Page 1

Cat. No. W353-E1-06

SYSMAC

CPM1/CPM1A/CPM2A/CPM2C/SRM1(-V2)

Programmable Controllers

PROGRAMMING MANUAL

Page 2

CPM1/CPM1A/CPM2A/CPM2C/SRM1(-V2)

Programmable Controllers

Programming Manual

Revised February 2008

Page 3

iv

Page 4

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

!

serious injury.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

!

serious injury.

Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

!

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers

to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 1999

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change

without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Note Indicates information of particular interest for efficient and convenient operation

of the product.

1, 2, 3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 5

vi

Page 6

TABLE OF CONTENTS

PRECAUTIONS xvii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Intended Audience xviii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xviii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xviii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions xx. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions xxi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1

PC Setup 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 PC Setup 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Basic PC Operation and I/O Processes 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 CPM2C Changes in SW2 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

Special Features 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1 CPM2A/CPM2C Interrupt Functions 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 CPM2A/CPM2C High-speed Counters 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 CPM1/CPM1A Interrupt Functions 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 SRM1(-V2) Interrupt Functions 94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5 CPM2A/CPM2C Pulse Output Functions 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6 CPM1A Pulse Output Functions 131. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7 Synchronized Pulse Control (CPM2A/CPM2C Only) 134. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8 Data Computation Standards 146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-9 Analog I/O Functions (CPM1/CPM1A/CPM2A/CPM2C Only) 147. . . . . . . . . . . . . . . . . . . .

2-10 Temperature Sensor Input Functions (CPM1A/CPM2A/CPM2C Only) 147. . . . . . . . . . . . . .

2-11 CompoBus/S I/O Slave Functions (CPM1A/CPM2A/CPM2C Only) 147. . . . . . . . . . . . . . . .

2-12 CompoBus/S I/O Master Functions (SRM1(-V2) and CPM2C-S Only) 148. . . . . . . . . . . . . .

2-13 Analog Controls (CPM1/CPM1A/CPM2A Only) 150. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-14 Quick-response Inputs 153. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-15 Macro Function 157. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-16 Calculating with Signed Binary Data 158. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-17 Differential Monitor 159. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-18 Expansion Instructions (CPM2A/CPM2C/SRM1(-V2) Only) 160. . . . . . . . . . . . . . . . . . . . . .

2-19 Using the CPM2A/CPM2C Clock Function 163. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3

Using Expansion Units 165. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1 Analog I/O Units 166. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Temperature Sensor Units 193. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 CompoBus/S I/O Link Units 214. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 DeviceNet I/O Link Unit 219. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4

Communications Functions 225. . . . . . . . . . . . . . . . . . . . . . . .

4-1 Introduction 226. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 CPM1/CPM1A Communications Functions 227. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 CPM2A/CPM2C Communications Functions 231. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4 SRM1(-V2) Communications Functions 268. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-5 Host Link Commands 281. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5

Memory Areas 307. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1 Memory Area Functions 308. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 I/O Allocation for CPM1/CPM1A/CPM2A PCs 313. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 I/O Allocation for CPM2C PCs 323. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vii

Page 7

SECTION 6

Ladder-diagram Programming 333. . . . . . . . . . . . . . . . . . . .

6-1 Basic Procedure 334. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2 Instruction Terminology 334. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3 Basic Ladder Diagrams 335. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4 Controlling Bit Status 354. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-5 Work Bits (Internal Relays) 356. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-6 Programming Precautions 358. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-7 Program Execution 360. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 7

Instruction Set 361. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1 Notation 364. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2 Instruction Format 364. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-3 Data Areas, Definer Values, and Flags 364. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-4 Differentiated Instructions 366. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-5 Coding Right-hand Instructions 367. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-6 Instruction Tables 370. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-7 Ladder Diagram Instructions 376. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-8 Bit Control Instructions 377. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-9 NO OPERATION – NOP(00) 381. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-10 END – END(01) 381. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-11 INTERLOCK and INTERLOCK CLEAR – IL(02) and ILC(03) 381. . . . . . . . . . . . . . . . . . .

7-12 JUMP and JUMP END – JMP(04) and JME(05) 383. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-13 User Error Instructions:

FAILURE ALARM AND RESET – FAL(06) and

SEVERE FAILURE ALARM – FALS(07) 385. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-14 Step Instructions:

STEP DEFINE and STEP START–STEP(08)/SNXT(09) 385. . . . . . . . . . . . . . . . . . . . . . . . .

7-15 Timer and Counter Instructions 388. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-16 Shift Instructions 404. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-17 Data Movement Instructions 411. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-18 Data Control Instructions 421. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-19 Comparison Instructions 432. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-20 Conversion Instructions 439. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-21 BCD Calculation Instructions 457. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-22 Binary Calculation Instructions 467. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-23 Special Math Instructions 471. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-24 Logic Instructions 479. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-25 Increment/Decrement Instructions 483. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-26 Subroutine Instructions 484. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-27 Pulse Output Instructions 487. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-28 Special Instructions 497. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-29 Interrupt Control Instructions 501. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-30 Communications Instructions 505. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 8

PC Operations and Processing Time 511. . . . . . . . . . . . . . . .

8-1 CPM1/CPM1A Cycle Time and I/O Response Time 512. . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-2 CPM2A/CPM2C Cycle Time and I/O Response Time 523. . . . . . . . . . . . . . . . . . . . . . . . . . .

8-3 SRM1(-V2) Cycle Time and I/O Response Time 537. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

Page 8

TABLE OF CONTENTS

SECTION 9

Troubleshooting 549. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-1 Introduction 550. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-2 Programming Console Operation Errors 550. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-3 Programming Errors 551. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-4 User-defined Errors 552. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-5 Operating Errors 553. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-6 Error Log 555. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-7 Host Link Errors 557. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-8 Troubleshooting Flowcharts 557. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendices

A Programming Instructions 559. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Error and Arithmetic Flag Operation 565. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C Memory Areas 569. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D I/O Assignment Sheet 587. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E Program Coding Sheet 589. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F List of FAL Numbers 593. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G Extended ASCII 595. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 597. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History 603. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ix

Page 9

x

Page 10

About this Manual:

gp

This manual provides information on programming the CPM1, CPM1A, CPM2A, CPM2C (including the

CPM2C-S), and SRM1(-V2) PCs. The following manuals describe the system configurations and installation of the PCs and provide a basic explanation of operating procedures for the Programming Consoles.

Read the relevant manual first to acquaint yourself with the PC.

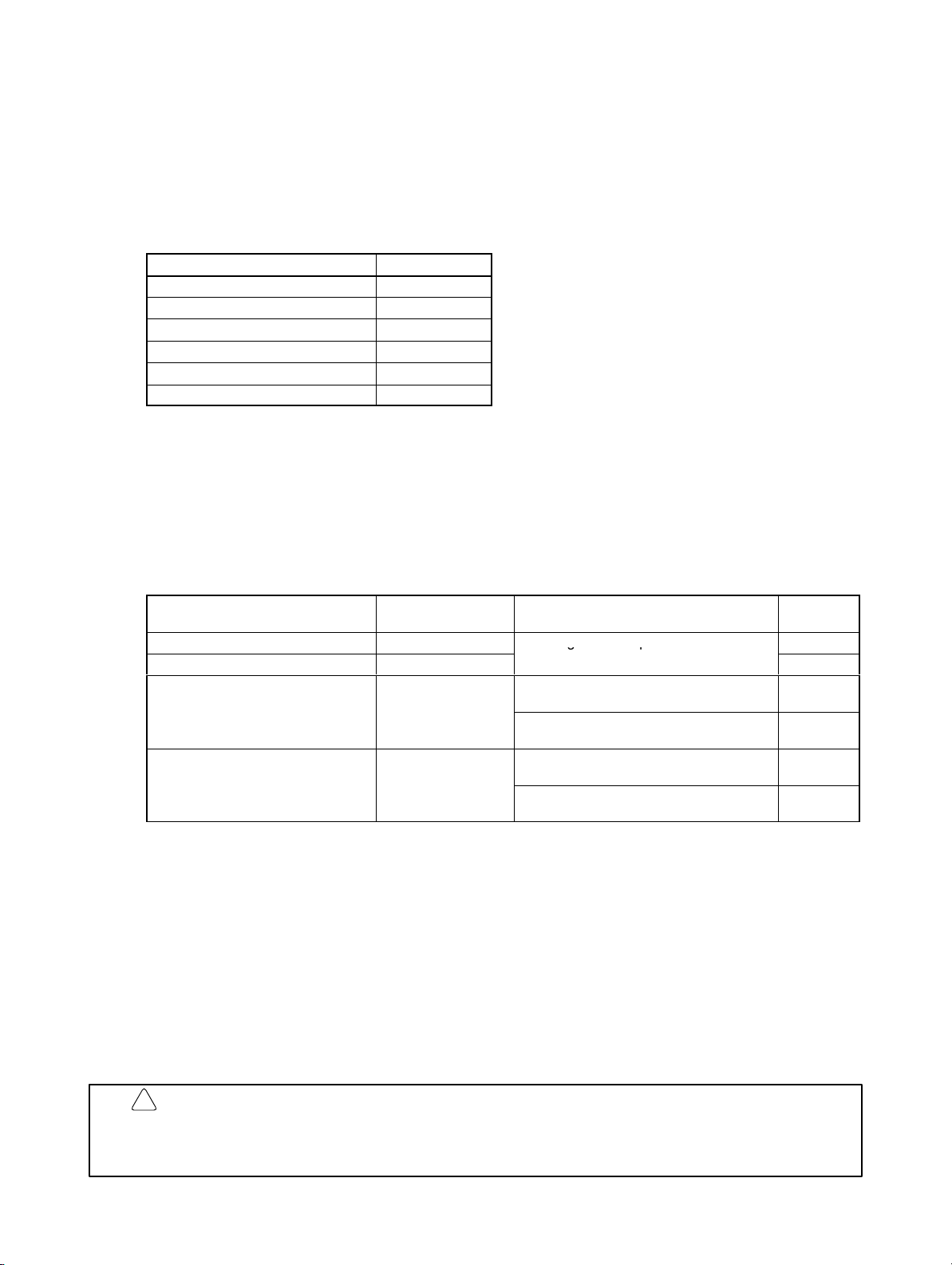

Manual Catalog No.

CPM1 Operation Manual W262

CPM1A Operation Manual W317

CPM2A Operation Manual W352

CPM2C Operation Manual W356

CPM2C-S Operation Manual W377

SRM1(-V2) Operation Manual W318

Note 1. Version 2 (-V2) of the SRM1 is included beginning with following revision of the manual:

W318-E1-3.

2. Refer to sections on the CPM2C for information on CPM2C instructions and Expansion

Units.

