Page 1

Up/Down Counting Pulse Indicator

For the most recent information on models that have been certified for

safety standards, refer to your OMRON website.

15

K3HB-C @

2

K33-@

3

K34-@

4

K35-@

1234 5

K3HB-C@-@@@

K3HB-C

Measure High-speed Up/down Pulses with this

Up/down Pulse Meter.

• Visual conf0rmation of judgement results through display colors that

switch between red and green. *1

•

Perfect for Measuring Rotary Encoder and ON/OFF Pulse Signals at High

Speed

Cumulative pulse input is 50 kHz, quadrature pulse inputs are 25 kHz, and up/

down pulse inputs are 30 kHz.

Note: No-voltage contacts of up to 30 Hz are supported.

• The count value can be converted to any value.

The length equivalent for any pulse can be set to any desired value. This is

effective for feed amount and position monitor displays.

• DeviceNet models added to the series. *2

*1 Visual confirmation of judgement results is not supported on models that do not have an

output or models that do not support DeviceNet.

You can change the display color by setting it, but you cannot switch it based on the judgement results.

*2 DeviceNet models have a depth of 97 mm.

Refer to Safety Precautions for All Digital Panel

Meters.

CSM_K3HB-C_DS_E_15_1

Model Number Structure

■ Model Number Legend

Base Units and Optional Boards can be ordered individually or as sets.

Base Units

1. Input Sensor Code

NB: NPN input/voltage pulse input

5. Supply Voltage

100-240 VAC: 100 to 240 VAC

24 VAC/VDC: 24 VAC/VDC

Optional Board

Sensor Power Supply/Output Boards

Relay/Transistor Output Boards

Event Input Boards

Note: The following combinations are not possible.

• Communications (FLK@A) + DeviceNet (DRT)

• Communications (FLK@A) + BCD output (BCD)

• Linear current/voltage (L@A) + DeviceNet (DRT)

Base Units with Optional Boards

2. Sensor Power Supply/Output Type Code

None: None

CPA: Relay output (PASS: SPDT) + Sensor power supply

L1A: Linear current output (0 to 20 or 4 to 20 mA DC) + Sensor power supply

L2A:

A: Sensor power supply (12 VDC ±10%, 80 mA)

FLK1A: Communications (RS-232C) + Sensor power supply

FLK3A: Communications (RS-485) + Sensor power supply

Note: 1. CPA can be combined with relay outputs only.

2. Only one of the following can be used by each Digital Indicator: RS-232C/

3. Relay/Transistor Output Type Code

None: None

C2: Relay contact (HH/H/LL/L: SPST-NO each)

T1: Transistor (NPN open collector: HH/H/PASS/L/LL)

T2: Transistor (PNP open collector: HH/H/PASS/L/LL)

BCD∗:BCD output + transistor output (NPN open collector: HH/H/PASS/L/LL)

DRT: DeviceNet (See note 2.)

∗ A Special BCD Output Cable (sold separately) is required.

4. Event Input Type Code

None: None

1: 5 inputs (M3 terminal block), NPN open collector

2: 8 inputs (10-pin MIL connector), NPN open collector

3: 5 inputs (M3 terminal block), PNP open collector

4: 8 inputs (10-pin MIL connector), PNP open collector

(12 VDC±10%, 80 mA) (See note 1.)

(12 VDC±10%, 80 mA) (See note 2.)

Linear voltage output (0 to 5, 1 to 5, or 0 to 10 VDC) + Sensor power supply

(12 VDC±10%, 80 mA) (See note 2.)

(12 VDC±10%, 80 mA) (See note 2.)

(12 VDC±10%, 80 mA) (See note 2.)

RS-485 communications, a linear output, or DeviceNet communications.

