Omron CS1W-SCU31-V1, CS1W-SCB21-V1, CJ1W-SCU31-V1, CJ1W-SCU41-V1, CS1W-SCU41-V1 Operation Manual

...Page 1

Cat. No. W336-E1-09

SYSMAC

CS/CJ Series

CS1W-SCB@@-V1

Serial Communications Boards

CS1W-SCU@@-V1 and

CJ1W-SCU@@-V1

Serial Communications Units

OPERATION MANUAL

Page 2

SYSMAC CS/CJ Series

Serial Communications Boards and

Serial Communications Units

Operation Manual

Revised February 2008

Page 3

iv

Page 4

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 1999

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3...

1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 5

vi

Page 6

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xx

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

7 Unit Versions of CS/CJ-series Serial Communications Boards/Units . . . . . . . . . . . . . . . . . xxiv

8 Functions Added in the Unit Version 1.3 Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxviii

9 Functions Added in the Unit Version 1.2 Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxviii

SECTION 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Using this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-3 Protocol Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-4 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1-5 System Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1-6 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1-7 Comparison to Previous Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

1-8 Selecting the Serial Communications Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

1-9 Basic Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

SECTION 2

Initial Settings and I/O Memory Allocations . . . . . . . . . . . . 61

2-1 Component Names and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

2-2 Data Exchange with the CPU Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

2-3 I/O Memory Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

SECTION 3

Installation and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

3-1 Installing a Serial Communications Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

3-2 Installing Serial Communications Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

3-3 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

3-4 RS-232C and RS-422A/485 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

SECTION 4

Using Host Link Communications . . . . . . . . . . . . . . . . . . . . 123

4-1 Host Link Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

4-2 Setup Area Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

4-3 Auxiliary Area and CIO Area Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

4-4 Communications Timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

4-5 Changes from Previous Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

4-6 Host Link Function for Replacing Existing PLCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

vii

Page 7

TABLE OF CONTENTS

SECTION 5

Using Protocol Macros . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

5-1 Overview of the Protocol Macro Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

5-2 Setup Area Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

5-3 Auxiliary Area and CIO Area Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

5-4 Using Protocol Macros . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

5-5 Simple Backup Function (Backup of Protocol Macro Data). . . . . . . . . . . . . . . . . . . . . . . . . 187

5-6 Enhanced Protocol Macro Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

SECTION 6

Serial Gateway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

6-1 Serial Gateway Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .196

6-2 DM Area Allocations (Using Serial Gateway Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

6-3 Auxiliary Area and CIO Area in Serial Gateway Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

6-4 Using the Serial Gateway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .208

6-5 Protocol Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

6-6 Serial Gateway. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

6-7 Conditions Requiring Routing Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

6-8 Communications Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

SECTION 7

No-protocol Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

7-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

7-2 Allocation DM Area for No-protocol Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

7-3 Auxiliary Area and CIO Area Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

7-4 Basic Operating Procedure in No-protocol Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

SECTION 8

Using 1:N NT Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

8-1 Overview of 1:N NT Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

8-2 Setup Area Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

8-3 Auxiliary Area and CIO Area Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

SECTION 9

Using Modbus-RTU Slave Mode

(Unit Version 1.3 or Later). . . . . . . . . . . . . . . . . . . . . . . . . . . 273

9-1 Modbus-RTU Slave System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

9-2 Setup Area Allocations (Modbus-RTU Slave Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

9-3 Auxiliary Area and CIO Area Allocations (Modbus-RTU Slave Mode) . . . . . . . . . . . . . . . 278

9-4 Communications Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

9-5 Changes from Previous Products. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

9-6 Modbus-RTU Slave Function for Replacing Existing PLCs. . . . . . . . . . . . . . . . . . . . . . . . . 298

viii

Page 8

TABLE OF CONTENTS

SECTION 10

Loopback Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

10-1 Executing Loopback Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .304

10-2 Setup Area Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

10-3 CIO Area Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

SECTION 11

Troubleshooting and Maintenance . . . . . . . . . . . . . . . . . . . . 307

11-1 Indicator Error Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

11-2 Status Area Error Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .311

11-3 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

11-4 Error Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

11-5 Cleaning and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 354

11-6 Replacement Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .355

Appendices

A Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

B CompoWay/F Master Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

C C-mode (Host Link) Command Master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 393

D Host Link FINS Command Master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 417

E Mitsubishi Computer Link Master (A-compatible 1C Frame, Model 1) . . . . . . . . . . . . . . . 441

FE5@K Digital Controller Read Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 465

GE5@K Digital Controller Write Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 485

H E5ZE Temperature Controller Read Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 501

I E5ZE Temperature Controller Write Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 523

JE5@J Temperature Controller Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 543

KES100@ Digital Controller Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 559

LK3T@ Intelligent Signal Processor Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 599

M V500/V520 Bar Code Reader Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 621

N 3Z4L Laser Micrometer Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 633

O Visual Inspection System Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 669

P V600/V620 ID Controller Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 689

Q Hayes Modem AT Command Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 727

R Changing Communications Port Settings Using STUP(237) . . . . . . . . . . . . . . . . . . . . . . . 735

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 739

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 749

ix

Page 9

x

Page 10

About this Manual:

This manual describes the installation and operation of the SYSMAC CS/CJ-series CS1W-SCB@@-V1

Serial Communications Boards and CS1W-SCU@@-V1 and CJ1W-SCU@@-V1 Serial Communications Units and includes the sections described on the next page.

The Serial Communications Boards are classified as Inner Boards and the Serial Communications

Unit is classified as a CPU Bus Unit.

Please read this manual and all related manuals listed in the following table carefully and be sure you

understand the information provided before attempting to install and operate a Serial Communications

Board or Unit.

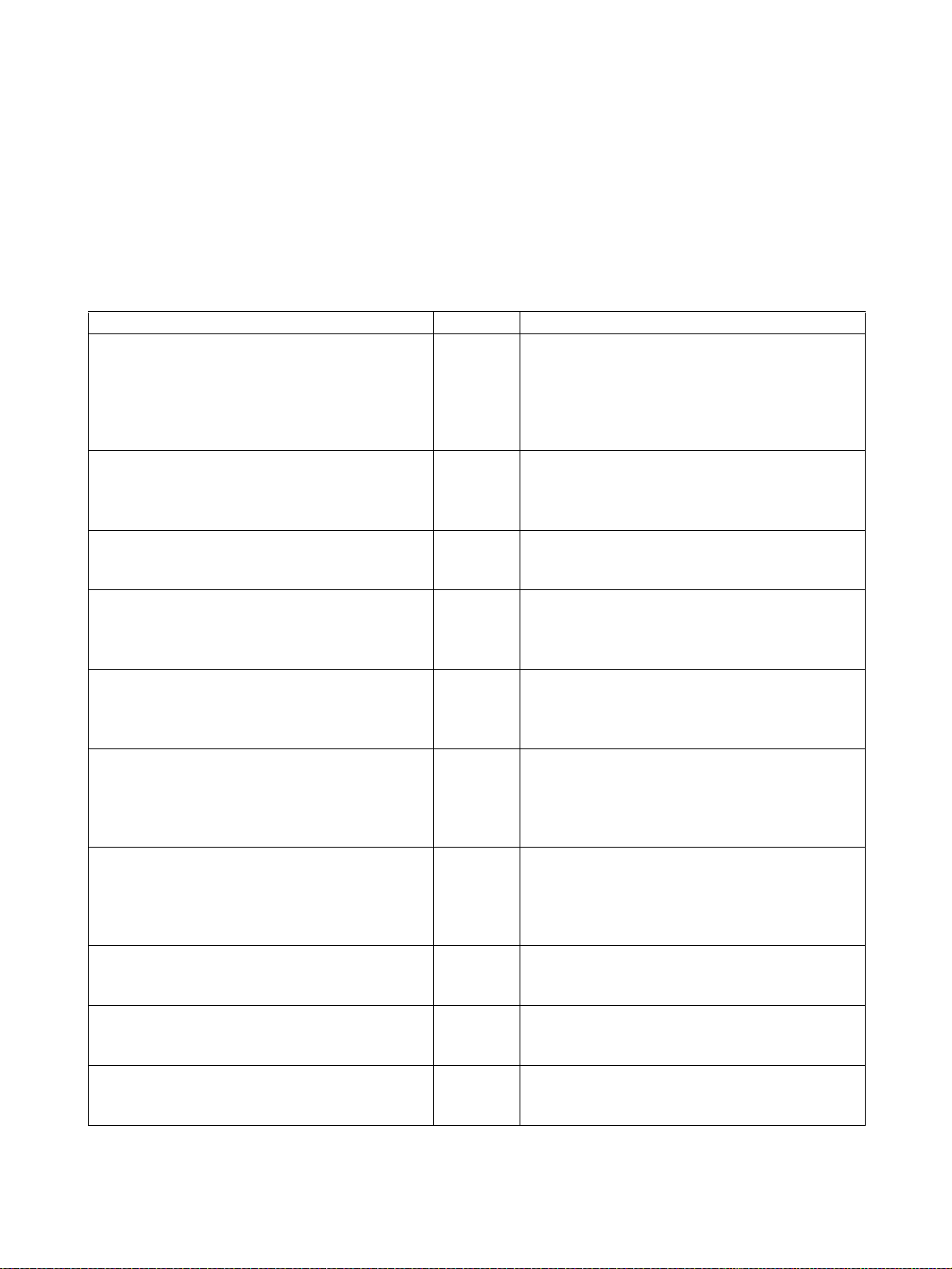

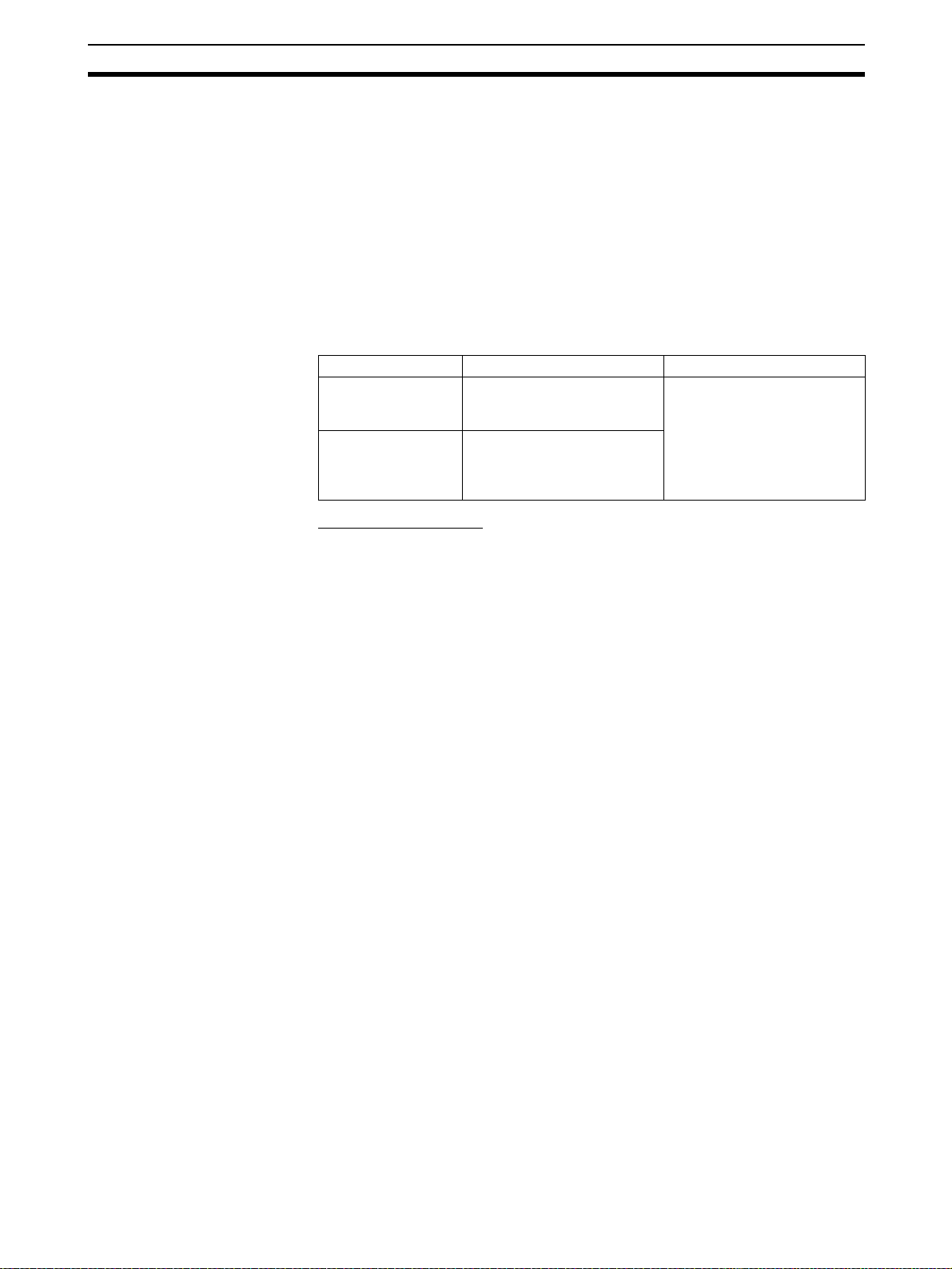

Name Cat. No. Contents

SYSMAC CS/CJ-series

CS1W-SCB@@-V1, CS1W-SCU@@-V1,

CJ1W-SCU@@-V1

Serial Communications Boards and

Serial Communications Unit Operation Manual (this

manual)

