1

Overview

2

Device Components

Motor Condition

Monitoring Device

User's Manual

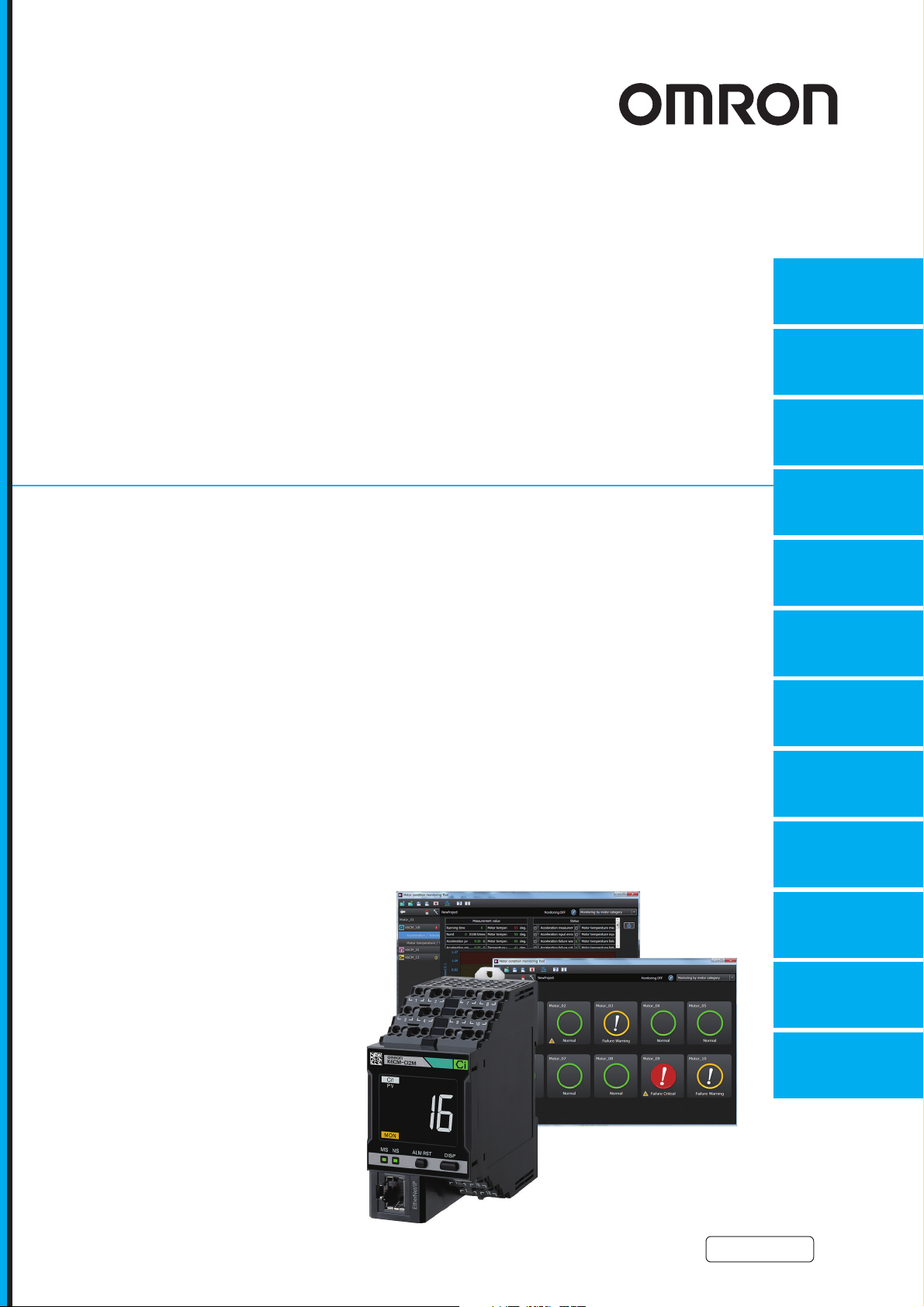

K6CM

3

Measuring and

Monitoring System

4

Introduction of

the Motor condition

monitoring Tool

5

Installation and Wiring

6

How to Use

the Motor condition

monitoring Tool

7

Monitoring with K6CM

and Motor condition

monitoring Tool

8

Monitoring and Setting

Using the EtherNet/IP

Devices

9

Monitoring and Setting

Using the Modbus TCP

Devices

N219-E1-12

10

Trouble shooting

A

Appendices

I

Index

NOTE

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of the information contained in this publication.

Trademarks

• Microsoft, Windows is either registered trademarks or trademarks of Microsoft Corporation in the United States

and other countries.

• CIP and EtherNet/IP

TM

are trademarks of ODVA.

• Modbus is a registered trademark or trademark of Schneider Electric USA, Inc. in Japan, the United States or

other countries.

Other company names and product names in this document are the trademarks or registered trademarks of their

respective companies.

Copyrights

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Preface

Thank you for purchasing K6CM Motor Condition Monitoring Devices.

This manual describes how to use the K6CM. Read this manual thoroughly and be sure you understand it before attempting to use the K6CM correctly according to the information provided. Keep this

manual in a safe place for easy reference.

PDF version of this manual can be downloaded from the OMRON website.

(http://www.omron.co.jp)

Preface

K6CM Motor Condition Monitoring Device User’s Manual (N219)

1

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship for a period of twelve months from the date of sale by Omron (or such other period expressed in

writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be

responsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of

any Products by Buyer must be approved in writing by Omron before shipment. Omron Companies

shall not be liable for the suitability or unsuitability or the results from the use of Products in combination with any electrical or electronic components, circuits, system assemblies or any other materials or substances or environments. Any advice, recommendations or information given orally or in

writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

2

K6CM Motor Condition Monitoring Device User’s Manual (N219)

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings

and limitations of use which apply to the Product. This information by itself is not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine, system, or other application or use. Buyer shall be solely responsible for determining appropriateness of

the particular Product with respect to Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY OR IN LARGE QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE

HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Terms and Conditions Agreement

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or

any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual performance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and other

reasons. It is our practice to change part numbers when published ratings or features are changed, or

when significant construction changes are made. However, some specifications of the Product may be

changed without any notice. When in doubt, special part numbers may be assigned to fix or establish

key specifications for your application. Please consult with your Omron’s representative at any time to

confirm actual specifications of purchased Product.

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

K6CM Motor Condition Monitoring Device User’s Manual (N219)

3

Safety Precautions

Safety Precautions

Definition of Precautionary Information

The following notation is used in this manual to provide precautions required to ensure safe usage of

the K6CM Motor Condition Monitoring Devices.

The safety precautions that are provided are extremely important to safety. Always read and heed the

information provided in all safety precautions.

Symbols

The following notation is used.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury or in property damage.

Symbol Meaning

• General Caution

Indicates non-specific general cautions, warnings, and dangers.

Caution

Prohibition

Mandatory

Caution

• Electrical Shock Caution

Indicates possibility of electric shock under specific conditions.

• General Prohibition

Indicates non-specific general prohibitions.

• Disassembly Prohibition

Indicates prohibitions when there is a possibility of injury, such as from electric

shock, as the result of disassembly.

• General Caution

Indicates non-specific general cautions, warnings, and dangers.

CAUTION

The following are common to the Motor Condition Monitoring Devices.

Electric shock or injury may occasionally occur. Follow the instructions below to use this product.

Electrical shock may cause minor injury. Do not touch the product except for the front-panel buttons

while electricity is being supplied.

There is a risk of minor electrical shock, fire, or device failure. Do not allow any pieces of metal,

conductors, or cutting chips that occur during the installation process to enter the product.

Explosions may cause minor injuries. Do not use the product in locations with inflammable or explosive gases.

4

K6CM Motor Condition Monitoring Device User’s Manual (N219)

Safety Precautions

CAUTION

There is a risk of minor electrical shock, fire, or device failure. Do not disassemble, modify, repair, or

touch the inside of the product.

If the product fails, monitoring and alarm outputs may fail to operate. This may result in physical

damage to the facilities, equipment, or other devices that are connected to it. To reduce this risk,

inspect the product regularly. To make the product fail-safe, take alternative safety measures, such

as the installation of monitoring devices on a separate circuit.

Incorrect wiring the input and output may occasionally result in fire and may occasionally occur

resulting in property damage to connected equipment and machinery. Wire the input and output terminals correctly before power is supplied.

If installation of wiring material is shallow, material damage due to ignition may occur in rare cases.

When wiring, be sure to insert the wiring material all the way in.

The following are for K6CM-CI2 and K6CM-IS.

Electric shock may occasionally occur. Follow the instructions below to use this product.

Electric shock may occasionally occur.

Always turn OFF the power supply before connecting the special CT or special ZCT (IRT).

Electric shock may occasionally occur. As for the primary wire clamped with the special CT, be sure

to use the insulated wires at temperatures below 65°C that have rated minimum 600 V and at least

basic insulation. When clamping with conductive materials like busbar etc., use the special CT after

ensuring equal to or more than basic insulation e.g. covering with insulating objects.

Electric shock may occasionally occur. When wiring voltage input wires to the special ZCT (IRT), be

sure to wire after checking that the system power supply is in non-energized state.

Electric shock may occasionally occur. As for the wires for clamping with the special ZCT (IRT), be

sure to use the insulated wires that have rated minimum 600 V and at least basic insulation.

Keep the secondary terminal cover of the special CT and ZCT (IRT) securely closed.

Touching any of electrode may result in electric shock.

K6CM Motor Condition Monitoring Device User’s Manual (N219)

5

Safety Precautions

K6CM-VB K6CM-IS K6CM-CI2

UL certification 480 V 480 V 480 V

Not UL certification 600 V 480 V 600 V

Conformance to Safety Standards

• Reinforced insulation is provided between input power supply, output, and between other terminals.

• To install a recommended fuse for this product according to the instruction manual is necessary.

• If the equipment is used in a manner not specified by the manufacturer, the protection provided

by the equipment may be impaired.

• Connect the wiring of the special ZCT (IRT) to the terminal block corresponding to the thickness

of AWG 18 or more.

• K6CM must be installed within a control panel as an embedded device, if using as a UL certified

product.

• The motor rated voltage in regards to safety standard is as follows:

• K6CM is Over-voltage category II.

