Page 1

Cat. No. W356-E1-08

SYSMAC

CPM2C

Programmable Controller

OPERATION MANUAL

Page 2

CPM2C Programmable Controller

Operation Manual

Revised February 2008

Page 3

iv

Page 4

Notice:

r

f

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything

else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 1999

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 5

vi

Page 6

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xviii

6 EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

SECTION 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 CPM2C Features and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 System Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-3 Structure and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1-4 Functions Listed by Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

1-5 Comparison with the CPM1A and CPM2A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1-6 Preparation for Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

1-7 Changes in SW2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

SECTION 2

Unit Components and Specifications . . . . . . . . . . . . . . . . . . 35

2-1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2-2 Unit Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

SECTION 3

Installation and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

3-1 Design Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

3-2 Selecting an Installation Site. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

3-3 Installing the CPM2C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

3-4 Wiring and Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

SECTION 4

Using a Programming Console . . . . . . . . . . . . . . . . . . . . . . . 151

4-1 Using a Programming Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

4-2 Programming Console Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

4-3 Programming Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

vii

Page 7

TABLE OF CONTENTS

SECTION 5

Test Runs and Error Processing . . . . . . . . . . . . . . . . . . . . . . 193

5-1 Initial System Checks and Test Run Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

5-2 Self-diagnostic Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

5-3 Programming Console Operation Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

5-4 Programming Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

5-5 Troubleshooting Flowcharts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

5-6 Maintenance Inspections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .208

5-7 Battery Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

SECTION 6

Expansion Memory Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

6-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

6-2 Specifications and Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

6-3 Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

SECTION 7

Simple Communications Unit . . . . . . . . . . . . . . . . . . . . . . . . 221

7-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

7-2 Unit Components and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

7-3 Preparation for Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

7-4 Data Memory (DM) Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

7-5 DM Settings and Component Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

7-6 Precautions for Component Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

7-7 Error Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

7-8 Data Refresh Intervals (Reference Data) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

7-9 Example Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Appendices

A Standard Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

B Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

C DM Settings Assignment Sheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

D SYSMAC and SYSMAC-CPT Support Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

viii

Page 8

About this Manual:

The CPM2C is a compact, high-speed Programmable Controller (PC) designed for control operations

in systems requiring from 10 to 120 I/O points per PC. There are two manuals describing the setup and

operation of the CPM2C: The CPM2C Operation Manual (this manual) and the CPM1/CPM1A/

CPM2A/CPM2C/SRM1(-V2) Programming Manual (W353). (The CPM1/CPM1A/CPM2A/CPM2C/

SRM1(-V2) Programming Manual is referred to as simply the Programming Manual in this manual.)

This manual describes the system configuration and installation of the CPM2C and provides a basic

explanation of operating procedures for the Programming Consoles.

The Programming Manual (W353) provides detailed descriptions of the CPM2C’s programming func-

tions. The CX-Programmer Operation Manual (W437) provides details of operations for the WS02-

CXPC1-E CX-Programmer.

Please read this manual carefully and be sure you understand the information provided before

attempting to install and operate the CPM2C.

Section 1 gives a brief overview of the steps involved in developing of a CPM2C System, describes

the possible system configurations, and describes the CPM2C’s special features and functions.

Section 2 provides the technical specifications of the Units that go together to create a CPM2C PC

and describes the main components of the Units.

Section 3 describes how to install and wire a CPM2C PC.

Section 4 describes how to connect the Programming Console, and how to perform the various pro-

gramming operations.

Section 5 describes how to perform a test run and how to diagnose and correct the hardware and software errors that can occur during PC operation.

Section 6 describes how to use the CPM1-EMU01-V1 Expansion Memory Unit.

Section 7 describes the features and functions of the CPM2C-CIF21 Simple Communications Unit,

the settings required to use the Unit, and an example application. DM Settings Assignment Sheets are

provided in Appendix C to record data settings.

Appendix A provides tables of CPM2C Units and related products.

Appendix B provides the dimensions of CPM2C Units.

Appendix C provides DM setting assignment sheets for use with the CPM2C-CIF21 Simple Communi-

cations Unit.

Appendix D describes SYSMAC and SYSMAC-CPT Support Software capabilities and how to connect the CPM2C to the personal computer with this Support Software installed.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

ix

Page 9

x

Page 10

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xi

Page 11

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xii

Page 12

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xiii

Page 13

xiv

Page 14

PRECAUTIONS

This section provides general precautions for using the Programmable Controller (PC) and related devices.

The information contained in this section is important for the safe and reliable application of the Programmable

Controller. You must read this section and understand the information contained before attempting to set up or

operate a PC system.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

6 EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

xv

Page 15

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual close at hand for reference during operation.

!WARNING It is extremely important that a PC and all PC Units be used for the specified

purpose and under the specified conditions, especially in applications that can

directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PC System to the above-mentioned applications.

3 Safety Precautions

!WARNING Connect the ground terminal of the Power Supply Unit (CPM2C-PA201) to a

ground or 100

!WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing

so may result in electric shock.

!WARNING Do not touch any of the terminals or terminal blocks while the power is being

supplied. Doing so may result in electric shock.

!WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do

so may result in malfunction, fire, or electric shock.

!WARNING Provide safety measures in external circuits (i.e., not in the Programmable

Controller), including the following items, in order to ensure safety in the system if an abnormality occurs due to malfunction of the PC or another external

factor affecting the PC operation. Not doing so may result in serious accidents.

Ω or less. Not doing so may result in electric shock.

xvi

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

Page 16

Safety Precautions 3

• The PC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instruction is executed.

As a countermeasure for such errors, external safety measures must be

provided to ensure safety in the system.

• The PC outputs may remain ON or OFF due to deposition or burning of

the output relays or destruction of the output transistors. As a countermeasure for such problems, external safety measures must be provided

to ensure safety in the system.

• If the 24-VDC output (service power supply) of the Power Supply Unit

(CPM2C-PA201) is overloaded or shorted, the voltage may drop causing

outputs to turn OFF. External safety measures must be provided to

ensure safety in the system in such an event.

!WARNING When handling the Memory Backup Battery, never drop, disassemble, distort,

short-circuit, recharge, heat to a temperature exceeding 100

fire. Otherwise the Battery may explode, catch fire, or leak fluid.

!WARNING When transferring programs to other nodes, or when making changes to I/O

memory, confirm the safety of the destination node before transfer. Not doing

so may result in injury.

°C, or throw into

!Caution Execute online edit only after confirming that no adverse effects will be

caused by extending the cycle time. Otherwise, the input signals may not be

readable.

!Caution Tighten the screws on the terminal block of the Power Supply Unit (CPM2C-

PA201) to a torque of 0.74 to 0.9 N•m. Loose screws may result in burning or

malfunction.

!Caution Do not connect the 24-VDC output (service power supply) or the Power Sup-

ply Unit (CPM2C-PA201) to an AC power supply. Connecting it to an AC

power supply will damage the internal circuit.

!Caution When connecting a personal computer or other peripheral device to the

CPM2C, either ground the 0 V side of the CPM2C or do not ground at all.

Depending on the method of grounding, the 24-V power supply may short-circuit; do not ground the 24-V side as shown in the following diagram.

Example: Connections where 24-V Power Supply Will Short-circuit

Non-isolated DC

24 V

0 V 0 V

FG FG

power supply

0 V

CPM2C Peripheral device

xvii

Page 17

Operating Environment Precautions 4

4 Operating Environment Precautions

!Caution Do not operate the control system in the following places:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

!Caution Take appropriate and sufficient countermeasures when installing systems in

the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

!Caution The operating environment of the PC System can have a large effect on the

longevity and reliability of the system. Improper operating environments can

lead to malfunction, failure, and other unforeseeable problems with the PC

System. Be sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life

of the system.

5 Application Precautions

Observe the following precautions when using the PC System.

!WARNING Always heed these precautions. Failure to abide by the following precautions

could lead to serious or possibly fatal injury.

• Always connect to a ground such that the grounding resistance does not

exceed 100

ground may result in electric shock.

• Always turn OFF the power supply to the PC before attempting any of the

following. Not turning OFF the power supply may result in malfunction or

electric shock.

• Assembling the Units.

• Connecting or disconnecting the Expansion I/O Units or Expansion

Units.

• Connecting or wiring the cables.

• Connecting or disconnecting the connectors.

• Setting DIP switches.

• Replacing the battery

Ω when installing the Units. Not connecting to the correct

xviii

Page 18

Application Precautions 5

!Caution Failure to abide by the following precautions could lead to faulty operation of

the PC or the system, or could damage the PC or PC Units. Always heed

these precautions.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal

lines, momentary power interruptions, or other causes.

• Use the correct power supply voltage.

• Construct a control circuit so that power supply for the I/O circuits does

not come ON before power supply for the Unit. If power supply for the I/O

circuits comes ON before power supply for the Unit, normal operation may

be temporarily interrupted.

• If the operating mode is changed from RUN or MONITOR mode to PROGRAM mode, with the IOM Hold Bit ON, the output will hold the most

recent status. In such a case, ensure that the external load does not

exceed specifications. (If operation is stopped because of an operation

error (including FALS instructions), the values in the internal memory of

the CPU Unit will be saved, but the outputs will all turn OFF.)

• For models with only the super-capacitor installed, the contents of the

READ/WRITE enable area of the DM area, HR area, AR area, and CNT

data area may be damaged if the power is turned OFF for a long time. To

prevent such damage, provide ladder program that will check AR 1314 in

order to ensure proper operation of the system.

• The life expectancy of the output relay varies considerably according to its

switching capacity and switching conditions. If the output relay is used

beyond its life expectancy, its contacts may become fused or burned.

• Install the Units properly so that they will not fall off.

• Be sure that all the mounting screws, terminal screws, and cable connector screws are tightened to the torque specified in the relevant manuals.

Incorrect tightening torque may result in malfunction.

• Be sure that the terminal blocks and other items with locking devices are

properly locked into place. Improper locking may result in malfunction.

• Be sure that terminal blocks and connectors are connected in the specified direction with the correct polarity. Not doing so may result in malfunction. If the power supply for the I/O circuits is turned ON with the input and

output connectors reversed, the fuse of output transistor may be blown.

• Use the Unit with the battery housing cover in place to prevent dust or foreign matter from entering inside the Unit. Not doing so may result in malfunction.

• Install the expansion I/O connector cover to the last Unit (Expansion Unit

or Expansion I/O Unit) to prevent dust or foreign matter from entering

inside the Unit. Not doing so may result in malfunction.

• Be sure to attach the labels supplied with the CPM2C or provide other

protective covers when wiring in order to prevent dust or wiring cuttings

from entering the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Use round crimp terminals for wiring the AC power supply input to the AC

Power Supply Unit (CPM2C-PA201). For wiring the ground terminals or

power supply service terminals, use crimp terminals or solid wires. Do not

connect bare stranded wires directly to terminals. Connection of bare

stranded wires may result in burning.

xix

Page 19

Application Precautions 5

• Be sure to perform wiring in accordance with the CPM2C Operation Manual. Incorrect wiring may result in burning.

• Use specified connectors and wiring materials (connector models: C500CE241/C500-CE242/C500-CE243; terminal block models: AWG28-16

with stripped length of 7 mm; Power Supply Unit terminal block: AWG2214 with stripped length of 7 mm).

