Page 1

Cat. No. W435-E1-05

Programmable Controller

SYSMAC CS/CJ-series

CS1W-MCH71

CJ1W-MCH71

Motion Control Unit

OPERATION MANUAL

Page 2

CS1W-MCH71 CJ1W-MCH71 Motion Control Unit

Operation Manual

Revised June 2008

Page 3

iv

Page 4

Notice:

r

f

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 2004

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 5

Introduction

We are flattered that you have purchased OMRON SYSMAC CS/CJ-series advanced Motion Control

Unit.

Motion control Unit CS1W-MCH71/CJ1W-MCH71 (the abbreviation “MC Unit” is in this mean) is a high

performance CPU unit of the programmable controller SYSMAC CS/CJ-series that has been produced

by OMRON's advanced technology for control and abundant experience.

This instruction manual describes MC Unit's specifications and procedures for operation.

Please read each section in its entirety and be sure you understand the information provided in the

section and relate sections before attempting any of the procedures or operation given.

vi

Page 6

MC Units

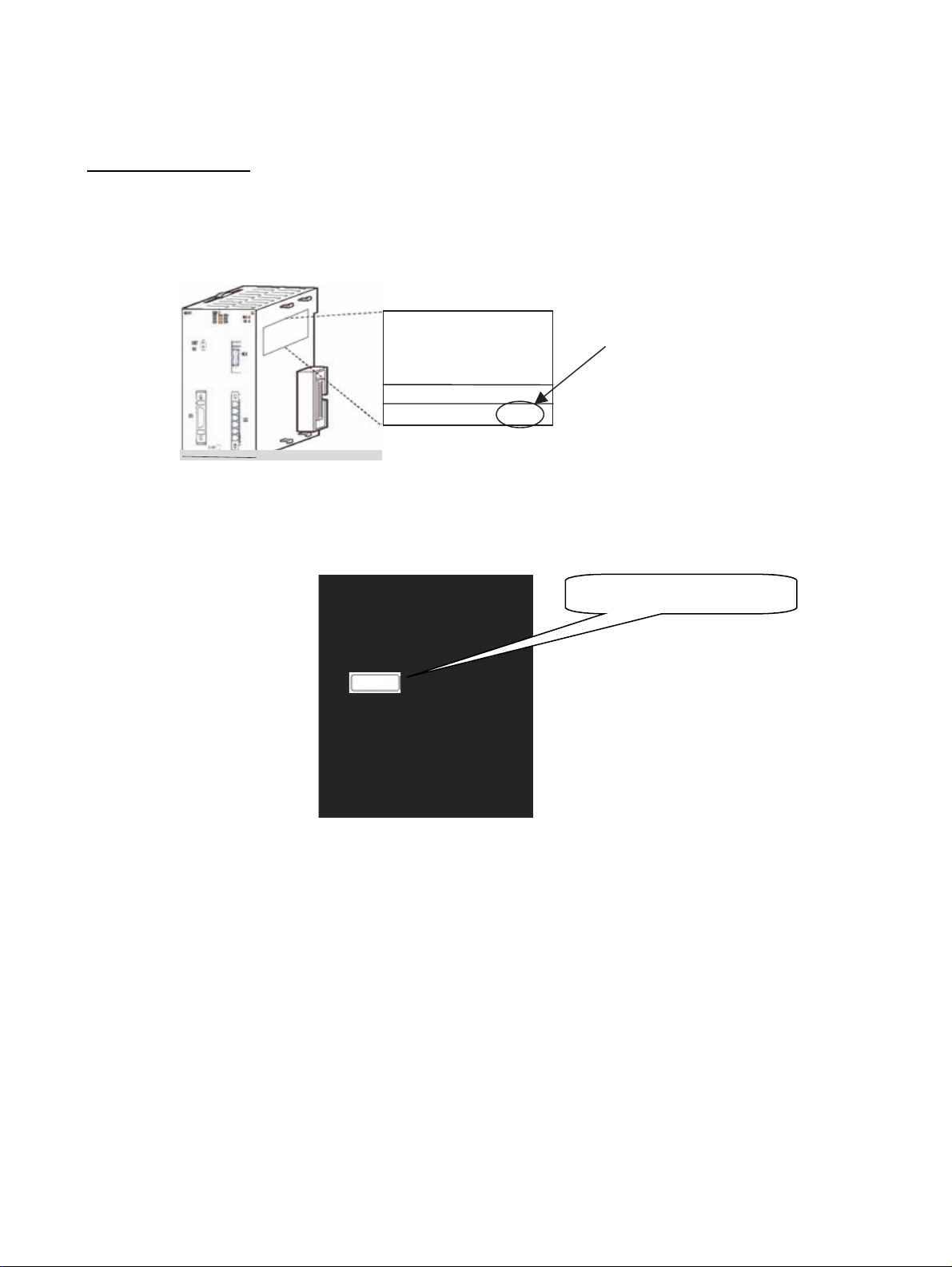

Unit Versions A “unit version” has been introduced to manage MC Units according to differ-

ences in functionality accompanying Unit upgrades.

Notation of Unit Versions

on Products

MC Unit

The unit version is given to the right of the lot number on the nameplate of the

applicable MC Units, as shown below.

Product nameplate

OMRON CJ1W- MCH71

MC UNIT

Lot No. 031001 0000 Ver.3.1

Unit version

Example for unit version 3.1

The unit version of the MC Units begins at version 2.0.

Identifying Unit Versions A unit version label is provided with the Advanced Motion Control Unit. This

label can be attached to the front of the Motion Control Unit to differentiate

between Motion Control Units of different Unit versions.

Attach the unit version label here.

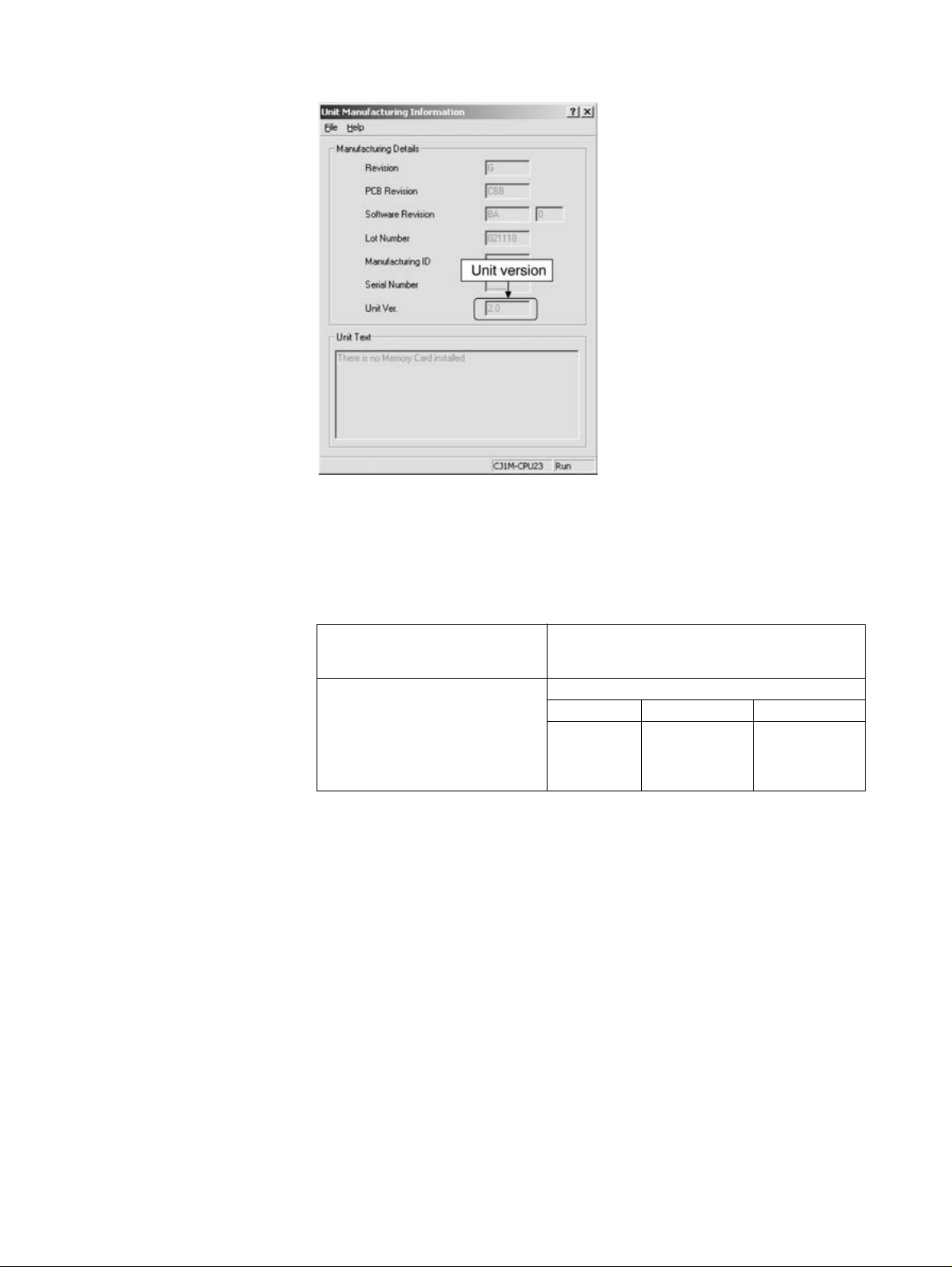

Confirming Unit Versions

with Support Software

Ver. 3.1

The unit version 2.1 or later can be confirmed in Unit Manufacturing Informa-

tion of CX-Programmer version 4.0 or higher. Unit version 2.0 cannot be confirmed in Unit Manufacturing Information. Use the CX-Motion-MCH Support

Tool for Motion Control Units to confirm the unit version.

Example: Confirming Unit Version 2.1 or Later Using CX-Programmer

Version 4.0 or Higher

1. In the I/O Table Window, right-click the Motion Control Unit and select Unit

Manufacturing Information.

2. The following Unit Manufacturing Information Dialog Box will be displayed.

vii

Page 7

3. Unit version 3.1 will be displayed in the Unit Manufacturing Information Dialog Box.

Example: Confirming Unit Version 3.0 Using CX-Motion-MCH Support

Tool

Use the CX-Motion-MCH Support Tool for Motion Control Units to confirm the

unit version, as shown in the following table.

Method for confirming the internal

system software version

Corresponds to the unit version Internal system software version

The system software version in the Motion Control Unit can be checked in the Unit information

from the online menus.

CJ1W-MCH71 CS1W-MCH71

Unit Ver. 2.0:

Unit Ver. 2.1:

Unit Ver. 3.0:

Unit Ver. 3.1

1.05xxxx

1.06xxxx

1.07xxxx

1.09xxxx

1.05xxxx

---

1.08xxxx

1.09xxxx

viii

Page 8

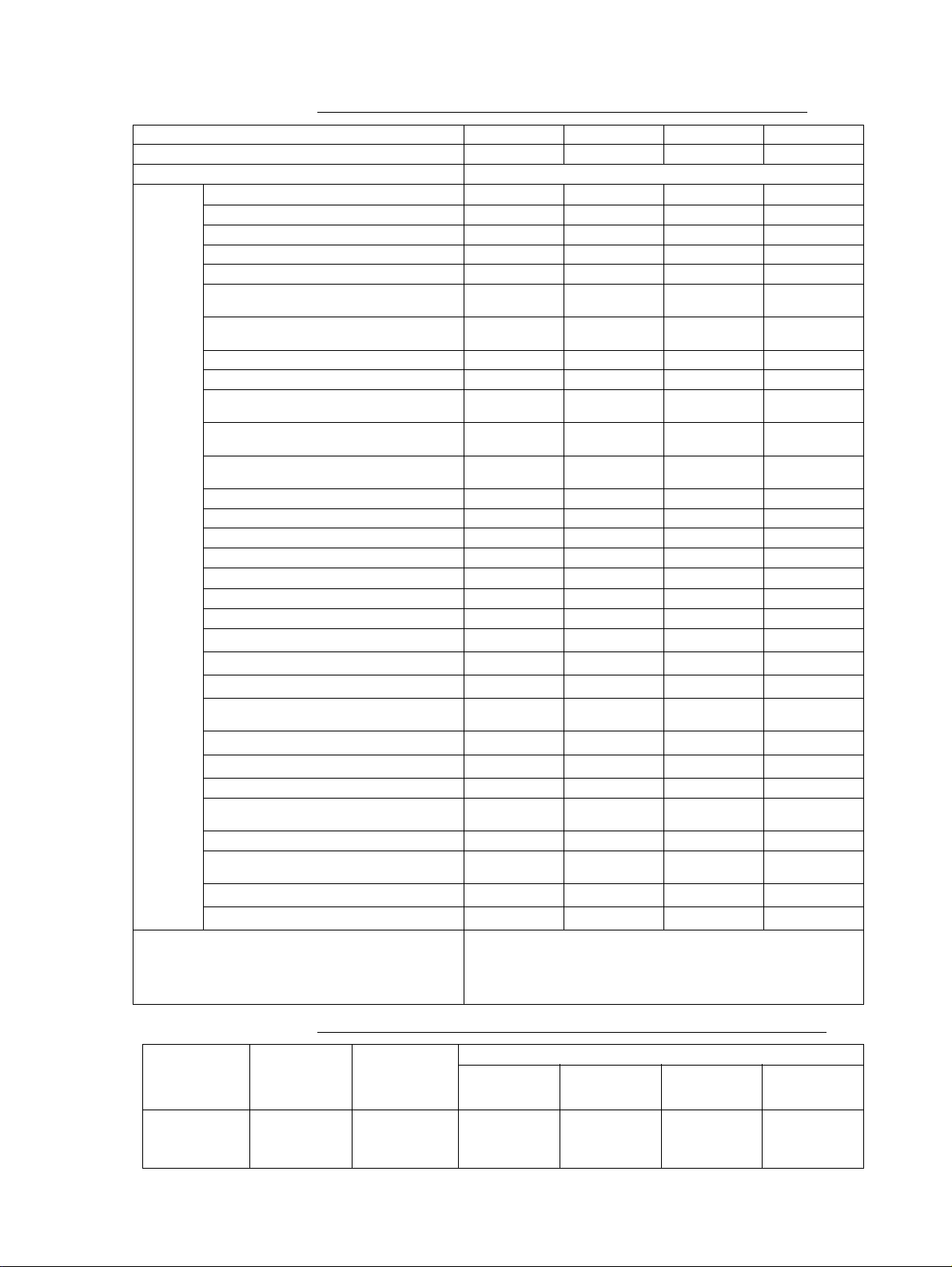

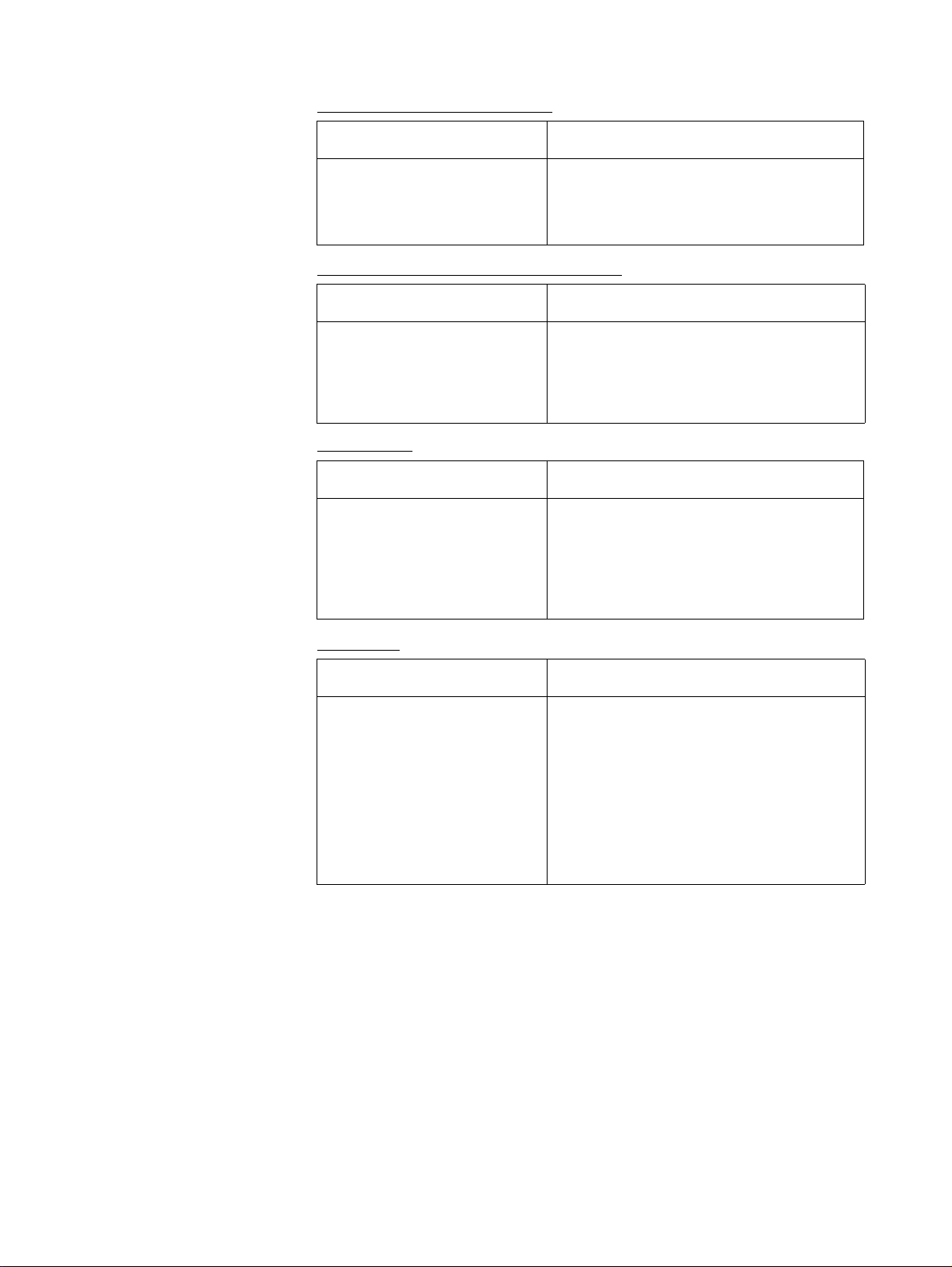

Functions Supported by CJ1W-MCH71 Units Version 2.1 or Later

Unit version Unit Ver. 2.0 Unit Ver. 2.1 Unit Ver. 3.0 Unit Ver. 3.1

Internal system software version 1.05 1.06 1.07 1.09

MC Unit model CJ1W-MCH71

Functions Reading unit version function Not supported Supported Supported Supported

Expanded allocations in Custom

I/O Area

Data tracing Not supported Not supported

Debugging Not supported Not supported

Zones Not supported Not supported

Signed master axis MOVELINK command

Indirect writing of position data Not supported Not supported Supported Supported

Setting the number of parallel

branches for each task

Present position preset to establish

origin

Status of program start bit Not supported Not supported Supported Supported

Servo OFF for deceleration stop signal Not supported Not supported

Re-execution of WAIT command Not supported Not supported Supported Supported

Main power status Not supported Not supported Supported Supported

Servo Driver status Not supported Not supported Supported Supported

Increased precision of CAMBOX command

Improved restarting after restoration --- --- --- Supported

Expanded bank switching for interpolation acceleration/deceleration times

Internal overrides --- --- --- Supported

Connecting to SMARTSTEP Junior

Servo Drivers

Improved backup and restore functions

Program and CAM data read protection

Applicable Support Tool CX-Motion-MCH

Not supported Supported Supported Supported

*1

*1

*1

Supported

Supported

Supported

Supported

Supported

Supported

Not supported Not supported Supported Supported

Not supported Not supported

Not supported Not supported

Supported

Supported

Supported

*1

*1

*1

Supported

Supported

Supported

Not supported Not supported Supported Supported

--- --- --- Supported

--- --- ---

--- --- ---

--- --- ---

• Functions for unit version 3.0 indicated by “*1” can be used with CXMotion-MCH version 2.0 or higher.

Supported

Supported

Supported

• Functions for unit version 3.1 indicated by “*2” can be used with CXMotion-MCH version 2.1 or higher.

*1

*1

*1

*1

*1

*1

*2

*2

*2

CJ1W-MCH71 Unit Versions and Manufacturing Dates/Lot Numbers

Classification Type Model Manufacturing dates

Up to early

November

2004

CPU Bus Unit MC Unit CJ1W-MCH71 Unit version 2.0 Unit version 2.1

From middle of

November

2004

(Lot No.:

041117 and

later)

From early

Unit version 3.0

(Lot No.:

050615 and

later)

June

2005

From early

July

2007

Unit version 3.1

(Lot No.:

070615 and

later)

