Page 1

User’s Guide

Model PX751 Pressure Transmitter

http://www.omega.com

e-mail: info@omega.com

Pressure Transmitter

PX751

Page 2

OMEGAnet® On-Line Service Internet e-mail

http://www.omega.com info@omega.com

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGASM

Customer Service: 1-800-622-2378 / 1-800-622-BESTSM

Engineering Service: 1-800-872-9436 / 1-800-USA-WHENSM

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico and

Latin America: Tel: (95) 800-826-6342 FAX: (95) 203-359-7807

En Espan˜ol: (95) 203-359-7803 e-mail: espanol@omega.com

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: (31) 20 6418405 FAX: (31) 20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: nl@omega.com

Czech Republic: ul. Rude armady 1868, 733 01 Karvina-Hranice

Tel: 420 (69) 6311899 FAX: 420 (69) 6311114

Toll Free: 0800-1-66342 e-mail: czech@omega.com

France: 9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400 FAX: (33) 130-699-120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Germany: 0130 11 21 66

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5EX, England

Tel: 44 (161) 777-6611 FAX: 44 (161) 777-6622

Toll Free in the United Kingdom: 0800-488-488

e-mail: info@omega.co.uk

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing certification of

its products to the European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

Page 3

Table of Contents

SECTION 1 Introduction

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Models Covered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Using this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

New Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-4

SECTION 2 Commissioning

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Setting the Loop to Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Fast key sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Configure the Analog Output Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Set the Process Variable Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Set the Output Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Rerange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Set the Damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

LCD Meter Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Diagnostics and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Transmitter Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Loop Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Calibration Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Sensor Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Analog Output Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Compensating Model PX751 Range 4 and 5

Differential Pressure Transmitters for Line Pressure . . . . . . . . . . . . . . . 2-16

EN

i

Page 4

EN

SECTION 3 Installation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Mechanical Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Mounting Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Housing Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Mounting Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Electrical Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Failure Mode Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Failure Mode Alarm vs. Saturation Output Values . . . . . . . . . . . . . . . . . . 3-12

SECTION 4 Troubleshooting

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

SECTION 5 Reference Data

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Transmitter Range and Sensor Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Bolt Identification and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

APPENDIX A HART® Communicator

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

iiiiiiii

Page 5

SECTION

1

Introduction

OVERVIEW

This section outlines the models covered and the organization of this manual.

The following performance limitations may inhibit efficient or safe operation. Critical applications

should have appropriate diagnostic and backup systems in place.

Pressure transmitters contain an internal fill fluid. It is used to transmit the process pressure

through the isolating diaphragms to the pressure sensing element. In rare cases, oil leak paths

in oil-filled pressure transmitters can be created. Possible causes include: physical damage to

the isolator diaphragms, process fluid freezing, isolator corrosion due to an incompatible

process fluid, etc.

A transmitter with an oil fill fluid leak can continue to perform normally for a period of time.

Sustained oil loss will eventually cause one or more of the operating parameters to exceed

published specifications while a small drift in operating point output continues. Symptoms of

advanced oil loss and other unrelated problems include:

n Sustained drift rate in true zero and span or operating point output or both

n Sluggish response to increasing or decreasing pressure or both

n Limited output rate or very nonlinear output or both

n Change in output process noise

n Noticeable drift in operating point output

n Abrupt increase in drift rate of true zero or span or both

n Unstable output

n Output saturated high or low

EN

1-1

Page 6

MODELS COVERED

This manual provides basic installation, commissioning, and troubleshooting

EN

information for the following Omega® Model PX751 Pressure Transmitters:

Model PX751CD — Differential Pressure Transmitter

measures differential pressure from 0.5 inH

superior performance including 0.075% accuracy and 100:1 rangeability.

Model PX751CG — Gage Pressure Transmitter

measures gage pressure from 2.5 inH

proven capacitance cell technology.

Model PX751CA — Absolute Pressure Transmitter

measures absolute pressure from 0.167 to 4,000 psia (8.6 mmHga to 27580 kPa)

using patented piezoresistive silicon sensor.

Model PX751H — High Process Temperature Pressure Transmitter

provides high process temperature capability to 375 °F (191°C), without the use of

remote diaphragm seals or capillaries. These transmitters are available for

differential and gage configurations (PX751HD and PX751HG).

Model PX751P —

provides 0.05% accuracy. The Model PX751P is the most accurate pressure transmitter

available and is ideal for fiscal and allocation metering. Eliminates the need to stack

multiple transmitters.

Model PX751T – Gage and Absolute Pressure Transmitter

measures absolute and gage pressures from 2,000 to 10,000 psi (13800 to 68900

kPa). The Model PX751T uses a single isolator design and microprocessor-based

electronics.

Reference Class

2

Pressure Transmitter

O to 2,000 psi (0.12–13800 kPa) with

2

O to 2,000 psig (0.62–13800 kPa) using

1-2

Page 7

USING THIS MANUAL

This manual is designed to assist in basic installation and operation of Model PX751

Family of Smart Pressure Transmitters. For more detailed information, contact an

Omega product specialist.

Section 2 Commissioning

provides a description of common commissioning tasks.

Section 3 Installation

provides a flowchart outlining installation procedures and installation wiring

diagrams.

Section 4 Troubleshooting

provides basic troubleshooting techniques for common diagnostic messages

associated with the transmitter and the communicator.

Section 5 Reference Data

provides range tables, a typical model structure, and bolt torque specifications for

Model PX751 Transmitters.

Appendices

contain menu trees and fast key sequences for the HART Communicator.

EN

1-3

Page 8

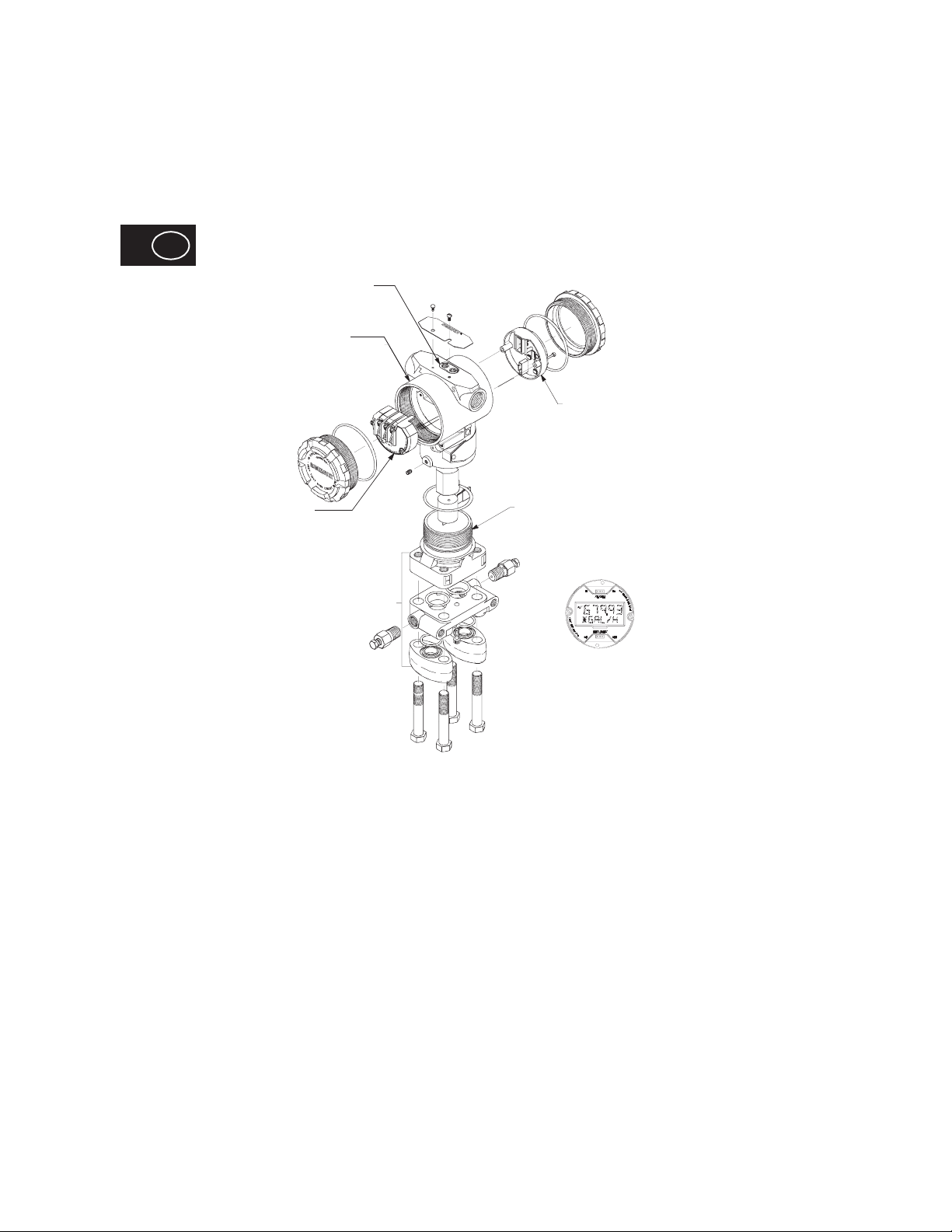

NEW FEATURES

The latest line of Omega Model PX751 pressure transmitters feature physical and

EN

software enhancements for additional functionality and increased ease of use.

