Omega Products PX750 Installation Manual

User’s Guide

http://www.omega.com

e-mail: info@omega.com

PX750

Pressure Transmitter

OMEGAnet® On-Line Service Internet e-mail

http://www.omega.com info@omega.com

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGASM

Customer Service: 1-800-622-2378 / 1-800-622-BESTSM

Engineering Service: 1-800-872-9436 / 1-800-USA-WHENSM

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico and

Latin America: Tel: (95) 800-826-6342 FAX: (95) 203-359-7807

En Espan˜ol: (95) 203-359-7803 e-mail: espanol@omega.com

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: (31) 20 6418405 FAX: (31) 20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: nl@omega.com

Czech Republic: ul. Rude armady 1868, 733 01 Karvina-Hranice

Tel: 420 (69) 6311899 FAX: 420 (69) 6311114

Toll Free: 0800-1-66342 e-mail: czech@omega.com

France: 9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400 FAX: (33) 130-699-120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Germany: 0130 11 21 66

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5EX, England

Tel: 44 (161) 777-6611 FAX: 44 (161) 777-6622

Toll Free in the United Kingdom: 0800-488-488

e-mail: info@omega.co.uk

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing certification of

its products to the European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

TableofContents

SECTION1Introduction

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Models Covered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Using this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

SECTION2Installation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Load Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

SECTION3CommissioningtheSmartTransmitter

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Fast key sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Configure the Analog Output Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Setting Process Variable Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Reranging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Setting the Output Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Setting Damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Calibrate the sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Digital Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Calibrate the 4–20 mA Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Digital to Analog Converter Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

EN

iii

EN

SECTION4CommissioningtheAnalogTransmitter

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Setting the EZ/SZ Jumper Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Adjusting for Zero and Span . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Adjusting Damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Adjusting Linearity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

SECTION5Troubleshooting

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

SECTION6ReferenceData

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

APPENDIXAHART®Communicator

HART Communicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

iv

SECTION

1

Introduction

OVERVIEW

This section outlines the models covered and the organization of this manual.

The following performance limitations may inhibit efficient or safe operation. Critical

applications should have appropriate diagnostic and backup systems in place.

Pressure transmitters contain an internal fill fluid. It is used to transmit the process pressure

through the isolating diaphragms to the pressure sensing element. In rare cases, oil leak

paths in oil-filled pressure transmitters can be created. Possible causes include: physical

damage to the isolator diaphragms, process fluid freezing, isolator corrosion due to an

incompatible process fluid, etc.

A transmitter with an oil fill fluid leak can continue to perform normally for a period of time.

Sustained oil loss will eventually cause one or more of the operating parameters to exceed

published specifications while a small drift in operating point output continues. Symptoms of

advanced oil loss and other unrelated problems include:

Sustained drift rate in true zero and span or operating point output or both

n

Sluggish response to increasing or decreasing pressure or both

n

Limited output rate or very nonlinear output or both

n

Change in output process noise

n

Noticeable drift in operating point output

n

Abrupt increase in drift rate of true zero or span or both

n

Unstable output

n

Output saturated high or low

n

EN

MODELSCOVERED

This manual provides basic installation, commissioning, and troubleshooting

information for the following PX750

Model PX750 - Differential Pressure Transmitter

measures differential pressure from 2 inH

Model PX750 - Gage Pressure Transmitter

measures gage pressure from 2 inH

Pressure Transmitters:

O to 1,000 psi (0.497 to 6895 kPa).

2

O to 1,000 psi (0.497 to 41369 kPa).

2

1-1

EN

Model PX750– Alphaline Draft Range Differential Pressure Transmitter

designed for monitoring low pressure flow rates with positive and/or negative static

pressure capabilities and 0–½ to 0–6 inH

O rangeability.

2

USINGTHISMANUAL

This manual is designed to assist in basic installation and operation of Model PX750

Pressure Transmitters.

Section 2 Installation

provides a flowchart outlining installation procedures and installation wiring

diagrams.

Section 3 Commissioning

provides a description of common commissioning tasks for the Model PX750 Smart

Pressure Transmitter.

Section 4 Commissioning

provides a description of common commissioning tasks for the Model PX750 Analog

Pressure Transmitter.

Section 5 Troubleshooting

provides basic troubleshooting techniques for common diagnostic messages

associated with the transmitter and the communicator.

Section 6 Reference Data

provides range tables, a typical model structure, and bolt torque specifications for

Model PX750 Transmitters.

Appendix

contains menu tree and fast key sequence for the HART Communicator.

