Page 1

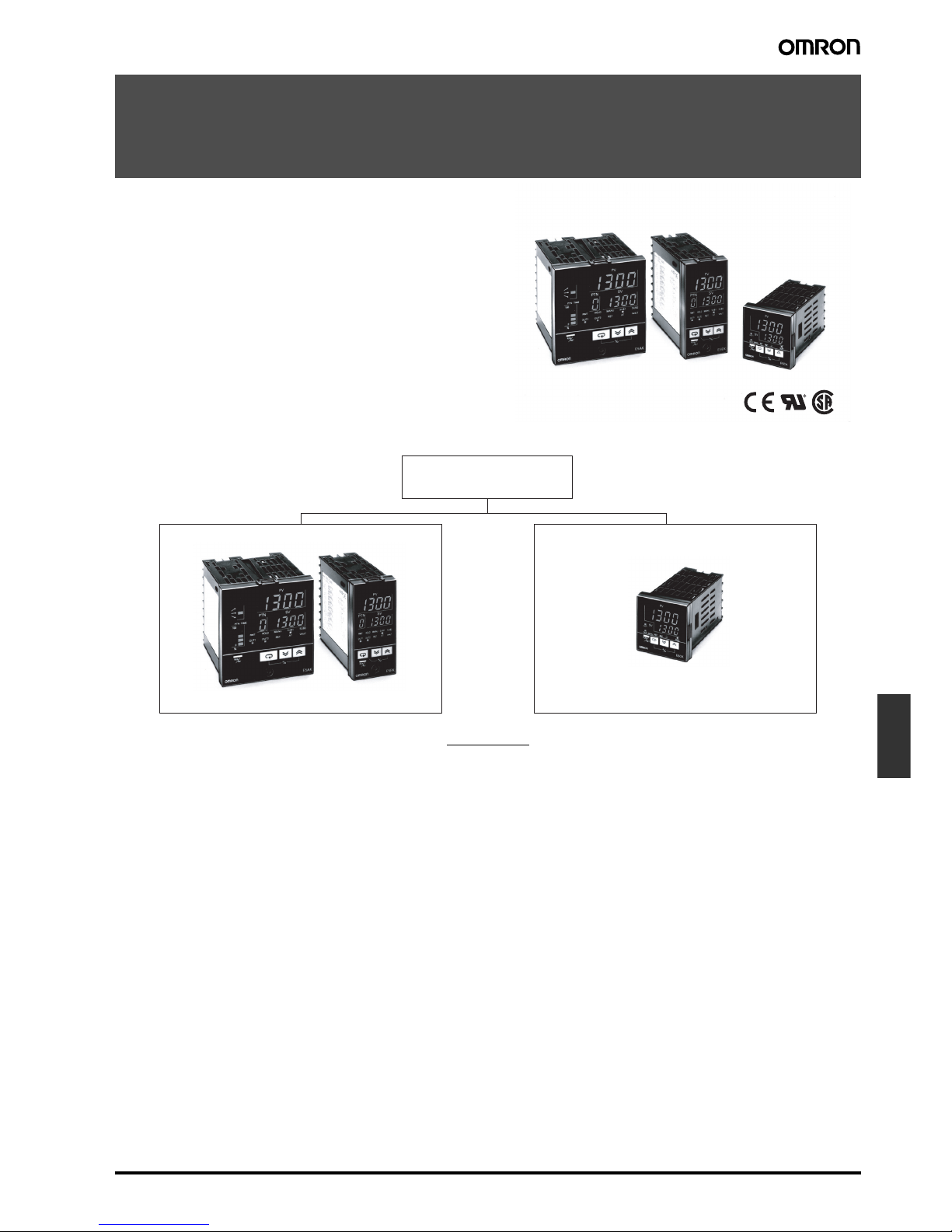

Digital Controller E5@K-T I-123

Temperature

Controller

Digital Controller

E5@K-T

The E5@K-T Programmable Type Digital

Controllers Expand the Variety of E5@K

Digital Controllers and are Available in Three

Sizes (1/4, 1/8, and 1/16 DIN).