SYSMAC CS/CJ-series

CQM1H-PRO-E1, CQM1-PRO01-E,

C200H-PRO27-E

Programming Consoles Operation Manual

SYSMAC CS-series CS1G/H-CPU@@H, CS1G/H-

CPU@@-EV1

Programmable Controllers Operation Manual

SYSMAC CJ-series

CJ1G/H-CPU@@H, CJ1M-CPU@@,

CJ1G-CPU@@

Programmable Controllers Operation Manual

SYSMAC CS/CJ-series CS1G/H-CPU@@-EV1,

CS1G/H-CPU@@H,

CJ1G-CPU@@-E, CJ1G/H-CPU@@H

Programmable Controllers Programming Manual

SYSMAC CS/CJ-series CS1G/H-CPU@@H, CS1G/

H-CPU@@-EV1, CJ1G/H-CPU@@H, CJ1G-CPU@@,

CJ1M-CPU@@

Programmable Controllers

Instructions Reference Manual

SYSMAC CS/CJ-series

CS1G-/H-CPU@@H, CS1G/H-CPU@@-E, CS1WSCB@@-V1, CS1W-SCU@@-V1, CJ1G/H-CPU@@H,

CJ1G-CPU@@, CJ1W-CPU@@, CJ1W-SCU@@-V1

Communications Commands Reference Manual

SYSMAC WS02-CXPC1-E-V60

CX-Programmer Operation Manual

SYSMAC WS02-PSTC1-E

CX-Protocol Operation Manual

SYSMAC CS/CJ-series

CS1W-ETN01, CS1W-ETN11, CJ1W-ETN11

Ethernet Unit Operation Manual

W336 Describes the use of Serial Communications Unit

and Boards to perform serial communications with

external devices, including the usage of standard

system protocols for OMRON products.

W341 Provides information on how to program and operate

CS/CJ-series PLCs using a Programming Console.

W339 Describes the installation and operation of the CS-

series PLCs.

W393 Describes the installation and operation of the CJ-

series PLCs.

W394 Describes the ladder diagram programming functions

and other functions supported by CS-series and CJseries PLCs.

W340 Describes the ladder diagram programming instruc-

tions supported by CS-series and CJ-series PLCs.

W342 Describes the Host Link and FINS communications

commands used with CS-series and CJ-series PLCs.

W446 Provides information on how to use the CX-Program-

mer, a programming device that supports the CSseries and CJ-series PLCs.

W344 Describes the use of the CX-Protocol to create proto-

col macros as communications sequences to communicate with external devices.

W343 Describes the installation and operation of CS1W-

ETN01, CS1W-ETN11, and CJ1W-ETN11 Ethernet

Unit.

xi

Page 11

About this Manual, Continued

This manual contains the following sections.

Section 1 introduces the hardware and software functions of the Serial Communications Boards and

the Serial Communications Units, including the communications modes, system configurations, and

specifications.

Section 2 describes the components of the Serial Communications Boards and the Serial Communications Units, the settings required for operation, and the memory allocated in the I/O memory of the

CPU Unit for controlling and monitoring communications.

Section 3 describes how to mounting the Serial Communications Boards and Serial Communications

Units, and how to connect the ports to external devices.

Section 4 describes the procedure and other information required to use Host Link communications.

Section 5 describes the procedure and other information required to use protocol macros.

Section 6 provides an overview of the Serial Gateway, information on I/O memory allocations, and

procedures for using the functions. Information on protocol conversion, routing table requirements, and

communications frames is also provided. The Serial Gateway can be used only for Unit Ver. 1.2 or

later.

Section 7 describes the procedure and other information required to use the no-protocol mode. This

mode is supported for Unit Ver. 1.2 or later only.

Section 8 describes the procedure and other information required to use 1:N NT Links to Programmable Terminals.

Section 9 describes the procedure and other information required to use Modbus-RTU slave mode.

Section 10 describes the procedure and other information required to conduct loopback test to check

the serial ports.

Section 11 describes the troubleshooting and maintenance procedures for the Serial Communications

Boards and the Serial Communications Units.

Appendix A to Appendix Q provide the specifications of the standard system protocols.

Appendix R provides information on using STUP(237) to change serial port settings.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

xii

Page 12

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xiii

Page 13

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xiv

Page 14

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xv

Page 15

xvi

Page 16

PRECAUTIONS

This section provides general precautions for using the CS/CJ-series Serial Communications Boards and Units.

The information contained in this section is important for the safe and reliable application of Programmable

Controllers. You must read this section and understand the information contained before attempting to set up or

operate a PLC system.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

6-1 Applicable Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

6-2 Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

6-3 Conformance to EC Directives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

6-4 EMI Measures for Serial Communications Boards and Units . . . . . xxiii

6-5 EMS Measures for Serial Communications Units . . . . . . . . . . . . . . xxiv

7 Unit Versions of CS/CJ-series Serial Communications Boards/Units . . . . . . xxiv

8 Functions Added in the Unit Version 1.3 Upgrade . . . . . . . . . . . . . . . . . . . . . xxviii

9 Functions Added in the Unit Version 1.2 Upgrade . . . . . . . . . . . . . . . . . . . . . xxviii

xvii

Page 17

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual close at hand for reference during operation.

!WARNING It is extremely important that a PLC and all PLC Units be used for the speci-

fied purpose and under the specified conditions, especially in applications that

can directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PLC System to the above-mentioned applications.

3 Safety Precautions

!WARNING Provide safety measures in external circuits (i.e., not in the Programmable

Controller), including the following items, to ensure safety in the system if an

abnormality occurs due to malfunction of the PLC or another external factor

affecting the PLC operation. Not doing so may result in serious accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PLC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instruction is executed.

As a countermeasure for such errors, external safety measures must be

provided to ensure safety in the system.

• The PLC outputs may remain ON or OFF due to deposition or burning of

the output relays or destruction of the output transistors. As a countermeasure for such problems, external safety measures must be provided

to ensure safety in the system.

• When the 24-V DC output (service power supply to the PLC) is overloaded or short-circuited, the voltage may drop and result in the outputs

xviii

Page 18

Operating Environment Precautions 4

being turned OFF. As a countermeasure for such problems, external

safety measures must be provided to ensure safety in the system.

!WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing

so may result in electric shock.

!WARNING Do not touch any of the terminals or terminal blocks while the power is being

supplied. Doing so may result in electric shock.

!WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do

so may result in malfunction, fire, or electric shock.

!Caution Execute online edit only after confirming that no adverse effects will be

caused by extending the cycle time. Otherwise, the input signals may not be

readable.

4 Operating Environment Precautions

!Caution Do not operate the control system in the following places:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

!Caution Take appropriate and sufficient countermeasures when installing systems in

the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

!Caution The operating environment of the PLC System can have a large effect on the

longevity and reliability of the system. Improper operating environments can

lead to malfunction, failure, and other unforeseeable problems with the PLC

System. Be sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life

of the system. Follow all installation instructions and precautions provided in

the operation manuals.

xix

Page 19

Application Precautions 5

5 Application Precautions

Observe the following precautions when using the PLC System.

!WARNING Always heed these precautions. Failure to abide by the following precautions

could lead to serious or possibly fatal injury.

• Always connect to a ground of 100

connecting to a ground of 100

• Always turn OFF the power supply to the PLC before attempting any of

the following. Not turning OFF the power supply may result in malfunction

or electric shock.

• Mounting or dismounting Power Supply Units, I/O Units, CPU Units,

Serial Communications Units, or any other Units.

• Assembling the Units.

• Setting DIP switches or rotary switches.

• Connecting cables or wiring the system.

• Mounting or dismounting terminal blocks.

!Caution Failure to abide by the following precautions could lead to faulty operation of

the PLC or the system, or could damage the PLC or PLC Units. Always heed

these precautions.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal

lines, momentary power interruptions, or other causes.

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied. Be particularly careful in places

where the power supply is unstable. An incorrect power supply may result

in malfunction.

• Tighten the mounting screws at the bottom of Serial Communications

Units to a torque of 0.4 N

malfunction.

• Leave the label attached to the Unit when wiring. Removing the label may

result in malfunction if foreign matter enters the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Always check polarity before wiring RS-422A/485 connectors. The polarity for the SDA/B and RDA/B signals can be different for some external

devices.

• Check to be sure that terminating resistors have been correctly installed

for RS-422A/485 systems before starting operation.

• Disconnect the LG terminal of the Power Supply Unit from the GR terminal when performing insulation and dielectric strength tests.

• Never turn OFF the power supply while writing protocol macro data.

• Wire all connections correctly according to instructions in this manual.

• Check terminal blocks completely before mounting them.

• Double-check all wiring and switch settings before turning ON the power

supply. Incorrect wiring may result in burning.

⋅m. An incorrect tightening torque may result in

Ω or less when installing the Units. Not

Ω or less may result in electric shock.

xx

Page 20

Application Precautions 5

• Be sure that the Bus Connection Unit and other items with locking devices

are properly locked into place. Improper locking may result in malfunction.

• Check the user program for proper execution before actually running it on

the Unit. Not checking the program may result in an unexpected operation.

• Confirm that no adverse effect will occur in the system before attempting

any of the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PLC (including the setting of the

startup operating mode).

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Do not install the product near devices generating strong high-frequency

noise.

• Do not drop the product or subject it to excessive vibration or shock.

• Observe the following precautions for communications cables.

• Do not lay communications cables near power lines or high-voltage

lines.

• Always lay communications cables in ducts.

• Do not pull on the communications cables or bend the communications

cables beyond their natural limit. Doing either of these may break the

cables.

• Do not place objects on top of the communications cables or other wiring lines. Doing so may break the cables.

• Before touching a Unit, be sure to first touch a grounded metallic object in

order to discharge any static built-up. Not doing so may result in malfunction or damage.

• Resume operation only after transferring to the new CPU Unit the contents of the DM Area, HR Area, and other data required for resuming

operation. Not doing so may result in an unexpected operation.

• Do not touch circuit boards or the components mounted to them with your

bare hands. There are sharp leads and other parts on the boards that

may cause injury if handled improperly.

• When transporting or storing Boards, wrap them in material that will protect LSIs, ICs, and other components from static electricity and be sure

that they remain within the storage temperature range.

• When creating Host Link FINS command frames using the CMND(490)

instruction, always set the unit number for Host Link incremented by one

(1 to 32) for the remote destination (send destination) node address (word

C+3, bits 08 to 15 of the CMND(490) instruction). Do not set the unit number of the actual Host Link slave (0 to 31). Using the Host Link unit number without incrementing by one will access the PLC with the entered

Host Link unit number less one.

For example, specify the remote PLC with Host Link unit number 2 by

entering 3 for the remote destination node address. If 2 is entered, the

PLC with Host Link unit number 1 will be accessed.

To access a PLC on a Host Link FINS network using the Serial Gateway

from CX-Programmer, however, enter the actual Host Link unit number,

without incrementing by one. (Select Change PLC, click the Display

Serial Gateway Guide Button, and set unit number in the Host Link

SYSWAY Settings field of the Serial Gateway Guide Dialog Box.

xxi

Page 21

Conformance to EC Directives 6

• When the Serial Gateway is executed during protocol macro execution,

the communications sequence contents and the FINS command reception timing may suspend step transition of the communications sequence

(when the next step does not contain the RECEIVE command, the Serial

Gateway will be executed by interrupting the sequence before the next

step, and the step transition will be suspended).