For programming the CPM1, CPM1A, CPM2A, CPM2C (including the CPM2C-S), and SRM1(-V2) PCs,

use the CX-Programmer, special Support Software that runs in a Windows environment. The SYSMAC

Support Software and SYSMAC-CPT Support Software can also be used. Please refer to the relevant

manuals listed in the following table when using any one of Support Software.

Name Model No. Manual Catalog

No.

CX-Programmer version 3.1 WS02-CXPC1-EV3

CX-Programmer version 4.0 WS02-CXPC1-EV4

SYSMAC Support Software C500-ZL3AT1-E

SYSMAC-CPT Support Software WS02-CPTB1-E

CX-Programmer Operation Manual

SYSMAC Support Software

Operation Manual: Basic

SYSMAC Support Software

Operation Manual: C-series PCs

SYSMAC-CPT Support Software Quick

Start Guide

SYSMAC-CPT Support Software

User Manual

W414

W425

W247

W248

W332

W333

Please read this manual carefully and be sure you understand the information provided before attempting

to program or operate the PC.

Section 1 explains the PC Setup. The PC Setup can be used to control the operating parameters.

Section 2 explains special features of the PC.

Section 3 describes how to use the CPM1A-MAD01 and CPM2C-MAD11 Analog I/O Units, the CPM1A-

TS and CPM2C-TS Temperature Sensor Units, and the CPM1A-SRT21 and CPM2C-SRT21

CompoBus/S I/O Link Units.

!

WARNING Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section in its entirety and be sure you understand the information provided in the section

and related sections before attempting any of the procedures or operations given.

xi

Page 11

About this Manual, Continued

Section 4 describes how to use the communications functions provided in the PCs.

Section 5 describes the structure of the PC memory areas and explains how to use them. Details of some

areas are provided in Appendix C.

Section 6 explains the basic steps and concepts involved in writing a basic ladder diagram program. It

introduces the instructions that are used to build the basic structure of the ladder diagram and control its

execution.

Section 7 explains instructions individually and provides the ladder diagram symbol, data areas, and

flags used with each.

Section 8 explains the internal PC processing, as well as the time required for processing and execution.

Section 9 describes how to diagnose and correct hardware and software errors that can occur during

operation.

Various Appendices are also provided for easy reference. Refer to the table of contents for a list of appendices.

xii

Page 12

Read and Understand this Manual

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON’s exclusive warranty is that the products are free from defects in materials and workmanship for

БББББББББББББББББББББББББББББББ

a period of one year (or other period if specified) from date of sale by OMRON.

БББББББББББББББББББББББББББББББ

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

БББББББББББББББББББББББББББББББ

NON–INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

БББББББББББББББББББББББББББББББ

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

БББББББББББББББББББББББББББББББ

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

БББББББББББББББББББББББББББББББ

БББББББББББББББББББББББББББББББ

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL

DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

БББББББББББББББББББББББББББББББ

PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR

БББББББББББББББББББББББББББББББ

STRICT LIABILITY.

БББББББББББББББББББББББББББББББ

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on

БББББББББББББББББББББББББББББББ

which liability is asserted.

БББББББББББББББББББББББББББББББ

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

БББББББББББББББББББББББББББББББ

REGARDING THE PRODUCTS UNLESS OMRON’S ANALYSIS CONFIRMS THAT THE PRODUCTS

БББББББББББББББББББББББББББББББ

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

БББББББББББББББББББББББББББББББ

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xiii

Page 13

Application Considerations

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to

БББББББББББББББББББББББББББББББ

the combination of products in the customer’s application or use of the products.

БББББББББББББББББББББББББББББББ

At the customer’s request, OMRON will provide applicable third party certification documents identifying

БББББББББББББББББББББББББББББББ

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

БББББББББББББББББББББББББББББББ

complete determination of the suitability of the products in combination with the end product, machine,

БББББББББББББББББББББББББББББББ

system, or other application or use.

БББББББББББББББББББББББББББББББ

The following are some examples of applications for which particular attention must be given. This is not

БББББББББББББББББББББББББББББББ

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the

БББББББББББББББББББББББББББББББ

uses listed may be suitable for the products:

БББББББББББББББББББББББББББББББ

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions

БББББББББББББББББББББББББББББББ

or uses not described in this manual.

БББББББББББББББББББББББББББББББ

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

БББББББББББББББББББББББББББББББ

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

БББББББББББББББББББББББББББББББ

industry or government regulations.

БББББББББББББББББББББББББББББББ

• Systems, machines, and equipment that could present a risk to life or property.

БББББББББББББББББББББББББББББББ

Please know and observe all prohibitions of use applicable to the products.

БББББББББББББББББББББББББББББББ

БББББББББББББББББББББББББББББББ

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

БББББББББББББББББББББББББББББББ

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

БББББББББББББББББББББББББББББББ

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

БББББББББББББББББББББББББББББББ

БББББББББББББББББББББББББББББББ

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user’s programming of a programmable product, or any

БББББББББББББББББББББББББББББББ

consequence thereof.

xiv

Page 14

Disclaimers

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

CHANGE IN SPECIFICATIONS

БББББББББББББББББББББББББББББББ

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

БББББББББББББББББББББББББББББББ

БББББББББББББББББББББББББББББББ

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be

БББББББББББББББББББББББББББББББ

changed without any notice. When in doubt, special model numbers may be assigned to fix or establish

БББББББББББББББББББББББББББББББ

key specifications for your application on your request. Please consult with your OMRON representative

БББББББББББББББББББББББББББББББ

at any time to confirm actual specifications of purchased products.

БББББББББББББББББББББББББББББББ

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

БББББББББББББББББББББББББББББББ

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and

БББББББББББББББББББББББББББББББ

does not constitute a warranty. It may represent the result of OMRON’s test conditions, and the users

БББББББББББББББББББББББББББББББ

must correlate it to actual application requirements. Actual performance is subject to the OMRON

БББББББББББББББББББББББББББББББ

Warranty and Limitations of Liability.

БББББББББББББББББББББББББББББББ

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

БББББББББББББББББББББББББББББББ

ERRORS AND OMISSIONS

xv

Page 15

xvi

Page 16

PRECAUTIONS

This section provides general precautions for using the Programmable Controller (PC) and related devices.

The information contained in this section is important for the safe and reliable application of the Programmable Controller. You must read this section and understand the information contained before attempting to set up or operate a

PC system.

1 Intended Audience xviii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Precautions xviii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety Precautions xviii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operating Environment Precautions xx. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Application Precautions xxi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xvii

Page 17

1 Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications

described in the operation manuals.

Before using the product under conditions which are not described in the manual

or applying the product to nuclear control systems, railroad systems, aviation

systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that

may have a serious influence on lives and property if used improperly, consult

your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide the

systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual

close at hand for reference during operation.

4Safety Precautions

WARNING It is extremely important that a PC and all PC Units be used for the specified

!

purpose and under the specified conditions, especially in applications that can

directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PC System to the above-mentioned

applications.

3 Safety Precautions

WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing so

!

may result in electric shock.

WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do so

!

may result in malfunction, fire, or electric shock.

WARNING Always turn OFF the power supply to the PC before attempting any of the

!

following. Not turning OFF the power supply may result in malfunction or electric

shock.

• Assembling the Units.

• Mounting or dismounting I/O Units, CPU Units, or any other Units.

• Connecting or wiring the cables.

• Connecting or disconnecting the connectors.

• Setting DIP switches.

• Replacing the battery

xviii

WARNING Do not touch any of the terminals or terminal blocks while the power is being

!

supplied. Doing so may result in electric shock.

Page 18

WARNING Always ground the system to 100 Ω or less when installing the Units. Not

!

connecting to a ground of 100 Ω or less may result in electric shock.

WARNING Provide safety measures in external circuits (i.e., not in the Programmable

!

Controller), including the following items, to ensure safety in the system if an

abnormality occurs due to malfunction of the PC or another external factor

affecting the PC operation. Not doing so may result in serious accidents.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PC will turn OFF all outputs when its self-diagnosis function detects any

error or when a severe failure alarm (FALS) instruction is executed. As a countermeasure for such errors, external safety measures must be provided to ensure safety in the system.

• The PC outputs may remain ON or OFF due to deposition or burning of the

output relays or destruction of the output transistors. As a countermeasure for

such problems, external safety measures must be provided to ensure safety in

the system.

• When the 24-VDC output (service power supply to the PC) is overloaded or

short-circuited, the voltage may drop and result in the outputs being turned

OFF. As a countermeasure for such problems, external safety measures must

be provided to ensure safety in the system.

3Safety Precautions

WARNING When handling the Memory Backup Battery, never drop, disassemble, distort,

!

short-circuit, recharge, heat to a temperature exceeding 100°C, or throw into

fire. The Battery may explode, catch fire, or leak fluid if mishandled in any of

these ways.

Caution Execute online edit only after confirming that no adverse effects will be caused

!

by extending the cycle time. Otherwise, input signals may not be readable.

Caution When transferring programs to other nodes, or when making changes to I/O

!

memory, confirm the safety of the destination node before transfer. Not doing so

may result in injury.

Caution Tighten the screws on the terminal block of the AC Power Supply Unit to the

!

torque specified in the operation manual. The loose screws may result in fire or

malfunction.