1-2

SECTION

2

Installation

OVERVIEW

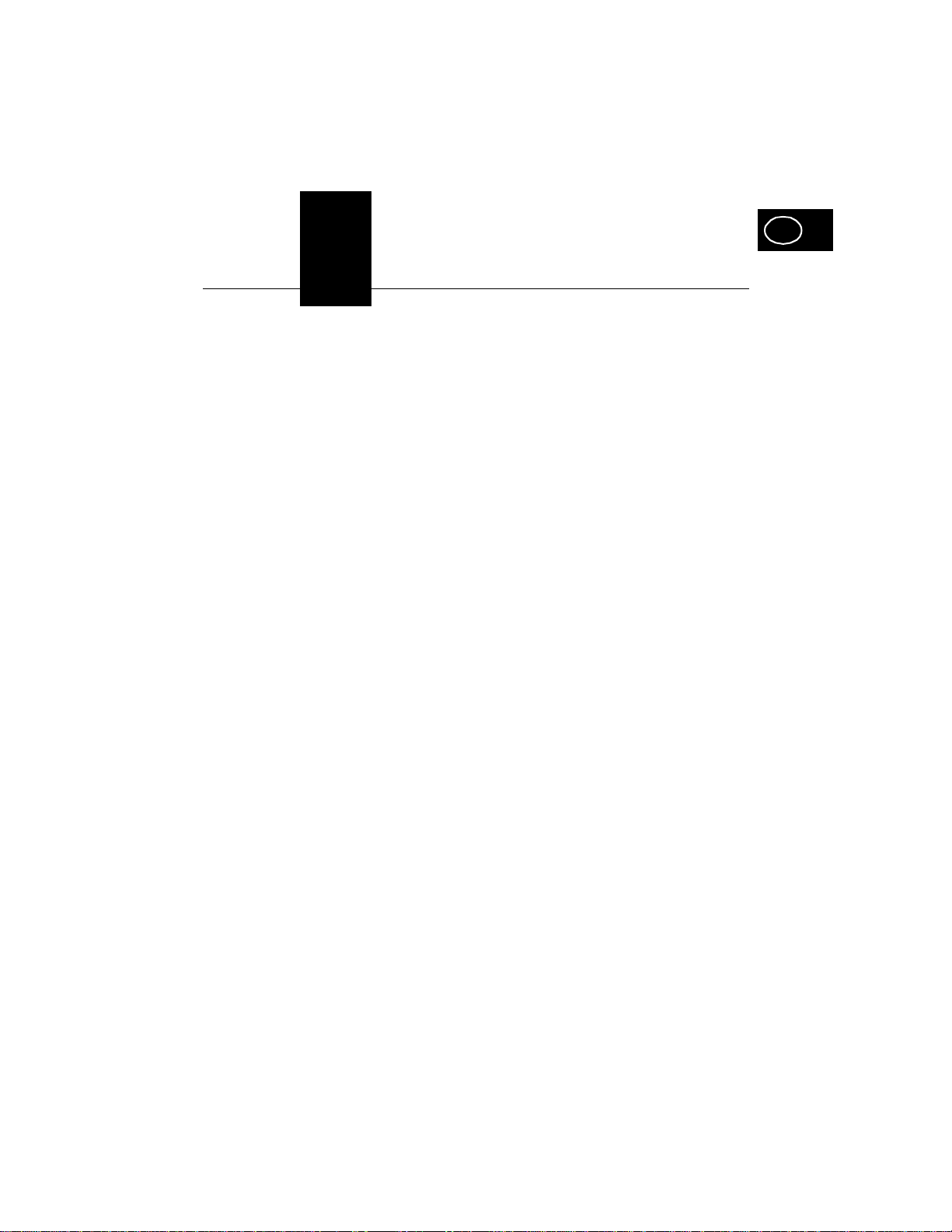

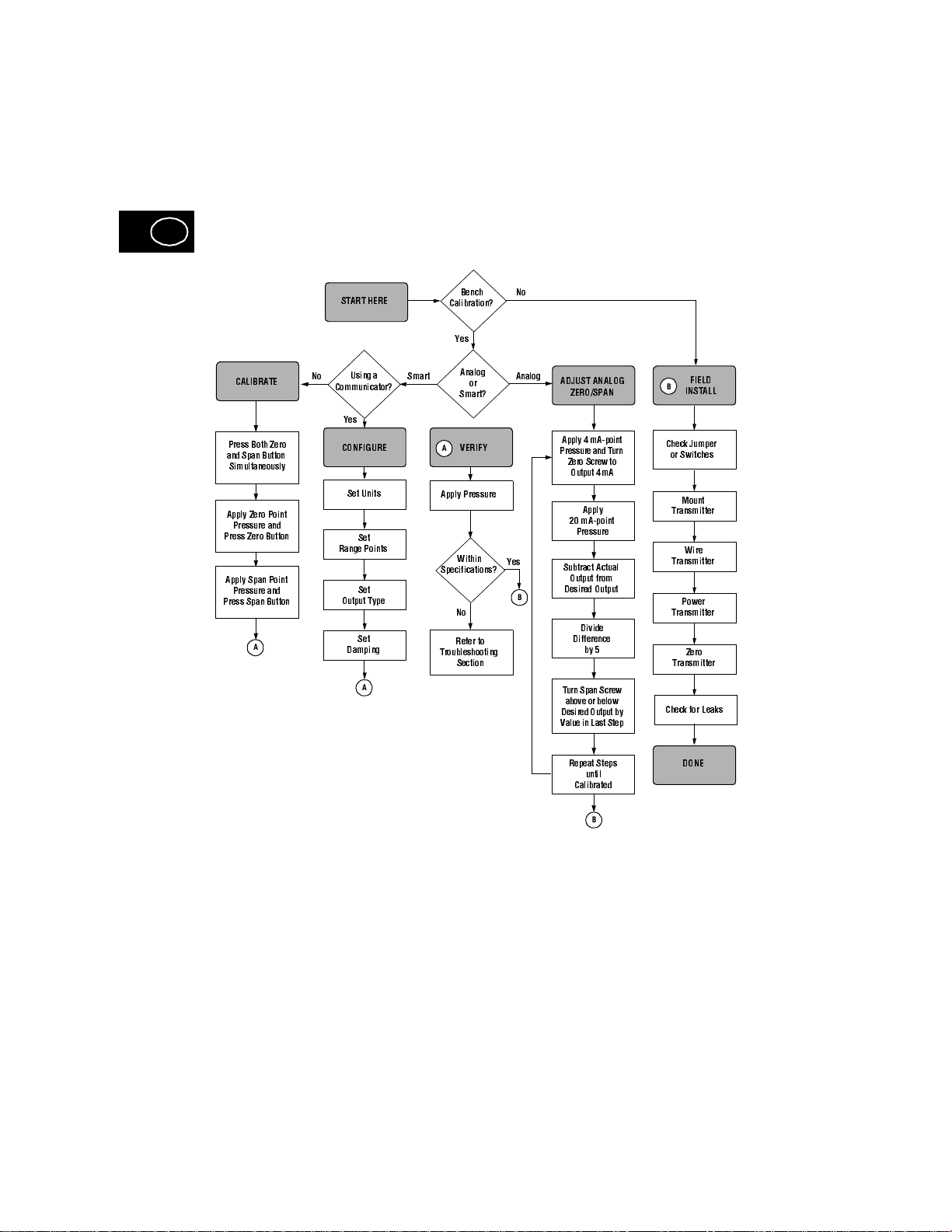

This section contains a flowchart in Figure 2-1 and wiring diagrams in Figures 2-2

through 2-5 to guide you to a successful Model PX750 installation. Shielded cable

should be used for best results in electrically noisy environments.

Failure to follow safe installation guidelines can cause death or serious injury. Please

review the following safety messages before installing a Model PX750 Pressure

Transmitter.

To avoid output shifts in critical applications, do not plug the low side with a solid plug.

■

To avoid process leaks, install and tighten all four flange bolts before applying pressure, or

■

process leakage may result. Attempting to remove the flange bolts while the transmitter is in

service may cause process fluid leaks.

To avoid explosions, do not remove the instrument cover or make electrical connections in

■

explosive atmospheres when the circuit is alive. Make sure the instrument is installed in

accordance with intrinsically safe or nonincendive field wiring practice.

To meet explosion proof requirements, make sure that both transmitter covers are fully

■

engaged.

EN

2-1

FIGURE 2-1. Installation Flowchart.

EN

CALIBRATE

Press Both Zero

andSpan Button

Simultaneously

Apply Zero Point

Pressure and

Press Zero Button

Apply Span Point

Pressure and

Press Span Button

A

START HERE

Using a

No Smart Analog

Communicator?

Yes

CONFIGURE

Set Units

Set

RangePoints

Set

Output Type

Set

Damping

A

Bench

Calibration?