®

Contents

Digital Controllers

E5AK-T/E5EK-T ........................................... I-125

E5CK-T......................................................... I-127

E5@K-T Series

E5CK-TE5AK-T/E5EK-T

1/4 DIN 1/8 DIN

1/16 DIN

Page 2

I-124 Digital Controller E5@K-T

Compact and Easy-to-use Controllers

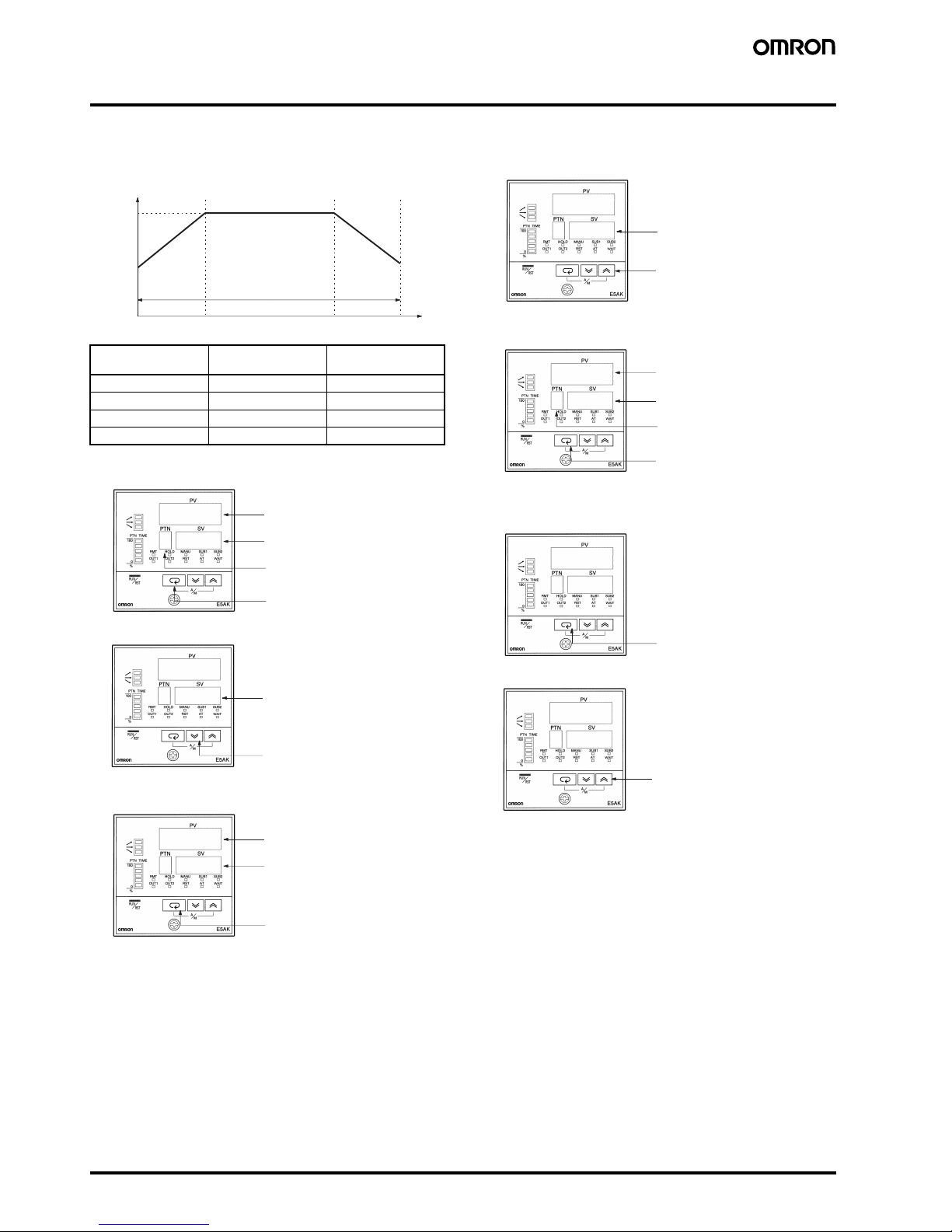

■ Programming is as easy as following the steps below.