• Do not apply voltages to the input terminals in excess of the rated input

voltage. Excess voltages may result in burning.

• Do not apply voltages or connect loads to the output terminals in excess

of the maximum switching capacity. Excess voltage or loads may result in

burning.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may result in burning.

• Always use the power supply voltage specified in the operation manuals.

An incorrect voltage may result in malfunction or burning.

• Check the user program for proper execution before actually running it on

the Unit. Not checking the program may result in an unexpected operation.

• Double-check all wiring and switch settings before turning ON the power

supply. Incorrect wiring or switch settings may result in burning.

• Confirm that no adverse effect will occur in the system before attempting

any of the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Before touching the Unit, be sure to first touch a grounded metallic object

in order to discharge any static built-up. Not doing so may result in malfunction or damage.

• Do not pull on the cables or bend the cables beyond their natural limit.

Doing either of these may break the cables.

• Do not apply forces exceeding 50 N to connector sections.

• Do not place objects on top of the cables. Doing so may break the cables.

• Resume operation only after transferring to the new CPU Unit the contents of the DM and HR Areas required for resuming operation. Not doing

so may result in an unexpected operation.

• Install the Unit properly as specified in the operation manual. Improper

installation of the Unit may result in malfunction.

• When transporting the Units, use special packing boxes. Be careful not to

apply excessive vibration or shock during transportation and not to drop

the product.

• Store the Units within the following temperature and humidity ranges:

Storage temperature: –20 to 75

icing or condensation)

• When using a thermocouple-input Temperature Sensor Unit, do not touch

the cold junction compensator. Doing so may result in incorrect temperature measurement.

°C, storage humidity: 10% to 90% (with no

xx

Page 20

EC Directives 6

6 EC Directives

6-1 Applicable Directives

•EMC Directives

• Low Voltage Directive

6-2 Concepts

EMC Directives

OMRON devices that comply with EC Directives also conform to the related

EMC standards so that they can be more easily built into other devices or the

overall machine. The actual products have been checked for conformity to

EMC standards (see the following note). Whether the products conform to the

standards in the system used by the customer, however, must be checked by

the customer.

EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions of

the equipment or control panel on which the OMRON devices are installed.

The customer must, therefore, perform the final check to confirm that devices

and the overall machine conform to EMC standards.

Note Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN61131-2

EMI (Electromagnetic Interference): EN61000-6-4

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 VAC and 75

to 1,500 VDC meet the required safety standards for the PC (EN61131-2).

6-3 Conformance to EC Directives

The CPM2C PCs comply with EC Directives. To ensure that the machine or

device in which the CPM2C PC is used complies with EC Directives, the PC

must be installed as follows:

1,2,3... 1. The CPM2C PC must be installed within a control panel.

2. Reinforced insulation or double insulation must be used for the DC power

supplies used for the communications and I/O power supplies.

3. Basic insulation is provided between the commons of different polarities of

the output relay for the CPM2C-20@@R (model with 20 relay output

points).

When connecting devices that operate at voltages higher than 50 VAC and

those that operate on DC power supplies to adjoining relay output terminals, use different DC power supplies for output devices from those for input devices and the CPM2C power supply.

4. CPM2C PCs complying with EC Directives also conform to the Common

Emission Standard (EN61000-6-4). Radiated emission characteristics

(10-m regulations) may vary depending on the configuration of the control

panel used, other devices connected to the control panel, wiring, and other

conditions. You must therefore confirm that the overall machine or equipment complies with EC Directives.

(Radiated emission: 10-m regulations)

xxi

Page 21

EC Directives 6

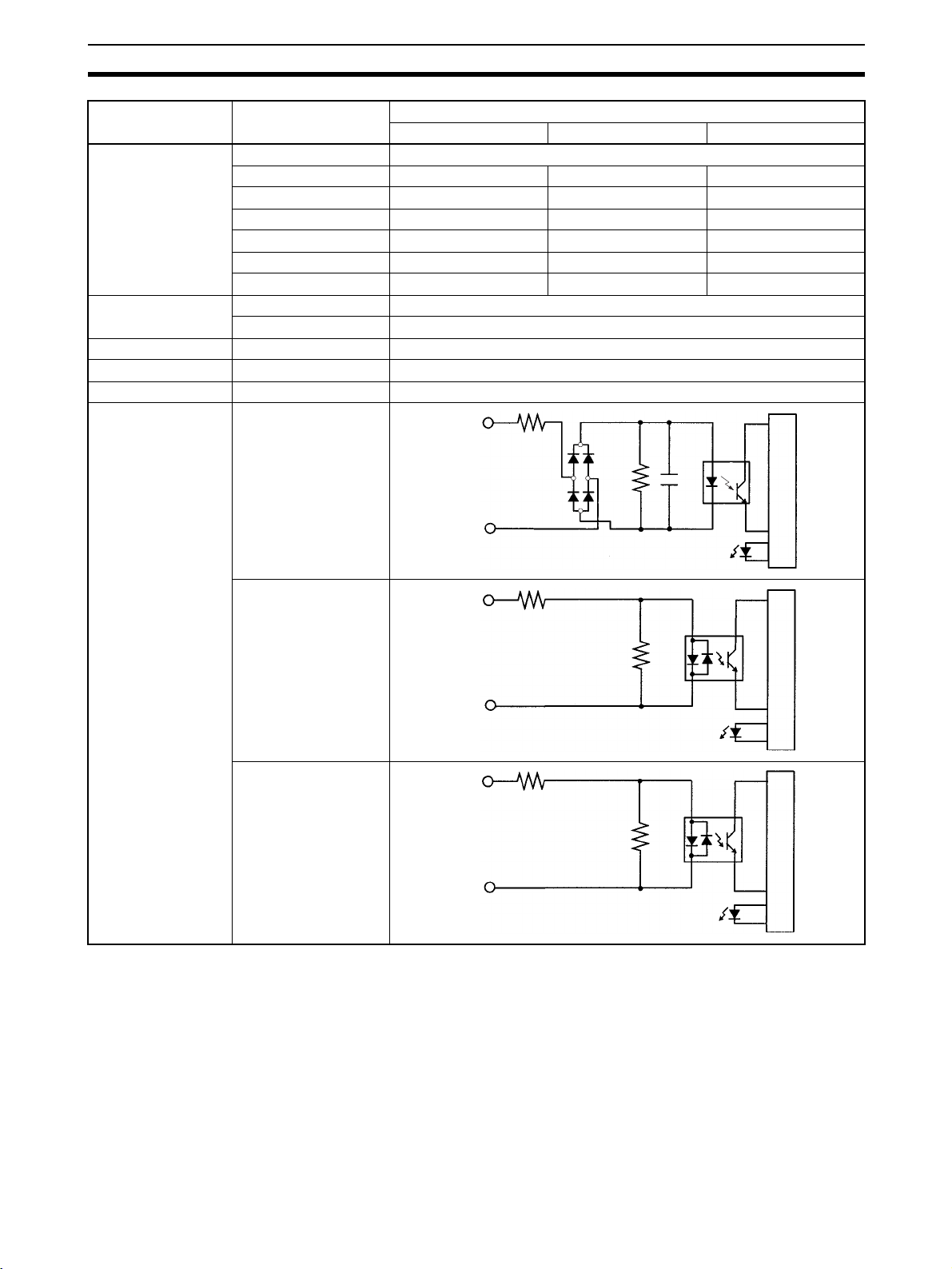

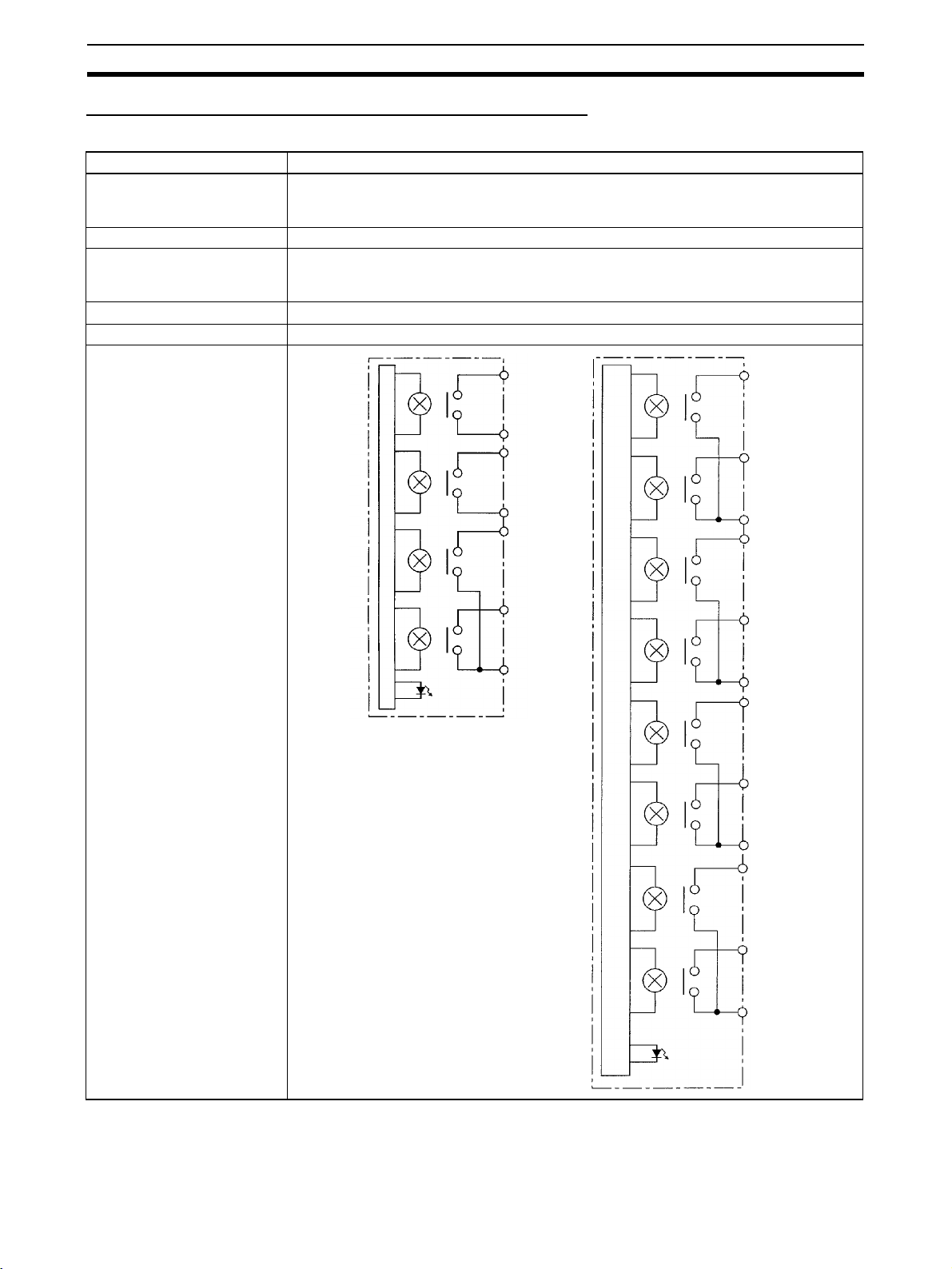

6-4 Relay Output Noise Reduction Methods

The CPM2C PCs conform to the Common Emission Standards (EN61000-6-

4) of the EMC Directives. However, the noise generated when the PC is

switched ON or OFF using the relay output may not satisfy these standards. In

such a case, a noise filter must be connected to the load side or other appropriate countermeasures must be provided external to the PC.

