Page 1

SUBMERSIBLE PRESSURE

TRANSDUCERS

FOR LEVEL, DEPTH OR GROUND WATER MEASUREMENTS

Gage, Sealed Gage or

Absolute Pressure

mV/V, 0 to 5 Vdc, 0 to 10 Vdc, or

4 to 20 mA Outputs

0-10 inH2O to 0-1000 psi

PX709GW Series

Level/Submersible

Standard

U Precision Micromachined

Silicon Sensor

U 5-Point NIST Traceable

Calibration

U Lightning/Surge

Protection Available on

Amplified Models

U 316L SS Case and

Diaphragm

U Fused Polyurethane Cable

U Premium Temperature

Performance

U Broad Compensated

Temperature Range

U 0.20% Standard Accuracy

or Optional 0.08% High

Accuracy Models for

Precise Depth

Measurement

U Available in Gage

Pressure: Vented to

Atmosphere Through the

Cable; Sealed Gage: Not

Vented to Atmosphere;

or Absolute Pressure:

Vacuum Reference

U

Reverse Polarity Protected

U Protective Nose Cone and

Desiccant Available

U Standard or Custom

Cable Lengths

The PX709GW Series submersible

depth transducers are designed

to make precision level or depth

measurements in fresh water or

liquids compatible with 316 SS

reliably for years in harsh industrial

environments. The PX709GW

Economical Price

High Performance

series has the proven Omega

micromachined silicon technology as

its core sensor. The Piezoresistive

technology uses precision solid state

strain gages molecularly embedded

into a highly stable silicon wafer.

The silicon is mounted in a sealed

chamber and protected from the

environmental fluids by a pressure

sensitive stainless steel diaphragm.

A very small volume of silicone

oil transfers the pressure from the

diaphragm to the silicon sensor.

The cable is molded onto the case

using a unique high pressure, high

temperature system to assure the

best possible quality seal for long

life and durability. This technology

produces a very rugged, high

stability sensor with exceptional

accuracy, minimal thermal effects

and long term reliability.

B-1

Nose cone included.

Applications

• Level Monitoring and Control

• Depth Measurement

• Surface Water Monitoring

• Tank Level

• Well Water Depth

• Waste Water Applications

• Dewatering Installations

• Construction Bypass

Inconel® models are also available for

oceanic research and highly corrosive

or salt water applications. See model

PX709SW.

