminal screw tightening torque 0.49 to 0.59 N·m

Terminal wiring method

Case color N1.5

Case material PC and ABS, UL 94 V-0

Weight Approx. 150 g

Mounting Mounts to DIN Track.

Dimensions 22.5 × 90 × 100 mm (W×H×D)

Isolated power supply

24 VAC/DC

100 to 240 VAC

24 VAC/DC: 2.0 VA/1.1 W max.

100 to 240 VAC: 4.6 VA max.

10% to 100% of maximum setting range

K8AK-VS2: 1 to 10 V AC/DC

K8AK-VS3: 20 to 200 V AC/DC

Manual reset/automatic reset (switchable)

Note: Manual reset: Turn OFF power supply for 1 s or longer.

Rated load

Resistive load

5 A at 250 VAC

5 A at 30 VDC

Maximum switching capacity: 1,250 VA, 150 W

Minimum load: 5 VDC, 10 mA (reference values)

Mechanical life: 10 million operations min.

Electrical life: 5 A at 250 VAC or 30 VDC: 50,000 operations

Recommended wire

Solid wire: 2.5 mm

Twisted wires: AWG16, AWG18

Note: 1. Ferrules with insulating sleeves must be used with twisted wires.

Recommended ferrules

Al 1,5-8BK (for AWG16) manufactured by Phoenix Contact

Al 1-8RD (for AWG18) manufactured by Phoenix Contact

Al 0,75-8GY (for AWG18) manufactured by Phoenix Contact

3 to 30 V AC/DC

15 to 150 V AC/DC

30 to 300 V AC/DC

60 to 600 V AC/DC

3 A at 250 VAC or 30 VDC: 100,000 operations

2

2. Two wires can be twisted together.

2

Page 3

Specifications

Allowable operating voltage range 85% to 110% of rated power supply voltage

Allowable operating frequency range 50/60 Hz ±5 Hz

Input frequency 40 to 500 Hz

Overload capacity Continuous input at 115% of maximum input, 10 s at 125% (up to 600 VAC).

Repeat accuracy

Applicable standards

Insulation resistance

Dielectric strength

Noise immunity

Vibration resistance

Shock resistance 100 m/s2, 3 times each in 6 directions along 3 axes

Degree of protection Terminals: IP20

Operating value

Operating time ±50 ms (at 25°C and 65% humidity, rated power supply voltage)

Conforming standards

EMC EN 60947-5-1

Safety standards

±0.5% full scale (at 25°C and 65% humidity, rated power supply voltage, DC or 50/60 Hz sine

wave input)

EN 60947-5-1

Installation environment (pollution level 2, installation category III)

