Page 1

SMART PRESSURE TRANSMITTER

HIGH STABILITY, LOW DRIFT

PX751 Series

25 inH2O to 6000 psi

Starts at

$

1875

PX751, $1875,

shown smaller

than actual size.

2-Way Communications,

⻬

Remote

Reranging,

Access to Difficult-to-Reach

or Hazardous Areas

⻬ Improved Performance,

Increased Accuracy,

Greater Stability and

Noise Resistance

⻬ Diagnostic Capabilities,

Continuous On-Line

Self-Check, Selectable

Failure Alarm, Loop Test

⻬ Transmitter Data Base

Includes Configuration,

Calibration, and Materials

⻬ Greater Performance,

Wider Rangeability (100:1),

Transmitter Security,

Selectable Linear/Square

Root Output, Multi-Drop

⻬ High Stability and Low

Drift Ensure Accurate

Measurements for Years

⻬ Fast, Dynamic Response

⻬ Tighter Control

and Reduced

Maintenance Costs

⻬ Pressure and

Temperature Output

Troubleshooting,

Reconfiguring,

Coplanar Design—

Differential, Gage, or

Absolute Pressure!

PX751C coplanar transmitter,

$1875, with flange, $150, shown

smaller than actual size.

B-235

Page 2

PX751C SMART TRANSMITTER

LCD Meter Options

The LCD meter can be digitally

customized by the user to meet

process needs. The meter can be

configured to display engineering

units, percent of range, or custom

user scale, or to alternate between

any 2 of these.

Power Supply

The DC power supply should

provide power with less than 2%

ripple. The transmitter requires a

minimum of 250 Ω of loop resistance

to communicate with a HartTMbased

communicator. With 250 Ω drop, the

transmitter will require a minimum of

16 Vdc to output 20 mA.

Diagnostics and Service

The diagnostic and service functions

listed here are primarily for use after

the transmitter is installed in the field.

The Transmitter Test feature helps

verify that the transmitter is

operating properly, and can be

performed either on the bench or in

the field. The transmitter test

command initiates an extensive

diagnostics routine that can quickly

identify potential electronics

problems. If the transmitter detects

a problem, messages to indicate the

source of the problem are displayed

on the communicator screen.

The Loop Test feature is designed

to verify proper loop wiring and

transmitter output, and should only

be performed after the user installs

the transmitter. This function tests

the output of the transmitter, the

integrity of the loop, and the

operations of any recorders or

similar devices installed in the loop.

Calibration

Calibrating a smart transmitter is

different from calibrating an analog

transmitter. The smart transmitter

requires 3 steps:

⻬ Rerange—sets the 4 and 20 mA

points to the desired pressures.

⻬ Sensor Trim—adjusts the

position of the factory

characterization curve to optimize

the transmitter performance over a

specified pressure range or to

adjust for mounting effects.

PX751C

(Shown Installed with 3-Valve Manifold)

⻬ Analog Output Trim—adjusts the

analog output to match the plant

standard or the control loop.

Advanced Functions

Cloning: Quickly copies the same

configuration to multiple units. The

cloning process involves configuring

a transmitter, saving the configuration

data, then sending a copy of the

data to a separate transmitter.

Multidrop: Communication

between the host and the

transmitter takes place digitally with

the analog output of the transmitter

deactivated. With HartTMsmart

protocol, up to 15 units can be

connected on a single pair of twisted

wires or over leased phone lines.

B

Burst Mode: Provides faster digital

communications to control system

by eliminating the time required

for the control system to request

data from the transmitter. Burst

mode applies only to the

transmission of dynamic data

(pressure and temperature).

Low-Power Option

User-selectable

3-wire 1 to 5 Vdc or 0.8 to 3.2 Vdc

outputs are available with the

low-power option. The digital signal

is superimposed on the voltage

signal, available to any host

conforming to HartTMprotocol.

Low-power units operate on

6 to 12 Vdc with no load.

B-236

Page 3

PX751C SMART TRANSMITTER

SPECIFICATIONS AND REFERENCE DATA

Specifications

Service:

Liquid, gas and vapor applications

Zero and Span Adjustment:

Zero and span values can be set anywhere

within the range limits stated in tables.

Span values must be greater than or

equal to the minimum span stated in the

range limits tables.