ix

Page 9

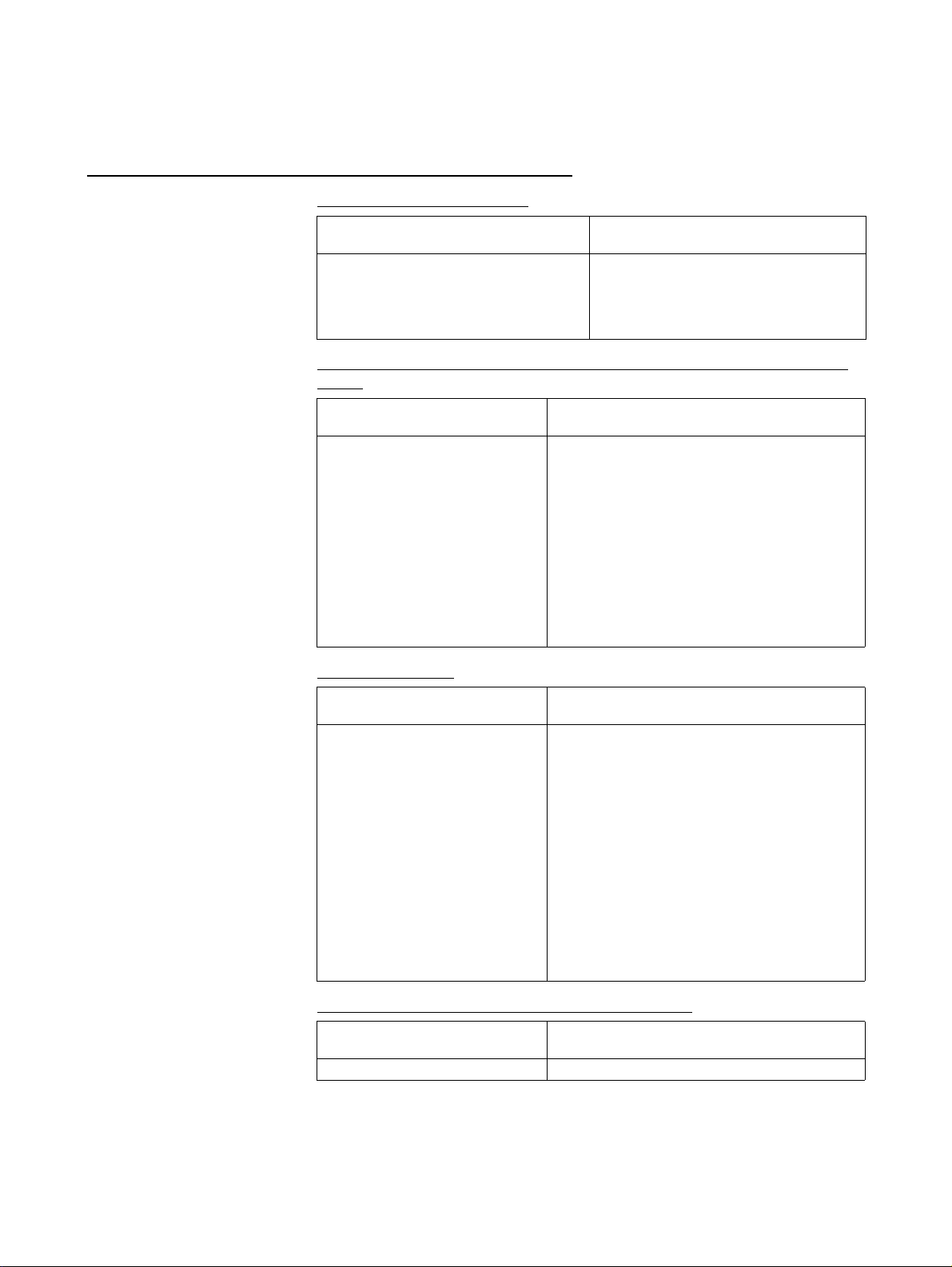

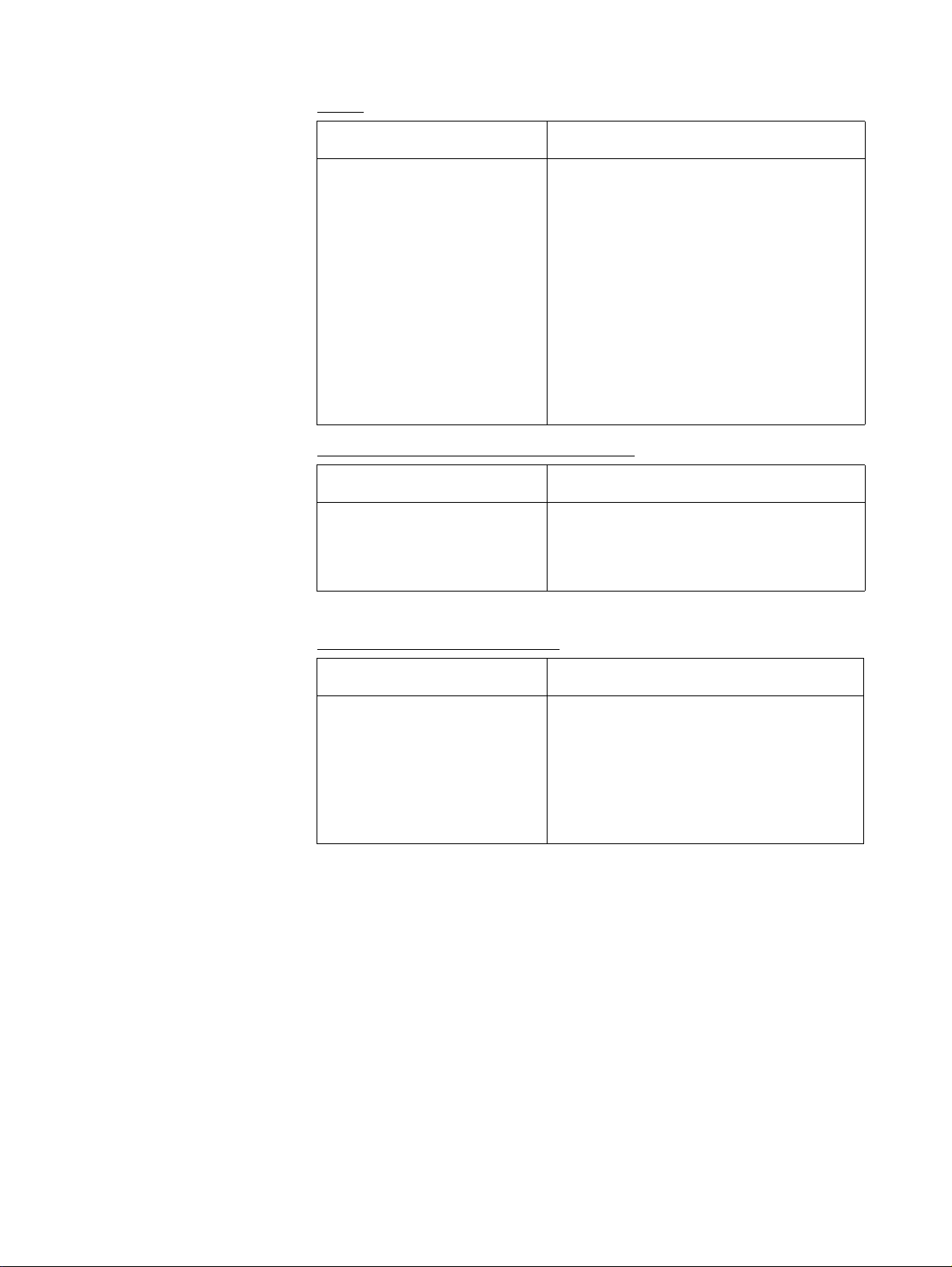

Functions Supported by CS1W-MCH71 Units Version 2.0 or Later

Unit version Pre-Ver. 2.0 Unit Ver. 2.0 Unit Ver. 3.0 Unit Ver. 3.1

Internal system software version 1.00 to 1.04 1.05 1.08 1.09

MC Unit model CS1W-MCH71

Functions Jogging --- Supported Supported Supported

Communications levels --- Supported Supported Supported

Communications cycle and unit cycle --- Supported Supported Supported

LATCH command processing time --- Supported Supported Supported

Latch status refresh time --- Suppor ted Supported Supported

Using interpolation commands during pass

operation

Acceleration/deceleration time during pass

operation

Deceleration time during pass operation --- Supported Supported Supported

Torque to position control switching --- Supported Supported Supported

Expanded allocations in Custom

I/O Area

Digital input values changed to improve

noise immunity

Faster unit cycle and communications cycle

times

Signed master axis MOVELINK command --- --- Supported Supported

Indirect writing of position data --- --- Supported Supported

Status of program start bit --- --- Supported Supported

Re-execution of WAIT command --- --- Supported Supported

Main power status --- --- Supported Supported

Servo Driver status --- --- Supported Supported

Increased precision of CAMBOX command --- --- Supported Supported

Data tracing --- ---

Debugging --- ---

Zones --- ---

Setting the number of parallel branches for

each task

Present position preset to establish origin --- ---

Servo OFF for deceleration stop signal --- ---

Improved restarting after restoration --- --- --- Supported

Expanded bank switching for interpolation

acceleration/deceleration times

Internal overrides --- --- --- Supported

Connecting to SMARTSTEP Junior Servo

Drivers

Improved backup and restore functions --- --- ---

Program and CAM data read protection --- --- ---

Applicable Support Tool CX-Motion-MCH

--- Supported Supported Supported

--- Supported Supported Supported

--- ---

Supported

*1

Supported

--- --- Supported Supported

--- --- Supported Supported

*1

*1

*1

*1

*1

*1

Supported

Supported

Supported

Supported

Supported

Supported

--- ---

Supported

Supported

Supported

Supported

Supported

Supported

--- --- --- Supported

--- --- ---

Supported

Supported

Supported

• Functions for unit version 3.0 indicated by “*1” can be used with CXMotion-MCH version 2.0 or higher.

• Functions for unit version 3.1 indicated by “*2” can be used with CXMotion-MCH version 2.1 or higher.

*1

*1

*1

*1

*1

*1

*1

*2

*2

*2

CS1W-MCH71 Unit Versions and Manufacturing Dates/Lot Numbers

Classification Type Model Manufacturing dates

From early

June

2004

CPU Bus Unit MC Unit CS1W-MCH71 Pre-Ver. 2.0 Unit version 2.0

From July 2004 From

March

2007

(Lot No.:

040715 and

later)

Unit version 3.0

(Lot No.:

070313 and

later)

From early

July

2007

Unit version 3.1

(Lot No.:

070615 and

later)

x

Page 10

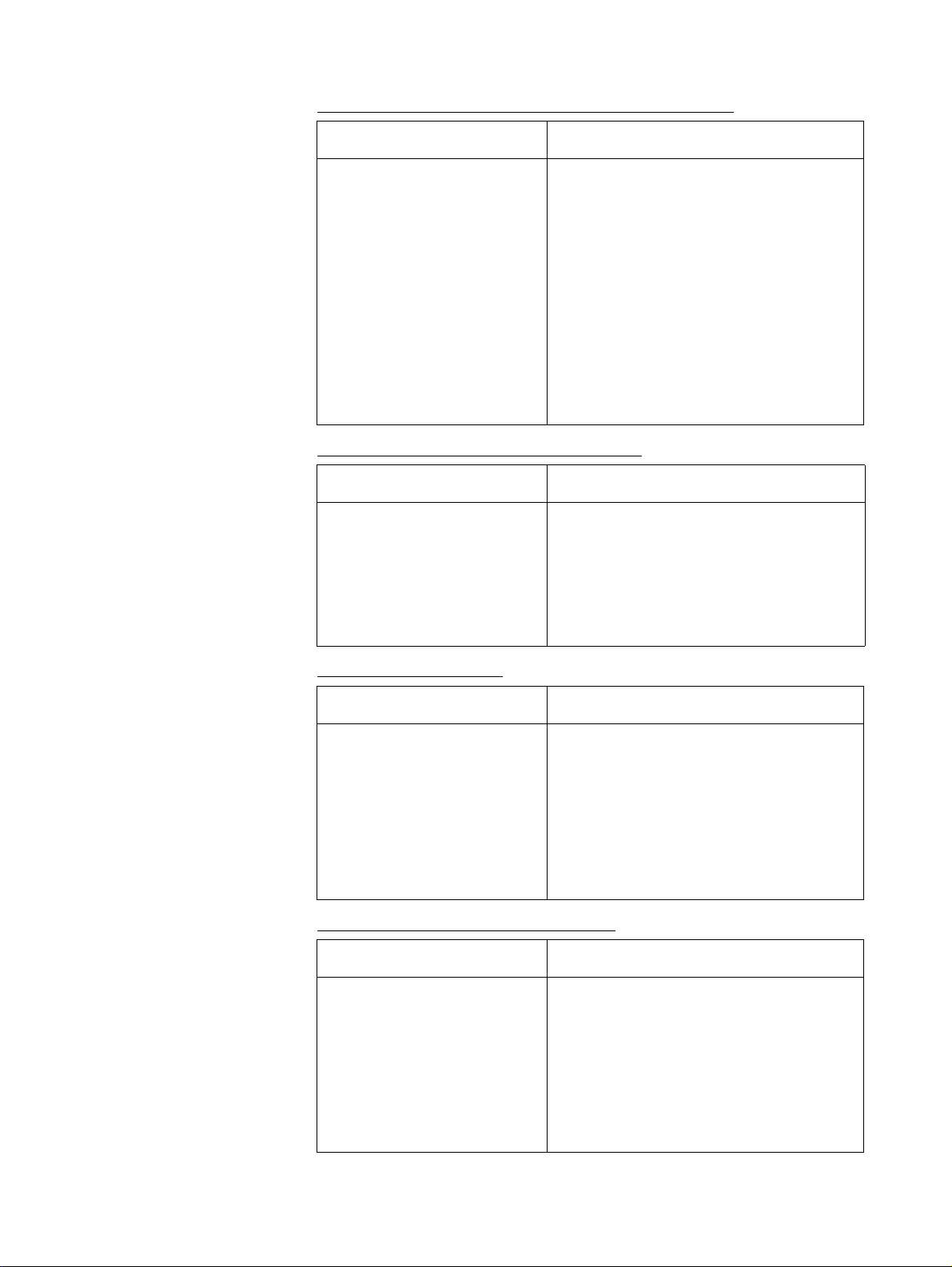

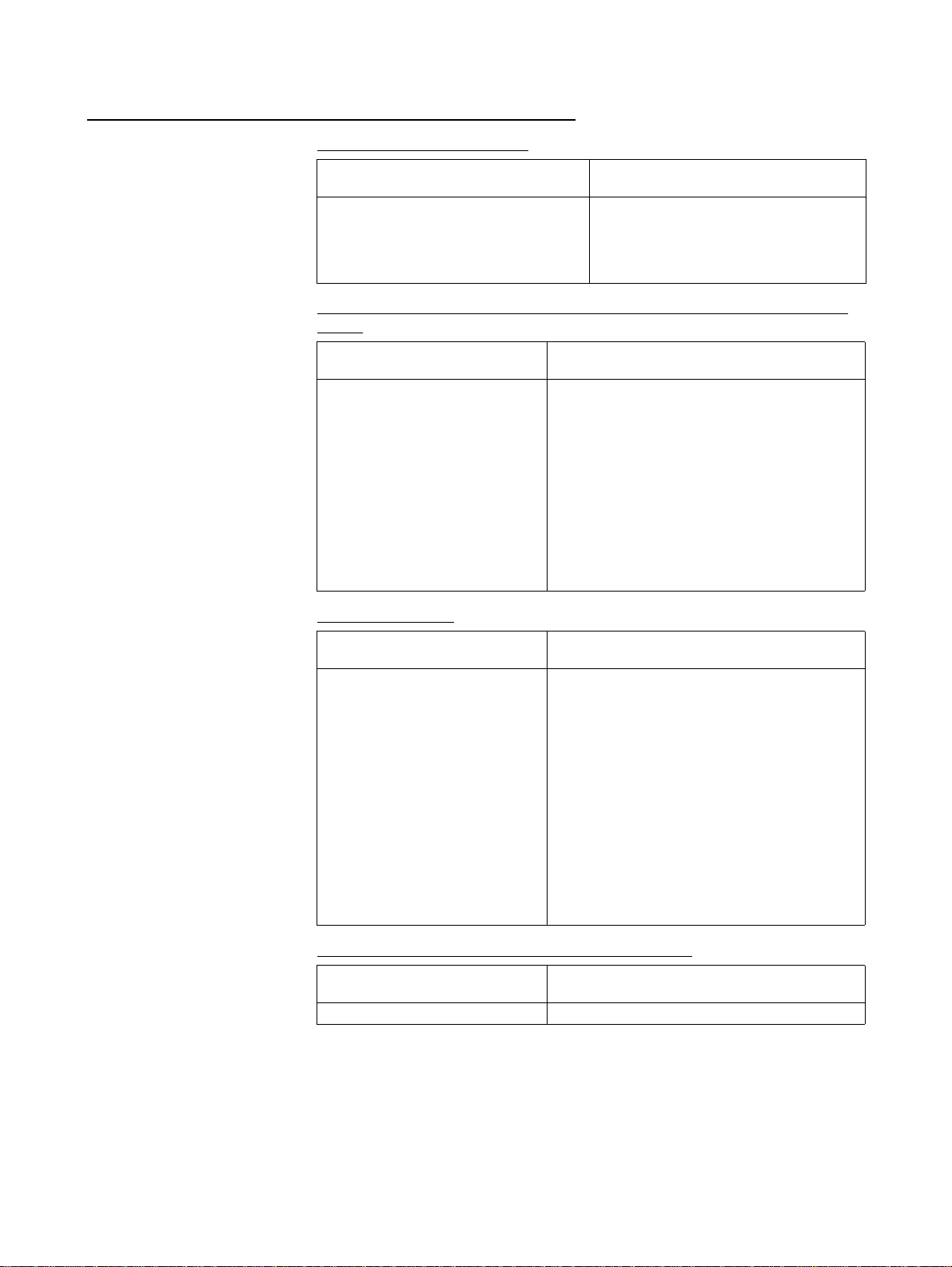

Guide to Version Upgrades

Guide to CJ1W-MCH71 Version Upgrade

Function Upgrades from

Unit Version 3.0 to 3.1

Restarting after Restoration

Previous versions

(Unit Ver. 3.0 and earlier)

After data has been restored from the

CPU Unit's flash memory, the Unit must

be restarted by cycling the CPU Unit's

power supply.

