Page 1

Cat.No. W317–E1–5

SYSMAC

CPM1A

Programmable Controllers

OPERATION MANUAL

Page 2

CPM1A Programmable Controllers

Operation Manual

Revised February 2000

Page 3

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

!

serious injury.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

!

serious injury.

Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

!

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 1997

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Note Indicates information of particular interest for efficient and convenient operation

of the product.

1, 2, 3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 4

TABLE OF CONTENTS

PRECAUTIONS xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Intended Audience xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 EC Directives xvii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1

Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 CPM1A Features and Functions 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 System Configuration 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 Revised Specifications 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

Unit Specifications and Components 19. . . . . . . . . . . . . . . .

2-1 Specifications 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Unit Components 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3

Installation and Wiring 35. . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1 Design Precautions 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Selecting an Installation Site 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Installing the CPM1A 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Wiring and Connections 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4

Using Peripheral Devices 67. . . . . . . . . . . . . . . . . . . . . . . . . .

4-1 Support Software Capabilities 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Using a Programming Console 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Programming Console Operations 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4 Programming Example 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5

Test Runs and Error Processing 109. . . . . . . . . . . . . . . . . . . .

5-1 Initial System Checks and Test Run Procedure 110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 The CPM1A Cycle 112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 Self-diagnosis Functions 113. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-4 Programming Console Operation Errors 115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5 Programming Errors 115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-6 Troubleshooting Flowcharts 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-7 Maintenance Inspections 125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-8 Handling Precautions 126. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6

Expansion Memory Unit 127. . . . . . . . . . . . . . . . . . . . . . . . . .

6-1 Overview 128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2 Specifications and Nomenclature 129. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3 Handling 130. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vii

Page 5

TABLE OF CONTENTS

Appendices

A Standard Models 137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Dimensions 141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary 147. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 163. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History 169. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

Page 6

About this Manual:

The CPM1A is a compact, high-speed Programmable Controller (PC) designed for control operations in

systems requiring from 10 to 100 I/O points per PC. There are two manuals describing the setup and

operation of the CPM1A: the CPM1A Operation Manual (this manual) and the CPM1/CPM1A/CPM2A/

CPM2C/SRM1(-V2) Programming Manual (W353).

This manual describes the system configuration and installation of the CPM1A and provides a basic

explanation of operating procedures for the Programming Consoles. It also introduces the capabilities of

the SYSMAC Support Software (SSS). Read this manual first to acquaint yourself with the CPM1A.

The CPM1/CPM1A/CPM2A/CPM2C/SRM1(-V2) Programming Manual (W353) provides detailed

descriptions of the CPM1A’s programming functions. The SYSMAC Support Software Operation Manu-

als: Basics and C-series PCs (W247 and W248) provide descriptions of SSS operations for the CPM1A

and other SYSMAC C-series PCs. The SYSMAC-CPT Support Software Quick Start Guide (W332) and

User Manual (W333) provide descriptions of ladder diagram operations in the Windows environment. The

WS02-CXPC1-E CX-Programmer User Manual (W361) and the CX-Server User Manual (W362) provide

details of operations for the WS02-CXPC1-E CX-Programmer.

Please read this manual carefully and be sure you understand the information provide before attempting

to install and operate the CPM1A.

Section 1 gives a brief overview of the steps involved in developing of a CPM1A System, describes the

possible system configurations, and describes the CPM1A’s special features and functions.

Section 2 provides the technical specifications of the Units that go together to create a CPM1A PC and

describes the main components of the Units.

Section 3 describes how to install and wire a CPM1A PC.

Section 4 describes SSS capabilities, how to connect the Programming Console, and how to perform th e

various Programming Console operations.

Section 5 describes how to perform a test run and how to diagnose and correct the hardware and soft-

ware errors that can occur during PC operation.

Section 6 describes how to use the CPM1-EMU01-V1 Expansion Memory Unit. Follow the handling pre-

cautions and procedures to properly use the Unit.

Appendix A provides tables of CPM1A Units and related products.

Appendix B provides the dimensions of CPM1A Units.

!

WARNING Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section in its entirety and be sure you understand the information provided in the section

and related sections before attempting any of the procedures or operations given.

ix

Page 7

PRECAUTIONS

This section provides general precautions for using the Programmable Controller (PC) and related devices.

The information contained in this section is important for the safe and reliable application of the Programmable Controller. You must read this section and understand the information contained before attempting to set up or operate a

PC system.

1 Intended Audience xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 EC Directives xvii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xi

Page 8

1 Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications

described in the operation manuals.

Before using the product under conditions which are not described in the manual

or applying the product to nuclear control systems, railroad systems, aviation

systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that

may have a serious influence on lives and property if used improperly, consult

your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide the

systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual

close at hand for reference during operation.

5Application Precautions

WARNING It is extremely important that a PC and all PC Units be used for the specified

!

purpose and under the specified conditions, especially in applications that can

directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PC System to the above-mentioned

applications.

3 Safety Precautions

WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing so

!

may result in electric shock.

WARNING Do not touch any of the terminals or terminal blocks while the power is being

!

supplied. Doing so may result in electric shock.

WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do so

!

may result in malfunction, fire, or electric shock.

WARNING Provide safety measures in external circuits (i.e., not in the Programmable

!

Controller), including the following items, in order to ensure safety in the system

if an abnormality occurs due to malfunction of the PC or another external factor

affecting the PC operation. Not doing so may result in serious accidents.

xii

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PC will turn OFF all outputs when its self-diagnosis function detects any

error or when a severe failure alarm (FALS) instruction is executed. As a countermeasure for such errors, external safety measures must be provided to ensure safety in the system.

Page 9

• The PC outputs may remain ON or OFF due to deposition or burning of the

output relays or destruction of the output transistors. As a countermeasure for

such problems, external safety measures must be provided to ensure safety in

the system.

• When the 24-VDC output (service power supply to the PC) is overloaded or

short-circuited, the voltage may drop and result in the outputs being turned

OFF. As a countermeasure for such problems, external safety measures must

be provided to ensure safety in the system.

WARNING When transferring programs to other nodes, or when making changes to I/O

!

memory, confirm the safety of the destination node before transfer. Not doing so

may result in injury.

Caution Execute online edit only after confirming that no adverse effects will be caused

!

by extending the cycle time. Otherwise, the input signals may not be readable.

Caution Tighten the screws on the terminal block of the AC Power Supply Unit to the

!

torque specified in the operation manual. The loose screws may result in burning

or malfunction.

5Application Precautions

4 Operating Environment Precautions

Caution Do not operate the control system in the following places:

!

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified in

the specifications.

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

Caution Take appropriate and sufficient countermeasures when installing systems in the

!

following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

Caution The operating environment of the PC System can have a large effect on the lon-

!

gevity and reliability of the system. Improper operating environments can lead to

malfunction, failure, and other unforeseeable problems with the PC System. Be

sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life of the system.

5 Application Precautions

Observe the following precautions when using the PC System.

WARNING Always heed these precautions. Failure to abide by the following precautions

!

could lead to serious or possibly fatal injury.

xiii

Page 10

• Always connect to a class-3 ground (to 100 Ω or less) when installing the Units.

Not connecting to a class-3 ground may result in electric shock.

• Always turn off the power supply to the PC before attempting any of the following. Not turning off the power supply may result in malfunction or electric

shock.

• Mounting or dismounting I/O Units, CPU Units, or any other Units.

• Assembling the Units.

• Connecting or wiring the cables.

• Connecting or disconnecting the connectors.

Caution Failure to abide by the following precautions could lead to faulty operation of the

!

PC or the system, or could damage the PC or PC Units. Always heed these precautions.

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal lines,

momentary power interruptions, or other causes.

• Construct a control circuit so that power supply for the I/O circuits does not

come ON before power supply for the Unit. If power supply for the I/O circuits

comes ON before power supply for the Unit, normal operation may be temporarily interrupted.

• If the operating mode is changed from RUN or MONITOR mode to PROGRAM

mode, with the IOM Hold Bit ON, the output will hold the most recent status. In

such a case, ensure that the external load does not exceed specifications. (If

operation is stopped because of an operation error (including FALS instructions), the values in the internal memory of the CPU Unit will be saved, but the

outputs will all turn OFF.)

• Always use the power supply voltage specified in the operation manuals. An

incorrect voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the rated

voltage and frequency is supplied. Be particularly careful in places where the

power supply is unstable. An incorrect power supply may result in malfunction.

• Install external breakers and take other safety measures against short-circuiting in external wiring. Insufficient safety measures against short-circuiting may

result in burning.

• Do not apply voltages to the Input Units in excess of the rated input voltage.

Excess voltages may result in burning.

• Do not apply voltages or connect loads to the Output Units in excess of the

maximum switching capacity. Excess voltage or loads may result in burning.

• Disconnect the functional ground terminal when performing withstand voltage

tests. Not disconnecting the functional ground terminal may result in burning.

• Install the Unit properly as specified in the operation manual. Improper installation of the Unit may result in malfunction.

• Be sure that all the mounting screws, terminal screws, and cable connector

screws are tightened to the torque specified in the relevant manuals. Incorrect

tightening torque may result in malfunction.

• Be sure to attach the supplied labels when wiring in order to prevent wiring cuttings from entering in the Unit.

• Remove the label after the completion of wiring to ensure proper heat dissipation. Leaving the label attached may result in malfunction.

• Use crimp terminals for wiring. Do not connect bare stranded wires directly to

terminals. Connection of bare stranded wires may result in burning.

• Double-check all the wiring before turning on the power supply. Incorrect wiring may result in burning.

5Application Precautions

xiv

Page 11

• Be sure that the terminal blocks, expansion cables, and other items with locking devices are properly locked into place. Improper locking may result in malfunction.

• Check the user program for proper execution before actually running it on the

Unit. Not checking the program may result in an unexpected operation.

• Confirm that no adverse effect will occur in the system before attempting any of

the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Resume operation only after transferring to the new CPU Unit the contents of

the DM and HR Areas required for resuming operation. Not doing so may result

in an unexpected operation.

• Do not pull on the cables or bend the cables beyond their natural limit. Doing

either of these may break the cables.

• Do not place objects on top of the cables. Doing so may break the cables.

• When replacing parts, be sure to confirm that the rating of a new part is correct.

Not doing so may result in malfunction or burning.

• Before touching the Unit, be sure to first touch a grounded metallic object in

order to discharge any static built-up. Not doing so may result in malfunction or

damage.

• Do not touch the Expansion I/O Unit Connecting Cable while the power is

being supplied in order to prevent any malfunction due to static electricity.

• When using a thermocouple-input type Temperature Sensor Unit, observe the

following precautions:

• Do not remove the cold junction compensator attached at the time of delivery. If the cold junction compensator is removed the Unit will not be able to

measure temperatures correctly.

• Each of the input circuits is calibrated with the cold junction compensator

attached to the Unit. If the Unit is used with the cold junction compensator

from other Units, the Unit will not be able to measure temperatures correctly.

• Do not touch the cold junction compensator. Doing so may result in incorrect temperature measurement.

5Application Precautions

Caution Always clear memory before beginning to program the CPM1A. Although

!

memory is cleared before the CPU Unit is shipped (except for bits with specific

functions), AR 1314, which turns ON when the internal capacitor cannot back up

memory, may have turned ON during shipment.

Caution If the CPM1A will be turned off for periods exceeding the data backup period of

!

the internal capacitor, design the system so that it will not be influenced if data in

the DM, HR, and CNT areas is cleared when power is turned off.

Caution Either switch the CPM1A to RUN or MONITOR mode, or turn off and on power to

!

the CPM1A after changing from a Programming Device any data that is backed

up in flash memory. This data includes the user program, read-only DM area

(DM 6144 to DM 6599), and the PC Setup (DM 6600 to DM 6655).

xv

Page 12

• The user program and memory area data in the CPM1A are backed up either

by an internal capacitor or in flash memory as shown in the following table.

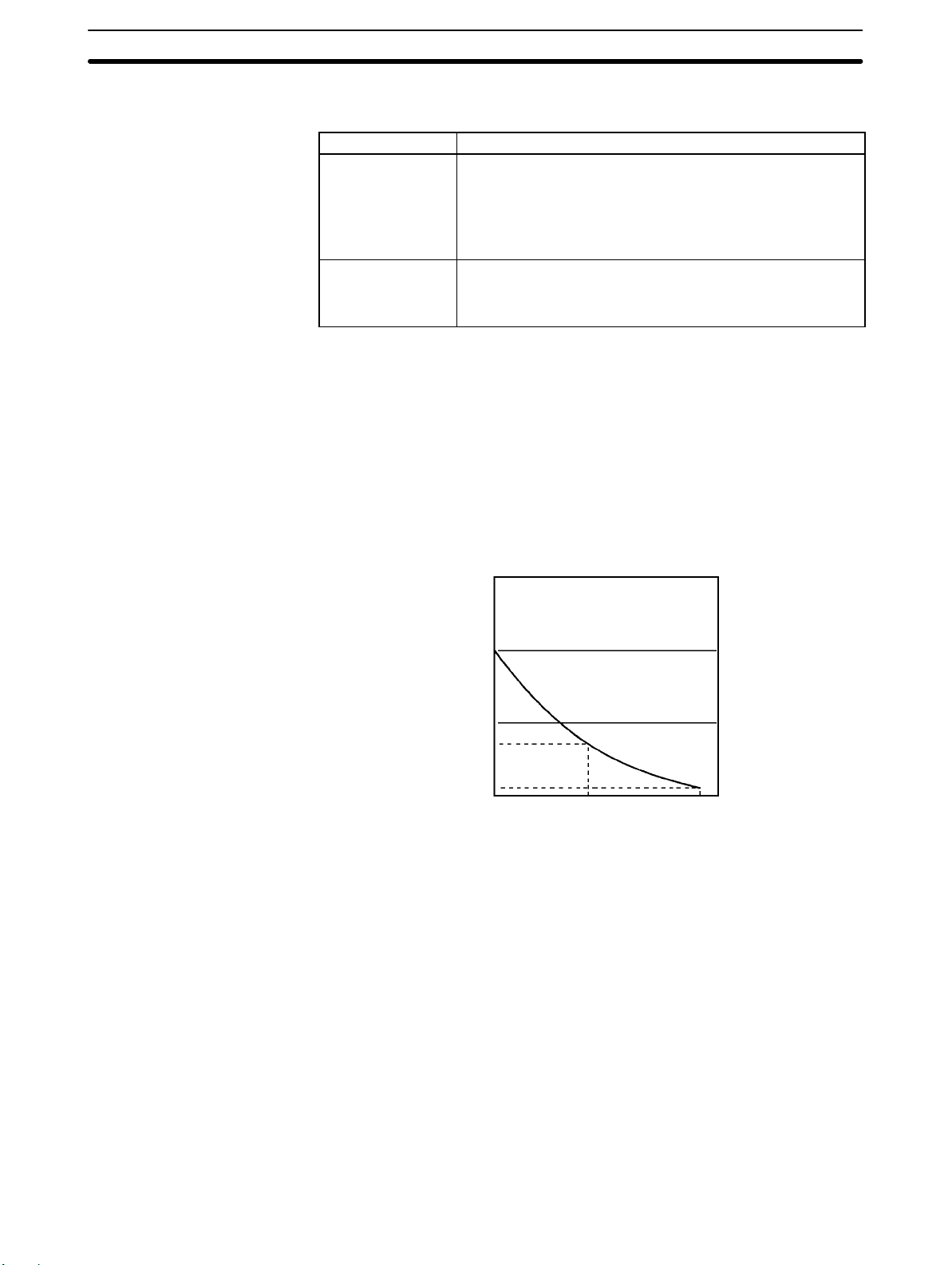

Backup method Data

Internal capacitor Read/write DM area (DM 0000 to DM 0999, DM 1022, and

DM 1023)

Error log area (DM 1000 to DM 1021)

HR area (HR 00 to HR 19)

Counter area (CNT 000 to CNT 127)

Flash memory User program

Read-only DM area (DM 6144 to DM 6599)

PC Setup (DM 6600 to DM 6655)

Note 1. The IR, TR, LR, and timer areas are not normally backed up when power is

turned off and all contents will be cleared the next time power is turned on.

