Page 1

E5J Temperature Controller

Operation Manual

Cat. No. Z103-E3-1

Page 2

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to the product.

DANGER Indicates information that, if not heeded, is likely to result in loss of life or serious

!

injury.

WARNING Indicates information that, if not heeded, could possibly result in loss of life or

!

serious injury.

Caution Indicates information that, if not heeded, could result in relatively serious or mi-

!

nor injury, damage to the product, or faulty operation.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 1998

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Note Indicates information of particular interest for efficient and convenient operation

of the product.

1, 2, 3...

1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 3

TABLE OF CONTENTS

SECTION 1

Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 Features 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Models 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 Specifications 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

Sensor and Mode Settings9. . . . . . . . . . . . . . . . . . . . . . . .

2-1 Disassembly 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Output Units 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 Internal Switch Settings 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3

Settings Before Operation 17. . . . . . . . . . . . . . . . . . . . . . . . .

3-1 Nomenclature 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Setting Flowchart 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 List of Parameters 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Parameters on Display Level 0 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5 Parameters on Display Level 1 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4

Fuzzy Self-tuning 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1 Fuzzy Self-tuning Operation 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Troubleshooting 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Terminology 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5

Installation and Wiring 35. . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1 Installation 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Wiring 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 Terminal Arrangement 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6

Troubleshooting 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1 Error Display and Output 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2 Troubleshooting 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 7

Event Input Function 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1 Event Input Function 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 8

Heater Burnout Detection 49. . . . . . . . . . . . . . . . . . . . . . . . .

8-1 Heater Burnout Detection 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-2 Heater Burnout Procedures 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-3 Wiring the Current Transformer 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-4 Heater Burnout Alarm Value 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 9

Engineering Level Settings 55. . . . . . . . . . . . . . . . . . . . . . . .

9-1 Engineering Level 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-2 Engineering Level Parameter List 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-3 Engineering Level Parameters 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vii

Page 4

TABLE OF CONTENTS

SECTION 10

Auto-tuning 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-1 Starting Auto-tuning 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-2 Conditions that Prevent Auto-tuning 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-3 Force-ending Auto-tuning 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-4 Changing Parameters during Auto-tuning 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendices

A Dimensions/Mounting Holes 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

Page 5

About this Manual:

This manual describes the installation and operation of the Thermac E5J Temperature Controller and

includes the sections described below.

Please read this manual carefully and be sure you understand the information provided before attempting

to install and operate the Thermac E5J Temperature Controller.

Section 1

Section 2

necessary before turning on the Thermac E5J Temperature Controller.

Section 3

operating the Thermac E5J Temperature Controller.

Section 4

to the characteristics of the device for ideal temperature control.

Section 5

Section 6

Section 7

Section 8

taken at the time of heater burnout, as well as the method of obtaining heater burnout alarm values.

Section 9

should be changed only when the values set before shipping do not suit the application. After these parameters are changed on the engineering level, record the contents of the changes for your future reference.

Section 10

The

perature Controller Units.

describes the specifications and basic features of the Thermac E5J Temperature Controller.

describes the sensor and mode settings of the Thermac E5J Temperature Controller that are

describes the settings of the Thermac E5J Temperature Controller that are necessary before

provides the procedures required to adjust all PID constants using fuzzy self-tuning according

describes the installation and wiring of the Thermac E5J Temperature Controller.

describes the troubleshooting of the Thermac E5J Temperature Controller.

describes how the event input function of the Thermac E5J Temperature Controller works.

describes the basic features of heater burnout detection and necessary steps that should be

describes the parameters that can be changed on the engineering level. These parameters

describes how to execute auto-tuning.

Appendix

provides the dimensions and mounting specifications for the various Thermac E5J Tem-

!

WARNING Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section in its entirety and be sure you understand the information provided in the section

and related sections before attempting any of the procedures or operations given.

ix

Page 6

SECTION 1

Introduction

This section describes the specifications and basic features of the Thermac E5J Temperature Controller.

1-1 Features 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Models 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 Specifications 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3-1 Ratings 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3-2 Characteristics 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

Page 7

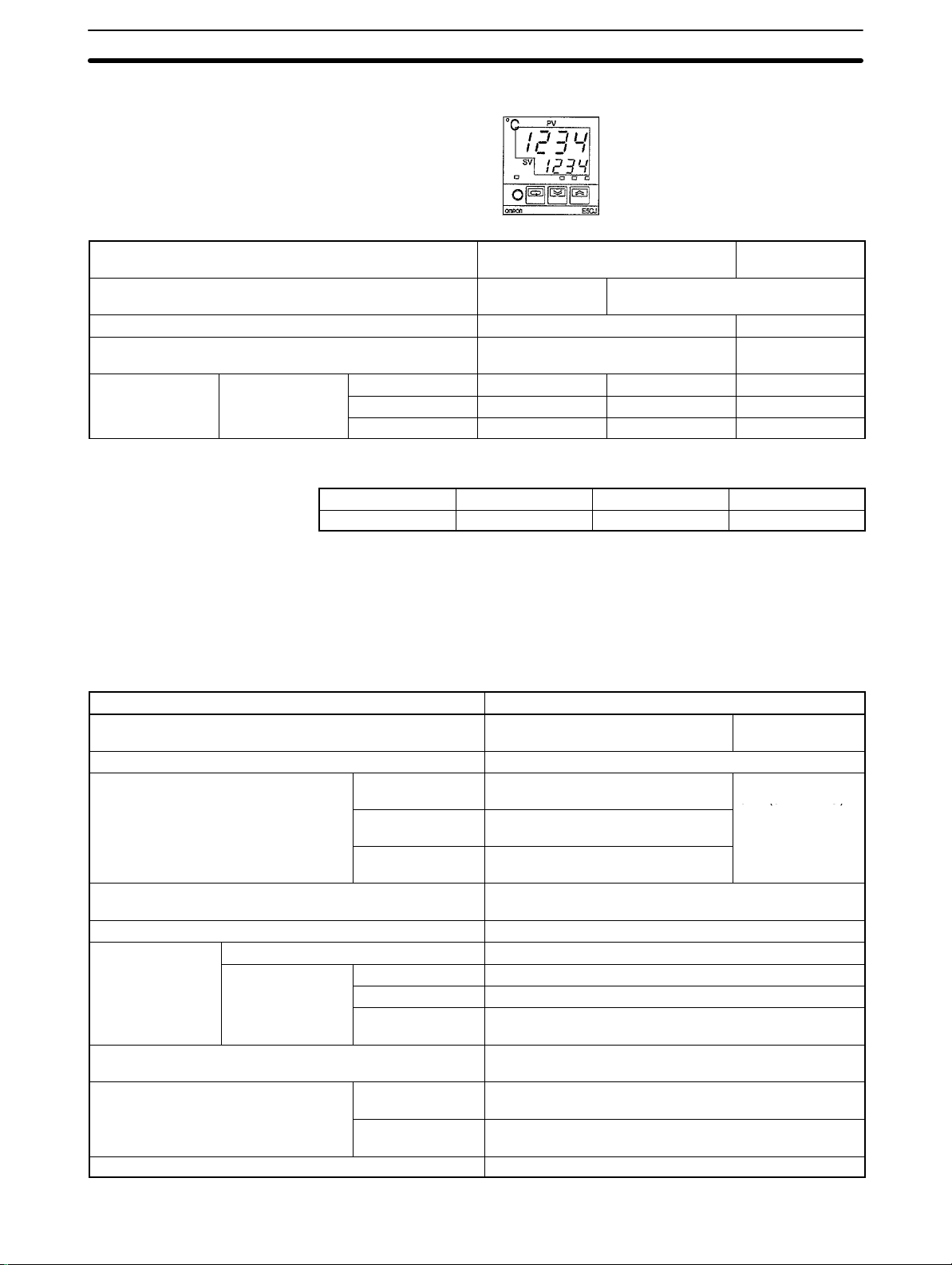

Models

Section 1-2

1-1 Features

The basic features of the Thermac E5J Temperature Controller are outlined

below.

Fuzzy Self-tuning When using a conventional temperature controller for ideal temperature control,

it is necessary to adjust the PID constants of the temperature controller according to the controlled device. The Thermac E5J Temperature Controller incorporates a fuzzy self-tuning function, thus allowing ideal temperature control

without any adjustment of the PID constants. The user needs only to set the

E5J to the desired temperature for ideal temperature control.

Auto-tuning Auto-tuning is also available. It is useful when appropriate results are not

obtained through fuzzy self-tuning. (Refer to

Section 10 Auto-tuning

Event Input Function It is possible to select a set point out of a maximum of two set values on the

E5CJ-B and four set values on the E5AJ-B via their event input terminals

from the PCs connected to these Temperature Controllers. The control operation of the E5AJ-B via can be stopped with an event input signal.

Watertight Construction The E5J can be used in places where water is sprayed onto the E5J, be-

cause the front panel of the E5J assures IP54 when the E5J is panelmounted (except for front panel of the E5CJ, which assures IP50). If greater watertightness is required, use the Y92A-N, a dedicated watertight cover (sold

separately).

.)

Advanced PID

The E5 J incorporates an advanced PID function, which is also incorporated by

the Thermac X Temperature Controller. The advanced PID function prevents

temperature overshooting the moment the Temperature Controller starts operating, assures a short startup time, and performs ideal temperature control by

quickly responding to external disturbances.

Output Units The E53-R Relay Unit, E53-Q, E53-Q3, and E53-Q4 Voltage Output Units for

driving SSRs, and E53-C3, E53-C3D, E53-V34, and E53-V35 Linear Output

Unit can be connected to any E5J Temperature Controller (except the E5CJ)

with ease according to the desired output configuration and application.

1-2 Models

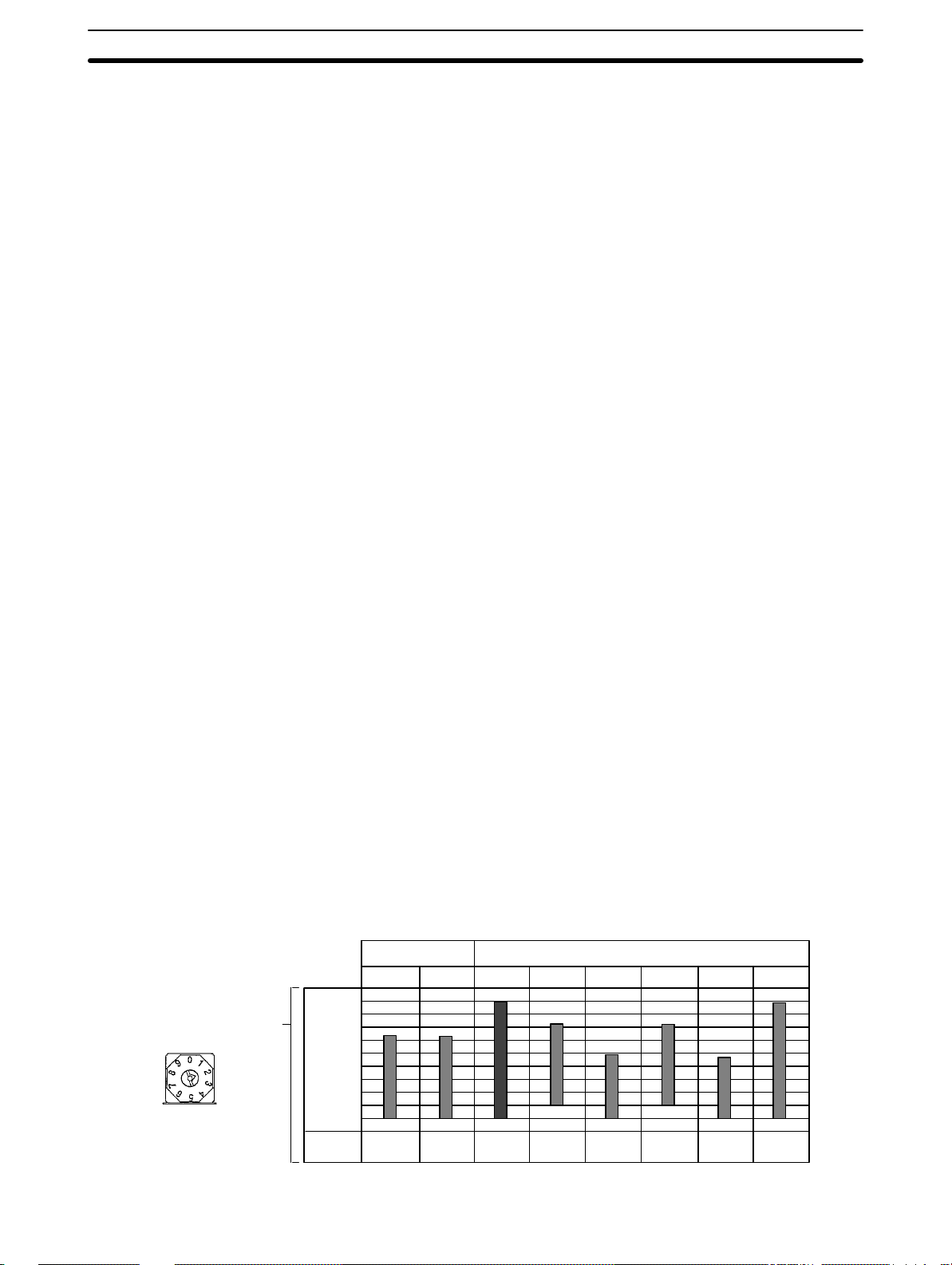

The thermocouples and platinum resistance thermometers listed in the following table can be connected to any Thermac E5J Temperature Controller.

Input

Temperature

range (°C)

INPUT

Factory-set to 2 (K)

Selectable

internally.

1300

1000

800

600

400

200

100

0

–100

–200

Setting

no.