Use the Serial Gateway send start timeout function to monitor at the

source of the FINS command whether step transition in the communications sequence has been suspended due to execution of the Serial Gateway. If the converted command does not start to be sent within the set

time, either retry executing the FINS command or change the communications sequence.

• When using 2-wire RS-422A/485 communications in Protocol Macro

Mode, set only modem controls for the send control parameters, and do

not use RS/CS flow controls.

• The following operations will result if the Serial Gateway is executed either

using a pre-Ver. 1.2 Board/Unit or using a Ver. 1.2 or later Unit/Board without Serial Gateway or protocol macro mode set for serial communications

at the serial port.

• If either NT Link or loopback test mode is used for serial communications, or if protocol macro mode is used with a pre-Ver. 1.2 Board/Unit,

an undefined command response will be returned (end code: 0401

hex).

• If Host Link mode is used for serial communications, the message will

be converted into a FINS command using Host Link slave-initiated

communications and transferred (this will mainly result in a response

timeout being returned, depending on the remote device (end code:

0205 hex))

• If a no-protocol instruction is sent to a pre-Ver. 1.2 Board/Unit or the serial

port of a Board/Unit with Unit Ver. 1.2 or later using a serial communications mode other than no-protocol mode, the following operations will

occur.

• If TXD(236)/RXD(235) is sent to the Board, Auxiliary Area bit A424204

(Inner Board Service Failure Flag) will turn ON.

• If TXDU(256)/RXDU(255) is sent to the Unit and the serial communications mode is set to protocol macro, NT Link, loopback test, or Serial

Gateway mode, an undefined command error (end code: 0401 hex)

will be returned.

If the serial communications mode is set to Host Link mode and the instruction will be converted to a slave-initiated function FINS command

and transferred. (Depending on the remote device, a response timeout

(end code: 0205 hex) is likely to be returned.)

6 Conformance to EC Directives

6-1 Applicable Directives

•EMC Directives

• Low Voltage Directive

6-2 Concepts

EMC Directives

OMRON devices that comply with EC Directives also conform to the related

EMC standards so that they can be more easily built into other devices or the

xxii

Page 22

Conformance to EC Directives 6

overall machine. The actual products have been checked for conformity to

EMC standards (see the following note). Whether the products conform to the

standards in the system used by the customer, however, must be checked by

the customer.

EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions of

the equipment or control panel on which the OMRON devices are installed.

The customer must, therefore, perform the final check to confirm that devices

and the overall machine conform to EMC standards.

Note Applicable EMS (Electromagnetic Susceptibility) and EMI (Electromagnetic

Interference) standards in the EMC (Electromagnetic Compatibility) standards

are as follows:

Unit/Board EMS EMI

CS1W-SCB21-V1/

SCB41-V1

CS1W-SCU21-V1

CJ1W-SCU21-V1

CJ1W-SCU31-V1

CJ1W-SCU41-V1

CS1W-SCU31-V1

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 VAC and 75

to 1,500 VDC meet the required safety standards for the PLC (EN61131-2).

EN61131-2

EN61000-6-2

EN61000-6-4

(Radiated emission: 10-m

regulations)

6-3 Conformance to EC Directives

The CS/CJ-series PLCs comply with EC Directives. To ensure that the

machine or device in which the CS/CJ-series PLC is used complies with EC

directives, the PLC must be installed as follows:

1,2,3...

1. The CS/CJ-series PLC must be installed within a control panel.

2. You must use reinforced insulation or double insulation for the DC power

supplies used for the communications power supply and I/O power supplies.

3. CS/CJ-series PLCs complying with EC Directives also conform to the

Common Emission Standard (EN61000-6-4). Radiated emission characteristics (10-m regulations) may vary depending on the configuration of the

control panel used, other devices connected to the control panel, wiring,

and other conditions. You must therefore confirm that the overall machine

or equipment complies with EC Directives.

6-4 EMI Measures for Serial Communications Boards and Units

The CS/CJ-series PLCs conform to the Common Emission Standards

(EN61000-6-4) of the EMC Directives. However, the noise generated from

Serial Communications Board or Unit communications cables may not satisfy

these standards. In such a case, commercially available ferrite cores must be

placed on the communications cable or other appropriate countermeasures

must be provided external to the PLC.

xxiii

Page 23

Unit Versions of CS/CJ-series Serial Communications Boards/Units 7

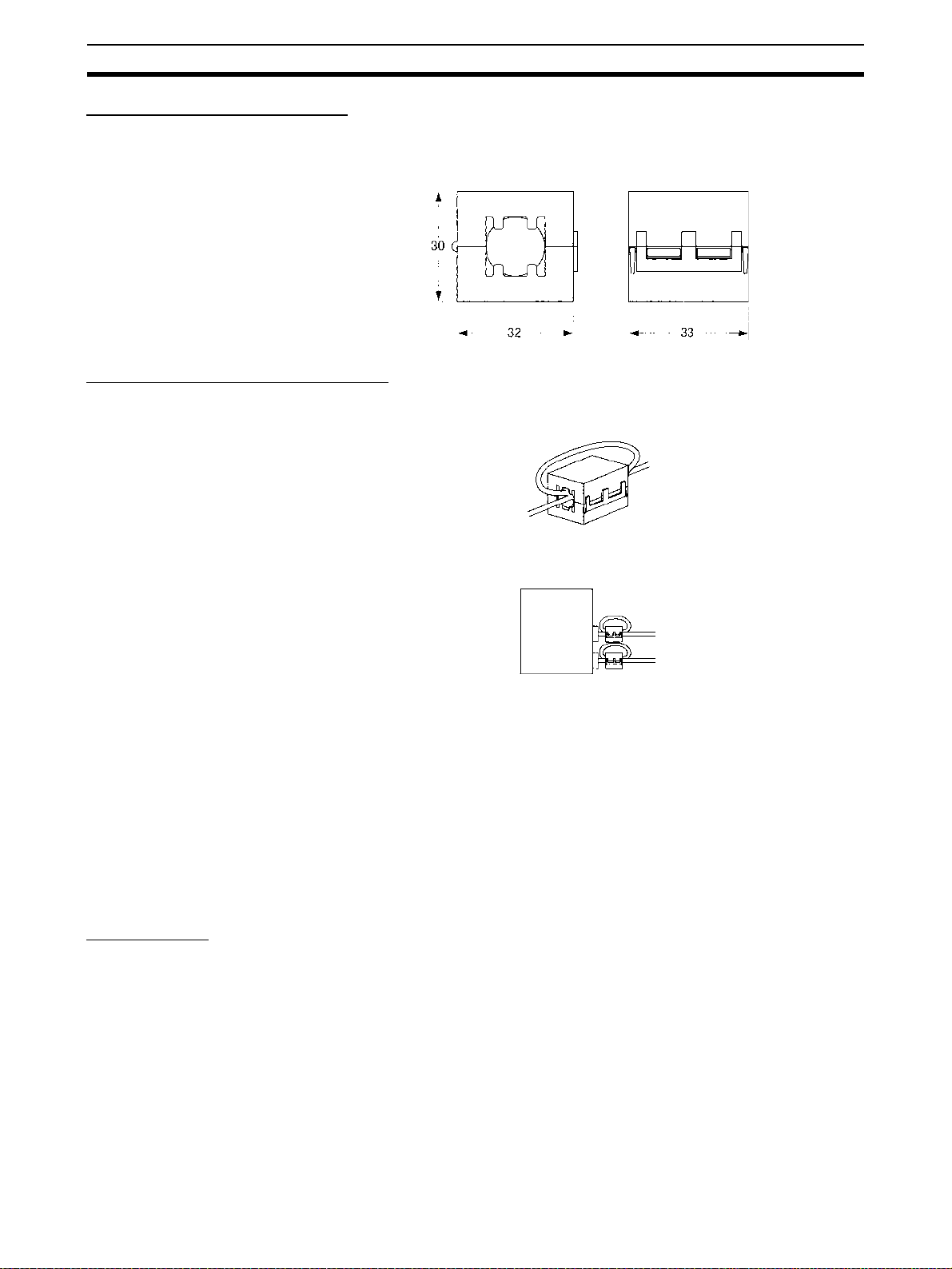

Recommended Ferrite Cores

The following ferrite core (data line noise filter) is recommended:

0443-164151 by Fair-Rite Products Corp.

Low impedance, 25 MHz: 90

Ω, 100 MHz: 160 Ω

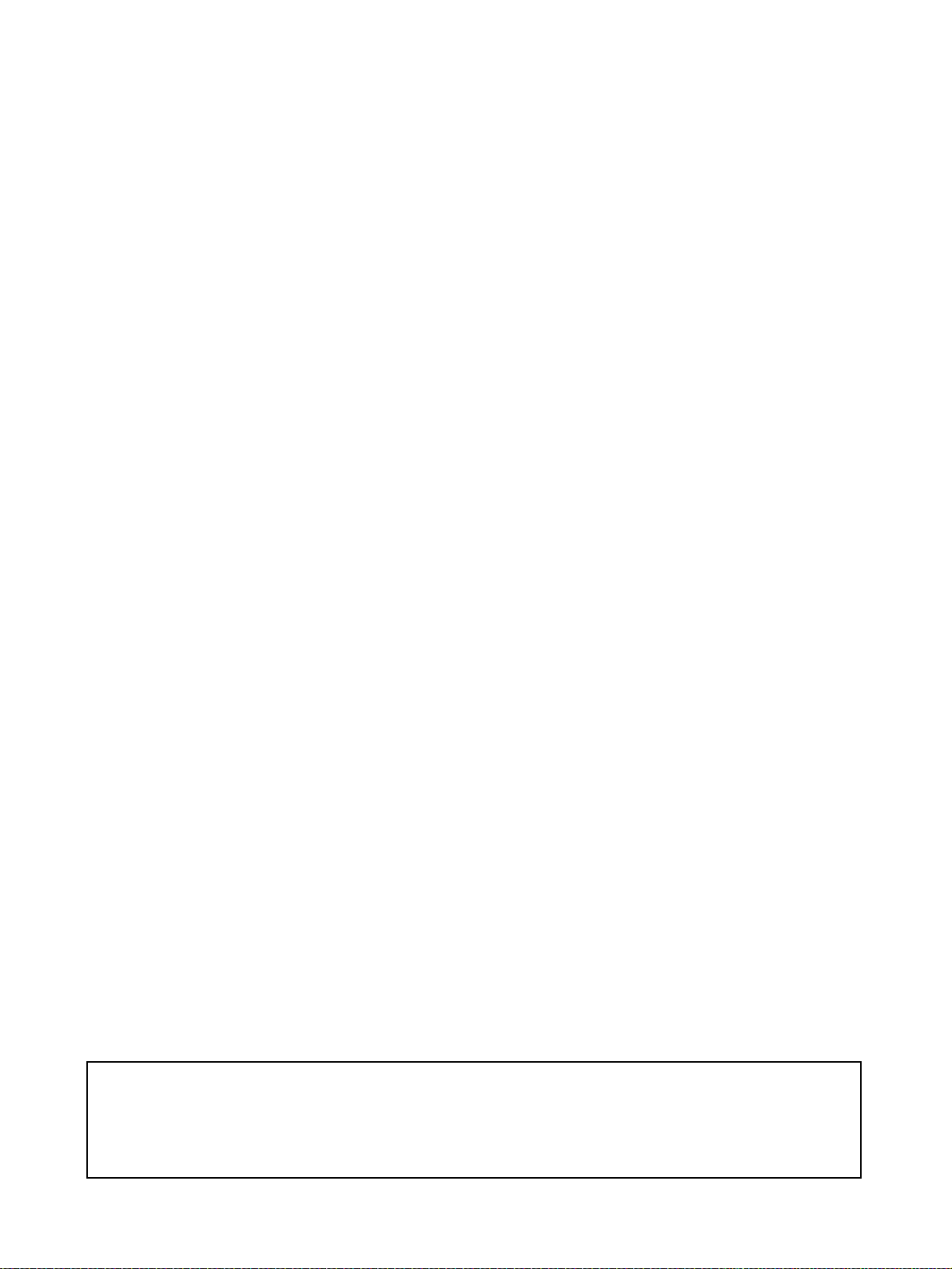

Recommended Mounting Method

Mount the core on one turn of the communications cable, as shown in the following illustration.