Countermeasures taken to satisfy the standards vary depending on the

devices on the load side, wiring, configuration of machines, etc. Following are

examples of countermeasures for reducing the generated noise.

Countermeasures

(Refer to EN61000-6-4 for more details.)

Countermeasures are not required if the frequency of load switching for the

whole system with the PC included is less than 5 times per minute.

Countermeasures are required if the frequency of load switching for the whole

system with the PC included is 5 times or more per minute.

Countermeasure Examples

When switching an inductive load, connect a surge protector, diodes, etc., in

parallel with the load or contact as shown below.

Circuit Current Characteristic Required element

AC DC

CR method

Powe r

supply

Yes Yes If the load is a relay or solenoid, there

Inductive

load

is a time lag between the moment the

circuit is opened and the moment the

load is reset.

If the supply voltage is 24 to 48 V,

insert the surge protector in parallel

with the load. If the supply voltage is

100 to 200 V, insert the surge protector

between the contacts.

The capacitance of the capacitor must

be 1 to 0.5 µF per contact current of

1 A and resistance of the resistor must

be 0.5 to 1 Ω per contact voltage of 1 V.

These values, however, vary with the

load and the characteristics of the

relay. Decide these values from experiments, and take into consideration that

the capacitance suppresses spark discharge when the contacts are separated and the resistance limits the

current that flows into the load when

the circuit is closed again.

The dielectric strength of the capacitor

must be 200 to 300 V. If the circuit is an

AC circuit, use a capacitor with no

polarity.

xxii

Page 22

EC Directives 6

o

e

y

Circuit Current Characteristic Required element

AC DC

Diode method

Powe r

supply

Varistor method

P

suppl

No Yes The diode connected in parallel with

the load changes energy accumulated

by the coil into a current, which then

flows into the coil so that the current

will be converted into Joule heat by the

Inductive

load

resistance of the inductive load.

This time lag, between the moment the

circuit is opened and the moment the

load is reset, caused by this method is

longer than that caused by the CR

method.

Yes Yes The varistor method prevents the impo-

sition of high voltage between the contacts by using the constant voltage

characteristic of the varistor. There is

time lag between the moment the cir-

Inductive

load

cuit is opened and the moment the load

is reset.

If the supply voltage is 24 to 48 V,

insert the varistor in parallel with the

load. If the supply voltage is 100 to

200 V, insert the varistor between the

contacts.

The reversed dielectric strength value

of the diode must be at least 10 times

as large as the circuit voltage value.

The forward current of the diode must

be the same as or larger than the load

current.

The reversed dielectric strength value

of the diode may be two to three times

larger than the supply voltage if the

surge protector is applied to electronic

circuits with low circuit voltages.

---

xxiii

Page 23

EC Directives 6

xxiv

Page 24

SECTION 1

Introduction

This section describes the CPM2C’s special features and functions, shows the possible system configurations, and outlines

the steps required before operation. Read this section first when using the CPM2C for the first time.

Refer to the CPM1/CPM1A/CPM2A/CPM2C/SRM1(-V2) Programming Manual (W353) for details on programming

operations.

1-1 CPM2C Features and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 CPM2C Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-2 Overview of CPM2C Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-2 System Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-2-1 CPU Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-2-2 Power Supply Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1-2-3 CPU Unit, Expansion Units, and Expansion I/O Units . . . . . . . . . . 10

1-3 Structure and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1-3-1 CPU Unit Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1-3-2 Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1-3-3 Operating Mode at Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1-3-4 PC Operation at Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1-3-5 Cyclic Operation and Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1-4 Functions Listed by Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1-5 Comparison with the CPM1A and CPM2A . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1-6 Preparation for Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1-7 Changes in SW2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

1

Page 25

CPM2C Features and Functions Section 1-1

(

1-1 CPM2C Features and Functions

1-1-1 CPM2C Features

The CPM2C PCs incorporate a variety of features in a compact Unit, including

synchronized pulse control, interrupt inputs, pulse outputs, and a clock function. The CPM2C CPU Unit is a stand-alone Unit that can handle a broad

range of machine control applications and it is small enough to be incorporated as the control unit in almost any free-standing machine.

The full complement of communications functions provide communications

with personal computers, other OMRON PCs, and OMRON Programmable

Terminals. These communications capabilities allow the user to design a lowcost distributed production system.

The communications port can be used simultaneously as two ports: Peripheral and RS-232C.

The peripheral port supports Programming Devices,

Host Link, and no-protocol communications.

The RS-232C port supports Host Link, no-protocol

serial),1:1 Link,and 1:1 NT Link communications.

CPU Units with 10 I/O points (relay or transistor

outputs) or with 20 or 32 I/O points (transistor

outputs only) are available. Expansion I/O Units

can be connected to increase capacity to 192 I/O

points.

Basic Functions

CPU Unit Variations The CPM2C PCs are one-piece PCs with 10, 20, or 32 I/O points in I/O termi-

nals or a built-in connector. There are 3 types of outputs available (relay outputs, sinking transistor outputs, and sourcing transistor outputs). All CPM2C

PCs require a 24-VDC power supply.

Expansion I/O Units Up to 5 Expansion I/O Units can be connected to the CPU Unit to increase the

PC’s I/O capacity to a maximum of 192 I/O points. There are 23 different

Expansion I/O Units available, including Units with 10 I/O points, 24 I/O points,

32 I/O points, 8 input points, 8 output points, 16 inputs points, and 16 output

points. The maximum I/O capacity of 192 I/O points is achieved by connecting

five 32-point Expansion I/O Units to a CPU Unit with 32 built-in I/O points.

Share Programming

Devices

Programming and monitoring for the CPM2C can be performed with CX-Programmer version 2.1 or higher or with a Programming Console. Programming

is also possible with the SYSMAC-CPT or SYSMAC Support Software.

2

Page 26

CPM2C Features and Functions Section 1-1

p

q

Built-in Motor Control Capability

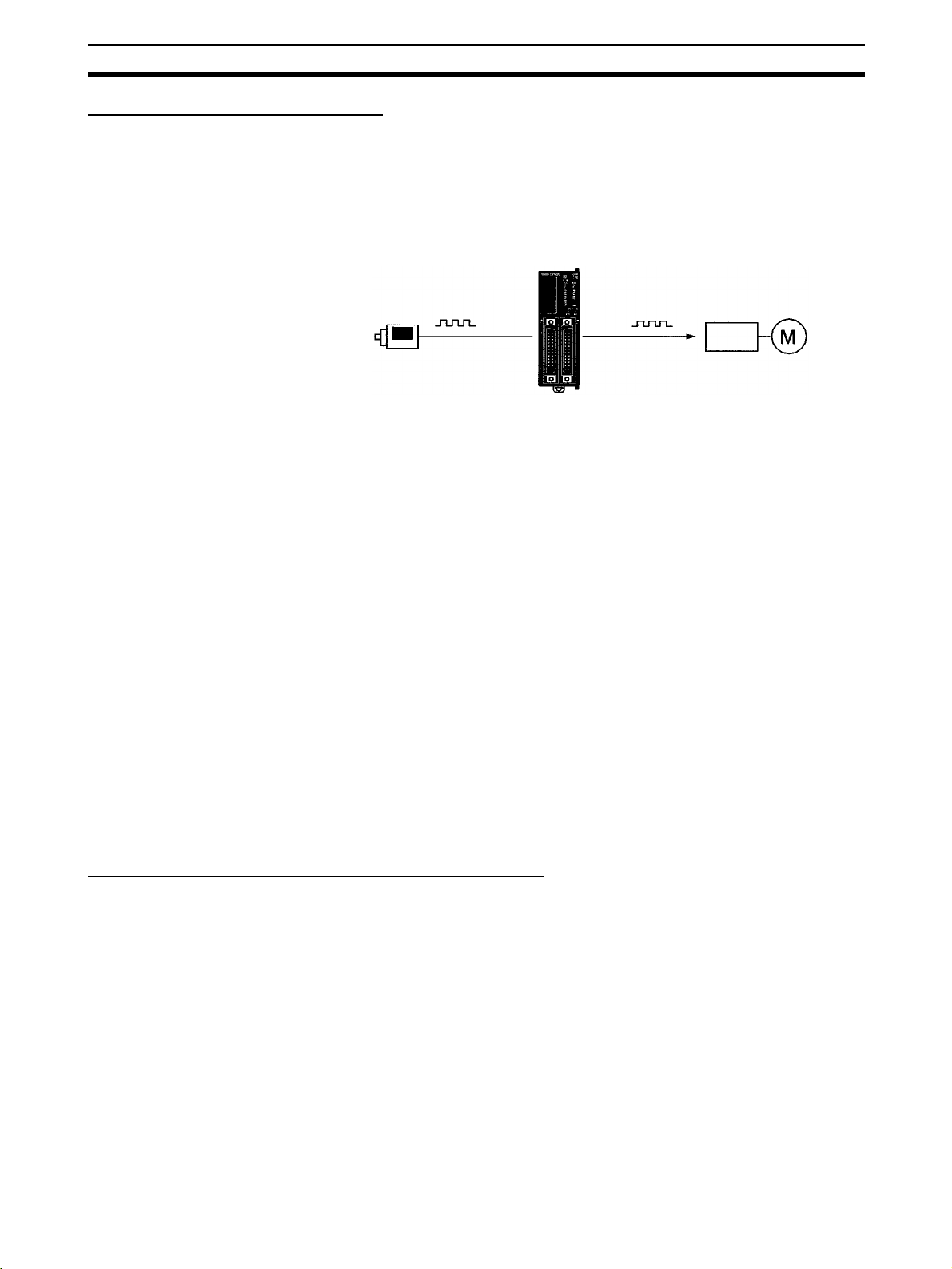

Synchronized Pulse

Control

(Transistor Outputs Only)

Synchronized pulse control provides an easy way to synchronize the operation of a peripheral piece of equipment with the main equipment. The output

pulse frequency can be controlled as some multiple of the input pulse frequency, allowing the speed of a peripheral piece of equipment (such as a supply conveyor) to be synchronized with the speed of the main piece of

equipment.

CPM2C

High-speed Counters and

Interrupts

Easy Position Control with

Pulse Outputs

(Transistor Outputs Only)

Encoder

Pulses are out

ut as a fixed multiple of the input fre

Motor driver

uency.

Motor

The CPM2C has a two kinds of high-speed counter inputs. The high-speed

counter input has a response frequency of 5 or 20 kHz and the interrupt inputs

(in counter mode) have a response frequency of 2 kHz.

The single high-speed counter can be used in any one of the four input

modes: differential phase mode (5 kHz), pulse plus direction input mode

(20 kHz), up/down pulse mode (20 kHz), or increment mode (20 kHz). Interrupts can be triggered when the count matches a set value or falls within a

specified range.

The interrupt inputs (counter mode) can be used for incrementing counters or

decrementing counters (2 kHz) and trigger an interrupt (executing the interrupt program) when the count matches the target value. Four interrupt inputs

can be used in the 20- and 32-point CPU Units and two interrupt inputs can be

used in the 10-point CPU Units.