PRESSURE TRANSDUCERS

B

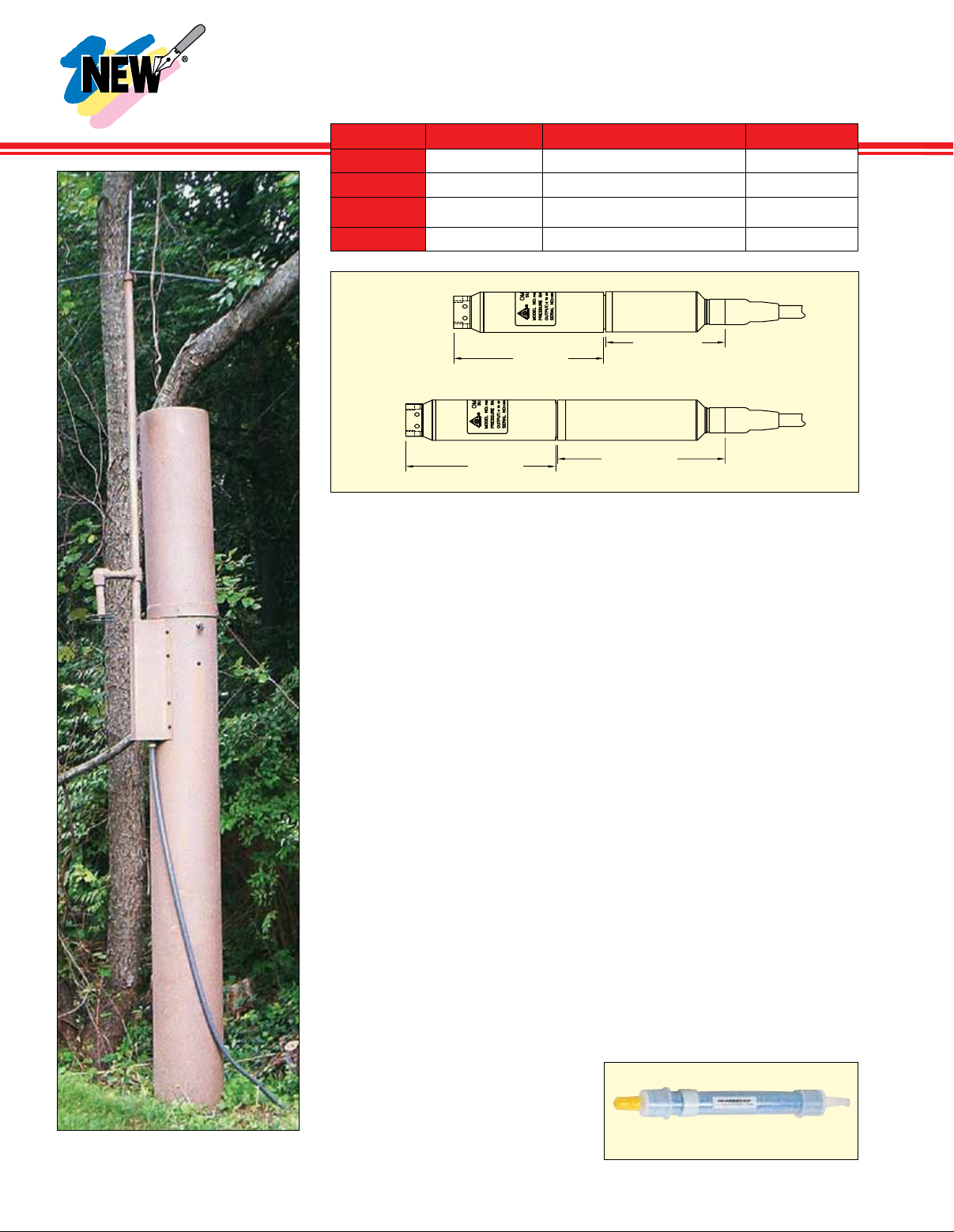

PX709GW available

with optional lightning

protection shown

smaller than actual size.

Page 2

SUBMERSIBLE PRESSURE TRANSDUCERS

FOR LEVEL, DEPTH OR GROUND MEASUREMENTS

PX709GW Connections

mV/V VO LTAGE CURRENT

Red

Black

(+) V in (+) V in (+) Supply

(-) V in (-) Common (-) Supply

Shown monitoring river level for

flood warning.

Green

White

* If 4-wire voltage output is chosen, see application note in manual.

Note: Conduit

fitting add

30 (1.2)

maximum to

Length

Dimensions: mm (inch)

COMMON SPECIFICATIONS

Approvals: RoHS compliant

Accuracy (Combined Linearity,

Hysteresis and Repeatability):

Standard ±0.20% BSL or high accuracy,

option “HH”, ±0.08% BSL

Setting Accuracy Zero: ± 0.5% FS

typical, ± 1.0% FS maximum (± 1.0% FS

typical, ± 2.0% FS maximum for ranges

≤ 2.5 psi)

Setting Accuracy Span: ± 0.5% FS

typical, ± 1.0% FS maximum (± 1.0% FS

typical, ± 2.0% FS maximum for ranges

≤ 1psi) calibrated in vertical direction with

fitting down

Minimum Resistance Between

Transducer Body and Any Wire:

100M Ω @ 50 Vdc (before surge

protection)

Pressure Cycles: 1 million minimum

Long Term Stability (1 yr.): ±0.1%

FS typical

Operating Temperature: -18 to 79°C

(0 to 175°F) with no solid freeze

Compensated Temperature: -1 to 32°C

(30 to 90°F)

Thermal Effects (Over Compensated

Range):

Zero Balance:

Ranges >5 psi: ±0.3% span

Ranges ≤5 psi: ±0.5% span

Span Setting:

Ranges >5 psi: ±0.3% span

Ranges ≤5 psi: ±0.5% span

Bandwidth: DC to 1 kHz typical

Response Time: 500 usec, 0 to 90%

step change

CE Compliant: Meets EN 61326-1: 2006

for industrial locations (certified with

91 m (300'))

Lightning Protection Option

(if included): Integral lightning surge

protection to IEC-61000-4-5 (Level 4)