• K6CM will not conform to safety standards if attaching the vibration sensor with adhesive. In the

case of disconnection, take safety measures such as fixing the cables.

Conformance to EN/IEC Standards

This is a class A product. In residential areas it may cause radio interference, in which case the

user may be required to take adequate measures to reduce interference.

6

K6CM Motor Condition Monitoring Device User’s Manual (N219)

Precautions for Safe Use

Be sure to observe the following precautions to prevent malfunction or adverse affects on the performance or functionality of the product. Not doing so may occasionally result in unexpected events. Do

not handle the K6CM in ways that exceed the ratings.

The followings are common to the Motor Condition Monitoring Devices.:

(1) Do not use or store the product in the following locations:

• Locations subject to water or oil (for K6CM devices and K6CM-VBS1 sensor preamplifier)

• Outdoor or locations subject to direct sunlight

• Locations subject to dust or corrosive gases (particularly sulfurizing gases, ammonia, etc.)

• Locations subject to rapid temperature changes

• Locations prone to icing and dew condensation

• Locations subject to excessive vibration or shock

• Locations subject to rain and wind damage

• Locations subject to influence of static electricity and noise

• Locations subject to bugs and small animals

(2) Use and store the product in a location where the ambient temperature and humidity are within the

specified ranges. If applicable, provide forced cooling.

(3) Mount the product in the correct direction for installation.

(4) Check terminal polarity when wiring and wire all connections correctly. The power supply terminals

do not have polarity.

(5) Do not wire the input and output terminals incorrectly.

(6) Make sure the power supply voltage and loads are within the specifications and ratings for the

product.

(7) Make sure the crimp terminals for wiring are of the specified size.

(8) Do not connect anything to terminals that are not being used.

(9) Use a power supply that will reach the rated voltage within 1 second after the power is turned ON.

(10) In order to prevent inductive noise, wire the lines connected to the product separately from power

lines carrying high voltages or currents. Also, do not wire in parallel with or on the same cables as

power lines. Other measures for reducing noise are to separate from ducts including noisy lines.

(11) Do not install the product near equipment that generates high frequencies or surges.

(12) Do not use the product near radio wave receivers. Doing so may cause incoming radio wave inter-

ference.

(13) Install an external switch or a circuit breaker and label it clearly so that the operator can quickly turn

OFF the power supply.

(14) When discarding the product, properly dispose of it as industrial waste.

(15) Make sure the LCD and the LEDs for output indicators operate correctly. Depending on the appli-

cation environment, the indicators and other plastic parts may wear prematurely and become diffi-

cult to see. Check and replace these parts regularly.

(16) The maximum terminal temperature is 80°C. Use wires with a heat resistance of 80°C min to wire

the terminals.

(17) Don't use because it may be damaged inside the product when the product fall by mistake.

(18) Read this manual carefully before using the product.

(19) Install product so that the load doesn't span the product body.

(20) Be sure to use power terminals carefully, because power supply terminals have hazardous voltage.

(for K6CM devices only. Except for K6CM-VBS1 sensors input.)

(21) Only a professional with an understanding of electricity and electric devices must handle it.

(22) Confirm the wiring the input and output terminals correctly before power is supplied.

Precautions for Safe Use

K6CM Motor Condition Monitoring Device User’s Manual (N219)

7

Precautions for Safe Use

(23) Do not install the product close contact with the heating element.

(24) Do not wire anything to the release holes.

(25) Do not tilt or twist a flat-blade screwdriver while it is inserted into a release hole on the terminal

block. The terminal block may be damaged.

(26) Insert a flat-blade screwdriver into the release holes at an angle. The terminal block may be dam-

aged if you insert the screwdriver straight in.

(27) Do not allow the flat-blade screwdriver to fall out while it is inserted into a release hole.

(28) The terminal block may be damaged if you insert a flat-blade screwdriver in the release hole with

excessive force. When inserting a flat-blade screwdriver into the release holes, operate with a

force of 15·N or less.

(29) Do not bend a wire past its natural bending radius or pull on it with excessive force. Doing so may

cause the wire disconnection.

(30) Do not insert more than one wire into each terminal insertion hole.

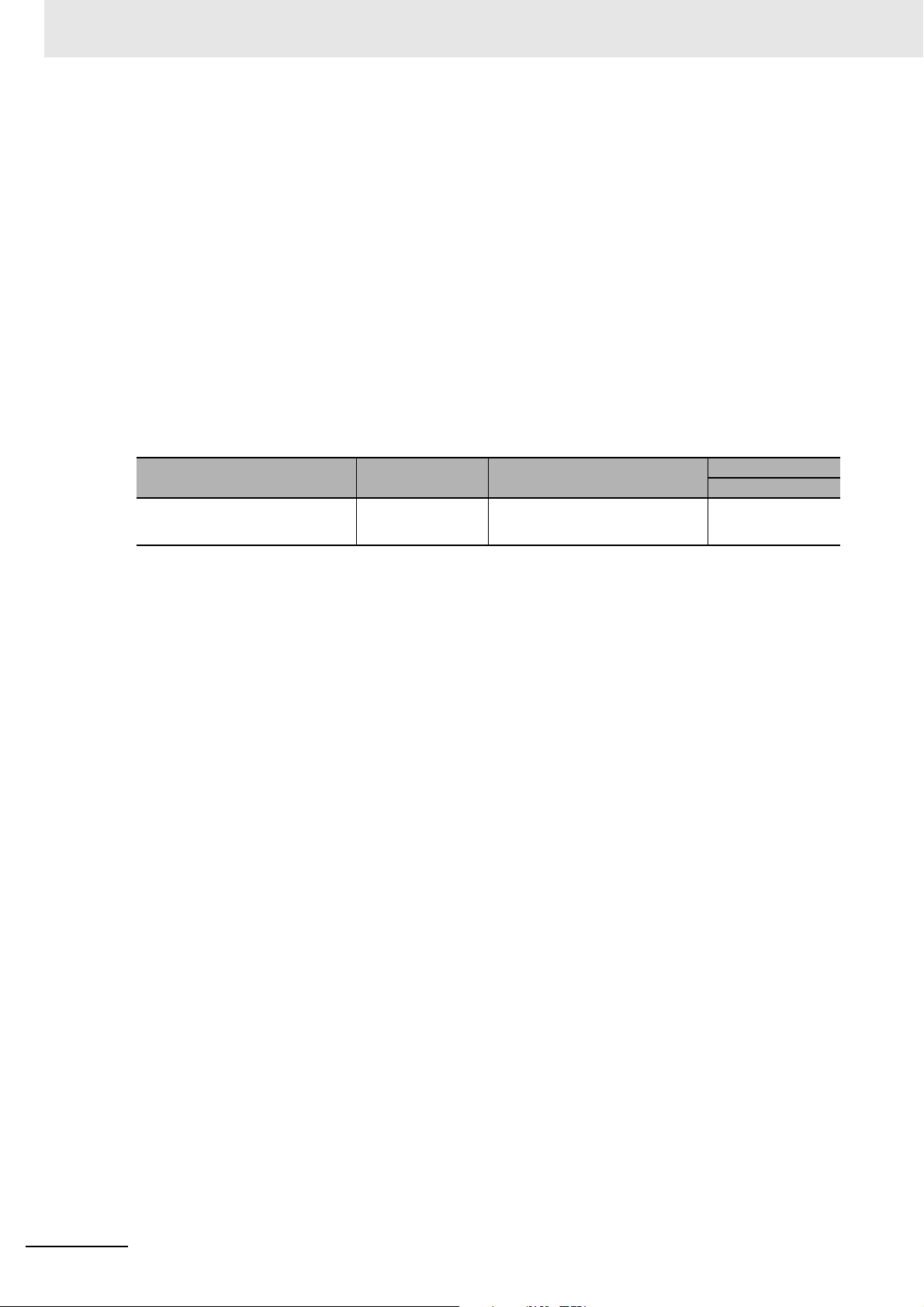

(31) To prevent wiring materials from smoking or ignition, use the wiring materials given in the following

table.

Wire type Wiring material Recommended wires

Solid/ Stranded wire Copper

(32) Use the wire given in this manual.

(33) When wiring, wire by enough length.

(34) Follow the directions indicated in the manual for connecting EtherNet/IP

result in communications failure.

TM

(35) If EtherNet/IP

tag data links (cyclic communications) are used with a repeating hub, the communications load on the network will increase. This will increase collisions and may prevent stable

communications. Do not use repeating hubs on networks where tag data links are used. Use an

Ethernet switch instead.

(36) Do not continue to use the product if the front surface peels.

2

0.25 to 1.5 mm

AWG24 to AWG16

Stripping length

Without ferrules

8 mm

TM

or the cable. It may

The followings are for K6CM-VB and K6CM-VBS1 sensors.

(37) Protection structure of the sensor head/cable

Do not use the product in the condition that the protection structure is deteriorated, e.g., swelling or

crack of housing material or sealing material. Continued use with deteriorated protective structure

will cause cutting oil to enter inside the product, possibly destroying or burning.

(38) Use the designated communications cable with the length between the sensor and the product

within specification requirements.

(39) Connect the preamplifier and the body after the power is turned OFF.

The followings are only for K6CM-CI2.

(40) Open locking hook and clamp to each phase. After clamping, firmly engage until a sound is heard.

(41) Use the special CTs and the CT cables that are specified by OMRON' s model number.

Special CTs (The cable is included with the special CT.):

K6CM-CICB005, K6CM-CICB025, K6CM-CICB100,

K6CM-CICB200, K6CM-CICB400, K6CM-CICB600

8

K6CM Motor Condition Monitoring Device User’s Manual (N219)

Precautions for Safe Use

The followings are for K6CM-VB, K6CM-VBS1 sensors, K6CM-IS and ZCT(IRT).

(42) Do not connect or disconnect the cables between the sensor and the product while power is being

supplied. Doing so may result in malfunction or failure of the product.

(43) Do not place heavy objects on the cables between the sensor and the Product, and do not apply

excessive force to bend or pull the cables. Doing so may cause a failure.

The following is for K6CM-IS and K6CM-CI2.

(44) The product is impossible to measure correctly in the state of open phase. Use the product in the

state of non-open phase.

The following is only for K6CM-IS.

(45) Use the product within the range of specifications and the rated input voltage.