CPM2C PCs with transistor outputs have two outputs that can produce 10 Hz

to 10 kHz pulses (single-phase outputs).

When used as single-phase pulse outputs, there can be two outputs with a

frequency range of 10 Hz to 10 kHz with a fixed duty ratio or 0.1 to 999.9 Hz

with a variable duty ratio (0 to 100% duty ratio).

When used as pulse plus direction or up/down pulse outputs, there can be

just one output with a frequency range of 10 Hz to 10 kHz.

High-speed Input Capabilities for Machine Control

High-speed Interrupt Input

Function

Quick-response Input

Function

Stabilizing Input Filter

Function

The 20-point and 32-point CPU Units have 4 inputs that can be used as interrupt inputs and the 10-point CPU Units have 2 inputs that can be used as

interrupt inputs. These inputs are shared with quick-response inputs and interrupt inputs in counter mode and have a minimum input signal width of 50

and response time of 0.3 ms. When an interrupt input goes ON, the main program is stopped and the interrupt program is executed.

Regardless of the cycle time, the 20-point and 32-point CPU Units have 4

inputs that can be used as quick-response inputs and the 10-point CPU Units

have 2 inputs that can be used as quick-response inputs. These inputs are

shared with interrupt inputs and interrupt inputs in counter mode; they can

reliably read input signals with a signal width as short as 50

The input time constant for all inputs can be set to 1 ms, 2 ms, 3 ms, 5 ms,

10 ms, 20 ms, 40 ms, or 80 ms. The effects of chattering and external noise

can be reduced by increasing the input time constant.

µs

µs.

3

Page 27

CPM2C Features and Functions Section 1-1

Other Functions

Interval Timer Interrupts The interval timer can be set between 0.5 and 319,968 ms and can be set to

generate just one interrupt (one-shot mode) or periodic interrupts (scheduled

interrupt mode).

Calendar/Clock In CPU Units with a built-in clock, the clock (accuracy within 1 minute/month)

can be read from the program to show the current year, month, day, day of the

week, and time. The clock can be set from a Programming Device (such as a

Programming Console) or the time can be adjusted by rounding up or down to

the nearest minute.

Long-term Timer TIML(

−−) is a long-term timer that accommodates set values up to 99,990

seconds (27 hours, 46 minutes, 30 seconds). When combined with the SECONDS TO HOURS conversion instruction (HMS(

vides an easy way to control equipment scheduling.

−−)), the long-term timer pro-

Greater Data Handling Capability with Expansion Units

Analog I/O Supported Up to 4 Analog I/O Units can be mounted to the CPM2C. For each Analog I/O

Unit mounted to the Unit, 2 analog input points and 1 analog output point are

available. By mounting 3 (see note) Analog I/O Units, a maximum of 8 analog

input points and 4 analog output points can be made available. (By using a

combination of the PID(

tional control is possible.)

• The ranges supported for analog input signals are 0 to 5 V, 0 to 10 V, –10

to 10 V, 0 to 20 mA, and 4 to 20 mA, and the resolution is 1/6000 (full

scale). The average processing function and power interruption detection

function can be used.

• The ranges supported for analog output signals are 1 to 5 V, 0 to 10 V,

–10 to 10 V, 0 to 20 mA, and 4 to 20 mA, and the resolution is 1/6000 (full

scale).

Note When using the CPM2C-PA201, there is a limit to the number of CPM2C-

MAD11 Units that can be connected. This limit ensures that the power consumption of the CPU Unit, Expansion Units, and Expansion I/O Units does not

exceed the total power capacity of the service power supply from the Power

Supply Unit (24 V x 600 mA = 14.4 W).

−−) instruction and PWM(−−) instruction, time propor-

• CPU Unit with 4-W power consumption: Connect no more than two

CPM2C-MAD11 Units

• CPU Unit with 3-W power consumption: Connect no more than three

CPM2C-MAD11 Units

Temperature Sensor Units Up to 4 Temperature Sensor Units can be mounted to the CPM2C. There are

2 models of Temperature Sensor Unit: One for input from a thermocouple sensor and one for input from a platinum resistance thermometer sensor. There

are 2 input points on each Temperature Sensor Unit.

CompoBus/S I/O Link

Units

• Thermocouple inputs (and measurement ranges): K (–200 to 1,300

0.0 to 500.0

• Platinum resistance thermometer inputs (and measurement ranges):

Pt100 (–200.0 to 650.0

The CPM2C can be used as a CompoBus/S Slave (with 8 built-in inputs and 8

built-in outputs) by connecting a CompoBus/S I/O Link Unit. Up to

5 CompoBus/S I/O Link Units can be connected to the CPM2C. In addition to

the conventional “PC + Remote I/O” type of distributed I/O control, “PC + miniature PC” distributed CPU control is now possible. This means increased

°C), J (–100 to 850°C, 0.0 to 400.0°C).

°C), JPt100 (–200.0 to 650.0°C).

°C,

4

Page 28

CPM2C Features and Functions Section 1-1

(Up

)

modularization, allowing greater standardization of design, improved suitability to special needs, and easier replacement of malfunctioning Units.

Simple Communications

Unit

A Simple Communications Unit can be added to achieve data transfers with

general-purpose communications components without preparing communications programs in the PC. Up to 32 communications components can be connected, including a combination of communications components supporting

the CompoWay/F protocol along with temperature controllers and Digital

Panel Meters supporting the SYSWAY protocol.

Complete Communications Capabilities

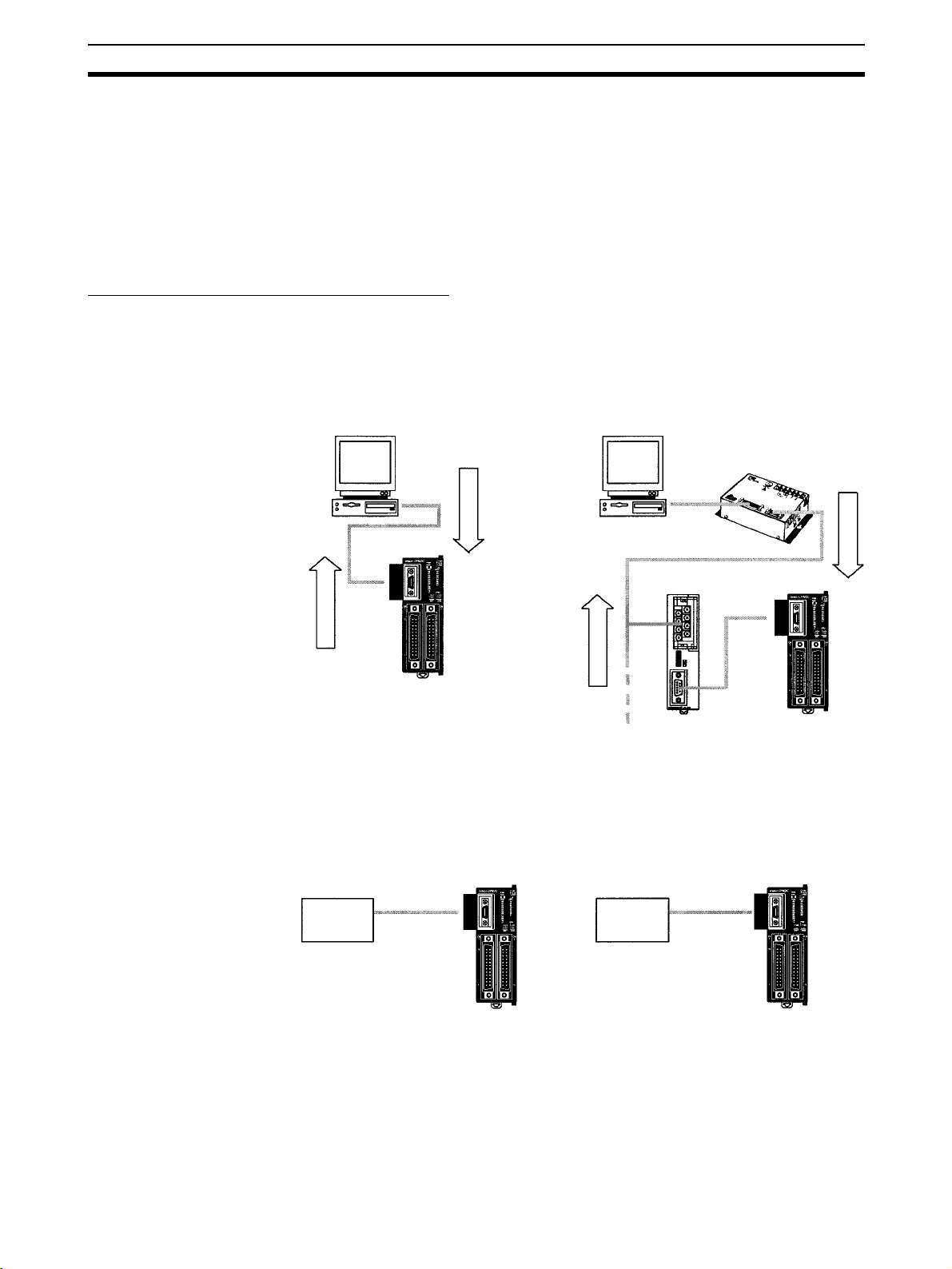

Host Link A Host Link connection can be made through the PC’s communications port

used as a RS-232C or peripheral port. A personal computer or Programmable

Terminal connected in Host Link mode can be used for operations such as

reading/writing data in the PC’s I/O memory or reading/changing the PC’s

operating mode.

1:1 Host Link Communications

Commands

CPM2C

1:N Host Link Communications

B500-AL004

Link Adapter

NT-AL001

Commands

CPM2C

No-protocol

Communications

High-speed 1:1 NT Link

Communications

Responses

Responses

to 32 PCs can be connected.

The TXD(48) and RXD(47) instructions can be used in no-protocol mode to

exchange data with standard serial devices. For example, data can be

received from a bar code reader or transmitted to a serial printer. The serial

devices can be connected to the communications port as a RS-232C or

peripheral port.

Inputting data from

a bar code reader

Bar code

reader

CPM2C CPM2C

Outputting data to

a serial printer

Serial

printer

In a 1:1 NT Link, an OMRON Programmable Terminal (PT) can be connected

directly to the CPM2C. The PT must be connected to the communications

port as an RS-232C port (not as a peripheral port).

5

Page 29

CPM2C Features and Functions Section 1-1

OMRON PT

CPM2C

One-to-one PC Link A CPM2C can be linked directly to another CPM2C, CQM1, CPM1, CPM1A,

CPM2A, SRM1(-V2), or a C200HS or C200HX/HG/HE PC. The 1:1 PC Link

allows automatic data link connections. The PC must be connected to the

communications port as an RS-232C port (not as a peripheral port).

CPM2C CPM2C

Expansion Memory Unit The CPM1-EMU01-V1 Expansion Memory Unit is a program loader for small-

size or micro PCs. Using the CPM1-EMU01-V1, simple on-site transfer of

user programs and data memory is possible with PCs.

