Page 1

Cat. No.W426-E1-09

Cat. No. Z264-E2-04-X Smart Sensor ZFX-C USER´S MANUAL

SYSMAC

CJ1W-NC271/NC471/

NCF71/NCF71-MA

CS1W-NC271/NC471/NCF71

Position Control Units

OPERATION MANUAL

Page 2

CJ1W-NC271/NC471/NCF71/NCF71-MA

CS1W-NC271/NC471/NCF71

Position Control Units

Operation Manual

Revised October 2008

Page 3

iv

Page 4

v

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

OMRON, 2004

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

r

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

f

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Page 5

vi

Page 6

vii

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

1 Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

2 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxv

5 Application Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxviii

SECTION 1

Features and System Configuration . . . . . . . . . . . . . . . . . . . 1

1-1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-3 Basic Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-4 List of Functions and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-5 List of Functions by Purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1-6 Comparison with Existing Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SECTION 2

Basic Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-1 Basic Flow of Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2-2 Starting Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

SECTION 3

Installation and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3-1 Nomenclature and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3-2 Installing the Position Control Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3-3 External I/O Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3-4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

SECTION 4

Data Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4-1 Overall Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

4-2 Data Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

4-3 Common Parameter Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

4-4 Axis Parameter Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

4-5 Servo Parameter Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

4-6 Common Operating Memory Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

4-7 Axis Operating Output Memory Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

4-8 Axis Operating Input Memory Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Page 7

viii

TABLE OF CONTENTS

SECTION 5

Transferring and Saving Data . . . . . . . . . . . . . . . . . . . . . . . . 201

5-1 Transferring Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

5-2 Transferring PCU Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

5-3 Transferring Servo Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

SECTION 6

MECHATROLINK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

6-1 MECHATROLINK Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

6-2 MECHATROLINK Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

6-3 MECHATROLINK Communications Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

6-4 Standard Settings for Servo Drives Using MECHATROLINK. . . . . . . . . . . . . . . . . . . . . . . 247

SECTION 7

Position Control Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

7-1 PCU Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

7-2 Control Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

7-3 Coordinate System and Present Position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

7-4 Acceleration and Deceleration Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

7-5 Limit Input Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

SECTION 8

Defining the Origin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

8-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

8-2 Origin Search Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

8-3 Present Position Preset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

8-4 Origin Return. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

8-5 Phase Z Margin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

8-6 Absolute Encoder Origin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .305

SECTION 9

Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

9-1 Direct Operation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .318

9-2 Direct Operation Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .319

9-3 PCU Data Settings for Direct Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

9-4 Using Direct Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

9-5 Interrupt Feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

9-6 Torque Limit Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

9-7 Linear Interpolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

Page 8

ix

TABLE OF CONTENTS

SECTION 10

Other Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

10-1 Servo Lock/Unlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 350

10-2 Jogging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351

10-3 Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 355

10-4 Torque Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

10-5 Speed Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 364

10-6 Torque Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 375

10-7 Backlash Compensation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 381

10-8 Software Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 383

10-9 Stop Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 388

10-10 DEVIATION COUNTER RESET. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 393

SECTION 11

Sample Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 397

11-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 398

11-2 Basic Program Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .399

11-3 Application Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 424

SECTION 12

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 455

12-1 Overview of PCU Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 456

12-2 Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .460

12-3 LED Error Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 461

12-4 Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 464

12-5 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 477

12-6 Error Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 482

12-7 CPU Unit Error Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 484

SECTION 13

Maintenance and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . 485

13-1 Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 486

13-2 Inspection Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 486

13-3 Handling Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 487

13-4 Procedure for Replacing a PCU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 487

Page 9

x

TABLE OF CONTENTS

Appendices

A Performance Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 491

B List of Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 495

C Operation Area I/O Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 559

D List of Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 571

E Changing to CS1W/CJ1W-NC271/471/F71 from CS1W/CJ1W-NC113/133/213/233/413/433 579

F Additional Functions for the CJ1W-NCF71-MA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 601

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 605

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 615

Page 10

xi

About this Manual:

This manual describes the installation and operation of the CJ1W-NC271/NC471/NCF71/NCF71-MA

and CS1W-NC271/NC471/NCF71 Position Control Units and includes the sections described below.

Please read this manual carefully and be sure you understand the information provided before

attempting to install or operate the Position Control Unit. Be sure to read the precautions provided in

the following section.

Precautions provide general precautions for using the Position Control Unit, Programmable Controller,

and related devices.

Section 1 introduces the features of the Position Control Unit, explains the system configuration in

which it is used, and also provides information on basic operations, functions and specifications.

Section 2 provides an overview of the procedures required to use the Position Control Unit.

Section 3 provides information on nomenclature and functions, and describes the procedures required

for wiring and installation. Information on the MECHATROLINK-II Application Module is also provided.

Section 4 provides an overview of the parameter and data settings used in Position Control Unit operation and provides information on memory allocations.

Section 5 explains how to transfer and save parameters and data using the data transfer bits.

Section 6 provides an overview of MECHATROLINK communications, and includes information on

settings and procedures required to use MECHATROLINK with the Position Control Unit.

Section 7 provides an overview of the control system used by the Position Control Unit, including information on the control units, coordinate system, acceleration/deceleration operations, and limit input

operations.

Section 8 provides information on the various operations used to determine the origin, including origin

searches, origin returns, presetting the present position, calculating phase Z margins, and using the

absolute encoder.

Section 9 provides an overview of direct operation and describes the parameter settings, data settings, and procedures required to perform direct operation. Information on interrupt feeding and torque

limits is also provided here.

Section 10 describes the servo lock/unlock, jogging, override, torque limits, speed control, torque control, backlash compensation, software limits, and stop functions.

Section 11 provides basic program examples and application examples for using the Position Control

Unit.

Section 12 provides information on troubleshooting errors that may occur, including details on the

meaning of indicator displays and error codes, and the procedures required to reset errors in the Unit

or axes.

Section 13 describes methods for inspecting and maintaining the Position Control Unit and the procedure required to replace a Position Control Unit.

The Appendices provide information on the performance characteristics, lists of parameters, I/O allocations in the operation areas, lists of error codes, alarm/warning displays, and information required

when changing to the CJ1W-NC271/NC471/NCF71/NCF71-MA or CS1W-NC271/NC471/NCF71 from

a CJ1W/CS1W-NC113/133/213/233/413/433 Position Control Unit.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