1

Page 2

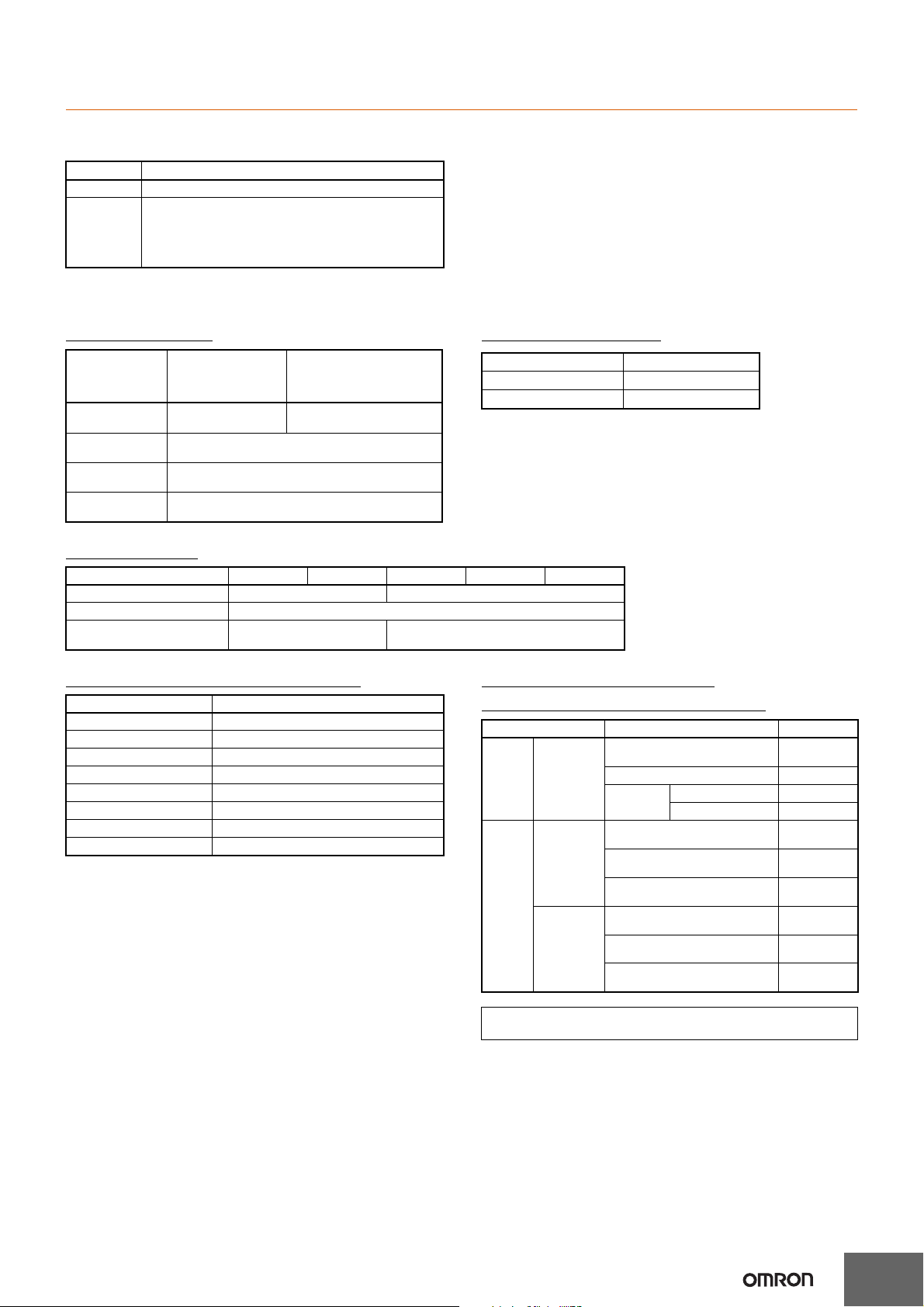

Accessories (Sold Separately)

K32-DICN: Special Cable (for event inputs with 8-pin connector)

K32-BCD: Special BCD Output Cable

Watertight Cover Rubber Packing

K3HB-C

Model

Y92A-49N

Model

K32-P1

Note: Rubber packing is provided with the Controller.

Specifications

■ Ratings

Supply voltage 100 to 240 VAC, 24 VAC/VDC, DeviceNet power supply: 24 VDC

Allowable power supply voltage

range

Power consumption

(See note 1.)

Current consumption DeviceNet power supply: 50 mA max. (24 VDC)

Input

External power supply

Event inputs Hold input NPN open collector or no-voltage contact signal

Reset input

Bank input

Output ratings

(depends on

the model)

Display method Negative LCD (backlit LED) display

Main functions Scaling function, measurement operation selection, output hysteresis, output OFF delay, output test, display value

Ambient operating temperature

Ambient operating humidity

Storage temperature

Altitude 2,000 m max.

Accessories

Note: 1. DC power supply models require a control power supply capacity of approximately 1 A per Unit when power is turned ON. Particular

2. For K3HB-series DeviceNet models, use only the DeviceNet Connector included with the product. The crimp terminals provided are for

Relay output 250 VAC, 30 VDC, 5 A (resistive load)

Transistor output Maximum load voltage: 24 VDC, Maximum load current: 50 mA, Leakage current: 100 μA max.

Linear output Linear output 0 to 20 mA DC, 4 to 20 mA DC:

attention is required when using two or more DC power supply models. The OMRON S8VS-series DC Power Supply Unit is

recommended.

Thin Cables.

85% to 110% of the rated power supply voltage, DeviceNet power supply: 11 to 25 VDC

100 to 240 VAC: 18 VA max. (max. load)

24 VAC/DC: 11 VA/7 W max. (max. load)

No-voltage contact, voltage pulse, open collector

12 VDC±10% 80 mA

ON residual voltage: 2 V max.

ON current at 0 Ω: 4 mA max.

Max. applied voltage: 30 VDC max.

OFF leakage current: 0.1 mA max.

Mechanical life expectancy: 5,000,000 operations, Electrical life expectancy: 100,000 operations

Load: 500 Ω max, Resolution: Approx. 10,000, Output error: ±0.5% FS

Linear output 0 to 5 VDC, 1 to 5 VDC, 0 to 10 VDC:

Load: 5 kΩ max, Resolution: Approx. 10,000, Output error: ±0.5% FS

(1 V or less: ±0.15 V; no output for 0 V or less)

7-segment digital display (Character height: PV: 14.2 mm (green/red); SV: 4.9 mm (green))

selection, display color selection, key protection, bank selection, display refresh period, maximum/minimum hold, reset

−10 to 55°C (with no icing or condensation)

25% to 85%

−25 to 65°C (with no icing or condensation)

Watertight packing, 2 fixtures, terminal cover, unit stickers, instruction manual. DeviceNet models also include a DeviceNet connector (Hirose HR31-5.08P-5SC(01)) and crimp terminals (Hirose HR31-SC-121) (See note 3.)

2

Page 3

■ Characteristics

Mode Input frequency

range

ON/OFF

pulse width

ON voltage OFF voltage Input

impedance

F1 0 to 30 kHz 16 μs min. 4.5 to 30 V −30 to 2 V 10 kΩ

F2 0 to 25 kHz 20 μs min.

F3 0 to 50 kHz 9 μs min.

Mode Input frequency

range

ON/OFF

pulse width

Note: The Up/Down Counting Pulse

Meter will malfunction if a pulse

greater than the input frequency

range is input. SYSERR may

appear on the display.

F1 0 to 30 kHz 16 μs min.

F2 0 to 25 kHz 20 μs min.

F3 0 to 50 kHz 9 μs min.

Display range −19,999 to 99,999

Measurement range Functions F1, F2: ±2 gigacounts

Functions F3: 0 to 4 gigacounts

Input signals • Contact input (dry contact input) (30 Hz max. with ON/OFF pulse width of 15 ms min.)

• No contact

voltage pulse

• Open collector

K3HB-C

Connectable sensors ON residual voltage: 3 V max.

Max. No. of display digits 5 (−19999 to 99999)

Comparative output response

time

Linear output response time 10 ms max. (time until the final analog output value is reached when there is a forced sudden change in the

Insulation resistance 20 MΩ min. (at 500 VDC)

Dielectric strength 2,300 VAC for 1 min between external terminals and case

Noise immunity 100 to 240 VAC models:

Vibration resistance

Shock resistance

Weight Approx. 300 g (Base Unit only)

Degree of

protection

Memory protection EEPROM (non-volatile memory)

Applicable standards UL61010-1, CSA C22.2 No. 61010-1-04

EMC EMI: EN61326 industrial applications

Front panel Conforms to NEMA 4X for indoor use (equivalent to IP66)

Rear case IP20

Termi nal s IP00 + finger protection (VDE0106/100)

OFF leakage current: 1.5 mA max.