Yes

Analog

or

Smart?

VERIFY

A

Apply Pressure

Within

Specifications?

No

Refer to

Troubleshooting

Section

No

Yes

B

ADJUST ANALOG

ZERO/SPAN

Apply 4 mA-point

Pressure and Turn

ZeroScrewto

Output 4 mA

Apply

20 mA-point

Pressure

Subtract Actual

Output from

Desired Output

Divide

Difference

by 5

Turn Span Screw

above or below

Desired Output by

Value in Last Step

FIELD

B

INSTALL

CheckJumper

or Switches

Mount

Transmitter

Wire

Transmitter

Power

Transmitter

Zero

Transmitter

Check for Leaks

2-2

RepeatSteps

until

Calibrated

B

DONE

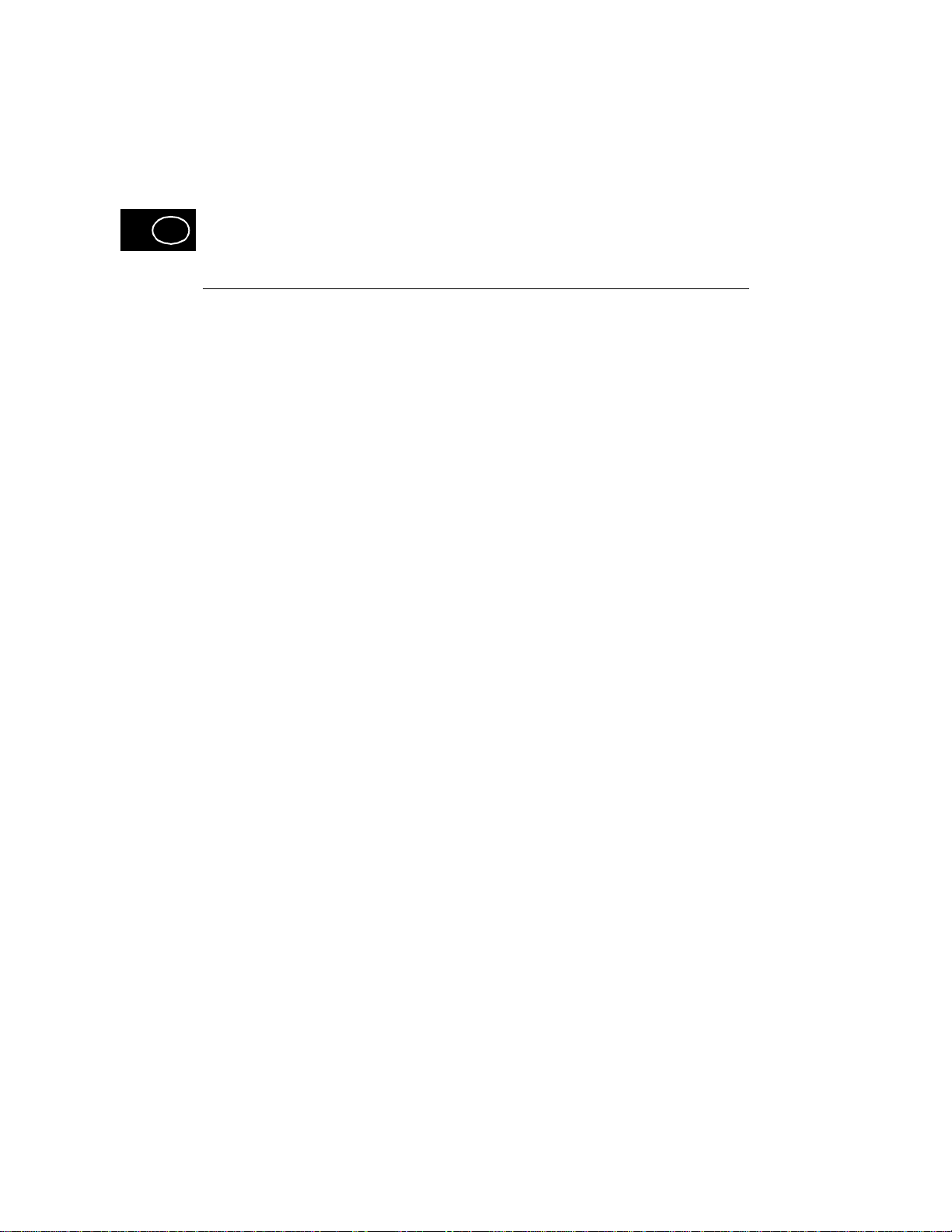