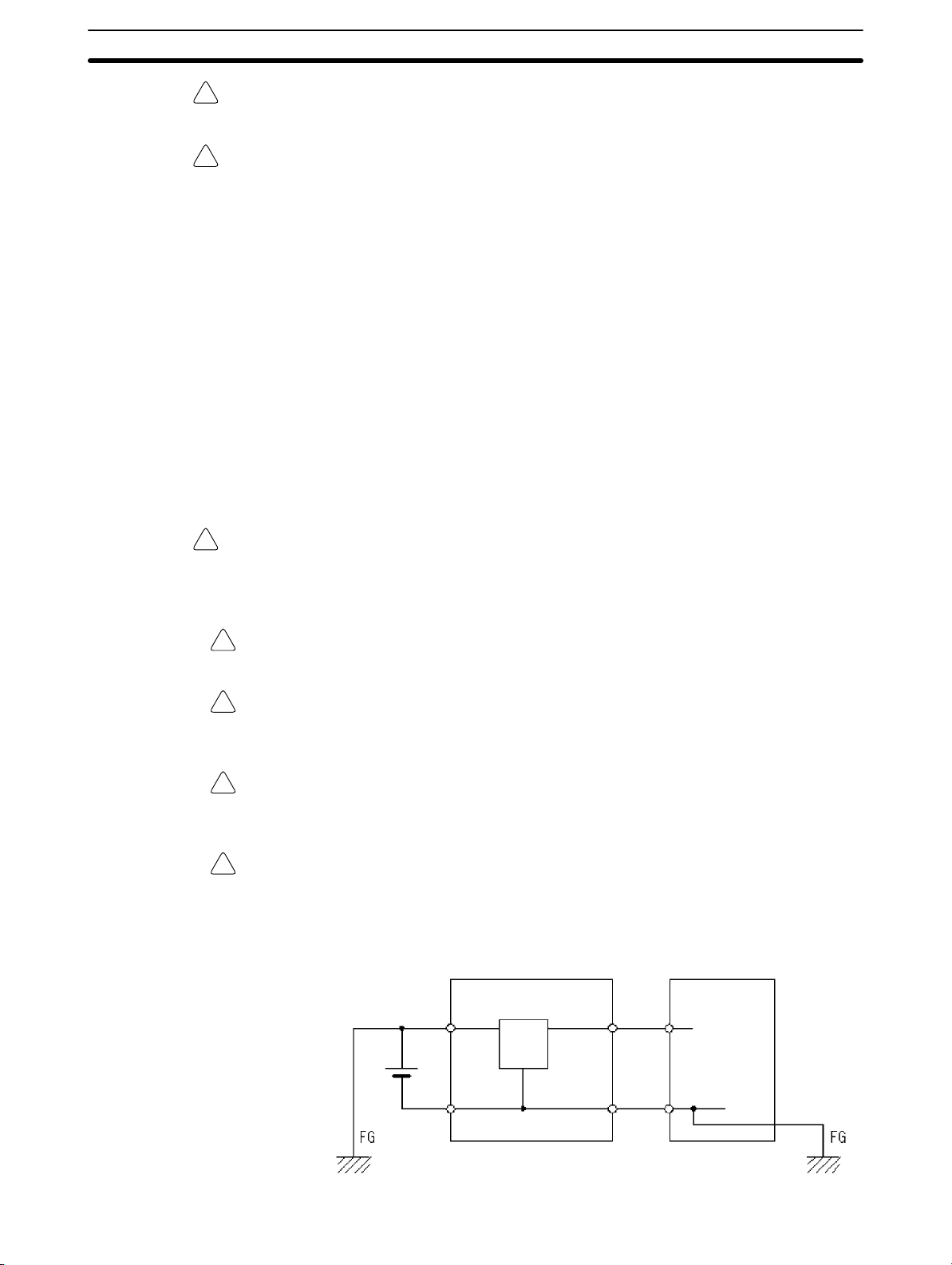

Caution When connecting the PC to a personal computer or other peripheral device,

!

either ground the 0-V side of the PC or do not ground the PC at all. Although

some grounding methods short the 24-V side, as shown in the following diagram, never do so with the PC.

INCORRECT Grounding: Shorting the 24-V side of the Power Supply

Non-isolated DC

24 V

power supply

0 V 0 V

PC

0 V

Peripheral device

xix

Page 19

4 Operating Environment Precautions

Caution Do not operate the control system in the following places:

!

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified in

the specifications.

• Locations subject to condensation as the result of severe changes in tempera-

ture.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

Caution Take appropriate and sufficient countermeasures when installing systems in the

!

following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

4Operating Environment Precautions

Caution The operating environment of the PC System can have a large effect on the lon-

!

gevity and reliability of the system. Improper operating environments can lead to

malfunction, failure, and other unforeseeable problems with the PC System. Be

sure that the operating environment is within the specified conditions at installation and remains within the specified conditions during the life of the system.

xx

Page 20

5 Application Precautions

Observe the following precautions when using the PC System.

Caution Failure to abide by the following precautions could lead to faulty operation of the

!

PC or the system, or could damage the PC or PC Units. Always heed these precautions.

Designing Circuits or Creating Ladder Programs

• Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal lines,

momentary power interruptions, or other causes.

• Construct a control circuit so that power supply for the I/O circuits does not

come ON before power supply for the Unit. If power supply for the I/O circuits

comes ON before power supply for the Unit, normal operation may be temporarily interrupted.

• If the operating mode is changed from RUN or MONITOR mode to PROGRAM

mode, with the IOM Hold Bit ON, the output will hold the most recent status. In

such a case, ensure that the external load does not exceed specifications. (If

operation is stopped because of an operating error, including errors generated

by FALS instructions, the values in the internal memory of the CPU Unit will be

saved, but the outputs will all turn OFF.)

• For models with only the super-capacitor installed, the contents of the READ/

WRITE enable area of the DM area, HR area, AR area, and CNT data area

may be damaged if the power is turned OFF for a long time. To prevent such

damage, provide ladder program that will check AR 1314 to ensure proper operation of the system.

• The life of relays largely varies depending on switching conditions. Be sure to

test operating conditions using actual Units and use the product within the specified number of switchings so as not to cause any performance problems. Using the product with performance problems may result in defective insulation

between circuits or burning of the relays.

5Application Precautions

Installation

Wiring and Connection

• Install the Units properly as specified in the relevant operation manual(s). Im-

proper installation of the Units may result in malfunction.

• Do not install the PC or PC Units in places where the Units may be affected by

excessive noise. Doing so may result in malfunction.

• Install the Units properly so that they will not fall off.

• Be sure that all the mounting screws, terminal screws, and cable connector

screws are tightened to the torque specified in the relevant manuals. Incorrect

tightening torque may result in malfunction.

• Install the Expansion I/O Unit connector cover to the last Expansion I/O Unit to

prevent dust or foreign matter from entering inside the Unit. Not doing so may

result in malfunction.

• Be sure that the terminal blocks, expansion cables, and other items with lock-

ing devices are properly locked into place. Improper locking may result in malfunction.

• Be sure to use cables as specified in the relevant manual(s).

• Install external breakers and take other safety measures against short-circuit-

ing in external wiring. Insufficient safety measures against short-circuiting may

result in burning.

• When wiring signal lines, do not place them in the same duct as high-voltage

lines or power lines. Doing so may result in malfunction.

xxi

Page 21

• Be sure that terminal blocks and connectors are connected in the specified

direction with the correct polarity. Not doing so may result in malfunction.

• Leave the labels attached CPM1 or CPM2A Units when wiring to prevent wir-

ing cuttings from entering the Units.

• Attach the labels supplied with CPM1A or CPM2C Units or provide other pro-

tective covers when wiring to prevent dust or wiring cuttings from entering the

Units.

• Remove the labels after the completion of wiring to ensure proper heat dissipa-

tion. Leaving the labels attached may result in malfunction.

• Use the connectors and wiring materials specified in the relevant manual(s).

• Be sure to wire according to the relevant manual(s). Incorrect wiring may result

in burning.

I/O Connection and System Startup

• Disconnect the functional ground terminal when performing withstand voltage

tests.

• Always use the power supply voltages specified in the operation manual(s). An

incorrect voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the rated

voltage and frequency is supplied. Be particularly careful in places where the

power supply is unstable.

• Do not apply voltages to the input terminals in excess of the rated input voltage.

Excess voltages may result in burning.

• Do not apply voltages or connect loads to the output terminals in excess of the

maximum switching capacity. Excess voltage or loads may result in burning.

• Double-check all wiring and switch settings before turning ON the power sup-

ply. Incorrect wiring may result in burning.

• Check the user program for proper execution before actually running it on the

Unit. Not checking the program may result in an unexpected operation.

5Application Precautions

Handling Precautions

• When using, storing, or transporting the product, keep within the specifications

listed in the relevant manual(s).

• Confirm that no adverse effect will occur in the system before attempting any of

the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• Before touching a Unit, be sure to first touch a grounded metallic object to dis-

charge any static built-up. Not doing so may result in malfunction or damage.

• Do not touch the Expansion I/O Unit Connecting Cable while the power is be-

ing supplied to prevent any malfunction due to static electricity.

• Do not pull on the cables or bend the cables beyond their natural limit. Doing

either of these may break the cables.

• Do not place objects on top of the cables. Doing so may break the cables.

• When disposing of Units or other products, be sure to do so according to local

laws and regulations.

• When using a Temperature Sensor Unit with a thermocouple input

(CPM1A-TS001/002, CPM2C-TS001), observe the following precautions:

• With the CPM1A-TS001/002, do not remove the cold junction compensa-

tor attached at the time of delivery. If the cold junction compensator is

removed the Unit will not be able to measure temperatures correctly.

xxii

Page 22

Maintenance

• When replacing a part, be sure to confirm that the rating of a new part is correct.

• When the CPU Unit is replaced, resume operation only after transferring to the

Transportation and Storage

• When transporting the Units, use special packing boxes. Do not subject the

• Store the Units within the following temperature and humidity ranges:

5Application Precautions

• With the CPM1A-TS001/002, each of the input circuits is calibrated with

the cold junction compensator attached to the Unit. If the Unit is used with

the cold junction compensator from other Units, the Unit will not be able to

measure temperatures correctly.

• With the CPM1A-TS001/002 or the CPM2C-TS001, do not touch the cold

junction compensator. Doing so may result in incorrect temperature measurement.

Not doing so may result in malfunction or burning.

new CPU Unit the contents of the DM and HR Areas required for operation. Not

doing so may result in an unexpected operation.

Units or other products to excessive vibration or shock during transportation

and do not to drop them.

Storage temperature: –25 to 65°C

Storage humidity: 25% to 85% (with no icing or condensation)

xxiii

Page 23

SECTION 1

PC Setup

This section explains the PC Setup in the CPM1, CPM1A, CPM2A, CPM2C (including the CPM2C-S), and SRM1(-V2) PCs.

The PC Setup can be used to control the operating parameters. To change the PC Setup, refer to the Operation Manual of the

PC for Programming Console procedures.

Refer to the SSS Operation Manual: C-series PCs for SSS procedures. Refer to the SYSMAC-CPT Support Software Quick

Start Guide (W332) and User Manual (W333) for SYSMAC-CPT Support Software procedures.

If you are not familiar with OMRON PCs or ladder diagram program, you can read 1-1 PC Setup as an overview of the operating parameters available for the CPM1/CPM1A, CPM2A/CPM2C, and SRM1(-V2). You may then want to read Section 5

Memory Areas, Section 6 Ladder-diagram Programming, and related instructions in Section 7 Instruction Set before completing this section.

1-1 PC Setup 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-1 Changing the PC Setup 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-2 CPM1/CPM1A PC Setup Settings 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-3 CPM2A/CPM2C PC Setup Settings 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-4 SRM1(-V2) PC Setup Settings 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Basic PC Operation and I/O Processes 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-1 Startup Mode 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-2 Hold Bit Status 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-3 Program Memory Write-protection 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-4 RS-232C Port Servicing Time (CPM2A/CPM2C/SRM1(-V2) Only) 18. . . . . . . . .

1-2-5 Peripheral Port Servicing Time 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-6 Cycle Monitor Time 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-7 Minimum Cycle Time 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-8 Input Time Constants 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-9 Error Log Settings 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 CPM2C Changes in SW2 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

Page 24

1-1SectionPC Setup

1-1 PC Setup

The PC Setup comprises various operating parameters that control PC operation. In order to make the maximum use of PC functionality when using interrupt

processing and communications functions, the PC Setup may be customized

according to operating conditions.