Page 11

xii

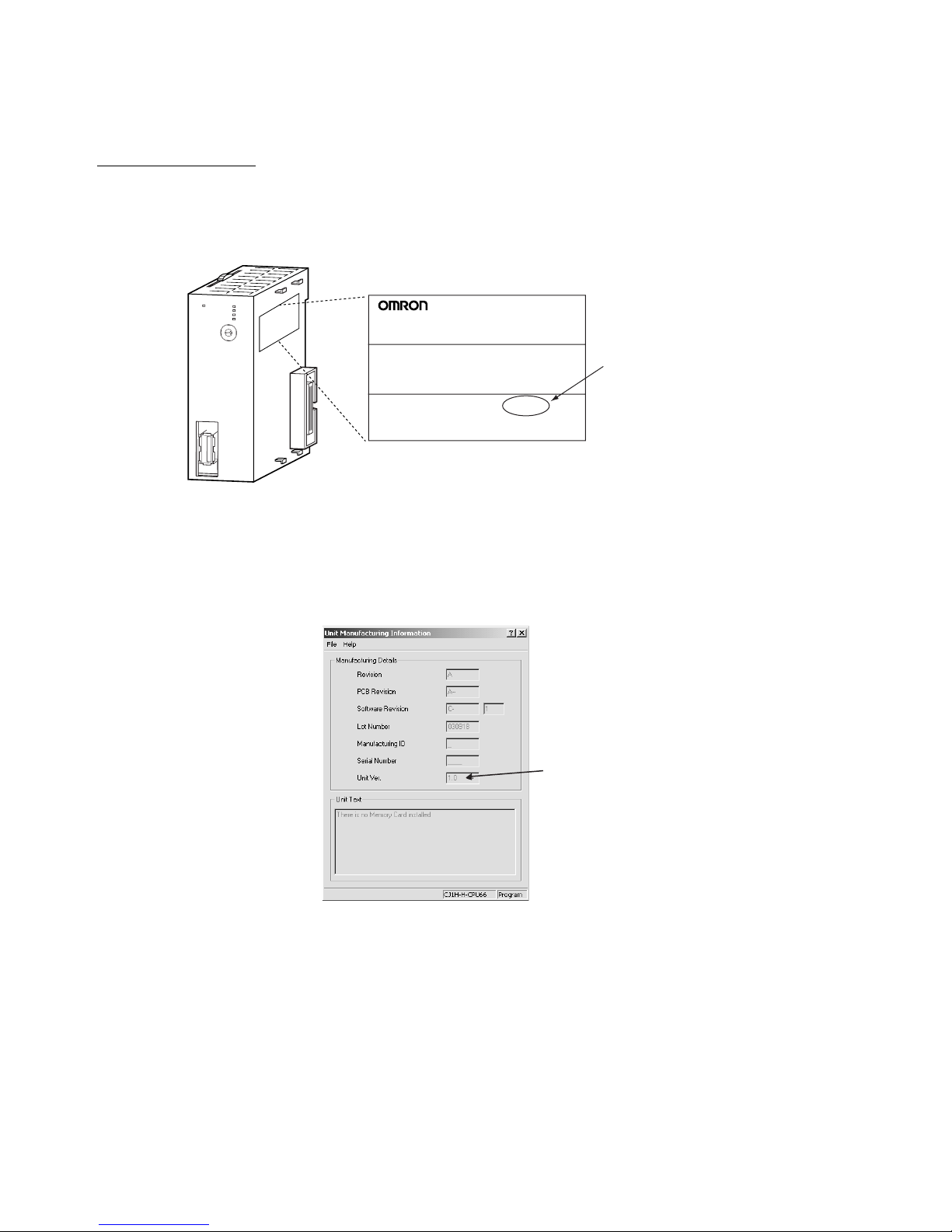

Unit Versions of Position Control Units

Unit Versions A “unit version” has been introduced to manage Position Control Units accord-

ing to differences in functionality accompanying Unit upgrades.

Notation of Unit Versions

on Products

The unit version is given to the right of the lot number on the nameplate of the

products for which unit versions are being managed, as shown below.

The unit version of Position Control Units starts with unit version 1.0.

Confirming Unit Versions

with Support Software

CX-Programmer version 4.0 can be used to confirm the unit version using the

Unit Manufacturing Information.

In the IO Table Window, right-click the Position Control Unit and select Unit

Manufacturing information.

The following Unit Manufacturing information Dialog Box will be displayed.

The unit version is displayed as 1.0 in the Unit Version Number field of the

above example. Use the above display to confirm the unit version of the Unit

connected online.

Using Unit Version Label A unit version label is provided with the Position Control Unit. This label can

be attached to the front of the Position Control Unit to differentiate between

Position Control Units with different unit versions.

CJ1W-NCF71

NC UNIT

Lot No. 040401 0000 Ver.1.0

OMRON Corporation MADE IN JAPAN

CJ1W-NCF71

R

U

N

E

R

C

E

R

H

E

R

M

M

LK

N

C

F71

U

N

IT

No.

M

LK

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

Unit version

Example for unit version 1.0

Product nameplate

Unit version

Page 12

xiii

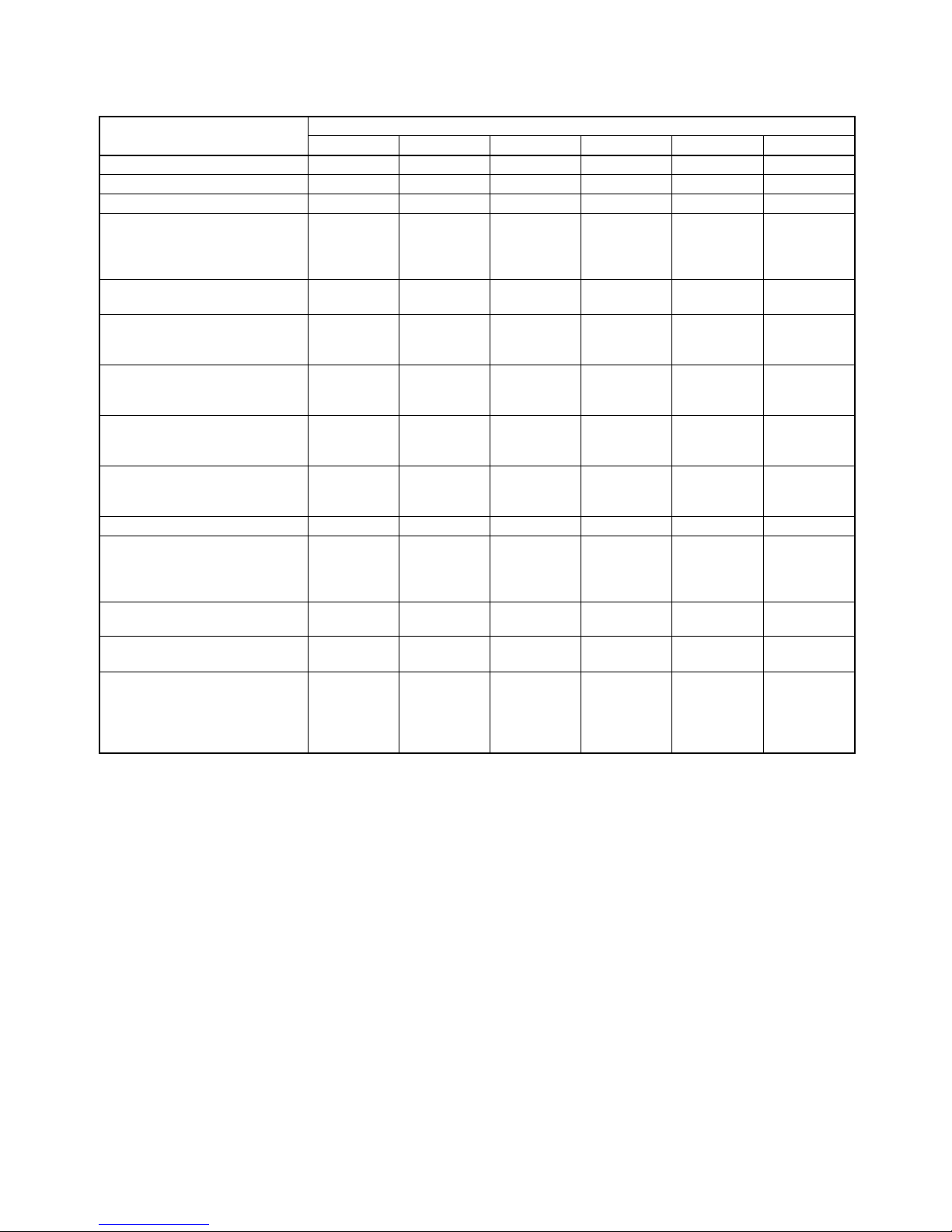

Functions Supported According to Position Control Unit Versions

Model CJ1W-NC@71/CS1W-NC@71

Unit Ver. 1 .0 Unit Ver. 1.1 Unit Ver. 1.2 Unit Ver. 1.3 Unit Ver. 2. 0 Unit Ver. 2.1

Linear interpolation --- Supported. Supported. Supported. Supported. Supported.

Absolute encoder setup function --- --- Supported. Supported. Supported. Supported.

Deviation counter reset --- --- --- Supported. Supported. Supported.

Establishing connections even

when there are unconnected

axes or axes with alarms that

cannot be cleared

--- --- --- Supported. Supported. Supported.

Transferring servo parameters

even when there is an axis error

--- --- --- Supported. Supported. Supported.

Creating servo locks during software limit detection when an

absolute encoder is used

--- --- --- Supported. Supported. Supported.

Driver main circuit OFF error

detection only when the servo is

locked

--- --- --- Supported. Supported. Supported.

Using Holding Area address

H512 and onwards for function

block address allocations

--- --- --- Supported. Supported. Supported.

Addition of supported models:

SMARTSTEP Junior Servo

Drives (R7D-ZN@-ML2)

--- --- --- --- Supported. Supported.

Addition of rejoin function --- --- --- --- Supported. Supported.

Eliminating connection restric-

tion when Servo Drive alarms

occur (enabling connection

when alarm A.C90 occurs)

--- --- --- --- Supported. Supported.

Addition of origin search operation modes

--- --- --- --- Supported. Supported.

Addition of origin search preset

function

--- --- --- --- Supported. Supported.

Faster setting for transfer cycle

and communications cycle

when setting the absolute

encoder PG zero point position

offset with an origin search

--- --- --- --- --- Supported.