Platinum resistance

thermometer

JPt100

650.0

–199.9 –200

0.8 1.9 2 3 4 5 6 7

Pt100

650.0

KJ T L U N

1300

–200–199.9 –199.9 –199.9

850

–100

Thermocouple

400.0

–100

1300

850

400.0

2

Page 8

Models

Section 1-2

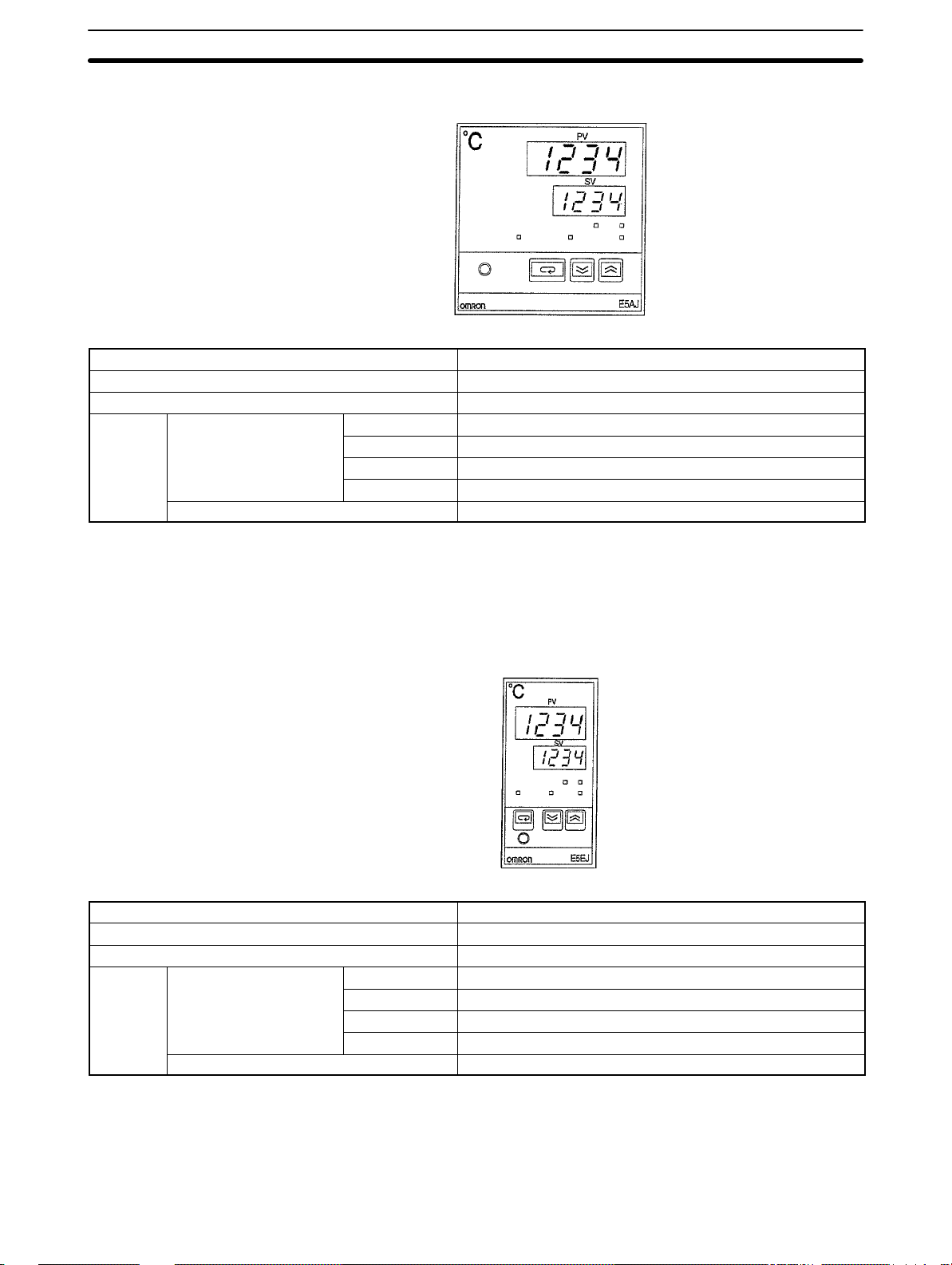

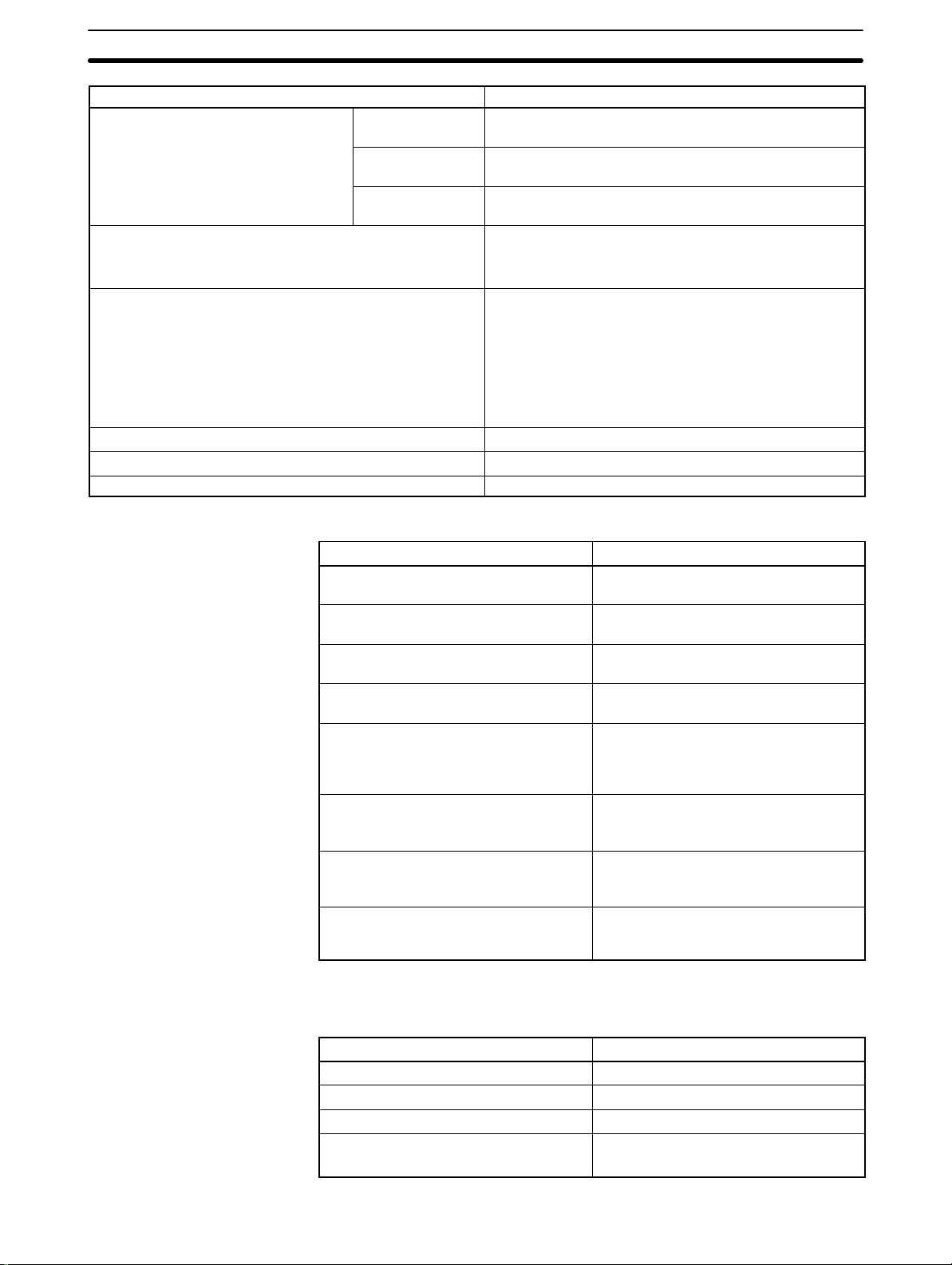

E5AJ (Standard Model with Communications Function)

96 X 96mm

Alarm 2 relay output points with heater burnout alarm (see note 1)

Event input 2 points (set point selection, RUN/STOP) (see note 2)

Control output Replaceable Output Unit (sold separately)

Model Communications function --- E5AJ-A2HB

RS-232C E5AJ-A2H01

RS-422 E5AJ-A2H02

RS-485 E5AJ-A2H03

Communications Board add-on model E5AJ-A2HM

Note 1. No heater burnout alarm is output if the E53-C3 Current Output Unit is used

with the E5AJ.

2. The event input function is not incorporated by models that have a communications function.

E5EJ (Standard Model with Communications Function)

48 X 96mm

Alarm 2 relay output points with heater burnout alarm (see note 1)

Event input 2 points (set point selection, RUN/STOP) (see note 2)

Control output Replaceable Output Unit (sold separately)

Model Communications function --- E5EJ-A2HB

RS-232C E5EJ-A2H01

RS-422 E5EJ-A2H02

RS-485 E5EJ-A2H03

Communications Board add-on model E5EJ-A2HM

Note 1. No heater burnout alarm is output if the Linear Output Unit is used with the

E5EJ.

2. The event input function is not incorporated by models that have a communications function.

3

Page 9

6 (at C)

Specifications

Section 1-3

E5CJ (Simple and Standard Models)

48 X 48mm

Type Simple model type Standard model

type

Alarm --- 2 replay output points with the same

common. (see note 1)

Heater burnout alarm --- Yes (see note)

Event input --- 1 point (set point

selection)

Model Control output Relay output E5CJ-R E5CJ-R2 E5CJ-R2HB

Voltage output E5CJ-Q E5CJ-Q2 E5CJ-Q2HB

Current output E5CJ-C E5CJ-C2 E5CJ-C2B

Note No heater burnout alarm is output if a current control output is used.

Communications Boards

Note For details, refer to the

Communications RS-232C RS-422 RS-485

Model E53-J01 E53-J02 E53-J03

E5AJ/E5EJ Communications Manual (Z102).

1-3 Specifications

1-3-1 Ratings

E5J

Item Specification

Supply voltage 100 to 240 VAC, 50 or 60 Hz 24 V AC/DC,

50 or 60 Hz

Operating voltage range 85 to 110% of supply voltage

Power consumption E5AJ 10 VA (at 100 VAC) to

14 V A (at 240 VAC)

E5EJ 10 VA (at 100 VAC) to

14 V A (at 240 VAC)

E5CJ 10 VA (at 100 VAC) to

12 V A (at 240 VAC)

Input Thermocouples (K, J, T, L, U, and N) and platinum

resistance thermometers (JPt100 and Pt100)

CT input Dedicated CT (E54-CT1 or E54-CT3)

Control output E5AJ/E5EJ Replaceable Output Unit (sold separately)

E5CJ Relay output SPST-NO, 3 A at 250 VAC (resistive load)

Voltage output 20 mA at 12 VDC (with short-circuit protection)

Current output 4 to 20 mA DC with a load of 600 Ω max. and a

resolution of approx. 2600

Control mode ON/OFF or advanced PID with fuzzy self-tuning and

auto-tuning

Alarm output E5AJ/E5EJ 2 SPST-NO relay output points, 3 A at 250 VAC

(resistive load)

E5CJ 2 SPST-NO relay output points (with the same common),

1 A at 250 VAC (resistive load)

Setting method Digital setting with Up Key and Down Key

10 V A (at 24 VAC)

6 W (at 24 VDC)

4

Page 10

Specifications

Item Specification

Indication method E5AJ All digital indication (PV: Red, 15 mm; SV: Green,

10.5 mm)

E5EJ All digital indication (PV: Red, 14 mm; SV: Green,

9.5 mm)

E5CJ All digital indication (PV: Red, 12 mm, SV: Green 8.0

mm)

Event input Contact input: ON: 1 kΩ max. OFF: 100 kΩ min.

No-contact input: ON: residual voltage of 3 V max; OFF:

current leakage of 1 mA max.

Other function • Key protect

• Cooling operation/Heating operation

• Heater burnout alarm

Model with event input (E5J-B)

• Set point selection (set point x 2)

• RUN/STOP (E5AJ-B and E5EJ-B only)

Ambient operating temperature –10°C to 55°C (with no condensation)

Ambient operating humidity 35 to 85%

Storage temperature –25°C to 65°C (with no condensation)

Section 1-3

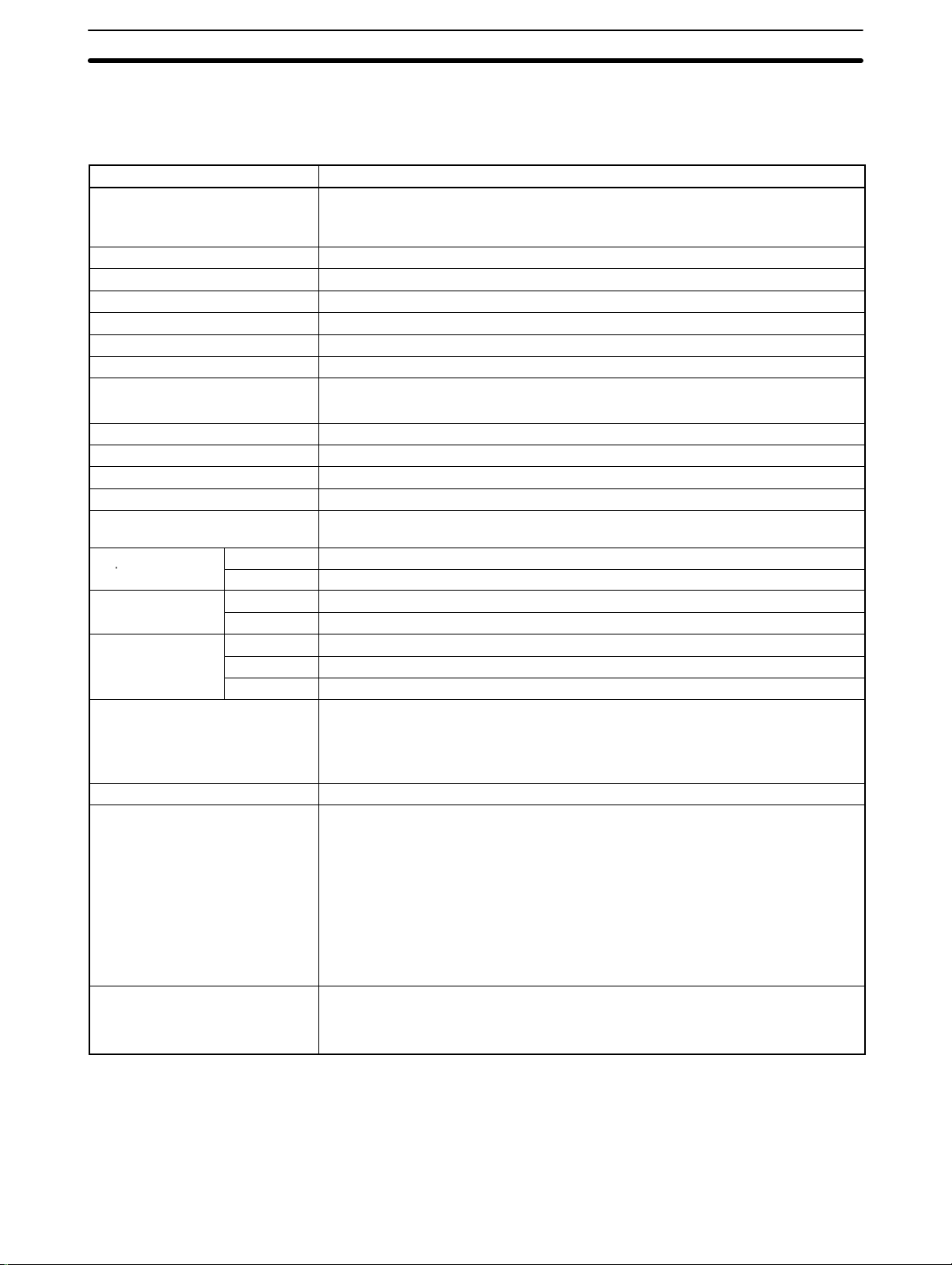

Output Units

Model Specification

E53-R Relay Output Unit SPDT (SPST-NO when used with the

E5J), 5 A at 250 VAC (resistive load)

E53-Q Voltage Output Unit NPN, 40 mA at 12 VDC (with

short-circuit protection)

E53-Q3 Voltage Output Unit NPN, 20 mA at 24 VDC (with

short-circuit protection)

E53-Q4 Voltage Output Unit PNP, 20 mA at 24 VDC (with

short-circuit protection)

E53-C3 Linear Output Unit 4 to 20 mA DC with a load of 600 Ω

max. (with a resolution of approximately

2600 when used with the E5J) (see

note)

E53-C3D Linear Output Unit 0 to 20 mA DC with a load of 600 Ω

max. (with a resolution of approximately

2600 when used with the E5J)

E53-V34 Linear Output Unit 0 to 10 VDC with a load of 1 kΩ min.

(with a resolution of approximately 2600

when used with the E5J)

E53-V35 Linear Output Unit 0 to 5 VDC with a load of 1 kΩ min.

(with a resolution of approximately 2600

when used with the E5J)

Note The E53-C cannot be used.

Current Transformer (CT)

Item Specification

Maximum continuous heater current 50 A

Dielectric strength 1,000 VAC

Vibration resistance 50 Hz, approx. 98 m/s2 (10G)

Weight E54-CT1: Approx. 11.5 g

E54-CT3: Approx. 50 g

5

Page 11

Specifications

Section 1-3

1-3-2 Characteristics

E5J

Item Specification

Indication accuracy ±0.5% or ±1°C whichever is larger ± 1 digit max.

Thermocouple K, T, or N at a temperature of –100°C; thermocouple U at ± 2°C ± 1

digit max.

Hysteresis (for ON/OFF control) 0.1 to 999.9°C/° F (in units of 0.1°C/°F)

Proportional band 0.1 to 999.9°C/°F (in units of 0.1°C/°F)

Integral time 0 to 3999 s (in units of 1 s)

Derivative time 0 to 3999 s (in units of 1 s)

Control period Relay or voltage output:1 to 99 s (in units of 1 s)

Manual reset value (I = 0) 0.0 to 100.0% (in units of 0.1%)

Alarm setting range With K, J, L, or N input: –1999 to 9999° C/°F (in units of 1°C/°F)

With JPt100, Pt100, T, or U input: –199.9 to 999.9° C/°F (in units of 0.1°C/°F)

Sampling period 500 ms

Output refresh period 500 ms

Display refresh period 500 ms

Insulation resistance 20 MΩ min. at 500 VDC (measured with an Output Unit)

Dielectric strength 2000 VAC, 50/60 Hz for 1 min. between charged terminals different from each other

in polarity

Vibration

resistance

Shock resistance Malfunction 196 m/s2 (20G) 3 times each in 3-axis 6 directions (98 m/s2 (10G) for the relay)

Weight E5AJ Approx. 360 g; mounting bracket: approx. 65 g

Enclosure rating Front panel: E5AJ/E5EJ: IEC standard IP54

Memory Protection Non-volatile memory

EMC Emission Enclosure: EN55011 Group 1 class A

Approved standards UL1092, CSA C22.2 No. 142

Malfunction 10 to 55 Hz, 9.8 m/s2 (1G) 10 min. in X, Y, and Z directions

Destruction 10 to 55 Hz, 19.6 m/s2 (2G) 2 hr. in X, Y, and Z directions

Destruction 294 m/s2 (30G) 3 times each in 3-axis 6 directions

E5EJ Approx. 280 g; mounting bracket: approx. 65 g

E5CJ Approx. 170 g; adapter: approx. 10 g

E5CJ: IEC standard IP50 (see note 1)

Rear case: IEC standard IP20

Terminals: IEC standard IP00

Emission AC Mains: EN55011 Group 1 class A

Immunity ESD: EN61000-4-2:4 kV contact discharge (level 2)

8 kV air discharge (level 3)

Immunity RF-interference: ENV50140: 10 V/m (amplitude modulated,

80 MHz to 1 GHz) (level 3)

10 V/m (pulse modulated,

900 MHz)

Immunity Conducted Disturbance: ENV50141: 10 V (0.15 to 80 MHz) (level 3)

Immunity Burst: EN61000-4-4:2 kV power-line (level 3)

2 kV I/O signal-line (level 4)

Conforms to EN50081-2, EN50082-2, EN61010-1 (IEC1010-1) (see note 2)

Conforms to VDE0106/part 100 (Finger Protection), when the separately-ordered

terminal cover is mounted.

