Period Meter

K3NP

An Ideal Interface for Easily Measuring the

Time Interval

• 50-kHz input range and 0.08% accuracy for sophisticated

control.

• A wide selection of outputs: relay, transistor, BCD, linear, or

communications.

• Maximum/Minimum value hold, set value write protection, and

more.

• Banks with four comparative output values and four prescale

values.

• Set value teaching, linear output range teaching, and prescale

teaching are available using actual measured values.

• Prescale function available, which displays in units of actual

physical parameters (length, volume, etc.).

• Displays values in hours, minutes, and seconds in operating

modes 2 to 4.

• Built-in sensor power supply (12 VDC, 80 mA).

• Compact 1/8 DIN size.

• Conforms to EMC standards, EN61010-1 (IEC1010-1).

• UL/CSA approved.

Timers

®

Model Number Structure

■ Model Number Legend

Base Units and Output Boards can be ordered individually or as sets. Refer to the Output Board Combinations table on page 194.

Base Units

K3NP -

1234

1, 2. Input Sensors Codes

NB: NPN inputs/Voltage pulse inputs

PB: PNP inputs

3. Supply Voltage

1: 100 to 240 VAC

2: 12 to 24 VDC

4. Display

A: Basic

C: Set Value LED Display

5, 6, 7, 8. Output Type Codes

C1: 3 comparative relay contact outputs (H, PASS, L: SPDT)

C2: 5 comparative relay contact outputs (HH, H, L, LL: SPST-

NO; PASS: SPDT)

C5: 5 comparative relay contact outputs (HH, H, L, LL: SPST-

NC; PASS: SPDT)

T1: 5 comparative transistor outputs (NPN open collector)

T2: 5 comparative transistor outputs (PNP open collector)

B2: BCD output (NPN open collector) (see note)

B4: BCD output + 5 transistor outputs (NPN open collector)

L1: Linear output (4 to 20 mA) (see note)

Note: These output types are available on Basic Models only.

Output Boards

K31 -

5 678

Base Units with Output Boards

K3NP - -

2345678

1

L2: Linear output (1 to 5 VDC) (see note)

L3: Linear output (1 mV/10 digits) (see note)

L4: Linear output, 4 to 20 mA + 5 transistor outputs (NPN open

collector)

L5: Linear output, 1 to 5 V + 5 transistor outputs (NPN open col-

lector)

L6: Linear output, 1 mV/10 digits+ 5 transistor outputs (NPN

open collector)

L7: Linear output, 0 to 5 VDC (see note)

L8: Linear output, 0 to 10 VDC (see note)

L9: Linear output, 0 to 5 VDC + 5 transistor outputs (NPN open

collector)

L10: Linear output, 0 to 10 VDC + 5 transistor outputs (NPN open

collector)

FLK1: Communication RS-232C (see note)

FLK2: Communication RS-485 (see note)

FLK3: Communication RS-422 (see note)

FLK4: RS-232C + 5 transistor outputs (NPN open collector)

FLK5: RS-485 + 5 transistor outputs (NPN open collector)

FLK6: RS-422 + 5 transistor outputs (NPN open collector)

Period Meter K3NP B-193

Ordering Information

■ Base Unit

Input type NPN/Voltage pulse PNP

Supply voltage 100 to 240 VAC 12 to 24 VDC 100 to 240 VAC 12 to 24 VDC

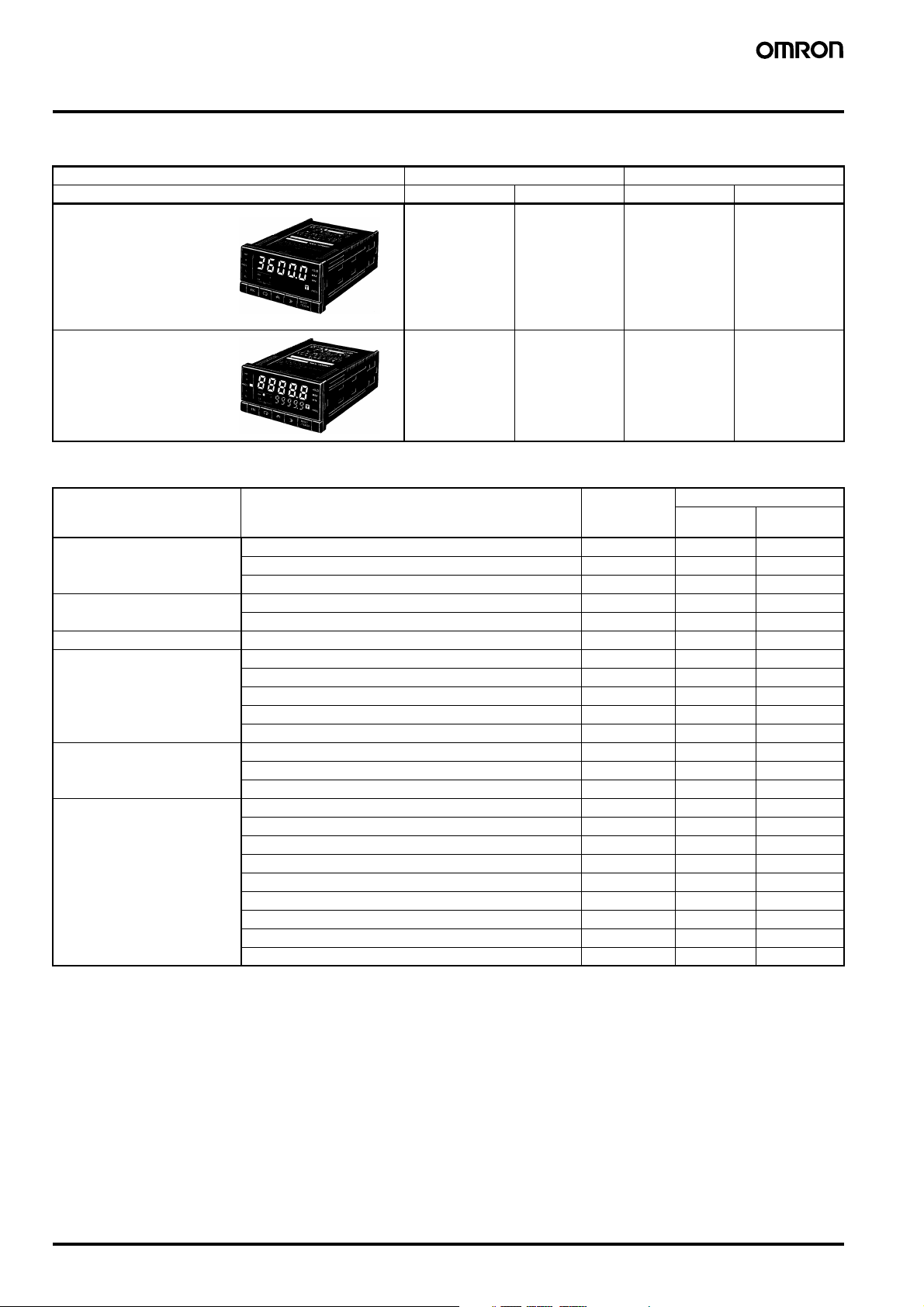

Basic Models

These models provide a

present value LED and

front-panel control keys. Can

be connected to any Output

Board, or can be used for

display only without an

Output Board.

Set Value LED Models

These models provide a

present value LED, set value

LED, and front-panel control

keys. Can be connected to

Relay, Transistor, or

Combination Output Boards.

■ Available Output Board Combinations

Output type Output configuration Output boards Base units

Relay contact 3 outputs: H, PASS, L (SPDT) K31-C1 Yes Yes

5 outputs: HH, H, L, LL (SPST-NO), and PASS (SPDT) K31-C2 Yes Yes

5 outputs: HH, H, L, LL (SPST-NC), and PASS (SPDT) K31-C5 Yes Yes

Transistor 5 outputs (NPN open collector) K31-T1 Yes Yes

5 outputs (PNP open collector) K31-T2 Yes Yes

BCD (see note) 5-digit output (NPN open collector) K31-B2 Yes ---

Linear 4 to 20 mA DC K31-L1 Yes ---

1 to 5 VDC K31-L2 Yes --1 mV/10 digits K31-L3 Yes --0 to 5 VDC K31-L7 Yes --0 to 10 VDC K31-L8 Yes ---

Communication boards

(see note)

Combination output and

communication boards

RS-232C K31-FLK1 Yes --RS-485 K31-FLK2 Yes --RS-422 K31-FLK3 Yes --BCD output + 5 transistor outputs (NPN open collector) K31-B4 Yes Yes

4 to 20 mA + 5 transistor outputs (NPN open collector) K31-L4 Yes Yes

1 to 5 V + 5 transistor outputs (NPN open collector) K31-L5 Yes Yes

1 mV/10 digits + 5 transistor outputs (NPN open collector) K31-L6 Yes Yes

0 to 5 VDC + 5 transistor outputs (NPN open collector) K31-L9 Yes Yes

0 to 10 VDC + 5 transistor outputs (NPN open collector) K31-L10 Yes Yes

RS-232C + 5 transistor outputs (NPN open collector) K31-FLK4 Yes Yes

RS-485 + 5 transistor outputs (NPN open collector) K31-FLK5 Yes Yes

RS-422 + 5 transistor outputs (NPN open collector) K31-FLK6 Yes Yes

K3NP-NB1A K3NP-NB2A K3NP-PB1A K3NP-PB2A

K3NP-NB1C K3NP-NB2C K3NP-PB1C K3NP-PB2C

Basic Set Value

LED Display

Note: For details, refer to the Communication Operation Manual.