Load current: Must have a switching capacity of 20 mA or higher.

1 ms max.: Transistor output; 10 ms max.: Relay contact output

(time until the comparative output is made when there is a forced sudden change in the input signal from 15%

to 95% or 95% to 15%)

input signal from 15% to 95% or 95% to 15%)

±1,500 V at power supply terminals in normal or common mode

(waveform with 1-ns rising edge and pulse width of 1 μs/100 ns)

24 VAC/VDC models:

±1,500 V at power supply terminals in normal or common mode

(waveform with 1-ns rising edge and pulse width of 1 μs/100 ns)

Frequency: 10 to 55 Hz; Acceleration: 50 m/s

2

150 m/s

Number of rewrites: 100,000

EN61010-1 (IEC61010-1): Pollution degree 2/Overvoltage category II

EN61326-1

Electromagnetic radiation interference

Terminal interference voltage

EMS: EN61326 industrial applications

Electrostatic Discharge Immunity

Radiated Electromagnetic Field Immunity

Electrical Fast Transient/Burst Noise Immunity

Surge Immunity

Conducted Disturbance Immunity

Power Frequency Magnetic Immunity

Voltage Dips and Interruptions Immunity

(100 m/s2 for relay outputs) 3 times each in 3 axes, 6 directions

CISPR 11 Group 1, Class A

CISPR 11 Group 1, Class A

EN61000-4-2: 4 kV (contact), 8 kV (in air)

EN61000-4-3: 10 V/m sine wave amplitude modulation (80 MHz to 1 GHz, 1.4 to 2 GHz)

EN61000-4-4: 2 kV (power line), 1 kV (I/O signal line)

EN61000-4-5: 1 kV with line (power line), 2 kV with ground (power line)

EN61000-4-6: 3 V (0.15 to 80 MHz)

EN61000-4-8: 30 A/m (50 Hz) continuous time

EN61000-4-11: 0.5 cycle, 0°/180°, 100% (rated voltage)

Must be able to properly switch load currents of 5 mA or less.

2

, 10 sweeps of 5 min each in X, Y, and Z directions

3

Page 4

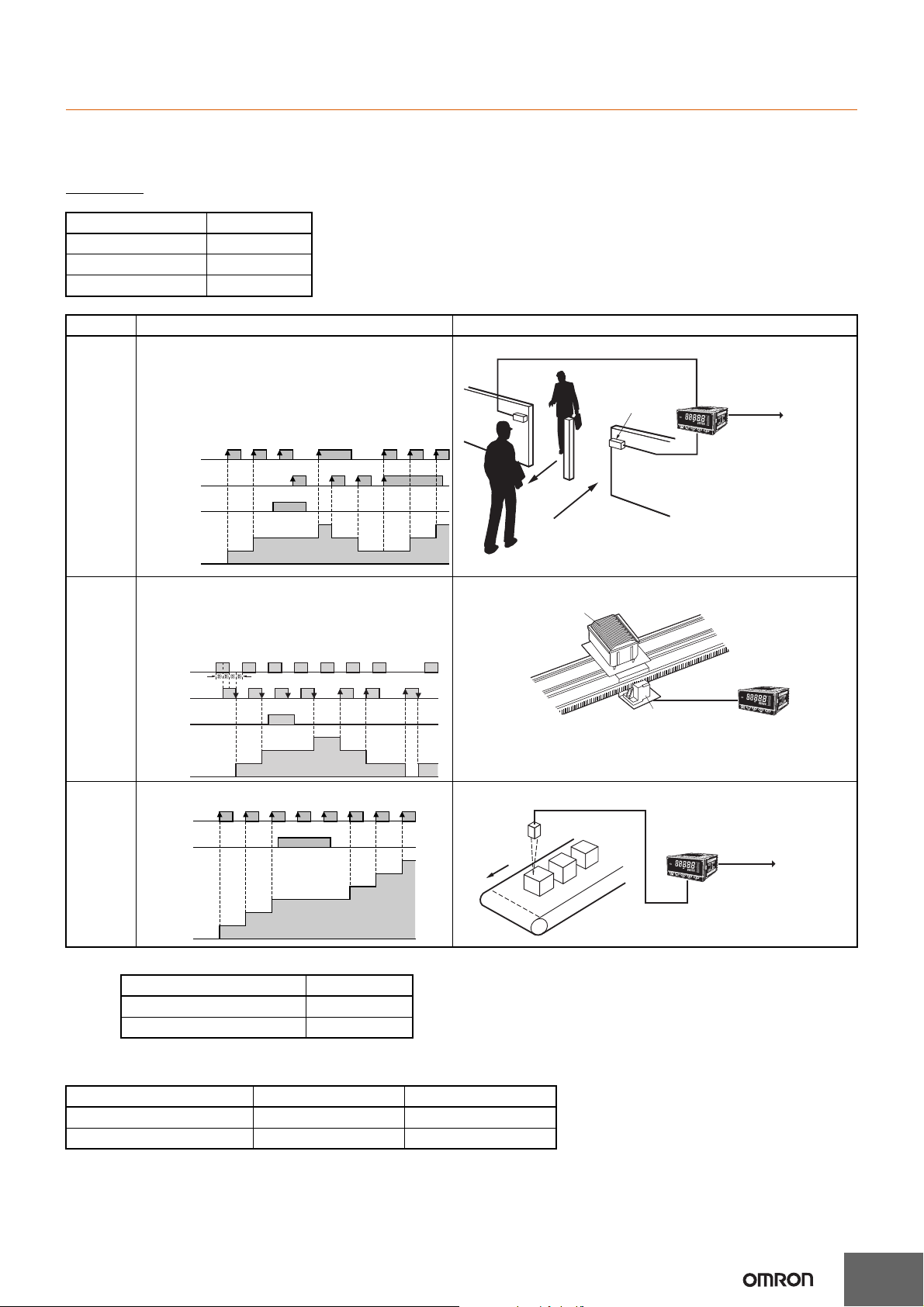

Operation

Input A

Input B

HOLD input

L

H

L

H

L

H

Count

0

1

2

3

2

11

2

3

Wafer

Input A

HOLD

input

L

H

L

H

Count

0

1

2

3

4

5

6

■ Functions (Operating Modes)

F1 to F3

Function name Function No.