Mount the cores as lost to the end of the communications cable as possible,

as shown in the following illustration.

Serial

Communications

Unit/Board

6-5 EMS Measures for Serial Communications Units

The immunity testing conditions for the CJ1W-SCU41-V1 Serial Communications Unit are as follows: A ferrite core is mounted on the test cable connected

to the RS-422A/485 port.

Refer to 6-4 EMI Measures for Serial Communications Boards and Units for

information on mounting the ferrite core.

7 Unit Versions of CS/CJ-series Serial Communications

Boards/Units

Unit Versions

A “unit version” has been introduced to manage CS/CJ-series Serial Communications Units/Boards according to differences in functionality accompanying

upgrades.

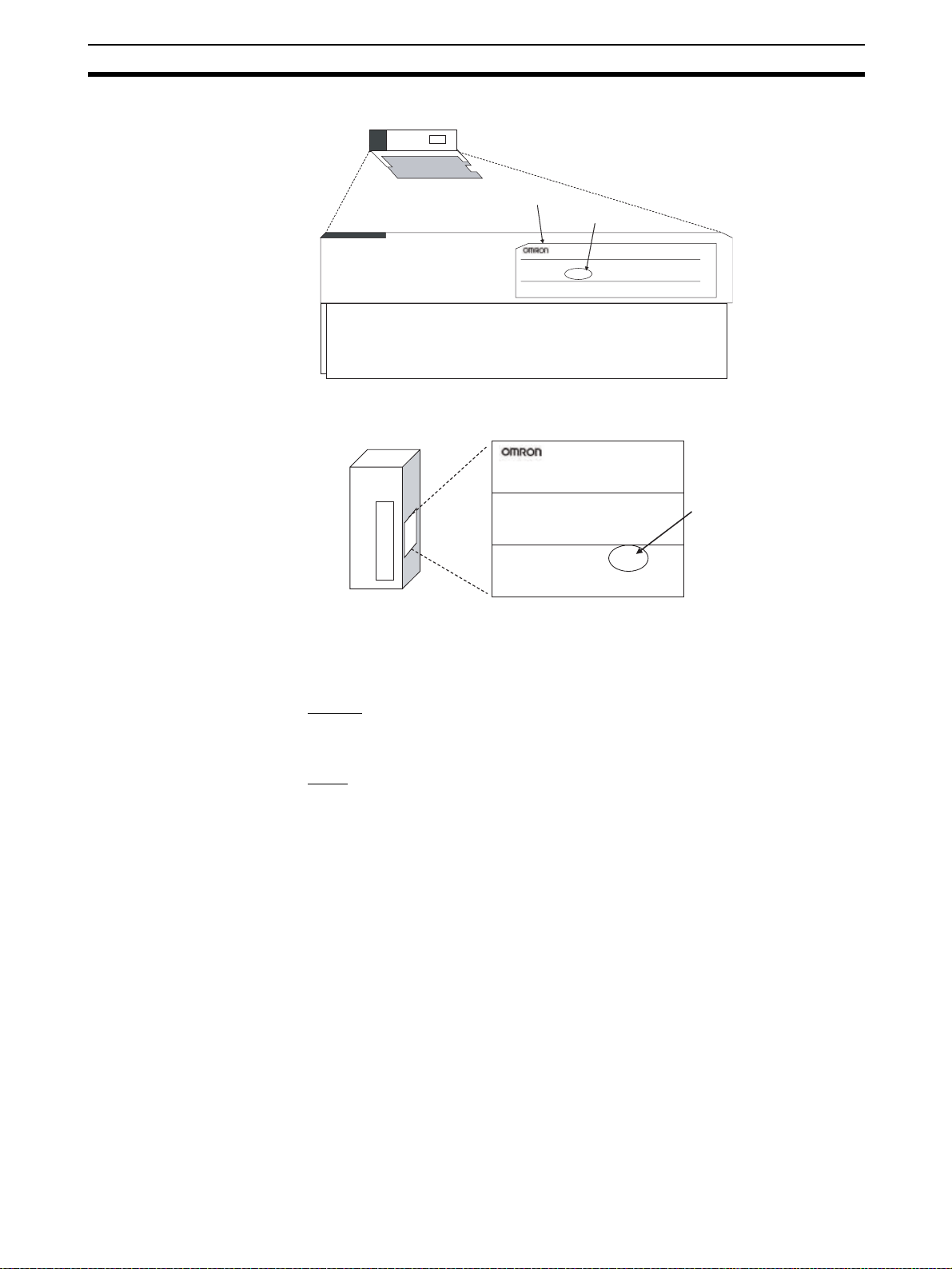

1. Unit Version Notation on Products

The unit version code is provided on the nameplate of the CS-series Serial

Communications Boards and Units for which unit versions are being managed, as shown below for the Loop Control Board. This system applies to

Serial Communications Units or Boards with unit version 1.2 or later.

• Serial Communications Boards

xxiv

Page 24

Unit Versions of CS/CJ-series Serial Communications Boards/Units 7

Example: CS1W-SCB21-V1 CS-series

Serial Communications Board

Nameplate

Unit version 1.3

CS1W-SCB21-V1

SERIAL COMMUNICATION BOARD

• Serial Communications Units

Example: CS1W-SCU21-V1 CS-series

Serial Communications Unit

Nameplate

SERIAL COMMUNICATION UNIT

:

Lot No. 051020 Ver.1.3

OMRON Corporation

CS1W-SCU21-V1

MADE IN JAPAN

Unit version 1.3

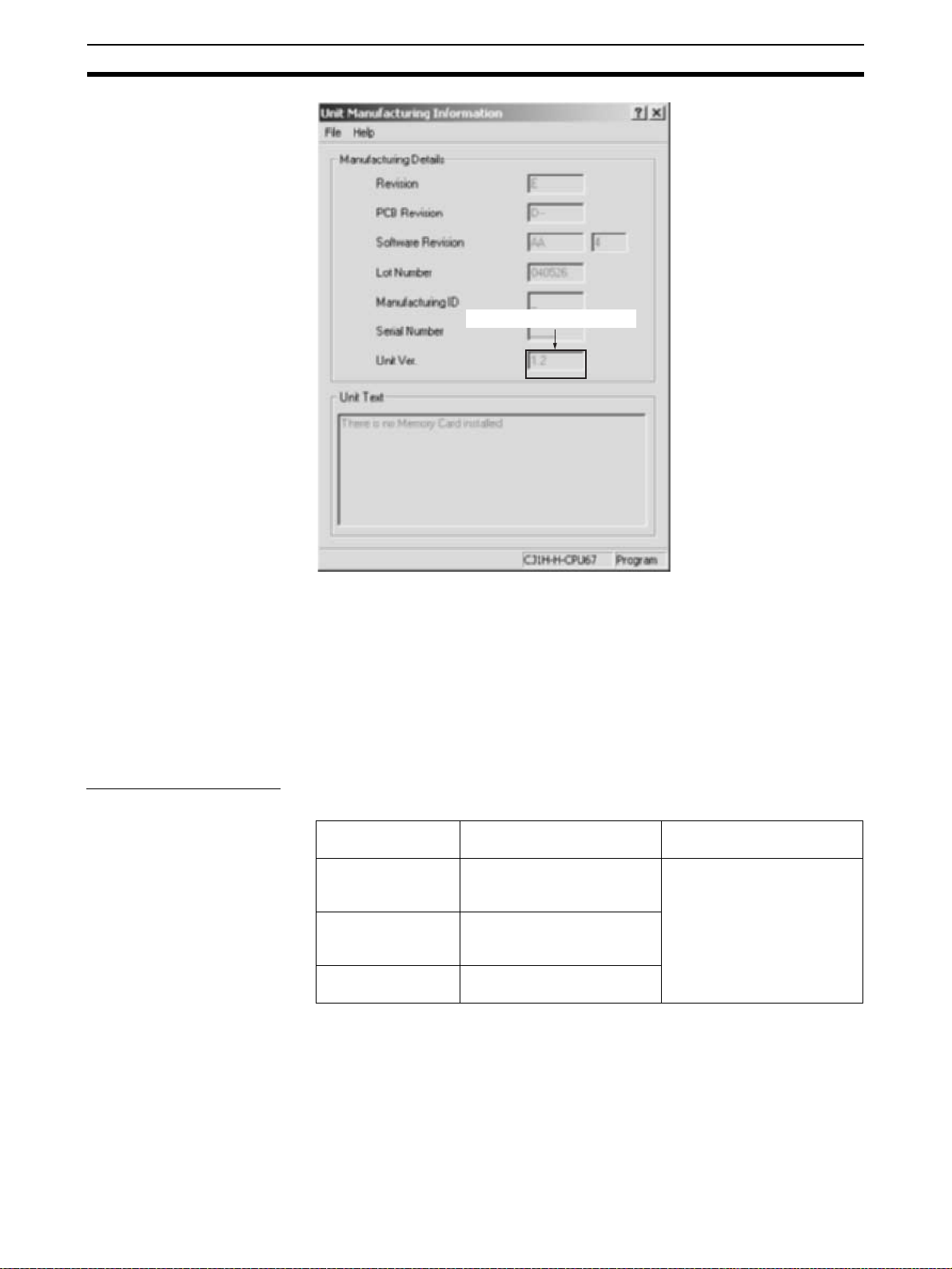

2. Confirming Unit Versions with Support Software

CX-Programmer version 5.0 can be used to confirm the unit version in the

Unit Manufacturing Information.

■Boards

In the I/O Table Window, right-click on the CPU Unit, and then select Unit

Manufacturing Information – Inner Board

■Units

1. In the I/O Table Window, right-click on the Serial Communications Unit,

and then select Unit Manufacturing Information.

2. The following Unit Manufacturing Information Dialog Box will be displayed.

Lot No. 051020 0000 Ver.1.3

OMRON Corporation

MADE IN JAPAN

xxv

Page 25

Unit Versions of CS/CJ-series Serial Communications Boards/Units 7

The unit version is displayed.

Example: In this Unit Manufacturing Information Dialog Box, unit version 1.3 is

displayed. Use this dialog box to confirm the unit version of the Serial Communications Unit that is connected online.

3. Using the Unit Version Labels

Unit version labels are provided with the product. These labels can be

attached to the front of previous Serial Communications Boards/Units to differentiate between Serial Communications Boards/Units of different unit versions.

Unit Version Notation

The unit versions are indicated in this manual as follows:

Notation in product

Ver. 1.3 or later after

the lot number

Ver.1.2 after the lot

number

Blank after the lot

number

nameplate

Notation in this manual Remarks

CS/CJ-series Serial Communications Units with unit version 1.3 or later

CS/CJ-series Serial Communications Units with unit version 1.2

Pre-Ver. 1.2 CS/CJ-series

Serial Communications Units

Information for which no particular version is specified

applies to all unit versions.