Shock: 50 g, 11 ms, half-sine horizontal

and vertical axis

(-) Signal no connection or Common* Shunt (option)

(+) Signal (+) Signal Shunt (option)

94 (3.7)

94 (3.7)

102 (4.0)

133 (5.2)

Vibration: ± 20 g

Overpressure

Gage and Sealed Gage:

10 inH

1 psi: 6 times span

2.5 to 1000 psi: 4 times span

Absolute: 5 psia: 6 times span;

Containment Pressure

Gage Pressure

10 inH

15 to 1000 psi: to 3000 psi

Absolute Pressure: 5 to 1000 psi: to

6000 psia

Wetted Parts: 316L stainless steel

Body Material: 316L stainless steel

Pressure Connection: 9/16-18 UNF

female

Transducer Weight: 285 g (10 oz)

typical depending upon configuration

Cable Construction: Polyurethane

jacket with double Kevlar

stringers, fused to case, with large

vent tube

Cable Pull Strength: 109 kg (240 lb)

Cable Conductors: Four 24 AWG

(19/36 stranded tinned copper) with

ETFE insulation. Meets

MIL-W-22759/16 & SAE AS22759/16

Cable Sealing: Fused to case via

molded Neoprene boot rated to 610 m

(2000') depth

Standard Cable Lengths (ft): 10, 15,

20, 25, 30, 40, 50, 60, 65, 74, 100, 150,

200, 300, for other lengths contact

factory for lead times (see page 6)

O: 10 times span

2

ranges >5 psia: 4 times span

O to 5 psi: to 1000 psi

2

Desiccant, shown smaller

than actual size.

B-2

Standard Unit

Lighting Protected Unit

®

reinforcing

Page 3

SUBMERSIBLE PRESSURE TRANSDUCERS

PX709GW SERIES WITH 100 mV OUTPUT

Submersible Level Transducer

To Order Visit omega.com/px709gw for Pricing and Details

10 mV/V OUTPUT, 0.2% ACCURACY1 WITH 3 m (10') CABLE [Maximum recommended cable length** on mV models 7.8 m (25')]

GAGE PRESSURE RANGES (INTERMEDIATE RANGES AVAILABLE, CONSULT PRESSURE ENGINEERING)

EQUIVALENT

DEPTH

RANGE PSIG

0 to 0.36 10.00 inH2O 250 mmH2O 3 m (10')

0 to 1 27.68 inH

0 to 2.5 69.24 inH

0 to 5 11.5 3.51 3 m (10')

0 to 10 23.1 7.04 3 m (10')

0 to 15 34.6 10.5 3 m (10')

0 to 30 69.2 21.1 3 m (10')

0 to 50 115 35.1 3 m (10')

0 to 100 231 70.4 3 m (10')

0 to 150 346 105 3 m (10')

0 to 250 577 176 3 m (10')

0 to 500 1153 351 3 m (10')

0 to 750 1730 527 3 m (10')

0 to 1000 2307 703 3 m (10')

ftH

O

2

EQUIVALENT

DEPTH

mH2O

O 670 mmH2O 3 m (10')

2

O 1757 mmH2O 3 m (10')

2

STD CABLE

LENGTH

SEALED GAGE PRESSURE RANGES (PSISG)

0 to 100 231 70.4 3 m (10')

0 to 150 346 105 3 m (10')

0 to 250 577 176 3 m (10')

0 to 500 1153 351 3 m (10')

0 to 750 1730 527 3 m (10')

0 to 1000 2307 703 3 m (10')

ABSOLUTE PRESSURE RANGES (PSIA)

0 to 5 11.5 3.51 3 m (10')

0 to 10 23.1 7.04 3 m (10')

0 to 15 34.6 10.5 3 m (10')

0 to 30 69.2 21.1 3 m (10')

0 to 50 115 35.1 3 m (10')

0 to 100 231 70.4 3 m (10')

0 to 150 346 105 3 m (10')

0 to 250 577 176 3 m (10')

0 to 500 1153 351 3 m (10')

0 to 750 1730 527 3 m (10')

0 to 1000 2307 703 3 m (10')

STANDARD PART

NUMBER

0.20% ACCURACY

PX709GW-10WGV-[**] PX709GW-10WGV-HH-[**]

PX709GW-001GV-[**] PX709GW-001GV-HH-[**]