B-194 Period Meter K3NP

Specifications

■ Ratings

Supply voltage 100 to 240 VAC (50/60 Hz); 12 to 24 VDC

Operating voltage range 85% to 110% of supply voltage

Power consumption (see note) 15 VA max. (max. AC load with all indicators lit)

Sensor power supply 80 mA at 12 VDC±10%

Insulation resistance 20 MΩ min. (at 500 VDC) between external terminal and case.

Dielectric strength 2,000 VAC for 1 min between external terminal and case.

Noise immunity ±1,500 V on power supply terminals in normal or common mode ±1 µs, 100 ns for square-wave noise

Vibration resistance Malfunction: 10 to 55 Hz, 0.5-mm for 10 min each in X, Y, and Z directions

Shock resistance

Ambient temperature Operating: −10°C to 55°C (with no icing)

Ambient humidity Operating: 25% to 85% (with no condensation)

EMC (EMI) EN61326+A1 Industry

Approved standards UL508, CSA22.2;

Weight Approx. 400 g

Note: A K3NP with DC supply voltage requires approximately 1 A DC as control power supply current the moment the K3NP is turned ON. Do not

forget to take this into consideration when using several K3NP units. When the K3NP is not in measuring operation (e.g., the K3NP has been

just turned ON or is operating for startup compensation time), the display will read “00000” and all outputs will be OFF.

10 W max. (max. DC load with all indicators lit)

Insulation provided between inputs, outputs, and power supply.

Insulation provided between inputs, outputs, and power supply.

with 1 ns

Destruction: 10 to 55 Hz, 0.75-mm for 2 hrs each in X, Y, and Z directions

2

Malfunction: 98 m/s

Destruction: 294 m/s

Storage: −20°C to 65°C (with no icing)

Emission Enclosure: CISPR 11 Group 1 class A: CISRP16-1/-2

Emission AC Mains: CISPR 11 Group 1 class A: CISRP16-1/-2

(EMS) EN61326+A1 Industry

Immunity ESD: EN61000-4-2: 4 kV contact discharge (level 2)

Immunity RF-interference: EN61000-4-3: 10 V/m (amplitude-modulated,

Immunity Fast Transient Noise: EN61000-4-4: 2 kV (power line) (level 3)

Immunity Burst Noise: 1 kV line to line (I/O signal line)

Immunity Surge: EN61000-4-5: 1 kV line to line

Immunity Conducted Disturbance EN61000-4-6: 3 V (0.15 to 80 MHz) (level 2)

Immunity Voltage Dip/Interrupting EN61000-4-11: 0.5 cycles, 0, 180°, 100% (rated voltage)

Conforms to EN61326+A1, EN61010-1 (IEC61010-1)

Conforms to VDE0106/P100 (finger protection) when the terminal cover is mounted.

(10G) for 3 times each in X, Y, and Z directions

2

(30G) for 3 times each in X, Y, and Z directions

8 kV air discharge (level 3)

80 MHz to 1 GHz) (level 3)

2 kV line to ground (power line)

Timers

Period Meter K3NP B-195

■ Characteristics

Input signal No-voltage contact (30 Hz max., ON/OFF pulse width: 15 ms min.)

Measuring accuracy

(at 23±5°C)

Measuring modes and

ranges

Max. displayed digits 5 digits (0 to 99999)

Display 7-segment LED

Polarity display Not available

Zero display Leading zeros are not displayed.

Prescale function

HOLD functions Max. value (peak) hold, Min. value (bottom) hold

External control HOLD (Process value held)

Other functions Variable linear output range (for models with linear outputs only) (see note)

Output configuration Relay contact output (3 or 5 outputs)

Delay in comparative

outputs (at transistor output)

Linear output response time 40 ms max.

Degree of protection Front panel: NEMA4 for indoor use (equivalent to IP66)

Memory protection Non-volatile memory (EEPROM) (possible to rewrite 100,000 times)

Note: The linear output range cannot be set when connected to a 1 mV/10-digit Linear Output Board.

Voltage pulse (50 kHz max., ON/OFF pulse width: 9 µs min., ON voltage: 4.5 to 30 V/OFF voltage: −30 to 2 V)

Open collector (50 kHz max., ON/OFF pulse width: 9 µs min.)

Connectable Sensors

ON residual voltage: 3 V max.

OFF leakage current: 1.5 mA max.

Load current: Must have switching capacity of 20 mA min.

±0.08%rdg±1 digit

Operating mode 1: Passing speed 10 ms to 3,200 seconds

Operating mode 2: Cycle 20 ms to 3,200 seconds

Operating mode 3: Time difference 10 ms to 3,200 seconds

Operating mode 4: Elapsed time 10 ms to 3,200 seconds

Operating mode 5: Length measurement 0 to 4G count (32-bit counter)

Operating mode 6: Interval 0 to 4G count (32-bit counter)

Programming via front-panel key inputs. (0.0001 x 10

Can be set using prescale value teaching.

RESET (Maximum/minimum data reset)

BANK (Selection of one bank out of 4 banks of set values)

(Selection of one bank out of 4 banks of prescale values)

Remote/Local processing (available for communications output models only)

Maximum/Minimum value data reset with front panel keys

Comparative output pattern selection

Time unit display

Security

Transistor output (NPN and PNP open collector), BCD (NPN open collector)

Parallel BCD (NPN open collector) + transistor output (NPN open collector)

Linear output (4 to 20 mA, 1 to 5 V) + transistor output (NPN open collector)

Communication functions (RS-232C, RS-485, RS-422)

Communication functions (RS-232C, RS-485, RS-422) + transistor output (NPN open collector)

20 ms max.

Rear case: IEC standard IP20

Terminals: IEC standard IP00

Must be able to dependably switch a load current of 5 mA max.

−9

to 9.9999 x 109, decimal point can be set freely)

B-196 Period Meter K3NP

■ Input/Output Ratings

Relay Contact Output

(Incorporating a G6B Relay)

Item Resistive load (cosφ = 1) Inductive load (cosφ = 0.4, L/R = 7 ms)

Rated load 5 A at 250 VAC; 5 A at 30 VDC 1.5 A at 250 VAC, 1.5 A at 30 VDC

Rated carry current 5 A max. (at COM terminal)

Max. contact voltage 380 VAC, 125 VDC

Max. contact current 5 A max. (at COM terminal)

Max. switching capacity 1,250 VA, 150 W 375 VA, 80 W

Min. permissible load

(P level, reference value)

Mechanical life 50,000,000 times min. (at a switching frequency of 18,000 times/hr)

Electrical life

(at an ambient temperature of 23°C)

Transistor Output

Rated load voltage

Max. load current 50 mA

Leakage current 100 µA max.

BCD Output

I/O signal name Item Rating

Inputs REQUEST, HOLD, MAX, MIN, RESET Input signal No-voltage contact input

Outputs DATA, POLARITY, OVERFLOW,

DATA VALID, RUN

Note: Logic method: negative logic

10 mA at 5 VDC

100,000 times min. (at a rated load switching frequency of 1,800 times/hr)

12 to 24 VDC

+10%

/

–15%

Input current with no-voltage input 10 mA

Signal level ON voltage: 1.5 V max.

Rated load voltage

Max. load current 10 mA

Leakage current 100 µA max.

OFF voltage: 3 V min.

12 to 24 VDC

+10%

/

−15%

Timers

Linear Output

Item 4 to 20 mA 1 to 5 V 1 mV/10 digits (see note)

Resolution 4,096

Output error ±0.5% FS ±1.5% FS

Permissible load resistance 600 Ω max. 500 Ω min. 1 KΩ min.

Note: For the 1 mV/10-digit output, the output voltage changes for every 40 to 50 increment in the display value.