At the time of shipping, the defaults are set for general operating conditions, so

that the PC can be used without having to change the settings. You are, however, advised to check the default values before operation.

Default Values The default values for the PC Setup are 0000 for all words (except for the low

battery error enable in DM 6655 bits 12 to 15 for CPM2A CPU Units). The default

values can be reset at any time by turning ON SR 25210 in PROGRAM mode.

Caution When data memory (DM) is cleared from a Programming Device, the PC Setup

!

settings will also be cleared to all zeros.

1-1-1 Changing the PC Setup

PC Setup settings are accessed at various times depending on the setting, as

described below.

• DM 6600 to DM 6614: Accessed only when PC’s power supply is turned

ON.

• DM 6615 to DM 6644: Accessed only when program execution begins.

• DM 6645 to DM 6655: Accessed regularly when the power is ON.

Since changes in the PC Setup become effective only at the times given above,

the PC will have to be restarted to make changes in DM 6600 to DM 6614 effective, and program execution will have to be restarted to make changes in

DM 6615 to DM 6644 effective.

When DM 6602 bits 00 to 03 are set to protect the program memory, DM 6602

cannot be changed using the PC Setup operation of the Support Software. To

change DM 6602, use the I/O Monitor or DM Edit operation.

Making Changes from a

Programming Device

Errors in the PC Setup If an incorrect PC Setup setting is accessed, a non-fatal error (error code 9B) will

The PC Setup can be read, but not overwritten, from the user program. Writing

can be done only by using a Programming Device.

Although the PC Setup is stored in DM 6600 to DM 6655, settings can be made

and changed only from a Programming Device (e.g., SSS, or Programming

Console). DM 6600 to DM 6644 can be set or changed only while in PROGRAM

mode. DM 6645 to DM 6655 can be set or changed while in either PROGRAM

mode or MONITOR mode. The cycle time will be rather long when the PC Setup

is changed in MONITOR mode.

The following settings can be made in PROGRAM mode from the SSS using

menu operations. All other settings must be made using the hexadecimal setting

operation.

• Startup Mode (DM 6600)

• I/O Hold Bit Status and Forced Status Hold Bit Status (DM 6601)

• Cycle Monitor Time (DM 6618)

• Cycle Time (DM 6619)

• RS-232C Port Settings (DM 6645 to DM 6649)

Note The RS-232C Port Settings (DM 6645 to DM 6649) are not used in

CPM1/CPM1A PCs because these PCs aren’t equipped with an RS-232C port.

be generated, the corresponding error flag (AR 1300 to AR 1302) will be turned

ON, and the default setting will be used instead of the incorrect setting.

2

Page 25

1-1-2 CPM1/CPM1A PC Setup Settings

The PC Setup is broadly divided into four categories: 1) Settings related to basic

PC operation and I/O processes, 2) Settings related to the cycle time, 3) Settings

related to interrupts, and 4) Settings related to communications. This section will

explain the settings according to these classifications.

The following table shows the settings for CPM1/CPM1A PCs in order. Refer to

the page number in the last column for more details on that setting.

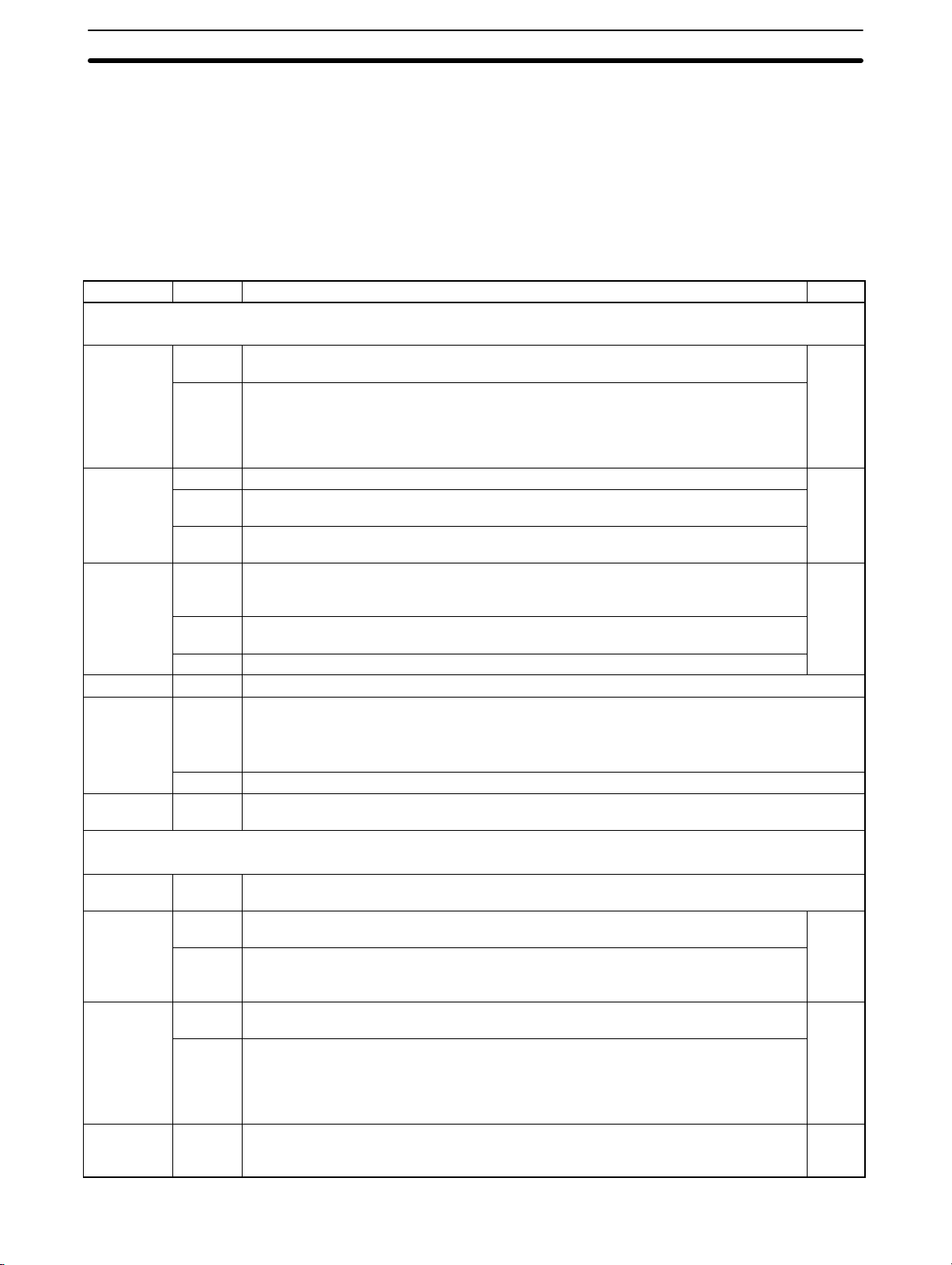

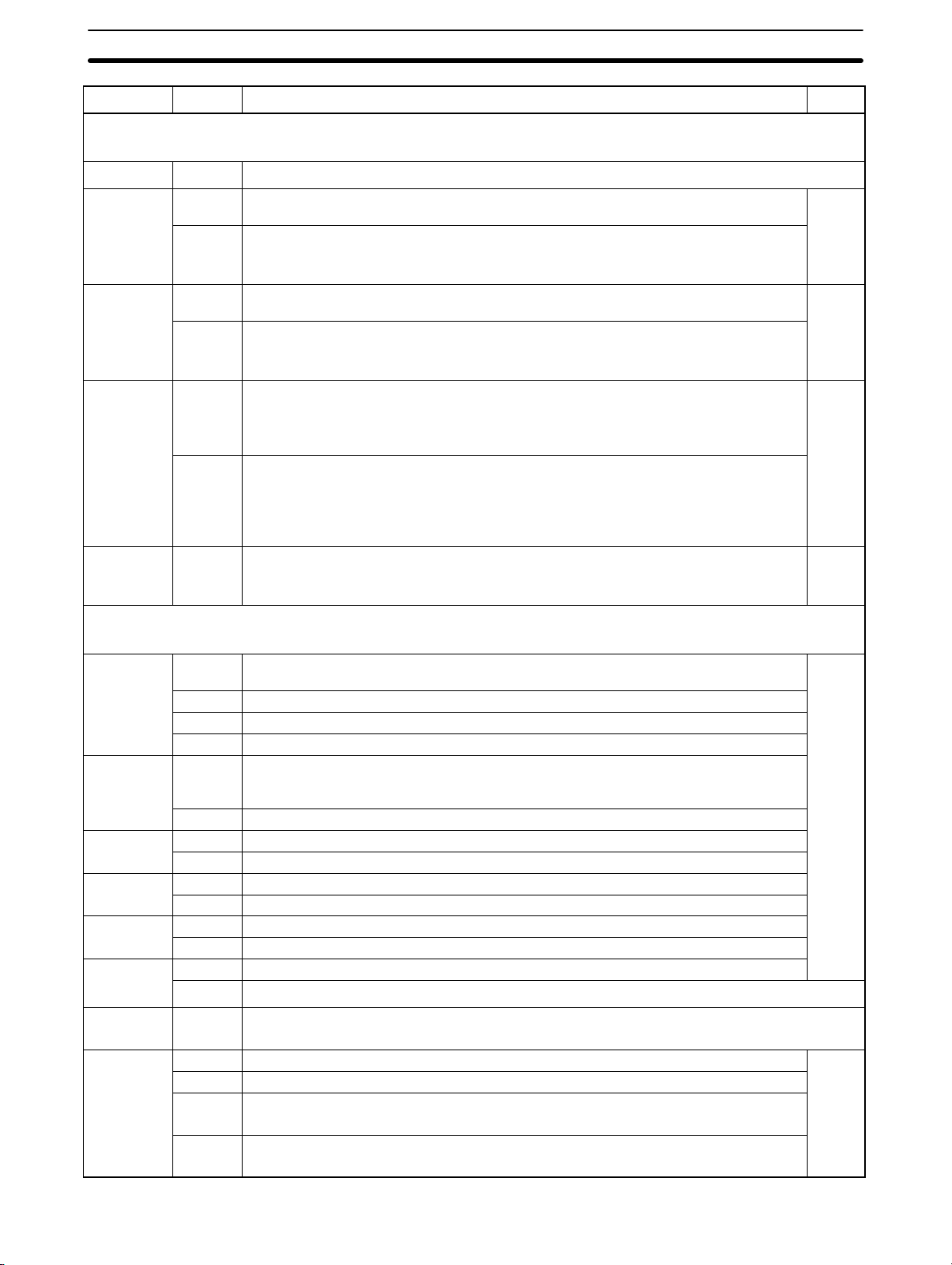

Word(s) Bit(s) Function Page

Startup Processing (DM 6600 to DM 6614)

The following settings are effective after transfer to the PC only after the PC is restarted.