Local Zero and Span Adjustments

•Simplified Push-Button Operation

Electronics Housing

•FOUNDATION™

Fieldbus Compatible

•More Space for Field Wiring

New Software Features

•Custom LCD Meter Units

•NAMUR Compliant Alarm and

Saturation Limits Available

Electronics Board

•“Plug-In” Shrouded Design

•Clear Labeling Simplifies Part

Identification

•Fully Backwards Compatible

Terminal Block

•3-Post Design Supports

External Meters

•Encapsulated Electronics for

Increased Robustness

•“Plug-In” Design for Easy

Installation

No Changes to the

Process Connections

Sensor Module

•Welded Metal Cap

•All Welded Design

•Fully Backwards Compatible

Optional LCD Meter

•2-line Display

•Capable of Displaying

Custom Flow, Level,

or Pressure Units

•Alarm and Security

Jumpers on Faceplate

3051-3031A08B, 3051LCD

1-4

Page 9

SECTION

2

Commissioning

OVERVIEW

This section summarizes Model PX751 Transmitter commissioning procedures.

SAFETY MESSAGES

Procedures and instructions in this section may require special precautions to

ensure the safety of the personnel performing the operations. Information that raises

potential safety issues is indicated by a warning symbol (). Refer to the following

safety messages before performing an operation preceded by this symbol.

Warnings ( )

Explosions can result in death or serious injury.

•Do not remove the transmitter covers in explosive environments when the

circuit is alive.

•Both transmitter covers must be fully engaged to meet

explosion-proof requirements.

•Before connecting a communicator in an explosive atmosphere, make sure the

instruments in the loop are installed in accordance with intrinsically safe or

nonincendive field wiring practices.

EN

Electrical shock can result in death or serious injury.

•Avoid contact with the leads and the terminals. High voltage that may be present on

leads can cause electrical shock.

2-1

Page 10

SETTING THE LOOP TO MANUAL

Whenever you are preparing to send or request data that would disrupt the loop or

EN

change the output of the transmitter, you will have to set your process application

loop to manual. The HART Communicator Model HC275

will prompt you to set the loop to manual when necessary. Keep in mind that

acknowledging this prompter does not set the loop to manual. It’s only a reminder;

you have to set the loop to manual yourself, as a separate operation.

FAST KEY SEQUENCES

For your convenience, fast key sequences are listed for common transmitter

functions. Complete tables of fast key sequences are located in Appendix A/

If you are unfamiliar with the communicator or how to follow fast key sequences,

please refer to Appendix A for communicator operations.

The fast key boxes in this section contain codes for the HART Communicator Model

HC275. From the Online menu (HART Communicator)

press these key sequences to access the desired transmitter function.

CONFIGURE THE ANALOG OUTPUT PARAMETERS

NOTE

The position of the transmitter security jumper may prevent configuration changes.

Refer to Section 5 for the proper placement of the transmitter security jumper.

Set the Process Variable Units

HART Comm.

The Model PX751 allows any of the following output units: inH2O, inHg, ftH2O,

2

mmH

O, mmHg, psi, bar, mbar, g/cm2, kg/cm2, Pa, kPa, torr, and atm.

1, 3, 2

2-2

Page 11

Set the Output Type

HART Comm.

You can set the transmitter output to either linear or square root. Activate the

transmitter square root output mode to make the analog output proportional to flow.

While in square root output mode, the Model PX751 switches to linear output at 0.8%

of ranged pressure input, or 9% of full scale flow output to avoid the extremely high

gain that results as the input approaches zero. The transition from linear to square

root output is smooth, with no step change or discontinuity in output.

1, 3, 5

Rerange

The Range Values command sets the 4 and 20 mA points (lower and upper range

values). Setting the range values to the limits of expected readings maximizes

transmitter performance; the transmitter is most accurate when operated within the

expected pressure ranges for your application. In practice, you may reset the

transmitter range values as often as necessary to reflect changing process

conditions.

NOTE

Regardless of the range points, the Model PX751 will measure and report all readings

within the digital limits of the sensor. For example, if the 4 and 20 mA points are set

to 0 and 10 inH20, and the transmitter detects a pressure of 25 inH20, it digitally

outputs the 25 in H

may be up to ±5.0% error associated with output outside of the range points.

You may use one of three methods to rerange the transmitter. Each method is

unique; examine all three closely before deciding which method to use.

0 reading and a 250% percent of span reading. However, there

2

EN

2-3

Page 12

Rerange with a Communicator Only

EN

HART Comm.

Reranging using only the communicator is the easiest and most popular way to

rerange the transmitter. This method changes the values of the analog 4 and 20 mA

points independently without a pressure input.

NOTE

Changing the lower or upper range point results in similar changes to the span.

NOTE

If the transmitter security jumper is in the “ON” position, you will not be able to

make adjustments to the zero and span. Refer to Figure 3-12 on Page 3-11 for the

appropriate placement of the transmitter security jumper.

4 -or- 5

Rerange with a Pressure Input Source and a Communicator

HART Comm.

Reranging using the communicator and a pressure source or process pressure is a

way of reranging the transmitter when specific 4 and 20 mA points are not known.

This method changes the values of the analog 4 and 20 mA points.

To rerange using the communicator and a pressure source or process pressure enter

the fast-key sequence above, select 2 Apply values, and follow the on-line

instructions.

1, 2, 3, 1, 2

NOTE

If the transmitter security jumper is in the “ON” position, you will not be able to

make adjustments to the zero and span. Refer to Figure 3-12 on Page 3-11 for the

appropriate placement of the transmitter security jumper.

2-4

Page 13

Rerange with a Pressure Input Source and t he Local Zero and Span Buttons

Reranging using the local zero and span adjustments (see Figure 2-1), and a pressure

sour c e i s a w a y o f r e r a n g i n g t h e t ra n s m i t t e r when specific

4 and 20 mA points are not known and a c o m m u n i c a t or i s n o t av a i l a b l e .

NOTE

When you set the 4 mA point the span is maintained; when you set the 20 mA point

the span changes. If you set the lower range point to a value that causes the upper

range point to exceed the sensor limit, the upper range point is automatically set to

the sensor limit, and the span is adjusted accordingly.

To rerange the transmitter using the span and zero buttons, perform the

following procedure.

1. Loosen the screw holding the ce rtif ications l abel on t op of t he transmit t er

housing, and rotate the label to expose the zero and span buttons (see Figure

2-1 on page 2-5).

2. Using a pressure source with an accuracy three to ten times the desired

calibrated accuracy, apply a pressure equivalent to the lower range value to

the high side of the transmitter.

3. To set the 4 mA point, press and hold the zero button for at least two seconds,

then verify that the output is 4 mA. If a meter is installed, it will display

ZERO PASS.

4. Apply a pressure equivalent to the upper range value to the high side of the

transmitter.

5. To set the 20 mA point, press and hold the span button for at least two seconds,

then verify that the output is 20 mA. If a meter is installed, it will display

SPAN PASS.

EN

NOTE

If the transmitter security jumper is in the “ON” p osition, or if the local zero a nd spa n

adjustments are disabled through the software, you will not be able to make adjustments

to the z e r o and s pan u s i ng th e local buttons. Ref e r t o Figure 3-12 on Page 3-1 1 for the

proper placement of the transmitter security jumper. Or refer to “Local Span and Zero

Control” on page 2-6 for instructions on how to enable the span and zero buttons.