■ Communications Specifications

Item RS-232C, RS-422 RS-485

Transmission method 4-wire, half-duplex 2-wire, half-duplex

Synchronization method Start-stop synchronization

Baud rate 1,200/2,400/4,800/9,600/19,200/38,400 bps

Transmission code ASCII (7-bit)

Communications Write Comparative set value, prescaling value, remote/local programming, reset control of maximum/mini-

Read Process value, comparative set value, maximum value, minimum value, model data, error code, and

For details, refer to Communication Operation Manual.

mum values, and other setting mode items excluding communications conditions.

others

Period Meter K3NP B-197

Connections

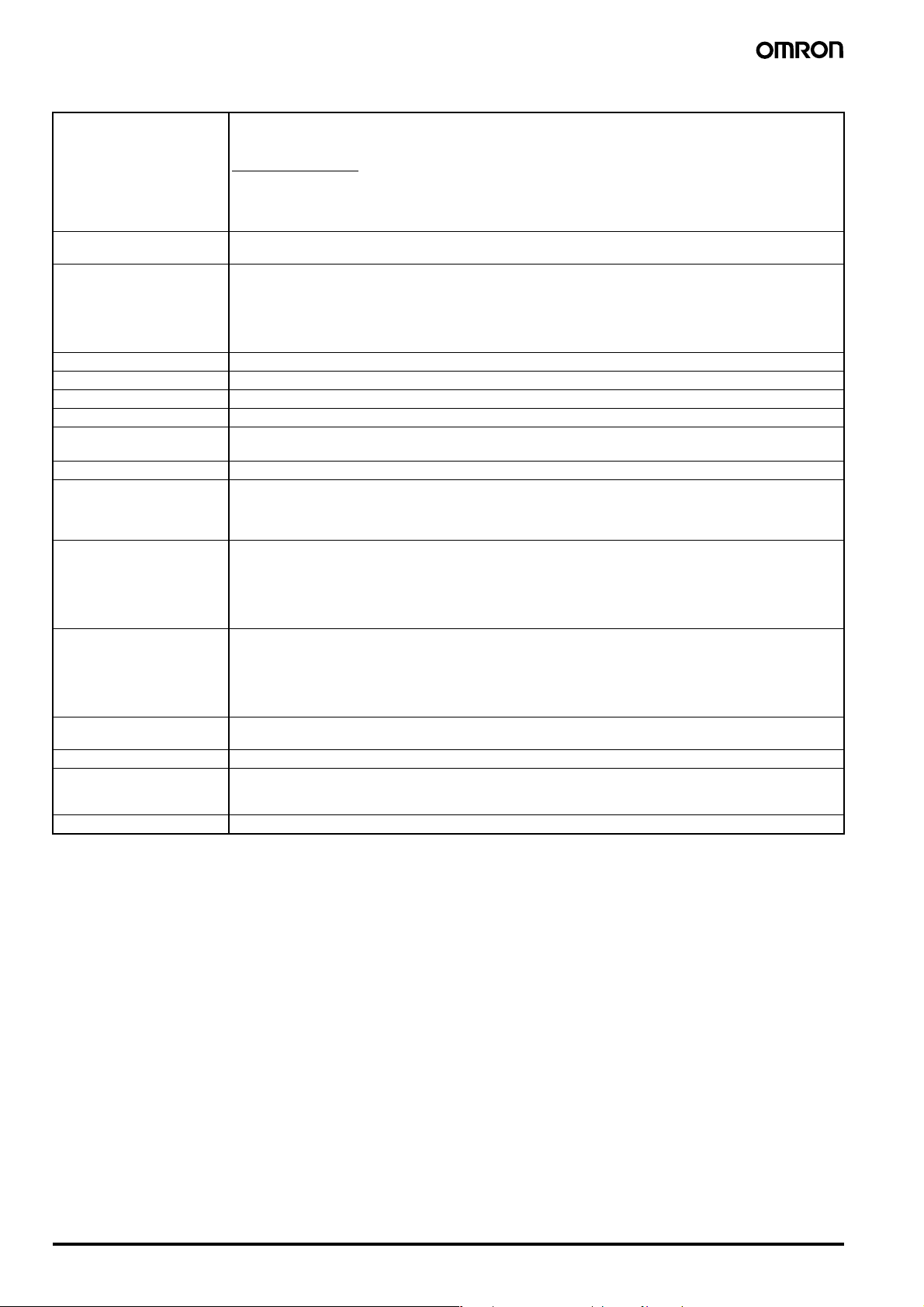

■ Terminal Arrangement

Output unit

Output

unit

Input

unit

Terminal Numbers

18 19 20 21 22 23 24 25 26

10 11 12 13 14 15 16 17

1 2 3 4 5 6 7 8 9

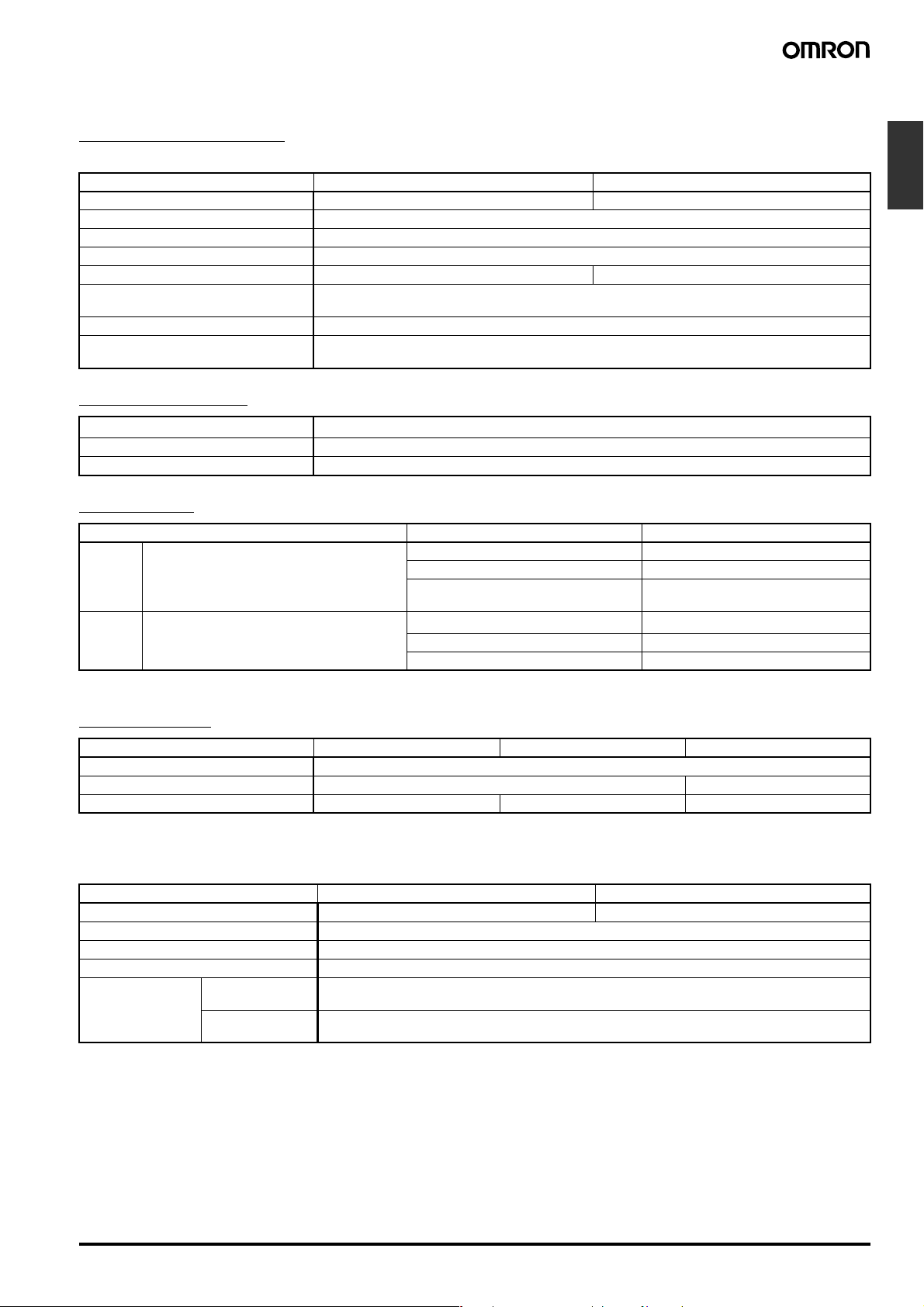

Input Unit

12 VDC

80 mA

Signal input terminal

NPN Inputs

External

sensor

power

supply (+)

Input A

Input B

External

sensor

power

supply (−)

+12 V

10

820 Ω

1

820 Ω

2

11

GND

Input unit

100 to 240 VAC

or 12 to 24 VDC

Note: Check the power supply specifications of the

model used before connecting the power supply.

Recommended 24VDC power supply;

eg. OMRON S8VS

Voltage Pulse Inputs

+12 V

10 k Ω

3

Input A

Input B

10 k Ω

4

11

GND

590 Ω

590 Ω

+12 V

Internal circuits

Note: Terminals 7 to 13 are connected internally.

Terminals 7 and 11 are mutually isolated.

When inputting the external control signals through the open

collector:

Transistor Inputs:

ON: Residual voltage must be 3 V max.

OFF: Leakage current must be 1.5 mA max.

The switching capacity must be 20 mA or greater.