PX709GW-2.5GV-[**] PX709GW-2.5GV-HH-[**]

PX709GW-005GV-[**] PX709GW-005GV-HH-[**]

PX709GW-010GV-[**] PX709GW-010GV-HH-[**]

PX709GW-015GV-[**] PX709GW-015GV-HH-[**]

PX709GW-030GV-[**] PX709GW-030GV-HH-[**]

PX709GW-050GV-[**] PX709GW-050GV-HH-[**]

PX709GW-100GV-[**] PX709GW-100GV-HH-[**]

PX709GW-150GV-[**] PX709GW-150GV-HH-[**]

PX709GW-250GV-[**] PX709GW-250GV-HH-[**]

PX709GW-500GV-[**] PX709GW-500GV-HH-[**]

PX709GW-750GV-[**] PX709GW-750GV-HH-[**]

PX709GW-1.0KGV-[**] PX709GW-1.0KGV-HH-[**]

PX709GW-100SGV-[**] PX709GW-100SGV-HH-[**]

PX709GW-150SGV-[**] PX709GW-150SGV-HH-[**]

PX709GW-250SGV-[**] PX709GW-250SGV-HH-[**]

PX709GW-500SGV-[**] PX709GW-500SGV-HH-[**]

PX709GW-750SGV-[**] PX709GW-750SGV-HH-[**]

PX709GW-1.0KSGV-[**] PX709GW-1.0KSGV-HH-[**]

PX709GW-005AV-[**] PX709GW-005AV-HH-[**]

PX709GW-010AV-[**] PX709GW-010AV-HH-[**]

PX709GW-015AV-[**] PX709GW-015AV-HH-[**]

PX709GW-030AV-[**] PX709GW-030AV-HH-[**]

PX709GW-050AV-[**] PX709GW-050AV-HH-[**]

PX709GW-100AV-[**] PX709GW-100AV-HH-[**]

PX709GW-150AV-[**] PX709GW-150AV-HH-[**]

PX709GW-250AV-[**] PX709GW-250AV-HH-[**]

PX709GW-500AV-[**] PX709GW-500AV-HH-[**]

PX709GW-750AV-[**] PX709GW-750AV-HH-[**]

PX709GW-1.0KAV-[**] PX709GW-1.0KAV-HH-[**]

2

STANDARD

HIGH ACCURACY MODELS

00.8% ACCURACY

PRESSURE TRANSDUCERS

B

mV/V OUTPUT SPECIFICATIONS

Output: 100 mV @ 10 Vdc (Ratiometric 5 to 10 Vdc)

**Cable Length: For lengths over 7.6 (25') output signal is

attenuated ½% per 30.5 m (100') nominal

Supply Voltage: 5 to 10 Vdc (ratiometric)

Current Draw: 5 mA @ 10 Vdc

Input Impedance: 1000 to 5000 Ω

Output Impedance: 5000 Ω ± 10% Typical

See Common Specifications for other parameters

Comes complete with 5-point NIST traceable calibration certificate.

[**] To order with additional cable length, specify total length in feet, PX709GW-001GV-25FT, additional cost for length over 10 feet.

Consult sales for stock cable length to assure fast delivery.

1.) To order with optional high accuracy for extra cost, insert code “-HH” for 0.08% accuracy after the V, PX709GW-100GV-HH-[**].

2.) To order with ½ NPT conduit fitting specify Model PX709C for additional cost, PX709CGW-010GV.

3.) Lightning protection is available on amplified voltage and mA output models for additional costs.

Ordering Examples: PX709GW-001GV, 1 psi gage submersible transducer with 10 mV/V output, 3 m (10') of cable and standard 0.2% accuracy.

PX709GW-005AV-HH-25FT, 5 psi absolute pressure submersible transducer with 10 mV/V output, 7.6 m (25') of cable and high 0.08% accuracy.

PX709CGW-2.5GV-20FT, 2.5 psi gage submersible transducer with 10 mV/V output, a ½ NPT conduit fitting, 6.1 m (20')of cable.