FIGURE 2-1. Local Zero and Span Adjustments.

Span and Zero Adjustment Bu tto ns

2-5

3051-3031D02A

Page 14

Local Span and Zero Control

EN

HART Comm.

1, 4, 4, 1, 7

The Local keys command allows software control over the use of the local span and

zero adjustments. To enable or disable the span and zero adjustment buttons on your

transmitter, perform the fast key sequence above.

NOTE

Disabling the local keys only disables transmitter configuration changes using the

zero and span buttons. With the local keys disabled, you can still make changes to

the transmitter configuration using a Hart Communicator.

Set the Damping

HART Comm.

The Model PX751 electronic damping feature changes the response time of the

transmitter to smooth variations in output readings caused by rapid changes in

input. Determine the appropriate damping setting based on the necessary response

time, signal stability, and other requirements of the loop dynamics of your system.

1, 3, 6

LCD Meter Options

HART Comm.

1, 4, 3, 4

The Meter Options command allows you to customize the LCD meter for use in your

application. You can configure the meter to display the following information:

nEngineering Units

nPercent of Range

nUser-Configurable LCD Scale

(1)

nAlternating between any two of the above

The user-configurable scale (2 CM Setup) is a new feature that enables you to

configure the LCD meter to a custom scale using a Model HC275 HART communicator.

With this feature you can define the decimal point position, the upper range value,

the lower range value, the engineering units, and the transfer function. For more

detailed LCD meter information, contact an Omega product specialist.

.

(1) The user -configurable LCD scale is a feature specific to the new 4–20 mA output transmitters. It

is not available with Low Power transmitters.

2-6

Page 15

DIAGNOSTICS AND SERVICE

The diagnostics and service functions are primarily for use after you install the

transmitter in the field. The transmitter test feature is designed to verify that the

transmitter is operating properly, and can be performed either on the bench or in the

field. The loop test feature is designed to verify proper loop wiring and transmitter

output, and should only be performed after you install the transmitter.

Transmitter Test

EN

HART Comm.

The transmitter test command initiates a more extensive diagnostics routine than

that performed continuously by the transmitter. The transmitter test routine can

quickly identify potential electronics problems. If the transmitter test detects a

problem, messages to indicate the source of the problem are displayed on the

communicator screen.

1, 2, 1, 1

Loop Test

HART Comm.

The Loop Test command verifies the output of the transmitter, the integrity of the

loop, and the operations of any recorders or similar devices installed in the loop. To

initiate a loop test, perform the following procedure:

1.Connect a reference meter to the transmitter. To do so, either connect the meter

to the test terminals on the transmitter terminal block, or shunt the power to

the transmitter through the meter at some point in the loop.

2.From the HOME screen, Select 1 Device Setup, 2 Diagnostics and Service, 2

Loop Test, to prepare to perform a loop test.

3.Select “OK” after you set the control loop to manual (see “Setting the Loop to

Manual” on page 2-2).

The communicator displays the loop test menu.

1, 2, 2

2-7

Page 16

4. Select a discreet milliamp level for the transmitter to output. At the “Choose

analog output” prompt, select 1 4mA, 2 20mA, or select

EN

3 other to manually input a value.

If you are performing a loop test to verify the output of a transmitter, enter a

value between 4 and 20 mA. If you are performing a loop test to verify the

transmitter alarm levels, enter the milliamp value at which the transmitter

should enter an alarm state (see Table 3-1 on page 3-12).

5. Check the electrical current meter installed in the test loop to verify that it

reads the value you commanded the transmitter to output. If the readings

match, the transmitter and the loop are configured and functioning properly.

If the readings do not match, there may be a fault in the wiring, the

transmitter may require an output trim, or the electrical current meter may

be malfunctioning.

After completing the test procedure, the display returns to the loop test screen and

allows you to choose another output value or to exit loop testing.

CALIBRATION

Calibrating a smart transmitter is different from calibrating an analog transmitter.

The one-step calibration pro ce ss of an ana lo g transmi tter is do ne in th ree s teps wi th

a smart transmitter:

n Rerange – sets the 4 and 20 mA points at the desired pressures;

n Sensor Trim – Adjusts the factory characterization curve to optimize the

transmitter performance over a specified pressure range or to adjust for

mounting effects;

n Analog Output Trim – Adjusts the analog output to match the plant standard

or the control loop.

2-8

Page 17

TABLE 2-1. Recommended Calibration Tasks.

Transmitter Bench Calibration Tasks Field Calibration Tasks

EN

PX751CD

PX751CG

PX751HD

PX751HG

PX751CA

PX751TA

PX751TG

1.Set output configuration

parameters:

a) Set the range points.

b) Set the Output Units.

c) Set the Output Type.

d) Set the Damping Value.

Optional:

2.

Trim (Accurate pressure source

required)

Optional:

3.

Output Trim (Accurate

multimeter required)

1.Set output configuration

parameters:

Optional:

2.

Trim if equipment is available

(accurate absolute

source required), otherwise

perform the Low Trim Value

section of Full Sensor Trim

procedure.

Optional:

3.

Output Trim (Multimeter

required)

Perform a Full Sensor

Perform an Analog

a) Set the range points.

b) Set the Output Units.

c) Set the Output Type.

d) Set the Damping Value.

Perform a Full Sensor

pressure

Perform an Analog

1.Reconfigure parameters

if necessary.

2.Zero Trim the transmitter

to compensate for

mounting position or

static pressure effects.

1.Reconfigure parameters

if necessary.

2.Perform Low Trim Value

section of Full Sensor

Trim procedure to correct

for mounting position

effects.

2-9

Page 18

Calibration Overview

Complete calibration of the Model PX751 Pressure Transmitter involves the following

EN

tasks:

Configure the Analog Output Parameters

nSet Process Variable Units (Page 2-2)

nSet Output Type (Page 2-3)

nRerange (Page 2-3)

nSet Damping (Page 2-6)

Calibrate the Sensor

nFull Trim (Page 2-14)

nZero Trim (Page 2-13)

Calibrate the 4–20 mA Output

n4–20 mA Output Trim (Page 2-14) or

n4–20 mA Output Trim Using Other Scale (Page 2-16) or

Deciding Which Trim Procedure to Use

To decide which trim procedure to use, you must first determine whether the analogto-digital section or the digital-to-analog section of the transmitter electronics is in

need of calibration. To do so, perform the following procedure:

1.Connect a pressure source, a HART communicator, and a digital readout device

to the transmitter.

2.Establish communication between the transmitter

and the communicator.

3.Apply pressure equal to the upper range point pressure

(100 in H

4.Compare the applied pressure to the Process Variable (PV) line on the

Communicator Online Menu. If the PV reading on the communicator does not

match the applied pressure, and you

are confident that your test equipment is accurate, perform a sensor trim.

5.Compare the Analog Output (AO) line on the communicator online menu to

the digital readout device. If the AO reading on the communicator does not

match the digital readout device, and you are confident that your test

equipment is accurate, perform an output trim.

0, for example).

2

2-10

Page 19

Determining Calibration Frequency

Calibration frequency can vary greatly depending on the application, performance

requirements, and process conditions. Use the following procedure to determine the

calibration frequency that meets the needs of your application.

1.Determine the performance required for your application.

2.Determine the operating conditions.

3.Calculate the Total Probable Error (TPE).

4.Calculate the stability per month.

5.Calculate the calibration frequency.

FIGURE 2-2. Calculating Calibration Frequency.

Step 2: Determine Operating Conditions

0.80

0.70

0.60

Transmitter = Model PX751CD, Range 2 (URL = 250 inH

Calibrated Span = 150 in H

Ambient Temperature Change = ± 50 °F

Line Pressure = 500 psig

Step 1: Required Performance = 0.50% of span

O

2

O)

2

EN

0.50

0.40

0.30

% of Span Error

0.20

0.10

0.00

Step 3: Calculate TPE

Step 4: Calculate Stability

Step 5: Calculate Calibration Frequency

12

24

Months in Service

36

48 60

2-11

Page 20

EN

SAMPLE CALCULATION

Step 1: Determine the Performance Required for your Application

Required Performance: 0.50% of span

Step 2: Determine the Operating Conditions

Transmitter: Model PX751CD, Range 2 (URL = 250 inH2O)

Calibrated Span: 150 inH

Ambient Temperature Change: ± 50 °F

Line Pressure: 500 psig

O

2

Step 3: Calculate the Total Probable Error (TPE)

TPE Reference Accuracy

()

Where:

Reference Accuracy = ± 0.075% of span

Ambient Temperature Effect =

Span Static Pressure Effect = 0.2% of reading per 1000 psi = ±0.1% of span at maximum span

(NOTE: There is no zero static pressure effect. The zero static pressure effect can be calibrated out at line pressure.)