Program can be set in pattern 0 according to the following procedure.

1. Press the Display Key to shift to the display for

the number of steps.

2. Press the Down Key and set the number of steps.

3. Press the Display Key to shift to the display for

the target value of step 0.

4. Set the target value to “50.”

5. Press the Display Key to shift to the display for

the time of step 0.

6. Press the Display Key again with the step time

set at 0 minutes, and the target value parameter

for step 1 will be displayed.

7. Press the Up Key to increment to “100.”

In the same manner, set the time for step 1, target

value for step 2, time for step 2, etc.

When the target value and time settings are

complete, press the Display Key.

Step No. Target value Time

(hours.minutes)

0 50 0.00

1 100 0.20

2 100 0.40

3 50 0.20

100

50

0.20 0.40 0.20

Step 1 Step 2 Step 3

SP

Time: hours and minutes

5-no

0 8

Pattern No.

Display key

Parameter for the number of

steps used

Number of steps

(Default setting: 8)

5-no

0 4

Four steps in this case

Down key

5p0

0 0

Display key

Step 0

Parameter of the target value

Target value

(Default setting: 0)

5p0

0 50

Target value

Up key

ti0

0 000

Time parameter for step 0.

Pattern No.

Display key

Step time

(Default setting: 0.00)

5p1

0 0

Display key

5p1

0 100

Up key

Page 3

Digital Controller E5AK-T/E5EK-T I-125

Temperature

Controller

Digital Controller

E5AK-T/E5EK-T

Advanced Programmable Digital Controllers

Ideal for Worldwide Use

• Offers up to eight patterns of simple programming control (16

steps per pattern).

• Modular structure, one-stock type

• High-accuracy: 100-ms sampling (for analog input)

• Conforms to international EMC and safety standards.

• IP66/NEMA4 (indoor use) front face

• Serial communications (RS-232C, RS-422 and RS-485) and

transfer output (4 to 20 mA)

• Position-proportional control model

• Heating/cooling control

• 24VAC/DC types are also available.

®

Model Number Structure

■ Model Number Legend

1. Size

A: 96 x 96 mm

E: 96 x 48 mm

C: 58 x 58 mm

2. Programmable type

T: Programmable type

3. Model

AA: Standard model

PRR: Position-proportional model

4. Number of alarms

2: Two alarms

Ordering Information

■ List of Models

Note: 1. When using the heater burnout alarm function with a standard model, the Linear Output Unit cannot be used for the control outputs (heat).

2. Be sure to specify the Current Transformer, Output Unit, and Option Unit when ordering.

1234

E5@K- T @@@ @ -500

Description Model Specification

Base Unit E5AK-TAA2 AC100-240 Standard model

E5AK-TAA2-500 AC100-240 Standard model with terminal cover

E5AK-TAA2 AC/DC24 Standard model

E5AK-TAA2-500 AC/DC24 Standard model with terminal cover

E5AK-TPRR2 AC100-240 Position-proportional model

E5AK-TPRR2-500 AC100-240 Position-proportional model with terminal cover

E5AK-TPRR2 AC/DC24 Position-proportional model

E5AK-TPRR2-500 AC/DC24 Position-proportional model with terminal cover

E5EK-TAA2 AC100-240 Standard model

E5EK-TAA2-500 AC100-240 Standard model with terminal cover

E5EK-TAA2 AC/DC24 Standard model

E5EK-TAA2-500 AC/DC24 Standard model with terminal cover

E5EK-TPRR2 AC100-240 Position-proportional model

E5EK-TPRR2-500 AC100-240 Position-proportional model with terminal cover

E5EK-TPRR2 AC/DC24 Position-proportional model

E5EK-TPRR2-500 AC/DC24 Position-proportional model with terminal cover

Page 4

I-126 Digital Controller E5AK-T/E5EK-T

Nomenclature

RUN/RST Key

Display Key

Display 1

Display 2

Operation indicators

Up Key/Down Key

Pattern Number

Operation Indicators

RUN/RST Key

Switches between RUN and RESET mode.