Individual inputs f1

Phase differential inputs f2

Pulse counting input f3

Function Operation Operation image (application)

F1

Individual

inputs

Counts input A as incremental pulses and input B as

decremental pulses. The count is incremented on the

rising edge of input A and decremented on the rising

edge of input B. If both inputs rise at the same time, the

count is not changed. The count is incremented when

input B is later than input A and decremented when input

B is earlier than input A.

Counting the number of people entering an area

Input A

Input B

Increment

Photoelectric

sensor

BCD output

K3HB-C

To

Programmable

Controller

Decrement

F2

Phase differential inputs

This function is normally used when connected to an

incremental rotary encoder. The count is incremented on

the falling edge of input B when input A is OFF. The count

is decremented on the rising edge of input B when input

Detecting position and speed on a semiconductor wafer conveyor line

A is OFF.

H

Input A

F3

L

H

Input B

L

HOLD

H

input

L

Count

Counted on the rising edge of input A Counting the number of workpieces

(See note 2.)

3

2

1

0

2

11

0

Pulse

counting

input

Note: 1. Meaning of H and L in Display

Symbol Input method No-voltage input

H Short-circuit

L Open

2. Requires at least half the minimum signal width. If there is less than half, a ±1 count error may occur.

Input Type Setting

NO: Voltage pulse high NC: Voltage pulse low

No-contact or voltage pulse input 00 01

Contact 10 11

E6L

BCD output

To

Programmable

Controller

4

Page 5

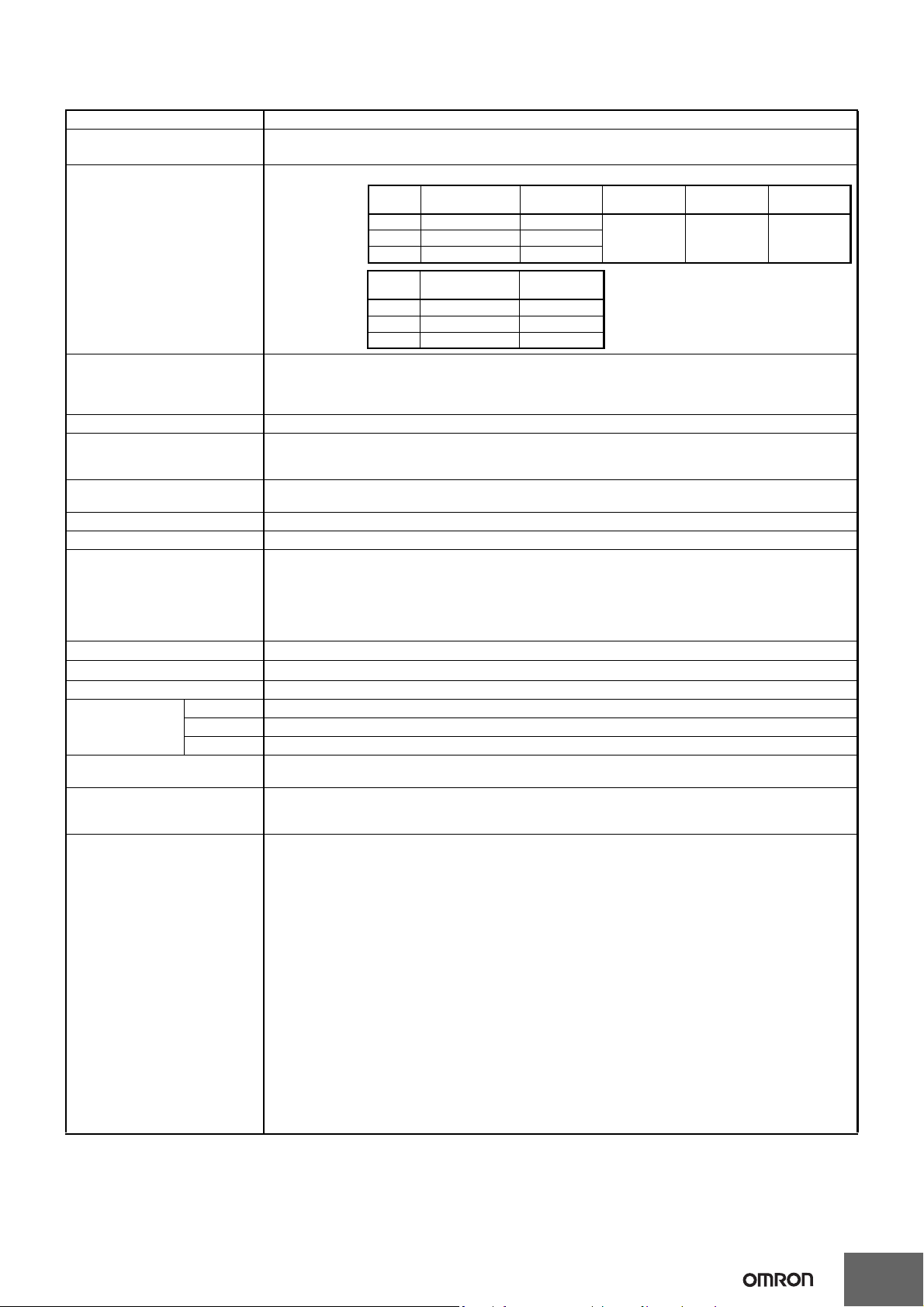

■ What Is Prescaling?

K3HB-C

Encoder

0.5 m

250 pulses

Prescaling converts the count value to any numeric value.

To d i sp l ay @@@@.@ mm in a system that outputs 250 pulses for a 0.5-m feed,

the length per pulse = 500 mm (0.5 m) ÷ 250 = 2.

1. The prescale value for the K3HB-C is set using the mantissa X × exponent Y,

so the prescale value = 2.0000 × 10°,

X = 2.000, and Y = 00.

2. Next, set the decimal point position for one digit to the right of the decimal point:

K3HB-C

5

Page 6

Common Specifications

■ Event Input Ratings

K3HB-P/-C HOLD, RESET, BANK1, BANK2, BANK4

Contact ON: 1 kΩ max., OFF: 100 kΩ min.

