Page 1

R

R

PX726A

Industrial Pressure Transmitter

R

R

R

R

R

R

R

R

R

R

R

R

R

R

M

An OMEGA Technologies CompanyAn OMEGA Technologies Company

E

R

Operator's Manual

Operator's Manual

M-3601/1101

M-3601/1101

Page 2

Page 3

Remove the Packing List and verify that you have received all equipment, including the following

(quantities in parentheses):

PX725A Gauge Pressure Transmitter (1)

Operator’s Manual (1)

If you have any questions about the shipment, please call the OMEGA Customer Service

Department.

When you receive the shipment, inspect the container and equipment for signs of damage. Note

any evidence of rough handling in transit. Immediately report any damage to the shipping agent.

Page 4

M-3601

GAUGE PRESSURE TRANSMITTERS - SERIES PX726

TABLE OF CONTENTS

SECTION TITLE PAGE #

Section 1 - INTRODUCTION

1.1 PRODUCT DESCRIPTION............................................................................................1-1

1.2 TRANSMITTER FEATURES.........................................................................................1-1

1.3 MODELS APPROVED FOR HAZARDOUS AREAS...................................................1-2

1.4 USING THIS MANUAL.................................................................................................1-3

Section 1A - GAUGE PRESSURE TRANSMITTERS series PX726A

1A.1 PRODUCT DESCRIPTION.........................................................................................1A-1

1A.2 THEORY OF OPERATION.........................................................................................1A-2

1A.3 IDENTIFYING TRANSMITTER OPTIONS..............................................................1A-3

1A.4 TRANSMITTER MOUNTING....................................................................................1A-3

Connection-Supported Mounting................................................................................1A-3

Optional Mounting Bracket.........................................................................................1A-4

1A.4.1 Transmitter Housing Rotation....................................................................................1A-4

1A.5 PRESSURE MEASUREMENT APPLICATIONS......................................................1A-6

Liquid Application........................................................................................................1A-6

Gas Application............................................................................................................1A-6

Steam Application........................................................................................................1A-7

Liquid Level Application .............................................................................................1A-8

1A.6 SERVICE CHECKS.....................................................................................................1A-9

1A.7 GP TRANSMITTER SPECIFICATIONS ...................................................................1A-9

Section 2 - INSTALLATION

2.1 INSTALLATION NOTES...............................................................................................2-1

2.2 INSTALLATION IN HAZARDOUS AREAS.................................................................2-1

2.3 ELECTRICAL WIRING NOTES ...................................................................................2-2

2.4 WIRING OF 4-20mA SIGNAL/POWER LOOP.............................................................2-3

2.5 WIRING OF 1-5V SIGNAL/POWER LOOP..................................................................2-6

2.6 EFFECTS OF LEAD & LOAD RESISTANCE & SUPPLY VOLTAGE.......................2-6

Section 3 - CALIBRATION

3.1 CALIBRATION SETUP..................................................................................................3-1

3.2 ACCESS TO ADJUSTMENTS.......................................................................................3-1

3.3 EXTERNAL CHECK PROCEDURE .............................................................................3-4

3.4 CALIBRATION ADJUSTMENTS .................................................................................3-4

3.5 TYPES OF RANGE CALIBRATION.............................................................................3-5

3.6 ZERO-BASED CALIBRATION......................................................................................3-8

3.7 ELEVATED ZERO CALIBRATION ..............................................................................3-8

3.7.1 Zero Elevation Example .................................................................................................3-9

3.8 SUPPRESSED ZERO CALIBRATION..........................................................................3-9

3.8.1 Zero Suppression Example...........................................................................................3-11

3.9 SELECTABLE DAMPING...........................................................................................3-11

M-3601 Contents / 0 - 1

Page 5

M-3601

GAUGE PRESSURE TRANSMITTERS - SERIES PX726A

TABLE OF CONTENTS

SECTION TITLE PAGE #

Section 4 - SERVICE

4.1 GENERAL.......................................................................................................................4-1

4.2 TROUBLESHOOTING...................................................................................................4-1

4.3 FACTORY REPAIRS......................................................................................................4-1

Section 5 - SPECIFICATIONS

5.1 FUNCTIONAL SPECIFICATIONS...............................................................................5-1

Current Loop Mode: .................................................................................................5-1

Voltage Mode: ...........................................................................................................5-1

Calibration Adjustments:.........................................................................................5-1

Response Time & Damping......................................................................................5-1

Linearity:...................................................................................................................5-2

5.2 PERFORMANCE SPECIFICATION.............................................................................5-2

Accuracy:...................................................................................................................5-2

Resolution: ................................................................................................................5-2

Long Term Stability: ................................................................................................5-2

Ambient Temperature Effect:..................................................................................5-2

Power Supply Effect:................................................................................................5-2

Ripple and Noise:......................................................................................................5-2

5.3 ENVIRONMENTAL SPECIFICATION ........................................................................5-2

Temperature Limits: ................................................................................................5-2

Humidity Limits:......................................................................................................5-3

EMI Effect:................................................................................................................5-3

Surge Protection:......................................................................................................5-3

Vibration Effect: .......................................................................................................5-3

5.4 PHYSICAL SPECIFICATIONS.....................................................................................5-3

Fill Media..................................................................................................................5-3

Electrical Housing....................................................................................................5-3

Electrical Connections:.............................................................................................5-3

APPENDICES

Class I, Division 2 Hazardous Locations .................................................................................. Appendix A

Loop Powered Indicator Option ................................................................................................ Appendix B

Material Safety Data Sheets ......................................................................................................Appendix Z

0 - 2 / Contents M-3601

Page 6

Section 1

INTRODUCTION

1.1 PRODUCT DESCRIPTION

Series PX726A Gauge Pressure Transmitters (with flush diaphragm) convert pressure

measurements into a proportional 4-20 mA or a 1 - 5 Vdc output signal that functions as the

input to a controller, recorder, indicator or similar device. These transmitters find

application in the gas, water, and process industries that require accurate measurements

over a wide range of environmental conditions.

1.2 TRANSMITTER FEATURES

The features that follow are common to all transmitter models are described in the following

listing:.

E Pressure Sensor. Strain gauge, piezo-resistive sensors perform pressure

measurements.

E Signal-Power Loop. The transmitter requires a nominal 24 Vdc power source to

operate the signal loop, a 2- wire 4-20 mA output.

E Available Voltage Output. For low power applications, a 1-5 Vdc output is user

configurable via an internal jumper.

E Adjustable Ranges. Transmitters are provided with coarse switch and fine pot

adjustments for range calibration. Span is adjustable from 16 to 100% of the upper range

limit, while zero is adjustable from -600 to 600% of the lower range limit for elevation

and suppression.

E Damping. A circuit jumper selects damping periods of .275 sec or 1 ms to control

transmitter response to a change of the measured variable.

E Mechanical Assembly. The transmitter electronics enclosure is constructed of cast

aluminum with an epoxy finish. The materials offered for diaphragms, process

connections, flanges, bolts, etc. are given in Section 1A.

E Fill System. The transmitter's diaphragm and sensor operate in a sealed fluid system.

These systems are furnished with DC 200 as the fill fluid.

E Electrical Conduit Port. Two 1/2 inch NPT female ports are provided for electrical

conduit.