OPTIONS FOR SUBMERSIBLE TRANSDUCERS

PX709-BOX1

PX709-BOX2

PX709-BOX3

A019385

Terminal enclosure without surge protection - for

use with all models

Terminal enclosure with surge protection - for use

with 4 to 20 mA without Shunt Cal (one surge

protection module)

Terminal enclosure with surge protection - for use

with voltage output sensors and 4 to 20 mA with

Shunt Cal option (two surge protection modules)

Replacement desiccant to keep moisture out of

vent tube

B-3

Page 4

SUBMERSIBLE PRESSURE TRANSDUCERS

PX709GW SERIES WITH 0 TO 5 Vdc OR 0 TO 10 Vdc OUTPUT

Submersible Level Transducer

To Order Visit omega.com/px709gw for Pricing and Details

5 Vdc OUTPUT, 0.2% ACCURACY1 WITH 3 m (10') CABLE [

GAGE PRESSURE RANGES (INTERMEDIATE RANGES AVAILABLE, CONSULT PRESSURE ENGINEERING)

Maximum

cable length 91 m (300')]

EQUIVALENT

DEPTH

RANGE PSIG

0 to 0.36 10.00 inH2O 250 mmH2O 3 m (10')

0 to 1 27.68 inH

0 to 2.5 69.24 inH

0 to 5 11.5 3.51 3 m (10')

0 to 10 23.1 7.04 3 m (10')

0 to 15 34.6 10.5 3 m (10')

0 to 30 69.2 21.1 3 m (10')

0 to 50 115 35.1 3 m (10')

0 to 100 231 70.4 3 m (10')

0 to 150 346 105 3 m (10')

0 to 250 577 176 3 m (10')

0 to 500 1153 351 3 m (10')

0 to 750 1730 527 3 m (10')

0 to 1000 2307 703 3 m (10')

ftH

O

2

EQUIVALENT

DEPTH

O

mH

2

O 670 mmH2O 3 m (10')

2

O 1757 mmH2O 3 m (10')

2

STD CABLE

LENGTH

SEALED GAGE PRESSURE (PSISG)

0 to 100 231 70.4 3 m (10')

0 to 150 346 105 3 m (10')

0 to 250 577 176 3 m (10')

0 to 500 1153 351 3 m (10')

0 to 750 1730 527 3 m (10')

0 to 1000 2307 703 3 m (10')

ABSOLUTE PRESSURE (PSIA)

0 to 5 11.5 3.51 3 m (10')

0 to 10 23.1 7.04 3 m (10')

0 to 15 34.6 10.5 3 m (10')

0 to 30 69.2 21.1 3 m (10')

0 to 50 115 35.1 3 m (10')

0 to 100 231 70.4 3 m (10')

0 to 150 346 105 3 m (10')

0 to 250 577 176 3 m (10')

0 to 500 1153 351 3 m (10')

0 to 750 1730 527 3 m (10')

0 to 1000 2307 703 3 m (10')

STANDARD PART

NUMBER

2

STANDARD

0.20% ACCURACY

PX709GW-10WG5V-[**] PX709LGW-10WG5V-[**]

PX709GW-001G5V-[**] PX709LGW-001G5V-[**]

PX709GW-2.5G5V-[**] PX709LGW-2.5G5V-[**]

PX709GW-005G5V-[**] PX709LGW-005G5V-[**]

PX709GW-010G5V-[**] PX709LGW-010G5V-[**]

PX709GW-015G5V-[**] PX709LGW-015G5V-[**]

PX709GW-030G5V-[**] PX709LGW-030G5V-[**]

PX709GW-050G5V-[**] PX709LGW-050G5V-[**]

PX709GW-100G5V-[**] PX709LGW-100G5V-[**]

PX709GW-150G5V-[**] PX709LGW-150G5V-[**]

PX709GW-250G5V-[**] PX709LGW-250G5V-[**]

PX709GW-500G5V-[**] PX709LGW-500G5V-[**]

PX709GW-750G5V-[**] PX709LGW-750G5V-[**]

PX709GW-1.0KG5V-[**] PX709LGW-1.0KG5V-[**]

PX709GW-100SG5V-[**] PX709LGW-100SG5V-[**]

PX709GW-150SG5V-[**] PX709LGW-150SG5V-[**]

PX709GW-250SG5V-[**] PX709LGW-250SG5V-[**]

PX709GW-500SG5V-[**] PX709LGW-500SG5V-[**]

PX709GW-750SG5V-[**] PX709LGW-750SG5V-[**]

PX709GW-1.0KSG5V-[**] PX709LGW-1.0KSG5V-[**]