CPM2C

Expansion Memory Unit

EEPROM

Indicator

UPLOAD+DM Button UPLOAD Button

CPM2C-CN111

CS1W-CN114

CPM2C

CPM2C-CIF01-V1

6

Page 30

CPM2C Features and Functions Section 1-1

1-1-2 Overview of CPM2C Functions

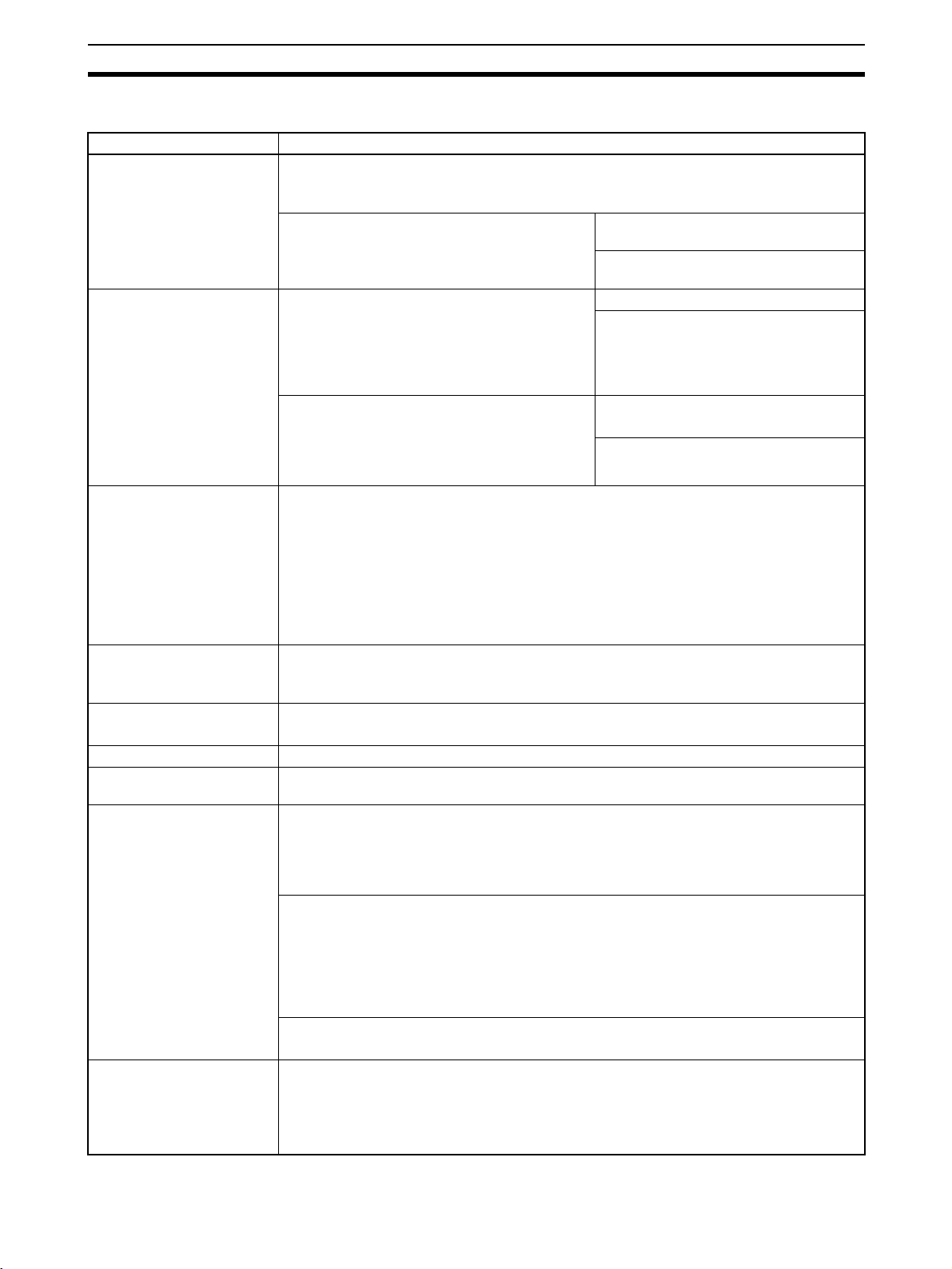

Main function Variations/Details

Interrupts Interrupt inputs

High-speed counters High-speed counter

Pulse outputs 2 outputs:

Synchronized pulse control 1 point, see notes 1 and 2.

Quick-response input 2 inputs in CPU Units with 10 I/O points, 4 inputs in CPU Units with 20/32 I/O points

Input time constant Determines the input time constant for all inputs. (Settings: 1, 2, 3, 5, 10, 20, 40, or 80 ms)

Calendar/Clock Shows the current year, month, day of the week, day of the month, hour, minute, and sec-

Expansion Unit functions Analog I/O functions using CPM2C-MAD11 Analog I/O Unit

Simple communications Simple communications functions using the CPM2C-CIF21 Simple Communications Unit

2 inputs in CPU Units with 10 I/O points, 4 inputs in CPU Units with 20/32 I/O points

Response time: 0.3 ms

Interval timer interrupts

1 input

Set value: 0.5 to 319,968 ms

Precision: 0.1 ms

1 input, see note 1.

Differential phase mode (5 kHz)

Pulse plus direction input mode (20 kHz)

Up/down input mode (20 kHz)

Increment mode (20 kHz)

Interrupt inputs (counter mode)

2 inputs in CPU Units with 10 I/O points,

4 inputs in CPU Units with 20/32 I/O points

Incrementing counter (2 kHz)

Decrementing counter (2 kHz)

Single-phase pulse output without acceleration/deceleration (See note 2.)

10 Hz to 10 kHz

2 outputs:

Variable duty ratio pulse output (See note 2.)

0.1 to 999.9 Hz, duty ratio 0% to 100%

1 output:

Pulse output with trapezoidal acceleration/deceleration (See note 2.)

Pulse plus direction output, up/down pulse output, 10 Hz to 10 kHz

Input frequency range: 10 to 500 Hz, 20 Hz to 1 kHz, or 300 Hz to 20 kHz

Output frequency range: 10 Hz to 10 kHz

Minimum input signal width: 50 µs

ond.

Two analog inputs: Input range of 0 to 5 V, 1 to 5 V, 0 to 10 V, –10 to 10 V, 0 to 20 mA, or

4 to 20 mA

One analog output: Output range of 1 to 5 V, 0 to 10 V, –10 to 10 V, 0 to 20 mA, or 4 to

20 mA

Temperature sensing functions using CPM2C-TS001/101 Temperature Sensor Unit

Thermocouple input (measurement range):K (–200 to 1,300°C)

K (0.0 to 500.0°C)

J (–100 to 850°C)

J (0.0 to 400.0°C)

Platinum resistance thermometer (measurement range):Pt100 (–200.0 to 650.0°C)

JPt100 (–200.0 to 650.0°C)

CompoBus/S Slave functions using CPM2C-SRT21 CompoBus/S I/O Link Unit

Data exchange with the Master Unit via 8 inputs and 8 outputs.

Up to 32 communications components can be connected, including communications components supporting the CompoWay/F protocol and temperature controllers and Digital

Panel Meters supporting the SYSWAY protocol.

Either RS-422 or RS-485 connections.

Scheduled interrupts

One-shot interrupt

No interrupt

Count-check interrupt

(An interrupt can be generated when the

count equals the set value or the count

lies within a preset range.)

No interrupt

Count-up interrupt

7

Page 31

CPM2C Features and Functions Section 1-1

Note 1. This input is shared by the high-speed counter and synchronized pulse

control functions.

2. This output is shared by the pulse output and synchronized pulse control

functions. These functions can be used with transistor outputs only.

8

Page 32

System Configurations Section 1-2

1-2 System Configurations

1-2-1 CPU Units

CPU Units with 10 I/O Points

CPU Unit with

Transistor Outputs

via MIL Connector

10 I/O points

(6 inputs,

4 outputs)

CPU Unit with

Relay Outputs via

Terminal Block

CPU Unit Inputs Outputs Clock Model

I/O terminal block 6 inputs (24 VDC) 4 relay outputs No CPM2C-10CDR-D*

I/O

connector

Fujitsucompatible

connector

MIL

connector

6 inputs (24 VDC) 4 transistor outputs

6 inputs (24 VDC) 4 transistor outputs

CPU Unit with

Transistor Outputs via

Fujitsu-compatible

Connector

(sinking)

4 transistor outputs

(sourcing)

(sinking)

4 transistor outputs

(sourcing)

Yes CPM2C-10C1DR-D*

No CPM2C-10CDTC-D*

Yes CPM2C-10C1DTC-D*

No CPM2C-10CDT1C-D*

Yes CPM2C-10C1DT1C-D*

No CPM2C-10CDTM-D

Yes CPM2C-10C1DTM-D

No CPM2C-10CDT1M-D

Yes CPM2C-10C1DT1M-D

Note The function of the SW2 is different from that described in this manual for all

CPU Units with 20 I/O Points

Relay Outputs via

CPU Unit Inputs Outputs Clock Model

20 I/O points

(12 inputs,

8 outputs)

I/O terminal block 12 inputs (24 VDC) 8 relay outputs No CPM2C-20CDR-D

I/O

connector

Fujitsucompatible

connector

MIL

connector

Units marked with an asterisk in the above table with lot numbers of 3180O

(August 2000) or earlier. Refer to

CPU Unit with

Terminal Block

12 inputs (24 VDC) 8 transistor outputs

12 inputs (24 VDC) 8 transistor outputs

CPU Unit with

Transistor Outputs via

Fujitsu-compatible

1-7 Changes in SW2 for details.

Connector

Yes CPM2C-20C1DR-D

(sinking)

8 transistor outputs

(sourcing)

(sinking)

8 transistor outputs

(sourcing)

No CPM2C-20CDTC-D*

Yes CPM2C-20C1DTC-D*

No CPM2C-20CDT1C-D*

Yes CPM2C-20C1DT1C-D*

No CPM2C-20CDTM-D

Yes CPM2C-20C1DTM-D

No CPM2C-20CDT1M-D

Yes CPM2C-20C1DT1M-D

CPU Unit with

Transistor Outputs

via MIL Connector

9

Page 33

System Configurations Section 1-2

Note The function of the SW2 is different from that described in this manual for all

Units marked with an asterisk in the above table with lot numbers of 3180O

(August 2000) or earlier. Refer to

CPU Units with 32 I/O Points

1-7 Changes in SW2 for details.