M-3601 Introduction / 1-1

Page 7

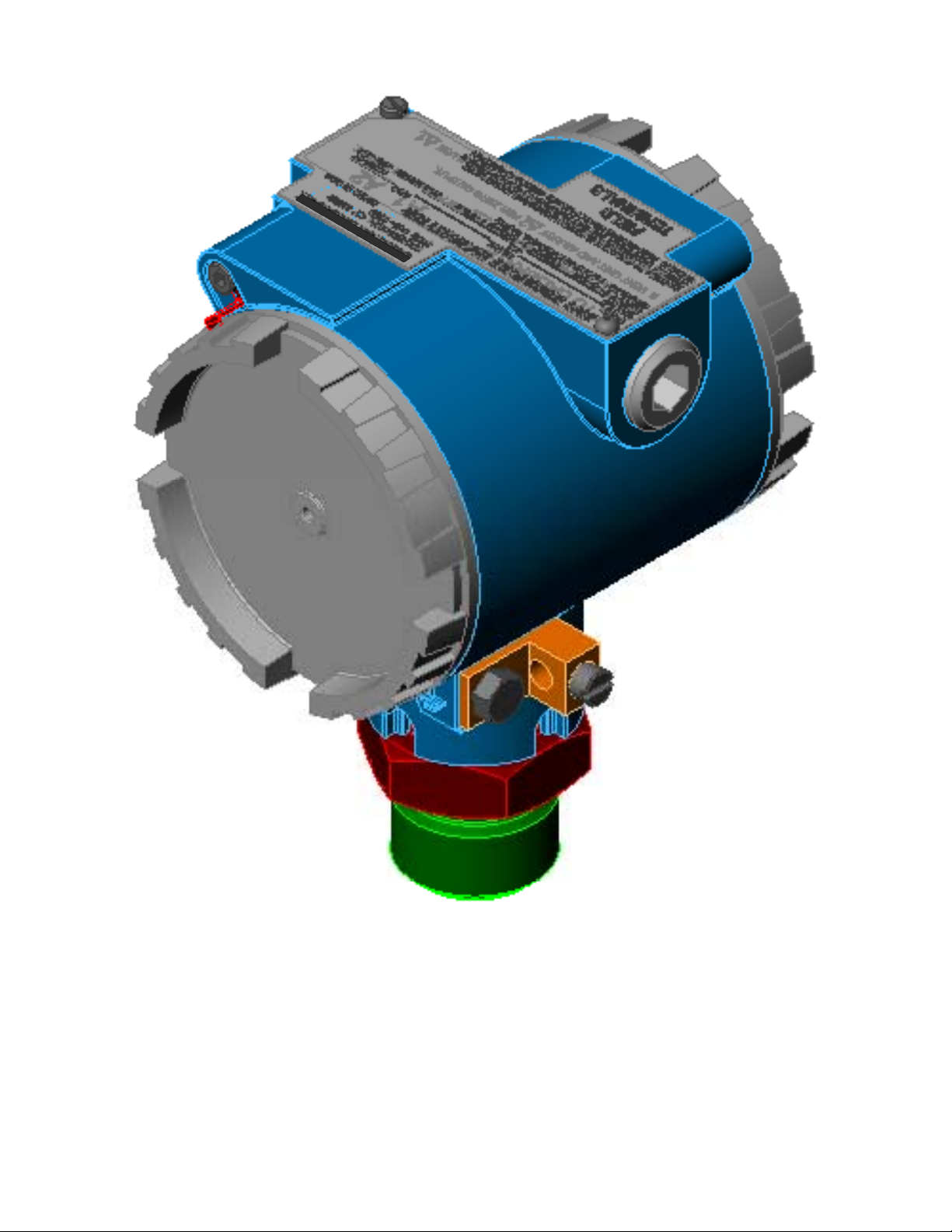

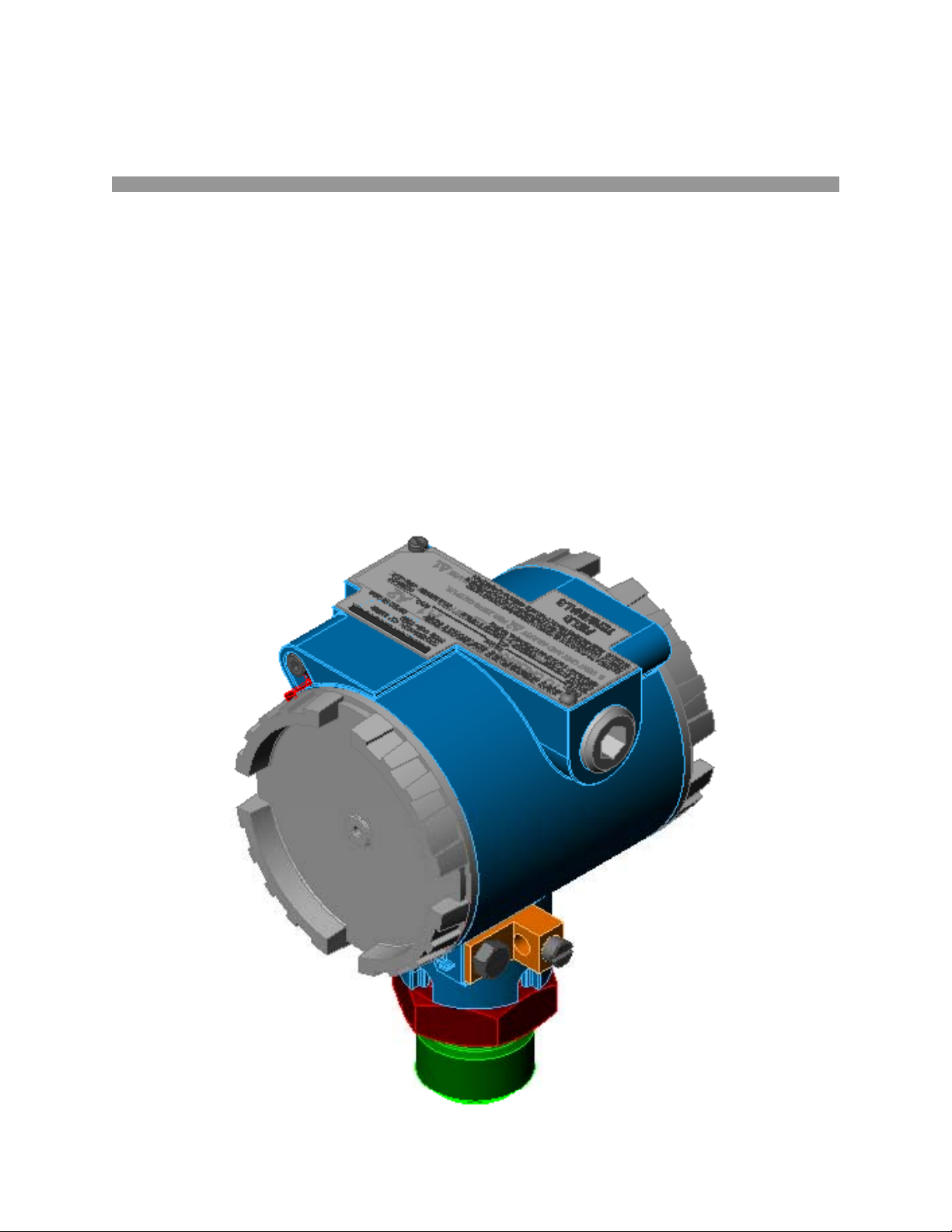

Figure 1-1 – PX726A Gauge Pressure Transmitter (with Internal Diaphragm)

1.3 MODELS APPROVED FOR HAZARDOUS AREAS

Transmitter mode l s ce rti fi e d fo r operation in h a za rdo us areas by Un de rwri ters Laborato ri e s

(UL) will have the appropriate logo inscribed on the instrument data plate. These models

are intended for use in t he following hazardous locations:

1-2 / Introduction M-3601

Page 8

Explosion-proof for Class I, Division 1, Groups C and D.

Nonincendive for Class I, Division 2, Groups A, B, C and D.

The National Electric Code, Article 500, defines the above classes and divisions as follows:

Class I Atmospheres: Contains flammable gases or vapors.

Class II Atmospheres: Contains combustible dust particles.

Class III Atmospheres: Contains ignitable fibers or flyings.

Division 1:

Where continuous expo su re, o r th reat o f fire o r ex plo sio n m ay b e presen t d u e to accid en t o r

uncommon occurrence.

Division 2:

Where threat of fire or explosion is not normally present, and not likely to result from

abnormal occurrence.

Groups A through D:

Cover various flammable gases an d liquids such as ethyl- ether vapor, gasoline, acetone,

etc.

Groups E through G:

Cover various combustible dusts such as dust fro m metalw o rk in g , co al, co k e carb o n b lack ,

grain, etc.

1.4 USING THIS MANUAL

Section 1A provides information relevant to product description, types of mounting,

measurement applications, service checks, and specificat ions.

Sections 2 through 5 describe installation, calibration, service and general specifications.

The Loop Powered Indicator option is covered in Appendix B.

M-3601 Introduction / 1-3

Page 9

Section 1A

GAUGE PRESSURE TRANSMITTERS

Series PX726A

1A.1 PRODUCT DESCRIPTION

Gauge Pressure Transmitters convert a pressure measurement into a proportional 4-20 mA

or a 1-5 Vdc outpu t si g n a l th a t ca n b e a ppl i e d to th e input of a co n tro l l er, recorder, i n di ca to r

or similar device. The Series PX726A, shown in Figure 1A-1, provides a standard 1-inch

flush diaphragm press ure connection.

Series PX726A Transmitters are offered in ranges from 0-100 inH

(max.). A listing of r anges for the Series PX726A is given in Table 1A-A.

Because of its compact size and light weight, the transmitter may be installed directly on a

process pipe. For installations that require other mounting arrangements, the transmitter

may be specified with a universal bracket. This bracket can be used to clamp the unit to a

two-inch pipe or secure it to a support structure.

O (max.) to 0-5000 psi

2

Figure 1A-1 - PX726A Gauge Pressure Transmitter (with Internal Diaphragm)

M-3601 GP Transmitters / 1A-1

Page 10

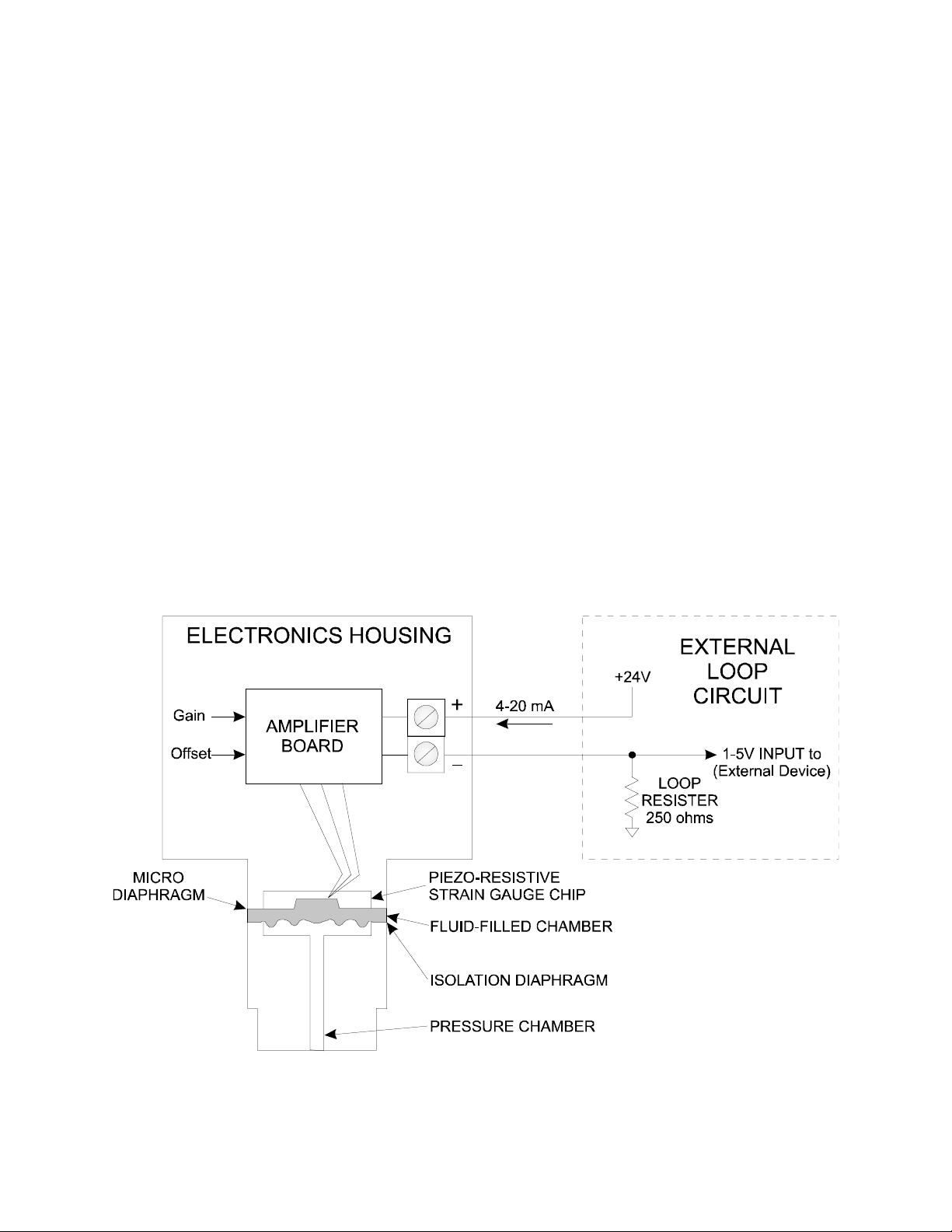

1A.2 THEORY OF OPERATION

The transmitter body is composed of an electronics housing and a sensor module assembly

as shown in the block diagram Figure 1A-2. The electronics housing contains the amplifier

circuitry and the field wiring terminals. The sensor module contains a pressure input

chamber, a fluid chamber, a recessed isolation diaphragm, and a micro diaphragm that

includes electronic sensing circuitry. (Transmitters with flush diaphragms omit the pressure

chamber and have the isolation diap hragm positioned at the very end of the sensor module.)

The input pressure applied to the pressure chamber is hydraulically transmitted through

the fill fluid contained by the isolation diaphragm. This pressure produces a strain on the

silicon diaphragm.

The micro diaphragm assembly contains four piezo-type, strain gauge resistors that are ionimplanted on the diaphragm's s urface and wired in a bridge configuration. The flexing of the

diaphragm causes changes of resistance in the bridge.