4 to 20 mA Models

Output:

2-wire 4 to 20 mA output, user selectable

for linear or square root; digital process

variable superimposed on 4 to 20 mA

signal, available to any host that conforms

to the HartTMprotocol

Power Supply:

External power supply required. Standard

transmitter operates on 10.5 to 55 Vdc

with no load. A minimum of 250 Ω of loop

resistance is required to communicate

with a Hart

TM

based communicator. With

250 Ω drop, the transmitter will require a

minimum of 16 Vdc to output 20 mA.

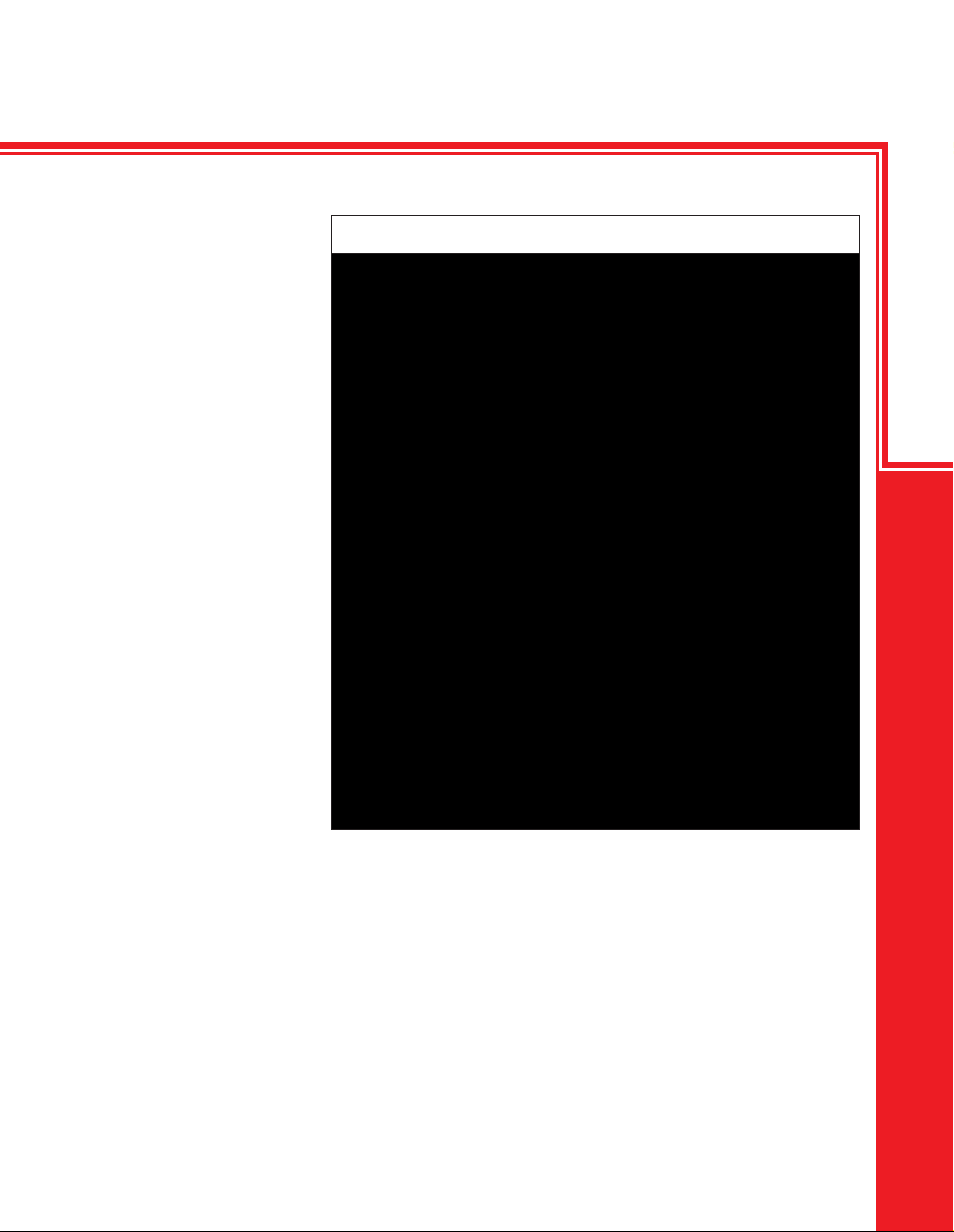

Load Limitations:

)

Load (Ω

1935

1500

1000

500

0

10.5 20 30 40 55

Communications require a minimum loop

resistance of 250 Ω.