(The PC Setup setting in DM 6601 can be used to back up this data. Refer to

details on the PC Setup later in this manual for details.)

2. The bits in the AR and SR areas have special functions and are set according to these functions when power is turned on.

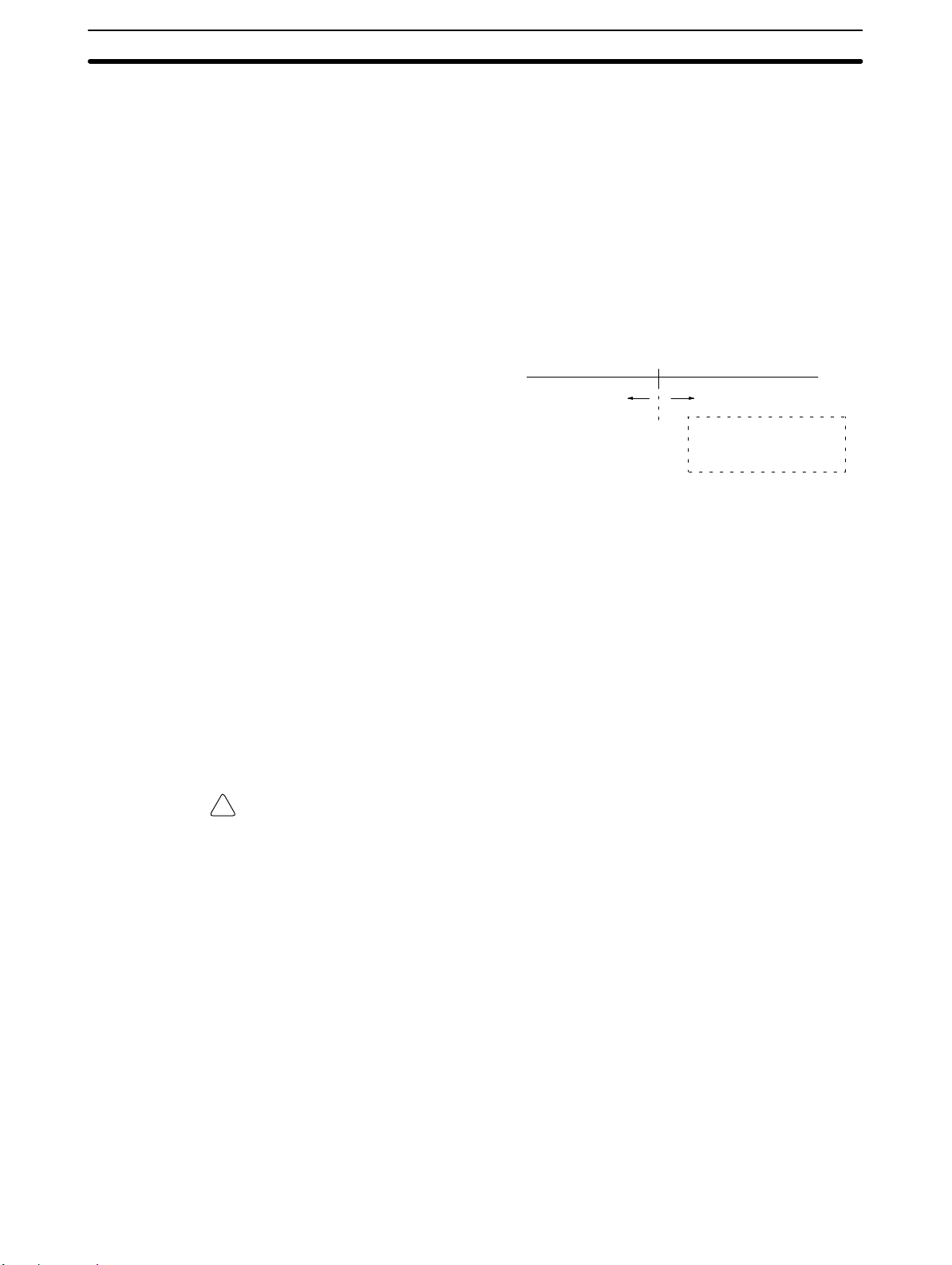

• The capacitor backup time depends on the ambient temperature, as shown in

the following graph. The backup time, however, assumes that the capacitor is

fully charged, which requires that power be supplied to the CPU Unit continuously for at least 15 minutes.

5Application Precautions

20

10

Backup time (days)

7

1

25 40 80

Ambient temperature (C)

If the power remains off for a period exceeding the data backup period,

AR 1314 will turn ON to indicate that the capacitor can no longer back up data

and the data backed up by the capacitor will be cleared. AR 1314 will remain

ON unless it is turned OFF using I/O monitor operations, using memory clear

operations, or from the user program.

If desired, the PC Setup setting in DM 6604 can be set to create a fatal error

and thus stop the system when AR 1314 goes ON.

• The data stored in flash memory will not be lost even if power remains off for a

period exceeding the data backup period, because the data stored in flash

memory will be read to the CPU Unit when the CPM1A is turned on.

• If the power is turned off without changing the mode from PROGRAM mode to

RUN or MONITOR mode after having made changes in the data that is backed

up in flash memory, the changes will not be written to flash memory. If the

power is then left off for more than 20 days (at 25C), the changes (i.e., the

contents of the RAM) will be erased and the data values will become undefined.

xvi

Page 13

6 EC Directives

6-1 Applicable Directives

• EMC Directives

• Low Voltage Directive

6-2 Concepts

EMC Directives

OMRON devices that comply with EC Directives also conform to the related

EMC standards so that they can be more easily built into other devices or the

overall machine. The actual products have been checked for conformity to EMC

standards (see the following note). Whether the products conform to the standards in the system used by the customer, however, must be checked by the

customer.

EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions of the

equipment or control panel on which the OMRON devices are installed. The customer must, therefore, perform the final check to confirm that devices and the

overall machine conform to EMC standards.

Note Applicable EMC (Electromagnetic Compatibility) standards are as follows:

5Application Precautions

EMS (Electromagnetic Susceptibility): EN61131-2

EMI (Electromagnetic Interference): EN50081-2

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 VAC and 75 to

1,500 VDC meet the required safety standards for the PC (EN61131-2).

6-3 Conformance to EC Directives

The CPM1A PCs (transistor output models) comply with EC Directives. Relay

output models do not conform to the EC Directives. To ensure that the machine

or device in which the CPM1A PC is used complies with EC directives, the PC

must be installed as follows:

1, 2, 3... 1. The CPM1A PC must be installed within a control panel.

2. Reinforced insulation or double insulation must be used for the DC power

supplies used for the communications and I/O power supplies.

3. CPM1A PCs complying with EC Directives also conform to the Common

Emission Standard (EN50081-2). Radiated emission characteristics (10-m

regulations) may vary depending on the configuration of the control panel

used, other devices connected to the control panel, wiring, and other conditions. You must therefore confirm that the overall machine or equipment

complies with EC Directives.

4. The CPM1A with relay output does not conform to the EC Directives. For

devices for use in the EC, use the CPM1, which meets the CE marking

requirements. Further information is available at any of the OMRON offices

or OMRON sales representatives listed on the inside back cover of this

manual.

(Radiated emission: 10-m regulations)

6-4 CPM1A-MAD01 Conformance to EMC Directives

Immunity testing conditions when using the current I/O of the CPM1A-MAD01

are as follows.

• Total accuracy: +10%/-1%

• Insert the following core in each line as shown below.

xvii

Page 14

Recommended core: 2643-002402

Manufacturer: Fair Rite Products Corp.

5Application Precautions

xviii

Page 15

SECTION 1

Introduction

This section describes the CPM1A’s special features and functions and shows the possible system configurations. Refer to the

Programming Manual (W353) for details on programming actual operation.

1-1 CPM1A Features and Functions 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-1 CPM1A Features 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-2 I/O Terminal and IR Bit Allocation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-3 CPM1A Functions 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 System Configuration 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-1 CPU Unit and Expansion I/O Unit Configuration 10. . . . . . . . . . . . . . . . . . . . . . . .

1-2-2 CPU Unit and Expansion Unit 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-3 Host Link Communications 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-4 One-to-one PC Link Communications 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-5 One-to-one NT Link Communications 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-6 CompoBus/S I/O Link Connections 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-7 Peripheral Device Connections 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 Revised Specifications 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

Page 16

CPM1A Features and Functions Section 1-1

1-1 CPM1A Features and Functions

1-1-1 CPM1A Features

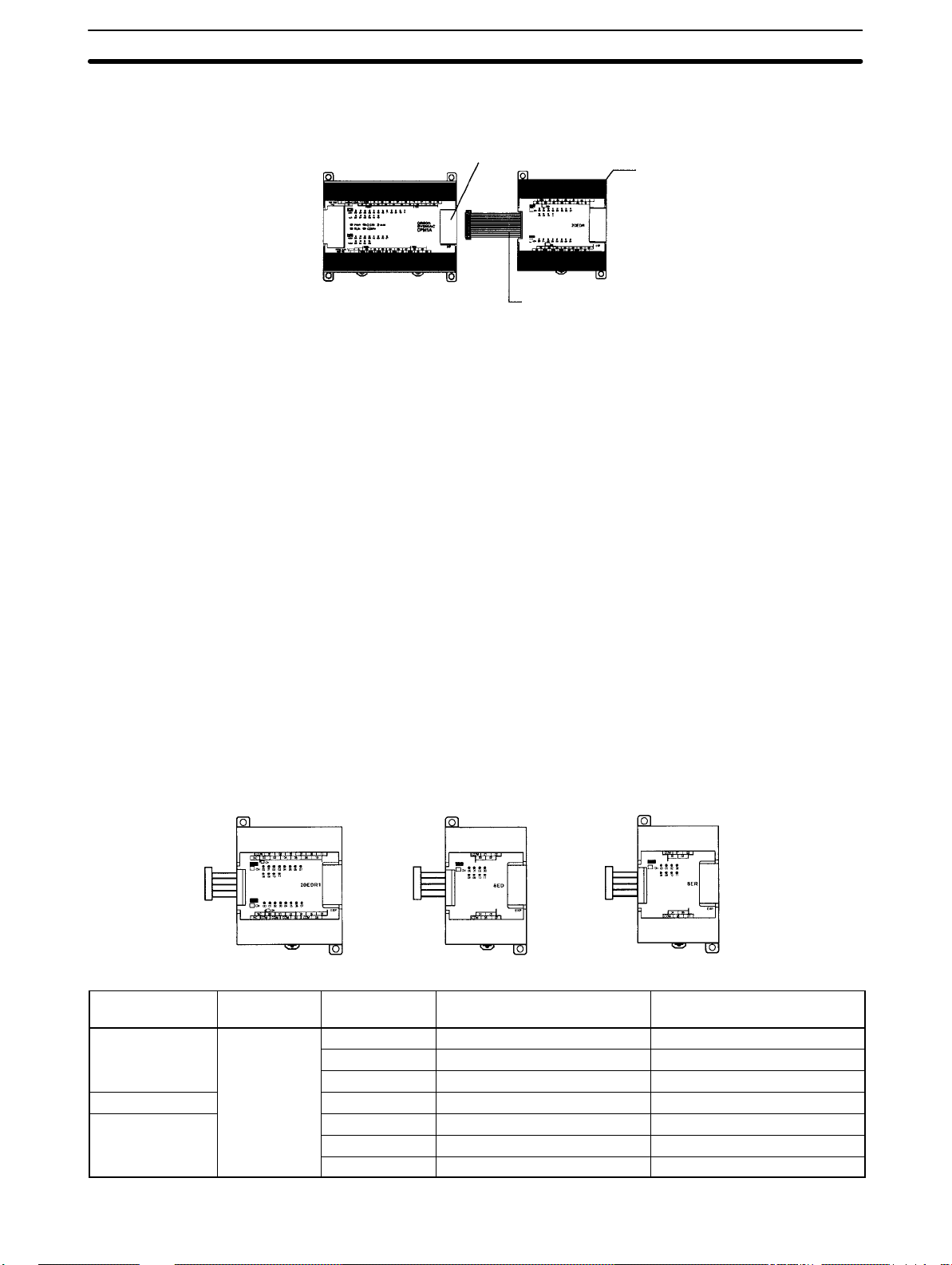

One-piece Construction The CPM1A CPU Units feature a one-piece construction including 10, 20, 30, or

40 built-in I/O terminals. The following three model groups are available: relay

output models, sink-type transistor output models, and source-type transistor

output models.

CPM1A-10CDR-/10CDT-D/10CDT1-D

(10 I/O terminals)

CPM1A-30CDR-/30CDT-D/30CDT1-D

(30 I/O terminals)

CPM1A-20CDR-/20CDT-D/20CDT1-D

(20 I/O terminals)

CPM1A-40CDR-/40CDT-D/40CDT1-D

(40 I/O terminals)

Extra I/O Capacity Up to three Expansion I/O Units can be connected to a CPM1A-30CDR-/

30CDT-D/30CDT1-D or CPM1A-40CDR-/40CDT-D/40CDT1-D CPU Unit to

add an extra 8 or 20 I/O points for each, for a maximum of up to 100 I/O points.

Input Filter Function The CPM1A is equipped with a filter function to prevent incorrect operation

caused by chatter or noise in the input signal. The user can select an input time

constant of 1 ms, 2 ms, 4 ms, 8 ms, 16 ms, 32 ms, 64 ms, or 128 ms.

Low-maintenance Design Flash memory provides memory backup without a battery.

Input Interrupts The CPM1A-10CDR-/10CDT-D/10CDT1-D CPU Units can handle 2 interrupt

inputs; the CPM1A-20CDR-/20CDT-D/20CDT1-D, CPM1A-30CDR-/

30CDT -D/30CDT1-D, and CPM1A-40CDR-/40CDT -D/40CDT1-D CPU Units

can handle 4 interrupt inputs. In addition to normal input interrupts, the CPM1A

has a counter mode that counts high-speed input signals and triggers interrupts

at fixed count multiples.

Quick-response Inputs Quick-response inputs can detect input signals with a pulse width as short as

0.2 ms regardless of their timing during the PC cycle. Quick-response inputs

and interrupt inputs use the same input terminals.

Interval Timer CPM1A PCs have a high-speed interval timer which can be set from 0.5 ms to

319,968 ms. The timer can be set to trigger a single interrupt (one-shot mode) o r

repeat scheduled interrupts (scheduled interrupt mode).

High-speed Counter CPM1A PCs have a high-speed counter that can be used in incremental mode

or up/down mode. The high-speed counter can be combined with input interrupts to perform target value control or zone comparison control that isn’t

affected by the PC’s cycle time.

Pulse Output Function The CPM1A transistor output models have an output function capable of output-

ting a pulse of 20 Hz to 2 kHz (single-phase output).

Analog Setting Function The CPM1A PCs have 2 analog volume controls that can be used to make

manual analog settings.

2

Page 17

CPM1A Features and Functions Section 1-1

Analog I/O Units

Up to 3 Analog I/O Units can be connected to provide analog inputs and outputs.

Each Unit provides 2 analog inputs and 1 analog output, so a maximum of 6 analog inputs and 3 analog outputs can be achieved by connecting 3 Analog I/O

Units.