UL 508 (Recognition), Korean Radio Waves Act (Act 10564),

CSA: C22.2 No.14, CCC: GB/T 14048.5

20 MΩ min.

Between external terminals and case

Between power supply terminals and input terminals

Between power supply terminals and output terminals

Between input terminals and output terminals

2,000 VAC for one minute

Between external terminals and case

Between power supply terminals and input terminals

Between power supply terminals and output terminals

Between input terminals and output terminals

1,500 V power supply terminal common/normal mode

Square-wave noise of ±1 μs/100 ns pulse width with 1-ns rise time

Frequency: 10 to 55 Hz, 0.35-mm single amplitude

10 sweeps of 5 min each in X,Y, and Z directions

K8AK-VS

3

Page 4

K8AK-VS

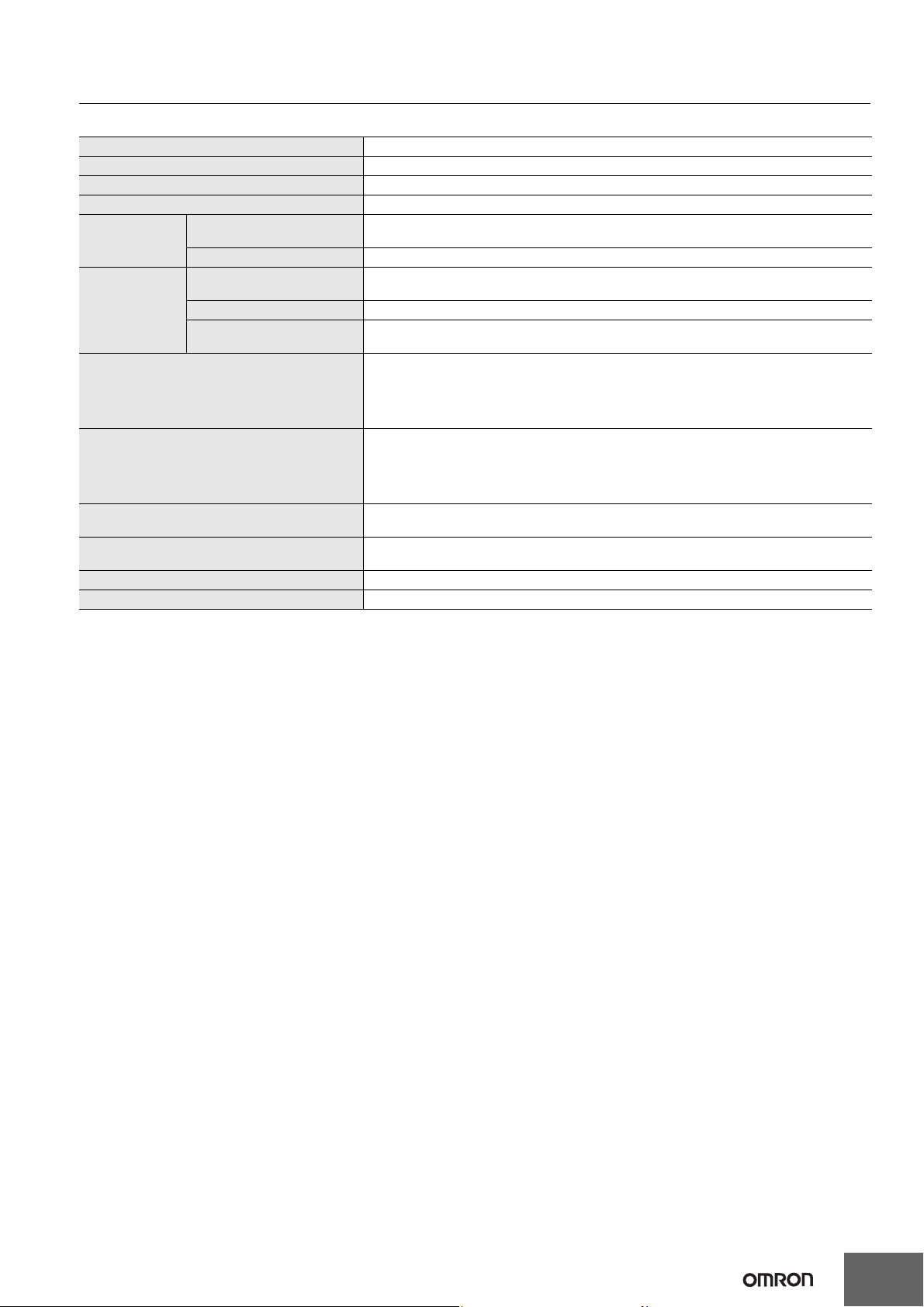

t1

t

Set value

Input

Power supply

voltage

Relay 11-14

Relay 11-12

Alarm indicator

t: Operating time (0.1 to 30 s)

t1: Power ON lock (1 or 5 s)

Lit

Flashing

Hysteresis

(−5% to 50% of operating value)

Delay: 250 ms

(reference value)

Lit

Flashing

t1

t1: Power ON lock (1 or 5 s)

t

t: Operating time (0.1 to 30 s)

Hysteresis

(5% to 50% of operating value)

Power supply

voltage

Relay 11-14

Relay 11-12

Set value

Alarm indicator

Input

Delay: 250 ms (reference value)