Note 1. The model numbers of the exclusive watertight covers conforming to IP66,

NEMA4 are as follows:

For E5AJ: Y92A-96N; For E5CJ: Y92A-48N; For E5EJ: Y92A-49N

2. Basic insulation is between the input and output.

6

Page 12

Specifications

Section 1-3

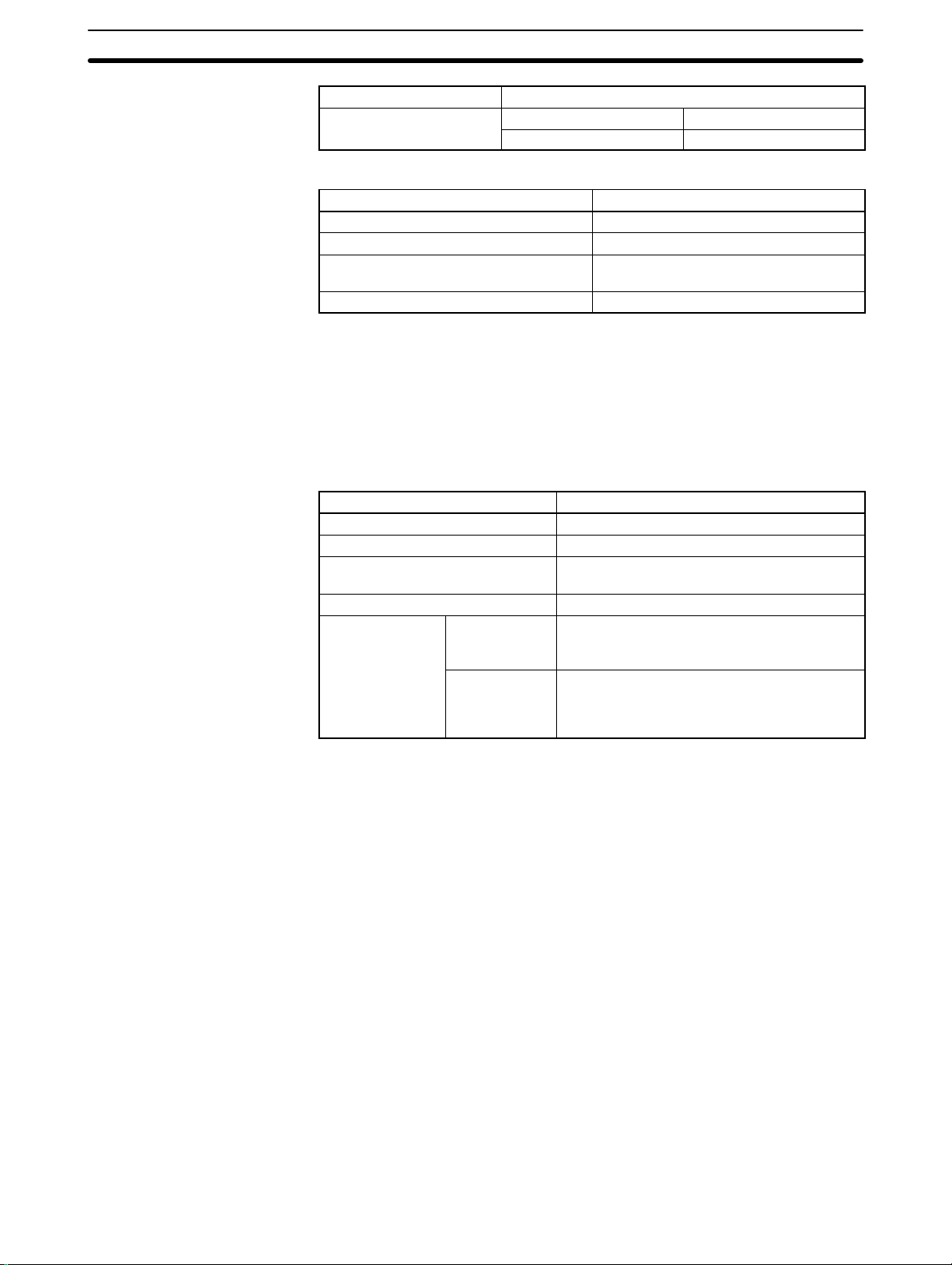

Output Unit

Heater Burnout Alarm

Note 1. Use the K2CU-FA-GS (with gate input terminals) for the detection of

Model with

Communications Function

Model Life expectancy

E53-R Relay Output Unit Mechanical 10,000,000 times min.

Electrical 100,000 times min.

Item Specification

Max. heater current Single-phase 50 A VAC (see note 1)

Heater current value display accuracy ±5% FS ± 1 digit max.

Heater burnout alarm setting range 0.1 to 49.9 A (in units of 0.1 A)

Min. detection ON time 190 ms (see note 3)

(see note 2)

three-phase heater burnout.

2. The heater burnout alarm is always OFF if the alarm is set to 0.0 A and always ON if the alarm is set to 50.0 A.

3. No heater burnout detection or heater current value measurement is possible if the control output is ON for less than 190 ms.

Refer to the

Interface RS-232C, RS-422, RS-485

Communications method Half duplex

Synchronization method Start-stop synchronization

Communications speed 1200, 2400, 4800, 9600, and 19200 bps

Communications

item

E5AJ/E5EJ Communications Manual (Z102)

Item Specification

(non-synchronization)

Writing to

Thermac J

Reading from

Thermac J

Set point, alarm value, heater burnout alarm

value, proportional band, derivative time,

integral time, and input shift value

Process value, set point, alarm value, heater

burnout alarm value, heater current value,

proportional band, derivative time, integral

time, output value, input shift and error code

for details.

7

Page 13

SECTION 2

Sensor and Mode Settings

This section describes the sensor and mode settings of the Thermac E5J Temperature Controller that are necessary before

turning on the Thermac E5J Temperature Controller.

2-1 Disassembly 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Output Units 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 Internal Switch Settings 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-1 Internal Switch Positions 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-2 Input Type Selector Setting 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-3 Alarm Mode Setting 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-4 Standby Sequence 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-5 Function Selector Settings 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-6 Key Protection Switch Settings 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9

Page 14

Output Units

2-1 Disassembly

2-2 Output Units

Section 2-2

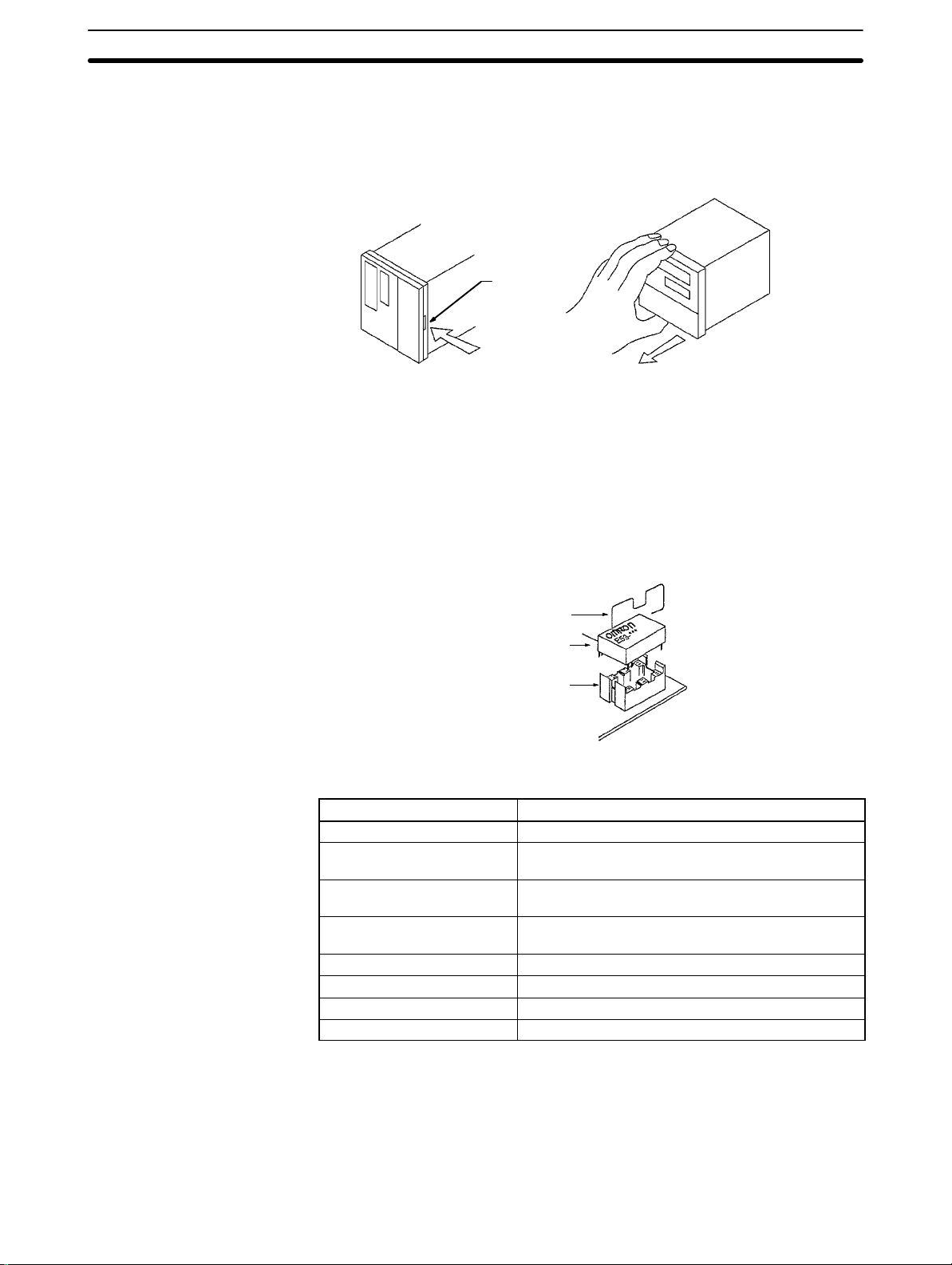

Before turning on the E5J, set its sensor type and control mode with the internal selectors. Refer to the following illustrations for disassembling the E5J to

access the internal switch settings.

Hook

Press the hook and

pull the front panel.

After setting the internal switches, insert the internal mechanism into the case

until the front panel snaps with the hook.

Select the Output Unit according to the application and mount the Output Unit

into the socket on the E5J PCB of the as shown in the following illustration. The

E5CJ does not require an Output Unit. Refer to

ratings of the E5J.

1-3 Specifications

for the output

Bracket

Output Unit

Socket

Output Units The following Output Units are available.

Model Rating

E53-R Relay Output Unit SPDT, 5 A at 250 VAC (resistive load)

E53-Q Voltage Output Unit NPN model, 40 mA at 12 VDC (with short-circuit

protecting circuit)

E53-Q3 Voltage Output Unit NPN model, 20 mA at 24 VDC (with short-circuit

protecting circuit)

E53-Q4 Voltage Output Unit PNP model, 20 mA at 24 VDC (with short-circuit

protecting circuit)

E53-C3 Linear Output Unit 4 to 20 mA DC with a load of 600 Ω max.

E53-C3D Linear Output Unit 0 to 20 mA DC with a load of 600 Ω max.

E53-V34 Linear Output Unit 0 to 10 VDC with a load of 1 kΩ min.

E53-V35 Linear Output Unit 0 to 5 VDC with a load of 1 kΩ min.

After mounting the Output Unit, be sure to secure it with the mounting bracket

provided with the Output Unit.

If the E53-C3, E53-C3D, E53-V34, and E53-V35 Linear Output Unit is used for

control output, no heater burnout alarm is available.