K6CM Motor Condition Monitoring Device User’s Manual (N219)

9

Precautions for Correct Use

Precautions for Correct Use

Observe the following operating methods to prevent failure and malfunction.

The followings are common to the K6CM.

(1) Use the power supply voltage, input power, and other power supplies and transformers with suit-

able capacities and rated outputs.

(2) When cleaning the product, do not use thinners or solvents. Use commercial alcohol.

(3) Confirm that wire does not stick up after wiring of stranded cable.

(4) In case of passage wiring, install these by 10 A per 1 terminal because when products are con-

nected more than one in parallel, quite many electric currents to be called off.

(5) The terminal block may be damaged if specialized tool is not used. Use a recommended flat-blade

screwdriver to inserted into a release hole on the terminal block.

(6) Do not apply excessive force to bend or pull the communications cables, and do not place heavy

objects on the cables. Doing so will damage the cables.

(7) Refer to the status information of the product on the data link communications and refer to the

received data only in case of no errors occur with the product.

The followings are for K6CM-VB and K6CM-VBS1 sensors.

(8) Wipe off the dirt on the mounting surface and screw mounting with 17 mm nominal size of wrench.

• Recommended mounting screw tightening torque: 4.4 to 5.4 N•m

• Mounting hole dimension: M6 holes (depth: 9 mm min.)

(9) The easy-positioning magnet is for the purpose of seeking the detected position. In the case of

using the product permanently, be sure to use it after it is mounted by screws.

(10) In the case of vertical mounting or reverse mounting with the easy positioning magnet, be careful

of the sensor falling.

(11) Refer to Installation of the Vibration Sensor Head on page 5-7 to install the sensor correctly. It may

be impossible to detect high frequency vibration.

(12) Do not disassemble the sensor. It may not operate correctly.

(13) Be careful of incorrect wiring or short circuit for wiring.

(14) Do not use the preamplifier connected to the other products.

(15) If there is a vibration reduction device such as dampers and rubbers between the vibration mea-

surement object and the sensor, it is difficult to detect the vibration and it will not be able to measure it correctly, so do not install as much as possible.

(16) In the case of insertion and removal of connector, be sure to do it by holding the connector with

hands.

(17) Do not remove the connector with holding the cable.

(18) Check the direction of the key groove before you use the connector.

(19) Do not wire with wet hands. It may result in operation failure or product damage when power is

being supplied to the product.

(20) When fitting the connector, be sure to do it with hands, not to use tools. It may result in damages if

the tool like plier is used.

(21) In the case of removal of the fitness of the connector between the sensor and the preamplifier, be

careful to do it not to adhere water or dirt on the fitting surface. It may result in faulty contact at the

connector.

(22) Install cables to avoid any force is applied to the connector. In case the any force is applied to the

connector, it causes that the performance of protection structure becomes incapable.

(23) Do not use the connector as a scaffold or put heavy objects on it. It may result in connector dam-

age.

10

K6CM Motor Condition Monitoring Device User’s Manual (N219)

Precautions for Correct Use

(24) Do not mount the way that the force is directly applied to the fitting part of the connector or the root

part of the cable connection. It may result in connector damage or cable disconnection.

(25) When bending cables, use cables with a minimum bending radius of 25 mm.

(26) Use preamplifier after it is fixed on the DIN rail or with screws. In case of using unfixed one, it is in

the condition that force is easily applied to the cable, and the cable may be broken.

(27) About oil-resistance of sensor head/cable; (Not tested by UL)

Follow the procedure below in case of using the product under the condition that uses cutting oil

since the life expectancy and the performance of the product are affected.

• Use the product in the specified condition for cutting oil

• Use the product at the dilution rate of cutting oil that is recommended by the cutting oil makers.

• Do not use the product in oil or water.

There are cases that the influence on the life expectancy of the product differs depending on the

type of the use oil. Make sure in advance that there is no deterioration of the sealing material by the

cutting oil, before using the product.

(28) Do not use the alarm output function for control. This function can be used only to detect abnormal

conditions and to output the alarm.

(29) Avoid using the product in places near a radio, a television set, or a wireless device.

The product may result in radio disturbance for these devices.

The followings are only for K6CM-IS.

(30) Do not clamp directly to the lines exceeding 480 VAC. UL certification complies with 480 VAC.

(31) Use the special ZCT (IRT) after fixing it with screws. If used without fixing, a load is easily applied

on the cable, and the cable may become disconnected.

(32) ZCT (IRT) is an special product. Do not use it for any other purposes. Otherwise, failure may occur.

(33) When clamping wires with special ZCT (IRT), do it in a right direction. If clamped in the wrong

direction, correct measurement cannot be taken.

(34) The distorted ratio of the input waveform should be 30% or less. If it is used in a circuit with large

distortion of waveform, it may cause unnecessary operation.

(35) Do not use in a circuit with the waveform is distorted. The error will increase due to the influence of

the distorted waveform.

The followings are only for K6CM-CI2.

(36) Make sure that the rating of the used special CT and the special CT setting of the product agree.

(37) Do not ground the special CT. Doing so may cause instability when measuring failure.

(38) Do not clamp directly to the lines exceeding 600 VAC. UL certification complies with 480 VAC.

(39) Place the cable between the special CT and the product at a distance of 6 mm or more from other

cables.

(40) Associated leads of the special CT shall be maintained within the same overall enclosure.

(41) The special CT are intended for installation within the same enclosure as the equipment. These

may not be installed within switchgears and panel boards.

K6CM Motor Condition Monitoring Device User’s Manual (N219)

11

Manual Structure

7 - 9

7 Motor Monitoring with the K6CM Devices and the Software Tool

K6CM Motor Condition Monitoring Device User’s Manual (N219)

7-3 Motor Monitoring Using Software Tools

7

7-3-1 Monitoring Procedure with Motor Condition Monitoring Tool

7-3 Motor Monitoring Using Software

Tools

This section describes how to monitor a motor using the software tools.

It depends on the following procedure.

1 Click the [Monitoring setting] Button and set "Monitoring cycle".

2 In the upper right corner of the screen, select [Monitoring by motor category] or [Monitoring by

monitoring category] from the pulldown list.

3 Monitoring is performed on the [Monitoring by motor category] screen or [Monitoring by monitor-

ing category] screen.

Precautions for Correct Use

In order to monitor the K6CM with the software tool, the communications service of the SYSMAC Gateway communication driver between the computer and the K6CM must be in the start

status.

The status of SYSMAC Gateway's communication service can be checked on the SYSMAC

Gateway Console screen.

The SYSMAC Gateway Console screen is activated by clicking [Device setting] on the startup

screen or by clicking the [SYSMAC Gateway Console] Button on the monitoring screen.

Click the [Monitoring setting] Button.

Set Monitoring cycle on the following screen.

The settable range is 5 to 99999 seconds. The default value is 600 seconds (10 minutes).

Version Information

With software tool version 1.2.0.0 or later, the unit of monitoring cycle can be set.

7-3-1 Monitoring Procedure with Motor Condition Monitoring Tool

7-3-2 Set the Monitoring Cycle

Using this pull down list allows you to

change the unit of monitoring cycle.

Selectable units are seconds, minutes,

hours, and days.

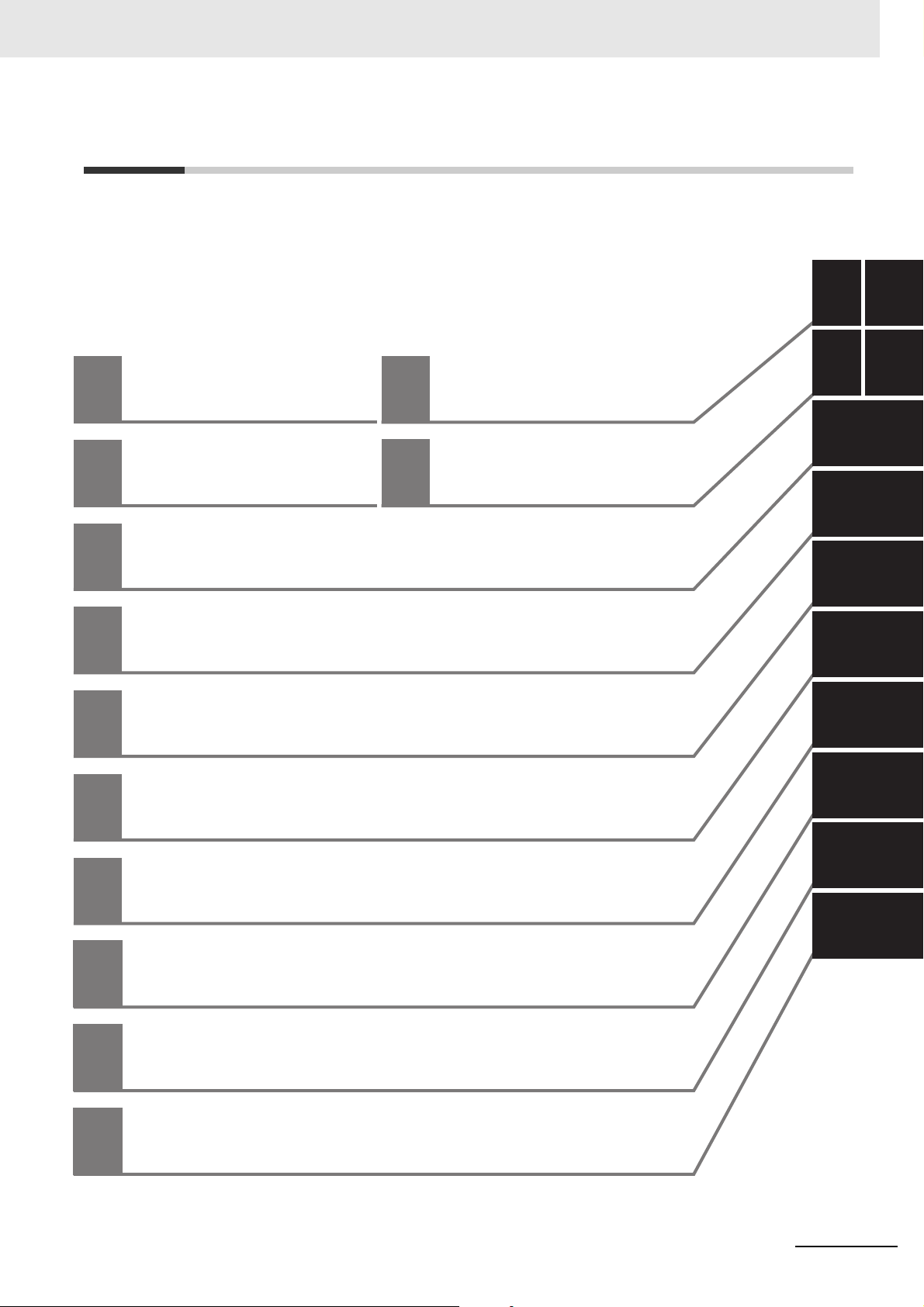

Level 1 heading

Level 2 heading

Level 3 heading

Gives the current

headings.