CPU Unit Inputs Outputs Clock Model

32 I/O points

(16 inputs,

16 outputs)

I/O

connector

Fujitsucompatible

connector

MIL

connector

1-2-2 Power Supply Unit

CPU Unit with

Transistor Outputs via

Fujitsu-compatible

Connector

16 inputs (24 VDC) 16 transistor out-

puts (sinking)

16 transistor out-

puts (sourcing)

16 inputs (24 VDC) 16 transistor out-

puts (sinking)

16 transistor out-

puts (sourcing)

AC Power Supply Unit

Transistor Outputs

via MIL Connector

CPU Unit with

No CPM2C-32CDTC-D

No CPM2C-32CDT1C-D

No CPM2C-32CDTM-D

No CPM2C-32CDT1M-D

Name Ratings Model

AC Power Supply Unit 100 to 240 VAC input

24 VDC, 600 mA output

CPM2C-PA201

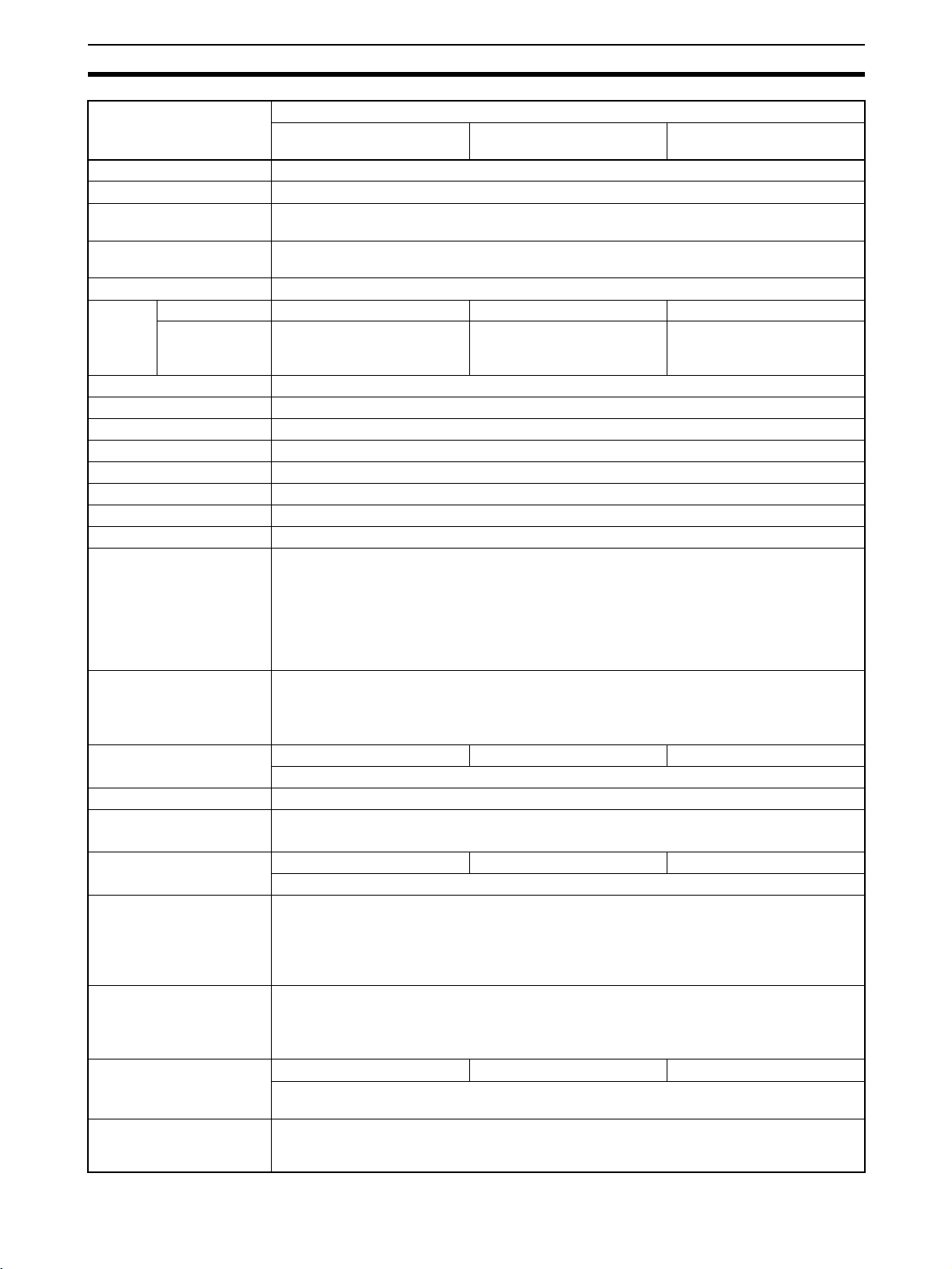

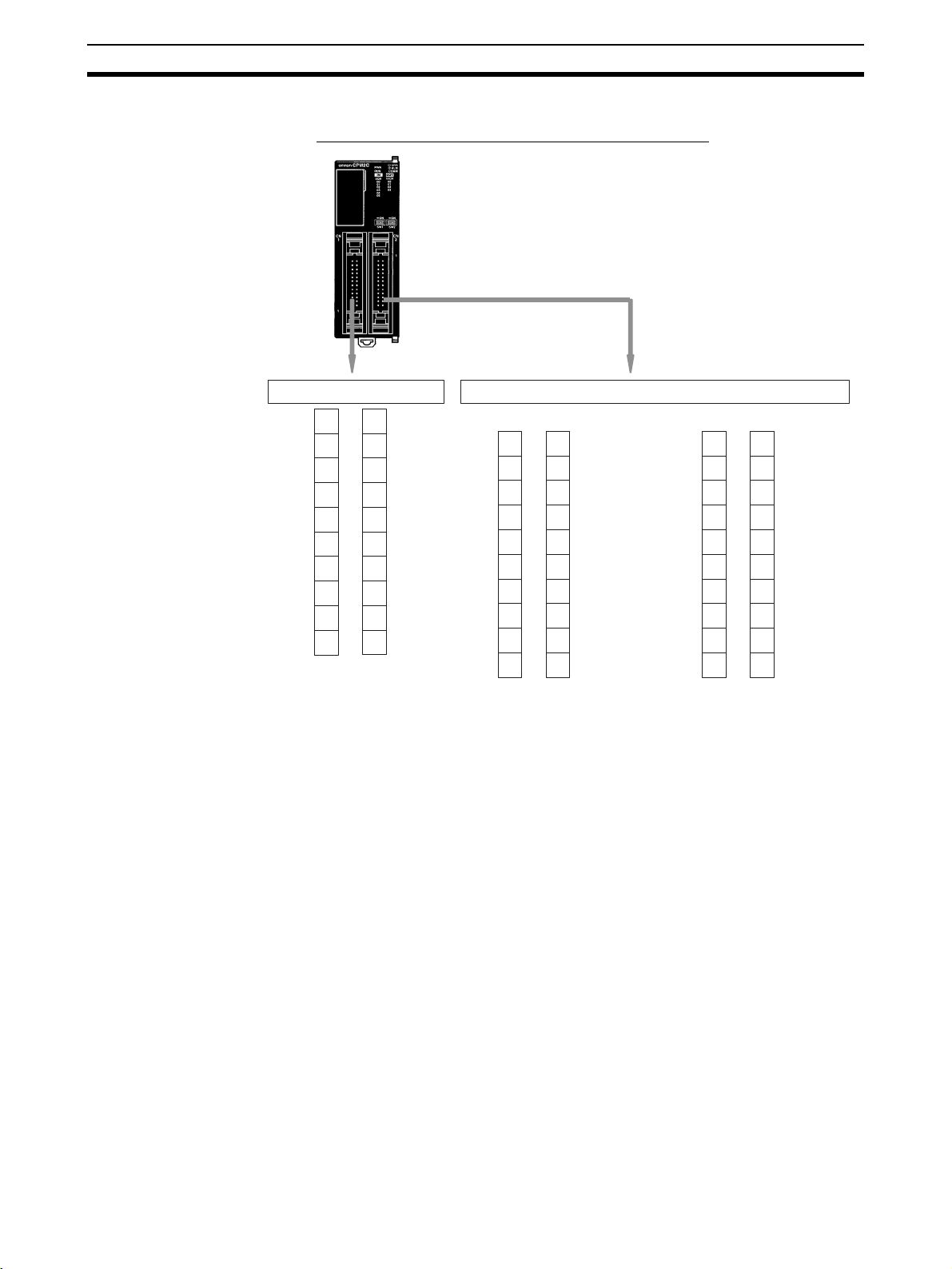

1-2-3 CPU Unit, Expansion Units, and Expansion I/O Units

A series of up to 5 Expansion I/O Units or Expansion Units can be connected

to the expansion I/O connector on the CPU Unit.

10

Page 34

System Configurations Section 1-2

(

)

(

)

There are five types of Units available: Expansion I/O Units, an Analog I/O

Unit, Temperature Sensor Units, a CompoBus/S I/O Link Unit, and a Simple

Communications Unit.

Expansion I/O Units

CPU Unit

Expansion I/O Connector

(with cover)

Expansion I/O Unit

or Expansion Unit

Expansion I/O Connector

(output side, no cover)

Expansion I/O Connector

(input side)

A PC with 192 I/O points (the maximum) can be assembled by connecting five

Expansion I/O Units to a CPU Unit with 32 I/O points.

CPM2C-32CDTC-D

16 inputs, 16 outputs

1 Unit + 5 Units = 96 inputs, 96 outputs

CPM2C-32EDTC

16 inputs, 16 outputs

Note Be sure that the power supply requirements of the CPU Unit, Expansion

Units, and Expansion I/O Units do not exceed the available capacity. Only

three Expansion I/O Units or Expansion Units can be connected when the NTAL001 Adapter is connected to the communications port (as a RS-232C port).

Units with Relay Outputs (via Terminal Block)