Page 13

xiv

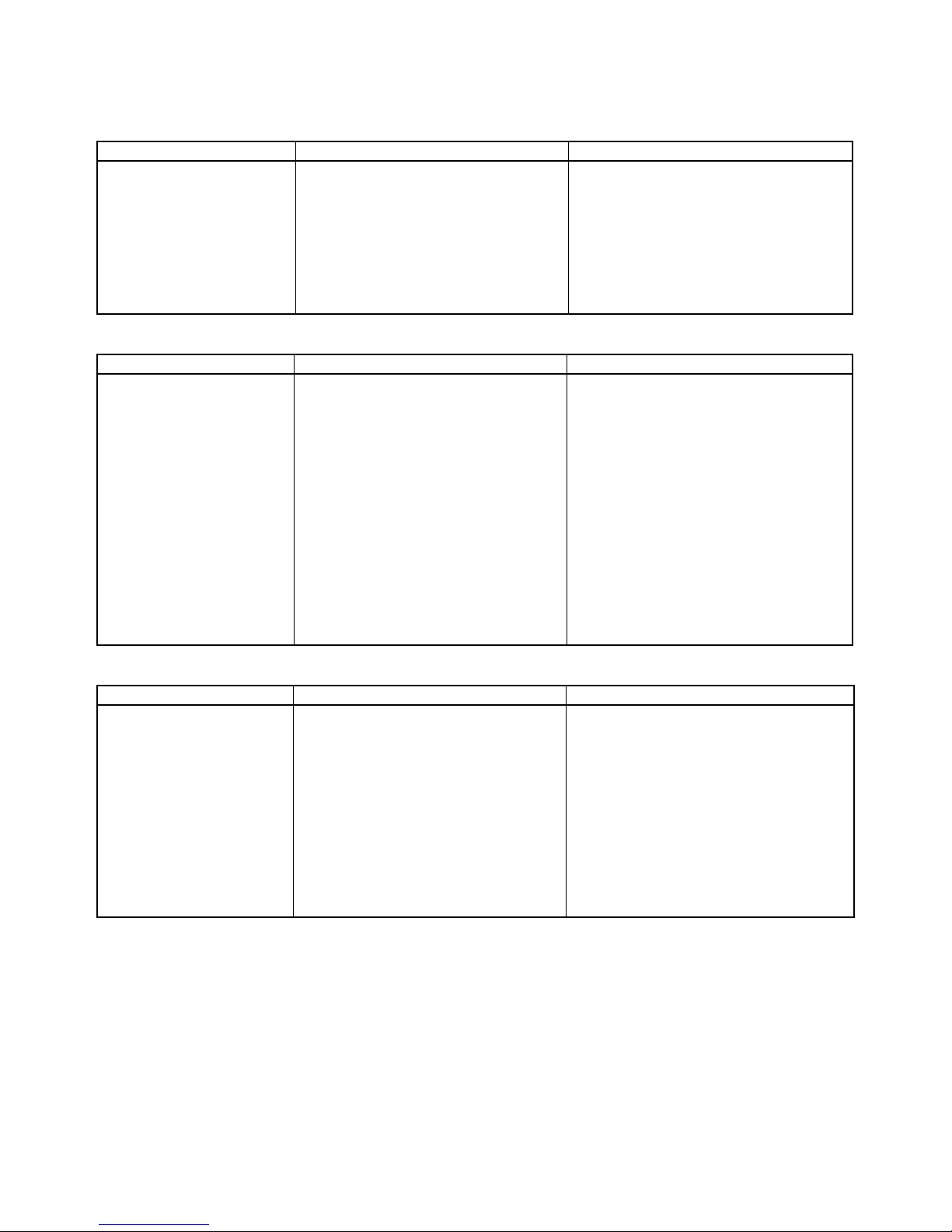

Upgrades Made According to Unit Versions of the Position Control Unit

Unit Version 1.0 to Unit Version 1.1

Unit Version 1.1 to Unit Version 1.2

Unit Version 1.2 to Unit Version 1.3

Functional upgrade Unit version 1.0 Unit version 1.1

Addition of linear interpolation

function

Linear interpolation cannot be used.

Linear interpolation can be performed for

positioning operations combining one or

more axes.

Linear interpolation can performed for up to

four axes each of axes 1 to 4 and axes 5 to 8

for Servo Drive axes connected to the Position Control Unit. (Refer to 9-7 Linear Inter-

polation.)

Functional upgrade Unit version 1.1 Unit version 1.2

Addition of setup function for

absolute encoders

An absolute encoder must be set up the

first time it is used, when the rotation data

is initialized to 0, or when the absolute

encoder is left for a long period of time

without the battery connected.

With Position Control Units with unit version 1.1 or earlier, the following operation

is used to set up the absolute encoder.

• Special software (personal computer

monitoring software) must be connected

to the Servo Drive to perform the setup

operation.

With Position Control Units with unit version

1.2 or later, the following operation can be

used to set up the absolute encoder.

• Special software (personal computer monitoring software) can be connected to the

Servo Drive to perform the setup operation.

• When the Position Control Unit is used with

a CPU Unit with unit version 3.0 or later, the

absolute encoder can be set up from the

program by using a function block from the

OMRON FB Library.

• The absolute encoder can be set up from

the CX-Motion-NCF. (Refer to 8-6-4

Absolute Encoder Setup.)

Functional upgrade Unit version 1.2 Unit version 1.3

Addition of deviation counter

reset function

The deviation counter in the Servo Drive

cannot be reset from the Position Control

Unit during position control operations.

The deviation counter in the Servo Drive can

be reset from the Position Control Unit during

position control operations.

To deviation reset function in the Position

Control Unit works by sending a movement

command in the opposite direction and of the

same size as the current position deviation

so that the current command position equals

the current feedback position.

(Refer to 10-10 DEVIATION COUNTER

RESET.)

Page 14

xv

Establishing connections

when there are unconnected

axes or axes with alarms that

cannot be cleared

If any of the axes registered in the scan list

are not connected, have the control power

supply interrupted, or have an alarm that

can be reset only by cycling the power

supply, an MLK initialization error (Unit

error code 0020 (hex) will occur after the

connections are established and operations using MECHATROLINK communications will not be possible any axes,

including those without errors.

To start MECHATROLINK communications

normally, all errors must be cleared for all

axes registered in the scan list before connections can be established.

Axis operations using MECHATROLINK communications are possible for any axes registered in the scan list and for which

MECHATROLINK communications have

been started (see note) regardless of

whether there are Servo Drive alarms.

If there are any axes with alarms, they will be

indicated by the Error Flags and error code in

the Axis Operating Input Memory Areas.

If there are alarms in the Servo Drive that can

be cleared only by recycling the power, they

will be detected as Unit errors (MLK initialization errors) for Units with unit version 1.1 or

earlier, but they will be detected in the individual axis areas.

Note If R88D-WN@-ML2 W-series Servo

Drives (Models with Built-in MECHATROLINK-II Communications) are connected, an encoder communications

error (A.C9@) will occur in the Servo

Drive and it will not be possible to start

MECHATROLINK communications for

Units with unit version 1.3 or earlier.

(Refer to 6-3-2 MECHATROLINK Communi-

cations Status.)

Transferring parameters when

there are axis errors

Servo parameters cannot be transferred

(i.e., written, read, or saved) for axes with

errors. The errors must first be reset to

clear the axis error status before Servo

parameters can be transferred.

Servo parameters can be transferred (i.e.,

written, read, or saved) for axes with errors. If

the axis error already exists, it will not be

overwritten even if an error occurs during

parameter transfer.

If Servo parameters are written when there is

an axis error, be sure to confirm that the

parameters were transferred correctly.

(Refer to 5-3 Transferring Servo Parameters.)

Locking the servo when a

software limit is being

detected for a Motor with an

absolute encoder

If an attempt is made to lock the Servo

when an absolute encoder is used, the

software limits are enabled, and the

present position is within the software limit

area, a software limit error will occur and

the Servo lock operation will be canceled.

To lock the Servo in the above situation,

the software limit must first be disabled.

The Servo can be locked at any position,

regardless of the type of encoder and the

software limit settings.

(Refer to 10-8-4 Software Limit Operation.)

Functional upgrade Unit version 1.2 Unit version 1.3

Page 15

xvi

Unit Version 1.3 to Unit Version 2.0

Detecting driver main circuit

OFF errors only when the

Servo is locked

Servo Drive main circuit OFF errors are

detected regardless of whether the Servo

is locked for the axis. Once a Servo Drive

main circuit OFF error is detected, it will

continue to be detected even if the error is

reset until the main circuit power supply is

restored.

Servo Drive main circuit OFF errors are

detected only when the Servo is locked for

the axis.

The Position Control Unit will automatically

unlock the Servo when a Servo Drive main

circuit OFF error is detected, allowing the

error to be cleared even while the main circuit

power supply is interrupted.

If an attempt is made to lock the Servo while

the main circuit power supply is interrupted, a

Servo Drive main circuit OFF error will be

detected again.

(Refer to 12-4-2 List of Error Codes.)

Allocating holding addresses

H512 and higher as function

block addresses

The function blocks in the OMRON FB

Library for the Position Control Unit cannot

be used if H512 (default setting) or higher

are allocated for non-holding areas of function block addresses.

If H512 or higher are allocated, a function

block error will occur when the function

block is executed.

The CX-Programmer must be used to

change the setting to other unused words

(e.g., in the DM or EM Area).