After data has been restored from the

CPU Unit's flash memory, the Unit is

restarted using a bit between A50100 and

A50115 in the Auxiliary Area of the CPU

Unit. For details, refer to 7-1 Overview.

Current version

(Unit Ver. 3.1)

Expanded Bank Switching for Interpolation Acceleration/Deceleration

Times

Previous versions

(Unit Ver. 3.0 and earlier)

The acceleration time and deceleration time used for interpolation

operations cannot be set separately.

The acceleration time and deceleration time

used for interpolation operations can be set separately.

P00004, bit 13: Bank switching method selection

0: Select the same bank for acceleration and

deceleration (same as for version 3.0).

1: Select different banks for the acceleration

time and deceleration time.

Parameters P00M11 to P00M15 are used to set

acceleration times, and P00M16 to P00M20 are

used to set deceleration times. For details, refer

to 6-1 Basic Information.

Current version

(Unit Ver. 3.1)

Internal Overrides

Previous versions

(Unit Ver. 3.0 and earlier)

There is a function for changing

the axis feed rate from a ladder

program, but not from a motion

program.

The feed rate when the following commands are

executed can be changed from a motion program.

Commands for which an override can be specified from the motion program:

MOVE Rapid feed rate

DATUM Origin return feed rate

MOVEI Rapid feed rate, external position-

MOVET Rapid feed rate

The actual speed is as follows:

Actual speed = Axis feed rate x (Axis override +

Internal override)

For details, refer to 6-1 Basic Information.

Current version

(Unit Ver. 3.1)

ing rate

Connecting to SMART STEP Junior Servo Drivers

Previous versions

(Unit Ver. 3.0 and earlier)

Cannot be connected. Can be connected.

Current version

(Unit Ver. 3.1)

xi

Page 11

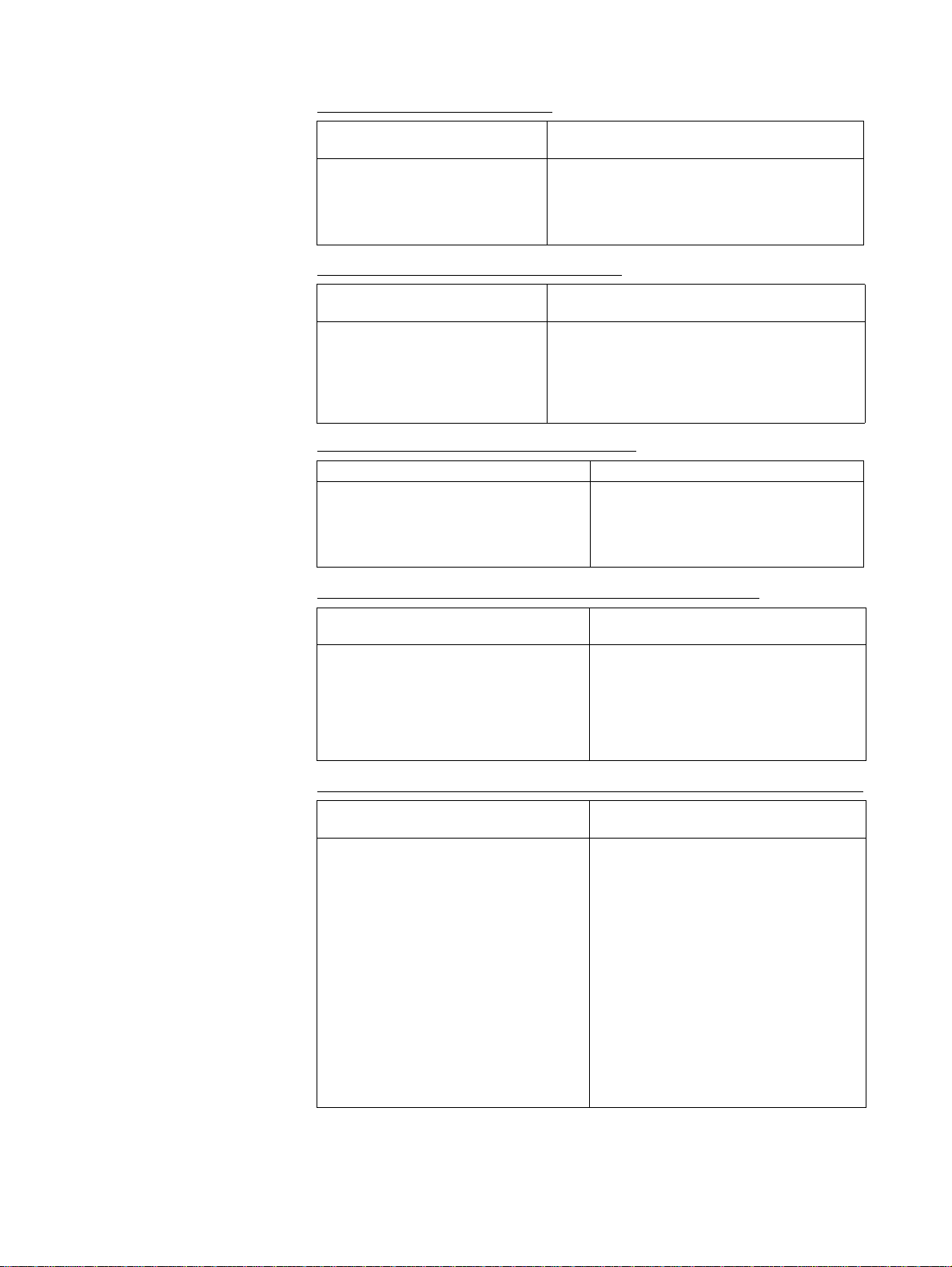

Backup and Restore Functions

Previous versions

(Unit Ver. 3.0 and earlier)

The origin compensation value

when an absolute encoder is used

is backed up using the CPU Unit's

easy backup function.

Origin compensation values can be backed up

even with CX-Motion-MCH version 2.1. For

details, refer to Section 11 Backup and Restore

in the CX-Motion-MCH Operation Manual (Cat.

No. W448).

Program and CAM Data Read Protection

Previous versions

(Unit Ver. 3.0 and earlier)

There is no program and CAM

data read protection.

The CX-Motion-MCH version 2.1 read protection

function (password setting), can be used to prevent third-parties from reading program and

CAM data. For details, refer to Section 12 Read

Protection in the CX-Motion-MCH Operation

Manual (Cat. No. W448).

Current version

(Unit Ver. 3.1)

Current version

(Unit Ver. 3.1)

Improved Functions from

Unit Ver. 2.1 Compared to

Unit Ver. 3.0

Data Tracing

Previous versions

(Unit Ver. 2.1 and earlier)

Data tracing is not supported. A data tracing function is provided that can

simultaneously collect a maximum of 32 data

items. This function does not affect previous

functionality. Previously reserved parameters

and variables are used to set and reference data

trace conditions and status.

For details, refer to 9-6 Data Tracing.

Current version

(Unit Ver. 3.0)

Debugging

Previous versions

(Unit Ver. 2.1 and earlier)

Breakpoints cannot be set. Debugging is supported using breakpoints that

are set using the Support Tool, and debugging is

supported for direct operation.

These functions do not affect previous functionality, but the following bit has been added to the

Unit status to indicate that debugging is being

executed from the Support Tool.

• CIO n+15, bit 09: Operating mode (Reserved in

previous unit versions.)

0: Normal mode

1: Support Tool mode (debugging)

Current version

(Unit Ver. 3.0)

xii

Page 12

Zones

Previous versions

(Unit Ver. 2.1 and earlier)

Zones are not supported. A maximum of 32 zone bits are available.

Zone bit: A bit that turns ON when any variable is

within the set range, and turns OFF when the

variable is outside of the range.

The previous function and the new function can

be switched using the following parameter.

• Parameter number: P00011 (Reserved in previ-

ous unit versions.)

• Setting: 0 to 32

0: Default. Same as previous function.

1 to 32: Use zone bits 1 to 32.

Parameters and variables that were previously

reserved are used to set zone upper and lower

limits.

For details, refer to 9-7 Zones.

Current version

(Unit Ver. 3.0)

Signed Master Axis MOVELINK Command

Previous versions

(Unit Ver. 2.1 and earlier)

The main axis input sign is ignored

and data is read as an absolute

travel distance.

The main axis input sign is evaluated and the

data is read as a signed travel distance.

This function enables the main axis to use the

feedback speed of an axis traveling at low

speed.

Current version (Unit Ver. 3.0)

Indirect Writing of Position Data

Previous versions

(Unit Ver. 2.1 and earlier)

Position data can be indirectly

read but cannot be indirectly written.

Current version (Unit Ver. 3.0)

Position data can be both read and written indirectly.

Example: Indirect Writing

@PL0000 = 1234;

“1234” will be assigned as the contents of the

address set in PL0000.

This function does not affect previous functionality.

xiii

Page 13

Setting the Number of Parallel Branches for Each Task

Previous versions

(Unit Ver. 2.1 and earlier)

The number of branches and the

number of commands that can be

executed are the same for each

task.

The number of branches and the number of

instructions that can be executed can be set

individually for each task, enabling fine adjustment of the Unit cycle.

The previous function and the new function can

be switched using the following parameter.

• Parameter number: P00004

• Bit 11 (Reserved in previous unit versions.)

Previously reserved parameters are used to set

the number of parallel branches individually for

each task.

Current version (Unit Ver. 3.0)

0: Default. Same as previous function.

1: Individually set the number of branches and

the number of commands that can executed

in each task.

Present Position Preset to Establish Origin

Previous versions

(Unit Ver. 2.1 and earlier)

The origin is not established when

the present position is set to the

preset value.

The origin is established when the present position is set to the preset value.

The previous function and the new function can

be switched using the following parameter.

• Parameter number: P00004

• Bit 12 (Reserved in previous unit versions.)

0: Default. Same as previous function.

1: Origin established for preset.

Current (Unit Ver. 3.0)

Program Start Bit Status

Previous versions

(Unit Ver. 2.1 and earlier)

An operation completed bit alone

cannot be used to detect the end

of programs with processing times

that are shorter than the Unit cycle

time.

The start bit ON/OFF status in the CPU Unit is

output to the task status bit.

Example for Axis 1:

• n+17 bit 06: start bit (Reserved in previous unit

versions.)

0: Start bit from CPU Unit OFF

1: Start bit from CPU Unit ON

The end of the relevant program can be

detected if this bit is ON and the operation completed bit is ON.

Servo OFF for Deceleration Stop Signal

Previous versions

(Unit Ver. 2.1 and earlier)

When the deceleration stop signal

for the Unit turns ON, all axes are

decelerated to a stop.

When the deceleration stop signal for the Unit

turns ON, the servo can be turned OFF for all

axes. The operation for servo OFF is set in the

Servo Driver parameters.

The previous function and the new function can

be switched using the following parameter.

• Parameter number: P00004

• Bit 10 (Reserved in previous unit versions.)

0: Default. Same as previous function.

1: Servo OFF

Current (Unit Ver. 3.0)

Current (Unit Ver. 3.0)

xiv

Page 14

Re-execution of WAIT Command

Previous versions

(Unit Ver. 2.1 and earlier)

If the program is stopped while

WAIT command execution is in

effect (i.e., when the deceleration

stop bit is ON) and then re-started

by setting the Start Mode to 1, the

program is started from the next

block after the WAIT command.

Main Power Status

Previous versions

(Unit Ver. 2.1 and earlier)

The main power status (ON/OFF)

is written to a system variable.

Servo Driver Status

Previous versions

(Unit Ver. 2.1 and earlier)

The Servo Driver warning and

alarm codes are stored in the error

log.

The Servo status (torque limit, limit

inputs, etc.) is output to system

variables (SW021C and SW021D

for axis 1.)

Current (Unit Ver. 3.0)

If the program is stopped while WAIT command

execution is in effect (i.e., when the deceleration

stop bit is ON) and then re-started by setting the

Start Mode to 1, the WAIT command is re-executed.

Current (Unit Ver. 3.0)

The main power status (ON/OFF) is written to

both a system variable and a status bit for each

axis.

Example for Axis 1:

• x+32 bit 12: Main power ON bit (reserved in

previous unit versions)

0: Main power OFF

1: Main power ON

The servo can be effectively locked from the

CPU Unit after confirming that this bit is ON.

Current (Unit Ver. 3.0)

In addition to the functionality supported in previous unit versions, Servo Driver warning codes,

alarm codes, and status (torque limit, limit

inputs, etc.) are also output to the following output variables that were reserved in previous unit

versions.