2

()

Temperature Effect

++ 0.150% of span = =

0.0125 URL

±

--------------------------------------0.06125+ per 50 °F

×

Span

2

()

Static Pressure Effect

2

0.0833% of span±=

Step 4: Calculate the Stability per Month

0.25% URL

Stability =

------------------------------------------

±

×()

span

% of span for 5 years = 0.417% of span for 5 years

= ± 0.007% of span per month

Step 5: Calculate Calibration Frequency

Calibration Frequency =

(Required Perfromance TPE)–

---------------------------------------------------------------------------------

Stability per Month

0.5%- 0.150%()

------------------------------------------ 50 months==

0.007%

2-12

Page 21

Sensor Trim

You can trim the sensor using either the full trim or the zero trim function. The trim

functions vary in complexity, and their use is application-dependent. Both trim

functions alter the transmitter’s interpretation of the input signal.

NOTE

Trimming the sensor adjusts the position of the factory characterization curve. It is

possible to degrade the performance of the transmitter if the sensor trim is done

improperly or with equipment that does not meet the accuracy requirements.

Zero Trim

EN

HART Comm.

To calibrate the sensor with a HART Communicator using the zero trim function,

perform the following procedure.

1.Vent the transmitter and attach a communicator to the measurement loop.

2.From the communicator main menu select 1 Device setup,

2 Diagnostics and service, 3 Calibration, 3 Sensor trim, 1 Zero trim to prepare

to adjust the zero trim.

NOTE

The transmitter must be within 3% of true zero (zero based) in order to calibrate

using the zero trim function.

3.Follow the commands provided by the communicator to complete the

adjustment of the zero trim.

1, 2, 3, 3, 1

2-13

Page 22

Full Trim

EN

HART Comm.

To calibrate the sensor with a HART communicator using the full trim function,

perform the following procedure.

1.Assemble and power the entire calibration system including a transmitter,

HART communicator, power supply, pressure input source, and readout device.

NOTE

Use a pressure input source that is at least three times more accurate than the

transmitter, and allow the input pressure to stabilize for 10 seconds before entering

any values.

2.From the communicator main menu select 1 Device setup,

2 Diagnostics and service, 3 Calibration, 3 Sensor trim, 2 Lower sensor trim to

prepare to adjust the lower trim point.

NOTE

Select pressure input values so that the low and high values are equal to or outside

the 4 and 20 mA points. Do not attempt to obtain reverse output by reversing the

high and low points. The transmitter allows approximately a 5% URL deviation from

the characterized curve established at the factory.

3.Follow the commands provided by the communicator to complete the

adjustment of the lower value.

4.Repeat the procedure for the upper value, replacing 2 Lower sensor trim with

3 Upper sensor trim in Step 2.

1, 2, 3, 3

Analog Output Trim

The Analog Output Trim commands allow you to adjust the transmitter’s current

output at the 4 and 20 mA points to match the plant standards. This command

adjusts the digital to analog signal conversion.

2-14

Page 23

Digital to Analog Trim

HART Comm.

To perform a digital-to-analog trim with a HART communicator, perform the

following procedure.

1.From the HOME screen, select 1 Device setup, 2 Diag/Service, 3 Calibration, 4

D/A trim. Select “OK” after you set the control loop to manual (see “Setting the

Loop to Manual” on page 2-2).

2.Connect an accurate reference ammeter to the transmitter at the “Connect

reference meter” prompt. To do so, connect the positive lead to the positive

terminal and the negative lead to the test terminal in the transmitter

terminal compartment, or shunt the transmitter power through the reference

meter at some point.

3.Select “OK” after connecting the reference meter.

4.Select “OK” at the “Setting fld dev output to 4 mA” prompt.

1, 2, 3, 2, 1

The transmitter outputs 4.00 mA.

5.Record the actual value from the reference meter, and enter it at the “Enter

meter value” prompt.

The communicator prompts you to verify whether or not the output

value equals the value on the reference meter.

6.Select 1 Yes if the reference meter value equals the transmitter output value,

or 2 No if it does not.

If you select 1 Yes, proceed to Step 7.

If you select 2 No, repeat Step 5.

7.Select “OK” at the “Setting fld dev output to 20 mA” prompt, and repeat Steps

5 and 6 until the reference meter value equals the transmitter output value.

8.Select “OK” after you return the control loop to automatic control.

EN

2-15

Page 24

Digital to Analog Trim Using Other Scale

EN

HART Comm.

The Scaled D/A Trim command matches the 4 and 20 mA points to a user-selectable

reference scale other than 4 and 20 mA (1 to 5 volts if measuring across a 250 ohm

load, or 0 to 100 percent if measuring from a DCS, for example). To perform a scaled

D/A trim, connect an accurate reference meter to the transmitter and trim the

output signal to scale as outlined in the Output Trim procedure.

NOTE

Use a precision resistor for optimum accuracy. If you add a resistor to the loop,

ensure that the power supply is sufficient to power the transmitter to a 20 mA

output with the additional loop resistance.

1, 2, 3, 2, 2

Compensating Model PX751 Range 4 and 5

Differential Pressure Transmitters for Line Pressure

Model PX751 Range 4 and Range 5 pressure transmitters require a special calibration

procedure when used in differential pressure applications. The purpose of this

procedure is to optimize transmitter performance by reducing the effect of static line

pressure in these applications. Model PX751 differential pressure transmitters

(Ranges 1, 2, and 3) do not require this procedure because the optimization occurs in

the sensor.

Applying high static pressure to Model PX751 Range 4 and Range 5 pressure

transmitters causes a systematic shift in the output. This shift is linear with static

pressure; correct it by performing the Full Trim procedure on page 2-14.

The following specifications show the static pressure effect for Model PX751 Range 4

and Range 5 transmitters used in differential pressure applications:

Zero Effect: ±0.1% of the upper range limit per 1,000 psi (6.9 MPa) for line

pressures from 0 to 2,000 psi (0 to 13.8 MPa).

±0.2% of the upper range limit per 1,000 psi (6.9 MPa) for line pressures above 2,000

psi (13.8 MPa).

Span Effect: Correctable to ±0.2% of reading per 1,000 psi for line pressures from 0

to 3,626 psi.

The systematic span shift caused by the application of static line pressure is –1.00%

of reading per 1,000 psi for PX751C Range 4 transmitters,

and –1.25% of reading per 1,000 psi for Range 5 transmitters.

Use the following example to compute corrected input values.

2-16

Page 25

Example

A transmitter with model number PX751CD-4 will be used in a differential pressure application

where the static line pressure is 1,200 psi. The transmitter is ranged so that the output is 4 mA

at 500 inH

O and 20 mA at 1,500 inH2O.

2

To correct for systematic error caused by high static line pressure, first use the following

formulas to determine corrected values for the low trim and high trim.

LT = LRV + S (LRV) P

Where:

LT = Corrected Low Trim Value

LRV = Lower Range Value

S = –(Span shift per specification)

P = Static Line Pressure

HT = URV + S (URV) P

Where:

HT = Corrected High Trim Value

URV = Upper Range Value

S = –(Span shift per specification)

P = Static Line Pressure

In this example:

URV = 1,500 inH2O

LRV = 500 inH

P = 1,200 psi

S = +0.01/1000

O

2

To calculate the low trim (LT) value:

LT = 500 + (0.01/1000)(500)(1200)

LT = 506 inH2O

To calculate the high trim (HT) value:

HT= 1500 + (0.01/1000)(1500)(1200)

HT= 1,518 inH2O

To complete a Model PX751 full trim and enter the corrected values for low trim (LT)

and high trim (HT) (see “Full Trim” on page 2-14).

Enter the corrected input values for low trim and high trim through the

communicator keypad after you apply the nominal value of pressure as the

transmitter input.