The function blocks in the OMRON FB

Library for the Position Control Unit can be

used if H512 (default setting) or higher are

allocated for non-holding areas of function

block addresses.

Functional upgrade Unit version 1.3 Unit version 2.0

Addition of applicable models

Applicable Models

•R88D-WT@W-series Servo Drives (with

JUSP-NS115 MECHATROLINK-II Application Module mounted)

•R88D-WN@-ML2 W-series Servo Drives

(Models with Built-in MECHATROLINK-II

Communications)

Applicable Models

•R88D-WT@W-series Servo Drives (with

JUSP-NS115 MECHATROLINK-II Application Module mounted)

•R88D-WN@-ML2 W-series Servo Drives

(Models with Built-in MECHATROLINK-II

Communications)

•R7D-ZN@-ML2 SMARTSTEP Junior Servo

Drive (Models with Built-in MECHATROLINK-II Communications)

Functional upgrade Unit version 1.2 Unit version 1.3

Page 16

xvii

Addition of rejoin function MECHATROLINK communications are

started and stopped at the same time for

all axes registered in the scan list.

The following functions are supported in

addition to starting and stopping MECHATROLINK communications for all axes at the

same time.

• Rejoin Function

An axis for which communications have

been stopped, e.g., due to a communications error, can be restarted without stopping communications for the other axes.

(Refer to 6-3-4 Rejoining the Connection.)

• Setting the Axes to Be Connected

Axes registered in the scan list can be set

temporarily so that they are not registered.

The axes can be set so that they are temporarily not used without resetting the scan

list. Operations can be performed without

errors occurring for these axes.

(Refer to 6-3-5 Specifying the Axes to Con-

nect.)

The Axis Communications Status Flags have

also been changed for the above functions.

Refer to the note following this table for

details.

Eliminating connection restriction when Servo Drive alarms

occur (enabling connection

when alarm A.C90 occurs)

If an encoder communications error

(A.C90) occurs for a R88D-WN@-ML2 Wseries Servo Drive (Model with Built-in

MECHATROLINK-II Communications),

MECHATROLINK communications cannot

be started with that Servo Drive.

MECHATROLINK communications can be

started under the conditions given at the left,

and operations, such as transferring Servo

Parameters, can be performed.

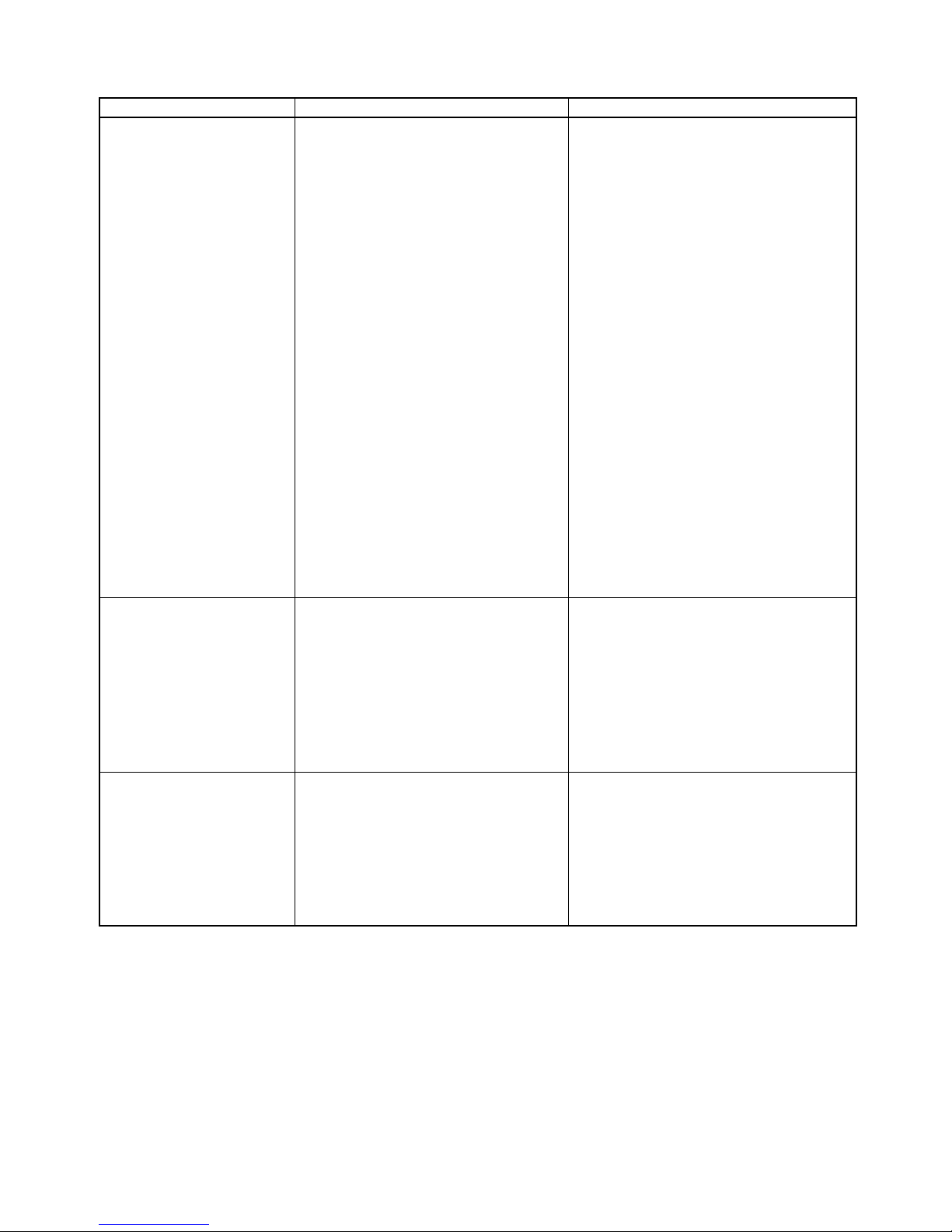

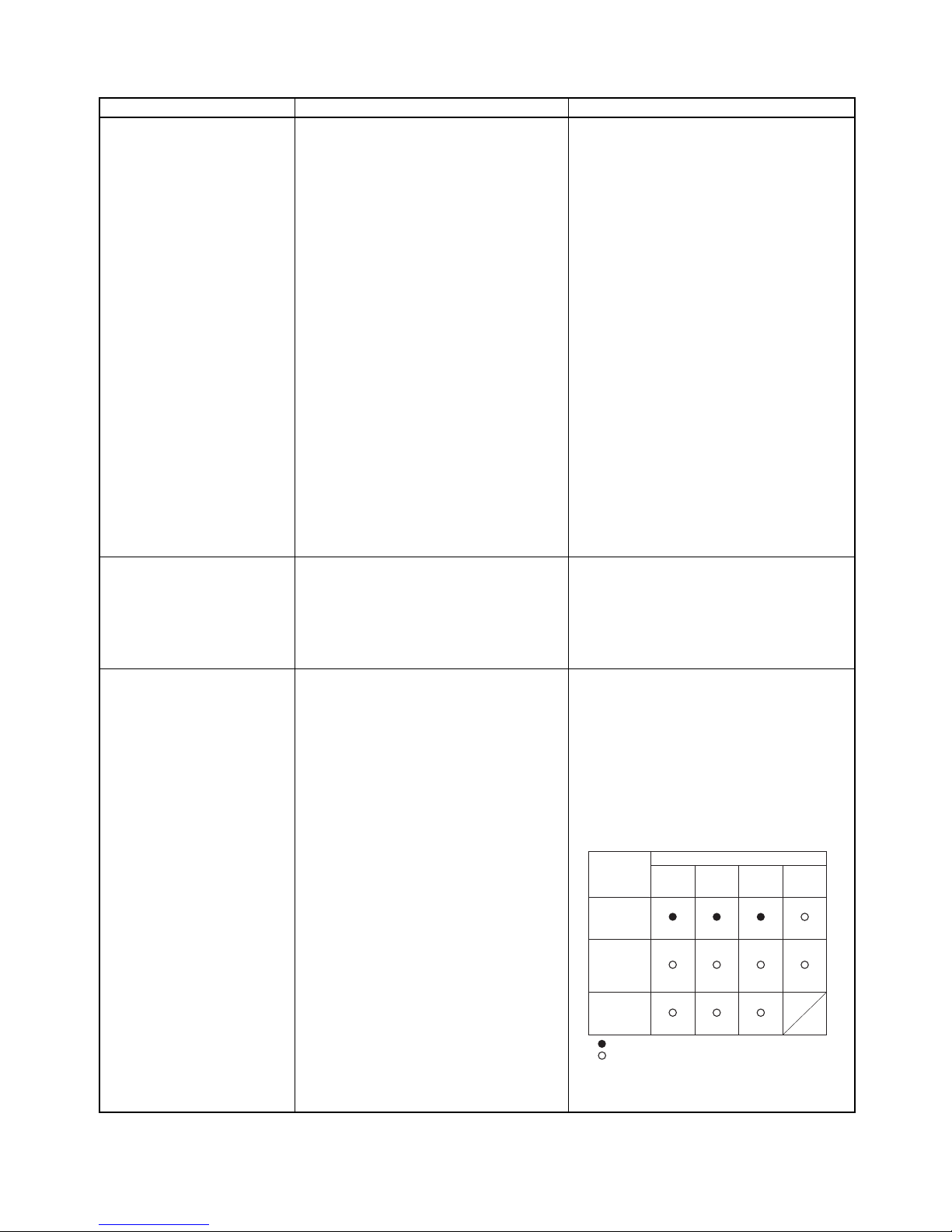

Addition of origin search operation modes

Three origin search operation pattern are

possible by combining the following settings:

• Origin search operations: 3 settings

(Reversal modes 1 and 2, and Singledirection mode)

• Origin detection method: 1 setting

(With origin proximity input signal reversal)

Eleven origin search operation pattern are

possible by combining the following settings:

• Origin search operations: 4 settings

(Reversal modes 1, 2, and 3, and Singledirection mode)

• Origin detection methods: 3 settings (With

origin proximity input signal reversal, Without origin proximity input signal reversal,

Not use origin proximity input signal)

(Refer to 8-2-4 Origin Search Operation.)

Functional upgrade Unit version 1.3 Unit version 2.0

:

Combinations supported by unit version 1.3 or earlie

r

:

Combinations supported by unit version 2.0 or later

Origin search operation

Origin

detection

method

Reversal

mode 1

Reversal

mode 2

Single-

direction

mode

Reversal

mode 3

(See note.)

(See note.)

(See note.)

Note: Origin search operation patterns supported by

absolute encoders.

With origin

proximity

input signal

reversal

Without

origin

proximity

input signal

reversal

Not use

origin

proximity

input signal

Page 17

xviii

Note Changes in Axis Communications Status Flags

The conditions for setting and resetting the Axis Communications Status

Flags in word n+22 of the Common Operating Memory Area have been

changed accompanying the addition of the rejoin function. New conditions are

underlined in the following table.

With unit version 1.3 or earlier, once MECHATROLINK communications have been started by establishing connections, the Axis Communications Status Flags will not change unless communications

are disconnected (including Unit errors that required disconnection).

With unit version 2.0 or later, the Axis Communications Status Flags will turn OFF after connections

have been established whenever axis operation becomes impossible due to a communications error

(synchronous communications alarm or communications alarm).

Unit Version 2.0 to Unit Version 2.1

Addition of origin search preset function

The preset function cannot be used during

origin searches.

The preset function can be used during origin searches.

For any of the origin search operations the

present position can be automatically set to

any specified value at the end of the origin

search. When using reversal mode 1 and an

absolute encoder, an offset can also be set

for the absolute origin.

(Refer to 8-2-6 Origin Search Preset and 8-6-

2 Absolute Encoder Operating Procedure.)

Functional upgrade Unit version 1.3 or earlier Unit version 2.0 or later

Setting conditions • The flags will turn ON when connections

are made for the axes registered in the

scan list and MECHATROLINK communications start.

• The flags will turn ON when connections

are made for the axes registered in the

scan list and MECHATROLINK communications start.

• The flag will turn ON when the rejoin function is used to start MECHATROLINK communications for an axis registered in the

scan list.

Resetting conditions • The flags will remain OFF when MECHA-

TROLINK communications cannot be

started when connections are made for

the axes registered in the scan list.

• The flags will turn OFF if MECHATROLINK communications stop because

the axis is disconnected.

• The flags will turn OFF if a Unit error

occurs that requires disconnection.

• The flags will remain OFF when MECHATROLINK communications cannot be

started when connections are made for the

axes registered in the scan list.

• The flags will turn OFF if MECHATROLINK

communications stop because the axis is

disconnected.

• The flags will turn OFF if a Unit error occurs

that requires disconnection.

• The flags will turn OFF whenever a communications error occurs after MECHATROLINK communications have been

started for the axis.

Functional upgrade Unit version 2.0 Unit version 2.1

Faster setting of transfer cycle

and communications cycle when

setting the absolute encoder PG

zero point position offset with an

origin search

A longer communications cycle must be

set using the settings given in a separate

table when the absolute encoder PG zero

point position offset is set with an origin

search.

The same communications cycle can be

set regardless of whether the absolute

encoder PG zero point position offset is

set with an origin search.

Functional upgrade Unit version 1.3 Unit version 2.0

Page 18

xix

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Page 19

xx

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

Page 20

xxi

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

Page 21

xxii

Page 22

xxiii

PRECAUTIONS

This section provides general precautions for using the Position Control Unit and related devices.

The information contained in this section is important for the safe and reliable application of Position Control Units. You

must read this section and understand the information contained before attempting to set up or operate a Position Control

Unit.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxv

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxviii

6-1 Applicable Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxviii

6-2 Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxviii

6-3 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxviii

6-4 Installation within Control Panels . . . . . . . . . . . . . . . . . . . . . . . . . . xxviii

Page 23

xxiv

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual close at hand for reference during operation.

!WARNING It is extremely important that a Position Control Units and related devices be

used for the specified purpose and under the specified conditions, especially

in applications that can directly or indirectly affect human life. You must consult with your OMRON representative before applying Position Control Units

and related devices to the above-mentioned applications.

3 Safety Precautions

!WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing

so may result in electric shock.

!WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do

so may result in malfunction, fire, or electric shock.

!WARNING Never touch any of the terminals while power is being supplied. Doing so may

result in serious electric shock.

!WARNING Provide safety measures in external circuits (i.e., not in the Programmable

Controller or Position Control Unit) to ensure safety in the system if an abnormality occurs due to malfunction of the PLC, malfunction of the PCU (Position

Control Unit), or external factors affecting the operation of the PLC or PCU.

Not providing sufficient safety measures may result in serious accidents.

Page 24

xxv

Operating Environment Precautions 4

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PLC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instruction is executed.

As a countermeasure for such errors, external safety measures must be

provided to ensure safety in the system.

• The PLC or PCU outputs may remain ON or OFF due to deposits on or

burning of the output relays, or destruction of the output transistors. As a

countermeasure for such problems, external safety measures must be

provided to ensure safety in the system.

• When the 24-V DC output (service power supply to the PLC) is overloaded or short-circuited, the voltage may drop and result in the outputs

being turned OFF. As a countermeasure for such problems, external

safety measures must be provided to ensure safety in the system.

• External safety measures must also be taken to ensure safety in the event

of unexpected operation when connecting or disconnecting the PCU’s

connectors.

!Caution Execute online editing only after confirming that no adverse effects will be

caused by extending the cycle time. Otherwise, the input signals may not be

readable.

!Caution Confirm safety at the destination node before transferring a program to

another node or changing contents of the I/O memory area. Doing either of

these without confirming safety may result in injury.

4 Operating Environment Precautions

!Caution Do not operate the control system in the following locations:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

!Caution Take appropriate and sufficient countermeasures when installing systems in

the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

Page 25

xxvi

Application Precautions 5

!Caution The operating environment of the PLC System can have a large effect on the

longevity and reliability of the system. Improper operating environments can

lead to malfunction, failure, and other unforeseeable problems with the PLC

System. Make sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the

life of the system.

5 Application Precautions

Observe the following precautions when using the PLC System.

!WARNING Always heed these precautions. Failure to abide by the following precautions

could lead to serious or possibly fatal injury.

• Always connect to a ground of 100

Ω or less when installing the Units. Not

connecting to a ground of 100

Ω or less may result in electric shock.

• Always turn OFF the power supply to the PLC before attempting any of

the following. Not turning OFF the power supply may result in malfunction

or electric shock.

• Mounting or dismounting Power Supply Units, I/O Units, CPU Units, Inner Boards, or any other Units.

• Assembling the Units.

• Setting DIP switches or rotary switches.

• Connecting cables or wiring the system.

• Connecting or disconnecting the connectors.

!Caution Failure to abide by the following precautions could lead to faulty operation of

the PLC, the PCU, or the system, or could damage the PLC or PCU. Always

heed these precautions.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal

lines, momentary power interruptions, or other causes. Not doing so may

cause malfunction resulting in serious injury.

• Interlock circuits, limit circuits, and similar safety measures in external circuits (i.e., not in the Programmable Controller) must be provided by the

customer.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may result in burning.

• For CS-series PLCs, always tighten the mounting screw at the bottom of

the PCU to a torque of 0.4 N

⋅m.