OW0210: Axis 1 Warning code/alarm code

OW0211: Axis 1 Status

(same as SW021C)

OW0212: Axis 1 Status

(same as SW021D)

to

OW026D: Axis 32 Warning code/alarm code

OW026E: Axis 32 Status

(Same as SW07EC)

OW026F: Axis 32 Status

(Same as SW07ED)

xv

Page 15

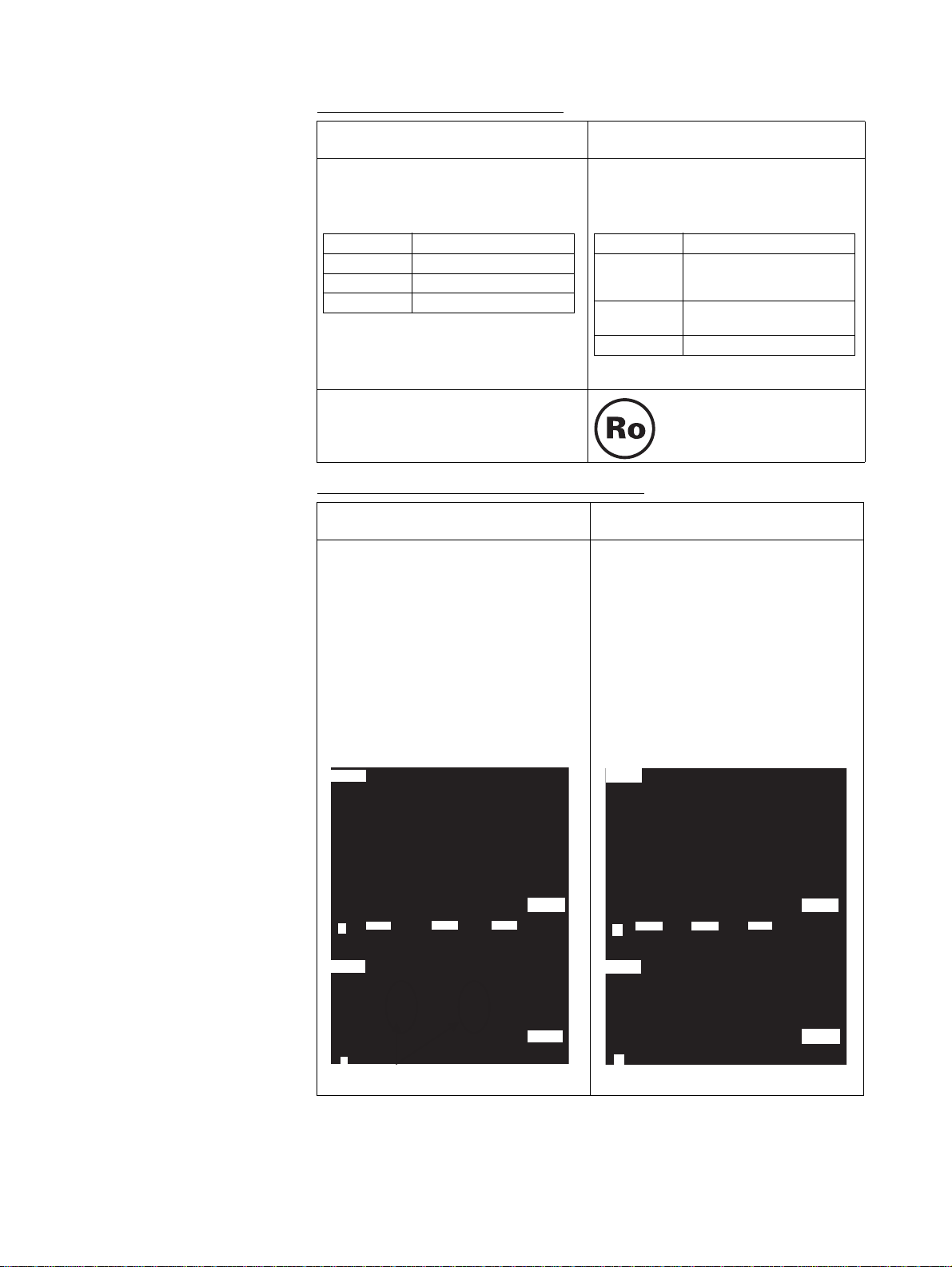

Compliance with RoHS Directive

Previous versions

(Unit Ver. 2.1 and earlier)

Lead was included in the cream solder

used to mount chip components, in the

flow solder used in assembly, and in

thread solder.

Solder type Main components

Cream solder Tin and lead

Flow solder Tin and lead

Thread solder Tin and lead

There is no mark indicating compliance

with the RoHS Directive.

Current version (Unit Ver. 3.0)

As shown below, lead is not used. There

is no change in specifications (including

outer appearance) resulting from this

change.

Solder type Main components

Cream solder (1) Tin, silver, indium, and

Flow solder (1) Tin and copper

Thread solder Tin, silver, and copper

Note: Either 1 or 2 shown above is used.

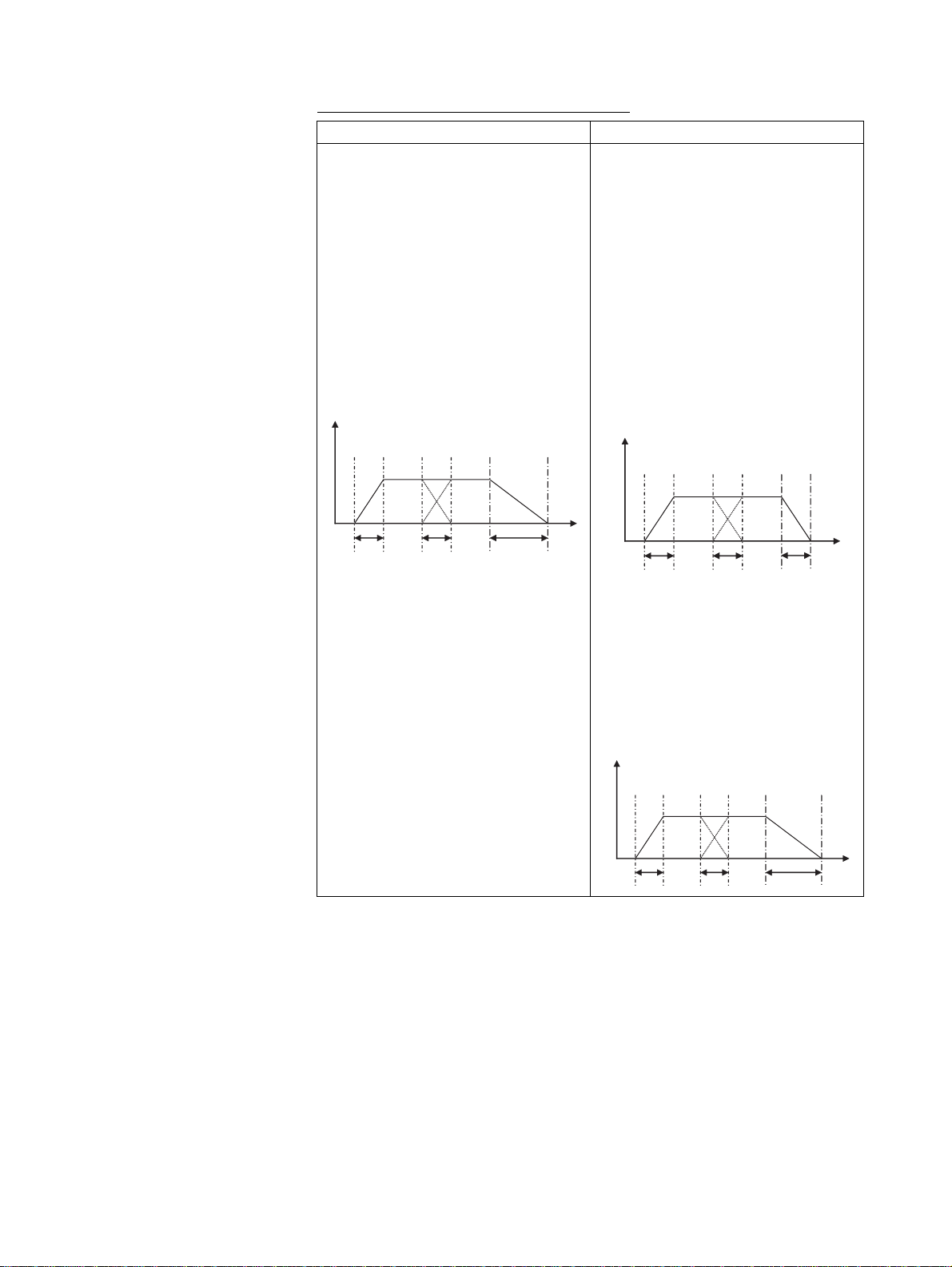

Increased Precision of CAMBOX Command

Previous versions

(Unit Ver. 2.1 and earlier)

If the slave axis CAM table is switched

during continuous master axis travel, part

of the slave axis travel is eliminated when

the CAM table is switched.

Example:

:

CAMBOX [J01]1 [J02]10000 K10000 Q8

B0;Cam 1

CAMBOX [J01]2 [J02]10000 K10000 Q8

B0;Cam 2

CAMBOX [J01]3 [J02]10000 K10000 Q8

B0;Cam 3

:

Slave axis

displacement

The slave axis will travel the set amount,

even if the slave axis CAM table is

switched during continuous master axis

travel.

Example:

:

CAMBOX [J01]1 [J02]10000 K10000 Q8

B0;Cam 1

CAMBOX [J01]2 [J02]10000 K10000 Q8

B0;Cam 2

CAMBOX [J01]3 [J02]10000 K10000 Q8

B0;Cam 3

:

Slave axis

displacement

bismuth

(2) Tin, silver, and copper

(2) Tin, silver, and copper

The RoHS compliance mark

is displayed.

Current (Unit Ver. 3.0)

xvi

Master axis phase

Cam 1 Cam 3Cam 2

0

Slave axis speed

Master axis

0

phase

This amount of travel is eliminated.

Cam 1 Cam 3Cam 2

0

Slave axis speed

0

Master axis phase

Master axis

phase

Page 16

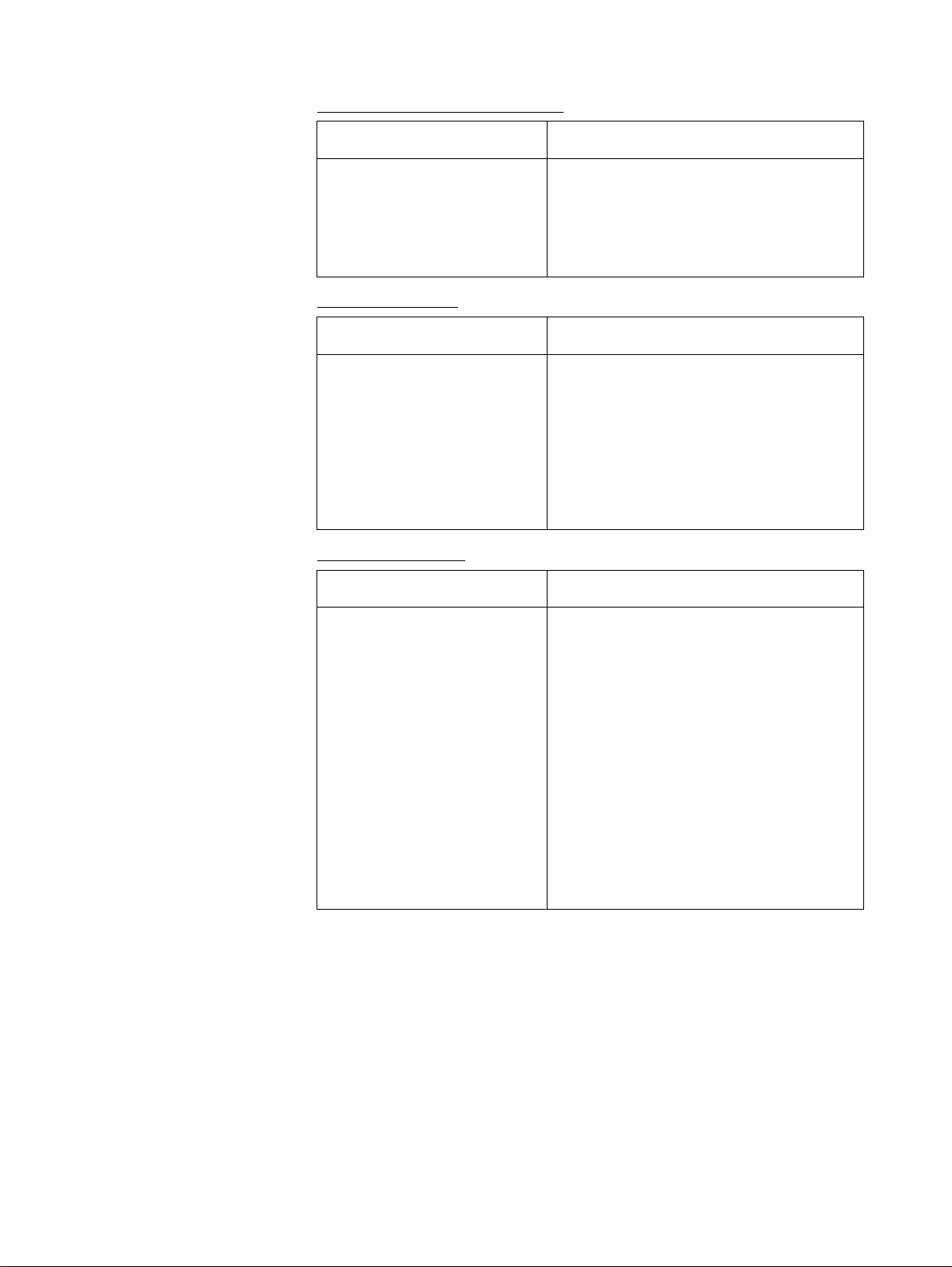

Functions Added in

Version Upgrade

The following table provides a comparison between the functions provided in

the upgrade to unit version 2.1 or later of CJ1W-MCH71 SYSMAC CJ-series

Motion Control Units from the previous unit version 2.0.