EN

NOTE

After calibrating Model PX751 Range 4 and Range 5 transmitters for high differential

pressure applications, rerange the 4 and 20 mA points using the communicator to

maintain the systematic static line pressure correction. You may re-zero the 4 mA point

after installation using the local zero button without affecting the completed calibration.

2-17

Page 26

EN

2-18

Page 27

SECTION

3

Installation

OVERVIEW

This section contains safety messages, an installation flowchart (see Figure 3-1 on

Page 3-2), and basic mechanical and electrical considerations to guide you through a

successful Model PX751 installation. For more detailed information, contact Omega.

SAFETY MESSAGES

Procedures and instructions in this section may require special precautions to

ensure the safety of the personnel performing the operations. Information that raises

potential safety issues is indicated by a warning symbol (). Refer to the following

safety messages before performing an operation preceded by this symbol.

Warnings ( )

Explosions can result in death or serious injury.

•Do not remove the transmitter covers in explosive environments when the

circuit is alive.

•Both transmitter covers must be fully engaged to meet

explosion-proof requirements.

•Before connecting a communicator in an explosive atmosphere, make sure the

instruments in the loop are installed in accordance with intrinsically safe or

nonincendive field wiring practices.

EN

Electrical shock can result in death or serious injury.

•Avoid contact with the leads and the terminals. High voltage that may be present on

leads can cause electrical shock.

3-1

Page 28

FIGURE 3-1. Installation Flowchart.

EN

START HERE

Bench

Calibration?

Yes

CONFIGURE

Set Units

Set

Range Points

Set

Output Type

Set

Damping

No

VERIFY

A

Apply Pressure

B

Within

Specifications?

A

No

Refer to

Troubleshooting

Section 4

Yes

FIELD

B

INSTALL

Check Jumper

or Switches

Mount

Transmitter

Wire

Transmitter

Power

Transmitter

Confirm Transmitter

Configuration

Zero

Transmitter*

Send Data

to Transmitter

Check for Leaks

DONE

* Not applicable with the Model PX751CA and Model PX751TA Pressure Transmitters.

3-2

Page 29

MECHANICAL CONSIDERATIONS

Mounting Brackets

The Model PX751C Transmitter weighs 5.5 pounds (2.5 kg) without additional options.

Optional mounting brackets allow you to mount the transmitter to a panel, a wall, or

a 2-inch pipe. The B4 bracket option is for use with the Coplanar flange, and the

Model PX751T (see Figure 3-2).

Bracket option B6 is for use with the Model PX751H(see Figure 3-5 on Page 3-5).

FIGURE 3-2. Mounting Configurations Using the Optional B4 Mounting Bracket.

COPLANAR FLANGE

5.2

(132)

1.3 (33)

6.0

(152)

3051-3031A04A, M04A

6.2

(156)

Panel Mount Pipe Mount

4.8

(120)

4.3

(110)

2.8

(72)

2.8

(71)

EN

6.2

(156)

Panel Mount Pipe Mount

2.8

(71)

4.8

(120)

(110)

6.9

(175)

4.3

2.8

(72)

MODEL PX751T

5.2

(132)

2 (50)

6.0

(152)

3-3

3051-3051TA4A, TC4A

Page 30

FIGURE 3-5. Mounting Configurations Using the Optional B6 Mounting Bracket.

Panel Mount Pipe Mount

Impulse Piping

2.7 (67)

4.4

(109)

Impulse Piping

2.7

(67)

0.7

(16)

Housing Rotation

You can rotate the electronics housing up to 180 degrees (left or right) to improve

field access to the two compartments or to better view the optional LCD meter. To

rotate the housing, release the housing rotation set screw and turn the housing not

more than 180 degrees from the orientation shown in Figure 3-6. Do not rotate the

housing more than 180 degrees in either direction. Over-rotation will sever

the electrical connection between the sensor module and the electronics

module, and will void the warranty.

EN

3051-3051HA3B, HA3A

FIGURE 3-6. Model PX751 Standard Housing Orientation.

3-5

3051-036AB

Page 31

Mounting Requirements

Refer to Figure 3-7 for examples of the following mounting configurations:

EN

Liquid Flow Measurement

nplace taps to the side of the line to prevent sediment deposits on the

transmitter’s process isolators,

nmount the transmitter beside or below the taps so gases can vent into the

process line,

nmount drain/vent valve upward to allow gases to vent.

Gas Flow Measurement

nplace taps in the top or side of the line,

nmount the transmitter beside or above the taps so liquid will drain into the

process line.

Steam Flow Measurement

nplace taps to the side of the line,

nmount the transmitter below the taps to ensure that the impulse piping will

stay filled with condensate,

nfill impulse lines with water to prevent the steam from contacting the

transmitter directly and to ensure accurate measurement start-up.

NOTE

In steam or other elevated temperature services, it is important that temperatures

at the coplanar process flanges not exceed 250 °F (121 °C) for transmitters with

silicone fill or 185 °F (85 °C) for inert fill. In vacuum service, these temperature

limits are reduced to 220 °F (104 °C) for silicone fill and 160 °F (71 °C) for inert fill.

Model PX751H, and the traditional flange allow higher temperatures.

FIGURE 3-7. Transmitter Installation Examples.

GAS OR LIQUID SERVICE

Flow

GAS SERVICE

3-6

Flow

STEAM SERVICE

Flow

3051-3051A03A, B03A, C03A

Page 32

ELECTRICAL CONSIDERATIONS

Power Supply

4–20 mA Transmitters

The dc power supply should provide power with less than 2 percent ripple. The total

resistance load is the sum of the resistance and signal leads and the load resistance

of the controller, indicator, and related pieces. Note that the resistance of intrinsic

safety barriers, if used, must be included. Refer to Figure 3-8 for power supply load

limitations.

NOTE

If a single power supply is used to power more than one Model PX751 Transmitter, the

power supply used and the circuitry common to the transmitters should not have

more than 20 ohms of impedance at 1200 Hz.

NOTE

A resistance of at least 250 ohms must exist between the communicator and the

power supply for communications.

FIGURE 3-8. Power Supply Requirements.

Max. Loop Resistance = 43.5 3 (Power Supply Voltage – 10.5)

Communication requires a minimum

loop resistance of 250 ohms.

Minimum terminal voltage for

transmitter is 10.5 V with no load.

Load (Ohms)

Operating

Region

EN

3051-0103A

Voltage (V dc)

(1) For CSA approval, power supply must not excee d 42.4 V.

Low Power Transmitters

Low power transmitters require a 6–12 V dc external power supply.

3-7

Page 33

Wiring

To make electrical connections, remove the housing cover on the side marked FIELD

EN

TERMINALS. Do not remove the instrument covers in explosive atmospheres when

the circuit is alive. All power to the transmitter is supplied over the signal wiring.

Connect the lead that originates at the positive side of the power supply to the

terminal marked “+” and the lead that originates at the negative side of the power

supply to the terminal marked “–” (see Figure 3-9). Avoid contact with the leads and

the terminals. Do not connect the powered signal wiring to the test terminals. Power

could damage the test diode in the test connection.

Plug and seal unused conduit connections on the transmitter housing to avoid

moisture accumulation in the terminal side of the housing. If you do not seal the

unused connections, mount the transmitter with the electrical housing positioned

downward for drainage. Install wiring with a drip loop. Arrange the drip loop so the

bottom is lower than the conduit connections and the transmitter housing.

NOTE

Signal wiring need not be shielded, but use twisted pairs for best results. In order to

ensure proper communication, use 24AWG or larger wire, and do not exceed 5,000

feet (1500 meters).

FIGURE 3-9. Model PX751 Transmitter Terminal Block.

STANDARD

LOW POWER

3-8

02A

, C

02A

1-3031F

305

Page 34

Wiring Diagrams

The following diagrams show the wiring connections necessary to power a Model

PX751 Transmitter and enable communications with a hand-held communicator. For

4–20 mA transmitters, refer to Figure 3-10. For Low Power transmitters, refer to

Figure 3-11 on Page 3-10. Do not remove the transmitter covers in explosive

environments when the circuit is alive.

FIGURE 3-10. 4–20 mA Transmitter Wiring Diagrams .