• For CJ-series PLCs, lock the sliders securely until they click into place

when connecting the Power Supply Unit, CPU Unit, I/O Units, Special I/O

Units, or CPU Bus Units. Functions may not work correctly if the sliders

are not locked properly.

• Always attach the End Cover provided with the CPU Unit to the Unit on

the right end of the PLC. The CJ-series PLC will not operate properly if

the End Cover is not attached.

Page 26

xxvii

Application Precautions 5

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied in places where the power supply

is unstable. An incorrect power supply may result in malfunction.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Disconnect the LG (line ground) terminal and GR (ground) terminal before

performing withstand voltage and insulation resistance tests.

• Confirm that set parameters and data operate properly.

• Perform wiring according to specified procedures.

• Double-check all wiring and switch settings before turning ON the power

supply. Incorrect wiring may result in burning.

• Check the user program for proper execution before actually running it on

the Unit. Not checking the program may result in unexpected operation.

• Confirm that no adverse effect will occur in the system before attempting

any of the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PLC (including setting the Startup

Mode).

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• After replacing Units, resume operation only after transferring to the new

CPU Unit, Special I/O Units, CPU Bus Units, and externally connected

devices the contents of the DM Area, Holding Area, and other data

required for resuming operation. Not doing so may result in an unexpected operation.

• Do not pull on the cables or bend the cables beyond their natural limit.

Doing either of these may break the cables.

• Do not place objects on top of the cables or other wiring lines. Doing so

may break the cables.

• Before touching a Unit, be sure to first touch a grounded metallic object in

order to discharge any static build-up. Not doing so may result in malfunction or damage.

• Never turn OFF the power to the Unit while transferring data.

Page 27

xxviii

Conformance to EC Directives 6

6 Conformance to EC Directives

6-1 Applicable Directives

•EMC Directives

6-2 Concepts

EMC Directives

OMRON devices that comply with EC Directives also conform to the related

EMC standards so that they can be more easily built into other devices or the

overall machine. The actual products have been checked for conformity to

EMC standards (see the following note). Whether the products conform to the

standards in the system used by the customer, however, must be checked by

the customer.

EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions of

the equipment or control panel on which the OMRON devices are installed.

The customer must, therefore, perform the final check to confirm that devices

and the overall machine conform to EMC standards.

Note Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN61000-6-2

EMI (Electromagnetic Interference): EN61000-6-4

(Radiated emission: 10-m regulations)

6-3 Conformance to EC Directives

The PCUs comply with EC Directives. To ensure that the machine or device in

which a PCU is used complies with EC Directives, the PCU must be installed

as follows:

1,2,3... 1. The PCU is defined as a in-panel device and must be installed within a

control panel.

2. Reinforced insulation or double insulation must be used for the DC power

supplies used for I/O.

3. PCUs complying with EC directives also meet the common emission standard (EN61000-6-4). The measures required to ensure that the standard

is met will vary with the overall configuration of the control panel, the other

devices connected to the control panel, wiring, and other conditions. The

customer must therefore confirm that EC directives are met for the overall

machine or device, particularly for the radiated emission requirement

(10 m).

6-4 Installation within Control Panels

Unnecessary clearance in cable inlet or outlet ports, operation panel mounting holes, or in the control panel door may cause electromagnetic wave leakage or interference. In this case, the product may fail to meet EC Directives. In

order to prevent such interference, fill clearances in the control panel with conductive packing. (In places where conductive packing comes in contact with

the control panel, ensure electrical conductivity by removing the paint coating

or masking these parts when painting.)

Page 28

1

SECTION 1

Features and System Configuration

This section introduces the features of the Position Control Unit, explains the system configuration in which it is used, and

also provides information on basic operations, functions and specifications.

1-1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-3 Basic Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-3-1 Position Control (Direct Operation) . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-3-2 Speed Control and Torque Control . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-3-3 Other Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-4 List of Functions and Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-4-1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-4-2 List of Functions and Specifications. . . . . . . . . . . . . . . . . . . . . . . . . 6

1-5 List of Functions by Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-6 Comparison with Existing Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Page 29

2

Fe at ur e s Section 1-1

1-1 Features

The Position Control Unit is a CS/CJ-series CPU Bus Unit. The Position Control Unit (PCU) receives commands from the CPU Unit's internal Auxiliary

Area and outputs positioning commands to MECHATROLINK-II Servo Drives.

MECHATROLINK is a registered trademark of MECHATROLINK Members

Association.

Compatible with the

MECHATROLINK-II Highspeed Field Network

A MECHATROLINK-II high-speed (10 Mbps) communications interface is

used to control Servo Drives for up to 16 axes with a single CS/CJ-series Unit.

Shielded twisted-pair cables in daisy-chain formation make wiring simple and

enable multi-axis systems that require less wiring and are smaller in size.

High-speed, Highprecision Control Using

Data Communications

Optimal motor performance can be achieved by transmitting data using communications between the Programmable Controller (PLC) and Servo Drives,

without having to set an upper limit for the designated speed. High-speed and

high-precision position control using high-resolution motors are possible.

Position Control (Direct

Operation)

Positioning can be performed simply by directly setting the target position and

target speed from the CPU Unit. Positioning to either absolute or relative positions is also possible. Interrupt feeding is also supported. With interrupt feeding, positioning is continued for a specified amount after an interrupt input

signal is received, and then the axis is stopped.

Speed Control and Torque

Control

The Servo Drive's speed and torque can be controlled by directly specifying

the target speed and torque from the CPU Unit.

Compatible with

Servomotors with

Absolute Encoders

The PCU is compatible with Servomotors that have absolute encoders. Using

such Servomotors eliminates the need to repeatedly perform origin searches.

Transfer Data between

Host PLC and Servo Drive

The Servo Drive's parameters and monitors can be set from the CPU Unit. All

the data for the multi-axis system can be centrally controlled from the host

PLC. This removes the difficulty in starting up devices or setting data when

replacing a Unit.

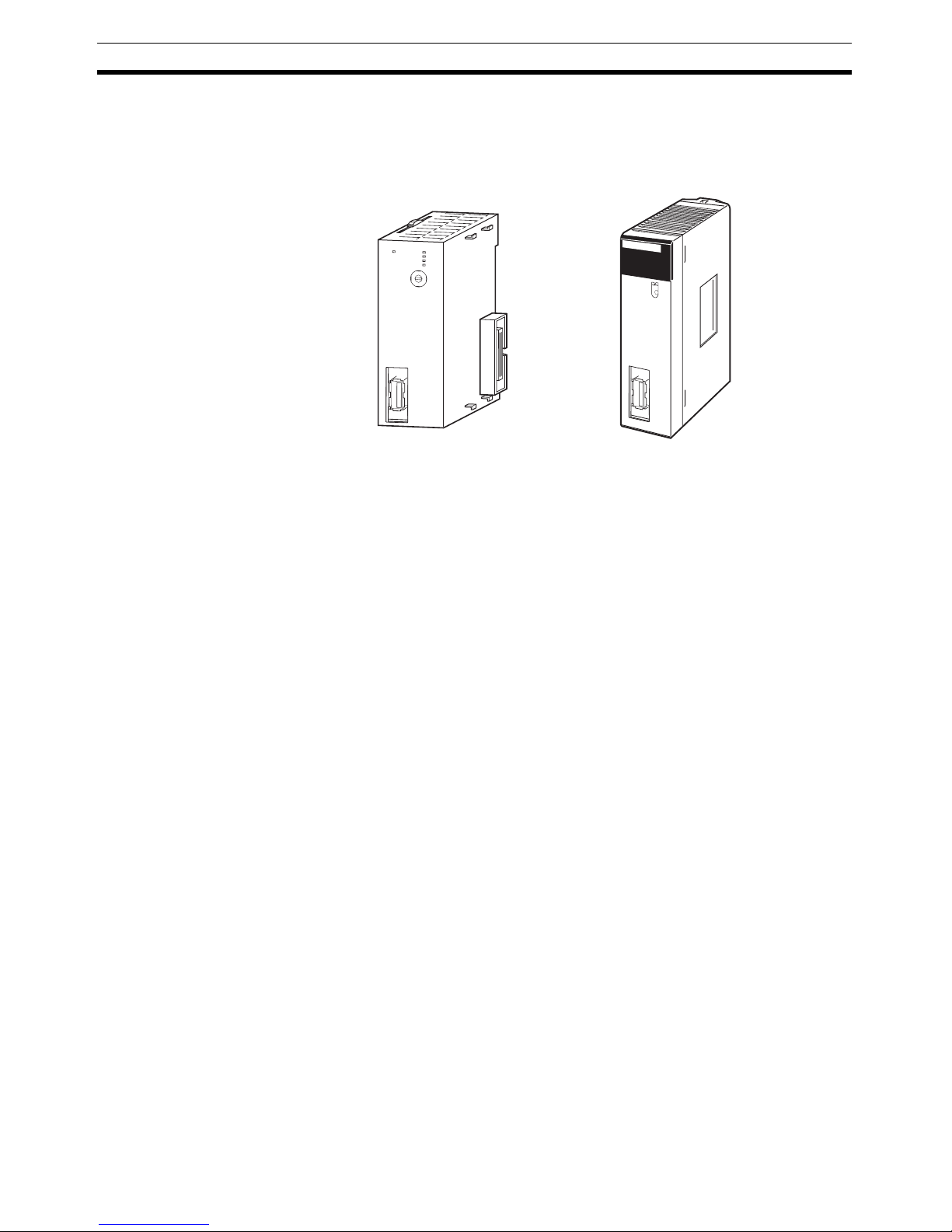

CJ1W-NC271/471/F71 CS1W-NC271/471/F71

R

U

N

E

R

C

E

R

H

E

R

M

M

L

K

N

C

F71

U

N

IT

No.