Page tab

Gives the number

of the main section.

Level 2 heading

Level 3 heading

A step in a procedure

Indicates a procedure.

Manual name

Special information

Icons indicate precautions,

additional information, or

reference information.

Manual Structure

Page Structure

The following page structure is used in this manual.

12

K6CM Motor Condition Monitoring Device User’s Manual (N219)

Special Information

Special information in this manual is classified as follows:

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

Version Information

Information on differences in specifications and functionality for CPU Units with different unit versions

and for different versions of the Sysmac Studio is given.

Manual Structure

Note References are provided to more detailed or related information.

K6CM Motor Condition Monitoring Device User’s Manual (N219)

13

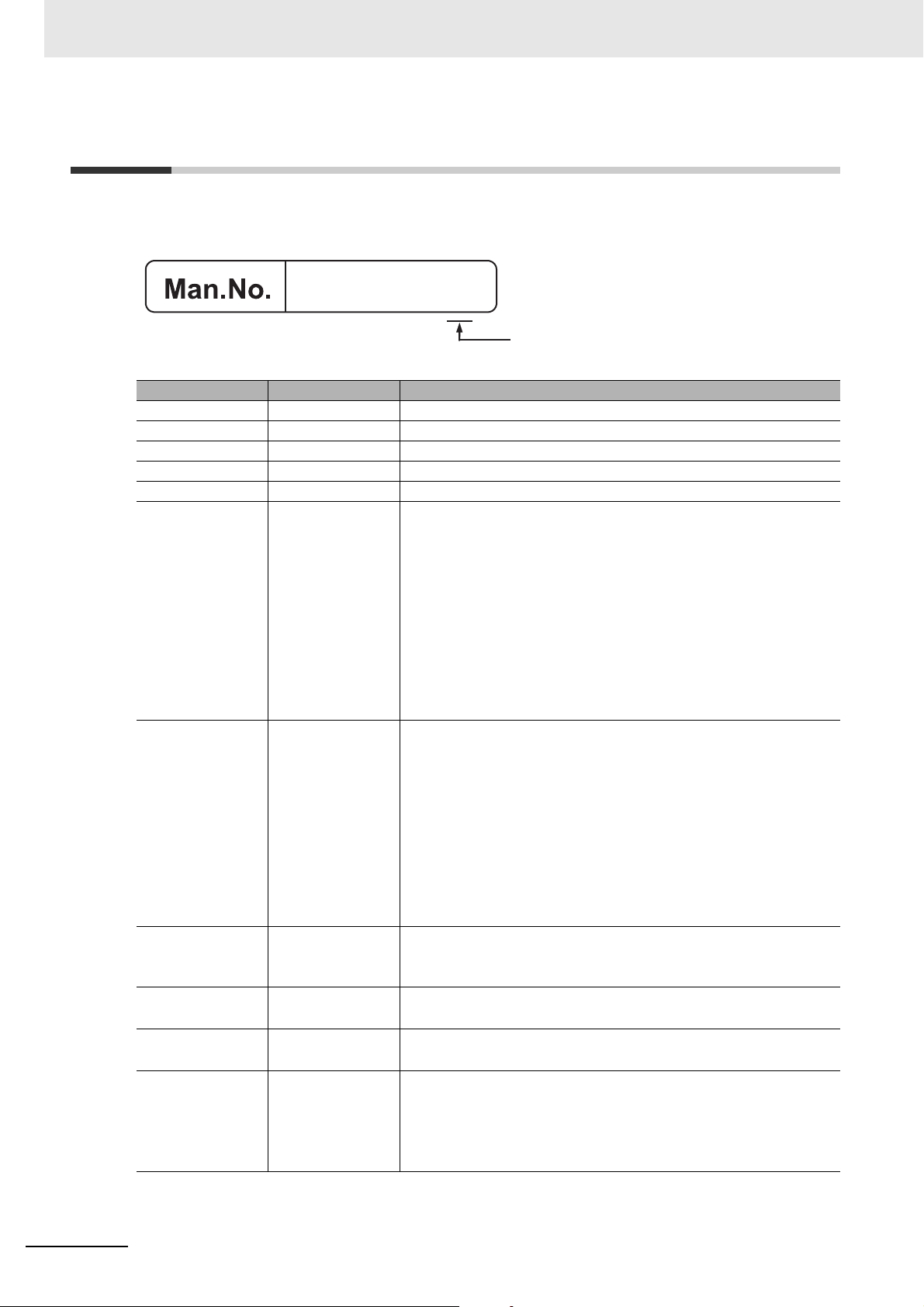

Revision History

Revision History

A manual revision code appears as a suffix to the catalog number on the front cover of the manual.

N219-E1-12

Revision code Date Revised content

01 December 2017 Original production

02 December 2017 Added descriptions and corrected mistakes.

03 December 2017 Added descriptions and corrected mistakes.

04 April 2018 Added descriptions and corrected mistakes.

05 April 2018 Corrected mistakes.

06 June 2018 • Added descriptions about the selection function of the Transistor

07 October 2018 • Added descriptions about the following functions according to the

08 December 2018 • Deleted the descriptions of "Adhesive attachment will be released

09 December 2018 • Added descriptions on the multicast of tag data link.

10 April 2019 • Changed descriptions on multicast communications of tag data link.

11 May 2019 • Added descriptions on the degradation level in motor or load imbal-

Revision code

output method with the version upgrade of the software tool Motor

condition monitoring Tool (version 1.0.0.2 to 1.1.0.0)

• Added following functions according to the upgrade of the Eip cpu

version (version 1.00 to 1.10) of the K6CM device

• Selection function of the Transistor output method

(Not that it can be selected only when using the software tool

Motor condition monitoring Tool version 1.1.0.0 or higher.)

• Trigger function with the external input of the insulation resistance

type K6CM-ISM device

• Corrected mistakes.

upgrade version of the software tool Motor condition monitoring

Tool (version 1.1.0.0 to 1.2.0.0)

• Graph vertical axis scale setting

• Graph time axis movement

• IP address list display

• Added descriptions according to the adhesive attachment which

is sold separately for a vibration sensor.

• Corrected mistakes.

• Added descriptions.

soon"

• Corrected mistakes.

• Added a side-view dimensions of adhesive attachment.

• Corrected mistakes.

ance when the motor is driven with an inverter.

• Added description on the monitoring cycle of the motor condition

monitoring tool.

• Corrected mistakes.

14

K6CM Motor Condition Monitoring Device User’s Manual (N219)

Revision History

12 April 2020 • Changed descriptions due to upgrading the comprehensive current

diagnosis model from K6CM-CIM to K6CM-CI2M.

• Upgrade version of the software tool Motor condition monitoring

Tool.

(version 1.2.0.0 to 1.3.0.0)

• Corrected mistakes.

K6CM Motor Condition Monitoring Device User’s Manual (N219)

15

Revision History

16

K6CM Motor Condition Monitoring Device User’s Manual (N219)

1A

2

3

4

5

6

7

8

9

1A

I

4

5

6

7

8

9

Overview

Device

Components

Appendices

I

Index

Monitoring System

Introduction of the Motor condition monitoring Tool

Installation and Wiring

Monitoring with K6CM and Motor condition

monitoring Tool

How to Use the Motor condition monitoring Tool

Monitoring and Setting Using the EtherNet/IP Devices

Monitoring and Setting Using the Modbus TCP Devices

9

10

Trouble shooting

10

3

2

Sections in this Manual

Sections in this Manual

K6CM Motor Condition Monitoring Device User’s Manual (N219)

17

CONTENTS

CONTENTS

Preface ......................................................................................................................1

Terms and Conditions Agreement.......................................................................... 2

Warranty, Limitations of Liability .................................................................................................................. 2

Application Considerations .......................................................................................................................... 3

Disclaimers .................................................................................................................................................. 3

Safety Precautions ...................................................................................................4

Definition of Precautionary Information........................................................................................................ 4

Symbols....................................................................................................................................................... 4

Precautions for Safe Use......................................................................................... 7

Precautions for Correct Use..................................................................................10

Manual Structure ....................................................................................................12

Page Structure........................................................................................................................................... 12

Special Information.................................................................................................................................... 13

Revision History .....................................................................................................14

Sections in this Manual .........................................................................................17

CONTENTS..............................................................................................................18

Section 1 Overview

1-1 Overview................................................................................................................................. 1-2

1-1-1 What is the K6CM Motor Condition Monitoring Devices For?.....................................................1-2

1-2 Features.................................................................................................................................. 1-3

1-2-1 Features Common for All Models................................................................................................1-3

1-2-2 Overview and Features of the Comprehensive Current Diagnosis Type.................................... 1-4

1-2-3 Features of Vibration & Temperature Type................................................................................. 1-6

1-2-4 Features of Insulation Resistance Type......................................................................................1-6

1-2-5 Features of Software Tool...........................................................................................................1-6

1-3 List of Models ........................................................................................................................ 1-7

1-3-1 Model Number Legend................................................................................................................ 1-7

1-3-2 List of Models.............................................................................................................................. 1-8

1-4 System Configurations ......................................................................................................... 1-9

1-4-1 Overall System Configuration ..................................................................................................... 1-9

1-4-2 I/O Configuration by Monitor Type............................................................................................1-10

1-5 Procedure............................................................................................................................. 1-14

Section 2 Device Components

2-1 Overview of K6CM Device .................................................................................................... 2-2

2-1-1 K6CM Device ..............................................................................................................................2-2

2-1-2 Label of the K6CM Device ..........................................................................................................2-2