Display 1

Display 2

Up Key/Down Key

Pattern Number

Indicates the pattern number.

Display Key

Program Status Indicators

Bar Graph

E5AK

E5EK

The top indicator indicates the rising

step, the middle indicator indicates the

constant step, and the bottom indicator

indicates the falling step.

Indicates the rate of pattern elapsing time at the rate of 20% (5 levels) per one segment.

• OUT1

Lights when the pulse output function

assigned to control output 1 turns ON.

• OUT2

Lights when the pulse output function

assigned to control output 2 turns ON.

• SUB1

Lights when the output function assigned

to auxiliary output 1 turns ON.

• SUB2

Lights when the output function assigned

to auxiliary output 2 turns ON.

• MANU

Lights when the manual operation mode.

• RST

Lights when the operation is reset.

• RMT

Lights during remote operation.

• AT

Flashes during auto-tuning.

• HOLD

Lights when the program is on hold.

• WAIT

Lights when the program is waiting.

Press to shift the display to the

next parameter.

Press to increase or decrease

the value on the No.2 display.

Displays the present SP, manipulated variable, or parameter

settings.

Displays the process value or

parameter code.

Page 5

Digital Controller E5CK-T I-127

Temperature

Controller

Digital Controller

E5CK-T

Advanced, Compact Programmable Digital

Controllers Ideal for Worldwide Use

• Offers up to four patterns of simple programming control (16

steps per pattern).

• IP66/NEMA4 (indoor use) front face.

• Modular structure, one-stock type.

• Heating/cooling control.

• Serial communications (RS-232C and RS-485).

• Temperature and analog inputs.

• High-accuracy: 100-ms sampling (for analog input).

• Conforms to international EMC and safety standards.

• 24 VAC/DC types are also available.

®

Ordering Information

■ List of Models

Note: A single Output Unit and Option Unit can be mounted to each Base Unit.

Inspection Report

The Digital Controller can be provided together with an inspection report.

Refer to the following legend with the suffix “K” when ordering a model provided together with an inspection report.

E5CK-TAA1-K

■ Accessories (Order Separately)

Description Model Specification

Base Unit E5CK-TAA1 AC100-240 Standard model

E5CK-TAA1-500 AC100-240 Standard model with terminal cover

E5CK-TAA1 AC/DC24 Standard model

E5CK-TAA1-500 AC/DC24 Standard model with terminal cover

Description Model Specification

Output Unit E53-R4R4 Relay/Relay

E53-Q4R4 Pulse (NPN)/Relay

E53-Q4HR4 Pulse (PNP)/Relay

E53-C4R4 Linear (4 to 20 mA)/Relay

E53-C4DR4 Linear (0 to 20 mA)/Relay

E53-V44R4 Linear (0 to 10 V)/Relay

E53-Q4Q4 Pulse (NPN)/Pulse (NPN)

E53-Q4HQ4H Pulse (PNP)/Pulse (PNP)

Description Model Specification

Option Unit E53-CK01 RS-232C

E53-CK03 RS-485

E53-CKB Event input: 1 point

E53-CKF Transfer output (4 to 20 mA)

Name Model

Terminal Cover E53-COV07

Page 6

I-128 Digital Controller E5CK-T

Precautions

!WARNING

Do not touch any of the terminals while the power is being supplied.

Doing so may result in electric shock.

■ General Precautions

Be sure to observe these precautions to ensure safe use.