No-contact

■ Output Ratings

Contact Output Transistor Outputs

Rated load 5 A at 250 VAC

Rated through

current

Mechanical life

expectancy

Electrical life

expectancy

ON residual voltage: 2 V max.

OFF leakage current: 0.1 mA max.

Load current: 4 mA max.

Maximum applied voltage: 30 VDC max.

Item

Resistive loads

(250 VAC, cosφ=1;

30 VDC, L/R=0 ms)

5 A at 30 VDC

5 A

5,000,000 operations

100,000 operations

Inductive loads

(250 VAC, closed

circuit, cosφ=0.4;

30 VDC, L/R=7 ms)

1 A at 250 VAC

1 A at 30 VDC

Maximum load voltage 24 VDC

Maximum load current 50 mA

Leakage current 100 μA max.

K3HB-C

Linear Output

Item Outputs 0 to 20 mA 4 to 20 mA 0 to 5 V 1 to 5 V 0 to 10 V

Allowable load impedance 500 Ω max. 5 kΩ min.

Resolution Approx. 10,000

Output error ±0.5% FS ±0.5% FS

(±0.15 V for 1 V or less and no output for 0 V)

Serial Communications Output BCD Output I/O Ratings

Item Type RS-232C, RS-485

Communications method Half duplex

Synchronization method Start-stop synchronization (asynchronous)

Baud rate 9600/19200/38400 bps

Transmission code ASCII

Data length 7 bits or 8 bits

Stop bit length 2 bits or 1 bit

Error detection Vertical parity and FCS

Parity check Odd, even

(Input Signal Logic: Negative)

I/O signal name Item Rating

Inputs REQUEST

Outputs DATA

CCOMPENSATION

RESET

POLARITY

OVER

DATA VALID

RUN

OUT1

OUT2

OUT3

OUT4

OUT5

Input signal No-voltage

Input current for no-voltage input 10 mA

Signal level ON voltage 1.5 V max.

OFF voltage 3 V min.

Maximum load voltage 24 VDC

Maximum load current 10 mA

Leakage current 100 μA max.

Maximum load voltage 24 VDC

Maximum load current 50 mA

Leakage current 100 μA max.

contact input

Refer to the K3HB Communications User's Manual (Cat. No. N129)

for details on serial and DeviceNet communications.

6

Page 7

DeviceNet Communications

Baud rate Network length

(max.)

Drop line length

(max.)

Total drop line length

(max.)

500 Kbps 100 m max.

(100 m max.)

6 m max. 39 m max.

250 Kbps 100 m max.

(250 m max.)

6 m max. 78 m max.

125 Kbps 100 m max.

(500 m max.)

6 m max. 156 m max.

Communications protocol

Supported

communications

Connection methods Combination of multi-drop and T-branch connections (for trunk and drop lines)

Baud rate DeviceNet: 500, 250, or 125 Kbps (automatic follow-up)

Communications media Special 5-wire cable (2 signal lines, 2 power supply lines, 1 shield line)

Communications distance

Communications power supply 24-VDC DeviceNet power supply

Allowable voltage fluctuation range 11 to 25-VDC DeviceNet power supply

Current consumption 50 mA max. (24 VDC)

Maximum number of nodes 64 (DeviceNet Configurator is counted as one node when connected.)

Maximum number of slaves 63

Error control checks CRC errors

DeviceNet power supply Supplied from DeviceNet communications connector

Remote I/O

communications

I/O allocations

Message

communications

Conforms to DeviceNet

Master-Slave connection (polling, bit-strobe, COS, cyclic)

Conforms to DeviceNet communications standards.

Allocate any I/O data using the Configurator.

Allocate any data, such as DeviceNet-specific parameters and variable area for Digital Indicators.

Input area: 2 blocks, 60 words max.

Output area: 1 block, 29 words max.

(The first word in the area is always allocated for the Output Execution Enabled Flags.)

Explicit message communications

CompoWay/F communications commands can be executed

(using explicit message communications)

The values in parentheses are for Thick Cable.

K3HB-C

7

Page 8

Connections

The BCD COMMON is shared.

The pins indicated in the above diagram

as blank (white) boxes have been removed.

*

Only one of the following can be used for each Digital Indicator: communications, BCD, or DeviceNet.

DeviceNet Connector (Included)

<DRT>

1 2 3 4 5

Relay Outputs

<C2>

Relay Outputs

<C1>

Transistor Outputs

<T1> <T2>

NPN

PNP

HH

H

PA SS

L

LL

COM

C1

C2

C3

C4

C5

C6

RS-232C

<FLK1A>

RS-485

<FLK3A>

B1

B2

B3

B4

B5

B6

B1

B2

B3

B4

B5

B6

B1

B2

B3

B4

B5

B6

<L2A> <L1A>

+

−

+

−

SD

RD

SG

N/C

12 VDC

80 mA

B (+)

A (−)

B (+)

A (−)

12 VDC

80 mA

12 VDC

80 mA

12 VDC

80 mA

0-20/

4-20 mA

N/C

0-5/1-5/

0-10 V

N/C

<A>

12 VDC

80 mA

+

−

+

−

+

−

<CPA>

12 VDC

80 mA

N/C

N/C

PA SS

Sensor

power

supply

B1

B2

B3

B4

B5

B6

HH

H

COM

L

H

L

LL

COM

C1

C2

C3

C4

C5

C6

C1

C2

C3

C4

C5

C6

Sensor

power

supply

Sensor

power

supply

Sensor power supply + communications

Sensor power supply

Sensor

power

supply

ABCDE

1

2

3

4

5

6

100 to 240 VAC

24 VAC/VDC

A1

A2

HH

H

L

LL

PASS

BCD (NPN Open Collector): <BCD>

Applicable Connector (Sold separately)

HDR-E50MAG1

(HONDA TSUSHIN KOGYO CO., LTD.)

Special Cable (Sold separately)

K32-BCD (OMRON)

(HDR-E50MAG1 with 0.3-m cable)

5 V

HH

H

L

LL

PA SS

A Operating Power Supply

*Check the required power supply type.

Sensor power supply + PASS output

Sensor power supply + linear output

B Sensor Power Supply/Output

C

Relays, Transistors, BCD and DeviceNet

1: V− (Power supply cable: Black)

2: CAN L (Communications cable: Blue)

3: Shield

4: CAN H (Communications cable: White)

5: V+ (Power supply cable: Red)

Applicable Connector:

HR31-5.08P-5SC (01)

(HIROSE ELECTRIC CO., LTD.)