10 I/O Points 8 Output Points20 I/O Points

Unit I/O Inputs Outputs Model

10 I/O points 6 inputs (24 VDC) 4 relay outputs CPM2C-10EDR

20 I/O points 12 inputs (24 VDC) 8 relay outputs CPM2C-20EDR

8 output points --- 8 relay outputs CPM2C-8ER

11

Page 35

System Configurations Section 1-2

Units with Transistor Outputs via Fujitsu-compatible Connector

8 Output Points 16 Input Points 16 Output Points8 Input Points32 I/O Points24 I/O Points

Unit I/O Inputs Outputs Model

24 I/O points 16 inputs (24 VDC) 8 transistor outputs (sinking) CPM2C-24EDTC

8 transistor outputs (sourcing) CPM2C-24EDT1C

32 I/O points 16 inputs (24 VDC) 16 transistor outputs (sinking) CPM2C-32EDTC

16 transistor outputs (sourcing) CPM2C-32EDT1C

8 input points 8 inputs (24 VDC) --- CPM2C-8EDC

16 input points 16 inputs (24 VDC) --- CPM2C-16EDC

8 output points --- 8 transistor outputs (sinking) CPM2C-8ETC

--- 8 transistor outputs (sourcing) CPM2C-8ET1C

16 output points --- 16 transistor outputs (sinking) CPM2C-16ETC

--- 16 transistor outputs (sourcing) CPM2C-16ET1C

Units with Transistor Outputs via MIL Connector

8 Input or

8 Output Points32 I/O Points24 I/O Points

Unit I/O Inputs Outputs Model

24 I/O points 16 inputs (24 VDC) 8 transistor outputs (sinking) CPM2C-24EDTM

8 transistor outputs (sourcing) CPM2C-24EDT1M

32 I/O points 16 inputs (24 VDC) 16 transistor outputs (sinking) CPM2C-32EDTM

16 transistor outputs (sourcing) CPM2C-32EDT1M

8 input points 8 inputs (24 VDC) --- CPM2C-8EDM

16 input points 16 inputs (24 VDC) --- CPM2C-16EDM

8 output points --- 8 transistor outputs (sinking) CPM2C-8ETM

--- 8 transistor outputs (sourcing) CPM2C-8ET1M

16 output points --- 16 transistor outputs (sinking) CPM2C-16ETM

--- 16 transistor outputs (sourcing) CPM2C-16ET1M

16 Input or

16 Output Points

12

Page 36

System Configurations Section 1-2

t

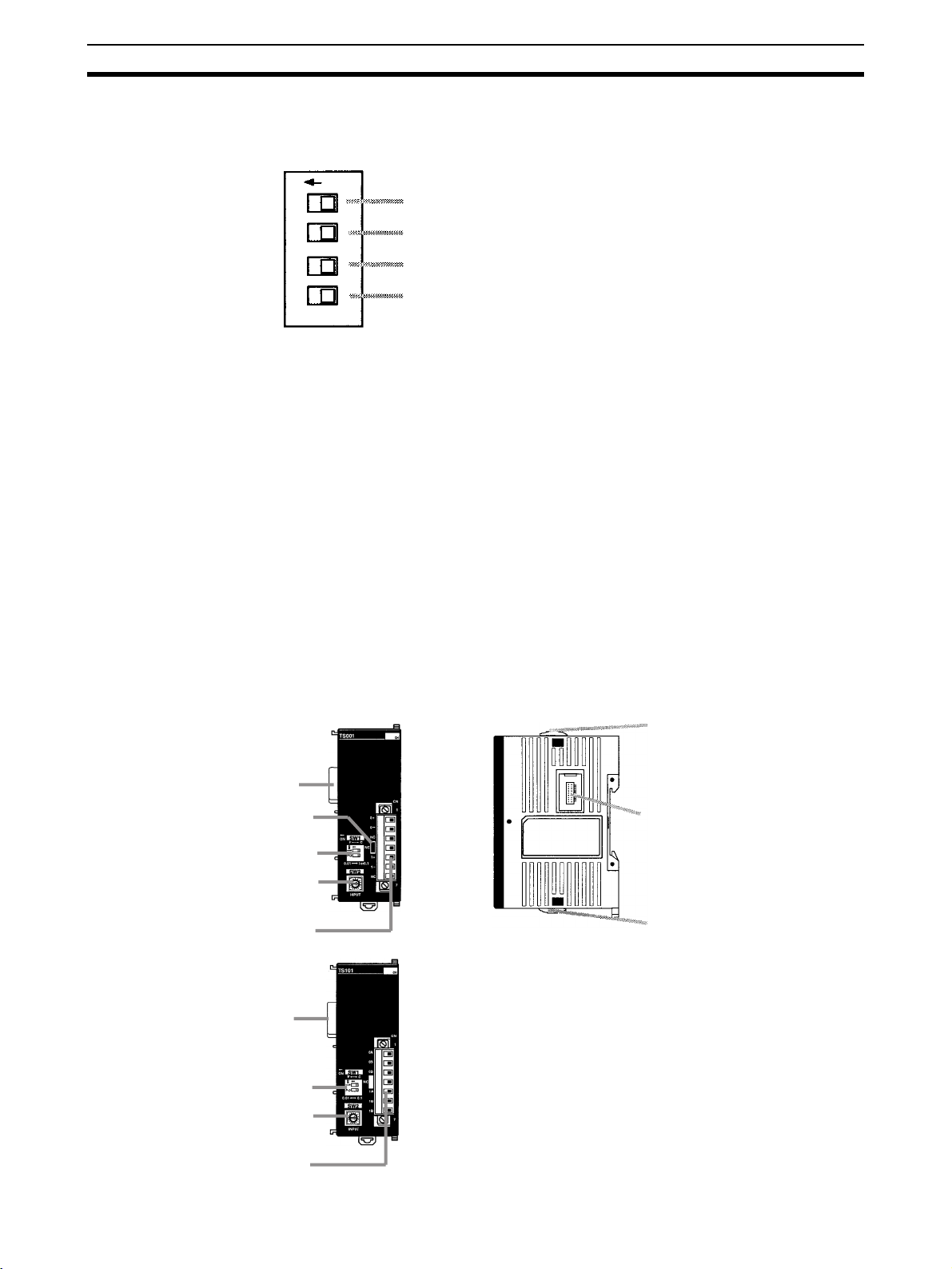

Expansion Units

CPM2C-MAD11

Analog I/O Unit

CPM2C-TS001

Temperature Sensor Unit

CPM2C-SRT21

CompoBus/S I/O Link Unit

CPM2C-CIF21

Simple Communications Unit

Unit Max. number

Analog I/O Unit 2 analog inputs

1 analog output

Temperature Sensor Unit

CompoBus/S I/O

Link Unit

Simple Communications Unit

(See notes 1 and 2.)

2 thermocouple

inputs

2 platinum resistance thermometer

inputs

8 input points and 8

output points for

the built-in outputs

and inputs of the

Master Unit

Note 1. Do not use the CPM2C-CIF21 Simple Communications Unit with an Units

Adapter Units

of Units

4 2 points, 2 words

4 2 points, 2 words

5 8 points, 1 word

--- CPM2C-CIF21

Inputs Outputs Model

1 point, 1 word allo-

allocated

allocated

2 points, 2 words

allocated

allocated

(Inputs from the

Master)

cated

--- CPM2C-TS001

--- CPM2C-TS101

8 points, 1 word

allocated

(Outputs to the

Master)

CPM2C-MAD11

CPM2C-SRT21

other than CPM2C Units.

2. The CPM2C-CIF21 Simple Communications Unit is due for release in December 2000.

Peripheral/RS-232C Adapter Unit RS-422/232C Adapter Uni

Unit Conversion Model

Peripheral/RS-232C Adapter Unit CPU Unit’s communications port →

RS-422/RS-232C Adapter Unit CPU Unit’s communications port →

Peripheral port + RS-232C port

RS422 port + RS-232C port

Note 1. The CPM2C-CIF01-V1 cannot be used with any PC model other than the

CPM2C. A CPM2C-CIF11 or another CPM2C-CIF01-V1 cannot be connected onto a CPM2C-CIF01-V1.

CPM2C-CIF01-V1

CPM2C-CIF11

13

Page 37

Structure and Operation Section 1-3

2. Although a CPM2C-CN111 can be connected to a CPM2C-CIF01-V1, it is

not possible to use the peripheral port and the RS-232C port on the

CPM2C-CN111 simultaneously. If an attempt is made to use both ports simultaneously, communications will not be performed properly and incorrect operation may result.

1-3 Structure and Operation

1-3-1 CPU Unit Structure

The following diagram shows the internal structure of the CPU Unit.

I/O memory

External

input

devices

Input circuits

Communications

port

Program

Settings

Settings

Communications

switch

PC Setup

Output circuits

Settings

External

output

devices

I/O Memory The program reads and writes data in this memory area during execution.

Part of the I/O memory contains the bits that reflect the status of the PC’s

inputs and outputs. Parts of the I/O memory are cleared when the power is

turned ON and other parts are retained.

Note Refer to Section 3 Memory Areas in the Programming Manual (W353) for

more details on I/O memory.

Program This is the program written by the user. The CPM2C executes the program

cyclically. (Refer to

1-3-5 Cyclic Operation and Interrupts for details.)

The program can be divided broadly into two parts: the “main program” that is

executed cyclically and the “interrupt programs” that are executed only when

the corresponding interrupt is generated.

PC Setup The PC Setup contains various startup and operating parameters. The PC

Setup parameters can be changed from a Programming Device only; they

cannot be changed from the program.

Some parameters are accessed only when PC’s power supply is turned ON

and others are accessed regularly while the power is ON. It will be necessary

to turn the power OFF and then ON again to enable a new setting if the

parameter is accessed only when the power is turned ON.

Note Refer to Section 1 PC Setup in the Programming Manual (W353) for more

details.

Communications Switch The Communications Switch controls the communications settings for the

peripheral port and the RS-232C port.

14

Page 38

Structure and Operation Section 1-3

1-3-2 Operating Modes

CPM2C CPU Units have 3 operating modes: PROGRAM, MONITOR, and

RUN.

PROGRAM Mode The program cannot be executed in PROGRAM mode. This mode is used to

perform the following operations in preparation for program execution.

• Changing initial/operating parameters such as those in the PC Setup

• Writing, transferring, or checking the program

• Checking wiring by force-setting and force-resetting I/O bits

!Caution The PC continues to refresh I/O bits even if the PC is in PROGRAM mode, so

devices connected to output points on the CPU Unit, Expansion Units, or

Expansion I/O Units may operate unexpectedly if the corresponding output bit

is turned ON by changing the contents of I/O memory.

MONITOR Mode The program is executed in MONITOR mode and the following operations can

be performed from a Programming Device. In general, MONITOR mode is

used to debug the program, test operation, and make adjustments.

• Online editing

• Monitoring I/O memory during operation

• Force-setting/force-resetting I/O bits, changing set values, and changing

present values during operation

RUN Mode The program is executed at normal speed in RUN mode. Operations such as

online editing, force-setting/force-resetting I/O bits, and changing set values/

present values cannot be performed in RUN mode, but the status of I/O bits

can be monitored.

1-3-3 Operating Mode at Startup

The operating mode of the CPM2C when the power is turned ON depends

upon the PC Setup settings and the Programming Console’s mode switch setting if a Programming Console is connected.

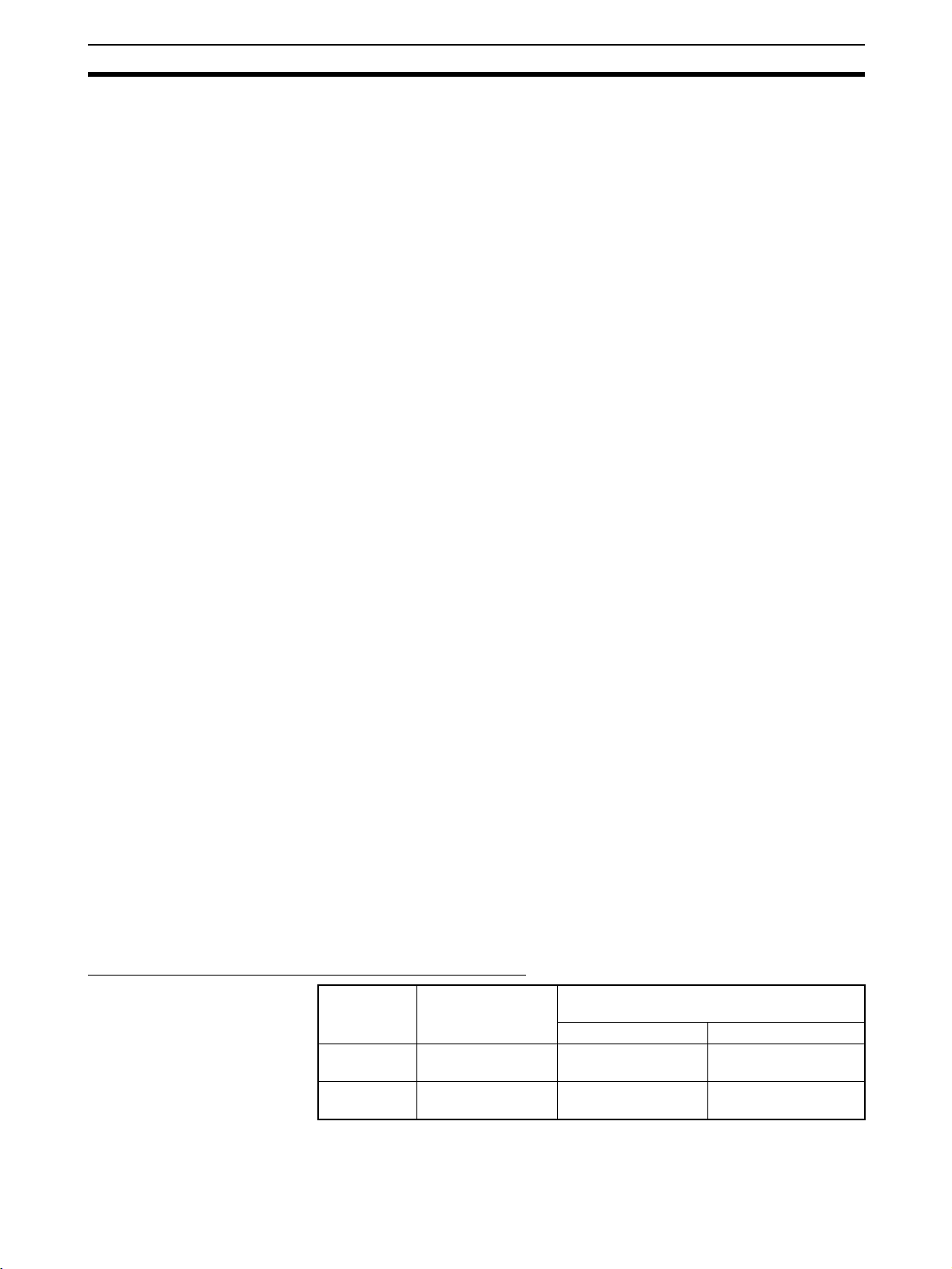

PC Setup setting Operating mode

Word Bits Setting Programming Device

connected

DM 6600 08 to 15 00 (Hex) Programming Console:

Mode set on Programming

Console mode switch

Other Programming Device:

PROGRAM mode

01 (Hex) Startup mode is the same as the operating mode before

power was interrupted.

02 (Hex) Startup mode is determined by bits 00 to 07.

00 to 07 00 (Hex) PROGRAM mode

01 (Hex) MONITOR mode

02 (Hex) RUN mode

Programming Device not

connected

RUN mode

Note 1. The default setting for DM 6600, bits 06 to 15 is 00 Hex, i.e., to start with

the mode set on the Programming Console’s mode switch. If a Programming Device is not connected to the peripheral connector on the CPU Unit,

the CPU Unit will start in RUN mode as soon as power is turned ON. Be

sure that adequate precautions are taken to ensure safety.

15

Page 39

Structure and Operation Section 1-3

2. The setting of SW2 will affect the startup operating mode for all Units with

lot numbers of 3180O (August 2000) or earlier. Refer to

SW2

for details.

1-7 Changes in

1-3-4 PC Operation at Startup

Time Required for

Initialization

Power OFF Operation

The time required for startup initialization depends on several factors, such as

the operating conditions (including power supply voltage, system configuration, and ambient temperature) and the program contents.

Minimum Power Supply Voltage

The PC will stop and all outputs will be turned OFF if the power supply voltage

falls below 85% of the rated value.

Momentary Power Interruption

A power interruption will not be detected and CPU Unit operation will continue

if the power interruption lasts less than 2 ms.

A power interruption may or may not be detected for power interruptions

somewhat longer than 2 ms.

When a power interruption is detected, the CPU Unit will stop operating and

all outputs will be turned OFF.

Automatic Reset

Operation will restart automatically when the power supply voltage is restored

to more than 85% of the rated voltage.

Timing Chart of Power OFF Operation

The power interruption detection time is the time required for a power interruption to be detected after the power supply voltage drops below 85% of the

rated value.

1,2,3... 1. Minimum power interruption detection time

Power interruptions that are shorter than 2 ms will not be detected.

16

Page 40

Structure and Operation Section 1-3

2. Undetermined additional time

Power interruptions only slightly longer than the minimum power interruption time may not be detected.

85% of rated voltage

Detection of

power interruption

Program execution

CPU reset signal

1. Minimum time 2. Additional

Executing

CPU Unit operation will

continue if voltage is

restored in this region.

time

Stopped

CPU Unit operation may

continue if voltage is

restored in this region.

Note If the power supply voltage fluctuates around 85% of the PC’s rated voltage,

PC operation may stop and restart repeatedly. When repeated stopping and

starting will cause problems with the controlled system, set up a protective circuit such as a circuit that shuts OFF the power supply to sensitive equipment

until the power supply voltage returns to the rated value.

17

Page 41

Structure and Operation Section 1-3

1-3-5 Cyclic Operation and Interrupts

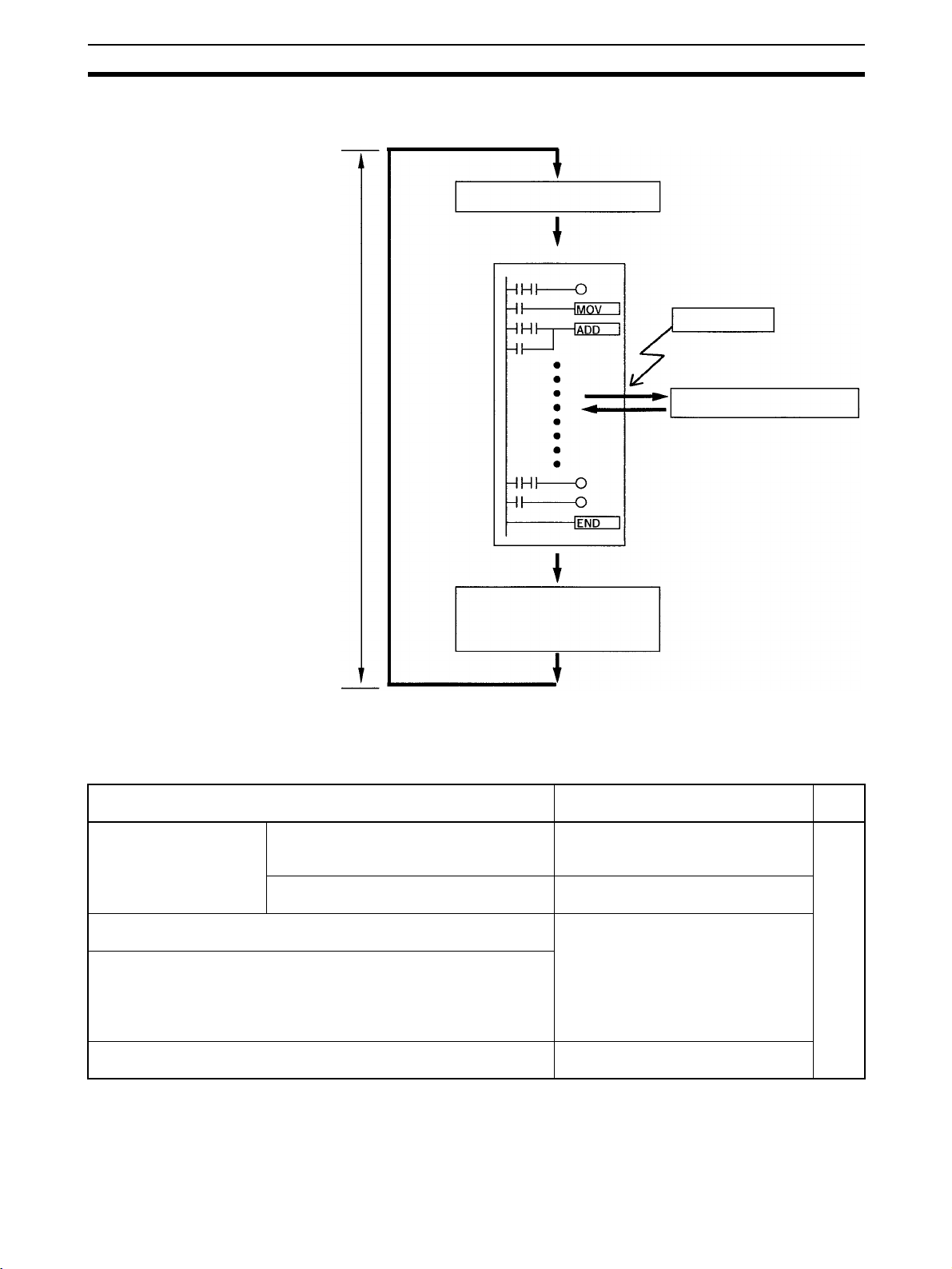

Basic CPU Operation Initialization processing is performed when the power is turned ON. If there

are no initialization errors, the overseeing processes, program execution, I/O

refreshing, and communications port servicing are performed repeatedly

(cyclically).

• Check hardware.

Startup initialization

Overseeing

processes

• Check memory.

• Read data from flash memory (program,

read-only DM data, and PC Setup settings).

• Check for battery error.

• Preset the watch (maximum) cycle time.

• Check program memory.

• Refresh bits for expansion functions.

Program execution

Cycle time

PC cycle time

calculation

I/O refreshing

RS-232C port

servicing

• Execute the program.

(Refer to the Programming Manual (W353) for

details on cycle time and I/O response times.)

• Wait for minimum cycle time if a minimum

cycle time has been set in the PC Setup

(DM 6619).

• Calculate cycle time.

• Read input data from input bits.

• Write output data to output bits.

• Perform RS-232C port communications

processing. (Can be changed in DM 6616.)

18

Peripheral port

servicing

• Perform peripheral port communications

processing. (Can be changed in DM 6617.)

The cycle time can be read from a Programming Device.

AR 14 contains the maximum cycle time and AR 15 contains the present

cycle time in multiples of 0.1 ms.

Page 42

Structure and Operation Section 1-3

C

t

The cycle time will vary slightly depending on the processing being performed

in each cycle, so the calculated cycle time will not always match the actual

cycle time.

Program Execution in

Cyclic Operation

The following diagram shows the cyclic operation of the CPM2C when the

program is being executed normally.

Normally, the results of program execution are transferred to I/O memory just

after program execution (during I/O refreshing), but IORF(97) can be used to

refresh a specified range of I/O words during program execution. The specified range of I/O words will be refreshed when IORF(97) is executed.

The cycle time is the sum of the time required for program execution, I/O

refreshing, and communications port servicing.

A minimum cycle time (1 to 9,999 ms) can be set in the PC Setup (DM 6619).

When a minimum cycle time has been set, CPU operation is paused after program execution until the minimum cycle time is reached. CPU operation will

not be paused if the actual cycle time is longer than the minimum cycle time

set in DM 6619.

Note A fatal error will occur and PC operation will stop if a maximum cycle time has

been set in the PC Setup (DM 6618) and the actual cycle time exceeds that

setting.

The default settings for RS-232C and peripheral port servicing are 5% each of

the cycle time, but these settings can be changed (between 0% and 99%) in

the PC Setup. The RS-232C port’s setting is in DM 6616 and the peripheral

port’s setting is in DM 6617.

Refer to Section 7 PC Operations and Processing Time in the Programming

Manual (W353) for more details and precautions on the cycle time.

Overseeing processes

Main program

ycle

ime

If a minimum cycle time has been

set in DM 6619, CPU operation is

paused until the minimum cycle

time is reached.

I/O refreshing

RS-232C port servicing

Peripheral port servicing

The servicing time can be set

in DM 6616.

The servicing time can be set

in DM 6617.

19

Page 43

Structure and Operation Section 1-3

t

Interrupt Program