Reading Unit Versions

Previous version (Unit Ver. 2.0) Present version (Unit Ver. 2.1)

The MC Unit's unit version code could not

be read by accessing the Unit Manufac-

turing Information in CX-Programmer

Ver.4.0.

The MC Unit's unit version code can be

read by accessing the Unit Manufacturing

Information in CX-Programmer Ver.4.0.

Expanded Allocations in Custom I/O Area

Previous version (Unit Ver. 2.0) Present version (Unit Ver. 2.1)

Only the I/O variable area determined in

advance could be allocated to the Custom I/O Area.

In addition to the I/O variable area, system variables, global general variables,

position data, and task variables for userspecified addresses can be allocated in

the Custom I/O Area.

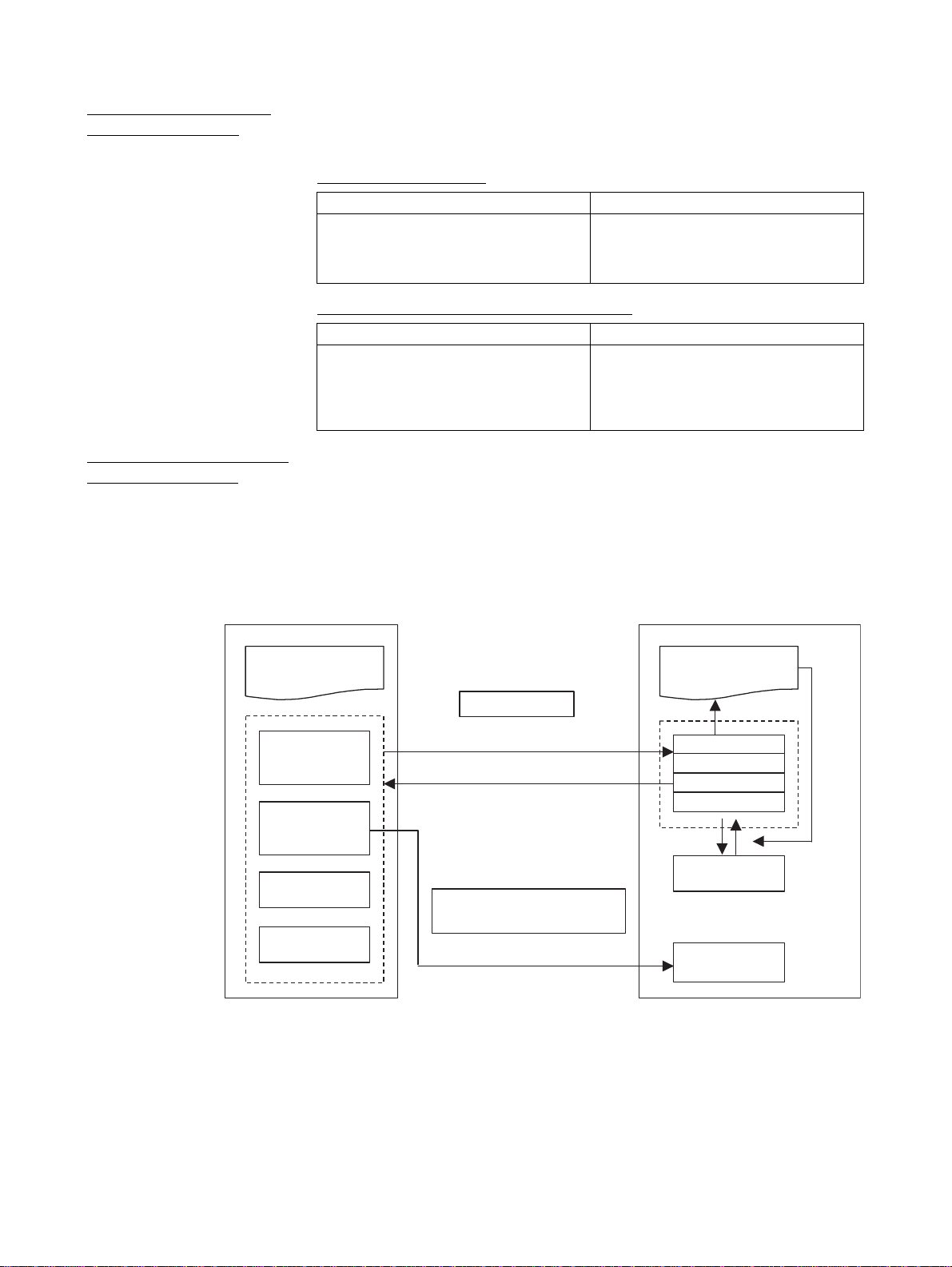

Expanded Custom I/O

Area Allocations

Ladder program

Overview

The CPU Unit can control MC Units with the following three different methods

of data I/O.

1. Data exchange with allocated bit area words.

2. Data exchange with allocated DM Area words.

3. Data exchange with allocated Custom Area words.

CPU Unit

Allocated Bit

Area words

Allocated DM

Area words

Custom Bit

Area words

Custom Data

Area words

I/O Refresh

Control

Status

When the power is

ON or restarting

Area range setting

MC Unit version 2.1 or higher

Motion program

Startup, Stop

Command analysis

General input

Status

General output

Variables

Set the Custom

Area range to use

Command

The function for exchanging data in the Custom I/O Area has been enhanced

with MC Units with unit version 2.1, as shown in the following table.

For details on previous specifications, refer to SECTION 7 PC Interface Area.

xvii

Page 17

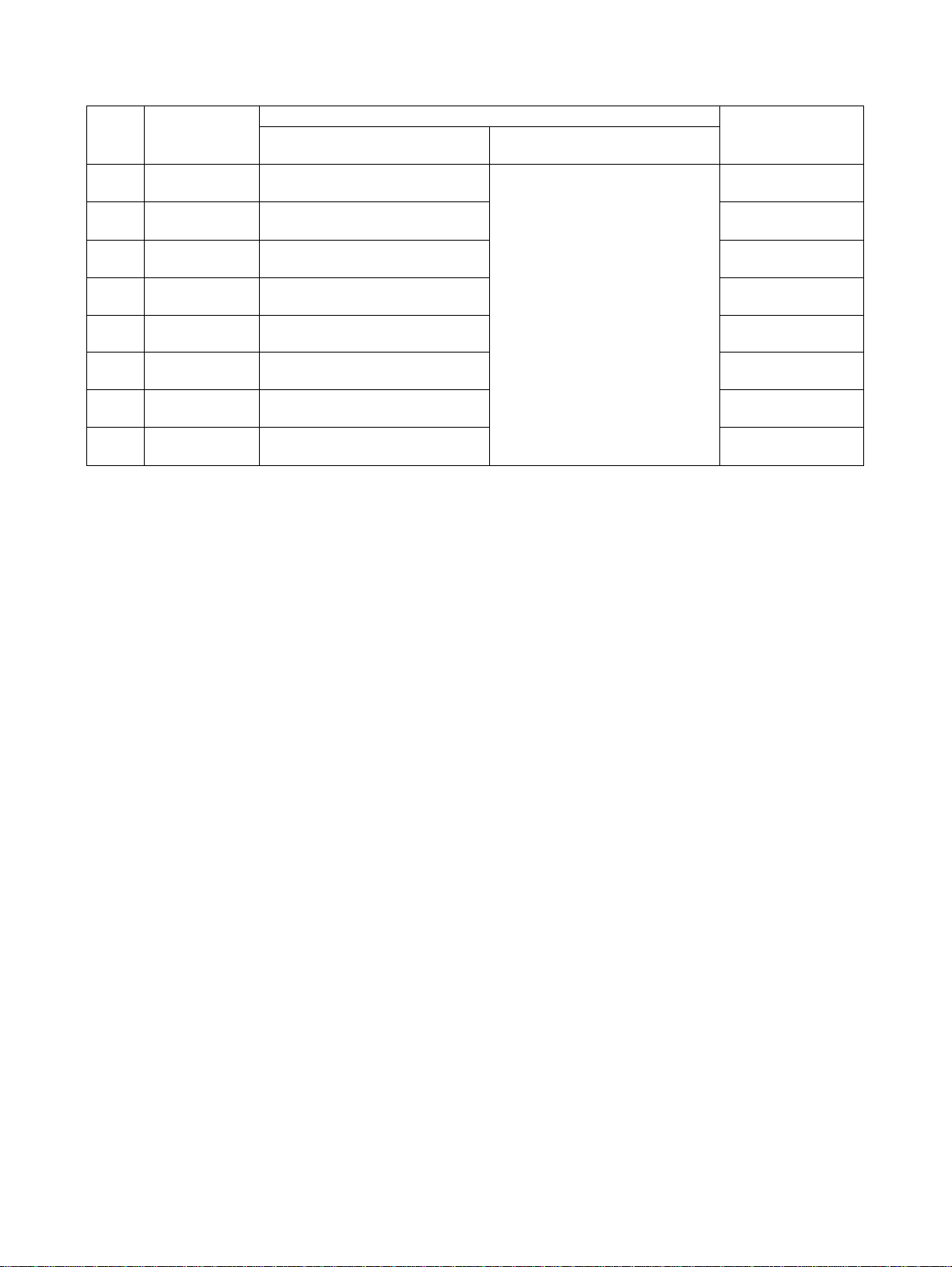

No. Classification MC Unit Variable Area Area size

Previous version

(Unit Ver. 2.0)

1 General I/O A IW0B00 to IW0B9F or OW0B00 to

OW0B9F

2 General I/O B IW0BA0 to IW0C3F or OW0BA0 to

OW0C3F

3 General I/O C IW0C40 to IW0CDF or OW0C40 to

OW0CDF

4 General I/O D IW0CE0 to IW0D7F or OW0CE0

to OW0D7F

5 General I/O E IW0D80 to IW0E1F or OW0D80 to

OW0E1F

6 General I/O F IW0E20 to IW0EBF or OW0E20 to

OW0EBF

7 General I/O G IW0EC0 to IW0F5F or OW0EC0 to

OW0F5F

8 General I/O H IW0F60 to IW0FFF or OW0F60 to

OW0FFF

The variable area and addresses

can be allocated for the following

variables.

•System variables

• Global general variables

• Input variables

• Output variables

• Position data

•Task variable

Present version

(Unit Ver. 2.1)

0 to 160 words

0 to 160 words

0 to 160 words

0 to 160 words

0 to 160 words

0 to 160 words

0 to 160 words

0 to 160 words

xviii

Page 18

Guide to CS1W-MCH71 Version Upgrade

Function Upgrades from

Unit Version 3.0 to 3.1

Restarting after Restoration

Previous versions

(Unit Ver. 3.0 and earlier)

After data has been restored from the

CPU Unit's flash memory, the Unit must

be restarted by cycling the CPU Unit's

power supply.

After data has been restored from the

CPU Unit's flash memory, the Unit is

restarted using a bit between A50100 and

A50115 in the Auxiliary Area of the CPU

Unit. For details, refer to 7-1 Overview.

Current version

(Unit Ver. 3.1)

Expanded Bank Switching for Interpolation Acceleration/Deceleration

Times

Previous versions

(Unit Ver. 3.0 and earlier)

The acceleration time and deceleration time used for interpolation

operations cannot be set separately.

The acceleration time and deceleration time

used for interpolation operations can be set separately.

P00004, bit 13: Bank switching method selection

0: Select the same bank for acceleration and

deceleration (same as for version 3.0).

1: Select different banks for the acceleration

time and deceleration time.

Parameters P00M11 to P00M15 are used to set

acceleration times, and P00M16 to P00M20 are

used to set deceleration times. For details, refer

to 6-1 Basic Information.

Current version

(Unit Ver. 3.1)

Internal Overrides

Previous versions

(Unit Ver. 3.0 and earlier)

There is a function for changing

the axis feed rate from a ladder

program, but not from a motion

program.

The feed rate when the following commands are

executed can be changed from a motion program.

Commands for which an override can be specified from the motion program:

MOVE Rapid feed rate

DATUM Origin return feed rate

MOVEI Rapid feed rate, external position-

MOVET Rapid feed rate

The actual speed is as follows:

Actual speed = Axis feed rate x (Axis override +

Internal override)

For details, refer to 6-1 Basic Information.