When the external signal input is short-circuited, a voltage of

approximately 5 V will be applied to between the terminals 5 to

7 and the COM terminal, and a current of approximately 18 mA

(nominal value) will flow.

PNP-input Models

External

sensor

power

supply (+)

Input A

Input B

External

sensor

power

supply (−)

+12 V

10

1

820 Ω

590 Ω

+12 V

2

820 Ω

11

GND

590 Ω

GND

Internal circuits

GND

820 Ω

820 Ω

GND

GND

+12 V

590 Ω

+12 V

590 Ω

Internal circuits

(NPN Linear 2-wire Output)

10 1 1

1234

+12 V

INA INB

0 V

Note: When the contact is short-

NPN output sensor

Note: Connect the + side of the NPN

linear 2-wire input to terminal 1

and the − side to terminal 11.

B-198 Period Meter K3NP

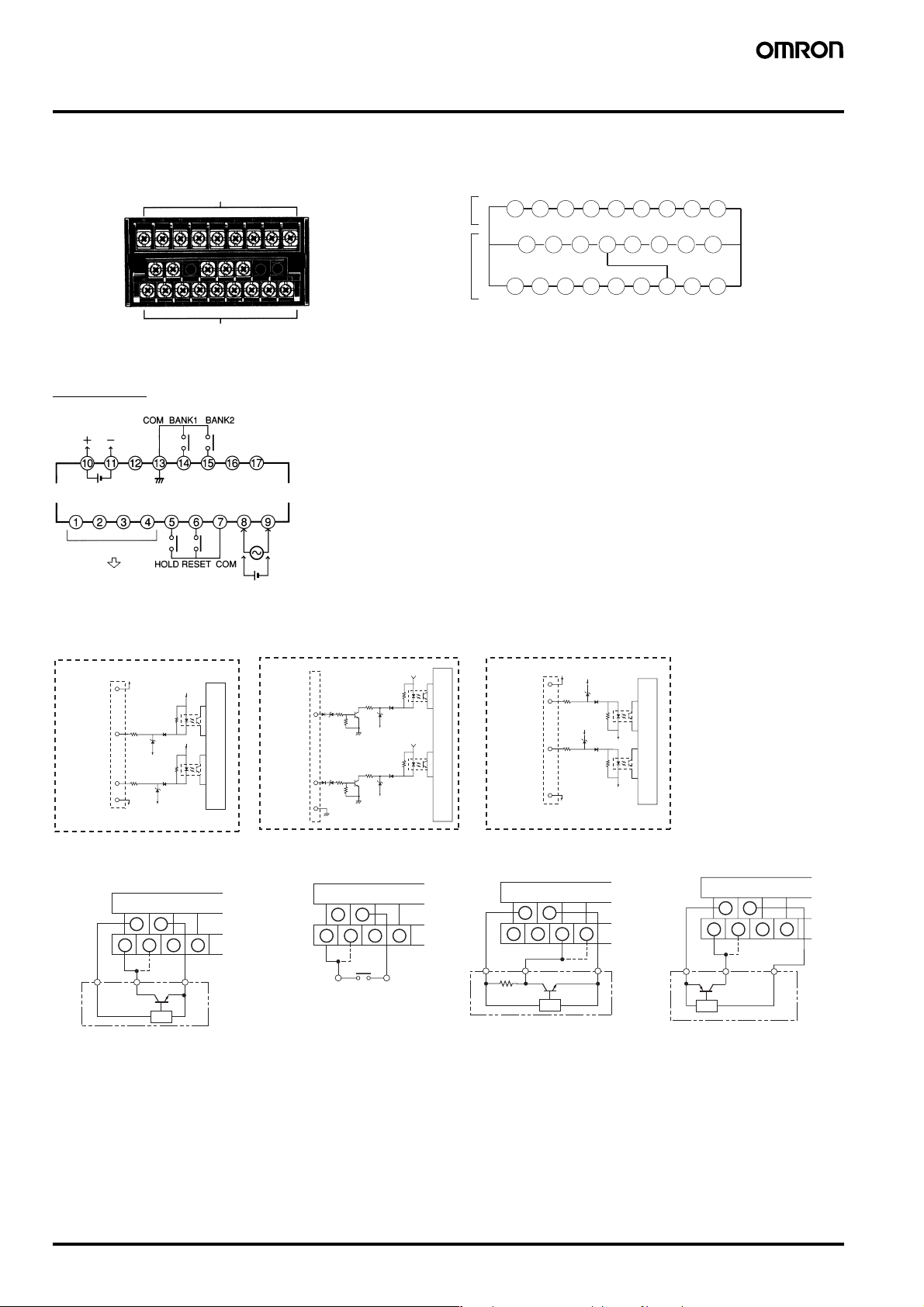

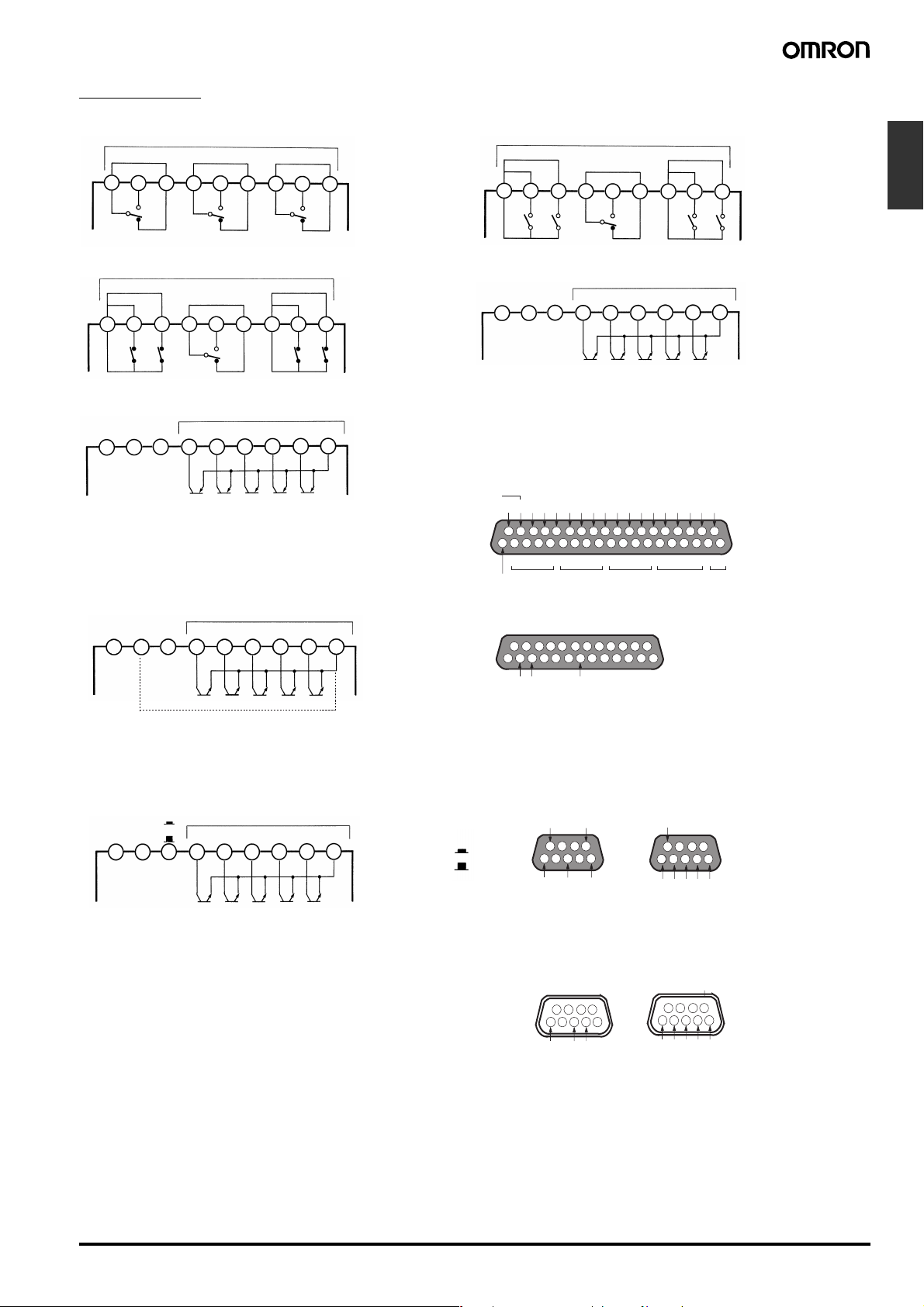

Contact Output Voltage Output PNP Open Collector OutputNPN Open Collector Output

10 11

1234

INA INB GND

Contact

circuited, a current of approximately 13 mA will flow at a voltage of approximately 12 V.

Input resistance: 10 kΩ

10 11

+12V

1234

INA INB

0 V

Voltage pulse output sensor

Note: With voltage pulse input

not from a 3-wire sensor,

connect the + side to terminal 3 and the − side to

terminal 11.