1

For CSA approval, power supply must not

exceed 42.2 V.

Operating Region

Voltage (Vdc)

42.4

1

Low Power Models

Output: 3-wire 1 to 5 Vdc or 0.8 to 3.2 Vdc

user selectable. Also user selectable for

linear or square root output configuration.

Digital process variable superimposed on

4 to 20 mA signal, available to any host

that conforms to the HartTMprotocol.

Power Consumption:

3 mA, 18 to 36 mW

Minimum Load Impedance:

100 kΩ (V

Indication:

Optional 2-line, 5-digit LCD meter

Overpressure Limits: Transmitters

withstand the following limits without

damage:

Gage/Differential Models (CA/CD):

Range 1:

0 to 2000 psig (0 to 13.8 MPa)

Ranges 2 to 5:

0 to 3626 psig (0 to 25 MPa)

OUT

+ wiring)

Absolute Models (CA):

Range 0: 0 to 60 psia (0 to 413.7 kPa)

Range 1: 0 to 120 psia (0 to 827.4 kPa)

Range 2: 0 to 300 psia (0 to 2070 kPa)

Range 3: 0 to 1600 psia (0 to 11030 kPa)

Range 4: 0 to 6000 psia (0 to 41370 kPa)

High-Process Temperature

Models (HP/HG)

All Ranges, 0 to 3626 psig

(0 to 25 MPa) “T” Style Gage and

Absolute Models (TA/TG):

Range 1: 0 to 750 psia (0 to 5.2 MPa)

Range 2: 0 to 1500 psia (0 to 10.3 MPa)

Range 3: 0 to 1600 psia (0 to 11.0 MPa)

Range 4: 0 to 6000 psia (0 to 41.4 MPa)

Range 5: 0 to 15000 psia (0 to 103.4 MPa)

Static Pressure Limits

Differential Pressure Models Only:

Operates within specification between

static line pressure of 0.5 psia and

3626 psig; 2000 psig for range 1 (ranges

2 and 3 for high-accuracy models)

Burst Pressure Limits:

All Except Type T:

10,000 psig (69 MPa)

Type T:

Ranges 1 to 4: 11,000 psi (75.8 MPa)

Range 5: 26,000 psig (179 MPa)

Failure Mode Alarm: User selectable to

drive output either high or low when gross

transmitter failure is detected

Temperature Limits

Ambient: -40 to 85°C (-40 to 185°F);

with integral meter, -20 to 80°C (-4 to 175°F)

Storage: -46 to 110°C (-50 to 230°F);

with integral meter, -40 to 85°C (-40 to 185°F)

Process Temperature Limits

Differential, Gage and Absolute:

Silicone Fill Sensor1with

Coplanar Flange -40 to 250°F

Side Flange -40 to 300°F

Level Flange

Horizontal Mount -40 to 250°F

Vertical Mount -40 to 300°F

Inert Fill Sensor Option10 to 185°F

High-Temperature Models:

Fill Material Temperature Range

D.C. Silicone 200

Inert -50 to 350°F

Neobee M-20

Type “T” Gage and Absolute:

Silicone Fill Sensor

Inert Fill Sensor

1

1

1

1

-40 to 375°F

0 to 375°F

-40 to 250°F

-22 to 250°F

Humidity: 0 to 100% RH

Turn-On Time: Performance within

specifications less than 2.0 seconds after

power is applied

Volume Displacement:

<0.08 cm

3

(0.005 in3)

Damping: User selectable from

0 to 36 seconds for one time constant.

This software damping is in addition to

sensor module response time.

3, 4

2

2

2

2

2

2

PX751H high-process temperature

traditional flange differential and

pressure gage, $2860, shown

smaller than actual size.

All Models

Response Time:

Dead Time (Td): 45 ms nominal

Time Constant (Tc): 55 ms

Update Rate: 20 times/s minimum

Vibration Effect: < ±0.1% of URL per

gram when tested from 15 to 2000 Hz

in any axis relative to pipe-mounted

process connection

Power Supply Effect:

<0.005% of calibrated span per volt

RFI Effects: ±0.1% of span from 20 to

1000 MHz, and field strength up to 30 V/m

Transient Protection (Optional):

Meets IEEE standard 587, Category B

meets IEEE standard 473,

surge withstand capability 2.5 kV crest,

1 MHz waveform

Process Connections (All Except

Level, High-Pressure Gage and

Absolute Models):