* Attach the provided crimp terminals.

Contact Outputs Transistor Outputs

(NPN Open Collector)

Safety Standards Conformance

Always use a EN/IEC-compliant power supply with reinforced insulation or double

insulation for the DeviceNet power supply.

The product must be used indoors for the above applicable standards to apply.

■ External Connection Diagrams

Terminal Arrangements

Note: Refer to Internal Block Diagram on page 10 for information on isolation.

K3HB-C

8

Page 9

K3HB-C

Models with Terminal Blocks

<1> <3>

1: N/C

3: HOLD

5:

COMPENSATION

7: BANK4

9: BANK1

2: S-TMR

4: RESET

6: COM

8: BANK2

10: COM

Models with Connectors

<2> <4>

2

10

1

9

E3

E2

E1

E6

E5

E4

COM

COM

• Use terminal pin D6 as the common terminal.

• Use NPN open collector or no-voltage contacts

for event input.

PNP types are also available.

• Up/Down Counting Pulse Meter:

K3HB-C

E3

E2

E1

E6

E5

E4

COM

COM

E Pulse Inputs

D6

3.9 kΩ

4.7 kΩ

HOLD: D3

RESET: D4

COMPENSATION: D5

12 V

COM

NPN

PNP

Input A

Voltage

NPN

PNP

Input B

Voltage

D Event Inputs

NPN Input:

K3HB-@NB

Input A

Input B

PNP Input:

K3HB-@PB

Note: E3 and E6,

as well as B6,

are internally

connected.

Note: A 2-wire DC sensor can also be connected. Check the ratings and characteristics tables,

however, for the connection conditions.

Note: The actual terminal label abbreviates "COMPENSATION" to "CMP."

Note: E3 and E6, as

well as B5,

are internally

connected.

COM

E3, E6

E2, E5

700 Ω

510 Ω

12 V

E3, E6

E1, E4

10 kΩ

700 Ω

510 Ω

12 V

NPN Input Model

•

NPN input section

•

Voltage pulse input section

• Applicable Connector (Sold separately)

XG4M-1030 (OMRON)

• Special Cable (Sold separately)

K32-DICN (OMRON)

(XG4M-1030 with 3-m cable)

N/C

COMPENSATION

HOLD

COM

N/C

RESET

Connectable

Sensors

ON residual voltage: 3 V

OFF leakage current:

1.5 mA max.

Connectable

Sensors

ON voltage: 4.5 to 30 V

OFF voltage: -30 to 2 V

38 mm 46.5 mm

300 mm

K3HB end

Connected device end

(PLC, display device, etc.)

Cover: HDR-E50LPA5

(manufactured by Honda Tsushin Co., Ltd.)

Connector: HDR-E50MAG1

(manufactured by Honda Tsushin Co., Ltd.)

D-sub connector (37-pin female)

Cover: 17JE-37H-1A (manufactured by DDK)

Connector: Equivalent to 17JE-13370-02

(manufactured by DDK)

Stud: 17L-002A (manufactured by DDK)

Pin No.

1

2

3

4

5

6

7

8

9

10

Signal name

N/C

S-TMR

HOLD

RESET

N/C

COM

BANK4

BANK2

BANK1

COM

BCD Output Cable

Model Shape Pin arrangement

K32-BCD

Note: The BCD Output Cable has a D-sub plug. Cover: 17JE-37H-1A (manufactured by DDK); Connector: equivalent to 17JE-23370-02 (D1)

(manufactured by DDK)

Special Cable (for Event Inputs with 8-pin Connector)

Model Appearance Wiring

K32-DICN

910

12

Cable marking

3,000 mm

(3 m)

COMMON

1

20

4

2

1

21

8

3

2

0

22

10

4

4

23

5

8

24

6

1

25

7

7

2

1

26

10

8

4

27

9

8

28

10

1

29

11

2

2

30

10

12

4

31

13

8

32

14

1

33

15

2

3

34

10

16

4

35

17

8

36

18

1

4

37

10

19

2

4

10

OVER

DATA VALID

RUN

COMMON

REQUEST

MAX REQ.

MIN REQ.

HOLD

RESET

POLARITY

HH

H

PA SS

L

LL

COMMON

9

Page 10

■ Derating Curve for Sensor Power Supply (Reference Values)

140

120

100

80

60

40

20

0

−20 −100 102030405060

Ambient temperature (°C)

Maximum current (mA)

1

Keys

Micro-

computer

Waveform

shaping circuit

Waveform

shaping circuit

Drive

circuit

Indications

EEPROM

Drive

circuit

Digital input

circuit

Linear output

circuit

Filter

Pulse input

circuit

BCD

• Input circuit

• Output circuit

• Transistor

output circuit

Drive

circuit

Drive

circuit

Drive

circuit

Drive

circuit

Transistor

output

Relay output

Pulse input

BCD I/O

Event input

Linear output

Sensor power

supply

DeviceNet

Communications

DeviceNet

circuit

Communi-

cations

driver

X

Power supply

Power supply circuit (isolated)

V

DD

V

COM

V

O

DC-DC

Converter (isolated)

V

O

For 12V

K3HB-C

Note: 1. The above values were obtained under test conditions with the standard mounting. The derating curve will vary with the mounting

conditions, so be sure to adjust accordingly.

2. Internal components may be deteriorated or damaged. Do not use the Digital Indicator outside of the derating range (i.e., do not use it in

the area labeled A, above).

■ Internal Block Diagram

10

Page 11

■ BCD Output Timing Chart

Approx.

30 ms

All data "High" All data "High"

40 ms

16 ms

Data

REQ.

MAX.MIN.

DATA

DATA

VALID

20-ms pulse min. (50 ms max.)

K3HB

(1)

Programmable

Controller

K3HB

(2)

K3HB

(3)

DATA (including POL and

OVER) and DATA VALID can

be used in a wired OR.

RUN, HH, H, PASS, L, and

LL are always output, with or

without a REQUEST signal.

Do not used a wired OR

connect for these signals.

DATA

REQ. (1)

(1) (2) (3)

REQ. (2)

REQ. (3)

DATA

VALID

Note: Leave 20 ms min. between DATA VALID turning OFF and the REQUEST signal.