WIRING ON THE BENCH

24 V dc

Supply

EN

WIRING IN THE FIELD

Current

Meter

Voltmeter

24 V dc

Supply

RL≥ 250 V

3051-3031G02B

3051-3031I02B

3-9

Page 35

FIGURE 3-11. Low Power Transmitter Wiring Diagrams .

EN

WIRING ON THE BENCH

WIRING IN THE FIELD

Voltmeter

24 V dc

Supply

3051-3031I02B

3-10

Voltmeter

Power

Supply

3051-3031E02B

Page 36

FAILURE MODE ALARM

As part of normal operation, the Model PX751 continuously monitors its own

operation. This automatic diagnostic routine is a timed series of checks repeated

continuously. If the diagnostic routine detects a failure, the transmitter drives its

output either below or above specific values depending on the position of the failure

mode jumper.

nFor 4–20 mA transmitters factory-configured for standard operation, the

transmitter drives its output either below 3.75 mA or above 21.75 mA.

nFor 4–20 mA transmitters factory-configured for NAMUR-compliant

operation, the transmitter drives its output either below 3.6 mA or above 22.5

mA.

nFor low-power transmitters configured for 1–5 Volts, the transmitter drives its

output either below 0.95 V or above 5.4 V.

nFor low-power transmitters configured for 0.8–3.2 Volts, the transmitter

drives its output either below 0.75 V or above 4.2 V.

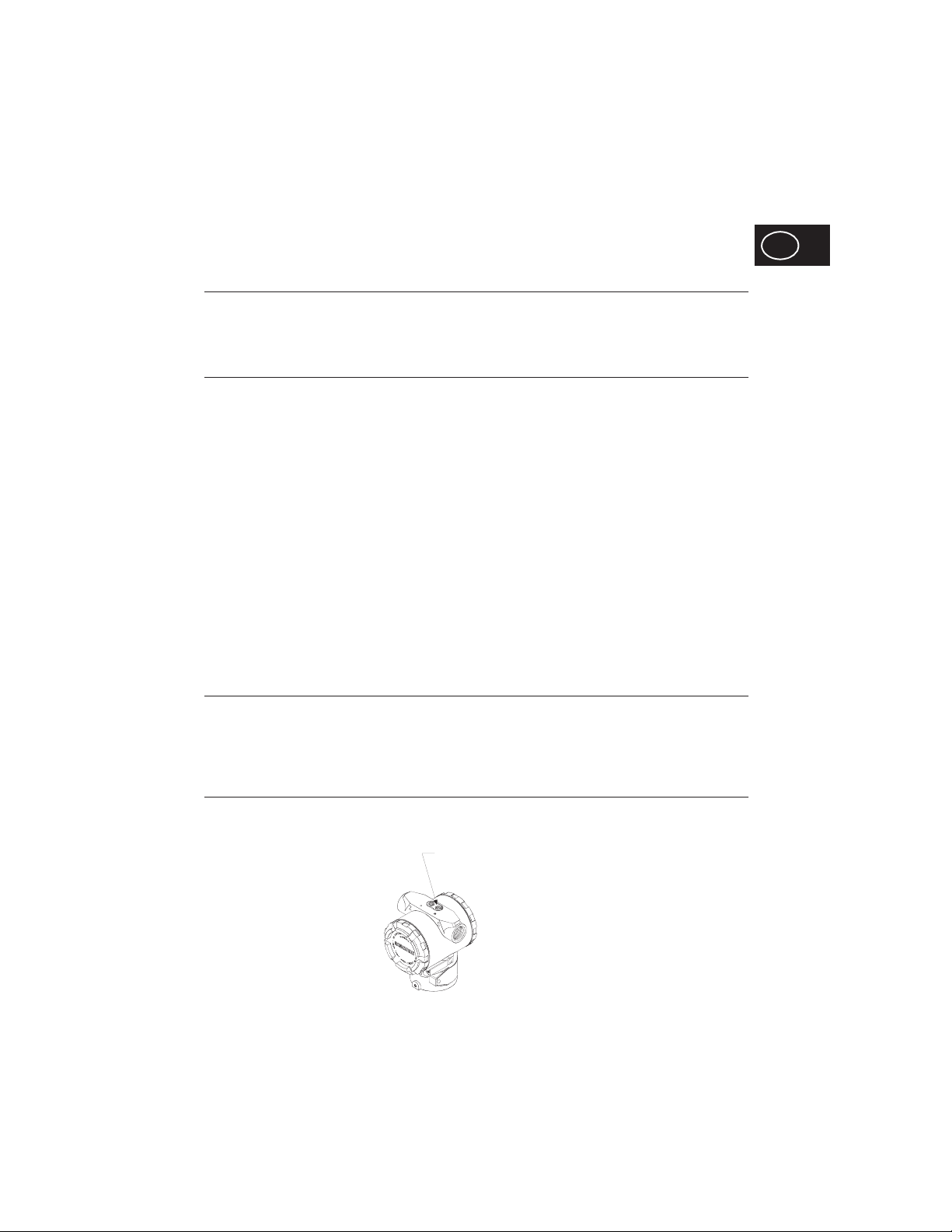

The failure mode alarm jumper is located on the front of the electronics board inside

of the electronics housing cover. The position of this jumper determines whether the

output is driven high or low when a failure is detected (see Figure 3-12). If the alarm

jumper is not installed, the transmitter will operate normally and the default alarm

condition will be high.

FIGURE 3-12. Transmitter Electronics Board.

EN

OFF

ON

3-11

HI

LO

Security

Alarm

3051-3051A, 3031A05C

Page 37

Failure Mode Alarm vs. Saturation Output Values

The failure mode alarm output levels differ from the output values that occur when

EN

applied pressure is outside of the range points. When pressure is outside of the

range points, the analog output continues to track the input pressure until reaching

the saturation value listed below; the output does not exceed the listed saturation

value regardless of the applied pressure. For example, with standard alarm and

saturation levels and pressures outside of the 4–20 range points, the output

saturates at 3.9 mA or 20.8 mA. When the transmitter diagnostics detect a failure,

the analog output is set to a specific alarm value that differs from the saturation

value to allow for proper troubleshooting.

TABLE 3 -1 . 4–20 m A Transmitter Alar m Values vs. Saturation Values.

Level

Saturation Alarm Saturation Alarm

Low 3.9 mA ≤ 3.75 mA

High 20.8 mA ≥ 21.75 mA

STANDARD NAMUR COMPLIANT

3.8 mA ≤ 3.6 mA

20.5 mA ≥ 22.5 mA

TABLE 3 -2 . Low Powe r Transmitter Alar m Values vs. Saturation Values.

Level

Saturation Alarm Saturation Alarm

Low 0.97 mA ≤ 0.95 mA

High 5.20 mA ≥ 5.4 mA

1 – 5 V 0.8 – 3.2 V

0.78 mA ≤ 0.75 mA

4.04 mA ≥ 4.2 mA

3-12

Page 38

SECTION

4

Troubleshooting

OVERVIEW

Table 4-1 provides summarized troubleshooting suggestions for the most common

operating problems.

Failure to follow safe operating practices can cause death or serious injury. Please review the

following safety messages before troubleshooting the Model PX751 Pressure Transmitter.

nUsing improper procedures or parts can affect product performance and the output

signal used to control a process. To ensure safe transmitter performance, use only new

parts and follow Omega documented procedures. Questions regarding these

procedures or parts should be directed to Omega's customer service dept.

nIsolate a failed transmitter from its pressure source as soon as possible. Pressure that

may be present could cause death or serious injury to personnel if the transmitter is

disassembled or ruptures under pressure.

nTo avoid explosions, do not remove the instrument cover or make electrical connections

in explosive atmospheres when the circuit is alive. Make sure the instrument is installed

in accordance with intrinsically safe or nonincendive field wiring practice.

nTo meet explosion proof requirements, make sure that both transmitter covers are fully

engaged.

nTo avoid process leaks, use only the O-ring designed to seal with the corresponding

flange adapter. Omega supplies two unique styles of O-rings for Omega

flange adapters: one for Model PX751 flange adapters and another for Model PX750 flange

adapters. Each flange adapter is distinguished by its unique groove. Refer to the Spare

Parts List PPL 4001 for the numbers of the flange adapters and O-rings designed for the

Model PX751 Pressure Transmitter.