2-2 Nomenclature and Functions of the K6CM Device ............................................................ 2-3

2-2-1 K6CM Device ..............................................................................................................................2-3

2-2-2 Transition of Numeric LCD Display............................................................................................. 2-8

2-2-3 Status of Alarm Bar, Status Indication, and Transistor Output for Each Status.......................... 2-9

18

K6CM Motor Condition Monitoring Device User’s Manual (N219)

2-3 Special CT ............................................................................................................................ 2-10

2-4 Vibration & Temperature Sensor ....................................................................................... 2-11

2-5 Insulation Resistance Sensor (Special ZCT (IRT)) ........................................................... 2-13

Section 3 Measuring and monitoring System

3-1 Internal mechanism of K6CM ............................................................................................... 3-2

3-1-1 Measuring and monitoring by K6CM .......................................................................................... 3-2

3-2 Measurement System............................................................................................................ 3-3

3-2-1 Sampling of measurement values .............................................................................................. 3-3

3-2-2 Moving average .......................................................................................................................... 3-4

3-2-3 Monitoring Delay......................................................................................................................... 3-4

3-2-4 Trigger Mode .............................................................................................................................. 3-5

3-2-5 Maximum Value and Minimum Value of Measurement value................................................... 3-11

3-3 Monitoring System .............................................................................................................. 3-13

3-3-1 Types of Individual Alarms........................................................................................................ 3-13

3-3-2 What is Comprehensive Alarm? ...............................................................................................3-13

3-3-3 Relationship Between Alarm and Display/Output ..................................................................... 3-14

3-4 Guide for Setting Alarm ......................................................................................................3-19

3-4-1 Comprehensive Current Diagnosis Type (K6CM-CI2).............................................................. 3-19

3-4-2 Vibration & Temperature Type (K6CM-VB) .............................................................................. 3-23

3-5 How the Self-Diagnosis Function Works .......................................................................... 3-25

3-6 How the Replacement Timing Notification (i.e., Running Time Function) Works ......... 3-27

3-7 Initialization of Setting Value..............................................................................................3-28

CONTENTS

Section 4 Introduction of the Motor condition monitoring Tool

4-1 Overview................................................................................................................................. 4-2

4-1-1 What is the Motor condition monitoring Tool (Software Tool) for?.............................................. 4-2

4-1-2 Functions and Specifications of the Software Tool..................................................................... 4-3

4-1-3 Operating Environment of the Software tool............................................................................... 4-8

4-2 Installation and Uninstallation, Starting up ...................................................................... 4-10

4-2-1 Installation................................................................................................................................. 4-10

4-2-2 Uninstallation Procedures......................................................................................................... 4-23

4-3 IP Address Setting............................................................................................................... 4-24

4-3-1 IP Address Setting of Your PC ................................................................................................. 4-24

4-3-2 IP Address Setting of the K6CM Devices................................................................................ 4-26

Section 5 Installation and Wiring

5-1 Dimensions ............................................................................................................................ 5-2

5-1-1 K6CM device .............................................................................................................................. 5-2

5-1-2 Special CT .................................................................................................................................. 5-2

5-1-3 Vibration & temperature Sensor ................................................................................................. 5-3

5-1-4 Insulation resistance sensor (special ZCT (IRT)) ....................................................................... 5-4

5-2 Installation.............................................................................................................................. 5-5

5-2-1 Precautions at installation........................................................................................................... 5-5

5-2-2 Installing the K6CM Device......................................................................................................... 5-5

5-2-3 Installation of the Vibration & Temperature sensor..................................................................... 5-7

5-2-4 Installation of the insulation resistance sensor (special ZCT (IRT)) ......................................... 5-13

5-2-5 Installation of the special CT..................................................................................................... 5-15

K6CM Motor Condition Monitoring Device User’s Manual (N219)

19

CONTENTS

5-3 How to Connect to the Vibration & Temperature Sensor ................................................ 5-16

5-3-1 When Connecting Directly to the K6CM Device........................................................................5-16

5-3-2 When Connecting by Extending the Cable ............................................................................... 5-17

5-3-3 Recommended Ferrules and Crimp Tool..................................................................................5-18

5-4 How to Connect to the Push-In Plus Terminal Blocks ..................................................... 5-19

5-4-1 the Push-In Plus Terminal Block...............................................................................................5-20

5-4-2 How to use the Push-In Plus Terminal Block ............................................................................5-20

5-4-3 Recommended Ferrules and Crimp Tools ................................................................................5-22

5-5 Diagram of Terminal Description ....................................................................................... 5-24

5-6 I/O wiring .............................................................................................................................. 5-25

5-7 Network Wiring .................................................................................................................... 5-29

Section 6 How to Use the Motor condition monitoring Tool

6-1 Screens................................................................................................................................... 6-2

6-1-1 Start Screen ................................................................................................................................6-2

6-1-2 Monitoring Screen and Setting Screen .......................................................................................6-5

6-1-3 Common Menu and Toolbar List...............................................................................................6-11

6-1-4 Buttons on Device Setting......................................................................................................... 6-13

6-1-5 Software Tool Version Display Screen......................................................................................6-18

6-2 Setting of K6CM Devices .................................................................................................... 6-19

6-2-1 Settings for Each Monitor Type of K6CM devices.....................................................................6-19

6-2-2 Setting Parameters ...................................................................................................................6-23

6-2-3 Add a Device to an Existing Project..........................................................................................6-24

6-2-4 Motor (Device Group) Rename.................................................................................................6-25

6-2-5 Save Overwriting Project...........................................................................................................6-26

6-2-6 Exit Project................................................................................................................................ 6-26

Section 7 Monitoring with K6CM and Motor condition monitoring

Tool

7-1 Motor Monitoring and Operation Procedure ....................................................................... 7-2

7-2 Motor Monitoring Using the K6CM devices ........................................................................ 7-3

7-2-1 Start measurement...................................................................................................................... 7-3

7-2-2 Monitoring Type Switching.......................................................................................................... 7-5

7-2-3 Monitoring method ......................................................................................................................7-6

7-2-4 Monitoring Completed.................................................................................................................7-8

7-3 Motor Monitoring Using Software Tools ............................................................................. 7-9

7-3-1 Monitoring Procedure with Motor Condition Monitoring Tool ...................................................... 7-9

7-3-2 Set the Monitoring Cycle.............................................................................................................7-9

7-3-3 Start Monitoring.........................................................................................................................7-10

7-3-4 Saving Log Files........................................................................................................................ 7-11

7-3-5 Graph Vertical Axis Scale Setting .............................................................................................7-12

7-3-6 Graph Time Axis Movement......................................................................................................7-13

Section 8 Monitoring and Setting Using the EtherNet/IP Devices

8-1 Overview................................................................................................................................. 8-2

8-1-1 What is Monitoring Using EtherNet/IP?.......................................................................................8-2

8-1-2 EtherNet/IP Communications Specifications...............................................................................8-4

8-2 Monitoring Using the Tag Data Link ................................................................................... 8-5

8-2-1 Connection setting ......................................................................................................................8-5

8-2-2 Data to be Tag Data Link Target in the K6CM Device................................................................8-9

20

K6CM Motor Condition Monitoring Device User’s Manual (N219)

CONTENTS

8-3 Monitoring and Setting Using the CIP Message Communications and Examples of

Communications Instructions............................................................................................ 8-12

8-3-1 Datatype List of Variables......................................................................................................... 8-12

8-3-2 Services Supported by Objects in K6CM.................................................................................. 8-12

8-3-3 Monitor Object (Class ID: 370 hex)........................................................................................... 8-13

8-3-4 Setting Object (Class ID: 371 hex) ........................................................................................... 8-18

8-3-5 Identity Object (Class ID: 01 hex)............................................................................................. 8-24

8-3-6 TCP/IP Interface Object (Class ID: F5 hex).............................................................................. 8-26

8-3-7 Examples of CIP Message Communications Instruction.......................................................... 8-28

8-4 Sample Program for the NJ/NX-series............................................................................... 8-30

8-4-1 Sample Program Overview....................................................................................................... 8-30

8-4-2 Sample Program Processing Flow and Function Block Specifications..................................... 8-33

8-4-3 Sample Program Execution Procedures................................................................................... 8-39

8-4-4 Sample Program Code Descriptions ........................................................................................ 8-40

Section 9 Monitoring and Setting Using the Modbus TCP Devices

9-1 Outline .................................................................................................................................... 9-2

9-2 Function Codes ..................................................................................................................... 9-3

9-2-1 Function Code List...................................................................................................................... 9-3

9-2-2 03 hex: Reading of Multiple Registers........................................................................................ 9-3

9-2-3 06 hex: Operation Command...................................................................................................... 9-5

9-2-4 10 hex: Writing of Multiple Registers .......................................................................................... 9-6

9-2-5 Exception Code List.................................................................................................................... 9-7

9-3 Register Address Lists ......................................................................................................... 9-8

9-3-1 Monitoring Information................................................................................................................ 9-8

9-3-2 Setting Information.................................................................................................................... 9-12

9-3-3 Product Information .................................................................................................................. 9-18

9-3-4 IP Address ................................................................................................................................ 9-18

9-3-5 Operation Command ................................................................................................................ 9-19

9-3-6 Modbus TCP Connection Timeout Time................................................................................... 9-19

Section 10 Trouble shooting

10-1 K6CM Devices ...................................................................................................................... 10-2

10-2 Using the Software tool ...................................................................................................... 10-4

10-3 Using the Ethernet communications ................................................................................. 10-6

Appendices

A-1 Specifications ........................................................................................................................A-2

A-2 Measurement values by Each Monitor Type.......................................................................A-3

A-3 K6CM Common Specifications ............................................................................................A-4

A-4 K6CM device Individual Specifications ...............................................................................A-8

A-5 Individual Specifications of the Dedicated Sensor ..........................................................A-10

A-6 Internal Data of K6CM Devices...........................................................................................A-14

A-7 Setting Values......................................................................................................................A-15

A-8 Present Values.....................................................................................................................A-21

A-9 Tag Data Link Connection Setting Procedures ................................................................A-26

A-9-1 Using the CS/CJ-series ............................................................................................................ A-26

A-9-2 Using the NJ/NX-series ............................................................................................................A-38

K6CM Motor Condition Monitoring Device User’s Manual (N219)

21

CONTENTS

A-10 Expansion Error Code of the CIP Message Communications ........................................A-48

A-11 Version Compatibility..........................................................................................................A-51

Index

A-10-1 General Status ..........................................................................................................................A-48

A-10-2 Additional Status When General Status Is 01 hex ....................................................................A-50

A-11-1 Version Upgrades of the K6CM Series .....................................................................................A-51

A-11-2 Support Correspondence between the K6CM Device and Motor Condition Monitoring Tool ...A-51

A-11-3 Motor Condition Monitoring Tool Version Compatibility ............................................................A-52

A-11-4 BOOTP Server Connection Error State LED Lighting Differences............................................A-52

22

K6CM Motor Condition Monitoring Device User’s Manual (N219)

Overview

This section describes an overview, the features, the models, the system configurations, and the procedures of the K6CM Motor Condition Monitoring Device.