+12V

10 11

1234

INA INB

0 V

PNP output sensor

Output Units

K31-C1: Relay (3 Outputs)

Outputs (5 A max. at 250 VAC)

H PASS L

18 19 20 21 22 23 24 25 26

K31-C5: Relay (5 Outputs)

18 19 20 21 22 23 24 25 26

Outputs (5 A max. at 250 VAC)

H

HH PASS L

LL

K31-T2: Transistor (PNP Open Collector)

Outputs (50 mA max. at 24 VDC)

HH H PASS L LL COM

18 19 20 21 22 23 24 25 26

K31-L1, L2, L3,-L4, -L5, -L6, -L7, -L8, -L9,

-L10: Linear

(Terminals 21 to 26 are provided only on K31-L4,

-L5, -L6, -L9, -L10.)

L1, L4: 4 to 20 mA

L2, L5: 1 to 5 V

L3, L6: 1 mV/10 digit

L7, L9: 0 to 5 VDC

L8, L10: 0 to 10 VDC

+ −

18 19 20 21 22 23 24 25 26

Outputs (50 mA max. at 24 VDC)

HH H PASS L LL COM

K31-C2: Relay (5 Outputs)

Outputs (5 A max. at 250 VAC)

HH PASS L

18 19 20 21 22 23 24 25 26

LLH

K31-T1: Transistor (NPN Open Collector)

Outputs (50 mA max. at 24 VDC)

18 19 20 21 22 23 24 25 26

HH H PASS L LL COM

K31-B2, -B4: BCD (NPN Open Collector)

(Terminals 32 to 36 are provided only on K31-B4.)

4

10

DATA OVERFLOW

DATA VALID

RUN

COMMON

REQUEST

MAX. REQ.

MIN. REQ.

HOLD

RESET

POLARITYHHH

PASSLLL

10310

COMMON

4

48

20

21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37

1 2 3 4 5 6 7 8 9 10111213141516171819

12 4812 48 12 48 12 48 12

COMMON

0

10

1

10

2

10

K31-FLK1: RS-232C

14

15 16 17 18 19 20 21 22 23 24 25

12345678910111213

Timers

Note: With K31-L4/-L5/-L6/-L9/-L10 models, terminals 19

and 26 are connected internally.

K31-FLK2, -FLK5: RS-485

(Terminals 21 to 26 are provided only on K31-FLK5.)

Terminator

ON

RS-485

+ −

18 19 20 21 22 23 24 25 26

Outputs (50 mA max. at 24 VDC)

OFF

HH H PASS L LL COM

• D-sub 37P Connectors for BCD output (attachment)

Plug: XM2A-3701

Hood: XM2S-3711

• D-sub 25P connectors for RS-232C output (K31-FLK1) (order

separately)

Plug: XM2A-2501

Hood: XM2S-2511

• D-sub 9P connectors for RS-422 output (K31-FLK3 and K31-

FLK6) (order separately)

Plug: XM2A-0901

Hood: XM2S-0911

• D-sub 9P connectors for RS-232C output (K31-FLK4) (order

separately)

Plug: XM2D-0901

Hood: XM2D-0911

SD

RD

SG

K31-FLK3, -FLK6: RS-422

(The right connector is provided only on K31-FLK6)

Output NPN Tr.

(50 mA max. at 24 VDC)

SDB

LL

6

789

12345

H

HH

COM

PASS

L

Terminator

ON

OFF

RS-422

RS-422

RDA

6

789

1

2345

RDB

SDA

SG

K31-FLK4: RS-232C + Transistor (NPN Open Collector)

Output NPN Tr.

RS-232C

87

9

5

4321

SG

SD

(50 mA max. at 24 VDC)

6

RD

87

9

5

4321

L

PASS

COM

LL

6

H

HH

Period Meter K3NP B-199

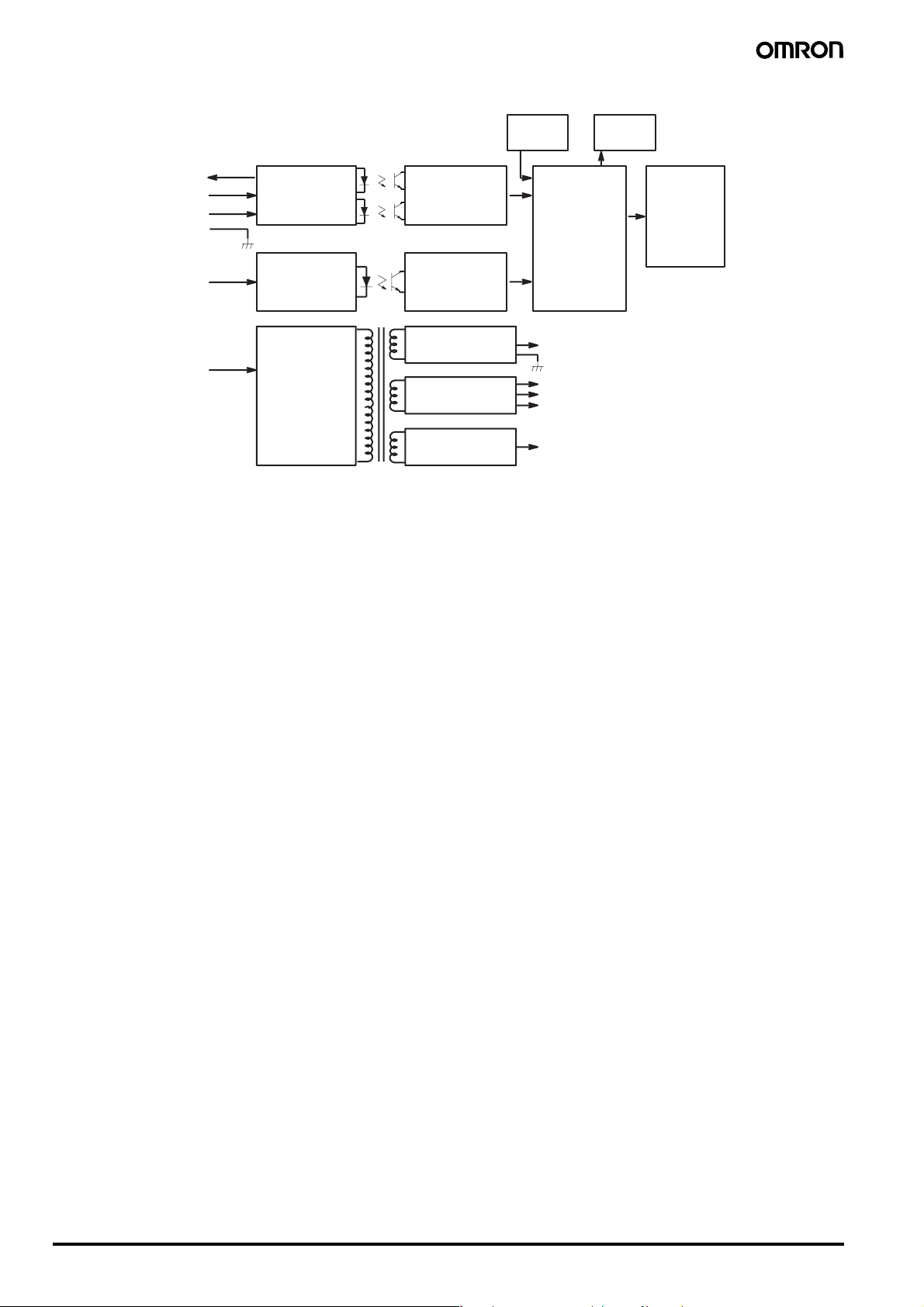

■ Block Diagram

Power supply

for sensor

Sensor A

Sensor B

GND

Control input

Control power

supply

Input circuit

Control input

circuit

Power supply

circuit

Frequency

measurement

circuit

Waveform

adjustment

circuit

Voltage stabilizing

circuit

Voltage stabilizing

circuit

Voltage stabilizing

circuit

Key

switch

8-bit

microcomputer

Power supply for

sensor (input circuit)

Frequency measurement circuit

Waveform adjustment circuit

8-bit microcomputer

Control input circuit

LED

Output

circuit

B-200 Period Meter K3NP

Operation

■ Main Functions

Output Pattern Selection c-out

The patterns of comparative output are selectable according to the

level change. Select the pattern according to the application.

Standard Output

Set value HH

Set value H

Set value L

Set value LL

Comparative output HH

Comparative output H

PASS

Comparative output L

Comparative output LL

Zone Output

Set value HH

Set value H

Set value L

Set value LL

Comparative output HH

Comparative output H

PASS

Comparative output L

Comparative output LL

Level Output

Set value HH

Set value H

Set value L

Set value LL

Remote/Local Selection r-l

Select remote programming when performing all settings through the

host devices and select local programming when performing settings

through key operation.