Current version

(Unit Ver. 3.1)

ing rate

Connecting to SMART STEP Junior Servo Drivers

Previous versions

(Unit Ver. 3.0 and earlier)

Cannot be connected. Can be connected.

Current version

(Unit Ver. 3.1)

xix

Page 19

Backup and Restore Functions

Previous versions

(Unit Ver. 3.0 and earlier)

The origin compensation value

when an absolute encoder is used

is backed up using the CPU Unit's

easy backup function.

Origin compensation values can be backed up

even with CX-Motion-MCH version 2.1. For

details, refer to Section 11 Backup and Restore

in the CX-Motion-MCH Operation Manual (Cat.

No. W448).

Program and CAM Data Read Protection

Previous versions

(Unit Ver. 3.0 and earlier)

There is no program and CAM

data read protection.

The CX-Motion-MCH version 2.1 read protection

function (password setting), can be used to prevent third-parties from reading program and

CAM data. For details, refer to Section 12 Read

Protection in the CX-Motion-MCH Operation

Manual (Cat. No. W448).

Current version

(Unit Ver. 3.1)

Current version

(Unit Ver. 3.1)

Function Upgrades from

Unit Version 2.0 to 3.0

Expanded Allocations in Custom I/O Area

Previous version (Unit Ver. 2.0) Present version (Unit Ver. 3.0)

Only the I/O variable area determined in

advance could be allocated to the Custom I/O Area.

In addition to the I/O variables, system

variables, global general variables, position data, and task variables for userspecified addresses can be allocated to

the Custom I/O Area.

Digital Input Values Changed to Improve Noise Resistance

Previous version

(Unit Ver. 2.0)

Rated input voltage: 24 VDC ±10%

Rated input current: 4.06 to 4.48 mA

ON voltage: 9.5 V min.

OFF voltage: 4.5 V max.

Rated input voltage: 24 VDC ±10%

Rated input current: 4.02 to 4.52 mA

ON voltage: 14 V min.

OFF voltage: 6V max.

(Any sensors that were previous used can

still be used.)

Current version

(Unit Ver. 3.0)

Parameter Added for Faster Unit Cycle and Communications Cycle Time

Previous version

(Unit Ver. 2.0)

Unit cycle [us] = (115.0 × Number of

axes) + (165 × Number of motion tasks ×

Number of parallel branches) + (0.3 ×

Number of general allocation words) +

350.0

Communications cycle [us] = ((Number of

allocated Units + Number of retries) ×

133.3+26.2) × 1.1

Unit cycle [us] = (85 × Number of axes) +

(120 × Number of motion tasks × Number

of parallel branches) + (0.3 × number of

general allocation words) + 200

Communications cycle [us] = ((Number of

allocated Unit + Number of retries) ×

102.7 + 19.2) × 1.1

Use the following parameter to switch the

performance.

• Parameter number: P00004

• Bit: 09 (previously reserved)

0: Initial value. Performance is the

1: Selects faster performance.

Current version

(Unit Ver. 3.0)

same as before.

xx

Page 20

Signed Master Axis MOVELINK Command

Previous version

(Unit Ver. 2.0)

The main axis input sign is ignored

and data is read as an absolute

travel distance.

The main axis input sign is evaluated and the

data is read as a signed travel distance.

This function enables the main axis to use the

feedback speed of an axis traveling at low

speed.

Indirect Writing of Position Data

Previous version

(Unit Ver. 2.0)

Position data can be indirectly

read but cannot be indirectly written.

Position data can be both read and written indirectly.

Example: Indirect Writing

@PL0000 = 1234;

“1234” will be assigned as the contents of the

address set in PL0000.

This function does not affect previous functionality.

Program Start Bit Status

Previous version

(Unit Ver. 2.0)

An operation completed bit alone

cannot be used to detect the end

of programs with processing times

that are shorter than the Unit cycle

time.

The start bit ON/OFF status in the CPU Unit is

output to the task status bit.

Example for Axis 1:

• n+17 bit 06: start bit (Reserved in previous unit

versions.)

0: Start bit from CPU Unit OFF

1: Start bit from CPU Unit ON

The end of the relevant program can be

detected if this bit is ON and the operation completed bit is ON.

Current version

(Unit Ver. 3.0)

Current version

(Unit Ver. 3.0)

Current version

(Unit Ver. 3.0)

Re-execution of WAIT Command

Previous version

(Unit Ver. 2.0)

If the program is stopped while

WAIT command execution is in

effect (i.e., when the deceleration

stop bit is ON) and then re-started

by setting the Start Mode to 1, the

program is started from the next

block after the WAIT command.

Current version

(Unit Ver. 3.0)

If the program is stopped while WAIT command

execution is in effect (i.e., when the deceleration

stop bit is ON) and then re-started by setting the

Start Mode to 1, the WAIT command is re-executed.

xxi

Page 21

Main Power Status

Previous version

(Unit Ver. 2.0)

The main power status (ON/OFF)

is written to a system variable.

Servo Driver Status

Previous version

(Unit Ver. 2.0)

The Servo Driver warning and

alarm codes are stored in the error

log.

The Servo status (torque limit, limit

inputs, etc.) is output to system

variables (SW021C and SW021D

for axis 1.)

Current version

(Unit Ver. 3.0)

The main power status (ON/OFF) is written to

both a system variable and a status bit for each

axis.

Example for Axis 1:

• x+32 bit 12: Main power ON bit (reserved in

previous unit versions)

0: Main power OFF

1: Main power ON

The servo can be effectively locked from the

CPU Unit after confirming that this bit is ON.

Current version

(Unit Ver. 3.0)

In addition to the functionality supported in previous unit versions, Servo Driver warning codes,

alarm codes, and status (torque limit, limit

inputs, etc.) are also output to the following output variables that were reserved in previous unit

versions.

OW0210: Axis 1 Warning code/alarm code

OW0211: Axis 1 Status

(same as SW021C)

OW0212: Axis 1 Status

(same as SW021D)

to

OW026D: Axis 32 Warning code/alarm code

OW026E: Axis 32 Status

(Same as SW07EC)

OW026F: Axis 32 Status

(Same as SW07ED)

xxii

Page 22

Compliance with RoHS Directive

Previous version

(Unit Ver. 2.0)

Lead was included in the cream solder

used to mount chip components, in the

flow solder used in assembly, and in

thread solder.

Solder type Main components

Cream solder Tin and lead

Flow solder Tin and lead

Thread solder Tin and lead

As shown below, lead is not used. There

is no change in specifications (including

outer appearance) resulting from this

change.

Solder type Main components

Cream solder (1) Tin, silver, indium, and

Flow solder (1) Tin and copper

Thread solder Tin, silver, and copper

Note: Either 1 or 2 shown above is used.

There is no mark indicating compliance

with the RoHS Directive.

Increased Precision of CAMBOX Command

Previous version

(Unit Ver. 2.0)

If the slave axis CAM table is switched

during continuous master axis travel, part

of the slave axis travel is eliminated when

the CAM table is switched.

Example:

:

CAMBOX [J01]1 [J02]10000 K10000 Q8

B0;Cam 1

CAMBOX [J01]2 [J02]10000 K10000 Q8

B0;Cam 2

CAMBOX [J01]3 [J02]10000 K10000 Q8

B0;Cam 3

:

Slave axis

displacement

The slave axis will travel the set amount,

even if the slave axis CAM table is

switched during continuous master axis

travel.

Example:

:

CAMBOX [J01]1 [J02]10000 K10000 Q8

B0;Cam 1

CAMBOX [J01]2 [J02]10000 K10000 Q8

B0;Cam 2

CAMBOX [J01]3 [J02]10000 K10000 Q8

B0;Cam 3

:

Slave axis

displacement

Current version

(Unit Ver. 3.0)

bismuth

(2) Tin, silver, and copper

(2) Tin, silver, and copper

The RoHS compliance mark

is displayed.

Current version

(Unit Ver. 3.0)

Master axis phase

Cam 1 Cam 3Cam 2

0

Slave axis speed

Master axis

0

phase

This amount of travel is eliminated.

Cam 1 Cam 3Cam 2

0

Slave axis speed

0

Master axis phase

Master axis

phase

xxiii

Page 23

The following functions can be used with CX-Motion-MCH version 2.0 or higher (available from August

2006).

Data Tracing

Previous version

(Unit Ver. 2.0)

Data tracing is not supported. A data tracing function is provided that can

simultaneously collect a maximum of 32 data

items. This function does not affect previous

functionality. Previously reserved parameters

and variables are used to set and reference data

trace conditions and status.

Current version

(Unit Ver. 3.0)

Debugging

Previous version

(Unit Ver. 2.0)

Breakpoints cannot be set. Debugging is supported using breakpoints that

are set using the Support Tool, and debugging is

supported for direct operation.

These functions do not affect previous functionality, but the following bit has been added to the

Unit status to indicate that debugging is being

executed from the Support Tool.

• CIO n+15, bit 09: Operating mode (Reserved in

previous unit versions.)

0: Normal mode

1: Support Tool mode (debugging)

Current version

(Unit Ver. 3.0)

Zones

Previous version

(Unit Ver. 2.0)

Zones are not supported. A maximum of 32 zone bits are available.

Zone bit: A bit that turns ON when any variable is

within the set range, and turns OFF when the

variable is outside of the range.

The previous function and the new function can

be switched using the following parameter.

• Parameter number: P00011 (Reserved in previ-

ous unit versions.)

• Setting: 0 to 32

0: Default. Same as previous function.

1 to 32: Use zone bits 1 to 32.

Parameters and variables that were previously

reserved are used to set zone upper and lower

limits.

Current version

(Unit Ver. 3.0)

xxiv

Page 24

Setting the Number of Parallel Branches for Each Task

Previous version

(Unit Ver. 2.0)

The number of branches and the

number of commands that can be

executed are the same for each

task.

The number of branches and the number of

instructions that can be executed can be set

individually for each task, enabling fine adjustment of the Unit cycle.

The previous function and the new function can

be switched using the following parameter.

• Parameter number: P00004

• Bit 11 (Reserved in previous unit versions.)

0: Default. Same as previous function.

1: Individually set the number of branches and

the number of commands that can executed

in each task.

Previously reserved parameters are used to set

the number of parallel branches individually for

each task.

Current version

(Unit Ver. 3.0)

Present Position Preset to Establish Origin

Previous version

(Unit Ver. 2.0)

The origin is not established when

the present position is set to the

preset value.

The origin is established when the present position is set to the preset value.

The previous function and the new function can

be switched using the following parameter.

• Parameter number: P00004

• Bit 12 (Reserved in previous unit versions.)

0: Default. Same as previous function.

1: Origin established for preset.

Current version

(Unit Ver. 3.0)

Servo OFF for Deceleration Stop Signal

Previous version

(Unit Ver. 2.0)

When the deceleration stop signal

for the Unit turns ON, all axes are

decelerated to a stop.

When the deceleration stop signal for the Unit

turns ON, the servo can be turned OFF for all

axes. The operation for servo OFF is set in the

Servo Driver parameters.

The previous function and the new function can

be switched using the following parameter.

• Parameter number: P00004

• Bit 10 (Reserved in previous unit versions.)

0: Default. Same as previous function.

1: Servo OFF

Current version

(Unit Ver. 3.0)

xxv

Page 25

Function Improvements

for Unit Version 2.0

Jogging

Previous versions Current version (Unit Ver. 2.0)

The JOG feed direction is set or reversed

as follows:

• Use the JOG/STEP Direction Bit to

specify the feed direction.

• Turn ON the JOG Bit.

• To reverse the feed direction, turn OFF

the JOG Bit.

• After the axis is stopped, reverse the

JOG/STEP Direction Bit.

• Turn ON the JOG Bit. The feed direction

will be reversed.

Communications Levels

Previous versions Current version (Unit Ver. 2.0 or later)

The MC Unit supported communications

on up to three levels.

As shown below, a setting for reverse

operation has been added.

• Use the JOG/STEP Direction Bit to specify the feed direction.

• Turn ON the JOG Bit.

• The feed direction is reversed by reversing the JOG/STEP Direction Bit even

while the JOG Bit still ON.

Use the following parameter to switch the

previous function and the new one.

• Parameter number: P00004

• Bit: 05 (previously reserved)

0: Initial value. Same as previous func-

tion.

1: Selects new function.

The MC Unit supports communications on

up to eight levels, according to the eight

levels supported by the CPU Unit. The

CPU Unit supports eight levels with unit

version 2.0 or later.

Communications Cycle and Unit Cycle

Previous versions Current version (Unit Ver. 2.0 or later)

The MC Unit communications cycle and

unit cycle times are as follows:

Communications cycle: 1 ms, 2 ms, 4 ms

Unit cycle: 1 ms, 2 ms, 4 ms, 8 ms

• Supporting a communications cycle of

• Use the following parameter to switch the

LATCH Command Processing Time

Previous versions Current version (Unit Ver. 2.0 or later)

The time from when the LATCH command is executed until the external latch

signal is detected is as follows:

• When latch signals are received at any

position: 105 to 232 ms

• When only latch signals in a specified

position range are received: 105 to

232 ms

As shown below, performance is improved

in cases where latch signals are received

at any position.