xxvi

Page 26

Unit Versions of CS/CJ-series Serial Communications Boards/Units 7

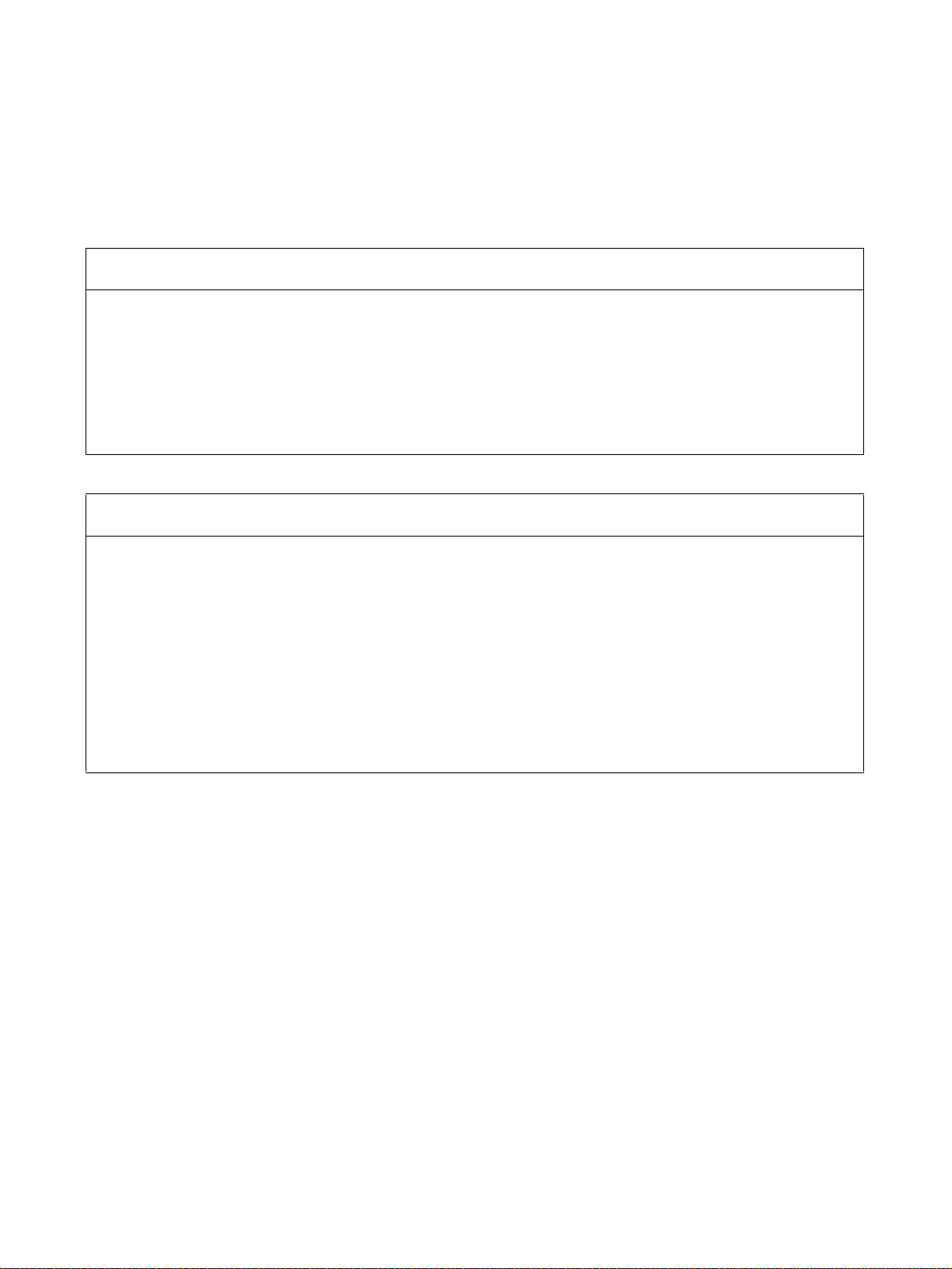

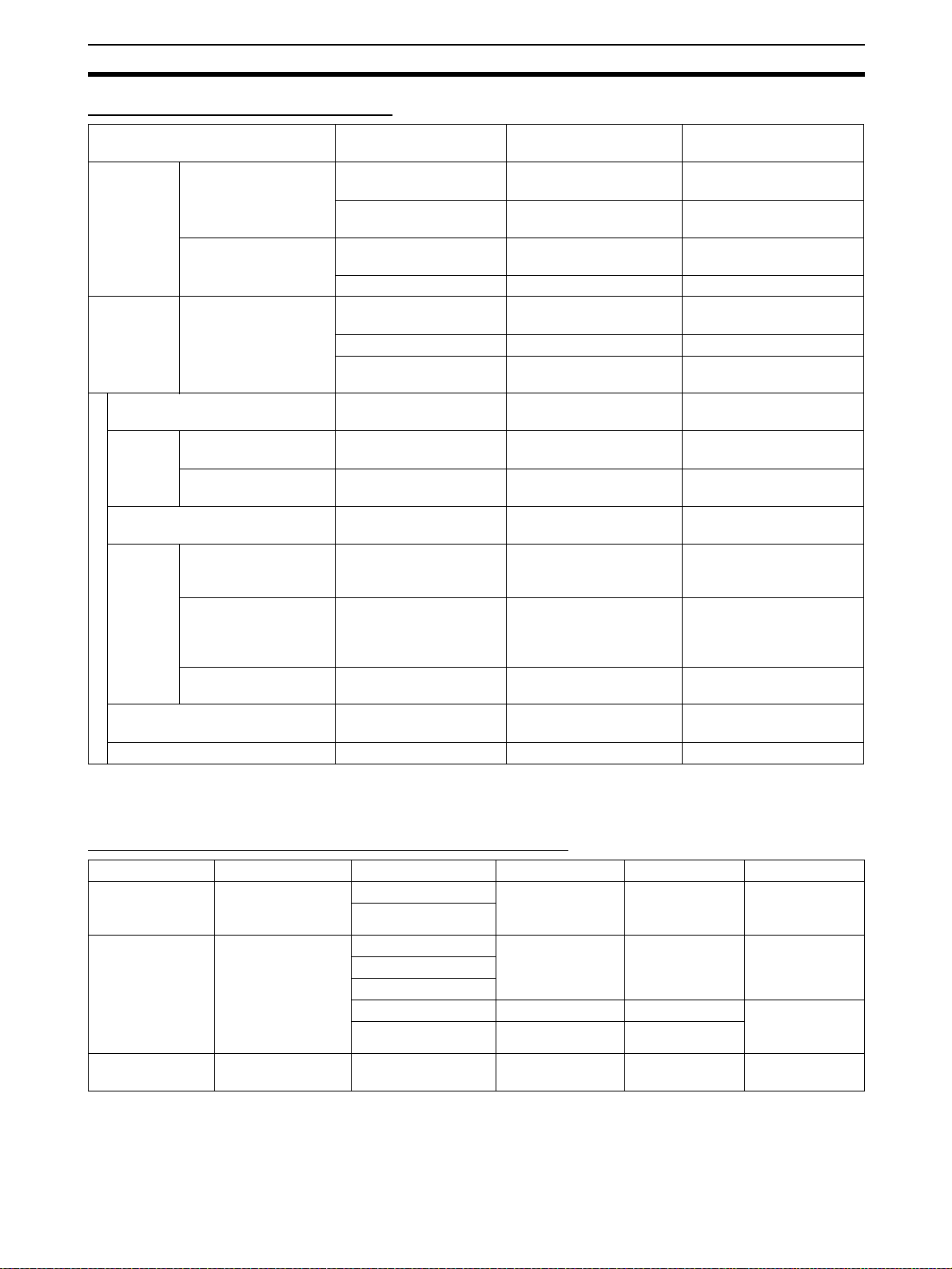

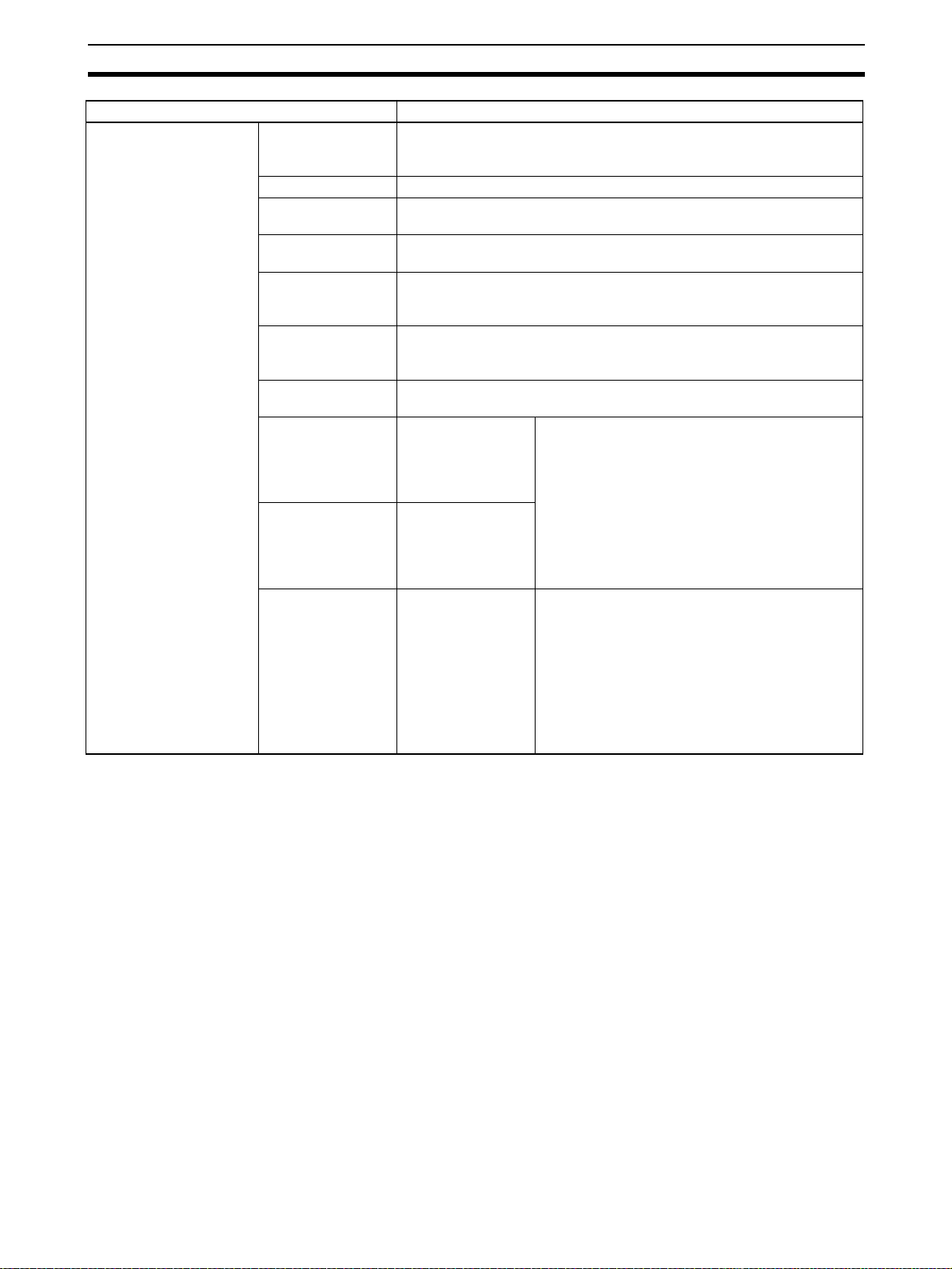

Function Support by Unit Version

Product Earlier version

CS Series Serial Communica-

tions Boards

Serial Communications Units

CJ Series Serial Communica-

tions Units

Serial gateway Not supported Supported Supported (Same as pre-

Host Link 1:1 links Not supported Supported Supported (Same as pre-

Host Link compatible

device selection

No-protocol Not supported Supported Supported (Same as pre-

Protocol

macro

Functions

Standard system protocol additions

MODBUS slave protocol added --- --- Supported

Link word specification data exchange

timing

Reception buffer processing for

PMCR(260) instruction execution

Baud rate (bps) 38,400 max. (57,600 and

(pre-ver. 1.2)

CS1W-SCB21-V1 CS1W-SCB21-V1 (Same

CS1W-SCB41-V1 CS1W-SCB41-V1 (Same

CS1W-SCU21-V1 CS1W-SCU21-V1 (Same

--- --- CS1W-SCU31-V1

CJ1W-SCU21 CJ1W-SCU21-V1 CJ1W-SCU21-V1 (Same

--- --- CJ1W-SCU31-V1

CJ1W-SCU41 CJ1W-SCU41-V1 CJ1W-SCU41-V1 (Same

Not supported Supported Supported (Same as pre-

On-request I/O refreshing only

Clearing only Select to clear or hold

115,200 not supported)

Not supported Supported Supported (Same as pre-

Unit version 1.2 Unit version 1.3

CS1W-SCB21-V1 (Same

as pre-ver. 1.2)

as pre-ver. 1.2)

as pre-ver. 1.2)

On-request I/O refreshing

Continuous I/O refreshing

contents.

57,600 supported. 57,600 supported. (Same

as pre-ver. 1.2)

CS1W-SCB41-V1 (Same

as pre-ver. 1.2)

CS1W-SCU21-V1 (Same

as pre-ver. 1.2)

as pre-ver. 1.2)

as pre-ver. 1.2)

ver. 1.2)

ver. 1.2)

ver. 1.2)

ver. 1.2)

On-request I/O refreshing

Continuous I/O refreshing

(Same as pre-ver. 1.2)

Select to clear or hold contents. (Same as pre-ver.