1-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-3 List of Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-4 System Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1-5 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

1

1-1-1 What is the K6CM Motor Condition Monitoring Devices For? . . . . . . . . . . . . . . 1-2

1-2-1 Features Common for All Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-2-2 Overview and Features of the Comprehensive Current Diagnosis Type . . . . . 1-4

1-2-3 Features of Vibration & Temperature Type . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1-2-4 Features of Insulation Resistance Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1-2-5 Features of Software Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1-3-1 Model Number Legend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-3-2 List of Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1-4-1 Overall System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1-4-2 I/O Configuration by Monitor Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

K6CM Motor Condition Monitoring Device User’s Manual (N219)

1 - 1

1 Overview

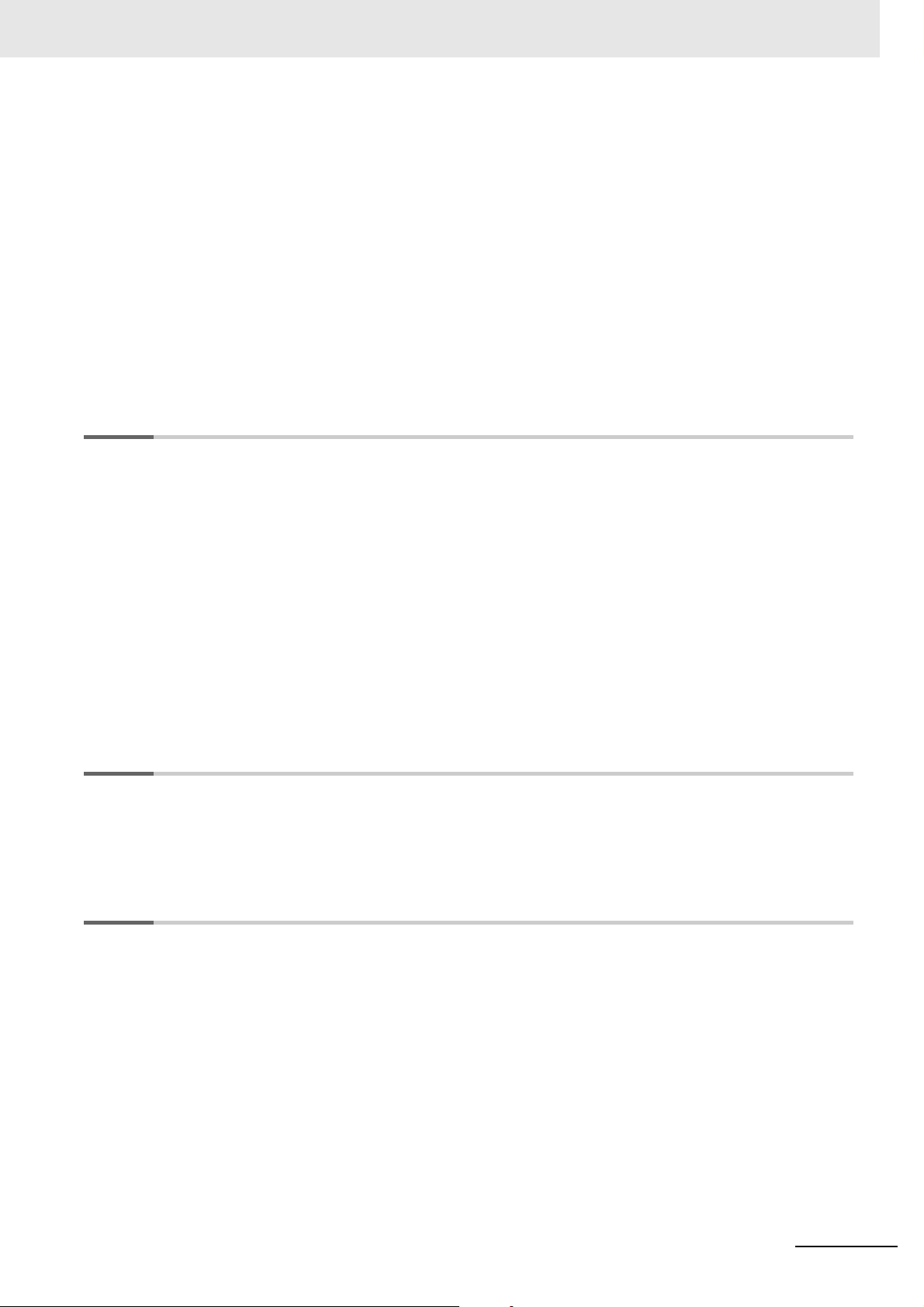

Setting and

monitoring

Discrete outputs

software tool

(standard

accessory)

K6CM Motor Condition

Monitoring Device

Monitor

EtherNet/IP or Modbus TCP

PLC

PCs

Supporting EtherNet/

IP or Modbus TCP

Sensors

Three-phase induction motor

1-1 Overview

This section describes an overview and features of the K6CM.

1-1-1 What is the K6CM Motor Condition Monitoring Devices For?

K6CM Motor Condition Monitoring Device is a device that visualizes and monitors the state of the motor

by measuring the feature quantity of the three-phase induction motor. Motors other than three-phase

induction motors (e.g., synchronous motor, single phase motor, servo motor, stepping motor) are

excluded.

Depending on the feature quantity to be measured, you can select from the following three types.

Type Outline Feature quantity measured

Comprehensive current diagnosis

type

K6CM-CIM

K6CM-CI2M

Vibration & temperature type

K6CM-VBM

Insulation resistance type

K6CM-ISM

*1. Two degradation levels, degradation level 1 and degradation level 2, are measured by using different algo-

rithms.

The K6CM-CIM measures only degradation level 1, so it is referred to as the degradation level in the software

tool.

Measures the current waveform of a

motor and the current waveform of an

inverter driving motor and monitors

the distortion of the current waveforms as the degradation levels.

Monitors motor bearing abnormalities from the vibration and temperature.

Monitors the motor insulation resistance.

Measures the degradation levels*1

and current of the motor.

Measures the motor vibration

(acceleration and velocity) and

motor temperature.

Measures the insulation resistance.

By properly using these three types as necessary, you can catch the state of the induction motor and

decide the appropriate maintenance time.

1 - 2

K6CM Motor Condition Monitoring Device User’s Manual (N219)

1-2 Features

1-2-1 Features Common for All Models

• Multiple K6CM devices can be connected to one PLC or one PC, and multiple motor statuses can be

monitored at one time.

• Status monitoring can be confirmed on site easily from the alarm bar display and numeric LCD display on the front of the K6CM device.

• Two levels of warning failure and critical failure are prepared as alarm monitoring levels. Two outputs

of the transistor are possible when the alarm occurs.

• A self-diagnosis function and replacement timing notification are incorporated. With these functions,

errors of the K6CM device and when to be replaced can be determined.

• Trigger functions using an external input or internal set value comparison enable monitoring only

when specified conditions such as startup of the motor are met. In addition, the maximum and minimum values can be automatically calculated and output during the period that those conditions are

met. (*1)

• EtherNet/IP (i.e., tag data link, CIP message communications) is supported. Measurement values

and internal data can be read, and alarm setpoints and other set values can be written from the PLC

or PC. (*2)

*1. For the insulation resistance type K6CM device, the trigger function using the external input can be supported

for the Eip cpu version 1.10 or higher.

*2. Tag data link can be read only. Write not possible.

1 Overview

1-2 Features

1

1-2-1 Features Common for All Models

Features of Main CPU Version 1.2 or Later

• Measurement is possible in a stable state even after starting up the motor using the trigger function

following a monitoring delay time.

• Modbus TCP is supported. Measurement values and internal data can be read, and alarm setpoints

and other set values can be written from the PLC or PC by using message communications.

• The indication for the unit of measurement value (monitoring type) on the K6CM device numeric LCD

display can be switched automatically at a 5-second interval. This allows you to confirm status monitoring without touching the operation keys of the K6CM device.