(See note.) (See note.)

(See note.)

• The K3HB BCD output model has an open collector output, so wired OR connection is possible

Programmable Controller Connection Example

Digital Indicator

SYSMAC Programmable Controller

DC Input Unit

1.COMMON

Connector pin No. (See note.)

COM

IN

IN

IN

IN

IN

IN

OUT

OUT

COM

24 VDC

(0 V)

2.1

3.2

4.4

5.8

23.DATA VALID

24.RUN

25.COMMON

26.REQUEST

30.RESET

31.POLARITY

(+/− polarity)

10°

240 Ω

240 Ω

240 Ω

240 Ω

+5 V

+24 V

0 V

DC power

supply

Transistor Output Unit

Internal circuit

Internal circuit

Internal circuit

Display Unit Connection Example

To 10

2

<M7E Digital Display Unit>

V

O

SEC

Digital Indicator

1.COMMON

Connector pin No. (See note.)

2.1

3.2

4.4

5.8

23.DATA VALID

24.RUN

25.COMMON

26.REQUEST

30.RESET

M7E-01D@N2, 01H@N2

31.POLARITY

(+/− polarity)

10°

To 10

1

240 Ω

240 Ω

240 Ω

240 Ω

+5 V

V

O

D

C

B

A

DP

LE

8

V

O

D

C

B

A

DP

LE

8

V

O

D

C

B

A

DP

LE

8

Shortcircuit

Note: The BCD output connector pin number is the D-sub connector pin number when

the BCD Output Cable (sold separately) is connected. This number differs from

the pin number for the Digital Indicator narrow pitch connector (manufactured by

Honda Tsushin Kogyo Co., Ltd.).

Refer to the following User's Manual for application precautions and other information required when using the Digital Indicator:

K3HB-R/P/C Digital Indicator User's Manual (Cat. No. N136)

The manual can be downloaded from the following site in PDF format: OMRON Industrial Web http://www.fa.omron.co.jp

A REQUEST signal from a Programmable Controller or other external device is required to read BCD data.

K3HB-C

Single Sampling Data Output

The data is set in approximately 30 ms from the rising edge of the

REQUEST signal and the DATA VALID signal is output.

When reading the data from a Programmable Controller, start

reading the data when the DATA VALID signal turns ON.

The DATA VALID signal will turn OFF 40 ms later, and the data will

turn OFF 16 ms after that.

Continuous Data Output

REQ.

MAX.MIN.

DATA

All data "High"

DATA

VALID

Approx.

30 ms

Measurement data is output every 64 ms while the REQUEST signal

remains ON.

Note: If HOLD is executed when switching between data 1 and data

2, either data 1 or data 2 is output depending on the timing of

the hold signal. The data will not go LOW.

Data 1 Data 2

40 ms 40 ms

24 ms 24 ms

64 ms 64 ms

11

Page 12

■ Component Names and Functions

K3HB-C

Max./Min. status indicator

Turns ON when the maximum value or minimum

value is displayed in the RUN level.

Level/bank display

In RUN level, displays the bank if the bank function is

ON. (Turns OFF if the bank function is OFF.)

In other levels, displays the current level.

Comparative output

status indicators

Display the status of comparative

outputs.

Status indicators

Display

CMW

Hold

Lit when communications writing is ON

(enabled) and not lit when OFF (prohibited).

Turns ON/OFF when hold input turns

ON/OFF.

Function

HH

H

P

L

LL

MAX/MIN

Max

Min

B

L

CMW

Hold

HH H

T LL L

SHIFT

UP MODE LEVEL

5 4 3

T 1 2

PV display

Displays PVs, maximum values,

minimum values, parameter

names, and error names.

Position meter

Displays the position of the PV

with respect to a desired scale.

SV display

Displays SV and monitor values.

SV display status indicators

Indicator

Turns ON when parameters for which

teaching can be performed are

T

displayed.

In RUN level, turn ON when the

5, 4, 3,

comparative set value 1, 2, 3, 4, or 5 is

2, 1

displayed.

Function

MAX/MIN Key LEVEL Key MODE Key SHIFT Key UP Key

display between the PV,

maximum value, and

minimum value and to

reset the maximum and

minimum values.

Used to switch level.Used to switch the

Used to switch the

parameters displayed.

Used to change

parameter settings.

When changing a set

value, this key is used

to move along the

digits.

When changing a set

value, this key is used

to change the actual

value.

12

Page 13

■ Dimensions

Character Size for Main Display (mm)

Terminal: M3, Terminal Cover: Accessory

Terminal cover (included)

PV display SV display

14.2

4.9

3.5

7.6

96

48

1.3

12

(112)

100

101.2

91

2

44.8

Panel Cutout Dimensions

45

+0.6

0

92

+0.8

0

75 min.

*1. DeviceNet models: 97 mm

*2. Leave a distance of at least 140 mm when using the Wate

Cover Y92A-49N.

95 *1

120 min. *2

Note: Mounting Recommended Panel Thickness

1 to 8 mm.

Mount the product horizontally.

5.8 mm max.

5.8 mm max.

10°

30°

Watertight Cover

Y92A-49N

Rubber Packing

K32-P1

If the rubber packing is lost or damaged, it can be ordered

using the following model number: K32-P1.

(Depending on the operating environment, deterioration, contraction, or hardening of the rubber packing may occur and so,

in order to ensure the level of waterproofing specified in

NEMA4, periodic replacement is recommended.)

Note: Rubber packing is provided with the Controller.

K3HB-C

Wiring Precautions

• For terminal blocks, use the crimp terminals suitable for M3 screws.

• Tighten the terminal screws to the recommended tightening torque

of approx. 0.5 N·m.

• To prevent inductive noise, separate the wiring for signal lines from

that for power lines.

Wiring

• Use the crimp terminals suitable for M3 screws shown below.

Unit Stickers (included)

• No unit stickers are attached to the Digital Indicator.

• Select the appropriate units from the unit sticker sheets provided.

Mounting Method

1. Insert the K3HB into the mounting cutout in the panel.

2. Insert watertight packing around the Unit to make the mounting

watertight.

Watertight

packing

3. Insert the adapter into the grooves on the left and right sides of

the rear case and push until it reaches the panel and is fixed in

place.