1.2)

as pre-ver. 1.2)

ver. 1.2)

Note Make sure that a CS/CJ-series CPU Unit with unit version 3.0 or later is used

when using no-protocol mode.

Unit Versions and Manufacturing Dates/Lot Numbers

Classification Type Model May 2004 June 2003 December 2005

Inner Boards Serial Communica-

CPU Bus Units Serial Communica-

CPU Unit Support Software

tions Boards

tions Units

CX-Programmer WS02-CXPC1-JV@ Ver. 4.0 or earlier Ver. 5.0 Version 6.1

CS1W-SCB21-V1 Pre-Ver. 1.2 Unit version 1.2

CS1W-SCB41-V1

CS1W-SCU21-V1 Pre-Ver. 1.2 Unit version 1.2

CS1W-SCU21-V1

CS1W-SCU41-V1

CS1W-SCU31-V1 --- --- Unit version 1.3

CJ1W-SCU31-V1 --- ---

(Lot No.: 040617

and later)

(Lot No.: 040617

and later)

Unit version 1.3

Unit version 1.3

(Available April,

2006)

xxvii

Page 27

Functions Added in the Unit Version 1.3 Upgrade 8

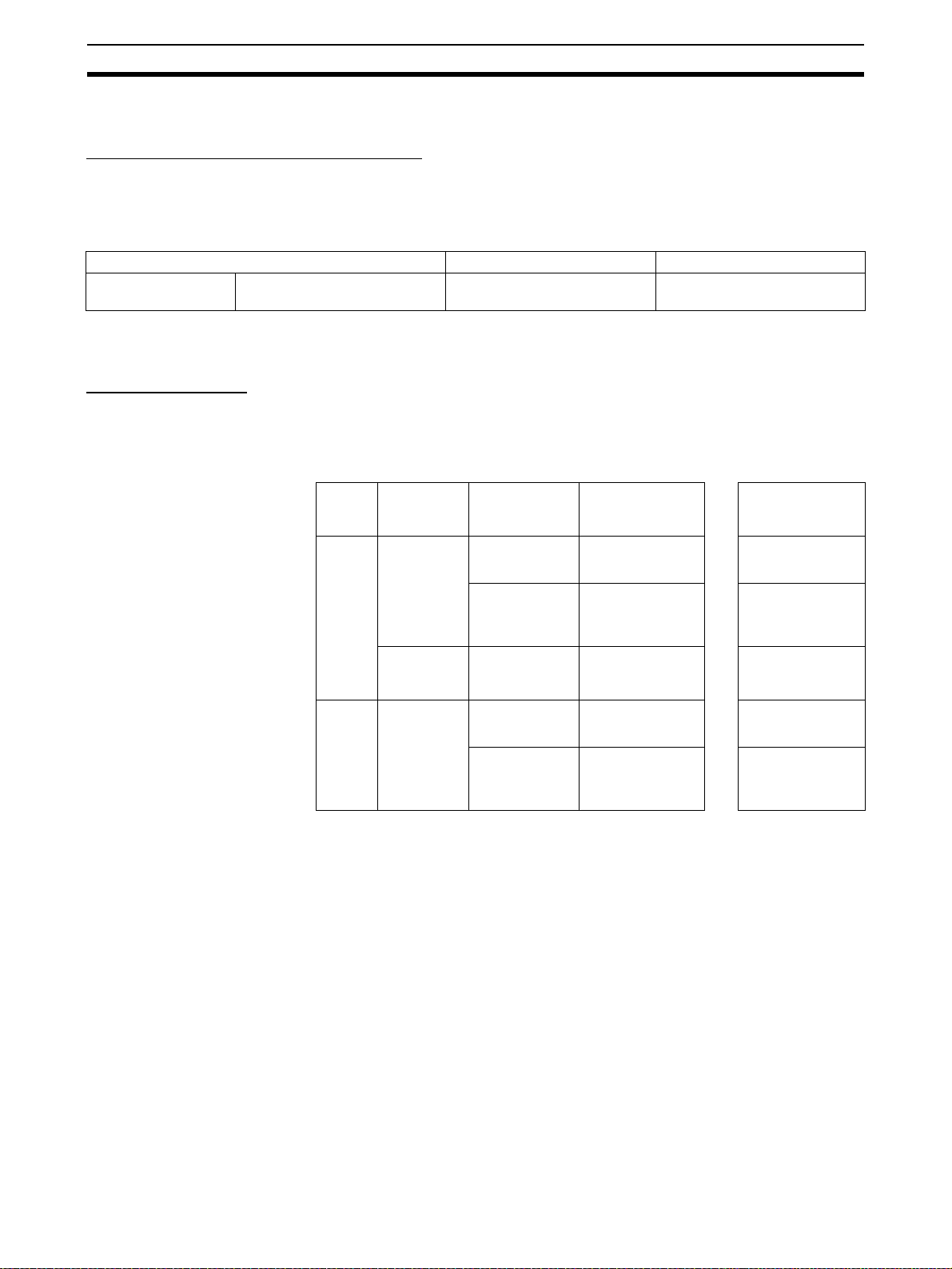

8 Functions Added in the Unit Version 1.3 Upgrade

Functions Added in Version Upgrade

The following table provides a comparison between the functions provided in

the upgrade to unit version 1.3 or later of CS1W-SCB@@-V1 Serial Communications Boards and CS1W-SCU@@-V1, CJ1W-SCU@@-V1 Serial Communications Units, and the functionality of earlier versions.

Item Previous unit versions Unit version 1.3 and later

Serial communications mode

Modbus-RTU slave mode Not supported Supported

9 Functions Added in the Unit Version 1.2 Upgrade

Upgraded Models

The model numbers of CS-series Serial Communications Units/Boards have

not changed. A “-V1” suffix has been added to the model numbers of CJseries Serial Communications Units with the unit version 1.2 upgrade, as

shown in the following table.