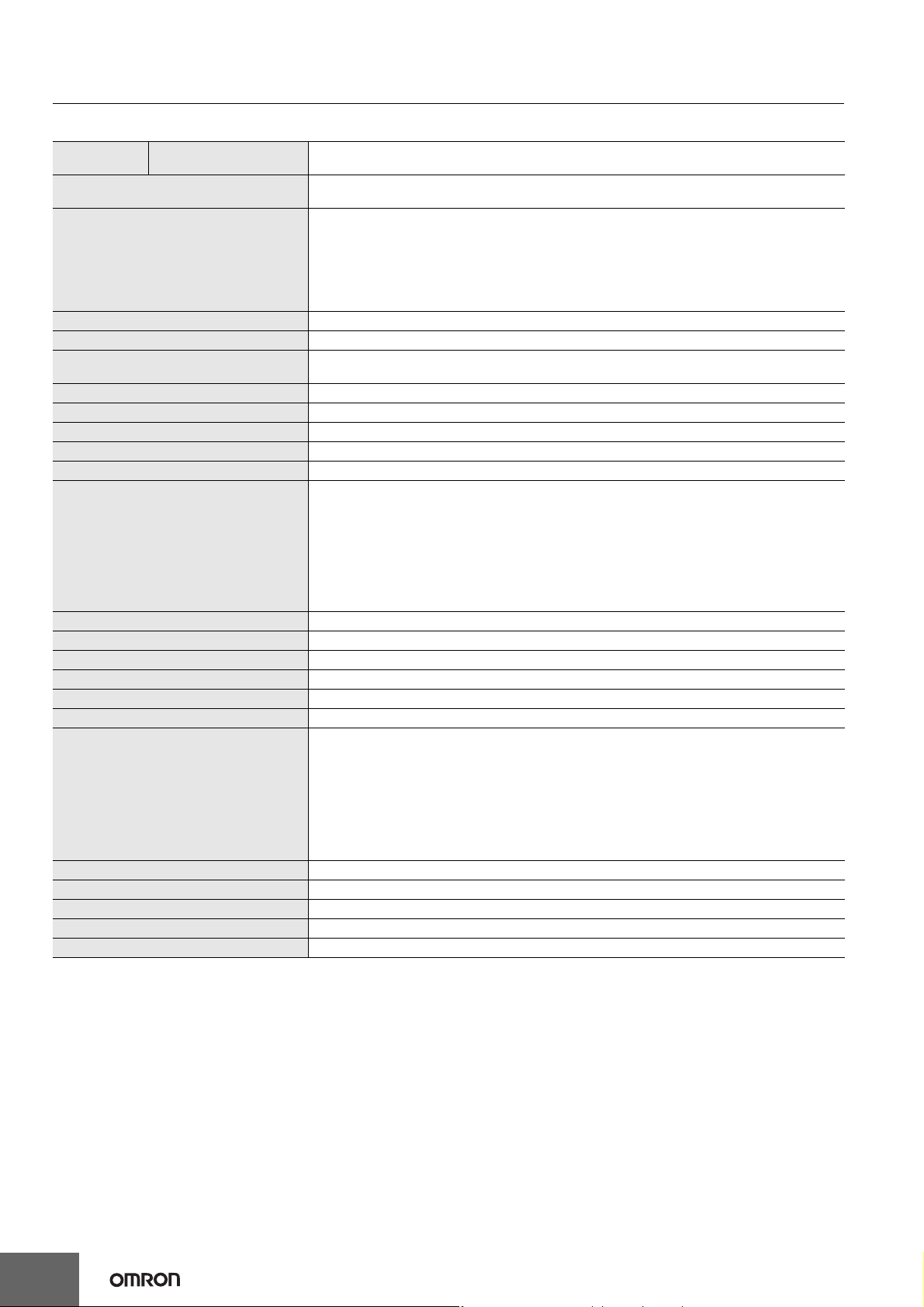

Connections

Terminal Diagram

K8AK-VS2 100-240VAC

AB

Control Output

Relay output

250 VAC, 5 A (resistive load)

30 VDC, 5 A (resistive load)

B Power Supply Voltage

100 to 240 VAC 24 VAC/DC

A2

A1

A1

(No polarity)

V2

V1

A2

A1

11 12

V3

A2

C

14

A Voltage Input

VS2

V2

V1

10 V max.

V3

30 V max.

C

Relay Output

Common

11 12 14

150 V max.

VS3

V1

200 V max.

V2

300 V max.

V3

600 V max.

C

Note: 1. There is no polarity for the DC power supply input.