K6CM Motor Condition Monitoring Device User’s Manual (N219)

1 - 3

1 Overview

1-2-2 Overview and Features of the Comprehensive Current Diagnosis

Type

Overview

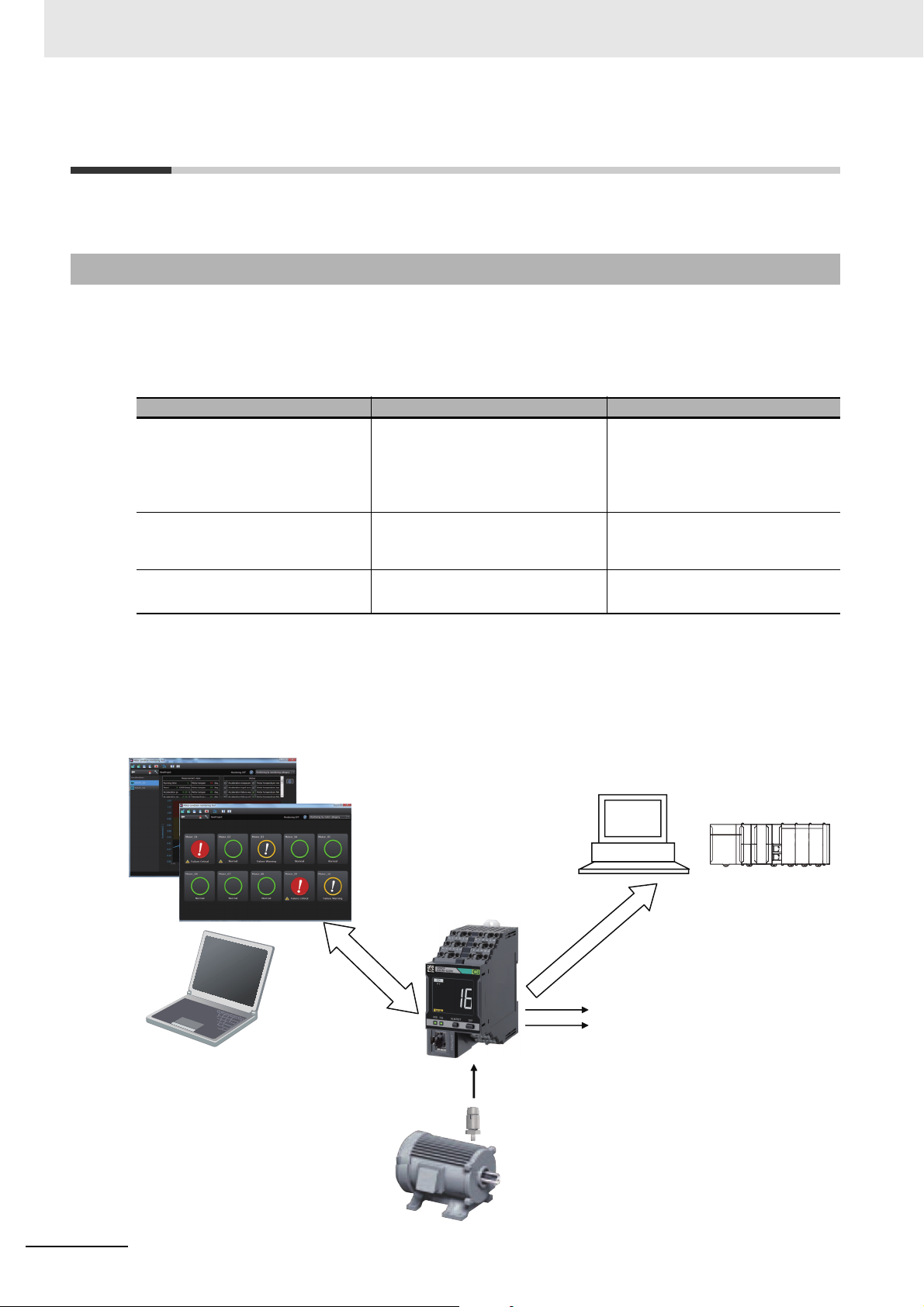

The current waveform of the motor is a smooth sine wave if the motor and load are in the normal ideal

states. If the motor or load are abnormal, noise appears in the current waveform as shown below.

(1) Motor and load are normal.

Cross-sectional view of the motor

The current is a smooth "sine wave".

Smooth rotation

(2) An abnormality is occurring.

Cross-sectional view of the motor

Abnormal vibration

Abnormality affecting degradation level Major factors

Misalignment Coupling abnormal, centering shortage, etc.

Load imbalance Unbalance of rotating objects such as fans

Rotor abnormality Breakage inside the motor

Cavitation, air contamination Vacuum bubbles in water stream, pipe internal pressure drop, etc.

Overload Excessive rotational load

Note The degradation level may appear differently depending on the failure condition of the motor or load, or

depending on the installation condition.

"Noise" may come up in the current.

Features

• A motor error can be detected by representing the degree of deviation of the current waveform

between a normal motor and an abnormal motor in numerical values (as degradation level 1).

• A motor error can be detected by analyzing the frequency components affecting the rotating shaft of

the motor and representing them in numerical values. It is suitable for monitoring of inverter drive (as

degradation level 2).

• Degradation levels 1 and 2 can be monitored simultaneously. (The K6CM-CIM can only monitor degradation level 1.)

• The K6CM can also detect motor peripheral malfunctions affecting the rotating shaft of the motor.

1 - 4

K6CM Motor Condition Monitoring Device User’s Manual (N219)

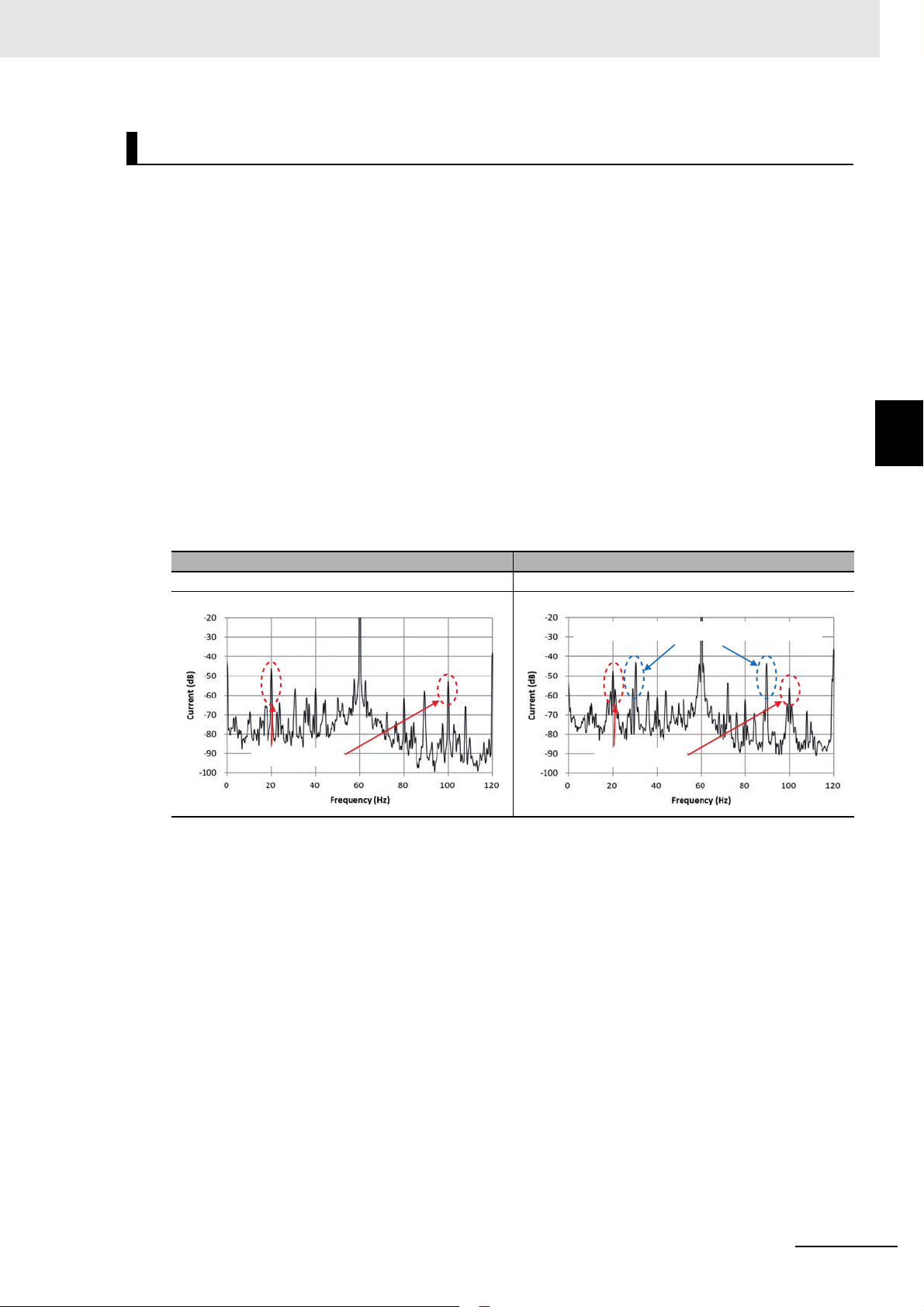

Mechanism of degradation level 1

Frequency components of abnormality

1 Overview

For degradation level 1, the K6CM device compares the current waveform of the motor with the

smooth sine wave of the ideal state, and represents the degree of deviation from the smooth sine

wave in numerical values. If the motor or load is abnormal, that degree of deviation will be large, and

the value of degradation level 1 will be large.

Motor and load are normal Motor and load are abnormal

Equivalent to smooth sine wave Deviated from smooth sine wave

If the current waveform of the motor contains many noise components such as with inverter driving,

the value of degradation level 1 will be large because there will be deviation from the ideal state

even if the motor and load are normal. Therefore, the difference between the normal state and

abnormal state will be small.

1-2 Features

1

1-2-2 Overview and Features of the Comprehensive Current Diagnosis Type

Mechanism of degradation level 2

For degradation level 2, the K6CM device determines what percentages of the frequency components affecting the rotating shaft of the motor were included in the drive frequency components

when frequency analysis was performed on the current waveform of the motor, and represents them

in numerical values. If the motor or load is abnormal, the frequency components affecting the rotating shaft of the motor will be large, and the value of degradation level 2 will be large.

Since the frequency components affecting the rotating shaft of the motor are clearly captured and

represented as numerical values, even in environment with many noise components such as

inverter driving, a motor or load abnormality is captured with excellent sensitivity and the variations

in the numerical values tend to be also small compared with degradation level 1. Therefore, it is suitable for monitoring an inverter-driven three-phase induction motor.

Motor and load are normal Motor and load are abnormal

Frequency components affecting the rotating shaft

are small

K6CM Motor Condition Monitoring Device User’s Manual (N219)

Frequency components affecting the rotating shaft

are large

1 - 5

1 Overview

1-2-3 Features of Vibration & Temperature Type

• Simultaneous monitoring of motor vibration (i.e., acceleration and velocity) and motor temperature

are possible.

• Mainly bearing wears can be detected by the acceleration.

• Mainly load imbalance and misalignment can be detected by the velocity.

• The acceleration and velocity alarm threshold values of K6CM-VBM vibration & temperature type can

be set automatically with the software tool (software tool version 1.3.0.0 or later).

1-2-4 Features of Insulation Resistance Type

• Insulation resistance can be monitored.

• Resistance leakage current (I0r) can be measured. (*1)

• Capacitive leakage current (I0c) can also be measured. (*2)

*1. Alarm output cannot be performed.

*2. Can be read via EtherNet/IP or Modbus TCP. Unit display and alarm output cannot be performed.