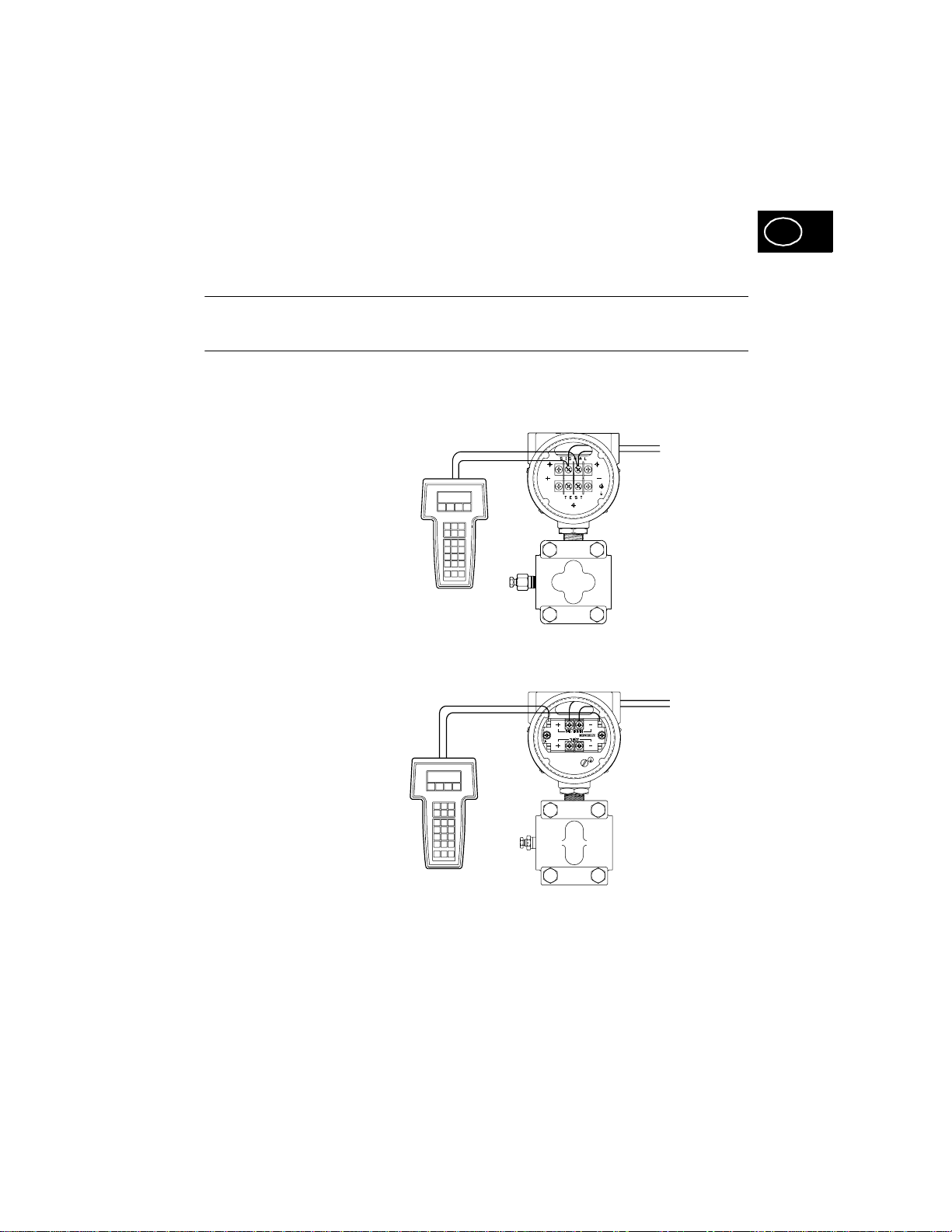

WIRINGCONNECTIONS

Figure 2-2 shows wiring connections necessary to power a Model PX750 Transmitter

and if smart, enable communications with a hand-held communicator. Shielded cable

should be used for best results in electrically noisy environments.

NOTE

A resistance of at least 250 ohms must exist between the communicator and the

power supply for communications.

FIGURE 2-2. Field Wiring Diagram.

+

Power Wires

–

Hand-Held

Communicator

(For Smart

Transmitters Only)

STANDARD TERMINAL BLOCK

EN

1151-G05D

+

Power Wires

–

OPTION CODE R1 TERMINAL BLOCK

2-3

1151-1151K05A

Loading...

Loading...