PLC Product Specifications Model Model number

CS

Series

CJ

Series

Serial Communications

Boards

Serial Communications

Units

Serial Communications

Units

RS-232C

RS-232C × 1

RS-232C

RS-422A/485

1

RS-232C

RS-232C × 1

RS-232C × 1,

RS-232C × 1

RS-232C

RS-422A/485

1

CS1W-SCB21-V1 → Same

× 1,

CS1W-SCB41-V1 → Same

× 1,

×

CS1W-SCU21-V1 → Same

× 1,

CJ1W-SCU21 → CJ1W-SCU21-V1

CJ1W-SCU41 → CJ1W-SCU41-V1

× 1,

×

after upgrade to

unit version 1.2

xxviii

Page 28

Functions Added in the Unit Version 1.2 Upgrade 9

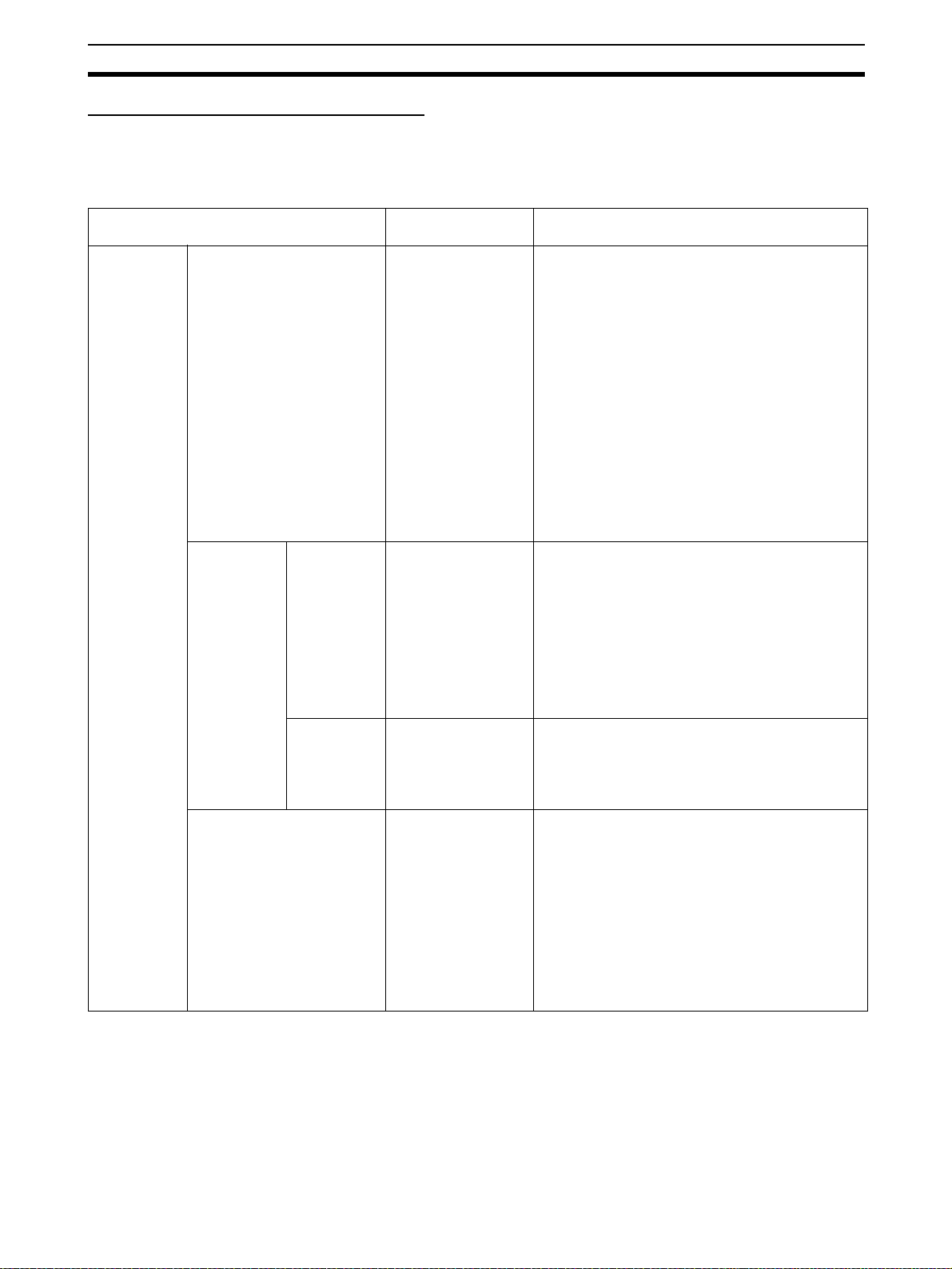

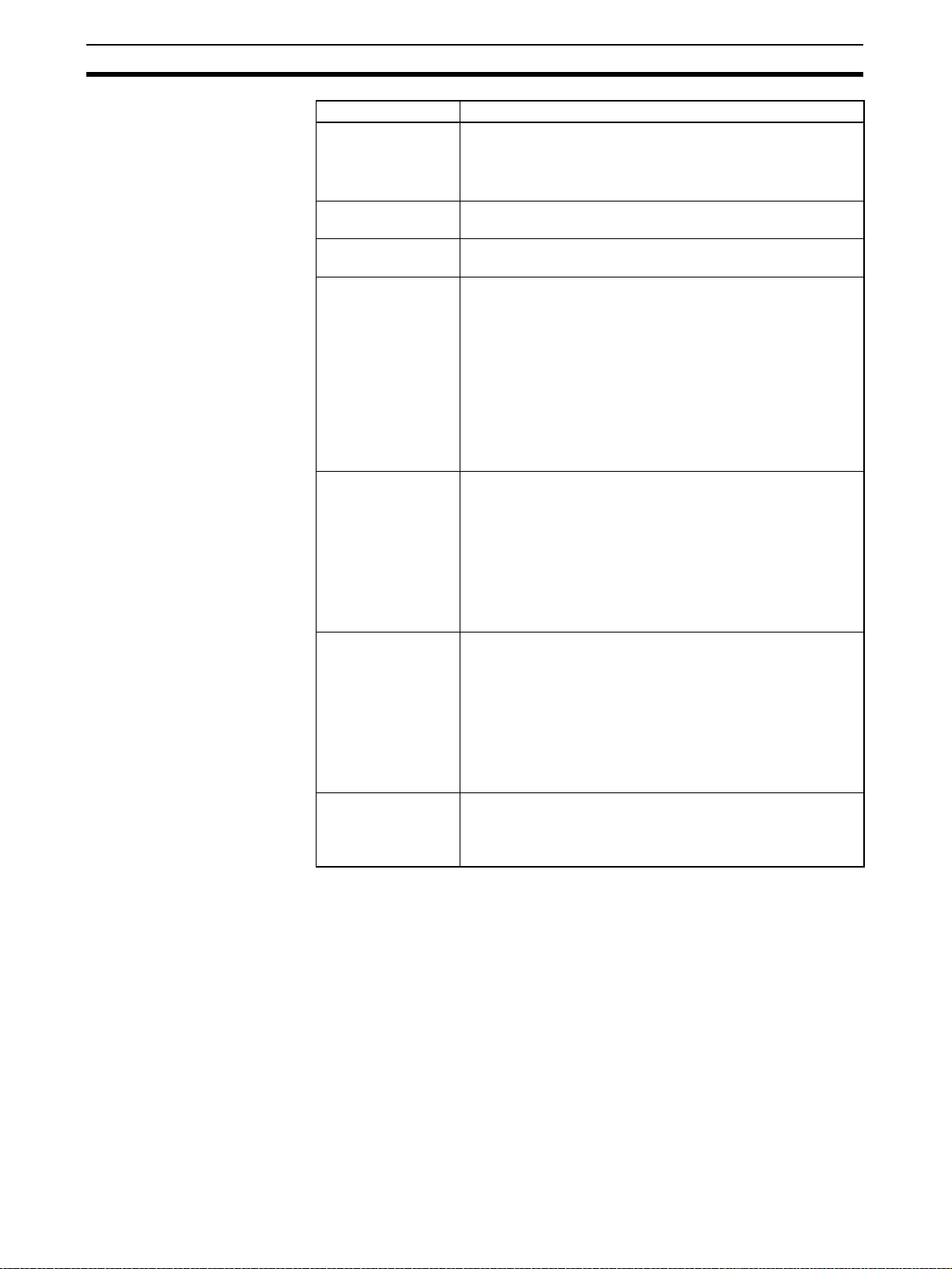

Functions Added in Version Upgrade

The following table provides a comparison between the functions provided in

the upgrade to unit version 1.2 or later of CS1W-SCB@@-V1 Serial Communications Boards and CS1W-SCU@@-V1, CJ1W-SCU@@-V1 Serial Communications Units, and the functionality of earlier versions.

Serial communications

mode

Item Earlier versions

Serial Gateway Not supported Supported

Host Link 1:1 protocol Not supported (1:N

Host Link

compatible

device selection

No-protocol Not supported Supported, but only when using a CS/CJ-series

(pre-Ver.1.2)

Host Links only)

Not supported (not

completely compatible with C-series

Host Link and CVM1/

CV-series Host Link)

The received FINS command can be converted

into serial communications protocol and then converted into either of the following protocols (using

the Serial Gateway mode).

• CompoWay/F

•Modbus-RTU

• Modbus-ASCII

• Host Link FINS (This protocol can be used to

make the PLC function as the Host Link Master.)

The Serial Gateway can also be used in protocol

macro mode. This option enables, for example, programming or monitoring of a serially connected

PLC from a CX-Programmer that is connected to

the PLC during execution of protocol macros (e.g.,

Host Link Master).

Supported

This protocol functions the same as the 1:1 Host

Link supported by the earlier C200H, C1000H, and

C2000H Series, thereby enabling the use of host

computer programs for 1:1 Host LInks created

using these earlier PLCs.

Note: CS/CJ-series, C200HS/HX/HG/HE(-Z),

@, CQM1@, and CVM1/CV Series all support

CPM

1:N Host Links only. C200H and C500 Host LInk

Units support both 1:1 and 1:N Host Links.

The compatible device mode enables full compatibility of Host Link functions (see note) with C-series

Host Link and CVM1/CV-series Host Link.

Note: E.g., differences in specifications for delimiter

words in response frame data

CPU Unit with unit version 3.0 or later.

(The no-protocol mode that was previously possible only at the built-in RS-232C port of CPU Unit is

now available for the Serial Communications

Boards and Units.)

This protocol is mainly used for communications

with devices that perform input or output only, such

as bar code readers and printers.

This mode enables no-protocol communications

even if the CPU Unit’s built-in RS-232C port is

being used for another application.

Unit version 1.2 or later

xxix

Page 29

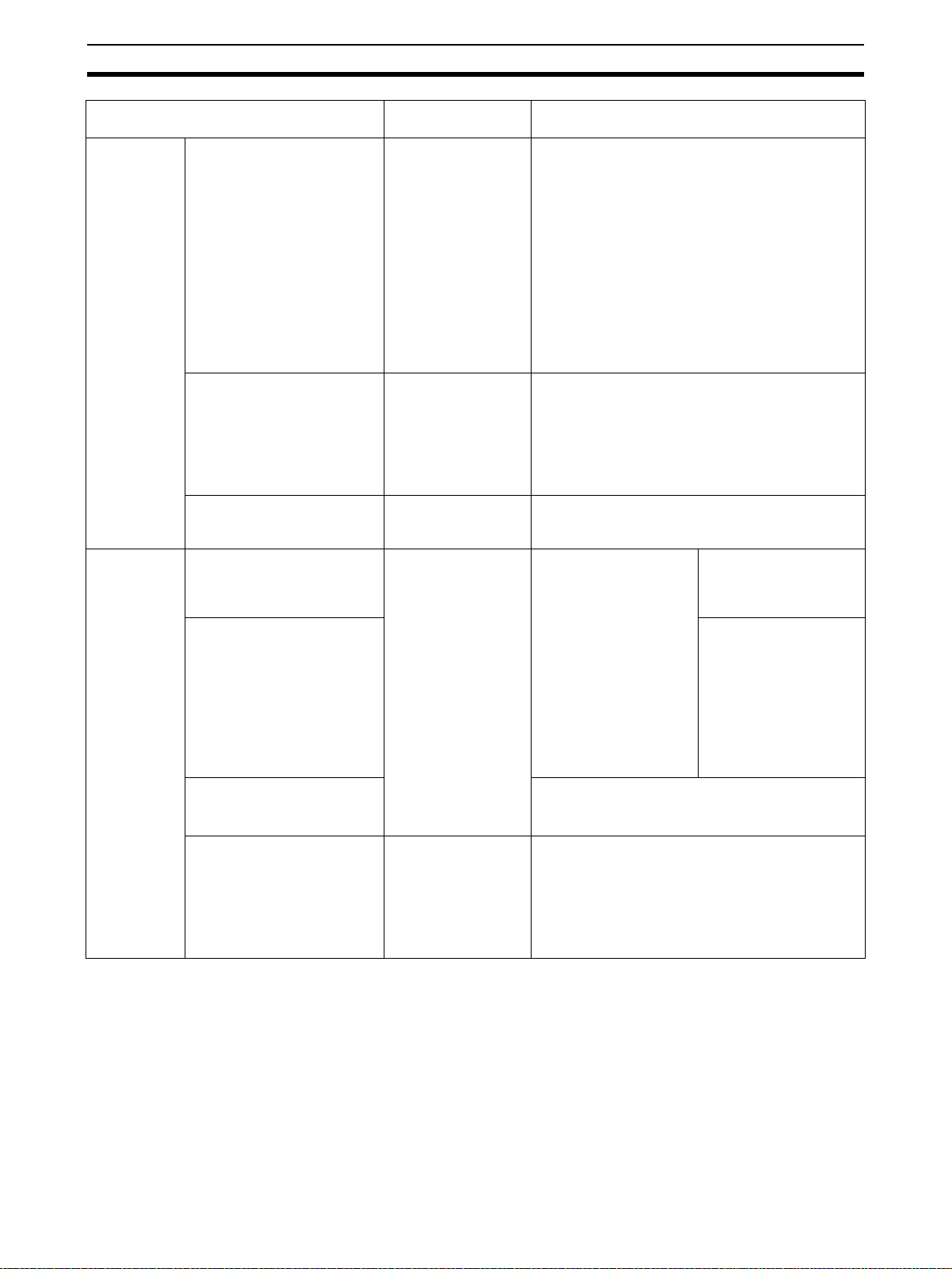

Functions Added in the Unit Version 1.2 Upgrade 9

Enhanced

protocol

macro functions

Standard system protocol

Item Earlier versions

Link word specification data

exchange timing

Reception buffer processing

for PMCR(260) instruction

execution (immediately

before communications

sequence execution)

Baud rate for protocol macro

mode

Host Link C-mode Command

Master

Host Link FINS Command

Master

(pre-Ver.1.2)

On-request I/O

refreshing only

(request to refresh

sent to CPU Unit at

every send/receive

command execution,

and data exchanged

during I/O refresh)

In this method, after

the send command is

executed, a delay

occurs before the

actual message is

sent.

Clearing to zero only Select to clear or hold the contents of the reception

38,400 bps max.

(57,600 bps not supported)

None (protocols must

be created using CXProtocol)

Unit version 1.2 or later

Continuous I/O refreshing (selected in DM Area

settings) is supported in addition to the on-request

I/O refreshing available in earlier models.

Continuous I/O refreshing is performed from the

CPU Unit during protocol macro execution, regardless of requests from the Board/Unit, and data in

the Board/Unit is accessed during send/receive

command execution. When the send command is

executed with this method, the actual message can

be sent immediately.

buffer during full-duplex communications (set in the

allocation DM Area).

This enables the data in the reception buffer

received in the previous communications sequence

to be held after switching the communications

sequence during full-duplex communications.

57,600 bps supported (115,200 bps not supported)

Provided

A Host Link Master can

be used to easily access

the Host Link slave PLC

(e.g., A PLC slave on a

moving body can be

accessed via a WMseries Wireless Modem

in a Host Link.)

Host Link C-mode commands can be used to

access a C-series or CS/

CJ-series PLC slave.

Host Link FINS commands can be used to

access a CS/CJ-series

or CVM1/CV-series PLC

slave.

This protocol can also

be used to access slave

PLCs on the network.

xxx

Mitsubishi Computer Link

Master (A-compatible, 1C

frame, model 1)

CompoWay/F Master --- Communications sequences with different send

Provided

Computer Link commands can be used to access a

Mitsubishi PLC (Sequencer CPU Module) slave.

and receive protocols are provided by using send/

receive commands with ASCII conversion.

The communications sequences have been

expanded to include CompoWay/F commands

such as VARIABLE AREA READ/WRITE and

OPERATING INSTRUCTIONS.

Page 30

SECTION 1

Introduction

This section introduces the hardware and software functions of the Serial Communications Boards and the Serial

Communications Units, including the communications modes, system configurations, and specifications.

1-1 Using this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-2-1 Serial Communications Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-2-2 Serial Communications Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-3 Protocol Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-3-1 Host Link Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-3-2 Protocol Macros . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-3-3 1:N NT Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1-3-4 Loopback Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-3-5 Serial Gateway Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-3-6 No-protocol Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-3-7 Modbus-RTU Slave Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1-4 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1-4-1 Serial Communications Boards and Units . . . . . . . . . . . . . . . . . . . . 12

1-4-2 Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1-5 System Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1-6 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1-6-1 Serial Communications Boards and Unit . . . . . . . . . . . . . . . . . . . . . 23

1-6-2 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1-6-3 Protocol Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1-7 Comparison to Previous Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

1-8 Selecting the Serial Communications Mode. . . . . . . . . . . . . . . . . . . . . . . . . . 41

1-9 Basic Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

1-9-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

1-9-2 Explanation of Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

1

Page 31

Using this Manual Section 1-1

1-1 Using this Manual

This manual is structured to provide information on Host Link, protocol macro,

and 1:N NT link communications in functional units, as would be required in

actual applications. You should read Section 1 Introduction first, and then read

information in the rest of the manual and related manuals as required by your

specific application.