1-2-5 Features of Software Tool

• Software tool "Motor condition monitoring Tool" that is provided with the K6CM device enables K6CM

device setup and simple status monitoring.

• It enables reading of measurement values at specified intervals and automatic data storage (with the

CSV format).

• The acceleration and velocity threshold values can be set automatically (software tool version 1.3.0.0

or later).

1 - 6

K6CM Motor Condition Monitoring Device User’s Manual (N219)

1 Overview

K6CM-

-EIPM

(1) (2)

*1

(3) (4) (5) (6) (7)

*1. For other than detection type CI2, this is 2 digits so read it with the 3rd digit truncated.

*2. The detection type CI2 is an upward compatible model of CI, so CI is planned to be integrated into CI2.

In the following description, the model name CI is referred to as CI2.

(1) (2) (3) (4) (5) (6) (7)

Function

Base

model

Detec-

tion type

Product

classifi-

cation

Power

specifi-

cation

Options

Special

specifica-

tions

Commu-

nications

K6CM Motor Condition Monitoring Device

CI

*2

Comprehensive current diagnosis type

CI2

Comprehensive current diagnosis type 2

VB Vibration & temperature type

IS Insulation resistance type

M K6CM device

A 100 to 240 VAC

D 24 VAC/VDC

Not used Not used

Not used Not used

EIP EtherNet/IP and Modbus TCP

1-3 List of Models

This section shows the model number legend of the K6CM devices, and models of the K6CM devices

and the dedicated sensors.

1-3-1 Model Number Legend

1-3 List of Models

1

1-3-1 Model Number Legend

K6CM Motor Condition Monitoring Device User’s Manual (N219)

1 - 7

1 Overview

1-3-2 List of Models

Comprehensive Current Diagnosis Type

K6CM device K6CM-CIMA-EIP 100 to 240 VAC

Sensor (special CT) K6CM-CICB005 Rated primary current: 5 A, rated voltage: 480 VAC

Vibration & Temperature Type

Model Specifications such as power supply voltage

K6CM-CIMD-EIP 24 VAC/VDC

K6CM-CI2MA-EIP 100 to 240 VAC

K6CM-CI2MD-EIP 24 VAC/VDC

K6CM-CICB025 Rated primary current: 25 A, rated voltage: 480 VAC

K6CM-CICB100 Rated primary current: 100 A, rated voltage: 480 VAC

K6CM-CICB200 Rated primary current: 200 A, rated voltage: 480 VAC

K6CM-CICB400 Rated primary current: 400 A, rated voltage: 480 VAC

K6CM-CICB600 Rated primary current: 600 A, rated voltage: 480 VAC

Model Specifications such as power supply voltage

K6CM device K6CM-VBMA-EIP 100 to 240 VAC

K6CM-VBMD-EIP 24 V AC/DC

Sensor (sensor head and pre-amplifier)*1

Adhesive attachment K6CM-VBSAT1 Material: Stainless steel

*1. The sensor head and the pre-amplifier are calibrated and inspected as a set at the factory shipment. Be sure

to use them with the combination shipped.

K6CM-VBS1 Mounting: M6 screw

Insulation Resistance Type

Model Specifications such as power supply voltage

K6CM device K6CM-ISMA-EIP 100 to 240 VAC

K6CM-ISMD-EIP 24 V AC/DC

Sensor (special ZCT (IRT)) *1

*1. ZCT (IRT) stands for Zero Current Transformer (Insulation Resistance Transformer).

K6CM-ISZBI52 Rated voltage: 200 to 480 VAC, through hole diameter

52 mm

1 - 8

K6CM Motor Condition Monitoring Device User’s Manual (N219)

1-4 System Configurations

Three-phase AC power

Industrial switching hub

(e.g., W4S1)

(*1)

Dedicated

cable

S-phase

ground

*1. When making initial settings,

connect this tool to each

motor status monitoring

device one to one using an

Ethernet cable.

Transistor Output

Alarm × 2 points, self-diagnosis × 1 point

Vibration & temperature

sensor pre-amplifier

Special ZCT (IRT)

Comprehensive

current diagnosis

type

• Settings

Insulation

resistance

type

Vibration &

temperature

type

K6CM

Motor Condition Monitoring Device

• Monitoring

General-purpose Inverter

Example: RX2 series

Special CT

(connected to secondary side)

• Monitoring

• Initial setting (*1)

Software tool

Ethernet cable

EtherNet/IP or Modbus TCP

PLC

PC

Three-phase induction

motor

Vibration &

temperature

sensor head

This section describes the overall system configurations of the K6CM and the I/O configuration for each

monitor type of K6CM devices.

1 Overview

1-4 System Configurations

1-4-1 Overall System Configuration

1

1-4-1 Overall System Configuration

K6CM Motor Condition Monitoring Device User’s Manual (N219)

1 - 9

1 Overview

Three-phase induction motor

(When necessary)

External trigger input

Special CT *1

K6CM-CI2M

Comprehensive current

diagnosis Type Device

Transistor Output

EtherNet/IP or Modbus TCP

(Ethernet cable)

To the software tool,

PC software and/or PLC

Self-diagnosis output

Comprehensive alarm (failure warning) output

Comprehensive alarm (failure critical) output

1-4-2 I/O Configuration by Monitor Type

K6CM-CI2 Comprehensive Current Diagnosis Type

Three-phase induction motor connection example

*1. The dedicated cable between the special CT and the K6CM device is 2.9 m long. It cannot be extended. Also,

there is no designation in the phase to be installed. Be careful of the installation direction stated on the CT

label and mount it to any one phase.

1 - 10

K6CM Motor Condition Monitoring Device User’s Manual (N219)

Inverter driving three-phase induction motor connection example

Precautions for Correct Use

(When necessary)

External trigger input

General-purpose Inverter

Example: RX2 series

Special CT *1

Inverter driving three-phase

induction motor

K6CM-CI2M

Comprehensive current

diagnosis Type Device

Transistor Output

To the software tool,

PC software and/or PLC

EtherNet/IP or Modbus TCP

(Ethernet cable)

Self-diagnosis output

Comprehensive alarm (failure warning) output

Comprehensive alarm (failure critical) output

1 Overview

1-4 System Configurations

1

1-4-2 I/O Configuration by Monitor Type

*1. The dedicated cable between the special CT and the K6CM device is 2.9 m long. It cannot be extended. Also,

there is no designation in the phase to be installed. Be careful of the installation direction stated on the CT

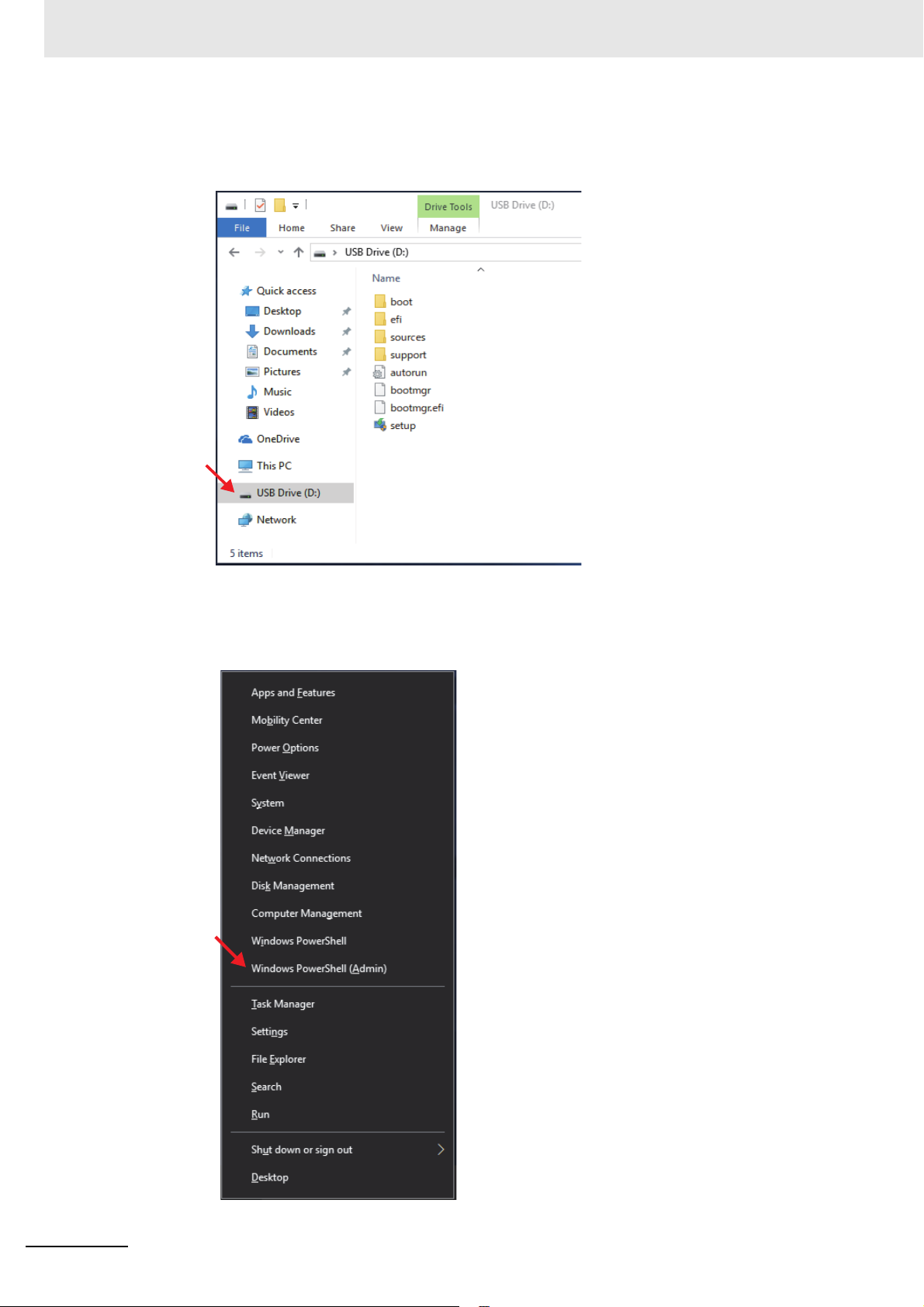

Using a K6CM-CIM