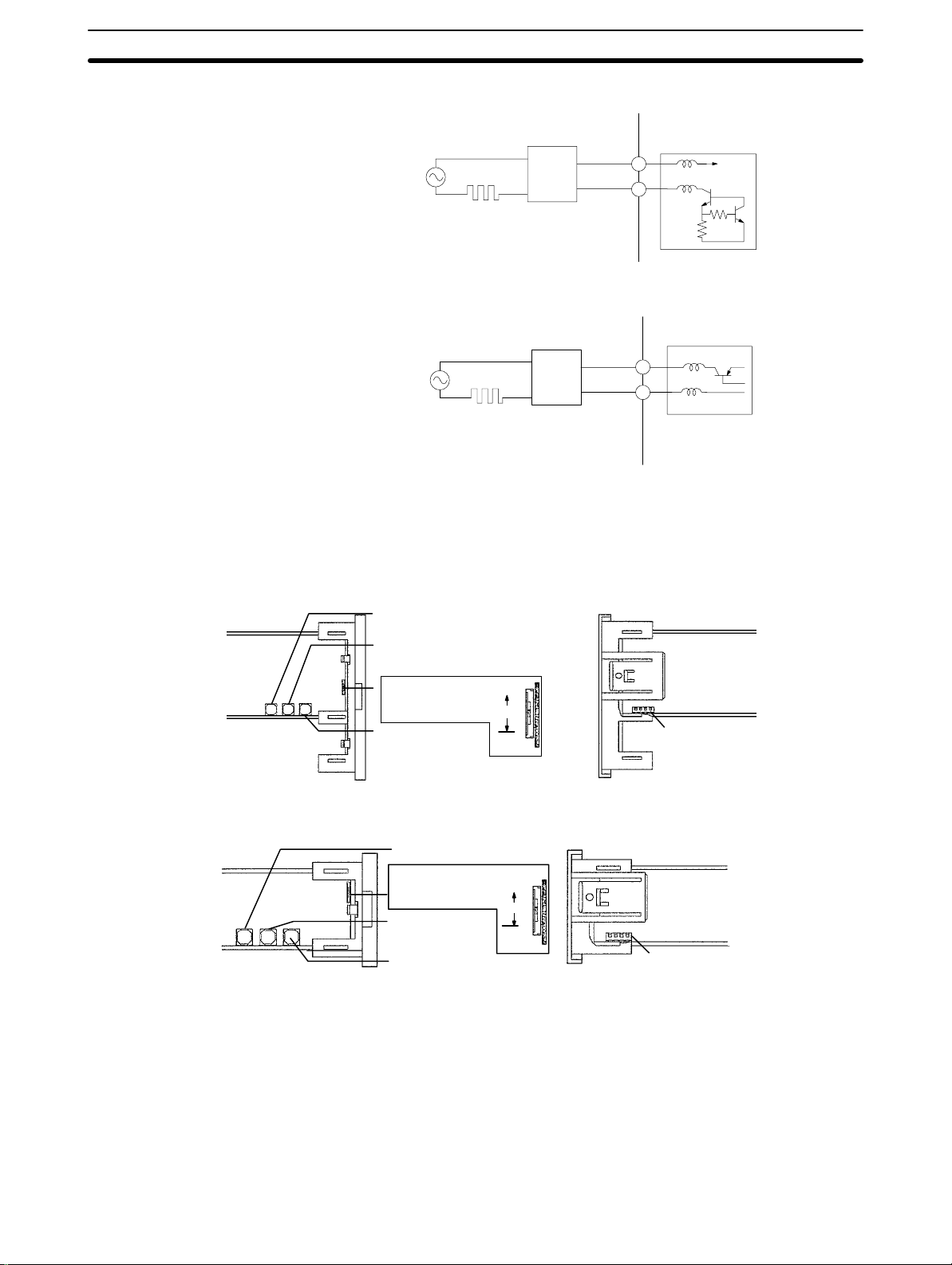

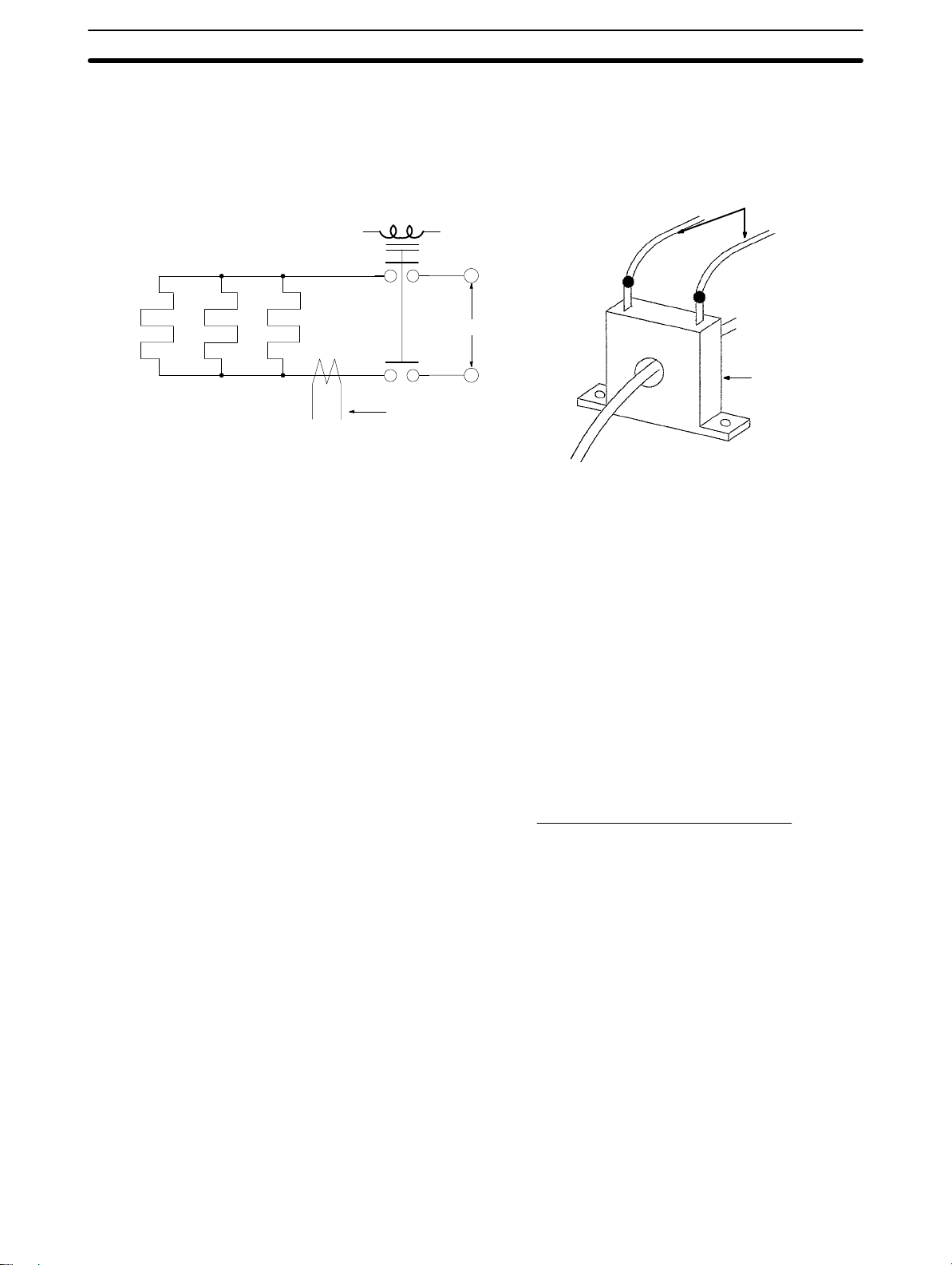

Each Voltage Output Unit is used for driving an SSR as shown in the following

illustrations.

10

Page 15

Internal Switch Settings

NPN Model: E53-Q (40 mA at 12 VDC) and E53-Q3 (20 mA at 24 VDC)

++

LOAD INPUT

PNP Model: E53-Q4 (20 mA at 24 VDC)

LOAD INPUT

SSR

––

++

SSR

––

Section 2-3

2-3 Internal Switch Settings

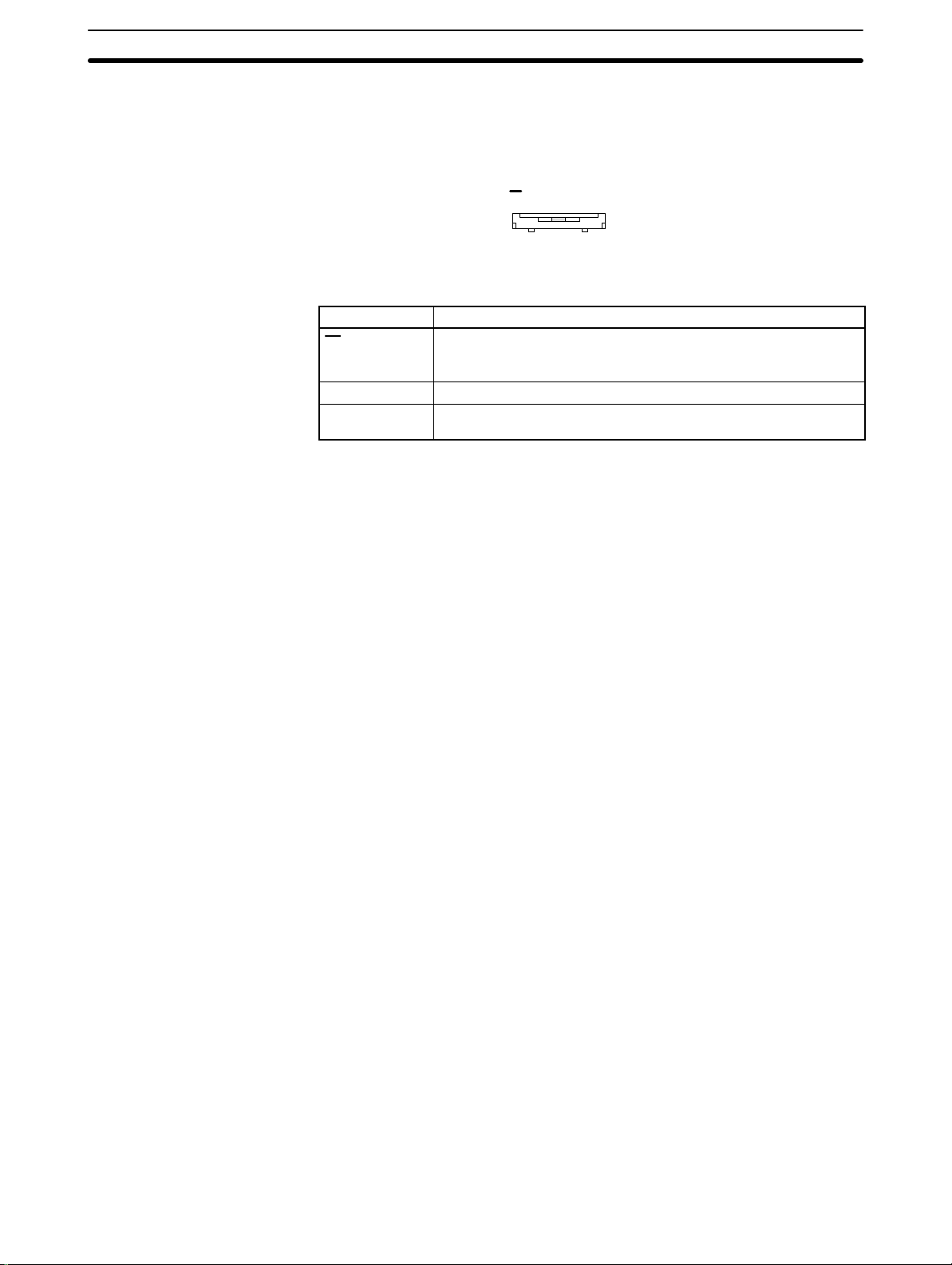

2-3-1 Internal Switch Positions

E5AJ

Top view

E5EJ

Top view

ALM2

Alarm mode selector 2

ALM1

Alarm mode selector 1

PROTECT

Key protection

switch

INPUT

Input type

selector

ALM2

Alarm mode selector 2

PROTECT

Key protection

switch

ALM1

Alarm mode

selector 1

INPUT

Input type selector

ALL

OFF

SP

ALL

OFF

SP

Bottom view

FUNCTION

Function selector

FUNCTION

Function selector

11

Page 16

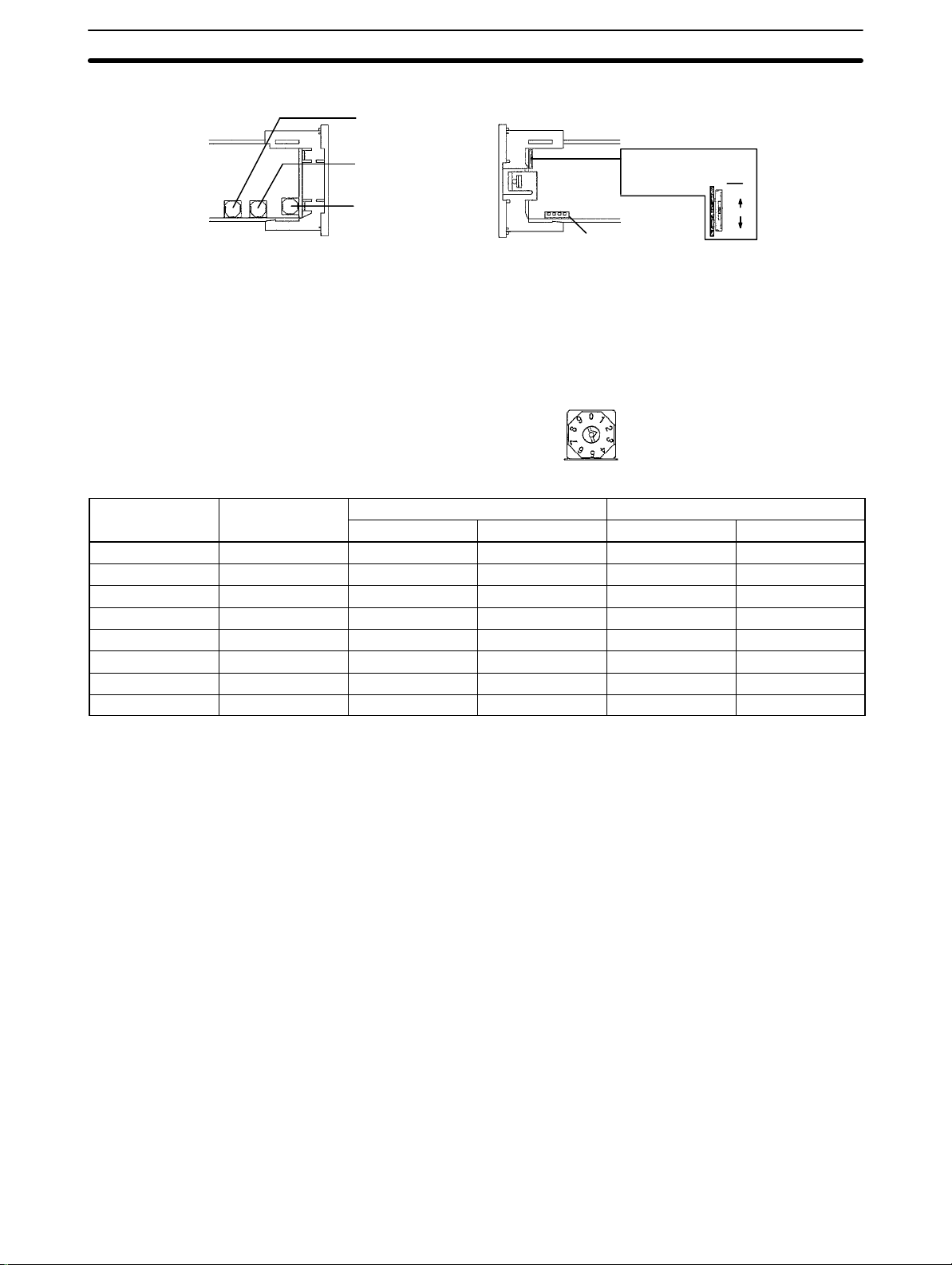

Internal Switch Settings

E5CJ

Top view

ALM2

Alarm mode selector 2

Section 2-3

Bottom view

ALM1

Alarm mode selector 1

INPUT

Input type selector

FUNCTION

Function selector

PROTECT

Key protection

switch

SP

OFF

ALL

Note The E5CJ with no alarm does not incorporate ALM1 or ALM2.

2-3-2 Input Type Selector Setting

The input type selector is factory-set to 2 (K). Refer to the following table for the selection

of the desired sensor.

INPUT

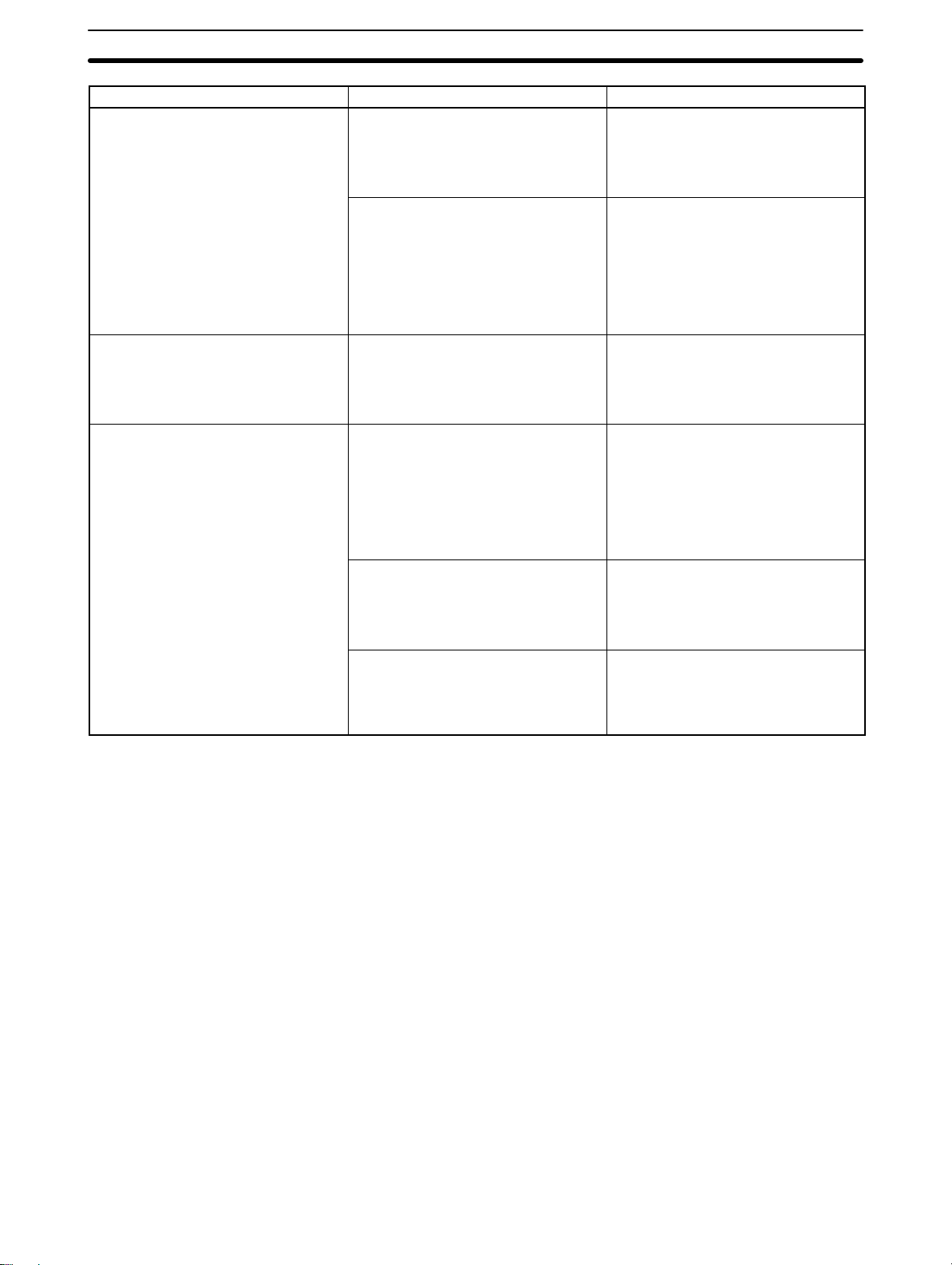

Selector no. Input Set temperature range Specified temperature range

°C °F °C °F

0, 8 JPt100 –199.9 to 650.0 –199.9 to 999.9 –199.9 to 735.0 –199.9 to 999.9

1, 9 Pt100 –199.9 to 650.0 –199.9 to 999.9 –199.9 to 735.0 –199.9 to 999.9

2 K –200 to 1300 –300 to 2300 –350 to 1450 –560 to 2560

3 J –100 to 850 –100 to 1500 –195 to 945 –260 to 1660

4 T –199.9 to 400.0 –199.9 to 700.0 –199.9 to 460.0 –199.9 to 790.0

5 L –100 to 850 –100 to 1500 –195 to 945 –260 to 1660

6 U –199.9 to 400.0 –199.9 to 700.0 –199.9 to 460.0 –199.9 to 790.0

7 N –200 to 1300 –300 to 2300 –350 to 1450 –560 to 2560

Note The resistance of the JPt100 at a temperature of 100°C is 139.16 Ω and that of

the Pt100 at a temperature of 100°C is 138.50 Ω.