The analog input range can be set to 0 to 1 0 VDC, 1 to 5 VDC, or 4 to 20 mA with a

resolution of 1/256. (The open-circuit detection function can be used with the 1 to

5 VDC and 4 to 20 mA settings.)

The analog output range can be set to 0 to 10 VDC, –10 to 10 VDC, or 4 to 20 mA

with a resolution of 1/256.

T emperature Sensor

Units

A Temperature Sensor Unit can be connected to provide up to 6 inputs for temperature input from sensors, such as thermocouples or platinum resistance

thermometers.

Host Link Communications The CPM1A PCs are compatible with the Host Link, which allows communica-

tions with personal computers. The CPM1A using the Host Link can also communicate with Programmable Terminal using host link commands.

An RS-232C Adapter is used for 1:1 communications and an RS-422 Adapter is

used for 1:N communications.

One-to-one PC Link A data link can be created with a data area in another CPM1A, CQM1, CPM1,

SRM1 or C200HS or C200HX/HE/HG PC. An RS-232C Adapter is used to make

the 1:1 connection.

NT Link Communications High-speed operations can be achieved by providing a direct access by con-

necting the CPM1A to the OMRON Programmable Terminal through the NT Link

Interface. An RS-232C Adapter is used for this connection.

CompoBus/S I/O Link

Units

Up to 3 CompoBus/S I/O Link Units can be connected to make the CPM1A a

Slave Device in a CompoBus/S Network. The I/O Link Unit has 8 input bits (internal) and 8 output bits (internal).

The CompoBus/S Network provides distributed CPU control based on a “PC +

compact PC” configuration, which is an improvement on the earlier distributed

I/O control based on a “PC + remote I/O” configuration. The distributed CPU

control makes equipment modular, so designs can be standardized, special

needs can be addressed, and modules can be replaced easily in the event of a

breakdown.

CompoBus/S Master Unit

Master PC

(or SRM1 CompoBus/S Master Control Unit)

CPM1A (Slave) CompoBus/S I/O Link Unit

CompoBus/S

Distributed CPU control

Standard Peripheral Devices The CPM1A uses the same Programming Consoles and SYSMAC Support

Software (SSS) as the C200H/HS, C200HX/HE/HG, CPM1, SRM1, and CQM1

PCs.

Programming is Possible

Using the PT

Programming operation is possible through the PT screen by using an OMRON

PT that has a built-in Programming Console function.

3

Page 18

CPM1A Features and Functions Section 1-1

Expansion Memory Unit

The CPM1-EMU01-V1 Expansion Memory Unit is a program loader for smallsize or micro PLCs. Using the CPM1-EMU01-V1, simple on-site transfer of user

programs and data memory is possible with PLCs.

Uploading

Downloading

EEPROM

1-1-2 I/O Terminal and IR Bit Allocation

SYSMAC

The following table shows which IR bits are allocated to the I/O terminals on the

CPM1A’s CPU Units and Expansion I/O Unit.

CPU Units

Number of I/O terminals on

the CPU Unit

Power supply AC DC AC DC AC DC AC DC

Model

number

CPU Unit

terminals

Relay output CPM1A-

Transistor

output

Sink

type

Source

type

Inputs 6 points:

Outputs 4 points:

10 20 30 40

10CDR-A

--- CPM1A-

--- CPM1A-

00000 to 00005

01000 to 01003

CPM1A10CDR-D

10CDT-D

10CDT1-D

CPM1A20CDR-A

--- CPM1A-

--- CPM1A-

12 points:

00000 to 00011

8 points:

01000 to 01007

CPM1A20CDR-D

20CDT-D

20CDT1-D

CPM1A30CDR-A

--- CPM1A-

--- CPM1A-

18 points:

00000 to 00011

00100 to 00105

12 points:

01000 to 01007

01100 to 01103

CPM1A30CDR-D

30CDT-D

30CDT1-D

CPM1A40CDR-A

--- CPM1A-

--- CPM1A-

24 points:

00000 to 00011

00100 to 00111

16 points:

01000 to 01007

01100 to 01107

Expansion I/O Units

CPM1A40CDR-D

40CDT-D

40CDT1-D

Unit I/O Relay output

Transistor output

Sink type Source type

20 I/O

points

12 inputs

8 outputs

CPM1A-20EDR

CPM1A-20EDR1

CPM1A-20EDT CPM1A-20EDT1

8 inputs 8 inputs CPM1A-8ED

8 outputs 8 outputs CPM1A-8ER CPM1A-8ET CPM1A-8ET1

4

Page 19

CPM1A Features and Functions Section 1-1

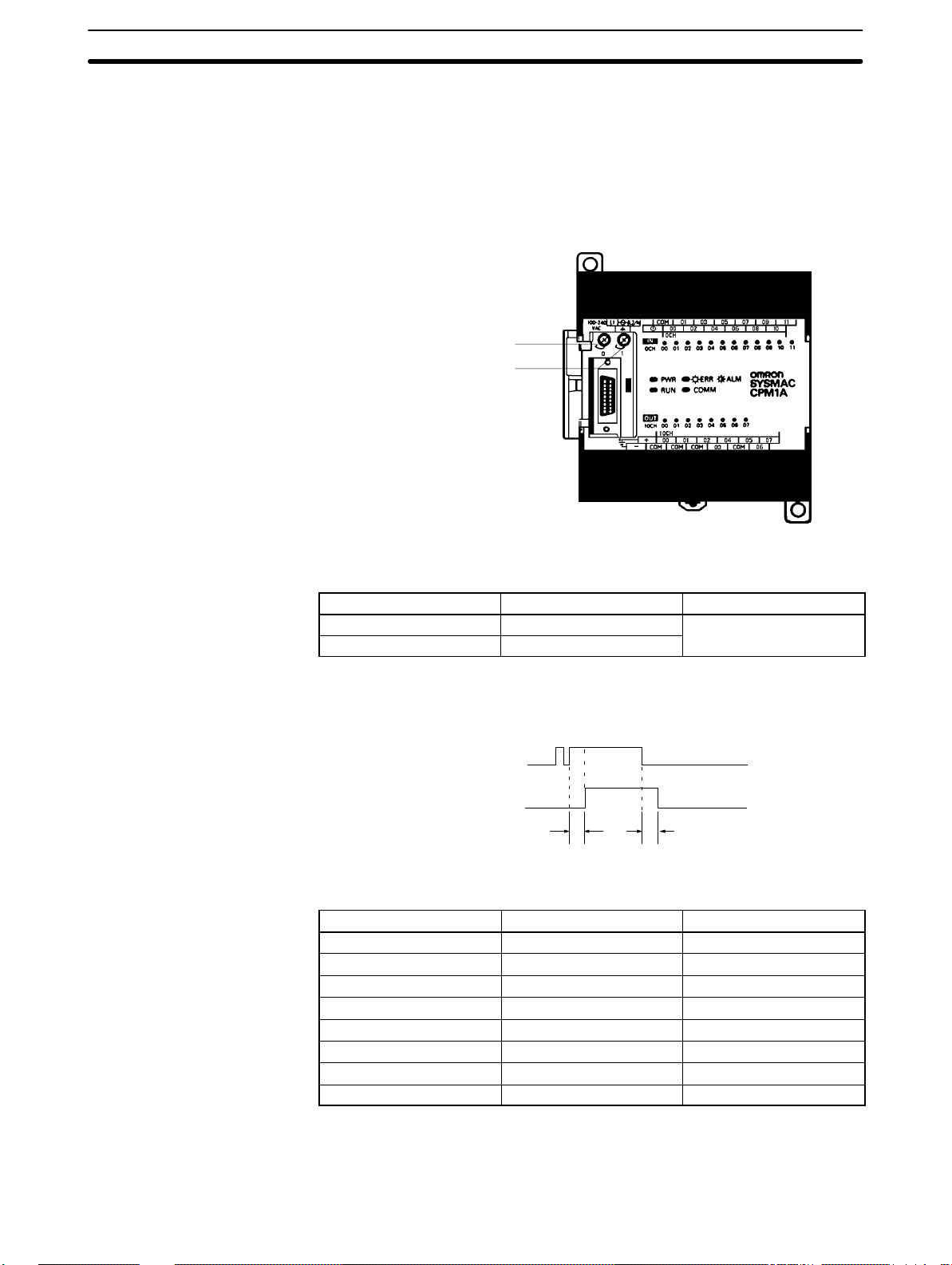

1-1-3 CPM1A Functions

Analog Setting Function CPM1A PCs have 2 variable-resistor adjustment knobs used to control analog

timer and counter settings manually. When one of the adjustments is turned, the

content of the corresponding IR word is set automatically between 0 and 200

(BCD).

Turn the adjustment knob with a Phillips screwdriver.

Analog adjustment 0

Analog adjustment 1

24 VDC 0.2 A

OUT PUT

The following table shows which IR words are allocated to the analog adjustments on the CPM1A’s CPU Unit.

Control Corresponding IR word Setting range (BCD)

Analog adjustment 0 IR 250

Analog adjustment 1 IR 251

0000 to 0200

Input Filter Function The input time constant for the CPM1A’s external inputs can be set to 1, 2, 4, 8,

16, 32, 64, or 128 ms. Increasing the input time constant can reduce the effects

of chatter or noise in the input signal.

Input from an input device

such as a limit switch

Input bit status

t

t

Input time constant

With the CPM1A, actual response time for each set input time constant for word

000 is different from that for word 001 or later.

Set value Word 000 Word 001 or later

1 ms 1 to 1.5 ms 0.1 to 0.3 ms

2 ms 2 to 2.5 ms 0.7 to 1.5 ms

4 ms 4 to 4.5 ms 1.5 to 2.5 ms

8 ms 8 to 8.5 ms 3 to 4.5 ms

16 ms 16 to 16.5 ms 6 to 9 ms

32 ms 32 to 32.5 ms 12 to 18 ms

64 ms 64 to 64.5 ms 24 to 35 ms

128 ms 128 to 128.5 ms 50 to 70 ms

The input response time of the CPM1A is obtained with the following:

2 ms max. (hardware performance) + input time constant (see above table)

+ cycle time

5

Page 20

CPM1A Features and Functions Section 1-1

Input Interrupts The CPM1A-10CDR-/10CDT -D/10CDT1-D PCs have 2 interrupt input termi-

nals and the CPM1A-20CDR-/20CDT-D/20CDT1-D, CPM1A-30CDR-/

30CDT-D/30CDT1-D, and CPM1A-40CDR-/40CDT-D/40CDT1-D PCs have

4 interrupt input terminals. There are two modes for input interrupts: input interrupt mode and counter mode.

1, 2, 3... 1. When a n interrupt occurs in Input Interrupt Mode, the main program is inter-

rupted and the interrupt program is executed immediately , regardless of the

cycle time.

2. In Counter Mode, external input signals are counted at high speed (up to

1 kHz) and an interrupt is generated each time the count reaches the set

value. When an interrupt occurs, the main program is interrupted and the

interrupt program is executed. The set value can be set from 0 to 65,535.