M

LK

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

Position Control Unit

RUN

ERC

ERH

ERM

MLK

NCF71

CS

UNIT

No.

9

8

5

4

3

2

1

0

M

L

K

Page 30

3

System Configuration Section 1-2

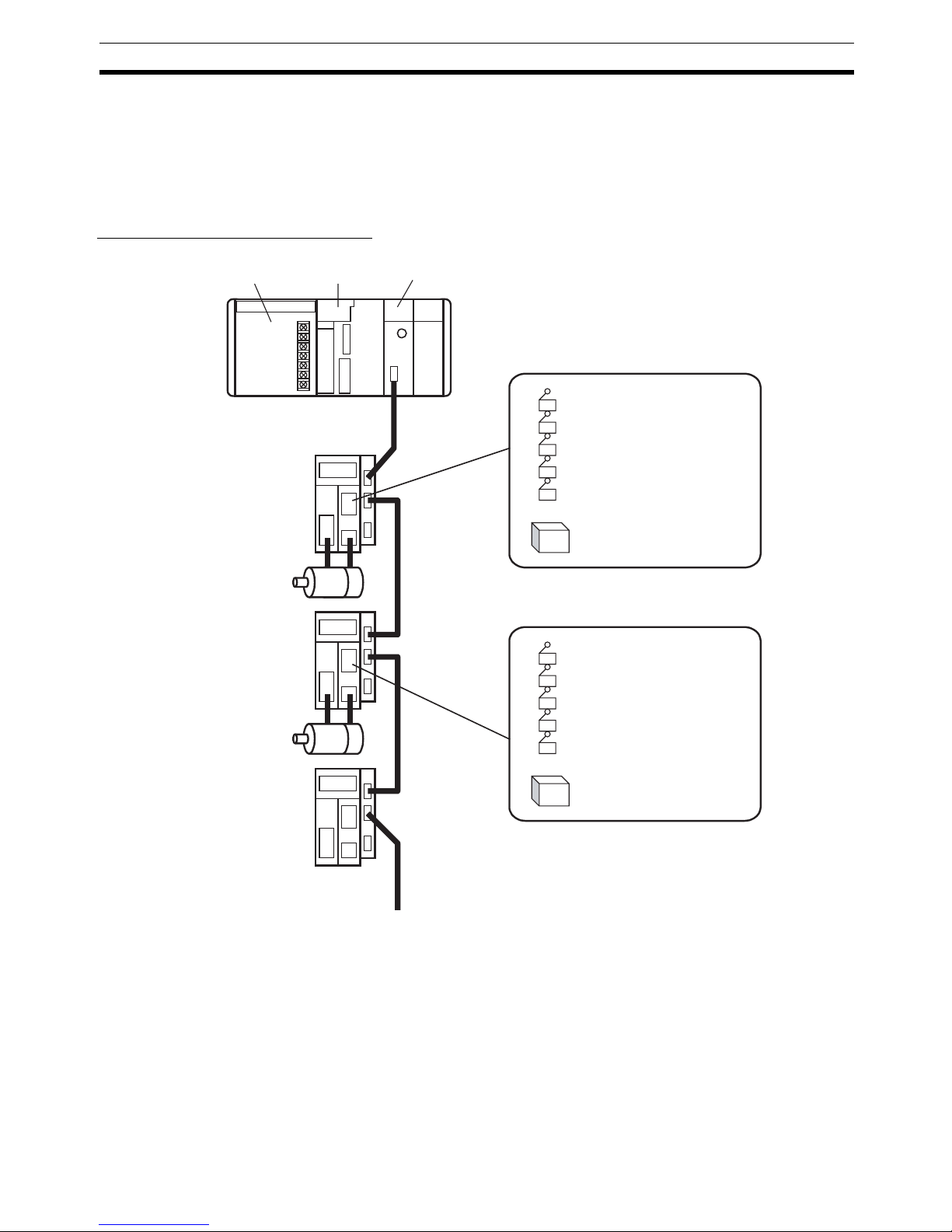

1-2 System Configuration

The PCU receives commands from the CPU Unit's ladder program and control signal status (forward/reverse rotation limit, origin, origin proximity, and

interrupt input signals) from devices connected externally to the Servo Drive,

and uses them to control Servo Drive positioning.

System Configuration Example

Power Supply Unit

CJ-series

CPU Unit

CJ1W-NCF71

Position Control Unit

Servo Drive

Servomotor

Servo Drive

Servomotor

Servo Drive

MECHATROLINK-II

(16 axes max.)

External inputs

External inputs

Forward rotation limit input signal

Reverse rotation limit input signal

Origin input signal

Origin proximity input signal

Interrupt input signal

Etc.

24-V DC power supply

for interface

Forward rotation limit input signal

Reverse rotation limit input signal

Origin input signal

Origin proximity input signal

Interrupt input signal

24-V DC power supply

for interface

Etc.

Page 31

4

Basic Operations Section 1-3

1-3 Basic Operations

The PCU's operations are as follows:

1-3-1 Position Control (Direct Operation)

Positioning can be executed either to an absolute position (i.e., to an absolute

position from the origin) or to an incremental position (i.e., to a position relative to the present position). Interrupt feeding is also possible, whereby an

axis is moved a specified amount when an interrupt input signal is received

and then stopped.

Absolute Movements and

Relative Movements

With absolute and relative movements, position and speed data are set

directly from the ladder program in the CPU Unit. Positioning is executed

according to operating commands sent to the PCU from the CPU Unit. It is

also possible to change the speed or to send commands to move axes to different positions while positioning is being performed.

Origin searches

CJ1W-NC@71/CS1W-NC@71

Position Control Unit functions

Position control

(direct operation)

Speed control

Torque control

Other operations

Absolute movement

Relative movement

Interrupt feeding

Jogging

Overrides

Present position preset

Stop functions

Backlash compensation

Time

Speed

Start

Start

Position changed, start

New target position

X

Y

Speed changed

Target position before

position changed

Page 32

5

Basic Operations Section 1-3

Interrupt Feeding When an interrupt input signal is received, positioning is continued for the

specified amount of movement and then stopped.

Linear Interpolation Linear interpolation can be performed for a combination of axes (Unit Ver. 1.1

or later).

1-3-2 Speed Control and Torque Control

Speed command data and torque command data are set from the CPU Unit.

Speed control and torque control of the Servomotor are executed by sending

operating commands to the PCU from the CPU Unit.

1-3-3 Other Operations

Origin Searches The origin search operations find the origin for a designated axis.

Jogging Jogging moves a specified axis at a designated speed and then stops it.

Overrides When an override is enabled during positioning, the target speed is changed

to the override speed.

Present Position Preset

(Changing the Present

Position)

The PRESENT POSITION PRESET command changes the present position

to a specified position.

Stop Functions The DECELERATION STOP command decelerates positioning to a stop.

The EMERGENCY STOP command cancels operating commands immediately and stops the axis after moving it for the number of pulses remaining in

the Servo Drive's deviation counter.

Time

Speed

Interrupt input

Specified amount of movement (a

negative direction can also be set)

Time

Speed

A

× 1.5

1

0

A

Override set value: 150%

Override Enable Bit

Page 33

6

List of Functions and Specifications Section 1-4

1-4 List of Functions and Specifications

1-4-1 General Specifications

Specifications not listed above conform to general CS/CJ Series specifications.

1-4-2 List of Functions and Specifications

Item Specification

Model CJ1W-NC271/471/F71 CS1W-NC271/471/F71

Internal current

consumption

360 mA max. at 5 V DC

Dimensions 31 × 90 × 65 mm (W × H × D) 130 × 35 × 101 mm (W × H × D)

Weight 95 g max. 188 g max.