The bridge is powered by a constant current supply and produces a millivolt signal that corresponds to the me asured pressure. A circuit associ ated with the bri dge circuitry provides

measurement stability by compens ating for changes of ambient temperature.

The millivolt signal developed by the bridge is applied to a high-gain, linear amplifier and

converted to a tw o-wire, 4-20 m A current output. F igure 1A-2 sho ws this outpu t wired to a

typical external loop circuit that uses a 250-ohm load resistor and a 24 Vdc power source.

Figure 1A-2 - Simplified Diagram of GP Transmitters

1A-2 / GP Transmitters M-3601

Page 11

The 4-20 mA current flowing through the resistor provides a 1-5 Vdc input for the external

device.

The amplifie r circuit contains gain and o ffset adjustments for setting range calibration. A

jumper selects the damping op tion.

The unit may also be converted, at the users option, to a three-wire 1-5 Vdc output through

jumper selection.

1A.3 IDENTIFYING TRANSMITTER OPTIONS

A data plate affixed to the transmitter body lists the model number, serial number, and

instrument range. To identify the features and options furnished with your model, refer to

the complete model number contained in the sales order. This n umber includes a sequence

of suffix numbers that are identified in Tables 1A-A.

TABLE 1A-A - MODEL NUMBER BREAKDOWN FOR SERIES PX726A

PX726A - (1) – (2) ßßßß (see Codes below)

(1) INPUT RANGE (2) OPTIONS

CODE RANGE

CODE DESCRIPTION

100WCGI 0-17 to 0-100 inH

300WCGI 0-50 to 0-300 inH

400WCGI 0-67 to 0-400 inH

025GI 0-4 to 0-25 psi

050GI 0-8 to 0-50 psi

100GI 0-17 to 0-100 psi

300GI 0-50 to 0-300 psi

500GI 0-83 to 0-500 psi

1KGI 0-167 to 0-1000 psi

3KGI 0-500 to 0-3000 psi

2

2

2

MB Mounting bracket

O

M Local digital indicator

O

O

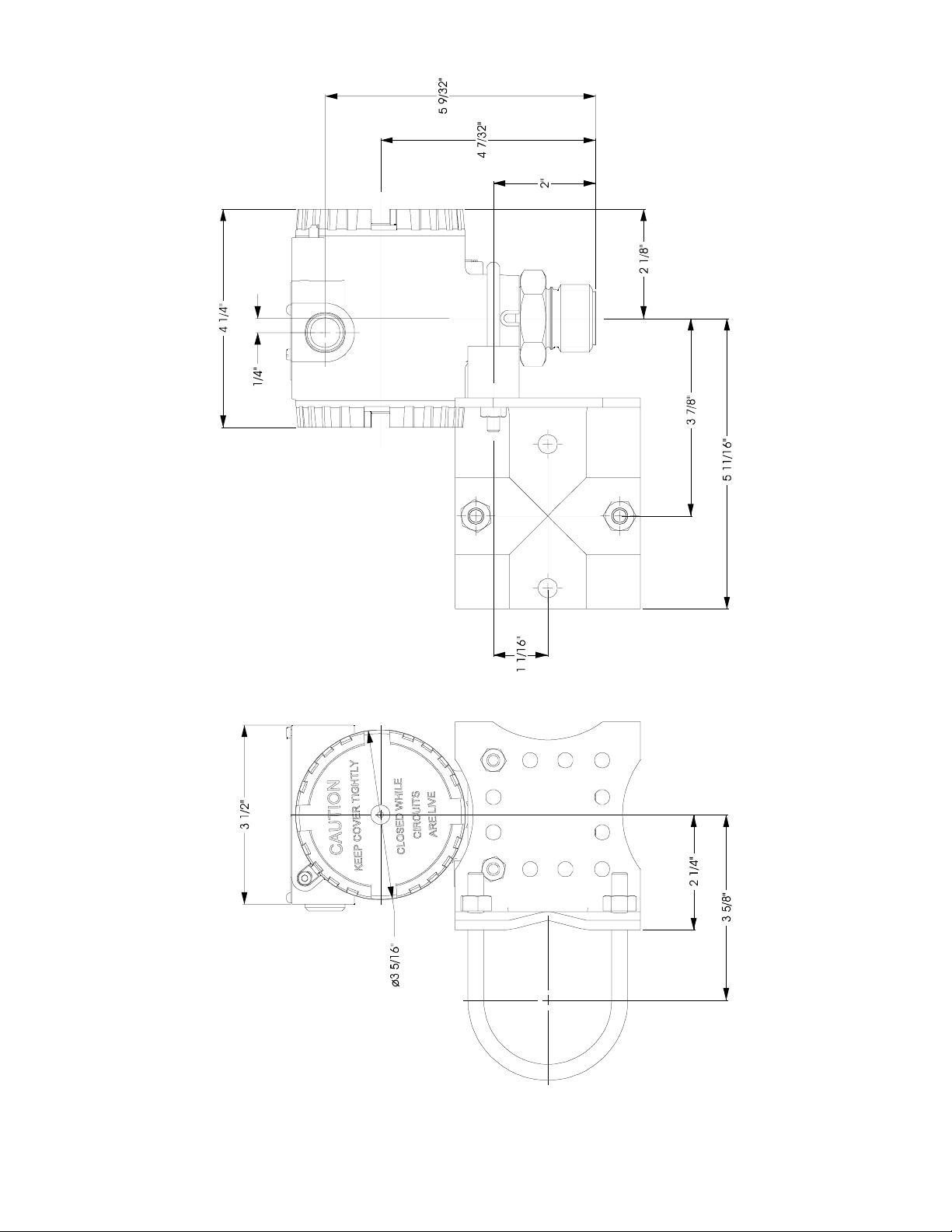

1A.4 TRANSMITTER MOUNTING

The transmitter may be mounted in any position. However, when it leaves the factory it is

calibrated for operation in the upright position with the electronics enclosure at the top and

the process connection at the bottom as shown in Figure 1A-1. If it is installed in a different

position, the transmitter may require a slight zero adjustment. This procedure is described

in Section 3 - Calibration.

The transmitter may be installed using connection-supported mounting or the optional

mounting bracket as follows:

Connection-Suppo rted Mounting. The tra nsmitter provides a m ale pressure connection

(1-inch NPT) which can also be used for mounting purposes (Figure 1A-4). This method of

mounting allows the transmitter to be connected directly to the pressure pipe or a pipe

fixture. If connection-supported mounting is not feasible, the optional mounting bracket

should be considered.

M-3601 GP Transmitters / 1A-3

Page 12

Optional Mounting Bracket. The brackets shown in Figure 1A-4 can be used when connection-supported mounting is not feasible or it is desired to mount the transmitter away

from the process. This bracket permits the transmitter to be clamped to a standard 2-inch

pipe with a single 2-1/4 inch u-bolt. The bracket may be positioned on the transmitter to

accommodate either a vert ical or horizontal running pipe.

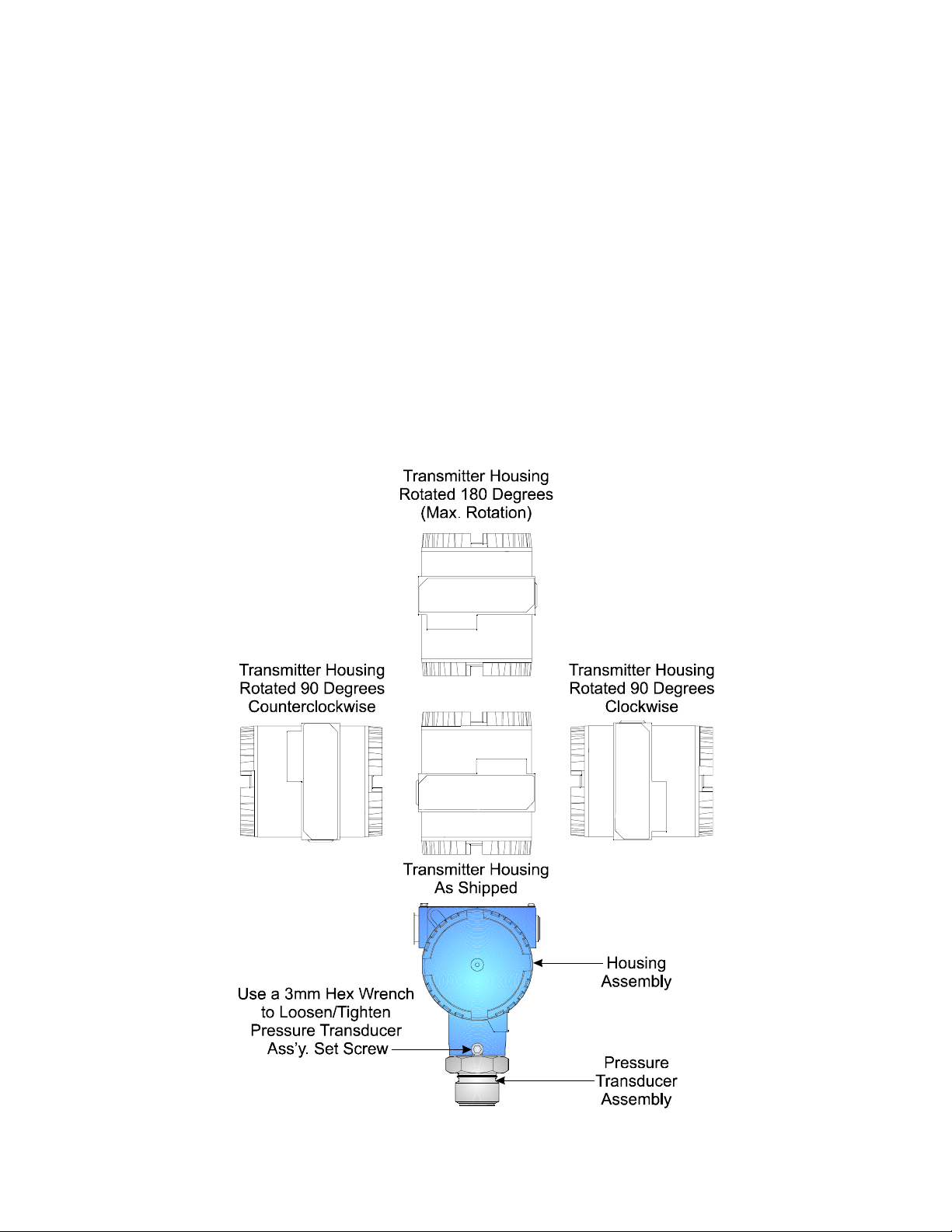

1A.4.1 Transmitter Housing Rotation

Once mounted, the Transmitter Housing can be rotated up to 180° in either direction, i.e.,

clockwise or counterclockwise. The Transmitter Housing must not be rotated from its

shipped position any more than 180° clockwise or counterclockwise. CAUTION: Trans-

mitter will be damaged if the Trans mitter Housing is rotated more than 180° from

its shipped position.