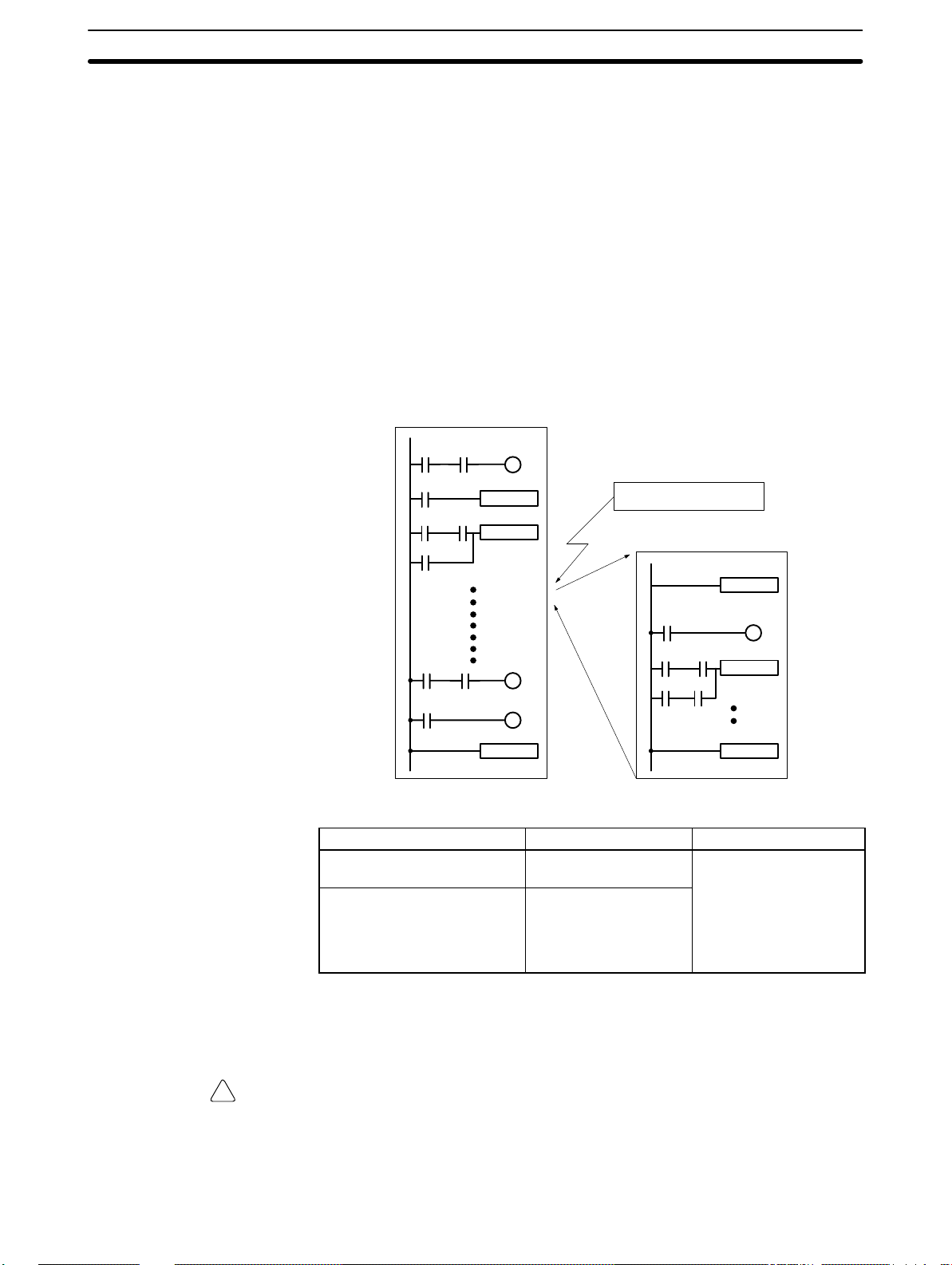

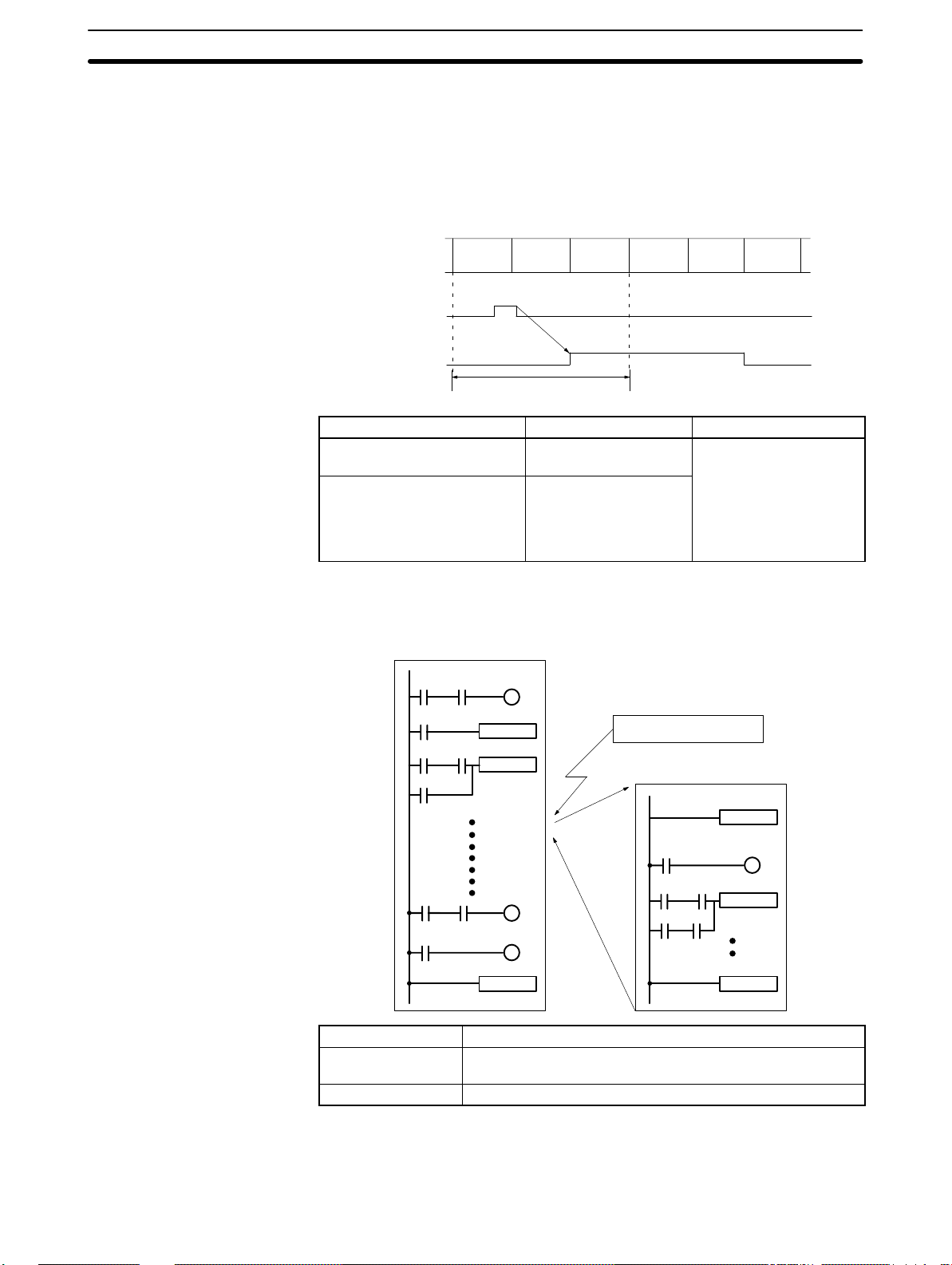

The following diagram shows the program execution when an interrupt occurs.

Main program

MOV

ADD

END

PC model Input bits Response time

CPM1A-10CDR-/10CDT-D/

10CDT1-D

CPM1A-20CDR-/20CDT-D/

20CDT1-D/30CDR-/

30CDT-D/30CDT1-D/

40CDR-/40CDT-D/

40CDT1-D

Input interrupt

Interrupt program

IR 00003 to IR 00004

IR 00003 to IR 00006

SBN00

MOV

RET

0.3 ms

(1 kHz in Counter Mode)

Note When not using as interrupt input terminals, the input bits IR 00003 to IR 00006

can be used as normal input terminals.

Caution Although IORF(97) can be used in interrupt subroutines, you must be careful of

!

the interval between IORF(97) executions. If IORF(97) is executed too frequently, a fatal system error may occur (FALS 9F), stopping operation. The interval

between executions of IORF(97) should be at least 1.3 ms + total execution time

of the interrupt subroutine.

6

Page 21

CPM1A Features and Functions Section 1-1

Quick-response Inputs The CPM1A-10CDR-/10CDT -D/10CDT1-D PCs have 2 quick-response input

terminals and the CPM1A-20CDR-/20CDT-D/20CDT1-D, CPM1A30CDR-/30CDT-D/30CDT1-D and CPM1A-40CDR-/40CDT-D/40CDT1-D

PCs have 4 quick-response input terminals. (The same terminals are used for

quick-response inputs and interrupt inputs.)

Quick-response inputs have an internal buffer, so input signals shorter than one

cycle can be detected.

Interval Timer Function

(Scheduled Interrupts)

Input signal

(00003)

IR 00003

Overseeing

processes

Program

execution

One cycle

I/O

refreshing

Overseeing

processes

Program

execution

I/O

refreshing

PC model Input bits Min. input pulse width

CPM1A-10CDR-/10CDT-D/

IR 00003 to IR 00004

0.2 ms

10CDT1-D

CPM1A-20CDR-/20CDT-D/

IR 00003 to IR 00006

20CDT1-D/30CDR-/

30CDT-D/30CDT1-D/

40CDR-/40CDT-D/

40CDT1-D

CPM1A PCs are equipped with an interval timer which can be set from 0.5 ms to

319,968 ms in units of 0.1 ms. The timer can be set to trigger a single interrupt

(one-shot mode) or to trigger scheduled interrupts (scheduled interrupt mode).

Main program

MOV

ADD

END

Interval timer time-out

Interrupt program

SBN00

MOV

RET

Mode Function

One-shot Generates a single interrupt the first time that the timer times

out.

Scheduled interrupt Generates an interrupt each time that the timer times out.

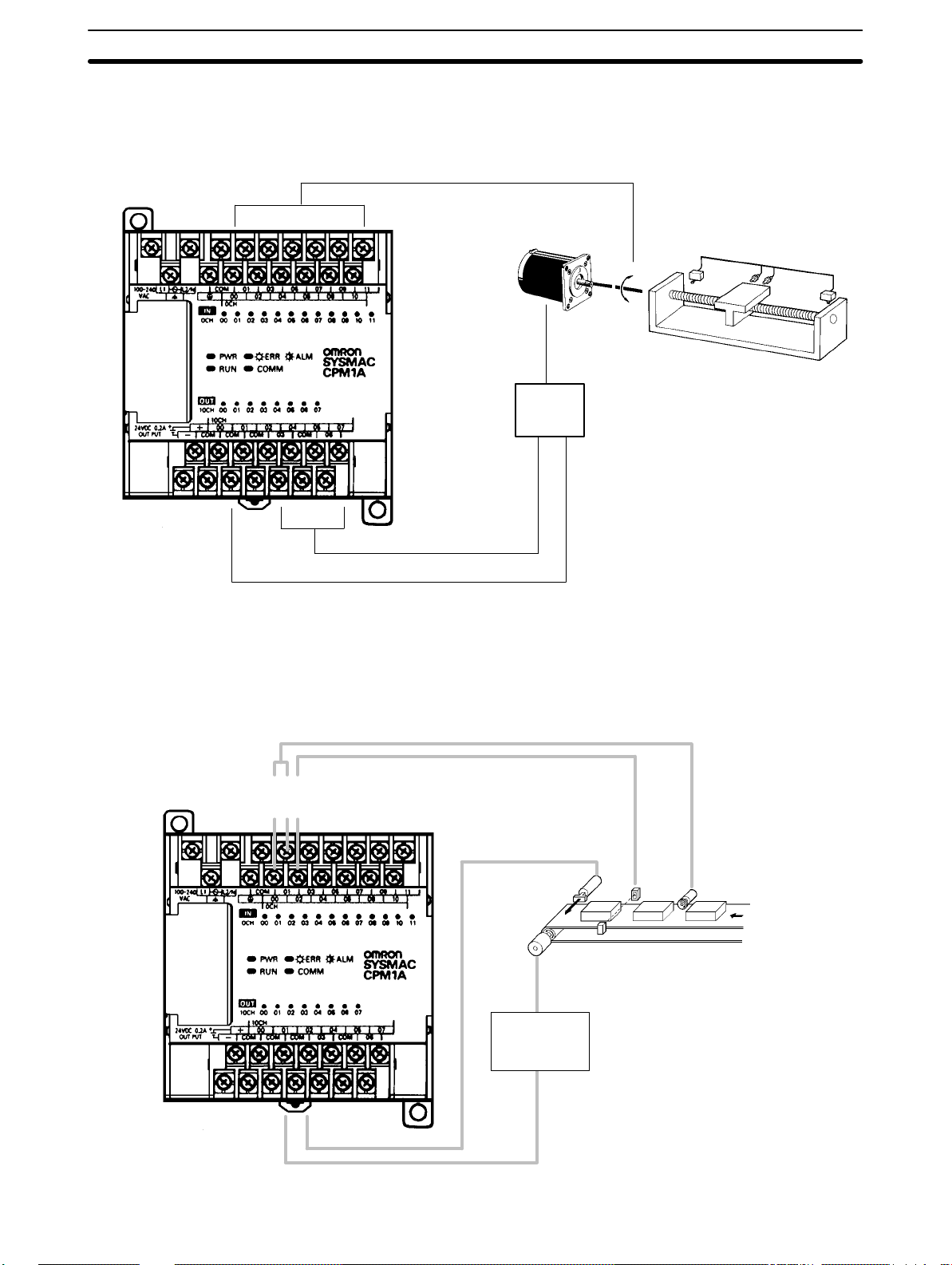

Pulse Output Function Since the CPM1A with transistor output has a pulse output function capable of

outputting a pulse of 20 Hz to 2kHz (single-phase output), a stepping motor can

be controlled by the CPU Unit alone.

7

Page 22

CPM1A Features and Functions Section 1-1

The pulse output can be set to either the continuous mode, under which the output can be stopped by an instruction, or the single mode, under which the output

can be stopped by the preset pulse rate (1 to 16,777,215).

Stepping motor

Pulse output

(single-phase output)

Stepping motor

Motor

controller

CW/CCW control output

Control input

High-speed Counter CPM1A PCs have a high-speed counter that can be used in incremental mode

or up/down mode. The high-speed counter can be combined with input interrupts to perform target value control or zone comparison control that isn’t

affected by the PC’s cycle time.

00000

00001

Count input

Reset input

00002

Solenoid

Sensor Rotary encoder

Motor

controller

8

Page 23

CPM1A Features and Functions Section 1-1

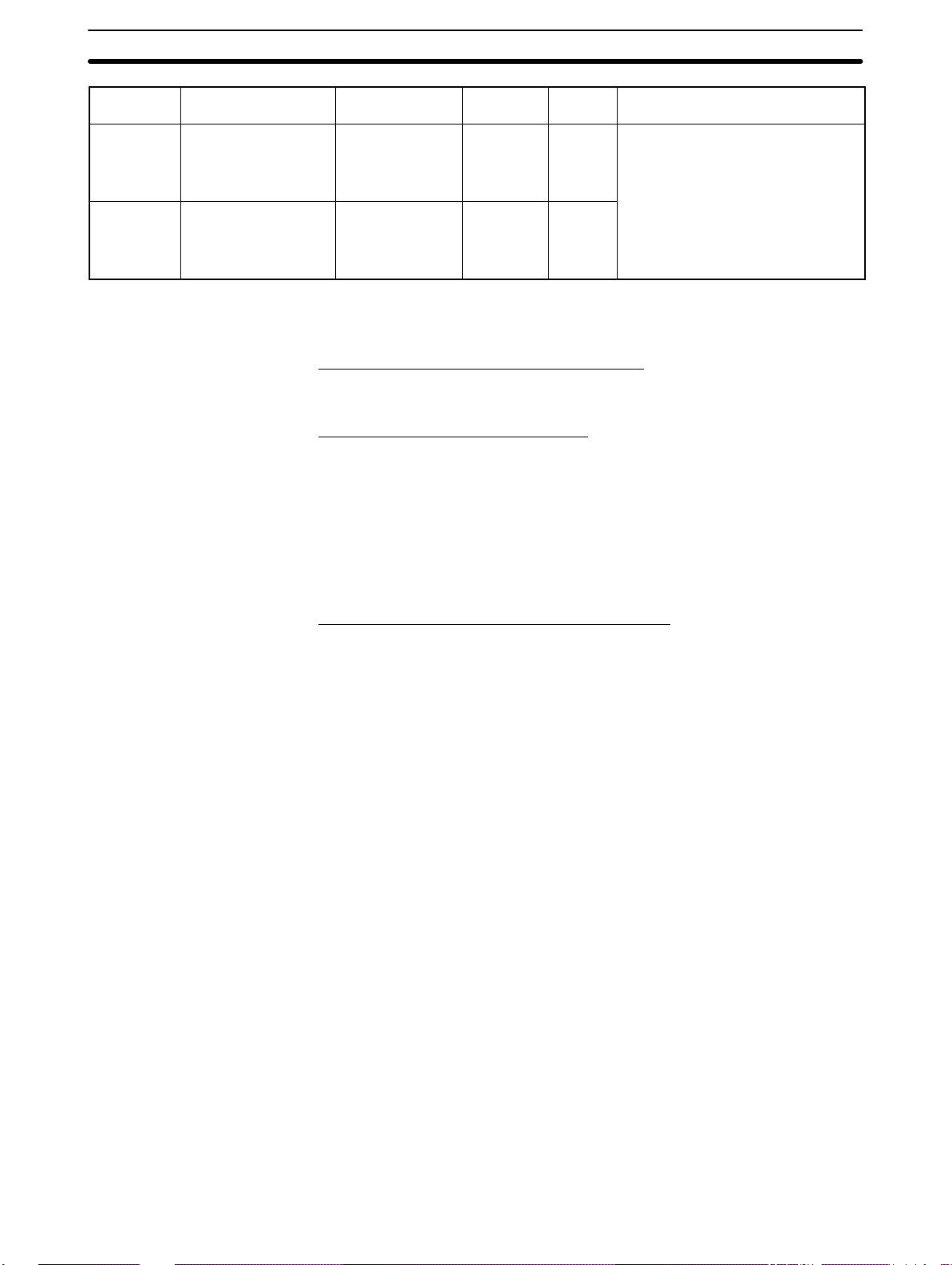

Mode Input functions Input method Count

Up/Down 00000: A-phase input

00001: B-phase input

00002: Z-phase input

Incremental 00000: Count input

00001: See note.

00002: Reset input

Phase-difference,

4× inputs

Individual inputs 5.0 kHz 0

Note In incremental mode, this input (00001) can be used as an regular input.

Expansion Unit Functions

Analog I/O Unit Functions (CPM1A-MAD01)

Two analog inputs: input range 0 to 10 V, 1 to 5 V, or 4 to 20 mA

One analog output: output range 0 to 10 V, –10 to 10 V, or 4 to 20 mA

Temperature Sensor Unit Functions

Thermocouple input (CPM1A-TS001/002; 2/4 input points):

K: –200° to 1,300°C (–300° to 2,300°F)

0.0° to 500.0°C (0.0° to 900.0°F)

J: –100° to 850°C (–100° to 1,500°F)

0.0° to 400.0°C (0.0° to 750.0°F)

Platinum resistance thermometer input (CPM1A-TS101/102; 2/4 input points):

Pt100: –200.0° to 650.0°C (–300.0° to 1,200.0°F)

JPt100:–200.0° to 650.0°C (–300.0° to 1,200.0°F)

frequency

2.5 kHz –32767

Count

range

to

32767

to

65535

Control methods

Target value control:

Up to 16 target values and interrupt

subroutine numbers can be

registered.

Zone comparison control:

Up to 8 sets of upper limit values,

lower limit values, and interrupt

subroutine numbers can be

registered.

CompoBus/S Slave Functions (CPM1A-SRT21)

Exchanges 8 input bits and 8 output bits of data with the Master Unit.