PX709GW-005A5V-[**] PX709LGW-005A5V-[**]

PX709GW-010A5V-[**] PX709LGW-010A5V-[**]

PX709GW-015A5V-[**] PX709LGW-015A5V-[**]

PX709GW-030A5V-[**] PX709LGW-030A5V-[**]

PX709GW-050A5V-[**] PX709LGW-050A5V-[**]

PX709GW-100A5V-[**] PX709LGW-100A5V-[**]

PX709GW-150A5V-[**] PX709LGW-150A5V-[**]

PX709GW-250A5V-[**] PX709LGW-250A5V-[**]

PX709GW-500A5V-[**] PX709LGW-500A5V-[**]

PX709GW-750A5V-[**] PX709LGW-750A5V-[**]

PX709GW-1.0KA5V-[**] PX709LGW-1.0KA5V-[**]

LIGHTNING3 PROTECTED

MODELS STANDARD

0.20% ACCURACY

5V and 10V OUTPUT SPECIFICATIONS

Output: 0 to 5 Vdc or 0 to 10 Vdc (3 or 4 wire user

selectable) see application note/manual

Supply Voltage: 5V output: 10 to 30 Vdc @ 10 mA, 10V

output: 15 to 30 Vdc @ 10 mA

Lightning Protection: See application note/manual

See Common Specifications for other parameters

Comes complete with 5-point NIST traceable calibration certificate.

[**] To order with additional cable length, specify total length in feet, PX709GW-001G5V-25FT, additional cost for length over 10 feet.

Consult sales for stock cable length to assure fast delivery.

1.) To order with optional high accuracy for extra cost, insert code “-HH” after 5V for 0.08% accuracy, PX709-150G5V-HH-[**].

2.) To order with ½ NPT conduit fitting for extra cost, specify Model PX709C, for additional cost PX709CGW-010G5V.

3.) To order with optional Lightning/Surge protection for extra cost, specify model PX709LGW, PX709LGW-001G5V.

4.) To order with optional Lightning/Surge protection and conduit fitting for extra cost, specify model PX709CLGW, PX709CLGW-001G5V.

Ordering Examples: PX709GW-001G5V, 1 psi gage submersible transducer with 0 to 5 Vdc output, 3 m (10') of cable and standard 0.2%

accuracy. PX709LGW-005A5V-HH-25FT, 5 psi absolute pressure, lightning protected submersible transducer with 0 to 5 Vdc output, 7.6 m (25')

of cable and high 0.08% accuracy.

PX709CGW-2.5G10V-20FT, 2.5 psi gage submersible transducer with 0 to 10 Vdc output, a ½ NPT conduit fitting and 6.1 m (20') of cable.

OPTIONS FOR SUBMERSIBLE TRANSDUCERS

PX709-BOX1

PX709-BOX2

PX709-BOX3

A019385

Terminal enclosure without surge protection - for

use with all models

Terminal enclosure with surge protection - for use

with 4 to 20 mA without Shunt Cal (one surge

protection module)

Terminal enclosure with surge protection - for use

with voltage output sensors and 4 to 20 mA with

Shunt Cal option (two surge protection modules)

Replacement desiccant to keep moisture out of

vent tube

B-4

Page 5

SUBMERSIBLE PRESSURE TRANSMITTER

PX709GW SERIES WITH 4 TO 20 mA OUTPUT

Submersible Level Transducer

To Order Visit omega.com/px709gw for Pricing and Details

4 to 20 OUTPUT, 0.2% ACCURACY1 WITH 3 m (10') CABLE [

GAGE PRESSURE RANGES (INTERMEDIATE RANGES AVAILABLE, CONSULT PRESSURE ENGINEERING)

EQUIVALENT

DEPTH

RANGE PSIG

0 to 0.36 10.00 inH2O 250 mmH2O 3 m (10')

0 to 1 27.68 inH

0 to 2.5 69.24 inH

0 to 5 11.5 3.51 3 m (10')

0 to 10 23.1 7.04 3 m (10')

0 to 15 34.6 10.5 3 m (10')

0 to 30 69.2 21.1 3 m (10')

0 to 50 115 35.1 3 m (10')

0 to 100 231 70.4 3 m (10')

0 to 150 346 105 3 m (10')

0 to 250 577 176 3 m (10')

0 to 500 1153 351 3 m (10')