1

⁄4-18 NPT on 21⁄8" centers;

1

⁄2-14 NPT on 2, 21⁄8, or 21⁄4" centers

Level Models:

High-Pressure Side: 2, 3 or 4",

Class 150, 300 or 600 flange

50, 80 or 100 mm: PN40 or

High Gage or Absolute Pressure:

1

⁄4-18, 1⁄2-14 female, G1⁄2 A DIN 16288

male (available in stainless steel for

ranges 1 to 4) or autoclave type F-250-C

(pressure relieved

1

⁄4 OD high pressure tube 60° cone;

9

⁄16-18 gland thread;

available in stainless steel for range 5 only)

Wetted Parts:

Flanges: Plated carbon steel standard;

stainless steel, Hastelloy C or Monel

optional (available on PX751C only)

Wetted O-Rings: Glass-filled TFE

Housing: Low-copper aluminum with

polyurethane paint

Cover O-Rings: Buna-N

Note: Calibrations at 20°C (68°F) per

ANSI Z210.1

1

Process temperatures above 185°F (85°C)

require derating the ambient limits by a 1.5:1

ratio (0.06:1 ratio for Type H).

2

104°C ( 220°F) limit in vacuum service;

71°C (130°F) for pressures below 0.5 psia.

3

71°C (160°F) limit in vacuum service.

4

Not available on model PX751CA.

10

⁄16 flange

B-237

Page 4

COMMERCIAL GRADE—TYPE “C”

DIFFERENTIAL, GAGE, AND ABSOLUTE PRESSURES

Specifications

Differential and Gage CD/CG Models

Accuracy: ±0.075% of span ±0.100%

of span for differential range 1. For

rangedowns greater than 10:1 of URL

(15:1 for differential range 1), accuracy

= ±[0.025 + 0.005 ( URL

Ambient Temperature Effect

per 10°C (50°F):

Spans 1:1 to 10:1:

±(0.0125% URL + 0.0625% span)

Spans 10:1 to 100:1

±(0.025% URL + 0.125% span)

Range 1: ±(0.1% URL + 0.25% span)

Static Pressure Effect

(DP Model Only):

Zero Error: ±0.1% of URL/1000 psi

(6.9 MPa) for line pressures from

0 to 2000 psi (0 to 13.7 kPa)—can be

calibrated out at line pressure;

±0.2% of URL/1000 psi (6.9 MPa) for

line pressure above 2000 psi (13.7 MPa)

Range 1:

±0.25% URL/1000 psi (6.9 MPa)

Span Error*:

±0.2% rdg/1000 psi (6.9 MPa)

Range 1:

±0.4% rdg/1000 psi (6.9 MPa)

*Ranges 4 and 5 must be field calibrated

Total Performance**:

±0.25% of span for ±28°C (50°F)

temperature changes, up to

1000 psi (6.9 MPa) line pressure,

from 1:1 to 5:1 rangedown

** Total performance is based on the

combined errors of reference accuracy,

ambient temperature effect, and span line

pressure effect.

Stability: ±0.25% of URL for 5 years

for ±28°C (50°F) temperature changes,

up to 1000 psi (6.9 MPa) line pressure

Range 1: ±0.2% URL for 1 year

Mounting Position Effect:

Zero shifts up to 2.5 inH

(0.62 kPa), which can be calibrated out;

no span effect

Weight:

Type C: 6.0 lb (2.7 kg)

Span

RANGES: PX751CD, CG, PD, PG, HD, HG, AND LEVEL MODELS

R

A

N

G

E

1

2

3

4

5

MINIMUM SPAN UPPER RANGE AND SENSOR LIMITS

GAGE AND HIGH-

DIFFERENTIAL

TYPE C TYPE H MODELS CD/HD CG/HG DIFFERENTIAL GAGE HD HG

0.5 inH

(0.12 kPa) (6.22 kPa) (-6.22 kPa)

2.5 inH

(0.62 kPa) (0.62 kPa) (62.2 kPa) (-62.2 kPa) (-62.2 kPa) (-62.2 kPa) (-62.2 kPa) (-62.2 kPa) (-62.2 kPa)

10 inH

(2.48 kPa) (24.8 kPa) (248 kPa) (-248 kPa) (3.5 kPa abs) (-248 kPa) (3.5 kPa abs) (-248 kPa) (3.5 kPa abs)