1, 2, 3...

1. To use Fahrenheit, set function selector 4 to ON, which is usually set to OFF.

2. Insert the internal mechanism into the case.

3. Turn on the E5J so that d-u will be displayed on the process value display.

Then press the Up Key so that f will be displayed on the set value display .

4. Turn off the power in two seconds.

5. Draw the internal mechanism from the case and set function selector 4 to

OFF and turn on the E5J.

12

Page 17

Internal Switch Settings

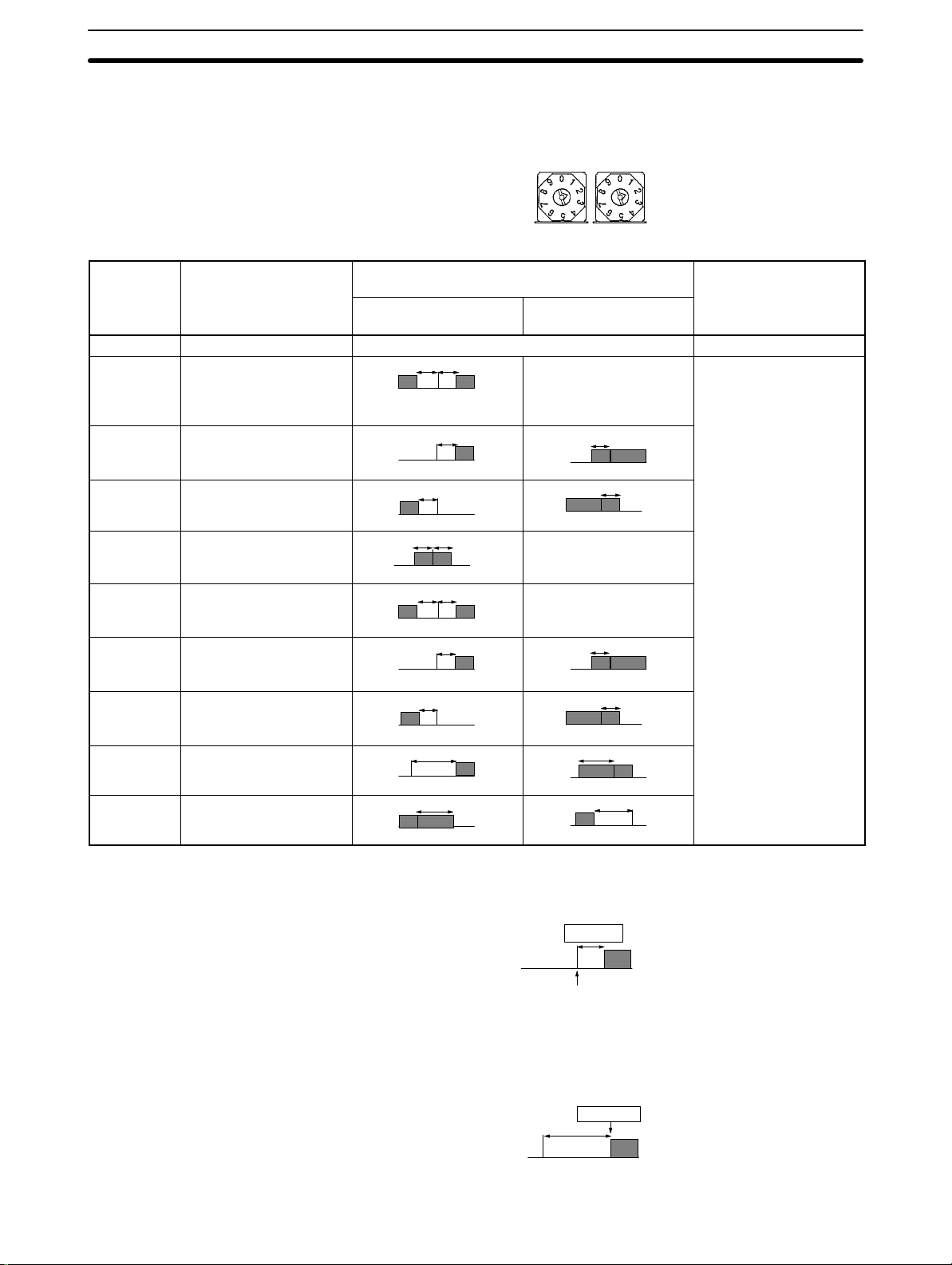

2-3-3 Alarm Mode Setting

ALM1 and ALM2 are both factory-set to 2 (upper limit alarm). Refer to the following table for the selection of the desired alarm mode.

Section 2-3

ALM2 ALM1

Selector

Alarm mode Alarm output Setting range

no.

Positive alarm set

value

Negative alarm set

value

0 No alarm function OFF --1 Upper and lower limit

alarm (deviation)

XSPX

Always ON –1999 to 9999 or –199.9

to 999.9 (the decimal

position varies with the

input type)

2 Upper limit alarm

(deviation)

3 Lower limit alarm

(deviation)

4 Upper and lower limit

SP

X

SP

XSPX

X

Always OFF

X

SP

X

SP

range alarm (deviation)

5 Upper and lower limit

XSPX

Always OFF

alarm with standby

sequence (deviation)

6 Upper limit alarm with

standby sequence

(deviation)

7 Lower limit alarm with

standby sequence

(deviation)

8 Absolute value upper

limit alarm

9 Absolute value lower

limit alarm

X

SP

X

SP

X

0

X

0

X

SP

X

SP

X

0

X

0

If the alarm mode switch is set to 1 to 7, the alarm value is set with the deviation

width from the set point as shown in the following diagram.

Alarm value

10°C/°F

Set point (SP)

100°C/°F

If the alarm mode switch is set to 8 or 9, the alarm value is set with the absolute

value from 0°C/°F as shown in the following diagram.

Alarm value

110°C/°F

0°C/°F

13

Page 18

Internal Switch Settings

2-3-4 Standby Sequence

The alarm output is ON the moment the E5J is turned on because the process

value is within the alarm range. To prevent this, select a mode with a standby

sequence. If a mode with a await sequence is selected, the alarm output will not

be ON even if the process value is within the alarm range unless the process

value once goes out of the alarm range. The following diagram shows the operation of the E5J in lower limit alarm mode with a standby sequence.

OFF point due to

alarm hysteresis

It is possible to change the alarm hysteresis (set to 0.2°C before shipping) on the

engineering level.

2-3-5 Function Selector Settings

All the function selector pins are factory-set to OFF.

Section 2-3

Standby sequence releasing

point

Alarm point

Alarm output

ON

OFF

To set these pins to

FUNCTION

ON, use a small flatblade screwdriver.

Refer to the following table for function switch setting.

Pin no. 1 2 3 4

Output Cooling operation (Normal) ON --- --- --operation Heating operation (Reverse) OFF

Control ON/OFF control --- ON See note

mode Advanced PID --- OFF ON

Advanced PID with fuzzy self-tuning --- OFF OFF

Level Engineering level --- --- --- ON

Normal operation --- --- --- OFF

Note The E5 J will be in ON/OFF control mode regardless of the setting of pin 3 if pin

2 is set to ON.

Output Operation (Pin 1)

Heating Operation If pin 1 of the E5J is set to OFF, when the process temperature is lower than the

set point, the E5J will operate so that the heater output will increase.

Cooling Operation If pin 1 of the E5J is set to ON, when the process temperature is higher than the

set point, the E5J will operate so that the output of cooling water will increase.

Control Mode (Pins 2 and 3)

ON/OFF Control The ON/OFF control is also called two-position operation.

Advanced PID Set the E5J in this mode for P, PI, or PD control or if the most suitable PID

constants for the controlled device are already known.

Advanced PID with Fuzzy

Self-tuning

Set the E5J in this mode so that Fuzzy self-tuning adjusts the PID constants to

the most suitable values according to the controlled device for ideal temperature

control. Refer to

Section 4 Fuzzy Self-tuning

for details.

Level (Pin 4)

14

Set pin 4 to ON if it is necessary to change any parameter on the engineering

level. Set this pin to OFF for normal operation.

Page 19

Internal Switch Settings

2-3-6 Key Protection Switch Settings

The key protection switch is used to prohibit parameter changes as shown in the

following table. The key protection switch is factory-set to OFF.

Mode Protection

SP

OFF All keys are available.

ALL Prohibits all set value changes. The Level Key, Down Key, and

Prohibits all set value changes except the set point. The Level

Key is not available. The Down Key and Up Key are available

only for set point setting.

Up Key are not available.

Section 2-3

SP OFF ALL

PROTECT

15

Page 20

SECTION 3

Settings Before Operation

This section describes the settings of the Thermac E5J Temperature Controller that are necessary before operating the

Thermac E5J Temperature Controller.

3-1 Nomenclature 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Setting Flowchart 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 List of Parameters 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Parameters on Display Level 0 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5 Parameters on Display Level 1 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17

Page 21

Nomenclature Section 3-1

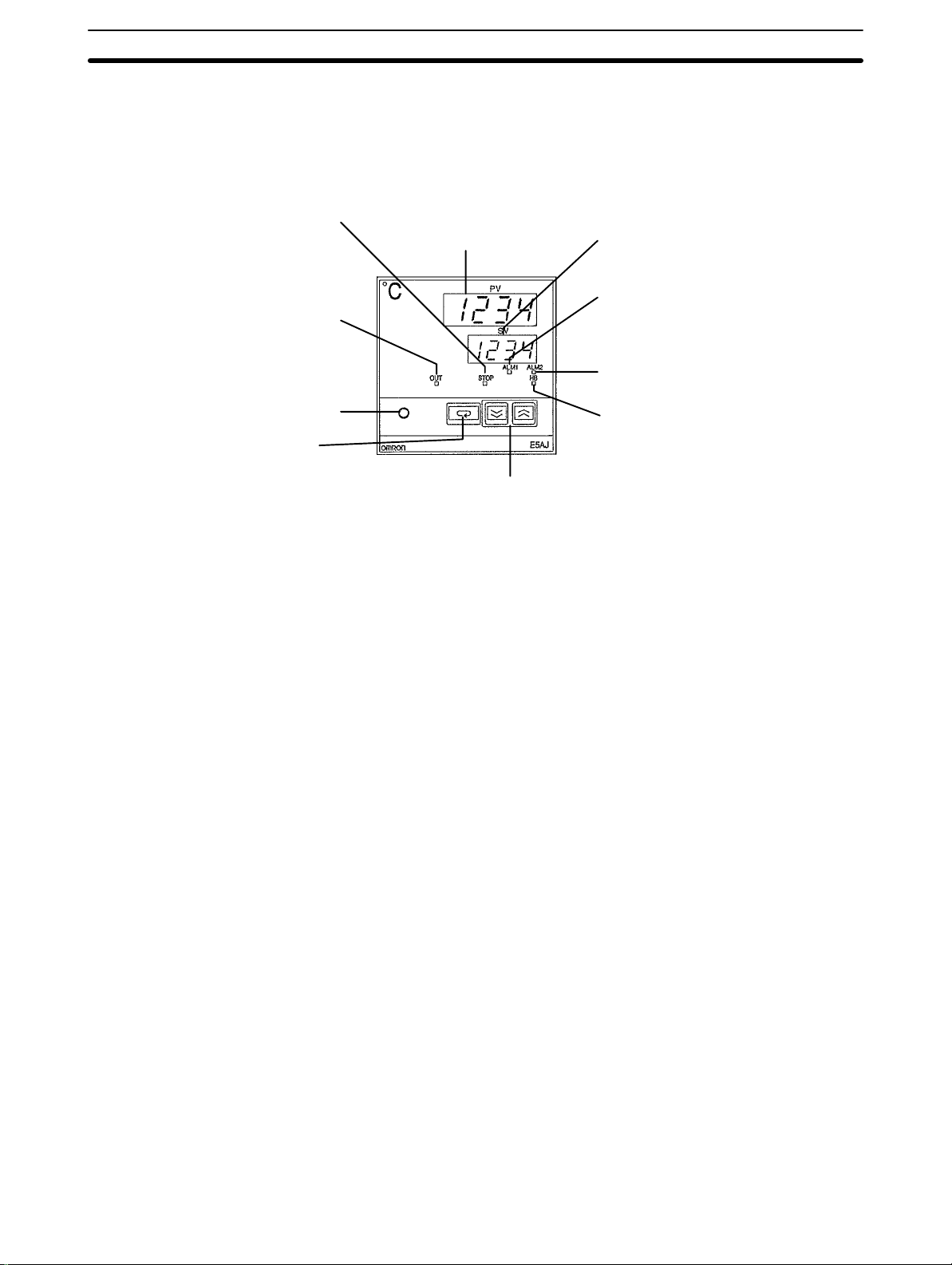

3-1 Nomenclature

The following is the front panel of the E5AJ-A2HB. The front panels of the E5EJ

and E5CJ are similar to the front panel of the E5AJ-A2HB.

Process Value (PV) display

Displays not only the process

value but also indicates the pa-

Stop indicator

Lit when the E5J is not operating.

The E5CJ does not incorporate this

indicator.

Output indicator

Lit when the control output is ON.

This indicator is, however, not lit

when the E5J has a current output.

Level Key

Press for 1 s minimum to change levels to set different groups of parameters.

Display Key

Use this key when shifting the

display to the next parameter.

rameter being displayed on the

SV display and error messages.

Down Key and Up Key

The Down Key, when pressed, decreases the set temperature or other parameters. The value successively decreases

when the Down Key is held down for 1 s minimum. The Up

Key, when pressed, increases the set temperature or other

parameters. The value successively increases when the Up

Key is held down for 1 s minimum. The value set will be effective on pressing the Display Key or Level Key or 2s after it

is set if Display Key or Level Key is not pressed.

Set Value (SV) display

Displays the set temperature

and other parameters.

Alarm 1 indicator

Lit when alarm output 1 is ON.

Alarm 2 indicator

Lit when alarm output 2 is ON.

Heater burnout alarm

Lit when there is heater burnout.

Once heater burnout is detected, the

alarm output will be on hold.

Note Refer to the

E5AJ/E5EJ Communications Manual

models incorporating a communications function.

for the operation of E5J

18

Page 22

Setting Flowchart

Section 3-2

3-2 Setting Flowchart

The Thermac E5J Temperature Controller starts control at the set point and

continues controlling even while set values are being input for each display level.

Therefore, when operating the E5J after inputting all the set values, turn the

power supply to the Temperature Controller off and then on again.

All parameters for the E5J Temperature Controller are divided into three levels

according to how frequently they are used.

Display Level 0 Parameters that are changed frequently are ranked as display level 0 parame-

ters.

Display level 1 Parameters that are not changed frequently are ranked as display level 1 pa-

rameters.

Engineering Level Parameters that are changed with only a few applications are ranked as engi-

neering level parameters.

OFF ON

Level Key

Press for 1 s min.

Display level 0 Display level 1

Set point setting

Alarm 1 setting

Alarm 2 setting

Each parameter is set with the Up Key or Down

Key. Each value set will be effective on pressing

the Display Key or Level Key or 2 s after it is selected if Display Key or Level Key is not pressed.

No value can be, however, changed when the

key protection switch is ON.

The parameters in parentheses are changed if their initial

values are changed on the engineering level.

Level Key

Press for 1 s min.

Output display

Control period setting

Hysteresis setting

Set point 0 setting

Set point 1 setting

(Set point 2 setting)

(Set point 3 setting)

(Input shift value setting)

Heater current value display

Heater burnout alarm setting

Proportional band setting

Integral time setting

Derivative time setting

Manual reset value setting

Pin 4 of the func-

tion selector

Engineering level

°C/°F selection

Stable range

Alpha

Automatic return of display mode

Standby sequence reset method

Input shift display selection

Alarm 1 hysteresis

Alarm 2 hysteresis

Set point lower limit

Set point upper limit

Event input 2 function selection

Refer to

Settings

on the engineering level and how to

change them.