Ambient operat-

ing temperature

0 to 55°C

Approved standards

CE, cULus, and C-tick

Item Specification

Unit classification CPU Bus Unit

Applicable PLCs CS/CJ Series

Possible unit number settings 0 to F

I/O allocations Common Operating Memory Area Words allocated in CPU Bus Unit Area: 25 words (15 output words,

10 input words)

Axis Operating Memory Area Allocated in one of the following areas (user-specified):

CIO, Work, Auxiliary, Holding, DM, or EM Area.

Number of words allocated: 50 words (25 output words, 25 input

words) × Highest axis No. used

Compatible devices • OMRON G-series Servo Drives

(Built-in MECHATROLINK-II communications)

• OMRON W-series Servo Drives

(equipped with MECHATROLINK-II Application Module or built-in

MECHATROLINK-II communications)

• OMRON SMARTSTEP Junior Servo Drives

(Built-in MECHATROLINK-II communications)

Note SMARTSTEP Junior Servo Drive are supported by Position

Control Units with unit version 2.0 or later.

Control method Control commands executed using MECHATROLINK-II synchro-

nous communications.

Maximum number of controlled axes CS1W/CJ1W-NC271: 2 axes, CS1W/CJ1W-NC471: 4 axes,

CS1W/CJ1W-NCF71: 16 axes

Control units Position command unit Command unit: Depends on the Electronic Gear Setting in the

Servo Parameters.

Default setting: Pulses

Speed command unit for position

control

Command units/s

Acceleration/deceleration speeds

for position control

10,000 command units/s

2

Speed command unit for speed

control

0.001% of the motor's momentary maximum rotation speed

Torque command unit for torque

control

0.001% of the motor's momentary maximum torque

Page 34

7

List of Functions and Specifications Section 1-4

Control command range

Position command range −2,147,483,648 to 2,147,483,647 (command units)

Speed command range for position

control

0 to 2,147,483,647 (command units/s)

Acceleration/deceleration speeds

for position control

1 to 65,535 (10,000 command units/s

2

)

Speed command range for speed

control

−199.999% to 199.999%

The upper limit of the speed command range depends on the

specifications of the Servo Drive.

Torque command range for torque

control

−199.999% to 199.999%

The upper limit of the torque command range depends on the

specifications of the Servo Drive.

Control functions

Servo lock/unlock Creates (Servo lock) or releases (Servo unlock) the position loop

on the PCU.

Position control Positions to an absolute position or relative position according to

the target position and target speed specified from the ladder program.

Origin determination • Origin search: Establishes the origin using the specified search

method.

• Present position preset: Changes the present position to a specified position to establish the origin.

• Origin return: Returns the axis from any position to the established origin.

• Absolute encoder origin: Establishes the origin using a Servomotor that has an absolute encoder, without having to use an origin

search.

Jogging Outputs pulses at a fixed speed in the forward rotation or reverse

rotation direction.

Interrupt feeding Performs positioning by moving the axis a fixed amount when an

external interrupt input is received while the axis is moving.

Speed control Performs speed control by sending a command to the Servo Drive

speed loop.

Torque control Performs torque control by sending a command to the Servo Drive

current loop.

Stop functions • Deceleration stop: Decelerates the moving axis to a stop.

• Emergency stop: Positions the moving axis for the number of

pulses remaining in the deviation counter and then stops the axis.

Auxiliary functions

Acceleration/deceleration curves Sets one of the following: a trapezoidal (linear) curve, an exponen-

tial curve, or an S-curve (moving average).

Torque limit Restricts the output torque during axis operation.

Override Multiplies the axis command speed by a specified ratio.

Override: 0.01% to 327.67%

Servo parameter transfer Reads and writes the Servo Drive parameters from the ladder pro-

gram in the CPU Unit.

Monitoring function Monitors the control status of the Servo Drive, such as the com-

mand coordinate positions, feedback position, current speed, and

torque.

Software limits Limits software operation within the positioning range during posi-

tion control.

Backlash compensation Compensates for the amount of play in the mechanical system

according to a set value.

Deviation counter reset The position deviation in the Servo Drive’s deviation counter can

be reset to 0 (unit version 1.3 or later).

External I/O Position Control Unit One MECHATROLINK-II interface port

Servo Drive I/O Forward/reverse rotation limit inputs, origin proximity inputs, exter-

nal interrupt inputs 1 to 3 (can be used as external origin inputs)

Item Specification

Page 35

8

List of Functions by Purpose Section 1-5

1-5 List of Functions by Purpose

Self-diagnostic functions Watchdog, flash memory check, memory corruption check

Error detection functions Overtravel, Servo Drive alarm detection, CPU error, MECHA-

TROLINK communications error, Unit setting error

Purpose Category Name Basic function Details

Establishing the

mechanical origin of

the machine

Origin determination

Origin search The motor is operated to estab-

lished the origin.

8-2 Origin Search

Operation

Present position preset The position where the motor is

stopped is set to a specified position to establish the origin.

8-3 Present Position

Preset

Origin return The axis is returned to the estab-

lished origin.

8-4 Origin Return

Absolute encoder origin The origin is established using a

Servomotor with an absolute

encoder, so origin searches are

not required at machine startup.

8-6 Absolute

Encoder Origin

Point-to-point (PTP)

positioning

Position control

Direct operation (absolute movement or relative

movement)

The position and speed are specified to perform positioning using

an absolute or relative movement.

9-4 Using Direct

Operation

Changing the target

position and speed

as required during

positioning

Direct operation:

Changing target position

or changing target speed

The target position or target

speed is changed during positioning with direct operation.

9-4-3 Changing Target Position

9-4-4 Changing Target Speed

Performing positioning for a specified

distance from an

external input point

during positioning

Interrupt feeding When an interrupt input signal

turns ON during positioning with

direct operation, operation

switches to positioning for a fixed

amount.

9-5 Interrupt Feeding

Performing manual

feeding for adjustment or other purpose

Jogging The axis is moved at a fixed

speed in the forward rotation or

reverse rotation direction.

10-2 Jogging

Reducing shock

while device is operating

Auxiliary

functions

Acceleration/deceleration curves

Acceleration/deceleration is performed according to the basic

trapezoidal curve (linear acceleration/deceleration), an exponential

curve, or an S-curve, which

greatly helps to reduce mechanical vibration.

7-4 Acceleration and

Deceleration Operations

Temporarily multiplying the machine's

operating speed by a

constant ratio to perform startup adjustments

Overrides The axis command speed is mul-

tiplied by a constant ratio.

10-3 Override

Restricting output

torque during control operations such

as pushing control

Torque limit A constant limit is applied to the

output torque of the Servomotor

during positioning.

10-4 Torque Limits

Stopping the device

during operation

Stop function

Deceleration stop or

emergency stop

The moving axis is decelerated to

a stop or the axis is moved for the

number of pulses remaining in the

deviation counter and then

stopped.

10-9 Stop Functions

Changing the Servo

Drive settings from

the PLC

Data transfer

function

Reading/writing Servo

parameters

Servo Drive parameters are read

or written from the CPU Unit.

5-3 Transferring

Servo Parameters

Item Specification

Page 36

9

Comparison with Existing Models Section 1-6

1-6 Comparison with Existing Models

Performing speed

feeding in rotary control such as sheet

feeding.

Speed control

Speed control The speed command value is

directly specified to control the

Servomotor rotation.

10-5 Speed Control

Changing the output

torque sequentially

during control operations such as tightening.

Torque control

Torque control The torque command value is

directly specified to control the

Servomotor's output torque.

10-6 Torque Control

Functions and

performance

CJ1W-NC@71

CS1W-NC@71

CJ1W-NC@13/@33

CS1W-NC@13/@33

Unit type CPU Bus Unit Special I/O Unit

Unit number alloca-

tion

Unit numbers can be set from 0 to F

(CPU Bus Units).

Unit numbers can be set from 0 to 95.

• One-axis and two-axis PCUs: One unit number

used.

• Four-axis PCUs: Two unit numbers used.

Control method Commands are executed using MECHA-

TROLINK-II synchronous communications.

Open-loop control is performed using a pulse

train output.

Format of data

exchanged between

PLC and PCU

Binary (hexadecimal)

Example: Present position is output to the PLC

in 32-bit signed binary format.

Same as CJ1W-NC@71/CS1W-NC@71.

Position command

range

−2,147,483,648 to 2,147,483,647

(Unit depends on Servo Parameters)

−1,073,741,823 to 1,073,741,823 pulses

Present position

range

−2,147,483,648~2,147,483,647

(Unit depends on Servo parameters)

−2,147,483,647 to 2,147,483,647 pulses

Zone range No zone functions −1,073,741,823 to 1,073,741,823 pulses

Speed command

range

Position control:

0 to 2,147,483,647 (command units/s)