0 to 750 1730 527 3 m (10')

0 to 1000 2307 703 3 m (10')

ftH

O

2

2

2

EQUIVALENT

DEPTH

O

mH

2

O 670 mmH2O 3 m (10')

O 1757 mmH2O 3 m (10')

STD CABLE

SEALED GAGE PRESSURE (PSISG)

0 to 100 231 70.4 3 m (10')

0 to 150 346 105 3 m (10')

0 to 250 577 176 3 m (10')

0 to 500 1153 351 3 m (10')

0 to 750 1730 527 3 m (10')

0 to 1000 2307 703 3 m (10')

ABSOLUTE PRESSURE (PSIA)

0 to 5 11.5 3.51 3 m (10')

0 to 10 23.1 7.04 3 m (10')

0 to 15 34.6 10.5 3 m (10')

0 to 30 69.2 21.1 3 m (10')

0 to 50 115 35.1 3 m (10')

0 to 100 231 70.4 3 m (10')

0 to 150 346 105 3 m (10')

0 to 250 577 176 3 m (10')

0 to 500 1153 351 3 m (10')

0 to 750 1730 527 3 m (10')

0 to 1000 2307 703 3 m (10')

Maximum

LENGTH

cable length 91 m (300')]

STANDARD PART

NUMBER

2

STANDARD

0.20% ACCURACY

PX709GW-10WGI-[**] PX709LGW-10WGI-[**]

PX709GW-001GI-[**] PX709LGW-001GI-[**]

PX709GW-2.5GI-[**] PX709LGW-2.5GI-[**]

PX709GW-005GI-[**] PX709LGW-005GI-[**]

PX709GW-010GI-[**] PX709LGW-010GI-[**]

PX709GW-015GI-[**] PX709LGW-015GI-[**]

PX709GW-030GI-[**] PX709LGW-030GI-[**]

PX709GW-050GI-[**] PX709LGW-050GI-[**]

PX709GW-100GI-[**] PX709LGW-100GI-[**]

PX709GW-150GI-[**] PX709LGW-150GI-[**]

PX709GW-250GI-[**] PX709LGW-250GI-[**]

PX709GW-500GI-[**] PX709LGW-500GI-[**]

PX709GW-750GI-[**] PX709LGW-750GI-[**]

PX709GW-1.0KGI-[**] PX709LGW-1.0KGI-[**]

PX709GW-100SGI-[**] PX709LGW-100SGI-[**]

PX709GW-150SGI-[**] PX709LGW-150SGI-[**]

PX709GW-250SGI-[**] PX709LGW-250SGI-[**]

PX709GW-500SGI-[**] PX709LGW-500SGI-[**]

PX709GW-750SGI-[**] PX709LGW-750SGI-[**]

PX709GW-1.0KSGI-[**] PX709LGW-1.0KSGI-[**]

PX709GW-005AI-[**] PX709LGW-005AI-[**]

PX709GW-010AI-[**] PX709LGW-010AI-[**]

PX709GW-015AI-[**] PX709LGW-015AI-[**]

PX709GW-030AI-[**] PX709LGW-030AI-[**]

PX709GW-050AI-[**] PX709LGW-050AI-[**]

PX709GW-100AI-[**] PX709LGW-100AI-[**]

PX709GW-150AI-[**] PX709LGW-150AI-[**]

PX709GW-250AI-[**] PX709LGW-250AI-[**]

PX709GW-500AI-[**] PX709LGW-500AI-[**]

PX709GW-750AI-[**] PX709LGW-750AI-[**]

PX709GW-1.0KAI-[**] PX709LGW-1.0KAI-[**]

LIGHTNING3 PROTECTED

MODELS STANDARD

0.20% ACCURACY

PRESSURE TRANSDUCERS

B

OPTIONS FOR SUBMERSIBLE TRANSDUCERS

4 to 20 mA SPECIFICATIONS

Output: 4 to 20 mA

Supply Voltage: 10 to 30 Vdc [(10 to 20 Vdc above 105°C

(229°F)] maximum loop res Ω = (Vs-10) x 50

PX709-BOX1

PX709-BOX2

Lightning Protection: See application note/manual

See Common Specifications for other parameters

PX709-BOX3

A019385

Comes complete with 5-point NIST traceable calibration certificate.