Section 9 Engineering Level

for details on each parameters

19

Page 23

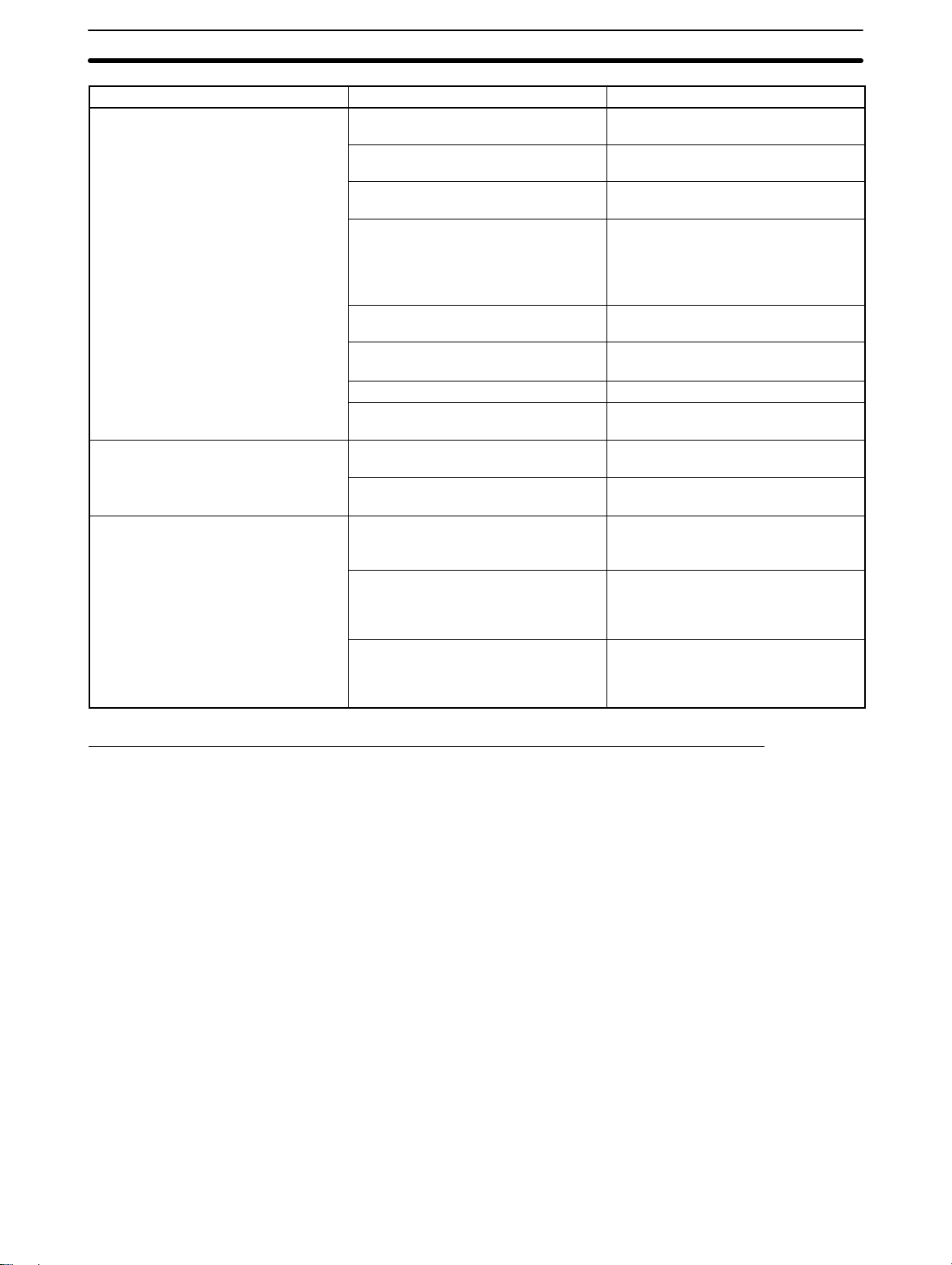

List of Parameters

3-3 List of Parameters

Display Level 0

Display Name Setting range Setting

--- Process value

display and set

point setting

AL-1 Alarm set value 1 –1999 to 9999 °C/°F

AL-2 Alarm set value 2 –1999 to 9999 °C/°F

To go to the next level, press the Level Key for 1 s min.

Note The values shown in Fahrenheit are applicable only for E5J--F Mod-

els.

Set point lower limit

to set point upper

limit (°C/°F)

The decimal position

varies with the kind

of input.

The decimal position

varies with the kind

of input.

Section 3-3

Remarks

before

shipping

0 The present set point is

displayed and can be

changed if the E5J

incorporates an event input

function

0 Not displayed if alarm mode

switch 1 is set to 0.

0 Not displayed if alarm mode

switch 2 is set to 0.

Display Level 1

Display Name Setting/Display

0 Output value

display

CP Control period 1 to 99 s 20 Displayed and can be set if

HYS Hysteresis 0.1 to 999.9 °C/°F 1.0 (1.8) Displayed and can be set

SP-0 Set point 0 Set point lower limit

SP-1 Set point 1 Set point lower limit

SP-2 Set point 2 Set point lower limit

SP-3 Set point 3 Set point lower limit

in-S Input shift value –199.9 to 999.9 °C/°F 0.0 Displayed and can be set if

0.0 to 100.0 %

to set point upper

limit (°C/°F)

to set point upper

limit (°C/°F)

to set point upper

limit (°C/°F)

to set point upper

limit (°C/°F)

Range

Setting

before

shipping

the E5J in PID control

operation has relay control

output or voltage control

output.

when the E5J is in ON/OFF

control operation.

0 For models incorporating an

event input function.

0 For models incorporating an

event input function.

0 For models incorporating an

event input 2 function.

Displayed and can be set if

the default value is changed

on the engineering level.

0 For models incorporating an

event input 2 function.

Displayed and can be set if

the default value is changed

on the engineering level.

the default value is changed

on the engineering level.

Remarks

20

Page 24

List of Parameters

Section 3-3

Display RemarksSetting

Ct Heater current

Hb Heater burnout

P Proportional band 0.1 to 999.9 °C/°F 8.0 (14.4) Displayed and can be set

8.0

i Integral time 0 to 3999 s

d Derivative time 0 to 3999 s

oFr Manual reset value 0.0 to 100.0 % 50.0 Displayed and can be set if

Name

value display

alarm value

Setting/Display

Range

0.0 to 55.0 A

If the current exceeds

55.0 A, ffff will be

displayed on the set

value display.

0.0 to 50.0 A

0.0: Always OFF

50.0: Always ON

0: No integral

operation

0: No derivative

operation

before

shipping

0.0 For models incorporating a

233 Displayed and can be set

40 Displayed and can be set

For models incorporating a

heater burnout alarm.

Nothing is displayed if the

E5J has current control

output.

heater burnout alarm.

Nothing is displayed if the

E5J has current control

output.

when the E5J is in

advanced PID operation.

when the E5J is in

advanced PID operation.

when the E5J is in

advanced PID operation.

the integral time is set to 0

when the E5J is in

advanced PID operation.

Note The value in the parentheses is the E5J--F setting before shipping.

21

Page 25

Parameters on Display Level 0

3-4 Parameters on Display Level 0

Note: The process value will not be displayed if the

alarm mode switch is set to 0 or if the E5J does

not incorporate any alarm.

Section 3-4

The value set before

shipping appears

(Set point setting)

Displays when the E5J incorporates

an alarm function (see note).

(Alarm 1 setting)

Displays when the E5J incorporates

an alarm function (see note).

(Alarm 2 setting)

Set Point Setting (°C or °F) It is possible to alter the present set point (SP0 or SP1).

al1 and al2 (°C or °F) The alarm mode is factory-set to the upper limit alarm (deviation). It is possible to

change the alarm mode with the alarm mode selector. Refer to

Mode Setting

. The alarm value can be set with the deviation width or absolute

2-3-3 Alarm

value according to the alarm mode.

Deviation alarm Absolute value alarm

Upper and lower limit alarm, upper limit

alarm, lower limit alarm and upper and

lower limit range alarm.

Set with the deviation width from

the set point

Alarm value

10°C/°F

Set point (SP) 100°C/°F

Absolute value upper limit alarm and

absolute value lower limit alarm.

Set with the absolute value from 0°C/°F.

Alarm value

110°C/°F

0°C/°F

22

Page 26

Parameters on Display Level 1

3-5 Parameters on Display Level 1

Section 3-5

The value set before

shipping appears

(Output value display)

Displays when the E5J in PID control

operation has a relay or voltage output.

(Control period setting)

Displays when the E5J is in ON/

OFF control operation.

(Hysteresis setting)

Displays if the E5J has an

event input.

(Set point 0 setting)

(Set point 1 setting)

Displays only if the event input 2

function is used for set point selection (see note 1).

(Set point 2 setting)

(Set point 3 setting)

Displays if the input shift value display is selected (see note 1).

(Input shift value setting)

Displays if the heater burnout

alarm function is selected. (see

note 2).

(Heater current value

display)

(Heater burnout alarm

value setting)

Displays when the E5J in advanced PID operation.

8.0

(Proportional

band setting)*

*In case of °F:

(Integral time setting)

(Derivative time setting)

Displays if I is 0 .

(Manual reset value

setting)

14.4

Note 1. Displayed if the initial value is changed on the engineering level.

2. Not displayed if current output is used as control output or a model with no

heater burnout alarm function is used.

23

Page 27

Parameters on Display Level 1

Section 3-5

o Output Value Display The output value is displayed within a range of 0.0% to 100.0%.

cp Control Period Setting It is possible to set the control period within a range of 1 to 99 s. The control peri-

od is the period required by the E5J to turn ON and OFF its relay output or voltage output. The ON period increases in proportion to the output value. If the control period is short, smooth control operation will be possible although a short

control period shortens the life of the relay if relay output is used. Therefore, the

control period should not be less than 20 s if relay output is used. The following

are output examples with an output value of 50.0 %.

5 s 10 s

ON

ON

hys Hysteresis Setting (°C

or °F)

sp0, sp1, sp2, and sp3

(E5J-B Only)

OFF

Control period: 10 s Control period: 20 s

It is possible to set the hysteresis for the E5J in ON/OFF control operation within a range of 0.1° to 999.9°C/°F.

Heating

control

(Reverse)

Cooling

control

(Normal)

ON

OFF

Low temperature Set point High temperature

ON

OFF

Low temperature Set point High temperature

It is possible to set sp-0 (set point 0), sp-1 (set point 1), sp-2 (set point 2), and sp-3

(set point 3) all in Celsius or Fahrenheit regardless of the set point presently se-

OFF

Hysteresis

Hysteresis

lected. To select the set point, open or short-circuit terminals EV1 and EV2. Re-

Section 7 Event Input Function

fer to

for details.

in-s Input Shift Value It is possible to set the input shift value within a range of –199.9° to 999.9°C/°F.

When an input shift value is set, the process value will be the input value added

with the shift value.

Example

Input Input shift value Process value

100°C 0 (no compensation) 100°C

10.0 (compensation value) 110°C

–10.0 (compensation value) 90°C

ct Heater Current Value

Display (E5J-H Only)

hb Heater Burnout Alarm

Value Setting (E5J-H

Only)

24

After the input shift value is set, the it is effective even if the input shift value display is turned off on the engineering level.

It is possible to set the heater current value within a range of 0.0 to 55.0 A. If the

current value exceeds 55.0 A, ffff will be displayed on the set value display.

The heater current will be processed and displayed if the control output is ON.

It is possible to set the heater burnout alarm value within a range of 0.0 to 50.0 A,

which will be used to detect heater burnout. If the heater burnout alarm value is

set to 0.0 A, the heater burnout alarm output will be always OFF. If the heater

burnout alarm value is set to 50.0 A, the heater burnout alarm output will be always ON. Refer to

Section 8 Heater Burnout Detection

for details.

When the E5J is in advanced PID with fuzzy self-tuning mode, the following

parameters (p, i, d, ofr) will not be displayed (i.e., there is no need to set the

following parameters). The fuzzy self-tuning always adjusts the PID constants to

the most suitable values according to the characteristics of the controlled device.

Page 28

Parameters on Display Level 1

p Proportional Band Setting It is possible to set the proportional band within a range of 0.1 to 999.9°C/°F.

i Integral Time Setting It is possible to set the integral time within a range of 0 to 3999 s.

d Derivative Time Setting It is possible to set the derivative time within a range of 0 to 3999 s.

Section 3-5

ofr Manual Reset Value

Setting

It is possible to set the necessary output value when the E5J is in constant operation within a range of 0.0% to 100.0%. The E5J will be balanced with a deviation between the set point and process value in P or PD control mode. This

deviation is called offset. The offset can be removed by changing the manual

reset value.

25

Page 29

SECTION 4

Fuzzy Self-tuning

This section provides the procedures required to adjust all PID constants using fuzzy self-tuning according to the characteristics of the device for ideal temperature control.

4-1 Fuzzy Self-tuning Operation 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1-1 Step Response Tuning (SRT) 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1-2 Disturbance Tuning (DT) 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1-3 Hunting Tuning (HT) 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Troubleshooting 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Terminology 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3-1 Stable Value, Stable Range, and Stability Judgement Time 32. . . . . . . . . . . . . . . . .

4-3-2 Hunting 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3-3 Characteristics and Characteristics Change 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3-4 External Disturbance 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3-5 Interference 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3-6 Startup 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27

Page 30

Fuzzy Self-tuning Operation Section 4-1

4-1 Fuzzy Self-tuning Operation

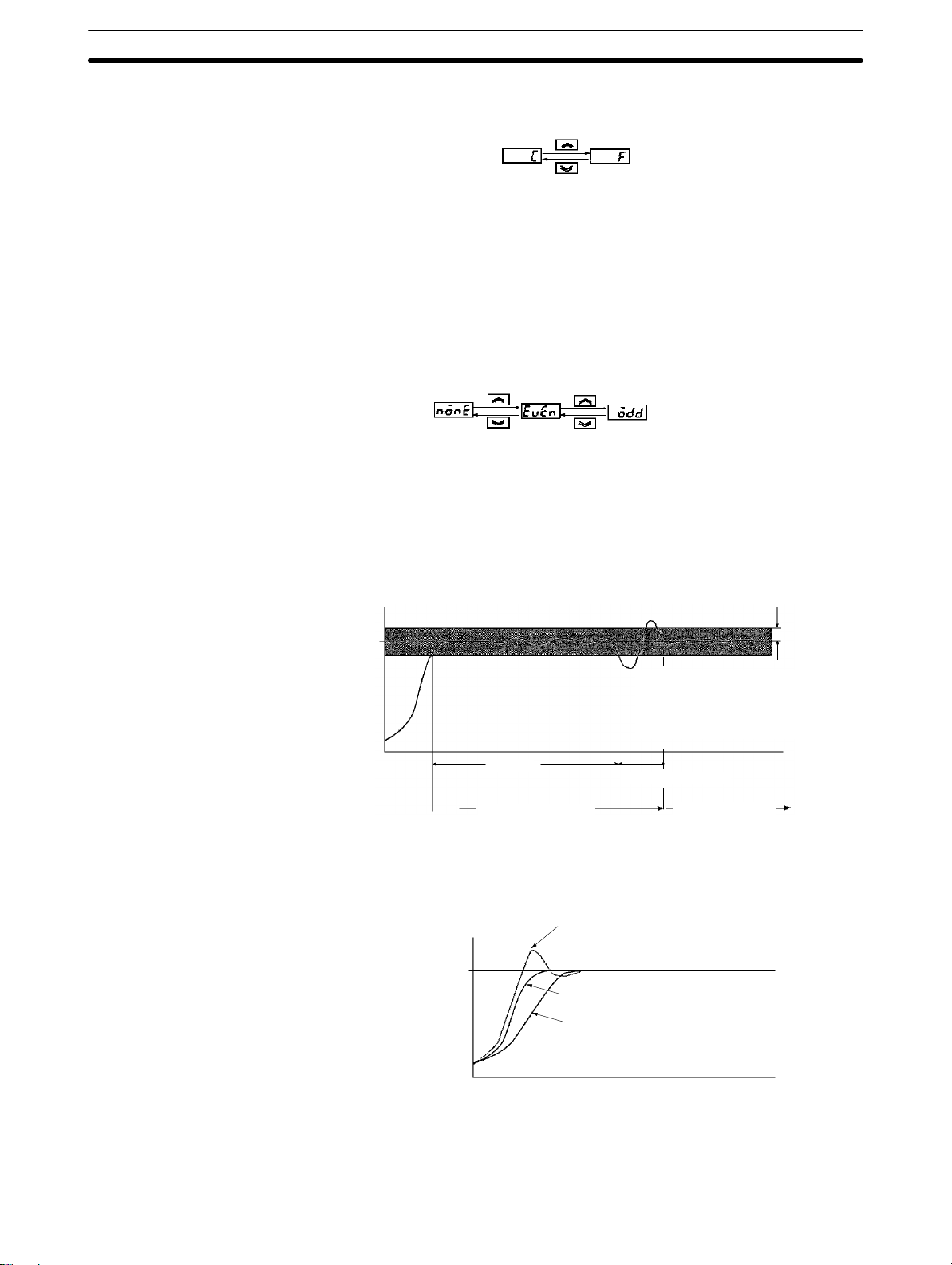

The fuzzy self-tuning function has three features, step response tuning (SRT),

disturbance tuning (DT), and hunting tuning (HT).