Prescaling

Input pulses are converted into desired values.

Timers

Comparative output HH

Comparative output H

Comparative output L

Comparative output LL

PASS

Note: The following setting conditions must be satisfied, otherwise no

zone output will turn ON correctly.

LL < L < H < HH

Linear Output Range lset

A linear output range can be set as required. A value corresponding

to the maximum output value and that corresponding to the minimum

output value can be set.

20 mA

Output

4 mA

Lower

limit

Upper

limit

For the 4- to 20-mA

output type

Display

Period Meter K3NP B-201

■ BCD Output Timing Chart

A request signal from an external device (such as a Programmable Controller) is required to read BCD data.

Single Sampling Data Output

Pulse with a width of no less than 20 ms.

REQ.

Max.

Min.

All data "high" All data "high"Data

DATA

DATA

VALID

Approximately 30 ms after the REQ signal rises, a sample is taken and the DATA VALID signal is output. Read the data when the DATA VA LID

signal is ON.

The DATA VALID signal will turn OFF in 40 ms, and then in 16 ms, the data will go OFF.

Models with a BCD output have an open collector output configuration so that wired-OR connection is possible.

K3NP (1)

K3NP (2)

K3NP (3)

(no more than 50 ms.)

Approx. 30 ms

Programmable

controller

40 ms

16 ms

DATA (incl. POL and OVER)

and DATA VALID are wired-OR

processed.

The RUN, HH, H, PASS, L, and

LL signals are always output

regardless of the status of the

REQ signal. Do not OR-wire

these signals.

REQ.

(1)

REQ.

(2)

REQ.

(3)

DATA

DATA

VALID

(1) (2)

***

*The period between the DATA VALID signal and the

REQ signal should be no less than 20 ms max.

(3)

Continuous Data Output

REQ.

Max.

Min.

All data "high"

DATA

DATA

VALID

Approx.

30 ms

The K3NP outputs each measurement at an interval of 64 ms when a REQ signal is ON continuously.

If the HOLD signal is ON at the moment the DATA output is switched from Data 1 to Data 2 or vice versa, the output BCD data will be either Data

1 or Data 2 according to the timing of the HOLD signal. However, output data will never be below.

Data 1 Data 2

40ms 40ms

24ms

64ms 64ms

24ms

B-202 Period Meter K3NP

Example of Connection to Programmable Controller

+5 V

K3NP

240 Ω

240 Ω

1. COMMON

2. 1

3. 2

0

10

4. 4

5. 8

23. DATA VALID

24. RUN

25. COMMON

26. REQUEST

PC (SYSMAC)

DC Input Unit

COM

IN

IN

IN

IN

IN

IN

Transistor Output Boards

OUT

Timers

Internal circuit

240 Ω

240 Ω

30. RESET

31. POLARITY

(Polarity: +, −)

OUT

COM

(0 V)

24 VDC

+24 V

DC power supply*

0 V

Internal circuit

* Recommended

Power supply;

eg. OMRON S8VS

Internal circuit

Period Meter K3NP B-203

Example of Connection to Display Unit

K3NP

1.COMMON

2.1

3.2

0

10

4.4

5.8

23.DATA VALID

24.RUN

25.COMMON

+5V

240 Ω

240 Ω

26.REQUEST

2

10

Connected

1

10

240 Ω

240 Ω

30.RESET

31.POLARITY

(Polarity: +, −)

V

D

O

V

B

A

C

O

LE

DP

8

M7E-01D@N2 or M7E-01H@N2

M7E Digital Display Unit

D

8

C

B

A

V

LE

DP

SEC

O

V

B

A

C

D

O

LE

DP

8

B-204 Period Meter K3NP

■ Output Operation Timing in RUN Mode (Relay or Transistor Outputs)

The following timing chart is for a 5-comparative Output Board when the standard output pattern in selected.

HH set value

H set value

L set value

LL set value

RESET

HH comparative output

H comparative output

PASS output

L comparative output

LL comparative output

0

Display

Reset display

Display value

%%%%%

Note: Because measuring is not continuous, the comparative output turns ON when the measuring operation is completed.

Timers

■ Operating Modes

The K3NP provides 6 operating modes for converting input pulses to display values. The mode can be selected via key operations on the front

panel.

The time between pulses or the pulse ON time is measured using the

internal system clock, and time and other display values are calculated accordingly.

Example: F1 Passing Speed

INA

INB

T

System

clock

Operating mode no. Use

01 Passing speed

02 Cycle

03 Time difference

04 Elapsed time

05 Length measurement

06 Interval

The time (T) between the INA pulse and the INB pulse is counted

using the internal system clock.

If the count between the pulses is 100,000, then

T = System clock pulse (0.5 µs) x 100,000

= 0.05 s

For operating mode 1 (Passing Speed), 1/T x 60 (m/min) is used.

The display value is thus 1/0.05 s x 60, or 1,200 (m/min)

Period Meter K3NP B-205

Operating Mode 1: Passing Speed

The inverse of the time between input A coming ON and input B

coming ON is multiplied by 60 and displayed.

A 20-ms recovery time (T

ment operation.

Input A

) is required at the start of each measure-

R

Application Example

Measuring the Speed of Workpieces between Points A

and B

Input B

T

T

T

1

2

R

T

3

T

R

T

4

T

R

Hold input

Display

1/T1 x 60 1/T2 x 60 1/T4 x 60

Units: mm/s; m/s; m/min; km/h; etc.

Operating Mode 2: Cycle

The period (T) of input A is displayed.

The K3NP is in measuring operation during every other period of

input A ON.

Input A

T1T

T

T

3

2

4

T

5

Hold input

Display

T

1

T

2

T

5

Units: s; min; h, min, s; min, s, 1/10 s; etc.

Operating Mode 3: Time Difference

The time between input A turning ON and input B turning ON is displayed.

A 20-ms recovery time (T

ment operation.

) is required at the start of each measure-

R

Application Example

Measuring the Rate at which Parts are Fed

Application Example

Measuring the Time Required

for Workpieces to Pass from

Point A to Point B

Can be Used with Prescaling to Measure Lengths of

Steps

Input A

Input B

T

T

2

T

1

R

T

3

T

R

T

4

T

R

Hold input

Display

T

1

T

3

Units: s; min; h, min, s; min, s, 1/10 s; etc.

Operating Mode 4: Elapsed Time

The time (T) that input A is ON is displayed.

A 20-ms recovery time (T

ment operation.

Input A

Hold input

Display

Units: s; min; h, min, s; min, s, 1/10 s; etc.

) is required at the start of each measure-

R

T

T

1

2

T

R

T

T

1

T

R

3

T

3

T

4

Application Example

Monitoring the Time That

a Press is Activated

Controlling the Time

That a Valve is Open

Communication

output

B-206 Period Meter K3NP

Operating Mode 5: Length Measurement

The number of pulses received on input A while input B is ON is displayed.

123456 12345

Input A

Input B

Hold input

Application Example

Measuring Workpiece Length

BCD

To PC

Timers

Display

Units: mm; cm; m; etc.

65

Operating Mode 6: Interval

The number of pulses received on input A between two pulses on

input B is displayed.

123456 123456

Input A

Input B

Hold input

Display

Units: mm; cm; m; etc.

66

Application Example

Measuring Slot Spacing

H

PA SS

L

Pass/fail

determination

Period Meter K3NP B-207

Nomenclature

1. SV Display

2. PV Display

3. Comparative Output

Status Indicators

4. SV Display Status

5. ESC Key

6. Mode Key

Name Functions

1. SV display Displays the set value or parameter. Available for Set Value LED Models only.

2. PV display Displays the process value in addition to the maximum value or parameter.

3. Comparative output

status indicators

4. SV display status Indicates which comparative set value is currently on the SV display.

5. ESC Key Used to return to the RUN mode from the Setting, Protect, or Maintenance mode.

6. Mode Key Used to enter the Setting mode.

7. Status indicators HOLD:Lit when HOLD input is ON.

8. Teaching indicator Lit when the teaching function is enabled and flashes when the K3NP is in teaching operation.

9. RESET/TEACH Key The measurement data, maximum value, and minimum value are reset by pressing this key.

10. Up Key and Shift Key The digit being set is scrolled by pressing the Shift Key. The set value increases by one whenever the Up Key is

Displays the status of comparative output.

The process value, maximum value, or minimum value to be displayed can be selected.

Used to allow the PV display to indicate set values sequentially. Available for Basic Models only.

Used to indicate set values sequentially on the SV display. Available for Set Value LED Models only.

MAX:Lit when the maximum value is indicated on the PV display.

MIN:Lit when the minimum value is indicated on the PV display.

PROG:Lit or flashes while parameters are being set.

Teaching is available when the teaching function is enabled.

pressed.

7. Status Indicators

8. Teaching Indicator

9. RESET/TEACH Key

10. Up Key and Shift Key

B-208 Period Meter K3NP

Engineering Data

Derating Curve for Sensor Power Supply

Timers

Max. current (mA)

Ambient temperature (°C)

Dimensions

Note: All units are in millimeters unless otherwise indicated.