DM 6600

DM 6601

DM 6602

DM 6603 00 to 15 Not used.

DM 6604

DM 6605 to

DM 6614

Cycle Time Settings (DM 6615 to DM 6619)

The following settings are effective after transfer to the PC the next time operation is started.

DM 6615,

DM 6616

DM 6617

DM 6618

DM 6619 00 to 15 Cycle time

00 to 07 Startup mode (effective when bits 08 to 15 are set to 02).

00: PROGRAM; 01: MONITOR 02: RUN

08 to 15 Startup mode designation

00: According to communications port setting switch and peripheral port connection

(See table at the bottom of this page.)

01: Continue operating mode last used before power was turned OFF.

02: Setting in 00 to 07

00 to 07 Not used.

08 to 11 IOM Hold Bit (SR 25212) Status at Startup

0: Reset; 1: Maintain (See note 3.)

12 to 15 Forced Status Hold Bit (SR 25211) Status at Startup

0: Reset; 1: Maintain (See note 3.)

00 to 03 Program memory write-protection

0: Program memory unprotected

1: Program memory write-protected (except DM 6602 itself)

04 to 07 Programming Console display language

0: English; 1: Japanese

08 to 15 Not used.

00 to 07 00: If data could not be saved with the built-in capacitor (AR 1314 ON), a memory error will not

be generated.

01: If data could not be saved with the built-in capacitor (AR 1314 ON), a memory error will be

generated.

08 to 15 Not used.

00 to 15 Not used.

00 to 15 Not used.

00 to 07 Servicing time for peripheral port (effective when bits 08 to 15 are set to 01)

00 to 99 (BCD): Percentage of cycle time used to service peripheral.

08 to 15 Peripheral port servicing setting enable

00: 5% of the cycle time

01: Use time in 00 to 07.

00 to 07 Cycle monitor time (effective when bits 08 to 15 are set to 01, 02, or 03)

00 to 99 (BCD): Setting (see 08 to 15)

08 to 15 Cycle monitor enable (Setting in 00 to 07 x unit; 99 s max.)

00: 120 ms (setting in bits 00 to 07 disabled)

01: Setting unit: 10 ms

02: Setting unit: 100 ms

03: Setting unit: 1 s

0000: Variable (no minimum)

0001 to 9999 (BCD): Minimum time in ms

16

17

17

18

18

19

1-1SectionPC Setup

3

Page 26

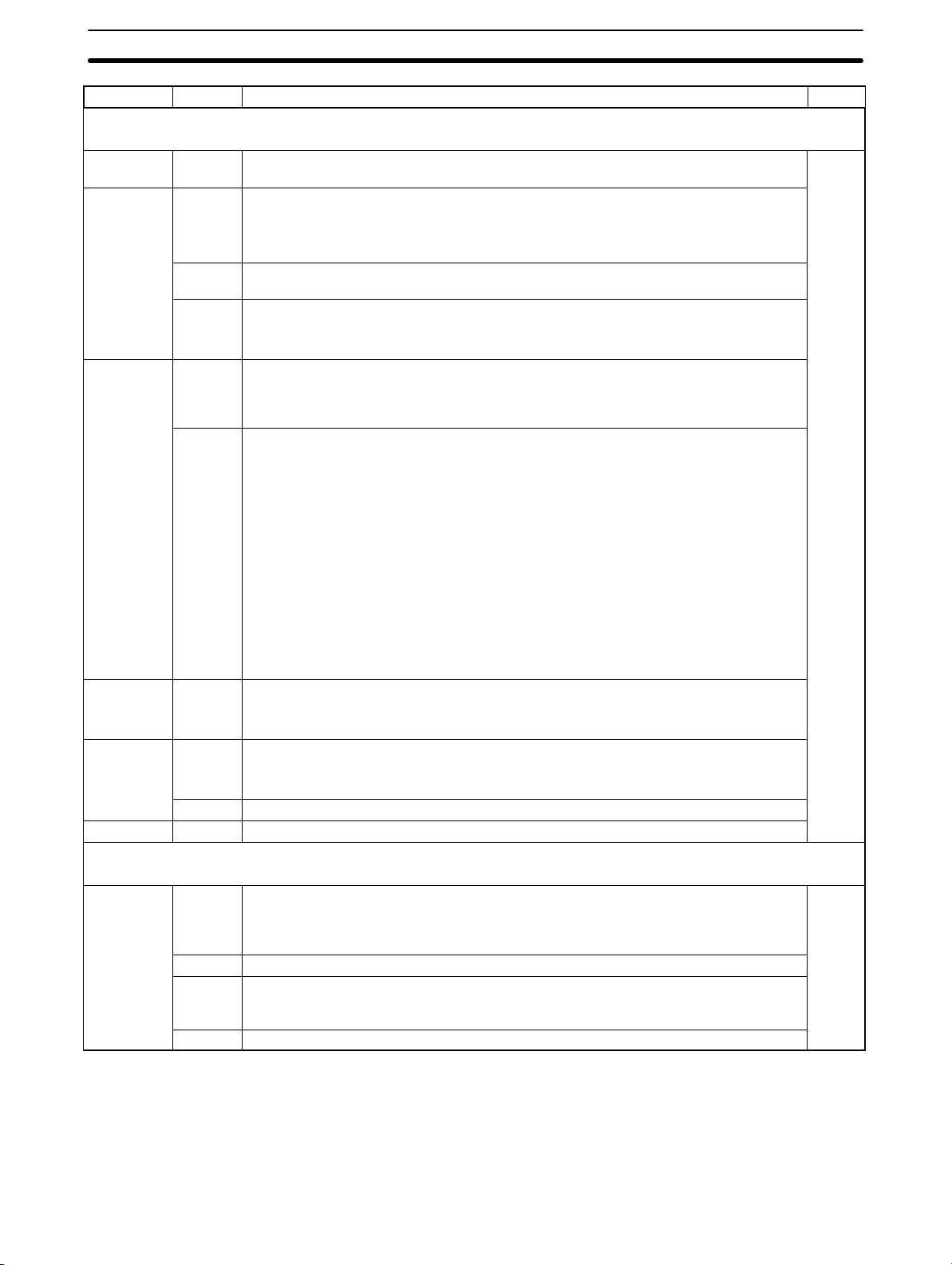

Word(s) PageFunctionBit(s)

Interrupt Processing (DM 6620 to DM 6639)

The following settings are effective after transfer to the PC the next time operation is started.

DM 6620

DM 6621

DM 6622

DM 6623

DM 6624

DM 6625

DM 6626 to

DM 6627

DM 6628

DM 6629 to

DM 6641

High-speed Counter Settings (DM 6640 to DM 6644)

The following settings are effective after transfer to the PC the next time operation is started.

DM 6640 to

DM 6641

DM 6642

DM 6643,

DM 6644

00 to 03 Input constant for IR 00000 to IR 00002

0: 8 ms; 1: 1 ms; 2: 2 ms; 3: 4 ms; 4: 8 ms; 5: 16 ms; 6: 32 ms; 7: 64 ms; 8: 128 ms

04 to 07 Input constant for IR 00003 and IR 00004 (Setting same as bits 00 to 03)

08 to 11 Input constant for IR 00005 and IR 00006 (Setting same as bits 00 to 03)

12 to 15 Input constant for IR 00007 to IR 00011 (Setting same as bits 00 to 03)

00 to 07 Input constant for IR 001

00: 8 ms; 01: 1 ms; 02: 2 ms; 03: 4 ms; 04: 8 ms; 05: 16 ms; 06: 32 ms; 07: 64 ms; 08:

128 ms

08 to 15 Input constant for IR 002 (Setting same as for IR 001.)

00 to 07 Input constant for IR 003 (Setting same as for IR 001.)

08 to 15 Input constant for IR 004 (Setting same as for IR 001.)

00 to 07 Input constant for IR 005 (Setting same as for IR 001.)

08 to 15 Input constant for IR 006 (Setting same as for IR 001.)

00 to 07 Input constant for IR 007 (Setting same as for IR 001.)

08 to 15 Input constant for IR 008 (Setting same as for IR 001.)

00 to 07 Input constant for IR 009 (Setting same as for IR 001.)

08 to 15 Not used.

00 to 15 Not used.

00 to 03 Interrupt enable for IR 00003 (0: Normal input; 1: Interrupt input; 2: Quick-response)

04 to 07 Interrupt enable for IR 00004 (0: Normal input; 1: Interrupt input; 2: Quick-response)

08 to 11 Interrupt enable for IR 00005 (0: Normal input; 1: Interrupt input; 2: Quick-response)

12 to 15 Interrupt enable for IR 00006 (0: Normal input; 1: Interrupt input; 2: Quick-response)

00 to 15 Not used.

00 to 15 Not used.

00 to 03 High-speed counter mode

0: Up/down counter mode; 4: Incrementing counter mode

04 to 07 High-speed counter reset mode

0: Z phase and software reset; 1: Software reset only

08 to 15 High-speed counter enable

00: Don’t use high-speed counter; 01: Use high-speed counter with settings in 00 to 07

00 to 15 Not used.

1-1SectionPC Setup

19

79

86

4

Page 27

Word(s) PageFunctionBit(s)

Peripheral Port Settings

The following settings are effective after transfer to the PC.

DM 6645 to

DM 6649

DM 6650

DM 6651

DM 6652 00 to 15 Transmission delay (Host Link) (See note 4.)

DM 6653

DM 6654 00 to 15 Not used.

Error Log Settings (DM 6655)

The following settings are effective after transfer to the PC.

DM 6655

00 to 15 Not used.

00 to 07 Port settings

00: Standard (1 start bit, 7-bit data, even parity, 2 stop bits, 9,600 bps)

01: Settings in DM 6651

(Other settings will cause a non-fatal error and AR 1302 will turn ON.)

08 to 11 Link area for 1:1 PC Link via peripheral port:

0: LR 00 to LR 15

12 to 15 Communications mode

0: Host Link; 2: 1:1 PC Link Slave; 3: 1:1 PC Link Master; 4: 1:1 NT Link

(Other settings will cause a non-fatal error and AR 1302 will turn ON.)

00 to 07 Baud rate

00: 1.2K, 01: 2.4K, 02: 4.8K, 03: 9.6K, 04: 19.2K, 05 to 07: Cannot be used (see note

2)

(Other settings will cause a non-fatal error and AR 1302 will turn ON.)

08 to 15 Frame format

Start Length Stop Parity

00: 1 bit 7 bits 1 bit Even

01: 1 bit 7 bits 1 bit Odd

02: 1 bit 7 bits 1 bit None

03: 1 bit 7 bits 2 bits Even

04: 1 bit 7 bits 2 bits Odd

05: 1 bit 7 bits 2 bits None

06: 1 bit 8 bits 1 bit Even

07: 1 bit 8 bits 1 bit Odd

08: 1 bit 8 bits 1 bit None

09: 1 bit 8 bits 2 bits Even

10: 1 bit 8 bits 2 bits Odd

11: 1 bit 8 bits 2 bits None

(Other settings will cause a non-fatal error and AR 1302 will turn ON.)