EN

4-1

Page 39

Troubleshooting

EN

TABLE 4-1. Model PX751 Troubleshooting Chart.

Symptom Corrective Actions

Milliamp Reading is Zero • Check if Power Polarity is Reversed

Transmitter is not Communicating

with Communicator

Milliamp Reading is Low or High • Check Pressure Variable Reading for Saturation

No Response to

Changes in Applied Pressure

Pressure Variable

Reading is Low or Hig

Pressure Variable

Reading is Erratic

• Verify Voltage Across Terminals (should be 10 to 55 V dc)

• Check for Bad Diode in Terminal Block

• Replace Transmitter Terminal Block

• Check Power Supply Voltage at Transmitter (Minimum 10.5 V)

• Check Load Resistance (250 V minimum)

• Check if Unit is Addressed Properly

• Replace Electronics Board

• Check if Output is in Alarm Condition

• Perform 4–20 mA Output Trim

• Replace Electronics Board

• Check Test Equipment

• Check Impulse Piping for Blockage

• Check for Disabled Span Adjustment

• Check Transmitter Security Jumper

• Verify Calibration Settings (4 and 20 mA Points)

• Replace Sensor Module

• Check Impulse Piping for Blockage

• Check Test Equipment

• Perform Full Sensor Trim

• Replace Sensor Module

• Check Impulse Piping for Blockage

• Check Damping

• Check for EMF Interference

• Replace Sensor Module

4-2

Page 40

SECTION

5

Reference Data

OVERVIEW

This section contains the following reference data for the Model PX751 family of

pressure transmitters:

nTransmitter Range and Sensor Limits

nBolt Installation

nOrdering Information

TRANSMITTER RANGE AND SENSOR LIMITS

TABLE 5-1. Model PX751CD, PX751CG, PX751P, and PX751H Range and Sensor Limits.

Minimum Span Range and Sensor Limits

Lower (LRL)

–1,000 inH2O

PX751H

Differential

–250 inH2O

(–62.2 kPa)

(–248 kPa)

–300 psi

(–2070 kPa)

– 2,000 psi

(–13800 kPa)

–250 inH2O

(–62.2 kPa)

(3.5 kPa abs)

(3.5 kPa abs)

(3.5 kPa abs)

Model

Range

PX751 CD,

CG, L, H

0.5 inH2O

1

(0.12 kPa)

2.5 inH2O

2

(0.62 kPa)

10 inH2O

3

(2.48 kPa)

3 psi

4

(20.7 kPa)

20 psi

5

(138 kPa)

(1) This range not available for Model PX751P Reference Class Transmitters.

Model

PX751P

NA

25 inH2O

(6.22 kPa)

100 inH2O

(24.8 kPa)

30 psi

(207 kPa)

200 psi

(1380 kPa)

Upper

(URL)

25 inH2O

(6.22 kPa)

250 inH2O

(62.2 kPa)

1,000 inH2O

(248 kPa)

300 psi

(2070 kPa)

2,000 psi

(13800 kPa)

PX751C/P

Differential

–25 inH2O

(–6.22 kPa)

–250 inH2O

(–62.2 kPa)

–1,000 inH2O

(–248 kPa)

–300 psi

(–2070 kPa)

– 2,000 psi

(–13800 kPa)

PX751C/P

Gage

(1)

NA NA NA

–250 inH2O

(–62.2 kPa)

0.5 psia

(3.5 kPa abs)

(1)

0.5 psia

(3.5 kPa abs)

(1)

0.5 psia

(3.5 kPa abs)

PX751H

Gage

0.5 psia

0.5 psia

0.5 psia

EN

TABLE 5-2. Model PX751CA Range and Sensor Limits.

Range and Sensor Limits

Upper

(URL)

5 psia

(260 mmHga)

30 psia

(206.8 kPa)

150 psia

(1034.2 kPa)

800 psia

(5515.8 kPa)

4,000 psia

(27580 kPa)

Range

0

1

2

3

4

Minimum

Span

0.167 psia

(8.6 mmHga)

0.3 psia

(2.07 kPa)

1.5 psia

(10.34 kPa)

8 psia

(55.16 kPa)

40 psia

(275.8 kPa)

5-1

Lower

(LRL)

0 psia

(0 mmHga)

0 psia

(0 kPa)

0 psia

(0 kPa)

0 psia

(0 kPa)

0 psia

(0 kPa)

Page 41

TABLE 5-3. Model PX751T Gage and Absolute Range and Sensor Limits

EN

Range

1

2

3

4

5

Minimum

Span

0.3 psi

(2 kPa)

1.5 psi

(10 kPa)

8 psi

(55 kPa)

40 psi

(276 kPa)

2,000 psi

(13800 kPa)

Range and Sensor Limits

Upper

(URL)

30 psi

(207 kPa)

150 psi

1034 kPa)

800 psi

(5516 kPa)

4,000 psi

(27579 kPa)

10,000 psi

(68948 kPa)

(1) For absolute limits, substitute psia for units.

BOLT IDENTIFICATION AND INSTALLATION

Bolts supplied by Omega can be identified by their head markings. Refer to

Figure 5-1 to verify that you are using the proper types of bolts.

FIGURE 5-1. Omega Bolt Identification Markings.

Carbon Steel Head Markings (CS)

B7M

(1)

.

Lower

(LRL)

0 psi

(0 kPa)

0 psi

(0 kPa)

0 psi

(0 kPa)

0 psi

(0 kPa)

0 psia

(0 kPa)

Stainless Steel Head Markings (SST)

316

*

The last digit in the F593_ head marking may be any letter between A and M.

B8M

F593_

*

TABLE 5-4. Bolt Installation Torque Values.

Bolt Material Initial Torque Value Final Torque Value

Carbon Steel (CS) 300 in-lb (34 N-m) 650 in-lb (73 N-m)

Stainless Steel (SST) 150 in-lb (17 N-m) 300 in-lb (34 N-m)

5-2

3051-3031I06A

Page 42

APPENDIX

A

HART

OVERVIEW

The HART Communicator provides communication capabilities for Model PX751

Smart Pressure Transmitters. The HART Communicator menu tree provides a

schematic overview of configuration functions, and the fast key sequences provide

direct access to software functions.

Online Menu

The Online menu appears automatically if the HART Communicator is connected to

an active loop with an operating transmitter. From the Online menu, press the

appropriate key sequence to access the desired function. Follow the on-screen

instructions to complete the function.

FIGURE 1-1. HART Communicator Onli ne Menu .

HART Fast Key Feature

The fast key sequences for the HART Communicator use the following convention for

their identification:

1 through 9–Refer to the keys located in the alphanumeric keypad located below

the dedicated keypad.

®

Communicator

50

12

EN

NOTE

HART fast key sequences are operational only from the Online menu. To access the

Online menu from any other menu, select the HOME (F3) key.

HART Fast Key Example

Fast key sequences are made up of the series of numbers corresponding to the

individual options in each step of the menu structure. For example, from the Online

menu you can change the date. Following the menu structure, press 1 to reach

Device Setup, press 3 for Basic Setup, press 4 for Device Info, press 1 for Date.

The corresponding HART fast key sequence is 1, 3, 3, 1.