PV Display

14.2

8.2

Note:

The derating curve shown is for standard installation.

The derating curve depends on the mounting direction.

Panel Cutouts

+0.8

45

−0

+0.8

92

−0

75

Note: The K3NP uses M3.5 terminals.

A terminal cover is provided.

120

Period Meter K3NP B-209

Precautions

!WARNING

Do not touch any of the terminals while the power is being supplied. Doing so may result in electric shock.

!Caution

Do not allow metal objects or conductive wire cuttings to enter the

product. Doing so may result in electric shock, fire, or malfunction.

!Caution

Do not attempt to take the product apart or touch any internal parts

while the power is being supplied. Doing so may result in electric

shock.

!Caution

Do not use the product in locations subject to flammable or explosive gases. Doing so may result in explosion.

!Caution

The lifetime of output relays varies greatly with the switching capacity and conditions. Consider the actual operating conditions,

and use the relays within the rated load without exceeding the

number of operations specified as the rated electrical life. Using

relays beyond their rated electrical life may result in contact deposit or burning.

!Caution

Do not use loads exceeding the rated value. Doing so may result

in damage or burning.

!Caution

Use a power supply voltage within the specified range. Not doing

so may result in damage or burning.

!Caution

Use settings that are appropriate for the control system. Discrepancies between the settings and the actual control conditions may

result in unexpected operation leading to damage or accidents.

!Caution

Be sure to tighten terminal screws to the specified torque.

Specified torque for M3.5 screws: 0.74 to 0.90 N·m

Loose screws may result in burning or malfunction.

■ Application Precautions

• Use a power supply voltage within the specified range. Not doing

so may result in damage or burning.

• Be sure to perform wiring correctly, verifying the terminal names.

Incorrect wiring may result in burning.

• Be sure to tighten the screws on the terminal block properly.

• Do not connect anything to unused terminals.

■ Correct Use

Long-term Use

Use all products within the specified ranges. When using inside a

control panel, ensure that the temperature around the product, rather

than the temperature around the control panel, does not exceed the

specified temperature range. Electronic products, such as this product, have a lifetime that is dependent on the lifetime of internal electronic components, as opposed to the lifetime related to the number

of relay switching operations. The lifetime of these components varies with the temperature; the higher the temperature, the shorter the

lifetime. Therefore, the product lifetime can be extended by lowering

the internal temperature of the product.

When several Period Meters are mounted close together (either horizontally or vertically), the internal temperature of the Period Meters

may rise, leading to a reduction in the lifetime. In this case, take measures to cool the Period Meters, such as installing fans. Ensure, however, that the terminals are not cooled as this may lead to incorrect

measurement.

Operating Environment

Do not use the product in locations subject to temperatures or humidity levels above the specified ranges, or in locations subject to condensation.

Do not use the product in locations subject to severe shocks or vibrations.

Separate the product from machines that generate high-frequency

noise, such as high-frequency welding machines and high-frequency

sewing machines.

Do not use the product in locations subject to dust or corrosive

gases.

Do not use the product outdoors or in locations subject to direct sunlight.

Operation

When using models with comparative outputs, if an error occurs at

the Period Meter, comparative output may not operate correctly. We

therefore recommend that you consider providing an alarm system

separately as a countermeasure.

Parameter settings that allow the functions to operate properly are

made, using the setting menu, at the factory prior to delivery. When

using the product, change the settings as required for the application.

Mounting

Recommended panel thickness is 1 to 3.2 mm.

B-210 Period Meter K3NP

Panel

Attach the mounting bracket on the left and right sides of the Period

Meter as shown in the illustration above and gradually tighten each

screw evenly in turn by considering the balance of the tightening

force until the ratchets start slipping without being further tightened.

Mount the Period Meter as horizontally as possible.

Unit Label (Provided)

No product is shipped with the unit label attached. Select a unit label

from the sheet provided and attach it to the Period Meter.

Waterproof Specifications

Products for which the degree of protection is not specified or models

with IP@0 degree of protection do not have waterproof specifications.

Noise Countermeasures

Separate the product as far as possible from machines that generate

high-frequency noise, such as high-frequency welding machines and

high-frequency sewing machines, and machines that generate

surges.

Attach surge absorbers or noise filters to noise-generating peripheral

devices (in particular, devices with inductance such as motors, transformers, solenoids, and magnet coils).

Line filter

K3NP

Power input

+

K3NP

Signal

input

−

Surge absorber

In order to prevent inductive noise, wire the lines connected to the

terminal block separately from power lines carrying high voltages or

large currents. Also, do not wire in parallel to, or in the same cable as

power lines. There are other methods that are effective for reducing

noise, such as running wires along ducts and using shield lines.

When using a noise filter for the power supply, check the voltage and

current and install as close to the Period Meter as possible.

Power input

Timers

Inductive Noise Countermeasure for Input

Line

Analog Input

+

Signal

input

Two-conductor shield wire

Temperature Input

In order to prevent the influence of induction, separate the lead wire

joining the temperature sensor and the Period Meter from power and

load lines.

Using the product near radios, television sets, or other wireless

devices may result in reception interference.

Processor

−

Period Meter K3NP B-211

Operating Procedures

■ Operation in RUN Mode

Reset

The initial status before any measurements were made can be

returned to using the RESET/TEACH Key . (This status is

RESET

/TEACH

referred to as the "reset status.") The status of the K3NP when it is in

the reset status is as follows:

Display: All 5 digits in the PV display are 0 (00000).

Comparative output: HH, H, PASS, L, and LL outputs are all OFF.

Maximum/minimum values: These values are reset.

Checking the Bank Number

Press the Shift Key for 1 s min. during measurement to display

the bank number in the PV display. (The display will return to the

measurement value if there is no key operation for 5 seconds.)

Bank Selection

BANK1

BANK2

COM

• Switch between the comparative set values and the prescaling val-

ues for banks 1 to 4 using the BANK 1 and BANK 2 signals.

• The relationship between the BANK 1 and BANK 2 signals and the

bank numbers is shown in the following table.

Bank

number

BANK 1 BANK 2 Comparat

ive set

Prescaling

value

value

1OFFOFFsU1.** ps1.**

2ONOFFsU2.** ps2.**

3OFFONsU3.** ps3.**

4ONONsU4.** ps4.**

Note: If the prescale value bank is set to OFF, then the prescaling val-

ue for each bank is fixed.

Confirming Maximum and Minimum

Values

Press the ESC Key during measurement to display the maximum and minimum values.

Measurement

value

Press the RESET/TEACH Key while the maximum or minimum

Maximum

value

RESET

/TEACH

Minimum

value

value is displayed to reset the value. (This is not possible, however, if

maximum/minimum value reset was prohibited in Protect Mode.)

Confirming and Setting Comparative Set Values

When the measurement value, the maximum value, or the minimum value is displayed, press the Mode Key repeatedly to display the comparative set values in the order HH, H, L, and LL. (With models that have an SV display, the comparative set values are displayed in the SV display.)

Measurement value

Maximum value

Minimum value

Comparative

set value HH

No key operation for 5 s

Comparative

set value H

No key operation for 5 s No key operation for 5 s

Note: When a comparative set value is displayed, it can be changed using the Up Key and Shift Key (if key protection is OFF).

Comparative

set value L

Comparative

set value LL

No key operation for 5 s

B-212 Period Meter K3NP

■ Setting Procedures

The K3NP has four modes: RUN mode for normal operations, Setting mode for initial parameter input, Protect mode for lock-out configuration, and

Maintenance mode for initializing set values. The parameters that are accessible on any individual K3NP will vary depending on the Output Board

installed. Refer to the K3NP Operation Manual for details.

RUN Mode: Remains in this mode under normal operation.

Setting Mode: Used for making initial settings.

Protect Mode: Used for locking the front key operation or parameter changes.

Maintenance Mode: Used for initializing set values.

The process value or the max./min. value can be monitored.

Using the front panel keys, the comparative set value can be changed and max./min. values reset can be performed.

Includes settings for four menus (Set value (sUset), prescaling (pscl), setup (setup), option (opt)) and the output test.