3 psi 30 psi 300 psi -300 psi 0.5 psia -300 psi 0.5 psia -300 psi 0.5 psia

(20.7 kPa) (207 kPa) (2070 kPa) (-2070 kPa) (3.5 kPa abs) (-2070 kPa) (3.5 kPa abs) (-2070 kPa) (3.5 kPa abs)

20 psi 200 psi 2000 psi -2000 psi 0.5 psia

(138 kPa) (1380 kPa) (13800 kPa) (-13800 kPa) (3.5 kPa abs) (-13800 kPa) (3.5 kPa abs)

ACCURACY

O

2

O 2.5 inH2O 250 inH2O -250 inH2O -250 inH2O -250 inH2O -250 inH2O -250 inH2O -250 inH2O

2

O 100 inH2O 1000 inH2O -1000 inH2O 0.5 psia -1000 inH2O 0.5 psia -1000 inH2O 0.5 psia

2

N/A

)

O

2

% of span

]

PX751CD coplanar

design, $2040, shown

smaller than actual size.

RANGES: PX751CA

ABSOLUTE PRESSURE MODELS

RANGE MINIMUM UPPER LOWER

0

1

2

3

4

(URL) LOWER (LRL)

ALL DIFFERENTIAL GAGE LEVEL LEVEL HIGH-TEMP HIGH-TEMP

25 inH2O -25 inH2O

SPAN (URL) (LRL)

0.167 psia 5 psia 0 psia

(8.7 mmHgA) (26 mmHgA) (0 mmHgA)

0.3 psia 30 psia 0 psia

(2.07 kPa) (206.8 kPa) (0 kPa)

1.5 psia 150 psia 0 psia

(10.34 kPa) (1034.2 kPa) (0 kPa)

8 psia 800 psia 0 psia

(55.16 kPa) (5515.8 kPa) (0 kPa)

40 psia 4000 psia 0 psia

(275.8 kPa) (27580 kPa) (0 kPa)

RANGE AND SENSOR LIMITS

** Total performance is based

on the combined errors of

reference accuracy, ambient

temperature effect, and span

line pressure effect.

N/A N/A N/A N/A N/A

N/A N/A

-2000 psi 0.5 psia

B

B-238

Page 5

COMMERCIAL GRADE—TYPE “C”

HIGH-PRECISION GRADE—TYPE “P”

ORDERING GUIDE

Vacuum to 2000 psi

⻬ Coplanar Flange

⻬ Plated Carbon Steel

Flange

⻬ Stainless Steel

Diaphragm

⻬ 0.075% Accuracy

⻬ 0.25% Long-Term

(5-Year) Stability

⻬ 5-Year Calibration Cycle

PX751C coplanar transmitter,

$1875, with flange, $150, shown

smaller than actual size.

COMMERCIAL GRADE—TYPE C

AVAILABLE FOR FAST DELIVERY!

To Order (Specify Model Number)

MODEL NO. PRICE URL COMPATIBLE METERS

ABSOLUTE PRESSURE

PX751CA-1 $2310 30 psia DP41-E, DP25B-E, DP24-E

PX751CA-2 2310 150 psia DP41-E, DP25B-E, DP24-E

PX751CA-3 2310 800 psia DP41-E, DP25B-E, DP24-E

PX751CA-4 2310 4000 psia DP41-E, DP25B-E, DP24-E

GAGE PRESSURE

PX751CG-2 $1875 250 inH2O DP41-E, DP25B-E, DP24-E

PX751CG-3 1875 1000 inH2O DP41-E, DP25B-E, DP24-E

PX751CG-4 1875 300 psig DP41-E, DP25B-E, DP24-E

PX751CG-5 1875 2000 psig DP41-E, DP25B-E, DP24-E

DIFFERENTIAL PRESSURE

PX751CD-1 $2330 25 inH2O DP41-E, DP25B-E, DP24-E

PX751CD-2 2040 250 inH2O DP41-E, DP25B-E, DP24-E

PX751CD-3 2040 1000 inH2O DP41-E, DP25B-E, DP24-E

PX751CD-4 2245 300 psid DP41-E, DP25B-E, DP24-E

PX751CD-5 2305 2000 psid DP41-E, DP25B-E, DP24-E

Standard features include plated carbon steel flange, stainless steel diaphragm, 4 to 20 mA

output with digital signal based on HartTMprotocol, glass-filled TFE O-ring and silicone fill fluid.