2. For the voltage input, you can input only from the C terminal and one other terminal.

3. Refer to Setting Ranges and Wiring Connections for information on the V1, V2, and V3 voltage input terminals.

4. Use the recommended ferrules if you use twisted wires.

Wiring Example

Single-phase

power supply

Load

4

V1 V2 V3

Power

supply voltage

A2

A1

A1 A2

C

11 12

14

Timing Charts

●Overvoltage Operation Diagram

(Output Relay Drive Method: Normally Closed)

DIP switch setting: SW3 ON.

Note: The power ON lock prevents unnecessary alarms from being

generated during the instable period when the power is first

turned on. There is no relay output during timer operation.

Power supply

AC/DC

●Undervoltage Operation Diagram

(Output Relay Drive Method: Normally Open)

DIP switch setting: SW3 OFF.

Note: The power ON lock prevents unnecessary alarms from being

generated during the instable period when the power is first

turned on. There is no relay output during timer operation.

Page 5

Nomenclature

K8AK-VS

Front

(See notes 1 and 2.)

Relay status indicator

(See notes 1 and 2.)

Terminal block

Power indicator

Alarm indicator

Terminal block

Voltage knob (SV)

Hysteresis knob (HYS.)

Operating time knob (T)

●Indicators

Item Meaning

Power indicator

(PWR: Green)

Relay status indicator

(RY: Yellow)

Lit when power is being supplied.

Lit when relay is operating

Lit when there is an overvoltage or under-

voltage.

Alarm indicator

(ALM: Red)

The indicator flashes to indicate the error

status after the input has exceeded the set

value while the operating time is being

clocked.

●Setting Knobs

Item Usage

Voltage knob (SV)

Hysteresis knob

(HYS.)

Operating time knob

(T)

Note: 1. Use either a solid wire of 2.5 mm2 maximum or a ferrule with

insulating sleeve for the terminal connection.

The length of the exposed current-carrying part inserted into

the terminal must be 8 mm or less to maintain dielectric

strength after connection.

Used to set the voltage to 10% to 100% of

maximum setting range.

Used to set the rest value to 5% to 50% of

the operating value.

Used to set the operating time to 0.1 to 30 s.

For 2.5 mm2 or

smaller solid wires

8 mm max. 8 mm max.

For ferrules with

an insulation sleeve.

Recommended ferrules

Phoenix Contact

• Al 1,5-8BK (for AWG16)

• Al 1-8RD (for AWG18)

• Al 0,75-8GY (for AWG18)

2. Tightening torque: 0.49 to 0.59 N·m

5

Page 6

K8AK-VS

Operation Methods

Setting Ranges and Wiring Connections

Model Setting range Wiring connection

1 to 10 V AC/DC V1-COM

K8AK-VS2

K8AK-VS3

Connections

●Input

Connect the input between terminals V1-COM, V2-COM, or V3-COM, depending on the input

voltage.

Malfunctions may occur if the input is connected to unused terminals and the Unit will not operate

correctly.

●Power Supply

Connect the power supply to terminals A1 and A2.

●Outputs

SPDT relays are output to terminals 11, 12, and 14.

Note: Use the recommended ferrules if using twisted wires.

3 to 30 V AC/DC V2-COM

15 to 150 V AC/DC V3-COM

20 to 200 V AC/DC V1-COM

30 to 300 V AC/DC V2-COM

60 to 600 V AC/DC V3-COM

Single-phase power

Power supply

voltage

Voltage input

A1

A2

V1

V2

V3

C (COM)

Load

Signal output

14

12

Relay

signal

output

11

DIP Switch Settings

The power ON lock time, resetting method, relay drive method, and operating mode are set using the DIP switch located on the bottom of the Unit.