[**] To order with additional cable length, specify total length in feet, PX709GW-001GI-25, additional cost for length over 10 feet.

Consult sales for stock cable length to assure fast delivery.

1.) To order with optional high accuracy for extra cost, insert code “-HH” after “I” for 0.08% accuracy, PX709-150GI-HH-[**]

2.) To order with ½ NPT Conduit fitting for extra cost, specify Model PX709C, for additional cost PX709CGW-010GI

3.) To order with optional Lightning/Surge protection for extra cost, specify model PX709LGW, PX709LGW-001GI

4.) To order with optional Lightning/Surge protection and conduit fitting for extra cost, specify model PX709CLGW, PX709CLGW-001GI

Ordering Examples: PX709GW-001GI, 1 psi gage submersible transducer with 4 to 20 mA output, 3 m (10') of cable and standard 0.2% accuracy

PX709LGW-005AI-HH-25FT, 5 psi absolute pressure, lightning protected submersible transducer with 4 to 20 mA output, 7.6 m (25') of cable and

high 0.08% accuracy

PX709CGW-2.5GI-20FT, 2.5 psi gage submersible transducer with 4 to 20 mA output, a ½ NPT conduit fitting with 6.1 m (20') of cable.

Terminal enclosure without surge protection - for

use with all models

Terminal enclosure with surge protection - for use

with 4 to 20 mA without Shunt Cal (one surge

protection module)

Terminal enclosure with surge protection - for use

with voltage output sensors and 4 to 20 mA with

Shunt Cal option (two surge protection modules)

Replacement desiccant to keep moisture out of

vent tube

B-5

Page 6

SUBMERSIBLE PRESSURE TRANSMITTERS

BUILD A TRANSDUCER TO YOUR SPECIFICATIONS

Build a Transducer to your Specifications

1 2 3 4 5 6 7

SERIES TYPE

RANGE

CODE

PRESSURE

TYPE

OUTPUT

ACCURACY

PX709 GW – 015 G I – HH – 50 FT

GW = Stainless

PX709 = Cable

PX709C = Conduit

Optional Higher Accuracy: Add suffix “-HH” after the “V”

or “I” in the model number

Optional Conduit Fitting Cable Exit: Specify model

PX709CGW

Optional Lightning Protection: Specify model PX709LGW

Optional Lightning Protection and Conduit fitting: Specify

model PX709CLGW

Steel Wetted Parts

LGW = Lightning

Protected (amplified

models only)

Range

(psi) xxx

G = Gage

A = Absolute

SG = Sealed

gage

To select your submersible

transducer all you have to do is

V = mV/V

5V = 5 Vdc

10V = 10 Vdc

I = 4 to 20 mA

SELECT:

Range

Pressure Type

Output

Blank = Std.

0.2%

Accuracy

HH = High

0.08%

Accuracy

Accuracy

Total Cable Length

(see table of stocked

lengths)

STANDARD CABLE LENGTHS FOR FAST DELIVERY

OMEGA® has designed the PX709 Series to be highly

modular so we can configure and ship most models in

1 week. We stock the modules and can quickly

assemble and do precision calibrations for any of our

several thousand possible combinations. The cable molded

onto the transducer using a high pressure, temperature

molding process to assure complete sealing. We stock a

series of molded cable assemblies in standard lengths to

suit most common applications which we can build onto your

transducer and deliver in 1 week (see the list below). We also

can provide custom lengths with slightly longer lead times to

allow for the molding process.

PX709-BOX1

PX709-BOX1 Waterproof terminal box for PX709 provides a

waterproof environment for electrical terminations and housing

the desiccant. Also available with optional lightning protection

for downstream instruments.

PX709C with

½ NPT conduit

fitting.

B-6

PX709 with

standard cable

fitting.

TOTAL

CABLE

LENGTH (FT)

Total Length in

Feet if not 10'

Extra cost for

additional length

over 10'

Fast Delivery –

Highlighted Typically

Stock to 2 Weeks!

STANDARD

LENGTHS

3 m (10')

4.6 m (15')

6.1 m (20')

7.6 m (25')

9.1 m (30')

12.2 m (40')

15.2 m (50')

18.3 m (60')

19.8 m (65')

22.5 m (74')

30.5 m (100')

45.7 m (150')

91.4 m (300')

Loading...

Loading...