Ordering Examples: PX751CD-1-B4, smart differential pressure sensor with coplanar flange

and range of -2.5 to 25 inH2O, 2" pipe mounting bracket, $2330 + 50 = $2380.

PX751CG-2-B4, smart gage pressure sensor with coplanar flange and range of

-25 to 250 inH2O, 2" pipe mounting bracket, $1875 + 50 = $1925.

PX751C coplanar

design, $1875, shown

smaller than actual size.

OPTIONS FOR ALL MODELS AND INTEGRAL 2-, 3-, or 5-VALVE MANIFOLDS

SUFFIX PRICE DESCRIPTION

-M $100 Low power 1 to 5 Vdc (not avail. w/haz location cert)

-SS 150 All stainless steel flanges for Type “C”

-IN 155 Inert fill fluid (N/A on CA models)

-B4 50 2" pipe mounting bracket for coplanar flange

-B6 70 2" pipe mounting bracket for H-style transmitters

-M5 275 51⁄2 digit LCD meter

B-239

Page 6

HIGH PROCESS TEMPERATURE—TYPE “H”

DIFFERENTIAL AND GAGE PRESSURES

ALL STAINLESS STEEL FLANGES

Starts at

$

2475

Vacuum to 2000 psi

⻬ Stainless Steel Side

Flanges Standard

⻬ Process Temperatures

to 191°C (375°F) with

No Isolating Elements

⻬ 4 to 20 mA and Digital

Communications

⻬ 0.075% Accuracy

⻬ 100:1 Rangedown

⻬ Long-Term Stability

⻬ D.C. 200 Silicone

Fill Fluid

SPECIFICATIONS

“H”—High-Process Temperature

Accuracy: ±0.075% of span; for

rangedowns greater than 10:1 of URL,

accuracy =

±[0.025 + 0.005(URL

Span

Ambient Temperature Effect

per 10° C (50°F):

±(0.025% URL + 0.125% span + 0.35 inH2O);

for spans below 30:1 rangedown,

±(0.035% URL + 0.125% span + 0.35 inH2O)

Static Pressure Effect:

Zero Error: ±0.1% of URL/1000 psi

(6.9 MPa) for line pressures from

0 to 2000 psi (0 to 13.7 MPa)—can be

calibrated out at line pressure;

±0.2% of URL/1000 psi (6.9 MPa)

for line pressures above 2000 psi

(13.7 MPa)

Span Error*:

±0.2% of rdg/1000 psi (6.9 MPa)

* Ranges 4 and 5 must be field calibrated.

Stability:

Ranges 2 and 3:

±0.1% of URL

for 12 months

Ranges 4 and 5:

±0.2% of URL

for 12 months

Mounting Position Effect:

Zero shifts up to 5 inH

which can be calibrated out;

no span effect

Weight: 6.2 kg (13.6 lb)

% of span

]

)

O (1.27 kPa),

2

PX751H, high-process

temperature flange,

$2475, shown with

standard stainless steel

side flanges, smaller

than actual size.

AVAILABLE FOR FAST DELIVERY!

To Order (Specify Model Number)

MODEL NO. PRICE RANGE (psi) COMPATIBLE METER

GAGE PRESSURE

PX751HG-2 $2475 250 inH2O DP41-E, DP25B-E, DP24-E

PX751HG-3 2475 1000 inH2O DP41-E, DP25B-E, DP24-E

PX751HG-4 2475 300 psi DP41-E, DP25B-E, DP24-E

PX751HG-5 2475 2000 psi DP41-E, DP25B-E, DP24-E

DIFFERENTIAL PRESSURE

PX751HD-2 $2590 250 inH2O DP41-E, DP25B-E, DP24-E

PX751HD-3 2590 1000 inH2O DP41-E, DP25B-E, DP24-E

PX751HD-4 2750 300 psi DP41-E, DP25B-E, DP24-E

PX751HD-5 2860 2000 psi DP41-E, DP25B-E, DP24-E

Standard features include stainless steel side flanges, stainless steel diaphragm, 4 to 20 mA output

with digital signal based on HartTMprotocol, glass-filled TFE O-ring and D.C. 200 silicone fill fluid.

Ordering Examples: PX751HD-2-B6, smart high-process temperature differential pressure

sensor with stainless steel side flanges, D.C. 200 silicone fill and ranging of 2.5 to 250 inH2O and

2" pipe mounting bracket, $2590 + 70 = $2660.