Information Section or Manual

Overview and appearance of the Serial Communications Boards and Serial Communications Unit

Overview, features, and specifications of serial

communications

Basic procedures and operations 1-9 Basic Operating Procedure

Selecting serial communications modes 1-8 Selecting the Serial Communications Mode

System configurations for serial communications

modes

Memory Area allocations to the Serial Communica-

tions Boards and Serial Communications Unit

Installing and wiring the Serial Communications

Boards and Serial Communications Unit

Memory Area allocations to individual serial communications modes

Communications timing for slave-initiated Host Link

communications

Ladder diagram programming in protocol macros 5-4 Using Protocol Macros

Loopback tests for ports Section 10 Loopback Test

Changing the communications port settings during

operation

Troubleshooting and maintenance Section 11 Troubleshooting and Maintenance

The contents of standard system protocols and

connection methods to OMRON components

Details on Host Link communications (including

ladder diagram programming for slave-initiated

communications)

Details on C-mode commands

Details on FINS commands

Details on the protocol macro function SYSMAC WS02-PSTC1-E

1-2 Overview

2-1 Component Names and Functions

1-3 Protocol Overview

1-4 Features

1-6 Specifications

4-1 Host Link Communications

5-1 Overview of the Protocol Macro Functions

8-1 Overview of 1:N NT Links

1-5 System Configurations

2-2 Data Exchange with the CPU Unit

2-3 I/O Memory Allocations

Section 3 Installation and Wiring

4-2, 5-2, and 8-2 Setup Area Allocations

4-3, 5-3, and 8-3 Auxiliary Area and CIO Area Allo-

cations

4-4 Communications Timing

Appendix R Changing Communications Port

Settings Using STUP(237)

Appendix A to Appendix N

SYSMAC CS/CJ-series

CS1G/H-CPU@@-E, CS1W-SCB21/41,

CS1W-SCU21 Communications Commands

Reference Manual (W342)

CX-Protocol Operation Manual (W344)

2

Page 32

Overview Section 1-2

1-2 Overview

This section gives an overview of the Serial Communications Boards and the

Serial Communications Unit.

1-2-1 Serial Communications Boards

Serial Communications Boards are Inner Boards for the CS-series PLCs. One

Board can be installed in the Inner Board slot of a CPU Unit. Two serial ports

are provided for connecting host computers, Programmable Terminals (PTs),

general-purpose external devices, and Programming Devices (excluding Programming Consoles). This makes it possible to easily increase the number of

serial ports for a CS-series PLC.

Serial Communications

Board

Inner Board slot

Models The following two models are available:

CS1W-SCB21-V1

Two RS-232C ports

RS-232C port

RS-232C port

CS1W-SCB41-V1

One RS-232C port + one RS-422A/485 port

RS-232C port

RS-422A/485 port

Connectable Devices The following serial communications modes are supported by the Serial Com-

munications Unit: Host Link (SYSMAC WAY) (see note 1), protocol macro,

1:N NT Link (see note 2), no-protocol (see note 1), Modbus-RTU slave (see

note 3), and loopback test modes. The devices shown in the following diagram

can be connected.

Programming

General-purpose

external device

Programmable

Terminal (PT)

Device (excluding

Programming

Console)

Host computer

Serial Communications Board

CPU Unit

General-purpose

external device

Programmable

Terminal (PT)

Programming

Device (excluding

Programming

Console)

Host computer

3

Page 33

Overview Section 1-2

Note (1) The Host Link 1:1 and no-protocol modes are supported by unit version

1.2 or later.

(2) Only a 1:N NT Link is supported. A 1:1 NT Link is not supported.

(3) The Modbus-RTU slave mode is supported by unit version 1.3 or later.

A serial communications mode for the Serial Gateway is also provided,

enabling connection with the following devices.

Modbus-RTU-compatible

device (e.g., Inverter)

Modbus-ASCII-compatible

CompoWay/Fcompatible

OMRON

component

device (e.g., Servo)

PLC (Host Link)

FINS message

Serial Communications Board

with unit version

1.2 or later

Protocol

conversion

Protocol

conversion

CPU Unit

FINS message

CompoWay/Fcompatible

OMRON

component

Modbus-RTU-compatible

device (e.g., Inverter)

Modbus-ASCII-compatible

device (e.g., Servo)

1-2-2 Serial Communications Units

The Serial Communications Units are CPU Bus Unit. One or more Units can

be mounted to the CPU Unit or a CS/CJ Expansion Rack. A total of up to 16

CPU Bus Units can be controlled by one CPU Unit. The CS-series Serial

Communications Unit must be used for a CS-series PLC and a CJ-series

Serial Communications Unit must be used for a CJ-series PLC.

Two serial ports are provided for connecting host computers, Programmable

Terminals (PTs), general-purpose external devices, and Programming

Devices (excluding Programming Console). This makes it possible to easily

increase the number of serial ports for the CS/CJ-series PLC.

CS Series

Serial Communications Unit

PLC (Host Link)

4

Page 34

Overview Section 1-2

t

t

CJ Series

CS1W-SCU21-V1

(Two RS-232C ports)

RS-232C port

RS-232C port

P

A

2

0

5

R

P

O

W

E

R

L1

AC100-240V

INPUT

L2/N

RUN

OUTPUT

AC240V

DC24V

CS1W-SCU31-V1

(Two RS-422A/485 ports)

Serial Communications Unit

SYSMAC

R

U

N

E

R

R

/A

L

M

CJ1G-CPU44

IN

H

P

R

O

G

R

A

M

M

A

B

L

E

P

R

P

H

L

C

O

N

T

R

O

L

L

E

R

C

O

M

M

O

P

E

N

M

C

P

W

R

B

U

S

Y

P

E

R

IP

H

E

R

A

L

P

O

R

T

RS-422A/485 por

RS-422A/485 por

SCU41

RUN

ERC

SD1

RD1

TER1

RDY

ERH

SD2

RD2

TERM

OFF

ON

UNIT

5

4

6

3

7

2

8

1

9

NO.

0

A

F

B

E

C

D

WIRE

2

4

PORT1

(RS422

/485)

PORT2

CJ1W-SCU21-V1

(Two RS-232C ports)

CJ1W-SCU41-V1

(One RS-232C and One RS422A/485 Port)

RS-232C port

RS-232C port

RS-422A/485 port

RS-232C port

CJ1W-SCU31-V1

(Two RS-422A/485 ports)

RS-422A/485 port

RS-422A/485 port

Connectable Devices The following serial communications modes are supported by the Serial Com-

munications Boards: Host Link (SYSMAC WAY) (see note 1), protocol macro,

1:N NT Link (see note 2), no-protocol (see note 1), Modbus-RTU slave (see

note 3), and loopback test modes. The devices shown in the following diagram

can be connected.

5

Page 35

Overview Section 1-2

)

Programming

General-purpose

external device

Programmable

Terminal (PT)

Device (excluding

Programming

Console)

Host computer

Serial Communications Unit

CS/CJ-series PLC

General-purpose

external device

Programmable

Terminal (PT)

Programming

Device (excluding

Programming

Console

Host computer

Note (1) The Host Link 1:1 and no-protocol modes are supported by unit version

1.2 or later.

(2) Only a 1:N NT Link is supported. A 1:1 NT Link is not supported.

(3) The Modbus-RTU slave mode is supported by unit version 1.3 or later.

A serial communications mode for the Serial Gateway is also provided,

enabling connection with the following devices.

Modbus-RTU-compatible

device (e.g., Inverter)

Modbus-ASCII-compatible

CompoWay/Fcompatible

OMRON

component

device (e.g., Servo)

PLC (Host Link)

FINS message

Serial Communications Unit with

unit version 1.2 or

later

Protocol

conversion

Protocol

conversion

CPU Unit

FINS message

Functions Added in the

“-V1” Upgrade

6

CompoWay/Fcompatible

OMRON

component

Modbus-RTU-compatible

device (e.g., Inverter)

Modbus-ASCII-compatible

device (e.g., Servo)

PLC (Host Link)

The CS1W-SCB21-V1 and CS1W-SCB41-V1 Serial Communications Boards

and CS1W-SCU21-V1 Serial Communications Unit* were upgraded to support the Simple Backup Function in the “-V1” upgrade.

Simple Backup Function

The CPU Unit’s Simple Backup Function can be used to automatically

backup, restore, and compare the Protocol Macro data (both standard system

protocol and user-set protocol data) in the Serial Communications Board or

Unit’s flash memory with the data in the CPU Unit’s Memory Card. The Protocol Macro data is backed up, restored, or compared along with all of the data

in the CPU Unit. (The Simple Backup Function can be used with CS1-H, CJ1H, and CJ1M CPU Units only.)

Page 36

Protocol Overview Section 1-3

Note *The CS-series Serial Communications Boards/Units without the “-V1” suffix

do not support this Simple Backup Function, but the CJ1W-SCU21/41 does

support this function even though the model number lacks the “-V1” suffix.

1-3 Protocol Overview

A Serial Communications Board is an Inner Board for CS-series CPU Units

that provides RS-232C and/or RS-422A/485 serial ports. An Inner Board is an

option and is installed in the CPU Unit.

A Serial Communications Unit is a CPU Bus Unit that provides two RS-232C

serial ports or one RS-232C and one RS-422A/485 port. The following eight

serial communications modes can be used as required for each serial port.

• Host Link: For connections between host computers and PLCs

• Protocol macro: For communications between PLCs and general-purpose

external devices

• 1:N NT Link: For communications between PLCs and Programmable

Terminals (PTs)

• Loopback test: For testing the communications ports

•Serial Gateway

• No-protocol

• 1:1 Host Link

• Modbus-RTU slave mode

Note (1) The Serial Gateway can also be executed in protocol macro mode.

(2) Modbus-ASCII mode is not supported.

PLC

Series

CS Serial

CJ Serial

--- Device to be connected Host computer

Supporting unit versions All unit versions Unit version 1.2 or later Unit version 1.3

Product Model

Communications

Boards

Serial

Communications Unit

Communications Unit

number

CS1WSCB21-V1

CS1WSCB41-V1

CS1WSCU21-V1

CS1WSCU31-V1

CJ1WSCU21-V1

CJ1WSCU31-V1

CJ1WSCU41-V1

Serial ports Serial communications mode

Host Link Protocol

RS-232C OK OK OK OK OKOKOKOKOK

RS-232C OK OK OK OK OKOKOKOKOK

RS-232C OK OK OK OK OKOKOKOKOK

RS-422A/485 OK (See note 1.) OK OK OK OK OK OK OK OK

RS-232C OK OK OK OK OKOKOKOKOK

RS-232C OK OK OK OK OKOKOKOKOK

RS-422A/485 OK (See note 1.) OK OK OK OK OK OK OK OK

RS-422A/485 OK (See note 1.) OK OK OK OK OK OK OK OK

RS-232C OK OK OK OK OKOKOKOKOK

RS-232C OK OK OK OK OKOKOKOKOK

RS-422A/485 OK (See note 1.) OK OK OK OK OK OK OK OK

RS-422A/485 OK (See note 1.) OK OK OK OK OK OK OK OK

RS-422A/485 OK (See note 1.) OK OK OK OK OK OK OK OK

RS-232C OK OK OK OK OKOKOKOKOK

or Programming

Device

macro

Generalpurpose

external

device

1:N NT Link

(See note 2.)

PT None Depends on the

Loop-

back

test

Serial

Serial

Gate-

Gate-

way

way in

proto-

col

macro

mode

protocol used at

the conversion

destination

No-

proto-

col

(See

note

3.)

Generalpurpose

external

device

1:1

Mod-

Host

bus-

Link

RTU

slave

Host Link computer

or later

Note 1. A 4-wire connection must be used when using Host Link communications

for an RS-422A/485 connector.

7

Page 37

Protocol Overview Section 1-3

2. A 1:1 NT Link is not supported.

3. No-protocol mode can be used with CS/CJ-series CPU Units with Unit Ver.

3.0 or later only.

A connection example for each serial communications mode is shown in the

following sections for a Serial Communications Unit. The examples apply

equally as well to the Serial Communications Boards.

1-3-1 Host Link Mode

In Host Link mode, C-mode commands (Host Link commands) or FINS commands can be sent from a host computer to read or write I/O memory in the

PLC or to control the PLC’s operating modes. The host computer can be a

personal computer or a Programmable Terminal. The FINS commands are

sent with other data, such a Host Link header and terminator.

In Host Link mode, SEND(090), RECV(098), and CMND(490) instructions can

be used to send FINS commands from PLC to the host computer to read

data, write data, or perform other operations. This is called slave-initiated

communications or unsolicited communications. The FINS commands are

sent with other data, such a Host Link header and terminator.

Note 1. FINS commands can be sent across up to three different networks (count-

ing the local network) to a PLC on a remote network or to a host computer

connected to a PLC on a remote network.

2. Programming Devices can also be connected in Host Link mode.

Sending C-mode Commands

Sending FINS Commands

Host Link

FINS

command

Host Link

header

Host Link

terminator

Host Link

C-mode (Host Link)

command

FINS commands can also be sent to

PLCs on remote networks.

Host Link

FINS

command