0000 to 9999: In ms.

(Other settings will cause a non-fatal error and AR 1302 will turn ON.)

00 to 07 Node number (Host Link)

00 to 31 (BCD)

(Other settings will cause a non-fatal error and AR 1302 will turn ON.)

08 to 15 Not used.

00 to 03 Style

0: Shift after 7 records have been stored

1: Store only first 7 records (no shifting)

2 to F: Do not store records

04 to 07 Not used.

08 to 11 Cycle time monitor enable

0: Detect long cycles as non-fatal errors

1: Do not detect long cycles

12 to 15 Not used.

1-1SectionPC Setup

226

21

Note 1. When the startup mode is set to continue the operating mode last used be-

fore the power was turned off, that operating mode will be retained by the

built-in capacitor. If the power remains off for longer than the backup time of

the capacitor, the data may be lost. (For details on the holding time, refer to

the CPM1A or CPM1 Operation Manual.)

5

Page 28

1-1SectionPC Setup

2. Do not set to “05” to “07.” If set to this value, the CPM1/CPM1A will not operate properly and the RUN PC Setup Error Flag (AR 1302 ON) will not turn

ON.

3. Retention of IOM Hold Bit (SR 25212) Status

If the “IOM Hold Bit Status at Startup” (DM 6601, bits 08 to 11) is set to “Maintain” with the IOM Hold Bit (SR 25212) turned ON, operation can be started

with the I/O memory (I/O, IR, LR) status just as it was before the power was

turned OFF. (The input area is refreshed at startup, however, so it is overwritten by the most recently updated input status.)

Retention of Forced Status Hold Bit (SR 25211) Status

If the “Forced Status Hold Bit Status at Startup” (DM 6601, bits 12 to 15) is

set to “Maintain” with the Forced Status Hold Bit (SR 25211) turned ON, operation can be started with the forced set/reset status just as it was before

the power was turned OFF. (When starting up in RUN Mode, however, the

forced set/reset status is cleared.)

Even if the “IOM Hold Bit Status at Startup” or “Forced Status Hold Bit Status

at Startup” is set to “Maintain,” the IOM Hold Bit (SR 25212) or Forced Status

Hold Bit (SR 25211) status may be cleared if the power remains OFF for

longer than the backup time of the built-in capacitor. (For details on the holding time, refer to the CPM1A or CPM1 Operation Manual.) At this time the

I/O memory will also be cleared, so set up the system so that clearing the I/O

memory will not cause problems.

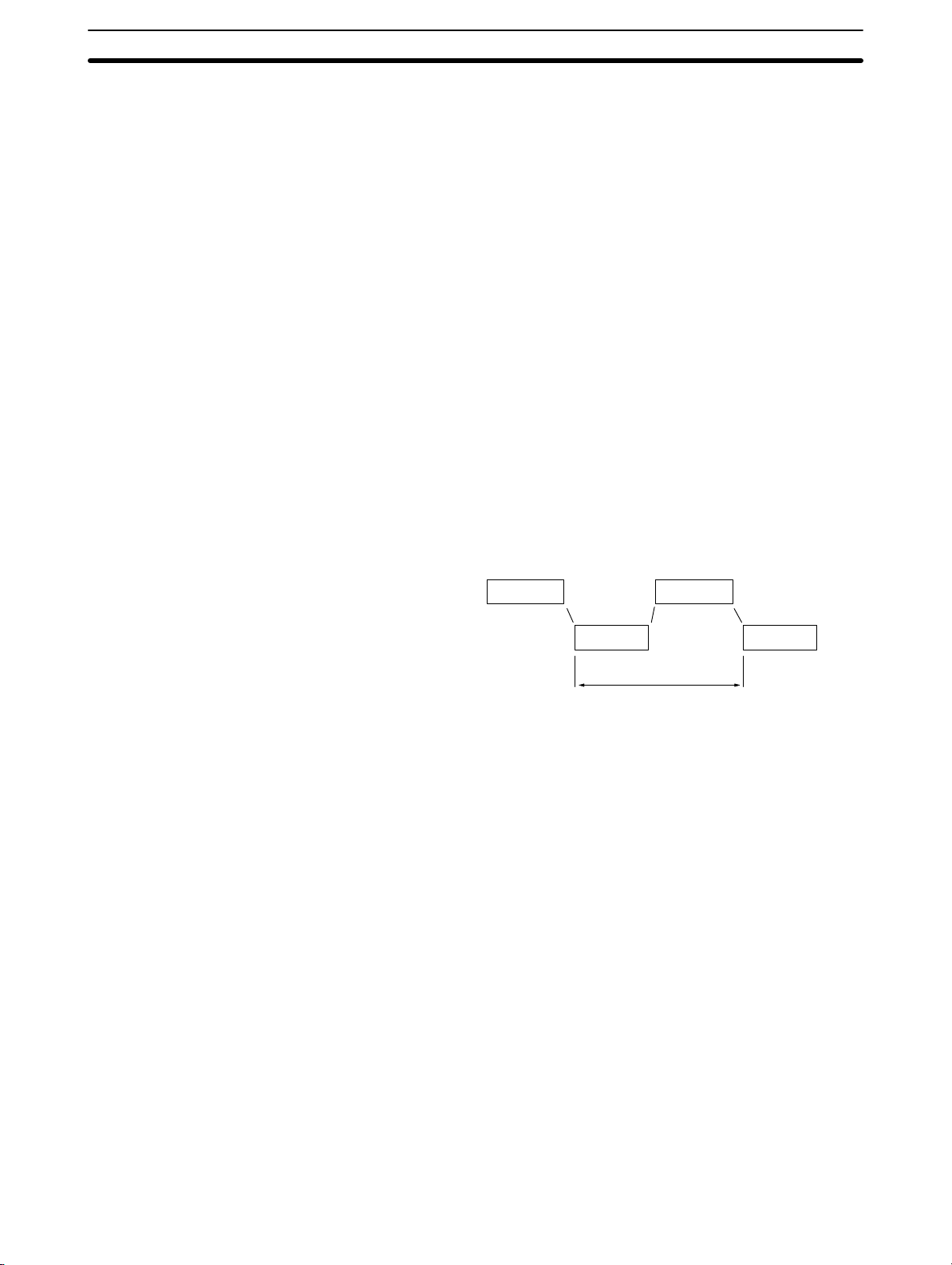

4. The transmission delay is the delay between the previous transmission and

the next transmission.

Host computer

Programmable Controller

Command

Command

Response

Transmission delay time

Response

5. If an out-of-range value is set, the following communications conditions will

result. In that case, reset the value so that it is within the permissible range.

Communications mode: Host Link

Communications format: Standard settings

(1 start bit, 7-bit data; even parity, 2 stop bits,

9,600 bps)

Transmission delay: No

Node number: 00

6

Page 29

1-1-3 CPM2A/CPM2C PC Setup Settings

pp

The PC Setup is broadly divided into four categories: 1) Settings related to basic

PC operation and I/O processes, 2) Settings related to pulse output functions, 3)

Settings related to interrupts, and 4) Settings related to communications. This

section will explain the settings according to these classifications.

The following table shows the setting in order in the DM area. For details, refer to

the page numbers shown.