To rotate the T ransmitte r Housin g, the set scre w that lock s the Pressu re Tran sducer to the

Transmitter Housing must be removed with a 3mm Hex Wrench. Once the Transmitter

Housing has been turned to the desired position, be sure to replace and tighten the set

screw (see Figure 1A-3).

Figure 1A-3 -Transmitter Housing Rotation Diagram

1A-4 / GP Transmitters M-3601

Page 13

Figure 1A-4 - Overall Dimensions - Model PX726A

(With Neck Type Mounting Bracket)

M-3601 GP Transmitters / 1A-5

Page 14

1A.5 PRESSURE MEASUREMENT APPLICATIONS

The PX726A transmitter measures the pressure of a process medium flowing through a pipe

or contained in a tank. A discussion of some basic applications follows:

Figure 1A-5 - Process Pipe Mounting

Liquid Application. When measuring pressurized liquids in a process pipe, the

transmitter may be attached to the process line using a valve fixture as shown in Figure 1A-

5. However, if temperature or vibration characteristics at the site exceed the specified limits

of the transmitter, the transmitter should be placed in a more hospitable location with a

connection made through appropriate pressure tubing as shown in Figure 1A-6. Both

arrangements should include shutoff and drain valves to purge connection lines and the

transmitter.

Gas Application. The gas industry typically measures differential pressure, static pressure

and other variables associated with gas flow. A gas installation could use a GP Transmitter

to monitor the static pre ssure an d a DP T ransm itter to me asu re the di ffere ntia l pressu re as

shown below.

Figure 1A-7 sh ows the transmitters conn ected to a horizontal pipe. For these install ations

both transmitters are physically mounted above the connecting line to allow internal

moisture to drain away.

In Figure 1A-8, the gas flow is in a downward direction to minimize the accumulation of

moisture above the orifice plate. Otherwise, both transmitters are mounted and connected

in the same manner as described for horizontal pipes.

Figure 1A-6 - Pipe Tap Connection

Gas installations should include shutoffs and union fittings for both transmitters so that

they can be disconnected from the line without disrupting the process.

1A-6 / GP Transmitters M-3601

Page 15

Figure 1A-7 - Horizontal Gas Run

Figure 1A-8 - Vertical Gas Run

Steam Application. When measuring steam pressure, the maximum temperature of the

transmitter's electronic circuitry must be strictly observed. Temperatures above the

specified limit (see Environmental Temperature under topic 2.1) will cause output errors and

possibly result in dama ge to the transmitter. One method of prote cting the transmi tter can

be achieved by installing an extended, liquid-filled connecting line as shown in Figures 1A-9

and 1A-10. The liquid functions as a buffer and prevents live steam from entering the

transmitter.

When using liquid-filled system, the connecting line must be installed in a descending step

so that the transmitter is below the level of the process pipe tap and filling tee; this slope

will maintain the liquid in the connecting line and prevent it from being drawn into the

process pipe. Liquid-filled lines must also be properly filled and bled, and checked on a

regular basis.

A liquid-filled line is one way to isolate the transmitter from a steam process. As an

alternate method, a steam trap may be installed in the connecting line. Several

manufacturers offer traps for this application.

Figure 1A-9 - Horizontal Steam Pipe Figure 1A-10 - Vertical Steam Pipe

M-3601 GP Transmitters / 1A-7

Page 16

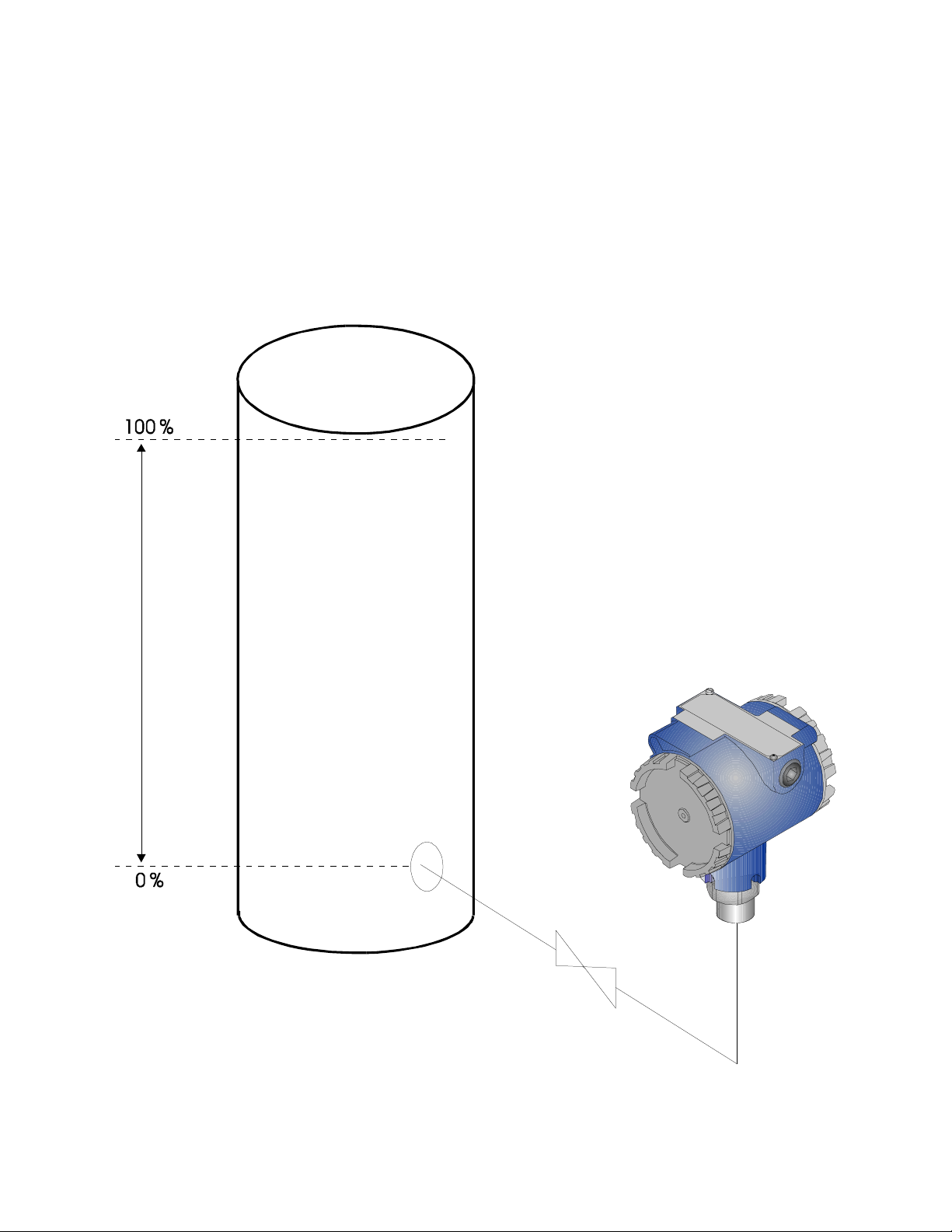

Liquid Level Application. GP Transmitters can be used to measure the head pressure of

a column of liquid in an open tank. For this application the transmitter is connected at the

bottom of the tank as shown in Figure 1A-11 (the transmitter co uld also be attached to the

tank through an appropr iate fitting).

The transmitter may be installed at, below, or above the 0% liquid level of the tank. If the

transmitter is exactly at the 0% level, it may be calibrated directly to the zero-base level. If

it is installed below or above the 0% level, a head error will occur. This error must added to

the measuring range during calibration otherwise the transmitter output reading will have

an offset error. Section 3 - Ca libration provides details for zero-based, elevated zero, and

suppressed zero calibration.

Figure 1A-11 - Liquid Leve l - Open Tank

1A-8 / GP Transmitters M-3601

Page 17

1A.6 SERVICE CHECKS

General troubleshooting hints are listed in Table 1A-B. Some of these checks will require a

digital multimeter (DMM). The DMM may be connected across the (+) and (V) terminals to

measure current directly without opening the current loop. See Section 4 Service for details.

TABLE 1A-B - TROUBLESHOOTING CHECKS

SYMPTOM RECOMMENDED CHECK

Low or no output:

Consistent Output Errors:

Fixed Output:

Erratic Output:

Check power supply for low dc output.

Check field wiring for shorts, opens, grounds or

excessive resistance.

Check that shutoff val ves are fully open.

Check for leaks in the connecting line or at

the transmitter connection.

Check for sediment or clogging in the connecting

line or at the transmitter connection.

Check for gas in liquid lines, or liquid in gas

lines.

Check zero and span adjustments using calibration

test setup.

Check that shutoff valves are fully open. Pressure

may be trapped in the connecting line.

Amplifier board may be defective.

Check loop wiring for shorts, opens, grounds or

intermittent connections.

Check piping for gas in liquid lines, or liquid in

gas lines.

Amplifier board may be defective.

1A.7 GP TRANSMITTER SPECIFICATIONS

Specifications that apply to the Series PX726A Transmitters are listed below. Those

specifications that are common to all PX726A transmitters are contained in Section 5

Specifications.

Maximum Input Ranges: 0-100 inH

details)

Overpressure Effect: +0.2% URL at maximum operating pressure

Wet End Materials: 316 SS

M-3601 GP Transmitters / 1A-9

O to 0-5000 psi (see Table 1A-C for

2

Page 18

Process Connections: 1 in. NPT male

Mounting Position Effect

on Transmitter Accuracy: ±2.0 inH

O which can be corrected by calibration

2

TABLE 1A-C - TRANSMITTER INPUT RANGES

Model

Suffix (1)

(Code)

100WCGI

300WCGI

400WCGI

025GI

050GI

100GI

300GI

500GI

1KGI

3KGI

See Table 1A-A for Series PX726A Model Number Codes.

0%

Minumum

Range

0-17 inH

0-50 inH

0-67 inH

2

2

2

0-4 psi

0-8 psi

0-17 psi

0-50 psi

0-83 psi

0-167 psi

0-500 psi

O

O

O

100%

Maximum

Range

0-100 inH

0-300 inH

0-400 inH

0-25 psi

0-50 psi

0-100 psi

0-300 psi

0-500 psi

0-1000 psi

0-3000 psi

O

2

O

2

O

2

Maximum

Working

Pressure

300 inH

900 inH

1200 inH

75 psi

150 psi

300 psi

900 psi

1500 psi

3000 psi

4500 psi

Offered

For Series

PX725A

O

2

O

2

O

2

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

1A-10 / GP Transmitters M-3601

Page 19

Section 2

INSTALLATION

2.1 INSTALLATION NOTES

Prior to installing the transmitter, factors such as environmental temperature, maintenance access, and transmitter construction materials will require consideration.