9

Page 24

System Configuration

1-2 System Configuration

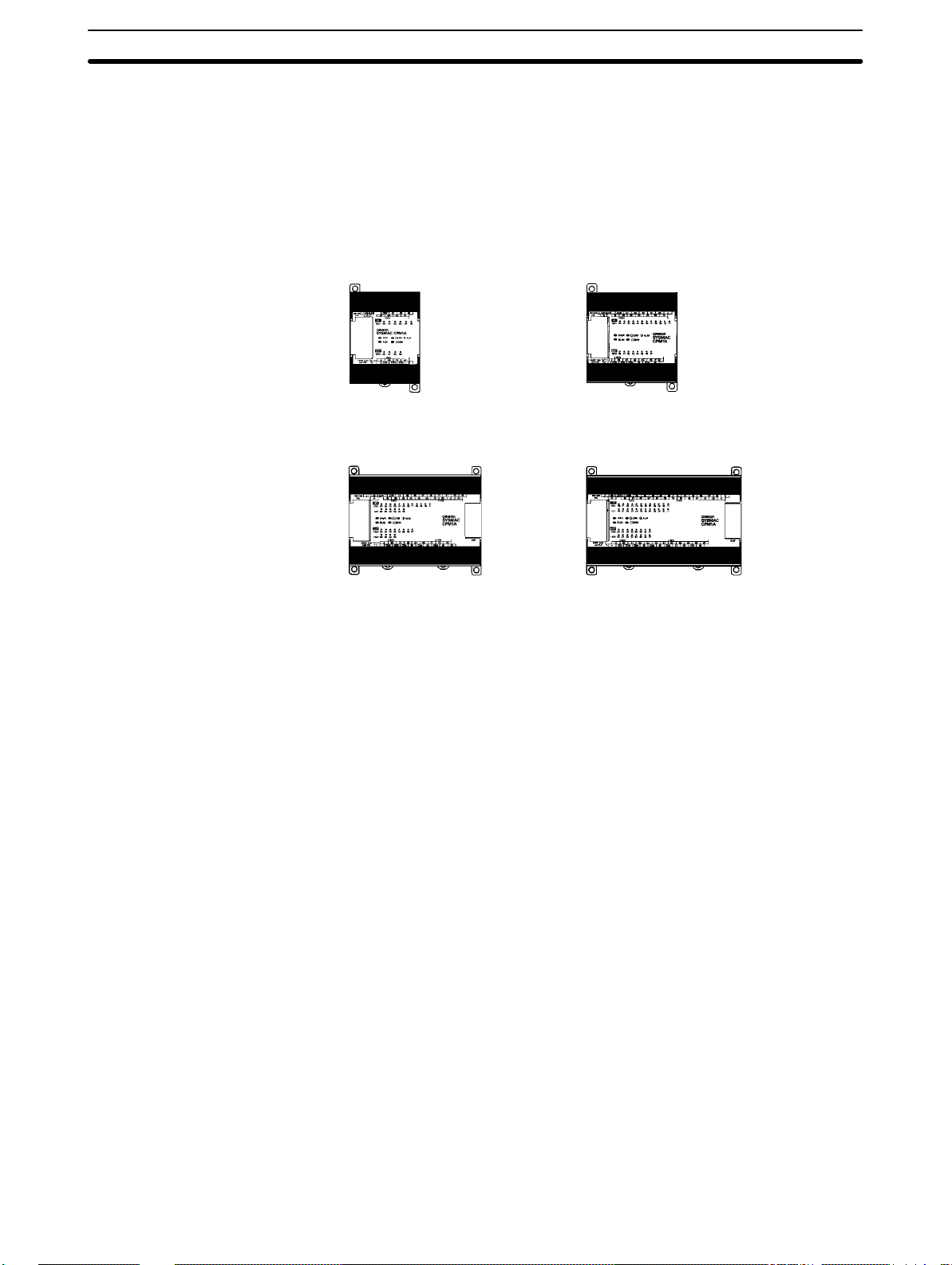

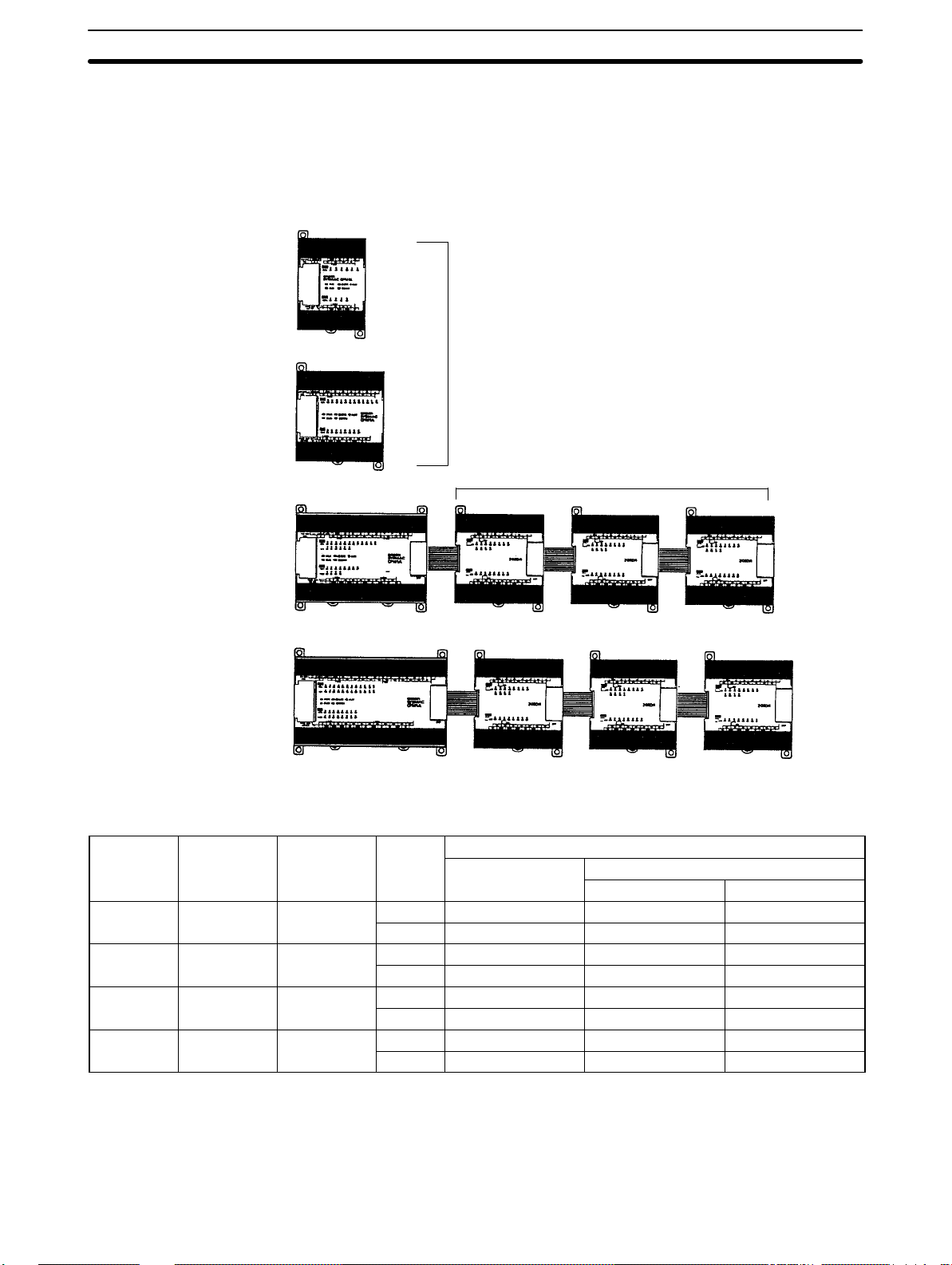

1-2-1 CPU Unit and Expansion I/O Unit Configuration

CPM1A CPU Units

10 I/O points

CPM1A-10CDR-

CPM1A-10CDT-D

CPM1A-10CDT1-D

Not possible to add Expansion I/O Units

or Expansion Units.

20 I/O points

CPM1A-20CDR-

CPM1A-20CDT-D

CPM1A-20CDT1-D

Expansion I/O Units/Expansion Units

Section 1-2

30 I/O points

CPM1A-30CDR-

CPM1A-30CDT-D

CPM1A-30CDT1-D

40 I/O points

CPM1A-40CDR-

CPM1A-40CDT-D

CPM1A-40CDT1-D

CPM1A CPU Units

Number of Inputs Outputs Power

I/O supply

terminals

10 6 points 4 points

20 12 points 8 points

30 18 points 12 points

40 24 points 16 points

AC CPM1A-10CDR-A --- --DC CPM1A-10CDR-D CPM1A-10CDT-D CPM1A-10CDT1-D

AC CPM1A-20CDR-A --- --DC CPM1A-20CDR-D CPM1A-20CDT-D CPM1A-20CDT1-D

AC CPM1A-30CDR-A --- --DC CPM1A-30CDR-D CPM1A-30CDT-D CPM1A-30CDT1-D

AC CPM1A-40CDR-A --- --DC CPM1A-40CDR-D CPM1A-40CDT-D CPM1A-40CDT1-D

Relay output

Model number

Transistor output

Sink type Source type

1-2-2 CPU Unit and Expansion Unit

Up to 3 Expansion I/O Units or Expansion Units can be connected to a CPU Unit

with 30 or 40 I/O points.

10

Page 25

System Configuration

Section 1-2

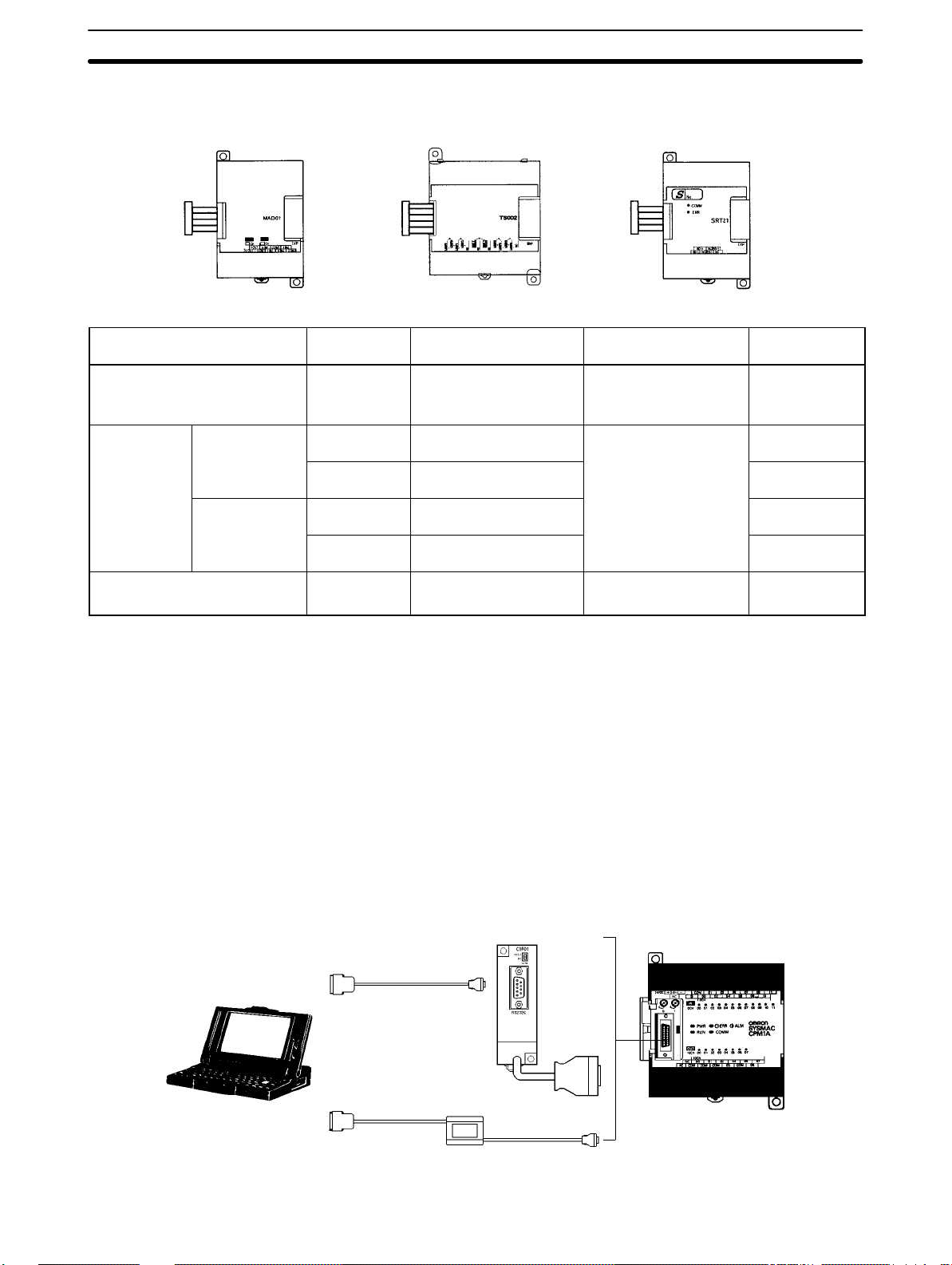

There are three models of Expansion Units available: the Analog I/O Unit, CompoBus/S I/O Link Unit, and Temperature Sensor Units.

Expansion Connector

Expansion I/O Connecting Cable

Expansion I/O Unit, Analog I/O Unit,

CompoBus/S I/O Link Unit, or Temperature Sensor Unit)

A PC with 100 I/O points (the maximum) can be assembled by connecting three

Expansion I/O Units.

CPM1A-40CDR-A

(24 inputs, 16 outputs)

× 1 Unit + × 3 Units = 60 inputs, 40 outputs

CPM1A-20EDR1

(12 inputs, 8 outputs)

A PC with 6 analog inputs and 3 analog outputs (the maximum) can be assembled by connecting three Analog I/O Units.

A PC with up to 6 temperature inputs for input from thermocouples or platinum

resistance thermometers can be assembled by connecting Temperature Sensor

Units.

CompoBus/S I/O Link Units (Slave Units) can be connected to a CPU Unit. I/O

data (8 inputs and 8 outputs) is transferred between the CPU Unit and the area

allocated to the CompoBus/S Slave. (The I/O data exchanged with the Slave is

internal data; there are no external input or output terminals.)

Note Different types of Expansion Units can be connected at the same time. For ex-

ample, an Expansion I/O Unit, Analog I/O Unit, and CompoBus/S I/O Link Unit,

or an Expansion I/O Unit, Analog I/O Unit, and Temperature Sensor Unit can be

connected to the CPU Unit.

Expansion I/O Units

8-point Input Unit 8-point Output Unit20-point I/O Unit

Unit Max. number

20 I/O points 3 Units max.

12 inputs

12 inputs

8 outputs

8 inputs 24 VDC --- CPM1A-8ED

8 outputs

of Units

(See note.)

Inputs Outputs Model

24 VDC Relays CPM1A-20EDR1

24 VDC Sinking transistors CPM1A-20EDT

24 VDC Sourcing transistors CPM1A-20EDT1

--- Relays CPM1A-8ER

--- Sinking Transistors CPM1A-8ET

--- Sourcing Transistors CPM1A-8ET1

11

Page 26

System Configuration

Expansion Units

Section 1-2

Temperature Sensor Unit CompoBus/S I/O Link UnitAnalog I/O Unit

Unit Max. number

Analog I/O Unit

2 analog inputs (2 words)

1 analog output (1 word)

Temperature

Sensor Unit

CompoBus/S I/O Link Unit

8 inputs and 8 outputs

Thermocouple

inputs

Platinum

resistance

thermometer

inputs

of Units

3 Units max. 2 analog inputs 1 analog output CPM1A-MAD01

3 Units max. 2 inputs (K, J)

1 Unit max.

(See note.)