●DIP Switch Functions

OFF

ON

SW4

SW3

SW2

SW1

DIP switch pins

OFF ● ↑

Pin

ON ❍ ↓

Power ON

lock time

Resetting

method

Relay drive

method

Operating

mode

1 s ● --- --- ---

5 s ❍ --- --- ---

Manual reset --- ● --- ---

Automatic reset --- ❍ --- ---

Normally open --- --- ● ---

Normally closed --- --- ❍ ---

Overvoltage --- --- --- ●

Undervoltage --- --- --- ❍

Note: All pins are set to OFF at the factory.

OFF

ON

1

2 3 4

6

Page 7

K8AK-VS

22.5

90

100

72

5

K8AK-VS2

K8AK-VS3

●DIN Tracks

PFP-100N

PFP-50N

Setting Method

●Setting Voltage

The voltage knob (SV) is used to set the voltage.

The voltage can be set to 10% to 100% of the maximum

Turn the knob while there is an input to the input terminals until the alarm indicator flashes (when the set value and the input have reached the

same level.)

Use this as a guide to set the voltage.

The maximum

Example: K8AK-VS3 Using Input Terminal V3-COM

The maximum

setting range

setting range

will differ depending on the model and the input terminal.

will be 600 VAC/VDC and the setting range will be 60 to 600 V.

●Hysteresis

Hysteresis is set using the hysteresis knob (HYS.)

The setting range is 5 to 50% of the operating value.

Example: Maximum Setting of 600 VAC/VDC, Voltage Set Value (SV) of 50%, and Overvoltage Operation

Operation will be at 300 V and resetting at 270 V when the hysteresis (HYS.) is set to 10%.

●Operating Time

The operating time is set using the operating time knob (T).

The operating time can be set to between 0.1 and 30 s.

If the input voltage exceeds (or drops lower than) the voltage set value, the alarm indicator will start flashing for the set period and then stay lit.

setting range

.