Adaptor

LCD Field of Vision

The K3HB is designed to have the best visibility at the angles shown

in the following diagram.

Note: For measurements for commercial purposes, be sure to use

the unit required by any applicable laws or regulations.

13

Page 14

Main Functions

■ Main Functions and Features

K3HB-C

Measurement

Function

The K3HB-R has the following six functions for receiving and

displaying input pulses.

F1: Rotation (rpm)/circumferential speed

F2: Absolute ratio

F3: Error ratio

F4: Rotational difference

F5: Flow rate ratio

F6: Passing time

The K3HB-P has the following six functions for receiving and

displaying input pulses.

F1: Passing speed

F2: Cycle

F3: Time difference

F4: Time band

F5: Measuring length

F6: Interval

The K3HB-C has the following three functions for receiving and

displaying input pulses.

F1: Individual inputs

F2: Phase differential inputs

F3: Pulse counting input

func

Outputs

Comparative Output Pattern

Zone and level comparative output patterns can be selected for

comparative outputs.

Output OFF Delay

Delays turning OFF comparatives for a set period. This can be used

to provide sufficient time to read the comparative output ON status

when the comparative result changes at short intervals.

Shot Output

Turns ON the comparative output for a specific time.

Output Logic

Reverses the output logic of comparative results.

Output Test

Output operation can be checked without using actual input signals

by using the keys to set a test measurement value.

Linear Outputs lset.c, lset.v, lset.h, lset.l

A current or voltage proportional to the change in the measurement

value can be output.

out-p

off-d

shot

out-n

test

Filters

Input Types

Specify the types of sensor connected to input A and input B.

in-ta, in-tb, in-ta

Compensation

Compensation

The display can be changed to a preset compensation value using

the compensation input.

compn, com-p

Key Operations

Teaching

The present measurement value can be used as a scaling value.

Key Protection

Key protection restricts level or parameter changes using the keys to

prevent unintentional key operations and malfunctions.

Standby Sequence

The comparison outputs can be kept OFF until the measurement

value enters the PASS range.

stdby

14

Page 15

K3HB-C

In the interest of product improvement, specifications are subject to change without notice.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Display

Display Value Selection

The display value can be set to the present value, the maximum

value, or the minimum value.

Display Color Selection

The present value display color can be set to green or red. The color

of the present value can also be switched according to the

comparative output.

Display Refresh Period

When the input changes rapidly, the display refresh period can be

lengthened to control flickering and make the display easier to read.

Position Meter

The present measurement value can be displayed as a position in

relation to the scaling width on a 20-gradation position meter.

Prescale ps.ax, ps.ay, ps.bx, ps.by

The input signal can be converted and displayed as any value.

Comparative Set Value Display

Select whether or not to display the comparative value during

operation.

disp

color

d.ref

pos-t, pos-h, pos-l

sv.dsp

Other

Bank Selection

Switch between 8 comparative value banks using the keys on the

front panel or external inputs. A set of set comparative values can be

selected as a group.

Bank Copy

Any bank settings can be copied to all banks.

Interruption Memory

The measured value can be recorded when the power supply is

interrupted.

bnk-c

copy

memo

Display auto-return

Automatically returns the display to RUN level when there are no key

operations (e.g., max./min. switching, bank settings using keys).

ret

15

Page 16

Terms and Conditions Agreement

Read and understand this catalog.

Please read and understand this catalog before purchasing the products. Please consult your OMRON representative if you

have any questions or comments.

Warranties.

(a) Exclusive Warranty. Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship

for a period of twelve months from the date of sale by Omron (or such other period expressed in writing by Omron). Omron

disclaims all other warranties, express or implied.

(b) Limitations. OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF THE PRODUCTS. BUYER

ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based on infringement by the

Products or otherwise of any intellectual property right. (c) Buyer Remedy. Omron’s sole obligation hereunder shall be, at

Omron’s election, to (i) replace (in the form originally shipped with Buyer responsible for labor charges for removal or

replacement thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount

equal to the purchase price of the non-complying Product; provided that in no event shall Omron be responsible for warranty,

repair, indemnity or any other claims or expenses regarding the Products unless Omron’s analysis confirms that the Products

were properly handled, stored, installed and maintained and not subject to contamination, abuse, misuse or inappropriate

modification. Return of any Products by Buyer must be approved in writing by Omron before shipment. Omron Companies shall

not be liable for the suitability or unsuitability or the results from the use of Products in combination with any electrical or

electronic components, circuits, system assemblies or any other materials or substances or environments. Any advice,

recommendations or information given orally or in writing, are not to be construed as an amendment or addition to the above

warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc.

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED IN CONTRACT, WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on which liability is asserted.

Suitability of Use.

Omron Companies shall not be responsible for conformity with any standards, codes or regulations which apply to the

combination of the Product in the Buyer’s application or use of the Product. At Buyer’s request, Omron will provide applicable

third party certification documents identifying ratings and limitations of use which apply to the Product. This information by itself

is not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine,

system, or other application or use. Buyer shall be solely responsible for determining appropriateness of the particular Product

with respect to Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY OR IN LARGE

QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS,

AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE

OVERALL EQUIPMENT OR SYSTEM.

Programmable Products.

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or any consequence

thereof.

Performance Data.

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for the user in determining

suitability and does not constitute a warranty. It may represent the result of Omron’s test conditions, and the user must correlate

it to actual application requirements. Actual performance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications.

Product specifications and accessories may be changed at any time based on improvements and other reasons. It is our

practice to change part numbers when published ratings or features are changed, or when significant construction changes are

made. However, some specifications of the Product may be changed without any notice. When in doubt, special part numbers

may be assigned to fix or establish key specifications for your application. Please consult with your Omron’s representative at

any time to confirm actual specifications of purchased Product.

Errors and Omissions.

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is

assumed for clerical, typographical or proofreading errors or omissions.

In the interest of product improvement, specifications are subject to change without notice.

2014.9

OMRON Corporation

Industrial Automation Company

http://www.ia.omron.com/

(c)Copyright OMRON Corporation 2014 All Right Reserved.

Page 17

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Omron:

K3HB-CNB 24VAC/VDC K3HB-CNB 100-240VAC

Loading...

Loading...