Environmental Temperature: The temperature operating ranges for the wet end and electronics assemblies of the transmitter are as follows:

1. Wet end w/ DC 200 fill: -40 to 220°F (-40 to 104°C)

2. Electronic - Amplifier Board -25 to 185°F (-32 to 85°C)

3. Electronic - Digital Indicator -22 to 158°F (-30 to 70°C)

When installing a transmitter, it is important to consider the temperature range of all

items listed above as each has different limits. For example, if item 1 were at the upper

limit of its range (220°F), item 2 would be 35°F over its limit of 185°F. Likewise, if the

same transmitter included a digital indicator, item 3, the indicator would be 62°F above its

158°F limit.

Under no circumstances should the internal temperature of the electronics housing be allowed to go above the upper limits specified above for items 2 and 3. Doing so will cause

output errors, and possibly result in damage to the electronic assemblies. Going below the

lower temperature limit can also lead to performance or failure problems. If temperature

extremes are anticipated, the transmitter should be installed in a more favorable environment or be provided with other means of protection.

Caution: The transmitter must always be operated within the temperature range of its wet

end and electronic assemblies. Prolonged operation under extreme conditions could result

in eventual transmitter damage.

Maintenance Access: Select a site that provides ease of access for maintenance and repairs.

Inspect the site for any potential hazards that could result in accidental damage to equipment or injury to persons. Clearly post any dangers that may not be apparent to operators.

Construction Materials : Prior to mounting the transmitter, check its construction materials

to insure that they are compatible with the process medium. Some gases or liquids will

react with certain metals and result in permanent damage to the transmitter. This type of

damage is not covered under the warranty agreement.

2.2 INSTALLATIONS IN HAZARDOUS AREAS

The information that follows only applies to transmitter models approved for use in

hazardous areas. Models without approval must never

M-3601 Installation / 2-1

be used for these installations.

Page 20

The installation of equipment in hazardous areas must comply with the National Electrical

Code ANSI/NFPA-70, and ANSI/ISA S82.01, S82.02, & S82.03 standards. Transmitters

certified for use in hazardous areas will have the mark of the certifying agency inscribed on

the transmitter data plate.

The checklist that follows emphasizes some key points of safety with regard to installations

in hazardous areas.

1. All transmitter wiring that passes through hazardous areas must be enclosed in metal

conduit. The point where the conduit connection feeds into the transmitter’s housing

must be properly secured to prevent entry of gases or other ignitable substances into

the transmitter. Explosion-proof wiring practices must be followed to prevent flashback

through the conduit.

2. The cover of the transmitter must be screwed in hand tight and fully seated. The cover

must be replaced if it is damaged or shows stripped threads.

3. The cover of the unit must always be in place and secured when the transmitter is

powered. The cover must never be loosened or removed unless the atmosphere is made

safe or all electrical power is removed from the transmitter.

WARNING: Removing the cover of a transmitter while it is operating in a hazardous area

is dangerous and could result in fire or explosion.

WARNING: EXPLOSION HAZARD

Do Not disconnect equipment unless power has been disconnected and the area

is known to be nonhazardous.

Figure 2-1 - Dressing of Wire Leads

2.3 ELECTRICAL WIRING NOTES

All wiring connections cited in the text and illustrations must conform to the National

Electrical Code, and local authority. Only technically qualified persons should perform

wiring procedures.

2-2 / Installation M-3601

Page 21

Conduit Connection: The transmitter provides a ½ inch NPT threaded female port for

electrical conduit. This port can mate with threaded conduit or an appropriate threaded

pipe adapter.

Note: The conduit connections must be secured with no less than five threads fully

engaged.

In some applications, condensation could form in the conduit, and seep into the transmitter

electronics housing. If allowed to continue, moisture build-up will degrade the transmitter

performance, and eventually cause damage. Installing the transmitter above the level of

the process connection can prevent this condition. Any moisture forming in the conduit will

then drain away by gravity.

Access to Wiring Terminals: Remove the threaded end cover to access the wiring terminals

(see Figure 3-2). If the cover cannot be loosened by hand, insert a flat metal bar or similar

tool between the cover protrusions and apply moderate counter-clockwise leverage. Before

re-installing the cover, make sure that the threads are clean. Tighten the cover by hand

until all threads are engaged, and the gasket is compressed.

Lead Dress: When feeding wire through the conduit opening of the transmitter, add about

six inches of slack for terminal connections. Dress the leads in a circular path around the

terminals as seen in Figure 2-1. The additional slack will make the connections more

manageable and prevent mechanical strain on the terminals.

2.4 WIRING OF 4-20mA SIGNAL/POWER LOOP

The 4-20mA signal/power loop can be powered in two ways. Figure 2-2 shows the loop

powered by the receiving device (controller, recorder, etc.), while Figure 2-3 shows the loop

powered by an external supply. In both instances, the 4-20mA current flows through a

250Ω load resistor and develops a corresponding 1-5V input for the receiving device.

Signal Shielding: Use twisted wire, shielded cable covered by insulating material for the

signal/power wiring. When properly grounded, this cable will minimize pickup of electromagnetic, and radio frequency interference.

The shield lead of the cable is typically grounded at the input of the receiving device

(computer controller, recorder, etc.) as shown in Figures 2-2 and 2-3. Never connect the

other end of this shield to the transmitter enclosure or attempt to ground the shield at

more than one point along the wire path. Multiple grounds will cause signal errors at the

input of the receiving device.

Although it is recommended to connect the cable’s shield to the power common return of

the receiving device, the actual connection point may differ depending on the design and

application of the device. In some instances, better noise immunity can be had by

connecting the cable shield to the chassis or a designated shield terminal on the device.

Check the instruction manual of the receiving device for the recommended connection

points.

M-3601 Installation / 2-3

Page 22

* The device may be an indicator, recorder, tone modulator, etc.

1

*

Connect the shield to earth ground or to a shield terminal on the device, if so equipped.

2

*

Refer to Figure 3-2 and set the Jumper Block for Current Operation.

Figure 2-2 - Transmitter Wired to Instrument Supply Source (4-20mA Circuit)

* The device may be an indicator, recorder, tone modulator, etc.

1

*

Connect the shield to earth ground or to a shield terminal on the device, if so equipped.

2

*

Refer to Figure 3-2 and set the Jumper Block for Current Operation.

Figure 2-3 - Transmitter Wired to External DC Supply (4-20mA Circuit)

2-4 / Installation M-3601

Page 23

* The device may be an indicator, recorder, tone modulator, etc.

1

*

Connect the shield to earth ground or to a shield terminal on the device, if so equipped.

2

*

Refer to Figure 3-2 and set the Jumper Block for Current Operation.

Figure 2-4 - Transmitter Wired to Instrument Supply Source (1-5V Circuit)

* The device may be an indicator, recorder, tone modulator, etc.

1

*

Connect the shield to earth ground or to a shield terminal on the device, if so equipped.

2

*

Refer to Figure 3-2 and set the Jumper Block for Current Operation.

Figure 2-5 - Transmitter Wired to External DC Supply (1-5V Circuit)

M-3601 Installation / 2-5

Page 24

2.5 WIRING OF 1-5V SIGNAL/POWER LOOP

The 1-5V signal/power loop can be powered in two ways, by the receiving device (controller,

recorder, etc.), or by an external supply. Provide a setup similar to that shown in either

Figure 2-4 or 2-5. Apply +24V across the + and - terminals of the transmitter as shown,

whether supplied by an external supply, or by the receiving device. Next, connect the 1-5V

output, or the terminal block labeled V to the input of the device. Notice: Unlike the

current loop, this input must be analog ground referenced, and not passed through a

sampling resistor.

Signal Shielding: Use twisted, three wire, shielded cable covered by insulating material for

the signal/power wiring. For further information regarding signal shielding, consult section

2.4.

2.6 EFFECTS OF LEAD & LOAD RESISTANCE & SUPPLY

VOLTAGE

The total loop resistance consists of the load (loop resistor) plus the resistance of both

conductors in the signal/power loop. For any given power supply voltage, the total loop

resistance must be kept within the specified limits. The graphs of Figures 2-6 and 2-7

illustrate the minimum and maximum loop resistance that may be used with various

supply voltages for models with and without digital indicators.

Figure 2-6 - Transmitter without Digital Indicator

2-6 / Installation M-3601

Page 25

Figure 2-7 - Transmitter with Digital Indicator

The graph of Figure 2-8 shows the cable length in feet vs. the cable resistance of both conductors for wire gauges between AWG 14 and AWG 22. For cable runs less than 1000 feet,

the resistance can be ignored.

Figure 2-8 - Cable Lead Length Vs. Total Lead Resistance

M-3601 Installation / 2-7

Page 26

Section 3

CALIBRATION

3.1 CALIBRATION SETUP

Equipment Required: Transmitter calibration requires a laboratory bench setup with the

following equipment:

1. Test source capable of generating fixed pressure values equivalent to 0%, and 100%

values of transmitter’s range (URL).

2. Pressure monitor device to read test source (±.025% accuracy)

3. Electrical supply source capable of producing 24V-DC power to the transmitter.

4. Digital Multimeter (DMM) w ith a 5- 1/ 2 digit s cale ( ±.005% accuracy)

5. Current Sam p li ng Res i s t or ( 250Ω9, ±.01%, 1/4W)

Lab Vs. On-Site Setup: Although it is more convenient and recommended to perform this

procedure using a laboratory setup, calibration can also be performed on site providing that

the connecting line or flange is equipped with a calibration tap and appropriate shutoff and

bypass valves. This added equipment allows you to feed in an external test pressure source

or use the process pressure as a reference signal. In the latter setup, the valves are closed

to seal a fixed pressure in the connecting line. Only fine calibration using the external

adjustments should be attempted in wet, dusty, or hazardous environments.

Before attempting on-site calibration, carefully check the application. If the transmitter is

operated in a closed control loop configuration, either the transmitter must be isolated

from the process, or the process must be turned off. If this is not done, a critical process

could accidentally be driven into a dangerous region causing damage to equipment and

property, and injury to persons.

Note: Before starting any test procedures, make sure that the transmitter is firmly

anchored in its intended operating position. A different mounting position can affect zero

calibration for some ranges and necessitate re-calibration.

Electrical Connections: The electrical connections for a voltage output calibration setup are

made to the transmitter as shown in Figure 3-1a. However, refer to Figure 3-1b if the

transmitter is configured for current mode operation. The Current Sampling Resistor will

convert the 4-20mA-output signal to a 1-5V signal, which generally allows for a more

accurate reading. A series milliammeter may also be used as discussed in Section 4.2.

3.2 ACCESS TO ADJUSTMENTS

The external adjustments are for fine offset and fine gain settings. The offset adjustment

screw will not affect the gain. That is, adjusting the offset (A1) screw will move both

calibration points equally. The gain adjustment will also affect the offset of the instrument.

That is, adjusting the gain (A2) screw moves the end point unequally. To minimize the

interaction of the gain, it is best to adjust the offset screw for full scale output while full

scale pressure is applied and adjust the gain screw for a zero output while minimum

pressure is applied.