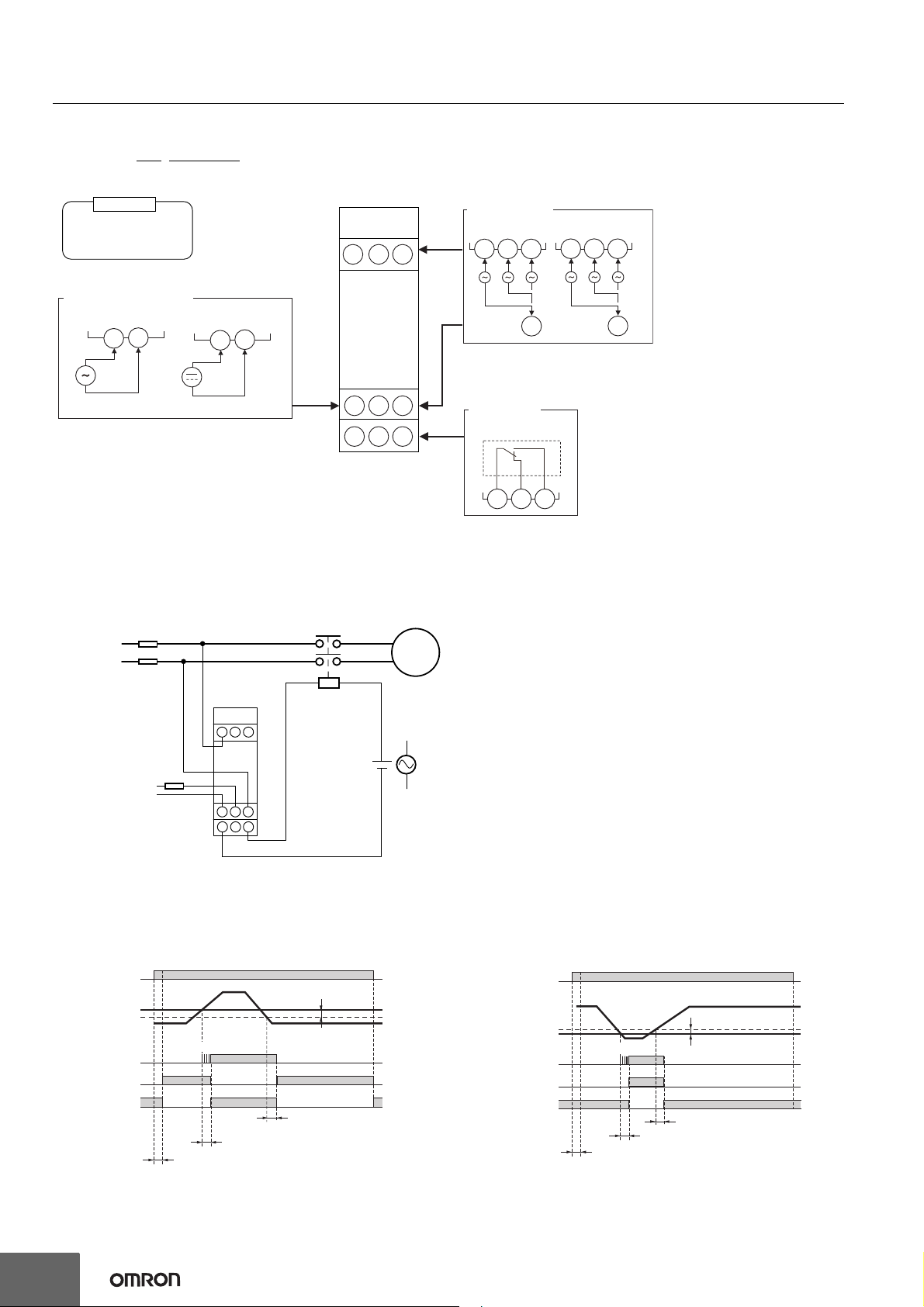

Dimensions

Single-phase Voltage Relays

Optional Parts for DIN Track Mounting

4.5

15 25 25

10

1,000 (500)*

±0.15

7.3

±0.3

35

25 25

10

*Dimensions in parentheses are for the PFP-50N.

15 (5)*

27

1

(Unit: mm)

±0.15

7

Page 8

K8AK-VS

Questions and Answers

Checking Operation

Q

Q

Overvoltages

Gradually increase the input from 80% of the set value.

The input will equal the operating value when the input

exceeds the set value and the alarm indicator starts flashing.

Operation can be checked by the relay outputs that will start

after the operating time has passed.

Undervoltage

Gradually decrease the input from 120% of the set value and

check the operation using the same method as for

overvoltage.

Example: Overvoltage Operating Mode and an Operating Time of 5 s

Note: K8AK-VS@ output relays are normally operative.

Set value

Input voltage

Alarm indicator

Relay output

Connection Diagram

200 VAC

Variable

autotransformer

0 to 300 V

V

Flashing

5 s

Input terminals

Power supply

Lit

A1

A2

How to Measure the Operating Time

Q

Q

Overvoltage

Change the input suddenly from 0% to 120% of the set value

and measure the time until the Unit operates.

Undervoltage

Change the input suddenly from 120% to 0% of the set value

and measure the time until the Unit operates.

±

C 200 V

Cycle counter

8

Page 9

K8AK-VS

Safety Precautions

Be sure to read the precautions for all models in the website at the following URL: http://www.ia.omron.com/.

Warning Indications

Indicates a potentially hazardous situation

which, if not avoided, will result in minor or

WARNING

CAUTION

Precautions for Safe

Use

Precautions for

Correct Use

moderate injury, or may result in serious

injury or death. Additionally there may be

significant property damage.

Indicates a potentially hazardous situation

which, if not avoided, may result in minor or

moderate injury or in property damage.

Supplementary comments on what to do or

avoid doing, to use the product safely.

Supplementary comments on what to do or

avoid doing, to prevent failure to operate,

malfunction, or undesirable effects on

product performance.

Meaning of Product Safety Symbols

Used to warn of the risk of electric shock under

specific conditions.

Used for general prohibitions for which there is no

specific symbol.

Used to indicate prohibition when there is a risk of

minor injury from electrical shock or other source if

the product is disassembled.