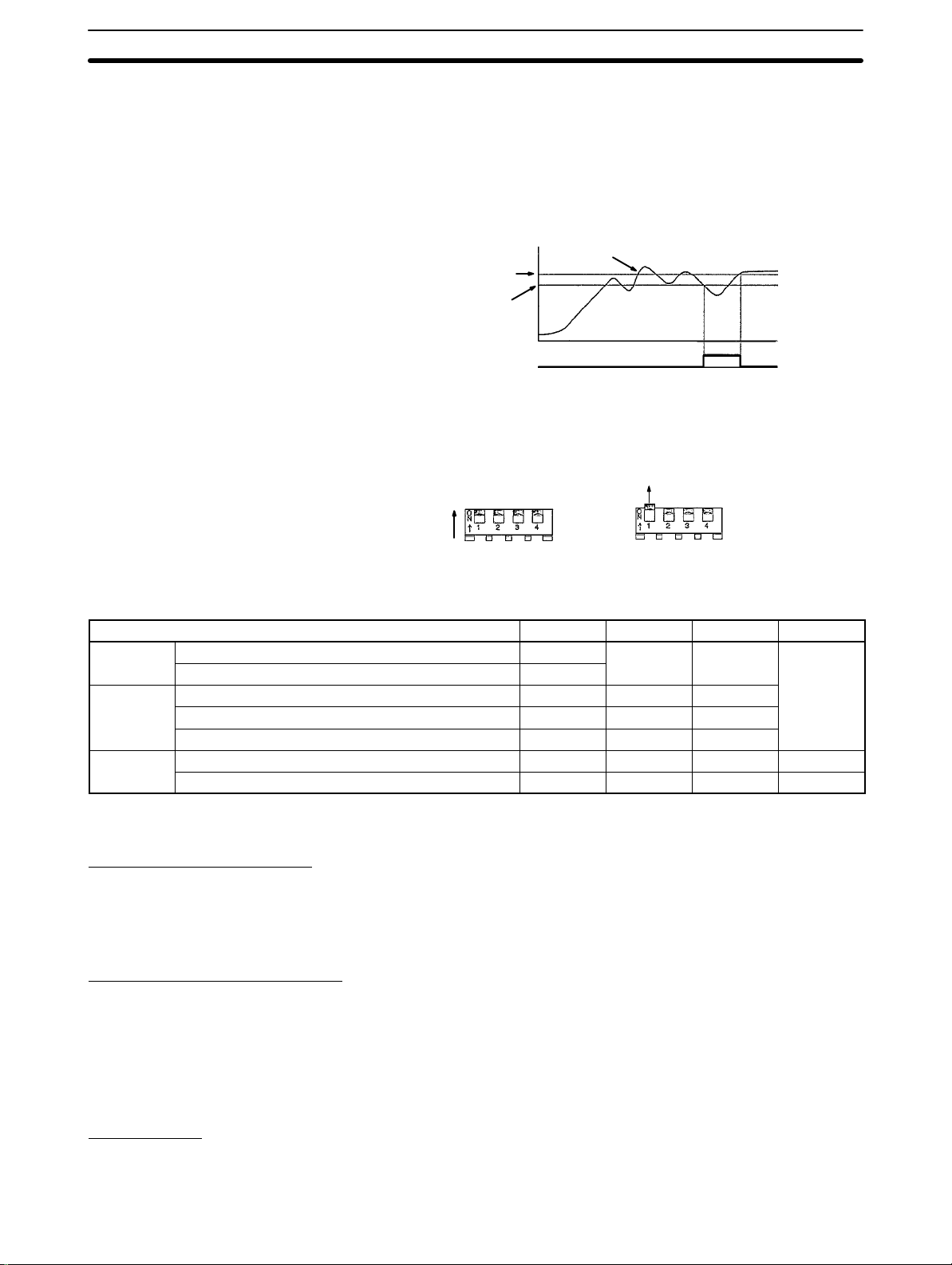

4-1-1 Step Response Tuning (SRT)

SRT is used to obtain all PID constants using a step response method when the

Temperature Controller starts operations.

SRT is also used when the set point changes value exceeding a set range while

the Temperature Controller is operating. After SRT has been executed, no SRT

will be executed the next time the Temperature Controller starts operating, unless the set point has been changed.

Set point

Max. temperature slope R

Dead time L

Tuning at startup

P X 1.27

In step response tuning, control is completely imposed stepwise to measure the maximum temperature slope (R) and

dead time (L), and the most ideal PID constants for the device are obtained from R and L.

Output (%)

100

100% imposed

step-wise control

amount.

Note Be sure to turn on the power supply to the load either before or simultaneously

Advanced PID

with the start of Temperature Controller operation. When using the E5AJ-A2HB

or E5EJ-A2HB, you can change the RUN/STOP setting to RUN via event input

2 after supplying power to the load.

Dead time will be measured from the time the Temperature Controller starts

operating. If a load such as a heater is turned on after the Temperature Controller is turned on, dead time longer than the actual value will be measured and

inappropriate PID constants will be obtained. If an extremely large amount of

dead time is measured, the control amount will be set to 0% for a short period of

time before being returned to 100%, and the constants will then be retuned.

Retuning is performed only for large amounts of dead time, so be sure to follow

the precaution given above when starting operation.

28

Page 31

Fuzzy Self-tuning Operation Section 4-1

SRT Startup Condition SRT will be ON if the following conditions are satisfied simultaneously when the

Temperature Controller is turned on or the set point is changed.

Imposition Completion

Condition of Step Control

Amount

PID Constant Refreshing

Conditions

At the time the Temperature Controller

starts operating

1) The set point at the time the

Temperature Controller starts operating

is different from the set point used at

the time SRT was last executed (see

note).

2) The difference between the set point

and the process value at the time the

Temperature Controller starts operating

is larger than the present proportional

band value (P) x 1.27 + 4.

3) The process value at the time the

Temperature Controller starts operating

is smaller than the set point in reverse

operation and larger than the set point

in normal operation.

At the time set point is changed

1) The new set point is different from

the set point used at the time SRT

was executed last (see note).

2) The set point changing range is

larger than the present

proportional band value (P) x 1.27

+ 4.

3) The process value is in stable

condition before the set point is

changed.

4) A larger set point value is set in

reverse operation and a smaller

set point is set in normal operation.

Note The last SRT-executed set point is set to 0 before shipping and when changing

from advanced PID control to advanced PID control with fuzzy self-tuning.

In order to prevent overshooting, the step controlled amount must be imposed

continuously only while the present deviation is the same as or greater than the

value obtained from the proportional band (P)1.27. The step control will not be

applied when the deviation becomes smaller than this value.

If the step control amount is applied before the maximum temperature slope (R)

is obtained, SRT will not renew any PID constant. If the proportional band obtained from the R and L values that were measured before the imposition had

been completed is larger than the present proportional band, the PID constants

will be renewed because the measured value is in the direction towards the suitable proportional band value, and the set point at that time will be the SRTexecuted set point.

4-1-2 Disturbance Tuning (DT)

DT is used to measure the control waveform and adjust the PID constants when

the measured temperature becomes unstable. When there are control characteristic changes after the PID constants are refreshed with SRT or when the PID

constants are not suitable to the object to be controlled because SRT was not

executed, the PID constants will be adjusted with DT.

DT at the Time of Operation

Start and Set Value Change

Set point

PID before tuning PID after tuning

If there is overshooting at the time the Temperature Controller restarts operating

after SRT has been executed, DT adjusts the PID constants so that the set point

response waveform will be as close as possible to the most ideal response waveform aft e r i t i s deemed that there has been a characteristics change in the control system.

Stable range (set to 15.0°C before shipping)

Stability judgement time

Measurement of

set point response

waveform

The set point response waveform

at the time the Temperature Controller restarts operation will be

closer to the most ideal response

waveform.

29

Page 32

Fuzzy Self-tuning Operation Section 4-1

DT at the Time of External

Disturbance Response

After the process value reaches the set point and becomes stable, if the process

value is disturbed and the disturbance exceeds the stable range, the disturbance is regarded as external disturbance At the time of disturbance, DT measures the external disturbance waveform and adjusts the PID constants so that

the external disturbance waveform will be as close as possible to the most ideal

external disturbance response waveform.

Stable range

(set to 15.0°C before shipping)

Set point

External disturbance

Stability judgement time

Measurement of

external disturbance

response waveform

External disturbance

The external disturbance response waveform is approaching to

the most ideal response waveform even if the same kind of

external disturbance reoccurs. The waveform will not, however,

change if the most ideal PID constants are already set.

PID after tuningPID before tuning

Startup Conditions of DT DT is used to monitor the control waveform if there is external disturbance or

SRT does not work at the time the Temperature Controller starts operating or at

the time of set point change. If the measured waveform is not an ideal waveform,

DT will be ON. If either one of the following conditions is satisfied, the control

waveform will be monitored.

1, 2, 3...

1. SRT Startup conditions 3 and 4 on page 29 are satisfied but neither 1 nor 2 is

satisfied.

2. There has been an external disturbance exceeding the stable range after

the process value was in stable condition.

Note The stable range is set to 27°F with the E5J--F.

4-1-3 Hunting Tuning (HT)

If there is hunting due to characteristics changes of the control system, HT is

used to measure the hunting waveform and adjust the PID constants to suppress the hunting.

Set point

PID before tuning PID after tuning

Extreme value

Stable range

(set to 15.0°C before shipping)

Measurement of

hunting waveform

Startup Conditions of HT HT will be ON when there is hunting with four or more maximum temperature

values while SRT is not being executed.

Note If the periodic temperature changes of the application exceed the stable range

(set to 15.0°C at the factory) due to continuous external disturbance (i.e., the

temperature is a ffected by an external disturbance before stabilizing after a previous external disturbance (refer to figure A below)), the user should change the

stable range to a value greater than the temperature changing range, otherwise

30

Page 33

Troubleshooting

Section 4-2

HT may change the PID constants even though the PID constants are ideal for

the control system. Refer to

External disturbance

Figure A: Waveform with HT turned ON

External disturbance

9-1 Engineering Level

for details.

Note The stable range is set to 27°F with the E5J--F.

4-2 Troubleshooting

Fuzzy self-tuning may not exhibit its full capability due to the characteristics and

conditions of the controlled object.

Refer to the following table for troubleshooting when Unit operation is not

smooth.

Phenomenon Probable cause Countermeasure

The temperature does not reach the

set point.

T1 T2

Figure B: Waveform with HT turned OFF

The dead time measured was longer

than the actual value and

inappropriate PID constants were

obtained because the load (such as a

heater) was turned on after the

Temperature Controller started

operating. (Refer to

details.)

The PID constants were changed from

the most ideal value because HT is

ON continuously when there was a

periodic temperature change larger

than the stable range due to an

external disturbance. Refer to the note

under 4-1-3.

4-3-6 Startup

for

T1<T2

Do the following to execute SRT

again.

1) Set the control mode to the

advanced PID and set the

proportional band to 0.1°C.

2) Set the control mode to the

advanced PID with fuzzy

self-tuning again.

3) Wait until the temperature of the

control system is stable, and then

turn on the Temperature Controller

and the load simultaneously or

turn on the load first for SRT.

Do either one of the following so that

HT will not be ON.

• Change the stable range to a

wider setting than the range of the

temperature change and execute

SRT again by executing steps 1)

to 3) above.

• After obtaining the most ideal PID

constants by executing steps 1) to

3) above, set the control mode to

advanced PID.

31

Page 34

Terminology

Phenomenon CountermeasureProbable cause

Hunting does not stop. The control period is too long for the

characteristics of the controlled

device, which causes hunting in

synchronization with the control

period.

The temperature is influenced by

continuous external disturbance (i.e.,

the temperature is affected by an

external disturbance before a previous

disturbance has be stabilized. and it

looks as if hunting did not stop at all).

The response fluctuates, becoming

good and bad.

The response fails to reach

operational requirements.

There is a heater or cooling device not

controlled by the control output of the

Temperature Controller (e.g., forced

heating or cooling is executed using

alarm outputs).

There are continuous characteristics

changes.

The response speed of the controlled

device is so fast that it cannot be

retrieved by a sampling period of 500

ms.

The temperature is affected by

devices near the system.

Section 4-3

Shorten the control period.

In this case, however, 100%

improvement will not be possible

because the temperature is influenced

by a continuous external disturbance

instead of hunting. Change the stable

range to a wider setting than the

range of the temperature change so

that HT will not be ON.

In this case fuzzy self-tuning may not

work. Set the control mode to the

advanced PID and adjust the PID

constants manually.

Do either one of the following.

• Adjust the stable range so that

fuzzy self-tuning will not be turned

ON.

• Set the control mode to the

advanced PID and adjust the PID

constants manually.

The Thermac E5J Temperature

Controller cannot support a sampling

period of less than 500 ms. Use an

ES100-series Digital controller, which

has a shorter sampling period.

Fuzzy self-tuning does not support

any countermeasure against

interference. Set the control mode to

the advanced PID and adjust the PID

constants manually.

4-3 Terminology

4-3-1 Stable Value, Stable Range, and Stability Judgement Time

If the measured value continuously coincides with the set point, it can be said

that the measured value is stable. The measured value will not continuously

coincide perfectly with the set point if there is noise inference. It is, however, possible to make the measured value stay within a permissible range called the

stable range. Even if the temperature is within the stable range, the Temperature

Controller may respond to external disturbance or hunting. Therefore, it cannot

be said that the temperature is stable unless the temperature stays within the

stage range continuously for a certain time. This time is called stability judgement time. Like PID constants, stability judgement time is adjusted with fuzzy

self-tuning according to the characteristics of the object to be controlled. Fuzzy

32

Page 35

Terminology

Section 4-3

self-tuning will not be activated if the temperature is stable because the Temperature Controller deems that temperature control is smooth.

Shorter than the stability judgement time.

Set point

4-3-2 Hunting

Set pointSet point

Stable range

Stable range

(Set to 15.0°C before shipping)

Stability judgement time

Stable Stable

Note The stable range is set to 27°F with the E5J--F.

If the PID constants are not suitable to the controlled device, the measured value

will fluctuate and will not coincide with the set point, this phenomenon is called

hunting. Hunting is also called cycling.

4-3-3 Characteristics and Characteristics Change

The angle of the maximum temperature slope (R) of the controlled device (i.e.,

whether the temperature rise of the device is fast or slow) and the dead time (L)

of the controlled device (i.e., how fast the change in the output of the Temperature Controller influences the temperature) vary with the characteristics of the

controlled device. The PID constants must be set according to the characteristics of the controlled device. A characteristics change is the change of the characteristics of the c o n t r o l l e d device due to the change of its thermal capacity and

the change of the supply voltage. If there is a characteristics change, the PID

constants must be adjusted according to the new characteristics.

4-3-4 External Disturbance

External disturbance is an external factor that disturbs the temperature that has

been stable within the most ideal PID constants for the controlled device.

4-3-5 Interference

If devices, such as heaters, controlled by different temperature controllers are

physically close to one another, the heaters are mutually influenced and the temperature of each heater are affected. This phenomenon is called interference. If

there is serious interference, it will be difficult for each temperature controller to

control the device, and special controlled methods taking this interference into

consideration will be required.

33

Page 36

Terminology

4-3-6 Startup

Section 4-3

Startup means that the Temperature Controller starts operating. The following

conditions are required to operate the Temperature Controller.

• The Temperature Controller must be turned ON.

• No sensor error has occurred.

• If a model with event input 2 is used, event input 2 must be set to RUN.

Event input 2 is set to RUN before shipping.

The Temperature Controller will not start operating until all the above conditions

are satisfied.

34

Page 37

Installation and Wiring

This section describes the installation and wiring of the Thermac E5J Temperature Controller.

5-1 Installation 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1-1 Dimensions and Mounting Holes 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1-2 Mounting Method 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Wiring 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2-1 Connection 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 Terminal Arrangement 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5

35

Page 38

Installation Section 5-1

5-1 Installation

Install the E5J in the following places.

1, 2, 3...

1. Where there is little mechanical vibration or shock.

2. Where there is no corrosive gas such as sulfide gas.

3. Where the ambient temperature is within –10° to 55°C.

4. Where there is no high heat radiation.

5. Where there is no high tension lines, welding machines or other devices

generating electrical noise.