When power is ON

Power ON

+

Maintenance mode

ESC

RUN mode

ESC

+

1 s

Timers

ESC

1 s

Setting mode

sUset - Program set values

s.bank Select bank no. of set values

sU*.hh Enter set value HH of bank 1

sU*. h Enter set value H of bank 1

sU*. l Enter set value L of bank 1

sU*. ll Enter set value LL of bank 1

Note: The above is an example when the bank number is set to 1.

pscl - Display prescaling

p.bank Select bank no. of prescale values

ps*.ax Set the mantissa (X) of the prescale value of input A

ps*.ay Set the exponent (Y) of the prescale value of input A

decp.* Select decimal point

Note: The above is an example when the bank number is set to 1.

setup - Program operating mode/input sensor/serial communications

func Specify operating mode

ina Select a sensor type of input A

inb Select a sensor type of input B

time Select the display time unit

u-no Enter the unit no. for the host

bps Select the baud rate

len Select the word bit length

sbit Select the stop bits

prty Select the parity bits

opt - Supplementary settings related to display or control

c-out Select the output pattern

lset.h Enter the upper limit (H) of linear output range

lset.l Enter the lower limit (L) of linear output range

r-l Select the remote/local programming

test - Generating simulated input for testing the output function

ESC

Protect mode

prot - Program lock-out configuration

all Enable all key protection

sUset Enable set value change prohibition

reset Enable prohibition of all the measurement data and

max./min. value reset using the front panel keys

secr Specify the menus to be protected against setting in the

setting mode

Period Meter K3NP B-213

■ Initial Settings ■ Parameters

h.mm.55

Power ON

Press the Mode Key for 1 s min. to move to the Setting

Mode.

Select the setup menu ( ) with the Mode Key

and set the operating mode, the input type, the time unit, and

other settings.

If required, set a prescale value in the prescaling menu

( ).

Set comparative set values in the set value menu ( ).

Make settings in the option menu ( ) as required.

If necessary, generate simulated input for testing the output

function in output test ( ).

After completing all the settings, press the

ESC Key to return to RUN Mode.

Power ON

RUN Mode

Refer to Operation in RUN Mode.

Setting Mode

1 s

Set value menu

1 s

Comparative set

value bank

Comparative

set value HH

Comparative

set value H

Comparative

set value L

Comparative

set value LL

Press the ESC Key and Up Key

for 1 s.

(See note 1.)

(See note 1.)

(See note 1.)

(See note 1.)

No key operation for 5 s

No key operation for 5 s

No key operation for 5 s

No key operation for 5 s

No key operation for 5 s

−

−

0

−

0

−

0

−

0

Measurement starts.

Prescaling

To display the passing speed between two points based on

input pulses, the time measured internally must be multiplied

by a fixed coefficient. The value of this coefficient will depend

on the distance between the two points and the display unit.

This coefficient is called the "prescale value." (Refer to the

Operation Manual for details.)

Time Unit Setting

Setting

Set in the prescaling menu

Seconds

Minutes

Minutes and seconds

Hours, minutes, and seconds

h.mm.55

Meaning

Selecting the Sensor Type

NO: Voltage

NC: Voltage

pulse H

pulse L

No-contact or

voltage pulse

input

Contact input

Note: If there are large discrepancies

in the display select or .

Note, however, that the

maximum counting frequency is

30 Hz.

Output test

B-214 Period Meter K3NP

func

f1

Changing Set Values

5cal

p5cl

By pressing the Shift Key while a parameter is displayed, the set value can be

changed (setting status). The PROG status indicator will flash. Change the set

value as required, and press the Mode Key to register the setting and move to

the next parameter.

Timers

Protect Mode

Prescaling menu

1 s

Prescale value

bank (See note 2.)

Input A prescale

value mantissa

Input A prescale

value exponent

Decimal point

(See note 1.)

(See note 1.)

No key operation for 5 s

No key operation for 5 s

No key operation for 5 s

(See note 1.)

No key operation for 5 s

func

Next parameter

−

−

−

Setting Status

If there is no key operation for

5 seconds, the setting is

registered and the parameter

is displayed again.

Setup menu

−

−−

Change the set value

using the Up Key and

f1

the Shift Key .

PROG flashes.

1 s

Operating

mode

Input A

sensor type

Input B sensor

type (See note 4.)

Time unit

(See note 3.)

Communications

unit number

Baud rate

No key operation for 5 s

No key operation for 5 s

No key operation for 5 s

No key operation for 5 s

No key operation for 5 s

1200/2400/4800/

9600 /19200/38400bps

No key operation for 5 s

−

−

Option menu

1 s

Output pattern

Upper limit (H) of

linear output range

Lower limit (L) of

linear output range

Remote/local programming

No key operation for 5 s

No key operation for 5 s

No key operation for 5 s

No key operation for 5 s

//

−

0

−

0

/

Word bit length

Stop bits

Parity bits

No key operation for 5 s

No key operation for 5 s

7 /8bit

1/ 2 bit

//

• In the Setting Mode, measurement stops and all

outputs turn OFF.

• Depending on the output type of the model used,

some parameters (indicated in ) are not displayed (and hence cannot be set).

• If the operating mode is changed, the prescale val-

ues and linear output range parameters will be reset to their initial values. Set the operating mode

first.

Note 1: A number in the range 1 to 4 will be displayed.

2: Set a number in the range 2 to 4 to set more than one

prescale value (i.e., to display measurements in more than

one unit).

3. These parameters will be displayed if F2, F3, or F4

(i.e., operating mode 2, 3, or 4) is set. If a parameter other than

is set, the prescaling menu ( ) will not be displayed.

5cal

4: This parameter will be displayed if F1, F3, F5, or F6 is

selected.

p5cl

Settings displayed in reverse colors are defaults.

Period Meter K3NP B-215

prot

all

sUset

reset

secr

kpon

kpoff

Power ON

prot

all

sUset

secr

reset

kpon

kpoff

kpon kpoff

0 1 2

RUN Mode

Press the ESC Key

and Up Key for 1 s.

· Measurement stops in Protect Mode.

· Depending on the output type of the model used, some parameters (indicated in ) are not

displayed (and hence cannot be set).

Protect Mode

(See

note.)

kpon

kpoff

Set value change

prohibition

sUset

Displayed only for

models with

comparative outputs.

Reset prohibition

reset

Protect menu

prot

All key protection

1 s

Key-protection ON:

Key-protection OFF:

all

Menu display Parameter display Meaning of parameter Setting range Setting key

All key protection:

All key operations are prohibited in

prot

prot

Press the Mode Key

to display the parameter.

all

all

Next parameter:

Setting:

RUN Mode. (If all key protection is

ON, only the key for going to Protect

Mode is enabled.)

Set value change prohibition:

sUset

sUset

Next parameter:

Setting:

Changes to comparative set values

are prohibited in RUN Mode. (Displayed only for models with comparative outputs.)

Menus protected

in Setting Mode

secr

Note: Press the Shift Key to make it

possible to set or change parameters.

Key protection ON:

Key protection OFF:

Use the Up Key to

change the setting.

➤

kpon kpoff

Use the Mode Key

ting and move to the

next parameter.

kpon

kpoff

(See note.)

➤

to enable the set-

Reset prohibition:

Press the ESC Key

to return to the menu.

reset

reset

Next parameter:

secr

secr

Next parameter:

Setting:

Setting:

Resetting using the front panel keys

is prohibited. (Resetting by external

signals is not prohibited.)

Menus protected in Setting Mode:

Setting operations in Setting Mode

are prohibited in the way shown below.

Setting menu Setting

012

Set value menu ×

Prescaling menu ×

00 /1/

Use the Up Key to

change the setting.

➤

➤

➤

0 1 2

Use the Mode Key

to enable the set-

2

ting and move to the

next parameter.

Setup menu ××

Option menu ×

Note: If there is no key operation for 5 seconds, the setting is automatically registered.

B-216 Period Meter K3NP

■ Troubleshooting

When an error occurs, error details will be displayed in the PV display. Take the appropriate countermeasures according to the error displayed.

Error display Error contents Output status Countermeasure

Comparative

output

m1.err (M1.ERR)

m2.err (M2.ERR)

m3.err (M3.ERR) OFF OFF (all outputs

err-o (ERR-O)

chg-o (CHG-O)

(Display value

flashes.)

rmt (RMT)

(Flashes for 3 s.)

Memory error OFF OFF (all outputs

Output error OFF OFF (all outputs

The input range and

display range were

exceeded.

The remote/local

section is set to remote.

Continues Continues

Continues Continues Continues Continues If an attempt to change a setting

BCD output Communications

in "H" status)

in "H" status)

in "H" status)

The OVER signal

turns ON.

output

OFF OFF Reset the power. If the same error

OFF OFF Reset the power while holding

OFF OFF

Continues

The OVER or UN-

DER signal turns

ON.

Linear

output

occurs, repair is necessary.

down the ESC Key, the Up Key, and

the RESET/TEACH Key. The settings will be returned to their default

values. If the same error occurs, repair is necessary.

(minimum

value)

Continues Take steps to ensure that the input

Reset the power. If the same error

occurs, repair is necessary. If normal operation is restored, it is possible that the original error was

caused by the influence of noise.

Check that there are no sources of

noise in the vicinity.

values and display values are within the allowable ranges.

using key operations is made with

the remote/local selection set to remote, this error will flash for 3 s. To

enable settings to be changed, set

the remote/local selection to local.

Timers

Period Meter K3NP B-217

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. N088-E1-02

In the interest of product improvement, specifications are subject to change without notice.

B-218 Period Meter K3NP

Loading...

Loading...