WARNING

Electrical shock may occasionally cause serious injury.

Confirm that the input voltage is OFF before starting any

wiring work and wire all connections correctly.

CAUTION

Electrical shock may cause minor injury.

Do not touch terminals while electricity is being supplied.

There is a risk of minor electrical shock, fire, or device failure.

Do not allow any pieces of metal, conductors, or cutting chips

that occur during the installation process to enter the product.

Explosions may cause minor injuries. Do not use the product

in locations with inflammable or explosive gases.

There is a risk of minor electrical shock, fire, or device failure.

Do not disassemble, modify, repair, or touch the inside of the

product.

Loose screws may cause fires. Tighten terminal screws to the

specified torque of 0.49 to 0.59 N·m.

Used for general mandatory action precautions for

which there is no specified symbol.

Use of excessive torque may damage the terminal screws.

Tighten terminal screws to the specified torque of 0.49 to

0.59 N·m.

Use of the product beyond its life may result in contact welding

or burning. Make sure to consider the actual operating

conditions and use the product within its rated load and

electrical life count. The life of the output relay varies

significantly with the switching capacity and switching

conditions.

9

Page 10

K8AK-VS

AB

Precautions for Safe Use

1. Do not use or store the product in the following locations.

• Locations subject to water or oil

• Outdoor locations or under direct sunlight

• Locations subject to dust or corrosive gases (particularly

sulfurizing gases, ammonia, etc.)

• Locations subject to rapid temperature changes

• Locations prone to icing and dew condensation

• Locations subject to excessive vibration or shock

• Locations subject to wind and rain

• Locations subject to static electricity and noise

• Habitats of insects or small animals

2. Use and store the product in a location where the ambient

temperature and humidity are within the specified ranges. If

applicable, provide forced cooling.

3. Mount the product in the correct direction.

4. Check terminal polarity when wiring and wire all connections

correctly. The power supply terminals do not have polarity.

5. Do not wire the input and output terminals incorrectly.

6. Make sure the power supply voltage and loads are within the

specifications and ratings for the product.

7. Make sure the crimp terminals for wiring are of the specified size.

8. Do not connect anything to terminals that are not being used.

9. Use a power supply that will reach the rated voltage within 1

second after the power is turned ON.

10.Keep wiring separate from high voltages and power lines that

draw large currents.

Do not place product wiring in parallel with or in the same path as

high-voltage or high-current lines.

11.Do not install the product near equipment that generates high

frequencies or surges.

12.The product may cause incoming radio wave interference. Do not

use the product near radio wave receivers.

13.Install an external switch or circuit breaker and label it clearly so

that the operator can quickly turn OFF the power supply.

14.Make sure the indicators operate correctly. Depending on the

application environment, the indicators may deteriorate

prematurely and become difficult to see.

15.Do not use the product if it is accidentally dropped. The internal

components may be damaged.

16.Be sure you understand the contents of this catalog and handle

the product according to the instructions provided.

17.Do not install the product in any way that would place a load on it.

18.When discarding the product, properly dispose of it as industrial

waste.

19.When using the product, remember that the power supply

terminals carry a high voltage.

20.The product must be handled only by trained electrician.

21.Prior to operation, check the wiring before you supply power to

the product.

22.Do not install the product immediately next to heat sources.

23.Perform periodic maintenance.

Precautions for Correct Use

Observe the following operating

methods to prevent failure and

malfunction.

1. Use the power supply voltage, input power, and other power

supplies and converters with suitable capacities and rated

outputs.

2. Use a precision screwdriver or similar tool to adjust the setting

knobs.

3. Do not use the product in circuits with waveform distortion. Error

will be large due to waveform distortion.

4. Error will be large if the product is used for thyristor or inverter

control.

5. To reduce the error in the setting knob, always turn the setting

knob from the minimum setting toward the maximum setting.

6. When cleaning the product, do not use thinners or solvents. Use

commercial alcohol.

Correct Mounting Direction, Mounting,

and Removing

• Mounting to DIN Track

1. Attach the product to the DIN Track with the tab at the top and

the hooks at the bottom.