A-1

Page 43

EN

FIGURE 1-2. HART Communicator Menu Tree for Model PX751

EN

Online Menu

1 DEVICE SETUP

2 PV

3 AO

4 LRV

5 URV

1 PROCESS

VARIABLES

2 DIAGNOSTICS

AND SERVICE

3 BASIC SETUP

4 DETAILED

SETUP

5 REVIEW

1Pressure

2 Percent Range

3 Analog Output

4 Sensor Temperature

1 TEST DEVICE

2 Loop Test

3 CALIBRATION

1Tag

2 Unit

3 RANGE

VALUES

4 DEVICE INFO

5 Transfer Function

6 Damp

7 METER OPTIONS

1 SENSORS

2 SIGNAL

CONDITION

3 OUTPUT

CONDITION

4 DEVICE

INFORMATION

1Self test

2 Status

1 RERANGE

2 TRIM ANALOG

OUTPUT

3 SENSOR TRIM

1Keypad Input

2 Apply Values

1Date

2 Descriptor

3 Message

4 Write Protect

5 Meter Type

1 Meter Type

2 CUSTOM METER

SETUP

1PRES. SENSOR

2 TEMP. SENSOR

1 PROCESS

VARIABLES

2 RANGE VALUES

3 Unit

4 Transfer Function

5 Damp

6 ALM/SAT LEVELS

1 PROCESS

VARIABLES

2 ANALOG

OUTPUT

3 HART OUTPUT

4 METER

OPTIONS

1 FIELD DEVICE INFO

2 SENSOR INFO

3 Self Test

4 DIAPHRAGM SEALS

INFO

1Keypad Input

2 Apply Values

1Digital-to-Analog Trim

2 Scaled D/A Trim

1Zero Trim

2 Lower Sensor Trim

3 Upper Sensor Trim

4 Sensor Trim Points

1 Dec. Pt. Position

2 CM Upper Value

3 CM Lower Value

4 CM Units

5 CM xfer Function

1 PROCESS

VARIABLES

2 SENSOR

SERVICE

3 Unit

1Snsr Temp

1Pressure

2 Percent Range

3 Snsr Temp

1Keypad Input

2 Apply Values

1Pressure

2 Percent Range

3 Analog Output

4 Snsr Temp

1Loop Test

2 Digital-to-Analog Trim

3 Scaled D/A Trim

4 AO Alarm Type

1Poll Address

2 Number of Request Preambles

3 Burst Mode

4 Burst Option

1 % Range

2 Alt. % Range

1 # of Diaph Seals

2 Diaph Seal Type

3 Diaph Seal Fill Fl

4 Diaph mat’l

1Pressure

2 % Range

3 Snsr temp

1 SENSOR

TRIM

1 Meter Type

2 CUSTOM METER

SETUP

3 Cust. Meter Value

1 High Alarm

2 Low Alarm

3 High Saturation

4 Low Saturation

5 AO Alarm Type

6 Alarm/Sat Type

1Meas. Type

2 Mod Config Type

3 Isolator Mtrl.

4 Fill Type

5 Proc Conn Type

6 Proc Conn Mat’l

7 O-Ring Mat’l

8 Drain Vent Mat’l

1Zero Trim

2 Lwr Snsr Trim

3 Upr Snsr Trim

4 Snsr Trim Pts.

1 Dec. Pt. Position

2 CM Upper Value

3 CM Lower Value

4 CM Units

5 CM xfer Function

1 Tag

2 Date

3 Descriptor

4 Message

5 Model

6 Write Protect

7 Local Keys

8 REVISION #S

9 Final Assy #

Device ID

Distributor

TABLE A-1. HART Communicator Fast Key Sequences for Model PX751 Transmitters.

Function HART Communicator Fast Keys

Alarm and Saturation Levels 1, 4, 2, 7

Analog Output 3

Analog Output Alarm Type 1, 4, 3, 2, 4

Burst Mode Control 1, 4, 3, 3, 3

Burst Operation 1, 4, 3, 3, 3

A-2

Page 44

EN

Function HART Communicator Fast Keys

Calibration 1, 2, 3

Clone Data

Custom Meter Configuration 1, 3, 7, 2

Custom Meter Value 1, 4, 3, 4, 3

Damping 1, 3, 6

Date 1, 3, 4, 1

Descriptor 1, 3, 4, 2

Digital To Analog Trim (4–20 mA Output) 1, 2, 3, 2, 1

Disable Local Span/Zero Adjustment 1, 4, 4, 1, 7

Field Device Info 1, 4, 4, 1

Full Trim 1, 2, 3, 3

Keypad Input – Rerange 1, 2, 3, 1, 1

Loop Test 1, 2, 2

Lower Range Value 4, 1

Lower Sensor Trim 1, 2, 3, 3, 2

Message 1, 3, 4, 3

Meter Options 1, 4, 3, 4

Number Of Requested Preambles 1, 4, 3, 3, 2

Percent Range 1, 1, 2

Poll Address 1, 4, 3, 3, 1

Poll a Multidropped Transmitter Left Arrow, 4, 1, 1

Pressure 2

Range Values 1, 3, 3

Rerange 1, 2, 3, 1

Scaled D/A Trim (4–20 mA Output) 1, 2, 3, 2, 2

Self Test (Transmitter) 1, 2, 1, 1

Sensor Info 1, 4, 4, 2

Sensor Temperature 1, 1, 4

Sensor Temperature Units 1, 4, 1, 2, 2

Sensor Trim Points 1, 2, 3, 3, 5

Status 1, 2, 1, 2

Tag 1, 3, 1

Transfer Function (Setting Output Type) 1, 3, 5

Transmitter Security (Write Protect) 1, 3, 4, 4

Trim Analog Output 1, 2, 3, 2

Units (Process Variable) 1, 3, 2

Upper Range Value 5, 2

Upper Sensor Trim 1, 2, 3, 3, 3

Zero Trim 1, 2, 3, 3, 1

EN

A-3

Page 45

WARRANTY/DISCLAIMER

problems relative to the product.

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 13 months from date of purchase. OMEGA Warranty adds an additional one (1) month grace period to

the normal one (1) year product warranty to cover handling and shipping time. This ensures that OMEGA’s

customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request. Upon

examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no charge.

OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser, including but not

limited to mishandling, improper interfacing, operation outside of design limits, improper repair, or

unauthorized modification. This WARRANTY is VOID if the unit shows evidence of having been tampered with

or shows evidence of having been damaged as a result of excessive corrosion; or current, heat, moisture or

vibration; improper specification; misapplication; misuse or other operating conditions outside of OMEGA’s

control. Components which wear are not warranted, including but not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither assumes

responsibility for any omissions or errors nor assumes liability for any damages that result from the use of its

products in accordance with information provided by OMEGA, either verbal or written. OMEGA warrants only

that the parts manufactured by it will be as specified and free of defects. OMEGA MAKES NO OTHER

WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED,

EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED.

LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence, indemnification, strict

liability or otherwise, shall not exceed the purchase price of the component upon which liability is based. In no

event shall OMEGA be liable for consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or activity,

medical application, used on humans, or misused in any way, OMEGA assumes no responsibility as set forth in

our basic WARRANTY / DISCLAIMER language, and, additionally, purchaser will indemnify OMEGA and

hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the Product(s) in such

a manner.

RETURN REQUESTS / INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN

(AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return package

and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage

in transit.

FOR WARRANTY RETURNS,

please have the following information available

BEFORE contacting OMEGA:

1. Purchase Order number under which

the product was PURCHASED,

2. Model and serial number of the

product under warranty, and

3. Repair instructions and/or specific

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible.

This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 1999 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the prior

written consent of OMEGA ENGINEERING, INC.

FOR NON-WARRANTY REPAIRS, consult OMEGA for

current repair charges. Have the following information available

BEFORE contacting OMEGA:

1. Purchase Order number to cover the

COST of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

Page 46

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

TEMPERATURE

√√ Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

√√ Wire: Thermocouple, RTD & Thermistor

√√ Calibrators & Ice Point References

√√ Recorders, Controllers & Process Monitors

√√ Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

√√ Transducers & Strain Gauges

√√ Load Cells & Pressure Gauges

√√ Displacement Transducers

√√ Instrumentation & Accessories

FLOW/LEVEL

√√ Rotameters, Gas Mass Flowmeters & Flow Computers

√√ Air Velocity Indicators

√√ Turbine/Paddlewheel Systems

√√ Totalizers & Batch Controllers

pH/CONDUCTIVITY

√√ pH Electrodes, Testers & Accessories

√√ Benchtop/Laboratory Meters

√√ Controllers, Calibrators, Simulators & Pumps

√√ Industrial pH & Conductivity Equipment

DATA ACQUISITION

√√ Data Acquisition & Engineering Software

√√ Communications-Based Acquisition Systems

√√ Plug-in Cards for Apple, IBM & Compatibles

√√ Datalogging Systems

√√ Recorders, Printers & Plotters

HEATERS

√√ Heating Cable

√√ Cartridge & Strip Heaters

√√ Immersion & Band Heaters

√√ Flexible Heaters

√√ Laboratory Heaters

ENVIRONMENTAL MONITORING AND CONTROL

√√ Metering & Control Instrumentation

√√ Refractometers

√√ Pumps & Tubing

√√ Air, Soil & Water Monitors

√√ Industrial Water & Wastewater Treatment

√√ pH, Conductivity & Dissolved Oxygen Instruments

M-3266/0799

Loading...

Loading...