• When latch signals are received at any

• When only latch signals in a specified

3 ms enable more precise performance.

Communications cycle: 1 ms, 2 ms,

3ms, 4 ms

Unit cycle: 1 ms, 2 ms, 3 ms, 4 ms, 6 ms,

8 ms

previous function and the new one.

Parameter number: P00004

Bit: 03 (previously reserved)

0: Initial value. Same as previous func-

tion.

1: Enables use of 3 ms.

position: 3 to 24 ms

position range are received: 105 to

232 ms

xxvi

Page 26

Latch Status Refresh Time

Previous versions Current version (Unit Ver. 2.0 or later)

After a LATCH command is executed, the

time from when the latch signal is input

until it is reflected in the system variable

(the variable showing latch completion) is

14.5 to 85.5 ms.

The performance has been improved as

follows:7.5 to 37.5 ms

Using Interpolation Commands during Pass Operation

Previous versions Current version (Unit Ver. 2.0 or later)

To execute pass operation from a

stopped axis, two interpolation commands are required for the initial operation.

Example:

:

PASSMODE;

MOVEL [J01]100 F10000;

MOVEL [J02]400 F10000;

WHILE #MW0000==0;

INC MOVEL [J02]100 F1000;

WEND;

:

To execute pass operation from a stopped

axis, only one interpolation command is

required.

Example:

:

PASSMODE;

WHILE #MW0000==0;

INC MOVEL [J02]100 F1000;

WEND;

:

Acceleration/Deceleration Times during Pass Operation

Previous versions Current version (Unit Ver. 2.0 or later)

Changing the acceleration/

deceleration times during pass

operation was complex at any

time. It was necessary to use

the PARALLEL command to

execute parallel processing.

• The acceleration/deceleration times can be

changed during pass operation.

• As shown below, switching is made easy by using

a newly added parameter.

MOVEL [J01]1000 F1000

#W0A00 = 2;

MOVEL [J01]5000 F1000

• The following ten newly added parameters use part

of the task parameter area that was previously

reserved. Setting range: 0 to 60,000 (ms)

Number Name

P00M11 Interpolation feed acceleration/

deceleration time, Bank 1

::

P00M20 Interpolation feed acceleration/

deceleration time, Bank 10

← The time set in bank 2

is used for passing to

the next position.

xxvii

Page 27

Deceleration Time during Pass Operation

e

Previous versions Current version (Unit Ver. 2.0 or later)

The interpolation feed deceleration time

is used to decelerate to a stop during

pass operation.

Example: Pass Mode Selection, P00M06

= 0

Interpolation feed acceleration time Ta =

P0MM02

Interpolation feed deceleration time Td =

P00M03

Program

PASSMODE;

INC MOVEL [J01]1000 F100000;

INC MOVEL [J01]1000 F100000;

END;

Speed

Ta Ta Td

• The interpolation time used during pass

operation (the interpolation feed acceleration time or the interpolation feed

deceleration time) is used to decelerate

to a stop during pass operation.

Example: Pass Mode Selection,

P00M06 = 0

Interpolation feed acceleration time Ta =

P0MM02

Interpolation feed deceleration time Td =

P00M03

Program

Speed

Tim

• To stop at the interpolation feed deceleration speed as previously, add STOPMODE before the final interpolation

command as shown below.

PASSMODE;

INC MOVEL [J01]1000 F100000;

INC MOVEL [J01]1000 F100000;

END;

Ta

Ta

Ta

PASSMODE;

INC MOVEL [J01]1000 F100000;

STOPMODE;

INC MOVEL [J01]1000 F100000;

END;

Time

Speed

Ta Ta Td

Time

xxviii

Page 28

Torque to Position Control Switching

Previous versions Current version (Unit Ver. 2.0 or later)

Switching from torque control to position

control using the TORQUR command is

executed when the axis feedback speed

reaches 0.

Speed to Position Control Switching

Previous versions Current version (Unit Ver. 2.0 or later)

Switching from speed control to position

control using the SPEEDR command is

executed when the axis feedback speed

reaches 0.

• Switching from torque control to position

control using the TORQUR command is

executed by switching to position control

when the axis feedback speed reaches

the speed specified in a parameter

(specified by a percentage of the rated

speed).

• The following newly added parameter

uses part of the axis parameter area

that was previously reserved.

Number Name

P3AA09 Position control switching

speed

Setting range: 0 to 32,767

(0.01%)

• Switching from speed control to position

control using the SPEEDR command is

executed when the axis feedback speed

reaches the speed specified in a parameter (specified by a percentage of the

rated speed).

• The following newly added parameter

uses part of the axis parameter area

that was previously reserved.

Number Name

P3AA09 Position control switching

speed

Setting range: 0 to 32,767

(0.01%)

xxix

Page 29

xxx

Page 30

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xli

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xlii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xlii

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xliii

4 Application Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xliv

5 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xlv

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xlvi

SECTION 1

Features and System Configuration . . . . . . . . . . . . . . . . . . . 1

1-1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-3 Basic Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-4 Control System Configuration and Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-5 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

1-6 Command List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1-7 Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

SECTION 2

Basic Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2-1 Basic Operation Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2-2 Overview of CX-Motion-MCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

SECTION 3

Installation and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3-1 Nomenclature and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3-2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3-3 External I/O Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3-4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3-5 Connecting MECHATROLINK Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

SECTION 4

MC Unit Internal Data Configuration and Setting . . . . . . . 55

4-1 Data Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4-2 System Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4-3 Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

4-4 Position Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

4-5 System Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

4-6 I/O Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

4-7 Present Position Preset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

4-8 Servo Parameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

4-9 CAM Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

xxxi

Page 31

TABLE OF CONTENTS

SECTION 5

Data Transfer and Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . 211

5-1 Data Transfer and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .212

5-2 IOWR Instruction to Transfer Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

5-3 IORD Instruction to Transfer Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

5-4 Saving Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

SECTION 6

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

6-1 Basic Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

6-2 Command Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .286

6-3 Command Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

SECTION 7

PC Interface Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

7-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 374

7-2 Operating Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 382

7-3 Allocations for the CPU Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 396

7-4 Interface Specifics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 420

SECTION 8

Establishing the Origin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 531

8-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 532

8-2 Input Signals Required for Origin search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 534

8-3 Origin Search Methods and Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 534

8-4 Origin Search Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .536

8-5 Absolute (ABS) Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .539

8-6 ABS Encoder Origin Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 540

SECTION 9

Other Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 545

9-1 Teaching. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 546

9-2 Debugging the Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .553

9-3 Coordinate System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 558

9-4 Backup and Restore Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 566

9-5 Servo Driver Status Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .569

9-6 Data Tracing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 570

9-7 Zones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 571

xxxii

Page 32

TABLE OF CONTENTS

SECTION 10

Program Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 573

10-1 Program Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 574

10-2 Slave Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 607

10-3 Others. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 619

SECTION 11

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 627

11-1 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 628

11-2 Countermeasures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 634

11-3 Error Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 638

11-4 Unit-related Alarm Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 639

11-5 Motion Task-related Alarm Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 642

11-6 Axis-related Alarm Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .648

11-7 MLK Device Alarm Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 653

11-8 Servo Driver Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 655

11-9 Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 656

SECTION 12

Maintenance and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . 659

12-1 Routine Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 660

Appendices

A Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 663

B Main Parameter Settings when Connecting W-series Servo Driver with

Built-in MECHATROLINK-II Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 667

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 671

xxxiii

Page 33

xxxiv

Page 34

About this Manual:

This manual describes the installation and operation of the CJ1W-MCH71 and CS1W-MCH71 Motion

Control Units (MC Units) and includes the sections described below.

Please read this manual carefully and be sure you understand the information provided before

attempting to install or operate the MC Unit. Be sure to read the precautions provided in the following

section.

Precautions provides general precautions for using the Motion Control Unit, Programmable Controller,

and related devices.

Section 1 introduces the features and system configuration of the CJ1W-MCH71 and CS1W-MCH71

Motion Control Units. It also describes product operating principles and provides product specifications.

Section 2 provides an overview of the basic procedures required to use the CJ1W-MCH71 and

CS1W-MCH71 Motion Control Units.

Section 3 describes the names of Unit parts and how to install and wire the CJ1W-MCH71 and CS1WMCH71 Motion Control Units.

Section 4 describes the data configuration uses to set up, operate, and monitor the CJ1W-MCH71 and

CS1W-MCH71 Motion Control Units and related devices.

Section 5 describes how to transfer data between the CPU Unit and the CJ1W-MCH71 and CS1WMCH71 Motion Control Units and how data is stored.

Section 6 describes how to program CJ1W-MCH71 and CS1W-MCH71 Motion Control Units operation, including the program configuration and the specific commands used in programming.

Section 7 describes the interface area in the CPU Unit used to control and monitor the CJ1W-MCH71

and CS1W-MCH71 Motion Control Units.

Section 8 describes how to establish the origin in the positioning system.

Section 9 describes special operations for the CJ1W-MCH71 and CS1W-MCH71 Motion Control

Units, including teaching, program debugging, coordinate systems, and backup functions.

Section 10 provides a programming example to demonstrate how the CJ1W-MCH71 and CS1WMCH71 Motion Control Units can be used.

Section 11 describes how to troubleshoot problems that may occur when using the CJ1W-MCH71

and CS1W-MCH71 Motion Control Units.

Section 12 describes the maintenance and inspection procedures required to keep the CJ1W-MCH71

and CS1W-MCH71 Motion Control Units in optimum condition.

The Appendix describes the performance of the Motion Control Units.

Registered Trademark

• MECHATROLINK is a registered trademark of the MECHATROLINK Members Association.

xxxv

Page 35

xxxvi

Page 36

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xxxvii

Page 37

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xxxviii

Page 38

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xxxix

Page 39

xl

Page 40

PRECAUTIONS

This section provides general precautions for using the CJ1W-MCH71and CS1W-MCH71 Motion Control Units and

related devices.

The information contained in this section is important for the safe and reliable application of the CJ1W-MCH71 or

CS1W-MCH71 Motion Control Unit. You must read this section and understand the information contained before

attempting to set up or operate a CJ1W-MCH71 or CS1W-MCH71 Motion Control Unit.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xlii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xlii

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xliii

4 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xliv

5 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xlv

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xlvi

6-1 Applicable Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xlvi

6-2 Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xlvi

6-3 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xlvi

6-4 Installation within Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . xlvi

xli

Page 41

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual close at hand for reference during operation.

!WARNING It is extremely important that a PLC and all PLC Units be used for the speci-

fied purpose and under the specified conditions, especially in applications that

can directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PLC System to the above-mentioned applications.

xlii

Page 42

Safety Precautions 3

3 Safety Precautions

DANGER

Never attempt to disassemble any Units while power is being supplied.

Doing so may result in serious electronic shock.

Never touch any of the terminals while power is being supplied.

Doing so may result in serious electronic shock.

Provide safety measures in external circuits (i.e., not in the Programmable Controller or MC Unit) to ensure

safety in the system if an abnormality occurs due to malfunction of the PLC or MC unit. Not providing sufficient safety measures may result in serious accidents.

• Emergency- stop circuits, interlock circuits, limit circuits, and similar safety measures must be provided in external control circuits.

• The PLC will turn OFF all outputs when its self-diagnosis function detects any error or when a severe failure alarm

(FALS) instruction is executed. As a countermeasure for such errors, external safety measures must be provided to

ensure safety in the system.

• The PLC or MC Unit outputs may remain ON or OFF due to deposits on or burning of the output relays, or destruction of

the output transistors. As a countermeasure for such problems, external safety measures must be provided to ensure

safety in the system.

• When the 24-VDC (service power supply to the PLC) is overloaded or short-circuited, the voltage may drop result in the

outputs being turned OFF. As a countermeasure for such problems, external safety measures must be provided to

ensure safety in the system.

• Provide safety measures in external circuits to ensure safety in system if an abnormality occurs due to malfunction of MC

Unit connectors.

WARNING

Execute online edit only after confirming that the cycle time extension will not cause any adverse effects.

Some input signals may not be read if the cycle time is extended.

Confirm the safety of the destination node before transferring program to the node or changing the contents

of I/O memory. Doing either of these without confirming safety may result in injury.

Do not save data into the flash memory during memory operation or while the motor is running. Otherwise,

unexpected operation may be caused.

Do not reverse the polarity of the 24-V power supply. The polarity must be correct. Otherwise, the motor may

start running unexpectedly and may not stop.

When positioning is performed using Teaching function, positioning specification in the motion program must

be [Absolute specification].

If [Incremental specification] is specified, positioning will be executed at the different point from where

Teaching conducted.

xliii

Page 43

Application Precautions 4

4 Application Precautions

Observe the following precautions when using the MC Unit or the PLC.

• Install external breakers and take other safety measures against short-circuiting in external wiring.

Insufficient safety measures against short-circuiting may result in burning.

• Always turn off after power supply to the Unit before attempting any of the following. Not turning OFF

the power supply may result in malfunction or electric shock.

• Mounting or dismounting the MC Unit or any other unit.

• Assembling the Units.

• Setting Rotary switches.

• Connecting Cables or wiring the system.