3 Units max. 2 inputs (Pt100, JPt100) CPM1A-TS101

1 Unit max.

(See note.)

3 Units max. 8 bits

4 inputs (K, J) CPM1A-TS002

4 inputs (Pt100, JPt100) CPM1A-TS102

(Inputs from the Master.)

Note Only one CPM1A-TS002/TS102 Temperature Sensor Unit can be connected to

the CPU Unit. If a CPM1A-TS002/102 is connected to the CPU Unit, only one

additional Expansion Unit (other than a CPM1A-TS002/102) or one Expansion

I/O Unit can be connected to the CPU Unit.

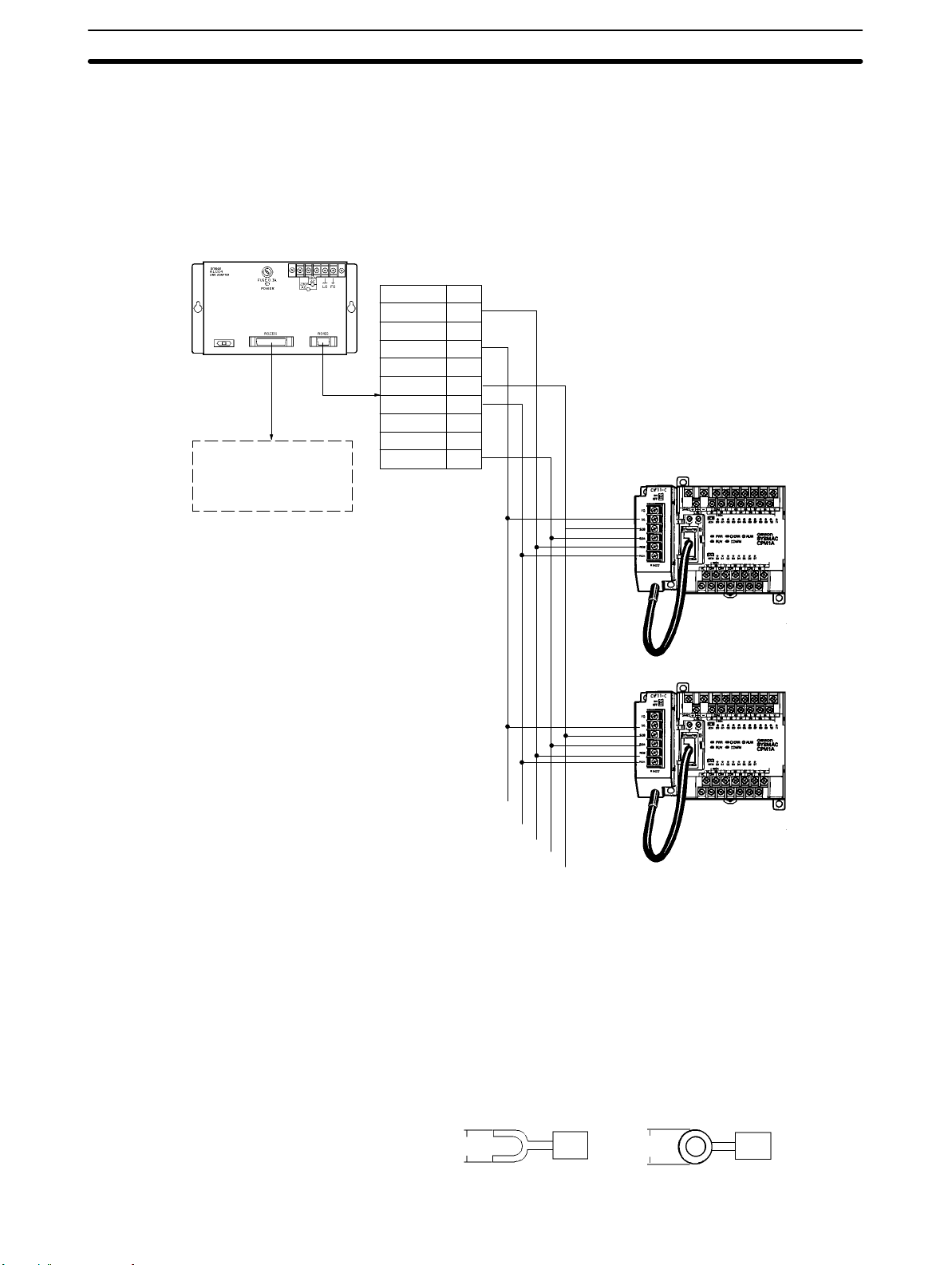

1-2-3 Host Link Communications

Host Link communications which allows up to 32 OMRON PCs to be controlled

from a host computer. The computer-PC connections can be made connectors

such as RS-232C and RS-422 Adapters.

Inputs Outputs Model

---

8 bits

(Outputs to the Master.)

CPM1A-TS001

CPM1A-SRT21

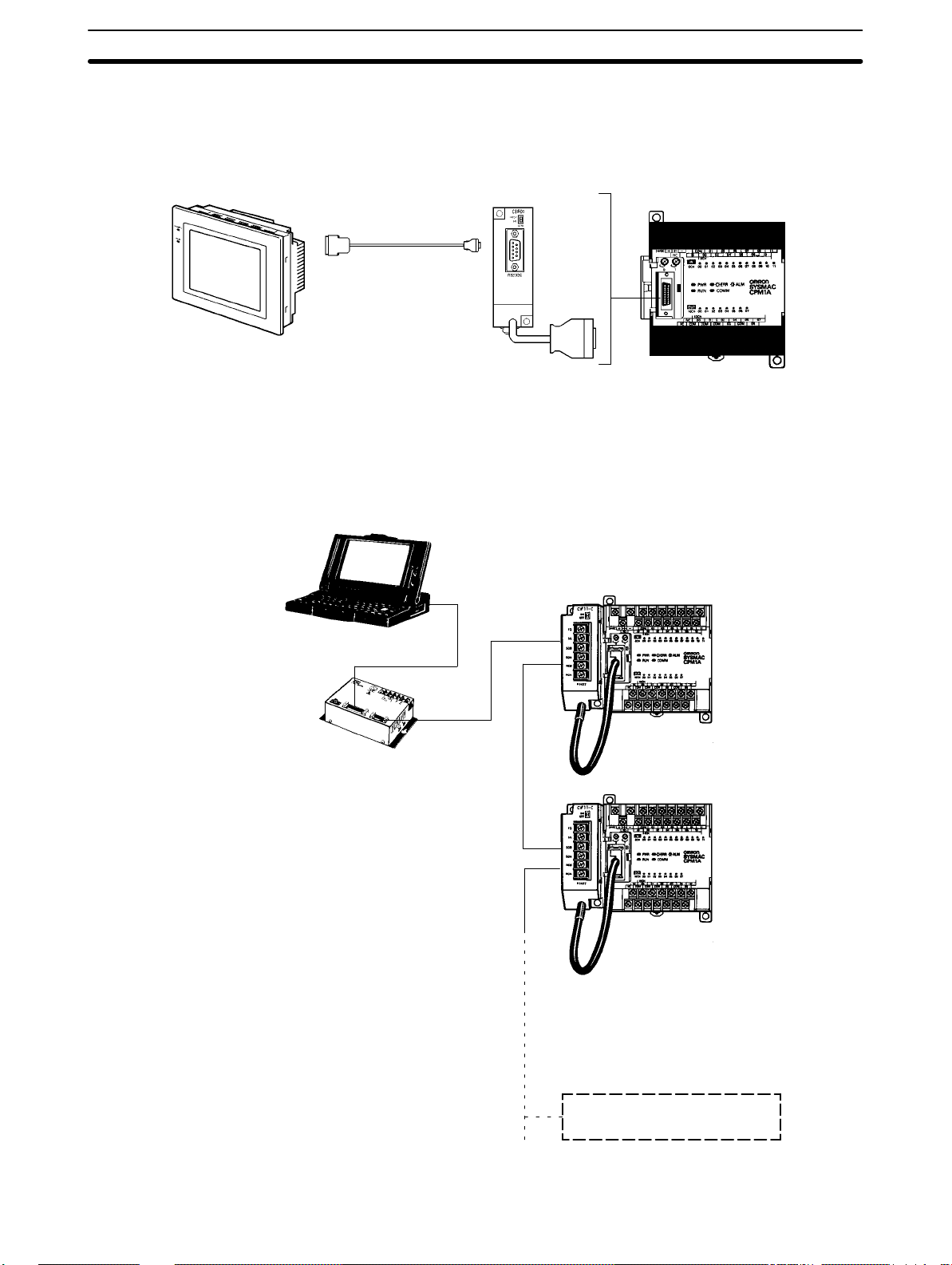

One-to-one Communications The following diagram shows the possible methods for a 1:1 connection

between a CPM1A and an IBM PC/AT or compatible computer.

IBM PC/AT or

compatible

RS-232C Adapter

RS-232C Cable

CQM1-CIF02

CPM1A CPU Unit

12

Page 27

System Configuration

Section 1-2

Connecting to a

Programmable Terminal

The following diagram shows the possible methods for a connection between a

CPM1A PC and an OMRON Programmable Terminal (a operator interface

device).

OMRON Programmable Terminal

RS-232C Cable

RS-232C Adapter

CPM1A CPU Unit

One-to-N Communications The following diagram shows how to connect up to 32 CPM1A PCs to an IBM

PC/AT or compatible computer.

IBM PC/AT or compatible

3G2A9-AL004-E

Link Adapter

RS-232C Cable

RS-422 Cable

Adapters

CPM1A CPU UnitsRS-422

The maximum cable length of RS-422 should be 500 m.

OMRON CPM1A PCs

(32 PCs max.)

13

Page 28

System Configuration

Section 1-2

Adapters and Cables The following table lists some of the Adapters and Cables used in Host Link com-

munications.

Name Usage Model number

RS-232C Adapter

RS-422 Adapter

Connecting Cables Used to connect IBM PC/AT or

Link Adapter Converts between the RS-232C and

Converts to peripheral port-level

communications.

compatible computers.

(Cable length: 3.3 m)

RS-422 formats.

CPM1-CIF01

CPM1-CIF11

CQM1-CIF02

3G2A9-AL004-E

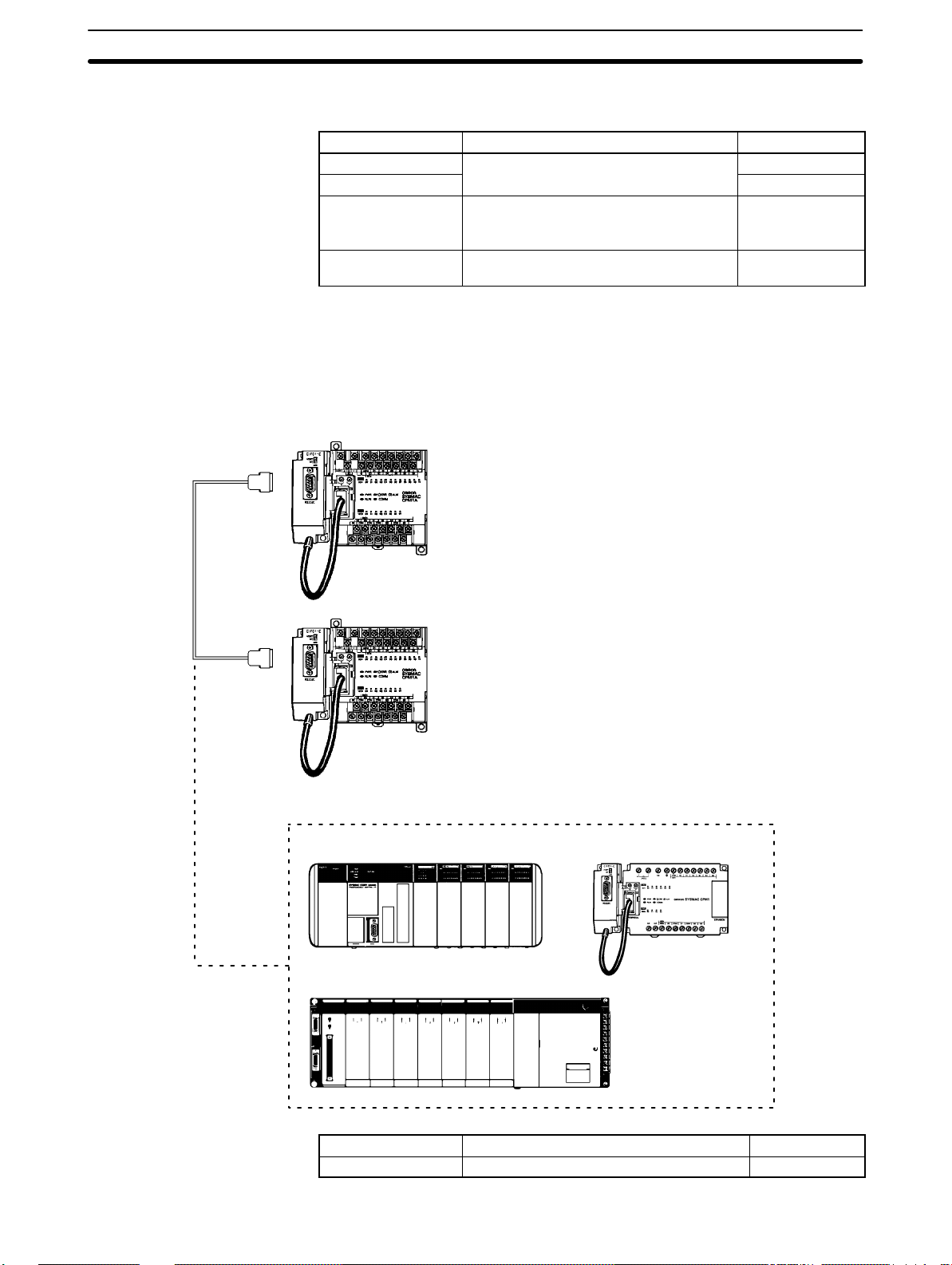

1-2-4 One-to-one PC Link Communications

A data link can be created with a data area in another CPM1A, CQM1, CPM1,

CPM2A, CPM2C, SRM1(-V2) or C200HS PC or a C200HX/HE/HG PC. An

RS-232C Adapter must be used to make the 1:1 connection.