PX751HG-4-B6, smart high-process temperature gage pressure sensor with stainless steel

side flange, D.C. 200 silicone fill fluid, 2" pipe mounting bracket and range of 3 to 300 psi,

$2475 + 70 = $2545.

OPTIONS FOR ALL MODELS

SUFFIX PRICE DESCRIPTION

-M $100 Low power 1 to 5 Vdc (not avail. w/haz location cert)

-SS 155 All stainless steel flanges for differential pressure

-IN 155 Inert fill fluid (N/A on CA models)

-B4 50 2" pipe mounting bracket for coplanar flange

-B6 70 2" pipe mounting bracket for H-style transmitters

-M5 275 51⁄2 digit LCD meter

B

B-239A

Page 7

SINGLE ISOLATOR—TYPE “T”

DIFFERENTIAL, GAGE, AND

ABSOLUTE PRESSURES

PX751TG, TA GAGE

AND ABSOLUTE

PRESSURE

Vacuum to 10,000 psi

⻬ Gage or Absolute Pressure

⻬ 0.075% Accuracy

⻬ All Stainless Steel

Wetted Parts

⻬ 0.25% Long-Term

(5-Year) Stability

SPECIFICATIONS

“T” Style Gage and Absolute:

Accuracy: ±0.075% of span;

for rangedowns greater than

10:1 of URL, accuracy =

±[0.0075 ( URL

For Absolute Range 0 With Turndown:

>5:1 of URL, accuracy =

±

0.025 + 0.01( URL

[

Total Performance

(Ranges 1 to 4 Only)**:

±0.25% of span for 28°C (±50°F)

temperature changes, from 1:1 to 5:1

rangedown

** Total performance is based on the

combined errors of reference accuracy,

ambient temperature effect, and span line

pressure effect.

Ambient Temperature Effect

per 10°C (50°F):

Spans 1:1 to 30:1:

±(0.025% URL + 0.125% span)

Spans 30:1 to 100:1:

±(0.035% URL + 0.125% span)

Range 0: ±(0.1% URL + 0.25% span)

Range 5: ±(0.1% URL + 0.15% span)

For High-Gage and Absolute

Range 1, Spans 1:1 to 10:1:

±(0.025% URL + 0.125% span)

Spans 10:1 to 100:1:

±(0.05% URL + 0.125% span)

Stability—Low Absolute Model:

Ranges 1 to 5:

±0.1% of URL for 12 months

Ranges 0:

±0.2% of URL for 12 months

Stability—High-Gage

and Absolute Models:

±0.25% of span

for 5 years for

28°C (±50°F)

temperature change

Mounting Position Effect: Zero shifts

up to 0.62 kPa (0.09 psi),

which can be calibrated out;

no span effect

Weight:

1.4 kg (3.0 lb)

Span

)

Span

% of span

]

% of span

]

)

Starts at

$

1680

PX751T, gage or absolute pressure

single input design, 1⁄2 NPT stainless

steel fitting, $2100, shown with meter

option, smaller than actual size.

RANGE AND SENSOR LIMITS

RANGE MINIMUM UPPER LOWER

SPAN (URL) (LRL)

1 0.3 psia (2 kPa) 30 psi (207 kPa) 0 psi (0 kPa)

2 1.5 psi (2.07 kPa) 150 psia (1034 kPa) 0 psi (0 kPa)

3 8 psi (55 kPa) 800 psia (5516 kPa) 0 psi (0 kPa)

4 40 psi (276 kPa) 4000 psia (27,579 kPa) 0 psi (0 kPa)

5 2000 psi (13,800 kPa) 10,000 psia (68,948 kPa) 0 psi (0 kPa)

AVAILABLE FOR FAST DELIVERY!

To Order (Specify Model Number)

MODEL NO. PRICE URL COMPATIBLE METERS

ABSOLUTE PRESSURE

PX751TA-1 $2100 30 psia DP41-E, DP25B-E, DP24-E

PX751TA-2 2100 150 psia DP41-E, DP25B-E, DP24-E

PX751TA-3 2100 800 psia DP41-E, DP25B-E, DP24-E

PX751TA-4 2100 4000 psia DP41-E, DP25B-E, DP24-E

PX751TA-5 2275 10,000 psia DP41-E, DP25B-E, DP24-E

GAGE PRESSURE

PX751TG-1 $1680 30 psig DP41-E, DP25B-E, DP24-E

PX751TG-2 1680 150 psig DP41-E, DP25B-E, DP24-E

PX751TG-3 1680 800 psig DP41-E, DP25B-E, DP24-E

PX751TG-4 1680 4000 psig DP41-E, DP25B-E, DP24-E

PX751TG-5 1850 10,000 psig DP41-E, DP25B-E, DP24-E

Standard features include SS diaphragm and 1⁄2 NPT process fitting, 4 to 20 mA output with

digital signal based on HartTMprotocol, glass-filled TFE O-ring and silicone fill fluid.