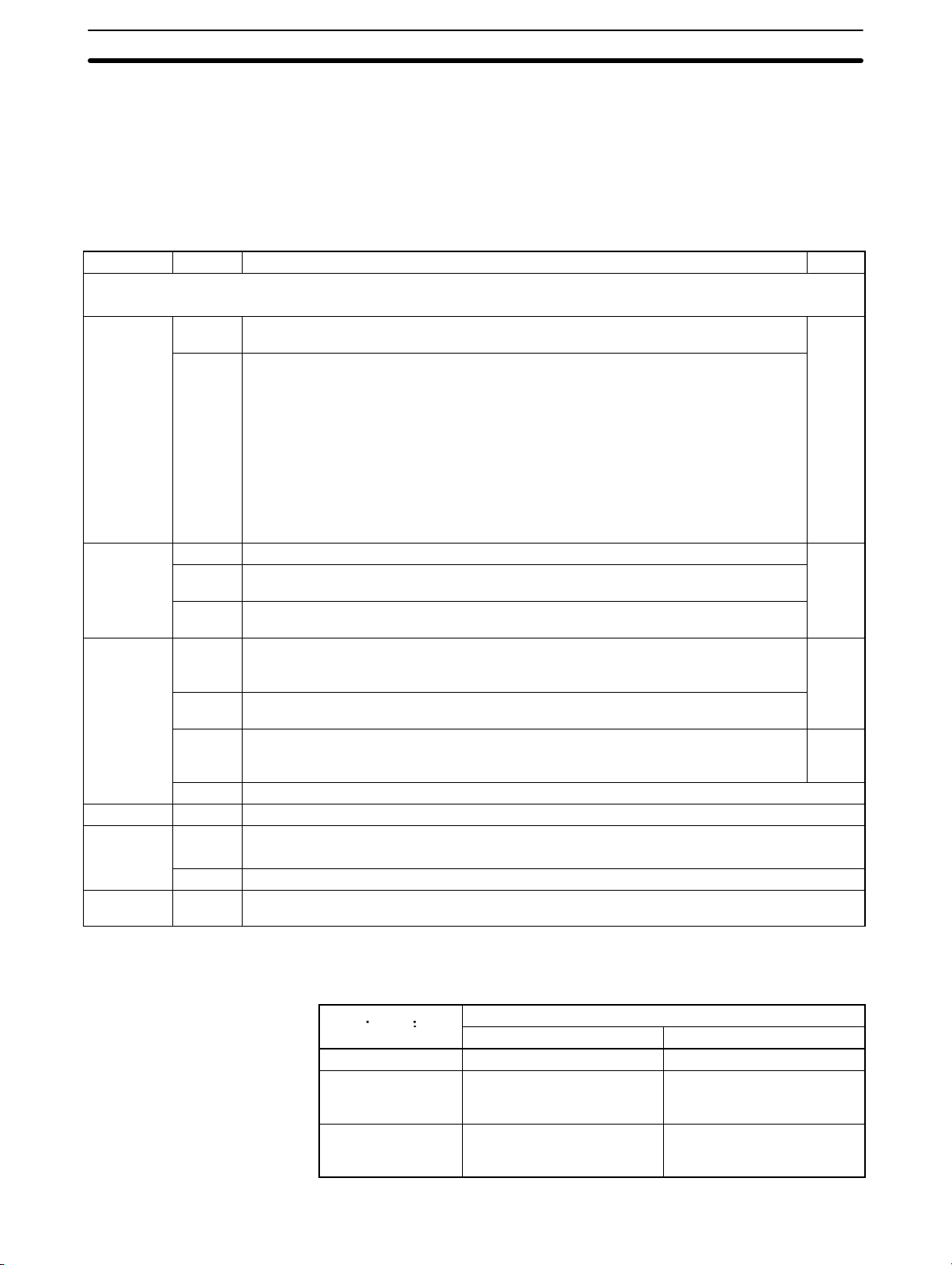

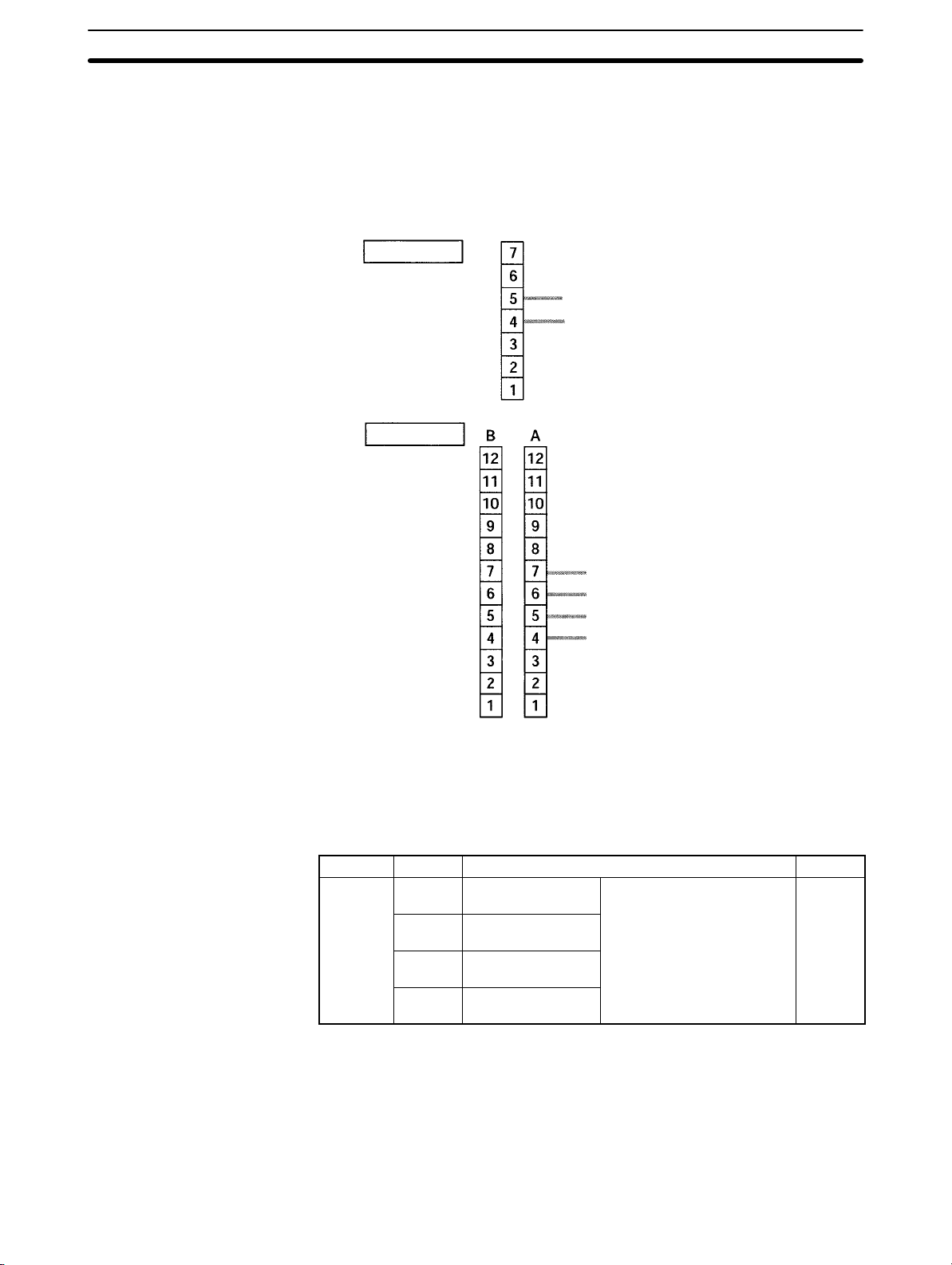

Word(s) Bit(s) Function Page

Startup Processing (DM 6600 to DM 6614)

The following settings are effective after transfer to the PC only after the PC is restarted.

DM 6600

DM 6601

DM 6602

DM 6603 00 to 15 Not used.

DM 6604

DM 6605 to

DM 6614

00 to 07 Startup mode (effective when bits 08 to 15 are set to 02).

00: PROGRAM; 01: MONITOR; 02: RUN

08 to 15 Startup mode designation

00: Mode set on Programming Console switch if Programming Console is connected.

No Programming Device connected: RUN Mode

Programming Console connected: Mode set on mode switch on Programming

Console

Other Programming Device connected: PROGRAM Mode

01: Continue operating mode last used before power was turned OFF.

02: Setting in 00 to 07

The setting of the switch SW2 will affect the operating mode for all CPM2C CPU Units

produced before 1 September 2000. Refer to 1-3 Changes in SW2 for details.

00 to 07 Not used.

08 to 11 IOM Hold Bit (SR 25212) Status at Startup

0: Reset to 0; 1: Maintain previous status

12 to 15 Forced Status Hold Bit (SR 25211) Status at Startup

0: Reset to 0; 1: Maintain previous status

00 to 03 Program memory write-protection

0: Program memory unprotected

1: Program memory write-protected (except DM 6602 itself)

04 to 07 Programming Console display language

0: English; 1: Japanese

08 to 11 Expansion instruction function code assignments

0: Default settings

1: User assignments

12 to 15 Not used.

00 to 07 00: A memory error will not be generated if data could not be retained by the battery.

01: A memory error will be generated if data could not be retained by the battery.

08 to 15 Not used.

00 to 15 Not used.

16

17

17

161

1-1SectionPC Setup

Note For CPM2C PCs with lot number of 3180O or earlier, the startup operating mode

will be as shown in the following table if bits 08 to 15 of DM 6600 are set to 00.

Peripheral port

connected to

Nothing PROGRAM RUN

Programming

Console

Other Programming

Device

Mode set on Programming

Console mode switch

PROGRAM (The CPM2C will

not be able to communicate

with Programming Device.)

Communications port setting switch

SW2 OFF SW2 ON

PROGRAM (The CPM2C will

not be able to communicate

with Programming Console.)

PROGRAM

7

Page 30

Word(s) Bit(s) Function Page

Cycle Time Settings (DM 6615 to DM 6619)

The following settings are effective after transfer to the PC the next time operation is started.

DM 6615 00 to 15 Not used.

DM 6616

DM 6617

DM 6618

00 to 07 Servicing time for RS-232C port (Effective when bits 08 to 15 are set to 01.)

00 to 99 (BCD): Percentage of cycle time used to service RS-232C port.

08 to 15 RS-232C port servicing setting enable

00: 5% of the cycle time

01: Use time in bits 00 to 07.

00 to 07 Servicing time for peripheral port (Effective when bits 08 to 15 are set to 01.)

00 to 99 (BCD): Percentage of cycle time used to service peripheral.

08 to 15 Peripheral port servicing setting enable

00: 5% of the cycle time

01: Use time in bits 00 to 07.

00 to 07 Cycle monitor time (Effective when bits 08 to 15 are set to 01, 02, or 03.)

00 to 99 (BCD): Setting (See bits 08 to 15, below.)

A fatal error will be generated and PC operation will stop if the cycle time exceeds the

cycle monitor time set here.

08 to 15 Cycle monitor enable (Setting in 00 to 07 × units; 99 s max.)

00: 120 ms (setting in bits 00 to 07 disabled)

01: Setting units: 10 ms

02: Setting units: 100 ms

03: Setting units: 1 s

18

18

18

1-1SectionPC Setup

DM 6619 00 to 15 Minimum cycle time

0000: Variable (no minimum)

0001 to 9999 (BCD): Minimum time in ms

Interrupt Processing (DM 6620 to DM 6639)

The following settings are effective after transfer to the PC the next time operation is started.

DM 6620

DM 6621

DM 6622

DM 6623

DM 6624

DM 6625

DM 6626 to

DM 6627

DM6628

00 to 03 Input time constant for IR 00000 to IR 00002

0: 10 ms; 1: 1 ms; 2: 2 ms; 3: 3 ms; 4: 5 ms; 5: 10 ms; 6: 20 ms; 7: 40 ms; 8: 80 ms

04 to 07 Input time constant for IR 00003 and IR 00004 (Setting same as bits 00 to 03)

08 to 11 Input time constant for IR 00005 and IR 00006 (Setting same as bits 00 to 03)

12 to 15 Input time constant for IR 00007 to IR 00011 (Setting same as bits 00 to 03)

00 to 07 Input time constant for IR 001

00: 10 ms 01: 1 ms 02: 2 ms 03: 3 ms 04: 5 ms

05: 10 ms 06: 20 ms 07: 40 ms 08: 80 ms

08 to 15 Input constant for IR 002 (Setting same as for IR 001.)

00 to 07 Input constant for IR 003 (Setting same as for IR 001.)

08 to 15 Input constant for IR 004 (Setting same as for IR 001.)

00 to 07 Input constant for IR 005 (Setting same as for IR 001.)

08 to 15 Input constant for IR 006 (Setting same as for IR 001.)

00 to 07 Input constant for IR 007 (Setting same as for IR 001.)

08 to 15 Input constant for IR 008 (Setting same as for IR 001.)

00 to 07 Input constant for IR 009 (Setting same as for IR 001.)

08 to 15 Not used.

00 to 15 Not used.

00 to 03 Interrupt enable for IR 00003 (0: Normal input; 1: Interrupt input; 2: Quick-response)

04 to 07 Interrupt enable for IR 00004 (0: Normal input; 1: Interrupt input; 2: Quick-response)

08 to 11 Interrupt enable for IR 00005 (0: Normal input; 1: Interrupt input; 2: Quick-response)

(Set to 0 in CPM2C CPU Units with 10 I/O points.)

12 to 15 Interrupt enable for IR 00006 (0: Normal input; 1: Interrupt input; 2: Quick-response)

(This input does not exist in CPM2C CPU Units with 10 I/O points.)

19

19

30

8

Page 31

Word(s) PageFunctionBit(s)

DM 6629

DM 6630 to

DM 6641

High-speed Counter Settings (DM 6640 to DM 6644)

The following settings are effective after transfer to the PC the next time operation is started.

DM 6640 to

DM 6641

DM 6642

DM 6643,

DM 6644

RS-232C Port Communications Settings

The following settings are effective after transfer to the PC.