CPM1A CPU UnitsRS-232C Adapters

RS-232C Cable

14

CQM1 CPM1 + RS-232C Adapter

C200HS/C200HX/HG/HE

Name Usage Model number

RS-232C Adapter Converts to the Peripheral Port format. CPM1-CIF01

Page 29

System Configuration

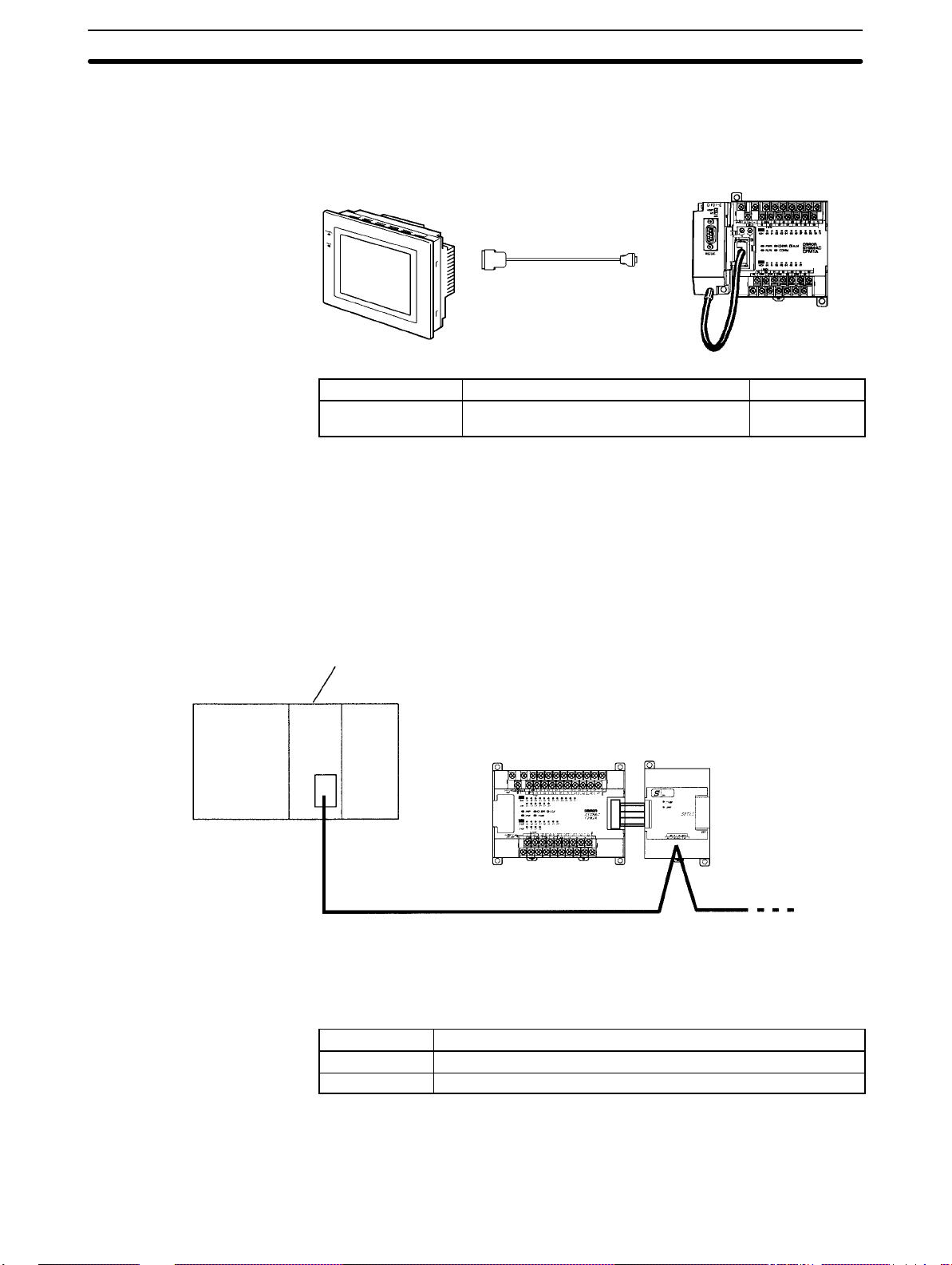

1-2-5 One-to-one NT Link Communications

Using the NT Link, the CPM1A PC can connected to the Programmable Terminal (NT Link Interface) through an RS-232C Adapter.

Section 1-2

OMRON Programmable Terminal

Name Usage Model number

RS-232C Adapter Converts to peripheral port-level

communications.

1-2-6 CompoBus/S I/O Link Connections

A CompoBus/S I/O Link can be used to create an I/O link (remote I/O) of 8 input

points and 8 output points with a CompoBus/S Master Unit or SRM1 PC. The

connection is made through a CompoBus/S I/O Link Unit.

From the standpoint of the CPM1A CPU Unit, the area allocated to the CompoBus/S I/O Link Unit can be treated just like the area allocated to an Expansion I/O

Unit. The difference is that the bits are not actual I/O points, but I/O bits in the

Master Unit.

RS-232C Cable

WX2Z-200T (2 m)

WX2Z-500T (5 m)

RS-232C

Adapter

CPM1A CPU Unit

CPM1-CIF01

SYSMAC CS1-series PC

CompoBus/S Master Unit (or SRM1 PC)

CPM1A CPU Unit

CompoBus/S I/O Link Unit

(Slave)

Cables

Use special flat cable or VCTF cable to connect the nodes in the CompoBus/S

I/O Link. (Special flat cables and VCTF cables cannot be combined in the same

system.)

Name Specifications

Flat cable 4-core flat cable, 0.75 mm

VCTF cable 2-core x 0.75 mm

2

2

1-2-7 Peripheral Device Connections

CPM1A programs can be created or edited with a Programming Console or a

personal computer running SYSMAC Support Software (SSS).

15

Page 30

System Configuration

Section 1-2

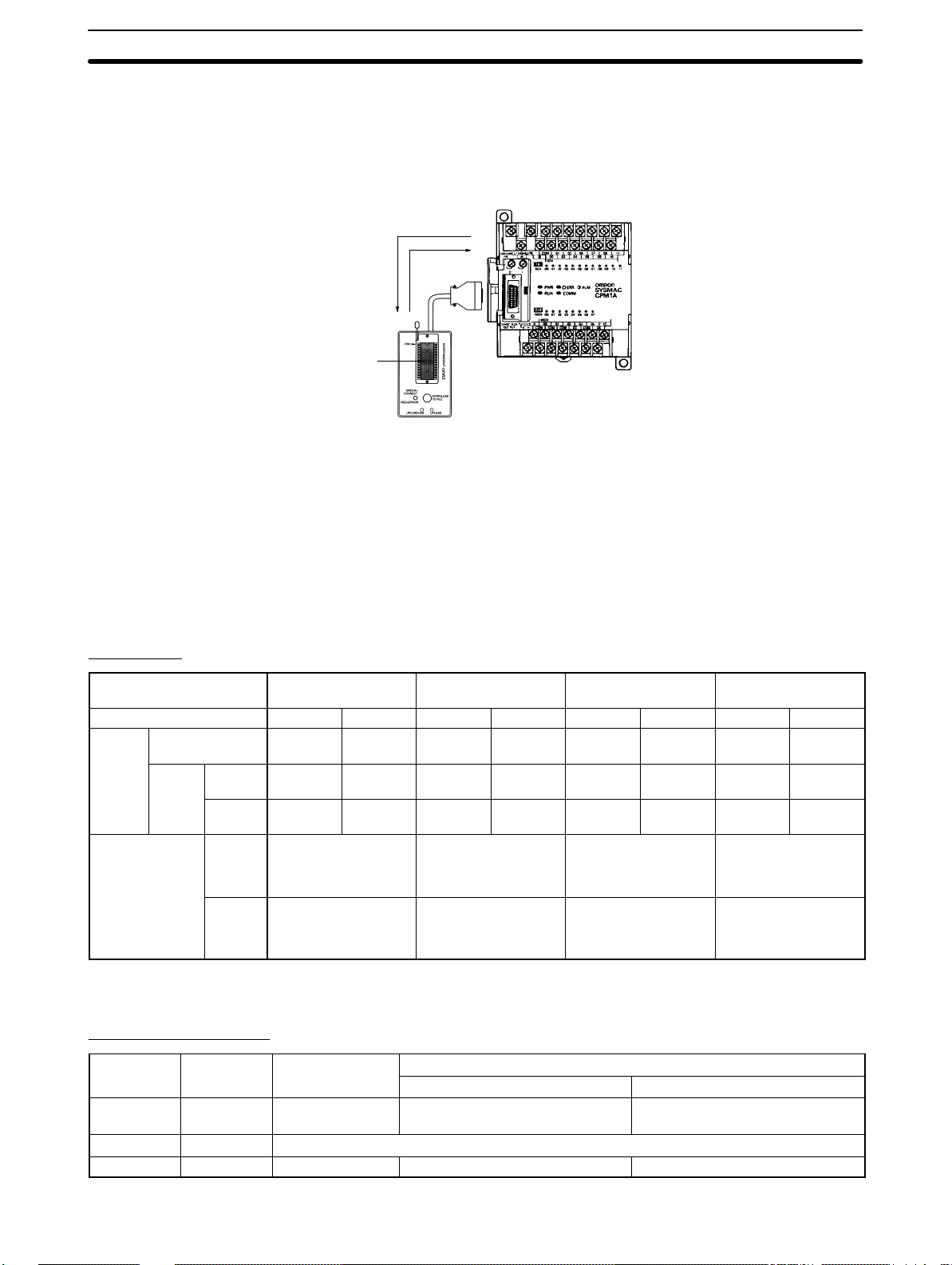

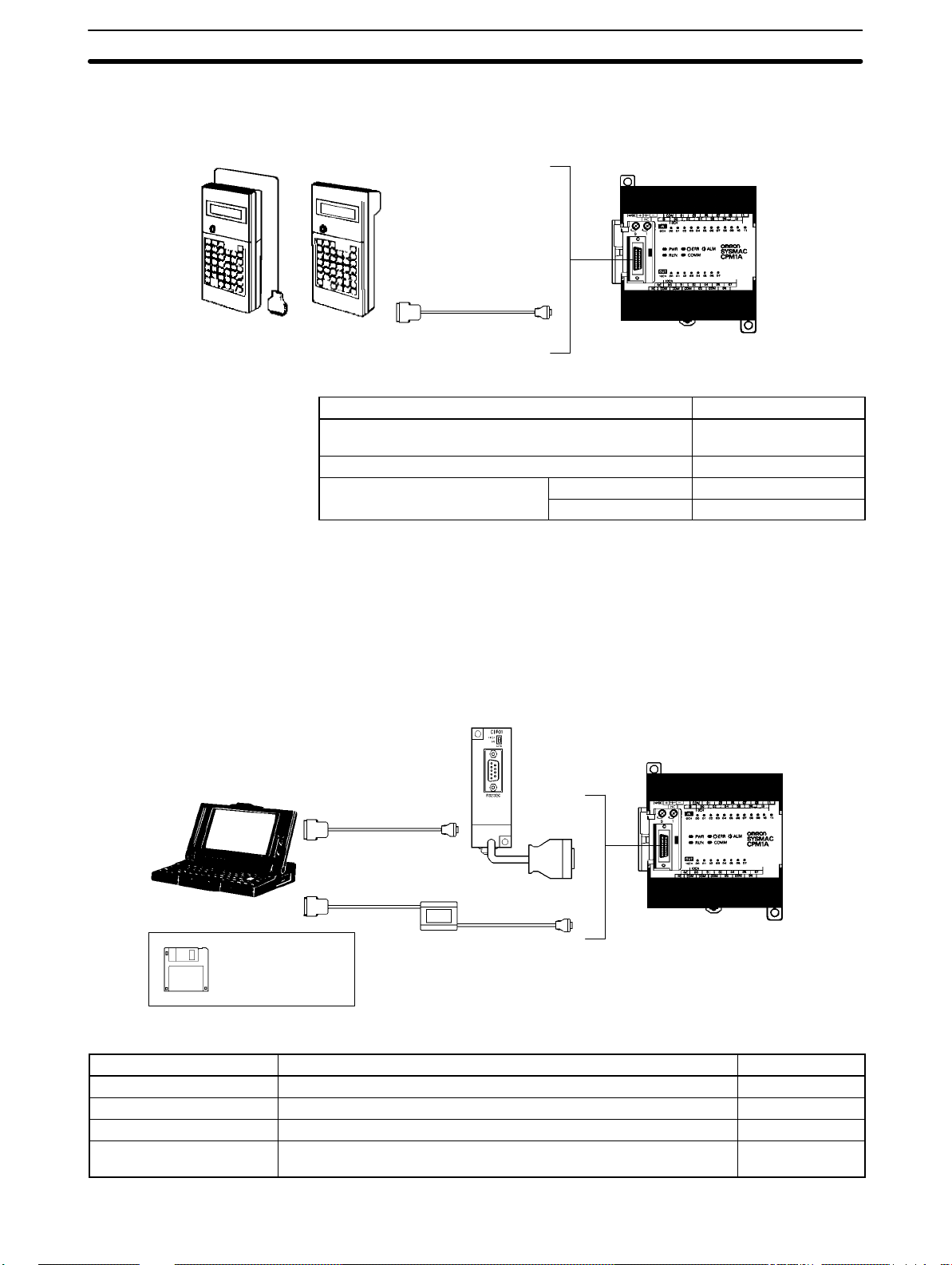

Programming Consoles A CQM1-PRO01-E or C200H-PRO27-E Programming Console can be con-

nected to the CPM1A as shown in the following diagram.

CPM1A CPU Unit

C200H-CN222/422

CQM1-PRO01-E C200H-PRO27-E

Name Model number

CQM1 Programming Console

(The Connecting Cable is included.)

C200H/HS and C200HX/HE/HG Programming Console C200H-PRO27-E

C200H-series Connecting Cables

Cable length: 2 m C200H-CN222

Cable length: 4 m C200H-CN422

CQM1-PRO01-E

SYSMAC Support Software

and SYSMAC-CPT Support

Software

IBM PC/AT or compatible

SSS,

SYSMAC-CPT

An IBM PC/A T or compatible personal computer running SSS or the SYSMACCPT Support Software can be connected to the CPM1A as shown in the following diagram. Refer to 3-4-7 Host Link Connections for a diagram showing the

standard wiring for the RS-232C cable.

Any version of the Support Software may be used. Refer to 4-1 Support Soft-

ware Capabilities for further details on installing and using Support Software.

RS-232C Adapter

CPM1A CPU Unit

RS-232C Cable

CQM1-CIF02

Name Usage Model number

RS-232C Adapter Converts to Peripheral Port format level communications. CPM1-CIF01

Connecting Cable Used to connect IBM PC/AT or compatible computers. (Length: 3.3 m) CQM1-CIF02

SYSMAC Support Software For IBM PC/AT or compatible computers (3.5” disks, 2HD) C500-ZL3AT1-E

SYSMAC-CPT Support

Software

For IBM PC/AT or compatible computers

(3.5” disks (2HD) and CDROM)

WS01-CPTB1-E

16

Page 31

Revised Specifications

1-3 Revised Specifications

The following table shows the changes that have been made in product specifications beginning with lots produced in January 1998 (December 1997 for some

models).

Item Previous specifications New specifications Relevant pages

Input indicator operation

when an error occurs

Memory holding operation

of built-in capacitor

Online editing and changing

set values from the SSS

Communications

parameters for the

peripheral port

The input indicators will

maintain the current status

and will not change with the

status of the input signal

when a memory error, no

END instruction error, or

system error occurs.

If the power remains OFF

for a period exceeding the

data backup period, the

capacitor will not be able to

back up data and the

status of the data backed

up by the capacitor

(Read/write DM area, Error

log area, HR area, and

Counter area) will become

unstable.

If unsupported addresses

are set in the program for

operands or for set values

for timers or counters from

the SSS during online

editing, the values will be

accepted, but a memory

error will occur in

MONITOR or RUN mode.

Communications are not

possible if unsupported

settings are made for the

peripheral port’s

communications

parameters.

The input indicators will

change with the status of

the input signal when a

memory error, no END

instruction error, or system

error occurs.

If the power remains OFF

for a period exceeding the

data backup period,

AR 1314 will turn ON to

indicate that the capacitor

can no longer back up data

and the data backed up by

the capacitor (Read/write

DM area, Error log area,

HR area, and Counter

area) will be cleared. The

PC Setup setting in

DM 6604 can be set to

create a fatal error and thus

stop the system when

AR 1314 goes ON.

If unsupported addresses

are set in the program for

operands or for set values

for timers or counters from

the SSS during online

editing, error messages will

be displayed and the

values will not be accepted.

Communications are

possible using the following

parameters if unsupported

settings are made for the

peripheral port’s

communications

parameters.

Mode: Host Link

Standard format

1 start bit

7-bit data

Even parity

2 stop bits

9,600 bps baud

Transmission delay: None

Unit number: 0

Section 1-3

Item 8., Input Indicators, on

page 29.