Ordering Examples: PX751TA-1-B4, smart absolute pressure sensor with stainless steel

input and range of 0.03 to 30 psia and 2" pipe mounting bracket, $2100 + 50 = $2150.

PX751TG-2-B4, smart gage pressure sensor with stainless steel input and range of

1.5 to 150 psig and 2" pipe mounting bracket, $1680 + 50 = $1730.

OPTIONS FOR ALL MODELS

SUFFIX PRICE DESCRIPTION

-M $100 Low power 1 to 5 Vdc (not avail. w/haz location cert)

-SS 150 All stainless steel flanges for Type “C”

-IN 155 Inert fill fluid (N/A on CA models)

-B4 50 2" pipe mounting bracket for coplanar flange

-B6 70 2" pipe mounting bracket for H-style transmitters

-M5 275 51⁄2 digit LCD meter

B-239B

Page 8

One Omega Drive | Stamford, CT 06907 | 1-888-TC-OMEGA (1-888-826-6342) | info@omega.com

EPG05

www.omega.com

UNITED KINGDOM

www. omega.co.uk

Manchester, England

0800-488-488

UNITED STATES

www.omega.com

1-800-TC-OMEGA

Stamford, CT.

CANADA

www.omega.ca

Laval(Quebec)

1-800-TC-OMEGA

GERMANY

www.omega.de

Deckenpfronn, Germany

0800-8266342

Karviná, Czech Republic

FRANCE

www.omega.fr

Guyancourt, France

088-466-342

CZECH REPUBLIC

www.omegaeng.cz

596-311-899

BENELUX

www.omega.nl

Amstelveen, NL

0800-099-33-44

More than 100,000 Products Available!

Temperature

Calibrators, Connectors, General Test and Measurement

Instruments, Glass Bulb Thermometers, Handheld Instruments

for Temperature Measurement, Ice Point References,

Indicating Labels, Crayons, Cements and Lacquers, Infrared

Temperature Measurement Instruments, Recorders Relative

Humidity Measurement Instruments, RTD Probes, Elements

and Assemblies, Temperature & Process Meters, Timers and

Counters, Temperature and Process Controllers and Power

Switching Devices, Thermistor Elements, Probes and

Assemblies,Thermocouples Thermowells and Head and Well

Assemblies, Transmitters, Wire

Flow and Level

Air Velocity Indicators, Doppler Flowmeters, Level

Measurement, Magnetic Flowmeters, Mass Flowmeters,

Pitot Tubes, Pumps, Rotameters, Turbine and Paddle Wheel

Flowmeters, Ultrasonic Flowmeters, Valves, Variable Area

Flowmeters, Vortex Shedding Flowmeters

pH and Conductivity

Conductivity Instrumentation, Dissolved Oxygen

Instrumentation, Environmental Instrumentation, pH

Electrodes and Instruments, Water and Soil Analysis

Instrumentation

Data Acquisition

Auto-Dialers and Alarm Monitoring Systems,

Communication Products and Converters, Data

Acquisition and Analysis Software, Data Loggers

Plug-in Cards, Signal Conditioners, USB, RS232, RS485

and Parallel Port Data Acquisition Systems, Wireless

Transmitters and Receivers

Pressure, Strain and Force

Displacement Transducers, Dynamic Measurement

Force Sensors, Instrumentation for Pressure and Strain

Measurements, Load Cells, Pressure Gauges, Pressure

Reference Section, Pressure Switches, Pressure Transducers,

Proximity Transducers, Regulators,

Strain Gages, Torque Transducers, Valves

Heaters

Band Heaters, Cartridge Heaters, Circulation Heaters,

Comfort Heaters, Controllers, Meters and Switching

Devices, Flexible Heaters, General Test and Measurement

Instruments, Heater Hook-up Wire, Heating Cable

Systems, Immersion Heaters, Process Air and Duct,

Heaters, Radiant Heaters, Strip Heaters, Tubular Heaters

click here to go to the omega.com home page

Loading...

Loading...