M-3601 Calibration / 3-1

Page 27

To access the fine offset (A1) and fine gain (A2) adjustment screws, loosen the screw that

secures the I.D. Plate to the top of the transmitter housing and pivot the I.D. Plate. The

fine offset and gain screws are labeled A1 and A2 respectively. The calibration label that

identifies A1 and A2 is affixed to the top of the transmitter housing and will be exposed

when the I.D. Plate has been pivoted.

Removing the end cover accesses the transmitter’s coarse calibration adjustments. Once

the cover is removed, the adjustments appear as shown in Figure 3-2.

The PX726A Series Transmitter can be configured for either voltage, or current output. To

change the setting, simply change the position of the voltage/current jumper (JP1-JP8).

Note that the field wiring must also change if converting from voltage to current mode.

Figure 3-1a - Calibration Test Setup (Voltage Configuration)

Figure 3-1b - Calibration Test Setup (Current Configuration)

To activate the selectable damping option, the damping jumper (JP9) must be in place on

the board.

3-2 / Calibration M-3601

Page 28

Figure 3-2 - Calibration Adjustments

M-3601 Calibration / 3-3

Page 29

3.3 EXTERNAL CHECK PROCEDURE

The general check procedure determines the accuracy of the transmitter at its calibrated

operating range. It uses the offset (A1) and the gain (A2) adjustment screws for minor

calibration corrections. Proceed as follows:

1. Provide a test setup as shown in Figure 3-1a or 3-1b depending on whether the unit has

been configured for current or voltage mode. Make sure that no electrical power is applied to the transmitter while making connections. The Multimeter must be set in

“Voltage” mode.

2. Set the DMM to a scale that will cover a 1-5Vdc range.

3. Apply 24Vdc power to the transmitter.

4. Set the pressure test source for a precise 0% range value. The DMM should display

1.00Vdc ± 4mV (4mA dc ± 0.016mA).

5. Similarly, adjust the pressure test source f or 100% range value. The DMM should read

5.00Vdc ± 4mV (20mA dc ± 0.016mA).

6. If the readings of steps 4 to 6 are within tolerance, no calibration is required. Testing is

complete. However, if any readings were in error, proceed to step 7.

7. Set the test pressure source to 100%. If this reading is out of tolerance, correct it by

turning the A1 adjustment screw (clockwise rotation increases the reading).

8. Reset the test pressure source to 0%. If this reading is out of tolerance, correct it by

turning the A2 adjustment screw (clockwise rotation decreases the reading).

9. Recheck the 0%, and 100% readings . Repeat steps 7 and 8 as needed. This may need to

be done two or three times. If errors are still present at full-scale pressure, recheck the

switch settings. If the DIP Switch is in the correct configuration, proceed to step 10. If

errors are encountered at 0%, recheck the Rotary Switch settings. If the switch is in the

correct position, proceed to step 10.

10. If the above three readings cannot be brought into proper calibration, the transmitter

may require service or replacement. See Section 5, Service, for troubleshooting hints.

3.4 CALIBRATION ADJUSTMENTS

The range changing procedure uses the coarse span (SW1) and zero switches (S1:1-8),

along with the fine offset (A1), and gain (A2) adjustment screws. The locations of the

switches are shown in Figure 3-2. The equipment setup required to perform range

changing is the same as that described in topic 3.1. The coarse zero switches are contained

in a single DIP switch package, with the switches labeled from 1 to 8, with either a “1” or a

“0” silk-screened on the board. The coarse span switch is a 10 position rotary switch.

Coarse Span: The coarse span is set, by rotating the switch SW1, such that the desired

range of full scale is available. Span can be calculated using the formula below.

3-4 / Calibration M-3601

Page 30

Coarse Span URL Range = P

max

- P

min

------------ X 100%

URL

Once span has been calculated the desired switch position can be determined from Table 3A or Table 3-B.

Coarse Zero: Coarse zero adjustments are provided by switches S1:8-1. When these

switches are all set to ON, the maximum zero suppression (600%) is provided; when all are

set to OFF, the maximum zero elevation (600%) is provided.

The coarse zero is set for the region of full scale that the user desires to be the zero

reference. Consequently the possible zero positions are listed in %URL. This is not to be

confused with the %URL from the span. Unlike the span this does not represent an actual

range, instead it describes a pressure level that the user desires to set as a zero. The

following equation shows how to calculate the zero level in %URL:

Coarse Zero URL Range = P

min

------ X 100%

URL

Once the zero levels are calculated, the respective coarse zero switch positions can be

determined

from Table 3-A.

Fine Adjustments: At full-scale pressure adjust A1 so that the output is either 5V or 20mA.

Then, decrease the unit to zero pressure and adjust A2 so that the output is 1V or 4mA.

The adjustment of A1 should be such that the setting is barely 5V or 20mA (i.e. A small

rotation in the opposite direction should result in an immediate decrease in the output

voltage.). If this is not the case the screw may be over rotated. Repeat this procedure until

the output yields the appropriate values for high and low pressure. Once calibrated the

output stage is set and should need no further attention besides periodic tweaking.

3.5 TYPES OF RANGE CALIBRATION

When selecting a range, one of three types of calibration schemes will be encountered. Each

of these three methods refers to the manner in which a 0 psi input signal is referenced to

the 1-5V output of the transmitter. The three methods are defined as follows:

Zero Based Calibration:

0 psi = 1V (4mA) output

Sample Ranges:

0 to 50 psi

0 to 100 psi

Elevated Zero Calibration:

0 psi > 1V (4mA) output [0 psi results in an output greater than 1V (4mA)]

Sample Ranges:

-10 (vacuum) to +20 psi

-30 to 0 inHg

M-3601 Calibration / 3-5

Page 31

TABLE 3-A - COARSE ZERO SWITCH SETT INGS (El evation)

3-6 / Calibration M-3601

Page 32

TABLE 3-B - COARSE ZERO SWITCH S ETTINGS (Suppression)

M-3601 Calibration / 3-7

Page 33

Suppressed Zero Calibration:

0 psi < 1V (4-20mA) output [0 psi results in an output less than 1V (4mA)]

Sample Ranges:

1 to 10 psi

10 to 60 psi

50 to 100 psi

The above procedures are described in topics 3.6, 3.7, and 3.8. Select the procedure you

require.

3.6 ZERO-BASED CALIBRATION

This procedure describes the process by which the zero and span settings are obtained for

the 1-5V and 4-20mA output stages of the Series PX726A transmitters.

The following parameters relate directly to the calibration process:

URL: Upper Range Limit of sensing element. The URL is the maximum input

pressure that can be applied without over-pressuring the sensing

element.

Span: The algebraic difference between the limits of the range (P

max

– P

min

The desired span must always be less than or equal to the upper range

limit (URL) of the sensing element. Span is expressed as a percentage

of the upper range limit of the sensing element.

Zero: The point within the available pressure range the user defines as a zero

pressure reference.

P

: Maximum input pressure of a desired range, not necessarily the

max

maximum range of the sensing unit.

: Minimum input pressure of a desired range.

P

min

Theory of Operation: The output stage can potentially take a user defined portion of the 0-

100% URL pressure input, and display it as a corresponding 1-5V or 4-20mA output. The

range, desired by the user, is obtained by setting the appropriate coarse and fine zero and

span settings. Each coarse setting is described in Tables 3-A and 3-B, whereas the fine

settings are adjusted manually until the desired output is achieved. Fine adjustments are

made with two external adjustment screws. The output stage is designed to yield a Turn

Down of better than 6, while the fine adjustment screws should affect the output zero and

span by no more than 1.5%/Turn.

).

3.7 ELEVATED ZERO CALIBRATION

1. Calculate the total span required for the elevated zero range. For example, if the

desired elevated zero range is -10 to +30 psi, the total span will be 30-(-10) = 40 psi.

3-8 / Calibration M-3601

Page 34

2. Calculate the desired output reading for 0 psi. For this example, 0 ps i = 25% of the span

from -10 to 30 psi. The output should therefore be 25% of the way from 1-5V, or

2V(8mA). Set the Dip and Rotary switches in accordance with Table 3-A. Elevated zero

values are expressed as positive percentages of calibrated span. Zero percent represents

zero elevation. If the desired percent elevation is in between values listed in the table,

try the next closest setting.

3. Apply a 100% pressure input to the transmitter equivalent to the upper range value

(URV). For this example, U RV = 30 p s i .

4. If transmitter output is not 5. 000V (20.00mA), adjust A1 to make a minor correction.

5. Vent the input pressure. Adjust A2 to set the output to the 0 psi reading calculated

above.

6. Recheck the transmitter output with the input press ure vented, and 100% inputs. The

DMM should provide respective readings of the output calculated above, and 5V (20mA)

(± 0.15% full scale).

7. If necessary, repeat the A1 and A2 adjustment procedures.

8. If problems persist, recheck the DIP switch settings. Try setting the switches to the

lower percentage. For instance, if the desired percent elevation is 15%, set the switches

for an elevation of 10%.

3.7.1 Zero Elevation Example (see Table 3-A)

A DP Sensor is mounted across an orifice plate to measure gas flow. Full-scale differential

pressure is 40” H

O in either direction (±40” H2O). The span is +40” - (-40”) = 80” H2O. If a

2

100” Transmitter is used, the Coarse Span Rotary Switch (SW1) setting is found by

dividing the span (80” H

O) by the Transmitter’s range; in this case 100” H2O, i.e., 80/100 =

2

80%. Therefore, the SW1 should be set to position 2 (64% - 84%).

Set the elevation to 50% of the calibrated range (00100010). This will set up the 2808 for

calibration of 1.000V (4.00mA) at -40” and 5.000V (20.00mA) at +40”. At 0 psid the output

will be ½ scale, i.e., 3V (12mA). Apply +40” H

O to the High Side of the Transmitter and

2

use Fine Adjustment Screw A1 to set the output to 5.000V (20.00mA). Vent the unit and

use Fine Adjustment Screw A2 to adjust the Transmitter’s output to 3V (12mA). Apply

+40” H

O to the Low Side of the Transmitter and observe the output. Maximum error is

2

the deviation from 1.000V (4.00mA).

Note: Transmitter factory calib ration and compensation is for positive DP pres-

sure only. Negative pressure indication is possible with the abovedescribed method of reduced accuracy. Full-scale negative indication cannot be achieved unless the DP range is at least 2 times the negative range.

3.8 SUPPRESSED ZERO CALIBRATION

1. Calculate the total span required for the suppressed zero range. For example, if the

desired suppressed zero range is +15 to +80 psi, the total span will be: 80 - 15 = 65 psi.

M-3601 Calibration / 3-9

Page 35

2. Set the Dip and Rotary switches in accordance with Table 3-B. Suppressed zero values

are expressed as negative percentages of upper range limit (URL). Zero percent URL

represents no suppression. If the desired percent suppression is in between values, try

the next closest setting.

3. Apply a 100% pressure input to the transmitter equivalent to the upper range value

(URV). For this example, U RV = 80 p s i .