• Do not use the product in places where explosive or flammable

gases may be present.

• Never disassemble, repair or modify the product.

• Tighten the terminal screws properly.

• Use the specified size of solderless terminals for wiring.

• Use the product within the rated supply voltage.

• Use the product within the rated load.

• The life expectancy of the output relay varies considerably accord-

ing to its switching capacity and operating conditions. Be sure to

use the output relay within its rated load and electrical life expectancy. If the output relay is used beyond its life expectancy, its contacts may become fused or burned.

■ Correct Use

If you remove the Controller from its case, never touch nor apply

shock to the electronic parts inside.

Do not cover the E5@K-T. (Ensure sufficient space around the Controller to allow heat radiation.)

Do not use the Controller in the following places:

• Places subject to icing, condensation, dust, corrosive gas (espe-

cially sulfide gas or ammonia gas).

• Places subject vibration and large shocks.

• Places subject to splashing liquid or oil atmosphere.

• Places subject to intense temperature changes.

• Places subject to heat radiation from a furnace.

Be sure to wire properly with correct polarity of terminals.

When wiring input or output lines to the Controller, keep the following

points in mind to reduce the influence from inductive noise:

• Allow adequate space between the high voltage/current power

lines and the input/output lines.

• Avoid parallel or common wiring with high voltage sources and

power lines carrying large currents.

• Using separating pipes, ducts, and shielded line is also useful in

protecting the Controller, and its lines from inductive noise.

Cleaning: Do not use paint thinner or organic solvents. Use standard

grade alcohol to clean the product.

Use a voltage (100 to 240 VAC at 50/60 Hz, or 24 VDC). At power

ON, the prescribed voltage level must be attained within two seconds.

Allow as much space as possible between the Controller and devices

that generate a powerful high frequency (high-frequency welders,

high-frequency sewing machines, etc.) or surge. These devices may

cause malfunctions.

If there is a large power-generating peripheral device and any of its

lines near the Controller, attach a surge suppressor or noise filter to

the device to stop the noise affecting the Controller system. In particular, motors, transformers, solenoids and magnetic coils have an

inductance component, and therefore can generate very strong

noise.

When mounting a noise filter on the power supply to the Controller,

be sure to first check the filter’s voltage and current capacity, and

then mount the filter as close as possible to the Controller.

Use within the following temperature and humidity ranges:

• Temperature: –10°C to 55°C (with no icing or condensation)

Humidity: 35% to 85% (with no icing or condensation)

If the Controller is installed inside a control board, the ambient temperature must be kept to under 55°C, including the temperature

around the Controller.

If the Controller is subjected to heat radiation, use a fan to cool the

surface of the Controller to under 55°C.

Store within the following temperature and humidity ranges:

• Temperature: –25°C to 65°C (with no icing or condensation)

Humidity: 35% to 85% (with no icing or condensation)

Never place heavy objects on, or apply pressure to the Controller

that may cause it to deform and deteriorate during use or storage.

Avoid using the Controller in places near a radio, television set, or

wireless installing. These devices can cause radio disturbances

which adversely affect the performance of the Controller.

Mounting

The dimensions of the Digital Controller conform to DIN 43700.

Recommended panel thickness is 1 to 8 mm (1 to 5 mm for E5CK).

Mount the Unit horizontally.

Connection

To reduce inductive noise influence, the lead wires connecting the

input type to the Digital Controller must be separated from the power

lines and load lines.

Use the specified compensating conductors for thermocouples. Use

lead wires having a small resistance for platinum resistance thermometers.

Connection Example

Wire the terminals of the Unit using solderless terminals.

The tightening torque applied to the terminal screws of the Unit must

be approximately 0.78 N·m or 8 kgf·cm.

Use the following type of solderless terminals for M3.5 screws.

7.2 mm max.

7.2 mm max.

In the interest of product improvement, specifications are subject to change without notice.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. H087-E1-03

Loading...

Loading...