6. Where the E5J is not influenced by any electromagnetic field.

7. Where there is little dust or oily smoke.

8. Where the E5J is not sprayed with water.

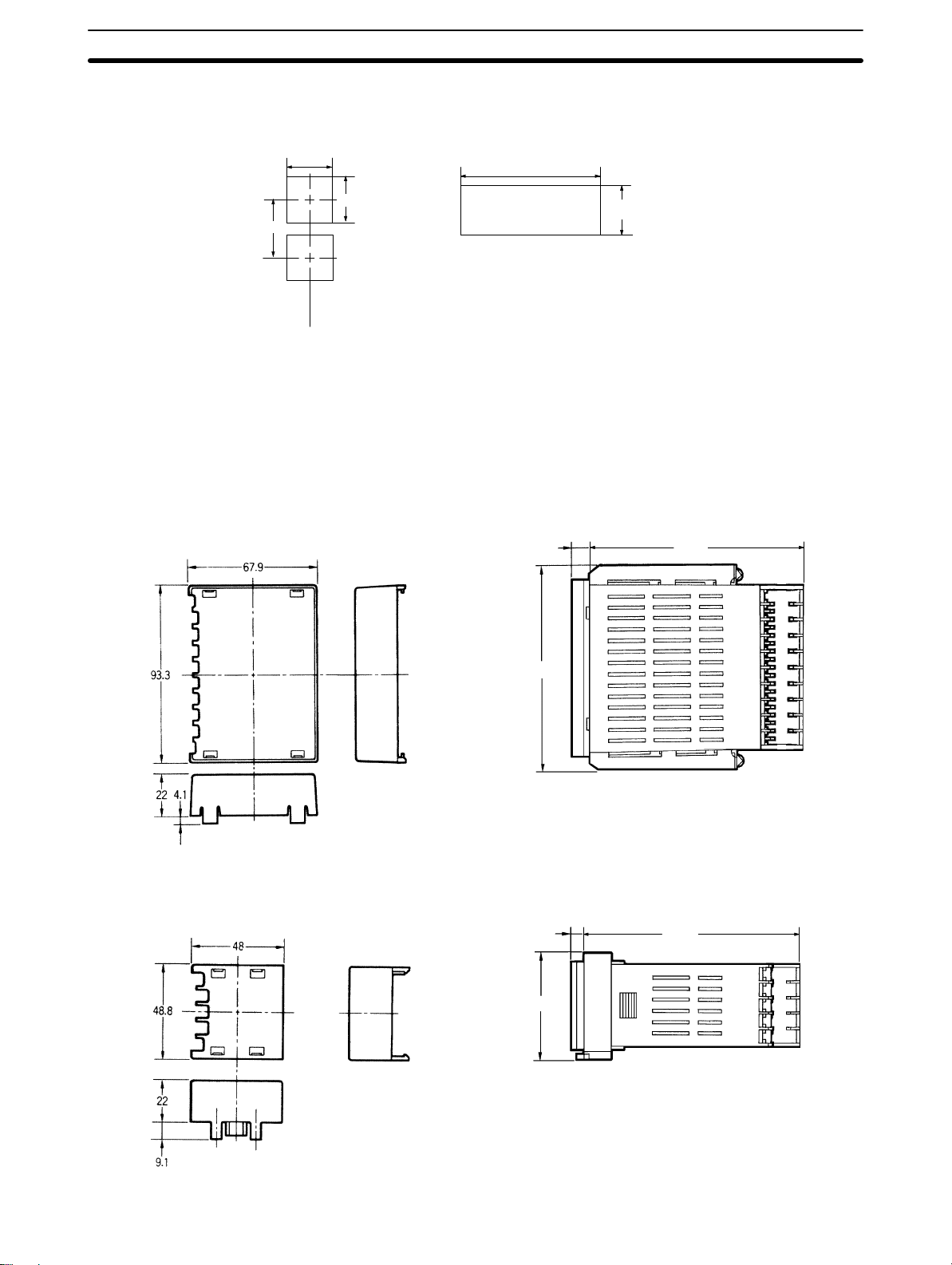

5-1-1 Dimensions and Mounting Holes

Refer to the

Appendix Dimensions and Mounting Holes

.

5-1-2 Mounting Method

E5AJ and E5EJ Open a square hole in the panel to which the E5J is to be mounted, mount the

E5J, attach the two mounting brackets provided with the E5J to the upper

and lower sides of the E5J, and secure them with a Phillips screwdriver by

turning the Phillips screwdriver clockwise until the ratchets of the mounting

brackets click.

Mounting bracket

Panel

Watertight packing

E5CJ Open a square hole in the panel to which the E5CJ is to be mounted, mount the

E5CJ, attach the adapter provided with the E5CJ as shown in the following illustration to reduce the space between the E5CJ and panel, and secure the

adapter with the tightening screw.

Panel

Adapter

36

Mounting screw

Page 39

Wiring

5-2 Wiring

Section 5-2

Refer to the terminal arrangements to wire the E5J. Before wiring, observe the

following.

1, 2, 3...

1. When connecting extension wires to the thermocouple, use proper compensating lead wires.

2. When connecting extension wires to the platinum resistance thermometer,

use three low-resistance wires of equal resistance.

3. The power supply must not be influenced by noise. If necessary use a noise

filter.

4. All the wires connected to the input circuitry must be separated from the

wires connected to the power supply or output circuitry.

5. Use shielded wires where static inductance noise is present.

6. Twist the input wires evenly and closely if there is any electromagnetic inductance noise.

5-2-1 Connection

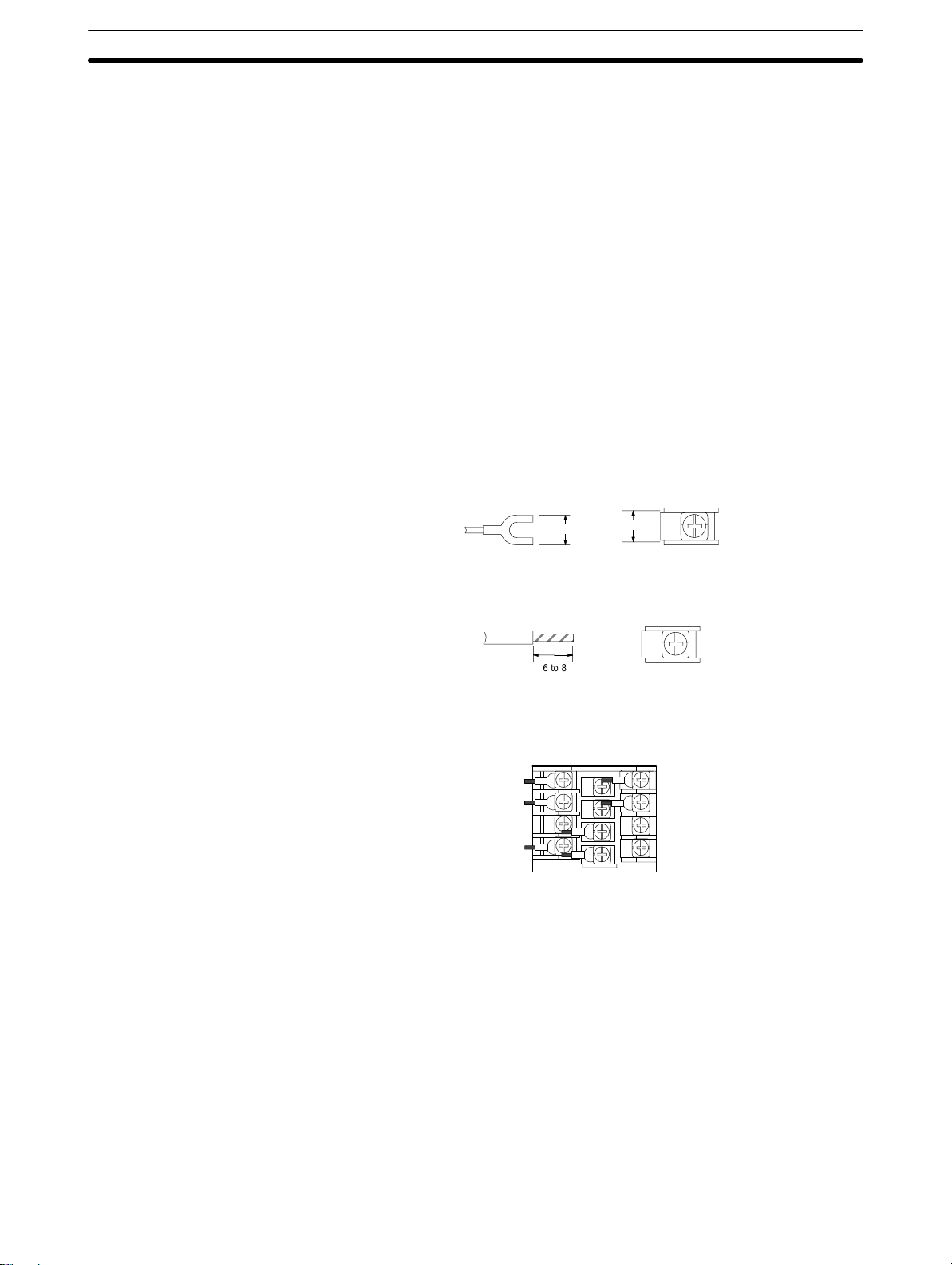

With Solderless Terminals Use solderless terminals for M3.5 screws. The terminal screws are M3.5 x 8 self-

up screws.

7.1 max.

Solder-dipped Leads It is possible to connect solder-dipped leads to the terminals with ease. The

length of each bare lead wire should be 6 to 8 mm.

7.3

6 to 8

For side-by-side mounting, Thermac J-series Temperature Controllers are designed so that all the lead wires can be connected to the terminals in the same

direction.

37

Page 40

Terminal Arrangement

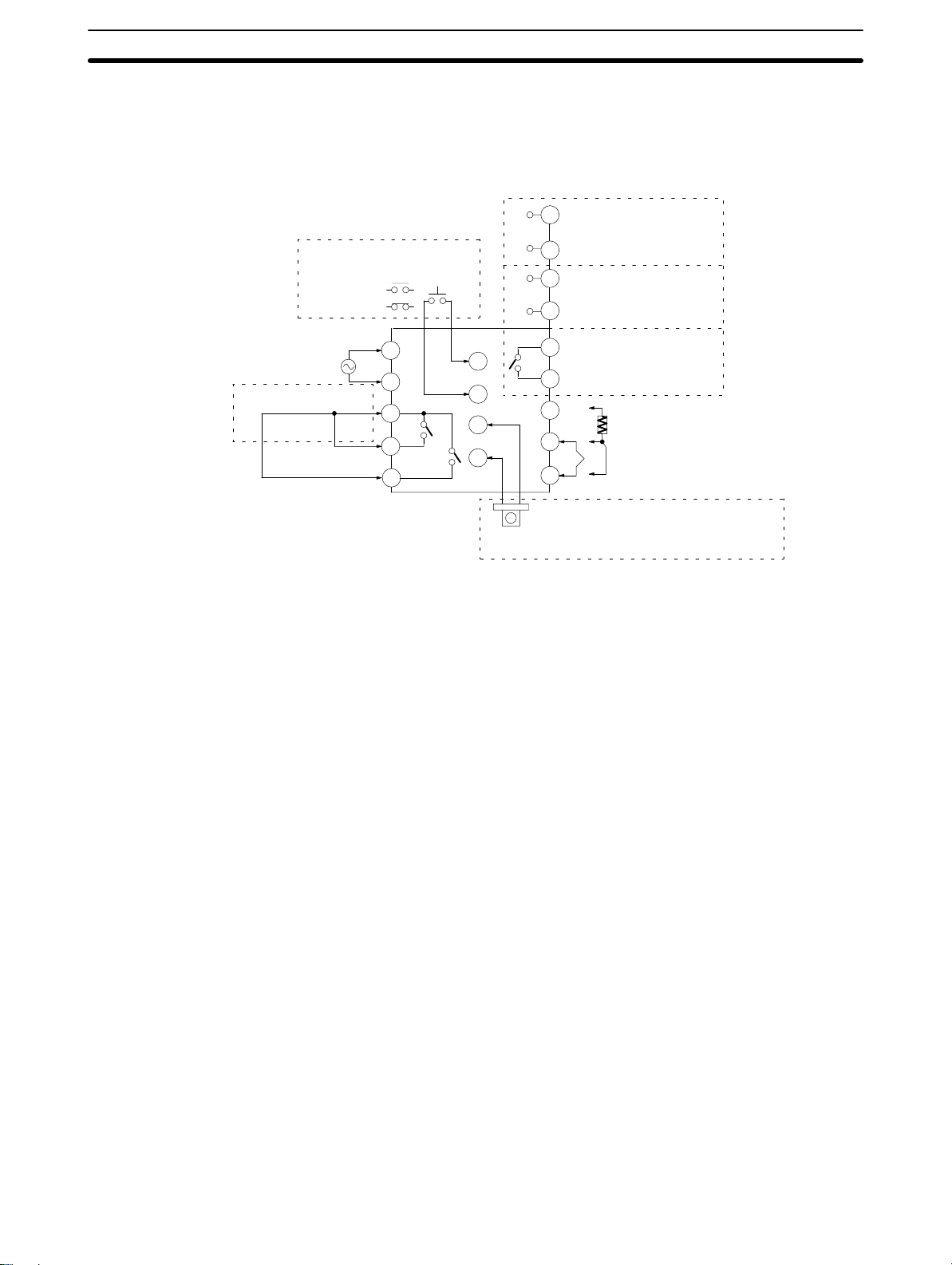

5-3 Terminal Arrangement

E5AJ/E5EJ Standard Model

Relay Output Unit

E53-R

8

250 VAC

5 A

100 to 240 VAC, 50 or 60 Hz, 14 V A

or

24 VAC, 50 or 60 Hz, 10 VA

24 VDC 6 W

Control outputSee note 1.

Alarm output 2

(ALM2)

(ALM1)

See note 3.

Alarm output 1

(Heater burnout

alarm and temperature alarm)

10

7

Current Output Unit

+53-C3

8

9

8

7

6

5

4

3

2

1

4 to 20 mA DC

7

– (600 Ω max.)

Voltage Output Unit

+E53-Q

8

12 VDC

7

– (40 mA max.)

+E53-Q3

8

– 24 VDC

7

(20 mA max.)

250 VAC

3A

250 VAC

3A

Q4

Write the name

of the Output

Unit to be used

on the nameplate on the

side of the

case.

20

29

28

27

26

25

24

23

22

21

+

19

+

18

17

–

16

15

14

13

12

11

CT

Section 5-3

See note 2.

Event input 1 (EV1)

Externally selects the set point.

Open

Short-circuit

Event input 2 (EV2)

Selects RUN or STOP.

Open

Short-circuit

A

–

B

+

B

Use the E54-CT1 with a hole diameter of

5.8 mm or E54-CT3 with a hole diameter

of 12 mm (both sold separately).

: Set point 0

: Set point 1

: RUN

: STOP

Note 1. The E53-C cannot be used.

2. The event input terminals and voltage output and current output terminals

are not insulated.

3. Only the heater burnout alarm will be output from the alarm output 1 terminals if alarm mode switch 1 is set to 0. Only the temperature alarm will be

output if the heater burnout alarm value is set to 0.0 A.

E5AJ/E5EJ with Communications Function

Relay Output Unit

8

10

7

Current Output Unit

+53-C3

8

9

8

7

6

5

4

3

2

1

4 to 20 mA DC

7

– (600 Ω max.)

Voltage Output Unit

+E53-Q

8

7

– 40 mA max.

+E53-Q3

8

– 24 VDC

7

250 VAC

3A

250 VAC

3A

100 to 240 VAC, 50 or 60 Hz, 14 V A

or

24 VAC, 50 or 60 Hz, 10 VA

24 VDC 6 W

Control outputSee note 1.

Alarm output 2

(ALM2)

(ALM1)

Alarm output 1

See note 2.

(Heater burnout

alarm and temperature alarm)

E53-R

250 VAC

5 A

12 VDC

Q4

(20 mA max.)

Write the name

of the Output

Unit to be used

on the nameplate on the side

of the case.

Communications

terminal

29

28

27

26

25

24

23

22

21

CT

Communications terminal

RS-232C RS-422 RS-485

20

RD

SG

SD

SG

29

19

28

18

27

17

26

16

25

RDB

RDA

SG

SDA

SDB

20

29

19

28

18

27

17

26

16

25

20

19

18

17

16

20

29

19

28

18

27

17

26

16

25

15

14

13

12

11

A

–

B

+

B

Use the E54-CT1 with a hole diameter of

5.8 mm or E54-CT3 with a hole diameter

of 12 mm (both sold separately).

B(+)

A(–)

SG

A(–)

B(+)

38

Note 1. The E53-C cannot be used.

Page 41

Terminal Arrangement

E5CJ Standard Model

100 to 240 VAC, 50 or 60 Hz, 12 V A

or

24 VAC, 50 or 60 HZ, 10 VA

24 VDC 6 W

See note 2.

(Heater burnout alarm