4. If transmitter output is not 5. 000V (20.00mA), adjust A1 to make a minor correction.

5. Lower the input pressure to P

. Adjust A2 to set the output to 1.000V (4.00mA).

min

6. Recheck the transmitter output with 0%, and 100% inputs. The DMM should provide

respective readings of 1.000V (4.00mA), and 5.000V (20.00mA) (± 0.15% full scale).

7. If necessary, repeat the A1 and A2 adjustment procedures.

8. If problems persist, recheck the DIP switch settings. Try setting the switches to the

lower percentage. For instance, if the desired percent suppression is -85%, set the

switches for a suppression of -90%.

Figure 3-3 - Water Tower Level Measurement - Zero Suppression

3-10 / Calibration M-3601

Page 36

3.8.1 Zero Suppression Example (see Figure 3-3 & Ta bl e 3-B)

The full water tower of Figure 3-3, produces 53.5 psi of pressure due to the 125 foot head,

i.e 10.7 psi plus 42.8 psi. To determine the Coarse Span Rotary Switch (SW1) setting,

divide the pressure produced by the 25 feet of water in the tank by the Transmitter’s

range; in this case 50 psi, i.e., 10.7/50 = 21.4%. Theref ore, the SW1 should be set to position

8 (18.5% - 23%).

To determine the zero suppression necessary for this example, divide the pressure

produced by 100 feet of water (height of tower to bottom of tank) by the Transmitter’s

range; in this case 50 psi, i.e., 42.8/50 = 85.6%. With the Coarse Span Rotary Switch SW1

set to its SW1-8 position, set the value of the Coarse Zero Switch (S1) to either -80%

(00001100) or -90% (00001010), or to a binary value between the two e.g., 00001011 ( - 85% ) .

Use Fine Adjustment Screw A2 to set 1.000V (4.00mA) @ 42.8 psi and use Fine Adjustment

Screw A1 to set 5.000V (20.00mA) @ 53.5 psi.

Note: When Zero Suppression is used, the maximum applied pressure may be up

to 125% of the URL.

3.9 SELECTABLE DAMPING

The damping feature provides compensation for applications with severe pressure

pulsation that cause the DC output of the transmitter to seem unstable. Controlling the

response time of the transmitter output can minimize this condition. Do not use damping

when the application requires dynamic pressure measurement.

Jumper JP9 can be set to apply damping to the output. With jumper JP9 in place, the

damping is on. If the jumper does not connect the two pins together, the damping is off.

M-3601 Calibration / 3-11

Page 37

Section 4

SERVICE

4.1 GENERAL

Servicing should only be performed by technically competent persons skilled in the use of

pneumatic and electronic test equipment and having knowledge of troubleshooting

procedures.

After any service procedures are completed, the transmitter cover must be installed and

properly tightened. A failure to secure the cover will result in a loss of the enclosure's dusttight, water-tight seal and explosion-proof rating.

Warning

No attempt should be made to service a transmitter while it is powered and

operating in a flammable or ex plosive environment. Either the area must be

made safe or the transmitter must be powered down, disco nnected, and taken

to a safe, non-hazardous area.

4.2 TROUBLESHOOTING

Some troubleshooting procedures will require that you use a digital multimeter (DMM) to

measure the loop current. Connect the DMM across the V and (+) terminals of the

transmitter as shown in Figure 4-1 and set it to its "milliampere" function. This method of

connection will not disturb the signal/power loop. The DMM reading will be proportional to

the input pressure and cover a range of 4-20 mA.

4.3 FACTORY REPAIRS

If you determine that a fa ult is pre sent i n the tra nsmitte r's PC b oard or pre ssure sen sor, do

not attempt any service as specialized factory equipment and test procedures will be

required. Defective transmitters may be returned to OMEGA for evaluation or repairs.

Transmitters in warranty will be repaired or replaced per the warranty agreement

contained at the end of this manual.

M-3601 Service / 4-1

Page 38

Figure 4-1 - Using Internal TEST Terminals to Measure Current

4-2 / Service M-3601

Page 39

Section 5

SPECIFICATIONS

NOTE: The specifications listed here are common to Series PX726A Transmitters

described in this manual.

5.1 FUNCTIONAL SPECIFICATIONS

Current Loop Mode:

Supply Voltage 24.0 Vdc nominal

7.00 Vdc min. at transm itter

10.0 Vdc min. with digital indicator option

37.0 Vdc max. at transmitter

42.0 Vdc with external load specified

Reverse polarity protection provided

Output 4-20 mA dc output, two wire analog (ISA 50.1

Type, Class U2)

Current limited to 28 mA max.

Minimum current is 2 to 3.5 mA.

Voltage Mode:

Supply Voltage 6-42 Vdc

Reverse polarity protected to 90 Vdc

Supply Current 1.6 mA nominal

Output 1-5 Vdc (3-wire)

Calibration Adjustments: Span Adjustment:

Adj. Range is 16 to 100% URL.

Coarse Span set by Rotary s w itch package.

Fine Span set via 25-turn pot .

Zero Adjustment:

Adj. range is -600 to 600% LRL for elevation

and suppression.

Coarse Zero provided by DIP switch

selections. Fine Zero set via 25- turn pot.

Response Time & Damping: Time Constant:

(Time required for 63% change in output

with a 100% input change)

Damping OFF ≅ 0.16 ms

Damping ON = 50 ms +20%

Damping:

User selectable by jumper circuit

M-3601 Specifications / 5-1

Page 40

Recovery:

Time to steady output after application of

24 volt supply with constant pressure is 5

ms maximum (With No Damping)

Linearity: On low-range models, full vacuu m can represent

an appreciable percentage of URL. If, on those

models, calibration contains 50% of zero

elevation, non-linearity errors can be as high as

+1%.

5.2 PERFORMANCE SPECIFICATIONS

Accuracy: (Includes independent linearity, hysteresis and

repeatability)

+0.1% of calibrated span

Resolution: Virtually infinite

Long Term Stability: At constant conditions. +0.25% of URL/6 mo.

Ambient Temperature Effect: Total including Zero & Span

+0.010% of URL per °F fr om -25 to 75 °F

+0.015% of URL per °F fr om 75 to 185 °F

+0.020% of URL per °F on 100 inH2O only

Power Supply Effect: + .005 %/Vdc

Ripple and Noise: In accordance with ISA 50.1, Section 4.6

5.3 ENVIRONMENTAL SPECIFICATIONS

Temperature Limits: Wet End using DC 200 Fill:

-40 to 220 °F (-40 to 104 °C)*

Amplifier:

-25 to 185 °F (-32 to 85 °C)

Digital Indicator:

-22 to 158 °F (-30 to 70 °C)

Storage:

-40 to 212 °F (-40 to 100 °C)

* The maximum permissible temperature inside

the enclosure (irrespective of sensor temperature)

is 185 °F (85 °C) for the amplifier board, and 158

°F (70 °C) for the digital indicator option.

5-2 / Specifications M-3601

Page 41

Humidity Limits: Specified with transmitter electronic

housing cover installed.

o

15-95% RH to 140 °

F (60 °C)

15-50% RH to 185 °F (85 °C)

EMI Effect: +1% of URL @ 10 V/M, 20 MHz to 500 MHz

Meets /SAMA PMC-33-1C with transmitter

cover in place and all wiring contained in

grounded conduit.

Surge Protection: Bipolar, differential surge

1000 watts for 1 ms (without digital

indicator option)

May be used with purchased surge protector

for additional protection (for non-hazardous,

non-approved installati ons only).

Vibration Effect: Less than +0.1% of URL for 10 to 500 Hz at

1 g on any axis. Meets SAMA PMC-31-1

5.4 PHYSICAL SPECIFICATIONS

Fill Media: DC 200 Silicone

Electronics Housing: Low copper alum inum, epoxy fin ish, NEMA

4X rating

Electrical Connections: 1/2 NPT conduit connection with internal

field wiring terminals.

M-3601 Specifications / 5-3

Page 42

Series PX726A Transmitter

Special Instructions for Class I, Division 2 Hazardous Locations

1. The OMEGA Series PX726A Gauge Pressure Transmitter is listed by Underwriters

Laboratories (UL) as nonincendive and are suitable for use in Class I, Division 2,

Groups A, B, C and D hazardous locations or non-hazardous locations. Read this

document carefully before installing a nonincendive OMEGA Series PX726A Pressure

Transmitter. In the event of a conflict between the Series PX726A Instruction Manual

(M-3601) and this document, always follow the instructions in this document.

2. Wiring must be performed in accordance with Class I, Division 2 wiring methods as

defined in Article 501-4 (b) of the National Electrical Code, NFPA 70 for installations

within the United States, or as specified in Section 18-152 of the Canadian Electrical

Code for installation in Canada.

3. Model equipped with the Loop Powered Indicator Option (Appendix B) are approved for

use in Class I, Division 2, Groups A, B, C and D hazardous locations.

4. WARNING: EXPLOSION HAZARD - Substitution of components may impair

suitability for use in Class I, Division 2 environments.

5. WARNING: EXPLOSION HAZARD - When situated in a hazardous location,

turn off power before servicing/replacing the unit and before installing or

removing I/O wiring.

6. WARNING: EXPLOSION HAZARD - Do Not disconnect equipment unless the

power has been switched off or the area is known to be nonhazardous.

05/08/2001 Appendix A of M-3601 Page 1 of 1

Page 43

Appendix B

R

R

R

R

R

R

R

R

R

LOOP POWERED INDICATOR OPTION

For

For

Series PX726A

Series PX726A

Industrial Pressure Transmitters

Industrial Pressure Transmitters

1

TB2

R

R

R

R

R

R

R

M

An OMEGA Technologies CompanyAn OMEGA Technologies Company

E

PSI

R

Operator's Manual

Operator's Manual

M-3601/1101 - Appendix B

M-3601/1101 - Appendix B

Page 44

Appendix B

LOOP POWERED INDICATOR OPTION

TABLE OF CONTENTS

SECTION TITLE

Section 1 - INTRODUCTION

1.1 INTRODUCTION .............................................................................................................. 1

1.1.1 Features............................................................................................................................... 1

1.1.2 Hardware Circuit Overview................................................................................................ 1

1.1.3 Adjustments ........................................................................................................................ 2

1.1.4 Connectors .......................................................................................................................... 2

Section 2 - INSTALLATION, OPERATION & SERVICE

2.1 INSTALLATION & REMOVAL/REPLACEMENT OF THE LPI................................... 3

2.1.1 Installation/Removal of the Loop Powered Indicator......................................................... 3

2.2 FIELD WIRING .................................................................................................................7

2.3 OPERATIONAL DETAILS............................................................................................... 7

2.3.1 Configuring the Loop Powered Indicator........................................................................... 7

2.3.2 Accuracy and Decimal Point Settings .............................................................................. 10

2.3.3 Displaying Current Using the LPI ....................................................................................10

2.3.4 Error Conditions ............................................................................................................... 11

2.3.4.1 Conversion and Display Error Conditions........................................................................ 11

2.4 SERVICE.......................................................................................................................... 11

Section 3 - SPECIFICATIONS

3.1 ENVIRONMENTAL SPECIFICATIONS ....................................................................... 12

M3601/1101 Appendix B Page 0-1 Table Of Contents

Page 45

Section 1

INTRODUCTION

1.1 INTRODUCTION

The loop powered indicator (LPI) option is used to provide local indication in engineering

units of the measurand represented by a 4-20 mA current loop. The LPI may be installed in

a Series PX725A, PX726A or PX771A Transmitter with the Display Cover Assembly or in a

stand-alone housing. The LPI is powered by the 4-20 mA current loop using less than 500

uA @ 3 V for the electronic circuitry.