If the CPM2A CPU Unit’s Communications Switch is ON, communications through the CPM2A’s RS-232C port are gov-

erned by the default settings (all 0) regardless of the settings in DM 6645 through DM 6649.

If pin 2 of the CPM2C CPU Unit’s DIP switch is ON, communications through the CPM2C’s RS-232C port are governed

by the default settings (all 0) regardless of the settings in DM 6645 through DM 6649.

DM 6645

00 to 03 PV coordinate system for pulse output 0

0: Relative coordinates; 1: Absolute coordinates

04 to 07 PV coordinate system for pulse output 1

0: Relative coordinates; 1: Absolute coordinates

08 to 15 Not used.

00 to 15 Not used.

00 to 15 Not used.

00 to 03 High-speed counter mode

0: Differential phase mode (5 kHz)

1: Pulse + direction input mode (20 kHz)

2: Up/down input mode (20 kHz)

4: Increment mode (20 kHz)

04 to 07 High-speed counter reset mode

0: Z phase and software reset; 1: Software reset only

08 to 15 High-speed counter/Synchronized pulse control for IR 00000 to IR 00002

00: Don’t use either function.

01: Use as high-speed counters.

02: Use for synchronized pulse control (10 to 500 Hz).

03: Use for synchronized pulse control (20 Hz to 1 kHz).

04: Use for synchronized pulse control (300 Hz to 20 kHz).

00 to 15 Not used.

00 to 03 Port settings

0: Standard (1 start bit, 7 data bits, even parity, 2 stop bits, 9,600 bps), Host Link unit

number: 0

1: Settings in DM 6646

(Any other setting will cause a non-fatal error and AR 1302 will turn ON.)

04 to 07 CTS control setting

0: Disable CTS control; 1: Enable CTS control

(Any other setting will cause a non-fatal error and AR 1302 will turn ON.)

08 to 11 Link words for 1:1 data link

0: LR 00 to LR 15 (Any other settings are ineffective.)

12 to 15 Communications mode

0: Host Link; 1: No-protocol; 2: 1:1 PC Link Slave; 3: 1:1 PC Link Master; 4: NT Link

(Any other setting causes a non-fatal error and turns ON AR 1302.)

101

47, 56

226

1-1SectionPC Setup

9

Page 32

Word(s) PageFunctionBit(s)

DM 6646

DM 6647 00 to 15 Transmission delay (0000 to 9999 BCD sets a delay of 0 to 99,990 ms.)

DM 6648

DM 6649

00 to 07 Baud rate

00: 1,200 bps; 01: 2,400 bps; 02: 4,800 bps; 03: 9,600 bps; 04: 19,200 bps

08 to 15 Frame format

Start bits Data bits Stop bits Parity

00: 1 bit 7 bits 1 bit Even

01: 1 bit 7 bits 1 bit Odd

02: 1 bit 7 bits 1 bit None

03: 1 bit 7 bits 2 bits Even

04: 1 bit 7 bits 2 bits Odd

05: 1 bit 7 bits 2 bits None

06: 1 bit 8 bits 1 bit Even

07: 1 bit 8 bits 1 bit Odd

08: 1 bit 8 bits 1 bit None

09: 1 bit 8 bits 2 bits Even

10: 1 bit 8 bits 2 bits Odd

11: 1 bit 8 bits 2 bits None

(Any other setting specifies standard settings (1 start bit, 7 data bits; even parity, 2 stop

bits, 9,600 bps), causes a non-fatal error, and turns ON AR 1302.)

(Any other setting specifies a delay of 0 ms, causes a non-fatal error, and turns ON

AR 1302.)

00 to 07 Node number (Host Link)

00 to 31 (BCD)

(Any other setting specifies a node number of 00, causes a non-fatal error, and turns

ON AR 1302.)

08 to 11 Start code selection for no-protocol communications

0: Disables start code; 1: Enables start code in DM 6649

(Any other setting disables the start code, causes a non-fatal error, and turns ON

AR 1302.)

12 to 15 End code selection for no-protocol communications

0: Disables end code; 1: Enables end code in DM 6649; 2: Sets end code of CR, LF.

(Any other setting disables the end code, causes a non-fatal error, and turns ON

AR 1302.)

00 to 07 Start code (00 to FF)

(This setting is valid only when bits 8 to 11 of DM 6648 are set to 1.)

08 to 15 When bits 12 to 15 of DM 6648 set to 0:

Sets the number of bytes to receive. (00: 256 bytes; 01 to FF: 1 to 255 bytes)

When bits 12 to 15 of DM 6648 set to 1:

Sets the end code. (00 to FF)

1-1SectionPC Setup

226

226

226

226

10

Page 33

1-1SectionPC Setup

Word(s) PageFunctionBit(s)

Peripheral Port Communications Settings

The following settings are effective after transfer to the PC.

If the CPM2A CPU Unit’s Communications Switch is ON, communications through the peripheral port are governed by

the default settings (all 0) regardless of the settings in DM 6650 through DM 6654.

The CPM2A’s Communications Switch setting has no effect on communications with a Programming Console connected

to the peripheral port or Support Software set for peripheral bus communications. The CPM2A CPU Unit will auto-detect

either Programming Device and automatically establish communications.

SW2 on the CPM2C CPU Unit must be OFF in order for communications through the CPM2C’s peripheral port to be governed by the settings in DM 6650 through DM 6654.

DM 6650

DM 6651

DM 6652 00 to 15 Transmission delay (0000 to 9999 BCD sets a delay of 0 to 99,990 ms.)

DM 6653

00 to 03 Port settings

00: Standard (1 start bit, 7 data bits, even parity, 2 stop bits, 9,600 bps), Host Link unit

number: 0

01: Settings in DM 6651

(Any other setting specifies standard settings, causes a non-fatal error, and turns ON

AR 1302.)

04 to 11 Not used.

12 to 15 Communications mode

0: Host Link or peripheral bus; 1: No-protocol

(Any other setting specifies Host Link, causes a non-fatal error, and turns ON

AR 1302.)

00 to 07 Baud rate

00: 1,200 bps; 01: 2,400 bps; 02: 4,800 bps; 03: 9,600 bps; 04: 19,200 bps

08 to 15 Frame format

Start bits Data bits Stop bits Parity

00: 1 bit 7 bits 1 bit Even

01: 1 bit 7 bits 1 bit Odd

02: 1 bit 7 bits 1 bit None

03: 1 bit 7 bits 2 bits Even

04: 1 bit 7 bits 2 bits Odd

05: 1 bit 7 bits 2 bits None

06: 1 bit 8 bits 1 bit Even

07: 1 bit 8 bits 1 bit Odd

08: 1 bit 8 bits 1 bit None

09: 1 bit 8 bits 2 bits Even

10: 1 bit 8 bits 2 bits Odd

11: 1 bit 8 bits 2 bits None

(Any other setting specifies standard settings (1 start bit, 7 data bits; even parity, 2 stop

bits, 9,600 bps), causes a non-fatal error, and turns ON AR 1302.)

(Any other setting specifies a delay of 0 ms, causes a non-fatal error, and turns ON

AR 1302.)

00 to 07 Node number (Host Link)

00 to 31 (BCD)

(Any other setting specifies a node number of 00, causes a non-fatal error, and turns

ON AR 1302.)

08 to 11 Start code selection for no-protocol communications

0: Disables start code; 1: Enables start code in DM 6649

(Any other setting disables the start code, causes a non-fatal error, and turns ON

AR 1302.)

12 to 15 End code selection for no-protocol communications

0: Disables end code; 1: Enables end code in DM 6649; 2: Sets end code of CR, LF.

(Any other setting disables the end code, causes a non-fatal error, and turns ON

AR 1302.)

226

226

11

Page 34

Word(s) PageFunctionBit(s)

DM 6654

Error Log Settings (DM 6655)

The following settings are effective after transfer to the PC.

DM 6655

00 to 07 Start code (00 to FF)

(This setting is valid only when bits 8 to 11 of DM 6648 are set to 1.)

08 to 15 When bits 12 to 15 of DM 6648 set to 0:

Sets the number of bytes to receive. (00: 256 bytes; 01 to FF: 1 to 255 bytes)

When bits 12 to 15 of DM 6648 set to 1:

Sets the end code. (00 to FF)

00 to 03 Style

0: Shift after 7 records have been stored

1: Store only first 7 records (no shifting)

2 to F: Do not store records

04 to 07 Not used.

08 to 11 Cycle time monitor enable

0: Generate a non-fatal error for a cycle time that is too long.

1: Do not generate a non-fatal error.

12 to 15 Low battery error enable

0: Generate a non-fatal error for low battery voltage.

1: Do not generate a non-fatal error.

Low battery error detection is disabled (i.e., set to 1) by default in CPU Units that do

not have a clock. If the PC Setup is cleared, the setting will changed to 0 and a low

battery error will occur.

Bits 12 to 15 should always be set to 0 when the optional CPM2C-BAT01 is mounted.

1-1SectionPC Setup

226

21

12

Page 35

1-1-4 SRM1(-V2) PC Setup Settings

The PC Setup is broadly divided into three categories: 1) Settings related to basic PC operation and I/O processes, 2) Settings related to the cycle time, and 3)

Settings related to communications. This section will explain the settings according to these classifications.

The following table shows the settings for SRM1(-V2) PCs in order. Refer to the

page number in the last column for more details on that setting.

Word(s) Bit(s) Function Page

Startup Processing (DM 6600 to DM 6614)

The following settings are effective after transfer to the PC only after the PC is restarted.

DM 6600

DM 6601

DM 6602

DM 6603

DM 6604

DM 6605 to

DM 6614

Cycle Time Settings (DM 6615 to DM 6619)

The following settings are effective after transfer to the PC the next time operation is started.

DM 6615 00 to 15 Not used.

DM 6616

DM 6617

00 to 07 Startup mode (effective when bits 08 to 15 are set to 02).

00: PROGRAM; 01: MONITOR 02: RUN

08 to 15 Startup mode designation

00: Programming Console switch

01: Continue operating mode last used before power was turned off

02: Setting in 00 to 07

00 to 07 Not used.

08 to 11 IOM Hold Bit (SR 25212) Status

0: Reset; 1: Maintain (See caution on page 17.)

12 to 15 Forced Status Hold Bit (SR 25211) Status

0: Reset; 1: Maintain

00 to 03 Program memory write-protection

0: Program memory unprotected

1: Program memory write-protected (except DM 6602 itself)

04 to 07 Programming Console display language

0: English; 1: Japanese

08 to 11 Expansion Instructions

0: Default settings; 1: User settings

12 to 15 Not used.

00 to 03 Maximum number of CompoBus/S devices

0: Max. no. 32

1: Max. no. 16

04 to 07 CompoBus/S communications mode setting (V2 only)

0: High-speed communications

1: Long-distance communications

08 to 15 Not used.

00 to 07 00: If data could not be saved for a power interruption (AR 1314 ON), a memory error will not be

generated.