2. Push the product onto the Track until the hooks lock into place.

• Removing from the DIN Track

Pull down on the bottom hook with a flat-blade screwdriver and lift

up on the product.

Applicable DIN Tracks:

PFP-100N (100 cm)

PFP-50N (50 cm)

10

Adjusting the Setting Knobs

• Use a screwdriver to adjust the setting knobs. The knobs have a

stopper that prevents them from turning beyond the full right or left

position. Do not force a knob beyond these points.

Setting knob

Page 11

Terms and Conditions Agreement

Read and understand this catalog.

Please read and understand this catalog before purchasing the products. Please consult your OMRON representative if you have

any questions or comments.

Warranties.

(a) Exclusive Warranty. Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship

for a period of twelve months from the date of sale by Omron (or such other period expressed in writing

by Omron). Omron disclaims all other warranties, express or implied.

(b) Limitations. OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF THE

PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE PRODUCTS WILL

SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based on infringement by the Products

or otherwise of any intellectual property right. (c) Buyer Remedy. Omron’s sole obligation hereunder shall be, at Omron’s election,

to (i) replace (in the form originally shipped with Buyer responsible for labor charges for removal or replacement thereof) the

non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal to the purchase price

of the non-complying Product; provided that in no event shall Omron be responsible for warranty, repair, indemnity or any other

claims or expenses regarding the Products unless Omron’s analysis confirms that the Products were properly handled, stored,

installed and maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of any Products by

Buyer must be approved in writing by Omron before shipment. Omron Companies shall not be liable for the suitability or

unsuitability or the results from the use of Products in combination with any electrical or electronic components, circuits, system

assemblies or any other materials or substances or environments. Any advice, recommendations or information given orally or in

writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc.

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED IN CONTRACT, WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on which liability is asserted.

Suitability of Use.

Omron Companies shall not be responsible for conformity with any standards, codes or regulations which apply to the

combination of the Product in the Buyer’s application or use of the Product. At Buyer’s request, Omron will provide applicable

third party certification documents identifying ratings and limitations of use which apply to the Product. This information by itself is

not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine, system,

or other application or use. Buyer shall be solely responsible for determining appropriateness of the particular Product with

respect to Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY OR IN LARGE

QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS,

AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE

OVERALL EQUIPMENT OR SYSTEM.

Programmable Products.

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or any consequence thereof.

Performance Data.

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for the user in determining

suitability and does not constitute a warranty. It may represent the result of Omron’s test conditions, and the user must correlate it

to actual application requirements. Actual performance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications.

Product specifications and accessories may be changed at any time based on improvements and other reasons. It is our practice

to change part numbers when published ratings or features are changed, or when significant construction changes are made.

However, some specifications of the Product may be changed without any notice. When in doubt, special part numbers may be

assigned to fix or establish key specifications for your application. Please consult with your Omron’s representative at any time to

confirm actual specifications of purchased Product.

Errors and Omissions.

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is

assumed for clerical, typographical or proofreading errors or omissions.

Page 12

OMRON Corporation Industrial Automation Company

Tokyo, JAPAN

Contact: www.ia.omron.com

Regional Headquarters

OMRON EUROPE B.V.

Wegalaan 67-69-2132 JD Hoofddorp

The Netherlands

Tel: (31)2356-81-300/Fax: (31)2356-81-388

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08 (Lobby 2),

Alexandra Technopark,

Singapore 119967

Tel: (65) 6835-3011/Fax: (65) 6835-2711

OMRON ELECTRONICS LLC

One Commerce Drive Schaumburg,

IL 60173-5302 U.S.A.

Tel: (1) 847-843-7900/Fax: (1) 847-843-7787

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120, China CSM_2_7_0619

Tel: (86) 21-5037-2222/Fax: (86) 21-5037-2200

Authorized Distributor:

© OMRON Corporation 2014 All Rights Reserved.

In the interest of product improvement,

specifications are subject to change without notice.

Cat. No. N181-E1-01

0314 (0314)

0513

Loading...

Loading...