The LPI option is a circuit board assembly with a micro-controller, a liquid-crystal display

(LCD) and active electronic circuitry contained on a single board, i.e., the “Meter/Display

Board.” The Meter/Display Board plugs into the “Meter Motherboard” that provides the

electrical connections from the transmitter interface and allows the display to be rotated in

90-degree increments.

1.1.1 Features

• Powered by a 4-20 mA current loop using less than 500 uA @ 3V

• Dual Board Set - Meter Motherboard allows the Meter/Display Board to be rotated in

90-degree increments.

• 4½ Digit Display allows display of numeric values as large as 19999.

• Eight selectable unit labels: mA, %, psi, IN H2O, bar, kg/cm2, °C, and °F.

• One selectable “no-label” position.

• Reverse polarity protection.

• Over current protection

1.1.2 Hardware Circuit Overview

The LPI option uses a micro-controller with integral LCD display drivers. The current

flowing through the LPI is sampled and converted to a corresponding digital word. Based

on user-configuration the digital value is displayed in engineering units along with a unit

label.

The 4½ digit display can show numeric values as large as 19999. The display contains eight

integral unit labels. These are: mA, %, psi, IN H2O, bar, kg/cm2, °C, and °F.

Calibration is done at the board level by injecting known current levels into the assembly,

reading the current and computing correction coefficients that are then stored in the LPI.

The coefficients are then used in a correction algorithm to linearize the current signal and

achieve a minimum accuracy of 0.1%FS at room temperature. The circuit uses precision

resistors to sample the current. The Meter/Display Board is burned-in for long-term

stability and reliability. Operating temperature is limited by the LCD display to -30 to +70

°C. Calibration is done once at the factory, but unit display selection may be done as often

as required by the user (see Section 2.3.1).

Reverse polarity protection is achieved by shunting the entire circuit with a diode. A 250

mA fuse provides overcurrent protection. A shunt capacitor is also included to minimize

EMI effects and provide secondary transient protec tion.

Appendix B Page 1 Loop Powered Indicator

Page 46

The two-board assembly is designed for field retrofit in Series PX725A, PX726A and

PX771A pressure transmitters.

1.1.3. Adjustment s

Adjustment potentiometers are unnecessary in the LPI. The indicator is always scaled to 420mA. The user configures the LPI in engineering units of their choice, i.e., mA, %, psi, IN

H2O, bar, kg/cm2, °C, ° F or Cus t om.

1.1.4 Connectors

The LPI Assembly comes in two parts: The Meter Motherboard and the Meter/Display

Board. The Meter Motherboard is assembled into the Series PX725A, PX726A or PX771A

Transmitter by connecting the transmitter’s terminal block to the spade fingers integral to

the Meter Motherboard and installing the mounting screws through the Meter

Motherboard to the cast-in mounting bosses in the transmitter housing. The customer cable

is then connected to the compression-type terminals of Terminal Block TB1 on the Meter

Motherboard. Finally, the Meter/Display Board plugs into the Meter Motherboard in any

one of four positions depending on the desired meter rotation; this is through a set of twoconductor “Berg” connectors. The Meter/Display Board is also secured to the Meter

Motherboard with four screws.

Figure 1-1 - PX725A, PX72 6A or PX771A Transmitter

with Loop Powered Indicator

Loop Powered Indicator Page 2 Appendix B

Page 47

Section 2

INSTALLATION, OPERATION & SERVICE

2.1 INSTALLATION & REMOVAL/REPLACEMENT OF THE LPI

2.1.1 Installation/Removal of the Loop Powered Indicator

The following parts are provided for field installation of the Loop Powered Indicator option:

One (1) - O-Ring, Size - 149

Two (2) - S tandoffs, #4 M/F Sh oulder

Two (2) - Standoffs, 4-40 x .750 M/F

One (1) - Meter Motherboard Ass’y.

One (1) - Meter/Display Board Ass’y.

Two (2) - Standoffs, 4-40 x .375 M/F

Four (4) -Screws, 4-40 x ¼ Pan Head

One (1) - 2808 Display Cover Ass’y.

WARNING

Never attempt to service a Series PX725A, PX726A or

PX771A Transmitter while it is operating in a hazardous

environment. Either the area must be made safe or the

unit must be unwired, unmounted, and taken to a safe,

non-hazardous area.

WARNING

Never attempt to install or remove any components (PCBs

or Field Wiring.) while the unit is running. Doing so can

cause sudden electrical transients or imbalances that

are capable of causing damage to the module or

component in question, as well as other associated

circuit boards. Always turn off ANY Transmitter to

Instrument circuits (at the instrument or External DC

Power Source) before changing or adding any components.

CAUTION

Place any related critical processes under manual or

auxiliary control prior to shutting down or performing

any of the steps discussed herein.

To install the Loop Powered Indicator (LPI) option into a Series PX725A, PX726A or

PX771A Transmitter, follow steps 1 through 9 below. To remove the LPI see step 10. Note:

The LPI is loop powered and may only be used with Transmitters configured in the “420mA” mode.

1. Remove the appropriate Cover Assembly from the instrument (see Figure 2-1). The

Cover Assembly is factory installed “hand tight,” i.e., there is no torque required.

Appendix B Page 3 Loop Powered Indicator

Page 48

2. Referring to Figure 2-2, install the two (2) 4-40 x .759 Standoffs into the Transmitter

at location A.

Figure 2-1 - Transmitter Cover Assembly Removal

3. Referring to Figure 2-2, install the two (2) 4-40 x .375 Standoffs into the Transmitter at

location B.

4. Disconnect the Field Wires (if installed) from the Transmitter’s Terminal Block.

5. Remove the three (3) Field Wiring Screws/Clamps from the Transmitter’s Terminal

Block.

6. Secure the Meter Motherboard to the Transmitter via the three (3) Field Wiring

Screws/Clamps removed in step 5. Using two (2) #4 M/F Shoulder Standoffs, secure the

Motherboard to the Standoffs installed in step 3.

7. Install the Meter/Display Board onto the Meter Motherboard after aligning the appropriate Meter/Display Board Interface Connector (P1 through P4) with J1 of the

Meter Motherboard. Secure the Meter/Display Board to the four standoffs (Locations A

& D of Figure 2-2) via four (4) 4-40 x ¼ Pan Head Screws.

Loop Powered Indicator Page 4 Appendix B

Page 49

Figure 2-2 - Loop Powered Indicator Installation Diagram

Appendix B Page 5 Loop Powered Indicator

Page 50

8. Connect the field wires to the compression-type terminals of Meter Motherboard

Terminal Block TB1 (see Section 2.2 & Figure 2-5). Configure the LPI for operation

(see Section 2.3.1).

9. Install the Transmitter Display Cover Assembly (with size 149 O-Ring) onto the

Transmitter (see Figures 2-3 & 2-4). Lubricate O-Ring with Dow Corning Silicone

Grease (Compound 4) or equivalent prior to assembly. Lubricate threads with

“NEVER-SEEZ” “Pure Nickel Special” or equivalent prior to assembly. Tighten until

Cover contacts the Transmitter Hou sing (no torque required).

Figure 2-3 – Series PX725A, PX 726A & PX771A Display Cover Assembly

Figure 2-4 - Transmitter with Loop Powered Indicator Option Installed

Loop Powered Indicator Page 6 Appendix B

Page 51

10. To remove the LPI Option from a Series PX725A, PX726A or PX771A Transmitter,

follow steps 7 through 9 in reverse order, removing rather than installing the item in

question.

2.2 FIELD WIRING

The LPI uses compression-type terminals that accommodate up to #14 AWG wire. A

connection is made by inserting the bared end (1/4 inch Max.) into the Meter Motherboard

Connector (TB1) clamp beneath the screw and then securing the screw. Insert the bared

end fully to prevent short circuits.

Allow some slack in the wires when making terminal connections. The slack makes the

connections more manageable and minimizes mechanical strain on the Meter Motherboard

and the wiring harness (see Section 2.4 of M3600, M3601, M3602 and Figure 2-5 below).

Figure 2-5 - Transmitter LPI Option Field Wiring

2.3 OPERATIONAL DETAILS

2.3.1 Configuring the Loop P o wer ed Indicator

Configuration involves selecting an engineering unit (called the Base Unit or BU) and then

establishing Zero and Full-scale values to be used when converting current into that unit.

The Mode (left-hand) and Select (right-hand) buttons are used to configure the LPI. The

LPI ships from the factory with a configuration that displays the flowing current in a BU of

percent (%). During configuration the Mode button is used to move through the

configuration sequence and the Select button is used to choose a particular setting from

those available at a particular point in the sequence.

Configuration begins with the selection of an engineering-unit followed by the choices for

the zero; minus sign, ten-thousandths half-digit, four full digits (thousands to units), then

the decimal point. Next is the Full-scale; minus sign, ten-thousandths half-digit,

Appendix B Page 7 Loop Powered Indicator

Page 52

thousandths to units, and decimal point. The final press of the Mode button causes an exit

from configuration mode to run mode. At any point in the sequence pressing the Mode

button selects the next item in the order i.e., to leave a previously configured item as is,

press Mode to skip over it. When configuration is started a one-minute timer is loaded; it is

reloaded whenever a Mode or Select button is pressed. If no button activity occurs for one

minute the timer will expire and restore the previously active configuration.

Figure 2-6 - Loop Powered Indicator - Mode (SW1) and Select (SW2) Buttons

During configuration any previously configured engineering unit, minus sign, tenthousandths digit and decimal point are ignored; the user MUST select them if they are to

be active in the new configuration. Configuration proceeds as follows:

1. Press and hold the Mode (left-hand) button until one of the unit labels begins blinking;

this typically takes 5 seconds. The display will be all blank except for a small lowercase letter ‘u’ located in the upper half of the rightmost digit. The label of the

previously configured engineering unit will be blinking. Remember that the previous

engineering unit label is only blinking as a convenient starting point - in order to

remain in effect it must be selected again unless another unit will be chosen. If the

previously configured BU was ‘Custom,’ the ‘u’ will be blinking.

2. Press the Mode button to change the displayed blinking engineering-unit label, then

press Select to make the selected unit active and move to minus sign selection. A unit

selection MUST be made otherwise repeated Mode presses will only cycle through the

unit selections. If the integral unit labels do not match the application unit, press the

Mode button until the small letter ‘u’ is blinking. This is the Custom unit selection,

meaning that the display will not show a unit label. In this case an external label