Pages xiii to xvi under 5

Application Precautions.

Page 22 under 2-1-2

Characteristics.

See also information on the

PC Setup in the

CPM1/CPM1A/CPM2A/CPM2

C/SRM1(-V2) Programmable

Controllers Programming

Manual (W353).

4-1-2 CPM1A Restrictions and

Precautions

See information on the PC

Setup in the

CPM1/CPM1A/CPM2A/CPM2

C/SRM1(-V2) Programmable

Controllers Programming

Manual (W353).

17

Page 32

SECTION 2

Unit Specifications and Components

This section provides the technical specifications of the Units that go together to create a CPM1A PC and describes the main

components of the Units.

2-1 Specifications 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-1 General Specifications 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-2 Characteristics 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-3 I/O Specifications 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-4 Communications Adapter Specifications 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Unit Components 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-1 CPU Unit Components 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-2 Expansion I/O Unit Components 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-3 Analog I/O Unit Components 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-4 Temperature Sensor Unit Components 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-5 CompoBus/S I/O Link Unit Components 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-6 Communications Adapter Components 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19

Page 33

Specifications Section 2-1

2-1 Specifications

2-1-1 General Specifications

Item

Supply voltage

Operating

voltage range

Power

consumption

Inrush current 30 A max. 38 A max.

External power

supply

supply

(AC type only)

(see note)

Insulation resistance 20 MΩ min. (at 500 VDC) between the external AC terminals and protective earth

Dielectric strength 2,300 VAC 50/60 Hz for 1 min between the external AC and protective earth

Noise immunity Conforms to IEC6100-4-4; 2 kV (power lines)

Vibration resistance 10 to 57 Hz, 0.075-mm amplitude, 57 to 150 Hz, acceleration: 9.8 m/s2 in X, Y, and Z

Shock resistance 147 m/s2 three times each in X, Y, and Z directions

Ambient temperature Operating: 0° to 55°C

Humidity 10% to 90% (with no condensation)

Atmosphere Must be free from corrosive gas

Terminal screw size M3

Grounding

Power interrupt time AC type: 10 ms min.

CPU Unit

weight

Expansion I/O Unit weight Units with 20 I/O points: 300 g max.

Expansion Unit weight Analog I/O Unit: 150 g max.

AC type 100 to 240 VAC, 50/60 Hz

DC type 24 VDC

AC type 85 to 264 VAC

DC type 20.4 to 26.4 VDC

AC type 30 VA max. 60 VA max.

DC type 6 W max. 20 W max.

Supply voltage 24 VDC

Output capacity 200 mA 300 mA

AC type 400 g max. 500 g max. 600 g max. 700 g max.

DC type 300 g max. 400 g max. 500 g max. 600 g max.

CPM1A-10CDR-

CPM1A-10CDT-D

CPM1A-10CDT1-D

terminals

terminals, leakage current: 10 mA max.

directions for 80 minutes each

(Time coefficient; 8 minutes × coefficient factor 10 = total time 80 minutes)

Storage: –20° to 75°C

Less than 100 W

DC type: 2 ms min.

(A power interruption occurs if power falls below 85% of the rated voltage for longer

than the power interrupt time.)

Units with 8 output points: 250 g max.

Units with 8 input points: 200 g max.

Temperature Sensor Units: 250 g max.

CompoBus/S I/O Link Unit:200 g max.

CPM1A-20CDR-

CPM1A-20CDT-D

CPM1A-20CDT1-D

CPM1A-30CDR-

CPM1A-30CDT-D

CPM1A-30CDT1-D

CPM1A-40CDR-

CPM1A-40CDT-D

CPM1A-40CDT1-D

20

Note Use the external power supply as the service power supply of input devices. The

power supply cannot be used for driving output devices.

Page 34

Specifications Section 2-1

2-1-2 Characteristics

Item

Control method Stored program method

I/O control method Cyclic scan with direct output; immediate refresh processing

Programming language Ladder diagram

Instruction length

Types of instructions

Execution time Basic instructions: 0.72 to 16.2 µs

Program capacity 2,048 words

Max. I/O

capacity

Input bits 00000 to 00915

Output bits 01000 to 01915

Work bits 512 bits: 20000 to 23115 (Words IR 200 to IR 231)

Special bits (SR area) 384 bits: 23200 to 25515 (Words IR 232 to IR 255)

Temporary bits (TR area) 8 bits (TR0 to TR7)

Holding bits (HR area) 320 bits:HR 0000 to HR 1915 (Words HR 00 to HR 19)

Auxiliary bits (AR area) 256 bits:AR 0000 to AR 1515 (Words AR 00 to AR 15)

Link bits (LR area) 256 bits:LR 0000 to LR 1515 (Words LR 00 to LR 15)

Timers/Counters 128 timers/counters (TIM/CNT 000 to TIM/CNT 127)

Data memory Read/Write: 1,024 words (DM 0000 to DM 1023)

Interrupt processing

(see note 2)

Interval timer interrupts 1 (0.5 to 319,968 ms in Scheduled Interrupt Mode or Single Interrupt Mode)

Memory protection HR and read/write DM area contents; and counter values maintained during power

Memory backup Flash memory:

Self-diagnostic functions CPU Unit failure (watchdog timer), I/O bus error, and memory failure

Program checks No END instruction, programming errors (continuously checked during operation)

High-speed counter One high-speed counter: 5 kHz single-phase or 2.5 kHz two-phase (linear count method)

Quick-response inputs The same inputs are used for quick-response inputs and external interrupt inputs.

Pulse output One point, 20 Hz to 2 kHz (single-phase output)

Input time constant Can be set to 1 ms, 2 ms, 4 ms, 8 ms, 16 ms, 32 ms, 64 ms, or 128 ms.

Analog controls 2 controls, setting range: 0 to 200 BCD

CPU Unit only 10 points 20 points 30 points 40 points

With

Expansion I/O

Units

CPM1A-10CDR-

CPM1A-10CDT-D

CPM1A-10CDT1-D

1 step per instruction, 1 to 5 words per instruction

Basic instructions: 14

Special instructions: 77 types, 135 instructions

Special instructions: 16.3 µs (MOV instruction)

--- --- 50, 70, or 90 points 60, 80, or 100 points

100-ms timers: TIM 000 to TIM 127

10-ms timers (high-speed counter): TIM 000 to TIM 127 (see note 1)

(the timer numbers used are the same as for the 100-ms timers)

Decrementing counters and reversible counters

Read-only: 512 words (DM 6144 to DM 6655)

External interrupts: 2 External interrupts: 4

interruptions.

The program, read-only DM area, and PC Setup area are backed up without a battery.

Capacitor backup:

The read/write DM area, error log area, HR area, and counter values are backed up by a

capacitor for 20 days at 25C. The capacitor backup time depends on the ambient

temperature. See the graph on the following page for details.

Increment mode: 0 to 65,535 (16 bits)

Up/Down mode: –32,767 to 32,767 (16 bits)

(Min. input pulse width: 0.2 ms)

Can preset the pulse rate (1 to 16,777,215).

CPM1A-20CDR-

CPM1A-20CDT-D

CPM1A-20CDT1-D

CPM1A-30CDR-

CPM1A-30CDT-D

CPM1A-30CDT1-D

Words not used for input or output bits can

be used for work bits.

CPM1A-40CDR-

CPM1A-40CDT-D

CPM1A-40CDT1-D

21

Page 35

Specifications Section 2-1

Note 1. Use TIM 000 to TIM 003 when creating a timer using the high-speed timer

instruction to perform interrupt processing.

2. The input interrupt response time is 0.3 ms max.

Memory Backup The user program and memory area data in the CPM1A are backed up either by

an internal capacitor or in flash memory as shown in the following table.

Backup method Data

Internal capacitor Read/write DM area (DM 0000 to DM 0999, DM 1022, and

Flash memory User program

Note 1. The IR, TR, LR, and timer areas are not normally backed up when power is

turned off and all contents will be cleared the next time power is turned on.

(The PC Setup setting in DM 6601 can be used to back up this data. Refer to

details on the PC Setup later in this manual for details.)

2. The bits in the AR and SR areas have special functions and are set according to these functions when power is turned on.

The capacitor backup time depends on the ambient temperature, as shown in

the following graph. The backup time, however, assumes that the capacitor is

fully charged, which requires that power be supplied to the CPU Unit continuously for at least 15 minutes.

DM 1023)

Error log area (DM 1000 to DM 1021)

HR area (HR 00 to HR 19)

Counter area (CNT 000 to CNT 127)

Read-only DM area (DM 6144 to DM 6599)

PC Setup (DM 6600 to DM 6655)

20

10

Backup time (days)

7

1

25 40 80

Ambient temperature (C)

If the power remains off for a period exceeding the data backup period,

AR 1314 will turn ON to indicate that the capacitor can no longer back up data

and the data backed up by the capacitor will be cleared. AR 1314 will remain

ON unless it is turned OFF using I/O monitor operations, using memory clear

operations, or from the user program.

If desired, the PC Setup setting in DM 6604 can be set to create a fatal error

and thus stop the system when AR 1314 goes ON.

The data stored in flash memory will not be lost even if power remains off for a

period exceeding the data backup period, because the data stored in flash

memory will be read to the CPU Unit when the CPM1A is turned on.

If the power is turned off without changing the mode from PROGRAM mode to

RUN or MONITOR mode after having made changes in the data that is backed

up in flash memory, the changes will not be written to flash memory. If the power

is then left off for more than 20 days (at 25C), the changes (i.e., the contents of

the RAM) will be erased and the data values will become undefined.

22

Page 36

Specifications Section 2-1

Either switch the CPM1A to RUN or MONITOR mode, or turn off and on power to

the CPM1A after changing from a Programming Device any data that is backed

up in flash memory. This data includes the user program, read-only DM area

(DM 6144 to DM 6599), and the PC Setup (DM 6600 to DM 6655).

2-1-3 I/O Specifications

CPU Unit Input Specifications

Item Specification

Input voltage 24 VDC

Input impedance IN00000 to IN00002: 2 kΩ; other inputs: 4.7 kΩ

Input current IN00000 to IN00002: 12 mA typical; other inputs: 5 mA typical

ON voltage 14.4 VDC min.

OFF voltage 5.0 VDC max.

ON delay 1 to 128 ms max. Default: 8 ms (see note.)

OFF delay 1 to 128 ms max. Default: 8 ms (see note.)

Circuit configuration

+10%

/

–15%

IN

4.7 kΩ

IN

(2 kΩ)

Input

LED

820 Ω

COM

Note Figures in parentheses are for IN00000 to IN00002.

(510 Ω)

Internal

Circuits

Note Using the PC Setup, 1, 2, 4, 8, 16, 32, 64, or 128 ms can be selected. When

IN00000 through IN00002 are used as high-speed counter inputs, the delays

are as shown in the following table.

Input Increment mode Differential phase mode

IN00000 (A-phase) 5 kHz

IN00001 (B-phase) Normal input

IN00002 (Z-phase) ON: 100 µs min.; OFF delay: 500 µs min.

2.5 kHz

The minimum delay is as follows.

Increment Mode (5 kHz Max.)

A phase

ON

OFF

200 µs min.

90 µs

min.

90 µs

min.

23

Page 37

Specifications Section 2-1

Differential Phase Mode (2.5 kHz Max.) IN00000 (A phase), IN00001 (B

phase)

400 µs min.

ON

Phase A

OFF

ON

Phase B

OFF

IN00002 (Z phase)

T

T

T

1

2

T

3

4

T

1

T

T

T

: 90 µs min.

2

3

4

ON

Phase Z

OFF

When IN00003 through IN00006 are used as interrupt inputs, th e d el a y i s 0 . 3 m s

max. The delay is measured from the time that the input goes ON until the interrupt subroutine is executed.

Expansion I/O Unit Input Specifications

Item Specification

Input voltage 24 VDC

Input impedance 4.7 kΩ

Input current 5 mA typical

ON voltage 14.4 VDC min.

OFF voltage 5.0 VDC max.

ON delay 1 to 128 ms max. Default: 8 ms (see note.)

OFF delay 1 to 128 ms max. Default: 8 ms (see note.)

Circuit configuration

+10%

/

–15%

IN

4.7 kΩ

IN

100 µs min.

500 µs

min.

Input

LED

24

COM

820 Ω

Internal

Circuits

Note Using the PC Setup, 1, 2, 4, 8, 16, 32, 64, or 128 ms can be selected.

Caution Do not apply voltage in excess of the rated voltage to the input terminal. It may

!

result in damage to the product or fire.

Page 38

Specifications Section 2-1

CPU Unit and Expansion I/O Unit Output Specifications

Relay Output

Item Specification

Max. switching capacity 2 A, 250 VAC (cosφ = 1)

Min. switching capacity 10 mA, 5 VDC

Service life of relay Electrical: 150,000 operations (resistive load, 24 VDC) 100,000 operations (inductive

ON delay 15 ms max.

OFF delay 15 ms max.

Circuit configuration

2 A, 24 VDC

(4 A/common)

load, 220 VAC, cos φ=0.4)

Mechanical: 10,000,000 operations

Output

LED

OUT

Internal

Circuits

OUT

COM

Maximum

250 VAC: 2 A

24 VDC: 2 A

Note The service life of relay output contacts shown in the table assumes the worst

conditions. The f o l l o w i n g g r a p h s h o w s t h e r e s u l t s o f O M R O N ’s service life tests

at a switching rate of 1,800 times/hour.

500

4

300

200

100

Life (x 10 )

50

30

20

10

5

3

2

0.1 0.2 0.3 0.5 0.7 1 2 3 5

120 VAC, resistive load

24 VDC, τ = 7 ms

120 VAC, cosφ = 0.4

240 VAC, cosφ = 0.4

24 VDC/240 VAC, resistive load

Contact current (A)

Switching rate: 1,800 times/hour

25

Page 39

Specifications Section 2-1

Transistor Output (Sink Type)

Item

CPM1A-10CDT-D CPM1A-20CDT-D

Max. switching capacity

24 VDC

+10%

/

, 0.3 A/point (see note)

–15%

0.9 A/Unit 0.9 A/common

1.8 A/Unit

Leakage current 0.1 mA max.

Residual voltage 1.5 V max.

ON delay 0.1 ms max.

OFF delay OUT01000/01001: 0.2 ms max. (load current: 100 to 300 mA)

Other than OUT01000/01001: 1 ms max. (load current: 5 to 300 mA)

Fuse 1.25 A/common (cannot be replaced by the user)

Circuit configuration

Specification

CPM1A-30CDT-D CPM1A-40CDT-D

/-20EDT

/-8ET

0.9 A/common

2.7 A/Unit

0.5 ms max. (load current: 5 to 100 mA)

Output LED

0.9 A/common

3.6 A/Unit

OUT

Internal

Circuits

OUT

COM (–)

Note When using the OUT01000 or OUT01001 as a pulse output, connect dummy

resistors as required to set the load current to 0.1 to 0.2 A. If the load current is

below 0.1 A, the ON-to-OFF response time will become longer and high-speed

pulse will not be output. On the other hand, if the load current is above 0.2 A, the

transistor may generate heat and components may be damaged.

Transistor Output (Source Type)

Item

CPM1A-

10CDT1-D

20CDT1-D

/-20EDT1

Max. switching capacity

24 VDC

+10%

/

, 0.3 A/point (see note)

–15%

0.9 A/Unit 0.9 A/common

1.8 A/Unit

Leakage current 0.1 mA max.

Residual voltage 1.5 V max.

ON delay 0.1 ms max.

OFF delay OUT01000/01001: 0.2 ms max. (load current: 100 to 300 mA)

Other than OUT01000/01001: 1 ms max. (load current: 5 to 300 mA)

Fuse 1.25 A/common (cannot be replaced by the user)